Triazine ring hexaphenyl phosphate-containing flame retardant and preparation method thereof

A hexaphenyl phosphate and flame retardant technology, which is applied in the field of triazine ring hexaphenyl phosphate flame retardant and its preparation, can solve the adverse effects of material mechanical properties, limit industrial production and application, matrix resin phase Poor compatibility and other problems, to achieve the effect of excellent P-N synergistic flame retardancy, excellent char formation ability, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

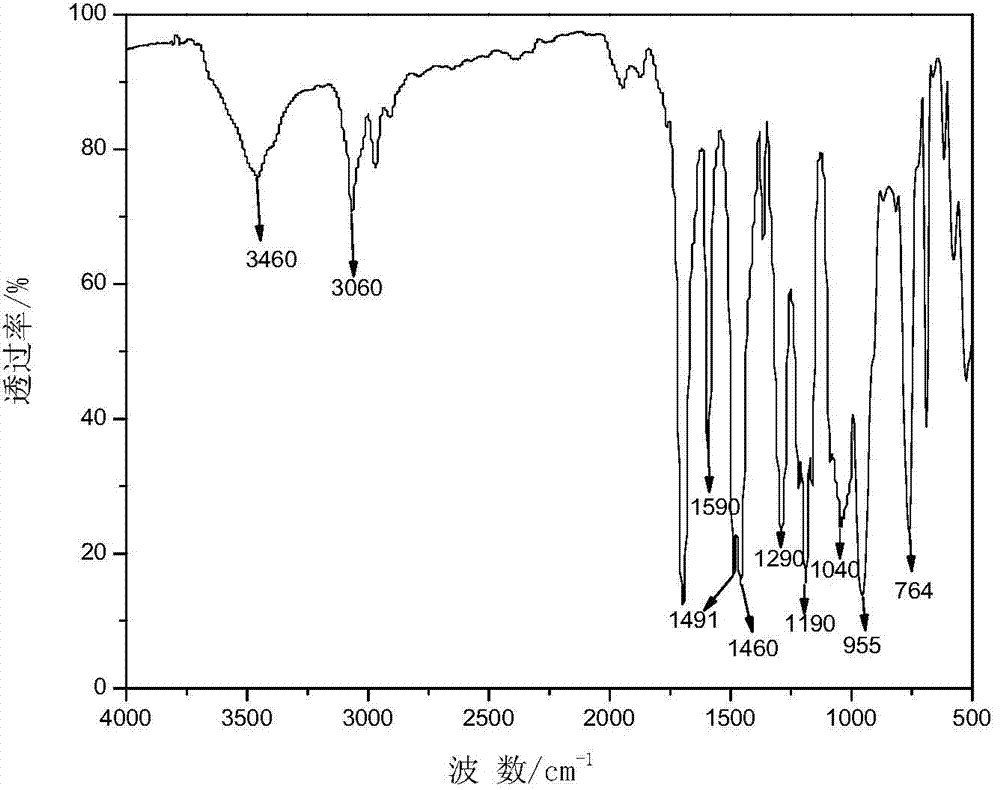

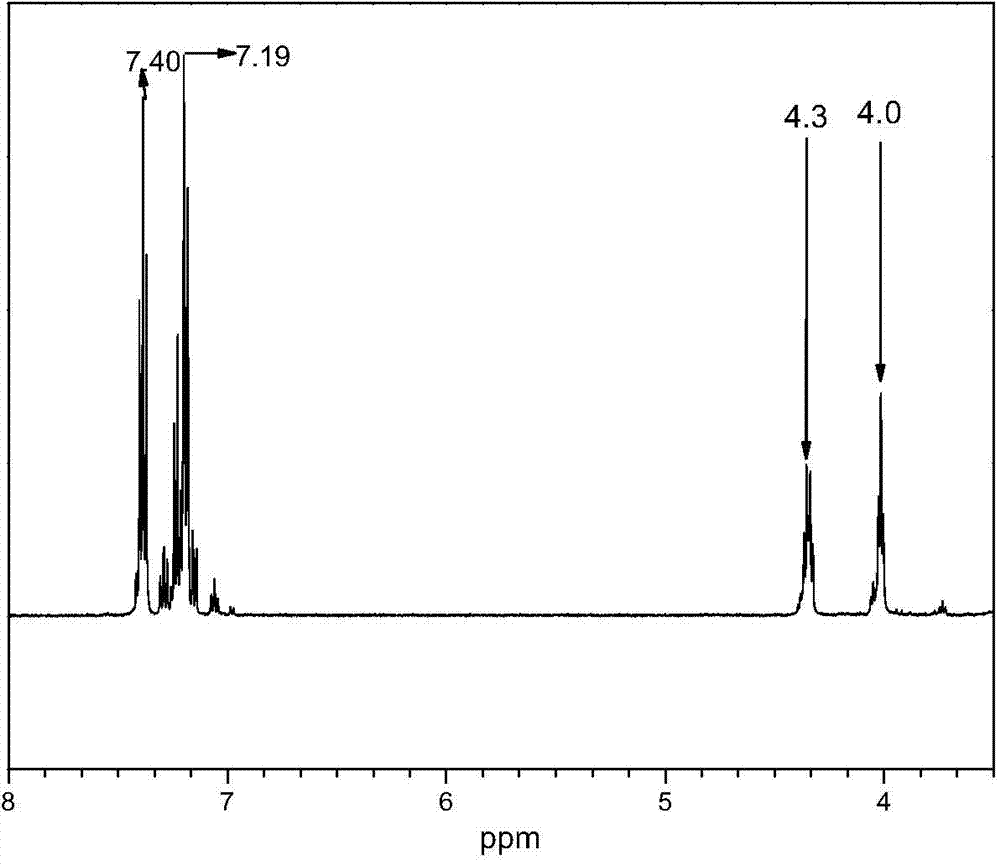

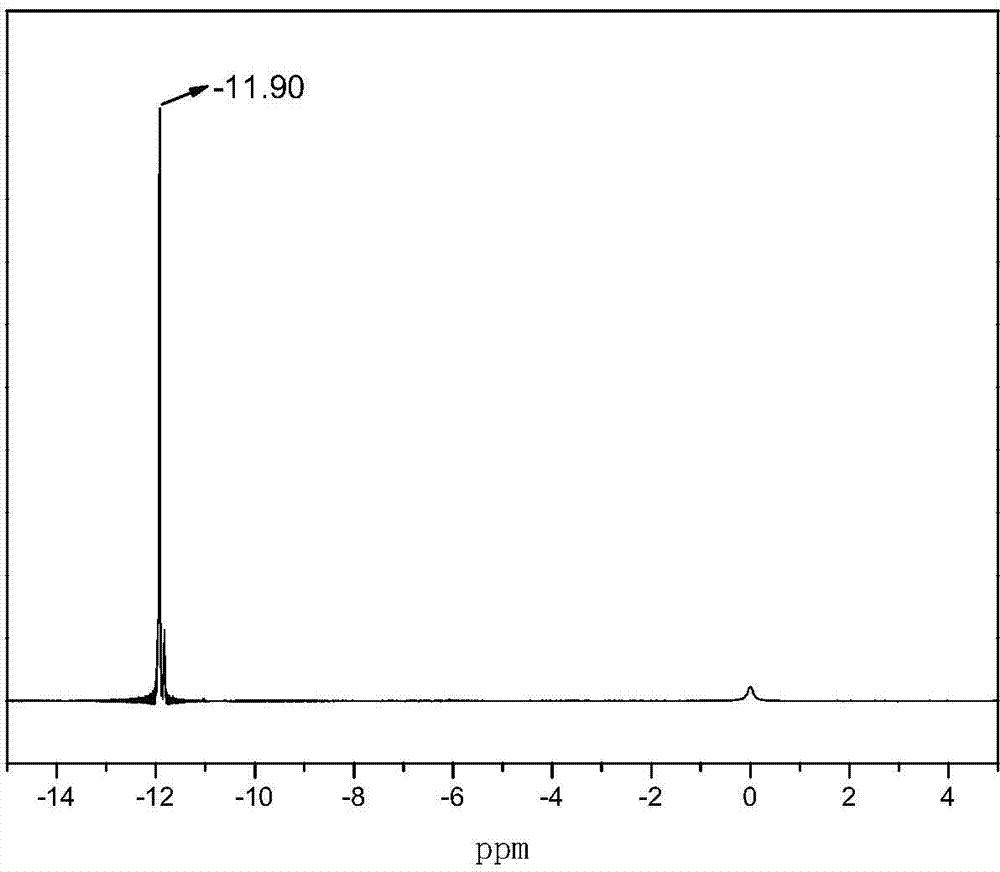

Embodiment 1

[0025] Add 60ml toluene, 11.63mmol Saike, 0.2840g dimethylaminopyridine and 34.89mmol triethylamine in the 100mL dry four-neck flask equipped with constant pressure dropping funnel, thermometer, electric stirrer, then in ice-salt bath condition and At a stirring speed of 500r / min, add 34.89mmol of diphenyl chlorophosphate and 15ml of toluene dropwise for 2 hours. After the dropwise addition, move to room temperature at 20°C for 8 hours, then filter to obtain the filtrate, and evaporate it under reduced pressure. Organic solvent, then wash with distilled water to 3-5 times successively, the sodium carbonate solution that mass fraction is 5% washs 3-5 times, distilled water washes to neutrality, finally obtain light yellow viscous liquid in vacuum drying, yield is 94%. According to the analysis of the characteristic peaks of the group by infrared spectrum and hydrogen nuclear magnetic resonance spectrum, it has been confirmed that the obtained product is a new type of phosphorus...

Embodiment 2

[0026] Embodiment 2, the synthetic method of novel phosphorus-nitrogen synergistic flame retardant is carried out according to the following steps:

[0027] Add 90ml of toluene, 17.43mmol of Saike, 0.4260g of dimethylaminopyridine and 57.52mmol of triethylamine into a dry four-neck flask equipped with a constant pressure dropping funnel, a thermometer, and an electric stirrer with a capacity of 250ml, and then add Under the condition of bath and stirring speed of 500r / min, add 57.52mmol of diphenyl chlorophosphate and 23ml of toluene dropwise, add dropwise for 2h, move to room temperature 20°C for 8h after the dropwise addition, and then filter to obtain the filtrate , evaporate the organic solvent under reduced pressure, then wash with distilled water for 3-5 times, then wash with 5% sodium carbonate solution for 3-5 times, then wash with distilled water until neutral, and finally dry in vacuum to obtain light yellow viscous Liquid, 94% yield. According to the analysis of th...

Embodiment 3

[0028] Embodiment 3, the synthetic method of novel phosphorus-nitrogen synergistic flame retardant is carried out according to the following steps:

[0029] Add 120ml of toluene, 23.26mmol of Saike, 0.5680g of dimethylaminopyridine and 65.93mmol of triethylamine into a dry four-neck flask equipped with a constant pressure dropping funnel, a thermometer, and a stirrer with a capacity of 250ml, and then place the mixture in an ice-salt bath With a stirring speed of 500r / min, add 65.78mmol of diphenyl chlorophosphate and 30ml of toluene dropwise, dropwise for 2h, move to room temperature at 20°C for 8h after the dropwise addition, and then filter to obtain the filtrate. Evaporate the organic solvent under reduced pressure, then wash with distilled water for 3-5 times, then wash with 5% sodium carbonate solution for 3-5 times, wash with distilled water until neutral, and finally dry in vacuum to obtain a light yellow viscous liquid , and the yield was 94%. According to the analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com