Patents

Literature

324results about How to "Meet processing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

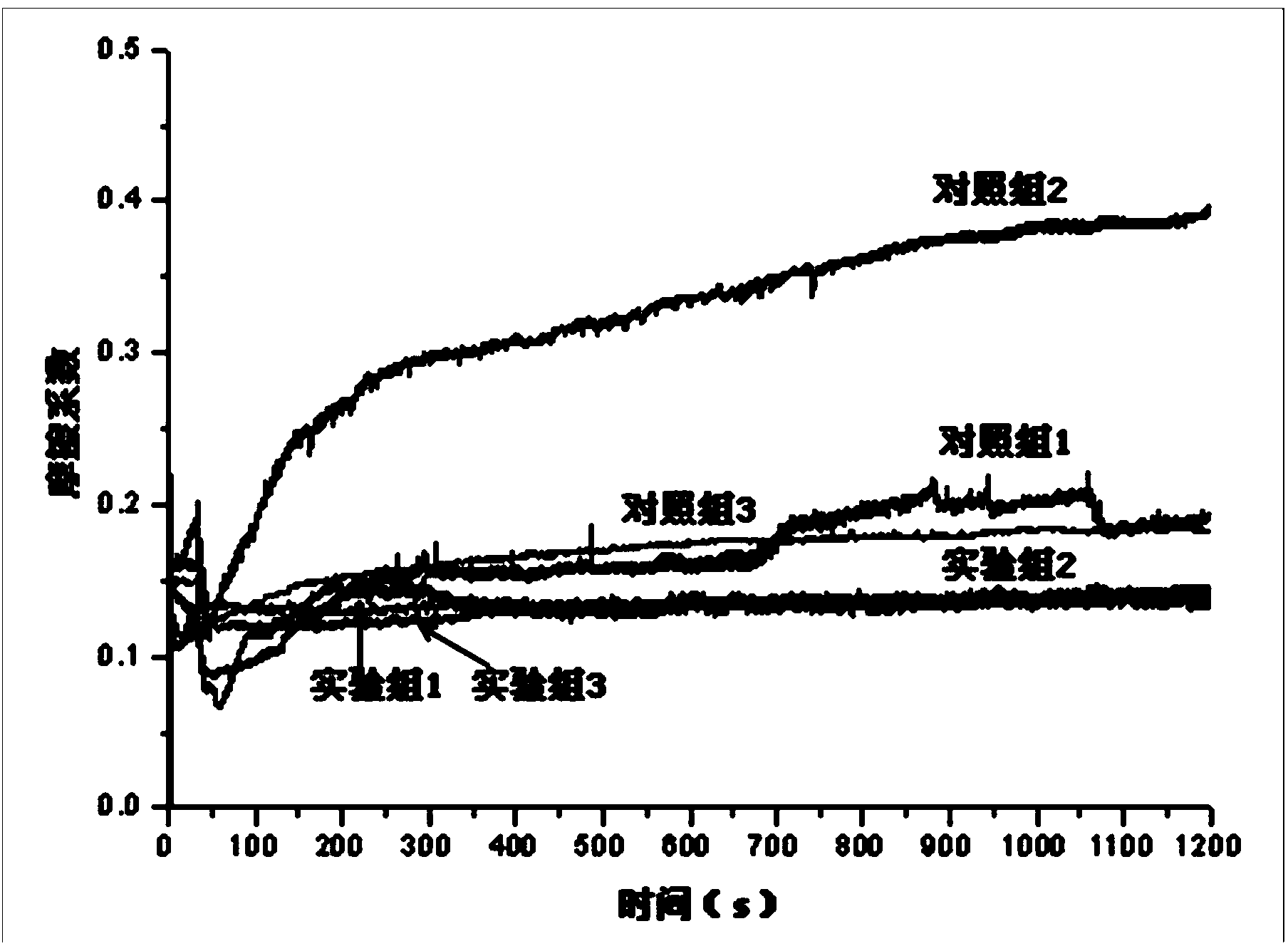

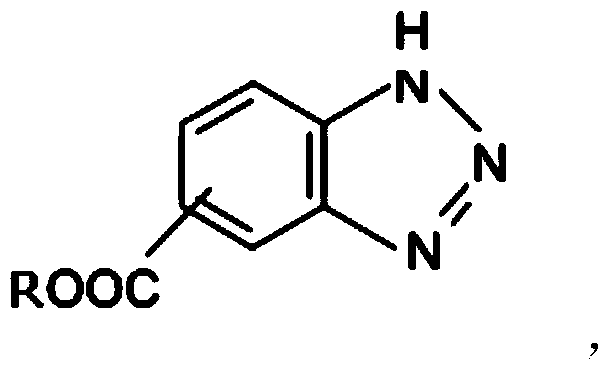

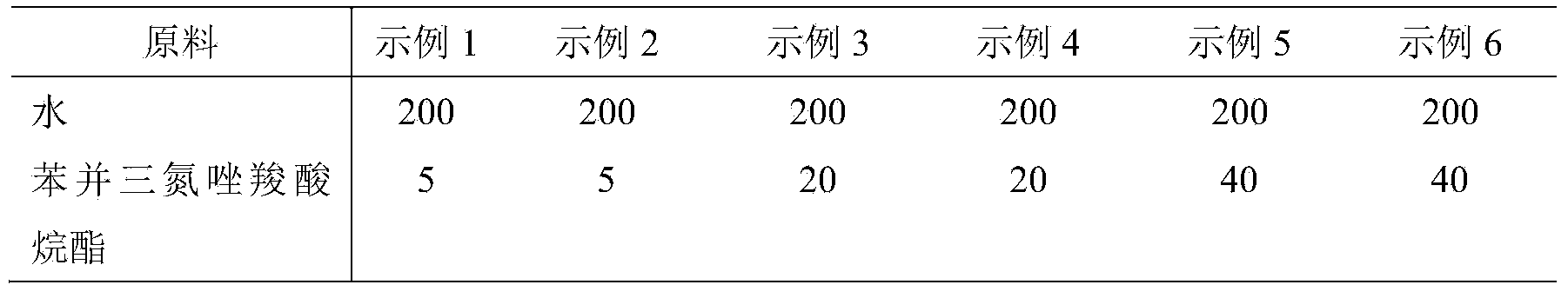

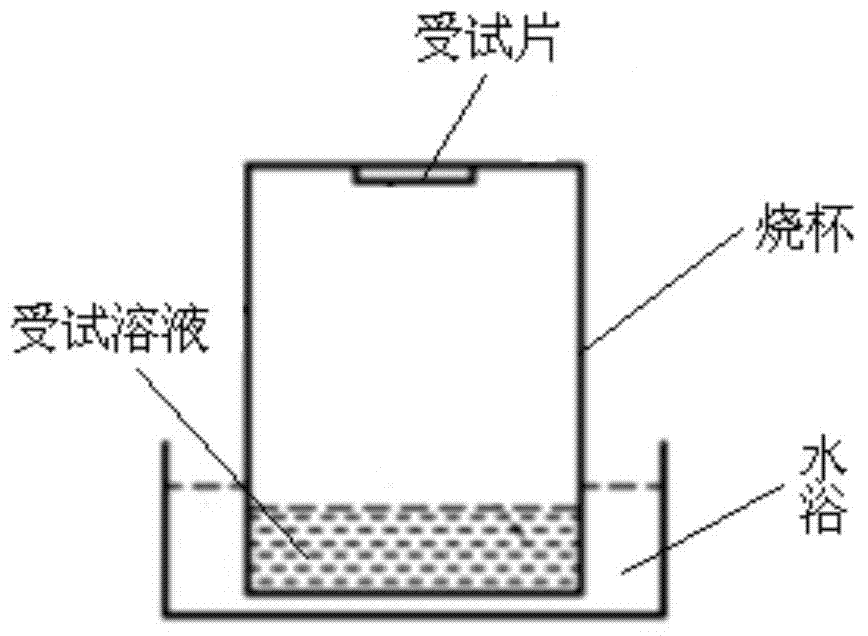

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

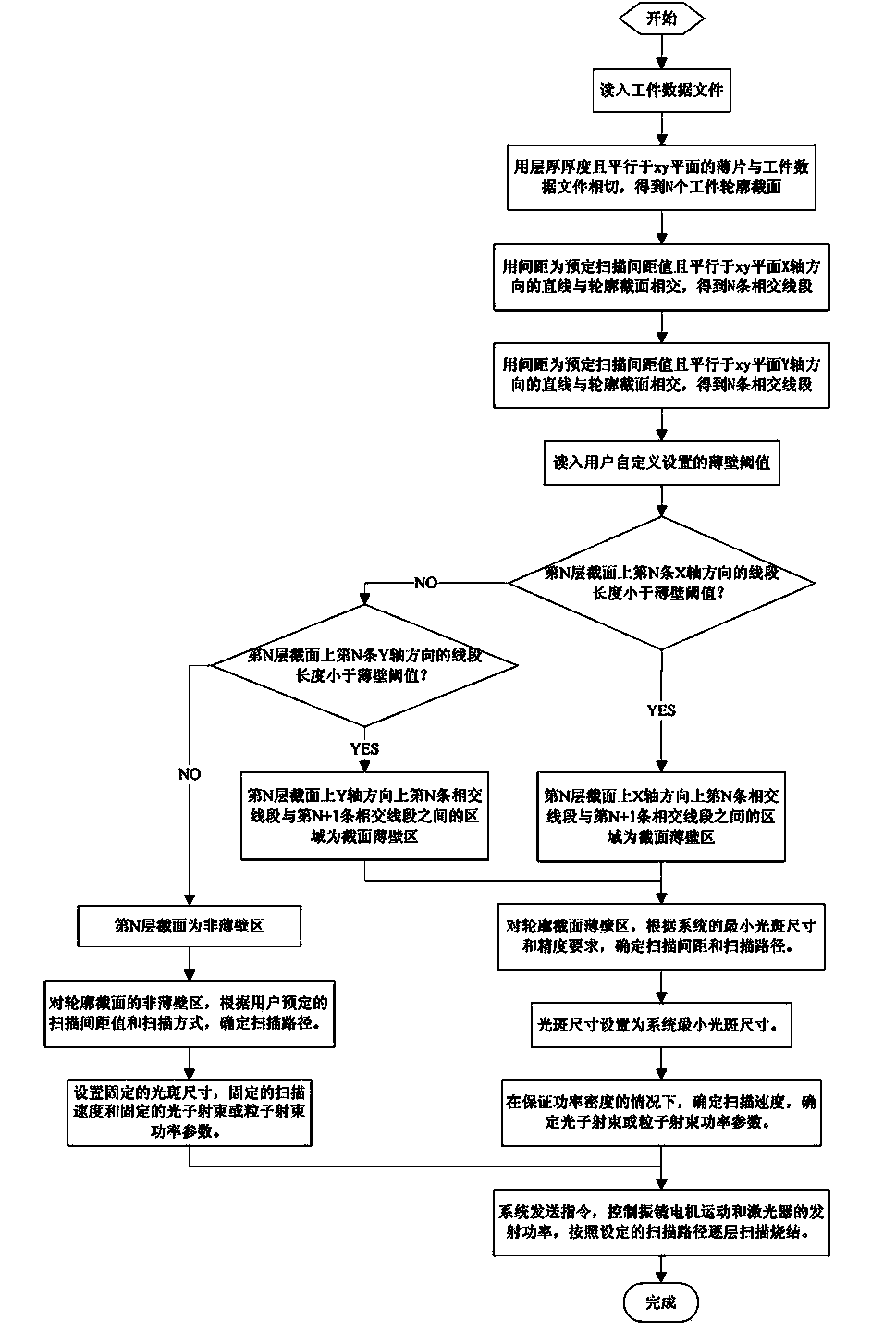

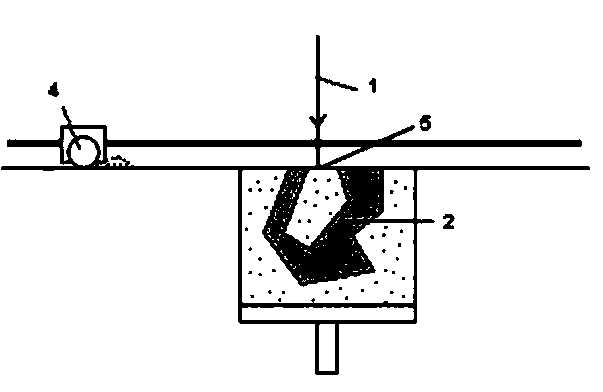

Scanning method for manufacturing three-dimensional object layer by layer

ActiveCN103639411AUniform efficiencyEqualization accuracyAdditive manufacturing apparatusCeramic shaping apparatusMachine partsParticle beam

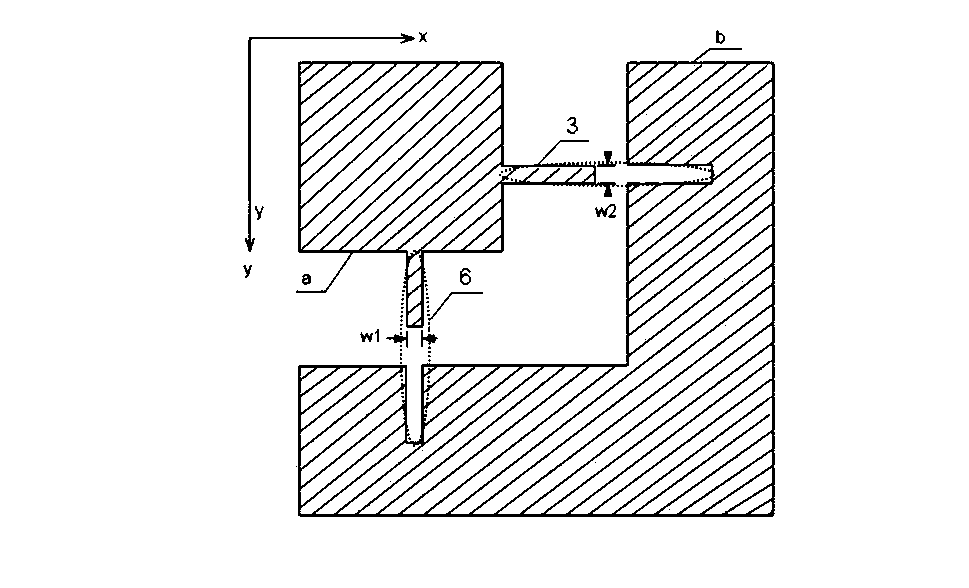

A scanning method for manufacturing a three-dimensional object layer by layer comprises the following steps: (1), dividing each section layer of a three-dimensional object to be manufactured into a thin-wall area and a non-thin-wall area: setting a threshold of the gap width of the section profile of the three-dimensional object, and according to the gap width of the section profile in x / y direction, dividing a coating area required to be scanned into a thin-wall area and a non-thin-wall area, wherein the thin-wall area is an area of which the gap width of the section profile is smaller than the threshold and the non-thin-wall area is an area of which the gap width of the section profile is greater than or equal to the threshold; (2), according to the thin-wall area and the non-thin-wall area, scanning area by area, wherein the non-thin-wall area is scanned, relatively high photon beam or particle beam power and relatively large light spot diameter are selected, and when the thin-wall area is scanned, relatively low photon beam or particle beam power and relatively large light spot diameter are selected. By the scanning method, constraints of efficiency and precision in the process of manufacturing the three-dimensional object layer by layer are balanced to the maximum extent, so that the efficiency is ensured and the accuracy and the surface quality of a machined part are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

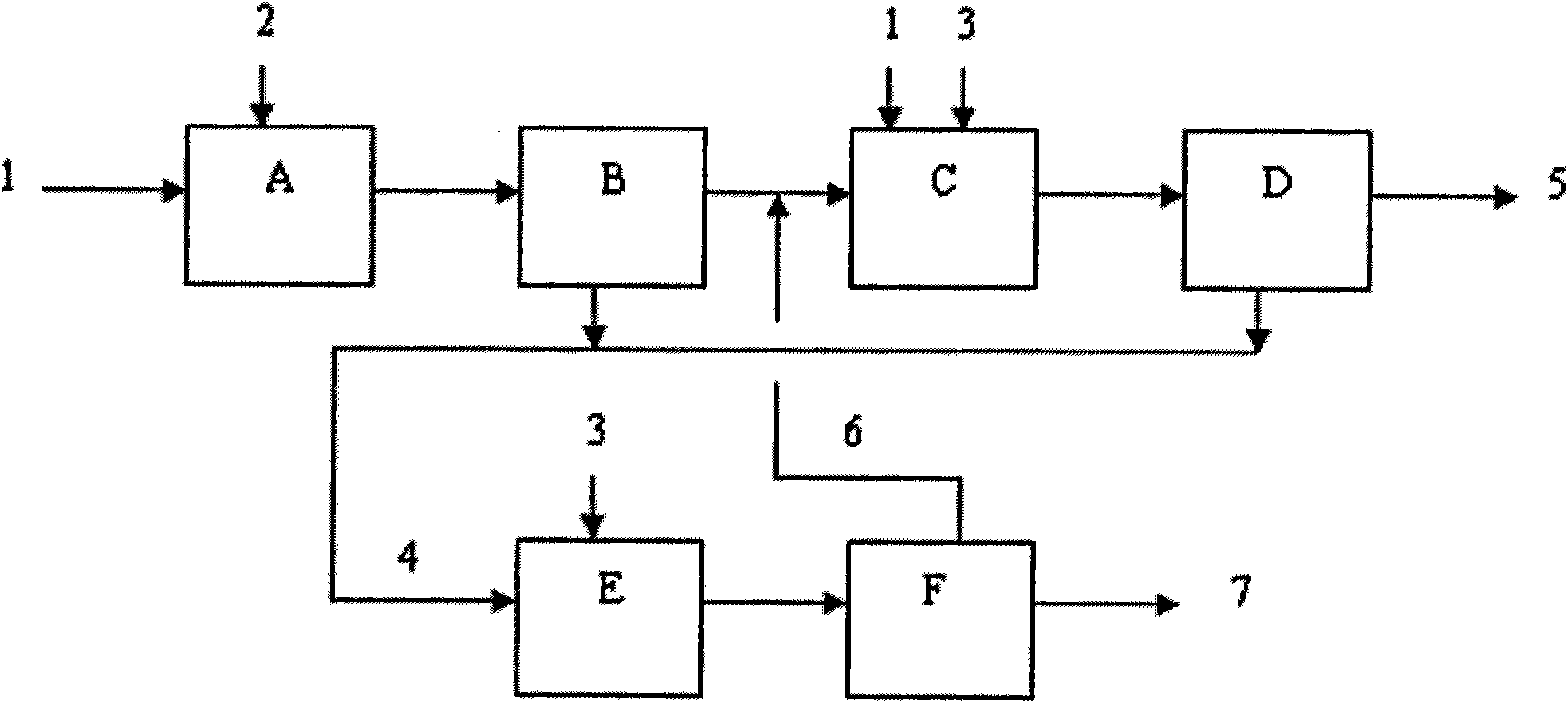

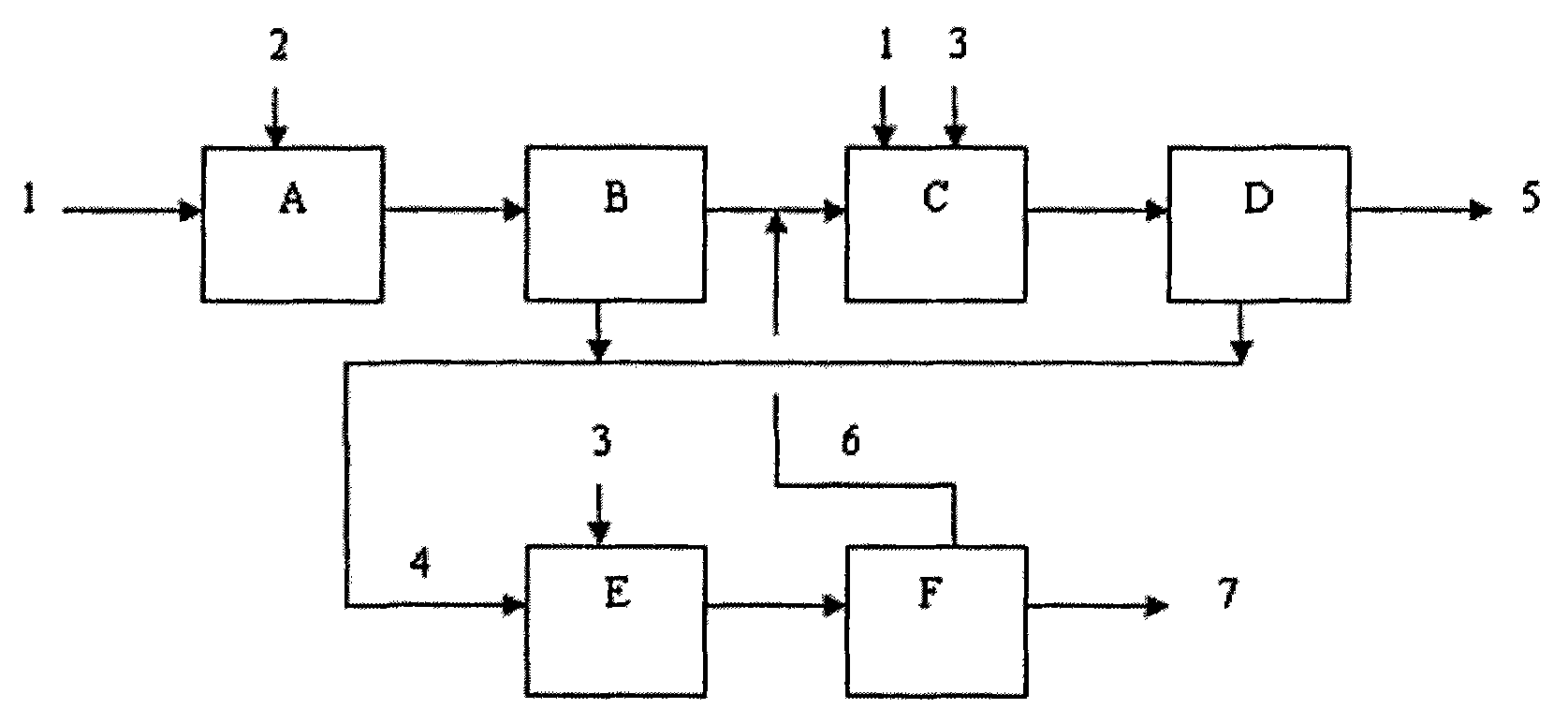

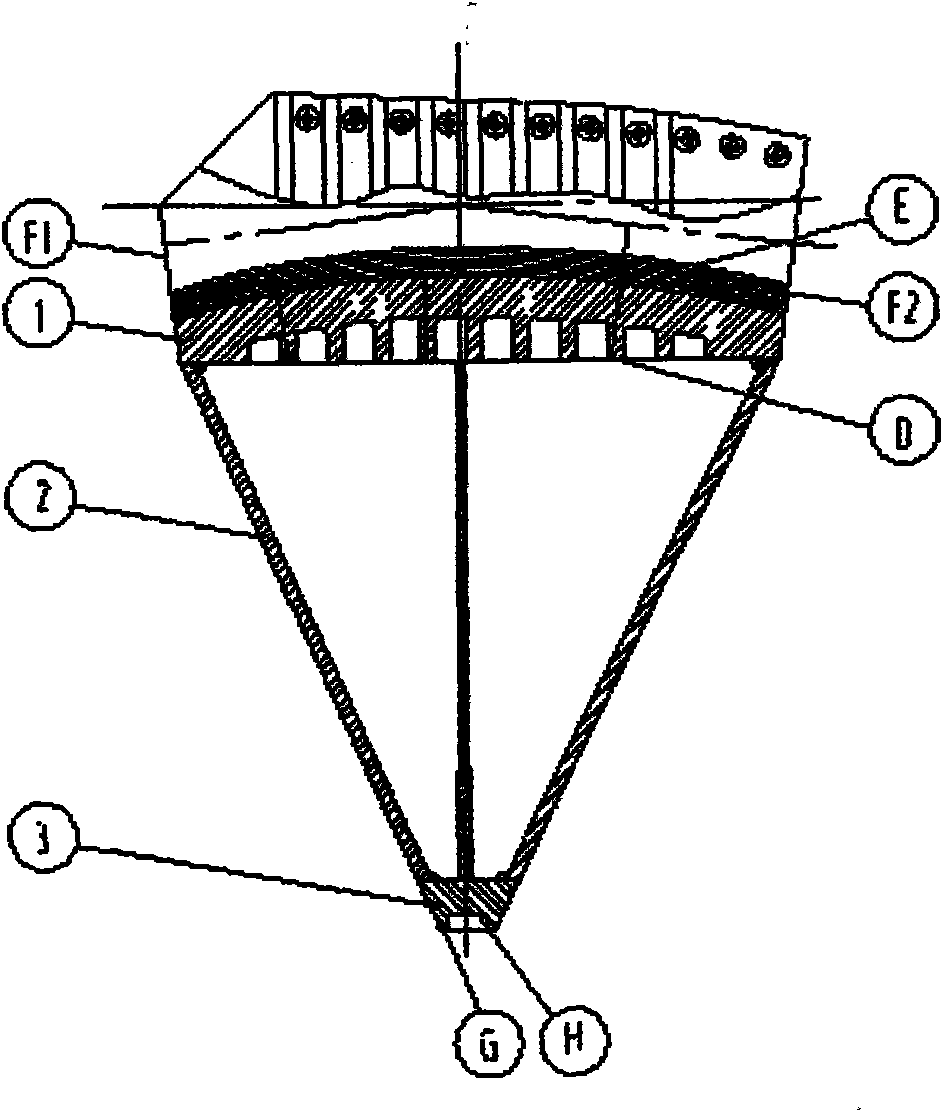

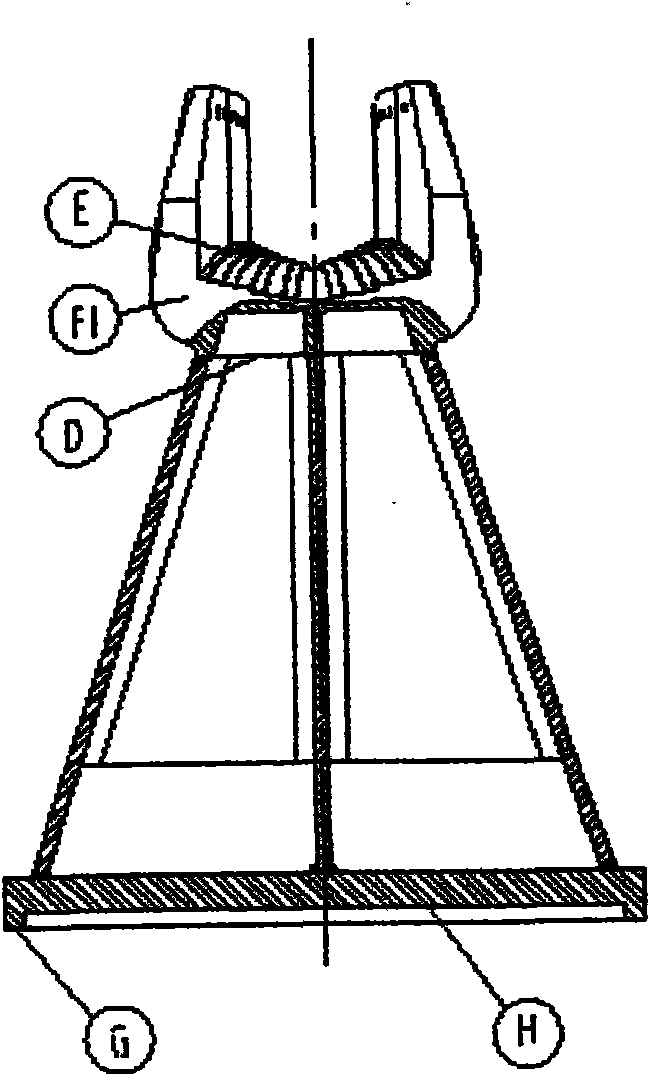

Stereo artificial wetland system for treating sewage

InactiveCN101186382AReduce closureHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandIndustrial waste water

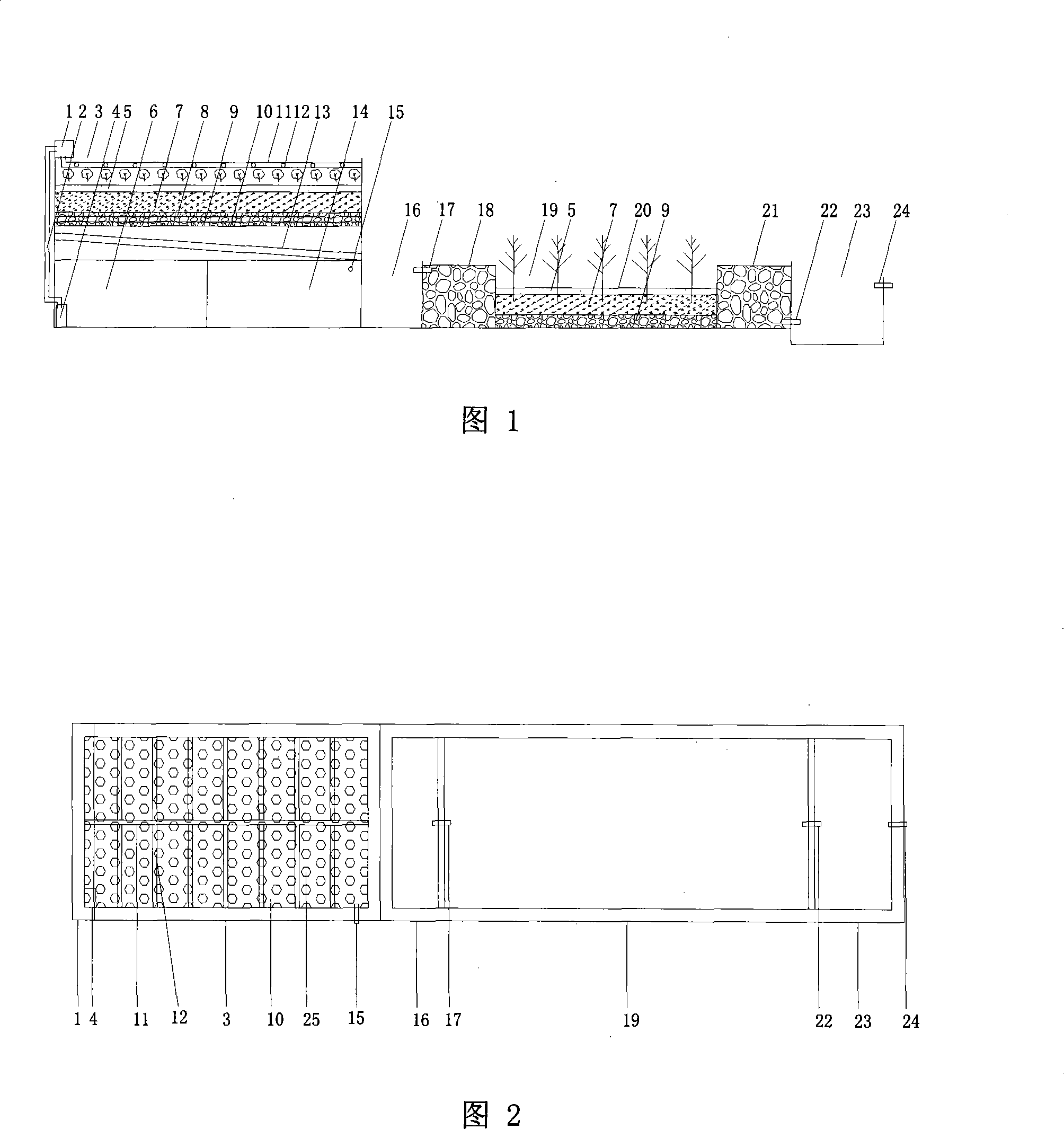

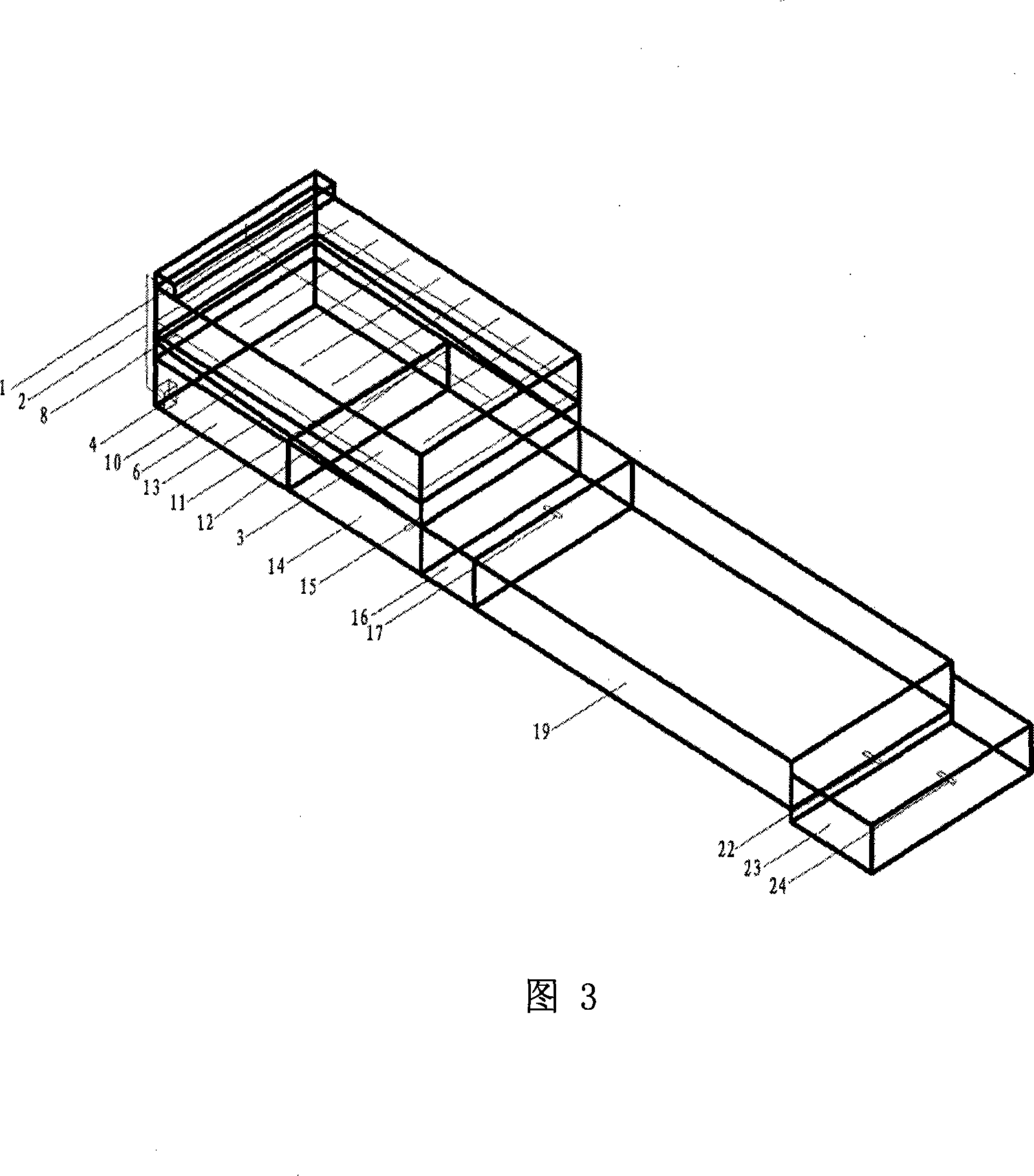

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment tridimensional artificial wetland system that is used for the industrial waste water treatment of small-scale isolated pollution sources. The invention aims at providing a tridimensional artificial wetland system that is used for sewage treatment and that has small floor occupancy, high hydraulic load, high pollution load and long service life so as to overcome the defects of the current sewage treatment of big artificial wetland floor occupancy, low hydraulic load, low pollution load and short system service life. The key points of the invention are that: the artificial wetland for sewage treatment adopts a tridimensional assembled structure of vertical current artificial wetland and horizontal subsurface flow artificial wetland, and base materials are filled in various directions to form the tridimensional artificial wetland system for sewage treatment; the tridimensional artificial wetland system for sewage treatment comprises a water collecting header, a porous water-filtering vertical current artificial wetland bed, a first-stage regulating tank, a water drop chute, a grid tank, a second-stage regulating tank, a horizontal subsurface flow artificial wetland bed and a water collecting tank.

Owner:ZHEJIANG NORMAL UNIVERSITY

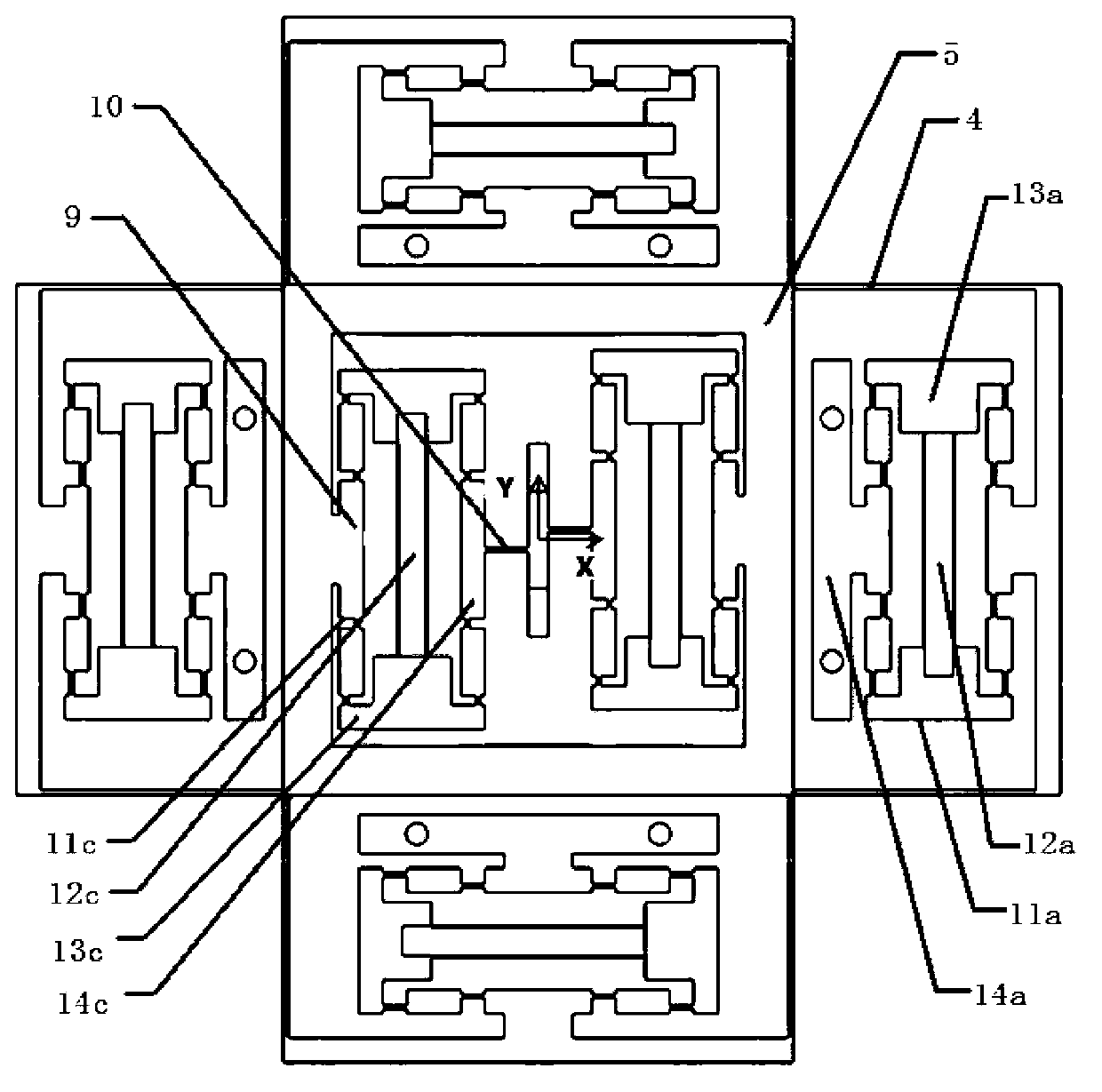

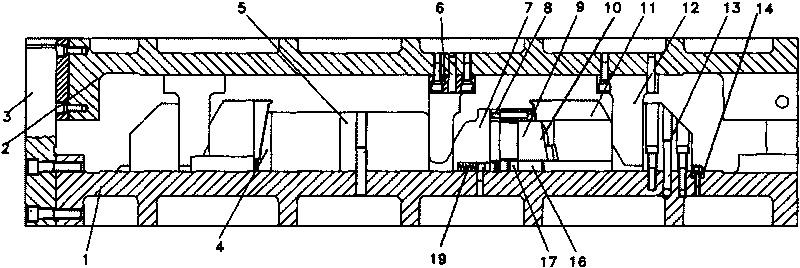

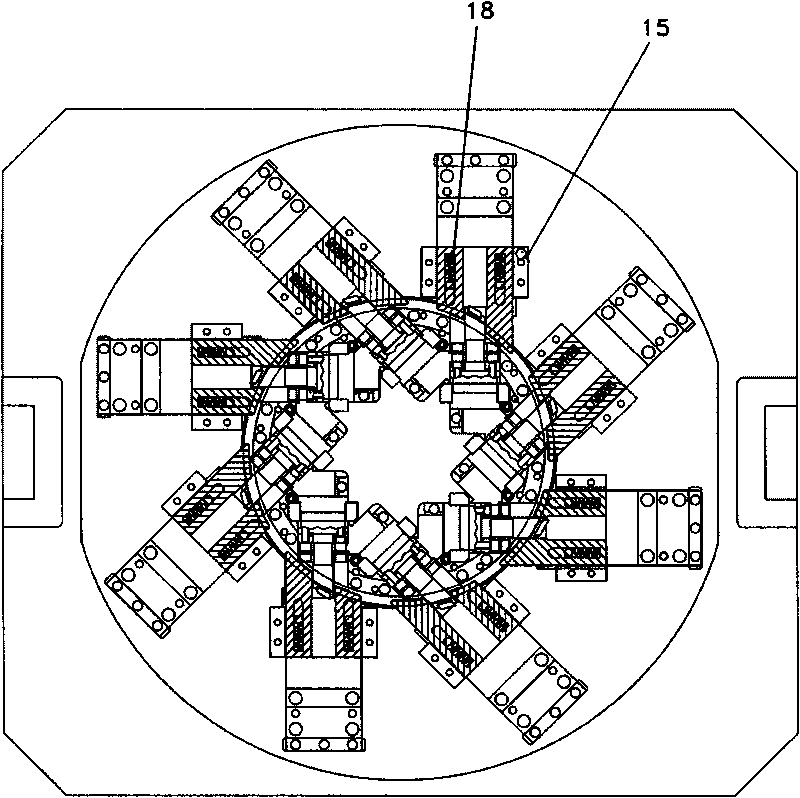

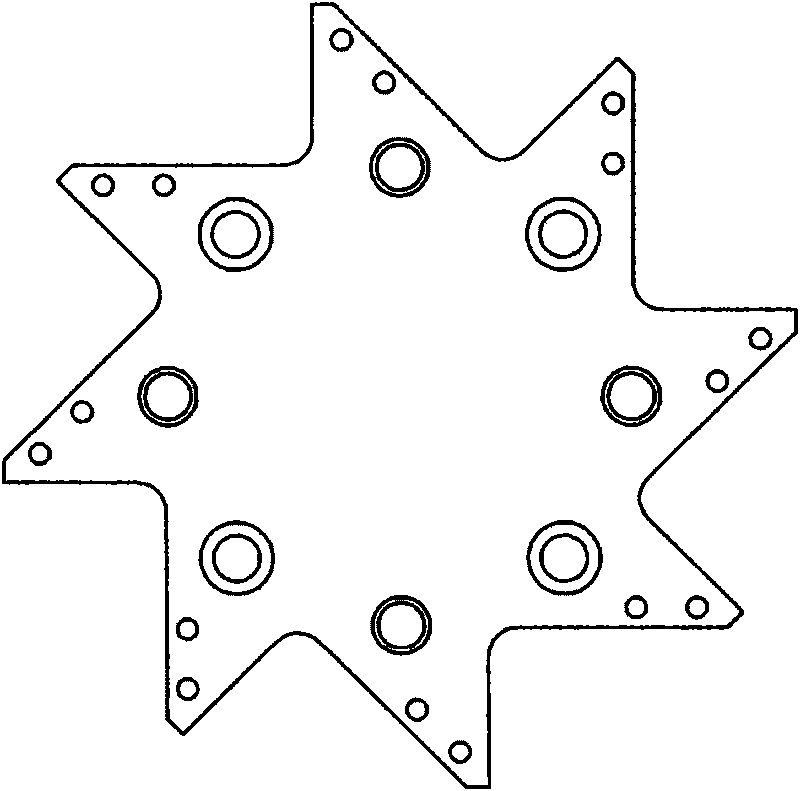

Integrated type six degrees of freedom precision positioning platform

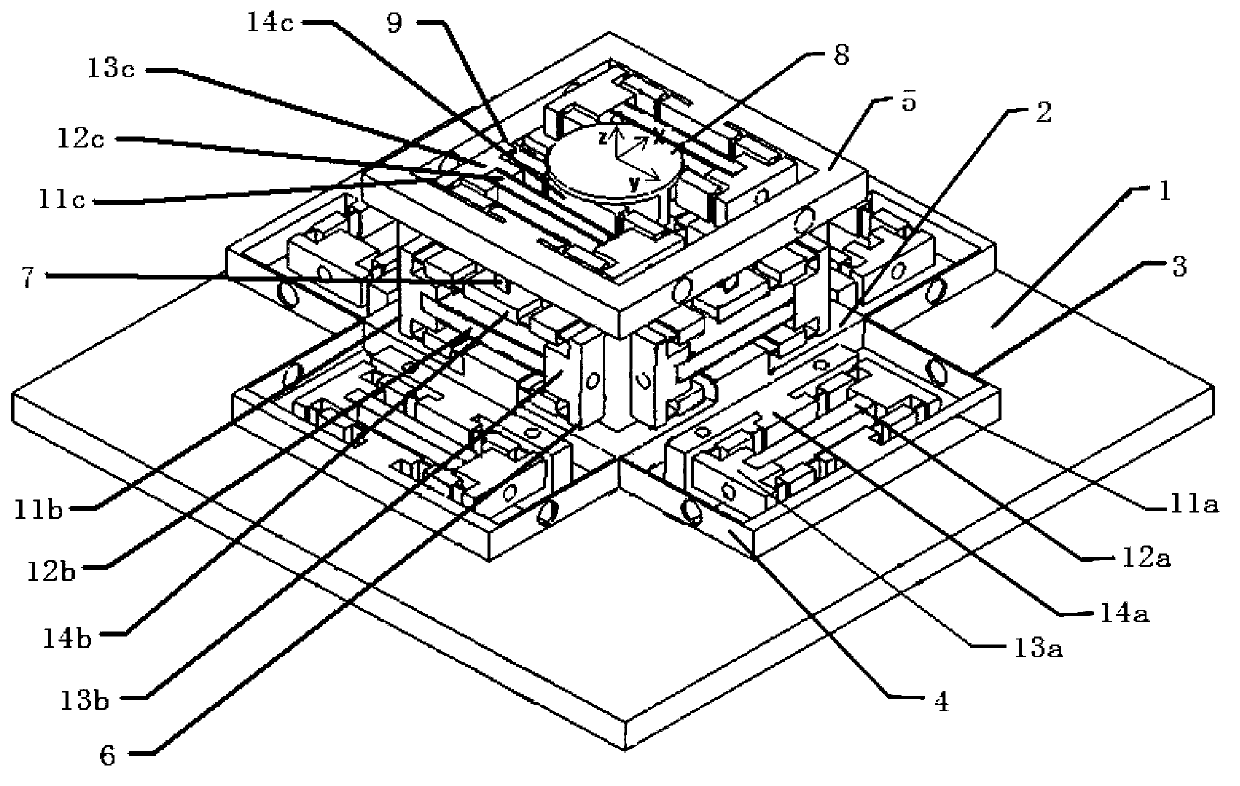

The invention discloses an integrated type six degrees of freedom precision positioning platform. The integrated type six degrees of freedom precision positioning platform comprises a base, a lower platform component, a middle platform component and an upper platform component. The integrated type six degrees of freedom precision positioning platform utilizes a piezoelectric ceramics brake to enable the lower platform component to achieve rectilinear motion along an X direction and a Y direction of a coordinate system, enable the middle platform component to achieve a rectilinear motion along an Z direction of the coordinate system and a rotary oscillation around an axis which is parallel to the X axis and an axis which is parallel to the Y axis, and enables the upper platform component to rotate around the Z axis. The integrated type six degrees of freedom precision positioning platform can achieve precise control position on the six degrees of freedom and effectively avoids displacement coupling among axes due to the fact that the middle platform component and the lower platform component are designed into a symmetric structure. Meanwhile, the transmission platform can achieve integral manufacture, is driven by the piezoelectric ceramics brake, has the advantages of being free from friction and coupling, being high in precision, long in journey and high in resolution rate and can meet complex manufacturing and operation requirements of nanometer science and technology studies.

Owner:CHONGQING UNIV

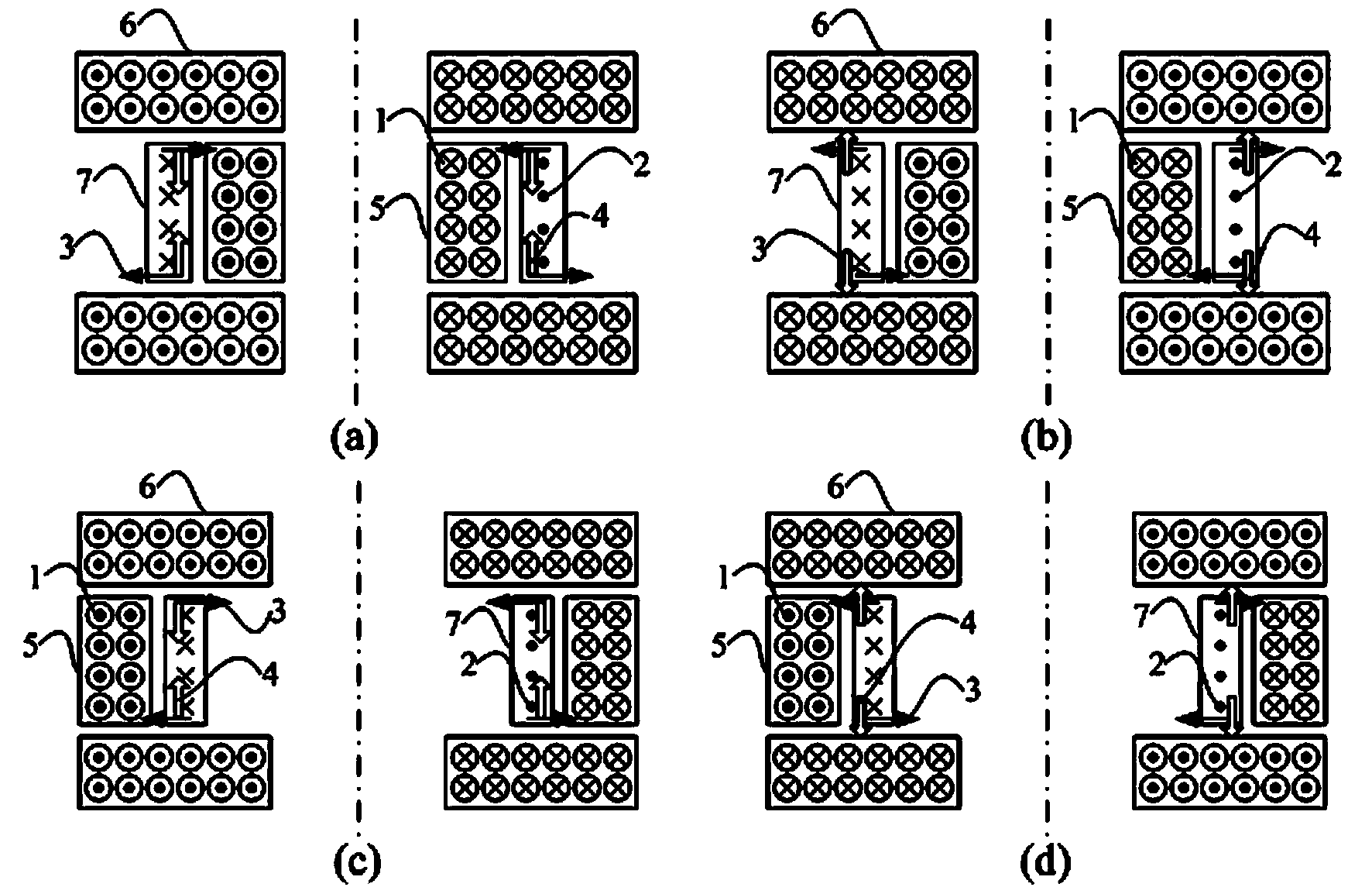

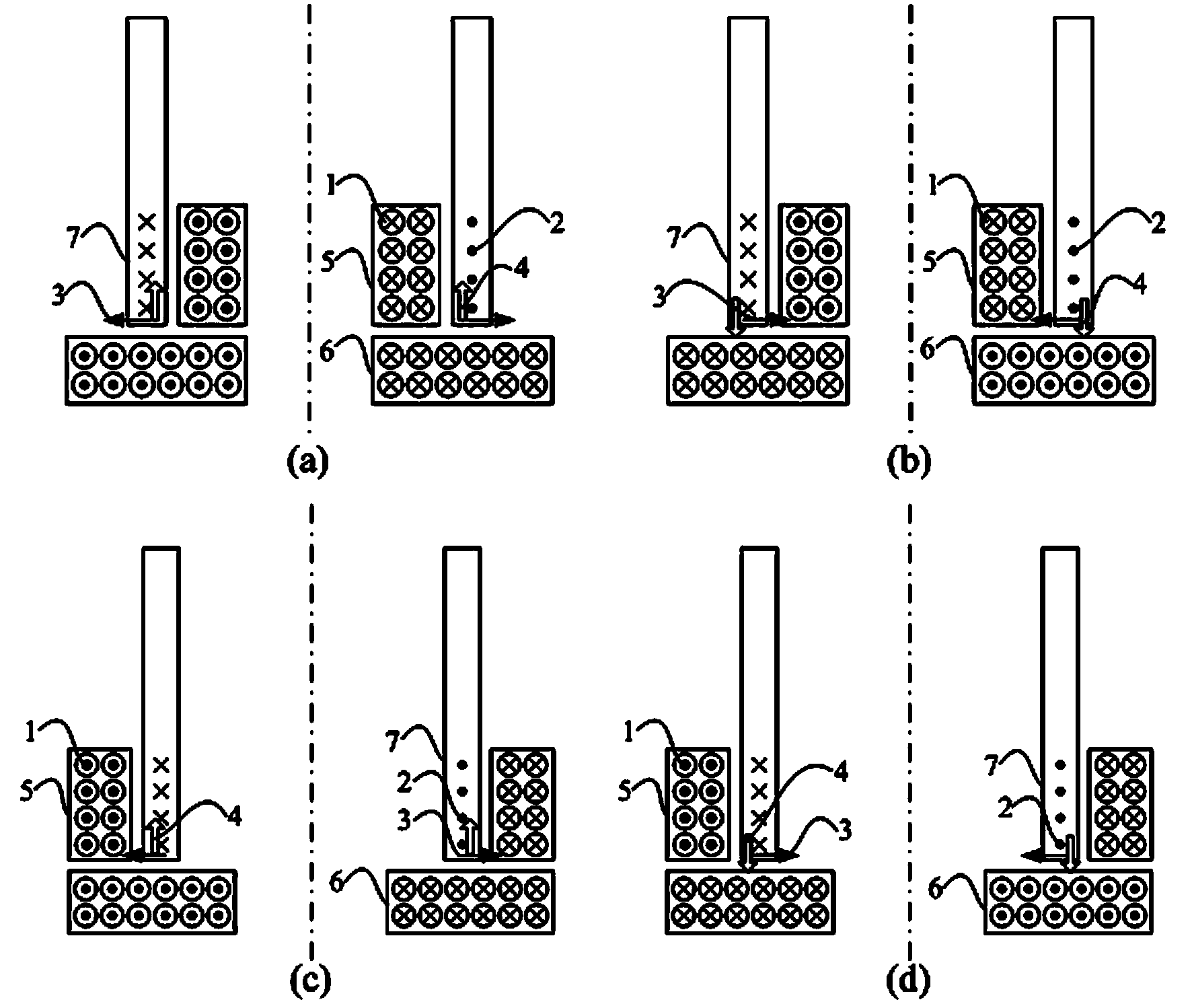

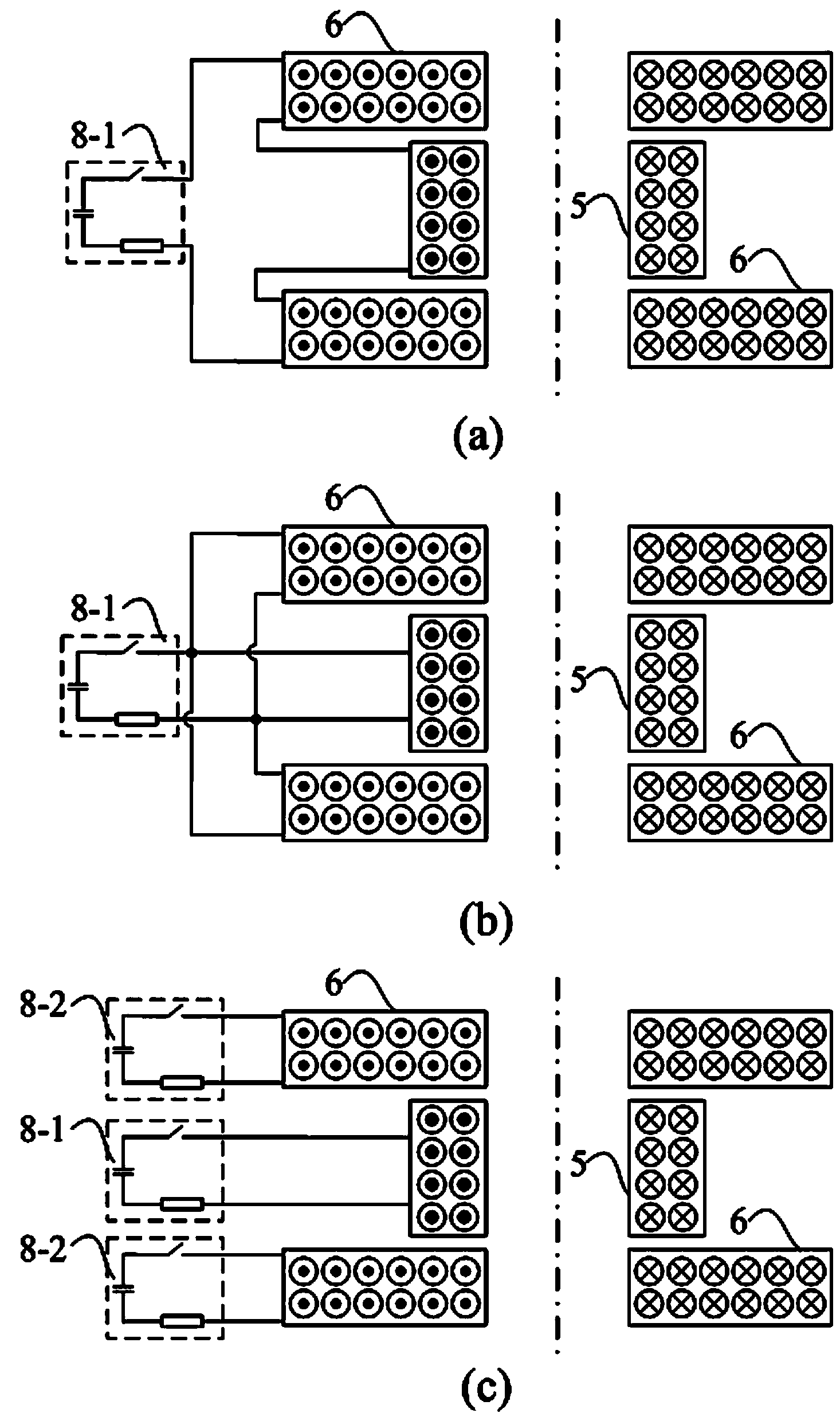

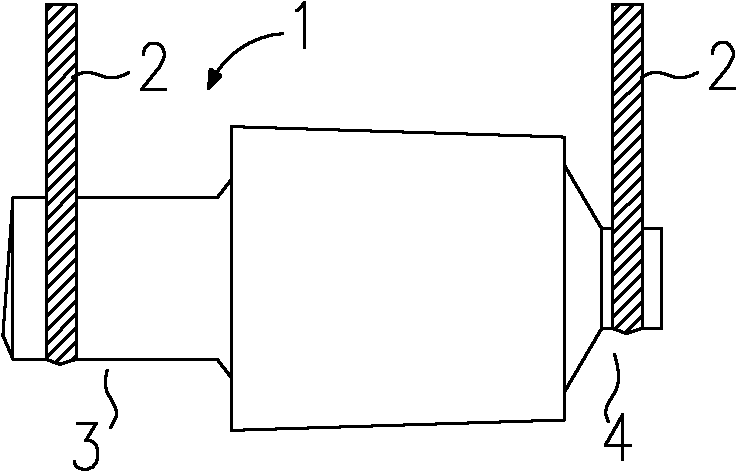

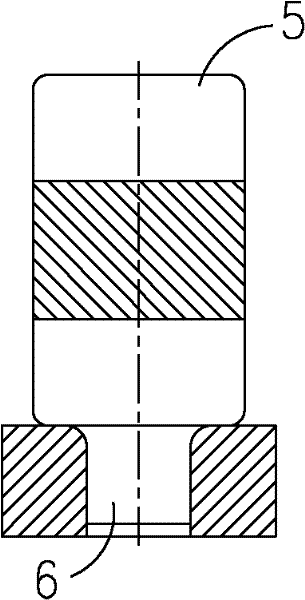

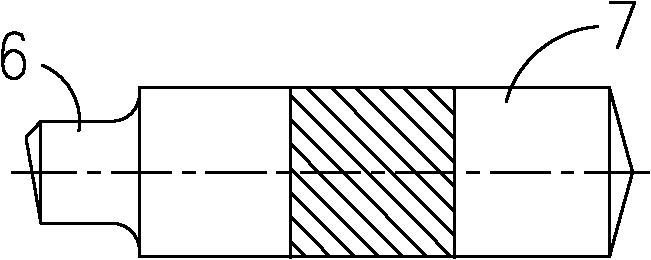

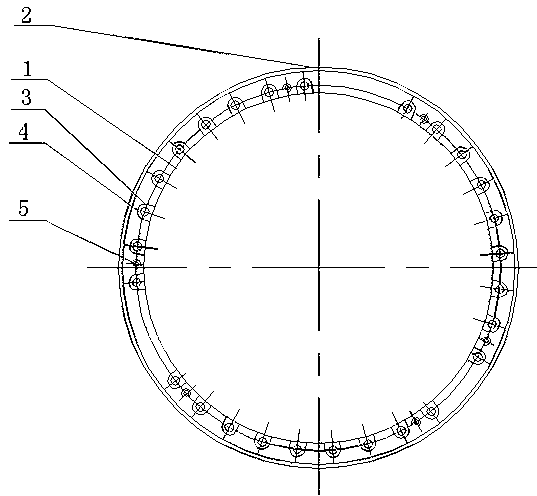

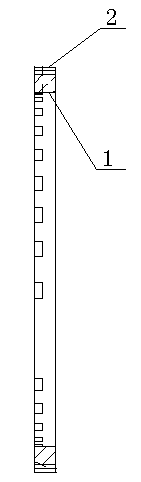

Method and device for electromagnetically forming metal pipe fitting in radial and axial loading mode

ActiveCN103406418ASolve the single load of electromagnetic forming factorSolve the problem caused byAxial compressionPipe fitting

The invention discloses a method and a device for electromagnetically forming a metal pipe fitting in a radial and axial loading mode. The device mainly comprises an eddy current coil, magnetic field coils and power systems. The eddy current coil generates induced eddy currents, the magnetic field coils generate radial magnetic fields, and the eddy current coil and the magnetic field coils are powered by the power systems. The method and the device have the advantages that electromagnetic force can be radially and axially loaded simultaneously in a procedure for electromagnetically forming the metal pipe fitting, an electromagnetic force loading mode can be adjusted, and accordingly machining requirements of different workpieces can be met; the axial compression type pipe fitting is electromagnetically expanded, so that the thickness reduction of a pipe wall in an expansion procedure can be effectively reduced, the forming limit of a formed workpiece is increased, and the forming performance of the formed workpiece is improved; high-speed deformation experiment conditions in different load forms can be provided for metal pipe fittings by the method for electromagnetically forming the metal pipe fitting in the radial and axial loading mode, and novel experiment measures are provided for research on high-speed deformation mechanisms of materials.

Owner:湖北继扬电力科技有限公司

Method for treating iron-containing acidic wastewater

InactiveCN101857325AShort processing timeReduce energy consumptionMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagFiltration

The invention discloses a method for treating iron-containing acidic wastewater. The method comprises the following steps of: performing neutralization reaction on the iron-containing acidic wastewater and carbide slag slurry or lime milk in a neutralization tank by mechanical mixing; delivering neutralized slag-containing wastewater into a sedimentation tank; delivering wastewater supernatant in the sedimentation tank into a wastewater oxidation tank, adjusting a pH value in a pH value adjustment zone of the wastewater oxidation tank by using a small amount of the iron-containing acidic wastewater, and delivering the wastewater supernatant into an aeration zone for oxidization; delivering wastewater containing a small amount of ferric suspended substances into a clarification tank, and discharging clarified clean wastewater directly; and delivering sediment settled in the sedimentation tank in the step two and sediment settled in the clarification tank in the step four into a sediment oxidation tank by pumping, performing aeration oxidation treatment, delivering the sediment into a filter press for filtration, returning filtered water to the wastewater oxidation tank for treatment together with the wastewater supernatant from the sedimentation tank, and treating filtered residue by the conventional method. The clarified clean wastewater treated by the method has the pH value of 6 to 9 and the iron concentration of 2 mg / L, and meets the national discharge standard.

Owner:XIANGTAN UNIV

Vanalium preparation method

The invention belongs to the field of metallurgy and particularly relates to a vanalium preparation method. The vanalium preparation method provided by the invention is low in cost and ensures high purity of obtained alloy. The technical scheme provided by the invention is as follows: in the vanalium preparation method, vanadium pentoxide and metallic aluminium are used as raw materials and are subjected to ignition reduction in a reaction device to obtain vanalium and furnace clinker; and a continuous feeding manner is adopted for the reaction device during feeding, and the feeding speed is 5-40kg / min. Compared with the prior art, the vanalium preparation method provided by the invention has the advantages that no coolant is added for controlling heat so that the cost is lower and the requirement for mass industrial production is completely met; and the produced vanalium is low in impurity content, the finished vanalium contains 65-91wt% of V, 9-35wt% of Al, not more than 0.3wt% of Fe and not more than 0.3wt% of Si, and the obtained vanalium has higher purity and meets the requirement of subsequent further processing.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

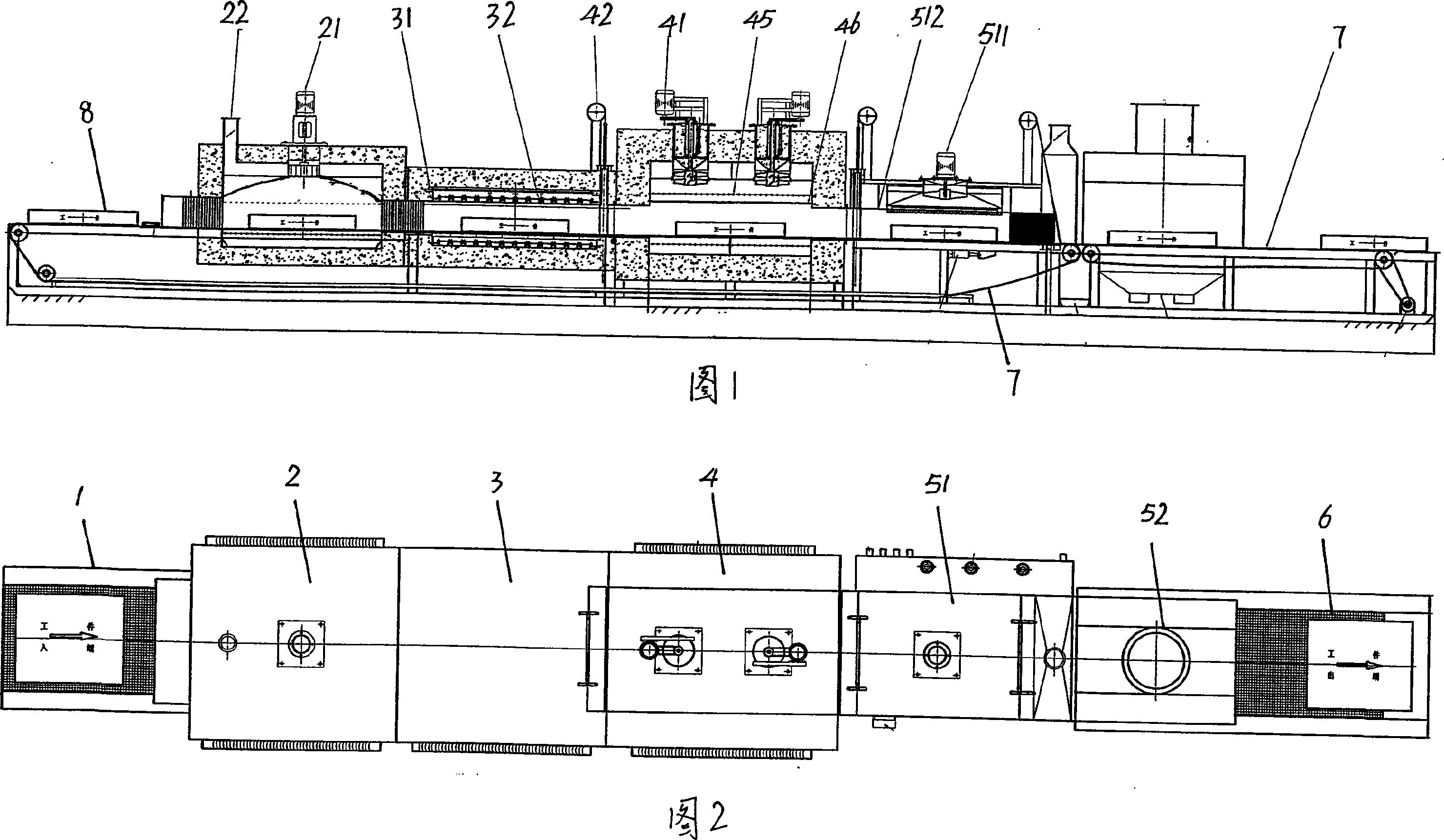

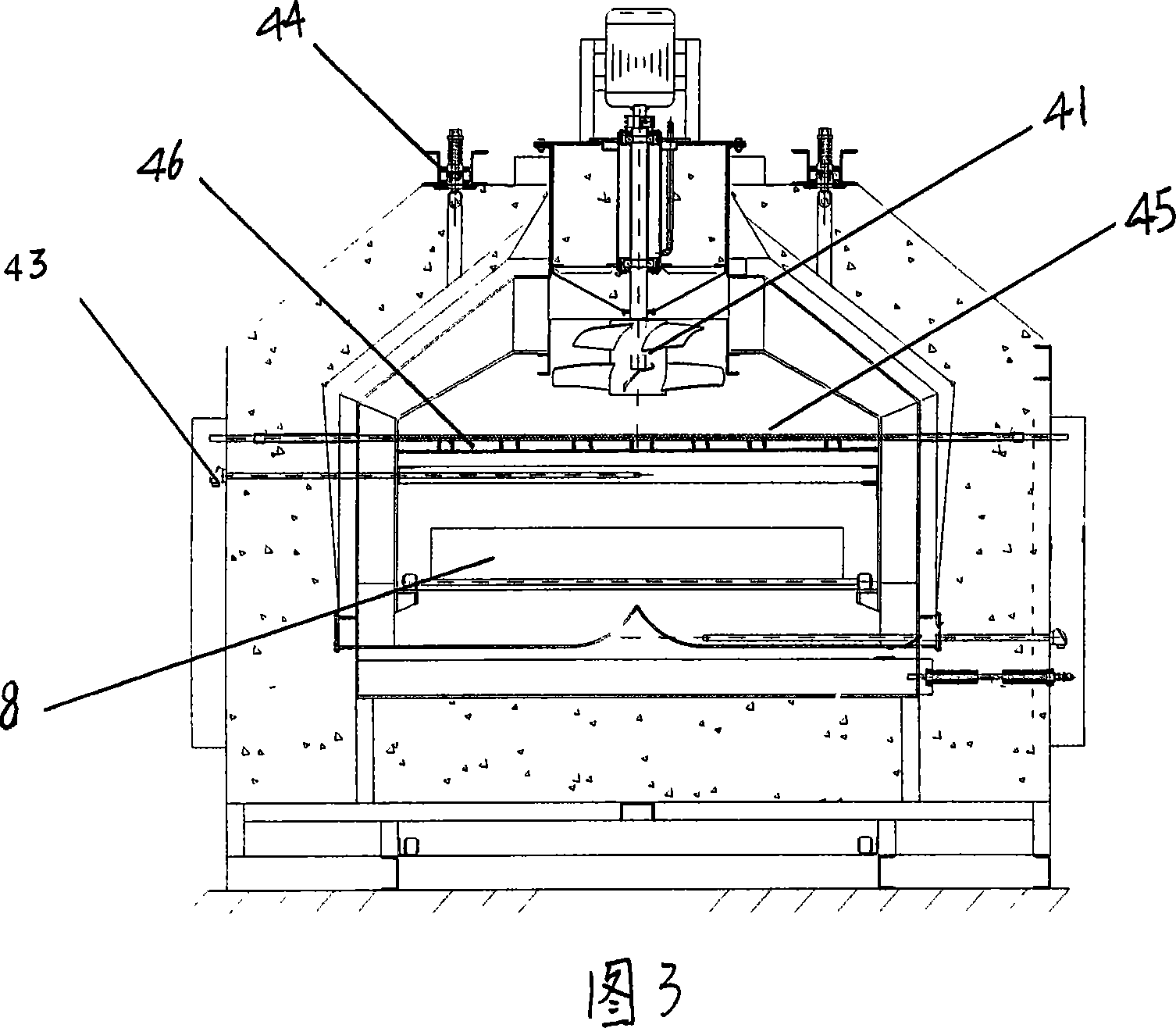

Intermittent type gas protecting soldering furnace

InactiveCN101104216AMeet processing requirementsEasy to adjustMetal working apparatusSoldering auxillary devicesWinding machineProcess engineering

The invention discloses an intermittent gas protecting braze welding furnace, comprising an upper part area, a heating and drying area, a preheating and purifying area, a heating and braze welding area, a cooling area, a lower part area and a driving belt. The preheating and purifying area is provided with an inert gas inlet. The heating and braze welding area is provided with an internal heat recycling wind machine that makes the inert gas preheated in the preheating and purifying area go evenly into the heating and braze welding area. The heating and drying area, inside which a heating device is arranged, will heat and dry a pretreated workpiece that is delivered from the upper part area, and then delivers the workpiece to the preheating and purifying area so that the workpiece can be treated , and the workpiece will be braze welded in the heating and braze welding area. The cooling area will cool the workpiece delivered from the heating and braze welding area, and then delivers the workpiece to the lower part area. The staying time of the workpiece in every area is adjusted by the driving belt and is determined by the time that the heating and braze welding area needs. The invention is quite flexible, can meet the processing requirements of the workpieces of different specifications and kinds, and can conveniently adjust the braze welding parameter in every area with fast reaction to the temperature changes and wide application.

Owner:JIANGSU KANGJIE MACHINERY

Laser deburring method and equipment

ActiveCN106862775AImprove processing efficiencyFast processingLaser beam welding apparatusLaser scanningComputer science

The invention discloses a laser deburring method and equipment. The method comprises the steps: according to the three-dimensional image of a workpiece to be deburred, obtaining the contour graph of the part needing to be deburred on the workpiece, and then obtaining multiple scanning paths during scanning machining of a laser beam; then, according to the positions of the scanning paths on the workpiece, positioning the workpiece for many times, thus enabling different side parts of the workpiece to face to a laser working head, and therefore conducting laser scanning for deburring in order. In the process of laser deburring, the position of the laser working head does not need to change basically, only the workpiece to be deburred needs to be repositioned, and therefore the laser beam scans the side parts, facing to the laser working head, of the workpiece in order. During laser scanning, the workpiece is scanned according to the scanning paths obtained in advance. The method has high processing speed, is particularly suitable for large batches of parts for laser deburring, and can effectively improve the efficiency of laser deburring.

Owner:苏州贝亚敏光电科技有限公司

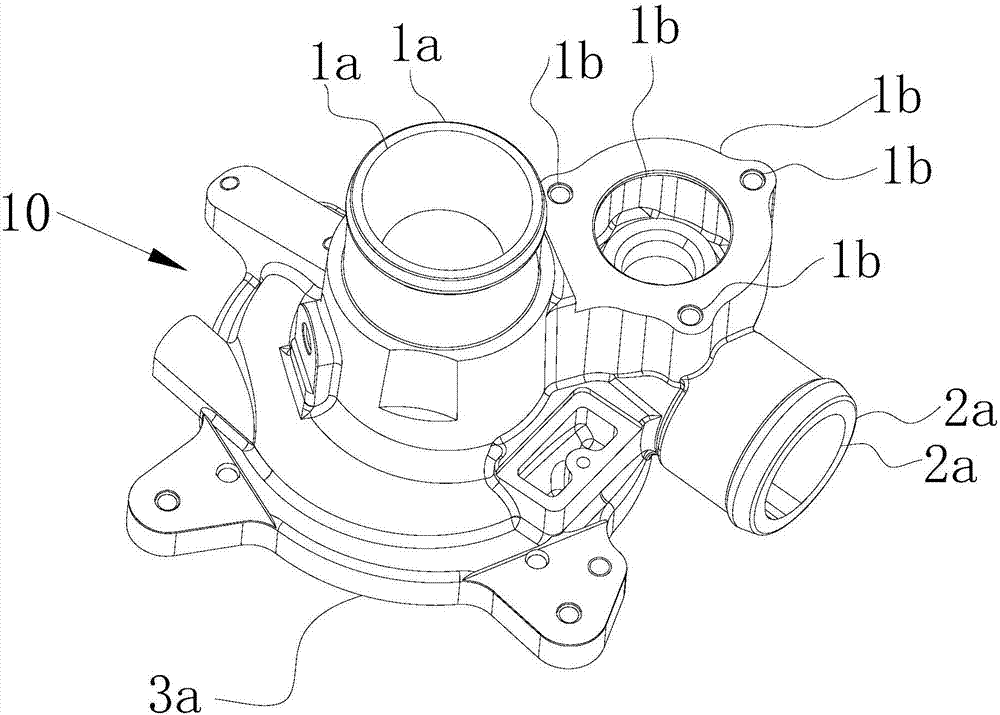

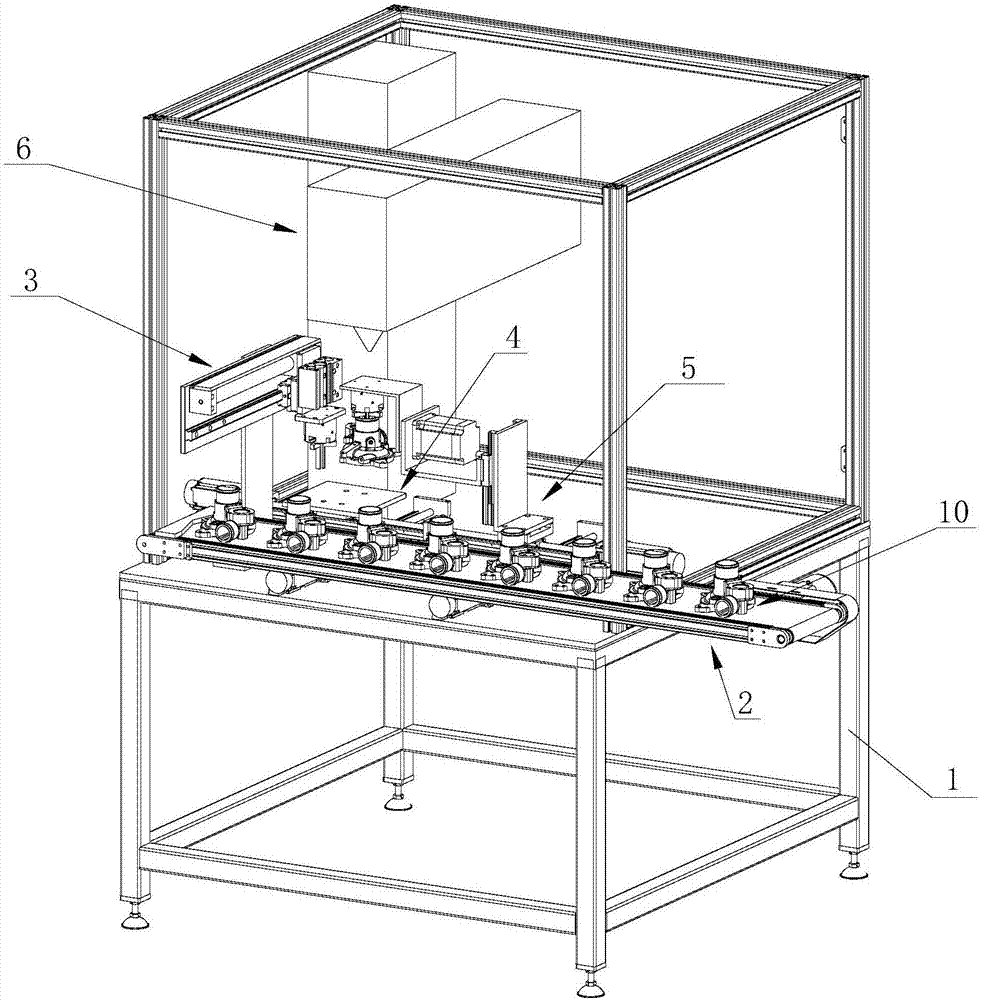

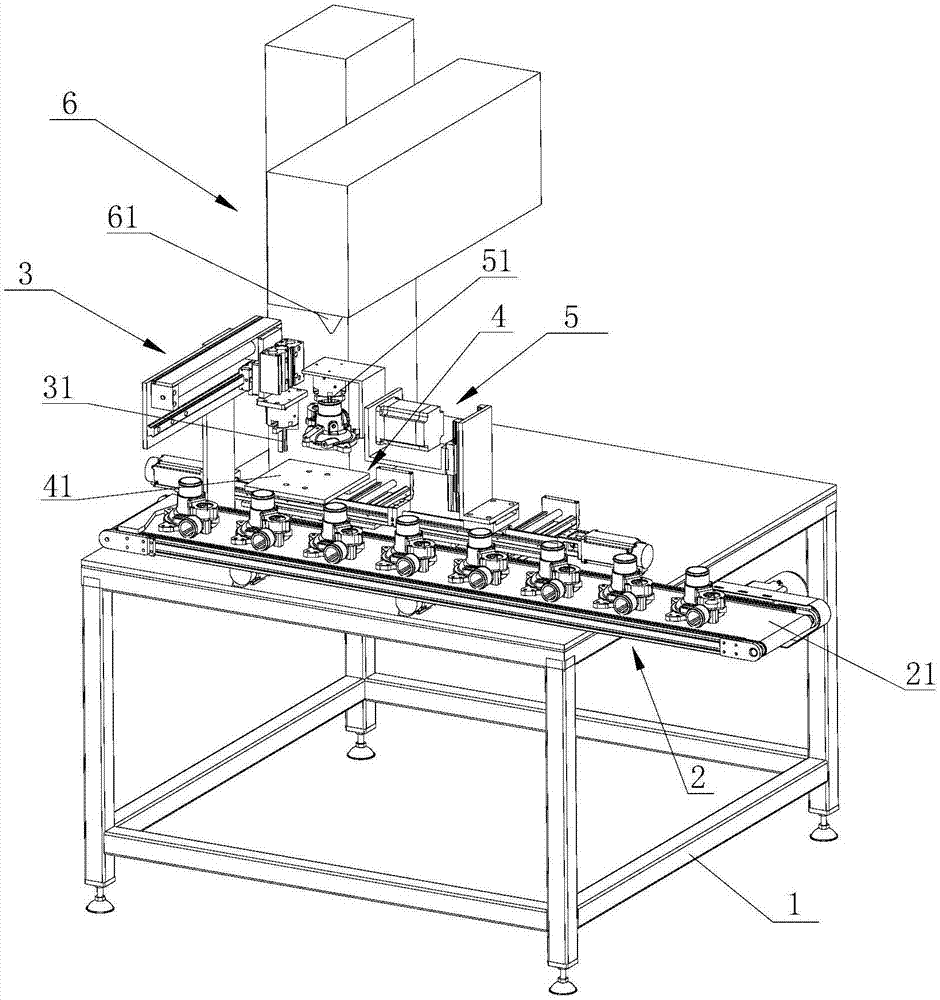

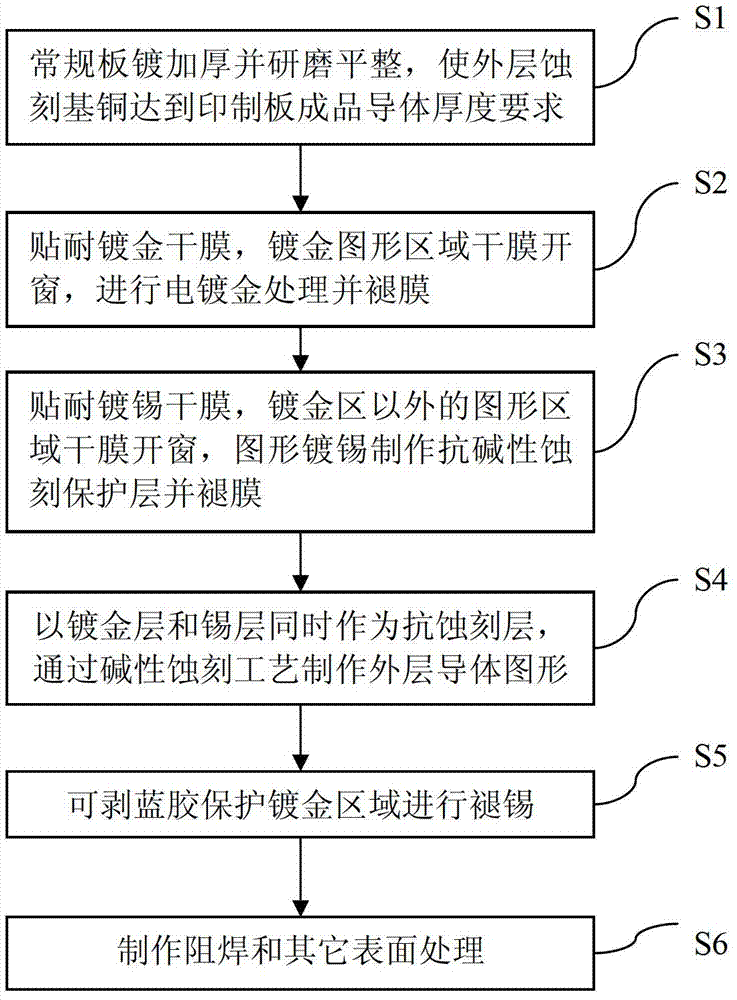

Making method of outer layer patterns of local gold-plating printed plate

ActiveCN103179795AMeet the process requirementsMeet the requirements of partial gold-plated surface treatmentConductive pattern reinforcementTinningResist

The invention provides a making method of outer layer patterns of a local gold-plating printed plate. A printed plate is conducted to conventional plate planting and thickening and is ground to be smooth, so that outer layer etched base copper is in accordance with the requirements on the thickness of a printed plate finished conductor. A gold-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in a gold-plating pattern area, and then electrogilding treatment and stripping are performed. Tin-plating resistant dry film is bonded on the printed plate, dry film window cutting is performed in an area corresponding to pattern design other than the gold-plating area, patterns exposed after window cutting are conducted to tin plating, so as to be served as a tin plate of an alkaline etching resistant protective layer, and stripping is performed after tin plating. The gold-plating layer and the tin layer are both served as etching resistant layers, and outer layer conductor patterns are prepared through an alkaline etching technology. Peelable blue gel is screen-printed on the outer layer gold-plating conductor patterns and is cured, so that the gold-plating area is protected, and then the tin layer is conducted to tin stripping treatment. Solder resist is prepared and other surface treatment is performed.

Owner:JIANGNAN INST OF COMPUTING TECH

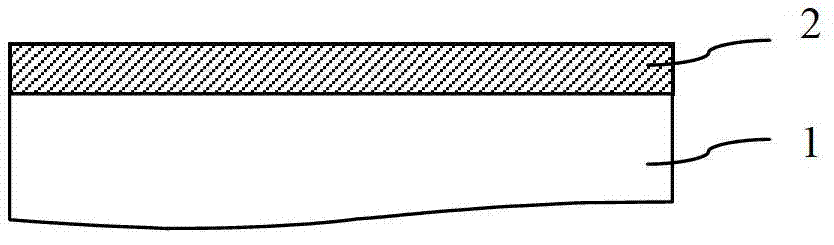

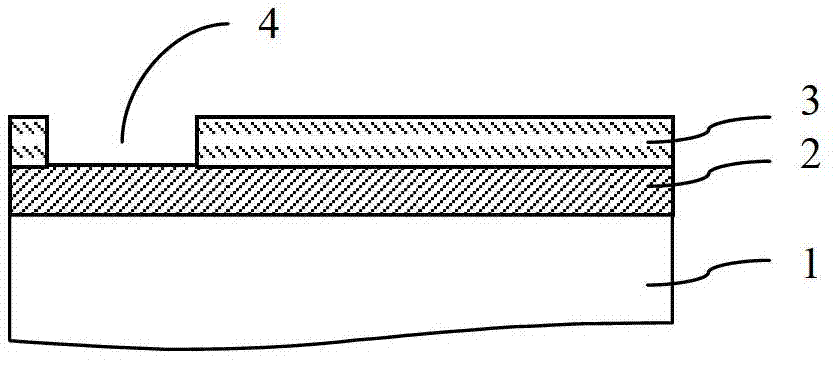

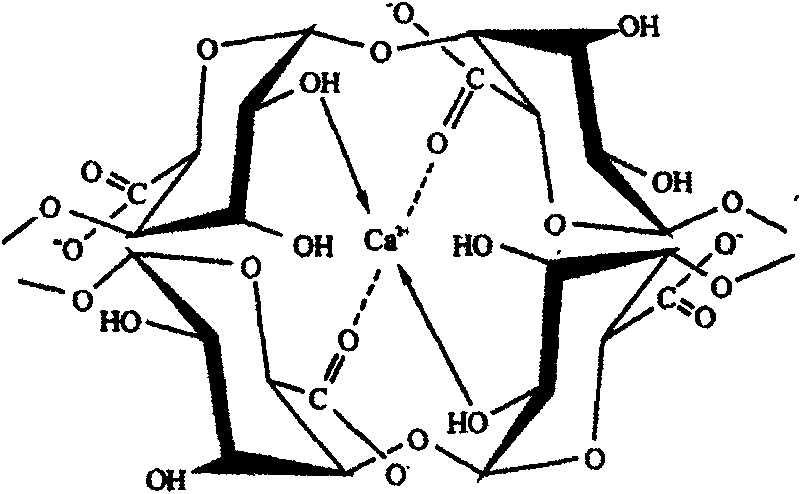

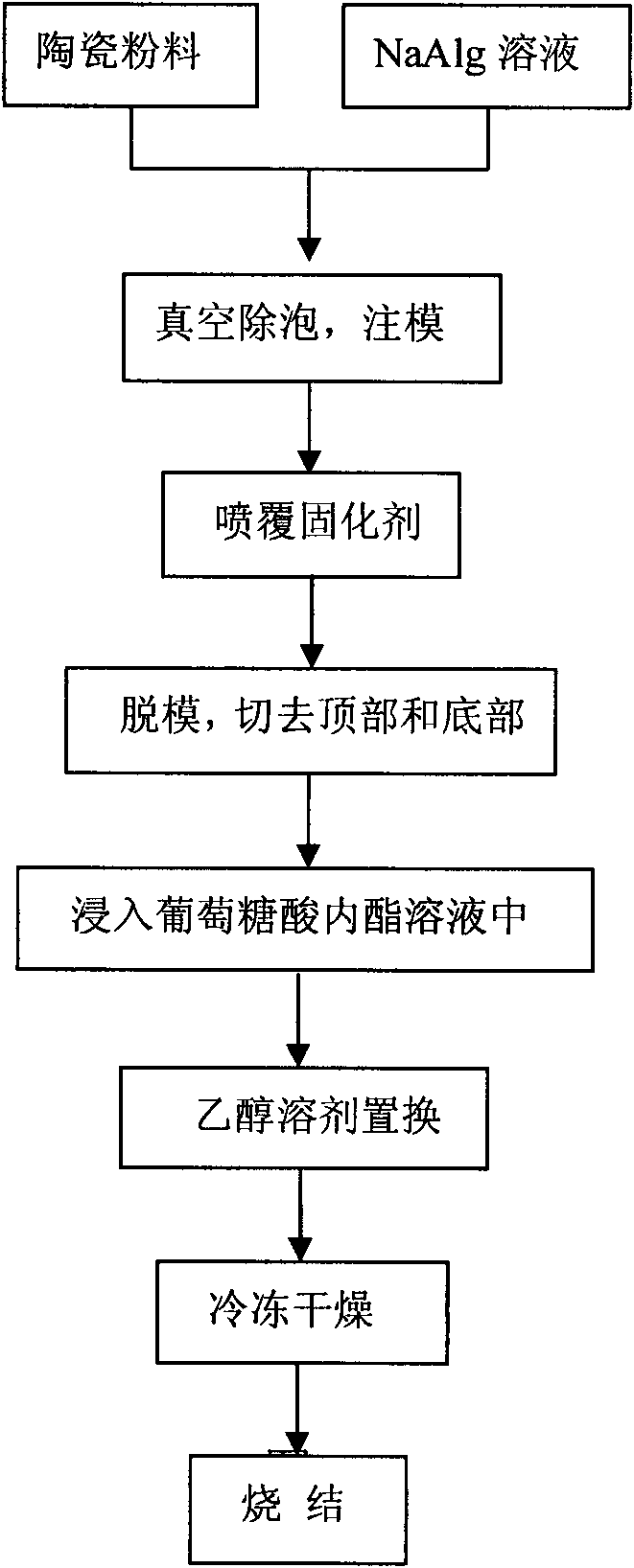

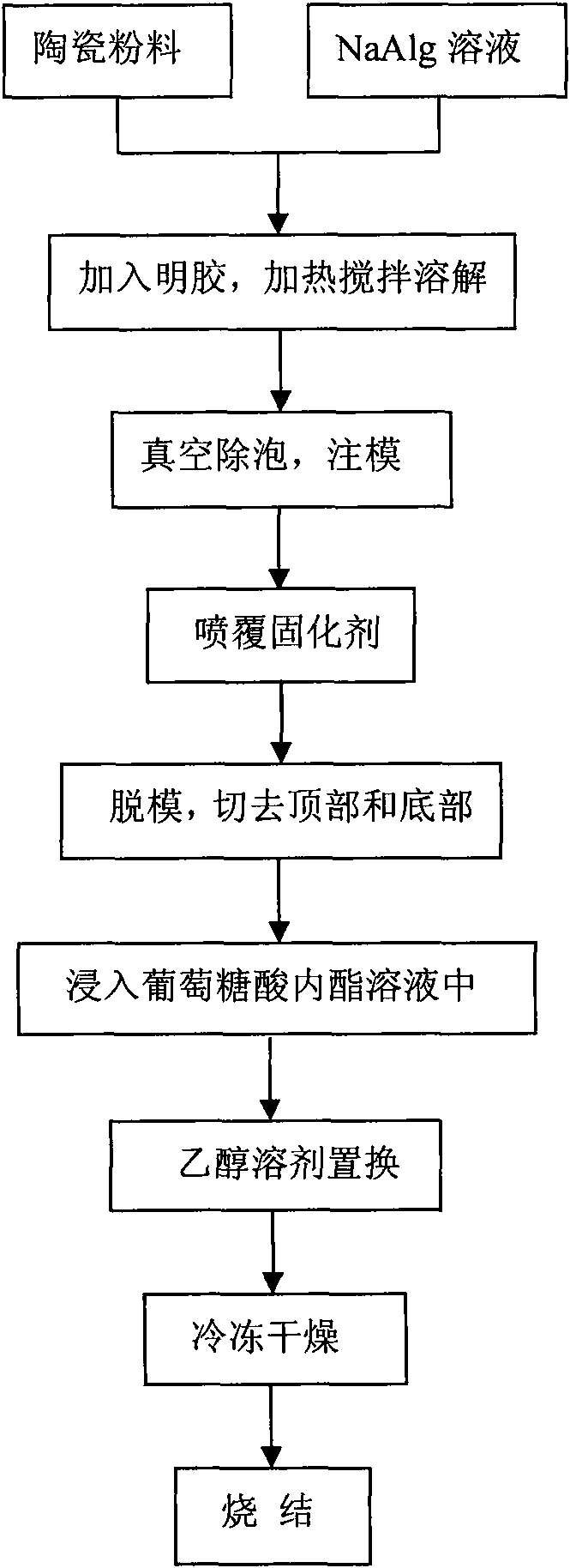

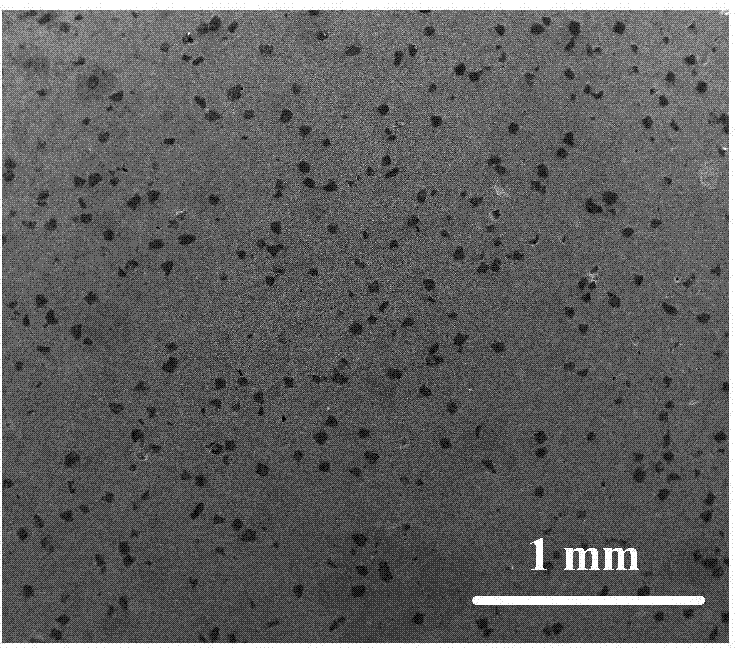

Porous ceramics and preparation method thereof

InactiveCN101618972ANo pollution in the processThe process is non-toxicCeramicwareFirming agentSolvent

The invention discloses a porous ceramics and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a sizing agent with solid content of 2-30 percent by sodium alginate and ceramic powder; (2) injecting the sizing agent obtained in the step (1) into a mold, spraying a firming agent and obtaining a wet greenware A after demoulding; (3) obtaining a wet greenware B after dehydrating the wet greenware A obtained in the step (2) in a sour environment; (4) obtaining a wet greenware C after performing solvent exchange on the wet greenware B obtained in the step (3); and (5) obtaining the porous ceramics after drying and sintering the wet greenware C obtained in the step (4). The sample of the porous ceramics has high and controllable open porosity of 40-80 percent and has higher strength, thereby being capable of satisfying the requirements of machine tooling and use.

Owner:TSINGHUA UNIV

Manufacturing method of lost foam casting foaming mold

InactiveCN101554645ASimple designEasy to modifyFoundry mouldsFoundry coresComposite ceramicMetallurgy

The invention provides a manufacturing method of a lost-foam casting foaming mold. The invention is characterized in that the manufacturing method comprises the following steps: firstly, the three-dimensional CAD model of a casting part is manufactured, and a colophony prototype used for casting a blank of the foaming mold is manufactured through a rapid molding machine; secondly, a colophony prototype used for casting an electric spark working electrode is manufactured; thirdly, the inner cavity structure of the blank of the foaming mold is copied by using a colophony prototype with the same size with the casing part and silica gel; fourthly, the blank of the foaming mold is cast by using the composite ceramic shell casting technology; fifthly, the electric spark working electrode is cast by using the colophony prototype for enlarging the size of the casting part by 0.5-1.5 mm and the composite ceramic shell casting technology; and sixthly, the blank of the foaming mold is processed by using the electric spark and assembled to obtain the foaming mold. The invention is suitable for manufacturing the foaming mold with a complex-shaped inner cavity, can rapidly obtain the blank and the electrode of the foaming mold, enables the chrematistics of the arbitrary prototype with a complex shape through the rapid molding technology to be displayed more obvious as for the more complex shape and realizes the rapid manufacture of the lost-foam casting foaming mold.

Owner:SHANDONG UNIV OF TECH

Method for preparing composite microsphere of polymer-nano magnesium hydroxide

A process for preparing the composite polymer-nano magnesium hydroxide microspheres includes sphericizing the magnesium hydroxide nanoparticles by use of polymer monomer, cross-linking agent and trigger, and the simulative emulsion polymerizing method and spray drying. Its advantages are high product performance in coated rate, quality, flame retarding, compatibility, etc.

Owner:ZHEJIANG UNIV

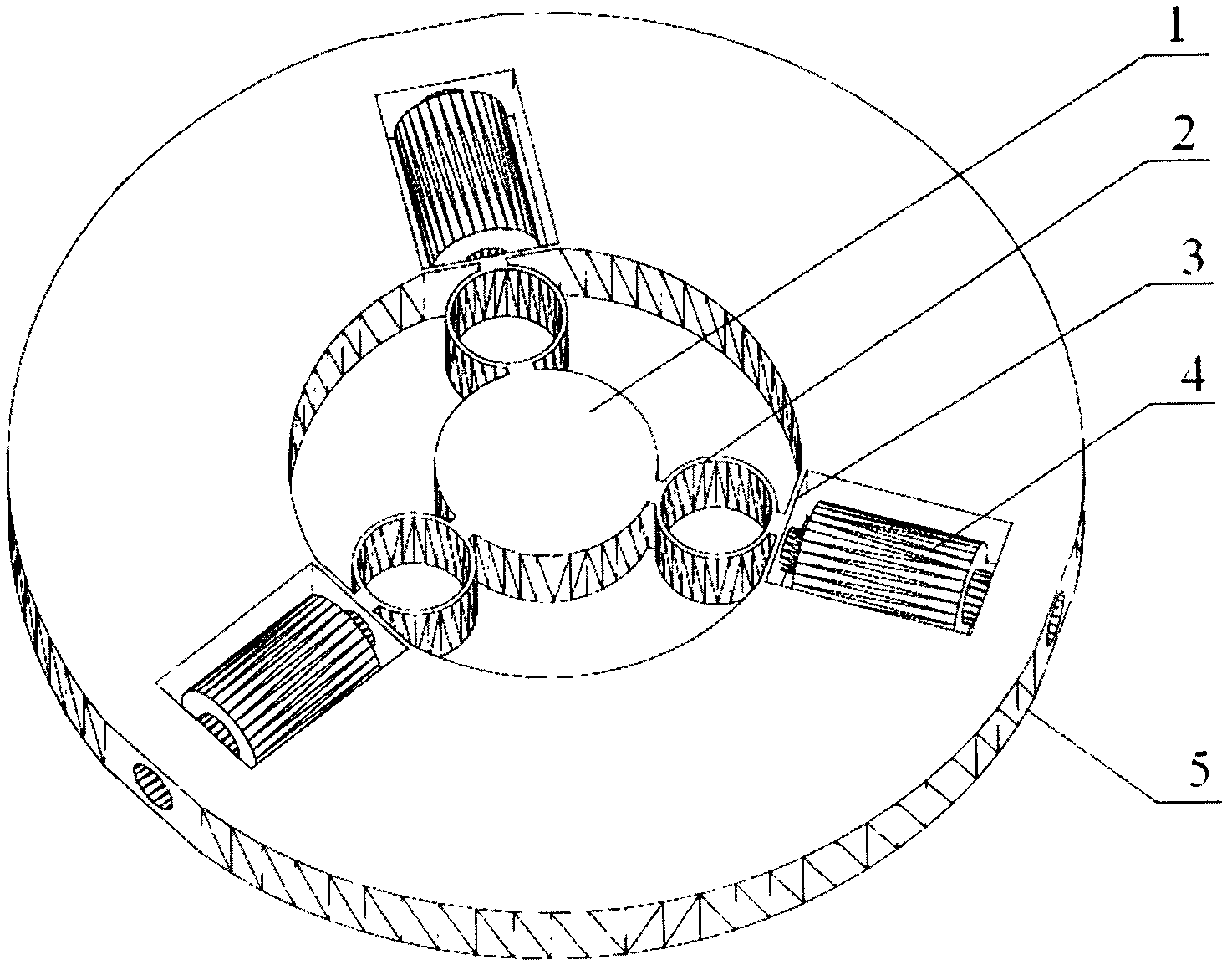

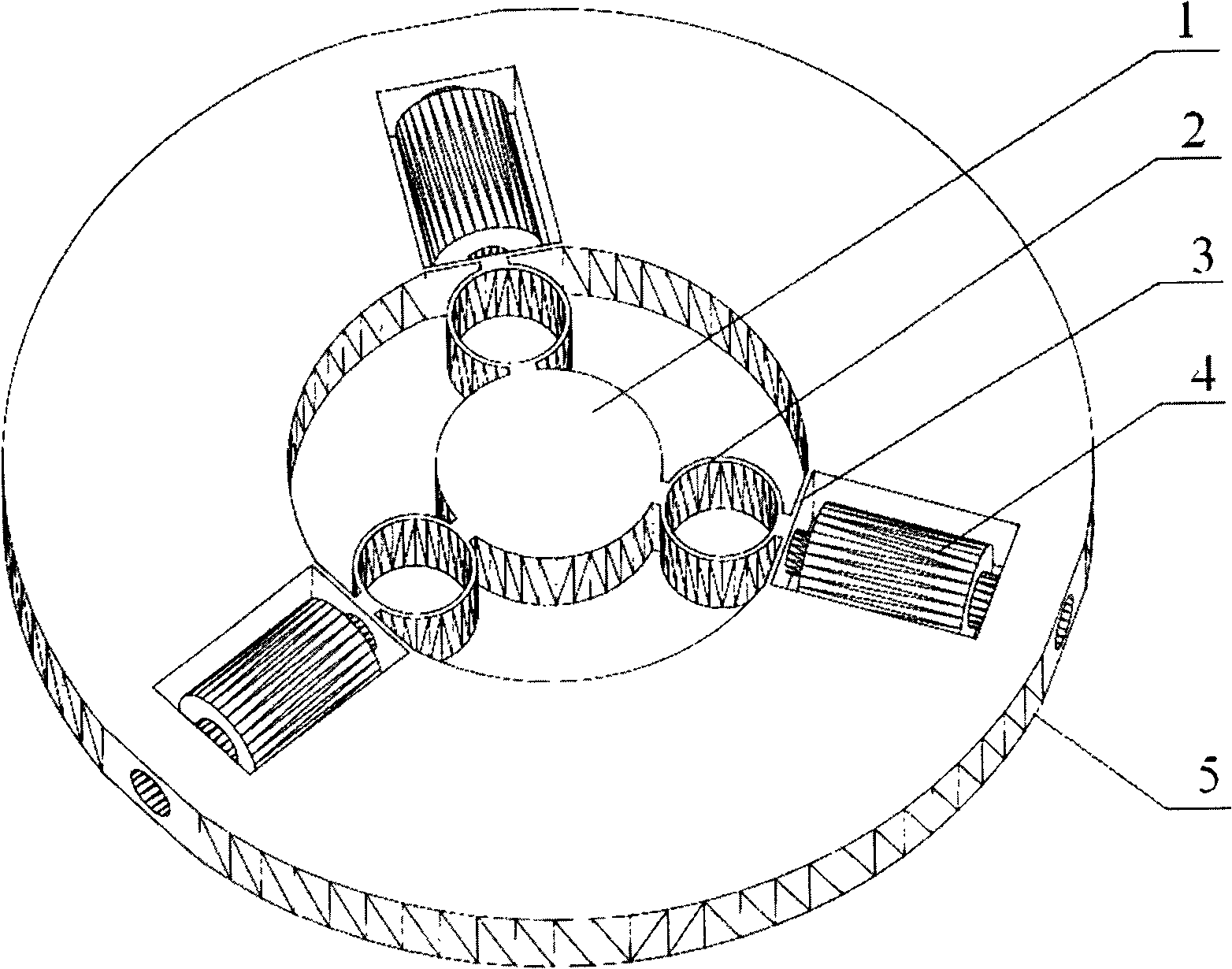

Annular elastic pair-containing three-degrees-of-freedom micro operating table

InactiveCN102009358AIncrease stiffnessImprove carrying capacityProgramme-controlled manipulatorLarge fixed membersThree degrees of freedomEngineering

The invention provides an annular elastic pair-containing three-degrees-of-freedom micro operating table, which comprises a fixed platform, a movable platform, micro-displacement driving devices and three branched chains connected between the fixed platform and the movable platform, and is characterized in that: three micro-displacement driving devices are arranged on the fixed platform; each branched chain comprises an elastic sliding pair and an annular elastic pair, wherein the side wall of the annular elastic pair is fixedly connected with the movable platform and one side of the elastic sliding pair respectively; two connecting parts are positioned on the same plane passing through a centre line of the annular elastic pair; and the middle part of the other side of the elastic sliding pair is fixedly connected with a driving end of each micro-displacement driving device. By introducing the annular elastic pair to construct a parallel micro operating table, due to the characteristic of short branched chains, the accumulative error is small, the operating table has higher bearing capacity and higher rigidity, and the movable platform can output two-dimensional translation and one-dimensional rotation around a normal vertical to a translational plane.

Owner:SHANDONG UNIV OF TECH

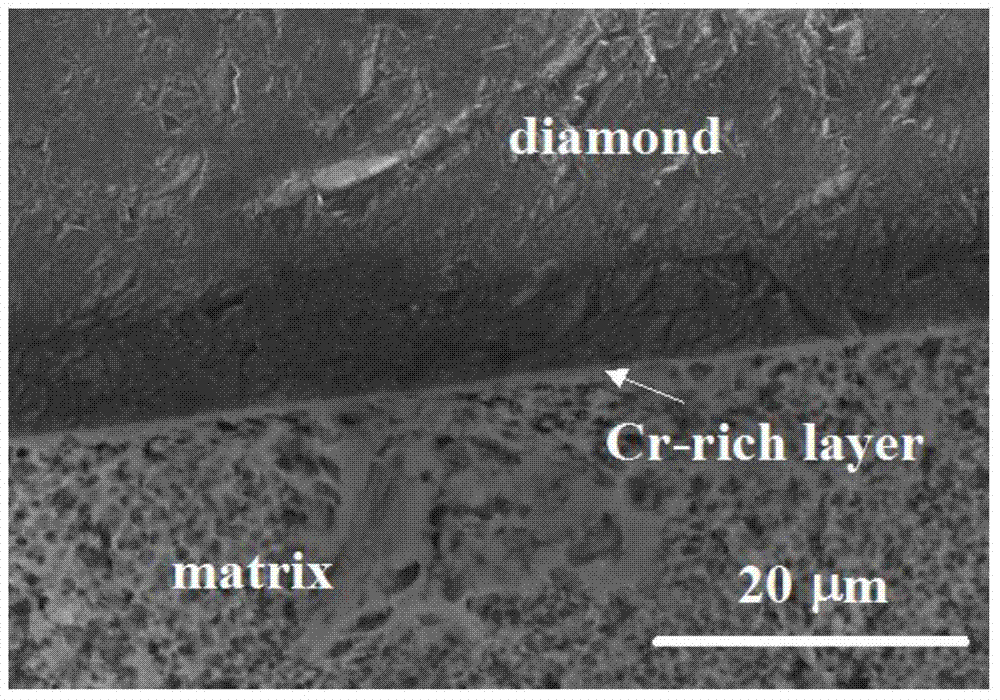

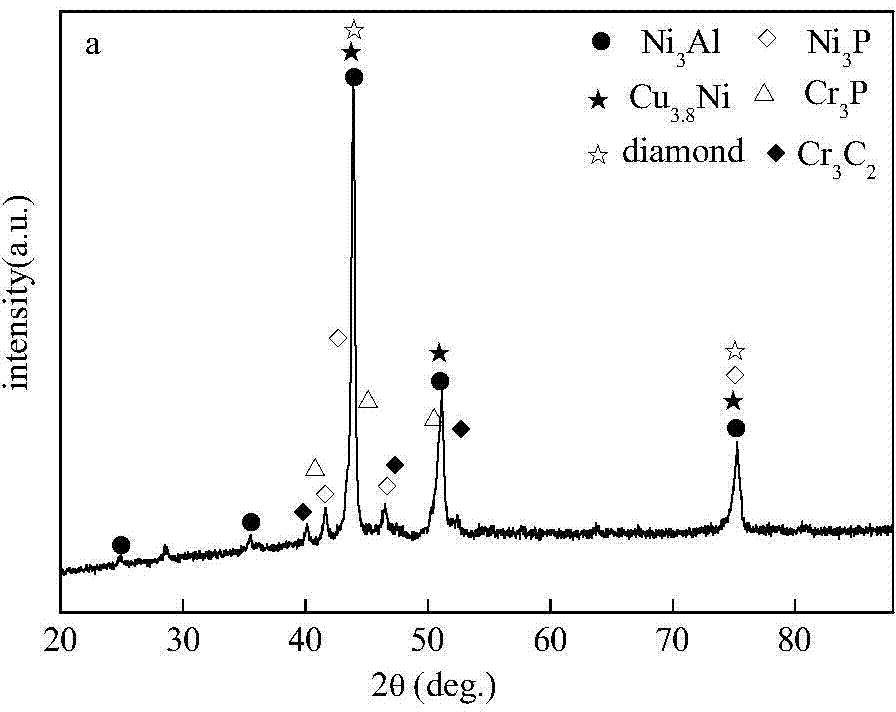

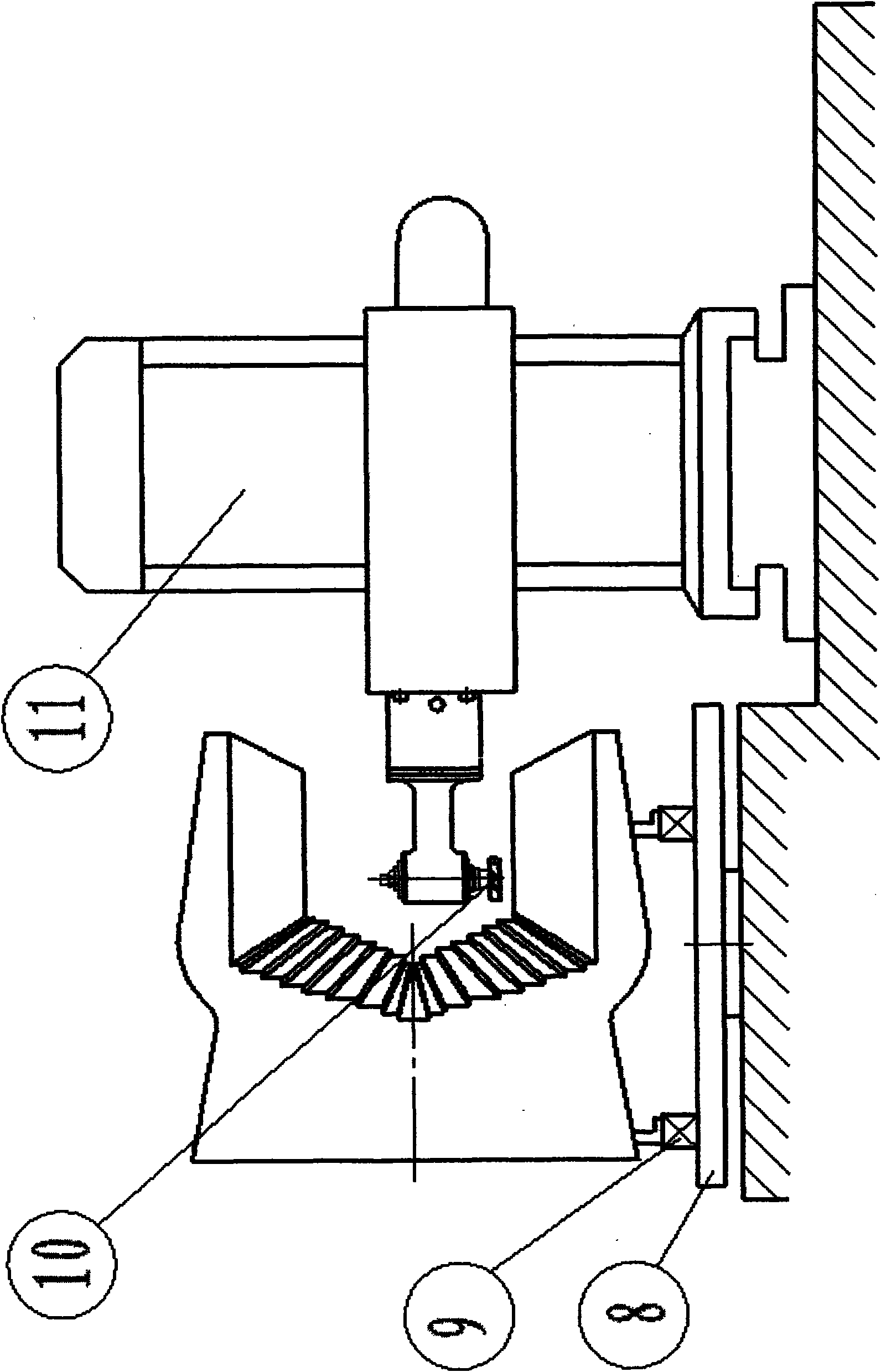

Superhard grinding tool and manufacturing method thereof

InactiveCN104842286AReduce heat damageHigh bonding strengthAbrasion apparatusGrinding devicesGranularityNi cr alloy

The invention discloses a superhard grinding tool which is composed of a binding agent and a grinding material. The binding agent comprises, by weight, 20-60 parts of Ni, Al, 8-50 parts of Cu and 20-60 parts of Ni-Cr alloy powder, wherein Ni and Al are proportioned according to a molar ratio of 3:1 or 1:1, and the grinding material is diamond which is 40-100% in concentration and 30 / 40-325-400 meshes in granularity. In addition, the invention further discloses a manufacturing method for the superhard grinding tool. The binding agent and the grinding material namely the diamond are taken as raw materials, the superhard grinding tool is manufactured through a method of compositing self-propagating and soldering, thereby being high in binding strength, good in performance, low in cost and small in thermal damage to diamond, high-speed and long-time grinding can be realized, needs on machining are met, and the superhard grinding tool has the advantages of high binding resistance, high hardness, grinding resistance, high sharpness and long service life. The manufacturing method has the advantages of simple process, pollution freeness, low energy consumption, quickness and low cost.

Owner:GUANGDONG UNIV OF TECH

Forging process of plate element

InactiveCN101823112AMeet processing requirementsAvoid Lamellar DefectsMetal-working apparatusCrystalliteForging

The invention discloses a forging process of a plate element with better processing quality. The process is characterized by comprising the following steps of: upsetting and punching a steel ingot and then forging the formed blank into a barrel-shaped intermediate blank; then splitting the barrel-shaped intermediate blank and then flattening to form a plate blank; and finally obtaining a finished product by cutting on the plate blank. In the invention, through forging the blank into the barrel-shaped intermediate blank to realize the axial-enlarging deformation mode of the blank, instead of a axial-upsetting deformation way, a laminated defect easily occurring when a cake-shaped part is forged is avoided, and the forging penetration performance is better; a forging tissue with more compact inner and outer surfaces is reserved by utilizing the finished product cut from the plate blank with uniform deformation and coincident final forging temperature, which is more beneficial to crystal grain refining and crystal grain uniformity and fully ensures the special requirement for the quality of a forging part; and in addition, the process also effectively avoids rigidity nonuniformity caused by the radial C segregation of the steel ingot. Thus, through the process, the processing quality of the product can be markedly improved, and the processing requirement of a large mirror plate or an end sealing plate blank is satisfied.

Owner:ERZHONG GROUP DEYANG HEAVY EQUIP

Profiling forging method of large cylinder forge piece provided with internal and external steps

The invention discloses a profiling forging method of a large cylinder forge piece provided with internal and external steps. According to the profiling forging method of the large cylinder forge piece provided with the internal and external steps, raw material consumption and machining allowance can be reduced under the premise that internal quality is guaranteed. The profiling forging method comprises steps as follows: A, tongs hold is performed; B, rolling, drawing and blanking are performed; C, upsetting and punching are performed; D, a common mandrel is subjected to pre-reaming until a step saddle can penetrate into a forging stock; E, step saddle pre-drawing is adopted to enable an inner hole of the forging stock to form the step, an outer contour of the forging stock forms a step cylinder shape, and meanwhile, the length of the forging stock meets the technical processing size; F, the step saddle and a step reaming anvil are adopted for hole reaming forming. With the adoption of the profiling forging method, natural streamline of metal can be prevented from being cut off, so that fibers of the forge piece are continuous, and improvement of synthesized mechanical properties of the forge piece is facilitated.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Forging process for nuclear power rotor and other large shaft parts

ActiveCN102172766AIncrease the number of pulling tripsIncrease the effect of forging through compactionEngine componentsNuclear powerIngot

The invention discloses a forging process for nuclear power rotor and other large shaft parts, which can be used for effectively solving the forging problem of a high-grade rotor with a super large specification. The process specifically comprises the following steps of: (1) drawing out a steel ingot to form a flat square by using a WHF (Wide die Heavy blow Forging) method; (2) performing erecting and upsetting on the flat square; (3) drawing out the upset steel billet to the flat square again by using the WHF method; and (4) compacting the four sides and the center of the flat square, wherein the 'flat square' specifically means a cuboid-shaped steel billet. In accordance with the result of flaw detection (UT(Ultrasonic Test) and MT (Magnetic particle Test)), no flaw (phi is above 0.6), for which recording is required, is found in a 1100MW rotor piece manufactured by using 550t steel billets, and the quality is superior; based on the dimension of a workpiece, all the dimensions of various parts of a forge piece can meet the processing requirement, and the forging allowance is uniform; the control state of forging grain size is deduced from a UT state subsequent to thermal treatment after forging, the desired effect is completely achieved, and no phenomenon of coarse crystal or mixed crystal happens.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

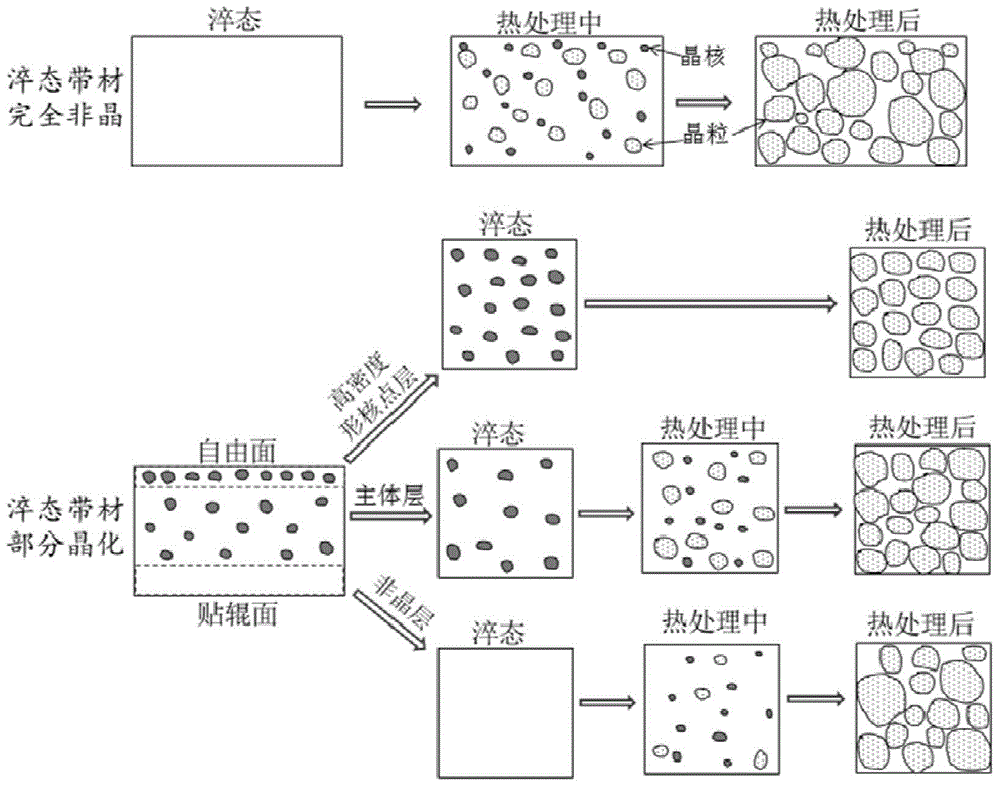

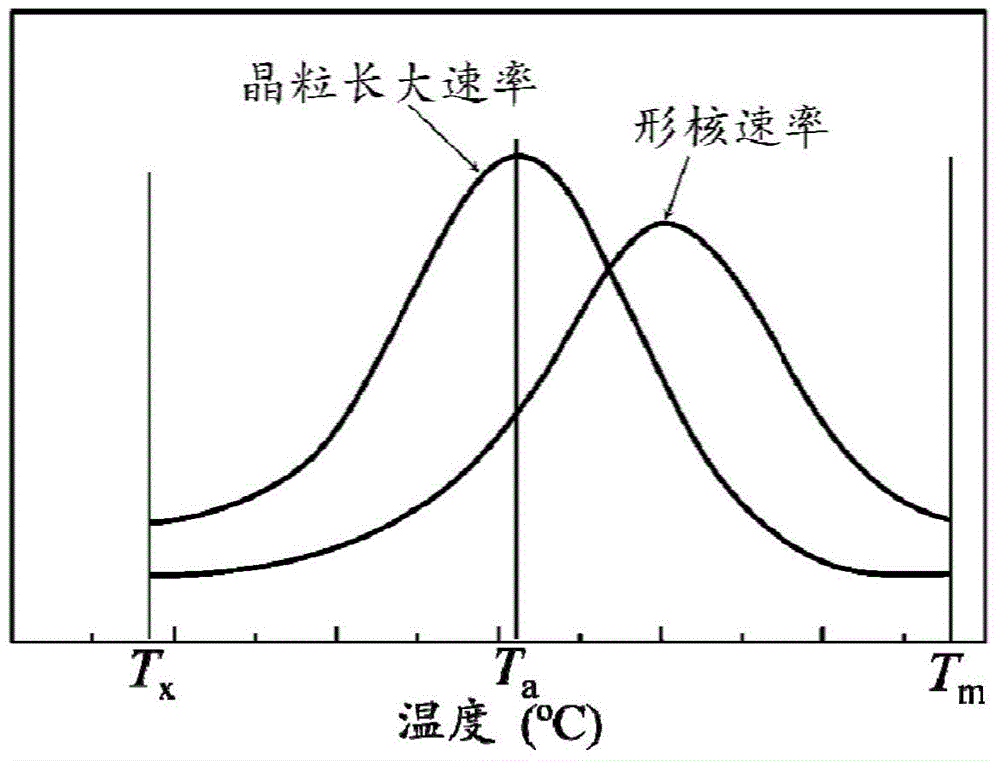

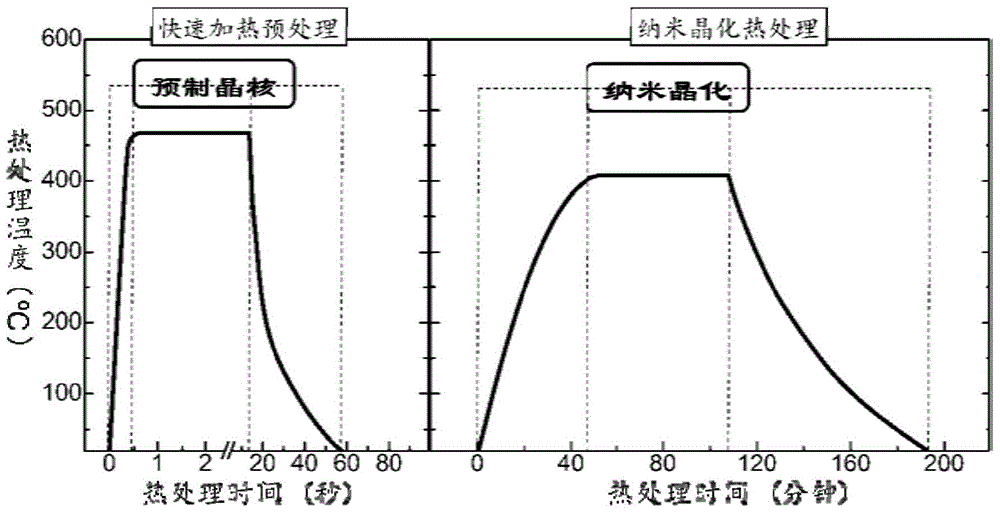

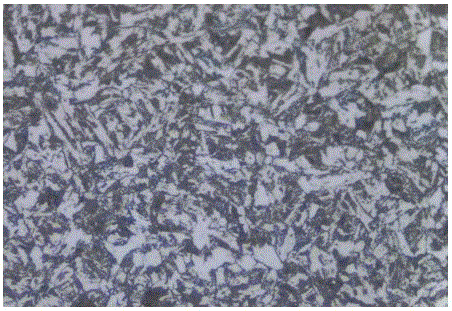

Heat treatment method for preparing nanocrystalline alloy

The invention discloses a heat treatment method for preparing nanocrystalline alloy. According to the method, during the nanocrystalline alloy material preparation by an amorphous crystallization method, a heat treatment process is divided into two steps; in the first step, the characteristics of high heat conductivity and low heat capacity of an amorphous crystallization alloy belt material are used; the fast temperature rise and short-time heat insulation pre-heating treatment is performed; high-density and uniformly-distributed crystal nucleuses are formed in the belt material through excitation; then, in the second step of conventional nano-crystallization heat treatment, high-density crystal particles grow synchronously; the competitive effect between the crystal particles is used for promoting the crystal particle refining. Compared with the existing heat treatment method, the method has the advantages that amorphous crystallization nucleation and crystal particle growth processes are controlled in a separated way; the crystal particle density and the crystallization degree are improved; the crystal particle dimension and the distribution uniformity are improved; in addition, the crystal particles are refined, so that the performance of the alloy is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

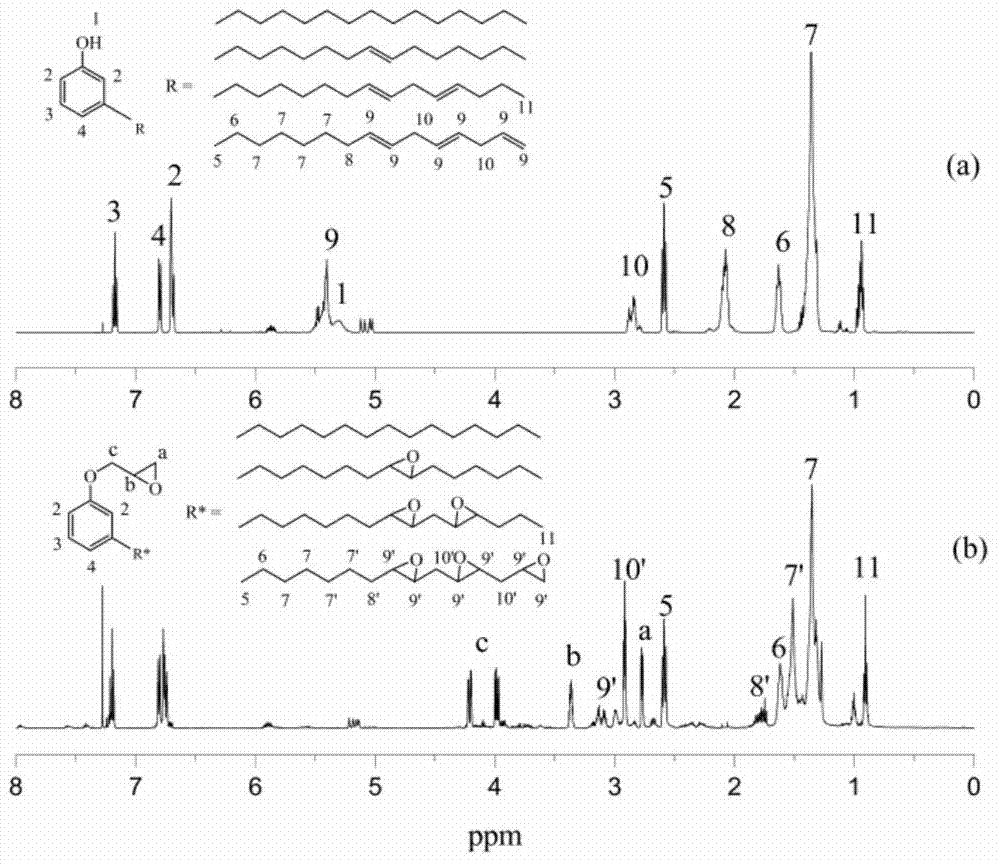

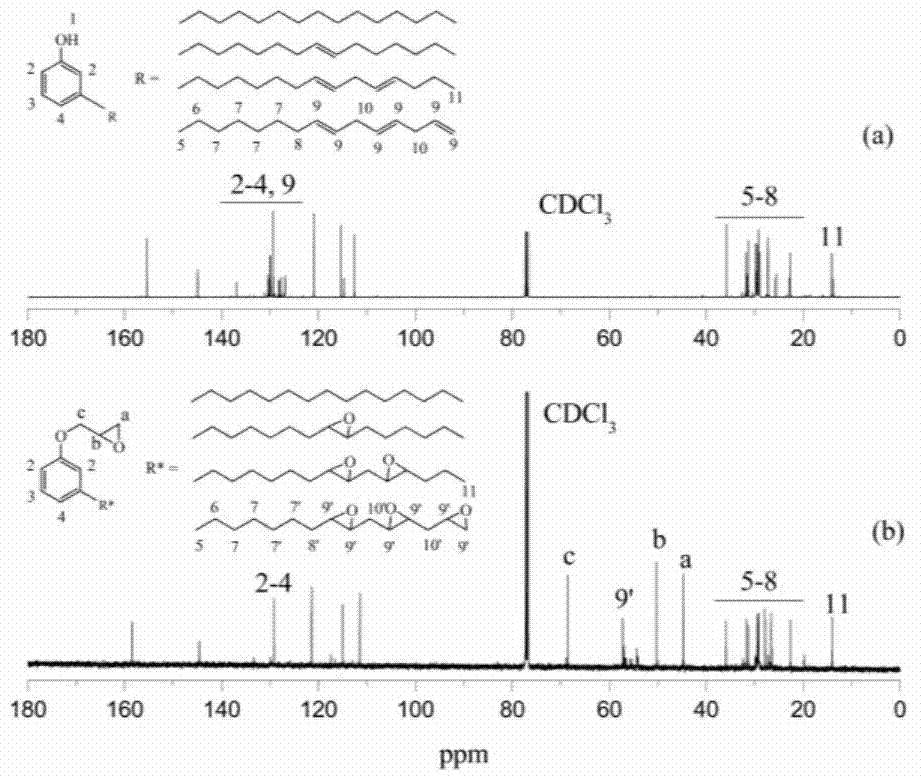

Epoxy cardanol-based glycidyl ether as well as preparation method and application thereof

InactiveCN104710388AEmission reductionSimple production processOrganic chemistryOrganic acidGlycidyl ethers

The invention discloses an epoxy cardanol-based glycidyl ether plasticizer as well as a preparation method and application thereof. The preparation method comprises the following steps: taking cardanol and epoxy chloropropane as main raw materials and carrying out ring-opening addition reaction and ring-closure reaction to synthesize an intermediate product cardanol-based glycidyl ether; and further uniformly mixing the intermediate product with organic acid and a catalyst, heating to a certain temperature, dripping a peroxide source to carry out epoxidation reaction to obtain a crude product, leaving the crude product to stand, layering, performing neutralization and dehydration on the crude product after the reaction so as to obtain an epoxy cardanol-based glycidyl ether plasticizer. The plasticizer is non-toxic, has relatively high plasticizing efficiency and can endowing resin products with favorable thermal stability and mechanical property; and moreover, by taking the cardanol which is low in cost and easy to get as raw material, the epoxy cardanol-based glycidyl ether plasticizer integrates the advantages of being environment-friendly and being reproducible, complies with the developing trend of the plastic additive industry and has wide application and favorable application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

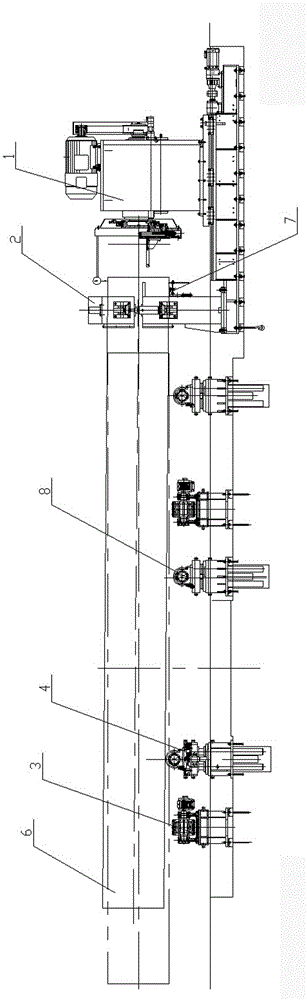

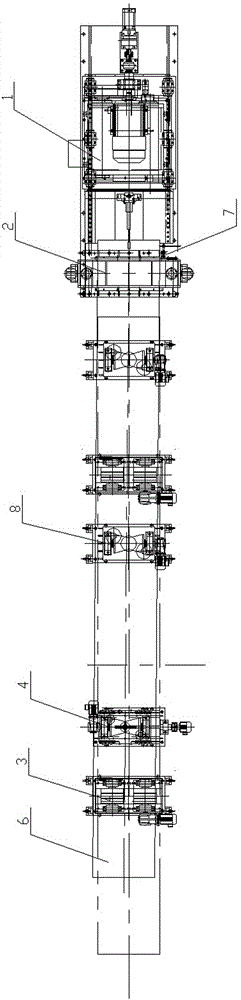

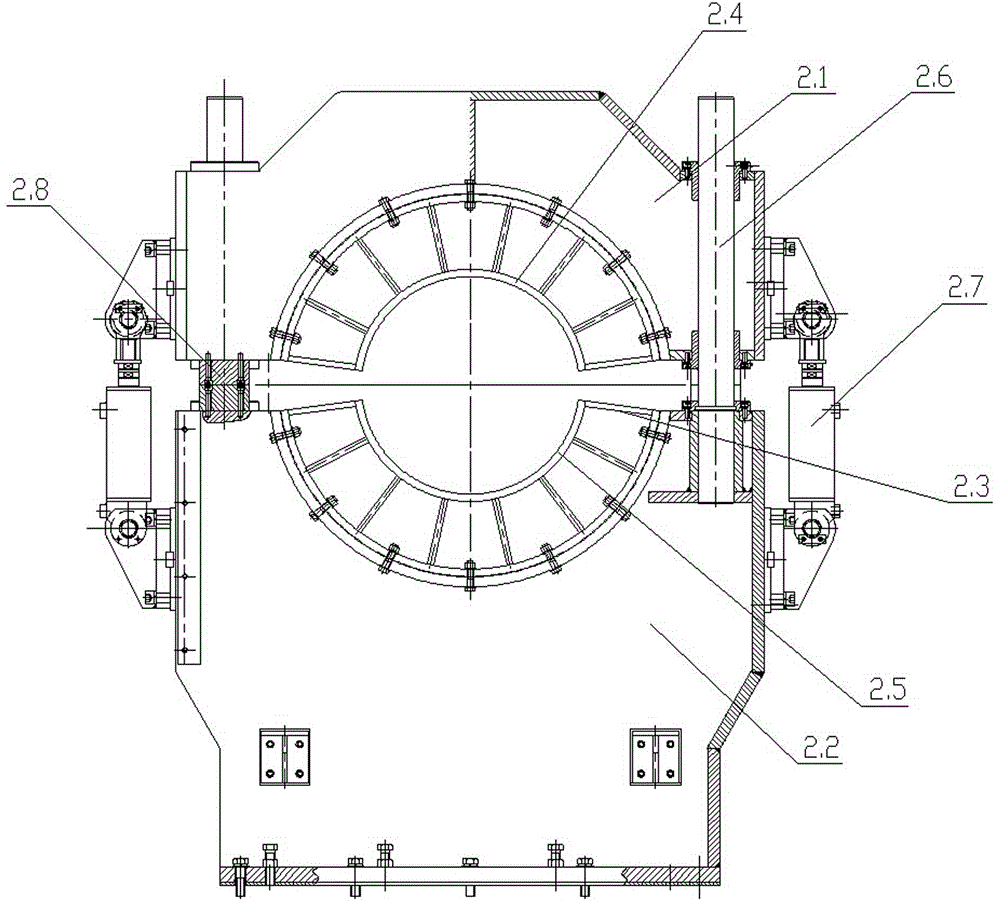

Steel pipe end alignment system and method

ActiveCN104440362AEliminate offsetMeet processing requirementsAutomatic control devicesAuxillary equipmentEngineeringMachine tool

The invention belongs to the technical field of steel pipe end machining and particularly relates to a system used for clamping and aligning the pipe end of a long steel pipe before the pipe end of the long steel pipe is milled and bored. The steel pipe end alignment system comprises a clamping device mounted in front of a machine tool, lifting and conveying roller ways, rotating devices, a transverse movement lifting and conveying roller way and detection devices. The steel pipe clamping device is arranged close to the machine tool and used for clamping the pipe end of the steel pipe and guaranteeing the roundness of the pipe end of the steel pipe. The transverse movement lifting and conveying roller way is arranged far from the machine tool and used for conveying the steel pipe and adjusting the position of the other end of the steel pipe, so that the center of the clamped end of the steel pipe is coaxial with the rotation center of a cutter head. The lifting and conveying roller ways and the rotating devices are alternately mounted in the axial direction of the steel pipe. The detection devices are mounted in the middle and on the lower portion of the end, close to the machine tool, of the clamping device respectively, one detection device is used for detecting a side mother line of the steel pipe, and the other detection device is used for detecting a lower mother line of the steel pipe. The steel pipe end alignment system is low in improvement cost; after the steel pipe is aligned by the steel pipe end alignment system, the percent of pass of the end, machined by the cutter head of the milling and boring machine tool, of the steel pipe is high, and the production efficiency is improved.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

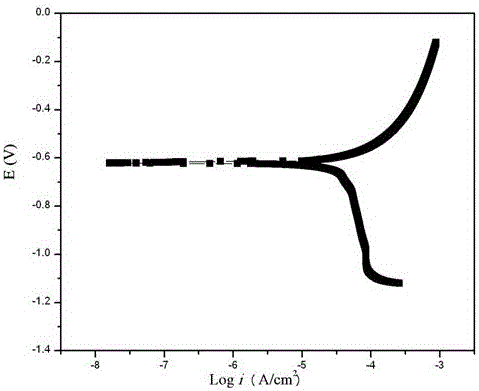

Atmosphere-corrosion-resistant cold heading steel hot rolled wire rod with grade being 10.9 and production method thereof

The invention discloses an atmosphere-corrosion-resistant cold heading steel hot rolled wire rod with the grade being 10.9. The atmosphere-corrosion-resistant cold forging steel hot rolled wire is composed of, by weight, 0.25-0.35% of C, 0.15-0.35% of Si, 0.60-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 0.60-0.90% of Cr, 0.20-0.50% of Ni, 0.20-0.50% of Cu and the balance of Fe and trace impurities. According to the hot rolled wire rod, through the optimal design of chemical components, and by adding alloy elements such as Cu and Cr, a compact amorphous metal film which is closely combined with a substrate is naturally formed on a fastener through surface rust in the using process, so that the material has the atmosphere-corrosion-resistant effect; by adding an alloy element of Ni, the material has the good surface quality during hot rolling, the surface is free of obvious cracking phenomenon in the subsequent drawing and cold heading processes; and the hot rolled wire rod has the characteristics of being good in mechanical performance, corrosion resistance and formability and the like.

Owner:XINGTAI IRON & STEEL

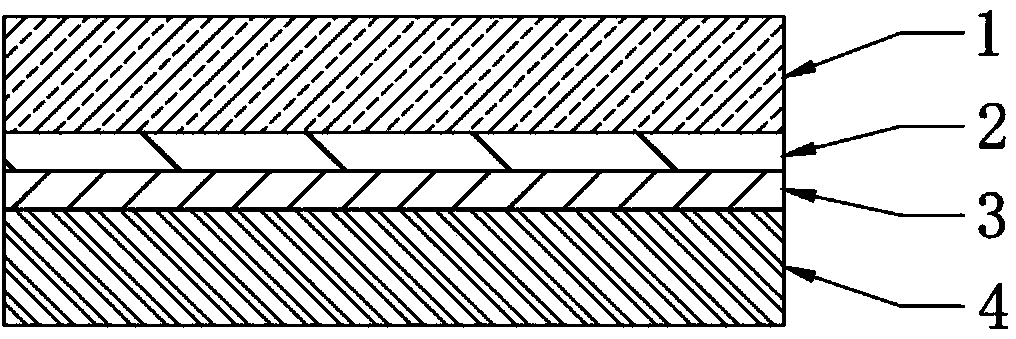

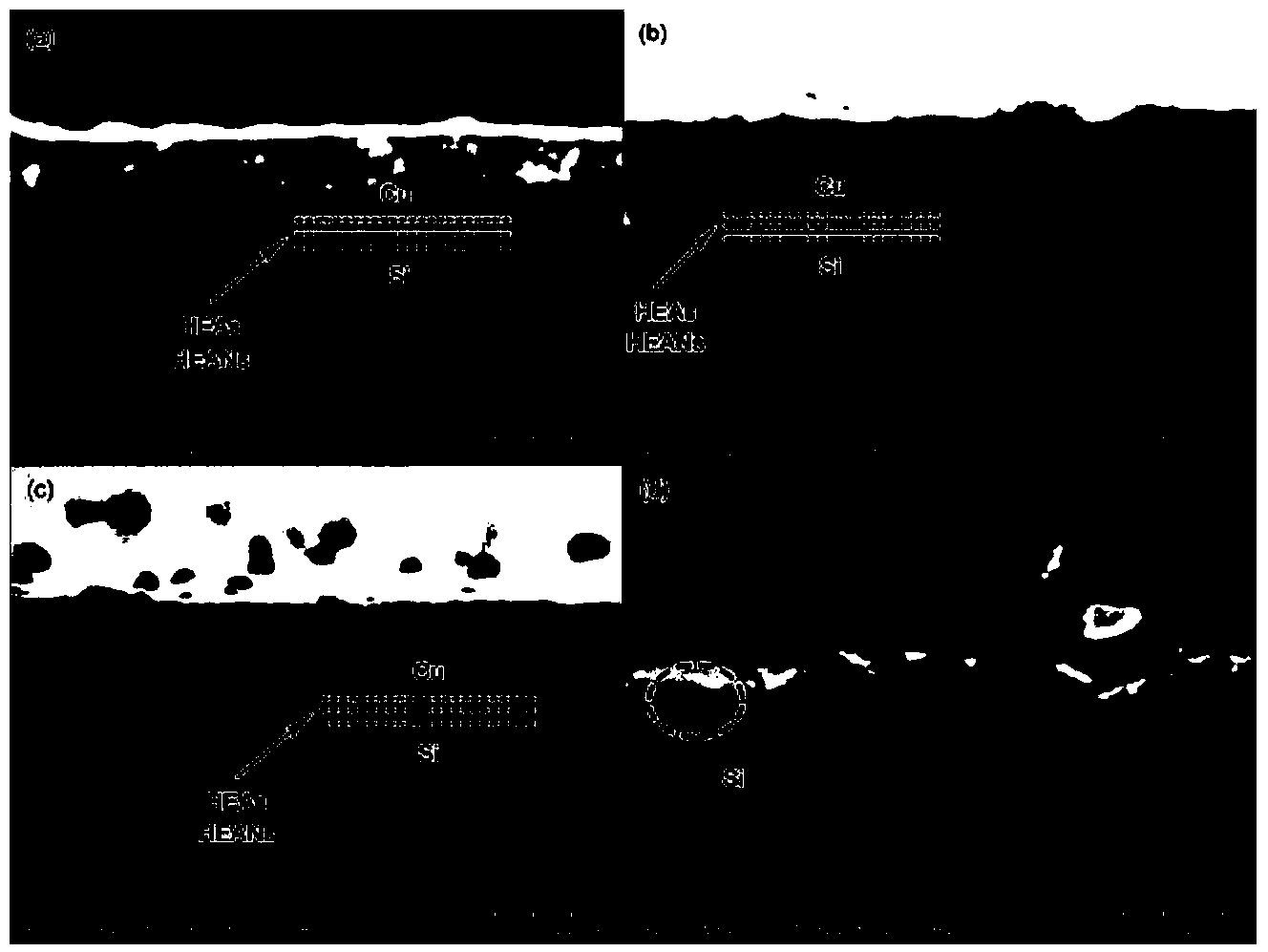

Preparing method for double-layer high-entropy alloy diffusion barrier layer

InactiveCN103966566AImprove thermal stabilityHigh bonding strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysMegasonic cleaning

The invention discloses a preparing method for a double-layer high-entropy alloy diffusion barrier layer. The method comprises the following steps: cleaning a single crystal Si base in an ultrasonic way; removing impurities in the single crystal Si base in an anti-sputtering cleaning way, and removing impurities in target materials and target sheets in a pre-sputtering cleaning way; depositing an HEANs thin film on the single crystal Si base in a sputtering way under the condition that the flow ratio of Ar to N is 1:(0.65-0.9); depositing an HEAs thin film on the ANs thin film in a sputtering way by using the Ar as the working gas when the thickness of the HEANs thin film reaches the designed thickness; adjusting the vacuum degree in a furnace to the degree not lower than 10-3 Pa when the thickness of the HEAs thin film reaches the designed thickness, and naturally cooling and releasing from the furnace to obtain the double-layer high-entropy alloy diffusion barrier layer. For the double-layer high-entropy alloy diffusion barrier layer obtained by the method, the method has the advantages that the bonding strength among the base, the Cu and the barrier layer is improved, and the whole heat stability of the diffusion barrier layer is improved. The method also has the characteristics of skillful technique for the preparing technology, low cost, low pollution and the like.

Owner:SICHUAN UNIV

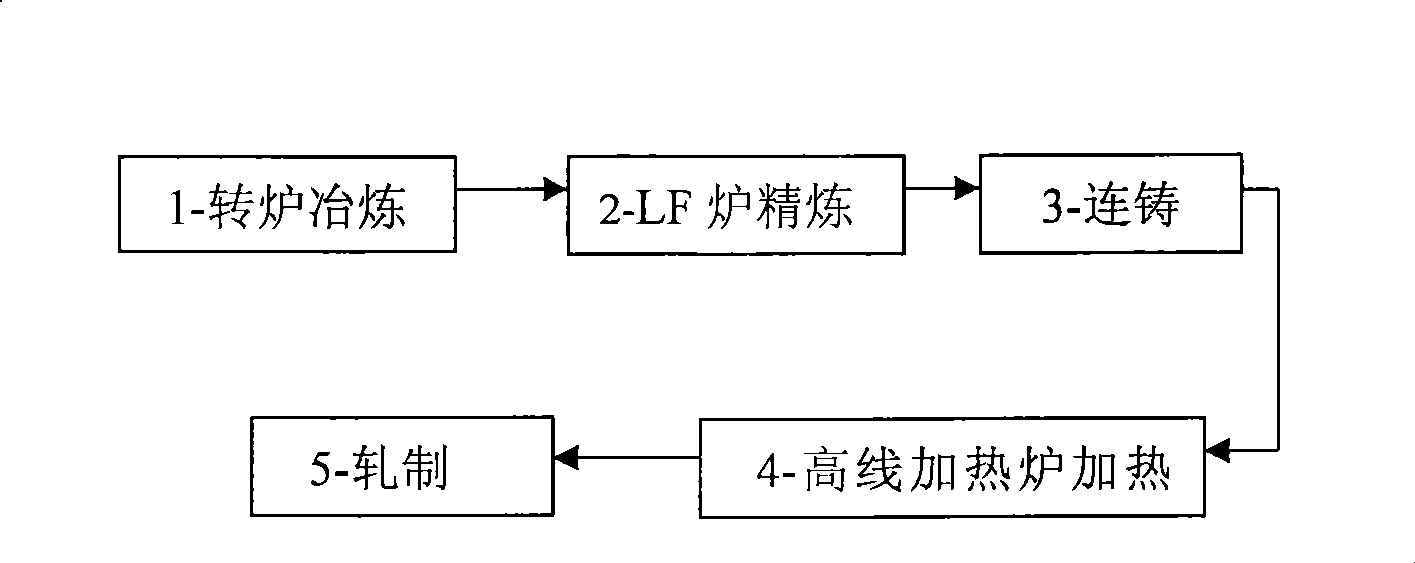

Production method of low-carbon free-cutting steel

InactiveCN101417384AUniform mechanical propertiesUniform tissueTemperature control deviceWork treatment devicesSulfideHeating furnace

The invention provides a production method of low-carbon free-cutting steel and is characterized in that when the free-cutting steel is rolled, the range of sensitive temperature of sulfide embrittlement is escaped in the heating temperature; the first heating temperature of a heating furnace of steel billets is 1050 to 1150 DEG C, the second heating temperature is 1150 to 1250 DEG C, the holding zone is provided with the temperature of 1180 to 1240 DEG C, the initial rolling temperature is 1120 to 1150 DEG C the spinning temperature is 860 to 900 DEG C and the time in the furnace is controlled to be equal to or more than 130 minutes; and delayed cooling is adopted and both a fan and a heat holding cover are shut down. The invention solves the phenomena of easy head cracking, collaring and slipping, difficult gripping, great operational difficulty, and the like in the rolling of S-system free-cutting steel, and has good cutting and processing performance.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Method for improving sheet annular titanium alloy gear part machining precision

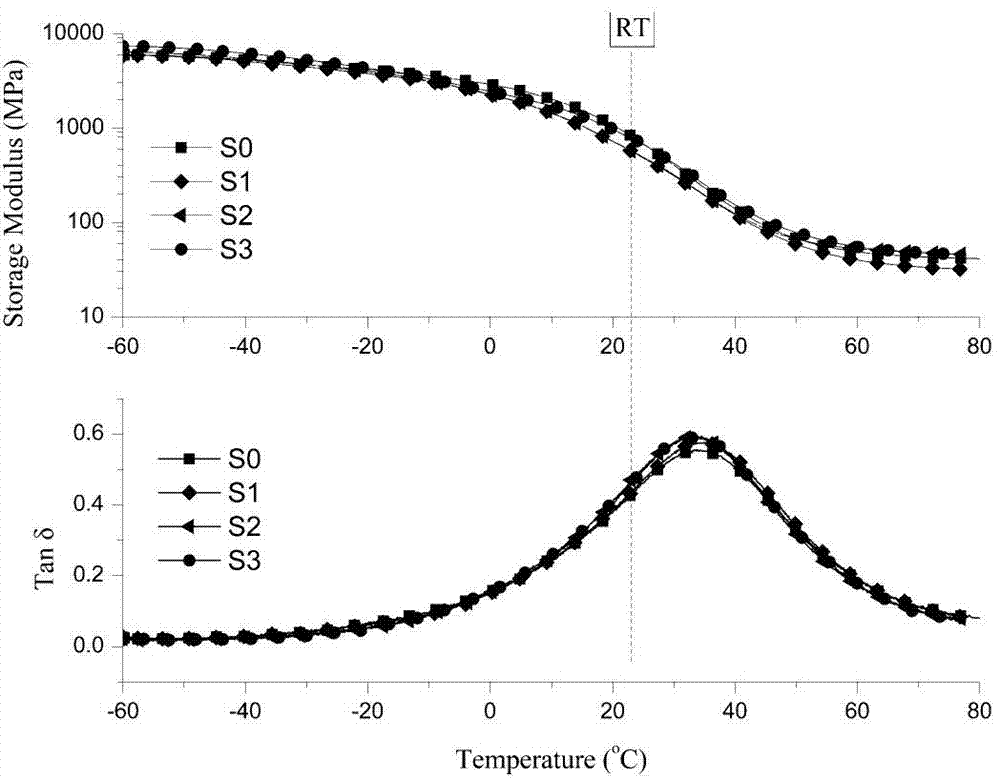

ActiveCN103240575ASolve processing deformationMeet processing requirementsCold treatmentRoom temperature

The invention relates to a method for improving the sheet annular titanium alloy gear part machining precision. The method includes the following steps: (1) rough turning a blank, pressing a part through a pressing plate along the axis direction, and conducting rough machining on the part; (2) recrystallization annealing; (3) rough turning a gear bank again; (4) thermocycling; (5) semi-finish-turning the gear blank; (6) stress relief annealing; (7) conducting auxiliary procedures, and machining and finishing other structural elements of the part thoroughly; (8) conducting subzero treatment; (9) finishing machining the gear blank; and (10) manufacturing teeth and conducting thermo-cold cycling. After the teeth are manufactured, conducting twice thermo-cold cycling, conducting cold treatment at the temperature of -50- -60 DEG C, keeping the temperature for 1.3-1.7h, air cooling to the room temperature for 1.5h, heating to 80-100 DEG C in a thermostat, keeping the temperature for 2.8-3.2h, air cooling to the room temperature, and finishing finish machining. By means of the method, deformation in a machining process can be eliminated.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

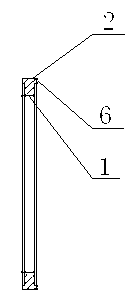

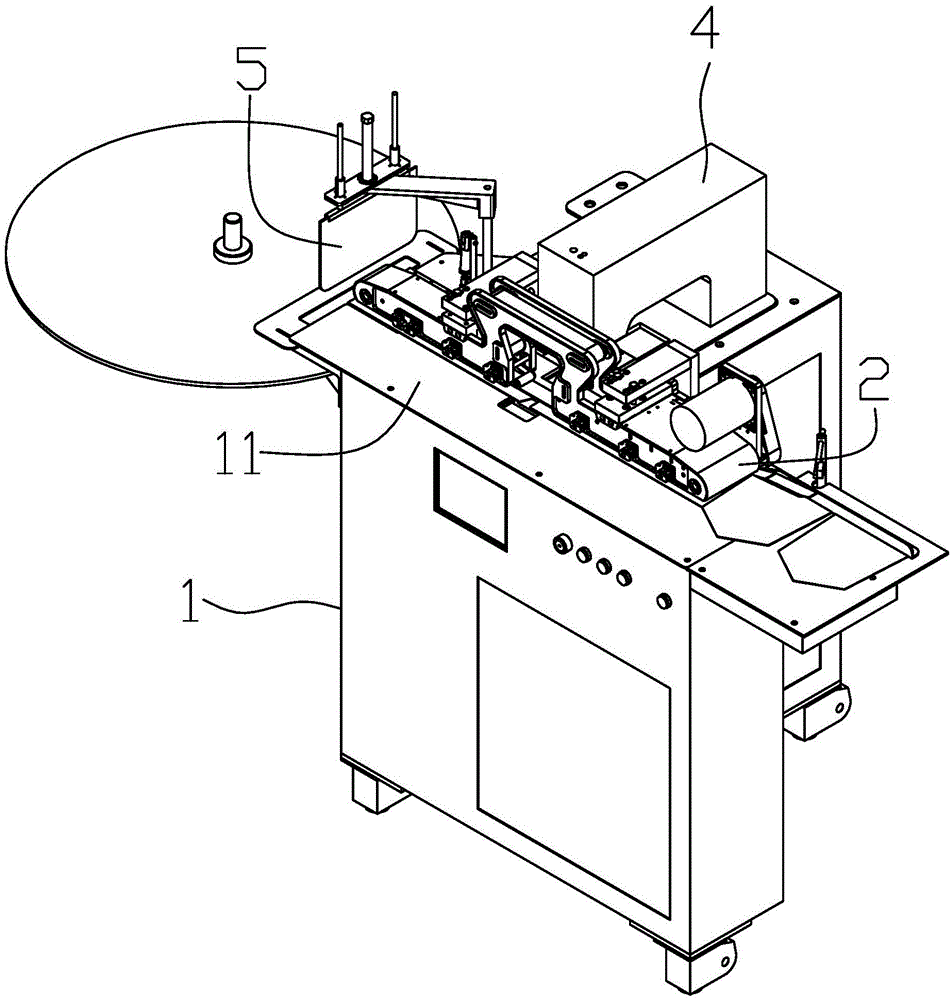

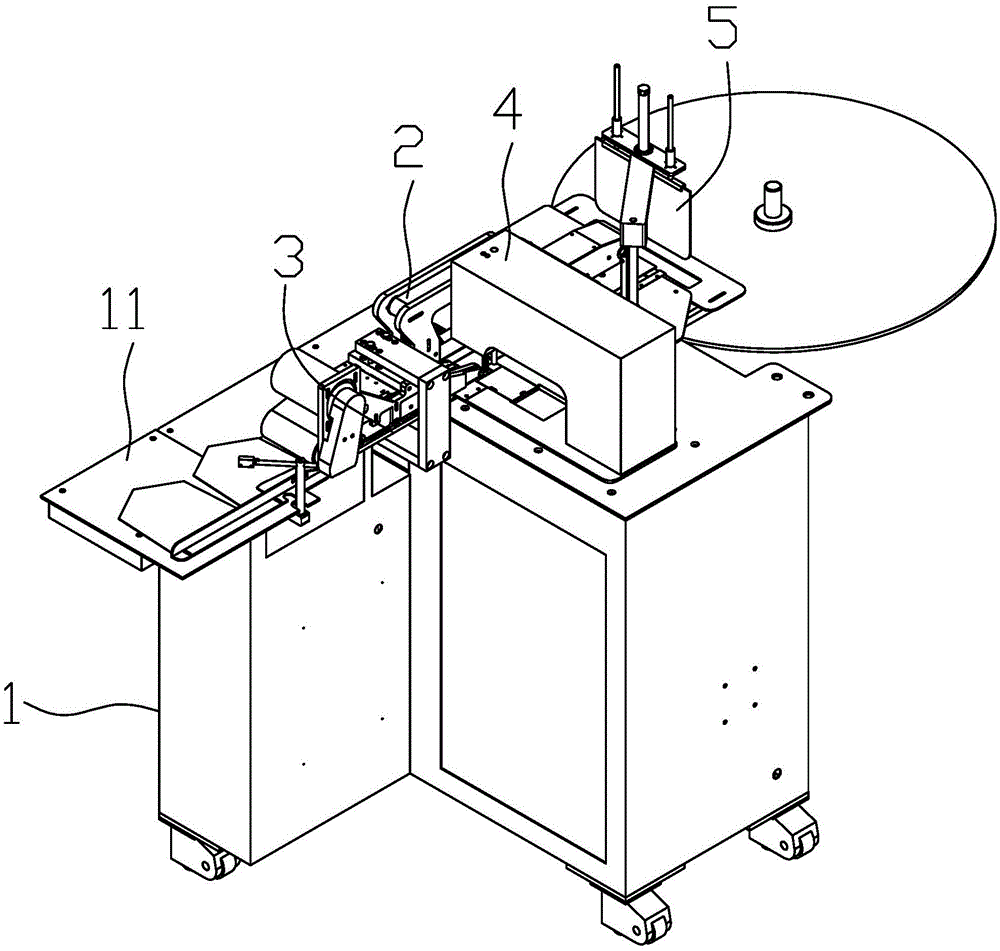

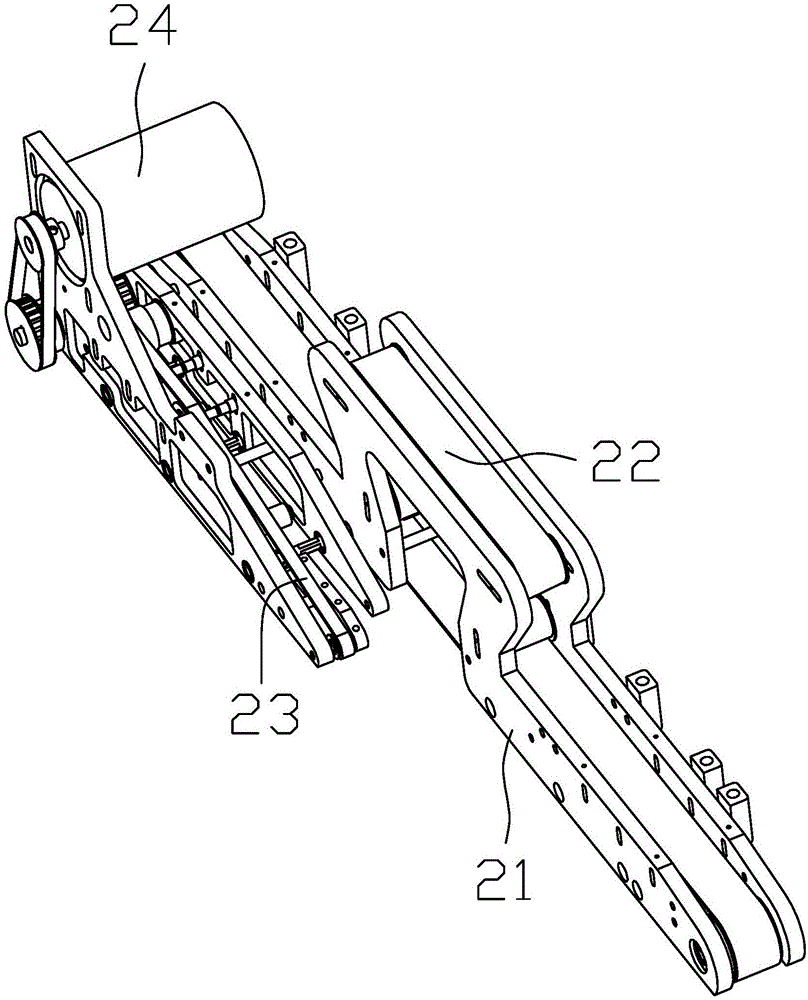

Automatic equipment for bag hemming and sewing

InactiveCN105040287ALow costMeet processing requirementsWork-feeding meansEngineeringMechanical engineering

The invention discloses automatic equipment for bag hemming and sewing. The automatic equipment comprises a machine base, a conveying module, a hemming mold, a sewing module and a collecting module. The machine base is provided with a horizontal working platform. The conveying module is installed on the machine base and can drive cloth to move along the working platform. The hemming mold and the sewing module are sequentially arranged in the cloth movement direction. The hemming mold is used for hemming the cloth, and the sewing module is used for sewing hemmed cloth. The collecting module is arranged at the tail end of the conveying module and used for collecting the hemmed and sewn cloth. According to the automatic equipment, the cloth can be automatically fed, hemmed, sewn, cut off, collected and the like, so that labor consumption can be greatly reduced, the enterprise cost is reduced, the processing speed is high, the production efficiency is significantly improved compared with a manual way, the hemming quality stability is high, and the processing requirements of high-grade clothes can be met.

Owner:SHENZHEN DEYE AUTOMATION TECH

Processing method of large-scale suspension bridge vice saddle

ActiveCN101664876AMeet processing requirementsImprove economyOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a processing method of a large-scale suspension bridge vice saddle. The vice saddle is constituted by combining and welding a saddle bow and a saddle body, wherein, the saddlebody is constituted by combining and welding a base block and a rib plate; and the bottom surface of the base block is provided with a key slot. The processing steps are as follows: (1) respectively processing well the saddle bow and the base block on the numerical control machine tool rotation workbench, wherein, the key slot on the base block is not processed temporarily; (2) welding the rib plate on the base block to form the saddle body on the ground workbench; (3) combining and welding the saddle bow and the saddle body to a whole on the ground workbench; and (4) processing the key slot on the ground workbench. The method can satisfy processing requirements by utilizing conventional general equipment without adding large-scale equipment, thus having prominent economic effect.

Owner:DEYANG TIANYUAN HEAVY IND

Preparation method of diamond micro-channel heat sink for superhigh heat flux cooling

ActiveCN108682662AIncreasing the thicknessQuality improvementSemiconductor/solid-state device detailsSolid-state devicesHeat fluxVolumetric Mass Density

The invention relates to a preparation method of a diamond micro-channel heat sink for superhigh heat flux cooling, and belongs to the field of semiconductor device cooling. The method comprises the steps: employing the special substrate technology and the improved CVD preparation technology for preparing a high-quality, no-crack and super-thick diamond self-supporting membrane; controlling the surface roughness of the super-thick diamond membrane through the mechanical grinding and polishing according to the requirements of a thermal contact interface; employing the unique laser processing technology for achieving the fixing of the structure size of the super-thick diamond membrane, carrying out the micro-channel engraving on the surface through a laser micro-beam flow, obtaining a diamond micro-channel heat exchanger with the size being matched with the groove type, and enabling the diamond micro-channel heat exchanger to meet the design requirements of a high heat flux heat exchangefor dissipation. The micro-channel heat sink can be used for the heat dissipation of a high-power-consumption electronic device of spatial loads, such as a phased array radar, a satellite, and a large-scale spacecraft.

Owner:UNIV OF SCI & TECH BEIJING

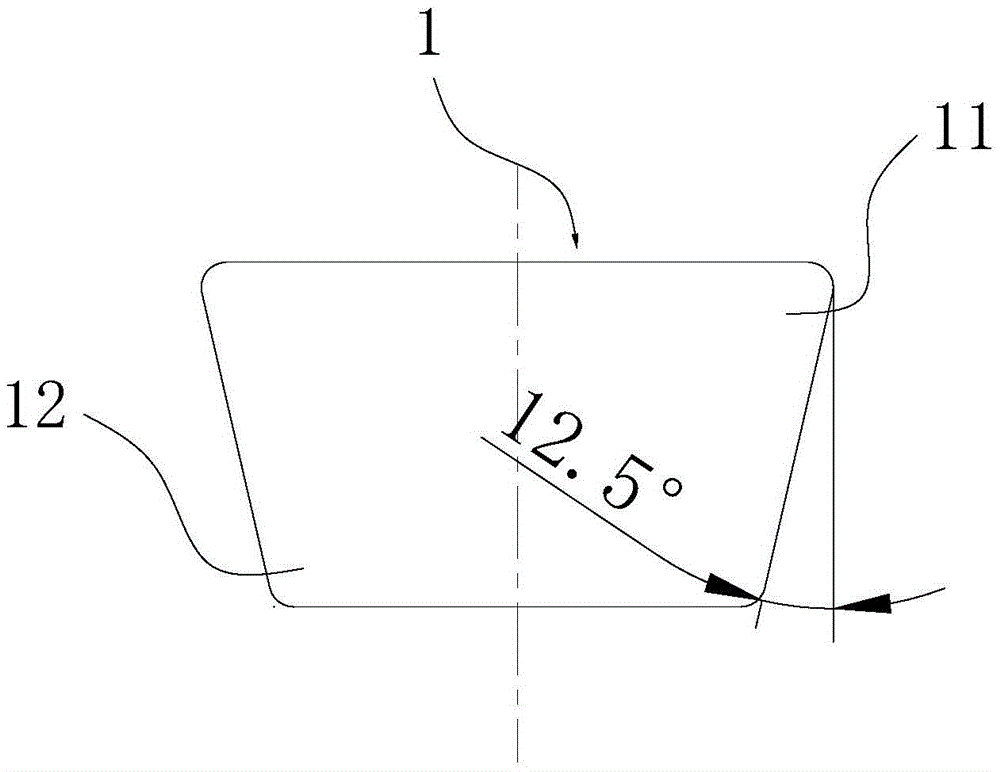

Method for flanging slant notch of cylindrical shell

The invention relates to a method for flanging a slant notch of a cylindrical shell, comprising the following steps: moulding and punching are carried out on 8 parts along the periphery of the cylindrical shell parts, 8 slant flanging notches are correspondingly arranged along the periphery of the cylindrical shell; first, sheet metal is produced into a sector and then rolled into a cone and then welded and corrected; afterwards, laser is adopted to cut the cone into kerves of the notches, the method of mould stamping is adopted to stamp all 8 notches in a stroke; a wedge block is adopted to transform vertical ram pressure of a punching machine into horizontal ram pressure which is exerted on 8 slotting parts, so that both internal mould and external mould can move; an active structure can be adopted to a female groove, when stamping is carried out, the outside female groove is first put in place, and then the inside male groove moves and is flanged.The invention has the advantages that high-accuracy part stamping is realized by using an ordinary pressure machine.The mechanism features good implementation effect, satisfies high-accuracy engine part processing requirements and enjoys good TOP.In addition, the processing efficiency is high; when specialized equipment is not used, the method of the invention is a reliable and economical method for processing similar parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com