Patents

Literature

551 results about "Plate element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

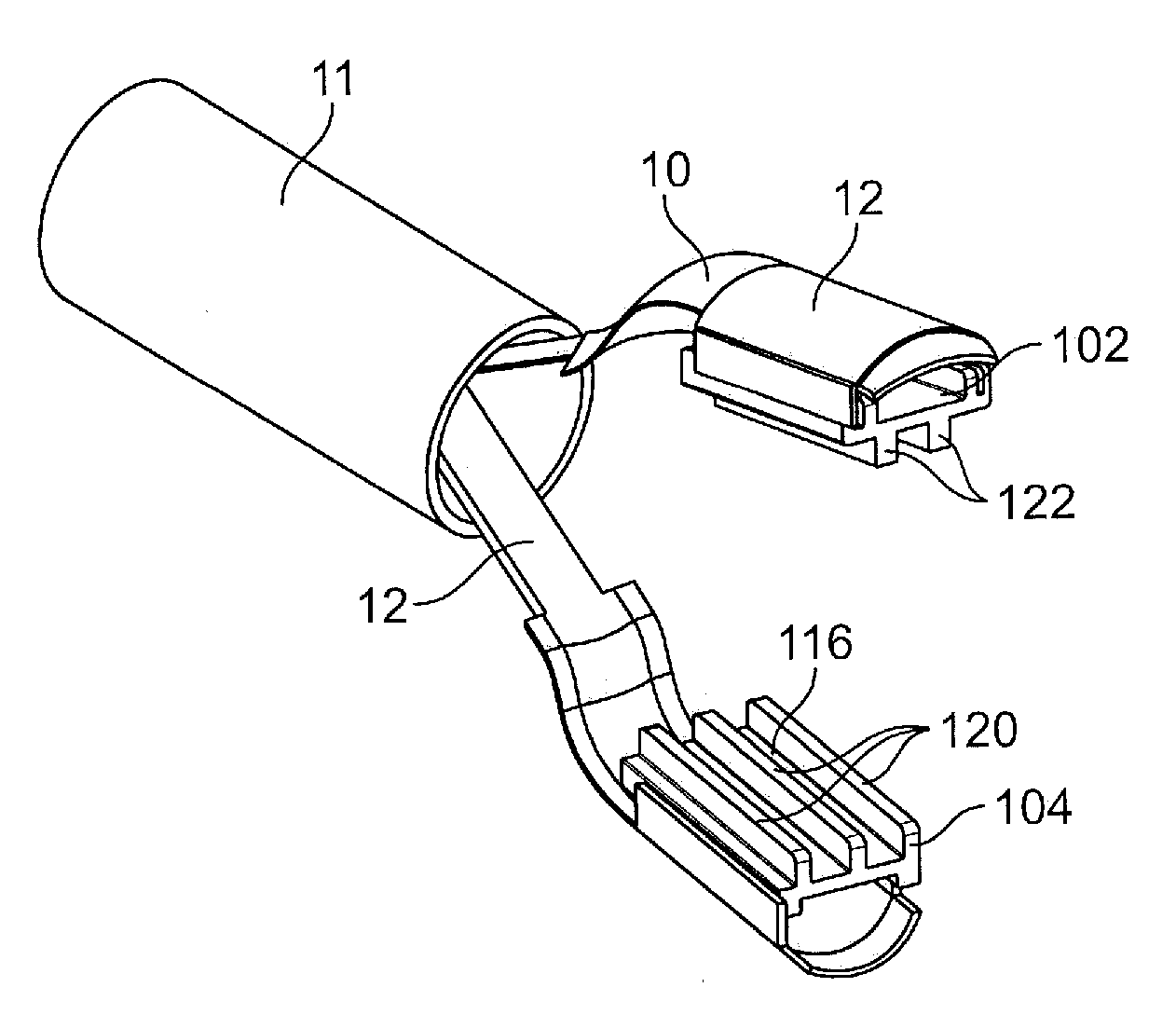

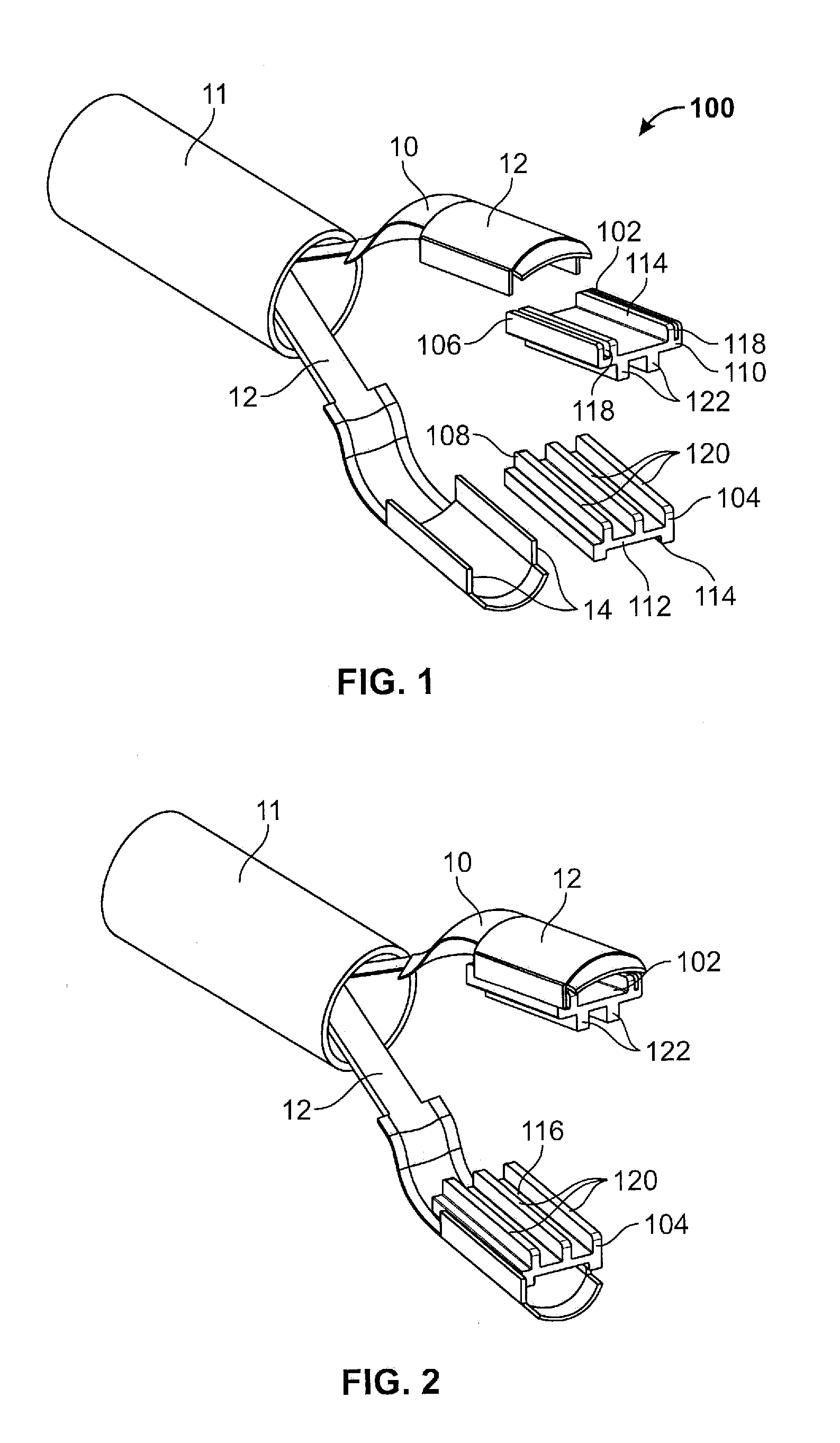

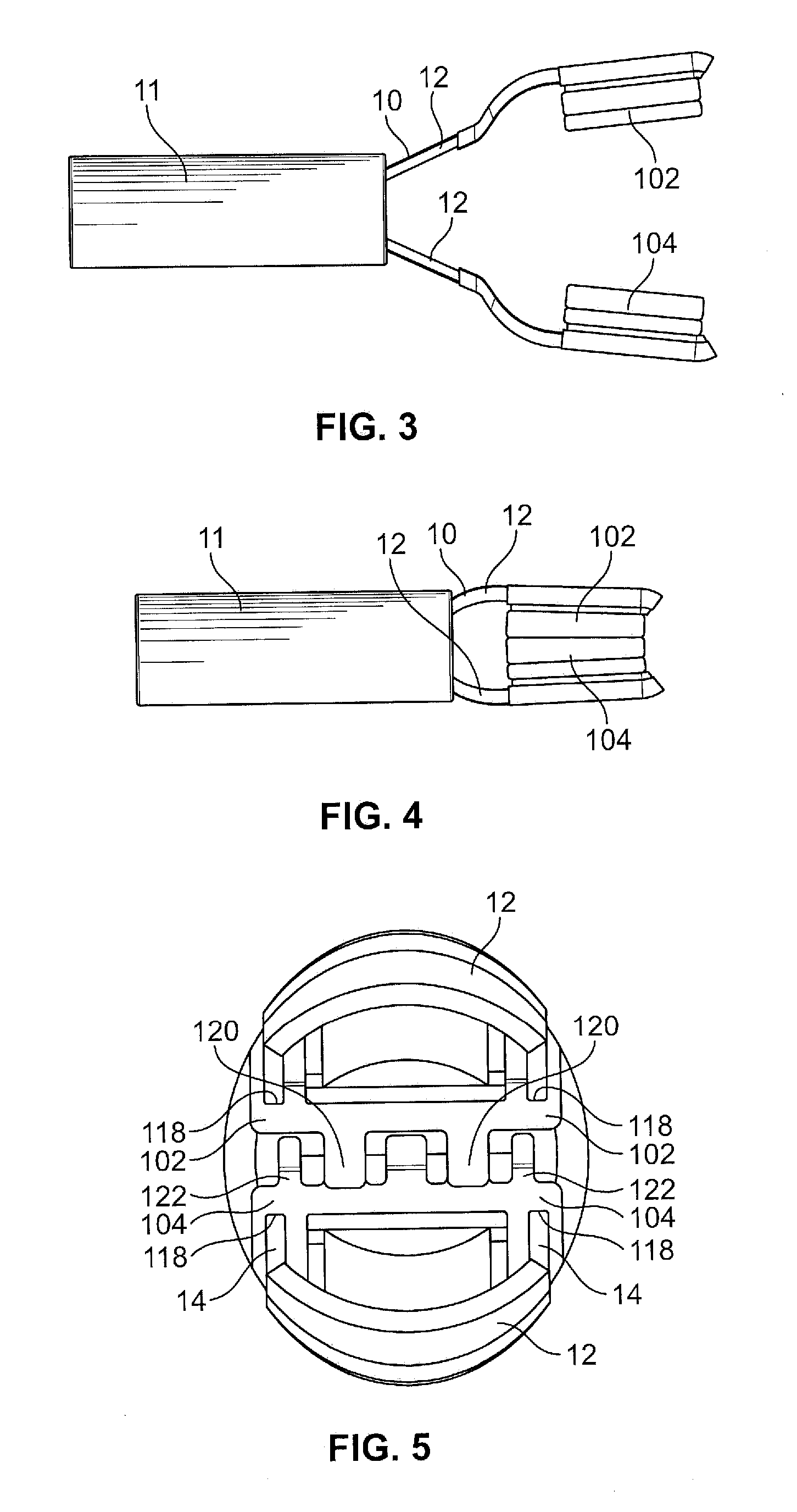

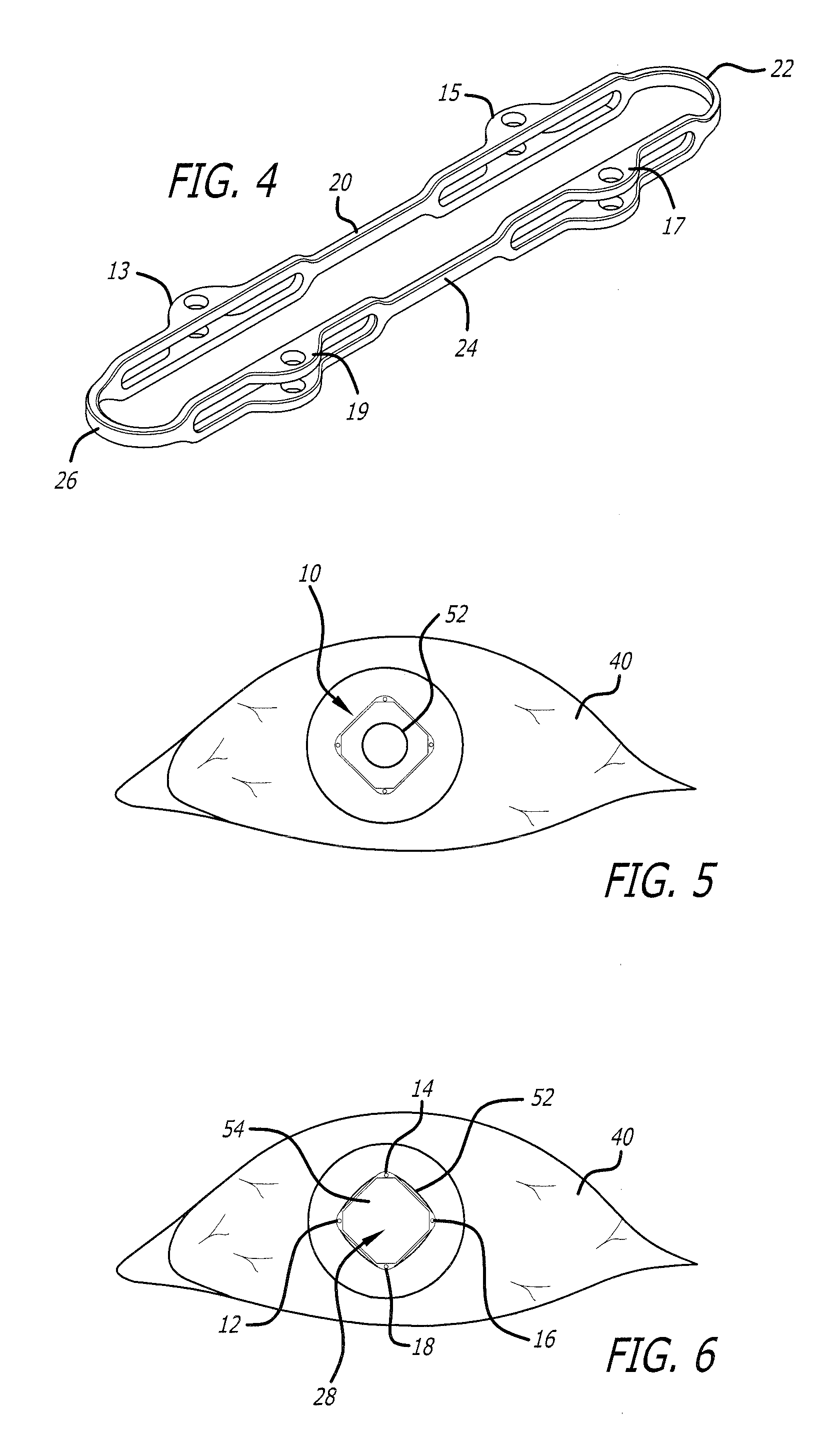

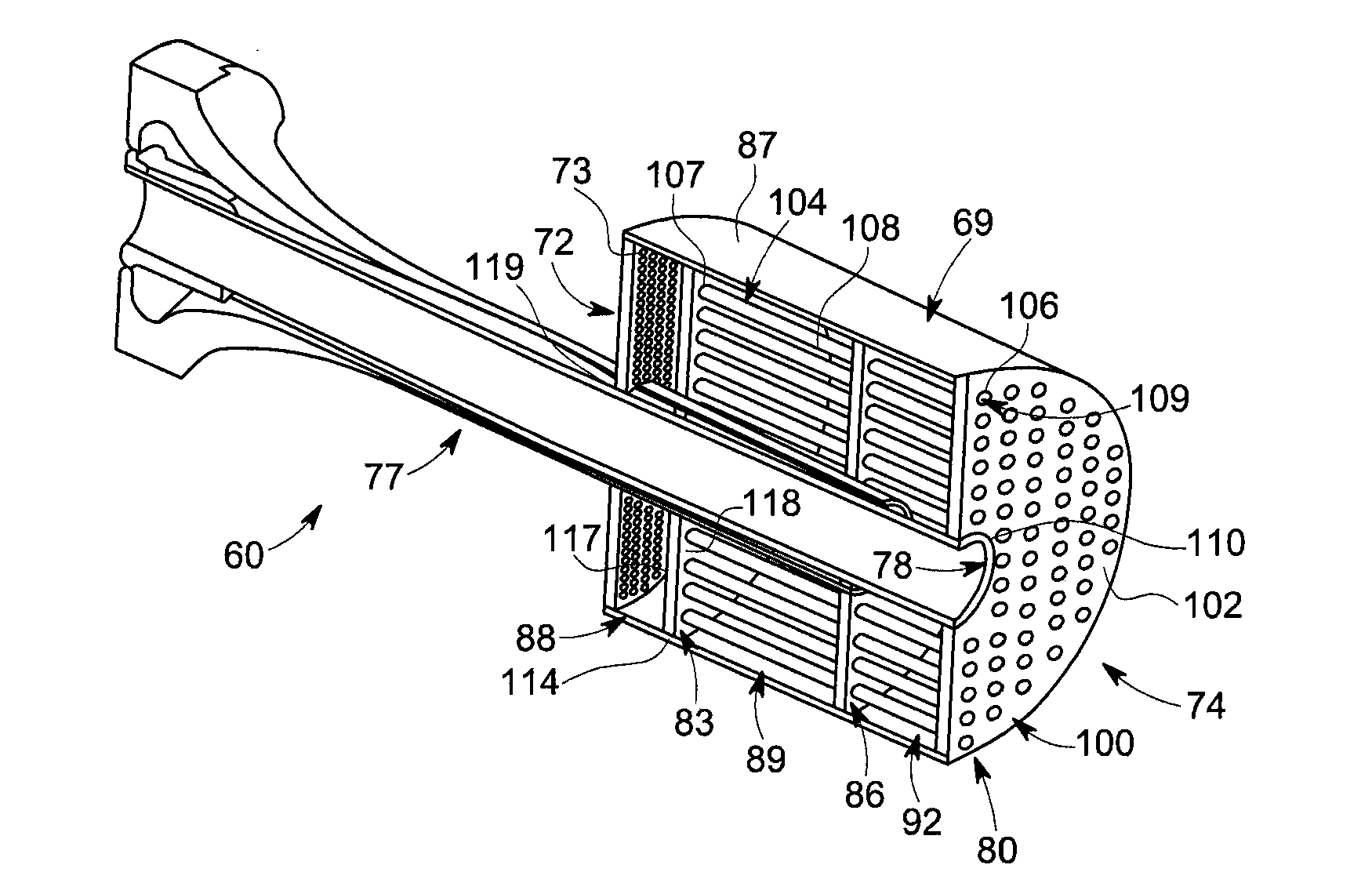

Clip applier

A system for performing a medical operation includes an end effector having first and second arms, each extending from a distal end to a proximal end, the proximal ends being connected to one another, the end effector being movable between a closed configuration wherein the first and second arms are separated from one another by a first distance and an open configuration wherein the first and second arms are separated from one another by a second distance greater than the first distance, a distance between the first and second arms being substantially constant from the proximal ends to the distal ends, wherein the end effector is biased to the open configuration. A first plate element extends from a first surface configured to engage a first wall of the first arm to a second surface configured to contact target tissue in an operative configuration. A second plate element extends from a first surface configured to engage a first wall of the second jaw to a second surface configured to contact target tissue in an operative configuration.

Owner:BOSTON SCI SCIMED INC

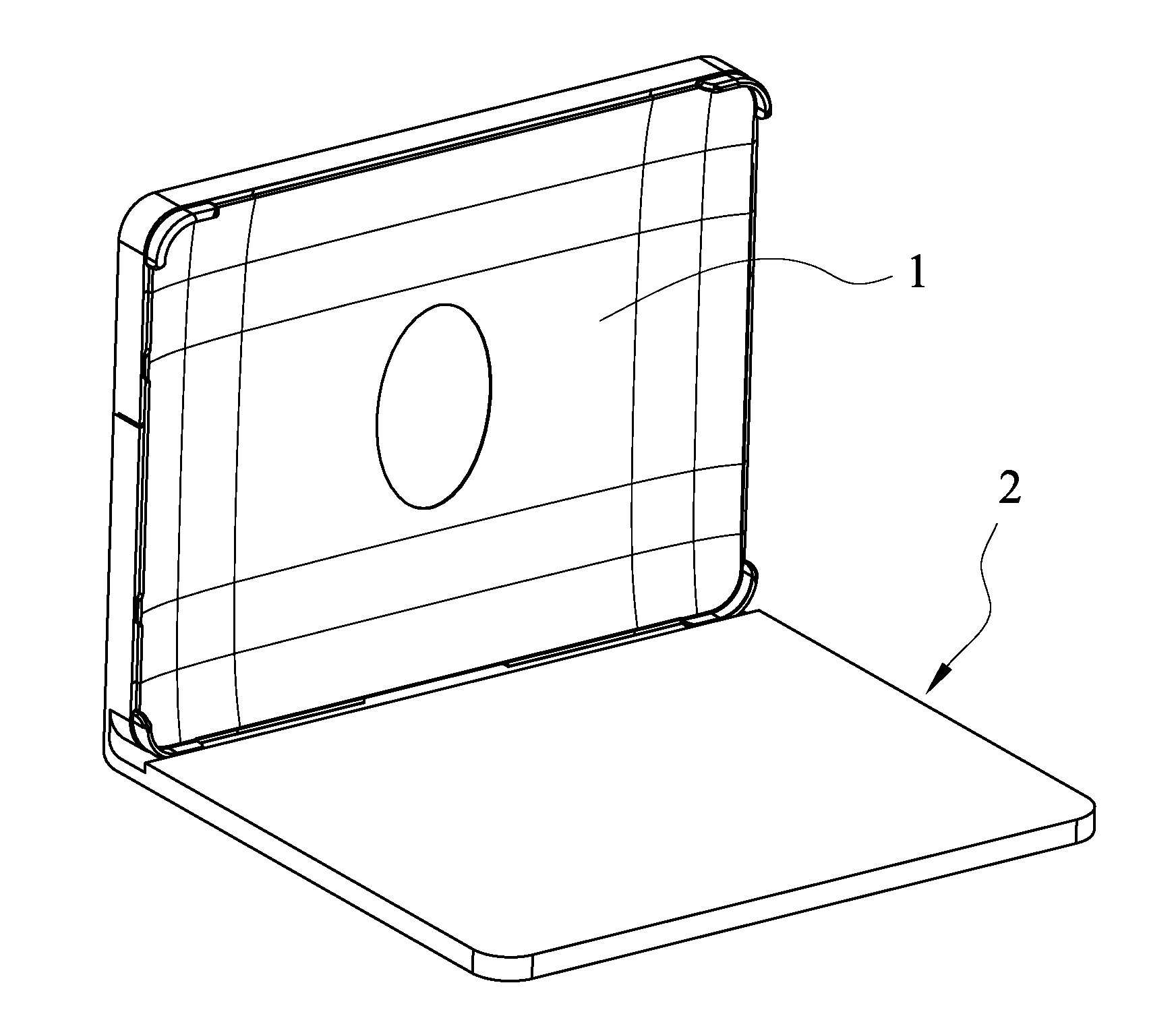

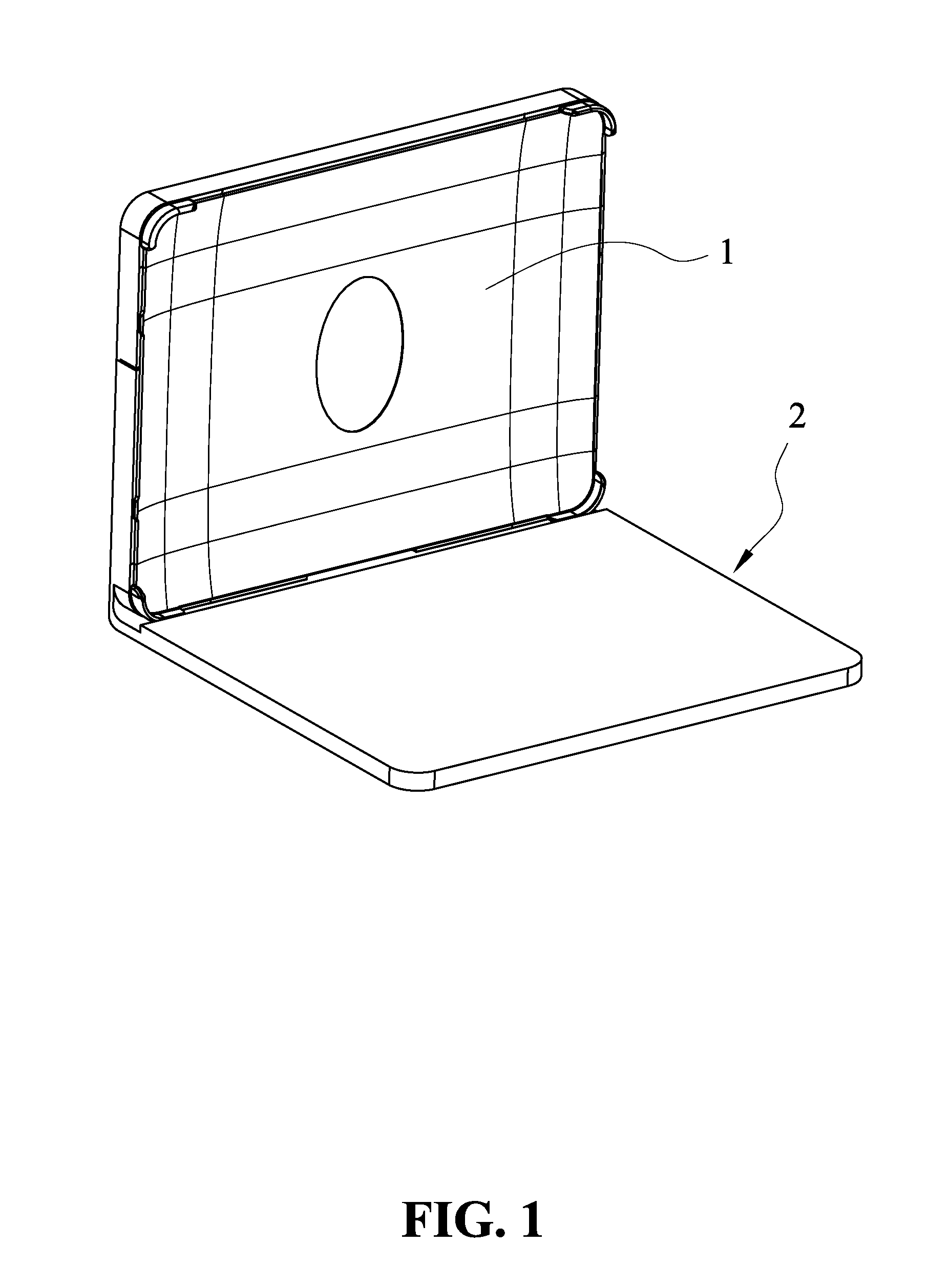

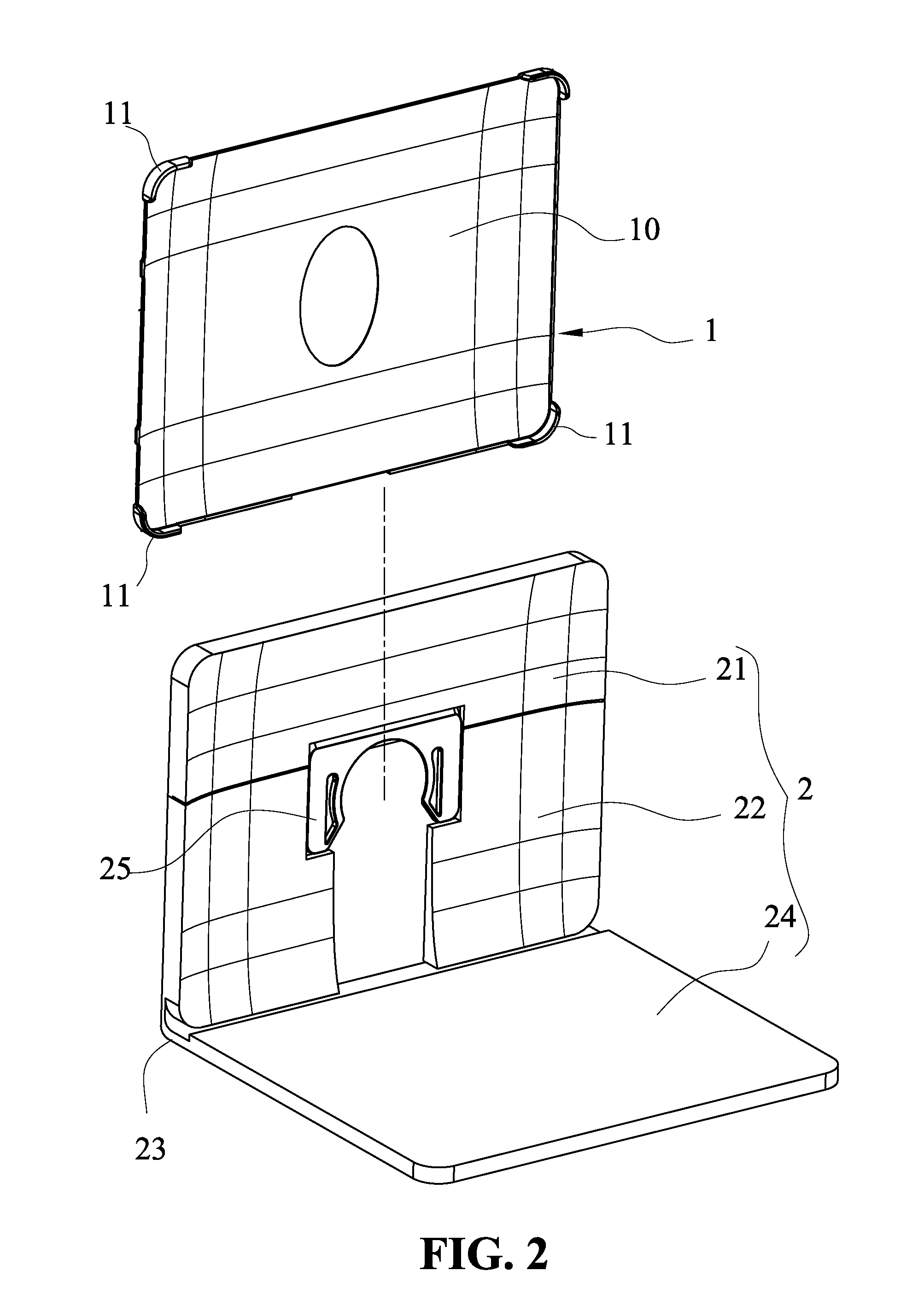

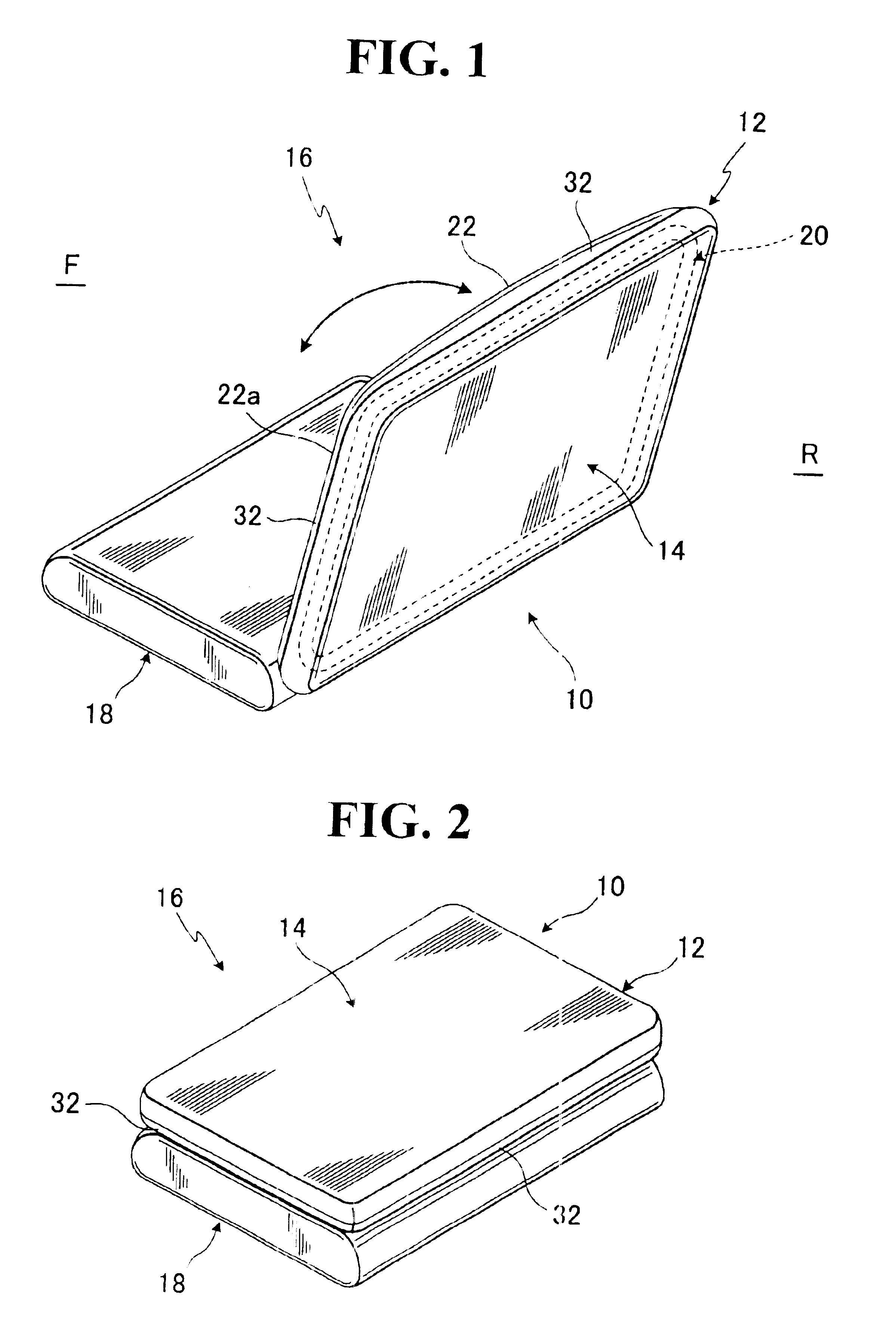

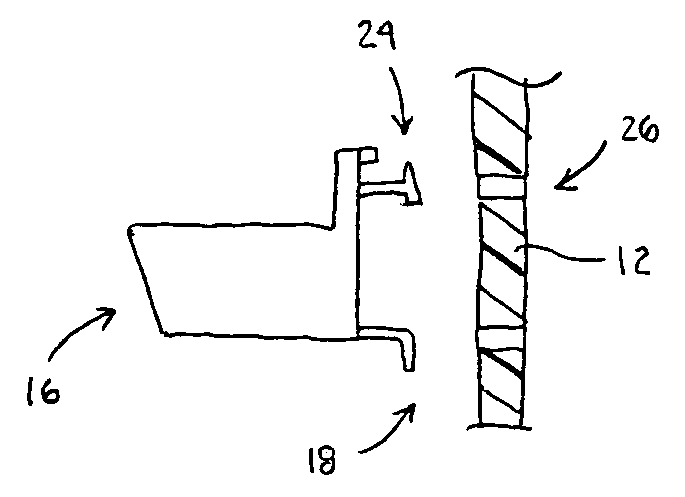

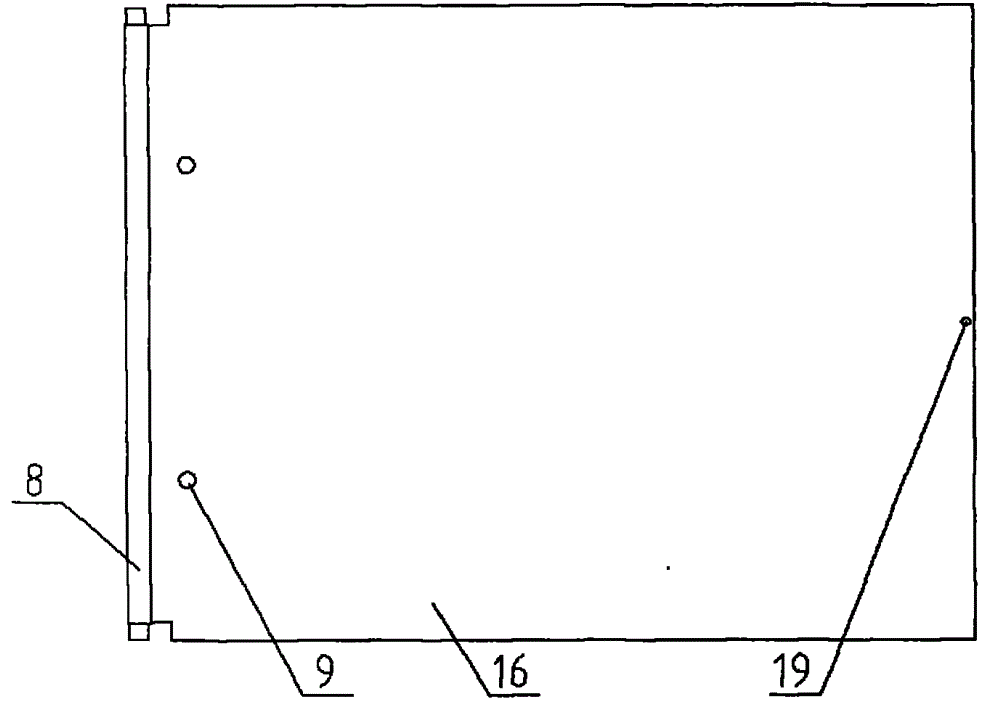

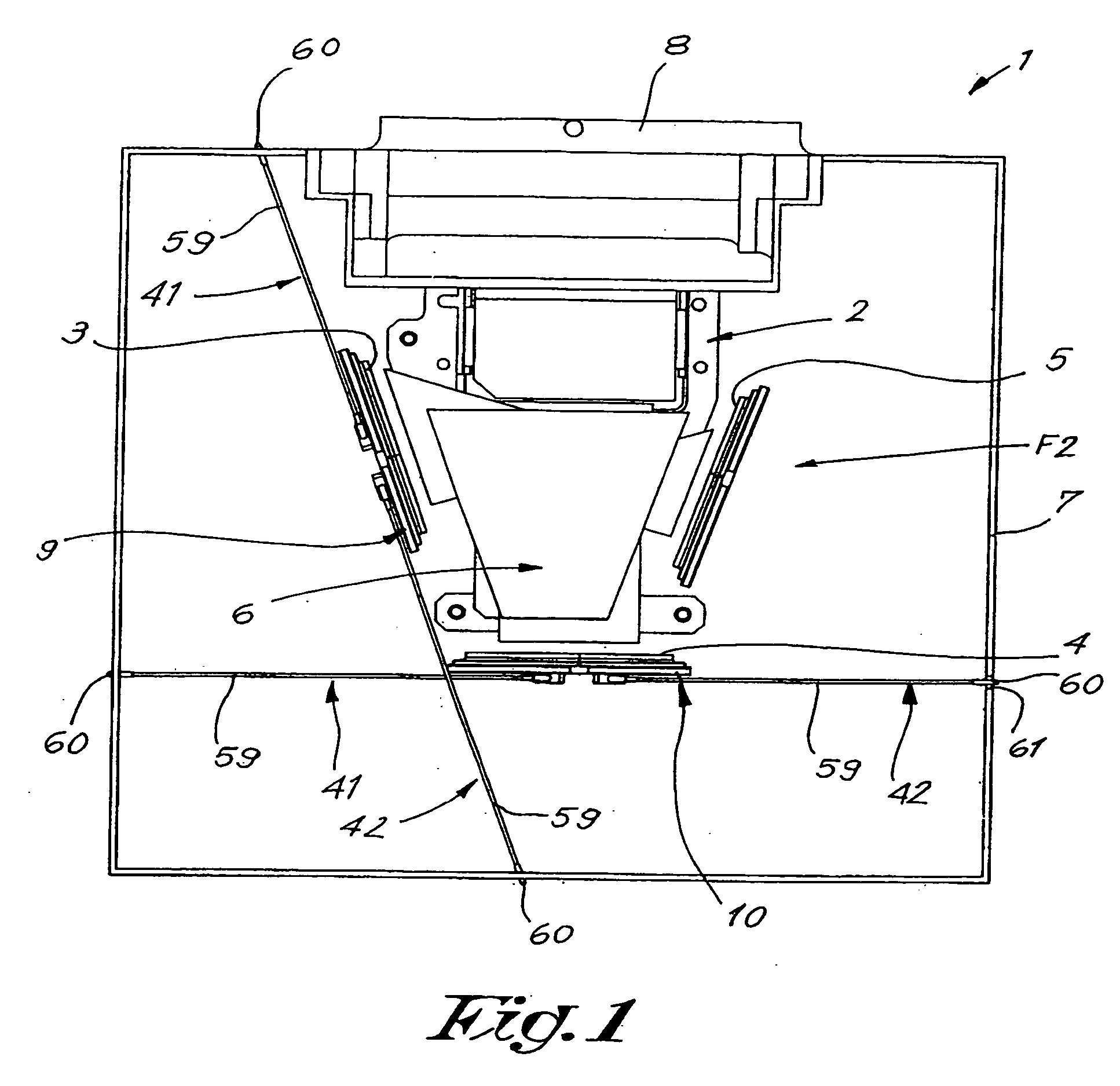

Protective apparatus for tablet electronic device

InactiveUS20120012483A1Easy to operateFor comfortable viewingDigital data processing detailsOther accessoriesBiomedical engineeringPlate element

A protective apparatus for tablet electronic device is provided, in a form of book jacket-like expandable structure, including a receiving unit and a protective cover. The protective cover is a foldable plate set. The plate set can be folded to shape into a three-dimensional U-shape. The element at the edge of the plate set is a first plate element, with a buckle seat. The front surface of the receiving unit can receive a tablet electronic device, and the back surface has formed a protruding element so that the protruding element of the receiving unit can be buckled to the buckle seat of the plate set. The receiving unit can rotate pivotedly around the buckle seat for angle adjustment. With this, the tablet electronic device can be wrapped and protected. The plate set can be folded to support at the back surface of the receiving unit so that the receiving unit can stand in landscape and portrait mode with a tilt angle.

Owner:FAN EAGLE

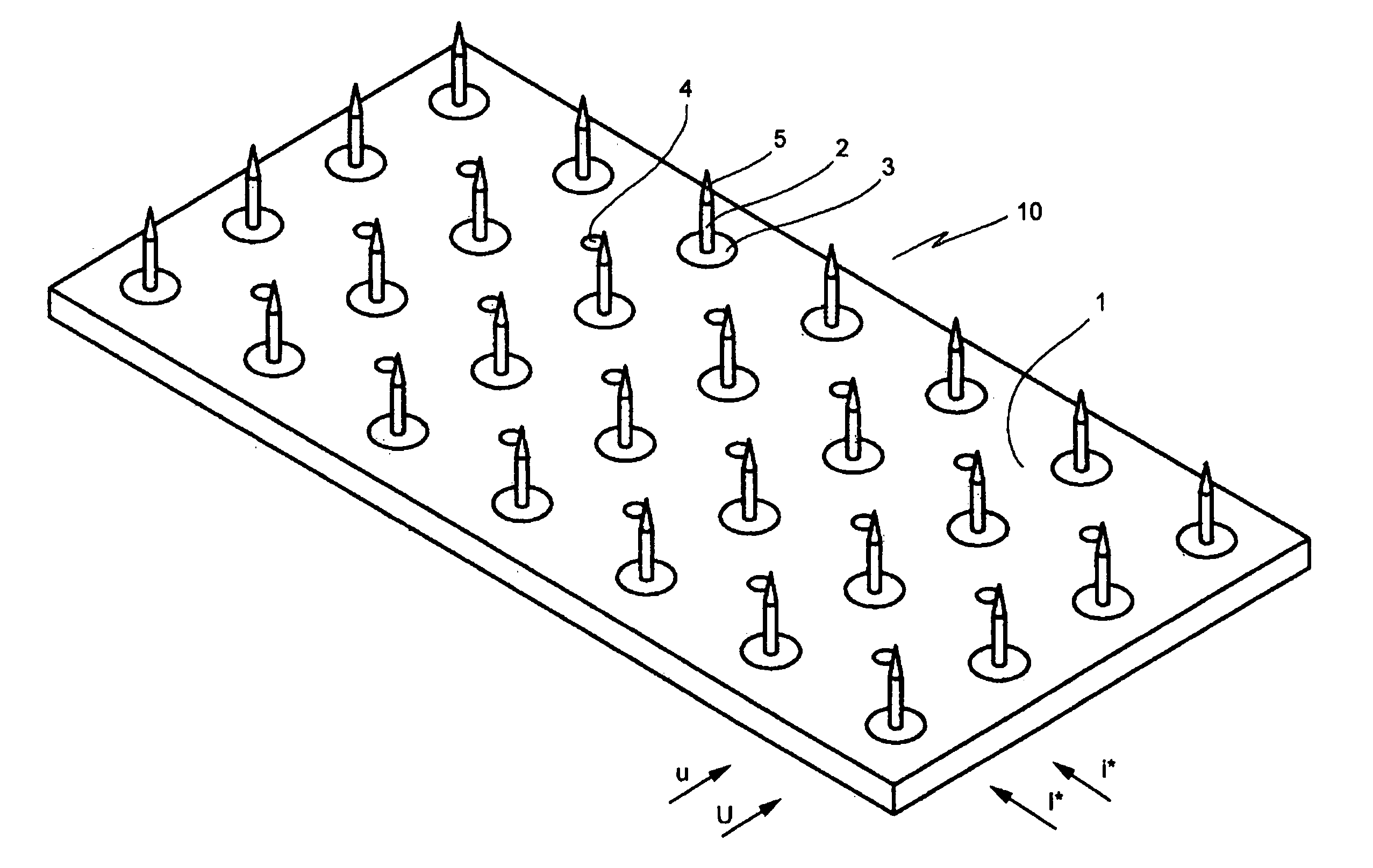

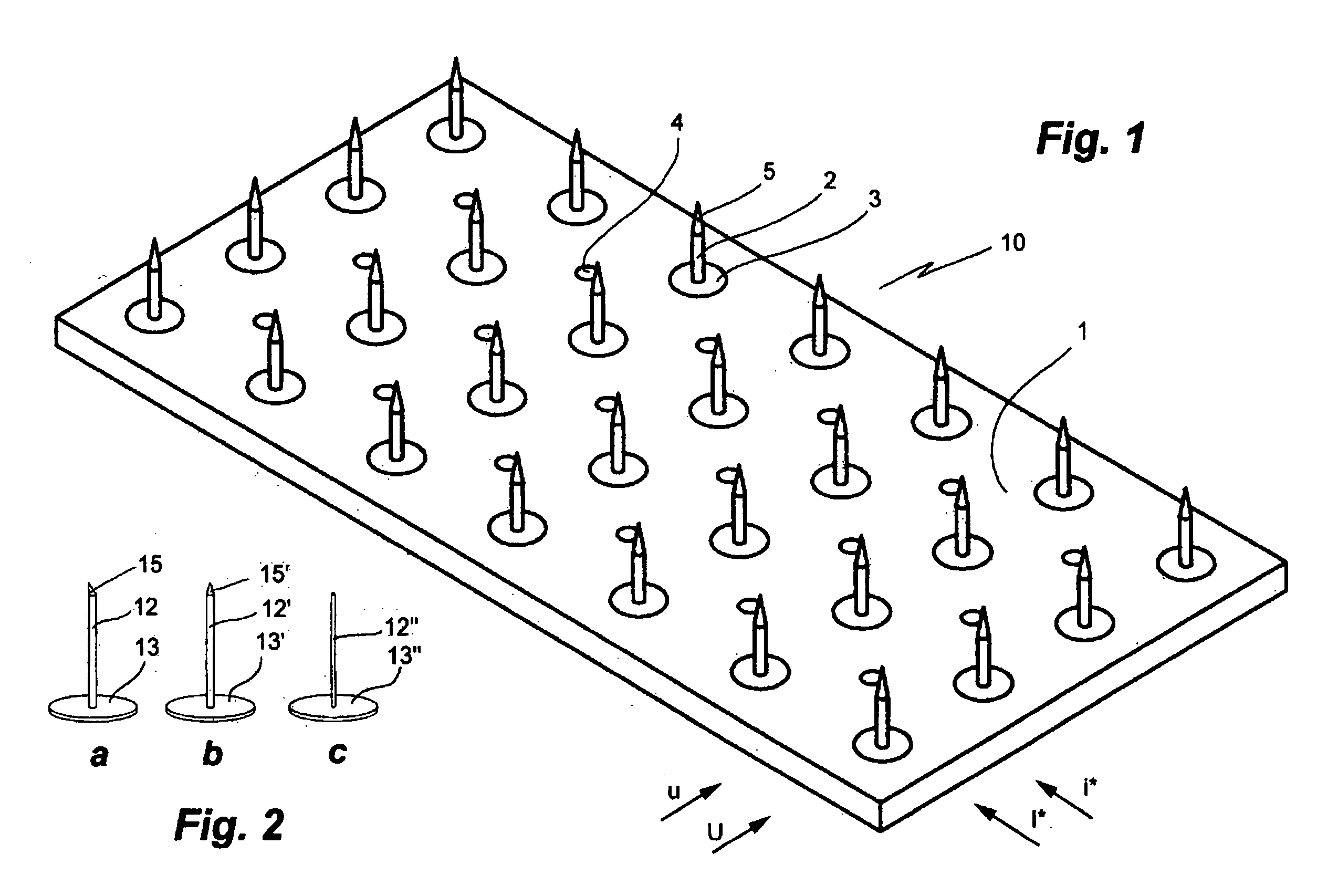

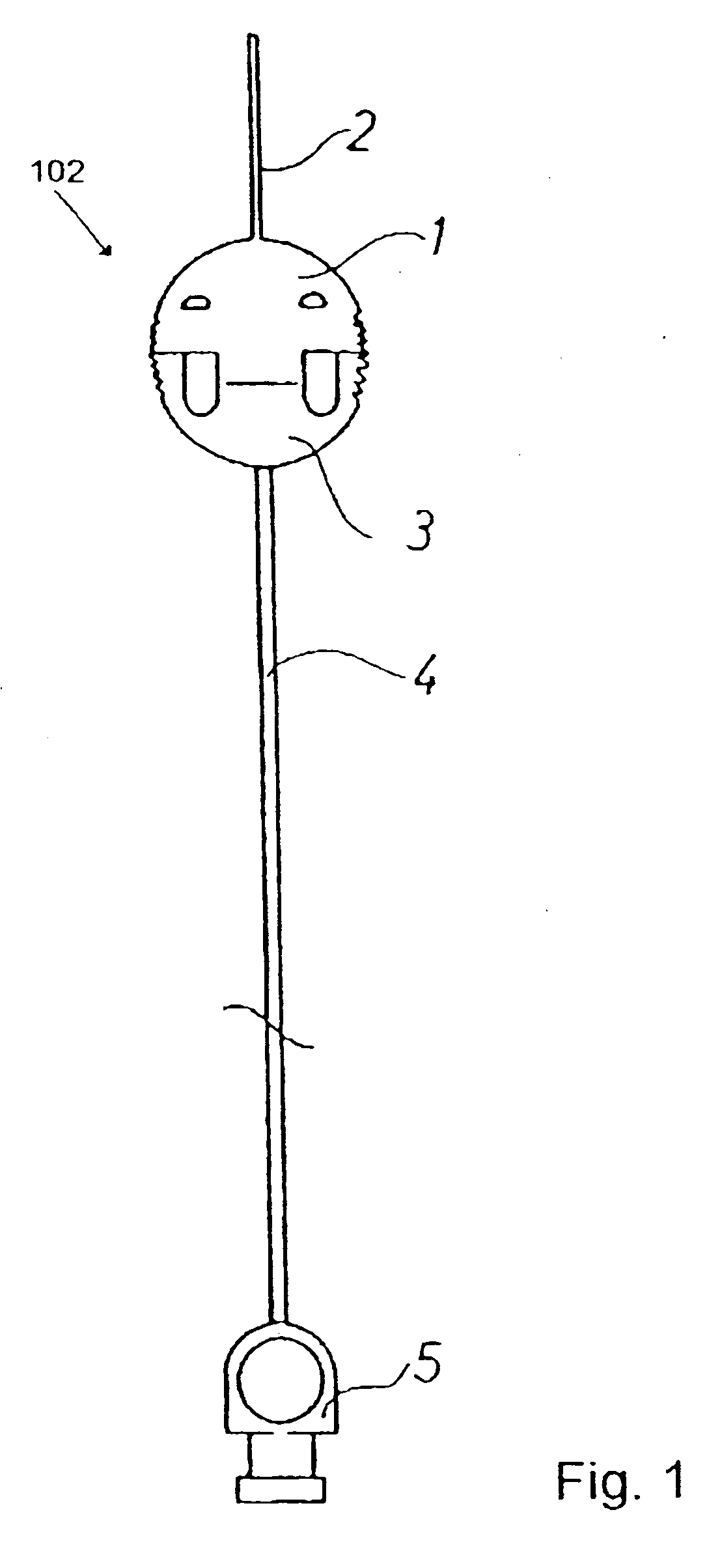

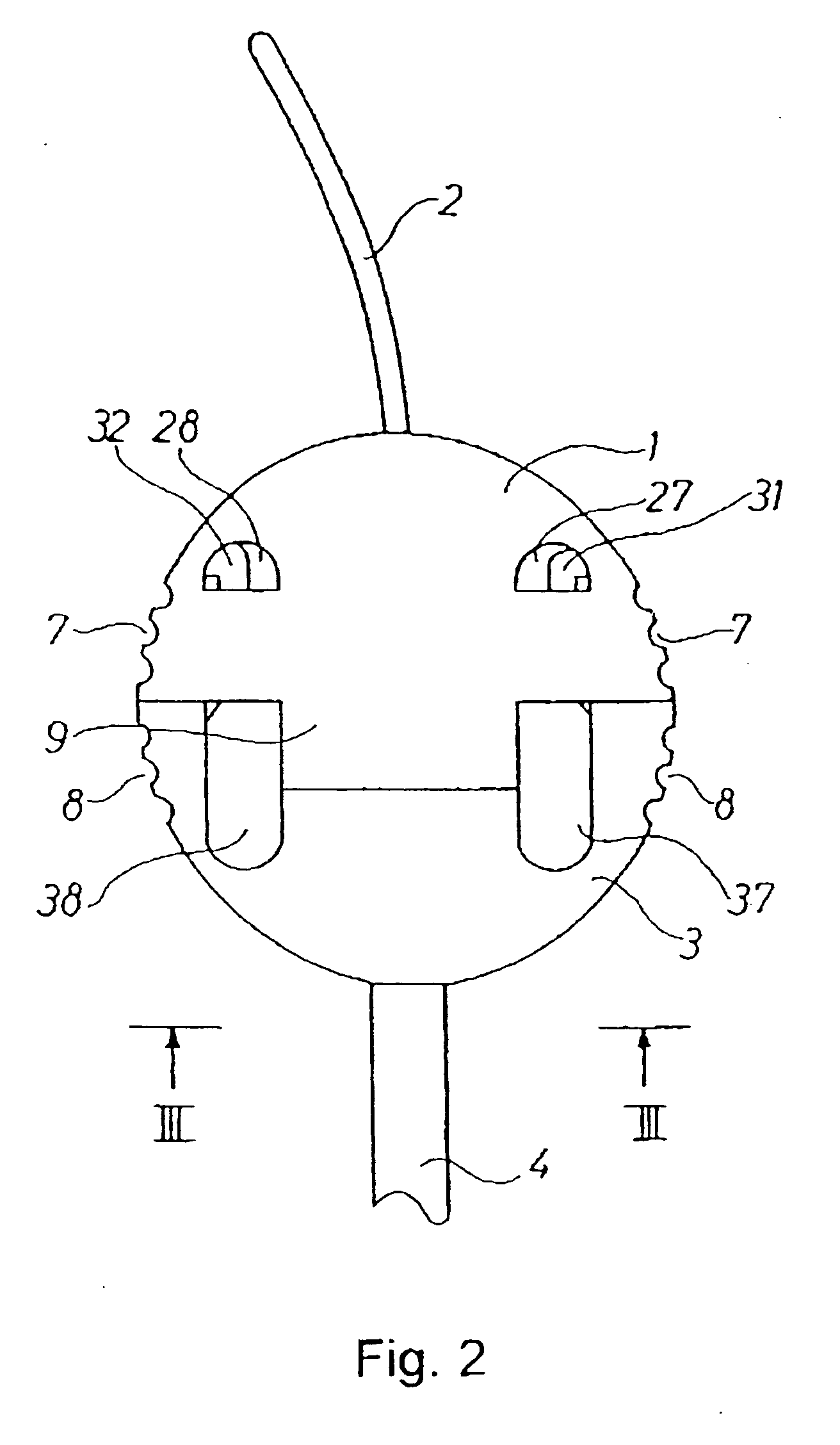

Method and means for electrical stimulation of cutaneous sensory receptors

ActiveUS20060085056A1Increase pressureIncrease vascularisationDiagnostic recording/measuringSensorsFiberEngineering

Electrode plate comprising a stiff or flexible electrically non-conductive plate element having a front face and a rear face and a pattern of needle-like (NL) electrodes for electrical stimulation of cutaneous thin Aδ / C fibers and conductive plate (CP) electrodes for electrical stimulation cutaneous large Aβ fibers disposed on the front face.

Owner:MEAGAN MEDICAL

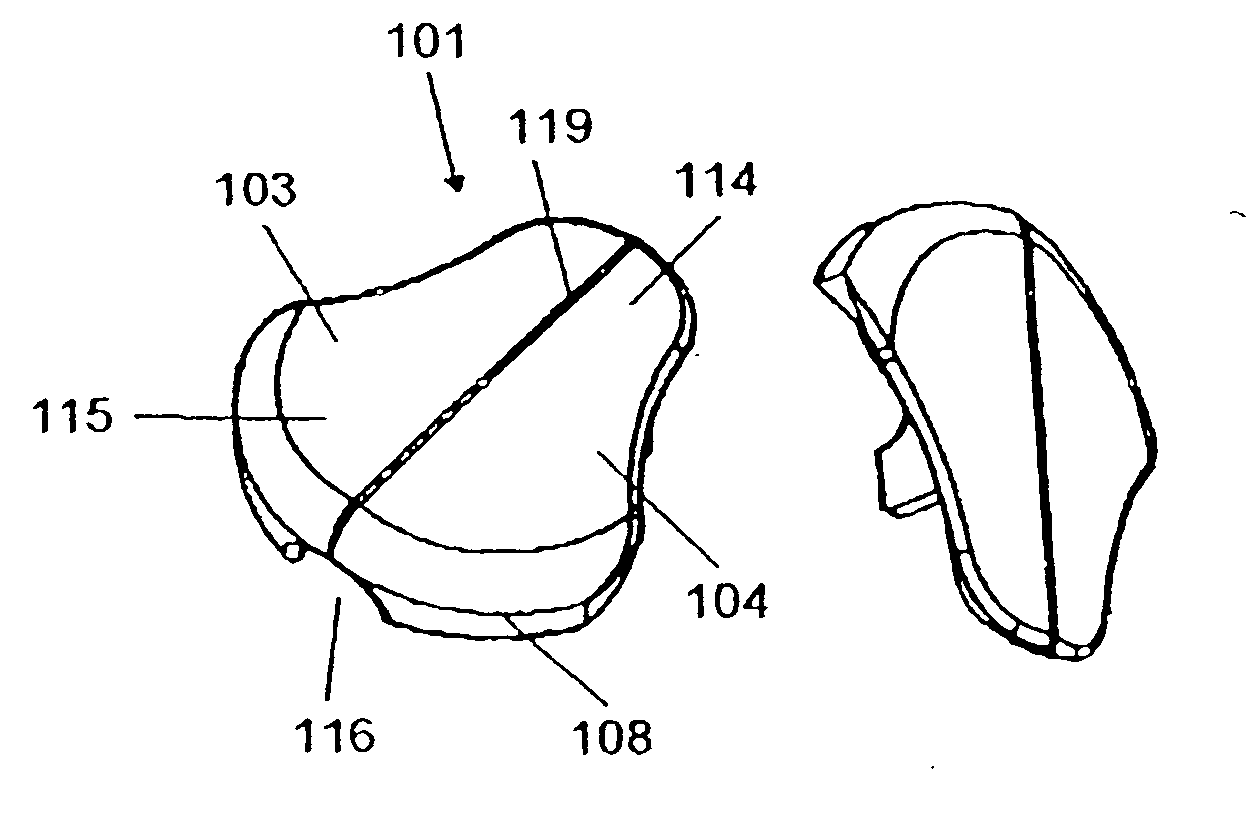

Cover

A cover (101) for being located on an infusion device, which cover (101) comprises an upper plate element (103) with an upper face (104) and a lower face (105) oriented towards the upper face of the infusion device, wherein the lower face (105) of the plate element (103) comprises attachment means (106), which means cooperate with elements on the infusion device. Hereby the risk of bacteria and soil collected thereon penetrating into the construction, is reduced considerably, and likewise the cover yields a smoother surface with an ensuing minimisation of the risk of the infusion device being torn off.

Owner:UNOMEDICAL AS

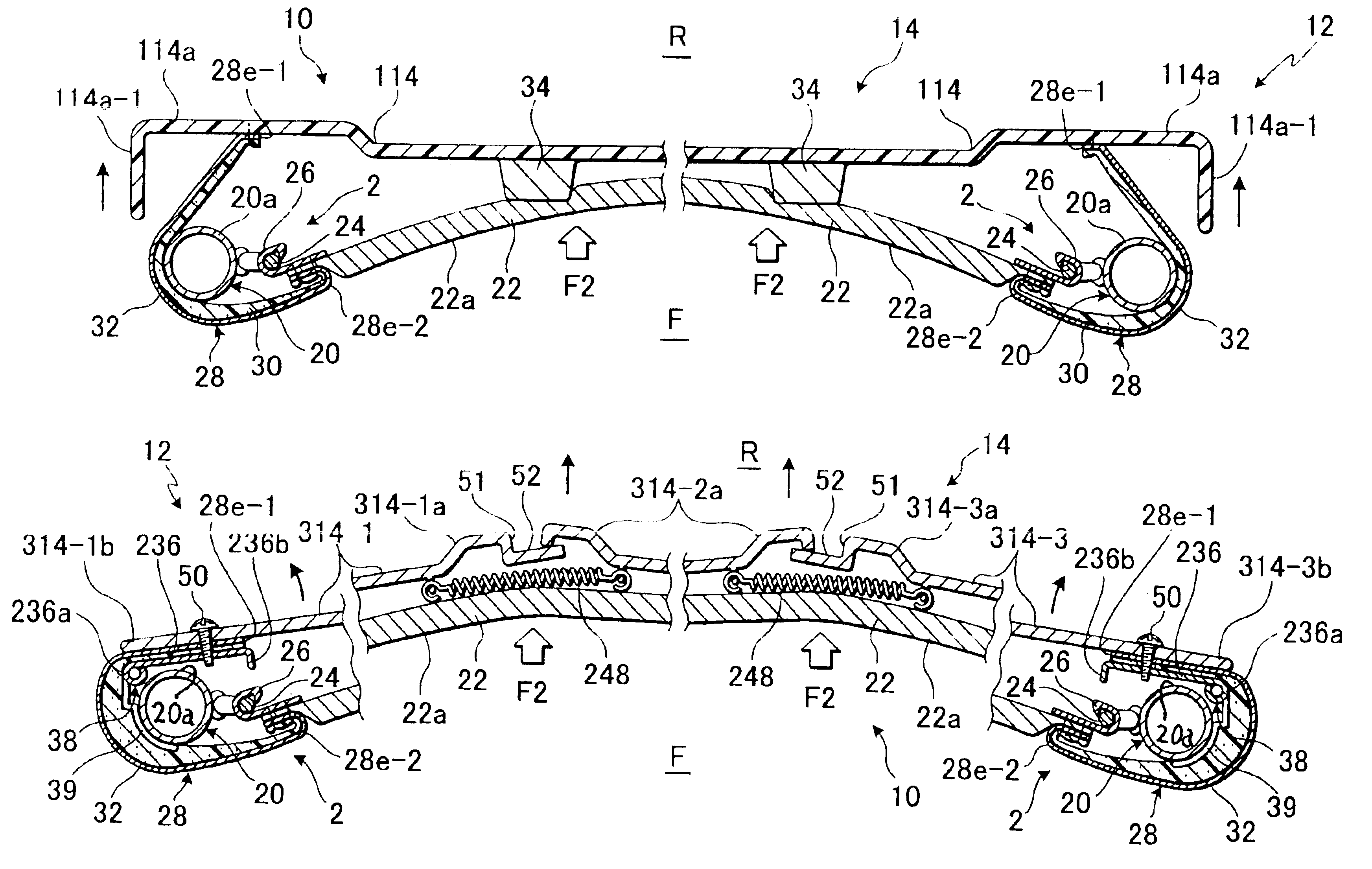

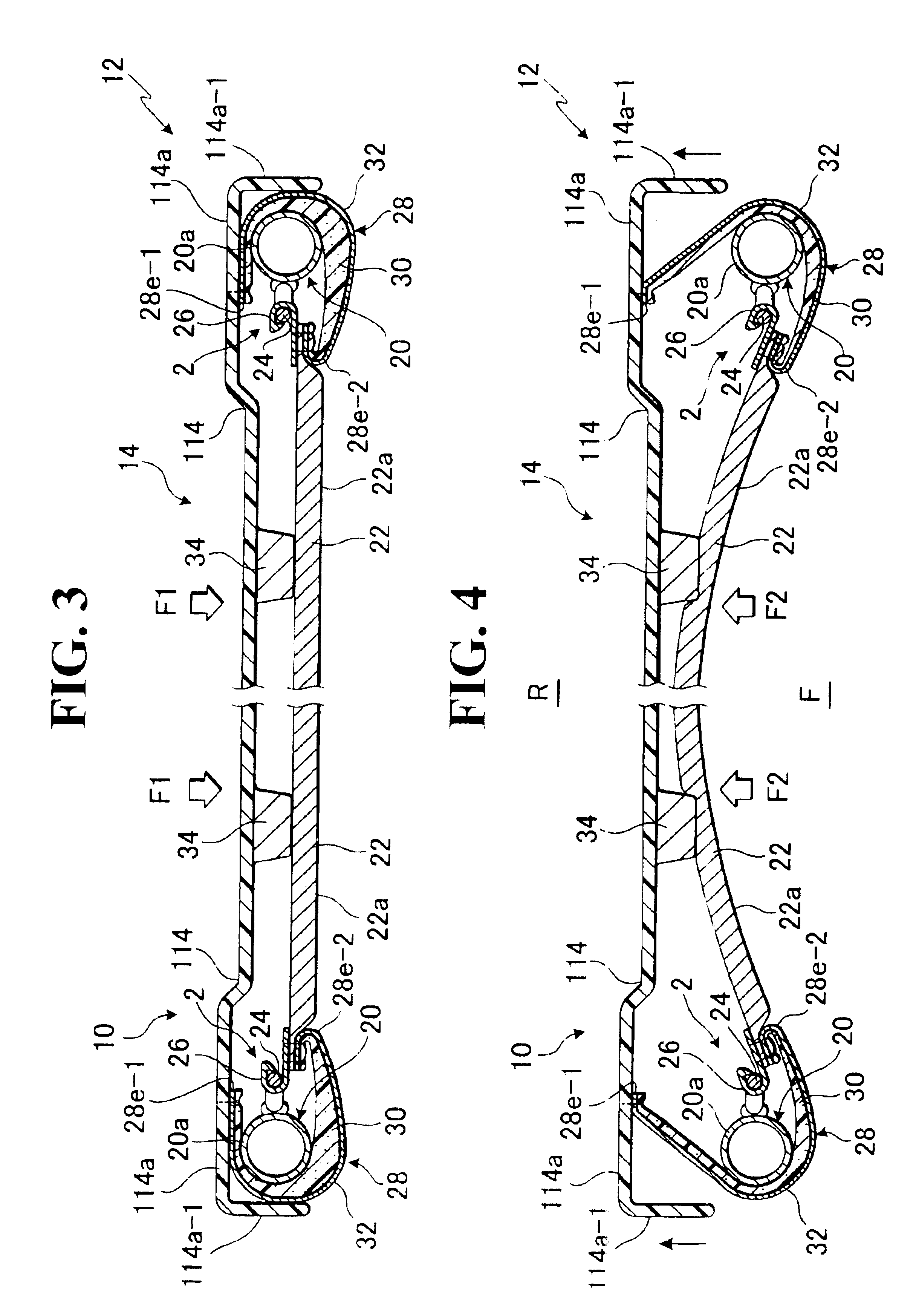

Seat back structure of vehicle seat

A seat back structure of vehicle seat which is reduced in thickness and yet deformable to provide a deep cushiony touch to a back of passenger. According thereto, an elastic back support element and a back board element are respectively provided in one and another sides of seat back, and a movable connection element is provided so as to allow displacement of the back board element from a home position, while allowing the elastic back support element to be resiliently warped. The back board element is normally biased by a biasing element of the home position. A stopper element is defined in the seat back for preventing movement of the back board element from the home position to the elastic back support element. The back board element per se may be formed by a plurality of plate elements connected movably with one another.

Owner:TACHI S CO LTD

Cover plate

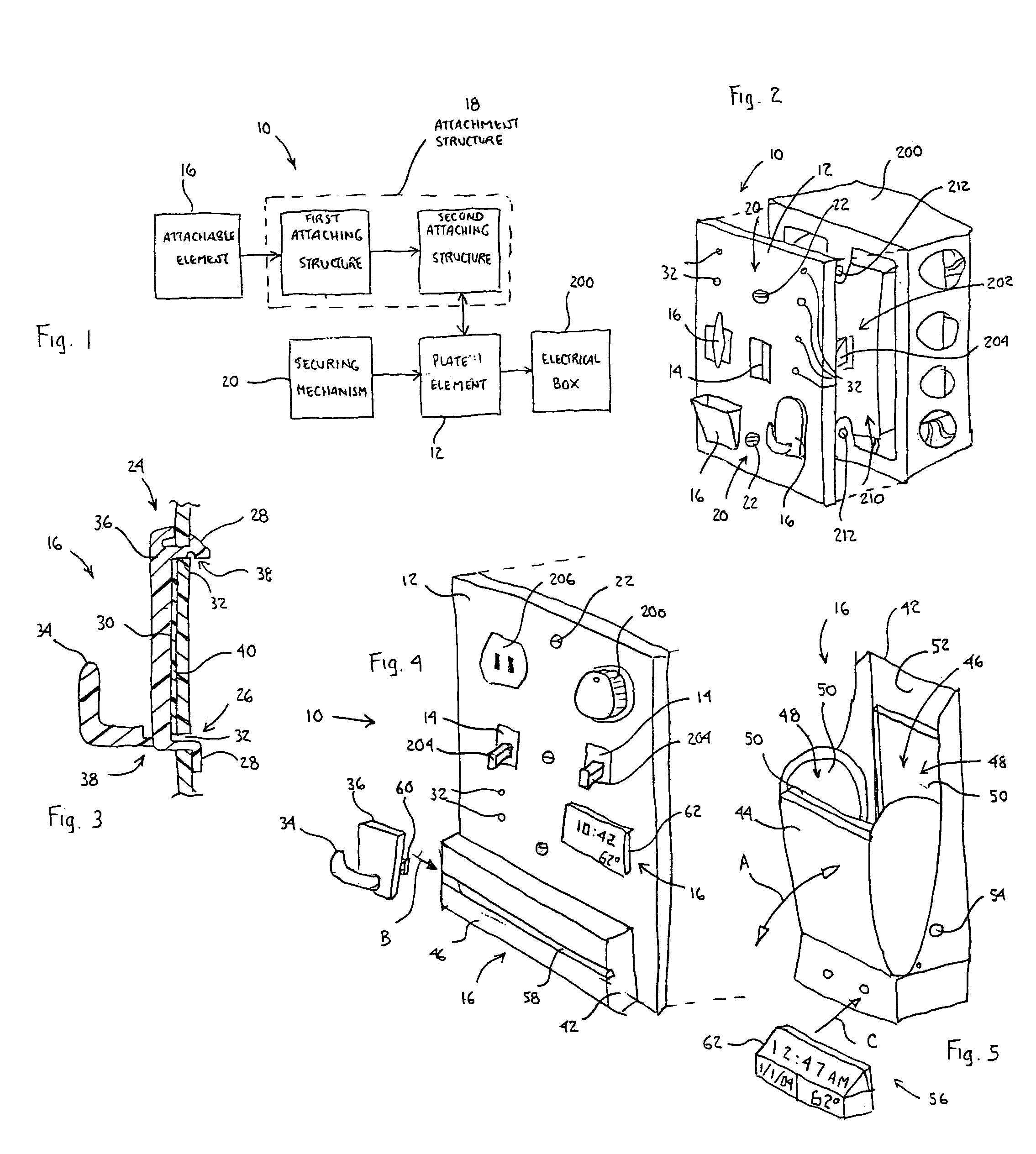

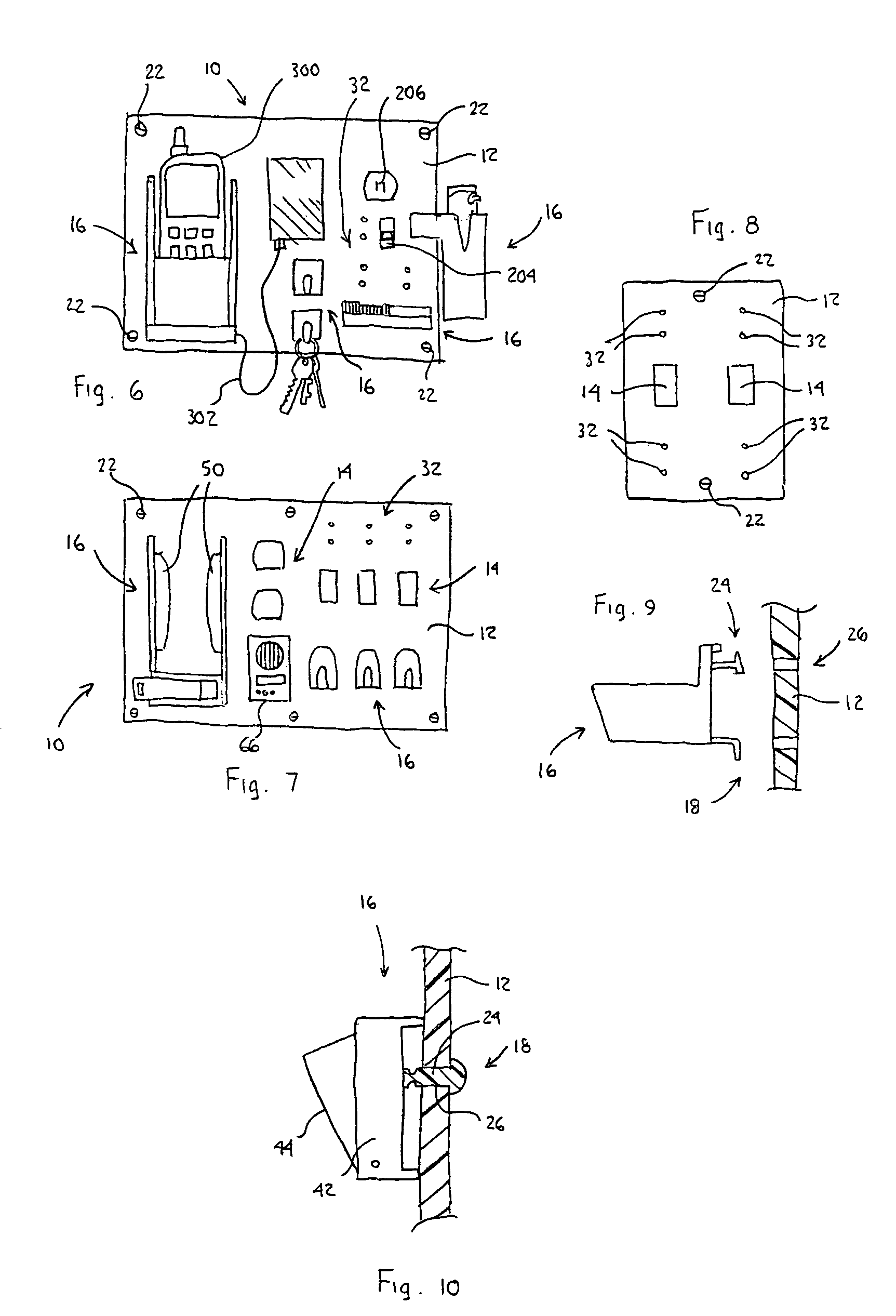

InactiveUS7067737B2Easy to manufactureEasy to installCasings/cabinets/drawers detailsEngineeringPlate element

Owner:MALLEN KENNETH J

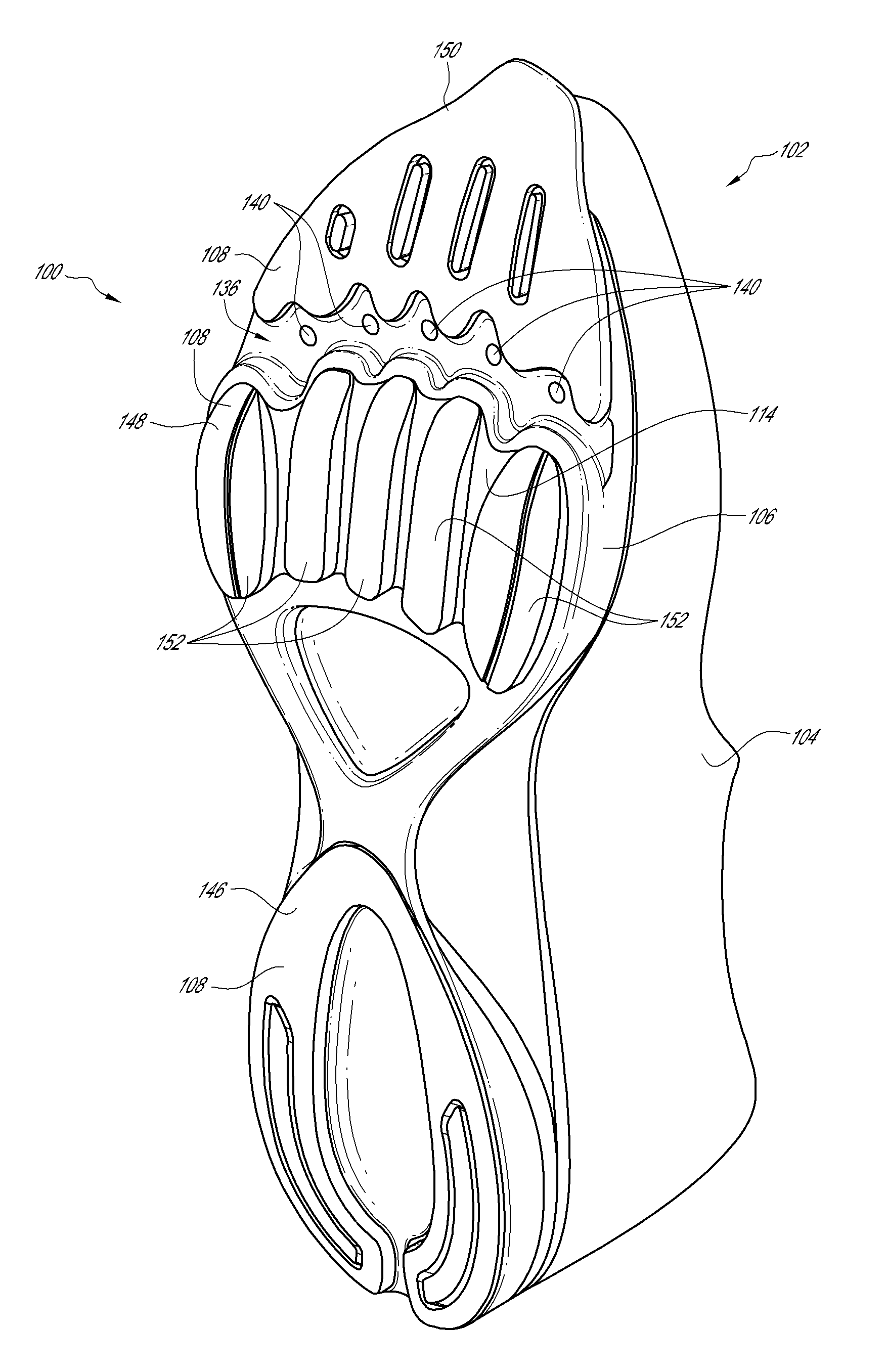

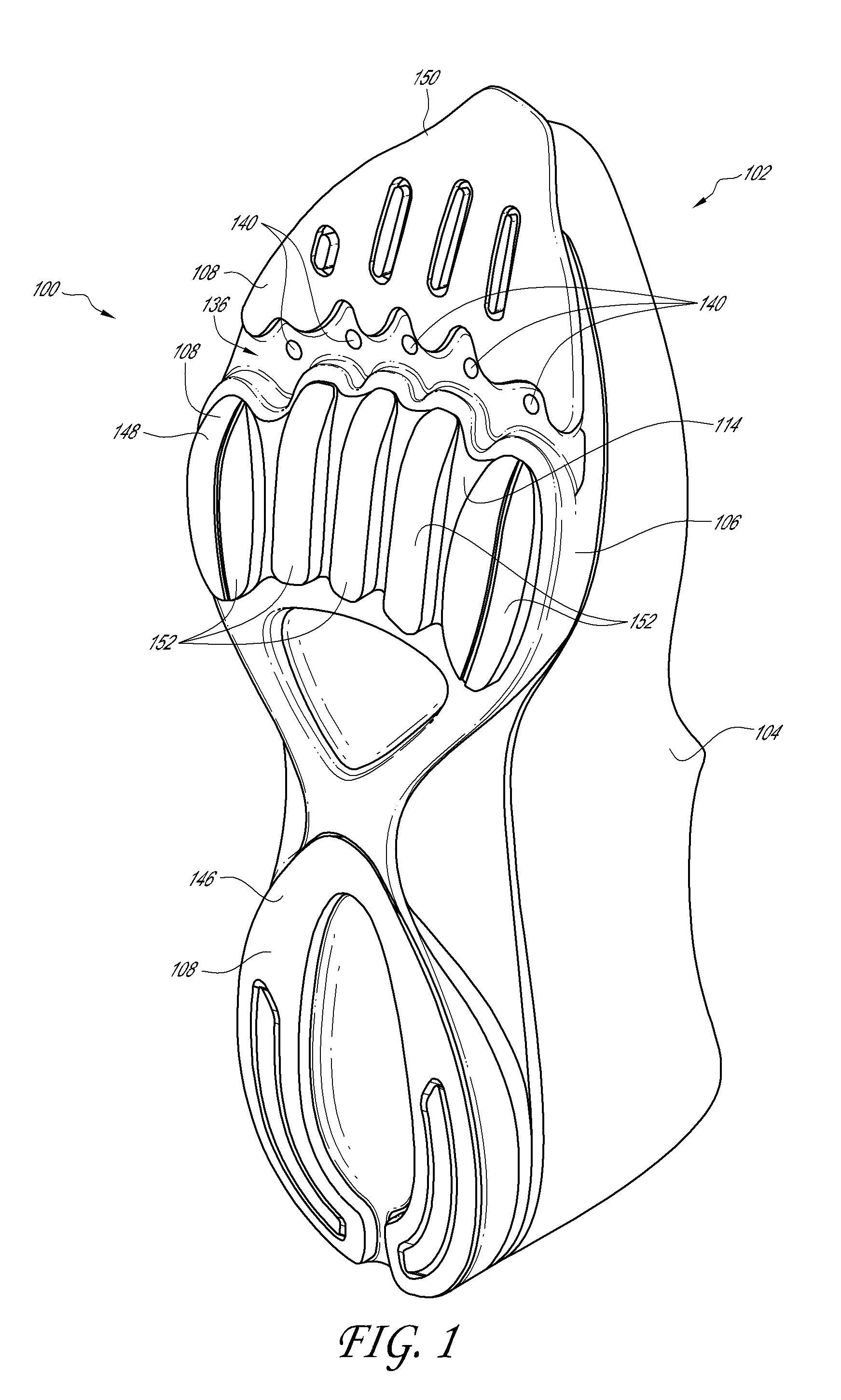

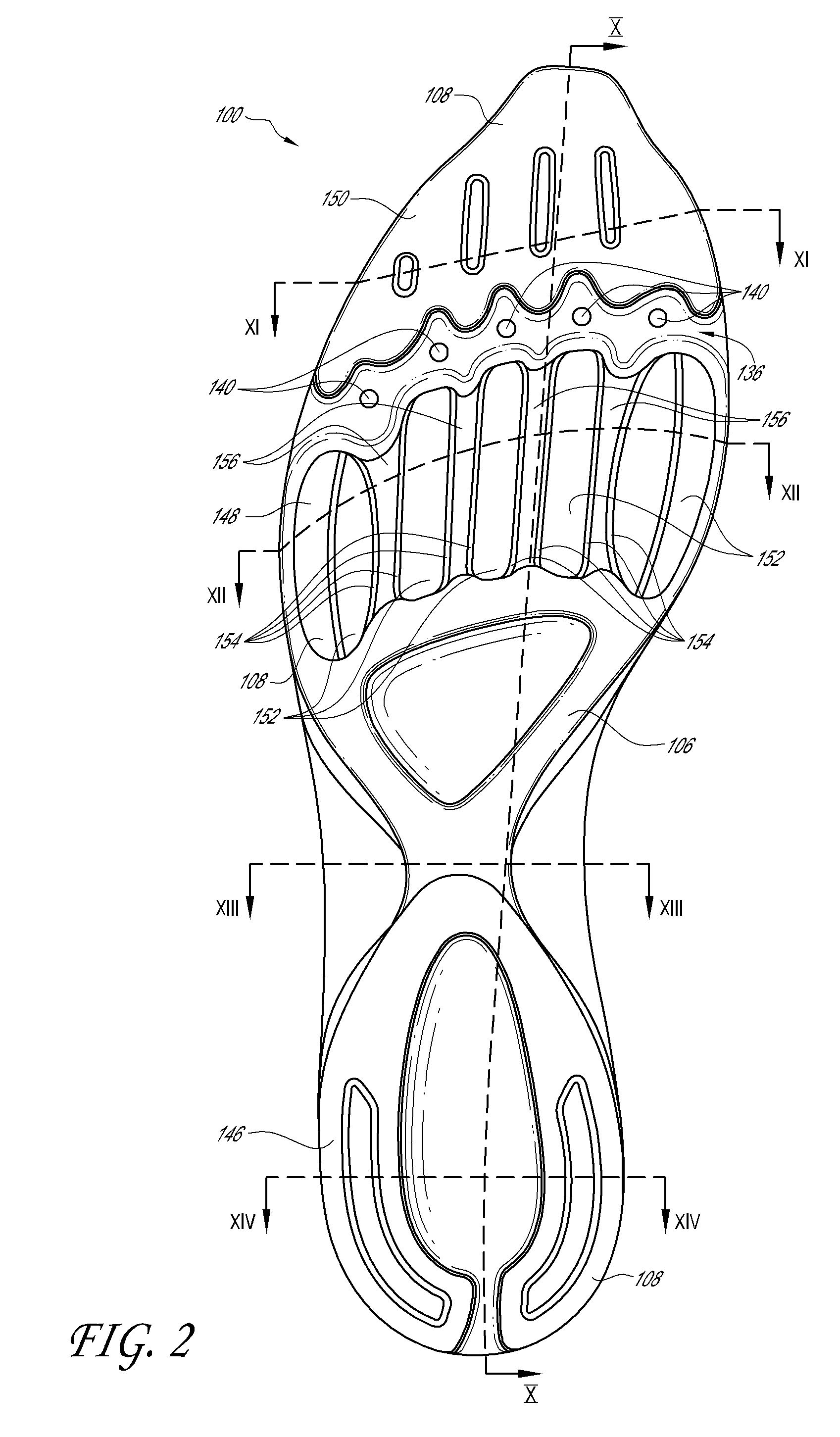

Shoe soles for shock absorption and energy return

A shoe sole can comprise one or more resiliently compressible elements received in a foundation and located by the foundation to underlie a portion of a foot, such as metatarsal heads, when the shoe is worn. The resiliently compressible element or elements can be shaped to reduce coupling of compression of adjacent regions of the resiliently compressible element. One or more plate elements can be positioned between the resiliently compressible elements and the foot, e.g. under the metatarsal heads. The plate elements can be separated from each other by spaces, such as slots, to reduce coupling of movement of adjacent plate elements. The plate elements can be elastically interconnected at the spaces between them. A plurality of lugs configured to contact the ground can be located on a lower surface of the foundation such that they are generally aligned with the plate elements. The plurality of lugs can be elastically interconnected.

Owner:NEWTON RUNNING CO INC

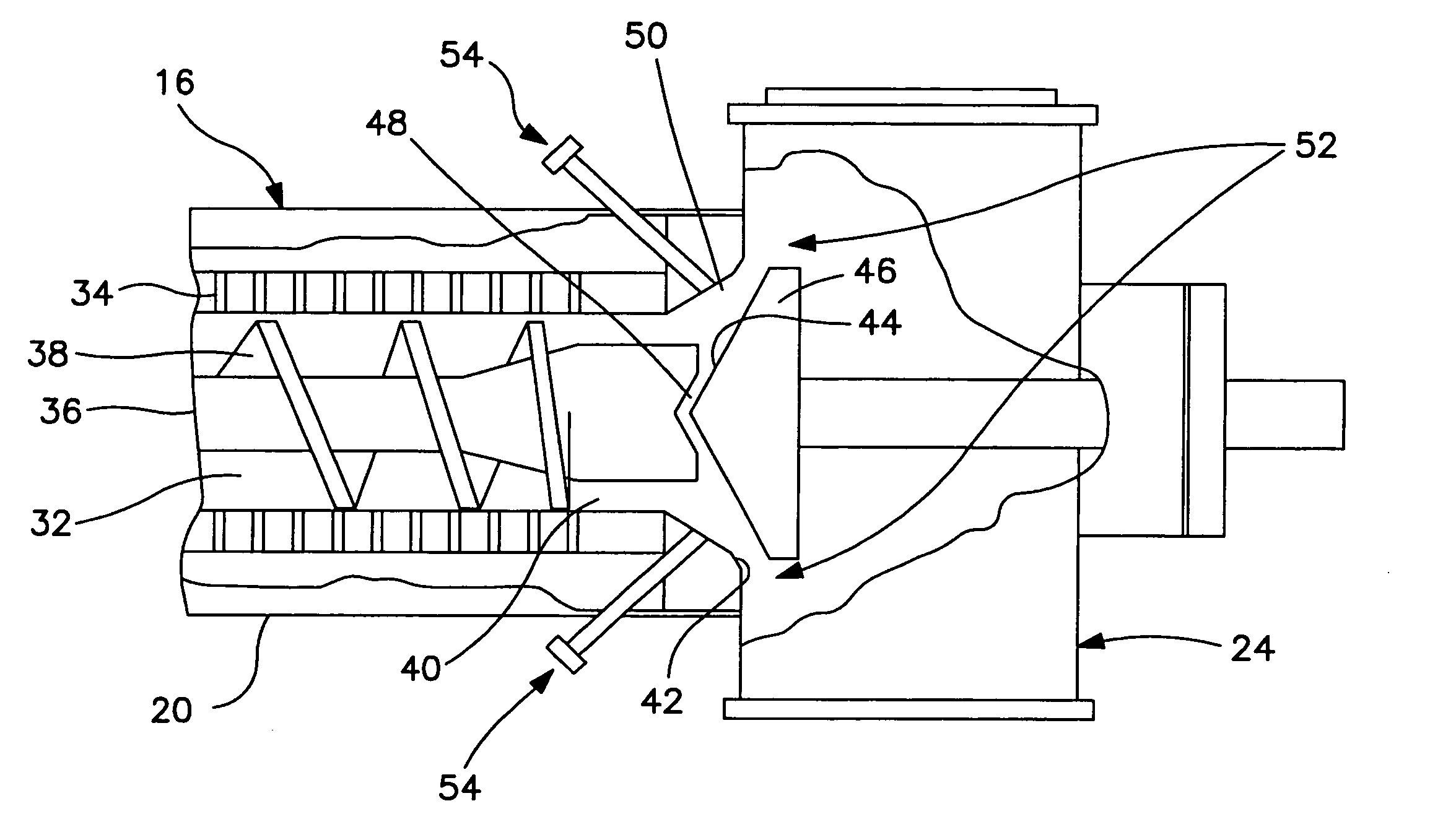

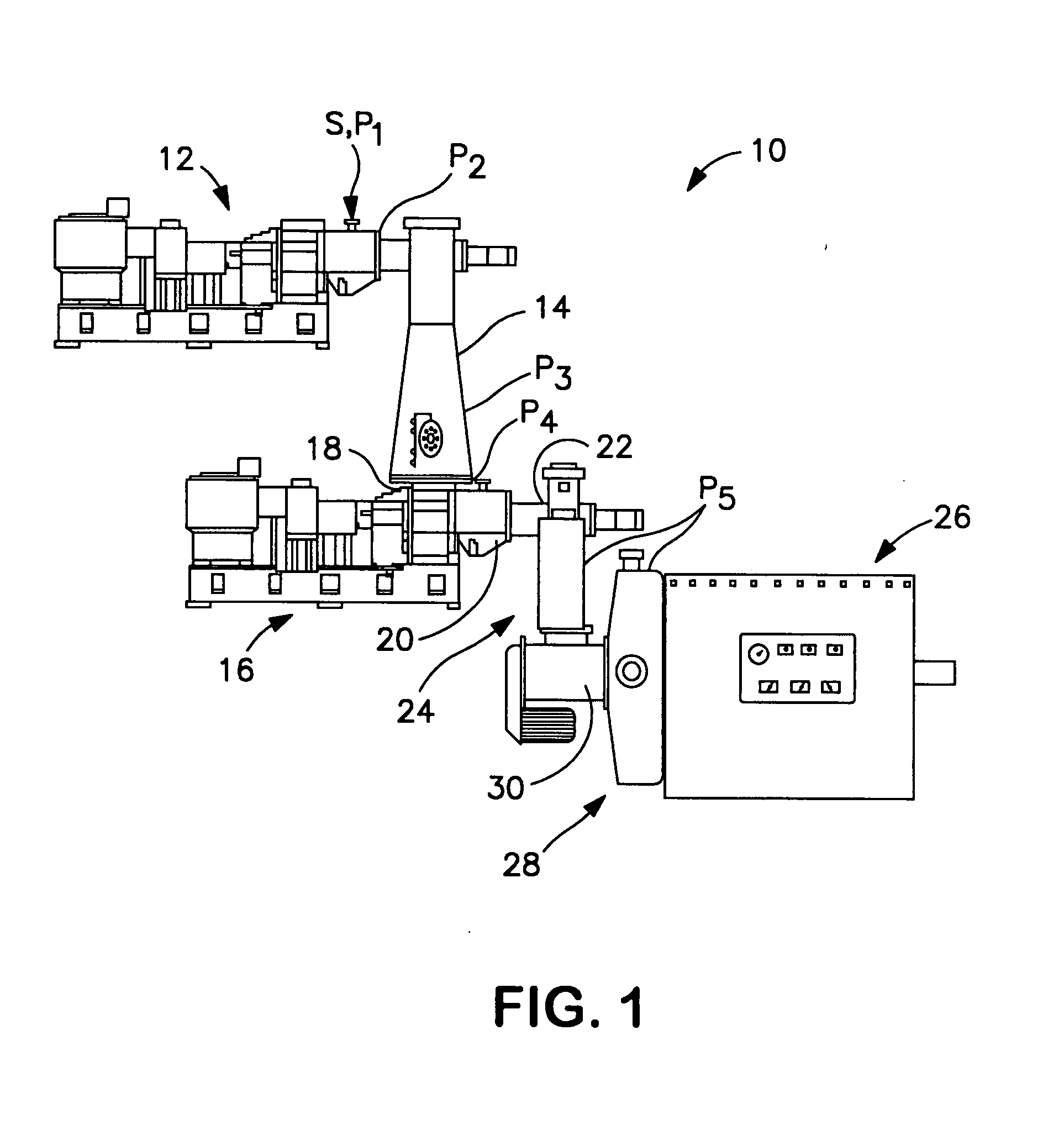

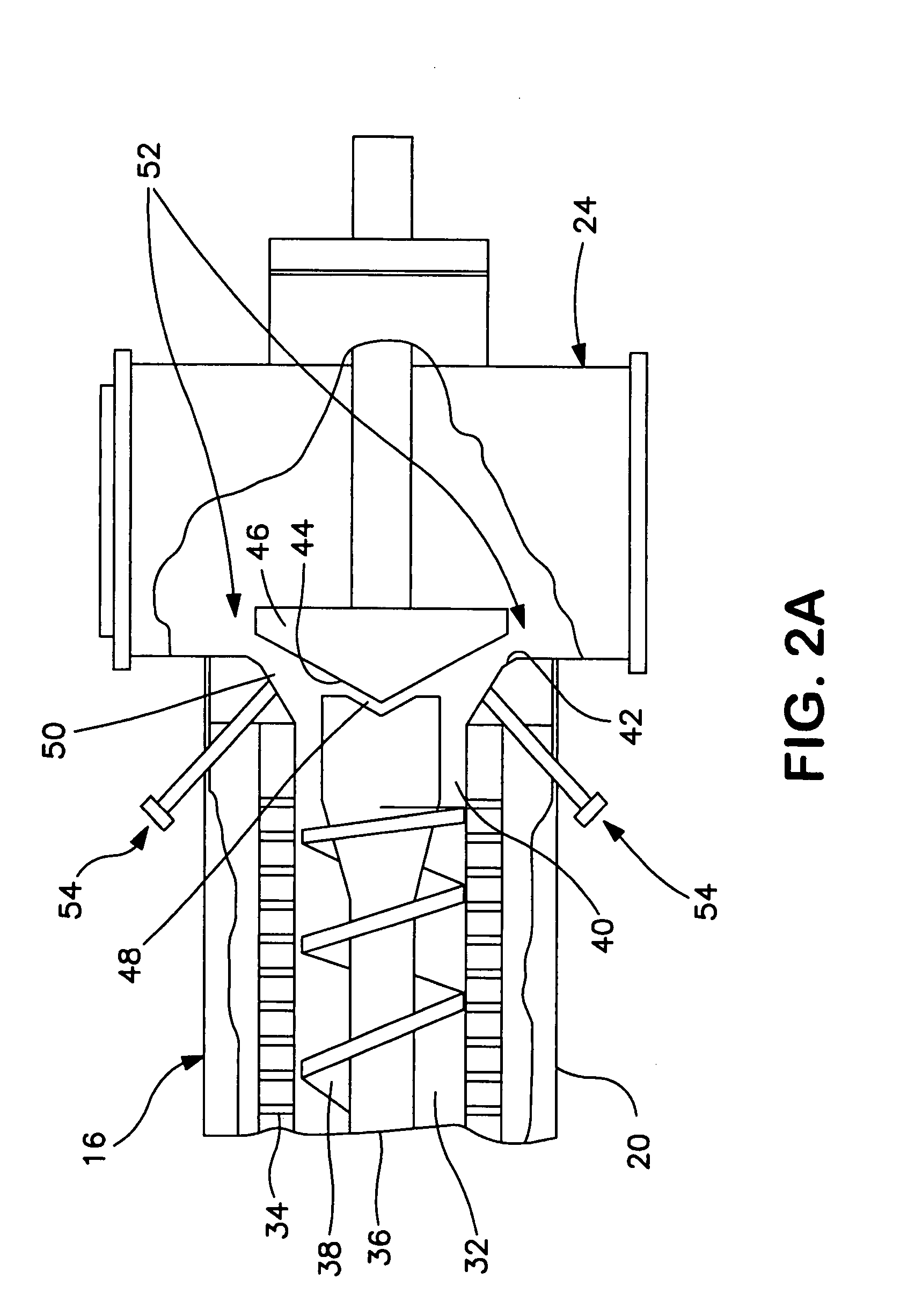

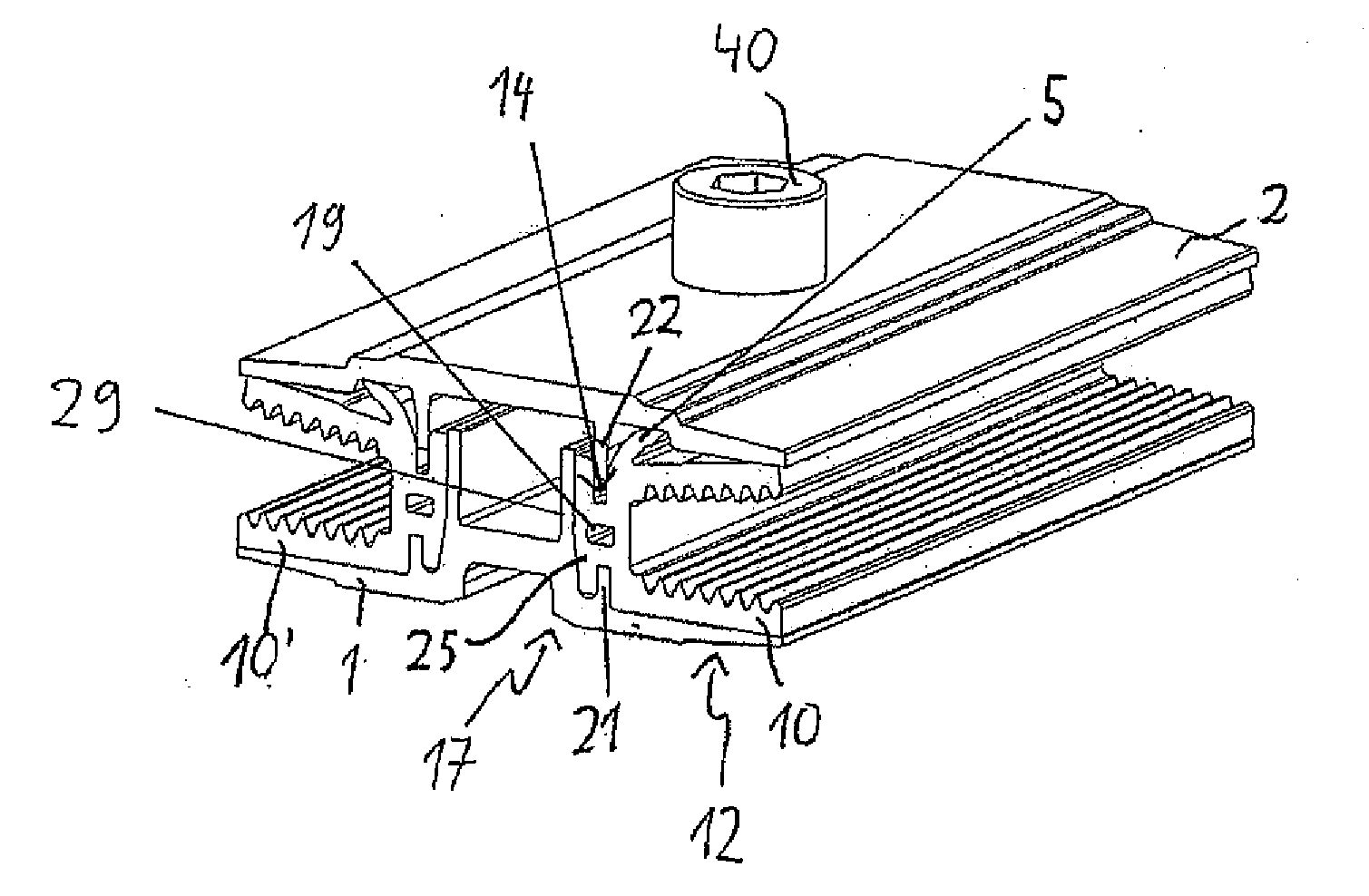

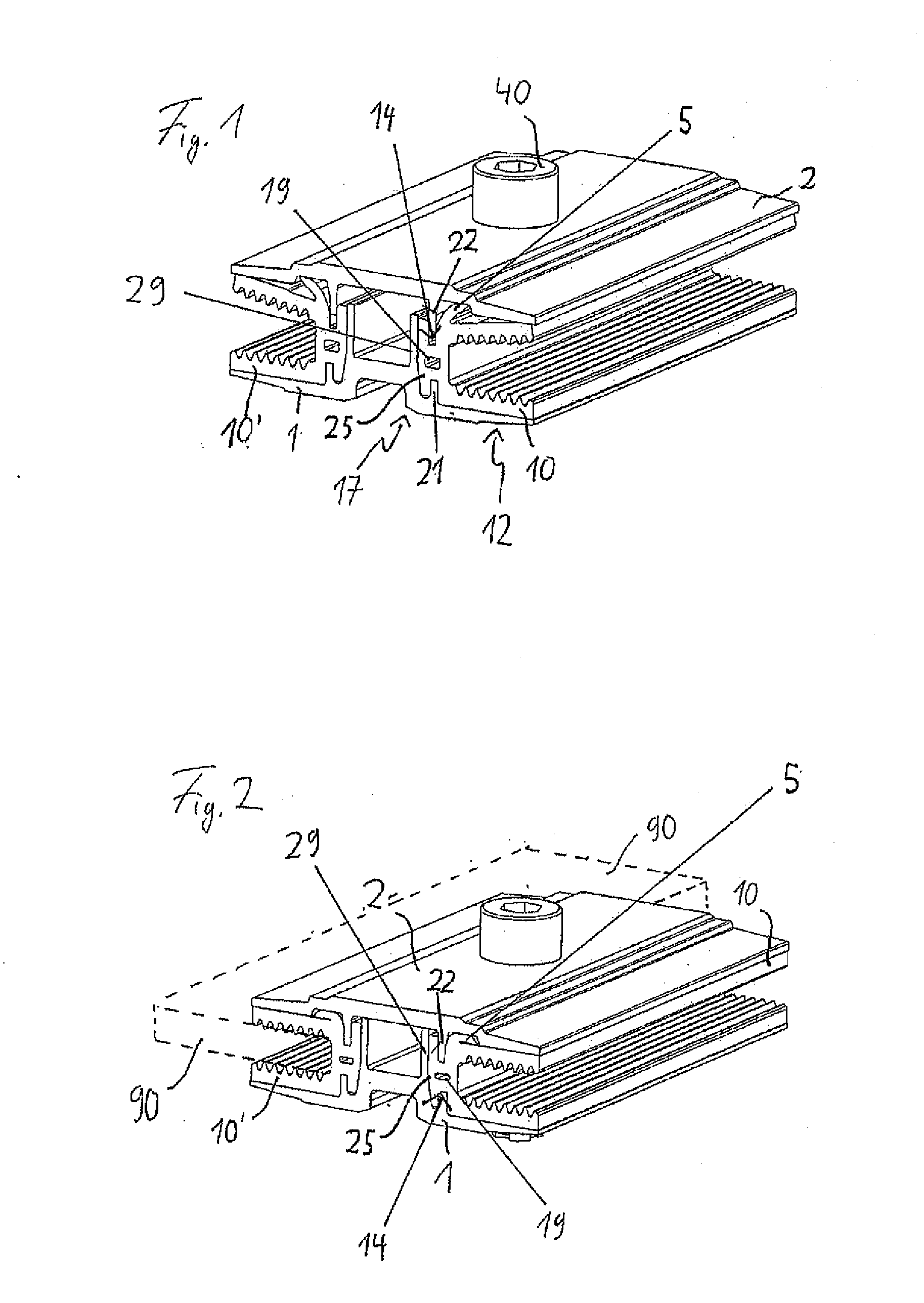

Disc refiner with increased gap between fiberizing and fibrillating bands

ActiveUS20070164143A1Minimizing componentSpace minimizationCocoaPulp beating/refining methodsFiberBand pattern

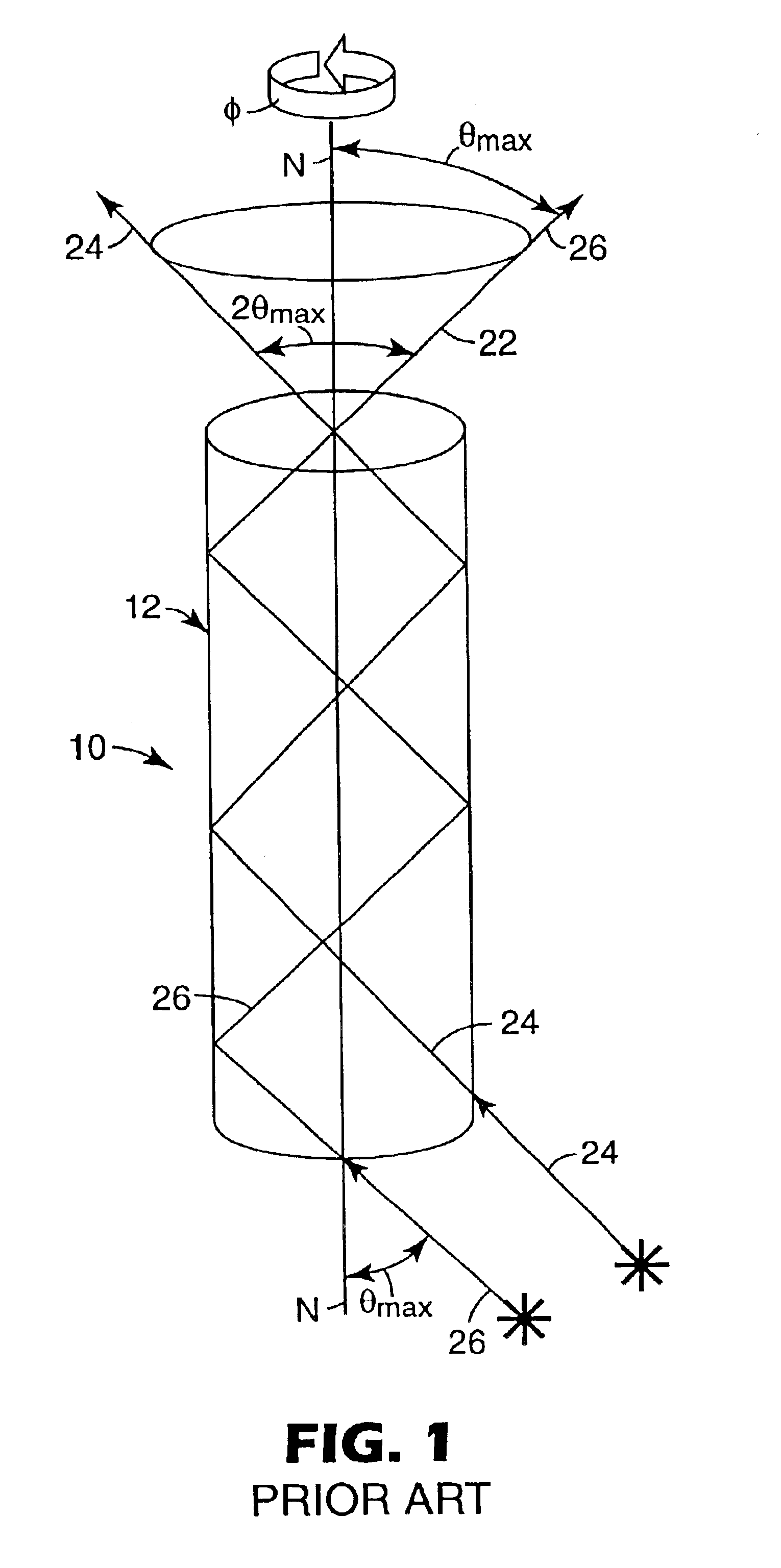

Plate elements, a plate configuration, and associated system for thermomechanical refining of wood chips wherein destructured and partially defibrated chips are fed to a rotating disc primary refiner, where opposed discs each have an inner band pattern of bars and grooves and outer band pattern of bars and grooves, such that substantially complete fiberization (defibration) of the chips is achieved in the inner band and the resulting fibers are fibrillated in the outer band. One embodiment is directed to a pair of opposed co-operating refining plate elements for a flat disc refiner wherein the bars and grooves on each of the inner bands form an inner feed region followed by an outer working region, the bars and groove on each of the outer bands form an inner feed region followed by an outer working region, and the gap and / or material flow area formed when the plates are placed in front of each other increases between the inner working region and the outer feed region.

Owner:ANDRITZ INC

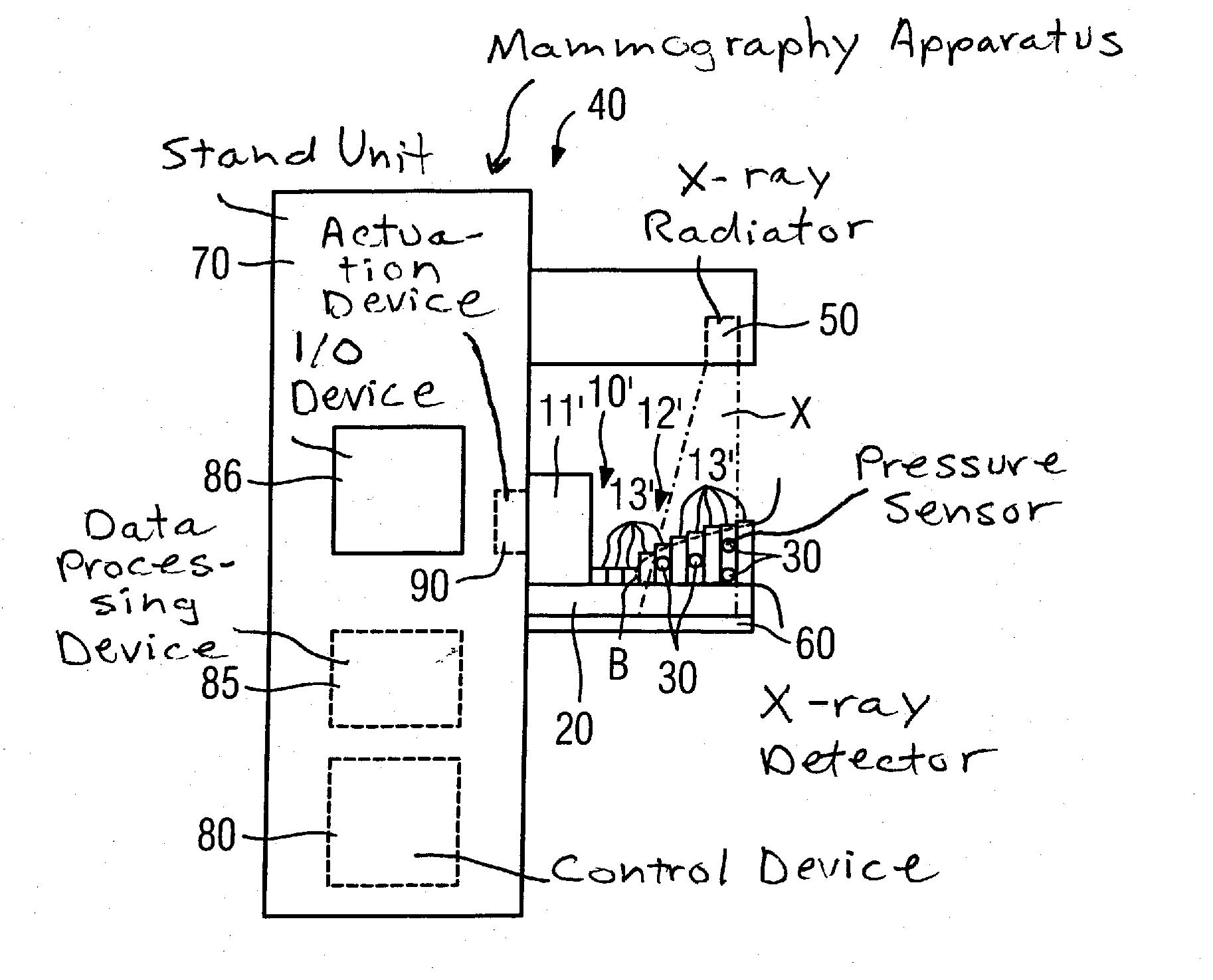

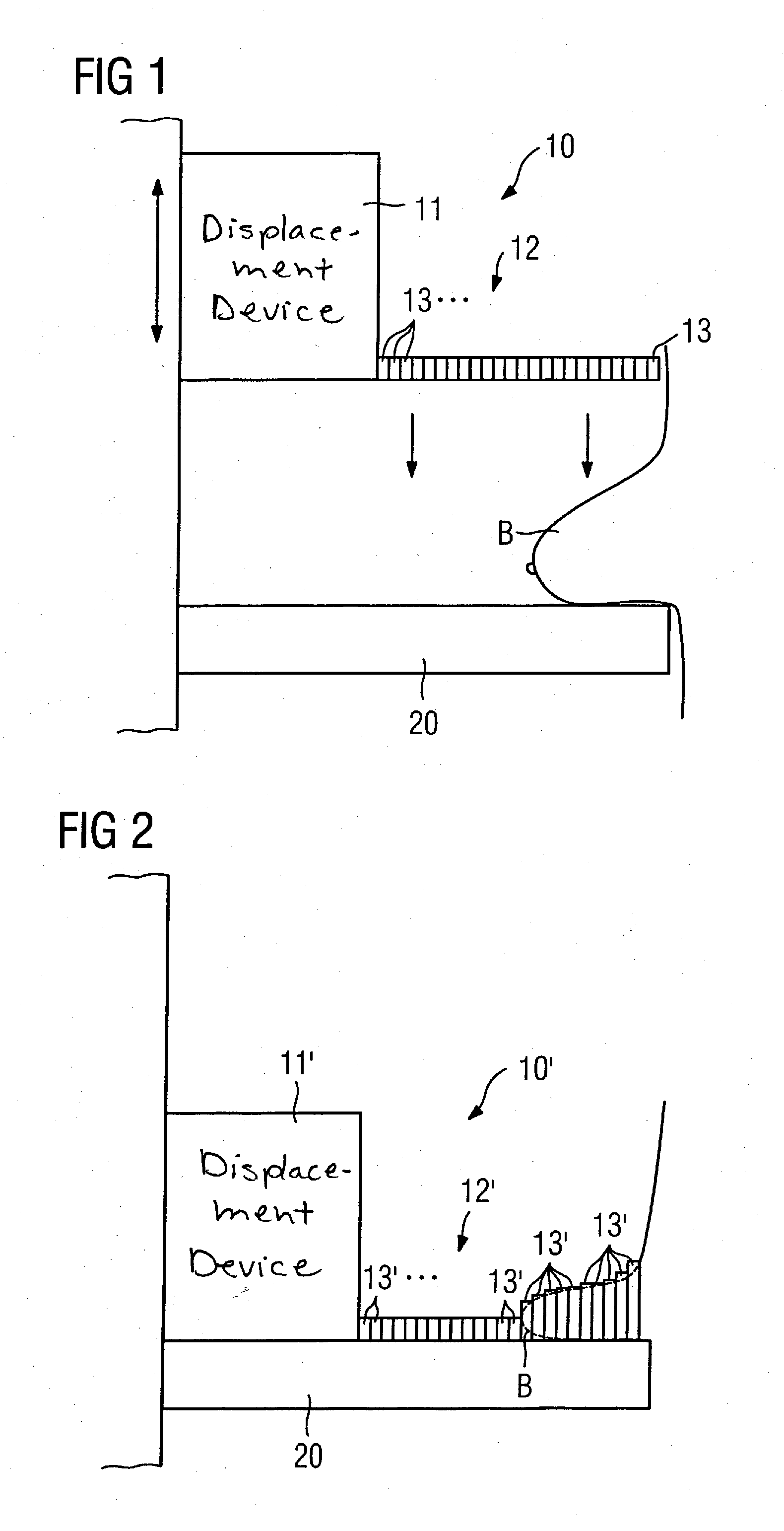

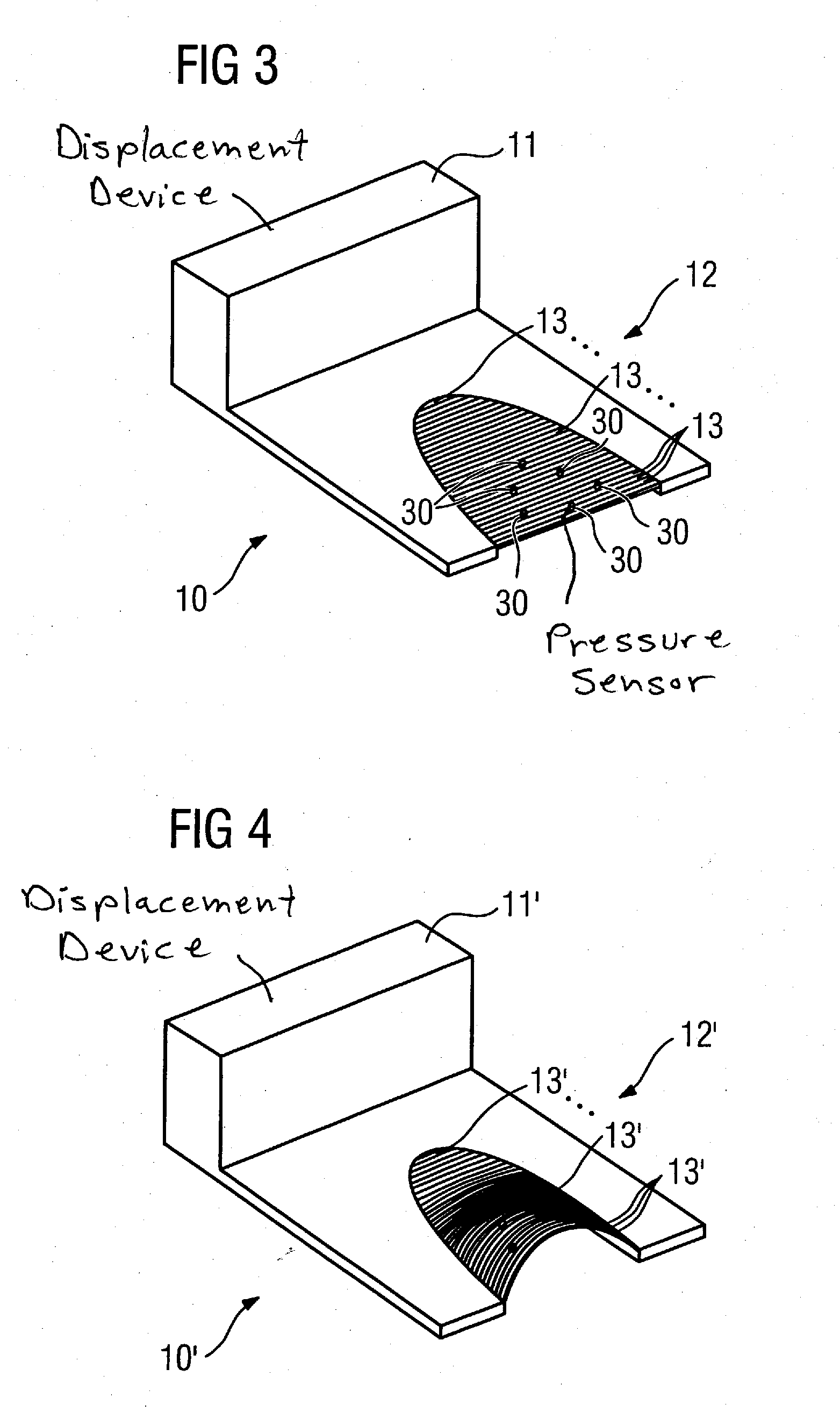

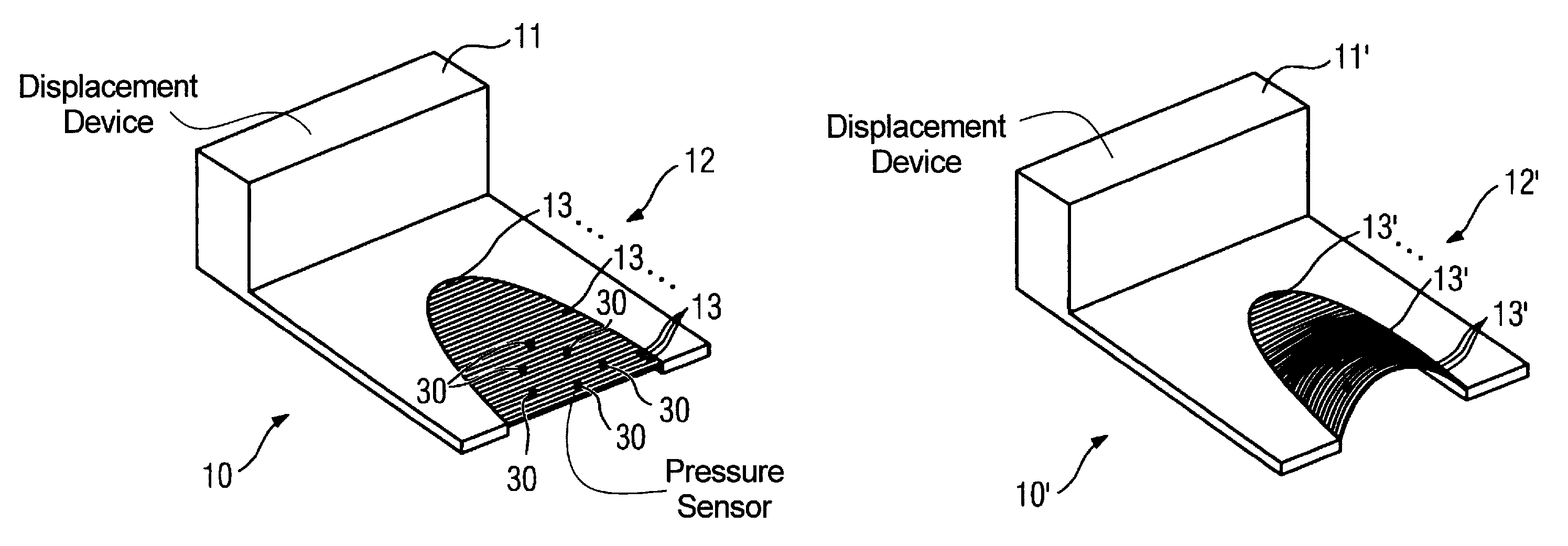

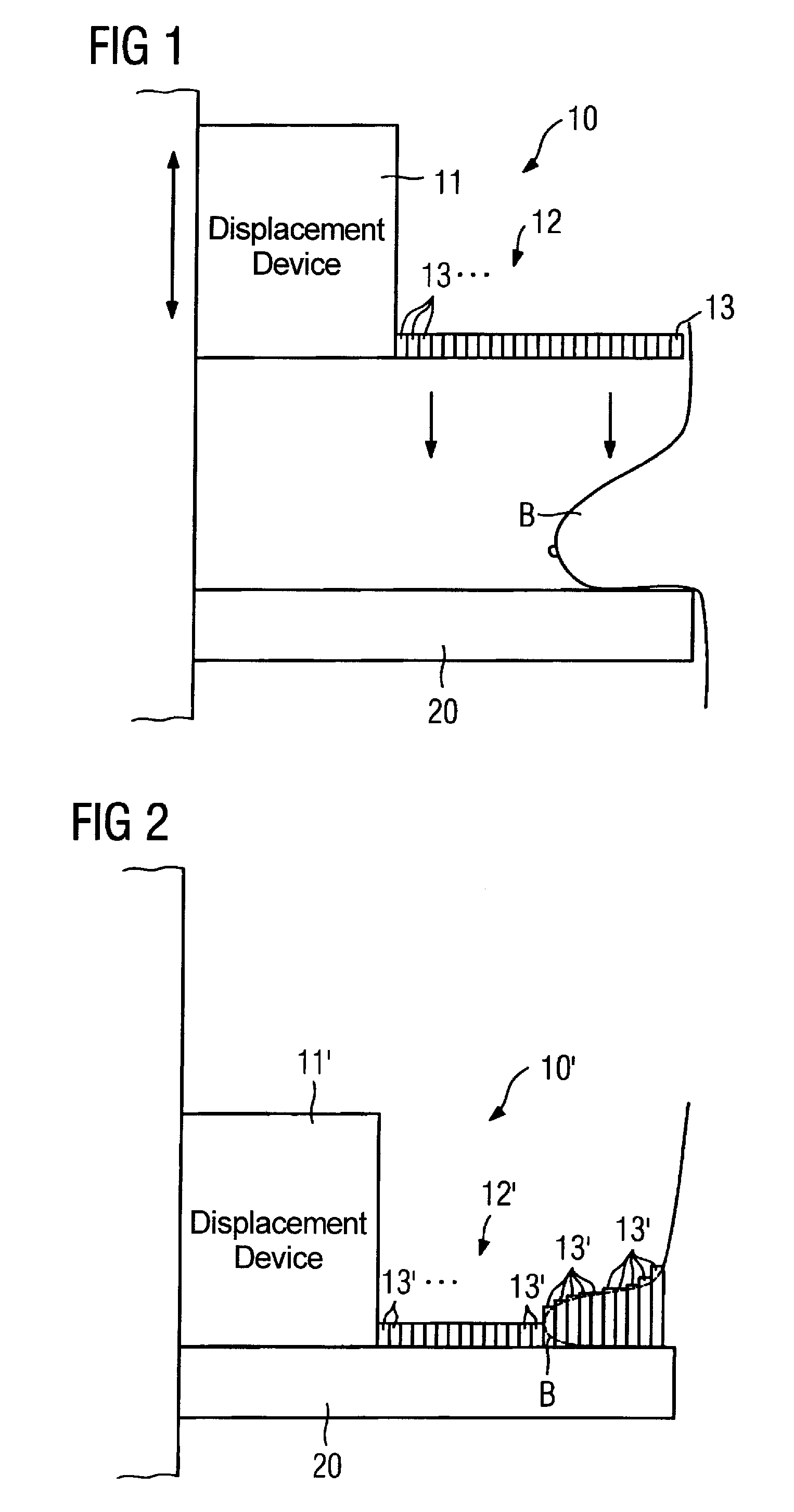

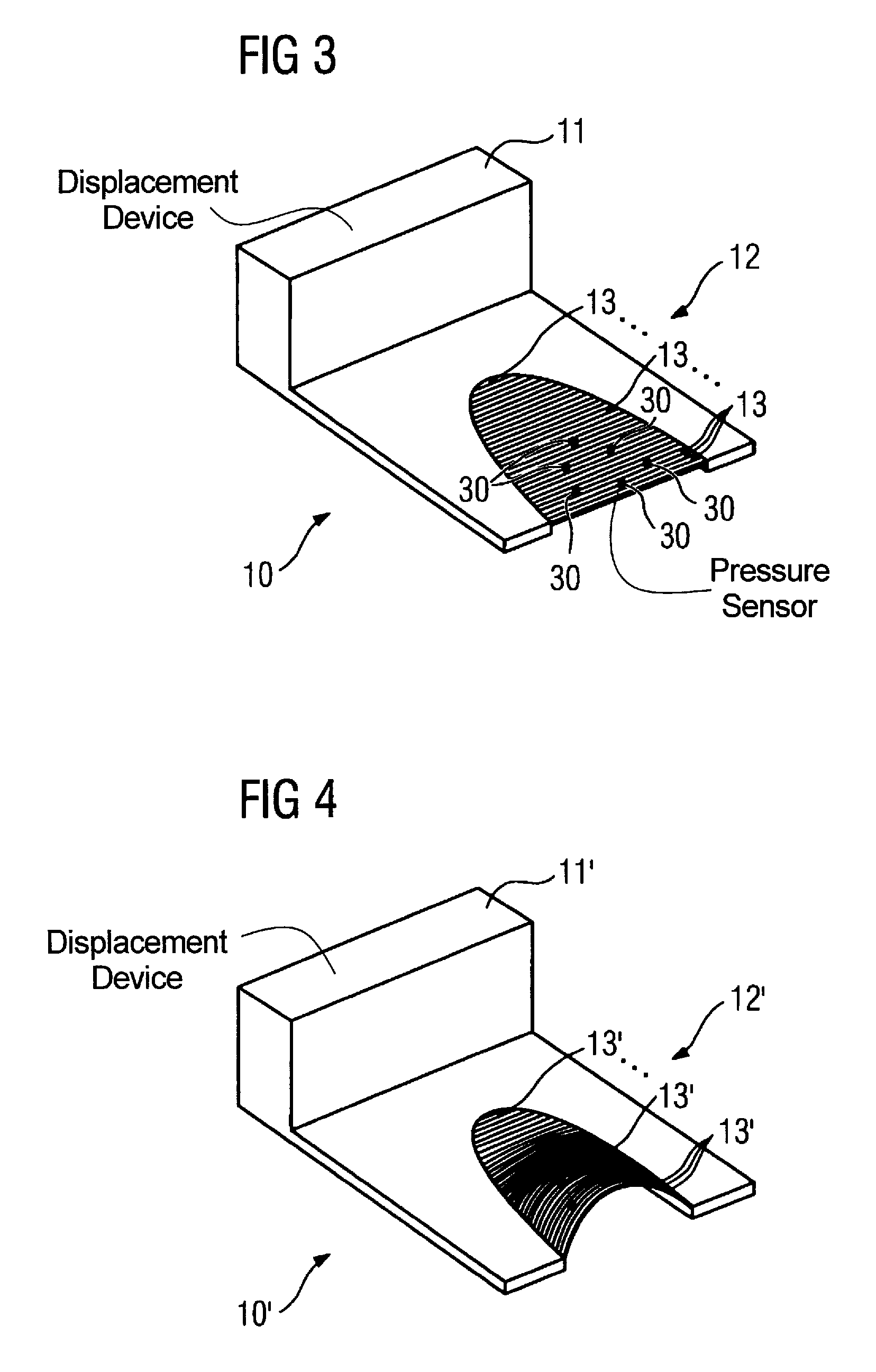

Compression device and method for adjustment of a compression pressure

InactiveUS20080043904A1Sufficient spatial resolutionImprove spatial resolutionOperating chairsPatient positioning for diagnosticsCompression deviceEngineering

A compression device has a compression plate that applies a pressure to a subject on a support plate. The compression plate has a number of elastically-deformable compression plate elements that are substantially transparent for an examination field used with the compression device. In a method for compressing a subject, at least one pressure sensor measures the pressure applied by a compression device to a subject, and wirelessly supplies a signal representing the detected pressure to a control unit, wherein the detected pressure is compared to a stored compression pressure value. The control device adjusts the pressure applied to the subject by the compression device so that the pressure detected by the sensor is equal to the stored compression pressure value.

Owner:SIEMENS HEALTHCARE GMBH

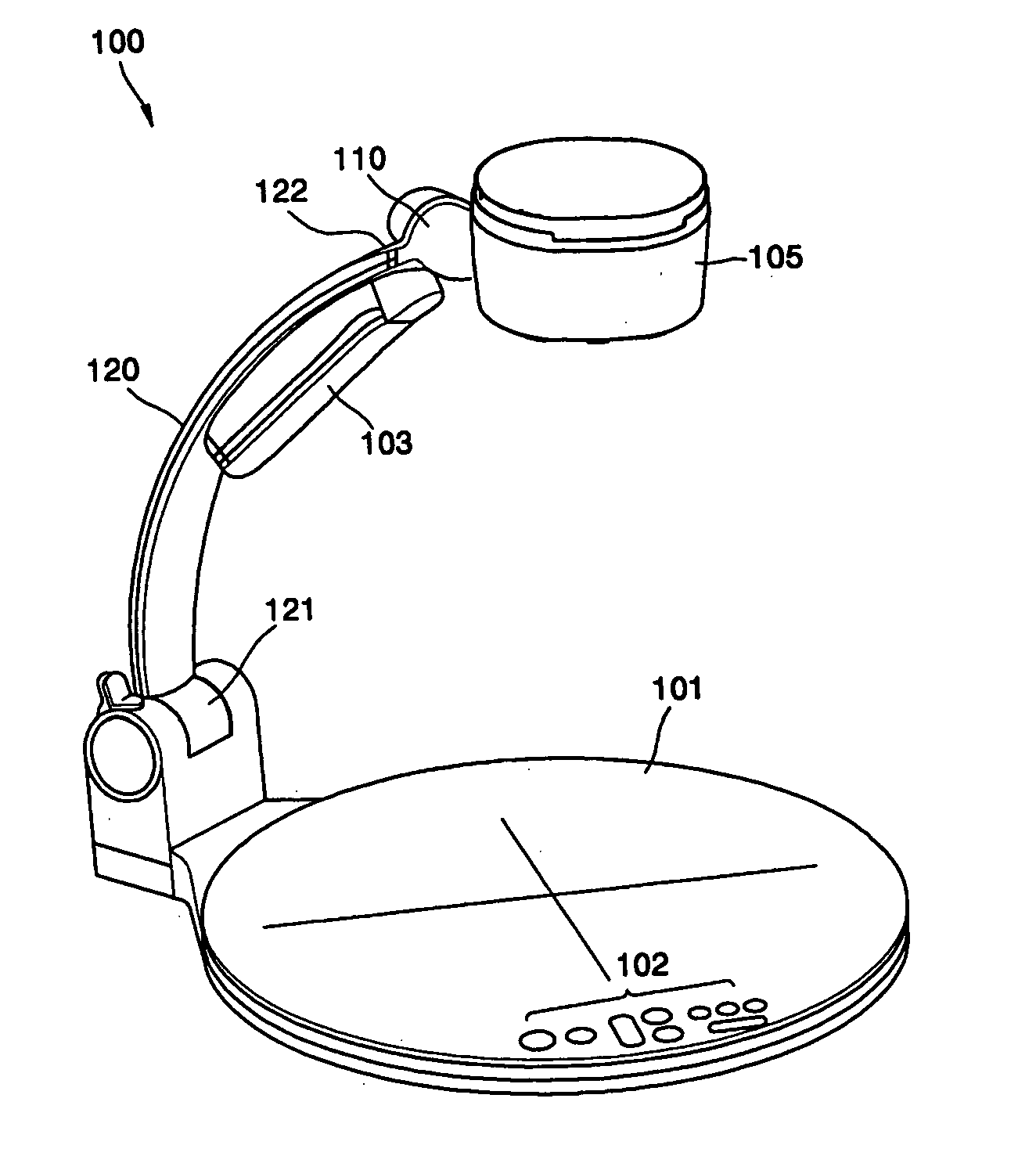

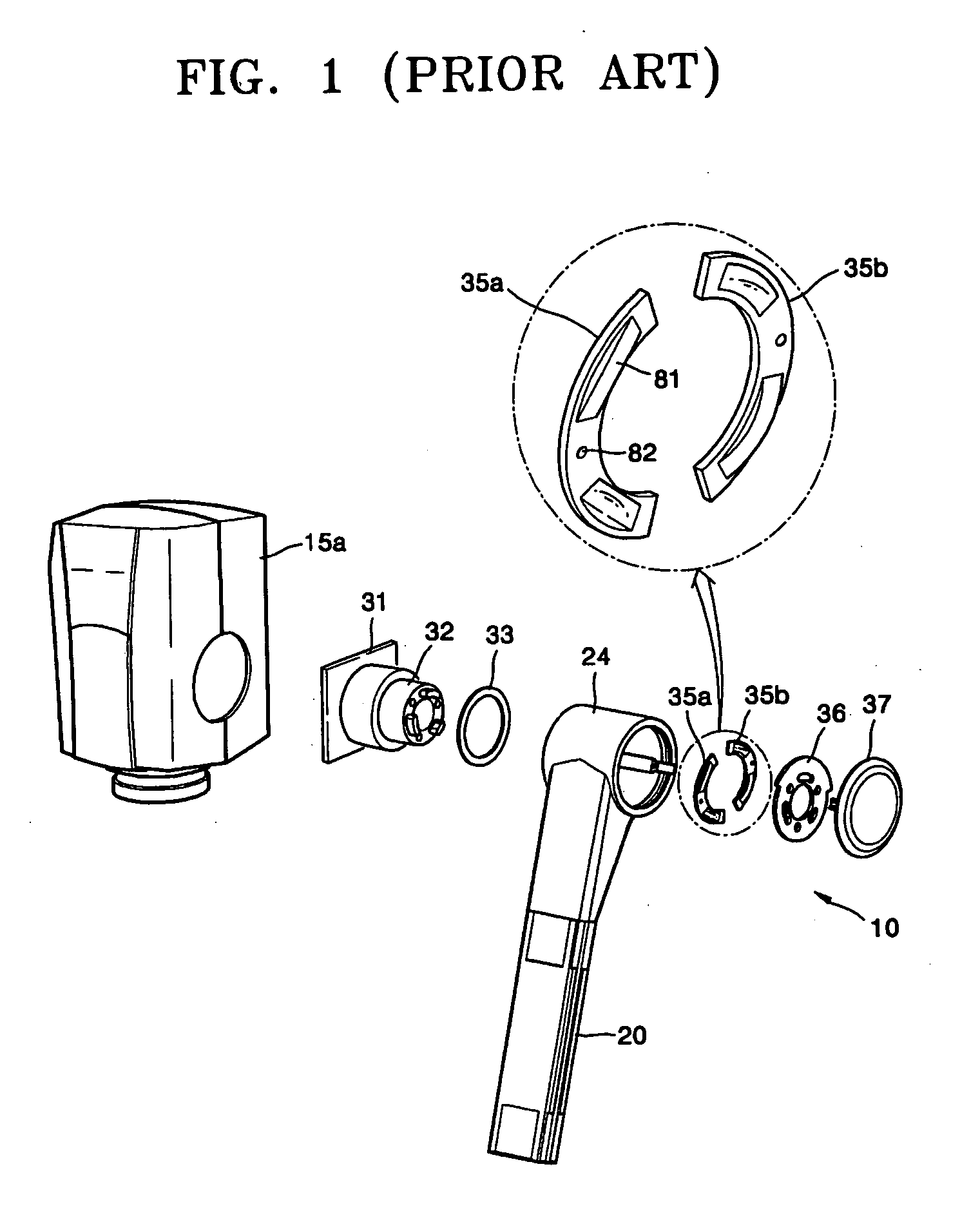

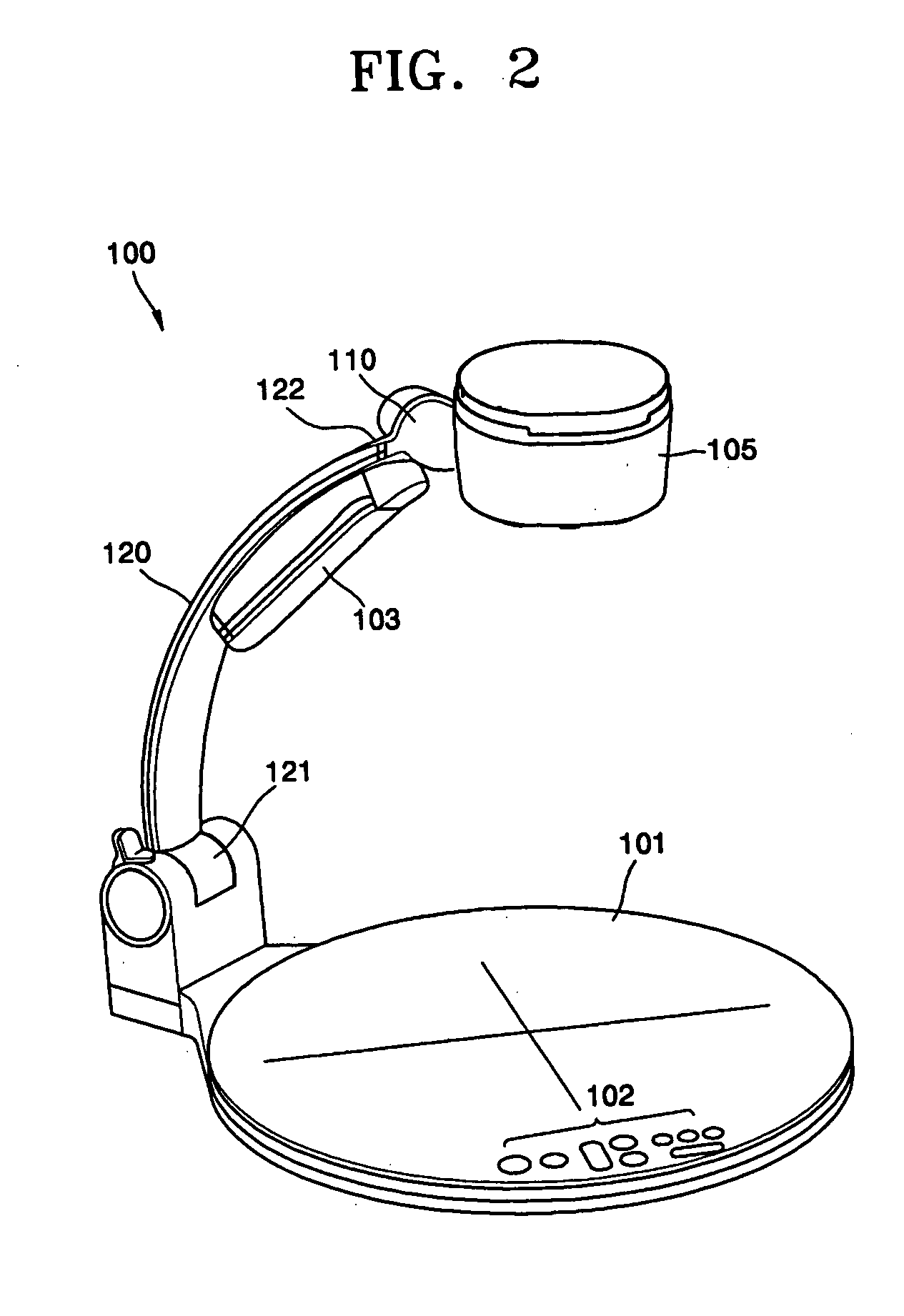

Camera rotation support apparatus for video presenter and video presenter having the same

InactiveUS20050237425A1Easy to adjustMeet convenient maintenanceTelevision system detailsProjectorsComputer sciencePlate element

Provided is a camera support structure for a video presenter which allows rotation of a camera connected to a base of the video presenter and supports the camera in an accurate location. The camera support structure of a video presenter includes a support arm, one end of which is joined with the base, an rotation guide member that includes an annular member having a ring shape in which a plurality of ball receiving holes are formed on one end part of the support arm, biasing elements that includes a plurality of rotation-fixing balls which are inserted into the ball receiving holes from an inner side of the annular member and a portion of the balls are elastically protruded to an outer side of the annular member, a annular plate element, the rotation of which can be prevented by fixing by the rotation-fixing balls and disposed to be able to be rotated on an outer side of the annular member of the rotation guide member, and a camera head that rotates with the annular plate element by coupling with the annular plate element and fixes a camera head having a camera.

Owner:HANWHA TECHWIN CO LTD

Clamp for a plate element, especially for a photovoltaic module

A clamp for at least one plate element, with a first clamp part and a second clamp part, the clamp parts adjustable relative to each other between an open position and a clamping position for the plate element, and with at least one elastomer profile that is arranged between the two clamp parts and that has an area with a U-shaped cross section for gripping the plate element. The elastomer profile has a clamping section that is clamped between the two clamp parts when the clamp parts are in the clamping position.

Owner:HILTI AG

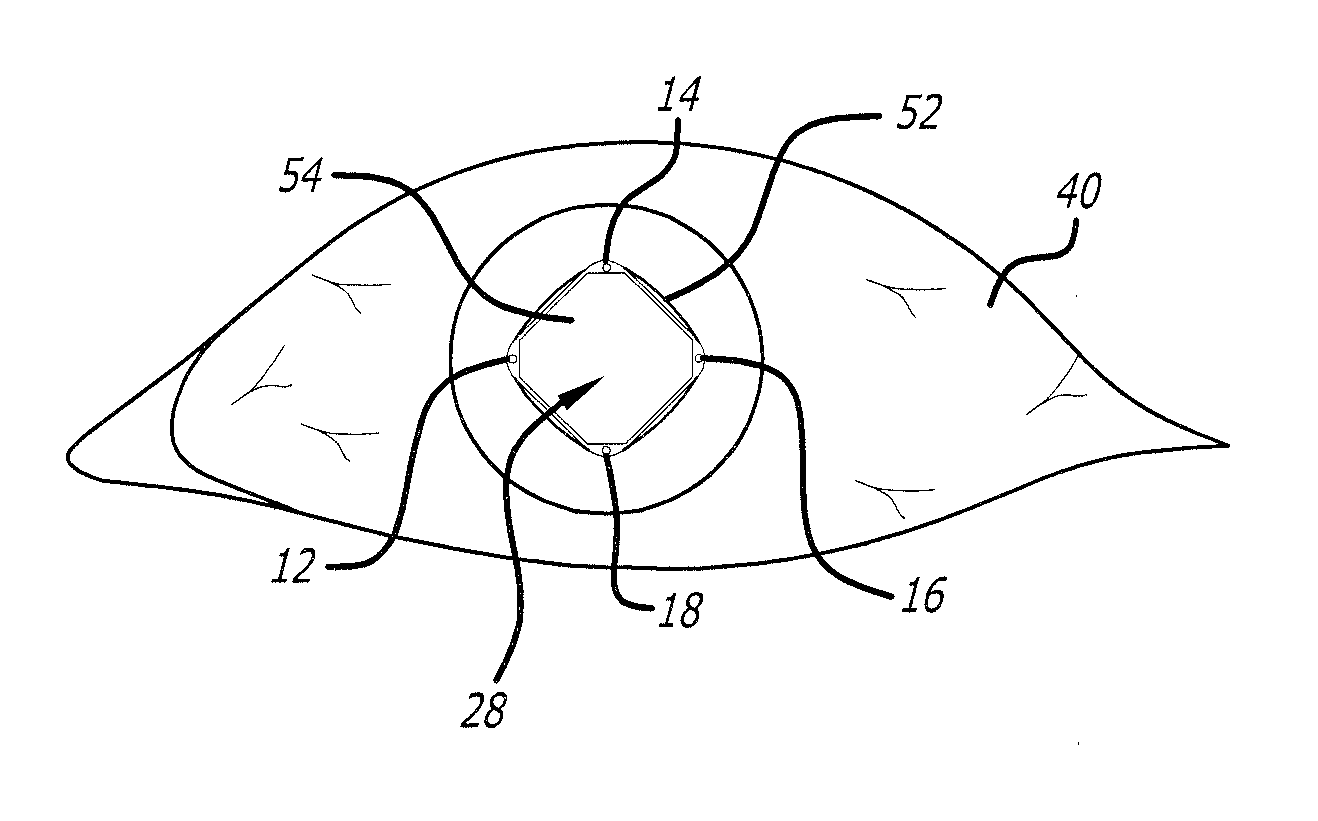

Ophthalmic structure

A ring for dilating a pupil during an ophthalmic procedure includes a series of spaced supports for engaging an iris perimeter. The supports are plate elements which form an open pocket directed outwardly for engaging the iris. The sides of the ring form a primary plane, and the plates are located in respective planes above and below the primary plane. The outer periphery of the top and bottom plates forms a lip feature which is the opening to the pocket which retains the iris.

Owner:OASIS MEDICAL

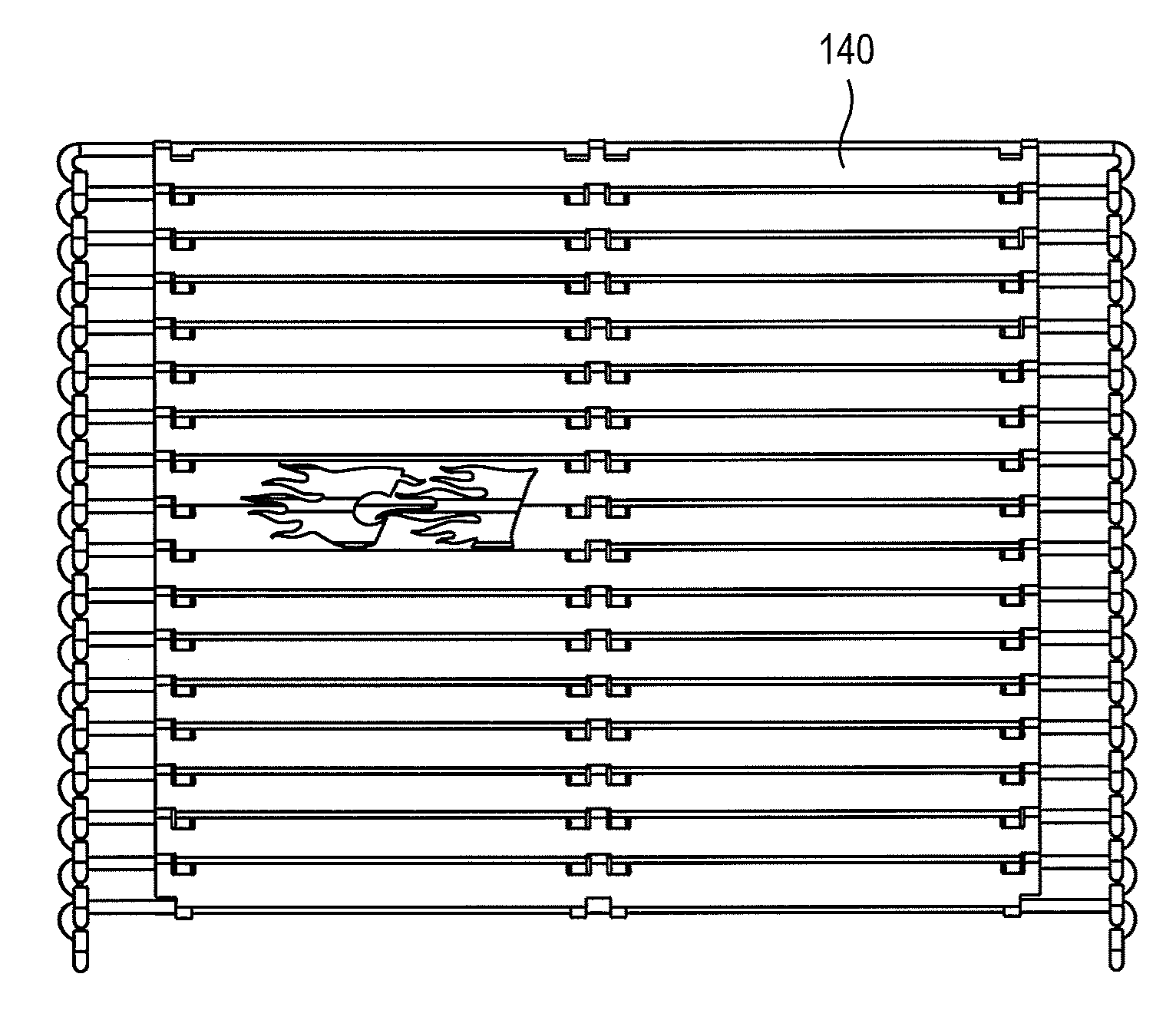

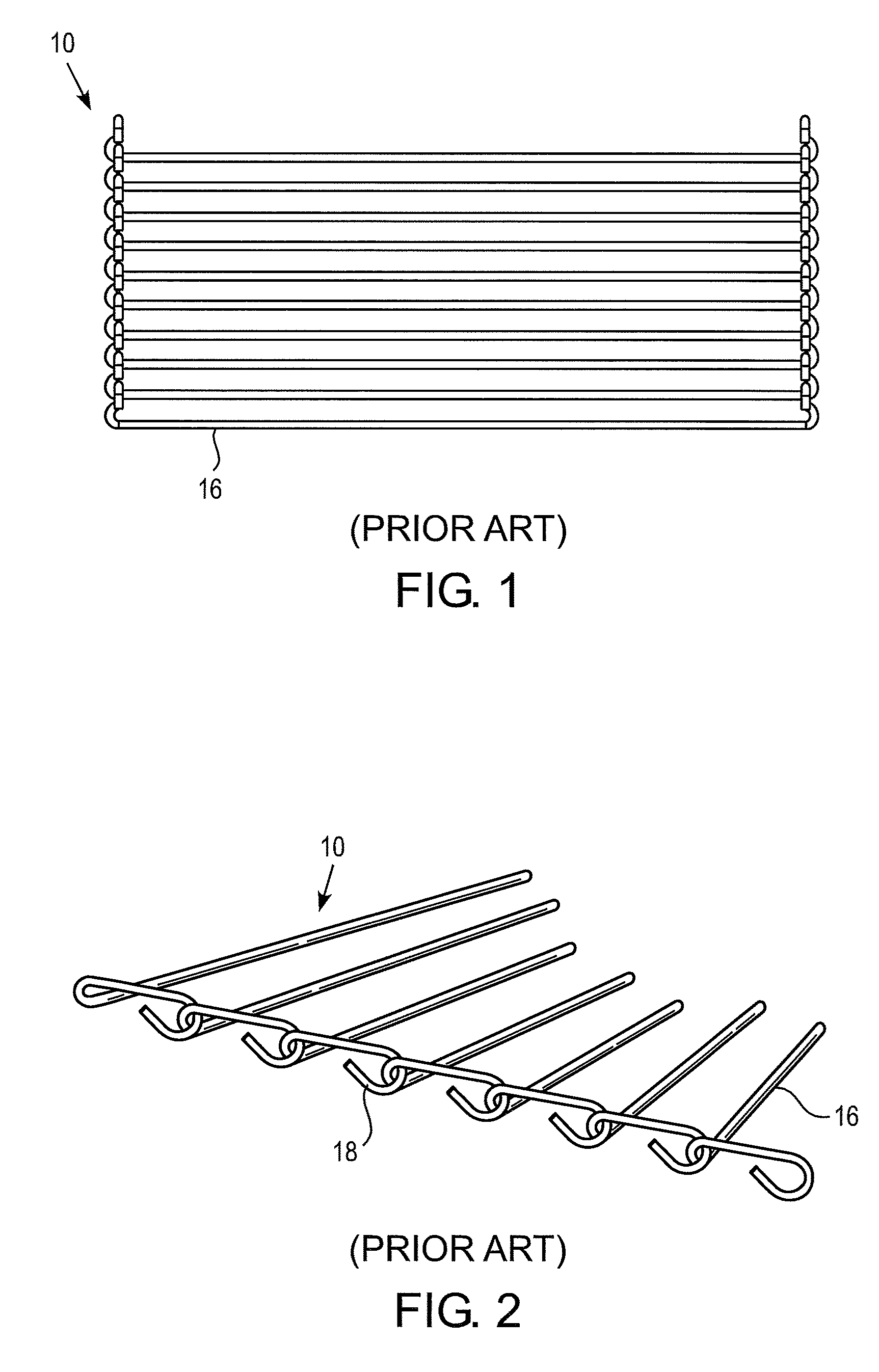

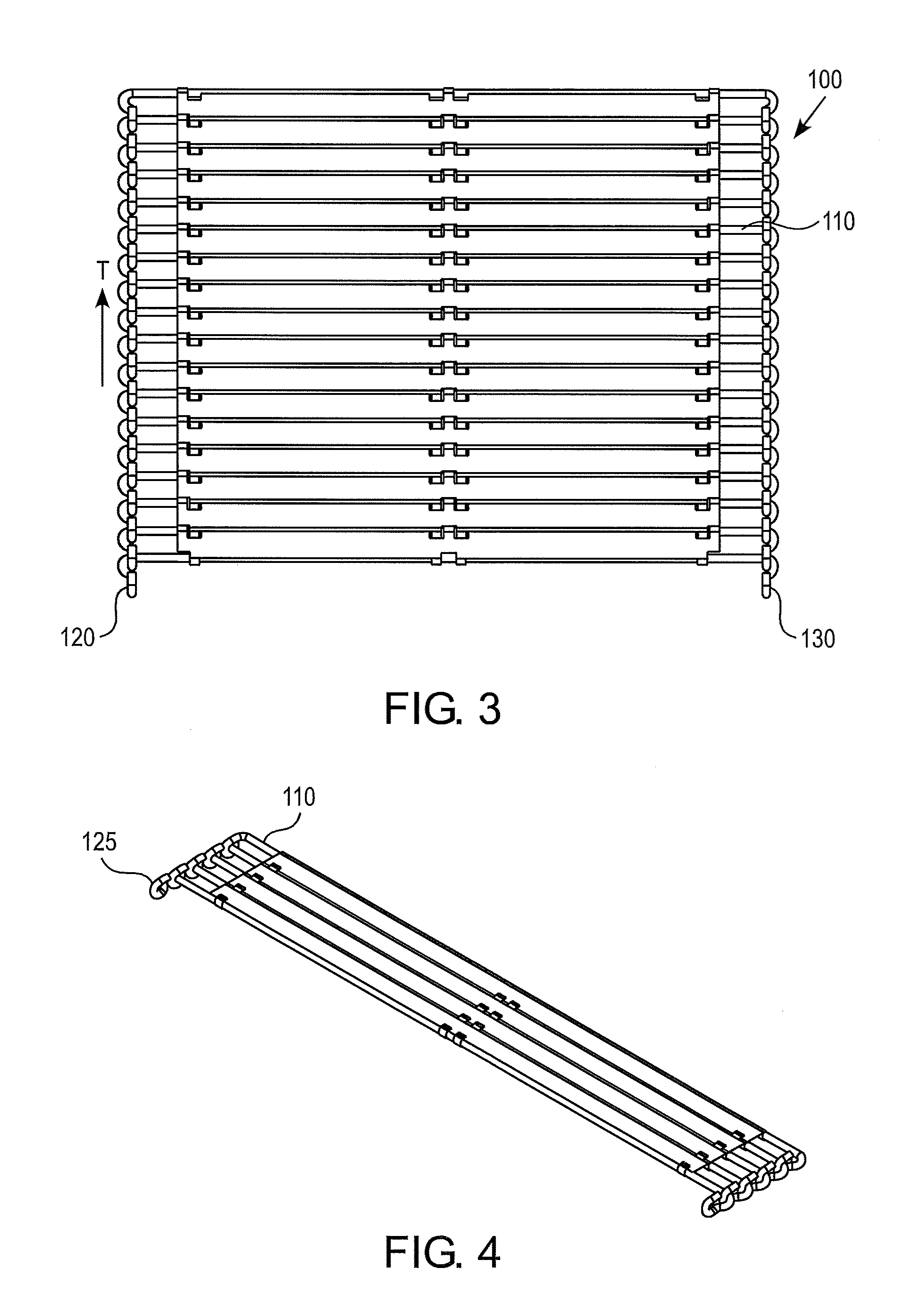

Wire plate conveyor belt

A conveyor belt includes a plurality of spaced rods transversely disposed with respect to a direction of travel and a plurality of plate elements overlying at least some of the rods so as to provide a support surface which imparts a predetermined marking or lack of marking to the product being conveyed.

Owner:CAMBRIDGE INT

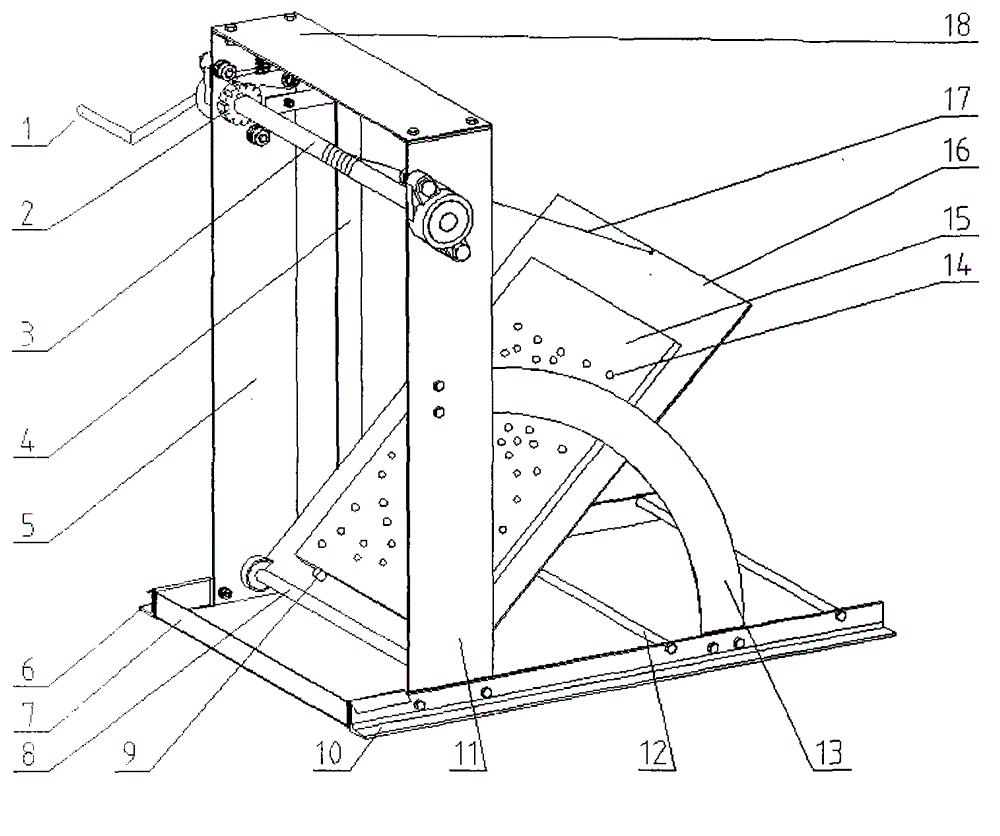

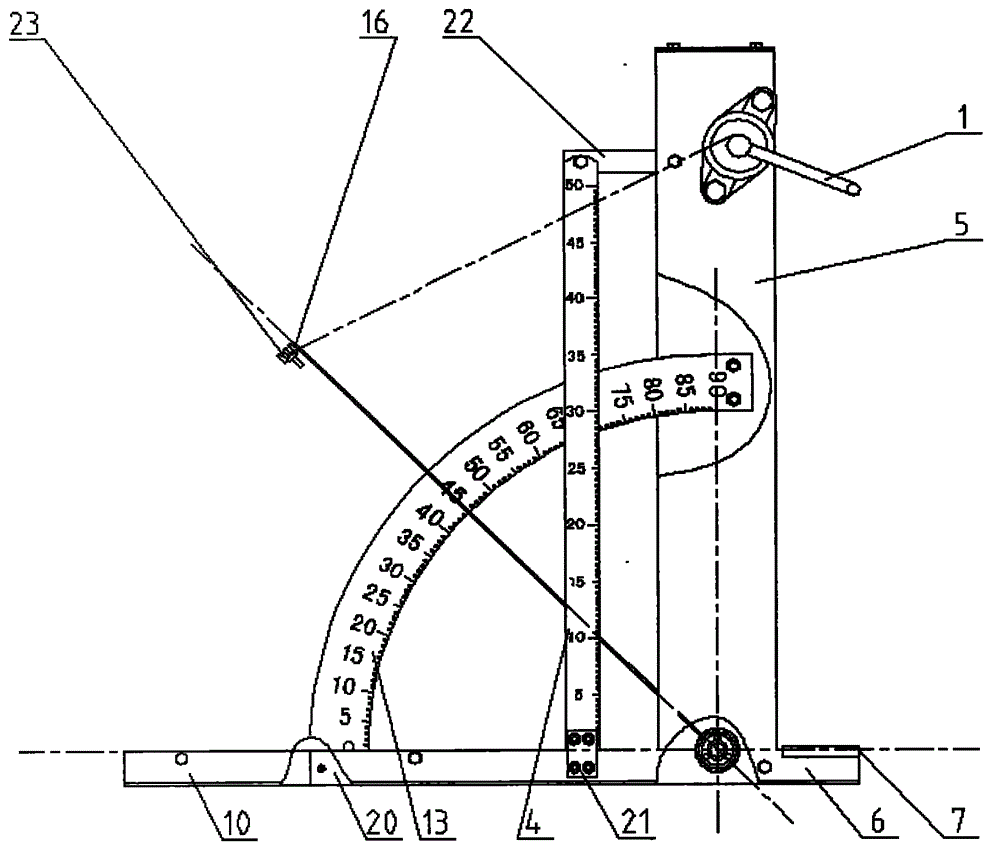

Inclined plane instrument device for measuring friction coefficient and friction angle of granular materials

InactiveCN102878910AAccurate measurementNo distortionAngles/taper measurementsMaterial analysisMeasurement deviceFriction angle

The invention belongs to the field of physical property detection of materials and particularly relates to an inclined plane instrument device for measuring the friction coefficient and the friction angle of granular materials on different material plate elements. Firstly, operators uniformly pave the granular materials to be measured onto a placed plate element, in addition, the included angle between the plate element and the horizontal plane is continuously increased until the materials on the plate element fall into a material collecting disc, and then, the friction angle or the friction coefficient is obtained through a measuring device. The device adopts a rocker mechanism and has a self locking function, and the measuring device comprises a circular arc ruler and a straight rule. Through the self locking function, the operators can release a rocker in experiments for intently regulating the sight line and observing readings. The fixed connection of the upper end and the lower end of the circular arc ruler and the straight ruler adopts a connecting plate with a certain thickness, and the warping in the vertical direction is avoided, so the measurement precision is ensured, and the effect of side plate reinforcing ribs is realized. The design of the material collecting disc at the lower part fully considers the requirements of multiple repeated experiments. The device has the advantages that the external connection of a power supply is not needed, and the device can be placed on the ground or a horizontal test table in a laboratory.

Owner:CHINA AGRI UNIV

Compression device and method for adjustment of a compression pressure

InactiveUS7656993B2Easy to adaptImprove spatial resolutionOperating chairsPatient positioning for diagnosticsCompression deviceEngineering

A compression device has a compression plate that applies a pressure to a subject on a support plate. The compression plate has a number of elastically-deformable compression plate elements that are substantially transparent for an examination field used with the compression device. In a method for compressing a subject, at least one pressure sensor measures the pressure applied by a compression device to a subject, and wirelessly supplies a signal representing the detected pressure to a control unit, wherein the detected pressure is compared to a stored compression pressure value. The control device adjusts the pressure applied to the subject by the compression device so that the pressure detected by the sensor is equal to the stored compression pressure value.

Owner:SIEMENS HEALTHCARE GMBH

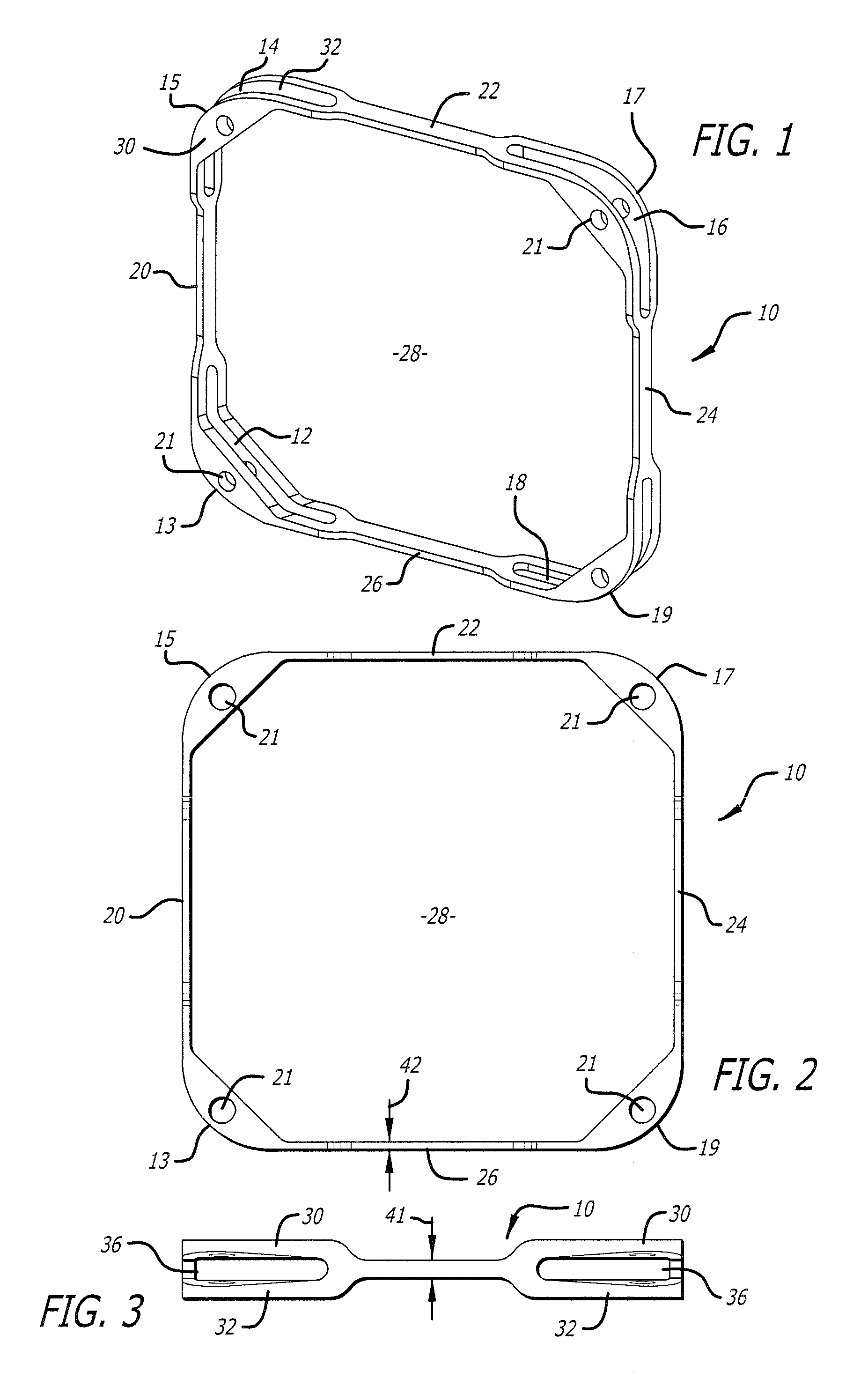

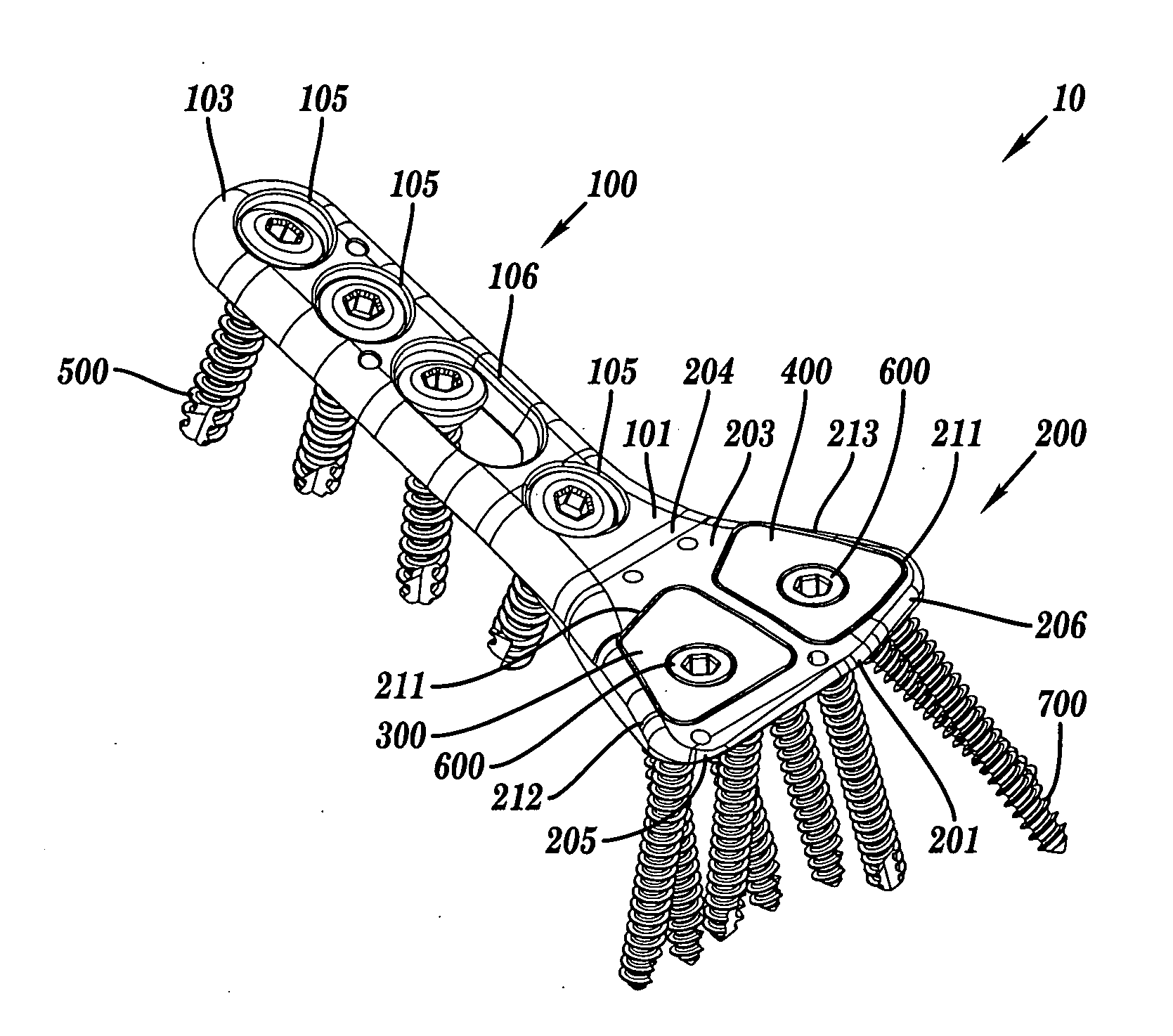

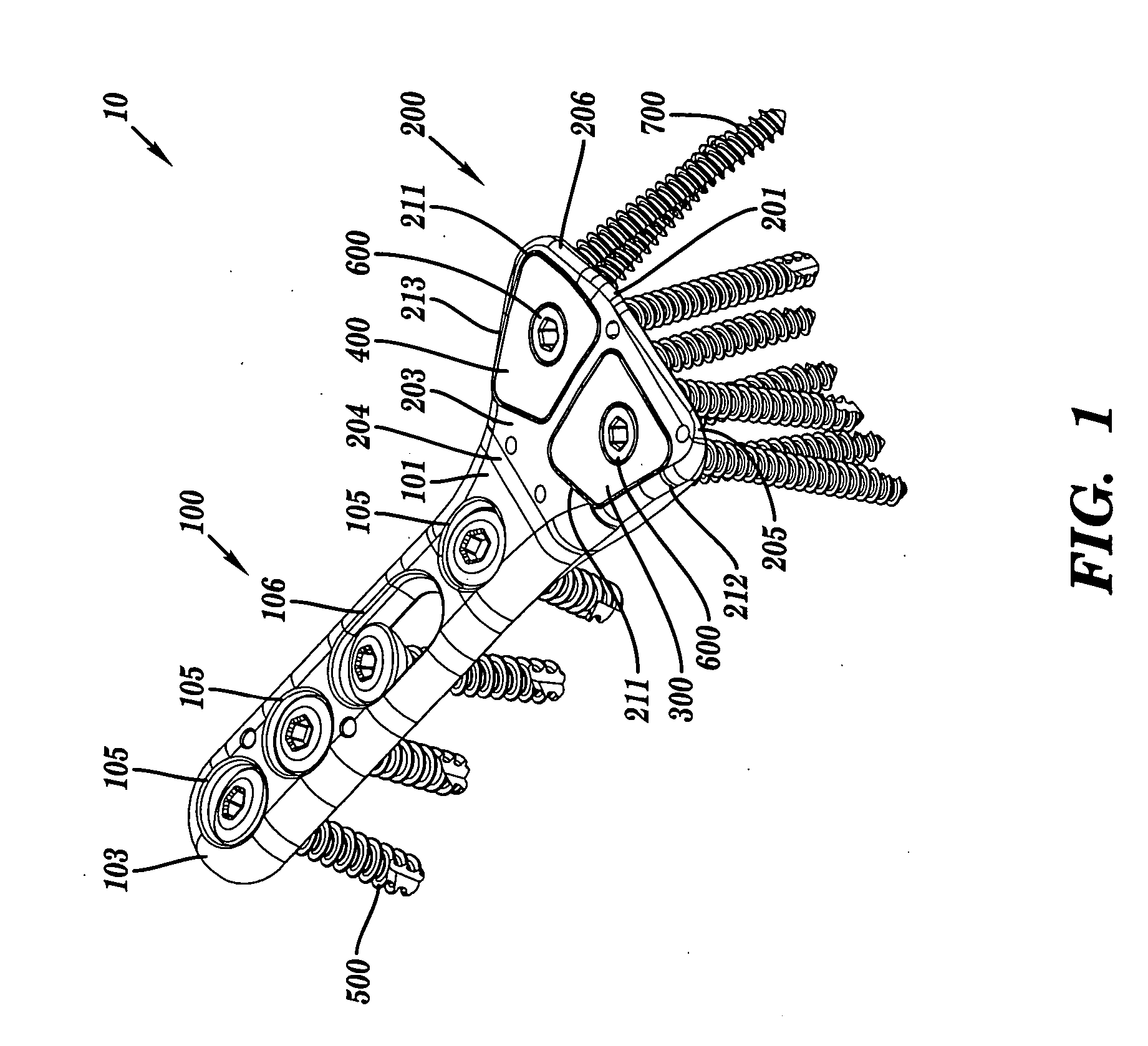

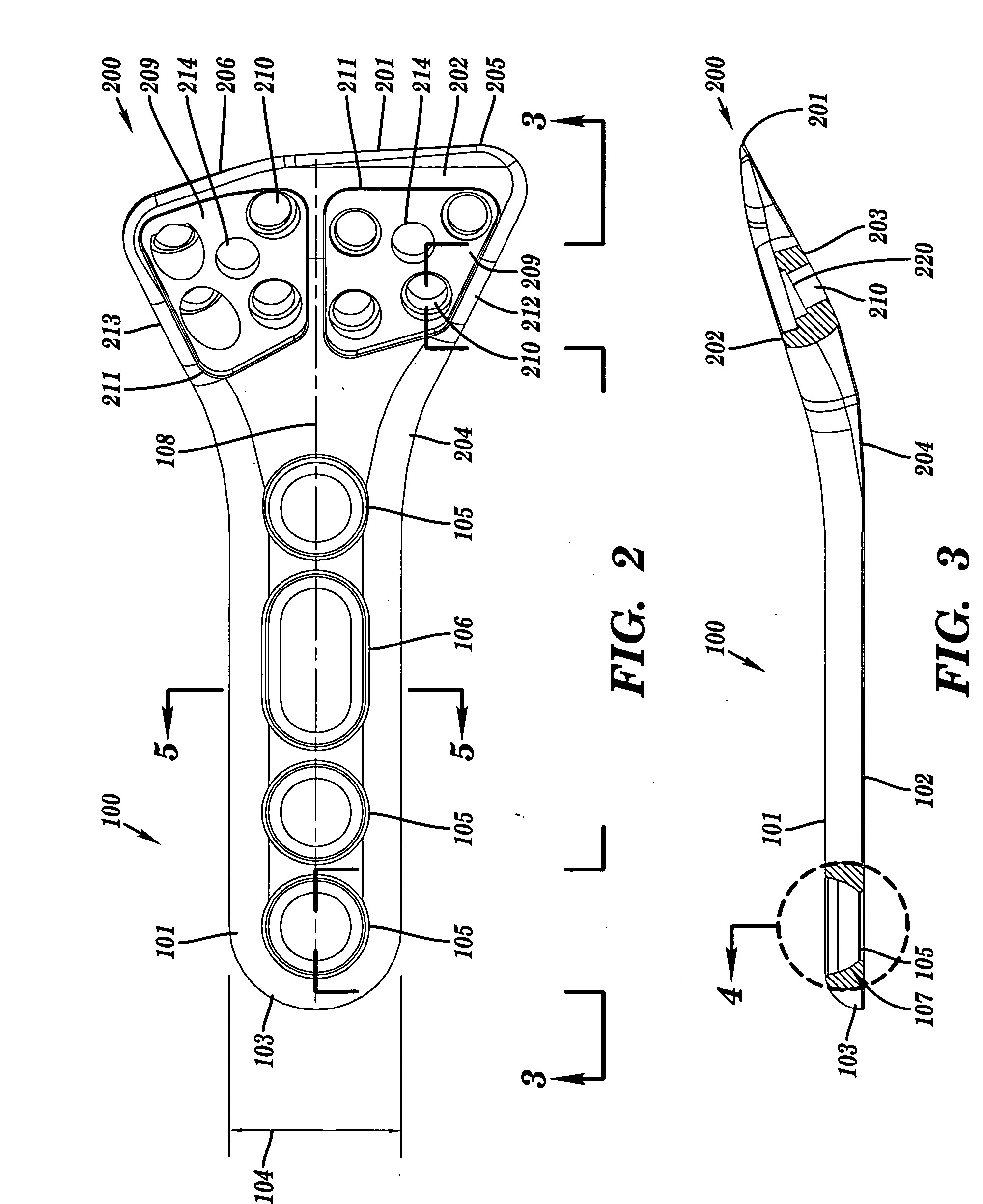

Fracture fixation plate with cover sheath

ActiveUS20070173839A1Minimize soft-tissue impingementAllow flexibilityInternal osteosythesisJoint implantsLateral recessFracture reduction

A fracture fixation plate with cover sheath having a head element that is rigidly connected to a plate element in an upwardly angled direction. The head element is anatomically shaped and includes medial and lateral sheath recesses wherein non-threaded bone screw holes and a threaded sheath screw hole are located. Cylindrical head bone screws are inserted through the sheath recess and oriented at set angles allowing for bone fragment fixation and fracture reduction. Medial and lateral sheath elements are placed within the boundaries of their respective sheath recesses and are secured with a sheath screw. The sheath elements contact the heads of the inserted bone screws restricting and maintaining their implanted positions. Alternative sheath elements with outreaching medial, lateral and distal fragment capture flanges may also be utilized. The plate element includes at least one longitudinal slot with several bone screw holes for use with pivotable spherical headed bone screws.

Owner:HOWMEDICA OSTEONICS CORP

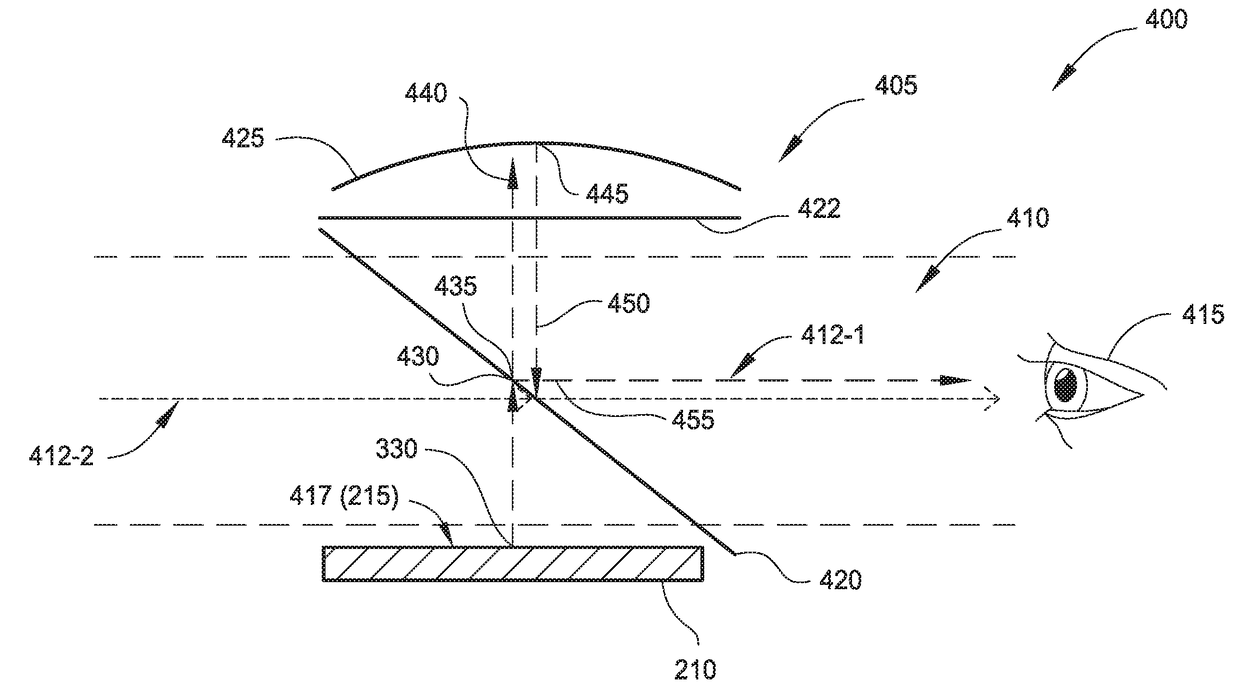

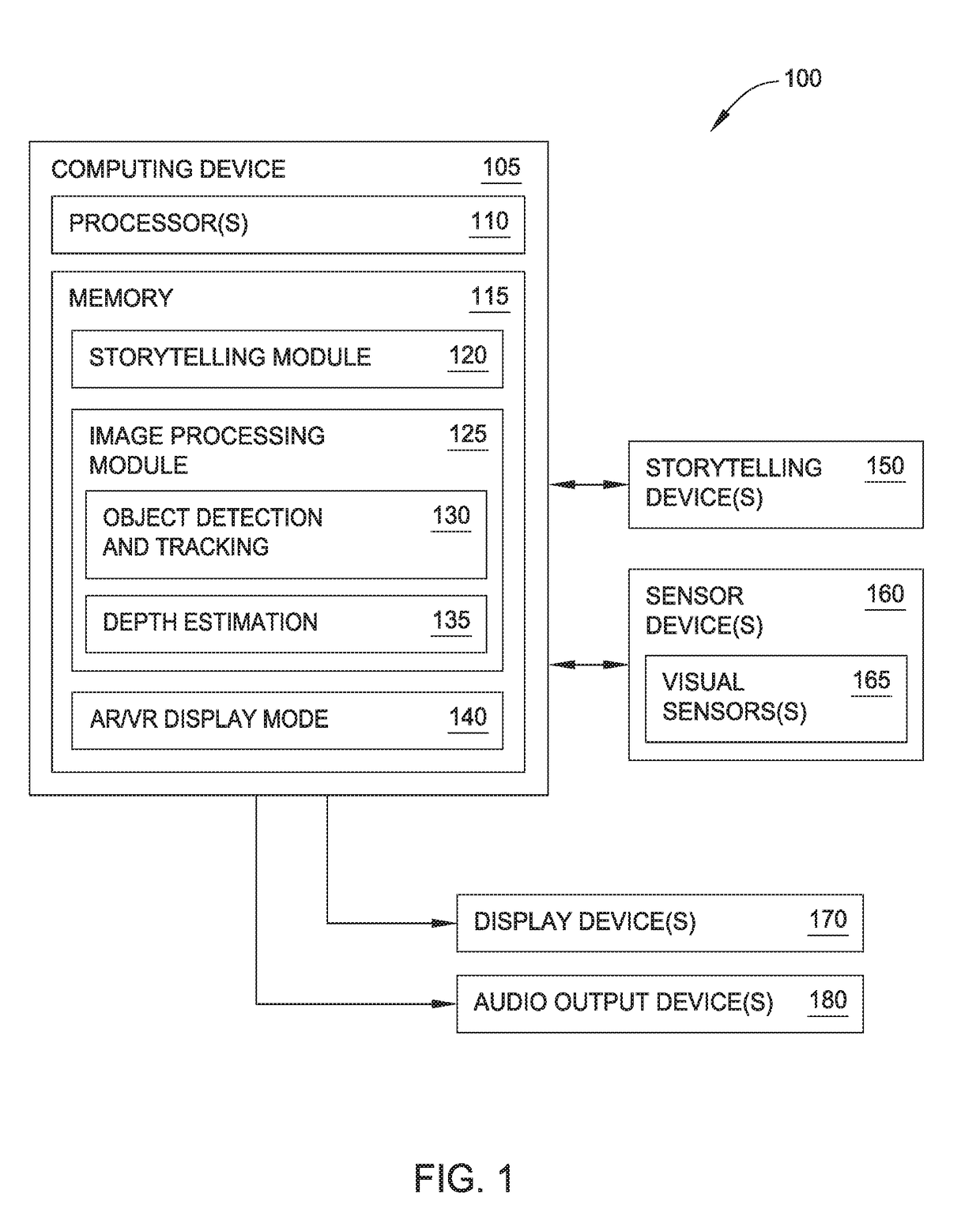

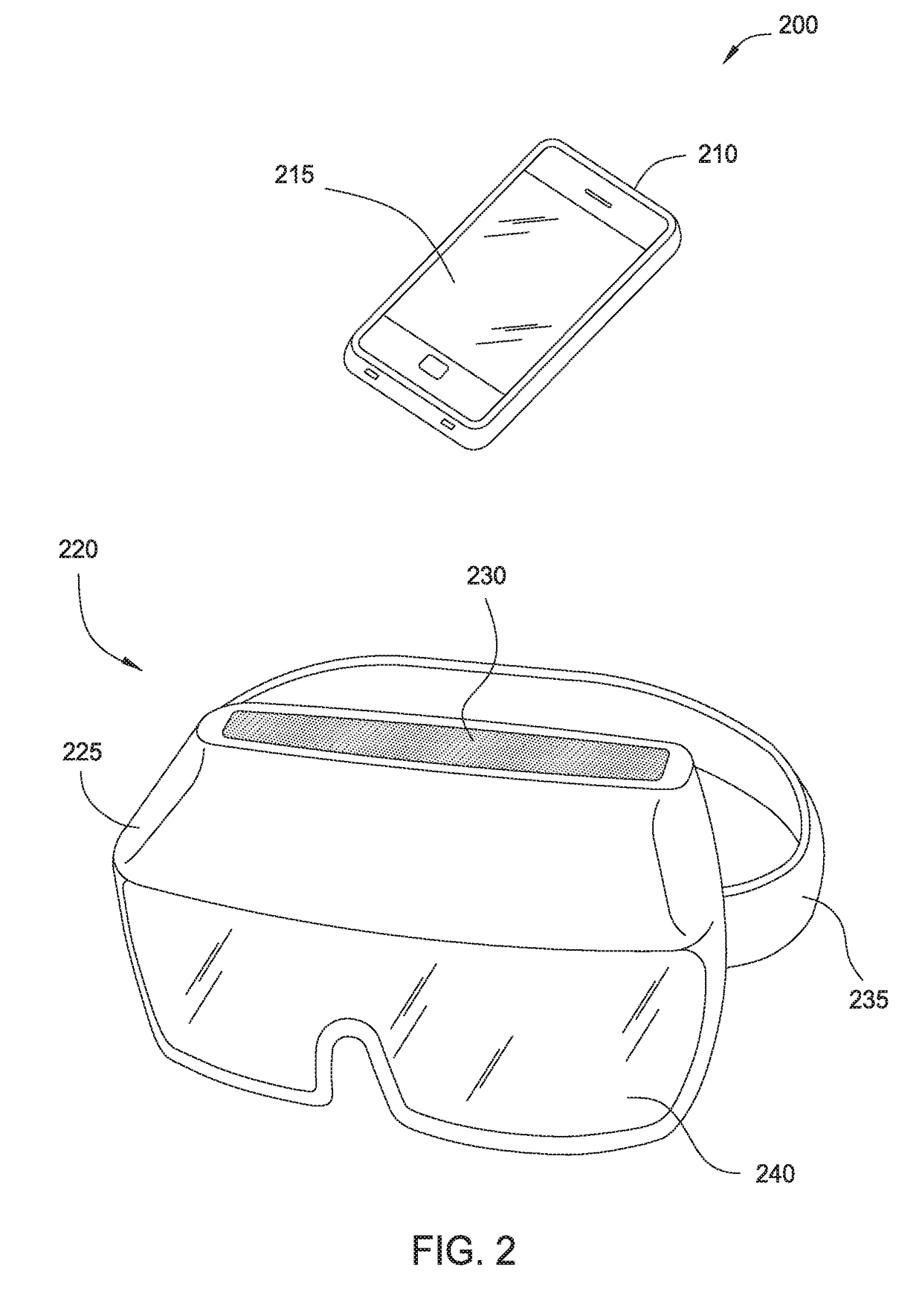

Increasing returned light in a compact augmented reality / virtual reality display

Implementations of an augmented reality (AR)-capable display device for displaying polarized light generated by a display onto a predefined field of view are disclosed herein. The display device comprises an optical arrangement having a predefined arrangement relative to a predefined position of the display and defining the field of view. The optical arrangement comprises a mirror element disposed within the field of view and at least partially transmissive of ambient light incident on a first surface and at least partially reflective of light incident on an opposite second surface, a polarized beam splitter element disposed within the field of view and closer to the second surface of the mirror element than the first surface, a half-wave plate element disposed between the polarized beam splitter element and the display and outside the field of view, and a quarter-wave plate element disposed between the polarized beam splitter element and the mirror element.

Owner:DISNEY ENTERPRISES INC

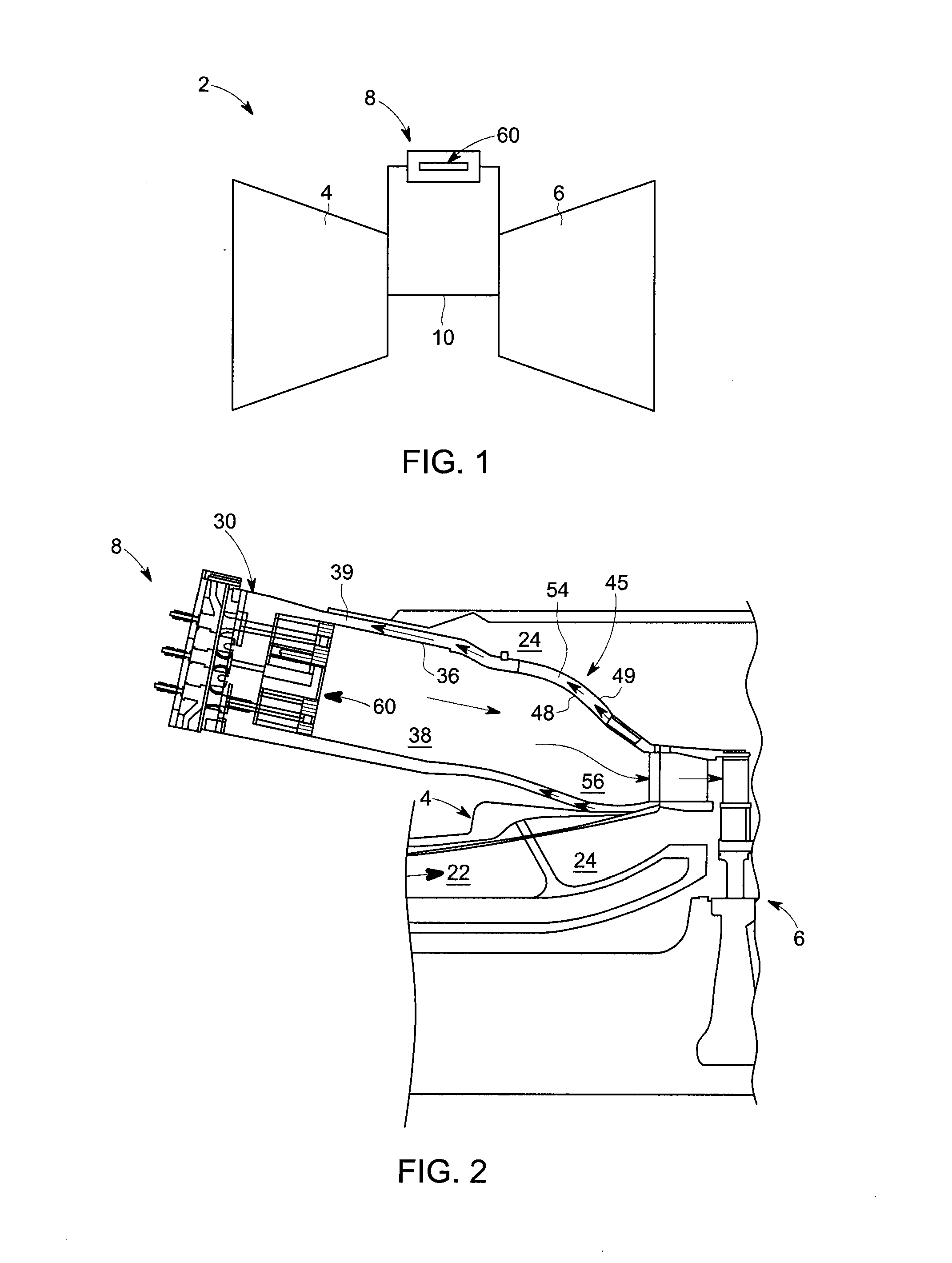

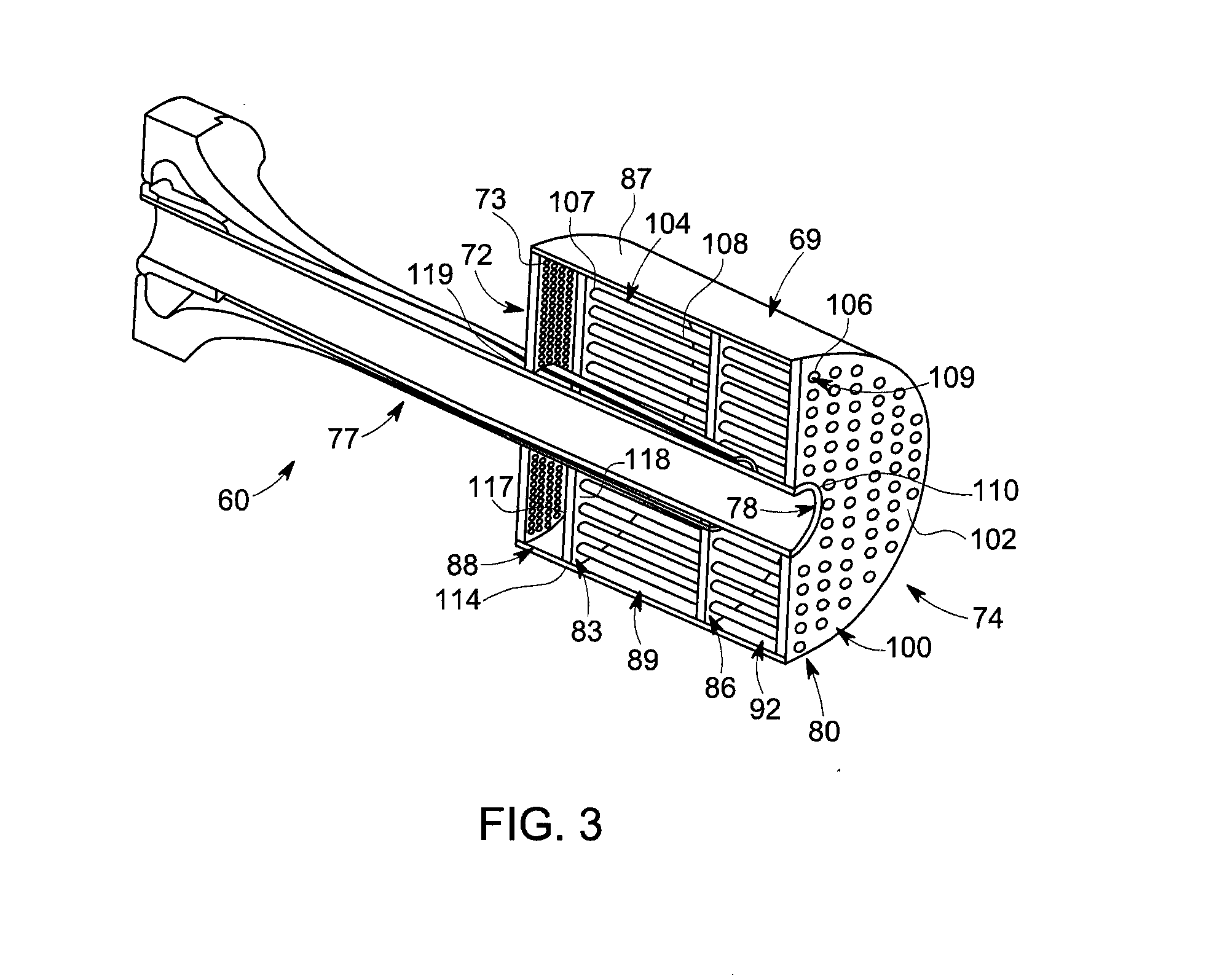

Turbomachine combustor nozzle including a monolithic nozzle component and method of forming the same

A turbomachine combustor nozzle includes a monolithic nozzle component having a plate element and a plurality of nozzle elements. Each of the plurality of nozzle elements includes a first end extending from the plate element to a second end. The plate element and plurality of nozzle elements are formed as a unitary component. A plate member is joined with the nozzle component. The plate member includes an outer edge that defines first and second surfaces and a plurality of openings extending between the first and second surfaces. The plurality of openings are configured and disposed to register with and receive the second end of corresponding ones of the plurality of nozzle elements.

Owner:GENERAL ELECTRIC CO

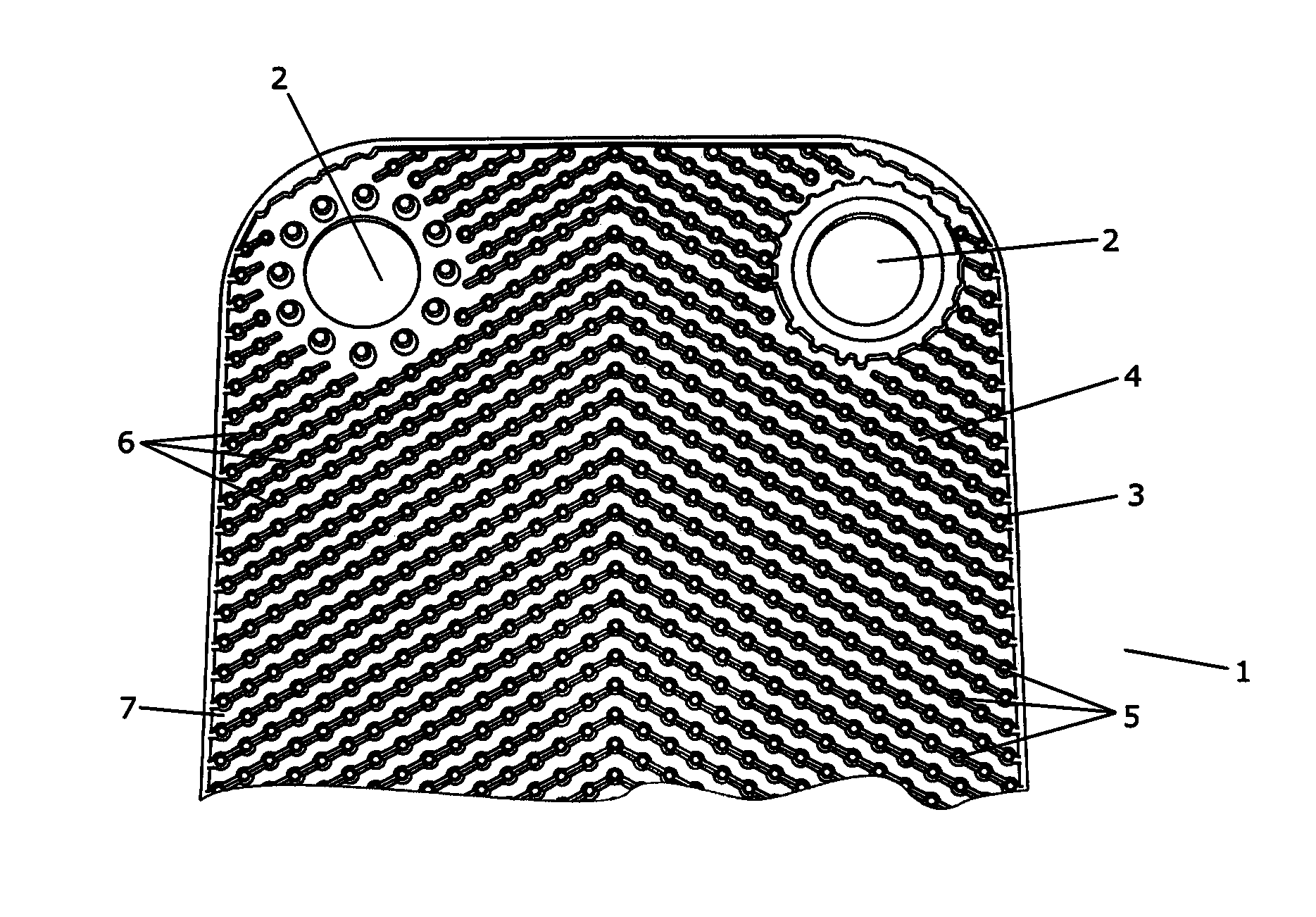

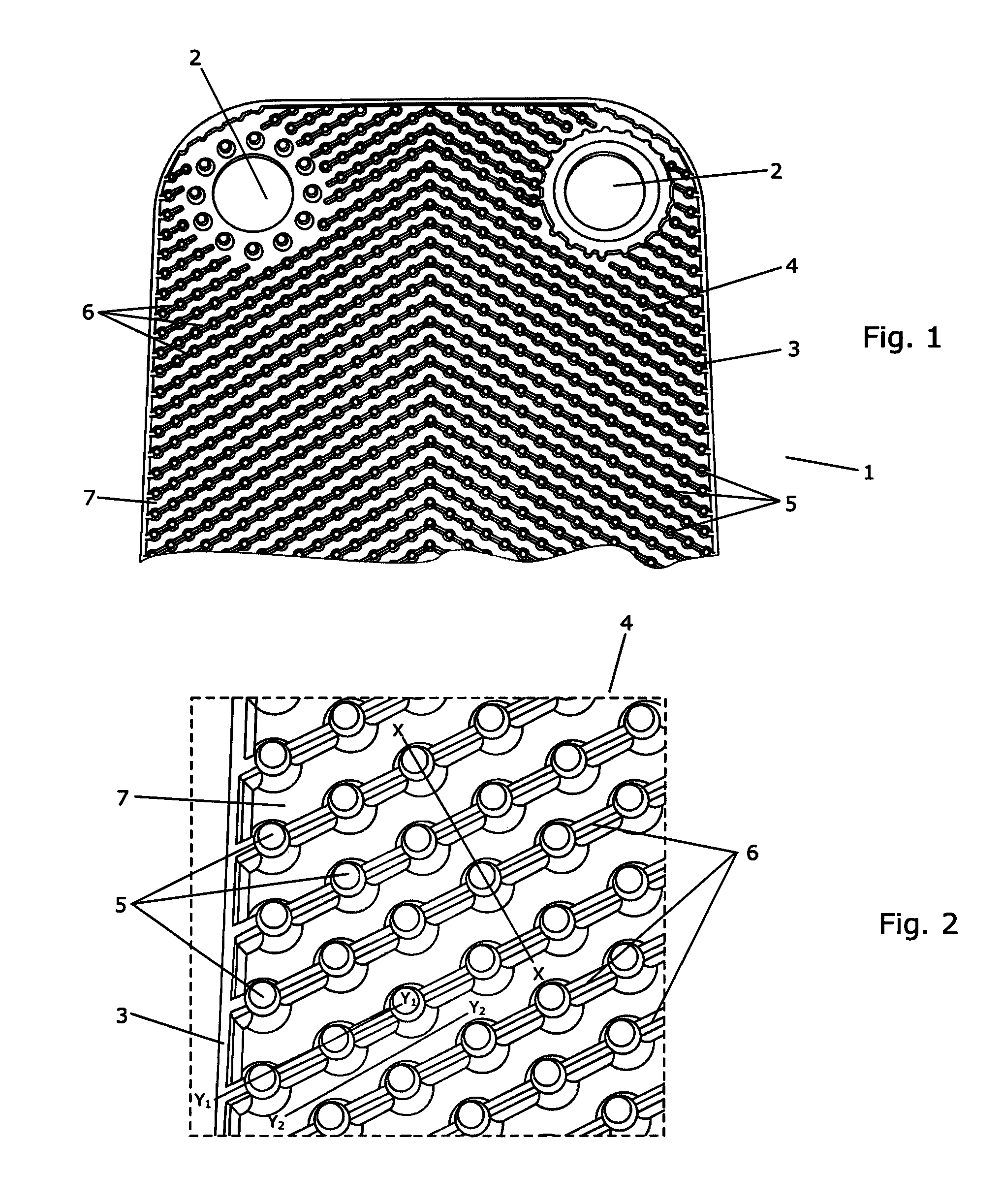

Double plate heat exchanger

ActiveUS20110088882A1Quick checkImprove heat transfer performanceMetal-working apparatusLaminated elementsSurface patternThermal contact

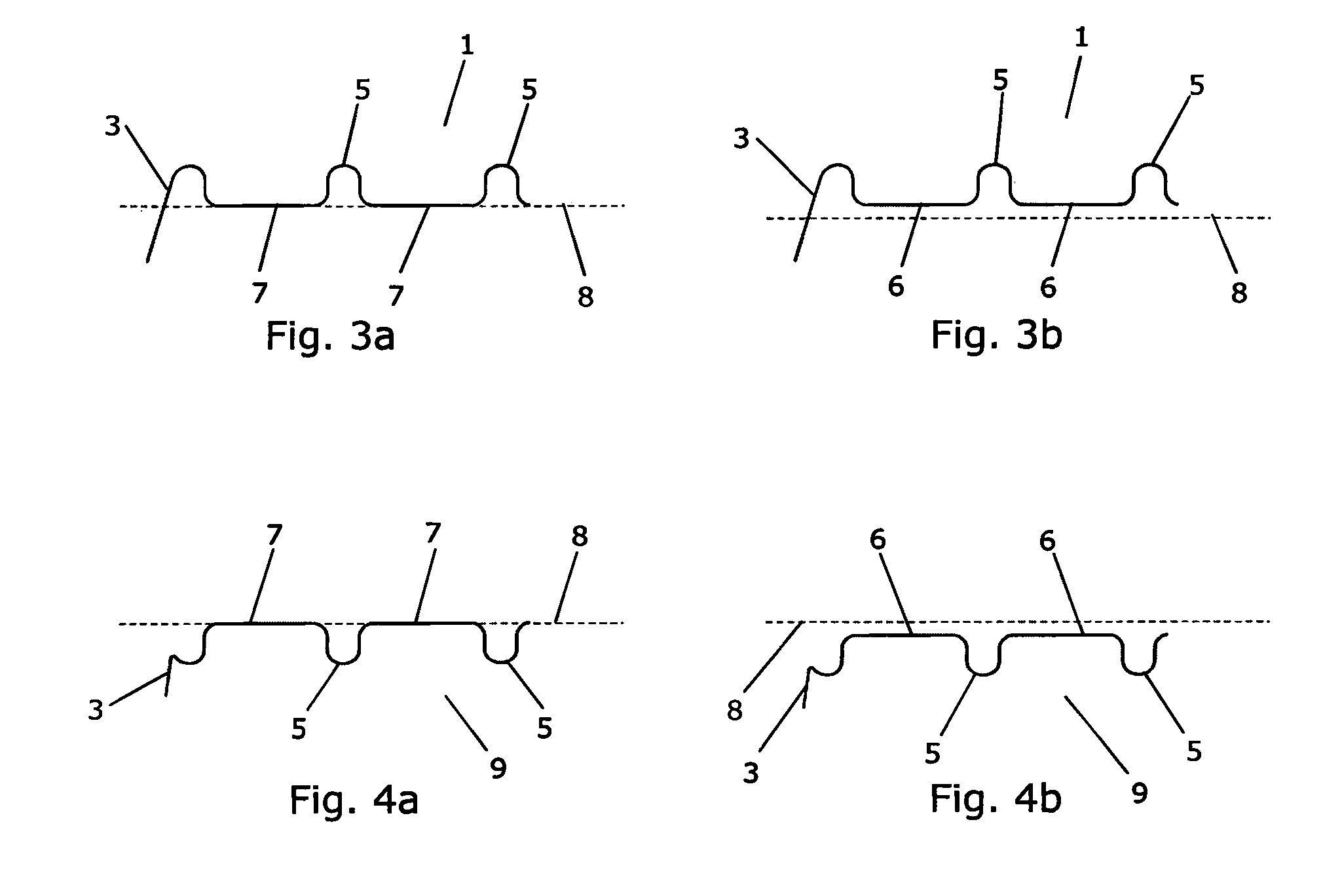

A plate heat exchanger (10) of the double plate type having a plurality of stacked plate elements, each comprising a first plate (1) and a second plate (9). At least the first plate (1) is provided with a surface pattern with a plurality of dimples (5) defining a first distance to a plate plane (8), and a plurality of canal parts (6) defining a second, smaller, distance to the plate plane (8). The first plate (1) and the second plate (9) are joined in such a manner that the protruding areas (5, 6) in combination form flow paths (11) being fluidly connected to rim portions (3) of the plates (1, 9). The heat exchanger (10) provides efficient leakage detection via the flow paths (11) while ensuring a good thermal contact between heat exchanging fluids through the plates (1, 9) via flat portions (7) between the protruding parts (5,6).

Owner:DANFOSS AS +1

Optical devices incorporating photo reactive polymers

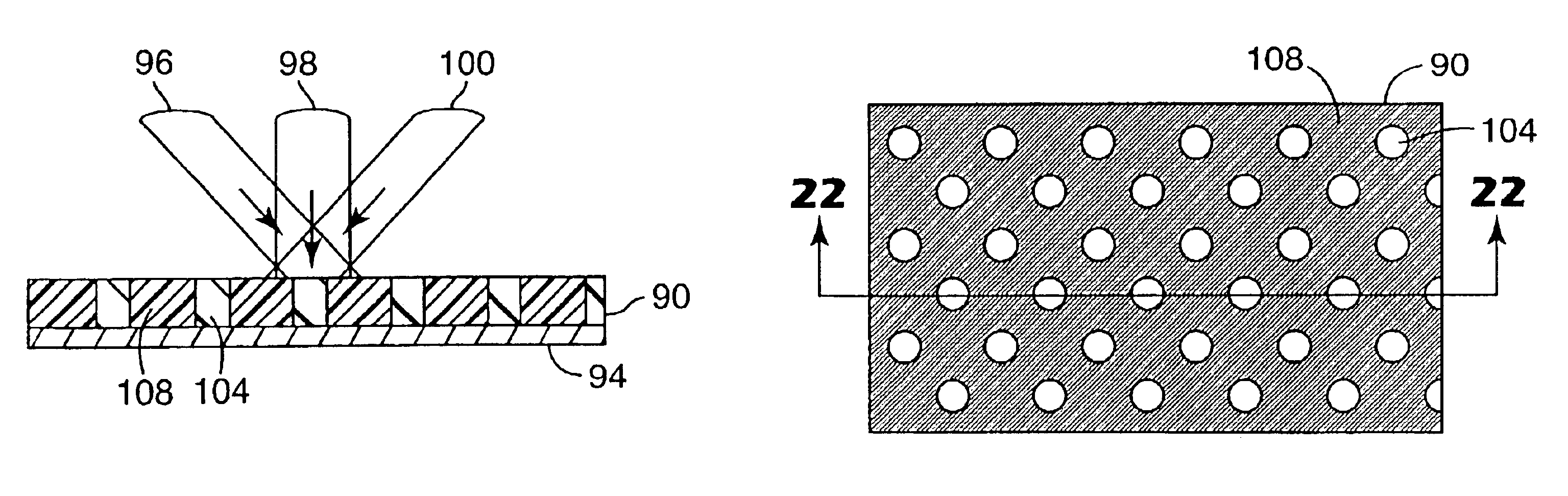

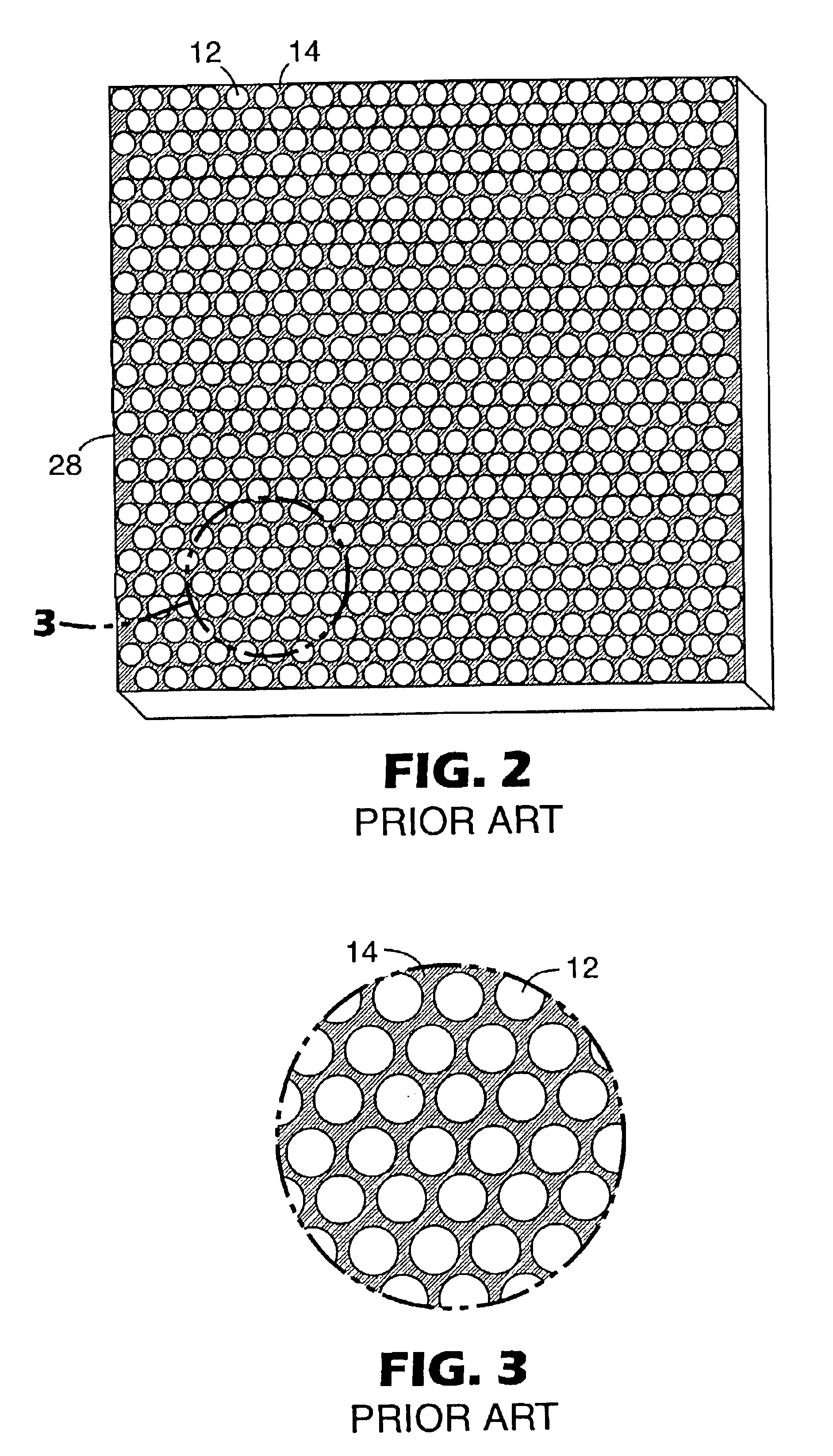

A method for forming a display device including generating a face plate element by providing a first substrate with a photoactive resin thereon and exposing the photoactive resin to a light interference pattern formed by three collimated and coherent light sources, resulting in columnar features. A display device including an optical display element and a polymer face plate that receives or directs light to the optical display element. The face plate includes columnar areas where an index of refraction of the columnar areas is different from the index of refraction of a cladding area surrounding the columnar areas. The columnar areas are formed by exposure of a photoactive resin to a light interference pattern formed by three collimated and coherent light sources. A method of manufacturing a wave guide including providing a first substrate with a photoactive resin thereon and creating a wave guide channel in a wave guide template. The wave guide channel is filled with a liquid crystal material that is exposed to a light grating to create a variation in an index of refraction of the liquid crystal material in the wave guide channel.

Owner:3M INNOVATIVE PROPERTIES CO +1

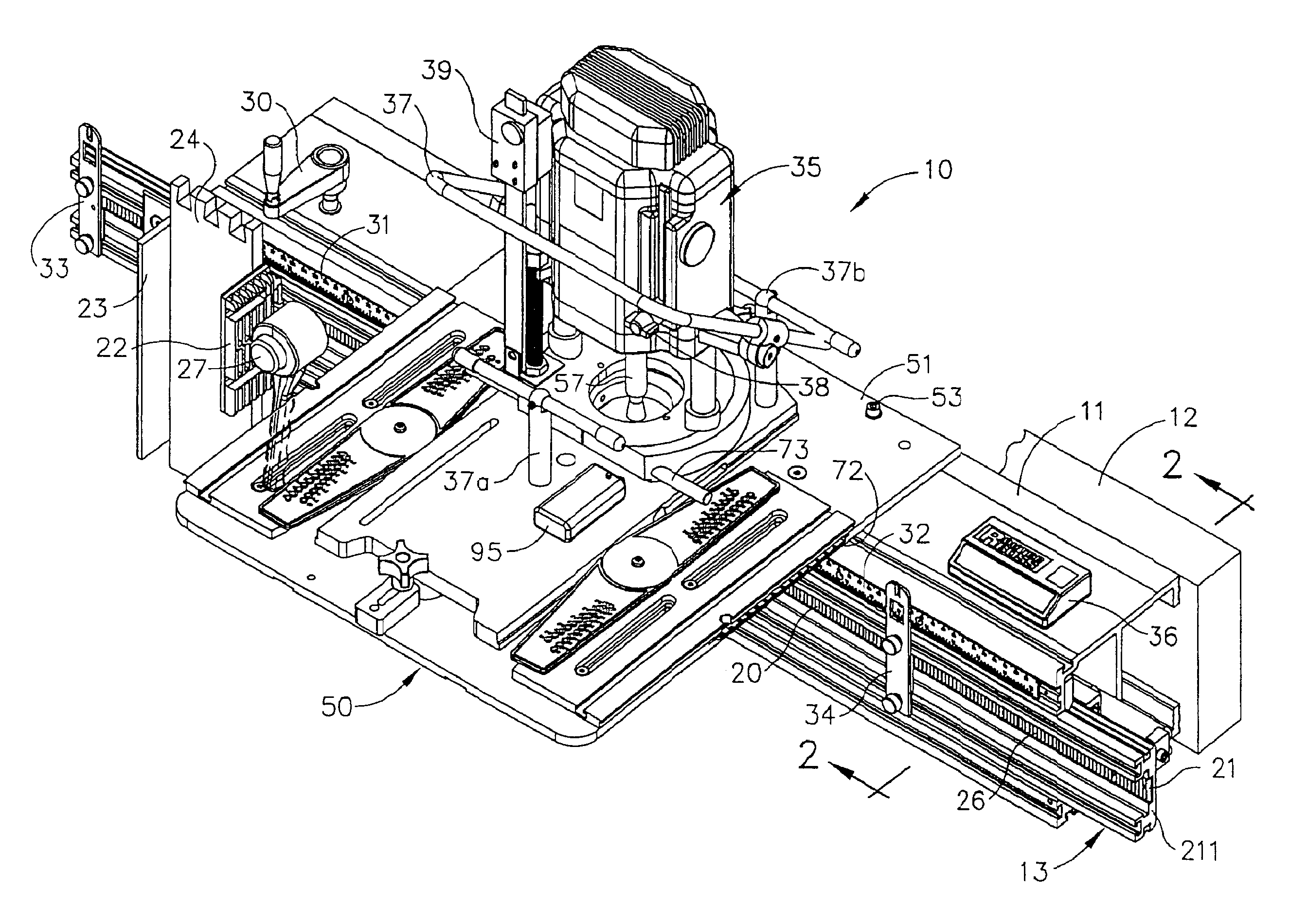

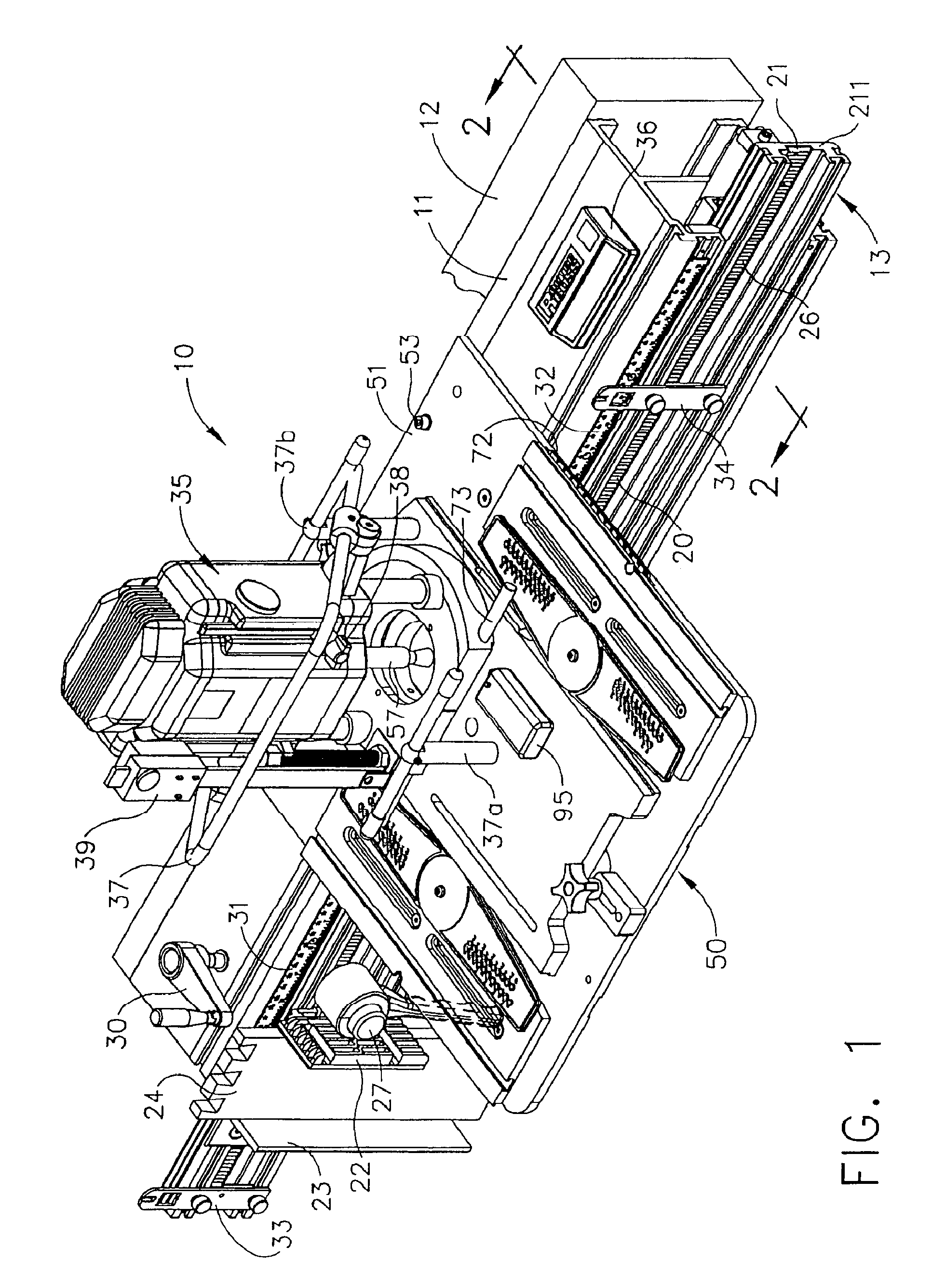

Wood Working Machine

InactiveUS20090188584A1Economy of workspaceMany of characteristicTongue/grooves making apparatusDovetailed workWoodworking machineLaser source

A wood working machine is described that includes a mounting plate assembly for supporting a cutting tool, the mounting plate assembly including a base plate, first and second spaced apart intermediate plates on the base plate, and first and second guide plate elements pivotally supported on respective first and second intermediate plates, and a cutting tool support plate slidably disposed between the first and second guide plate elements, the guide plate elements including means defined therein for positioning each of the guide plate elements at selected angular intervals with respect to the respective first and second intermediate plates, whereby the cutting tool support plate is slidably movable on the base plate between the guide plate elements at a prescribed angle. The mounting plate assembly may include laser sources providing crossed laser beams for accurately positioning the tool bit of the cutting tool near a work piece, and light sources for illuminating the tool bit. A digital sensor may be included for precise positioning of the work piece held beneath the base plate on a movable carrier.

Owner:STEPP LEWIS E

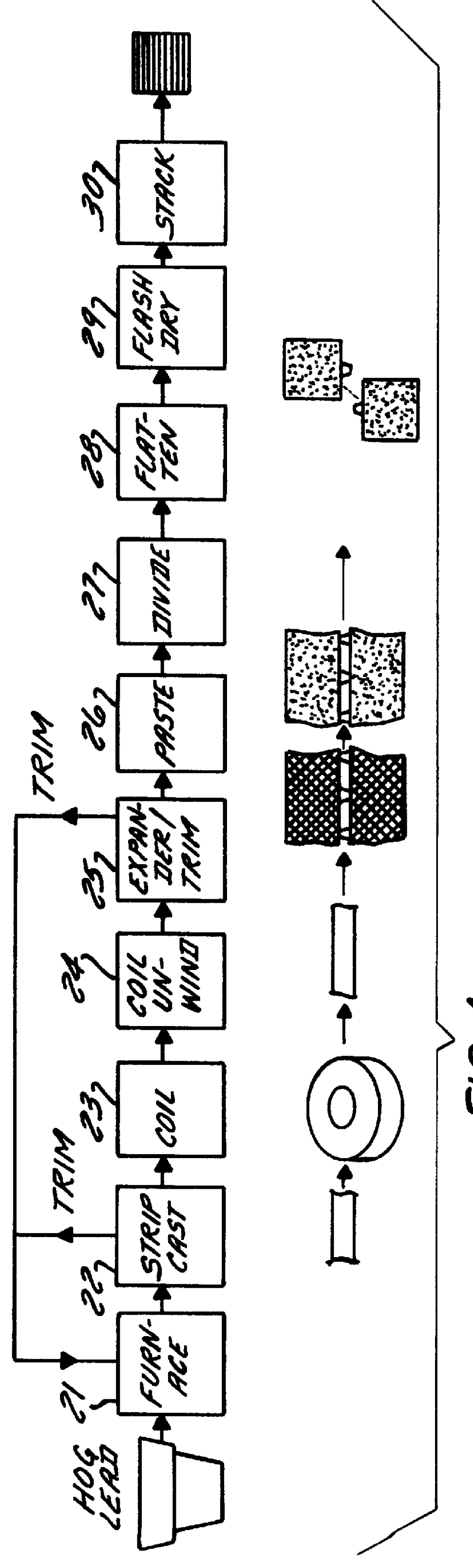

Battery plates having rounded lower corners

InactiveUSRE36734E1Electrode carriers/collectorsActive material electrodesLead–acid batteryVacuum manifold

A process for cutting a moving strip to form a series of plates, such as battery plates, includes the initial step of transporting the strip past a rotary divider including a cutter having radial blades configured to cut the strip into the plates. The cutter further has a set of blades for cutting individual pieces from the strip, which pieces are not part of the plates. As the cutter blades cut the strip to form the plates and pieces, a vacuum system applies suction to draw the pieces cut from the strip inwardly into the cutter through holes in the cutter, and then out of the cutter. The holes are each located adjacent each one of the corresponding blades and are shaped and positioned to permit the cut-away piece to pass through. In a preferred embodiment, the vacuum system includes a pair of vacuum manifolds that apply suction at opposite ends of the cylindrical cutter. An apparatus for carrying out the foregoing process accordingly includes a rotary divider as described above provided with a vacuum system. Battery plates made according to the foregoing process are improved in that the two lower corners have a rounded shape lacking a sharp edge which tends to tear an adjacent separator. Such a plate may be inserted bottom end first into a separator envelope to form a plate element for use in a lead-acid battery.

Owner:JOHNSON CONTROLS TECH CO

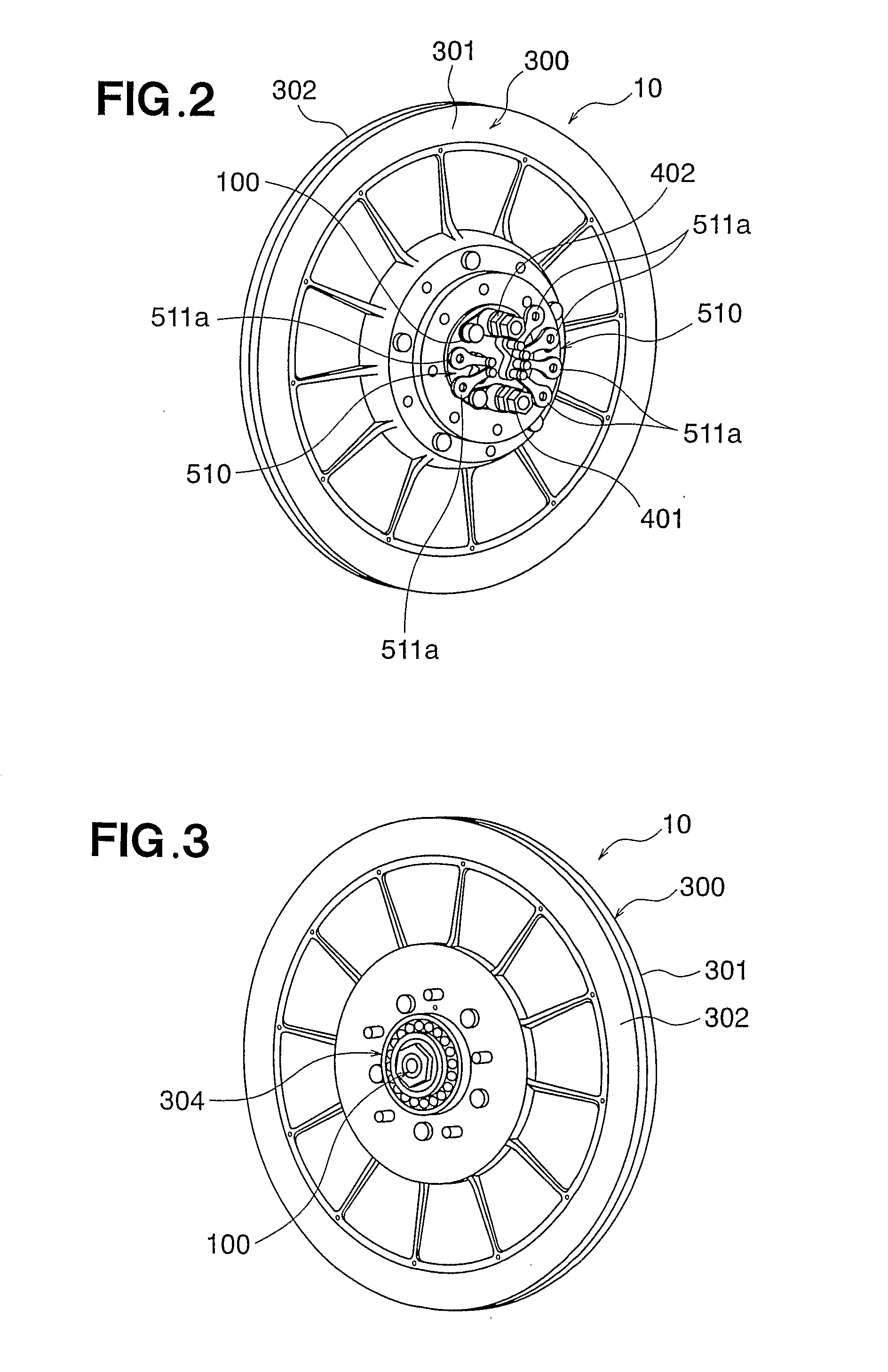

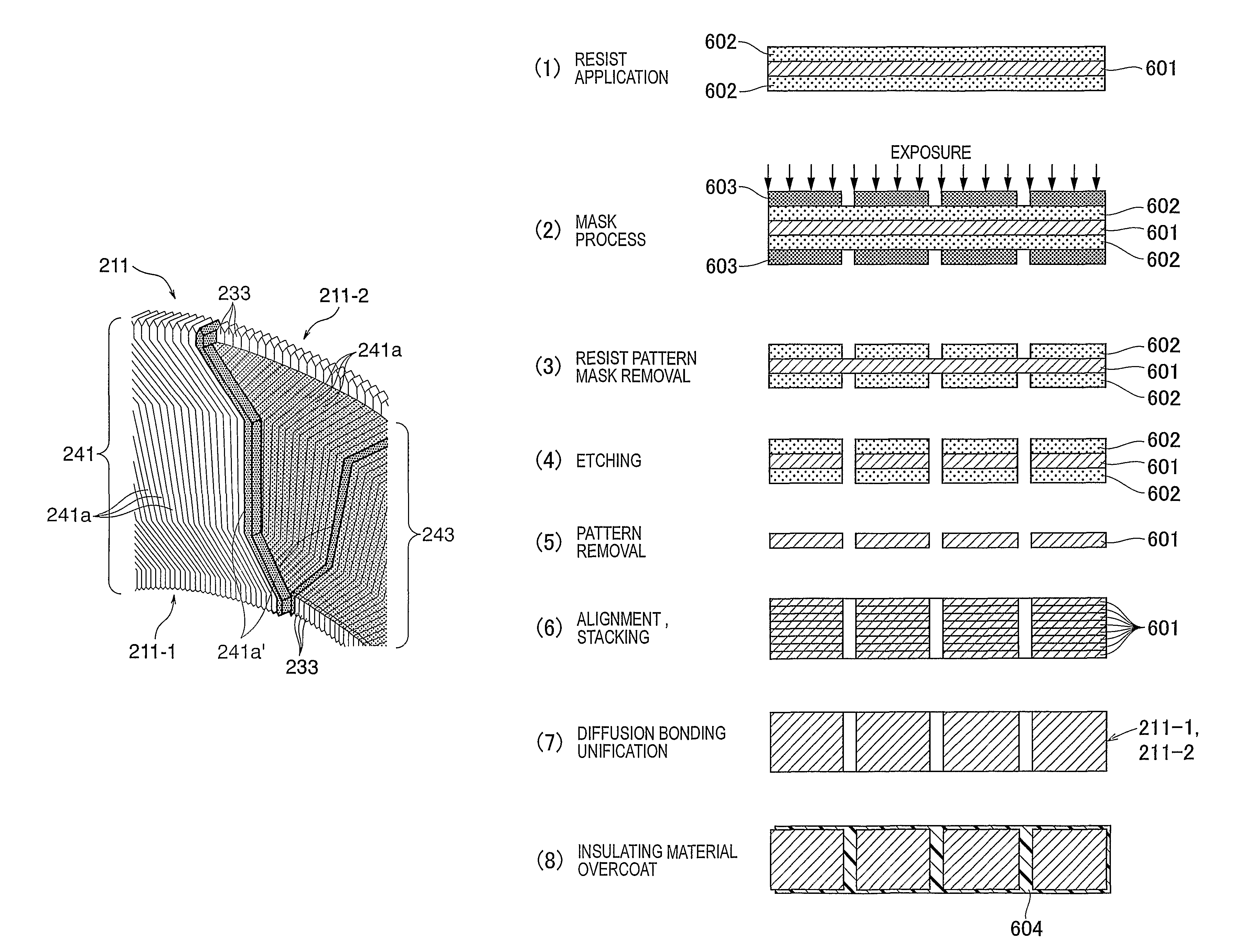

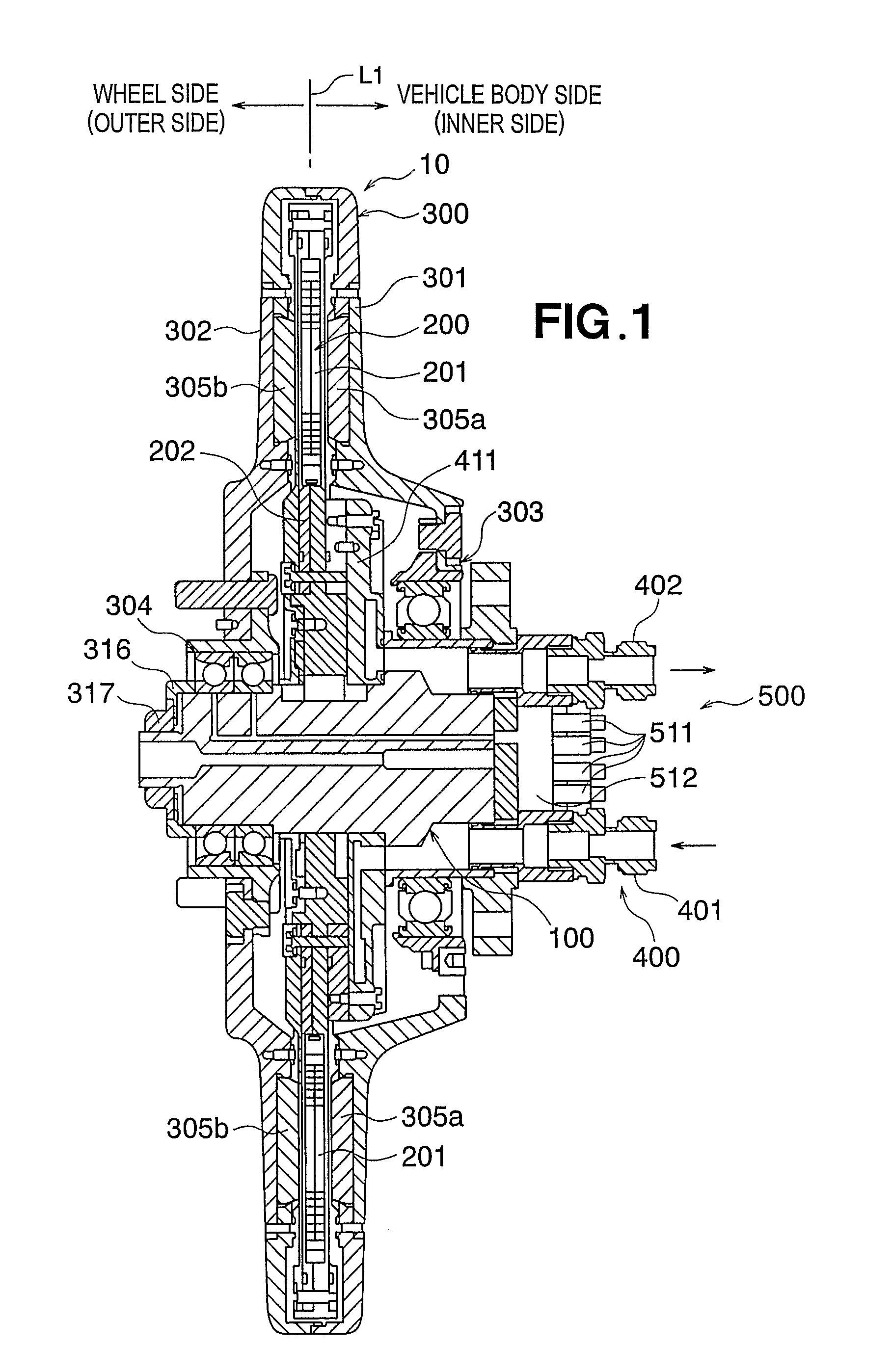

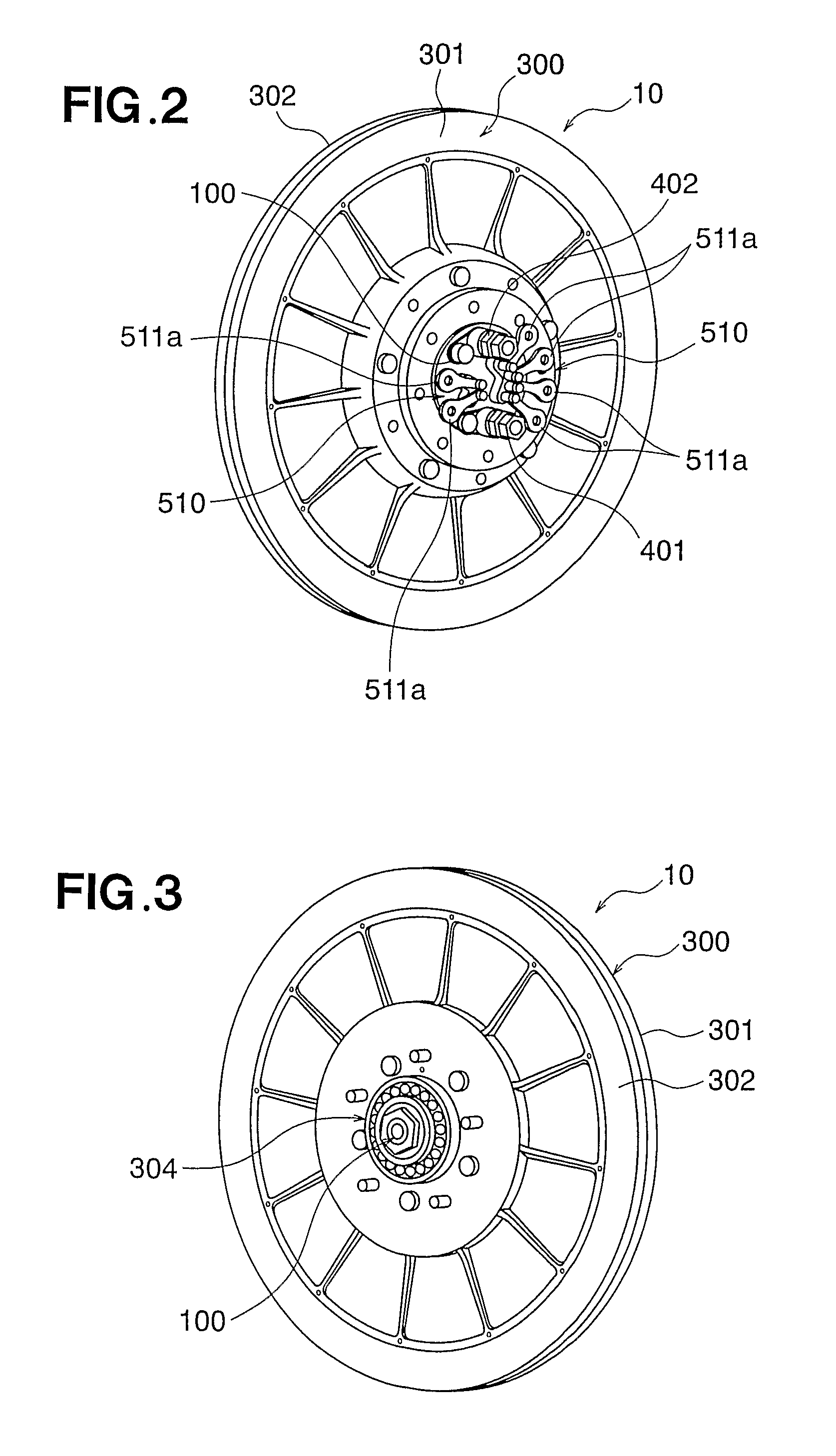

Coil assembly for rotating electric machine

InactiveUS20100001610A1Increase lamination factorSmall shapeAsynchronous induction motorsMagnetic circuit stationary partsElectric machineStator coil

A coil assembly for a rotating electric machine is a stator coil (201) for use in the stator of a motor (10) or the like, which comprises a coil plate (211) composed of at least two coil plate elements (211-1, 211-2) respectively provided with an internal peripheral portion and an external peripheral portion and having predetermined wiring patterns (241) formed by slits. The coil plate elements are bonded together at their internal peripheral portion and external peripheral portion while leaving the medial portion lying between the internal peripheral portion and the external peripheral portion spaced apart, so as to form the predetermined coil winding patterns (241).

Owner:HONDA MOTOR CO LTD

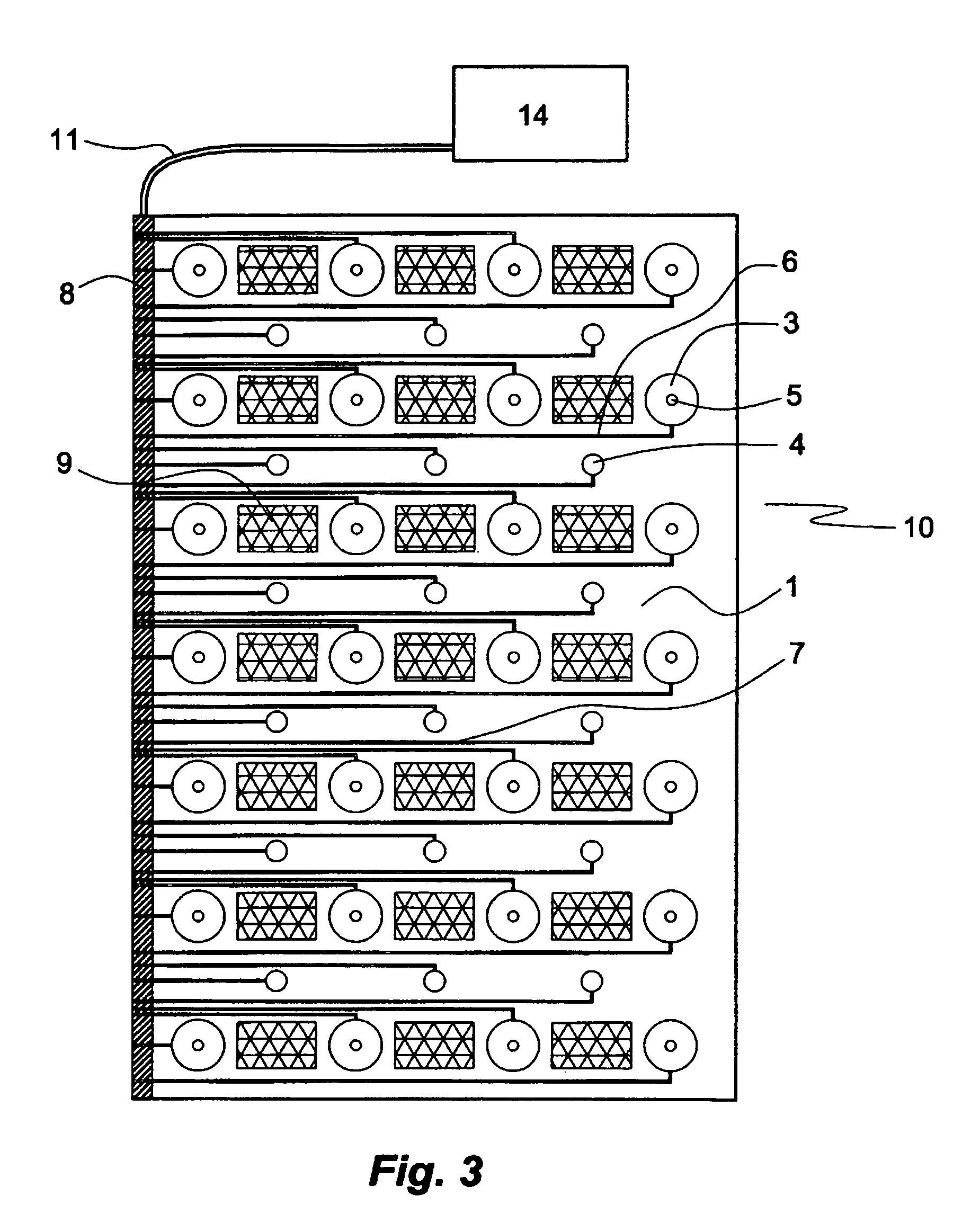

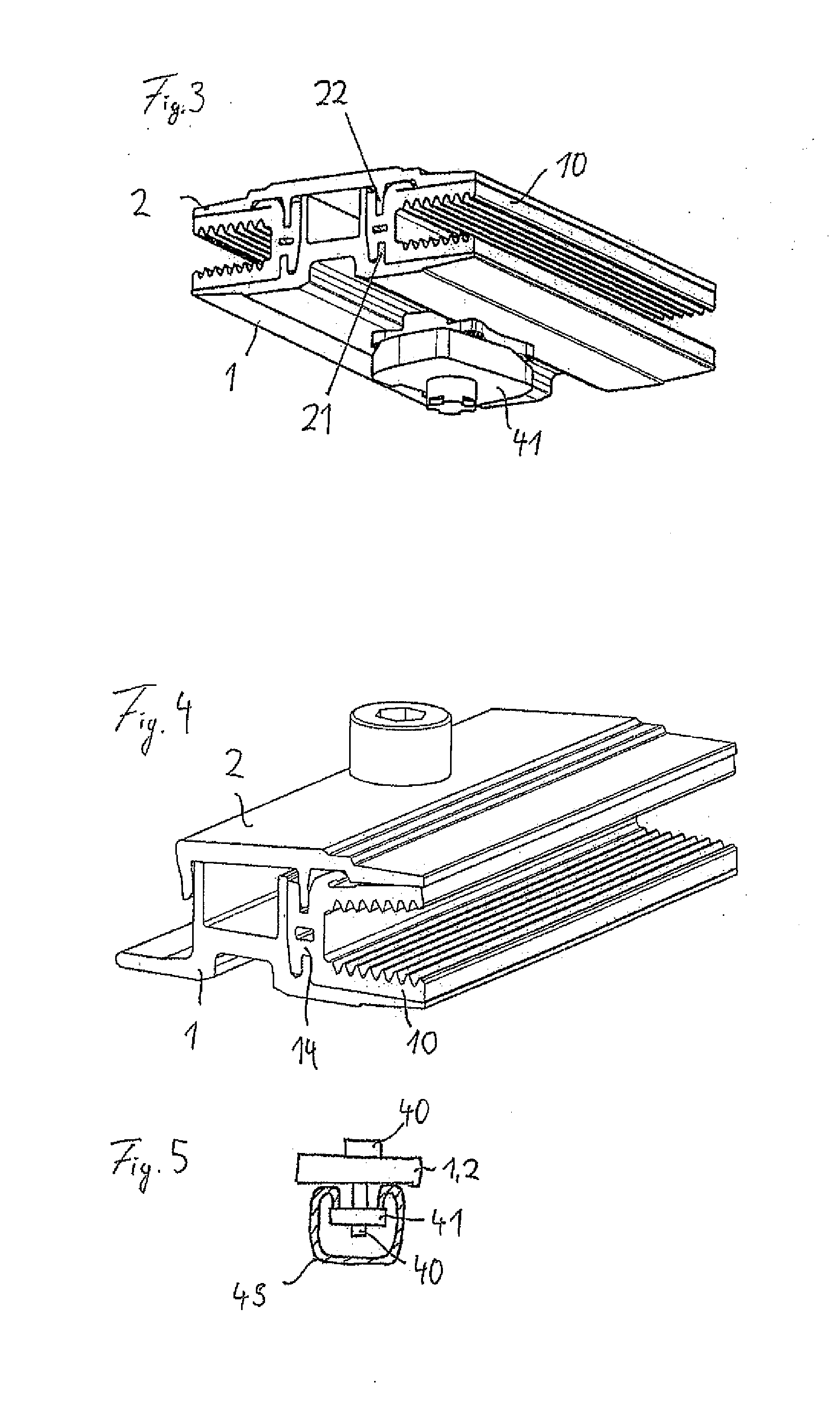

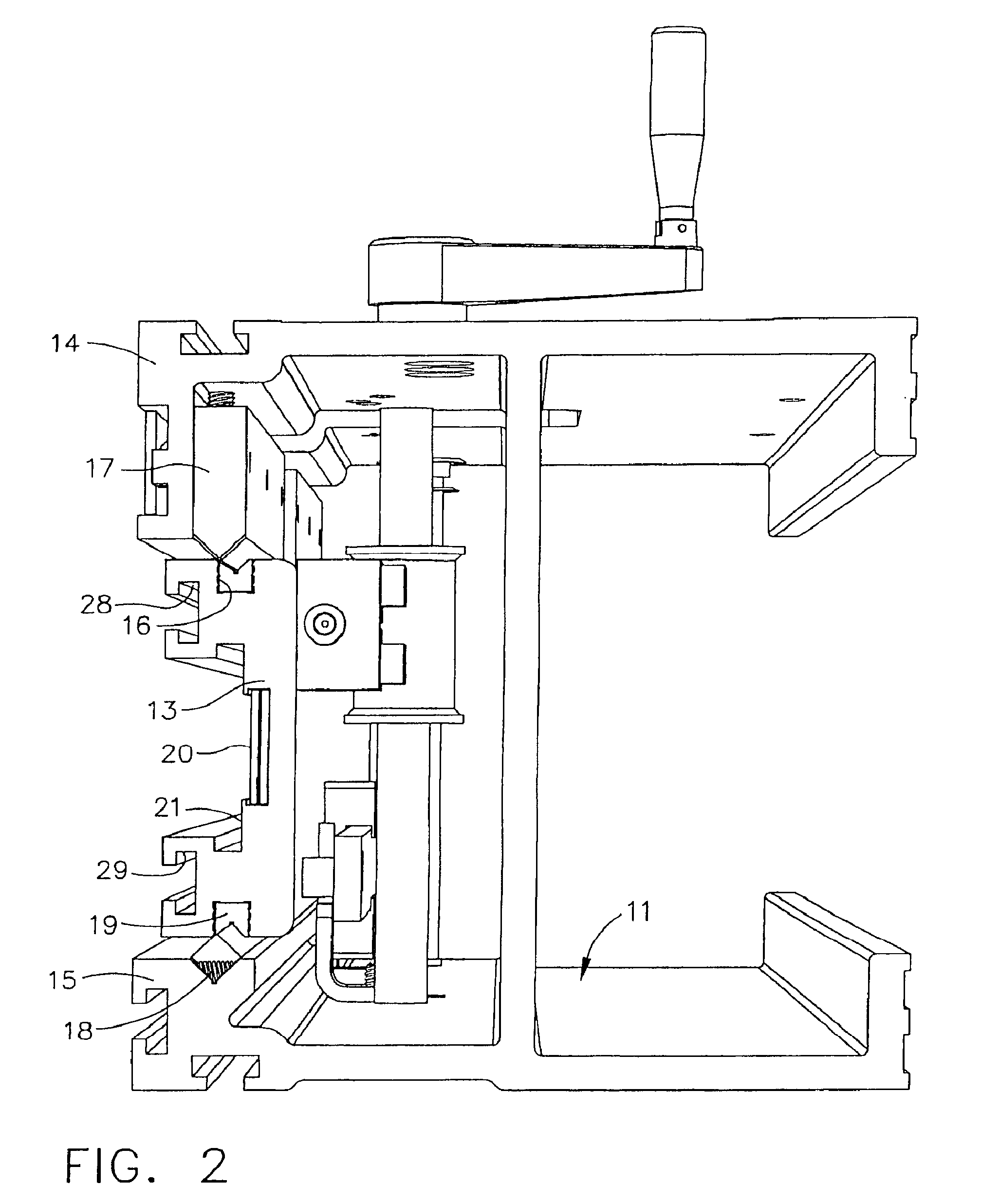

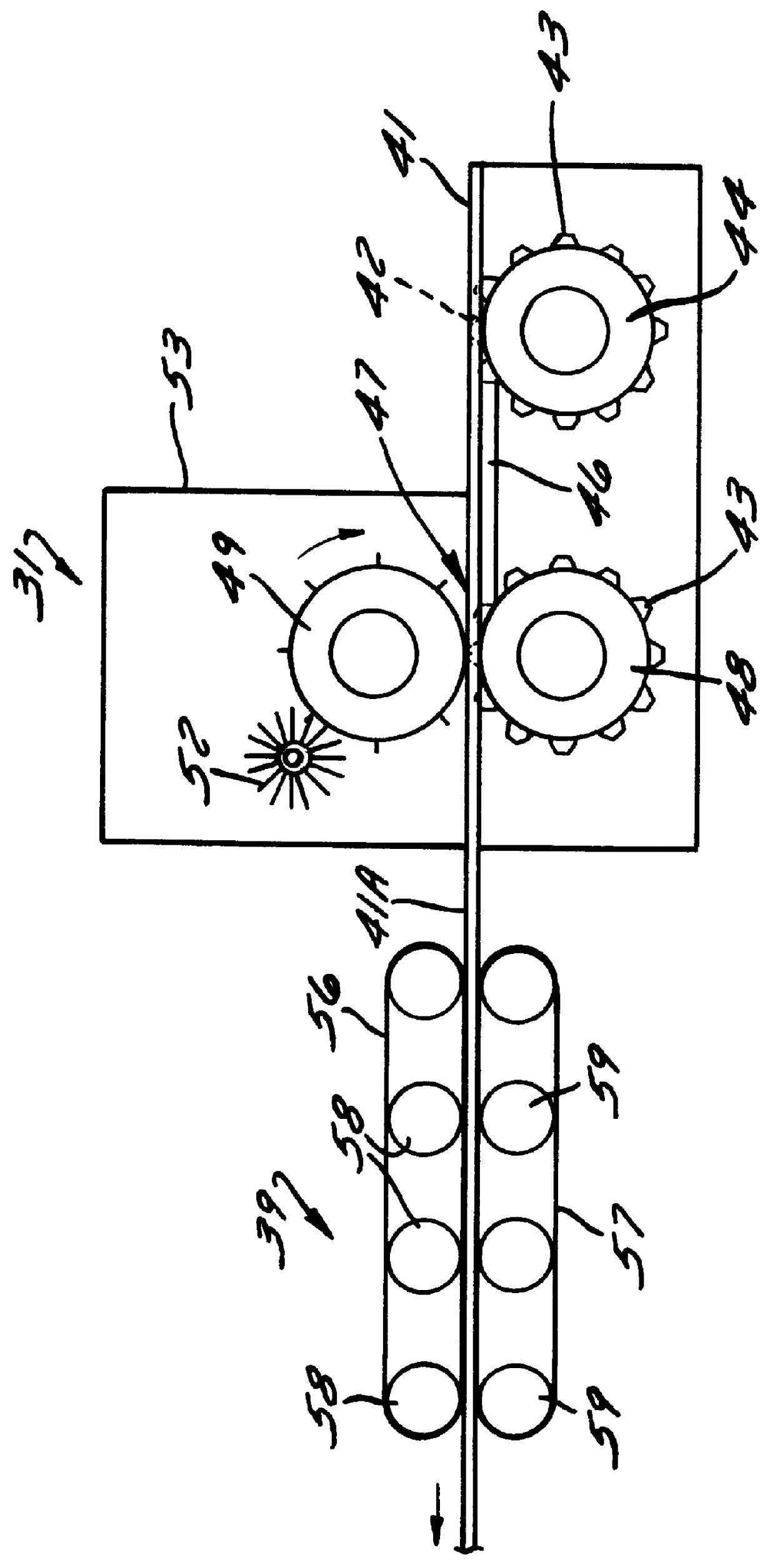

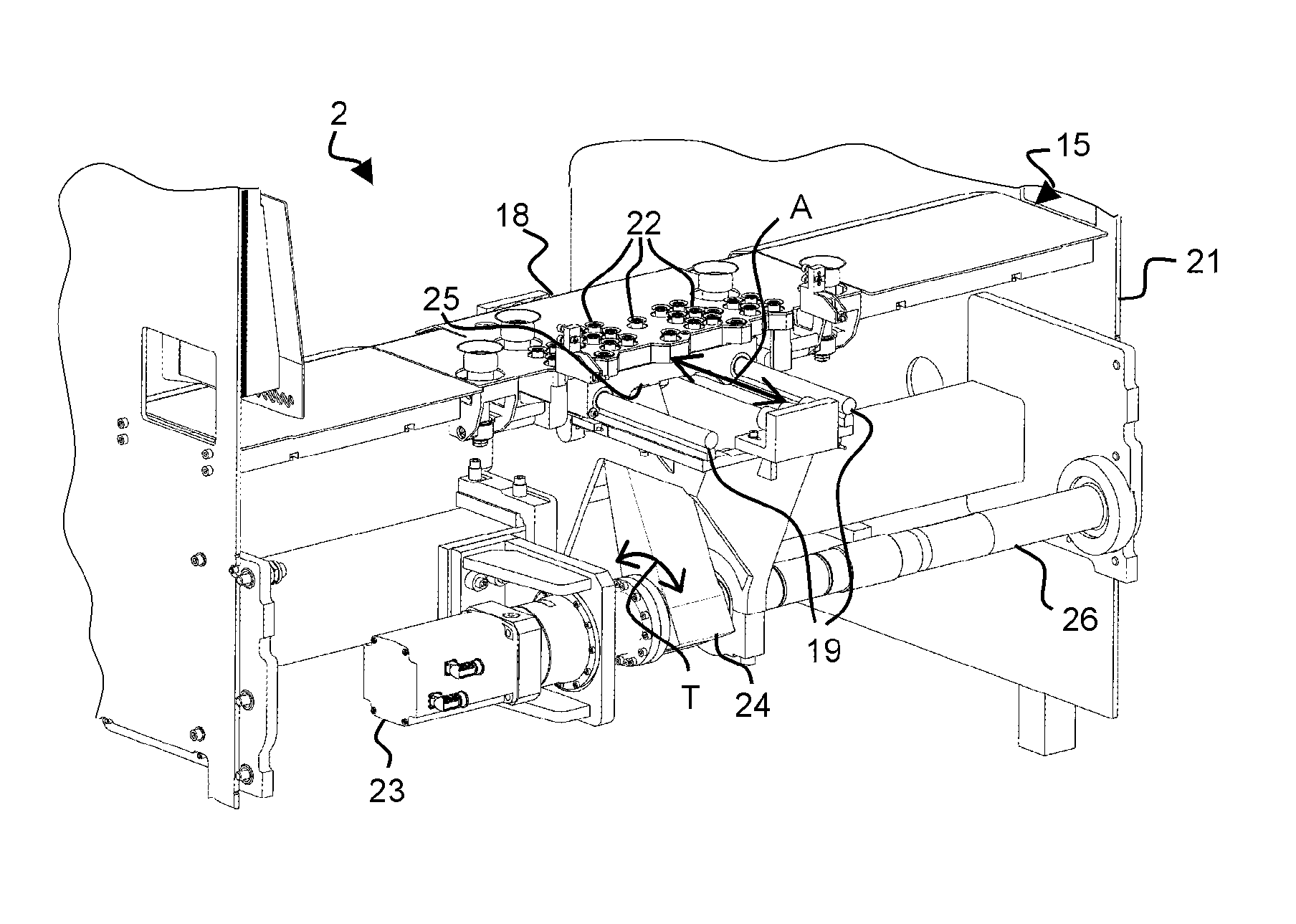

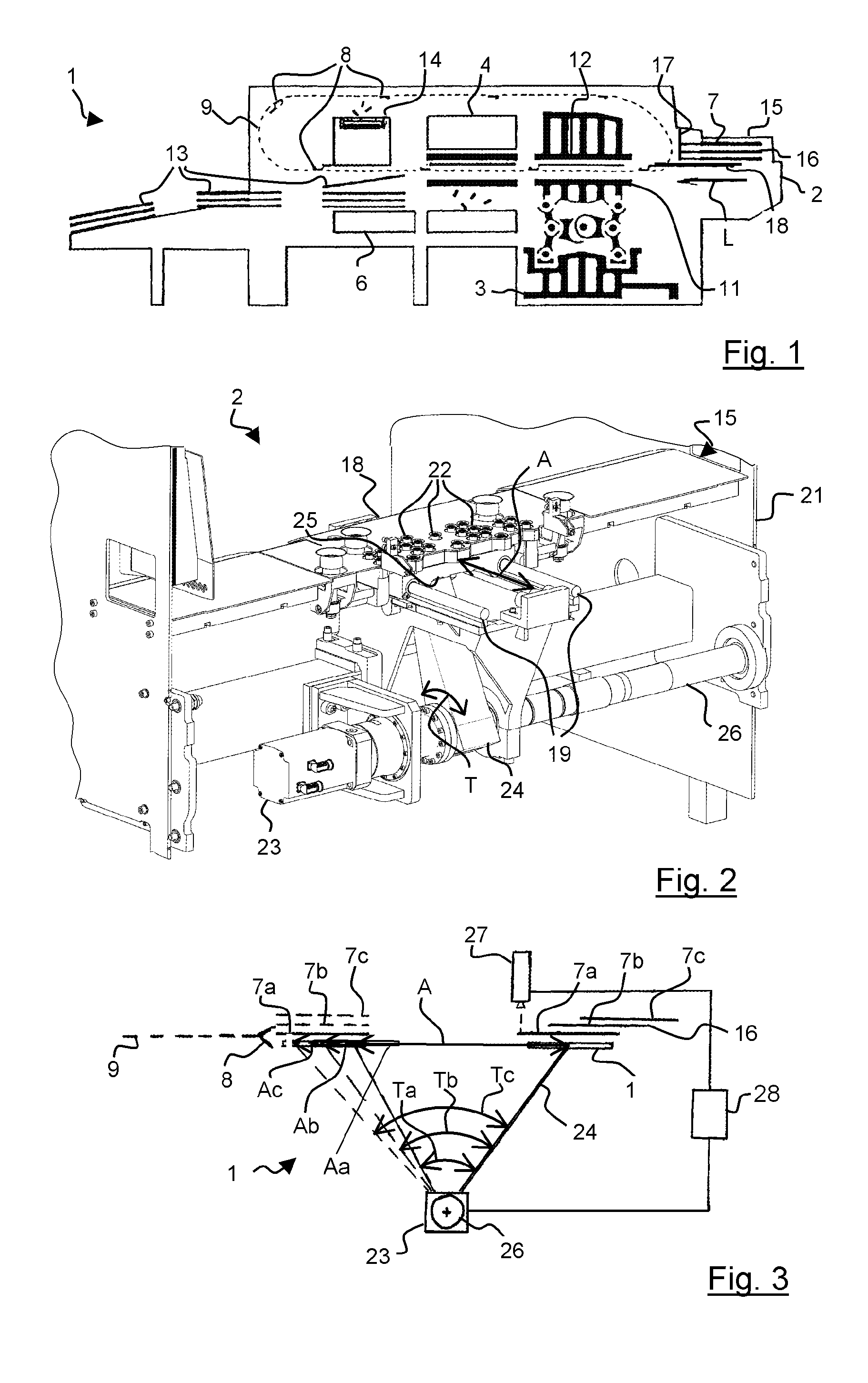

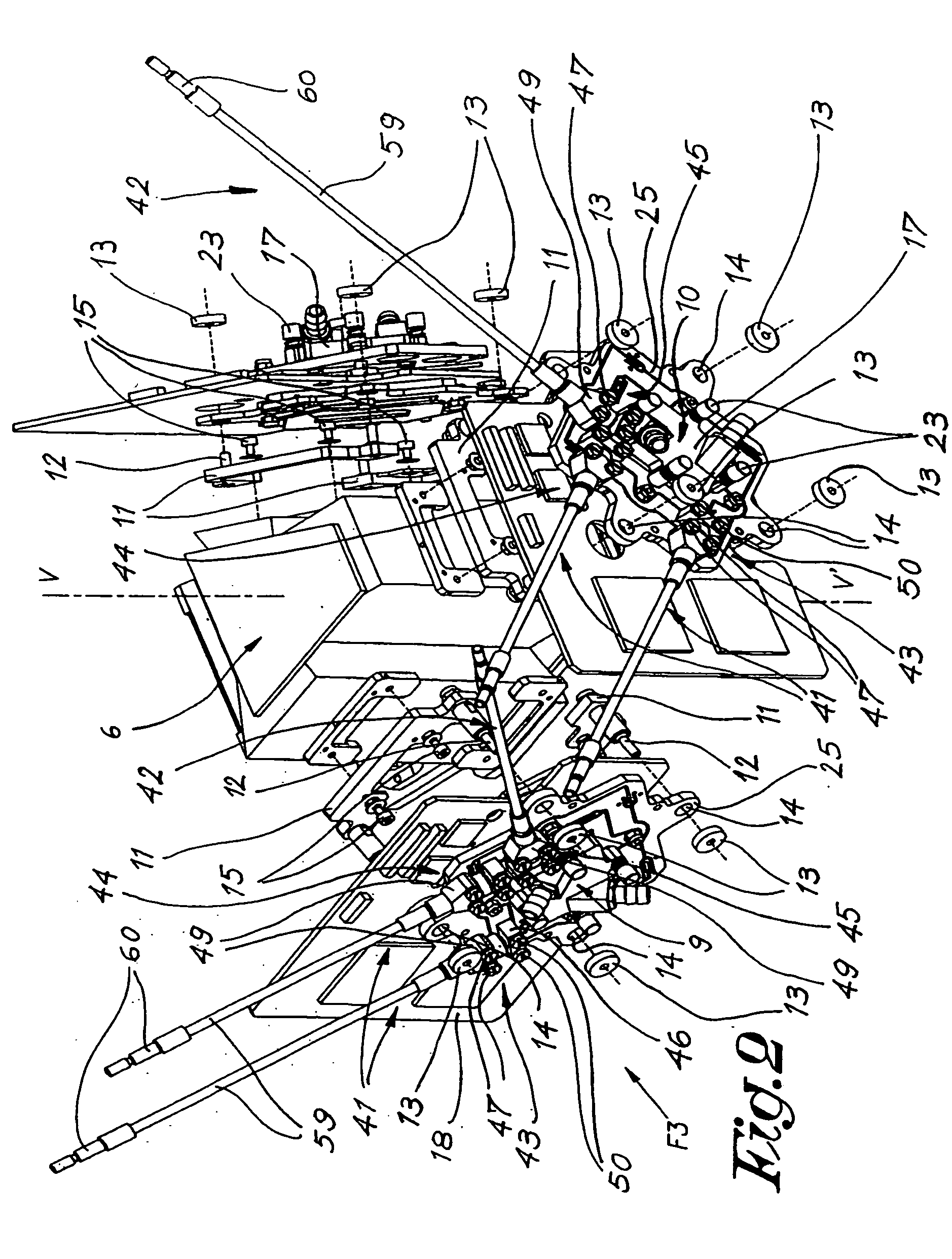

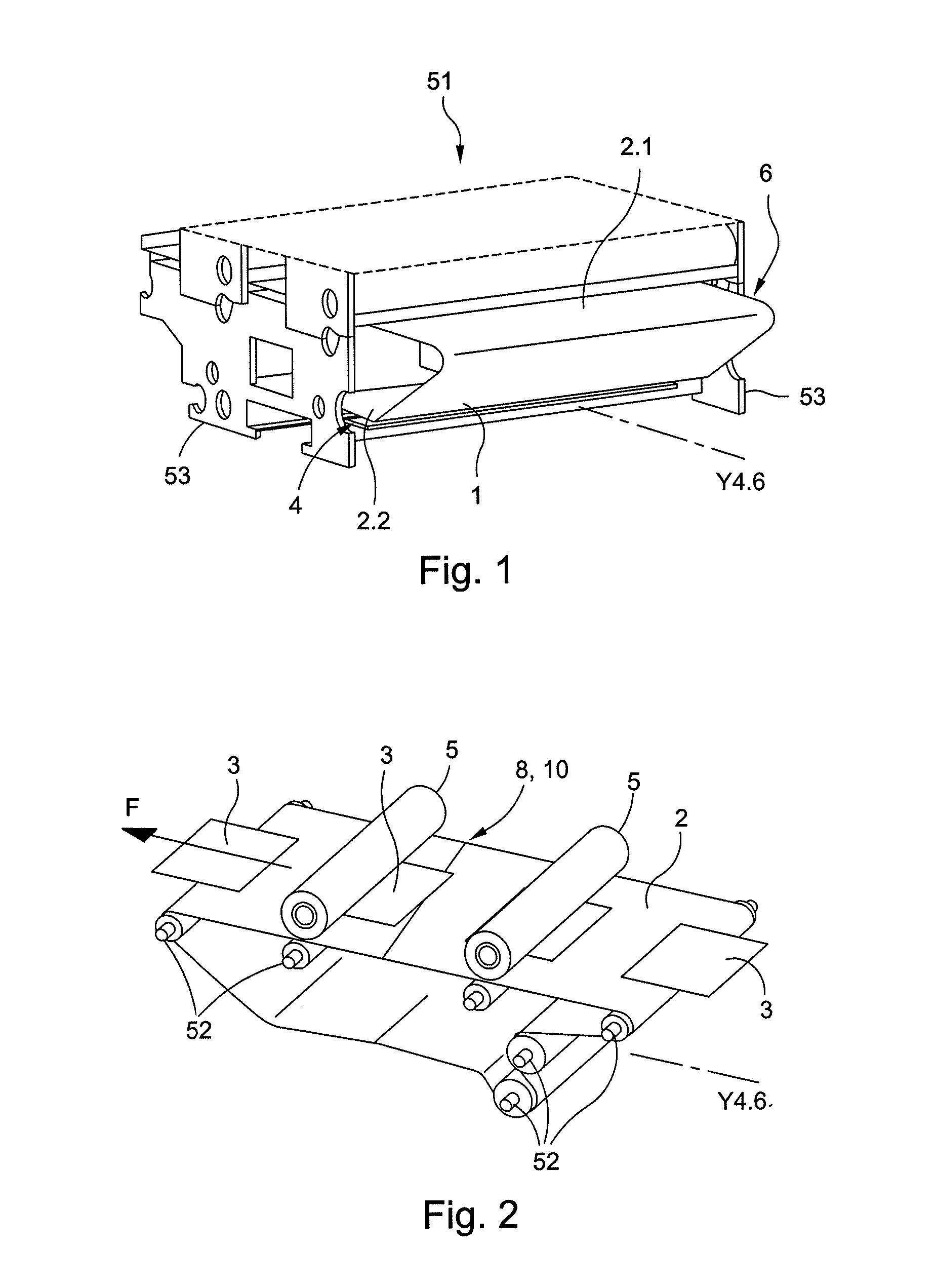

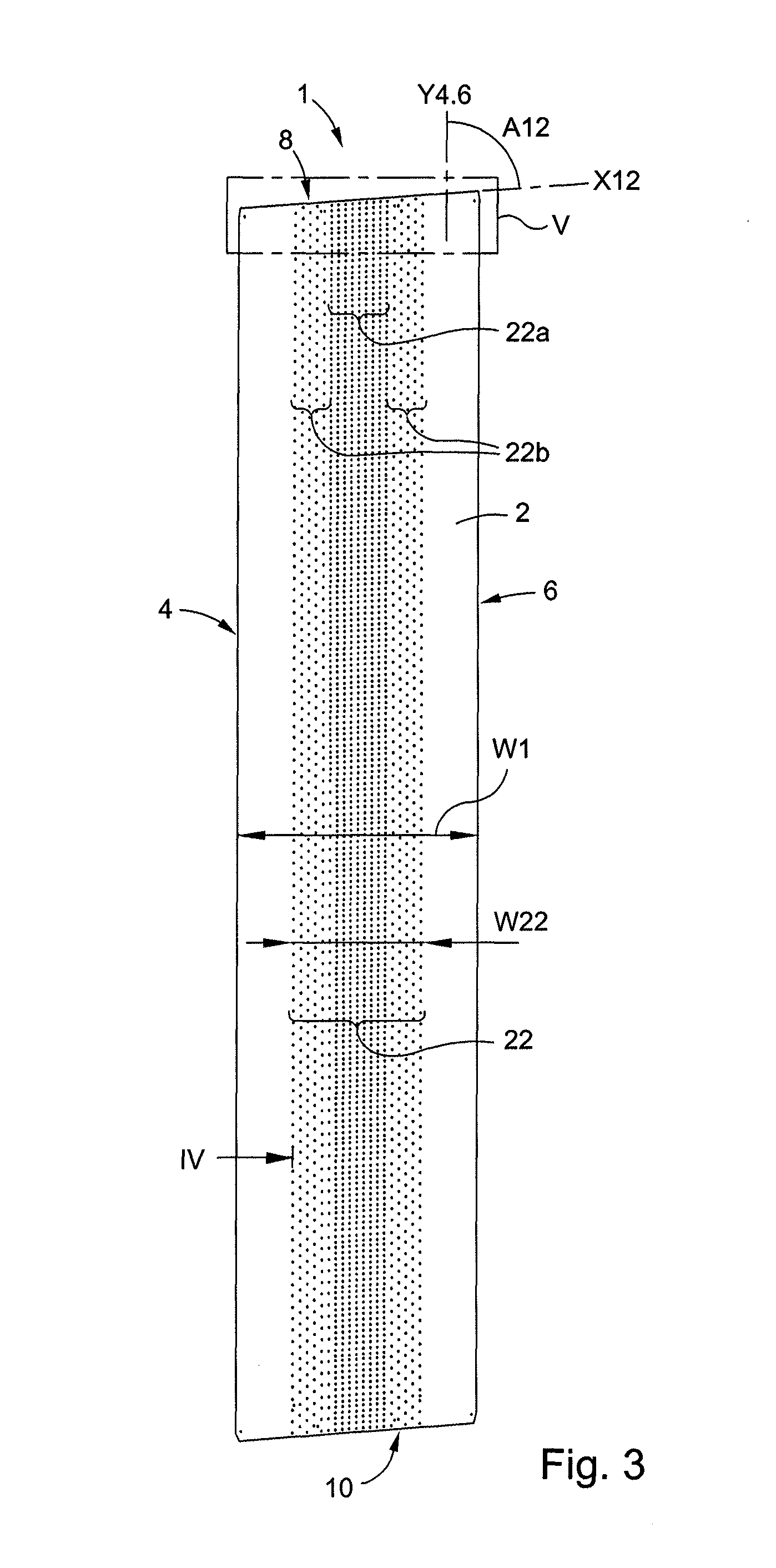

Device for positioning a plate element in an infeed station of a processing machine

ActiveUS8727346B2Easy to buildSimplicity of implementationRegistering devicesFunction indicatorsEngineeringMechanical engineering

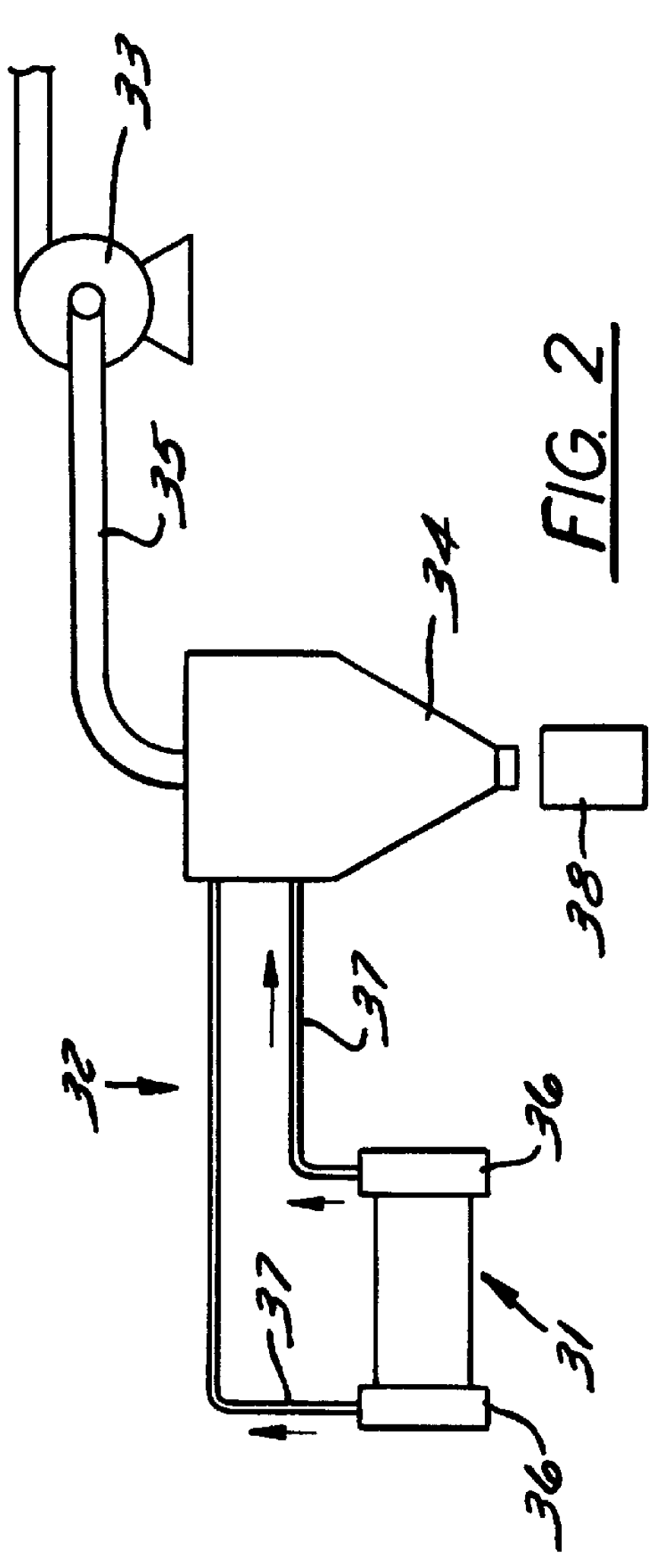

A device for positioning a plate element (7a, 7b, 7c) in an infeed station (2) of a machine for treating the element (1), fitted with a conveyor (8, 9), gripping the element (7a, 7b, 7c) which is found in a predetermined intermediate position, and carrying the element (7a, 7b, 7c) in a rated running into successive processing stations (3, 4, 6). The device includes a holding device (18) for temporarily holding the element (7a, 7b, 7c), the holding device moving longitudinally alternatively (A) from an upstream position to a downstream position, and vice-versa, to pick up the element (7a, 7b, 7c) in a rear position and bring it to the intermediate position, and to return empty. A motor (23) moves the holding device (18) longitudinally, from the upstream position to the downstream position, and vice-versa, as a function of the rated running. A detector (27) detects a rear longitudinal position in which the element (7a, 7b, 7c) is found, and emits a position signal. The motor (23) is able to move (A, Aa, Ab, Ac) the holding device (18) from the upstream position to various downstream positions, as a function of the signal emitted by the detection device (27), so as to bring the element (7a, 7b, 7c) from the rear position to the intermediate position.

Owner:BOBST MEX SA

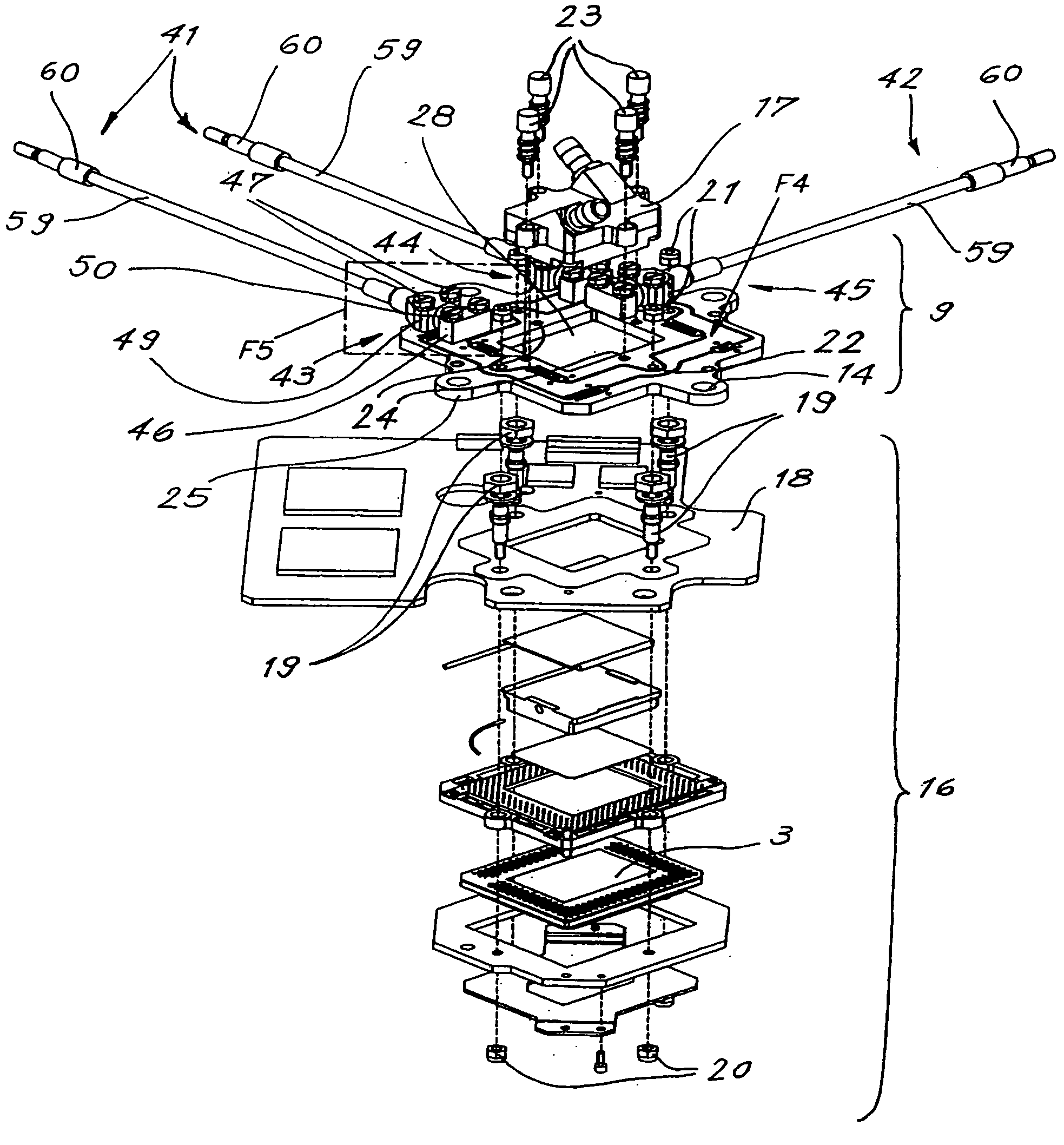

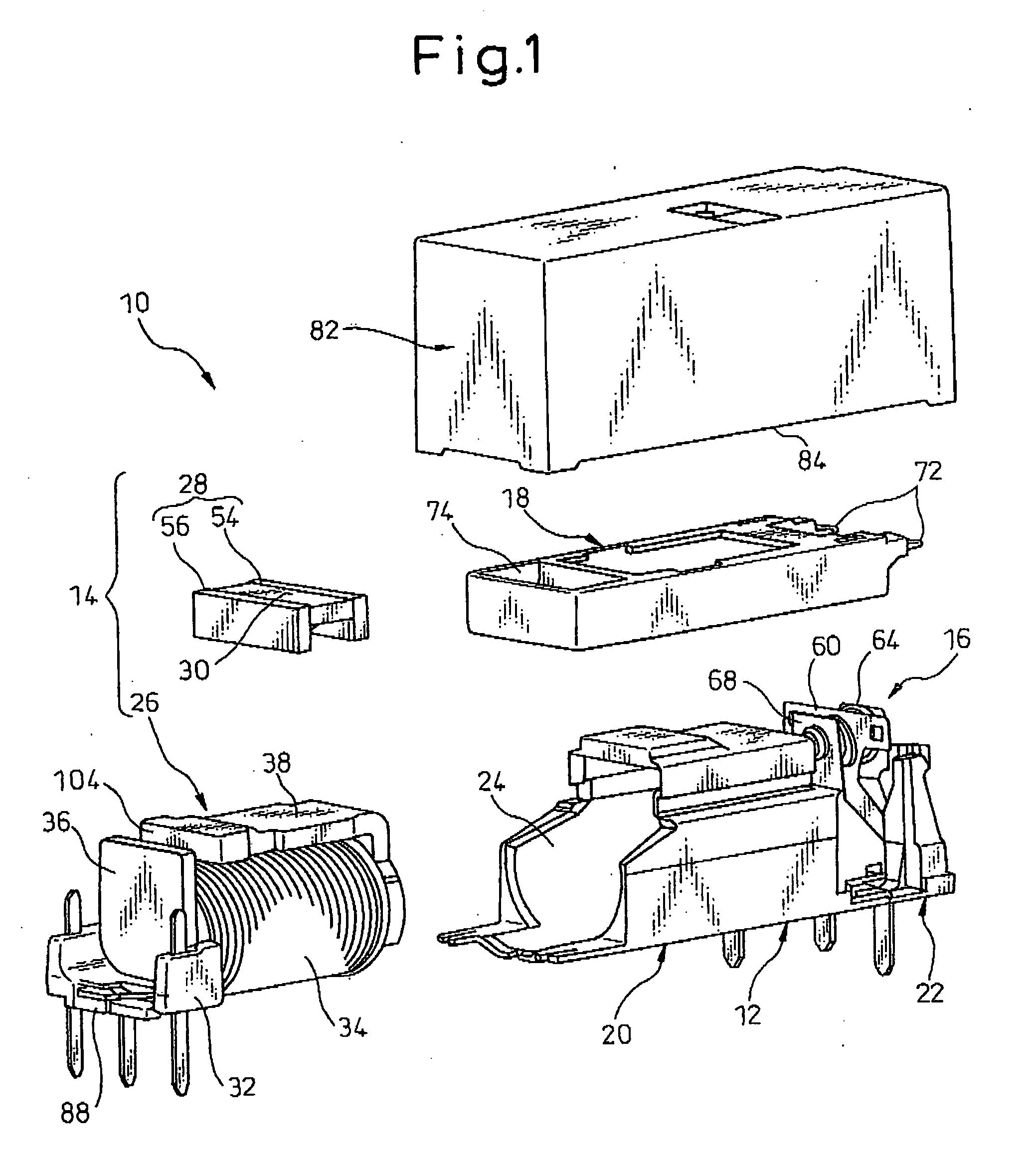

Adjustable convergence device for a projector and projector equipped with such a convergence device

ActiveUS20050195504A1Short timePrecise and accurate adjustmentTelevision system detailsPicture reproducers using cathode ray tubesEngineeringSelf locking

An improved adjustable convergence device for adjusting the position of a pixel light modulator of a projector comprising at least two such light modulators mounted on the frame of the projector, said convergence device comprising a plate assembly which is fixed on said supporting frame and which supports the light modulator to be adjusted, wherein said plate assembly is composed of at least two plate elements, respectively a plate element which is fixed to the supporting frame and a plate element on which the light modulator is fixed, whereby these plate elements are connected to each other by means of at least one elastic joint and whereby at least first self-locking adjusting means are provided for transmitting a force in an adjusting direction between these plate elements in order to adjust the relative position between said plate elements.

Owner:BARCO NV

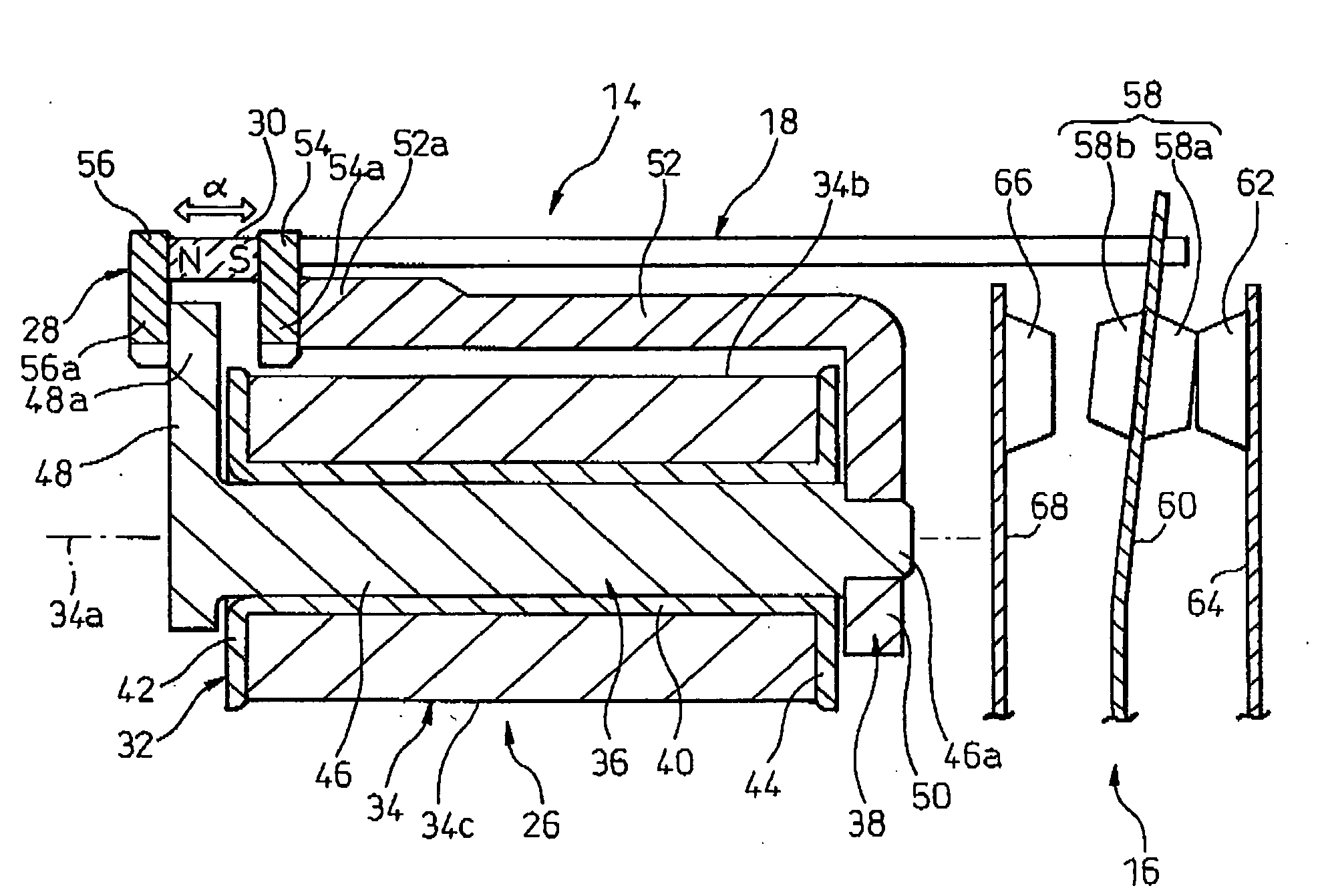

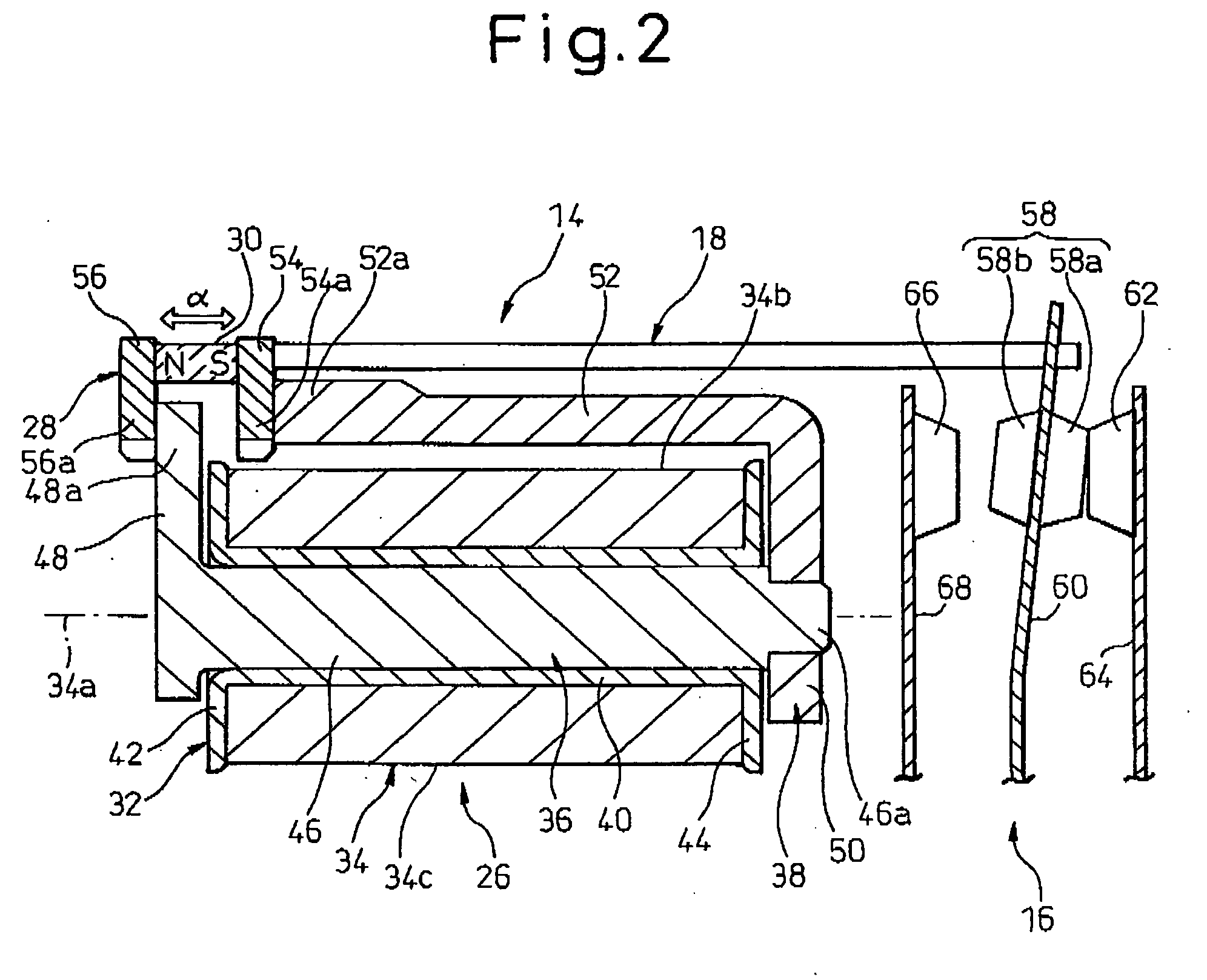

Polarized electromagnetic relay and coil assembly

ActiveUS20080180197A1Simple configurationSimple structureElectromagnetic relay detailsSelector switchesMagnetizationElectromagnet

A polarized electromagnetic relay including an electromagnet assembly, a contact section insulated from the electromagnet assembly, and a force transfer member disposed between the electromagnetic assembly and the contact section. The electromagnet assembly includes an electromagnet, an armature driven by the electromagnet, and a permanent magnet carried on the armature. The armature includes first and second electrically conductive plate elements holding the permanent magnet therebetween in a direction of magnetization of the permanent magnet and disposed to orient the direction of magnetization in parallel with the center axis of the coil. The armature is arranged linearly movably in a direction parallel with the center axis in a state where a part of the first electrically conductive plate element is inserted into a space between the outer peripheral region of the iron core head portion and the distal end region of the yoke major portion.

Owner:FUJITSU COMPONENENT LTD

Coil assembly for rotating electric machine

InactiveUS8148870B2Increase lamination factorSmall shapeMagnetic circuit stationary partsAsynchronous induction motorsElectric machineStator coil

A coil assembly for a rotating electric machine is a stator coil for use in the stator of a motor or the like, which includes a coil plate composed of at least two coil plate elements respectively provided with an internal peripheral portion and an external peripheral portion and having predetermined wiring patterns formed by slits. The coil plate elements are bonded together at their internal peripheral portion and external peripheral portion while leaving the medial portion lying between the internal peripheral portion and the external peripheral portion spaced apart, so as to form the predetermined coil winding patterns.

Owner:HONDA MOTOR CO LTD

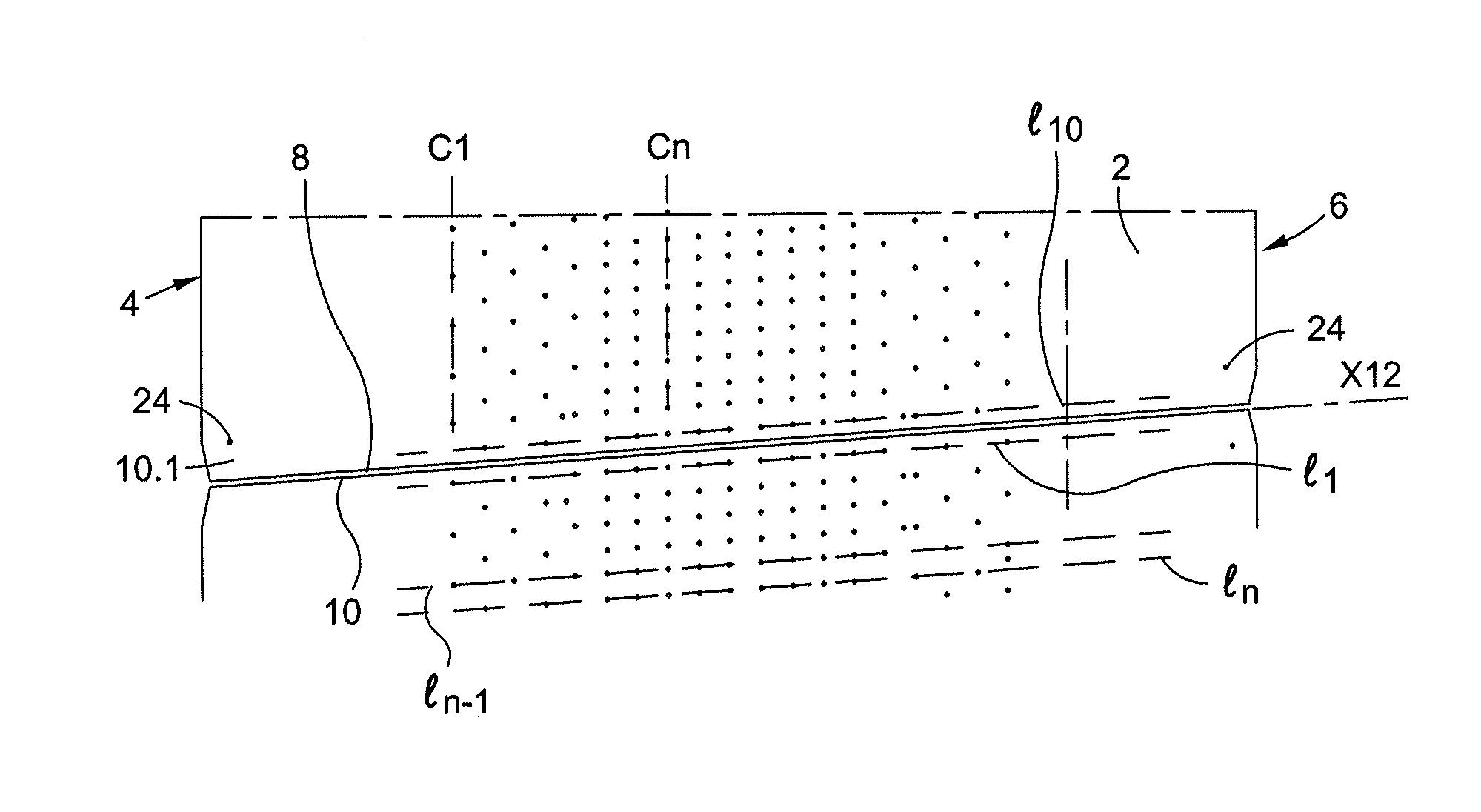

Conveyor belt for plate elements and converting machine comprising such a belt

A conveyor belt for conveying plate elements in a machine for converting the elements that includes a belt body with longitudinal edges, joining edges, and a support surface for supporting the elements, and at least one assembly member arranged to join the joining edges, and extending in a direction of assembly which is oblique to the longitudinal direction, the belt body having a plurality of perforations for obtaining a vacuum on the support surface to immobilize the elements.

Owner:BOBST LYON

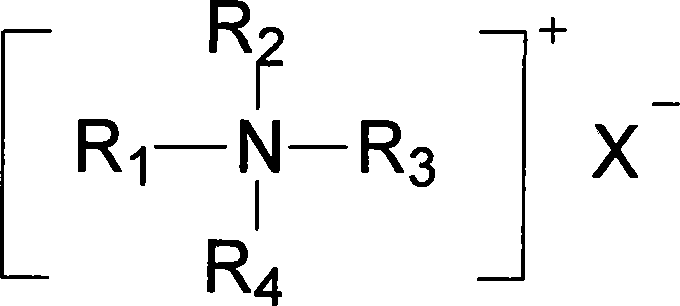

Additive for heat zinc coating auxiliary agent

InactiveCN101126142AHigh activityIncrease profitHot-dipping/immersion processesSlagSurface-active agents

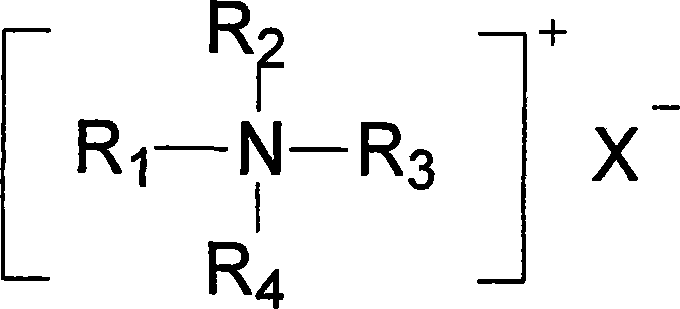

The invention provides an additive used in hot-dip galvanizing assistant plating agent, belonging to the technical field of metal material plating. The invention is used for solving the problem of assistant plating efficiency. The technical proposal of the invention is that the additive is a de-ionized water solution; the water solution contains cation surface active agent and organic solvent of the long chain alkyl; the content of the long chain alkyl cation surface active agent is 100 to 800 gram per liter; the organic solvent can be ethanol, isopropyl alcohol, acetone or one of nickel and N-dimethyl formamide, with adding content of 30 to 160 gram per liter. The invention has the advantages that the assistant plating agent is made and the made element have a plating face with excellent wettability and compatibility, which can increase the activity and the utilization rate, improve the assistant plating efficiency, prevent plated element from escaping, prevent the plated element which is assistant plated from being secondarily oxidized in air, reduce zinc slag, prevent the zinc liquid from splashing and increase the surface quality of the made element. Furthermore, the invention can be directly added into the assistant agent, and then is evenly mixed, with the character of easy operation. The invention is not limited by the temperature of the assistant plating agent so that the invention can be used under room temperature.

Owner:陈冬

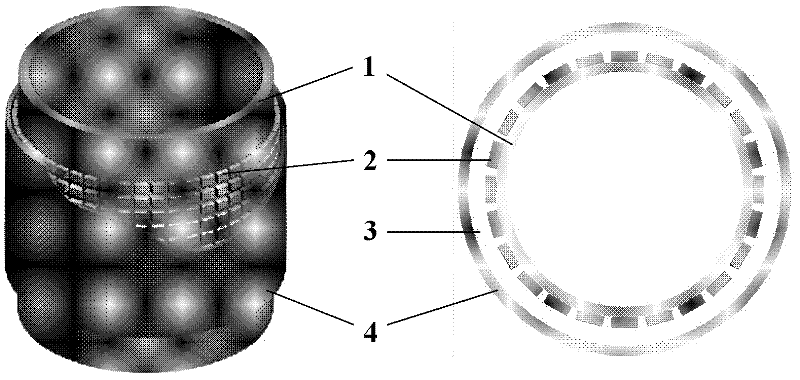

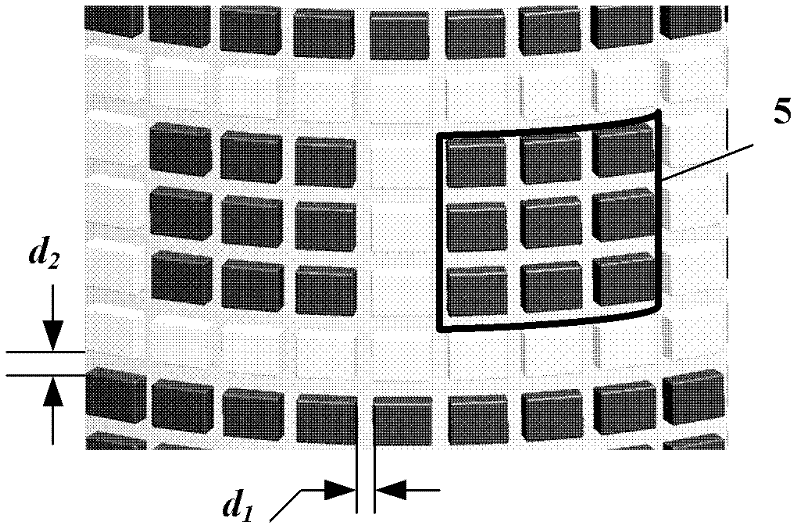

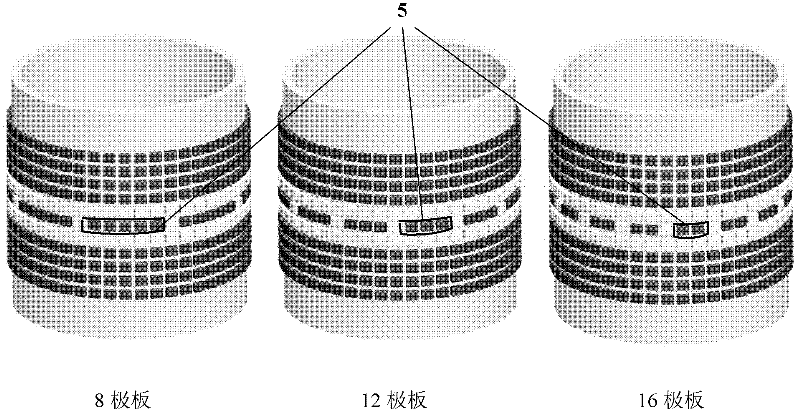

A multi-array adaptive capacitance tomography sensor device

InactiveCN102297884AImprove axial spatial measurement resolutionIncrease flexibilityMaterial capacitanceTomographySelf adaptive

A multi-array adaptive capacitance tomography sensor device belongs to the detection field. Including an empty insulating container, a multi-array electrode plate, an insulating layer and a shielding layer; the outer surface of the empty insulating container is fixedly connected with a multi-array electrode plate, and the outer layer of the multi-array electrode plate is an insulating layer and a shielding layer; the multi-array electrode plate It consists of multiple annular plate groups arranged at equal intervals along the axial direction from top to bottom, and each annular plate group is composed of multiple uniformly distributed unit plates; through the physical on-off control of the unit plates, Composite plates of different sizes can be formed. When the non-metallic mixture to be measured is placed in any position of the container, the position of the object to be tested is judged by the layer-by-layer detection of the multi-array adaptive ECT sensor, and the number of measuring plates, geometric dimensions, and axial shielding are selected according to the actual measurement requirements. And other parameters, so that the sensor always maintains a good measurement effect.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com