Patents

Literature

89 results about "Vacuum manifold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In quantum field theory, the vacuum state may be degenerate. Each pure vacuum state generates its own superselection sector. The space of all pure vacuum states often has a manifold structure and is called the vacuum manifold.

Vaccum support and transfer of flexible material

A transfer assembly and method for transferring a flexible sheet of material which is subject to wrinkling, folding and / or creasing. The assembly and method includes a vacuum manifold having a cavity which is connected to an evacuation source for drawing a vacuum on the cavity, and an opening on the manifold of a given size and shape and communicating with the cavity. A sheet of porous material for supporting the flexible sheet of material for transfer thereon covers the opening and has a plurality of fine pores extending therethrough. The pores are profusely and uniformly distributed entirely over an area of the sheet of porous material which area is at least substantially of the same size and shape as the flexible sheet of material which is to be transferred thereon, so that substantially the entire area of the flexible sheet of material which is to be transferred is exposed to the pores. The pores are subjected to the vacuum in the manifold cavity in the substantial absence of impairment of communication of the vacuum to the pores to uniformly pickup and hold the flexible sheet of material for transfer without folding, wrinkling or creasing of the flexible sheet of material.

Owner:TROPICANA PROD INC

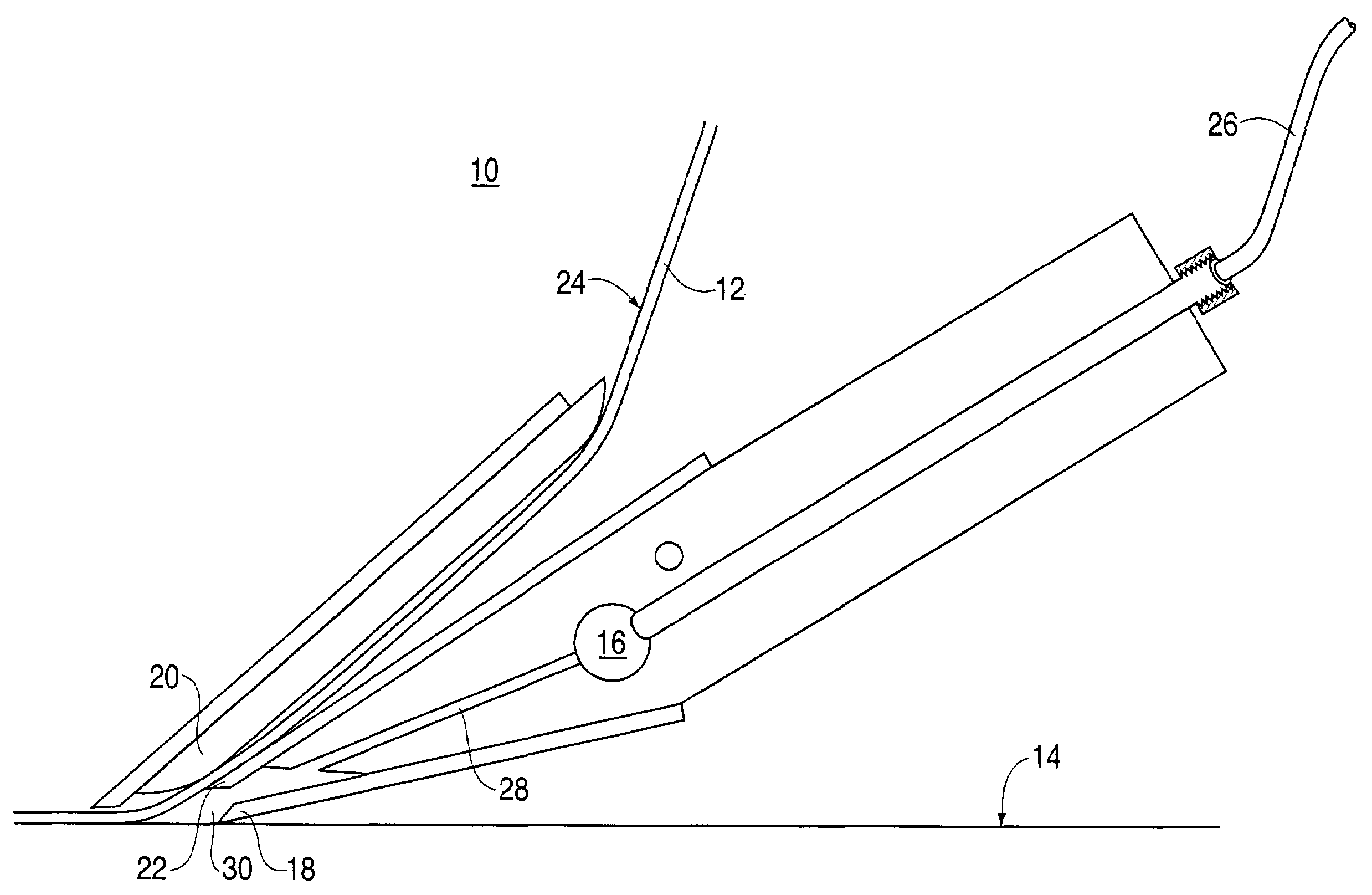

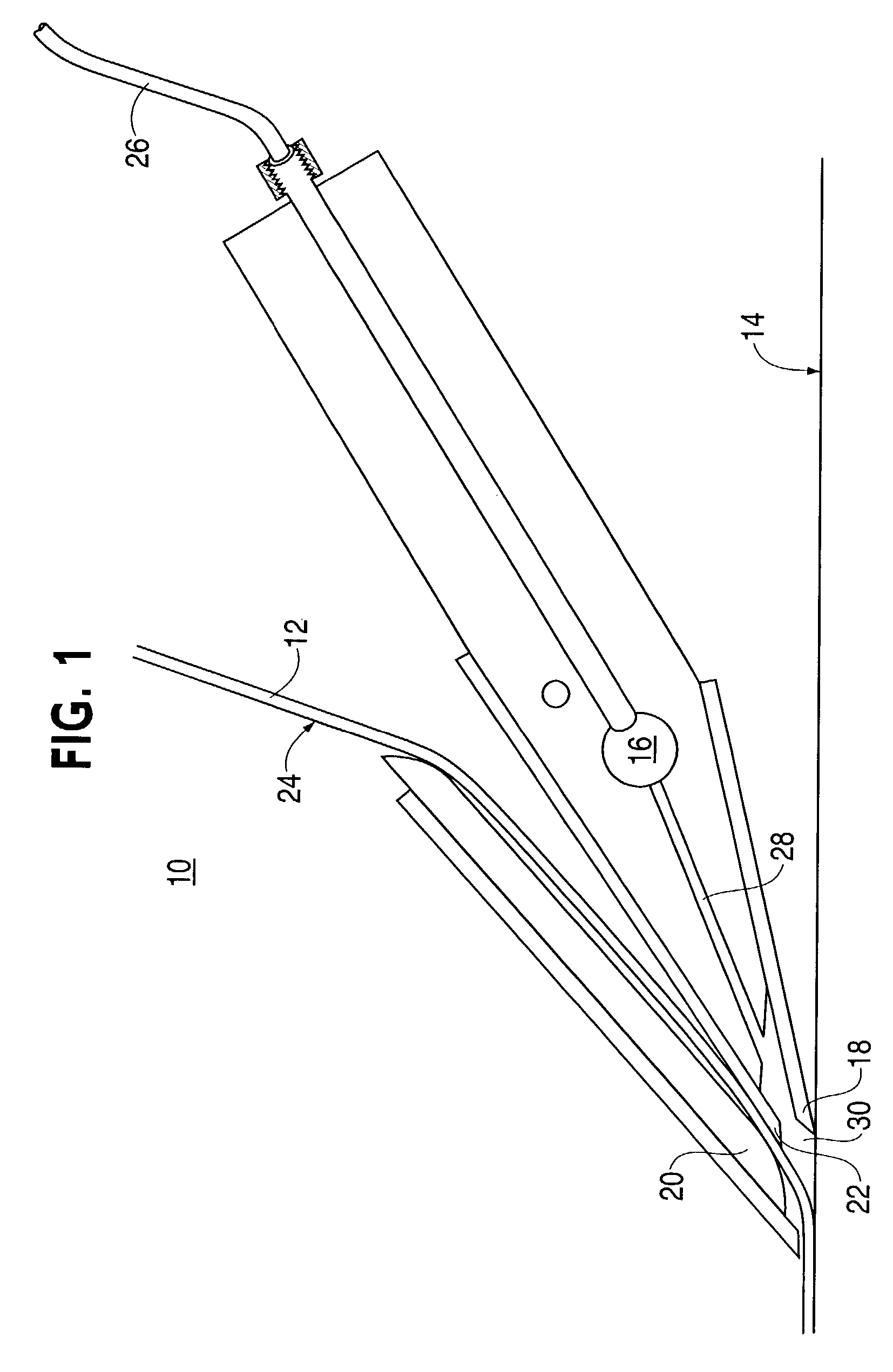

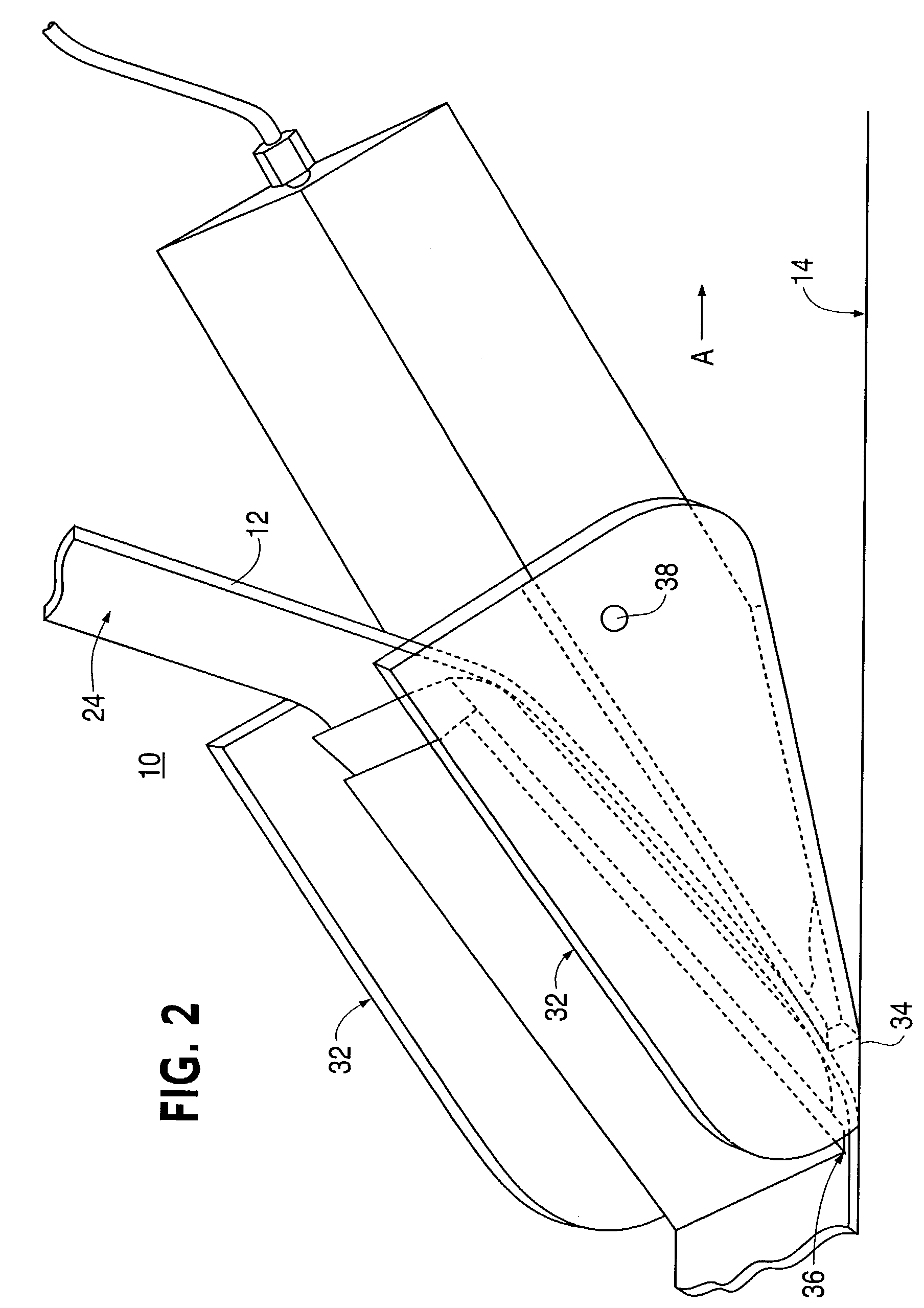

Vacuum assisted ply placement shoe and method

InactiveUS7213629B2Facilitate proper adhesionSufficient forceLamination ancillary operationsControlling laminationVacuum assistedEngineering

A device for placing a ply on a substrate surface includes a vacuum manifold assembly configured for attachment to a vacuum source and a substrate seal configured to provide a substantially gas impermeable interface with the substrate surface. This device further includes a ply seal configured to provide a substantially gas impermeable interface with the ply. In this manner, vacuum applied to the vacuum manifold assembly depressurizes an area between the ply and the substrate surface.

Owner:THE BOEING CO

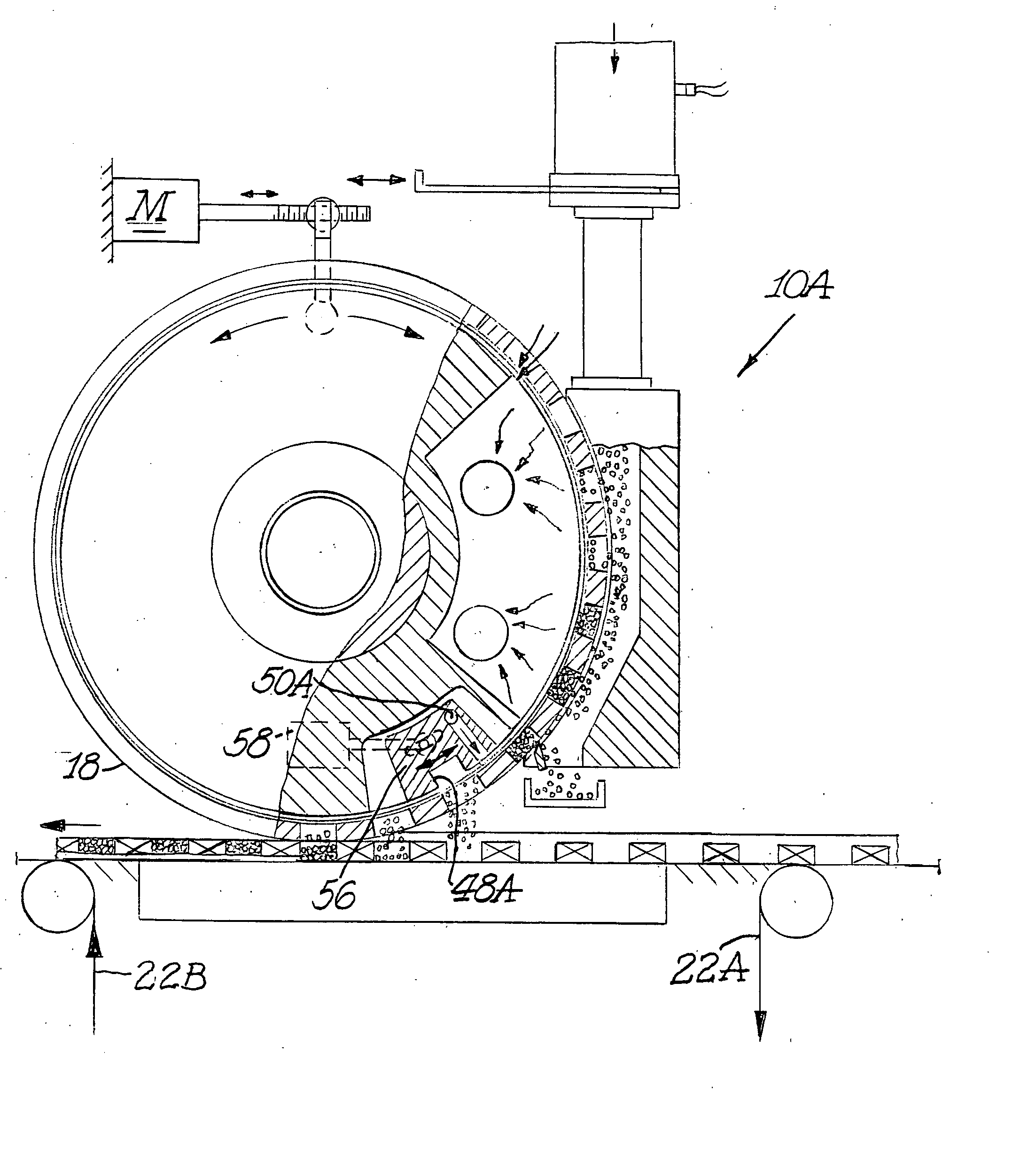

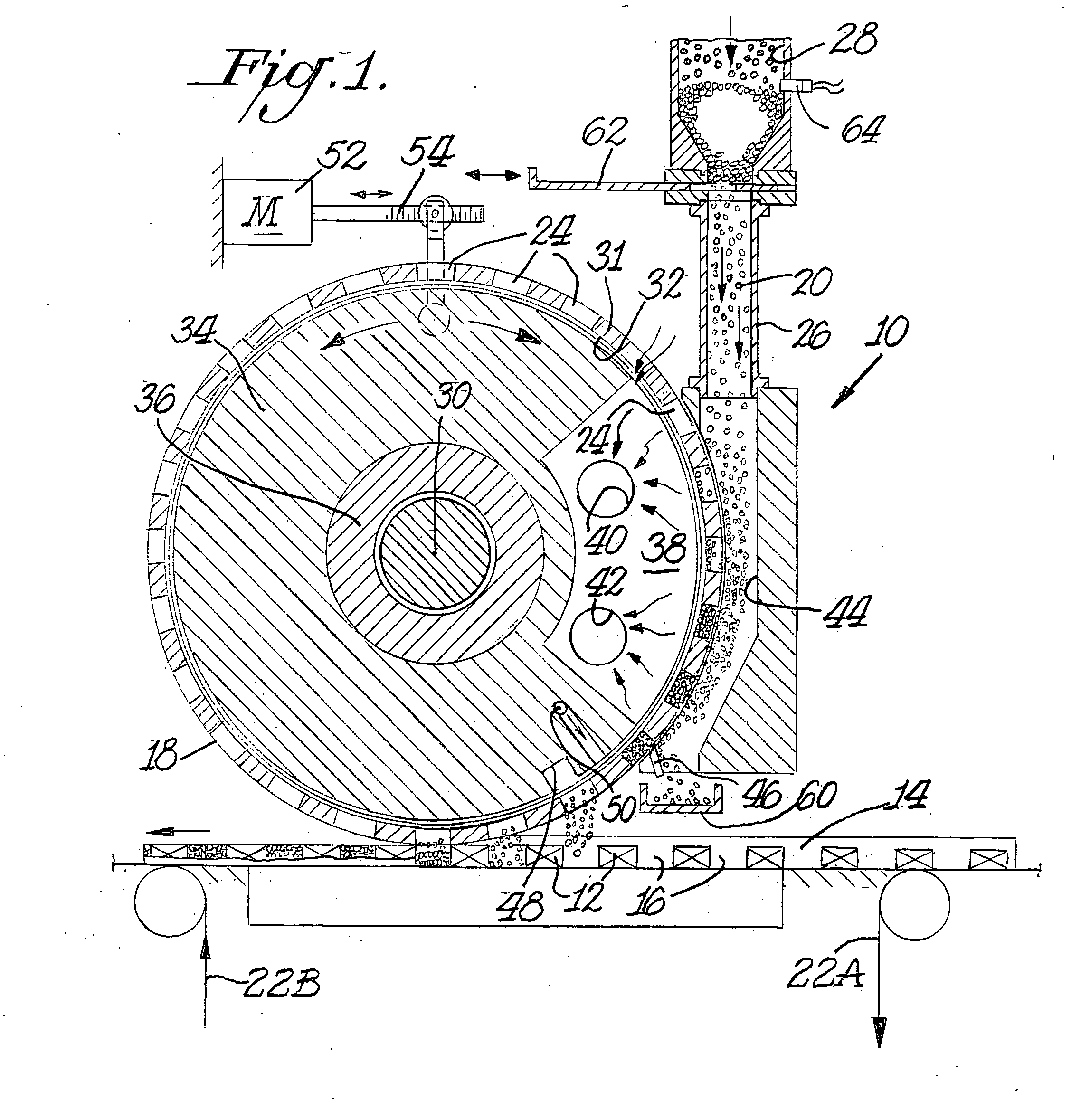

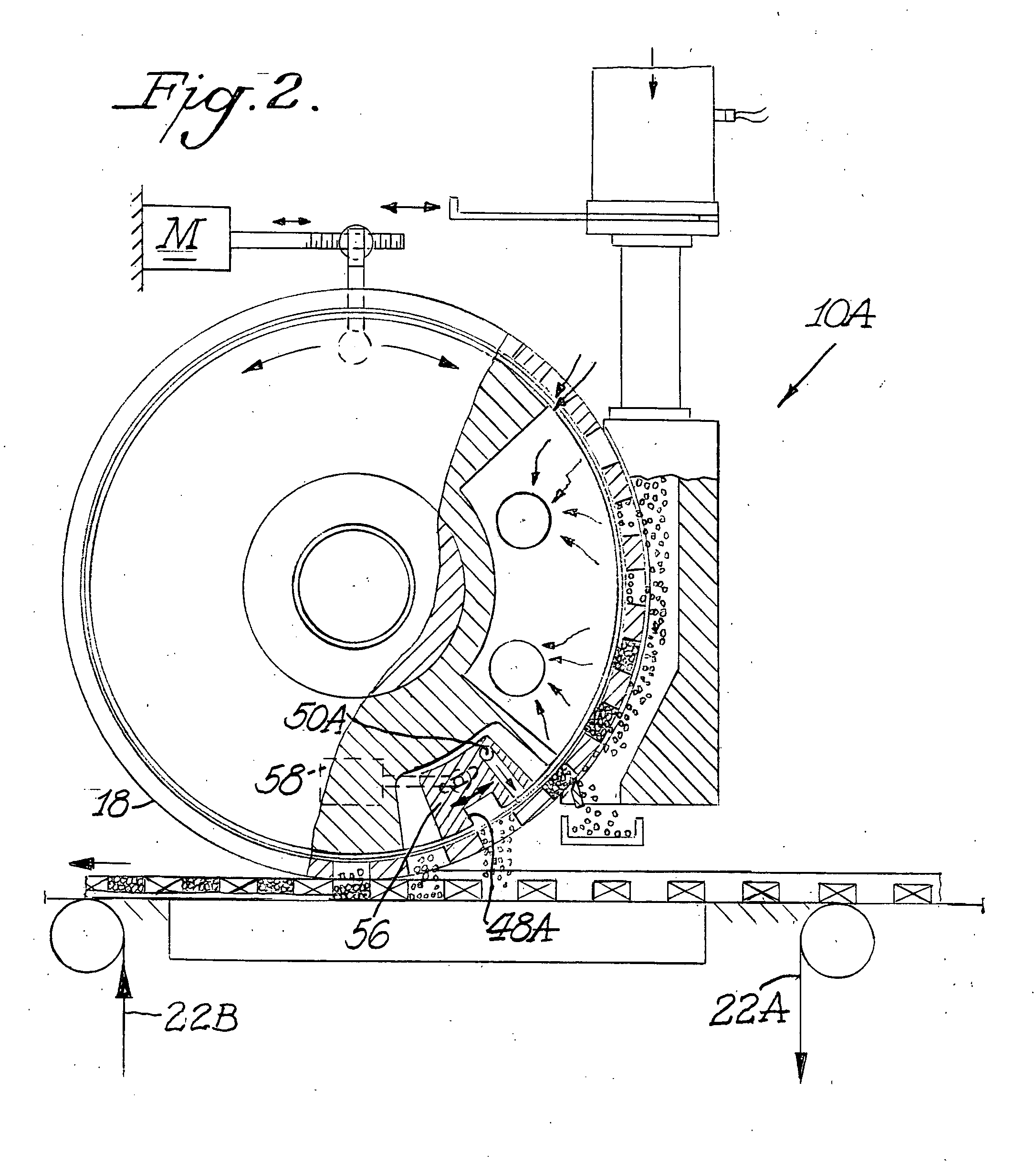

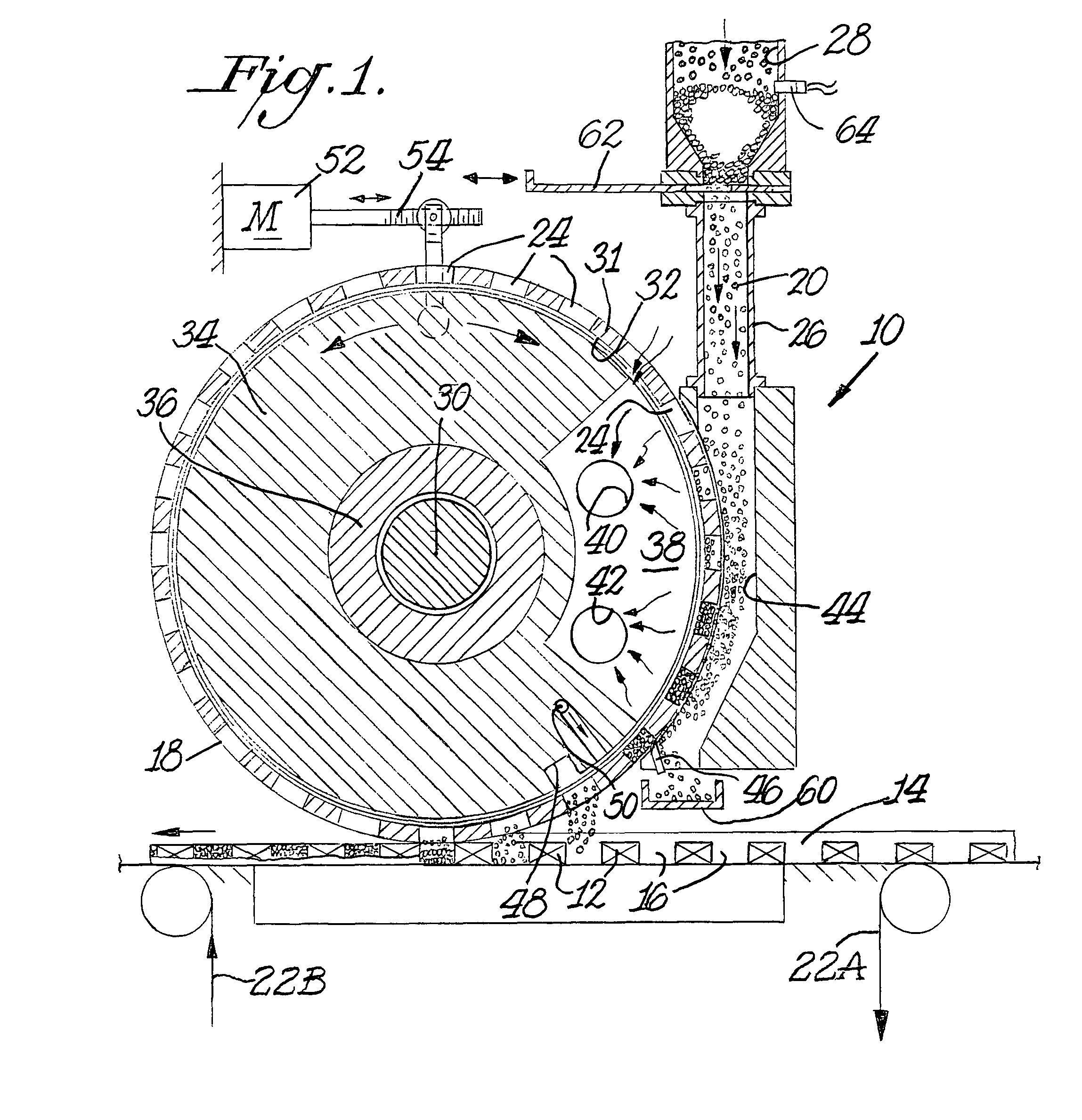

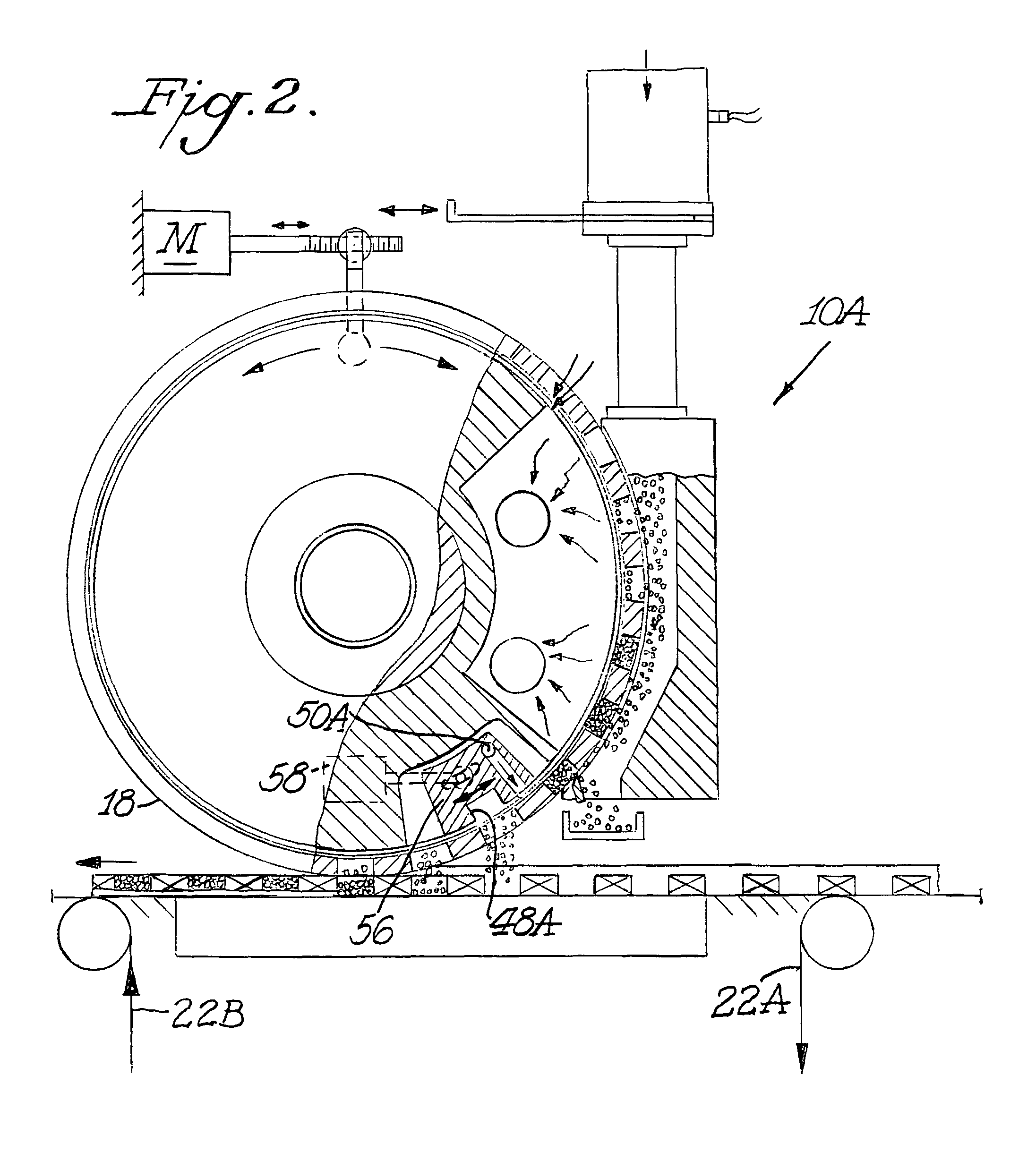

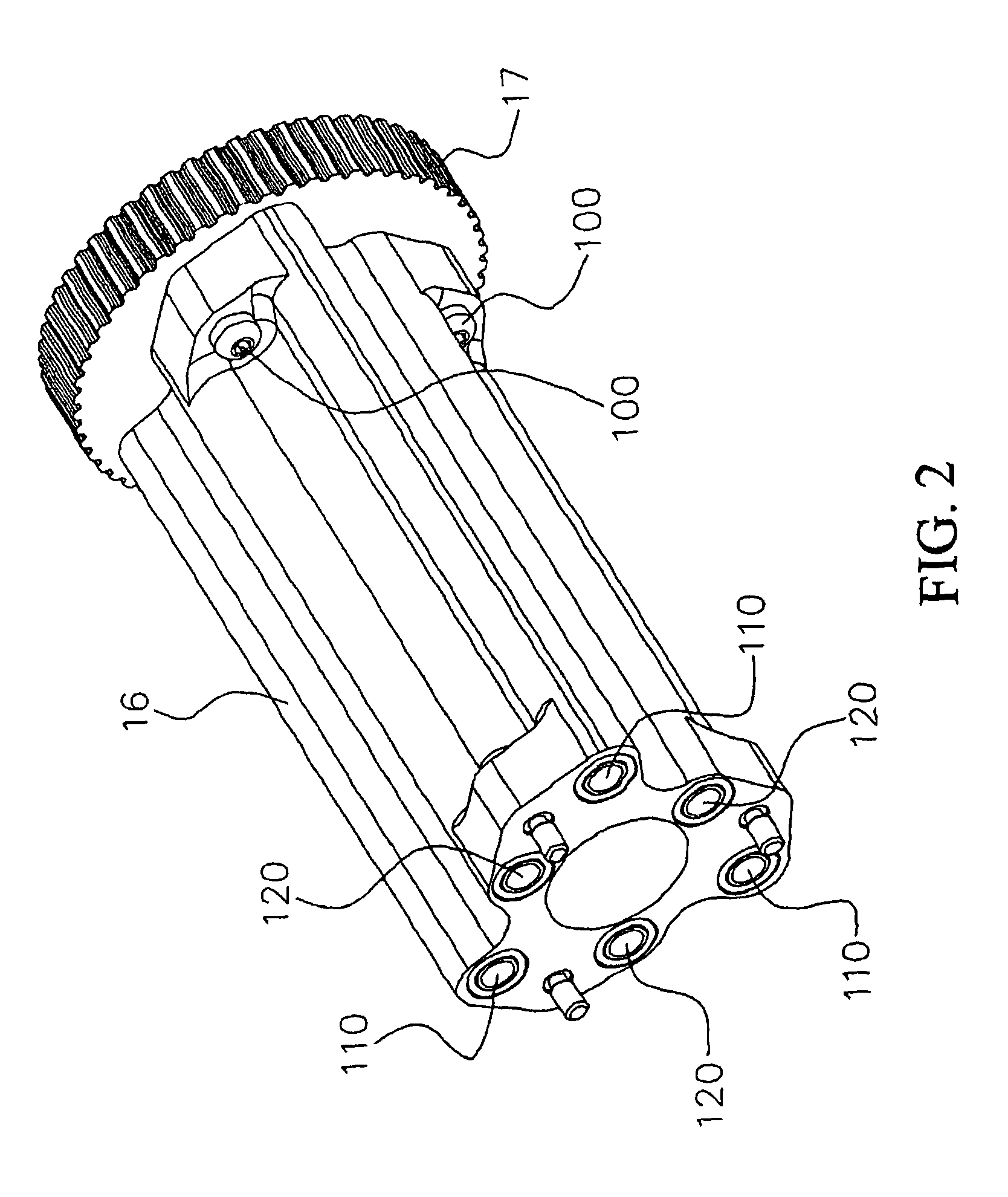

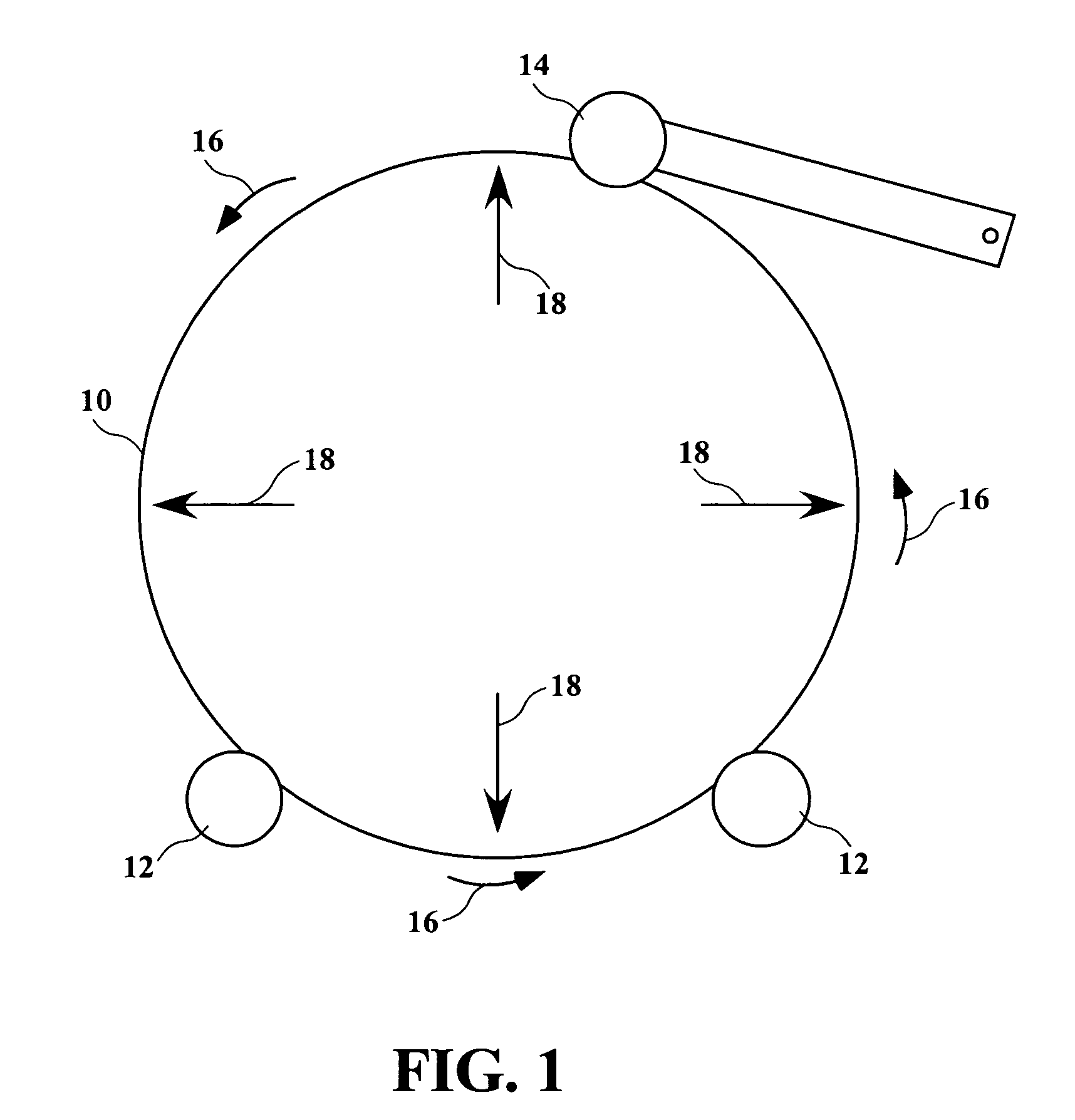

Applicator wheel for filling cavities with metered amounts of particulate material

ActiveUS20070284012A1Efficient mannerEfficient and timelyLiquid fillingTobacco smoke filtersProcess functionEngineering

A machine and process function to fill cavities with metered amounts of particulate material. An applicator wheel includes a series of equally spaced apart peripheral pockets each having a perforated bottom wall, and a vacuum manifold inside the wheel includes a vacuum chamber for supplying vacuum to the perforated bottom walls of the pockets as the wheel rotates. Particulate material from a filling chamber of such material outside the wheel is withdrawn into the pockets by the vacuum chamber. A downstream vacuum relief on the vacuum manifold functions to discharge particulate material from the pockets into the cavities at a predetermined discharge location on the wheel. Adjustment structure is connected to rotatably adjust the position of the vacuum manifold within the applicator wheel to thereby advance or retard the discharge location depending upon the speed of the machine.

Owner:PHILIP MORRIS USA INC

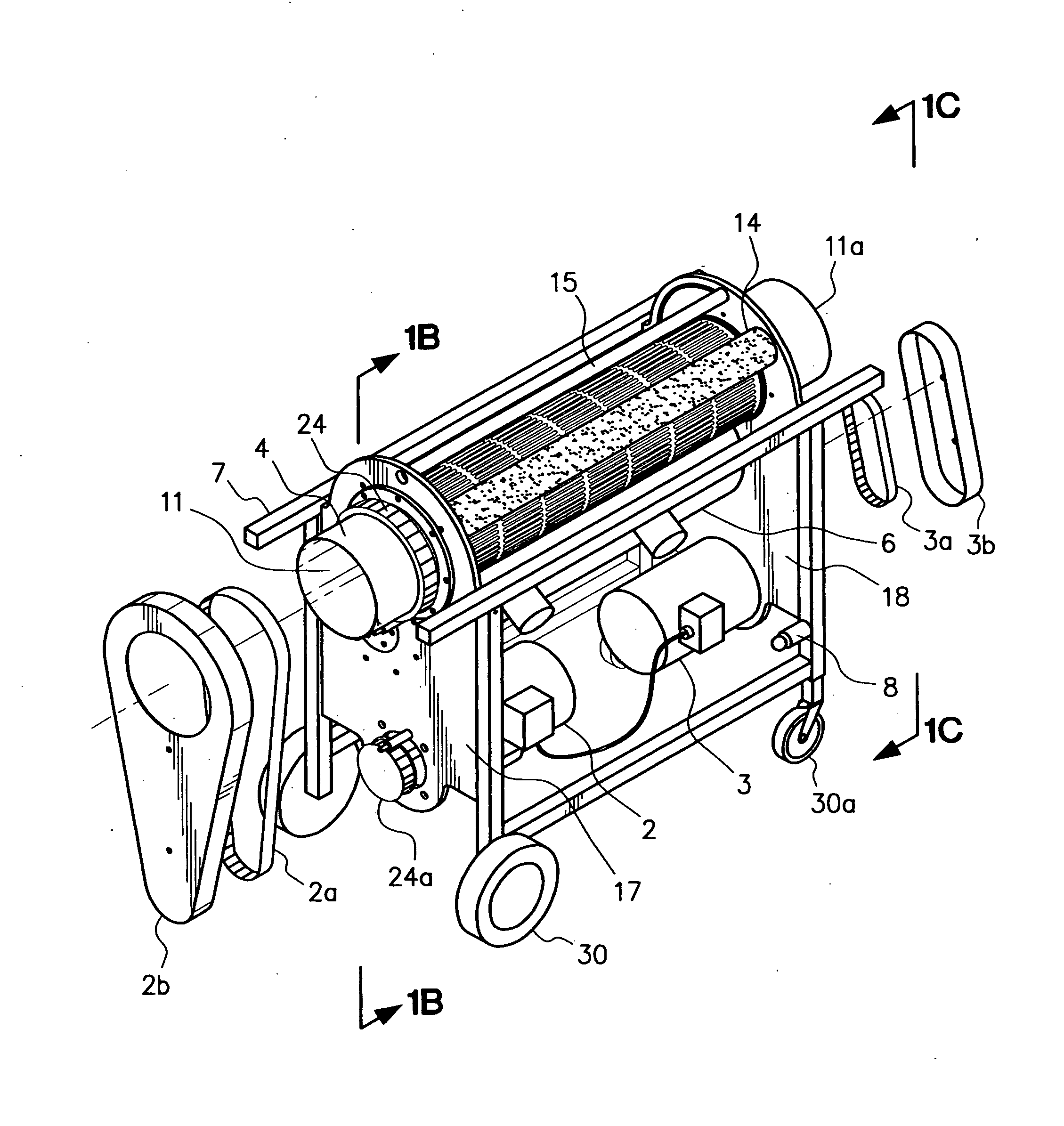

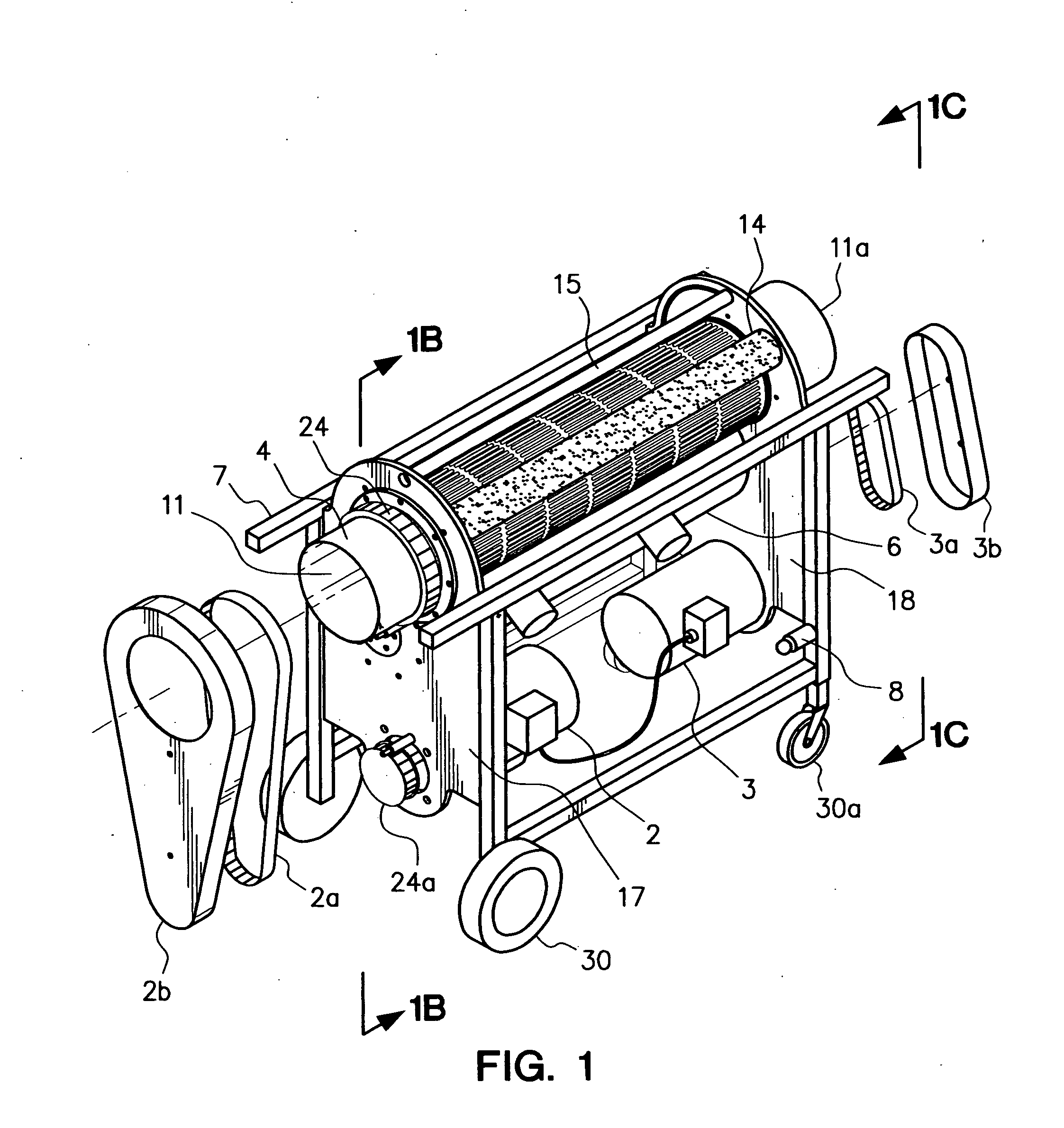

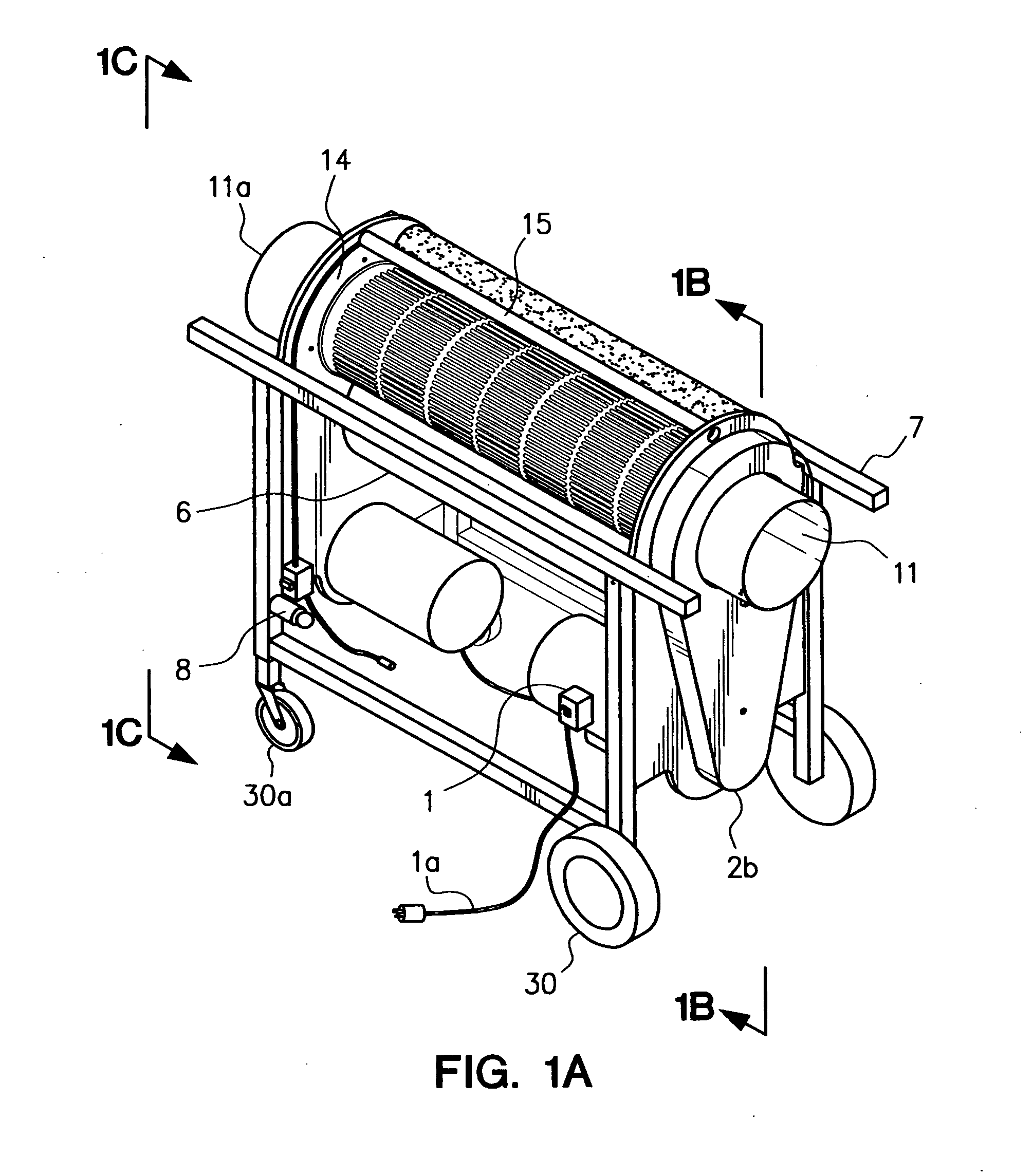

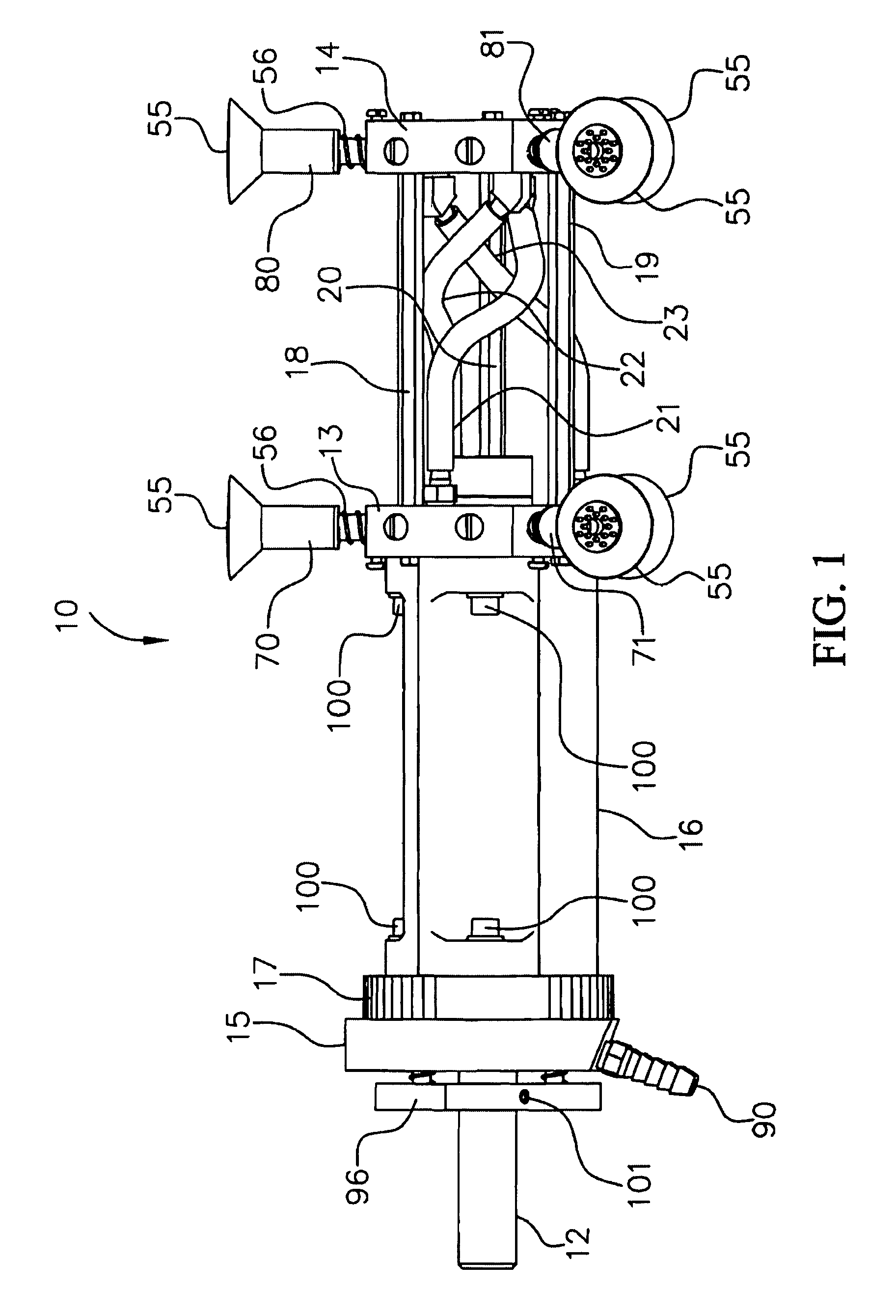

Method and apparatus for trimming buds and flowers

ActiveUS20120279193A1Enabling flowEnabling processingHedge trimming apparatusBud removersSprayerWaste collection

The present invention discloses an apparatus for trimming plants, in particular, buds and flowers, to remove unwanted plant material. A typical application would be to process a plant to leave only trimmed buds and flowers for use in potpourri, fragrant sashes, or as a prelude to further processing of essential oils. The invention enables faster and safer production of plant material than prior plant processing machines. The apparatus employs an original combination of a slotted metal drum and a lawn mower type cutting reel that are rotated in the same direction, but at different speeds, to create a cutting interface that shears the unwanted plant material off and then collect this debris though a novel vacuum manifold into a waste collection device. The cutting interface between the slotted drum and the cutting reel is adjustable to keep the distance between the two between 0.002 and 0.006 inches for a very sharp and clean cut. The invention includes a roller brush and sprayer system to keep the cutting interface clean, without buildup of oils and other organic plant material. The invention is built upon a frame that moves on wheels and that allows for adjustment for operation in a level or tilted configuration to best suit the processing of particular types of plant material. The manifold cover is easily removed for cleaning and for sharpening or adjustment of the cutting blades.

Owner:ETEROS TECH USA INC

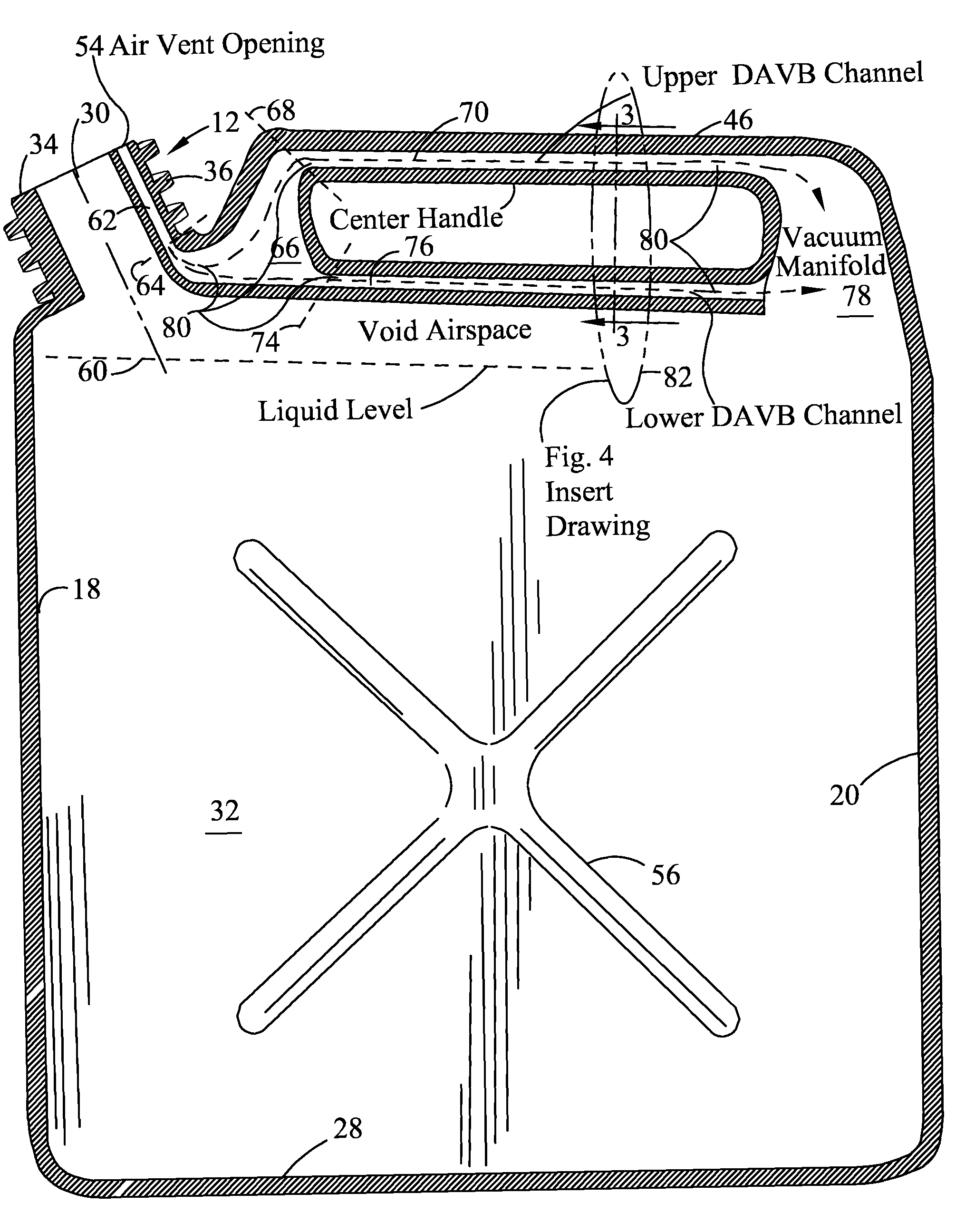

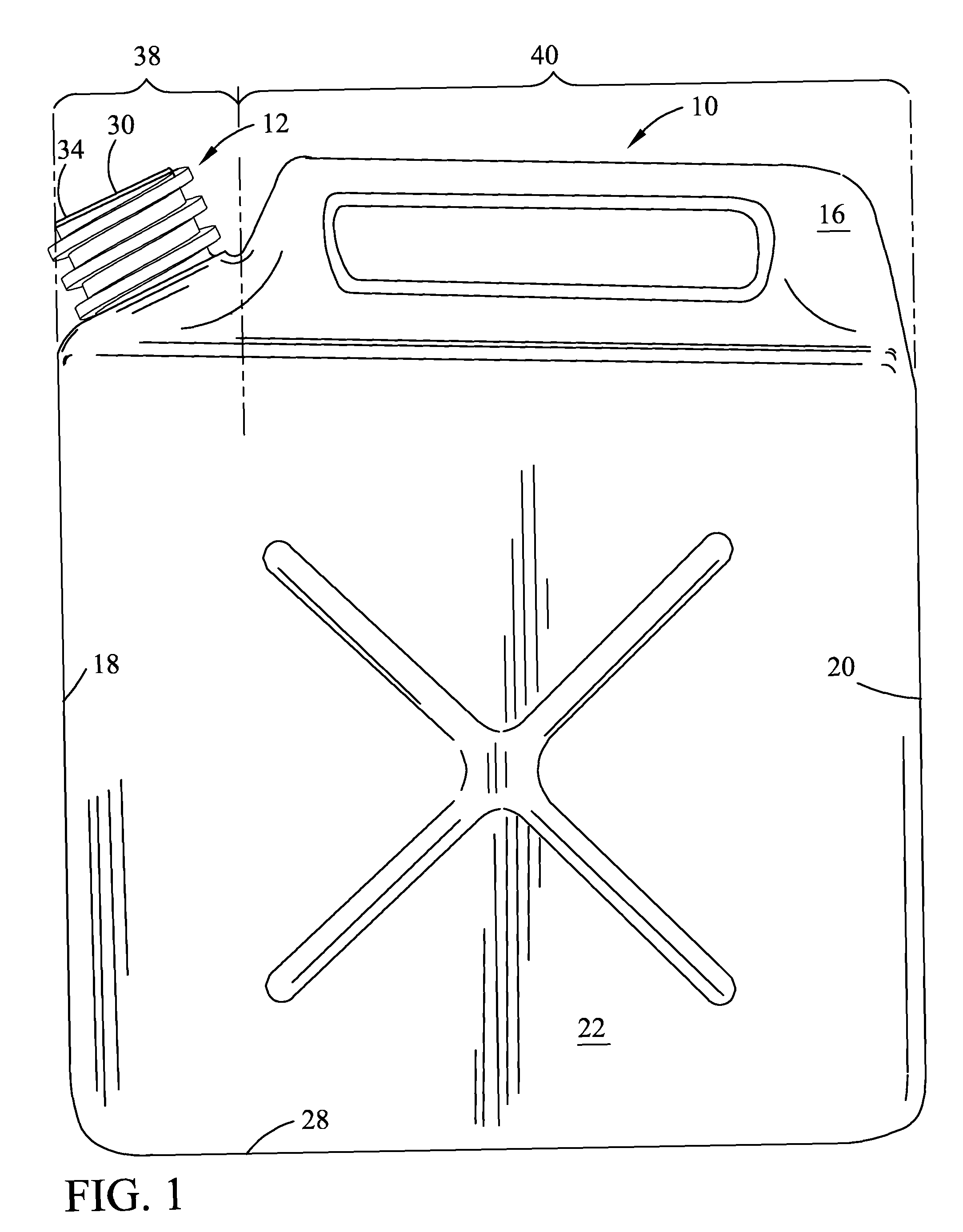

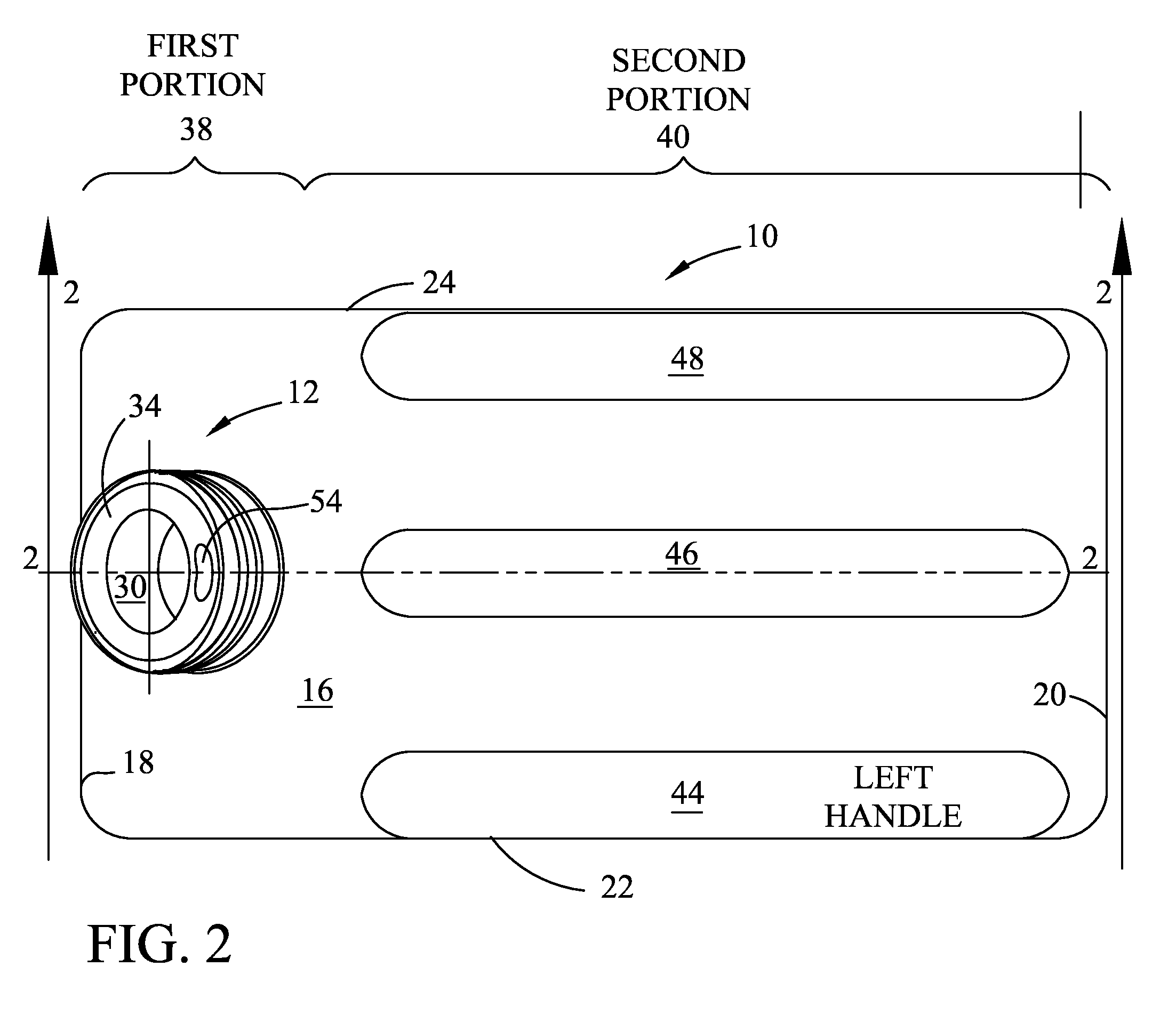

Dual air vent bypass (DAVB) container

ActiveUS7959044B1Eliminate the problemEliminate the contraction/expansion (glugClosuresDispensing apparatusEngineeringVoid space

A container for dispensing a fluid with no contraction / expansion “glug, glug” effect has a cover forming a sealed top with a pouring spout on top of the cover and at least one elongated handle on top of the cover. The elongated handle extends longitudinally away from the pouring spout and has a distant end coupled to a vacuum manifold formed under the cover as a void space distant from the pouring spout and above fluid within the fluid tight container. A pouring spout has a circular aperture leading into the fluid tight container. The circular aperture has a central axis; the circular aperture is bordered by a peripheral circular sealing surface that extends radially away from the aperture. An air vent opening is positioned on the circular aperture's highest radial central position on the circular sealing surface. A dual air vent bypass channel delivers air entering the air vent opening via a top channel through the elongated handle to the vacuum manifold, and via a bottom channel under the cover to the vacuum manifold.

Owner:ALHARR TECH

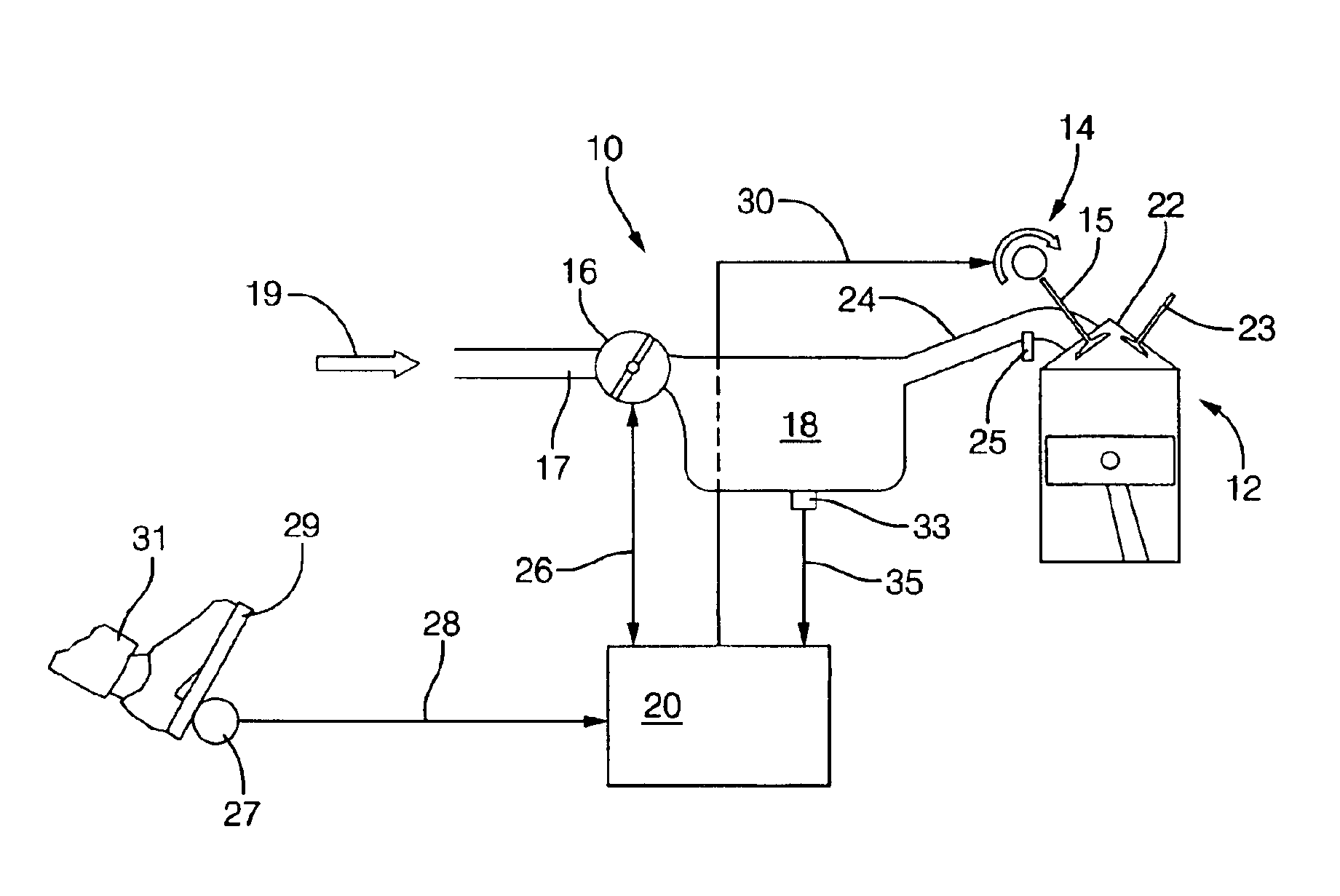

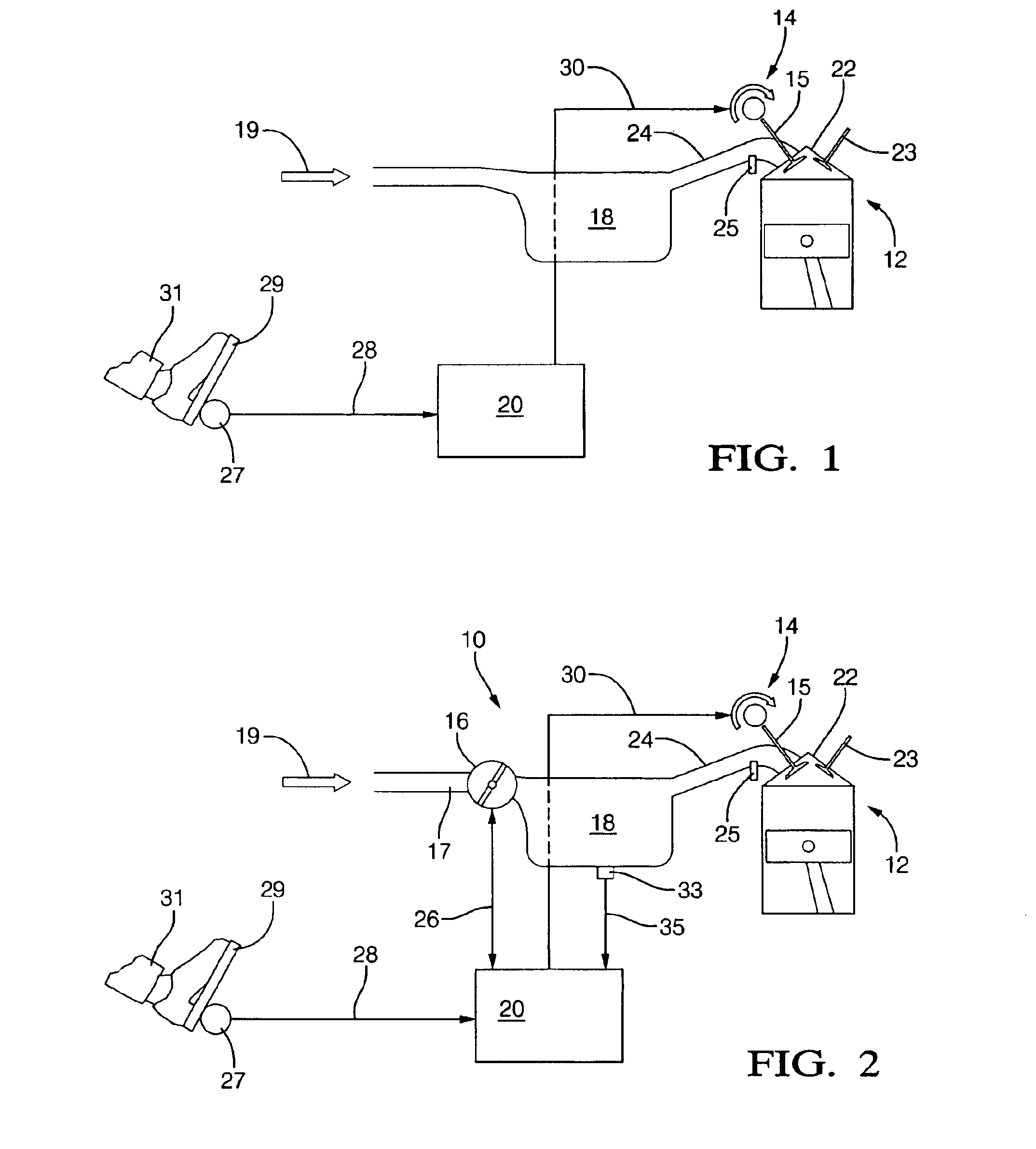

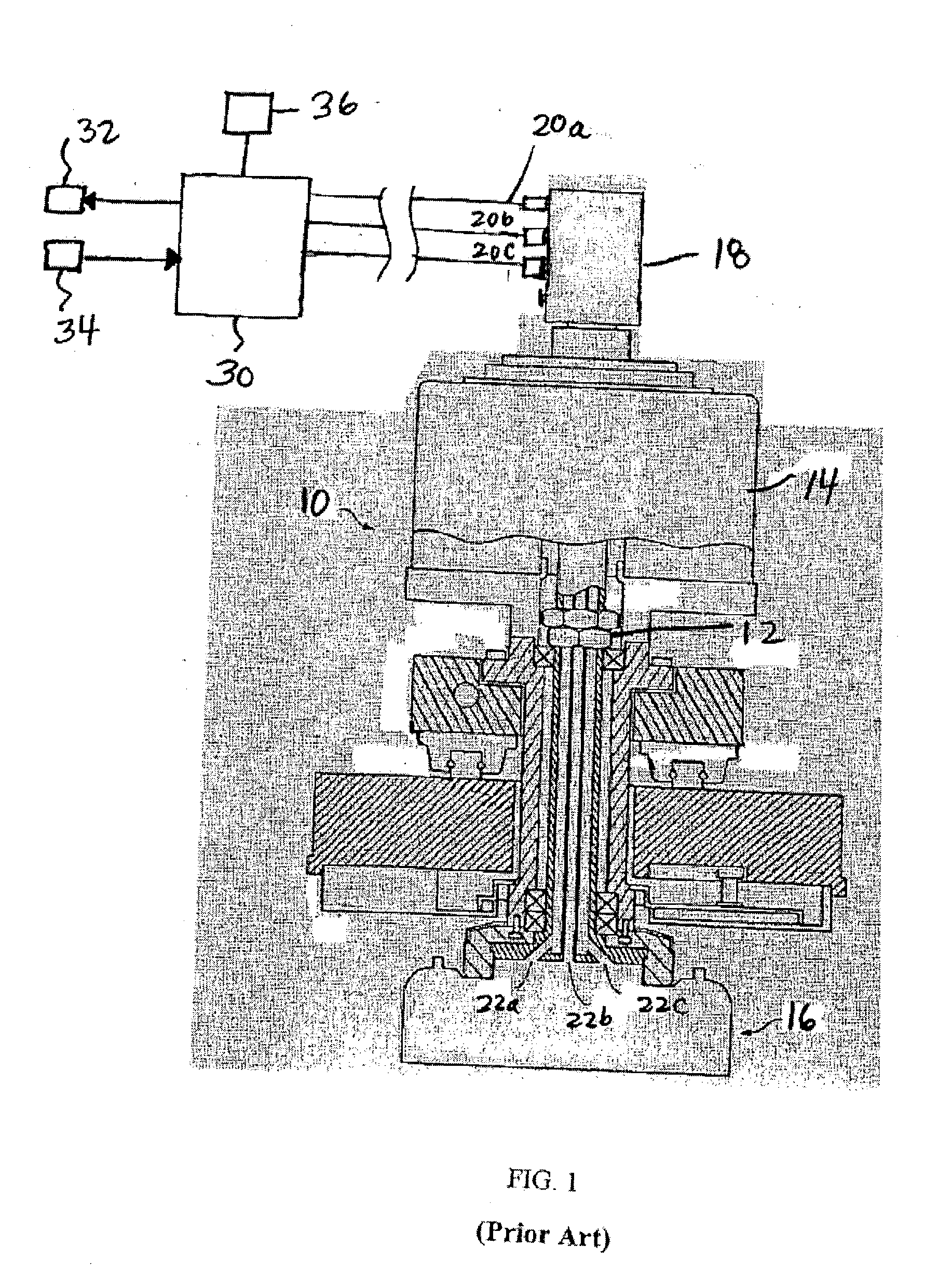

Vacuum system for engine with variable valve lift

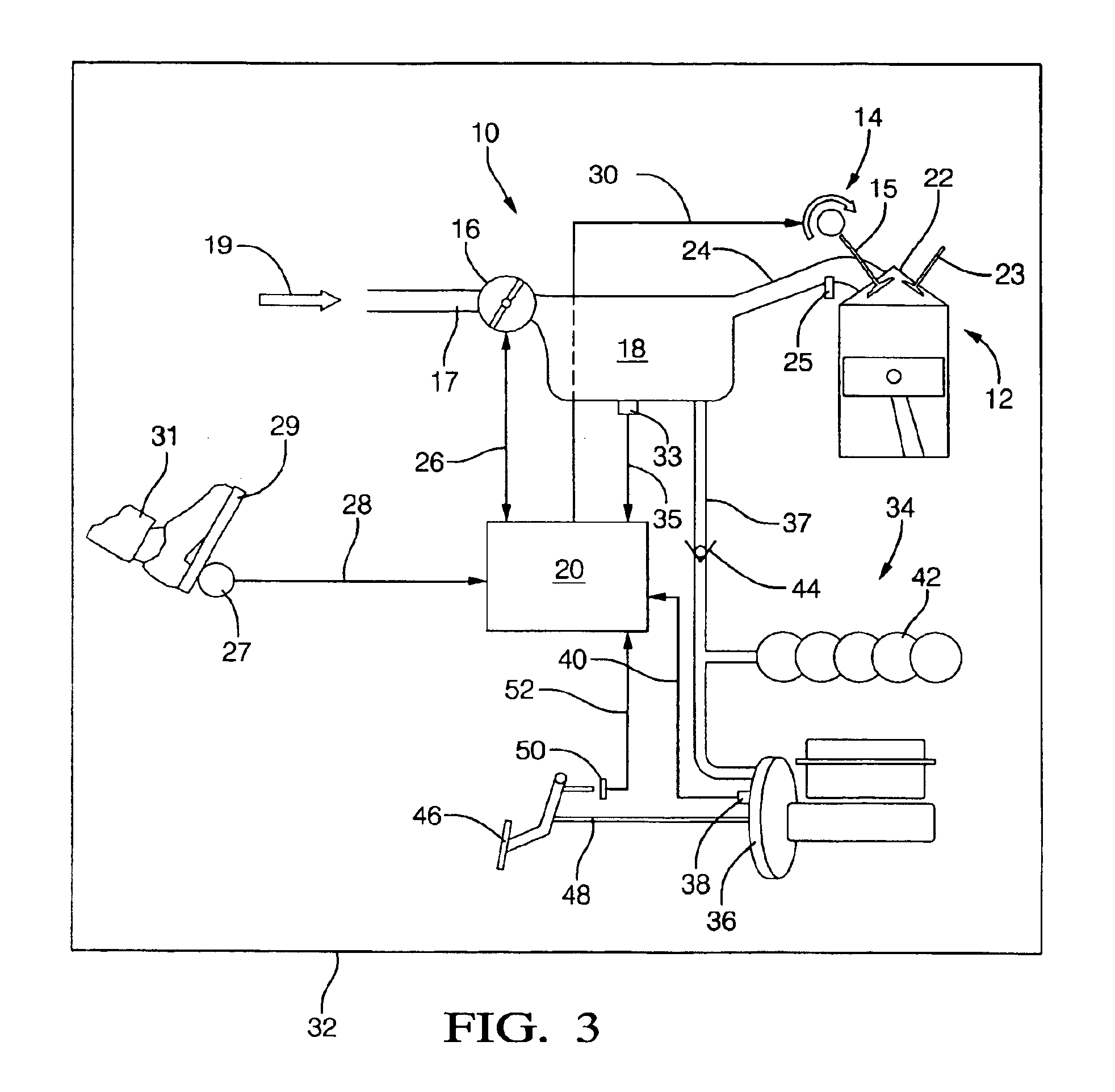

InactiveUS6863048B2Improve fuel economyElectrical controlInternal combustion piston enginesVariable valve timingInlet valve

A vacuum system for an engine with variable valve lift includes a controllable vacuum-forming valve at the entrance to the intake manifold and a programmable engine control module (ECM) to increase vacuum as desired within the manifold by modulating the valve as needed to optimize fuel economy. To provide vacuum brake assist, a brake booster diaphragm is connected conventionally to the manifold and a vacuum storage tank and check valve are disposed between the booster diaphragm and the manifold. During periods of vehicle deceleration, when engine load is low, the ECM may switch the VVL-controlled intake valves to a higher lift to increase the pumping capacity of the engine, while simultaneously partially closing the vacuum-forming valve to create vacuum in the intake manifold, the brake booster, and the vacuum storage tank at little or no expense to engine performance.

Owner:DELPHI TECH INC

Sealed spray cooling system

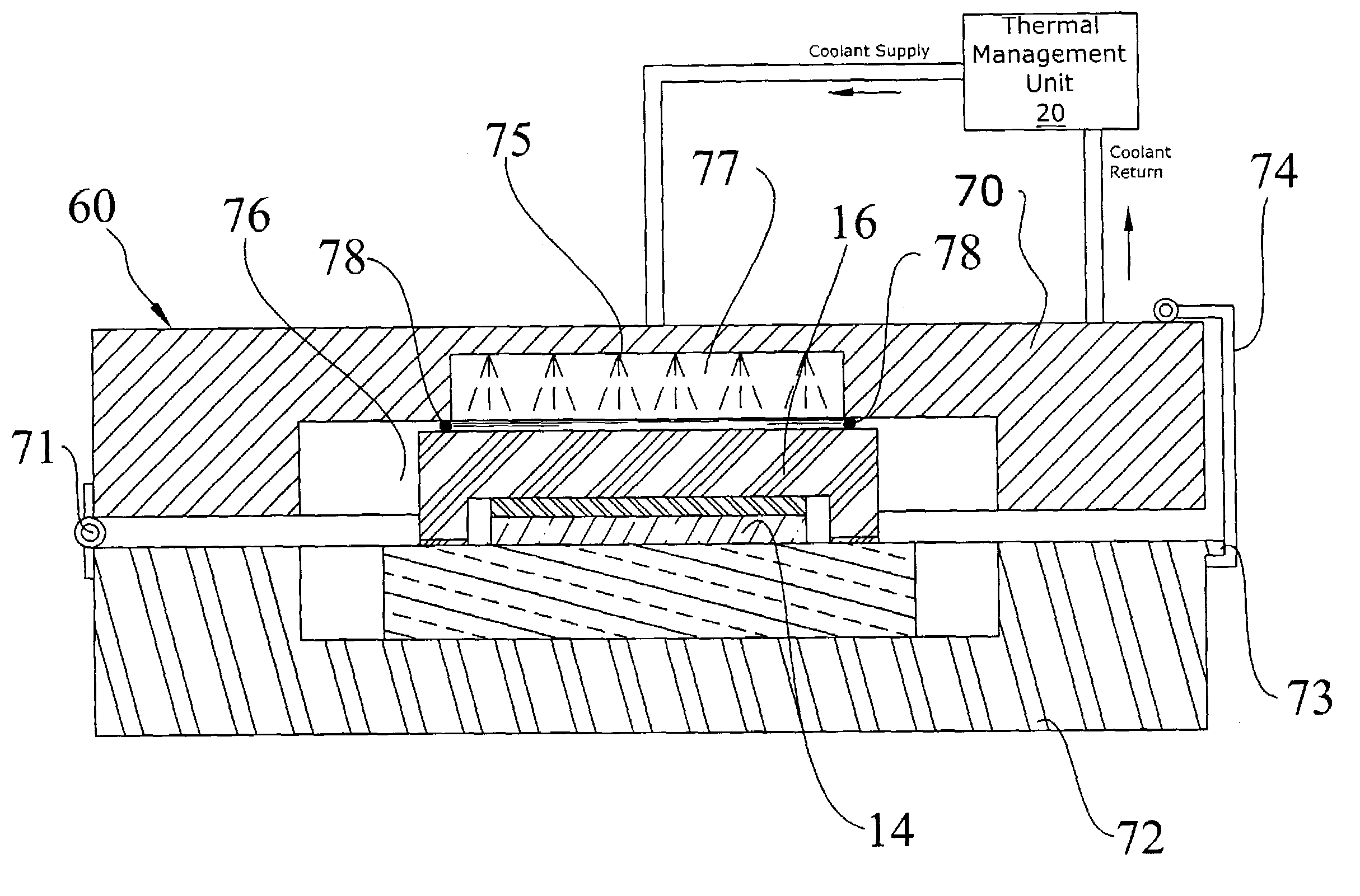

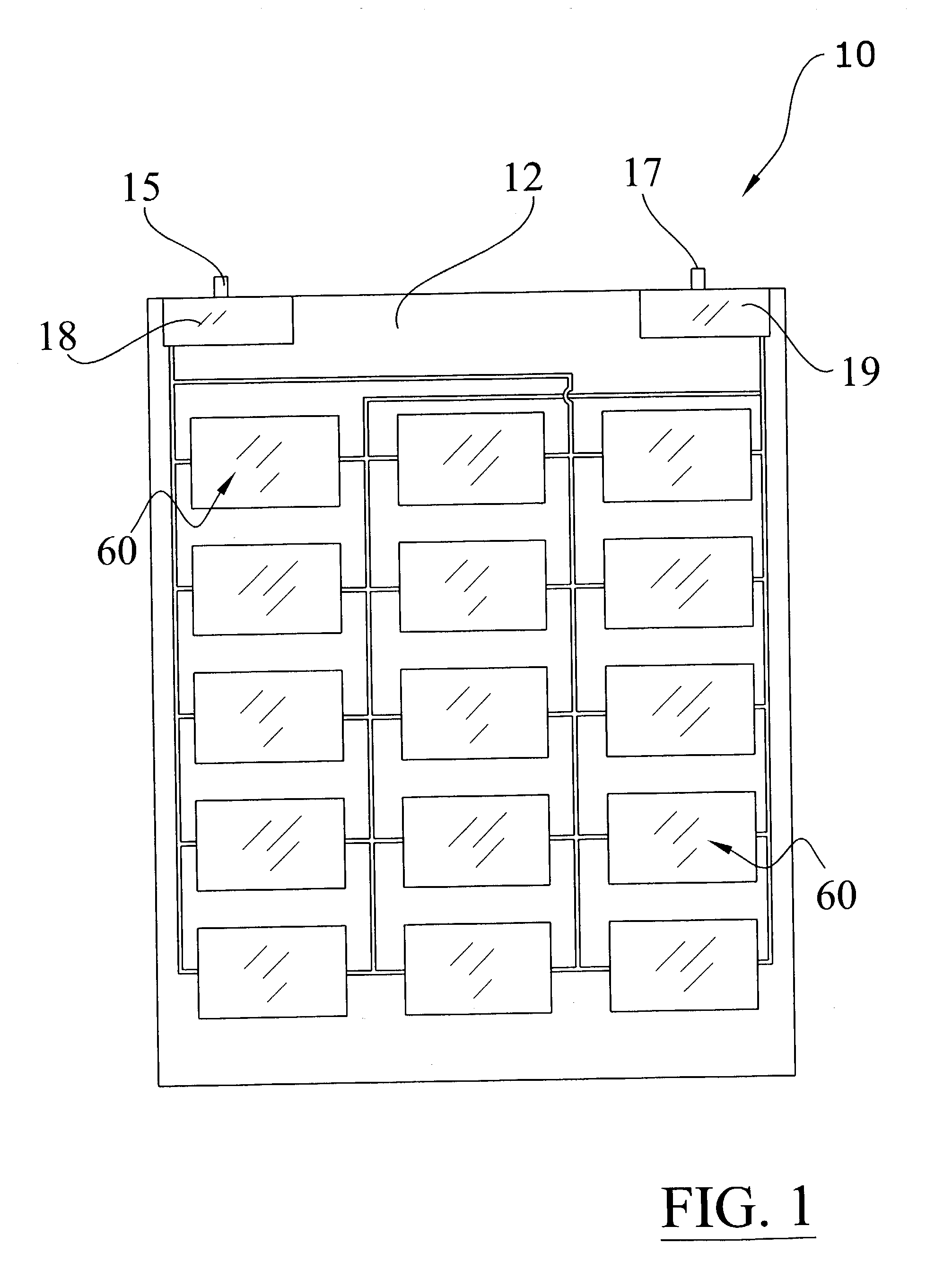

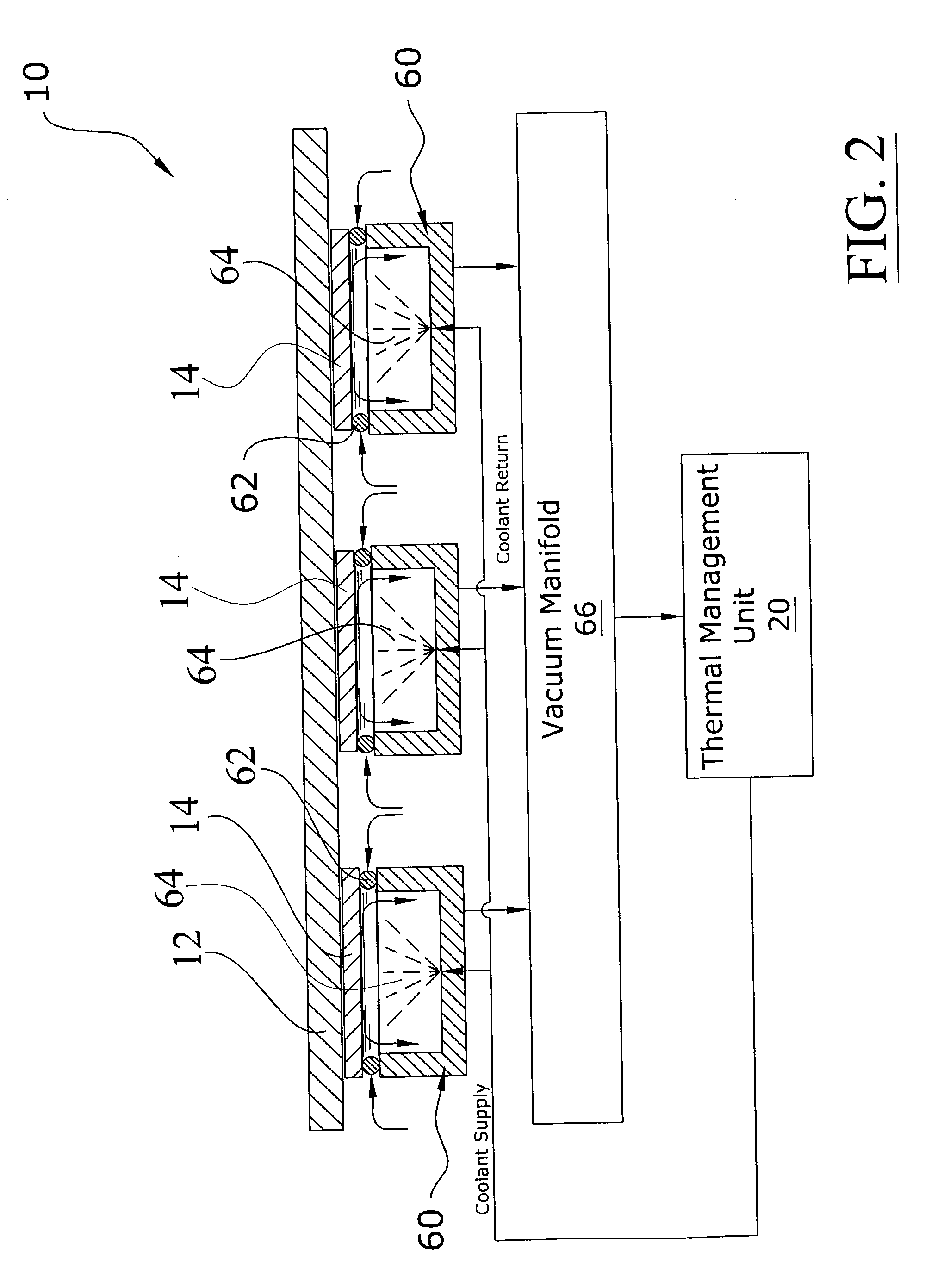

InactiveUS6996996B1Reducing coolant lossElectronic circuit testingLighting and heating apparatusEngineeringThermal management system

A sealed spray cooling system for reducing coolant loss within thermal management systems. The sealed spray cooling system includes a spray housing defining a spray chamber having at least one atomizer and a seal member attached to the spray housing about the spray chamber for sealing against a semiconductor forming a sealed spray area. Alternatively, the spray unit is comprised of a first member, a second member having at least one atomizer, the second member pivotally attached to the first member forming an interior cavity between thereof, and a seal member attached to the second member for sealing against a semiconductor within the first member thereby forming a sealed spray area. A vacuum manifold is preferably fluidly connected to the spray cavity thereby reducing the pressure within the spray cavity.

Owner:PARKER INTANGIBLES LLC

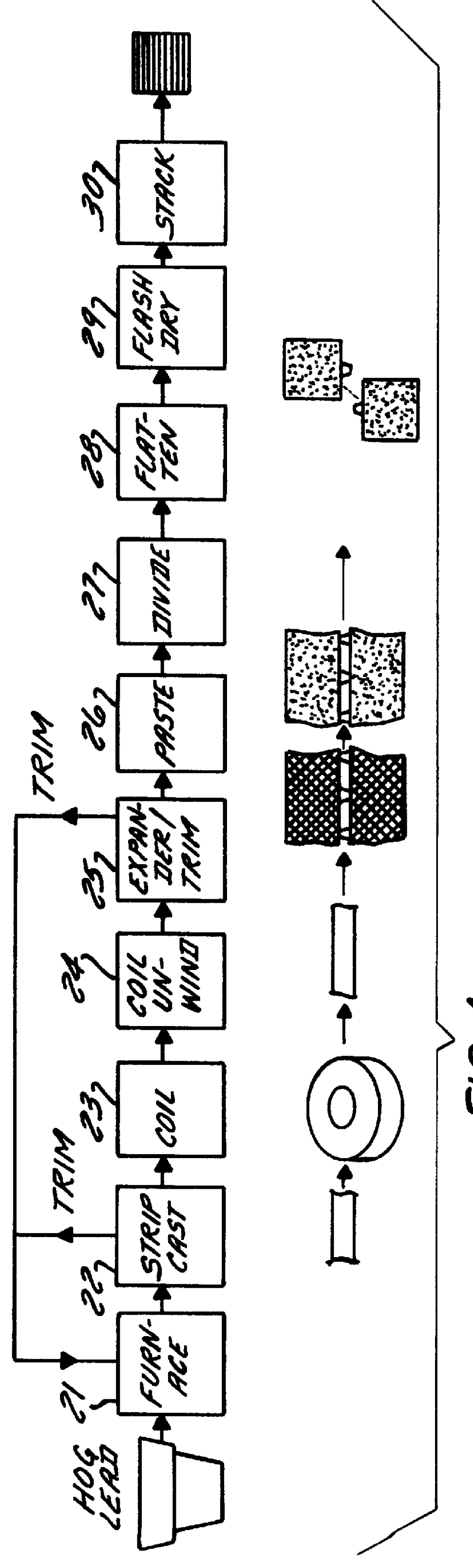

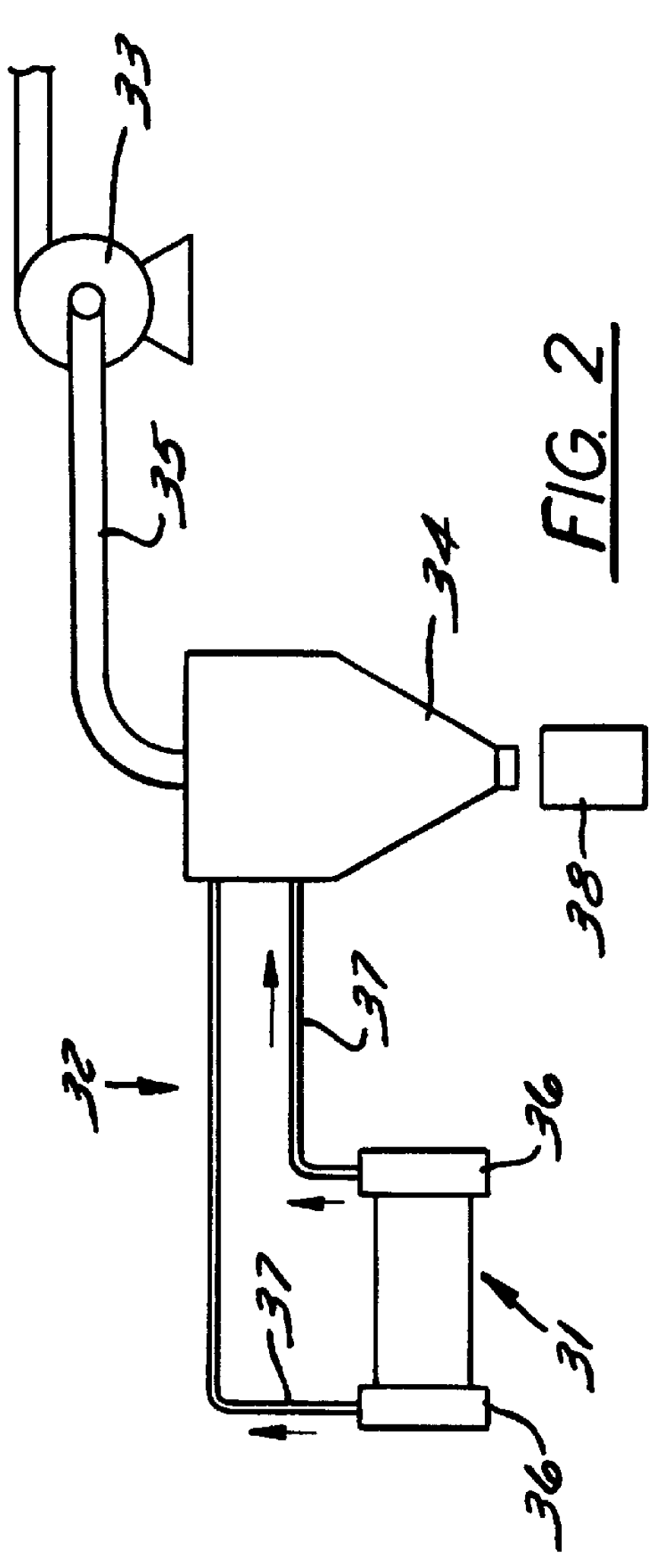

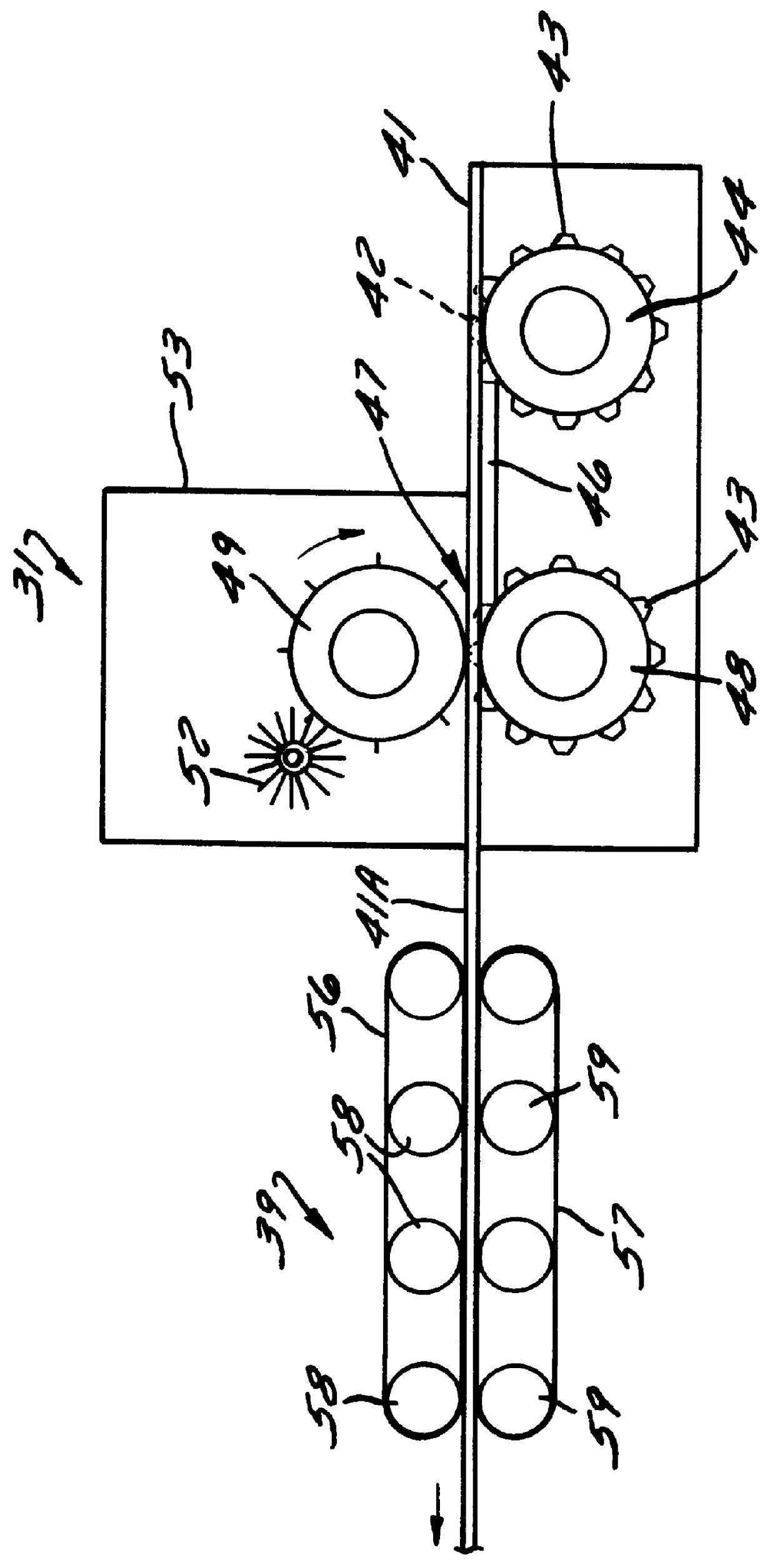

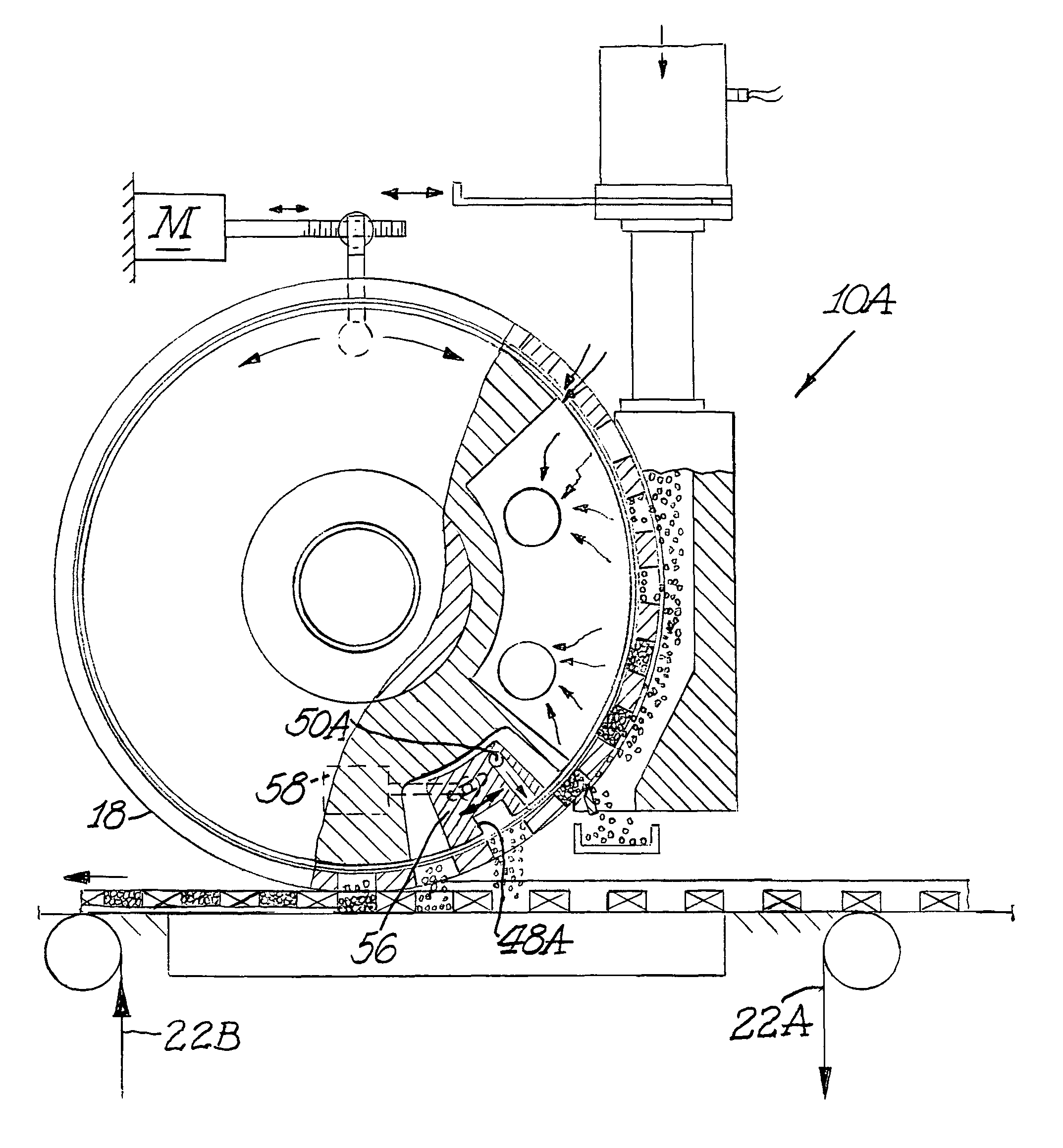

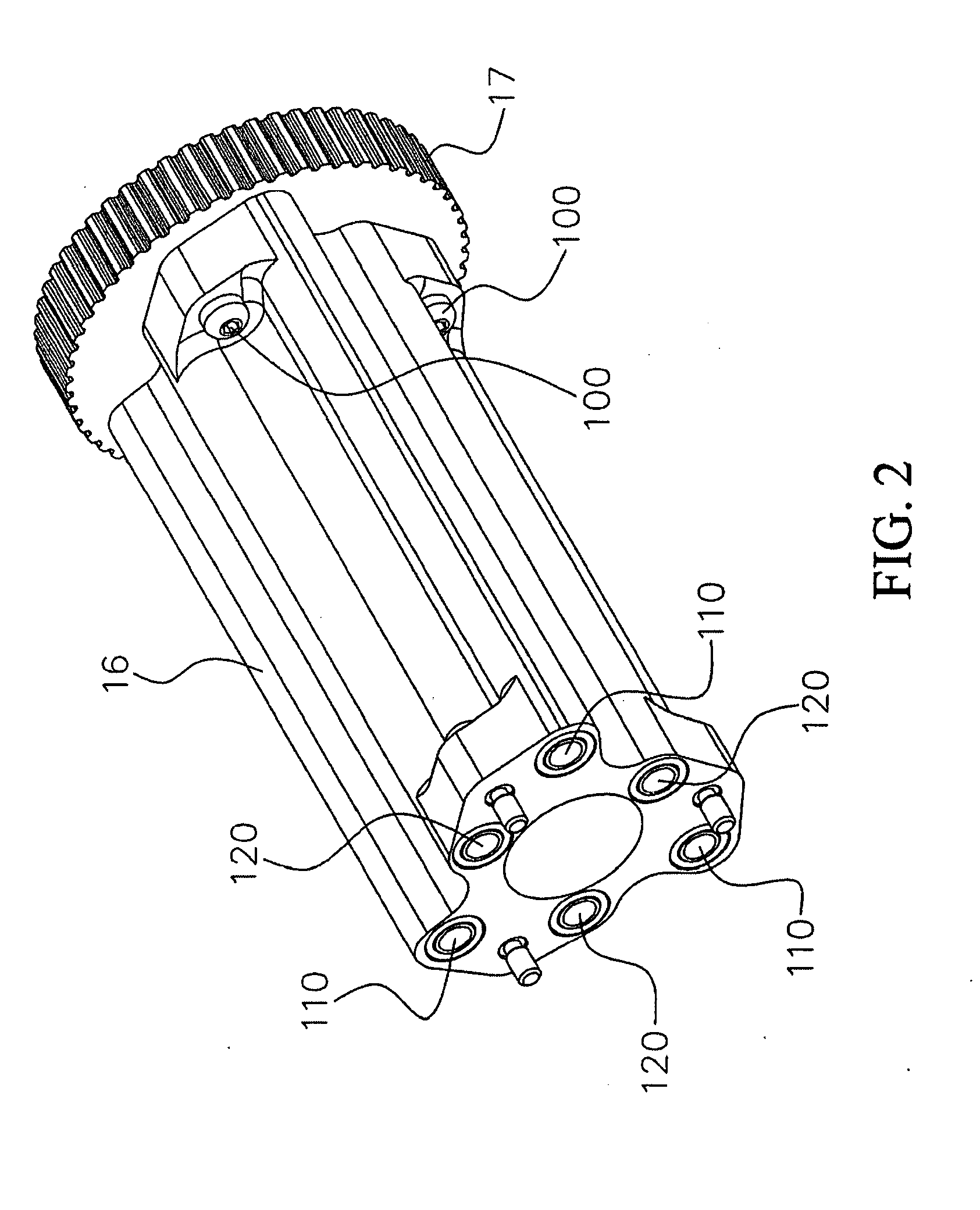

Battery plates having rounded lower corners

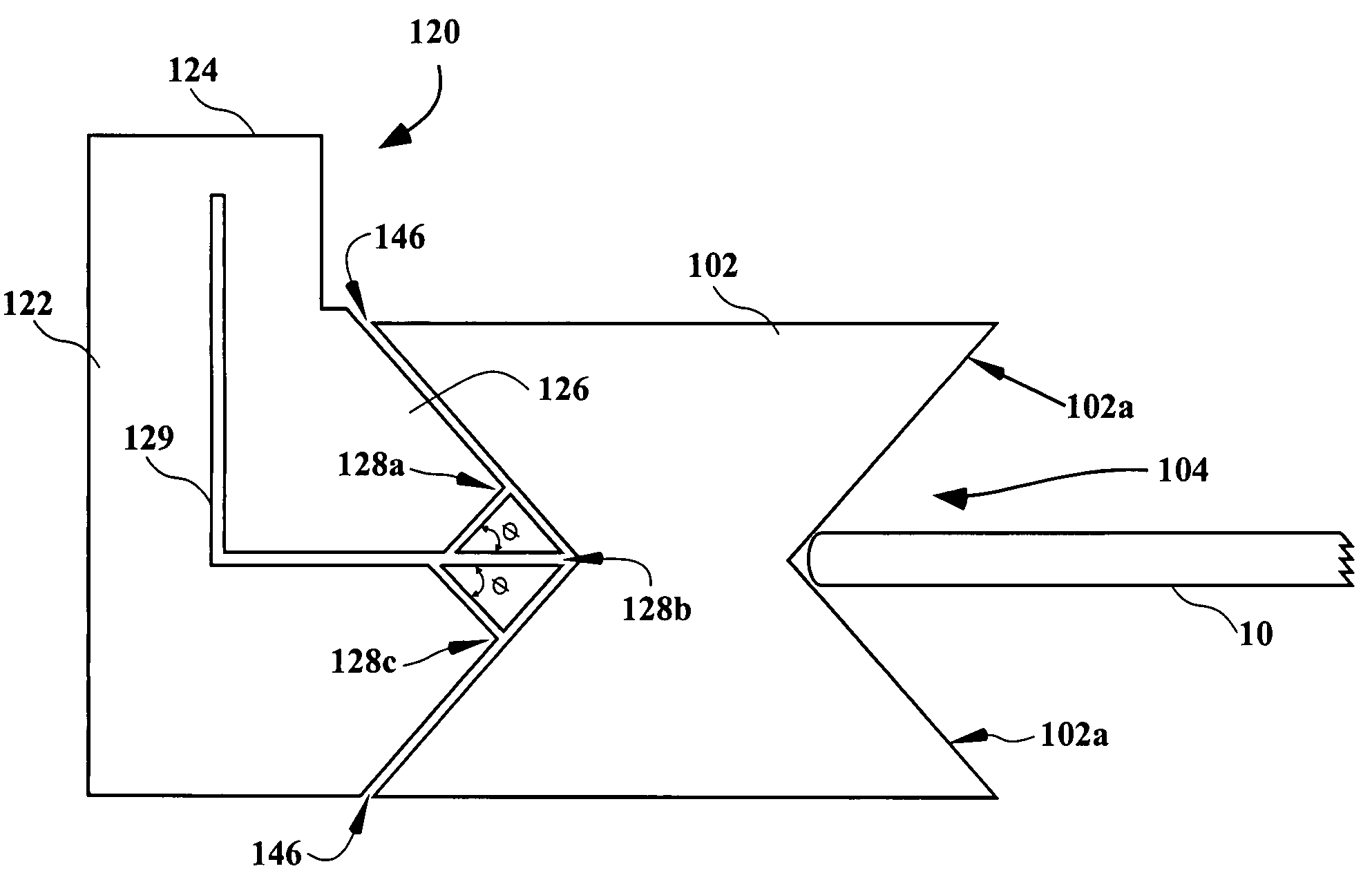

InactiveUSRE36734E1Electrode carriers/collectorsActive material electrodesLead–acid batteryVacuum manifold

A process for cutting a moving strip to form a series of plates, such as battery plates, includes the initial step of transporting the strip past a rotary divider including a cutter having radial blades configured to cut the strip into the plates. The cutter further has a set of blades for cutting individual pieces from the strip, which pieces are not part of the plates. As the cutter blades cut the strip to form the plates and pieces, a vacuum system applies suction to draw the pieces cut from the strip inwardly into the cutter through holes in the cutter, and then out of the cutter. The holes are each located adjacent each one of the corresponding blades and are shaped and positioned to permit the cut-away piece to pass through. In a preferred embodiment, the vacuum system includes a pair of vacuum manifolds that apply suction at opposite ends of the cylindrical cutter. An apparatus for carrying out the foregoing process accordingly includes a rotary divider as described above provided with a vacuum system. Battery plates made according to the foregoing process are improved in that the two lower corners have a rounded shape lacking a sharp edge which tends to tear an adjacent separator. Such a plate may be inserted bottom end first into a separator envelope to form a plate element for use in a lead-acid battery.

Owner:JOHNSON CONTROLS TECH CO

Applicator wheel for filling cavities with metered amounts of particulate material

A machine and process function to fill cavities with metered amounts of particulate material. An applicator wheel includes a series of equally spaced apart peripheral pockets each having a perforated bottom wall, and a vacuum manifold inside the wheel includes a vacuum chamber for supplying vacuum to the perforated bottom walls of the pockets as the wheel rotates. Particulate material from a filling chamber of such material outside the wheel is withdrawn into the pockets by the vacuum chamber. A downstream vacuum relief on the vacuum manifold functions to discharge particulate material from the pockets into the cavities at a predetermined discharge location on the wheel. Adjustment structure is connected to rotatably adjust the position of the vacuum manifold within the applicator wheel to thereby advance or retard the discharge location depending upon the speed of the machine.

Owner:PHILIP MORRIS USA INC

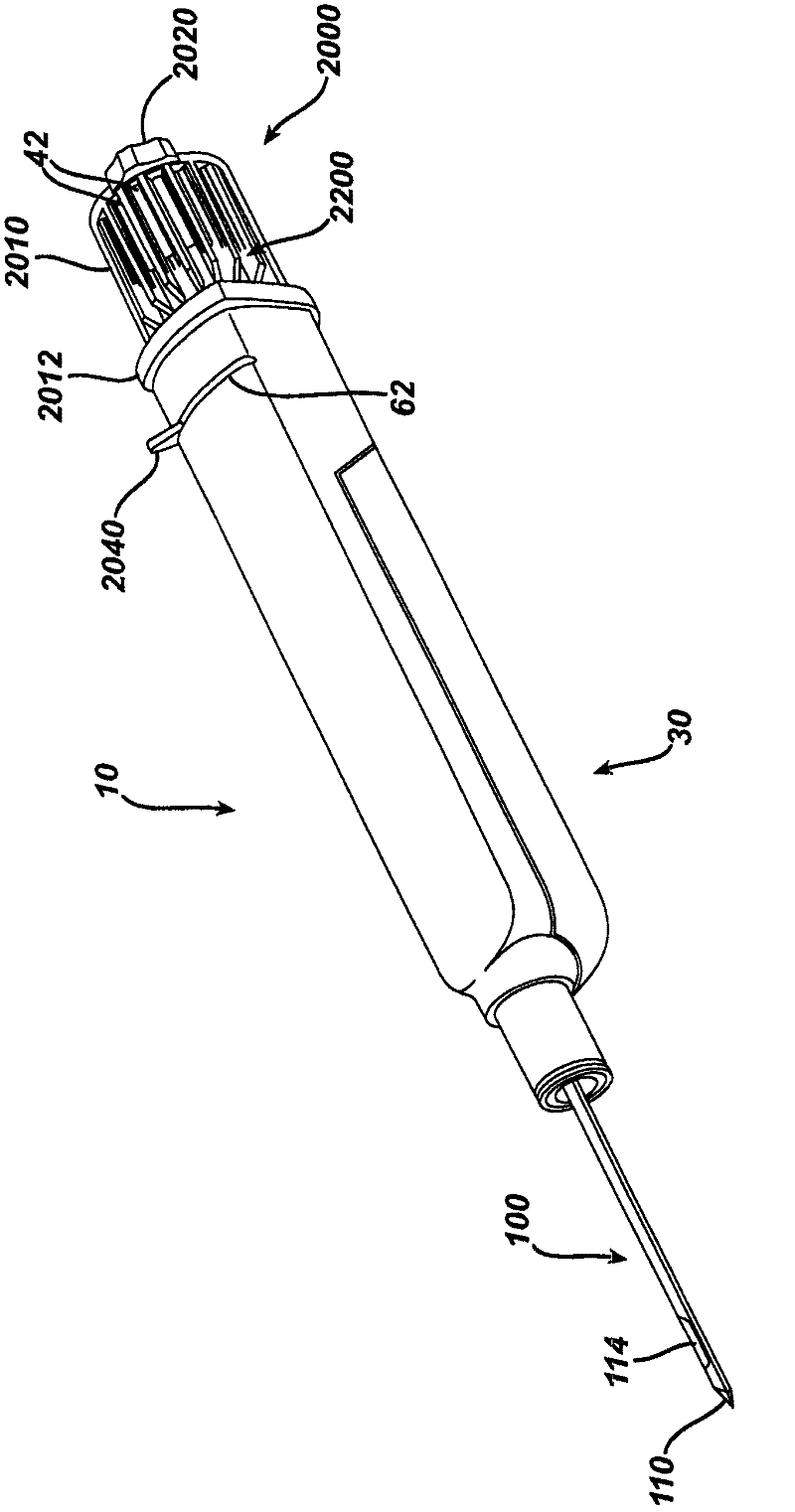

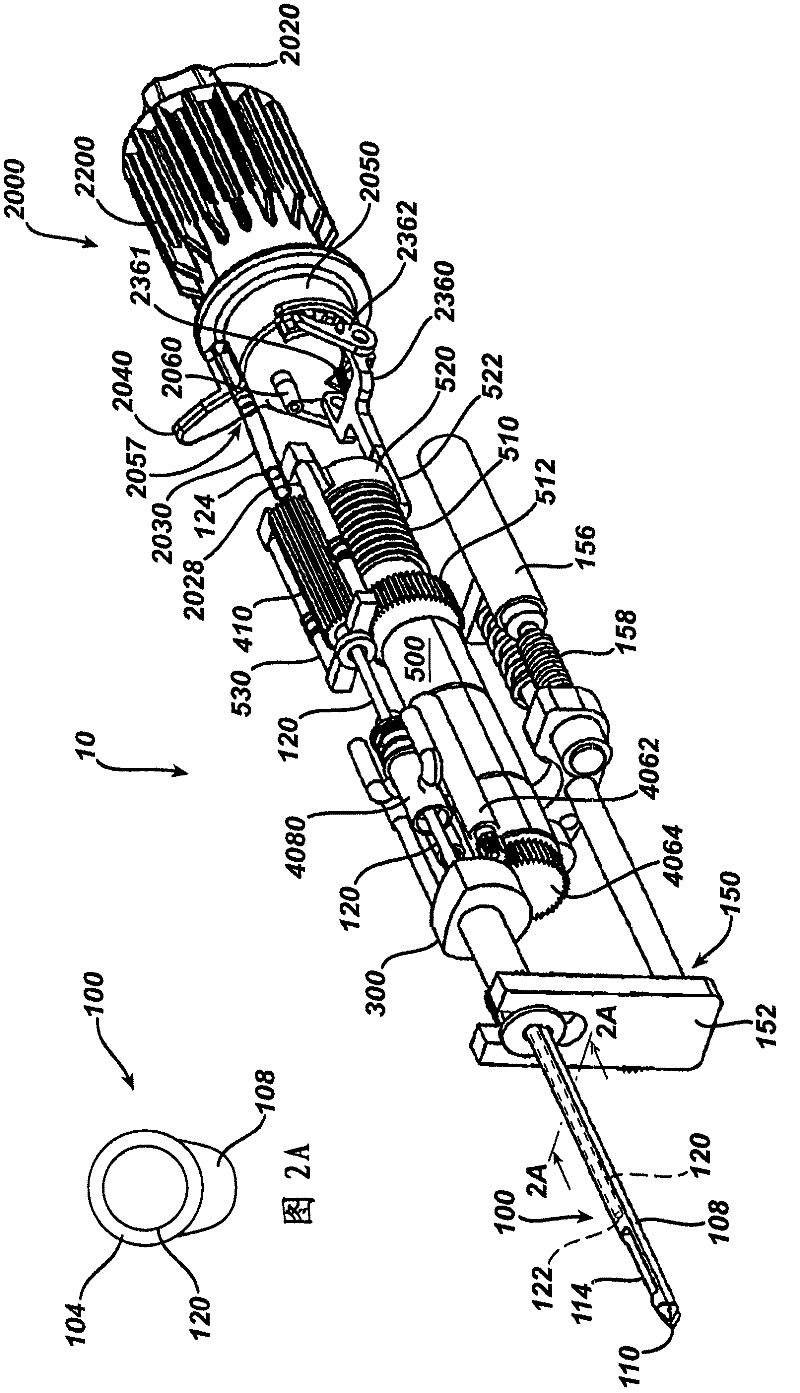

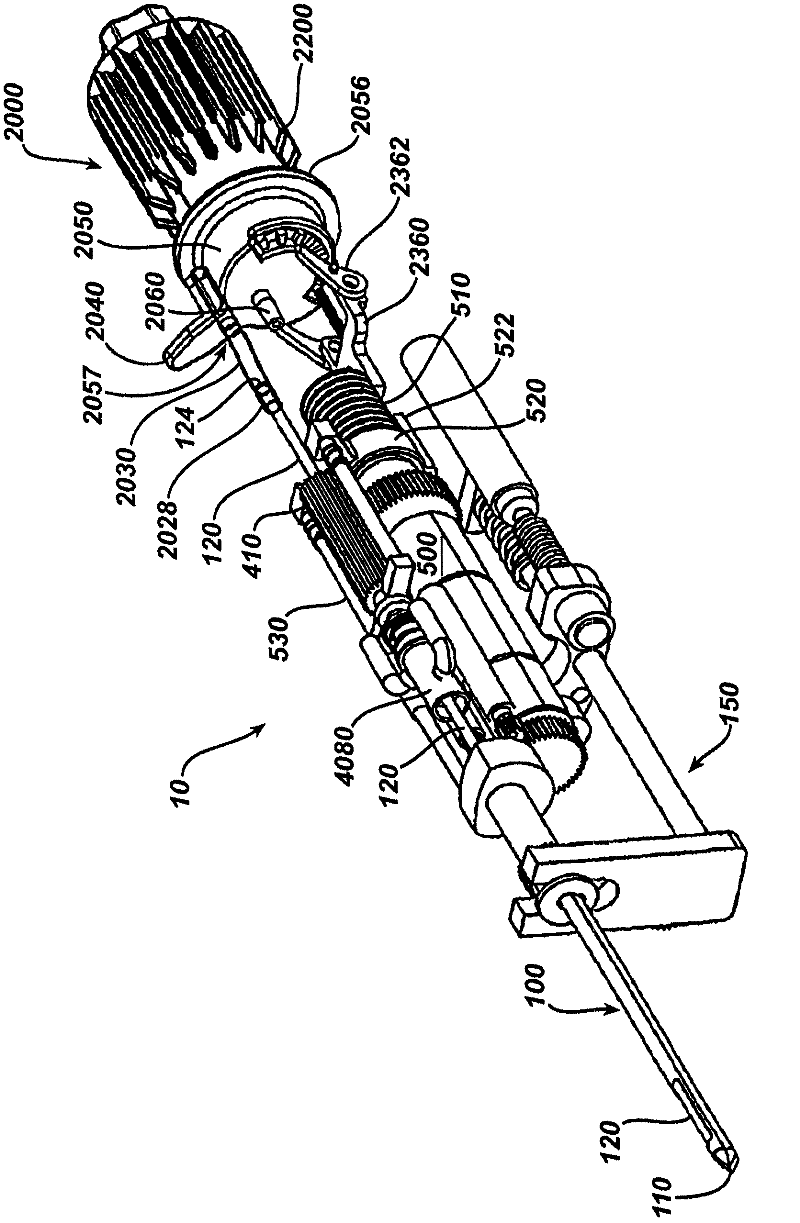

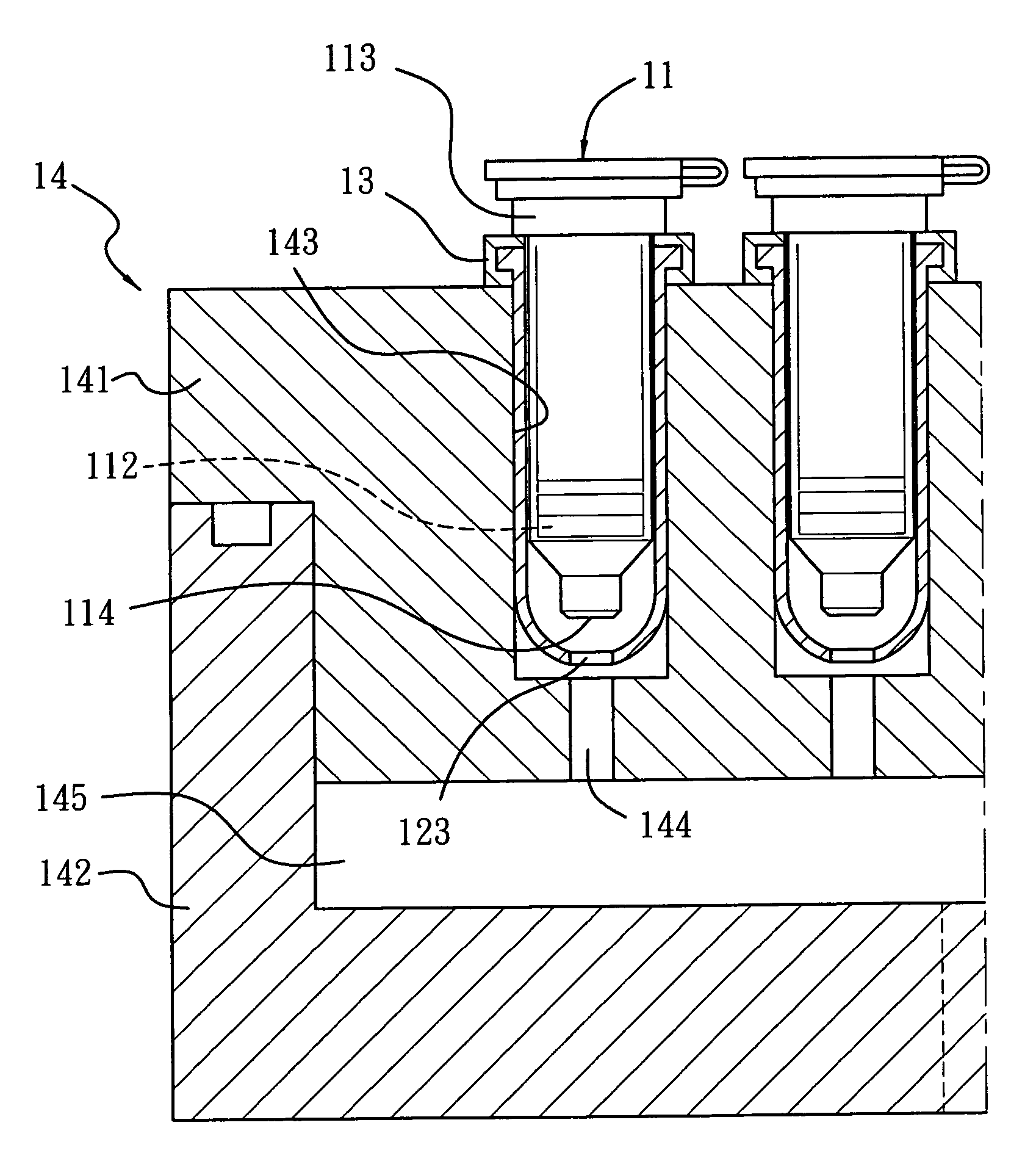

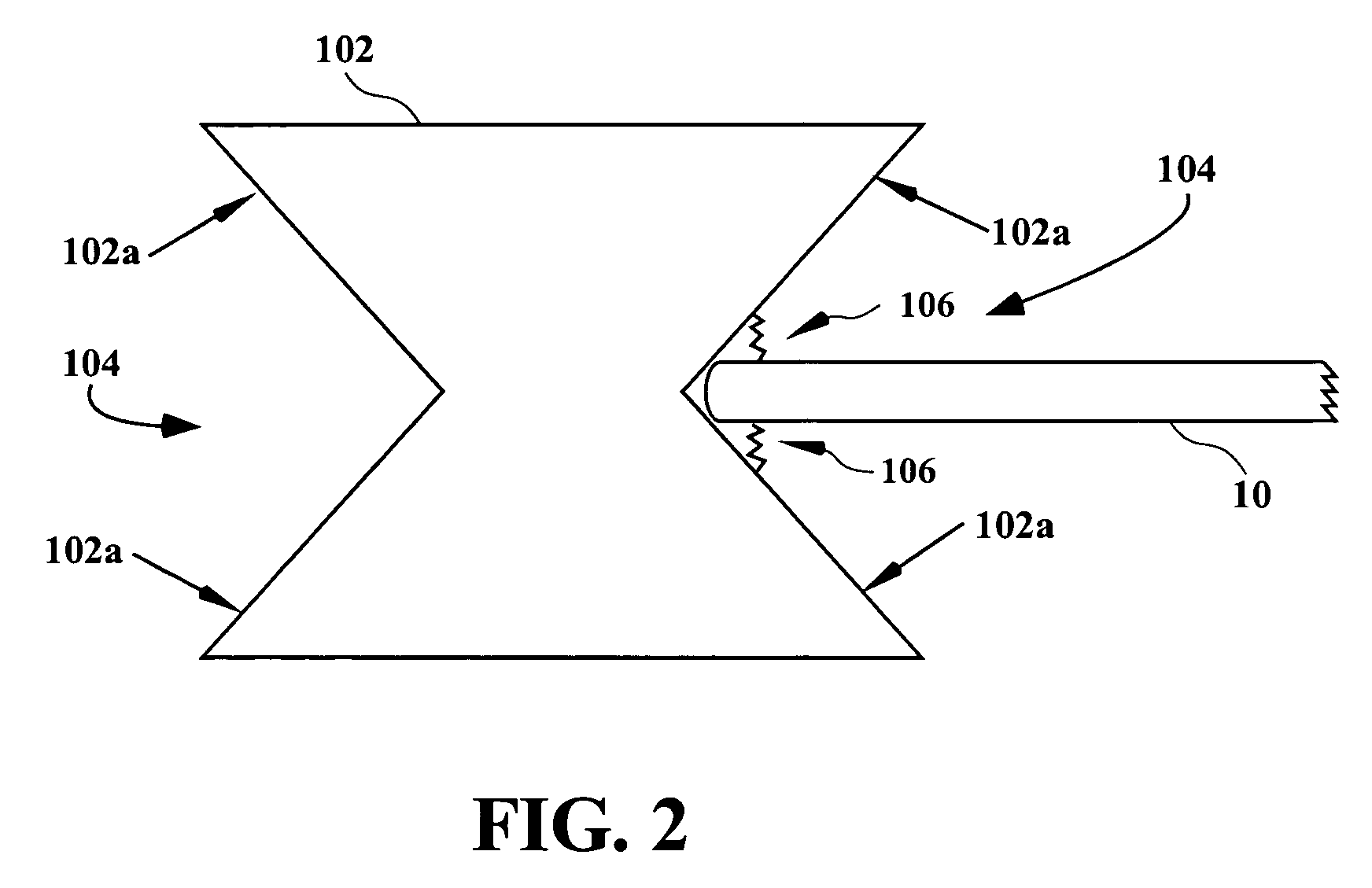

Biopsy device and biopsy sample storing assembly

The invention relates to a biopsy device and a biopsy sample storing assembly. Specifically, the biopsy device may be used to obtain and store multiple tissue samples. The device permits the tissue samples to be stored in a sequenced fashion within a generally transparent tissue storage chamber disposed at a proximal end of the biopsy device. The tissue samples can be stored on flexible tissue sample strips arranged around the circumference of a rotating vacuum manifold disposed within the chamber.

Owner:ETHICON ENDO SURGERY INC

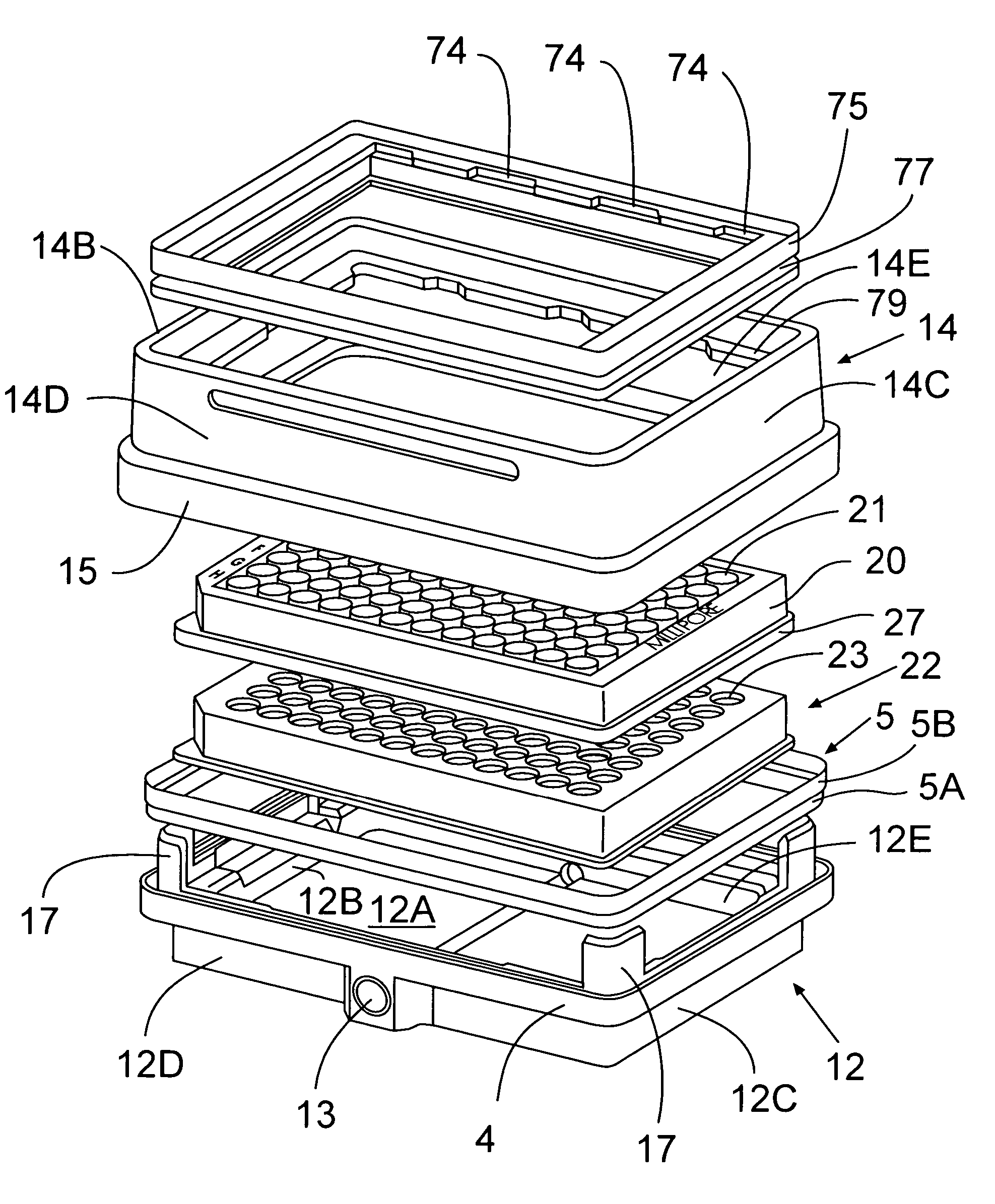

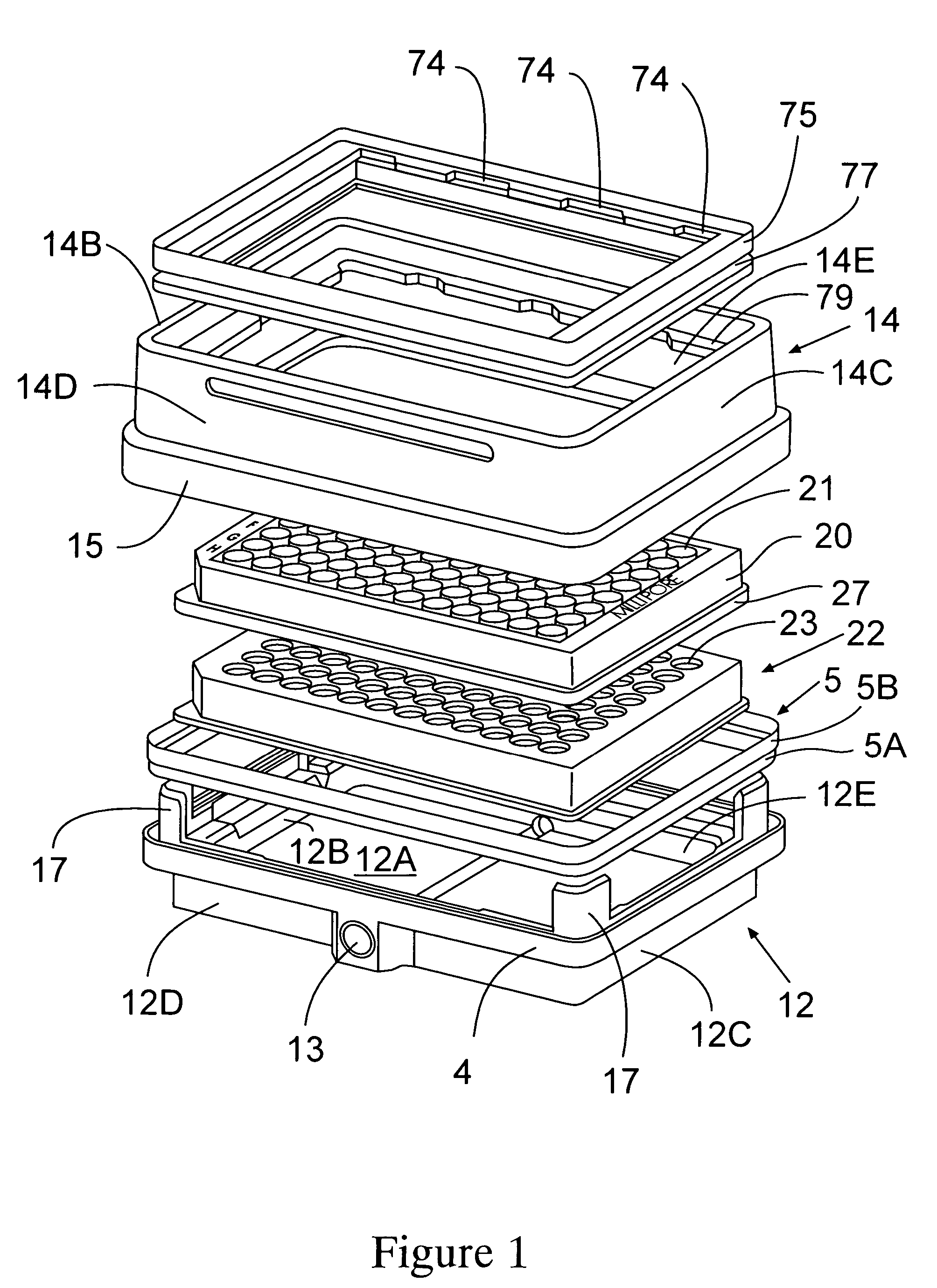

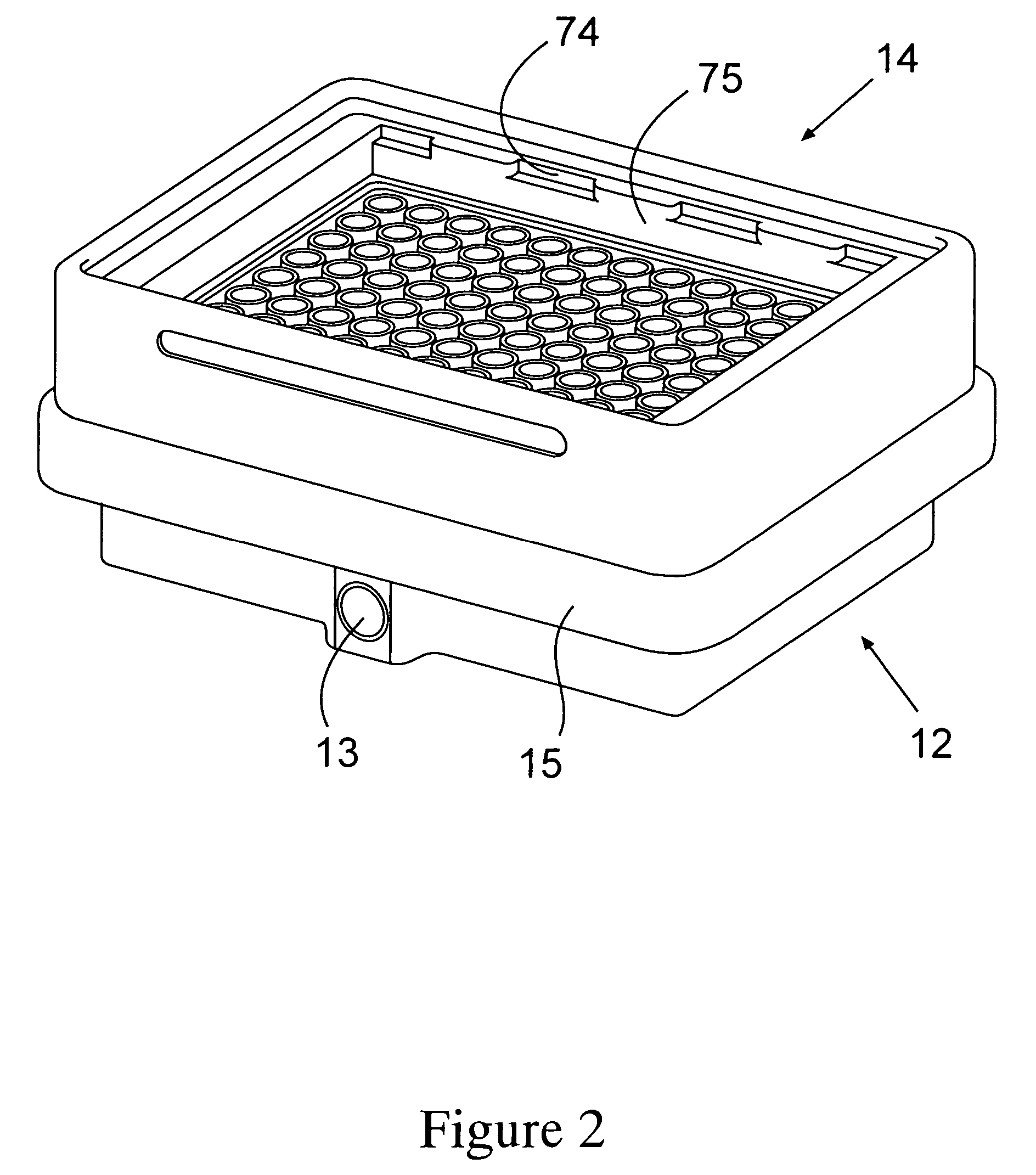

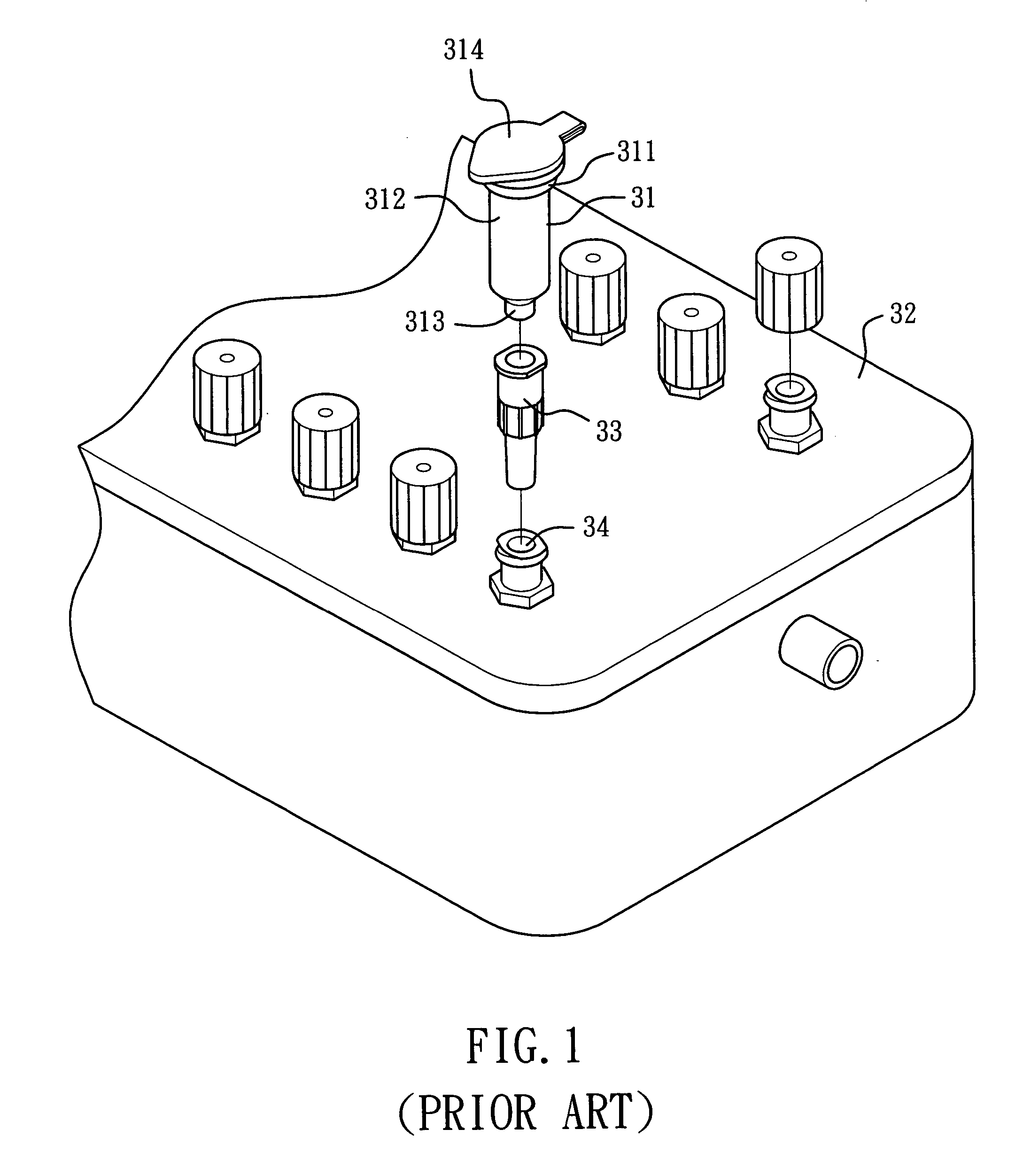

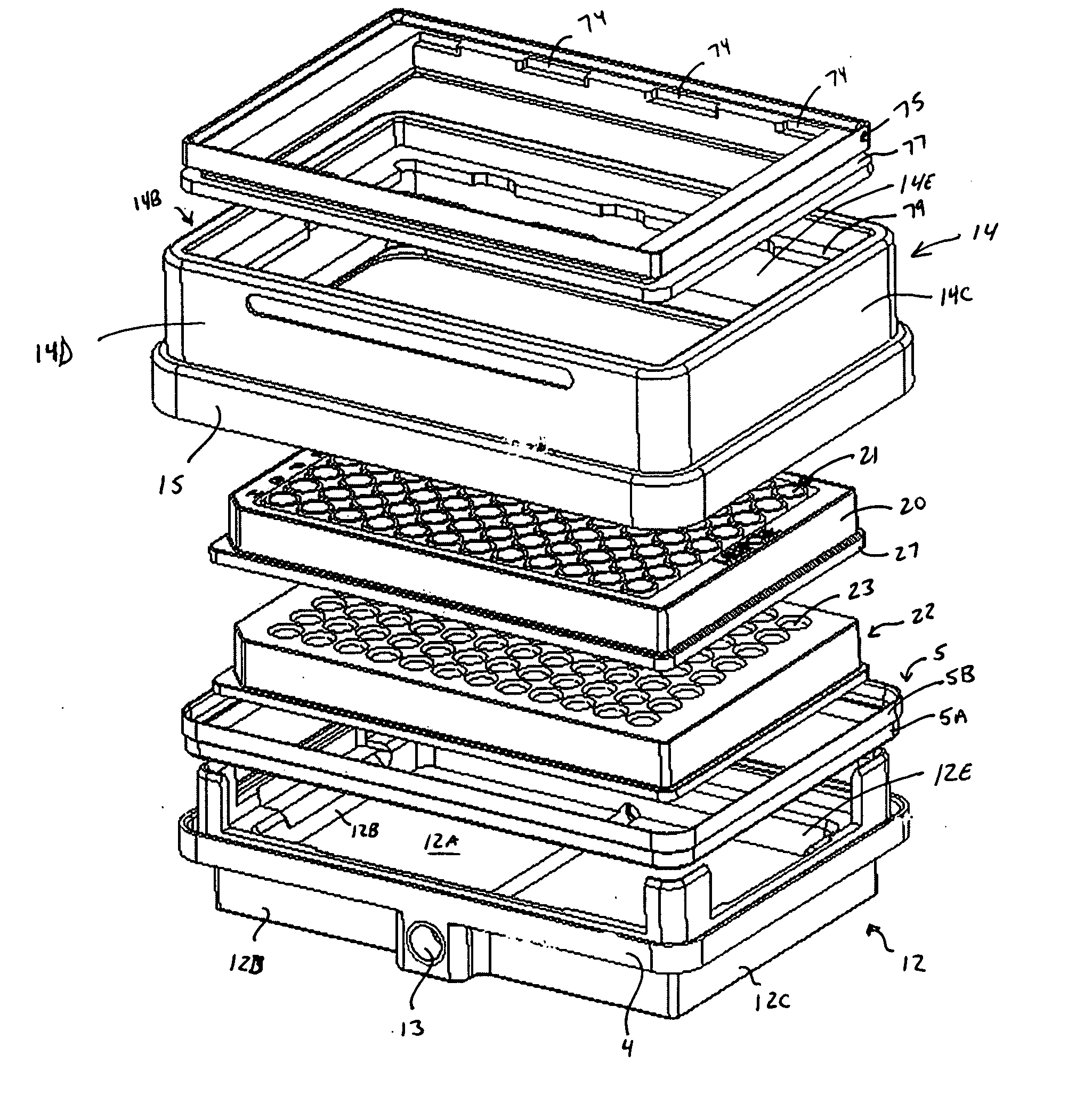

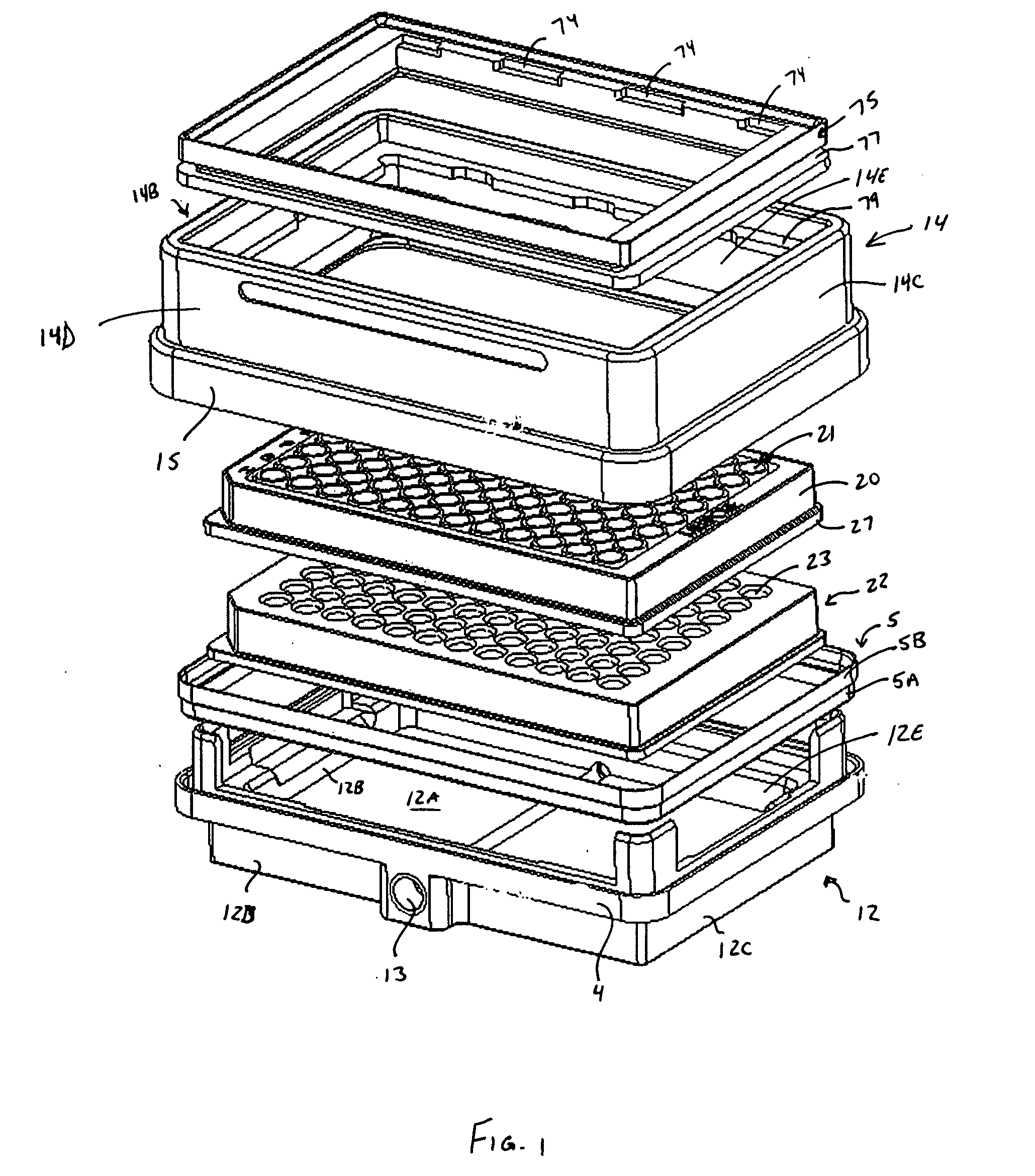

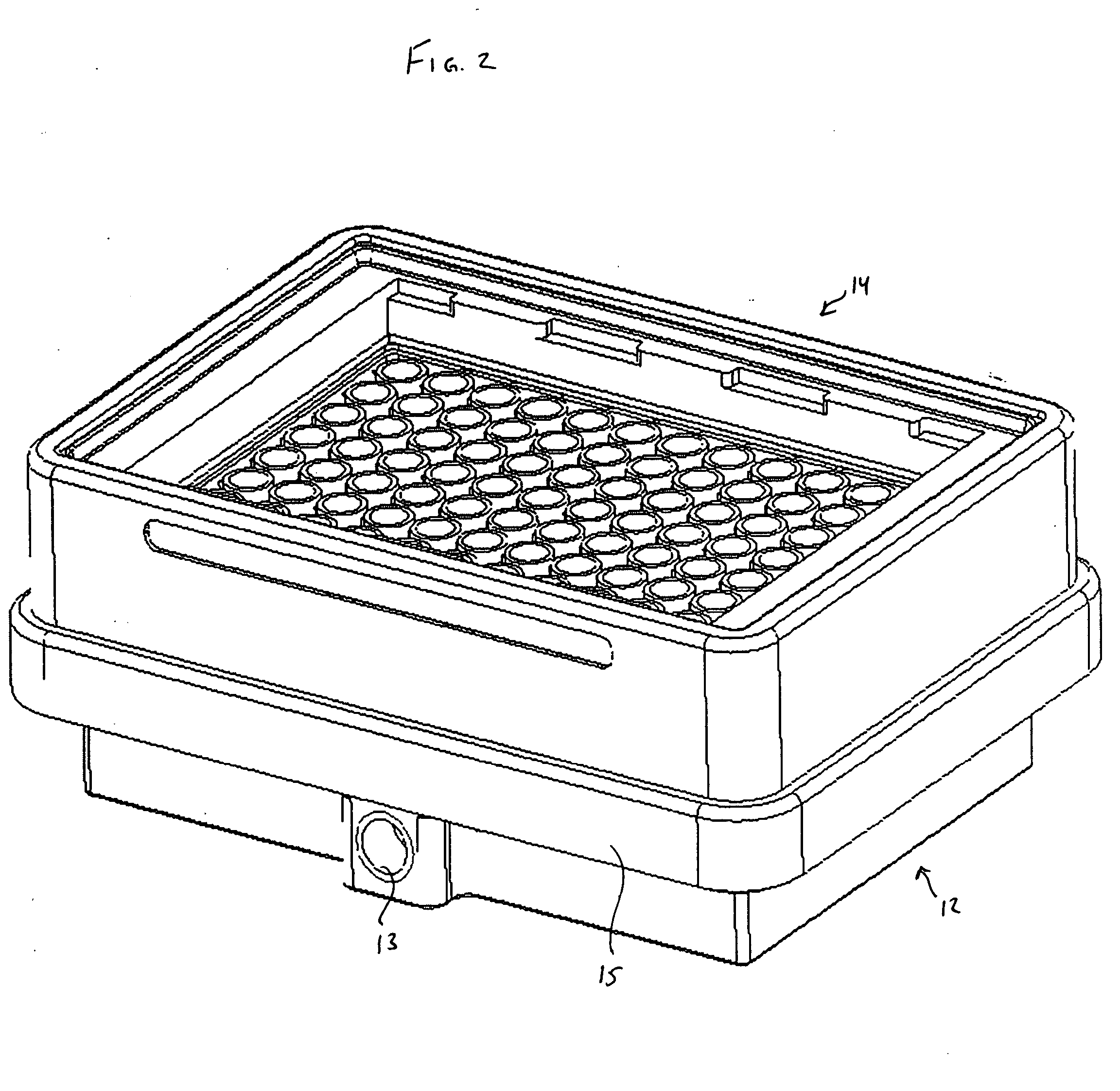

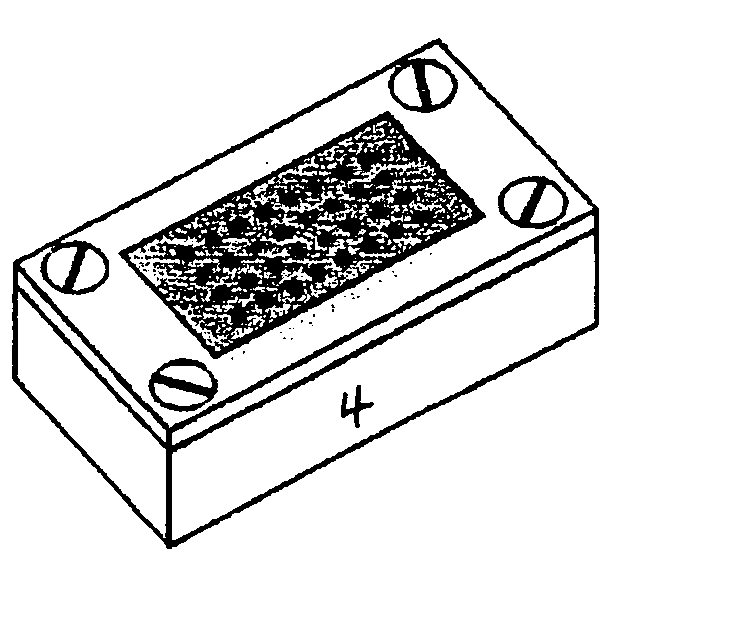

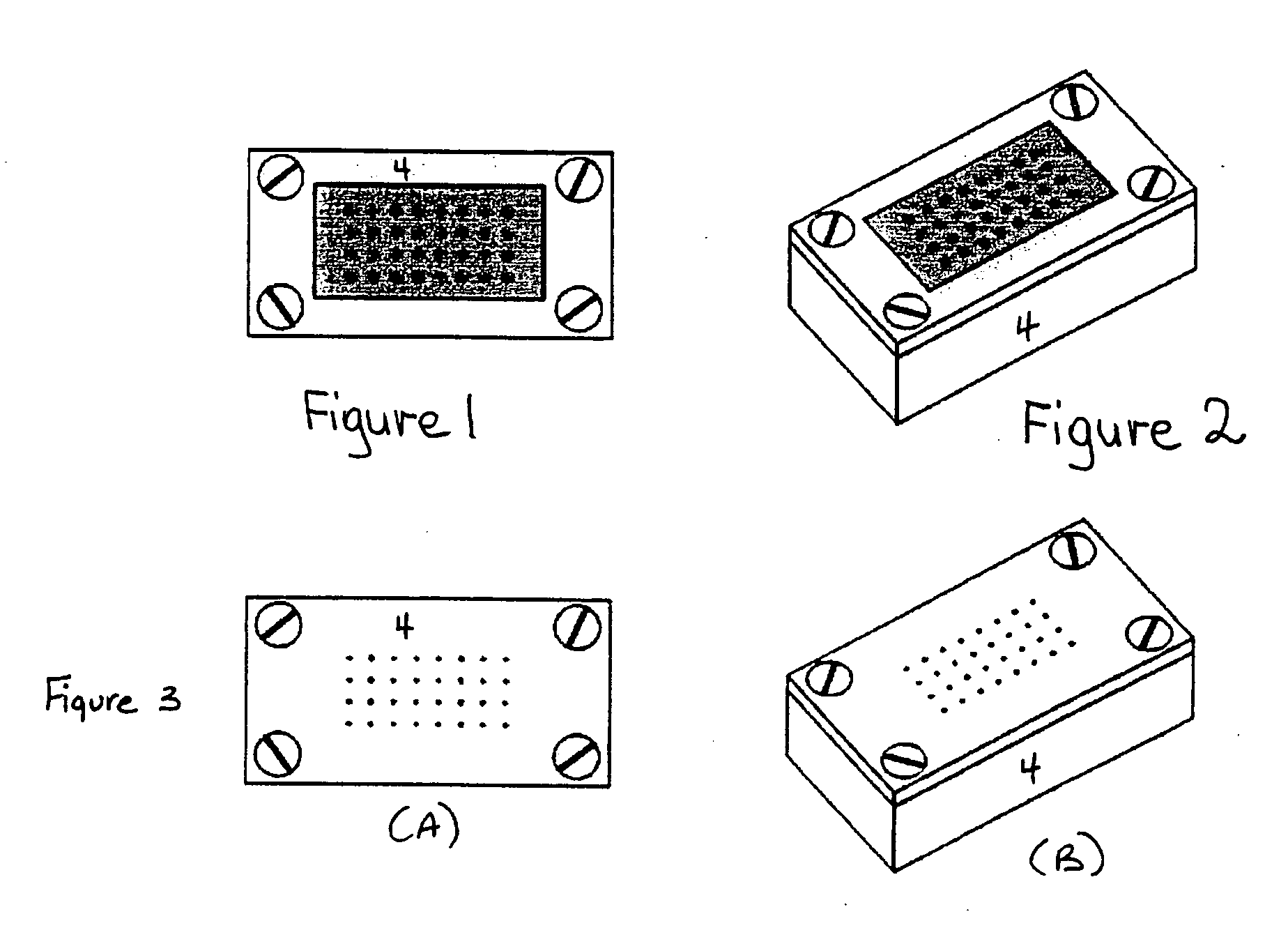

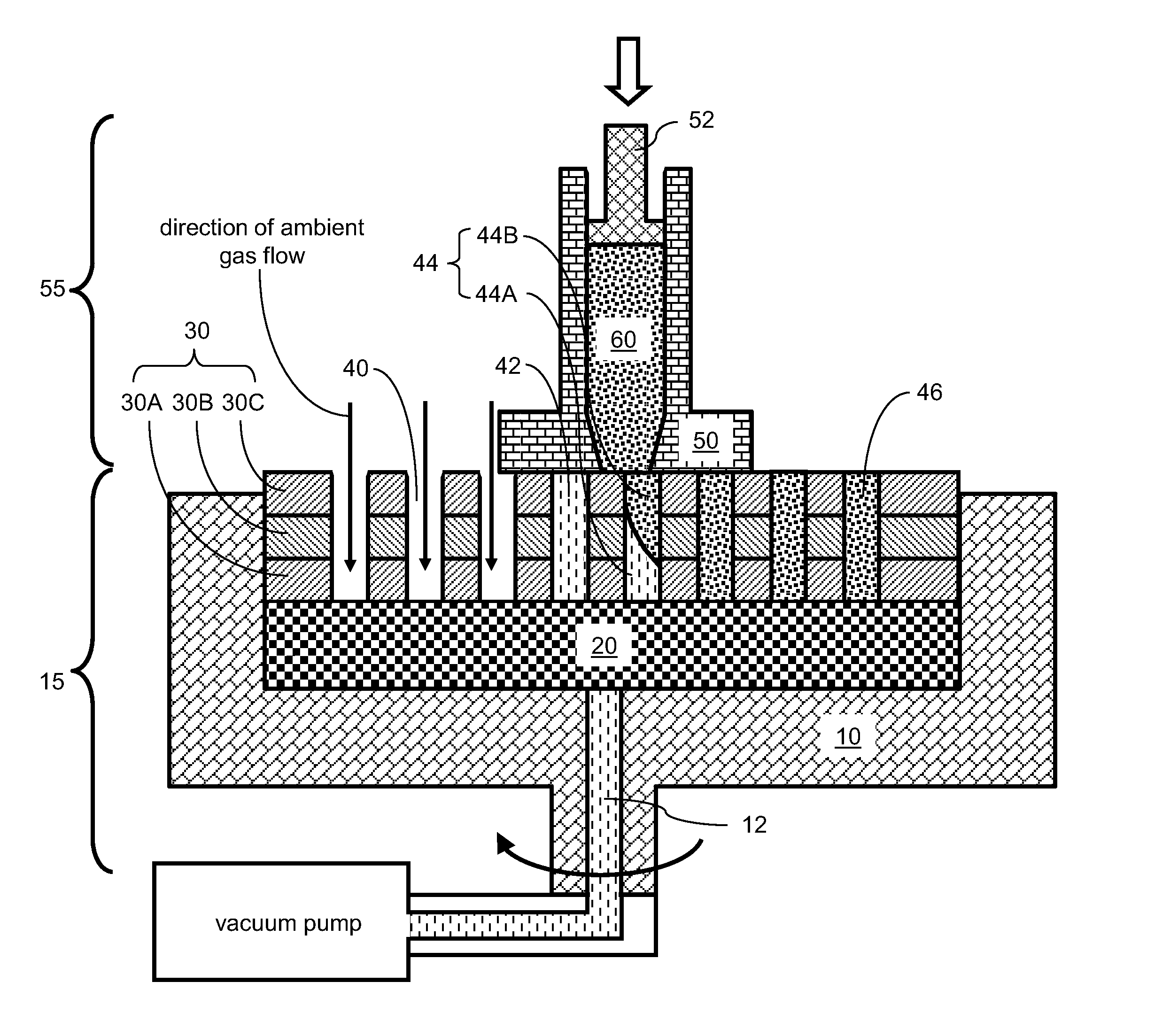

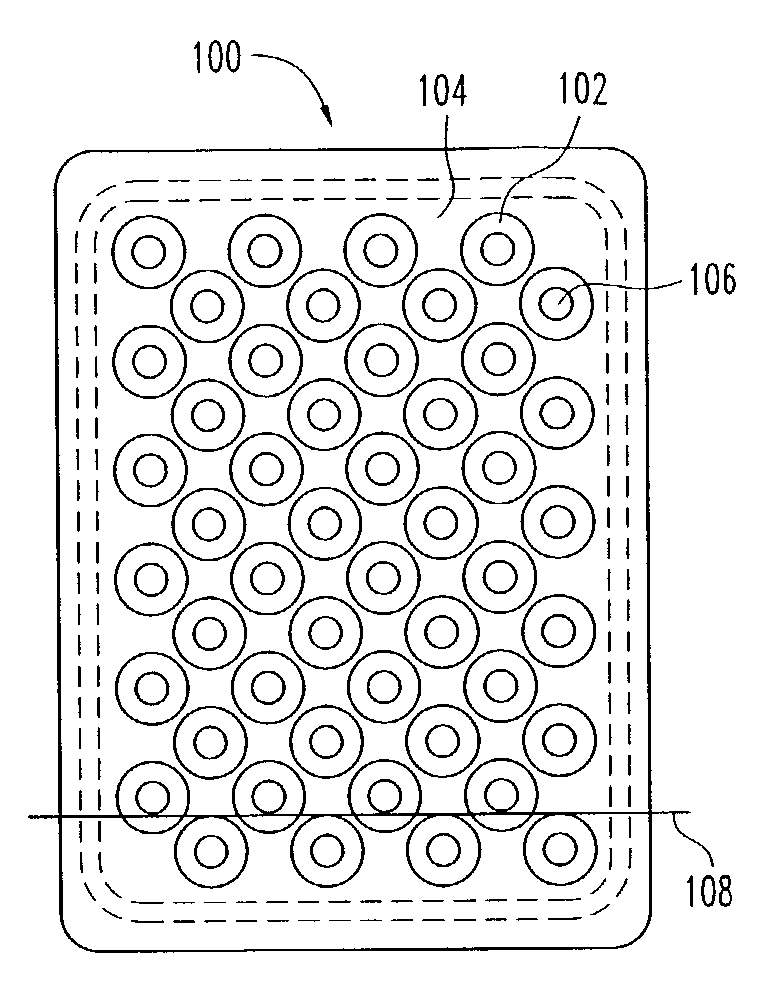

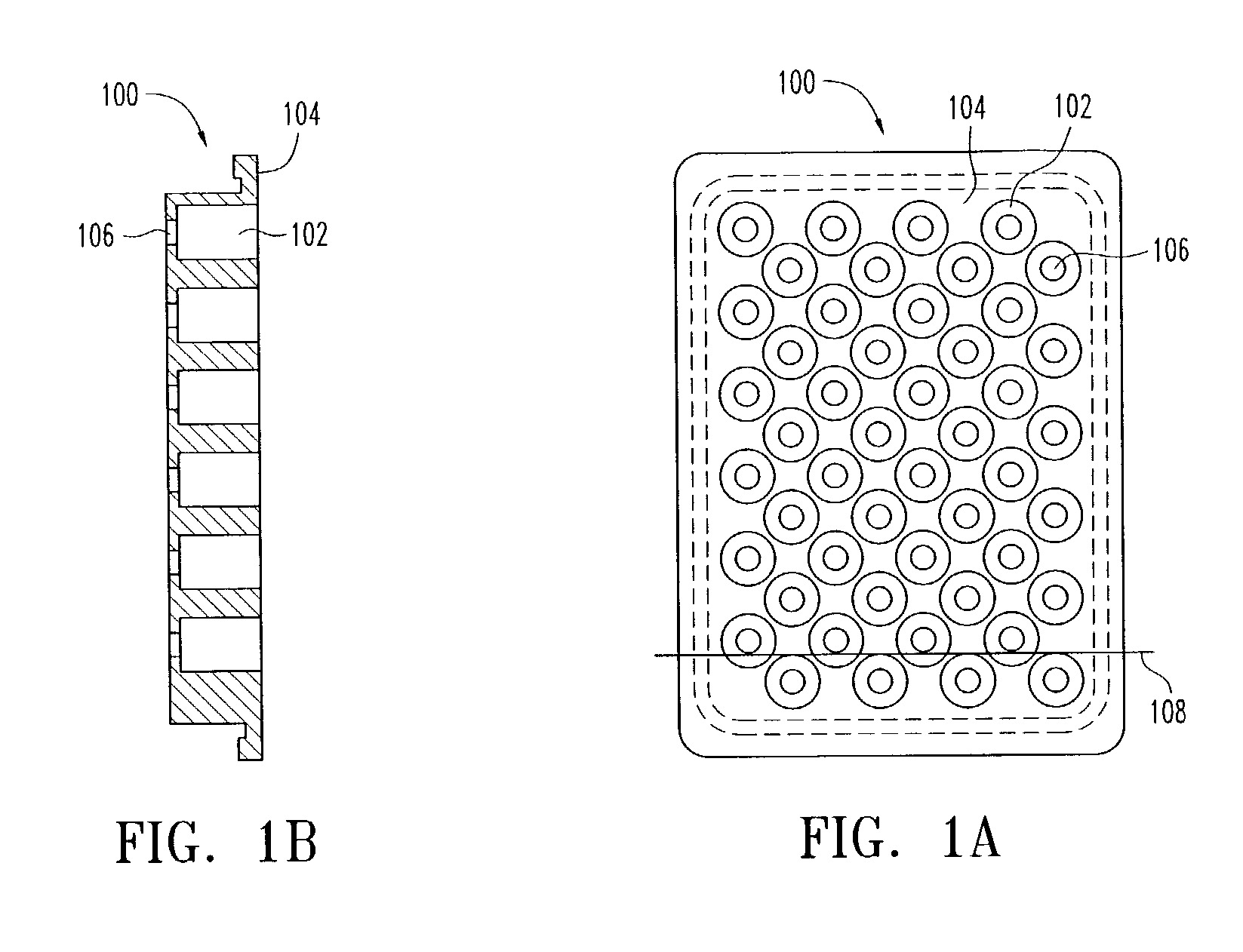

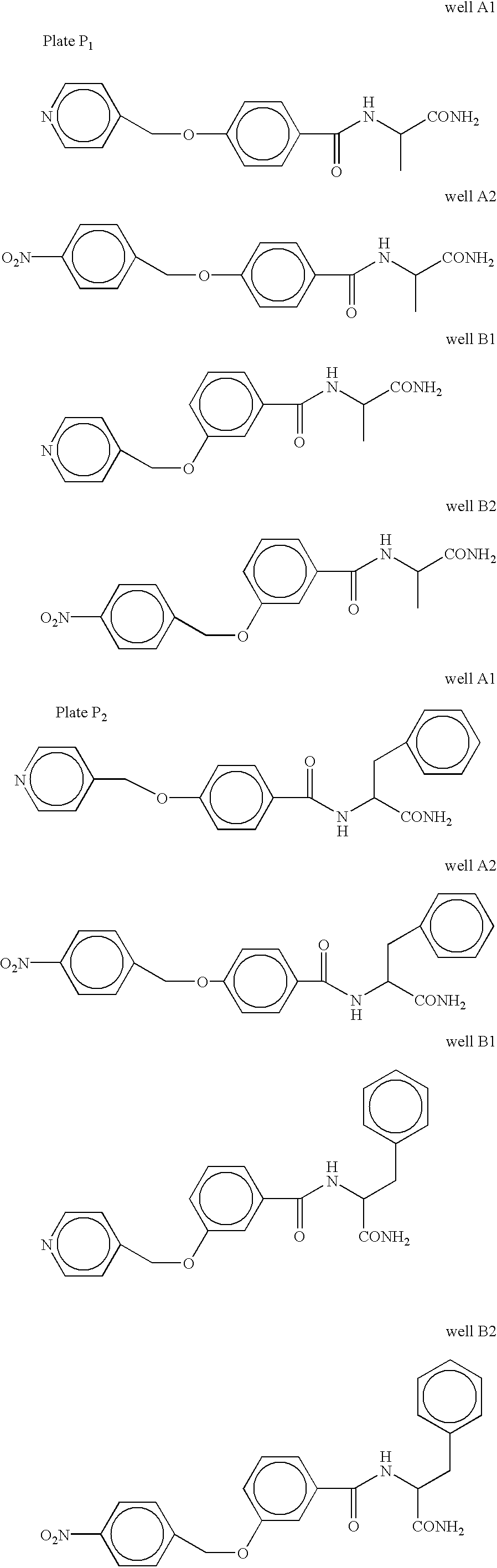

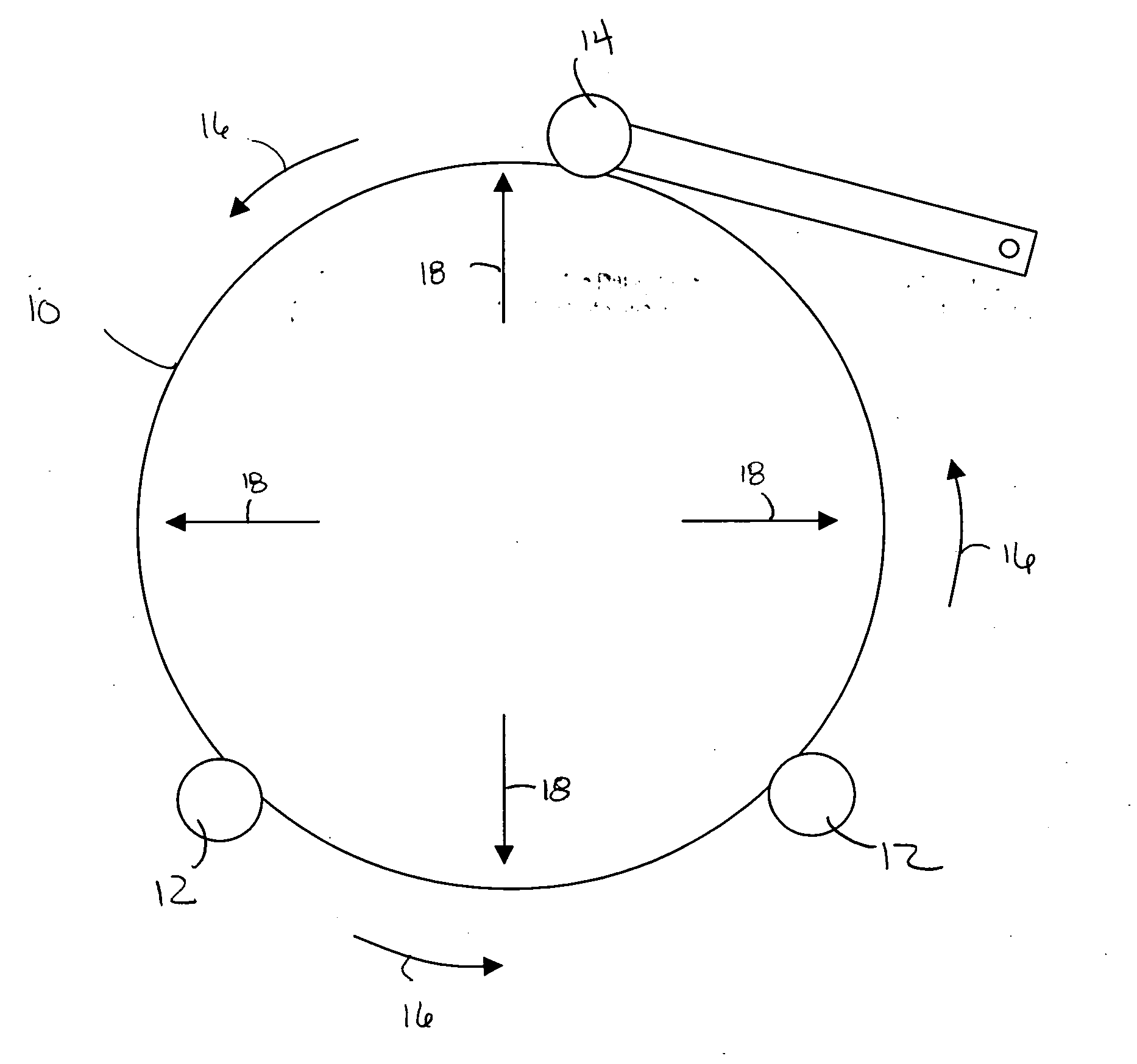

Multifunctional vacuum manifold

ActiveUS7588728B2Chemical analysis using titrationWithdrawing sample devicesModularityLaboratory device

A laboratory device design particularly for a multiplate format that includes a manifold wherein the position of the plate is not a function of gasket compression or vacuum rate applied. In one embodiment, the device has a modular design, wherein one or more removable inserts, preferably with different functionalities can be positioned between a base component and a collar component. The particular insert(s) chosen depend on the desired sample preparation or assay to be carried out. The insert(s) are stacked and are positioned between the base and collar as a unit, so that the stack within the manifold does not move during evacuation of the vacuum chamber. The consistent position of the insert(s) facilitates using vacuum sample processing with automated liquid handlers.

Owner:MILLIPORE CORP

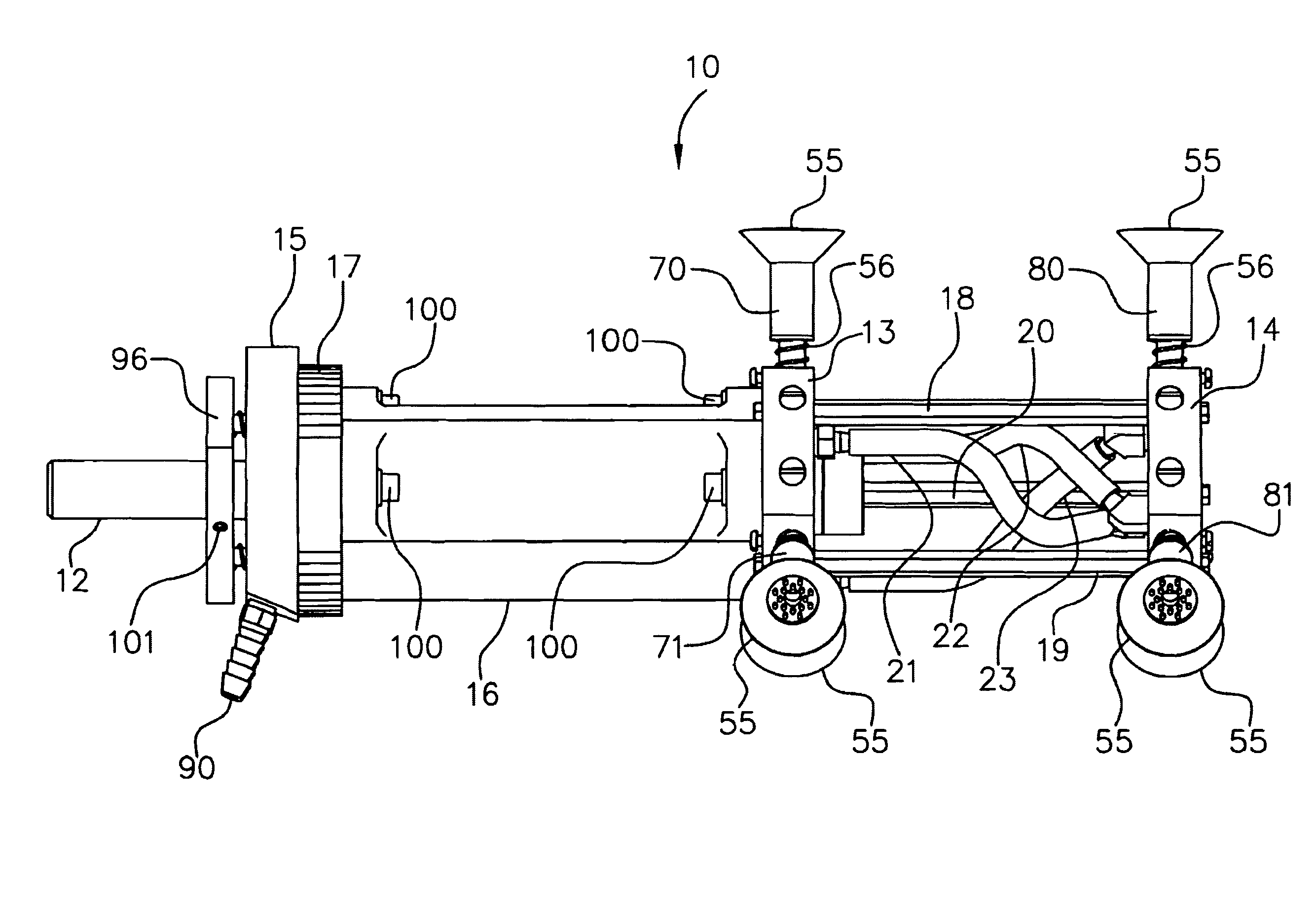

Package pick-off and delivery device

ActiveUS7841633B2Gripping headsPackaging under special atmospheric conditionsVacuum pressureEngineering

Owner:BEMIS COMPANY INC

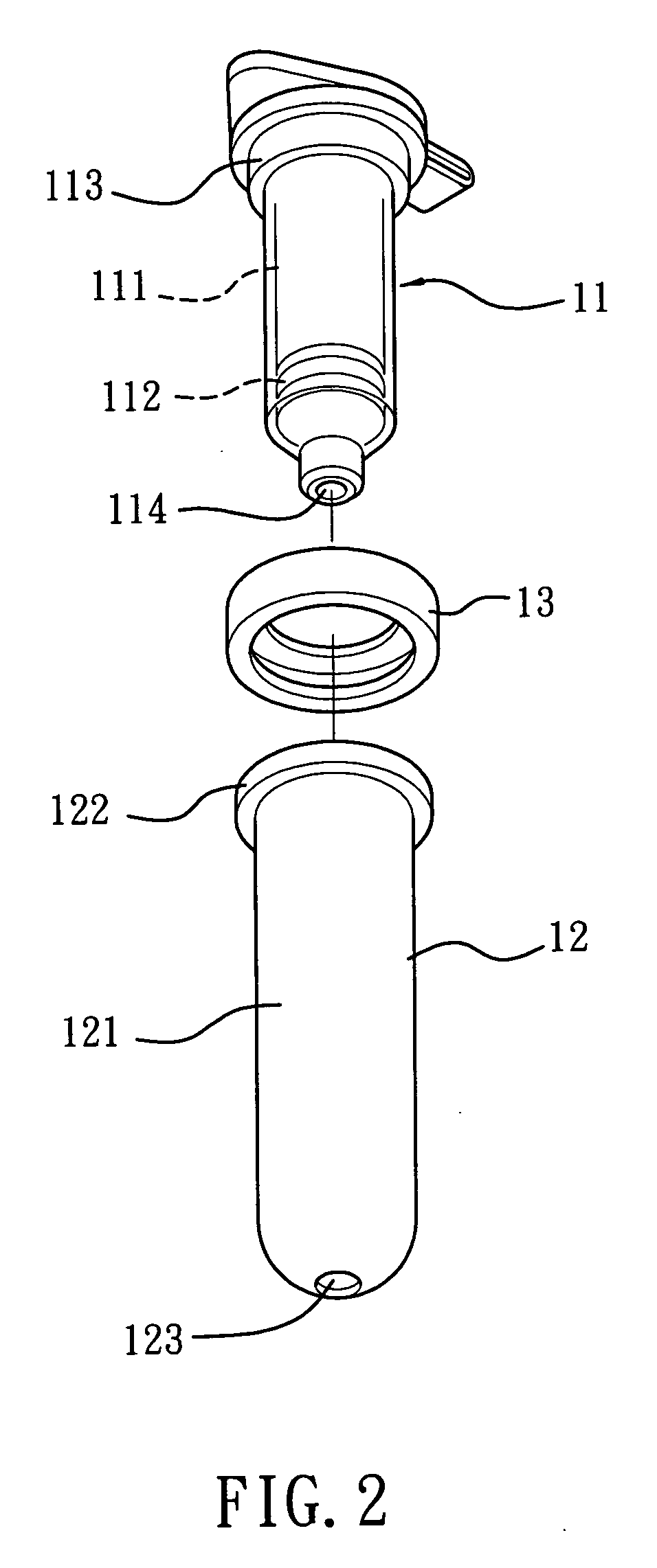

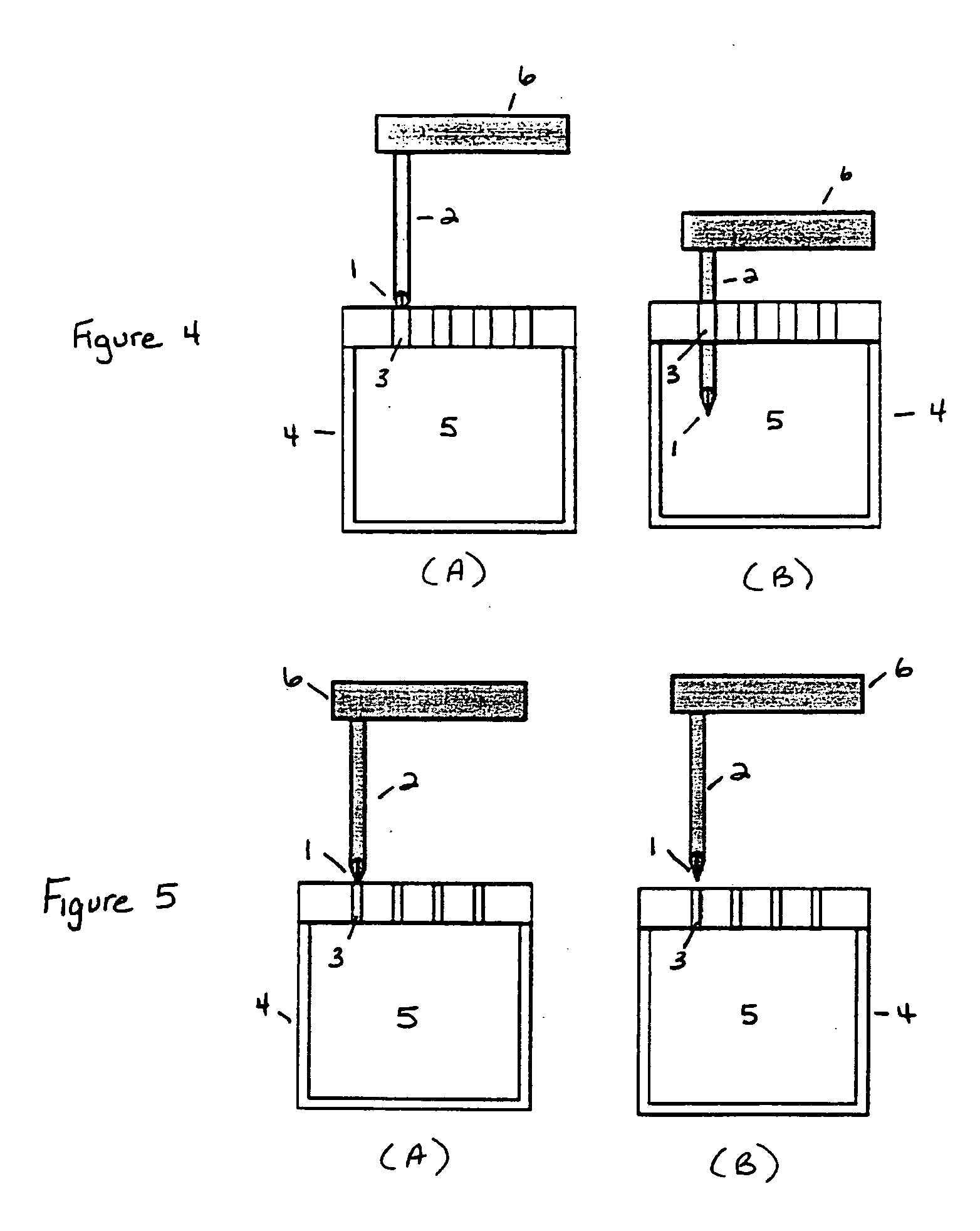

Apparatus for processing biological sample

InactiveUS20060177354A1Easy to disassembleAnalysis using chemical indicatorsLaboratory glasswaresAtmospheric pressureMembrane configuration

An apparatus for processing biological sample which are commonly used to wash, separate and purify biochemical molecules, such as DNA, RNA and protein. The apparatus comprises at least one liquid semi-permeable membrane column, at least one vacuum connected column and a vacuum manifold, which are all loosely received to each other. An air tight material such as an air tight elastic band is disposed at a position where the liquid semi-permeable membrane column, the one vacuum connected column and the vacuum manifold engage with each other, thereby when the atmospheric pressure in the liquid semi-permeable membrane column is larger than that in the vacuum manifold, the apparatus is formed and maintained in an air tight state. If a liquid sample is placed inside liquid semi-permeable membrane column, the atmospheric pressure can push the liquid out of the column through the liquid semi-permeable membranes. It is therefore much easier and convenient to assemble and disassemble the apparatus than a conventional one.

Owner:NOBEL BIOCARE AB

Multifunctional vacuum manifold

ActiveUS20040265186A1Analysis using chemical indicatorsChemical analysis using titrationModularityModular design

A laboratory device design particularly for a multiplate format that includes a manifold wherein the position of the plate is not a function of gasket compression or vacuum rate applied. In one embodiment, the device has a modular design, wherein removable inserts with different functionalities can be positioned between a base component and a collar component. The particular inserts chosen depend on the desired sample preparation or assay to be carried out. The inserts are stacked and are positioned between the base and collar as a unit, so that the stack within the manifold does not move during evacuation of the vacuum chamber. The consistent position of the multiplate facilitates using vacuum sample processing with automated liquid handlers.

Owner:MILLIPORE CORP

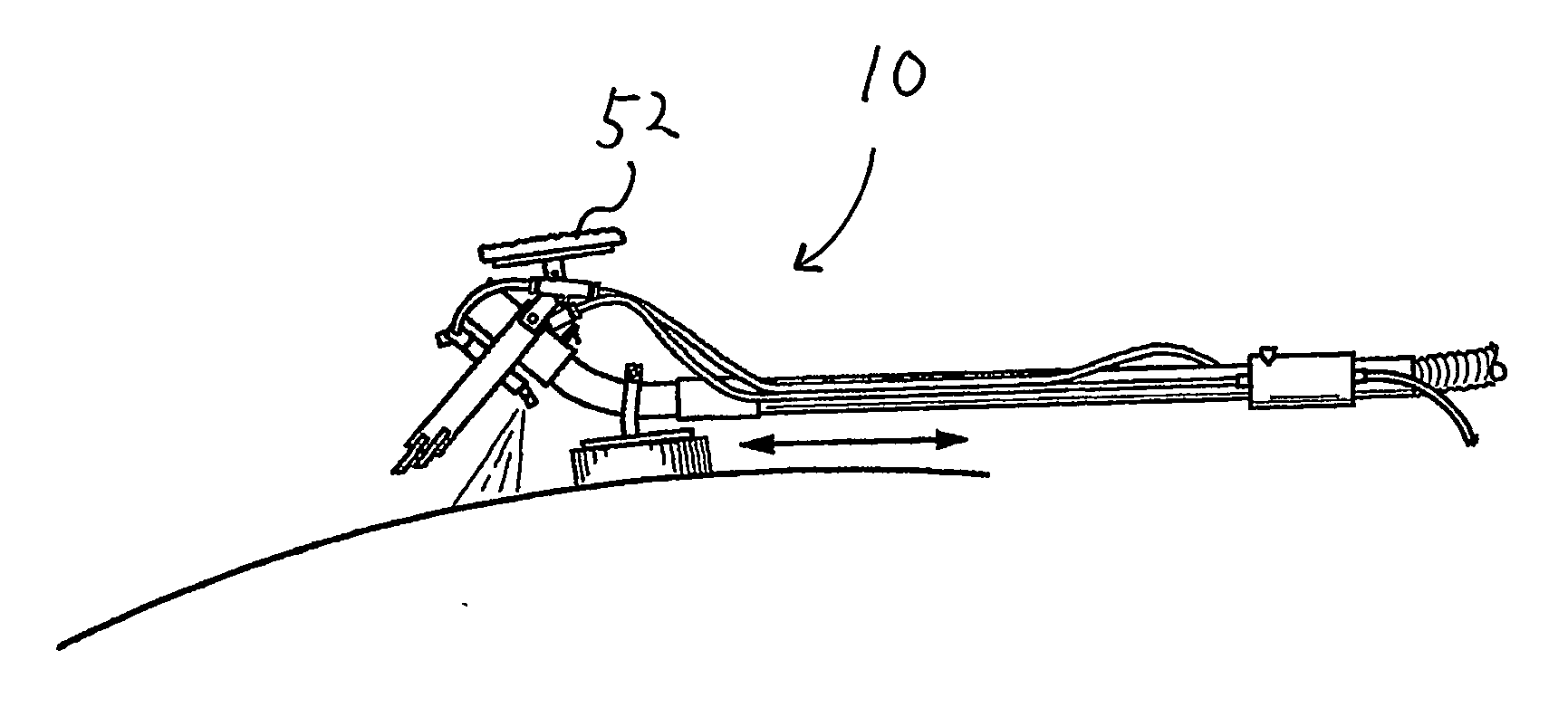

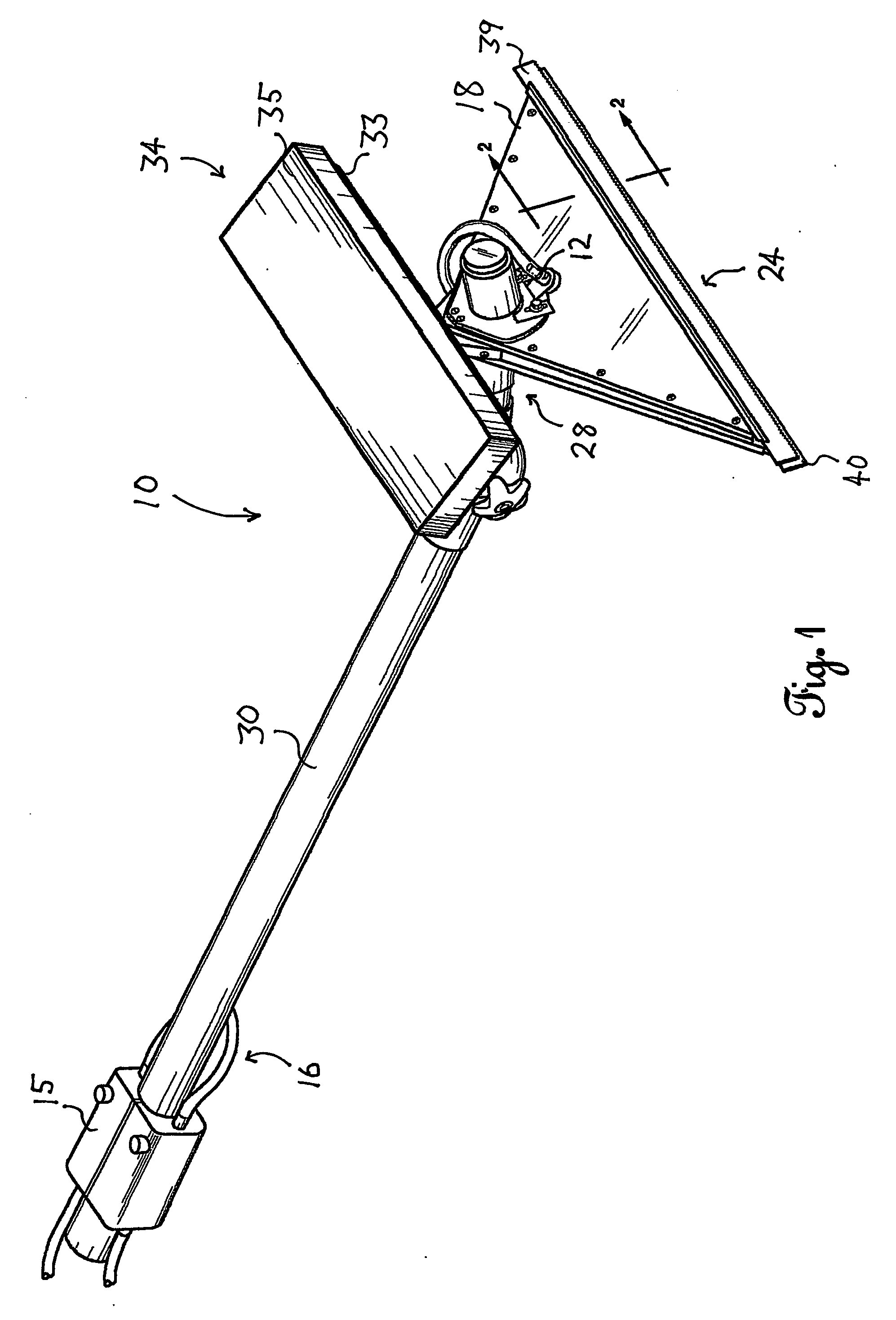

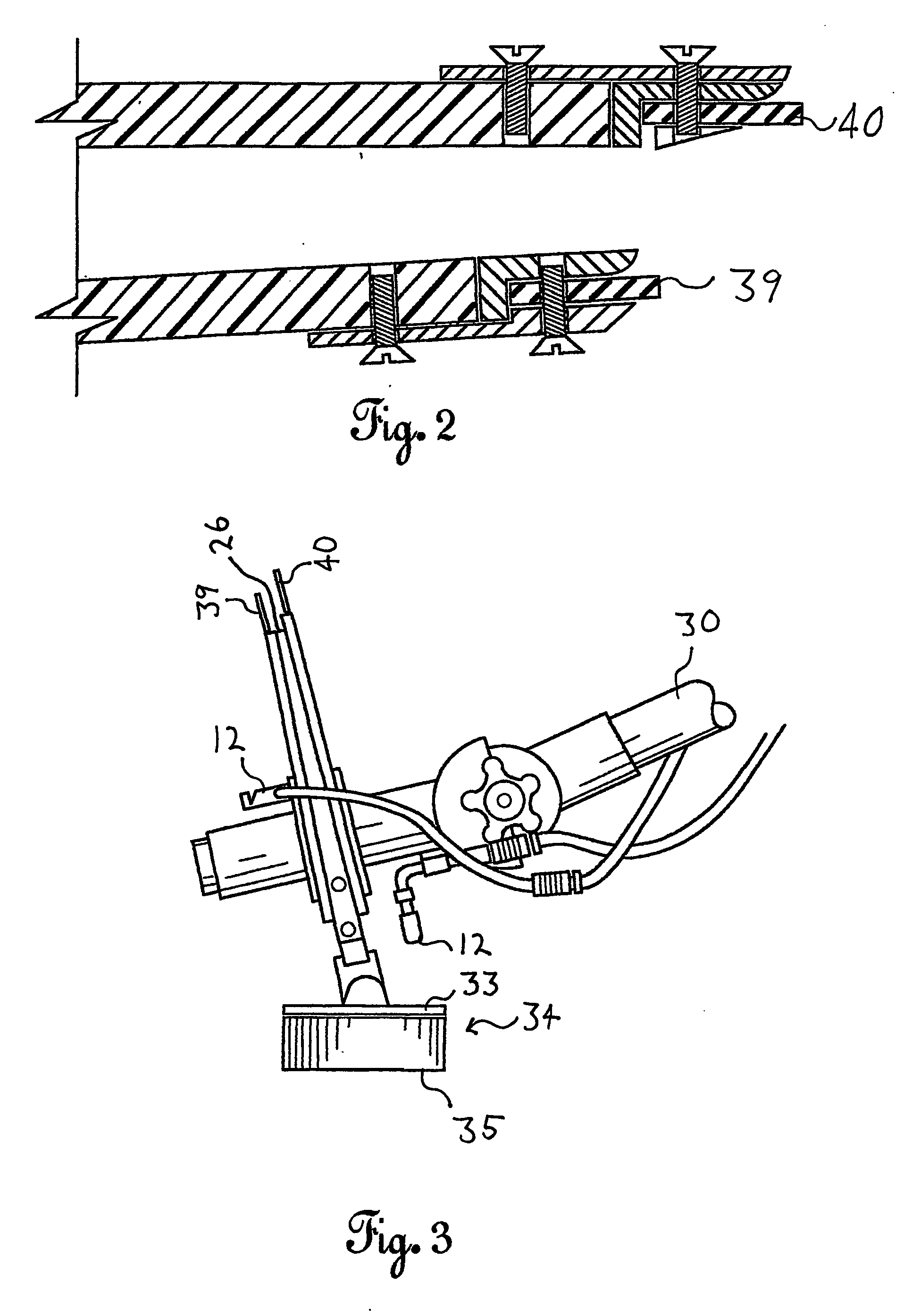

Apparatus and method for cleaning soiled surfaces with...

InactiveUS20060225241A1Reduce decreaseProvide efficiencyCarpet cleanersFloor cleanersGround water pollutionSoil surface

A method and apparatus for cleaning exterior surfaces, particularly aircraft exteriors, which method and apparatus applies cleaning solution to a soiled surface, scours the surface, squeegees the contaminated solution from the surface and evacuates it through a vacuum manifold for collection and environmentally appropriate disposal. Applicant's method and apparatus are designed principally to alleviate the problem of toxic run-off and ground water pollution as attends present-day wash-rack or bucket and brush type washing operations. Applicant's method and apparatus are also beneficial from a convenience standpoint, as an aircraft may be cleaned in any location without the necessity of removing the aircraft to a maintenance facility. Applicant's method and apparatus are also useful for other exterior surfaces, such as for cleaning skyscraper surfaces.

Owner:PHILLIPS BRIAN

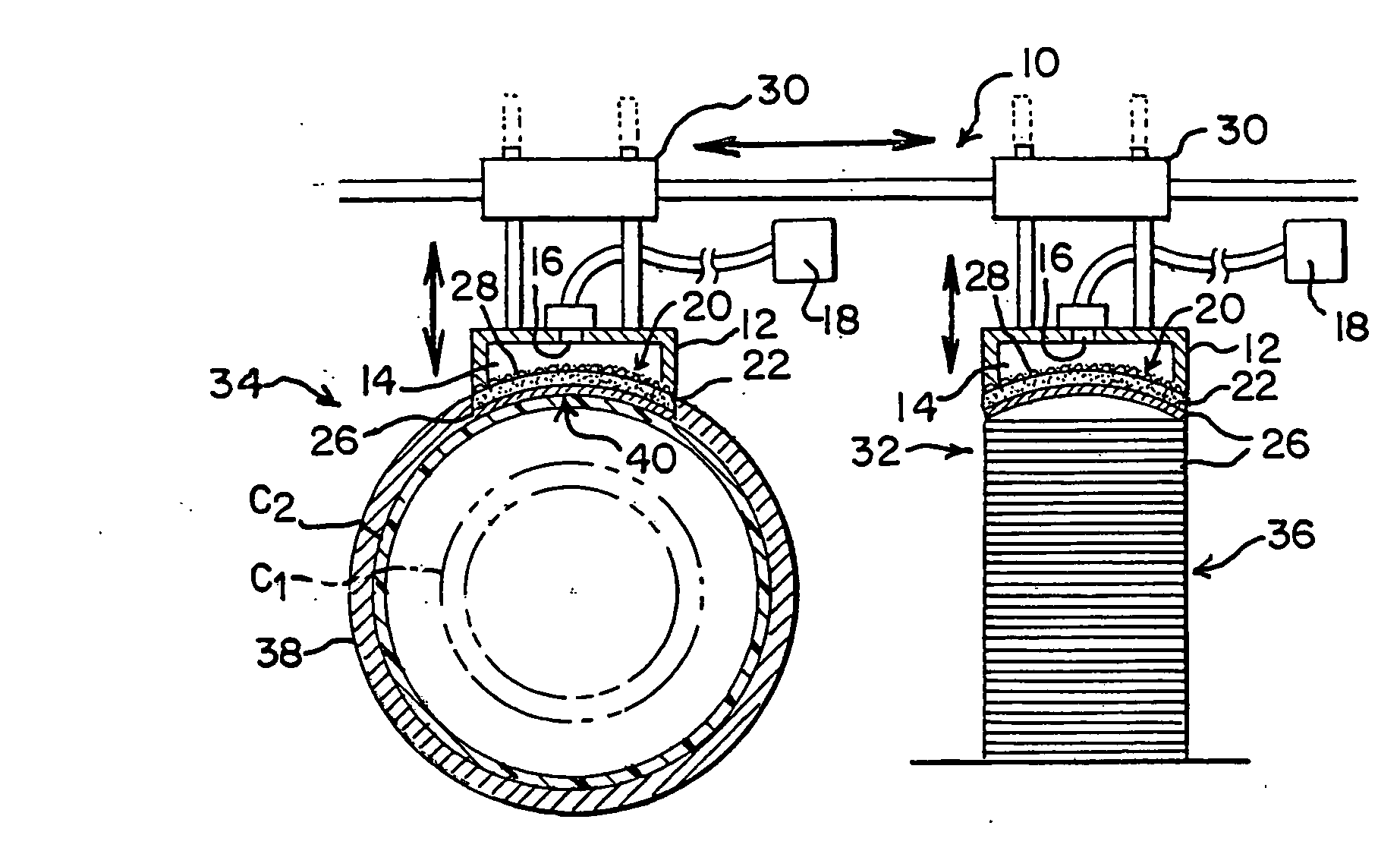

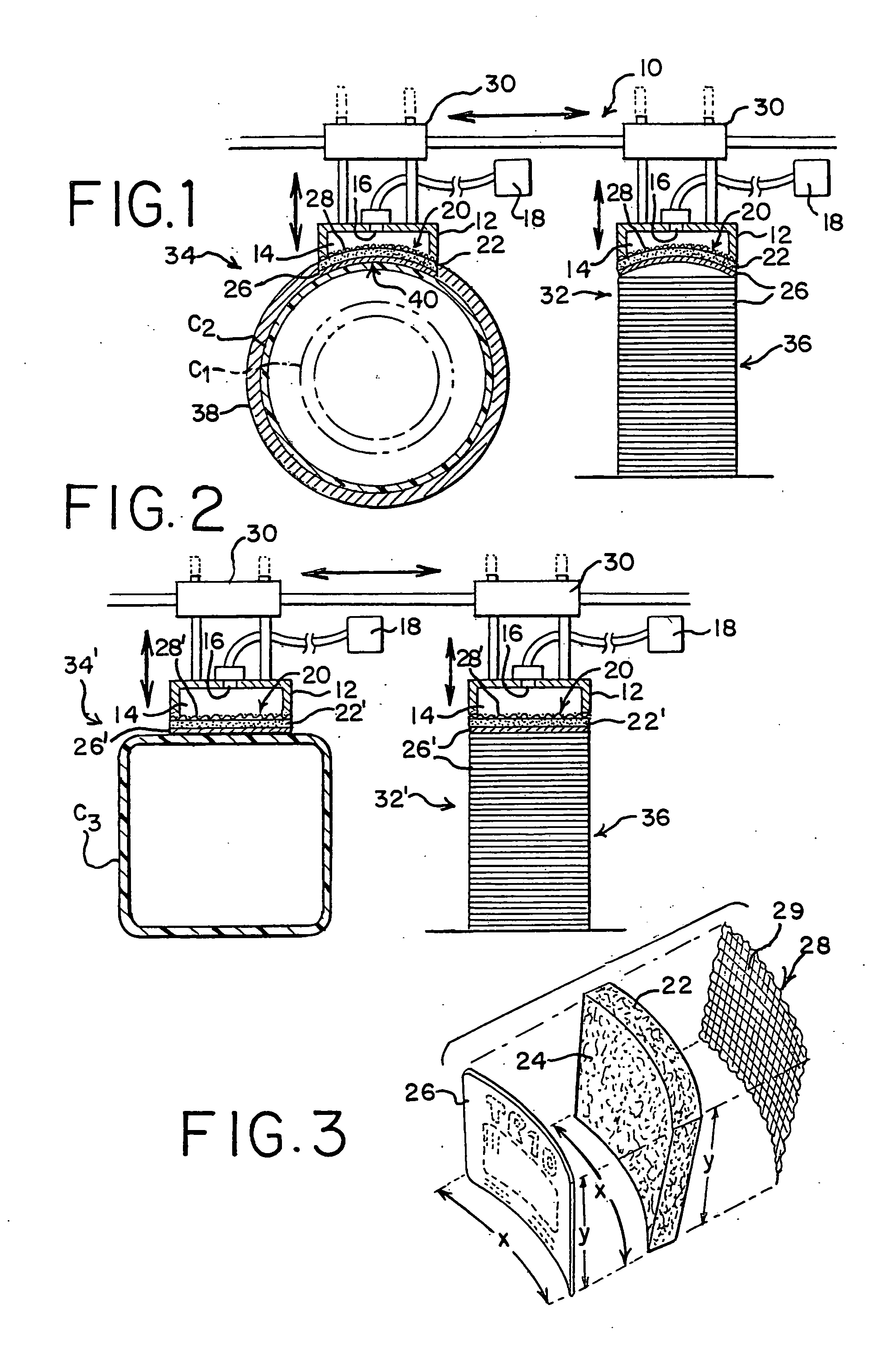

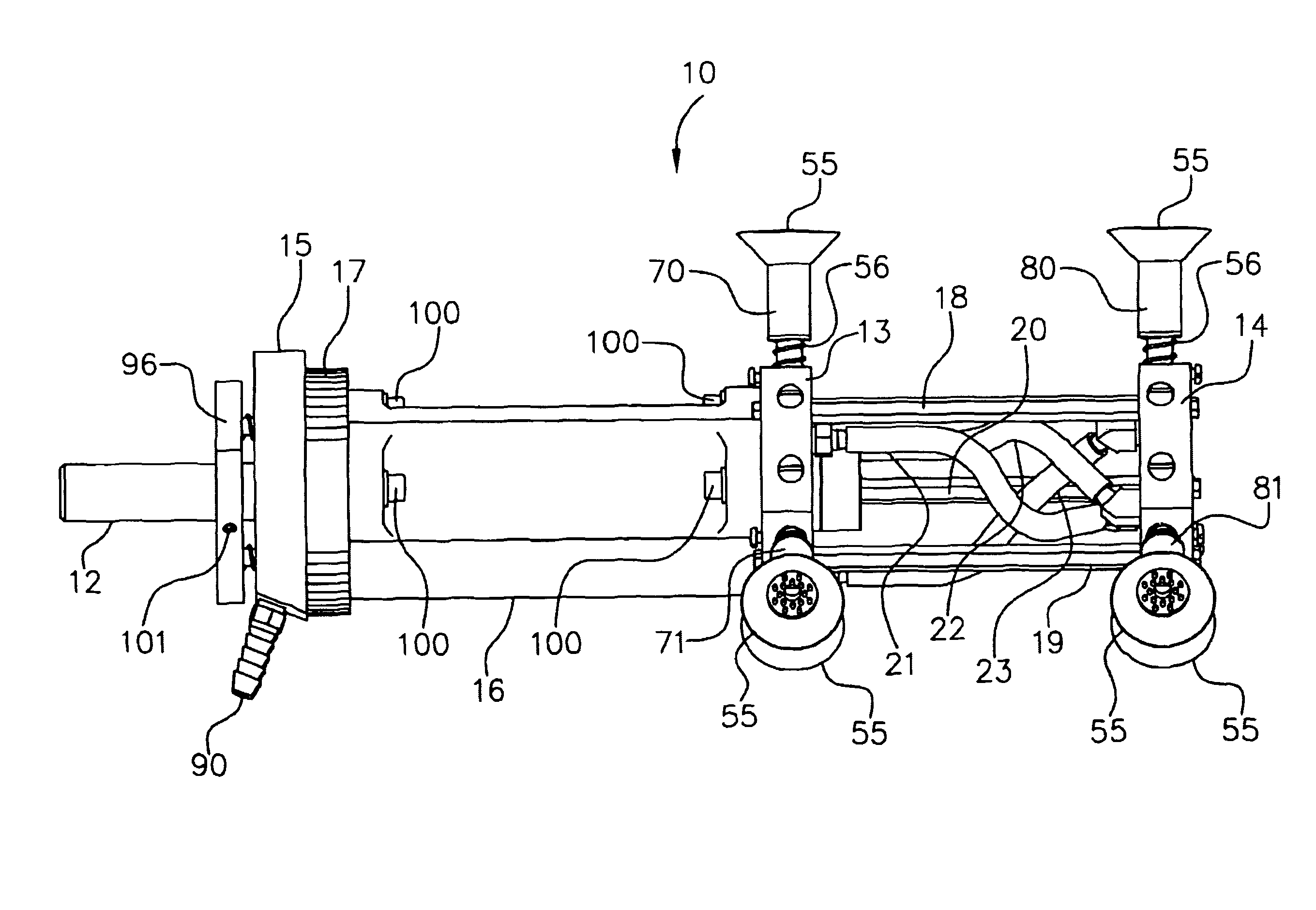

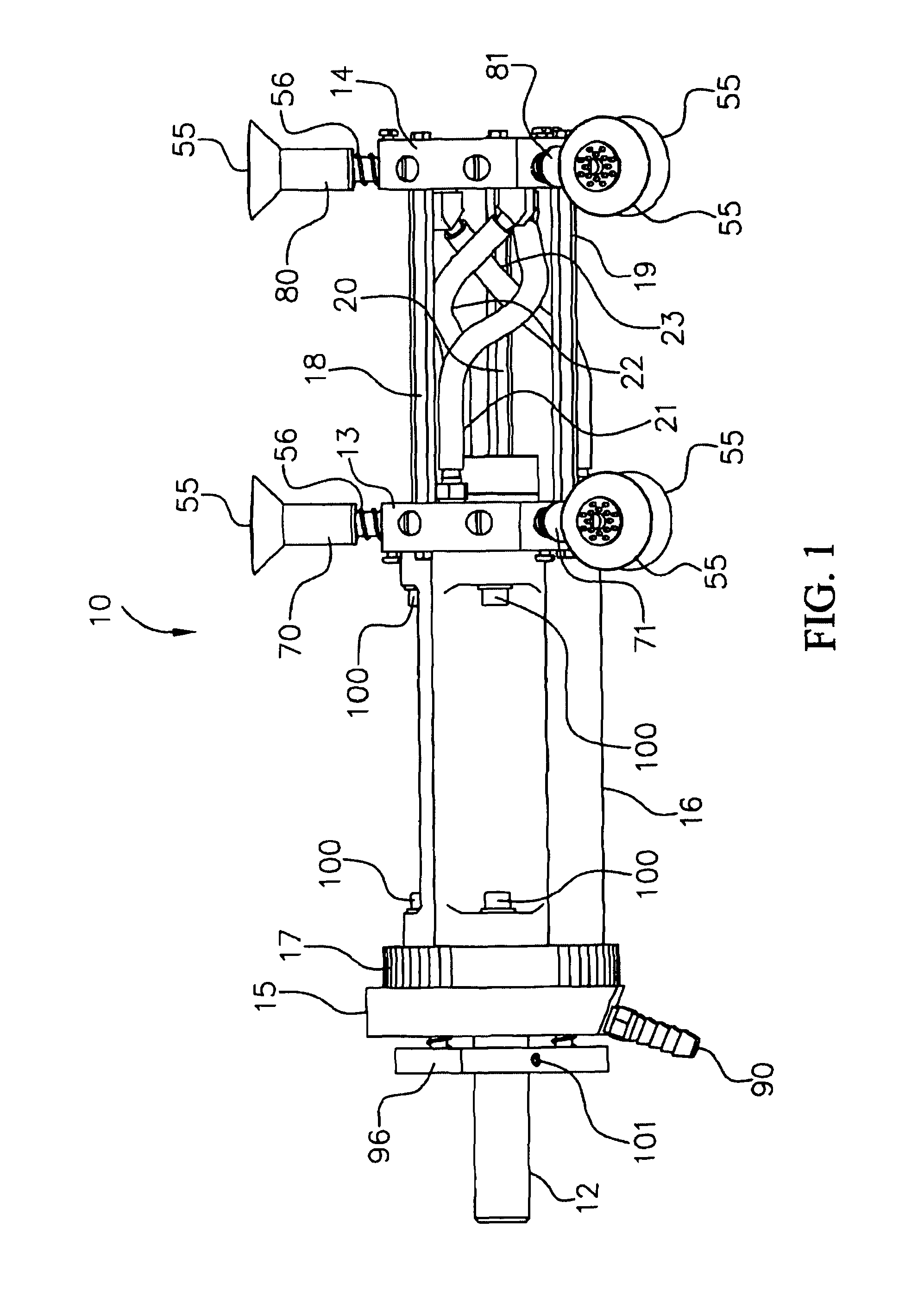

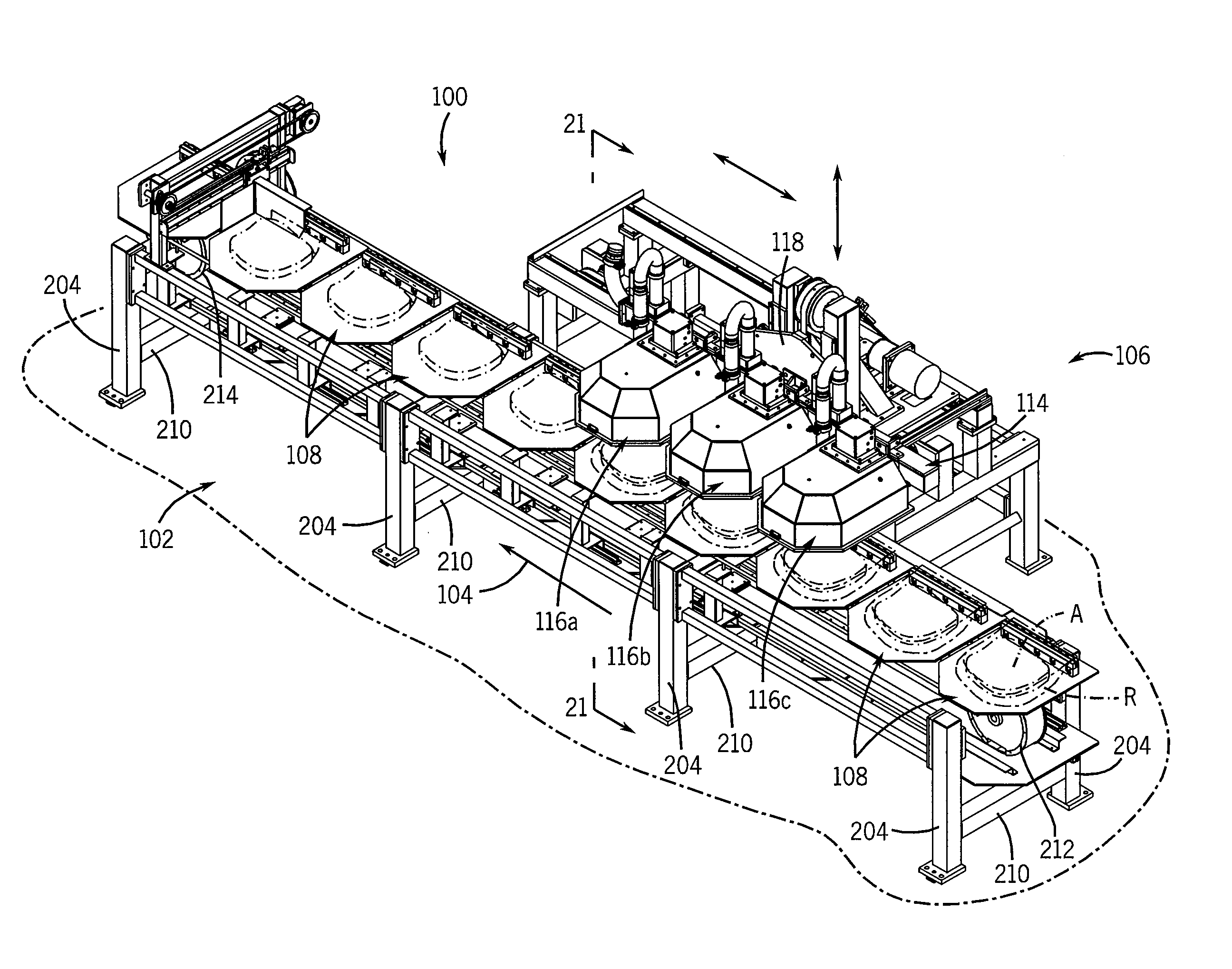

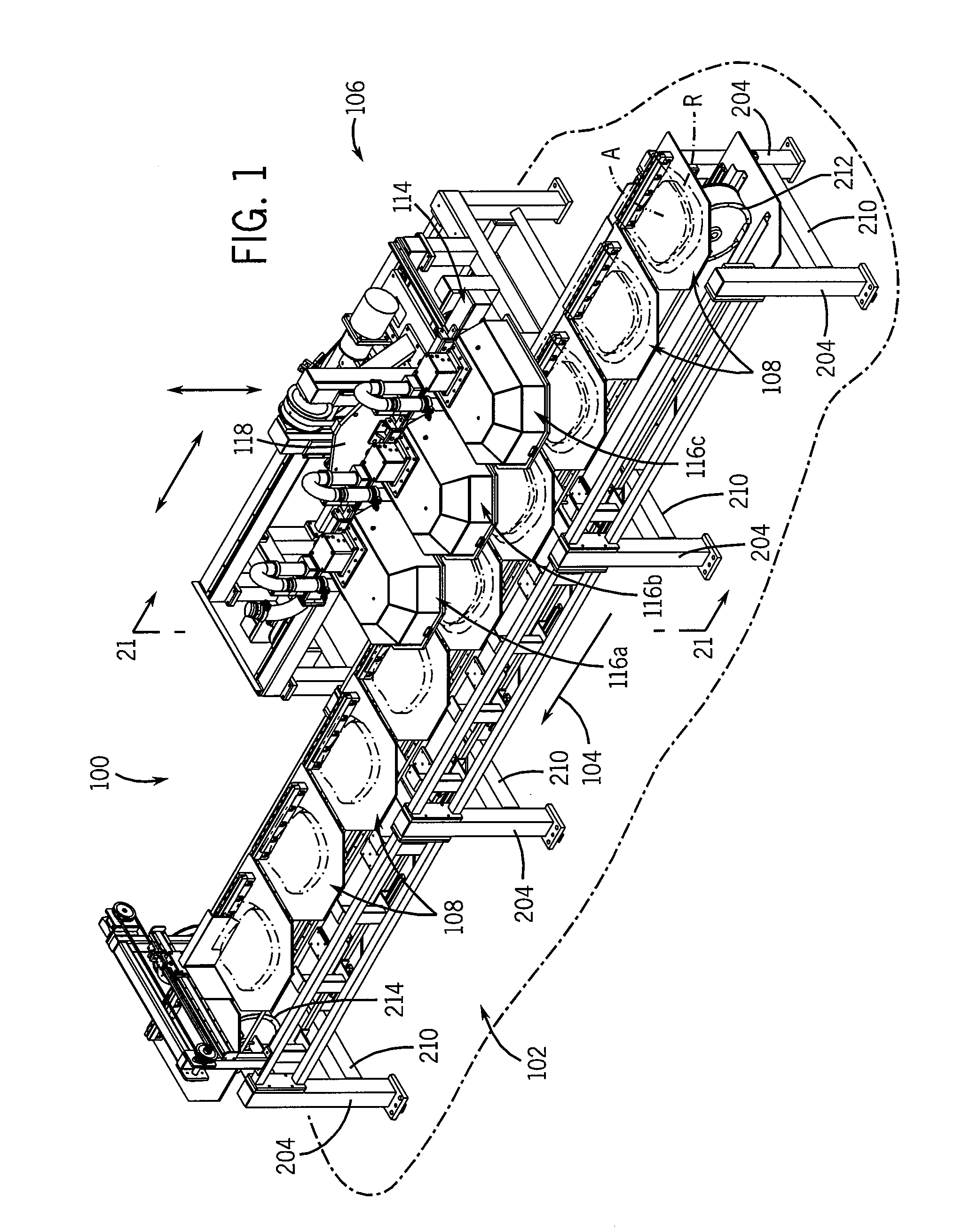

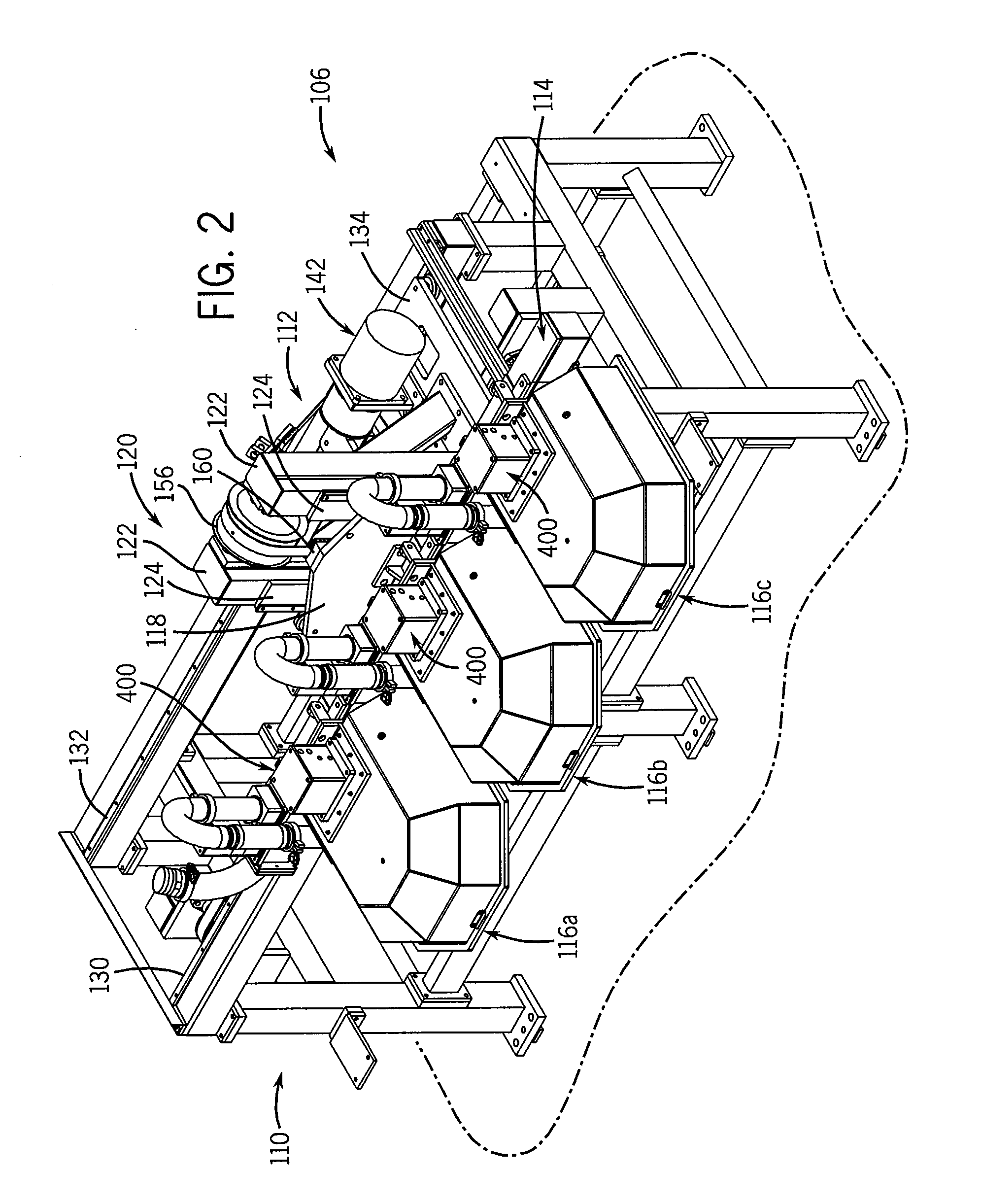

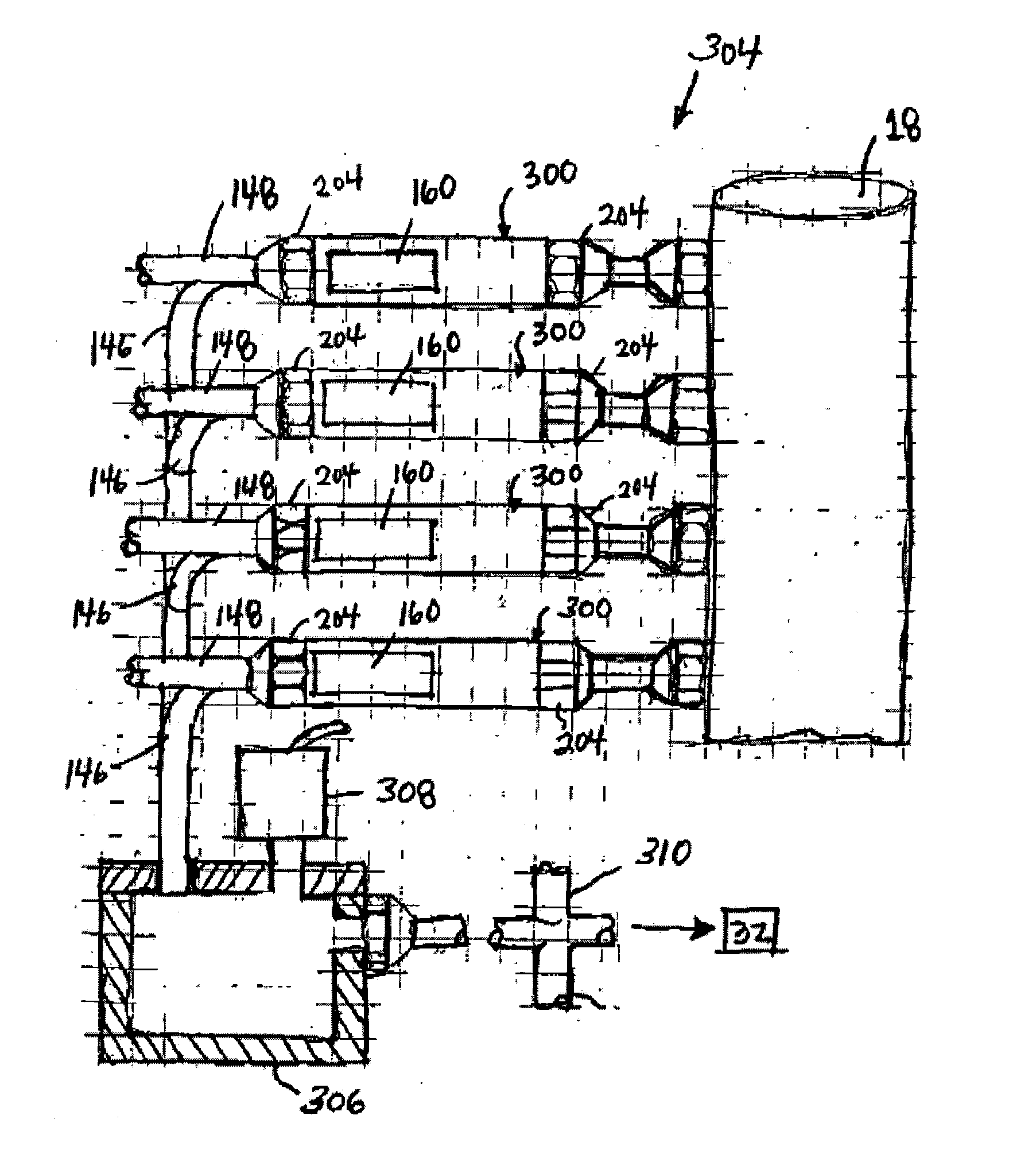

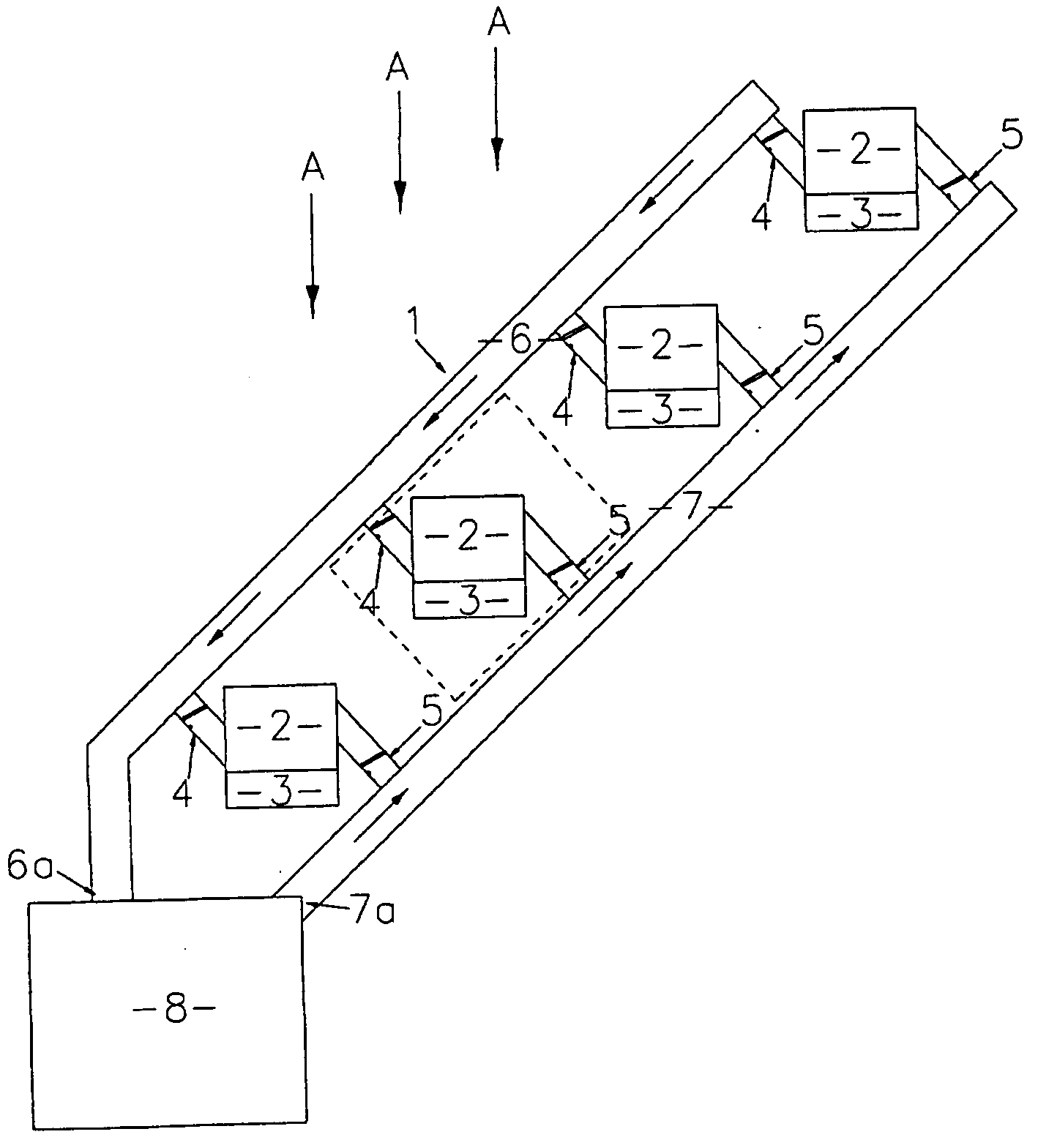

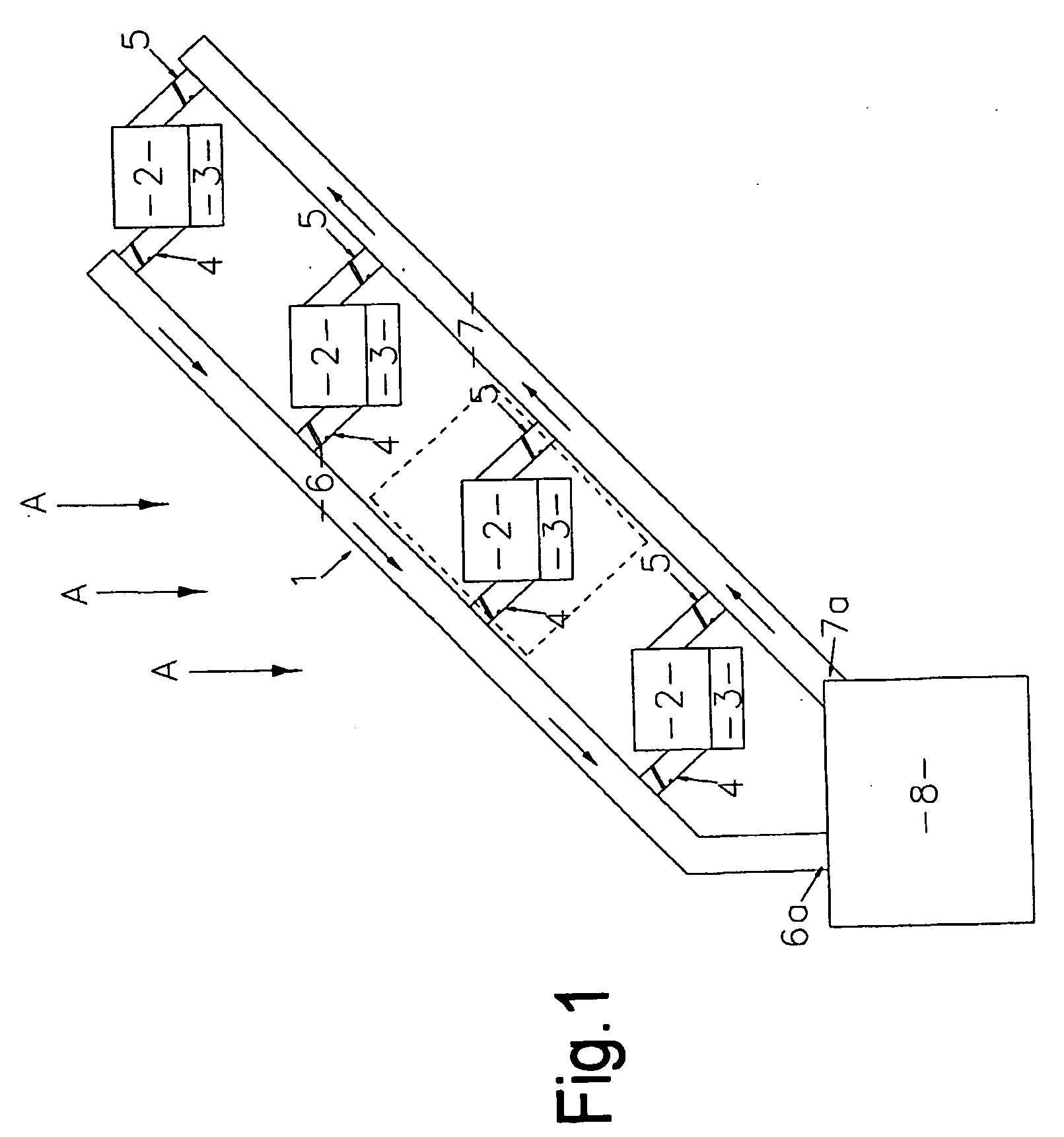

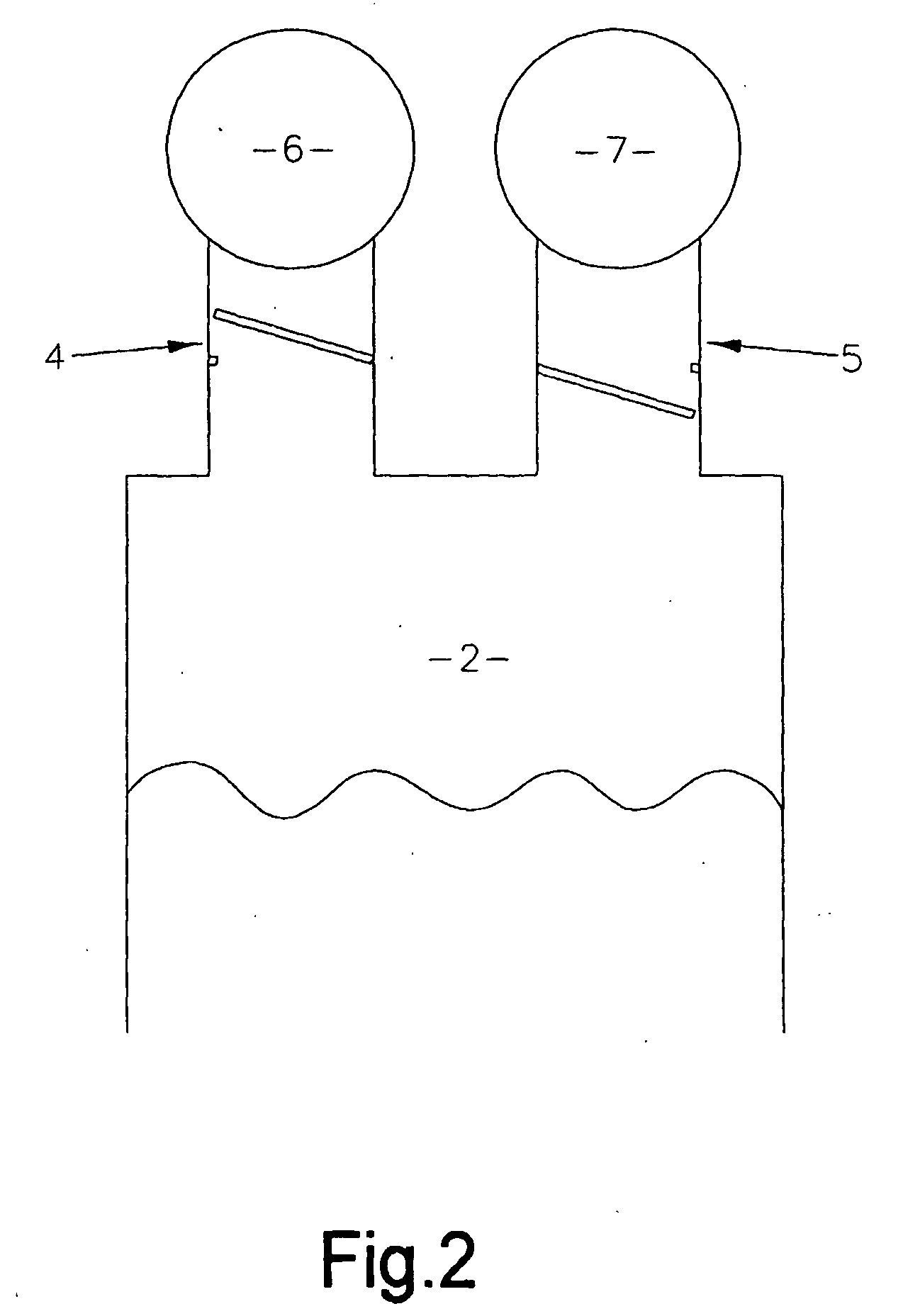

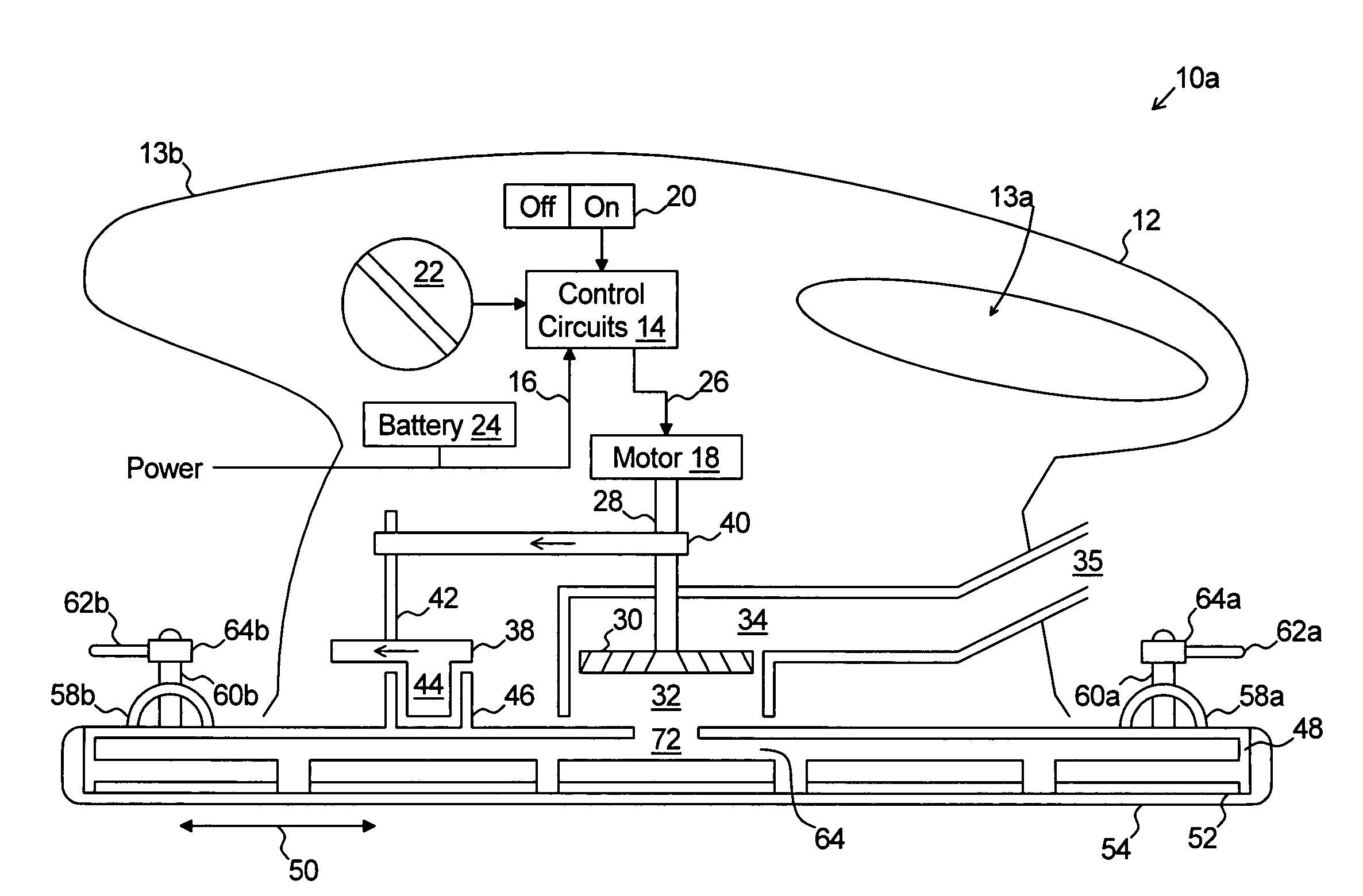

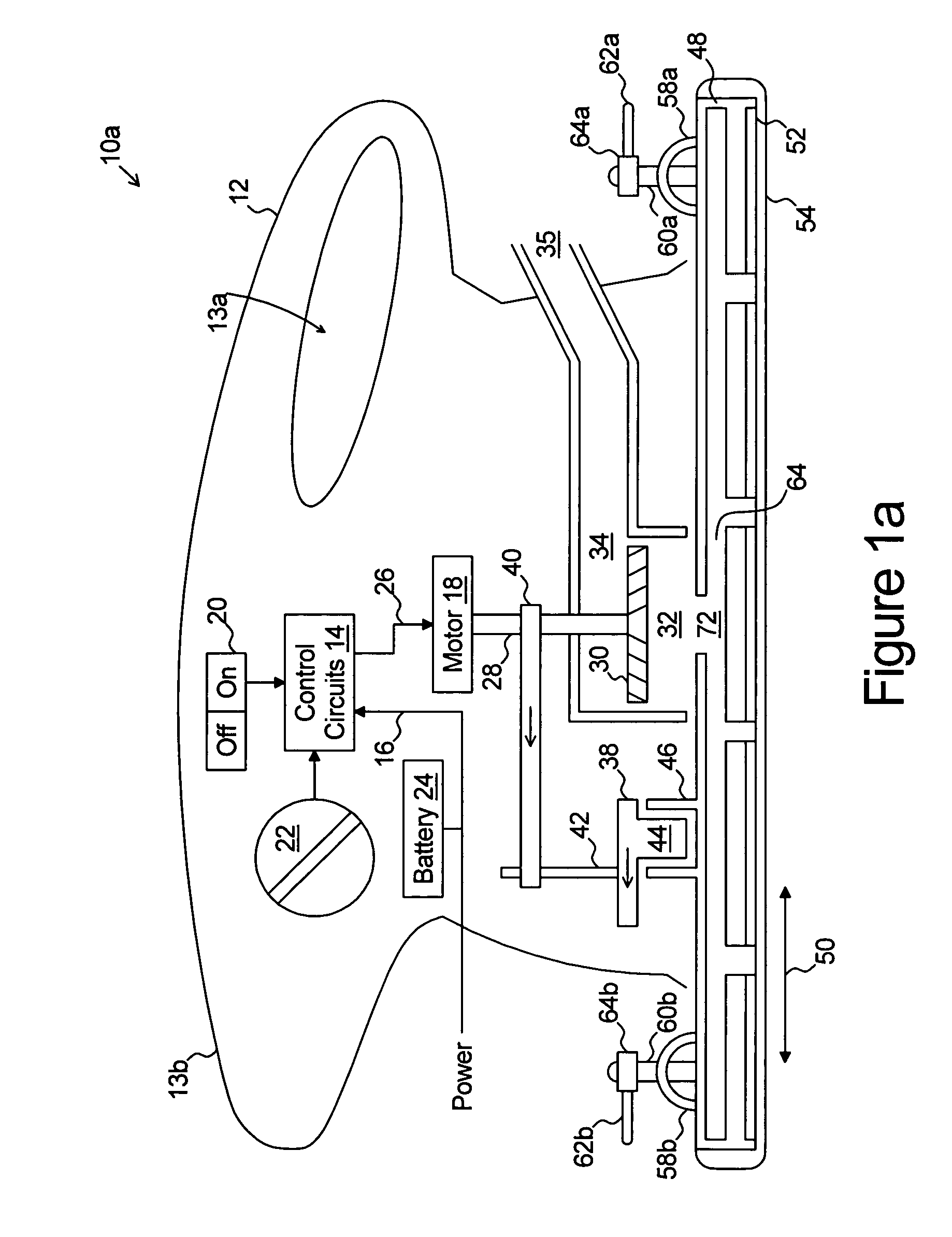

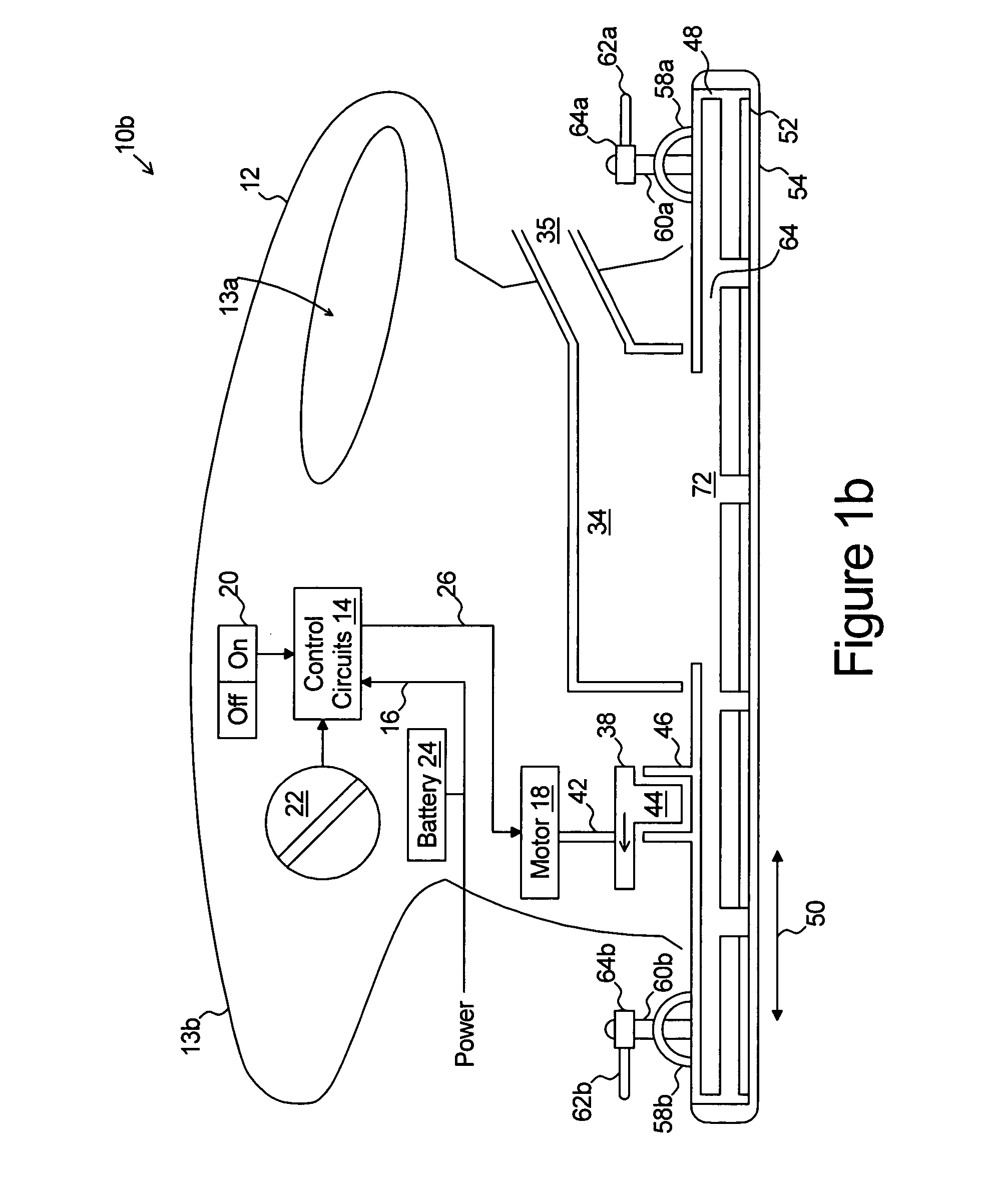

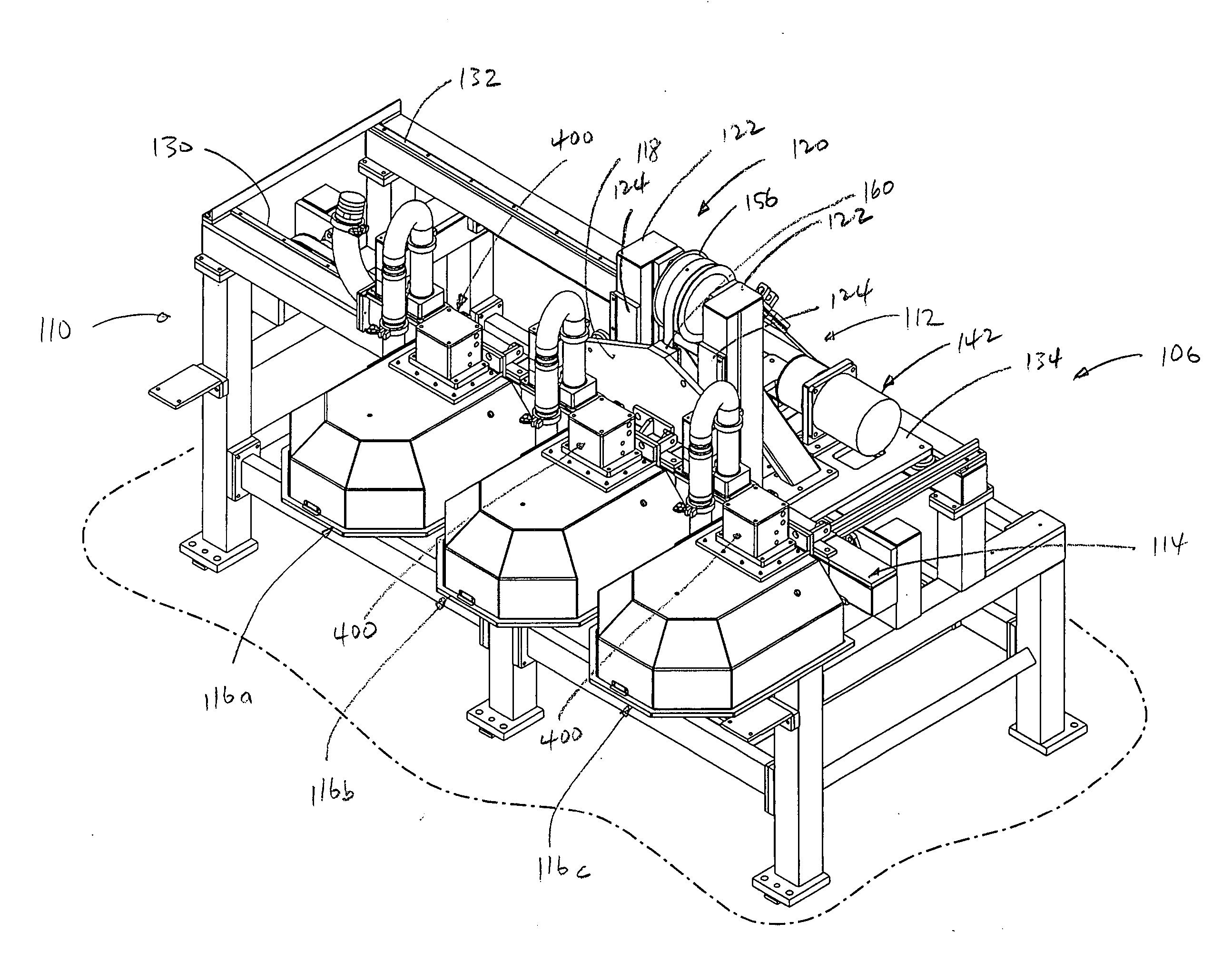

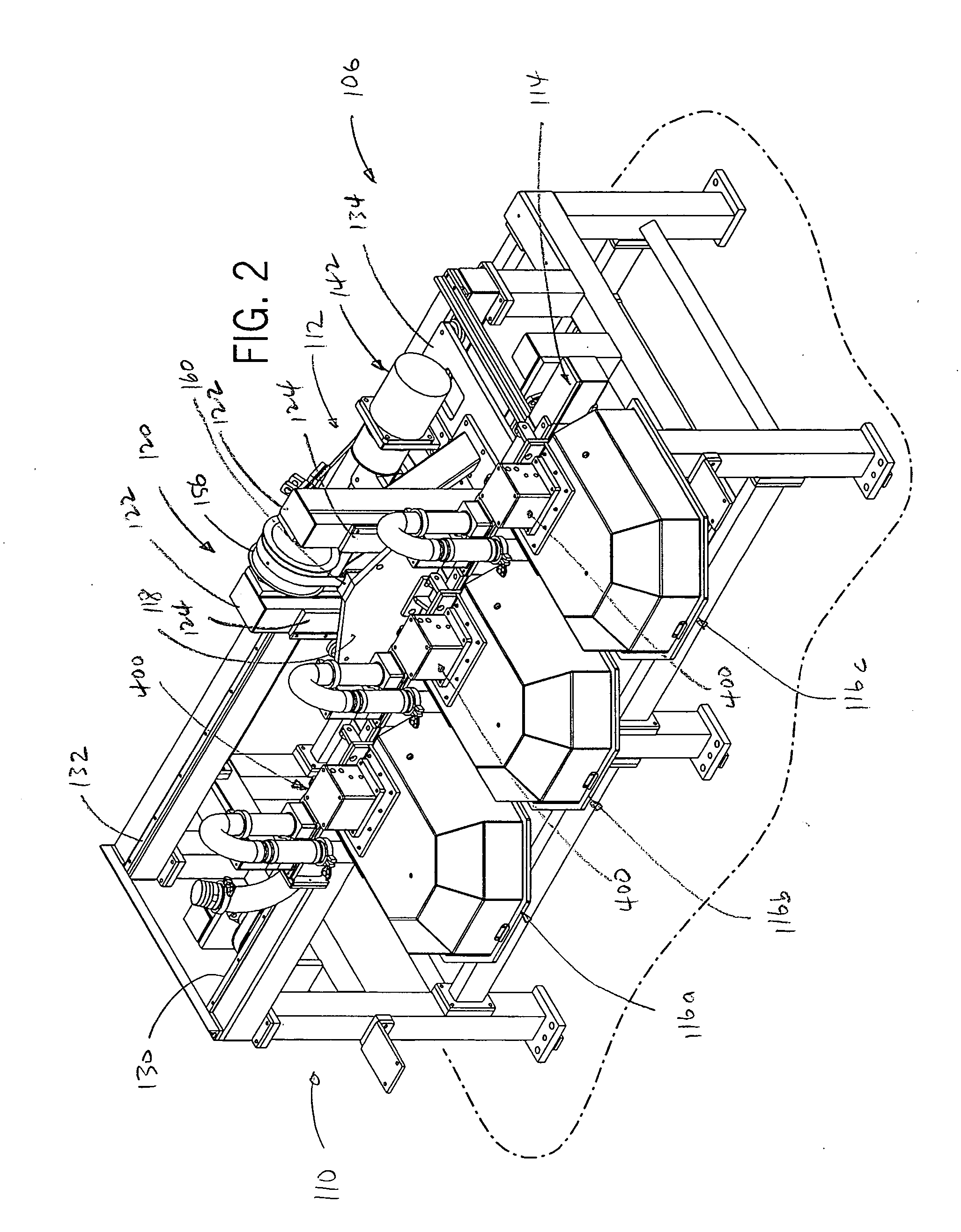

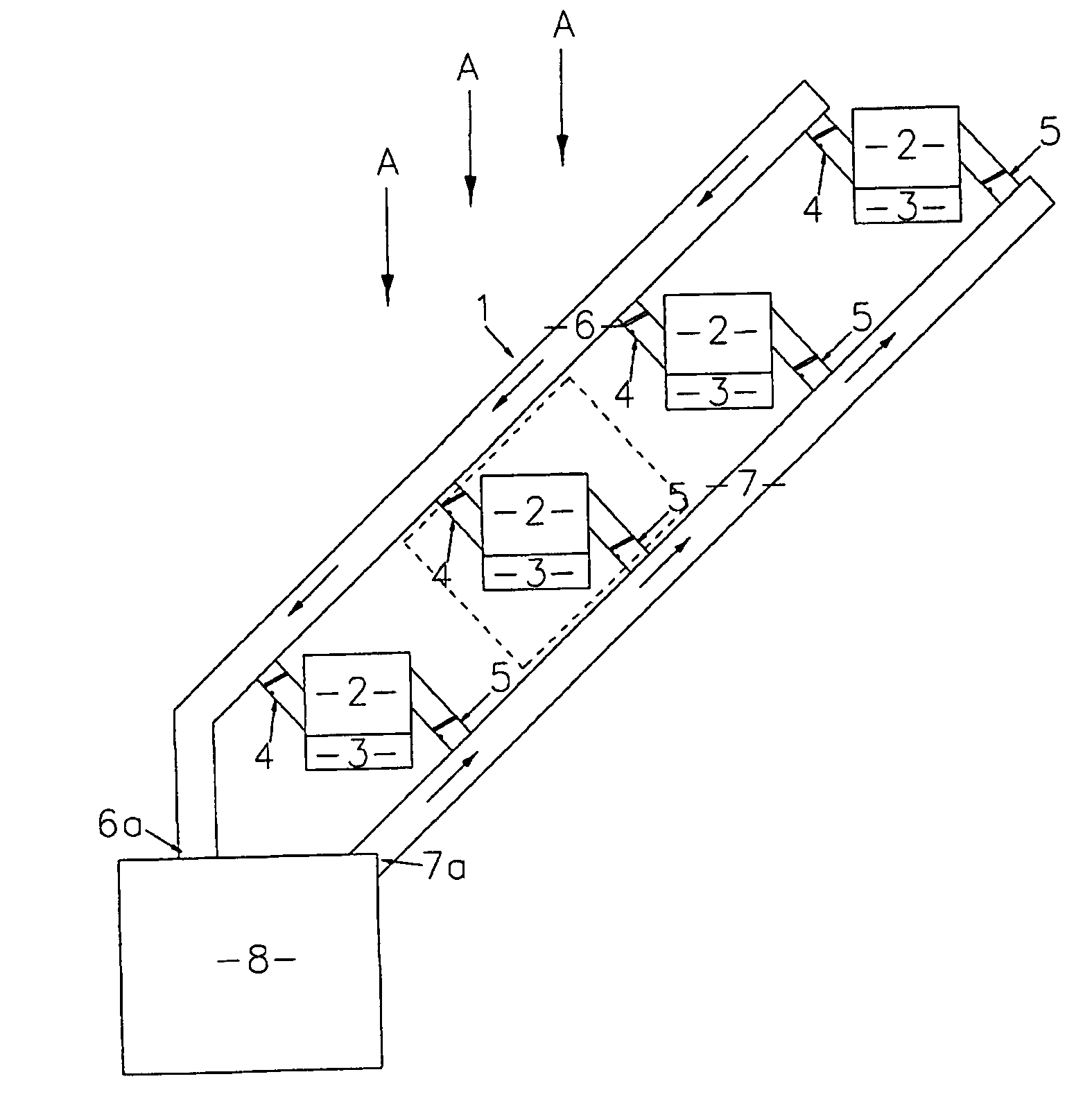

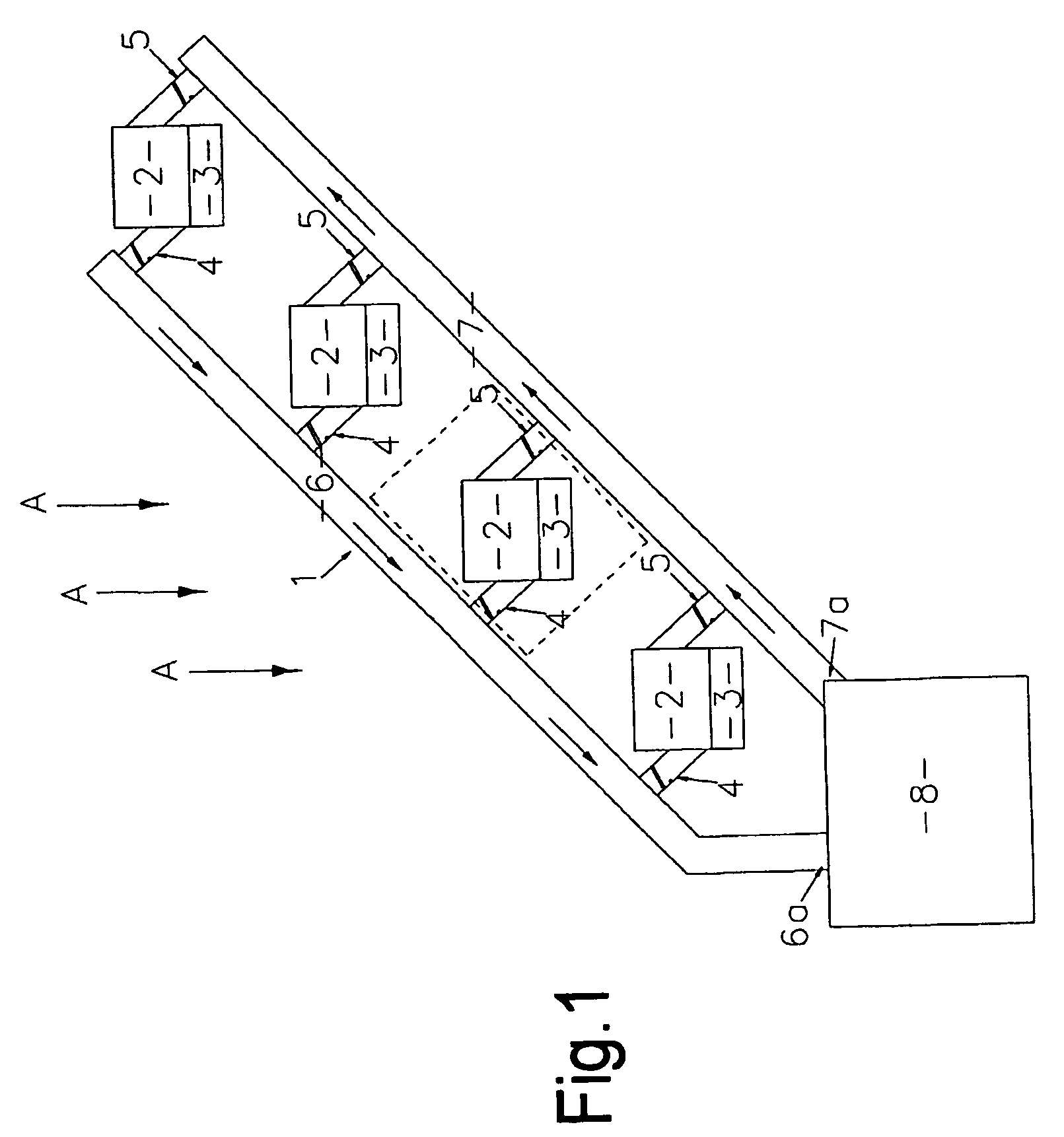

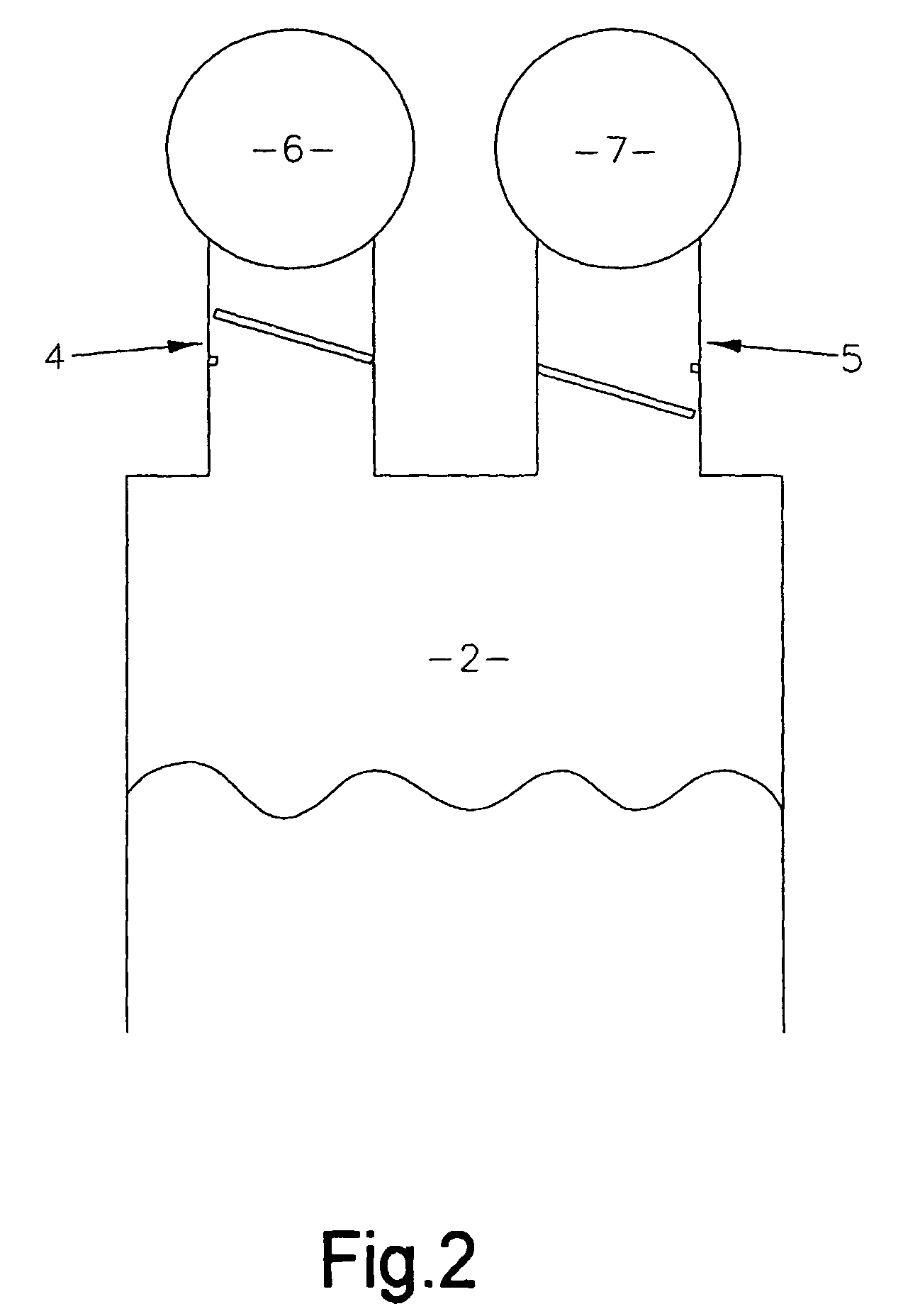

Combination vacuum manifold and support beam for a vacuum packaging system

ActiveUS7331161B2Simple actionReduce air volumePackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringGuide tube

A vacuum packaging system includes a series of vacuum chambers that are carried by a movable combination support member and vacuum manifold, which defines an interior connected to a vacuum source. The vacuum chambers are in communication with the interior of the combination support member and vacuum manifold, through vacuum valves carried by the combination support member and vacuum manifold and conduits that extend between the vacuum valves and the vacuum chambers. The combination support member and vacuum manifold is movable between a lowered position and a raised position, to move the vacuum chambers into and out of engagement with platens that support packages located below the vacuum chambers. The vacuum chambers and platens are movable in an upstream to downstream direction, to advance the packages while the packages are being evacuated by the vacuum chambers.

Owner:CP PACKAGING

Devices and methods for producing microarrays of biological samples

InactiveUS20050106621A1Bioreactor/fermenter combinationsMaterial nanotechnologyEngineeringBiological materials

The present invention is directed to systems and methods for producing microarrays of biological samples using an improved slide platform, vacuum manifold, and variable pin contact velocity. Slides onto which spotting pins produce the microarray of biological samples are secured on a flat slide platform using magnetic unit bars. The vacuum manifold effects optimal cleaning of the spotting pins by inducing increased air flow and turbulence. By reducing the velocity of the spotting pins before or after contact with the blot pad or the microarray slide, the morphology of biological samples deposited may be kept uniform. Similarly, low impact and separating velocities while acquiring biological materials prevent the pins from being overloaded with solution on the outside of the pin and causing sample wastage and non-uniform spotting.

Owner:UNIV HEALTH NETWORK

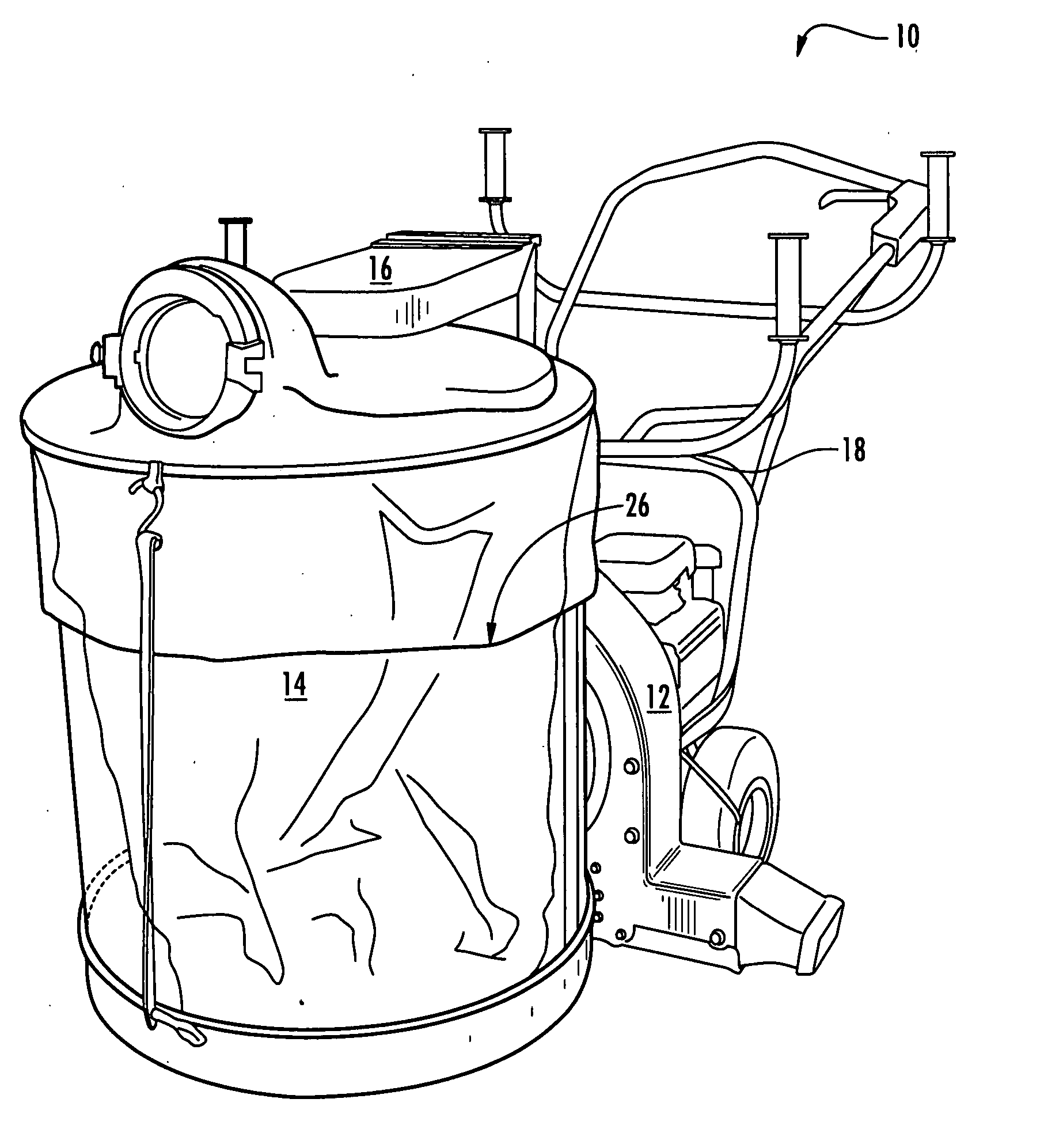

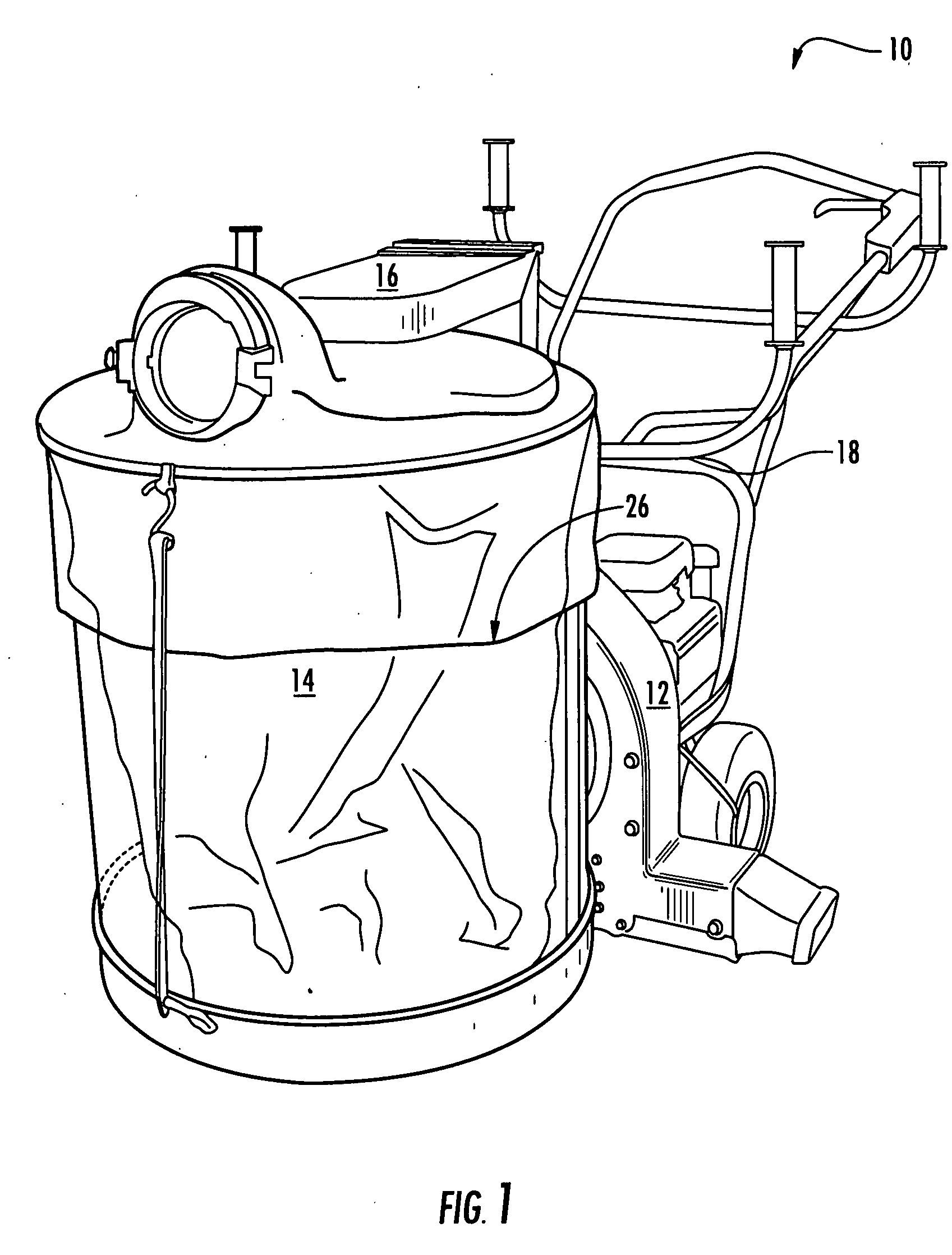

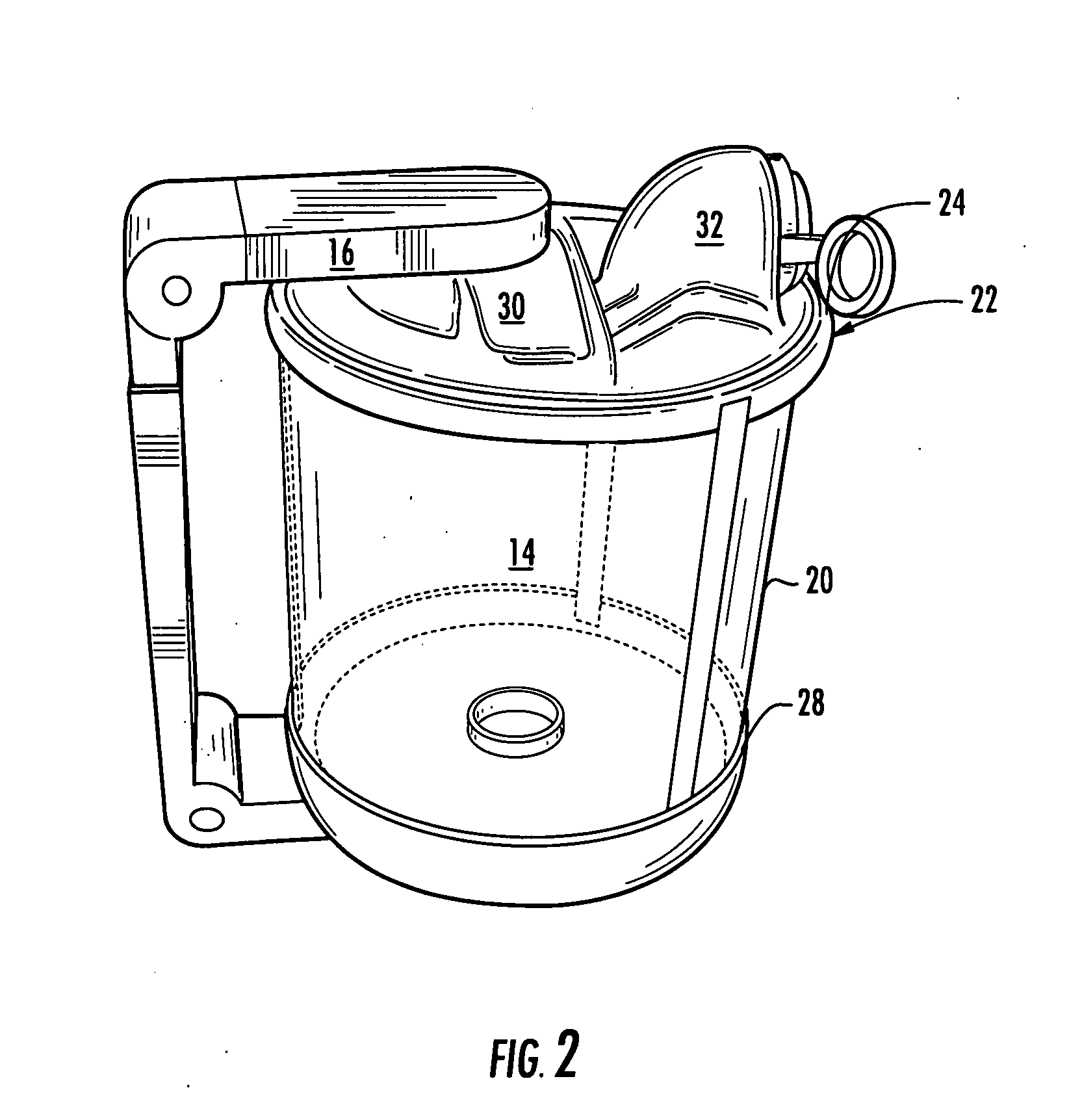

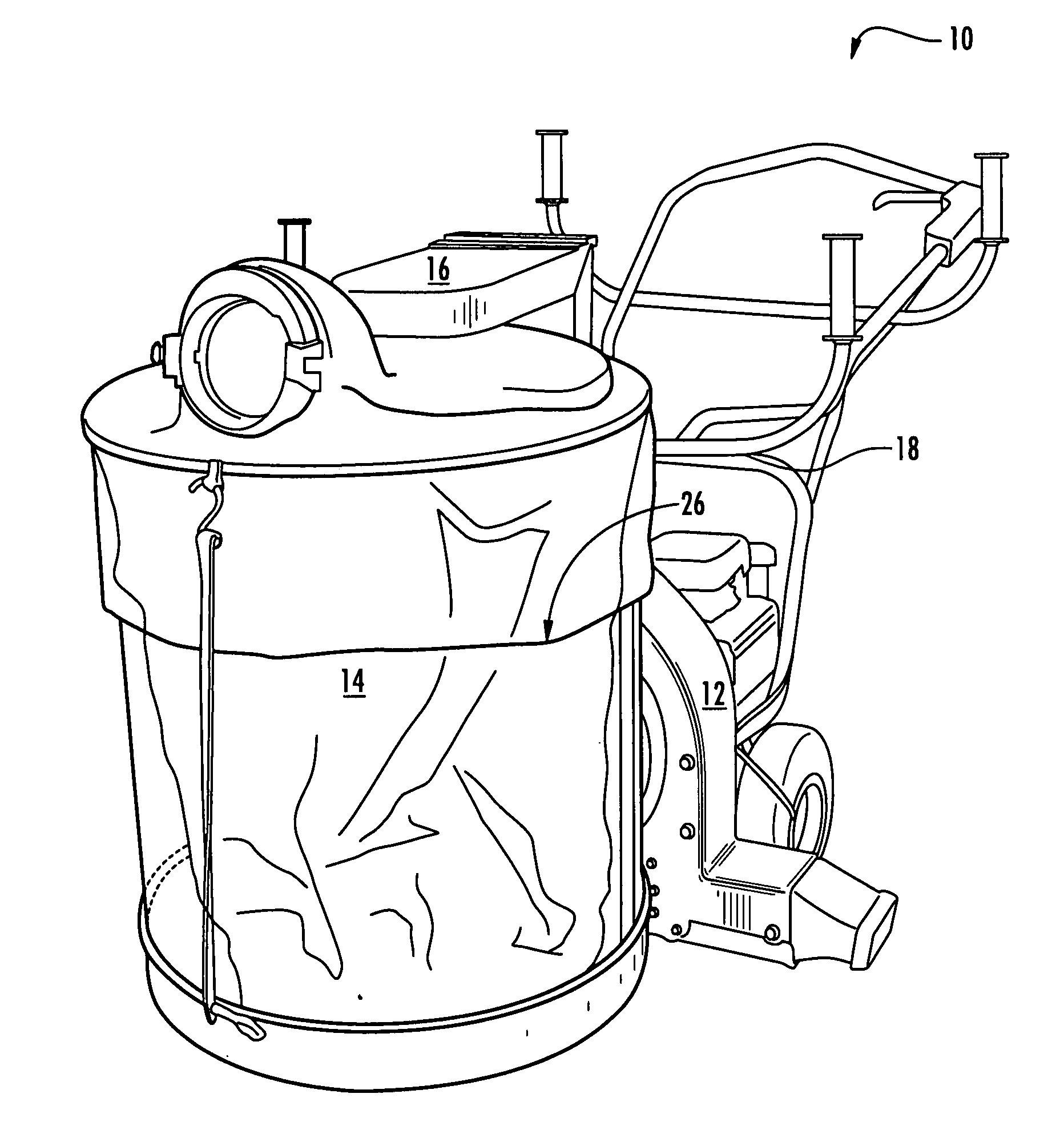

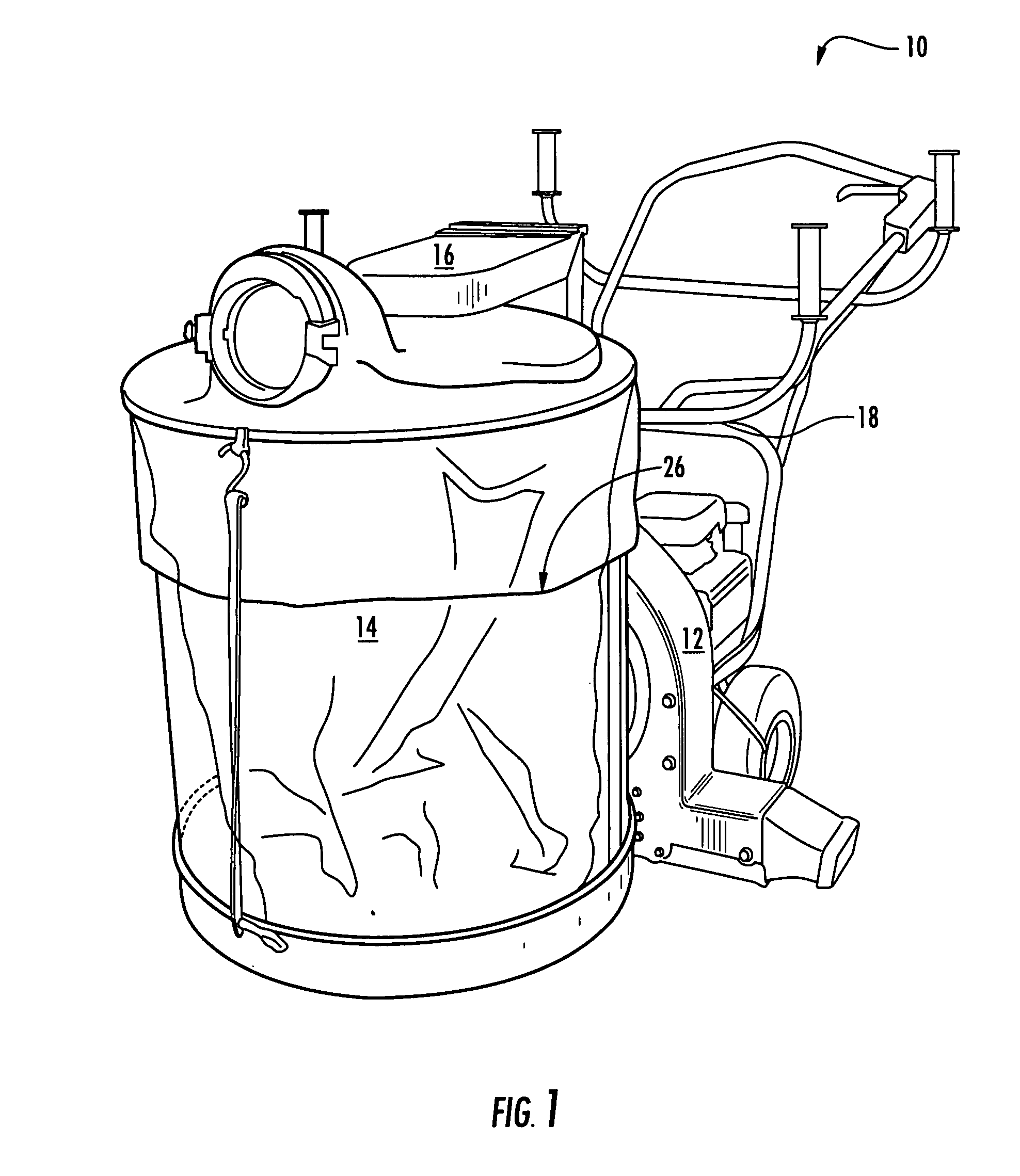

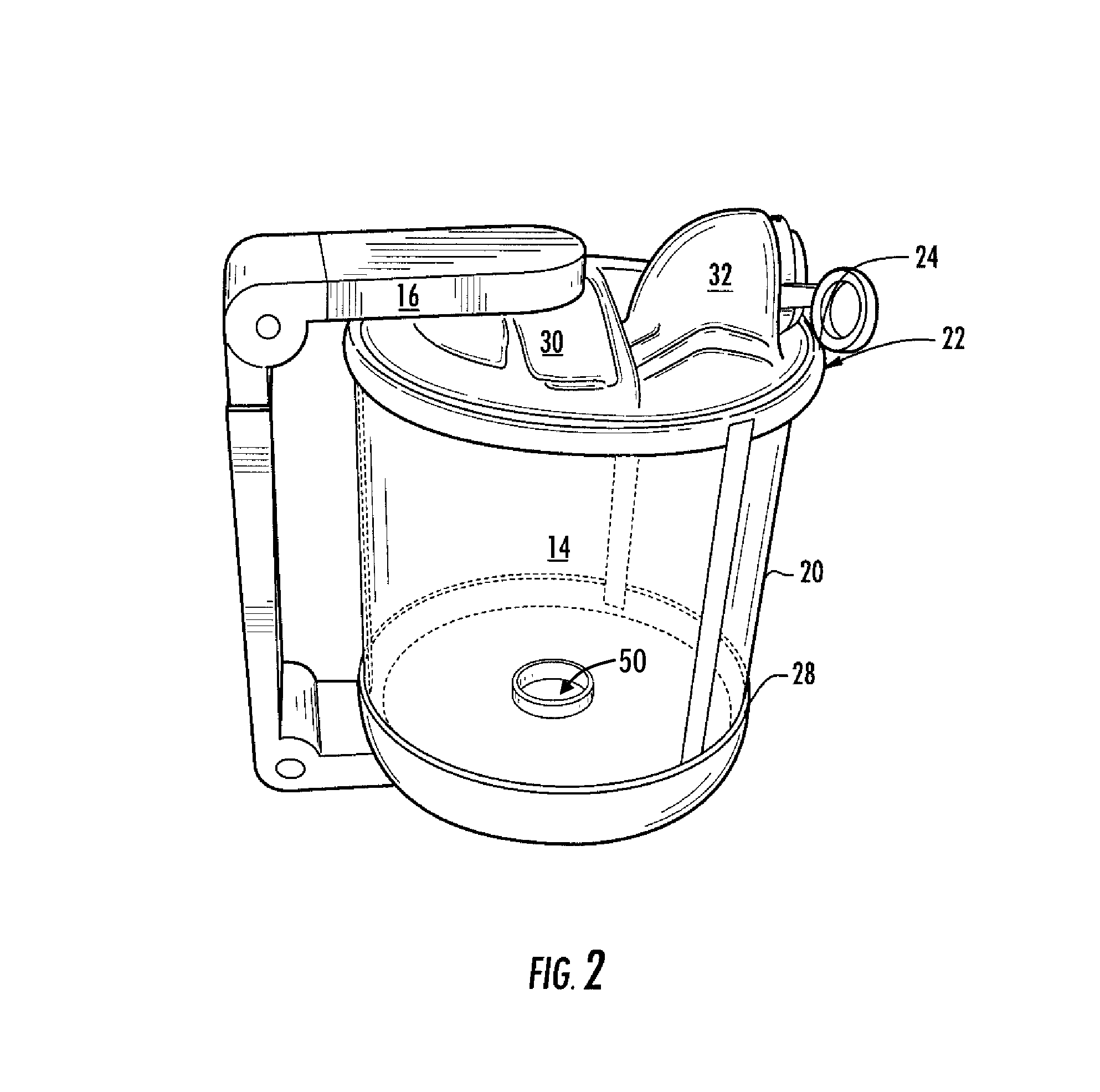

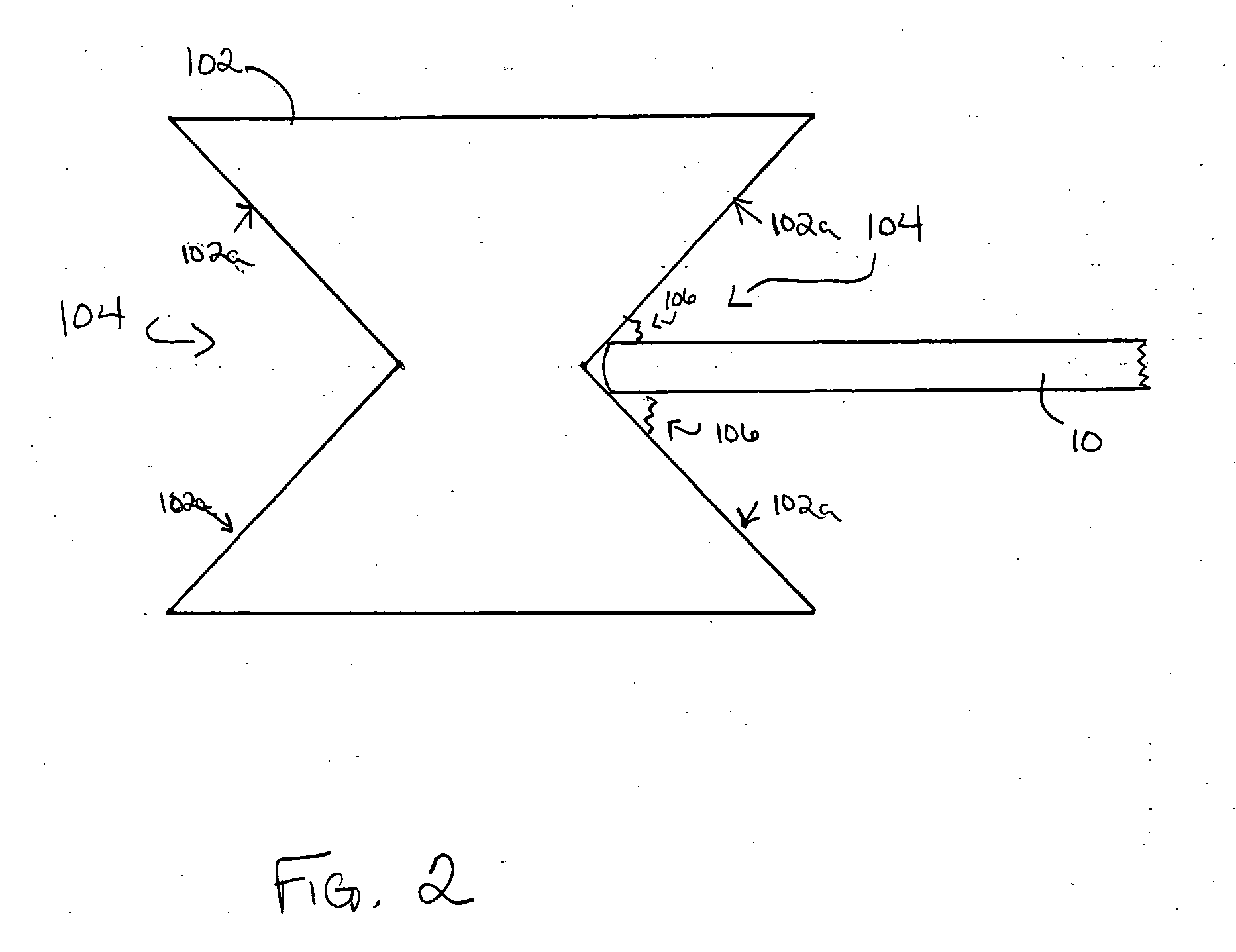

Gutter cleaning vacuum system including a novel hinged vacuum manifold assembly

InactiveUS20070226945A1Shorten the timeSufficient powerCleaning filter meansRoof coveringEngineeringHeavy duty

In various exemplary embodiments, the present invention provides a lightweight, maneuverable, thin-walled, transparent apparatus for use with a heavy-duty vacuum system for quickly and easily collecting and storing large volumes of bulky debris, thereby reducing the time needed for cleanup. The present invention also provides an improved vacuum manifold assembly that may be used in conjunction with various gas and electric blower / vacuum motors, both novel and conventional. The present invention further provides various gutter cleaning and other tools that may be used in conjunction with such a vacuum system. The gutter cleaning vacuum system including the improved hinged vacuum manifold assembly of the present invention has sufficient power and is designed such that the various gutter cleaning and other tools are effective, suction-wise, at great distances from the unit, such that an operator may use the gutter cleaning and other tools at great distances over his / her head, for example.

Owner:MCINTIRE PAUL CURTIS

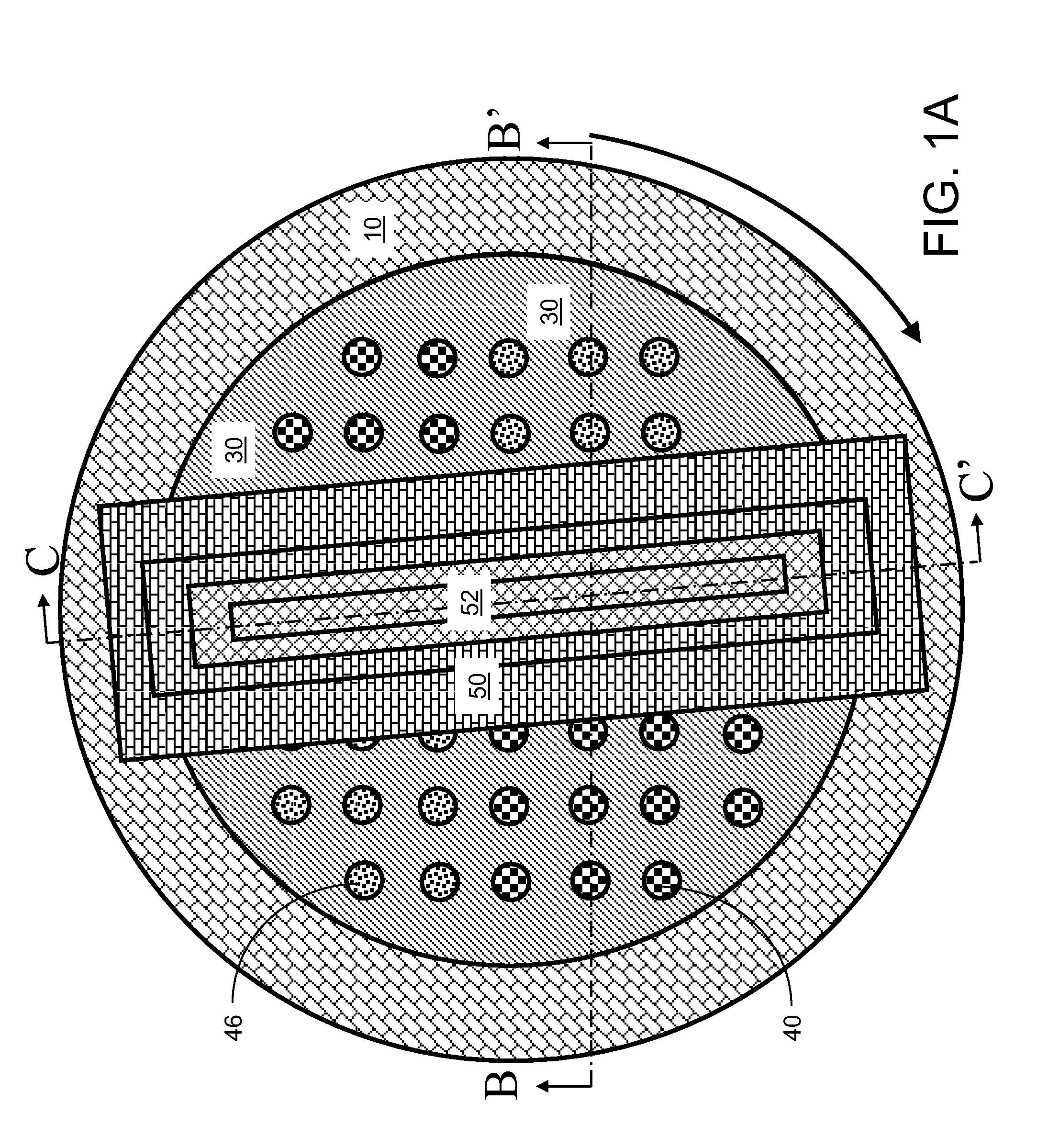

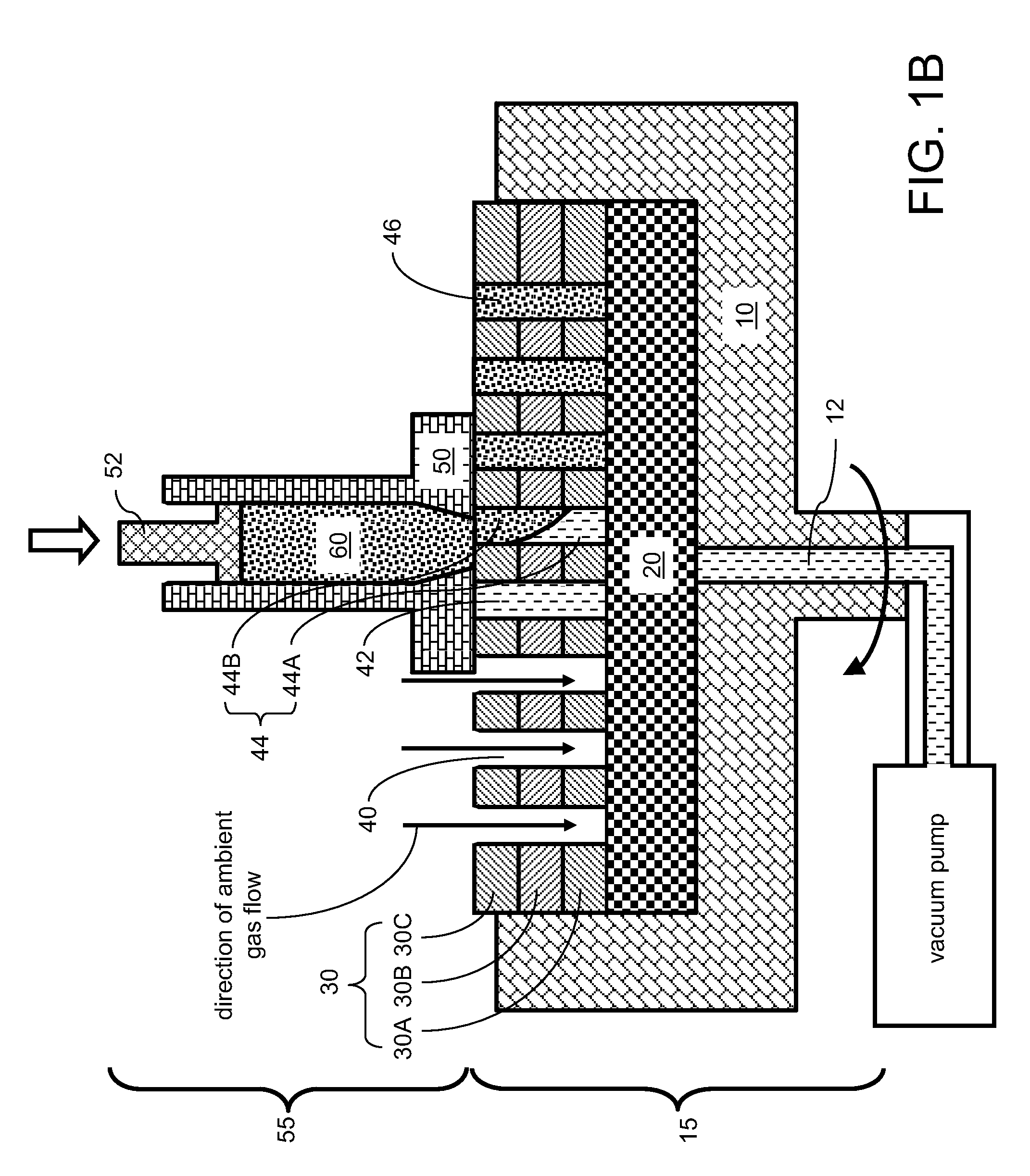

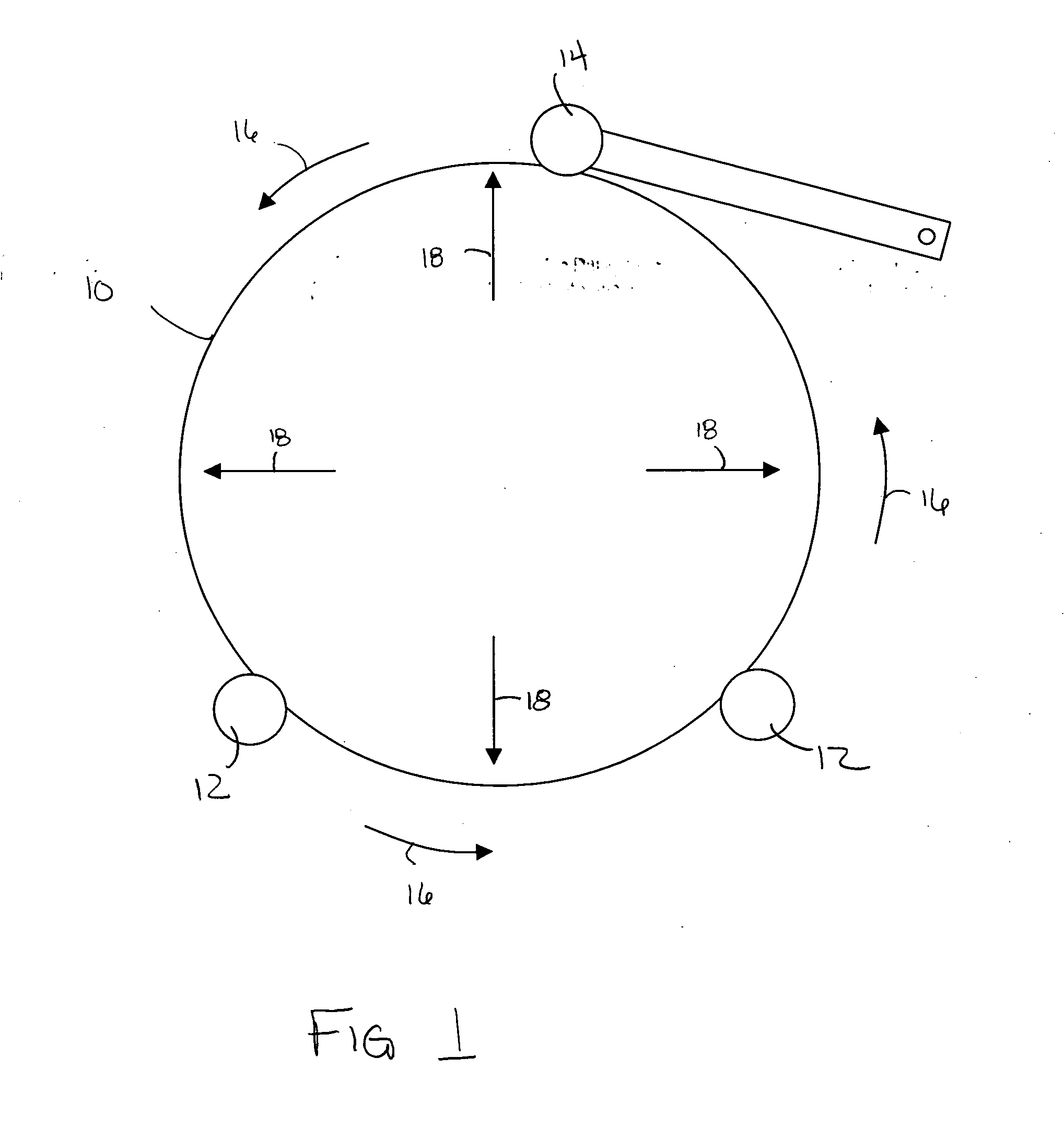

Edge wheel dry manifold

InactiveUS7350315B2Superior substrate drying.Easy to implementSemiconductor/solid-state device manufacturingDrying machines with progressive movementsEngineeringVacuum manifold

A apparatus for drying a substrate includes a vacuum manifold positioned adjacent to an edge wheel. The edge wheel includes an edge wheel groove for receiving a peripheral edge of a substrate, and the edge wheel is capable of rotating the substrate at a desired set velocity. The vacuum manifold includes a proximity end having one or more vacuum ports defined therein. The proximity end is positioned at least partially within the edge wheel groove, and using supplied vacuum removes fluids that accumulate in the edge wheel groove and prevents re-deposit of trapped fluids around the peripheral edge of the substrate.

Owner:LAM RES CORP

Gutter cleaning vacuum system including a novel hinged vacuum manifold assembly

InactiveUS7917992B2Sufficient powerQuickly and easily collecting and storing large volumesCleaning filter meansRoof coveringCombined useEngineering

In various exemplary embodiments, the present invention provides a lightweight, maneuverable, thin-walled, transparent apparatus for use with a heavy-duty vacuum system for quickly and easily collecting and storing large volumes of bulky debris, thereby reducing the time needed for cleanup. The present invention also provides an improved vacuum manifold assembly that may be used in conjunction with various gas and electric blower / vacuum motors, both novel and conventional. The present invention further provides various gutter cleaning and other tools that may be used in conjunction with such a vacuum system. The gutter cleaning vacuum system including the improved hinged vacuum manifold assembly of the present invention has sufficient power and is designed such that the various gutter cleaning and other tools are effective, suction-wise, at great distances from the unit, such that an operator may use the gutter cleaning and other tools at great distances over his / her head, for example.

Owner:MCINTIRE PAUL CURTIS

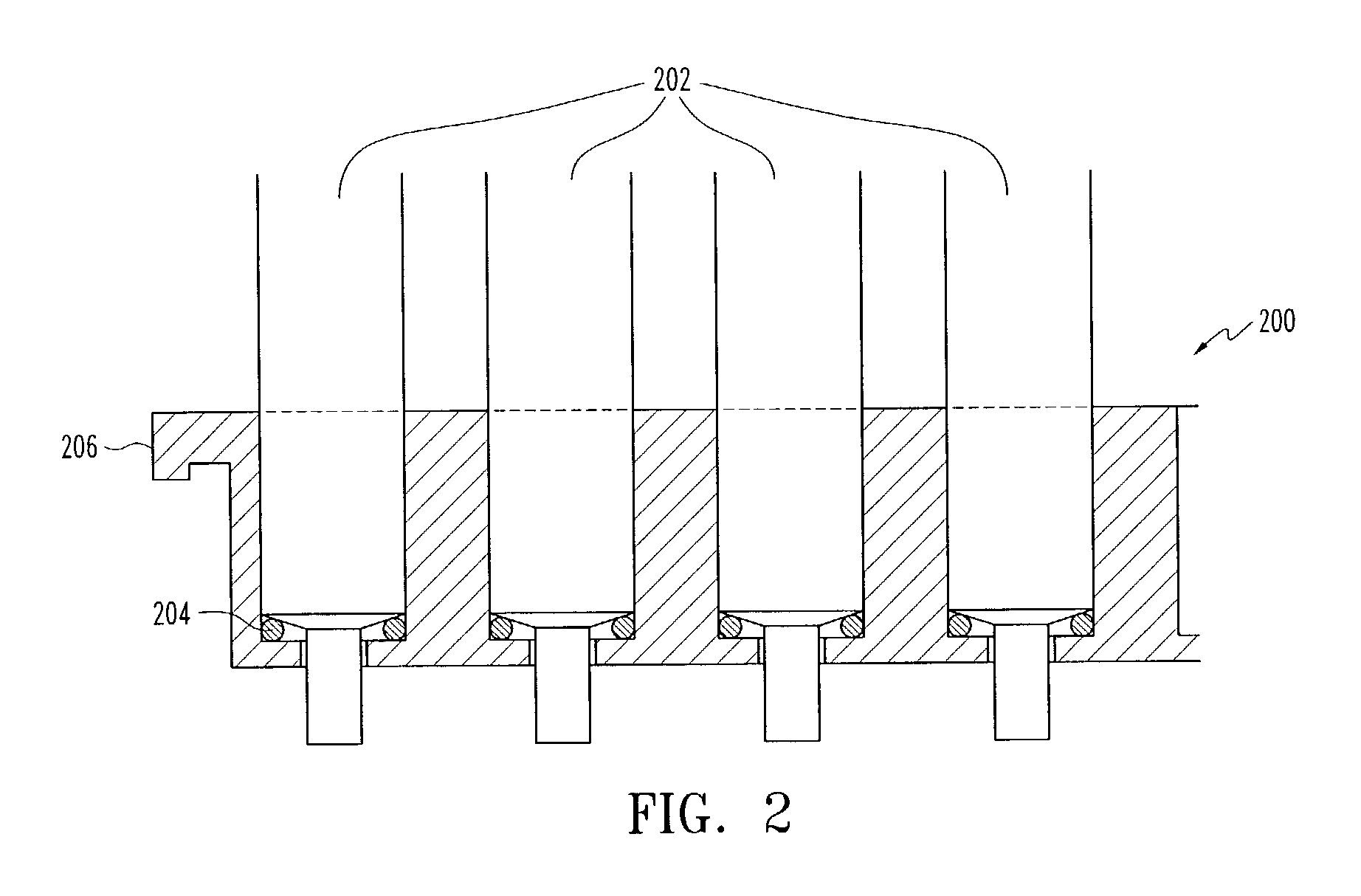

Multistack solder wafer filling

InactiveUS20120234902A1Inhibition formationWelding/cutting media/materialsMetal working apparatusEngineeringAir bubble

A plurality of through-substrate holes is formed in each of at least one substrate. Each through-substrate hole extends from a top surface of the at least one substrate to the bottom surface of the at least one substrate. The at least one substrate is held by a stationary chuck or a rotating chuck. Vacuum suction is provided to a set of through-substrate holes among the plurality of through-substrate holes through a vacuum manifold attached to the bottom surface of the at least one substrate. An injection mold solder head located above the top surface of the at least one substrate injects a solder material into the set of through-substrate holes to form a plurality of through-substrate solders that extend from the top surface to the bottom surface of the at least one substrate. The vacuum suction prevents formation of air bubbles or incomplete filling in the plurality of through-substrate holes.

Owner:IBM CORP

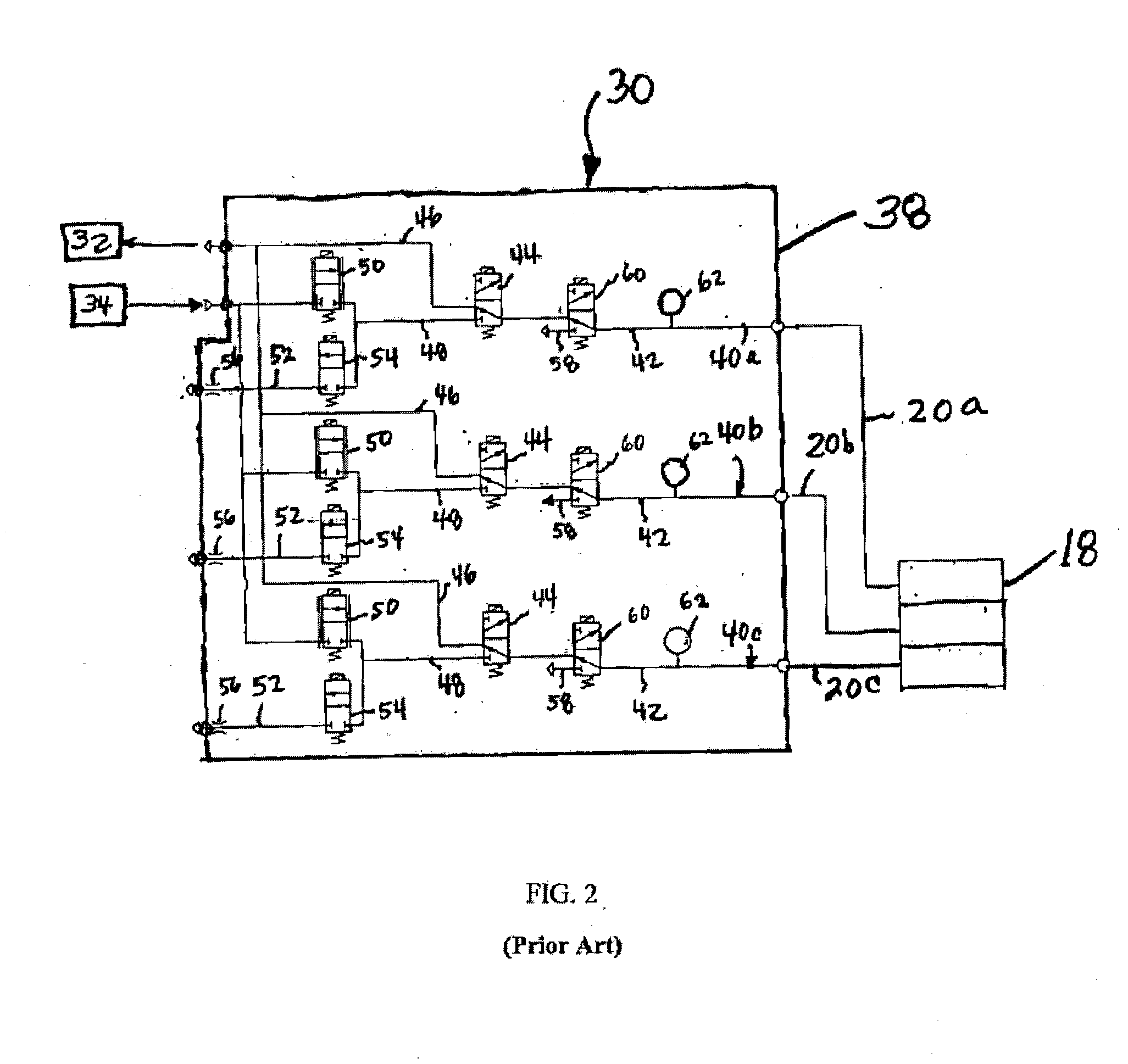

Method for protecting a pneumatic control system from ingested contamination

InactiveUS20040250859A1Valve arrangementsSemiconductor/solid-state device manufacturingControl systemControl line

A pneumatic control system including at least one flow control line having a connecting line connectable to a fluid line of a pneumatically operated machine, a vacuum line connectable to a vacuum source, a vacuum valve controlling flow between the connecting line and the vacuum line, a pressure line connectable to a source of fluid under pressure, and a pressure valve controlling flow between the connecting line and the pressure line. A pressure manifold defines the pressure line and a first portion of the connection line, and supports the pressure valve, and a vacuum manifold defines the vacuum line and a second portion of the connecting line, and supports the vacuum valve. The vacuum manifold is adapted for replacement independently of the pressure manifold.

Owner:MKS INSTR INC

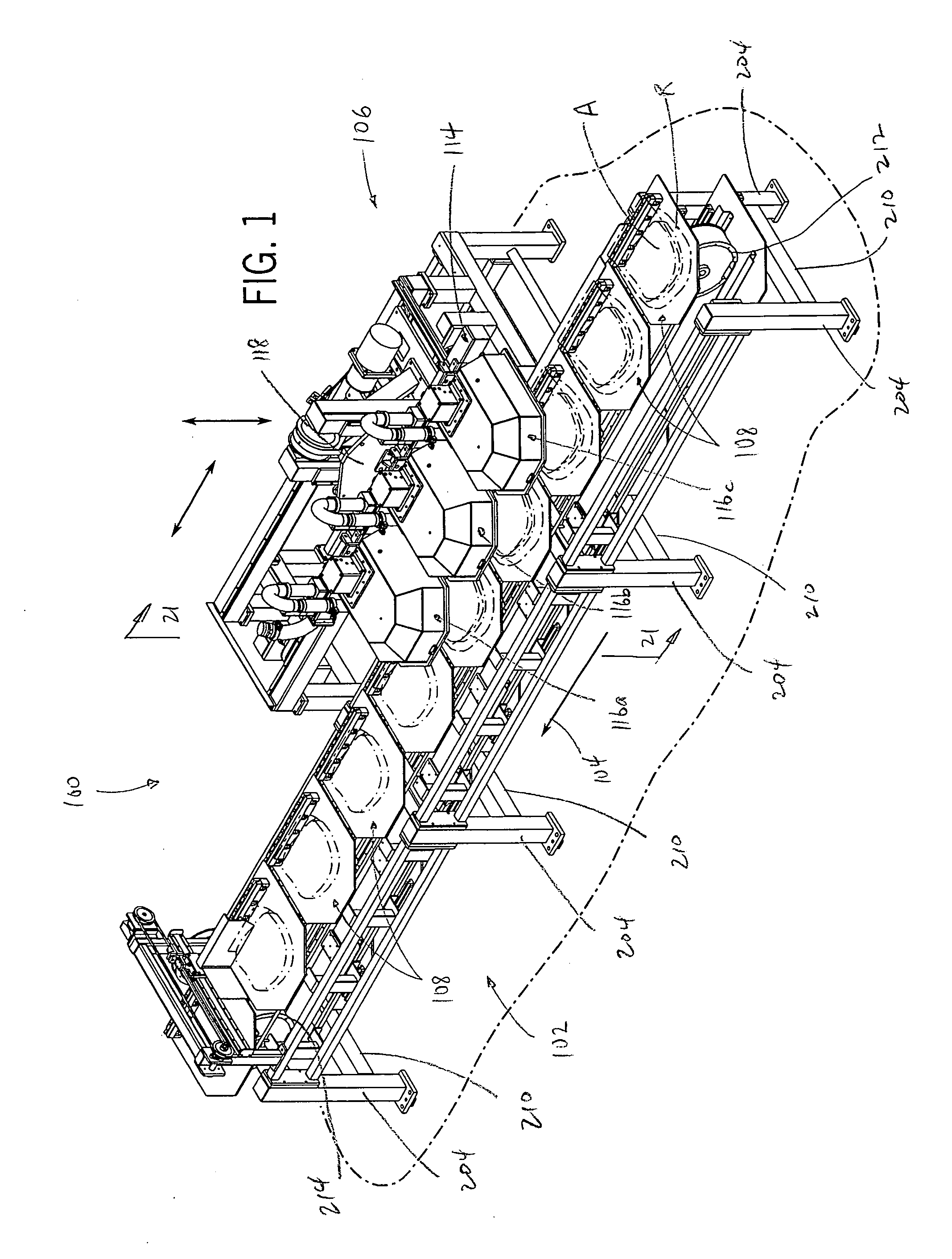

Modular Near-Shore Wave-Powerd Energy Collection System

InactiveUS20090001729A1Easy to installEasy maintenanceWater-power plantsPiston pumpsCollection systemComputer module

A modular near-shore wave-powered energy collection system, which includes a plurality of connected modules, each module including at least one flotation device and at least one OWC, wherein each OWC is connected to a common pressure manifold and a common vacuum manifold and the common pressure manifold and the common vacuum manifold are connectable to a device.

Owner:WAVE POWER SOUTH

Joint compound sander

A joint compound sanding device (10) comprises a hand held housing (12) and a bottom plate (66) coupled to the hand held housing (12). The bottom plate (66) includes a plurality of dust collection apertures (74) extending through the bottom plate (66) between a vacuum manifold (64) and a bottom surface (76). A plurality of dust collection channels (78) are formed in the bottom surface (76) defining mesas (80) there between. The mesas support a porous joint compound sanding screen (54). A motor is coupled to hand held housing (12) and includes a rotating shaft coupled and rotating to a dust collection fan (30) such that air is drawn through a porous joint compound sanding screen (54), through the channels (78), through the dust collection apertures (74) into the vacuum manifold (64) and through the fan inlet (32) and expelling the air into an exhaust manifold (34).

Owner:WATSON ADAM DEWAIN

Package Pick-Off and Delivery Device

ActiveUS20090256371A1Gripping headsPackaging under special atmospheric conditionsVacuum pressureEngineering

The present invention is directed to an article-handling device for the pickup, transfer and deposit of articles. The article-handling device includes a means of rotation, a vacuum conduit, and a first vacuum manifold, each rotatably mounted onto a stationary support shaft. The device further includes a second vacuum manifold affixed to the first vacuum manifold and a non-rotatable control valve which is operational synchronized with the rotation means to provide both vacuum pressure and atmospheric pressure independently to each of the first and second vacuum manifolds. Each of the vacuum manifolds comprises one or more tubular suction shafts each having a suction cup affixed thereto. The suction shafts of each vacuum manifold are spatially arranged such that at least a first suction shaft of the first vacuum manifold is substantially parallel to a first suction shaft of the second vacuum manifold thereby enabling the suction shafts to function as a paired unit. In this way, at least the first suction shaft of said first vacuum manifold and the first suction shaft of said second vacuum manifold are each independently adapted to attract and hold said article when the first and second vacuum manifolds are operationally connected with said vacuum pressure and release said article when the first and second vacuum manifolds are operationally connected with said atmosphere pressure.

Owner:BEMIS COMPANY INC

Combination vacuum manifold and support beam for a vacuum packaging system

ActiveUS20060096247A1Simple actionReduce air volumePackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringVacuum chamber

A vacuum packaging system includes a series of vacuum chambers that are carried by a movable combination support member and vacuum manifold, which defines an interior connected to a vacuum source. The vacuum chambers are in communication with the interior of the combination support member and vacuum manifold, through vacuum valves carried by the combination support member and vacuum manifold and conduits that extend between the vacuum valves and the vacuum chambers. The combination support member and vacuum manifold is movable between a lowered position and a raised position, to move the vacuum chambers into and out of engagement with platens that support packages located below the vacuum chambers. The vacuum chambers and platens are movable in an upstream to downstream direction, to advance the packages while the packages are being evacuated by the vacuum chambers.

Owner:CP PACKAGING

Apparatus for simultaneous processing of multiple samples

ActiveUS7438862B2Simple gravity filtrationBioreactor/fermenter combinationsBiological substance pretreatmentsPositive pressureCombined use

An apparatus is provided for simultaneous processing of multiple fluid samples. The apparatus comprises a multiple well plate for holding a plurality of sample reservoirs for simultaneous processing of multiple samples. The wells are configured in the plate in staggered rows. The well plate is dimensioned to be compatible with a vacuum manifold or positive pressure system either as a stand-alone unit or in conjunction with a separate fluid handling system. The apparatus may further comprise a sample collection plate having the same number of wells as the multiple well plate. The wells in the samples collection plate are arranged in the same staggered configuration as the wells in the well plate and are sized for holding sample collection vials. When the well plate and sample collection plate are assembled in a manifold, the vials in the sample collection plated are aligned directly beneath the sample exits of corresponding sample reservoirs in the well plate.

Owner:UNITED CHEM TECH

Modular near-shore wave-powered energy collection system

InactiveUS7554216B2Easy to installEasy maintenancePiston pumpsEngine componentsCollection systemEngineering

A modular near-shore wave-powered energy collection system, which includes a plurality of connected modules, each module including at least one flotation device and at least one OWC, wherein each OWC is connected to a common pressure manifold and a common vacuum manifold and the common pressure manifold and the common vacuum manifold are connectable to a device.

Owner:WAVE POWER SOUTH

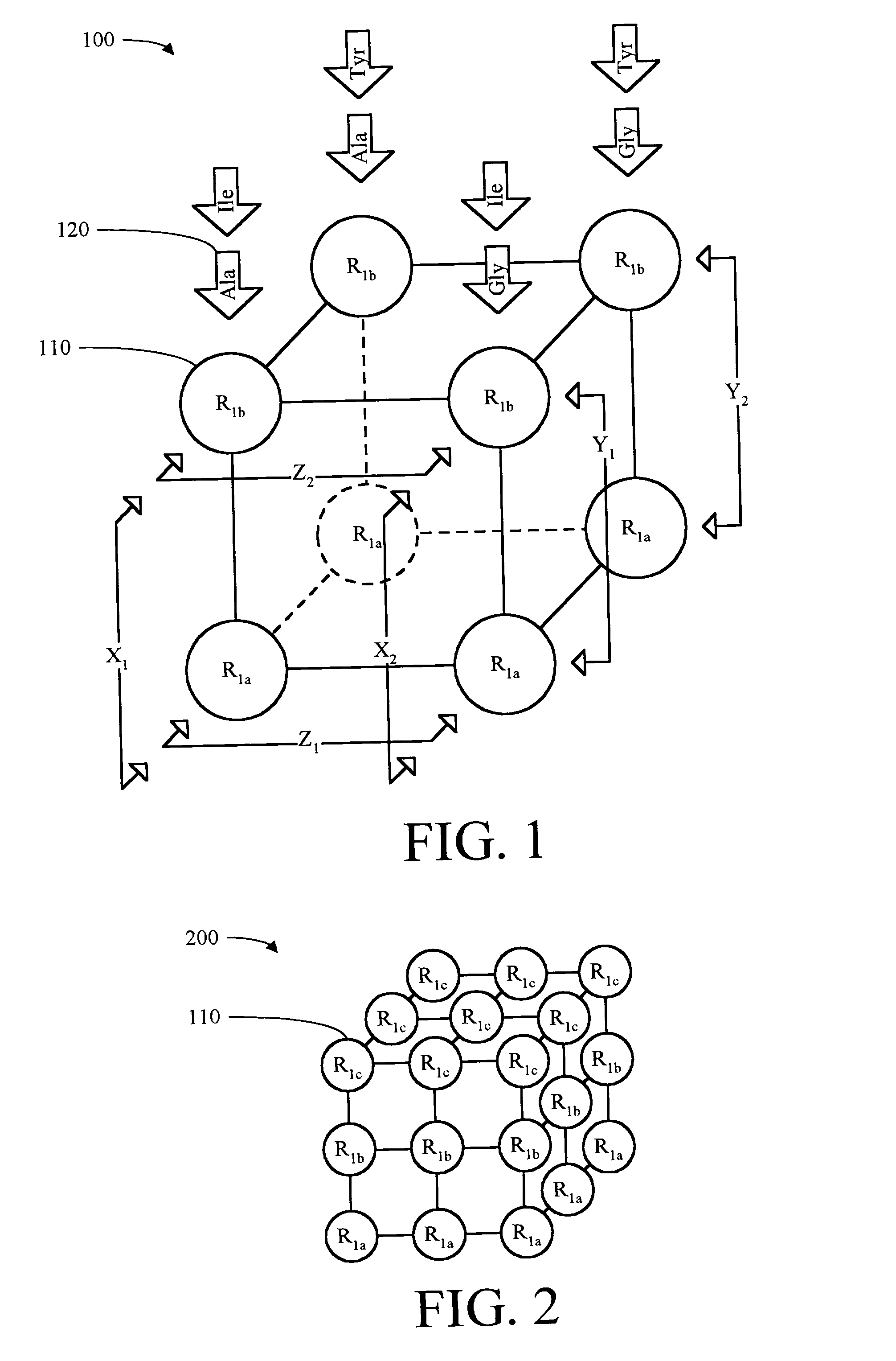

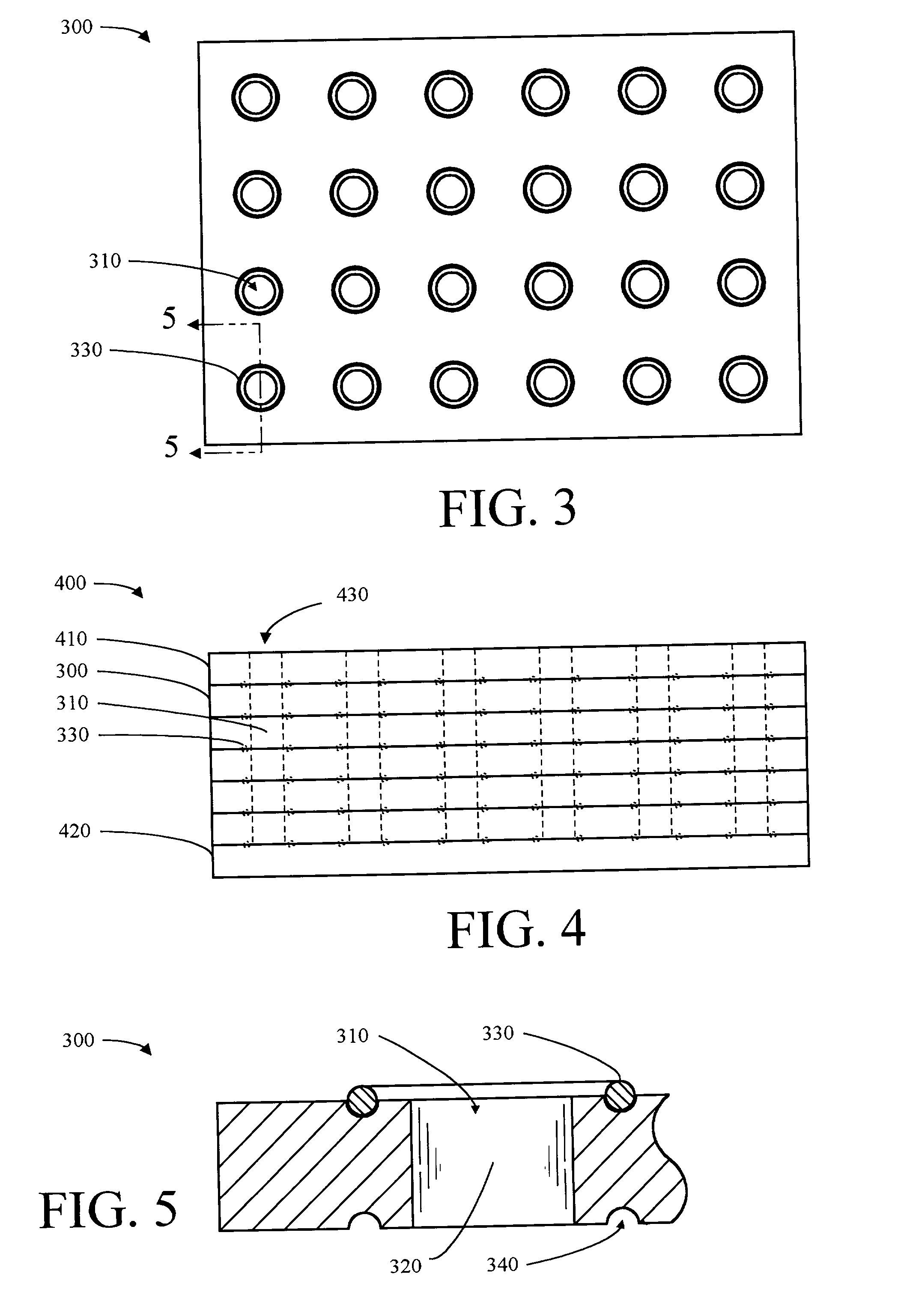

Three-dimensional array of supports for solid-phase parallel synthesis and method of use

InactiveUS20030068644A1Avoid cross contaminationIncrease surface areaStapling toolsBioreactor/fermenter combinationsEngineeringSolid phases

A three-dimensional (3D) array of solid-phase supports is adapted to provide parallel synthesis of a library of molecules with 3D diversity. Individual locations in the 3D array may be assigned to selected molecules in the library such that molecules may be synthesized at and retrieved from such locations. Also, the supports include aperture walls in stacked plates; the supports may be suspended within stacked plate apertures; the 3D array include discrete supports arranged in columns in one or more wells; the supports include tube inner walls or be suspended in tubes, the tubes being secured in stacked, two-dimensional (2D) frameworks; or the supports include beads contained in porous enclosures having non-porous side walls and being secured in stacked, 2D frameworks. A support transfer device enables transfer of solid-phase supports used in a 3D array. Such apparatus includes: a rack of rods sized to be inserted through supports and a mechanism to prevent supports from coming off the rack; tubes connected to a vacuum manifold to suction supports one Z plane at a time; or a transfer block having recesses to receive one or more support and at least one gate withholding supports from passing through the gate when in a closed position. A method of 3D synthesis includes: a) functionalizing solid-phase supports; b) placing supports in a 3D array; and c) performing parallel synthesis with 3D diversity. At least one unique R1 group member may be assigned to each Z plane.

Owner:HOECHST MARION ROUSSEL INC

Edge dry manifold

InactiveUS20050132953A1Easy and inexpensive to manufactureReduction of precision of manufacturePolycrystalline material growthSemiconductor/solid-state device manufacturingEngineeringFree space

A apparatus for drying a substrate includes a vacuum manifold positioned adjacent to an edge wheel. The edge wheel includes an edge wheel groove for receiving a peripheral edge of a substrate, and the edge wheel is capable of rotating the substrate at a desired set velocity. The vacuum manifold includes a proximity end having one or more vacuum ports defined therein. The proximity end is positioned at least partially within the edge wheel groove, and using supplied vacuum removes fluids that accumulate in the edge wheel groove and prevents re-deposit of trapped fluids around the peripheral edge of the substrate.

Owner:LAM RES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com