Patents

Literature

2336 results about "Spray cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

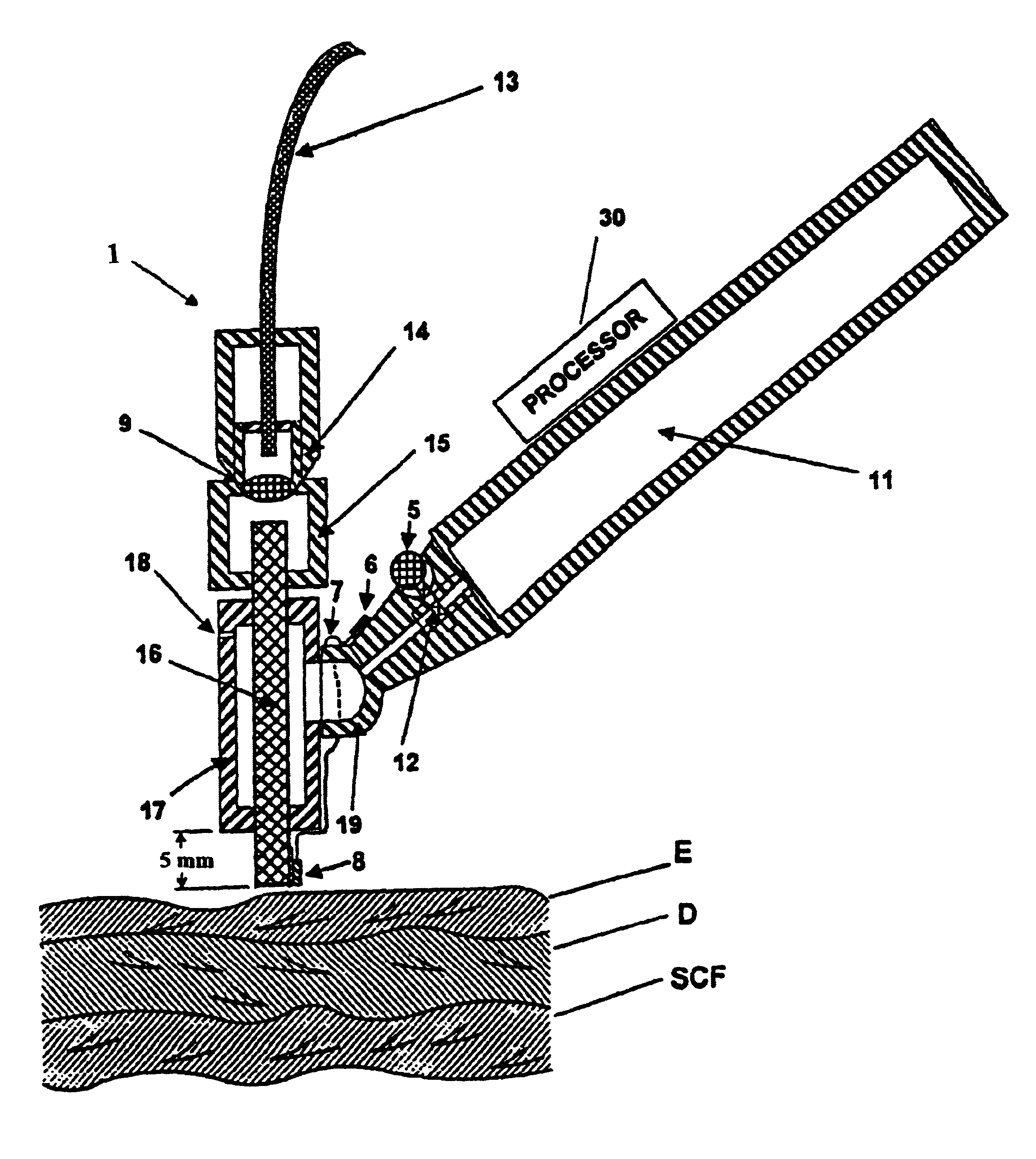

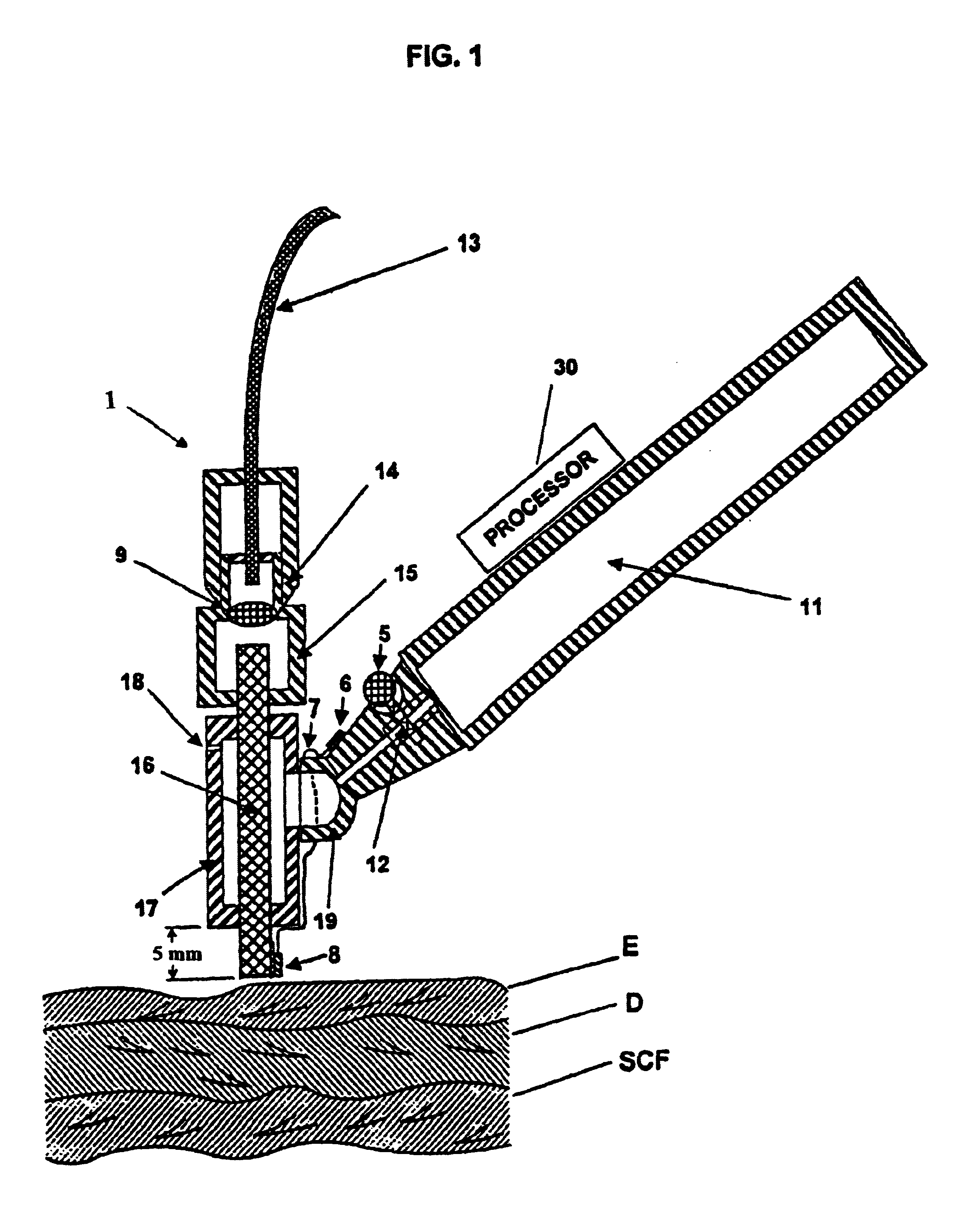

Tissue cooling rod for laser surgery

A laser treatment device and process with controlled cooling. The device contains a cooling element with high heat conduction properties, which is transparent to the laser beam. A surface of the cooling element is held in contact with the tissue being treated while at least one other surface of the cooling element is cooled by the evaporation of a cryogenic fluid. The cooling is coordinated with the application of the laser beam so as to control the temperatures of all affected layers of tissues. In a preferred embodiment useful for removal of wrinkles and spider veins, the cooling element is a sapphire plate. A cryogenic spray cools the top surface of the plate and the bottom surface of the plate is in contact with the skin. In preferred embodiments the wavelength of the laser beam is chosen so that absorption in targeted tissue is low enough so that substantial absorption occurs throughout the targeted tissue. In a preferred embodiment for treating large spider veins with diameters in the range of 1.5 mm, Applicants use an Er:Glass laser with a wavelength of 1.54 microns.< / PTEXT>

Owner:RELIANT TECH INC

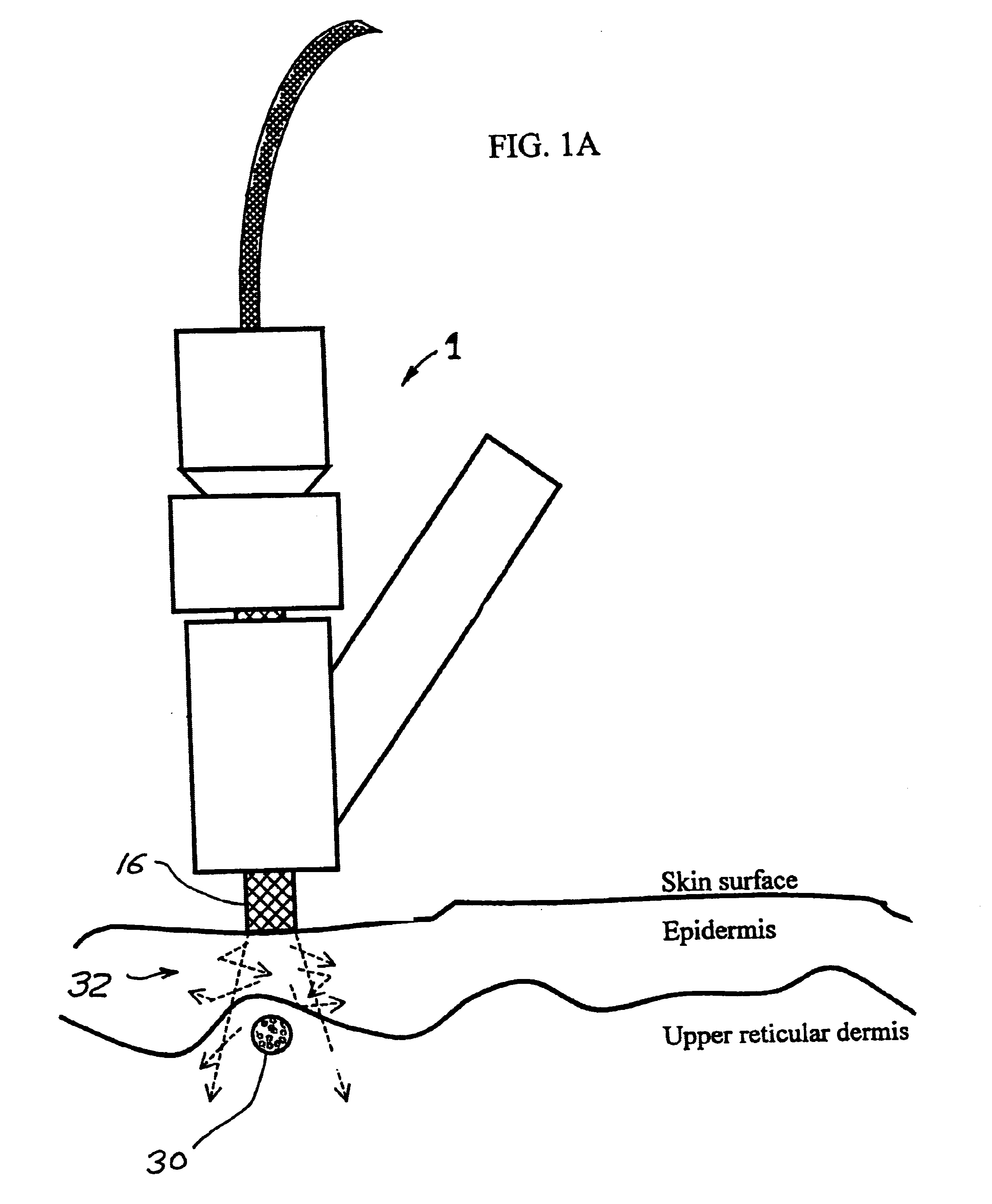

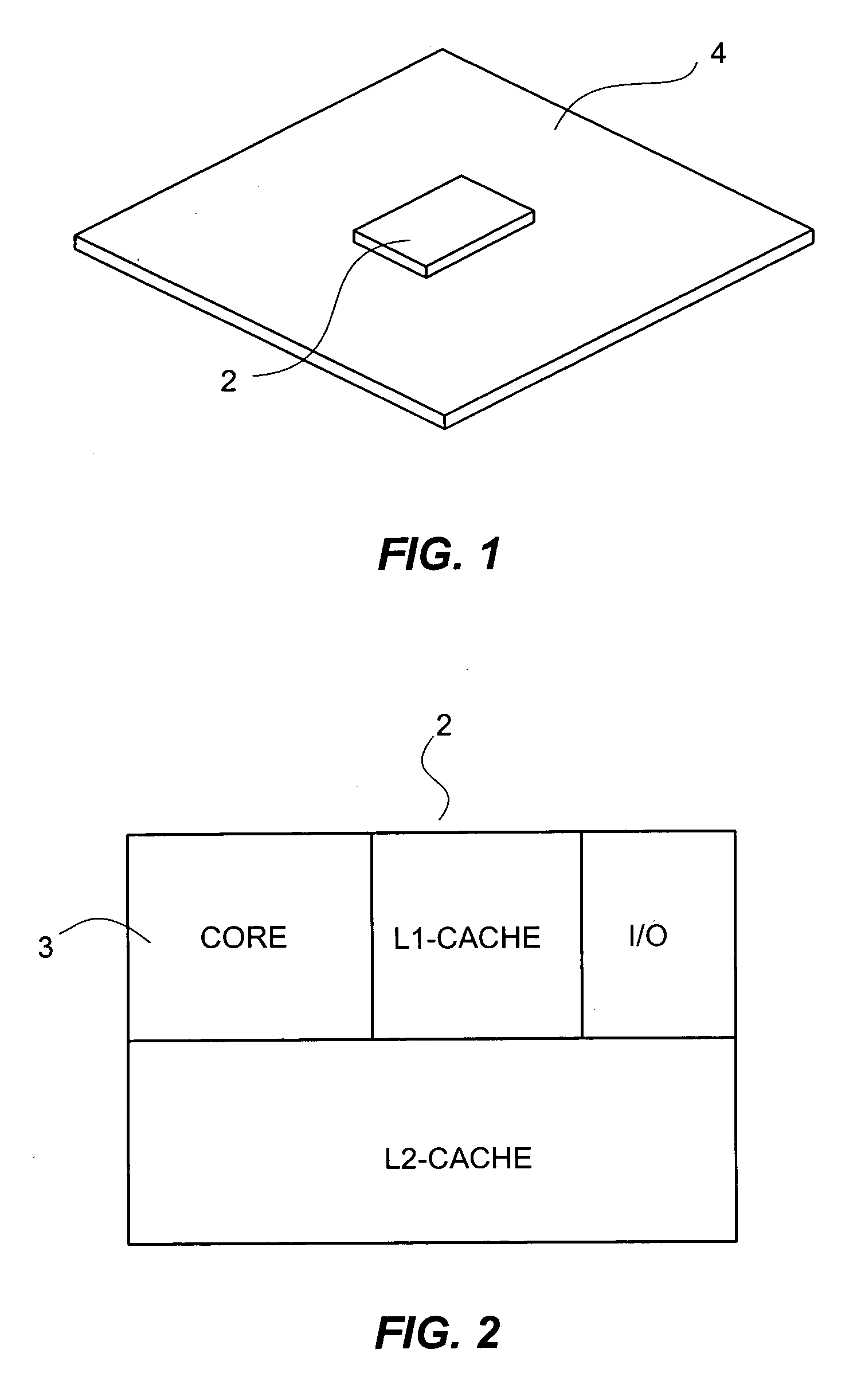

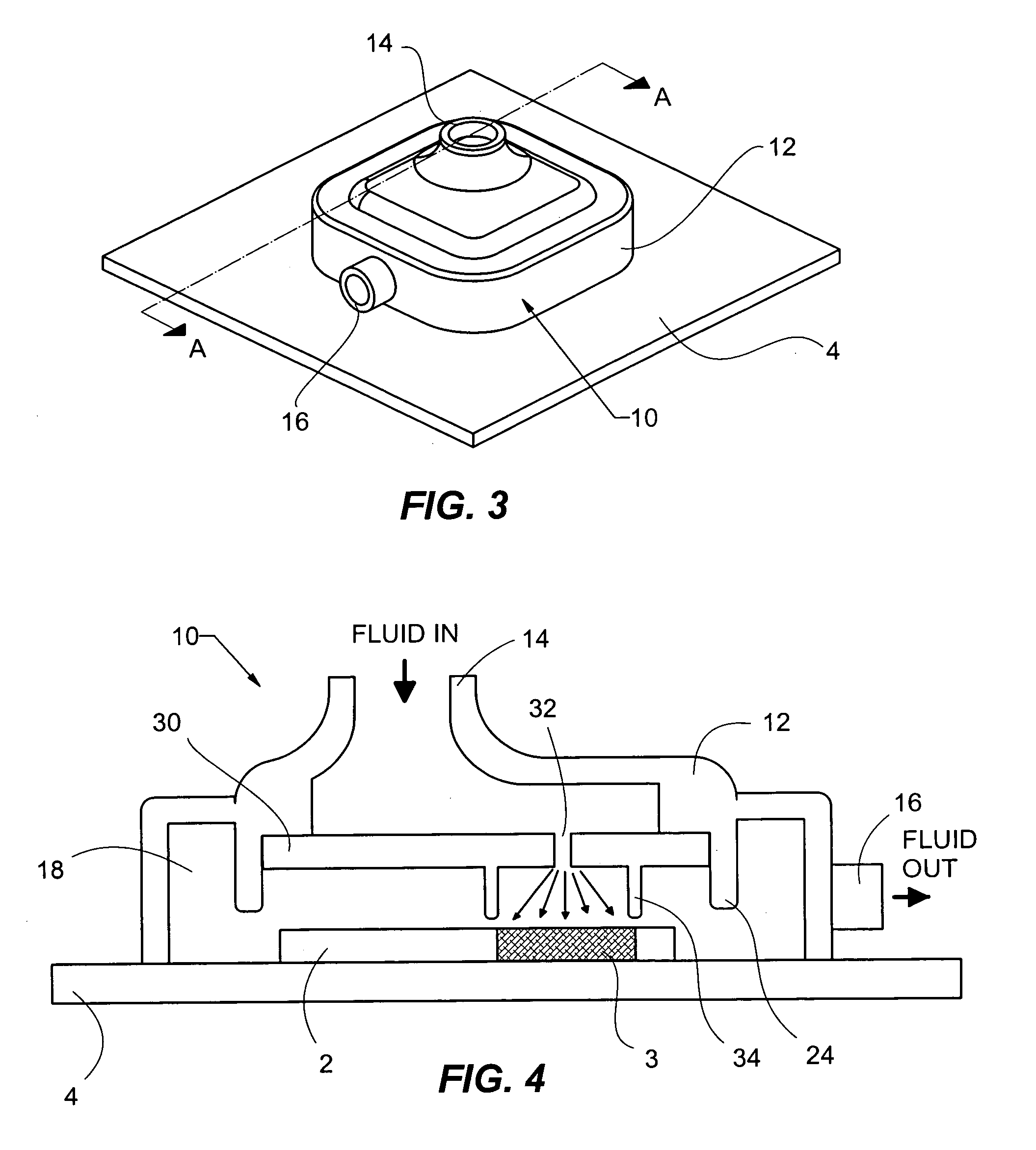

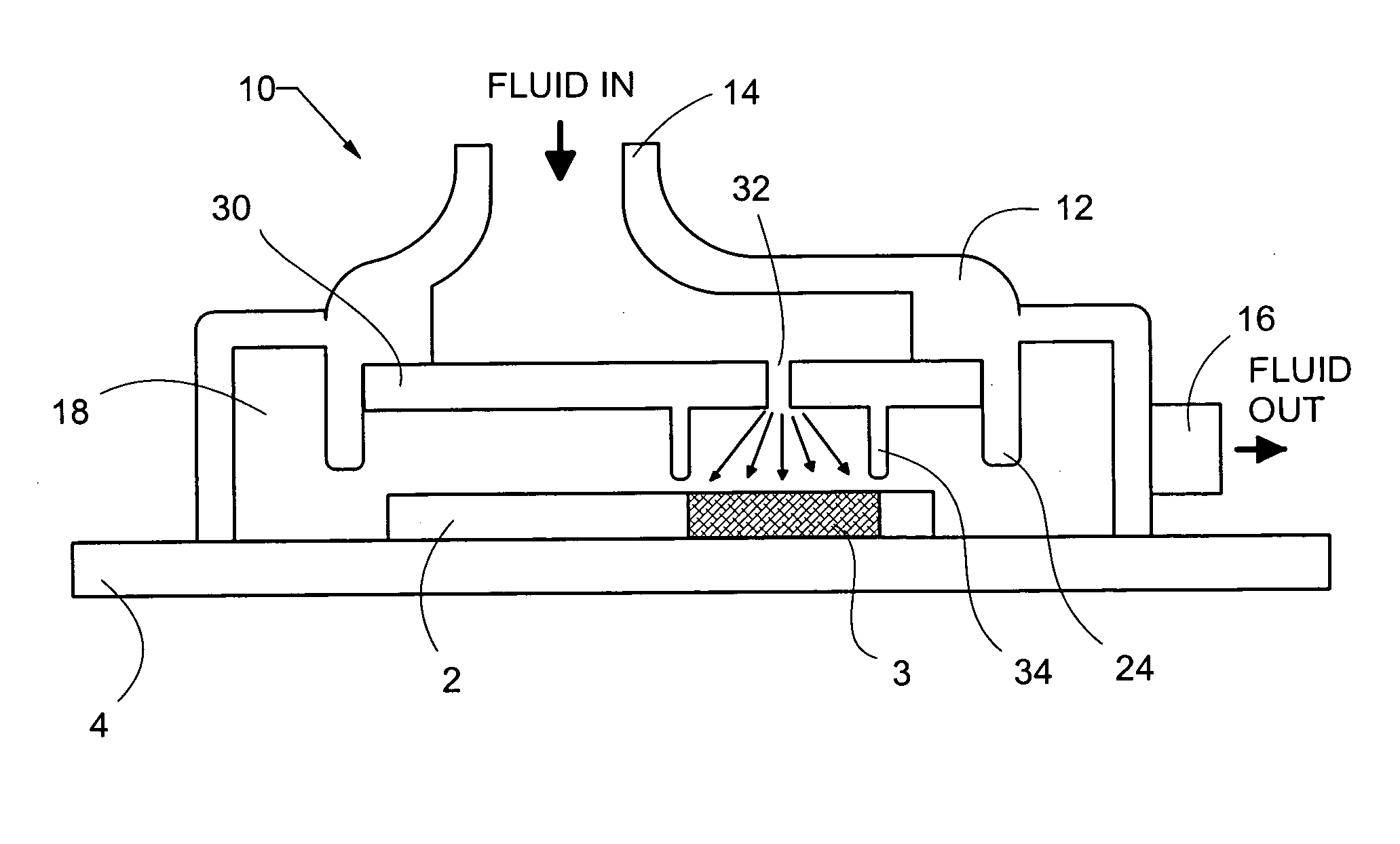

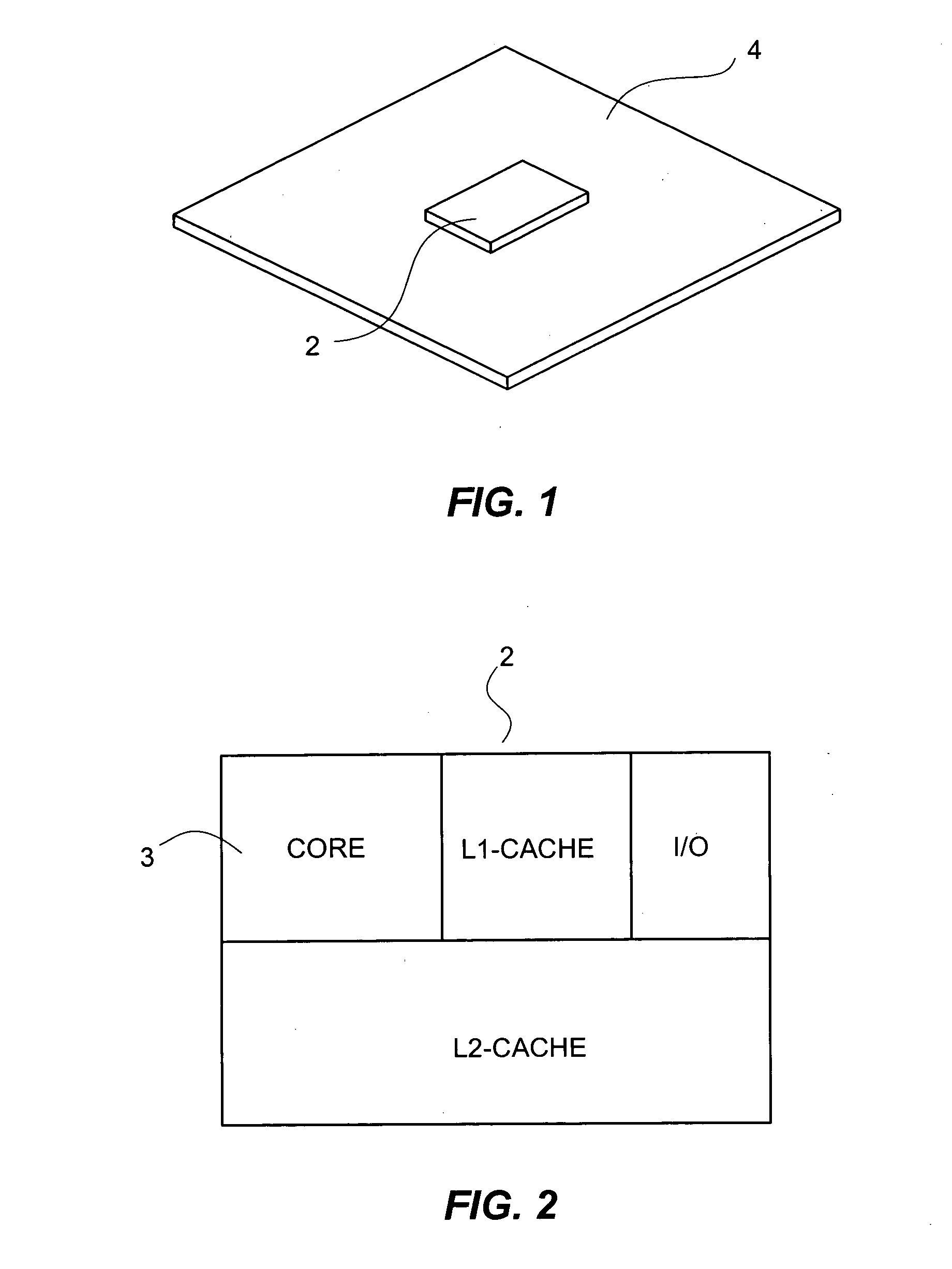

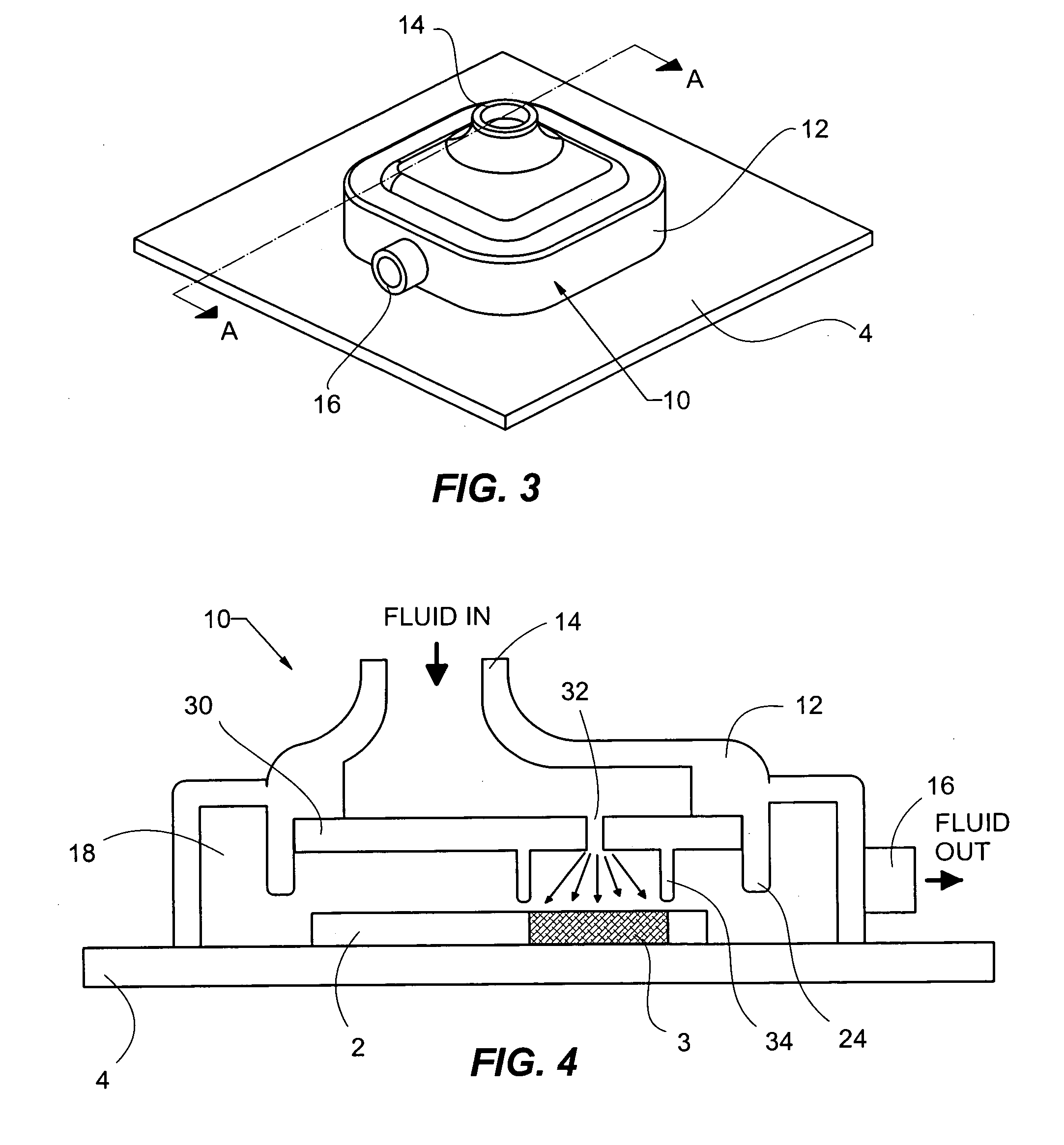

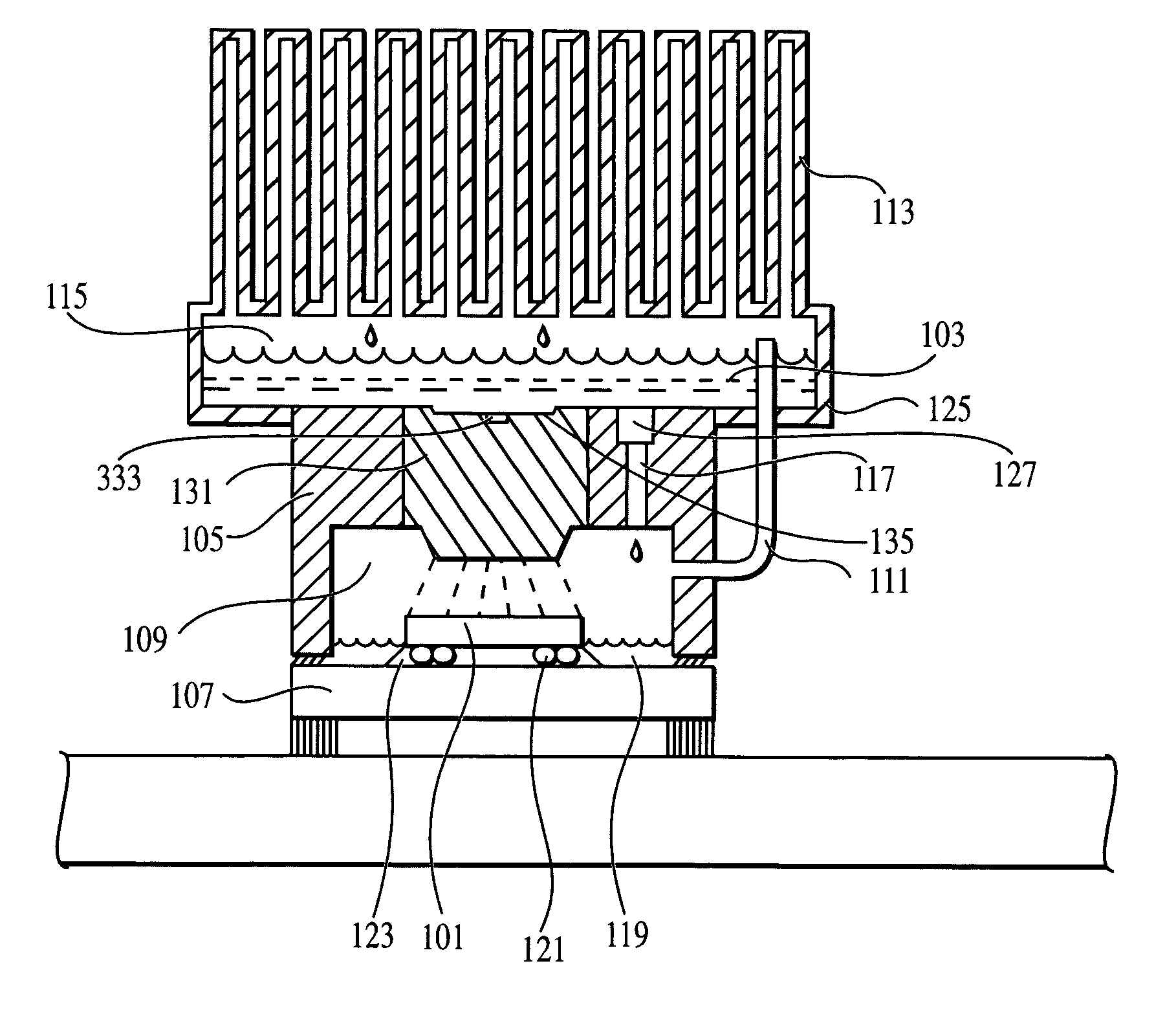

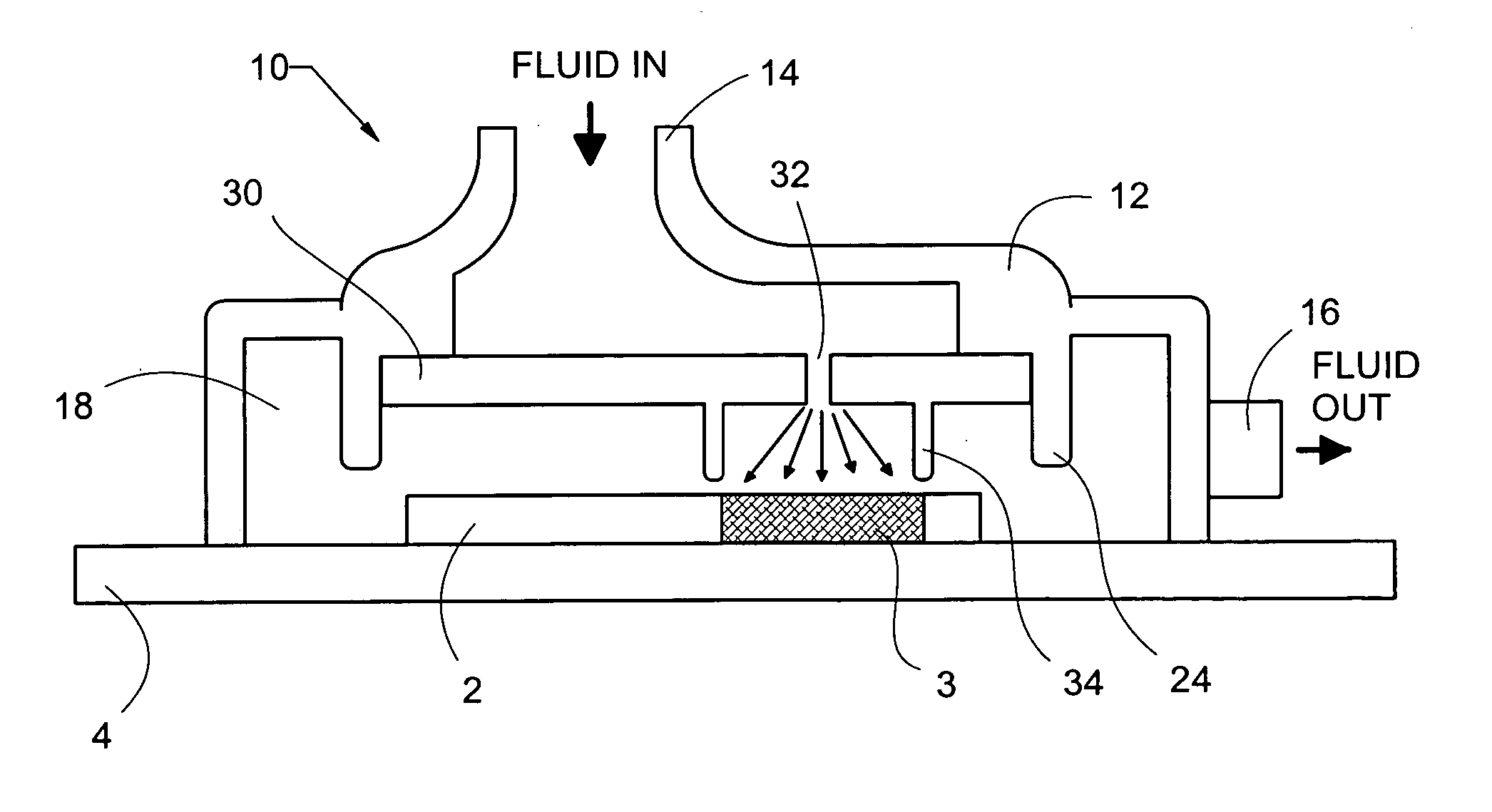

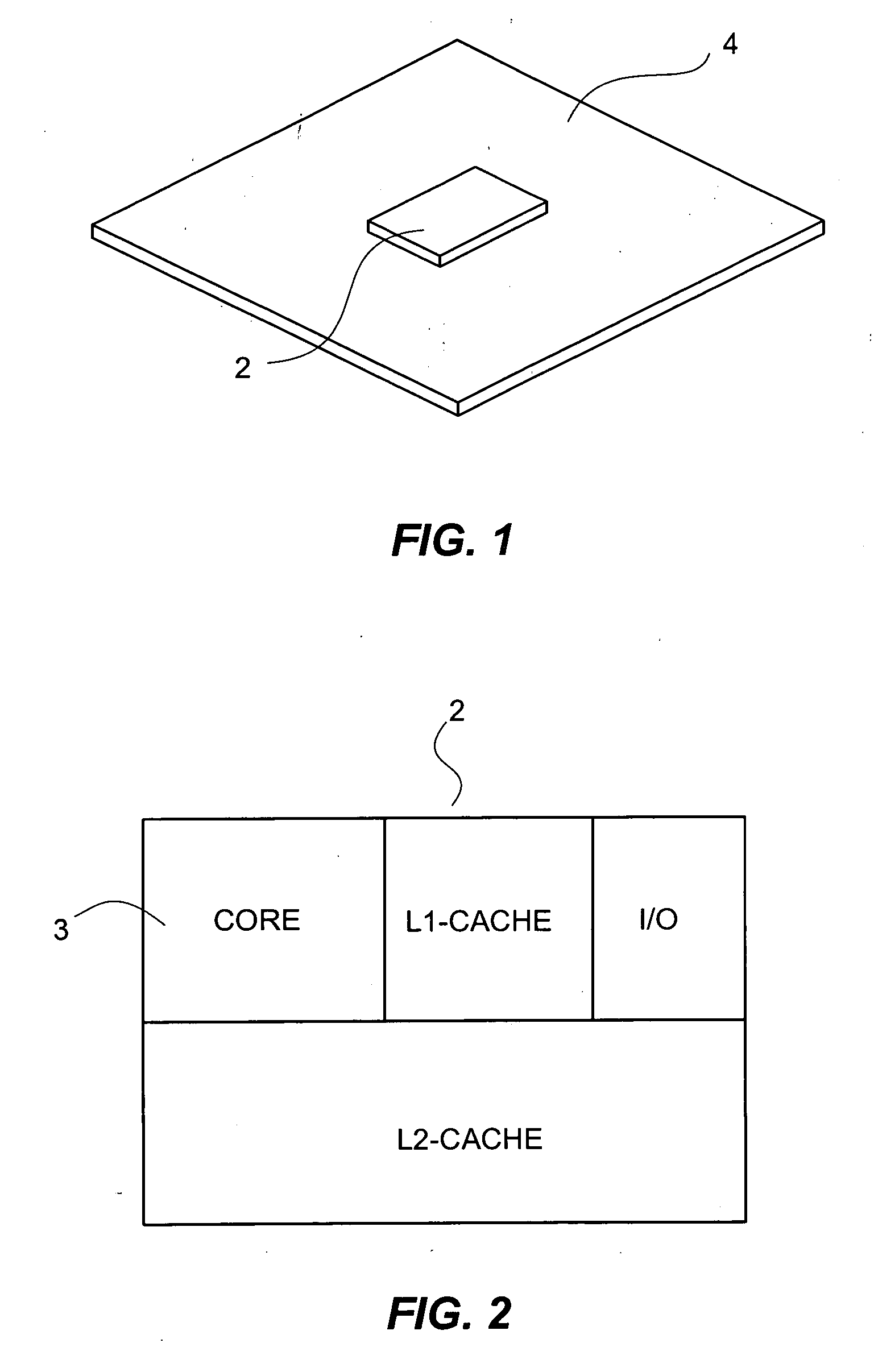

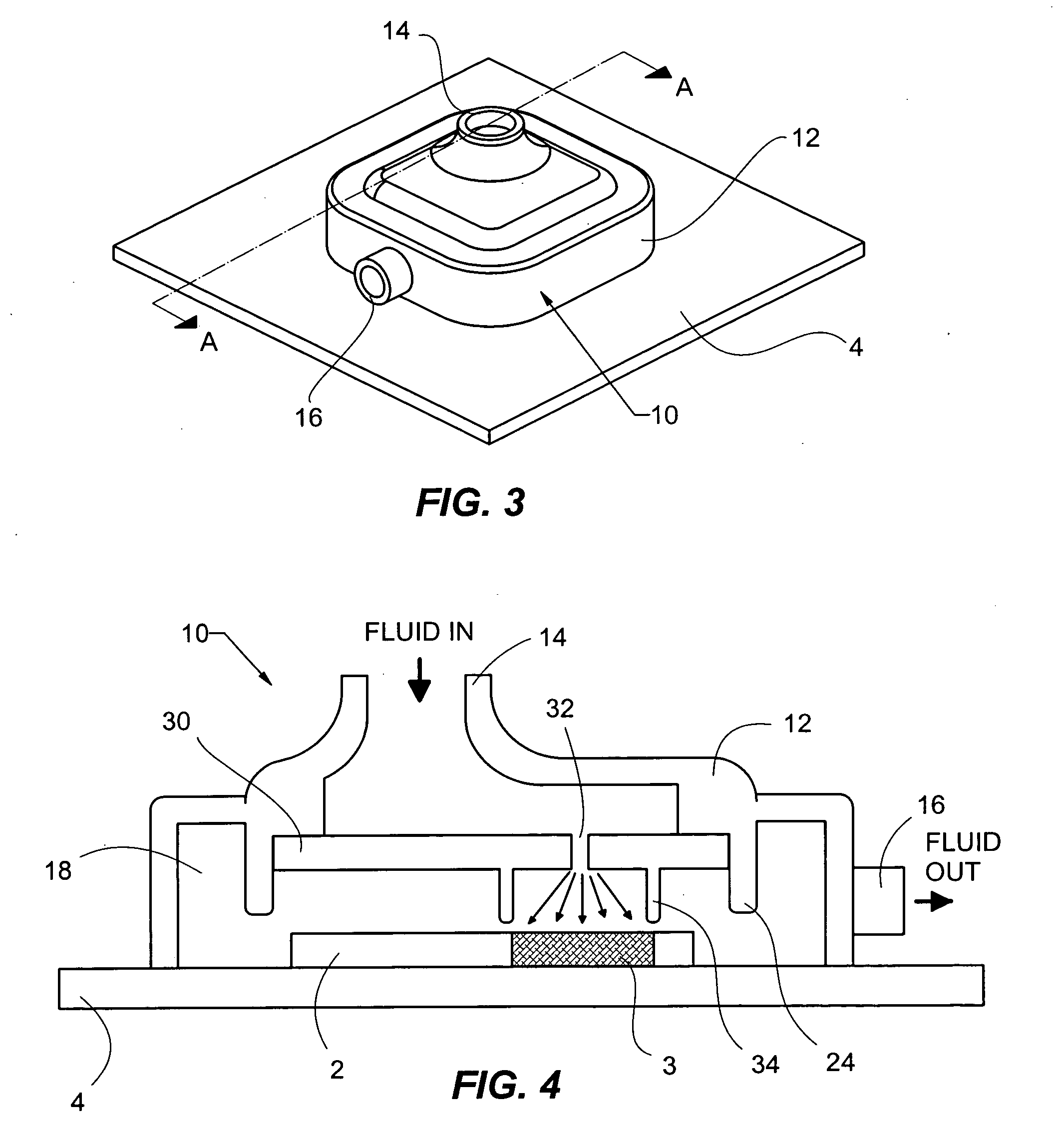

Etched open microchannel spray cooling

ActiveUS6952346B2Simple methodProvide flexibilityDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic componentSpray cooling

The present invention is a spray cooling thermal management device that cools an electronic component. Liquid coolant is dispensed upon a heated surface containing etched open microchannels.

Owner:PARKER INTANGIBLES LLC

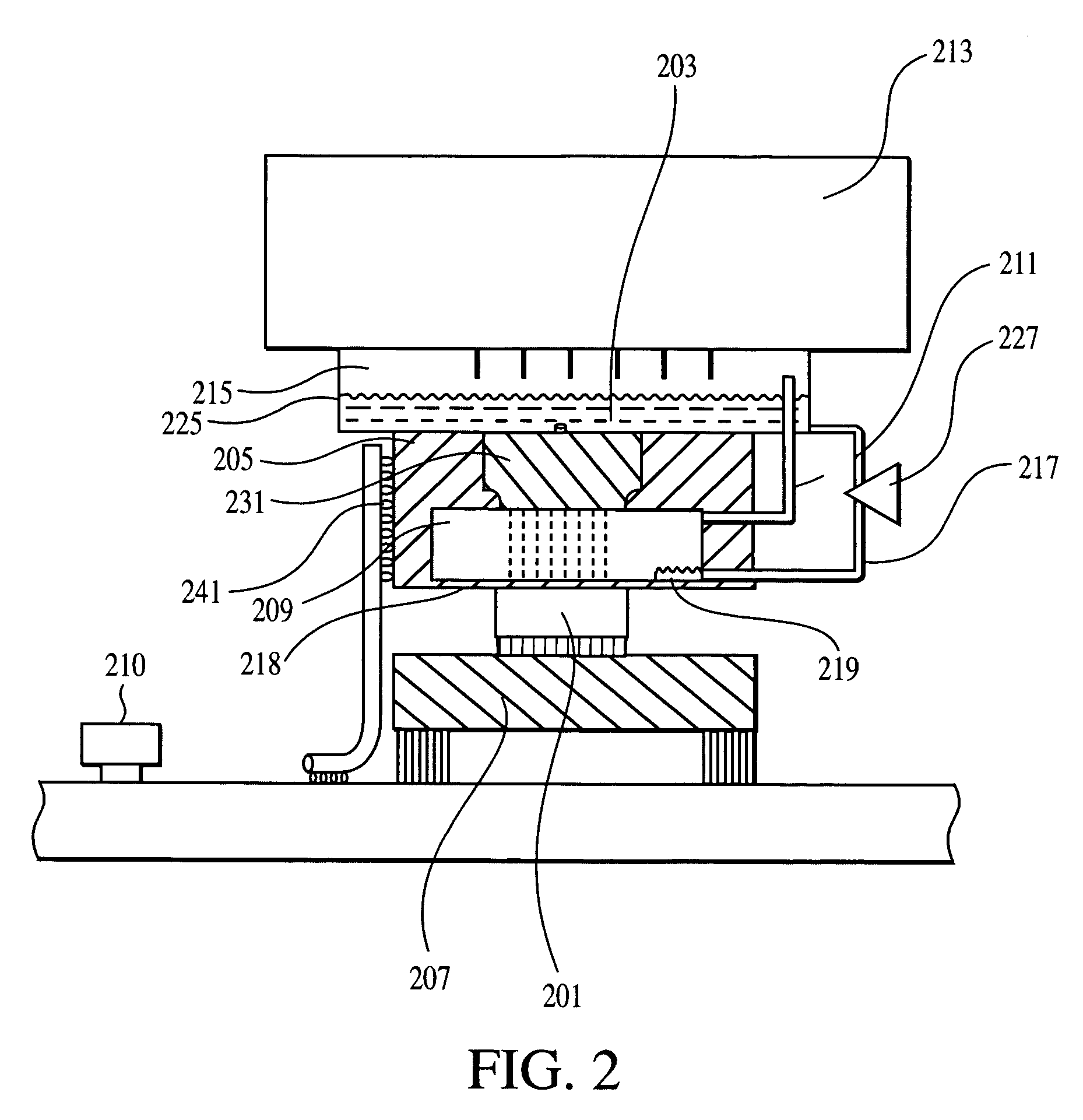

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

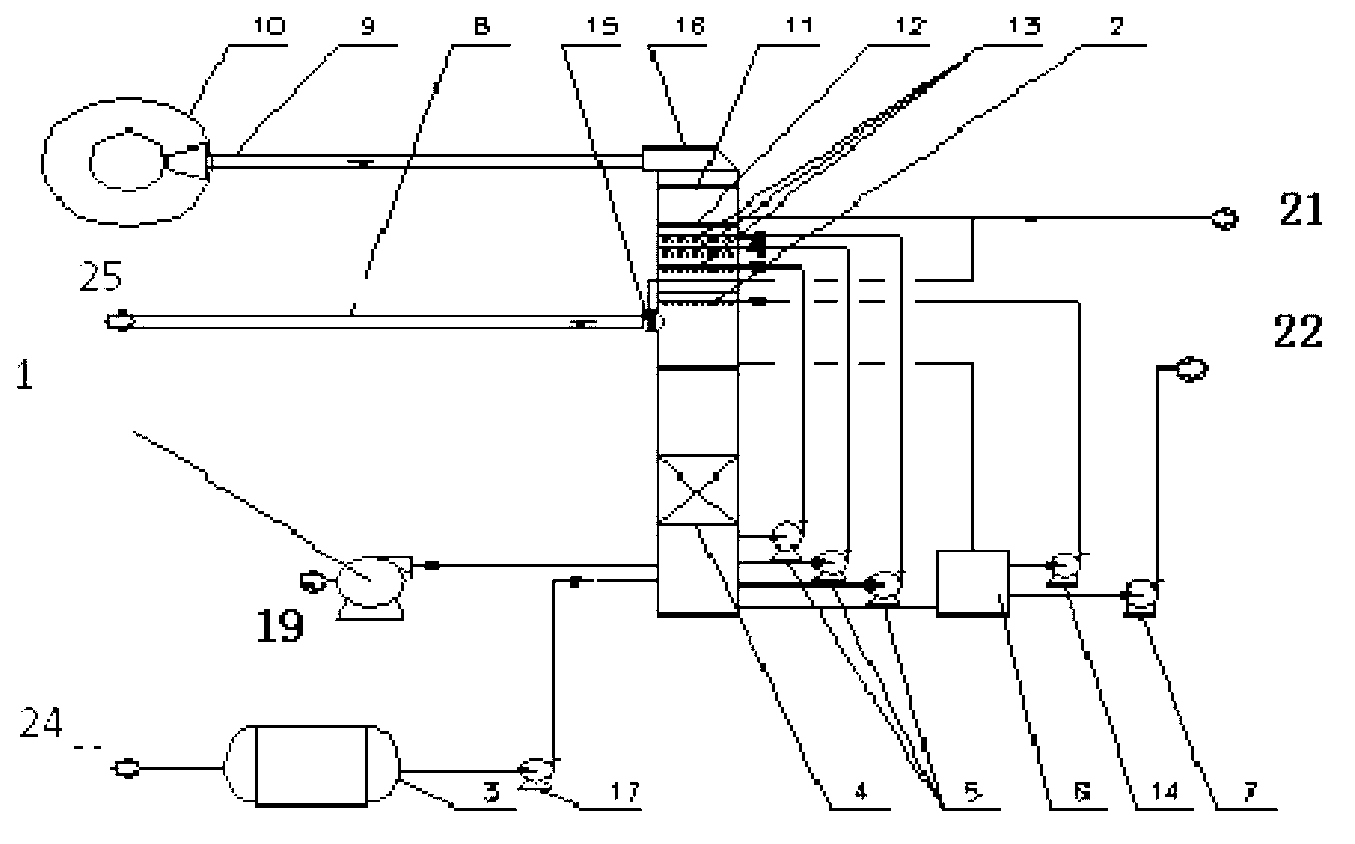

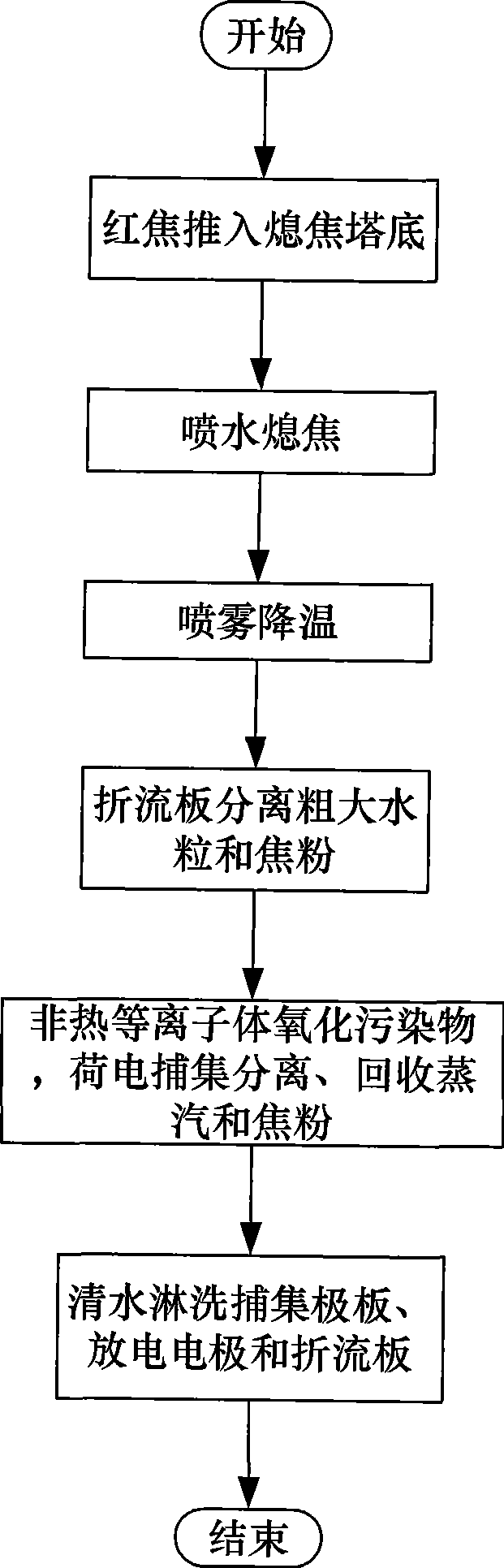

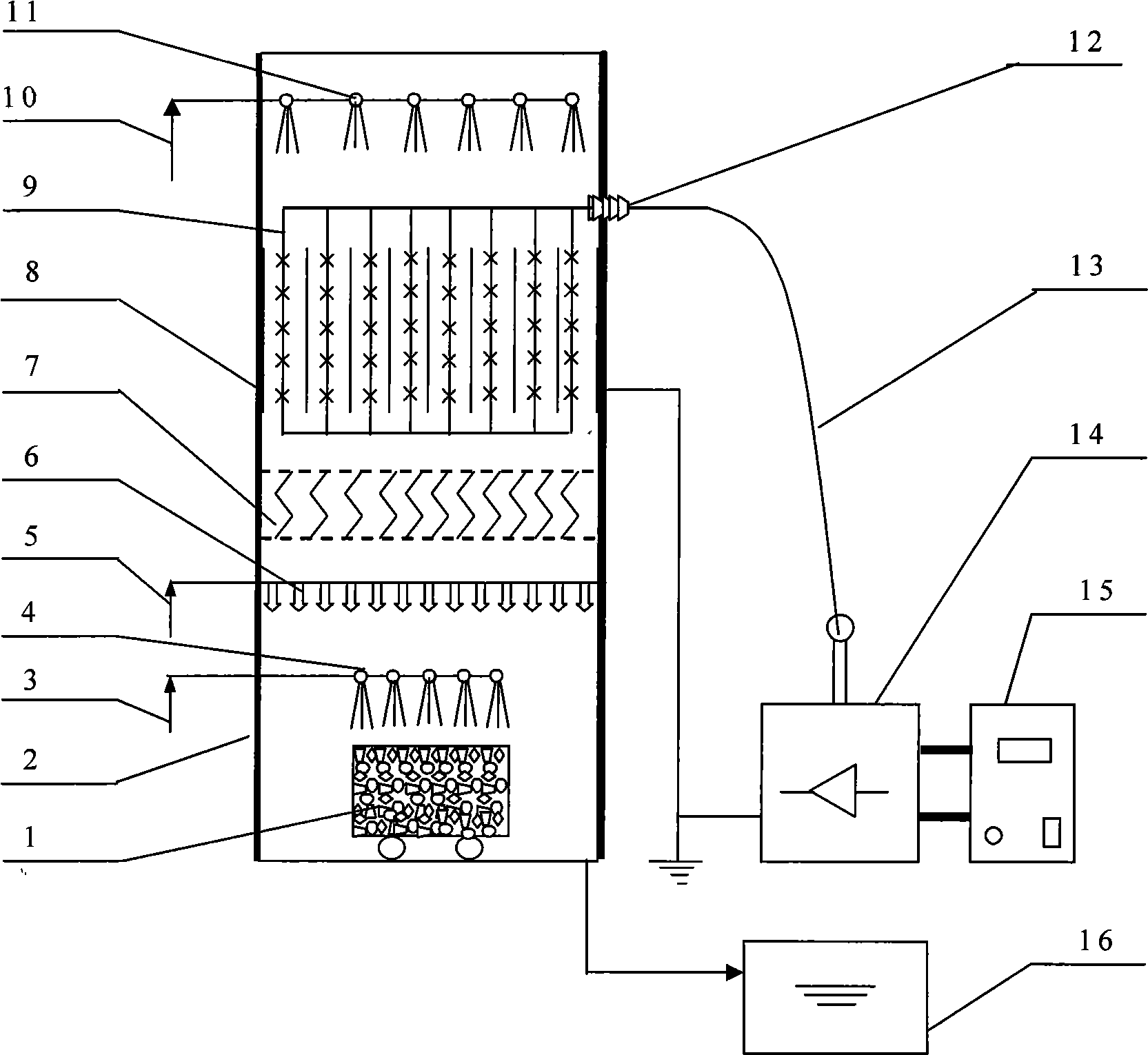

Wet coke-quenching aerial fog processing method and device based on non-thermal plasma injection

InactiveCN101486017AReduce the amount of pollutantsPrevent diverted emissionsCombination devicesCoke quenchingWater vaporHigh pressure

The invention discloses a method and a device for processing wet quenching coke gas fog on the basis of athermal plasma injection. The method comprises the following steps that: in the ascending process, the hot gas fog generated by wet quenching coke sequentially passes through three processing steps including spray cooling, pre-dedusting on a baffle plate and athermal plasma purification, and is cooled in a spray cooling area; the cooled gas fog enters a pre-dedusting area on the baffle plate where the thicker and bigger water particles and coke powder in the gas fog are separated from the gas fog and impact to the baffle plate under the action of inertia; the remaining gas fog continues to ascend and enter an athermal plasma purification area where organic components, ammonia nitrogen and cyanide in the gas fog are oxidized by the athermal plasma; the water particles and the coke powder are charged and are transferred to a trapping pole plate directionally under the action of a high voltage electric field; and then the gas flow after subjected to the athermal plasma purification area continuous to ascend to the top of a coke quenching tower to be discharged. After the processing steps, the contents of water vapor and the coke powder discharged outside after one ton of coke is produced are controlled to be less than 0.05 ton and 5 grams respectively, and the removal rate of the organic components, the ammonia nitrogen and the cyanide can reach more than 80 percent.

Owner:BEIHANG UNIV

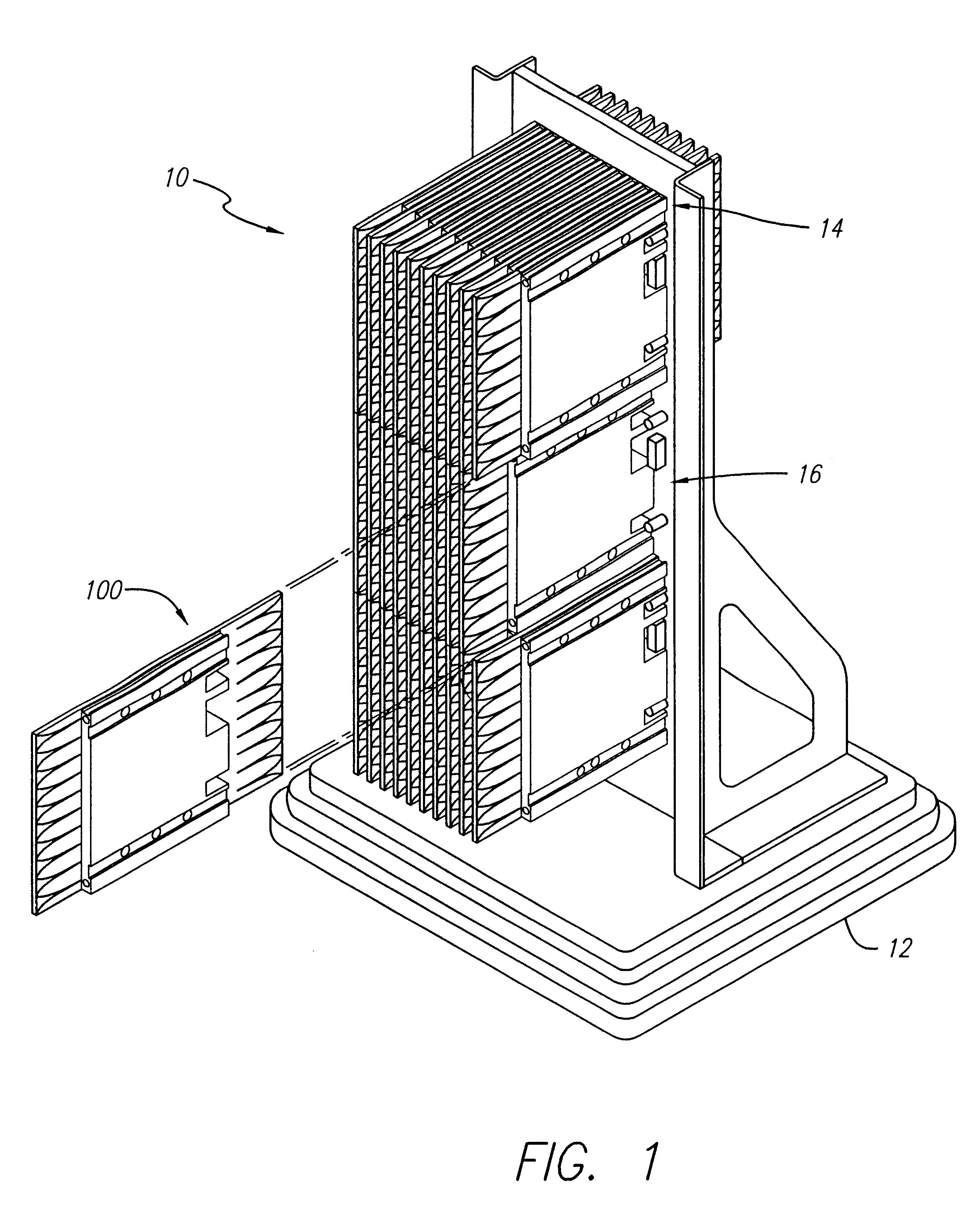

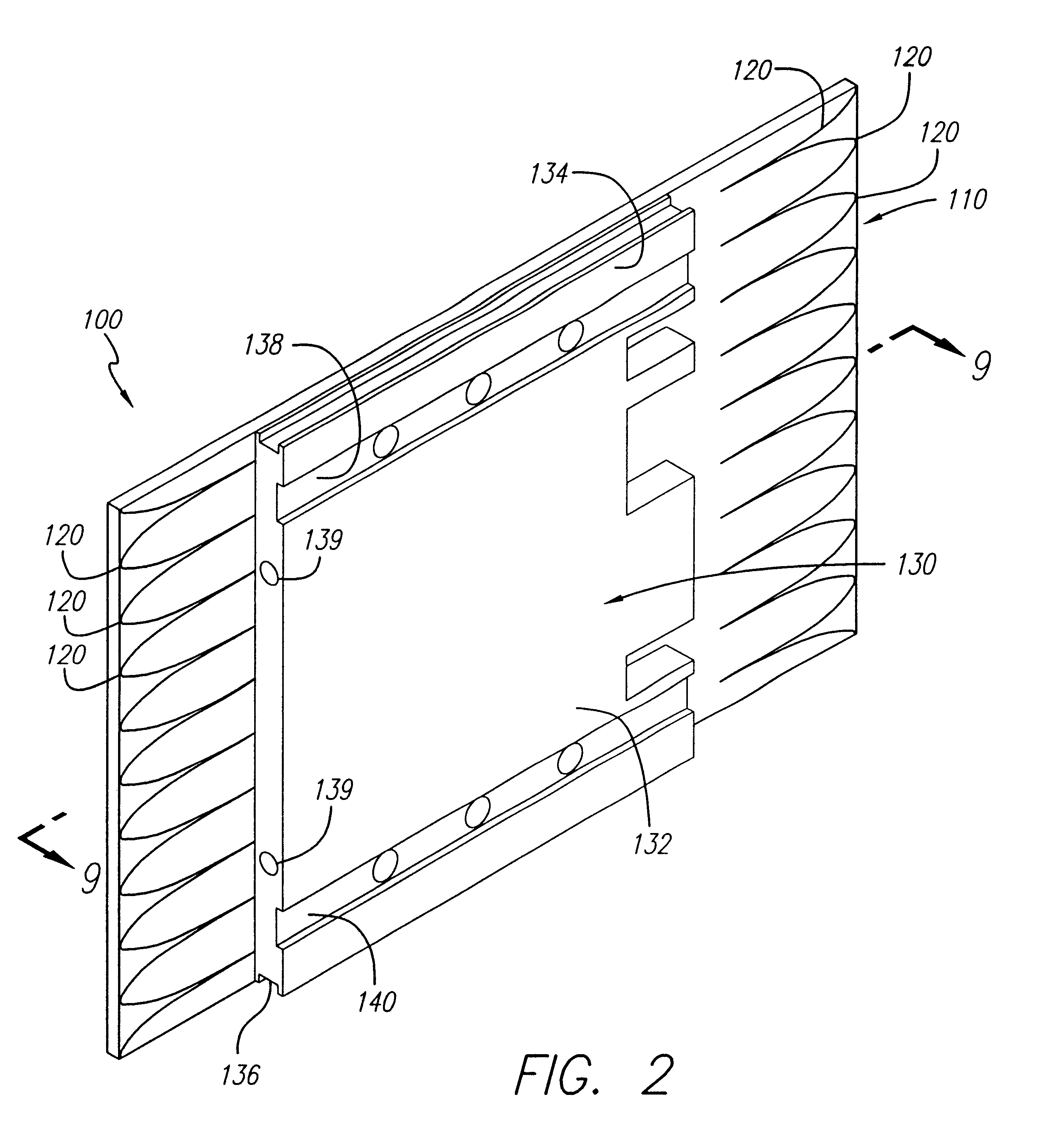

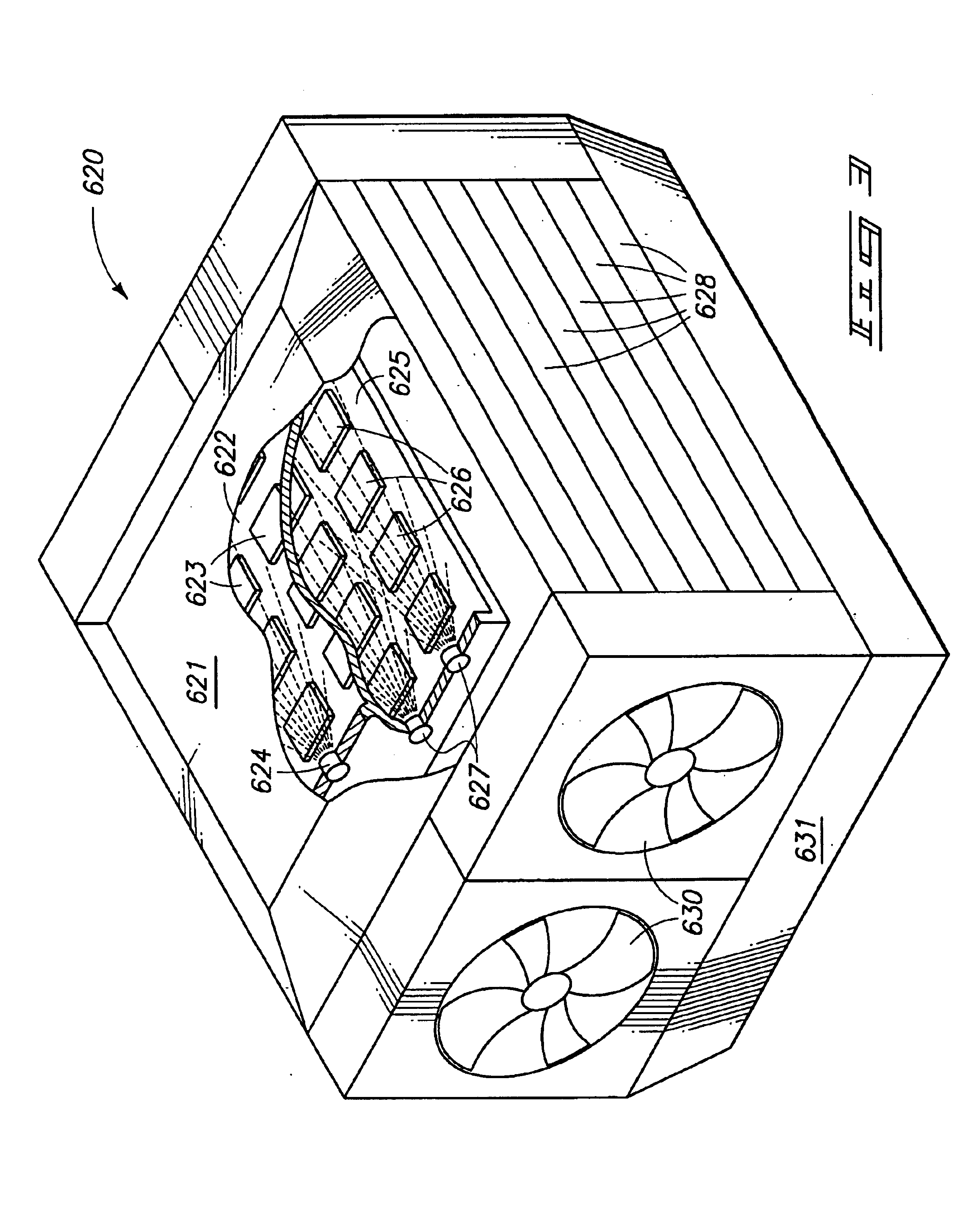

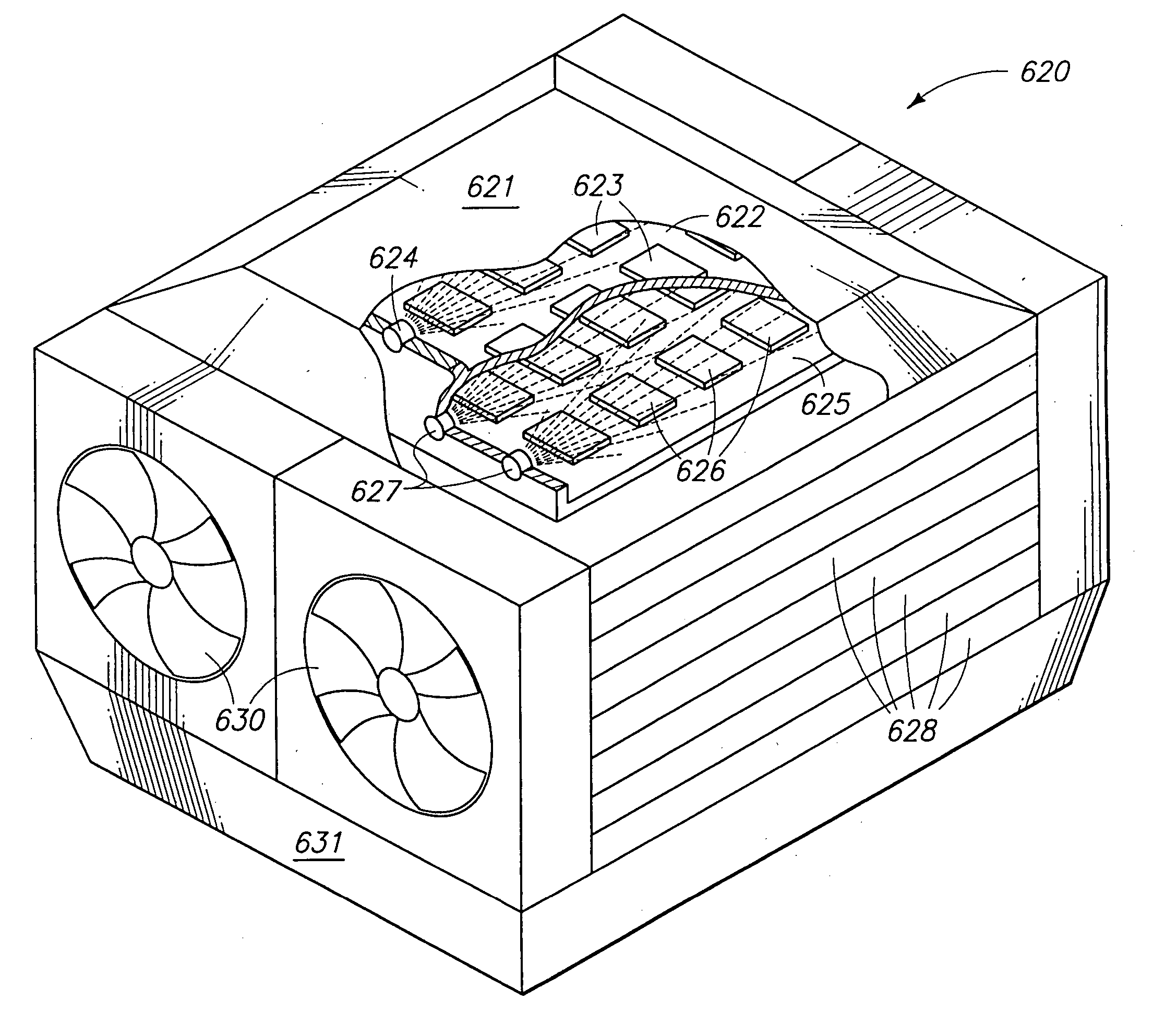

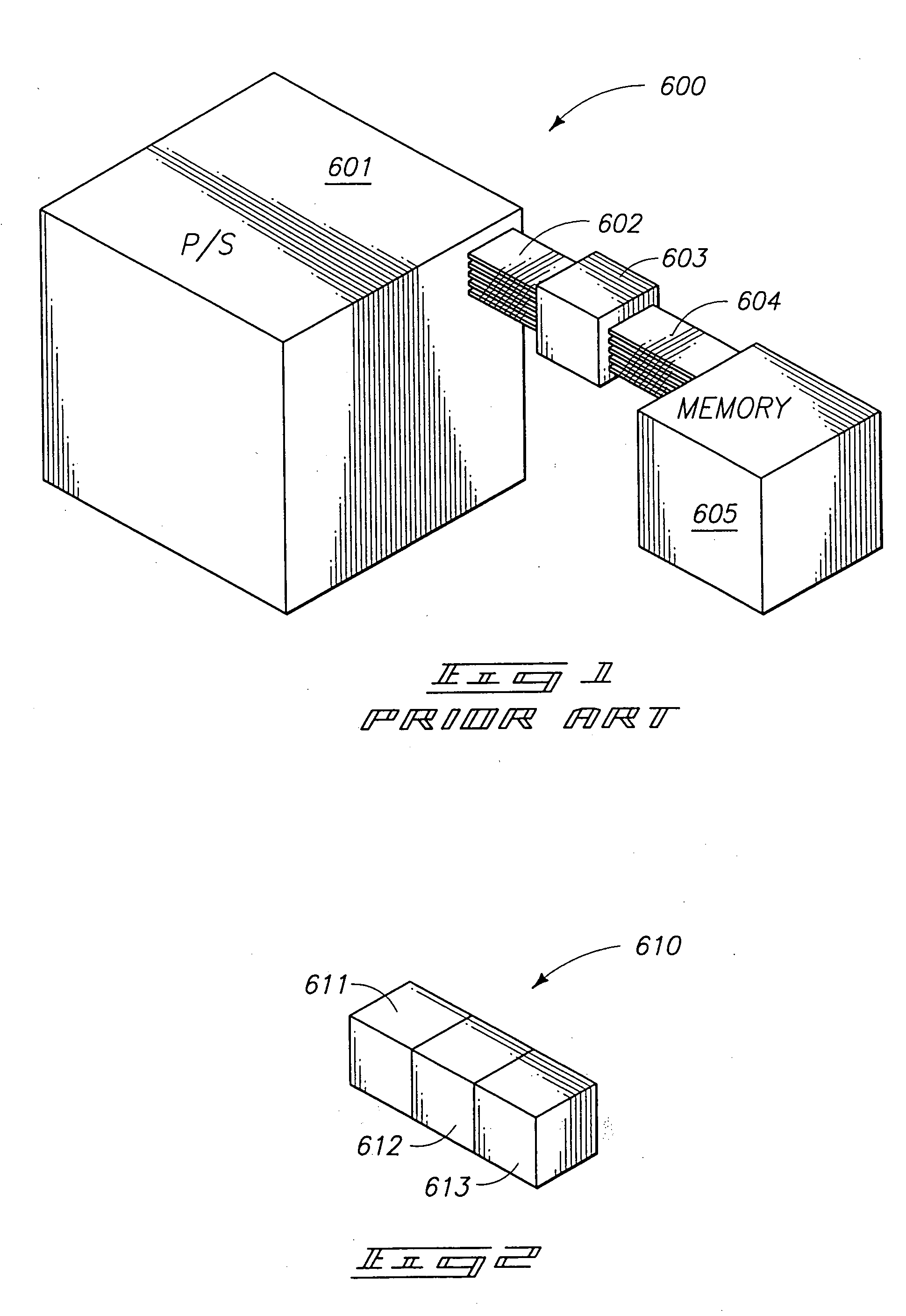

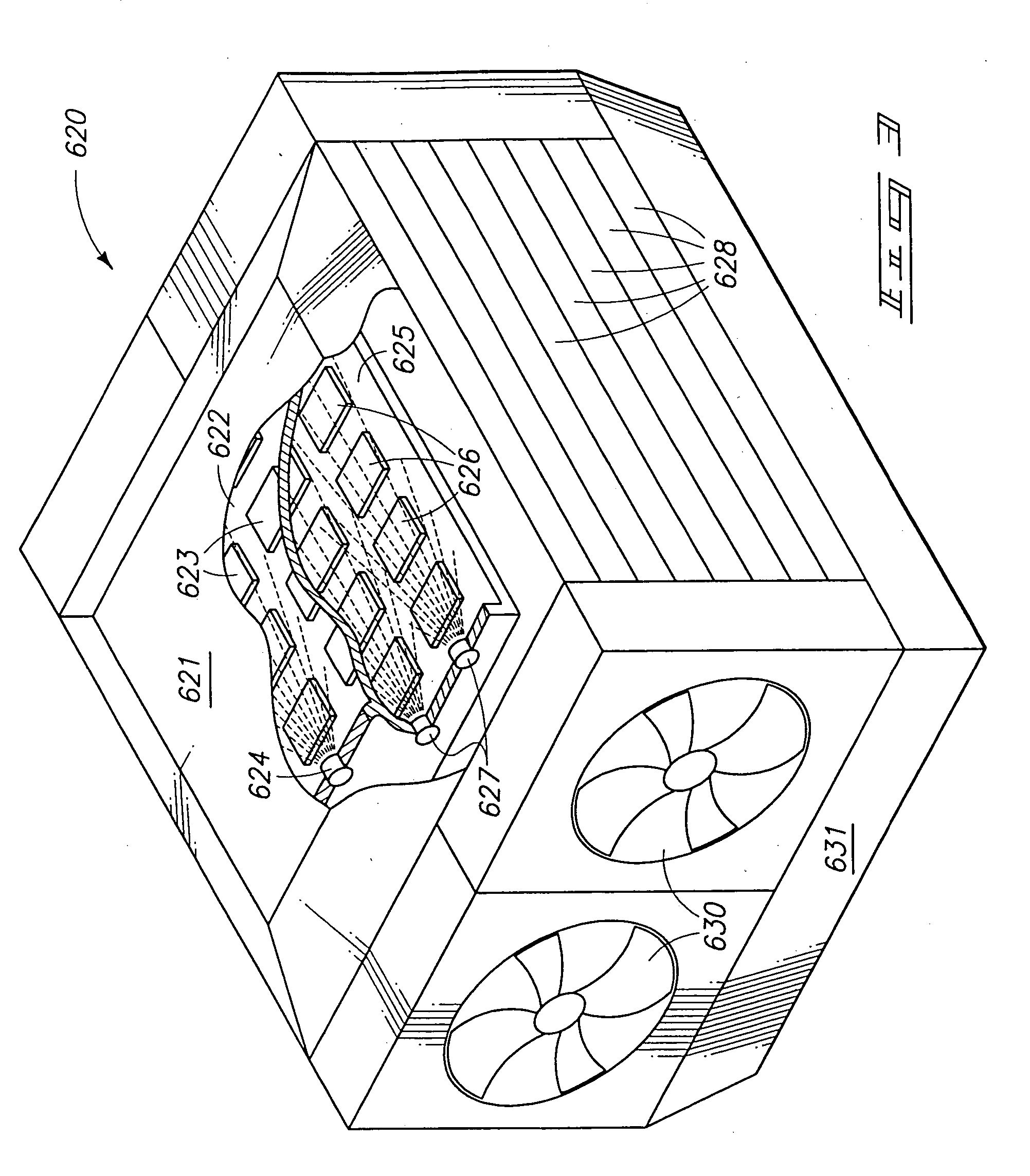

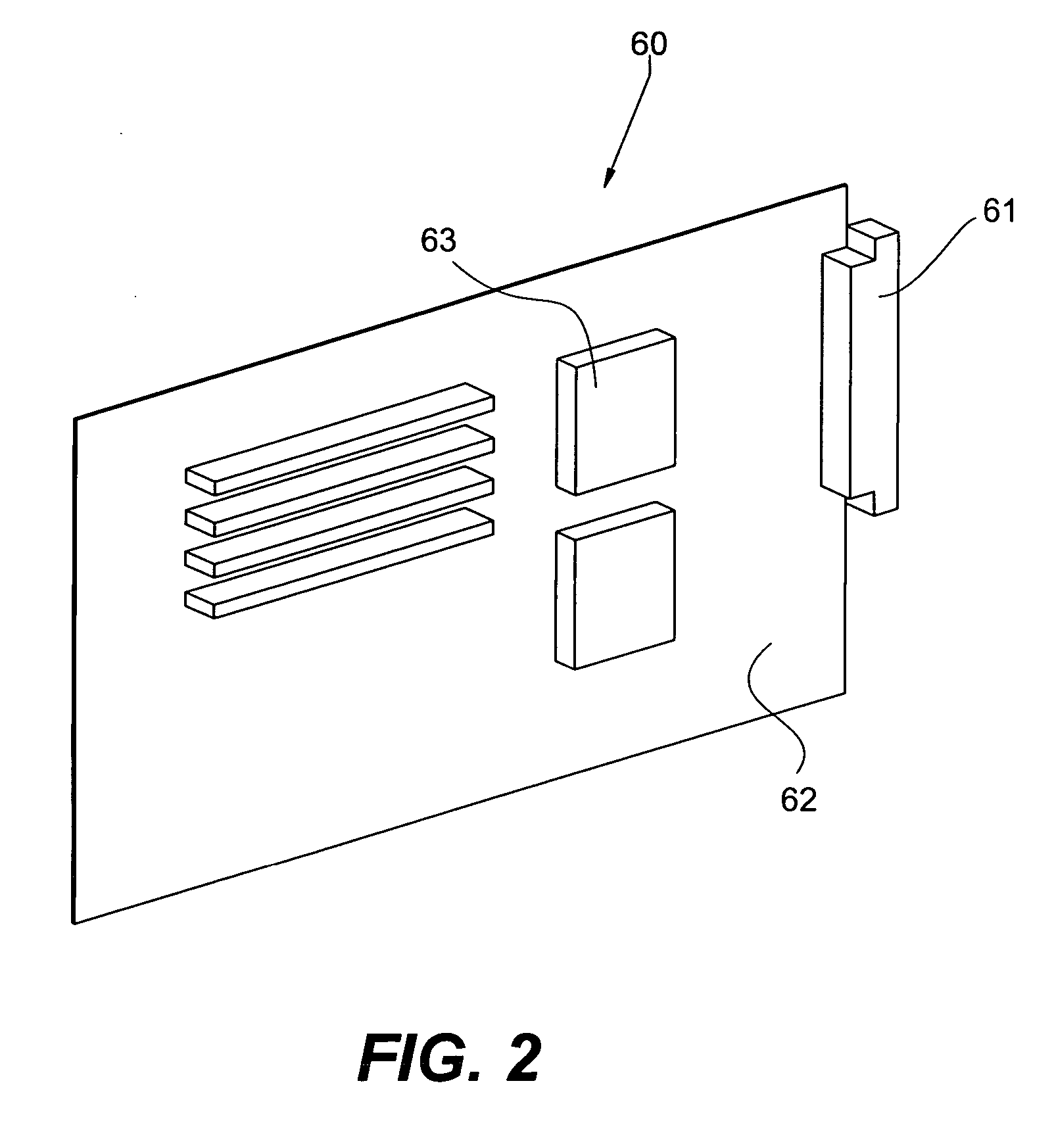

Liquid spray cooled module

InactiveUS6292364B1Domestic cooling apparatusSemiconductor/solid-state device detailsRadar systemsRadiating element

A radar system and method of cooling same. In the illustrative embodiment, the inventive system includes a radar array comprising a circuit board; a plurality of radiating elements printed on the circuit board; and a plurality of transmit and receive modules disposed on the circuit board in communication with the radiating elements. In a specific implementation, the invention further includes means for cooling the T / R modules. In the preferred embodiment, the modules are spray cooled. A particularly novel aspect of the invention is the provision of a mechanism for physically, electrically and hydraulically interconnecting the T / R modules or modules. The physical interconnect is achieved by rails mounted on the top bottom covers and sides of the circuit boards. The rails allow for the modules to be dovetailed together and thereby secured against vertical and lateral stresses.

Owner:RAYTHEON CO

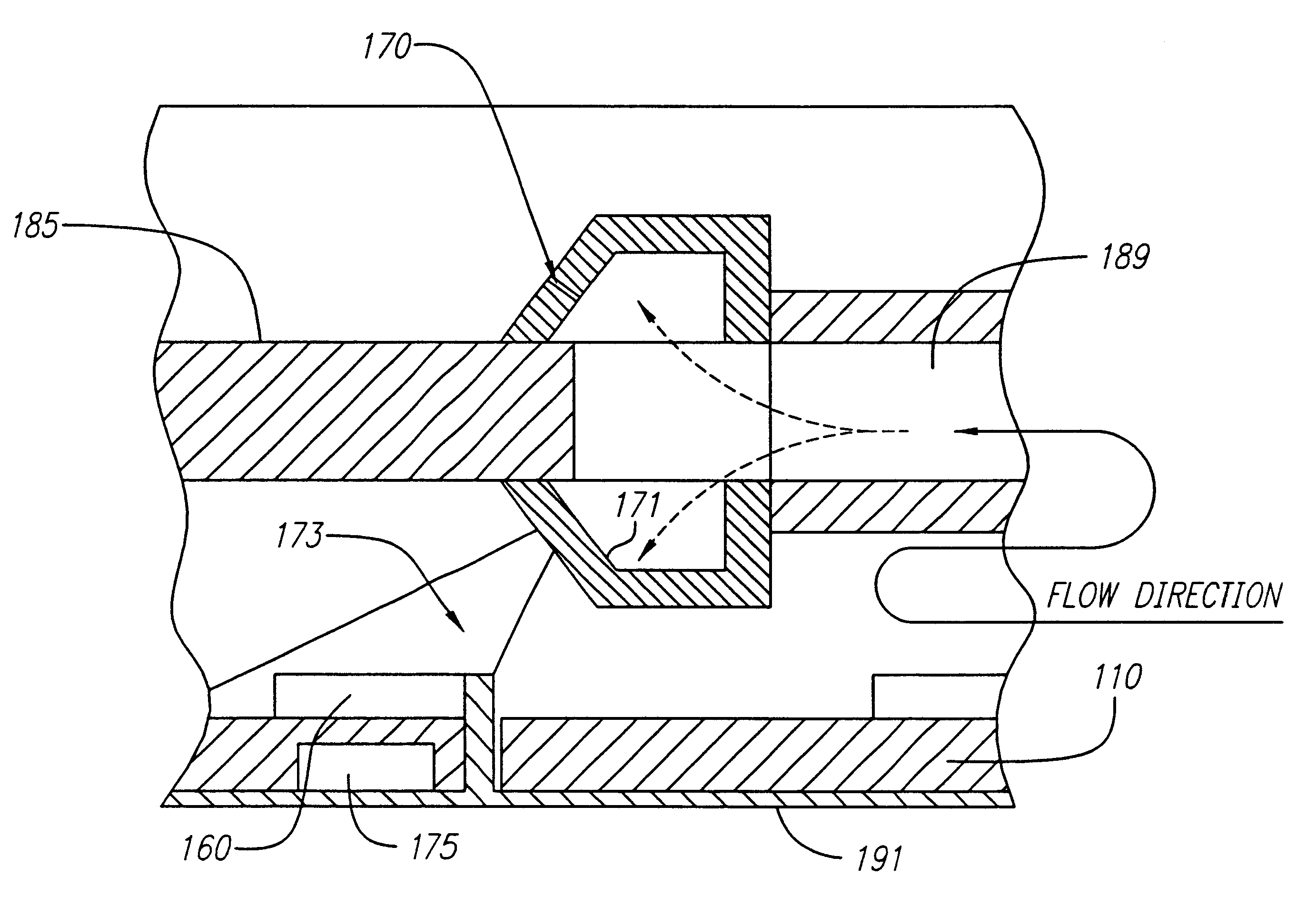

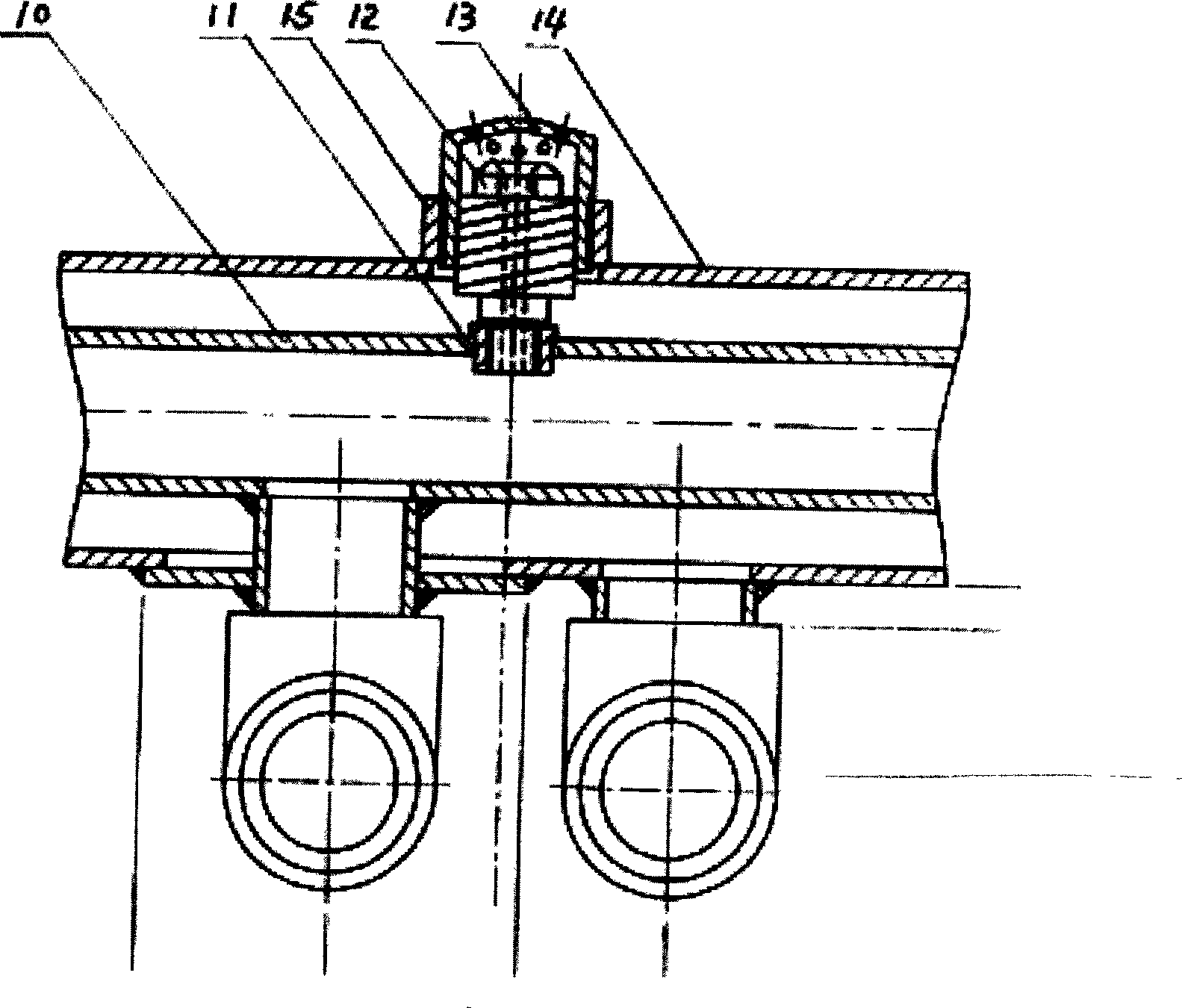

Spray cooling system for transverse thin-film evaporative spray cooling

InactiveUS6955062B2Domestic cooling apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

A spray cooling system for transverse thin-film evaporative spray cooling in a narrow gap which generally includes a framework, a cooling cavity, a plurality of atomizers oriented to transversely spray coolant across the electronic components to be cooled, and preferably a vapor recirculation system and a reduction in cross section from the inlet or spray side to the exit side.

Owner:PARKER INTANGIBLES LLC

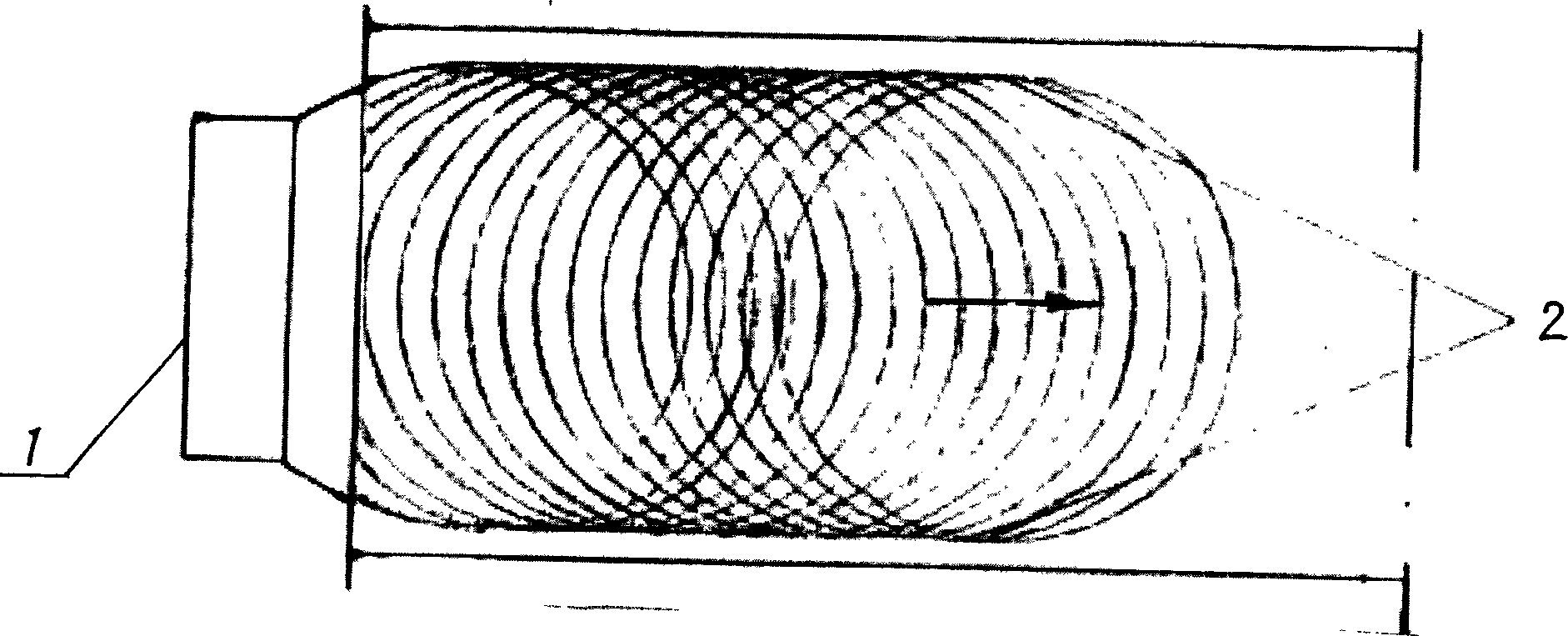

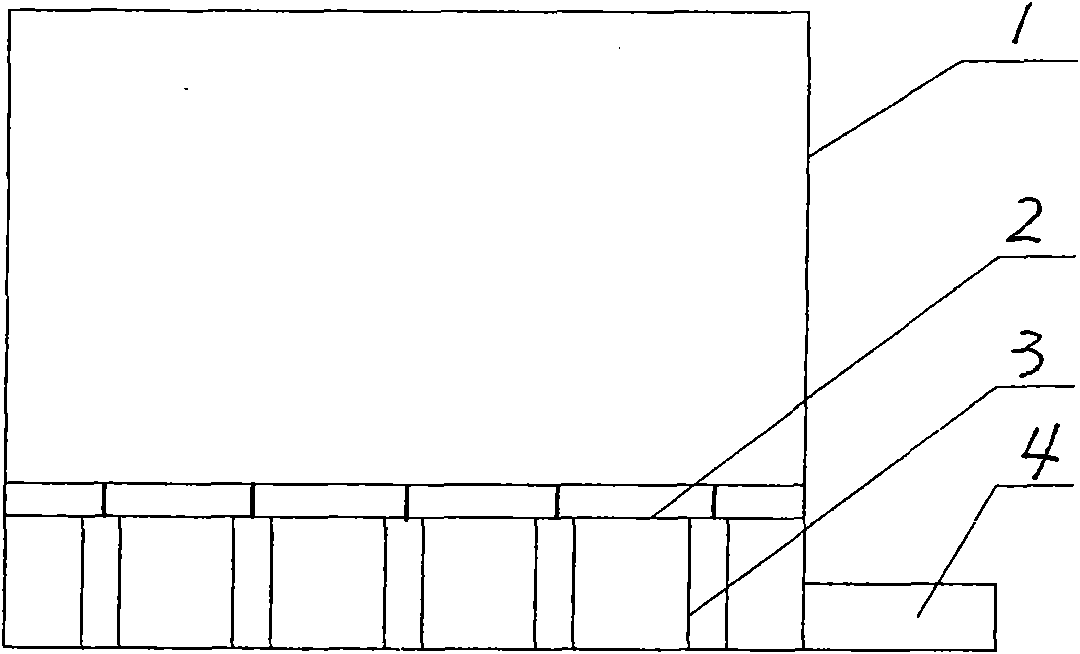

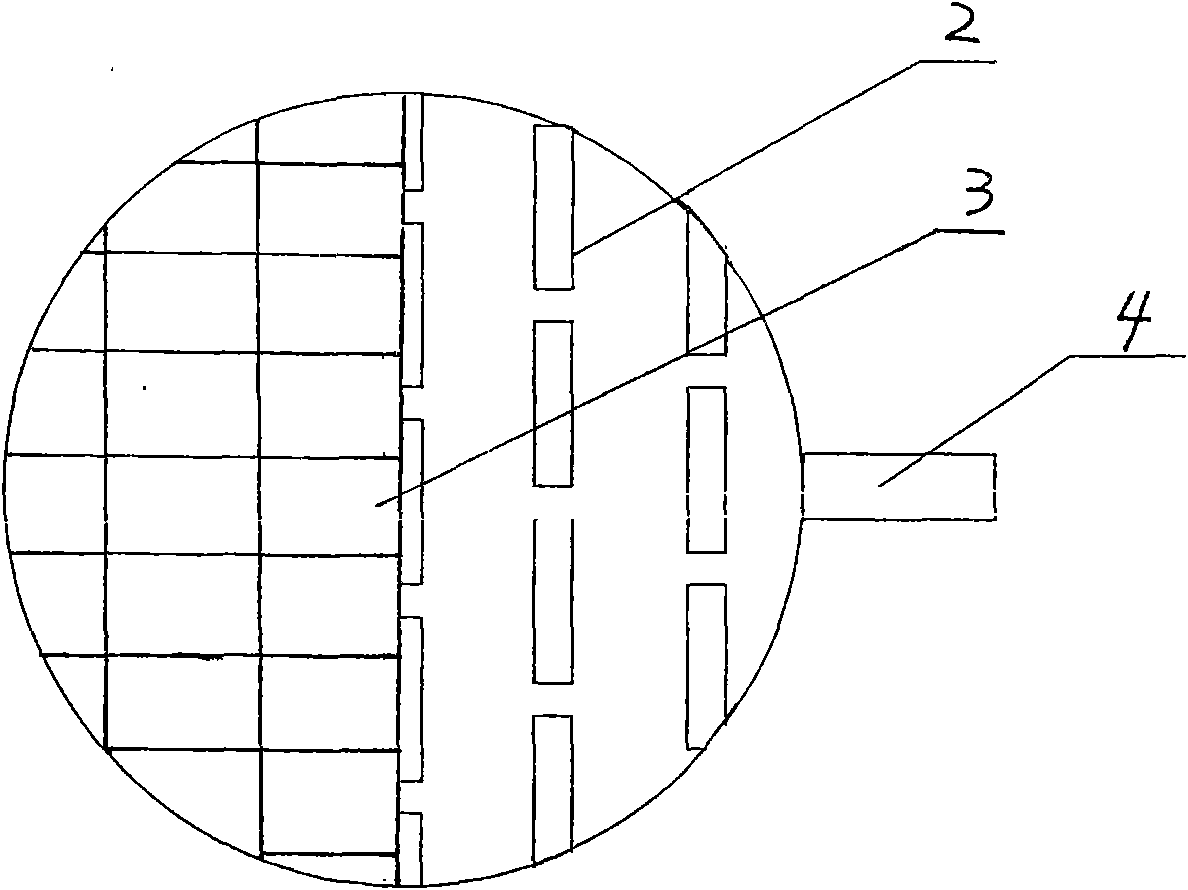

Stelmo line gas spray cooling device and method for high-speed wire rod mill

InactiveCN1603021AControllable water volumeWater pressure adjustableWork treatment devicesMetal rolling arrangementsForced-airEngineering

The invention simultaneously solves building the contact organization, the performance is uneven question. The invention has provides a kind of gas spray cooling system and the method, namely after the spinning machine, style touches in front of the air blower a section of air cooled table place above, two sides symmetrical establishes the gas spray chiller, first builds above the contact from the coil, key to builds the contact to leave the atomization to cool, then style touches the forced-air cooling line again from the underneath forced-air cooling, and uses the' good spirit installment concentratly blowing the contact place. The intensity difference between the line material build contact through the gas spray cooling system and the no build contact is fall to 5~7MPa; The overall intensity of the line material may enhance 20~25MPa; Improves the surface quality; Simultaneously decreases the ambient temperature, improves the operating environment.

Owner:UNIV OF SCI & TECH LIAONING

Spray cooling system for transverse thin-film evaporative spray cooling

InactiveUS20060026983A1Domestic cooling apparatusSemiconductor/solid-state device detailsEngineeringElectronic component

A spray cooling system for transverse thin-film evaporative spray cooling in a narrow gap which generally includes a framework, a cooling cavity, a plurality of atomizers oriented to transversely spray coolant across the electronic components to be cooled, and preferably a vapor recirculation system and a reduction in cross section from the inlet or spray side to the exit side.

Owner:PARKER INTANGIBLES LLC

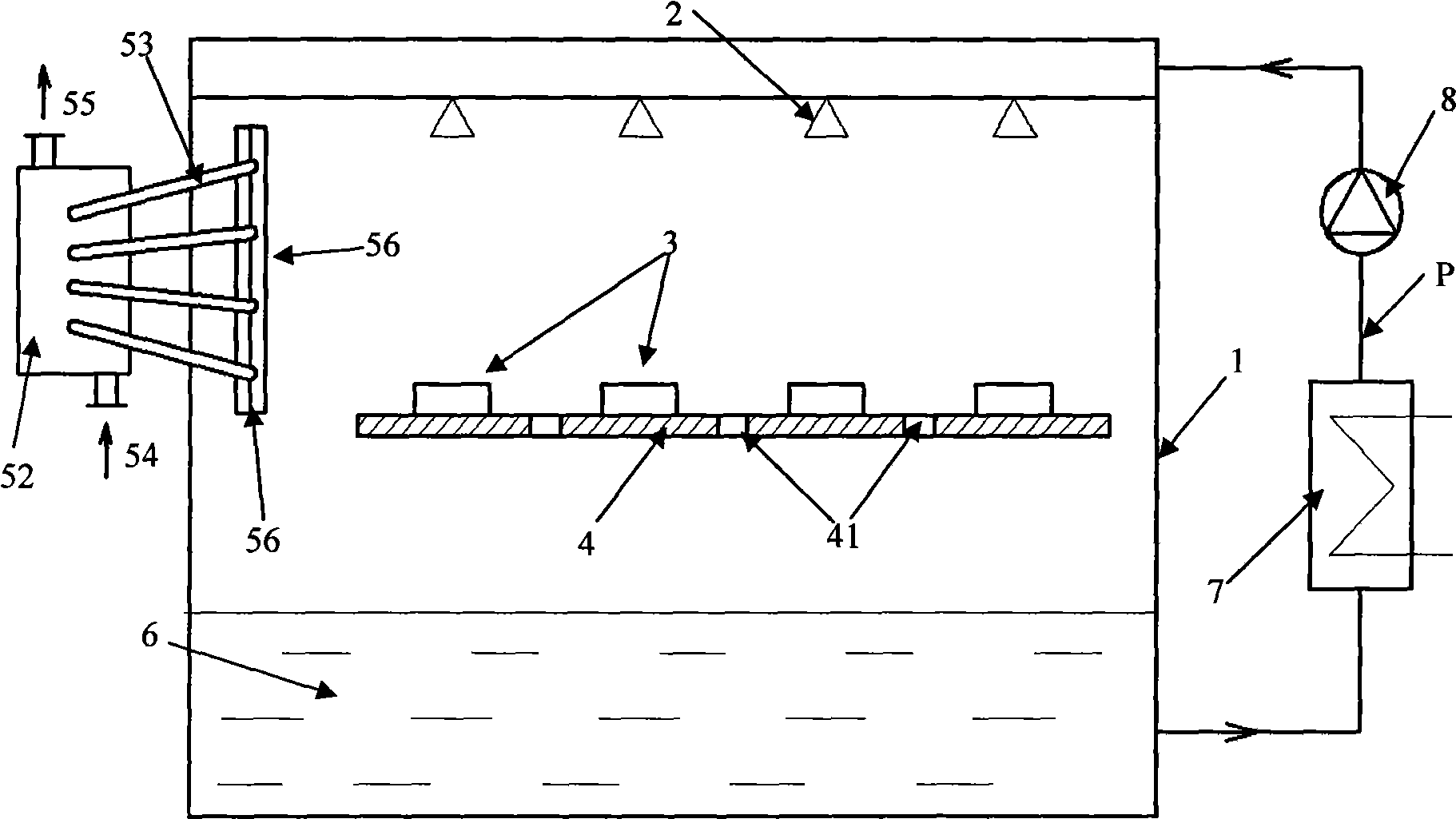

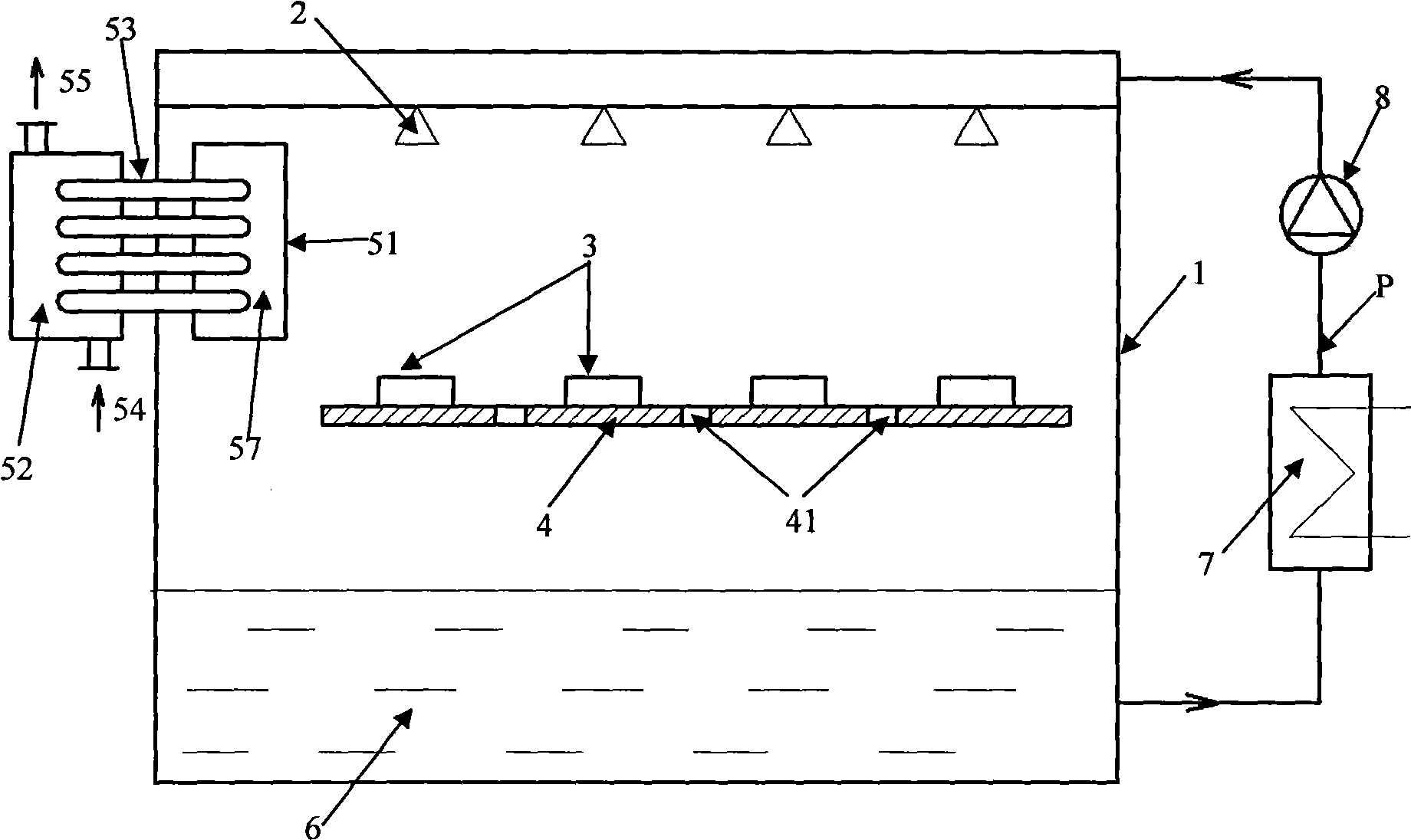

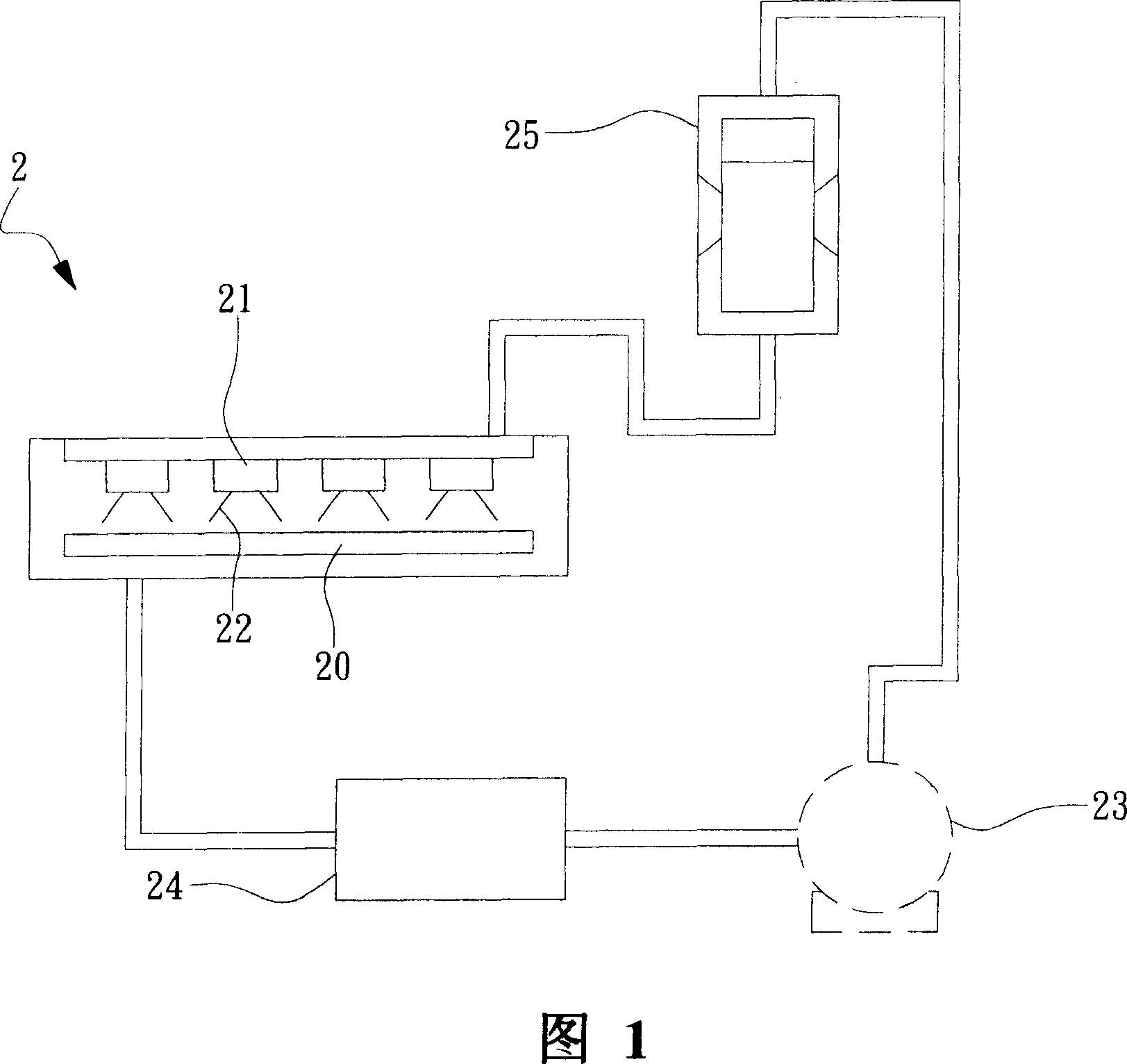

High-effective integral spray cooling system

InactiveCN101534627AReduce heat transfer areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention relates to a high-effective integral spray cooling system, which solves heat dissipation problem in field such as high power electron or laser system. The spray cooling system includes a spray cavity, a heat exchanger, a cooler, a circulating pump and a system working medium circulation pipeline, wherein the heat exchanger is a heat pipe heat exchanger; one end of the heat pipe of the heat pipe heat exchanger is a condensation end, and the other end is an evaporation end; the evaporation end is arranged in the spray cavity and is a steam condenser, and the condensation end is arranged in a water cooling shell-and-tube heat exchanger outside the spray cavity. The invention separates steam cooling and liquid cooling, which is beneficial to respectively increase heat transfer effect in condensation and cooling process; employs the heat pipe condenser to further increase heat transfer performance in condensation process and reduce heat exchange area of the condenser; and arranges the condenser in the spray cavity for making spray cooling structure more compact and reducing flow resistance of working medium steam, thereby reducing operating pressure of the spray cavity and being beneficial to increase general heat dispersion performance of spray cooling.

Owner:UNIV OF SCI & TECH OF CHINA +1

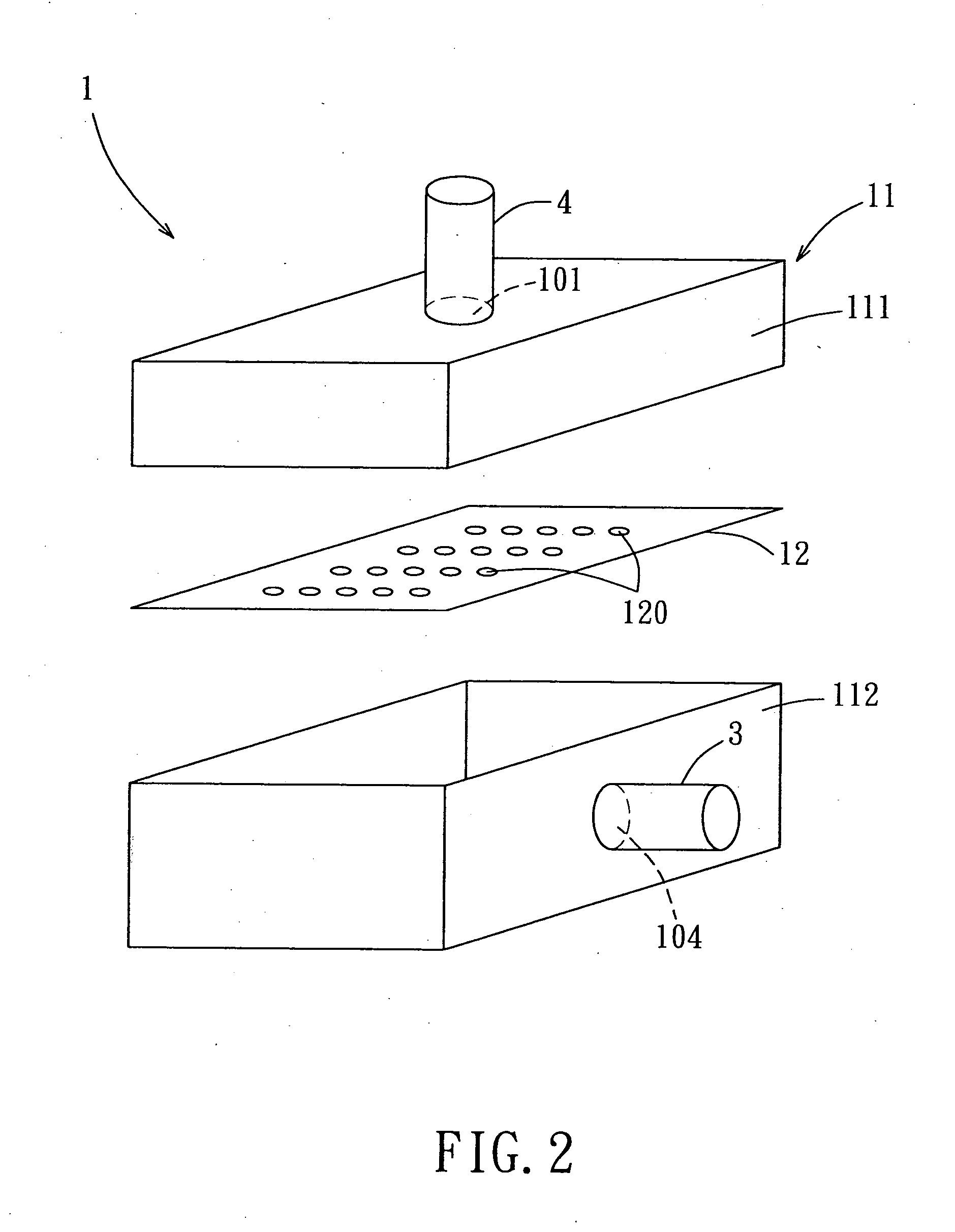

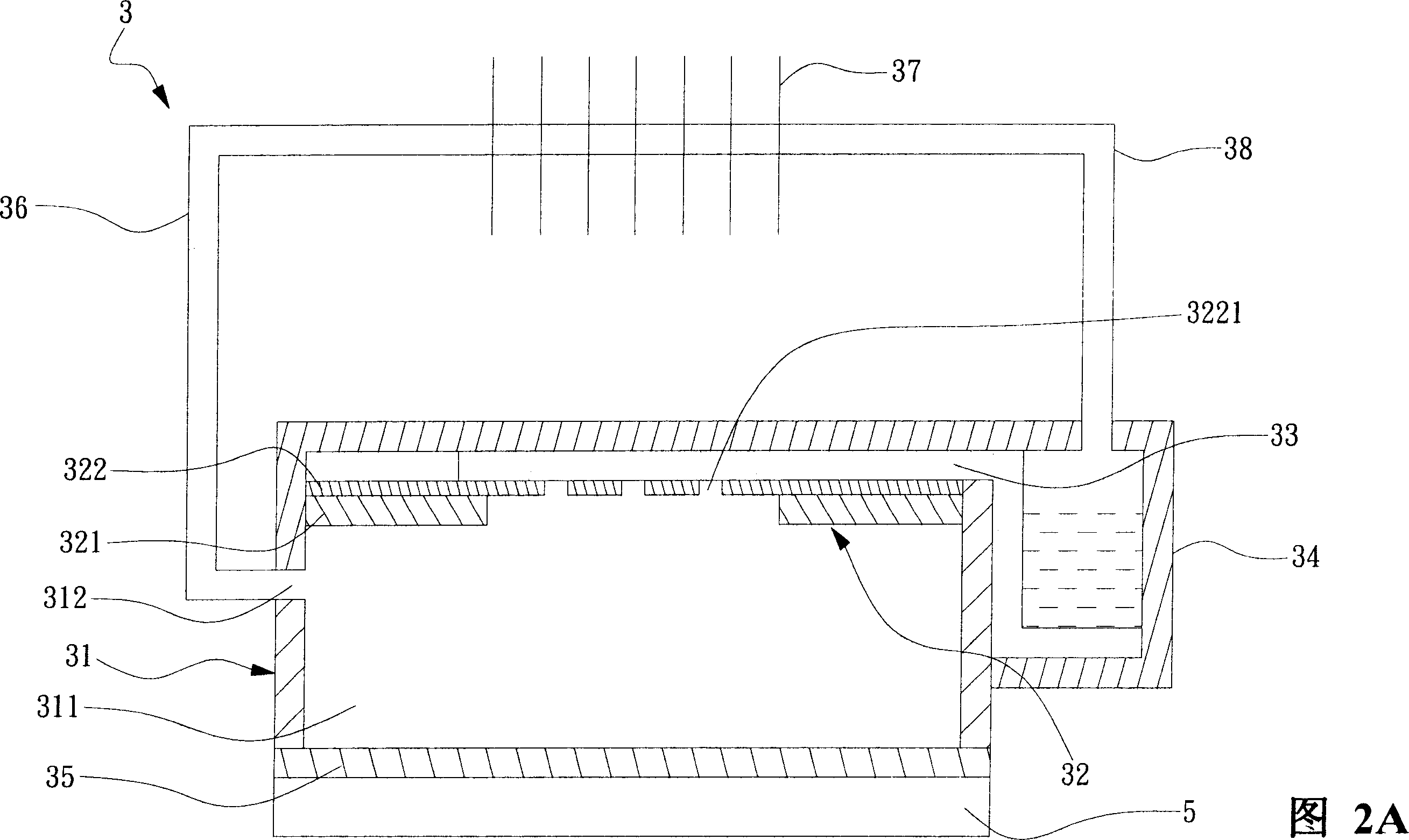

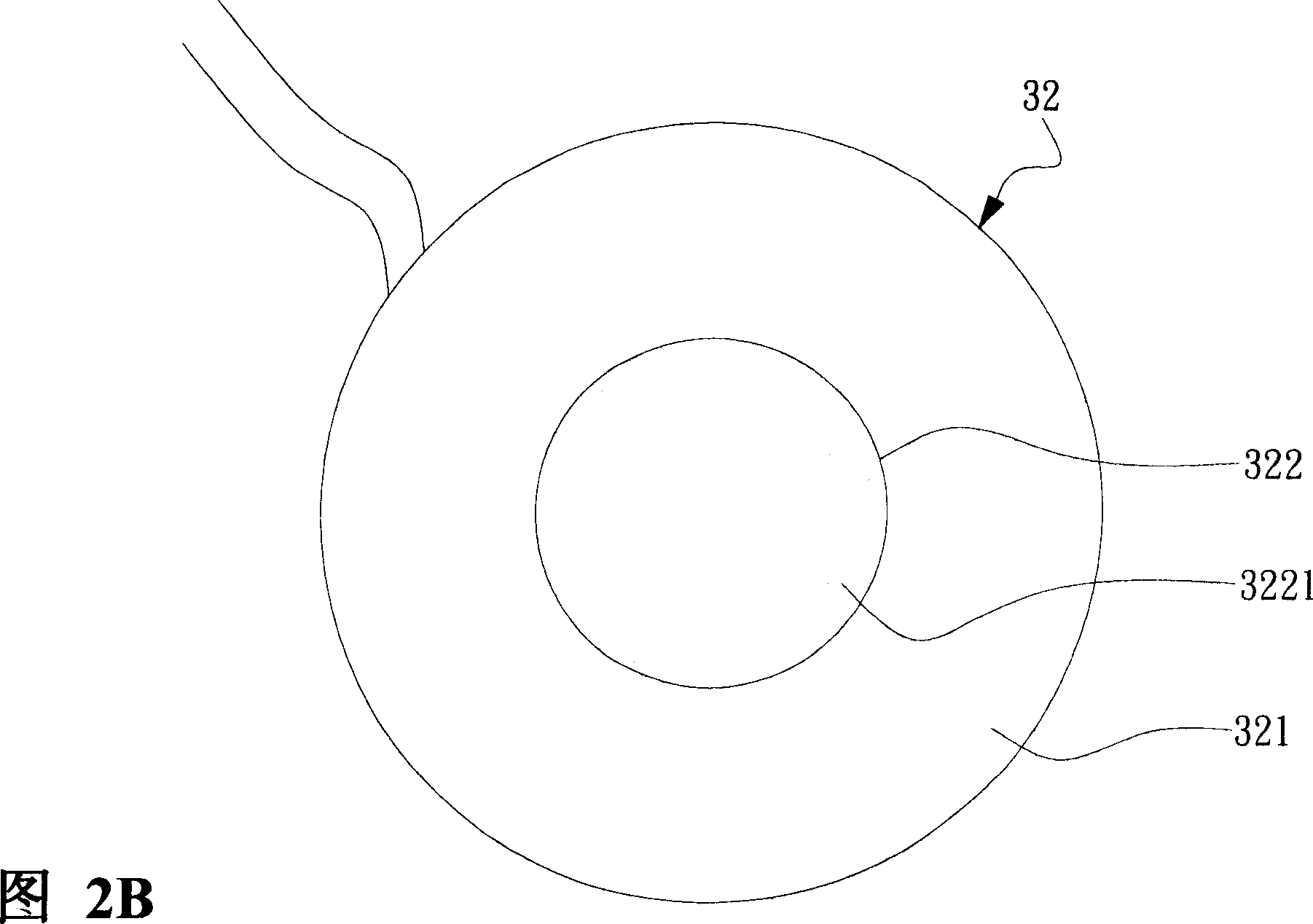

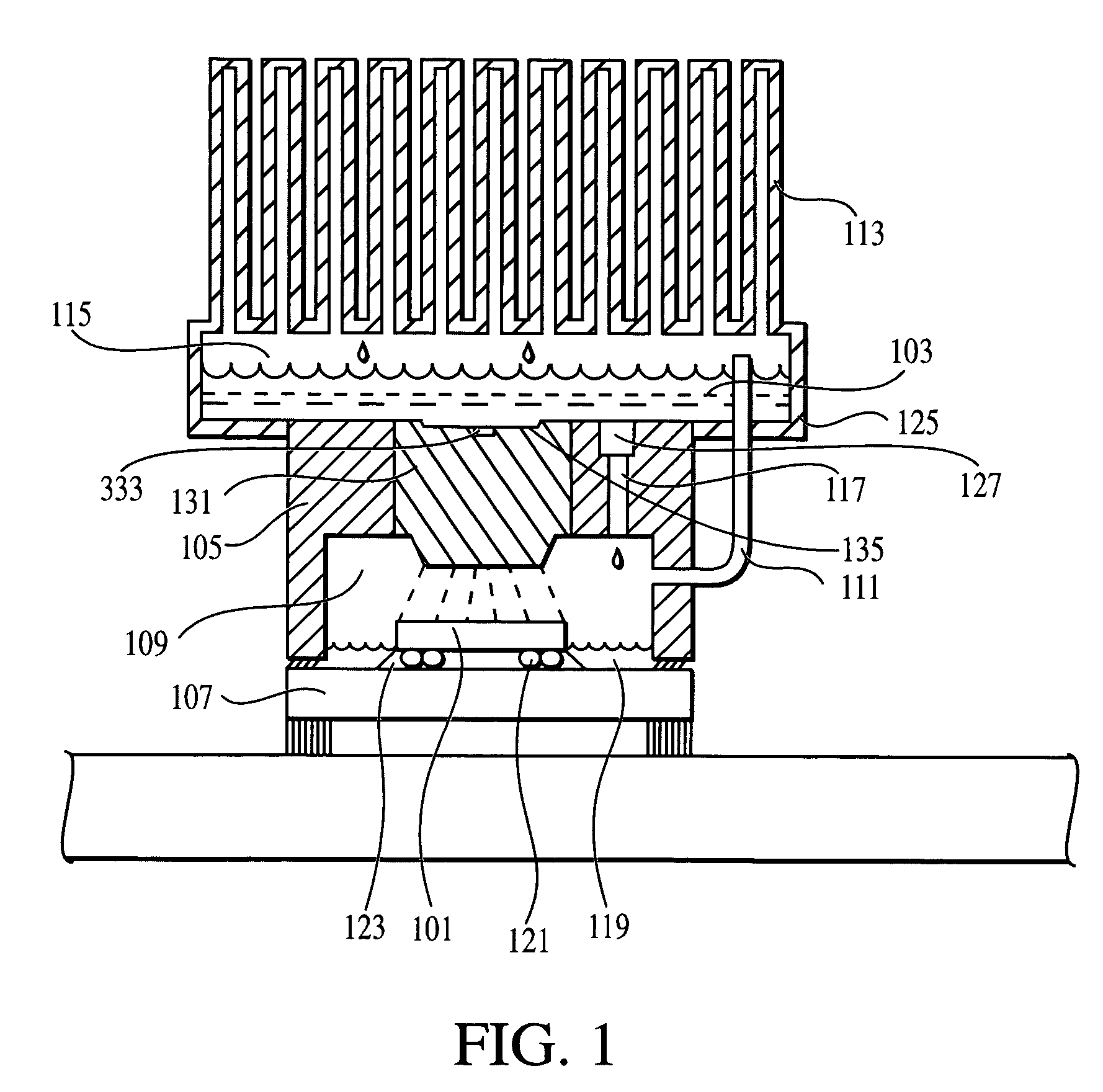

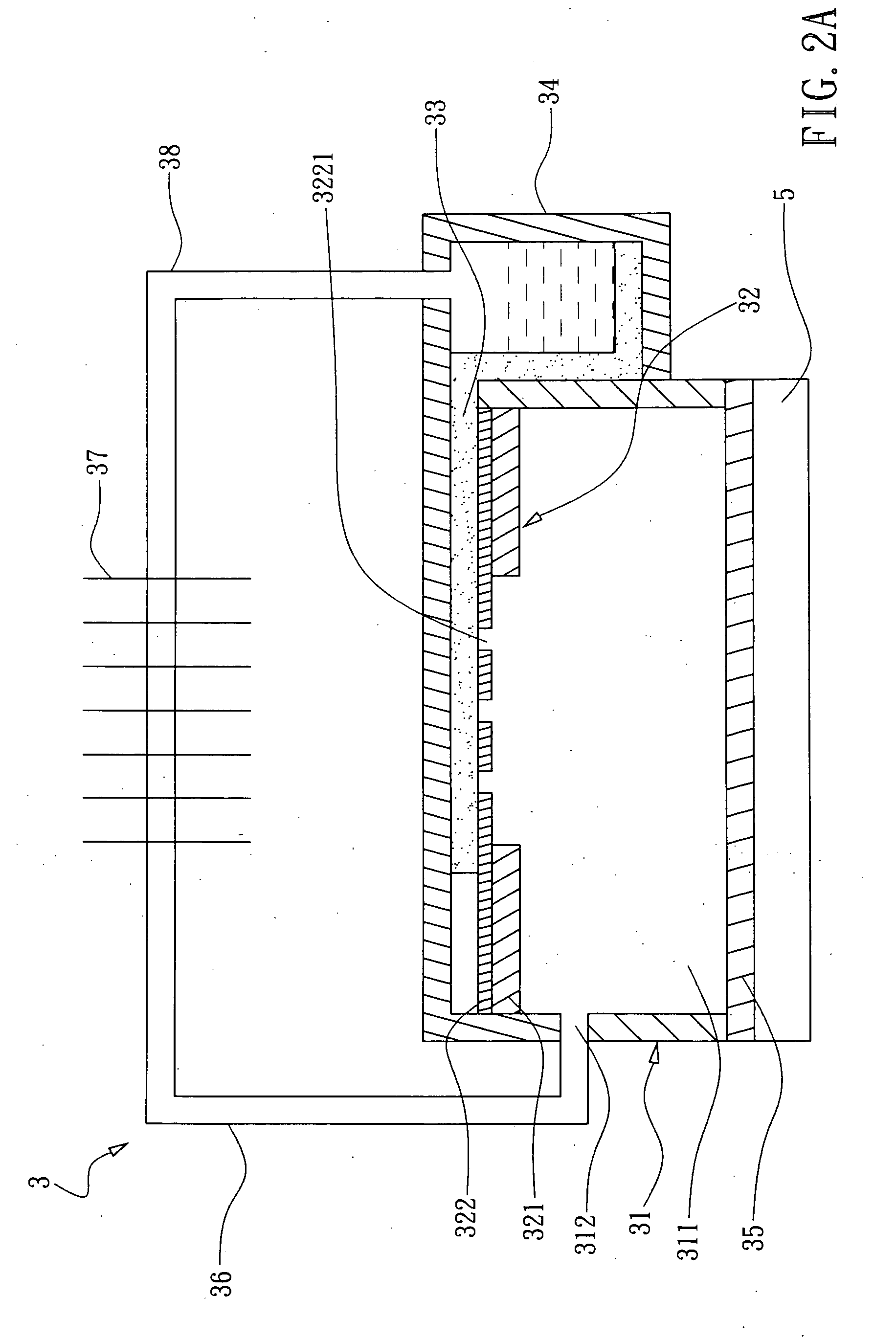

Heat dissipation system with a spray cooling device

InactiveUS20110277491A1Easy constructionSolve the low heat dissipation efficiencySemiconductor/solid-state device detailsSolid-state devicesVena contracta diameterMicrometer

A heat dissipation system includes a cooling device, a condenser, a vapor conveying duct and a cooling liquid conveying duct. The cooling device includes a housing, and an orifice plate dividing an inner space of the housing into a liquid supply chamber and an evaporation chamber proximate to the heat source, and formed with multiple micro orifices each having a diameter ranging from 5 to 1000 micrometers. The condenser includes a fluid inlet, a condensing chamber and a fluid outlet. The vapor conveying duct connects a vapor outlet of the housing and the fluid inlet of the condenser. The cooling liquid conveying duct connects a cooling liquid inlet of the housing and a fluid outlet of the condenser.

Owner:MICRO BASE TECH CORP

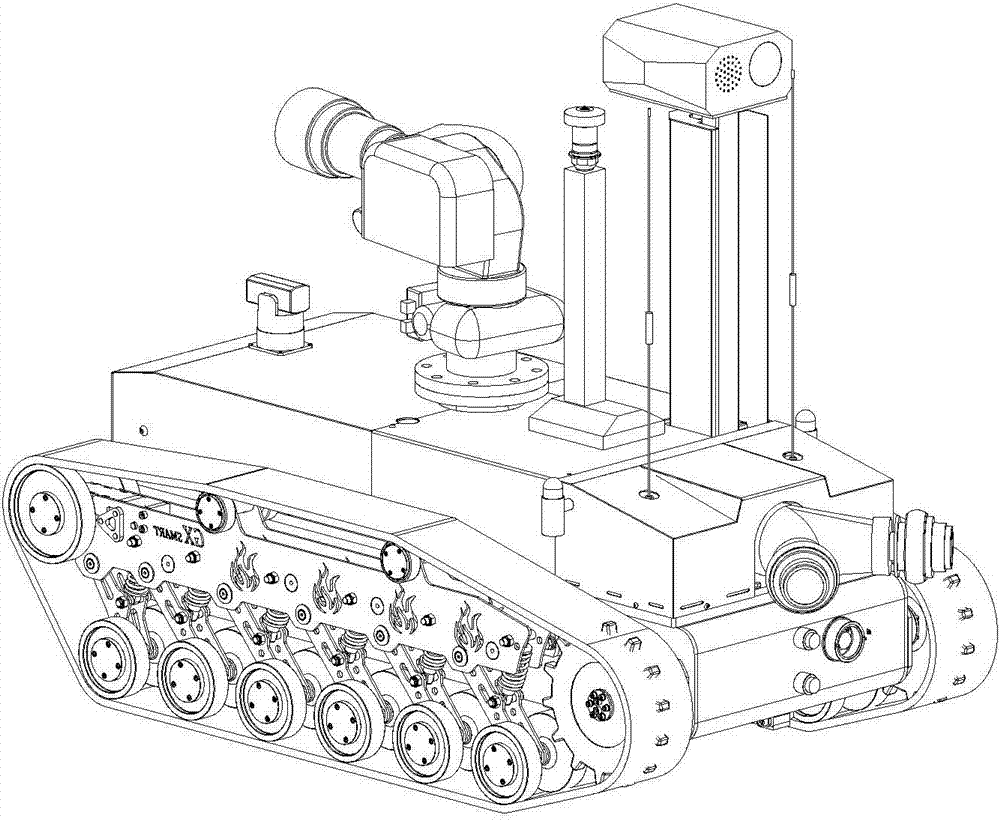

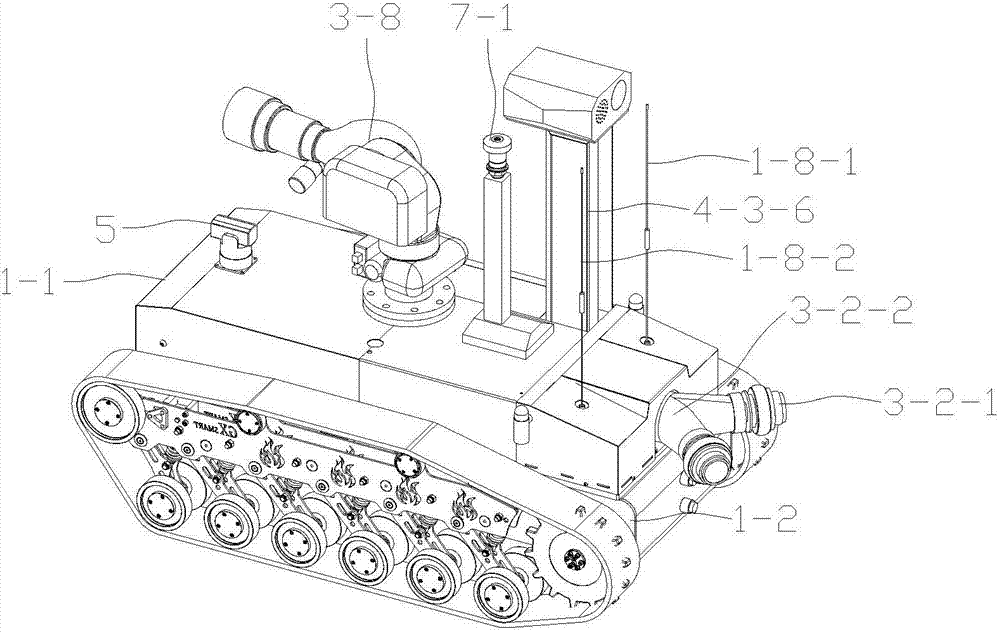

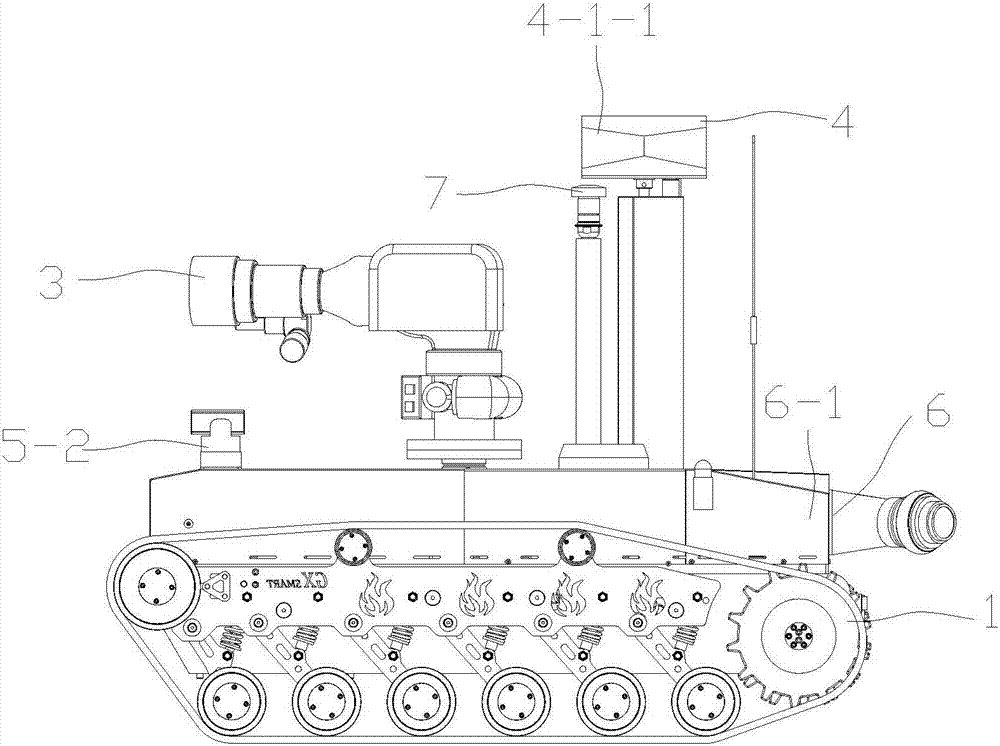

Anti-explosion fire reconnaissance firefighting robot and working method

The invention relates to an anti-explosion fire reconnaissance firefighting robot which comprises an anti-explosion fire reconnaissance firefighting robot movable base plate, a manipulation control box, an anti-explosion fire water monitor, an anti-explosion reconnaissance assembly, an anti-explosion road condition shooting assembly, an anti-explosion fire hose falling-off assembly and an anti-explosion self-spraying cooling assembly. The movement and safe properties of the fire reconnaissance firefighting robot under the environments of the complex ground and severe disasters are improved; the anti-explosion capacity and the waterproof property of the fire reconnaissance firefighting robot are improved; the loading capacity of the fire reconnaissance firefighting robot is improved; and the tensile capacity, the obstacle crossing ability, the stair climbing capacity and the capacity of passing of a 'unilateral bridge' with the left portion and the right portion being different in height during dragging of a fire hose from the rear portion are improved. It is ensured that when flames burn a fire reconnaissance firefighting robot body or a track, the fire reconnaissance firefightingrobot can still move; and the success self-protection rate during robot withdrawing is increased, the automation degree of the robot is increased, the application range of the fire reconnaissance firefighting robot is enlarged, and the practicability of the fire reconnaissance firefighting robot is improved.

Owner:SHANDONG GUOXING SMARTECH CO LTD +1

Etched open microchannel spray cooling

ActiveUS20050185378A1Improve performancePotentially efficientDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic componentSpray cooling

The present invention is a spray cooling thermal management device that cools an electronic component. Liquid coolant is dispensed upon a heated surface containing etched open microchannels.

Owner:PARKER INTANGIBLES LLC

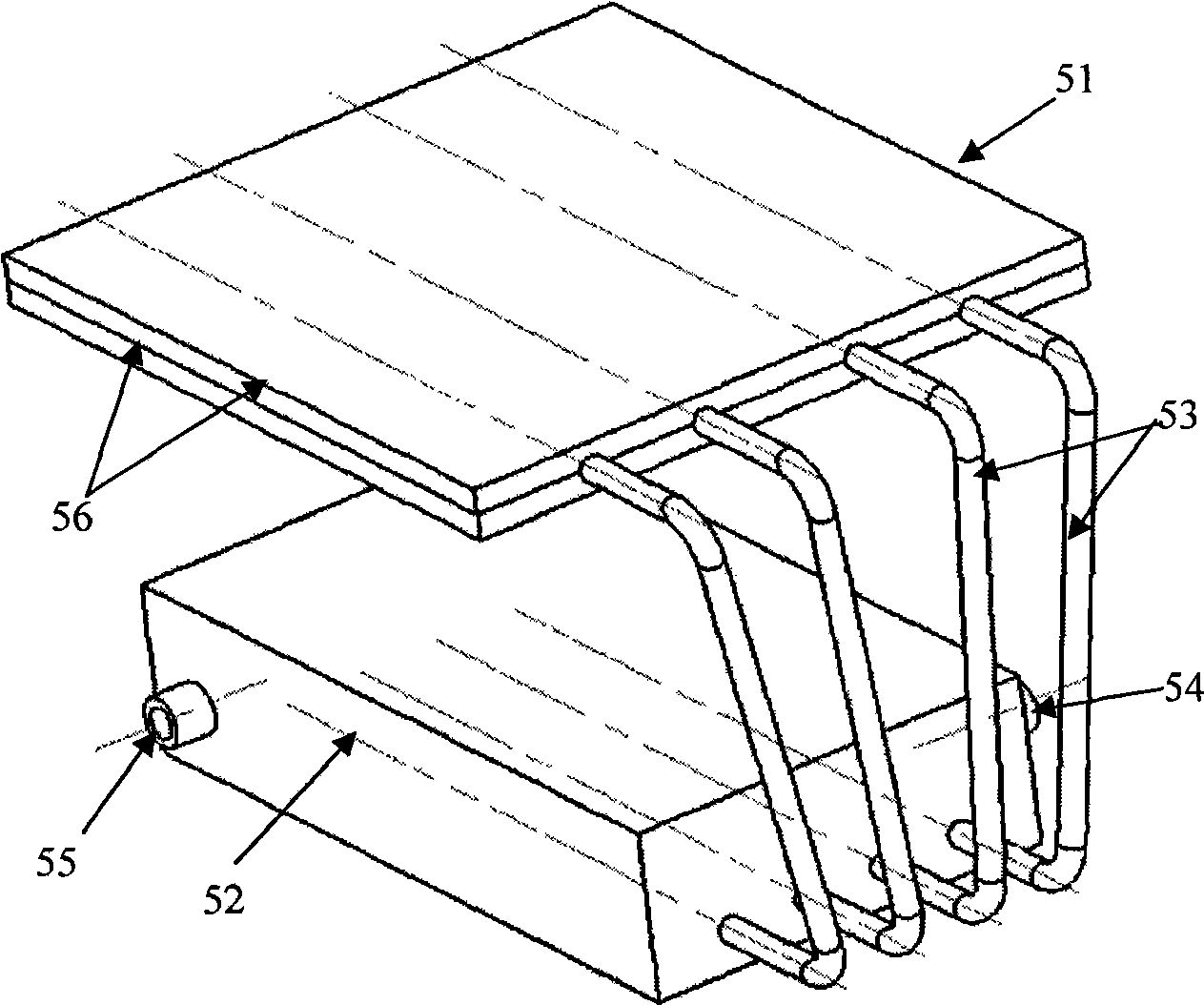

Compact spray cooling heat exchanger

InactiveCN1993030AReduce power consumptionReduce volumeSemiconductor/solid-state device detailsEvaporators/condensersThermal energyPlate heat exchanger

The invention relates to a compact atomization cooling radiator, which comprises liquid groove for storing cooling liquid; atomizing chamber connected to the thermal source; atomizer above the chamber which has piezoelectric plate and porous plate with several ejection holes; the atomizer can atomize the cooling liquid to generate atom in the atomizing chamber to take away thermal energy; and it also has one liquid transmitter for adsorbing the cooling liquid in the groove to the atomizer. The invention also can have condenser and transmission tube, to form a compact sealed atomization cooling radiator.

Owner:IND TECH RES INST

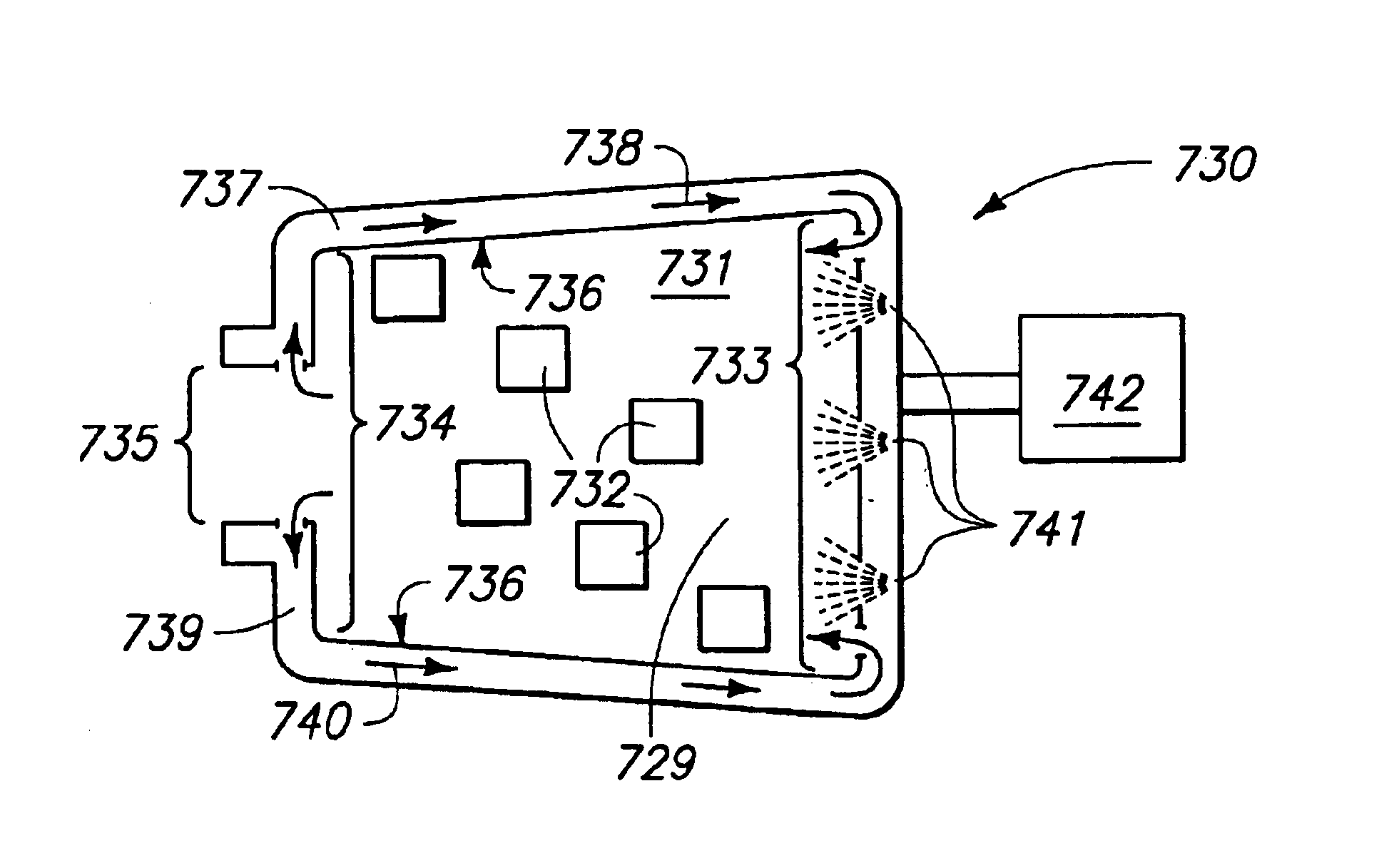

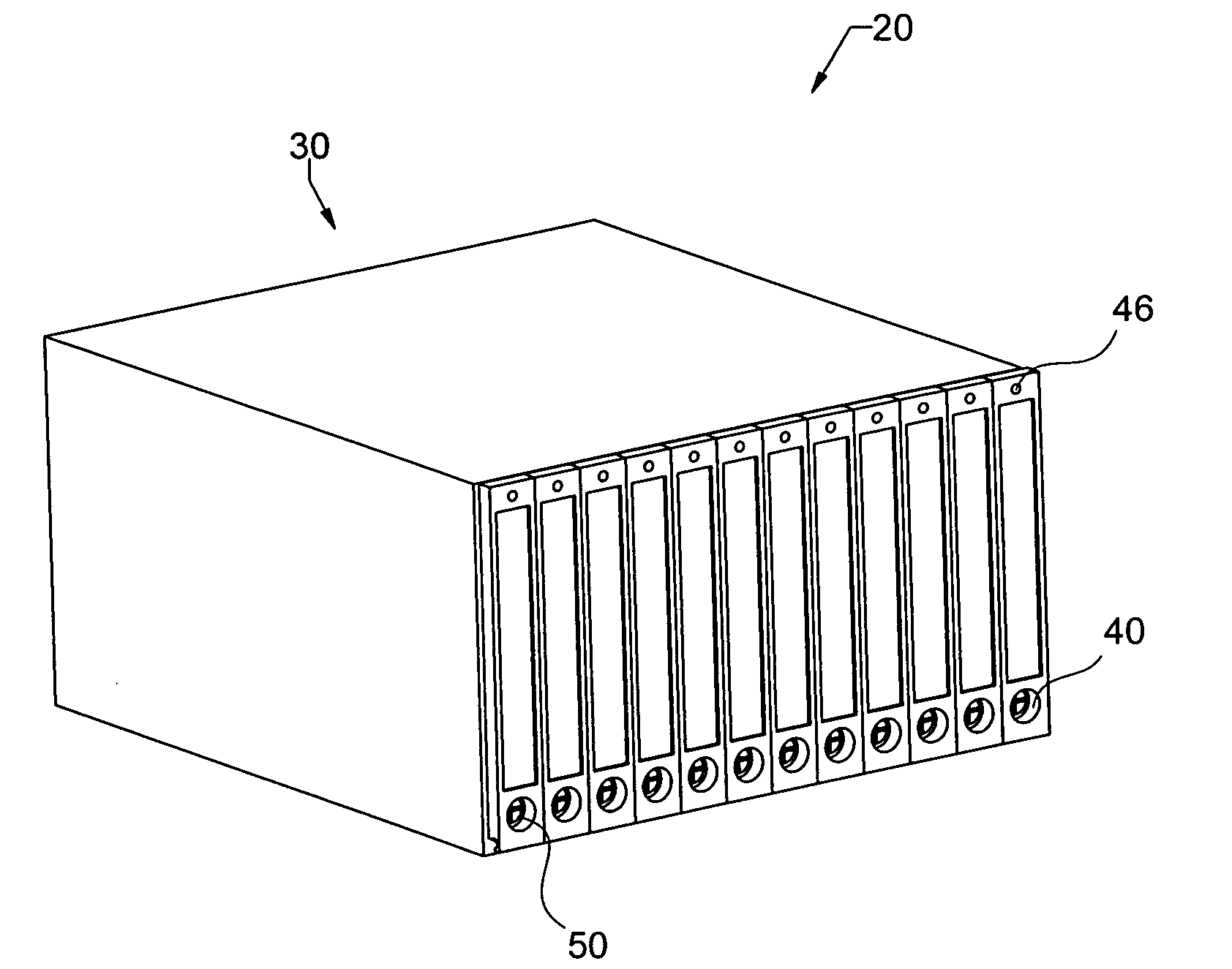

Multi-chamber spray cooling system

InactiveUS20070199340A1Effective heat transfer rateEffective isolationPrinted circuit board receptaclesDrying chambers/containersCooling chamberHot swapping

The present invention uses multiple global cooling chambers for providing liquid cooling to a plurality of electronic components. The global cooling chambers utilize a non-electrically conductive fluid which is in direct contact with the components to be cooled. The system provides very effective heat transfer rates, environmental isolation of the electronics components and can be deployed in a wide range of applications. Multiple global cooling chambers allows for the hot swapping of cards during operation of the system.

Owner:ISOTHERMAL SYST RES

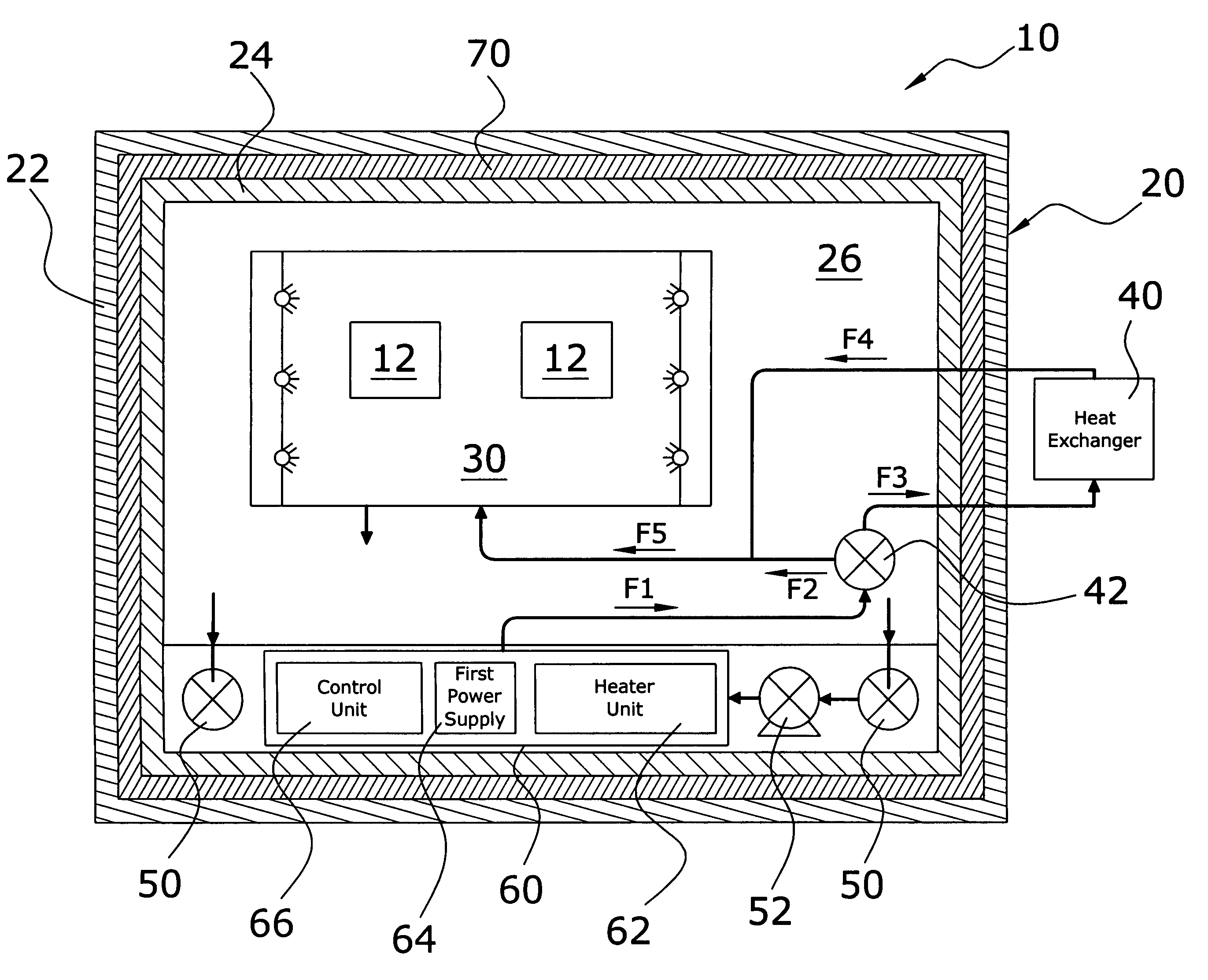

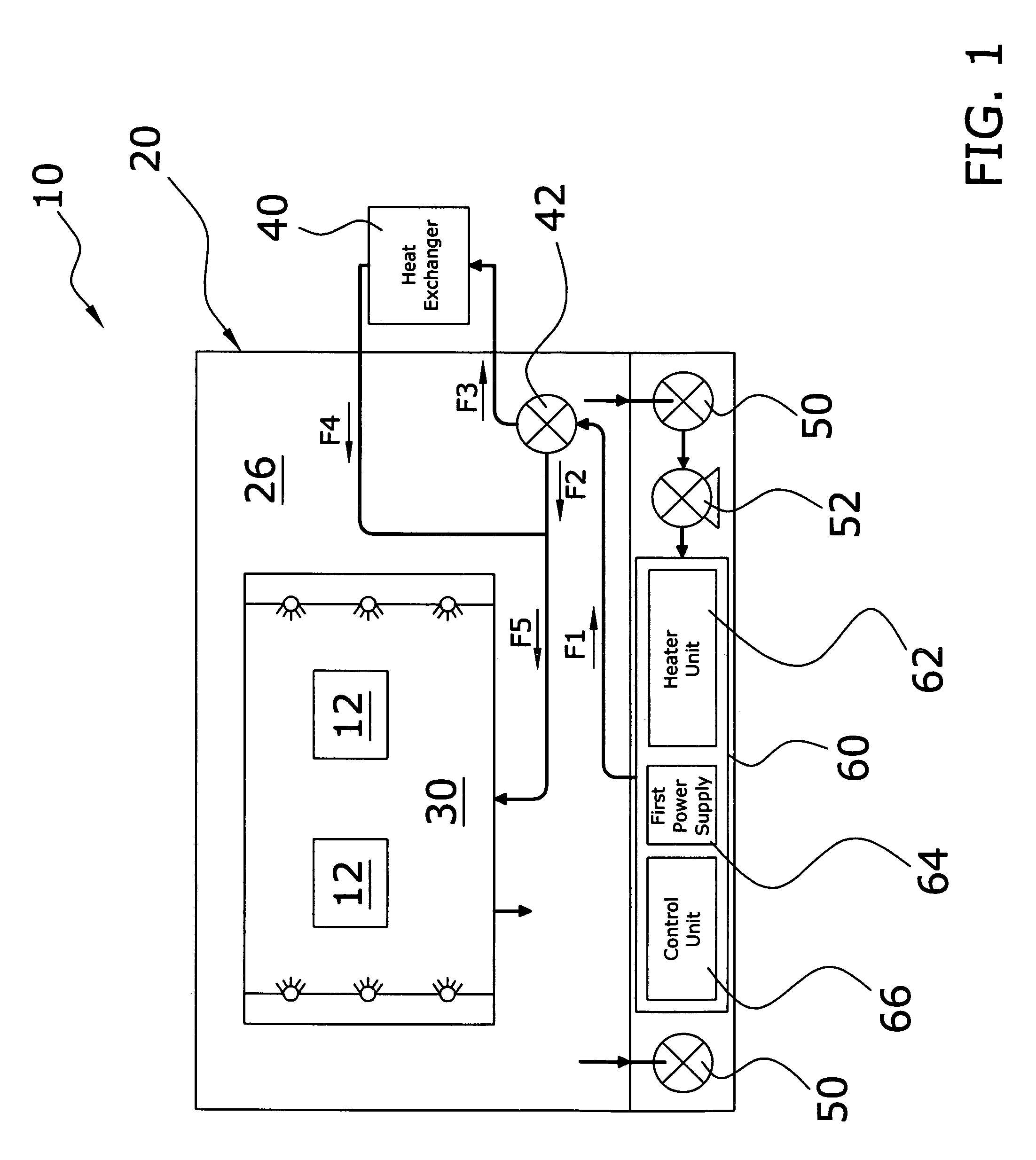

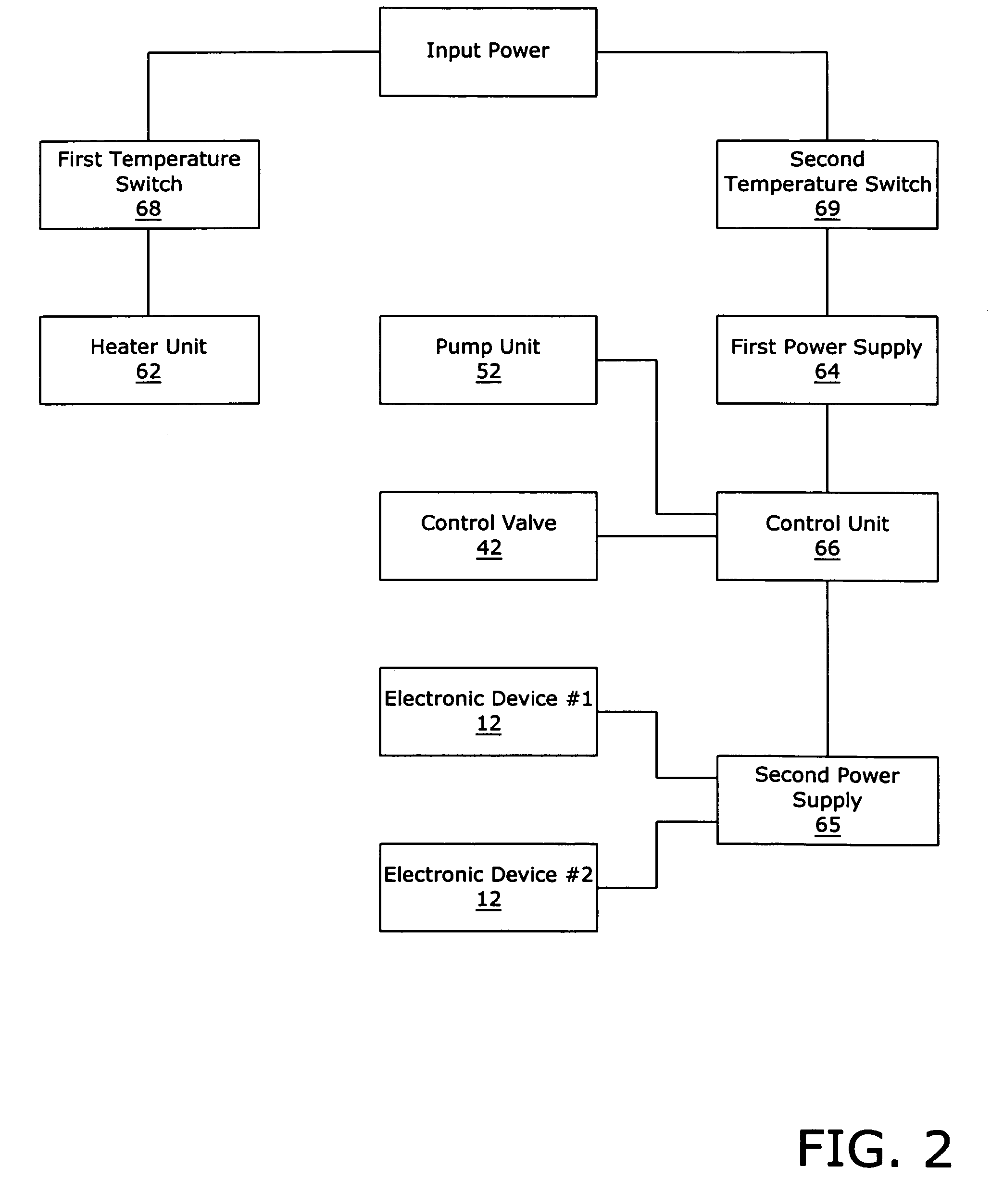

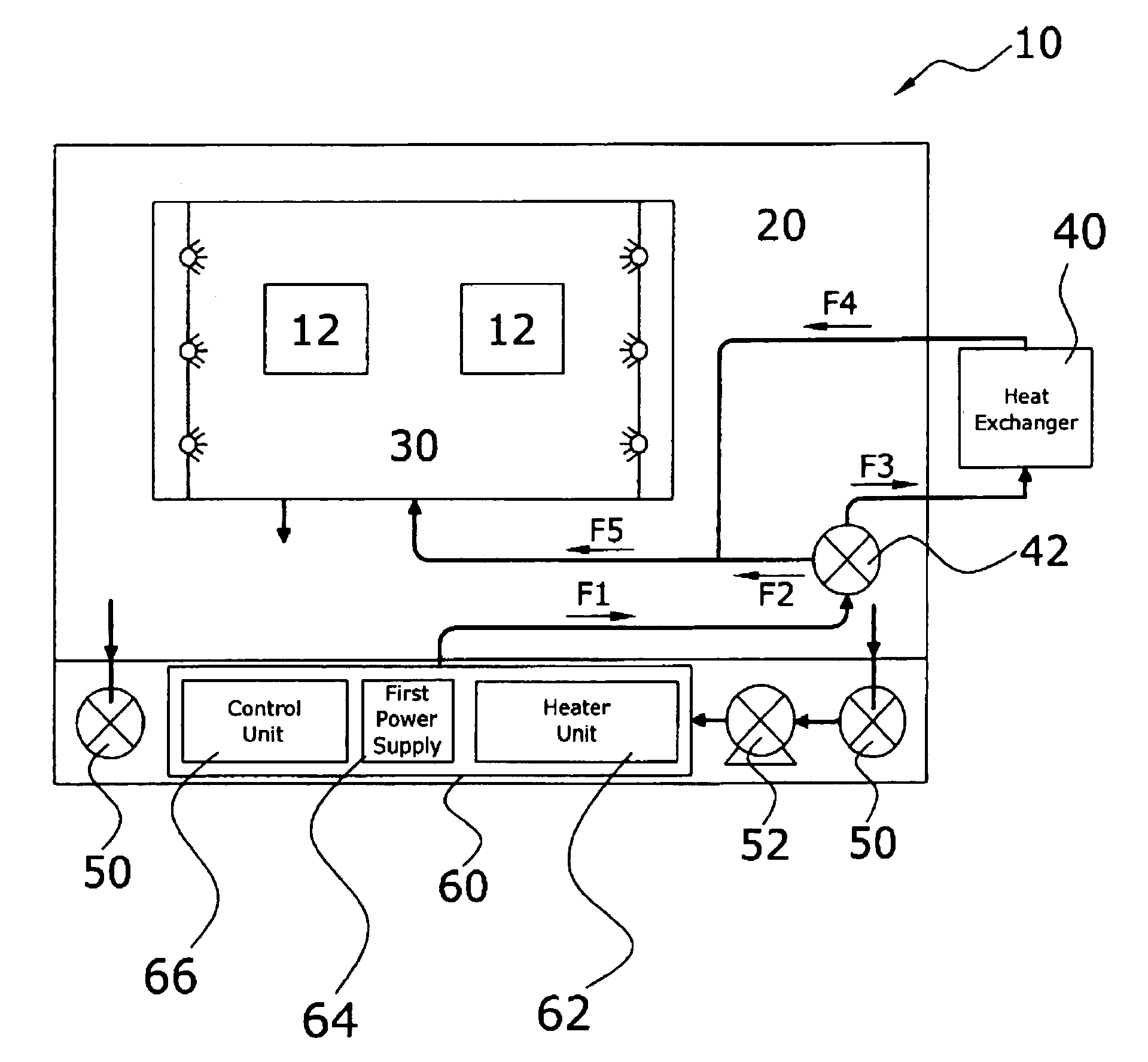

Insulated spray cooling system for extreme environments

ActiveUS7806166B1Improve electronic performanceLimitation for transferSemiconductor/solid-state device detailsSolid-state devicesSpray coolingExtreme environment

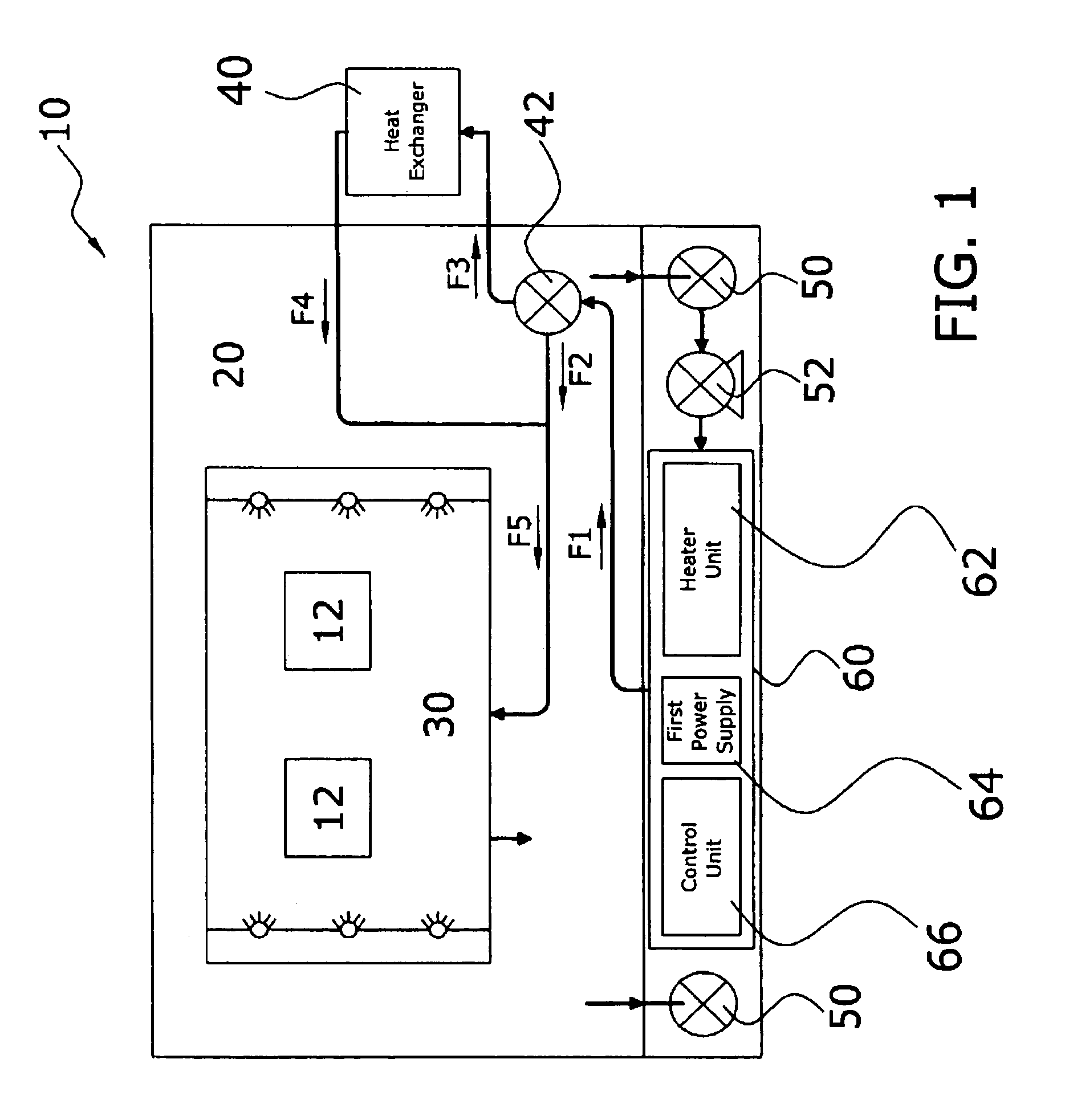

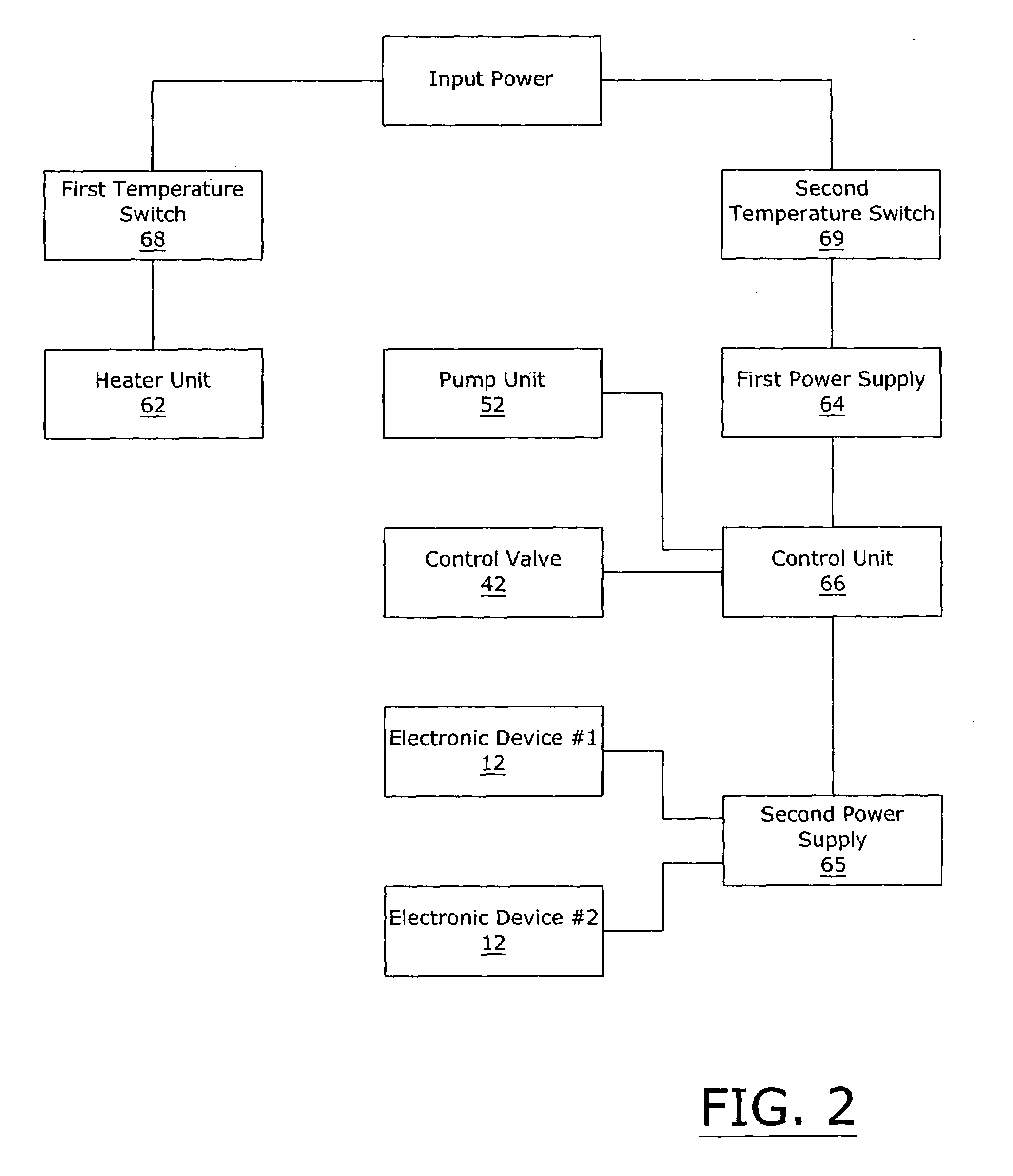

An insulated spray cooling system for extreme environments for providing a desired enclosed environment for electronic devices regardless of external environmental conditions. The insulated spray cooling system for extreme environments includes an insulated enclosure that isolates the electronic devices being thermally managed from the external environment and a thermal management unit within the enclosure for thermally managing electronic devices.

Owner:PARKER INTANGIBLES LLC

Multi-state spray cooling system

ActiveUS7134289B2Easy to operatePrecision coolingSemiconductor/solid-state device detailsEvaporators/condensersNuclear engineeringPower usage

A cooling system including a thermosyphon subsystem and a spray cooling subsystem, each being configured to evaporatively cool a component, and a controller configured to selectively operate the spray cooling subsystem based on the cooling requirements of the component. The controller controls a valve limiting the operation of the thermosyphon when the spray cooling system is active. The component is configured to run in a plurality of performance states including a low power state and a high power state. The spray cooling system operates when the component is in the high power state. The controller can order the component to operate in a lower power state if the cooling systems are inadequate to the cooling needs. The cooling needs are determined with a component temperature sensor, a vapor temperature sensor, a vapor pressure sensor, or a power usage sensor.

Owner:SK HYNIX INC

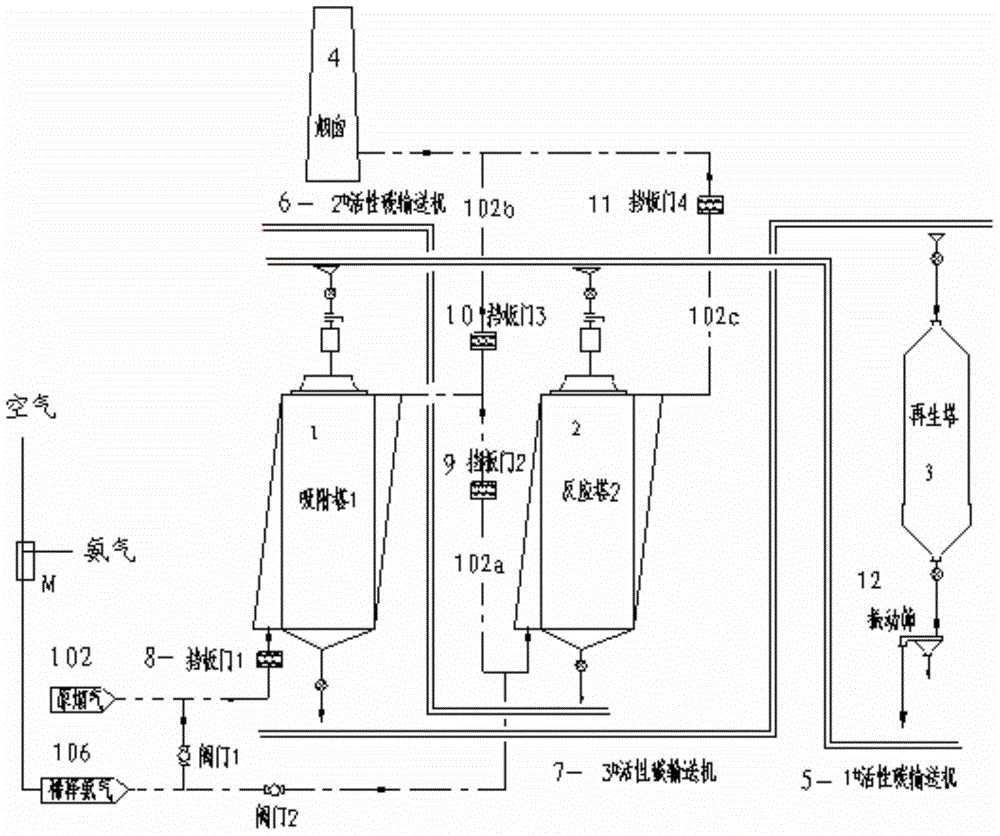

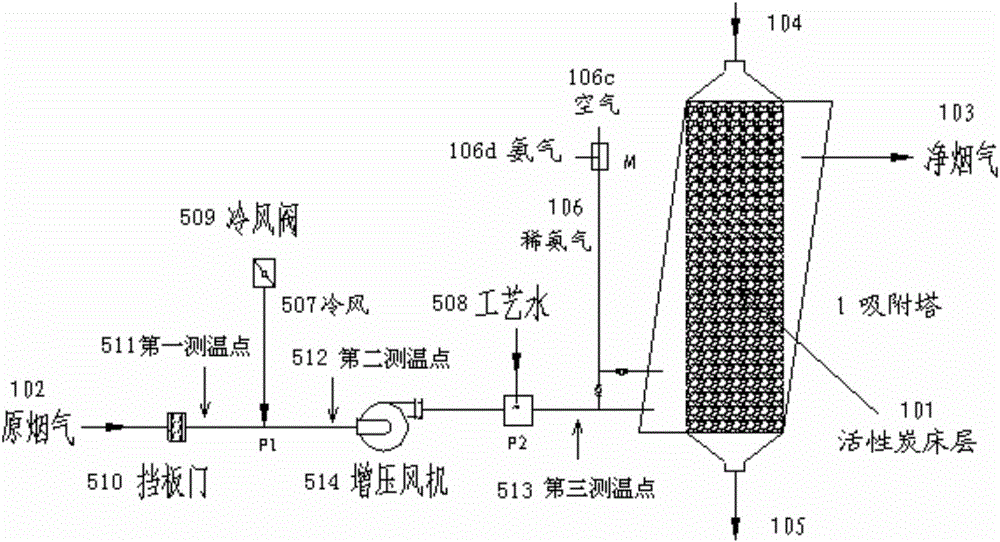

A flue gas desulphurization denitration method adopting two adsorption columns in series connection and a device therefor

ActiveCN105688622AIncrease flexibilityImprove denitrification rateDispersed particle separationSpray coolingEnvironmental geology

A flue gas desulphurization denitration method adopting two activated-carbon adsorption columns (1, 2) in series connection and comprising a flue gas temperature control apparatus and a device therefor are provided. The method includes I) a step of flue gas temperature control and II) a step of desulphurization and denitration, wherein the step of flue gas temperature control comprises (1) a step of subjecting flue gas to first time of cooling by feeding cold air into a flue conveying high-temperature flue gas to activated-carbon adsorption columns from a cold-air inlet at an upstream position (P1) of the flue, (2) spraying cooling water or cold water mist into the flue gas in the flue from a process water spray nozzle at the downstream position (P2) of the position (P1) from which the cold air is fed, and allowing the flue gas to flow along the flue to the adsorption columns, and (3) feeding diluted ammonia gas into the flue gas in the adsorption columns after the flue gas is fed into gas feeding chambers of the adsorption columns. The temperature of the flue gas fed into the adsorption columns is controlled by mixing with the cold air and spraying water. The two activated-carbon adsorption columns (1, 2) in series connection are adopted to significantly increase the denitration efficiency of the device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Hotspot spray cooling

InactiveUS20050183844A1Improve performancePotentially efficientSemiconductor/solid-state device detailsSolid-state devicesHeat fluxNuclear engineering

The present invention is a spray cooling thermal management device that cools an electronic component creating a varying amount of heat across its surfaces. Liquid coolant is dispensed upon the surface of the component. In areas of the chip that generate large heat fluxes, typically referred to as the core, the liquid coolant is dispensed as a continuous atomized droplet pattern. The atomized pattern creates a high heat flux evaporative cooling thin-film over the one or more core areas. Rather than optimize the atomized pattern and flow based upon complete thin-film vaporization, the present invention optimizes the atomized pattern for maximum heat removal rates. Any excess, non-vaporized, fluid flowing outward from the hotspot is used to cool the lower heat flux (non-core) areas of the component through the creation of a thick coolant film thereon.

Owner:ISOTHERMAL SYST RES

Composite biological activated carbon and rapid preparation method thereof

InactiveCN101643208AExtended service lifeSolve the technical problems of long carbonization timeSpontaneous combustionBiological activated carbon

The invention discloses a composite biological activated carbon and a rapid preparation method thereof, raw materials thereof comprise coconut shell, bamboo, rice hull, sawdust, wheat straw or rice straw, or the raw materials thereof comprise the rice hull, the sawdust, the wheat straw or the rice straw, corn stalk or corn core, the raw materials are smashed to prepare columnar granules, the direct heating method of the spontaneous combustion type granules is adopted for preparing the carbon, a fixed layer is paved at the bottom of a furnace by taking the granules as the raw materials, the fixed layer is ignited by using ignition materials, the feeding is adopted at the upper part of the furnace and the air induction is carried out at the lower part of the furnace for accelerating carbonization of the granules, the air induction is stopped after the carbonization of the granules, the temperature in the furnace is kept at 430-700 DEG C, the spray cooling method is adopted for activatingand cooling the granular carbon, and a finished product is prepared after 20-30 minutes. A plurality of raw materials are mixed, and more pores are naturally formed, thereby expanding the specific surface area of the carbon, greatly increasing effective micropores, leading the absorption performance to be greatly better than the existing activated carbon of single material and reflecting the unique advantages of the composite material.

Owner:徐克文

Slag washing water steam recycling and white fog removing system and recycling method

PendingCN107815514ADesaturationAvoid it happening againBlast furnace detailsDischarge devicesSlagDihydrogen oxide

The invention provides a slag washing water steam recycling and white fog removing system and a recycling method. The slag washing water steam recycling and white fog removing system comprises a slagwashing water steam chimney close to a blast furnace, at least one cooling spraying device and a hot air furnace assembly; the lower portion of the slag washing water steam chimney can contain waste slag discharged out of the blast furnace and carries out slag washing operation, the cooling spraying devices are arranged in the middle of the slag washing water steam chimney and spray atomized waterto the lower portion of the slag washing water steam chimney, the hot air furnace assembly is communicated with the blast furnace and the upper portion of the slag washing water steam chimney, the hot air furnace assembly can convey generated hot air into the blast furnace, and conveys the treated waste gas to the upper portion of the slag washing water steam chimney, the mist spraying cooling direct heat exchange manner is adopted, the cooling efficiency is high, in combination with the humidity and condensation effect of atomized water, a small amount of water is sprayed, and therefore a large amount of water steam can be recycled, water steam which is not condensed is subject to waste gas temperature rise dilution, the water steam saturability is reduced, and white smoke is prevented from being generated.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

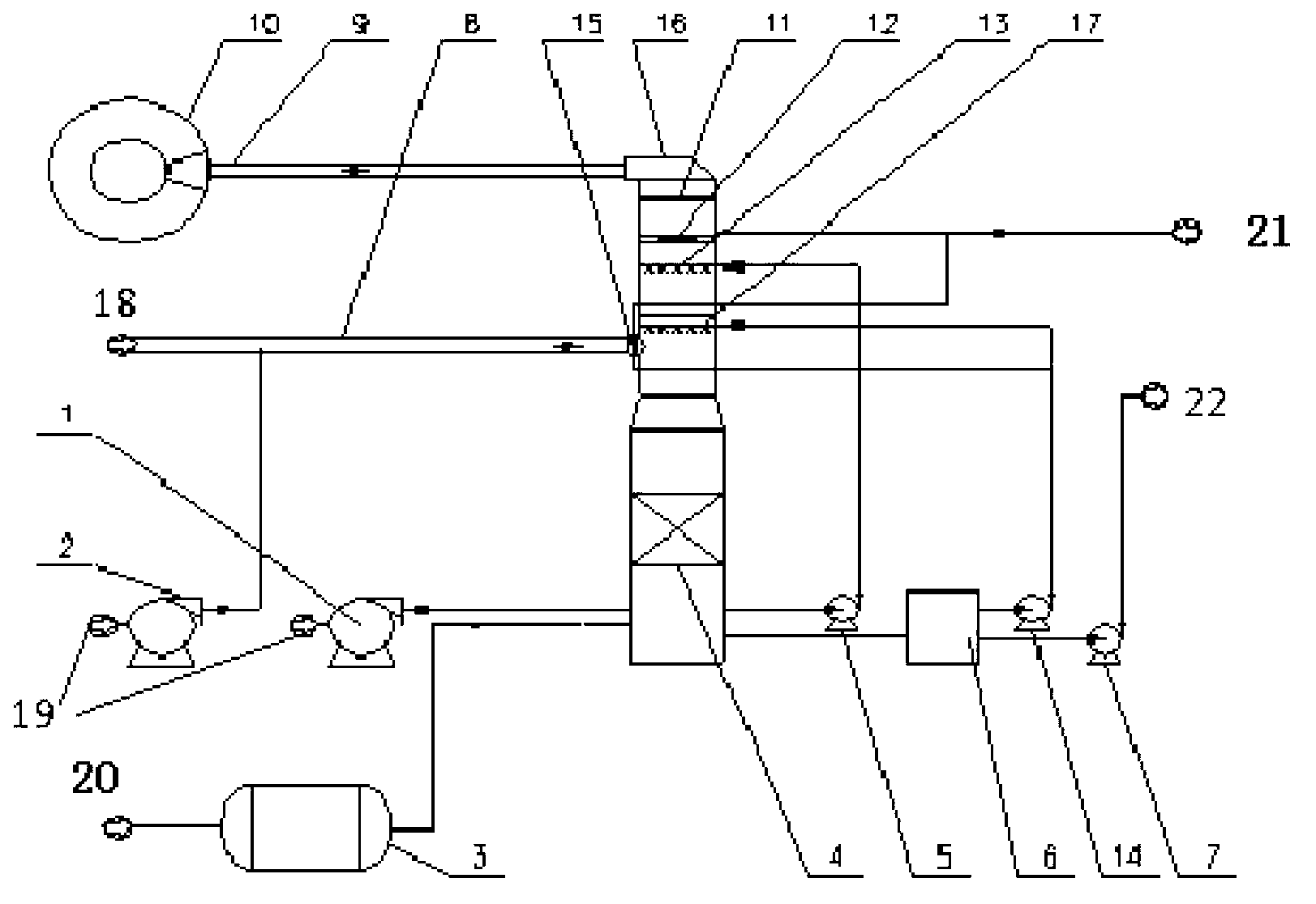

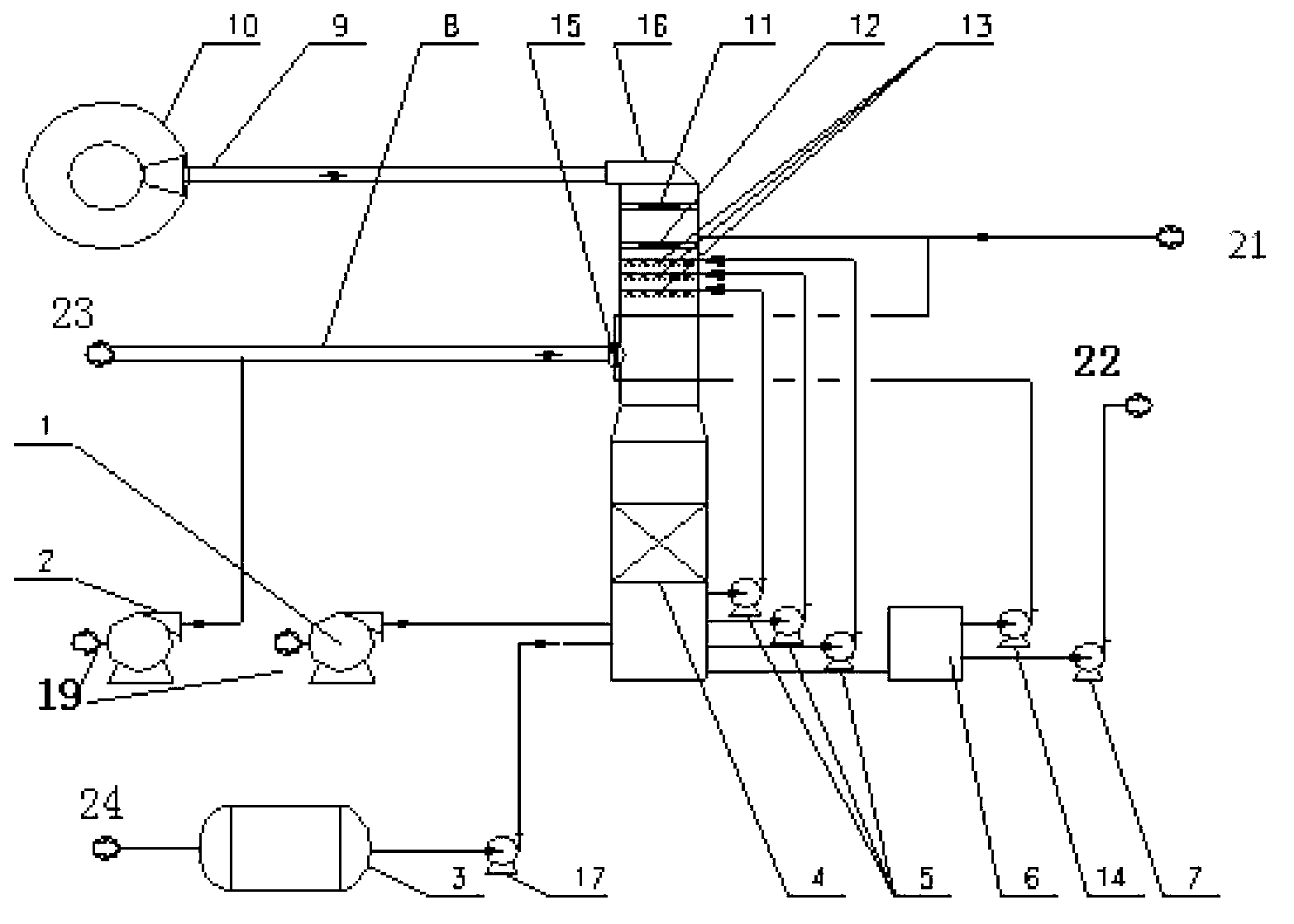

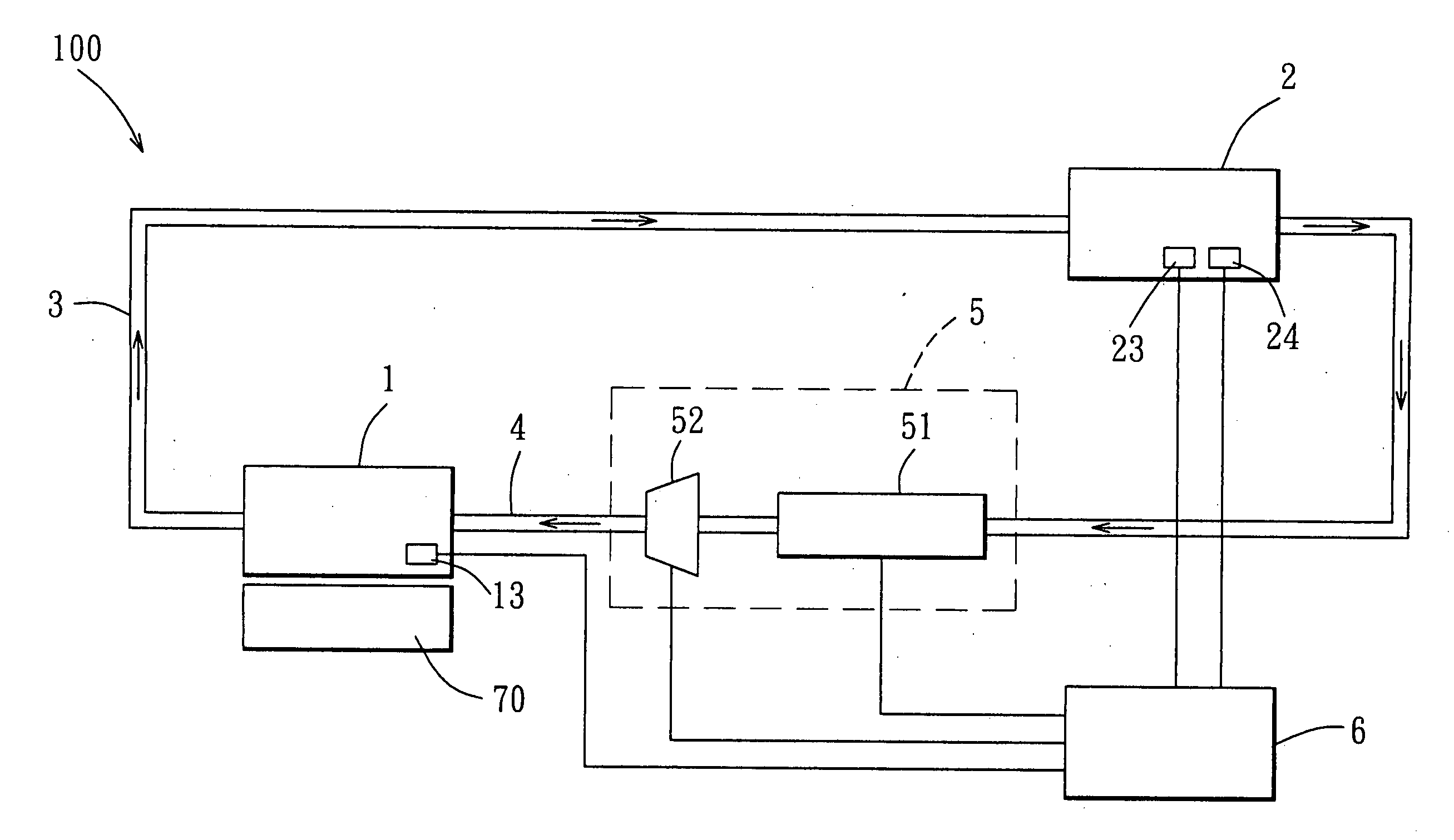

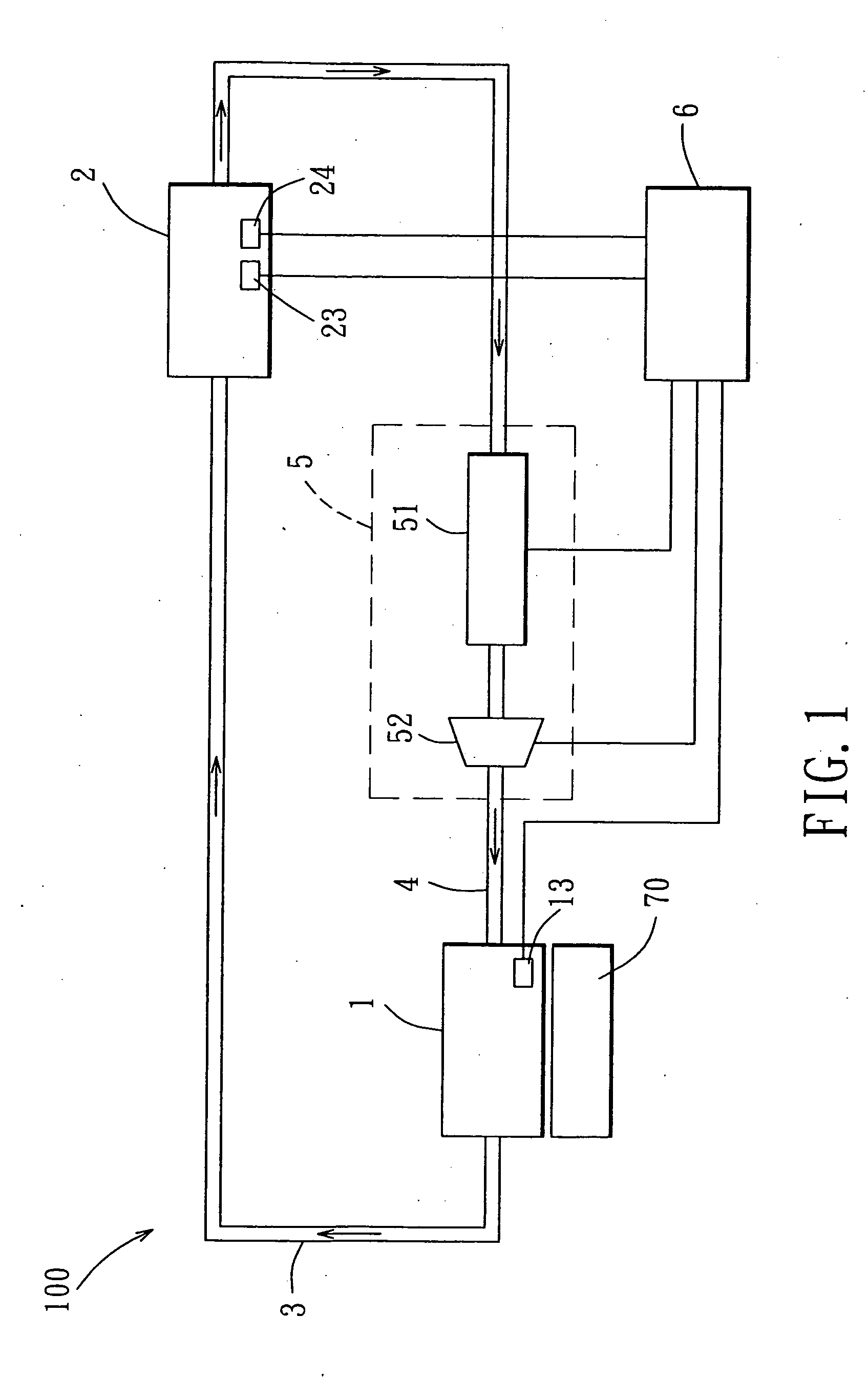

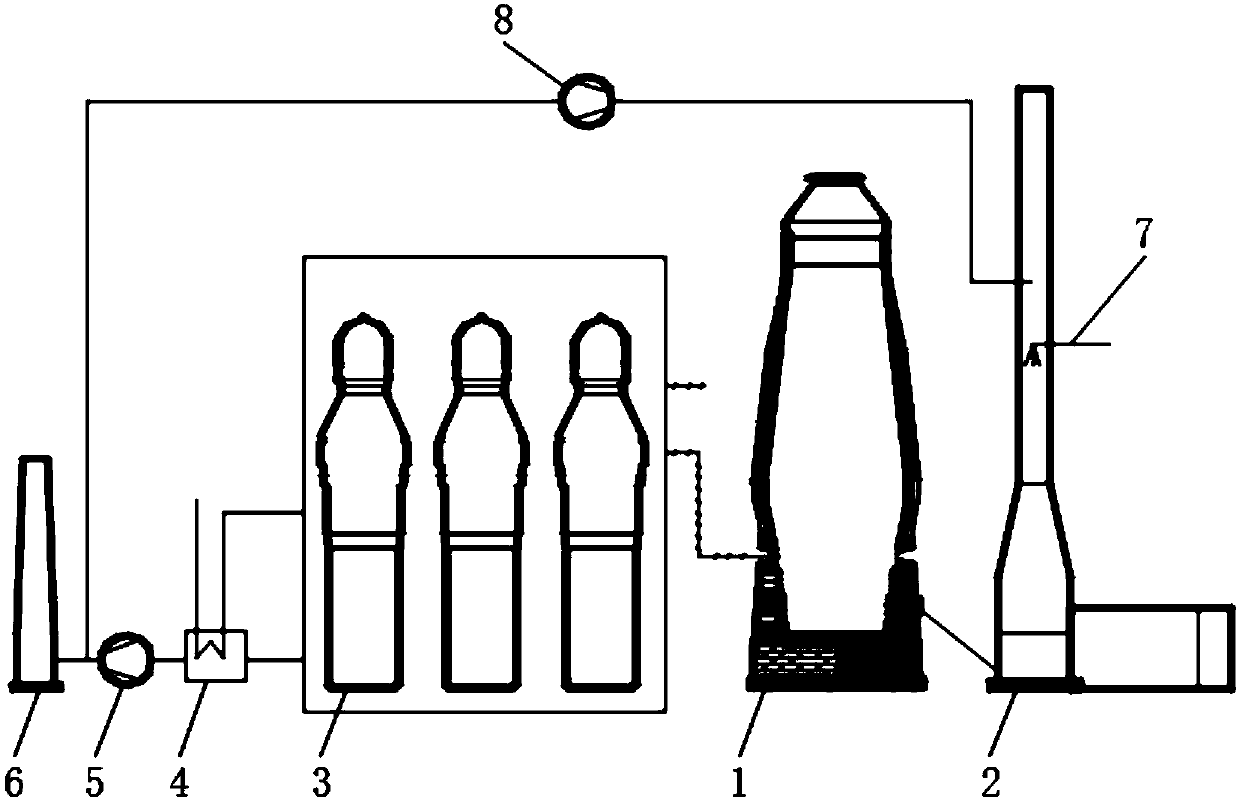

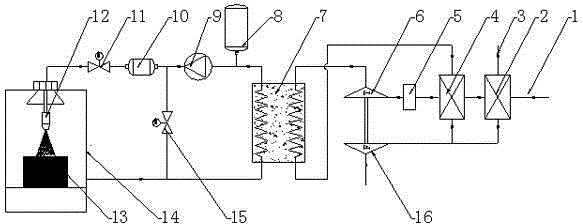

Cooling system and method of airborne heating element based on air expansion refrigeration

InactiveCN104684360AShort launch timeHigh calorific valueCooling/ventilation/heating modificationsEngineeringSpray cooling

The invention discloses a cooling system and method of an airborne heating element based on air expansion refrigeration, and belongs to the field of airborne equipment cooling. The cooling system comprises a high heat-flow heating element spray cooling circulation subsystem, an air expansion refrigeration circulation subsystem and a regenerator (7), wherein the high heat-flow heating element spray cooling circulation subsystem comprises a buffer tank (8), a circulation pump (9), a filter (10), a flow regulating valve (11), a spray chamber (14) and a bypass valve (15); the air expansion refrigeration circulation subsystem comprises a primary heat exchanger (2), a secondary heat exchanger (4), a water separator (5), a turbine (6) and a fan (16). The system can achieve rapid cooling of high heat-flow heating element, and achieve the purpose of circulation cooling for multiple times through the regenerator; an intermediate regenerator structure makes full use of the characteristics of large working time intervals of the heating element and large phase change latent heat of phase change materials, greatly reduces the volume of system equipment, and meets the requirements of airborne equipment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Low pressure casting wheel cooling technology

The invention discloses a mist-spraying cooling technology, which utilizes an electromagnetic type quantitative pump to pump water into an air and water mixing cooling channel so as to form water mist to be used as cooling medium, and is used for cooling a die by aiming at different air ducts via utilizing water mist cooling or air cooling, so the die is cooled to 430 DEG C-410 DEG C from 490 DEG C-470 DEG C within 40-60 seconds, and the temperature of the die is reduced about 40-80 DEG C. The invention utilizes the mist-spraying cooling technology to control the cooling rate so as to quench the die and can crystallize according to the progressive solidification principle, so an R angle is generated, and the shrinkage porosity defect probability of a rim part is smaller; and the cooling medium is the mixture of water and air and is directly acted on the surface of the die, so the mechanical property of a blank is correspondingly improved, the pinhole scrappage and rework rate are reduced, and the service life of the die is obviously prolonged at the same time.

Owner:BAODING CITY LIZHONG WHEEL MFG

Spray cooling system for extreme environments

ActiveUS6976528B1Short timeIncrease temperatureSemiconductor/solid-state device detailsSolid-state devicesEngineeringControl valves

Owner:PARKER INTANGIBLES LLC

Manufacturing process of pump body casting of super duplex stainless steel centrifugal pump

InactiveCN102626769AReduce manufacturing costReduce maintenance costsFoundry mouldsFoundry coresFuranTemperature control

The invention provides a manufacturing process of a pump body casting of a super duplex stainless steel centrifugal pump. The manufacturing process comprises steps of sand mould prefabricating, material smelting, casting, sand shakeout and heat treatment, wherein a runner core in a sand mould is composed of chromite furan resin sand of which the outer layer is filled with quartz furan resin sand;in material smelting, super duplex stainless steel material ZG00Cr25Ni7Mo4N is used, the chemical composition, ferrite content and PREN (Pitting Resistance Equivalent) value of molten steel are undercontrol and the casting temperature is from 1540 DEG C to1560 DEG C; after sand shakeout, forced air cooling is carried out, spray cooling is further carried out on the thick and large part of the casting, and after a casting system and a dead head are removed, the heat treatment is carried out. The pump body casting of a super duplex stainless steel centrifugal pump, which is manufactured by using the manufacturing method, has the advantages that the manufacturing and maintenance cost is reduced, abrasion resistance and pitting resistance are improved and the service life is prolonged.

Owner:遵义拓特铸锻有限公司

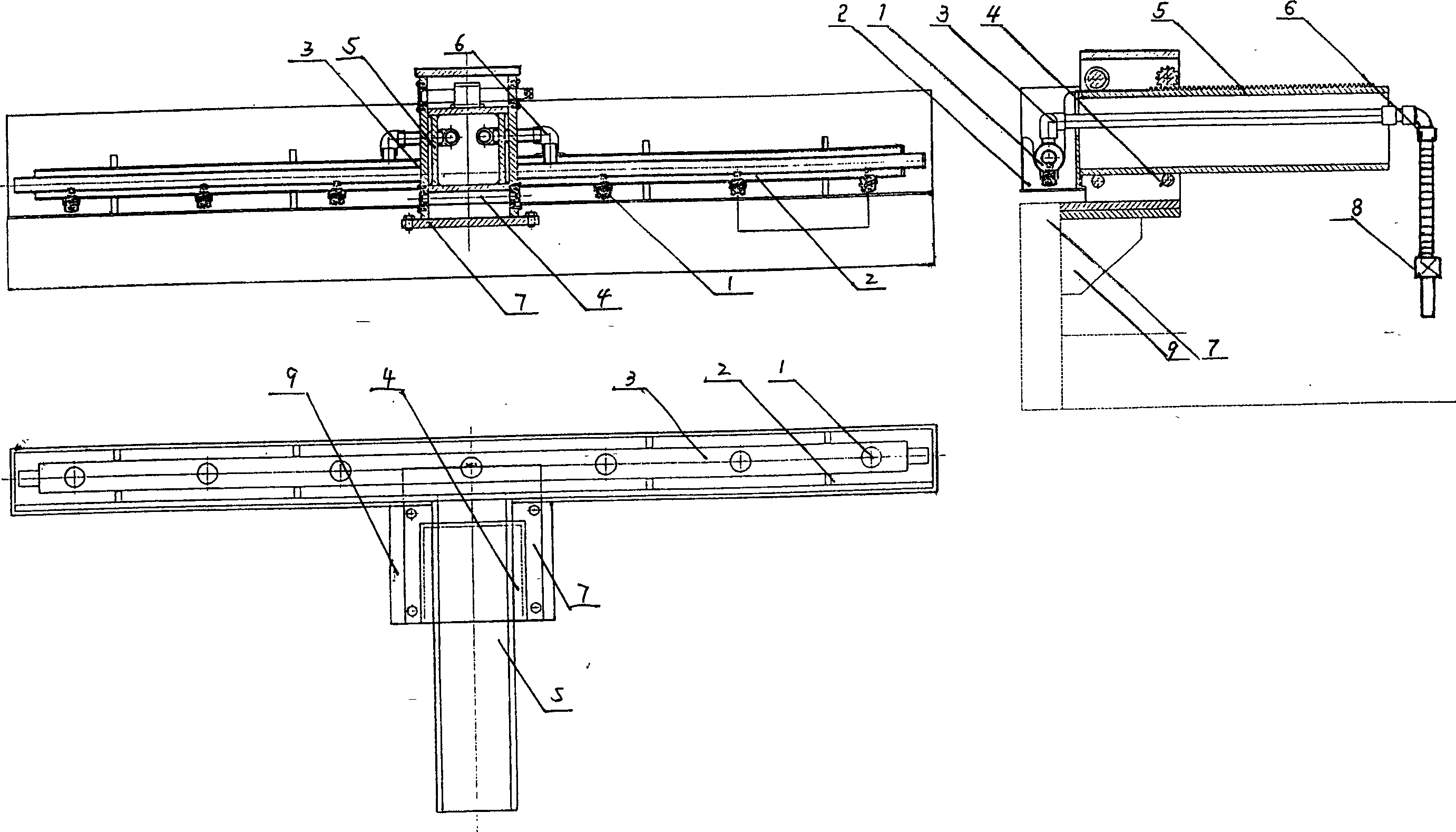

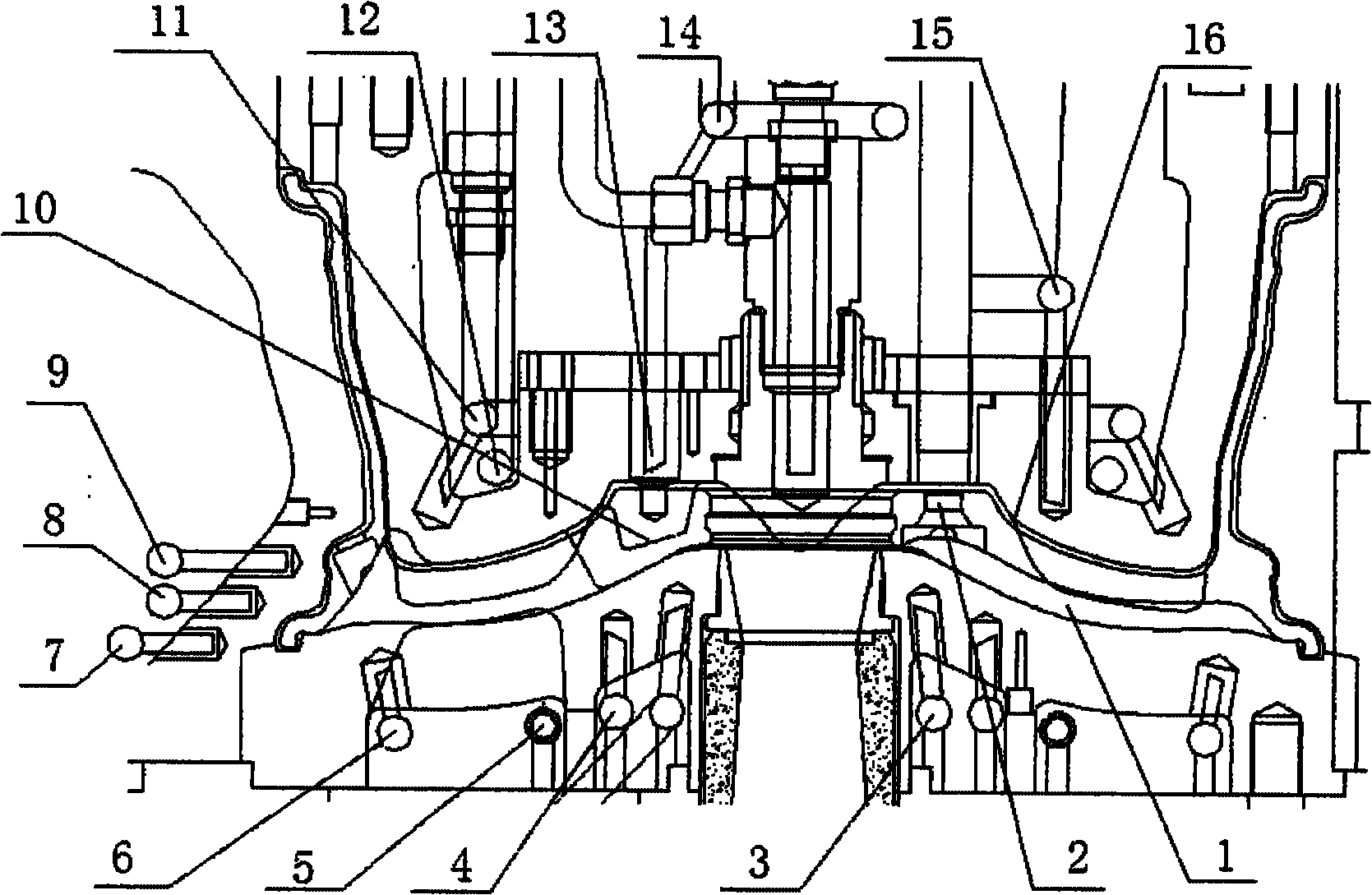

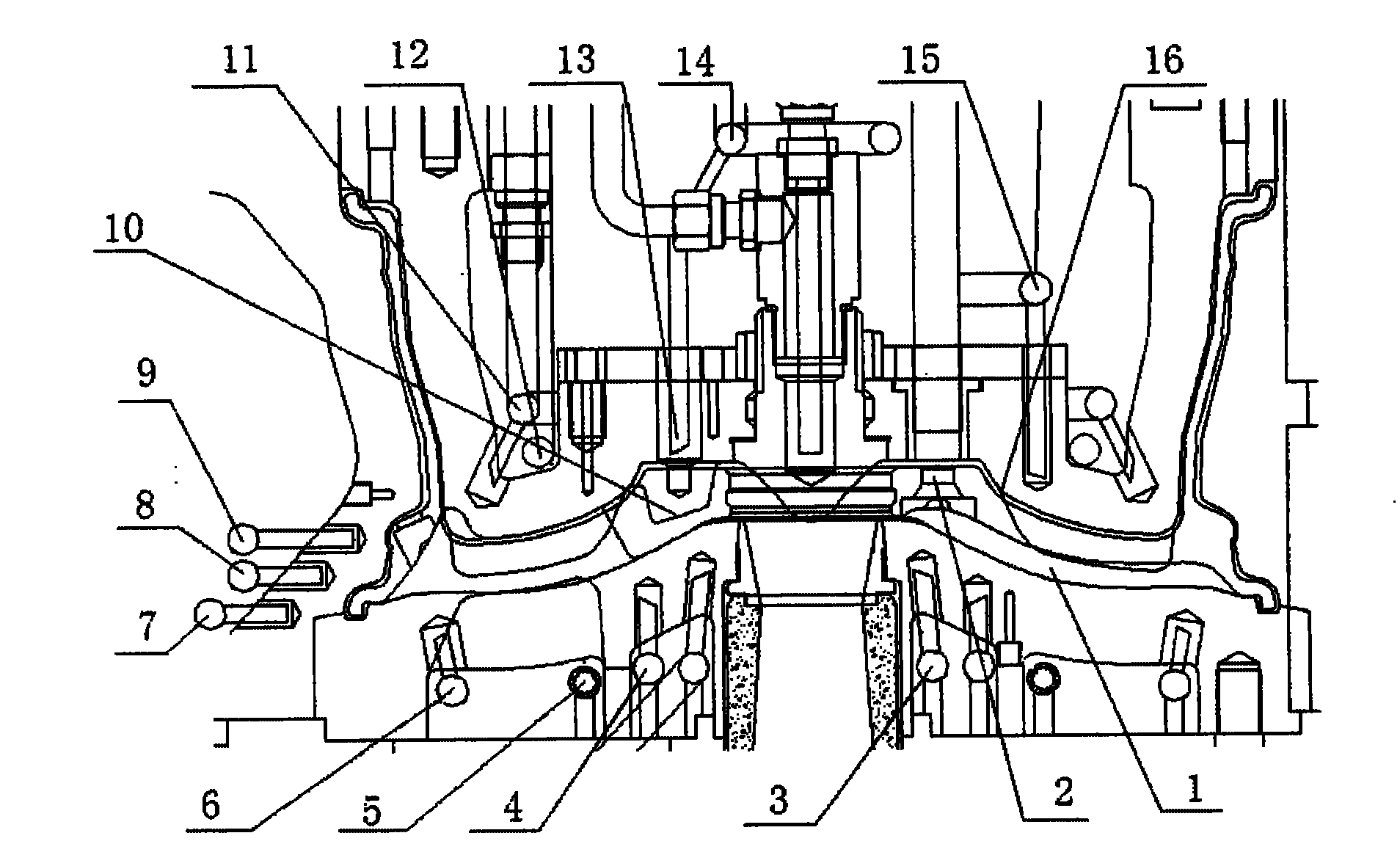

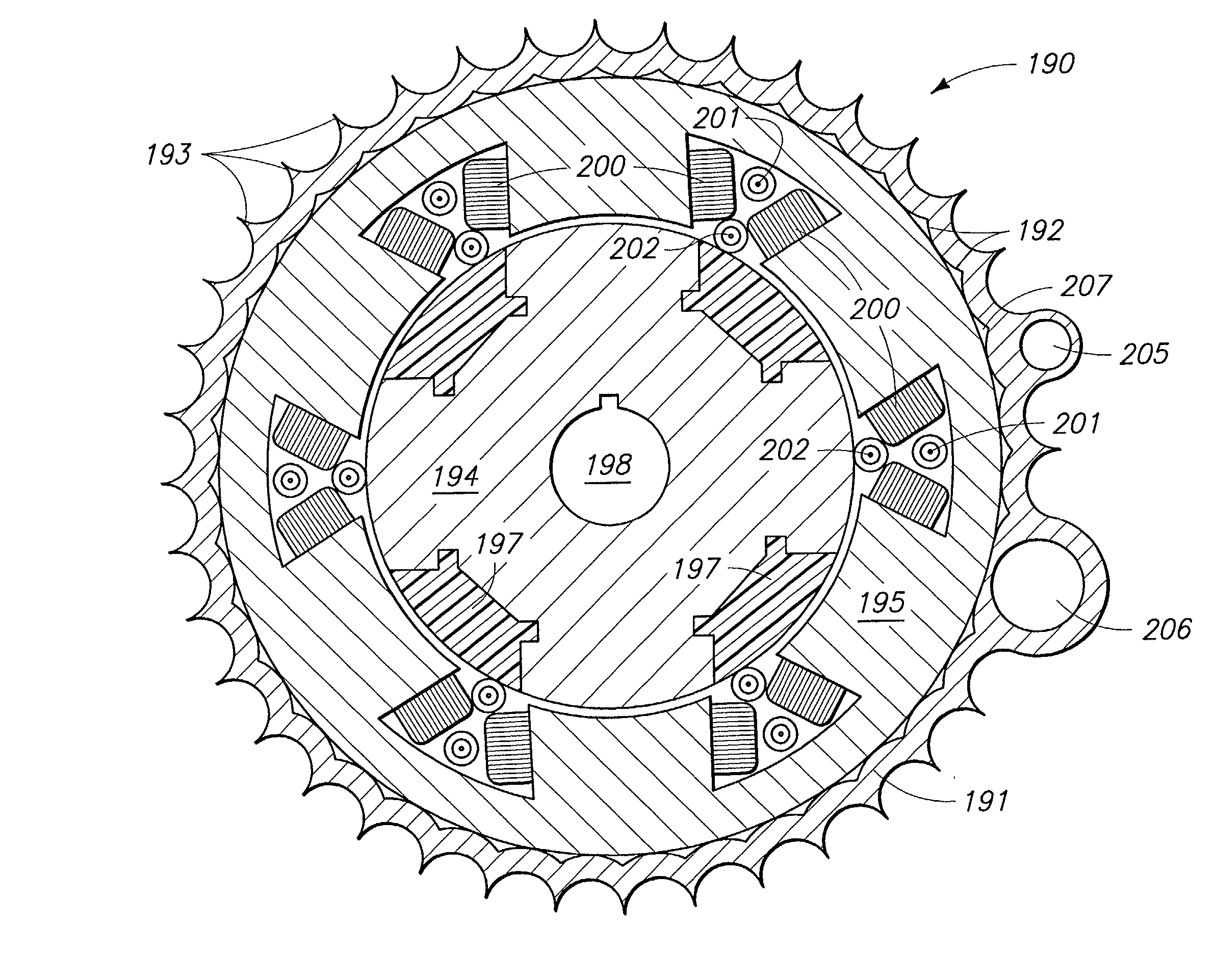

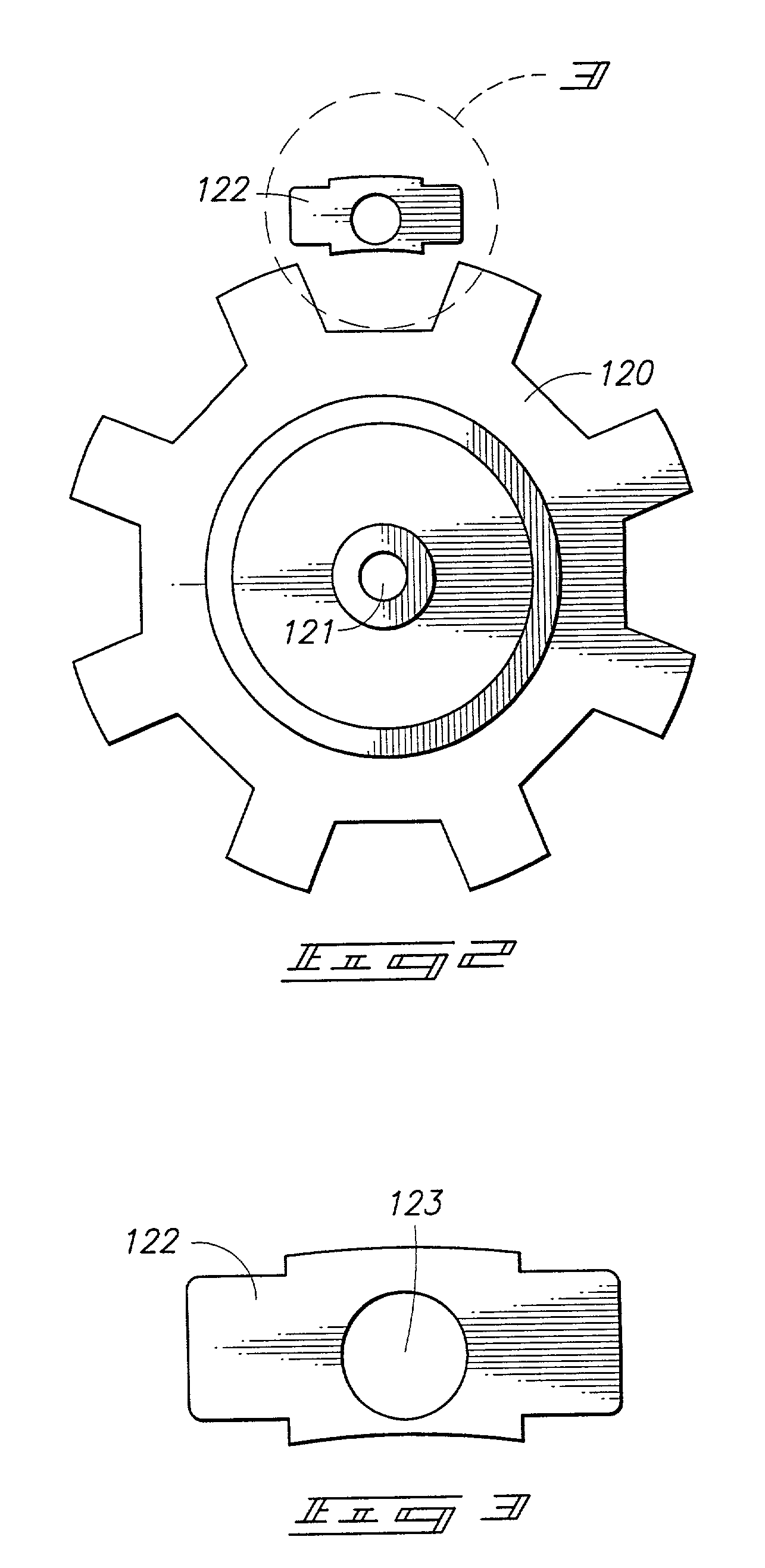

Spray cooled motor system

InactiveUS20020130565A1Association with control/drive circuitsMagnetic circuit rotating partsEngineeringControl theory

A spray cooled motor system with a motor housing with an interior and an exterior, a stator mounted within the interior of the motor housing, a rotor mounted within the interior of the motor housing, a coil winding mounted within the interior of the motor housing, a plurality of atomizers configured to spray a coolant on at least one of the stator and the rotor, a coolant pump in fluid communication with the plurality of atomizers; and an output shaft extending through an output shaft aperture from the interior to the exterior of the motor housing.

Owner:ISOTHERMAL SYST RES

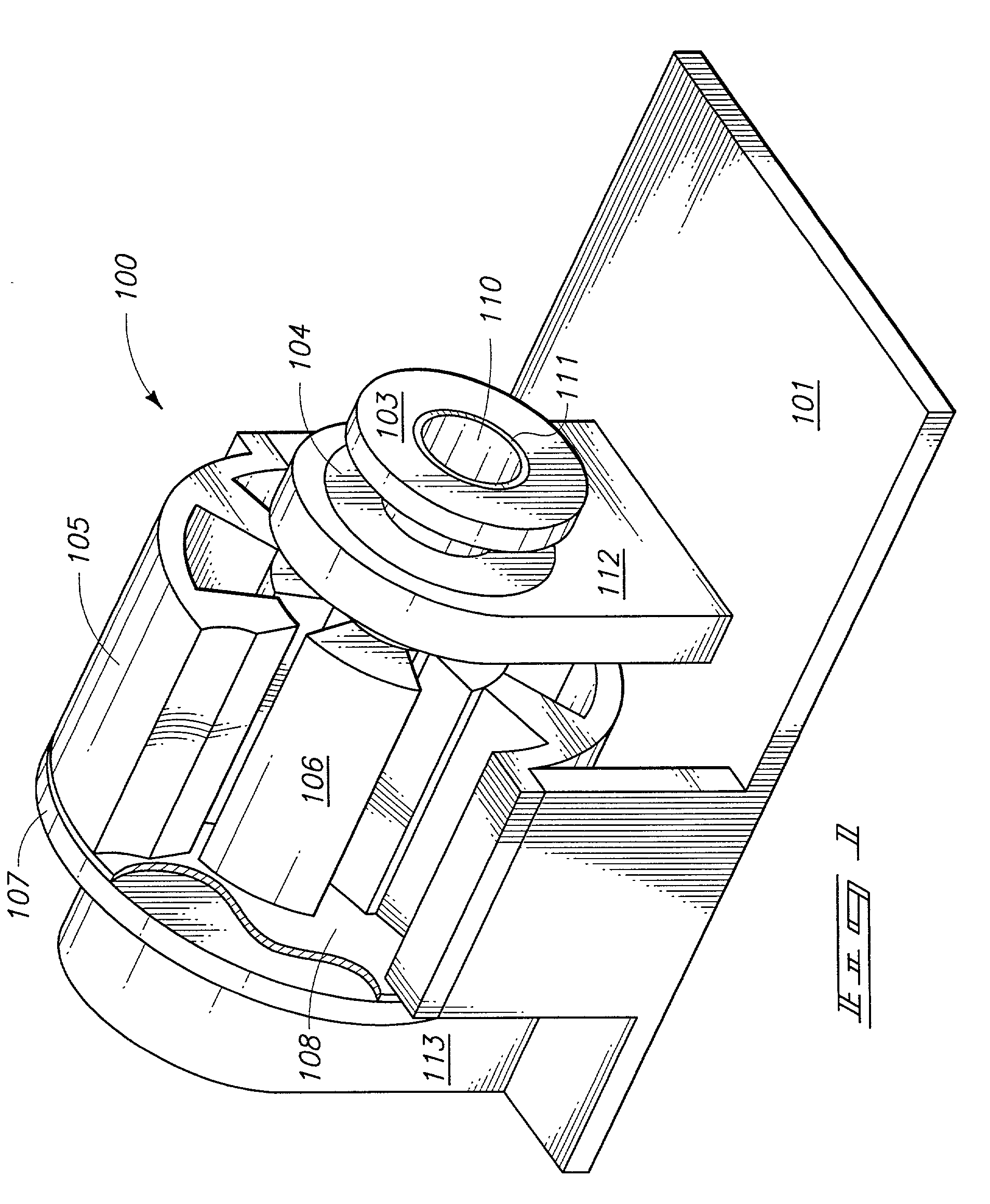

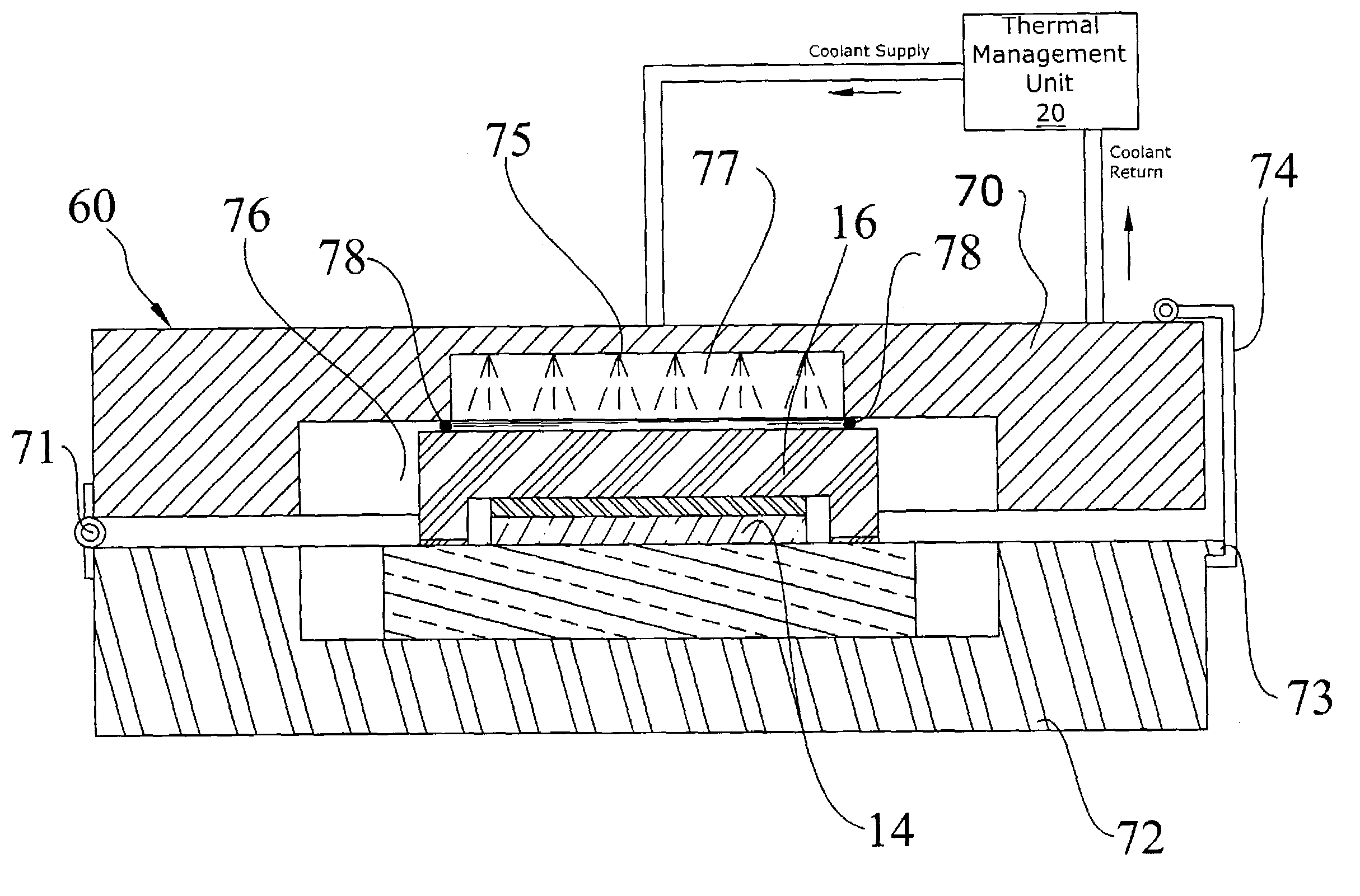

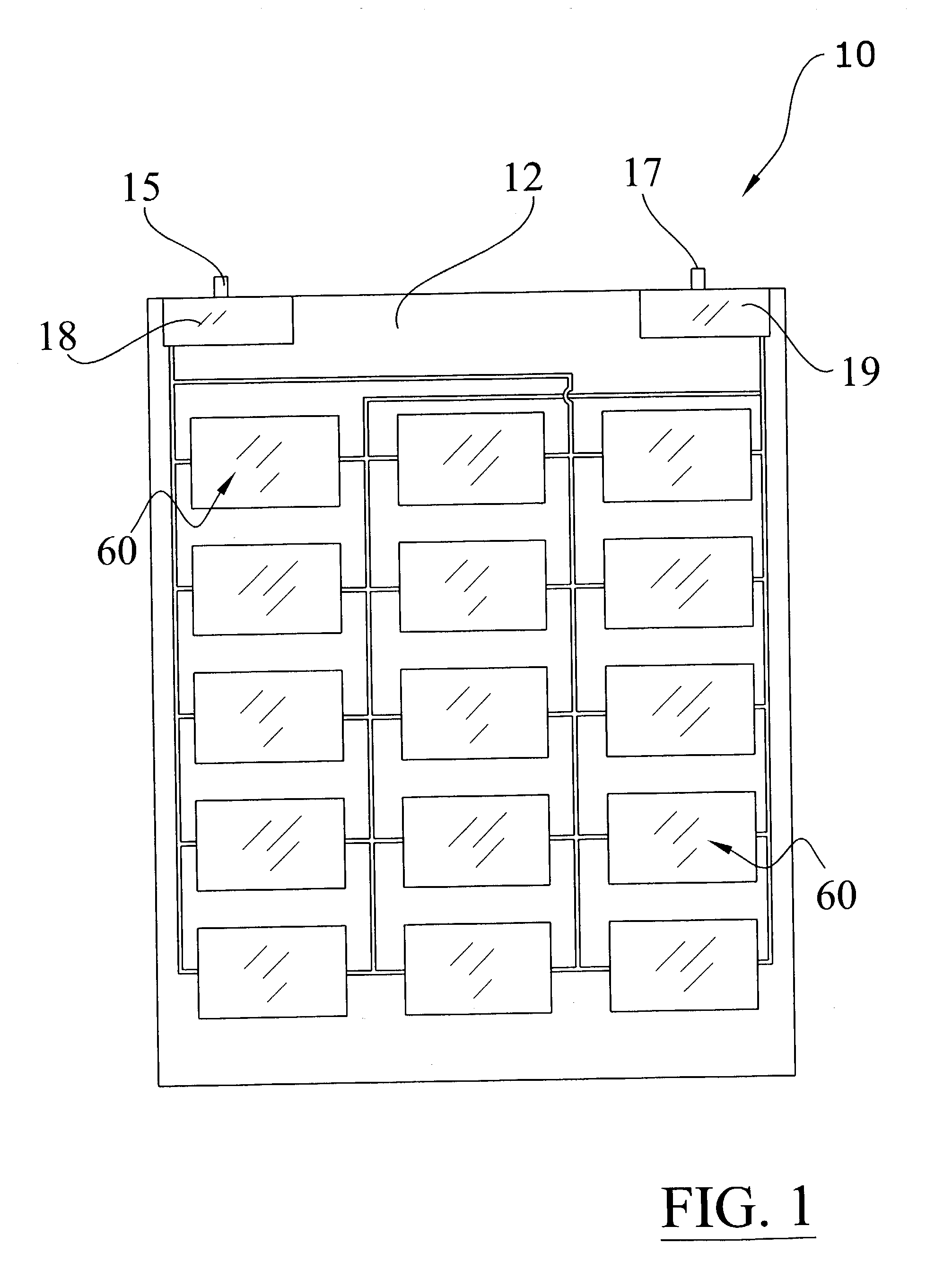

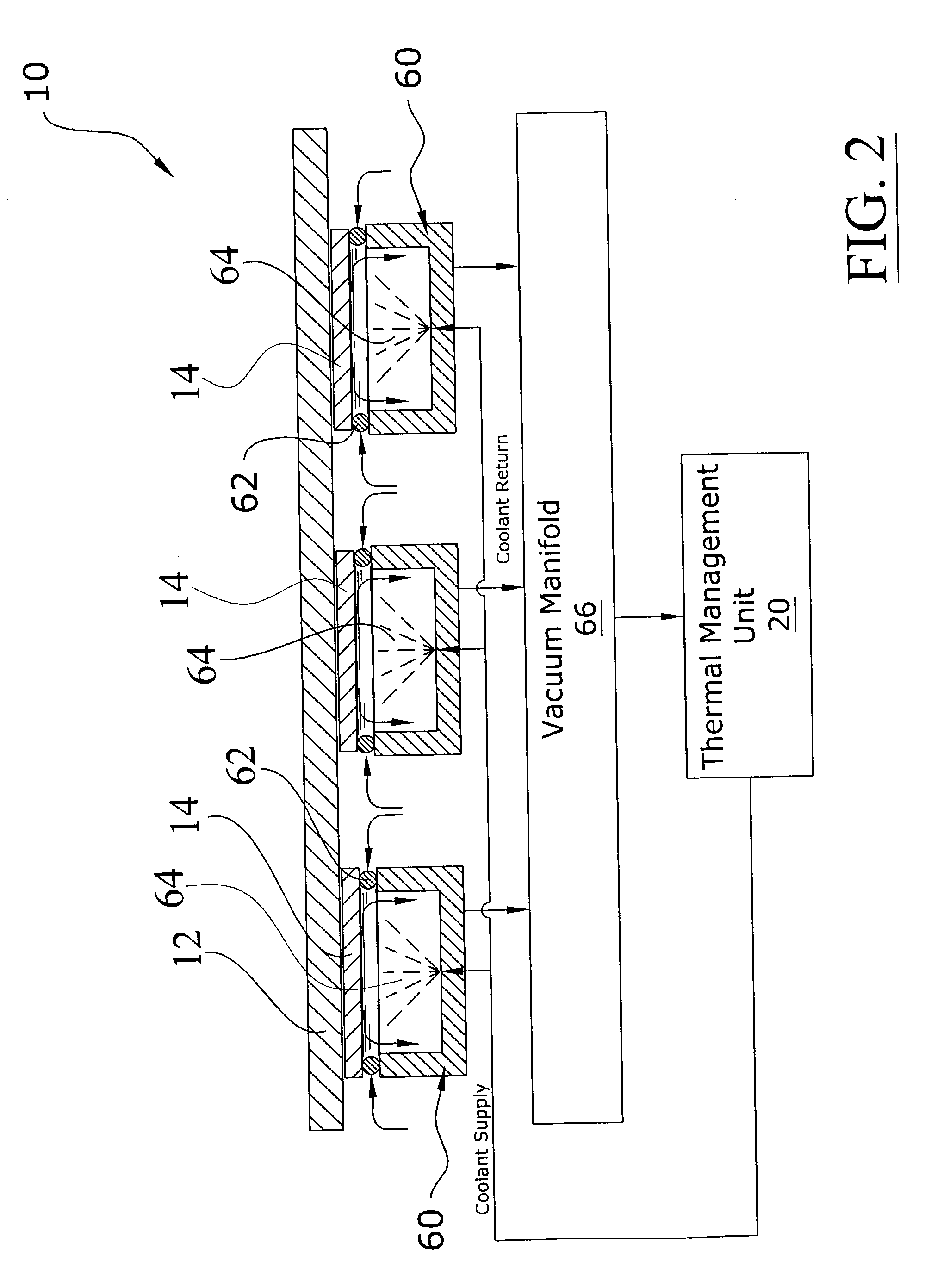

Sealed spray cooling system

InactiveUS6996996B1Reducing coolant lossElectronic circuit testingLighting and heating apparatusEngineeringThermal management system

A sealed spray cooling system for reducing coolant loss within thermal management systems. The sealed spray cooling system includes a spray housing defining a spray chamber having at least one atomizer and a seal member attached to the spray housing about the spray chamber for sealing against a semiconductor forming a sealed spray area. Alternatively, the spray unit is comprised of a first member, a second member having at least one atomizer, the second member pivotally attached to the first member forming an interior cavity between thereof, and a seal member attached to the second member for sealing against a semiconductor within the first member thereby forming a sealed spray area. A vacuum manifold is preferably fluidly connected to the spray cavity thereby reducing the pressure within the spray cavity.

Owner:PARKER INTANGIBLES LLC

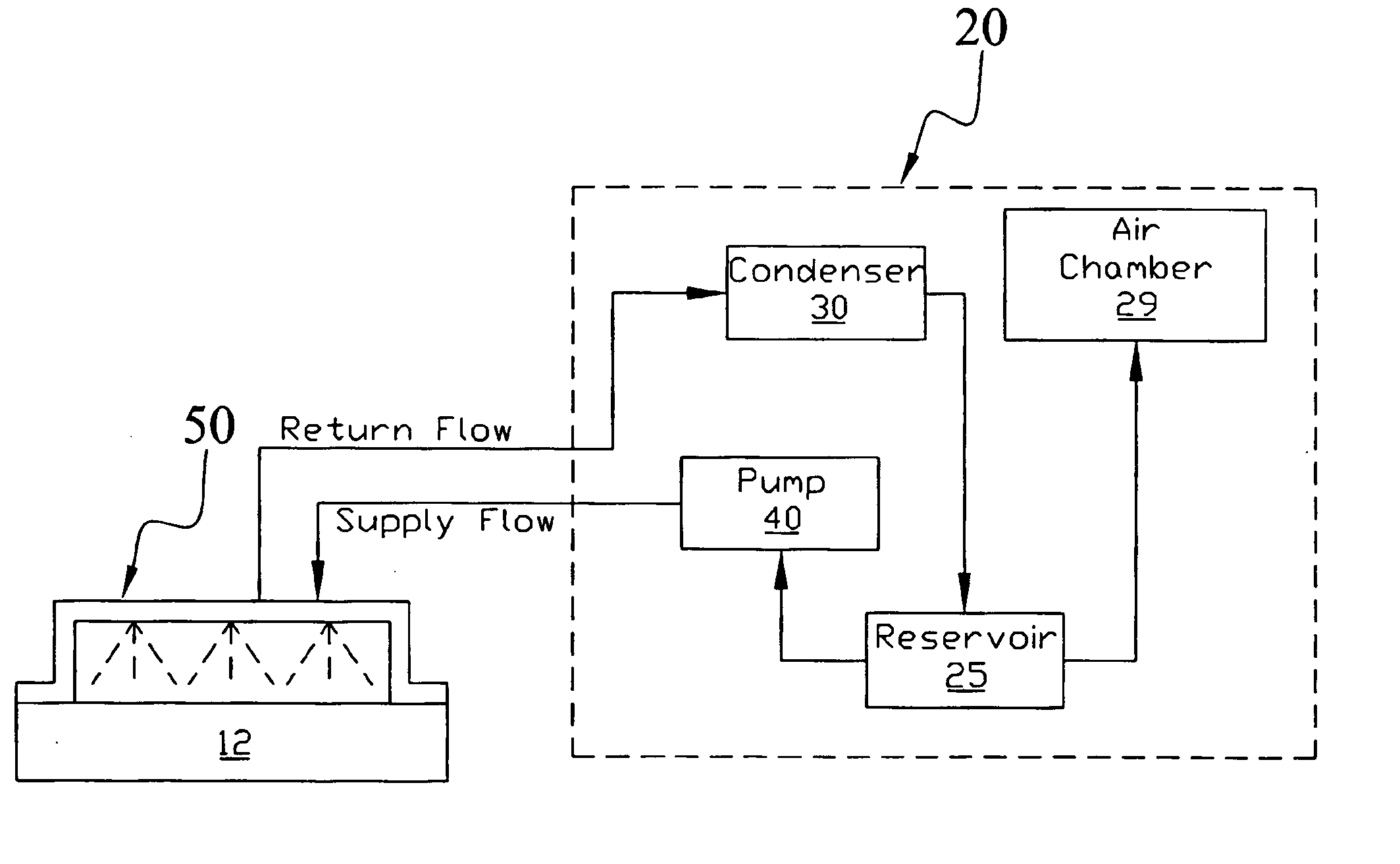

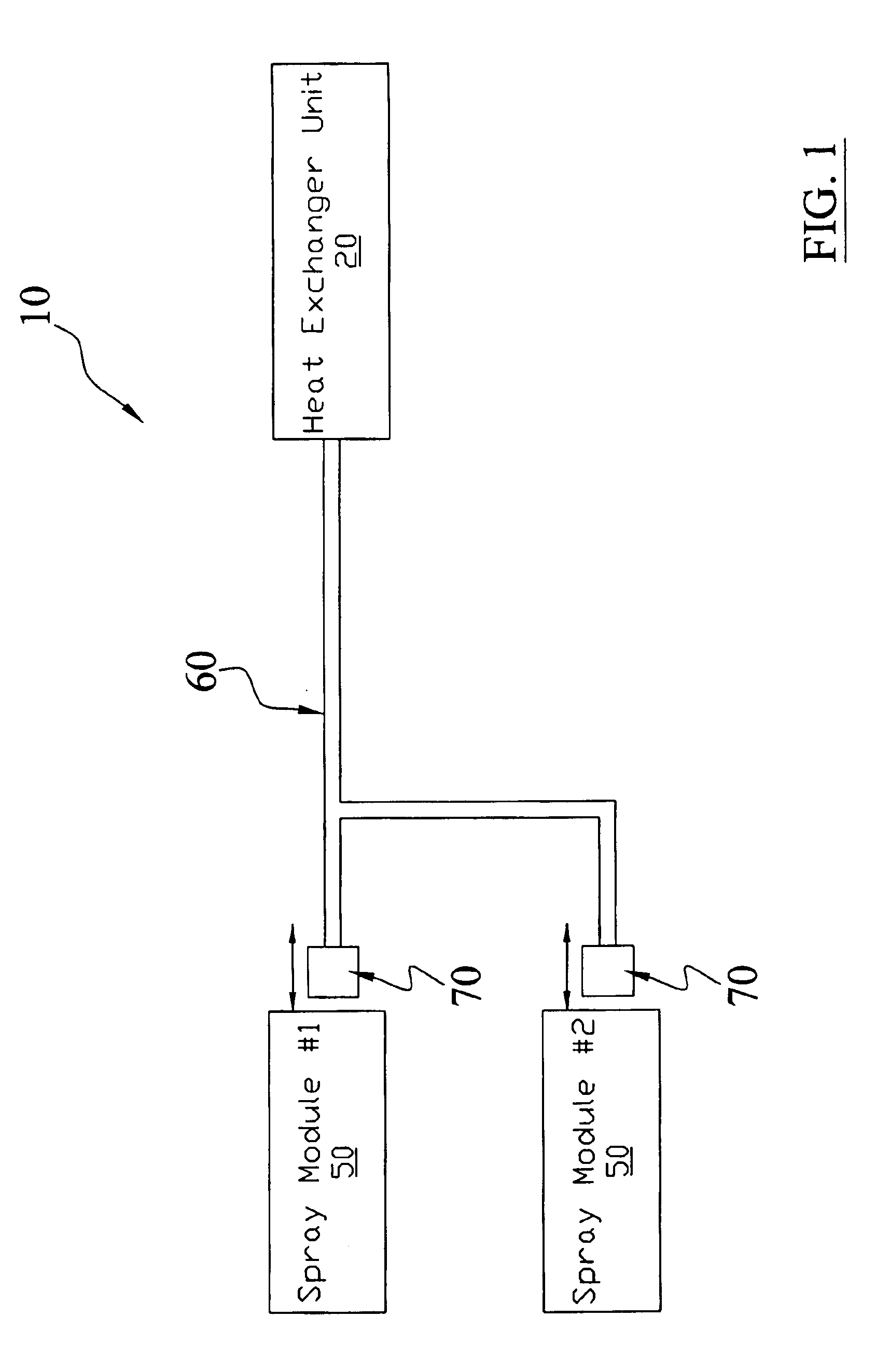

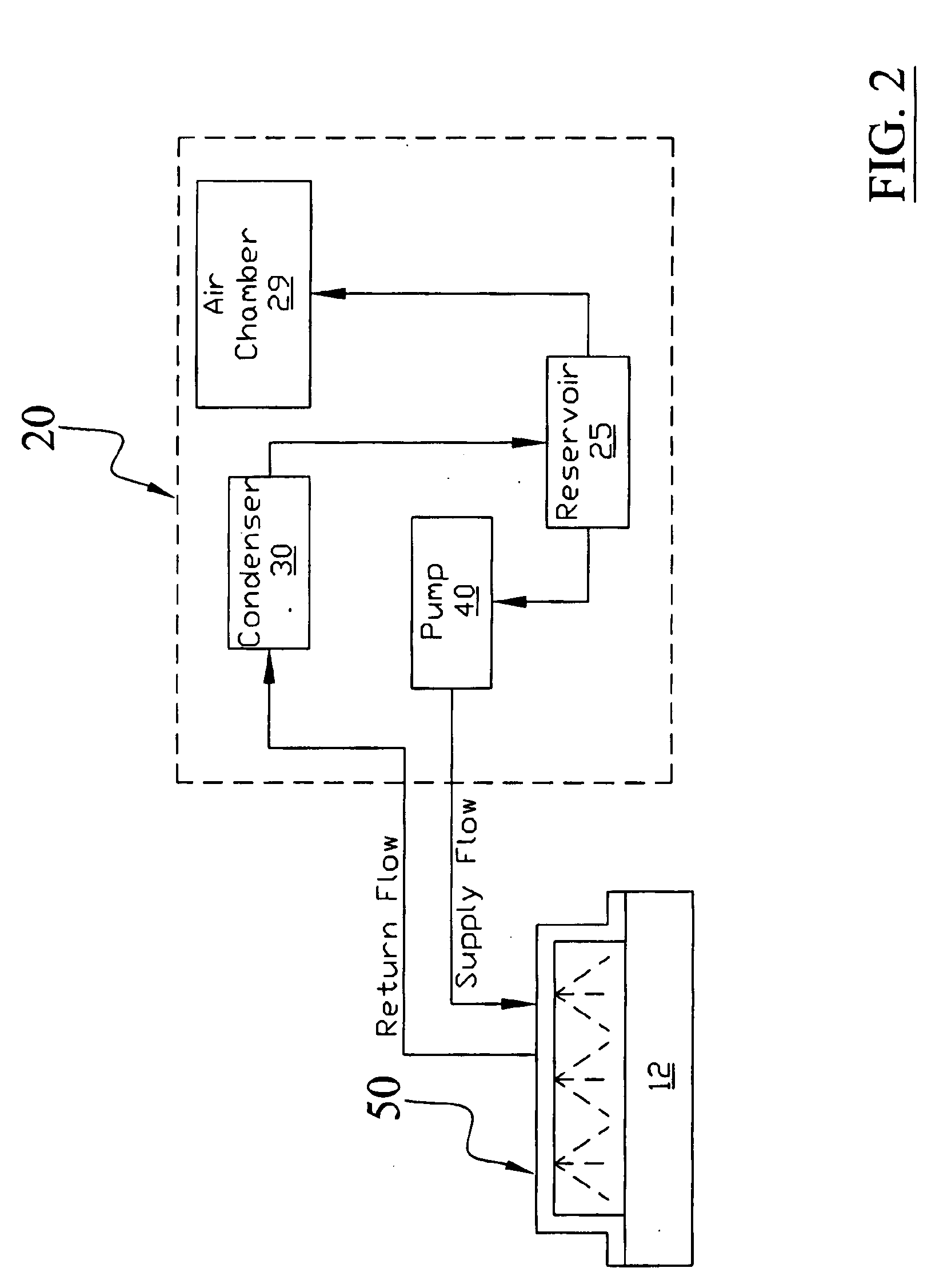

Spray cooling system

InactiveUS6889515B2Efficiently thermally managingDomestic cooling apparatusSemiconductor/solid-state device detailsCoaxial cableSemiconductor chip

A spray cooling system for efficiently thermally managing a single or multiple semiconductor chip package. The spray cooling system includes a heat exchanger unit having a pump unit and a reservoir, a coaxial tube fluidly connected to the heat exchanger unit, a coupler unit attached to the coaxial tube, and a spray module where the coupler unit is removably connected to the spray module. The heat exchanger unit has an air tolerant design that allows for the entry and release of air without interfering with the operation thereof.

Owner:PARKER INTANGIBLES LLC

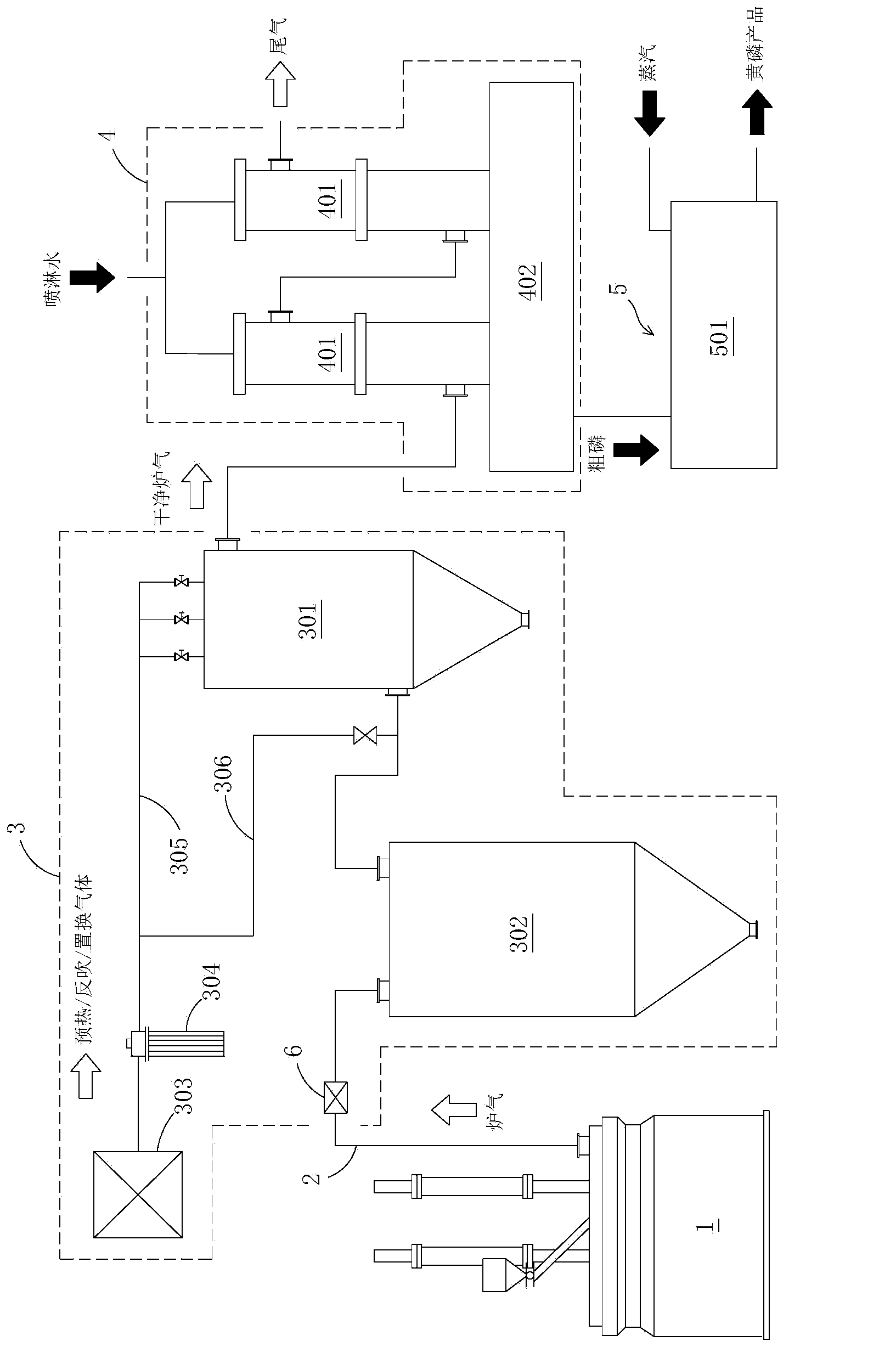

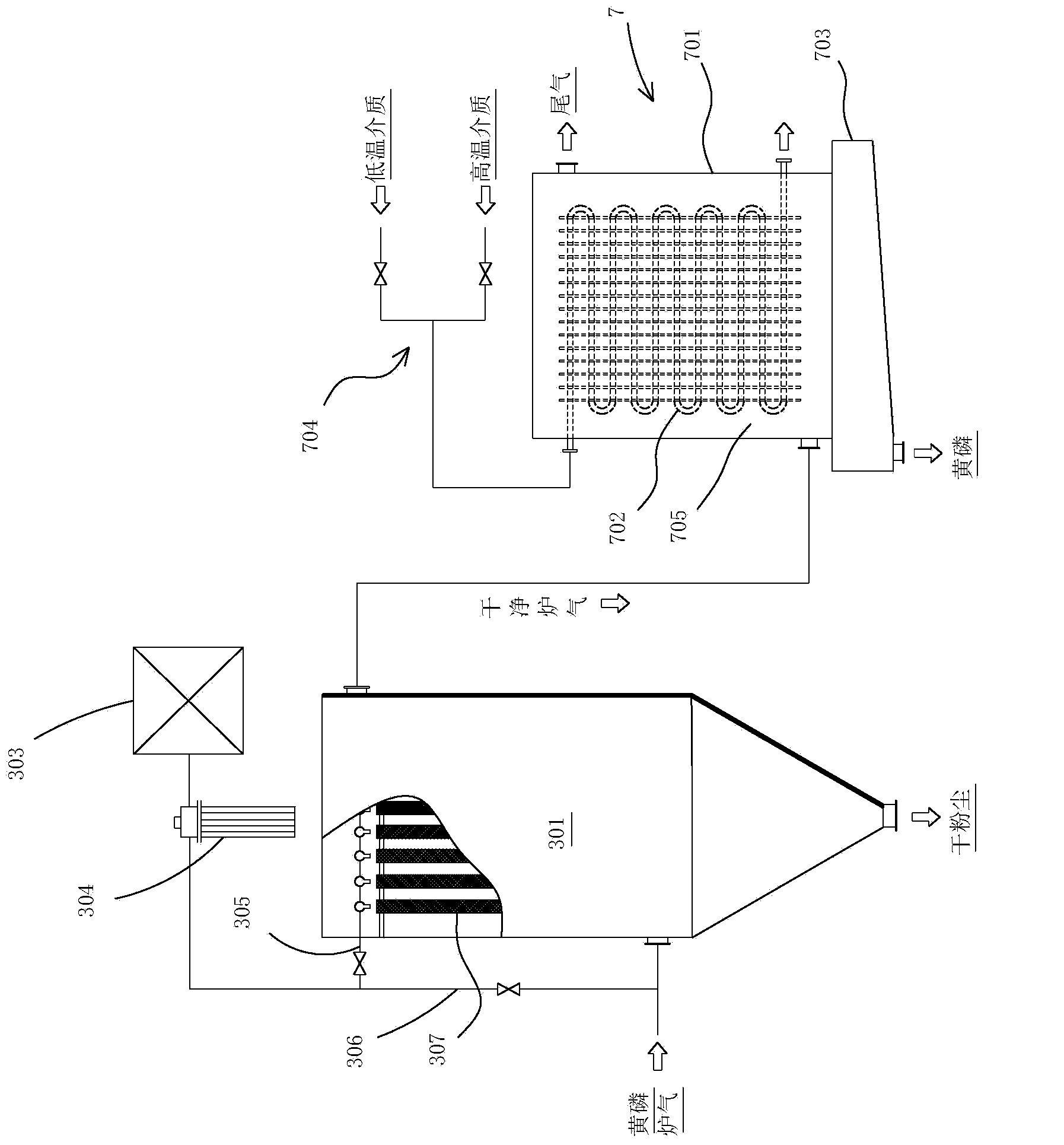

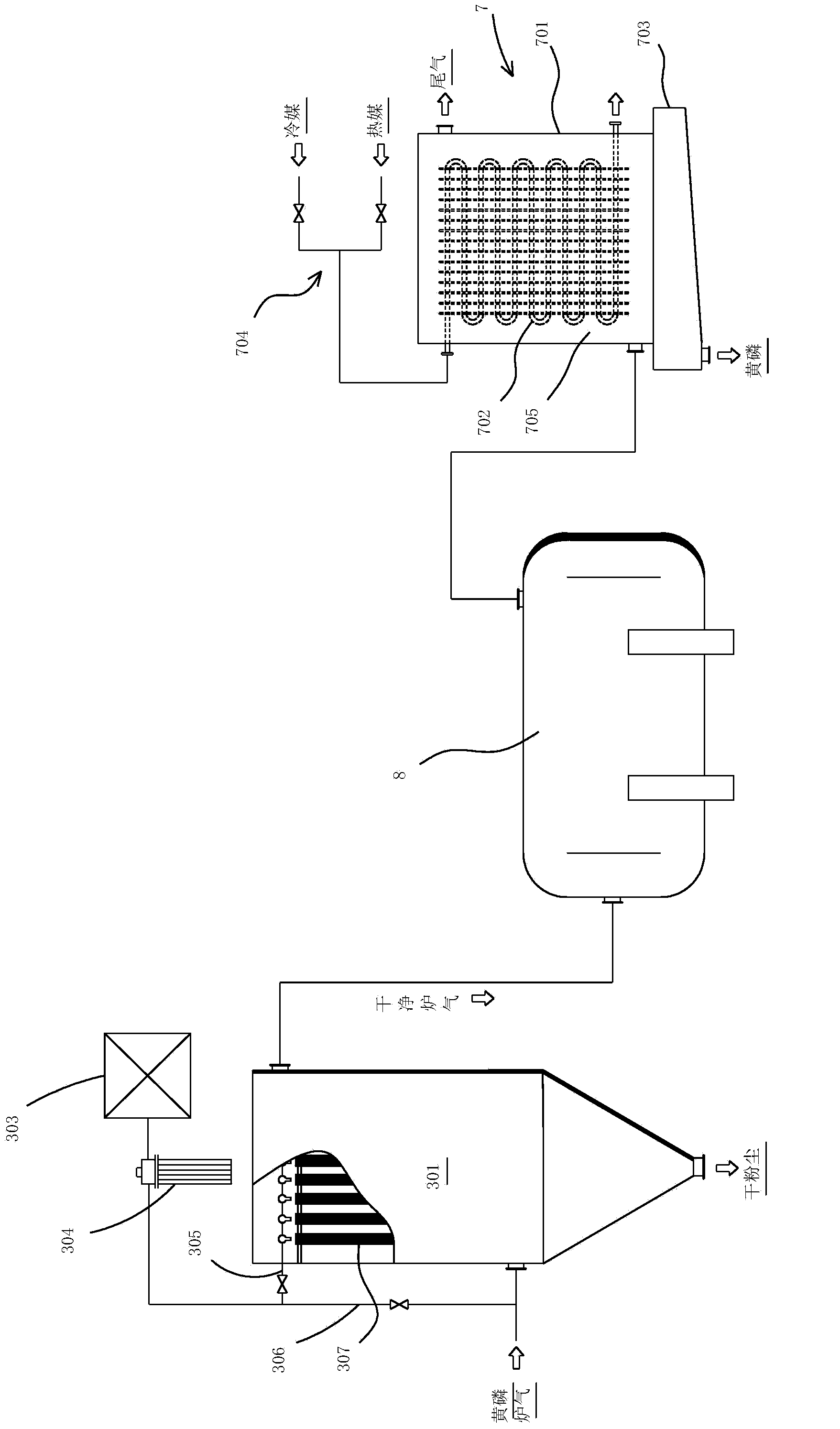

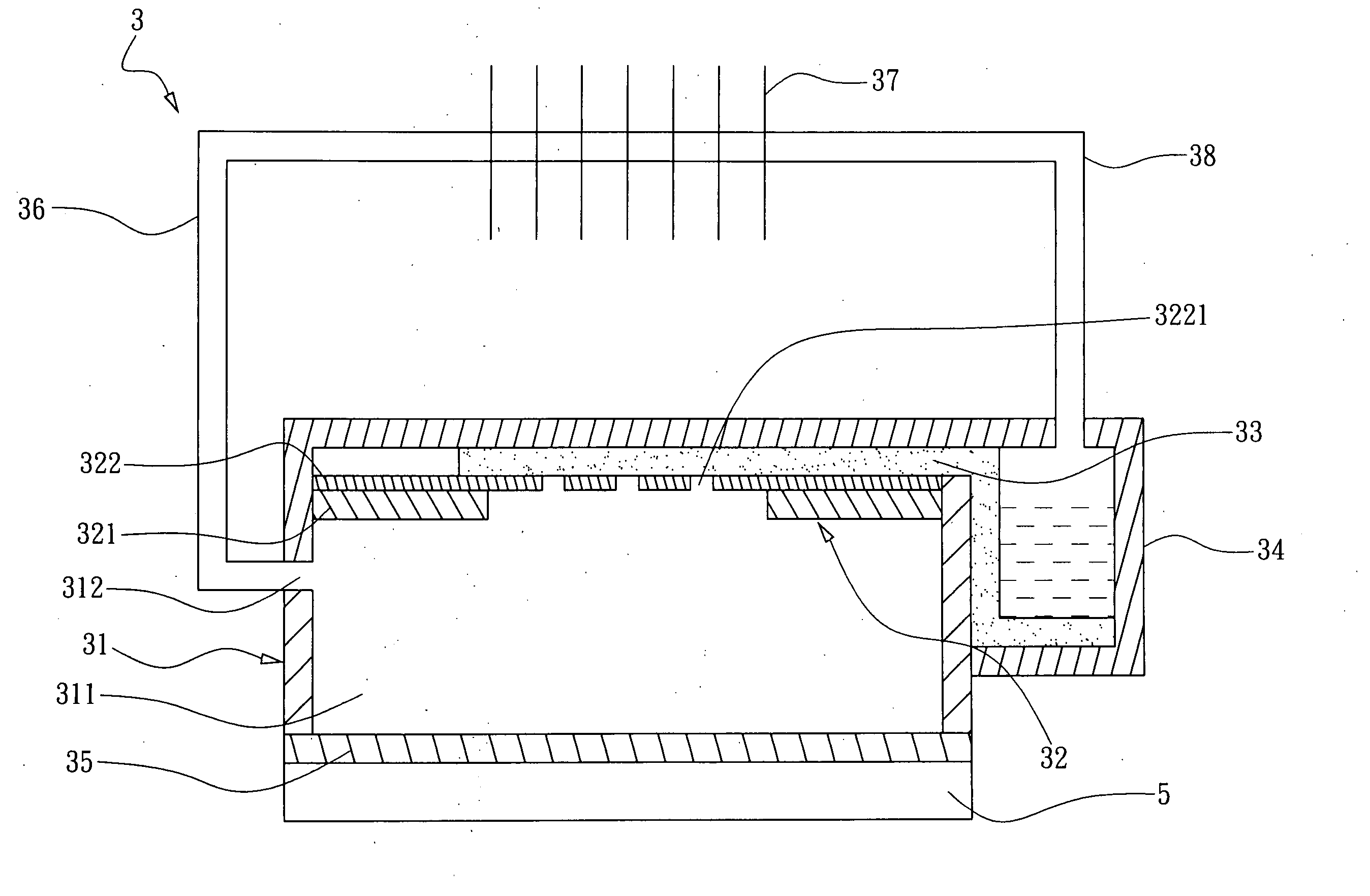

Method and equipment for recovering yellow phosphorus from electric furnace phosphorus-producing furnace gas and special phosphorus collecting device

ActiveCN103708432ADispersed particle separationChemical/physical/physico-chemical processesRecuperatorSolid content

The invention discloses a method and equipment for recovering yellow phosphorus from an electric furnace phosphorus-producing furnace gas without adopting a spray cooling mode in condensation of the electric furnace phosphorus-producing furnace gas, and a special phosphorus collecting device, so as to solve the common problem caused by the spray cooling mode at present. The method comprises the following steps: 1) dedusting and purifying the electric furnace phosphorus-producing furnace gas by using a dry-type dedusting system, so that the solid content of the electric furnace phosphorus-producing furnace gas achieves below 10-50mg / m<3>; 2) conveying the purified furnace gas to a phosphorus collecting device, wherein the phosphorus collecting device comprises a heat exchange chamber and a recuperator; the heat exchange chamber is formed by a shell; and the recuperator is arranged inside the heat exchange chamber; 3) leading in a low-temperature medium to an internal flow path of the recuperator, wherein the low-temperature medium and the furnace gas carry out non-mixing heat transfer under isolation of the recuperator, so that the yellow phosphorus is condensed and separated out and greatly attached on the surface of the recuperator, and the heat-exchange exhaust is discharged out of the phosphorus collecting device; 4) leading in a high-temperature medium for replacing the low-temperature medium to the internal flow path of the recuperator.

Owner:CHENGDU INTERMENT TECH

Compact spray cooling module

InactiveUS20070133173A1Reduce power consumptionIncrease heatSemiconductor/solid-state device detailsSolid-state devicesSpray nozzleEngineering

A compact spray cooling module is presented, which comprises: a storage tank, a spray chamber, a nebulizer, and a media of liquid transportation ability. The storage tank is used for storing a cooling liquid, and the spray chamber is connected to a heat source. Moreover, there is a nebulizer lay on the spray chamber, whereas the nebulizer is comprised of a piezoelectric plate and a micro-nozzle plate. The micro-nozzle plate has a large number of micro-nozzle disposed on it. Furthermore, the media located between the storage tank and the spray chamber has the capability of transporting the cooling liquid from storage tank to spray chamber by capillary attraction for the purpose of nebulizing the cooling liquid. Taking advantage of the latent heat from liquid phase change, the nebulized cooling liquid sprayed to the bottom of the spraying chamber can dissipate the heat generated from the heat source rapidly. Moreover, the cooling module of the invention can combine with a condenser and a transportation piping system to form a compact and closed spray cooling module.

Owner:IND TECH RES INST

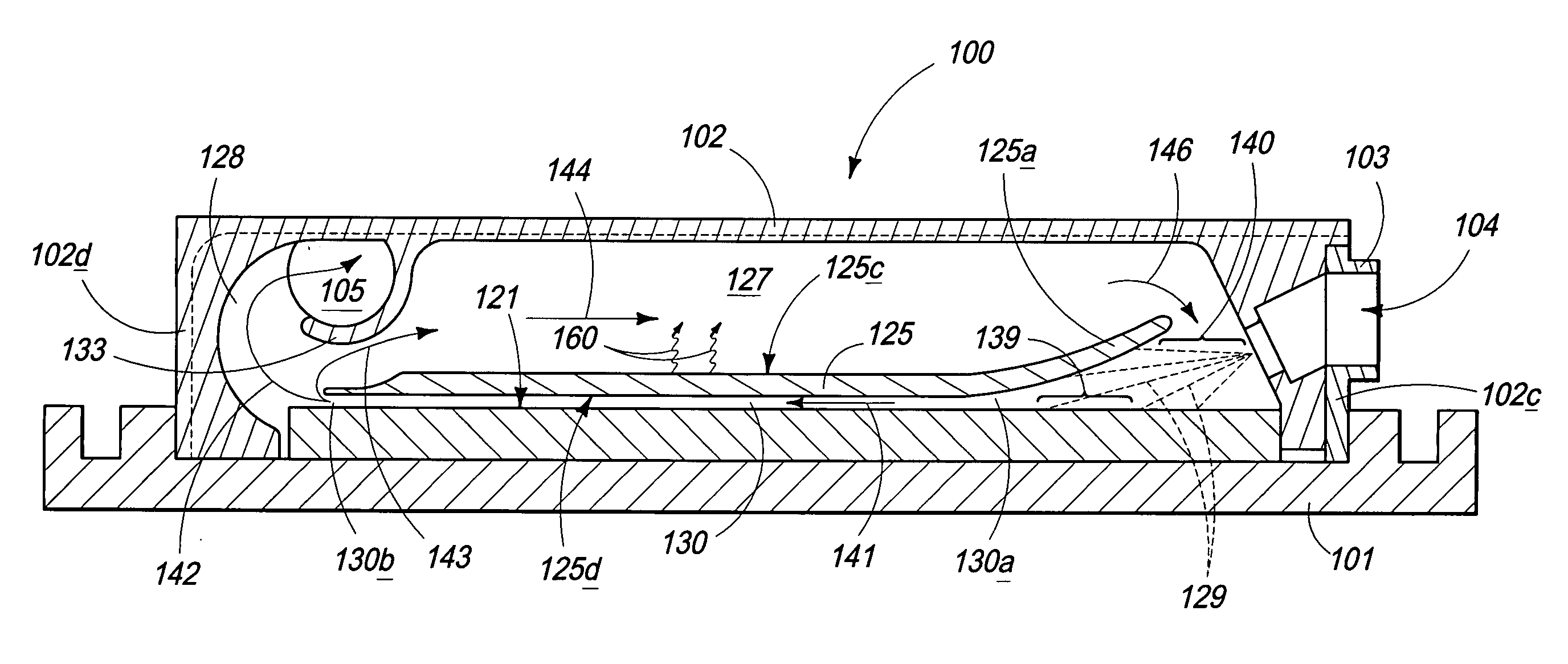

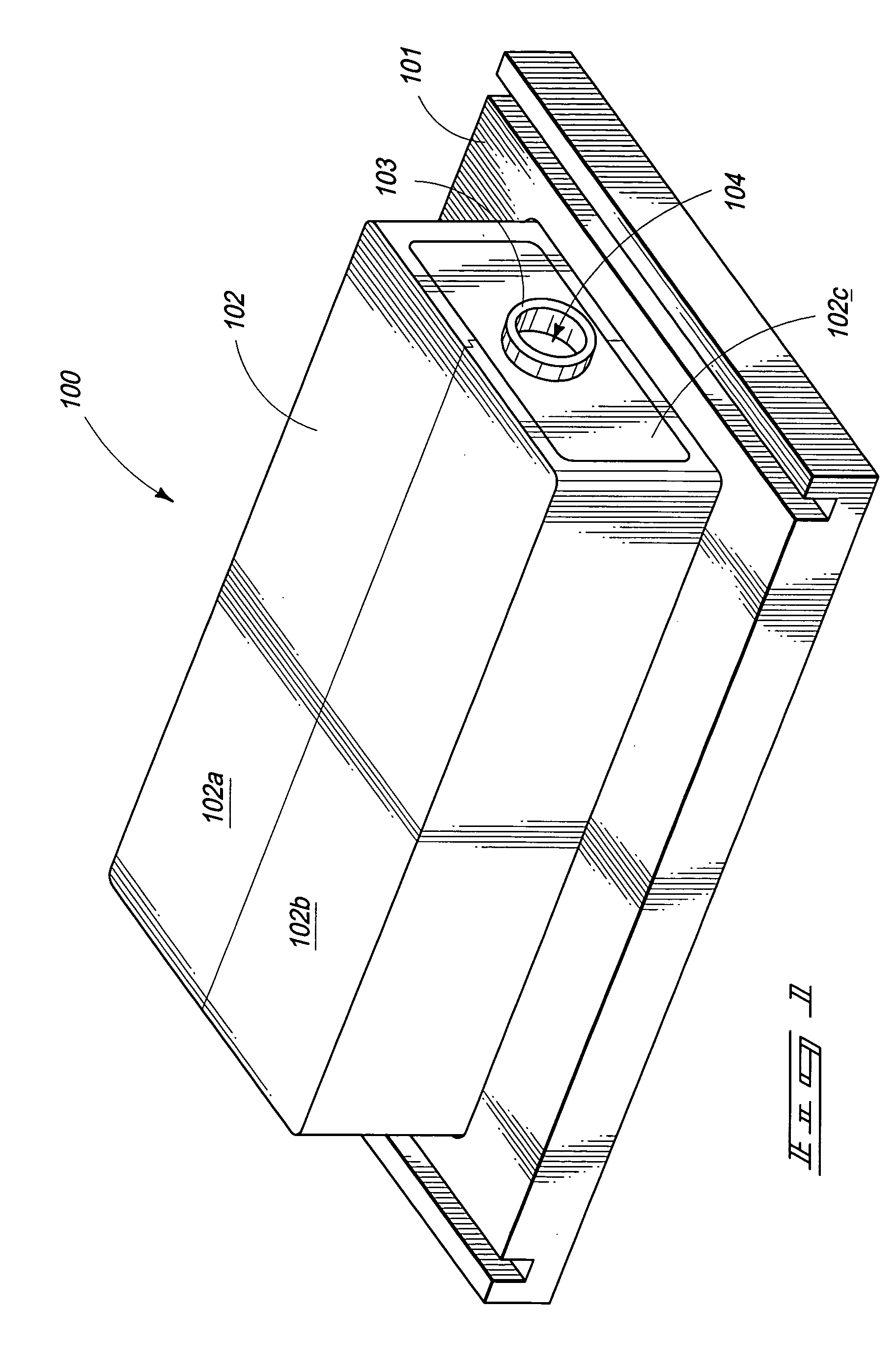

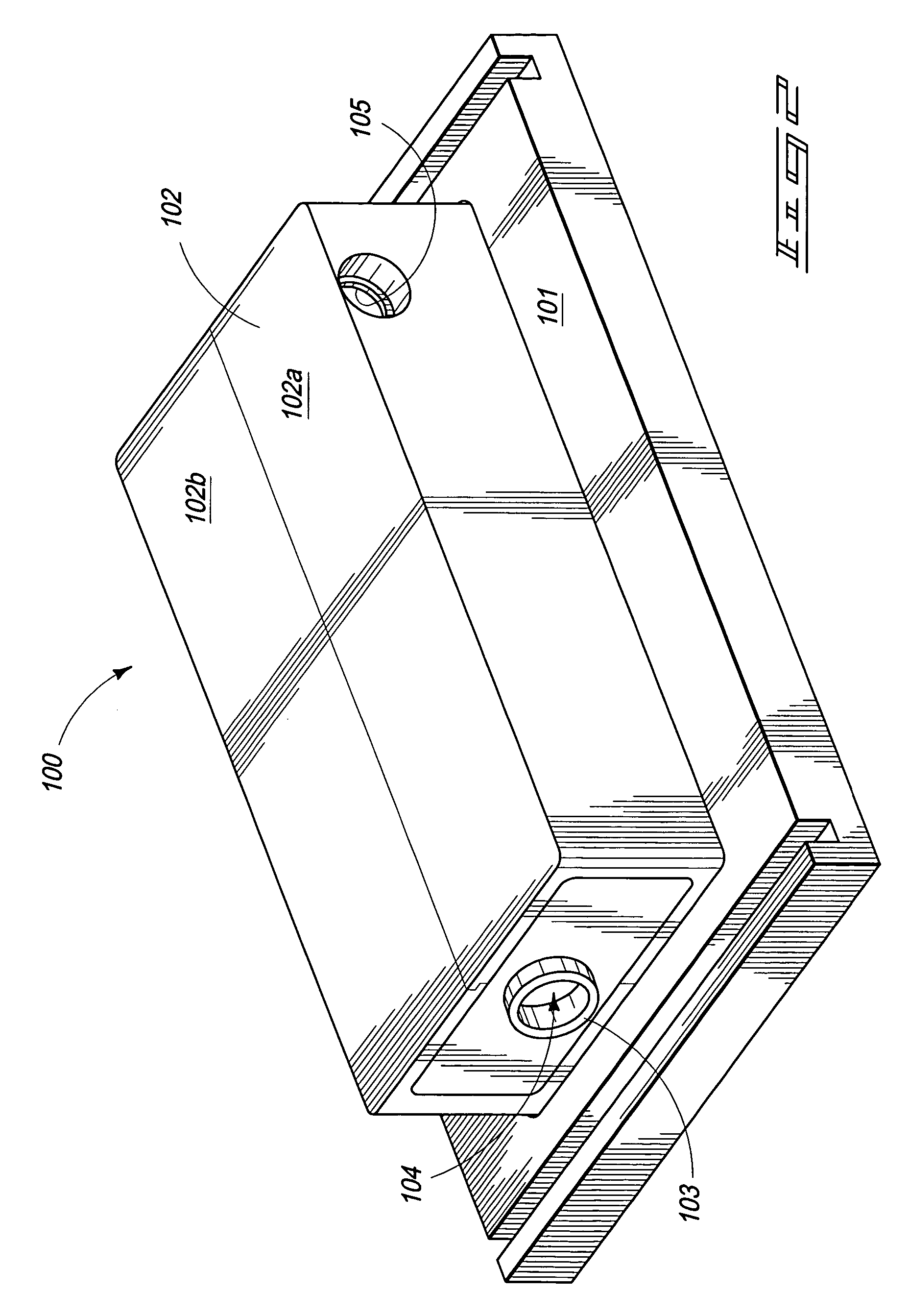

Spray cooling system for transverse thin-film evaporative spray cooling

ActiveUS7104078B2Semiconductor/solid-state device detailsEvaporators/condensersSpray coolingGuide tube

A spray cooling system for transverse evaporative spray cooling in a narrow gap which may generally include a mixing zone, a converging zone, a cooling conduit, and a re-circulation conduit. The spray cooling system in some of its embodiments, provides among other things, a feed system for narrow gap evaporative spray cooling, a method for reducing the pressure gradient across the surface from which heat is to be transferred and a housing system which utilizes a baffle to separate the cooling conduit from a re-circulation conduit and to re-circulate vapor to the entry of the cooling conduit.

Owner:PARKER INTANGIBLES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com