Heat dissipation system with a spray cooling device

a technology of heat dissipation system and cooling device, which is applied in the direction of lighting and heating apparatus, semiconductor/solid-state device details, and domestic cooling apparatus, etc. it can solve the problems of reducing the overall heat dissipation effect, increasing the temperature of working fluid, and not meeting the requirement for dissipating heat generated by high-powered electronic components. , to achieve the effect of high heat dissipation efficiency and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Before the present invention is described in greater detail with reference to the accompanying preferred embodiments, it should be noted herein that like elements are denoted by the same reference numerals throughout the disclosure.

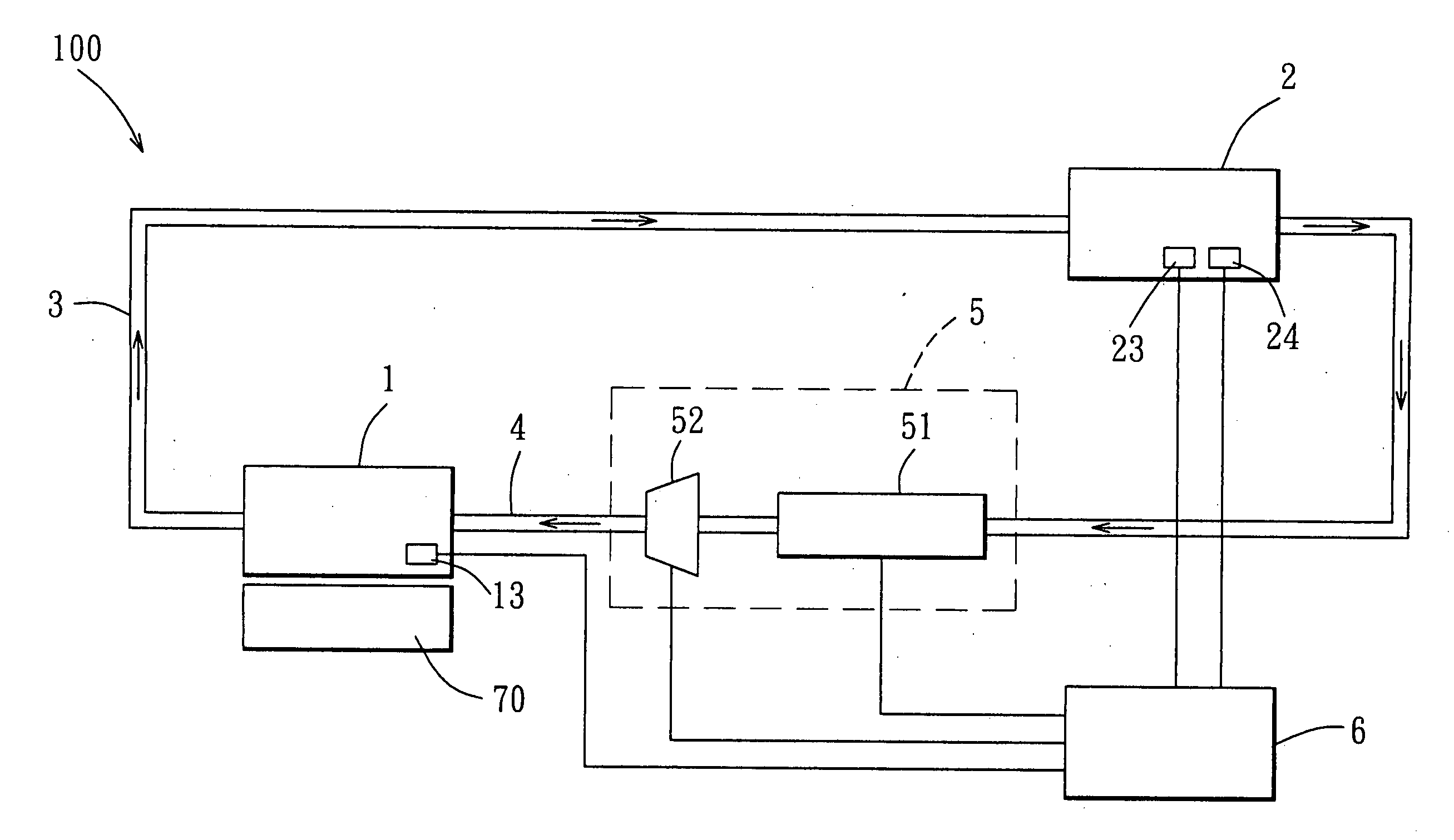

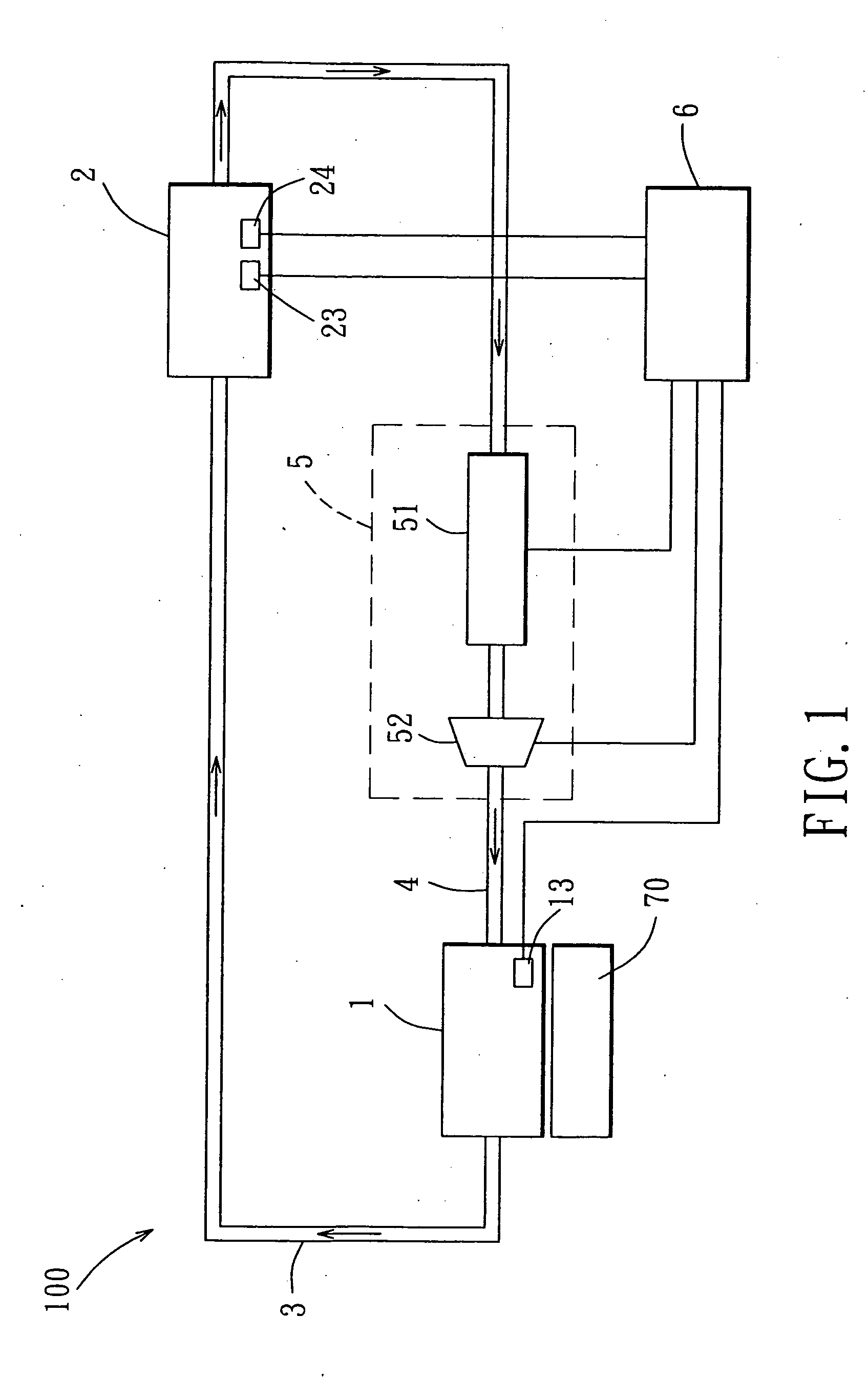

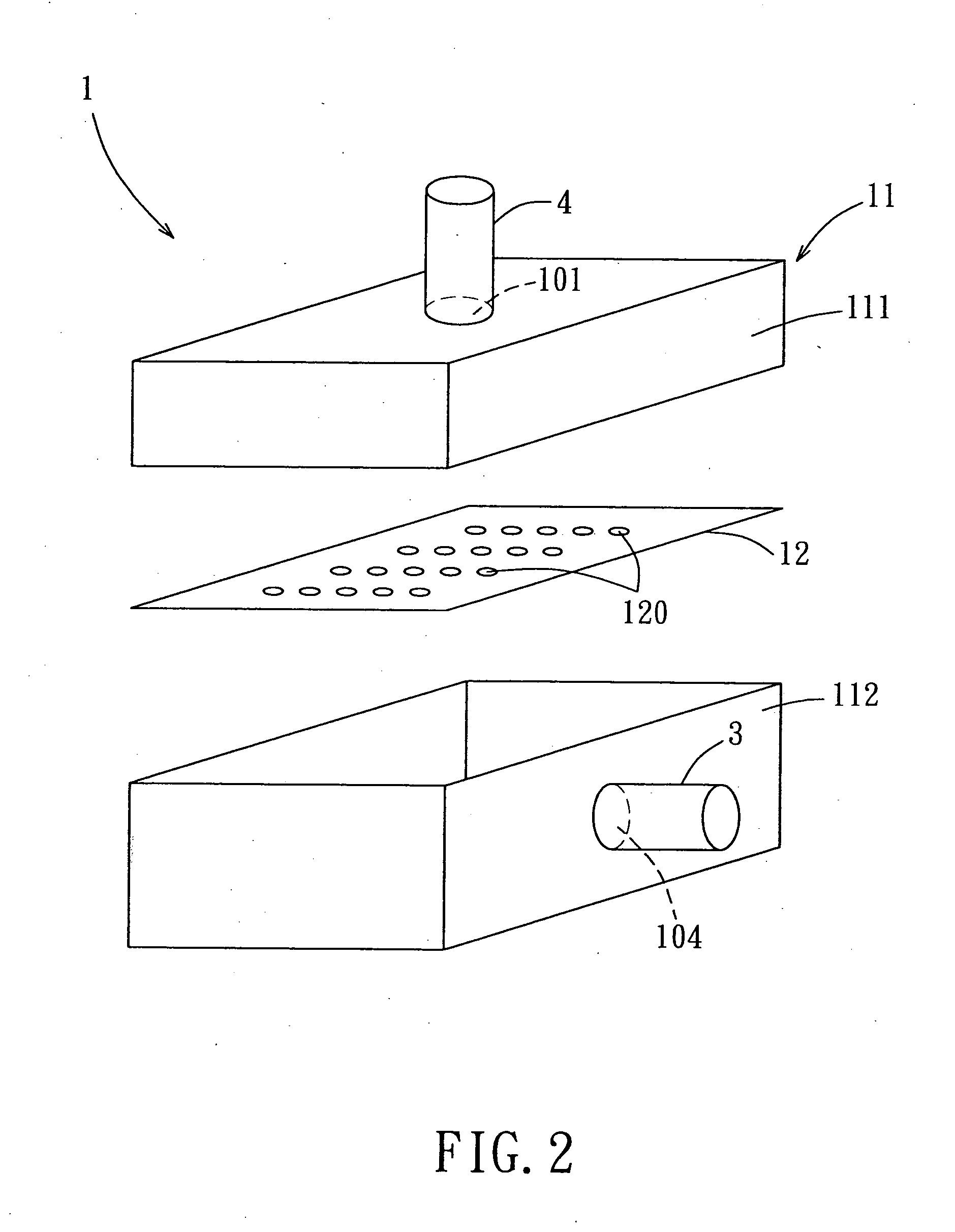

[0023]Referring to FIG. 1, there is shown a cooling system 100 according to the first preferred embodiment of the present invention for dissipating heat generated by a heat source 70. The cooling system includes a cooling device 1, a condenser 2, a vapor conveying duct 3, a cooling liquid conveying duct 4, a fluid driving module 5 and a power and control module 6. The cooling device 1, the condenser 2, the vapor conveying duct 3 and the cooling liquid conveying duct 4 cooperate to form a closed circuit. The fluid driving module 5 has a pump 51 connected to the closed circuit for driving a working fluid, and a control valve 52 connected to the closed circuit for controlling the working fluid. In this embodiment, the working fluid is one of the Flouri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com