Patents

Literature

1777results about How to "Safe and reliable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

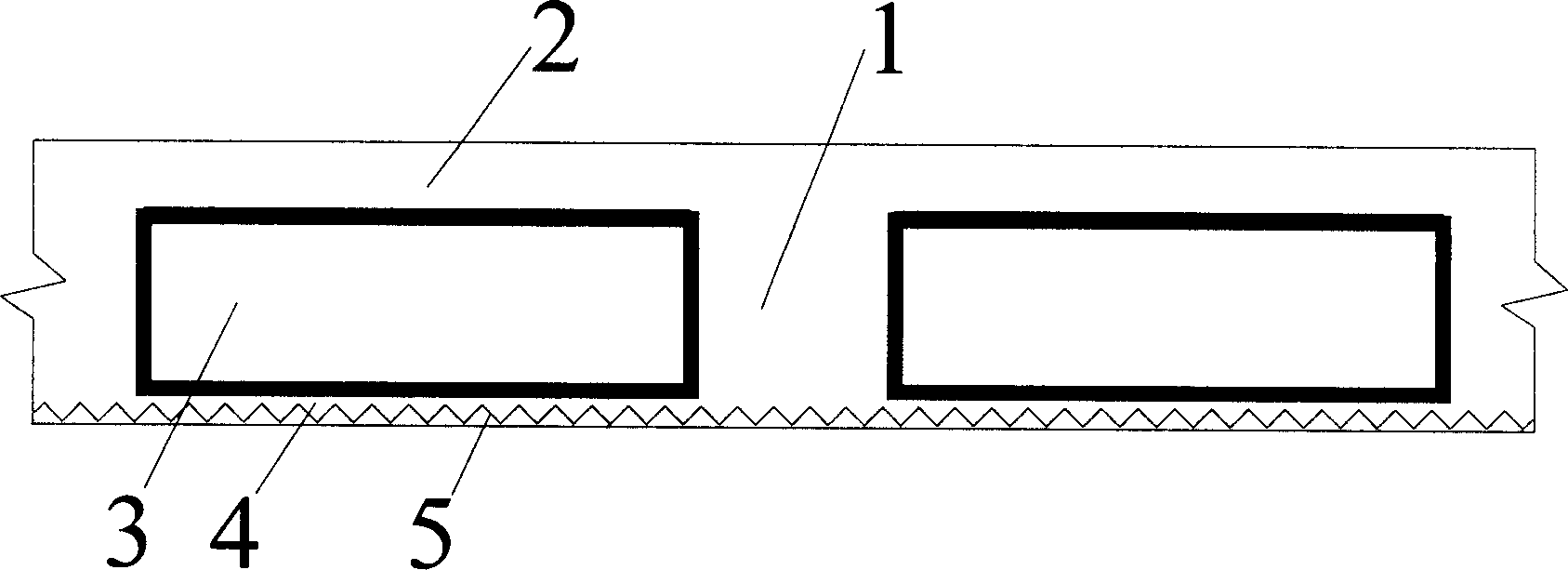

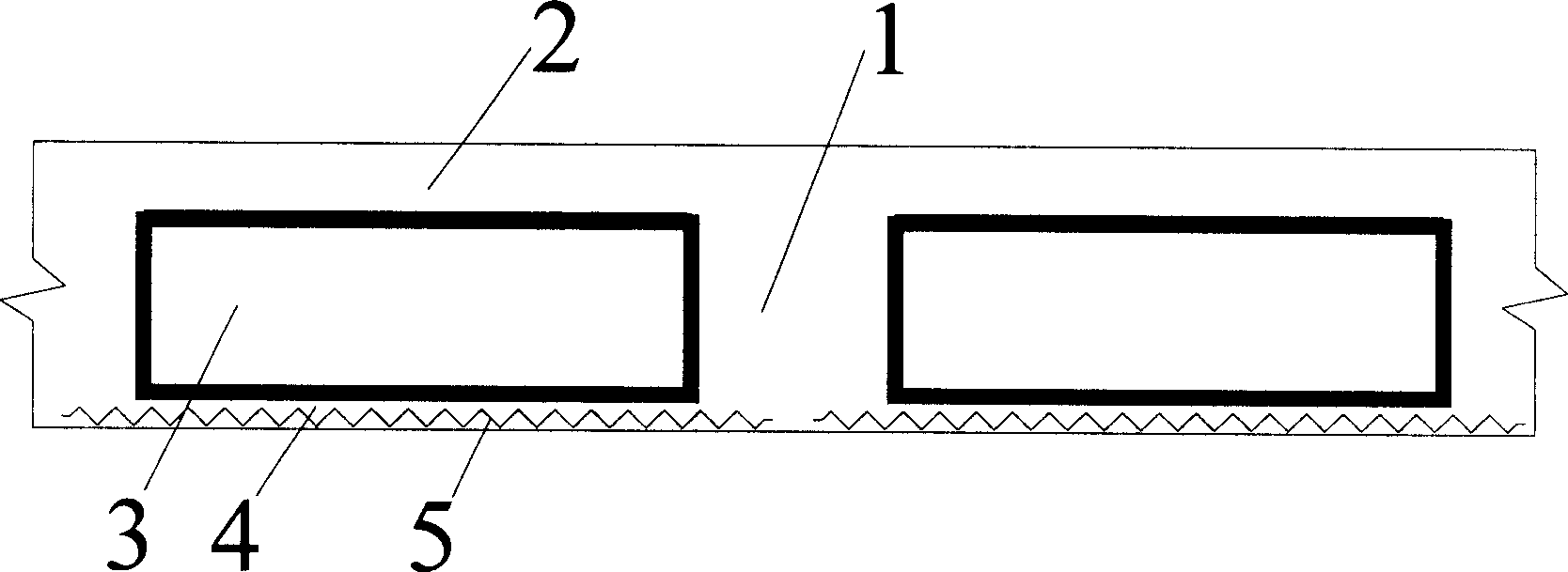

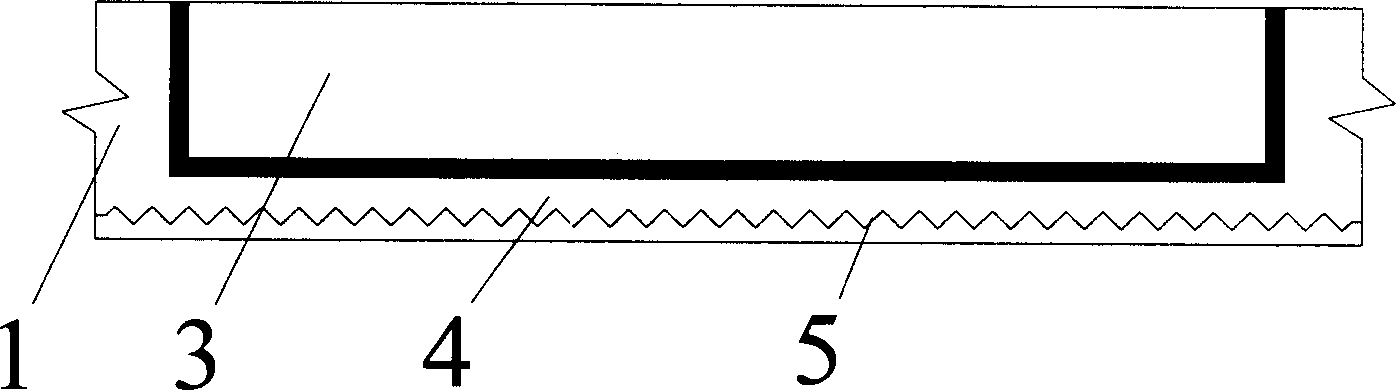

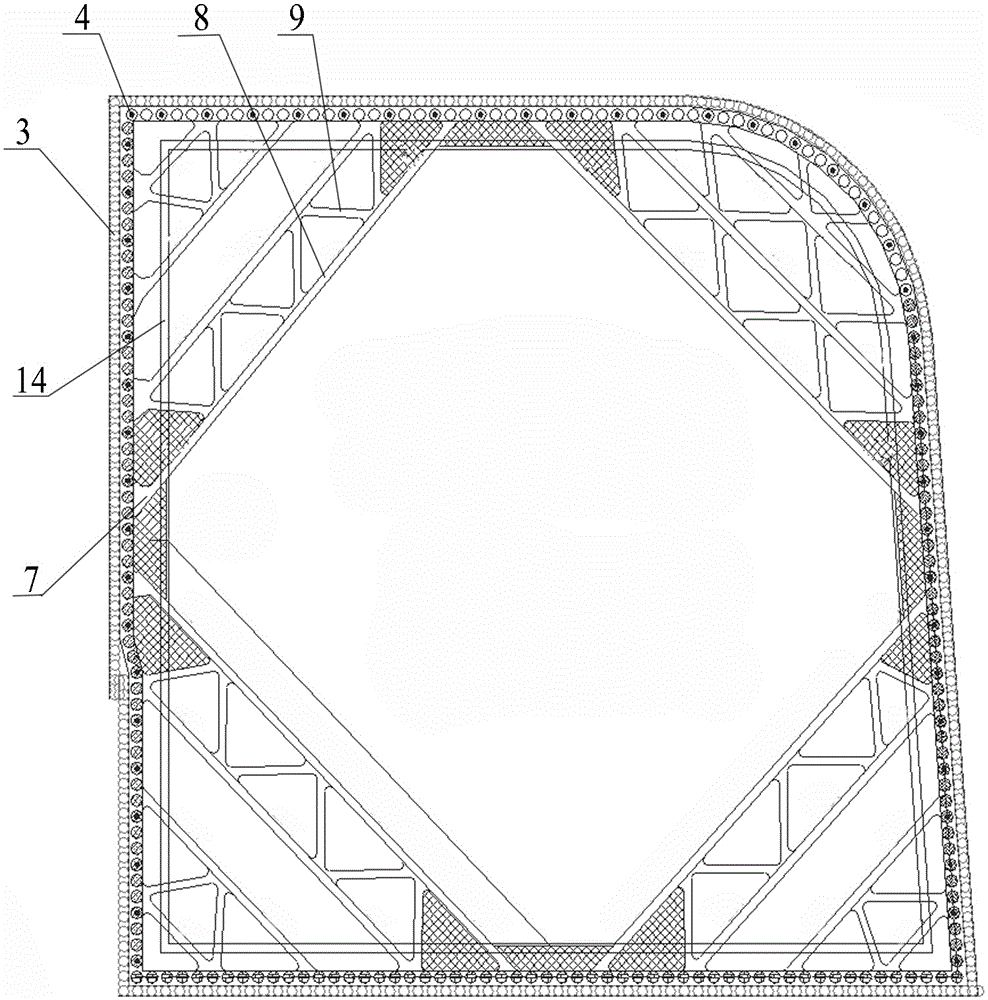

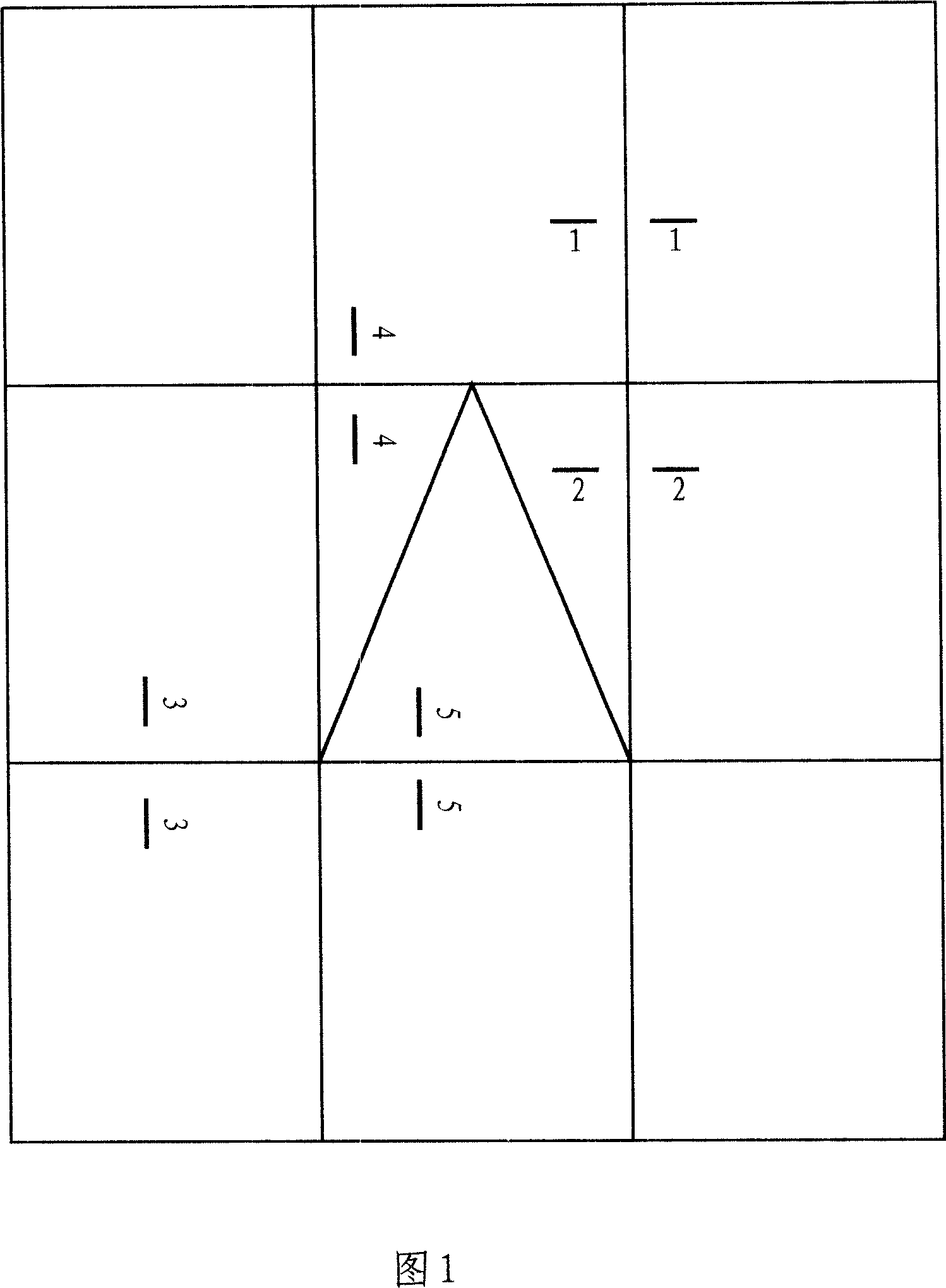

Hollow floor slab with small dense ribs and its production process

InactiveCN1637217ALarge spanSafe and reliable structureFloorsForms/shuttering/falseworksFloor slabLine tubing

The hollow floor slab includes column, solid belt, solid reinforced beam with dense ribs, reinforced facing board, and composite box with lower thin bottom board. The production process includes: a) laying and tying reinforcing steel bar in the floor slab formwork; b) laying the steel wire net and other reinforcing material; c) setting and fixing made composite thin box; d) tying reinforcing steel bar for the facing board; e) fixing reinforcing bars with iron wire; and f) embedding prefabricated pipeline inside the facing board and the dense ribs. The present invention may produce flat sealed floor slab cavity with dense ribs in once deposition.

Owner:HUNAN BDF ENERGY SAVING TECH

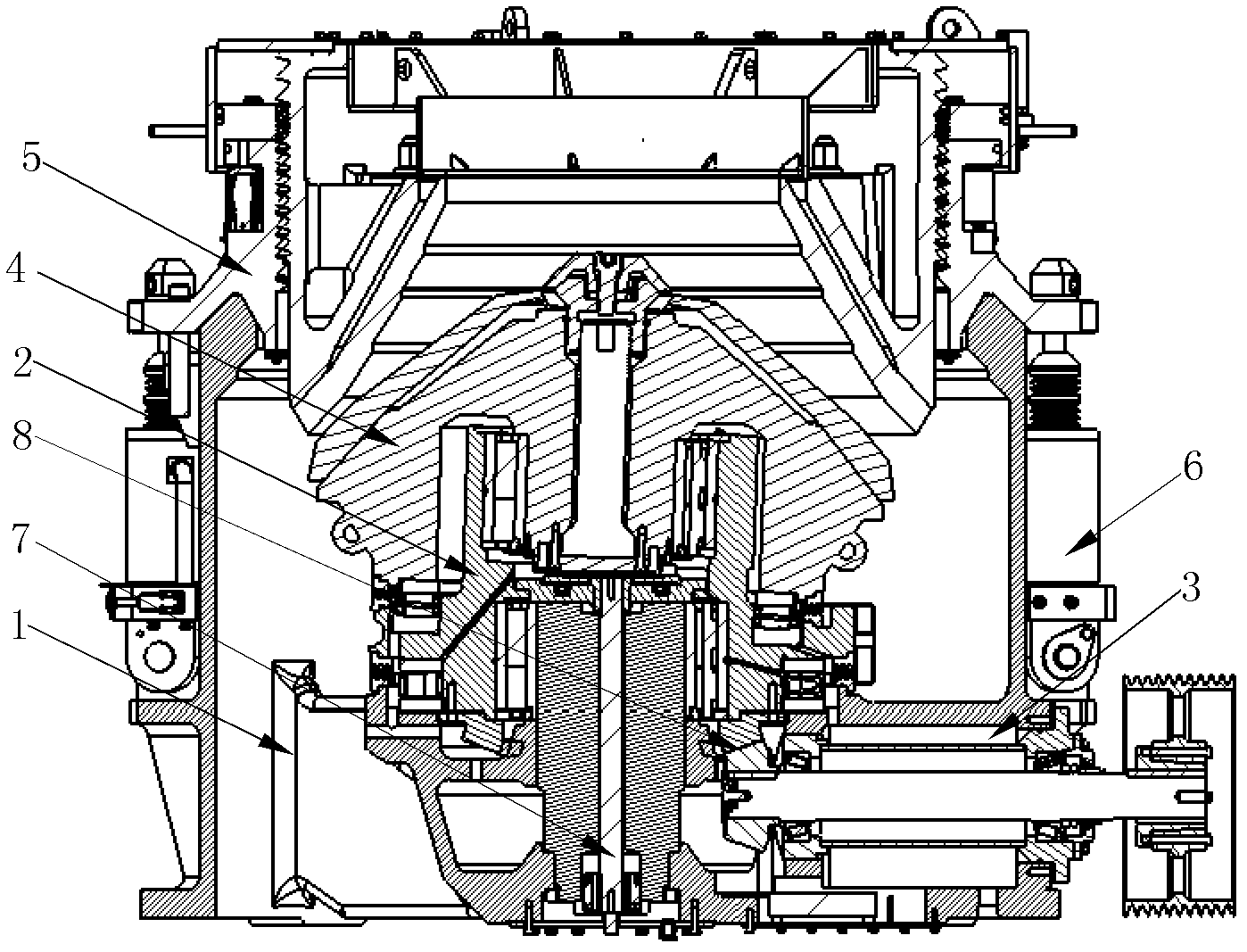

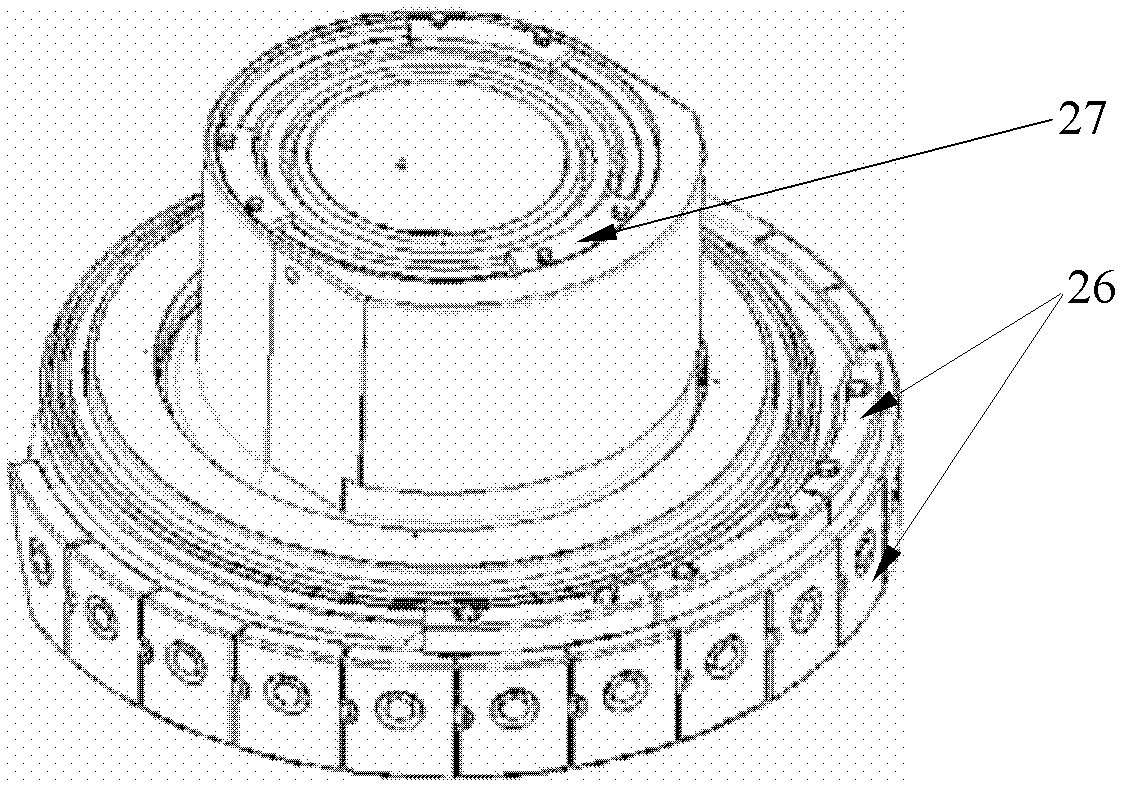

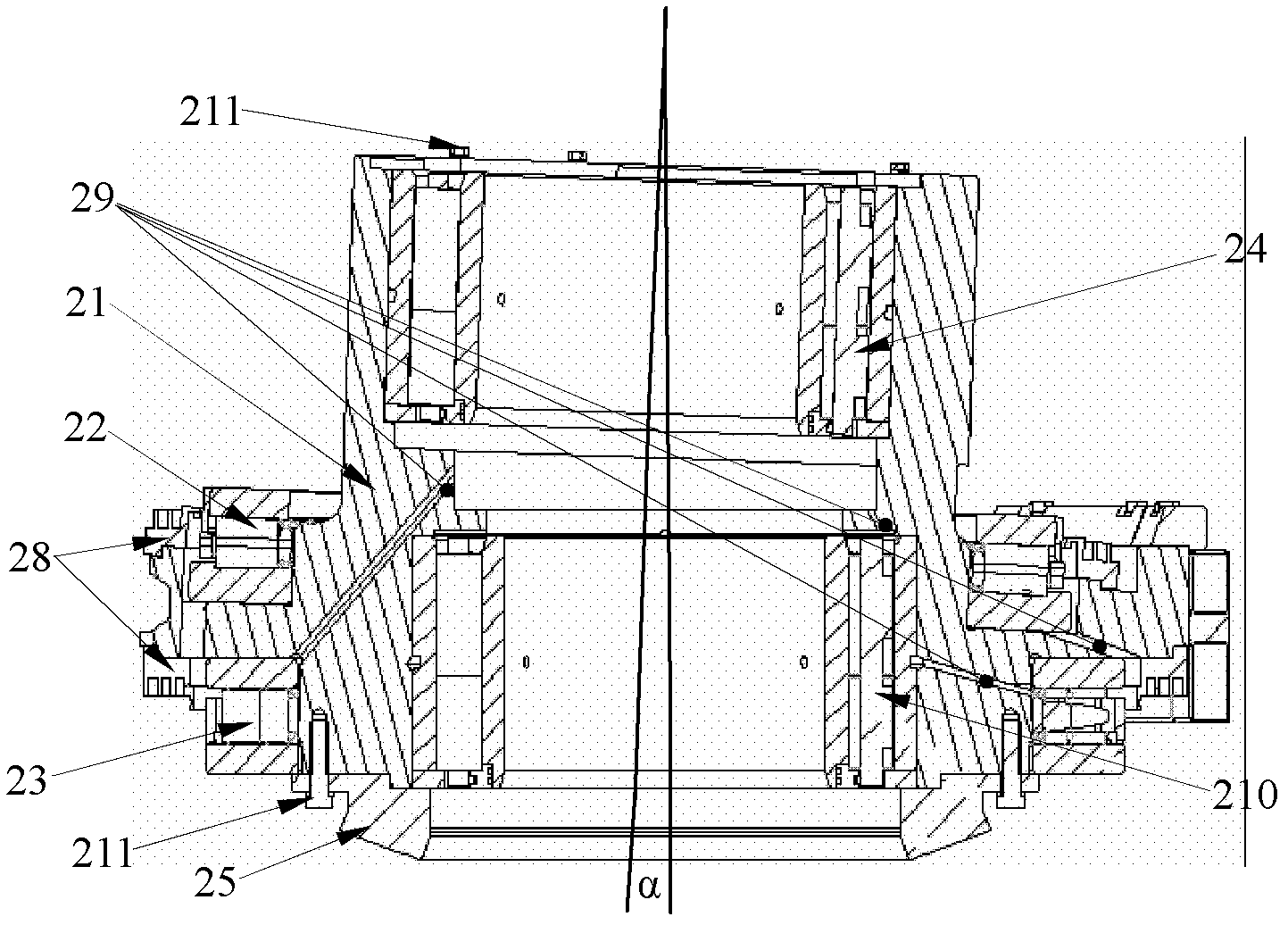

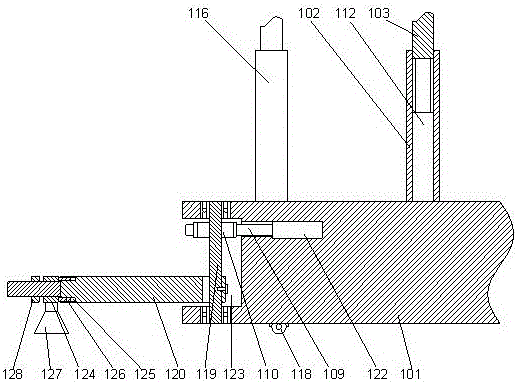

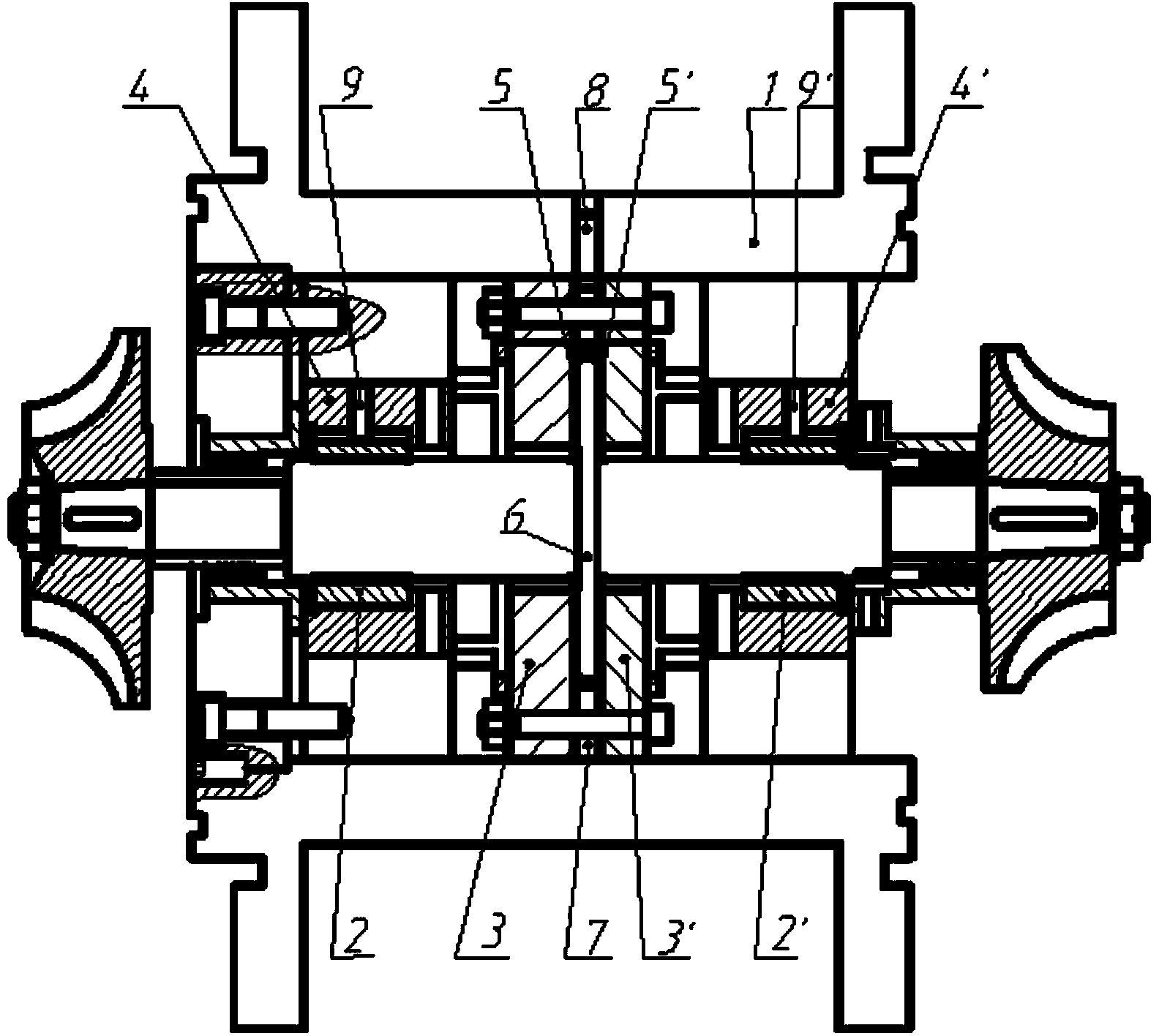

Multi-cylinder hydraulic antifriction bearing taper crusher

ActiveCN102357371AIncrease speedImprove crushing efficiencyGrain treatmentsRolling-element bearingWorking pressure

The invention discloses a multi-cylinder hydraulic antifriction bearing taper crusher, which comprises a lower machine frame, an eccentric sleeve mechanism, a transmission set, a movable tapper, an upper machine frame set and an iron passing and cavity clearing device. The upper machine frame set is arranged above the lower machine frame, the transmission set and the eccentric sleeve mechanism are both installed on the lower machine frame, the transmission set is connected with the eccentric sleeve mechanism where the movable tapper is arranged, the iron passing and cavity clearing device is directly installed on the lower machine frame and the upper machine frame set, the eccentric sleeve mechanism adopts an antifriction bearing type eccentric sleeve mechanism, the iron passing and cavity clearing device adopts a relief valve type iron passing and cavity clearing device, and a movable tapper body rotating-proof device is connected to the bottom of the movable tapper. The multi-cylinder hydraulic antifriction bearing taper crusher improves crushing efficiency and output of the taper crusher, and prolongs service life of a machine, reduces using cost of equipment. The iron passing and cavity clearing device can not only bear higher working pressure of a system, but also be safe and reliable, convenient to assemble and capable of controlling a tapper body to rotate according to certain direction, thereby improving production efficiency and saving energy.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

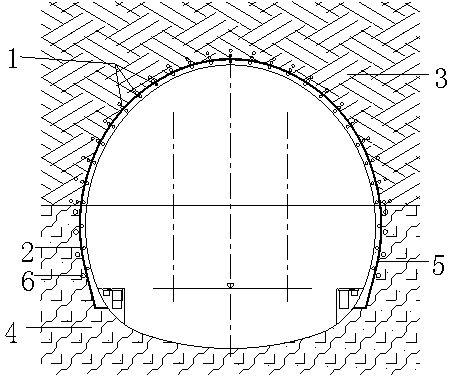

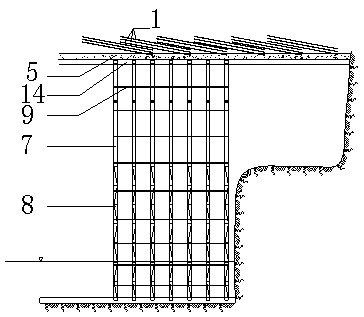

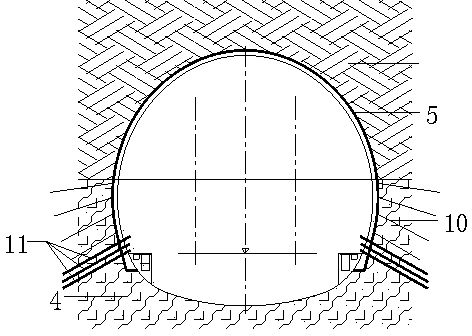

Preliminary bracing construction method for tunnel with surrounding rocks containing collapsible loess and soft rocks

InactiveCN103410527AEasy to operateEconomically reasonableUnderground chambersTunnel liningShotcreteMesh reinforcement

The invention discloses a preliminary bracing construction method for a tunnel with surrounding rocks containing collapsible loess and soft rocks. The method includes the following steps that a plurality of layers of advanced pipe sheds are arranged on a collapsible loess layer, and a single layer of advanced pipe shed is arranged on a soft rock layer; after the advanced pipe shed is set up, a working face is closed through sprayed concrete, a system anchor bolt is arranged on the soft rock layer, a foot locking small guide pipe is arranged at the arch springing position of the tunnel, and grouting is conducted on the rocks through permeation of the system anchor bolt and the foot locking small guide pipe; a pre-fabricated reinforcing mesh is paved on a concrete initial spraying layer formed by concrete initial spraying in a fluctuation mode, and a reinforcing mesh arranged at the collapsible loess layer is encrypted; a steel arch support is set on the collapsible loess layer, a reinforcing steel bar grid is set up at the soft rock layer, and the connecting position of the reinforcing steel bar grid and the steel arch support is welded; repeated spraying is conducted by adopting concrete spraying, and construction of tunnel preliminary bracing is finished. By means of the method, stress releasing and deformation coordination of two layers of surrounding rocks can be well controlled, operability is good, construction cost is low, and the safety is good.

Owner:CENT SOUTH UNIV

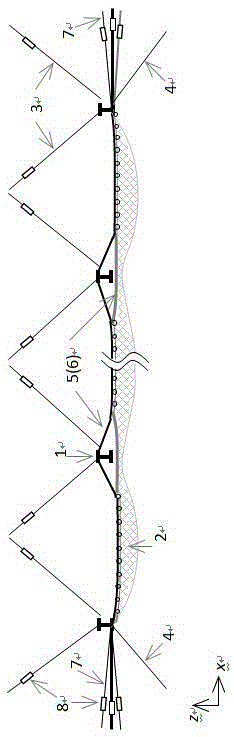

Rockfall prevention driven flexible protective net system designing method based on energy matching principle

ActiveCN105256731AClarify the design processOperableProtective constructionModel selectionEngineering

The invention discloses a rockfall prevention driven flexible protective net system designing method based on the energy matching principle. The rockfall prevention driven flexible protective net system designing method comprises the steps that 1, the energy consumption rate matching principle of components of a driven flexible protective net structure is established; 2, preliminary model selection and arrangement are performed on the components of the driven flexible protective net structure; 3, an explicit dynamics computation model capable of considering features such as the initial perpendicularity, large sliding of a supporting rope, large rotation of a supporting column and large deformation of an interception net is built through a finite element computing method; 4, impact loading is performed on the computation model, and dynamics response of the structure under the impact effect is analyzed; 5, structural design of the driven flexible protective net is performed. According to the method, the design principle of energy matching is adopted, both the force balance and the energy balance are considered, and the design is more scientific and reasonable; the component strength, stability, deformation and the like are used as design verification control indexes, and both the component design bearing capacity safety storage and the applicability of the protective net structural overall interception effect are considered.

Owner:SICHUAN OST SLOPE PROTECTION ENG

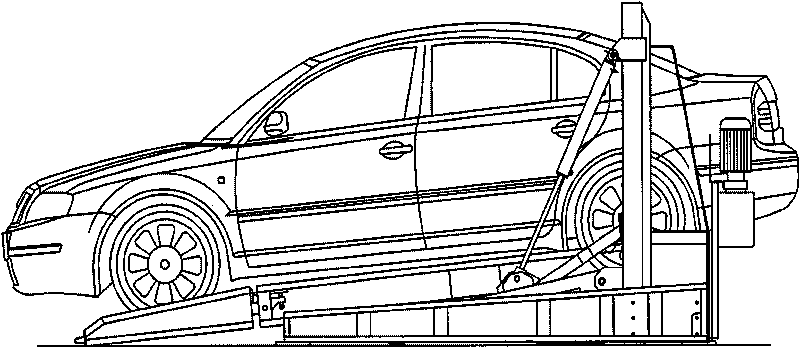

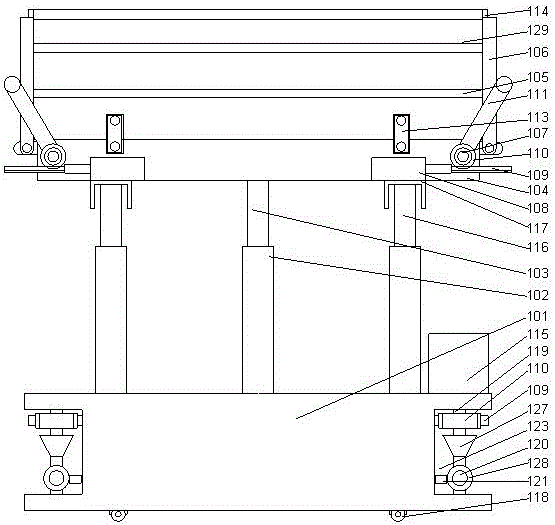

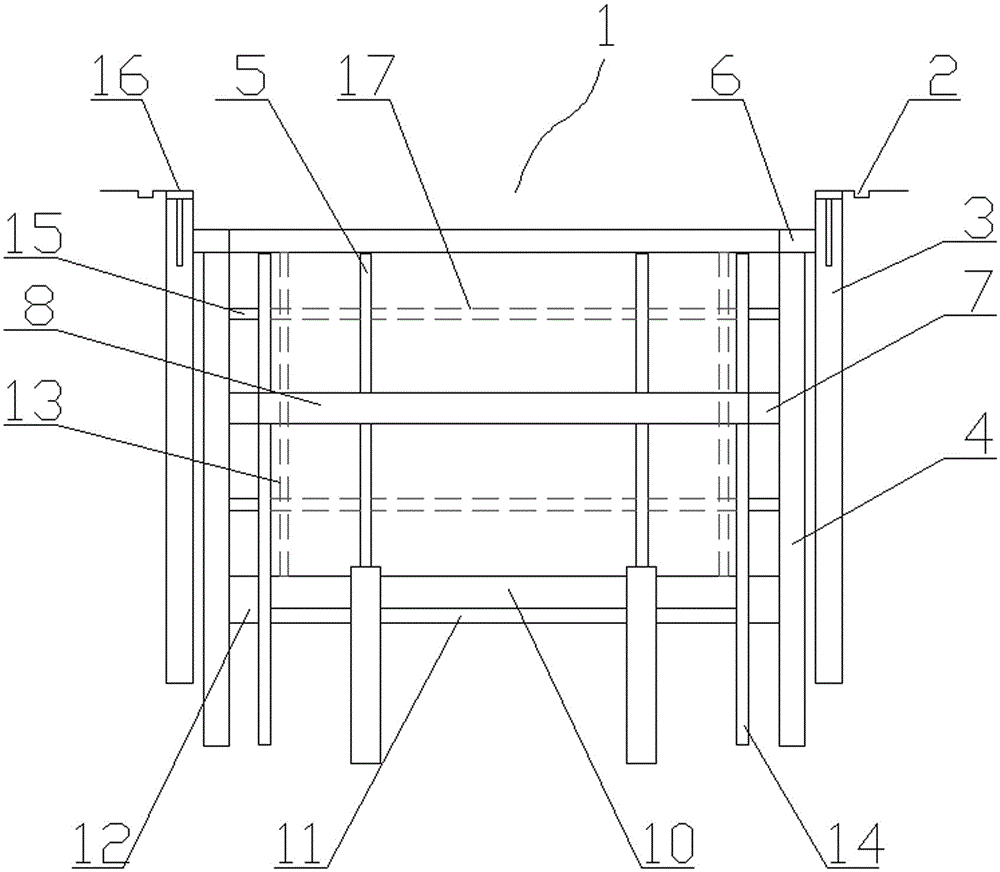

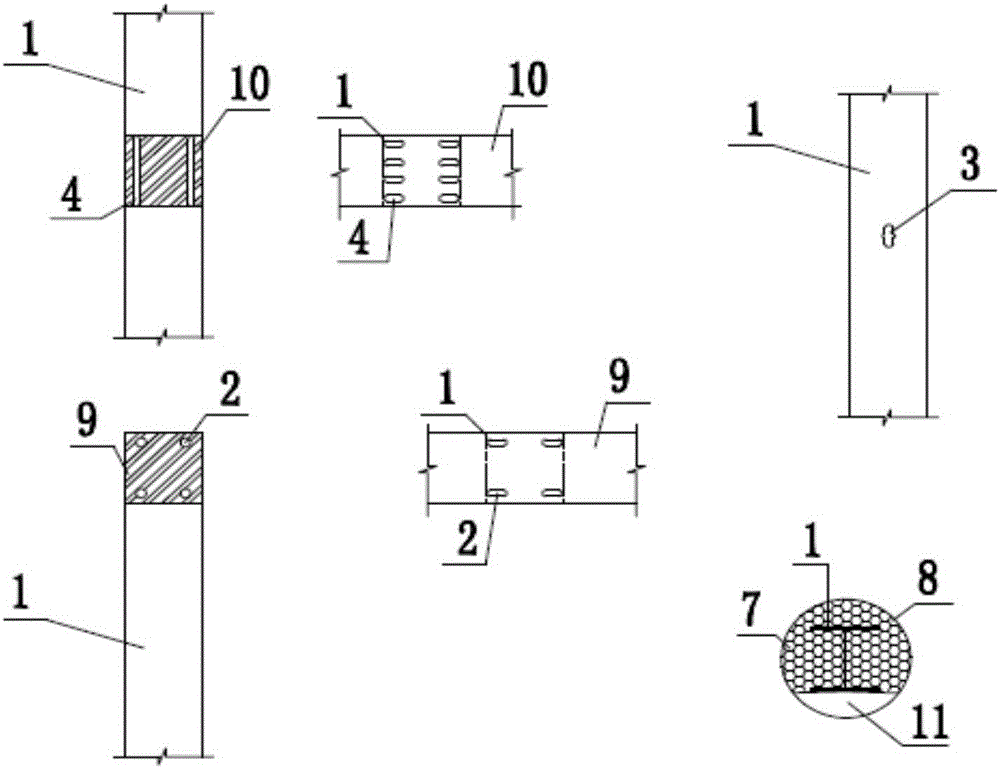

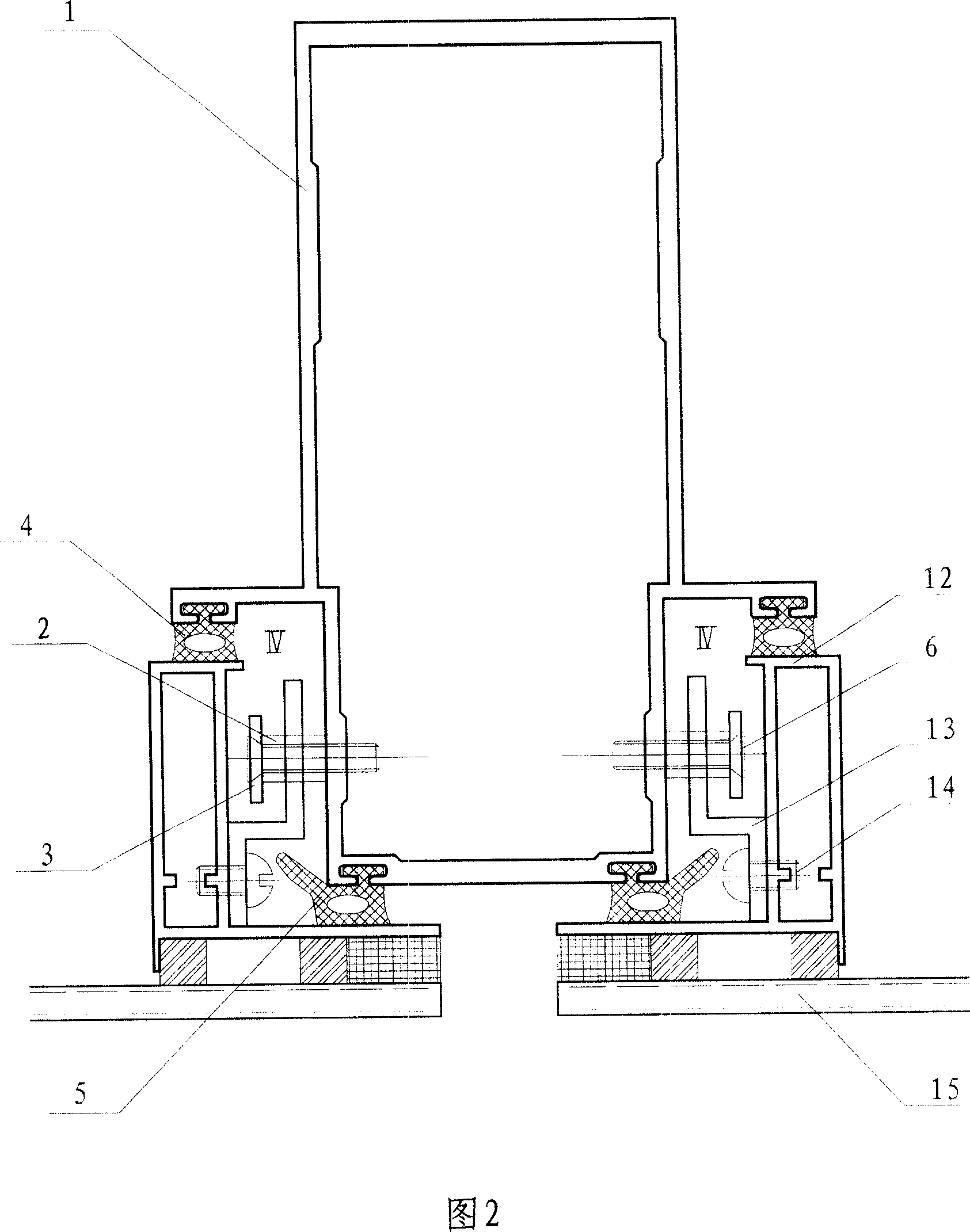

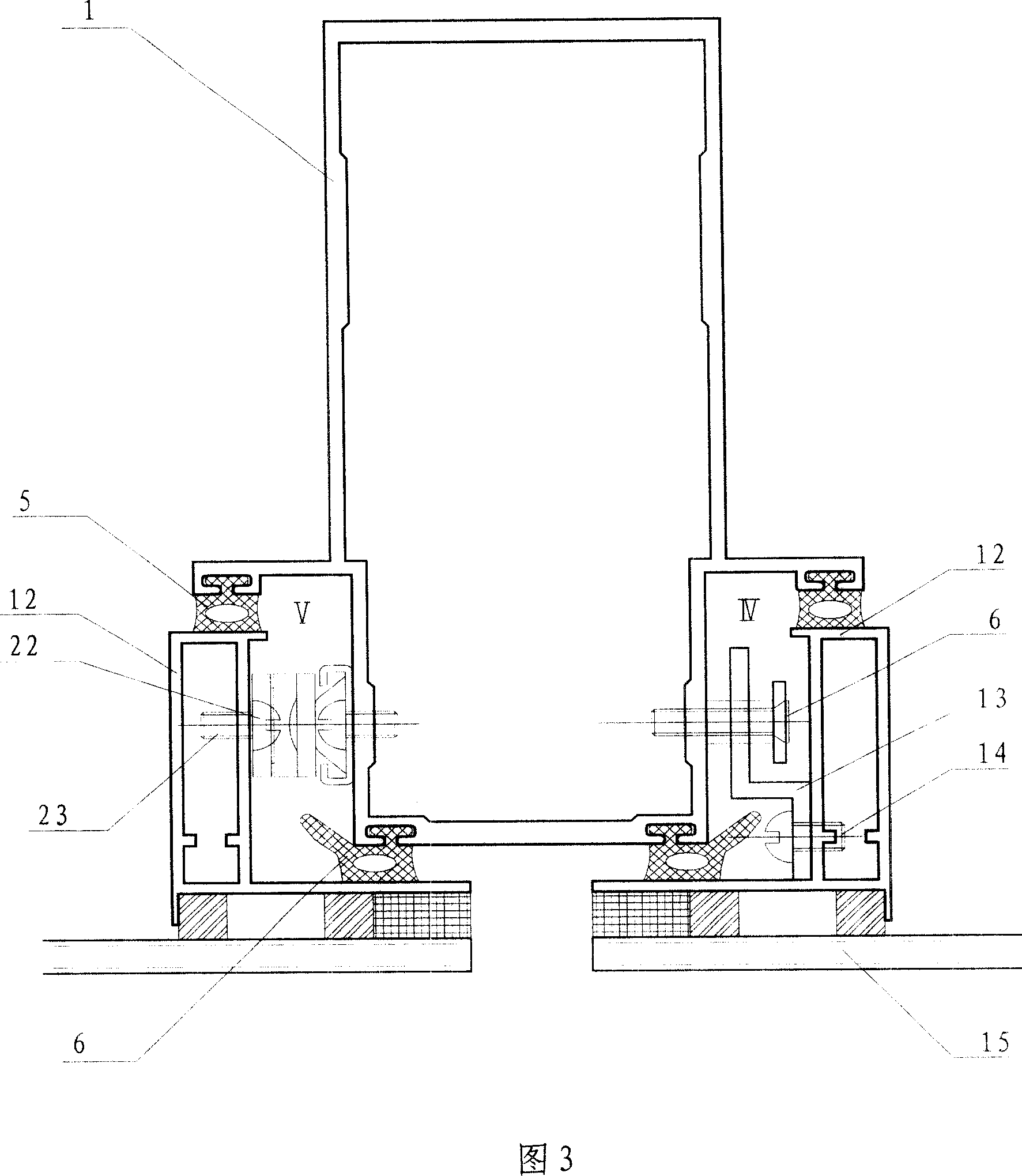

Miniature hydraulic garage

The invention relates to a miniature hydraulic garage, comprising two layers on the ground, wherein each layer has two spaces. The garage is simple lift type solid parking equipment with independent structure and control. The garage comprises a support mechanism, front and rear parking boards, a lifting arm mechanism, a dynamic control mechanism and a steel wire synchronous mechanism. The steel wire synchronous mechanism realizes synchronization of two lift cylinders; the parking boards are in horizontal state when on the ground, so that parking is convenient, while the parking plates are lifted, the parking space for the next space is increased. The garage adopts self-locking of a connecting rod type lifting arm instead of a safe hook, when the parking board is lifted to a right position, the included angle between the connecting rod and the lifting arm exceeds 180 degrees to form self locking. The miniature hydraulic garage has the characteristics of more convenient vehicle storage and pickup and simpler operation, has safer and more reliable structure, and can meet the requirement of different users.

Owner:HANGZHOU XIZI IUK PARKING SYST CO LTD

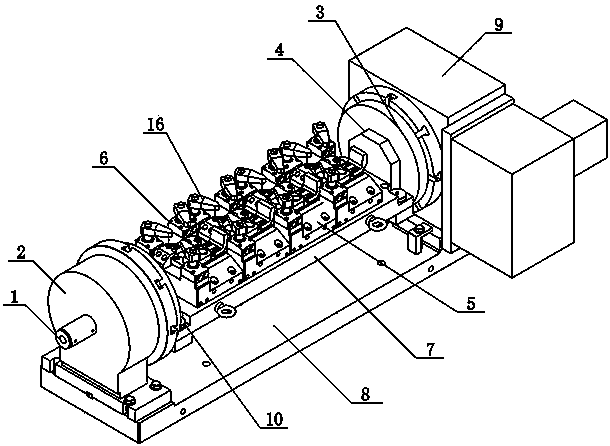

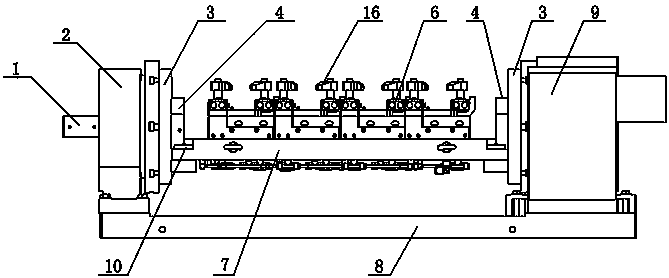

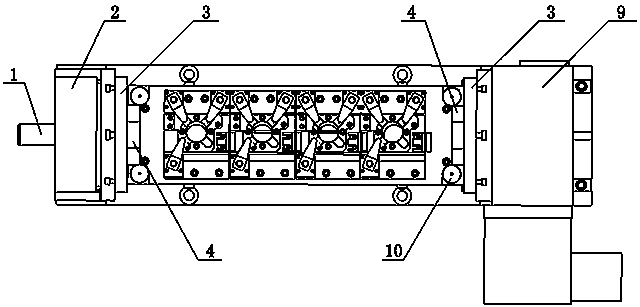

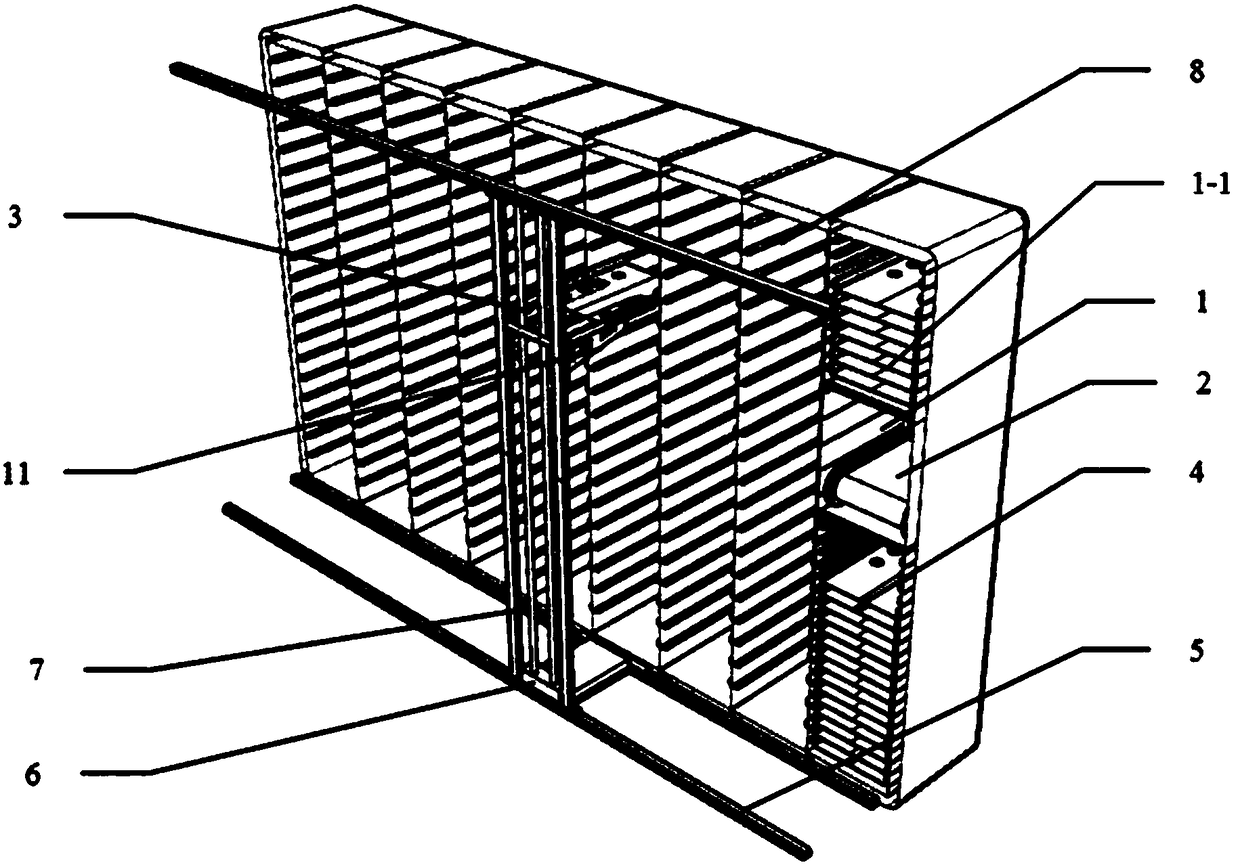

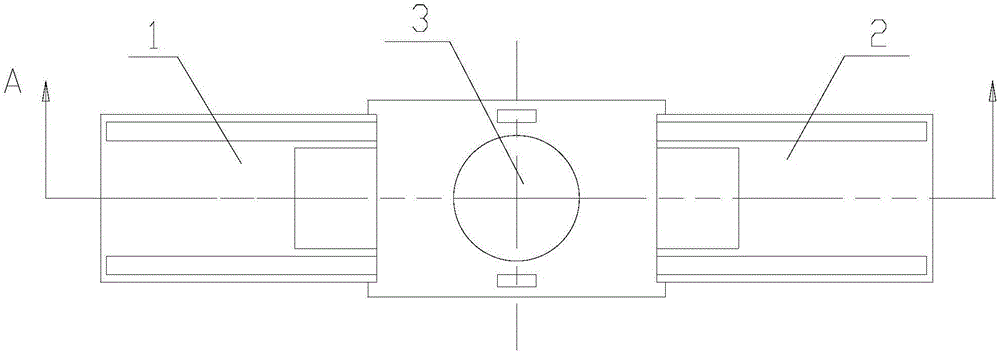

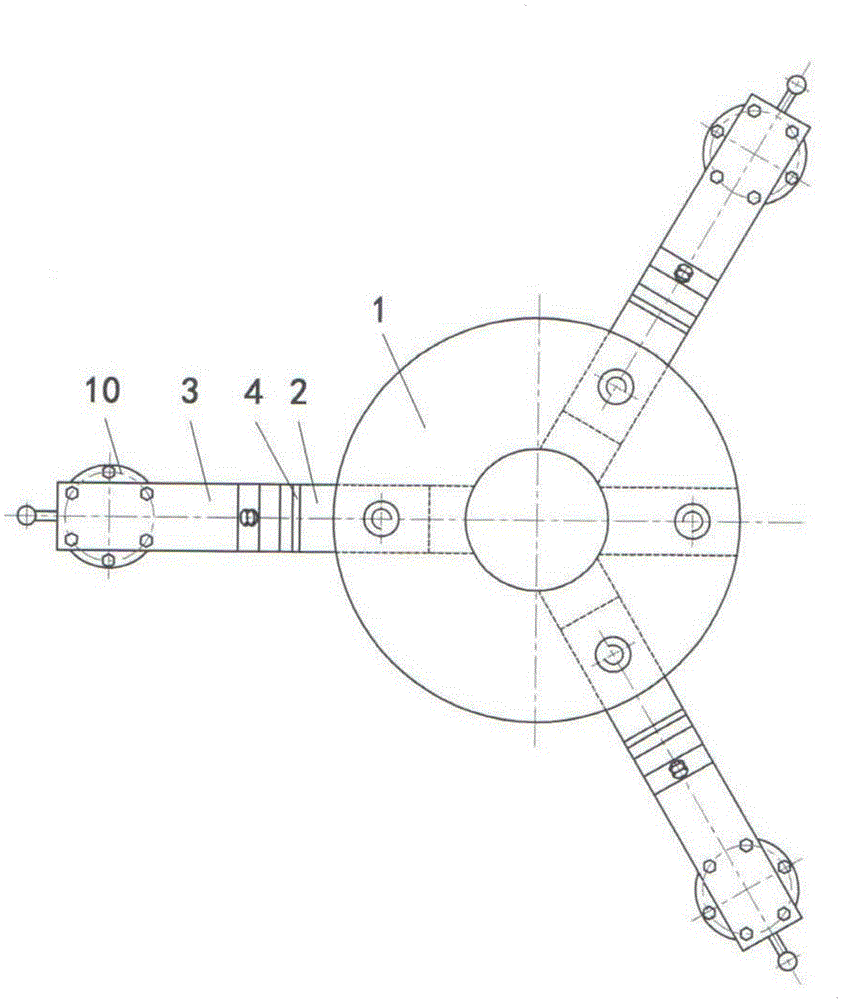

Machine and turntable clamp for four-axis processing center

InactiveCN104325324ASimple changeover operationQuick changeoverMeasurement/indication equipmentsPositioning apparatusProduction lineModular design

The invention relates to a machine and turntable clamp for a four-axis processing center. The clamp comprises a clamp bottom plate (8), a tail seat (2), a dividing head (9), an oil / gas path distributor component (1), L-shaped plates (4), a bridge plate (7) and clamp location clamping units, wherein the tail seat (2) and the dividing head (9) are fixedly arranged on the clamp bottom plate (8); the oil / gas path distributor component (1) is arranged on the outer side face of the tail seat (2); two L-shaped plates (4) are oppositely arranged and are respectively connected with the tail seat (2) and the dividing head (9) by a transition plate (3); two ends of the bridge plate (7) are respectively connected with the L-shaped plates (4); a plurality of clamp location units are provided and are uniformly spaced and fixed on the bridge plate (7) in sequence. The machine and turntable clamp has the advantages that a modular design and a ball lock location system are used for realizing fast changing the clamp when the type of a production line is changed; hydraulic clamping is used, so that a reliable clamping force is provided; an airtight detection technology and a fast assembling / disassembling limit block are used, so that an error proofing function is available.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

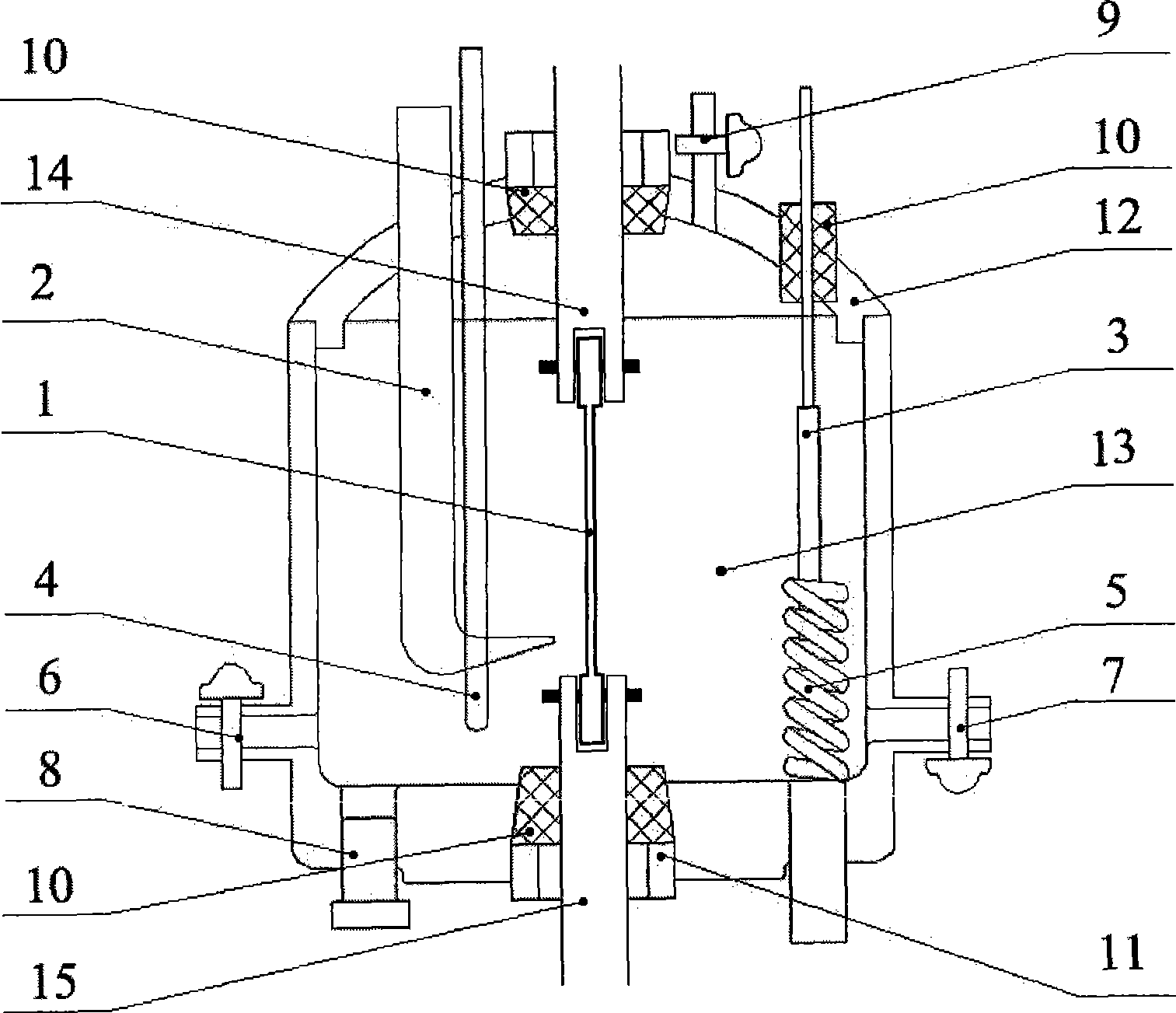

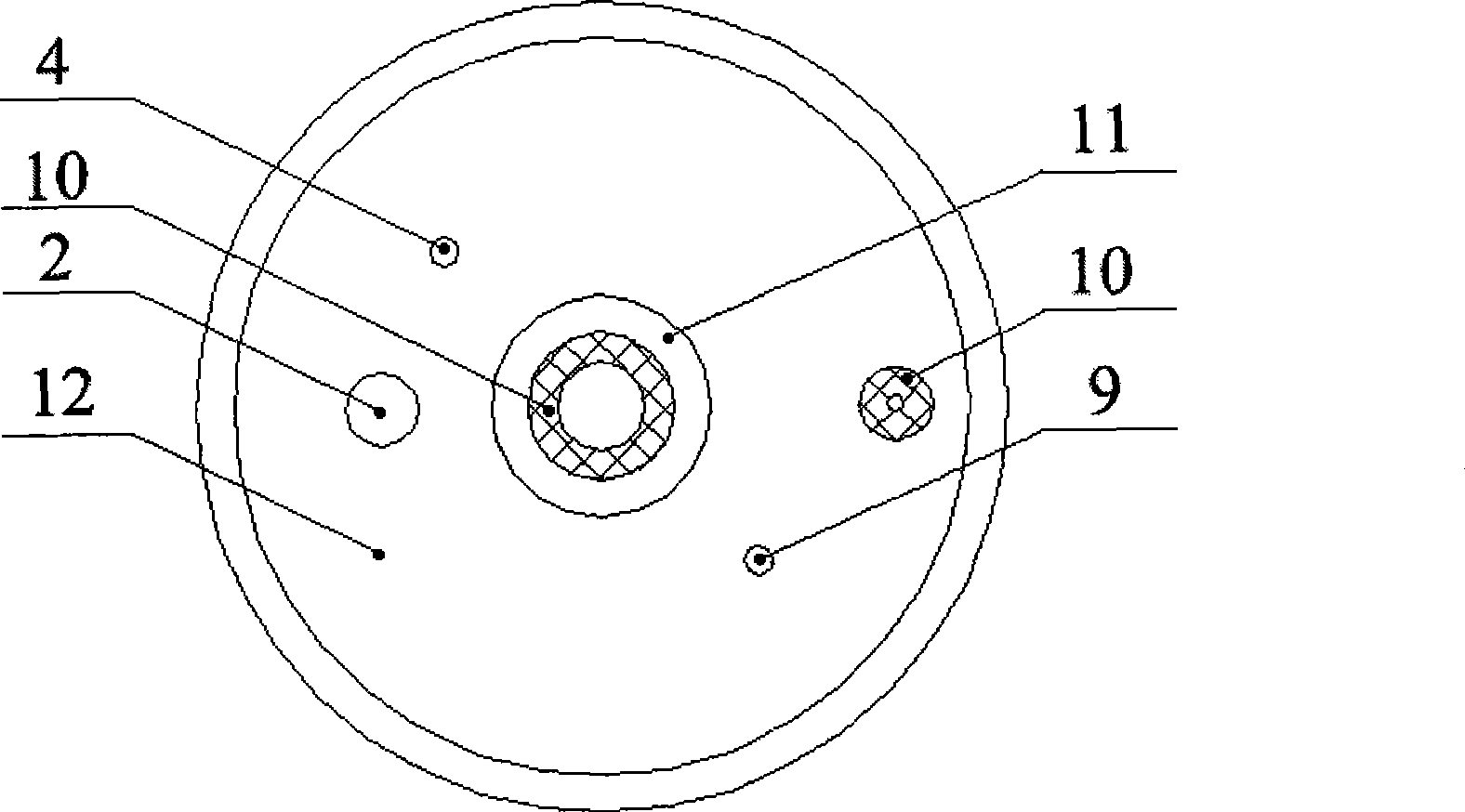

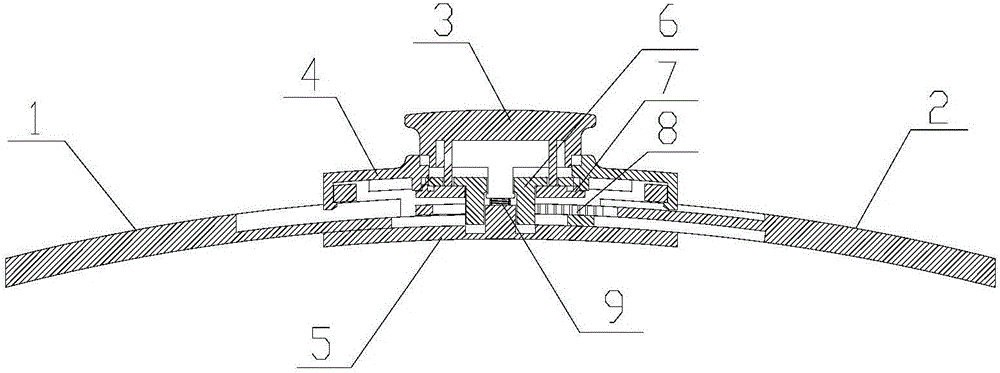

Multifunctional in-situ electro-chemical measuring apparatus for tensile test

InactiveCN101498648AImprove work efficiencyReduce mistakesWeather/light/corrosion resistanceAuxiliary electrodeEngineering

A multifunctional in-situ electrochemical measuring device used for the tension test belongs to the electrochemical field. The multifunctional in-situ electrochemical measuring device used for the tension test is characterized in that a reference electrode, an auxiliary electrode and a working electrode are arranged in a top cover of the multifunctional in-situ electrochemical measuring device according to design and measurement requirements; the conductive wires of all the electrodes are connected with an electrochemical workstation; the air input of an air inlet and the air output of an air outlet are adjusted; an installed heating resistor and a thermocouple are connected with a temperature controlling device; the water flow of a water inlet and the water flow of a water outlet are adjusted, and the water inlet and the water outlet are connected with an externally connected water pump. The rotation time of a stepping motor is set, electrochemical parameters of a tensile test sample are measured after the temperature and the pressure are increased to the parameters required by the tension test, and the tension test is conducted after the force of the tensile test sample is adjusted. The multifunctional in-situ electrochemical measuring device used for the tension test has simple and easy method, can measure the electrochemical parameters of the tensile test sample in a long time and can simulate the temperature, the moisture, the gas, the alternation of wetting and drying, the surface scouring, the multiphase medium and complex environment of the tensile test sample.

Owner:UNIV OF SCI & TECH BEIJING

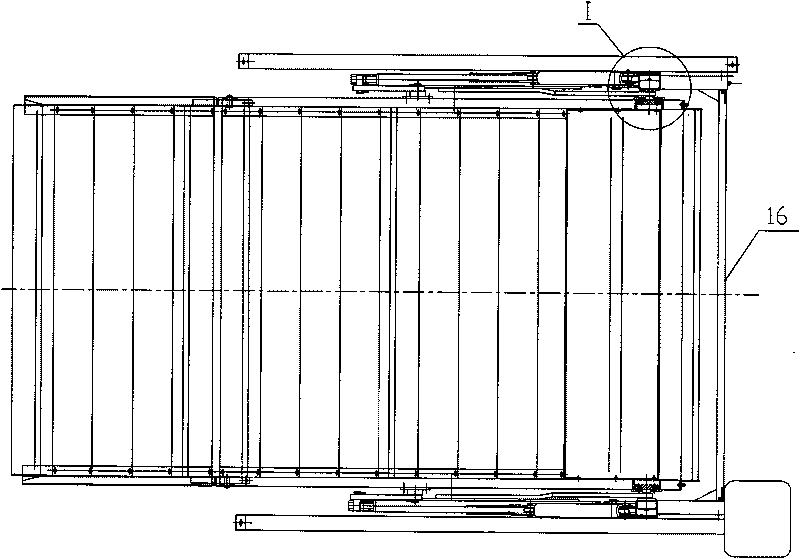

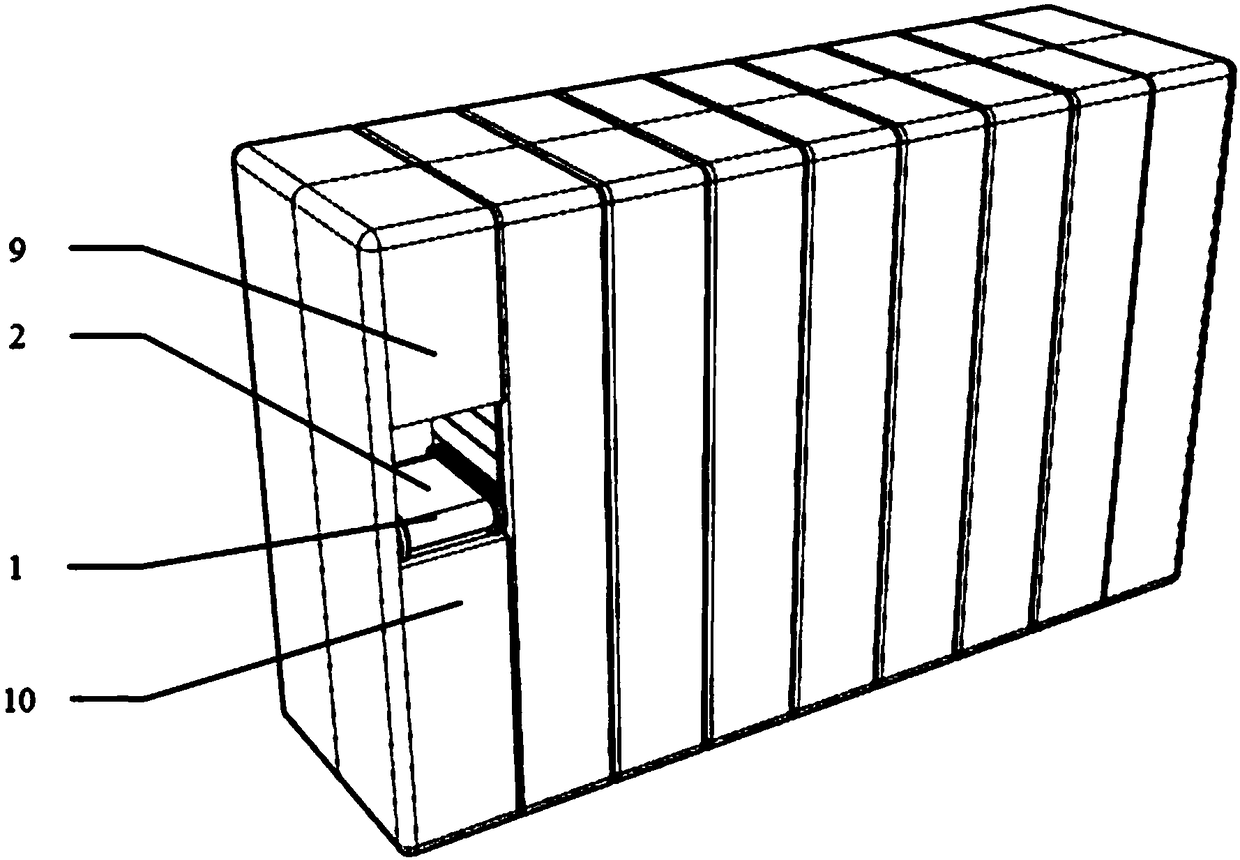

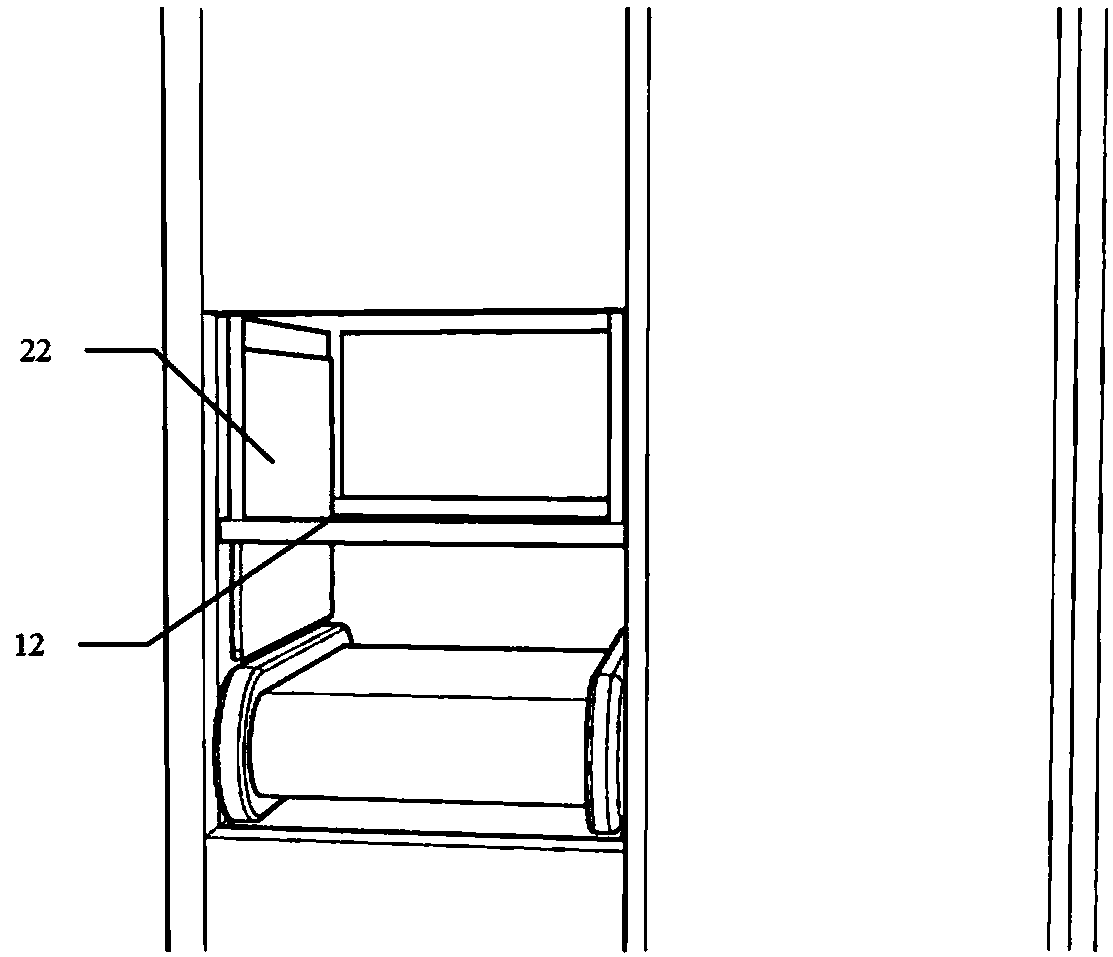

Self-adjusting adaptive large-capacity automatic access smart express item box

PendingCN108537978AMake the most of storage spaceIncrease storage spaceCoin-freed apparatus detailsApparatus for meter-controlled dispensingSelf adaptiveManipulator

The invention discloses a large-capacity smart express item box capable of automatically accessing items. The large-capacity smart express item box includes a cabinet body and a mechanical hand disposed at the rear end of the cabinet body. The cabinet body is provided with an access window, the bottom of the access window is provided with a conveying belt, and the top of the access window is provided with a detection unit. The detection unit is used for detecting the size of an item. A bracket is disposed in the cabinet body, a plurality of columns of storage grids for storing items are arranged in the cabinet body, a sliding mechanism is arranged between a partition plate and the cabinet body, a driving mechanism drives the partition plate to slide along the sliding mechanism, and each storage grid is separated through a clamping groove. A telescopic mechanism is arranged in the access window and connected with a push plate. When the items are stored, after the sizes of the items aredetected, the mechanical hand captures trays on the bracket to the rear end of the conveying belt, the conveying belt conveys the items to the trays, the mechanical hand conveys the trays storing theitems to the storage grids, and the trays are placed in different clamping grooves. When the items are taken, the mechanical hand captures the trays into the access window, and after the items are taken, the mechanical hand places the trays back to the bracket. The express item box is high in space utilization rate and facilitates users' taking and storing the express items.

Owner:NANJING UNIV OF SCI & TECH

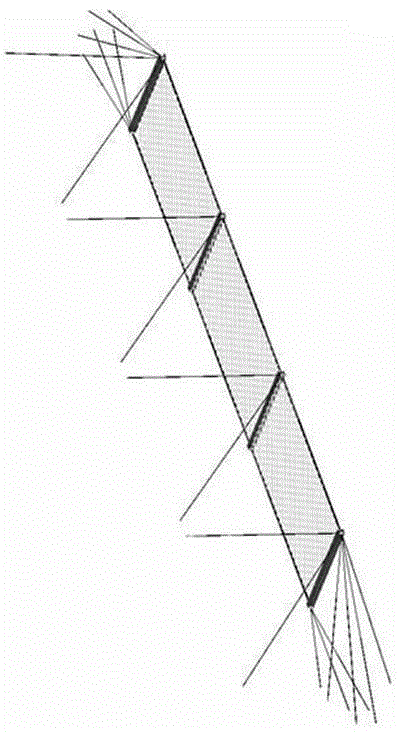

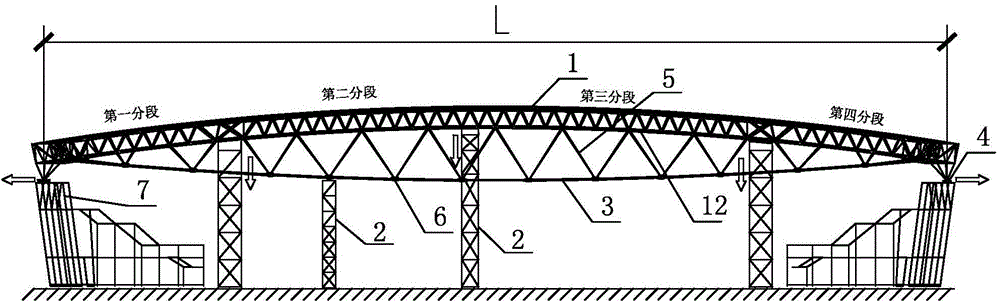

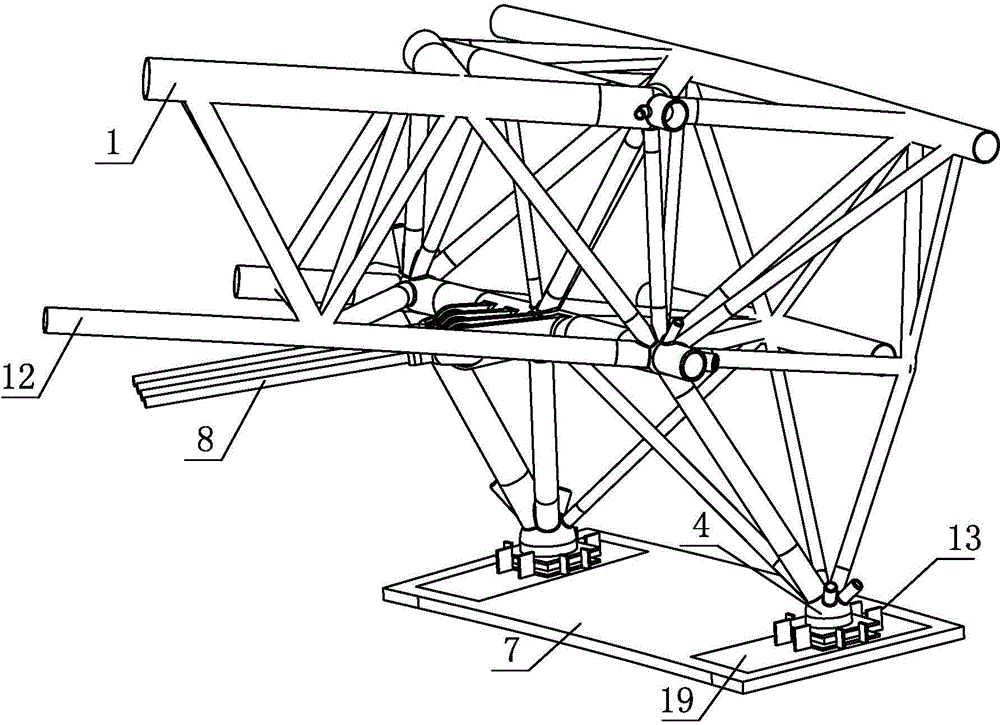

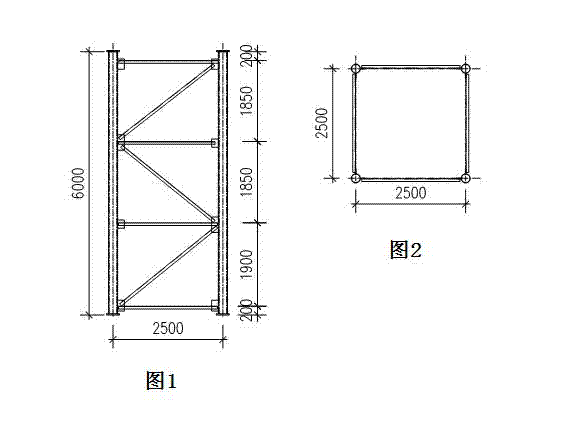

Construction method of large-scale parallel flexible lower-cord combined trusses

The invention belongs to the field of construction of steel structure trusses, and particularly relate to a construction method of large-scale parallel flexible lower-cord combined trusses. The construction method comprises the following steps: (1) assembling upper-cord layers of trusses by sections, and abutting overhead, wherein the trusses need to be arched in advance according to the deformation design in the process of assembling; (2) installing lower-cord web members and lower-cord panel points independently after finishing assembling the trusses of the upper layer; (3) measuring the actual installation spacial distances among the lower-cord panel points, and determining the initial installation geometrical lengths of flexible lower cords; (4) installing all flexible steel pull rods connected in parallel among all spans of the lower cords, and then pretightening the steel pull rods of the lower cords uniformly; and (5) grading synchronously and unloading equally proportionally by using a support frame. By adopting the construction method provided by the invention, the construction difficulty of tensioning the internal force of the lower cords of the ultralarge-scale parallel flexible trusses initiatively can be solved. The construction method has the advantages of high construction efficiency and good economic benefit.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP +1

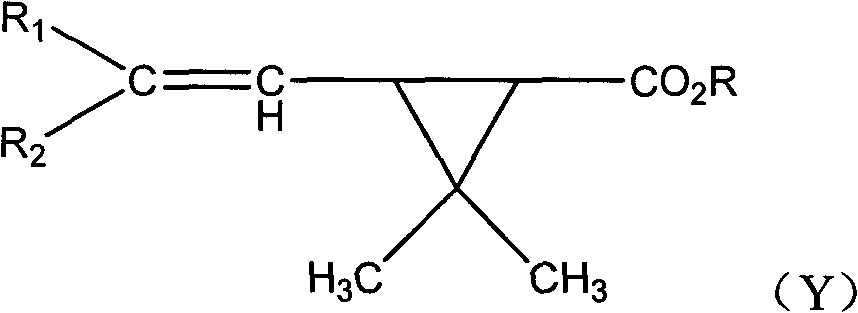

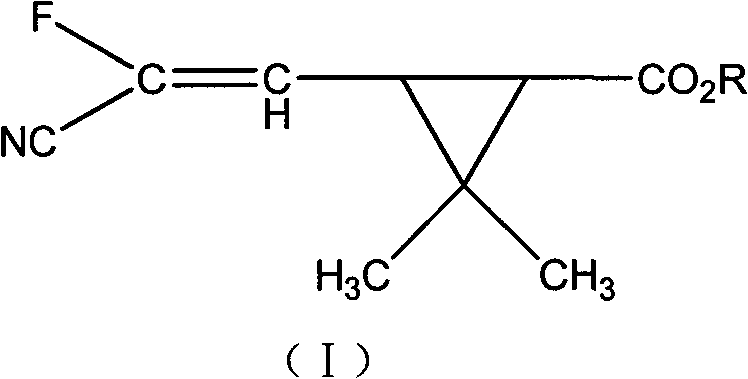

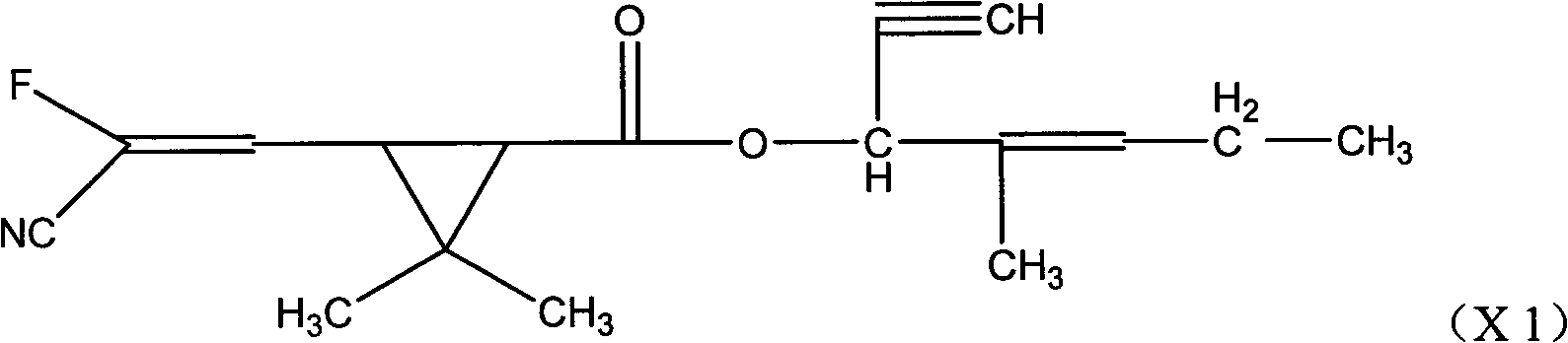

Fluorocyanogen-containing pyrethroid compound and synthesis method and application thereof

InactiveCN101880243AGood effectReduce toxicity and biological resistanceBiocideCarboxylic acid nitrile preparationChemistryChemical compound

The invention discloses a fluorocyanogen-containing pyrethroid compound and a synthesis method and an application thereof, which belong to the technical field of organic pesticides. The compound has a general structural formula (I) shown as the accompanying drawing, and in the general structural formula (I), R represents compounds applicable to the alcohol part contained in the conventional pyrethroid, which also include various stereoisomer forms thereof and the mixture of various stereo-configured compounds thereof. The invention also relates to an active component containing the fluorocyanogen-containing pyrethroid compound (I), which is used as an effective agent for controlling harmful insects, and a method for producing the ester compound (I). The invention discloses the application of the compound and a pesticidal mixture containing the compound as the active component in controlling pests.

Owner:BESTCHEN GUIYANG

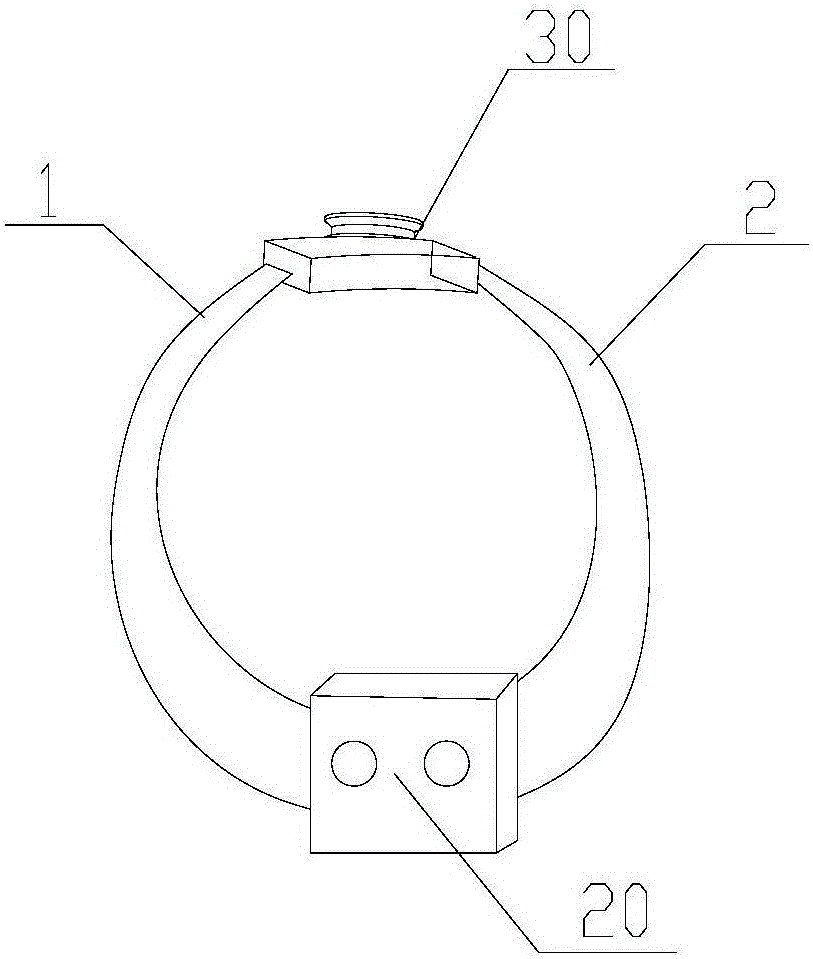

Bandage locking mechanism

The invention relates to a locking device and particularly relates to a bandage locking mechanism which comprises a button, a bandage, a housing, a drive structure and a locking structure, wherein the drive structure is held in the housing, the housing comprises a first housing, a through hole is formed in the first housing, the button passes through the through hole and can move along the axial direction or rotate along the circumference in the through hole, the button and the drive structure are stacked up and fixedly arranged, the drive structure moves along with the button and drives the bandage to stretch so as to adjust the length of the bandage, the locking structure is held in the housing and is fixedly connected with the drive structure, and the locking structure is matched with the first housing and used for locking the positions of the button and the drive structure so as to limit the driving of the button and the drive structure. The locking device has the advantages of saving space, realizing semi-automatic control, and being steady in structure transmission and excellent in locking and fine adjustment effects.

Owner:GEER TECH CO LTD

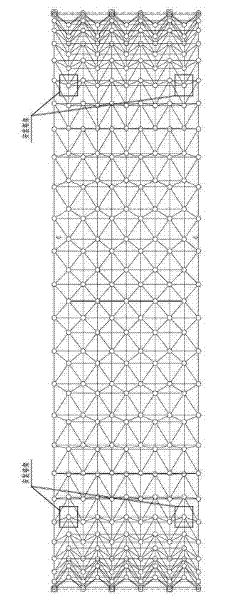

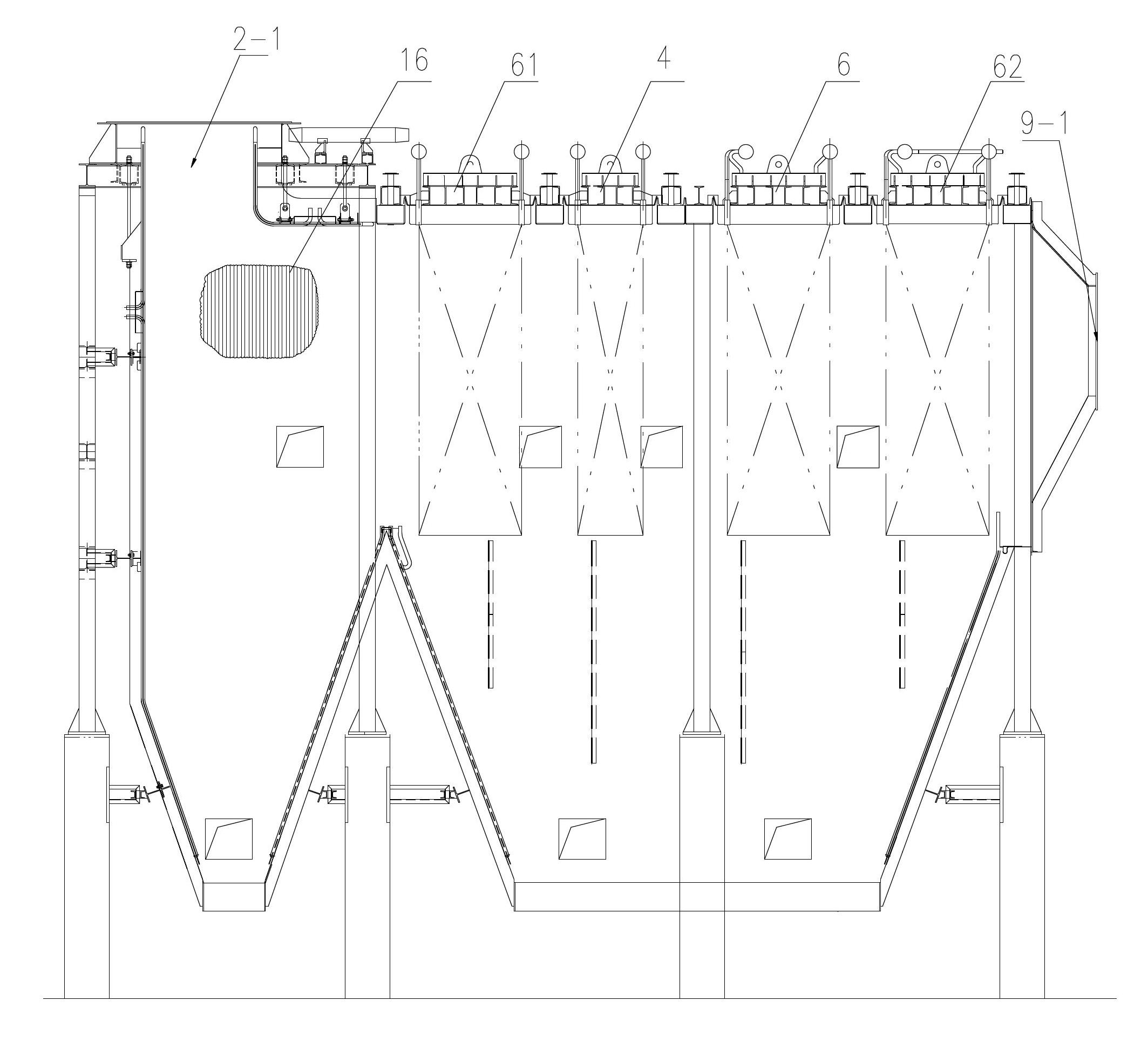

Construction process of ultra-large-span net-frame arch-shaped shed type storage silo

ActiveCN102337785AImprove accuracyShorten the timeLoad-supporting elementsBuilding material handlingFinite element algorithmEngineering

The invention relates to a construction process of an ultra-large-span net-frame arch-shaped shed type storage silo, which is characterized by comprising: obtaining dimensions of node rods of a net frame via a CFD (computational fluid dynamic) numerical wind tunnel computing technology and a finite element algorithm at first according to local weather conditions, the most adverse weather conditions and physical parameters of an arch-shaped shed, i.e. the ball head diameter of each node and geometric parameters of the rods on each node, and preparing a construction drawing, wherein the construction drawing at least comprises the serial number of each node and the number of rods on each node; and dividing construction steps into installation of basic units and installation of overhead cantilever units. Scaffolds are not needed to be erected in a whole house. The invention has the advantages that the time and materials can be saved, and the process is safe and reliable.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

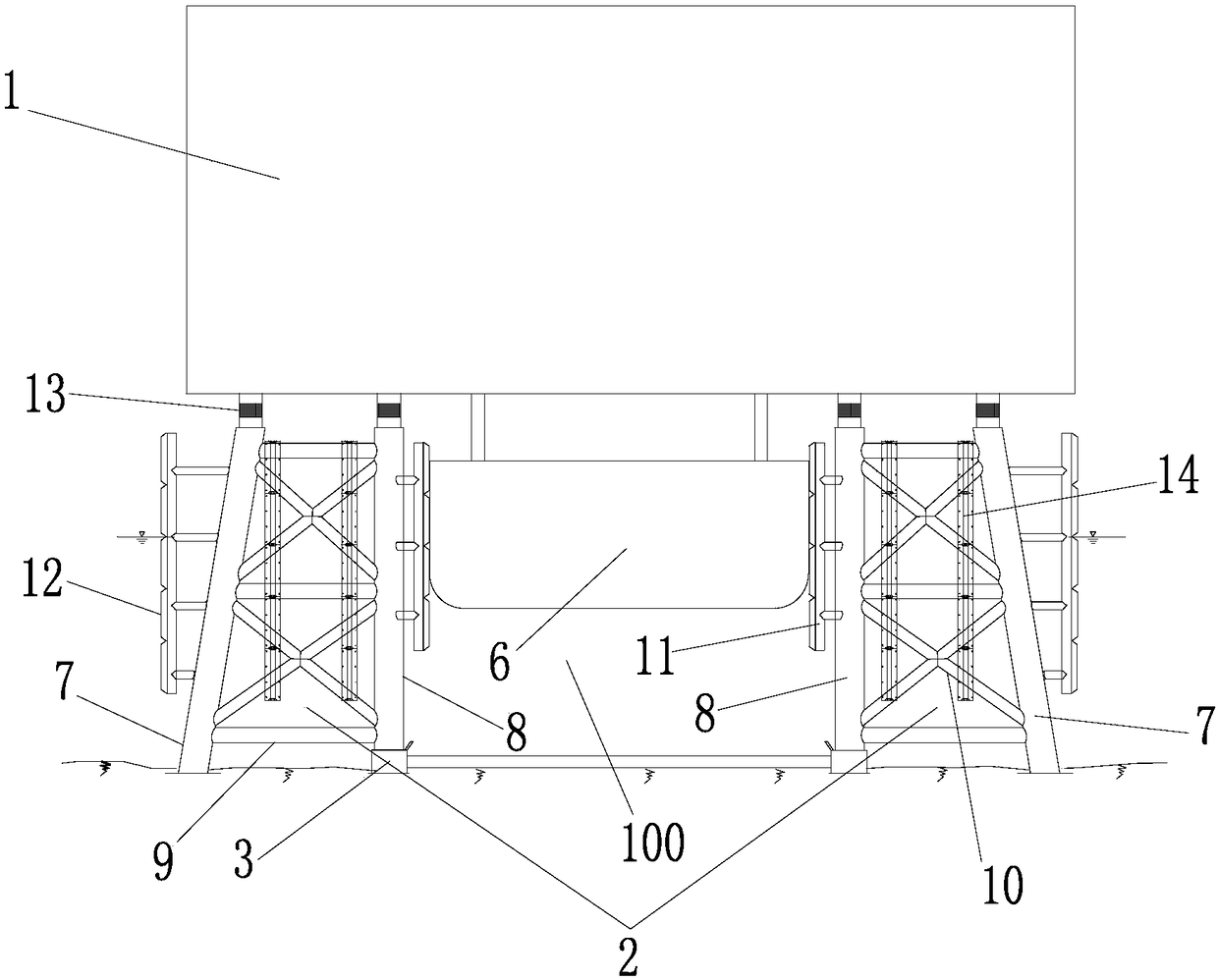

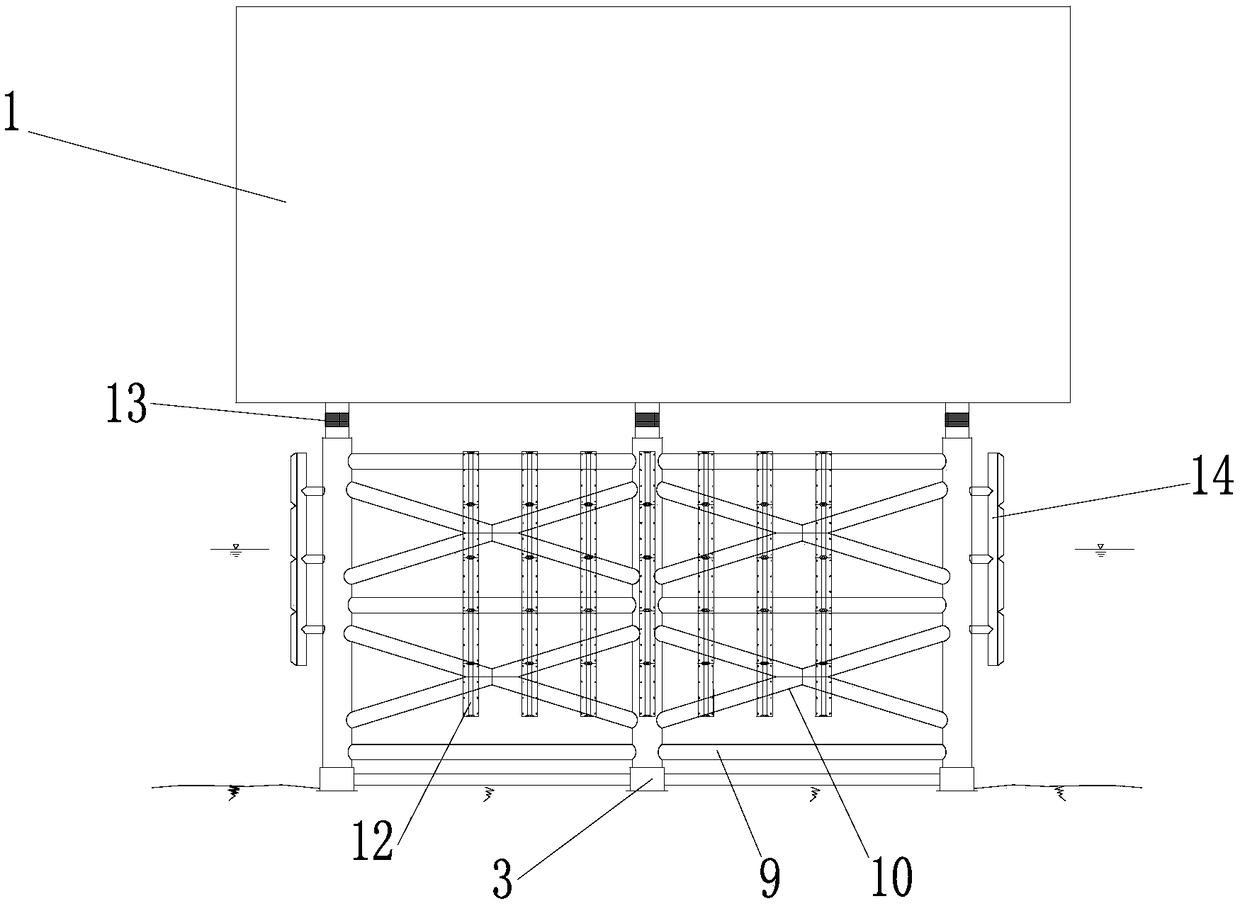

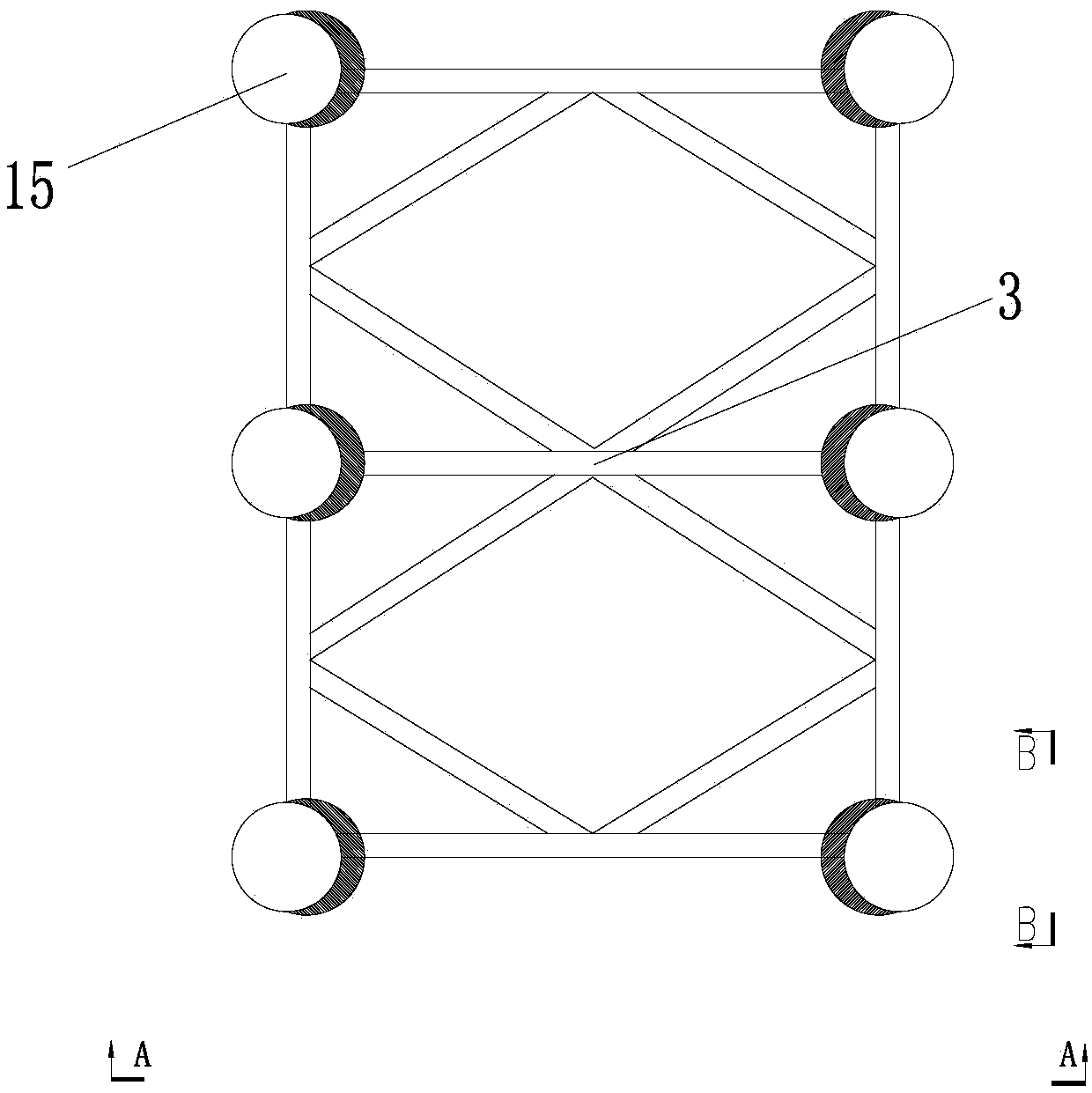

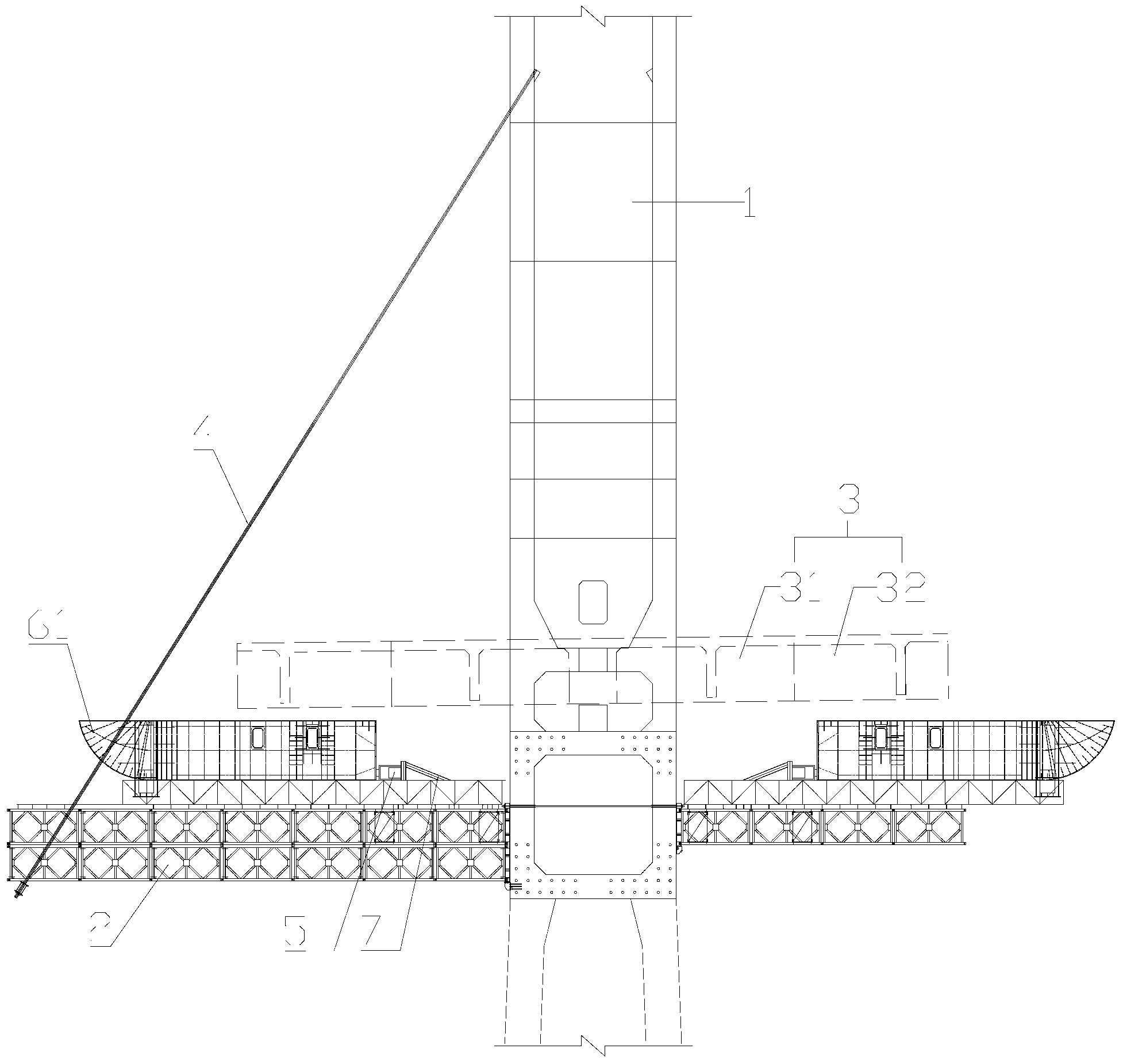

Large offshore platform split-type conduit frame structure suitable for shallow-water marine float-over mounting, and mounting method thereof

PendingCN109056684ASmall sizeReduce weightArtificial islandsUnderwater structuresMarine engineeringBuilding construction

The invention provides a large offshore platform split-type conduit frame structure suitable for shallow-water marine float-over mounting, and a mounting method thereof. The split-type conduit frame structure is provided with two split conduit frames which are arranged in the longitudinal direction of a platform, and a certain hollow area is reserved between the two split conduit frames to serve as a float-over ship entering area; the conduit frames are connected into a whole by inner side main conduits, outer side main conduits, steel pipe piles, transverse struts and inclined struts, and thesteel pipe piles are arranged in the inner side main conduits and the outer side main conduits; each split conduit frame transversely adopts a structure with multiple rows of piles and multiple trusses of conduit frame bodies, the steel pipe piles in the inner side main conduits adopt vertical piles, and the steel pipe piles in the outer side main conduits adopt inclined piles; and the main conduits in the two conduit frames are in positioning fit at the bottom through a positioning frame. The large offshore platform split-type conduit frame structure is structurally safe and reliable, convenient and precise in construction and can be used for shallow-water marine float-over mounting of the large offshore platform.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

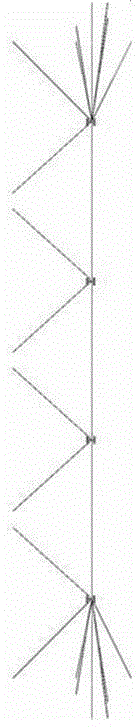

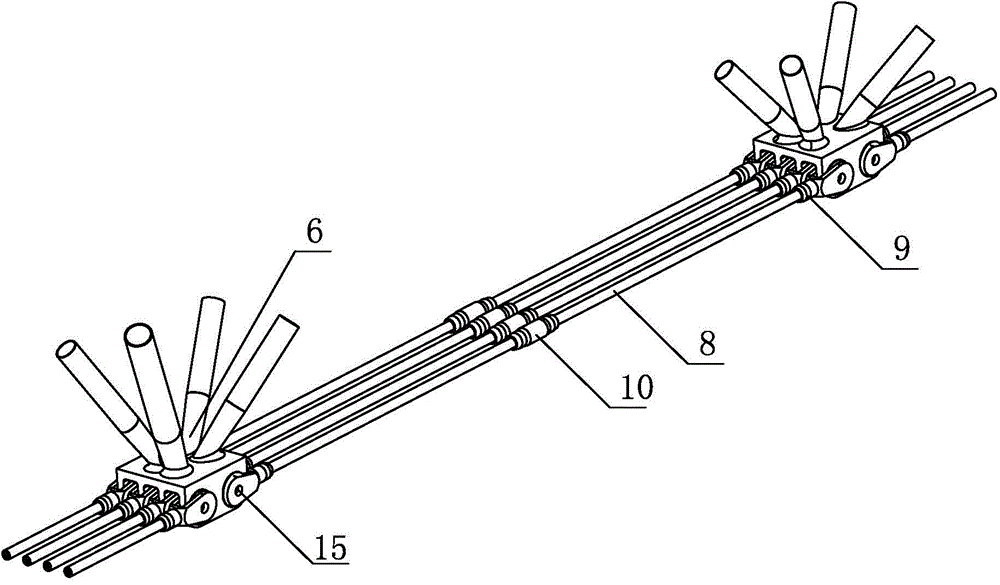

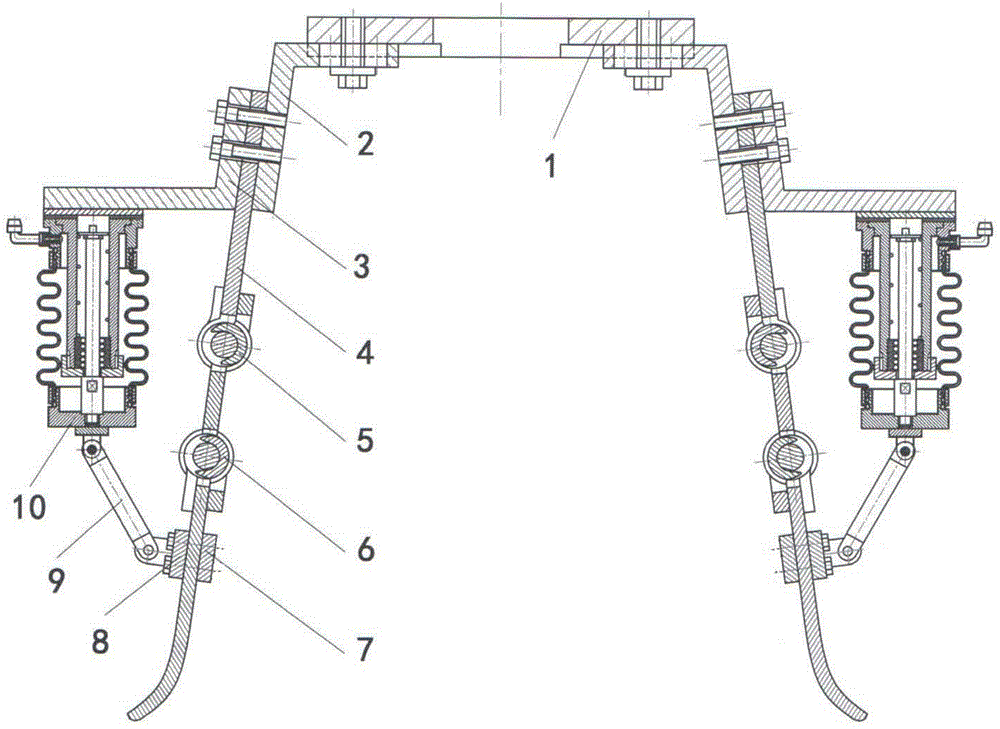

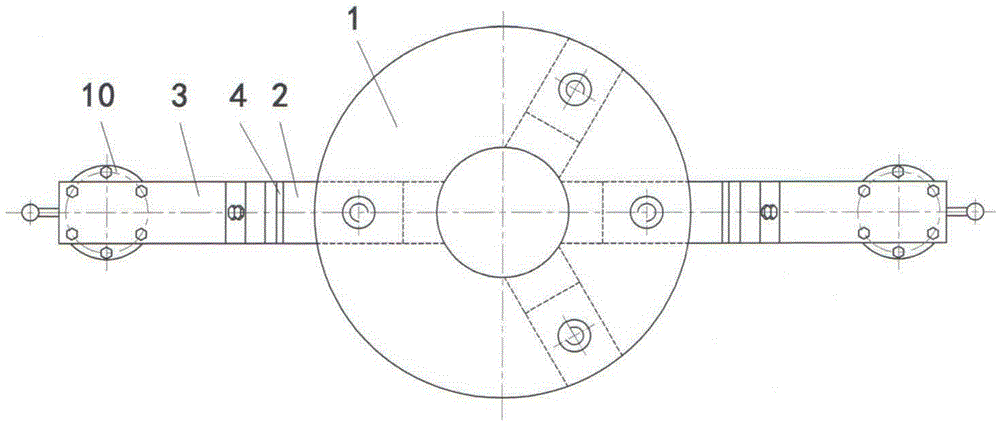

Elastic corrugated pipe single-acting cylinder-driven serial hinge framework manipulator

ActiveCN104802178ASynchronization control is simplePosition servo control is less difficultProgramme-controlled manipulatorJointsFinger structureEngineering

The invention relates to an elastic corrugated pipe single-acting cylinder-driven serial hinge framework manipulator. The manipulator consists of a palm and two flexible fingers, or consists of a palm and three flexible fingers, wherein each flexible finger is same in structure, and mainly comprises an elastic corrugated pipe single-acting cylinder and a serial hinge; a torsional spring is arranged on a hinge spindle of each serial hinge; the characteristic parameters and pre-tightening angles of the torsional springs are optimally designed according to the characteristics of a grabbed object; the manipulator generates grabbing force under the driving action of the elastic corrugated pipe single-acting cylinders. The manipulator is used for grabbing fragile crispy objects or special-shaped objects of variable shapes and sizes, and belongs to the application technical field of robots and mechanical and electronic integration; the manipulator is connected with a robot body, and is particularly suitable for grabbing, sorting, packaging and the like of foods, agricultural products and light industrial products in the production and physical distribution fields.

Owner:JIANGNAN UNIV

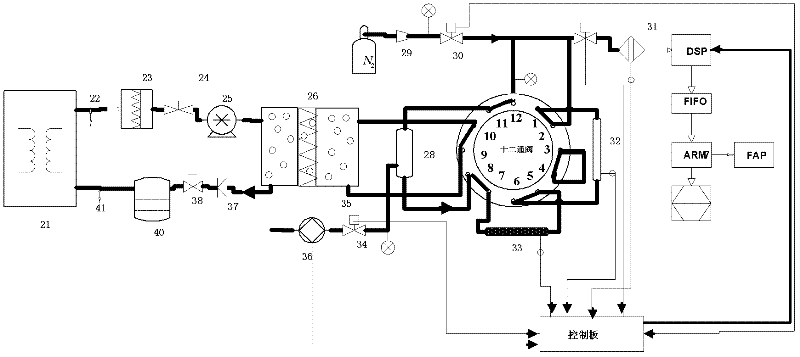

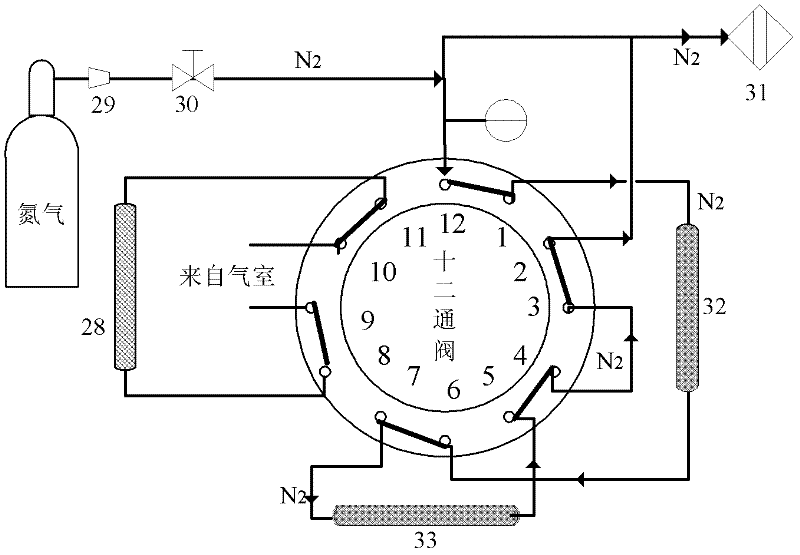

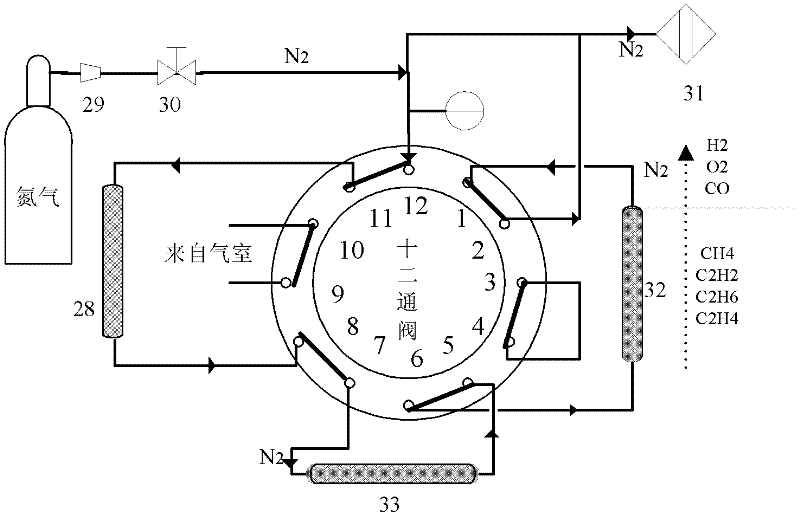

On-line detection system and method of trace dissolved gas in organic oil

InactiveCN102353724ASeparation EquilibriumEasy and quick passProgramme controlComponent separationRefluxFuel cells

The invention discloses an on-line detection system and method of trace dissolved gas in organic oil, characterized in that: a polymer degassing film with short oil-gas balance time is used, thus the structure is simple, and degasification speed is fast; the trace dissolved gas in organic oil is separated through the dual column chromatography, thus the number of channels of traditional chromatograph is simplified; the unique twelve-way valve structure is used, and double chromatographic columns are arranged, thus the system works respectively alternately in states of reflux and sample injection, and the problem of difficult separation of O2 and CO gas existing in the traditional chromatographic system is effectively solved; a trace flammable gas detection sensor produced by using a solidoxide fuel cell technique can simultaneously detect 7 kinds of dissolved gases in organic oil with high detection accuracy and good separating degree of different component gases, and the number of gas sensor in the system is reduced. According to the invention, an oil-gas separation, a gas separation detection unit and a control unit are combined together, thus the volume of the system device isreduced, the stability of the system is increased, and the system is convenient for installation and maintenance.

Owner:CENT SOUTH UNIV

Electric power overhaul equipment lifting device

ActiveCN105668470ASmall footprintEasy to storeSafety devices for lifting equipmentsLifting framesHydraulic cylinderFixed frame

The invention discloses an electric power overhaul equipment lifting device which comprises a base and a hydraulic lifting assembly arranged on the base. A lifting platform is arranged over the base, fixed frames are arranged over the positions, close to the two parallel edges, of the lifting platform respectively, moving frames are arranged on the other two parallel side walls of the lifting platform, and the moving frames are hinged to the side walls of the lifting platform; the side walls of the lifting platform are provided with two rotating shafts, the rotating shafts are sleeved with the moving frames respectively, the lower end face of the lifting platform is provided with a first hydraulic cylinder, the rotating shafts are provided with pressing rods, and the two ends of each pressing rod are bent by 90 degrees towards the same side. According to the electric power overhaul equipment lifting device, by adopting the fixed frames and the moving frames which are hinged to the lifting platform, the fixed frames and the moving frames can be conveniently combined to form a guard bar structure in use and can be contracted and folded on the lifting platform when the fixed frames and the moving frames are not used, and the equipment is conveniently stored.

Owner:STATE GRID CORP OF CHINA +1

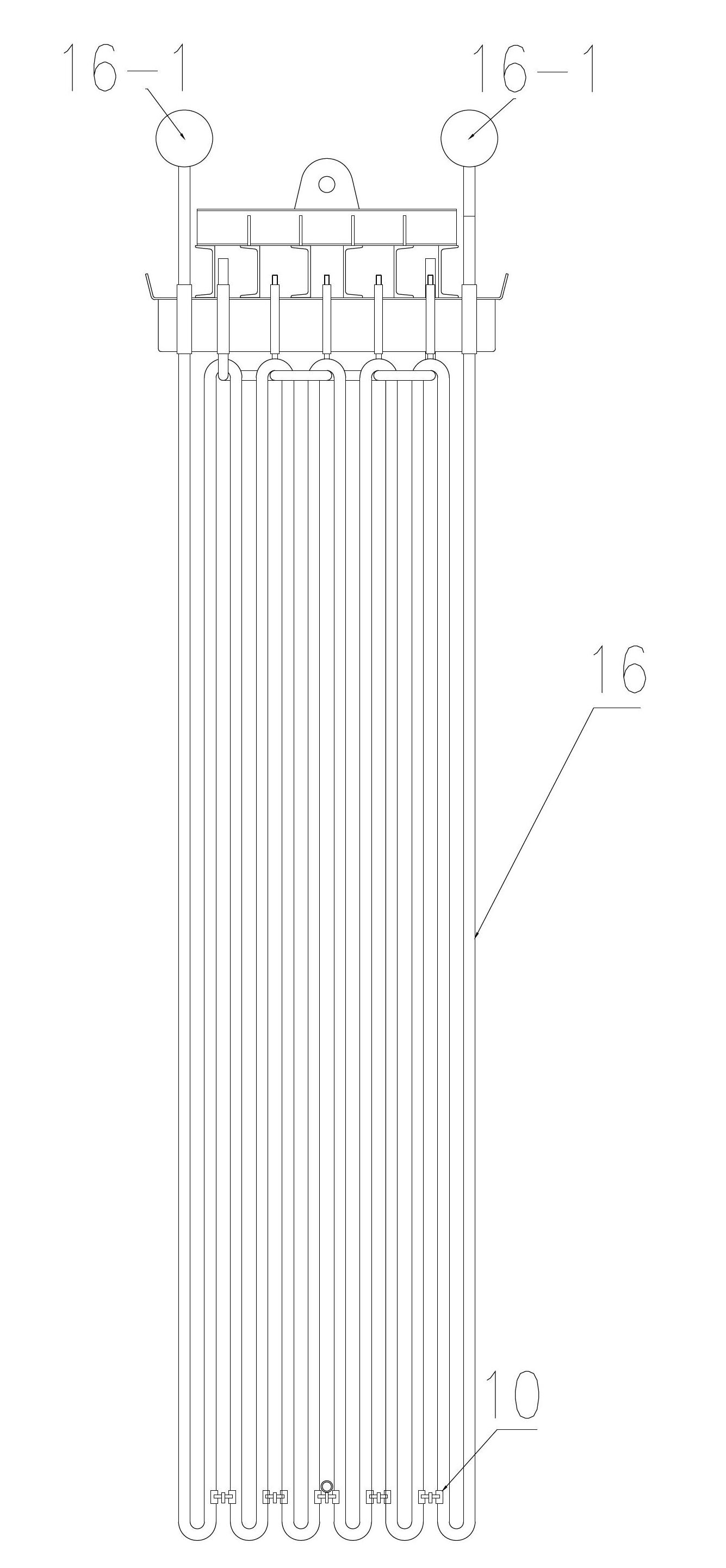

Boiler system using waste heat of flue gas of rotary hearth furnace

InactiveCN102635844ASave floor areaSave electricityIncreasing energy efficiencyCasings/liningsSteel frameHearth

The invention relates to the technical field of waste heat utilization, in particular to a boiler system using waste heat of flue gas of a rotary hearth furnace, which is characterized in that a steam drum is arranged on a steel frame on the flue type heat recovery boiler, and four upper collection boxes with water-cooled walls for a hearth, four upper collection boxes with water-cooled walls for a rear flue and a lower collection box for a roof pipe are suspended under the steel frame; and the flue type heat recovery boiler adopts a vertical structure which consists of the vertical hearth and the vertical rear flue. Compared with the prior art, since the vertical flue structure is adopted by the flue type heat recovery boiler, space is occupied, the area of the occupied plane is reduced, and prospects are created for development of systems of modified or new rotary hearth furnaces which can recycle waste heat of high-temperature flue gas; and the structural layout of boiler pipes is improved, so water in the boiler can circulate naturally depending on the height difference, and the additional power and a large number of maintenance costs required for a boiler water circulating pump can be saved.

Owner:中江能源回收(上海)有限公司

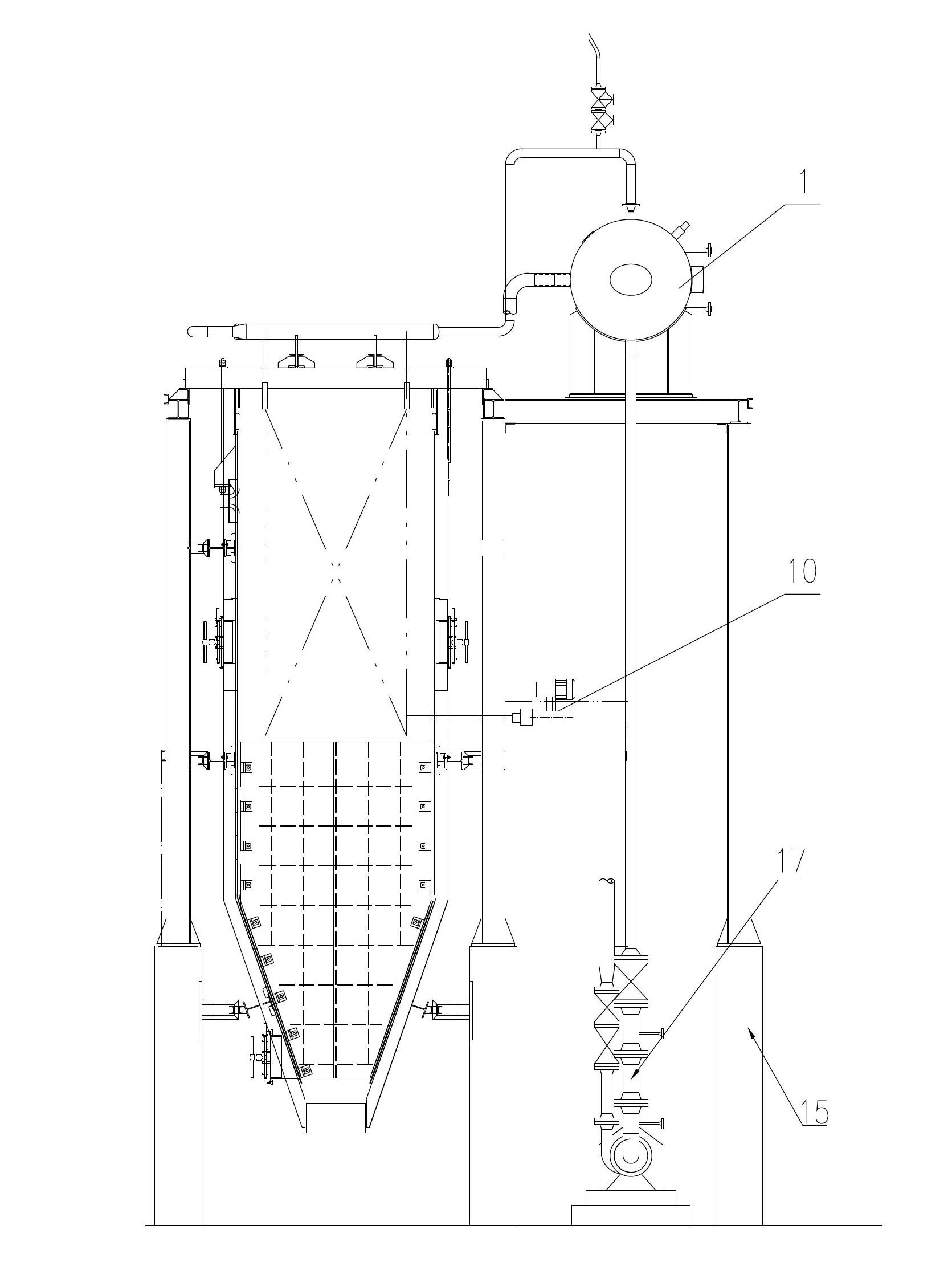

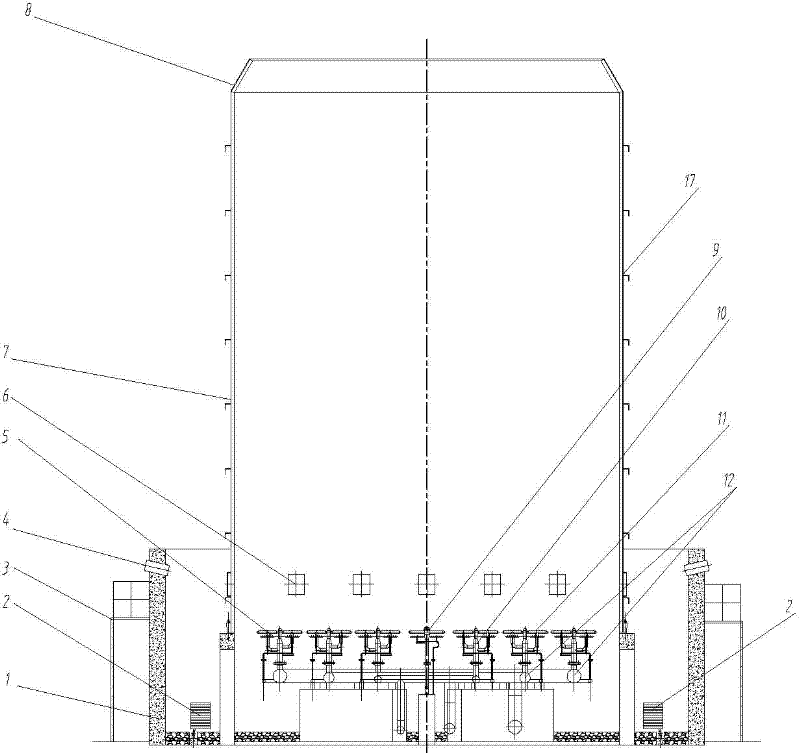

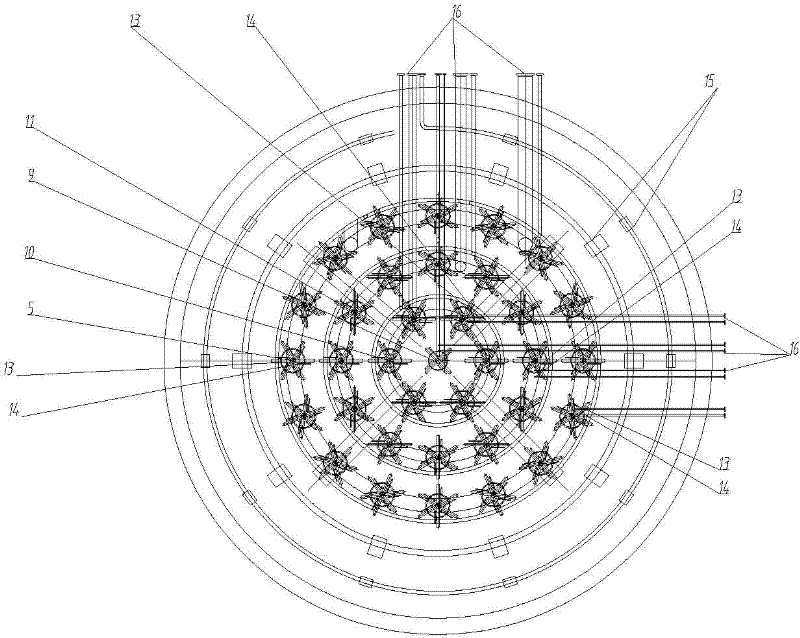

Efficient and energy saving ground flare gas system

InactiveCN102353041ATo achieve the purpose of energy savingSimple structureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

An efficient and energy saving ground flare gas system comprises a flare cylindrical shell (7) and a windproof noise reduction screen (1). The flare cylindrical shell (7) is arranged in the windproof noise reduction screen (1) and equipped with an air inlet at a lower part thereof; and a peep door (6) is arranged on the cylindrical shell above the air inlet. The ground flare gas system characterized in that the flare cylindrical shell (7) is provided with a first stage combustor (9) in the center thereof; a periphery of the first stage combustor (9) is provided with a circle of a second stage combustors (10), a circle of a third stage combustors (11) and a circle of a fourth stage combustors (5); the second stage combustors (10), the third stage combustors (11) and the fourth stage combustors (5) are respectively connected by annular distributor pipes (12) of themselves; an air inlet end of each annular distributor pipe is connected to a flare gas source through corresponding air inlet pipelines (16); each of the air inlet pipelines (16) is equipped with a pneumatic trip valve; and each combustor is provided with an incandescent light (13) and an igniter (14). The invention reaches purpose of energy saving through stage hierarchical control and optimized combustion and has advantages of simple structure, safety and small investment.

Owner:JIANGSU SUNPOWER TECH

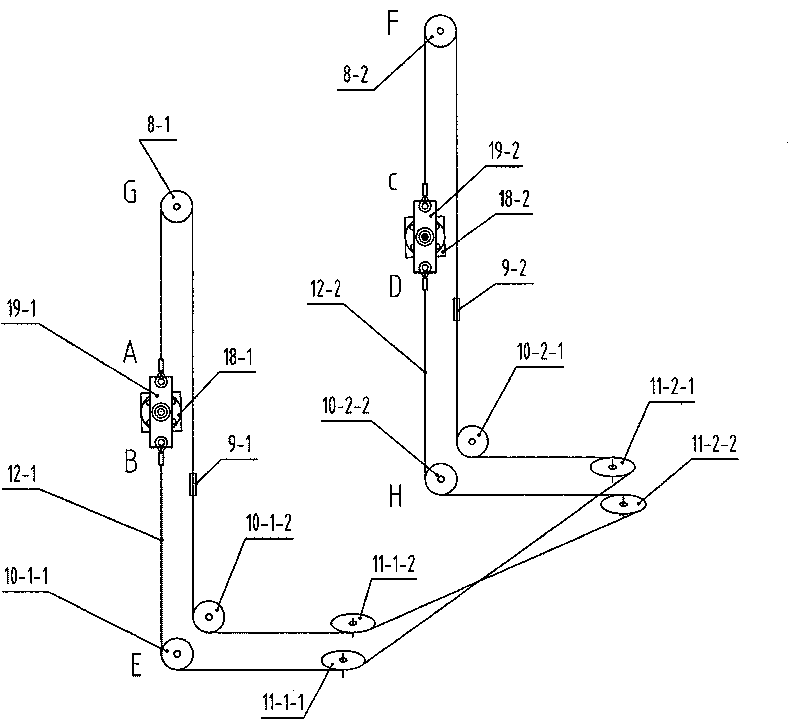

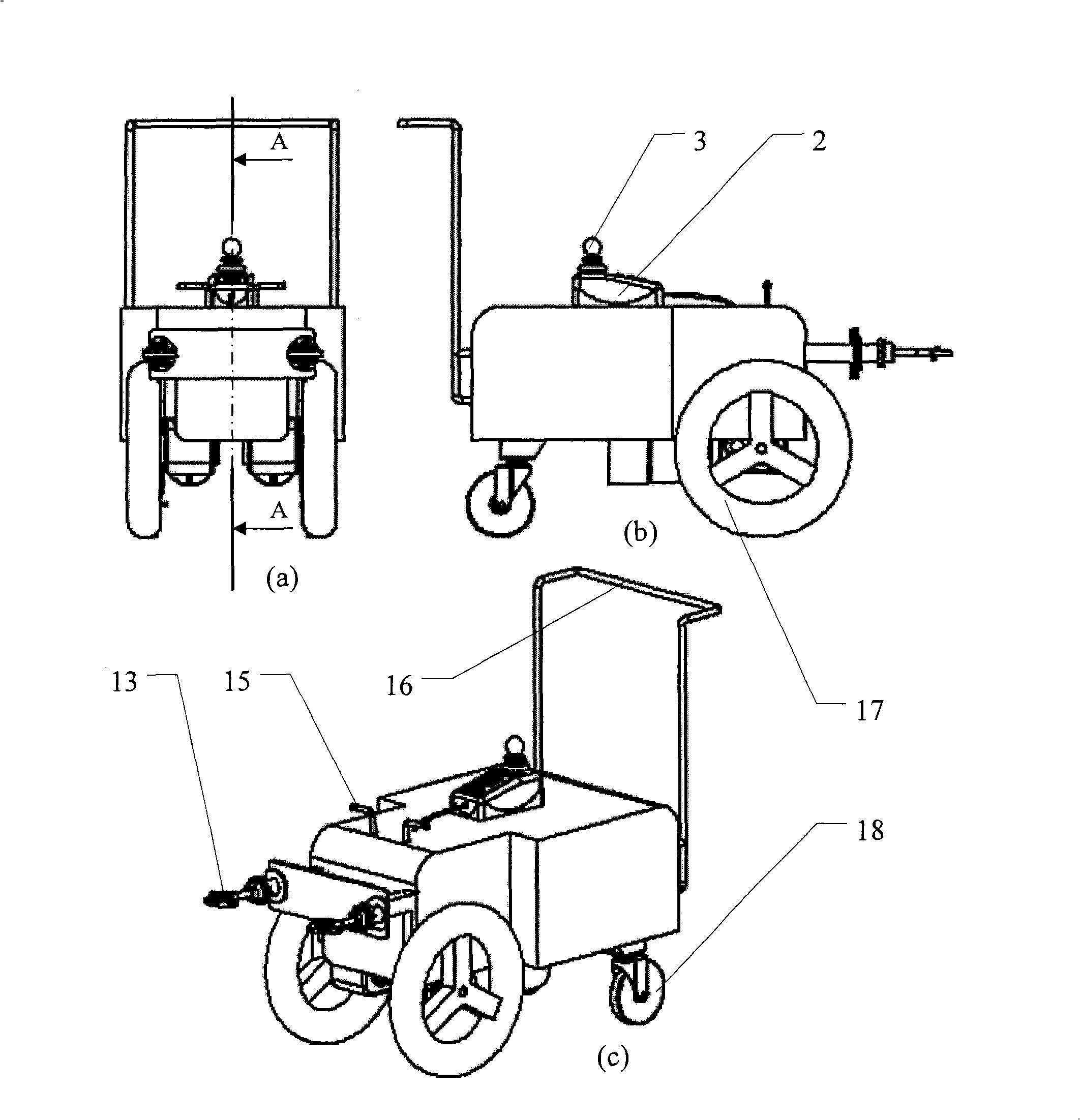

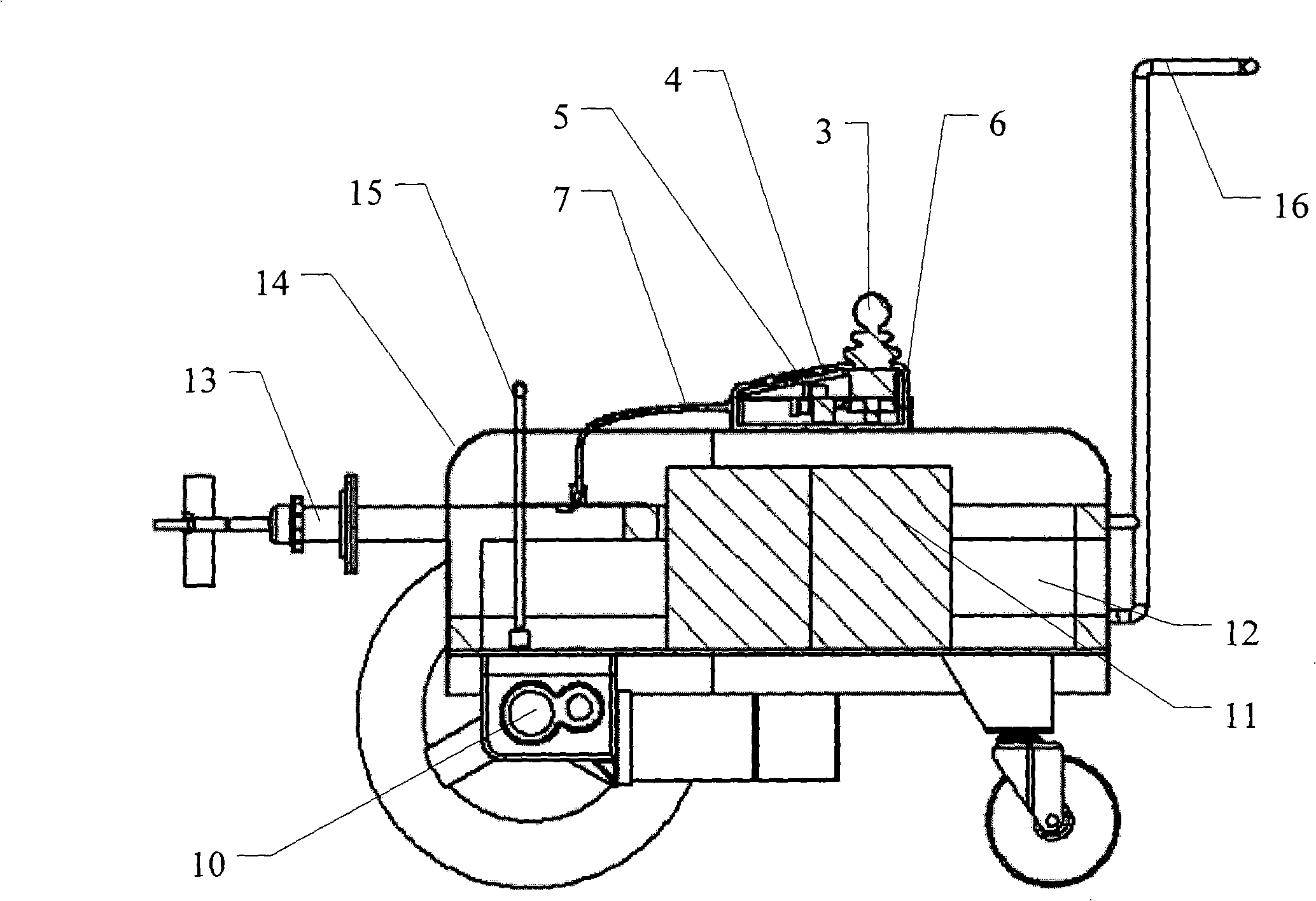

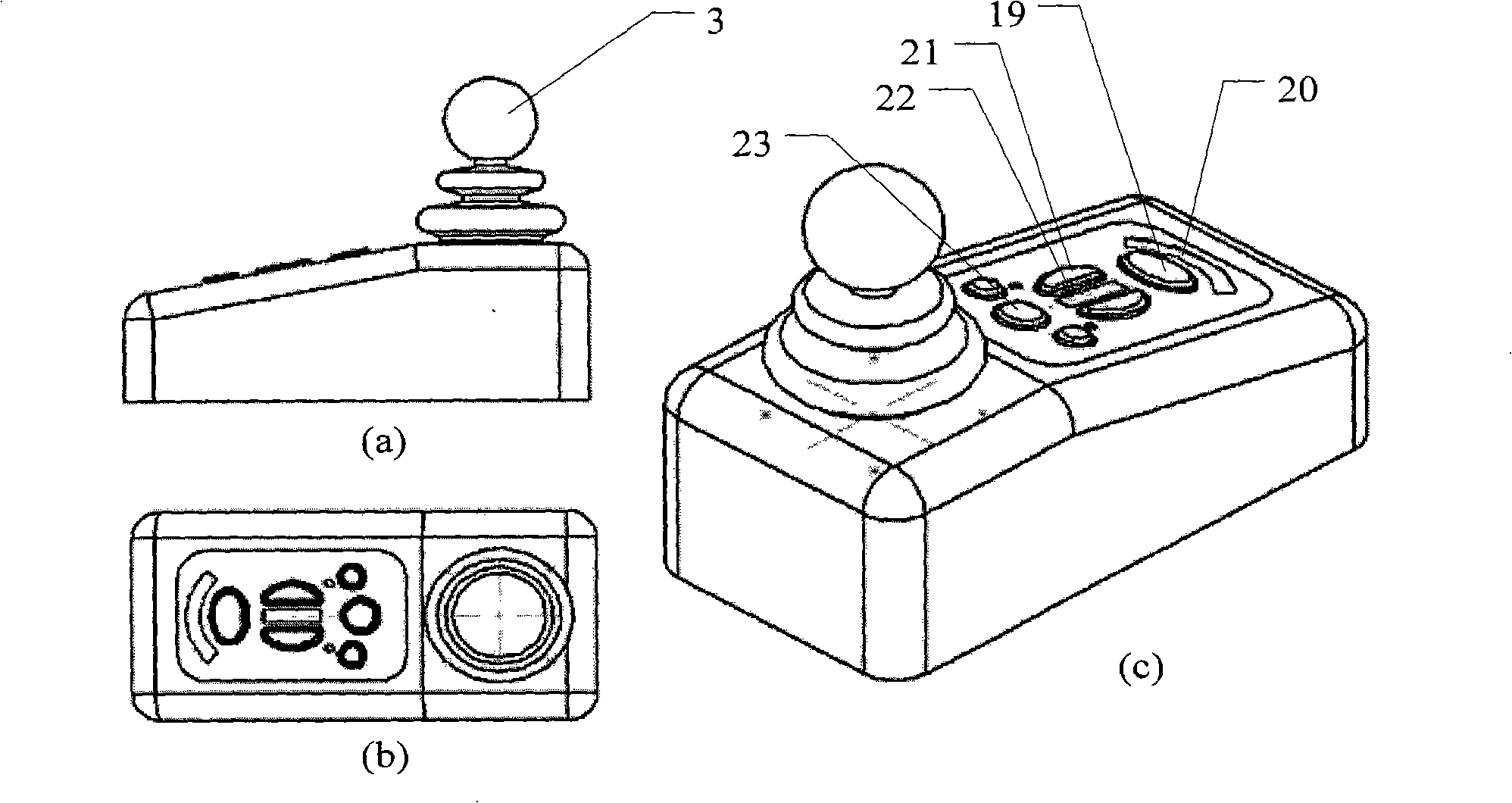

Auxiliary method and device for speeling stairway of wheelchair

InactiveCN101268977ASafe and reliable structureImprove applicabilityWheelchairs/patient conveyanceWheelchairOlder people

The invention provides an aiding method and a device which use a wheelchair for climbing stairs, and relates to the mechanical technology of helping old people and disabled people. A folding movable stay plate is installed at one side of the stairs close to the wall, and a moped consisting of a storage battery, a controller, a control module, a driving module, a framework, a shell, a DC electric machine, a reducer and wheels is also arranged at the side of the stairs close to the wall. After the movable stay plate is put down, an inclined plane is formed on the stairs, and the moped is connected with a connecting piece arranged at the back of a backrest of the wheelchair. Under the control of the auxiliary operating staff, the moped pushes the wheelchair to climb the stairs.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

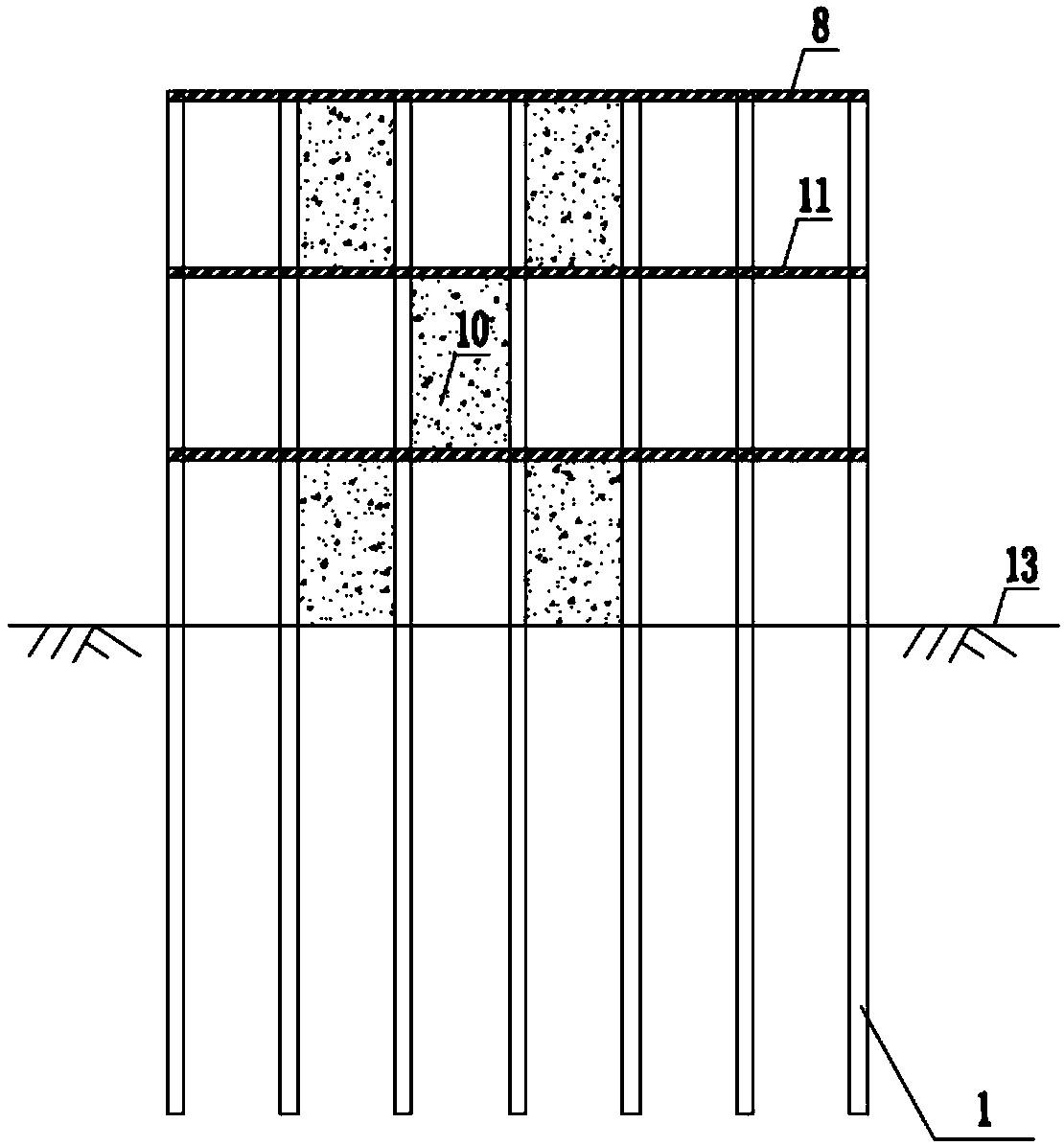

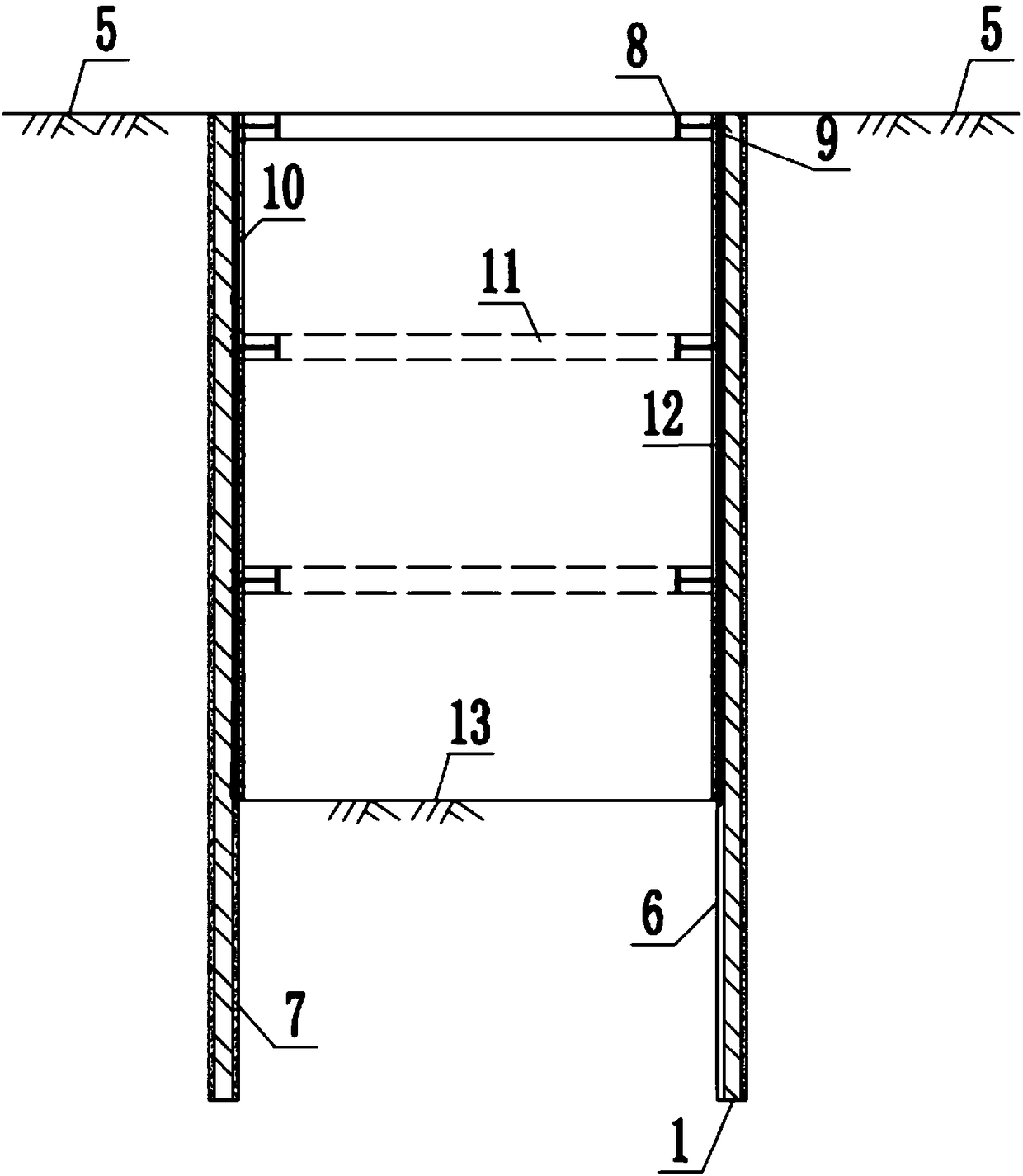

Ultra-deep foundation pit supporting method

ActiveCN105089061AGuaranteed continuitySafe and reliable structureExcavationsPurlinReinforced concrete

The invention relates to an ultra-deep foundation pit supporting method which comprises a single-row triaxial deep-mixing pile water-stop curtain, bored piles and upright steel posts, wherein the single-row triaxial deep-mixing pile water-stop curtain is lower than natural ground and is arranged along the periphery of a foundation pit in an enclosing way; the bored piles are sequentially arranged at intervals in the foundation pit and located on the inner side of the single-row triaxial deep-mixing pile water-stop curtain; the upright steel posts are arranged in the foundation pit and located on the inner sides of the bored piles; the tops of the bored piles are sequentially connected via reinforced concrete crown beams in a pulling way; reinforced concrete enclosing purlins along the periphery of the foundation pit are arranged in positions, which are not the height positions of floor slabs of underground floors, on the inner sides of the bored piles; the inner sides of the reinforced concrete enclosing purlins are connected in a pulling way via reinforced concrete enclosing purlin beams supported on the upright steel posts; the reinforced concrete enclosing purlin beams are in latticed pulling connection with the reinforced concrete enclosing purlins via a plurality of groups of inner reinforced concrete supports; filling plain concrete is arranged inwards at the bottoms of the bored piles; a baseplate is laid on the foundation pit and enclosed by the filling plain concrete; and more than one post-cast strip with support replacement pieces is arranged on the baseplate.

Owner:TAIXING FIRST CONSTR INSTALLATION

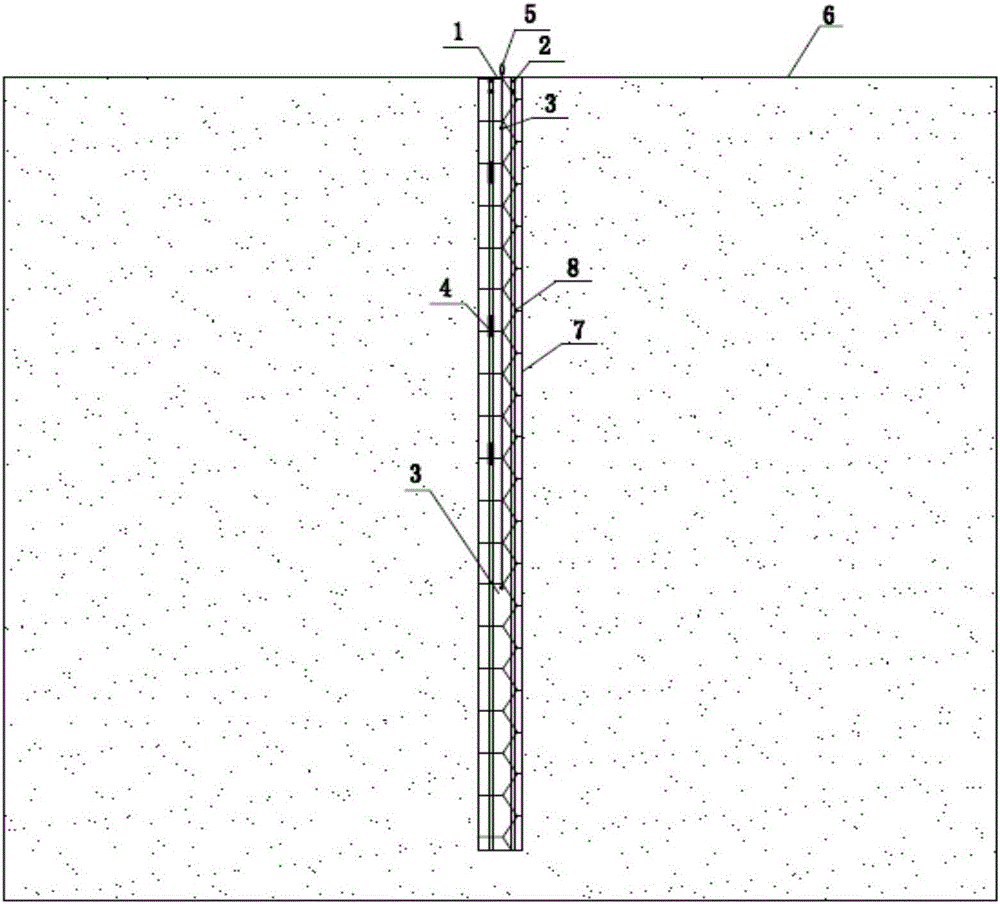

Design and construction method of rigid-flexible composite anti-seepage recoverable supporting structure

ActiveCN105735322AAdvanced technologyImprove economic indicatorsExcavationsSecurity MeasureStructure system

The invention relates to a design and construction method of a rigid-flexible composite anti-seepage recoverable supporting structure system. The method comprises steps as follows: (I) profile steel slope-protection piles are constructed; (II) H-shaped steel top beams and H-shaped steel breast beams are installed; (III) steel panels are installed; (IV) sequential vertical layered and sectioned excavation is performed, steps (II) and (III) are repeated, construction is performed to the design depth, and construction of the rigid-flexible composite anti-seepage recoverable supporting structure system is completed; (V) after the use function of a supporting structure is fulfilled, with the start of foundation pit backfill work, recovery work can be performed. The rigid-flexible composite anti-seepage recoverable supporting structure system constructed through the method really reflects characteristics of a temporary security measure adopted by foundation construction of foundation pit engineering and has the advantages of safety, reliability, quickness construction, advanced technology, capability of being recycled, excellent economic indices and the like.

Owner:SAFEKEY ENG TECHZHENGZHOU

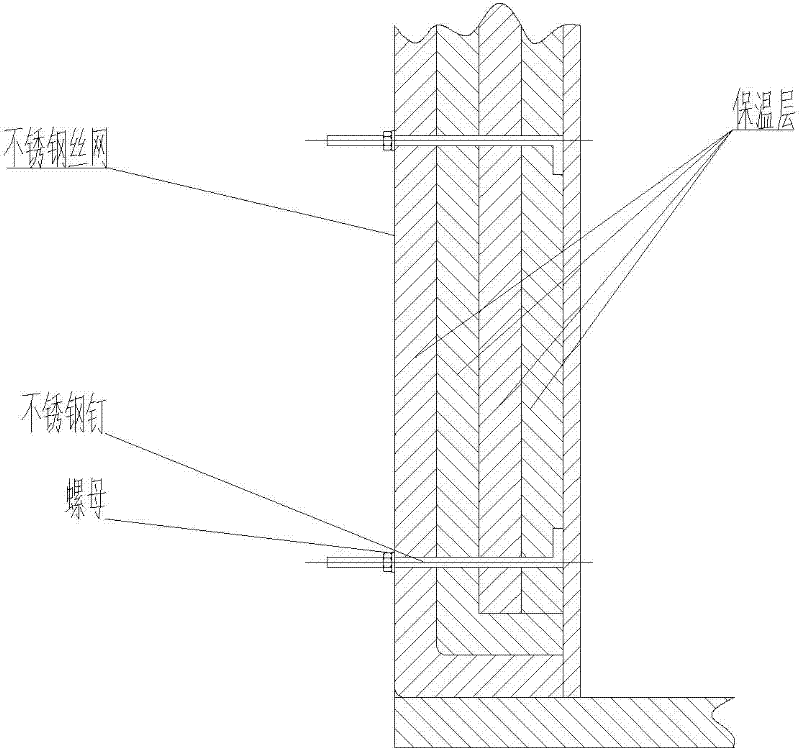

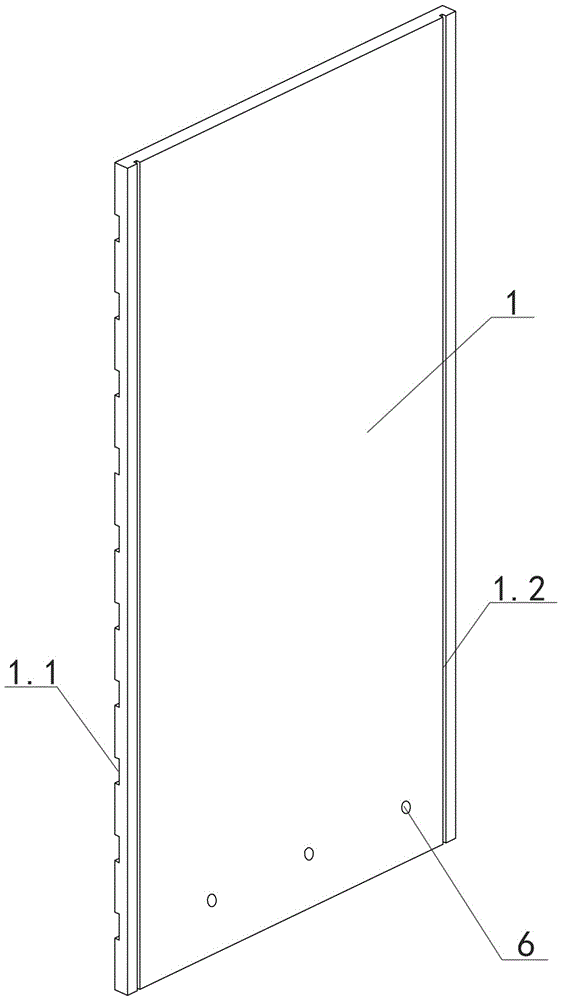

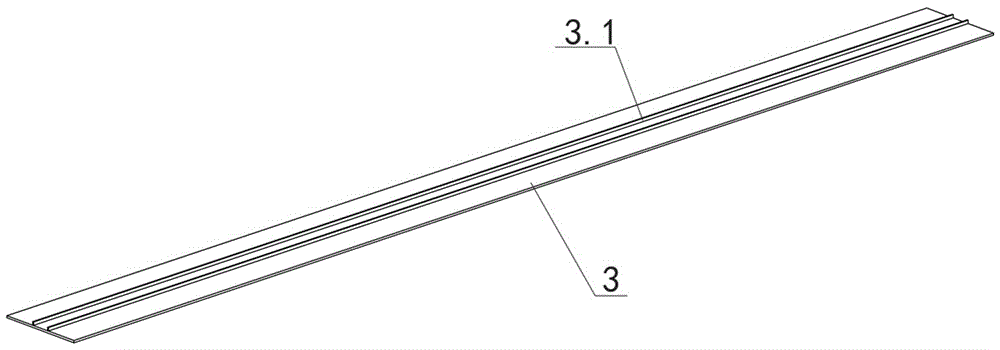

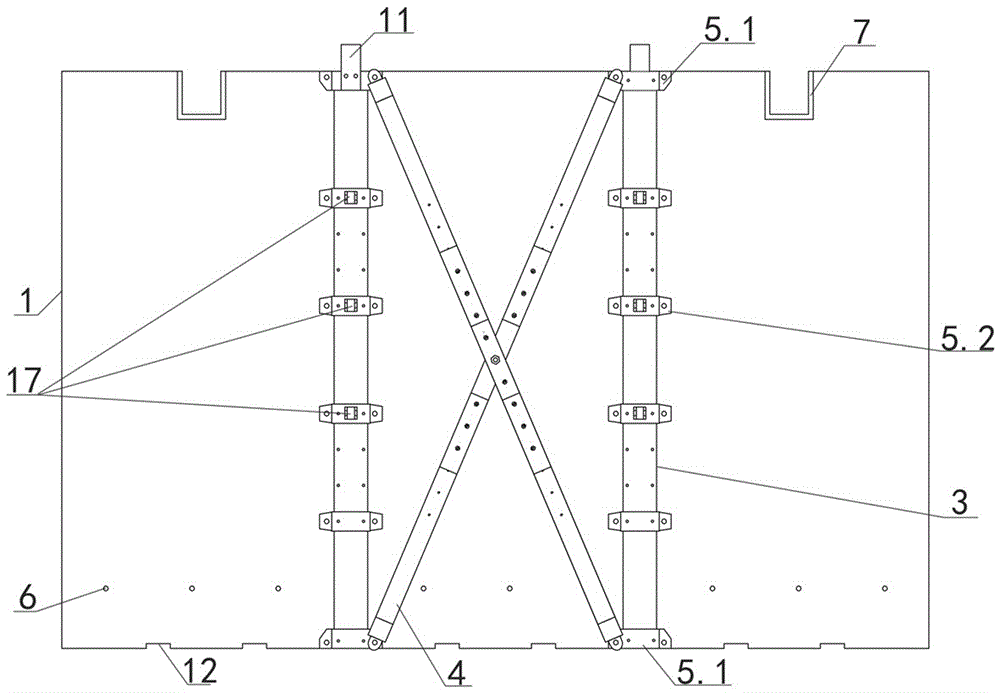

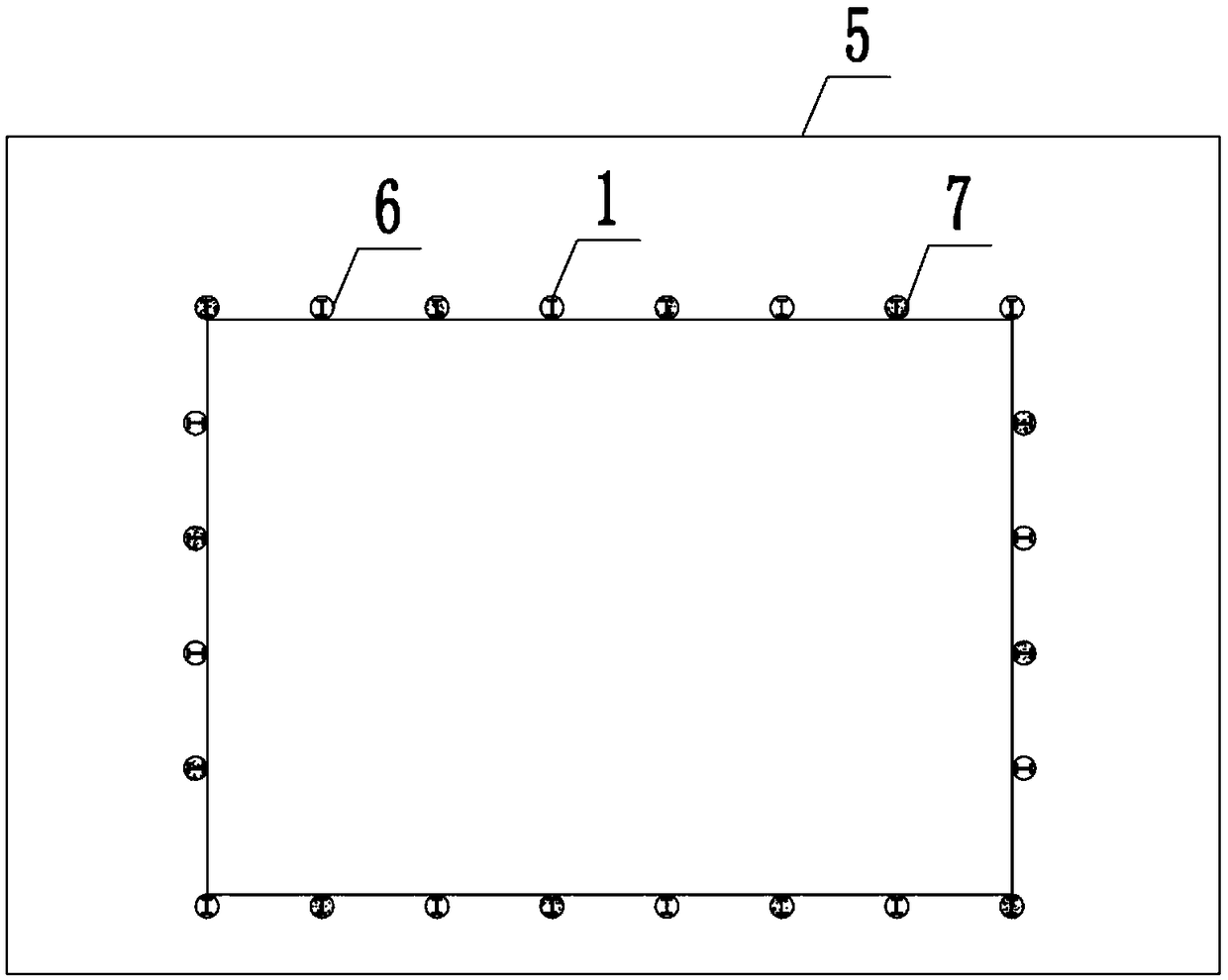

Glass fiber cement non-removal formwork system, connection structure and construction method of connection structure

The invention discloses a glass fiber cement non-removal formwork system, a connection structure and a construction method of the connection structure. The formwork system comprises a panel group, a support frame structure and a split bolt, wherein transverse interlocked strengthening grooves are formed in the inner side surface of a panel unit at intervals; the support frame structure comprises a frame steel sheet strip, a cross-panel connection assembly and a telescopic panel-attached brace; the frame steel sheet strip is arranged in a full length along the height direction of the panel unit; the cross-panel connection assembly comprises a one-way cross-panel connector; and the split bolt passes through the one-way cross-panel connector and tightens the formwork system from front to back. The connection structure comprises a floor, a formwork bottom locating assembly, a formwork top locator and the glass fiber cement non-removal formwork system. The glass fiber cement non-removal formwork system is simple in form, relatively large in combination rigidity, high in manufacturing accuracy, tight in seam, safe and reliable in structure, good in overall performance, relatively high in turnover frequency, energy-saving and environment-friendly. According to the connection structure and the construction method thereof, the construction efficiency of formwork engineering is improved and the construction cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

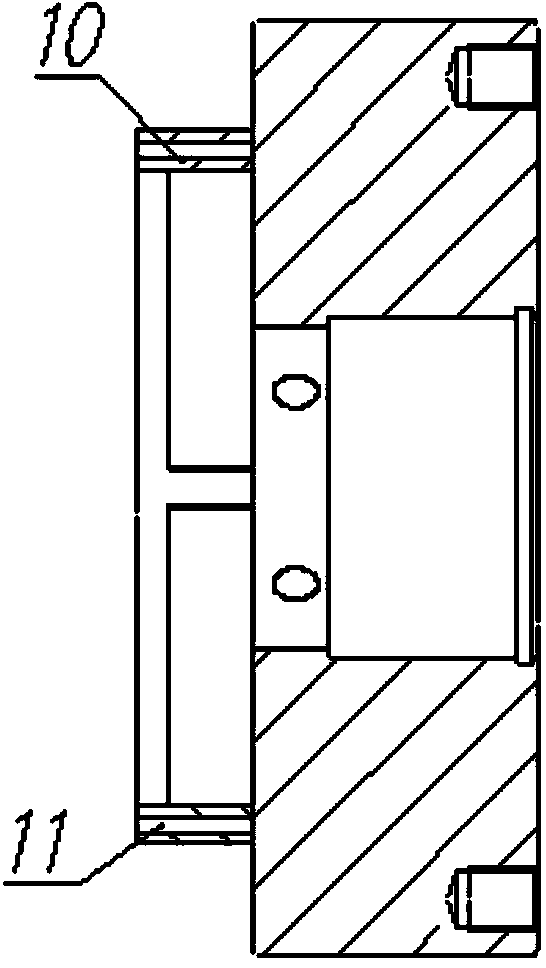

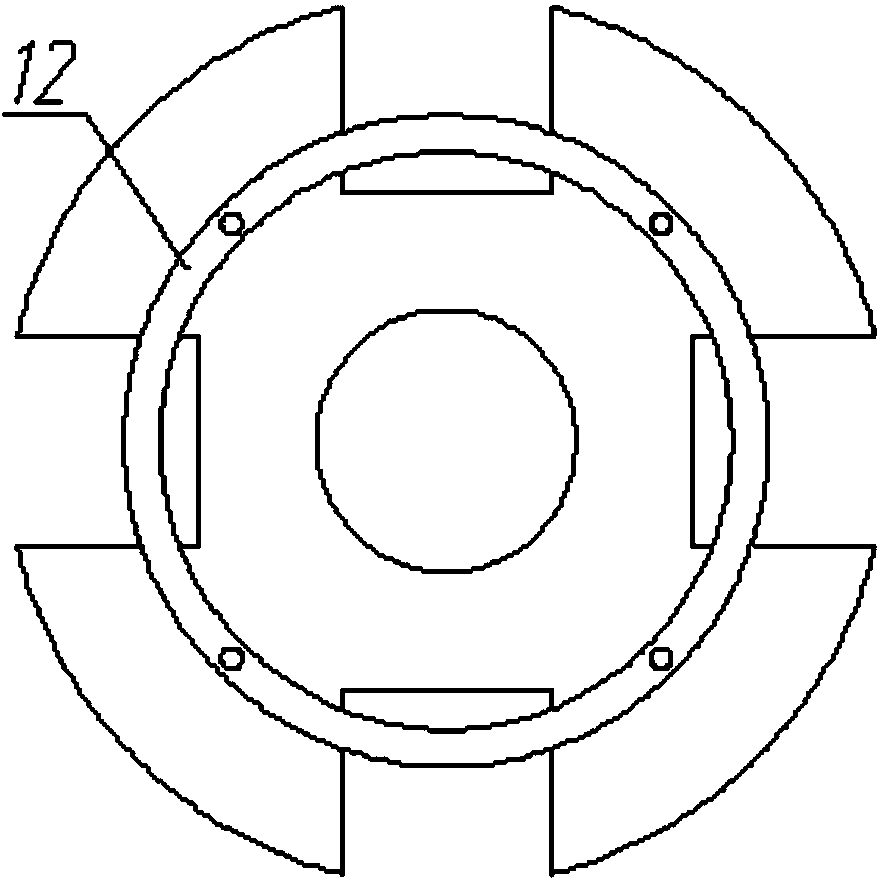

Axial force bearing test structure of elastic foil dynamic pressure gas thrust bearings

InactiveCN103884504AReal-time control of operating conditionsSafe and reliable structureMachine bearings testingThrust bearingAxial force

An axial force bearing test structure of elastic foil dynamic pressure gas thrust bearings comprises two thrust bearing force testing pieces, strain gages are attached to the two thrust bearing force testing pieces, two elastic foil dynamic pressure gas thrust bearings are fixed on two thrust bearing seats respectively, and the two thrust bearing seats and a distance ring are connected to constitute an assembly. The thickness the gas gap between the elastic foil dynamic pressure gas thrust bearings and a thrust disk is adjusted through the distance ring, it is guaranteed that the assembly slides freely in the axial direction in a shell through girder grinding, the periphery of the assembly is fixed, and the assembly is fixed in the shell through an end cover. Axial force borne by a rotor is applied to the two thrust bearing seats through the thrust disk, the axial force borne by the two thrust bearing seats is applied to the two thrust bearing testing pieces and is accurately measured by the strain gages, the sum of the stress borne by the strain gages is the axial force borne by the rotor, and the structure is safe and reliable.

Owner:XI AN JIAOTONG UNIV

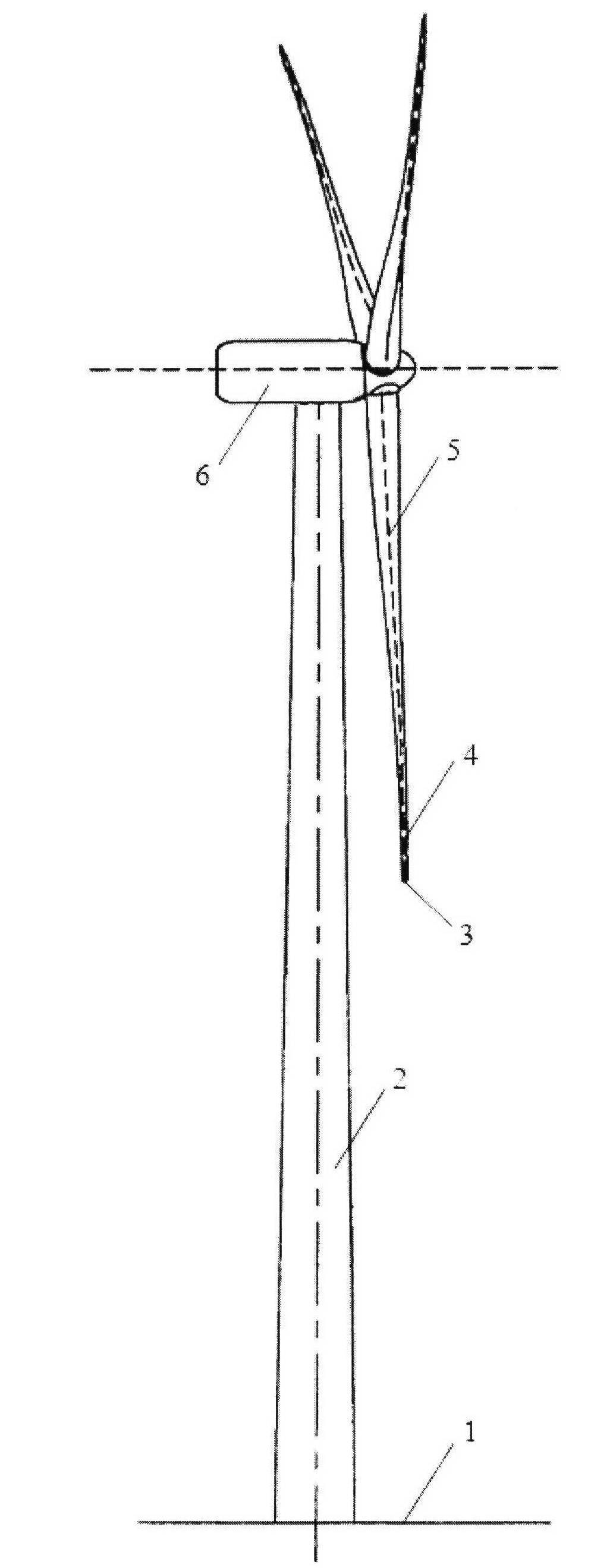

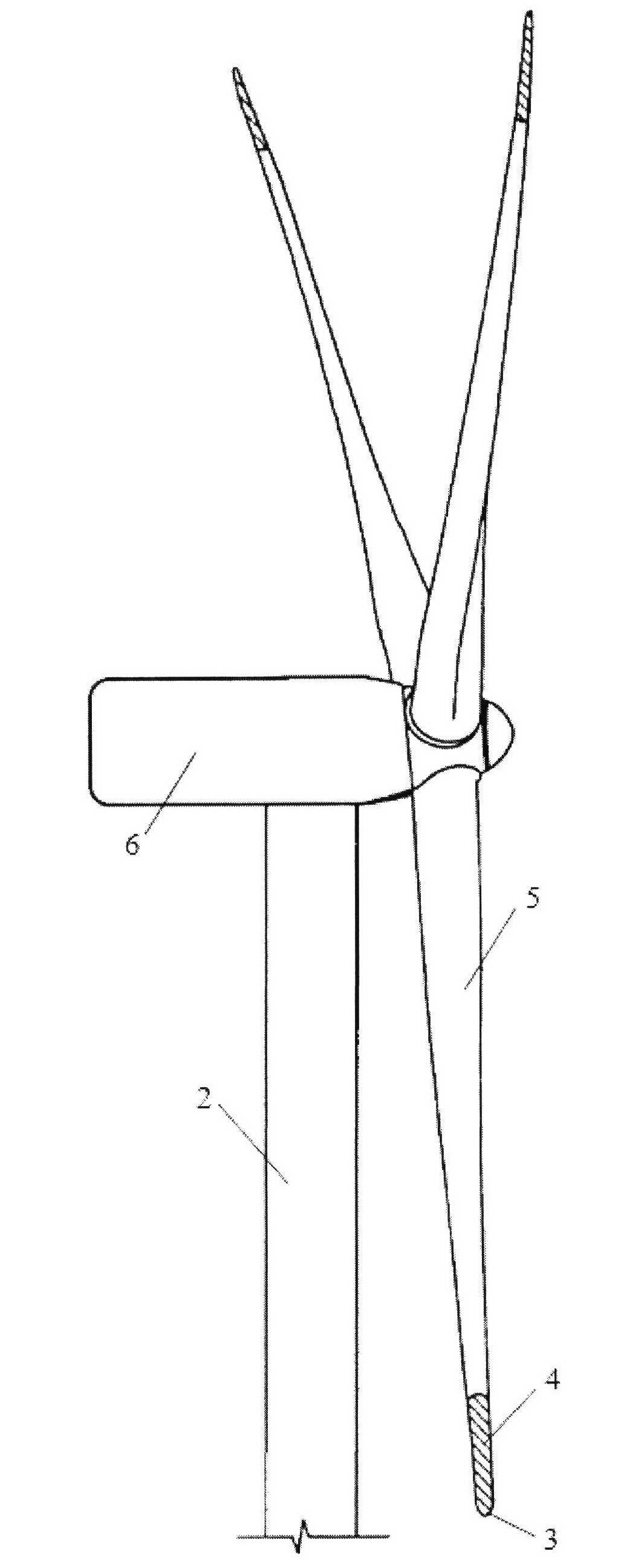

Method for lengthening wind power blade

The invention relates to a method for lengthening a wind power blade, in particular to a method for connecting a new tip to the tip of the wind wheel blade of the conventional wind driven generator. The invention comprises a blade tip lengthened connecting structure and a process scheme. According to the wind wheel blade tip lengthening scheme for the wind driven generator, the lengthened blade has a safe structure, and the method is simple in process, low in cost and high in implementation feasibility.

Owner:苏州可汗极米科技有限公司 +1

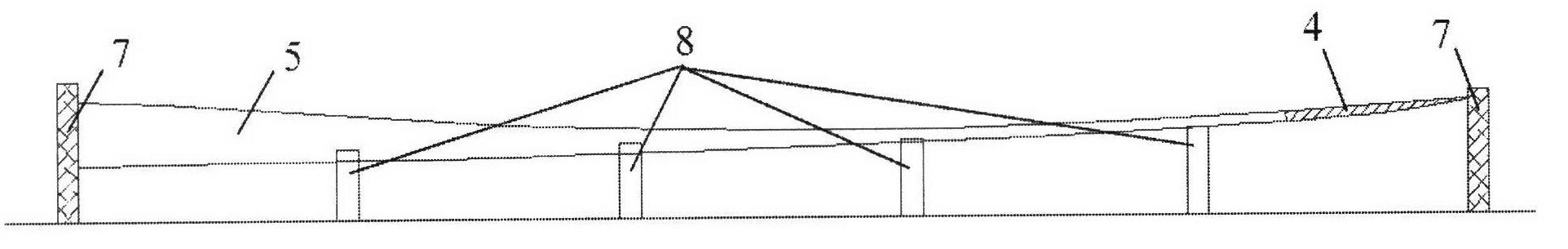

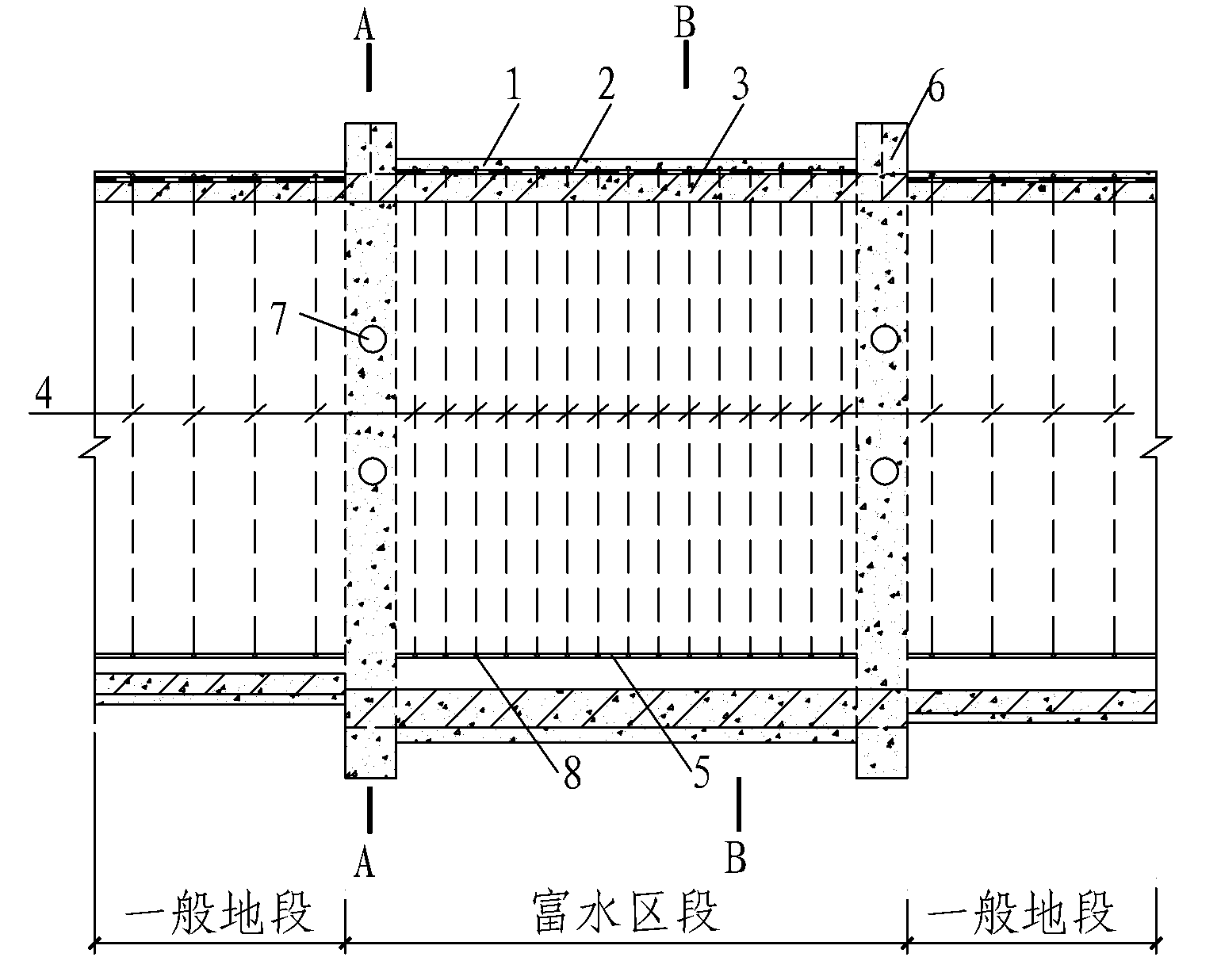

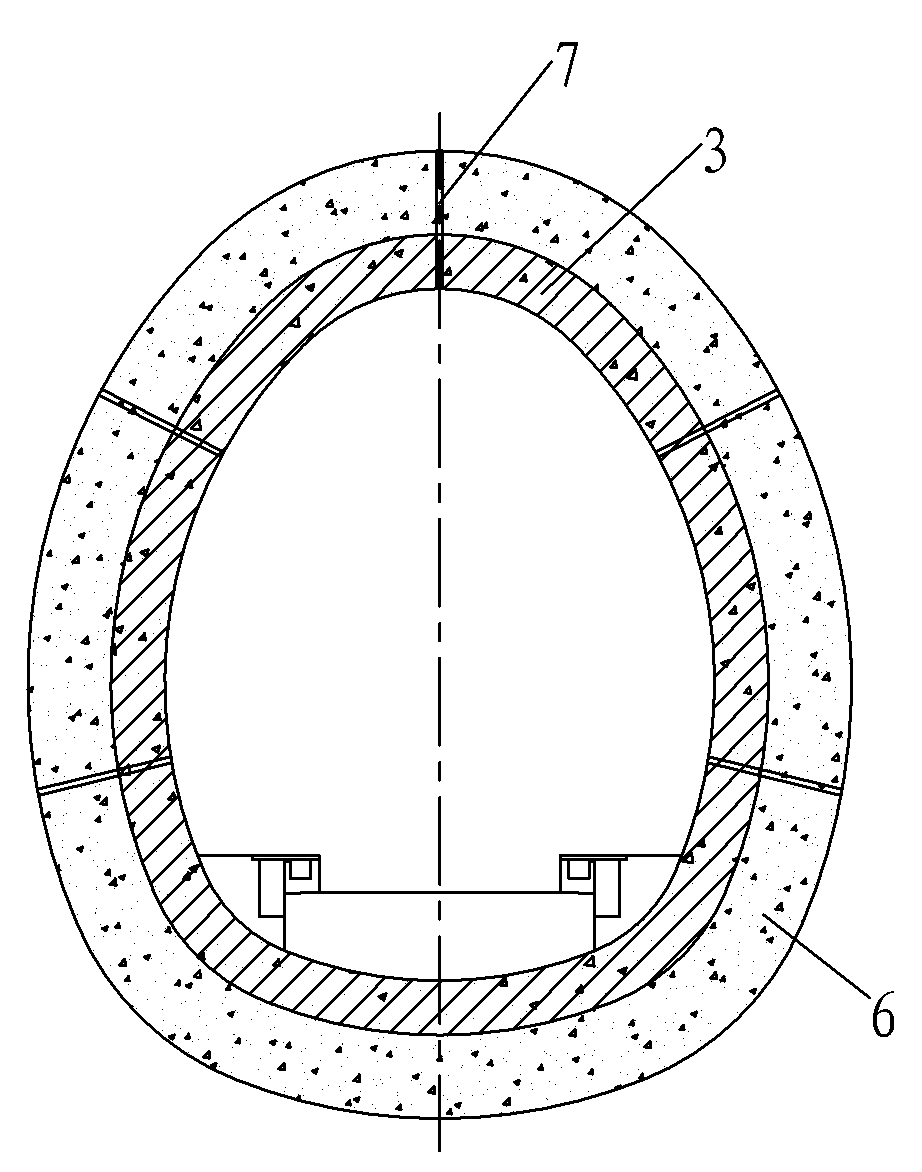

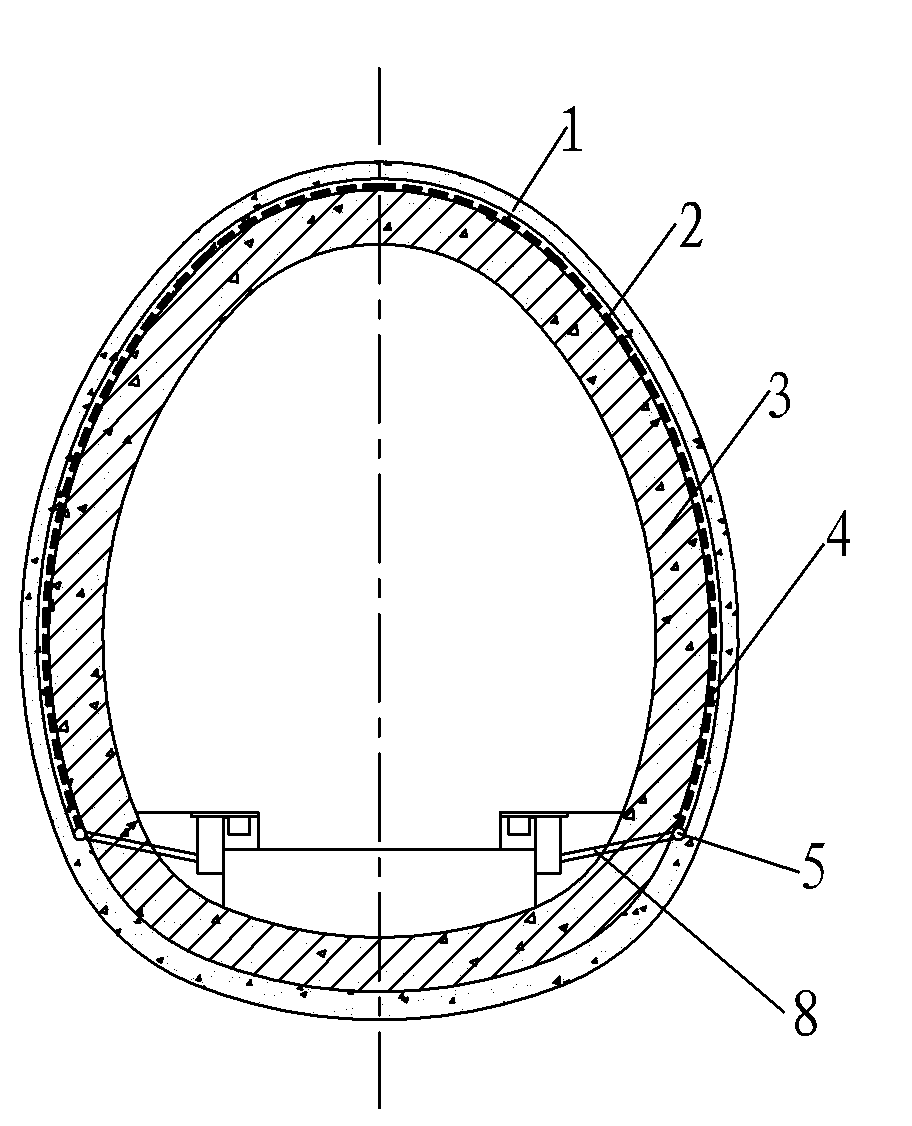

Structure for preventing water at back of tunnel lining from longitudinally streaming

ActiveCN101985884APrevent vertical streamingSafe and reliable structureUnderground chambersTunnel liningEngineeringWater block

The invention relates to a structure for preventing water at the back of a tunnel lining from longitudinally streaming, which is characterized in that: at least one convex water blocking ring is arranged on the outer surface of a secondary lining corresponding to a waterproof board along the circumferential direction; and the water blocking ring cuts off the waterproof board and a longitudinal water drain pipe and penetrates into a primary support and an adjoining rock so as to prevent underground water from longitudinally streaming. The structure can realize the zonal and sectional drainage of a tunnel in sections with different watery degrees; and a tunnel waterproof and drainage system is pertinently arranged according to the watery degree of the underground water, so that the requirement on the drainage capacity of the tunnel is met, engineering cost is saved, maintenance cost is reduced, and the phenomena of cracking, leakage, water jetting and the like of weak sections of the lining caused by the streaming of the underground water at the back of the lining are avoided.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Curtain wall system capable of discretionarily being demounted, mounted and changed

InactiveCN101059006AEasy to replaceRealize arbitrary disassemblyWallsWindow openingMaterial consumption

A baffle wall system can be disassembled, installed and replaced arbitrarily indoor or outdoor. It includes mullion components, fixed unit components, opening unit components and beam of sealed opening unit components. The mullion is equipped with hanging bar; the fixed unit components are equipped with hook and locking device; the opening unit components are equipped with sealed beam. The fixed unit components is hanged on the mullion to press the mullion sealing adhesive tape and realize confinement, the horizontal frames of the fixed unit components are inserted and connected with each other to press the sealing adhesive tape and realize confinement; the beam on the opening unit components, the mullion and the horizontal frames on the fixed unit components combine the opening window frame. The opening unit components are linked with the mullion through butt hinge, the sash lock locks and presses the sealing adhesive tape tightly and realizes sealing, opening can realizes window-opening and ventilation. The whole baffle wall system realizes the sealing and water discharging function of whole baffle wall through the interaction between the mullion and unit components. The advantages of the invention are: achieving the disassembling, installation and replacement arbitrarily indoor or outdoor; materials consumption is less, the outside need not be sealed by anti-weather sealant and the costs are reduced.

Owner:邱建平

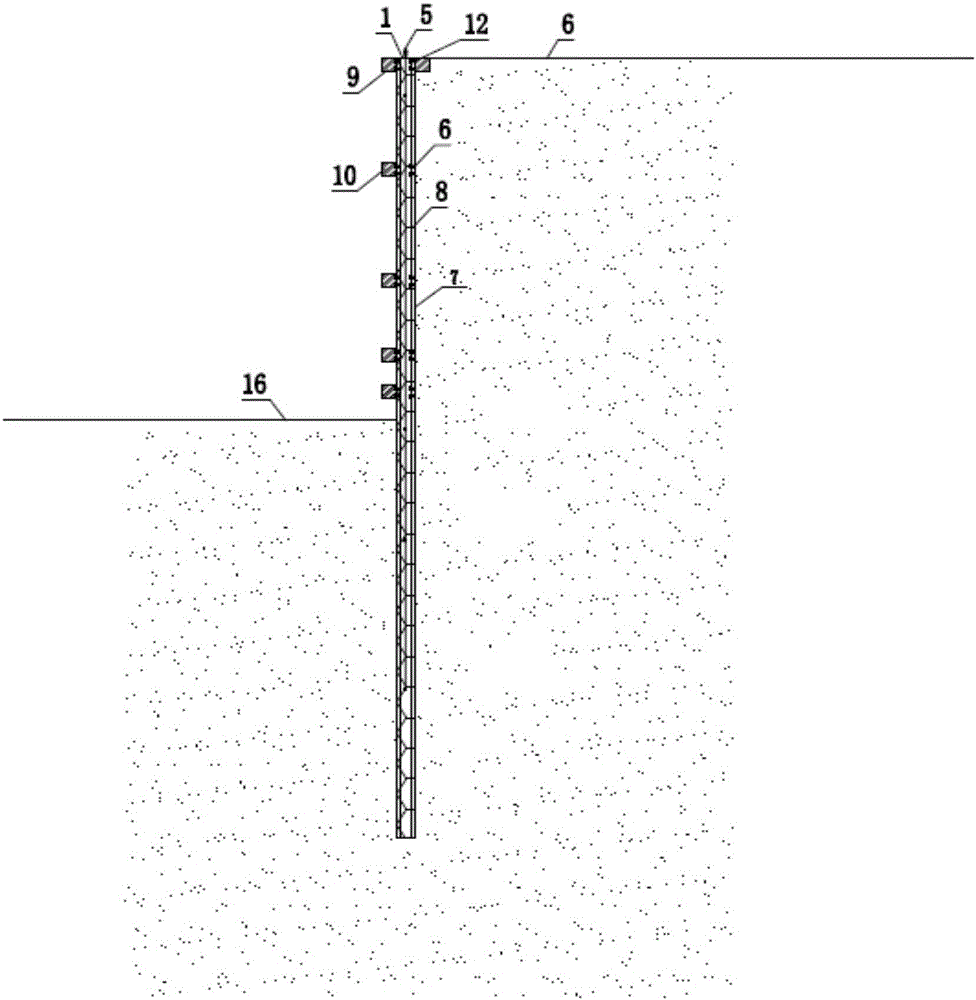

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

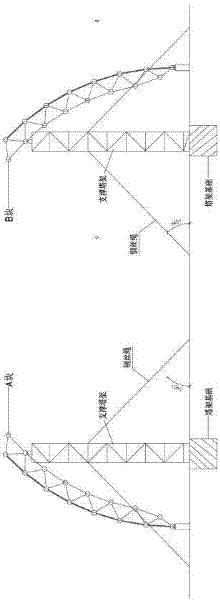

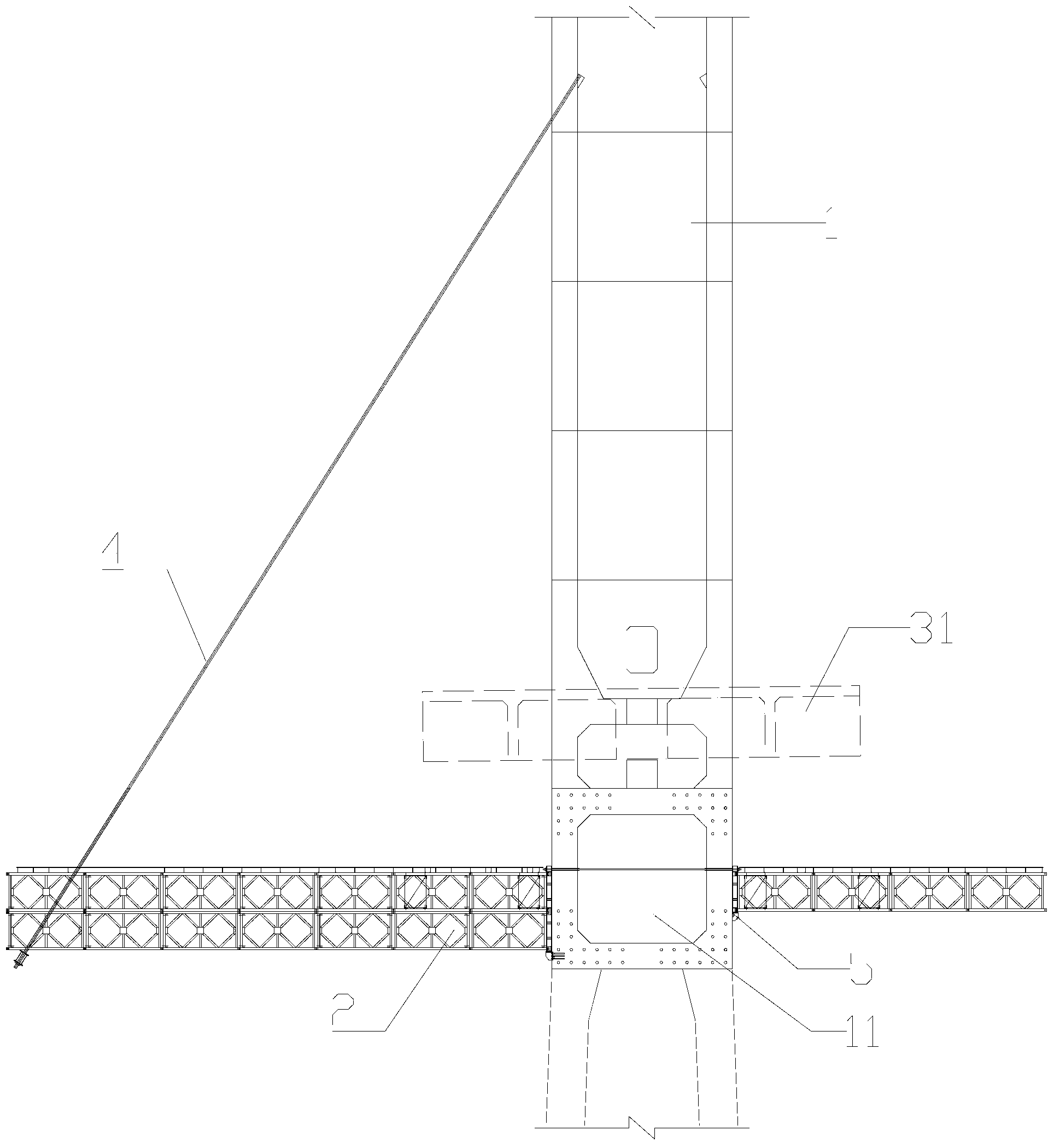

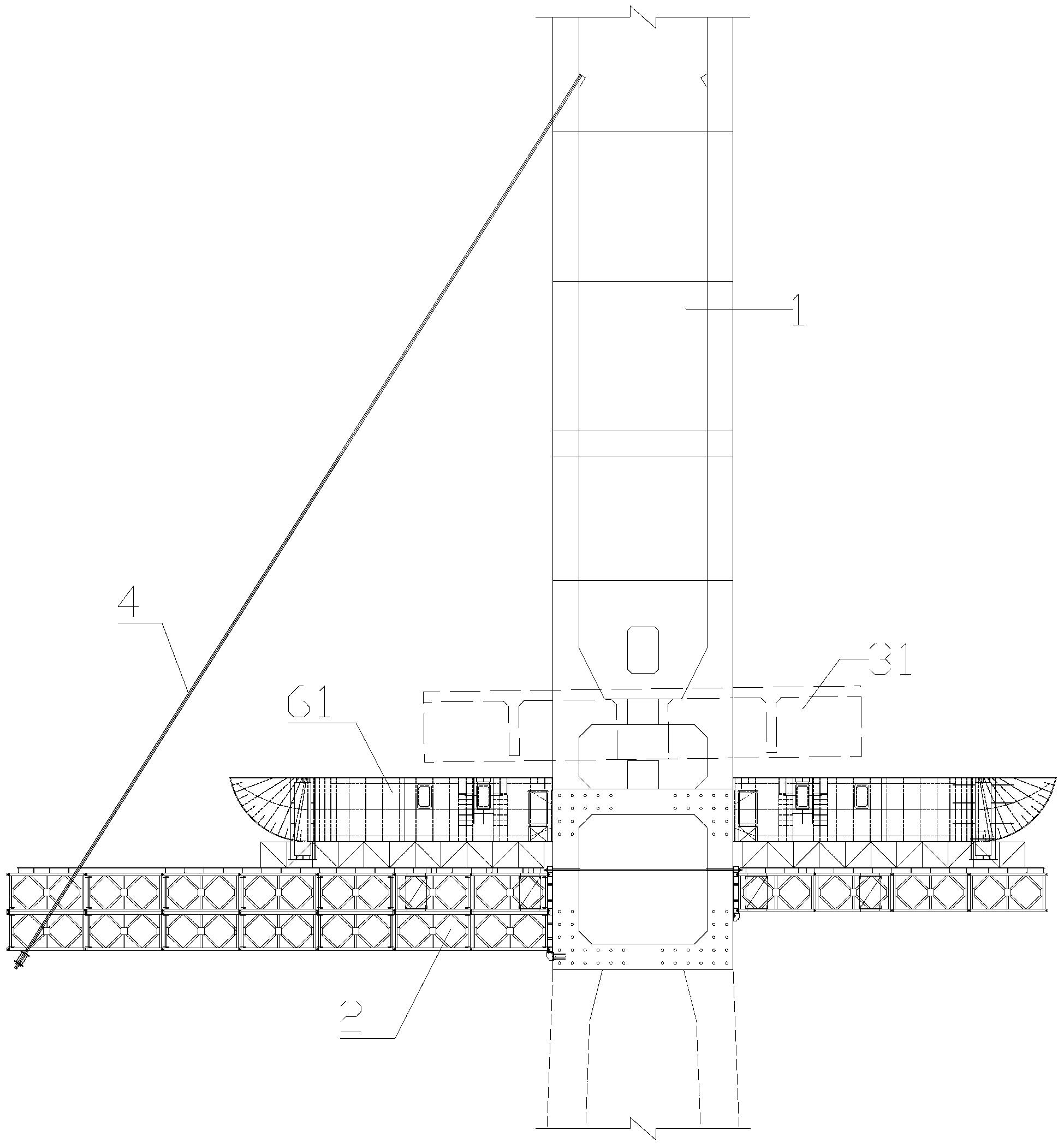

Guyed traveler for cable-stayed bridge and assembly method for guyed traveler

ActiveCN103243658AEasy to carry outOvercoming the narrow construction site in mountainous areasBridge erection/assemblyCable stayedTower

The invention discloses a guyed traveler for a cable-stayed bridge. The guyed traveler comprises a front half portion and a rear half portion which can be assembled together to be in a B-shaped frame structure. The front half portion comprises a pair of parallel main longitudinal girders and a front cross girder and a middle cross girder which are arranged between the main longitudinal girders; and the rear half portion comprises a pair of parallel tail longitudinal girders and a rear cross girder which is arranged close to the rear ends of the tail longitudinal girders. An assembly method for the guyed traveler comprises mounting a supporting frame through a cable bent tower lower cross girder, building a girder 0-1# on the supporting frame, mounting a traveler assembly platform by using a temporary cable reserved on a tower column, assembling the front half portion of the traveler, and pouring a girder 0-2#; dropping the front half portion of the traveler, pushing and moving the front half portion forwards on the platform, and assembling the rear half portion of the traveler; and lifting the assembled traveler integrally, and anchoring and connecting the assembled travel with the girder 0-2#. According to the guyed traveler for the cable-stayed bridge and the assembly method for the guyed traveler, the construction is simple and convenient, costs are reduced, and safety risks are low.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

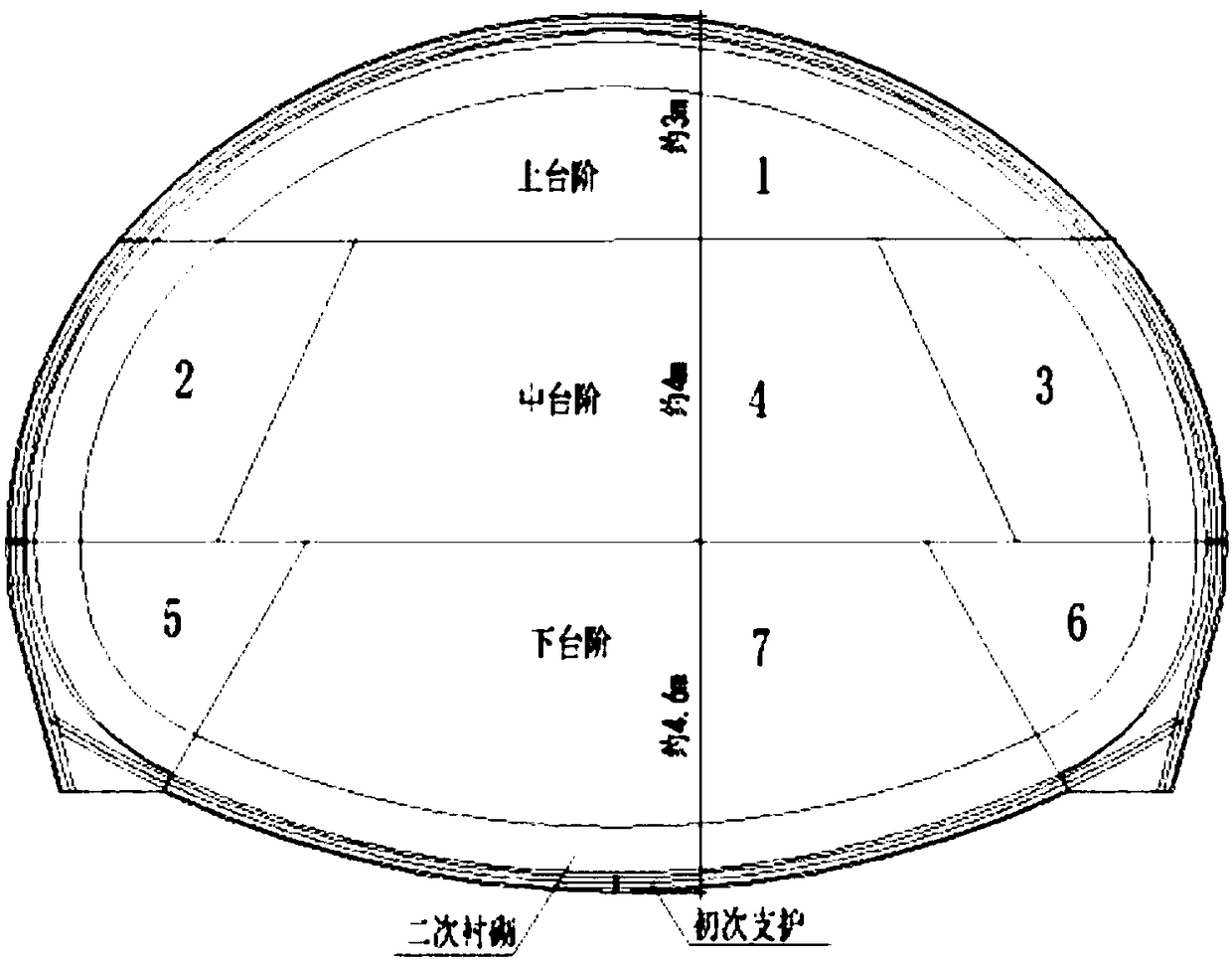

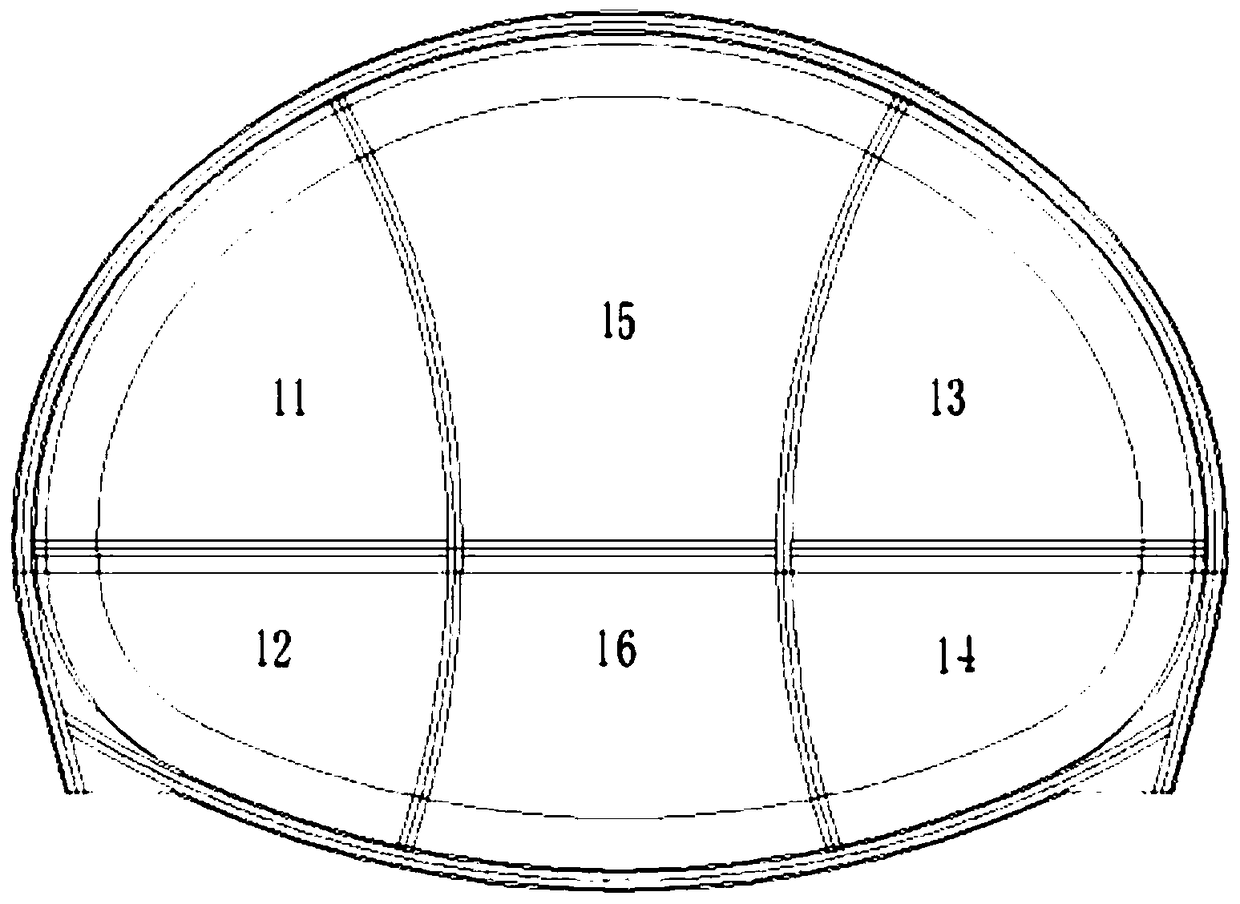

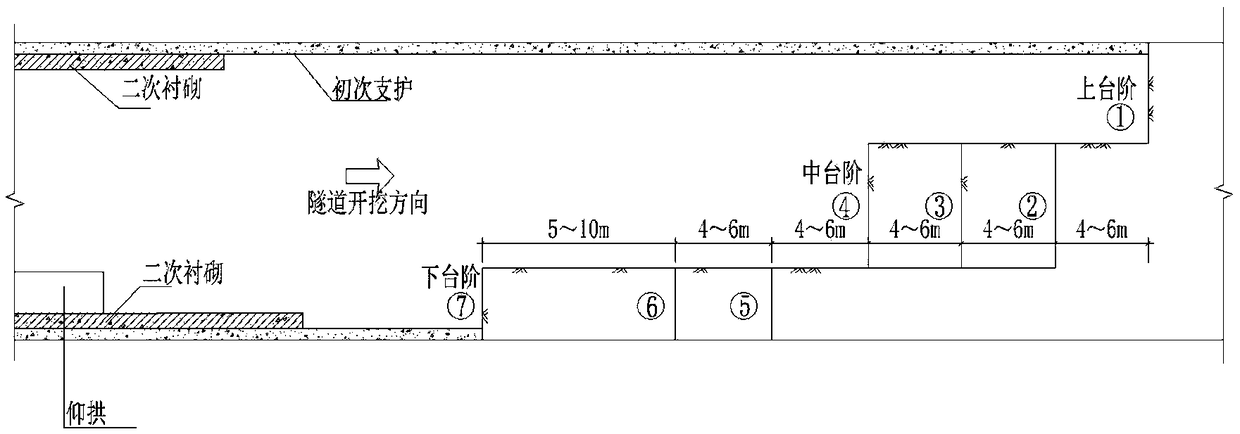

Construction method suitable for penetrating water supply pipe below tunnel in composite stratum with soft upper part and hard lower part

InactiveCN109372517ASmall deformation perturbationReduce disturbanceUnderground chambersBlastingStructure of the EarthSteel frame

The invention discloses a construction method suitable for penetrating a water supply pipe below a tunnel in a composite stratum with the soft upper part and the hard lower part, and belongs to the technical field of civil engineering. The construction method aims to strictly control tunnel arch settlement and prevent the situation that settlement overrun affects the water supply pipe to cause a structure (arch culvert) failure. By synthesizing the factors, the overall construction scheme is as follows: firstly, an advance support is constructed; after the design effect is achieved, the composite stratum with the soft upper part and the hard lower part is constructed through a three-step method, specifically, the upper step, namely the soft stratum is excavated through a mechanical method,the middle and lower steps, namely rock strata are excavated through a blasting method, and the circulation footage of a control area is one steel frame interval; manual work cooperates with mechanical excavation as far as possible, timely closure for ring forming is achieved, and arch sinking is inhibited; a secondary lining closely follows the excavation surface, and one-time pouring forming isachieved through a formwork trolley arch wall; and hole interior and ground surface settlement monitoring of the control area, as well as vibration speed monitoring within the blasting impact range are strengthened, and information is fed back in time to guide the design and construction.

Owner:BEIJING JIAOTONG UNIV +2

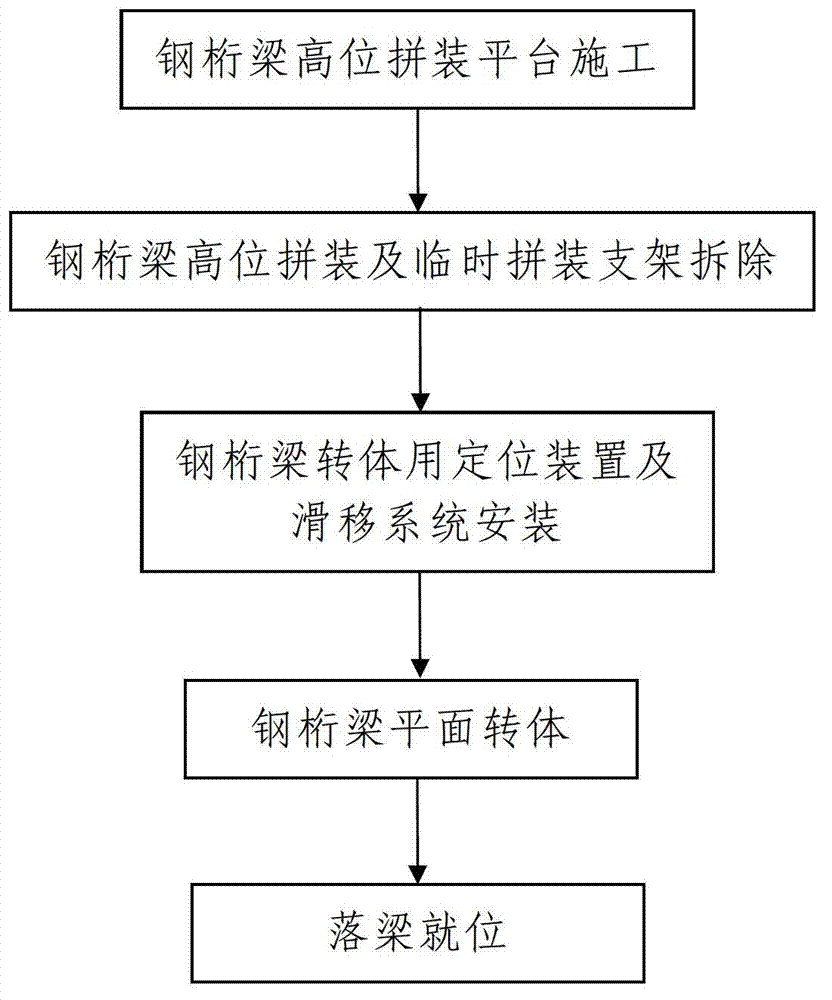

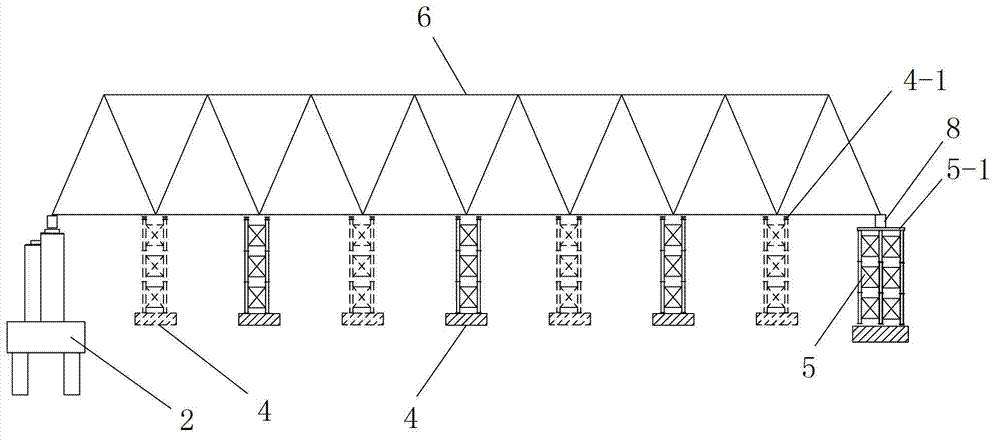

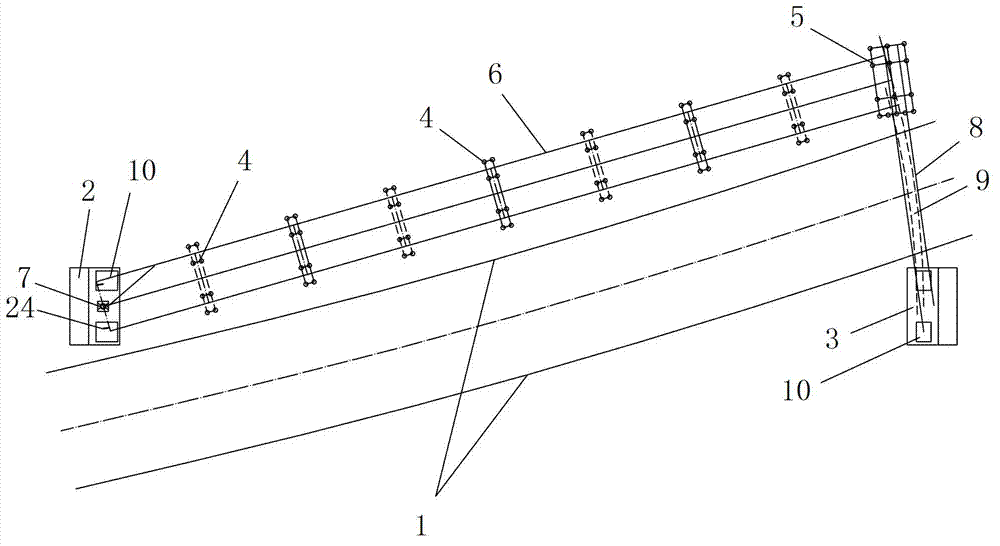

Plane rotation construction technique for steel truss girder for existing bridge spanning construction

The invention discloses a plane rotation construction technique for a steel truss girder for existing bridge spanning construction. A main girder of the constructed bridge is a steel truss girder spanning the existing bridge and obliquely crossing with the existing bridge; the technique comprises the following steps: firstly, constructing a high-altitude steel truss girder assembling platform which comprises a temporary buttress and a plurality of temporarily assembling brackets; secondly, assembling the steel truss girder at high altitude and removing the temporarily assembling brackets; thirdly, installing a steel truss girder rotation positioning device and a slippage system; before rotating the steel truss steel, firstly installing the steel truss girder rotation positioning device and the slippage system; fourthly, conducting plane rotation on the steel truss girder; and fifthly, dropping the girder in place. The construction technique is simple in steps, convenient to construct, fast to construct, safe and reliable in construction process and less in interference on the existing bridge, and can effectively solve the problems that the construction field is limited, the construction can not be normally conducted, the travelling interference on the existing bridge is large, the construction risk and hidden hazard are large and the like in construction with the existing in-situ falsework method and the dragging method.

Owner:NO 1 ENG LIMITED OF CR20G

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com