Elastic corrugated pipe single-acting cylinder-driven serial hinge framework manipulator

一种弹性波纹管、单作用气缸的技术,应用在机械手、程序控制机械手、夹头等方向,能够解决应用范围小、曲线斜率小、活页铰链难弯曲等问题,达到结构安全可靠、寿命长、受力均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below is working principle and working process of the present invention:

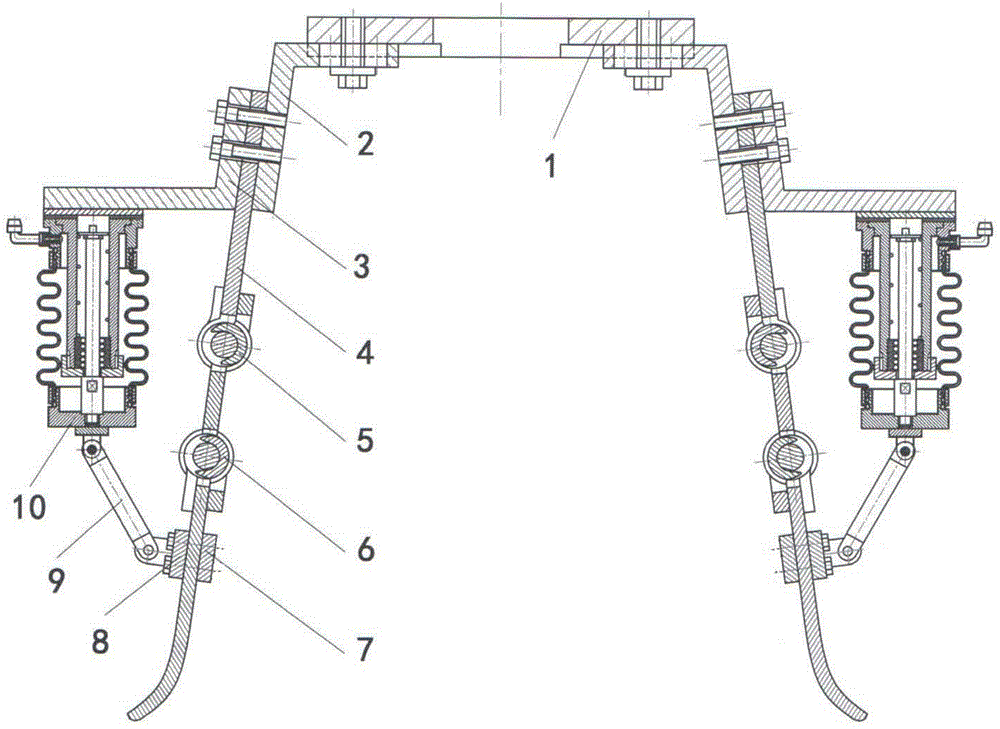

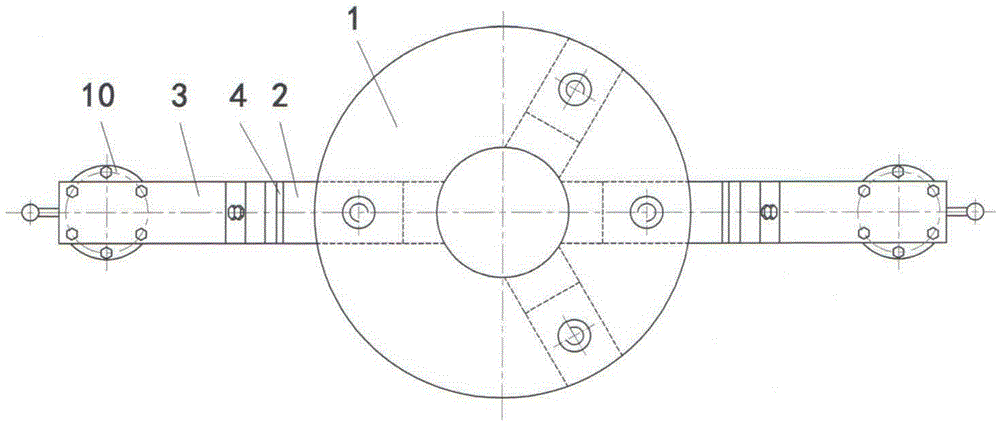

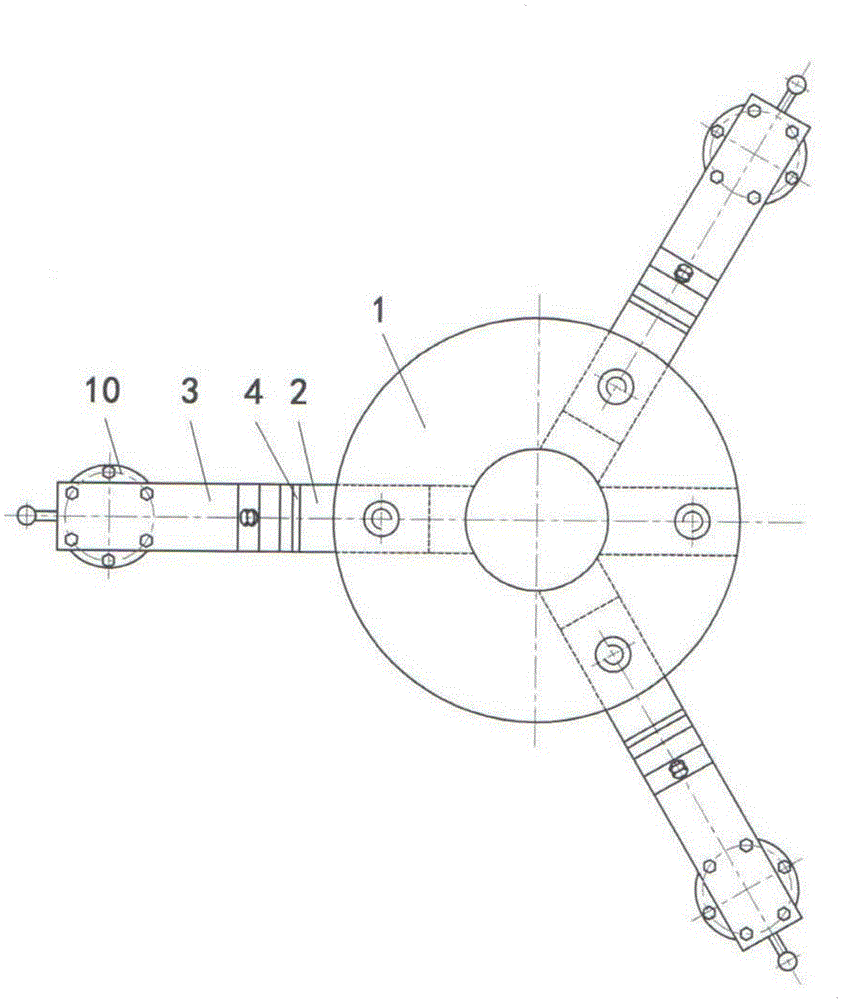

[0025] Such as Figure 1-2 And shown in 4-5, the working principle of the present invention:

[0026] For long and rectangular complex objects, after theoretical analysis and experimental research, determine the safe range of grasping contact force according to the shape and size of the grasped object, and determine the safety range of the grasping contact force, optimize the design of the manipulator structure size, large torsion spring5 and the characteristic parameters and pre-tightening angle of the small torsion spring 6, the characteristic parameters and the pre-tightening force of the compression spring 12a, thereby also determining the size of the installation position of the flexible finger on the palm plate 1, and determining the hinge seat 8 in the series hinge 4 Mounting location dimensions on the lower leaflet.

[0027]Simultaneously, when comprehensively designing the structural d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com