Elastic corrugated pipe single-acting cylinder-driven serial plate spring framework manipulator

A technology of elastic bellows and single-acting cylinders, applied in the direction of manipulators, collets, manufacturing tools, etc., can solve the problems of large difference between dynamic and static friction coefficients, enveloping grabbing method cannot be used, and poor flexibility of equal-section plate springs, etc. , to achieve the effect of uniform force, light weight and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below is working principle and working process of the present invention:

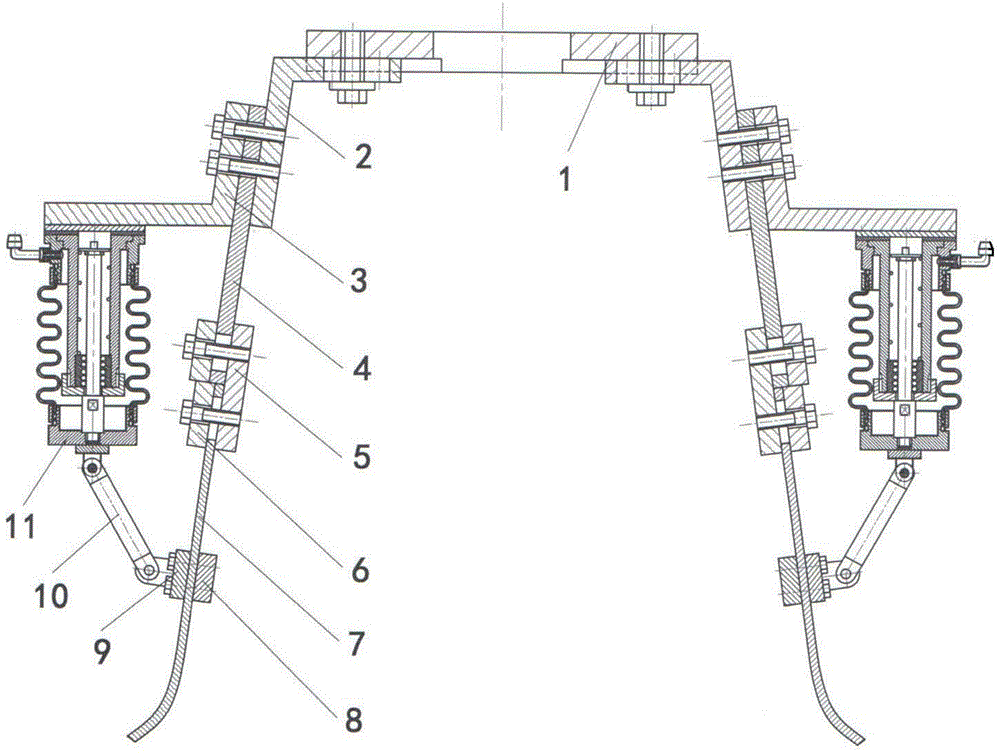

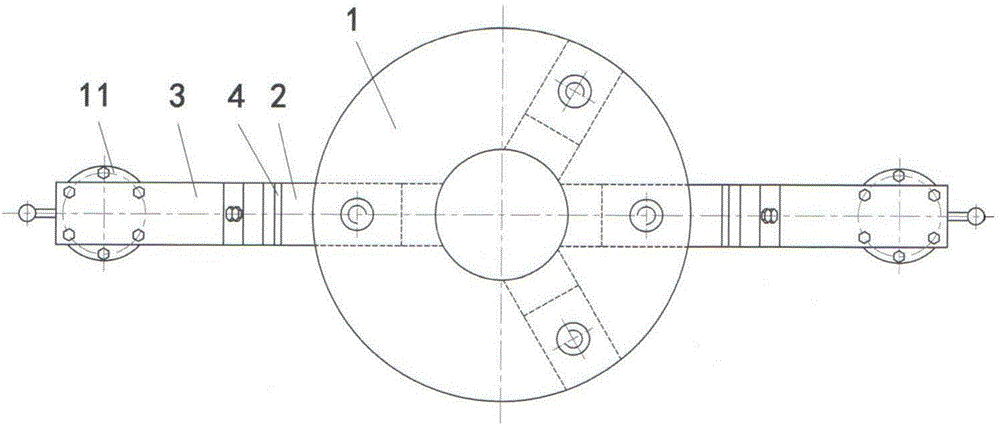

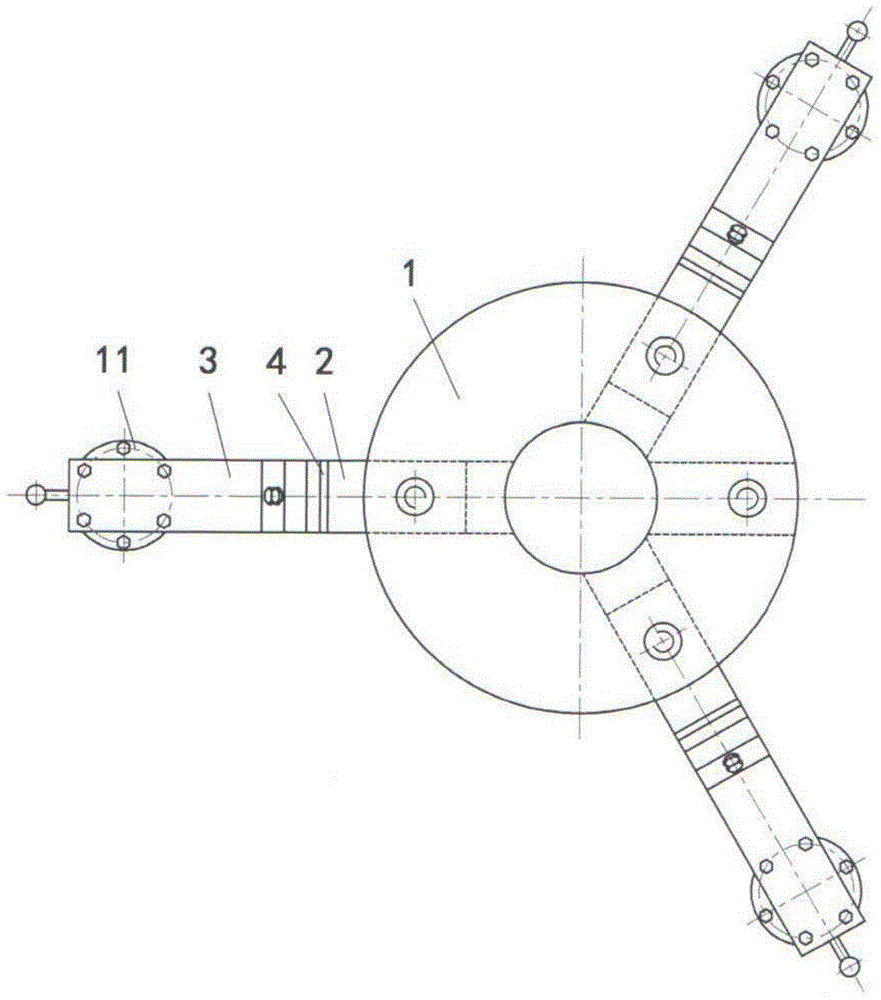

[0030] Such as Figure 1-2 And shown in 4-6, the working principle of the present invention:

[0031] For long and rectangular complex objects, after theoretical analysis and experimental research, determine the safe range of grasping contact force according to the shape and size of the grasped object, and determine the safety range of the grasping contact force, optimize the design of the manipulator structure size, thick plate spring4 , the shape and size of the thin plate spring 7, the characteristic parameters and pre-tightening force of the compression spring 12a, thereby also determining the installation position size of the flexible finger on the palm plate 1, and determining the installation position size of the hinge seat 9 on the thin plate spring 7.

[0032] Simultaneously, when comprehensively designing the structural dimensions of the tandem leaf spring skeleton manipulator and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com