Patents

Literature

6863 results about "Brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A material is brittle if, when subjected to stress, it breaks with little elastic deformation and without significant plastic deformation. Brittle materials absorb relatively little energy prior to fracture, even those of high strength. Breaking is often accompanied by a snapping sound. Brittle materials include most ceramics and glasses (which do not deform plastically) and some polymers, such as PMMA and polystyrene. Many steels become brittle at low temperatures (see ductile-brittle transition temperature), depending on their composition and processing.

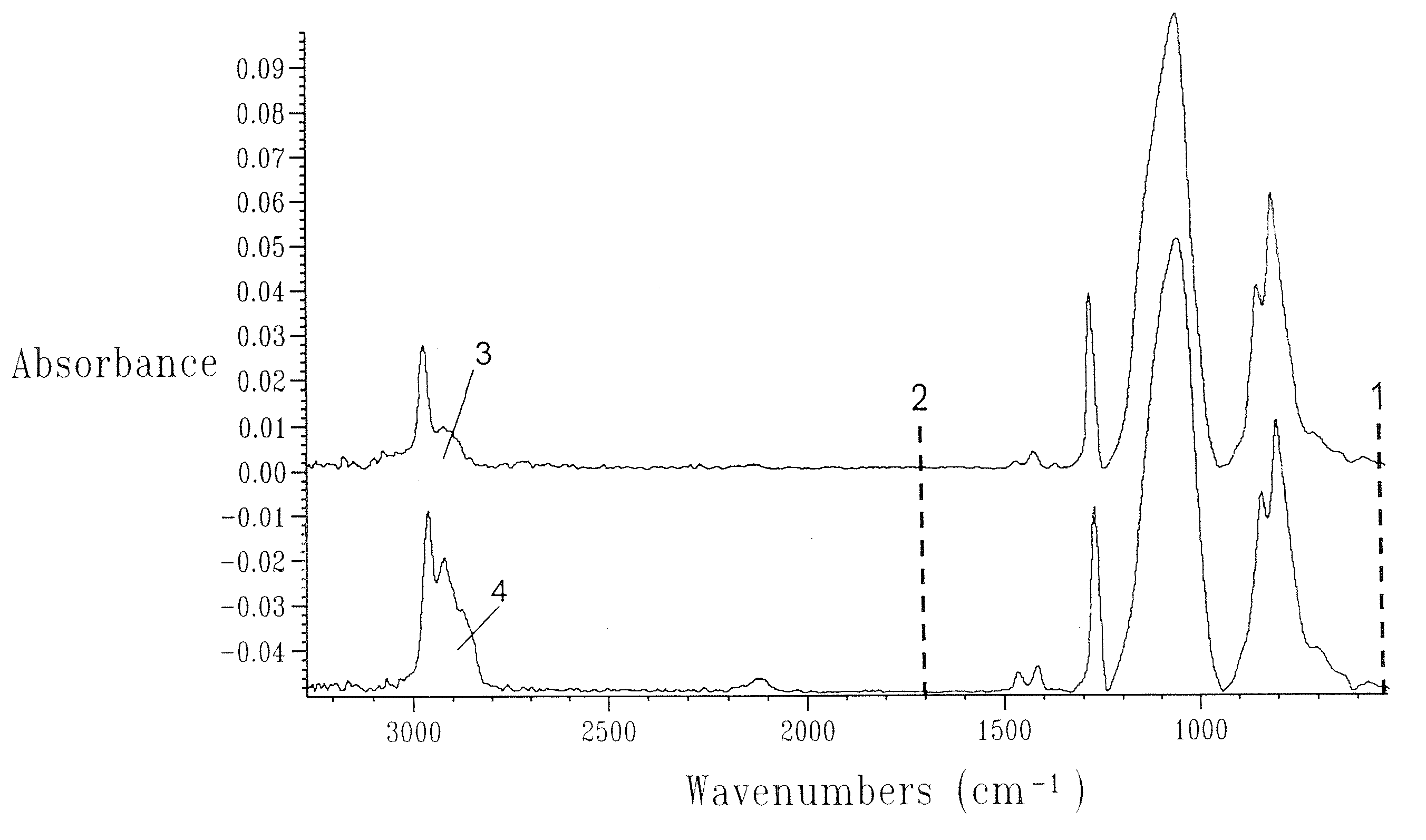

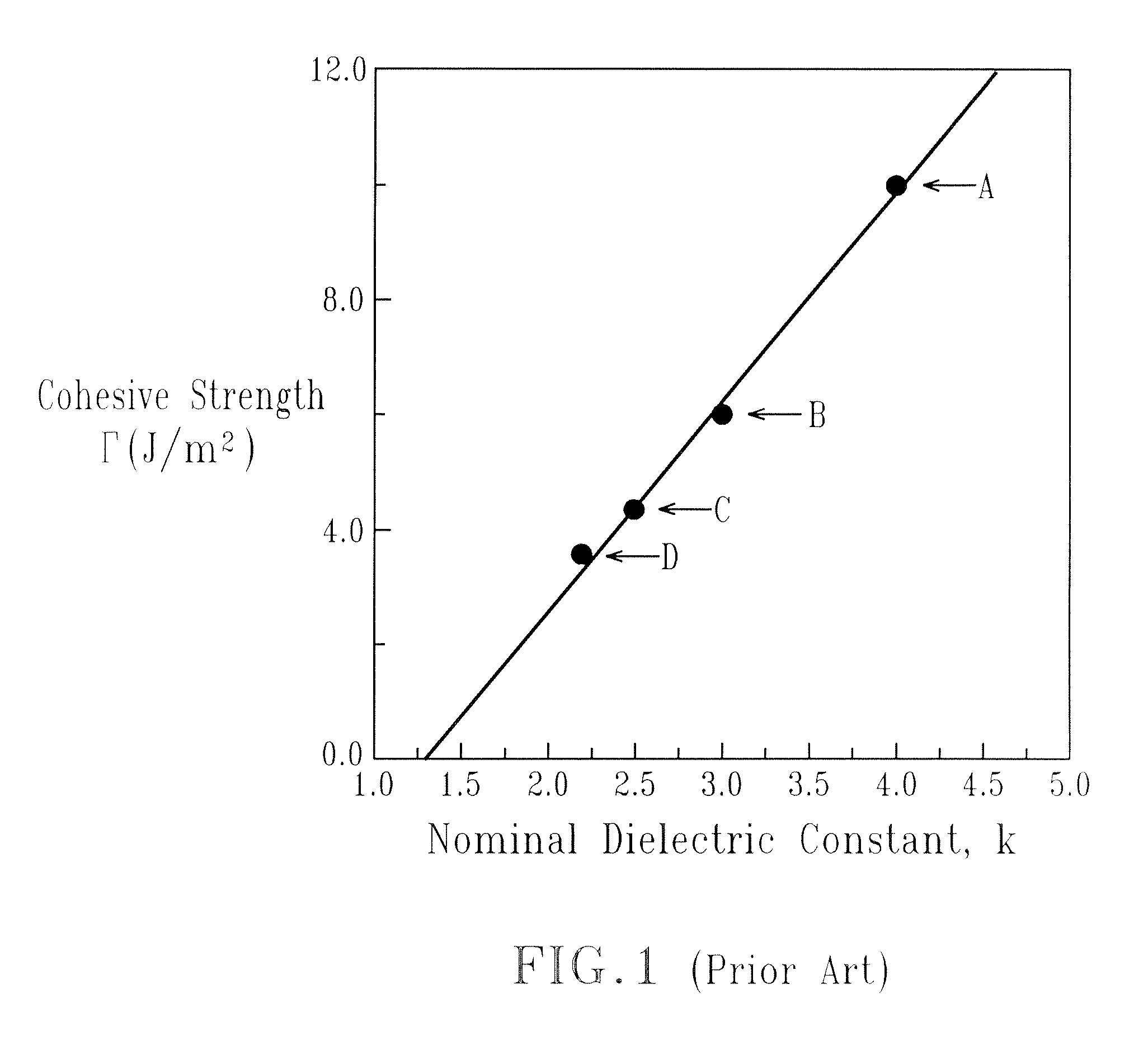

SiCOH dielectric

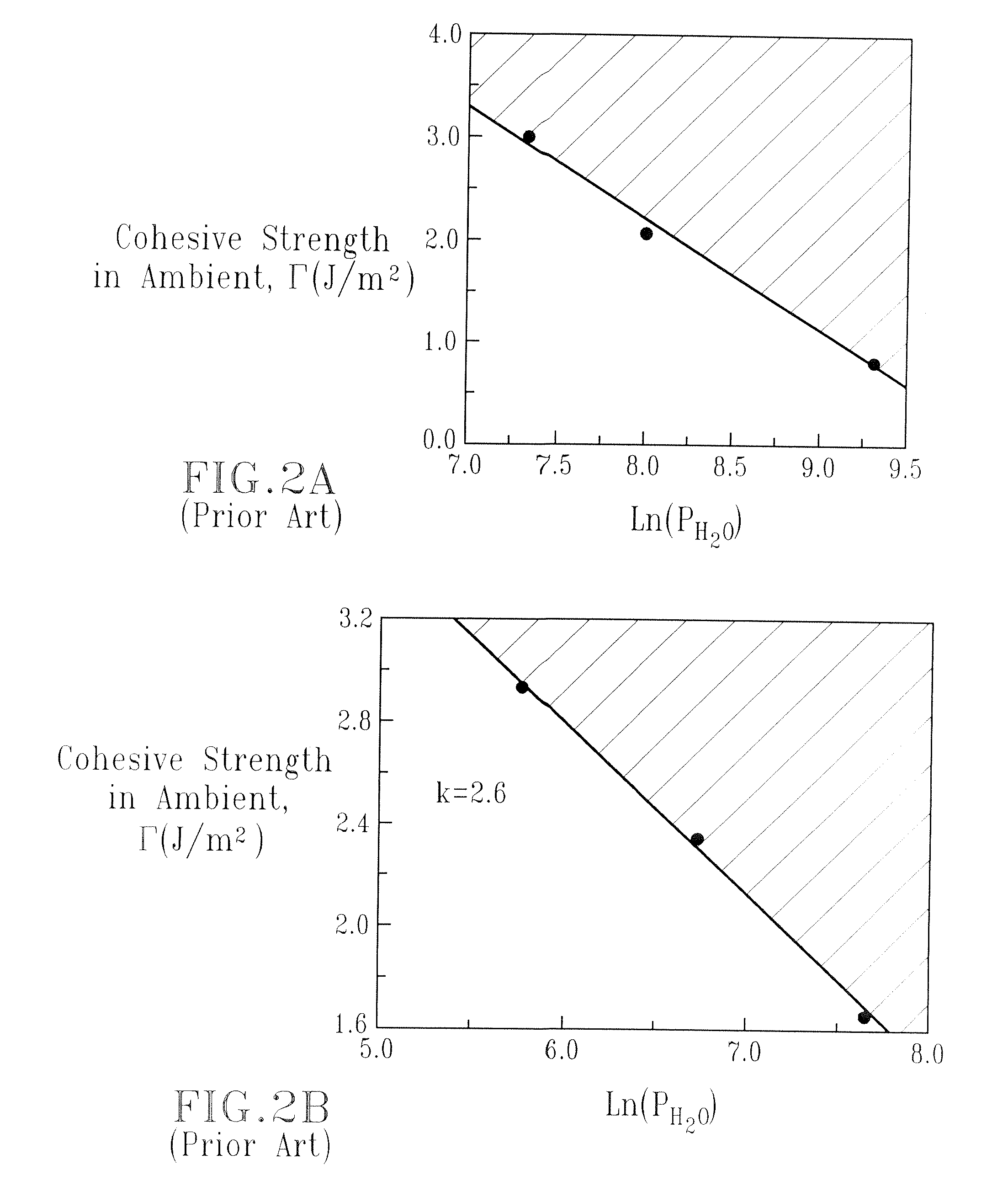

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

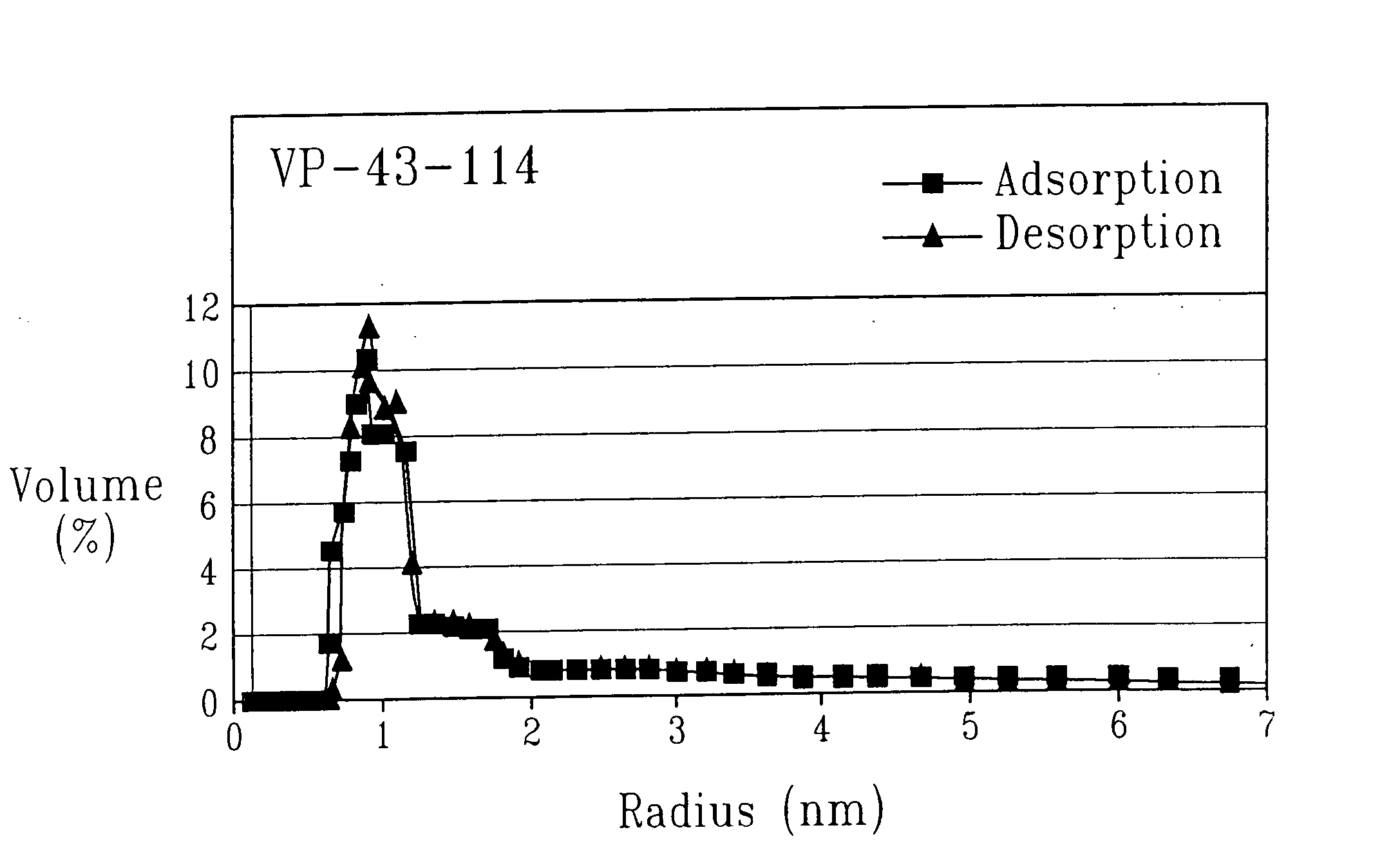

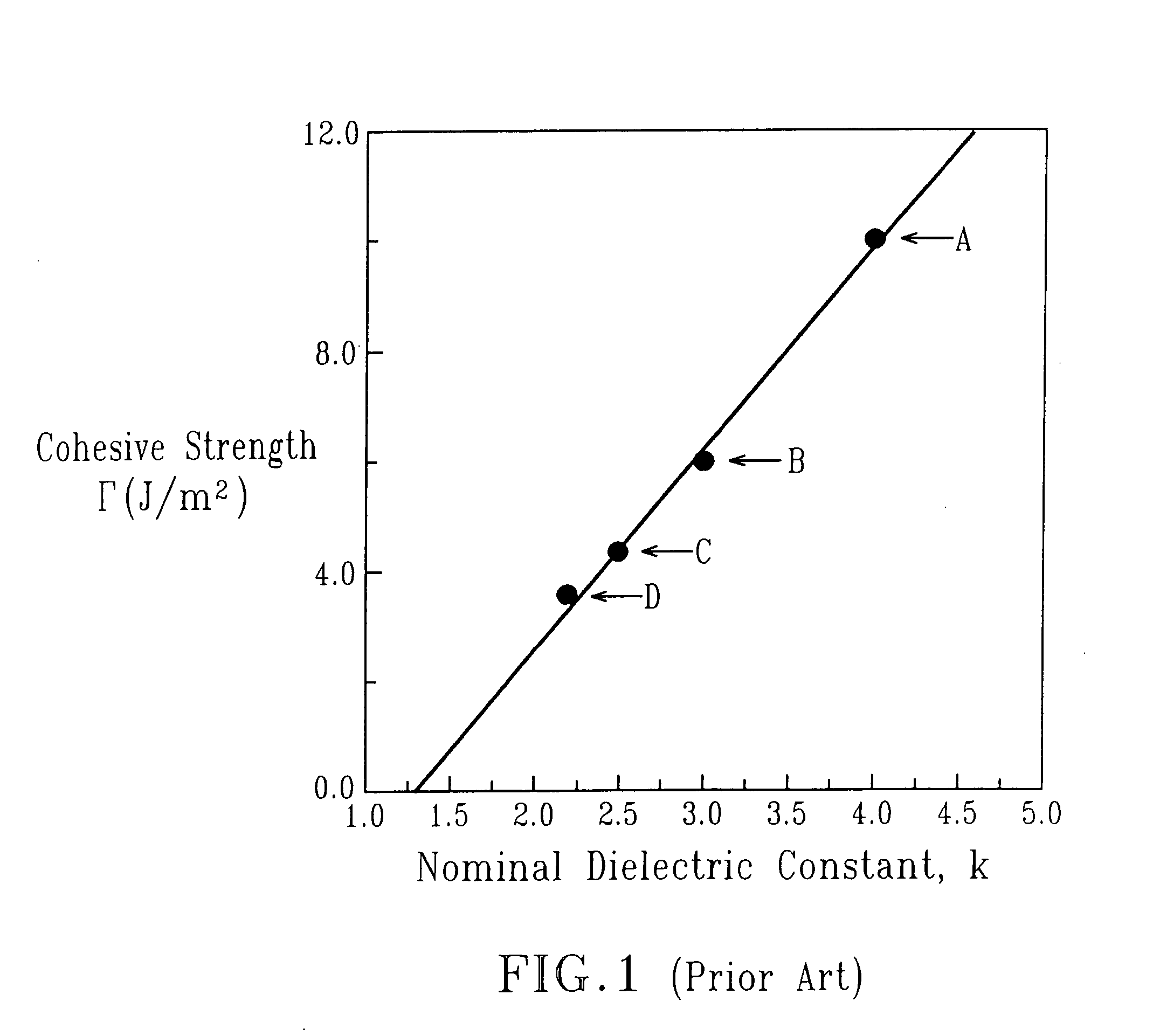

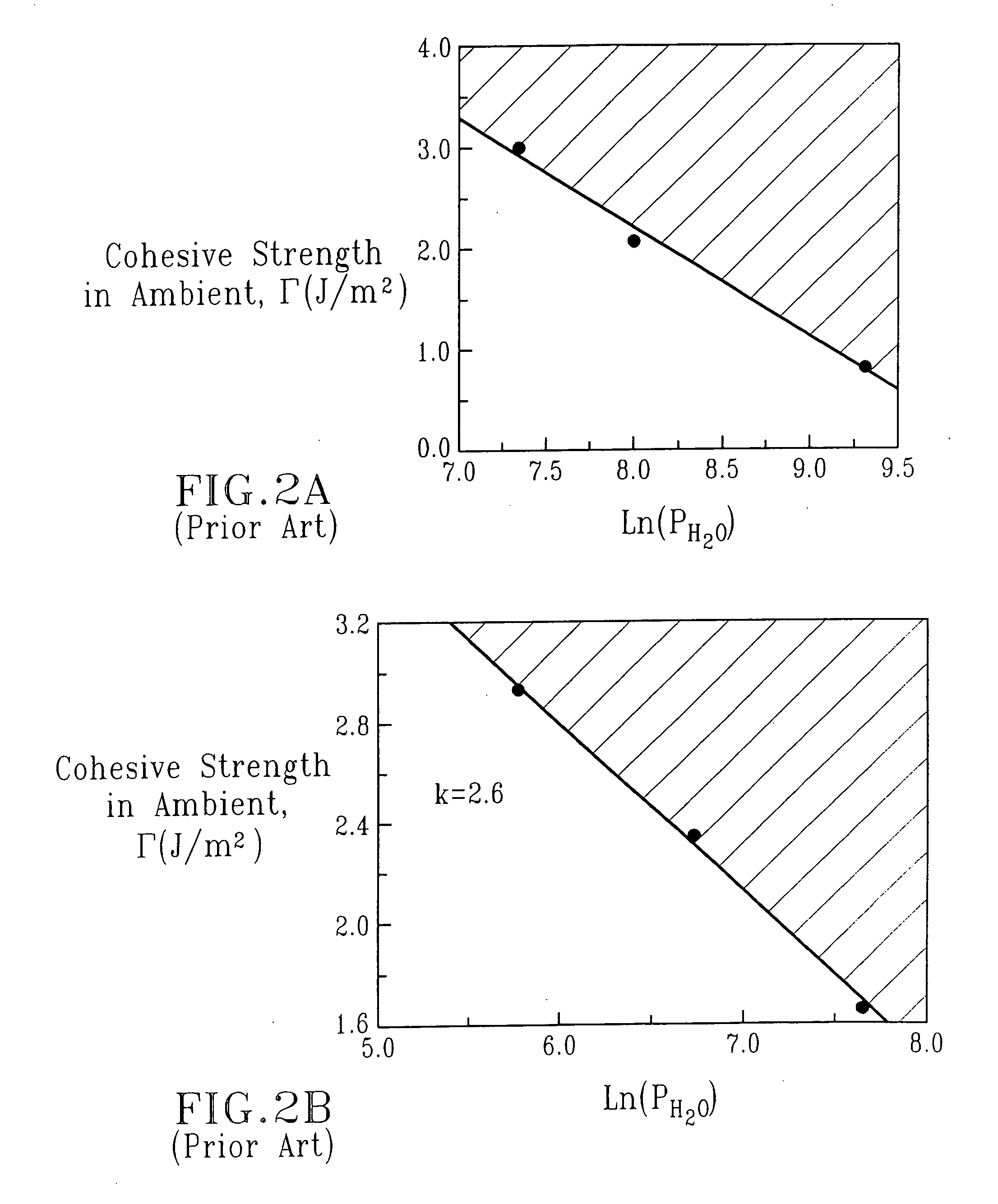

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

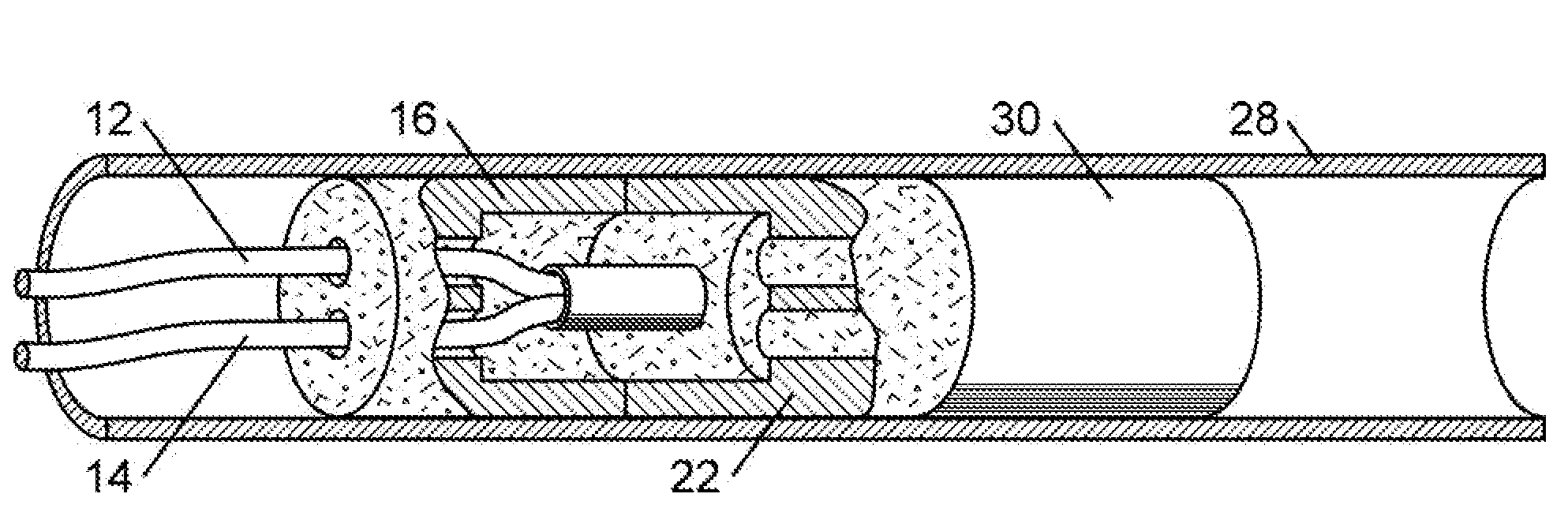

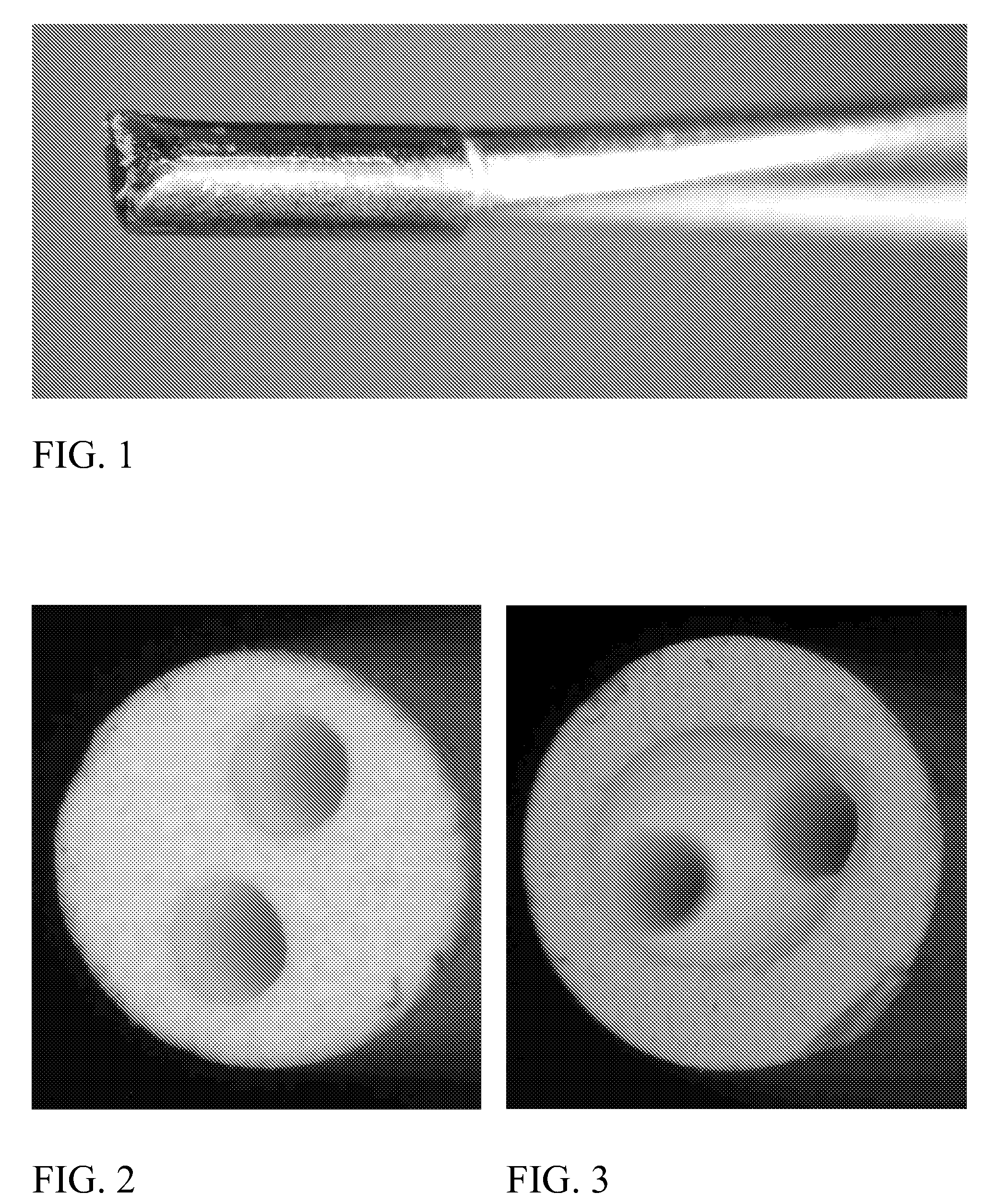

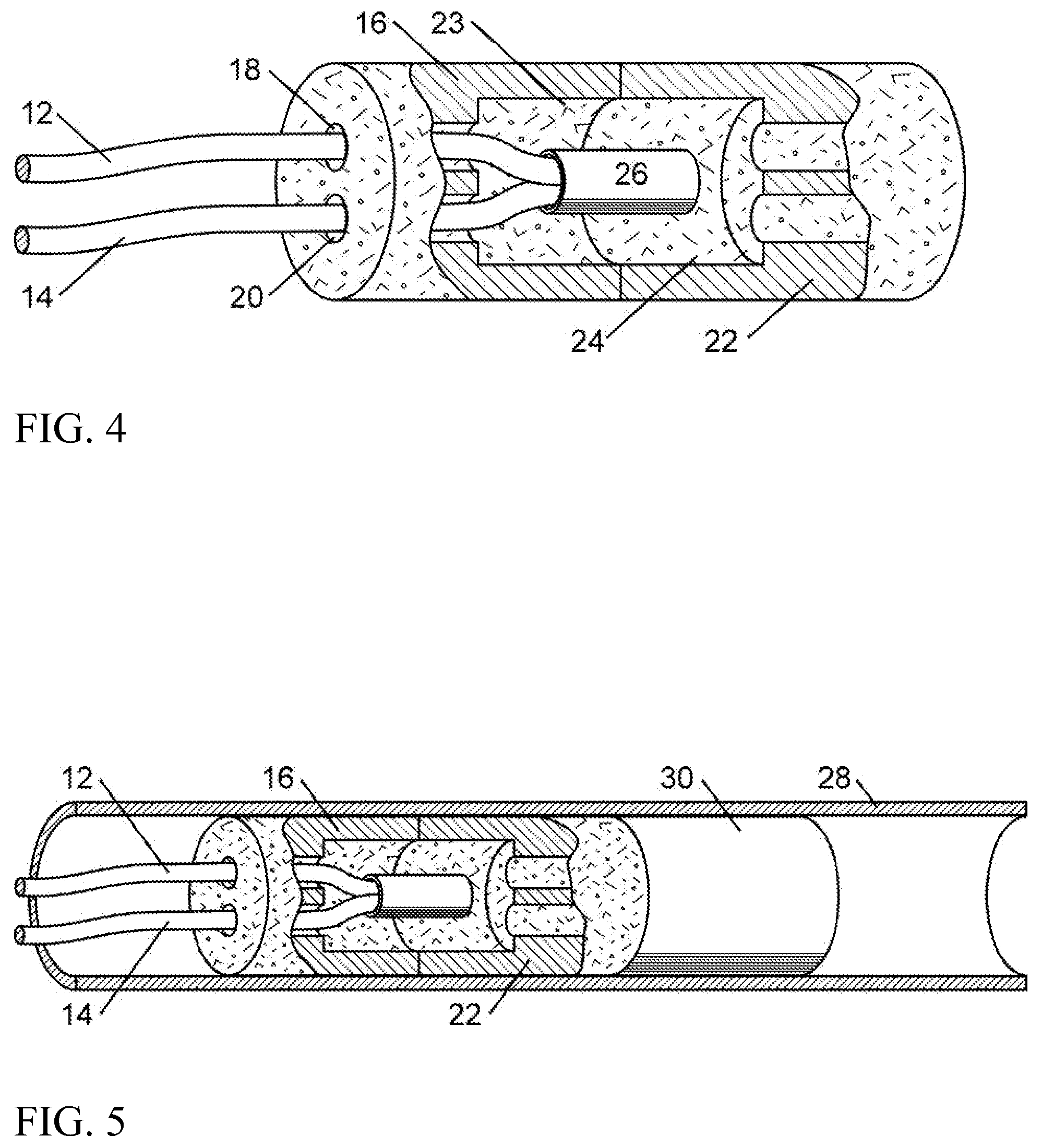

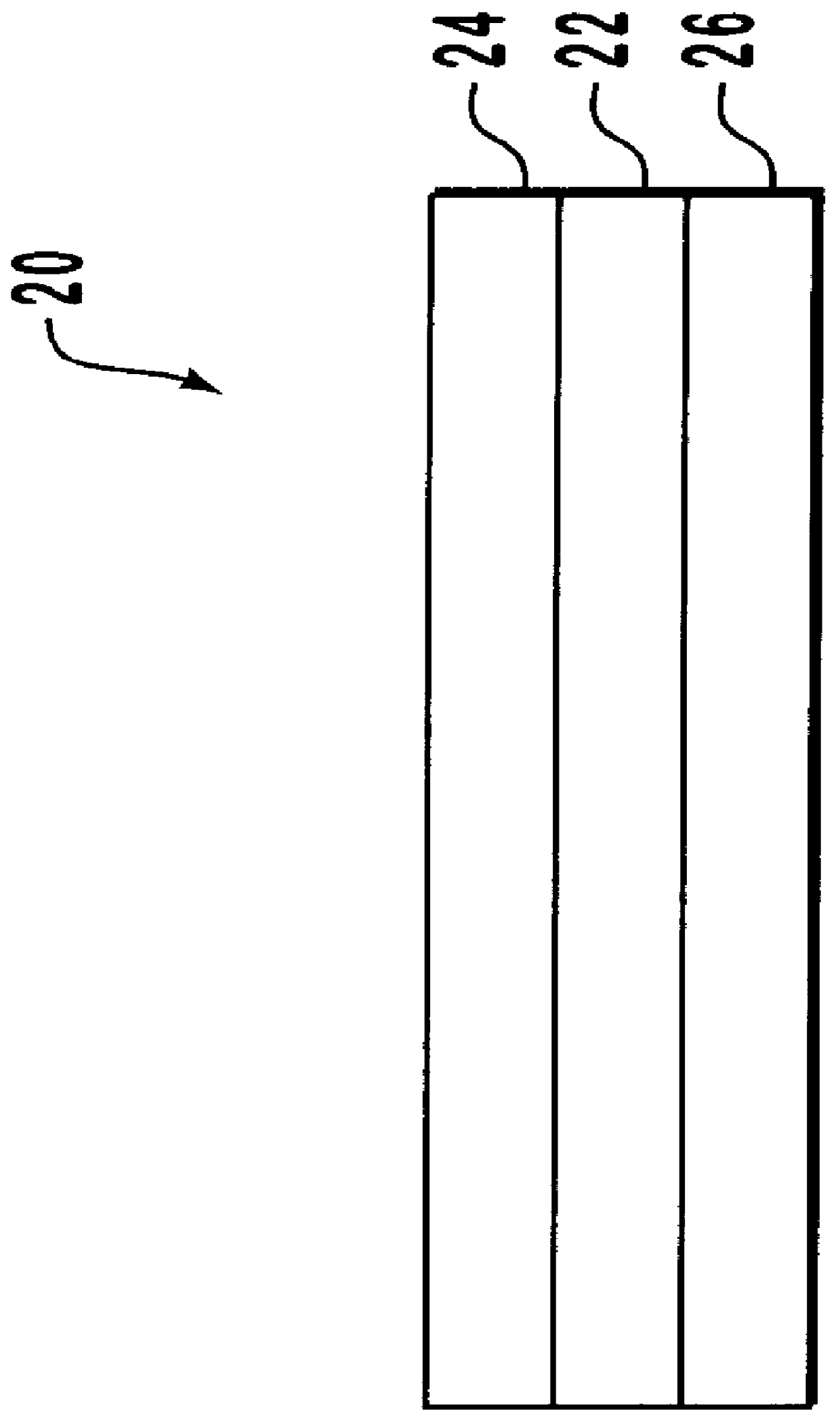

High temperature thermocouple design and fabrication

ActiveUS20080205483A1Low neutron cross-sectionsHigh melting temperatureThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsEngineeringThermocouple

A method for fabricating a thermocouple capable of long-term operation in high temperature, hostile environments without significant signal degradation or shortened thermocouple lifetime due to heat induced brittleness.

Owner:BATTELLE ENERGY ALLIANCE LLC

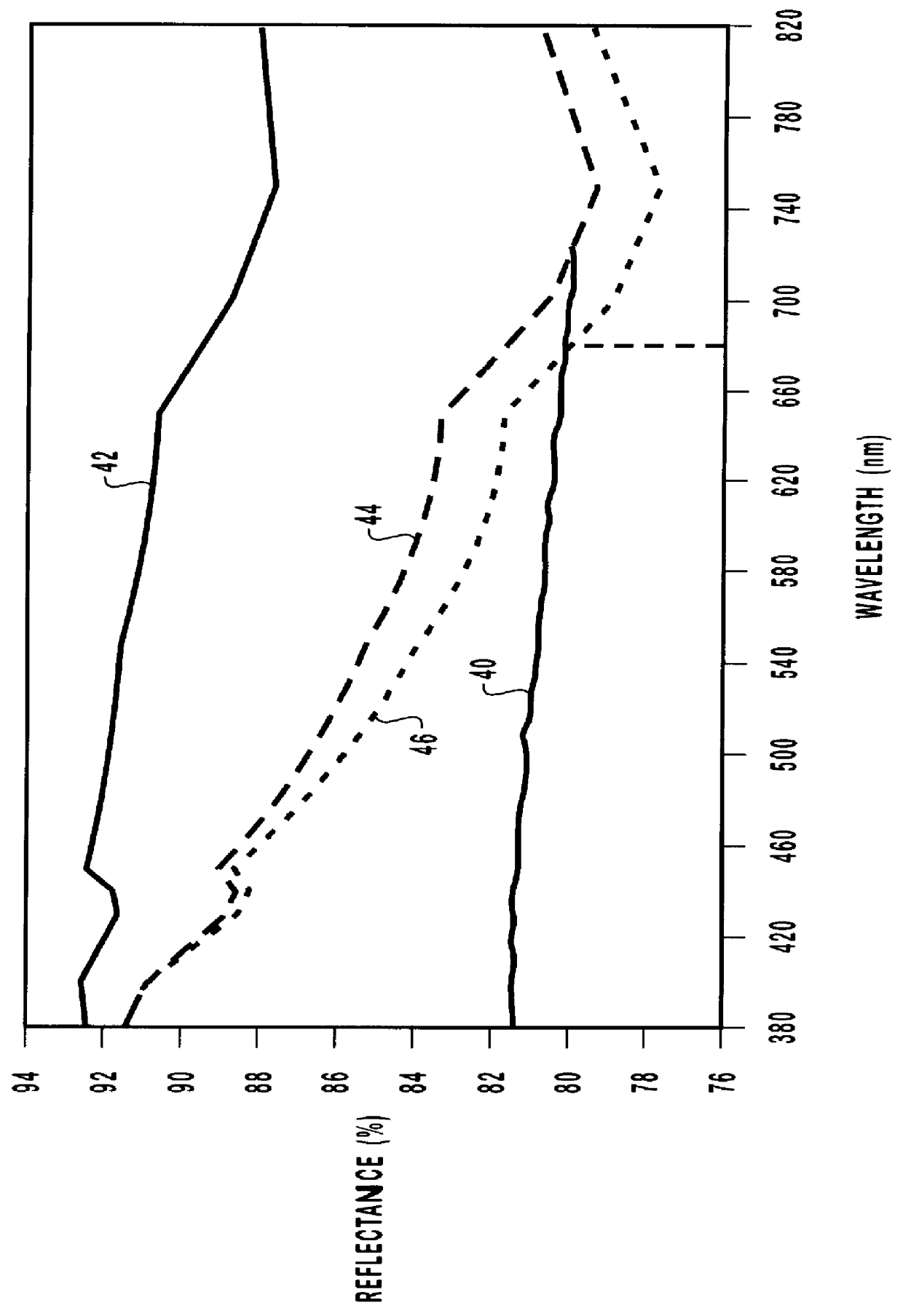

Bright metal flake based pigments

InactiveUS6150022AGood specular reflectance characteristicPigment preparation by PVD/CVD methodsSynthetic resin layered productsDielectricReflectivity

A flake-based pigment is provided having improved specular reflectance characteristics in the visible wavelength range. The flake-based pigment has a plurality of core flake sections each formed of a central reflector layer and dielectric support layers on opposing sides of the reflector layer. The resulting core flake section is a very thin three-layered structure that exhibits a uniaxial compressive strength much greater than a corresponding uniaxial tensile strength. This structure provides the benefits of rigidity and brittle fracture during manufacturing and application processes, which ultimately provides favorable planar and specular reflectance characteristics for the pigment in the visible wavelength range. A variety of outer coating layers can be formed around the core flake sections, such as various dielectric and absorber layers having thicknesses dependent upon the desired optical characteristics of the pigment.

Owner:JDS UNIPHASE CORP

Bright metal flake

InactiveUS6013370AGood specular reflectance characteristicHigh aspect ratioPigmenting treatmentRecord information storageSilicon dioxideReflectivity

A rigid and brittle bright metal flake is formed of a central layer of a reflective material supported on both sides by dielectric layers. In a preferred embodiment, the metal layer is aluminum having a thickness of about 100 nm and the dielectrics are either silicon dioxide or magnesium fluoride, each having a thickness of about 100 nm. The result is a very thin three-layered metal flake about 300 nm thick that exhibits a uniaxial compressive strength of about 8 times a corresponding uniaxial tensile strength. As a result, the metal flake is then afforded the benefits of rigidity and brittle fracture during the manufacturing and applicational processes which ultimately provides favorable planar and specular reflectance characteristics in the visible wavelength range.

Owner:JDS UNIPHASE CORP

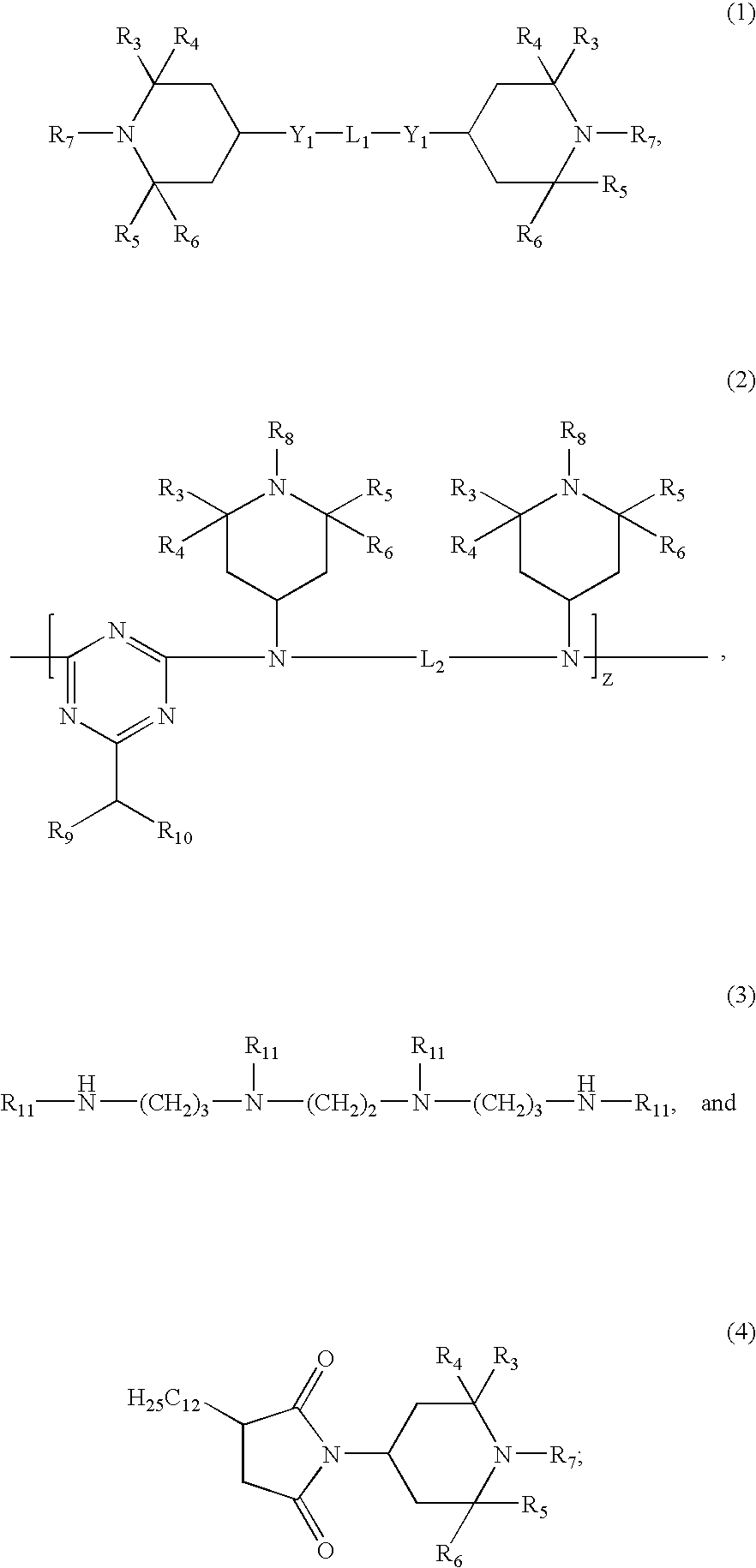

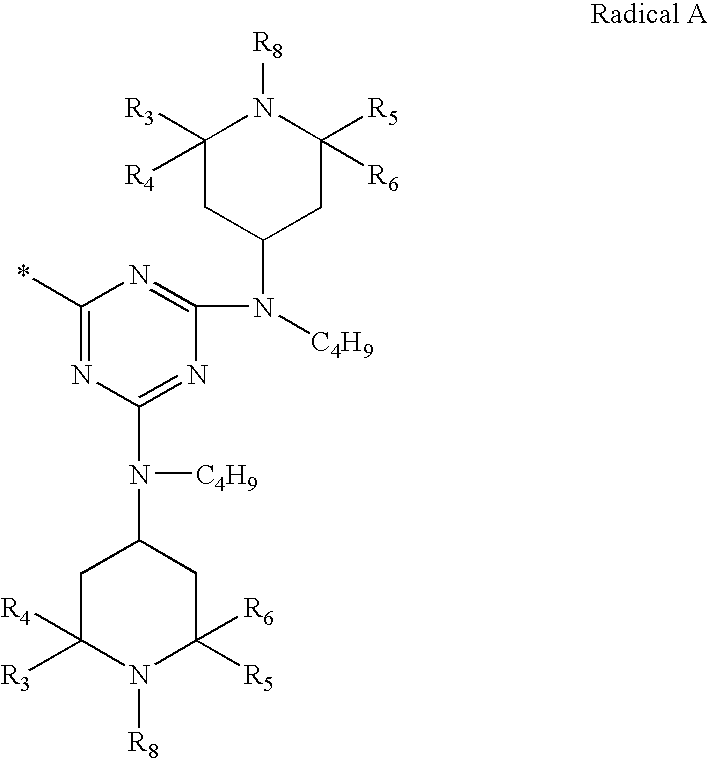

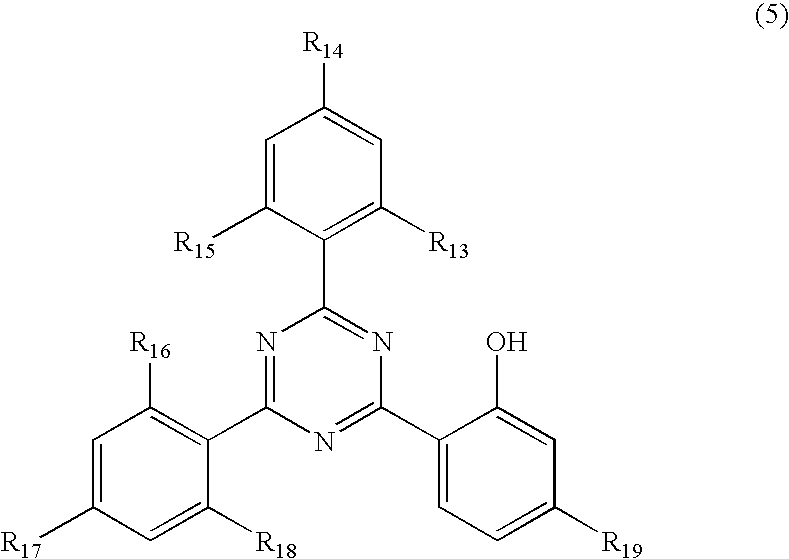

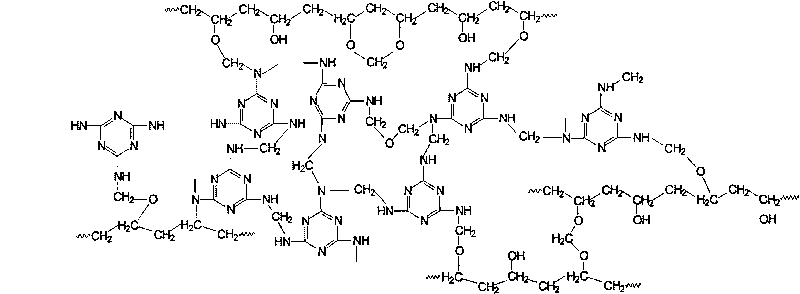

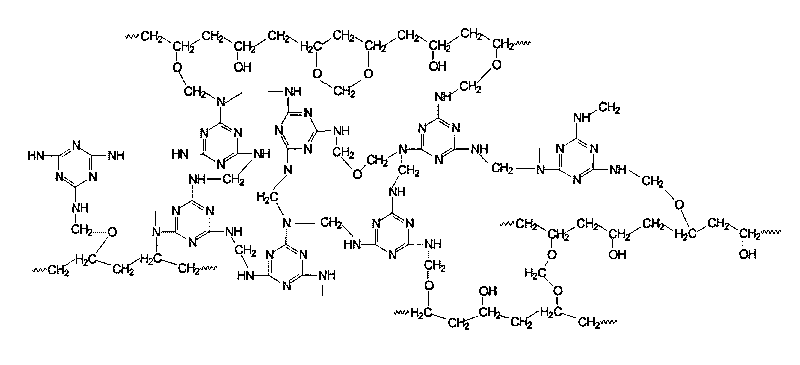

Stabilized aliphatic polyester compositions

Disclosed are stabilized aliphatic polyester compositions comprising an aliphatic polyester, a HALS, and a tris-aryl-S-triazine UV absorber that show low embrittlement, haze formation, and discoloration during weathering. Also disclosed are aliphatic polyester compositions comprising aliphatic polyester, a hindered amine light stabilizer, a triazine UV absorber, and a phosphite that exhibit low color prior to weathering but retain good clarity, color, and excellent impact strength after exposure to weathering conditions. The aliphatic polyester compositions may be used prepare shaped articles such as, for example, films, sheets, bottles, tubes, profiles, fibers, and molded articles.

Owner:EASTMAN CHEM CO

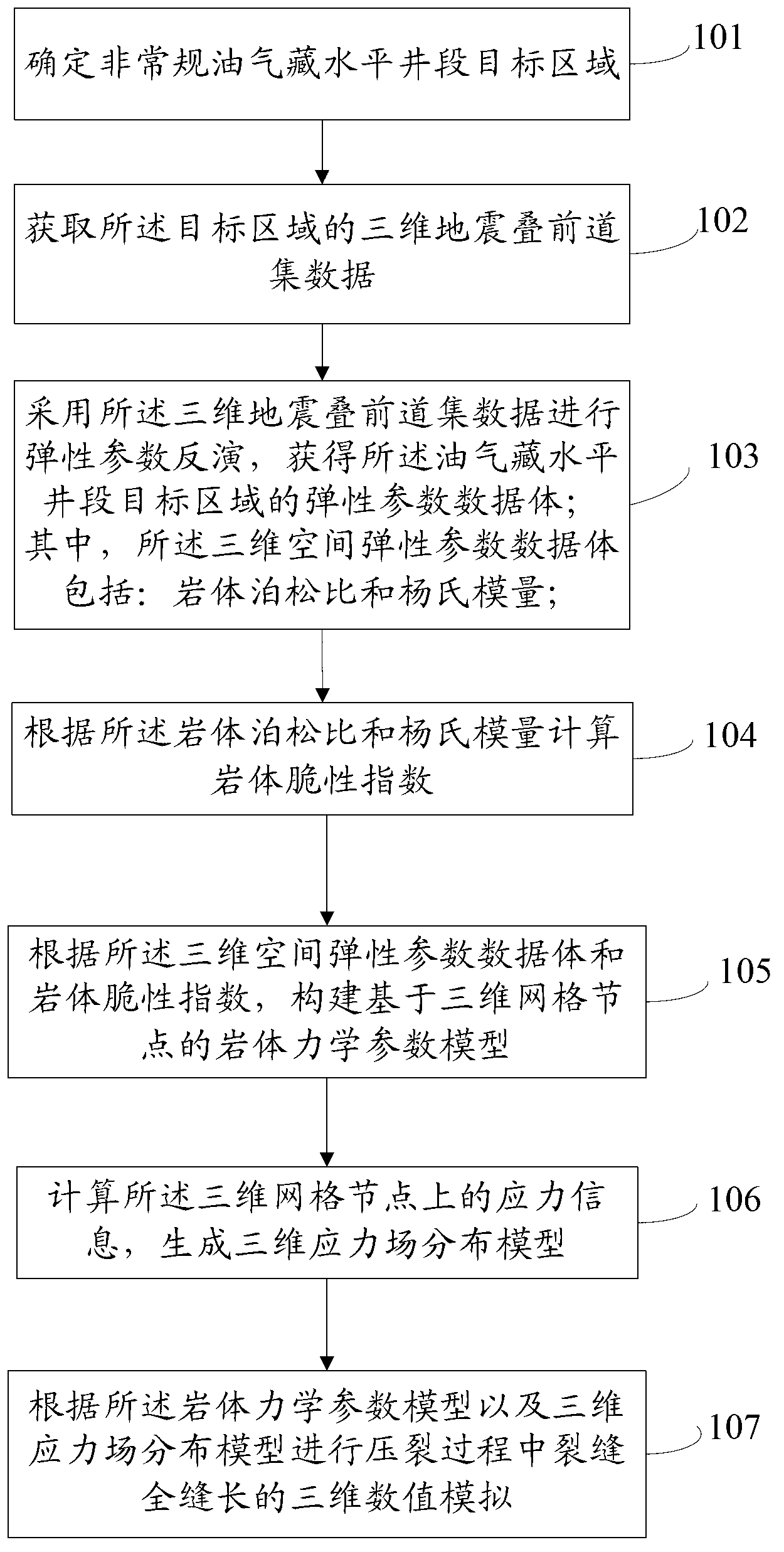

Unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device

InactiveCN103256046ASolve the problem that interwell information cannot be obtainedEasy accessBorehole/well accessoriesThree-dimensional spaceYoung's modulus

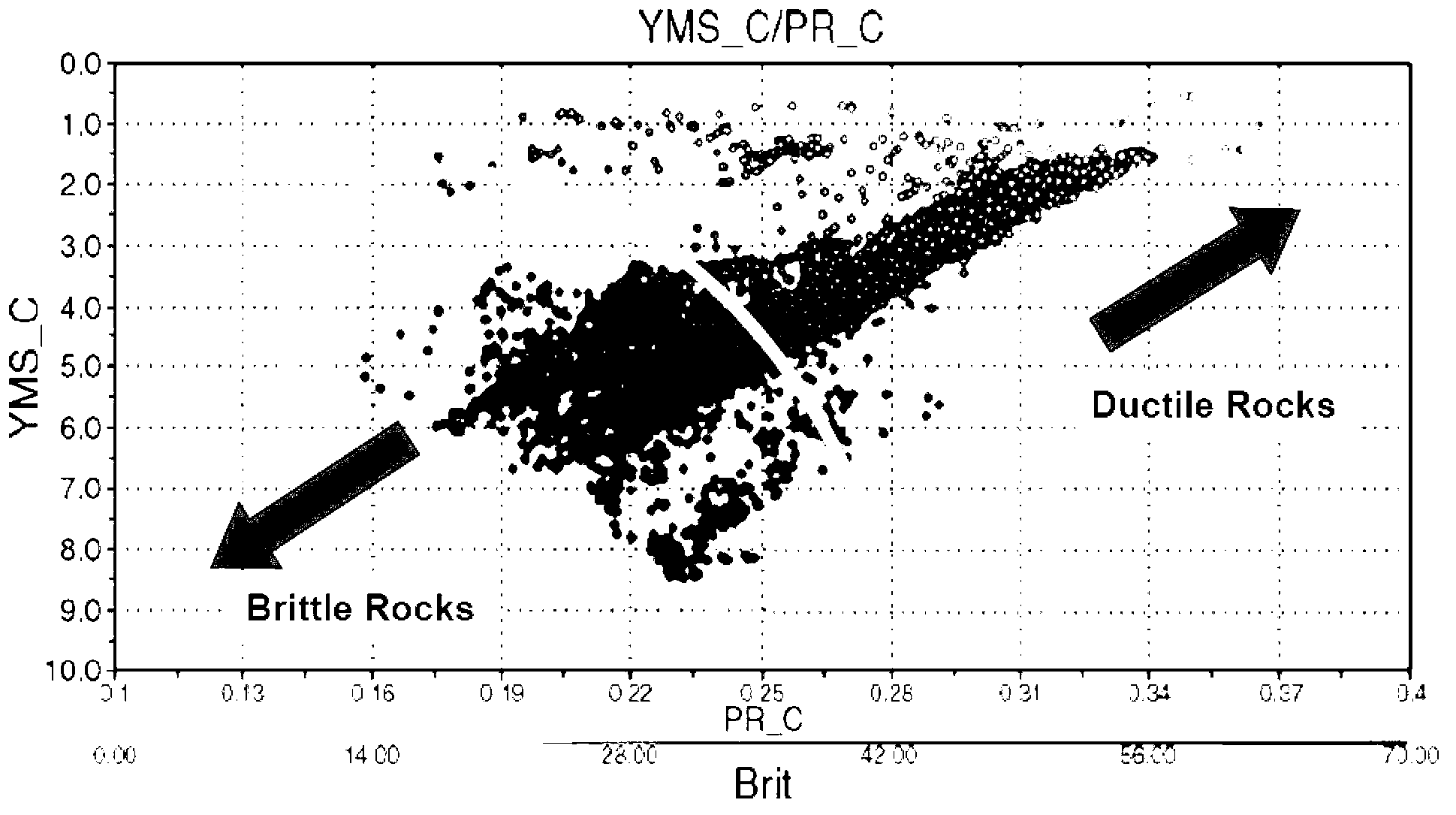

The invention provides an unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device. The method includes the steps of determining an unconventional oil and gas reservoir horizontal well section object region; obtaining three-dimensional earthquake prestack gathered data in the object region, conducting elastic parametric inversion and obtaining a three-dimensional space elastic parameter data body, wherein the three-dimensional space elastic parameter data body comprises a rock mass poisson ratio and Young modulus; calculating a rock mass brittleness index according to the rock mass poisson ratio and the Young modulus; establishing a rock mass mechanical parameter model based on three-dimensional grid nodes according to the three-dimensional space elastic parameter data body and the rock mass brittleness index; calculating stress information on the three-dimensional grid nodes, and generating a three-dimensional stress field distribution model; conducting full- fracture-length three-dimensional numerical simulation of fractures in the fracturing process according to the rock mass mechanical parameter model and the three-dimensional stress field distribution model. The unconventional oil and gas reservoir horizontal well section full-length-fracture fracturing parameter analog method and device can improve effectiveness and accuracy of unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog, and improve the reserve utilization degree of a reservoir stratum.

Owner:PEKING UNIV

Method of closed form release for brittle materials using burst ultrafast laser pulses

ActiveUS20150136743A1Low failure rateLow cost of executionGlass severing apparatusWelding/soldering/cutting articlesEngineeringLaser

A method for machining and releasing closed forms from a transparent, brittle substrate includes using a burst of ultrafast laser pulses to drill patterns of orifices in the substrate. Orifices are formed by photoacoustic compression and they extend completely or partially in the transparent substrate. A scribed line of spaced apart orifices in the transparent substrate comprise a closed form pattern in the substrate. A heat source is applied in a region about said scribed line of spaced apart orifices until the closed form pattern releases from the transparent substrate.

Owner:ROFIN SINAR TECH

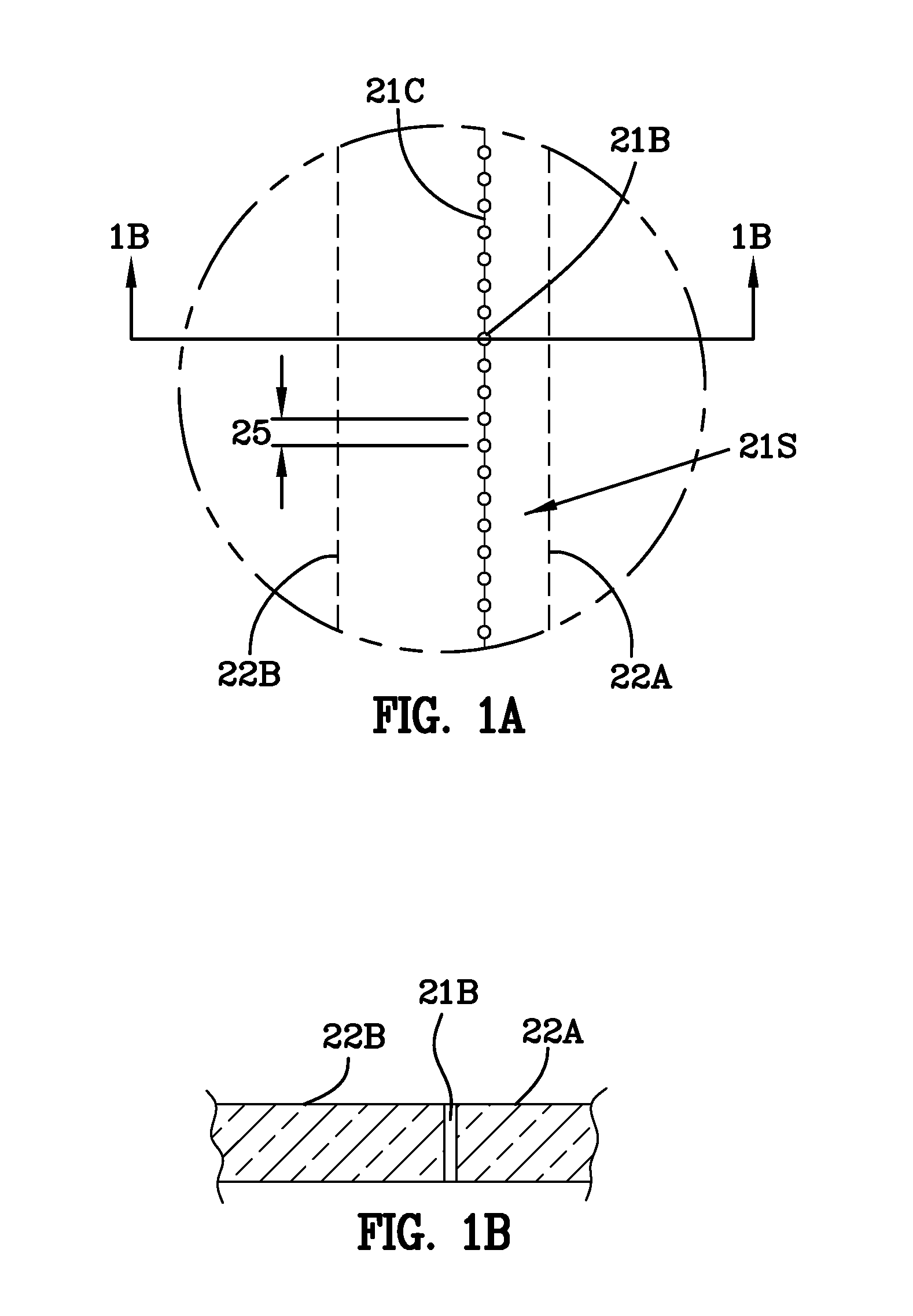

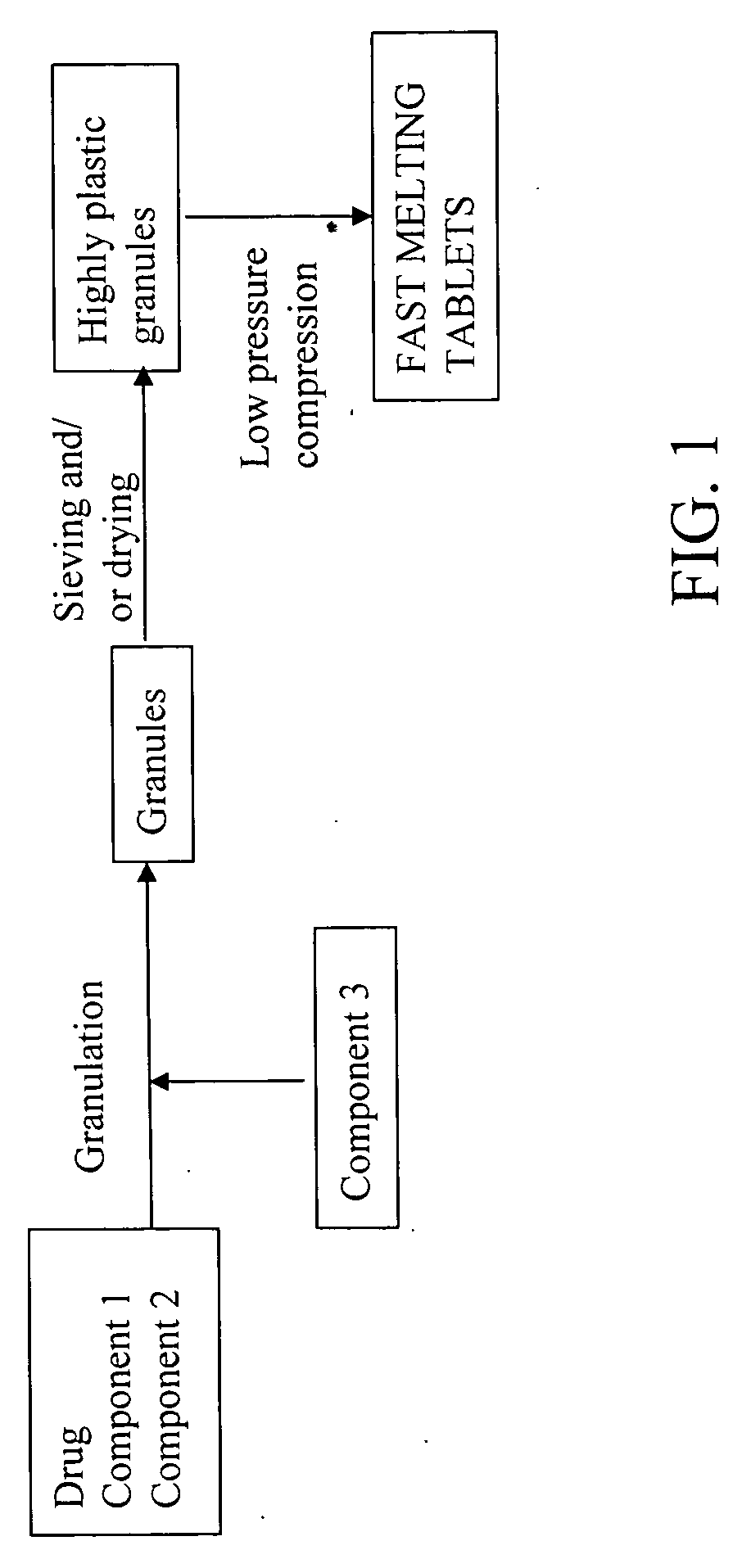

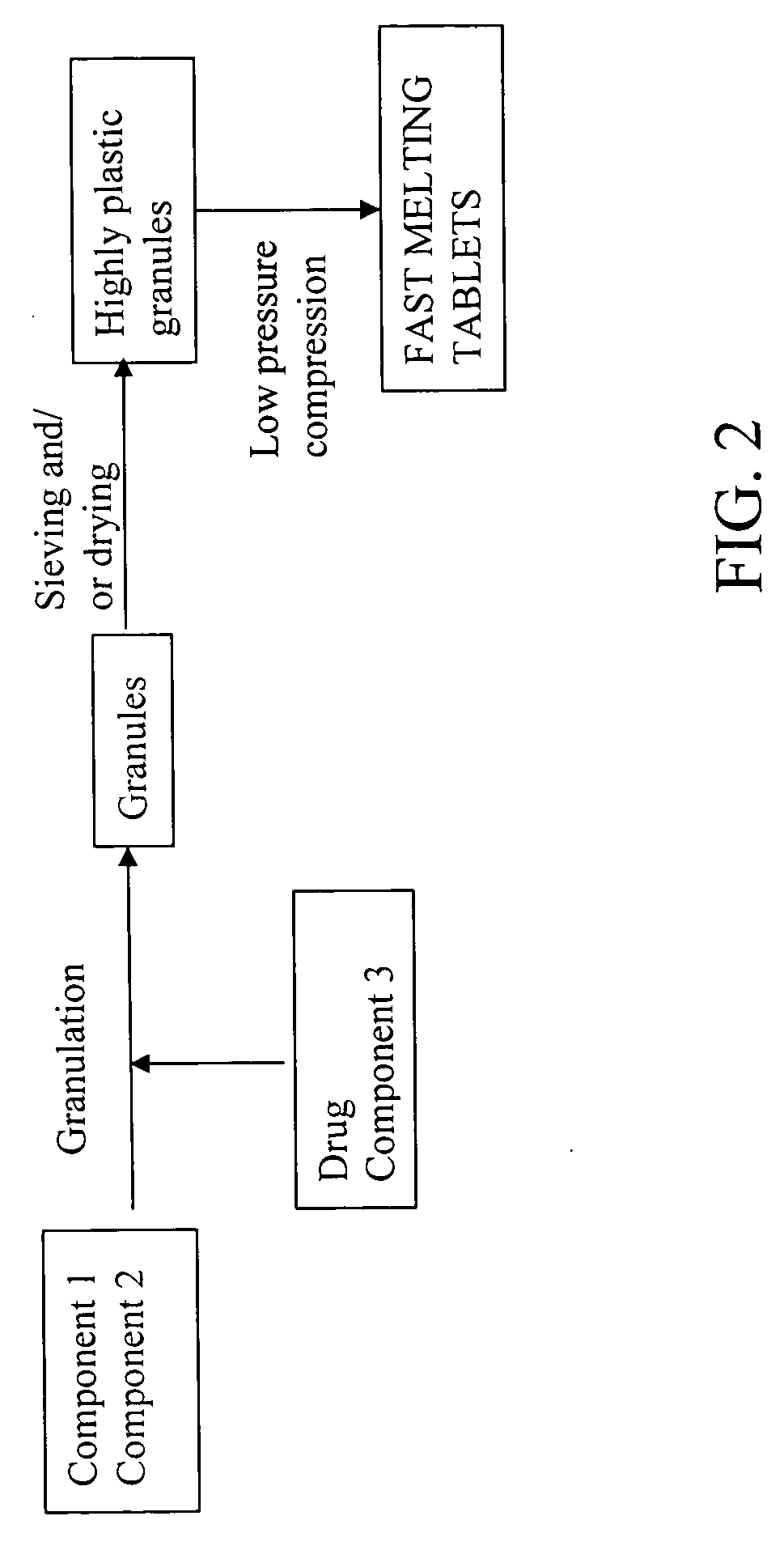

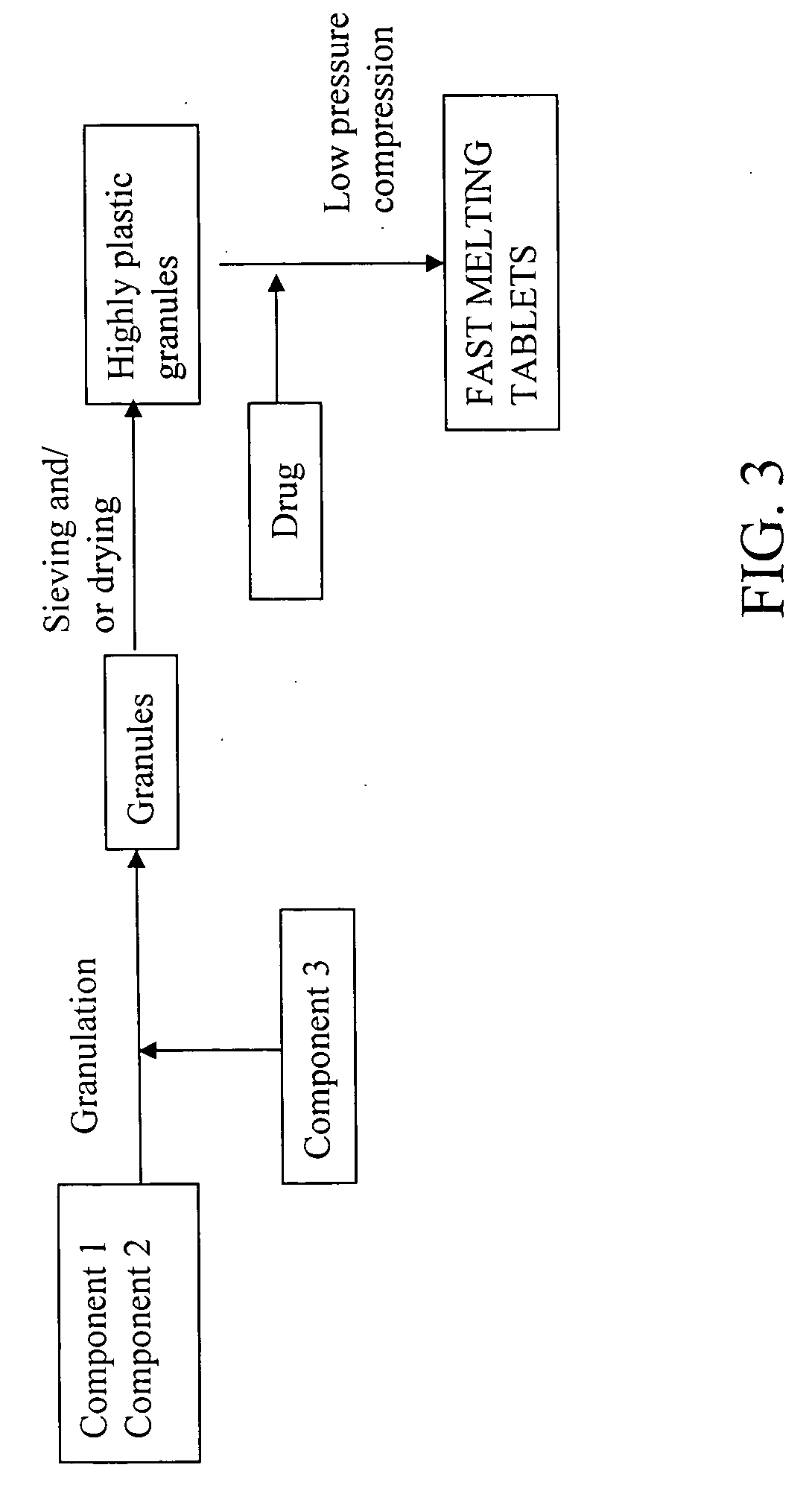

Highly plastic granules for making fast melting tablets

InactiveUS20050013857A1Increases tablet strengthIncrease tablet strengthPowder deliveryPill deliveryPlastic materialsHardness

A fast-melting pharmaceutical tablet comprises a porous, plastic substance, a water penetration enhancer and a binder. One or more drugs can be incorporated into the formulation at different stages of the process so as to afford a pharmaceutically active tablet. Methods of making the pharmaceutical tablet entail combining the porous, plastic material, the water penetration enhancing agent, and the binder so as to form highly plastic granules, which are compressed into tablets. The resulting tablets dissolve rapidly in the mouth and have good hardness with low brittleness. The tablets are particularly valuable to those who have difficulty swallowing conventional pills.

Owner:AKINA INC

Nicotine containing stimulant unit

InactiveUS6110495AIncrease stimulationLarge deformationTobacco treatmentConfectioneryStimulantAdditive ingredient

A saliva-soluble stimulant unit comprising an active ingredient and optional ingredients comprising flavor and aroma additives incorporated in a gel prepared by gelling a water-binding gelling agent, in which the active ingredient comprises nicotine or other alkaloids with the same direction of activity, said unit having i) a texture profile, determined by texture profile analysis, with parameter values of firmness, hardness, brittleness, adhesiveness, elasticity, and cohesiveness within given ranges; (ii) a disintegration time within the range 5-60 minutes; and (iii) a nicotine content from 0.5 to 10 mg or a corresponding content of said alkaloids.

Owner:DAM ANDERS

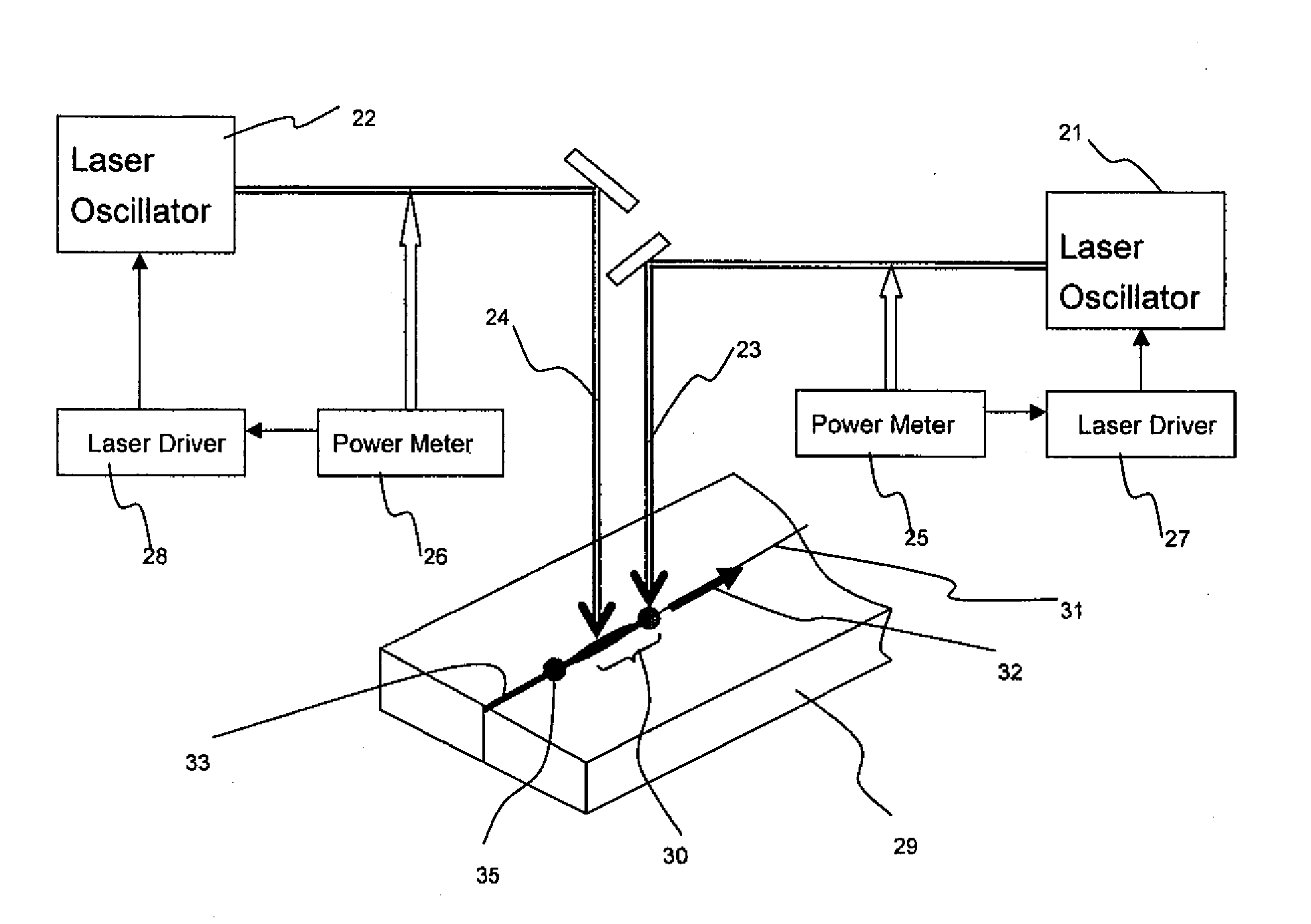

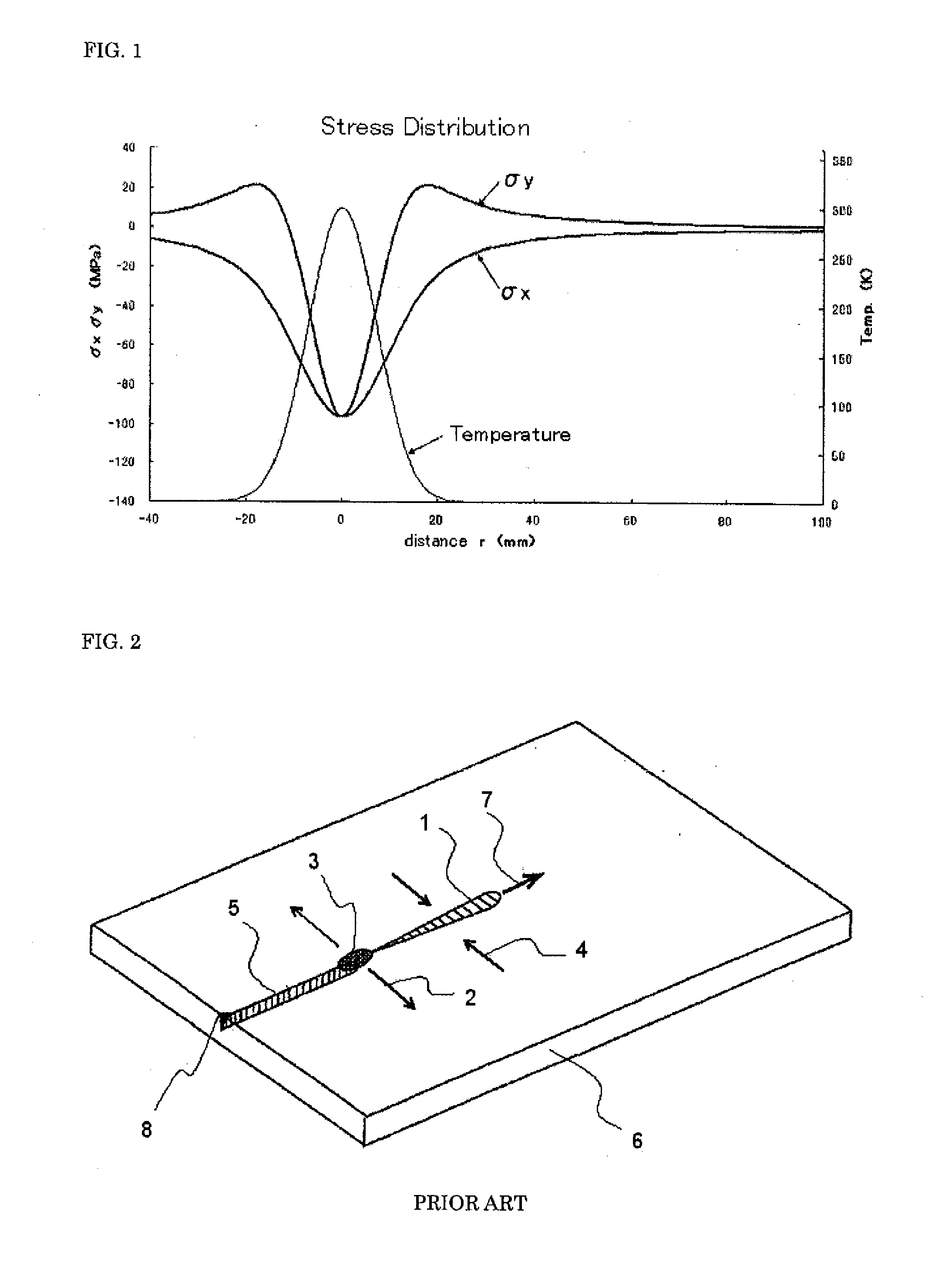

High speed laser scribing method of fragile material

InactiveUS20100089882A1Accelerate thermal stress scribingAvoid disadvantagesFine working devicesGlass severing apparatusLight beamOptoelectronics

In a method for scribing fragile material, a laser beam is irradiated onto a work plate of the fragile material. The work plate is heated by absorption of the irradiated laser beam and generating thermal stress by the heating. The laser beam is formed by a plurality of laser beam groups arranged along a beam scanning direction on a same line, and the plurality of laser beam groups are divided into two groups. One takes charge of initial heating and rising up temperature of the work plate, and another takes charge of temperature holding of the work plate. The laser beam intensity corresponding to each of the laser beam groups is adjusted so as to obtain optimum values.By the method, it is possible to remarkably increase scribing speed of the work plate of the fragile materials without increasing heating temperature.

Owner:GLOBALY TECH CO LTD

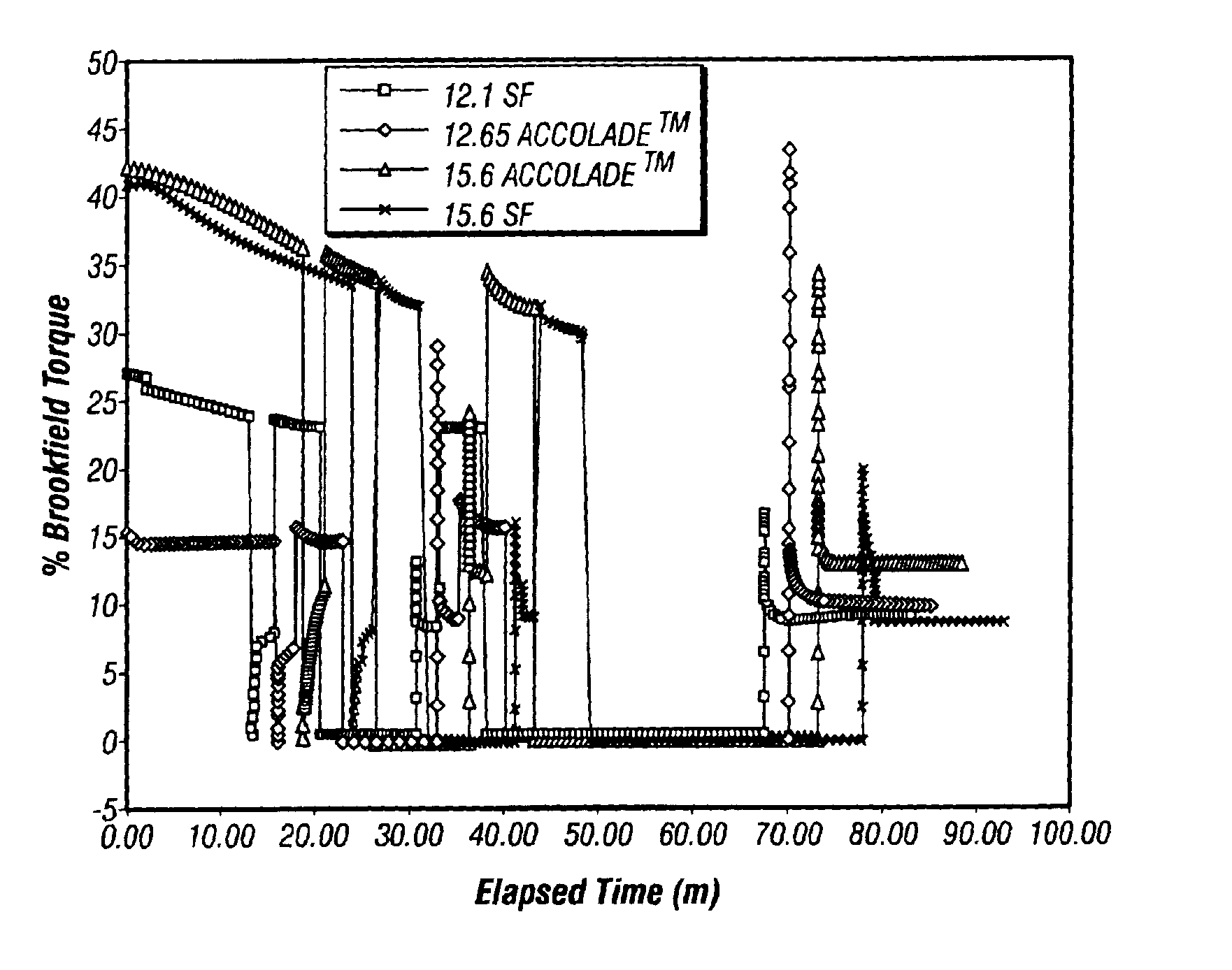

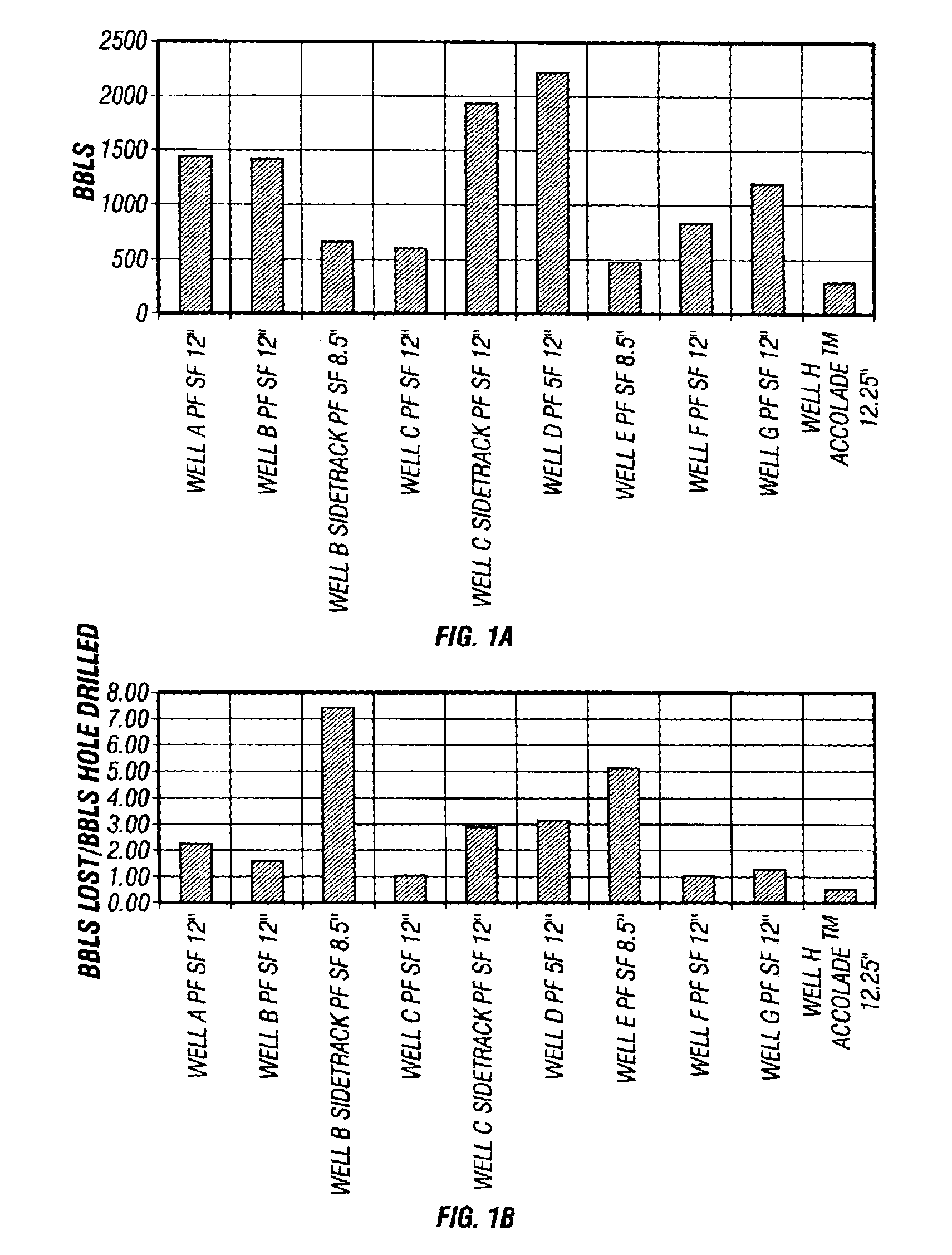

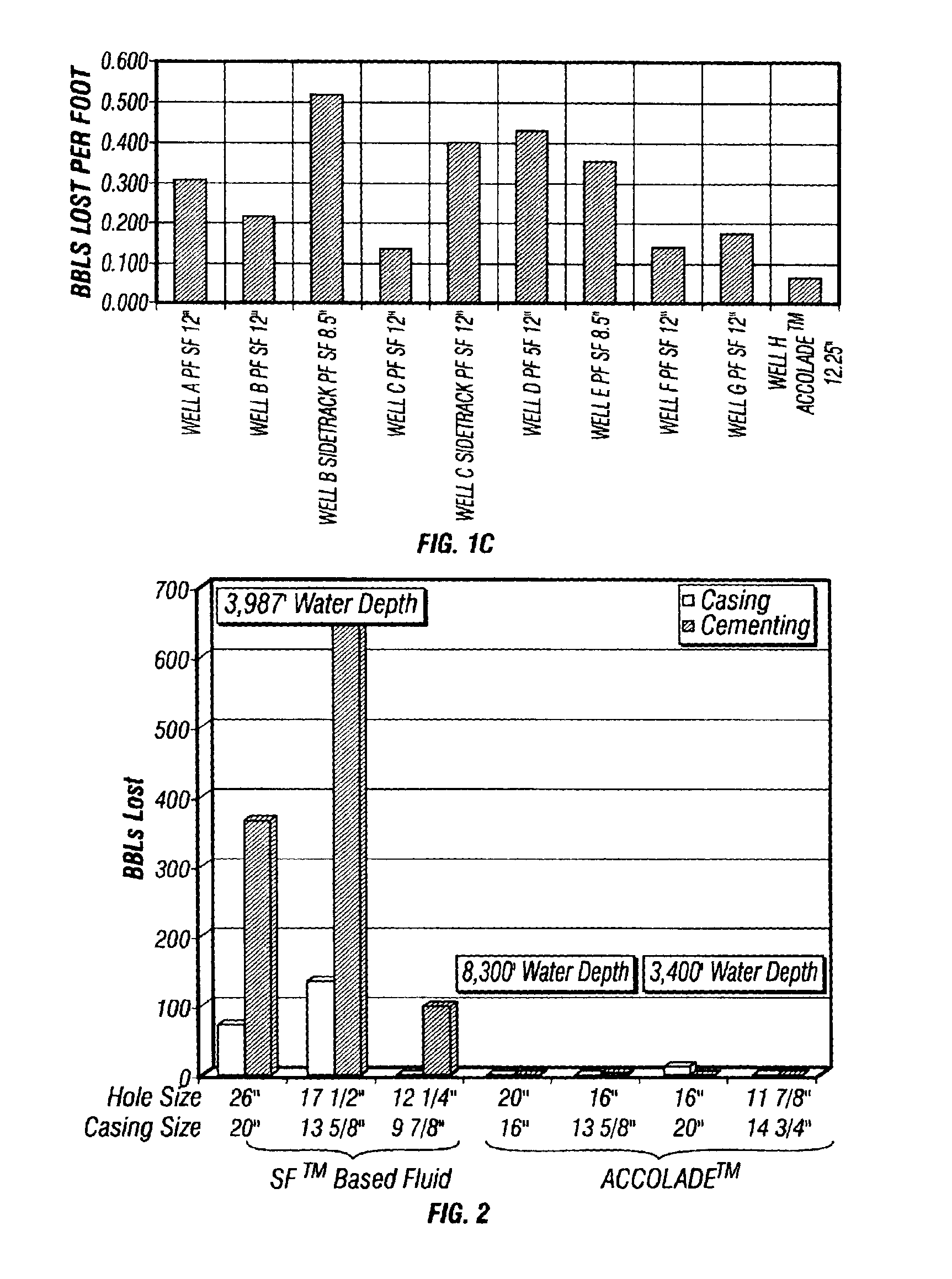

Method of formulating and using a drilling mud with fragile gels

A method for drilling, running casing in, and / or cementing a borehole in a subterranean formation without significant loss of drilling fluid is disclosed, as well as compositions for use in such method. The method employs a drilling fluid comprising a fragile gel or having fragile gel behavior and providing superior oil mud rheology and overall performance. The fluid is especially advantageous for use in deep water wells because the fluid exhibits minimal difference between downhole equivalent circulating density and surface density notwithstanding differences in drilling or penetration rates. When an ester and isomerized olefin blend is used for the base of the fluid, the fluid makes an environmentally acceptable and regulatory compliant invert emulsion drilling fluid. The fluid preferably contains no organophilic clays.

Owner:HALLIBURTON ENERGY SERVICES INC

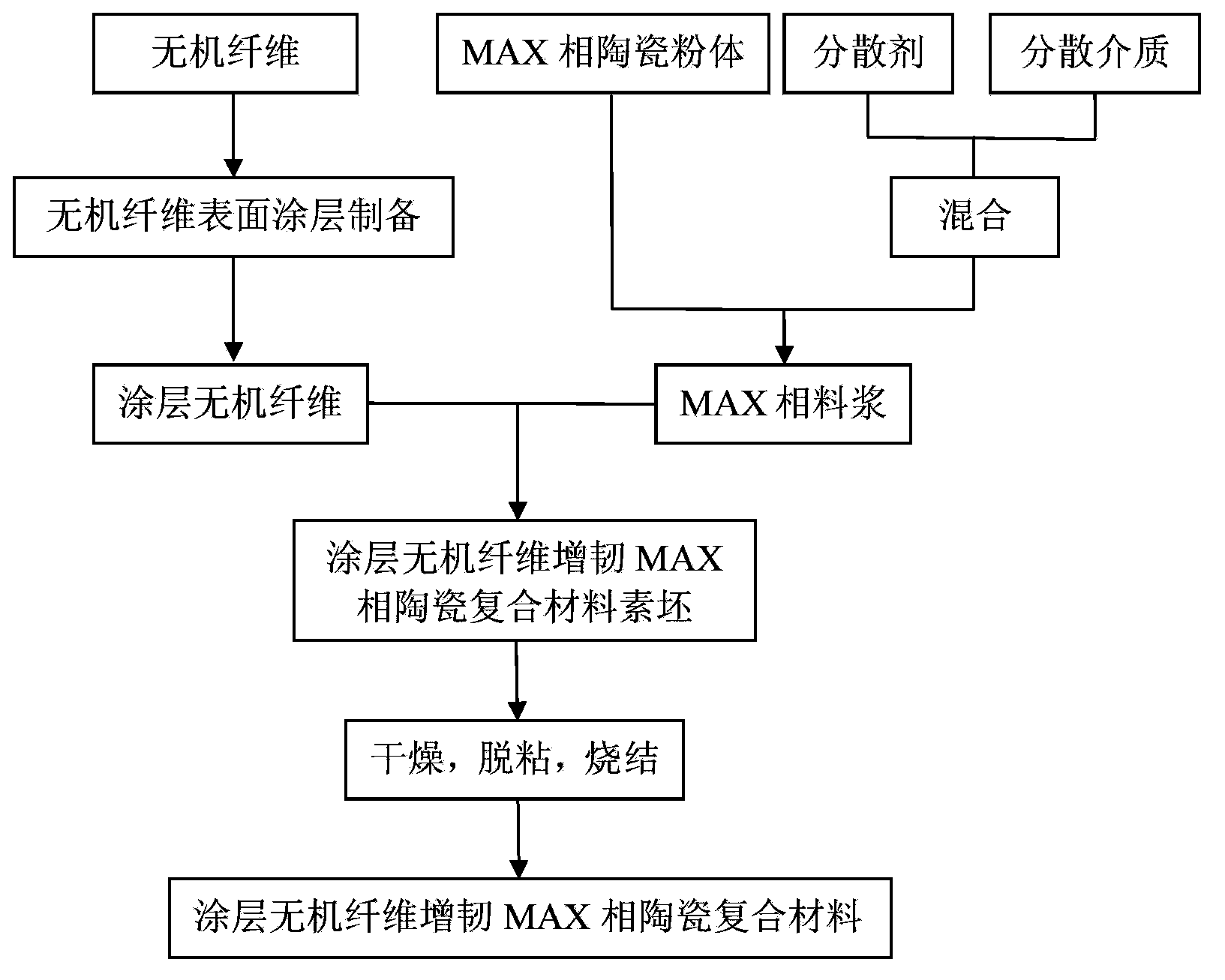

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Methods to form SiCOH or SiCNH dielectrics and structures including the same

InactiveUS20080009141A1Low costSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectronic structure

Methods of forming dielectric films comprising Si, C, O and H atoms (SiCOH) or Si, C, N and H atoms (SiCHN) that have improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties are provided. Electronic structures including the above materials are also included herein.

Owner:GLOBALFOUNDRIES INC

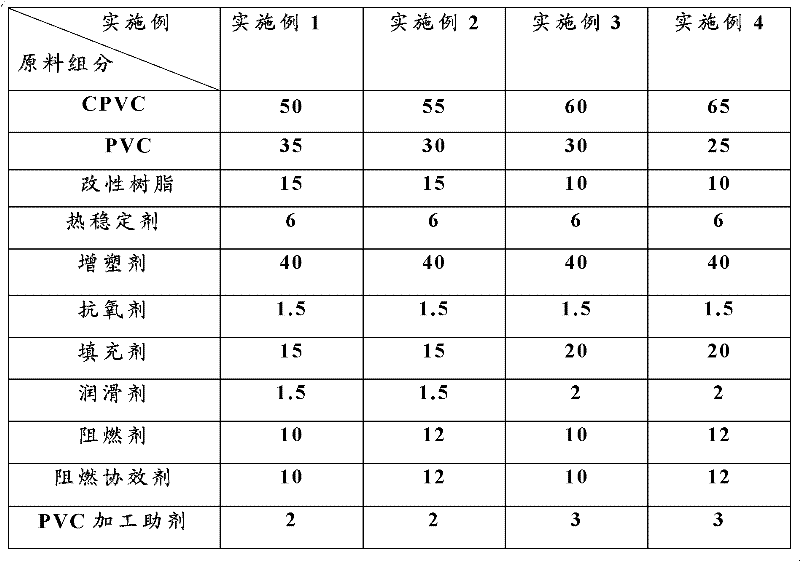

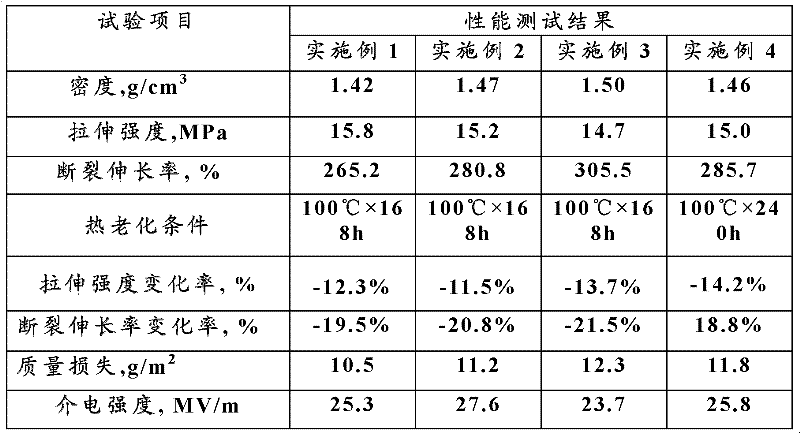

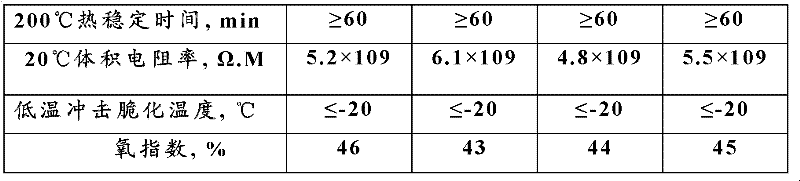

Chlorinated polrvinyl chloride modified material as well as preparation method and application thereof

ActiveCN102532763AGood physical and mechanical propertiesImprove brittlenessInsulated cablesInsulated conductorsAntioxidantShock resistance

The invention relates to a chlorinated polrvinyl chloride modified material as well as a preparation method and application thereof. The raw material formula of the chlorinated polrvinyl chloride modified material comprises the following components in parts by weight: 40-90 parts of chlorinated polrvinyl chloride, 20-70 parts of polrvinyl chloride, 5-30 parts of modified resin, 1.5-10 parts of heat stabilizing agent, 20-60 parts of plasticizer, 1-10 parts of antioxidant, 1-10 parts of lubricating agent, 5-40 parts of filling agent, 8-40 parts of fire retardant, 8-40 parts of flame retardant synergist and 1-20 parts of polrvinyl chloride processing aid. Compared with the known CPVC (chlorinated polrvinyl chloride) modified plastic, the CPVC modified plastic disclosed by the invention is more excellent in physical and mechanical properties and is relatively reduced in cost; and compared with the known CPVC modified plastic, the CPVC modified material disclosed by the invention is obviously improved in heat resistance and flame retardant property (oxygen index can reach about 45%, and simple root of CPVC modified material can be vertically burnt) besides more excellent processabilityand obviously improved material brittleness and shock resistance. Thus, the CPVC modified material disclosed by the invention is suitable for being used as a wire and cable sheath material.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

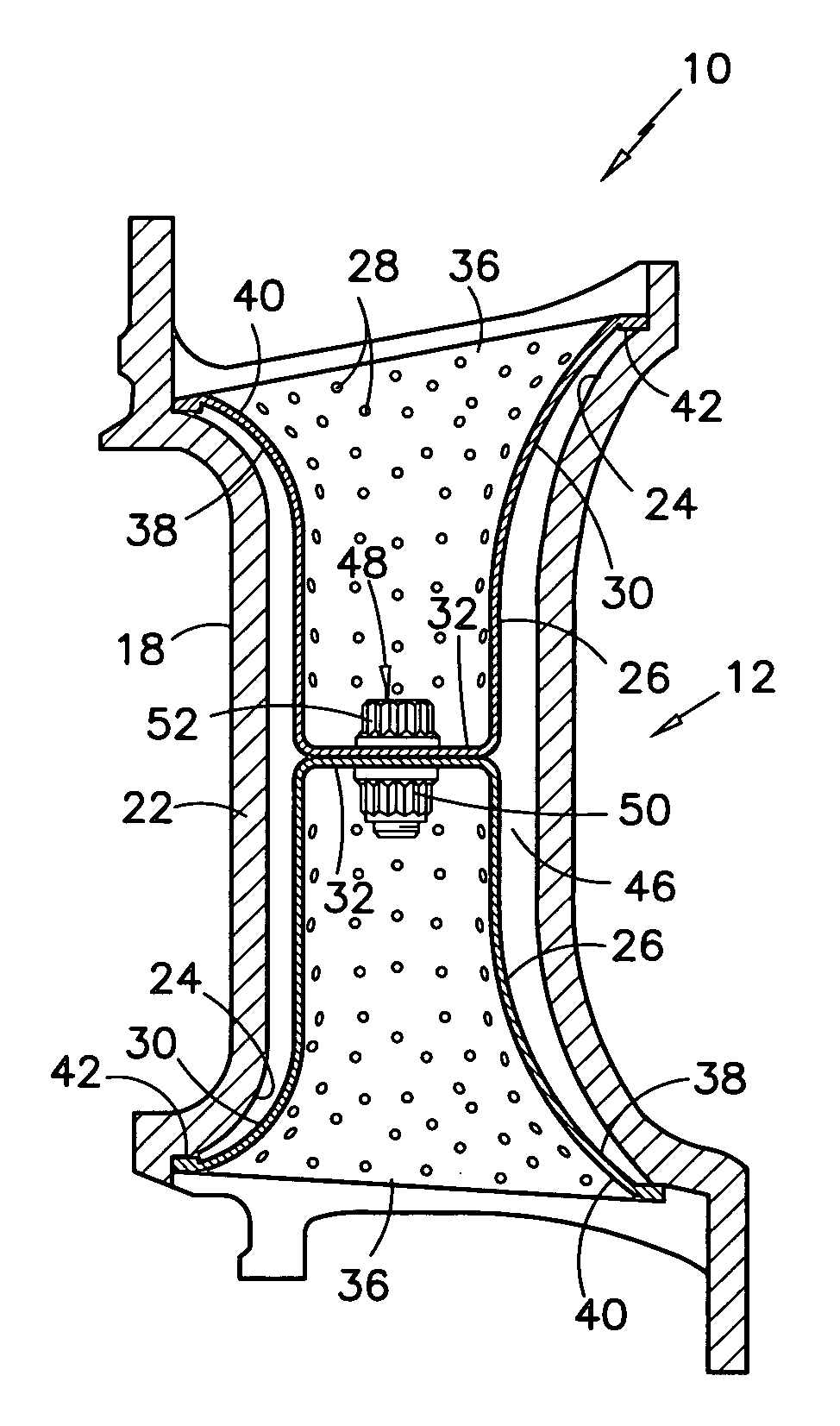

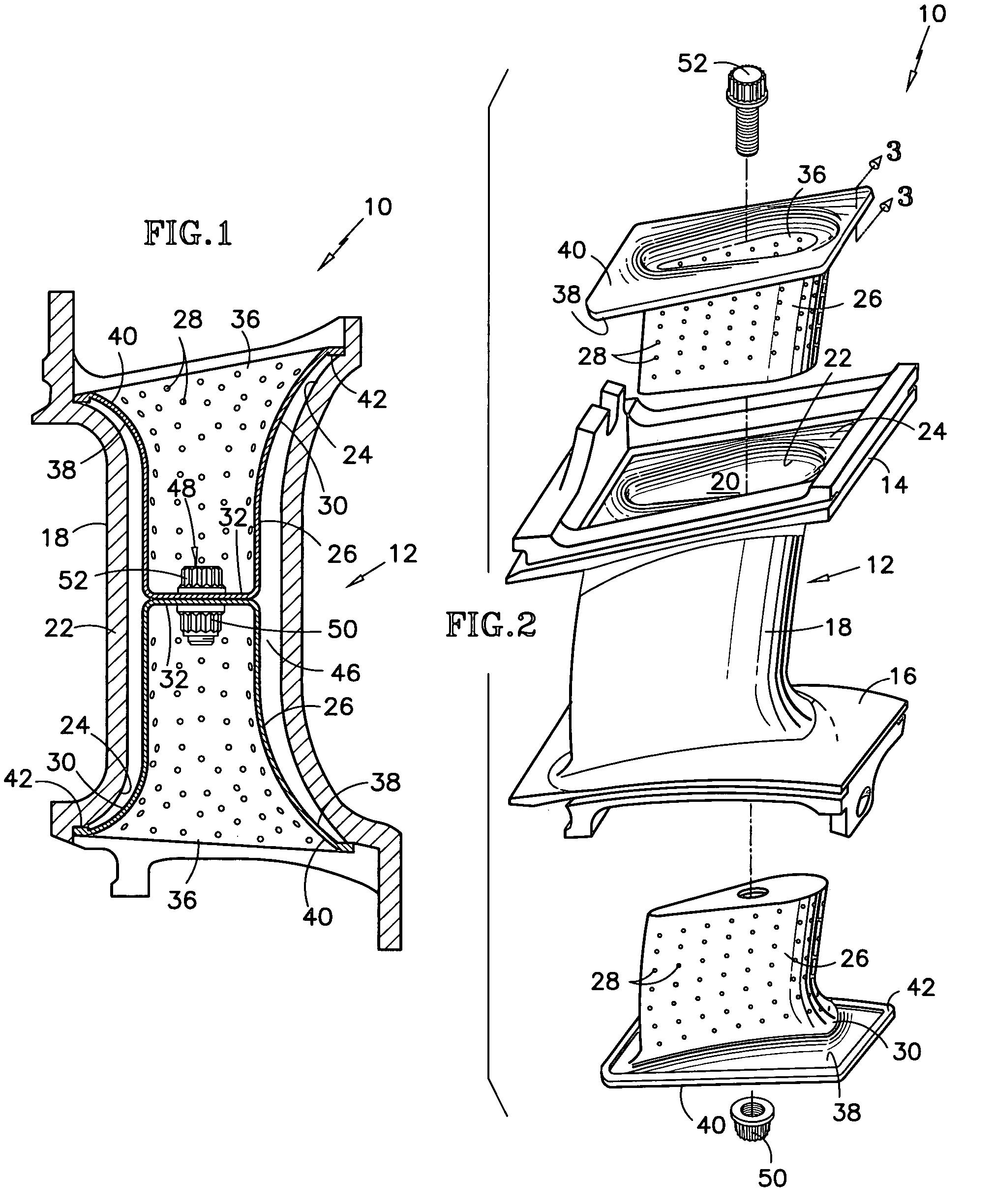

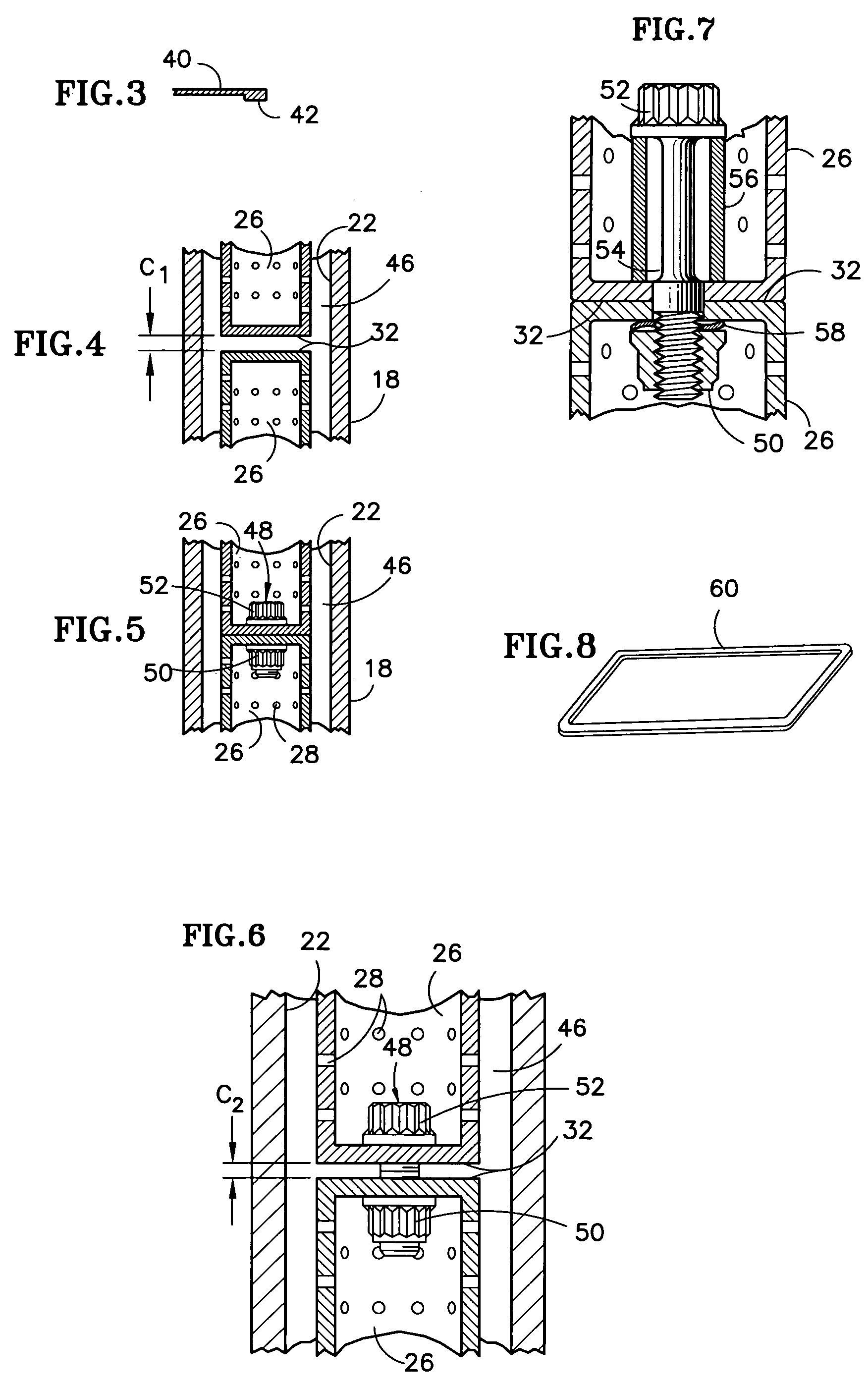

Temperature tolerant vane assembly

A vane assembly 10 suitable for a turbine engine features a refractory vane 12 with an internal cavity 20 and a pair of flexible metallic baffles 26 extending into the cavity from spanwisely opposite ends of the vane. A rigid fastener 48, such as a nut and bolt assembly applies a tensile load to the baffles. The tensile load is reacted out as a compressive load applied to the vane. In another embodiment, the baffle is relatively rigid but the fastener is flexible. The compressive loading exerted on the vane counteracts the brittleness customarily exhibited by refractory materials and imparts damage tolerance to the vane. The arrangement also allows the use of a metal baffle that can be easily secured to the vane and dispenses with any need for a potentially troublesome seal between the baffles and the spanwise extremities of the vane.

Owner:RTX CORP

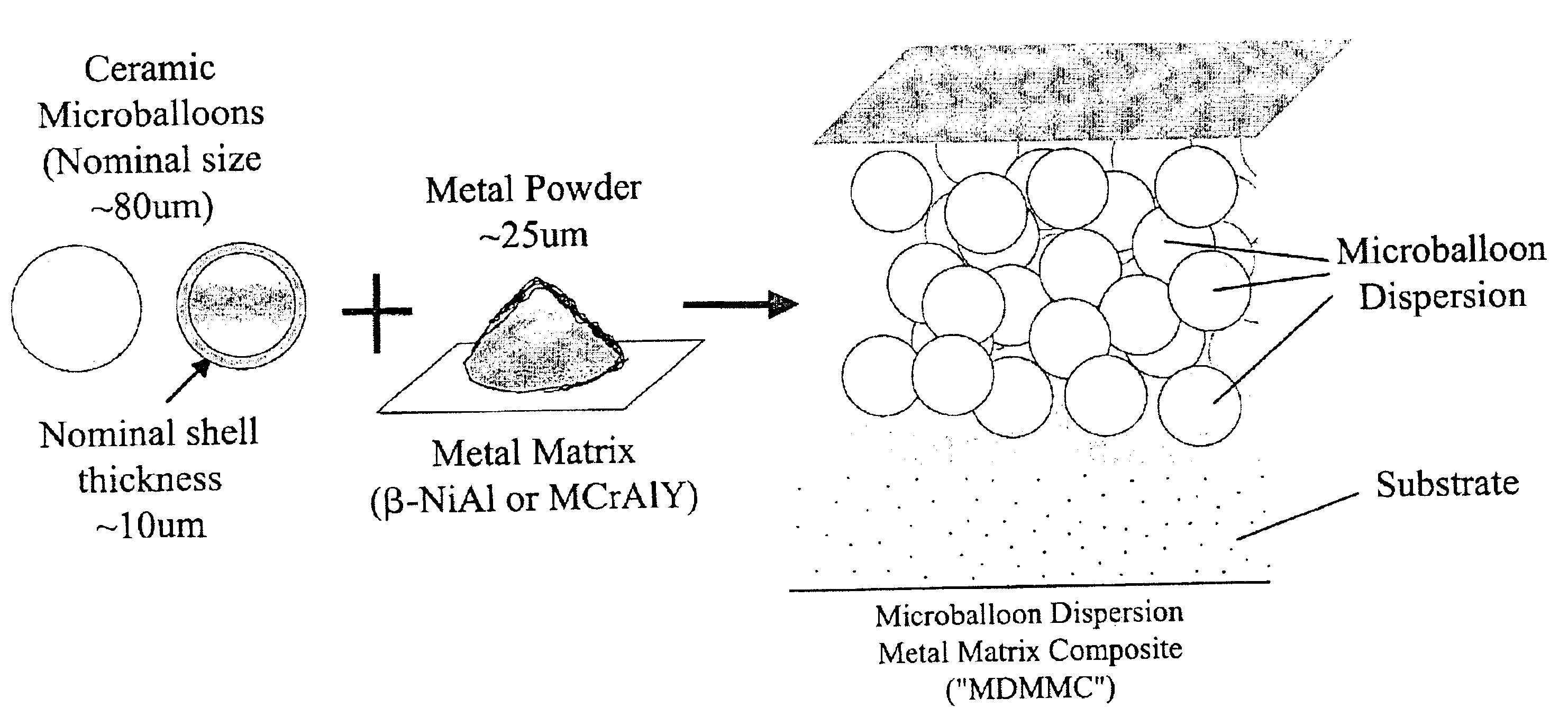

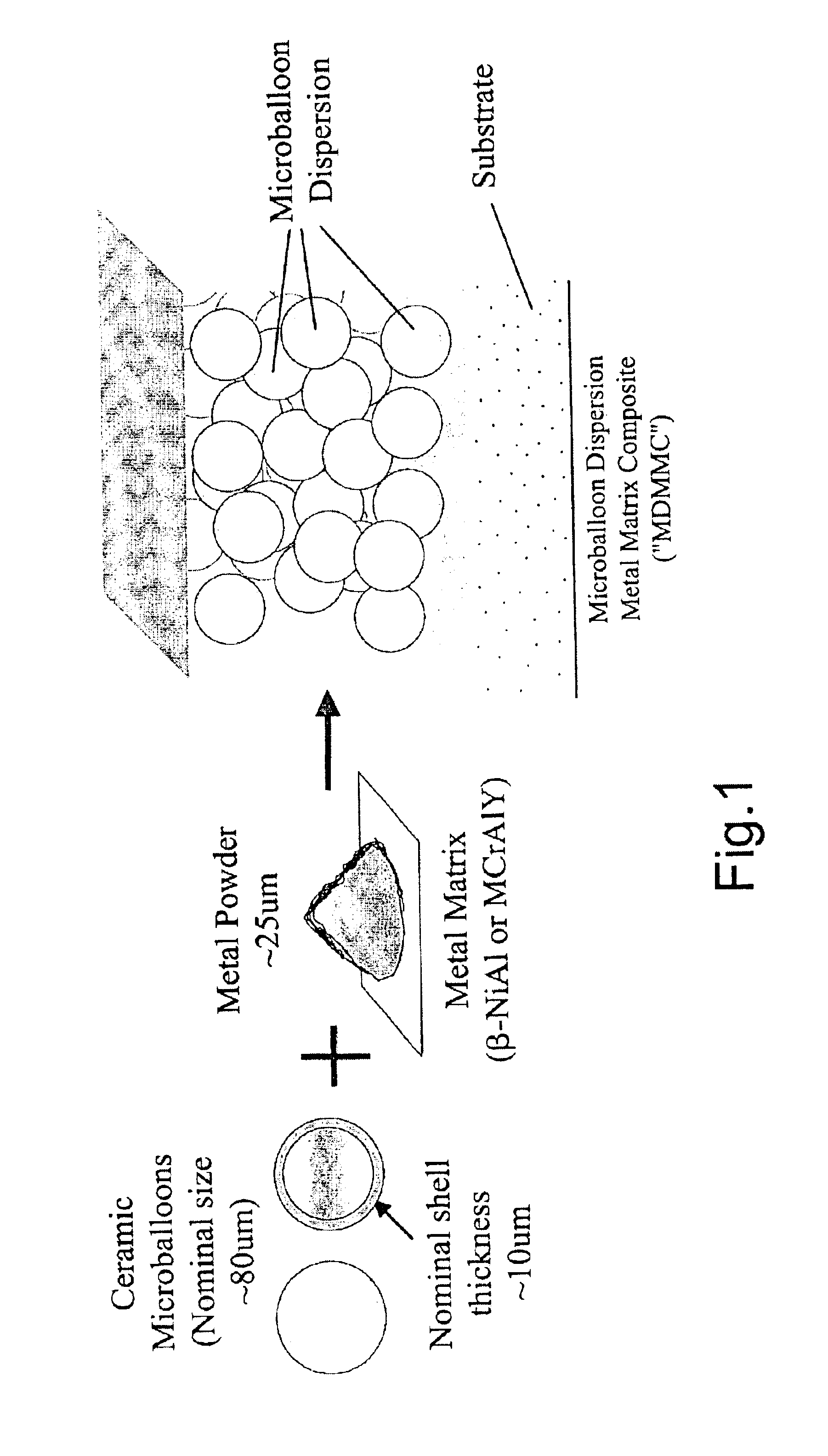

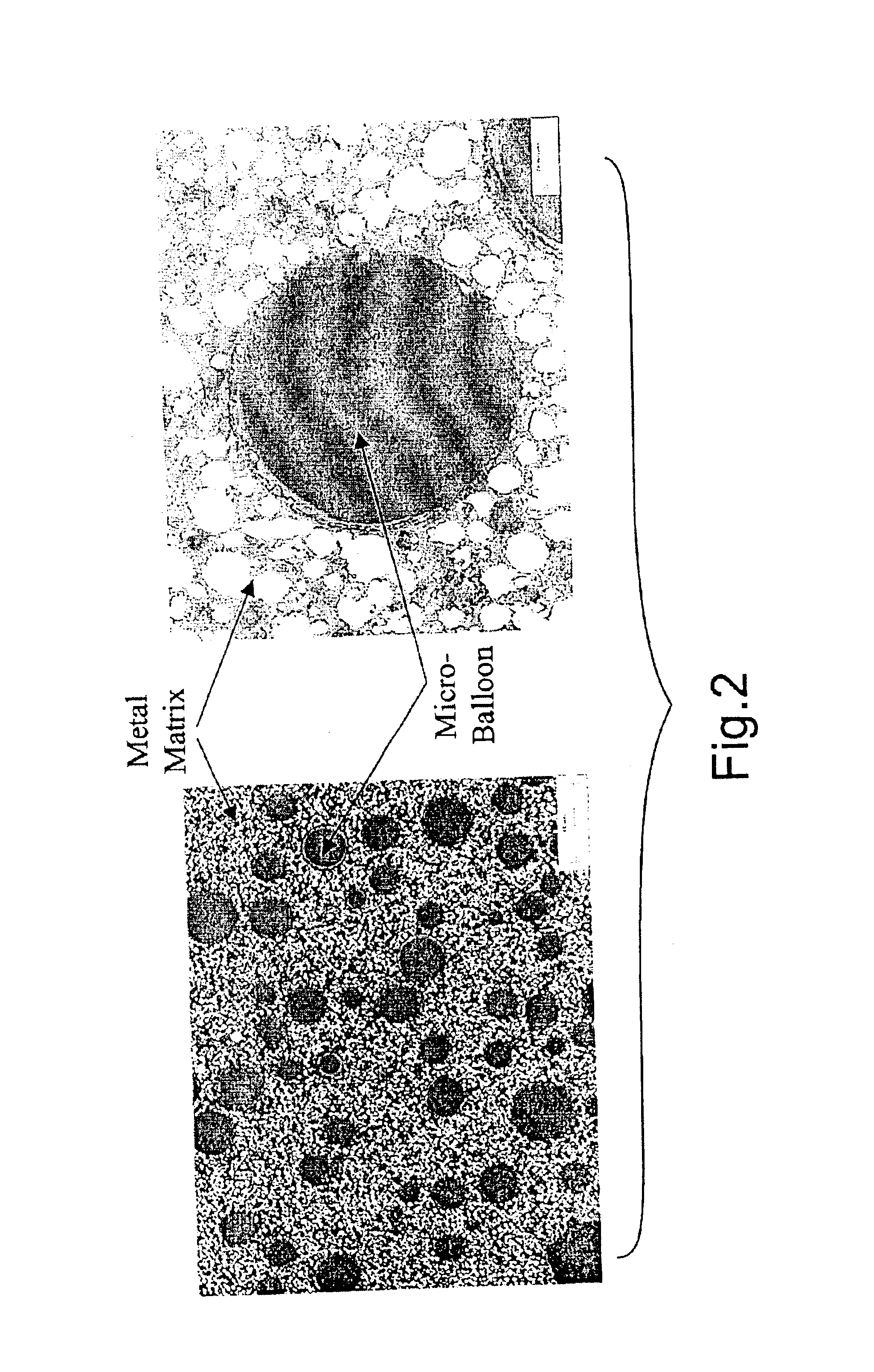

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

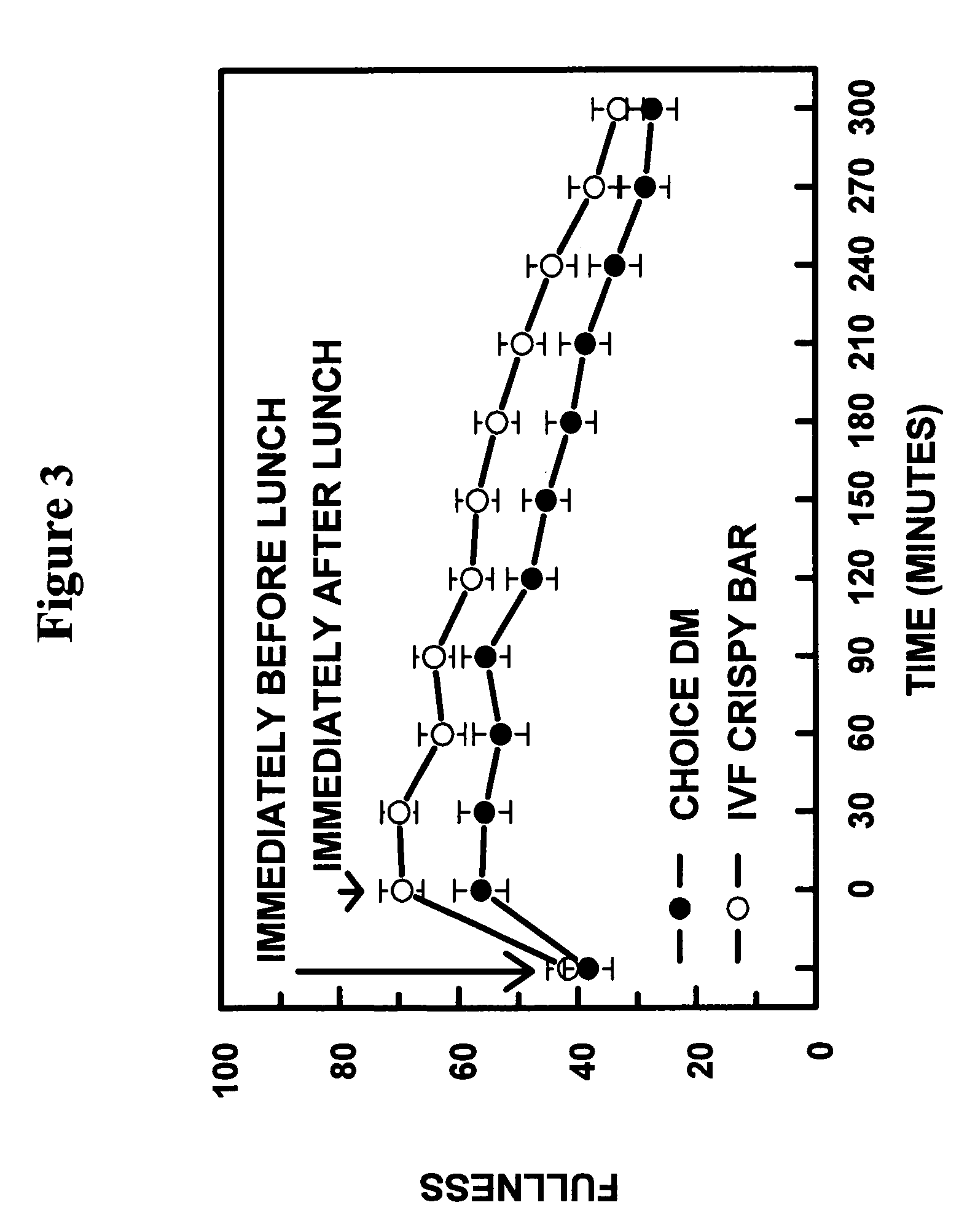

Nutritional compostions comprising a soluble viscous fiber in a solid crisp matrix

InactiveUS20060078593A1Great tasteReduced slimy feelingBiocidePharmaceutical non-active ingredientsVolumetric Mass DensityGuar gum

Disclosed are nutritional compositions having a solid crisp matrix, or a flour derived from the solid crisp matrix, said matrix comprising (A) from about 10% to about 50% by weight of a soluble viscous fiber, preferably guar; (B) from about 10% to about 99% by weight of a carbohydrate other than and in addition to the soluble viscous fiber; and (C) from about 1% to about 49% by weight of protein, wherein the matrix has a bulk density of less than about 0.4 g / cc. It has been found that soluble viscous fiber sources such as guar gum can be formulated into a solid crisp matrix, which then minimizes several limitations commonly associated with the formulation of such fiber sources into a conventional nutrition bar, e.g. slimy mouthfeel, tooth packing. These compositions are especially effective when formulated with gelled inclusions, including those containing or associated with acidulants, sour flavorants, or both. The nutritional compositions are especially useful as satiety agents, weight reduction agents, and / or for blunting the postprandial glycemic response in diabetics or other individuals in whom such a response would be beneficial.

Owner:ABBOTT LAB INC

Strengthening flat glass by edge coating

InactiveUS6120908AMaximumHigh strengthCeramic layered productsGlass/slag layered productsFlat glassOptoelectronics

A method is described for strengthening or restoring strength to a flat brittle oxide substrate which includes the steps of coating the edges of the brittle oxide substrate with a strengthening composition without coating a significate portion of the flat surfaces. The strengthen brittle oxide substrate such as glass and a window containing as the window pane the edge strengthen glass are also provided.

Owner:ARKEMA INC

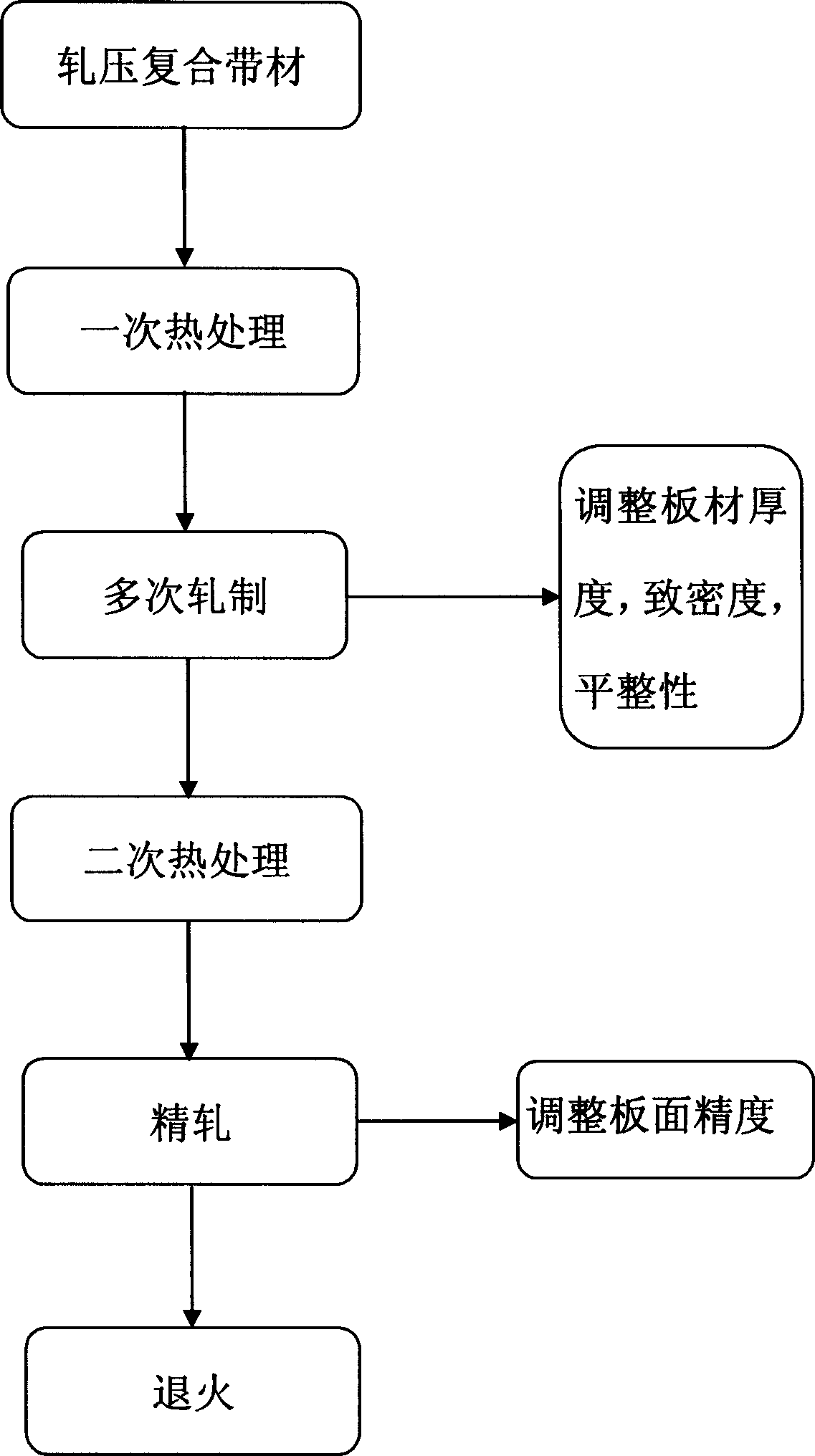

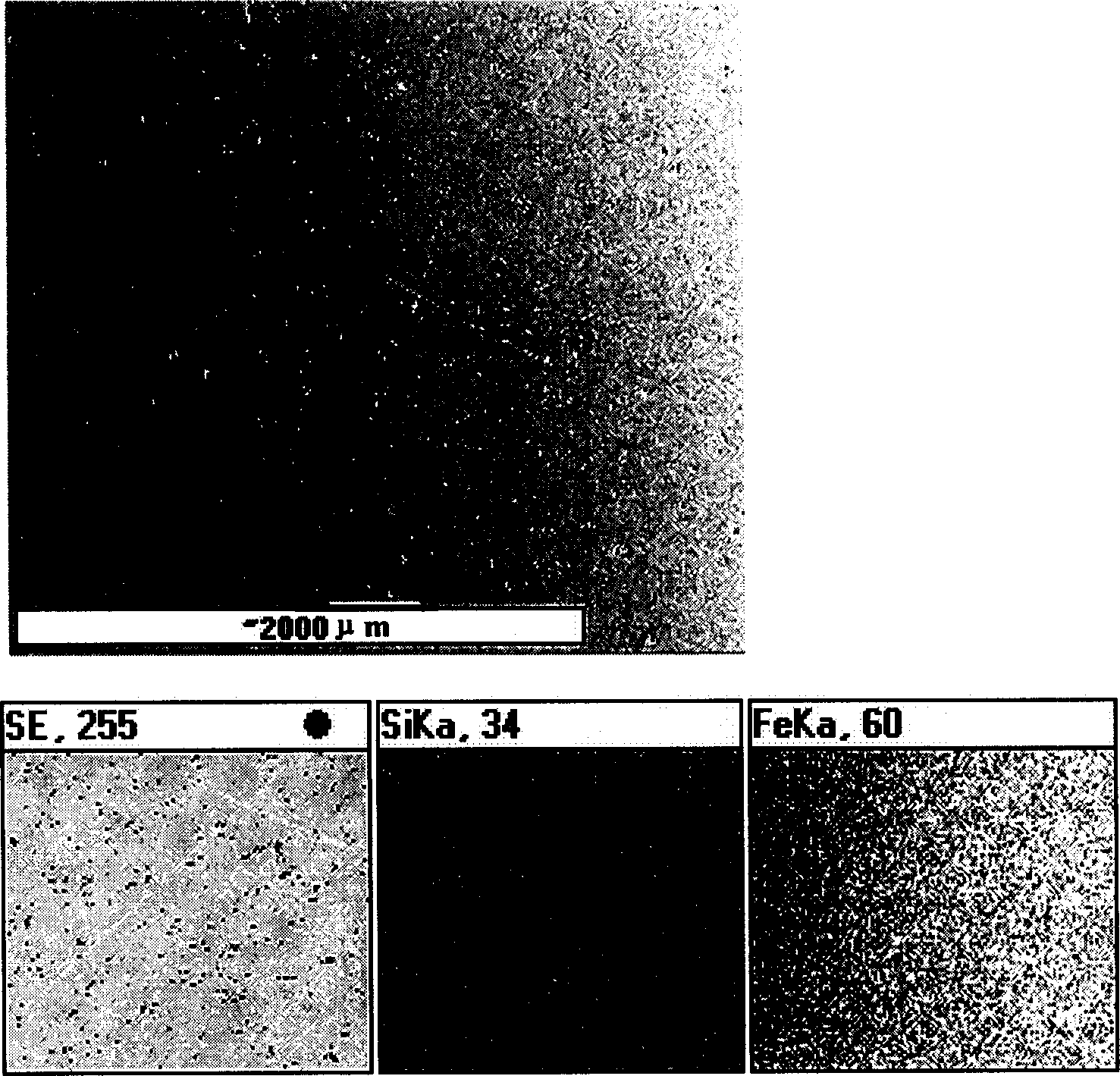

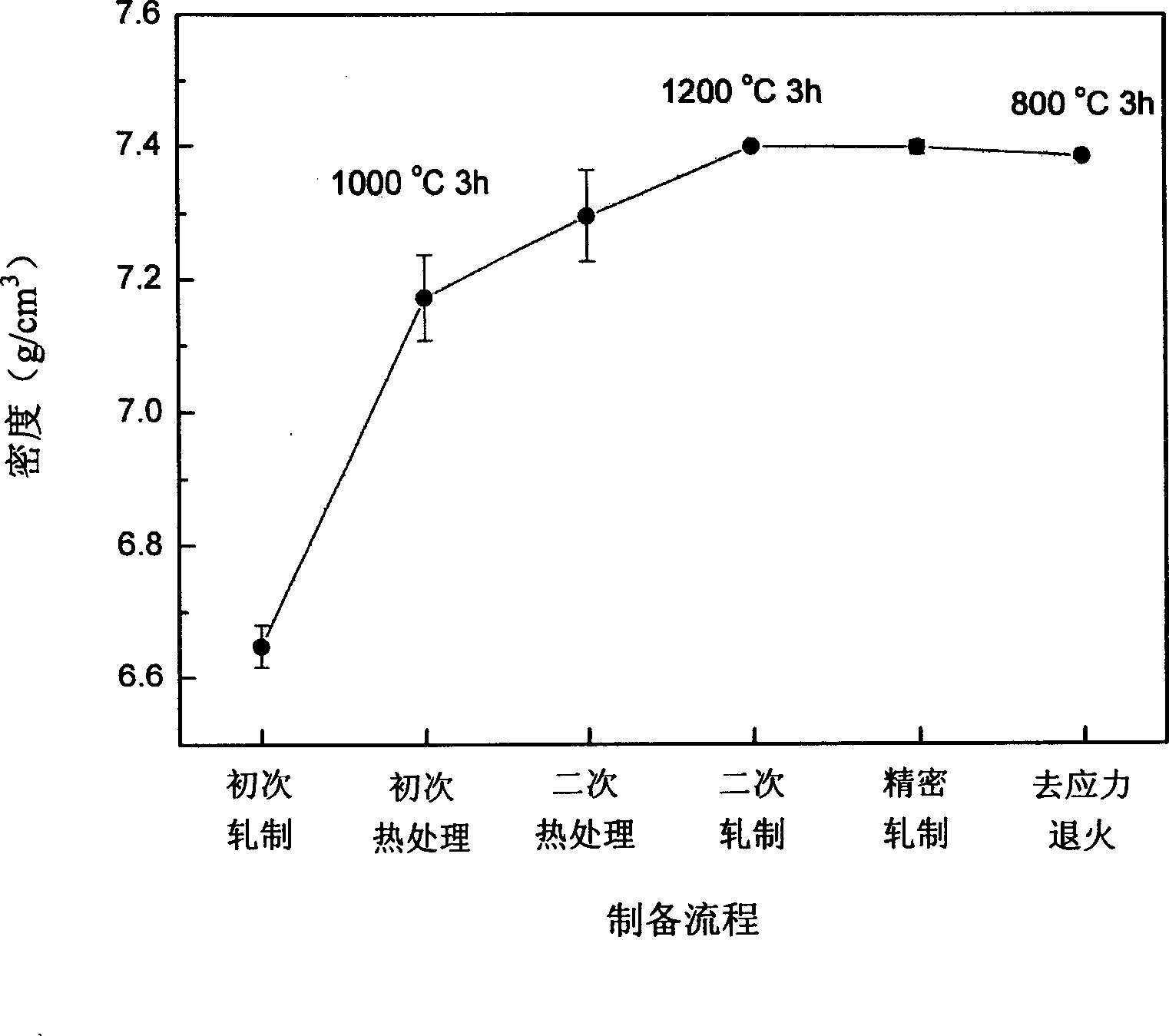

High-silica silicon-steel sheet heat treatment and multiple cold-rolling method

InactiveCN1528921AOvercoming limitations that cannot be processed by calenderingEasy to operateHigh silicaSilicon

The invention provides a method for producing high brittleness silicon steel board by using two times of heat process and multiple tracks cold-roll adjustment compound technology in different temperature range to control the extending performance of belt material rolling. It carries on baking process to high silicon steel shin board green compact produced by powder pressing method in low temperature range, controls the content of silicon in irn particles in shin boards, the board material can maintain the malleability. It carries on multiple rolling cold process when the silicon steel board is brittled, thus controls the thickness smooth property, and compactability of board. Then carries on secondary baking processing in high temperature, thus there obtains th even silicon steel board. Finally, carries on stress adjustment and relief annealing process, thus the product can be obtained.

Owner:WUHAN UNIV OF TECH

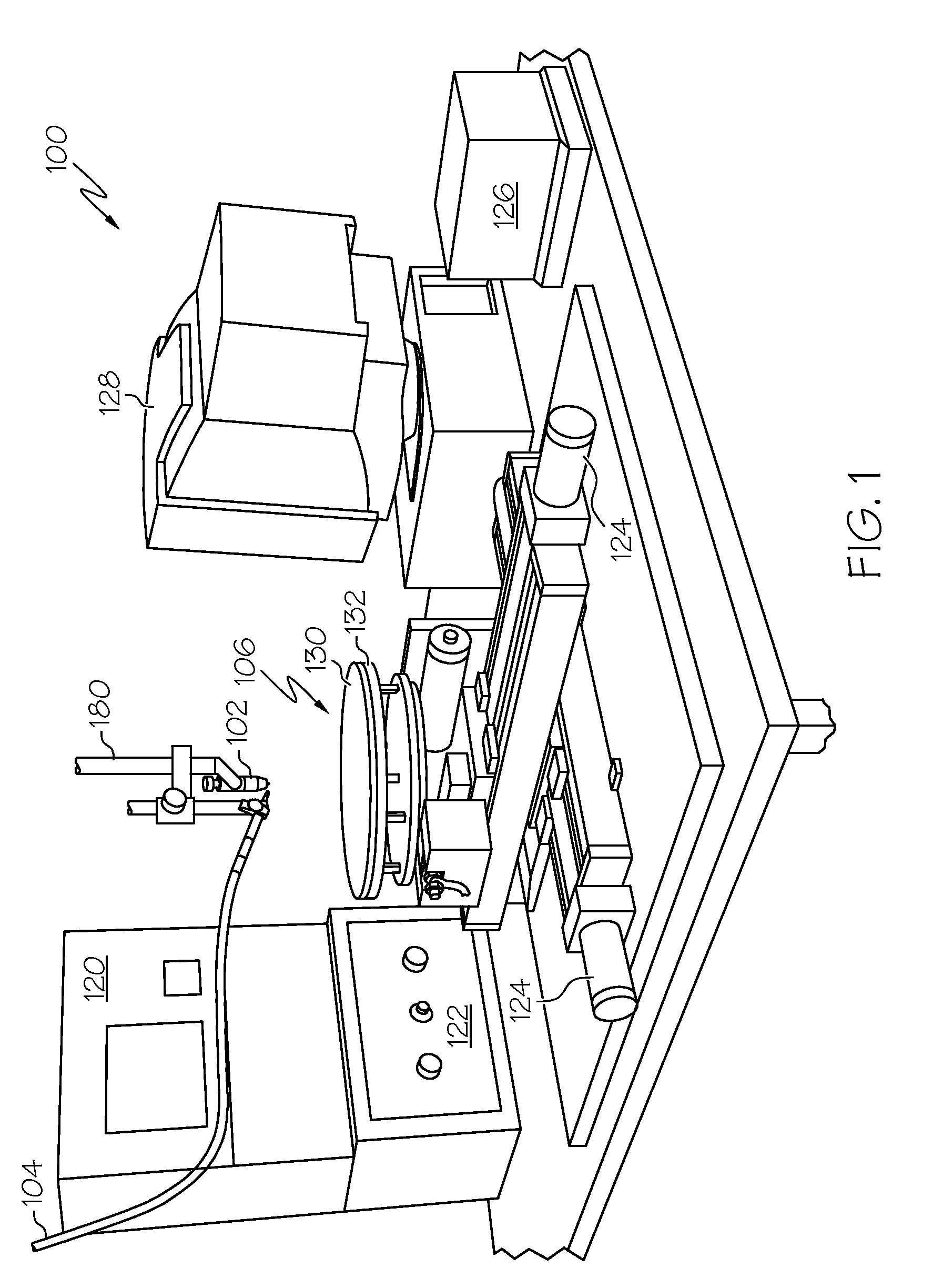

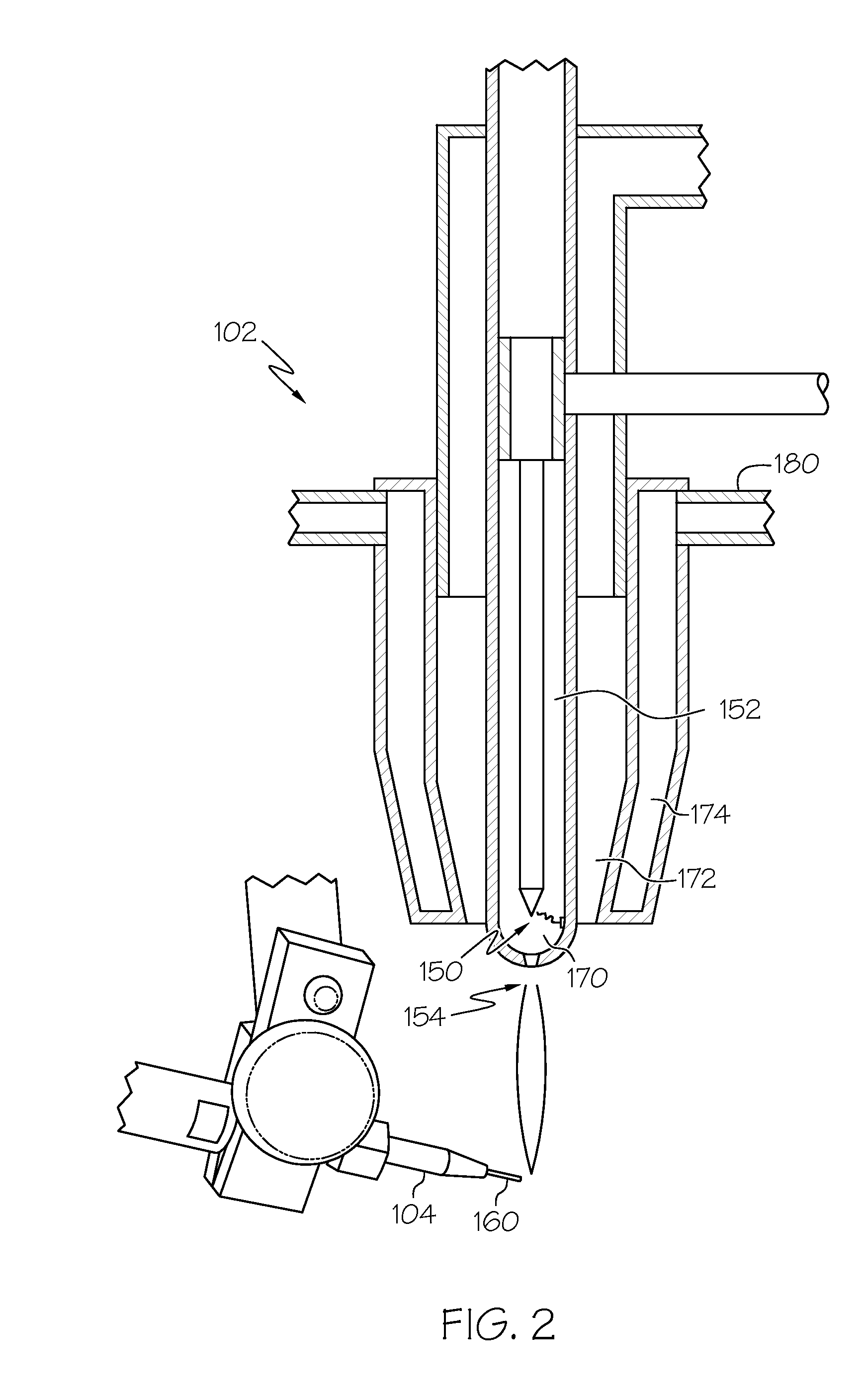

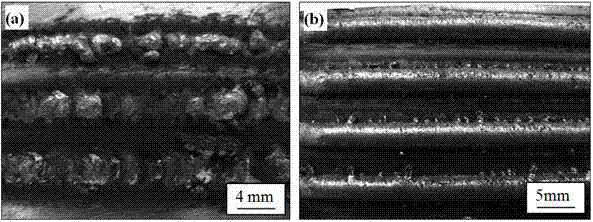

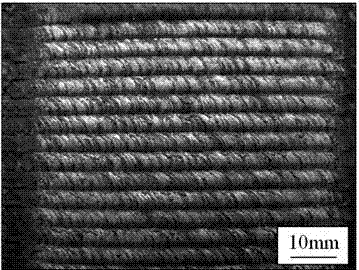

Deposition of materials with low ductility using solid free-form fabrication

InactiveUS20100193480A1Minimize occurrenceLow ductilityAdditive manufacturing apparatusArc welding apparatusFree formTransition temperature

A solid free-form (SFF) method is used to manufacture a component from successive layers of feedstock material with low ductility. A plasma stream is created by energizing a flowing gas using an arc electrode, the arc electrode having a variable magnitude current supplied thereto. The plasma stream is directed to a predetermined targeted region to preheat the predetermined targeted region prior to deposition. The current is adjusted and the feedstock material is introduced into the plasma stream to deposit molten feedstock in the predetermined targeted region. The current is adjusted and the molten feedstock is slowly cooled at an elevated temperature, typically above the brittle to ductile transition temperature of the feedstock material, in a cooling phase to minimize the occurrence of material stresses.

Owner:HONEYWELL INT INC

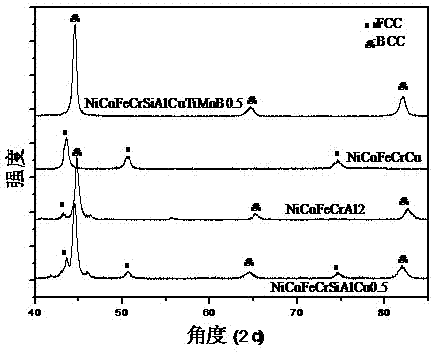

High-entropy alloy powder used for spraying

InactiveCN102828139AImprove self-fluxingImprove spraying effectMolten spray coatingHigh entropy alloysWear resistance

The invention discloses high-entropy alloy powder used for spraying, belonging to the technical field of alloy materials. The high-entropy alloy powder comprises five or more than five metal elements and non-metal elements Si and B, wherein addition amount of each metal element accounts for 5-35mol% of the total mole number of the high-entropy alloy powder, content of the added non-metal element Si accounts for 1-20mol% of the total mole number of the high-entropy alloy powder, and the content of the added non-metal element B accounts for 1-10mol% of the total mole number of the high-entropy alloy powder. The high-entropy alloy powder disclosed by the invention and a coating prepared by the high-entropy alloy powder after solidification can avoid precipitation of massive brittle phases after the traditional multi-element alloy is solidified, the coating has a simple fcc or bcc solid solution phase structure, brittleness of the multi-element alloy can be greatly reduced, the coating has multiple excellent performances such as high hardness, thermostability, wear resistance and corrosion resistance, and the high-entropy alloy powder can be applied to multiple surface coating technologies such as thermal spraying and laser cladding and has a wide application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

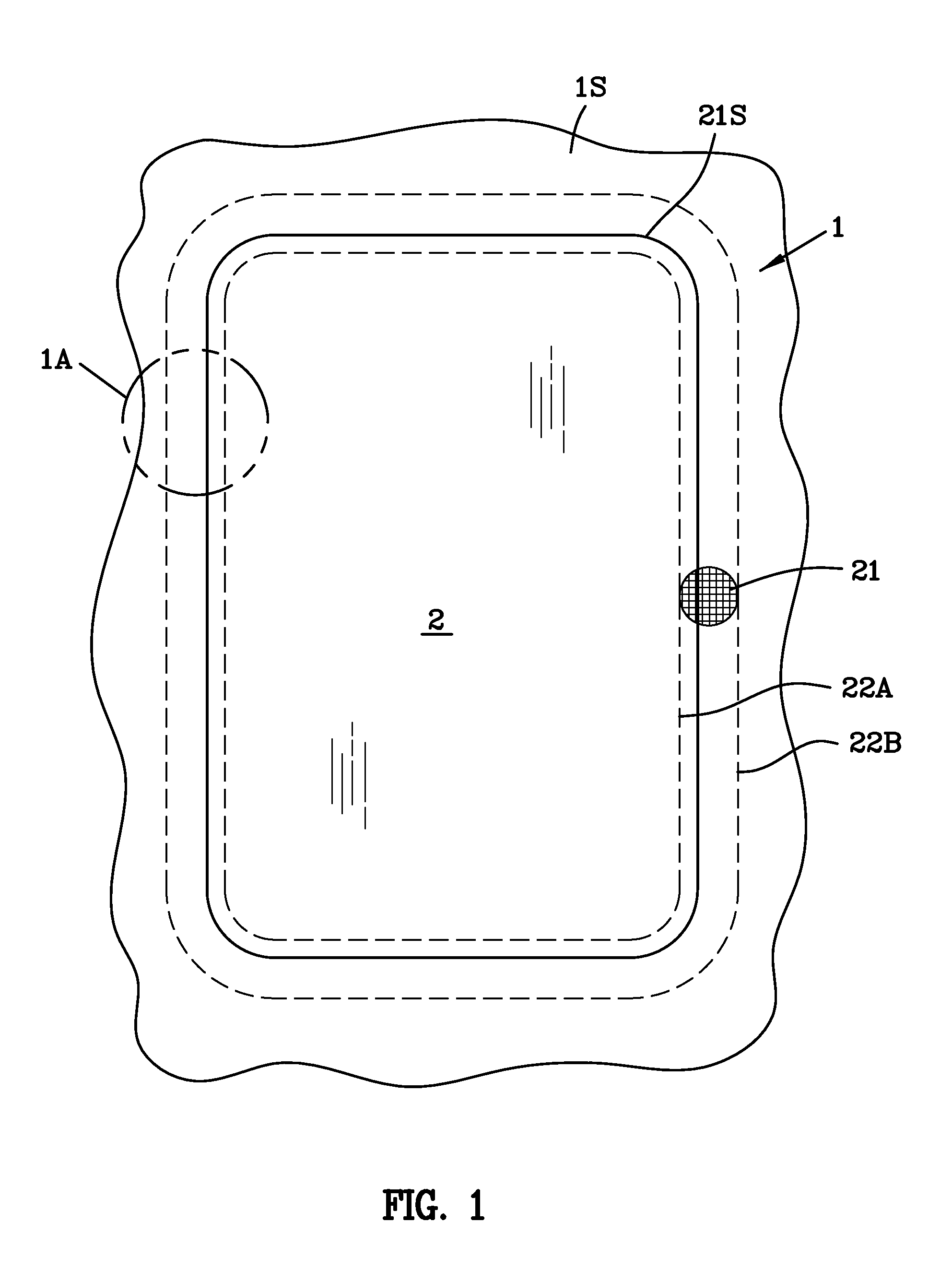

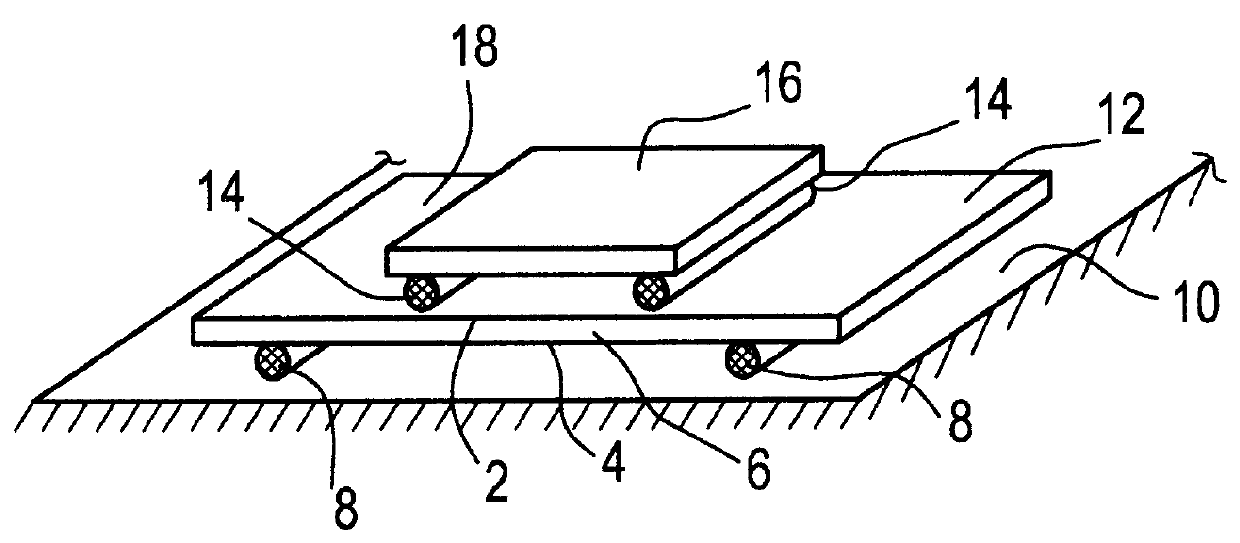

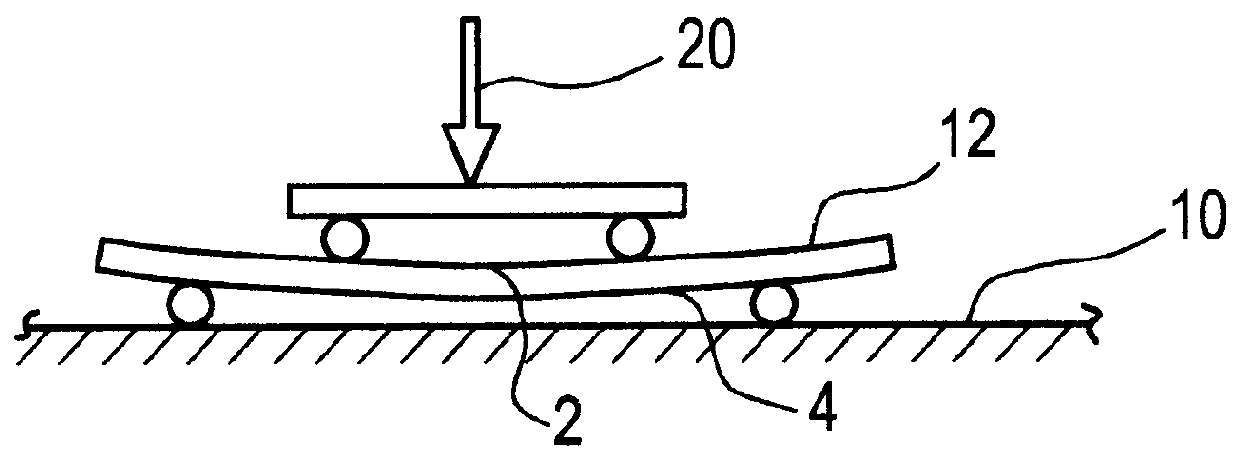

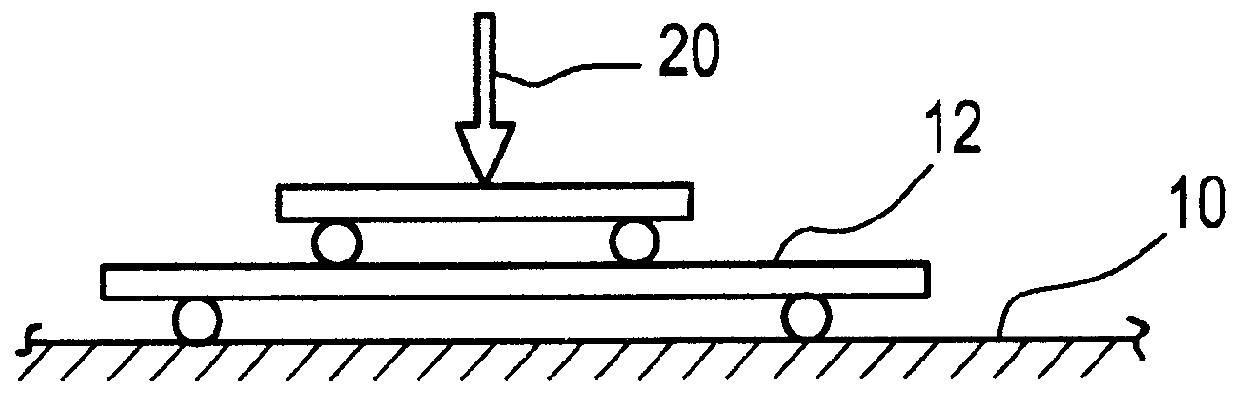

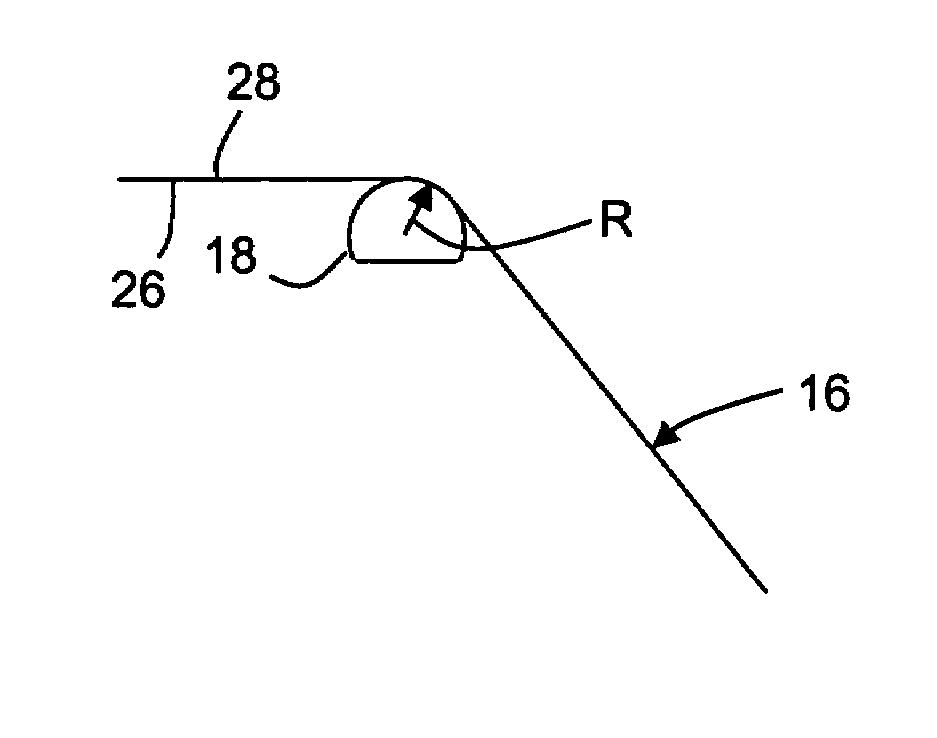

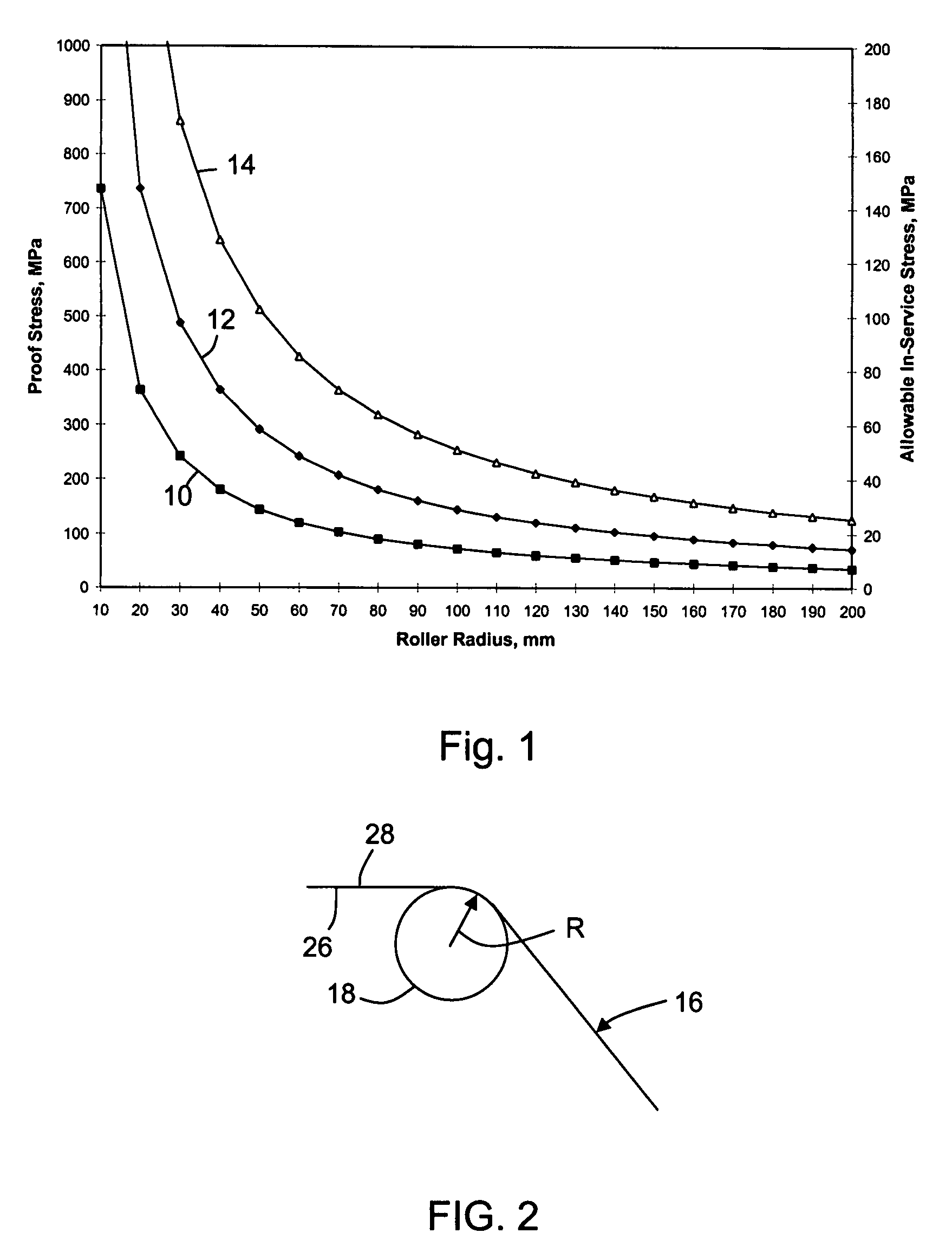

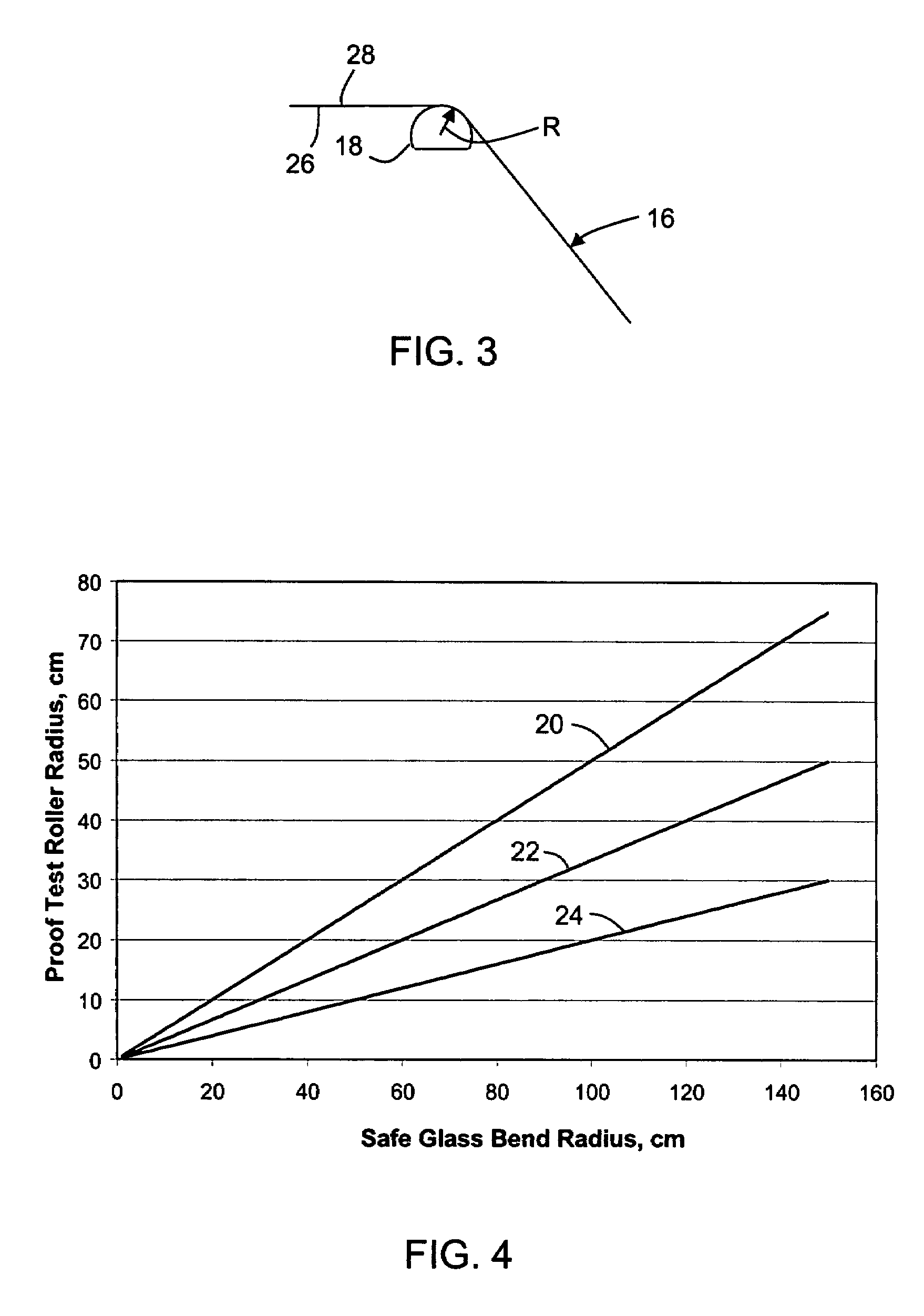

Method and apparatus for proof testing a sheet of brittle material

InactiveUS7461564B2Force measurementMaterial strength using tensile/compressive forcesStress inducedRelative motion

Disclosed is a method of proof testing a sheet of brittle material such as a glass or glass-ceramic based material. The method comprises bending the glass sheet over at least one arcuate member to detect sheets having a strength greater than a predetermined value. The method includes imparting a bend to the sheet and producing relative motion between the sheet and the bend such that the bend traverses the sheet, and wherein tensile stress induced in a surface of the sheet by the bend corresponds to the predetermined strength value. An apparatus for performing the proof testing is also disclosed.

Owner:CORNING INC

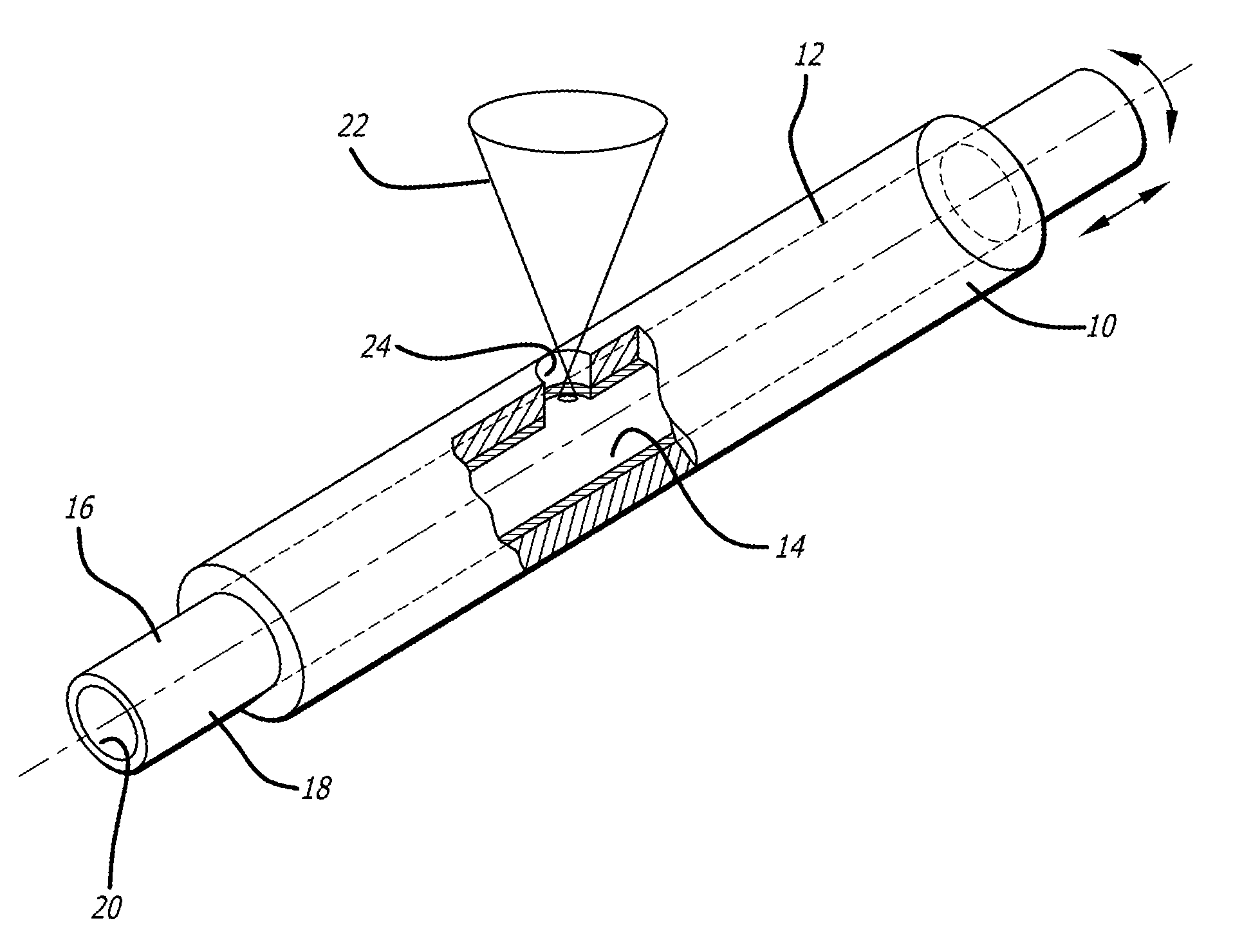

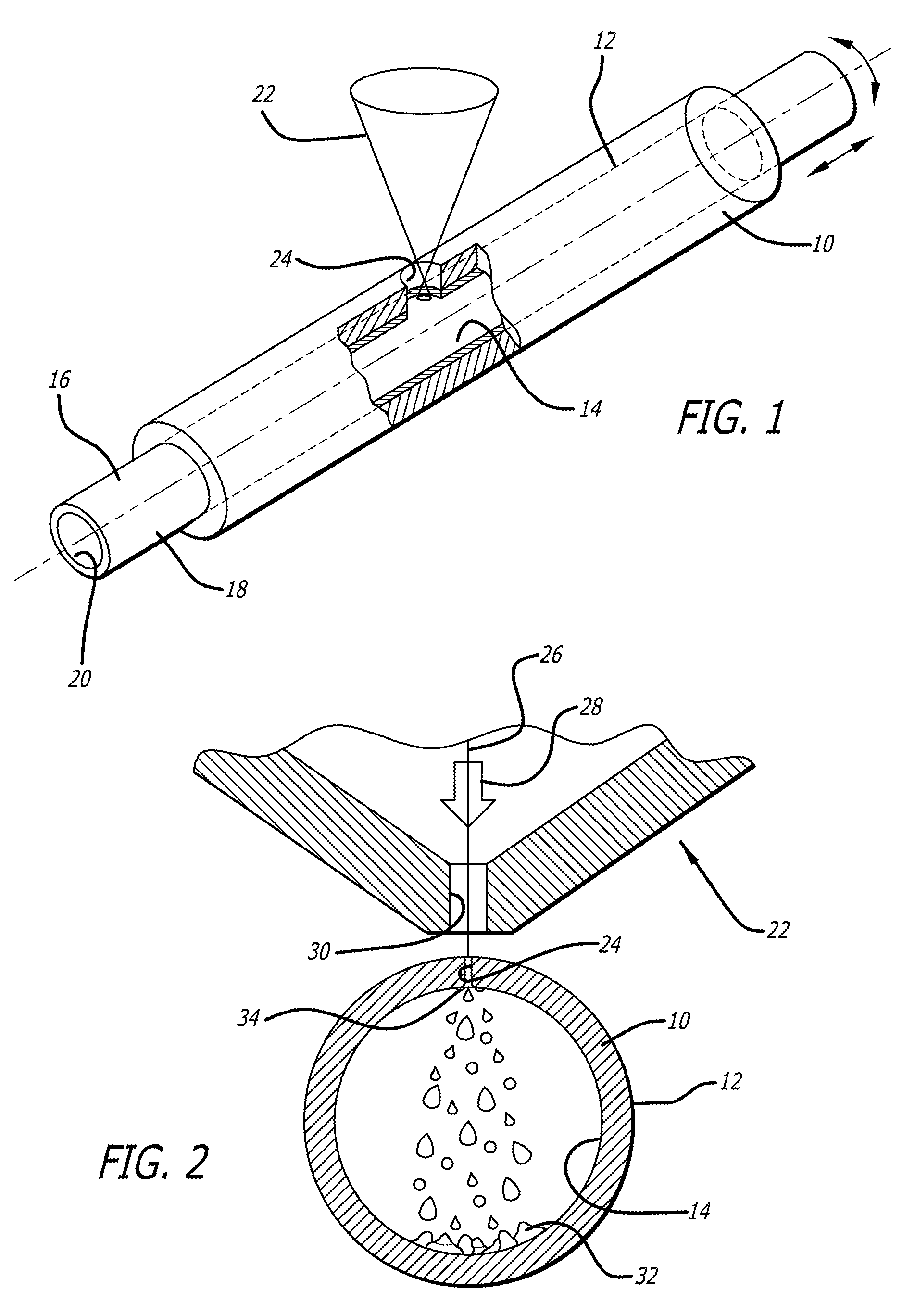

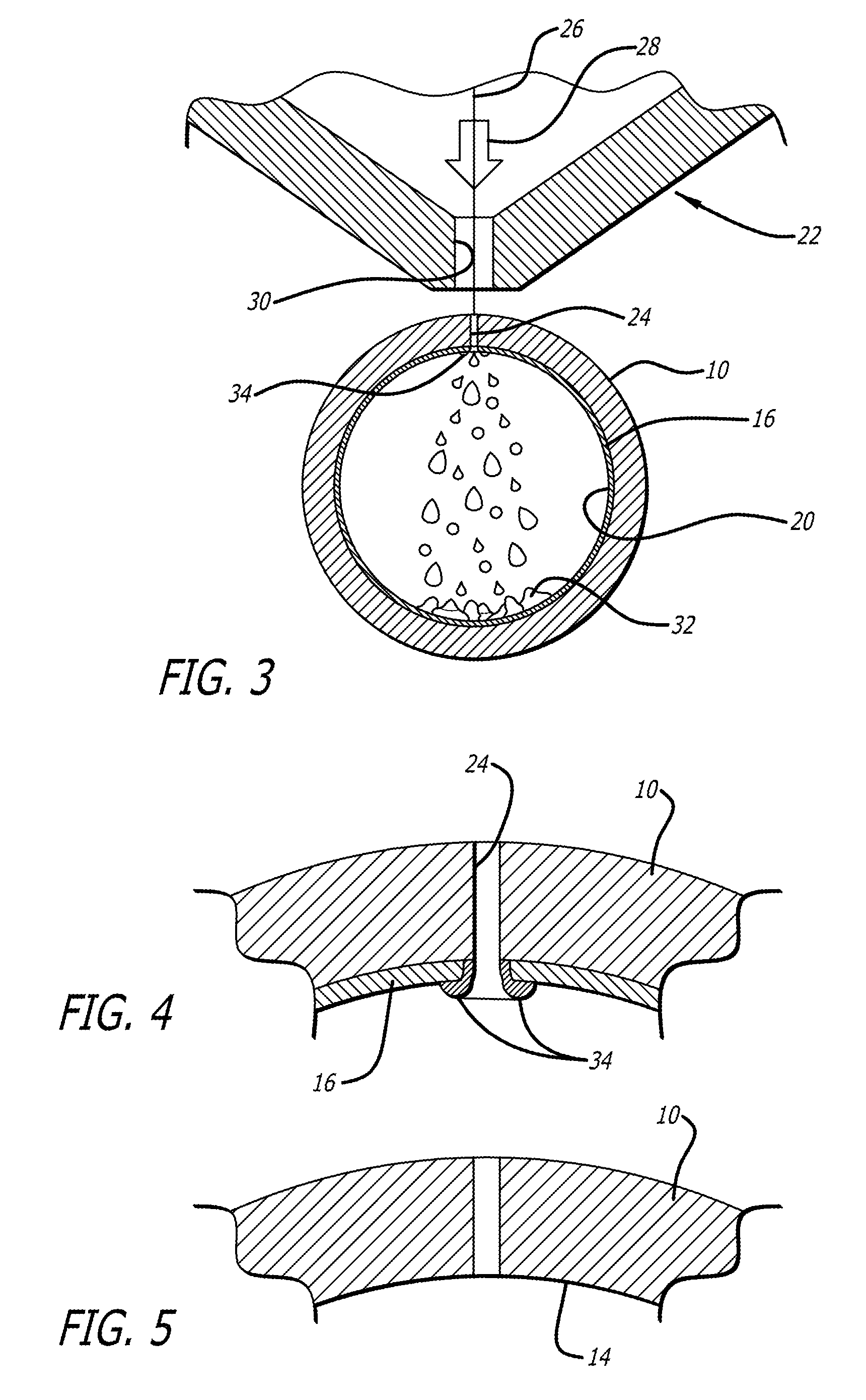

Methods and systems for laser cutting and processing tubing to make medical devices

Methods for making devices include providing a tubular member to be formed into a device, placing a removable sacrificial block material in the lumen of the tubular member and laser cutting the tubular member. A doping material can be added to the melted portion of the tubular member to promote the formation of brittle slag. A fixture can be used to hold a cut workpiece in order to ream sacrificial material from the surface of the workpiece. Pressurized gas can be supplied to the inner lumen of the tubular member to cause slag to form on the outside surface, rather than the inner surface, of the tubular member. A tubular member made from nickel-titanium alloy can be tightly adhered to a sacrificial sleeve utilizing the phase changes associated with nickel-titanium. A rotating mandrel can be placed within the lumen of the tubular member during laser cutting. A mandrel which includes an enlarged diameter section causes the workpiece to expand slightly within its elastic deformation range to dislodge islands from the workpiece. Such a mandrel could be formed from a tubular member which has a central lumen that can be used to deliver a pressurized medium to “blast” islands from the workpiece.

Owner:ABBOTT CARDIOVASCULAR

HIGH STRENGTH STEEL PLATE WITH ULTIMATE TENSILE STRENGTH OF 900 MPa OR MORE EXCELLENT IN HYDROGEN EMBRITTLEMENT RESISTANCE AND METHOD OF PRODUCTION OF SAME

ActiveUS20120222781A1Reduce resistanceImprove plasticityHot-dipping/immersion processesSurface reaction electrolytic coatingCarbideUltimate tensile strength

High strength steel plate with an ultimate tensile strength of 900 MPa or more which is excellent in hydrogen embrittlement resistance characterized in that, in the structure of the steel plate, (a) by volume fraction, ferrite is present in 10 to 50%, bainitic ferrite and / or bainite in 10 to 60%, and tempered martensite in 10 to 50%, and (b) iron-based carbides which contain Si or Si and Al in 0.1% or more are present in 4×108 (particles / mm3) or more.

Owner:NIPPON STEEL CORP

Method for strengthening a brittle oxide substrate

InactiveUS6013333AIncrease and restores strengthEasy to usePretreated surfacesCoatingsSilanesAqueous solution

A method is described for strengthening or restoring strength to a brittle oxide substrate which includes the steps of coating the brittle oxide substrate with an aqueous solution containing a silane-based composition, and curing the coating to form a transparent layer on the brittle oxide substrate. Also disclosed are novel compositions used to coat brittle oxide substrates, and silane-coated brittle oxide containers.

Owner:ATOCHEM OF NORTH AMERICA INC

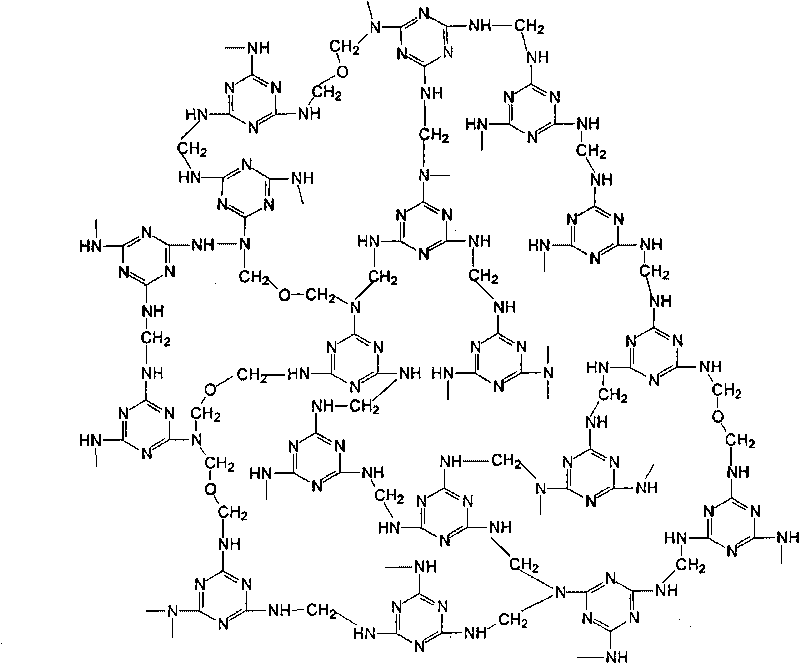

High-flexibility melamino-formaldehyde foam material and preparation method thereof

The invention discloses a high-flexibility melamino-formaldehyde foam material and a preparation method thereof. The preparation method comprises: firstly, preparing melamino-formaldehyde prepolymer modified by polyol into aqueous solution with definite weight concentration; weighting 100 parts by weight of prepolymer aqueous solution; adding 0-15 parts by weight of surfactant, 1-20 parts by weight of foaming agent, 0-10 parts by weight of accelerator and 0-10 parts by weight of curing agent to be fully stirred and mixed to prepare foaming liquid; filling foaming liquid into a microwave chemical reactor or a high-temperature oven; and foaming for 30s-15min at the temperature of 100-300 DEG C to prepare the foam material. The melamino-formaldehyde foam material disclosed by the invention solves the problems of big brittleness, poor flexibility, easy duslting of foam, complex preparation technology, high production cost and the like of the existing melamino-formaldehyde foam material and has wide application prospect.

Owner:SICHUAN UNIV

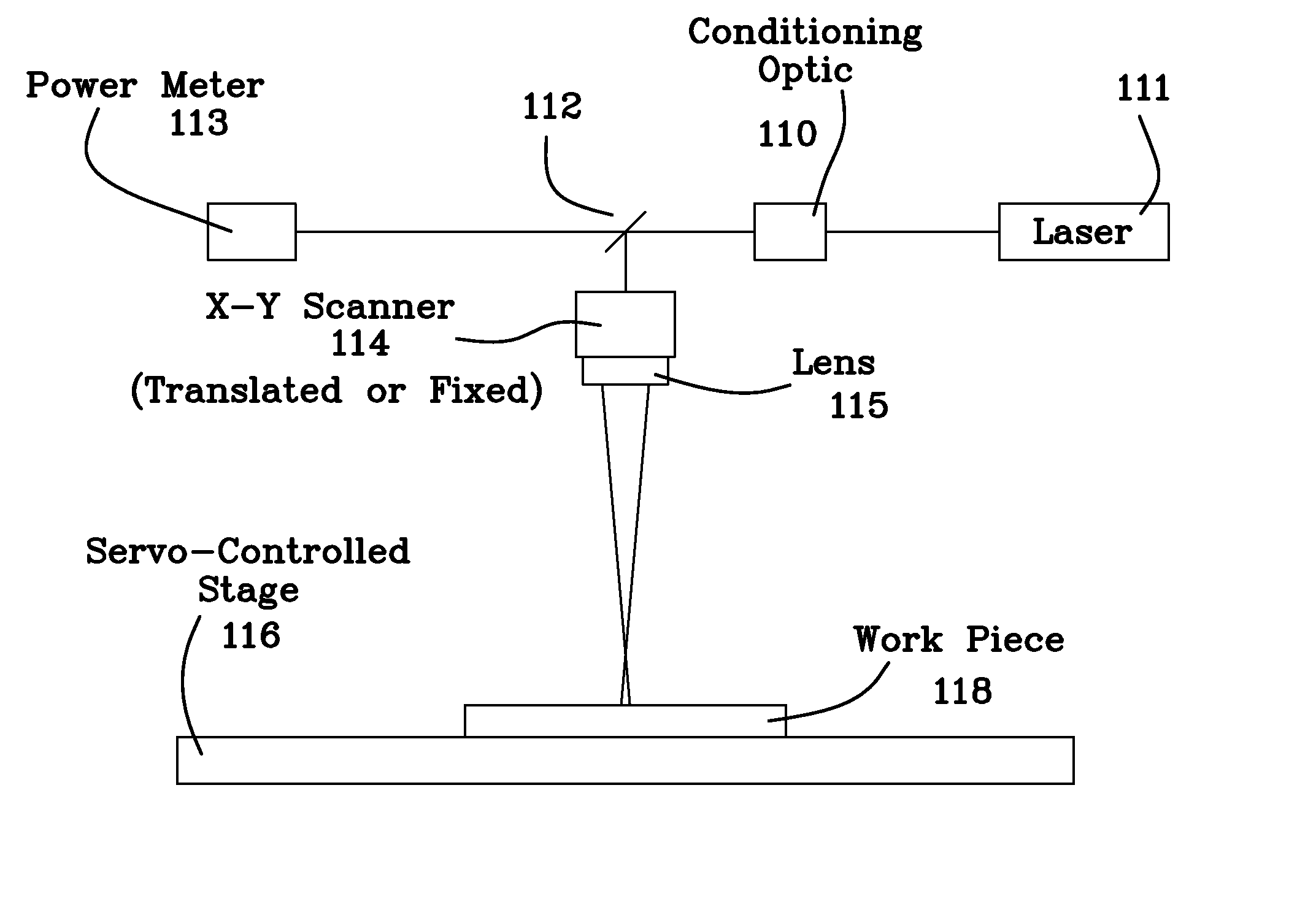

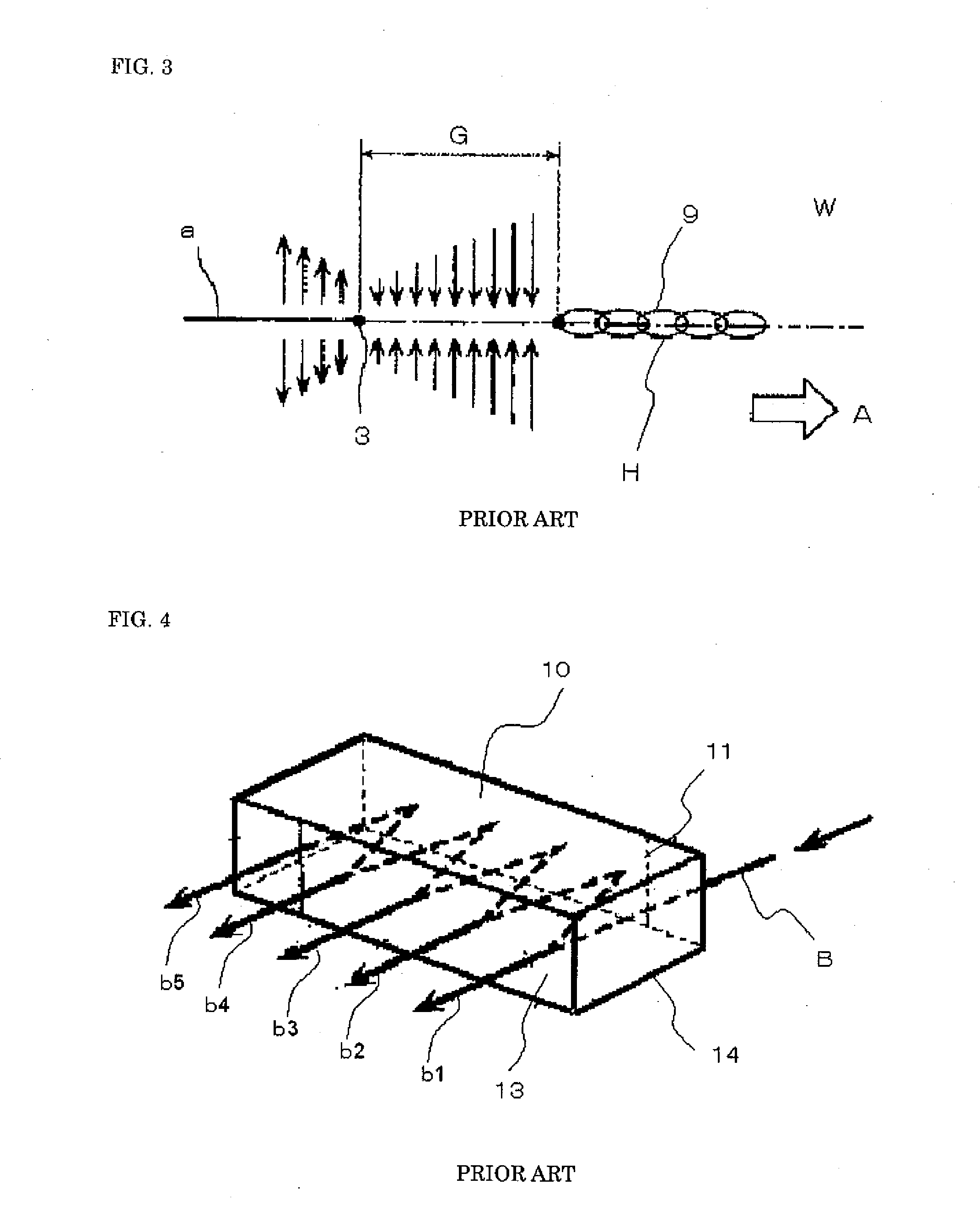

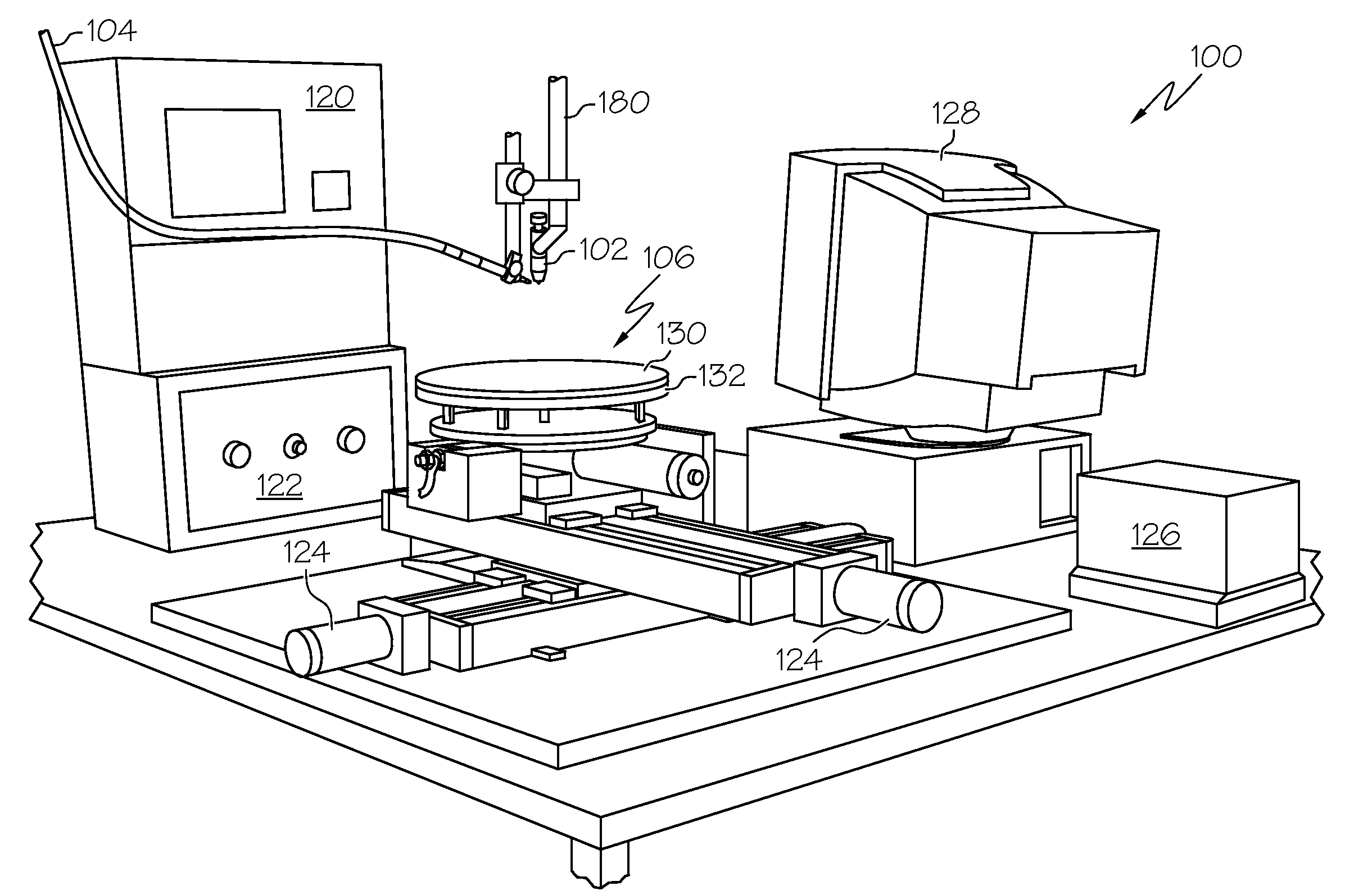

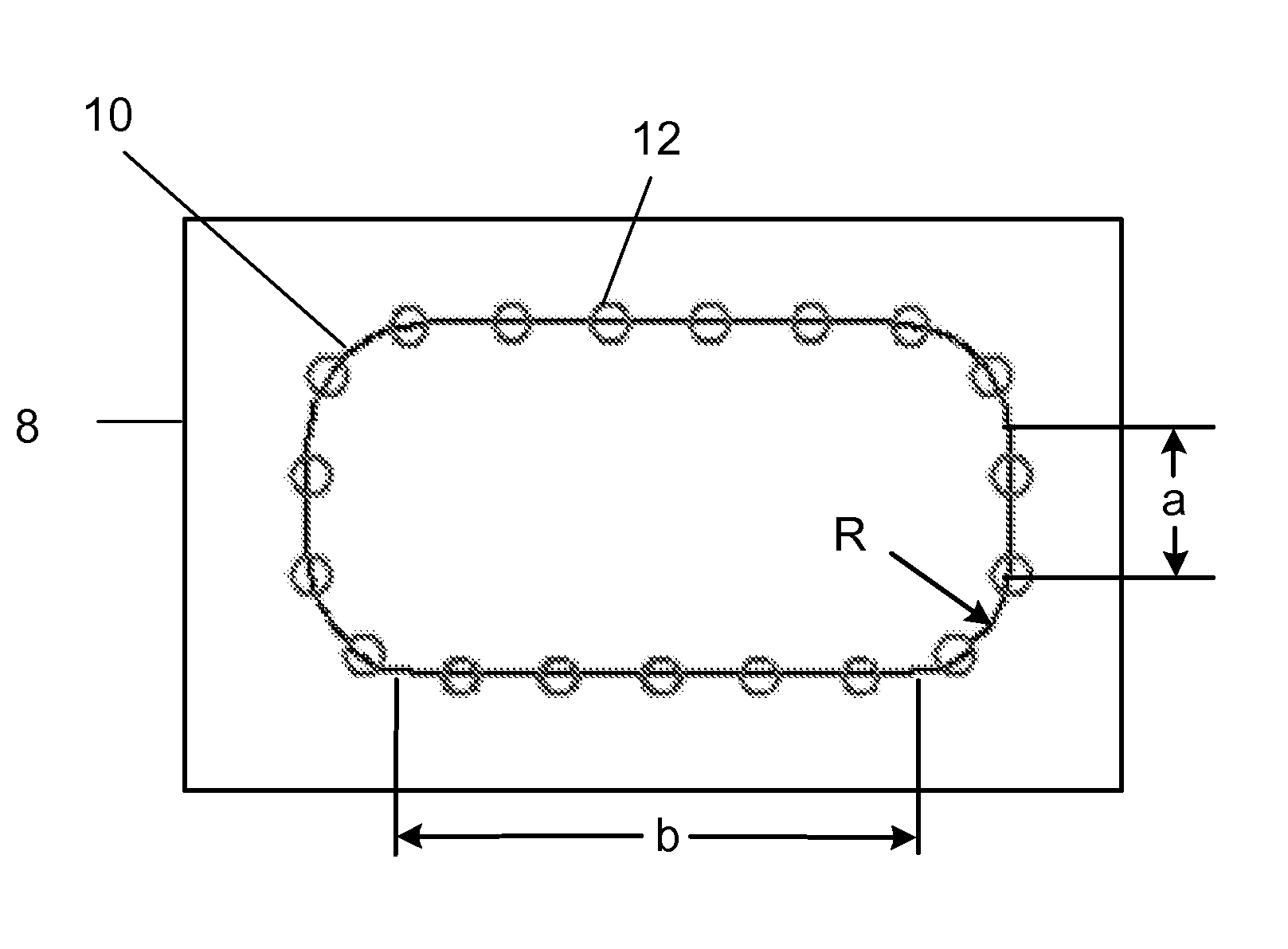

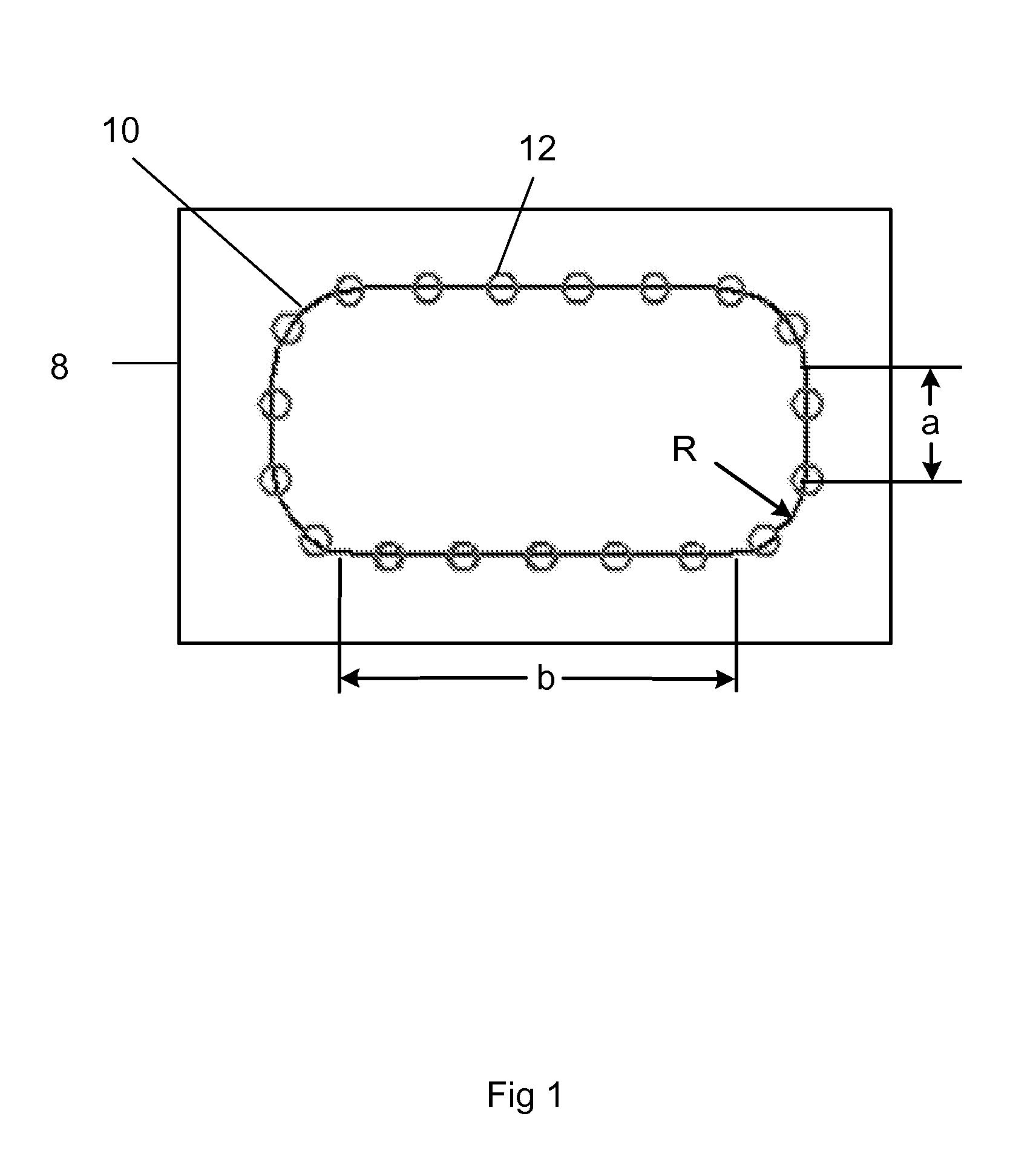

Method and apparatus for brittle materials processing

InactiveUS20100252540A1Avoids chipping and crackingExcessive heat build can be avoidedLaser detailsWelding/soldering/cutting articlesLaser processingOptoelectronics

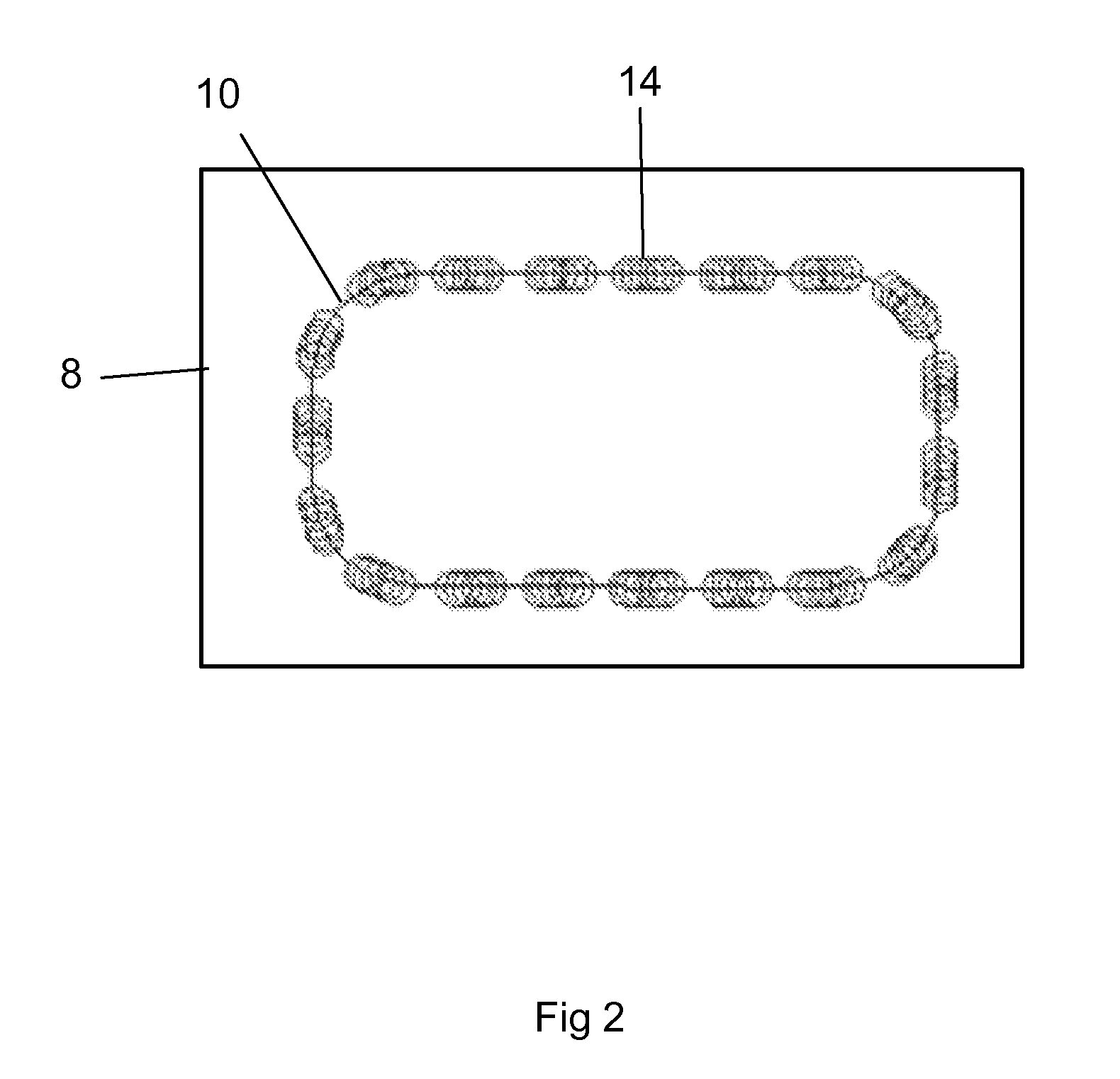

An improved method for laser machining features in brittle materials 8 such as glass is presented, wherein a tool path 10 related to a feature is analyzed to determine how many passes are required to laser machine the feature using non-adjacent laser pulses 12. Laser pulses 12 applied during subsequent passes are located so as to overlap previous laser spot locations by a predetermined overlap amount. In this way no single spot receives excessive laser radiation caused by immediately subsequent laser pulses 12 being applied adjacent to a previous pulse location.

Owner:ELECTRO SCI IND INC

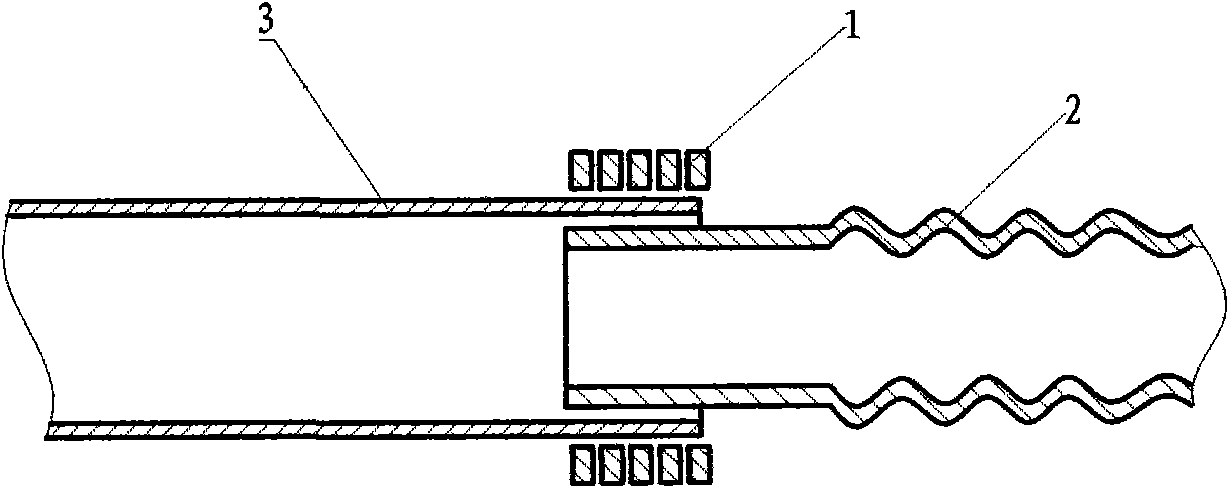

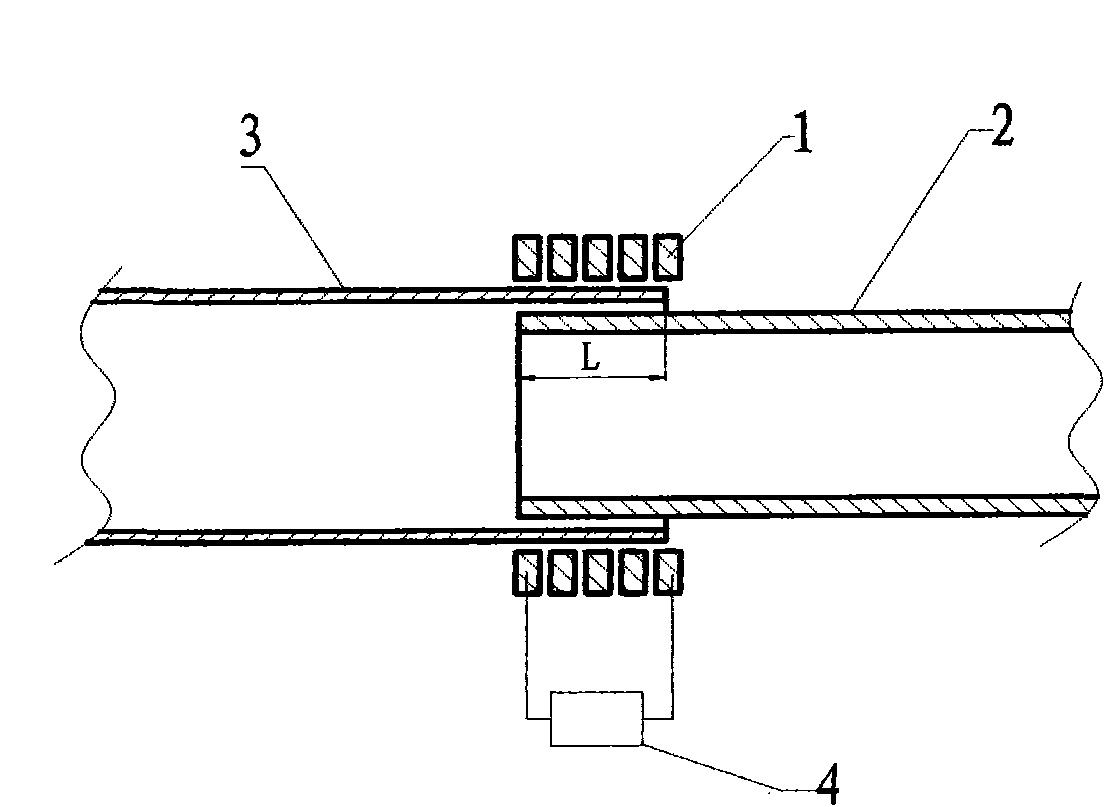

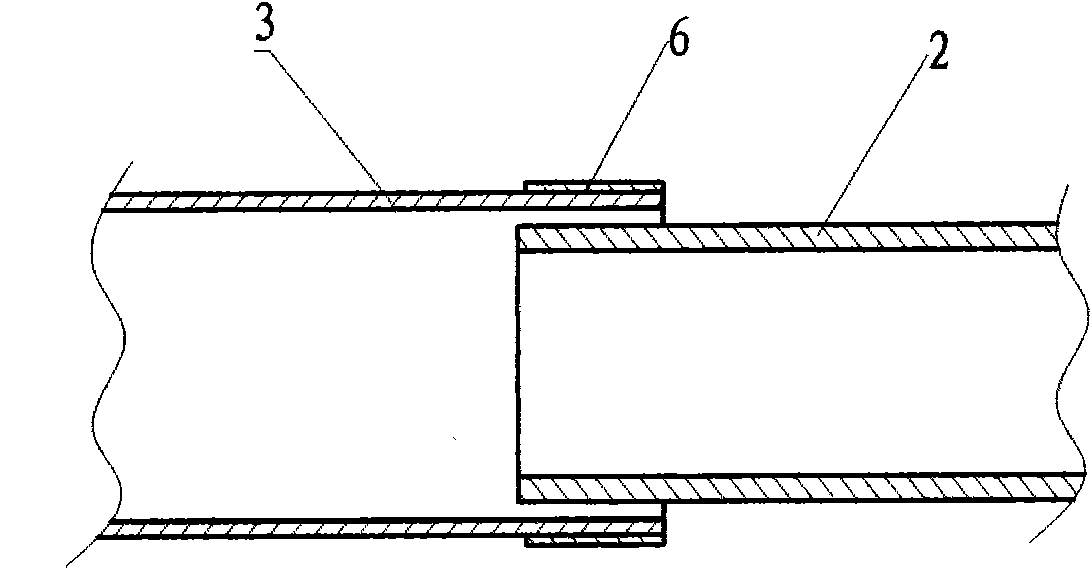

Magnetic pulse connecting method and joint structure for thin-wall metal pipelines

InactiveCN101905375AIncreased processing flexibilityHigh strengthNon-electric welding apparatusHeat-affected zoneEngineering

The invention discloses a magnetic pulse connecting method and a joint structure for thin-wall metal pipelines and provides a safe and high-efficiency magnetic pulse connecting method and a magnetic pulse connecting joint structure for similar and dissimilar thin-wall metal pipelines. A coil-magnetic concentrator composite inductor or a coil inductor is connected with electromagnetic pulse forming equipment so that the pipelines of various metal materials or various structure shapes can be connected in a magnetic pulse way. The transition area of the joint connecting interface is small, the brittle phase or intermetallic compound almost cannot be generated, and the joint almost has no heat affected area and torsion deformation and has high strength and corrosion-resistance property; the tension strength and torsion strength of the joint are respectively higher than those of weak base metal; the subsequent cleaning procedure and post-weld heat treatment are not needed; and the connected pipeline satisfies certain rigidity requirement, cannot be subjected to the plastic deformation in the magnetic pulse connecting process and has high process flexibility.

Owner:HARBIN INST OF TECH

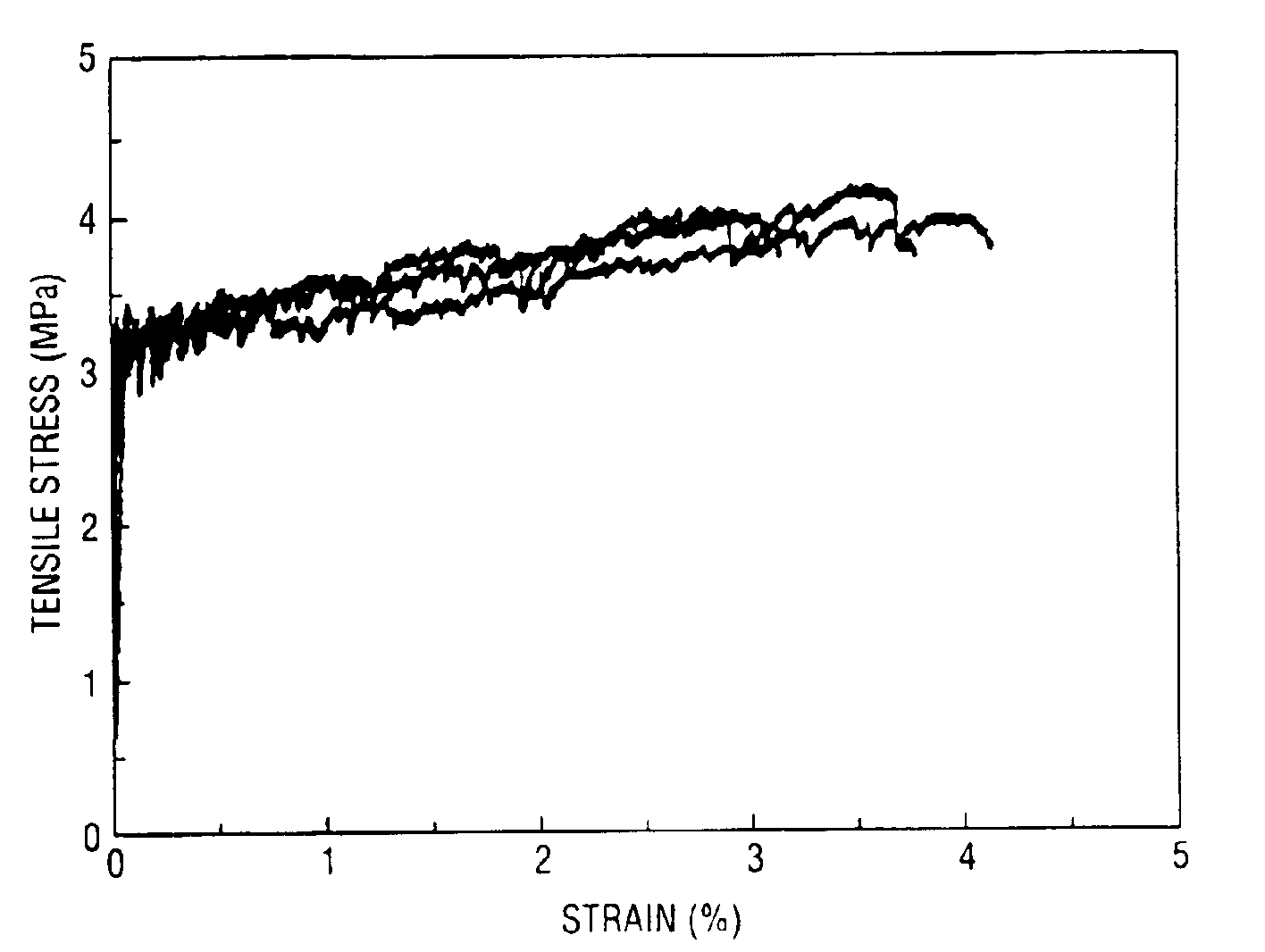

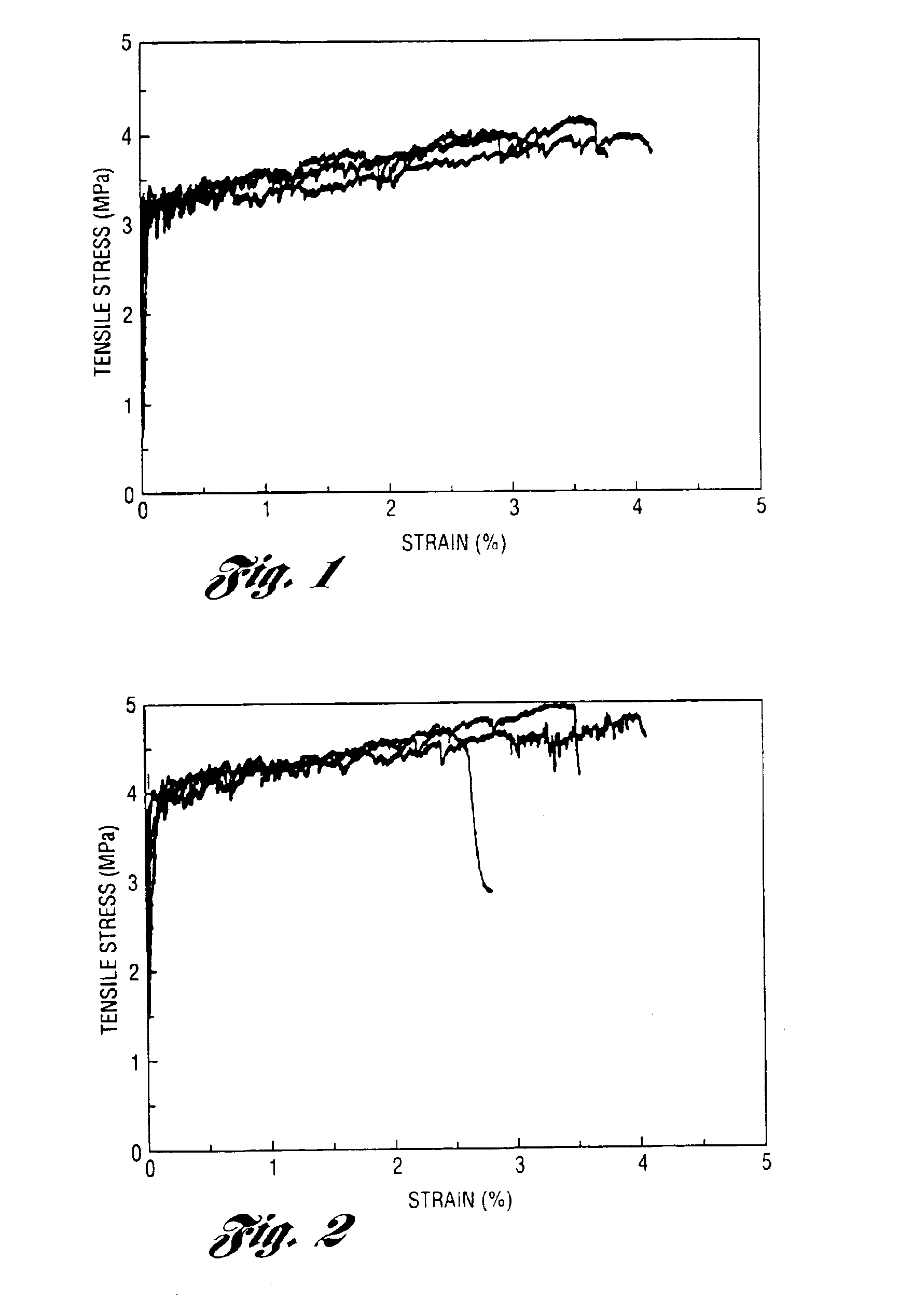

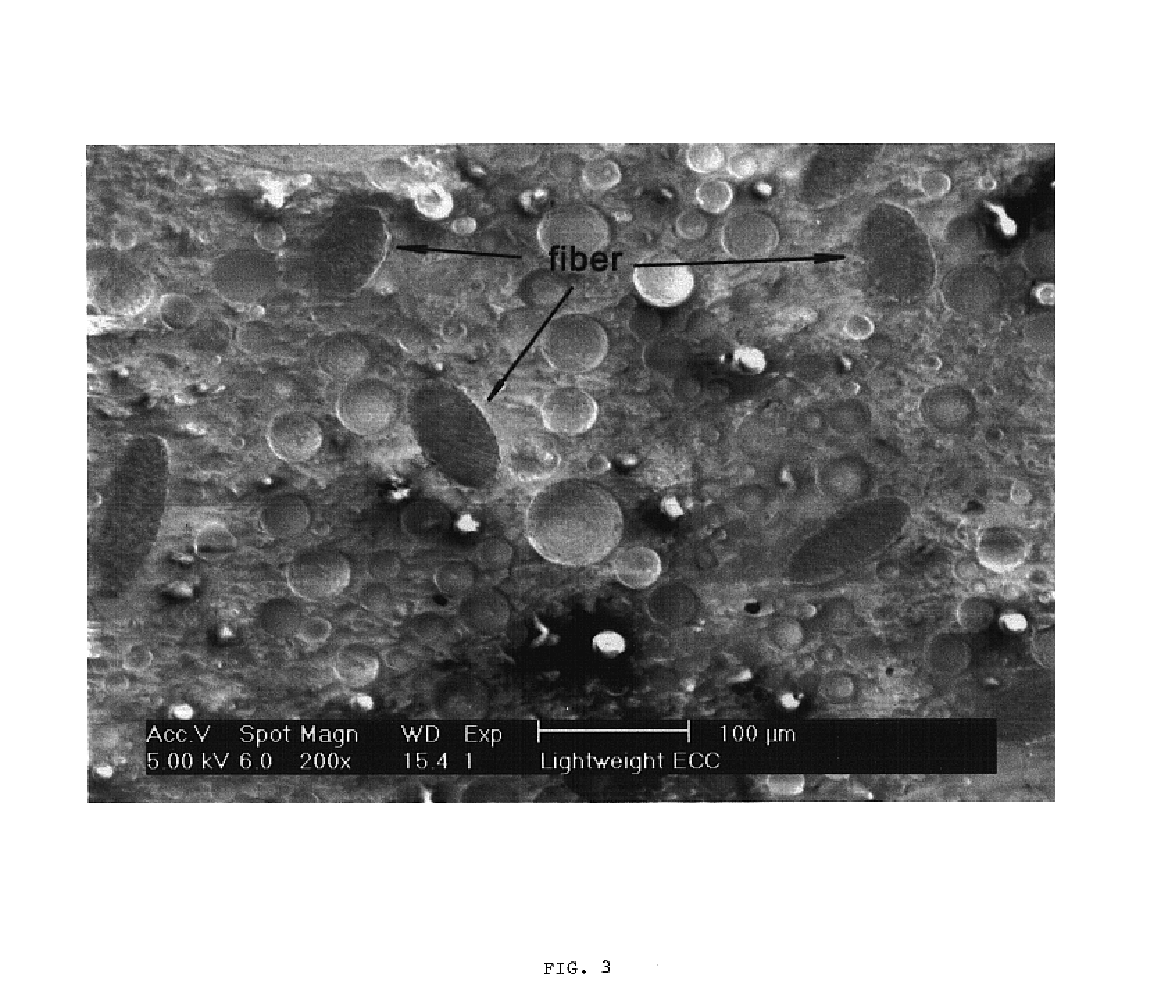

Lightweight strain hardening brittle matrix composites

Fiber reinforced lightweight concrete composites employ less than 4% by volume of reinforcing fibers in conjunction with small particulate lightweight aggregates or voids, and cure to composites which exhibit high tensile strain and strain hardening behavior. The composites are useful for numerous structures in civil engineering.

Owner:RGT UNIV OF MICHIGAN

Flexible composite middle layer brazing alloy and method of utilizing brazing ceramic and metal

InactiveCN102699558AEnables direct brazingIncreased shear strengthWelding/cutting media/materialsSoldering mediaHeating furnaceUltimate tensile strength

The invention discloses flexible composite middle layer brazing alloy and a method of utilizing brazing ceramic and metal, and relates to the composite brazing alloy and the method of utilizing the brazing ceramic and metal. The flexible composite middle layer brazing alloy and the method aim at solving the problems that the conventional method is high in cost and the forming of brittle compound of a joint can not be restrained. The flexible composite middle layer brazing alloy is prepared from upper layer brazing alloy, a flexible middle layer and lower layer brazing alloy. The brazing method comprises the steps of: cleaning greasy dirt and impurity on a pre-welding surface; processing the upper-layer brazing alloy, the flexible middle layer and the lower-layer brazing alloy into small sheets; and ultrasonically cleaning and airing ceramic to be welded, metal to be welded, the upper layer brazing alloy, the flexible middle layer and the lower layer brazing alloy by acetone, assembling a workpiece to be welded, and putting the workpiece to be welded into a vacuum heating furnace to braze. According to the method disclosed by the invention, the operation is simple; the residual stress of the joint is released by adding the flexible middle layer; and the forming of the brittle compound of the joint is restrained, and the shearing strength of the joint is improved by 30-109%. The method disclosed by the invention is used for brazing the ceramic and the metal.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com