Patents

Literature

362 results about "Heat induced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

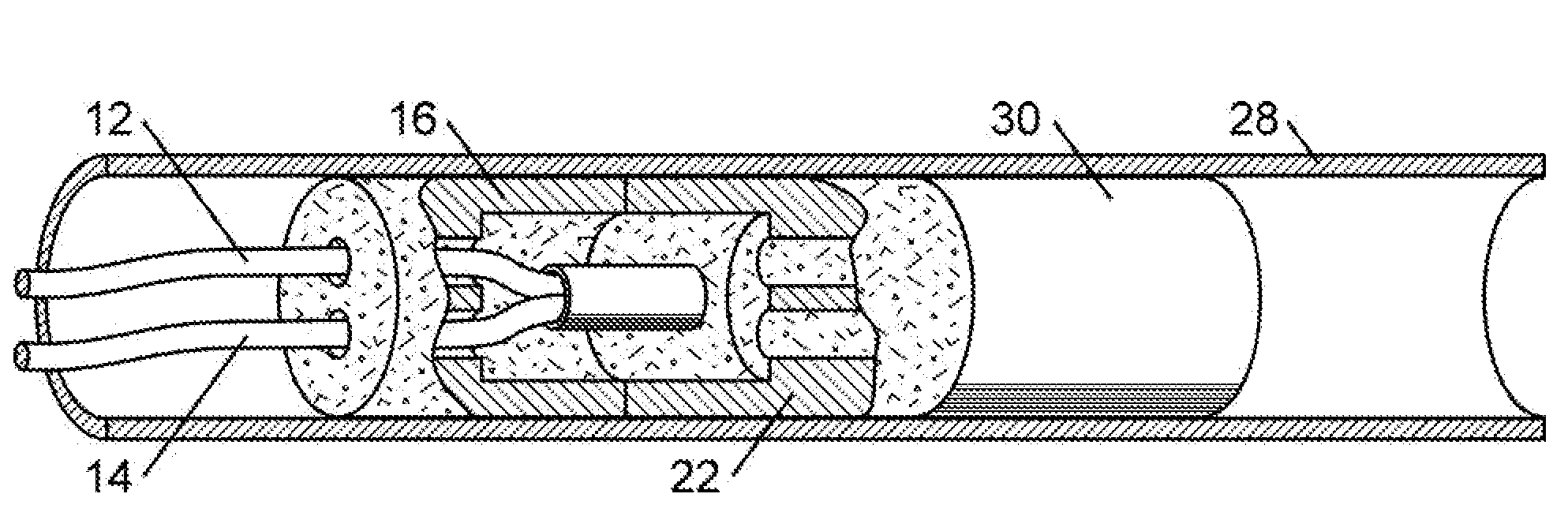

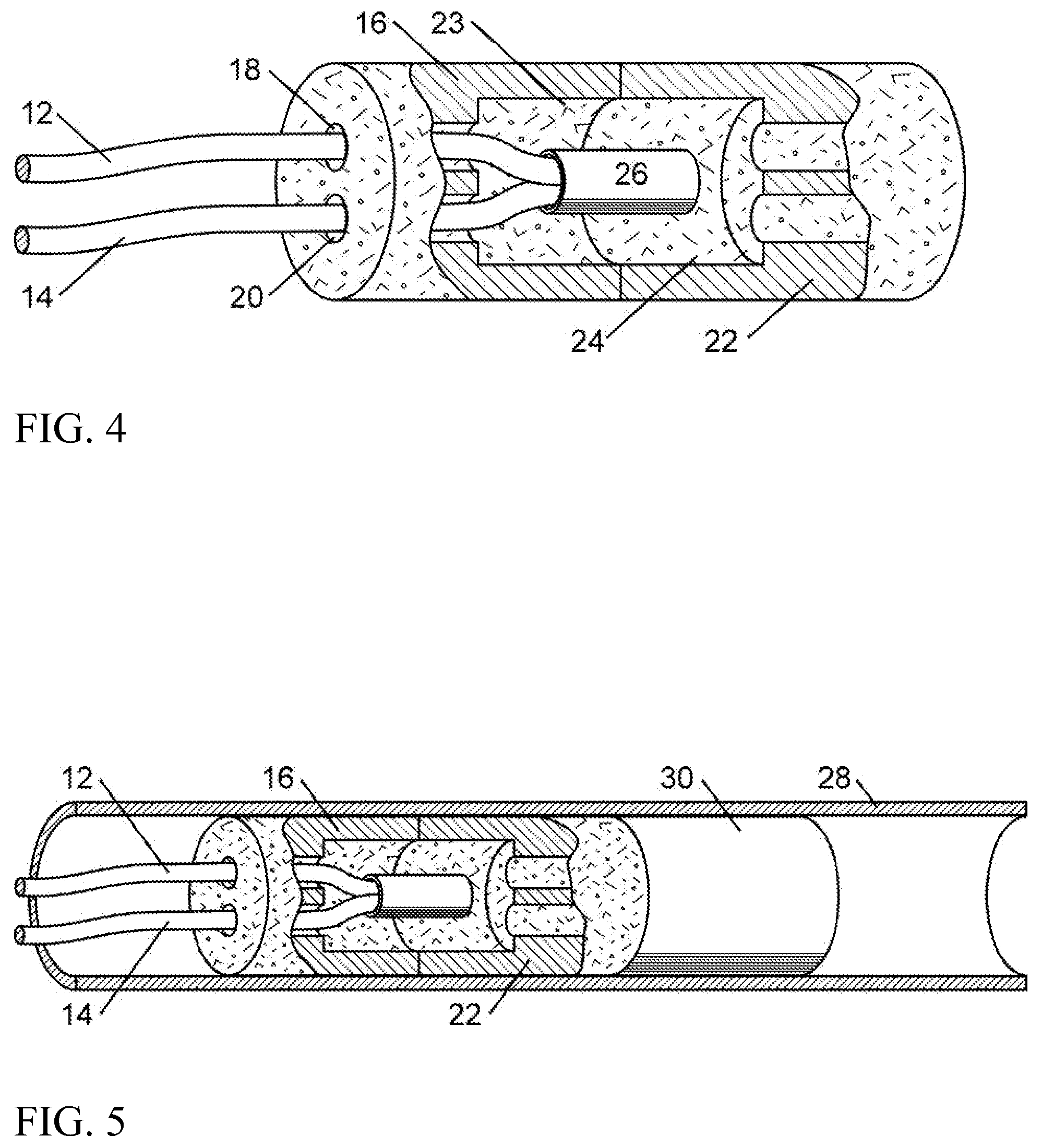

High temperature thermocouple design and fabrication

ActiveUS20080205483A1Low neutron cross-sectionsHigh melting temperatureThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsEngineeringThermocouple

A method for fabricating a thermocouple capable of long-term operation in high temperature, hostile environments without significant signal degradation or shortened thermocouple lifetime due to heat induced brittleness.

Owner:BATTELLE ENERGY ALLIANCE LLC

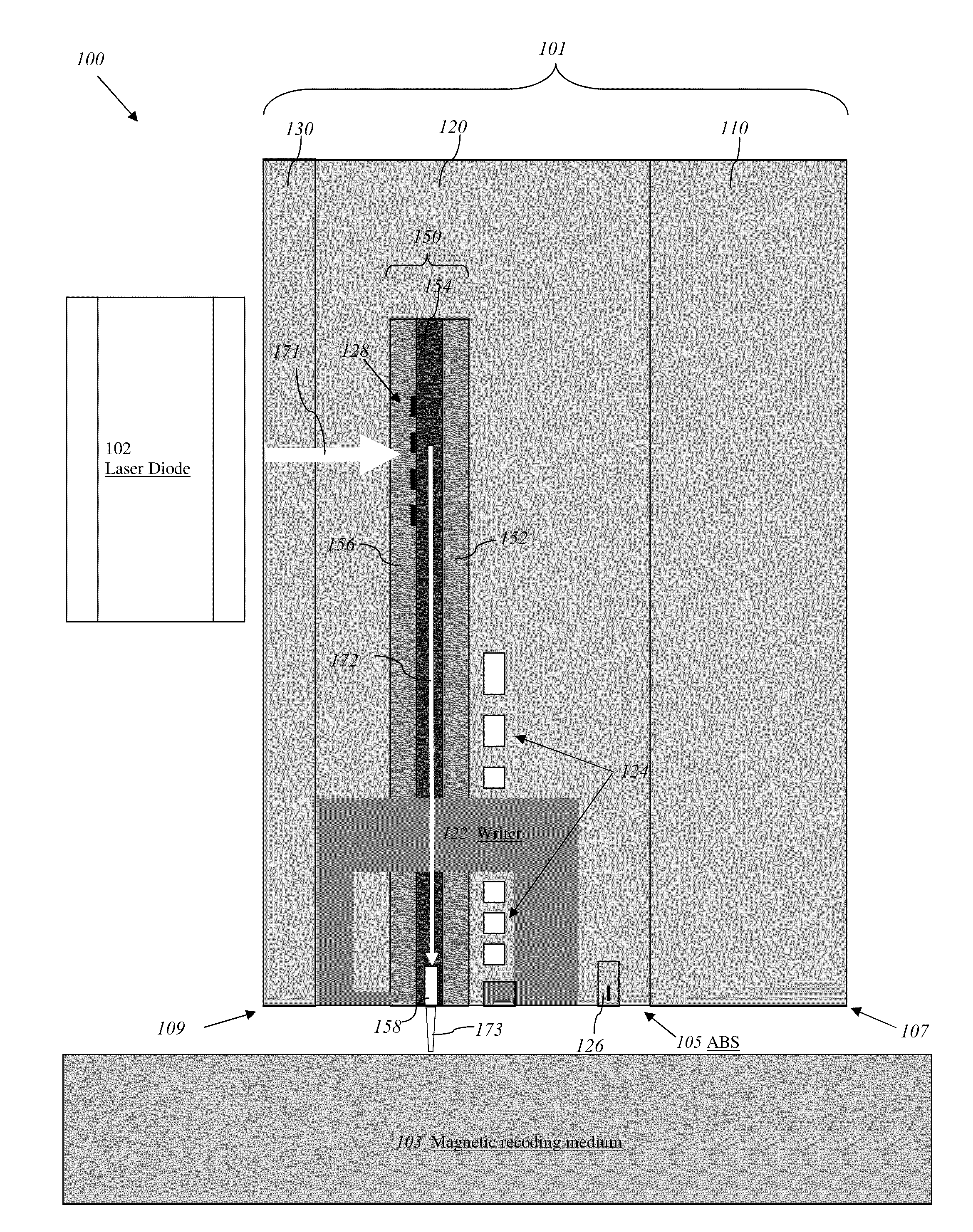

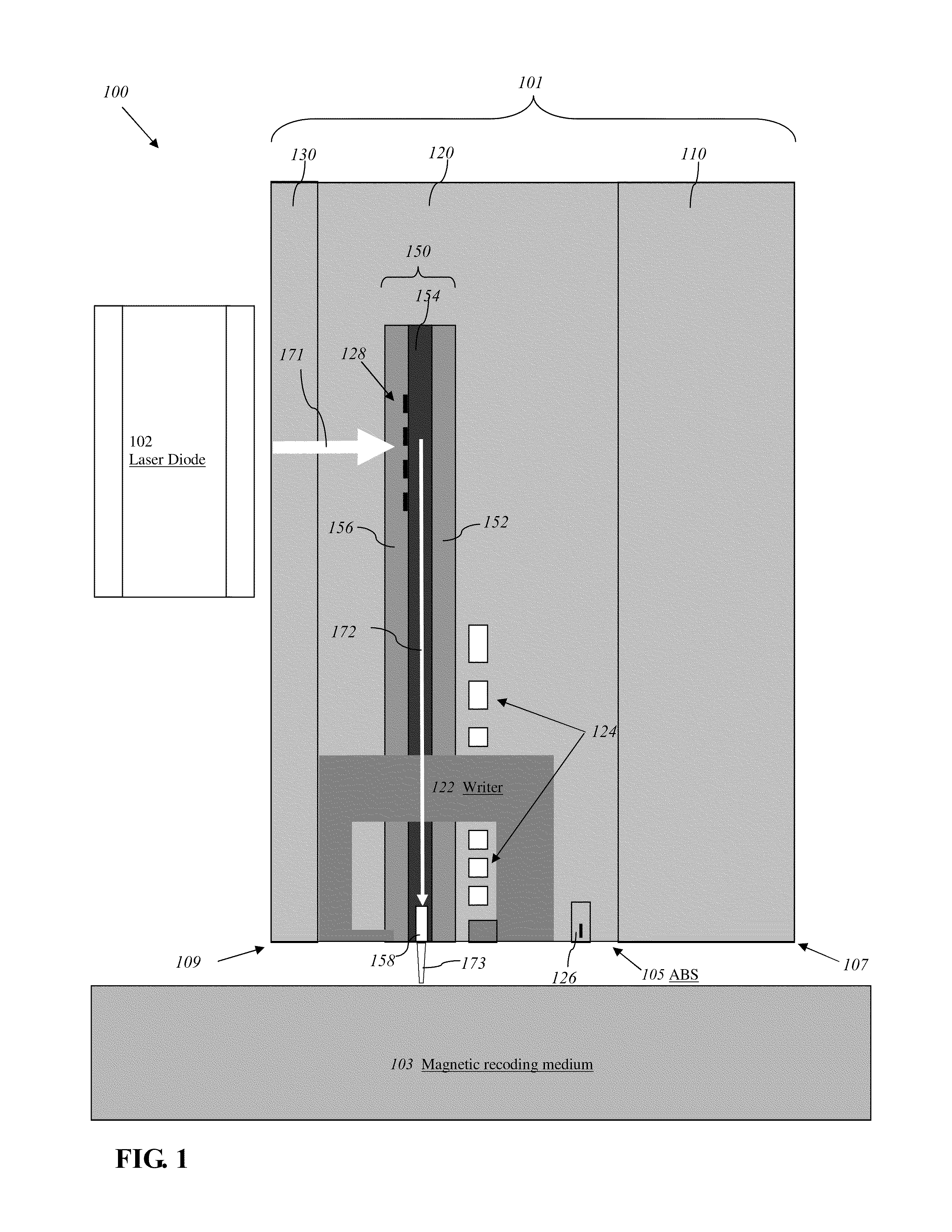

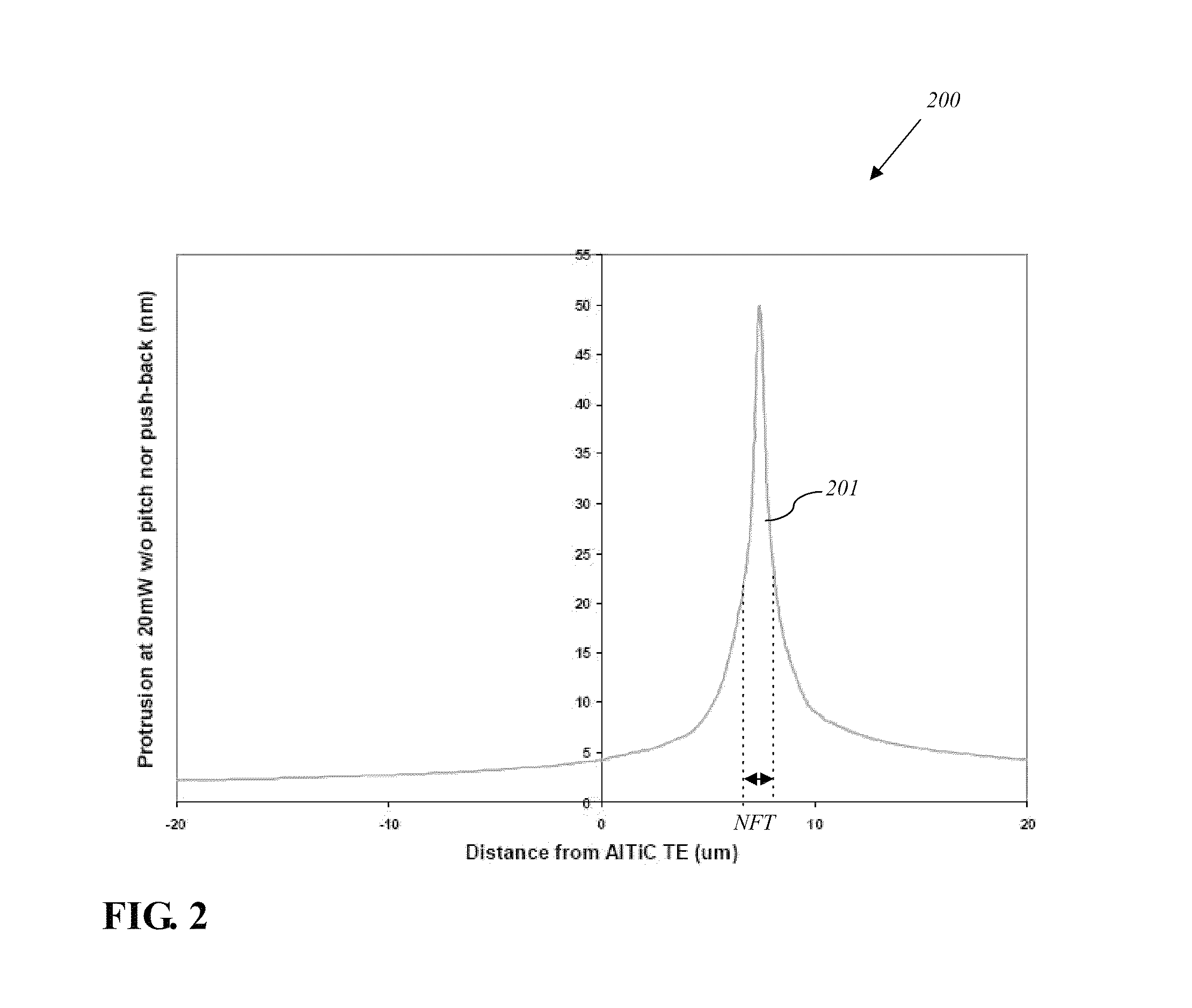

Reducing thermal protrusion of a near field transducer in an energy assisted magnetic recording head

ActiveUS8077418B1Preventing protrusion-related damageImprove reliabilityCombination recordingElectrical transducersTransducerOptical power

Methods of fabricating an energy-assisted magnetic recording (EAMR) head to compensate for a heat-induced protrusion of a near field transducer formed therein are disclosed. The methods can include applying optical power to the near field transducer to generate heat therein. The near field transducer protrudes beyond an air bearing surface of the EAMR head by the generated heat. The methods can further include removing a protruded portion of the near field transducer.

Owner:WESTERN DIGITAL TECH INC

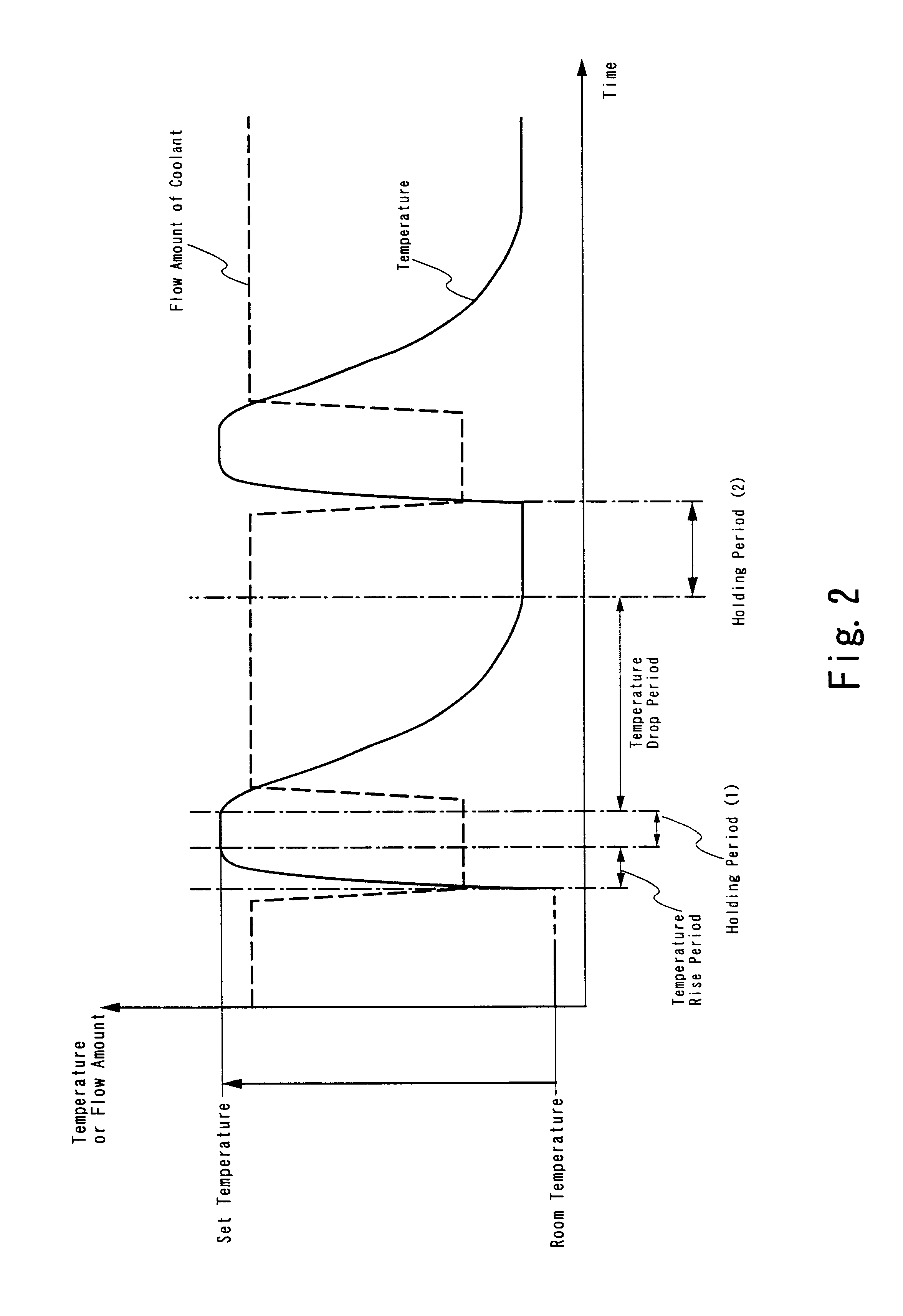

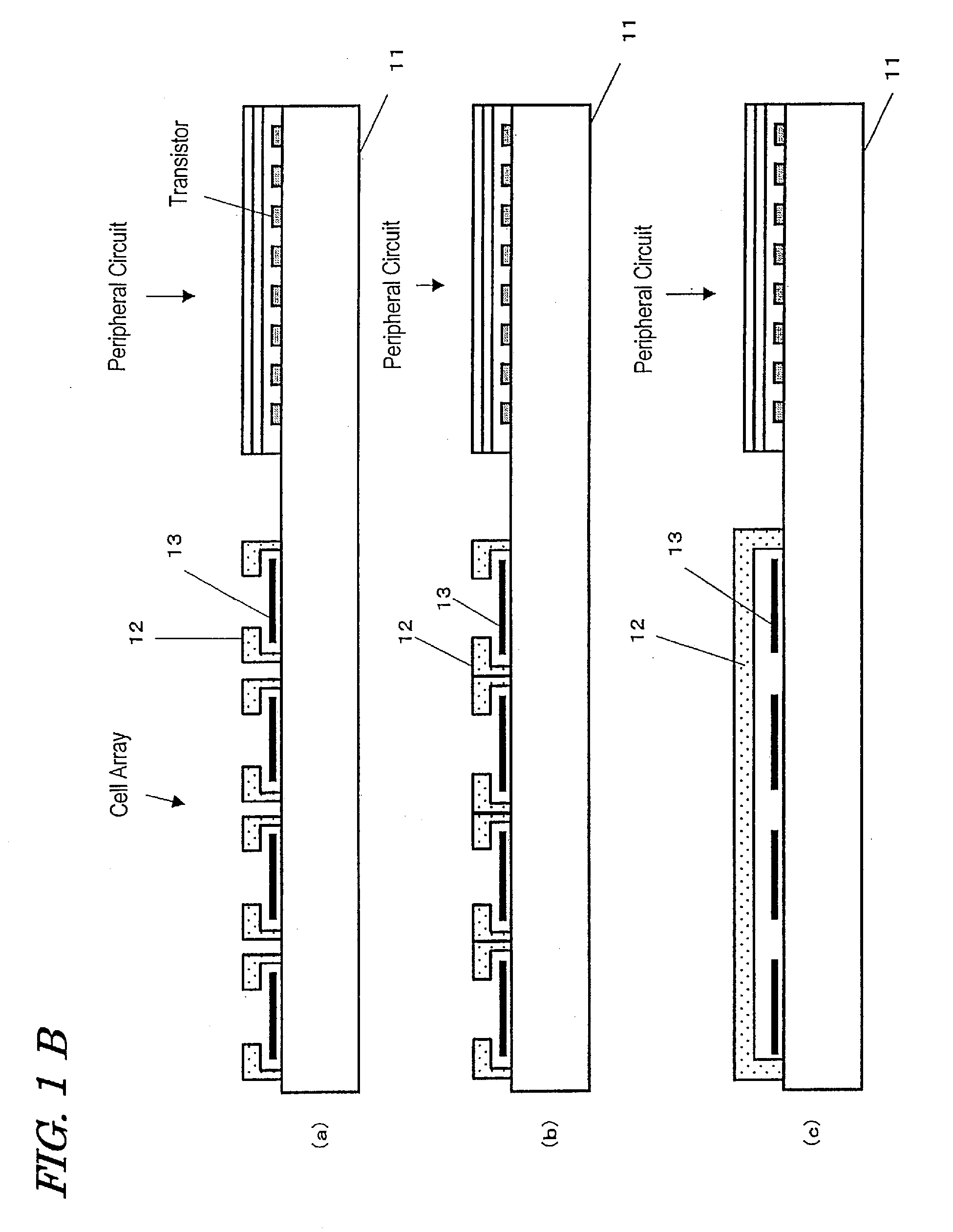

Semiconductor device manufacturing method, heat treatment apparatus, and heat treatment method

For manufacture of a semiconductor device using a low heat resistant substrate such as a glass substrate, a method of heat treatment for activating an impurity element that is used to dope a semiconductor film and for performing gettering on the semiconductor film in a short period of time without deforming the substrate, is provided. Also provided is a heat treatment apparatus for carrying out the above heat treatment. The heat treatment method of the present invention involves irradiating an object with light emitted from a lamp light source, and is characterized in that the lamp light source emits light for 0.1 to 20 seconds at a time and that light from the lamp light source irradiates the object several times. The method is also characterized in that the irradiated region is subjected to pulsating light from the lamp light source such that the irradiated region holds the temperature to its highest for 0.5 to 5 seconds. The method is also characterized in that the amount of coolant to be supplied is increased or reduced in accordance with blinking of the lamp light source to enhance the effect of the heat treatment on the semiconductor film and to prevent a heat-induced damage to the substrate.

Owner:SEMICON ENERGY LAB CO LTD

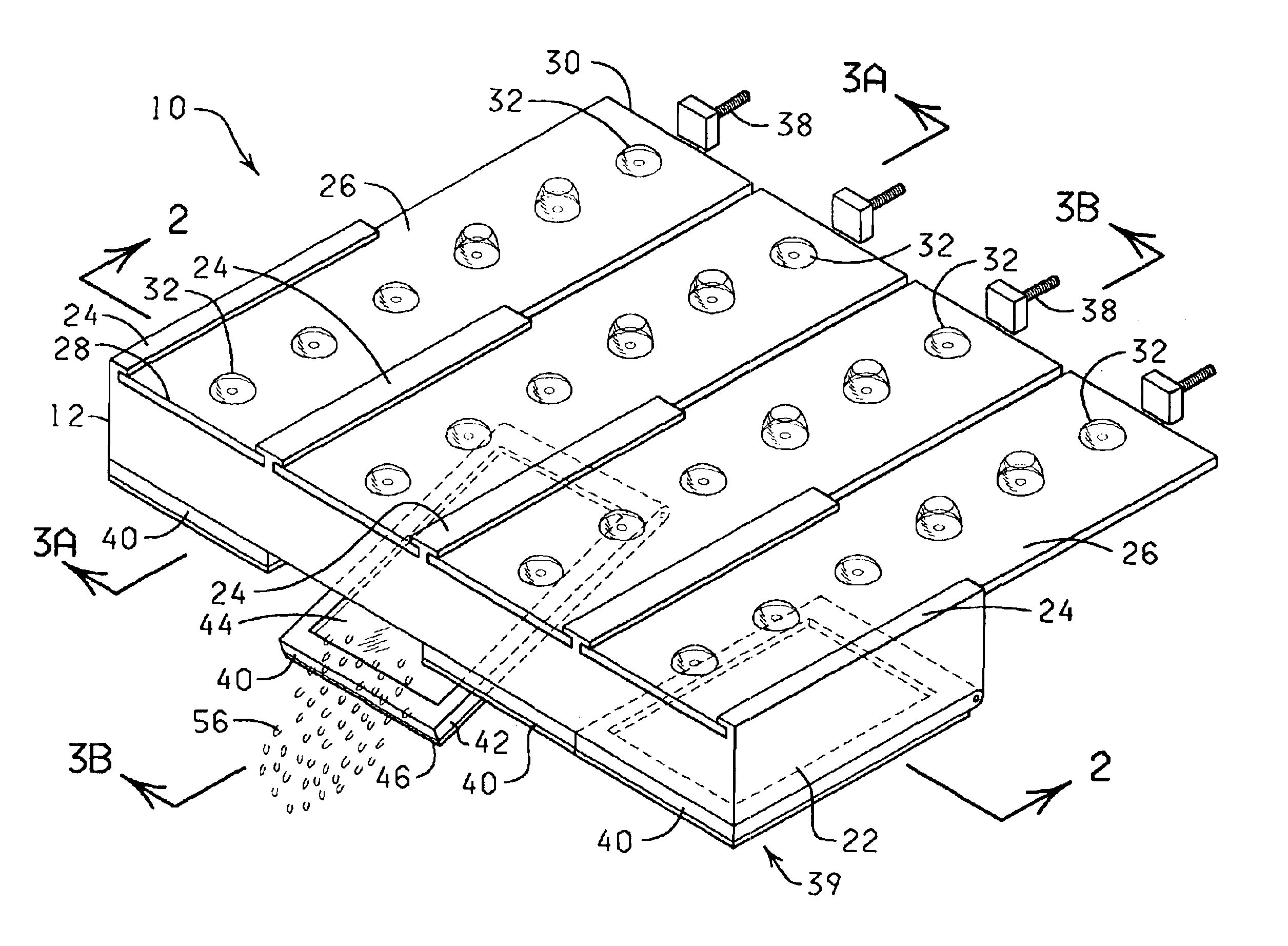

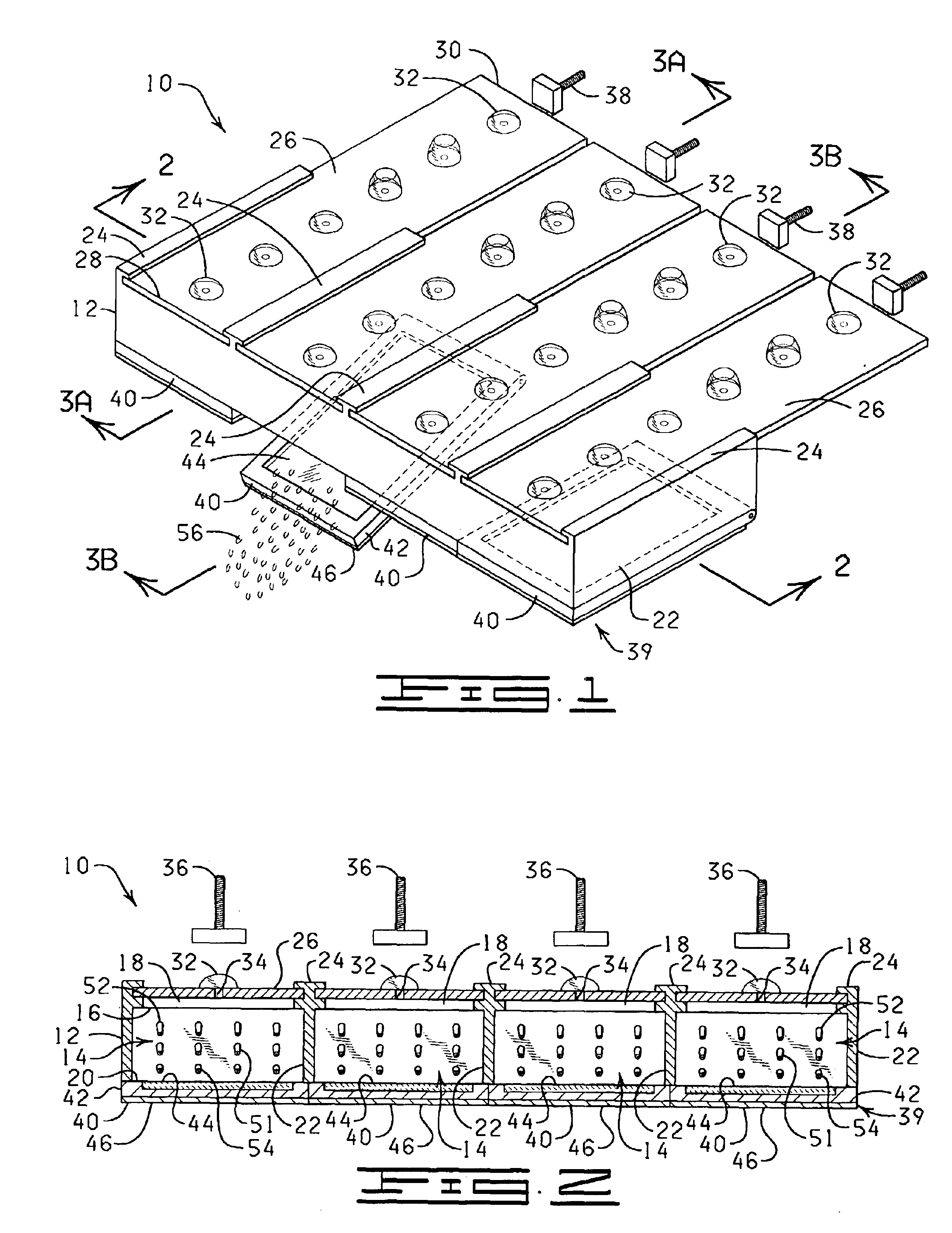

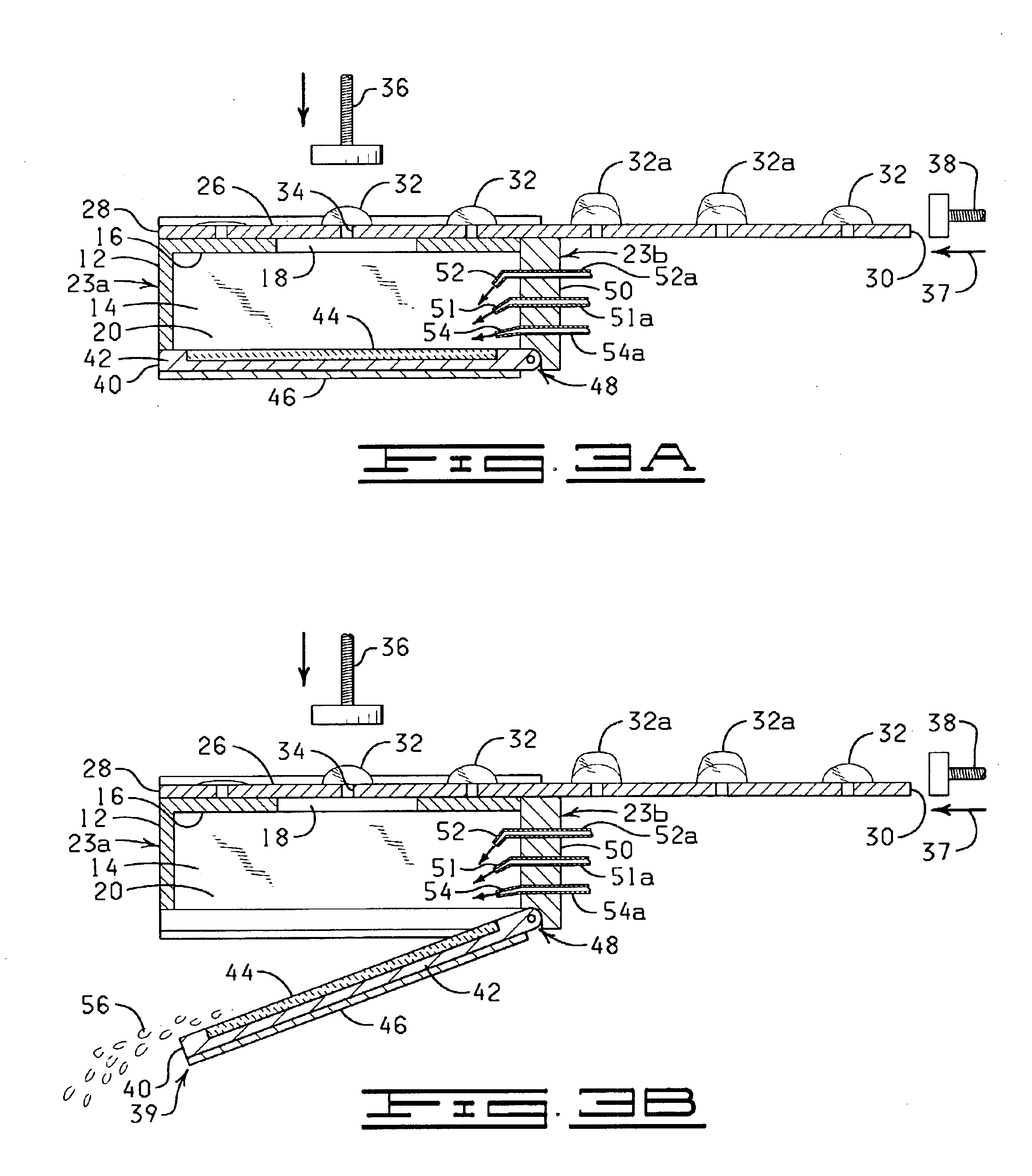

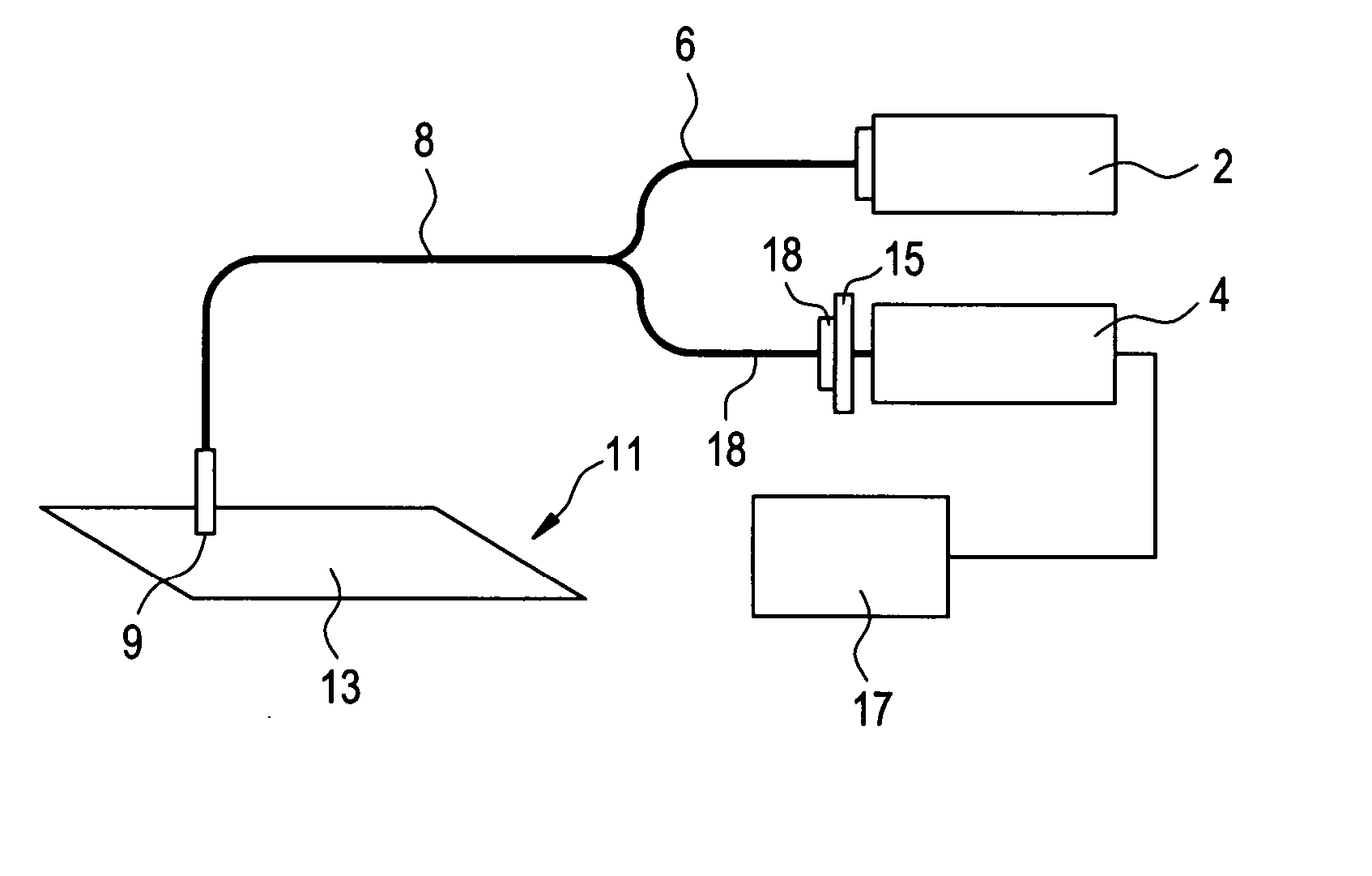

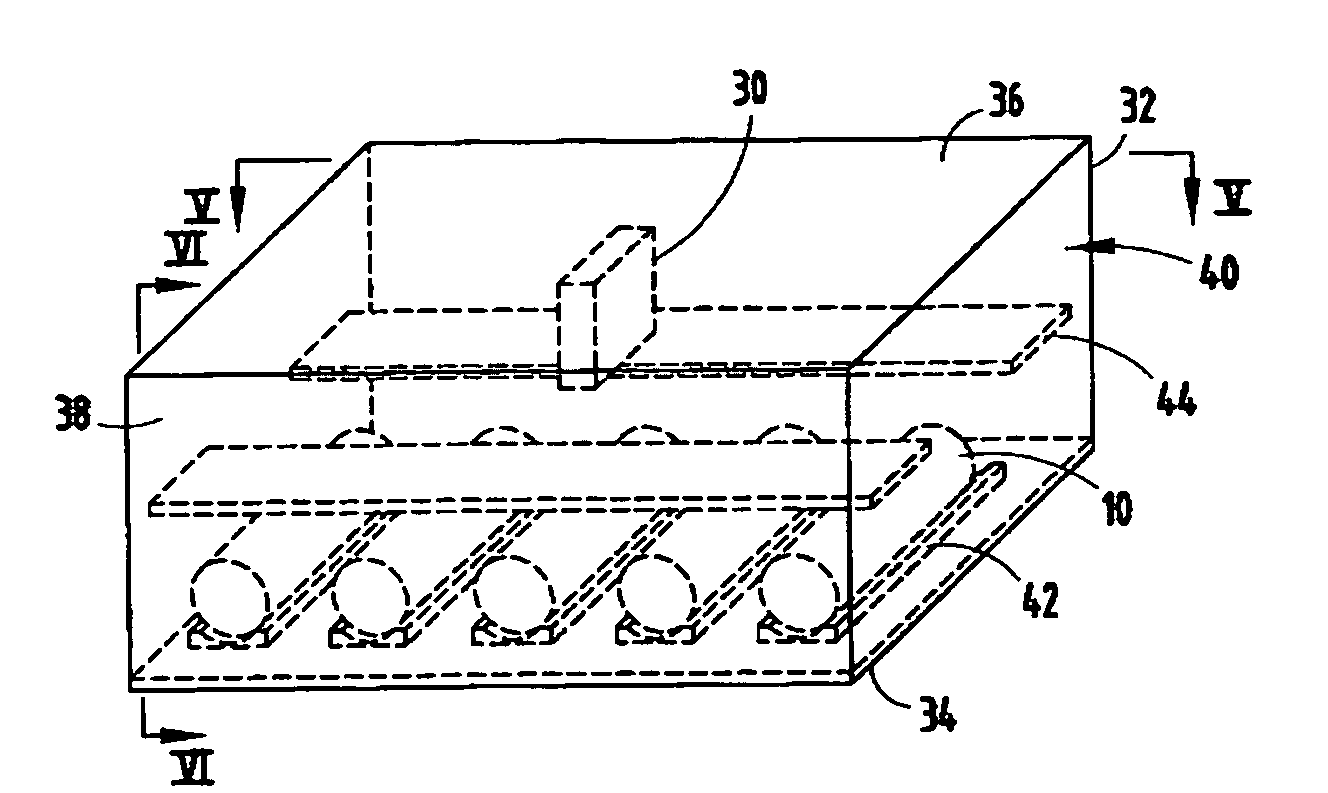

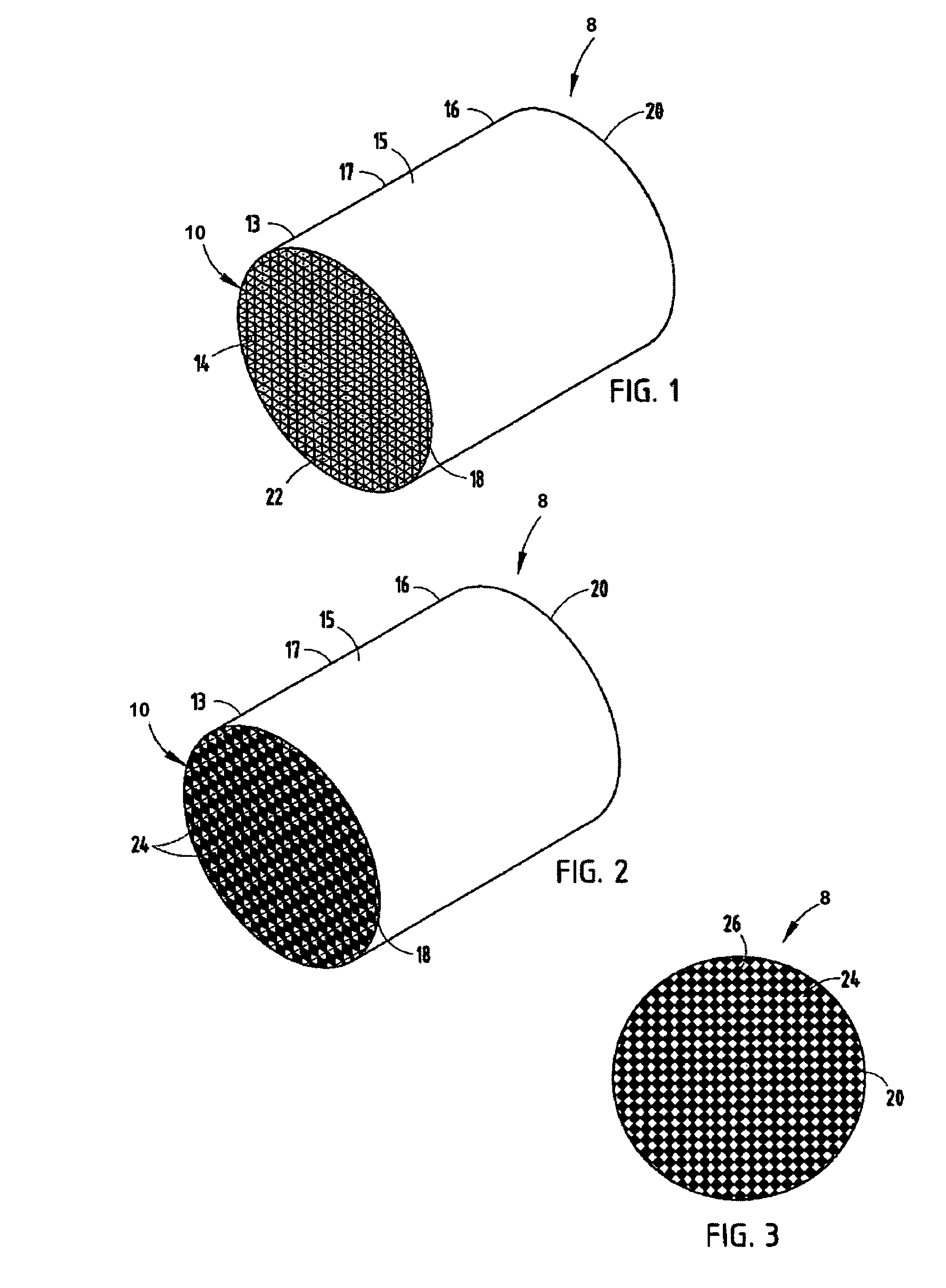

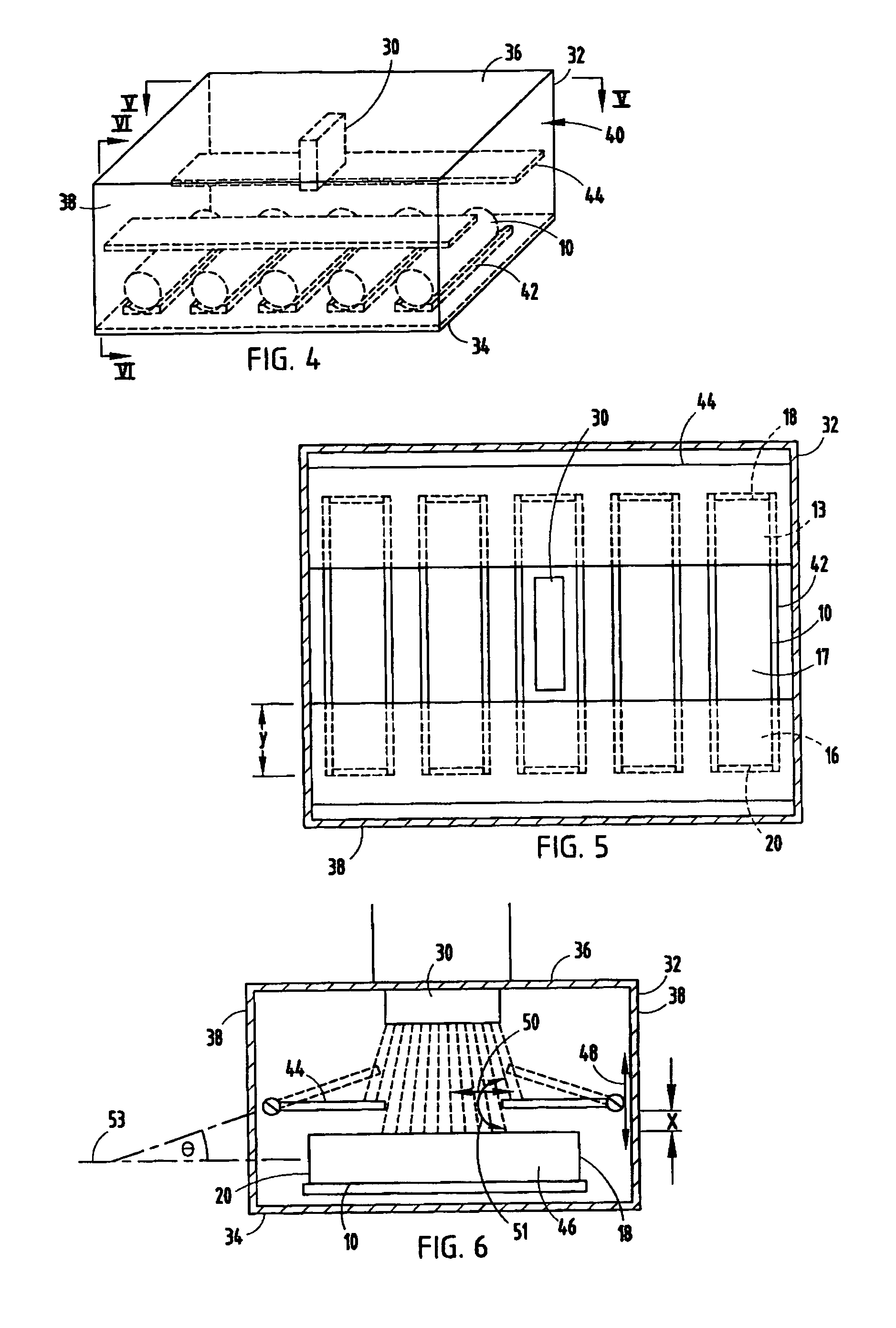

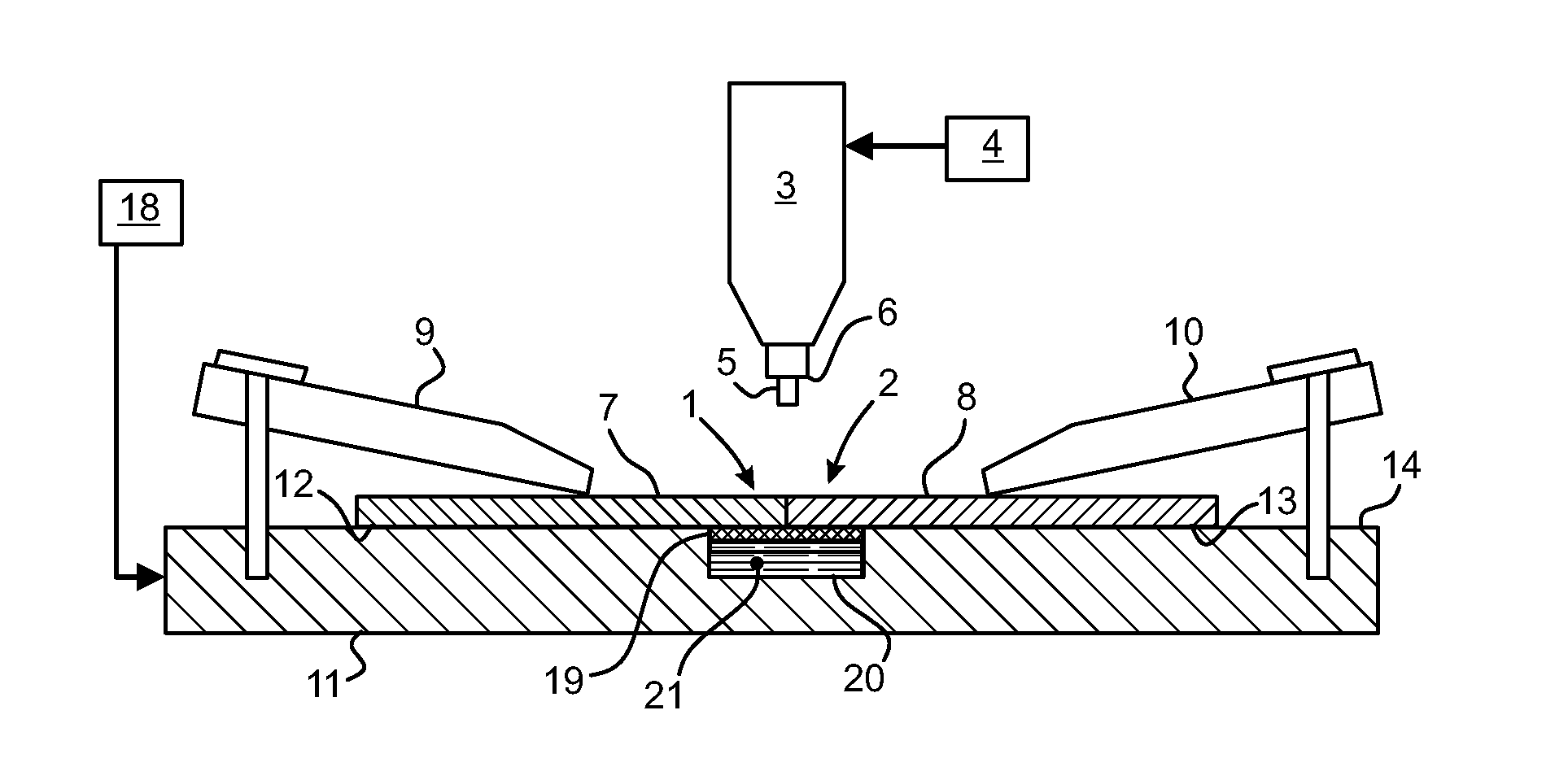

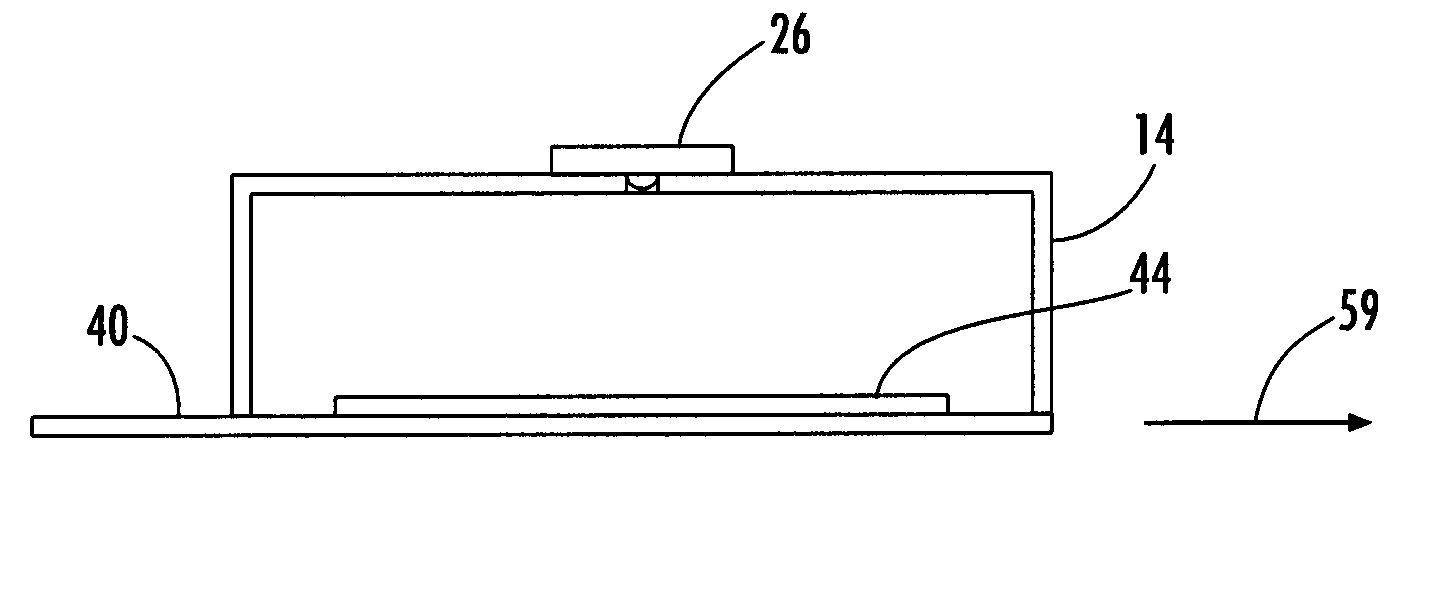

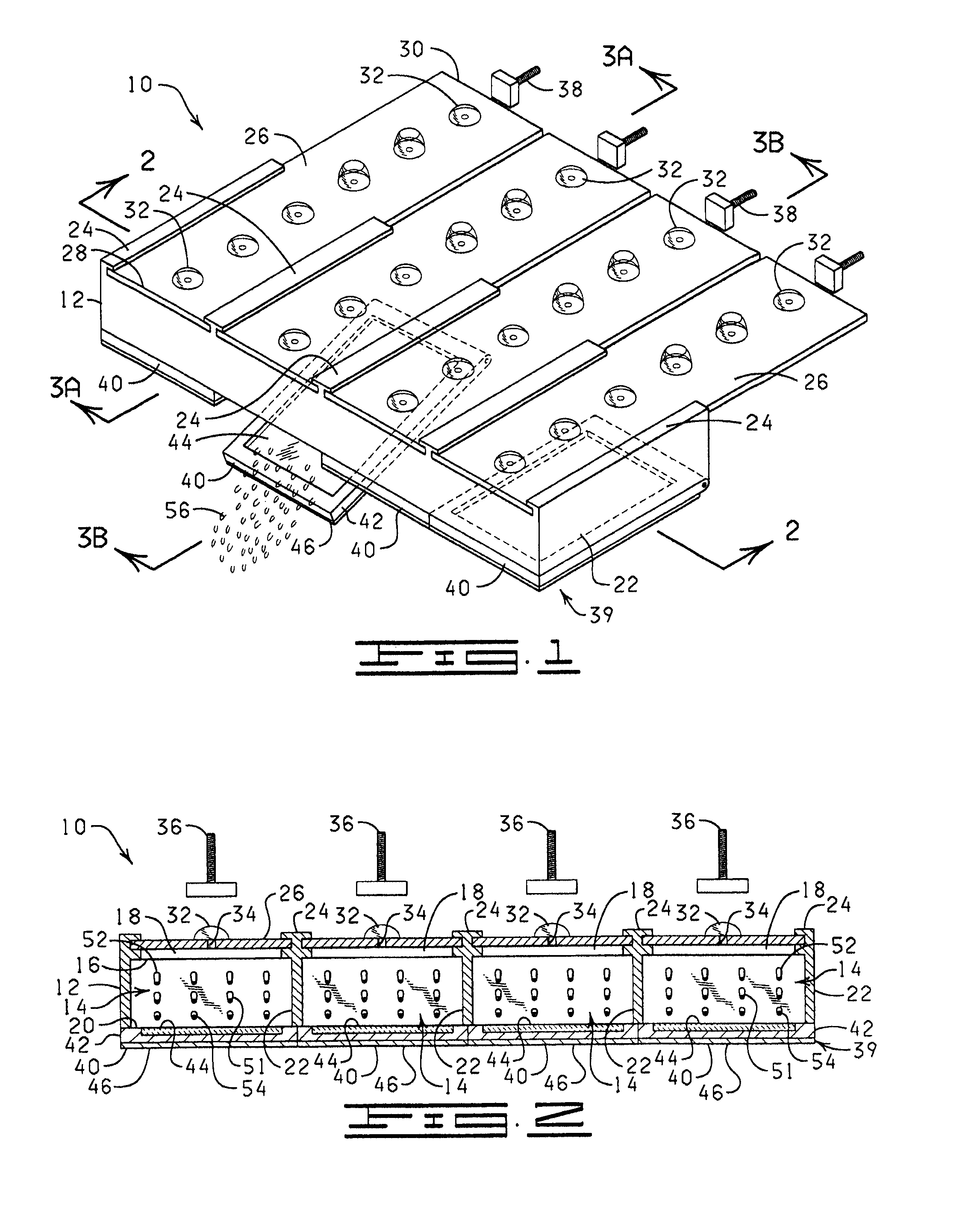

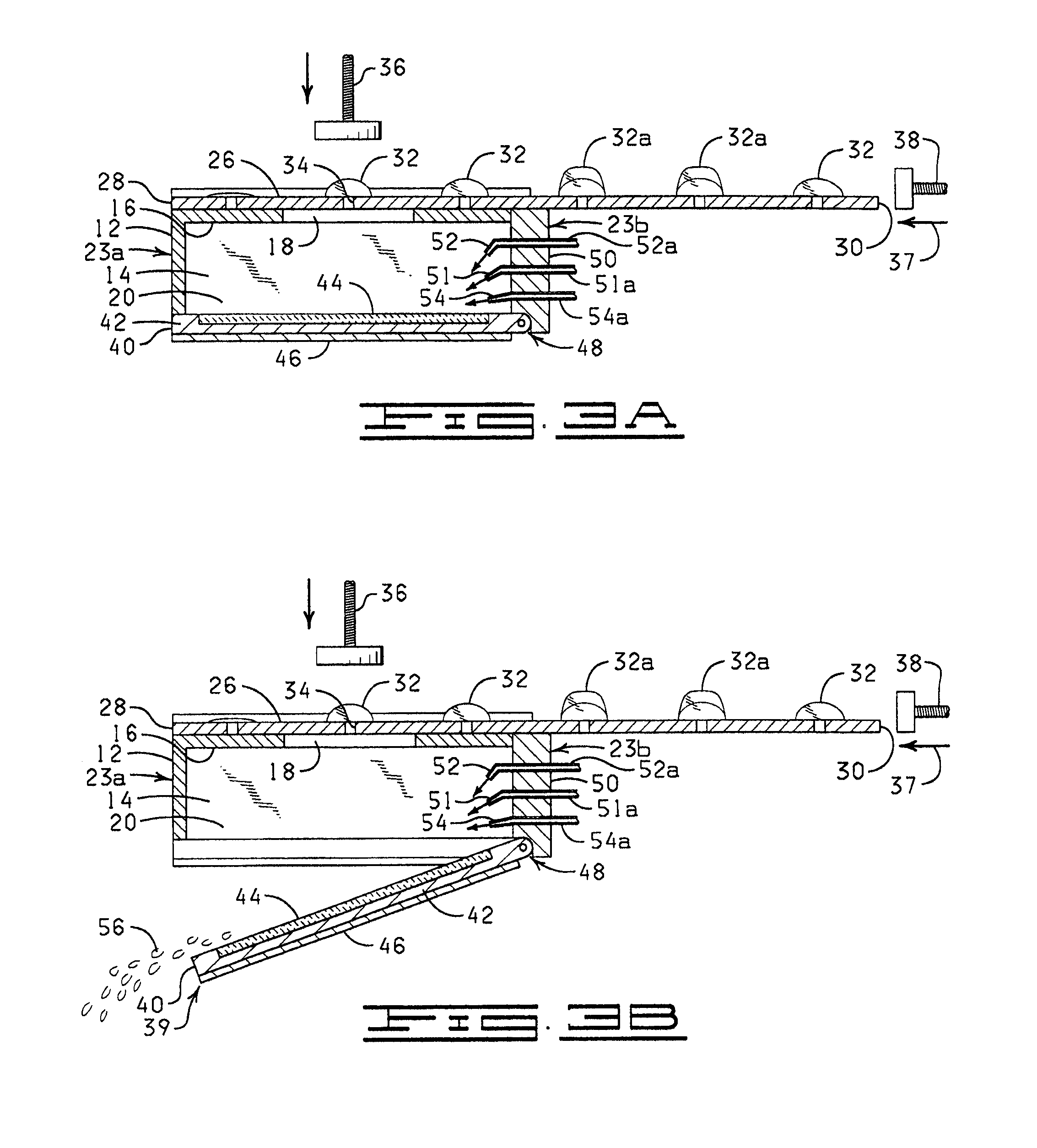

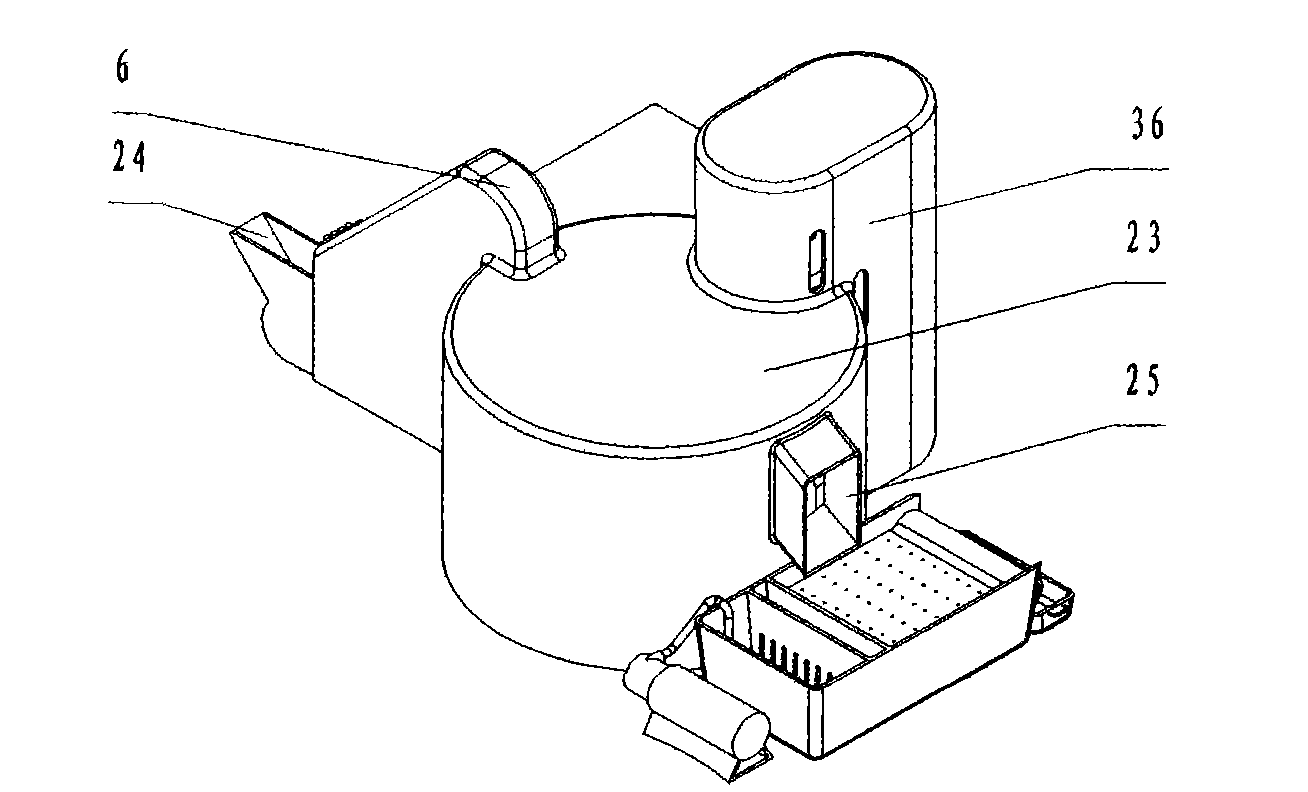

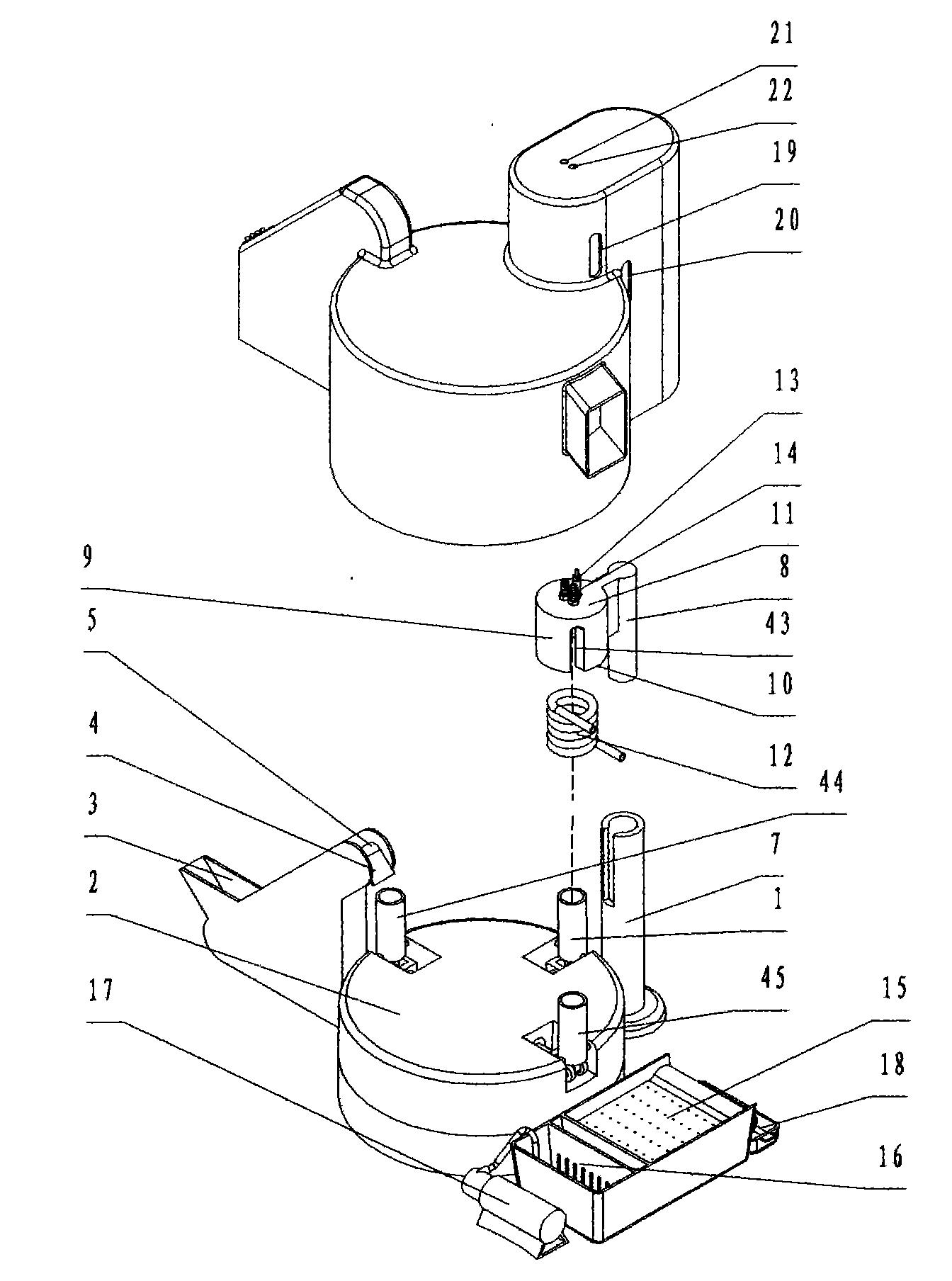

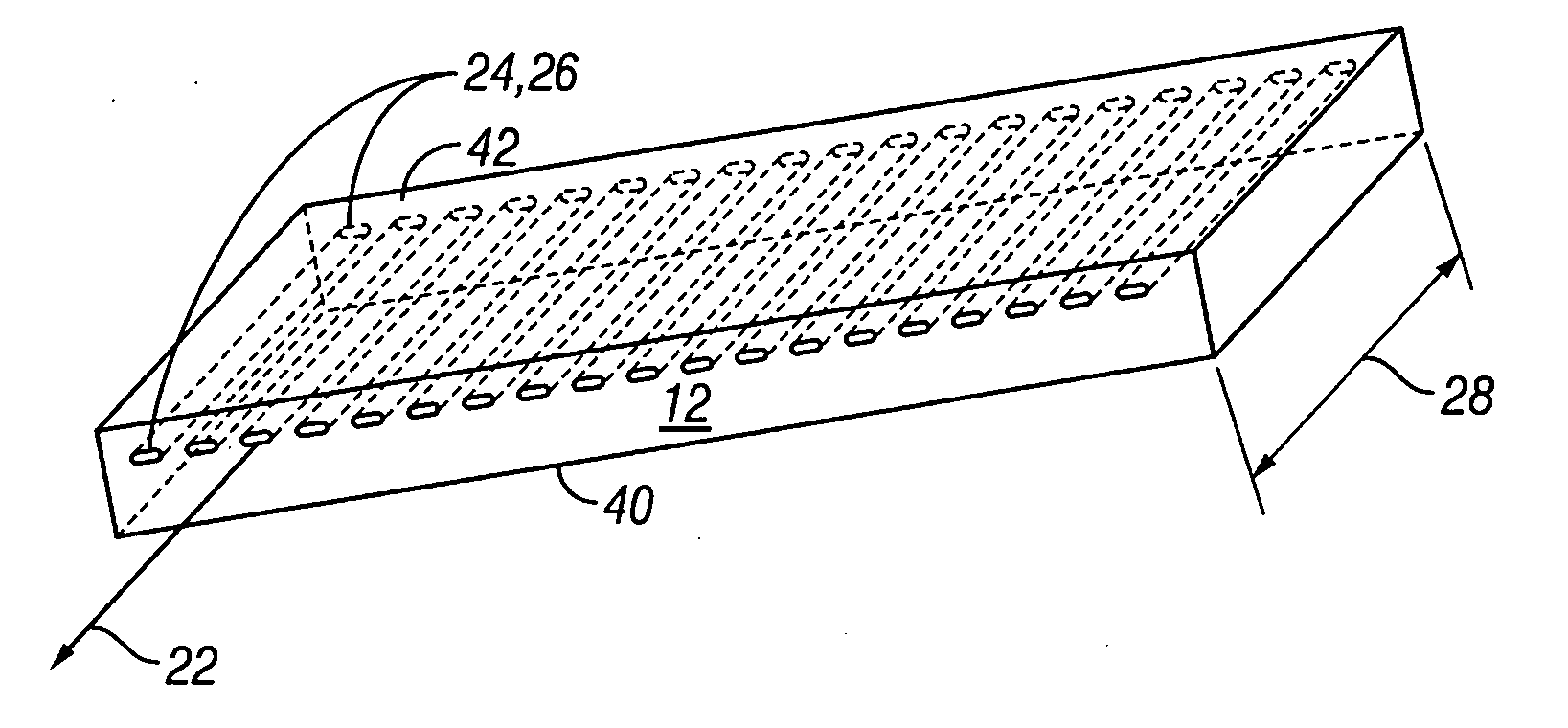

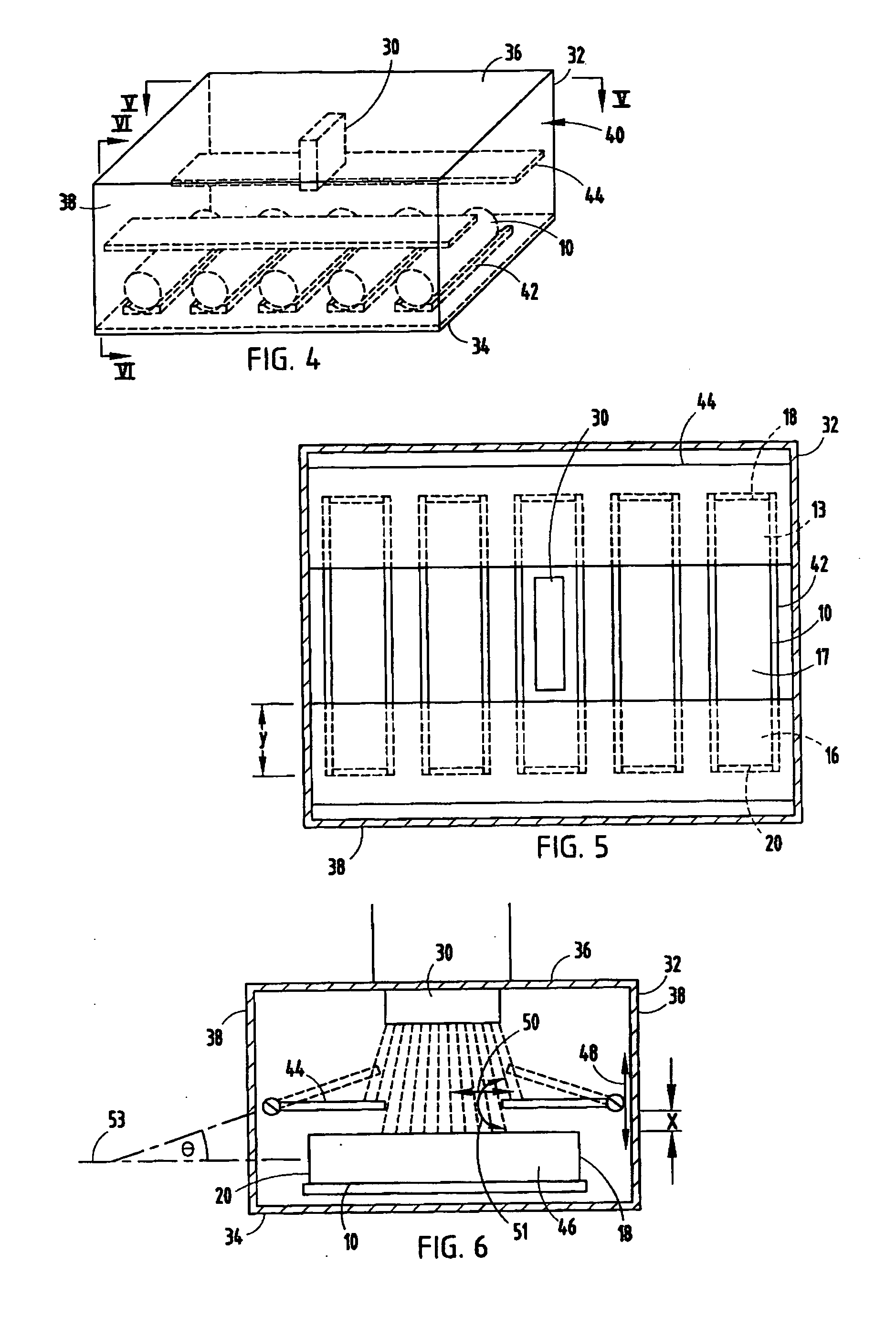

In situ heat induced antigen recovery and staining apparatus and method

InactiveUS6855292B2Bioreactor/fermenter combinationsBiological substance pretreatmentsAntigenMicroscope slide

An automated in situ heat induced antigen recovery and staining method and apparatus for treating a plurality of microscope slides. The process of heat induced antigen recovery and the process of staining the biological sample on the microscope slide are conducted in the same apparatus, wherein the microscope slides do not need to by physically removed from one apparatus to another. Each treatment step occurs within the same reaction compartment. The reaction conditions of each reaction compartment for treating a slide can preferably be controlled independently, including the individualized application of reagents to each slide and the individualized treatment of each slide. The reagents are preferably held in a reagent dispensing strip similar to a “blister pack”.

Owner:ANGROS LEE

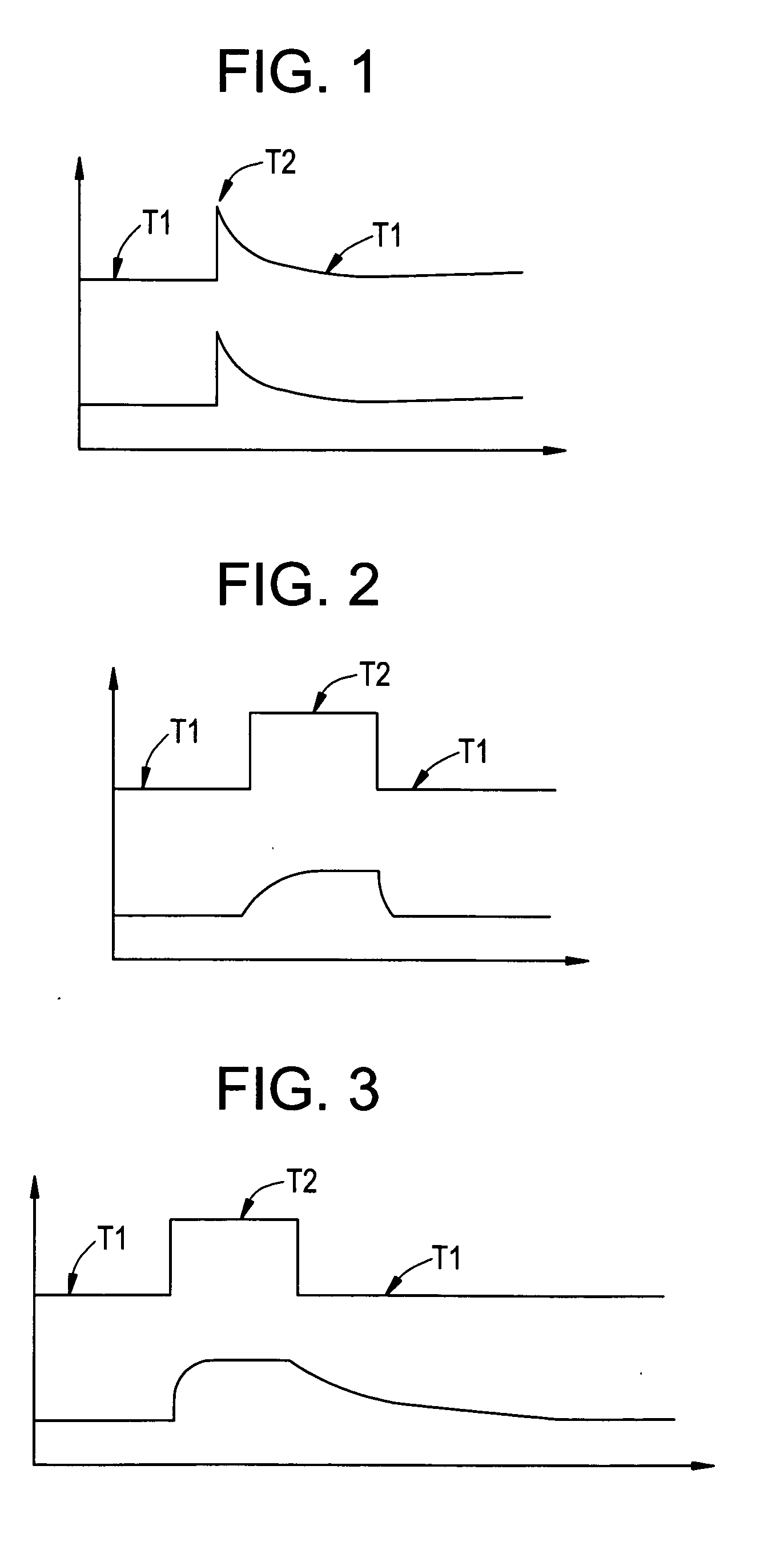

Method of authenticating articles, authenticatable polymers, and authenticatable articles

Disclosed is a method for authenticating that an article is an authenticatable article. The method uses an optical tester, the optical tester comprising an electromagnetic radiation source and a detector. The authenticatable article comprises a heat responsive compound having a temperature dependent optical interaction with the electromagnetic radiation source in the presence of a heat stimulus to produce a heat induced electromagnetic radiation signature. The method comprises placing a test portion of the article in interaction with the electromagnetic radiation source of the optical tester, creating a heated portion by exposing the test portion of the article to a heat stimulus sufficient to raise the temperature of the test portion from a temperature T1 to a temperature T2, measuring the heat induced electromagnetic radiation signature of the heated portion with the detector, and authenticating that the article is an authenticatable article if the heat induced electromagnetic radiation signature is present.

Owner:GENERAL ELECTRIC CO

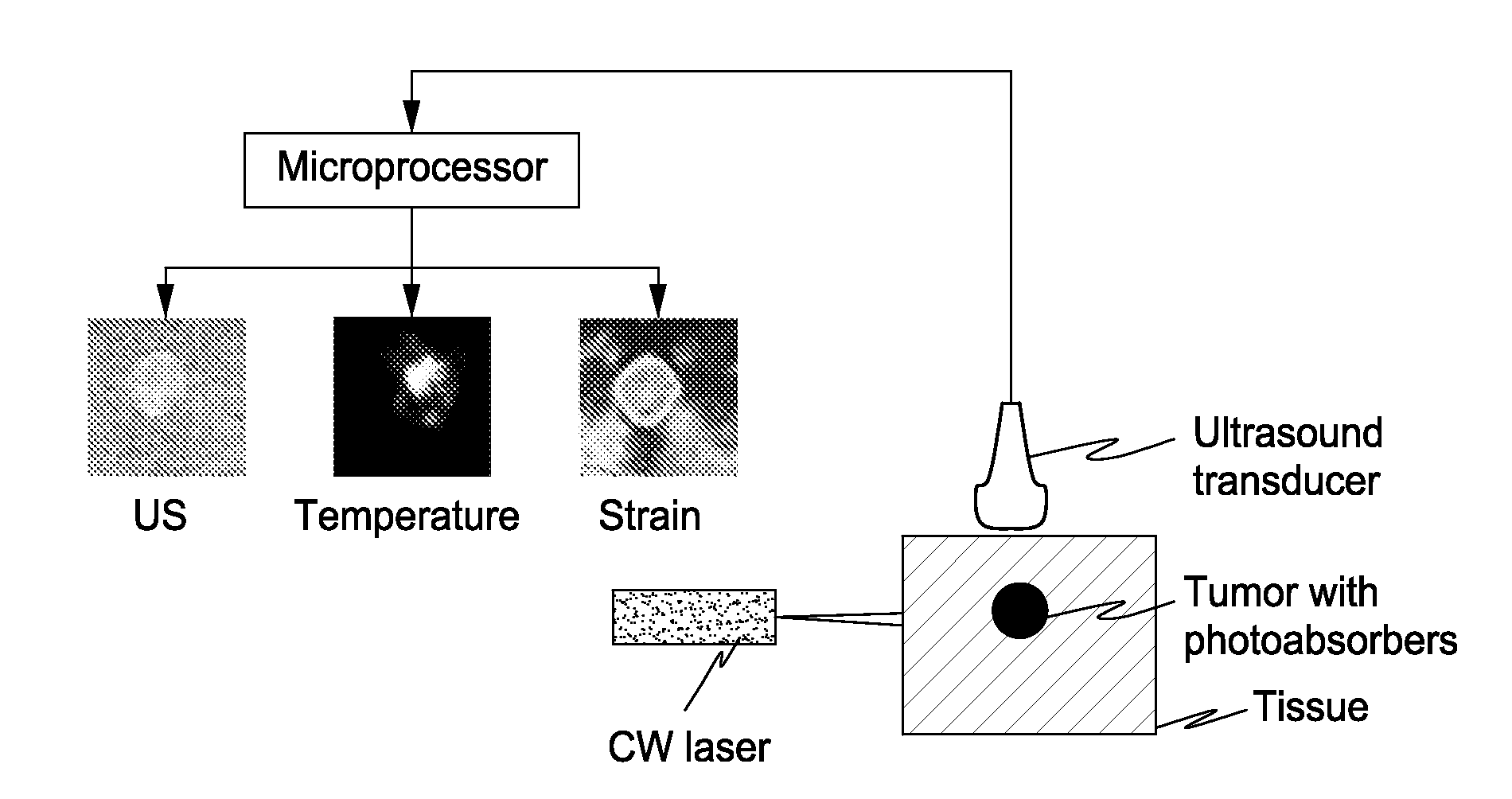

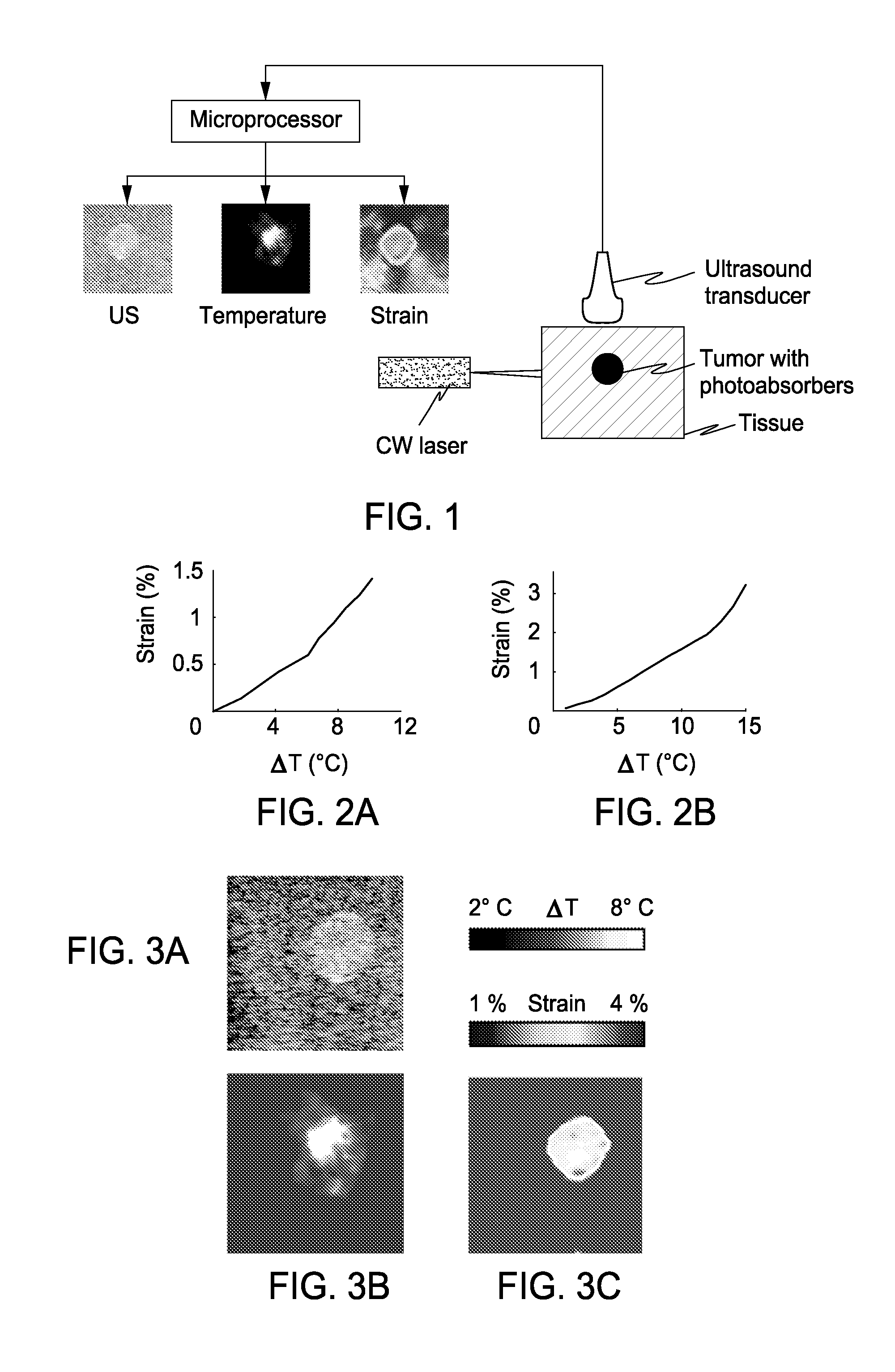

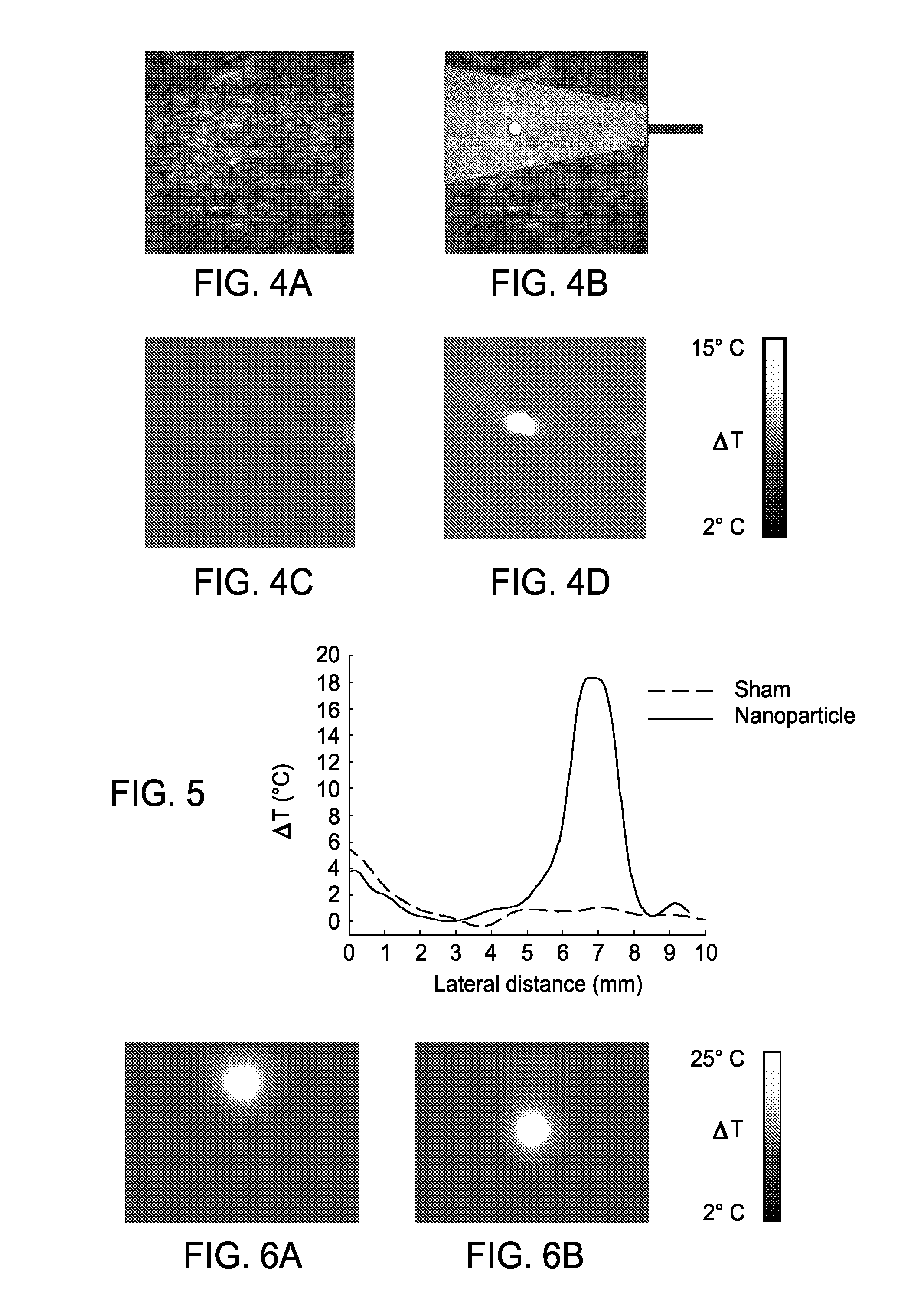

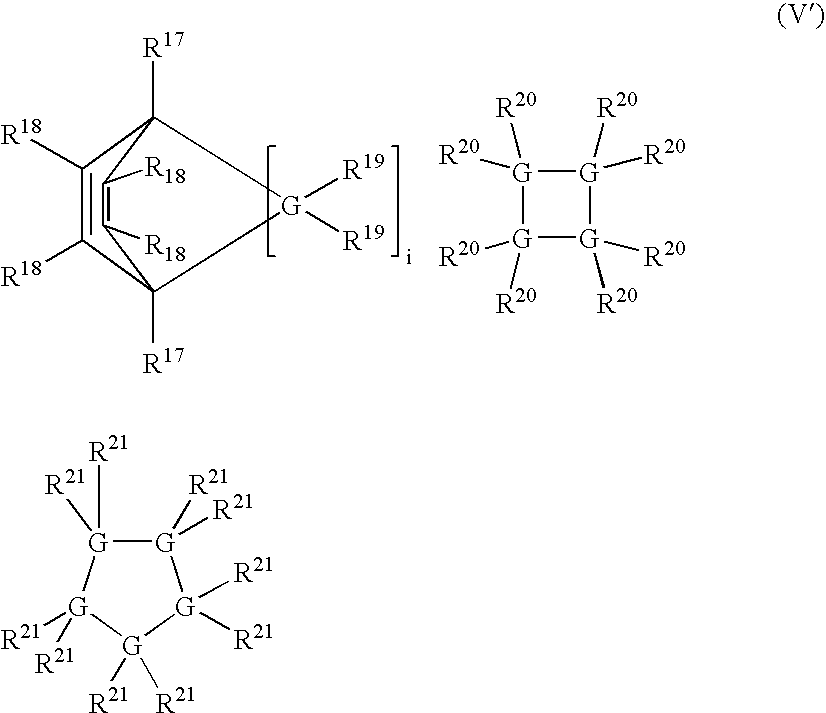

Real-Time Ultrasound Monitoring of Heat-Induced Tissue Interactions

InactiveUS20090105588A1Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsRadiation therapyReal time ultrasound

The present invention includes an apparatus, method and system for monitoring and controlling radiation therapy, the system including a radiative source that emits energy that enters a tissue and is absorbed at or a near a target site in the tissue to heat the tissue; an ultrasound transmitter directed at the target site, wherein the ultrasound transmitter emits ultrasound signals to the tissue that has been heated by the radiative source; an ultrasound receiver directed at the target site, wherein the ultrasound receiver receives ultrasound signals emitted from the ultrasound transmitter and reflected from the tissue that has been heated by the radiative source; and a signal processor that processes the received ultrasound signal to calculate a tissue composition scan or tissue temperature scan.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

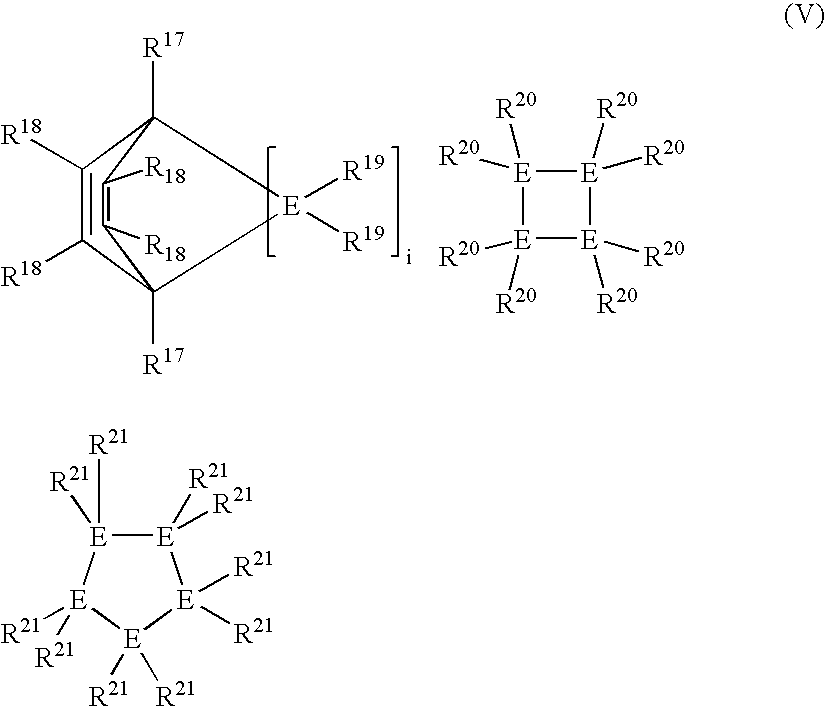

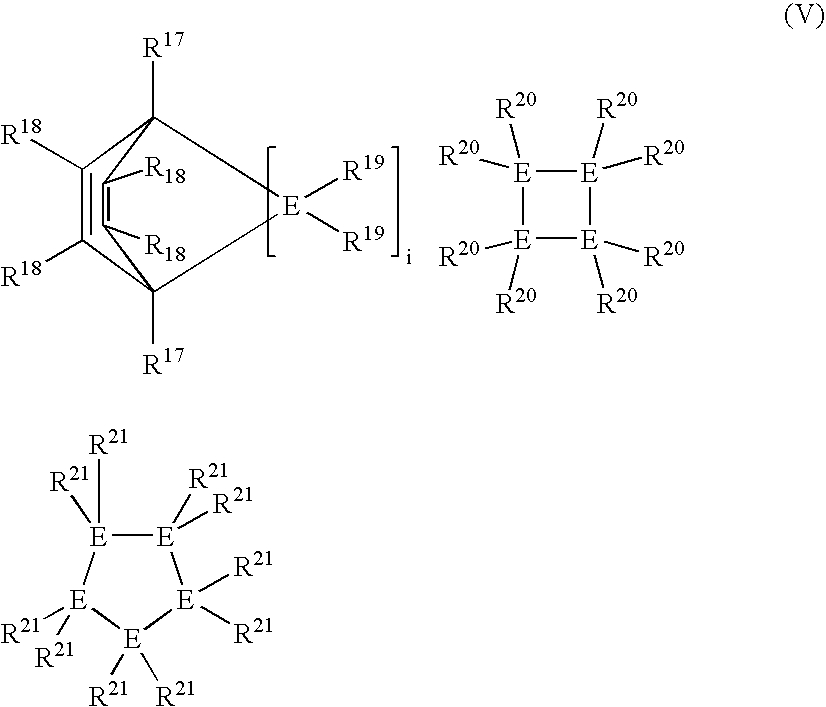

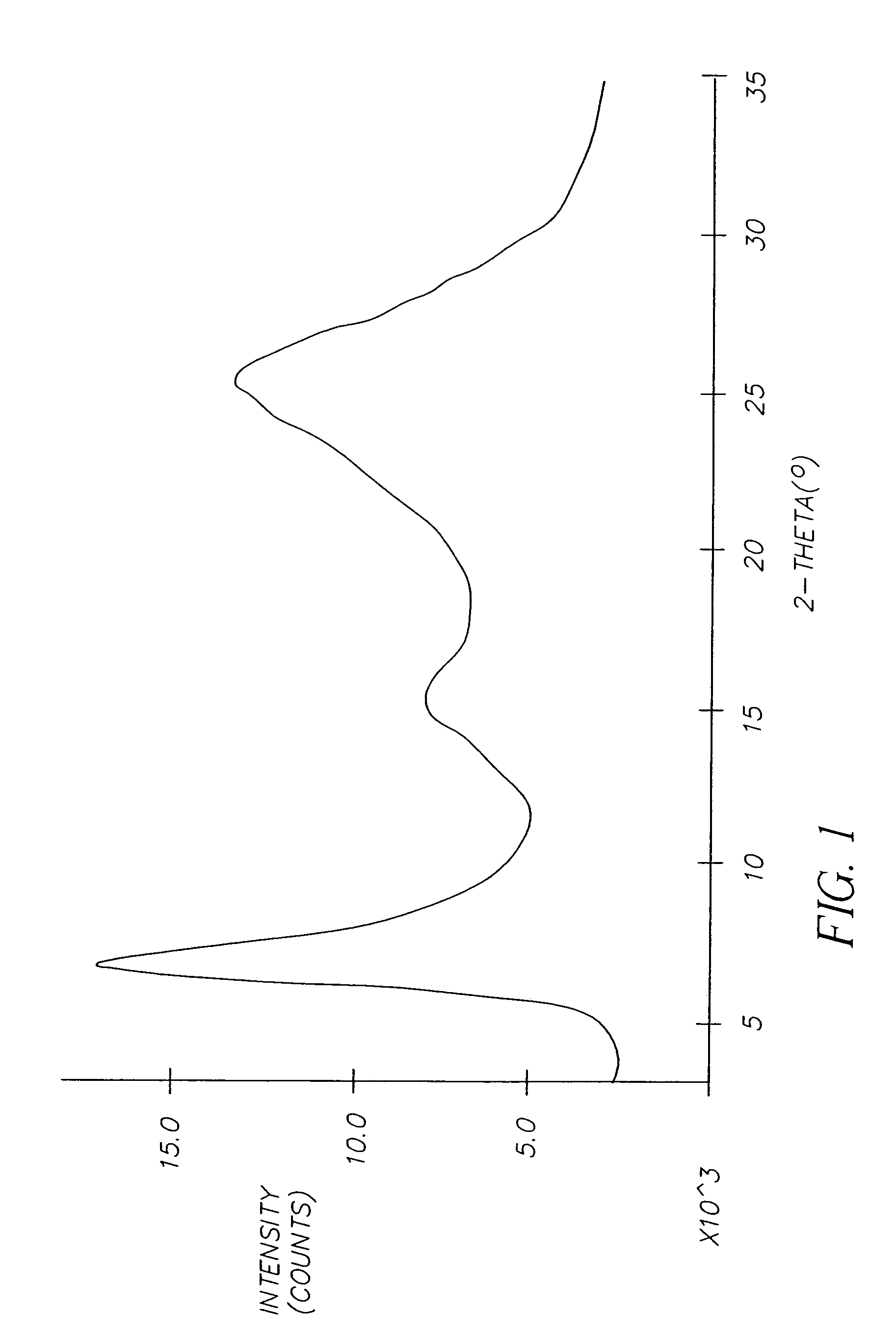

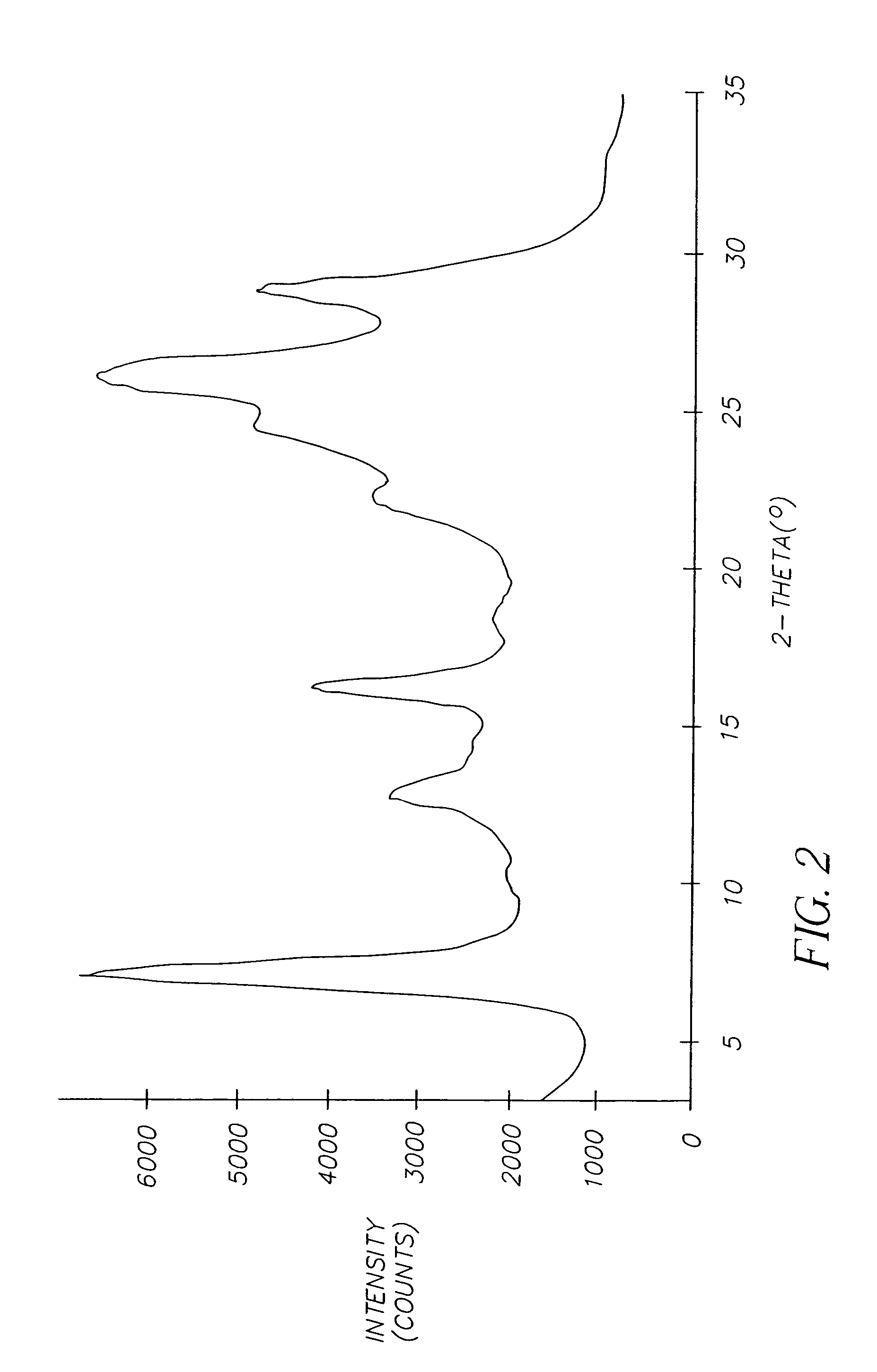

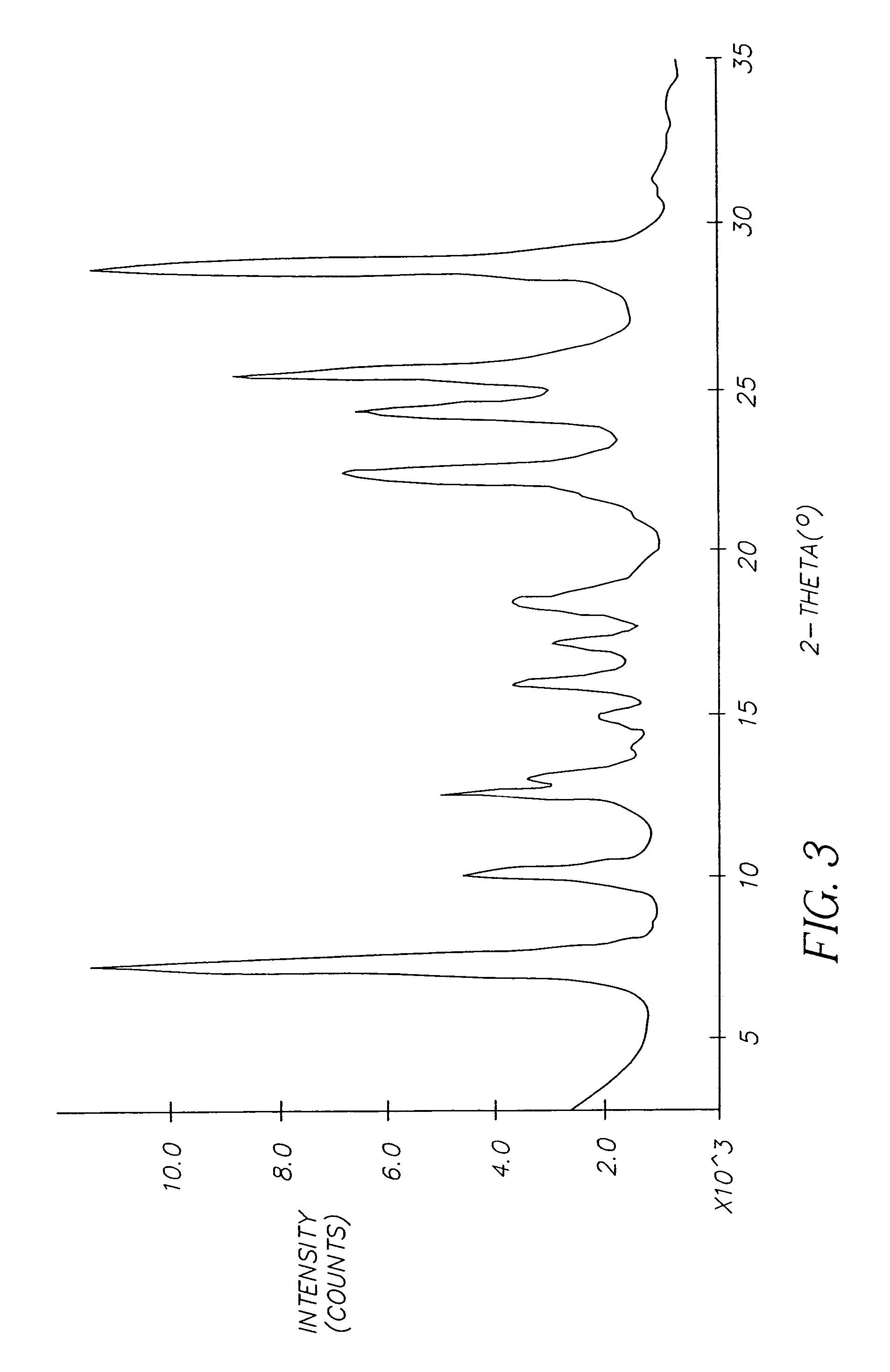

Linear and cross-linked high molecular weight polysilanes, polygermanes, and copolymers thereof, compositions containing the same, and methods of making and using such compounds and compositions

Methods are disclosed of making linear and cross-linked, HMW (high molecular weight) polysilanes and polygermanes, polyperhydrosilanes and polyperhydrogermanes, functional liquids containing the same, and methods of using the liquids in a range of desirable applications. The silane and germane polymers are generally composed of chains of Si and / or Ge substituted with R′ substituents, where each instance of R′ is, for example, independently hydrogen, halogen, alkenyl, alkynyl, hydrocarbyl, aromatic hydrocarbyl, heterocyclic aromatic hydrocarbyl, SiR″3, GeR″3, PR″2, OR″, NR″2, or SR″; where each instance of R″ is independently hydrogen or hydrocarbyl. The cross-linked polymers can be synthesized by dehalogenative coupling or dehydrocoupling. The linear polymers can be synthesized by ring-opening polymerization. The polymers can be further modified by halogenation and / or reaction with the source of hydride to furnish perhydrosilane and perhydrogermane polymers, which are used in liquid ink formulations. The synthesis allows for tuning of the liquid properties (e.g., viscosity, volatility, and surface tension). The liquids can be used for deposition of films and bodies by spincoating, inkjetting, dropcasting, etc., with or without the use of UV irradiation. The deposited films can be converted into amorphous and polycrystalline silicon or germanium, and silicon or germanium oxide or nitride by curing at 400-600 DEG C. and (optionally) laser- or heat-induced crystallization (and / or dopant activation, when dopant is present).

Owner:ENSURGE MICROPOWER ASA

Polyalkylene microporous diaphragm for lithiam ion battery and manufacturing method thereof

InactiveCN101000952AImprove securityImprove heat resistanceSynthetic resin layered productsCell component detailsPolyolefinPhase separation process

Owner:许贵斌

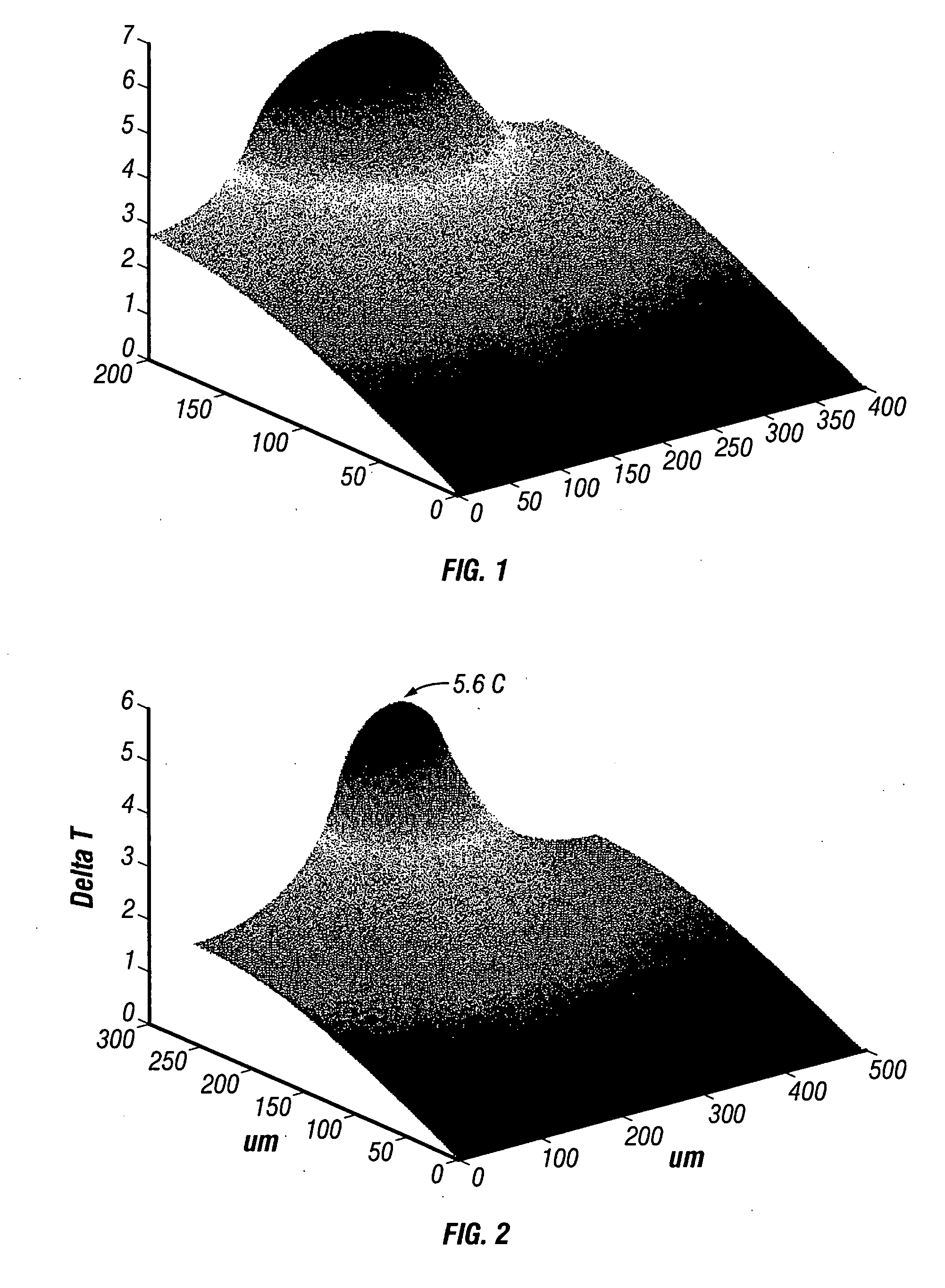

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

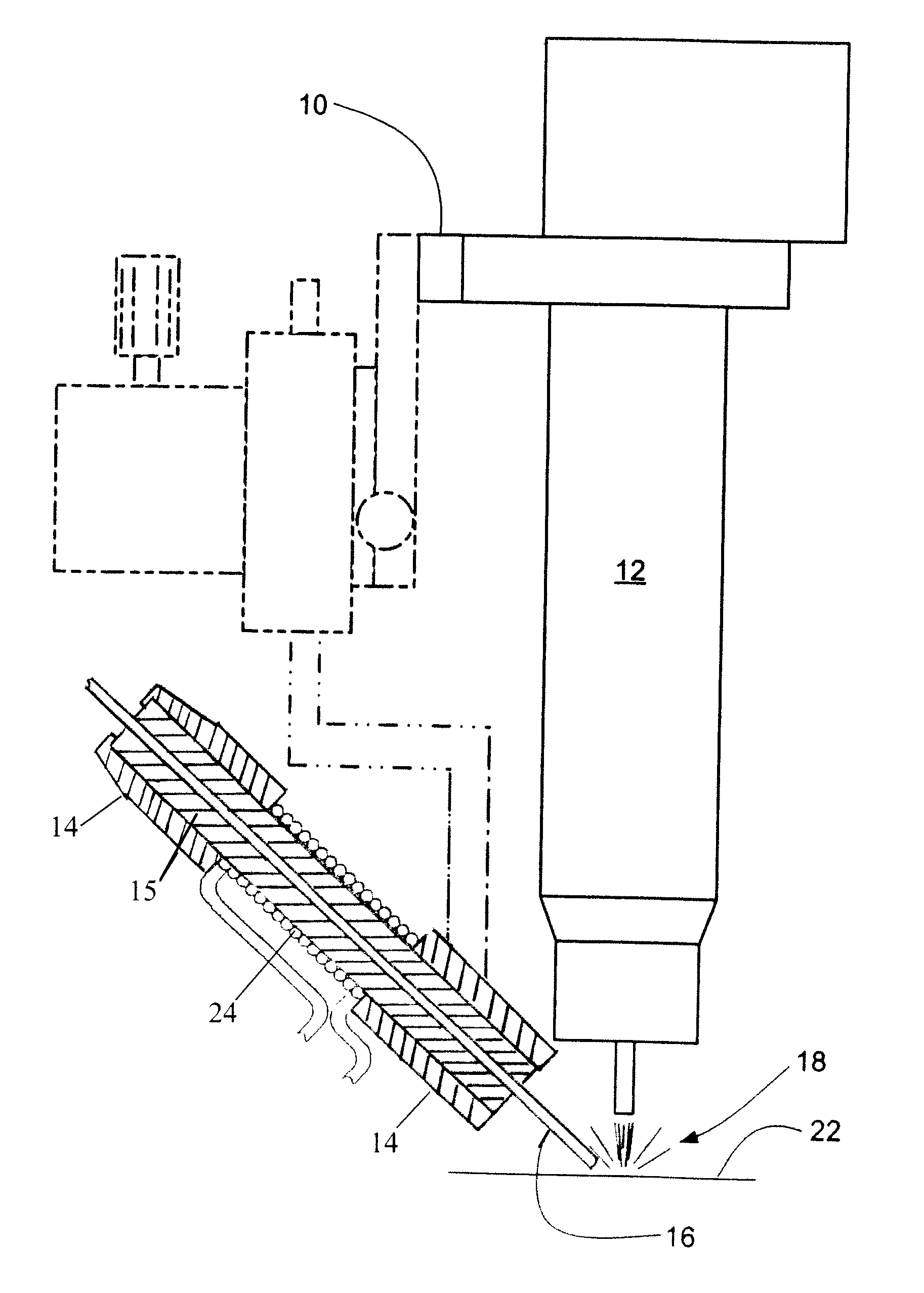

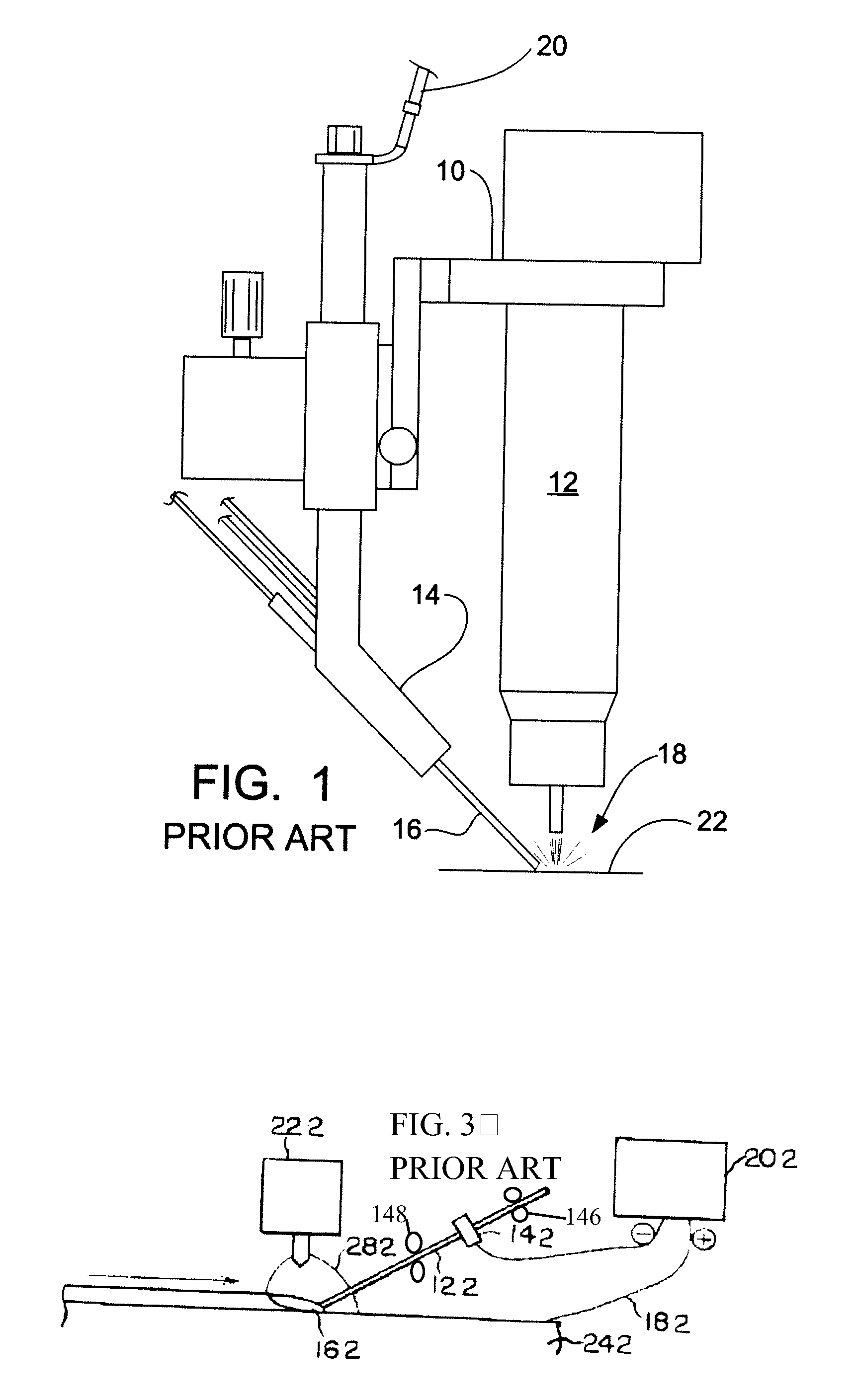

Induction heated, hot wire welding

InactiveUS20100059493A1Prevent heat lossImprove thermal shock resistanceArc welding apparatusLaser beam welding apparatusEngineeringElectric resistivity

A hot wire welding process. An induction coil is used to preheat the filler metal wire prior to its entering the welding puddle / arc region. An induction coil is placed in close proximity to the welding arc. The filler wire is guided and supported by a delivery guide so that the filler wire passes through the center of, and is insulated from, the induction coil. The induction coil induces a current flow in the filler wire. The current produces heat as a result of the electrical resistivity of the filler wire. The heat produced raises the temperature of the filler wire just before it is fed into the weld arc region, thus reducing the energy required from the welding arc to melt the filler metal wire into the weld puddle.

Owner:BABCOCK & WILCOX TECHNICALSERVICES GRP INC

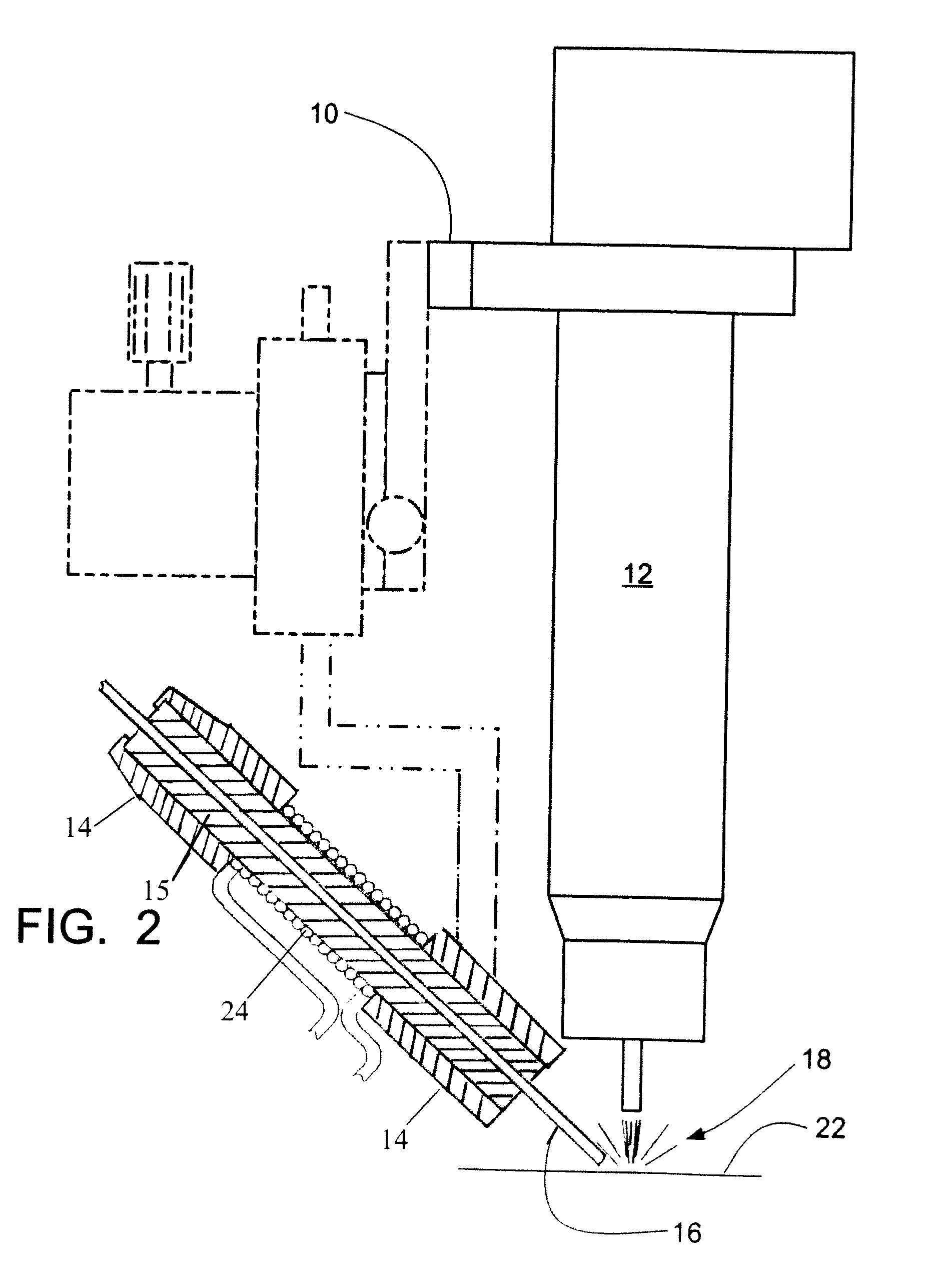

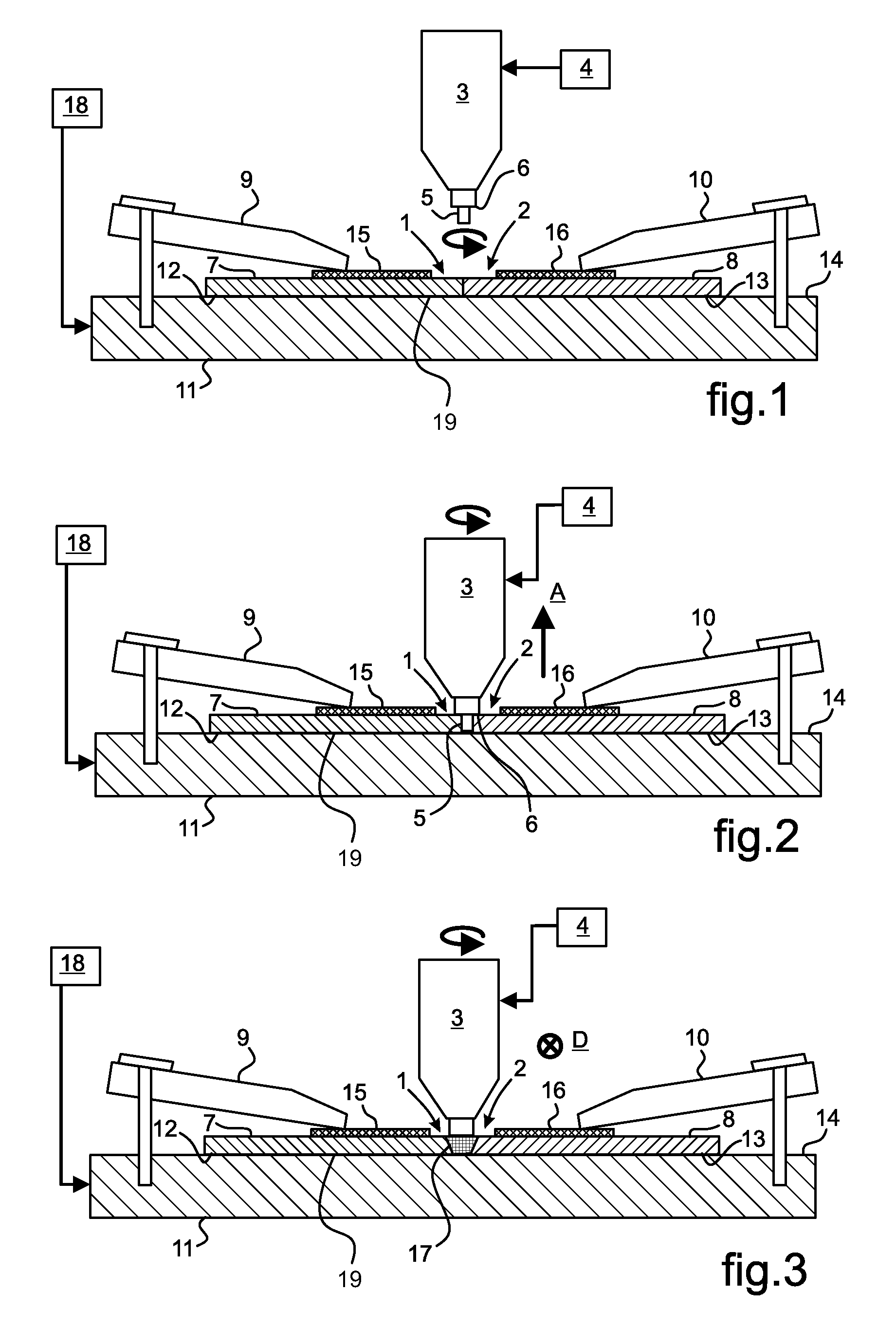

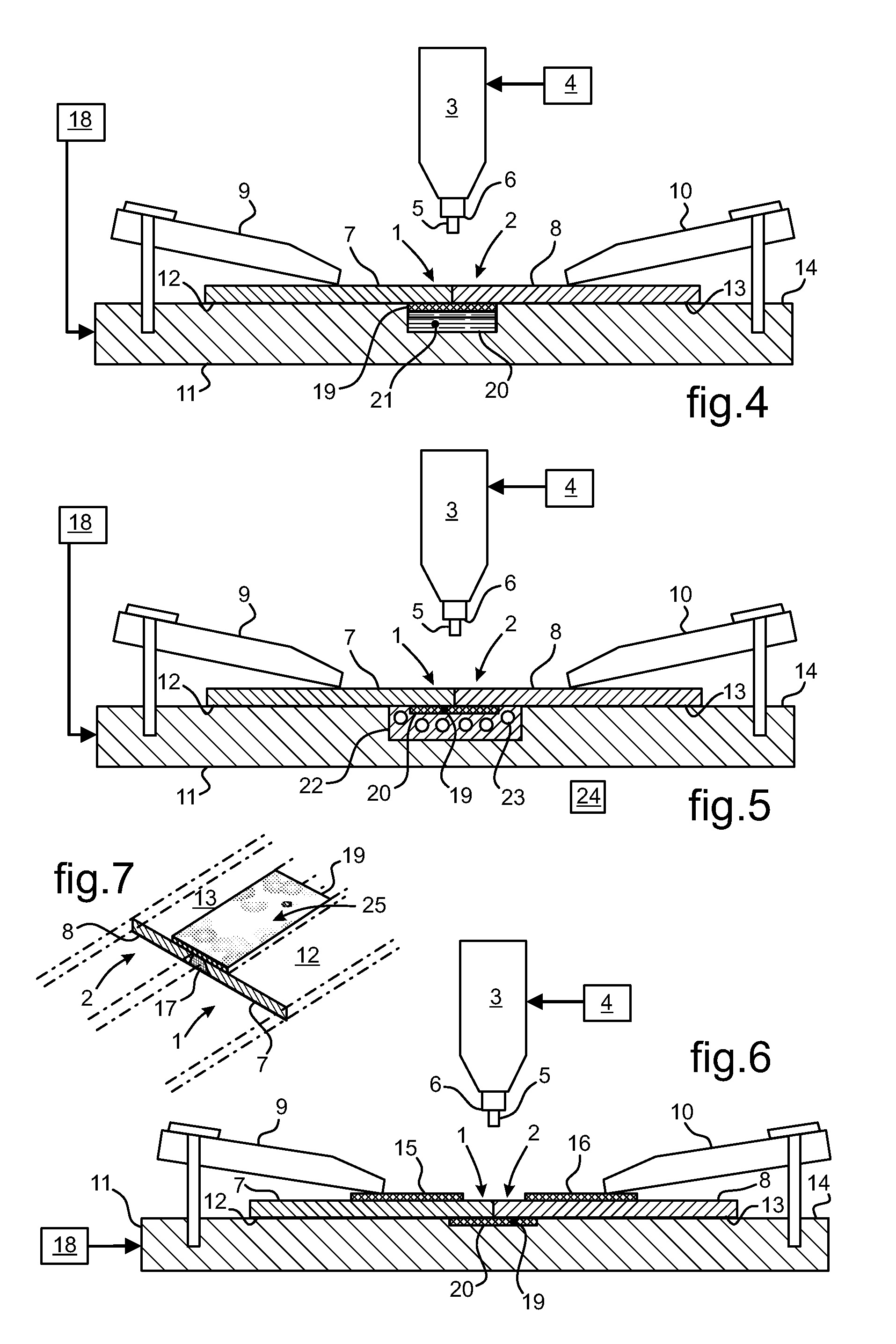

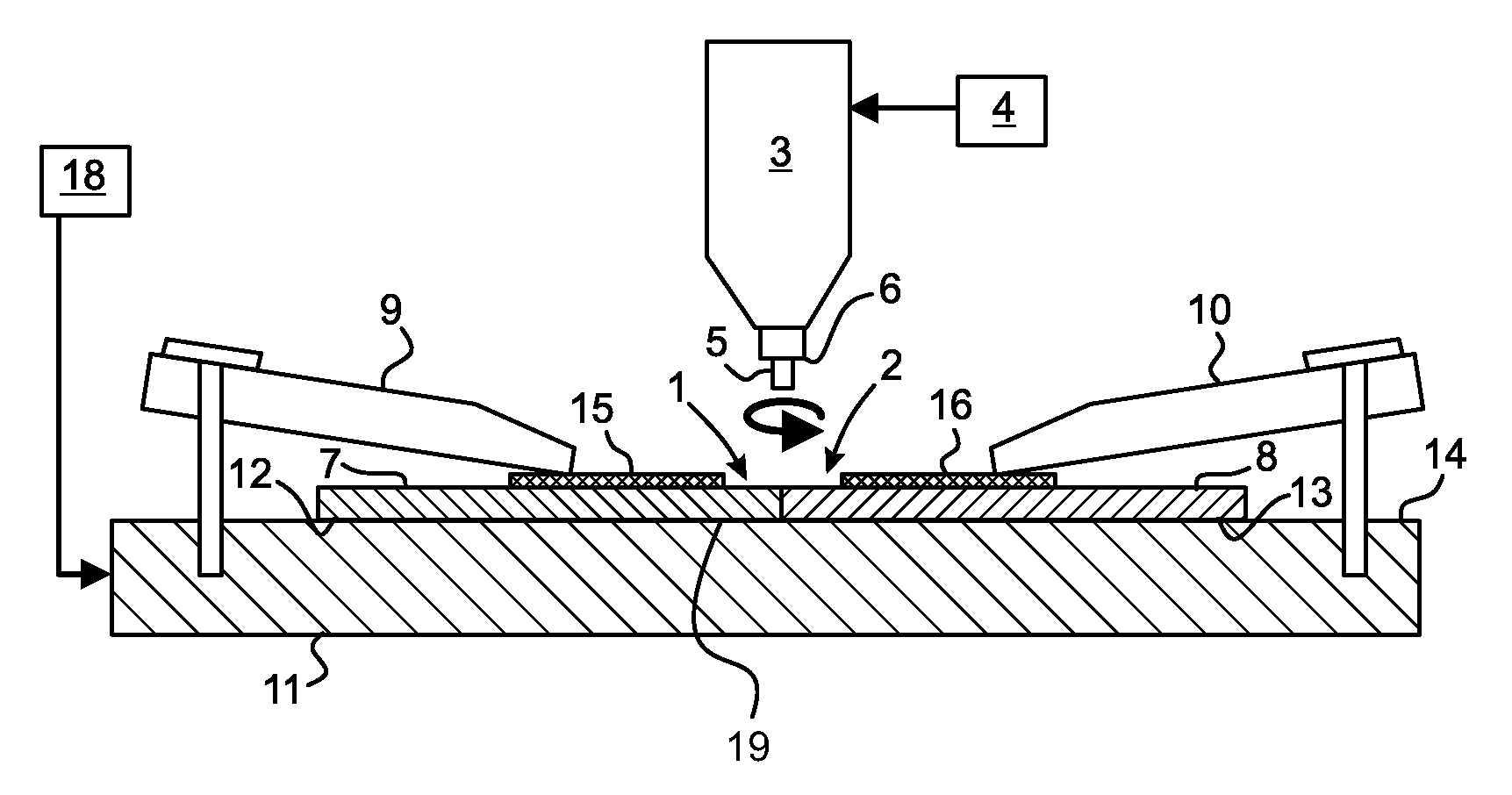

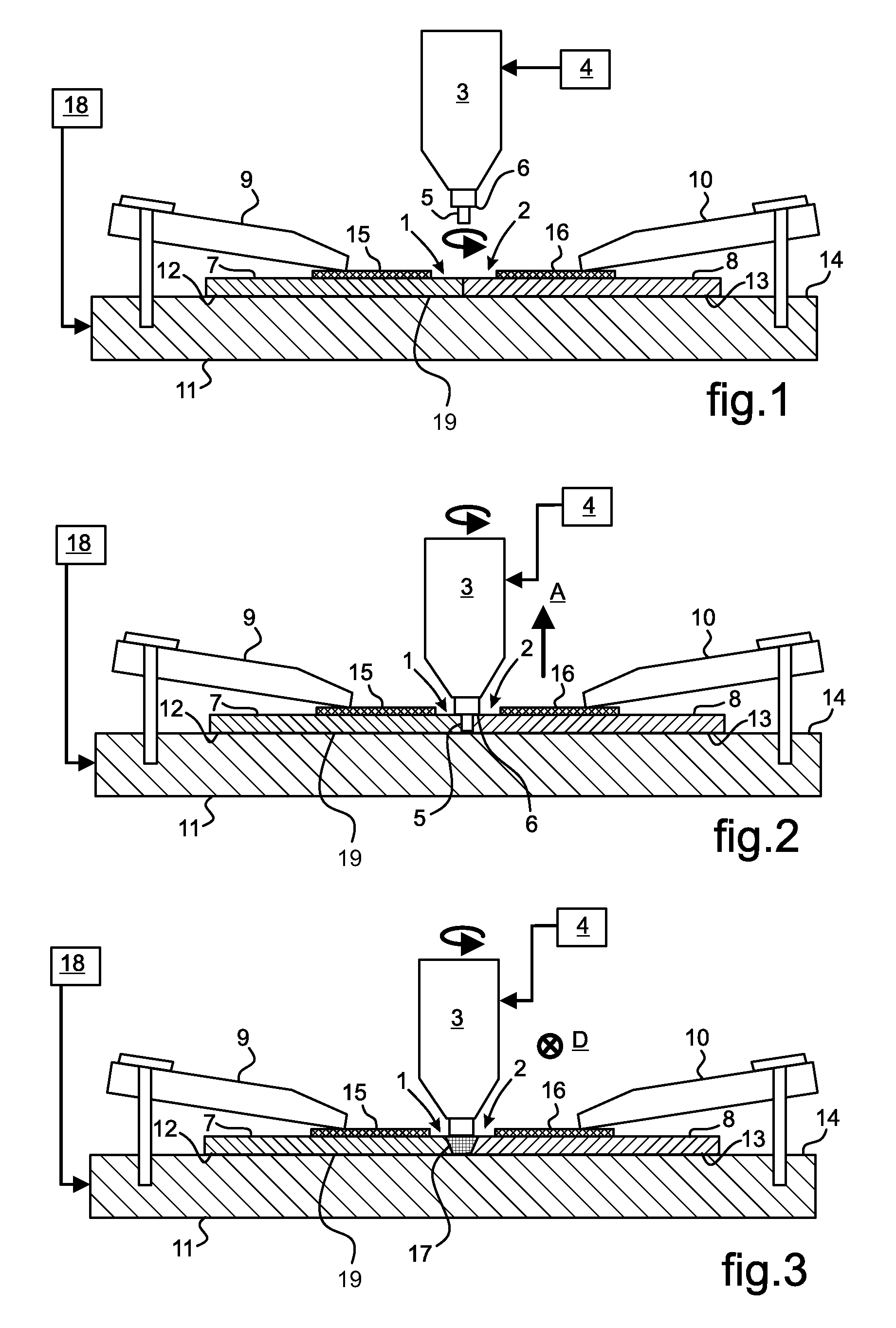

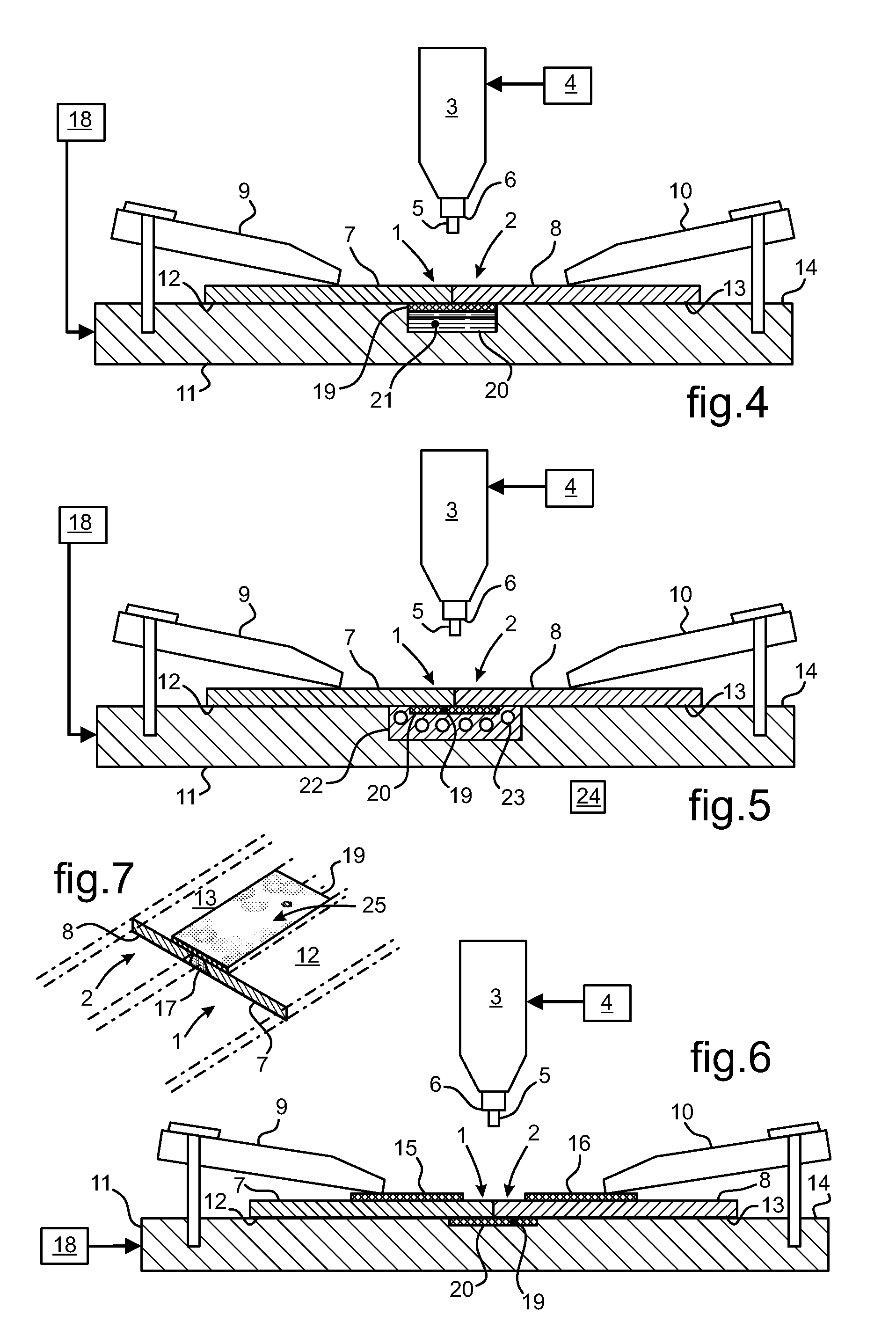

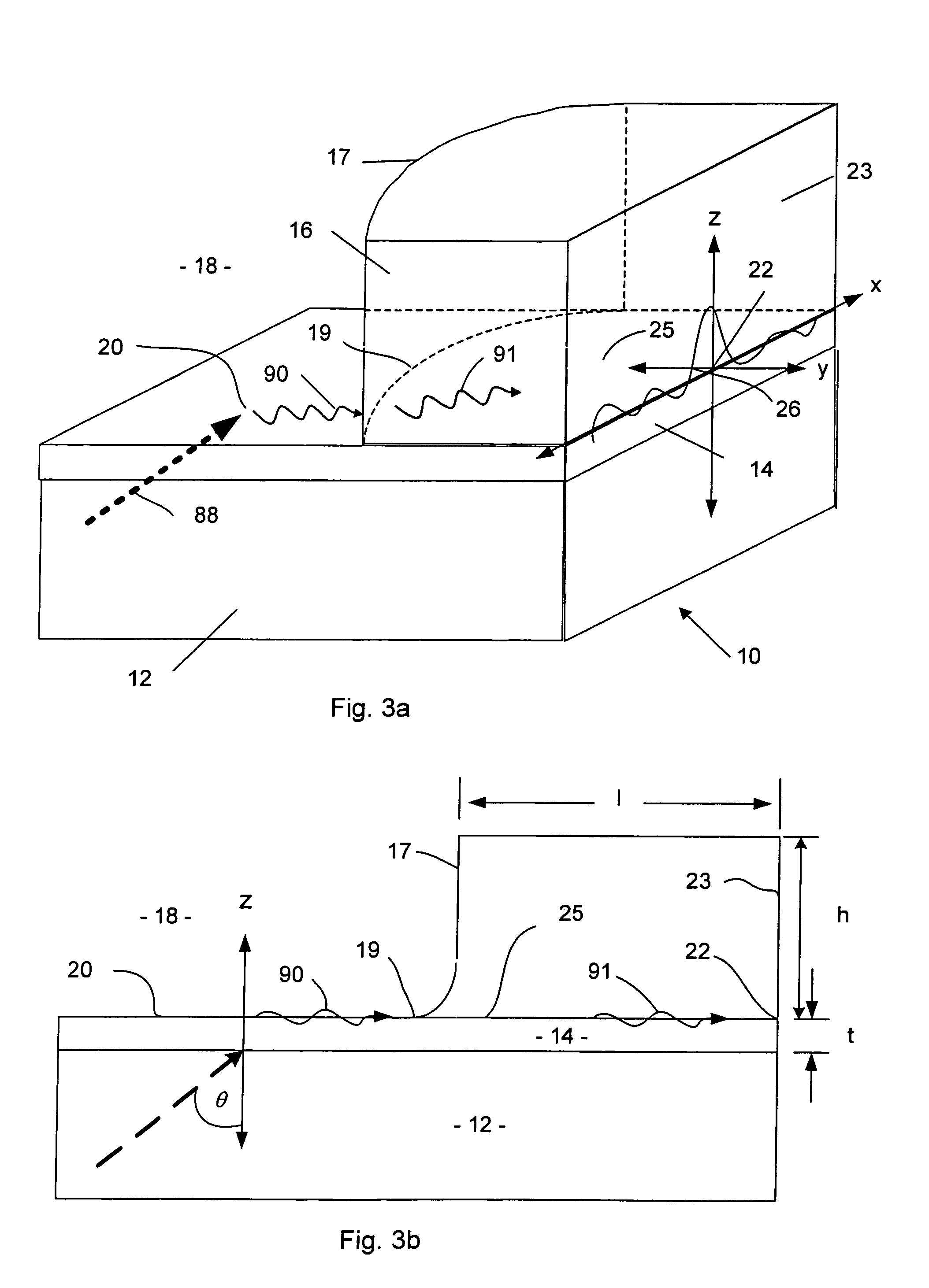

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS8393519B2Optimize rateHigh performance mechanical characteristicWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

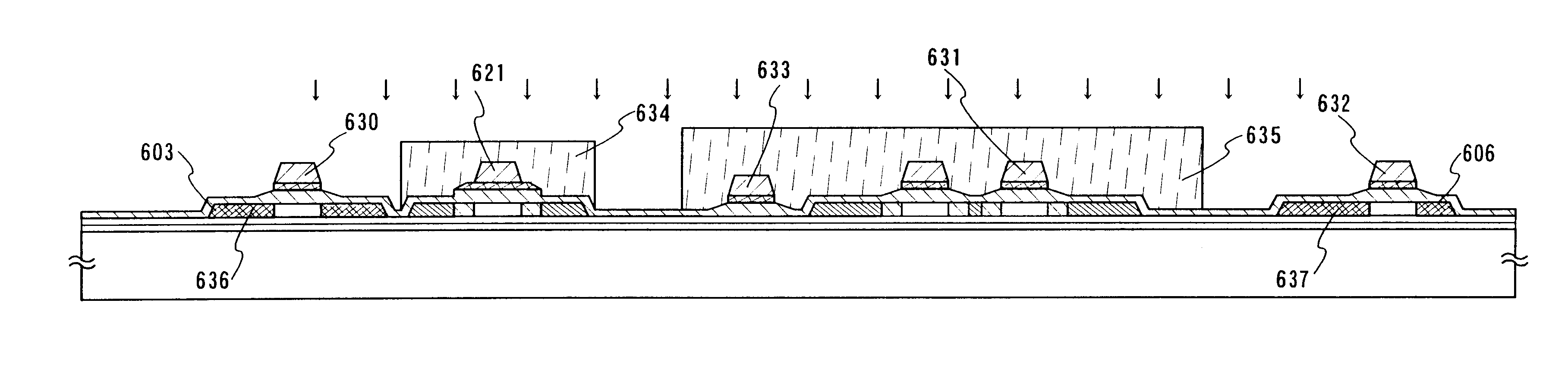

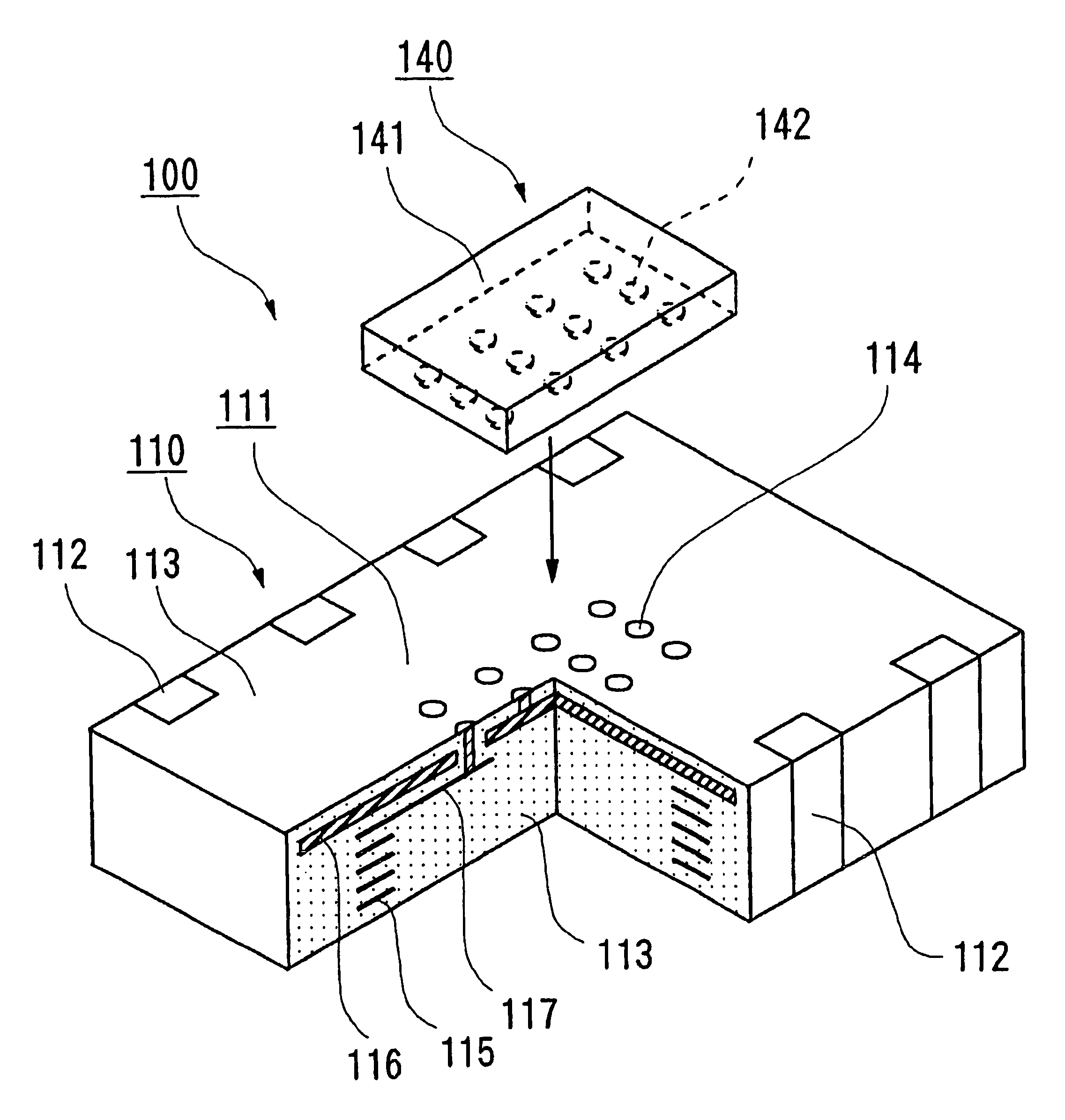

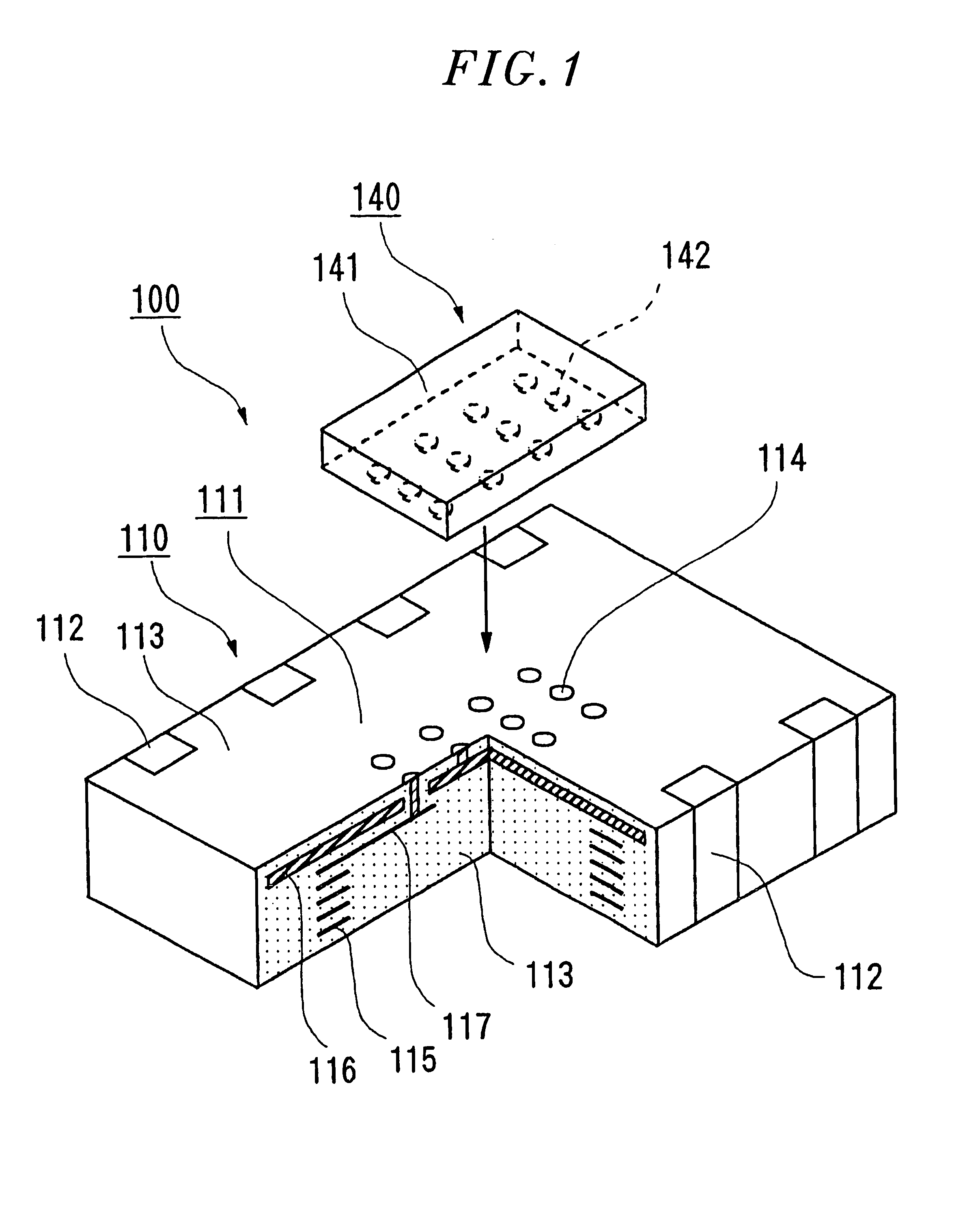

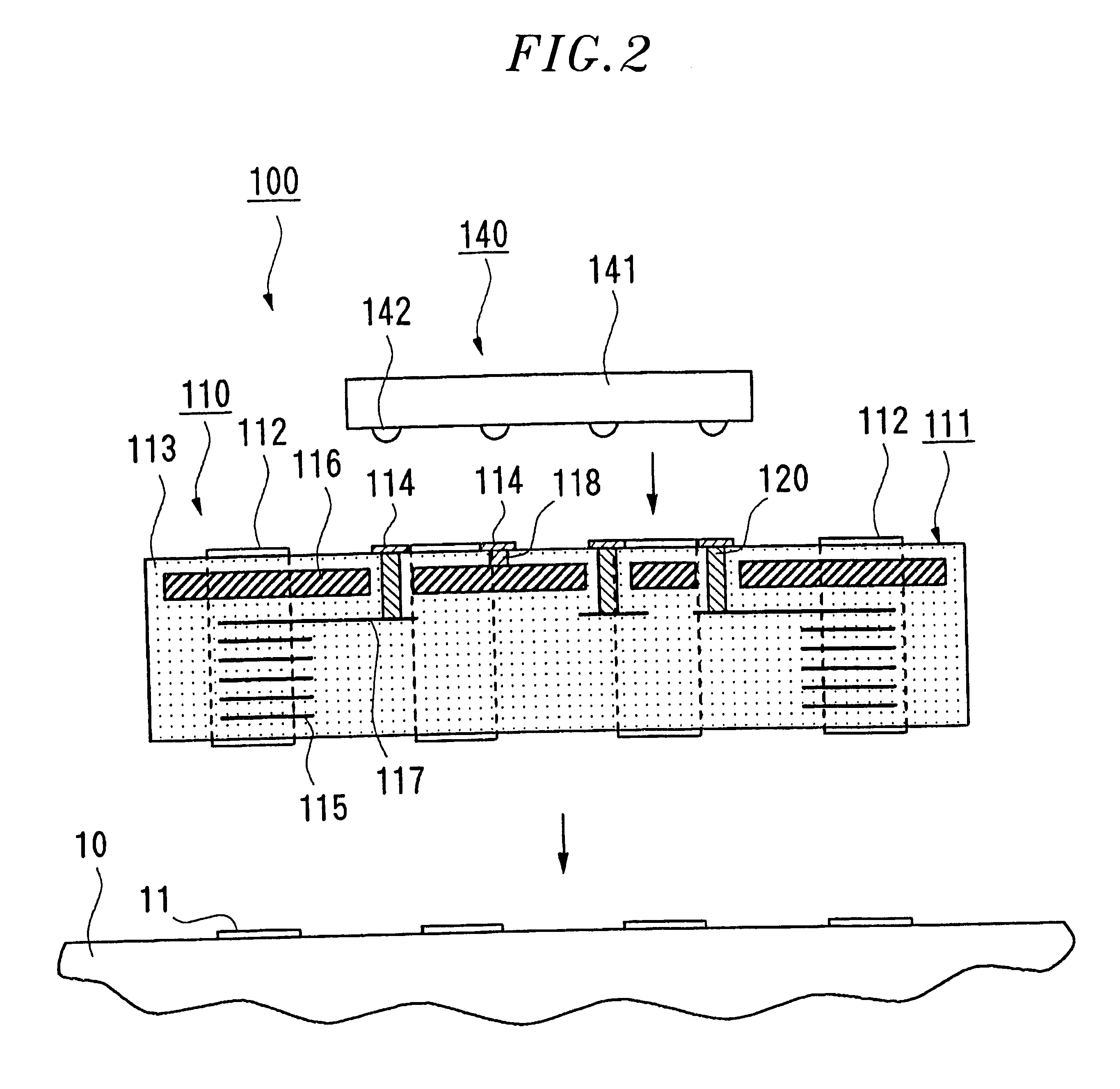

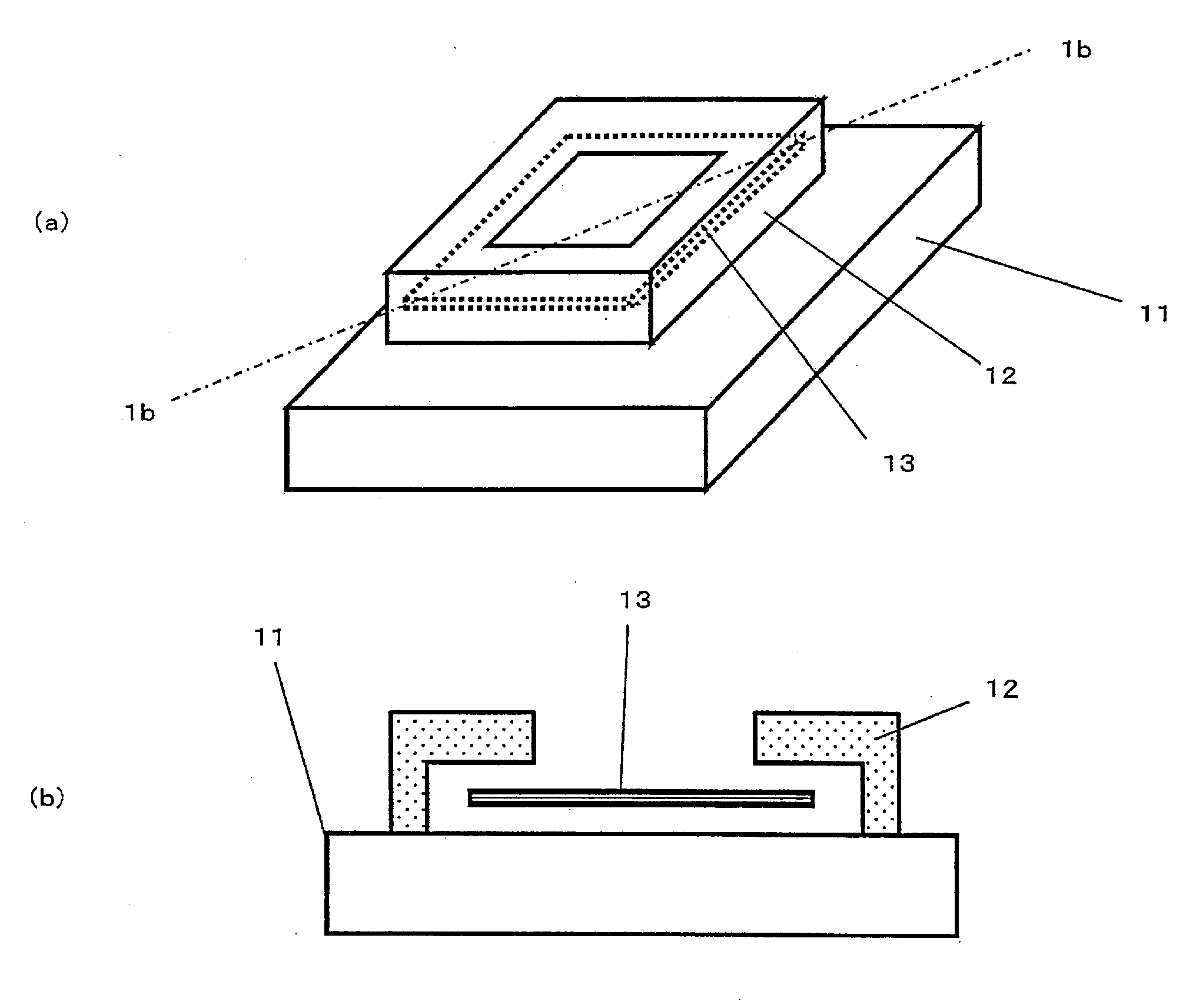

Multilayered electronic part and electronic circuit module including therein the multilayered electronic part

InactiveUS6301114B1Improve pyrolysis effectMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationSemiconductor chip

The present invention provides a multilayered electronic component (110) having improved thermolytic effect for an electronic circuit module (100), facilitating the realization of a miniaturization of the electronic circuit module (100). The multilayered electronic component (110) is provided with a first surface (111), a second opposite surface and side surfaces. A heat dissipation pattern (116) is formed in the multilayered electronic component (110) in a vicinity of the first surface (111) thereof on which a plurality of lands (114) is formed, in such a way that at least one land (114) is electrically connected to the heat dissipation pattern (116). A semiconductor chip (140) is mounted on the first surface (111) of the multilayered electronic component (110), thereby forming the electronic circuit module (100). Heat induced in the semiconductor chip (140) is emitted from the heat dissipation pattern (116), which will, in turn, make a thermolytic effect of the electronic circuit module (100) be improved.

Owner:TAIYO YUDEN KK

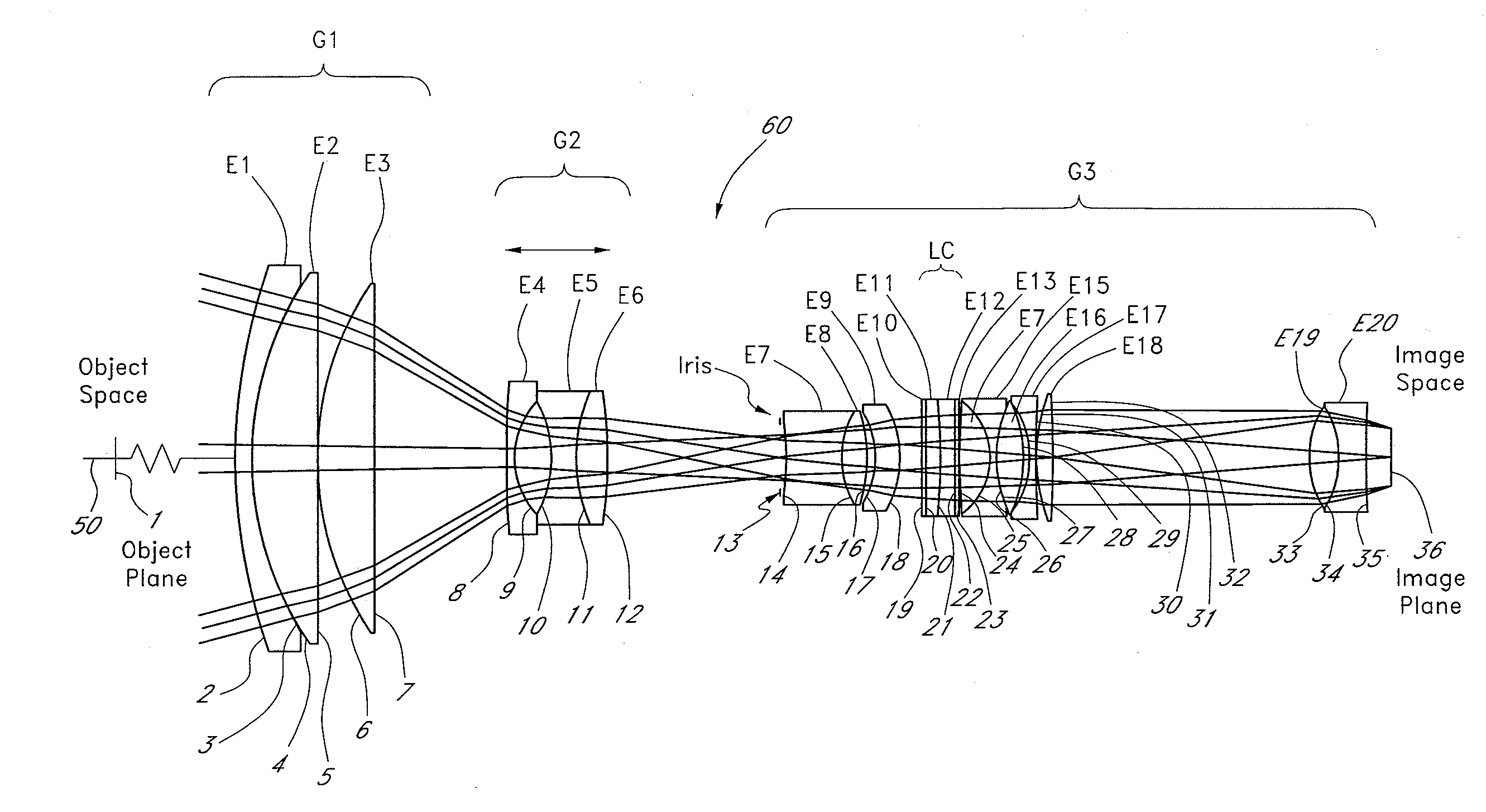

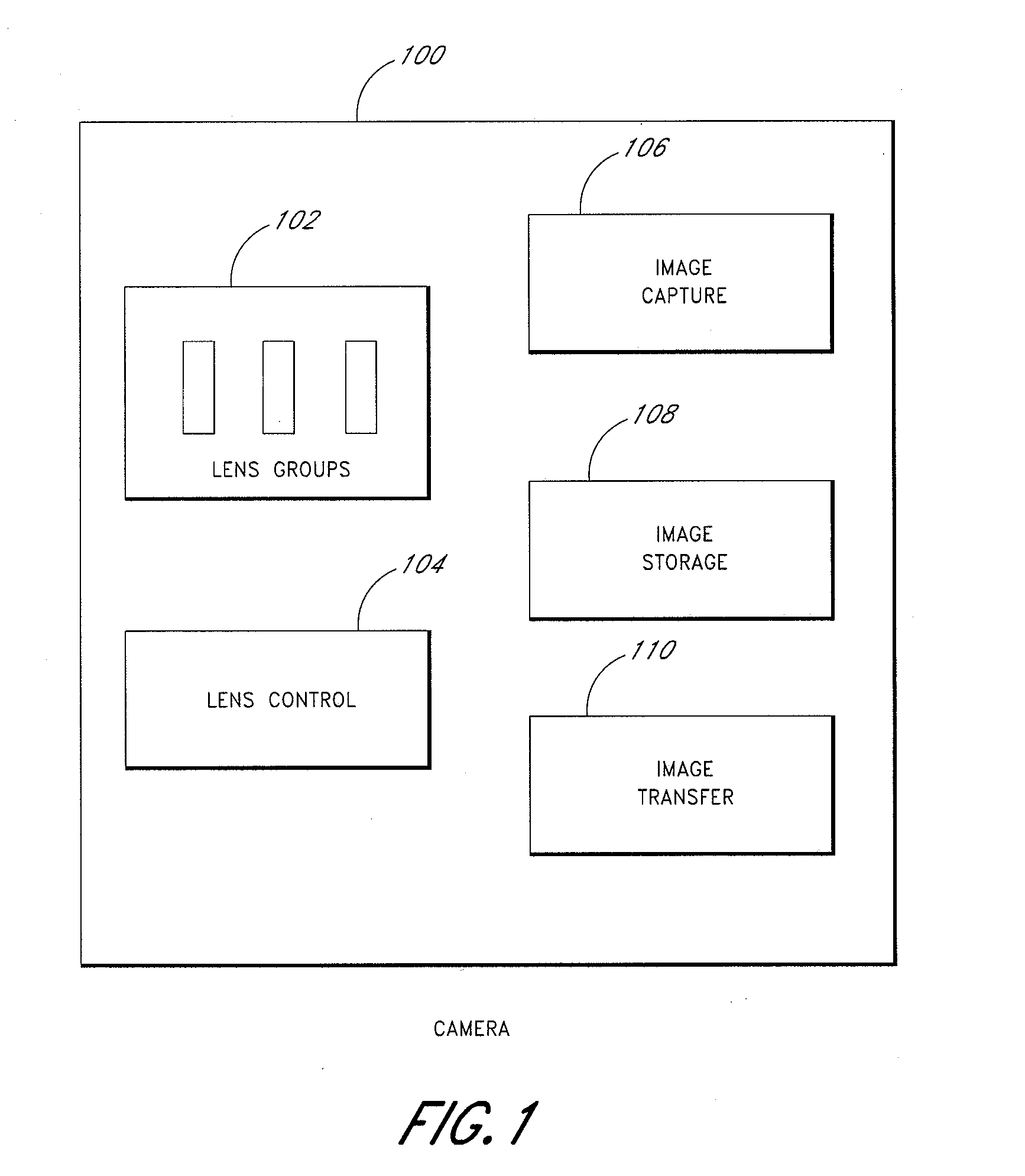

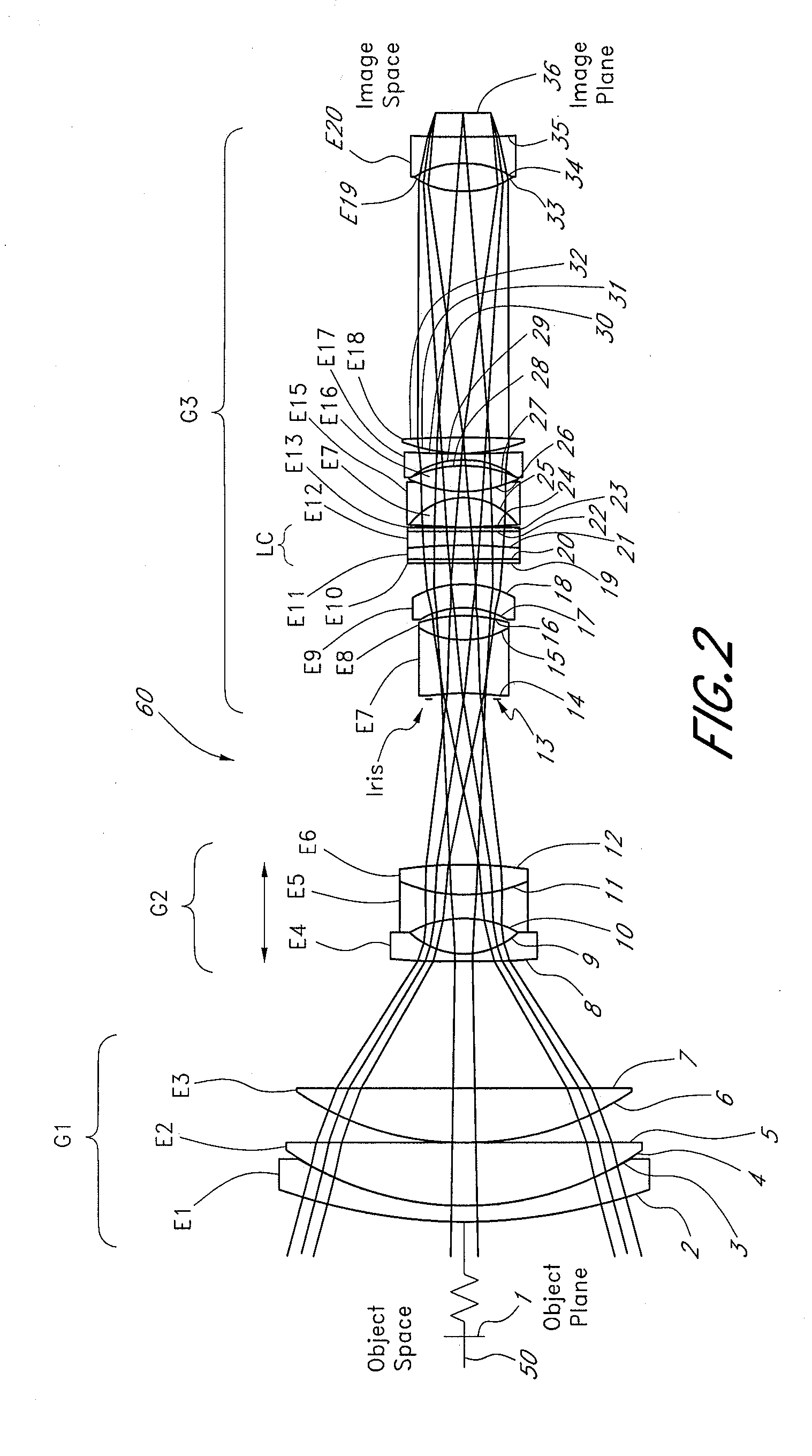

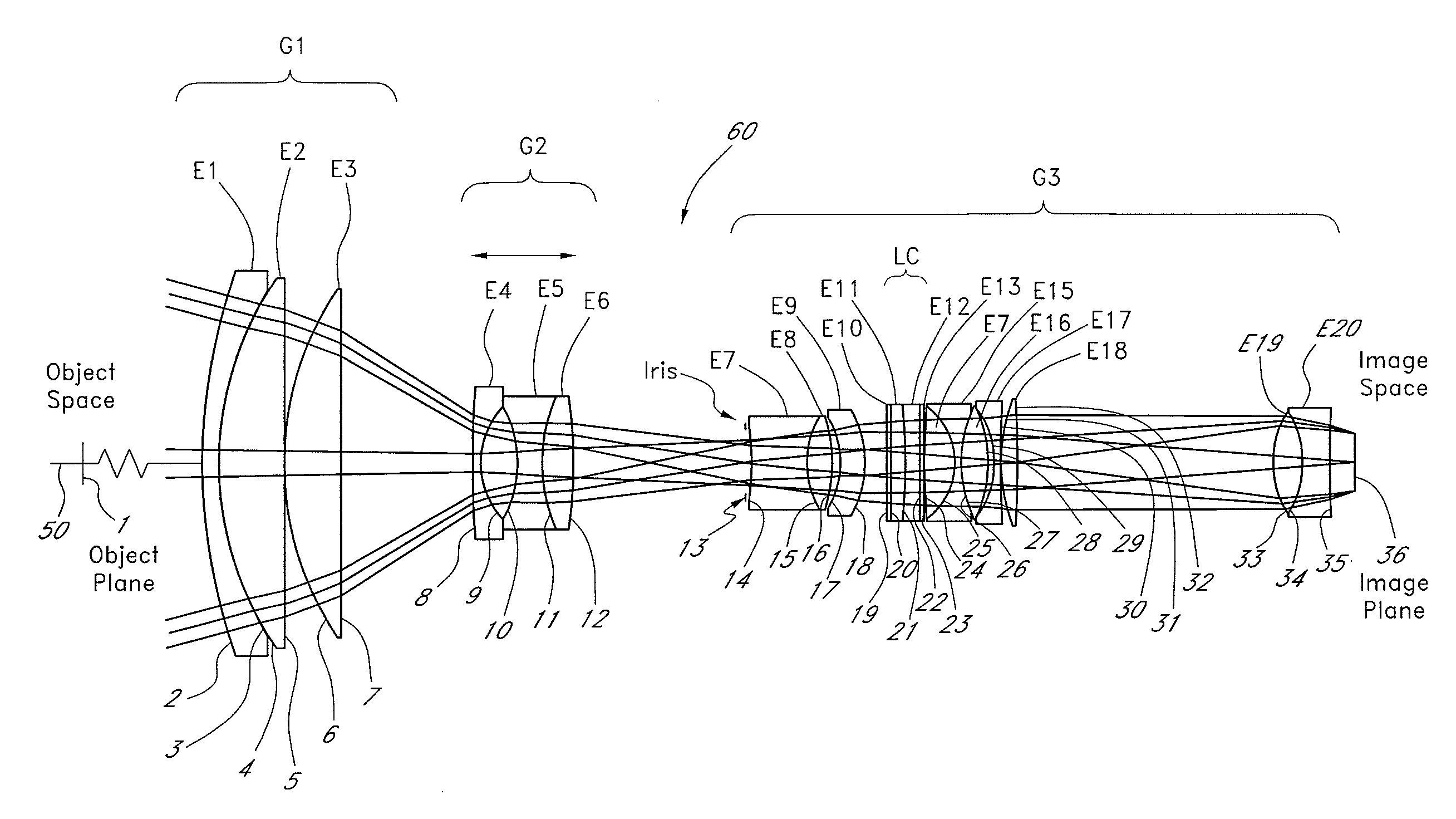

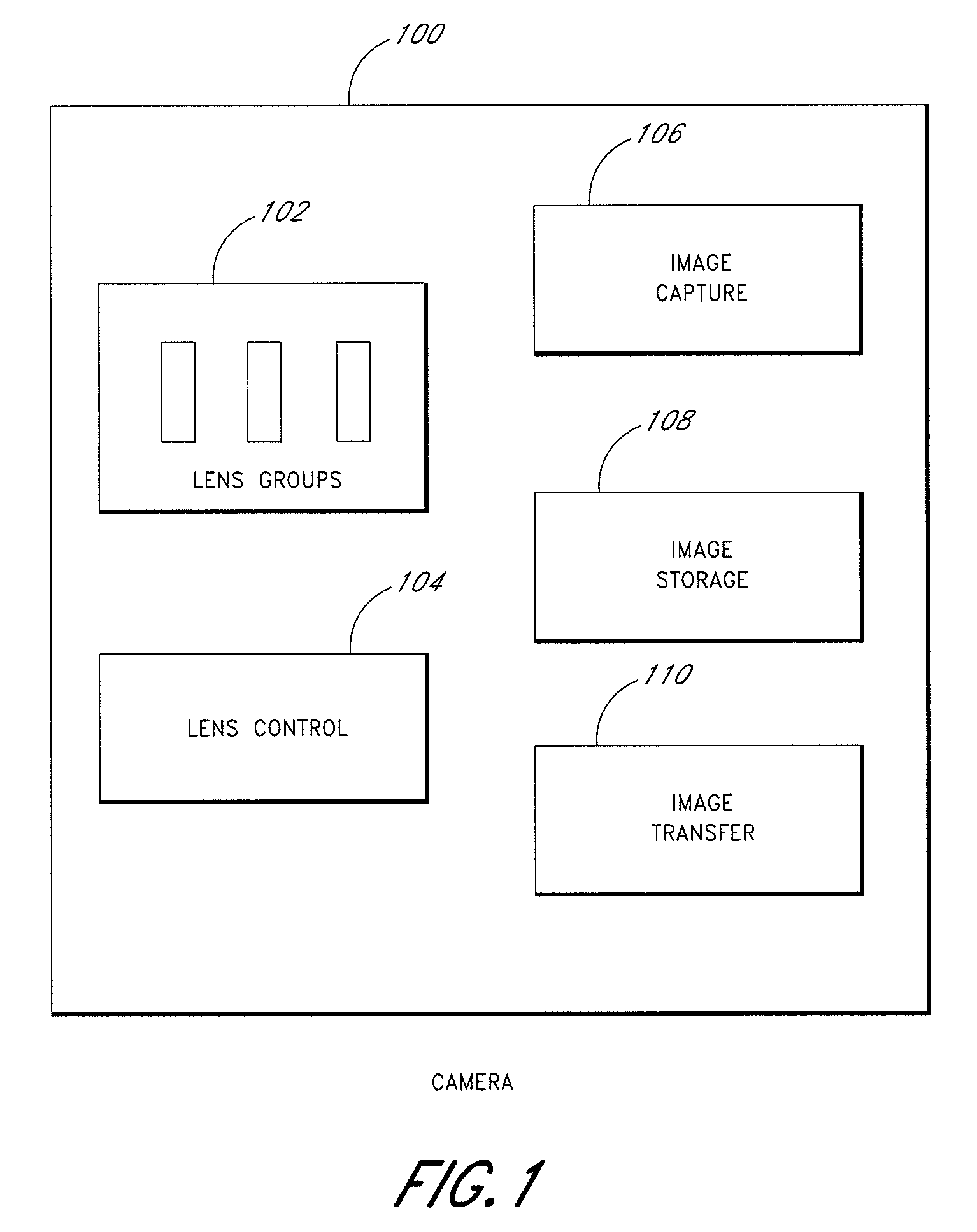

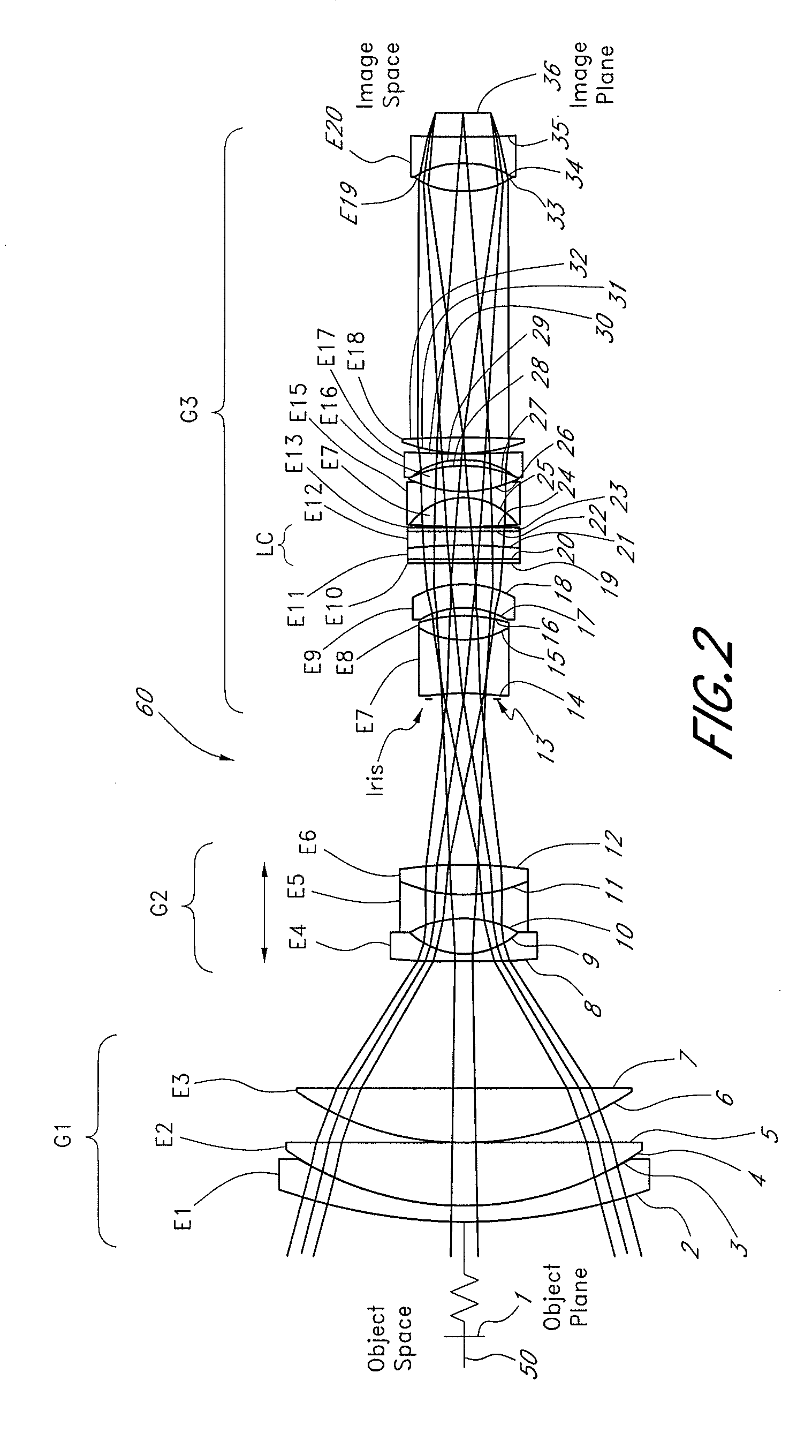

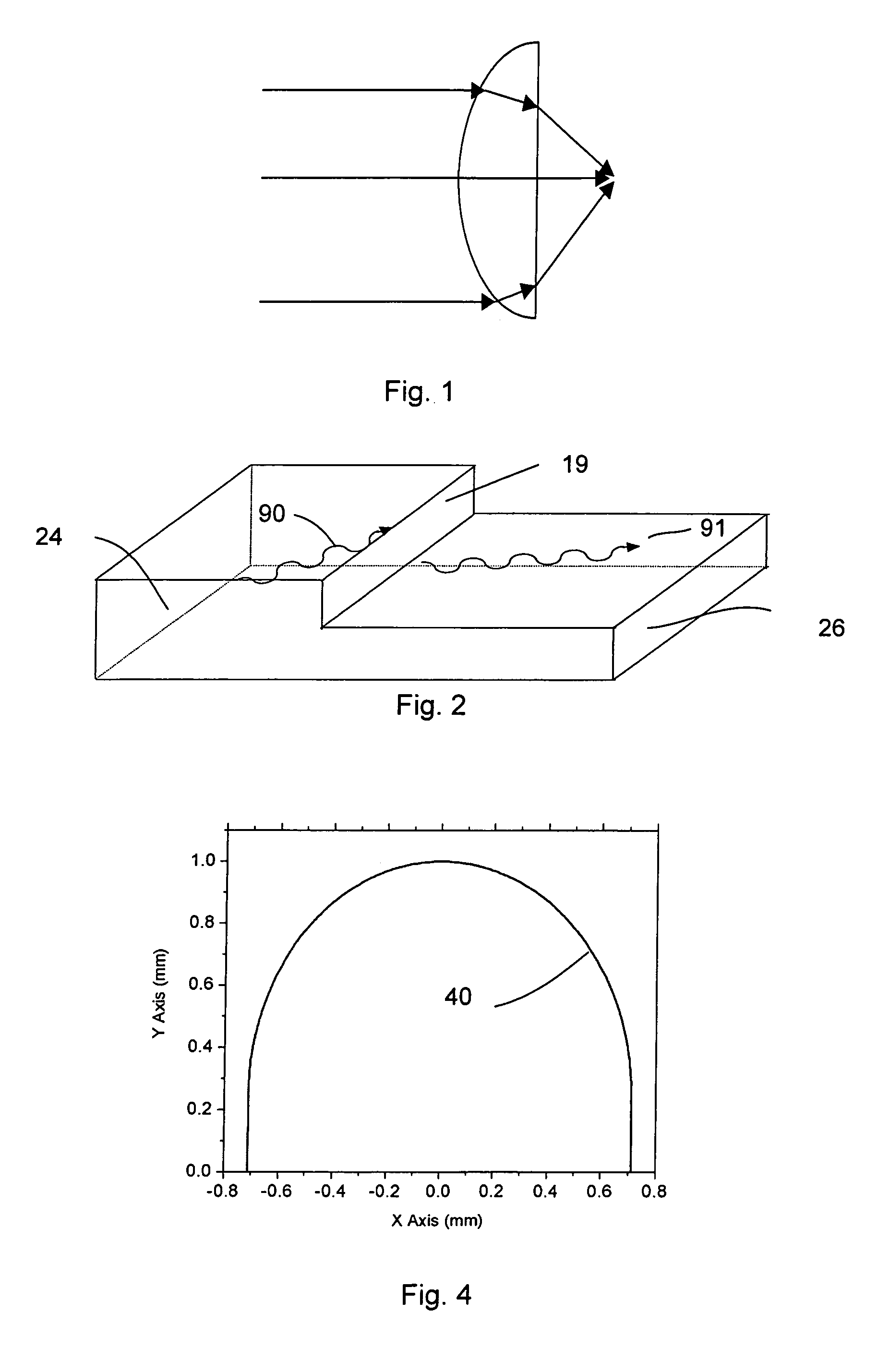

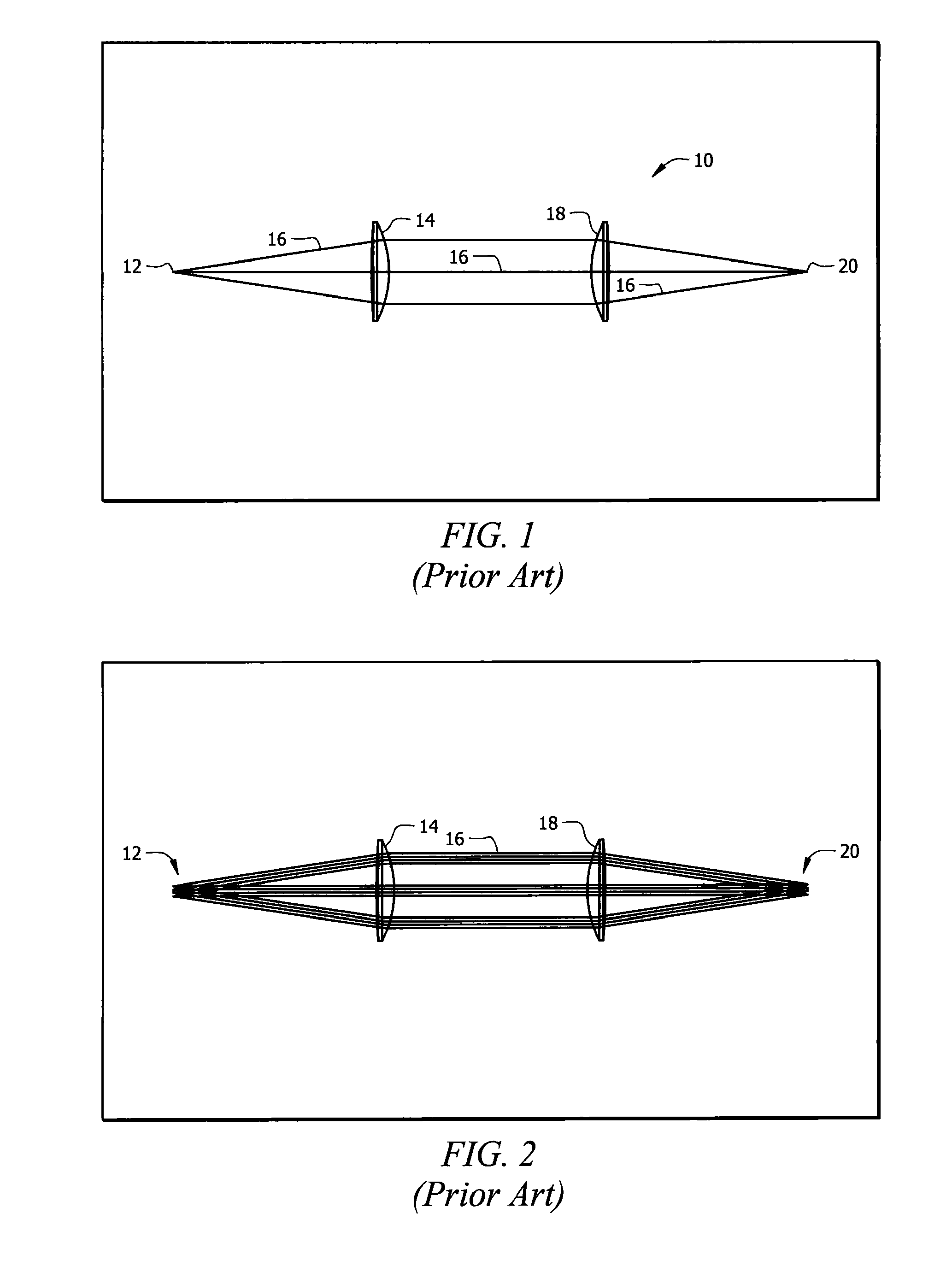

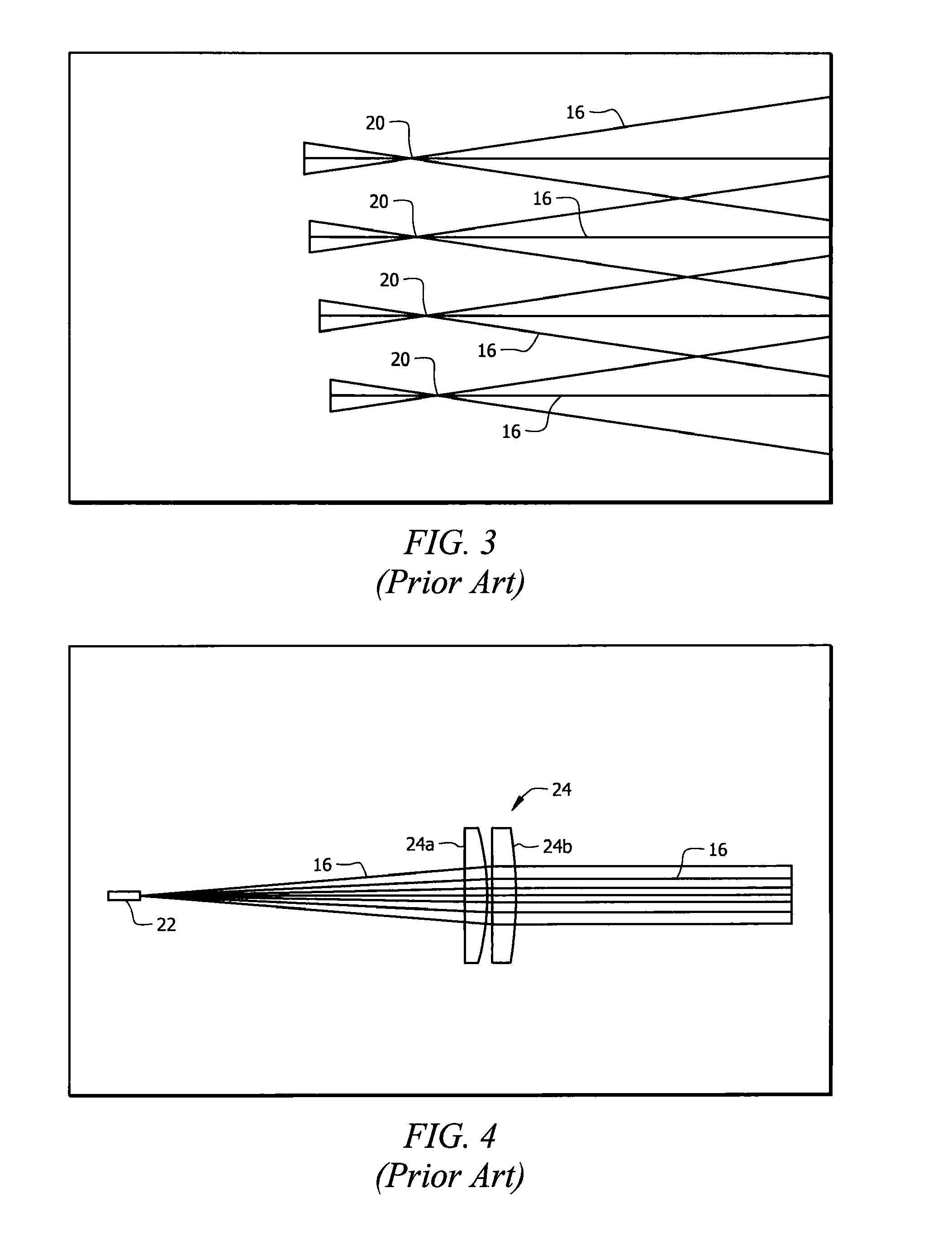

Liquid optics zoom lens and imaging apparatus

Owner:MONUMENT PEAK VENTURES LLC

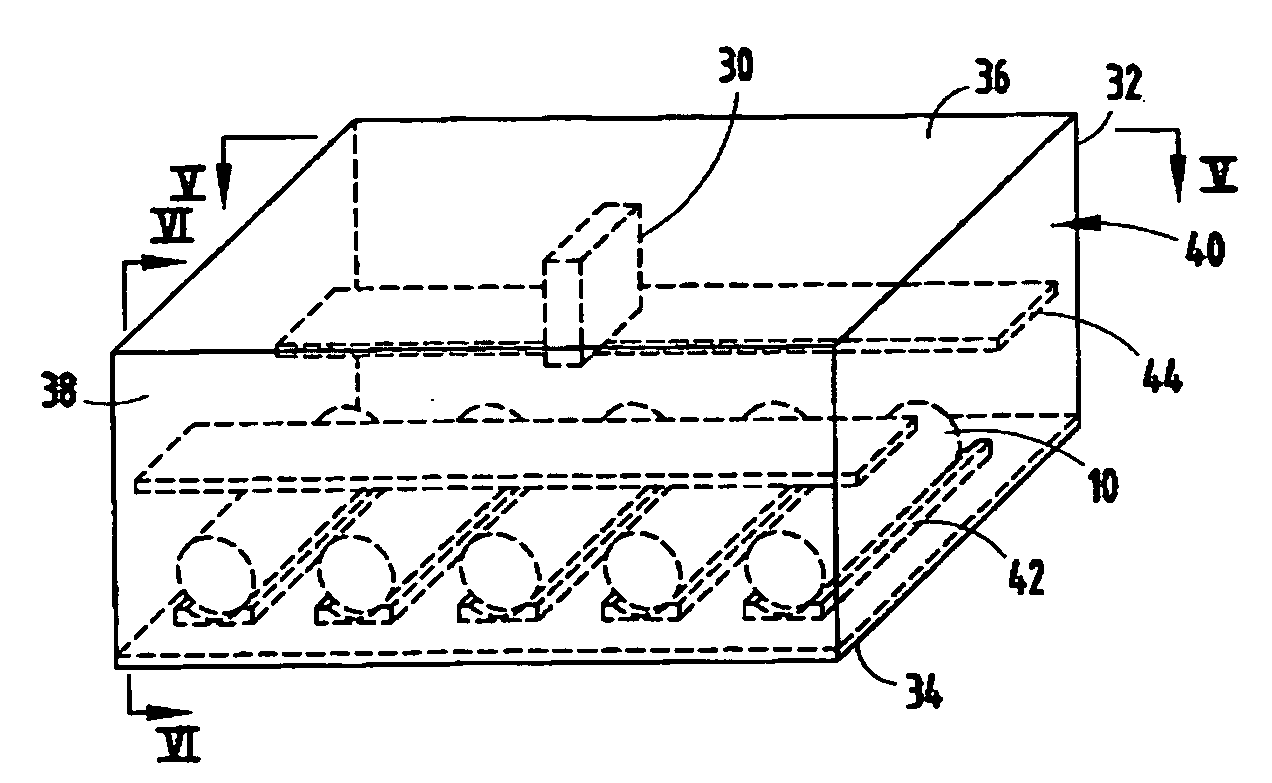

In situ heat induced antigen recovery and staining apparatus and method

InactiveUS8071023B2Microbiological testing/measurementPreparing sample for investigationMicroscope slideAntigen

An automated in situ heat induced antigen recovery and staining method and apparatus for treating a plurality of microscope slides. The process of heat induced antigen recovery and the process of staining the biological sample on the microscope slide are conducted in the same apparatus, wherein the microscope slides do not need to be physically removed from one apparatus to another. Each treatment step occurs within the same reaction compartment. The reaction conditions of each reaction compartment for treating a slide can preferably be controlled independently, including the individualized application of reagents to each slide and the individualized treatment of each slide.

Owner:ANGROS LEE

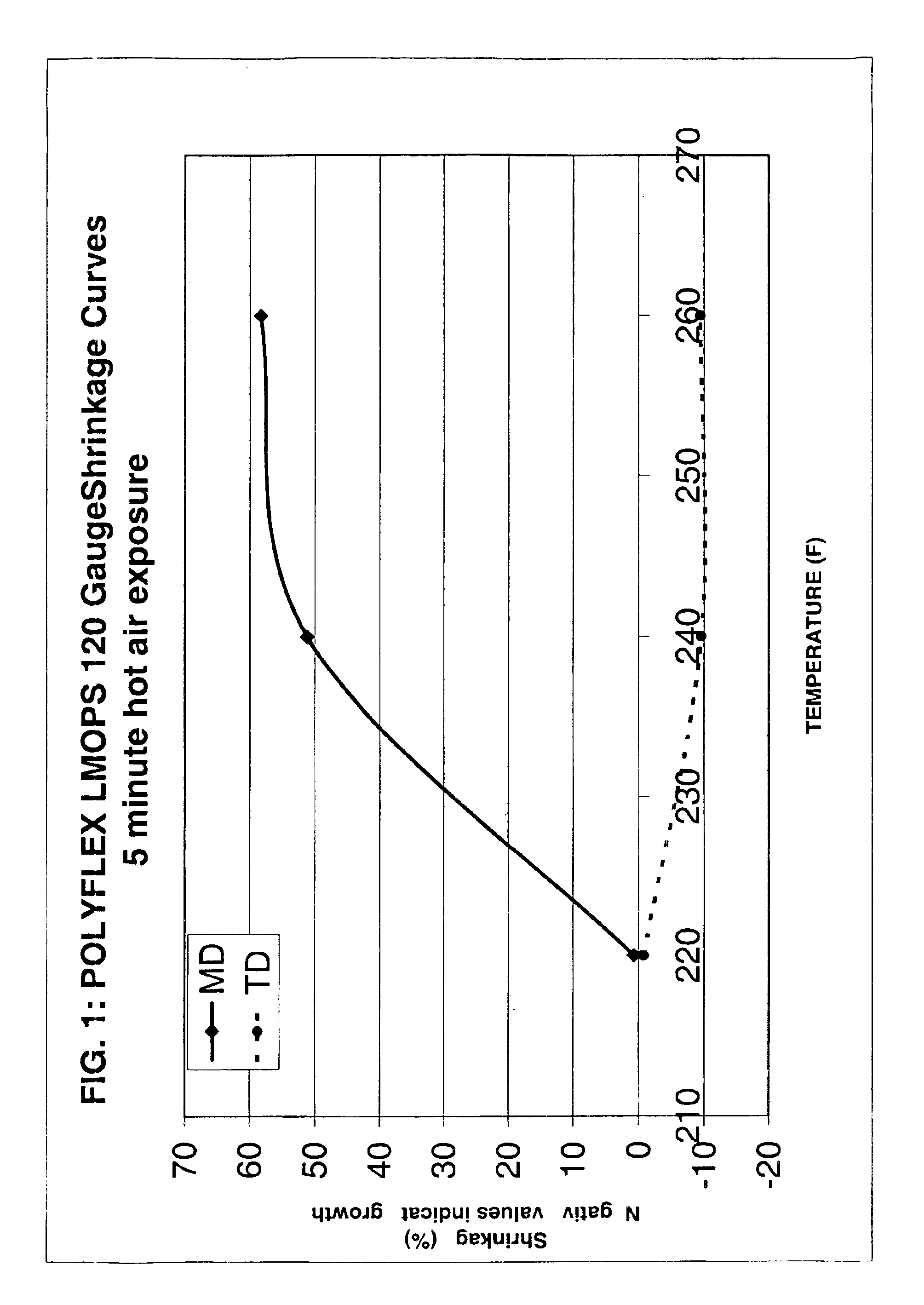

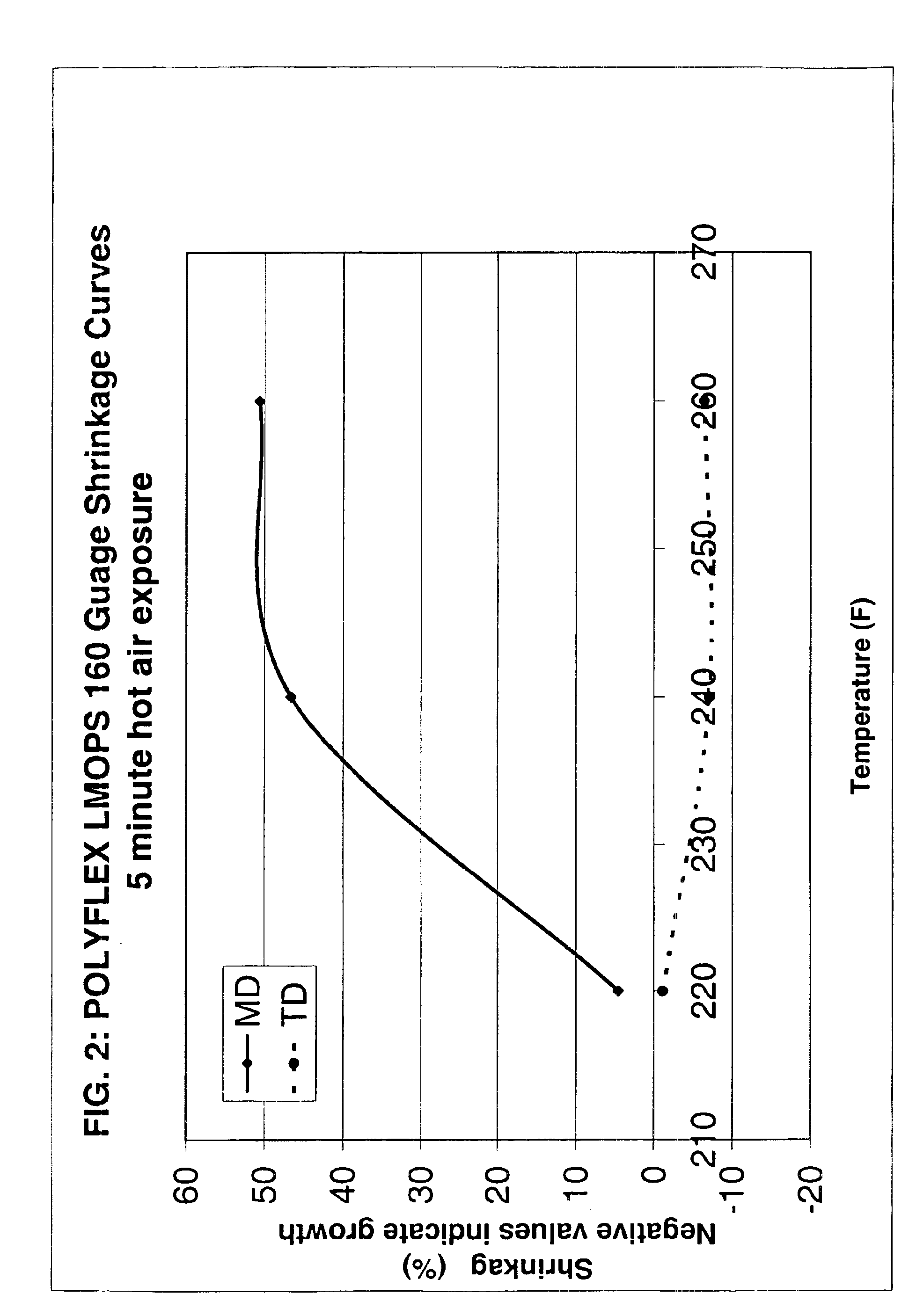

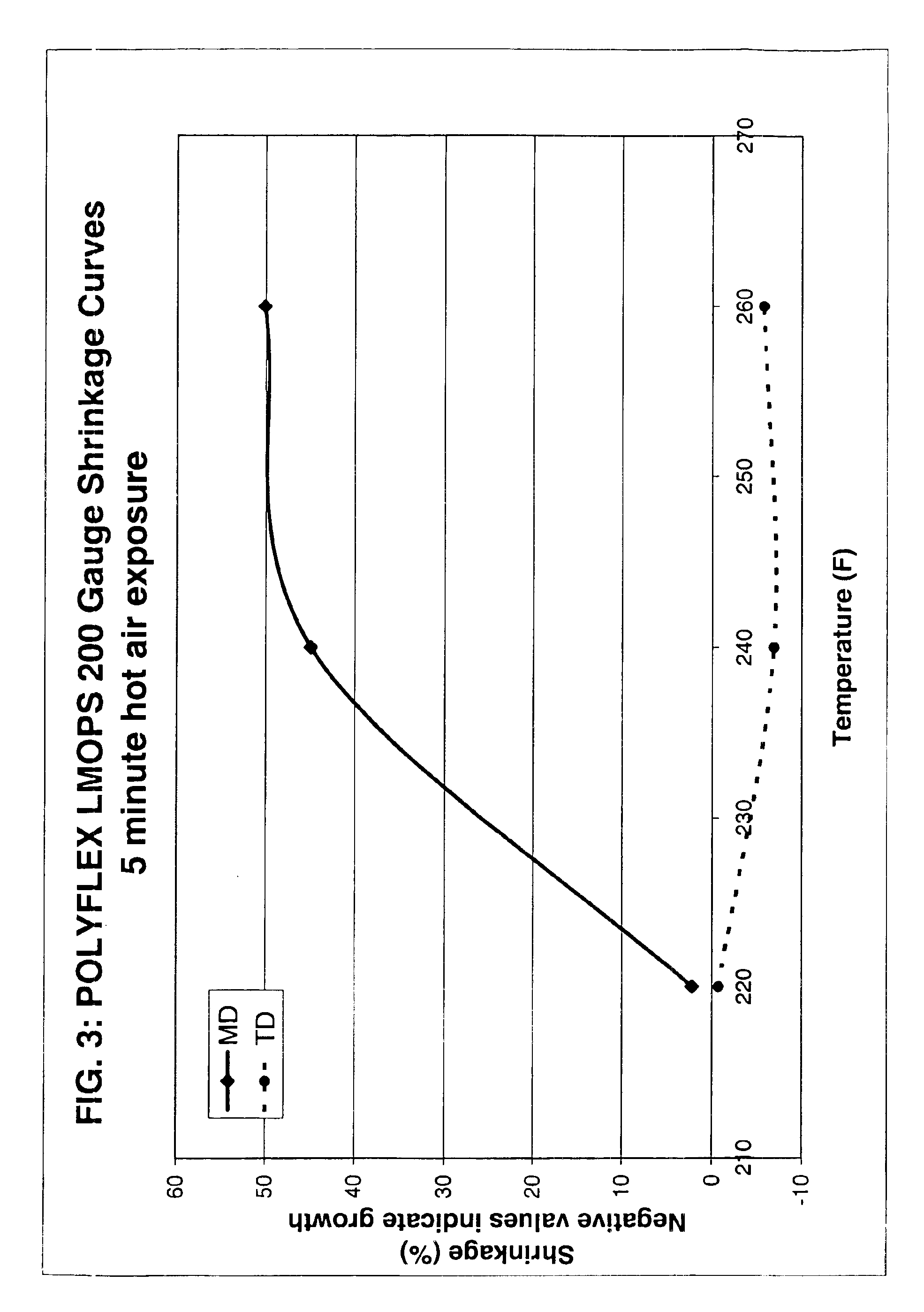

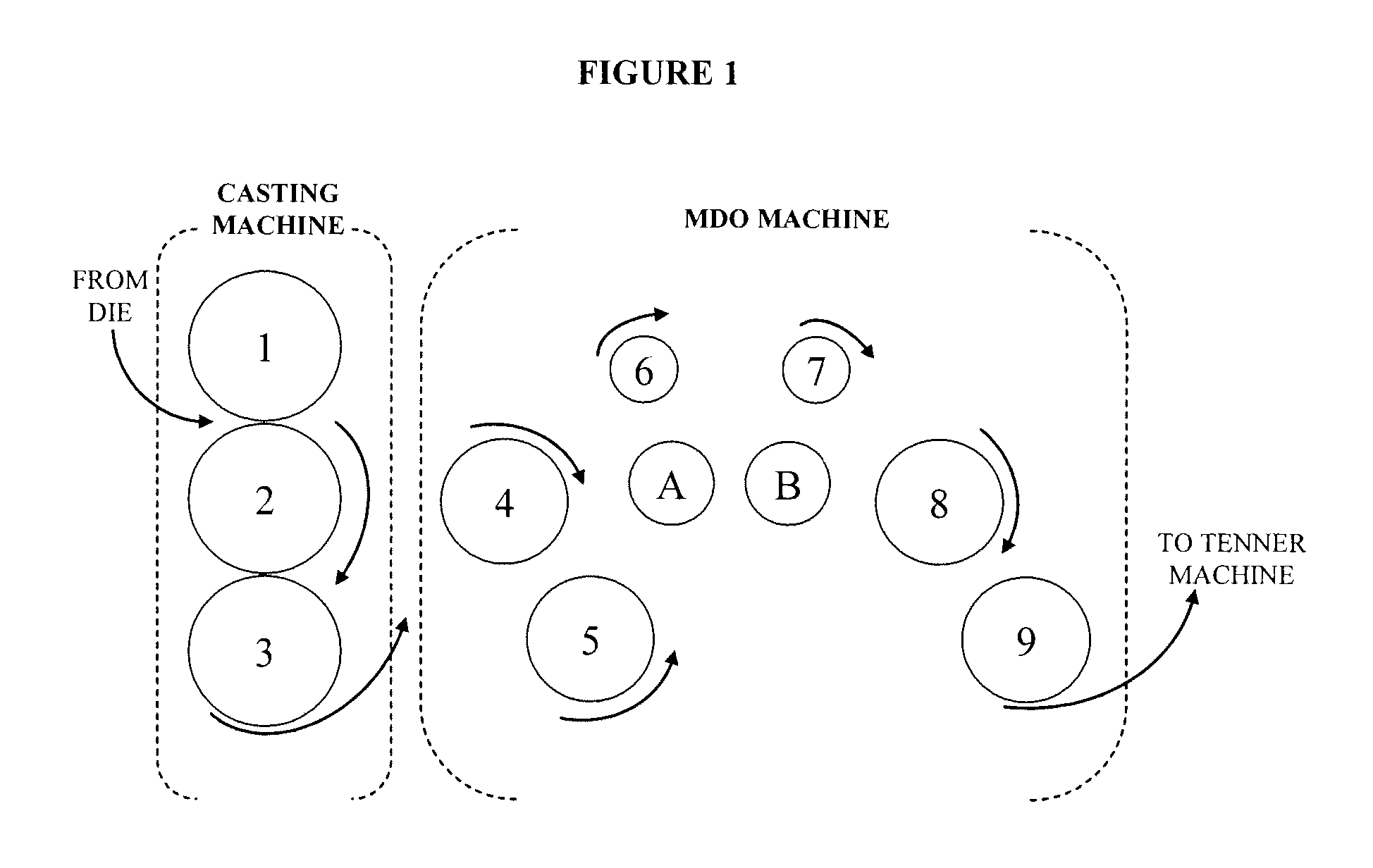

Longitudinal shrink films

A heat-shrinkable film and a method of its manufacture are provided. In an exemplary embodiment, a polystyrene film exhibits heat-induced growth in the cross direction of great than or equal to 5% with greater than or equal to 30% concomitant shrinkage in the machine direction. The films may comprise crystal polystyrene, high impact polystyrene, and / or elastomers. A method of manufacture is disclosed which includes a post-extrusion temperature conditioning step.

Owner:PLASTIC SUPPLIERS

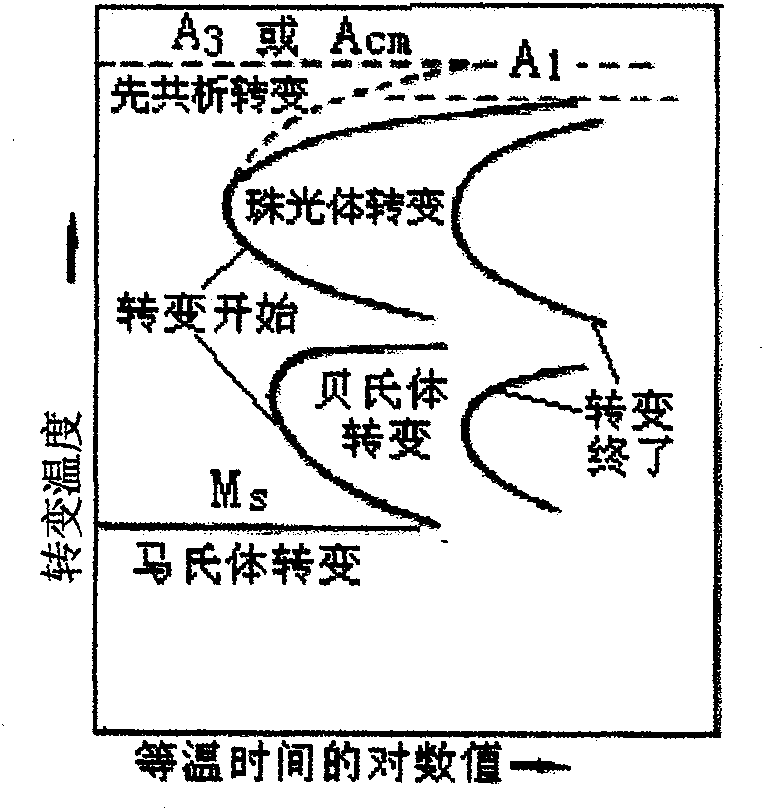

Heat treatment equipment and heat treatment method of metal parts

The invention relates to heat treatment equipment of metal parts, which comprises a heating device and charging barrels, wherein the charging barrels are installed on a rotating disk; the heating device is an electromagnetic induction heating device; the inner diameter of an induction coil is greater than the outer diameter of each charging barrel; when the induction coil is in a working state of energizing and heating, the induction coil is surrounded at the outer side of one of the charging barrels; and the inner cavity of each charging barrel for containing metal parts is a sealed space. The heat treatment method comprises the following steps: after the induction coil is lowered or the charging barrels are lifted and the corresponding charging barrel is sealed, filling inert gases, and heating to the set temperature; adding carbon and / or nitrogen, heating for the set time, and then, stopping heating; lifting the induction coil or lowering the charging barrels, rotating the rotating disk, pouring materials, quenching and cooling to complete the carburization and / or nitridation heat treatment process of the metal parts; simultaneously, rotating the charging barrels containing the metal parts to be treated by heating to the under part of the induction coil; and circularly working. The invention has the advantage of high efficiency and can realize continuous automatic production.

Owner:GUANGZHOU CCM ELECTRICAL APPLIANCE

Heat-induced transitions on a structured surface

InactiveUS20070059213A1Analysis using chemical indicatorsTransportation and packagingEngineeringHeat induced

A device comprising a substrate having a base layer, the base layer being connectable to a source of current. The device also includes fluid-support-structures located on the base layer. Each of the fluid-support-structures has at least one dimension of about 1 millimeter or less. The base layer is configured to impart heat to a fluid locatable over the base layer and convert at least a portion of the fluid to a vapor when a current is applied to the base layer.

Owner:ALCATEL LUCENT SAS

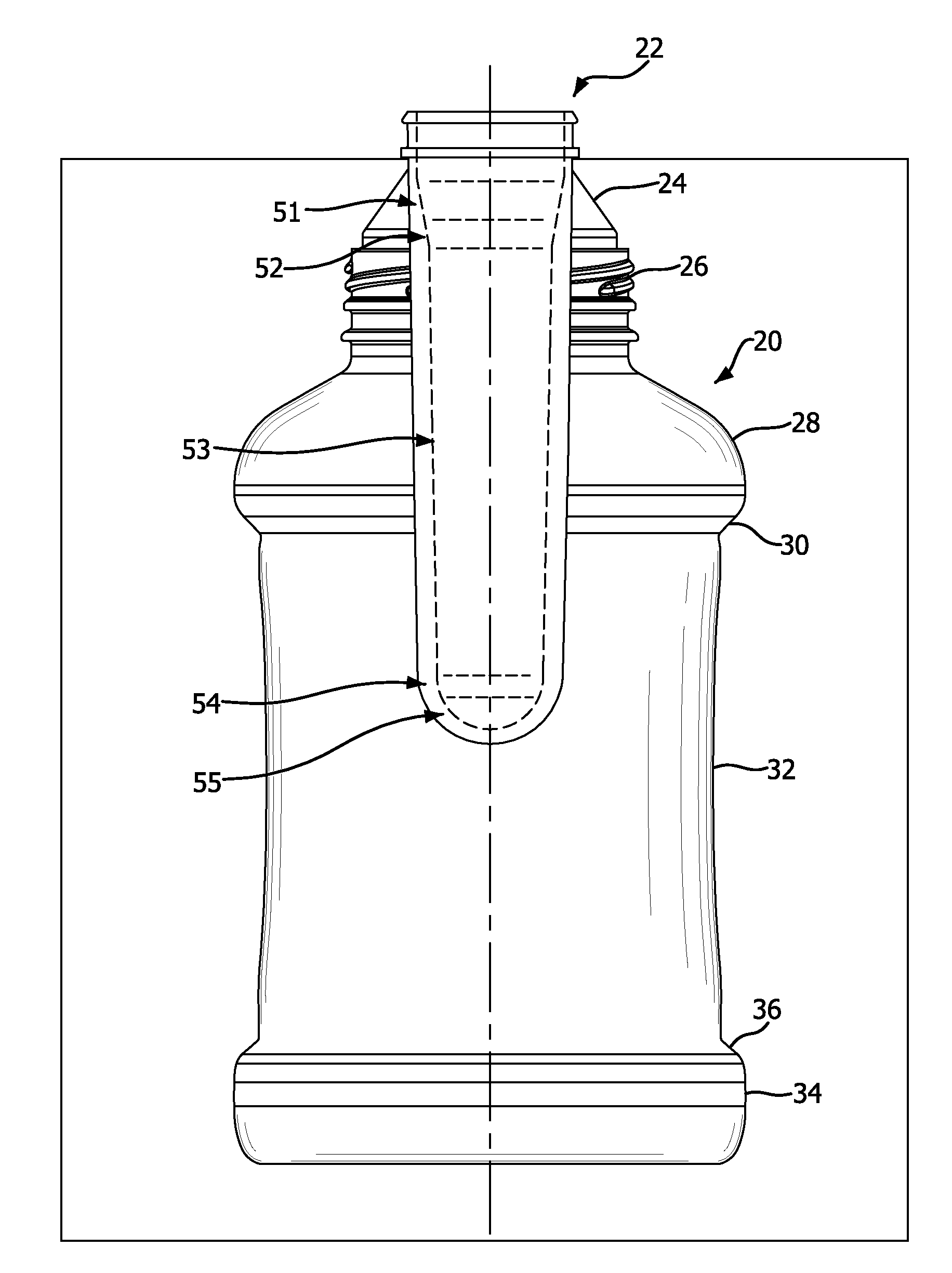

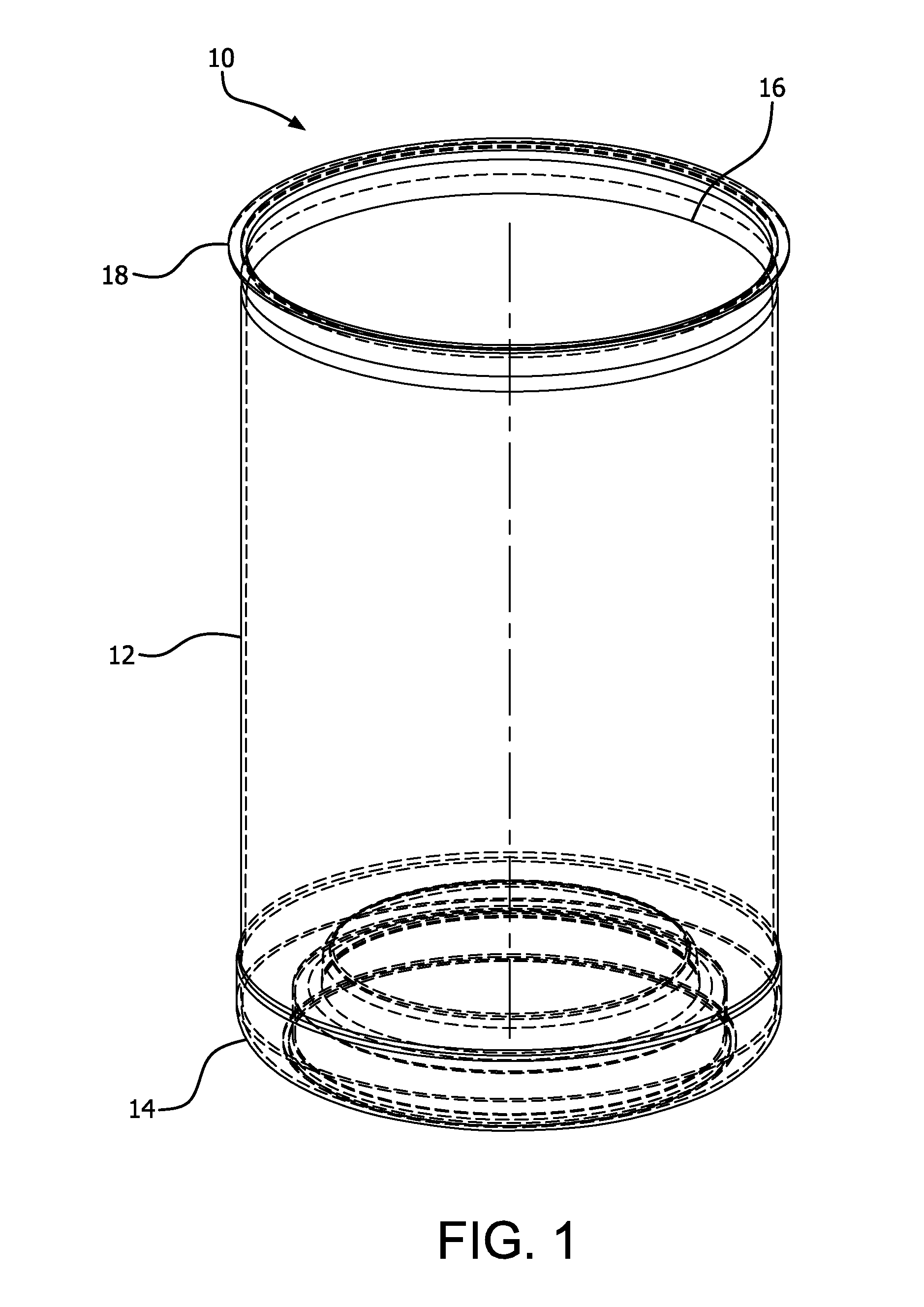

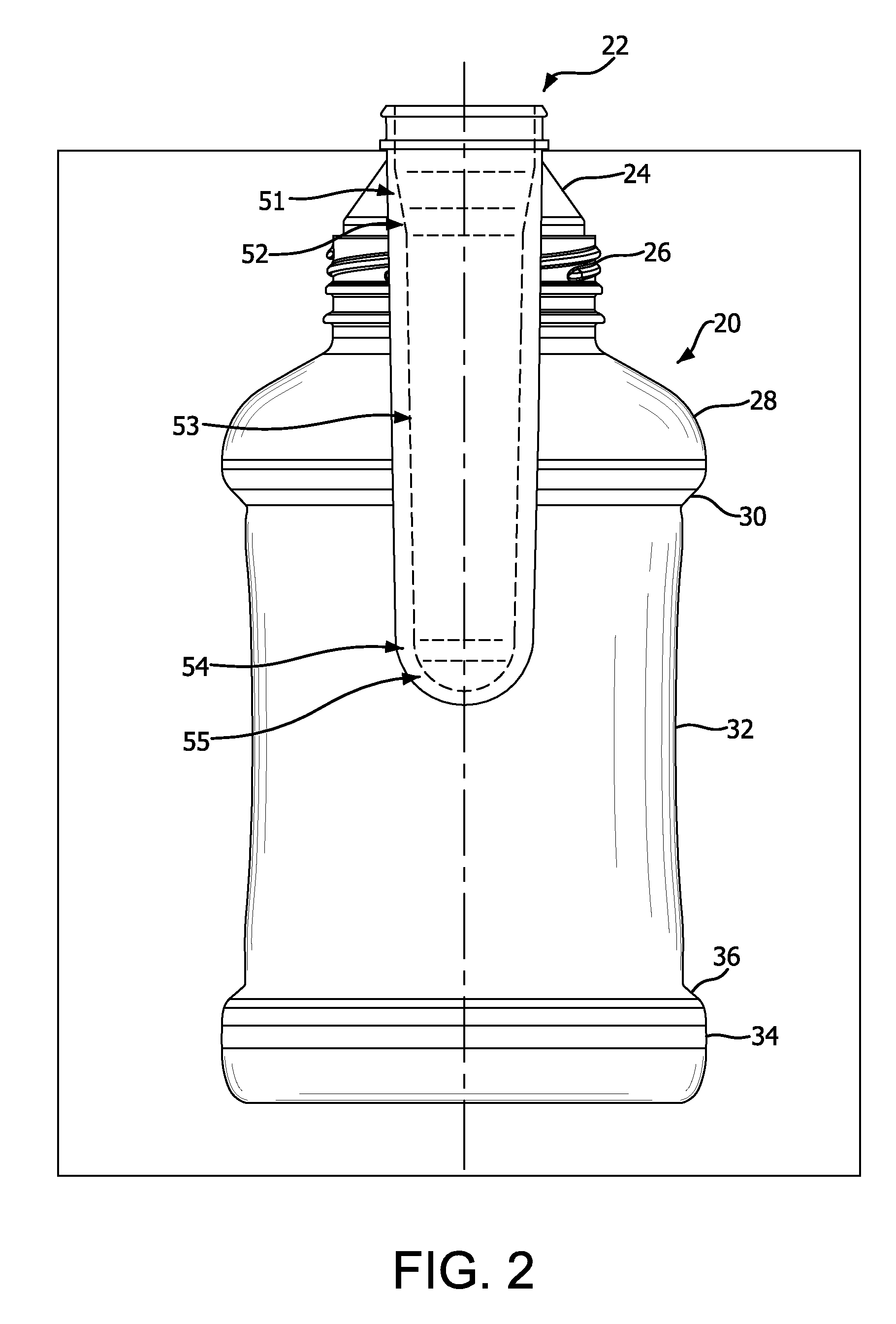

Pet containers with enhanced thermal properties and process for making same

ActiveUS20120076965A1Improve thermal performanceHigh transparencyLayered productsBottlesPasteurizationVolumetric Mass Density

A blow-molded PET container comprising a wall having a density of between about 1.370 g / cc and 1.385 g / cc, a heat-induced crystallinity of from about 18% to about 25%, and a strain-induced crystalinity of from about 55% to about 75%, wherein the PET container, when filled with a liquid having a temperature of from about 100° C. to about 132° C. or when subjected to a pasteurization or retort process, will not experience a change in volume of greater than 3%.

Owner:GRAHAM PACKAGING PET TECH

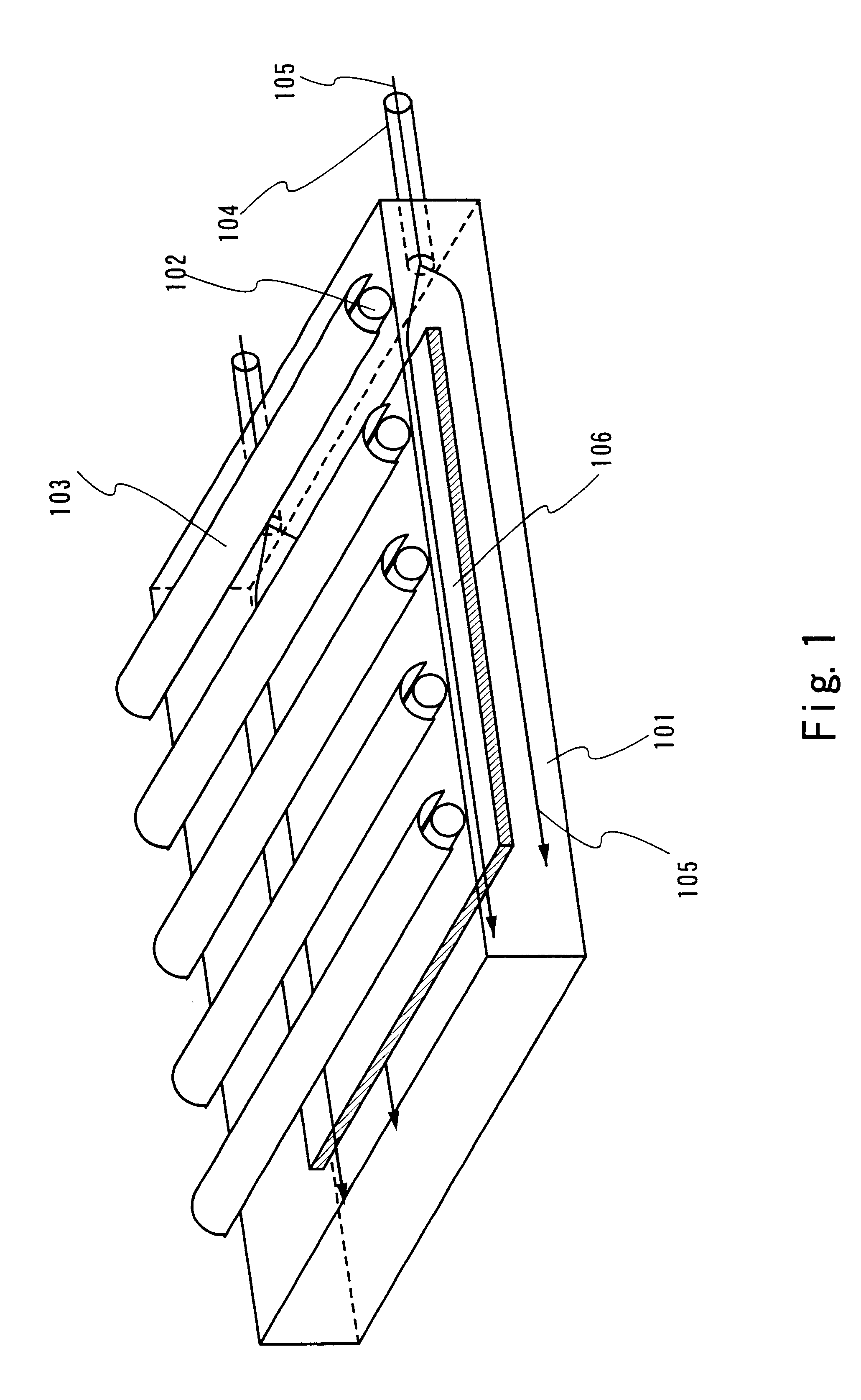

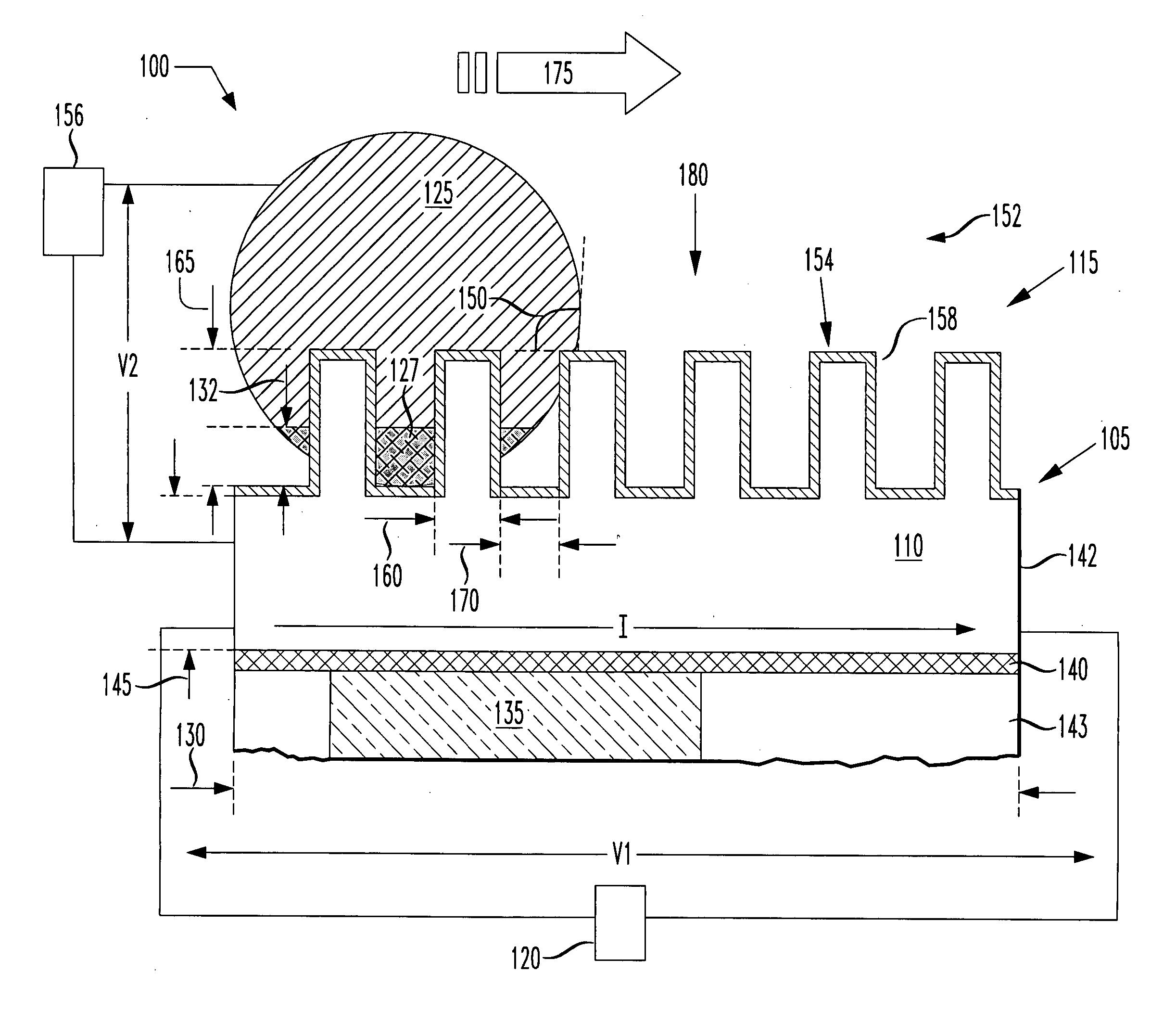

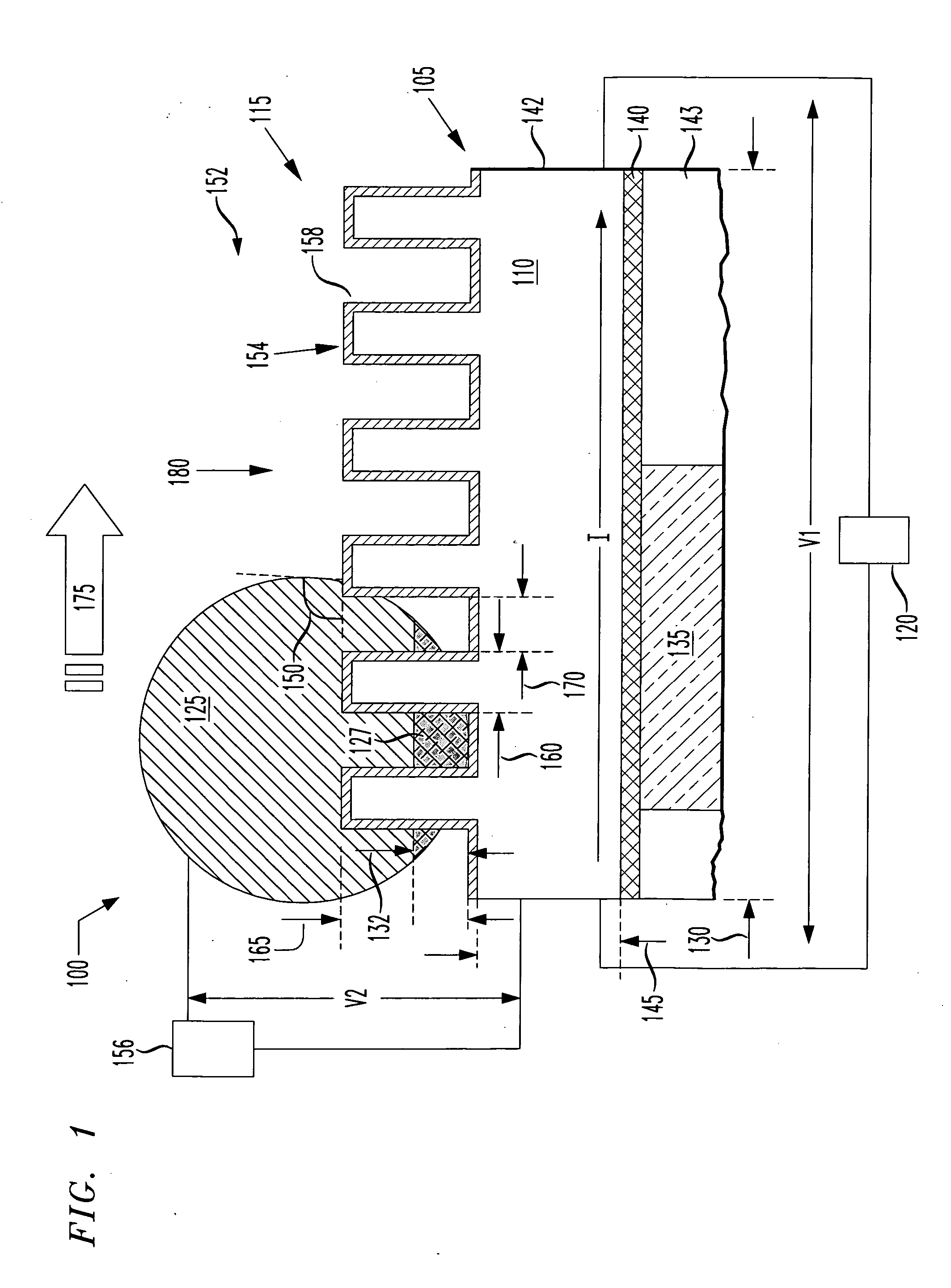

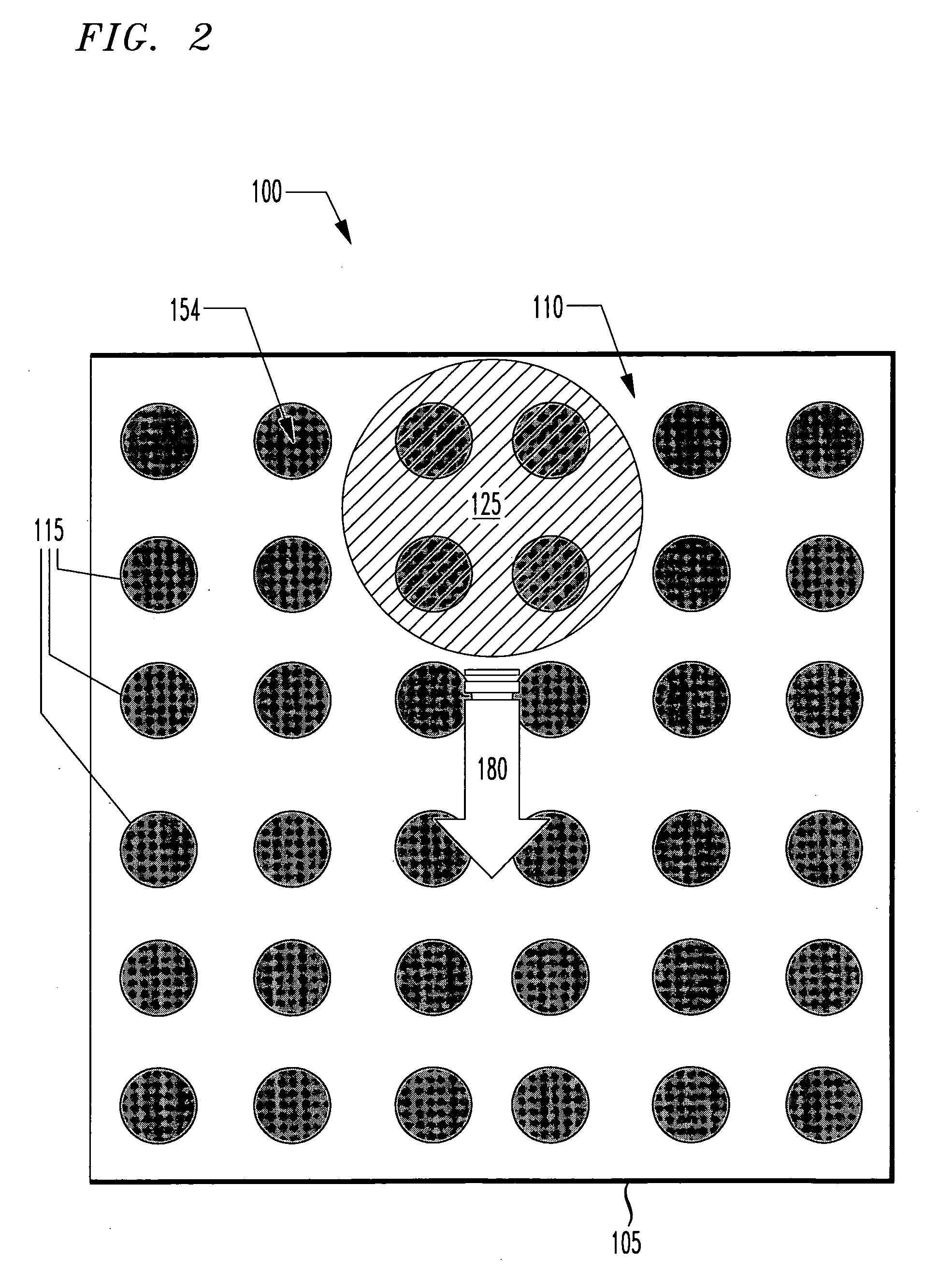

Laser diode arrays with reduced heat induced strain and stress

InactiveUS20060018355A1Improve reliabilityReduce disagreementLaser detailsSemiconductor lasersLaser transmitterHeat sink

A laser diode array has a semiconductor layered structure that includes at least one active layer. A heat sink is coupled to semiconductor layered structure. A plurality of laser emitters are formed in the active layer. A majority of the plurality of laser emitters have a spacing between adjacent laser emitters that provides for a more uniform heat distribution.

Owner:COMLASE

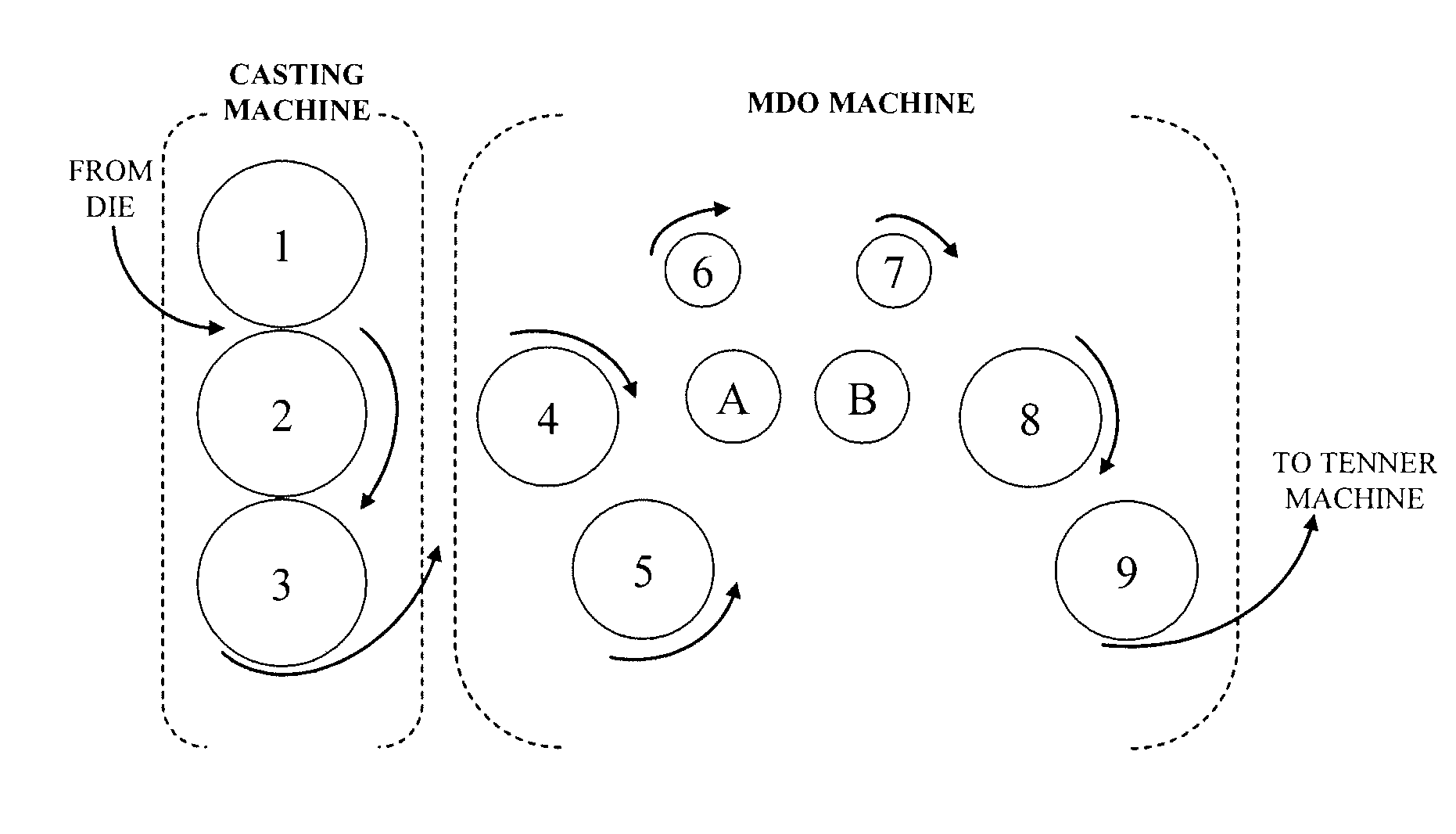

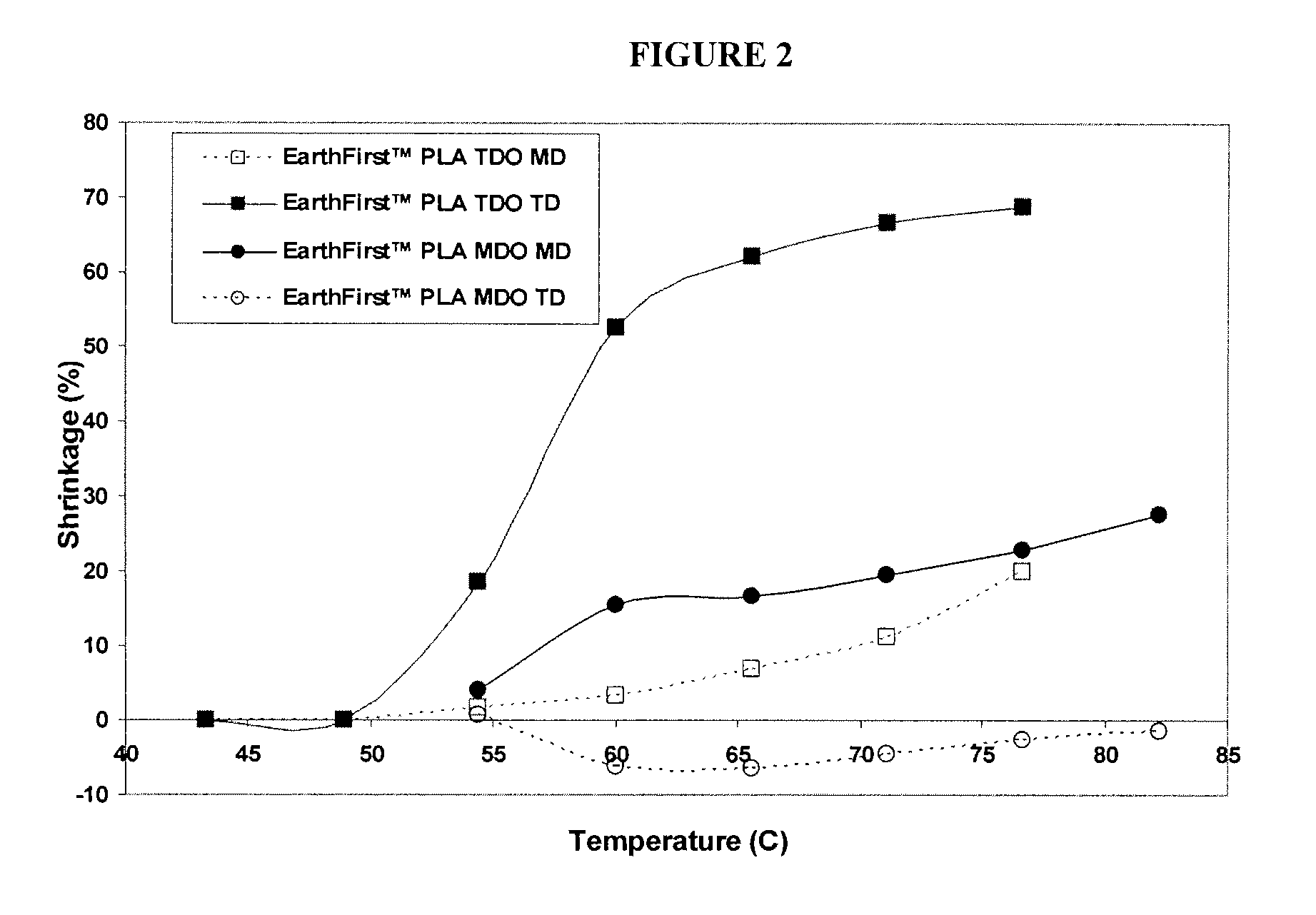

Polylactic acid shrink films and methods of casting same

A heat-shrinkable polylactic acid (PLA) film and a method of its manufacture are provided. In an exemplary embodiment, the PLA films exhibit heat-induced shrinkage in the transverse direction with little to no concomitant shrinkage in the machine direction. The films may comprise any grade of PLA polymer, optionally including additives, such as antiblock, slip, plasticizers, viscosity enhancers and combinations thereof. A method of cast and tenner manufacture is disclosed, which includes a temperature conditioning step.

Owner:PLASTIC SUPPLIERS

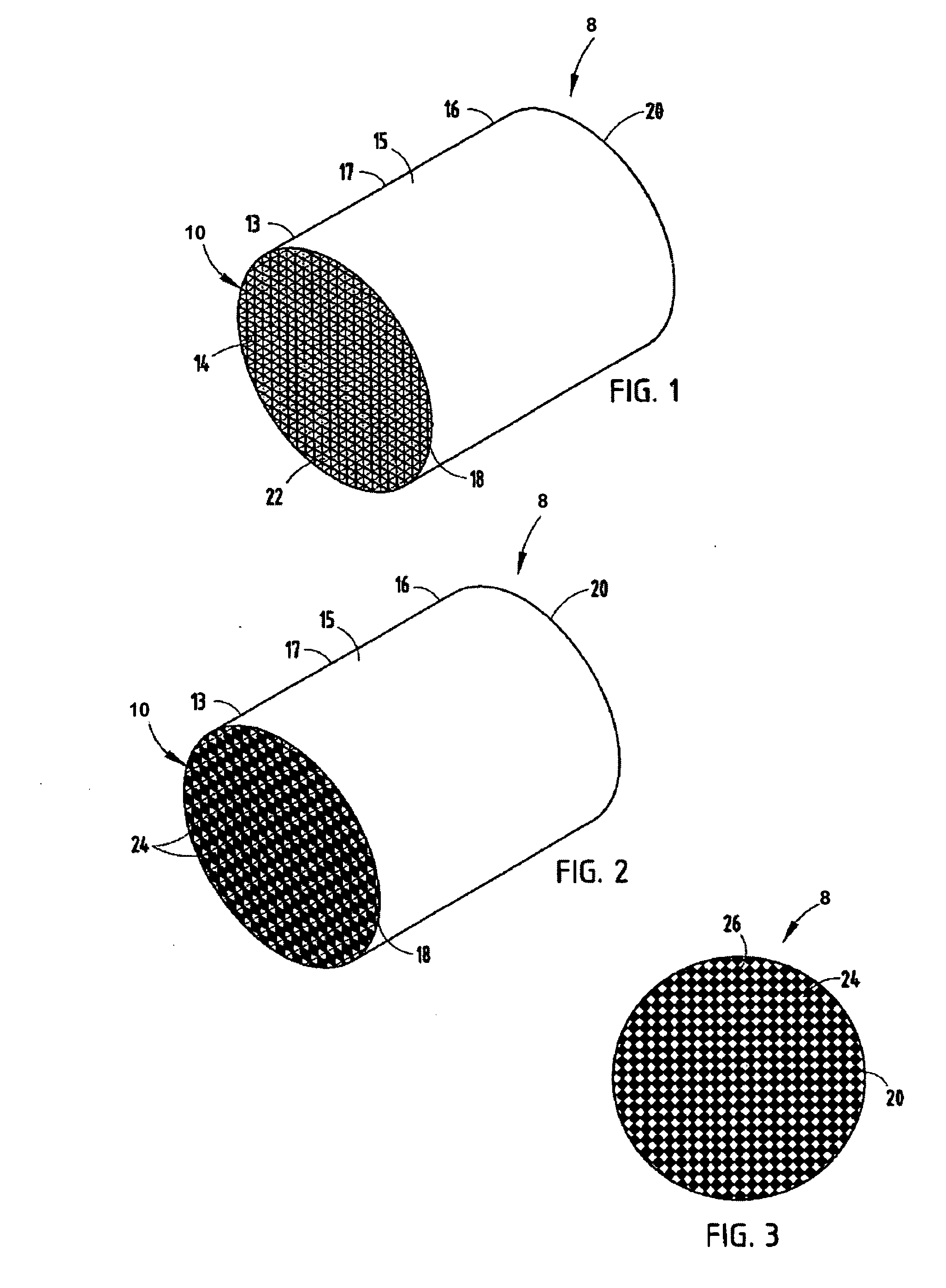

Microwave drying of ceramic structures

ActiveUS20080023886A1Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

A method for drying a ceramic article comprises providing microwave radiation from a microwave generating source, providing a ceramic honeycomb structure having a middle portion and at least one end, and exposing the ceramic honeycomb structure to the microwave radiation while shielding the at least one end from directly receiving the microwave radiation, such that the radiation absorbed by the middle portion is equal to or greater than the radiation absorbed by the at least one end, and the proper drying of the entire honeycomb structure without heat-induced structural degradation is thus ensured.

Owner:CORNING INC

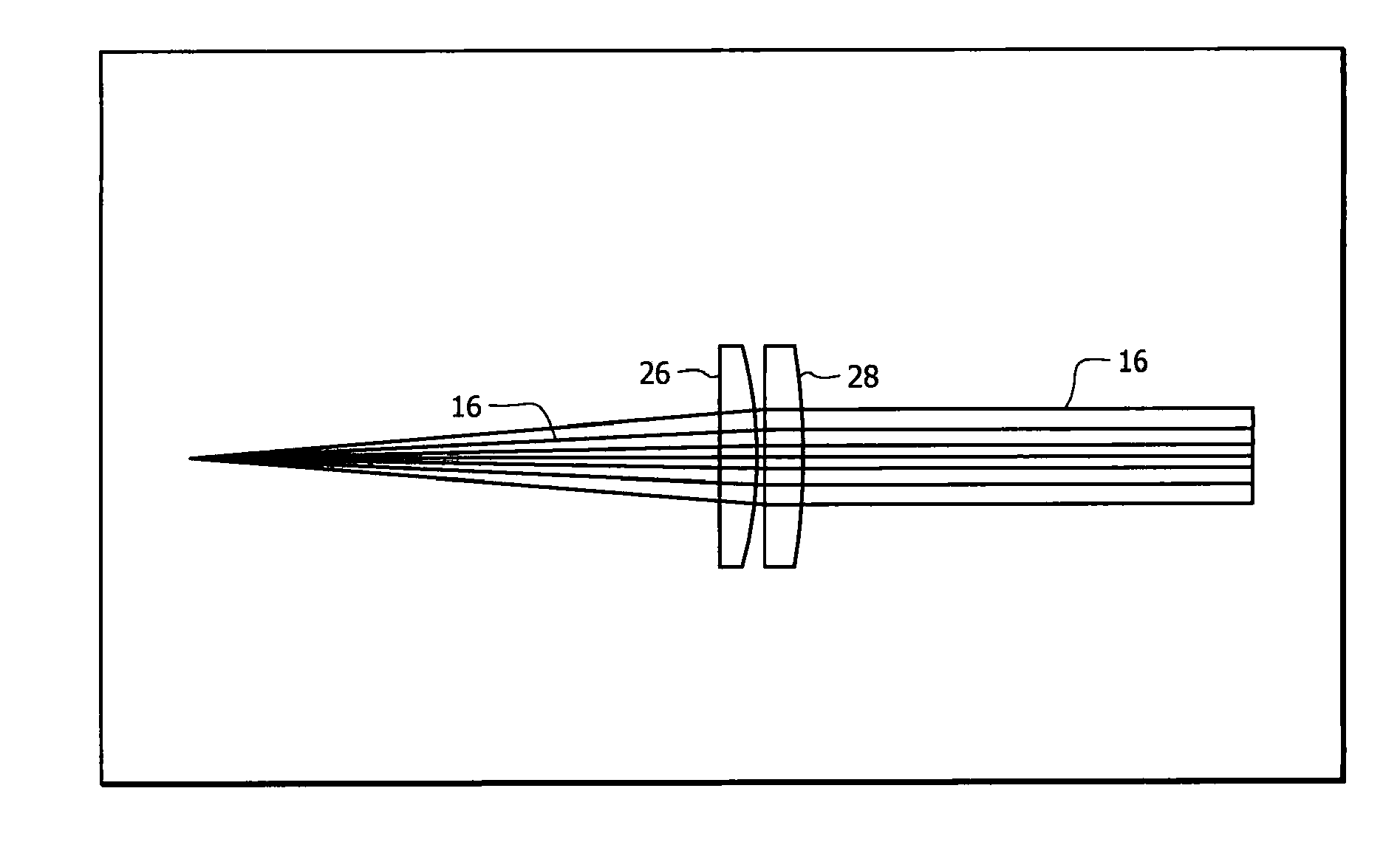

Liquid optics zoom lens and imaging apparatus

A high performance zoom lens system suitable for use with a camera is disclosed. The zoom lens systems employs liquid optics and a movable lens group to provide optical performance over the zoom focal length range at focus distances from close to infinity. The system also provides compensation for undesirable thermally induced effects by adjustments of the zoom group and the variably shaped optical surface in the liquid lens cell.

Owner:MONUMENT PEAK VENTURES LLC

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS20100243714A1Simple and easy to performHeat dissipationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingCopper

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

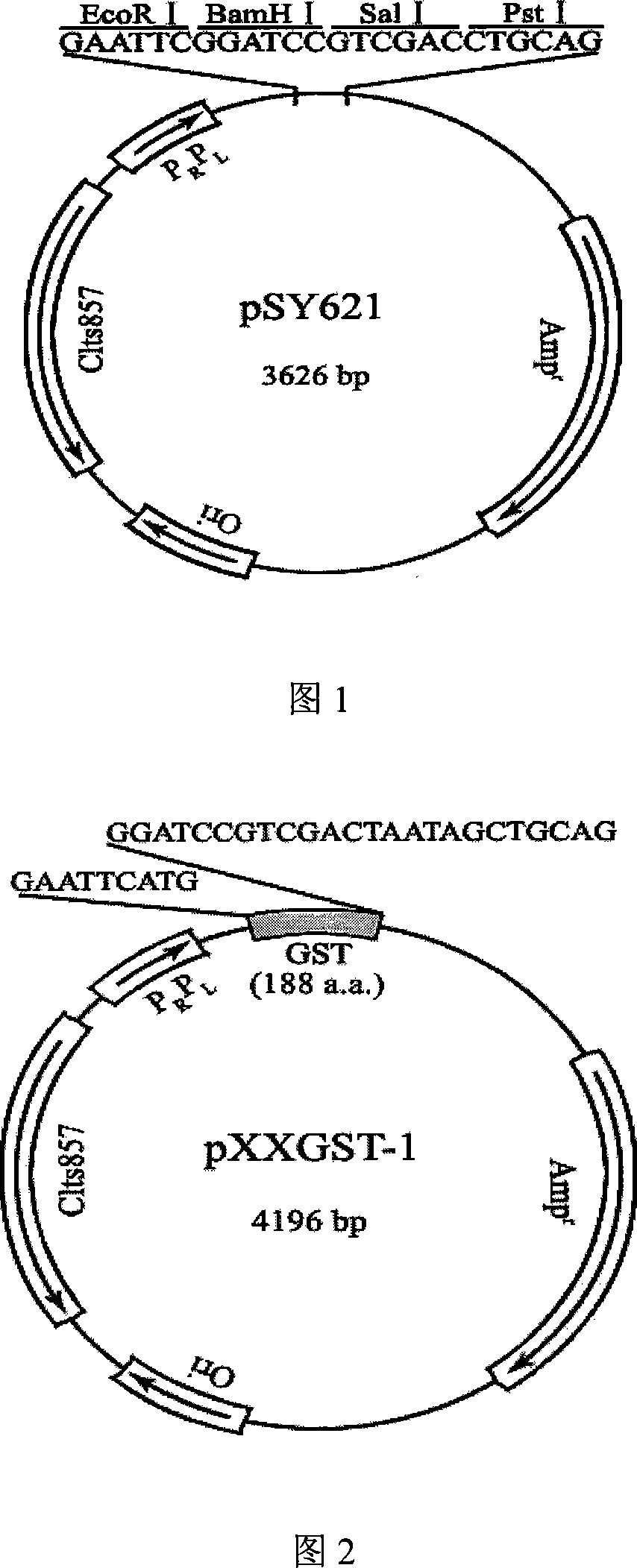

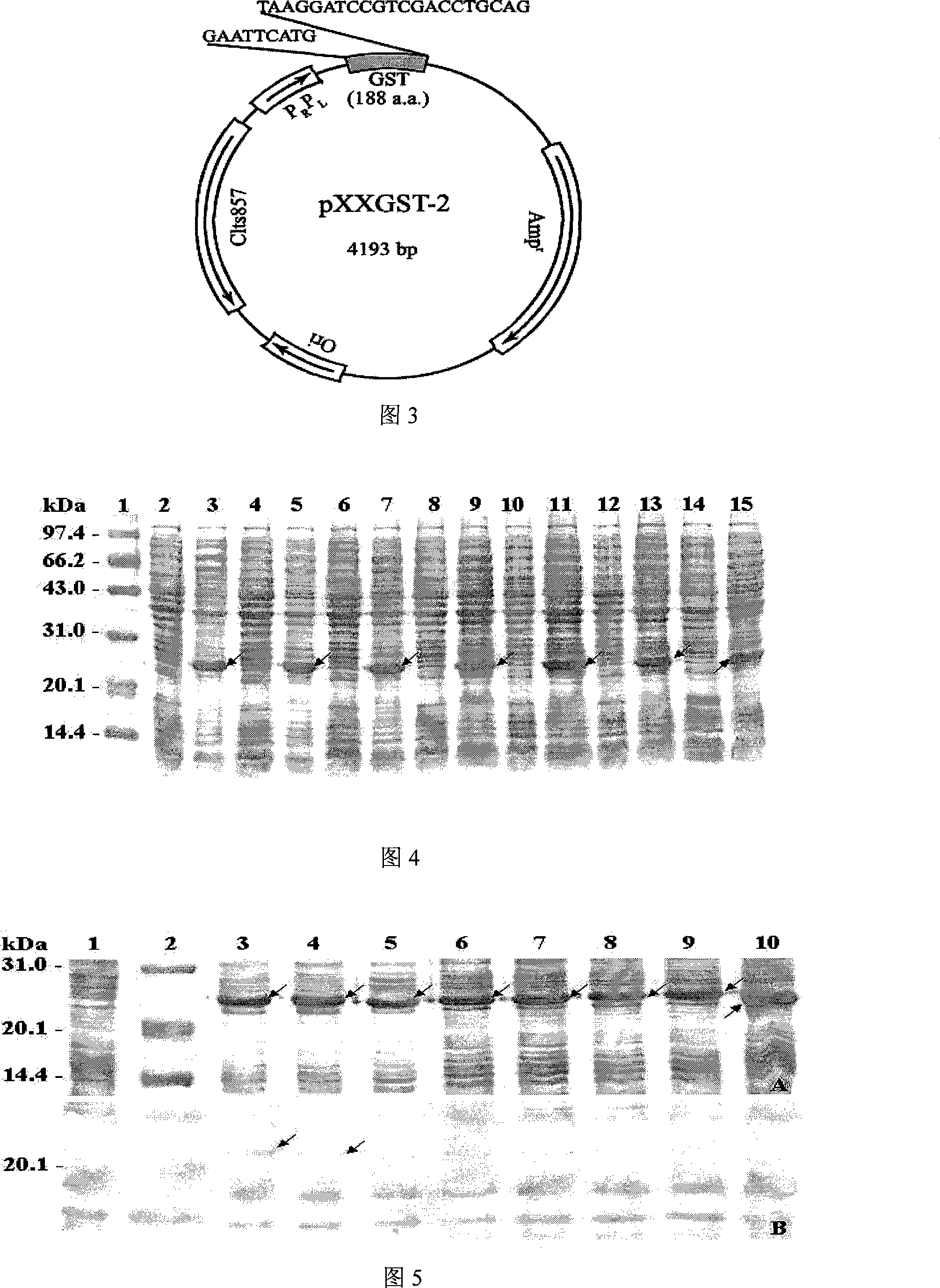

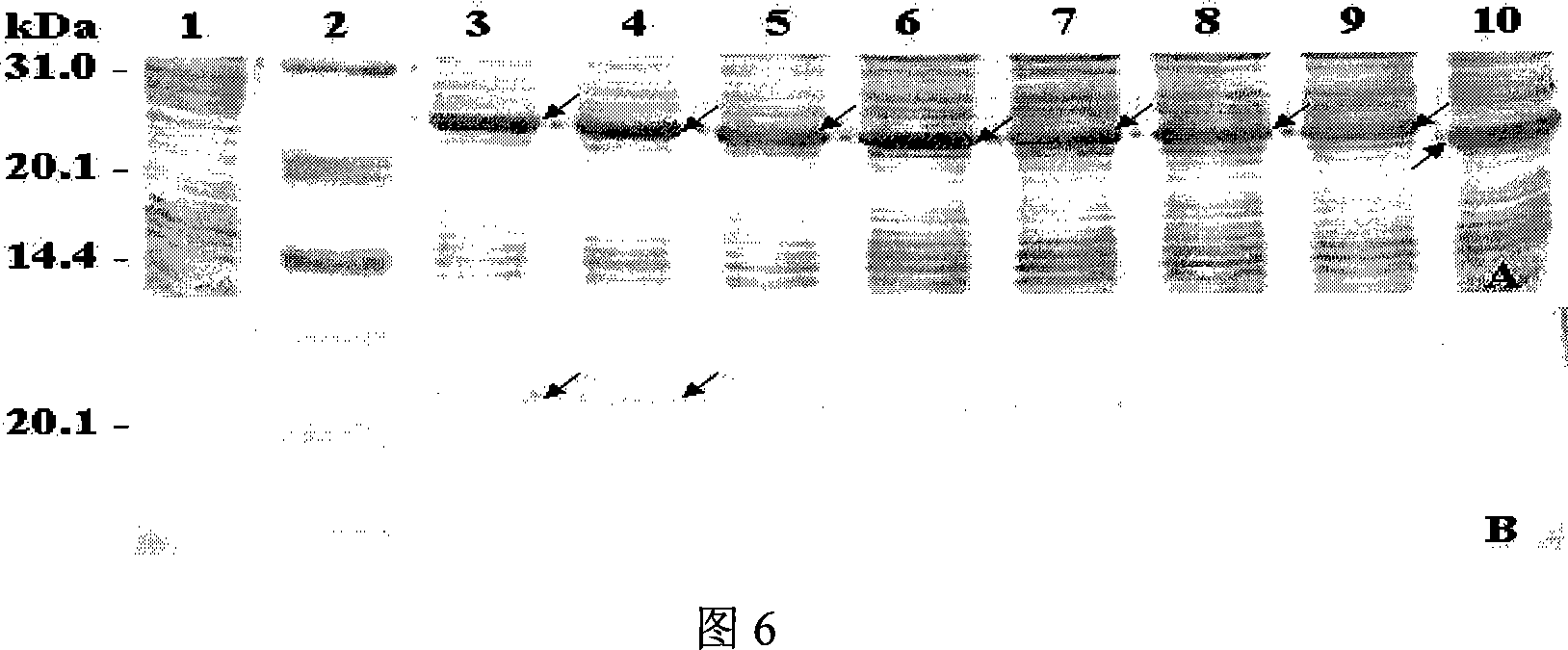

Cropping GST protein thermal induction fusion expression plasmid and preparation method thereof

InactiveCN101215573ASuitable for western blot experimentsWill not affect judgmentVector-based foreign material introductionDNA/RNA fragmentationEscherichia coliProtein target

The invention belongs to the technical field of biological engineering and in particular is a heat-induced fusion expression recombinant plasmid of truncated GST protein and a process for preparation. The invention selects utility truncated GST188 protein which is composed of 188aa as a carrier, a pXXGST-1 recombinant plasmid which expresses short peptide fusion protein in an escherichia coli heat-induced expression system and a heat-induced type pXXGST-2 recombinant plasmid which is used to express comparison to realize the aim of synthesizing short peptide creatures, which is especially provided for scanning, drawing, positioning antigen linear epitopes and identifying epitope motif. Experiments of the invention prove the adaptability and the applicability of the GST188 core protein which is used as the short peptide creatures expression vector, in antigen epitope scanning identification, and in particular when anti- recombinant target protein antiserum is used to indentify the epitope motif.

Owner:SHANGHAI INST OF PLANNED PARENTHOOD RES +2

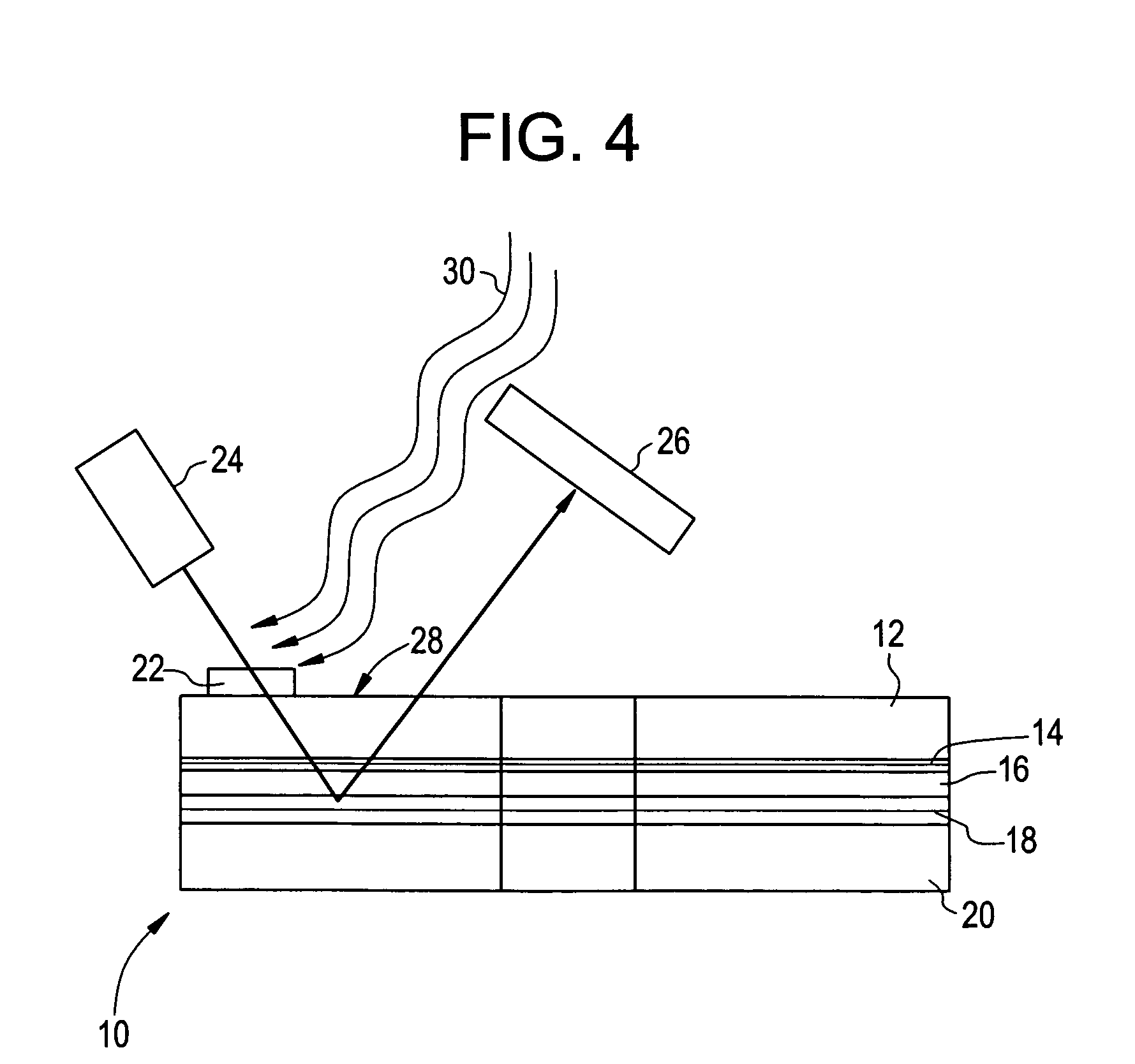

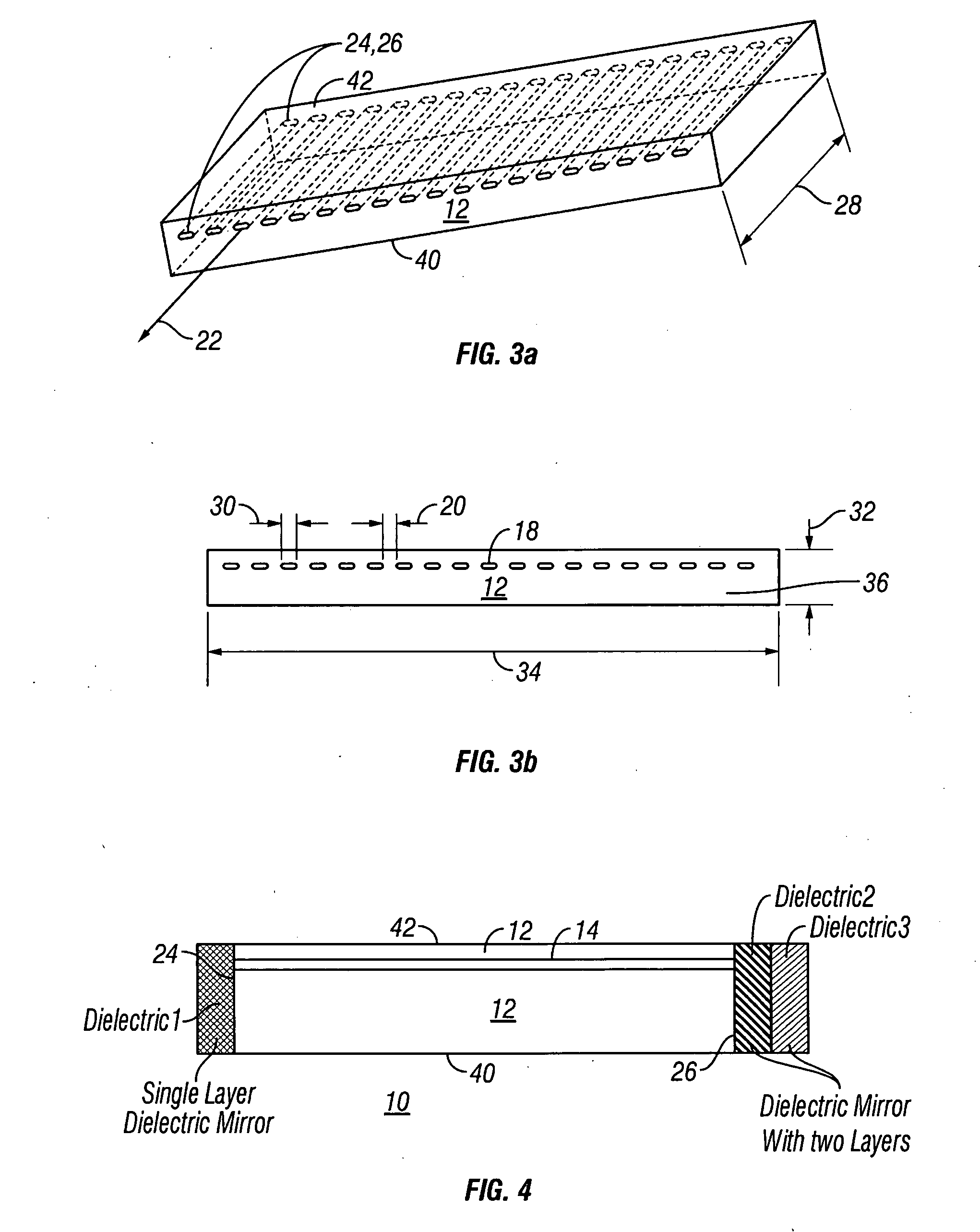

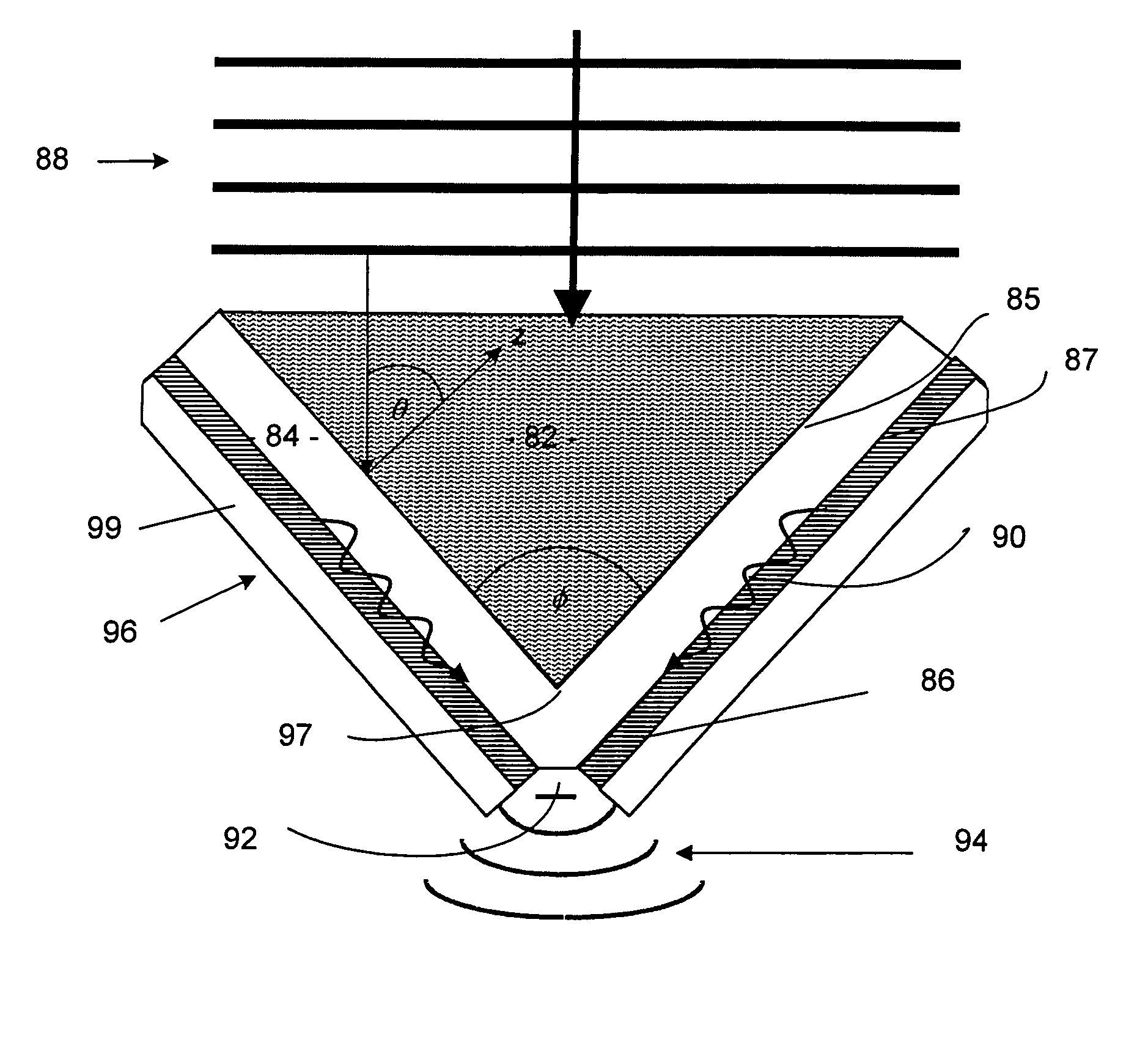

Apparatus for focusing plasmon waves

InactiveUS7106935B2Valid conversionManufacture head surfaceNanoinformaticsMagnetic polesHeat induced

An apparatus for focusing plasmon waves to a spot. The plasmon waves are there converted to light. In one application, the light is used for heat induced magnetic recording. In another application, the light is used as a part of near field scanning microscope. The plasmon waves may be induced on a converging rectangular cone having an aperture. The plasmon waves may also be focused on a flat surface by a curved dielectric lens. In the heat induced magnetic recording embodiment, a magnetic pole structure is integrated into the focusing apparatus, either as one surface of the rectangular cone, or as a layer upon which the curved dielectric lens is formed.

Owner:SEAGATE TECH LLC

Process of preparing porous ceramic material by ''freezing-gel forming''

The present invention discloses a 'freezing-gelling molding' process for preparing a porous ceramic material and belongs to the field of ceramic materials. By combining low temperature freezing molding with heat induced gelling solidification molding of ceramic materials and adopting macromolecule polymers, solvents, initiators or chelating agents as well as ceramic powders as raw materials, saidprocess prepares a suspension containing a certain solid phase volume; by adopting a quick continuous heat processing course of 'crystallization melting-gelling solidification-solvent vaporization hole formation' performed inwards from blanks surfaces to obtain ceramic bodies with a microstructure of a frozen sample maintained therein, wherein the appearance of the pores is similar to that of solvents in crystallization state, then a ceramic material having a variety of porous structures and exhibiting excellent mechanical properties is obtained. The process conditions of the present invention is easy to realize, the suitable material system range is broad, and then the process is suitable of a plurality of purposes, such as filters used in high temperature conditions and catalyzer carrier and the like.

Owner:TSINGHUA UNIV

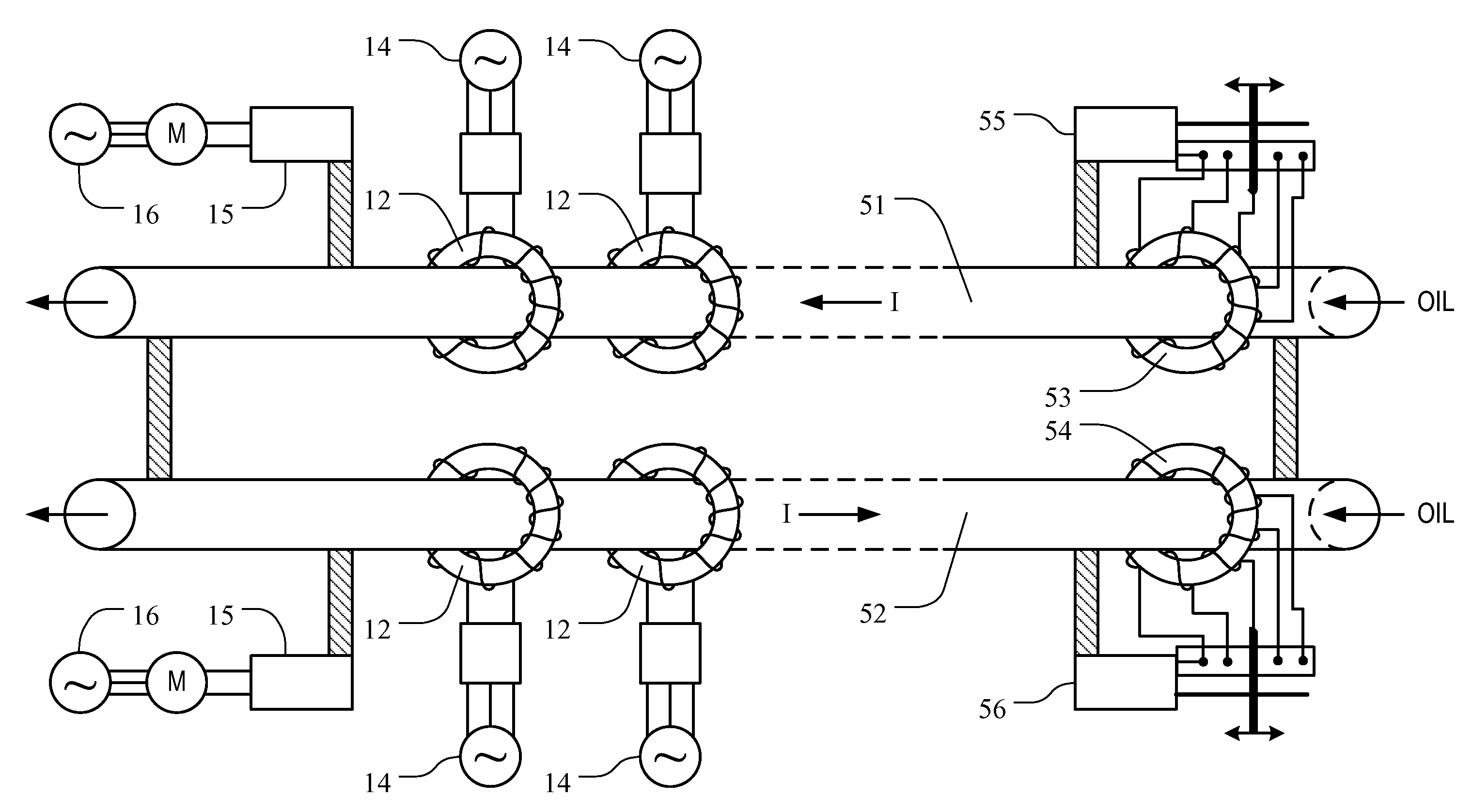

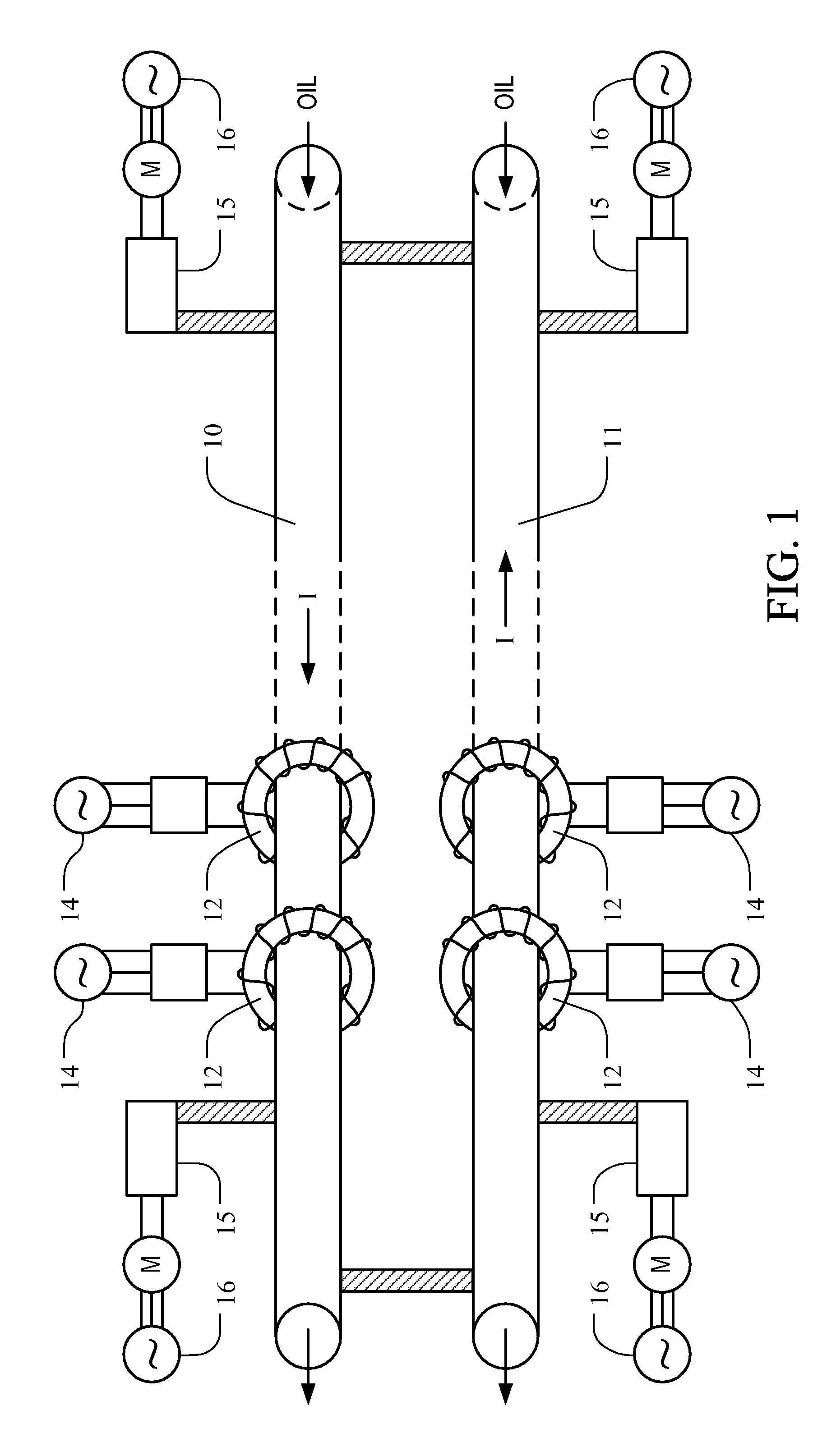

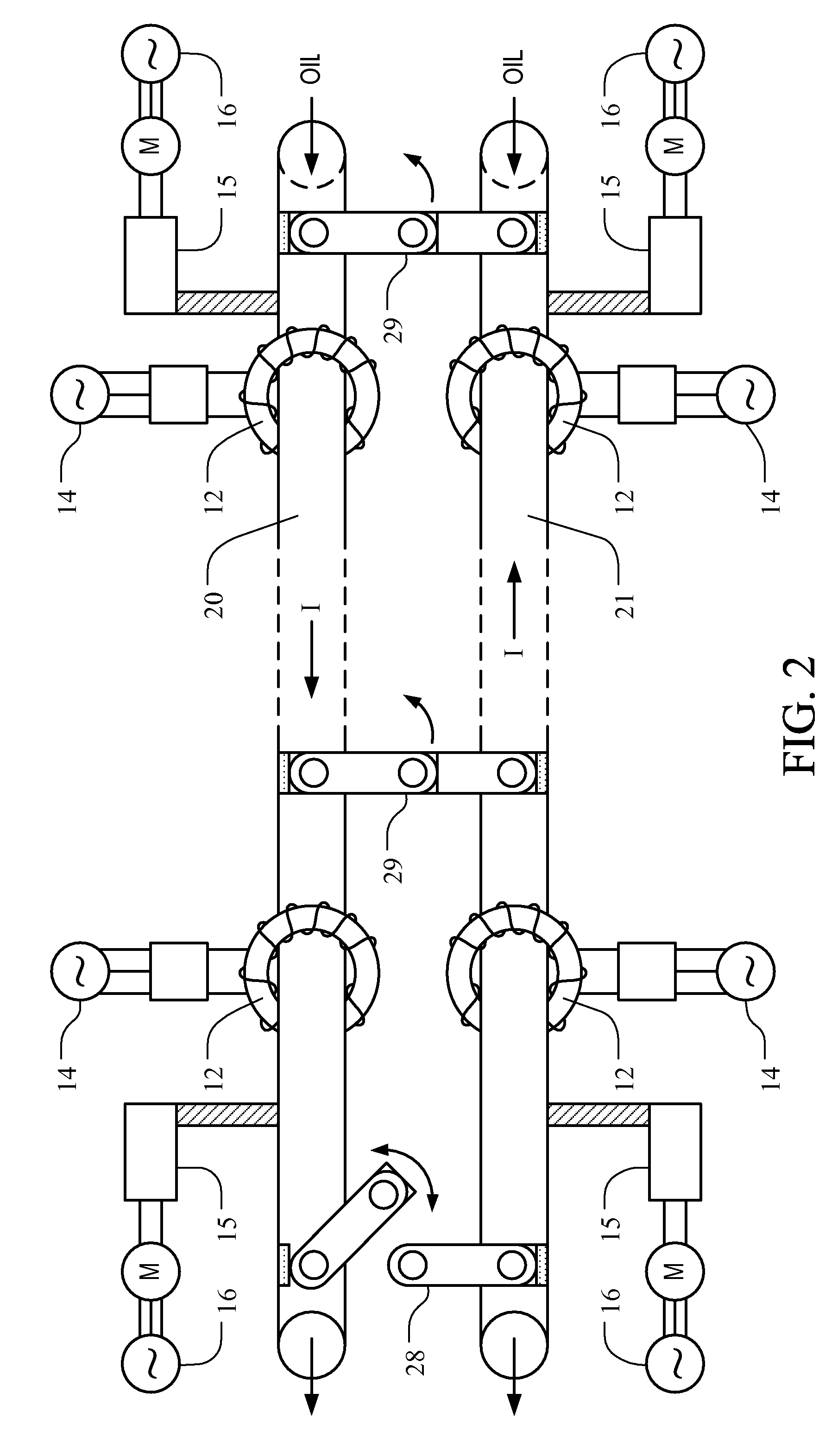

System and method for pipeline heating

InactiveUS20100101663A1Easy to transportEasy to controlValve members for heating/coolingPipe heating/coolingLow voltageTransformer

A fluid flow within a transportation pipeline is heated with low voltage, high current electrical energy induced into a conductive closed loop structure by one or more transformers. The closed loop structure is preferably a fluid transportation pipeline constructed of electrically conductive sections of pipeline. The amount of current induced is sufficient in relation to the inherent resistivity of the conductive sections to cause the generation of heat within the pipeline sections. By conductive and convective heat transfer, the heat induced into the pipeline structure is transferred to a fluid flow within the pipeline. The current is preferably an alternating current of frequency which causes a majority of the current to travel at or near the outer surfaces of the pipeline sections which increases the effective resistivity of the sections and heat generation therein.

Owner:GRANBORG BERTIL

Thermally compensating lens for high power lasers

ActiveUS20110249342A1Good optical performanceImproves conventional technologyMountingsLaser cooling arrangementsCamera lensHigh power lasers

A method for thermally compensating lenses in an optical system for high power lasers includes the steps of providing a fused silica lens to collimate a high power laser beam and positioning that lens in collimating relation to the laser beam. A focusing lens assembly is provided to focus the collimated laser beam and is positioned in focusing relation to the collimated laser beam. At least one lens having a negative dn / dT to offset a heat-induced change in index of refraction of the fused silica lens is included as a part of the collimating lens assembly and as a part of the focusing lens assembly. The lens having a negative dn / dT is selected from a group of glasses having a negative dn / dT. The power of the lenses is balanced with an offsetting negative dn / dT so that the optical system maintains its focus over a wide temperature range.

Owner:HAAS LASER TECH

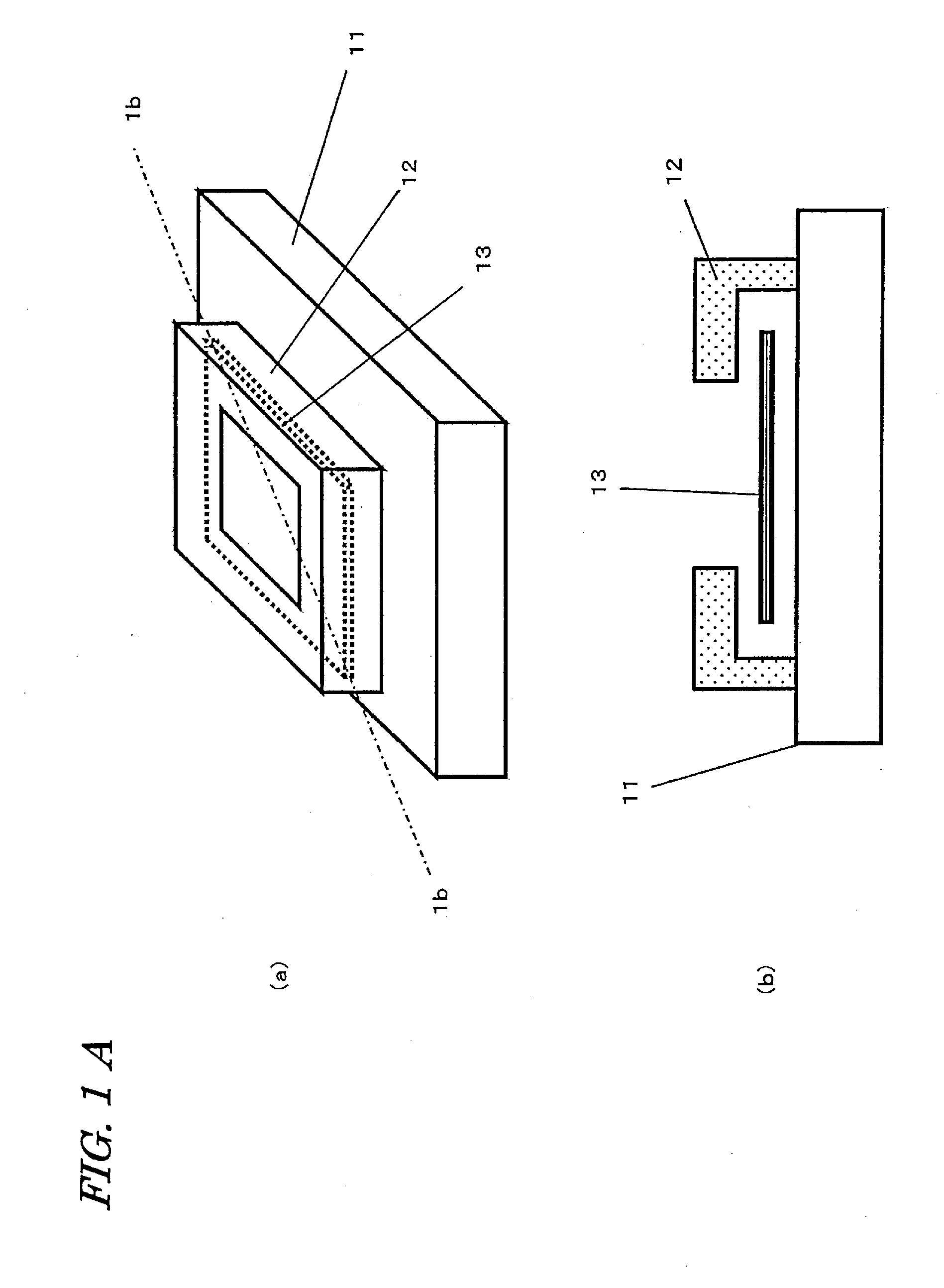

Electronic device and method for fabricating the same

InactiveUS20080179525A1Minimize escapeImprove insulation performanceWave amplification devicesSolid-state devicesInfraredDetector circuits

An electronic device according to the present invention includes: at least one heat sensing section (13), which includes a first contact portion (24) and of which a physical property varies responsive to an incoming infrared ray; a detector circuit section, which includes a second contact portion (42) and which senses the variation in the physical property of the heat sensing section (13); and a driving section (112), which is able to change a first state, in which the first and second contact portions (24, 42) are in contact with each other and electrically connected to each other, into a second state, in which the first and second contact portions (24, 42) are out of contact with each other and electrically disconnected from each other, and vice versa.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com