Patents

Literature

3190results about How to "Dry evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

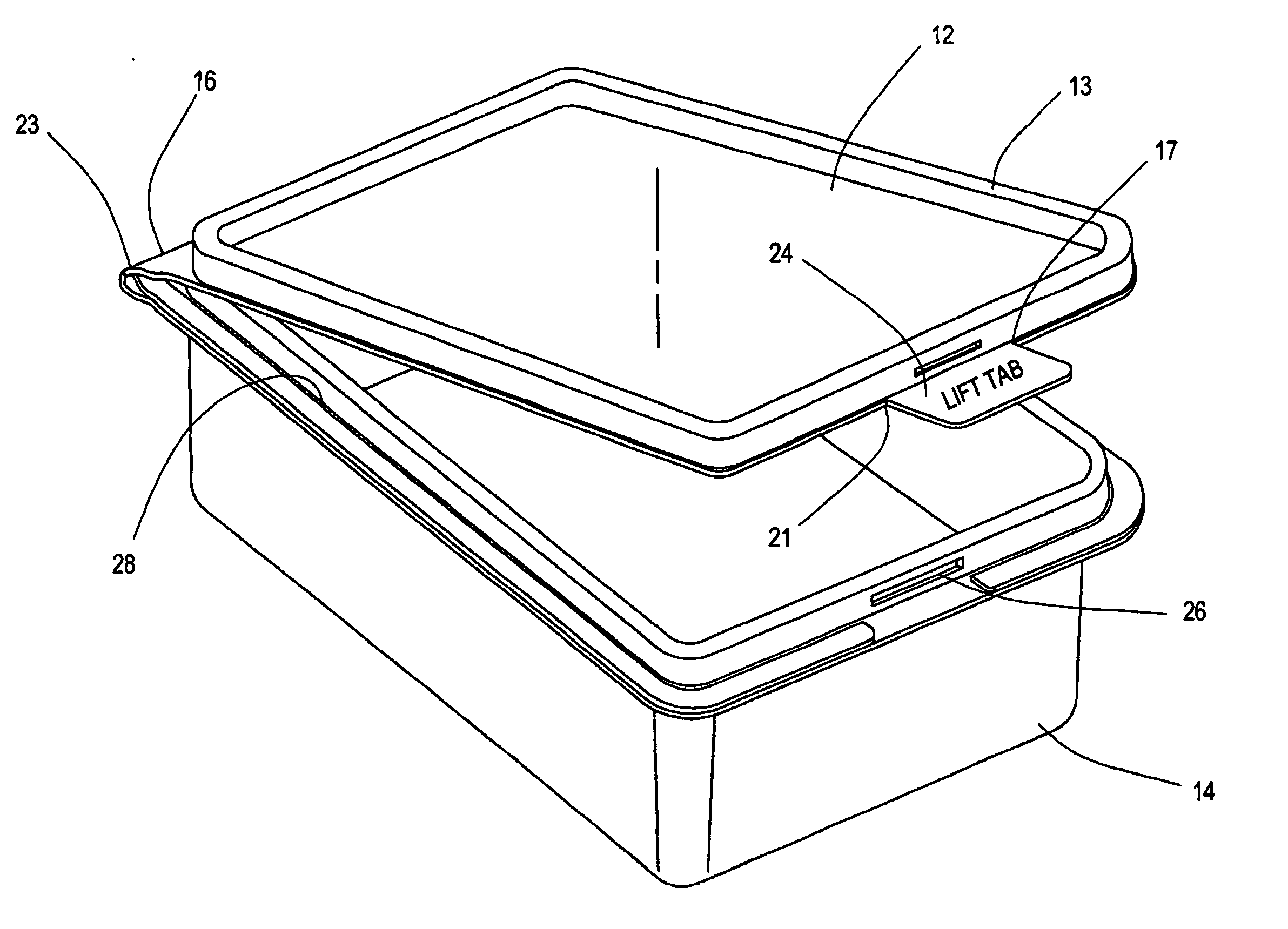

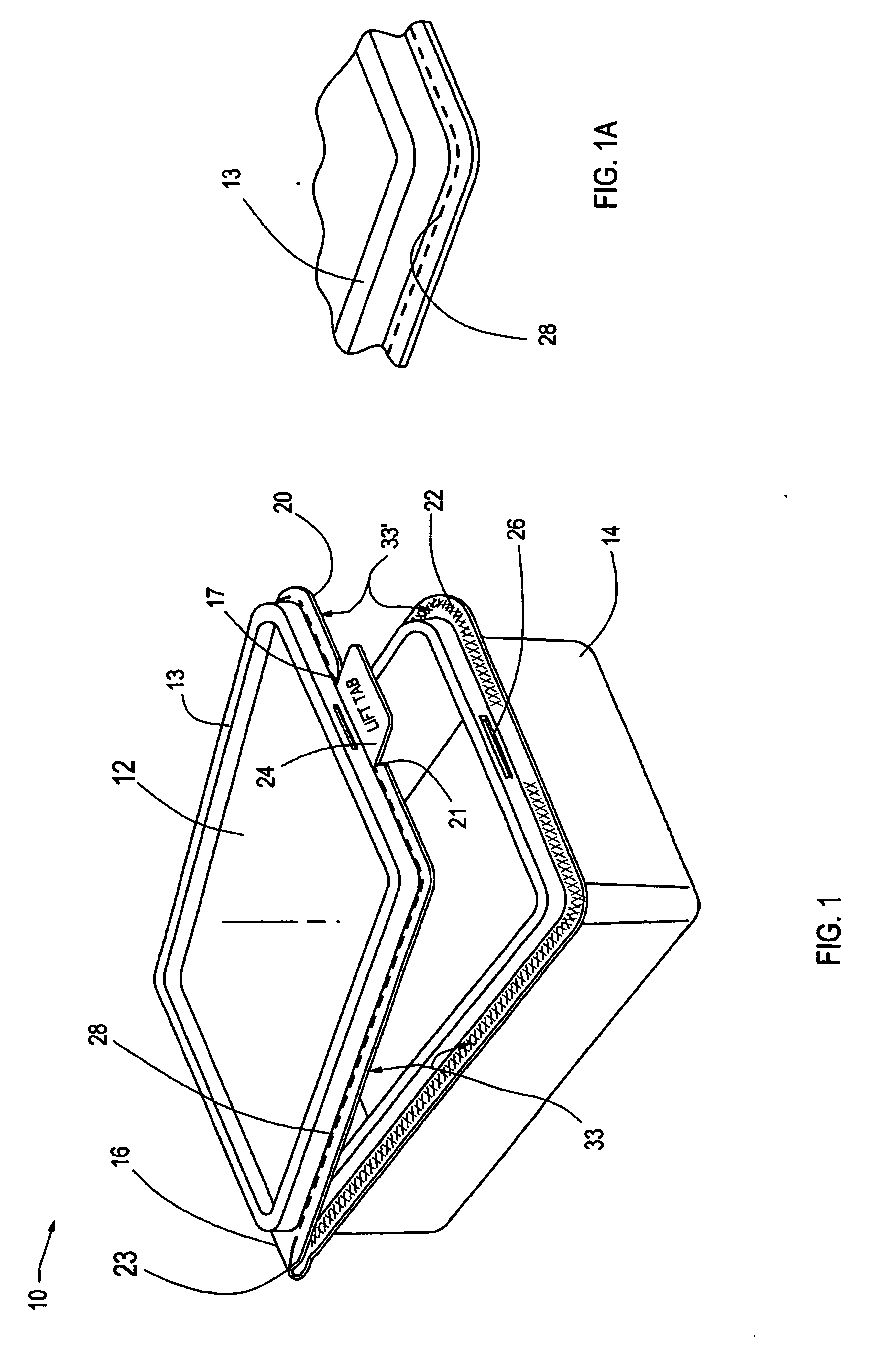

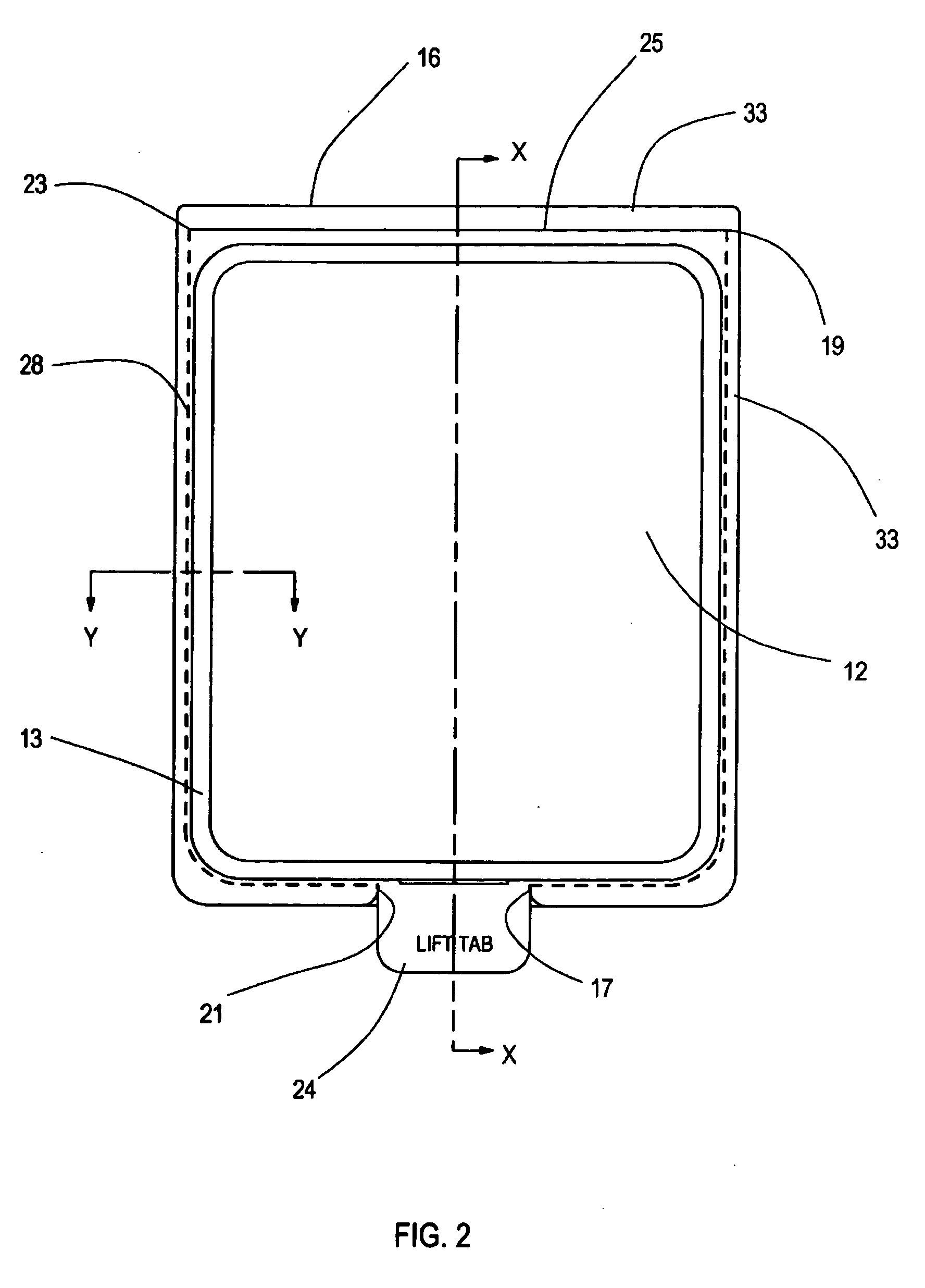

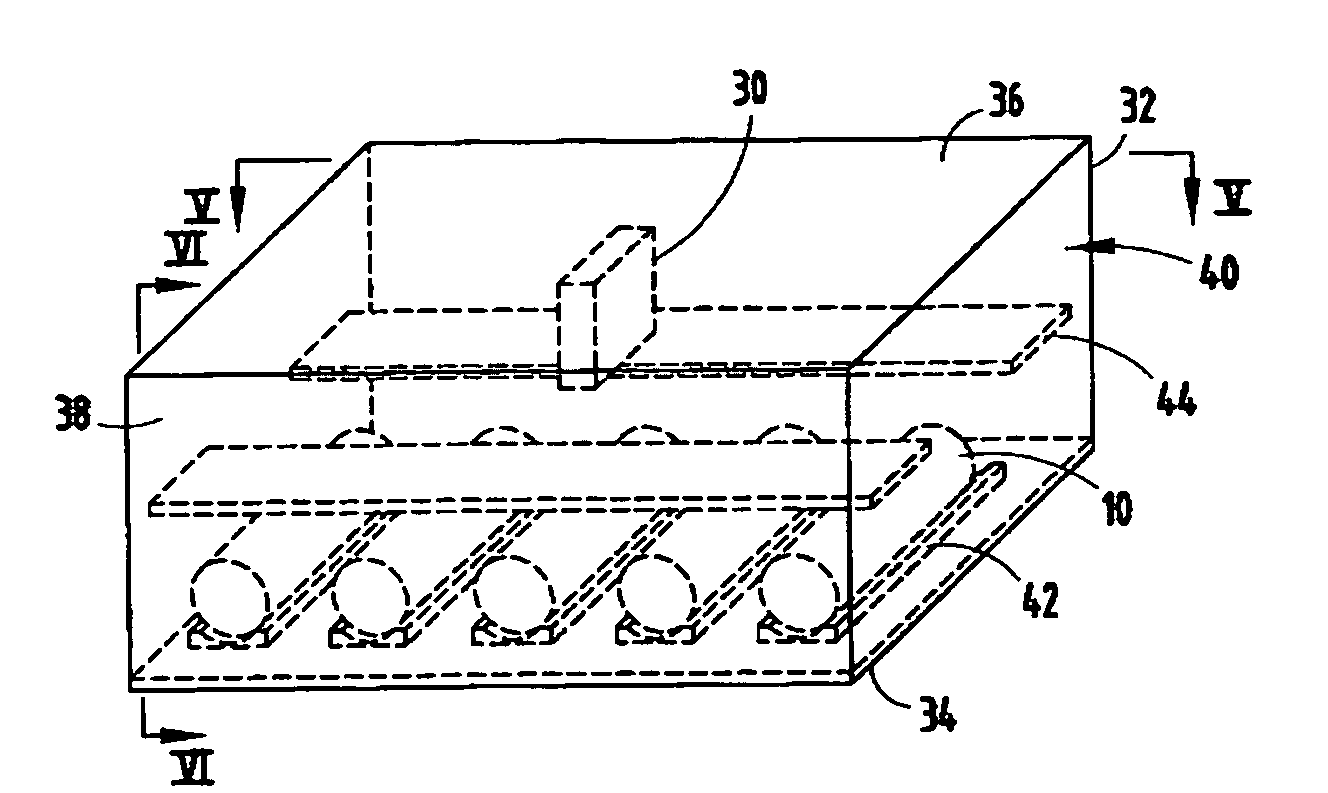

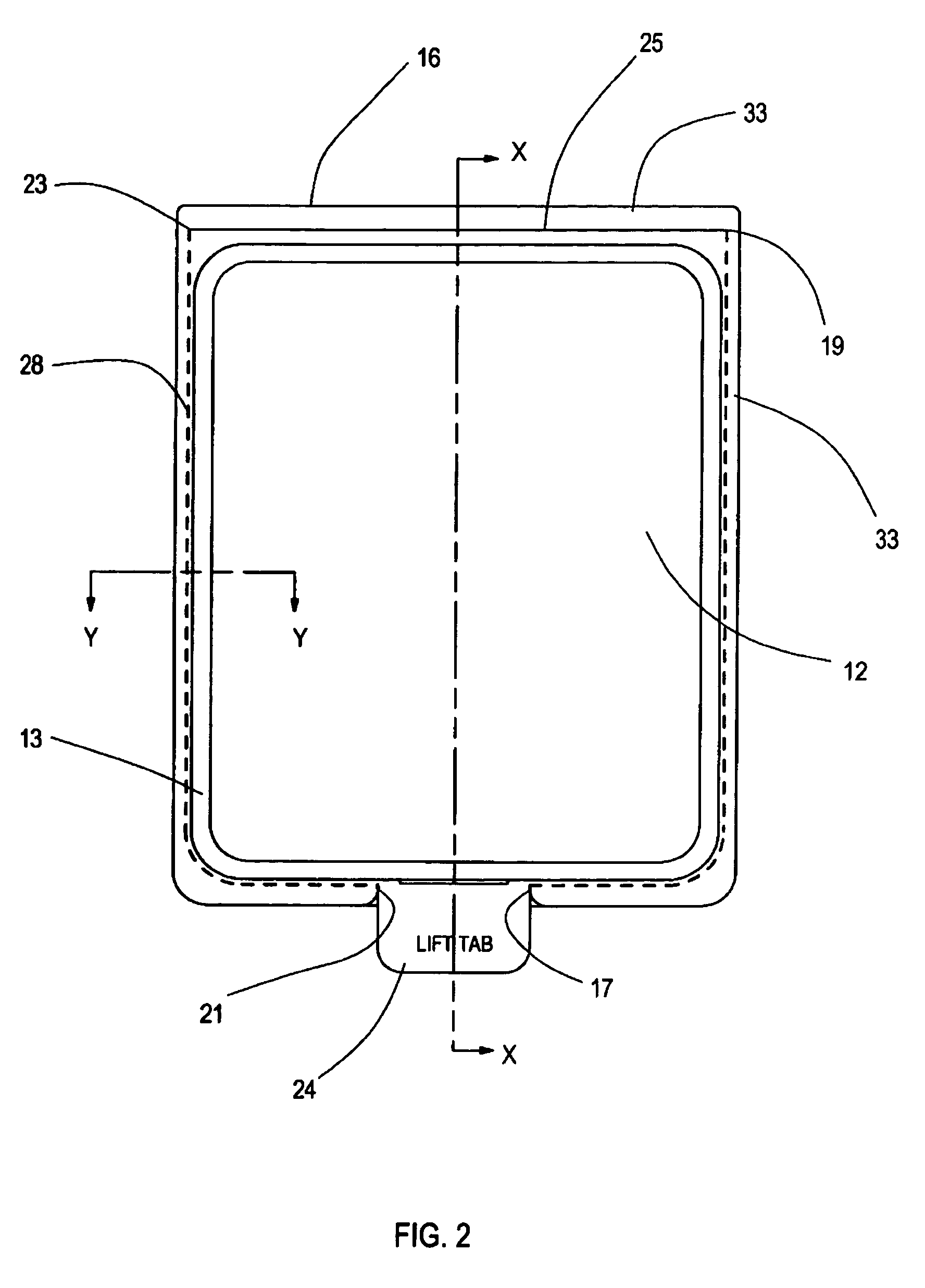

Versatile tamper-evident food container

ActiveUS20070012710A1Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitMaterial Perforation

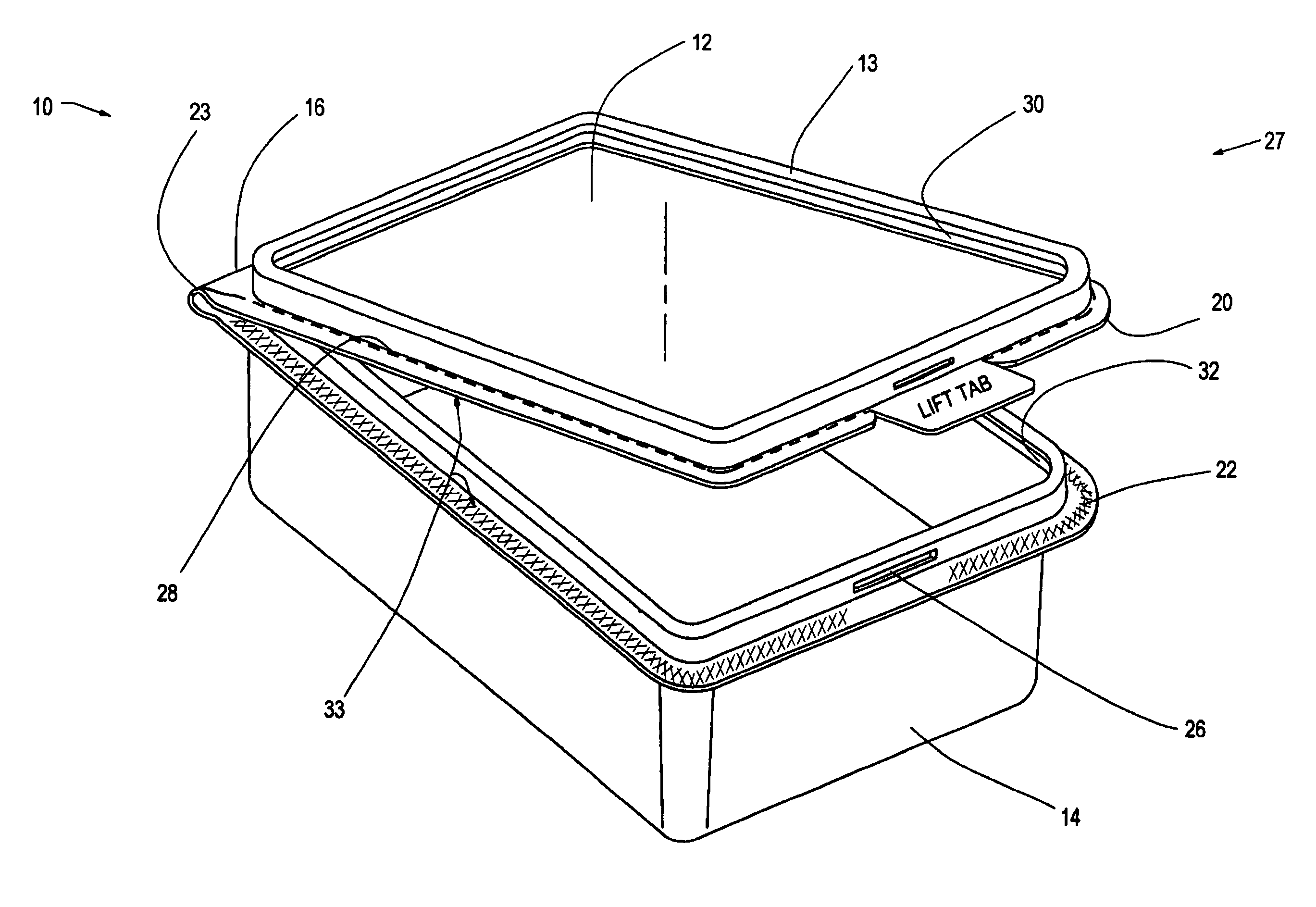

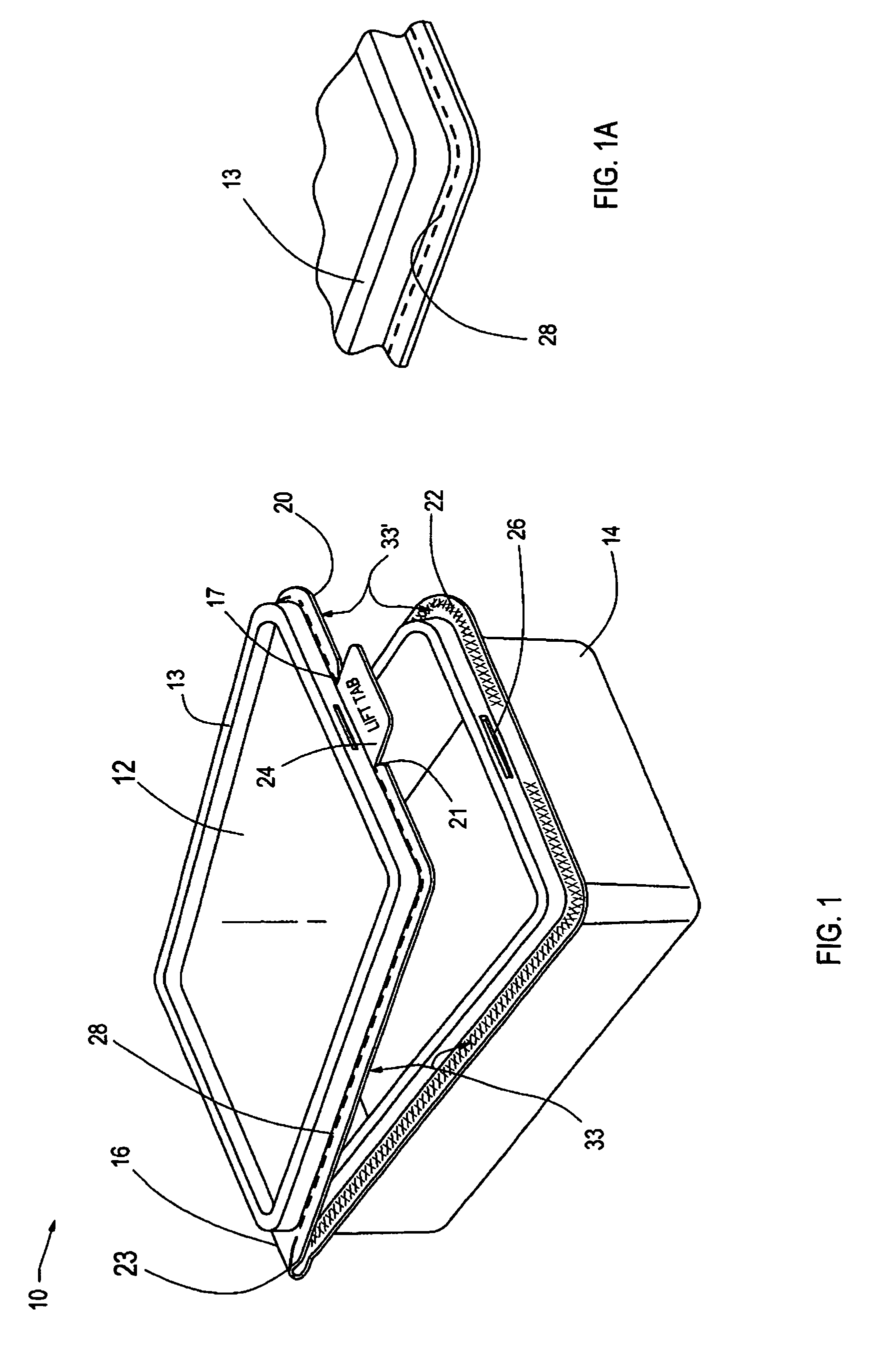

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releaseably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

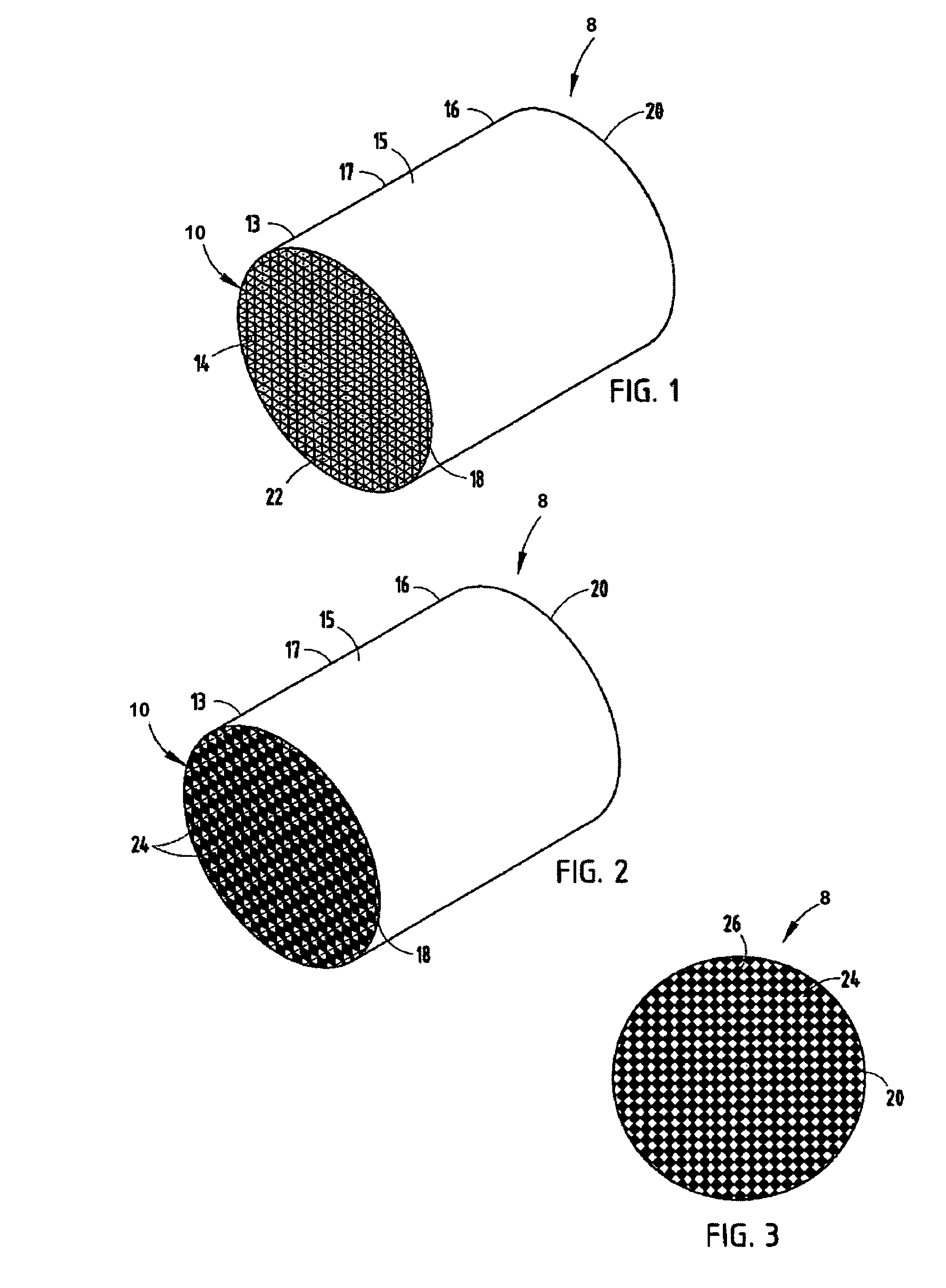

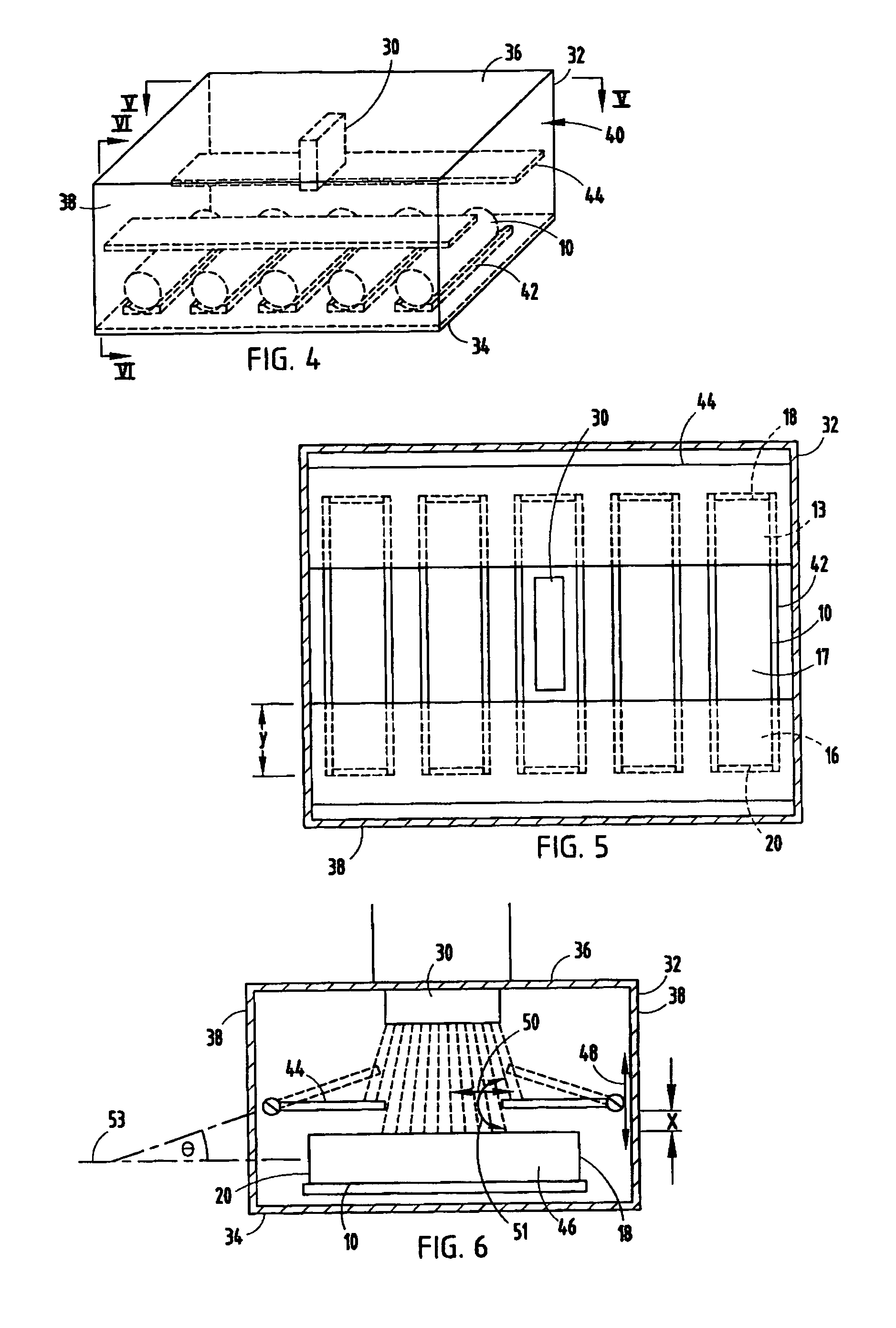

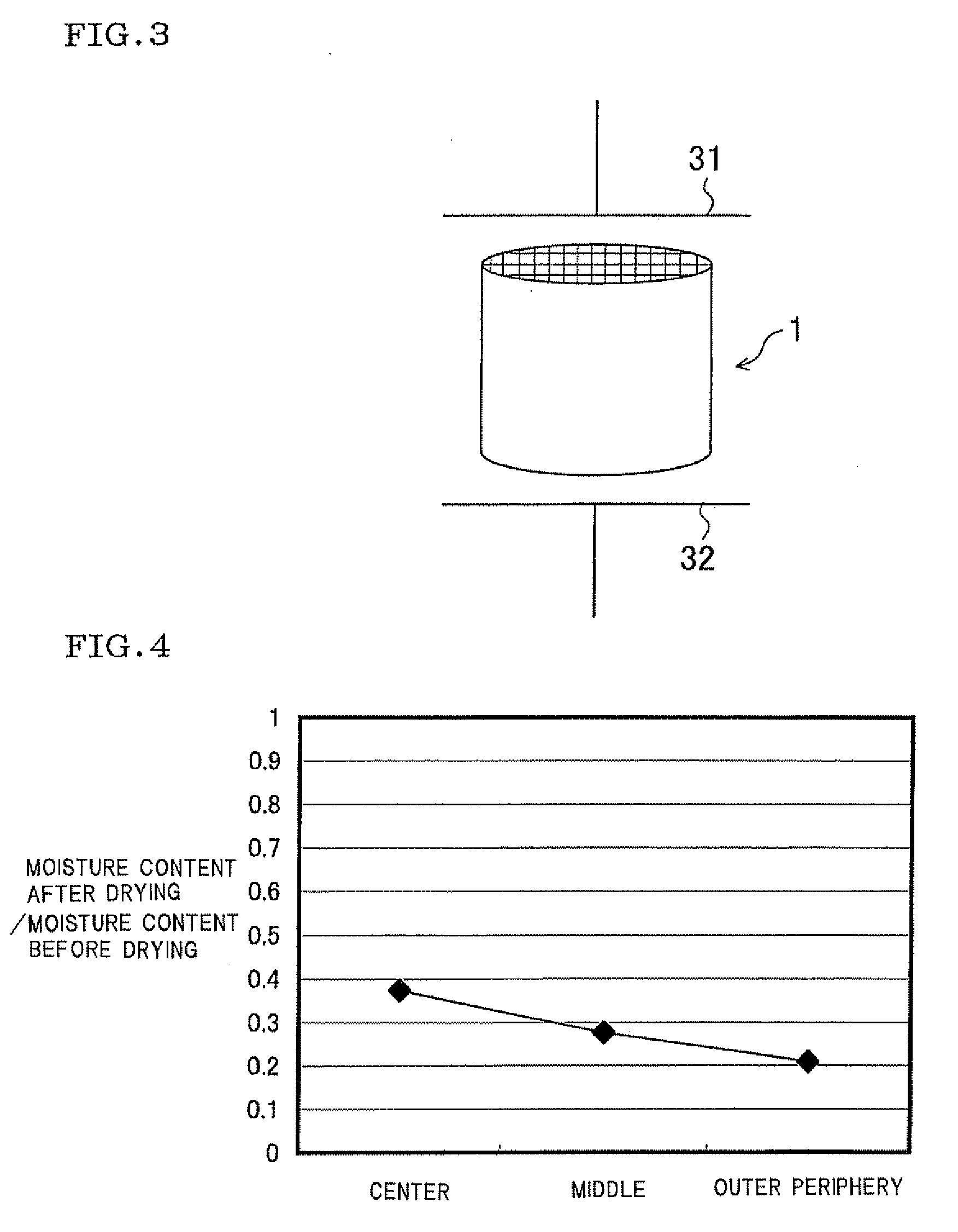

Microwave drying of ceramic structures

ActiveUS7596885B2Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

Owner:CORNING INC

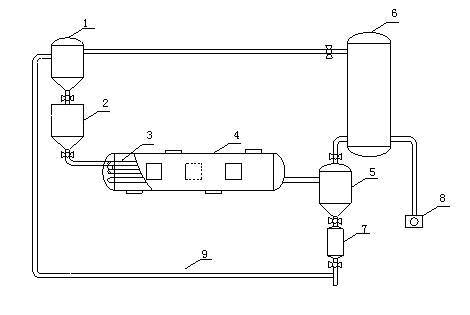

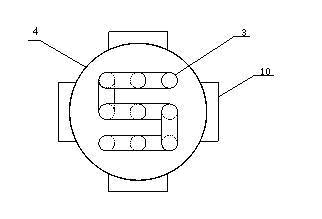

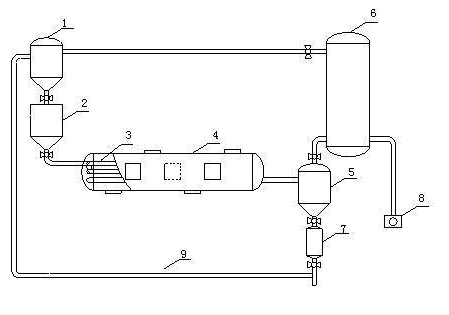

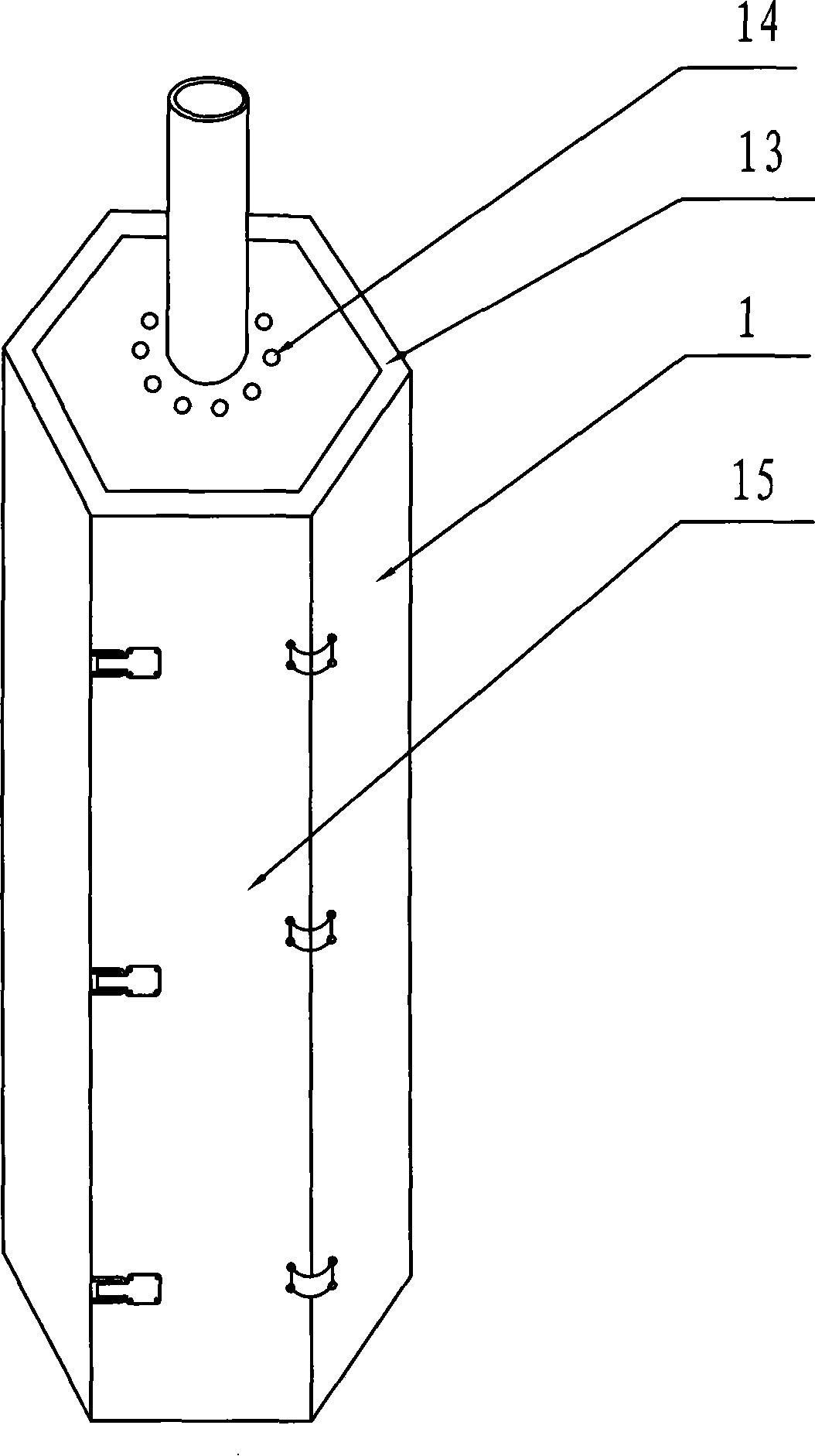

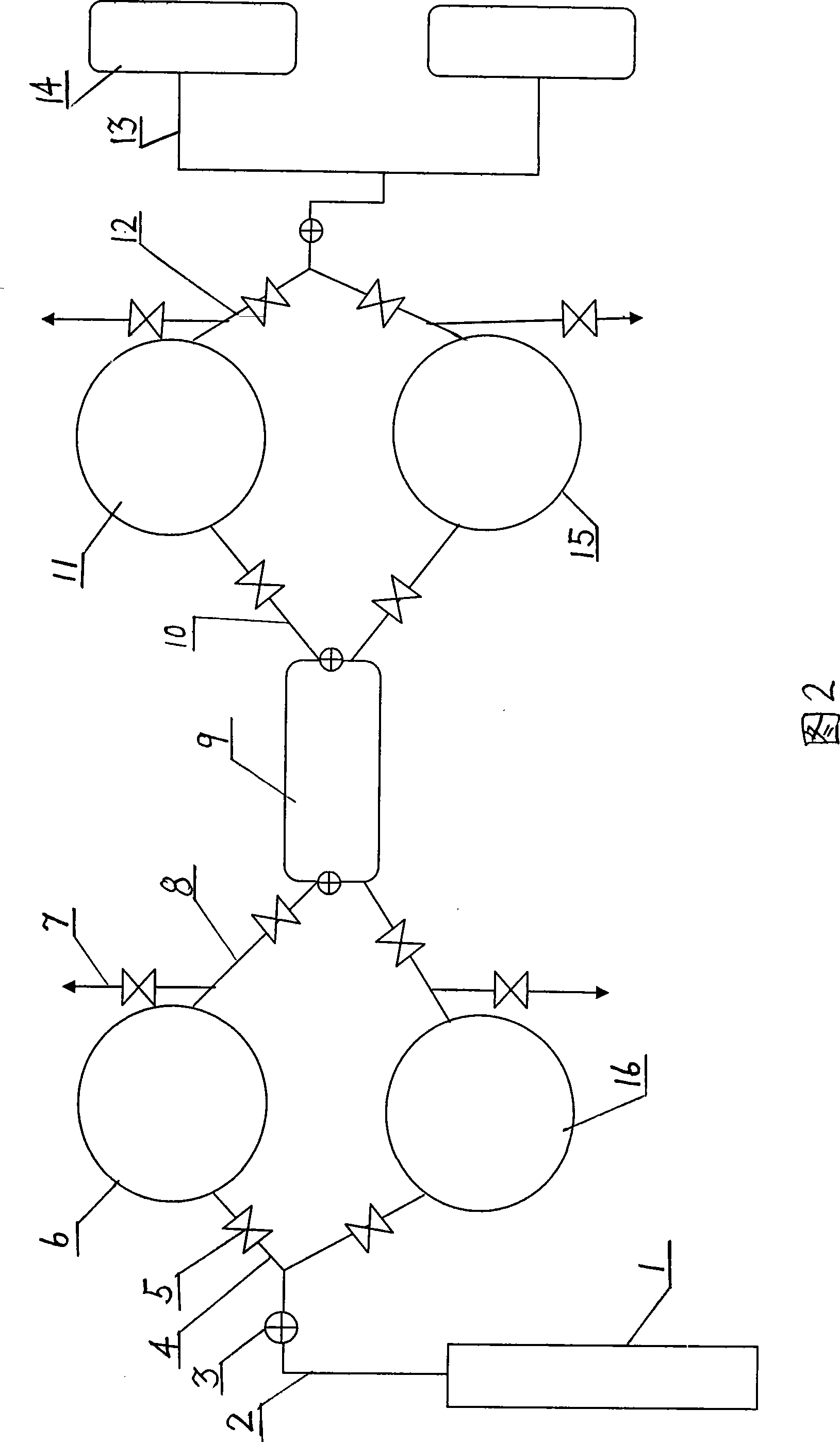

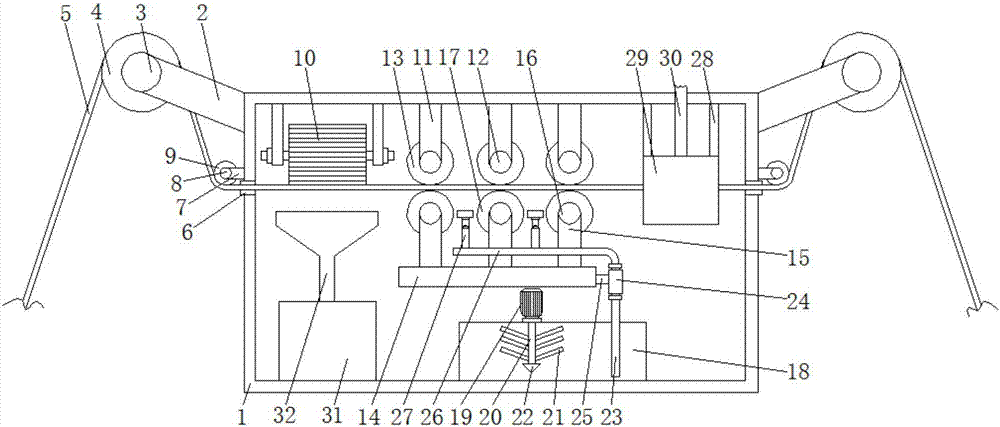

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

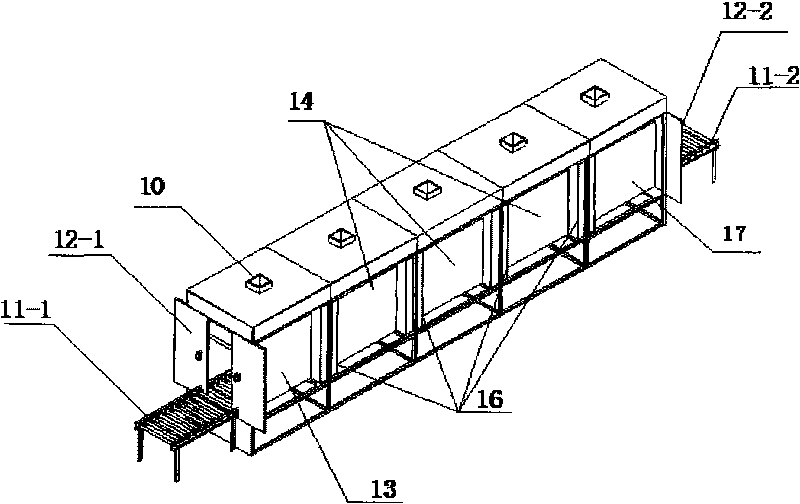

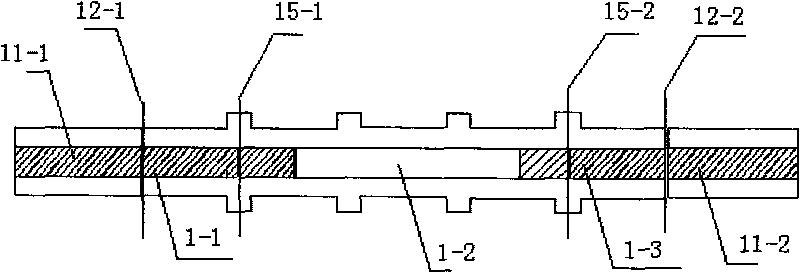

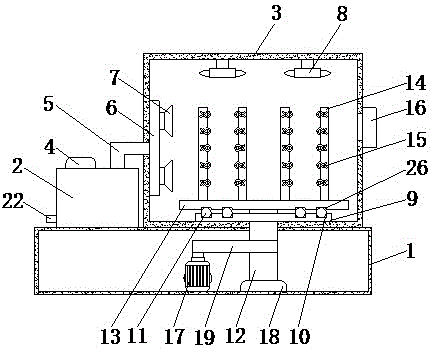

Device for drying fabric and method

ActiveCN101726165ADry evenlyControlled dryingDrying solid materials with heatDrying chambers/containersYarnProduction line

The invention discloses a device for drying fabric and a method, belonging to the field of drying the fabric. The device comprises a roller way, a drying support pan, a box body part, an on-line detection system and a PLC control system. The box body part comprises a plurality of heating boxes, the drying power of which are gradually reduced; the heating boxes are communicated with each other; and the inner walls of the heating boxes are provided with magnetic control pipes. The method comprises the steps of: leading the fabric to sequentially pass through the heating boxes with the function of microwave drying, and the drying power of the heating boxes are gradually reduced according to the pass sequence of the fabric. By adopting the technology of microwave drying, the device has high efficiency; is even, energy-saving and environment-friendly; can controllably dry the fabric; has high automation; can gradually and continuously dry the fabric by leading the fabric to sequentially pass through the heating boxes, the drying power of which are gradually reduced; leads the dried fabric to be evenly dried and have good quality; and is suitable for an unmanned automatic yarn dyeing and finishing production line.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

Microwave drying method

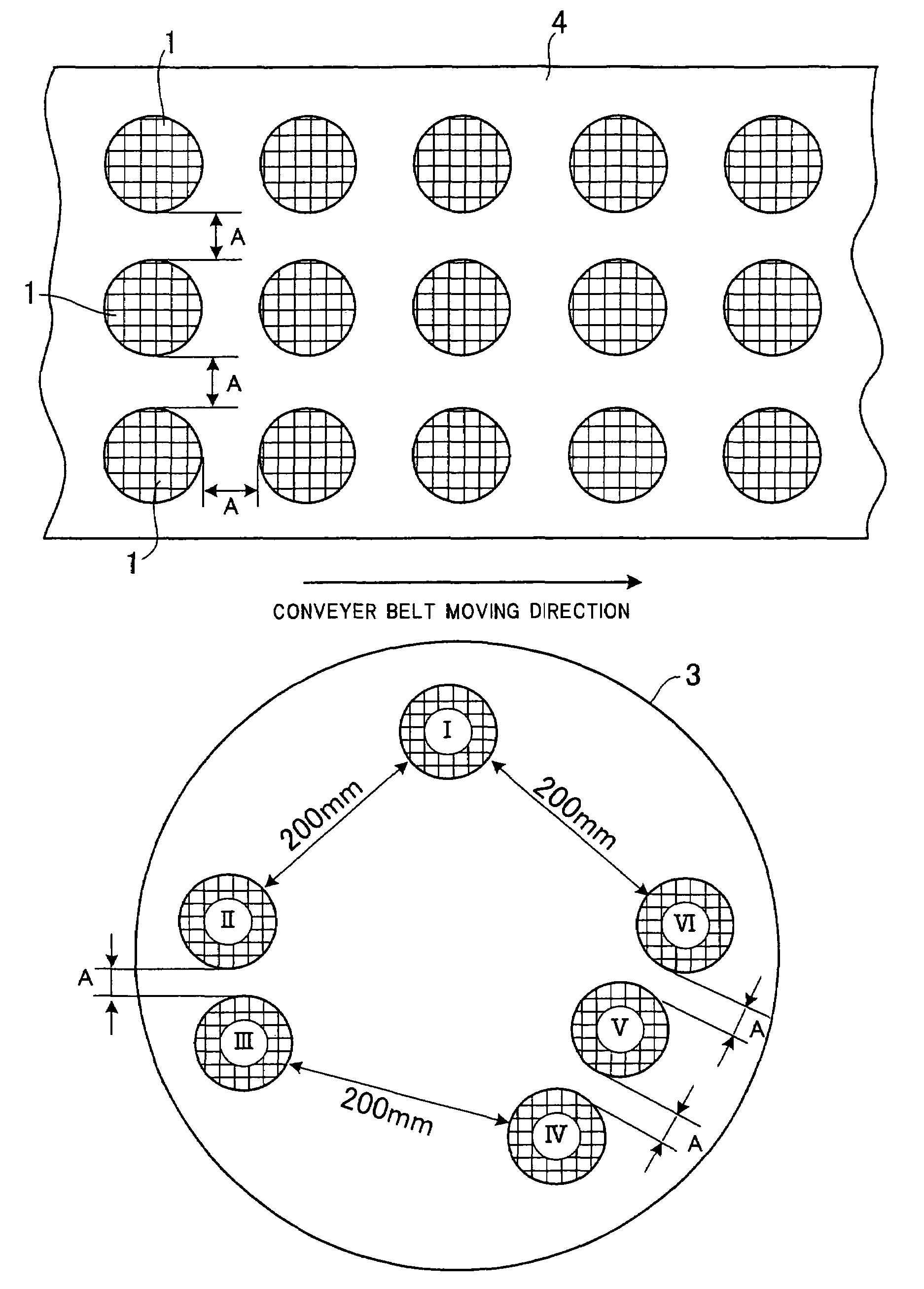

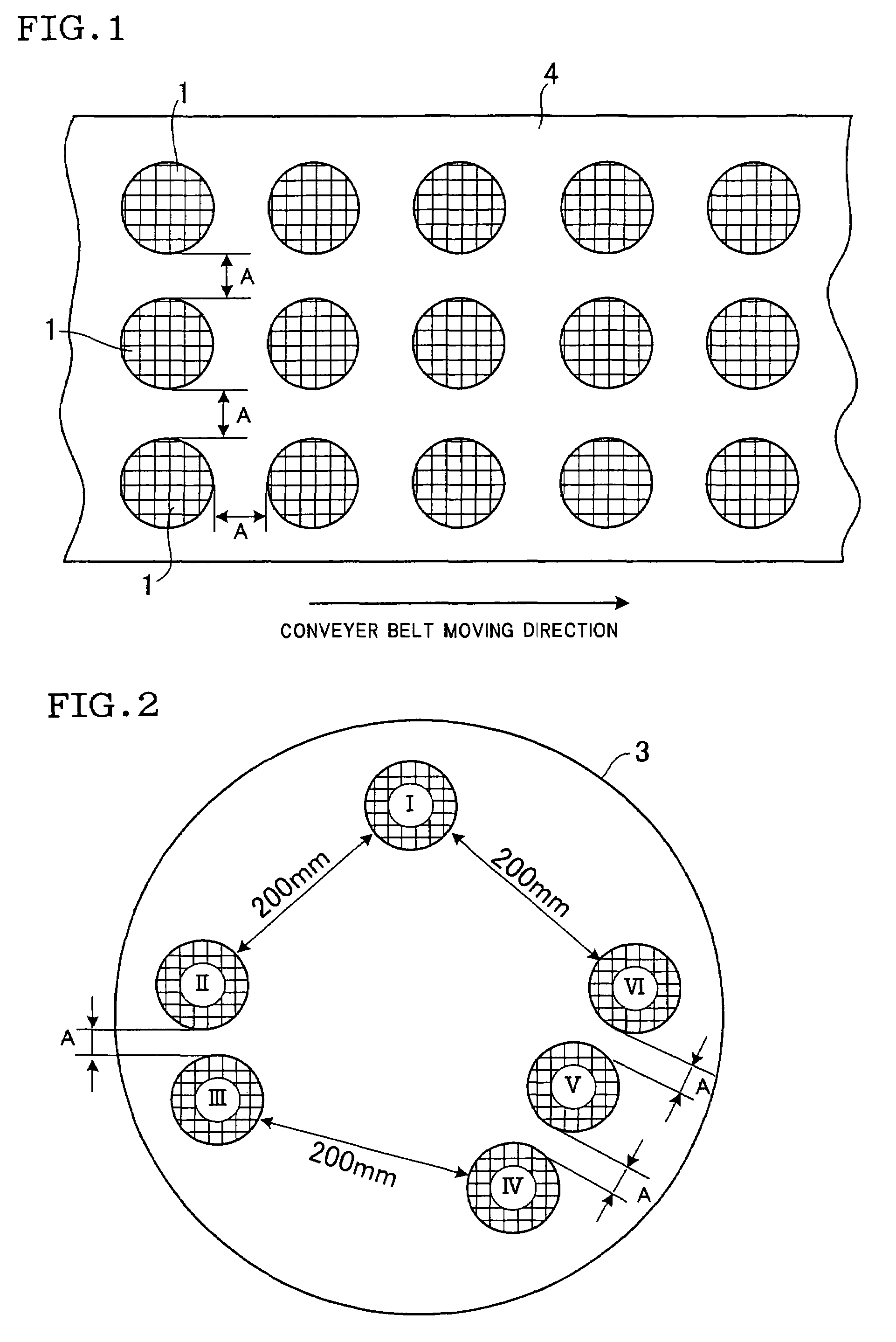

ActiveUS7017278B2Improve productivityEfficient dryingDrying solid materials with heatCeramic shaping apparatusMicrowaveShortest distance

A method for drying a plurality of objects in a same space using a microwave, a method of uniformly drying all the objects to be dried while retaining the high productivity (mass productivity) as much as possible is provided. The method comprises laying a plurality of objects to be dried apart from each other by keeping, as a shortest distance between at least one pair of adjacent objects among them a distance equivalent to ¾ or more of the wavelength of the microwave to be used and irradiating them with the microwave.

Owner:NGK INSULATORS LTD

Versatile tamper-evident food container

ActiveUS8083089B2Improved tamper-evident product packagingWithout riskCapsClosure capsInterference fitEngineering

A tamper-evident rigid plastic food container system wherein the outer periphery of the mating surfaces of the lid and tray are permanently bonded together after the food product has been placed in the tray, a set of perforated rows at an inner periphery, the interconnect of which needs to be torn into order to open the lid. Intentional, inadvertent or malicious ingress into the container can only be made by tearing at the perforations thereby evidencing the potential tampering and contamination of the packaging contents. The lid and tray edges may further include mechanical interference fits, including snap-fit grips that may be of the releasably lockable kind to permit sealing, release and re-sealing multiple times without deterioration in reliability, and which can further prevent or minimize leakage of liquid food product.

Owner:PACTIV PACKAGING

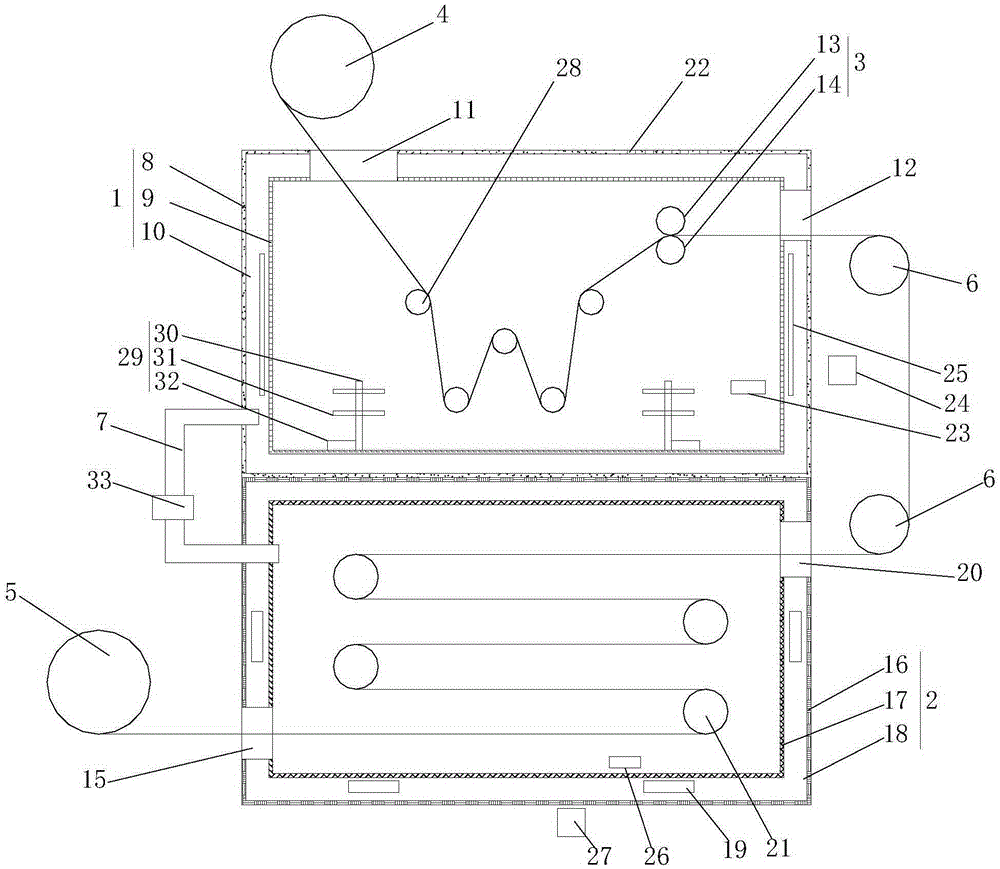

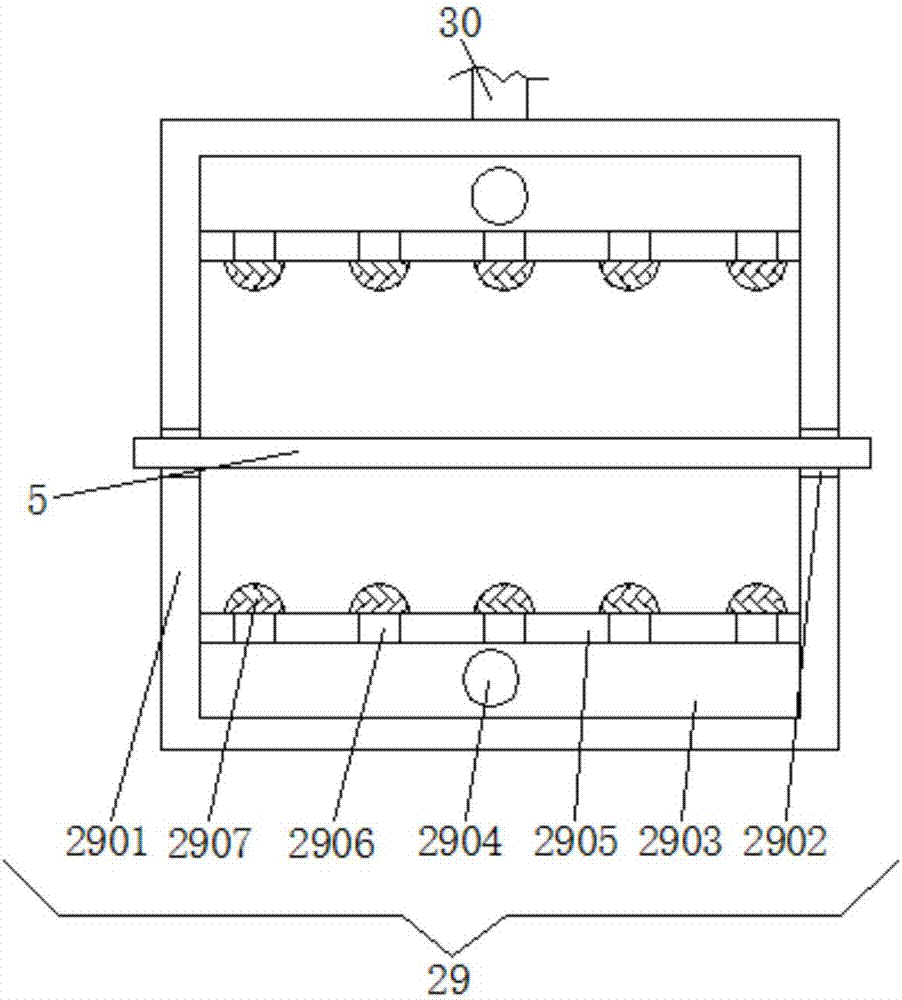

Cloth printing and dyeing device

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

Far infrared unit for dewatering vegetable

InactiveCN1689416AImprove qualityImprove quality, drying speedDrying solid materials with heatFood processingPulp and paper industryHeat transfer efficiency

The far infrared vegetable dewatering apparatus includes drying cabinet, transmission mechanical,, conveying mechanism and heater. The drying cabinet has material feeding port and induced draft port in the top and discharge port and air intake in the bottom. The present invention features that the drying cabinet is separated with partition boards into several layers with separated conveying mechanism, transmission mechanism, heating unit and guide board. The present invention has small size, convenient operation, fast drying speed, high heat efficiency and low power consumption, and the dried vegetable product has bright color and high quality.

Owner:SHANDONG UNIV OF TECH

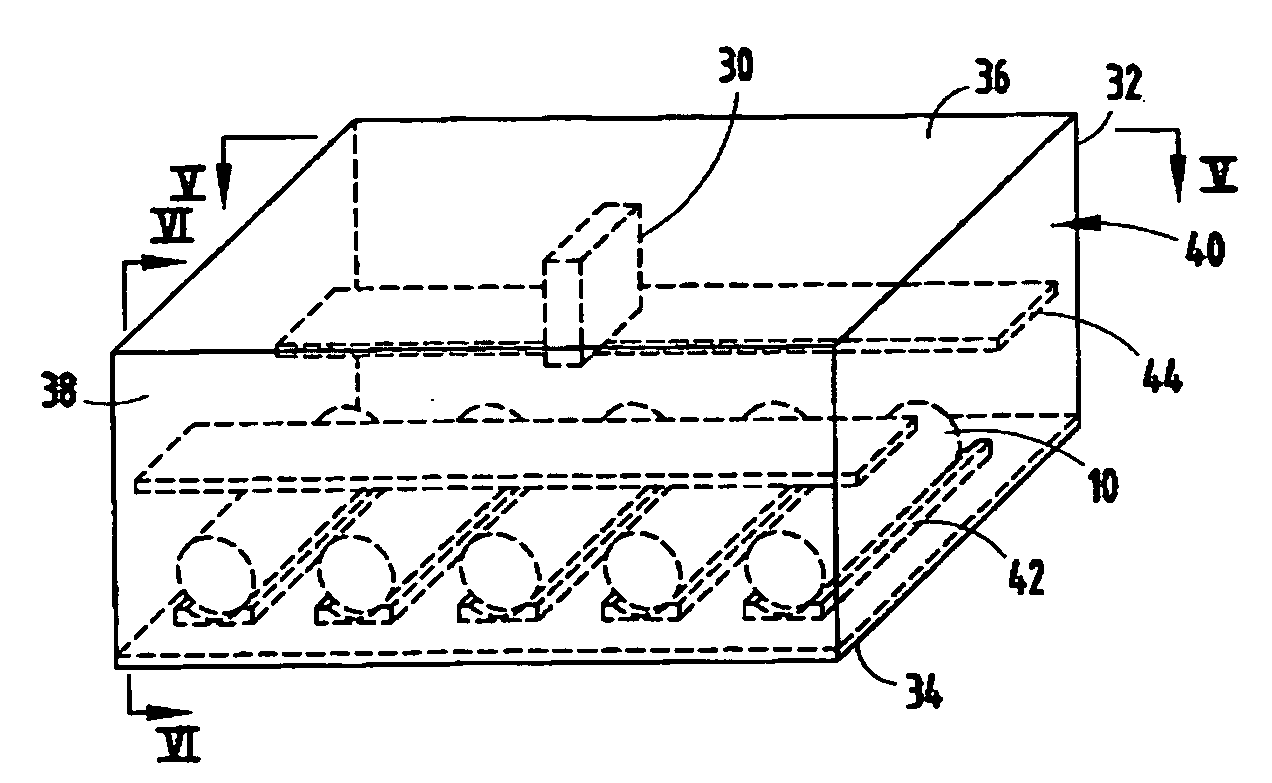

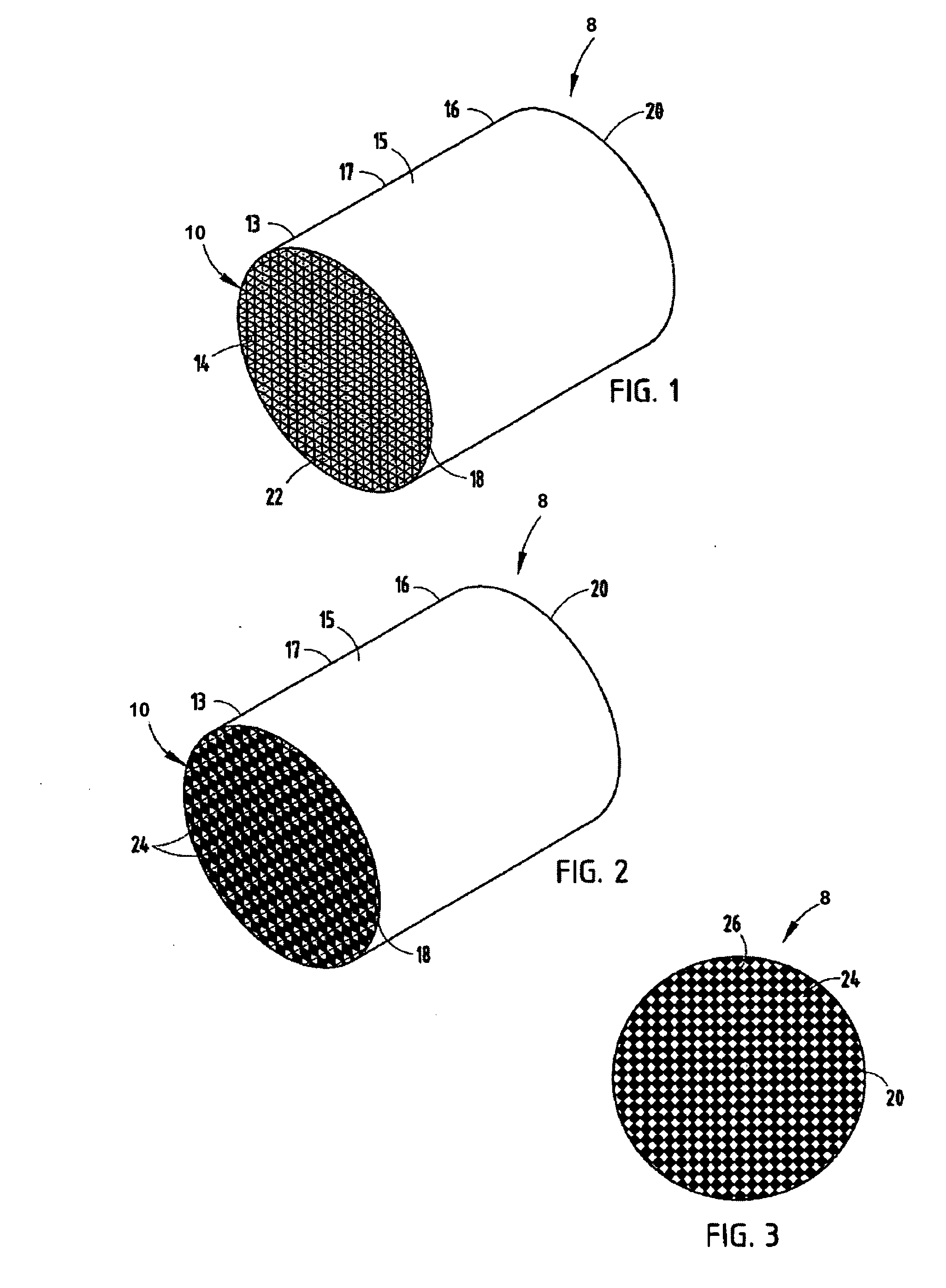

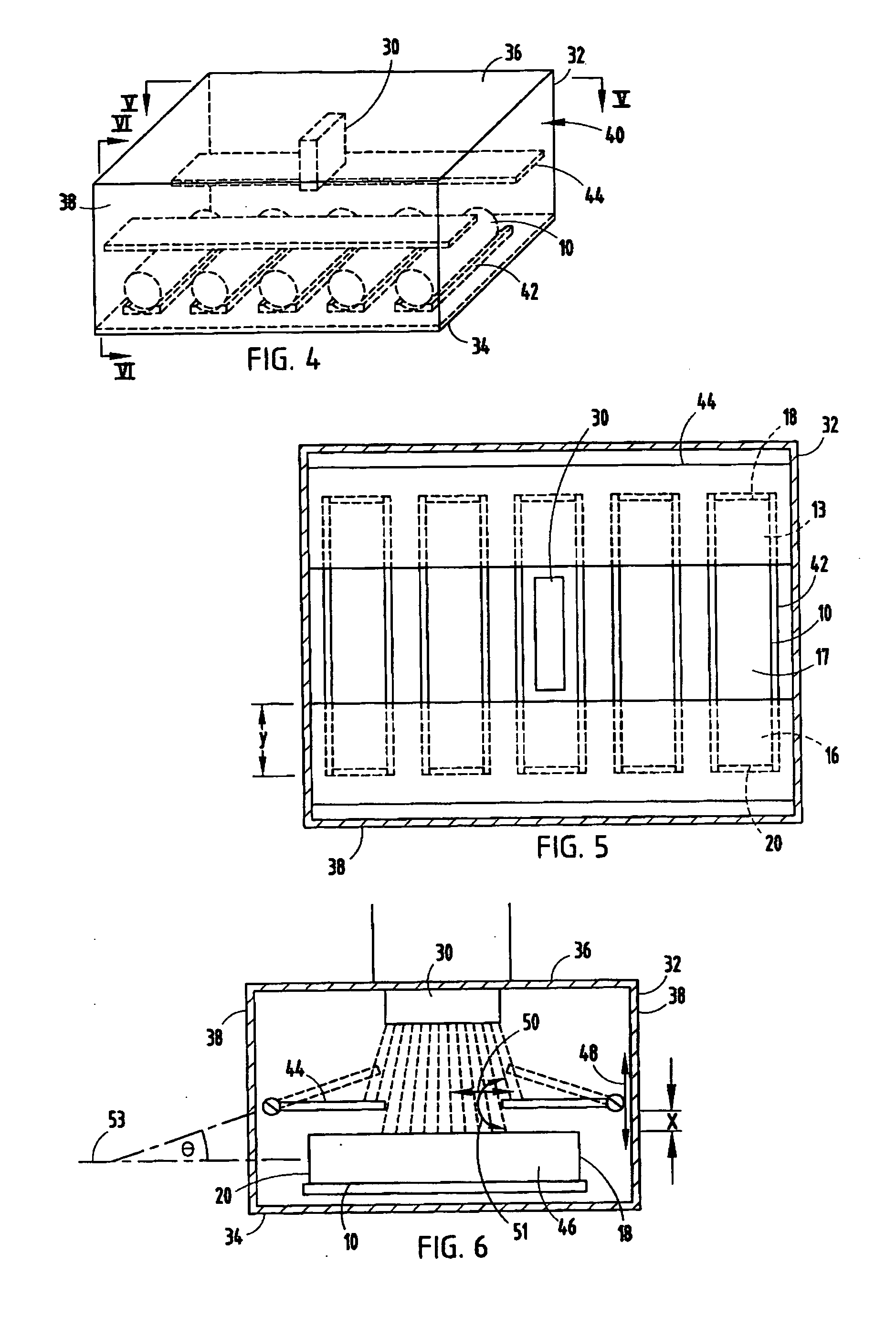

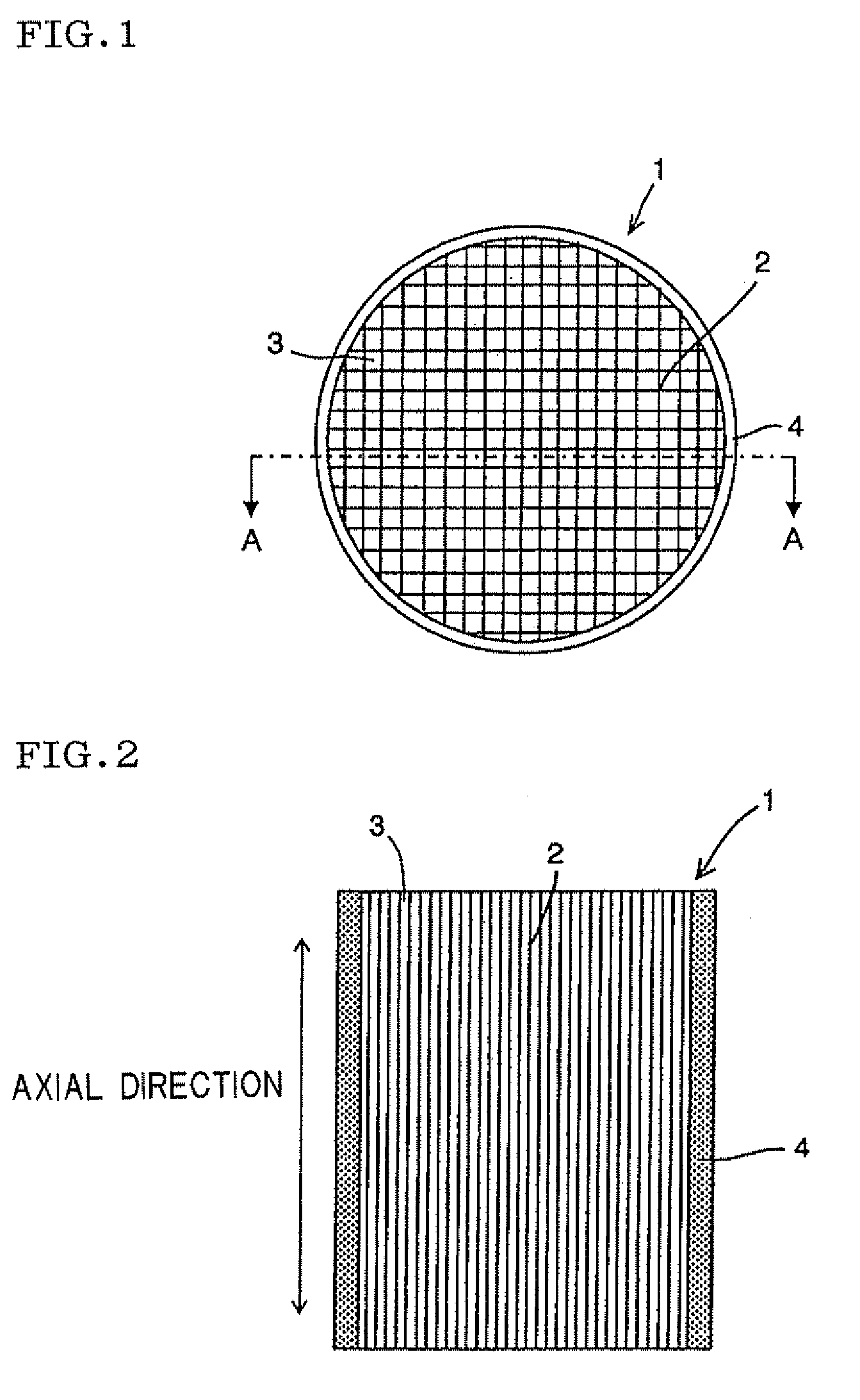

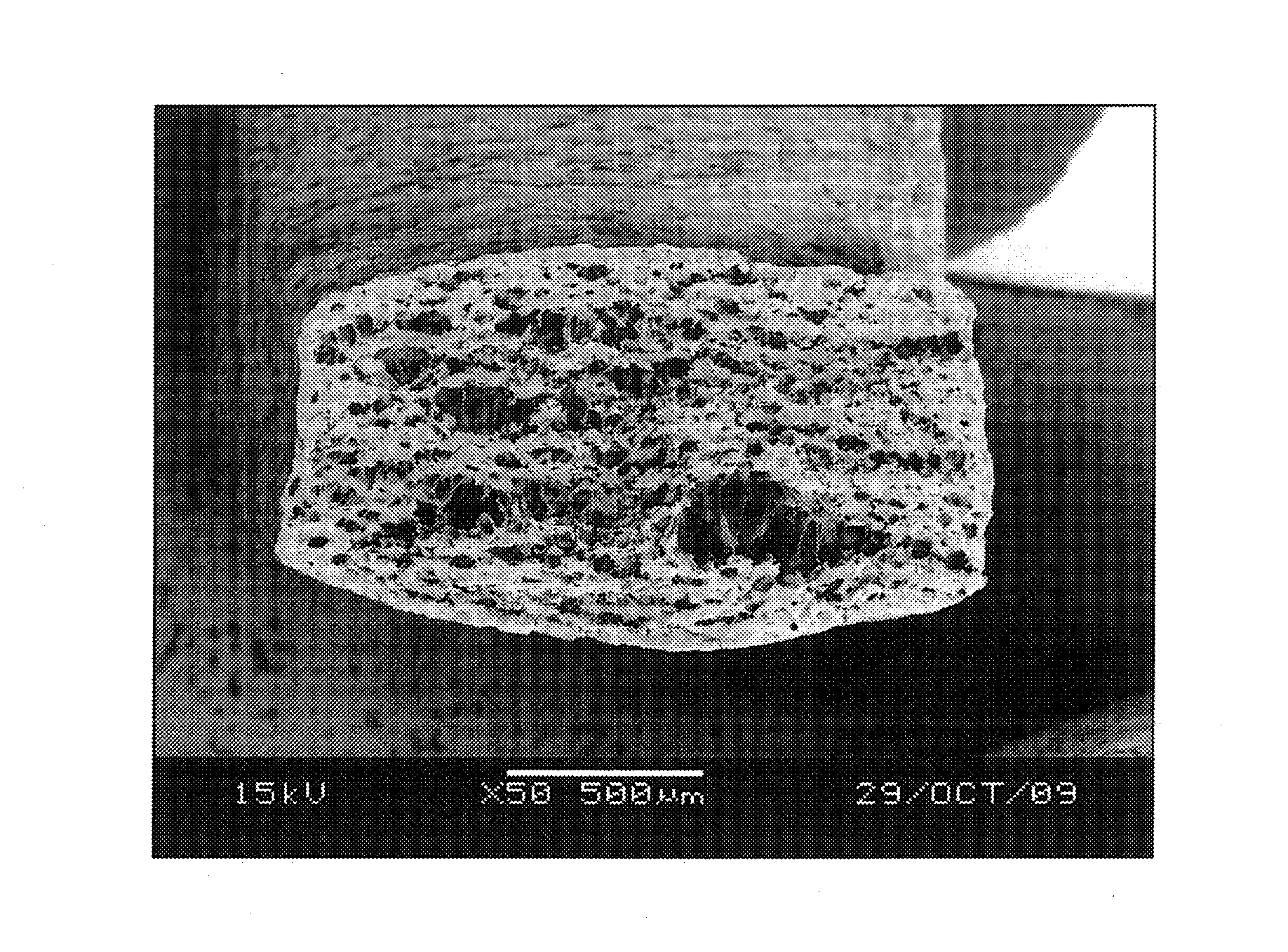

Microwave drying of ceramic structures

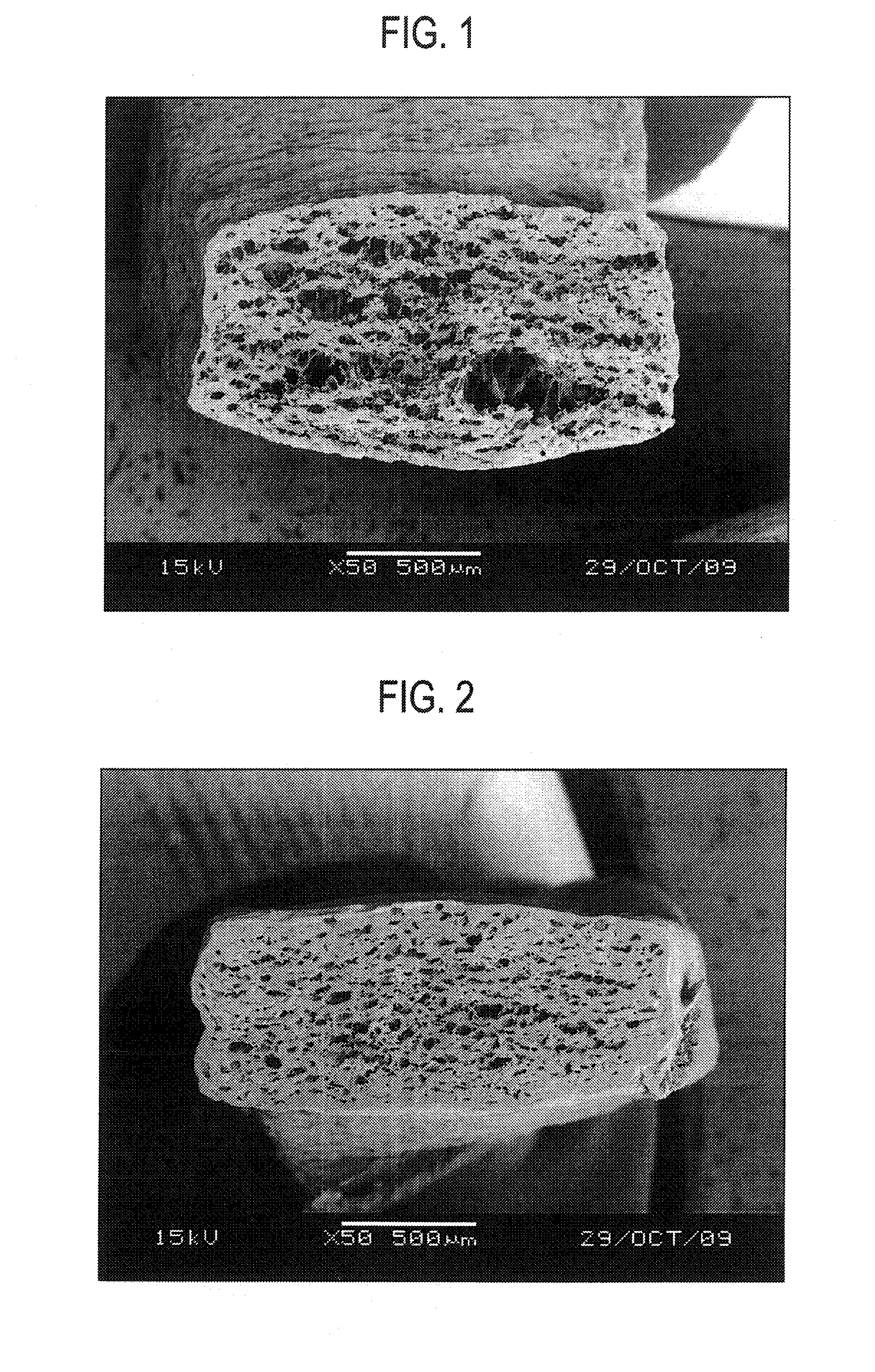

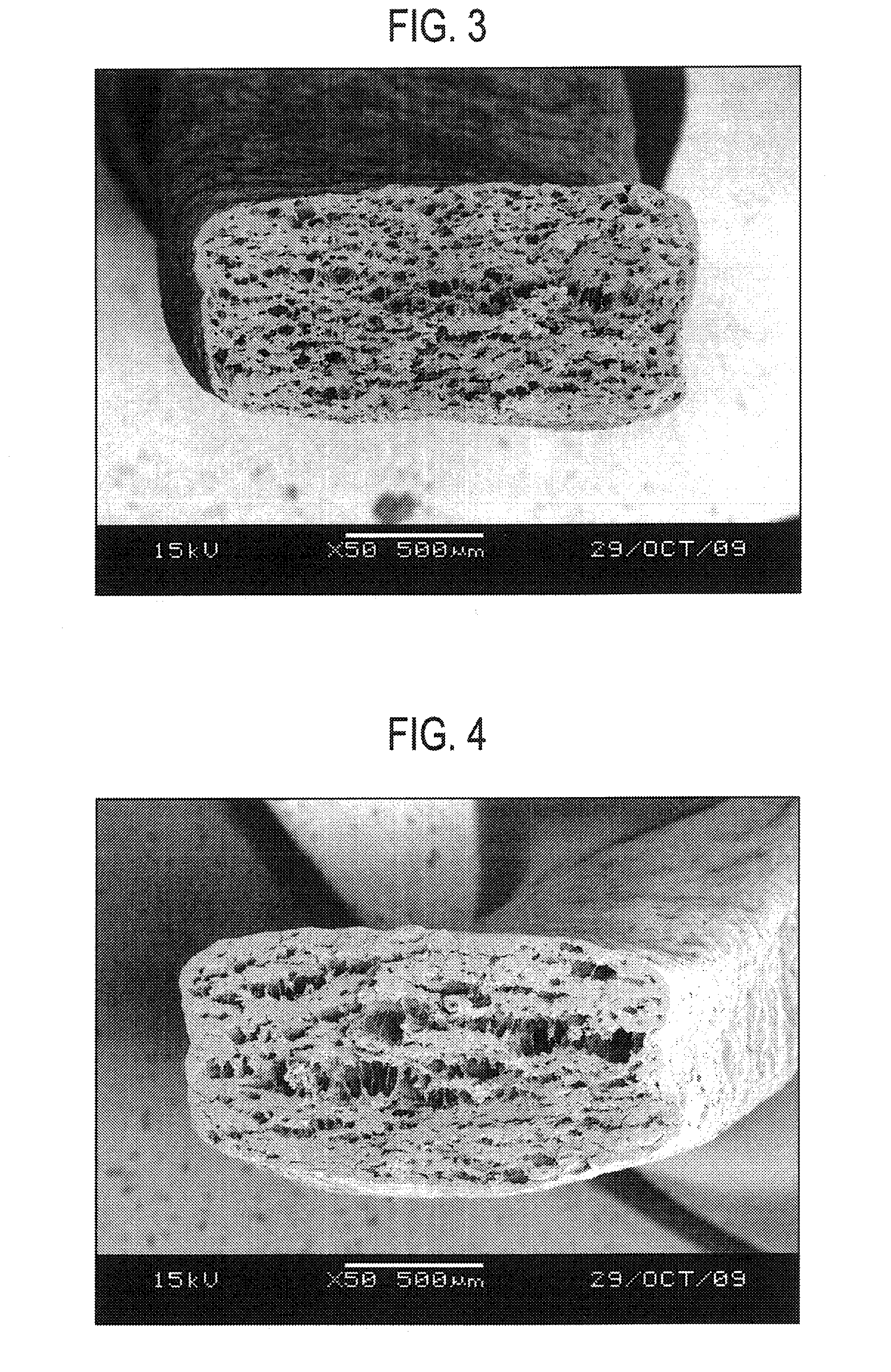

ActiveUS20080023886A1Dry evenlySimple structureDielectric heatingDrying solid materials with heatStructural degradationMetallurgy

A method for drying a ceramic article comprises providing microwave radiation from a microwave generating source, providing a ceramic honeycomb structure having a middle portion and at least one end, and exposing the ceramic honeycomb structure to the microwave radiation while shielding the at least one end from directly receiving the microwave radiation, such that the radiation absorbed by the middle portion is equal to or greater than the radiation absorbed by the at least one end, and the proper drying of the entire honeycomb structure without heat-induced structural degradation is thus ensured.

Owner:CORNING INC

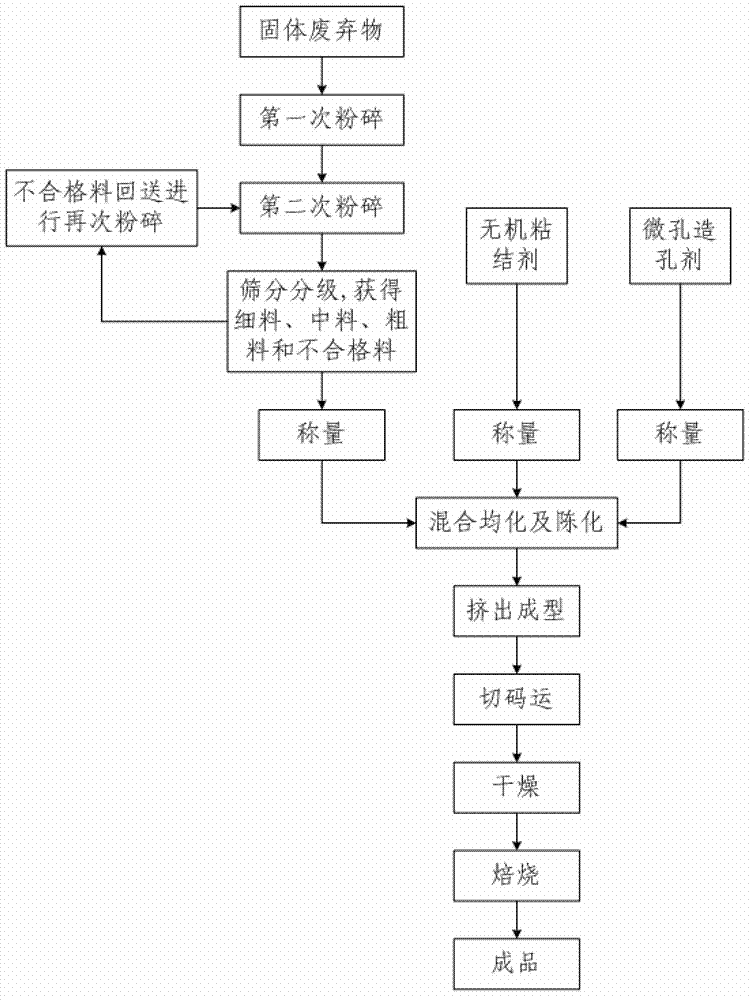

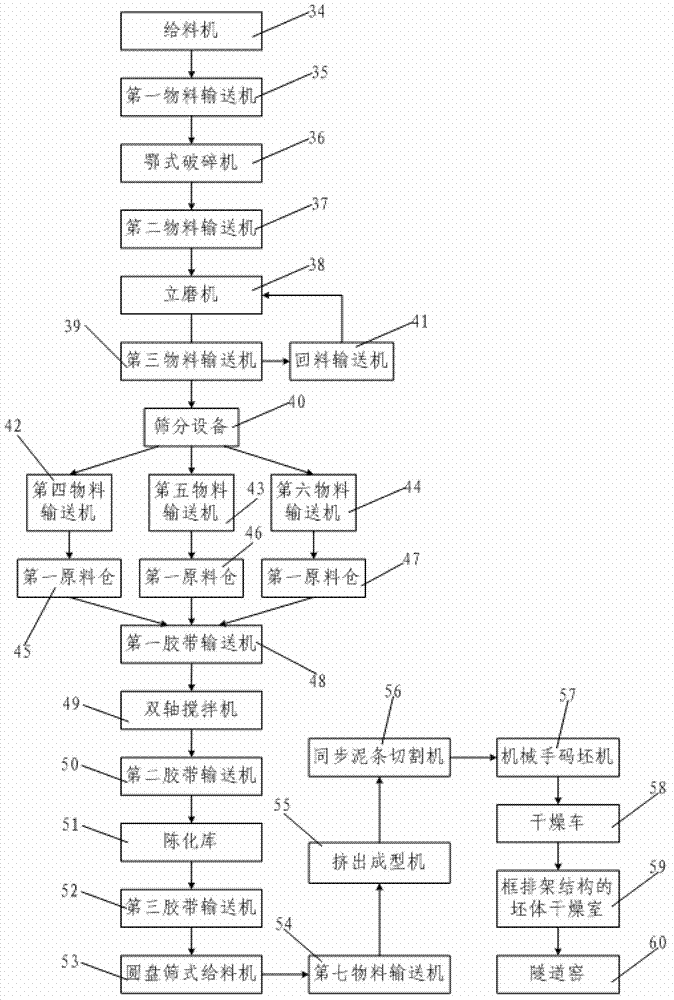

Porous sintering heat-insulating hollow block and manufacturing process thereof

ActiveCN102807390ASave resourcesPromote environmental protectionSolid waste managementCeramicwareSocial benefitsVoid ratio

The invention discloses a porous sintering heat-insulating hollow block and a manufacturing process thereof. According to the porous sintering heat-insulating hollow block, the void rate is 35 to 60 percent, the density is 700 to 1,000 kg / m<3>, and the coefficient of heat conductivity is less than or equal to 0.22 W / m.K. The porous sintering heat-insulating hollow block consists of the following ingredients in percentage by weight: 30 to 45 percent of solid waste, 45 to 55 percent of inorganic binder and 5 to 15 percent of micropore pore forming agent. The manufacturing process comprises the following steps of: 1, performing grain composition; 2, sieving for grading; 3, weighing raw materials; 4, mixing, homogenizing and aging; 5, extruding for forming; 6, cutting and stacking; 7, drying;and 8, sintering. The porous sintering heat-insulating hollow block is reasonable in design, convenient to realize, high in utilization rate of solid wastes, energy-saving, environment-friendly, highin void rate, low in density, high in thermal performance and strength, stable in size and difficult to crack, can be popularized and used in large areas, and has the excellent economic and social benefits.

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

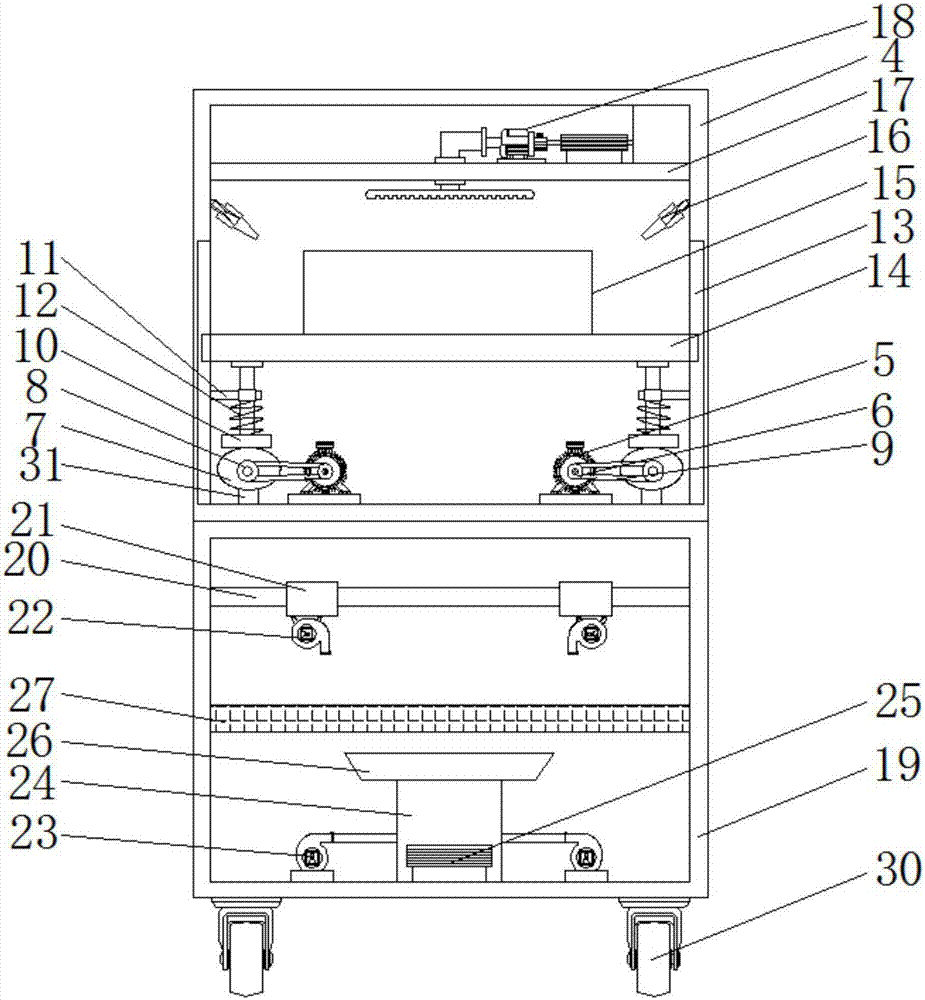

Medical operation instrument cleaning device

PendingCN107214134ATo achieve the purpose of high temperature disinfection of surgical equipmentClean upDrying gas arrangementsCleaning using liquidsEngineeringMedical treatment

The invention discloses a cleaning device for medical surgical equipment, comprising an outer frame, the outer frame includes a cleaning room and a drying room, the bottom end inside the cleaning outer frame is fixedly connected with a first motor, and the support column The top of the cam is rotatably connected with a cam, and the top of the cam is slidably connected with a push rod, and one side of the cleaning outdoor frame is fixedly connected with a support block, and the bottom end of the only support block of the push rod is provided with a return spring, and the cleaning Limiting grooves are provided inside the two sides of the outdoor frame, movable plates are slidably connected between the limiting grooves, the movable plates are fixedly connected to the push rod, and a high-temperature steam cleaning device is fixedly connected to the fixed plate. The present invention relates to The field of medical equipment technology. The cleaning device for medical surgical equipment solves the problems of unclean cleaning and poor disinfection and drying effects of existing surgical equipment cleaning devices, improves cleaning efficiency, and achieves a more comprehensive drying effect.

Owner:湖南丹尼尔智能科技有限公司

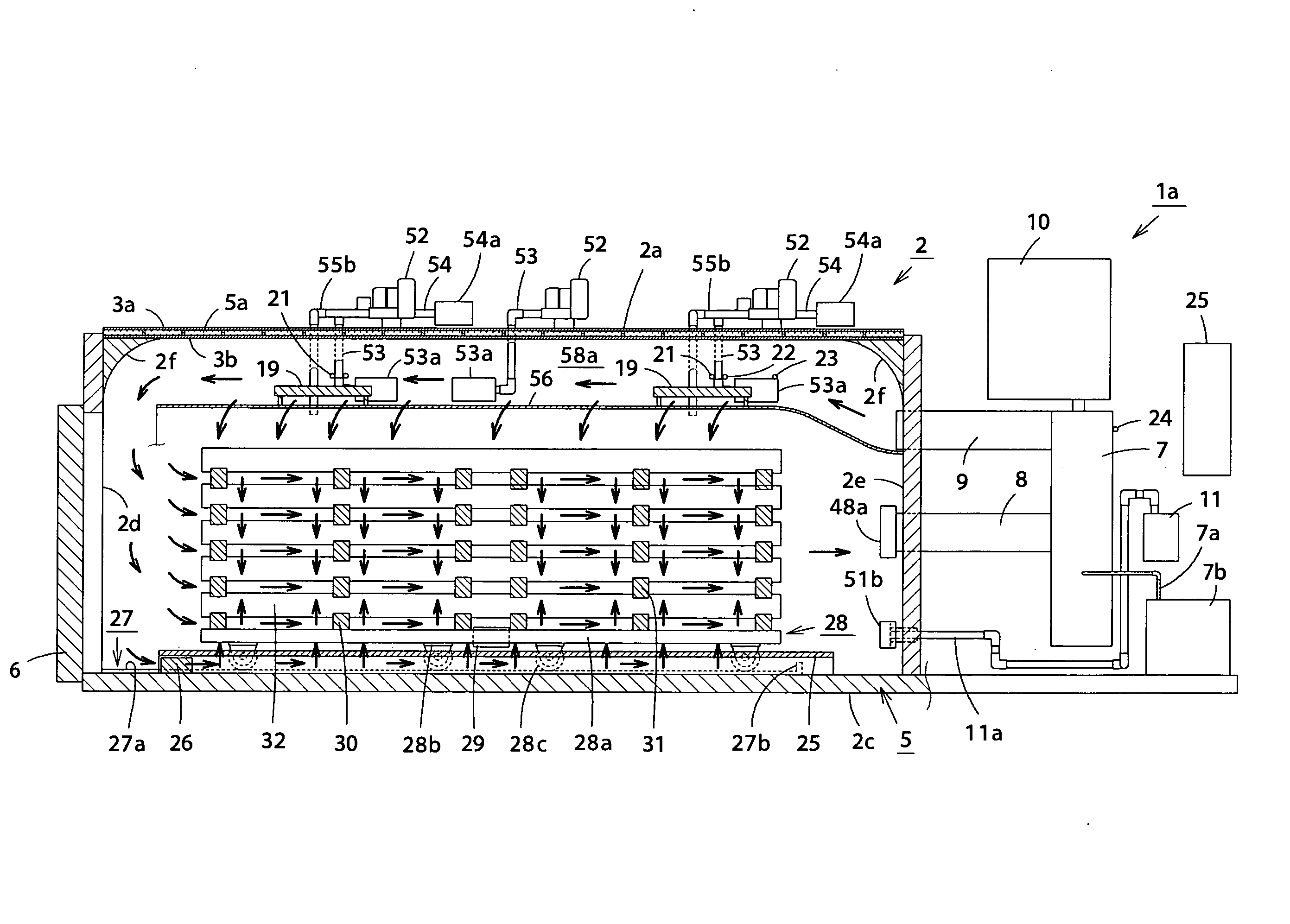

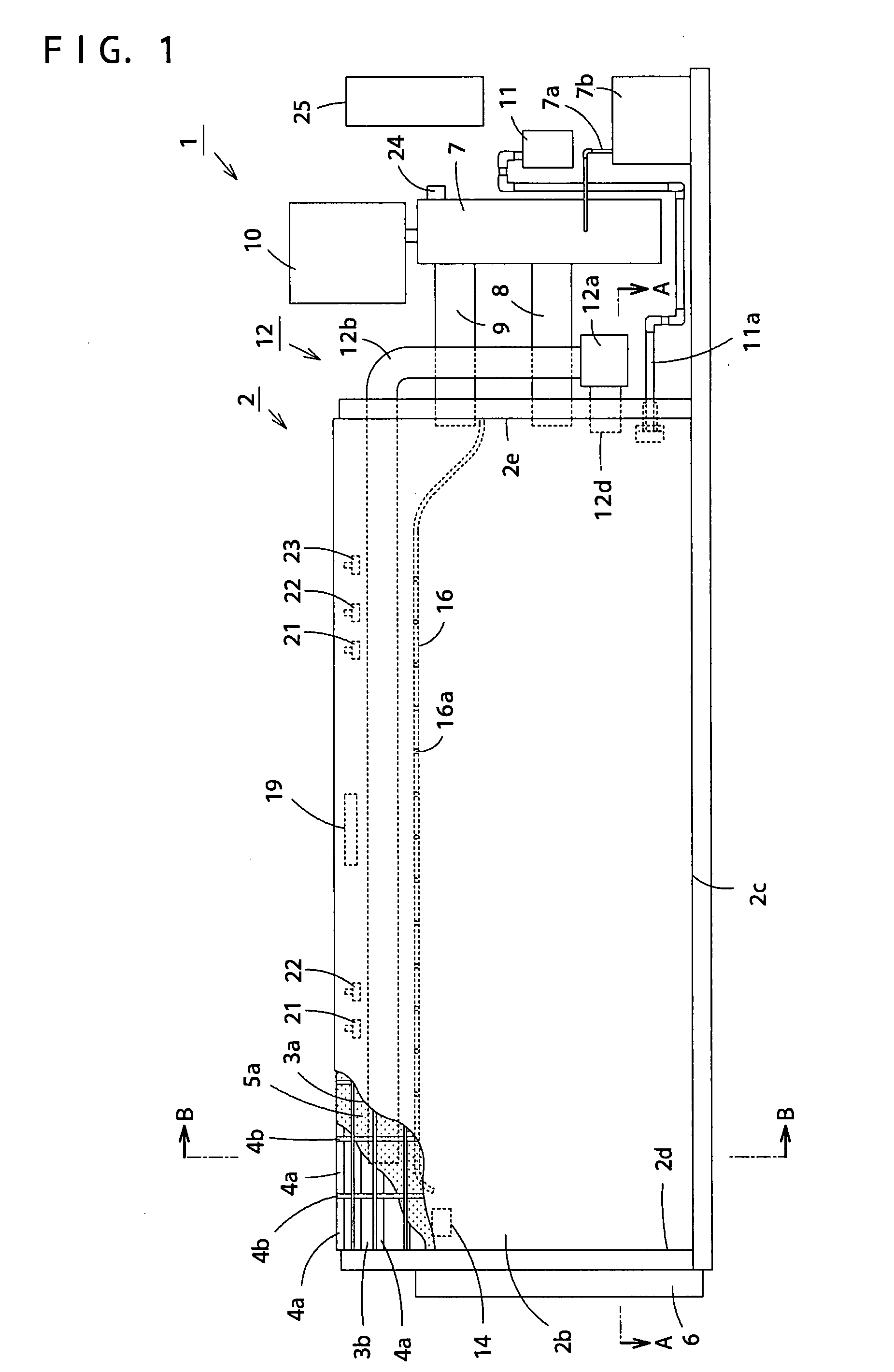

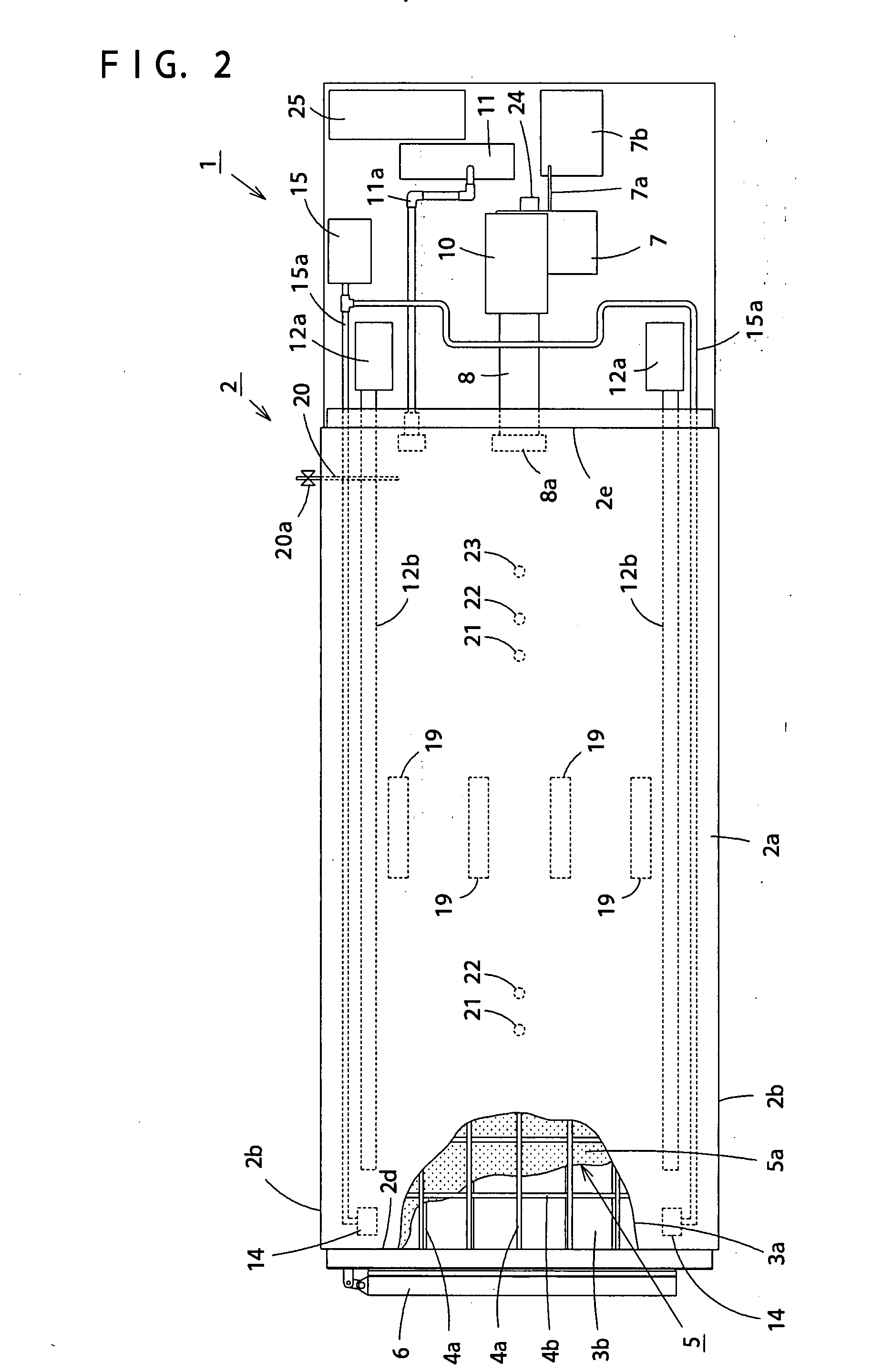

Drying method of formed ceramic article

InactiveUS20090235552A1High qualityHigh yieldDrying using combination processesCeramic shaping apparatusMicrowaveMetallurgy

There is disclosed formed ceramic article drying means capable of evenly and uniformly drying even a large formed ceramic article containing much moisture as a drying target for a short time without causing any crack or deformation, to efficiently obtain a dry formed ceramic article having a high quality with a satisfactory yield. There is provided a drying method of a formed ceramic article including the steps of subjecting an unfired formed ceramic article formed of a ceramic material as a main material to dielectric drying and then microwave drying.

Owner:NGK INSULATORS LTD

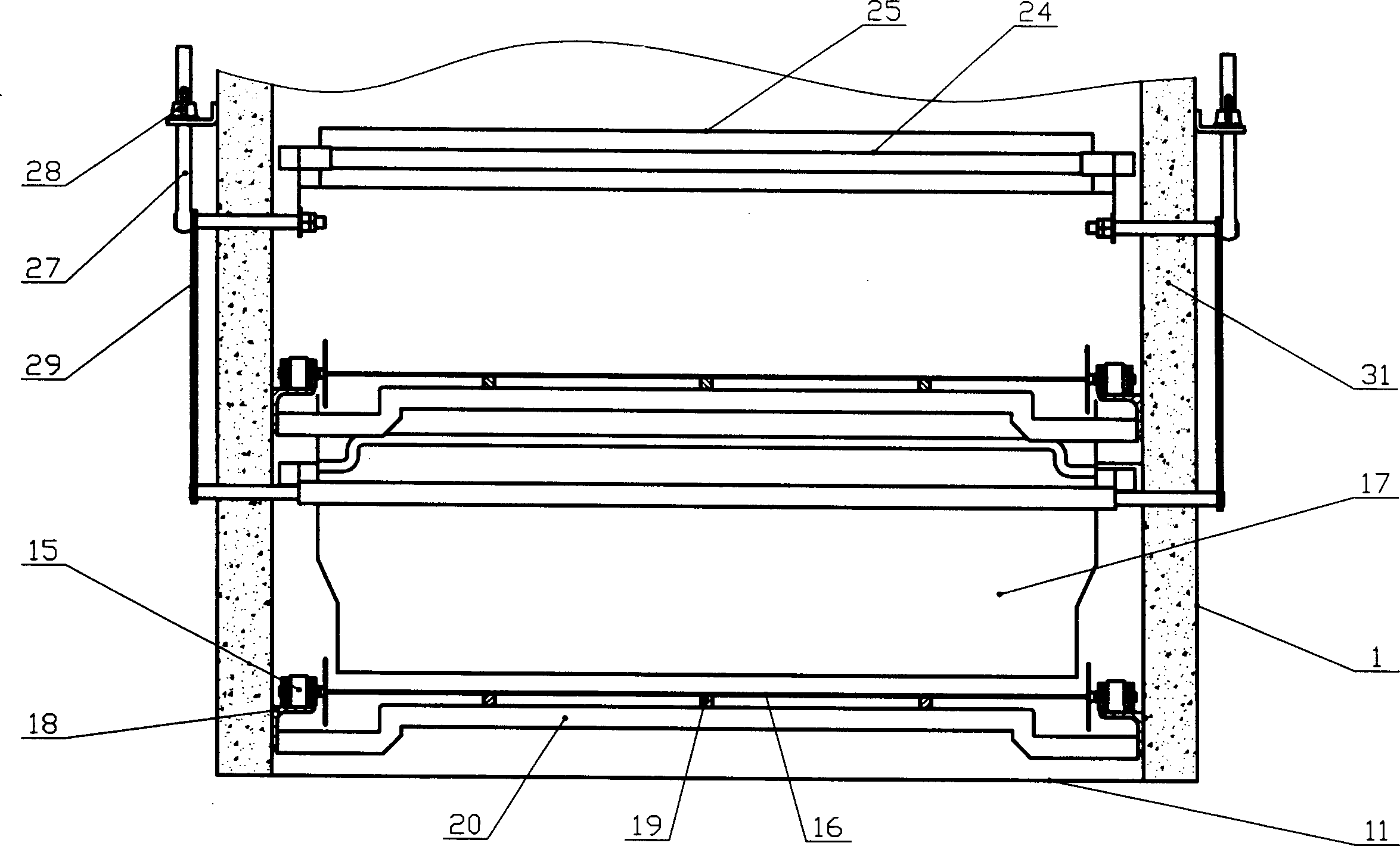

Depressurization Type Drying Machine and Method for Drying Lumber Using the Same

InactiveUS20080066340A1Improve efficiencyImprove reliabilityDrying using combination processesDrying solid materials with heatProduction rateEngineering

The present invention provides a depressurization type drying machine that is capable of repeatedly reducing the pressure, heating and humidifying during drying, uniformly drying a material to be dried, in a short time by applying vibrations to the material to be dried when reducing the pressure, and reducing consumption power without damaging the material to be dried, is excellent in reliability, productivity and energy-saving properties, brings about almost no flaws such as warping, internal cracking, breaking, shrinkage, bending, and surface cracking, especially when drying lumber, is also capable of leaving gloss on the surface of lumber after drying and scent without any discoloring, has high commercial value since the humidity in a building may be permanently controlled in response to the environment after being constructed, and is capable of extracting moisture contained in a material to be dried such as lumber without any waste and effectively utilizing the same as by-products. At least the ceiling portion and sidewall portions are formed roughly like a circular arc swelled outwardly, and reinforcement ribs are provided, which are disposed along the outer circumference of the inner wall parallel to and / or in orthogonal to the lengthwise direction of the drying chamber between the respective outer walls and inner walls of the ceiling portion, the sidewall portions and the floor portion.

Owner:KAKUNO SEISAKUSHO

Multi-angle automatic paint spray equipment for machining mechanical part

ActiveCN110773365ADry evenlyGood effectPretreated surfacesLiquid spraying apparatusHot blastTelescopic cylinder

The invention relates to the field of automatic machining equipment and particularly discloses multi-angle automatic paint spray equipment for machining a mechanical part. The multi-angle automatic paint spray equipment comprises a box body; a supporting cylinder realizing height adjustment by virtue of a telescopic cylinder is arranged inside the box body; a rotating partition plate and a rotating plate are arranged in a synchronous rotation manner inside the supporting cylinder; an inner chamber of the supporting cylinder is divided into an upper chamber and a lower chamber, namely a paint liquid chamber and a hot air chamber by virtue of the rotating partition plate and the rotating plate; an air pipe used for exhausting hot air out of the hot air chamber is fixedly installed at one side of the rotating plate; a hot air nozzle is arranged at the bottom end of the air pipe; a paint liquid pipe used for discharging paint liquid inside the paint liquid chamber is fixedly installed at the other side of the rotating partition plate; and a paint mist sprayer used for atomizing the paint liquid is arranged at the bottom end of the paint liquid pipe which extends to a position below therotating plate. The multi-angle automatic paint spray equipment provided by the embodiment of the invention can effectively widen the paint spraying range, guarantees the uniformity of paint spraying, can also guarantee timely drying of the paint liquid at the surface of the part, and also realizes uniform drying and a good effect.

Owner:SUZHOU ODIHUA ELECTRONIC CO LTD

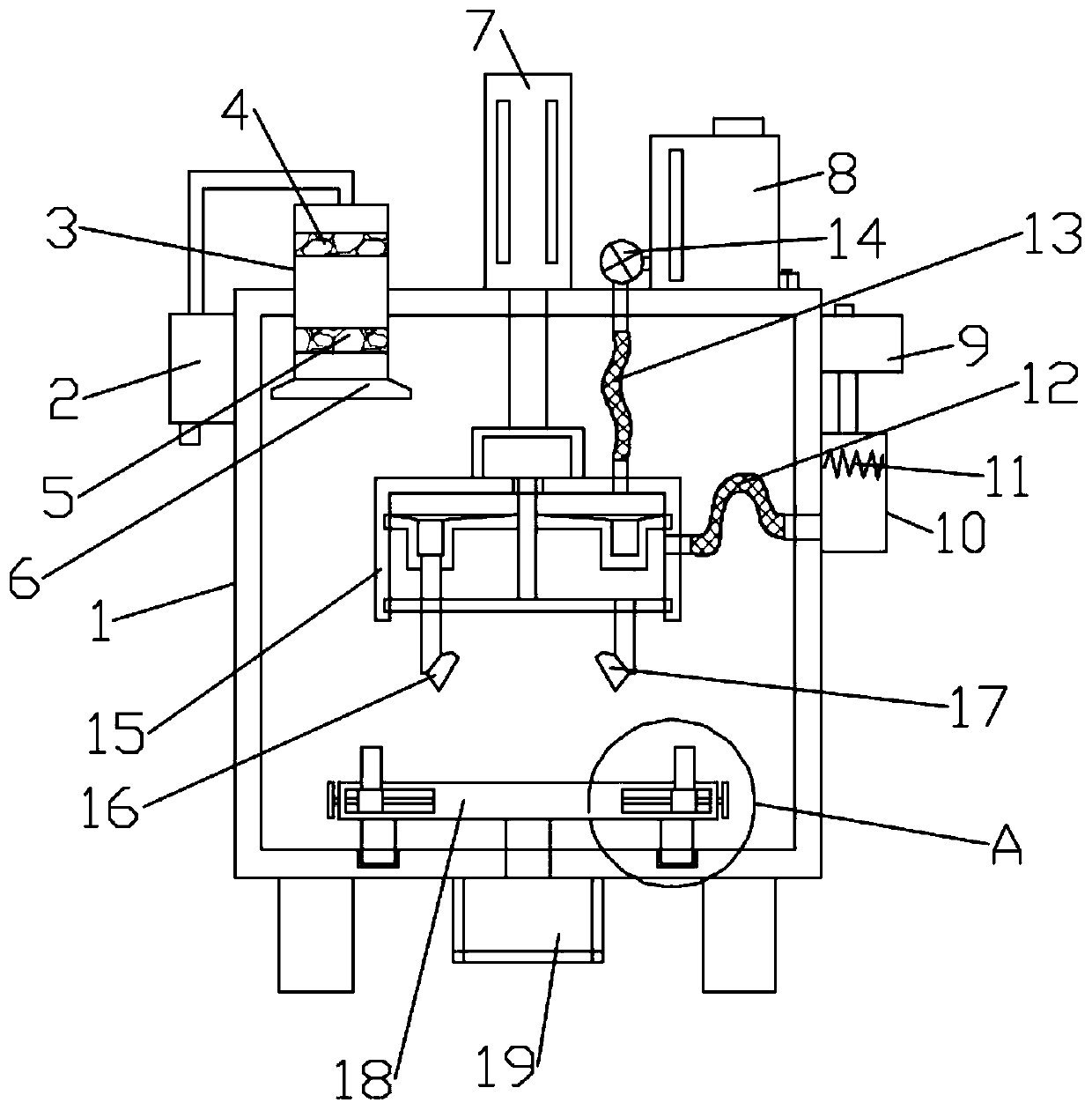

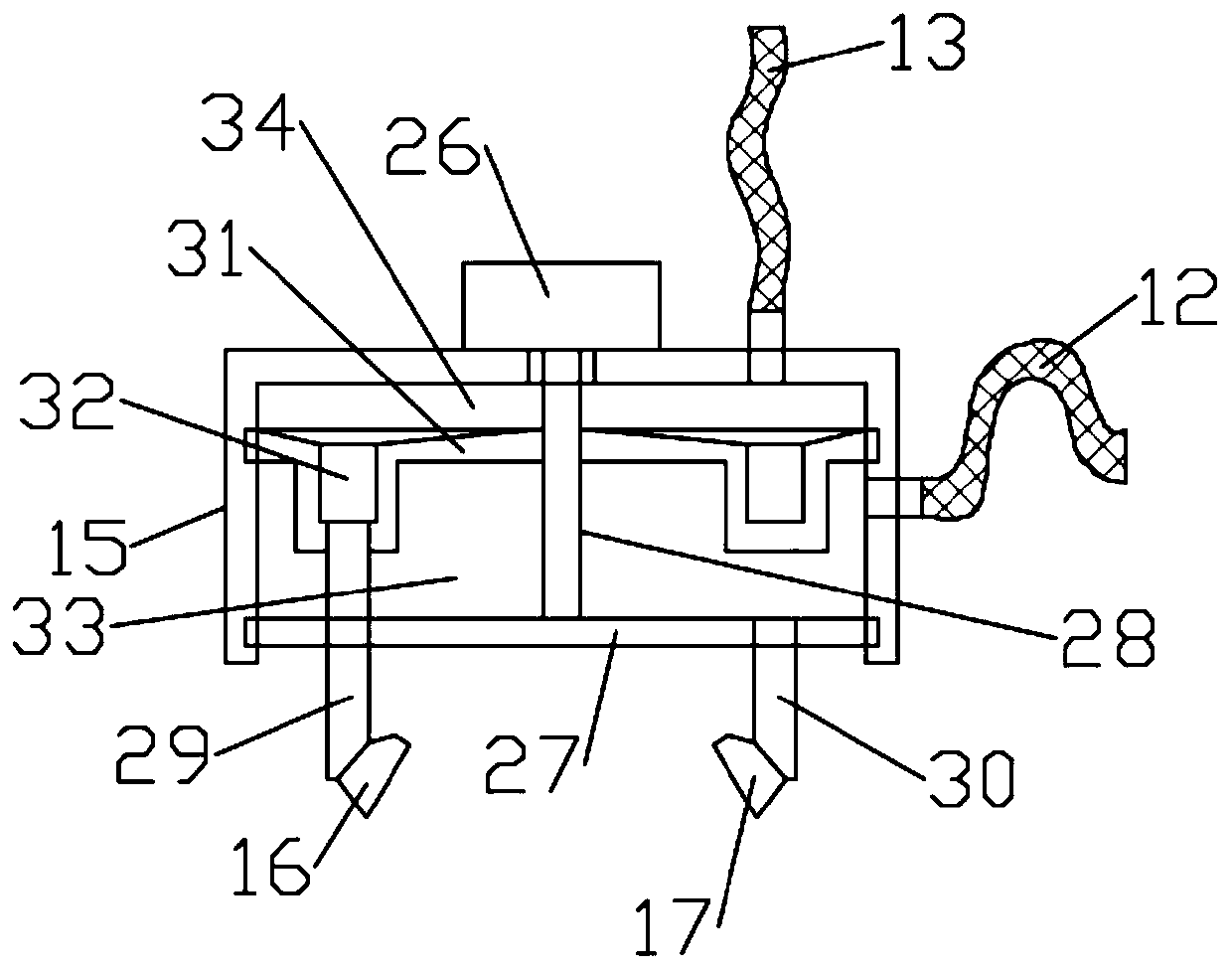

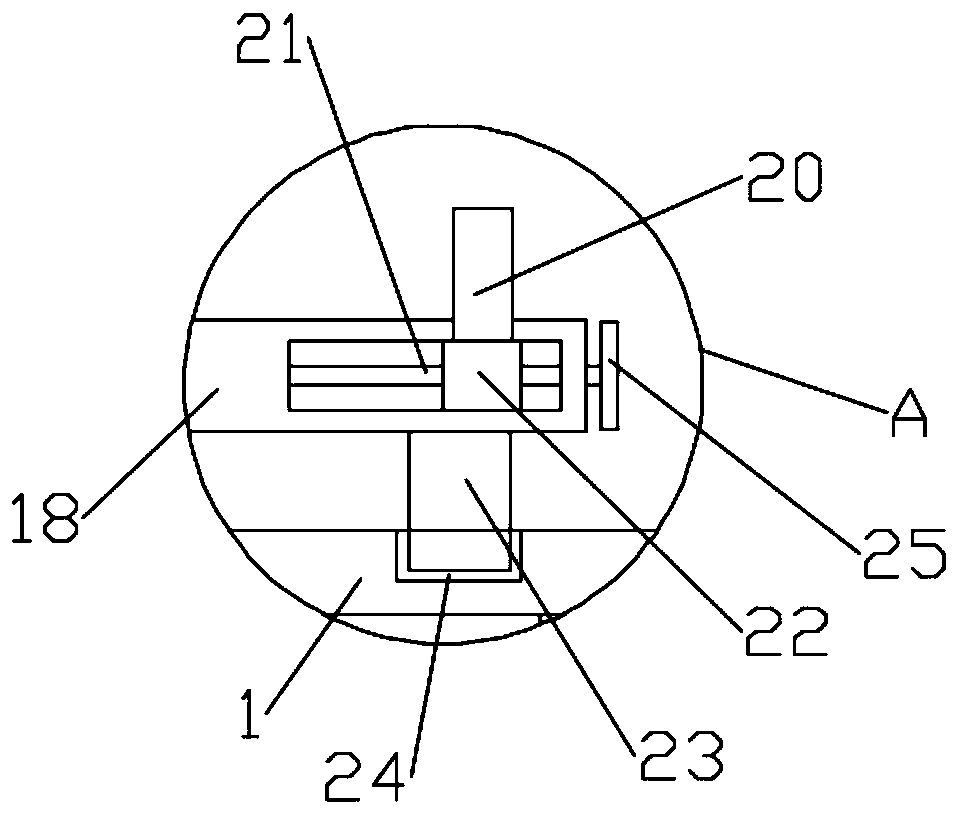

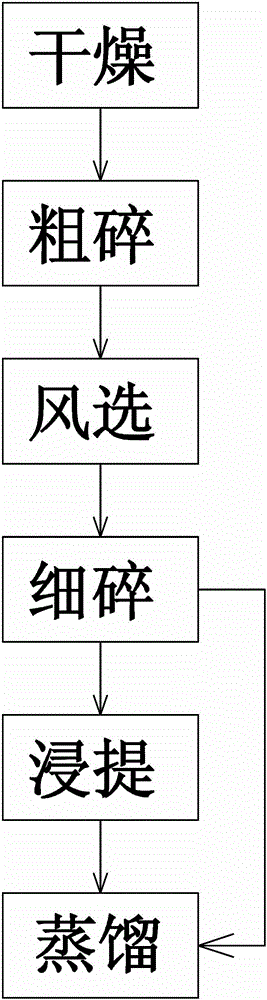

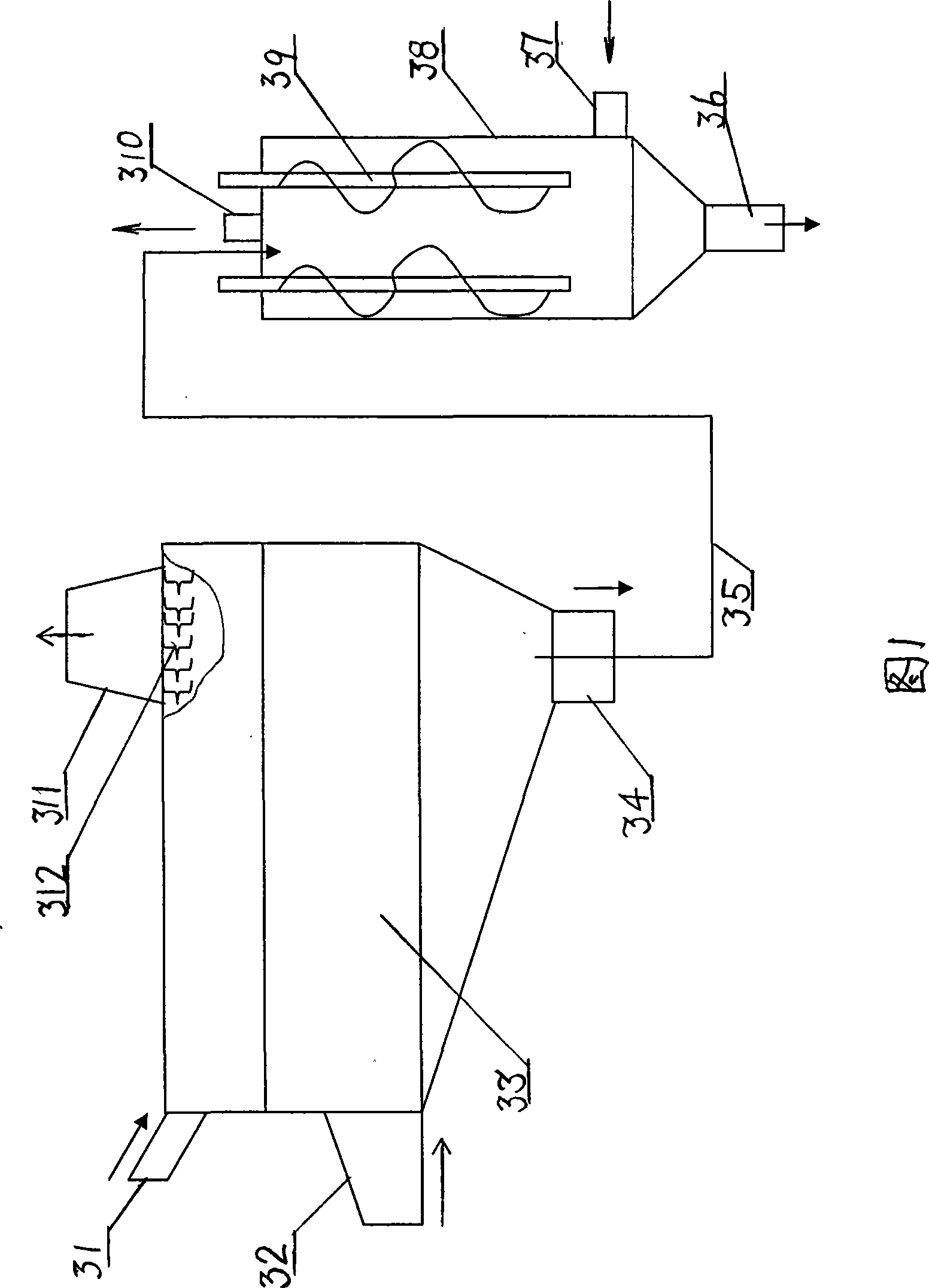

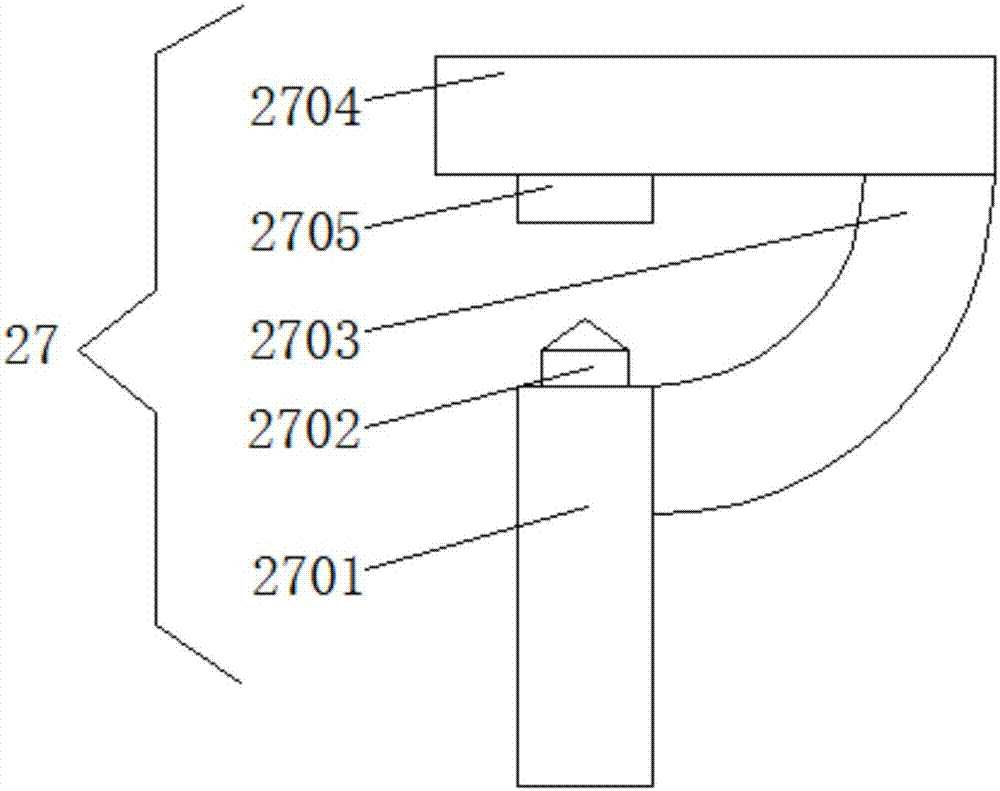

Extraction method and extraction equipment of natural borneol

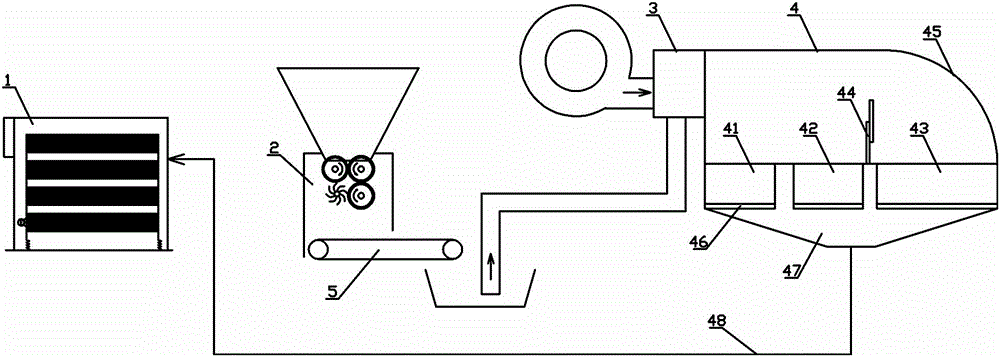

ActiveCN103601619AImprove drying efficiencyDry evenlyOrganic compound preparationEnergy based chemical/physical/physico-chemical processesBorneolHammer mill

An extraction method of natural borneol includes drying; crushing; sorting, to be more specific, sending crushed raw materials into a winnowing device for sorting out branches and leaves; fine crushing; and distillation condensation; and the natural borneol is obtained by the above steps. Extraction equipment of the natural borneol includes a pretreatment device, the pretreatment device comprises a crushing device, the pretreatment device is connected with the winnowing device through a wind delivery device, the winnowing device is provided with at least two discharging ports, a branch discharge port is connected with a hammer mill, a leaf discharge port is connected with a leaf crushing device; the hammer mill and the leaf crushing device are respectively connected with an extraction device or a distillation device by a conveying device. The extraction method and equipment have the advantages of improvement of production efficiency, improvement of the yield of large-scale industrialized production and reduction of energy consumption.

Owner:广东万森生态科技发展有限公司

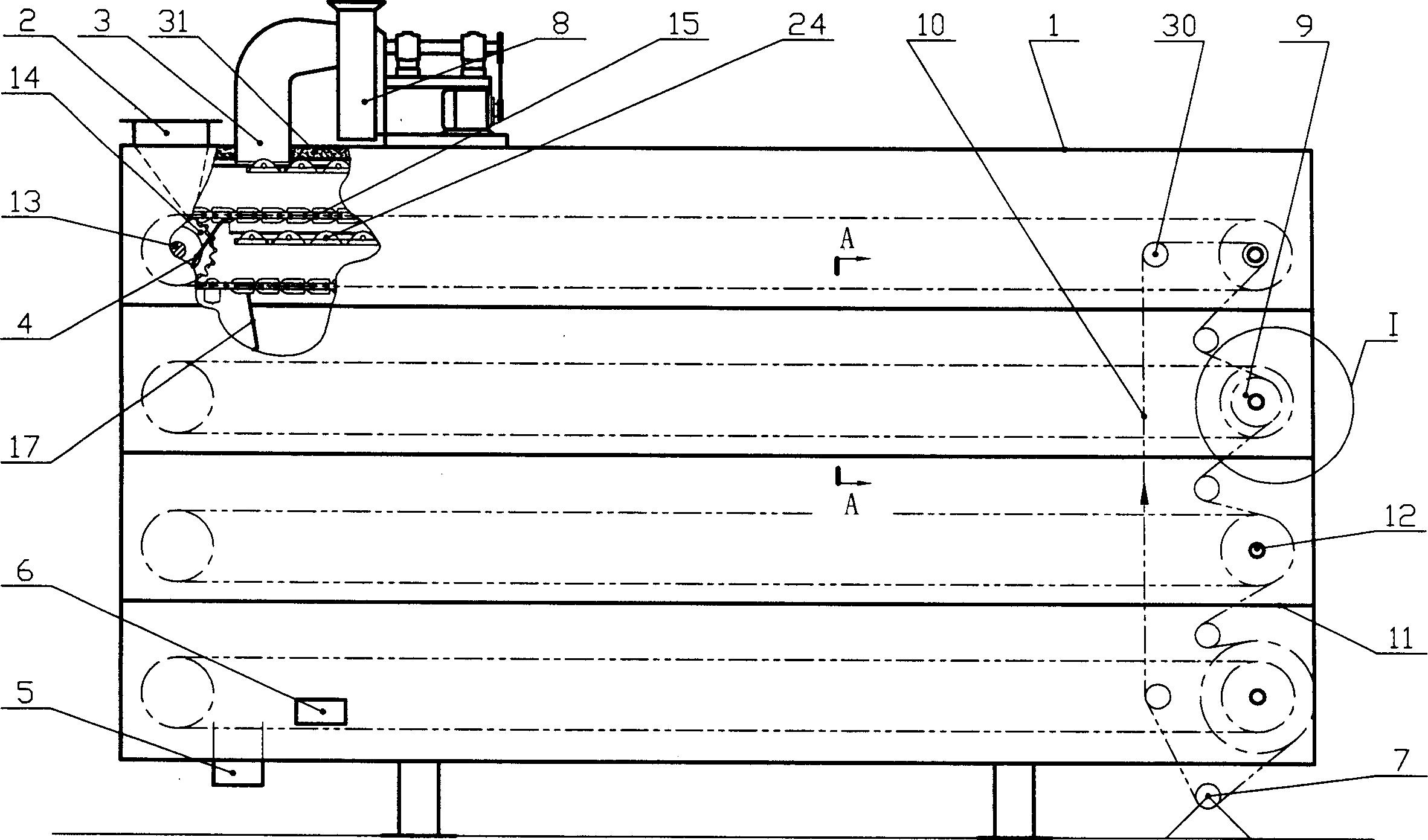

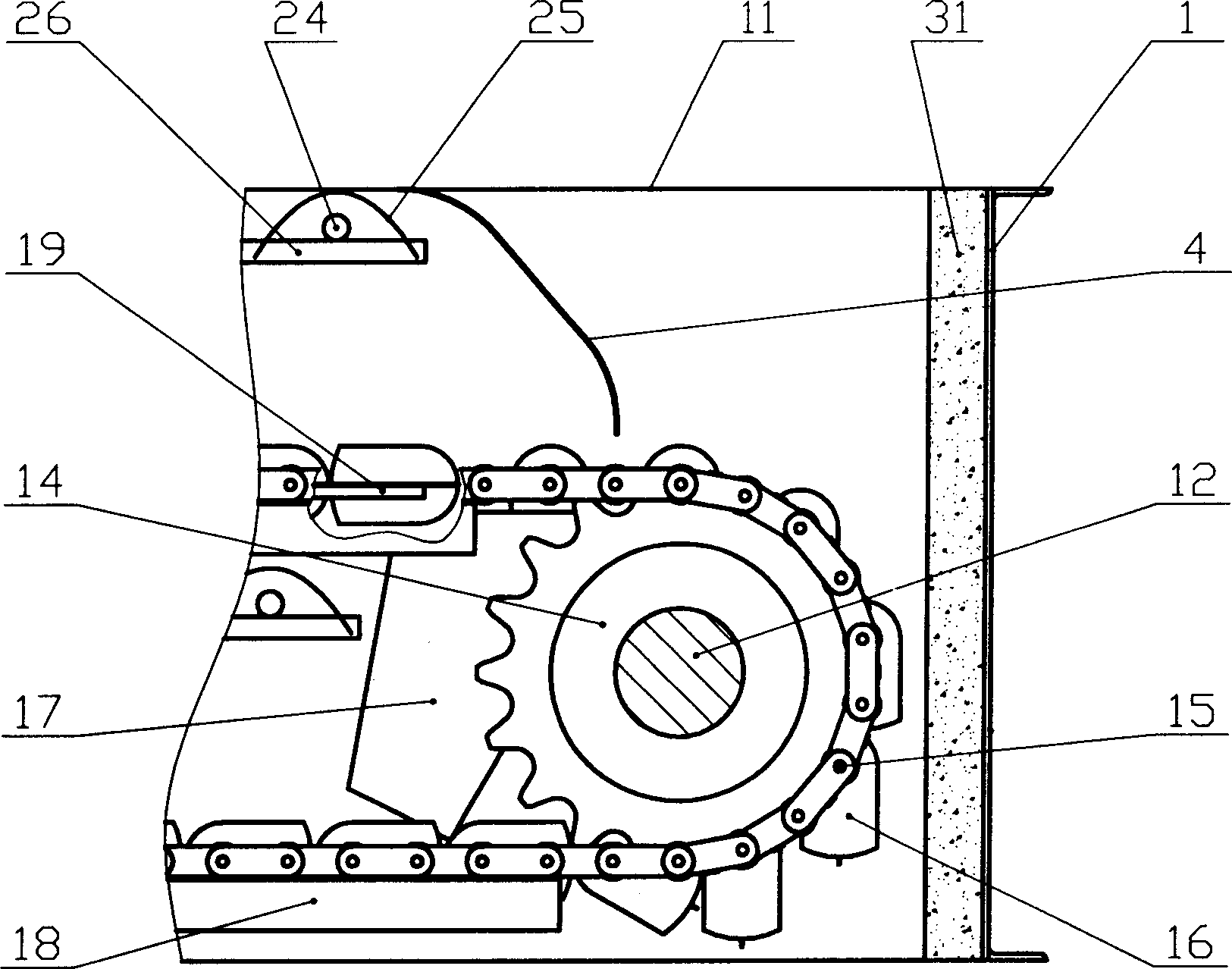

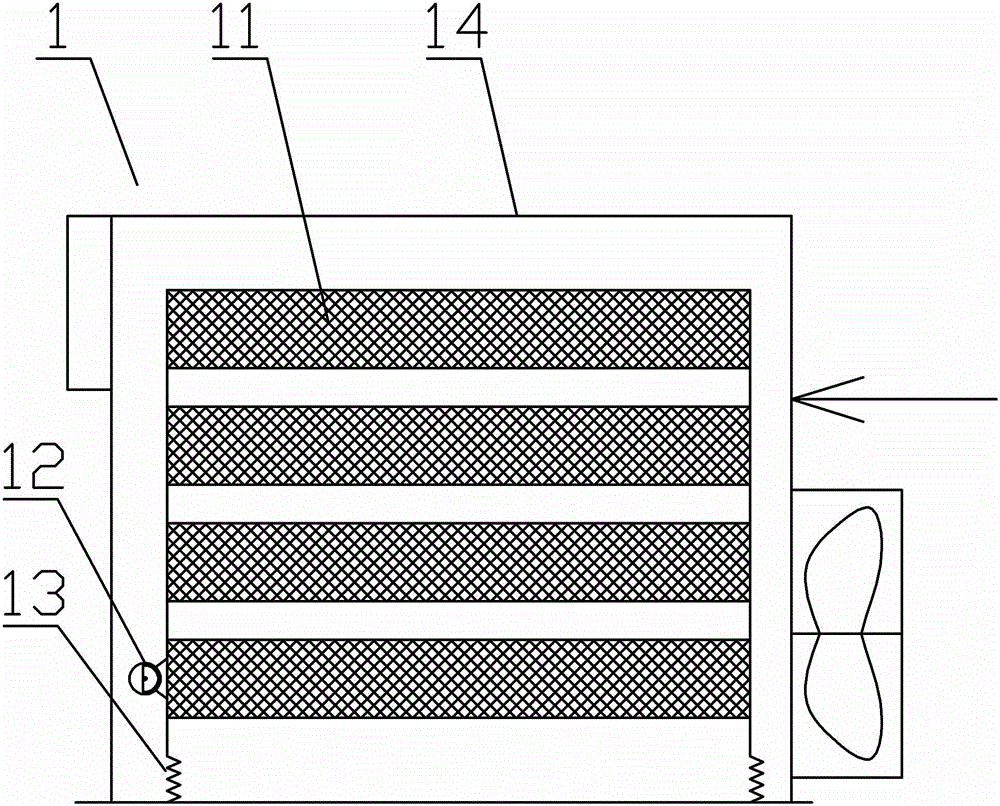

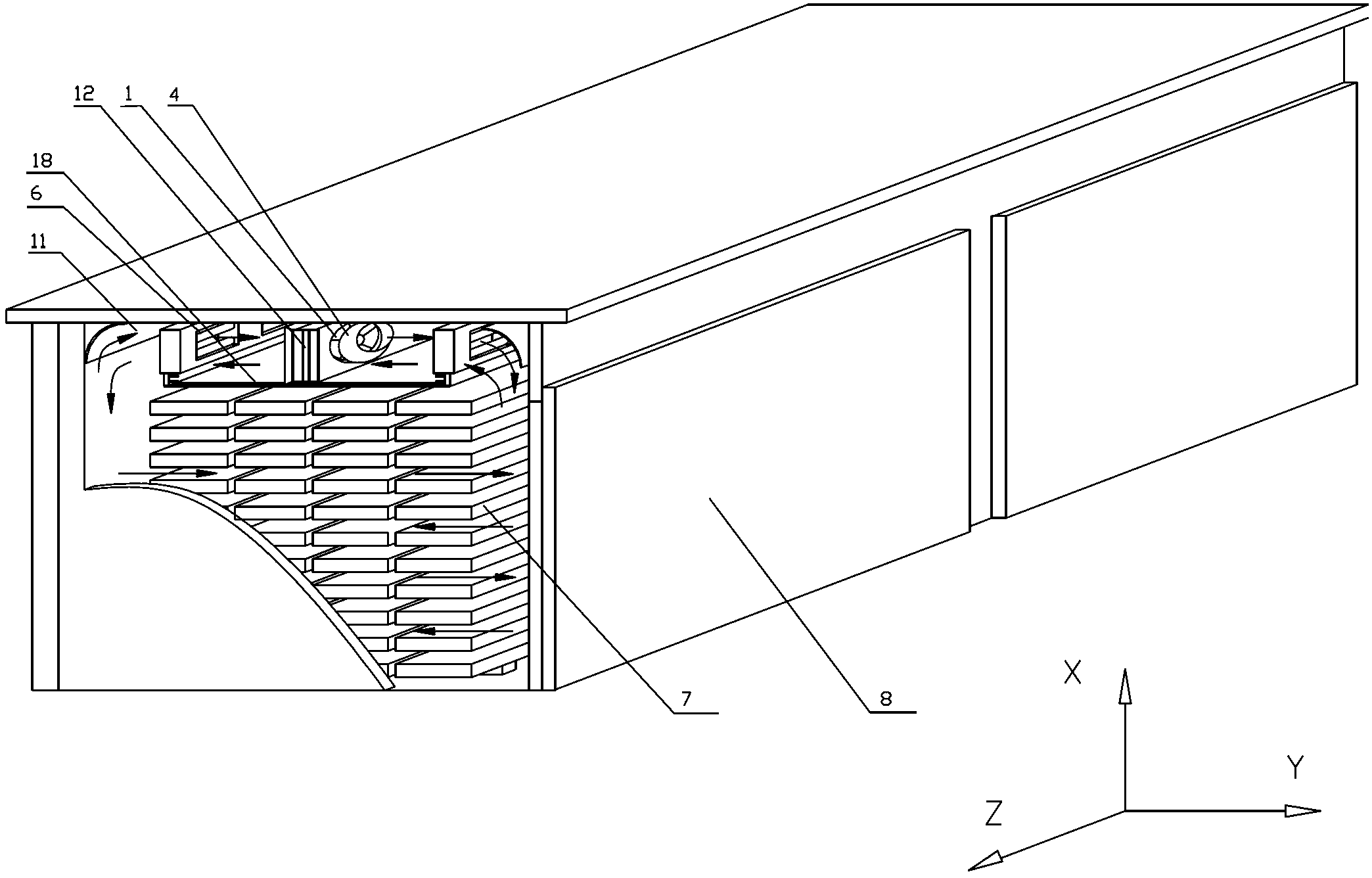

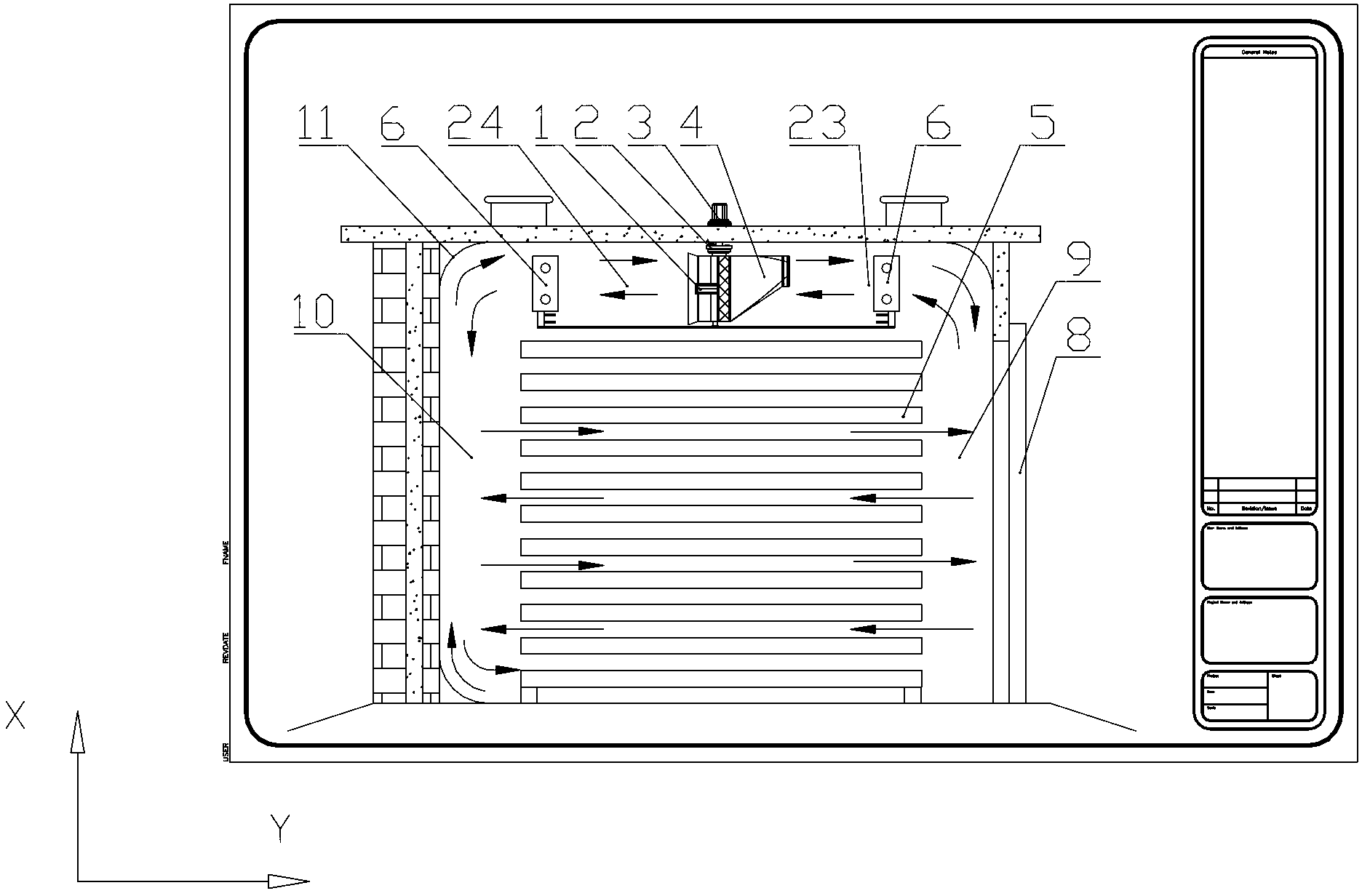

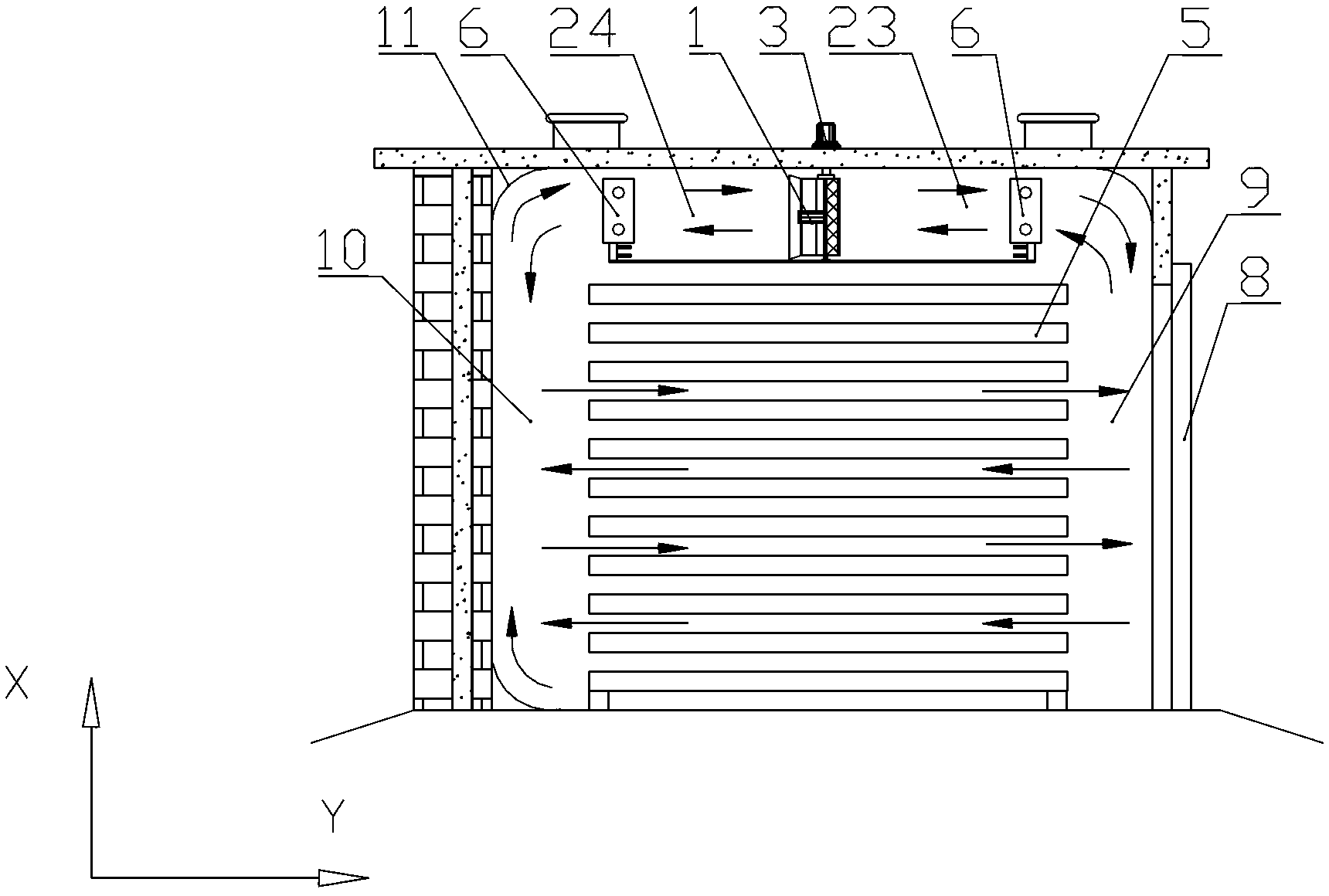

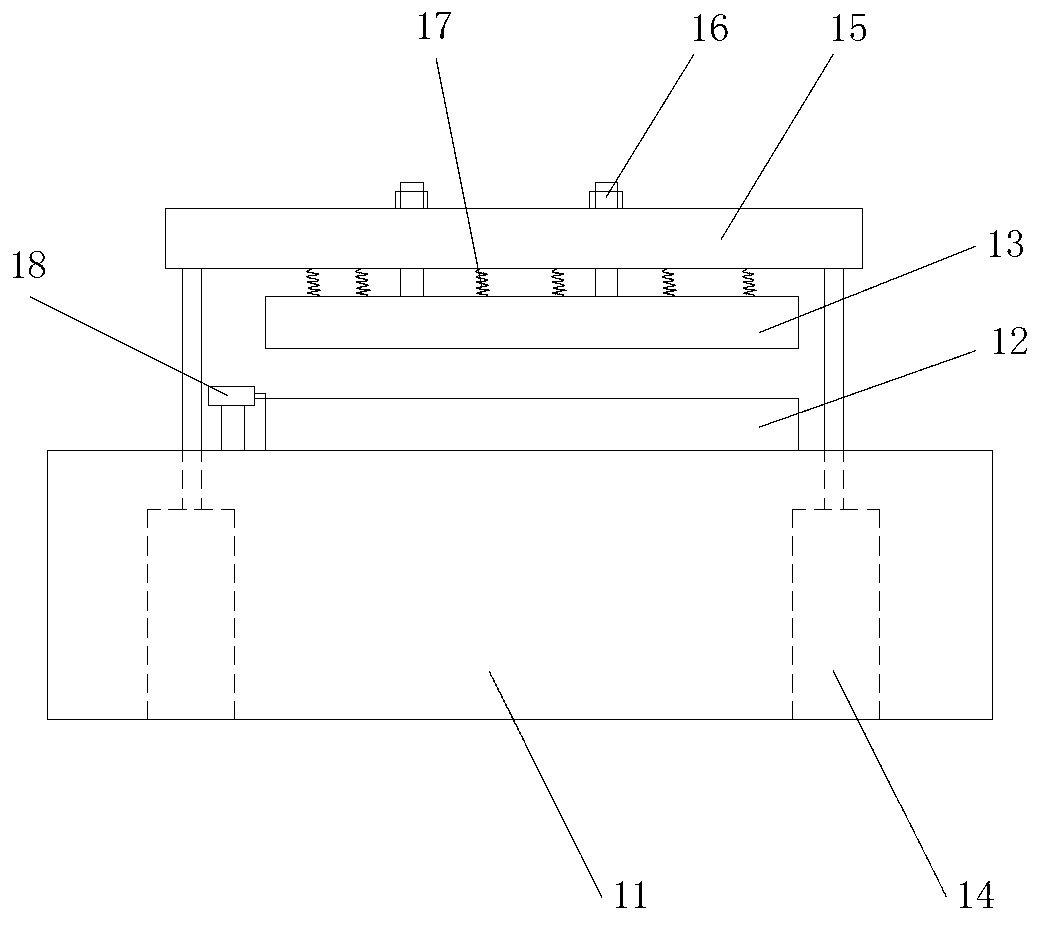

Heating and blowing device for large hot air drying room

InactiveCN103292590AStable forward and reverse air supplyThe same wind pressure and air volumeDrying gas arrangementsChemical productsEngineering

The invention relates to timbers, pharmaceuticals, foods and chemical products, in particular to a heating and blowing device for a large hot air drying room. A plurality of fans (1) are disposed in a rectangular fan support frame (12). Gaps among the fans (1) are blocked by air blocking plates (13). The fans are linked by a synchronization rotation linkage mechanism (2) for synchronous horizontal rotation. The fan support frame (12) is fixed on a rectangular movable frame (17). Rollers (19) embedded into guide rails (18) on two sides are disposed on two sides of the fan support frame (12). An air guide component (4) is disposed on a blowing side of each fan (1). A plurality of radiators (6) corresponding to the fans (1) are disposed at two ends of the guide rails. Three arc flow deflectors (11) are disposed at three inner included angles of the drying room. By the heating and blowing device, power consumption is lowered greatly, operation cost and drying cost are lowered, the drying room is enabled to be efficient, energy-saving and widely applicable, timbers of two or more different kinds or of different thicknesses can be evenly dried simultaneously, production efficiency is increased, and drying operations are highly flexible.

Owner:SHANGHAI UNIV OF ENG SCI

Tea cooling and roasting technique and tea cooling and roasting machine

InactiveCN101189993AReduce labor intensityIncrease productivityPre-extraction tea treatmentEngineeringHot blast

The invention relates to tea pan-frying technique and a tea pan-frying apparatus, which comprises a frame, a cylinder installed on the frame, a motor and a heating air source. The whole of the cylinder is in enclosed shape. Two sides of the cylinder are provided with at least an axle middle hole which is matched with the heating air source, and a temperature sensor is installed in the cylinder. The heating air source comprises a fan, a thermal generator and a hot blast pipe. The cylinder is wrapped with an insulating layer; meanwhile, two side surfaces of the cylinder are opened with a plurality of moisture discharging vents. The invention has the advantages of low labor intensity, high production efficiency, evenly drying inner-outer tea, discharging moisture, removing tea fannings, brightening tea and producing tea with good color, fragrance, taste and shape.

Owner:苏和生

Leather drying device with high efficiency

InactiveCN106282431AImprove efficiencyDry fastDrying gas arrangementsDrying chambers/containersEngineeringDrying time

The invention discloses a leather drying device with high efficiency, relating to the technical field of leather processing equipment. The leather drying device with high efficiency comprises a base, a heating box and a drying box are installed at the top of the base in sequence from left to right, a controller and an air supply pipe are arranged at the top of the heating box in sequence from left to right, one end of the air supply pipe, close to the heating box, penetrates through the heating box and extends into the heating box, the other end of the air supply pipe, away from the heating box, penetrates through the drying box and extends into the drying box, and a ventilation plate is fixedly connected to one side of the inner wall of the drying box. The leather drying device with high efficiency adopts an exhaust fan, a blower, a fan and an air heater, wherein the air heater can heat air sucked into the heating box, and the blower and the fan can blow air to dry leather, so that the leather can be quickly dried, so that not only is the leather drying time reduced and also the working efficiency is also improved.

Owner:陈明

Method for producing terylene POY filament in scale by recycling PET bottle sheet material

ActiveCN101435113ASolve the problem of water content inconsistencyHigh meshSolid waste disposalMelt spinning methodsEngineeringBottle

The invention provides a method for producing polyester POY filament in scale by recycling PET bottle chip. Recycled waste PET bottles are crushed into flaky bottle chip, dried after cleaning, and then sent into a crystallizing bed body; under the action of hot air entering the crystallizing bed body, crystallization is carried out, a crystallizing layer is formed on the bottle chip surface, and then the bottle chip is sent into a drying tower for drying; the dried bottle chip enters a screw extruder for melt extrusion, and the obtained melt is sent into a two-stage filtering device for filtering and then enters a spinning box; and a high-speed spinning process is adopted for spinning to produce the polyester POY filament. The method for producing the polyester POY filament adopts a filling type drying mode, the drying is even and the operating cost is low; a screw mixer is arranged in the drying tower, which solves the problem of 'arching' that happens to the recycled PET bottle chip during the drying process; and the two-stage filtering device is adopted, which ensures the filtering quality. Therefore, the high-end product-polyester POY filament can be continuously produced in large scale.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

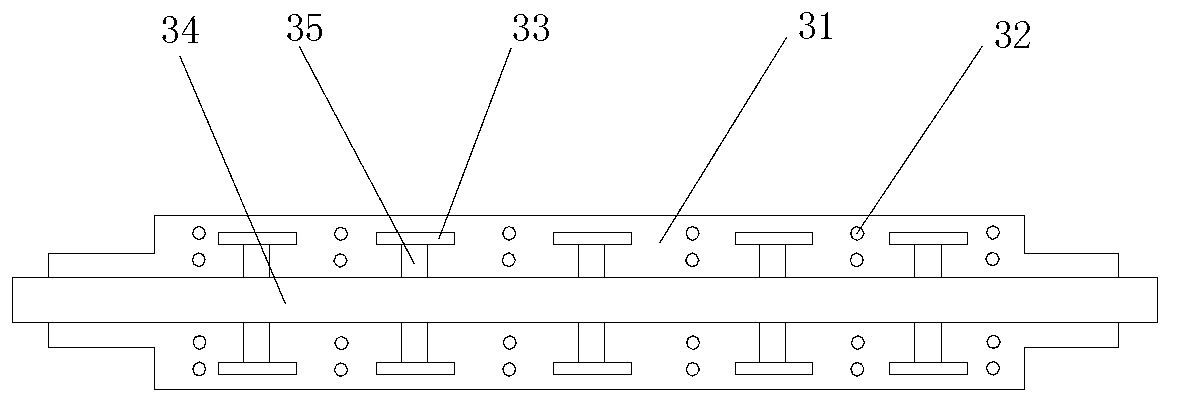

Double-point coating production line for hot-melt adhesive padding cloth

InactiveCN102697213APrevent flutteringAvoid wrinklesInspecting textilesGarmentsProduction linePulp and paper industry

The invention provides a double-point coating production line for hot-melt adhesive padding cloth, and the double-point coating production line comprises a cloth reception device, a wind shielding screen, a size discharging roller, a holt-melt rubber powder blowing / sucking device, a drying oven, a cooling device, an ultraviolet lamp perching device and a rolling device which are arranged in sequence from front to back, wherein the cloth reception device comprises a cloth reception underframe, a lower pressing mould which is arranged on the cloth reception underframe and an upper pressing mould which is arranged on the cloth reception underframe and matched with the lower pressing mould in a lifting manner to crimp padding cloth; the wind shielding screen comprises a screen underframe and a screen plate which is arranged on the screen underframe; the size discharging roller comprises a discharging roller main body and a discharging hole which is formed in the discharging roller main body; and a scraper is arranged in the discharging roller main body. According to the double-point coating production line for hot-melt adhesive padding cloth, the unrolling speed of the padding cloth is increased, the continuous production is realized, the work efficiency is improved, the production cost is reduced and the quality of the padding cloth is improved.

Owner:HANGZHOU AOKE GARMENT ACCESSORIES

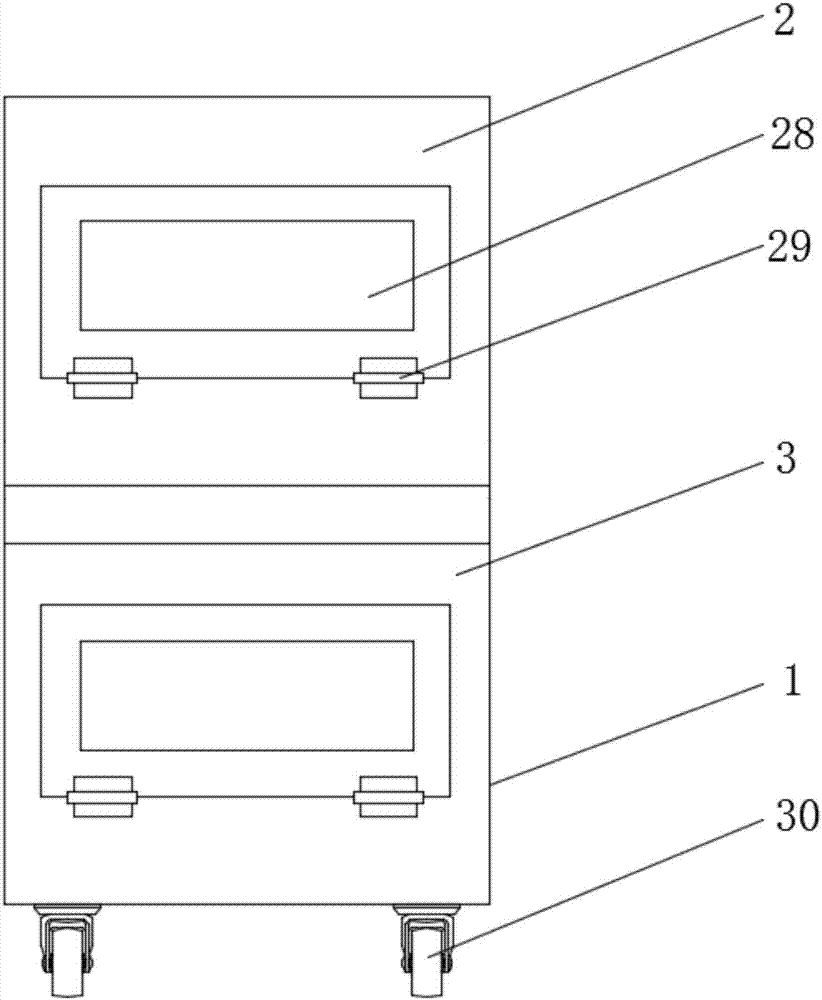

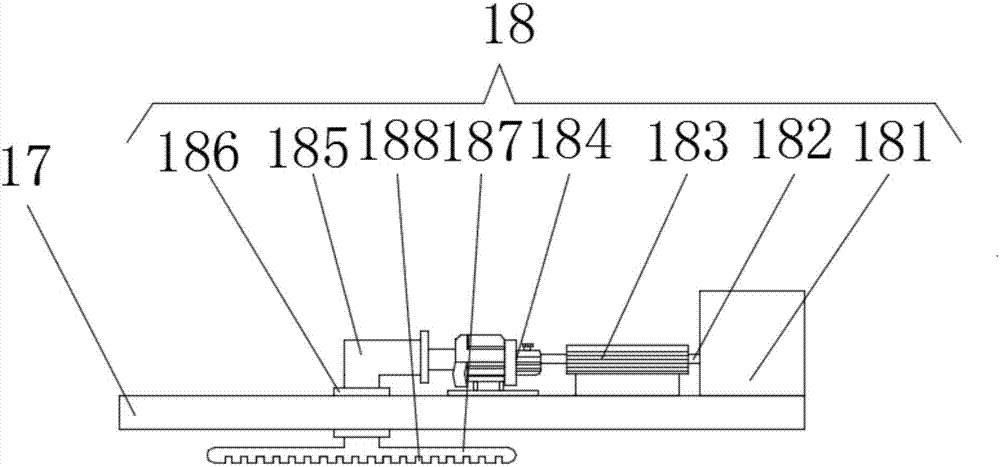

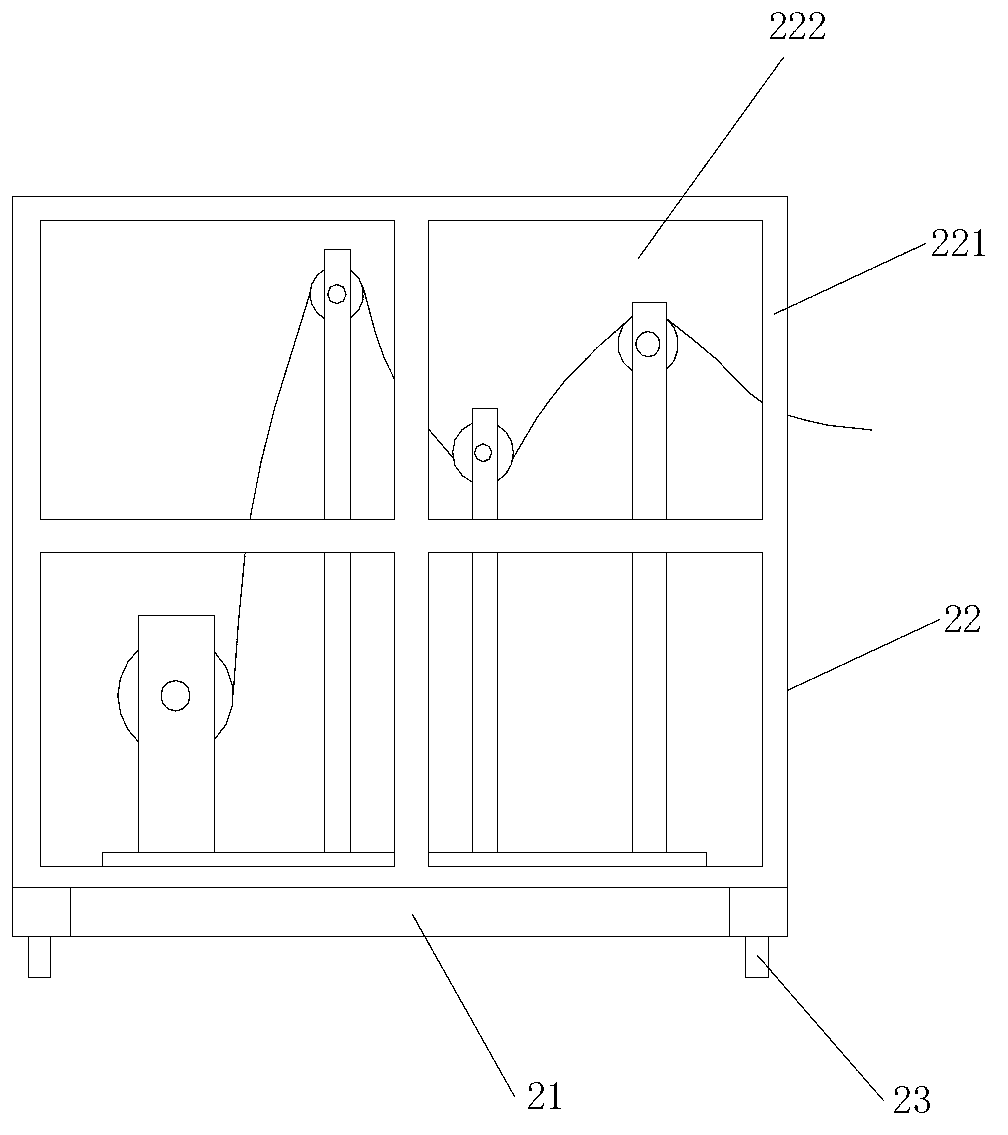

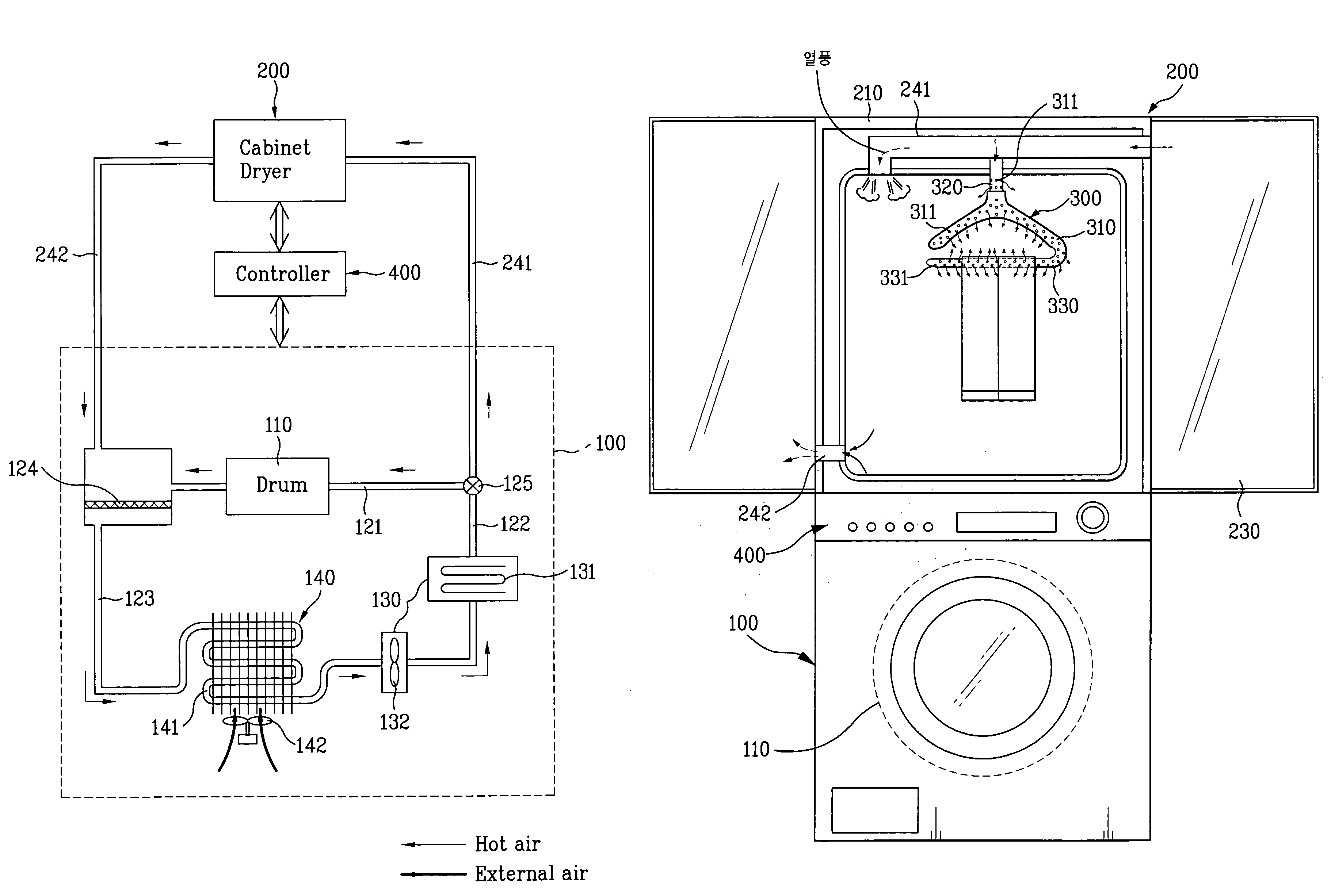

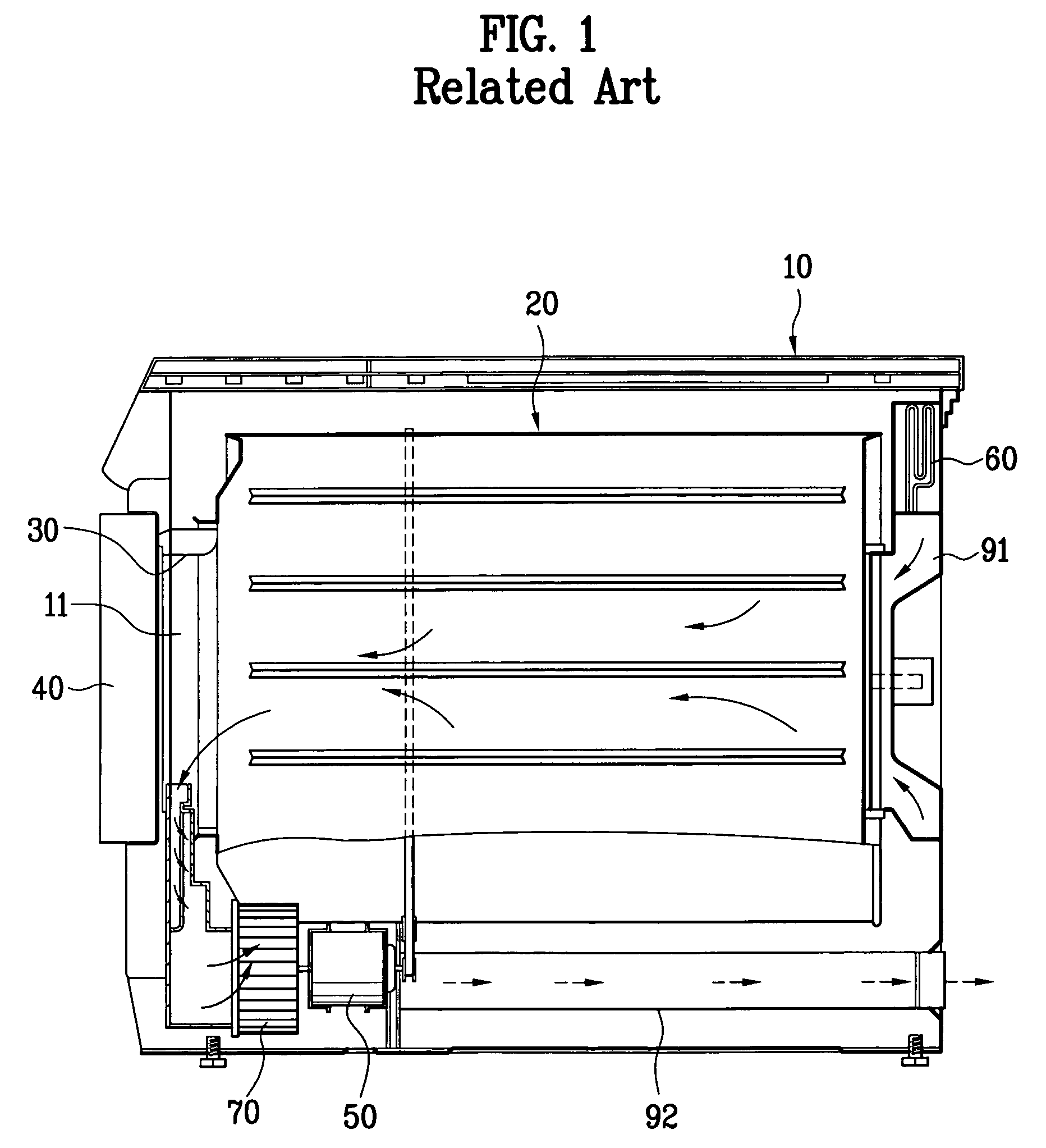

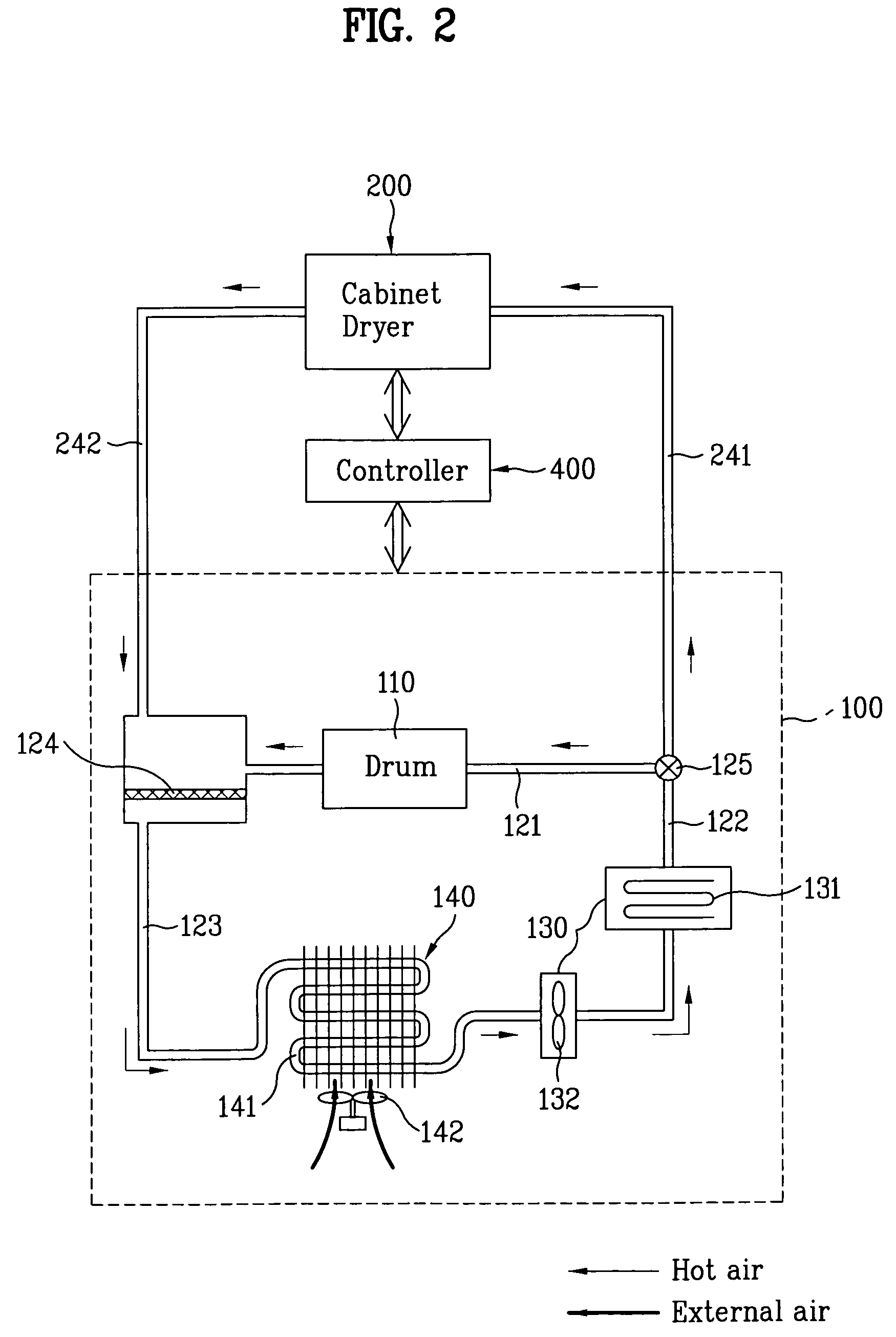

Composite washing system

InactiveUS8695228B2Dry evenlyIroning apparatusDrying machines with non-progressive movementsHot blastWaste management

A composite washing system is disclosed which is capable of continuously circulating laundry-drying air through dryers while obtaining a more efficient drying effect, so that the composite washing system has a suitable built-in structure having minimal influence on the indoor environment. The composite washing system includes a drum dryer which dries laundry to be dried, and includes a drying drum adapted to receive the laundry, a hot air supply path adapted to guide a flow of hot air, a hot air supplier arranged in the hot air supply path to generate the hot air, and an air condenser adapted to condense the hot air, a cabinet dryer which is coupled to one side of the drum dryer, and is defined with a laundry receiving compartment, the cabinet dryer including a hot air inlet duct adapted to receive the hot air flowing through the hot air supply path, and a hot air supplying device which is arranged in the cabinet dryer to receive the hot air from the hot air inlet duct and to supply the received hot air to an inside of the laundry.

Owner:LG ELECTRONICS INC

Method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on scale

ActiveCN102605454ASolve the problem of water content inconsistencyGuaranteed Filtration QualityFilament forming substance formingMonocomponent polyesters artificial filamentPolyesterPolyethylene terephthalate

The invention provides a method for producing industrial polyester filament by recycled PET (Polyethylene Terephthalate) bottle chips on a scale. The method comprises the steps of crushing the recycled PET bottles into chips, washing and drying, sending into a crystallization bed body for crystallization, forming crystallization layers on the surfaces of the bottle chips, sending the crystallizedbottle chips into a drying tower which is provided with a pair of spiral agitators, leading the dried bottle chips to enter a screw extruder for melting and extrusion, sending the obtained melt into a two-stage filtration device consisting of a coarse filter, a fine filter and a pressure pump between the coarse filter and the fine filter for filtration, leading the melt which is filtrated by two stages to enter a liquid phase tackifying kettle, conducting polycondensation reaction in the liquid phase tackifying kettle, leading the melt after being subjected to liquid phase tackifying to entera spinning box, and spinning by adopting a high-speed spinning process, thus obtaining the industrial polyester filament. In the method for producing the industrial polyester filament, the liquid phase tackifying step is added in the production process, so that the problems of low viscosity and poor stability of the PET bottle chip melts are solved.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

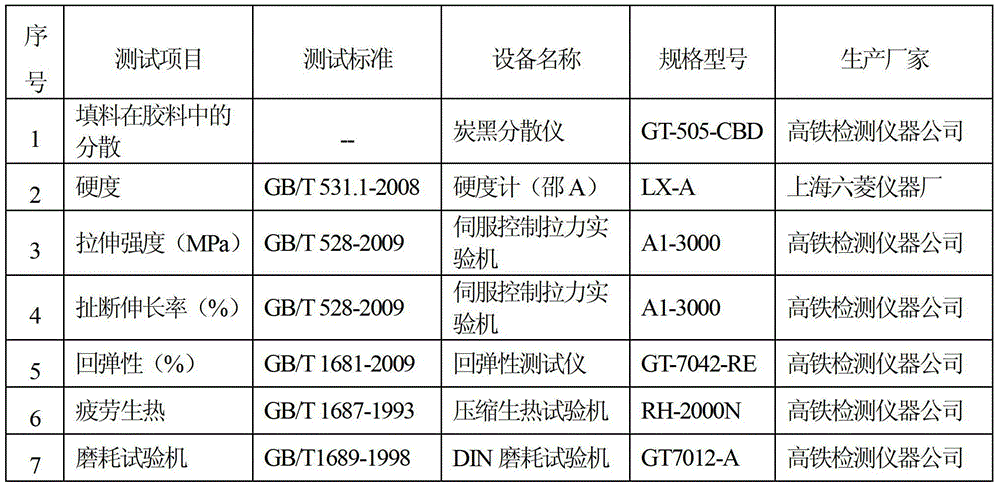

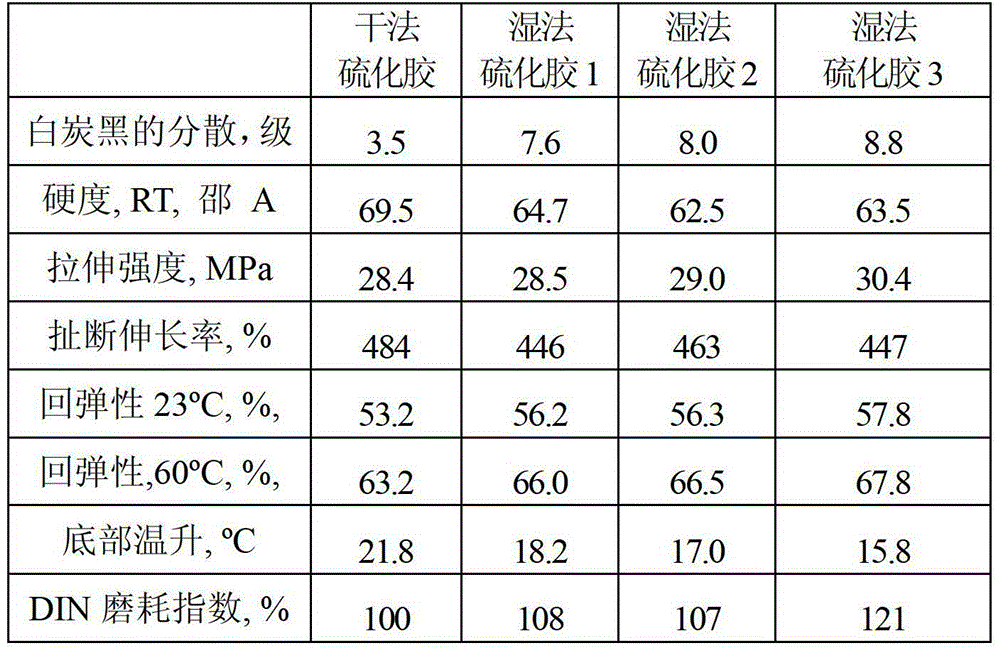

Rubber master batch continuous manufacturing method and rubber master batch prepared thereby

The invention discloses a rubber master batch continuous manufacturing method and rubber master batch prepared thereby. The manufacturing method comprises the following steps: step (1) adding a filler into a rubber solution, stirring so as to form a rubber / filler / solvent mixture; step (2) carrying out a coagulation treatment for the rubber / filler / solvent mixture so as to obtain a mixture of rubber / filler complex and solvent; (3) removing the solvent and drying the mixture so as to obtain the rubber / filler master batch. The invention also relates to a master batch prepared by the method mentioned above and rubber products prepared from the master batch. Compared with a drying technology in a conventional wet mixing process, the manufacturing method does not have special requirements on rubber and the filler and has a wider application range; the production technology has the advantages of continuity, high efficiency, low energy consumption, and little manpower, so the method has a low cost; the mater batch prepared by the method has excellent properties of processing performance, physical and mechanical performances, and product quality.

Owner:EVE RUBBER RES INST

Dedusting and drying integrated printing-and-dyeing drying equipment

InactiveCN107339871AGuaranteed smoothImprove cleanlinessDrying gas arrangementsDrying machines with progressive movementsWorking environmentEngineering

The invention discloses a printing and dyeing drying equipment integrating dust removal and drying. A rotating shaft, the outer surface of the first rotating shaft is sleeved with unwinding rollers. The printing and dyeing drying equipment integrating dust removal and drying can effectively ensure the cleanliness of the fabric, effectively maintain the working environment of the equipment, avoid dust falling into the fabric again, and cause the fabric to be polluted again, effectively making the fabric quality better. Effectively spray the dye evenly onto the second electric printing and dyeing roller, which ensures the automation of the equipment, ensures the stable flow of the dye liquid, and avoids the excessive impact of the dye during stirring, which causes the equipment to shake, effectively It ensures the drying of the fabric, solves the problem of the fabrics sticking together, improves the quality of the fabric, and saves the drying time.

Owner:姚飞

Method for producing instant noodles dried by hot air stream at high temperature

ActiveUS20110229613A1Moreish tasteMoreish textureFood preservationFood ingredient as taste affecting agentCaloric valuesFried noodles

A method for producing instant noodles dried by a high-temperature hot air stream, wherein the noodles have a moreish taste and texture similar to fried noodles and yet have a low caloric value. The method for producing instant noodles dried by a high-temperature hot air stream comprises: step (a) producing a noodle band from a noodle dough prepared by adding an edible oil to a noodle dough material containing a raw material flour, and then producing raw noodle strands from the noodle band, step (b) adhering an edible oil to the raw noodle strands, and then steaming the raw noodle strands to produce steamed noodles, step (c) forming a noodle block by packing a predetermined amount of the steamed noodles into a retainer, and step (d) swelling and drying the noodle block by blowing a hot air stream at a temperature of 120° C. to 160° C. onto the noodle block from above and below the retainer at a stream speed of 30 m / s to 70 m / s for a period of 3 to 15 minutes.

Owner:NISSIN YORK

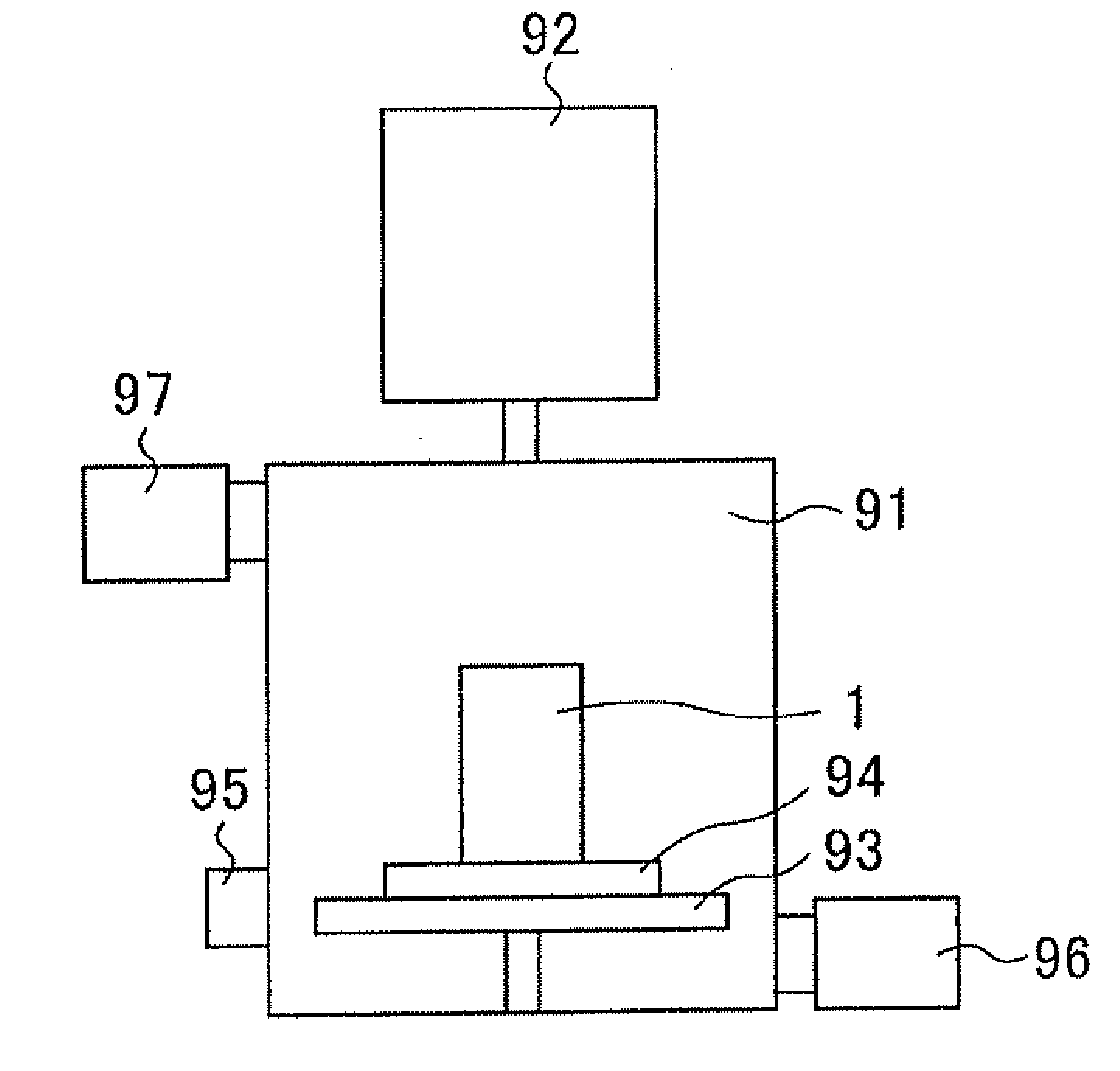

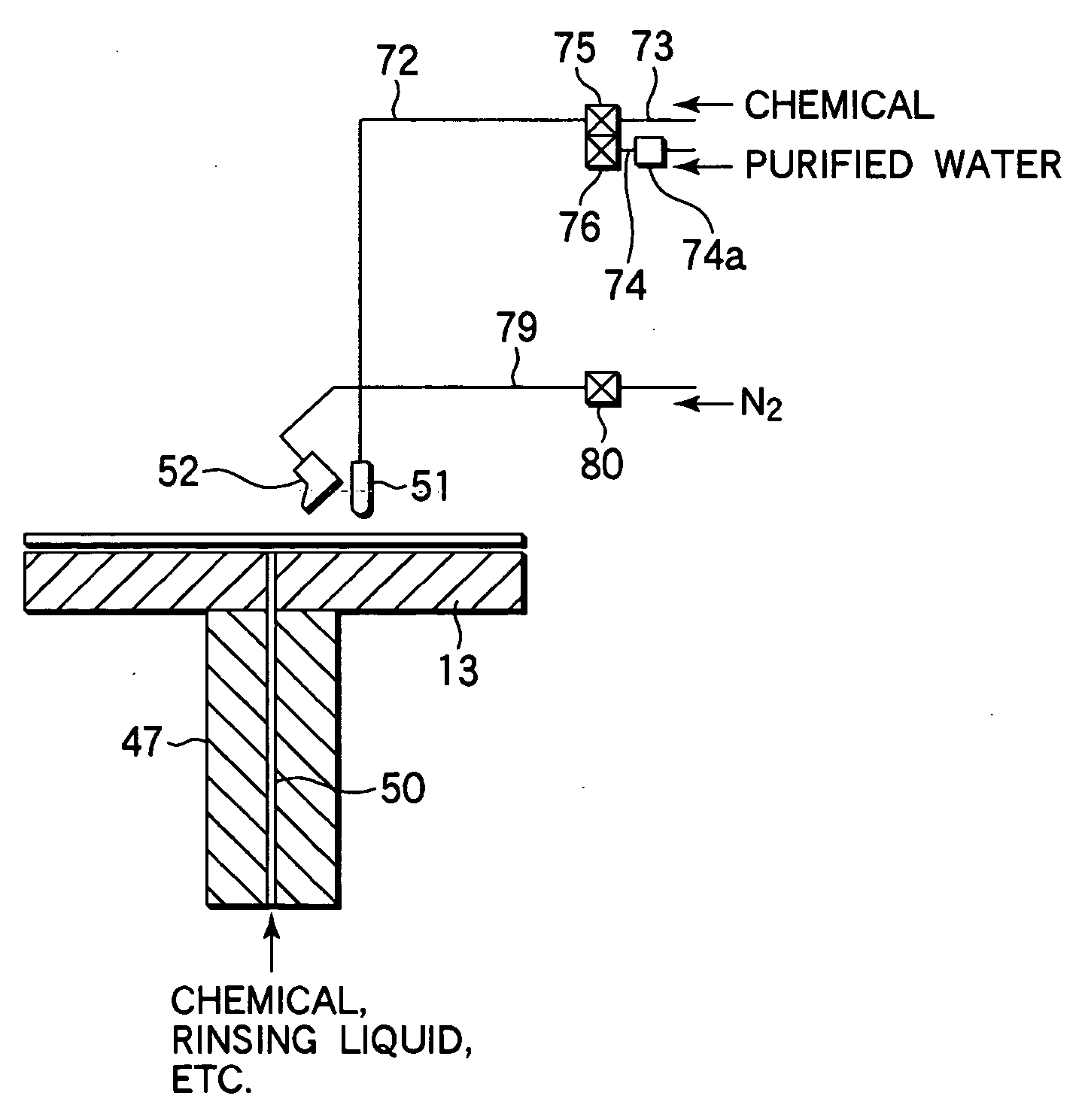

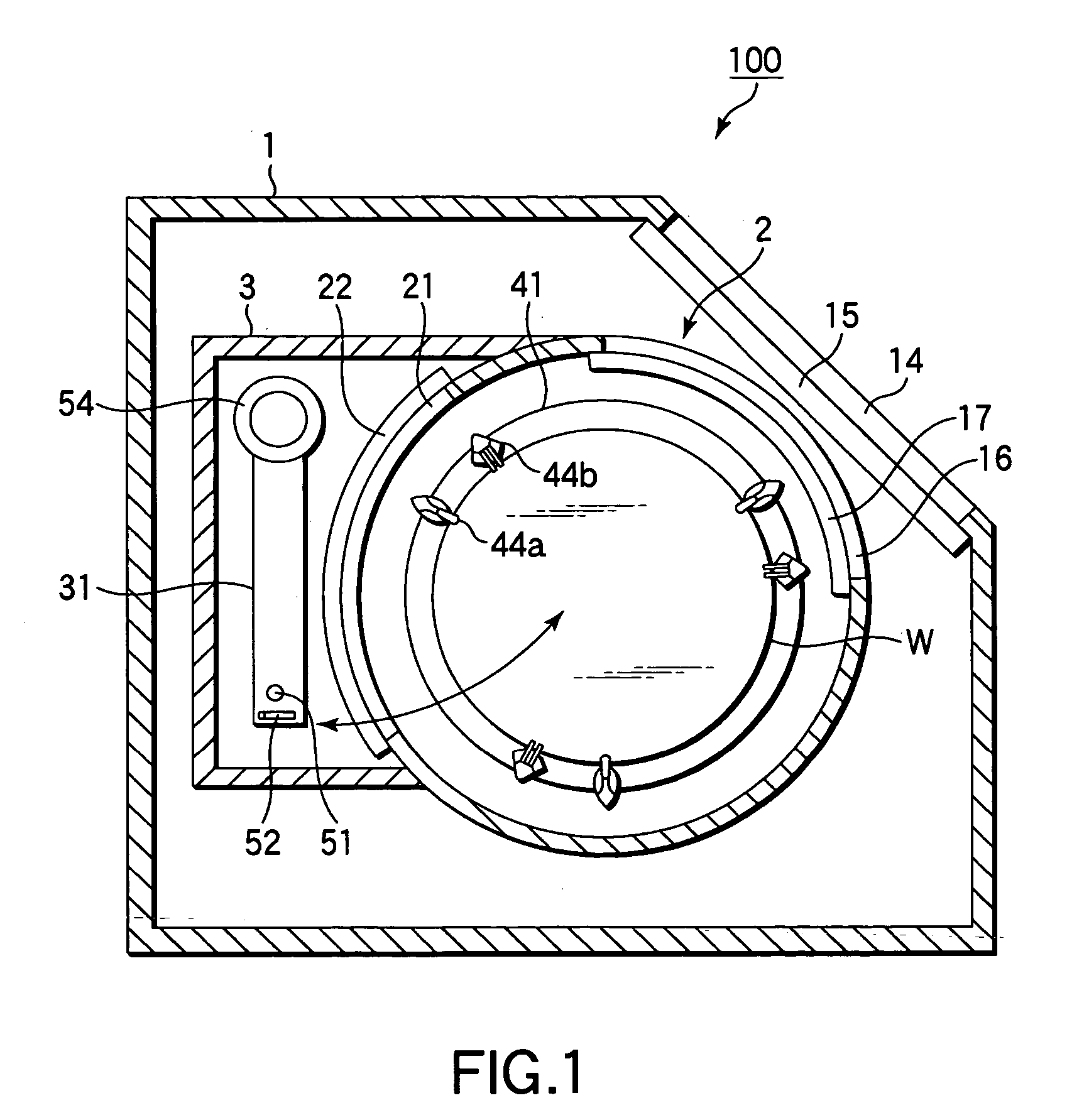

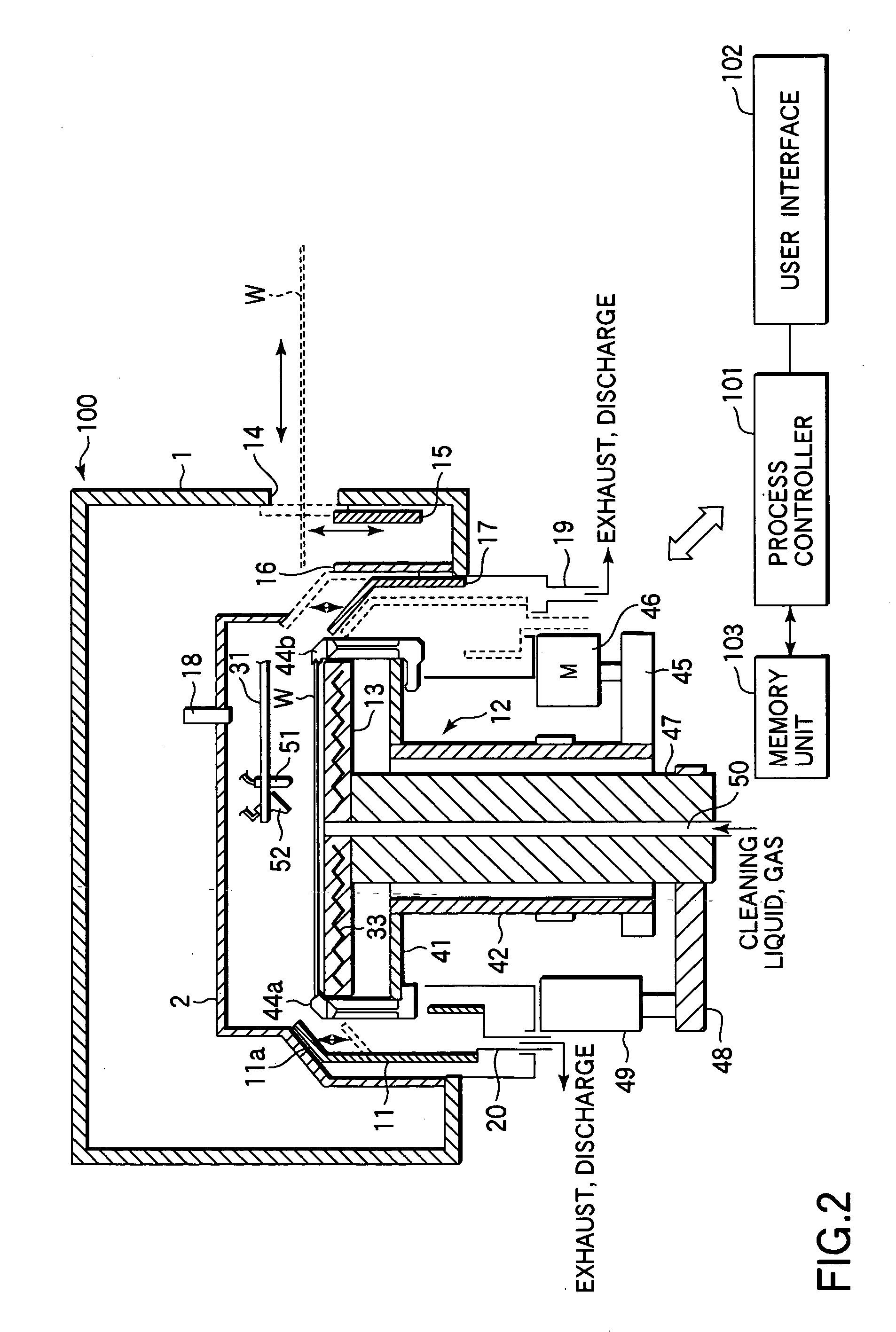

Substrate cleaning method and substrate cleaning apparatus

ActiveUS20070137677A1Difficulty remainReduce speedSemiconductor/solid-state device manufacturingCleaning using liquidsRotation velocityEngineering

A substrate cleaning method including rotating a substrate at least for a period, supplying a liquid to the front surface of the substrate and cleaning the substrate, and drying the substrate is provided. Said drying of the substrate includes: reducing a rotational speed of the substrate to a first rotational speed lower than a rotational speed for cleaning the substrate; starting to move a liquid supply position from approximately the center of the substrate towards a peripheral portion when the rotational speed of the substrate is reduced down to the first rotational speed; stopping liquid supply when the second rotational speed lower than the first rotational speed is reached; increasing the rotational speed from the second rotational speed; and supplying a gas towards the substrate while rotating the substrate at a higher rotational speed than the second rotational speed.

Owner:TOKYO ELECTRON LTD

Method for producing terylene pre-tropism continuous yarn by utilizing reclaimed polyester bottle

ActiveCN101144191ALow costReduce energy consumptionMelt spinning methodsSpinning solutions preparationYarnPolyester

The present invention belongs to the fiber producing method field, in particular relates to a method which uses a reclaimed PET bottle to produce the terylene preoriented filament in particular. The present invention mainly solves the problems of the prior art that the cost of raw materials for production is high, the drying efficiency is low, and the uniformity is poor, etc., and provides a method which uses the reclaimed PET bottle to produce the terylene preoriented filament with low cost of the raw materials for production, high drying efficiency, and good uniformity. The present invention has the major steps that the bottle piece of the PET bottle is produced; the bottle piece is continuously crystallized and dried by passing through a pre-crystallizer and a drying tower; the dried bottle piece directly enters a threaded rod extrusion machine, and is melted and extruded by a spinning threaded rod; the molten polyester material is continuously filtrated by a molten mass filter with a big filtering area of one level or two levels, to enter a spinning manifold; a thread line is cooled by passing through a cross air blasting, to wind to form the preoriented filament.

Owner:浙江聚元新材料股份有限公司

Preparation method of dried day lily

ActiveCN103918775AMaintain nutrientsBalance internal and external moistureFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationCooking & bakingFlavor

The invention belongs to the field of food processing, and particularly relates to a preparation method of dried day lily. The dried day lily is prepared by the working procedures of with fresh day lily buds as raw materials, destemming, rinsing by running water, leaching, putting into dishes, carrying out microwave heating for deactivating enzymes, cooling, carrying out once microwave drying for dehydrating, cooling, carrying out secondary microwave drying for dehydrating, cooling, carrying out three-segment far infrared rotary baking, and packaging. According to the invention, microwave heating for deactivation of enzymes for three times, dehydration and three-segment far infrared rotary baking and drying modes are adopted, the day lily is subjected to enzyme deactivation, dehydration and drying, and sterilization, and the prepared dried day lily can be directly eaten or can be eaten after rehydrated. The method provided by the invention is beneficial to preservation of the dried day lily, also keeps the color, fragrance, flavor and shape of the day lily well, and effectively solves the problem of nutritional ingredient loss in the processes of deactivating enzymes and drying. The dried day lily prepared by the method provided by the invention is straight and uniform in shape, is golden yellow and green in color, and can be preserved for 18 months with perfect packages under the normal temperature condition.

Owner:渠县琦鑫源花卉苗木开发有限公司

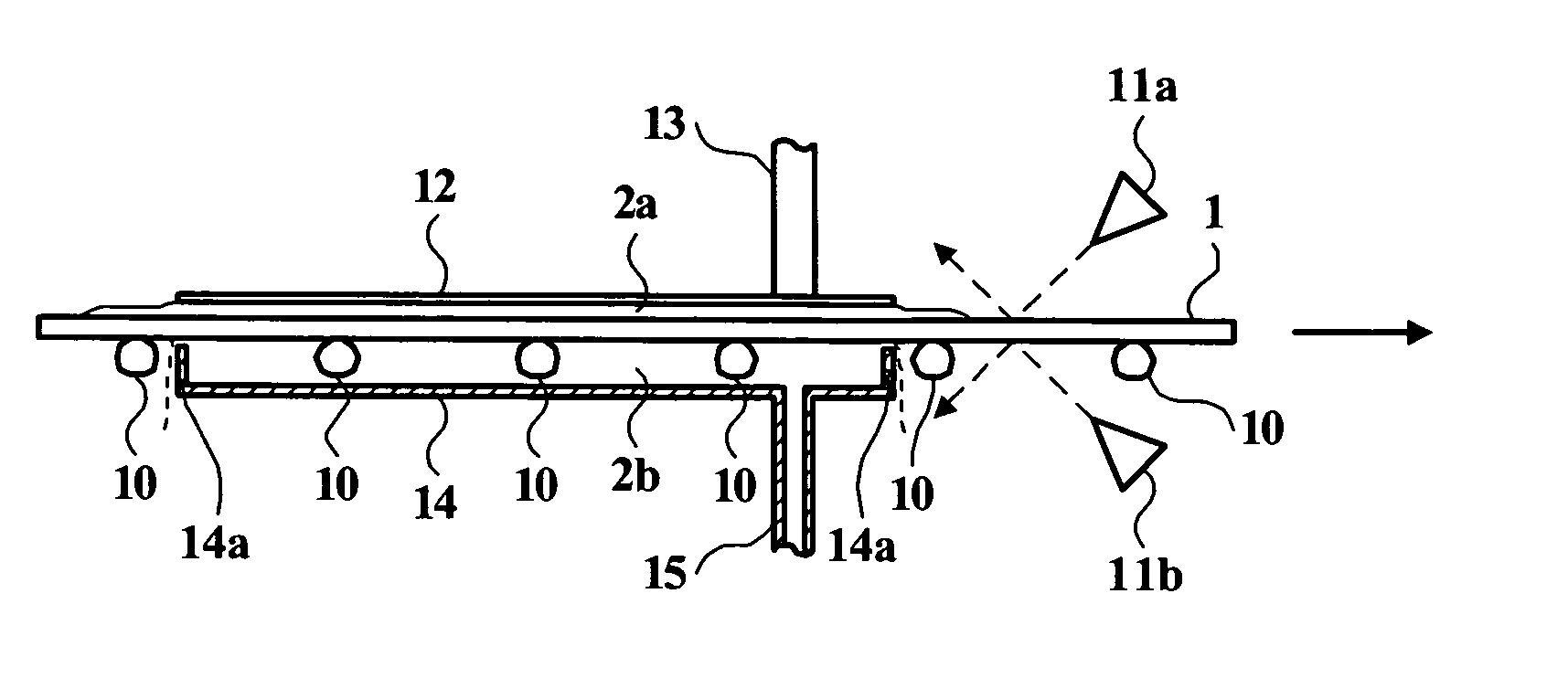

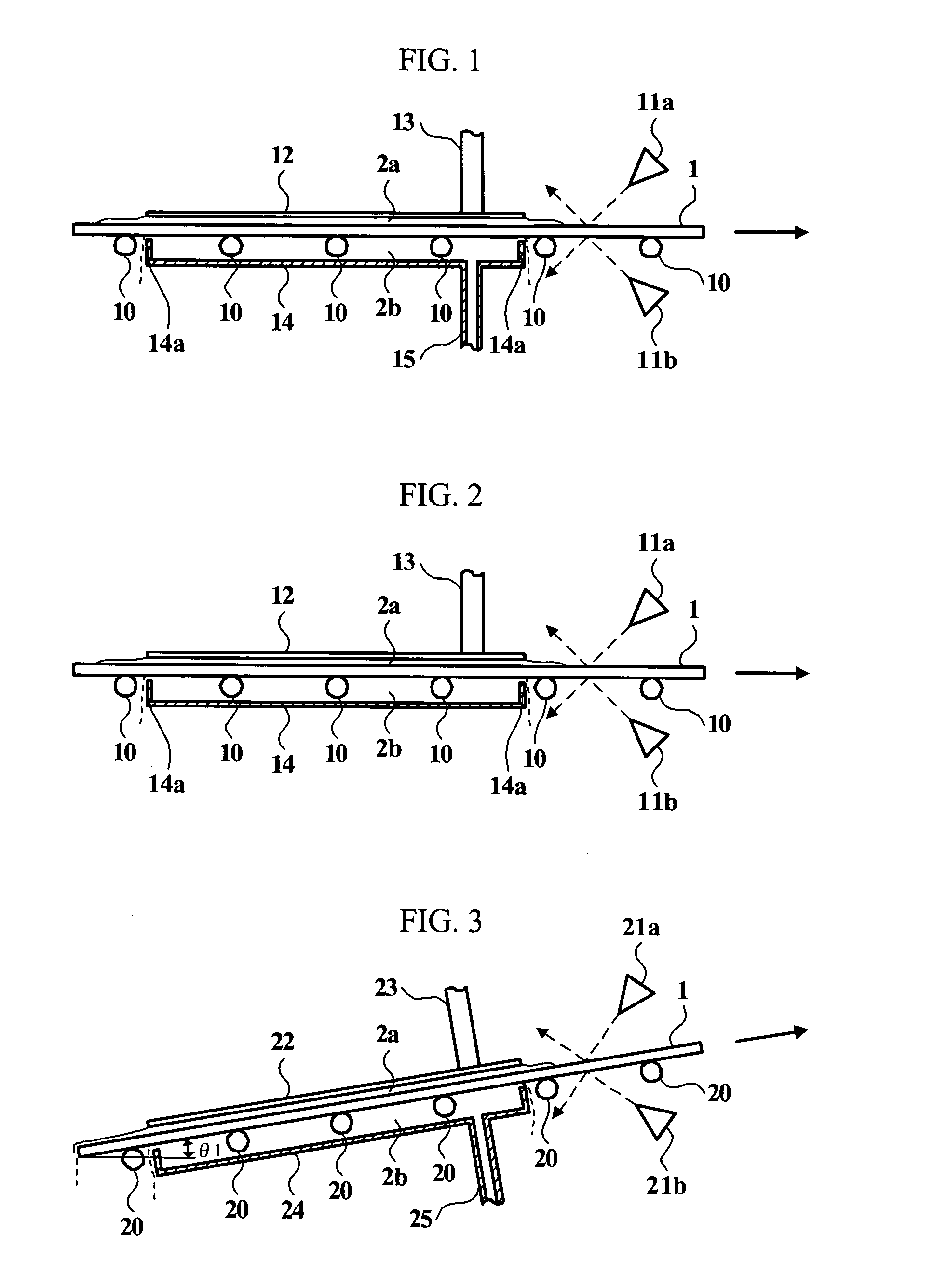

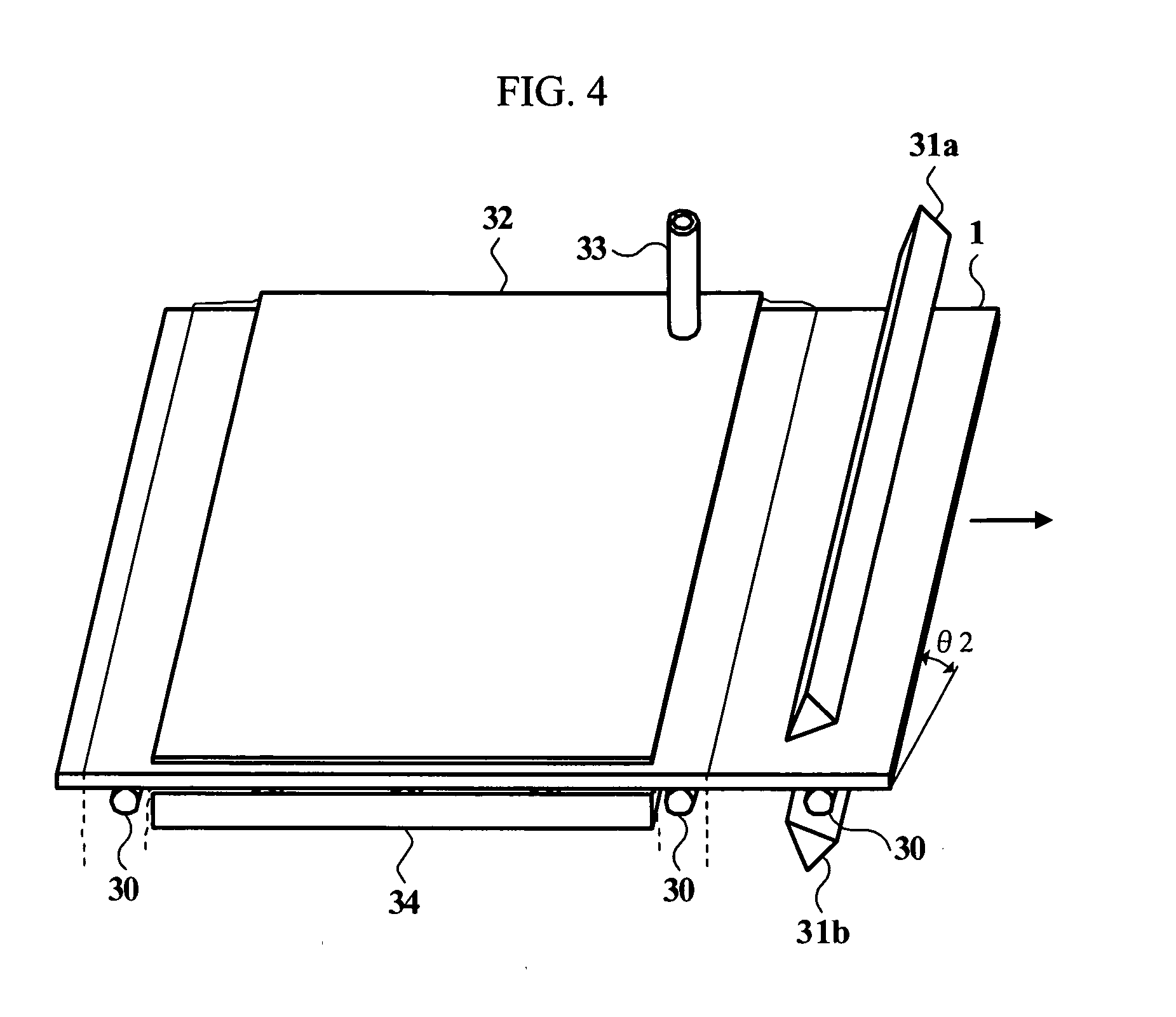

Substrate treatment apparatus, substrate treatment method and substrate manufacturing method

InactiveUS20050022930A1Improve washing effectReduce drying stainDrying solid materials without heatDrying gas arrangementsEngineeringAir knife

Above a substrate mounted on rollers, an upper board is prepared a predetermined distance apart from the substrate. A pipe fills a space between the upper board and the substrate with washing water by supplying the washing water at a predetermined flow rate. A washing water layer is formed evenly on an upper surface of the substrate when the substrate passes below the upper board. Below the substrate, a lower board is prepared a predetermined distance apart from the substrate. A pipe fills a space between the lower board and the substrate with the washing water by supplying the washing water at a predetermined flow rate. A washing water layer is formed evenly on a lower surface of the substrate when the substrate passes above the lower board. The air emitted from an air knife is sprayed to the upper / lower surface of the substrate slantingly at a predetermined incident angle in an opposite direction of a substrate moving direction. The washing water is pushed away and removed from the upper / lower surface of the substrate.

Owner:HITACHI HIGH-TECH ELECTRONICS ENGINEERING CO LTD

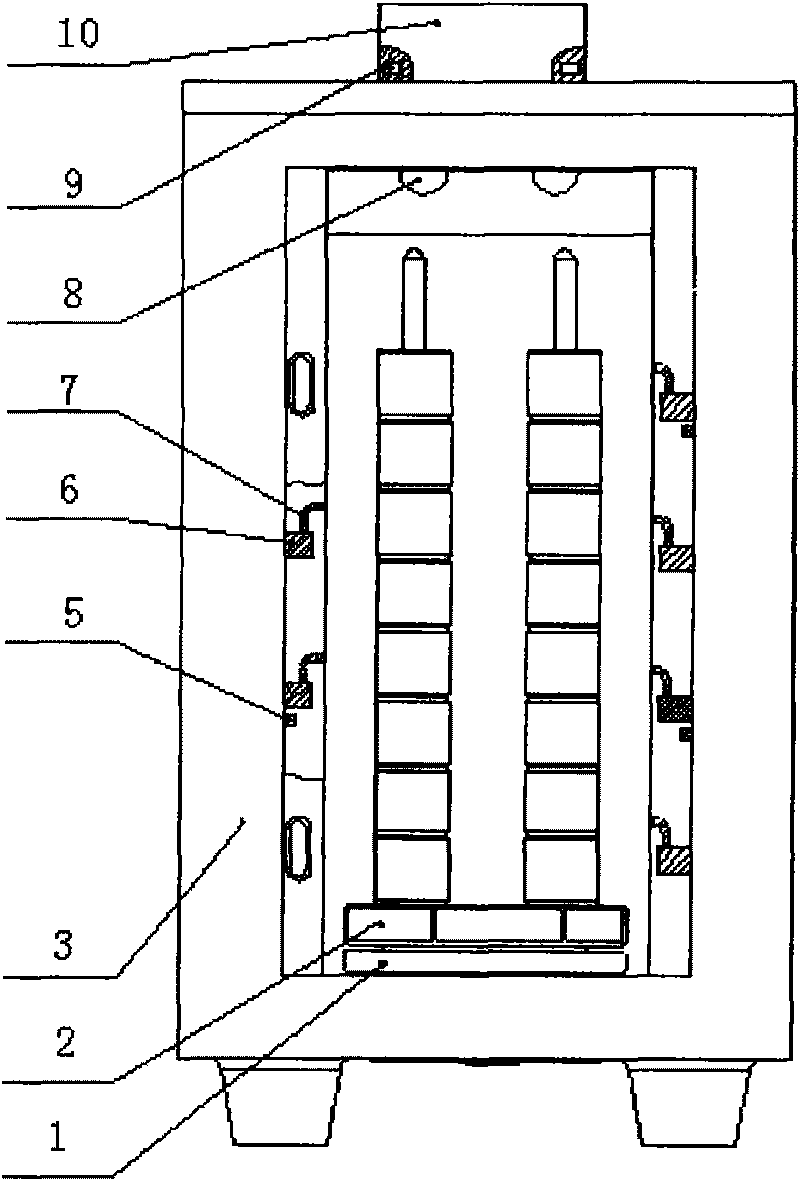

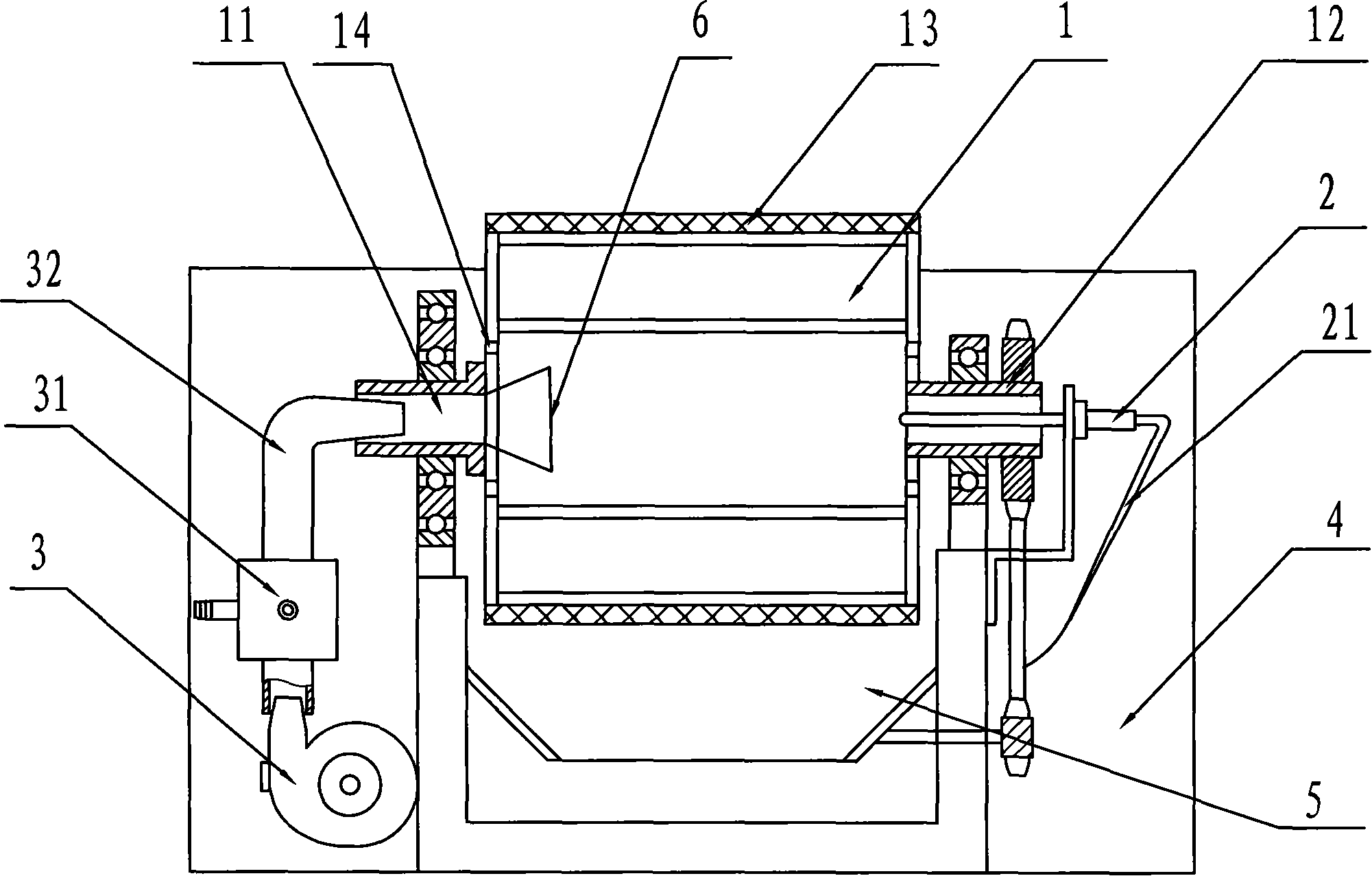

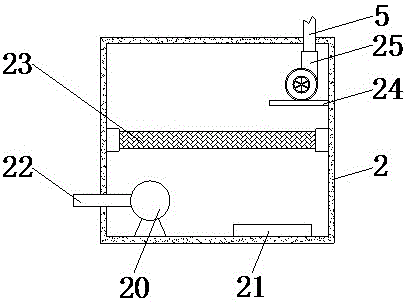

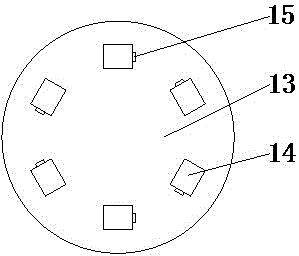

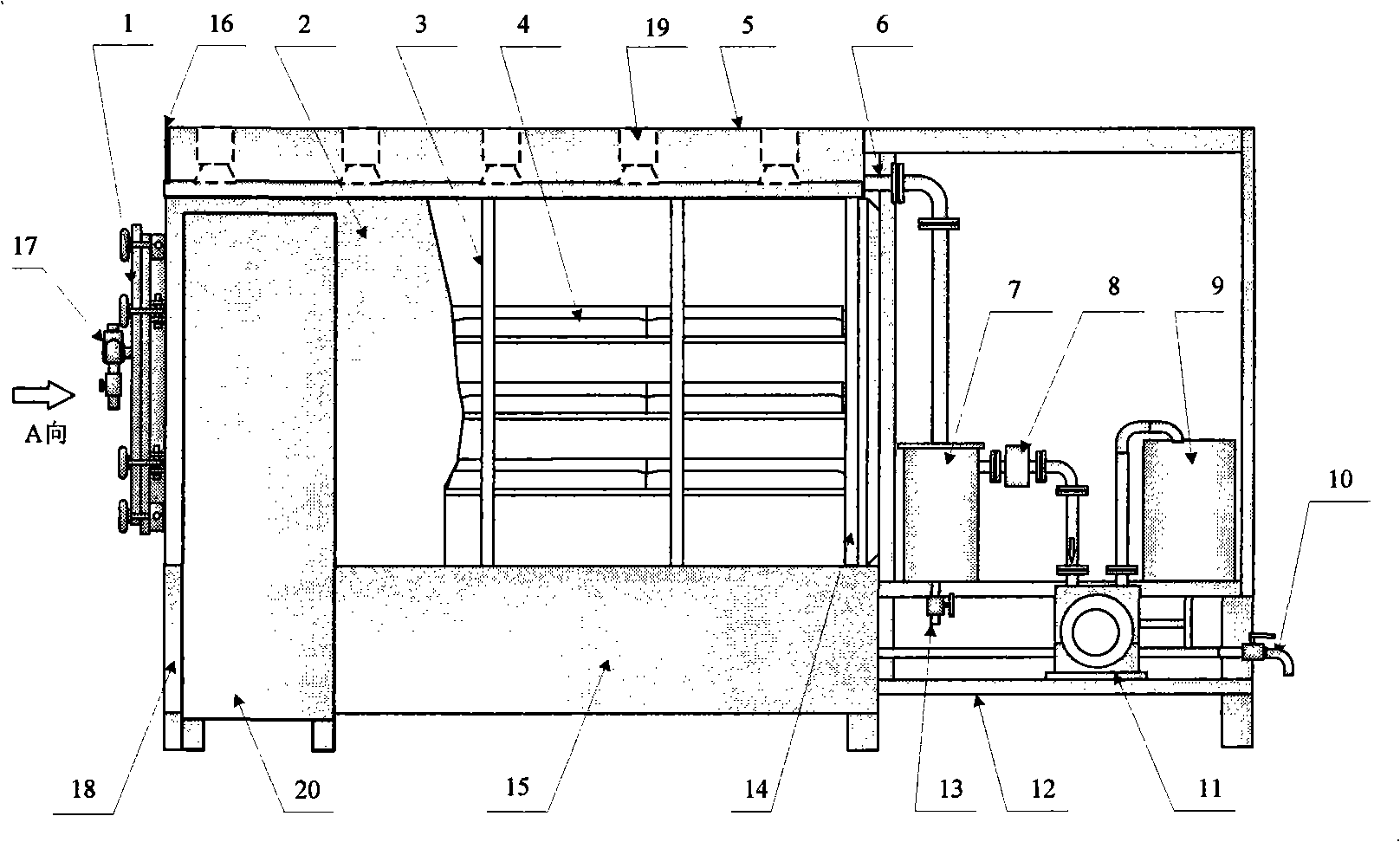

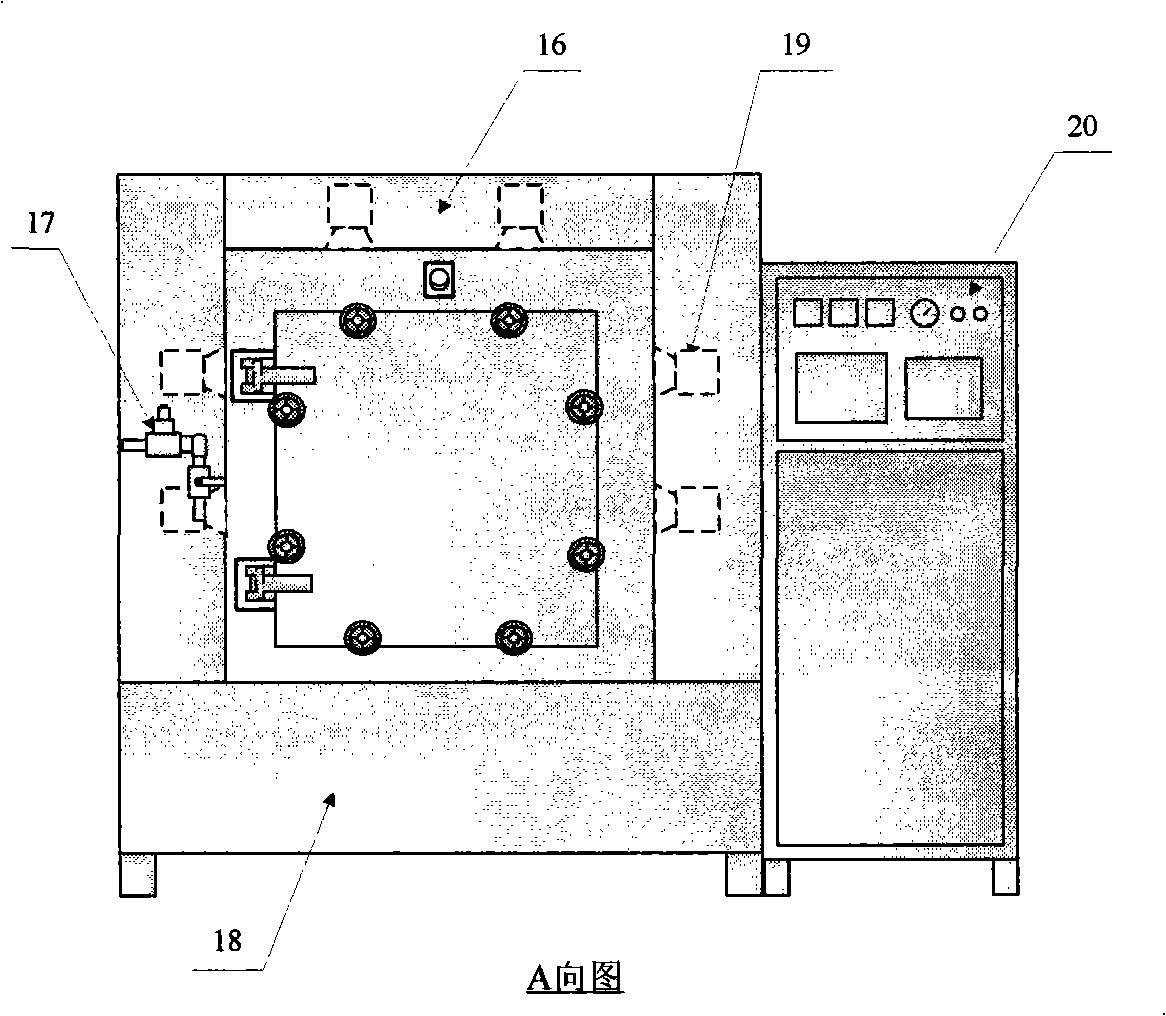

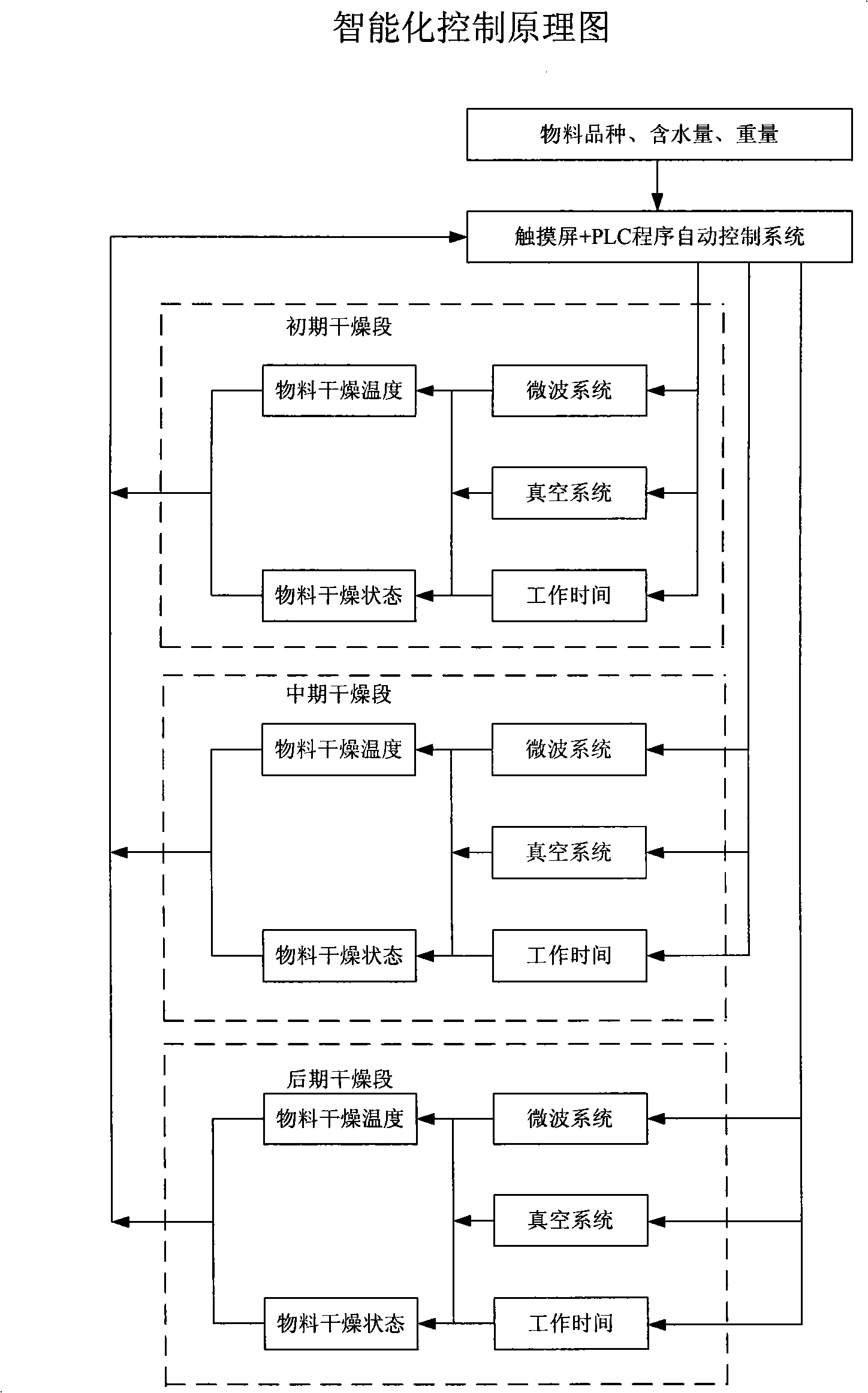

Intelligentized static microwave vacuum drying machine

InactiveCN101338968AReduce energy consumptionQuality improvementDrying using combination processesDrying solid materials with heatMicrowaveHigh energy

The invention provides an intelligent static microwave vacuum drier which is used for quickly drying plant extracts, foodstuff, subsidiary agricultural products, chemical products and so on under low temperature to get high quality dry products. In order to solve the defects of the prior art, namely, low dry quality, high energy dissipation, low output, long cycle, large investment, high cost, unstable operation of equipment and so on, the intelligent static microwave vacuum drier can dry materials quickly and uniformly at low temperature in static state. During the drying process, the power, the temperature and the time are intelligently and automatically controlled according to the varieties and the dryness of materials, thus getting high-quality dry materials with the moisture error less than positive or negative 2 percent. The equipment runs stably and dries uniformly; little energy is consumed; little money is invested on equipment without environmental pollution. By comparing the intelligent static microwave vacuum drier with the traditional electrothermal vacuum drying and electrothermal cabinet drying, the energy is saved by more than 90 percent; by comparing the intelligent static microwave vacuum drier with the spray drying, the energy is saved by more than 80 percent; by comparing the intelligent static microwave vacuum drier with the basket microwave vacuum drier, the energy is saved by more than 10 percent. The dry quality is better than the quality of other dry modes.

Owner:吴琦 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com