Heating and blowing device for large hot air drying room

A hot air drying and air supply device technology, which is applied in the direction of drying gas arrangement, lighting and heating equipment, drying, etc., can solve the adverse effects of drying quality and drying cost, affect the timely delivery of orders by enterprises, and affect the uniformity of wood drying and other problems, to achieve the effect of flexible drying operation, shortened drying cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

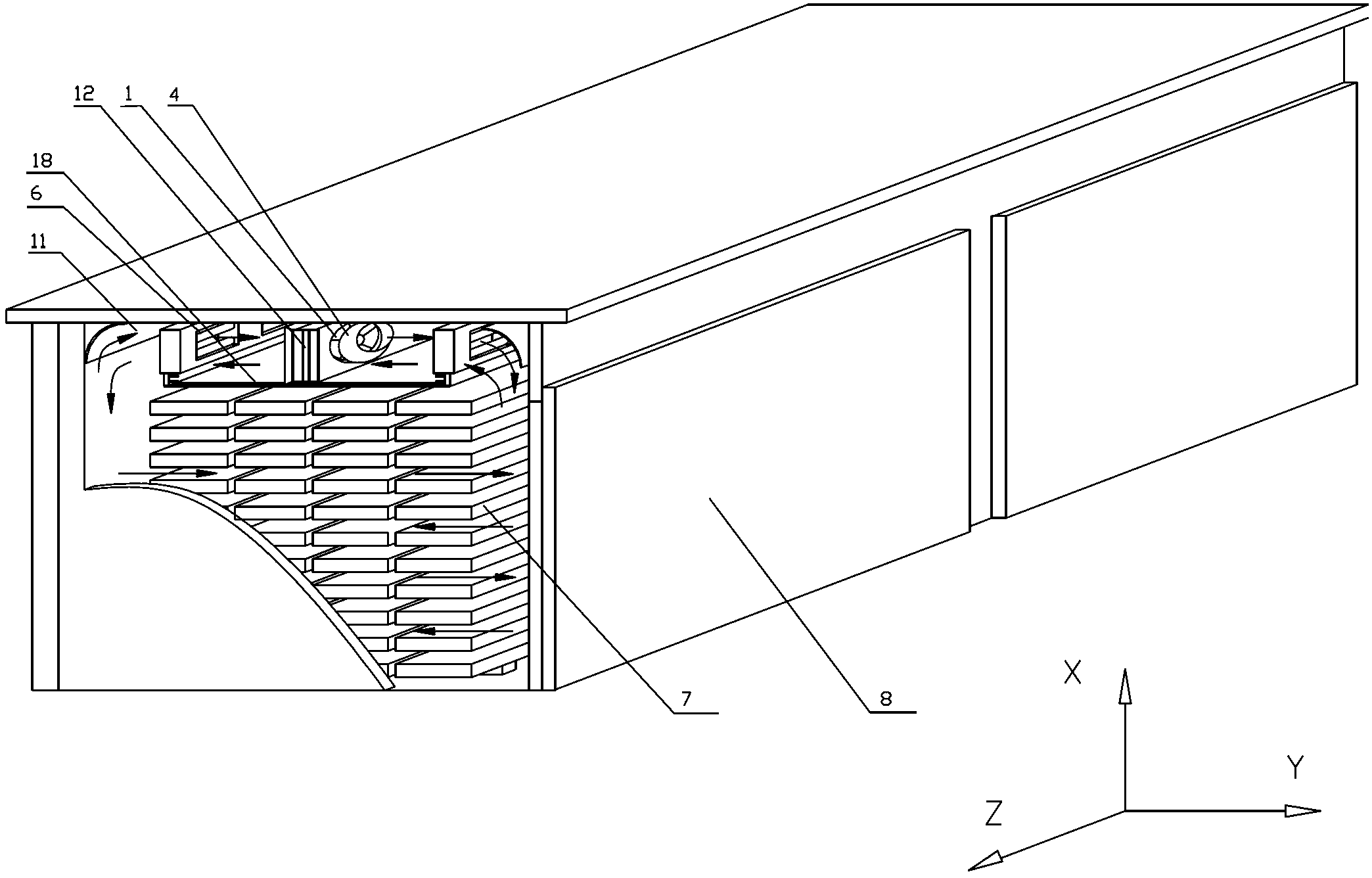

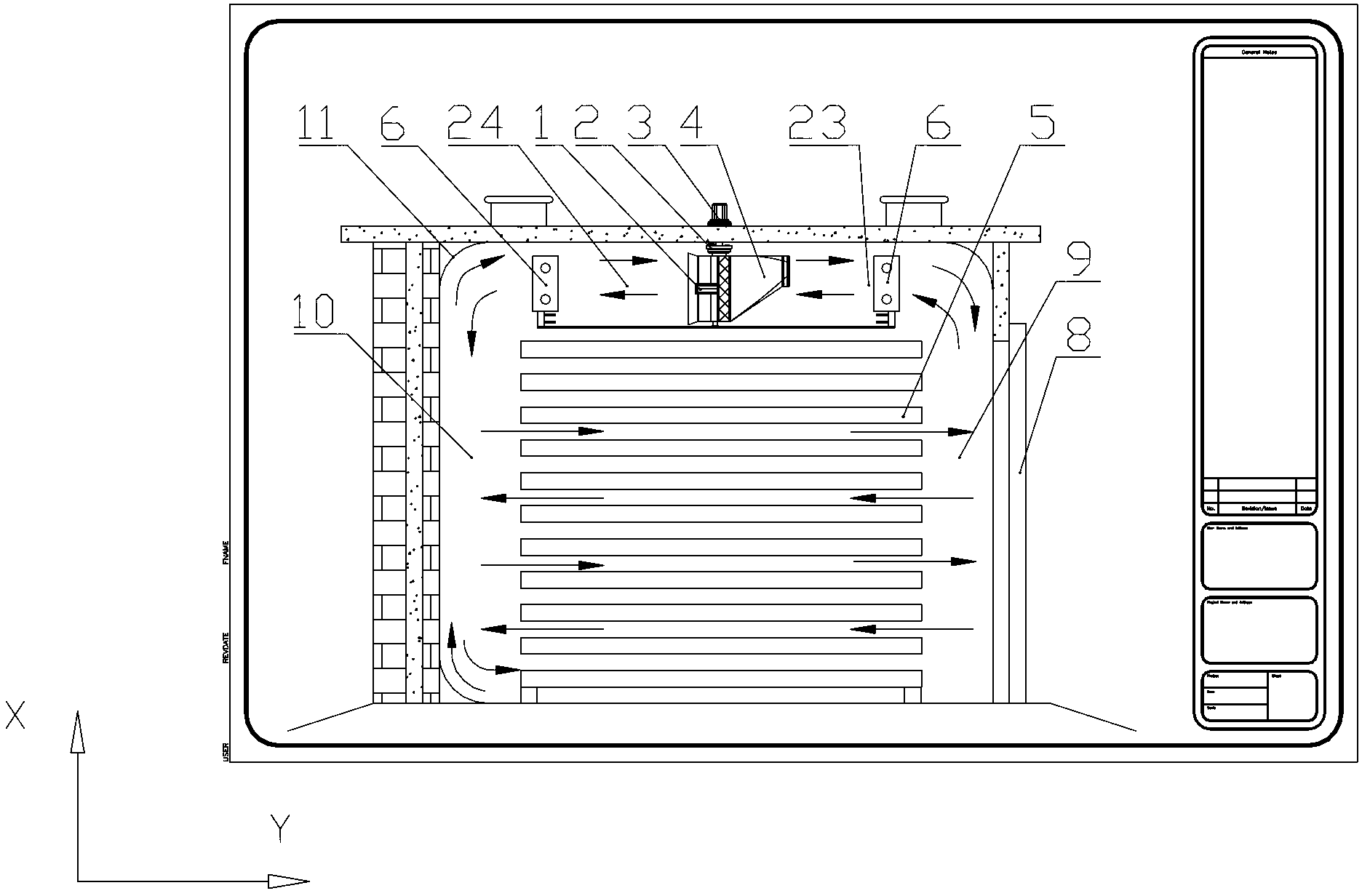

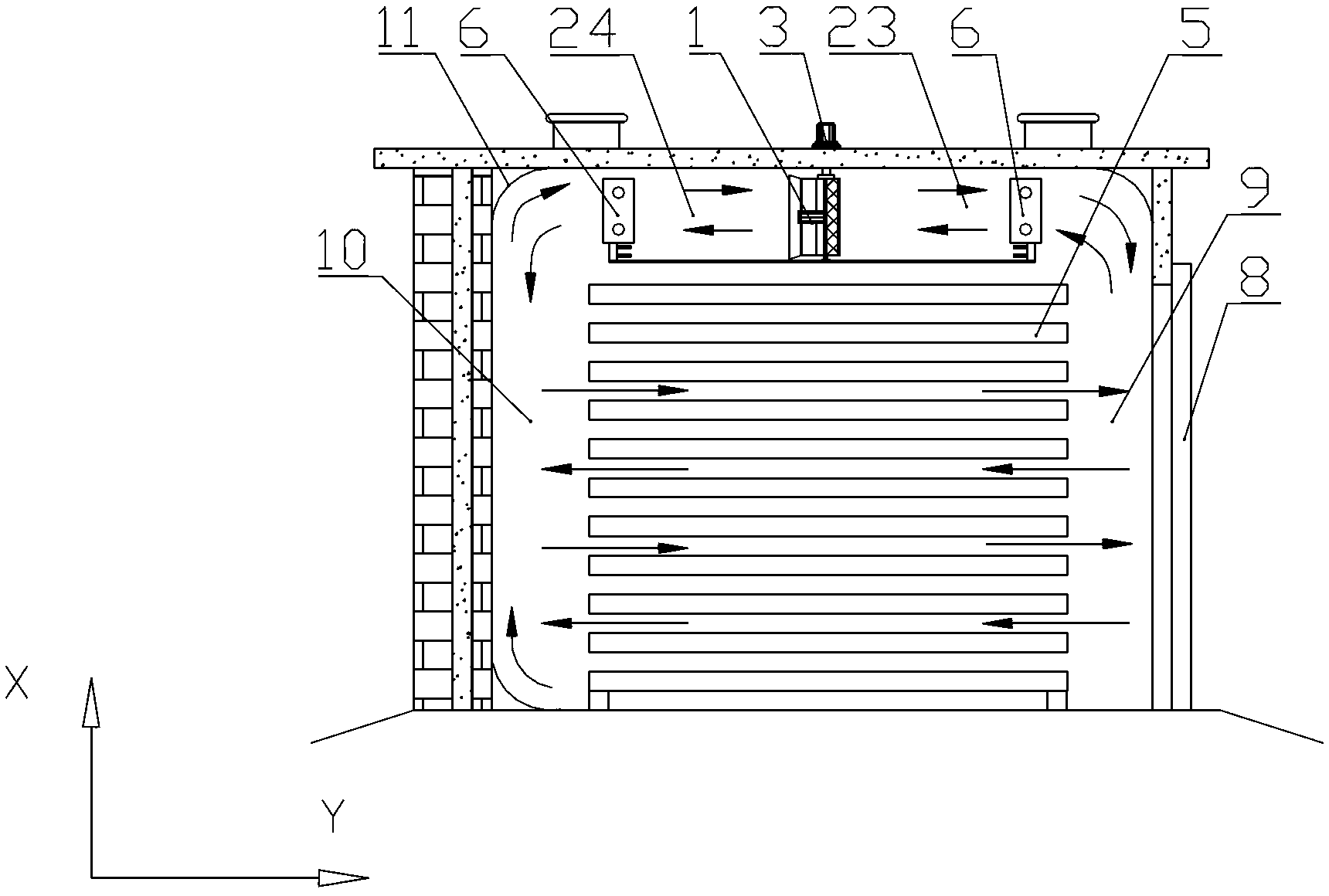

[0043] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0044] A heating and air supply device for a large-scale hot air drying room, set in the XYZ coordinate system, in the drying room where the length direction is Z, the height direction is X, and the width direction is Y, stack wood 7 from the ground up, the drying room The rectangular space at the top is equipped with a heating device.

[0045] In the rectangular fan support frame 12 parallel to the XZ plane, a number of fans 1 are arranged, and each fan 1 can rotate 180 degrees positively and negatively around the fan shaft 15 parallel to the X axis; Plate 13 blocks; each fan 1's own rotating shaft 15 is synchronously rotated horizontally through the upper synchronous rotary linkage mechanism 2; this technical solution, compared with the way of forward and reverse fan impellers, has obvious effects of improving air volume and wind intensity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com