Patents

Literature

581 results about "Wood drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as kiln-dried timber or lumber, whereas air drying is the more traditional method.

Wood rapid-drying method

InactiveCN1815115AFast dryingSave energyDrying solid materials with heatHearth type furnacesHeating timeTemperature gradient

Present invention refers to timber quick drying method. It contains 1, putting to be processed timber in timber drying chamber, heating from 30 degree centigrade to 70-98 degree centigrade within 4 to 10 hr and making timber drying vapour being saturated state, 2, keeping temperature for a period, holding time scaling up according to timber thickness, holding time hrs being equal to timber thickness cms, 3, fast reducing timber drying chamber temperature in a period according to timber thickness, 4, repeating step 1-3 by several time, wherein each time the timber heating time being 10-50 minutes, and removing filling saturated vapour process to reduce timber moisture content to demand value. Said invention has equal moisture content gradient and temperature gradient and saves energy source

Owner:张云辉

Wood drying method

InactiveCN101236048ADrying using combination processesDrying solid materials without heatPulp and paper industryEquilibrium moisture content

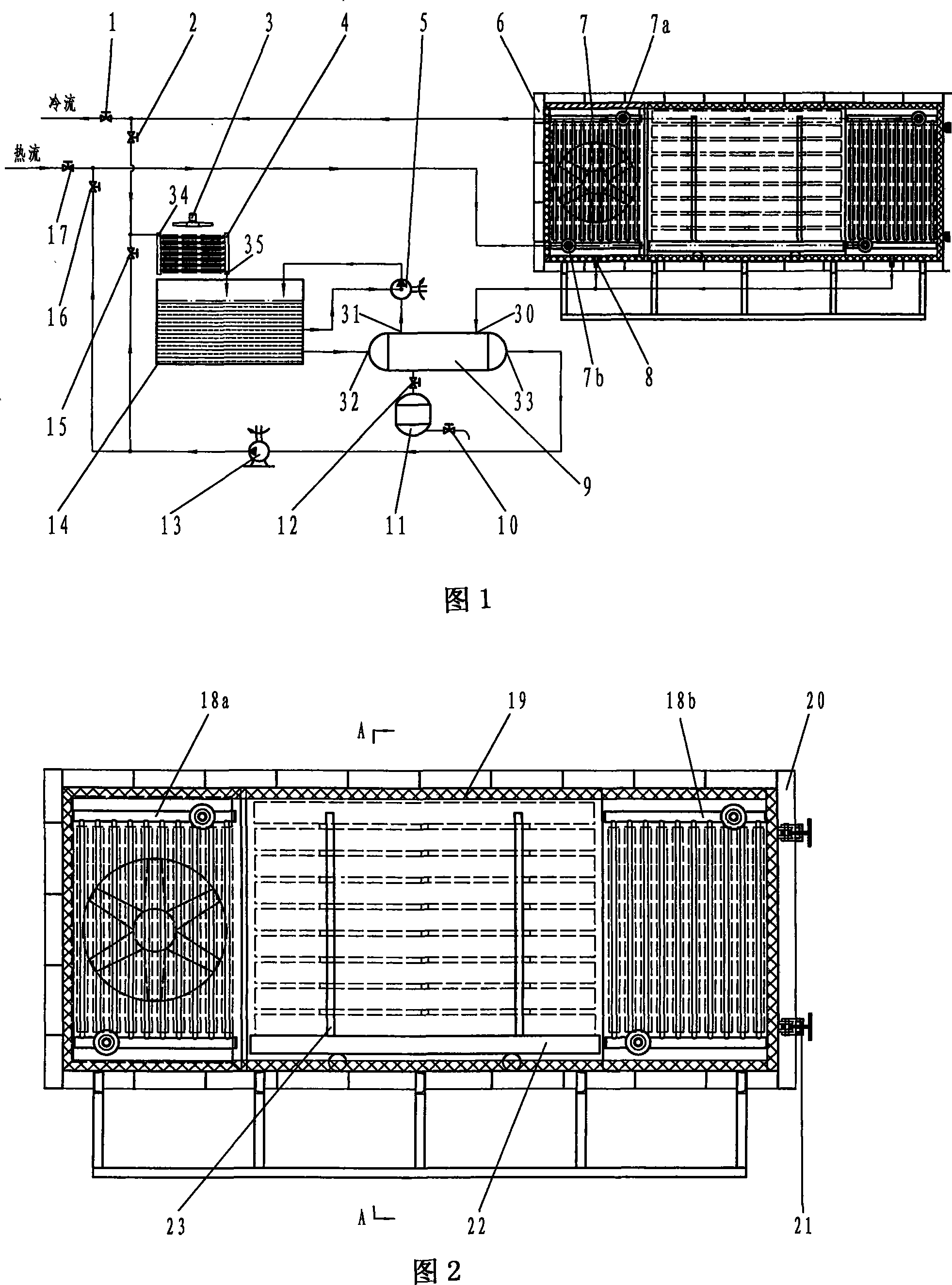

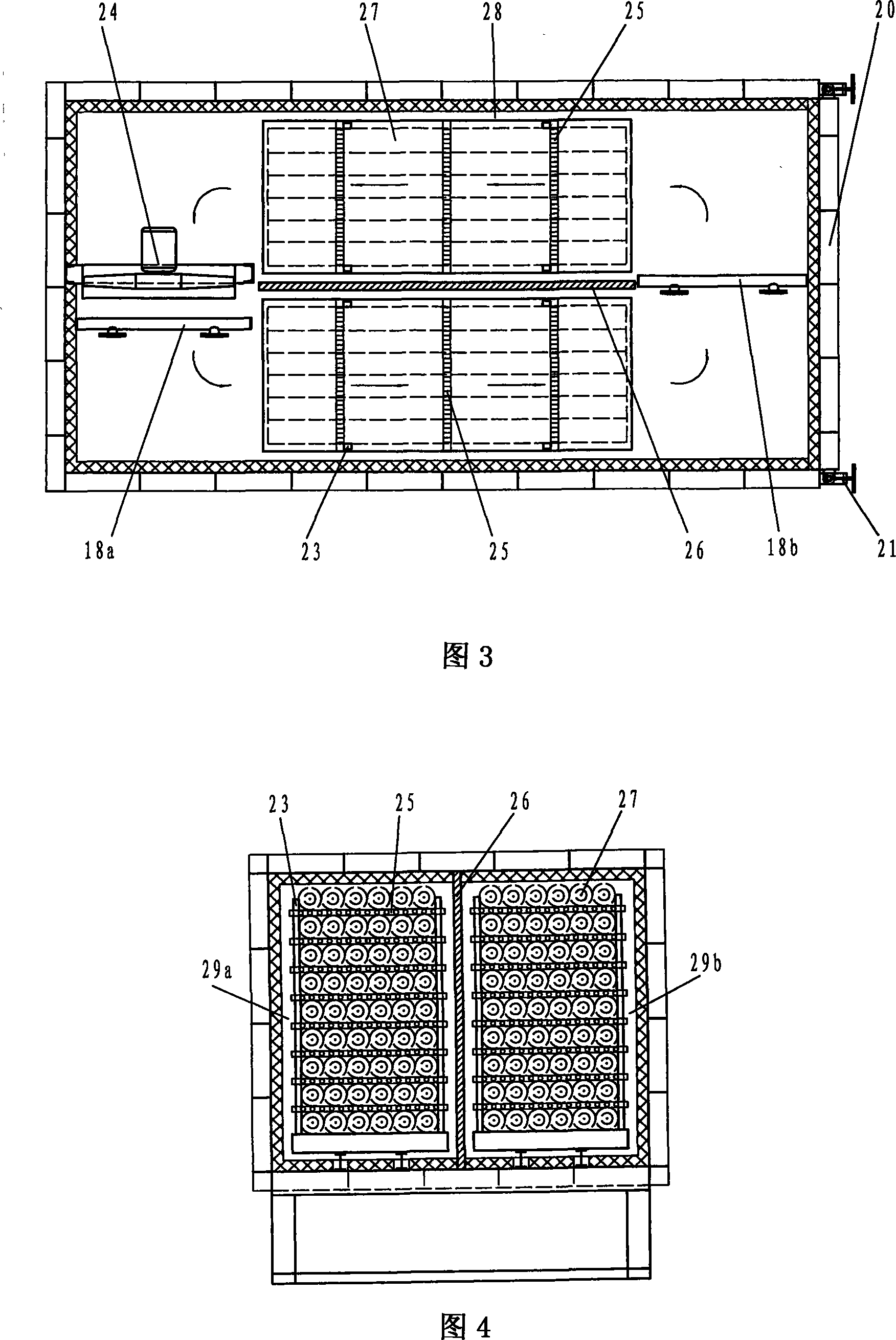

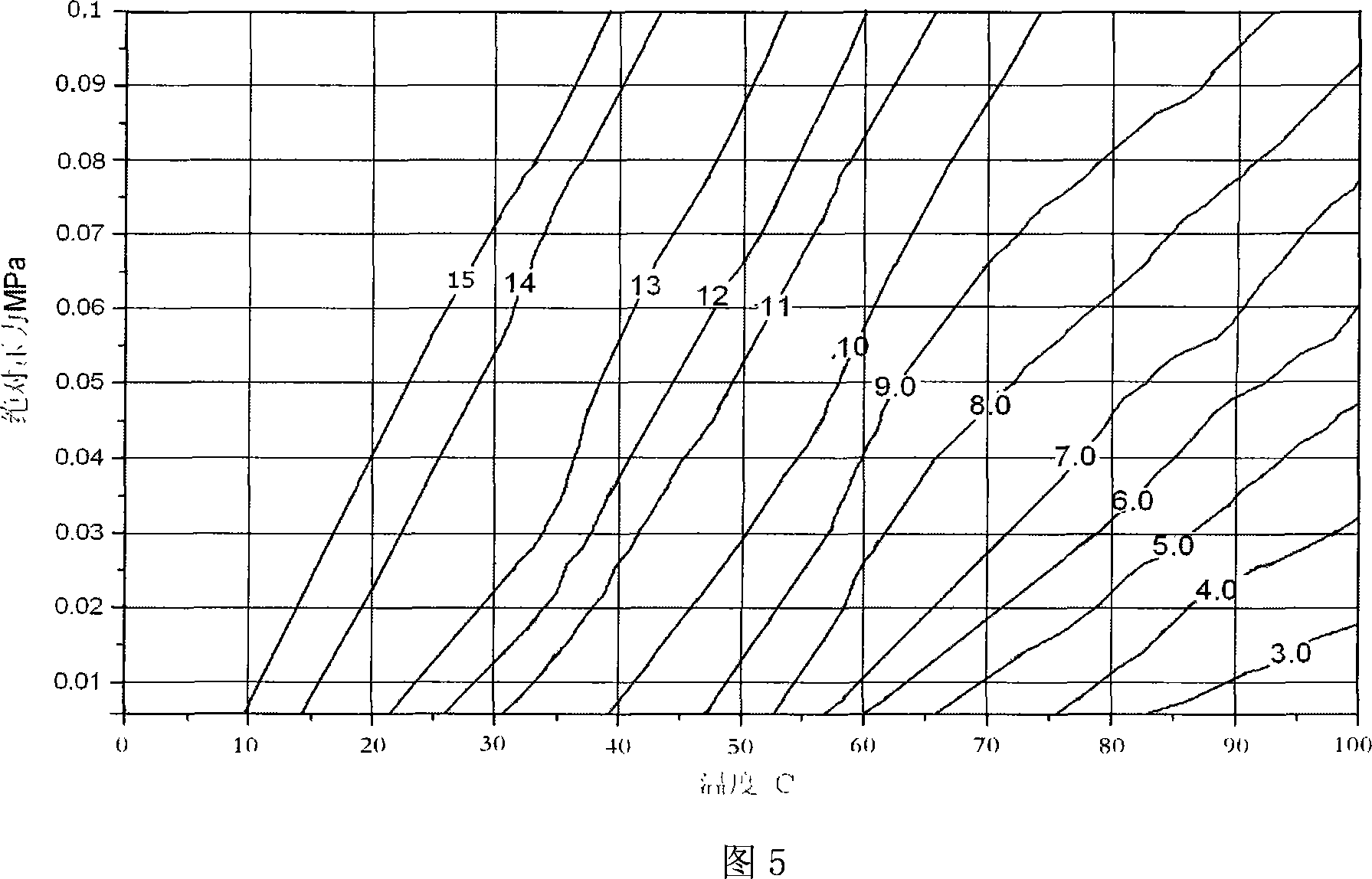

The invention discloses a method of log vacuum drying, which is adaptable to drying process of logs with minor diameter. The method comprises carrying out reheating to-be-dried wood, then keeping the reheating to-be-dried wood under vacuum circumstance, enabling drying media to flow along the longitudinal direction of the to-be-heated wood, controlling the temperature and value of absolute pressure according to corresponding graphs of previously determined medium temperature, the absolute pressure and equilibrium moisture content, charging cooling water in a heat exchange system when the final moisture content of the wood meeting the qualification and thereby realizing rapidly cooling and discharging, wherein the to-be-dried wood is log with minor diameter or plates and the ratio of the length of the to-be-dried wood and the average diameter or thickness is 5-15. The method of the invention enables the wood to be uniformly heated, and obviously shortens the time for the procedures of preheating the wood and drying, thereby largely increasing the production efficiency of drying the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY +1

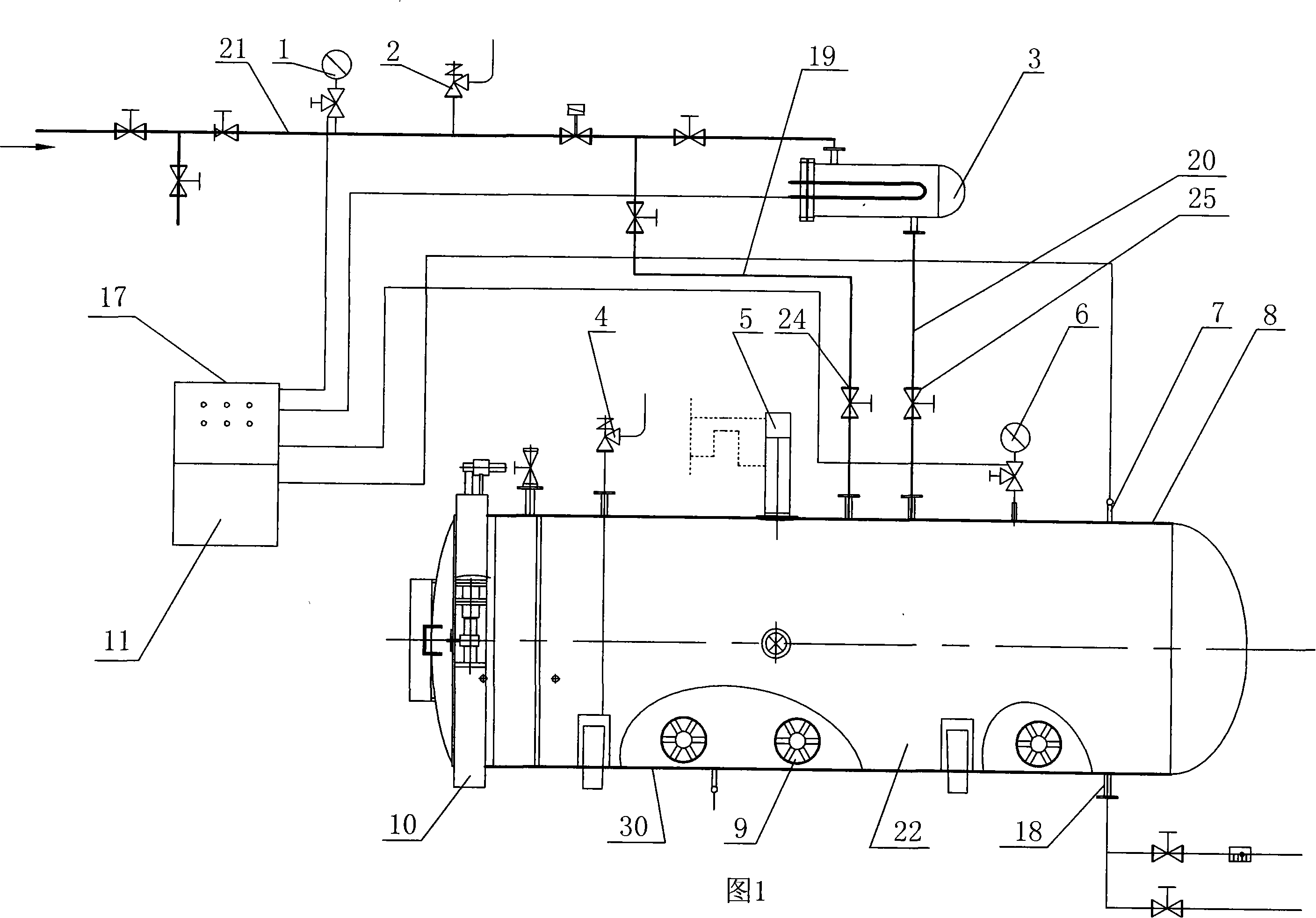

Method and system for drying wood

InactiveCN101561216ANo pollutionEfficient use ofDrying solid materials with heatDrying gas arrangementsControl systemProcess engineering

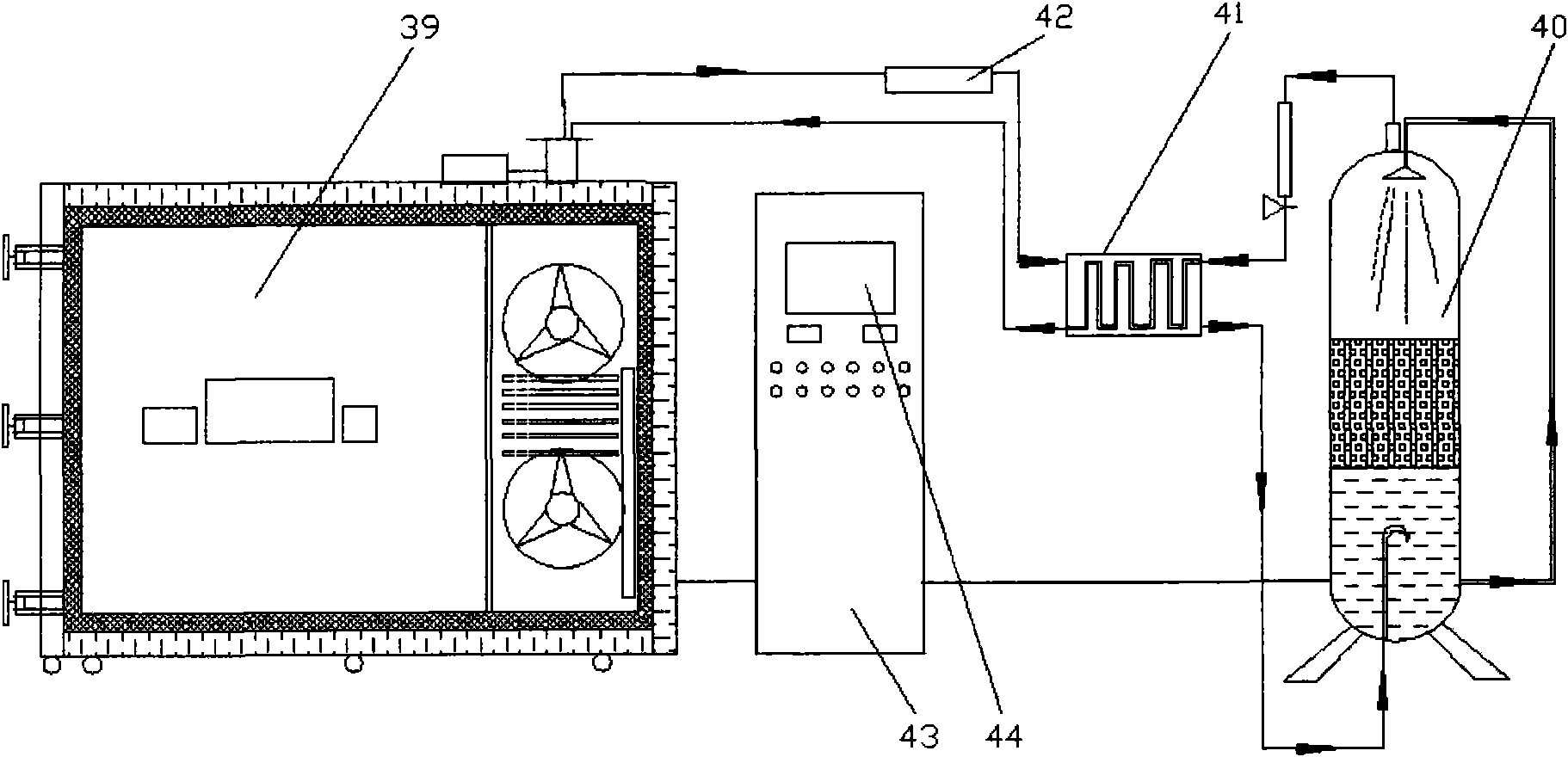

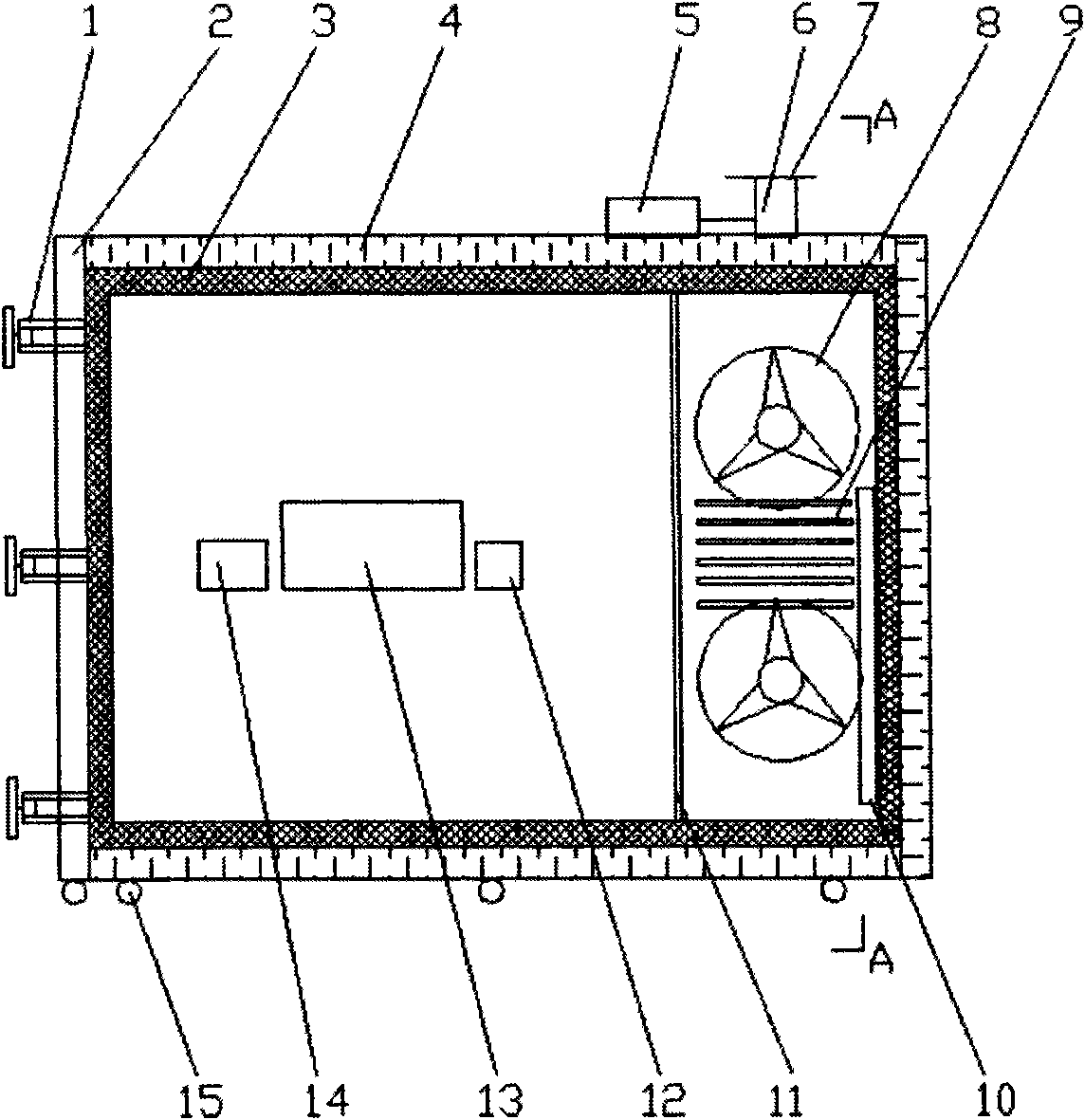

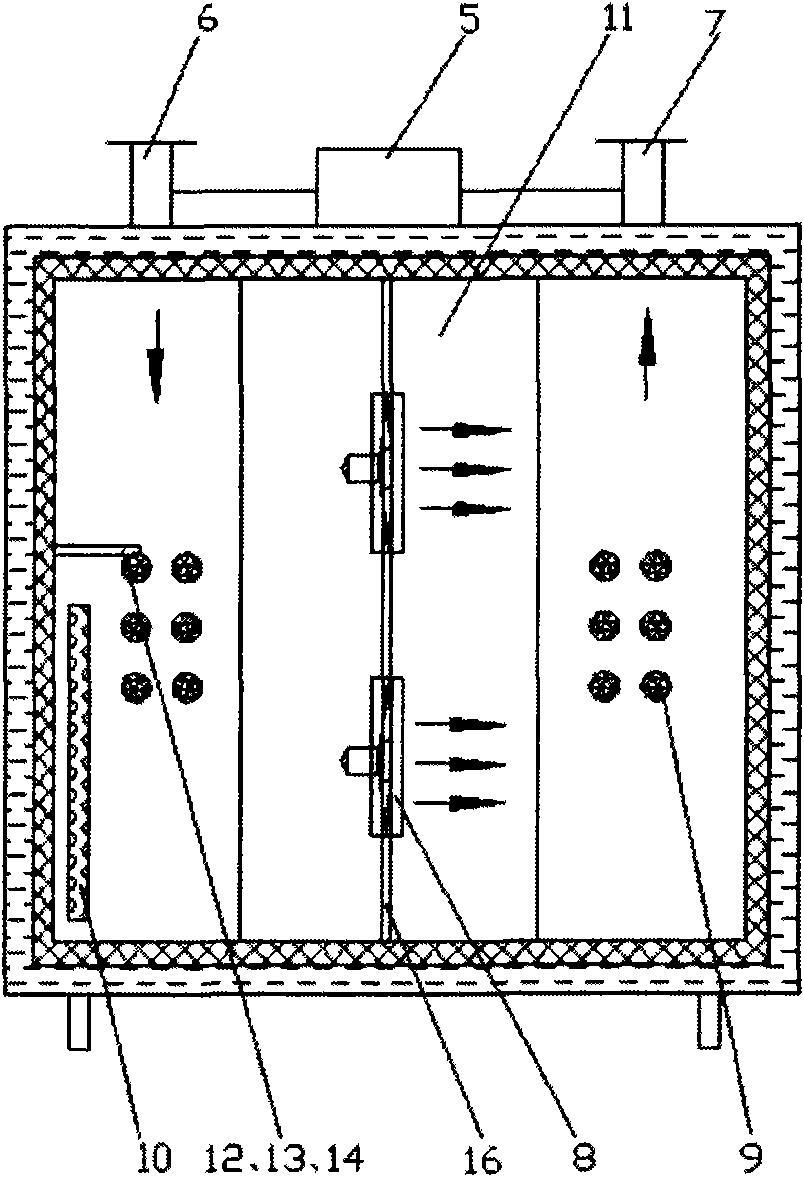

The invention discloses a system for drying wood, which comprises a drying kiln, a humidity generator, a heat energy recoverer, a filter and a control system, wherein the drying kiln is provided with a gas inlet and a gas outlet; high-temperature waste gas discharged out of the gas outlet of the drying kiln is filtered by the filter, then is input to the heat energy recoverer, and is discharged out after performing heat exchange with low temperature gas from the humidity generator in the heat energy recoverer, and the heated low temperature gas output by the heat energy recoverer is sent into the gas inlet of the drying kiln through a pipeline; and the control system controls the work of the drying kiln, and controls the humidity of the low temperature gas output by the humidity generator according to the temperature, the humidity and the moisture content of the wood to be controlled in the drying kiln so as to control the humidity of the gas input in the drying kiln. By setting the humidity generator and the heat energy recoverer, the system optimizes the drying quality of the wood and minimizes the energy consumption; and simultaneously, because the working gas is used circularly, the waste gas is prevented from being discharged to the atmosphere to pollute the environment.

Owner:周玉成

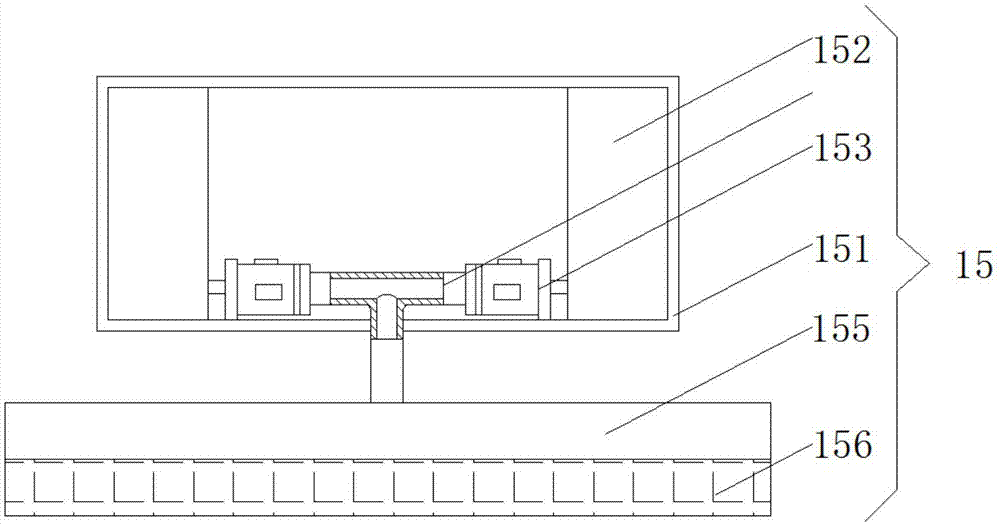

Bamboo wood toy paint spraying and drying device

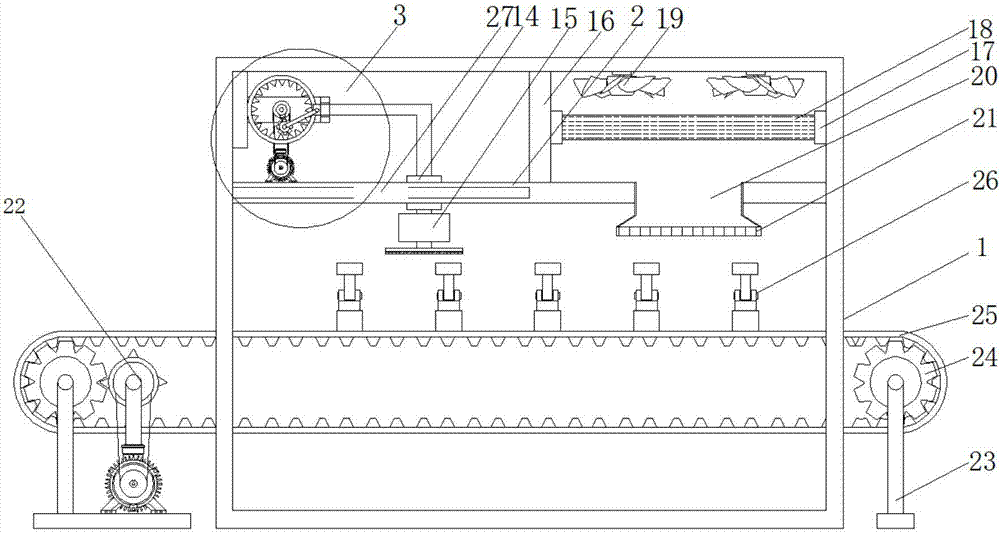

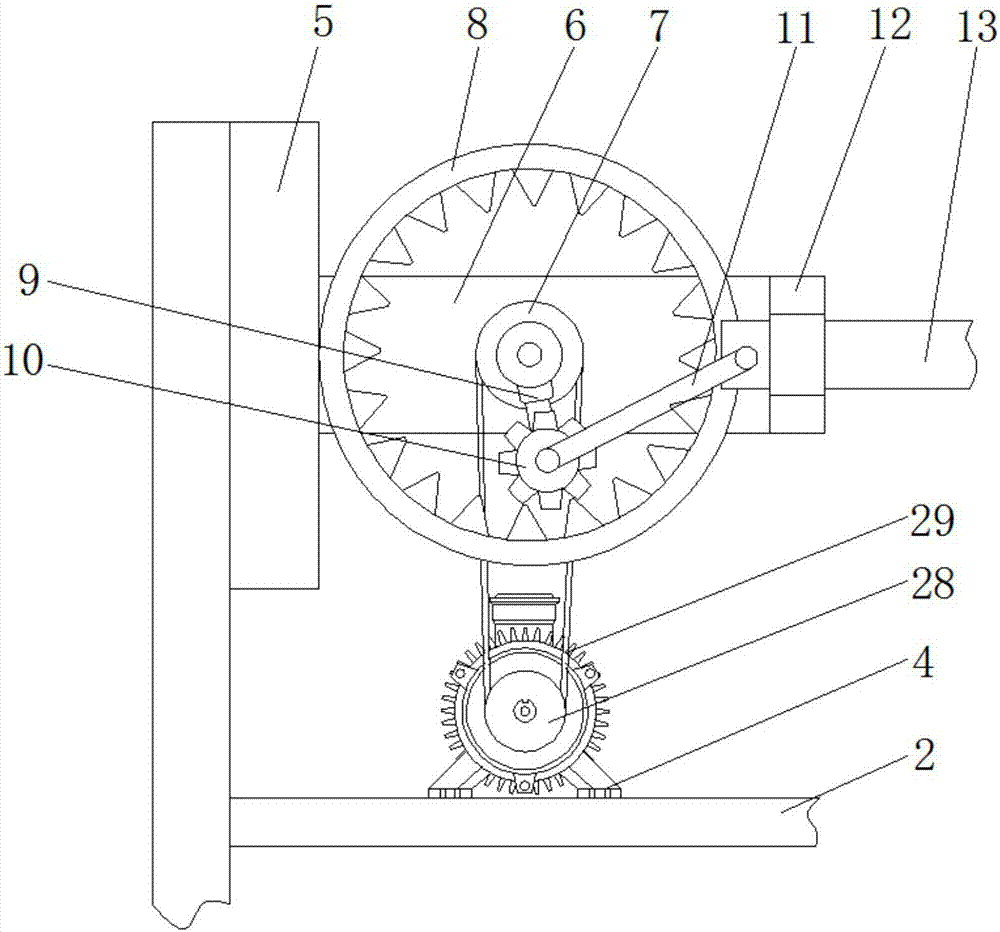

InactiveCN107309119ATo achieve the purpose of reciprocating movementAchieve the purpose of turningSpraying apparatusPretreated surfacesDrive wheelGear wheel

The invention discloses a paint spraying and drying device for bamboo and wood toys, which comprises an outer frame, a moving device is fixedly connected to the top of the support plate, an internal gear is fixedly connected to the right side of the vertical plate, and the concentric gear of the second driven wheel The pinion is rotatably connected to the shaft through the rotating shaft connecting rod, and the pinion is meshed and connected to the internal gear. The pinion is rotatably connected to a transmission link, and the transmission link is rotatably connected to a push rod. The bottom end is fixedly connected with a spraying device, and the left side outside the outer frame is provided with an output end of a transmission device, and the surface of the straight-toothed conveyor belt is fixedly connected with a bamboo and wood toy clamping device. The present invention relates to the technical field of bamboo and wood toy processing machinery . The paint spraying and drying device for bamboo and wood toys solves the problems that the existing bamboo and wood toy spray paint causes harm to the workers' bodies, and the spraying and drying are not comprehensive and the efficiency is low. s damage.

Owner:安吉县怡成竹木工艺品厂

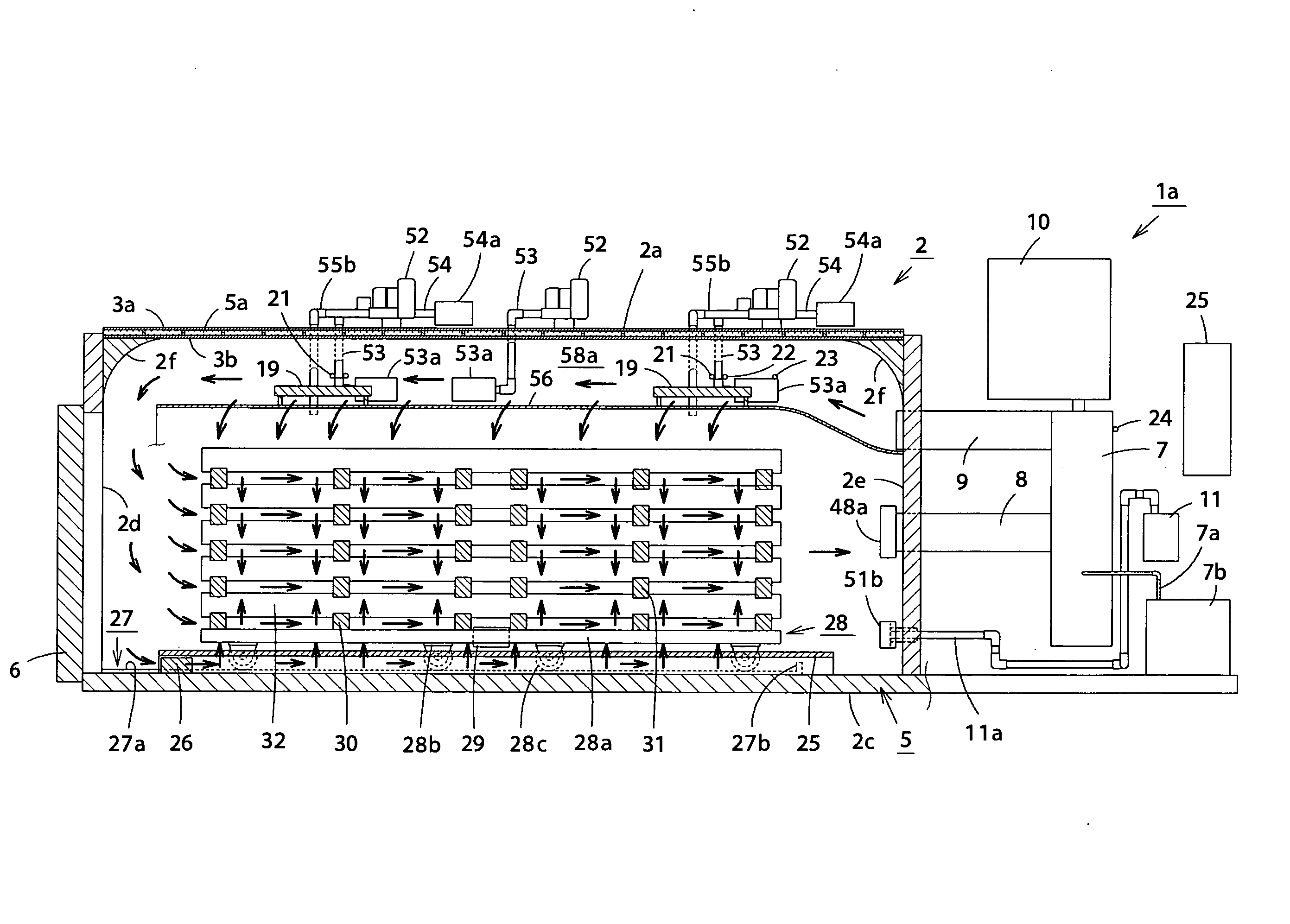

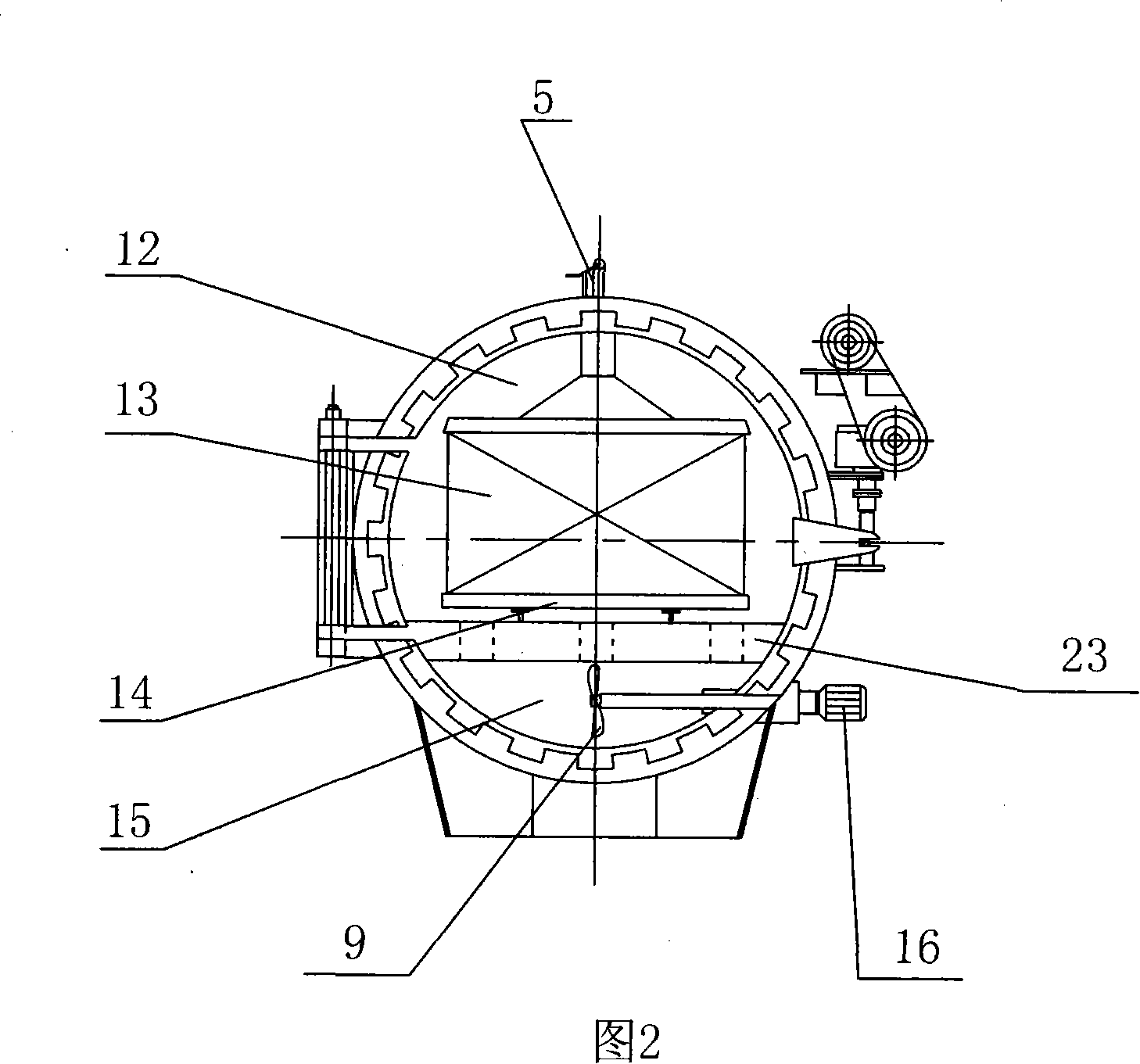

Depressurization Type Drying Machine and Method for Drying Lumber Using the Same

InactiveUS20080066340A1Improve efficiencyImprove reliabilityDrying using combination processesDrying solid materials with heatProduction rateEngineering

The present invention provides a depressurization type drying machine that is capable of repeatedly reducing the pressure, heating and humidifying during drying, uniformly drying a material to be dried, in a short time by applying vibrations to the material to be dried when reducing the pressure, and reducing consumption power without damaging the material to be dried, is excellent in reliability, productivity and energy-saving properties, brings about almost no flaws such as warping, internal cracking, breaking, shrinkage, bending, and surface cracking, especially when drying lumber, is also capable of leaving gloss on the surface of lumber after drying and scent without any discoloring, has high commercial value since the humidity in a building may be permanently controlled in response to the environment after being constructed, and is capable of extracting moisture contained in a material to be dried such as lumber without any waste and effectively utilizing the same as by-products. At least the ceiling portion and sidewall portions are formed roughly like a circular arc swelled outwardly, and reinforcement ribs are provided, which are disposed along the outer circumference of the inner wall parallel to and / or in orthogonal to the lengthwise direction of the drying chamber between the respective outer walls and inner walls of the ceiling portion, the sidewall portions and the floor portion.

Owner:KAKUNO SEISAKUSHO

Fire retardant treatment process for wood

InactiveCN102615684AAvoid churnCurb churnPressure impregnationWood impregnation detailsFire - disastersEngineering

A fire retardant treatment process for wood comprises the following steps: firstly, preparing a fire retardant solution 1 and a fire retardant solution 2; then putting the wood into an immersion tank; then vacuumizing the immersion tank to form negative pressure in the immersion tank; then using the negative pressure in the immersion tank to pump the fire retardant solution 1 into the immersion tank; then pressurizing the immersion tank to ensure that the fire retardant solution 1 is immersed into the wood as deep as possible; then discharging redundant fire retardant solution 1 into a fire retardant solution 1 storage tank; after that, vacuumizing the immersion tank to form negative pressure; then using the negative pressure in the immersion tank to pump the fire retardant solution 2 into the tank; then pressurizing the immersion tank to ensure that the fire retardant solution 2 is immersed into the wood as deep as possible; then discharging the redundant fire retardant solution 2 into a fire retardant 2 storage tank; then taking out the well immersed wood; and finally, drying the wood to complete the fire retardant treatment for the wood. According to the fire retardant treatment process for wood, the fire retardant efficiency is high, the fire retardant solution in the wood can be effectively prevented from losing, the smoke and poison gas in the wood can be inhibited from releasing in a fire disaster, and the fire retardant treatment cost for the wood is low.

Owner:GUANGDONG YIHUA TIMBER IND

Eucalypt artificial wood drying method

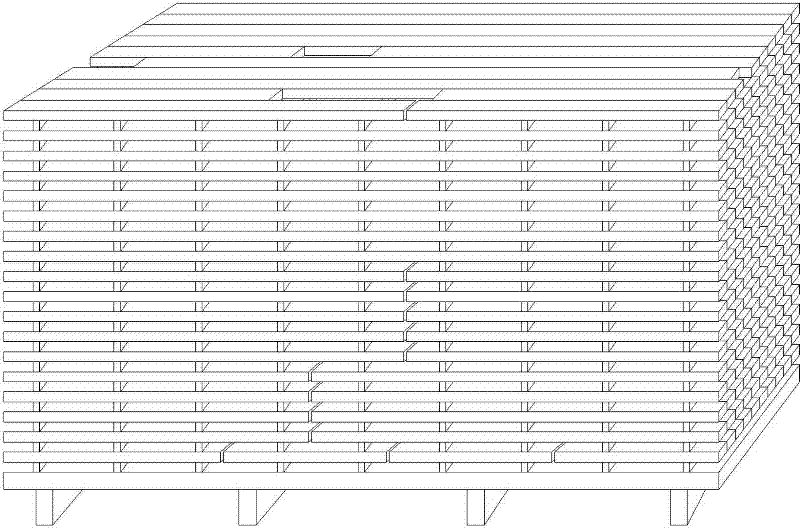

The invention belongs to a timber drying method for eucalyptus planted forests. The method comprises the following steps: selecting materials; measuring initial moisture content, in which, sawtimbers are detected to obtain moisture contents and the sawtimbers of different moisture contents are respectively dried; stacking, in which, reasonable circulation of airflow inside a kiln is ensured and the capacity of the kiln is fully utilized to prevent timber warping and end checking; placing a moisture content check plate inside the kiln, in which, the moisture content check plate of dried timber inside the same kiln is determined according to requirements to check the moisture content of the check plate; and controlling the temperature and humidity inside the kiln according to the drying standards of different eucalyptus species. The timber drying method has the advantages of preventing eucalypti from crimpling in the process of drying and ensuring drying quality of eucalypti.

Owner:国际竹藤网络中心

Processing equipment and processing method for improving wood breathability

InactiveCN103112069AAccurate temperature measurementUniform treatmentWood treatment detailsPulp and paper industryPre treatment

The invention discloses pre-processing equipment and a processing method for improving wood breathability. The device comprises a wood processing chamber in which a hollow cavity is arranged, an ultrasonic processing device, a wood holding assembly used for holding the wood to be processed, and a detecting device used for detecting the wood temperature, and the ultrasonic processing device is used for performing ultrasonic processing on the wood to be processed, wherein the wood to be processed is stacked on the wood holding assembly. The method disclosed by the invention is used for performing ultrasonic processing on the wood under a vacuum state so as to improve the wood breathability, get through the moisture passages in the wood to guarantee the smoothness of the passages when the moisture in the wood volatilizes during the drying process, improve the drying quality of the wood, reduce the drying defects during the drying process and shorten the drying period, and furthermore, the pre-processing equipment is simple, the operation is convenient, the processing technique conditions (pressure, ultrasonic power and frequency) are controllable, so that the equipment and the method are suitable for processing various types of wood.

Owner:BEIJING FORESTRY UNIVERSITY

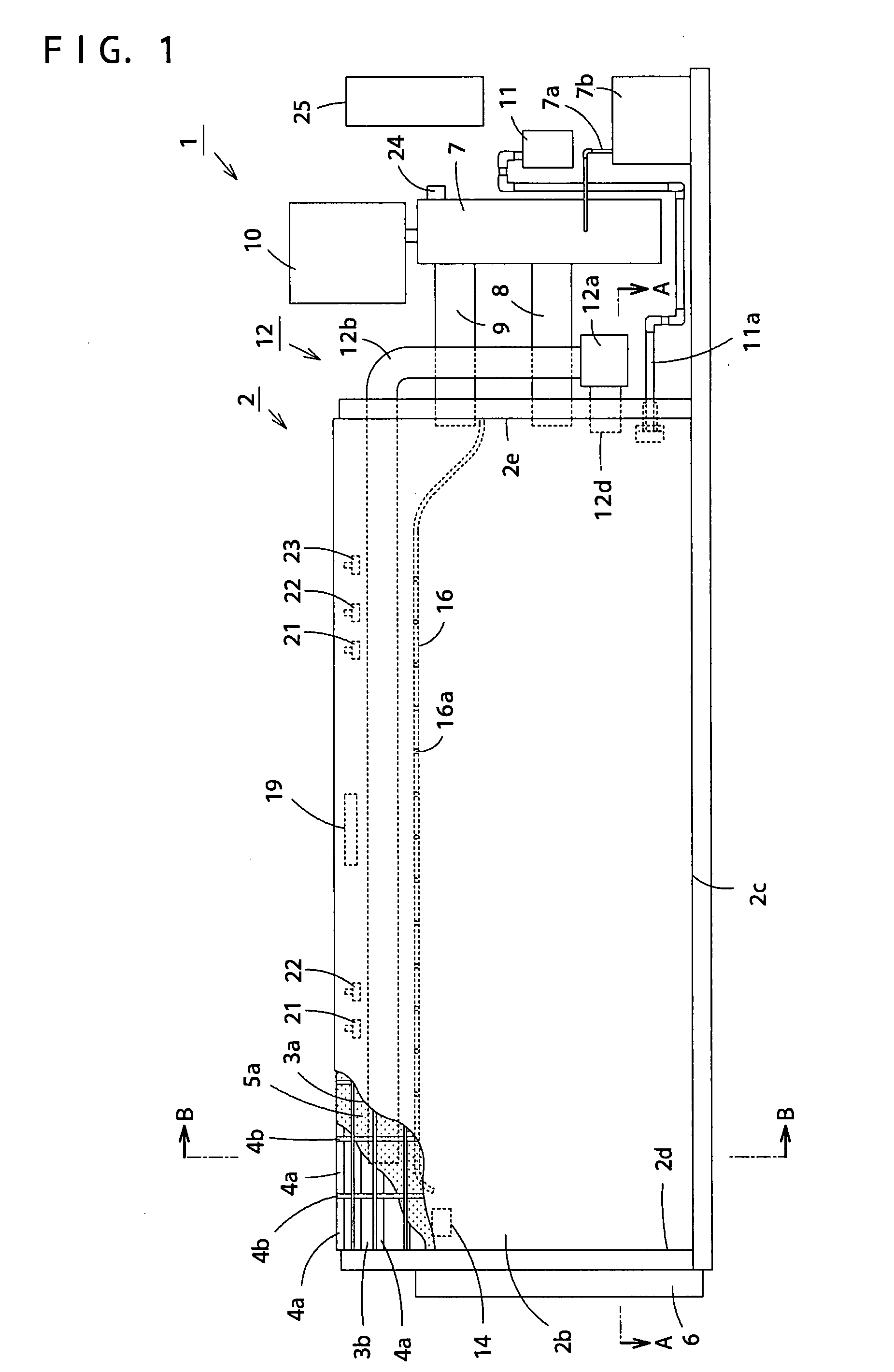

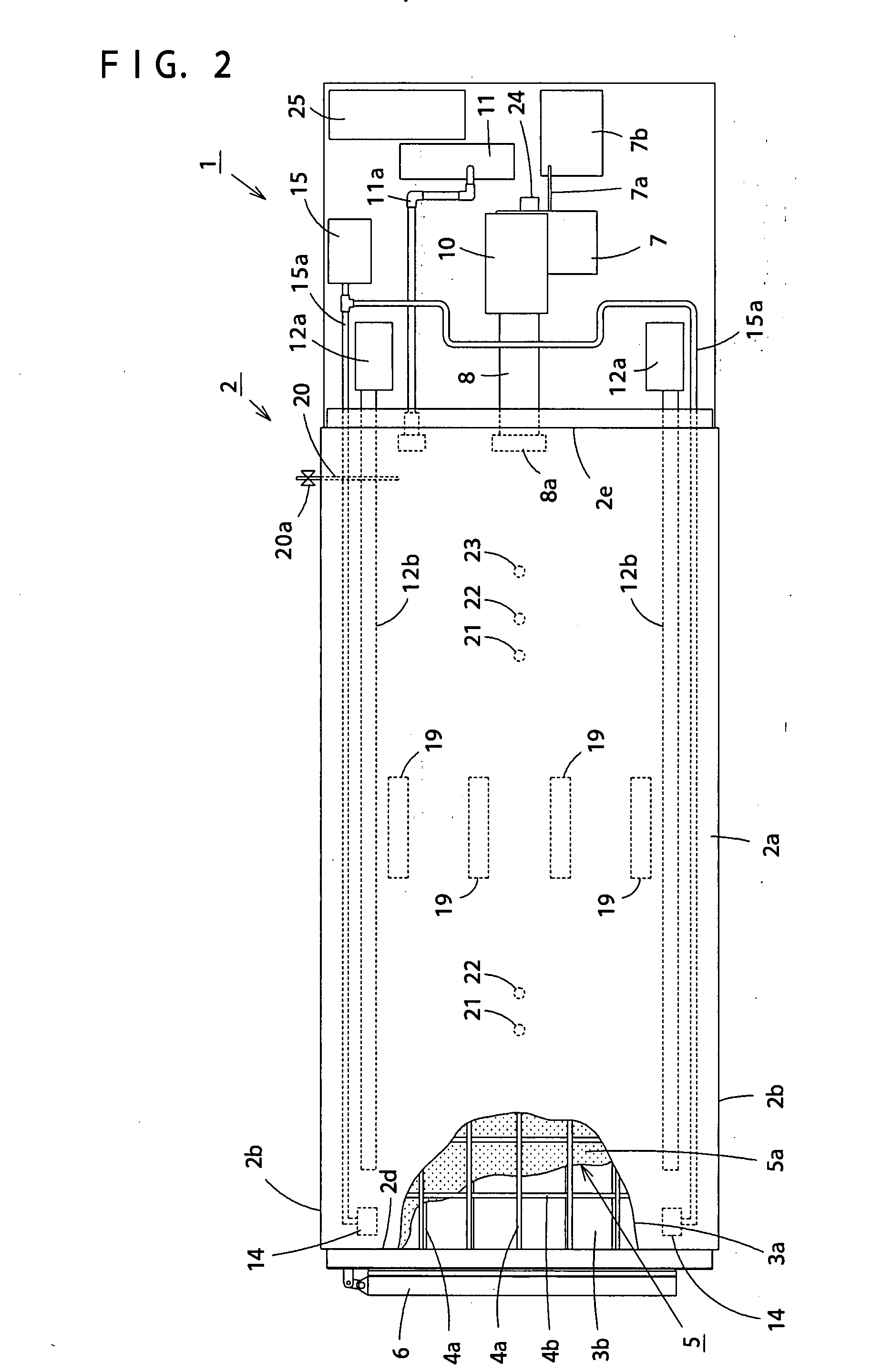

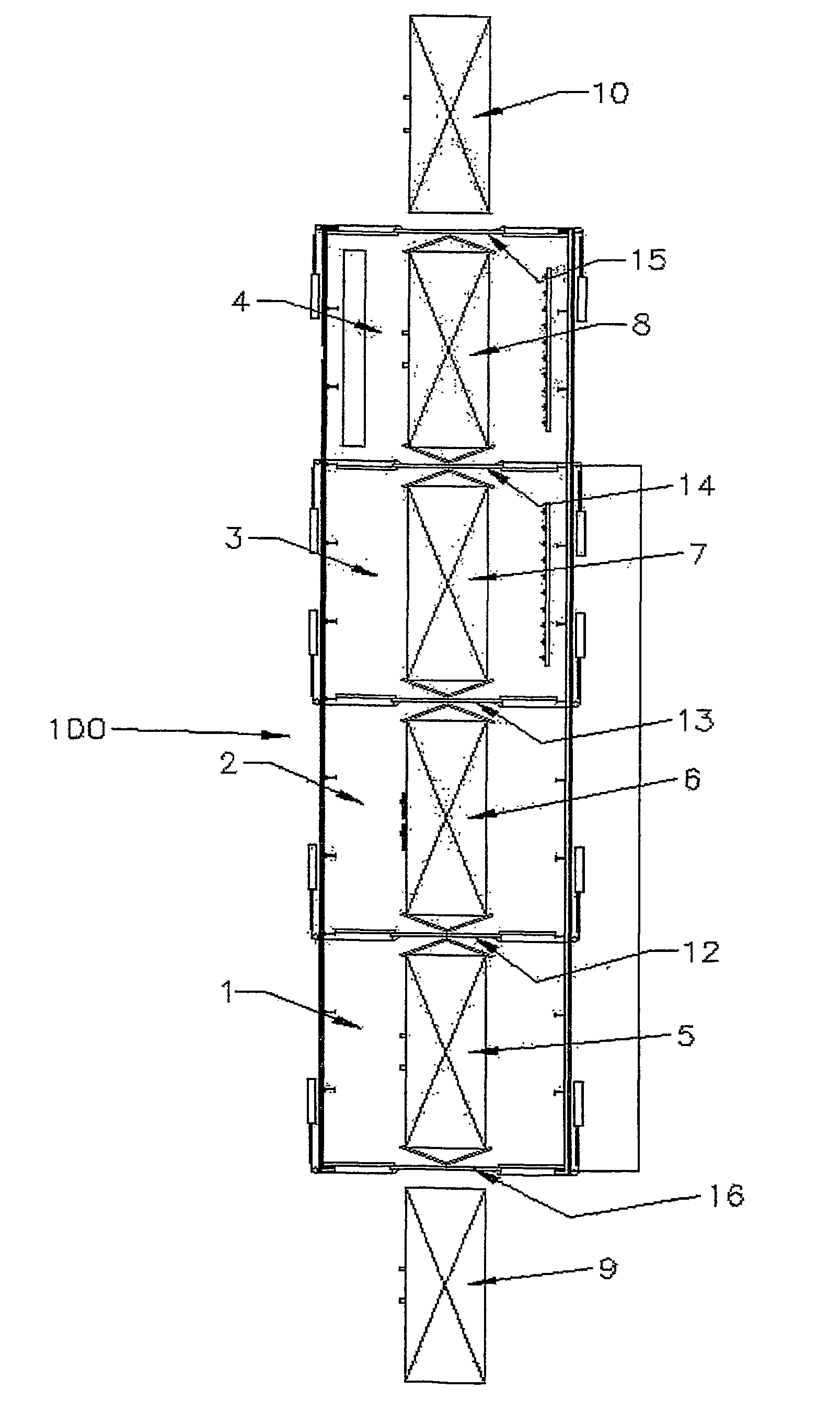

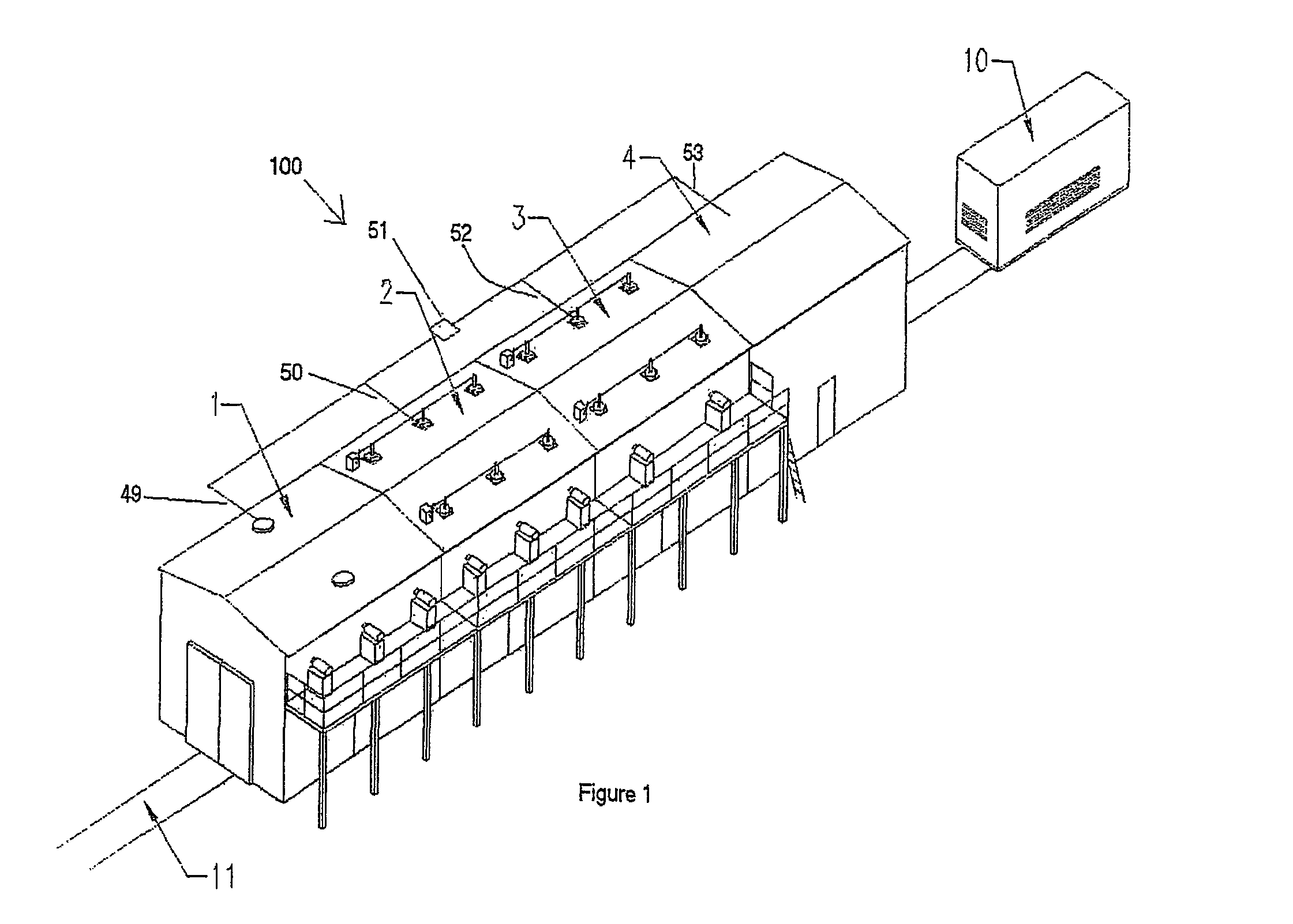

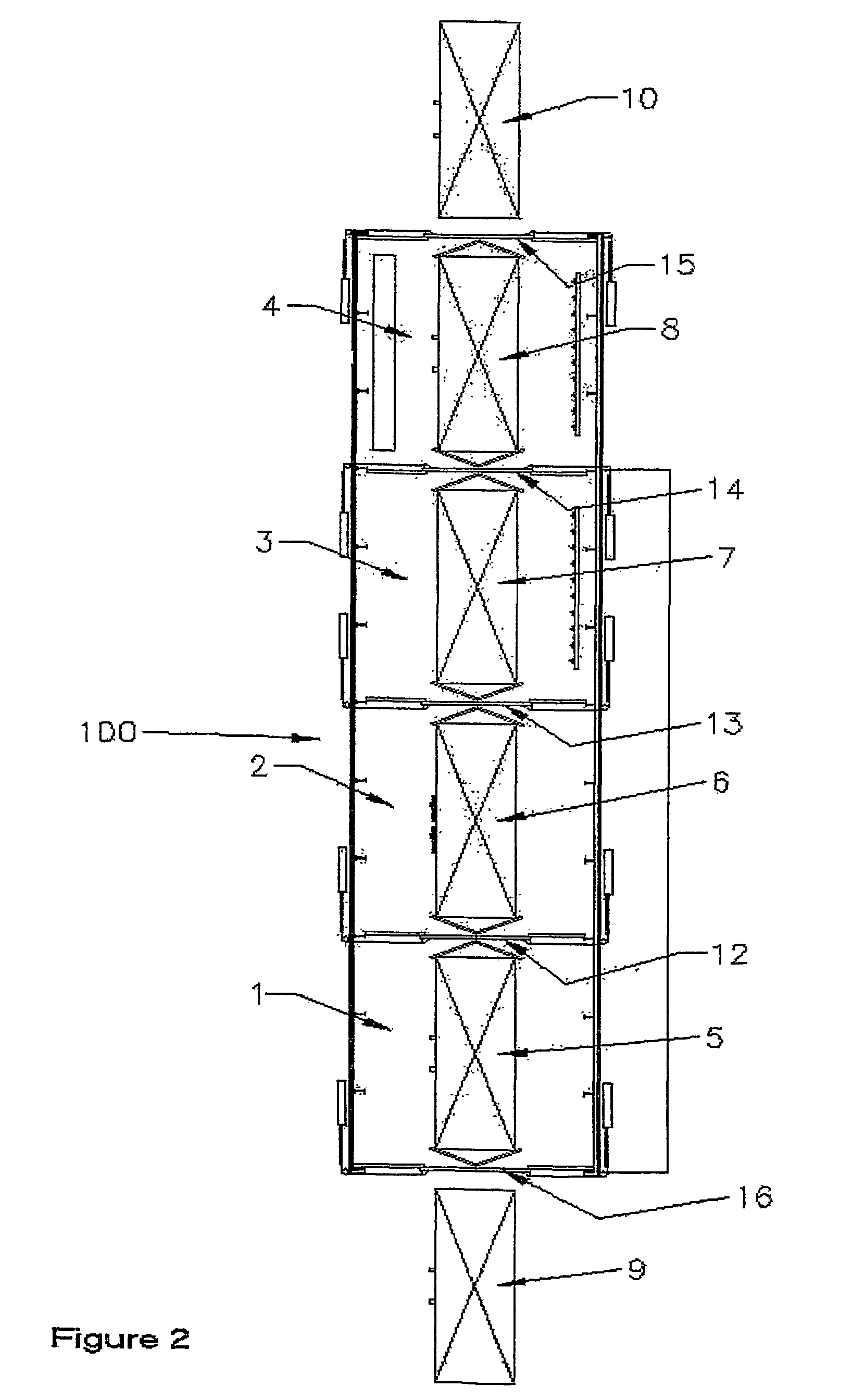

Timber drying kiln

InactiveUS7146747B2Drying using combination processesDrying solid materials with heatEnergy transferFiber saturation point

A multichamber timber drying kiln in which different conditions are maintained in each chamber and methods of drying timber using such a kiln. In one aspect timber is rapidly heated within a first chamber (2; 202; 207) and then transferred to a further chamber (3; 203; 208) for further drying. Timber may be transferred from the first chamber (2; 202; 207) when the moisture content of the timber approaches the fibre saturation point A preheating chamber (1; 201; 206) may be provided to preheat the timber before passing to the first chamber (2; 202; 207). A conditioning chamber (4; 204; 209) may be provided after the further chamber (3; 203; 208) to condition the timber. Energy transfer means (49–53; 54–58) may be provided to transfer energy between chambers.

Owner:WINDSOR ENG GRP

High-temperature and high-humidity rapid drying process method for wood

ActiveCN103017485AHigh yieldEvenly heatedDrying solid materials with heatDrying gas arrangementsHigh humidityEngineering

The invention relates to a wood drying process technology, in particular to a high-temperature and high-humidity rapid drying process method for wood, belonging to the field of wood processing. The high-temperature and high-humidity rapid drying process method comprise the following steps of: (1) humidifying and heating; (2) heating and humidifying pretreatment; and (3) high-temperature and high-humidity drying. According to the invention, the drying process problems that the traditional drying process cannot be used for drying hardwood, difficultly-dried hardwood and fast growing wood easily undergoing shrinkage and collapse after drying are solved, the dried wood is uniform in the distribution of moisture content and low in moisture content gradient in a thickness direction, and the defect that the fast growing wood is shrunk and collapsed after being dried is overcome. Meanwhile, the process flow of the traditional drying technology is simplified, and the most common drying process method with broadest applicable range is formed, is suitable for any varieties of tree wood with the thickness below 100mm and is easier to master by a technician.

Owner:贵州保城新材料有限公司

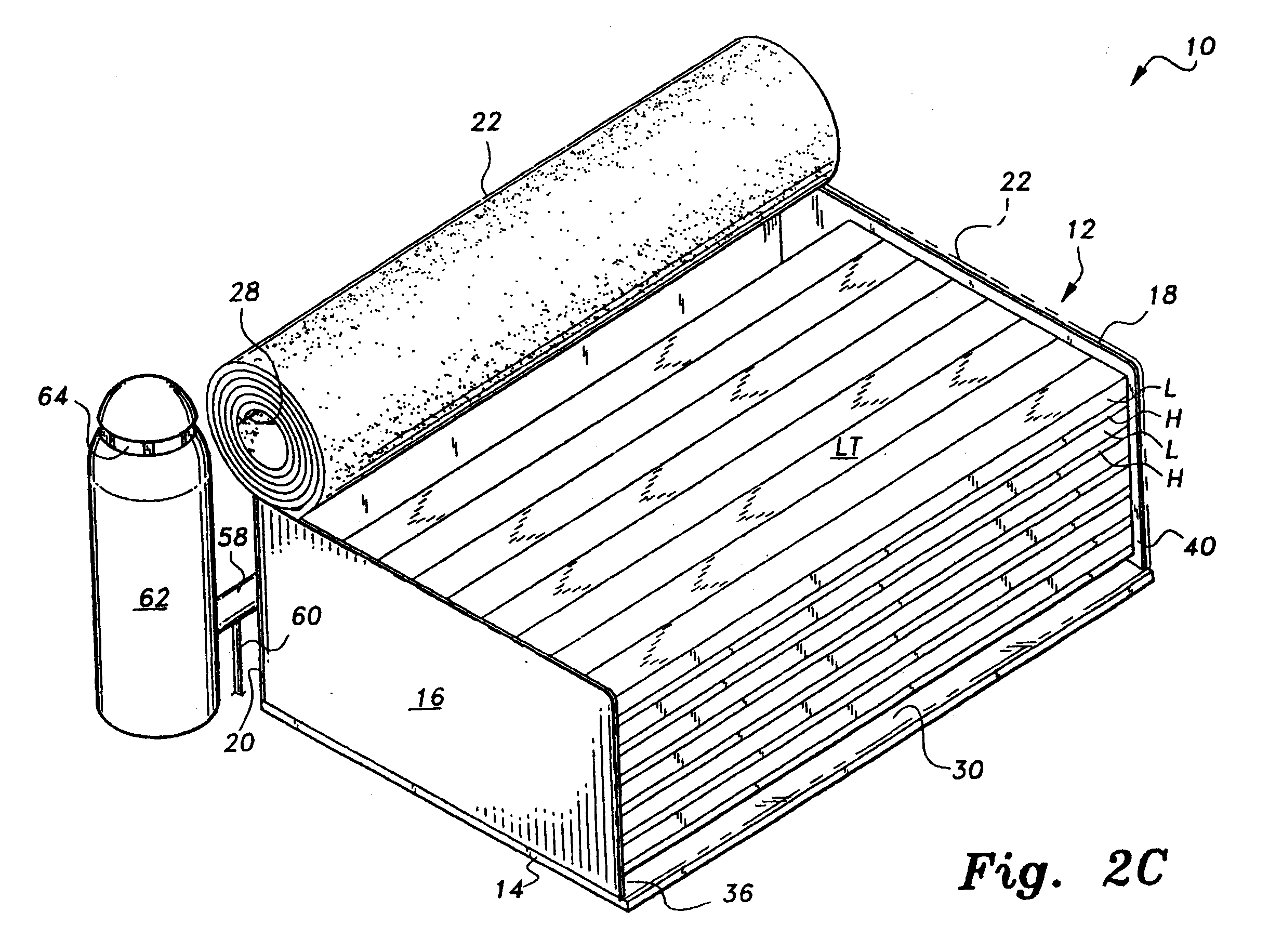

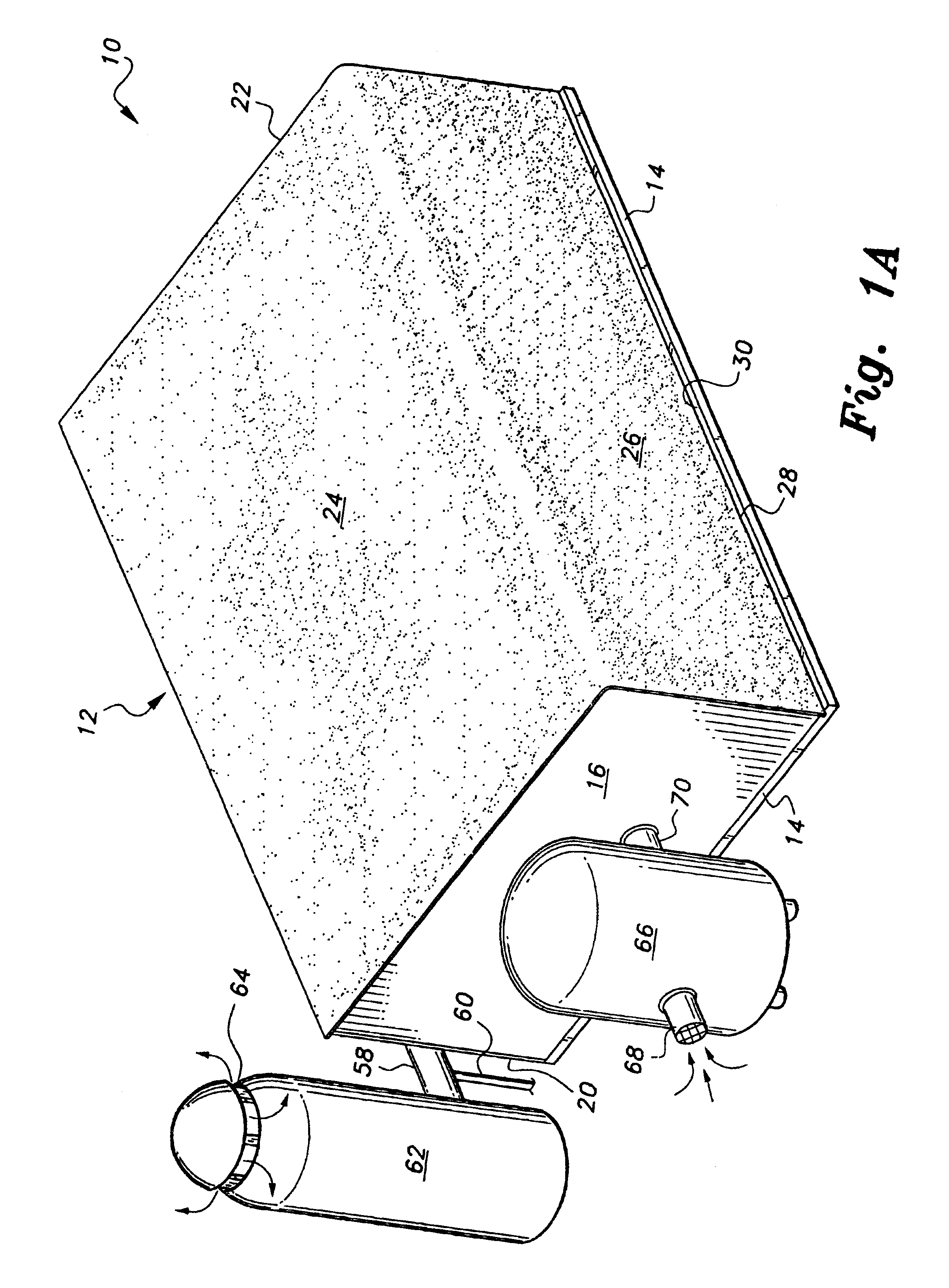

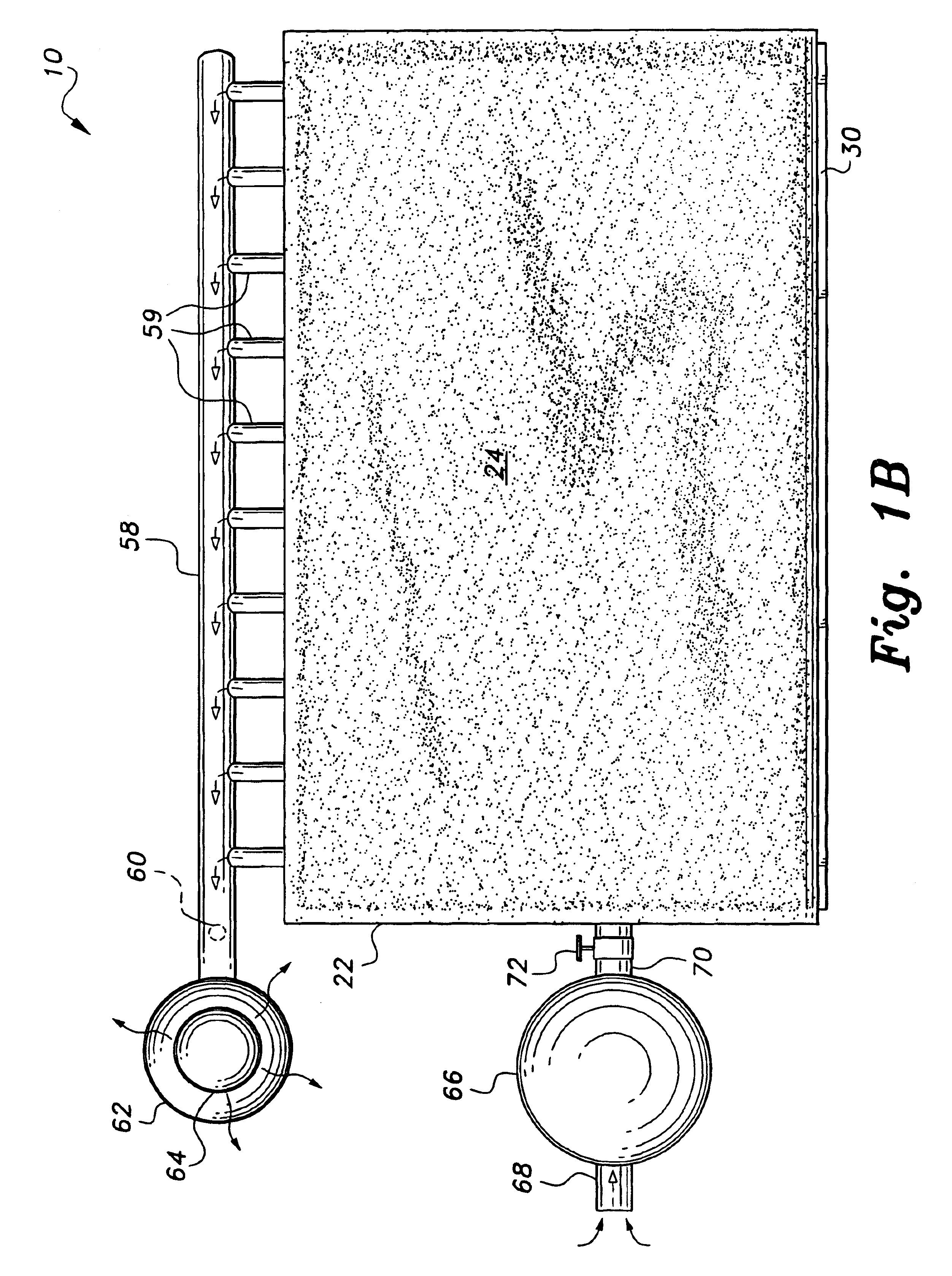

Vacuum lumber drying kiln with collapsing cover and method of use

InactiveUS6865821B2Low costFlexible in of operationDrying using combination processesDrying solid materials with heatEngineeringReinforced rubber

A lumber drying kiln employs outside air pressure uses a flexible collapsing bag or cover alone or in combination with walls. The collapsing bag seals against a base to maintain the vacuum. The air pressure against the flexible top keeps the lumber layers from warping or cupping during drying. The lumber stack has alternating layers of hot plates or stickers separating layers of lumber. A bag having an open bottom and made of nylon-reinforced rubber or other strong flexible material is placed over the wood and sealed to the stainless steel platform. A vacuum pump is connected with the bag by means of a manifold and operated to remove air from the enclosed lumber stack, the vacuum strengthening the seal between the base and the bottom of the bag. This chamber design is easily scaled up or down to provide a desired drying capacity.

Owner:MERSCHAT JOHN R

Biomass composite granular fuel, and manufacturing method and device thereof

InactiveCN101824347AHigh calorific valueMaintain particle shapeBiofuelsSolid fuelsAdhesivePellet fuel

The invention relates to a biomass composite granular fuel, and a manufacturing method and device thereof. Crop straws with low lignin content and heat value and wood materials with high lignin content and heat value are used as the raw materials, pulverized, mixed in a random ratio and granulated to obtain the granular fuel. The manufacturing method comprises the following steps: using crop straws with low lignin content and heat value and wood materials with high lignin content as the raw materials, respectively pulverizing and drying the crop straws and wood materials, mixing, softening with steam, molding, cooling and packaging to make the granular fuel. The manufacturing device comprises a wood chipping and pulverizing system, a pulverized wood drying system, a straw cutting and pulverizing system, a pulverized straw drying system, a granulating system and a product processing and packaging system. The composite granular fuel of the invention does not need adhesive or other additives with high heat value, thereby keeping the fixed granule shape and enhancing the heat value of the fuel.

Owner:北京泛欧瑞德科技有限公司 +1

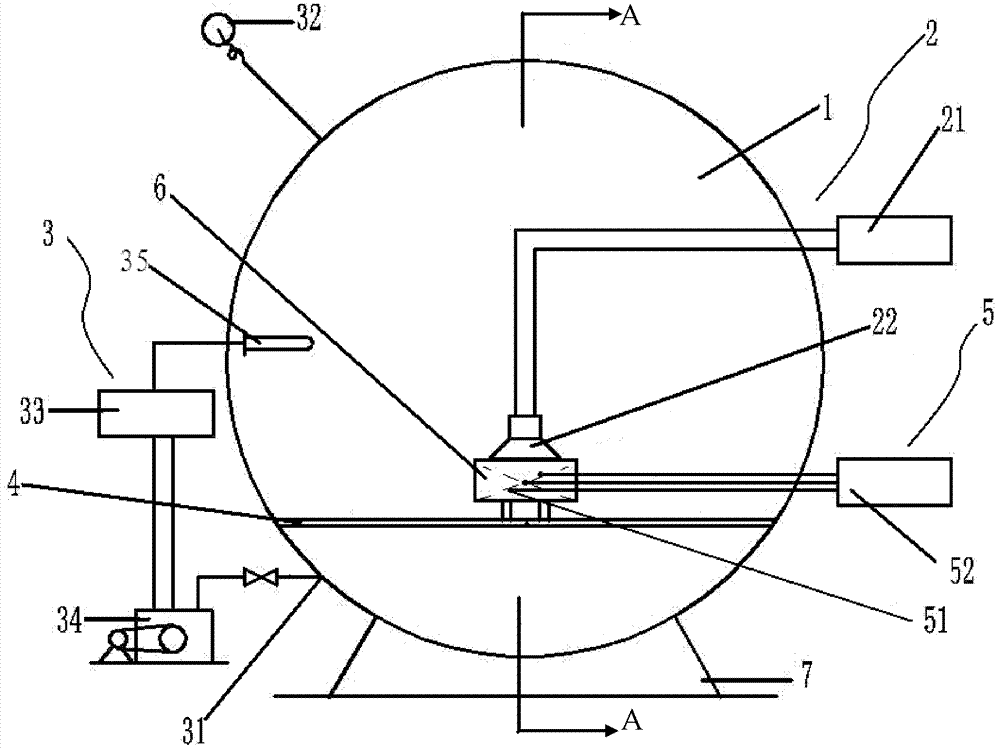

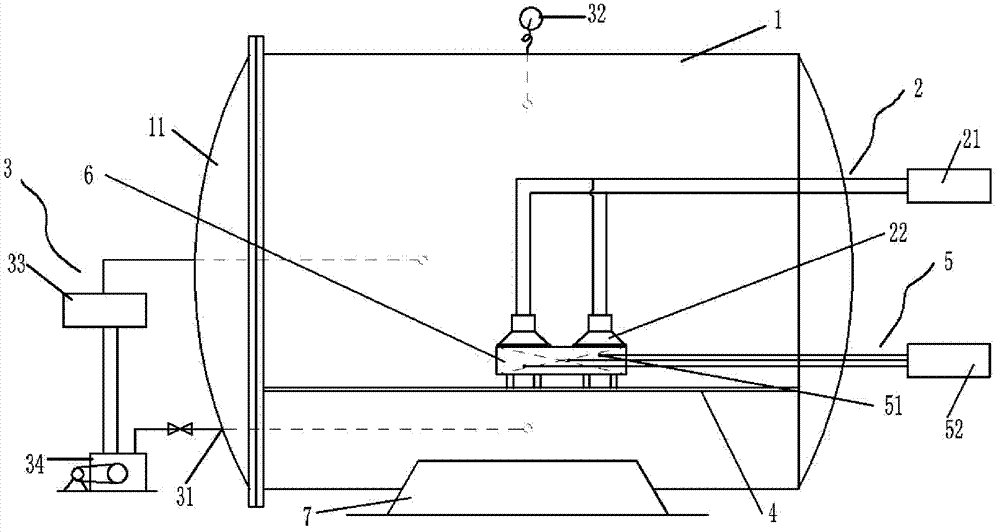

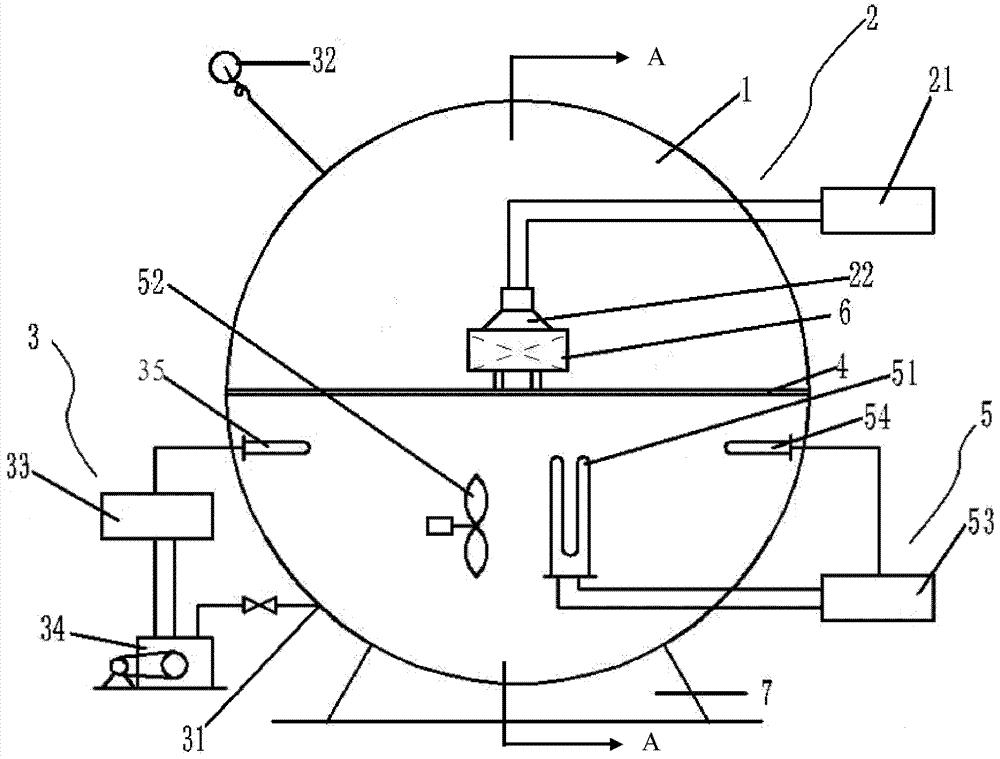

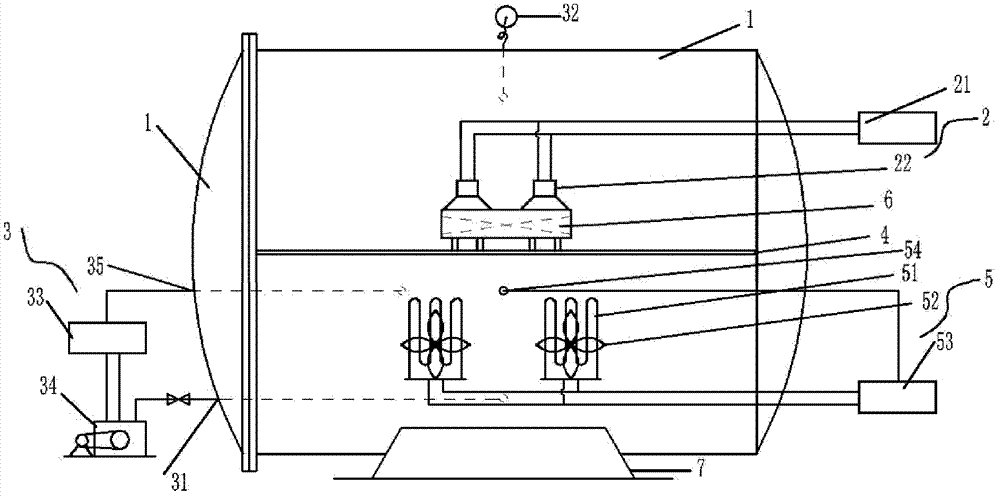

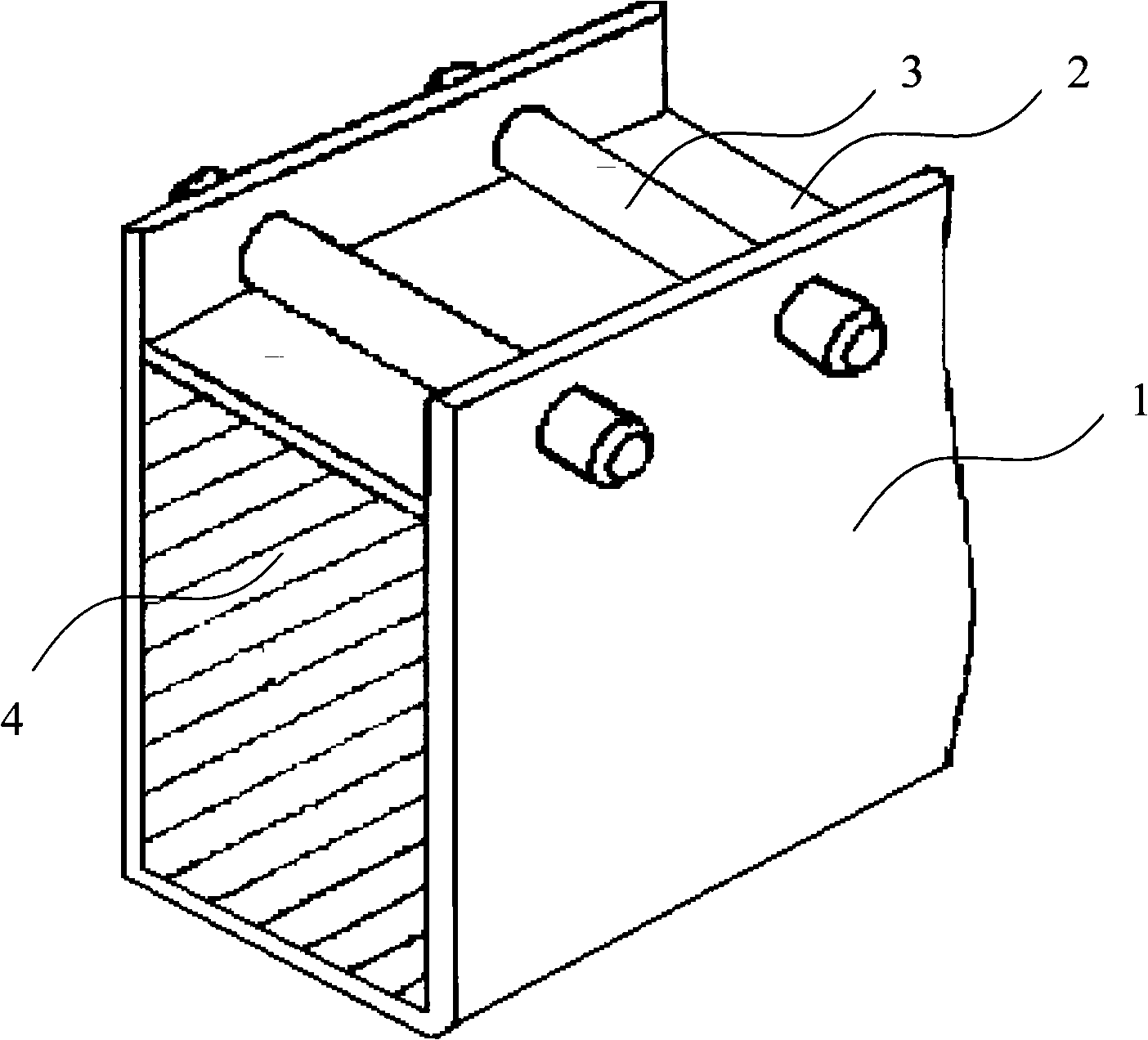

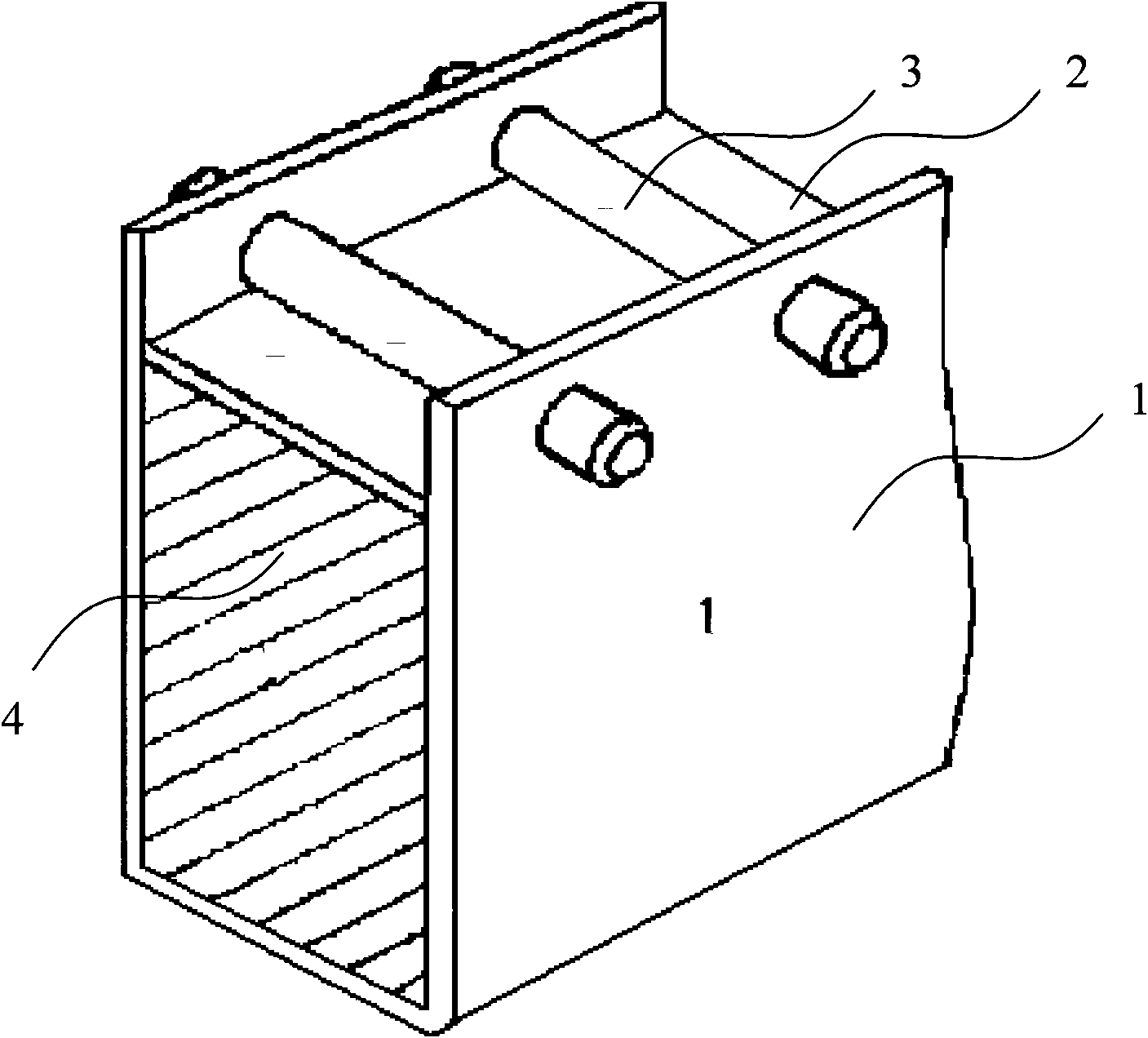

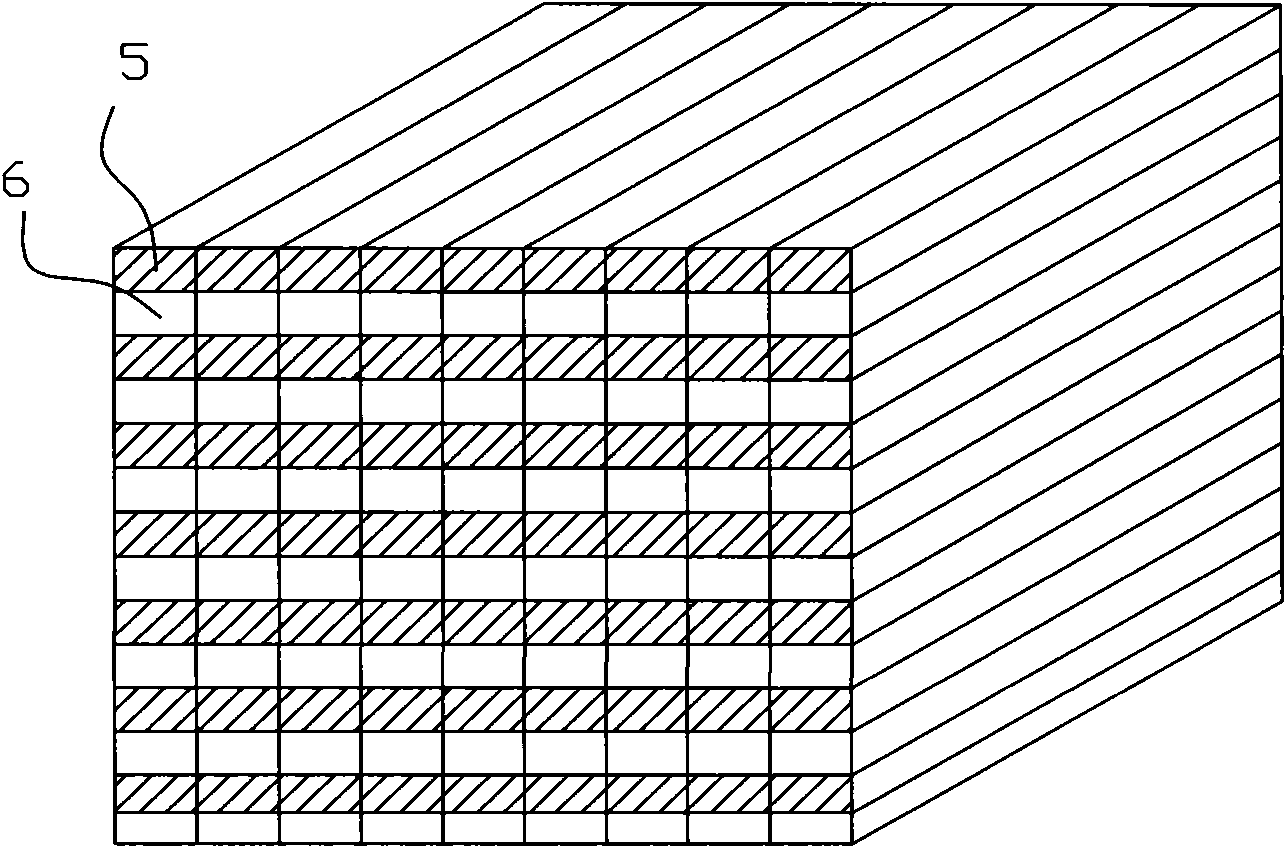

Lumber drying equipment and method of drying lumber by using equipment

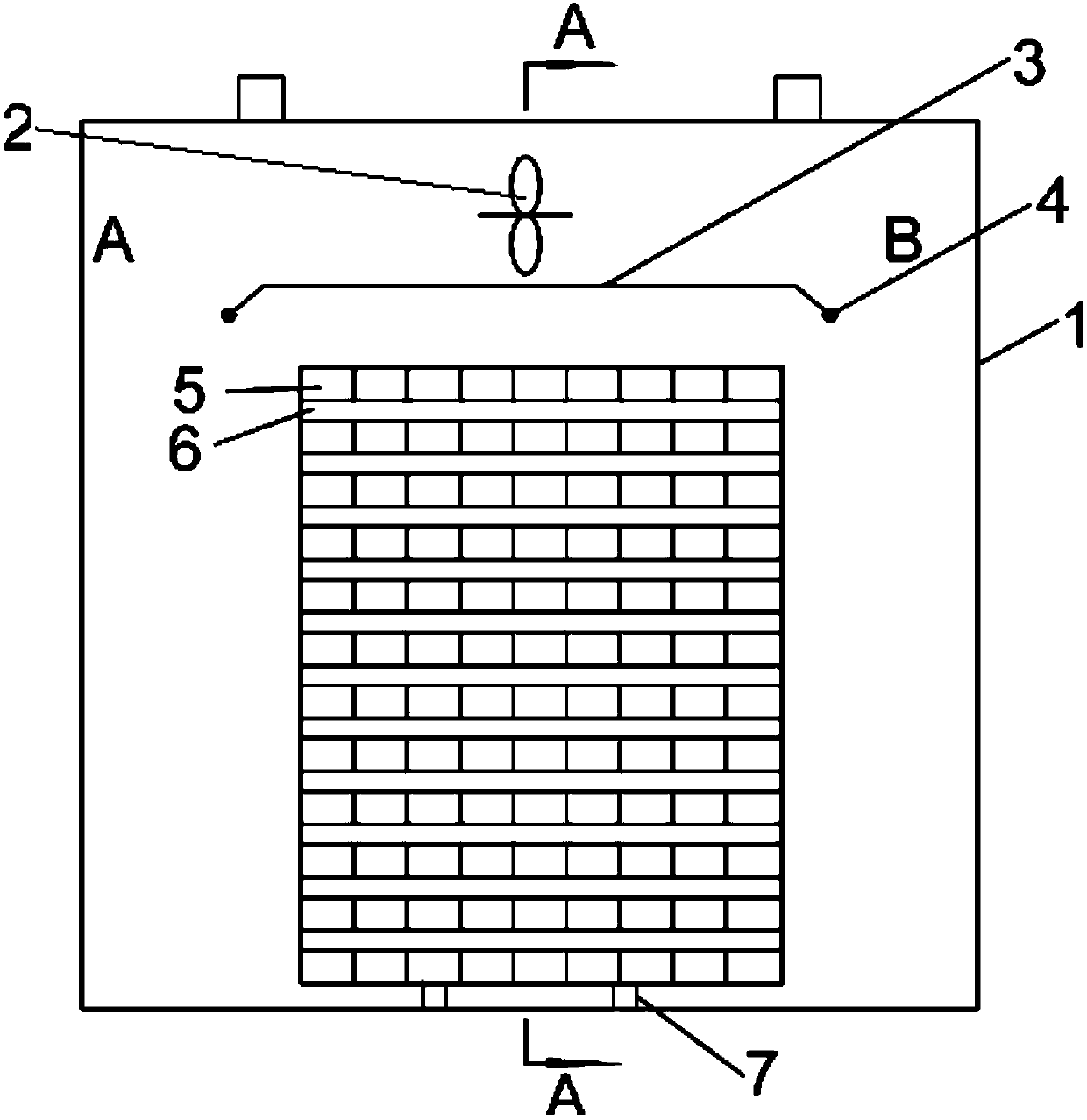

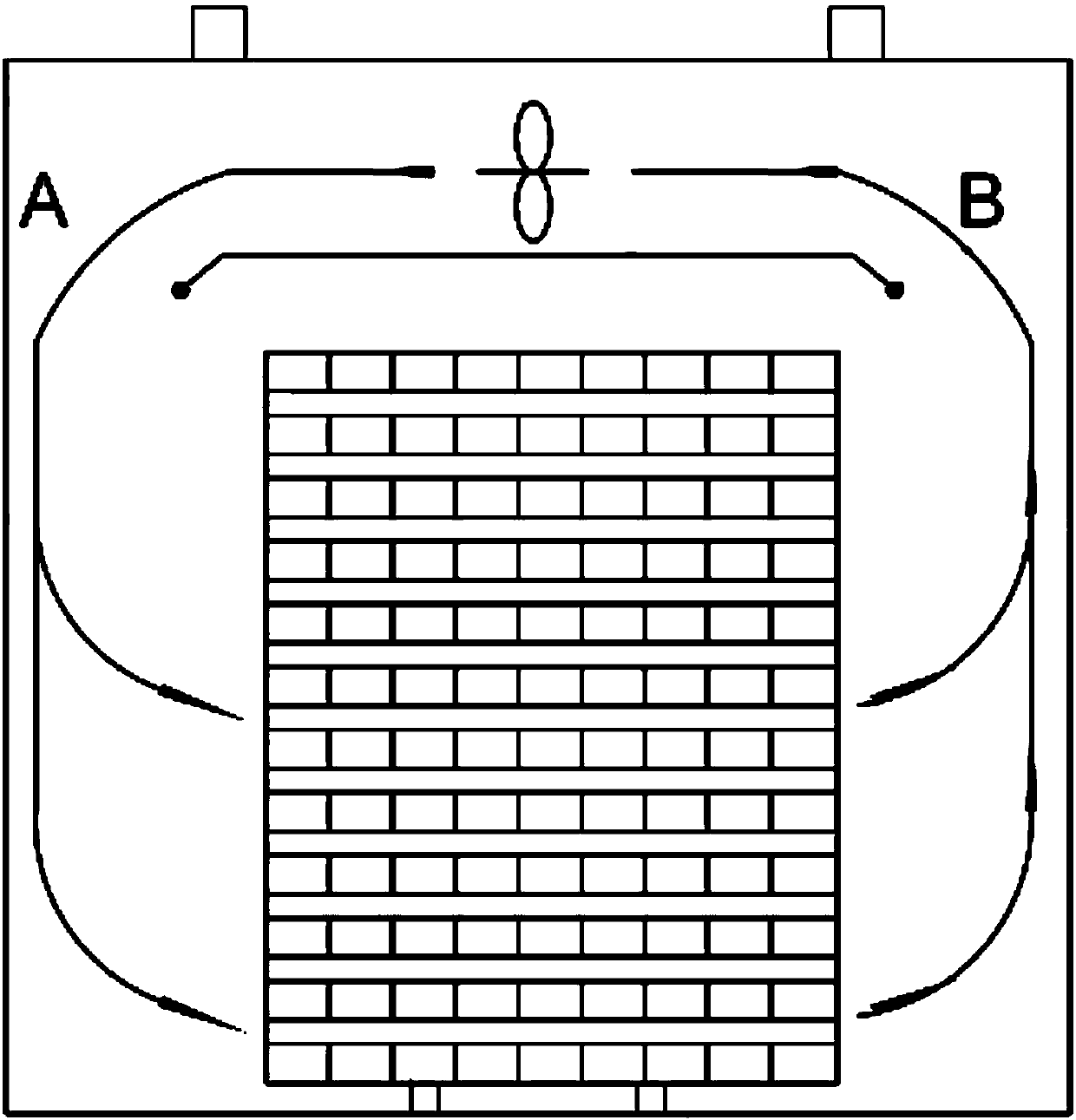

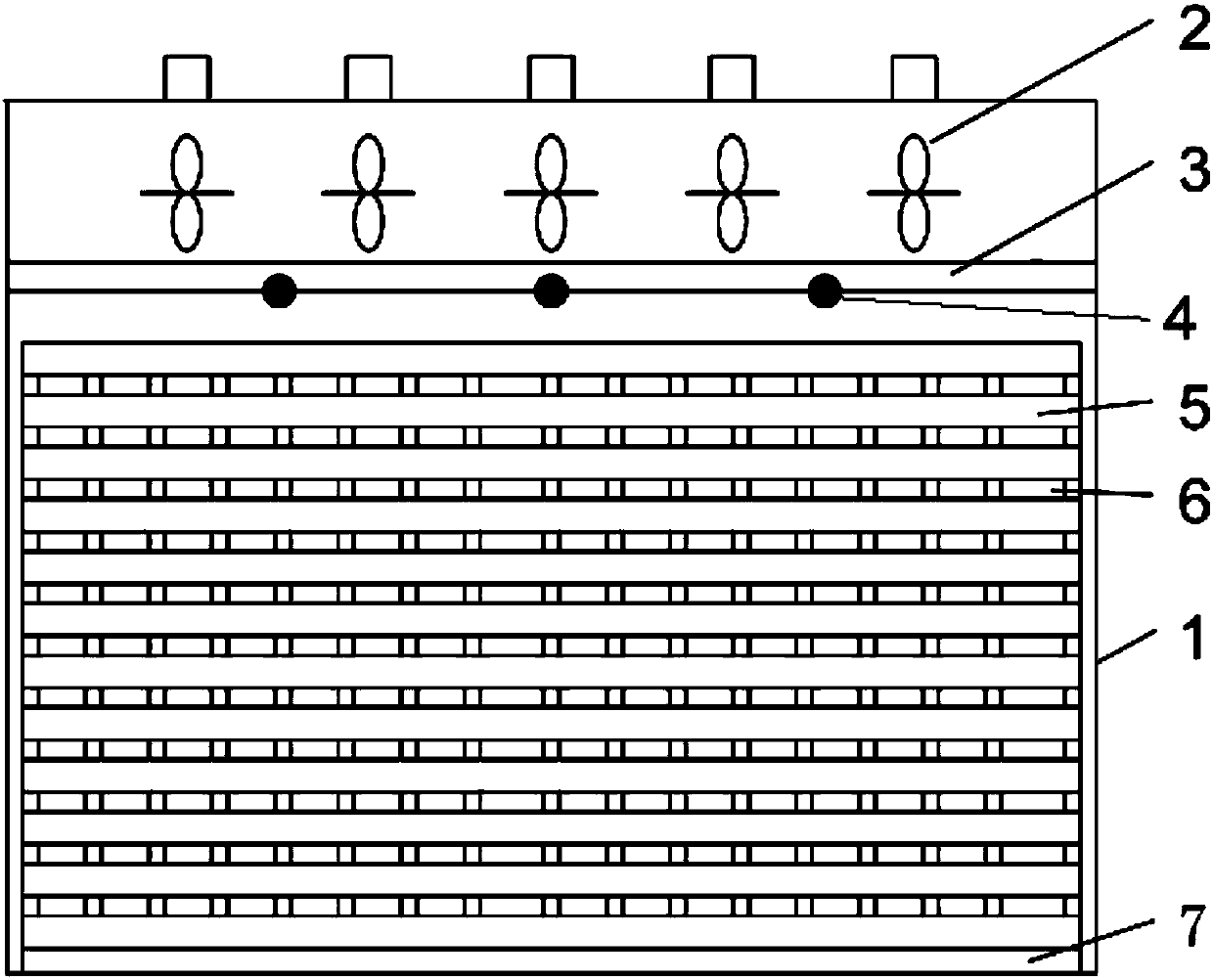

ActiveCN103115481AUniform treatmentImprove ultrasonic drying efficiencyDrying using combination processesDrying machines with local agitationProcess engineeringVacuum drying

The invention discloses lumber drying equipment and a method of drying lumber by using equipment. The device comprises a lumber drying room (1) with a hollow cavity in the inner portion, an ultrasonic wave processing device (2), a vacuum supply device (3) carrying out the vacuum supply processing to the hollow cavity of the lumber drying room (1), an installing material assembly (4) placing to-be processed lumbers and a heating device (5) carrying out heating processing to the to-be processed lumbers. An ultrasonic wave energy converter is directly contacted with the lumbers in the drying process. The lumbers are dried under the vacuum condition. An ultrasonic wave with certain frequency and power is added in the lumber vacuum drying process. The lumbers are dried under the low drying temperature. Drying rate is high and drying quality is good. Produced drying defects under the high temperature condition of the vacuum drying can be avoided. The drying equipment is simple. The drying method is convenient to operate.

Owner:简木(广东)定制家居有限公司

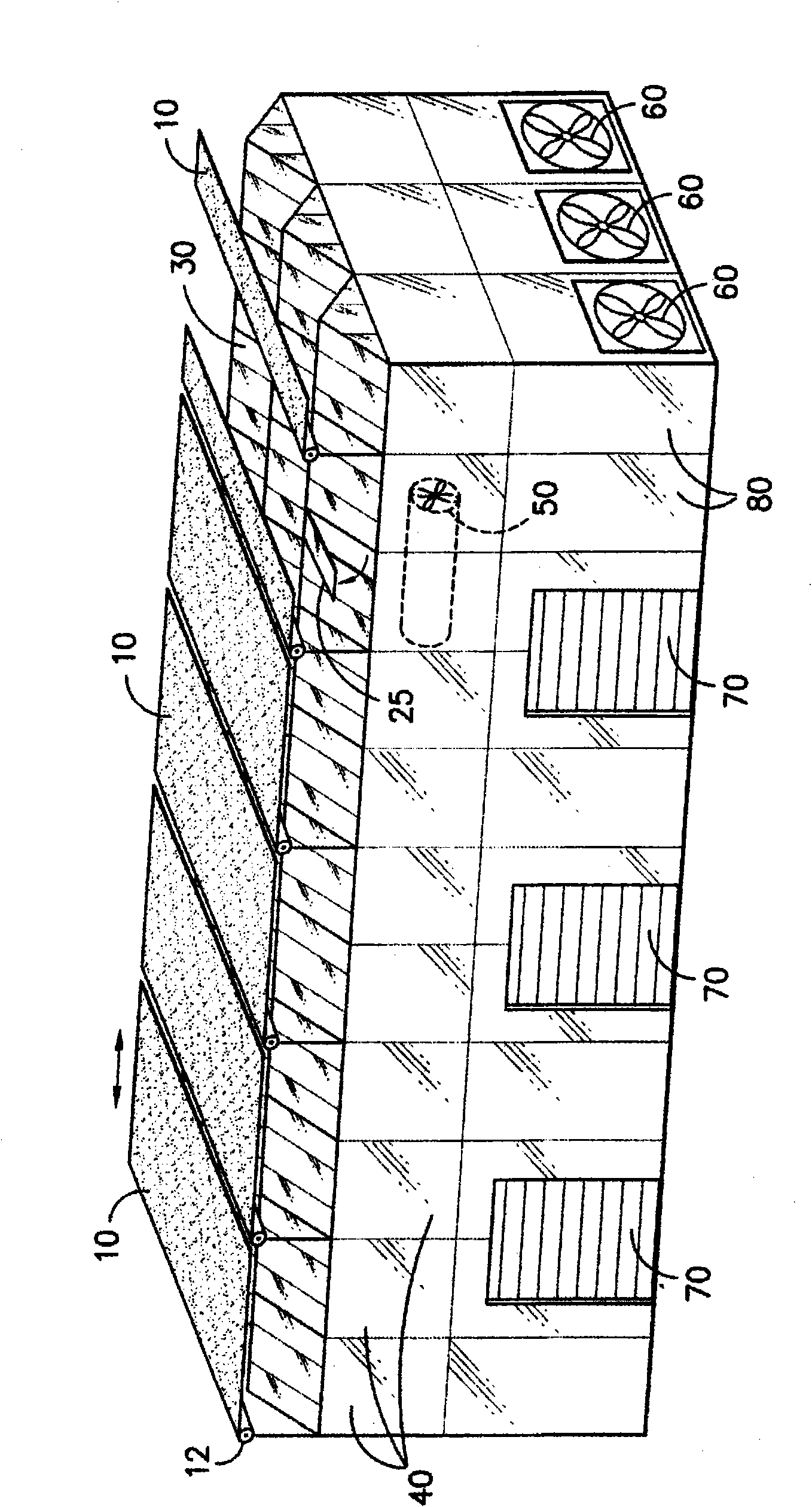

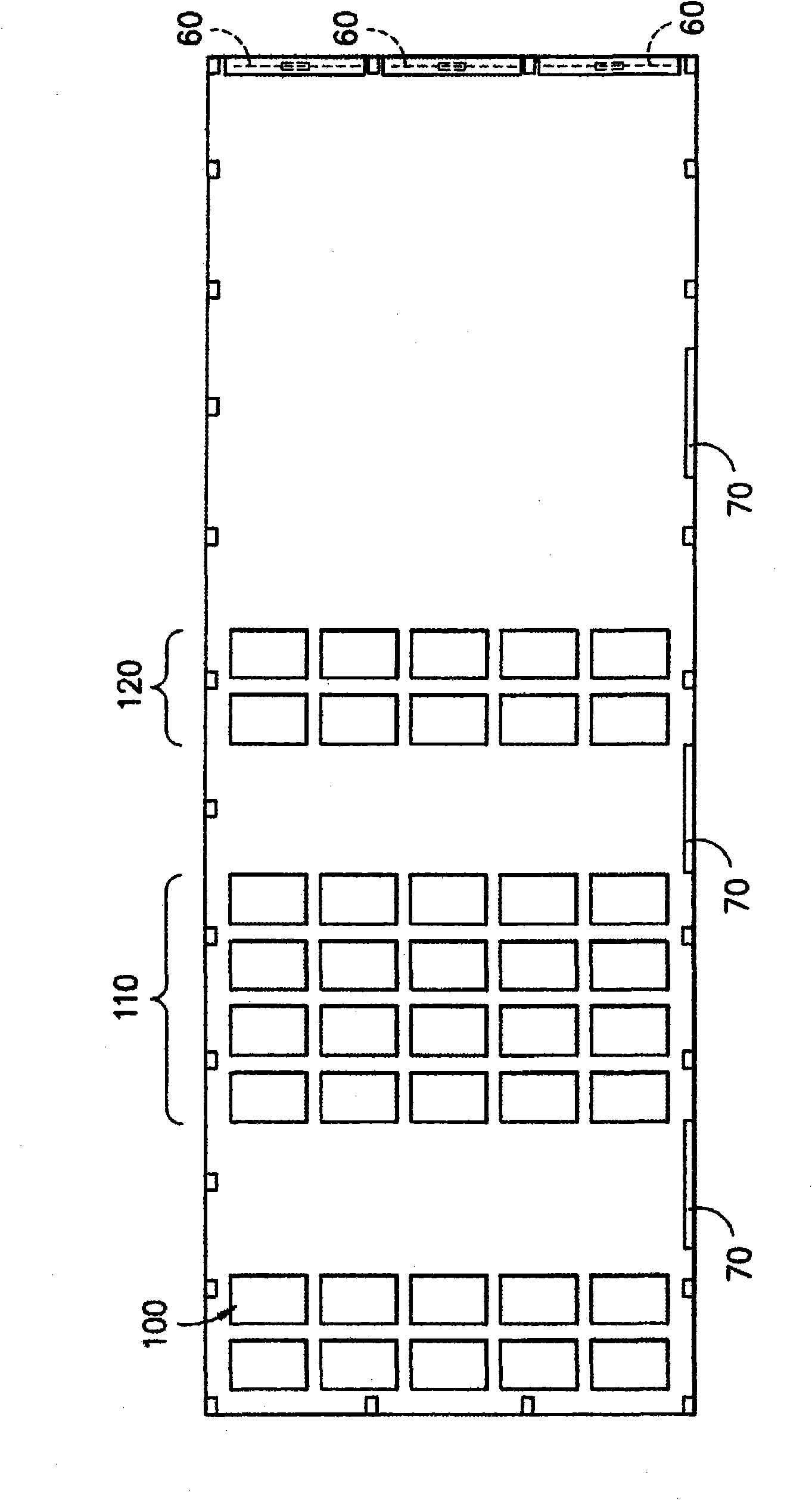

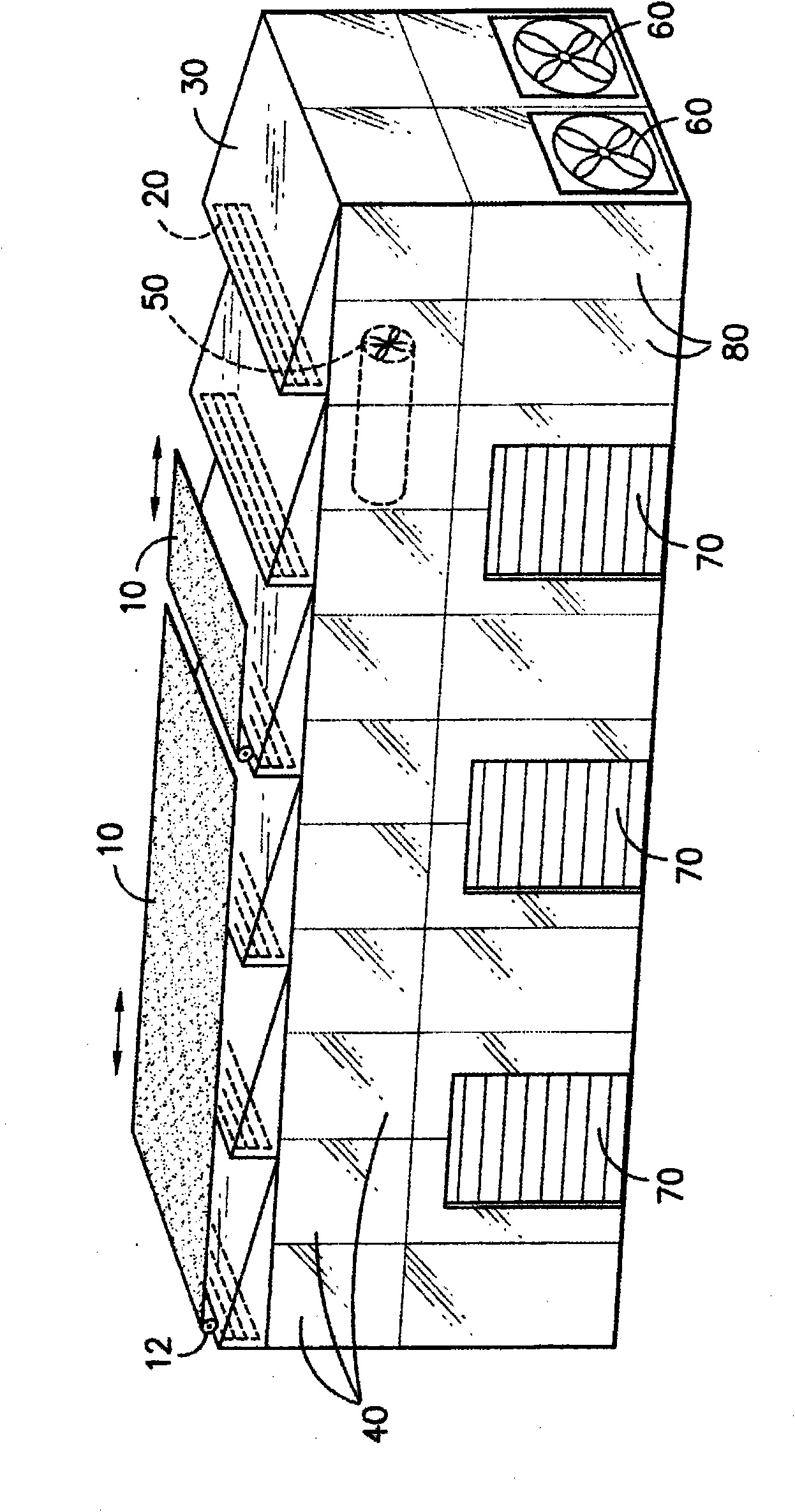

Wood-drying solar greenhouse

A method of drying comprises placing a moist material inside a substantially enclosed solar greenhouse. The greenhouse comprises at least one light transmission roof and / or wall panel that is substantially transparent to solar radiation, but resistant to convective and conductive heat transfer. The interior temperature and humidity of the greenhouse are maintained within their pre-determined ranges while the interior moisture of the greenhouse is effectively reduced to allow a controlled drying of the material. A solar greenhouse for the drying process is also disclosed.

Owner:格林百奥生态材料科技(上海)有限公司

Method for preparing zebra-strip upright post material for wood stair by bamboo recombination process

The invention discloses a method for preparing a zebra-strip upright post material for a wood stair by using moso bamboo. The method comprises the following steps of: 1, cutting 4 to 6-year old moso bamboo and cutting bamboo poles into bamboo sections with predetermined specifications; 2, splitting and breaking the bamboo sections; 3, putting a part of carded moso bamboo sections into a wood cooking kettle for overheat steam carbonization; 4, drying the carbonized carded moso bamboo sections and the remaining non-carbonized moso bamboo sections into a wood drying kiln for drying respectively;5, soaking the dried carded moso bamboo sections and the carbonized moso bamboo in a phenolic resin respectively; and 6, laminating and assembling the carded moso bamboo sections and the carbonized moso bamboo soaked with phenolic resin glue solution in a preset assembling mode and pressurizing and compacting the laminated and assembled carded moso bamboo sections and carbonized moso bamboo in a cold press. A recombined moso bamboo laminated material with attractive zebra strips prepared by the method can meet the use requirement on the upright post of the wood stair.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

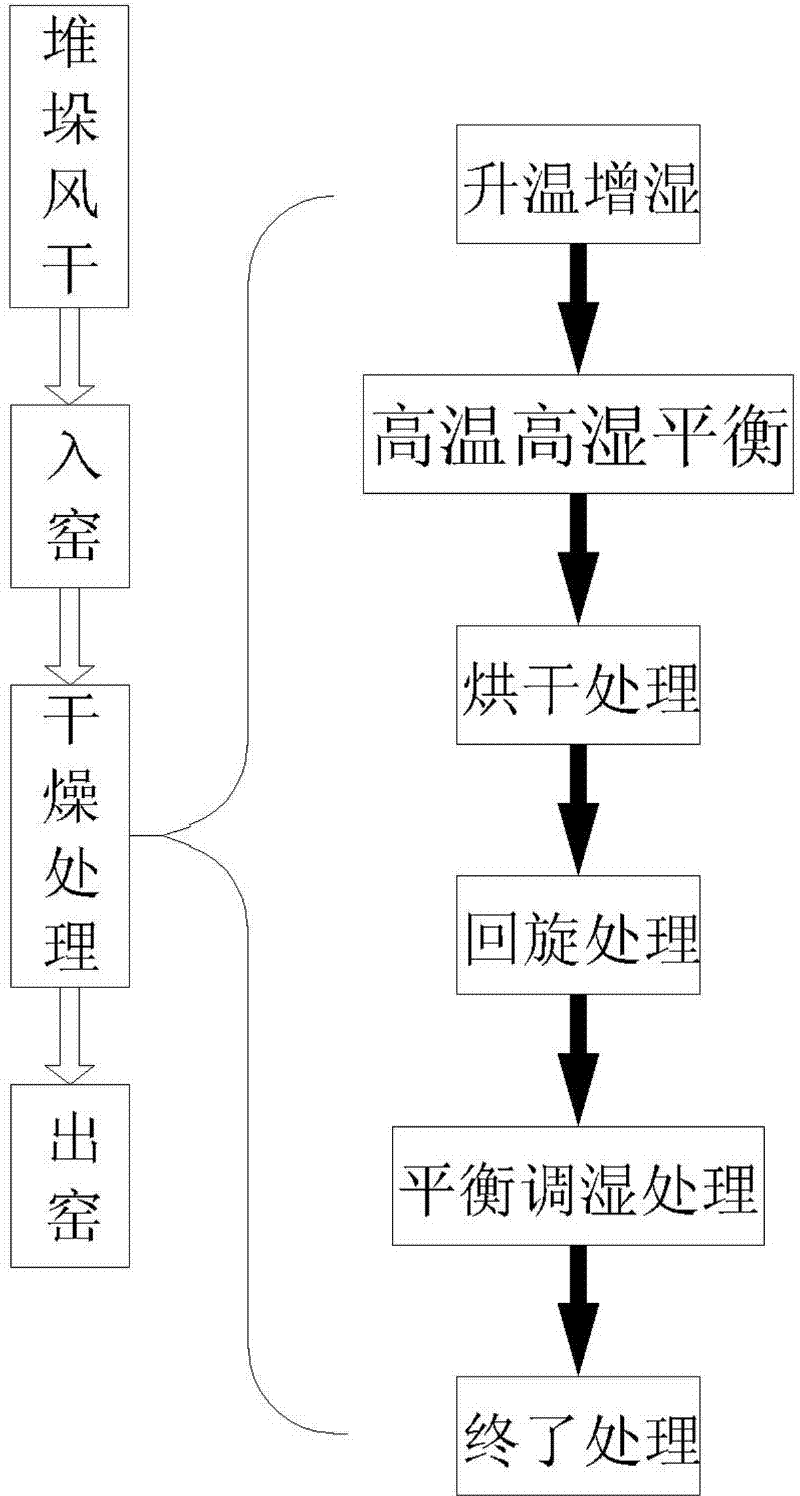

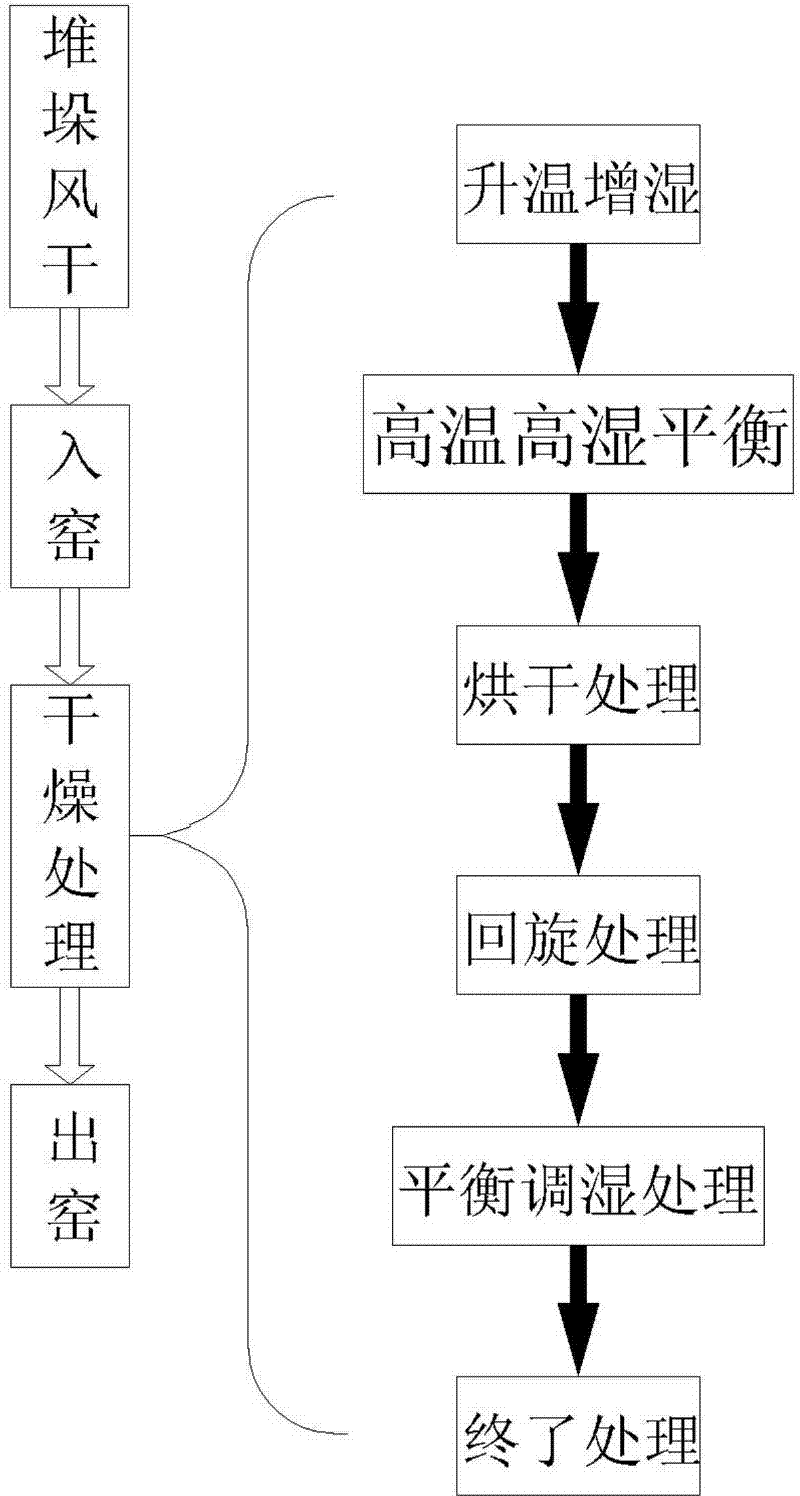

Rotary drying method for timbers

The invention provides a rotary drying method for timbers. The method comprises the following steps of: stacking the timbers and airing the timbers till the water content is about 30 percent; stacking the aired timbers, putting the timbers in a timber drying kiln, preheating, raising the temperature, humidifying, preserving heat and moisture, drying and dehydrating, finally treating and carrying out balanced humidification and rotary treatment many times. The method has the keys that a drying medium in a kiln is kept to form rotary vortex, and the water content of the timbers is not reduced in one step and is kept in rotary decline; by the rotary method, the internal stress of the timbers is dispelled in time, drying stress and surface hardening are eliminated, plasticizing deformation is prevented in the drying stage of the timbers, the defects of air shrinking, bending, deforming, cracking and the like are not caused, the degradation loss of the timbers is reduced to be below 6 percent, the drying period is shortened by about 20 percent, energy can be saved by about 15 percent, and limited timber resources are utilized more effectively; and the method has strong universality, is suitable for various different timbers, and can be widely applied to drying kilns with high automation degree.

Owner:GUANGDONG YIHUA TIMBER IND

Wood high-temperature high-pressure overheat steam drying method and its drying device

InactiveCN101148054AGood dimensional stabilityGood weather resistanceWood treatment detailsPressure impregnationEngineeringHigh pressure

The present invention is high temperature and high pressure steam timber drying process and apparatus. The timber drying process includes the following steps: stacking timber inside the drying apparatus, and drying timber with overheat steam in the pressure of 500-1000 kg / sq m, temperature of 120-180 deg.c, saturation degree of 20-80 % and flow rate of 6-12 m / s. The timber drying apparatus includes one medium temperature and pressure controlling system, one high pressure kettle assembly and one overheat steam generator connected through one pipeline. The present invention has high drying efficiency, low energy consumption, high drying quality, and capacity of greatly raising the size stability, corrosion resistance and weather resistance of timber.

Owner:NORTHEAST FORESTRY UNIVERSITY

Drying method by using solar energy and device thereof

ActiveCN101776377AImprove drying efficiencyQuality improvementDrying solid materials with heatSolar heat devicesSolar dryingSolar energy conversion efficiency

The present invention discloses a wood drying method by using solar energy, comprising the steps of: putting the wood to be dried in a drying cabinet (8); supplying heat to the drying cabinet; and stopping the supply of heat when the temperature T2 of the drying cabinet (8) is higher than the setting drying temperature of the wood to dry the wood under the setting drying temperature. The movable drying device by using solar energy has stable running, constant drying temperature and continuous drying function with lower power consumption, higher solar energy conversion efficiency and good drying quality, thereby reducing the drying cost.

Owner:潍坊恒远新材料科技有限公司

Wood drying technique

InactiveCN101231132AGuaranteed machining accuracyReduce energy consumptionDrying solid materials with heatWood dampingTreatment effectPulp and paper industry

The invention discloses a wood drying technology, which comprises a moist heat treatment, a drying step, a finishing step and a cooling step, wherein, the finishing step and the cooling step are combined to a finishing-cooling step. The invention adopts the progressive combination drying technology, namely, the moist heat treatment is controlled by a time base, and is controlled by a water-content coefficient base after the drying step, and the finishing-cooling step is a balancing water-content coefficient base. As the finishing step and the cooling step are combined to a finishing-cooling step, the wood drying technology of the invention assures the finishing treatment effect, and also saves energy and shortens drying period. The adoption of the progressive combination drying technology, namely, different base control method is adopted at different stage, assures machining accuracy, and the good versatility suits for various wood.

Owner:金国庆

High-temperature lumber convective treatment method for balancing lumber moisture content

InactiveCN101762139AConsistent drying conditionsAvoid moisture contentDrying using combination processesDrying solid materials with heatFurnace temperatureEngineering

The invention relates to a high-temperature wood convective treatment method for balancing lumber moisture content. The adopted technical scheme includes that lumber pieces are bonded and stored for over 72 hours in natural conditions; the naturally dried lumber pieces are piled in layers in a steam lumber drying furnace, stripped cushions are put in parallel on each layer of lumber, the lumber pieces are erected in the middle space of the furnace, the lumber volume takes up 60 percent of the cubage of the steam lumber drying furnace; the furnace is heated and the temperature is kept under 50-55 degrees Celsius to dry the lumber for 48 hours and moisture is discharged once every four hours; the furnace temperature is kept under 60-65 degrees Celsius for 36 hours to dry the lumber and moisture is discharged once every six hours; the furnace temperature is kept under 70-80 degrees Celsius for 24 hours to dry the lumber and moisture is discharged once every eight hours; the steam lumber drying furnace is stopped for 3-5 hours after drying for 10-14 hours; the furnace is cooled down and the temperature of the lumber being taken out of the furnace is controlled. The invention guarantees the moisture content difference between every two lumber pieces within 1 percent and prevents lumber from shrinkage, cave-in, warp, distortion and cracking in a long period; the woodwork produced by the invention has stable quality and long service life.

Owner:林小平

Wood drying method

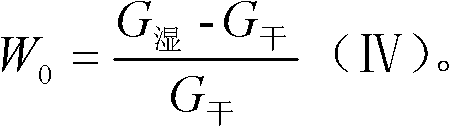

InactiveCN102538437AAccurate moisture contentReduce drying defectsDrying solid materialsVolumetric Mass DensityPulp and paper industry

The invention discloses a novel wood drying method. The wood drying method comprises the following steps in sequence: sawing wood to be dried into wood sections with required lengths and measuring the initial water content and the oven-dry density of the wood; stacking the wood in a drying room; measuring the temperature of a feeding end and a discharging end of a wood stack along the drying medium flowing direction; according to the relationship equation of the temperature of the wood stack, steam partial pressure in the drying medium and the water content of the wood, calculating the accurate water content of the wood; and drying the wood according to the water content of the wood and the common wood drying benchmark program so as to obtain the high-quality dry wood. According the method, the measured water content of the wood is accurate, and the defect of large error of the water content measured by an electrical measuring method in prior arts can be overcome. The method is suitable for drying wood with any water content, the factor to be controlled in the drying process is single, the system is stable, and the wood drying quality and the wood drying efficiency are improved.

Owner:BEIJING FORESTRY UNIVERSITY

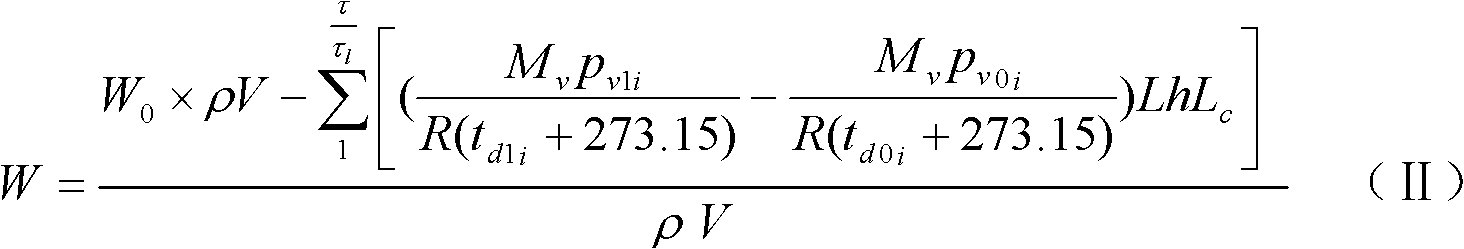

Wood drying and anticorrosive treatment method

ActiveCN106440671ASolve the anti-corrosion treatment methodSave energyDrying solid materials with heatFood processingFiberPreservative

The invention belongs to the technical field of wood processing technology, and particularly discloses a wood drying and anticorrosive treatment method. The wood drying and anticorrosive treatment method comprises the following steps: S1, wood loading; S2, prefreezing of a wood; S3, vacuum freeze drying; S4, heating; S5, soaking in a preservative; S6, extraction of the redundant preservative; S7, prefreezing of the wood; S8, vacuum freeze drying; and S9, heating. The wood drying and anticorrosive treatment method has the advantages that the wood is treated by the vacuum freeze drying method, so that corrugation of the wood due to the surface tension caused by liquid water is avoided, and the original tissue structure of wood fibers is retained. In the later anticorrosive treatment process, as the microstructure of the freeze-dried wood is not changed, and the effect of absorbing liquid is good, preservative liquid can be also quickly absorbed without injecting the preservative by pressure, and the leaching resistance is high; furthermore, energy required for injecting the preservative by pressure is saved; and meanwhile, worms and worm eggs in the wood can be killed in the vacuum freeze drying process.

Owner:太和县天顺工艺品有限公司

Wood drying process

InactiveCN105202870AIncrease temperatureIncrease moisture contentDrying solid materials with heatHearth type furnacesSurface stressHigh humidity

The invention discloses a wood drying process. The wood drying process comprises the steps of 1, preheating; 2, high-temperature and high-humidity treatment; 3, drying; 4, maintenance. When the wood drying process is adopted for drying wood, the surface stress and internal stress of wood can be eliminated, surface cracking or internal cracking of wood can be prevented, the original quality of wood is maintained, defects such as air shrinkage, bending, crinkling and deformation do not occur easily, the rate of wood damage caused by improper drying is reduced greatly, and meanwhile, energy is saved and drying time is shortened.

Owner:王璐

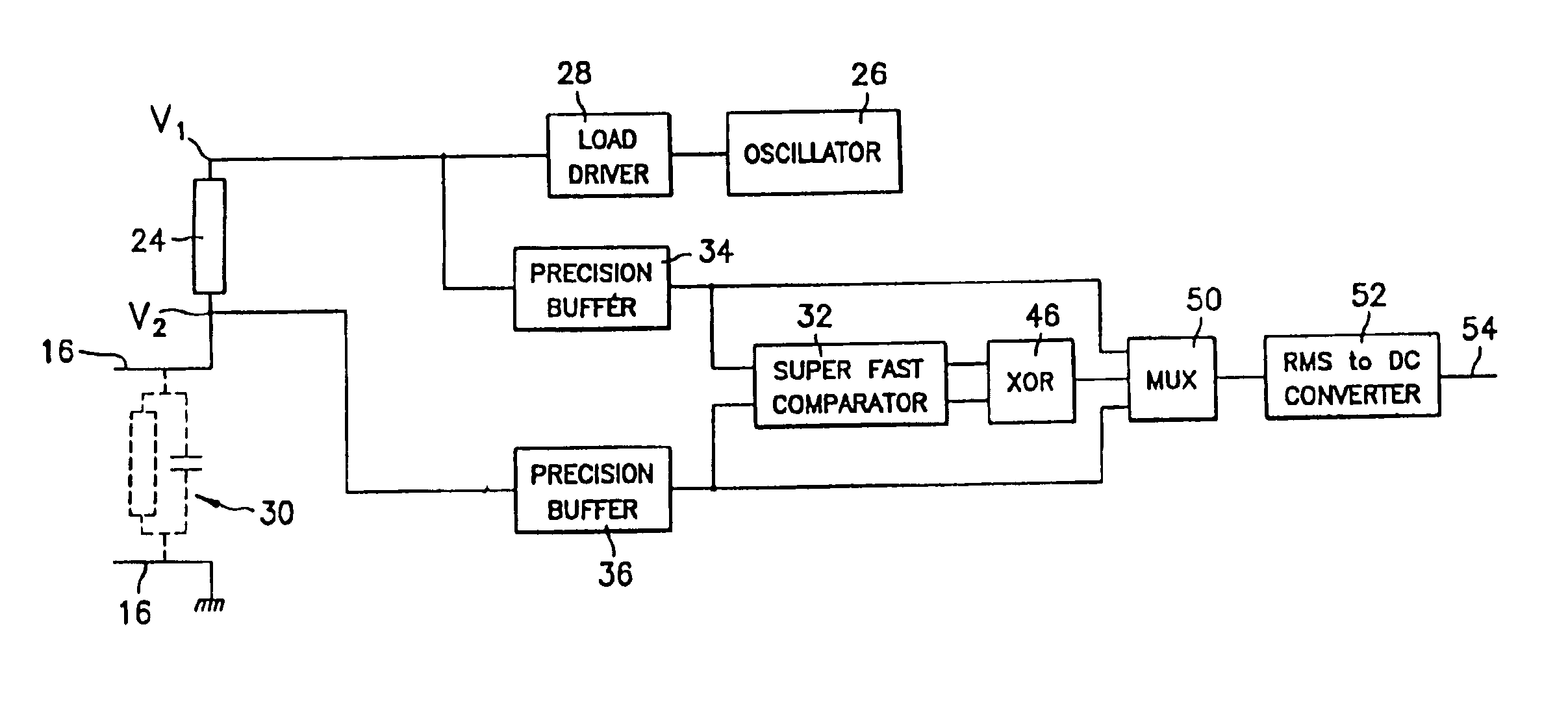

Determining the dielectric properties of wood

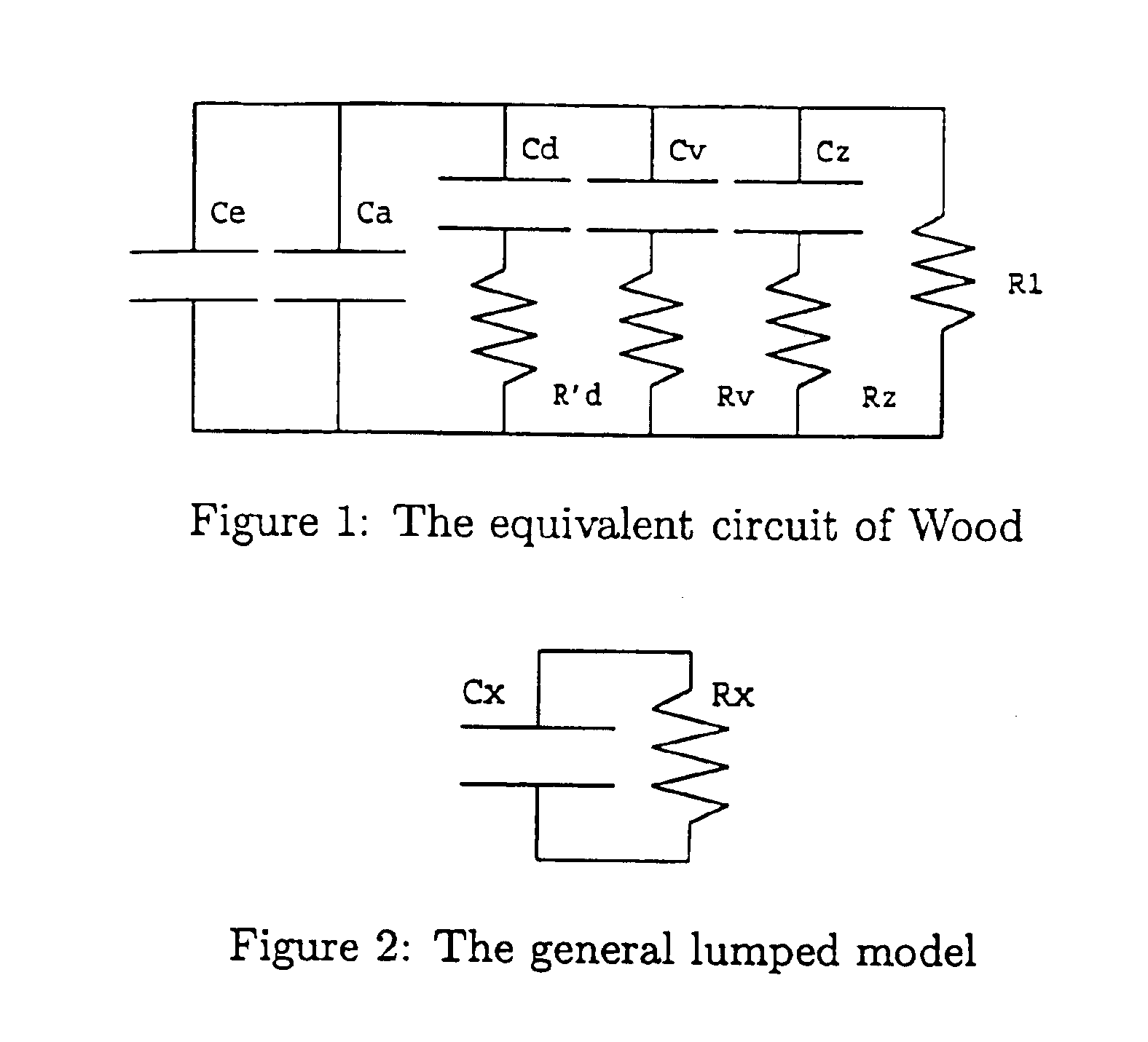

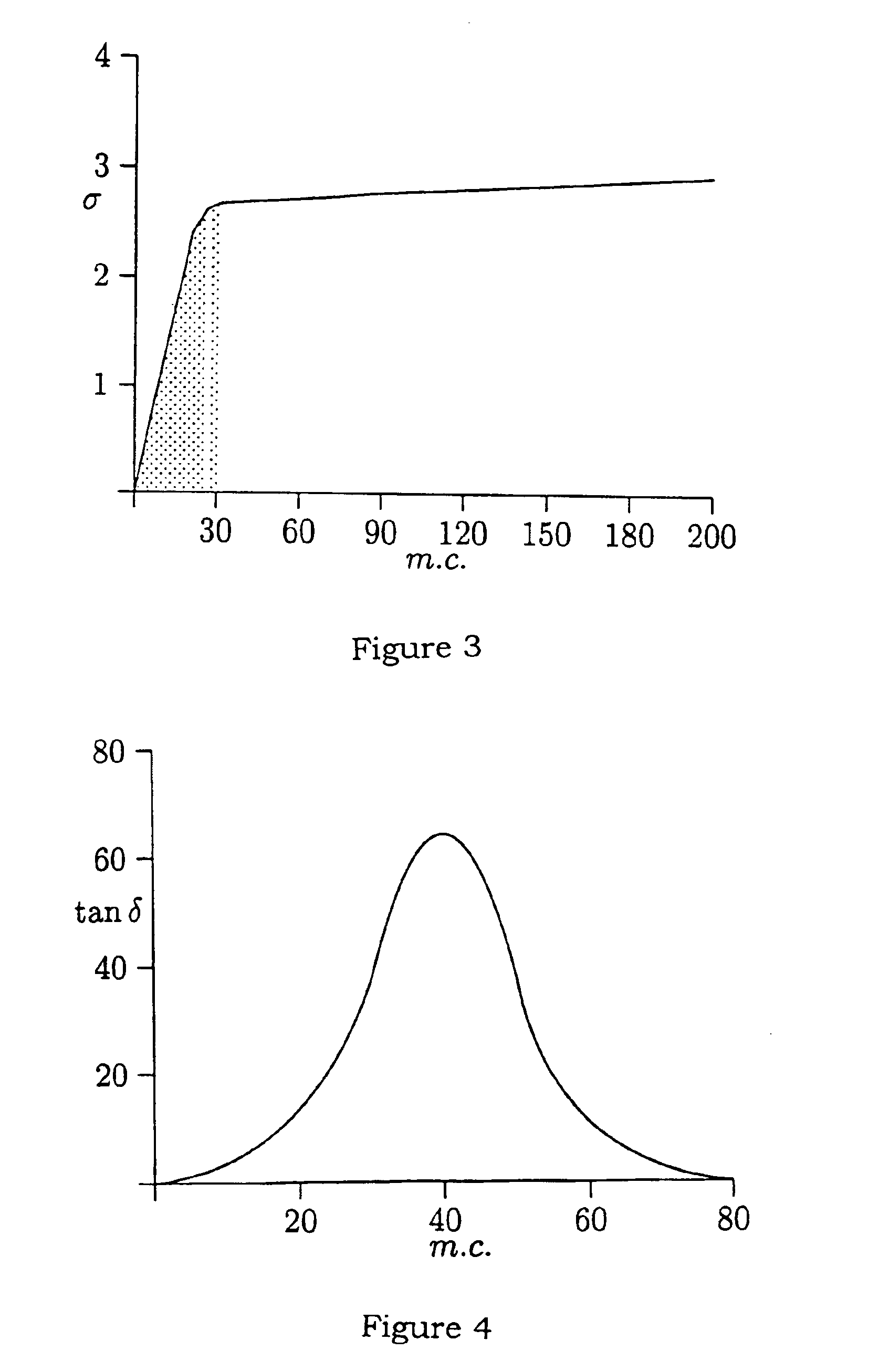

InactiveUS6989678B2Dependent on conductivityReduce conductivityResistance/reactance/impedenceWood testingCapacitanceElectrical resistance and conductance

A wood drying installation for a wood drying kiln including a pair of electrodes adapted to be inserted into a wood stack contained in the kiln, a resistance connected in a series circuit with the electrodes, an AC voltage source connected to apply an AC voltage across the series circuit, a phase detecting circuit connected to the series circuit operable to generate a signal representing the phase angle between AC voltages applied to different parts of the series circuit, and a processor to receive the signal. The system is operable to determine a moisture value corresponding to a capacitive component of the reactive impedance between the electrodes in accordance with a predetermined arithmetic algorithm relating the value to the phase angle.

Owner:VENTER LIEBRECHT +1

Anti-cracking technology of solid wood

InactiveCN102189578AAvoid crackingAvoid deformationWood treatment detailsWood impregnation detailsSolid woodPulp and paper industry

The invention relates to a processing method of wood of the furniture industry, in particular to an anti-cracking technology of solid wood. The anti-cracking technology of the solid wood sequentially comprises the following steps of: (1) soaking a raw wood in a water tank for 60 to 90 days; (2) cutting the soaked raw wood into boards according to the required size; (3) steaming the boards in a steam box for 2 to 4 days; and (4) drying the steamed boards to a required moisture content. The raw wood is soaked for long time so as to lead the raw wood to die really; the boards are steamed for days; the wood is plasticized so that the boards are more tougher; the boards and the wood are combined so as to lead the wood to be tough, tensile and firm and is not easy to crack; and a special drying technology of first natural drying and then alternating temperature drying prevents the wood from cracking and deforming in the drying process.

Owner:ZHEJIANG MOXIA IND

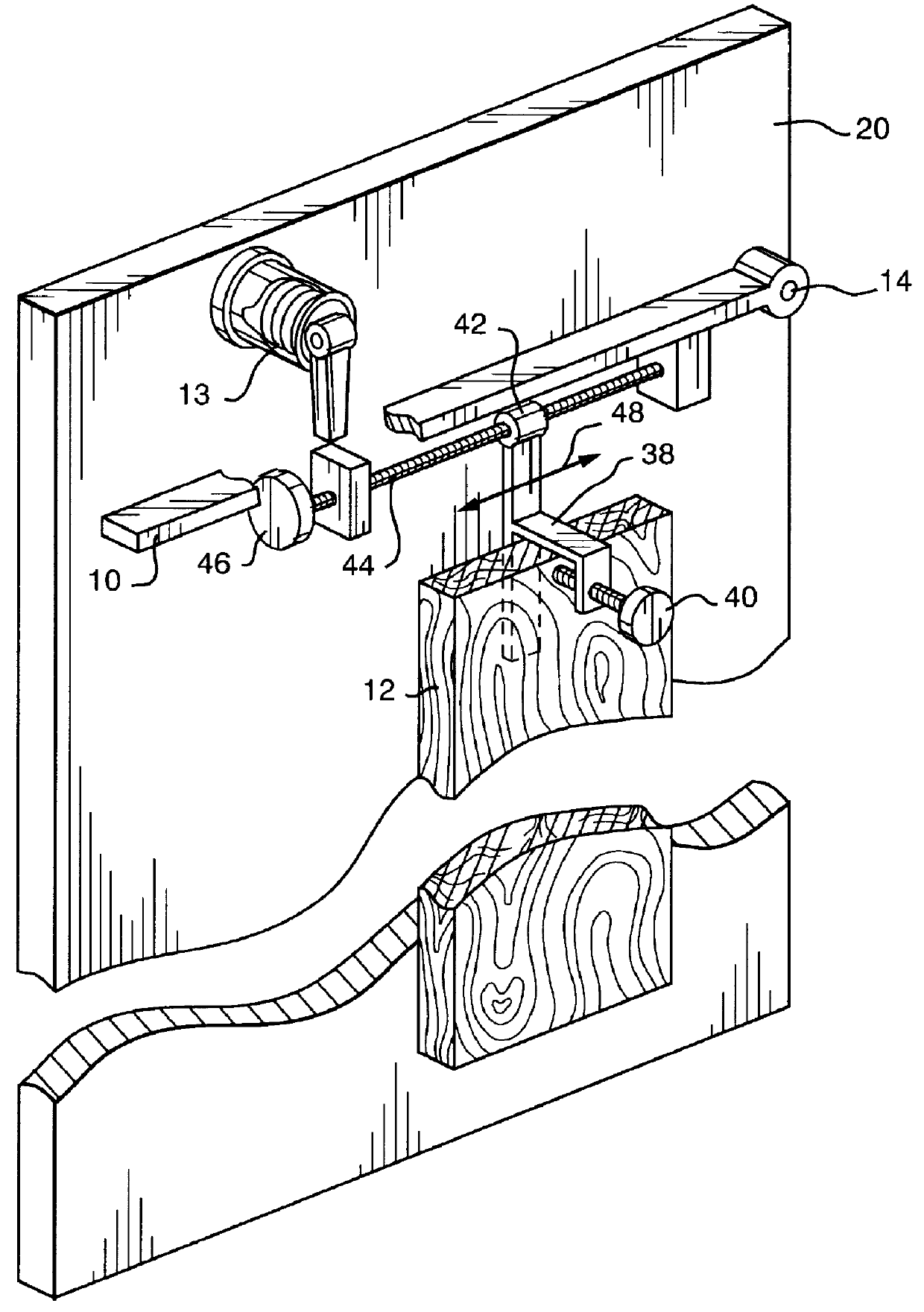

Monitoring wood sample weight with mechanical force proportioning

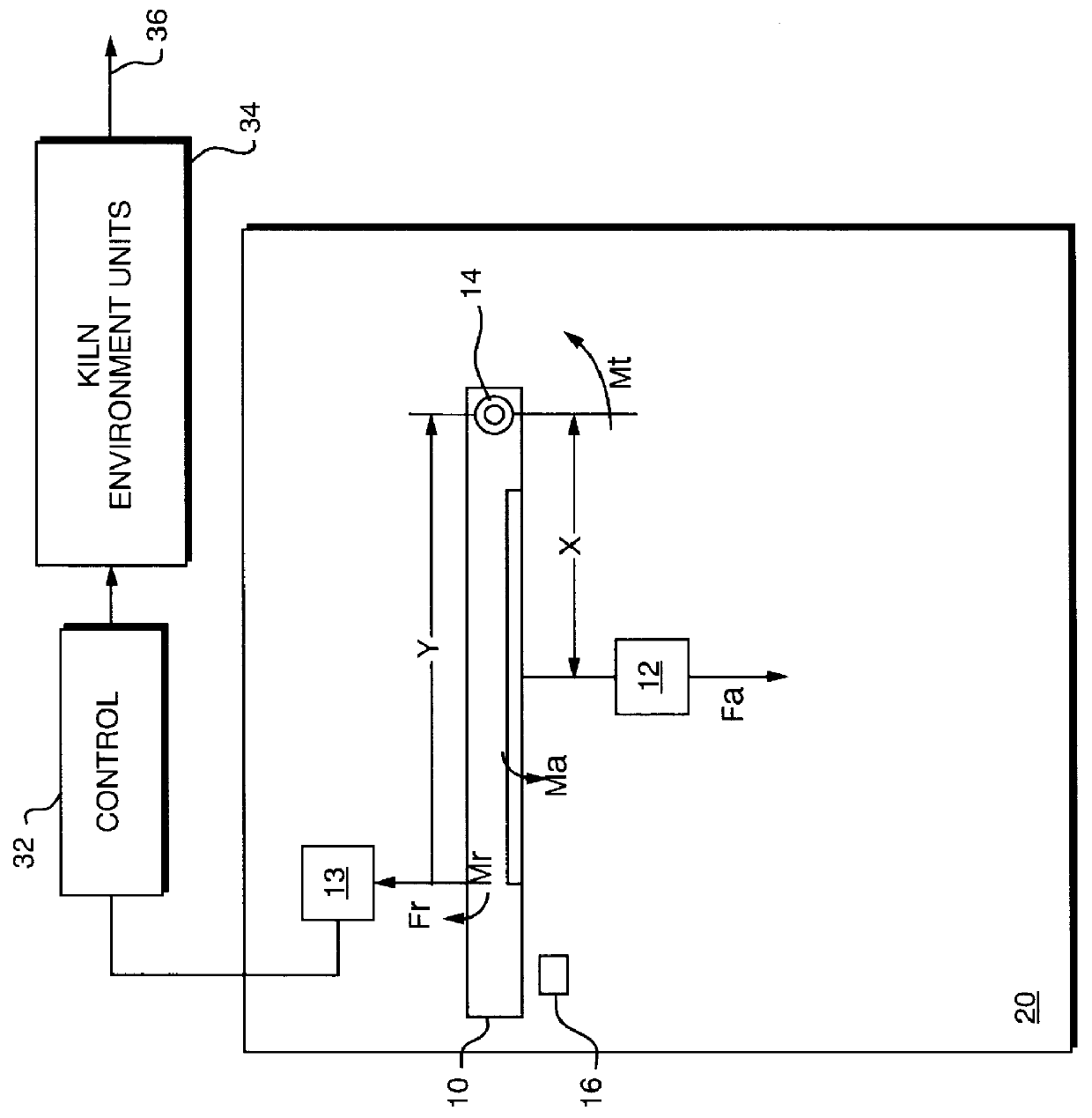

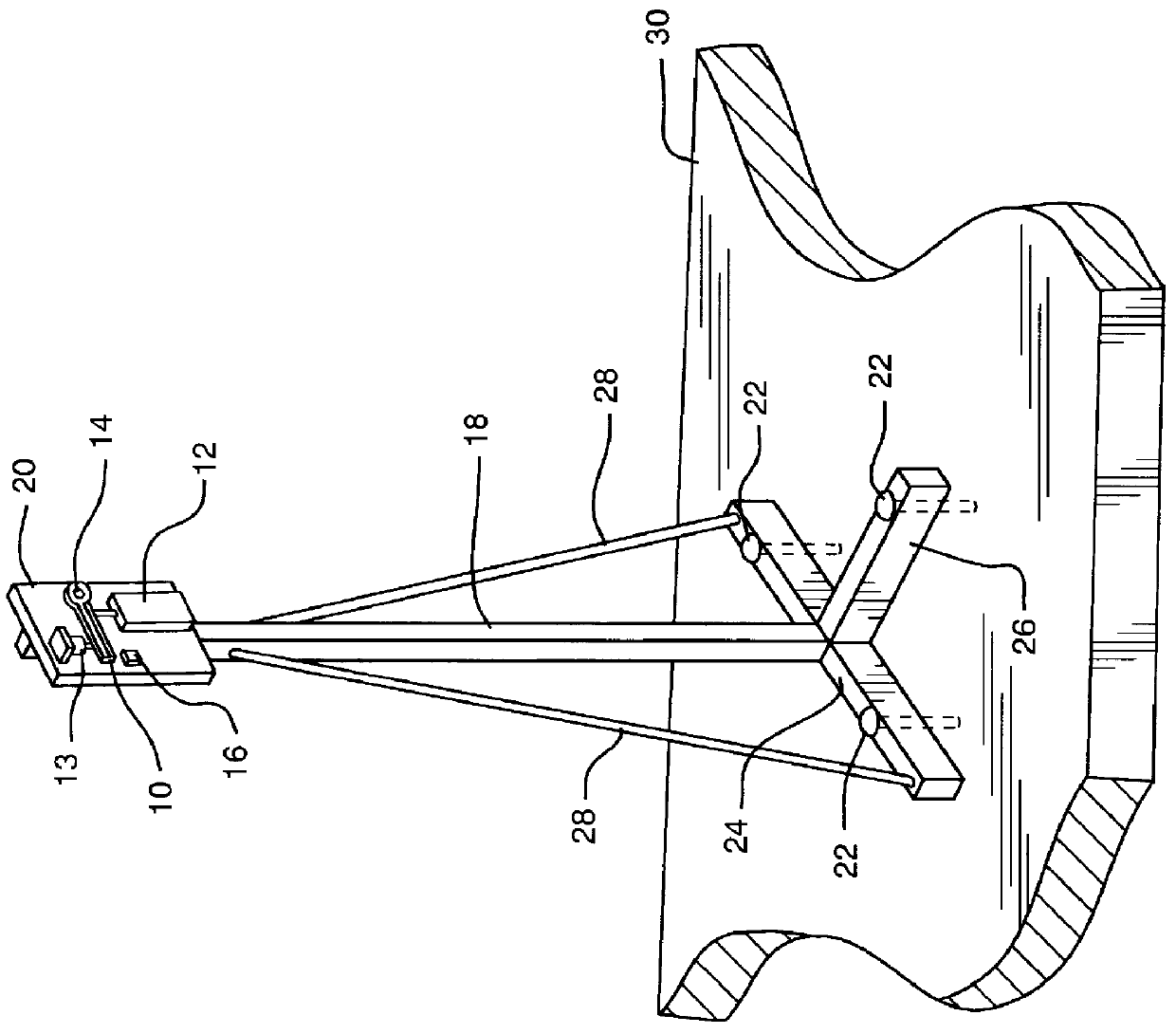

InactiveUS6141888AAvoid getting in the wayFree spaceWeighing by removing componentDrying gas arrangementsMonitoring systemEngineering

In a monitoring system for a wood drying kiln having a housing with an interior area for placement of a charge of wood for drying the charge of wood, the interior area having a floor, environment devices for adjusting heat and humidity in the interior area of the kiln, and a control unit for controlling the environment devices, the improvement is a support in the interior area for supporting a representative sample of the charge of wood, a sensor mounted to the support for sensing the weight of the sample which is a function of moisture content in the sample and a proportioning mechanism connected between the sensor and the sample for suspending the sample and for applying a proportioned force resulting from the weight of the sample to the sensor. The sensor is connected to the control unit for generating a signal which is proportional to the weight, and thus, to the moisture content of the sample. A stand on the kiln floor has a member for carrying the support at a location which is spaced from the wood charge without requiring and kiln wall space. The invention also includes the possibility of supporting the sensor from the ceiling and at any location in the kiln whether the sensor is supported from the ceiling or the floor. The invention is also useful in kilns for drying other materials than wood.

Owner:AMERICAN WOOD DRYERS

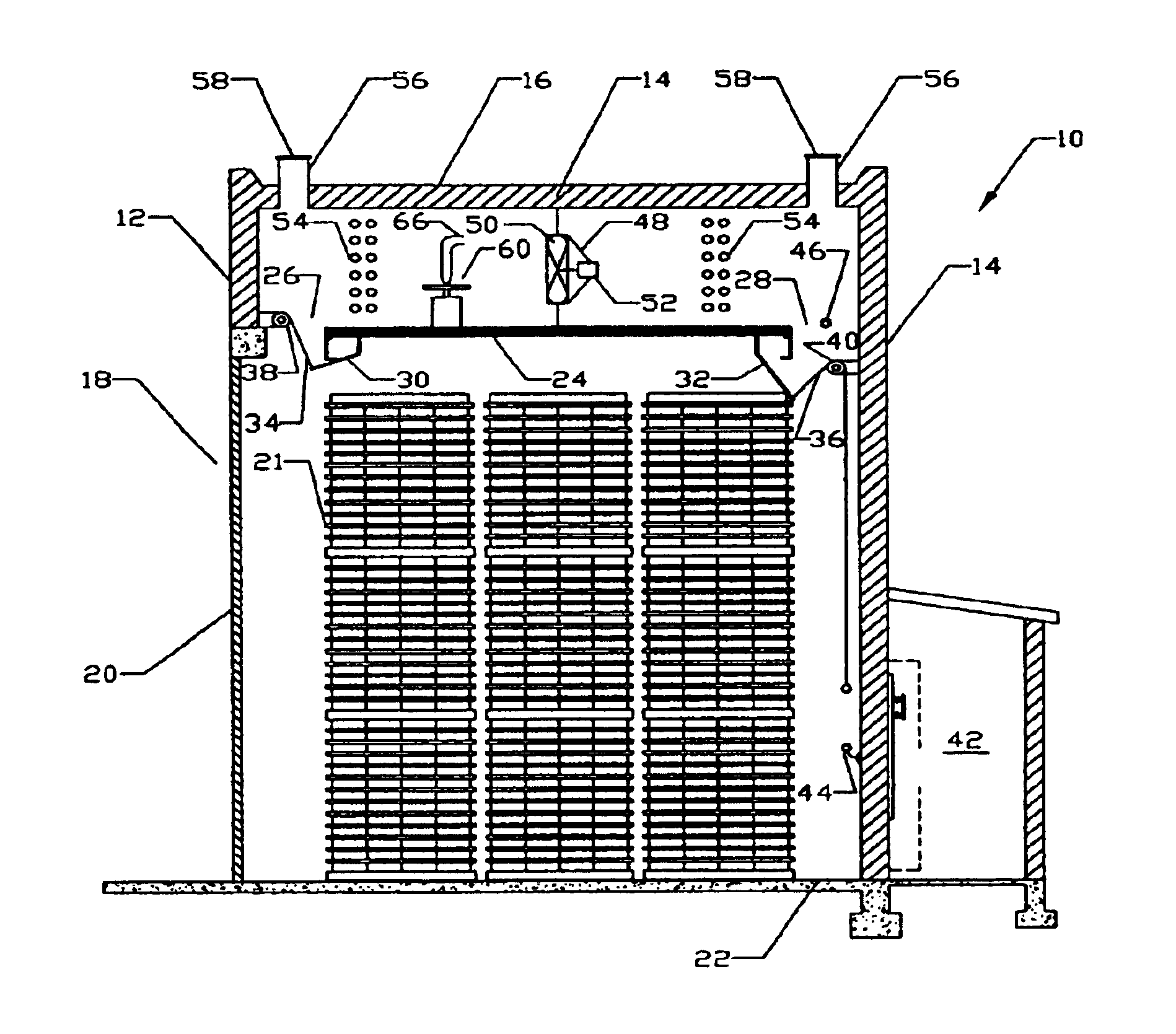

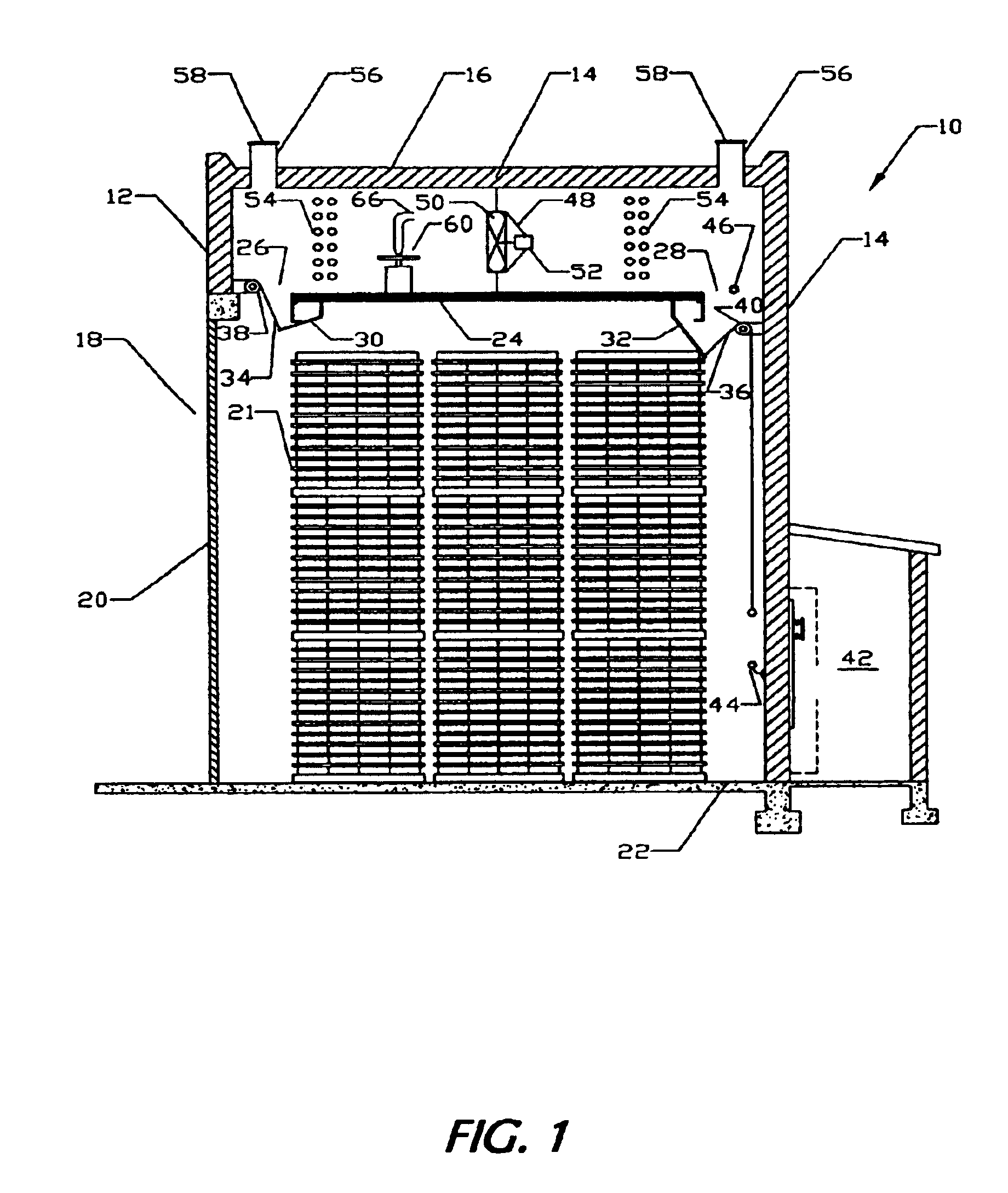

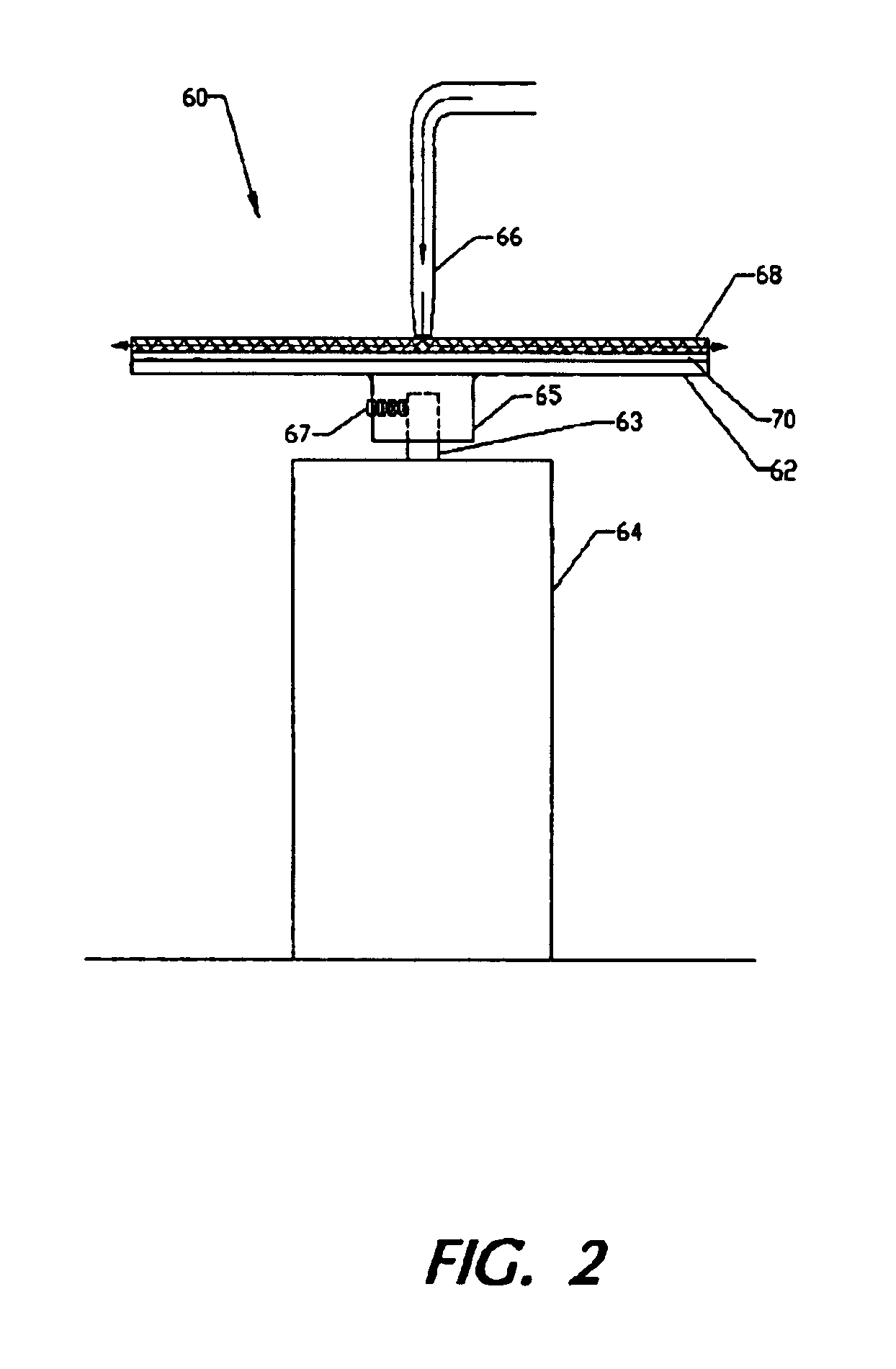

Humidity generating system and method and use in wood drying kiln

InactiveUS6772535B2Avoid it happening againInexpensively and efficiently controllingDrying using combination processesDrying gas arrangementsCircular discWater vapor

An apparatus and method for generating water vapor or humidity, useful in a variety of applications, including a wood drying kiln. The apparatus may contain a hydrophilic disk, a water supply structure that supplies water so that the water is deposited on the hydrophilic disk, and a motor for rotating the disk at a speed sufficiently high so that water which is deposited on the disk is caused to leave the disk in the form of a mist of particles or droplets which are sufficiently small to evaporate rapidly to generate the water vapor. The disk may be made hydrophilic by covering with a fabric.

Owner:KX TECH LLC (DW US)

Drying process for preventing eucalyptus wood shrinkage

InactiveCN102303331APrevent shrinkageEvenly distributedPressure impregnationWood impregnation detailsAdditional valuesHigh water content

The invention relates to a drying process for preventing eucalyptus wood shrinkage, and belongs to the technical field of eucalyptus wood drying. The process comprises the following steps of: (1) performing soaking treatment on fresh eucalyptus wood or raw eucalyptus wood with high water content; (2) after the soaked raw wood is placed for 3 to 5 days, processing the raw wood into boards with thickness of 5 centimeters or 7 centimeters; and (3) drying the eucalyptus wood boards by controlling the center temperature of the wood and the humidity of the drying medium, and performing heating, heat insulation, drying and humidifying treatment of multiple stages. By the process, the defects of shrinkage, bending, cracking and the like easily produced in the drying process of the eucalyptus wood boards are overcome, and a new path is developed for improving the additional value of the eucalyptus wood.

Owner:BEIJING FORESTRY UNIVERSITY

Moisture content measuring method for wood drying process and wood drying method

ActiveCN108802352AAccurate moisture contentReduce drying defectsWeighing by removing componentWood testingNarrow rangeSolid wood

The invention discloses a moisture content measuring method for a wood drying process and a wood drying method. The moisture content measuring method for the wood drying process and the wood drying method include: measuring an initial moisture content and initial weight of to-be-dried wood, and stacking the to-be-dried wood in a drying kiln; measuring temperature and wind speed of media flowing through two sides of the stacked to-be-dried wood, acquiring saturated vapor pressure of moist air according to dry-bulb temperature, acquiring relative humidity of the moist air according to temperatures of wet and dry bulbs, and finally acquiring density and moisture content of the moist air so as to obtain moisture contents of the to-be-dried wood at different times; according to the moisture contents of the to-be-dried wood, drying the to-be-dried word according to wood drying standards so as to obtain high-quality dry wood. The moisture content measuring method is precise, simple, low in input, applicable to any wood moisture content measurement, less in measuring parameters, simple in calculation, systematically stable, capable of overcoming the defects of large measuring error and narrow range of an electric measuring method and improving quality of solid wood plates, high in efficiency and low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

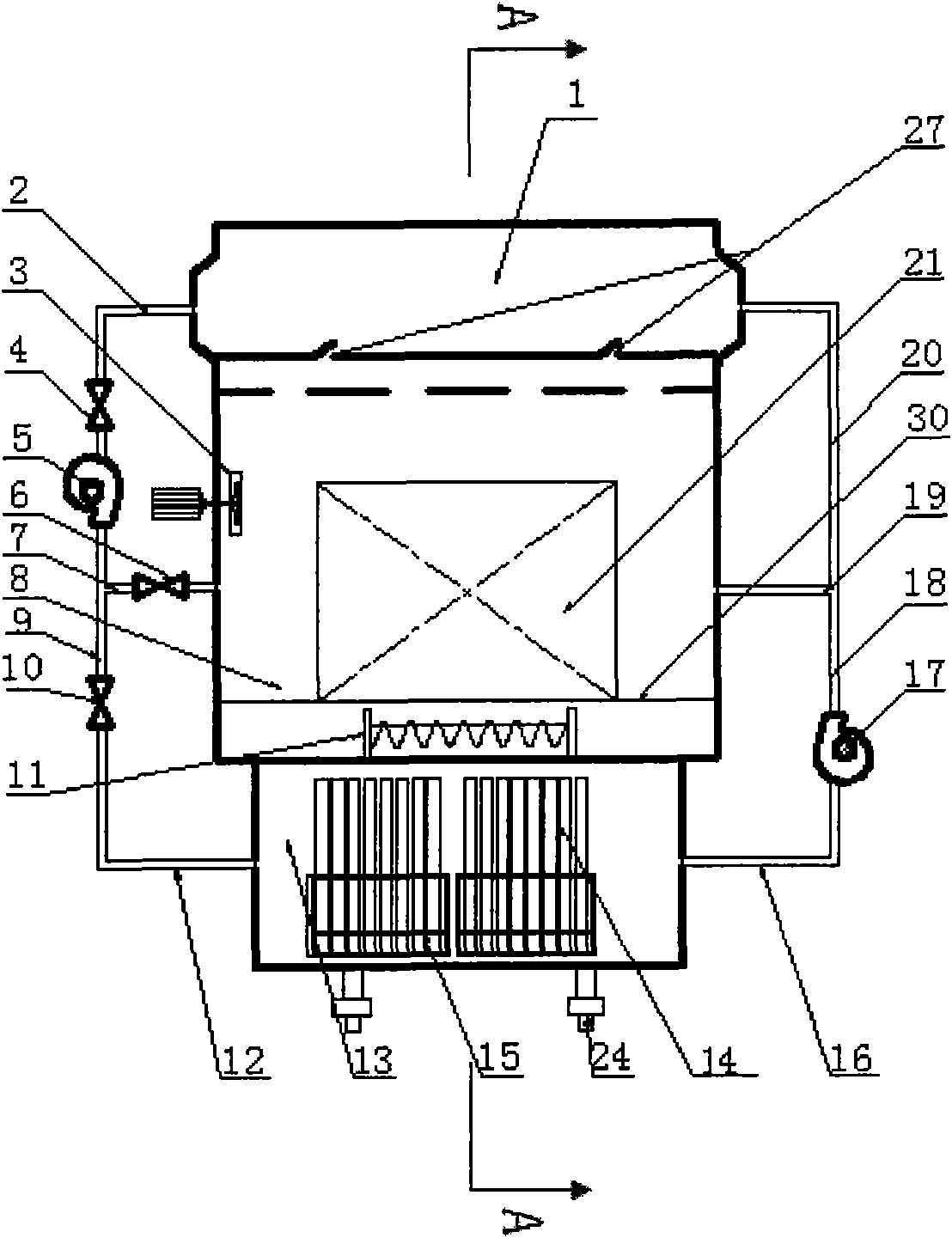

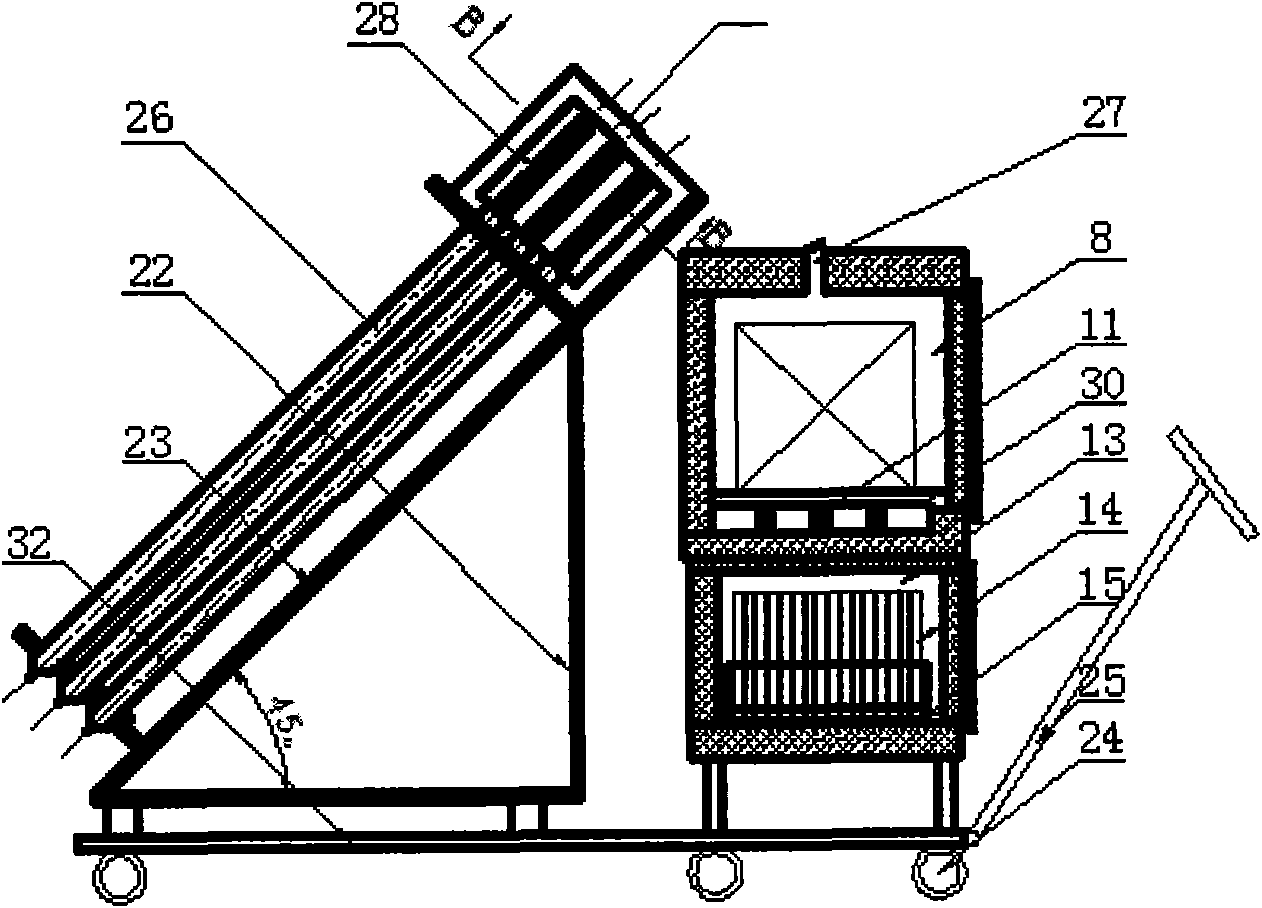

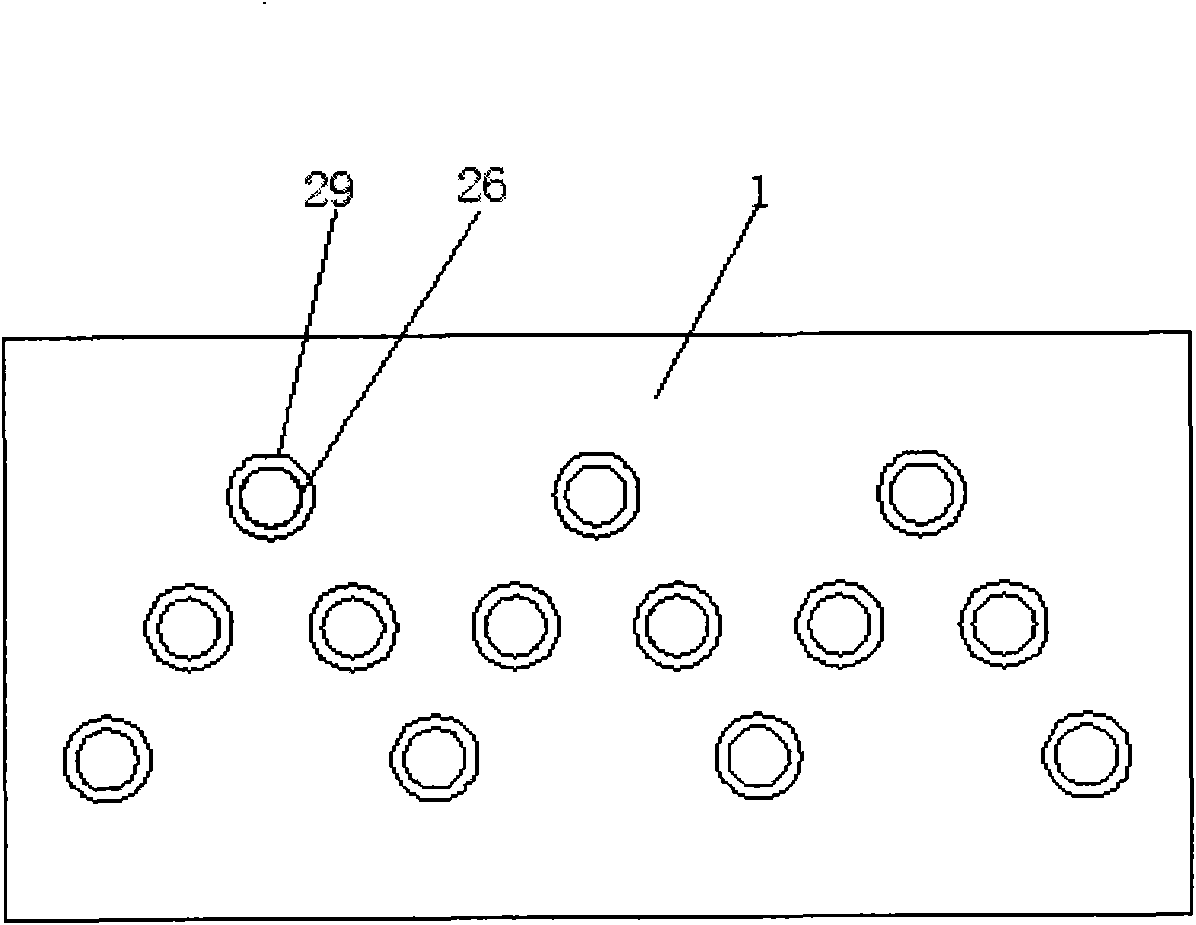

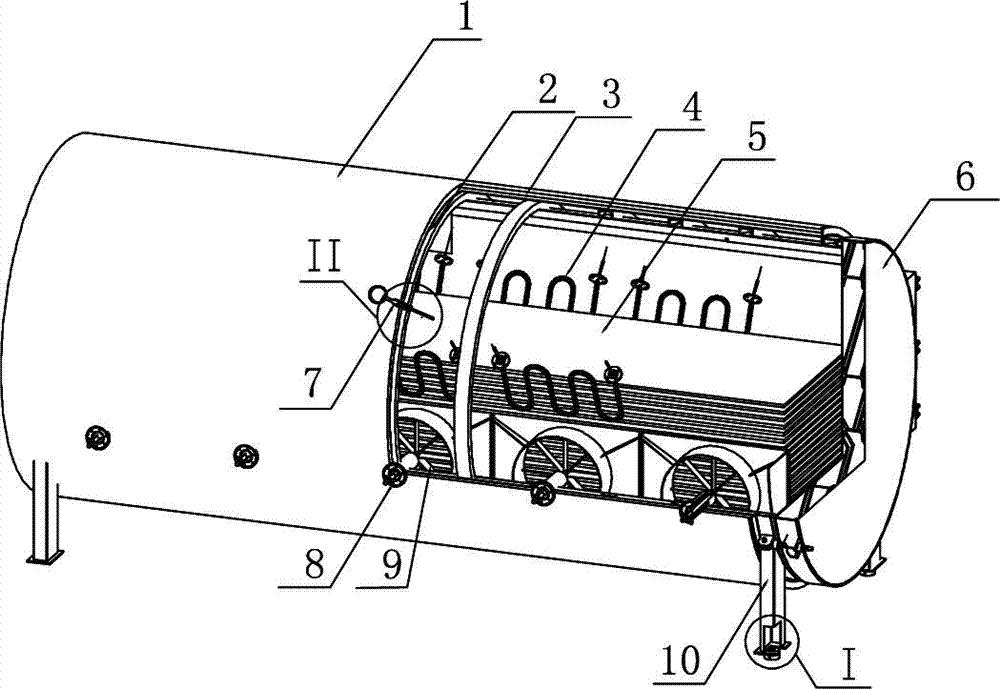

Wood vacuum drying-carbonization integrated kiln

ActiveCN103542696ASmall error in real-time moisture contentSmall footprintDrying chambers/containersDrying machines with local agitationThermal insulationCarbonization

The invention discloses a wood vacuum drying-carbonization integrated kiln which comprises a kiln body, a vacuum system connected with the kiln body, a vapor system, a water discharging system, an air discharging system, a compression system and an electric control system. A rapid-opening door is arranged on the kiln body, a heating pipe and a convection fan are arranged in the kiln body, stand bars are arranged at the bottom of the kiln body, the kiln body is separated from the ground through the stand bars in a suspended mode, a kiln body weight sensor is arranged at the bottom of each stand bar, the kiln body is an interlayer kiln body, a thermal insulation material covers the outer wall of the kiln body, the interlayer of the kiln body is filled with cooling water, and a cooling water circulating heat-dissipating system is arranged outside the kiln body. According to the wood vacuum drying-carbonization integrated kiln, vacuum drying and carbonization of wood are conducted in the same kiln, integration of a wood drying device and a carbonization device is achieved, and the wood vacuum drying-carbonization integrated kiln has the advantages of being small in occupied area, saving in energy, high in work efficiency and the like.

Owner:开原圣意达木材干燥设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com