Eucalypt artificial wood drying method

A wood drying and artificial forest technology, applied in the field of eucalyptus wood drying, can solve the problems affecting the quality of eucalyptus wood, and achieve the effect of avoiding shrinkage and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Material selection, eucalyptus of different tree species and sawn timber of different thicknesses should be dried separately. When the number of wood is less than one kiln, it is allowed to dry tree species with similar drying characteristics and initial moisture content in the same kiln;

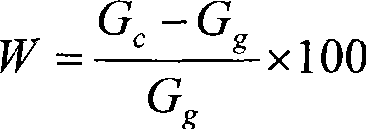

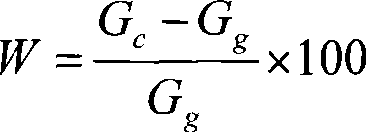

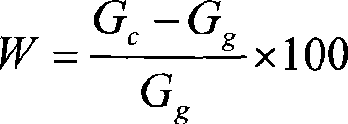

[0017] (2) Measure the initial moisture content, check the sawn timber to obtain the moisture content, and the sawn timber with different moisture content should be dried separately;

[0018] (3) For stacking, it is necessary to ensure the reasonable circulation of air flow in the kiln, make full use of the capacity of the kiln, and prevent wood warping and end cracking. The length, width and height of the pile should meet the design requirements of the drying kiln. When the amount of wood is less than one kiln, the width of the pile is allowed to be reduced, but the pile should be stable during operation. For forced circulation kilns, the sides of each layer of materials should ...

Embodiment 2

[0054] The difference from Example 1 is the drying standard, and the others are the same, so they will not be repeated.

[0055] Benchmarks for eucalyptus drying include:

[0056] (1) Preheating of sawn timber, keeping the dry bulb temperature in the kiln at 50°C and the wet bulb temperature at 49.5-50°C for 3 hours;

[0057] (2) At the stage of 30% moisture content of sawn timber, keep the dry bulb temperature in the kiln at 60°C and the wet bulb temperature at 59°C for 3 hours;

[0058] (3) At the stage of 20% moisture content of the sawn timber, keep the dry bulb temperature in the kiln at 70°C and the wet bulb temperature at 68°C, and perform intermediate treatments for 2-3 times, each time for 3 hours;

[0059] (4) At the stage of 8-10% moisture content of the sawn timber, carry out final treatment, keep the dry bulb temperature in the kiln at 80°C, and the wet bulb temperature at 74°C, shrinkage recovery treatment for 3 hours, and maintain for 5 hours.

[0060] The spe...

Embodiment 3

[0064] The difference from Example 1 is the drying standard, and the others are the same, so they will not be repeated.

[0065] Eucalyptus giant drying benchmarks include:

[0066] (1) Preheating of sawn timber, keeping the dry bulb temperature in the kiln at 55°C and the wet bulb temperature at 54-55°C for 3 hours;

[0067] (2) At the stage of 30% moisture content of the sawn timber, keep the dry bulb temperature in the kiln at 68°C and the wet bulb temperature at 67°C for 3 hours;

[0068] (3) At the stage of 20% moisture content of sawn timber, keep the dry bulb temperature in the kiln at 65°C and the wet bulb temperature at 63°C, and perform intermediate treatment for 2-3 times, each time for 3 hours;

[0069] (4) At the stage of 8-10% moisture content of the sawn timber, carry out final treatment, keep the dry bulb temperature in the kiln at 75°C, and the wet bulb temperature at 69°C, shrinkage recovery treatment for 3 hours, and maintain for 5 hours.

[0070] The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com