Patents

Literature

439 results about "Dry-bulb temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The dry-bulb temperature (DBT) is the temperature of air measured by a thermometer freely exposed to the air, but shielded from radiation and moisture. DBT is the temperature that is usually thought of as air temperature, and it is the true thermodynamic temperature. It indicates the amount of heat in the air and is directly proportional to the mean kinetic energy of the air molecules. Temperature is usually measured in degrees Celsius (°C), kelvins (K), or degrees Fahrenheit (°F).

Energy and cost savings calculation system

InactiveUS20060167591A1Accurate and reliable energyAccurate and reliable and cost savingMechanical power/torque controlData processing applicationsEngineeringCost savings

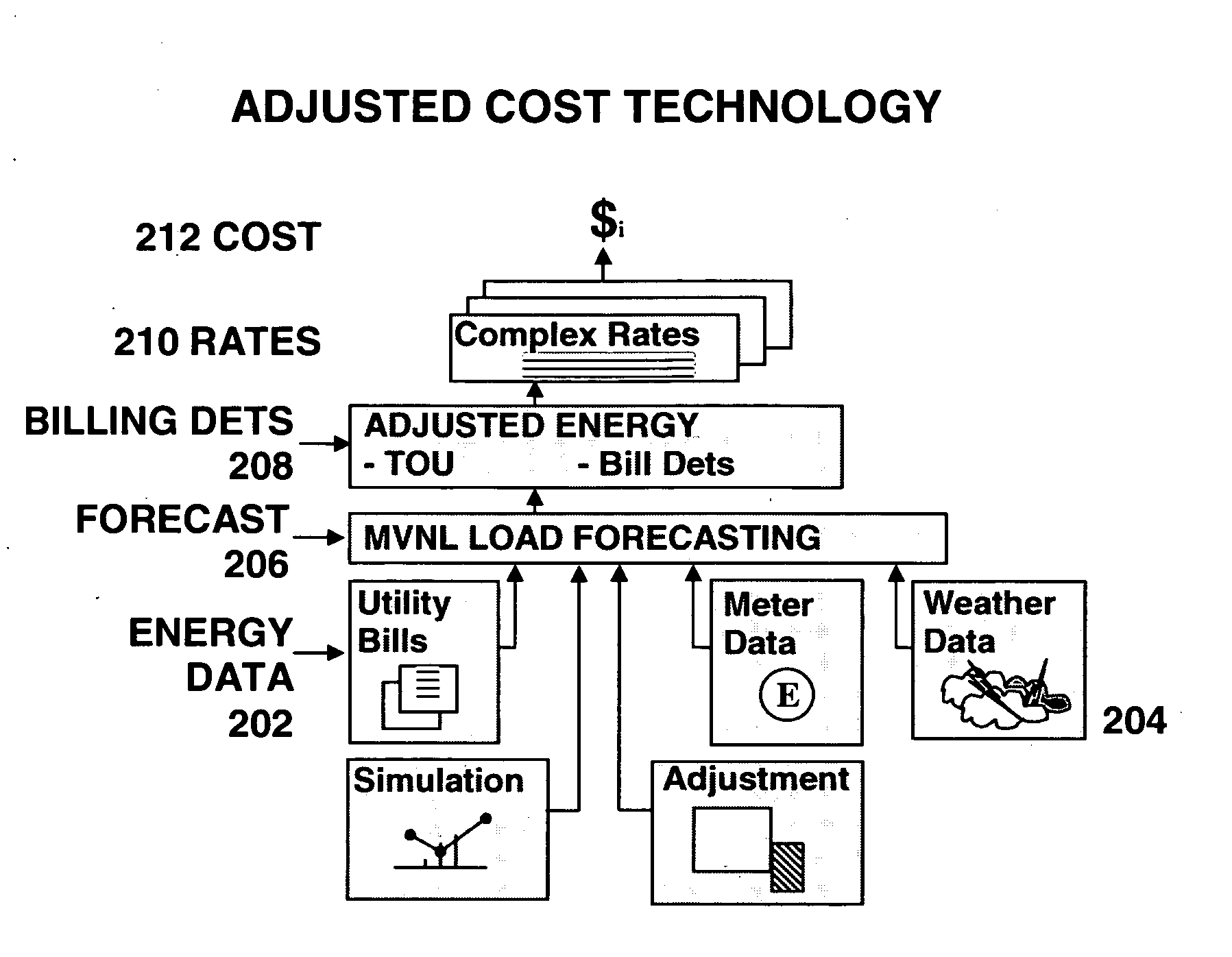

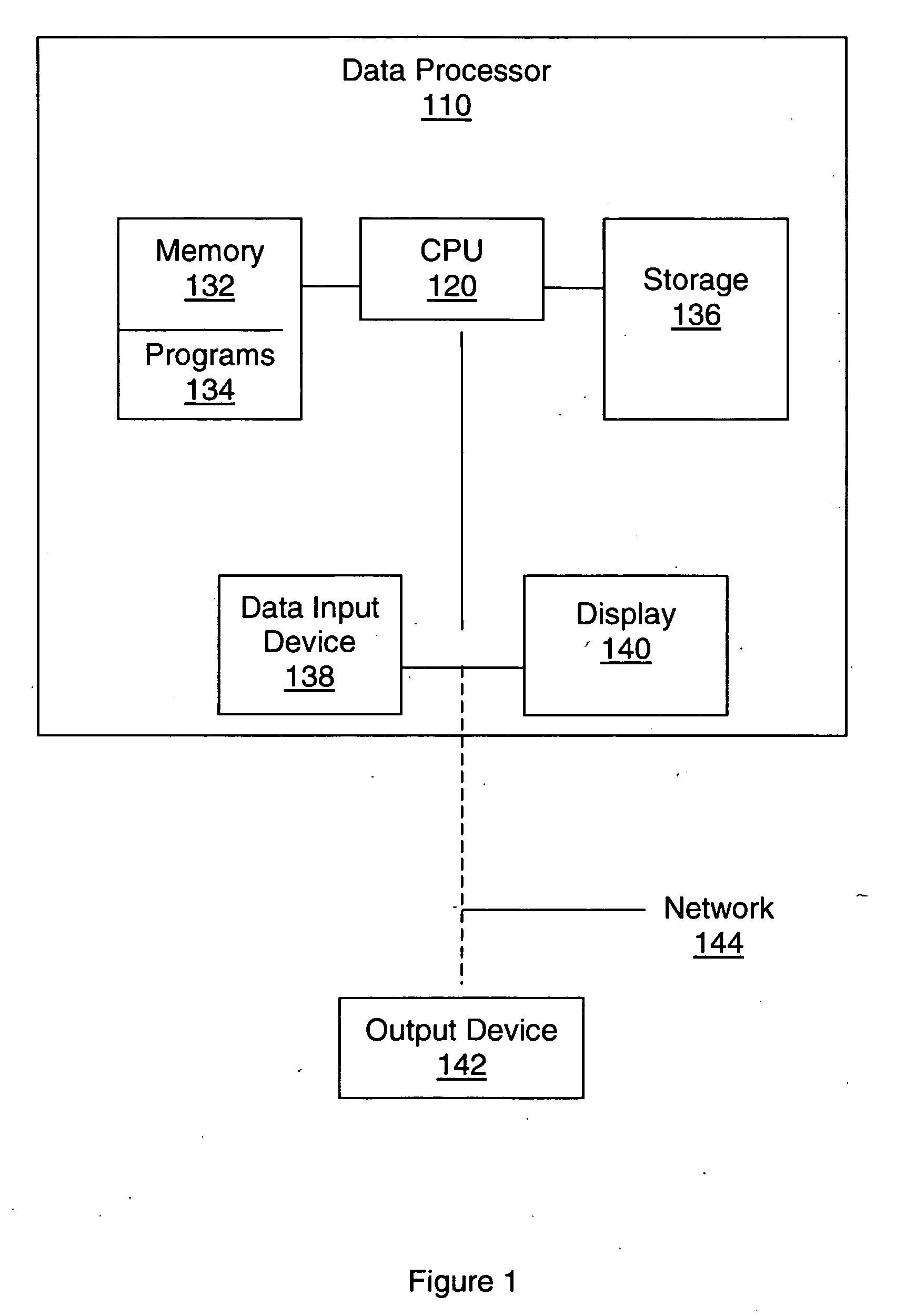

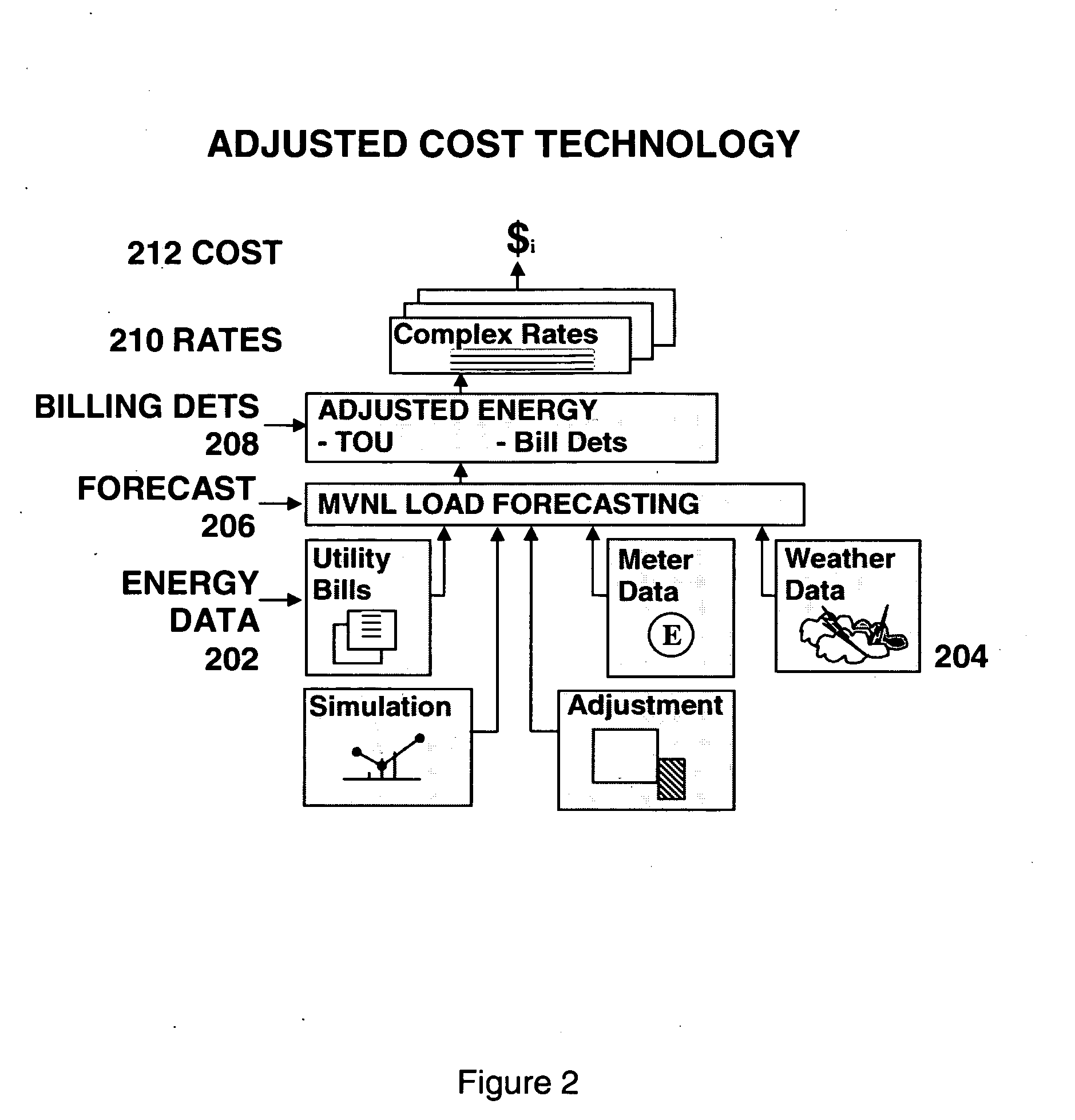

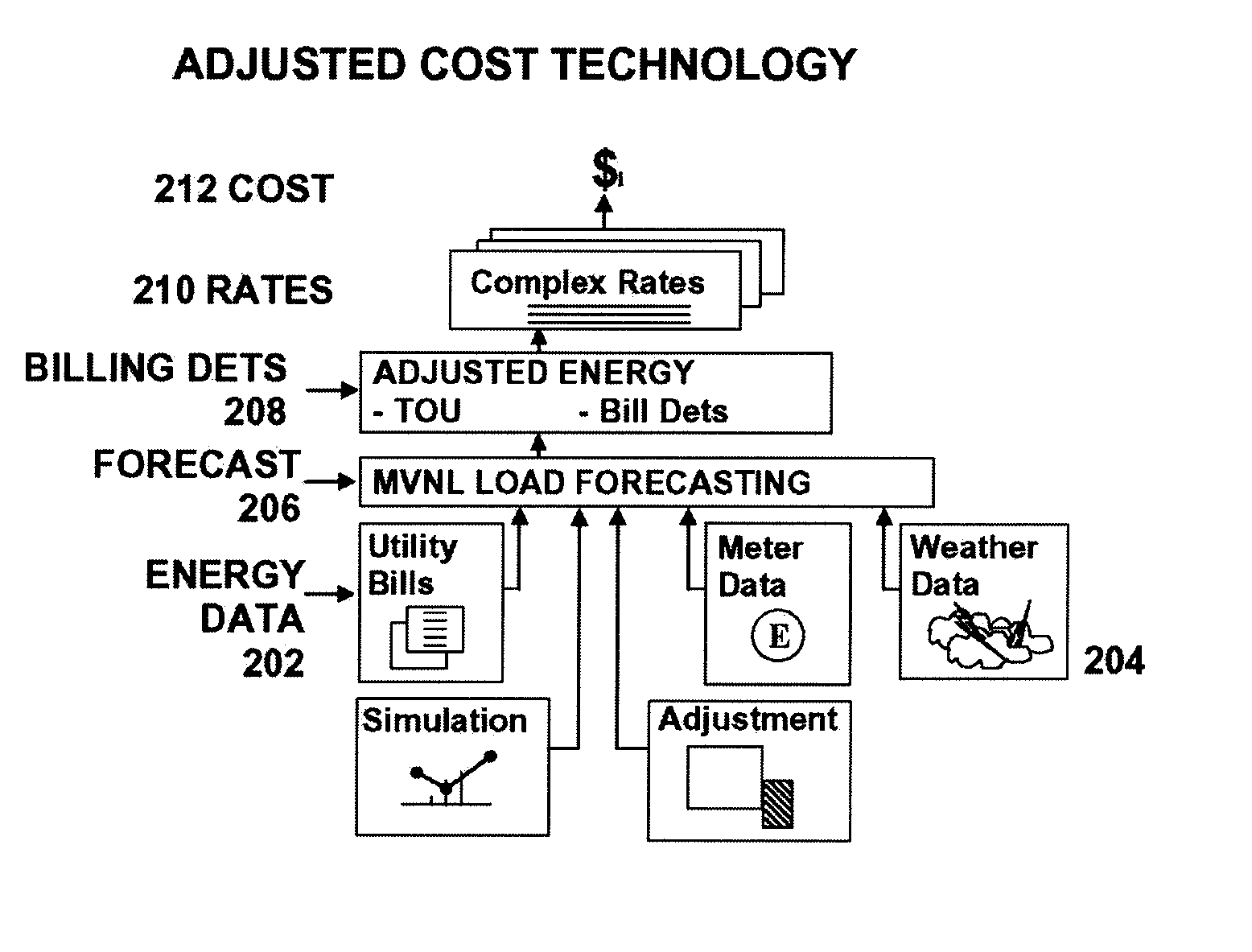

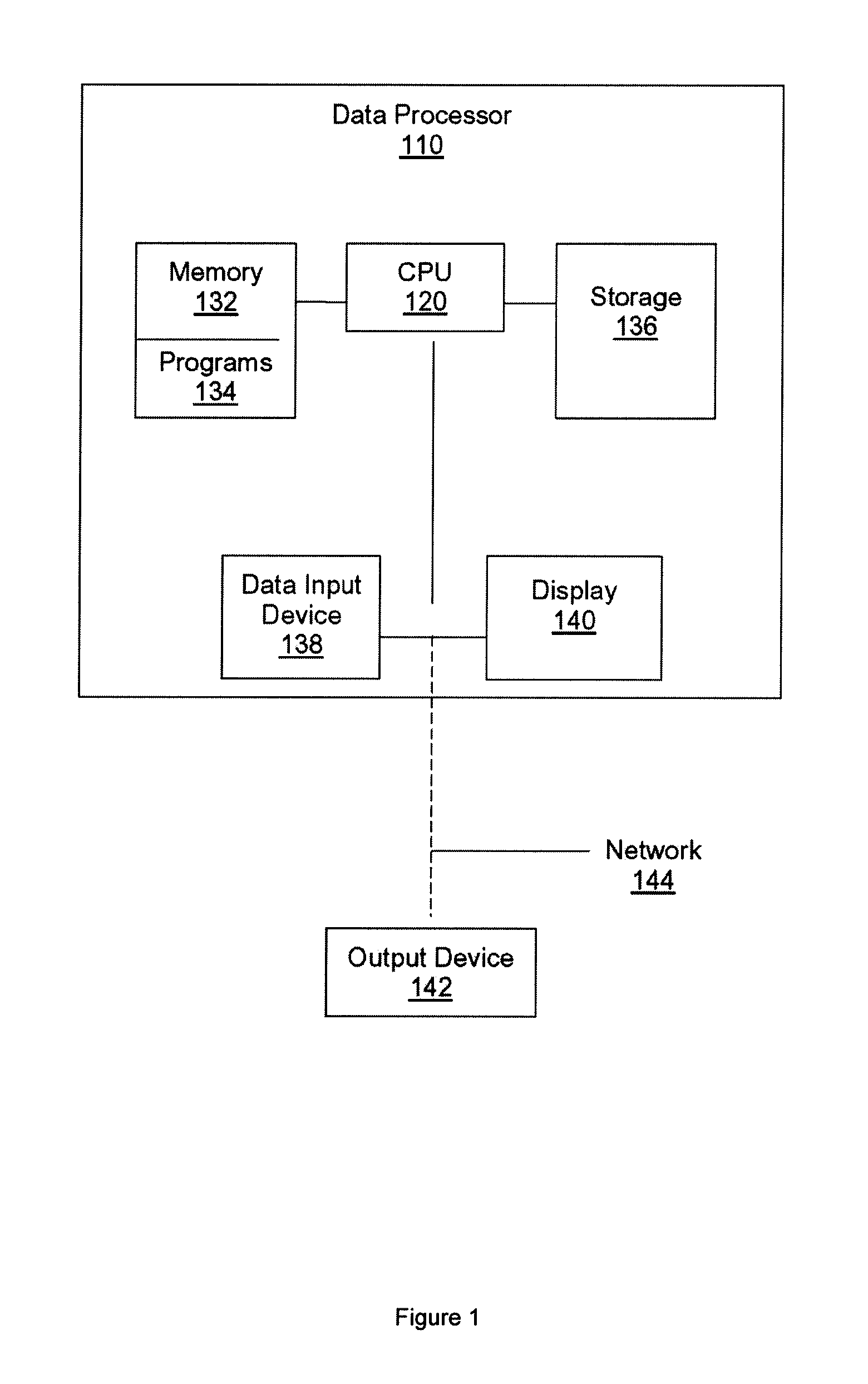

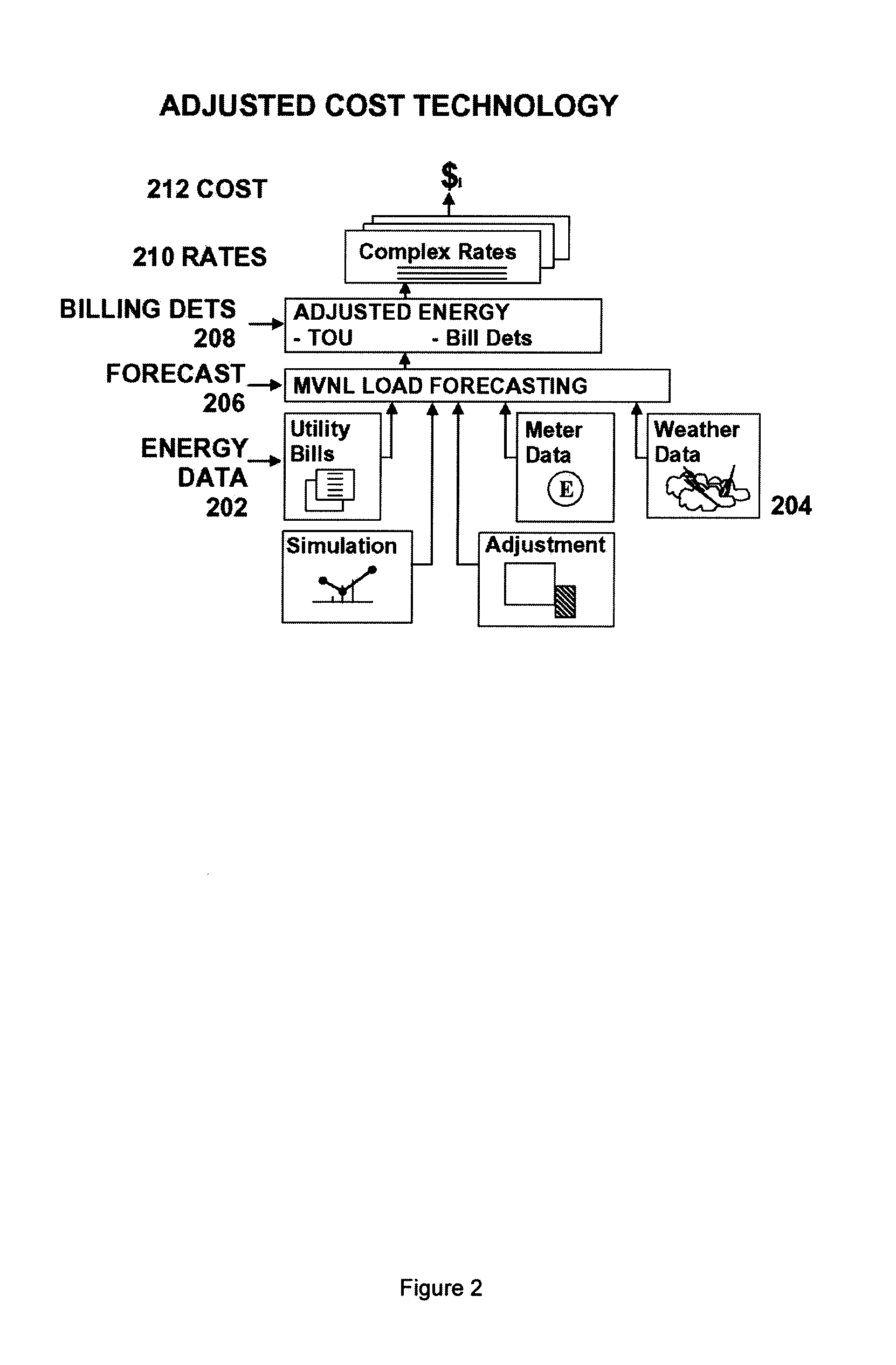

An Energy and Cost Savings Calculation System is provided that automates the determination of energy and cost savings due to energy conservation measures. The system provides Multi-Variant, Non-Linear (MVNL) load forecasting techniques, energy and cost savings calculations, and Weather Ranking. The load forecasting technique may accept numerous external parameters as input. The technique may use multiple Baselines. It may also use multiple Basic Reference Periods to reduce the load forecasting error. The load forecasting technique may utilize external parameters that are updated on a daily basis, such as dry bulb temperature, dew point temperature, solar condition, and interval meter data. The technique may use Baseline Extensions to perform forecasts and Reference Period Modifications to enhance accuracy. The system may calculate energy and cost savings using Complex Rates and time-of-use (TOU) energy data. The system may rank a plurality of sources providing weather data to identify the most accurate weather data.

Owner:SIEMENS IND INC

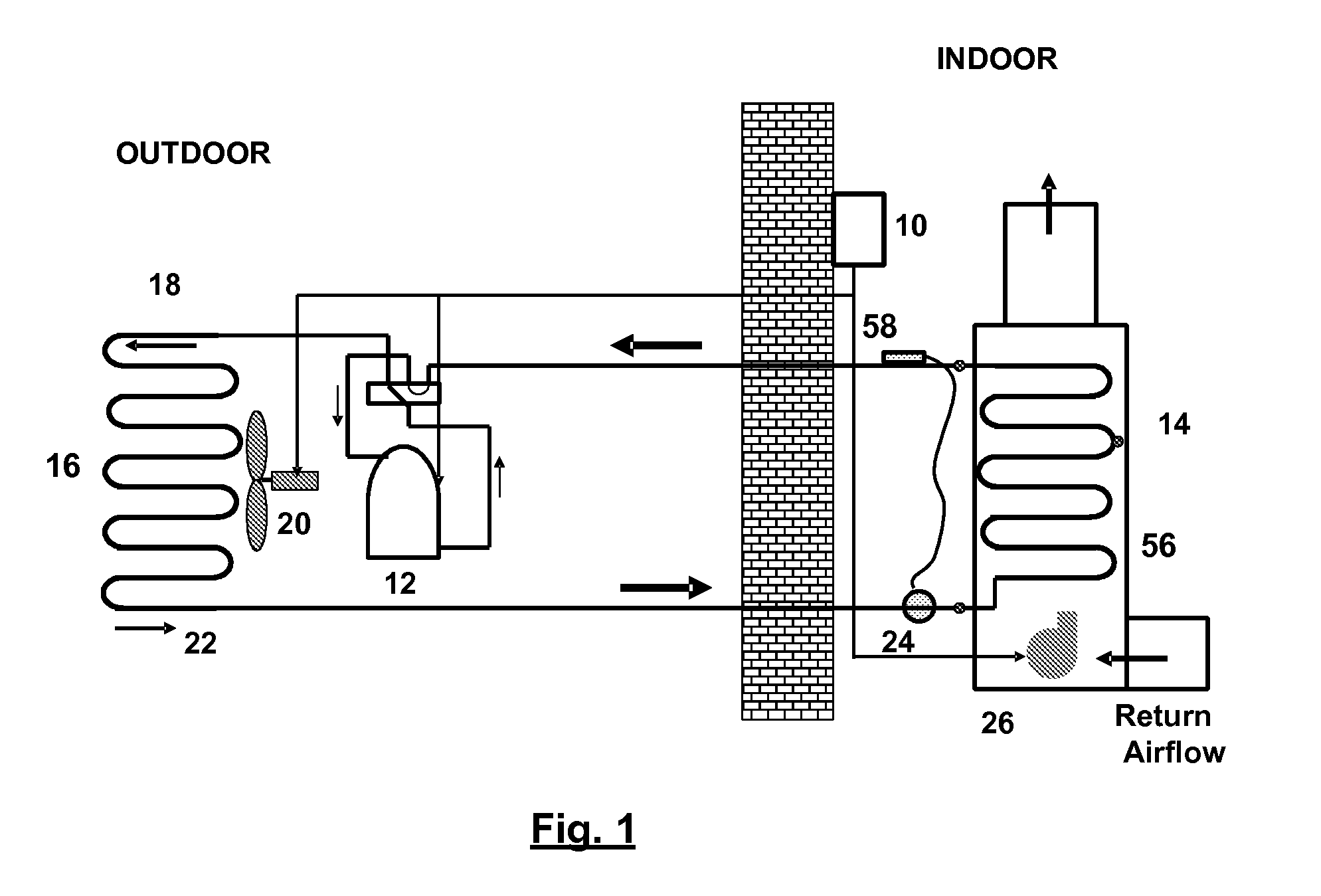

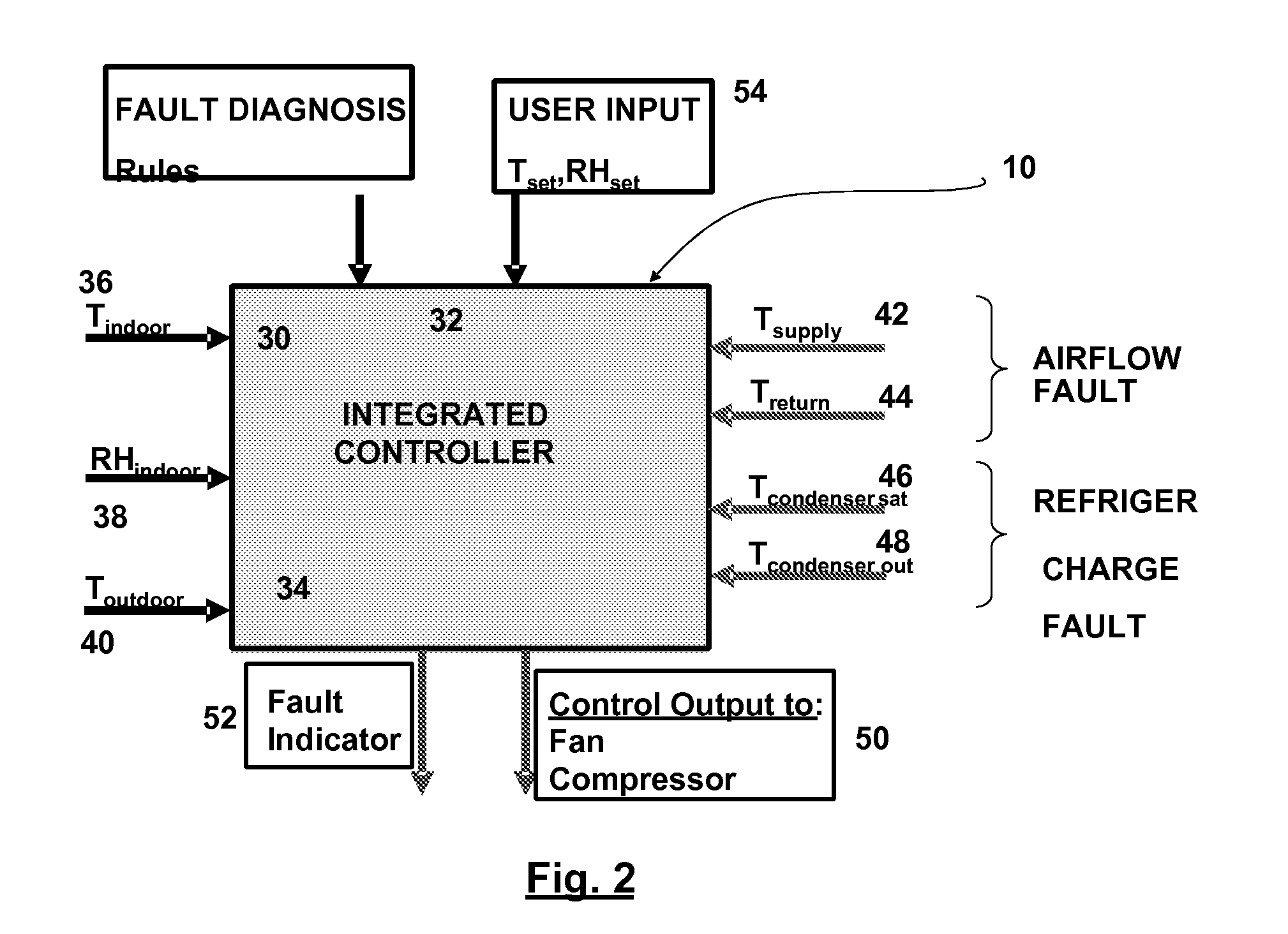

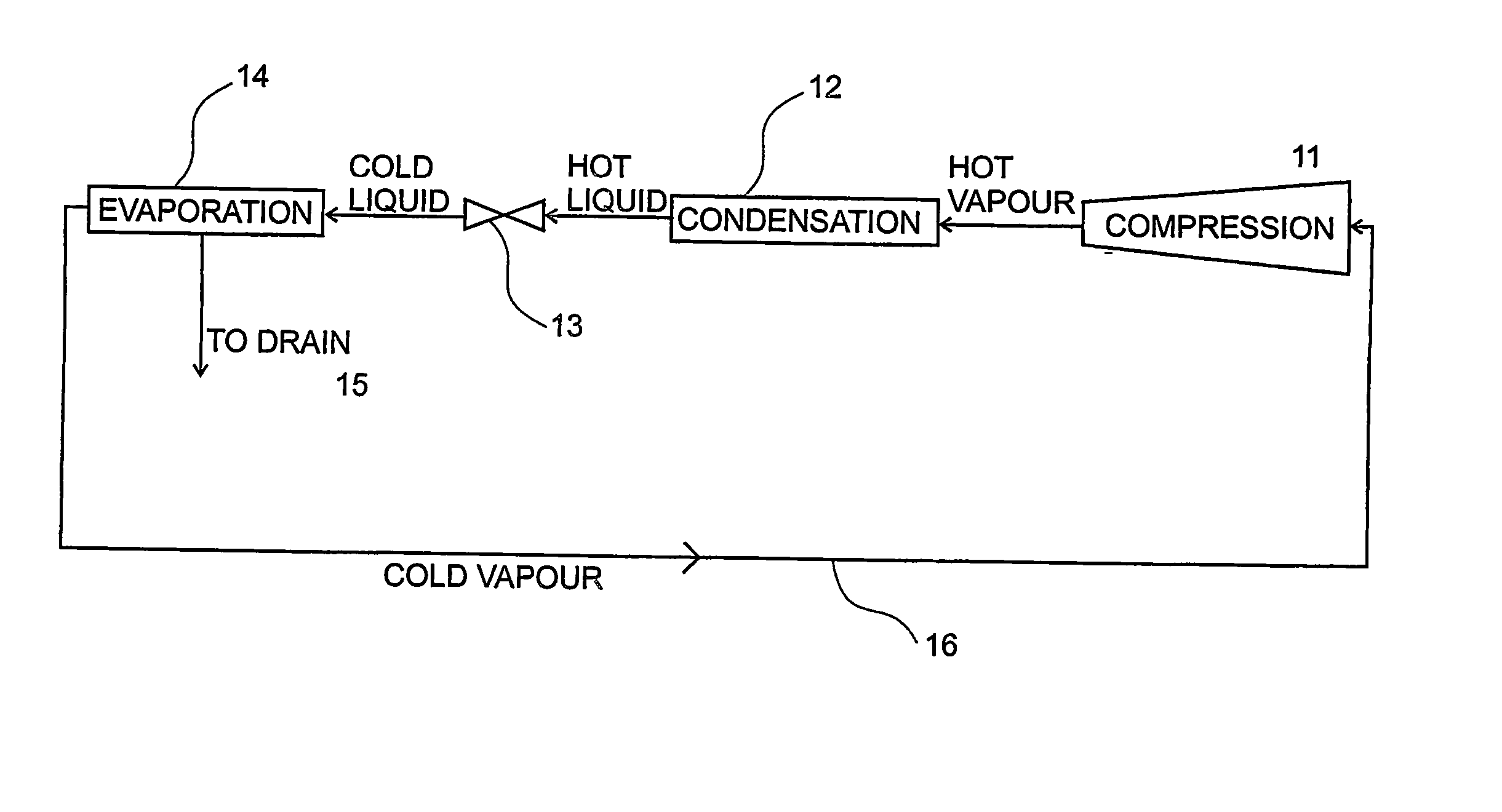

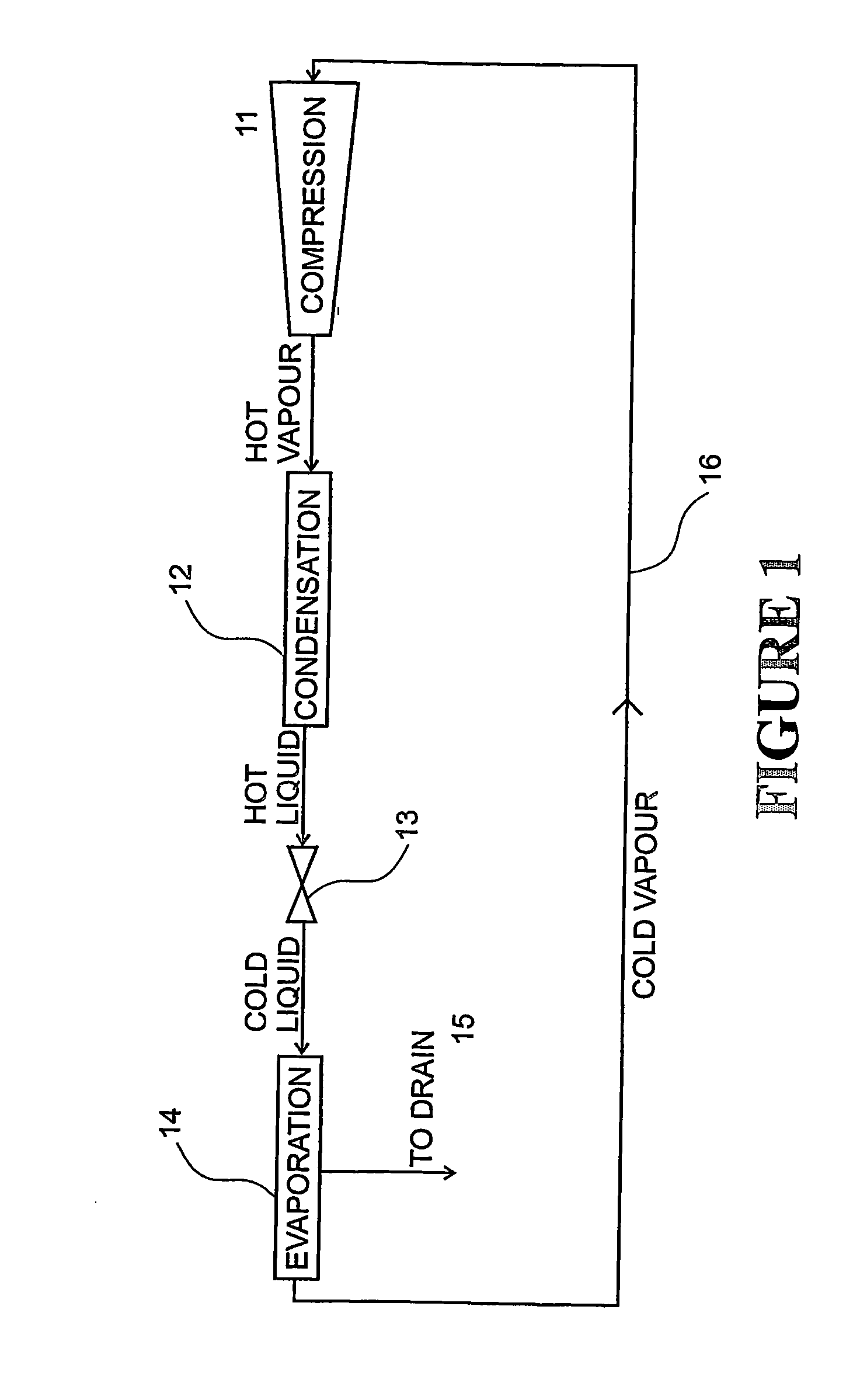

Integrated Controller And Fault Indicator For Heating And Cooling Systems

InactiveUS20080315000A1Promote mold growthShorten speedTemperature control using plurality of sensorsTesting/monitoring control systemsFault indicatorEngineering

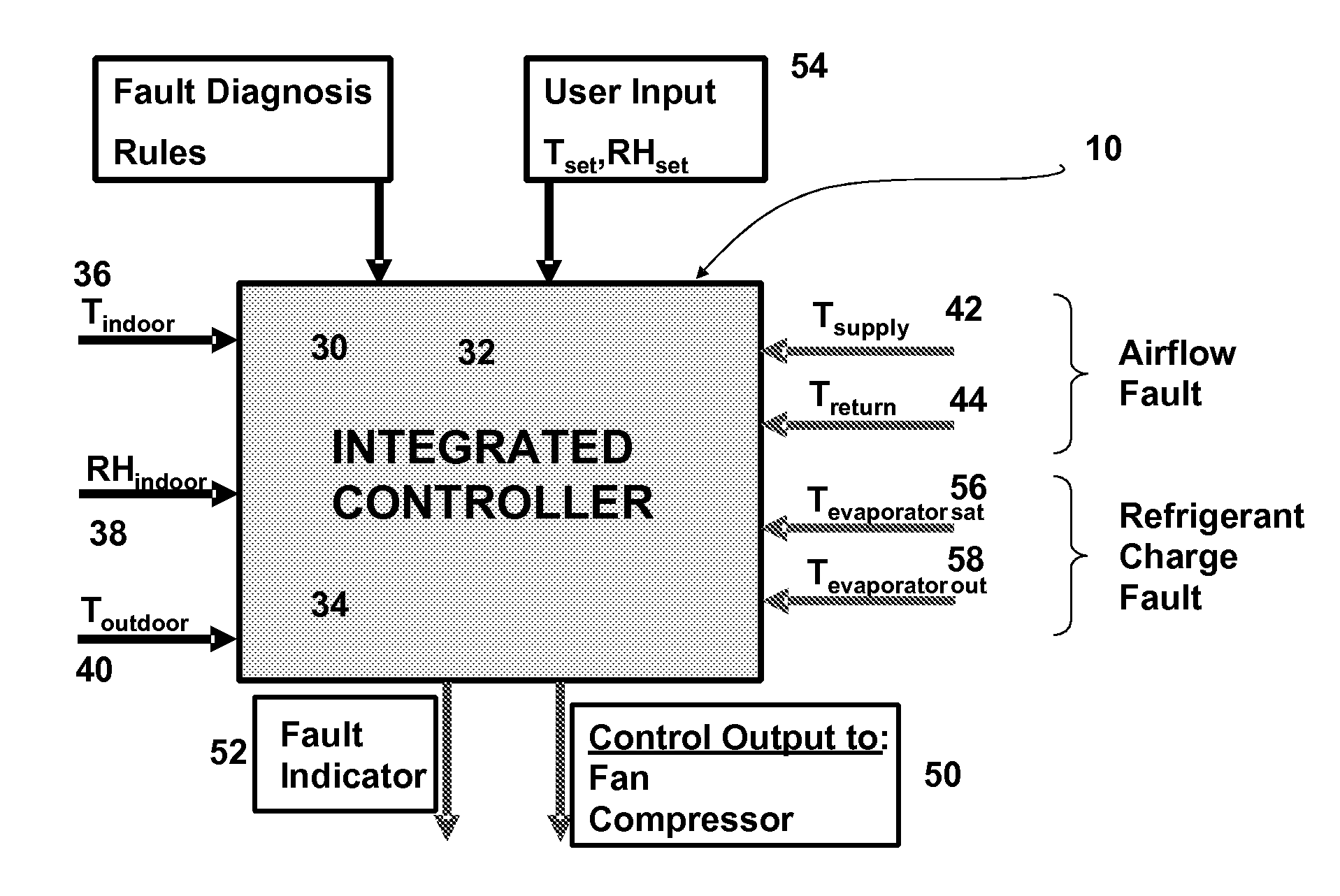

An integrated controller for controlling a vapor compression based heating and cooling system. The integrated controller includes modules for independently controlling dry bulb temperature, humidity level, and incorporating a fault detection module therewith. The fault detection module being capable of detecting abnormal refrigerant levels using only temperature sensors on the condenser with thermal expansion valve or evaporator with fixed orifice type of expansion valve.

Owner:HOME AUTOMATION INC

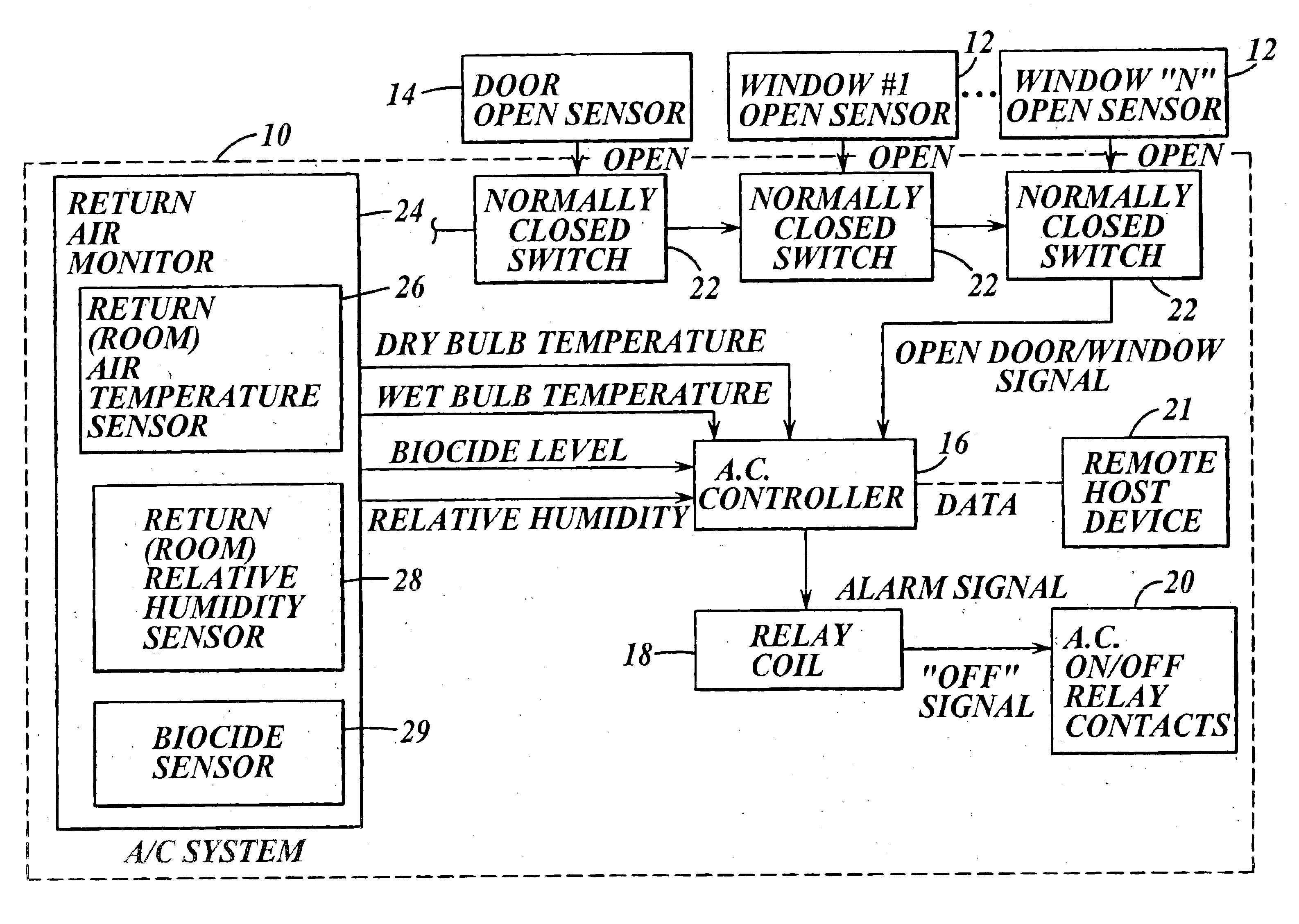

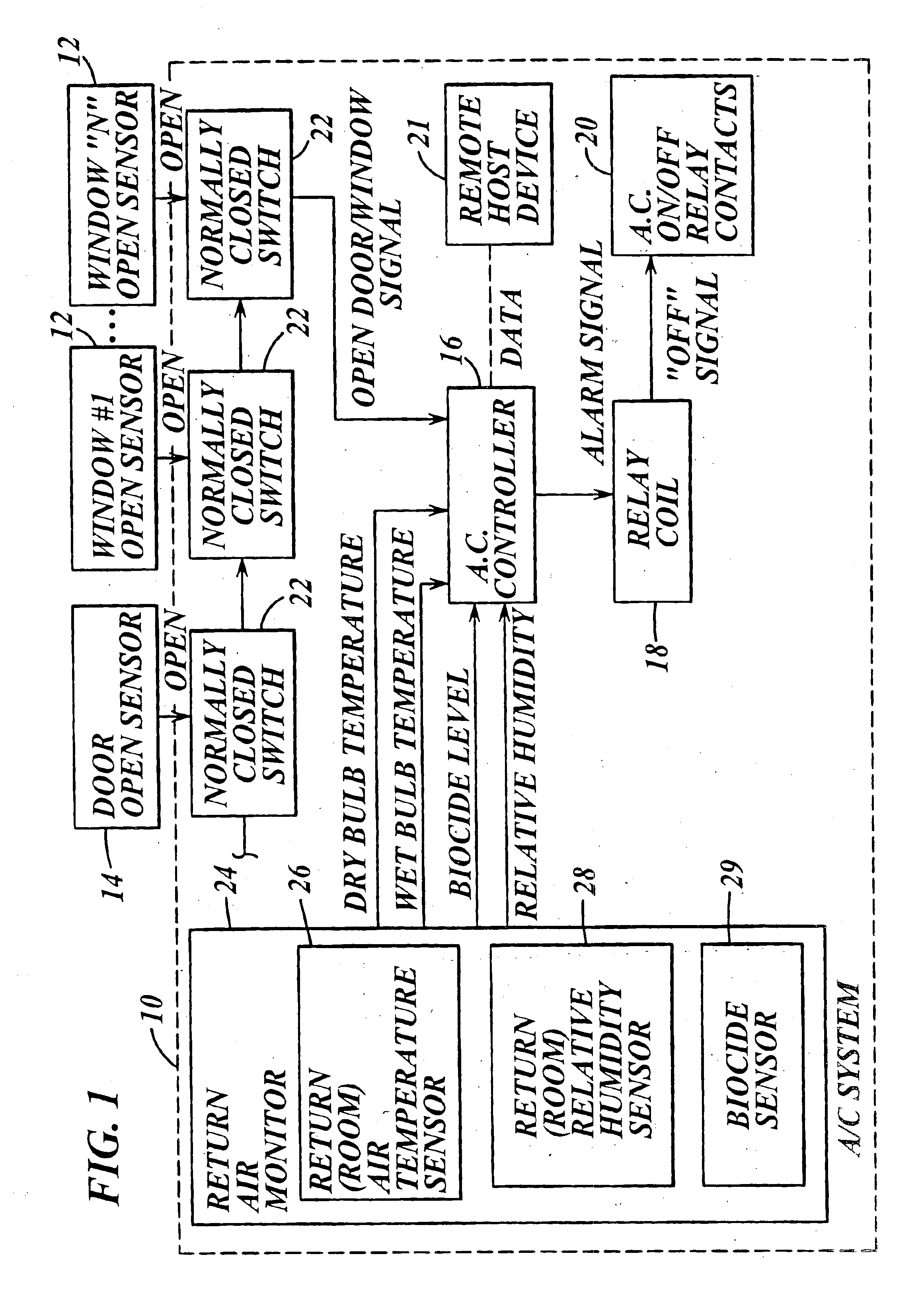

Air conditioning system

InactiveUS6840052B2Minimizing conditionEncouraging growthMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

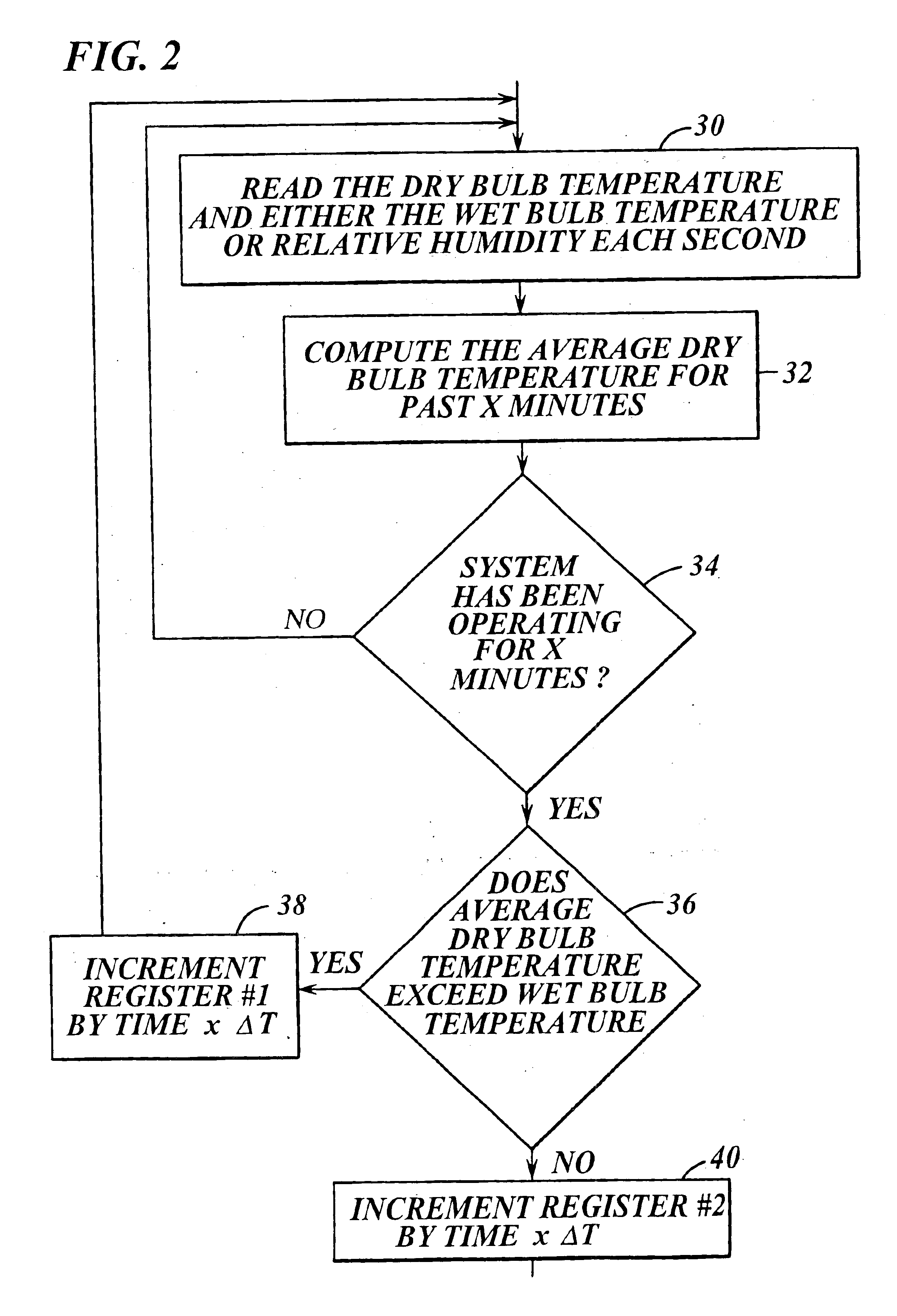

An air conditioning system cools air within an area. An air conditioner controller defines information based on input data from door and window open status sensors and a return air monitor sensing the dry bulb temperature and the wet bulb temperature or relative humidity of the air within the area being cooled by the air conditioning system and shuts down the system when specific conditions exist. The defined information is transmitted to a remote host device which retains and presents the transmitted information or information derived therefrom.

Owner:WELLSPRING WIRELESS A DE CORP

Energy and cost savings calculation system

ActiveUS20070244604A1Save energyAccurate and reliable and costLevel controlTemperatue controlEngineeringTime of use

An Energy and Cost Savings Calculation System is provided that automates the determination of energy and cost savings due to energy conservation measures. The system provides Multi-Variant, Non-Linear (MVNL) load forecasting techniques, energy and cost savings calculations, and Weather Ranking. The load forecasting technique may accept numerous external parameters as input. The technique may use multiple Baselines. It may also use multiple Basic Reference Periods to reduce the load forecasting error. The load forecasting technique may utilize external parameters that are updated on a daily basis, such as dry bulb temperature, dew point temperature, solar condition, and interval meter data. The technique may use Baseline Extensions to perform forecasts and Reference Period Modifications to enhance accuracy. The system may calculate energy and cost savings using Complex Rates and time-of-use (TOU) energy data. The system may rank a plurality of sources providing weather data to identify the most accurate weather data.

Owner:SIEMENS IND INC

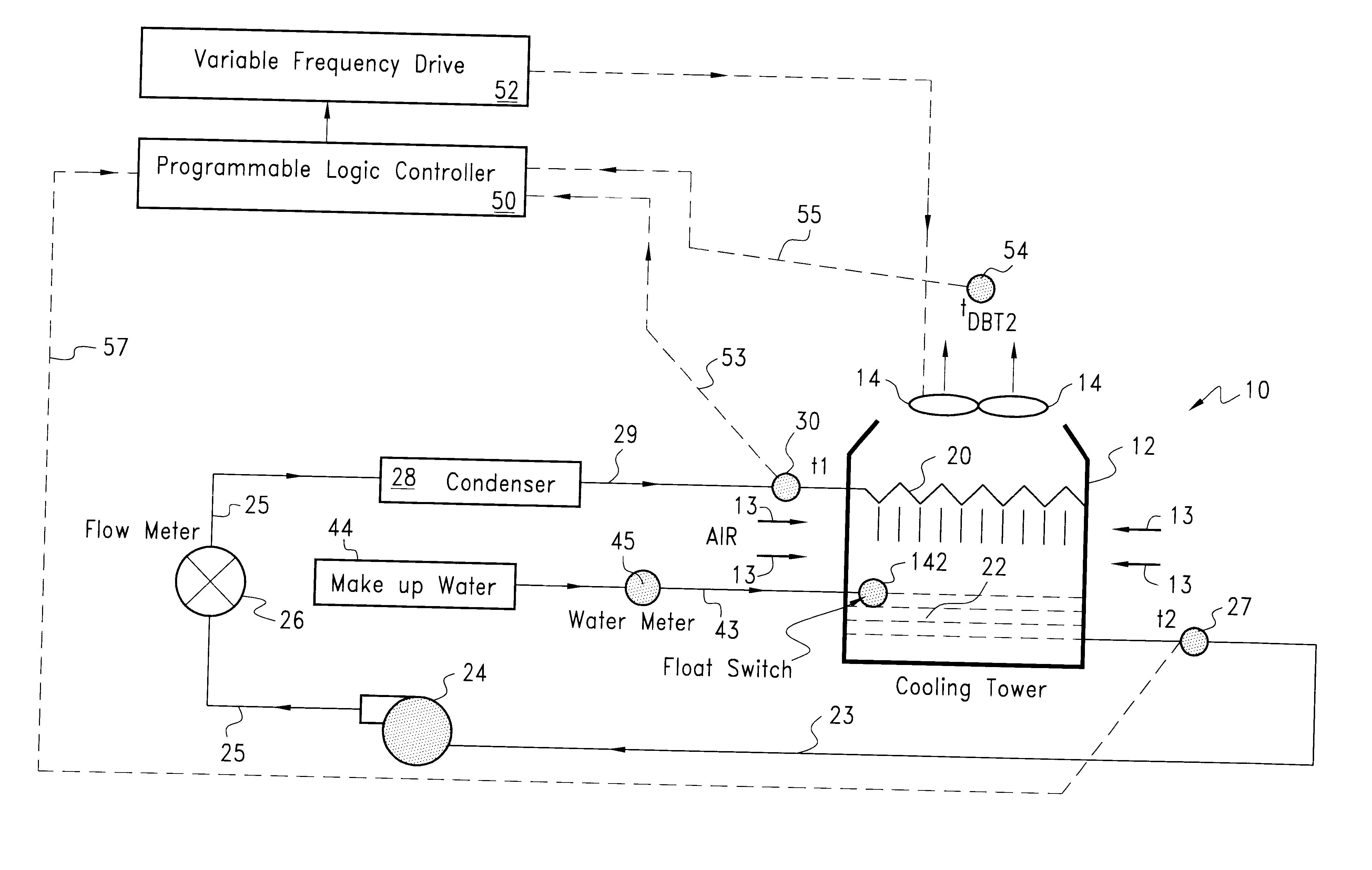

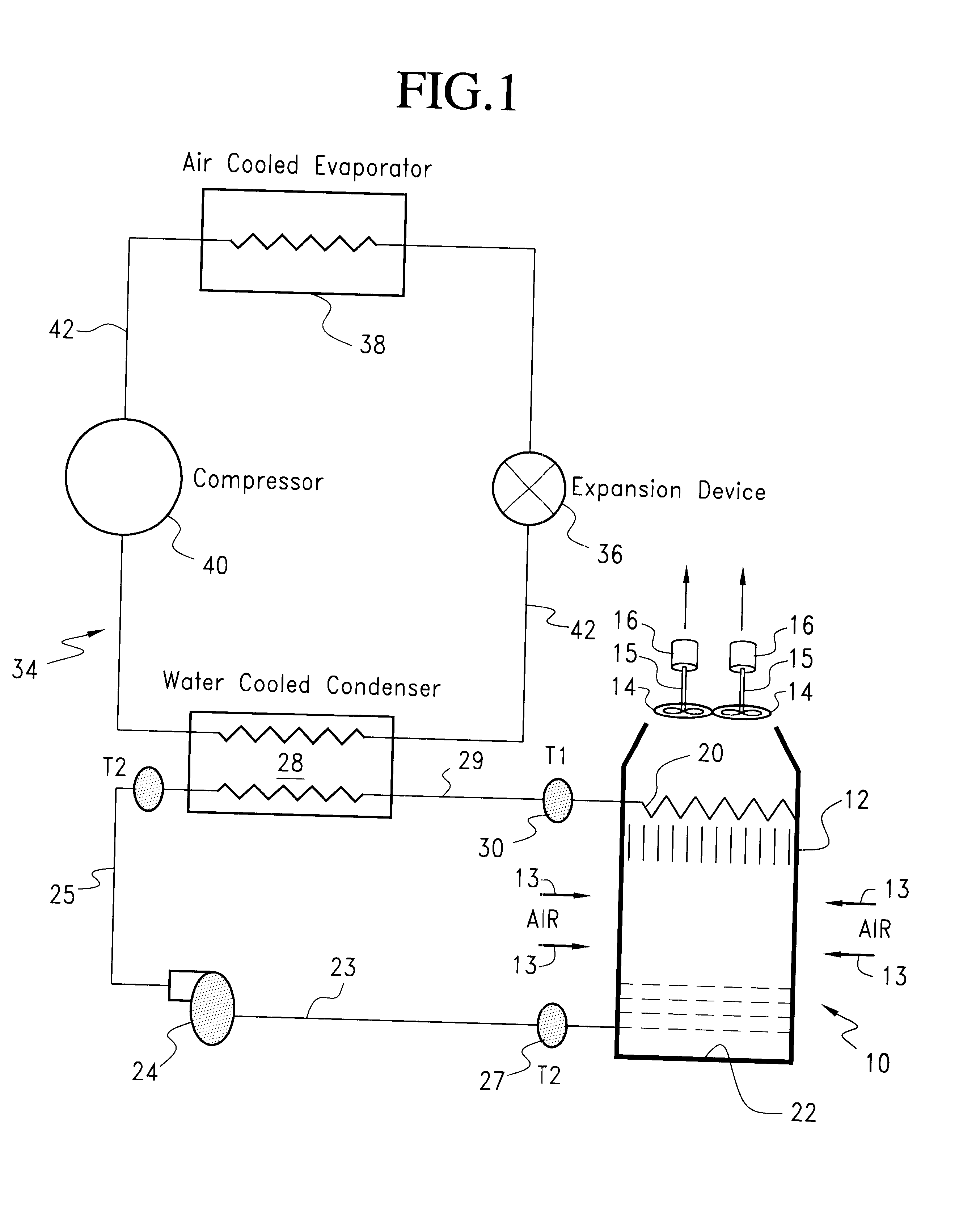

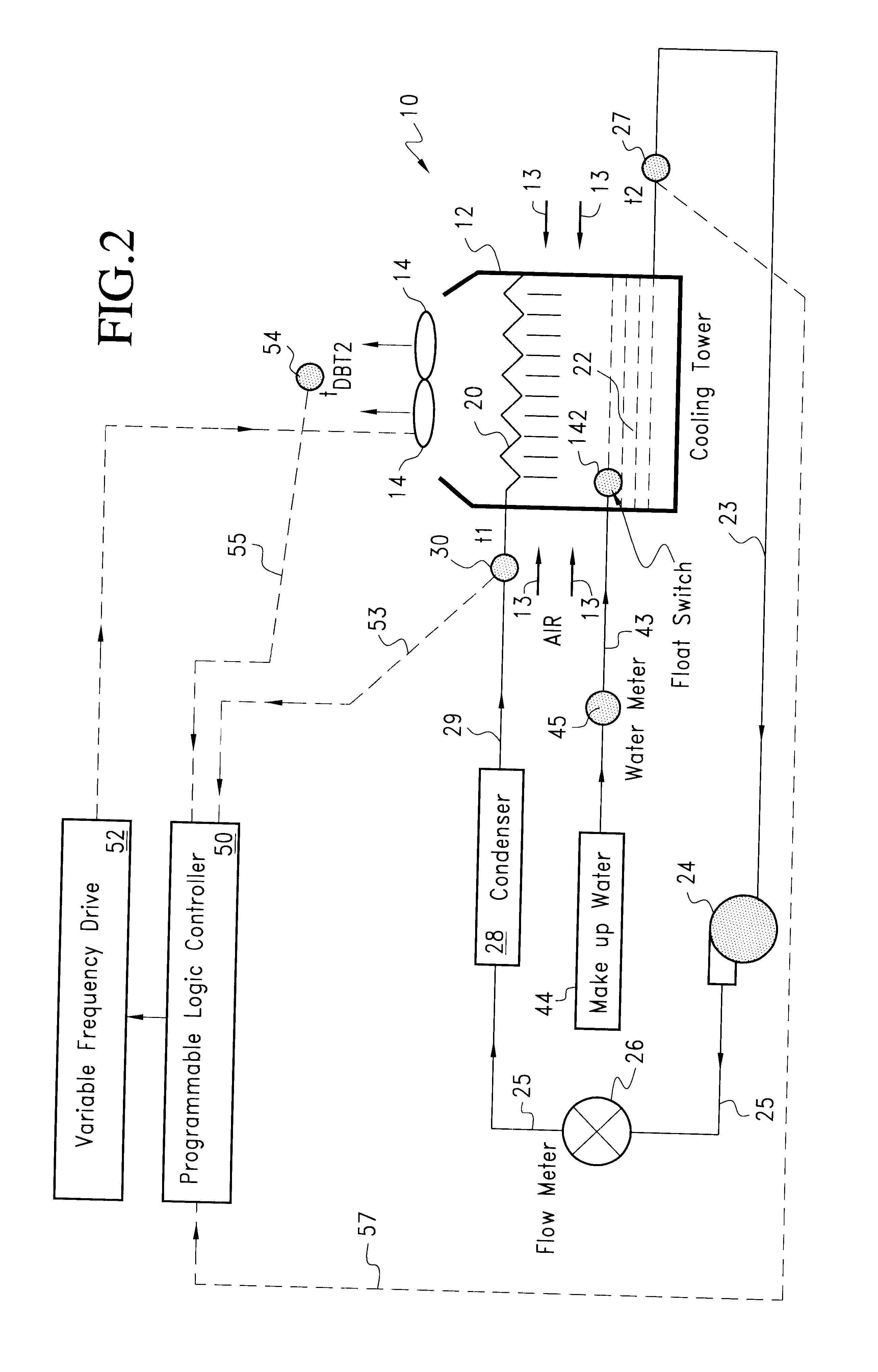

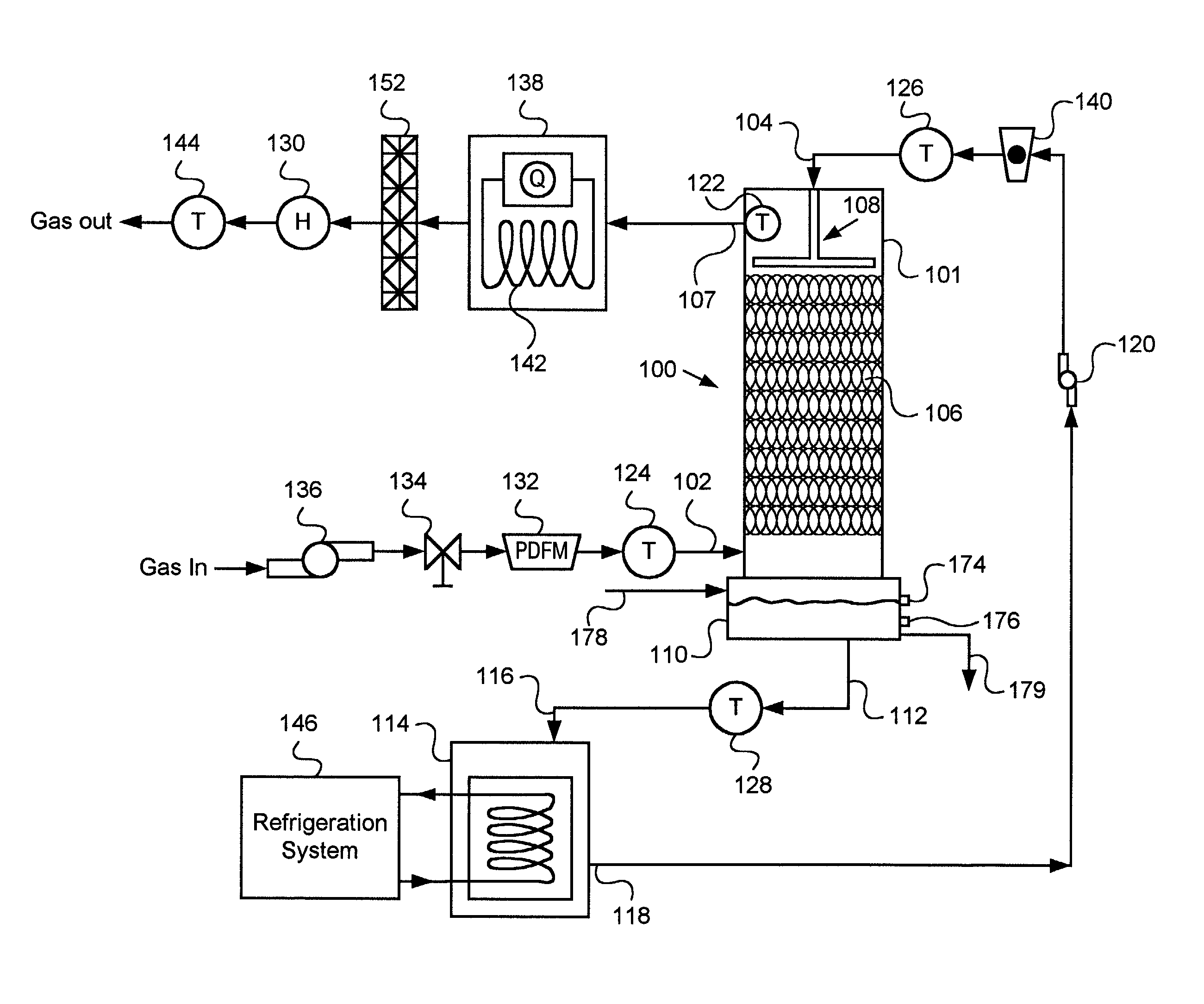

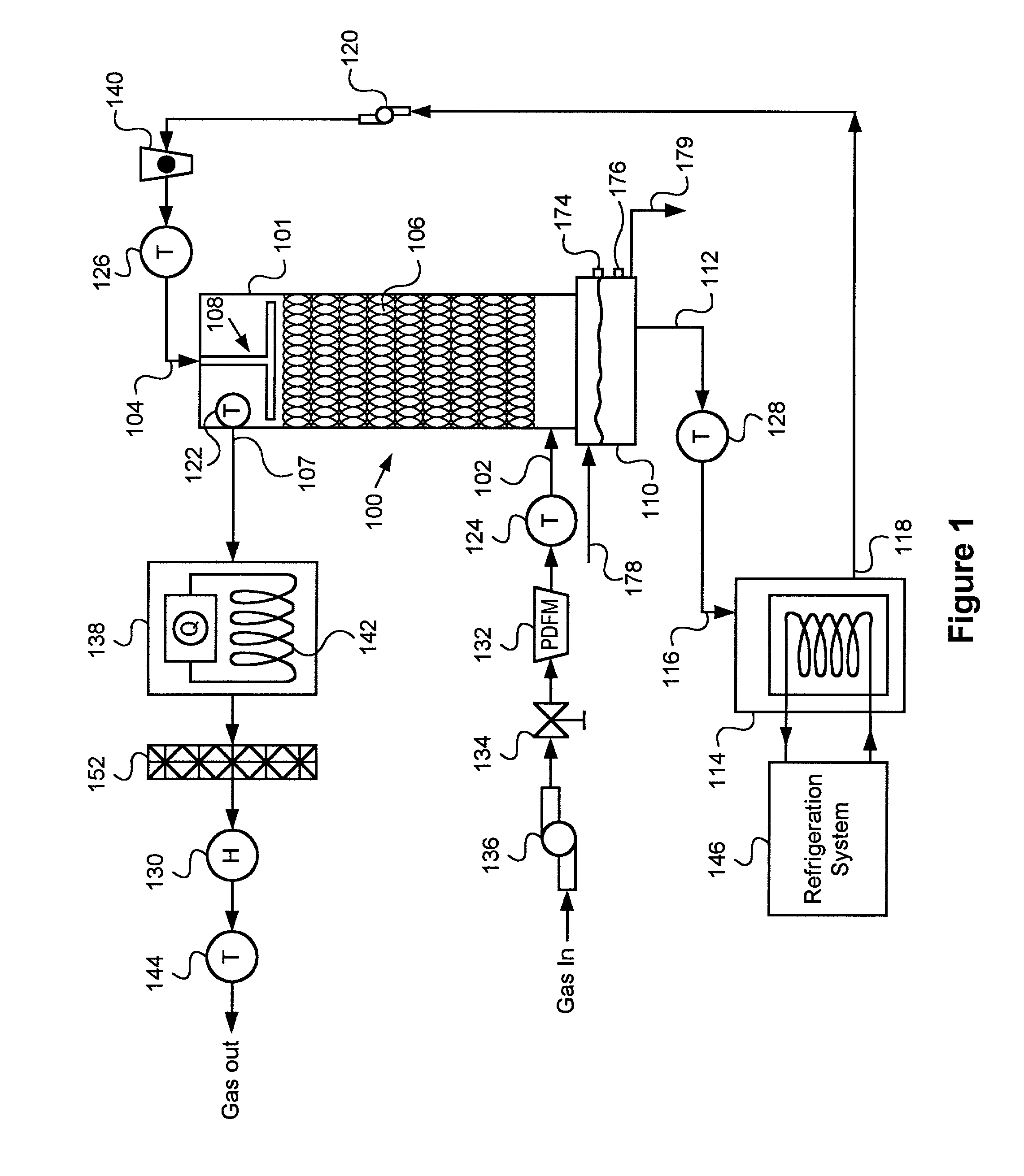

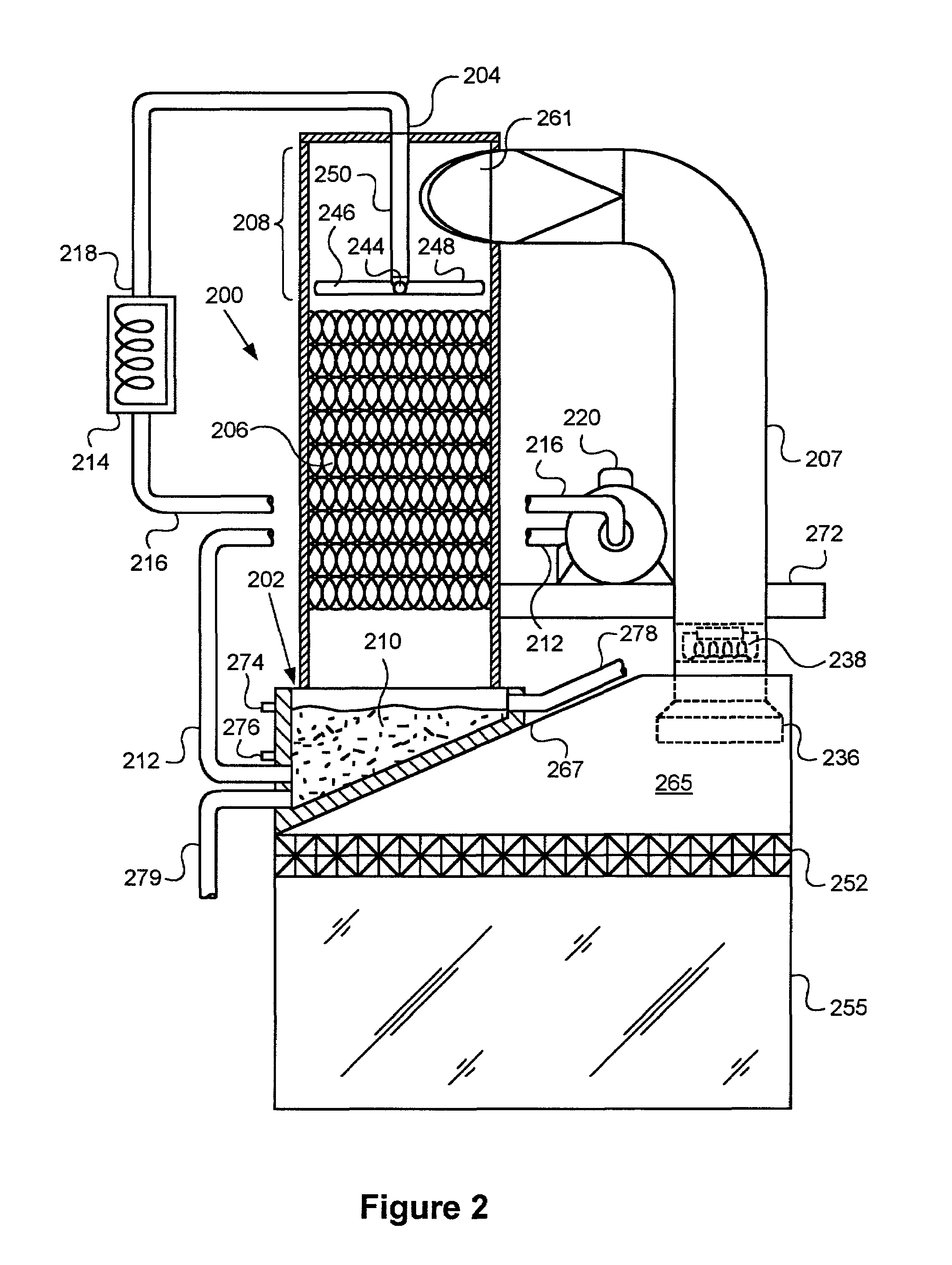

Cooling tower and method for optimizing use of water and electricity

A forced air cooling tower includes an upright casing, and elevated water distribution system disposed in an upper portion of the casing and one or more fans for drawing air through the tower. The tower also includes a catch basin for collecting the cooled air and a pump for circulating the cooled water through a condenser and back to the top of the tower and to the water distribution system. The cooling tower also includes a controller and a variable frequency device for regulating the flow of air through the tower. A first temperature sensor senses the temperature T1 of the hot process water delivered to the water distribution system and a second sensor senses the dry bulb temperature of the air leaving the tower Tdbt2. A third sensor senses the temperature of the cooled water leaving the tower. The controller such as a computer and variable frequency drive controls the speed of the fan to minimize the difference in T1 and Tdbt2. A submaster control prevents the fan speed from being further reduced when a predetermined T2 (temperature of the cooled water) is reached.

Owner:KUWAIT INST FOR SCI RES

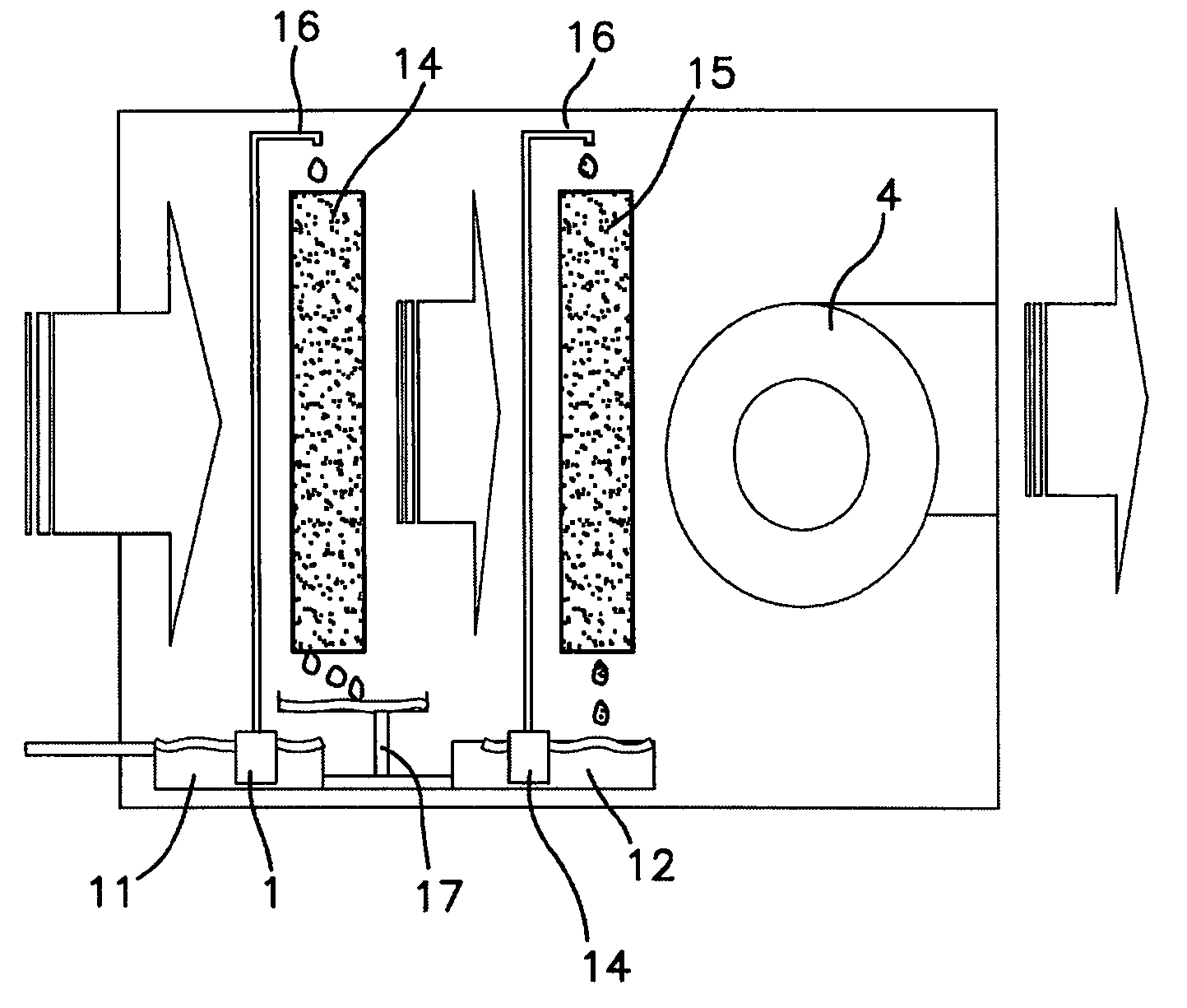

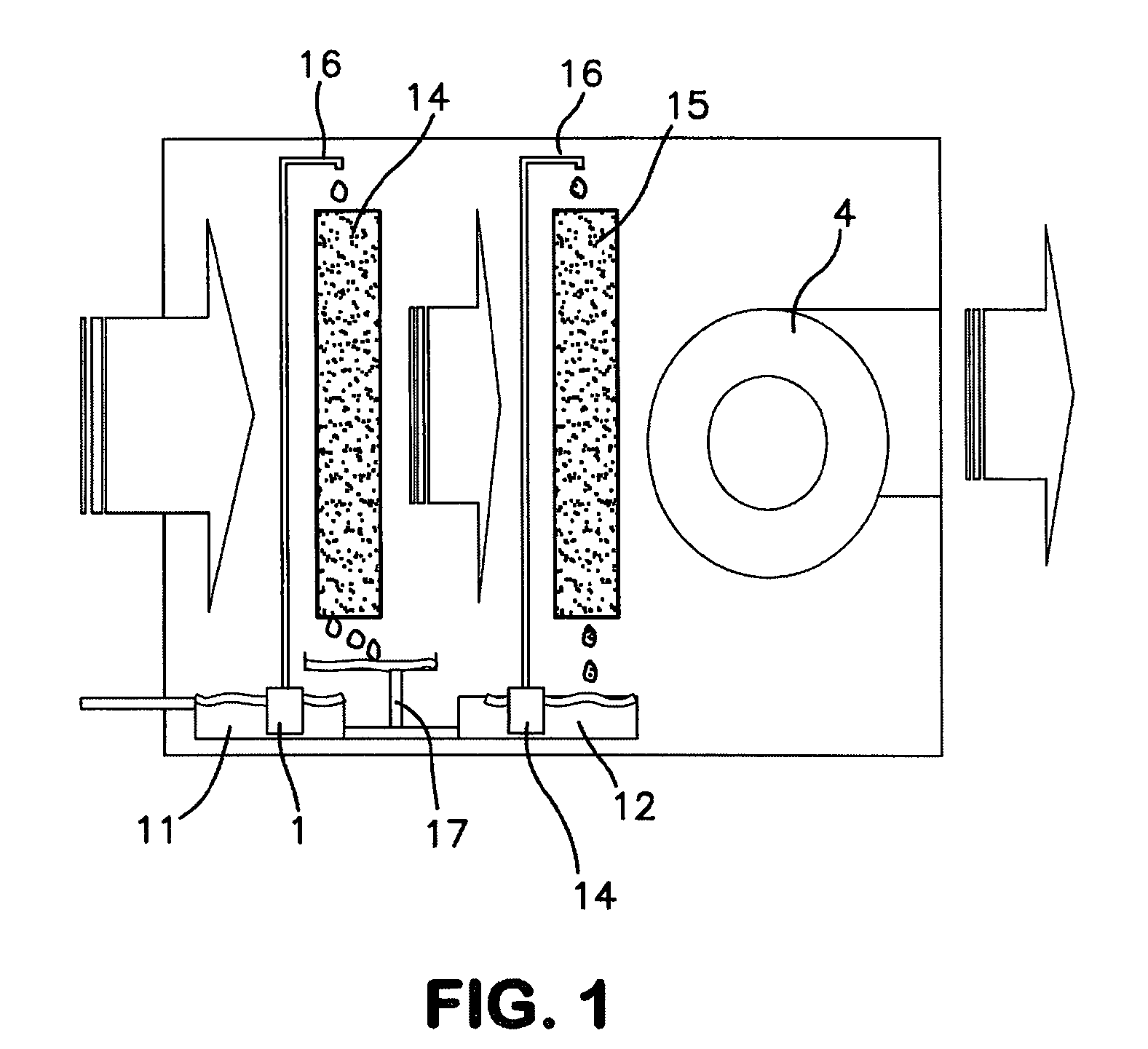

Evaporative Air Cooler With Multi Stages Cooling And Or Heating With Or Without Cooling Coil

InactiveUS20100281896A1Free-cooling systemsStationary conduit assembliesEvaporative coolerCooling coil

An outdoor air cooler with two stages includes a first stage for cooling and humidification with constant wet bulb temperature. The air cooler has a first stage pump circulating water over the first stage evaporative cooling media operating at conditions having a constant adiabatic wet bulb temperature line. The first stage tank is supplied with water from external source. The second stage includes a second set of evaporative cooling media using water from the first stage media, which is equal to or lower than outdoor air wet bulb temperature. The temperature of air leaving the second stage evaporative media follows the adiabatic wet bulb temperature line toward the second stage tank water temperature thereby cooling humidifying the treated air to stable wet and dry bulb temperatures.

Owner:AL WATBAN ALAA ABDULKAREEM

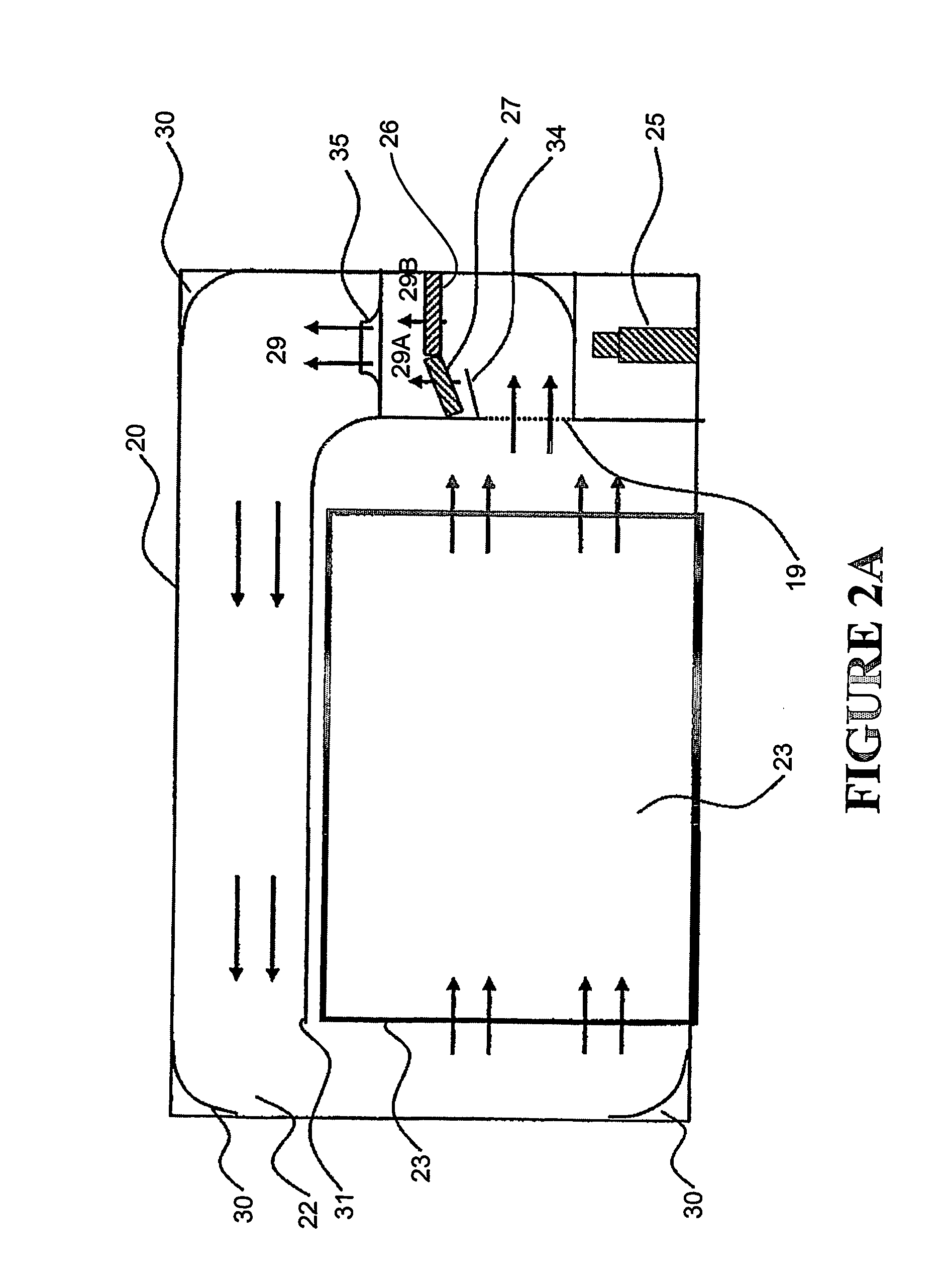

Anti-sweat heater demand supply module using temperature and humidity control

ActiveUS8434317B2Prevent short-cyclingLow costSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringPeak value

A refrigerated appliance such as a refrigerator receives a demand response signal indicating a peak demand period and operates the refrigerator in an energy savings mode by disabling an anti-sweat heater. Sensors monitor ambient temperature and humidity, and the dry bulb temperature of a preselected region where incipient moisture would likely form. Data from the sensors is sent to a controller which calculates ambient dew point and compares the dry bulb temperature of the preselected region with the calculated dew point to enable the anti-sweat heater during the peak demand period and prevent incipient formation of moisture.

Owner:HAIER US APPLIANCE SOLUTIONS INC

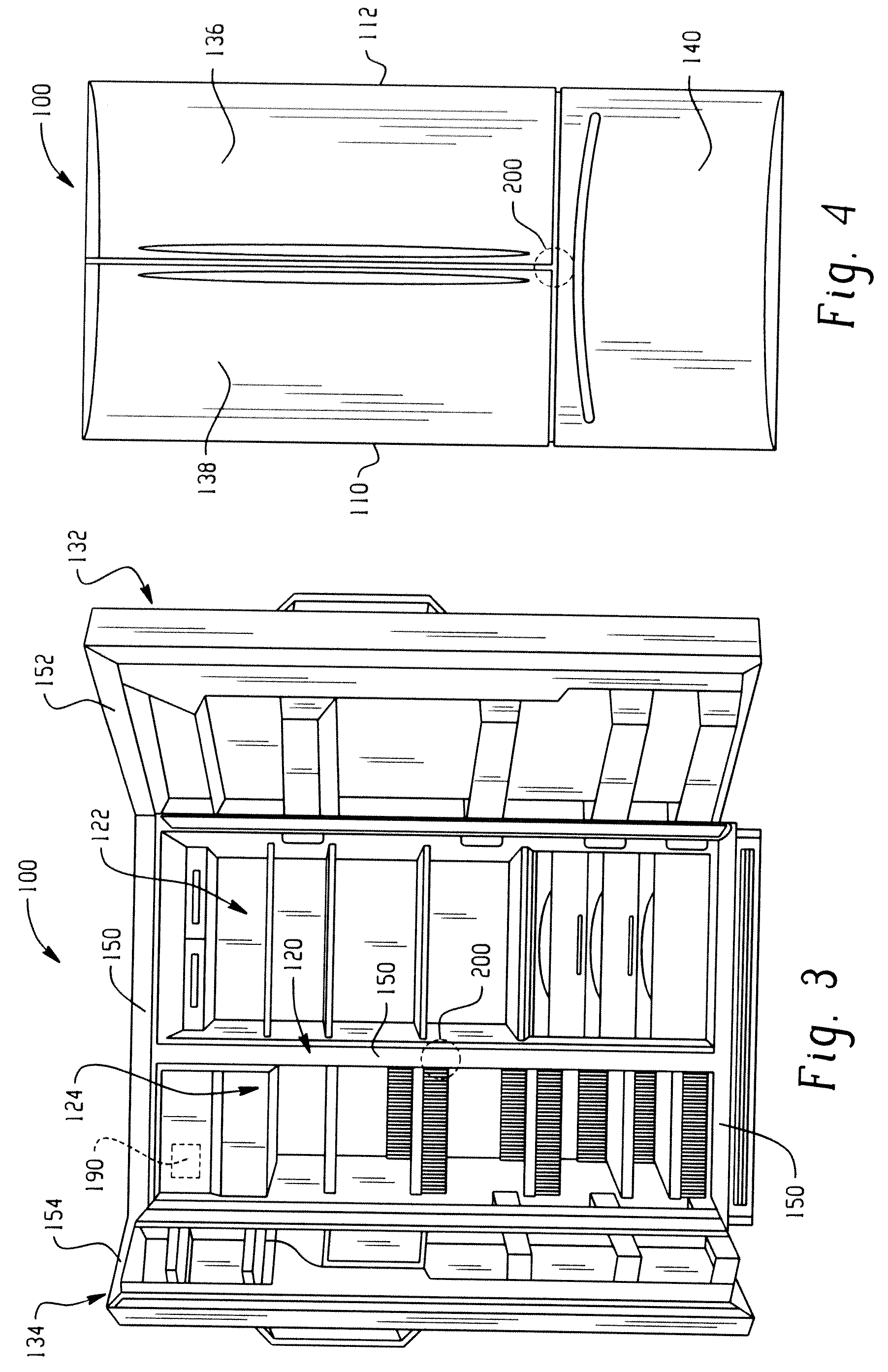

Efficiency dehumidifier drier with reversible airflow and improved control

InactiveUS20070017113A1Improve efficiencyReduce releaseDrying solid materials with heatDrying gas arrangementsProcess engineeringEngineering

An apparatus and process including a heat sink exchanger (26) to cool and condense liquid out of a drying gas with a heat transfer surface arranged to exchange heat with a first sub-stream of the drying gas and a heat source heat exchanger (27) arranged to exchange heat with a second sub-stream of a drying gas and arranged in a functionally parallel configuration with said heat sink heat exchanger (26) so that each of said drying gas sub-streams exchanges heat with one of the two said heat transfer surface per cycle through the heat exchange system and a gas movement device (35) for propelling the drying gas through the heat exchanger system in either a forward or reverse flow path direction. The apparatus and process can also include controlling the amount of heat rejected from apparatus (26) based on maintaining the wet bulb of the drying gas nominally constant and controlling the amount of refrigerant in the heat exchanger circuit based on maintaining the dry bulb temperature of the drying gas within certain limits.

Owner:DELTA V TECH

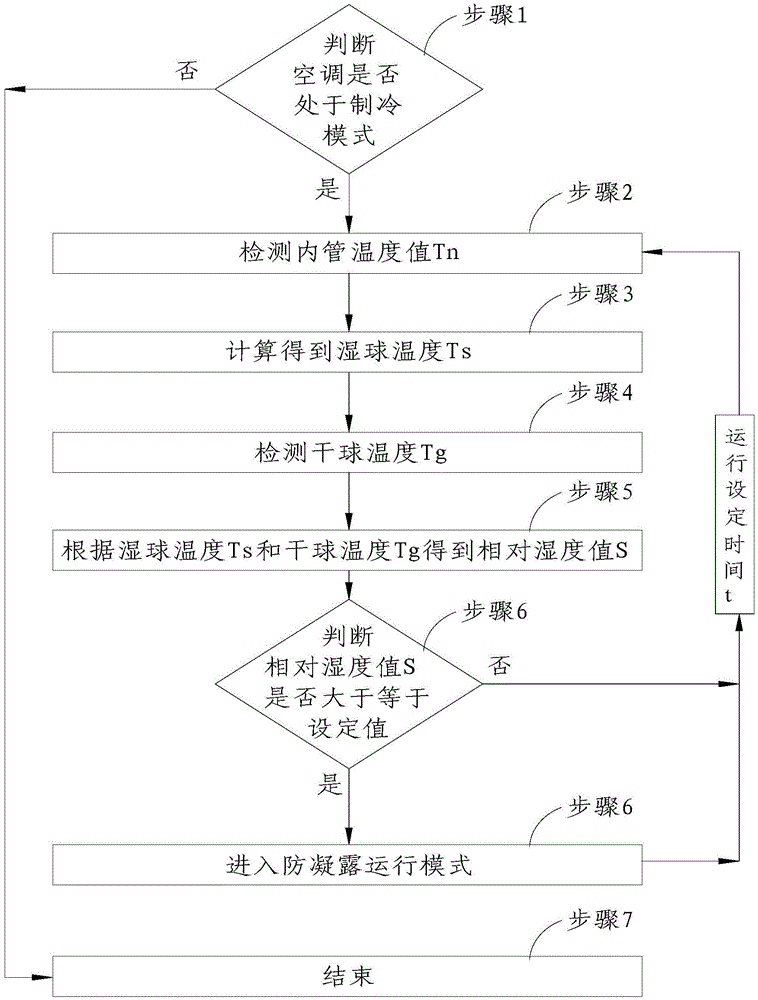

Air conditioner control method

InactiveCN104534618AReliable valuePracticalMechanical apparatusCondensate preventionWorking environmentOperation mode

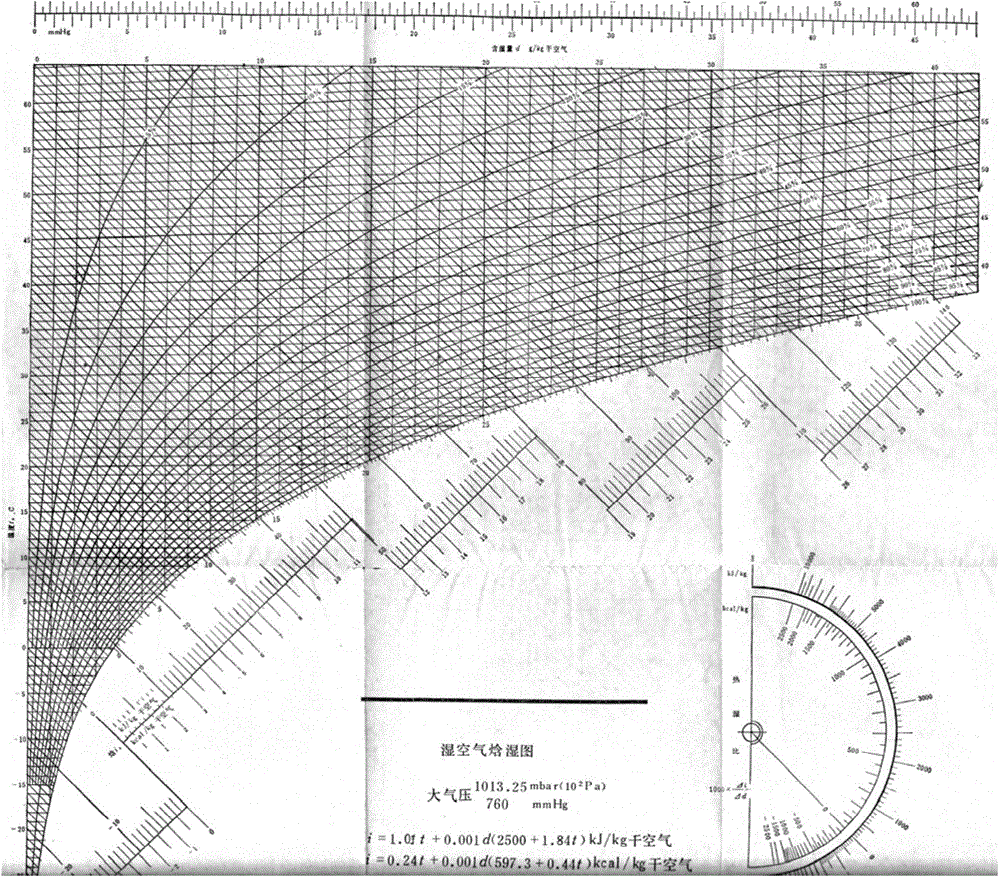

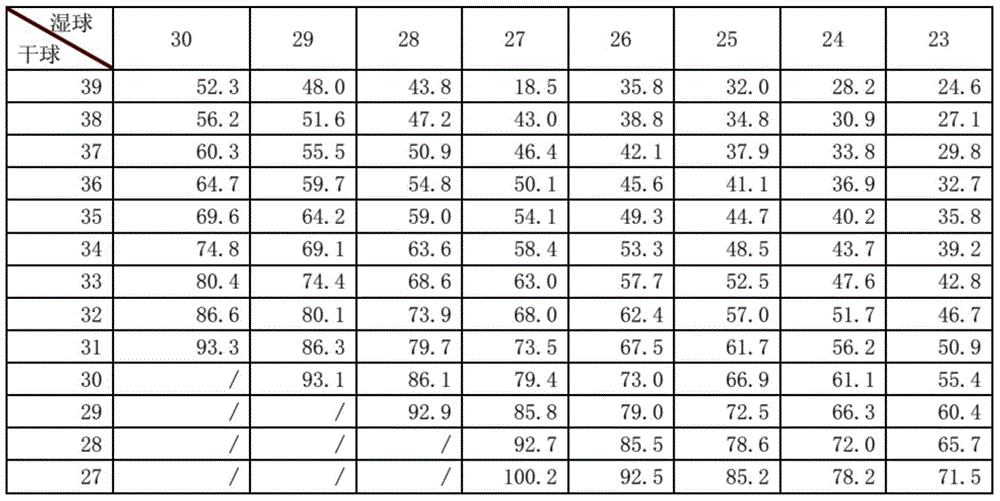

The invention discloses an air conditioner control method, belongs to the field of an anti-condensation control method of an air conditioning device and is designed for solving the problems of high cost, poor practicability and the like of the existing method. The air conditioner control method comprises the following steps: when judging that an air conditioner is in a refrigeration mode, substituting an inner pipe temperature value Tn detected by a first thermometer bulb of an indoor unit into a formula, namely a wet bulb temperature Ts=A* inner pipe temperature value Tn+B, so as to obtain the wet bulb temperature Ts, wherein A and B are constant numbers, the A belongs to [-10,10] and the B belongs to [-20,20]; obtaining a relative humidity value S by checking a psychrometric chart or checking a table composed of dry bulb temperatures Tg and wet bulb temperatures Ts in the psychrometric chart; and when the relative humidity value S is more than or equal to 60%, enabling the air conditioner to enter an anti-condensation operation mode. The air conditioner control method can be used for accurately judging according to an actual working environment of the air conditioner and has strong practicability and good anti-condensation effect.

Owner:GREE ELECTRIC APPLIANCES INC

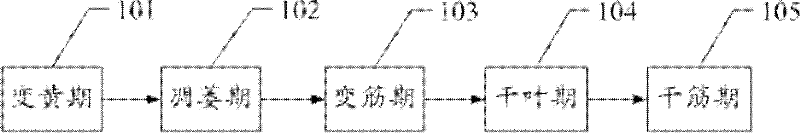

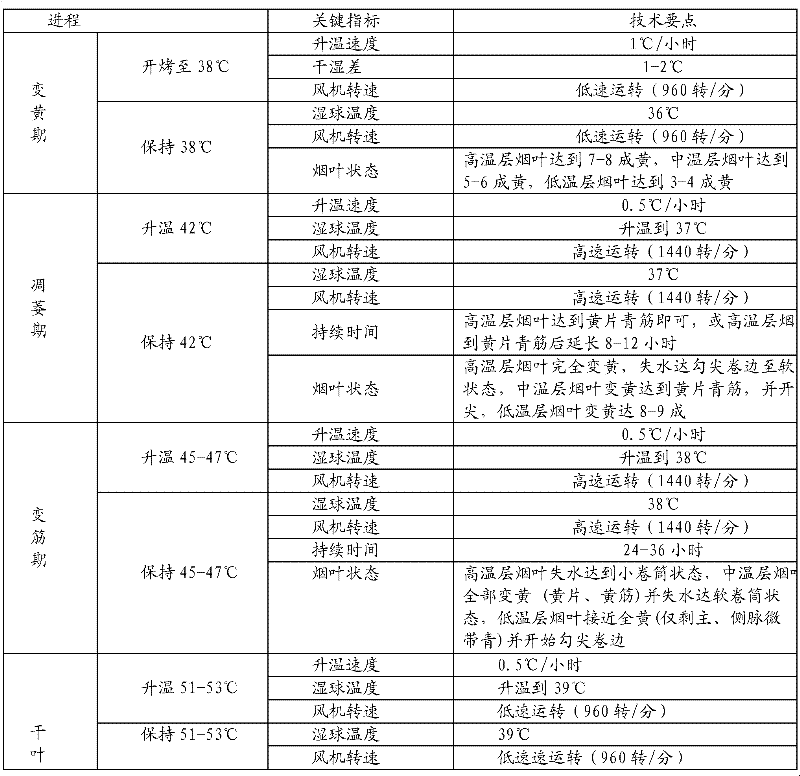

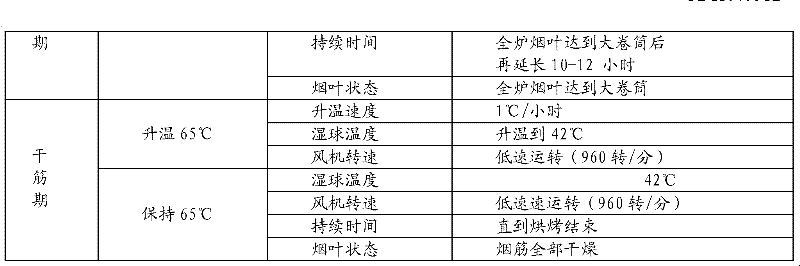

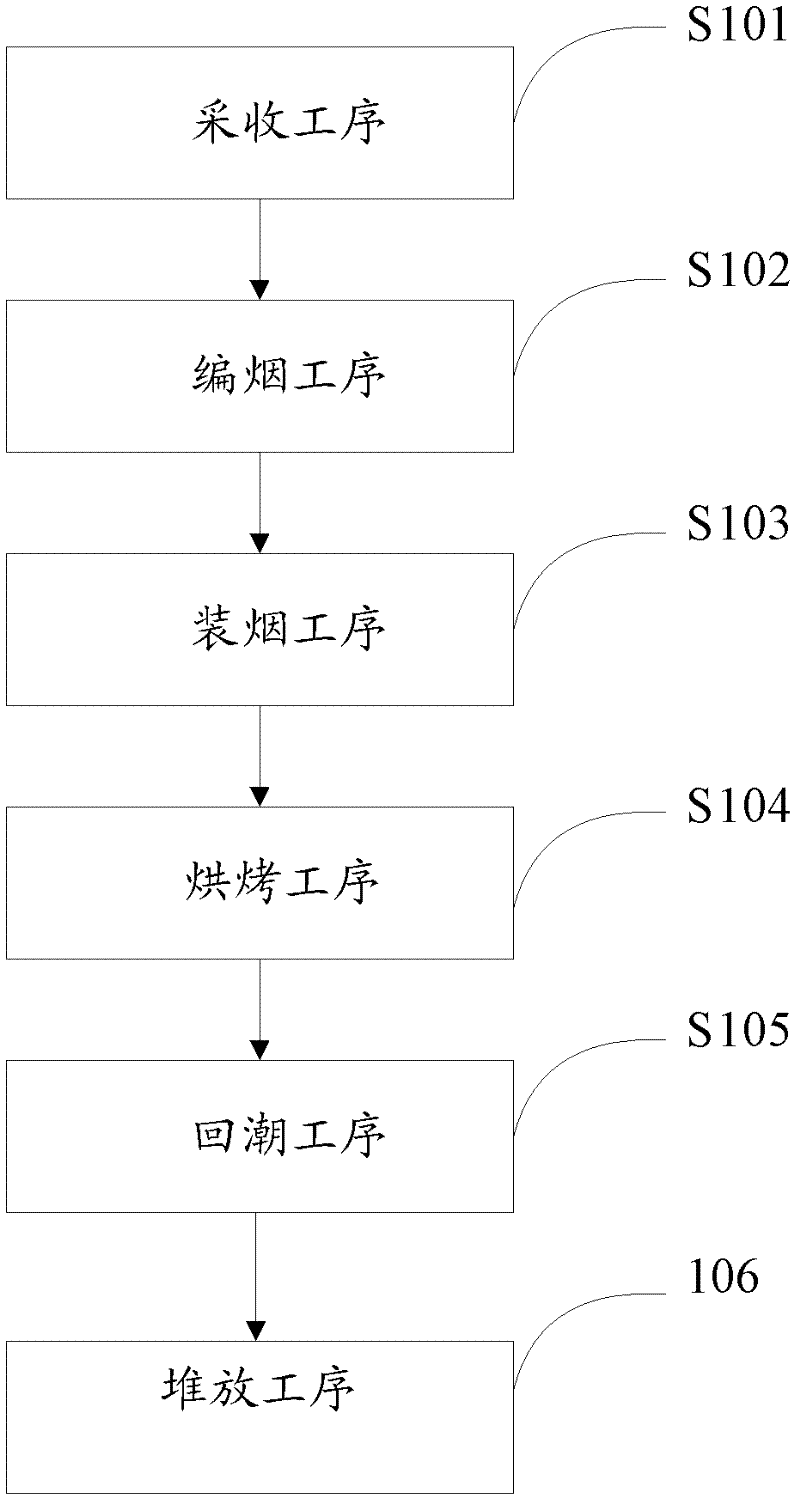

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

Evaporative cooler assisted automotive air conditioning system

InactiveUS20070163772A1Reduce sensible heat portionReduce the temperatureMachines/enginesStationary conduit assembliesEvaporative coolerPre conditioning

An automotive air conditioning system is disclosed comprising an evaporative cooler in series with the conventional vapor compression system. The evaporative cooler comprises an array of dry channels and a contiguous array of wet channels. The primary air stream to be conditioned by the evaporator of the conventional air conditioning system is preconditioned by the evaporative cooler by lowering its dry bulb temperature without changing its absolute humidity. An evaporator core is supported downstream of the evaporative cooler for receiving the primary air from the dry channels and thereby produces liquid condensate. The system is distinguished by conducting the liquid condensate from the evaporator core to the wicking tank for use in the wet channels of the evaporative cooler.

Owner:DELPHI TECH INC

Tobacco leaf curing process capable of improving curing quality of flue-cured tobacco variety KRK26

ActiveCN101991180AMaintain moisture contentImprove roast qualityTobacco preparationDecompositionCell membrane

The invention relates to a tobacco leaf curing process capable of improving the curing quality of a flue-cured tobacco variety KRK26, belonging to the technical field of flue-cured tobacco modulation processes. The curing process comprises the following steps of: regulating the humidity at low temperature to yellow tobacco leaves; stabilizing the temperature and removing moisture for withering; ventilating and dewatering for drying the leaves; and controlling the temperature and the humidity to dry leaf ribs. In the invention, the method of keeping the tobacco leaves at lower temperature to reduce water evaporation in the tobacco leaves and guarantee the water content of the tobacco leaves is adopted to solve the problems of less water and difficult yellowing of the tobacco leaves of the KRK26 variety in the yellowing period; the dry-bulb temperature is between 41 DEG C and 44 DEG C, and the tobacco leaves can be sufficiently dewatered and shrunk to reduce the cell membrane turgor; the tobacco leaf cell membranes cannot be broken between 45 DEG C and 48 DEG C so as to smoothly fix the color; and in the whole process of tobacco leaf curing, the wet bulb temperature is controlled tobe between 34 DEG C and 38 DEG C so as to actively promote the decomposition and the conversion of macromolecular substances and the synthesis of flavoring substances. The invention has the advantages of simple and convenient operation, safety and insurance, can ensure that the tobacco leaves of the variety KRK26 can be smoothly yellowed, timely subjected to color fixing and subjected to rib drying in good time and improves the tobacco leaf curing quality.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

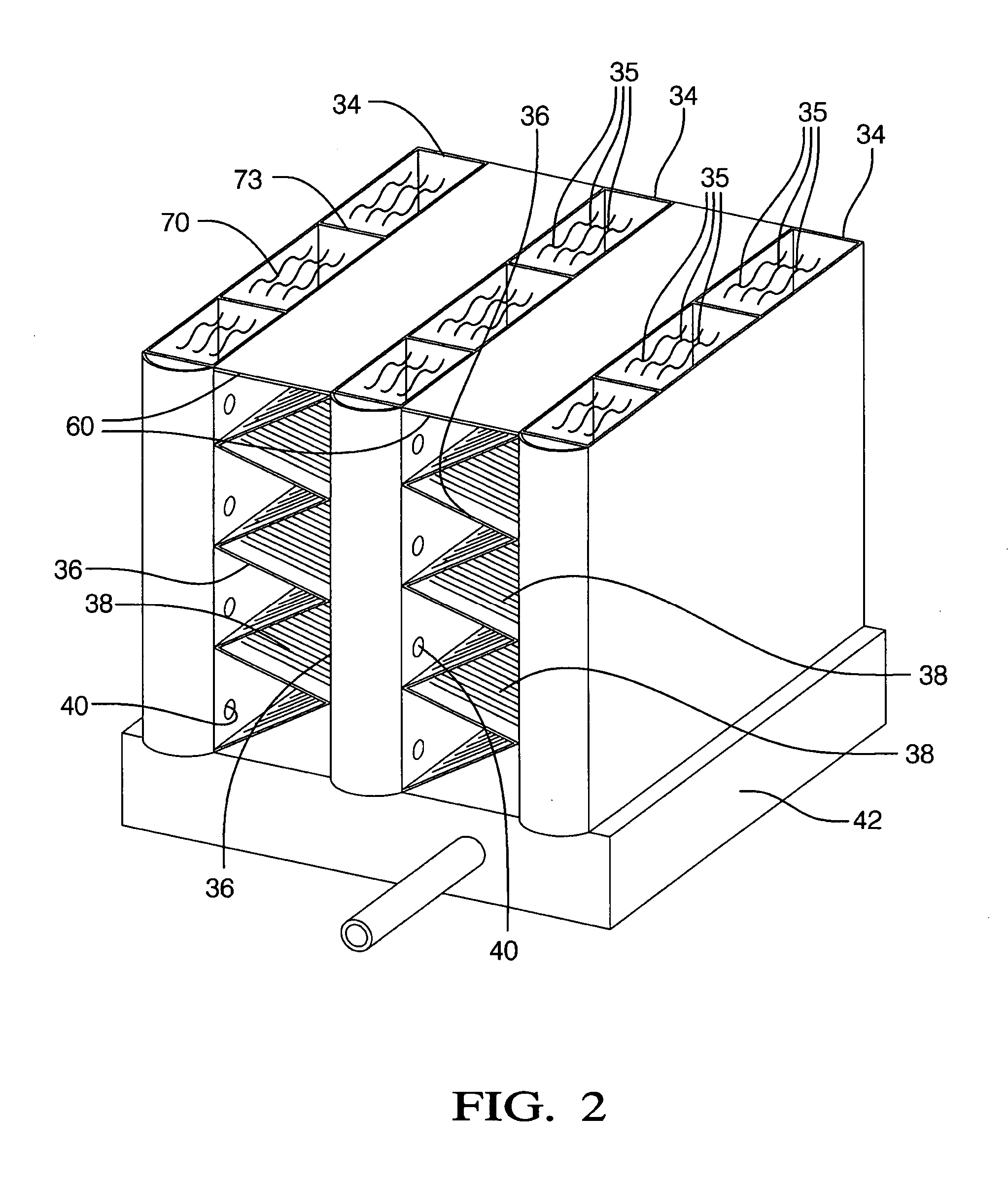

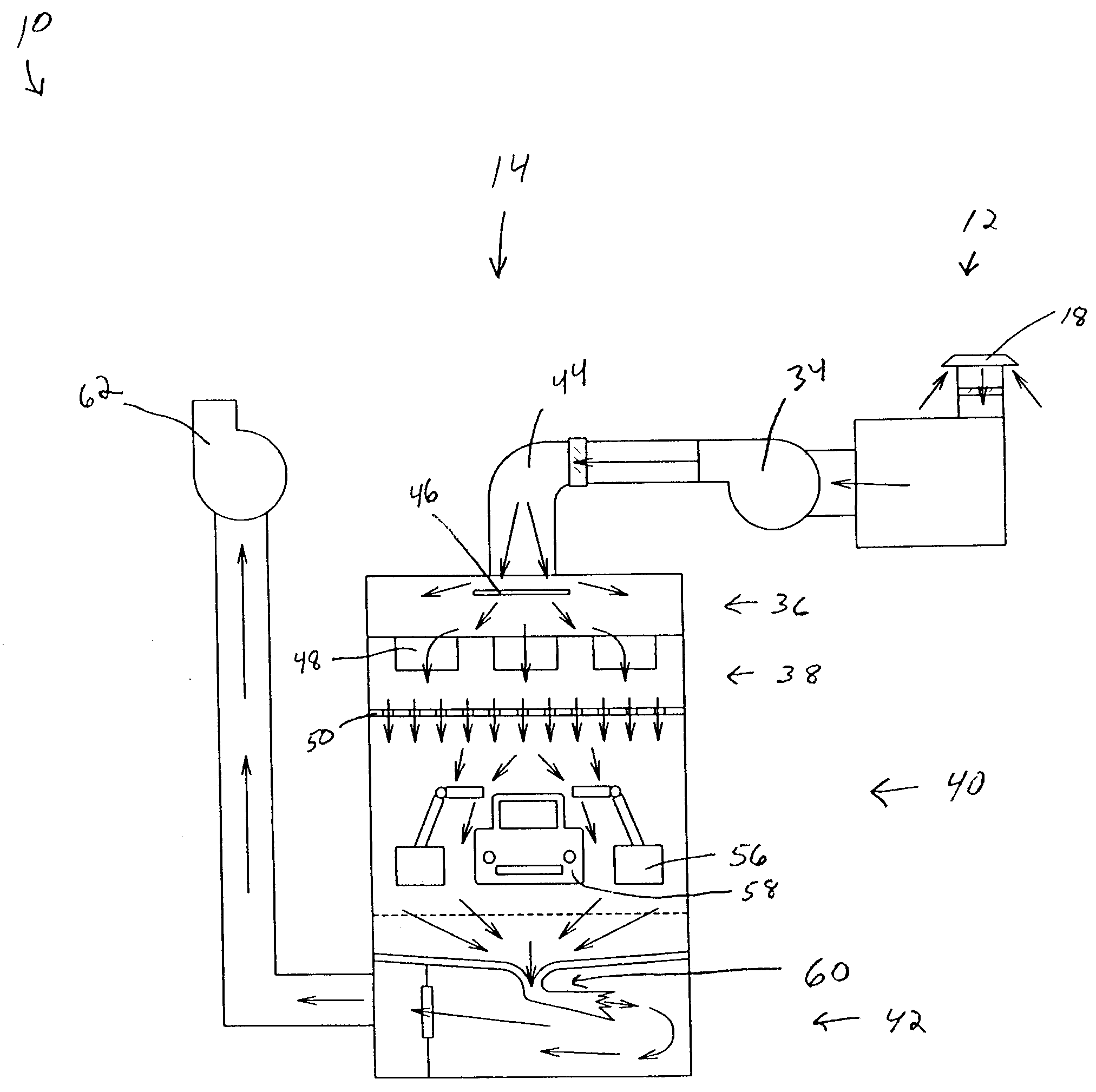

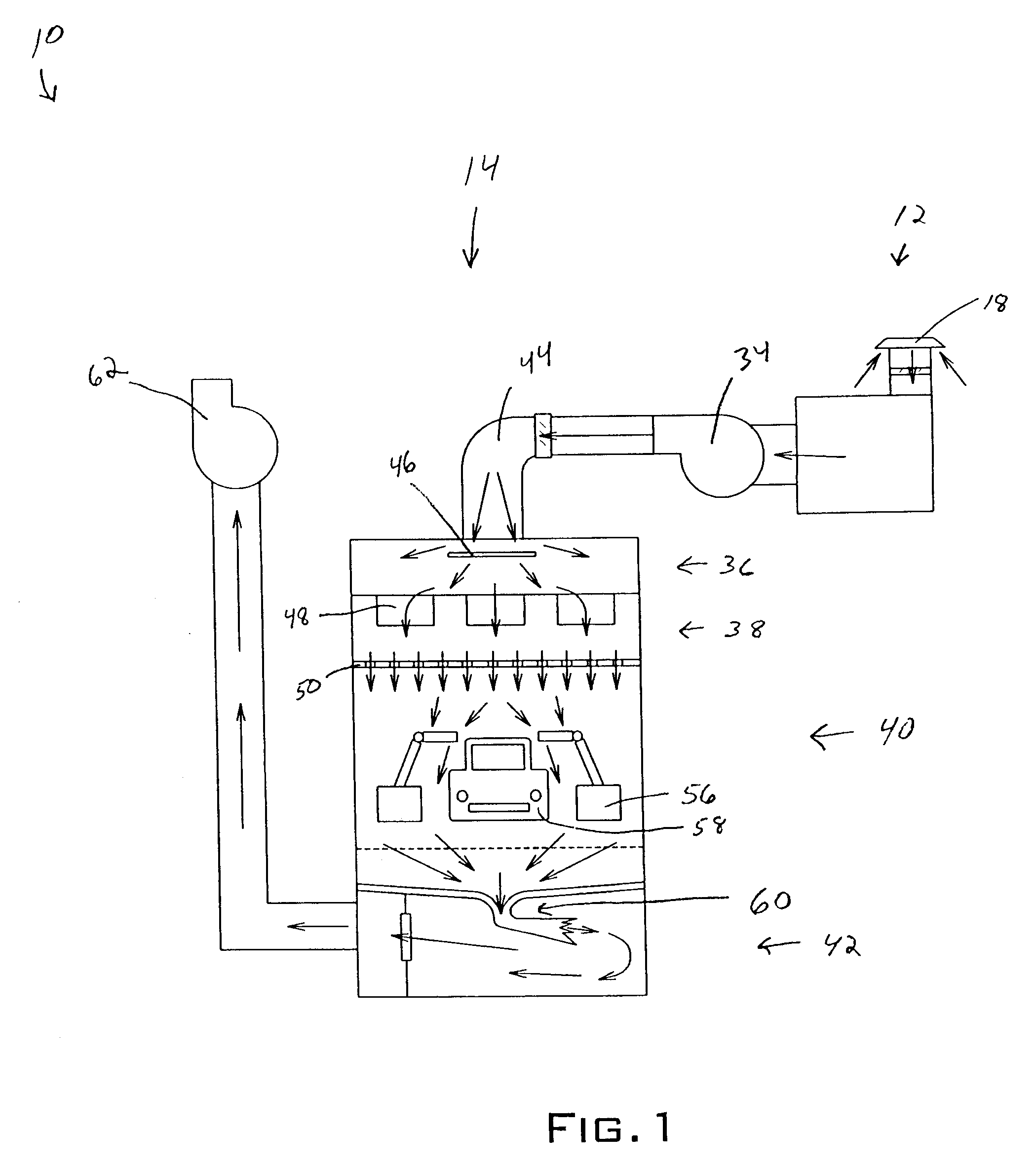

Intelligent air conditioning system for a paint booth

InactiveUS20080311836A1Minimizing quality defectLess energyLiquid surface applicatorsMechanical apparatusEnergy minimizationEngineering

A conditioning system that conditions exterior air for use in a spray booth. The exterior air is conditioned and subsequently used to carry away coating mist, dust, and contaminants from a spray area. The conditioning system heats, cools, humidifies, and dehumidifies the exterior air to a variable set point. The variable set point, while bounded by dry-bulb temperature and relative humidity constraints, is selected based upon cost and / or energy minimization. Additionally, the set point selection may be based upon future predicted weather conditions that are determined with a mathematical profile of previous weather conditions and weather trends in a localized domain, where the localized domain is a geographic area surrounding a manufacturing plant that includes a spray booth.

Owner:HONDA MOTOR CO LTD

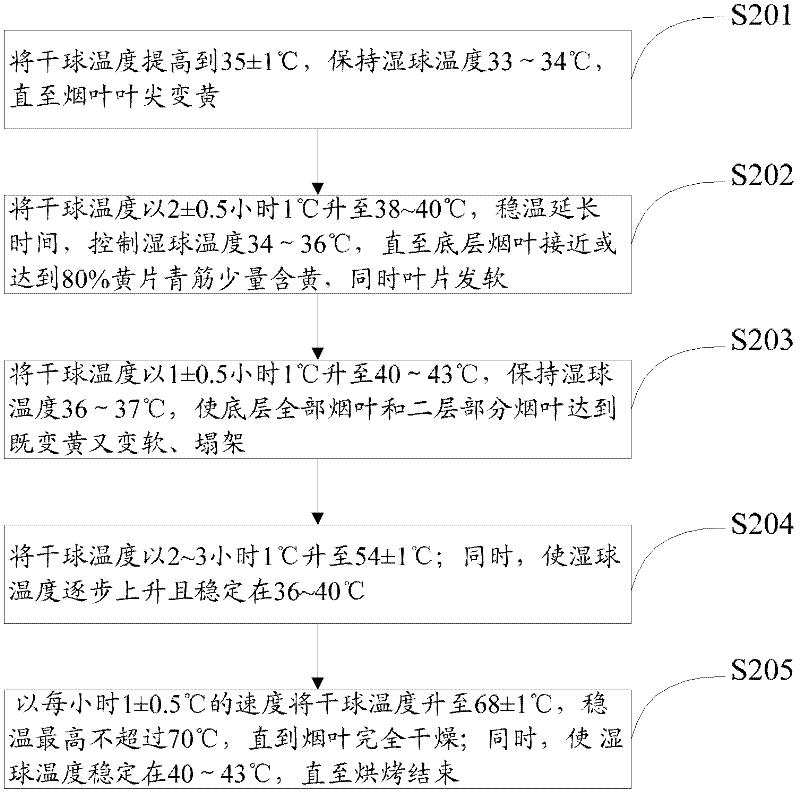

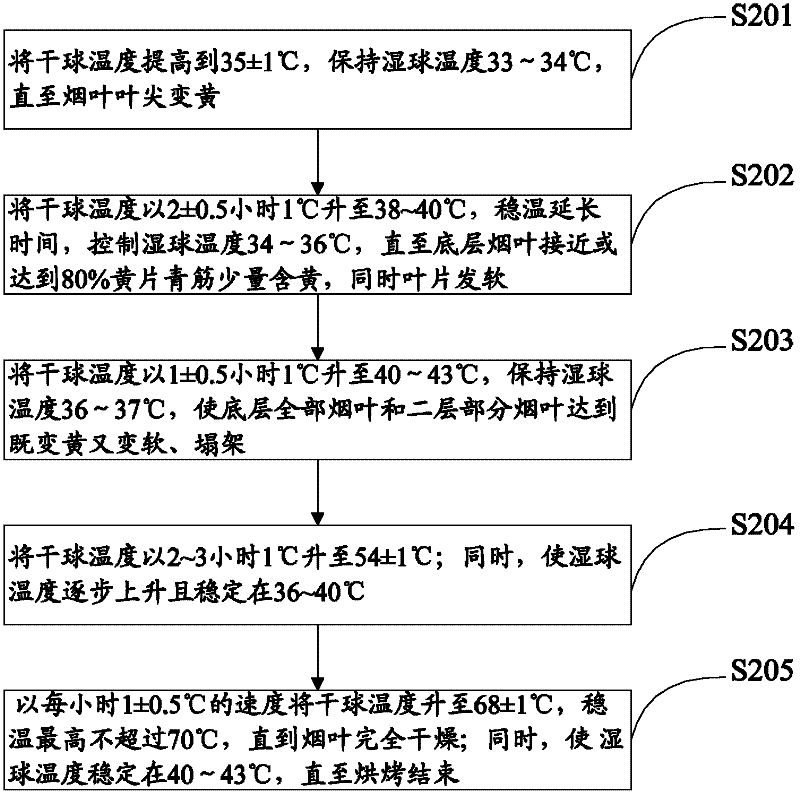

Tobacco leaf baking method

ActiveCN102499424AGood lookingIncrease the fragranceTobacco preparationTemperature controlEngineering

The invention discloses a tobacco leaf baking method, which comprises the following steps of: raising the dry ball temperature to 35+ / -1 DEG C, and maintaining the wet ball temperature at 33 to 34 DEG C until the tobacco leaf tops become yellow; raising the dry ball temperature to 38 to 40 DEG C at a speed being 1 DEG C in 2+ / -0.5 hours, prolonging the time after the temperature is stable, and controlling the wet ball temperature at 34 to 36 DEG C until the bottom layer tobacco leaves approach to or reach the state that yellow leaves account for 80 percent, green ribs become slightly yellow, and simultaneously, the leaves become soft; raising the dry ball temperature to 40 to 43 DEG C at a speed being 1 DEG C in 1+ / -0.5 hour, and maintaining the wet ball temperature being 36 to 37 DEG C so that all tobacco leaves at the bottom and partial tobacco leaves at the second layer become yellow and soft and are collapsed; raising the dry ball temperature to 54+ / -1 DEG C at a speed being 1 DEG C per hour, and simultaneously, gradually raising the wet ball temperature and stabilizing the wet ball temperature at 36 to 40 DEG C; raising the dry ball temperature to 68+ / -1 DEG C at a speed being 1+ / -0.5 DEG C per hour, stabilizing the temperature at the highest temperature not exceeding 70 DEG C until the tobacco leaves are completely dried; and simultaneously, stabilizing the wet bal temperature at 40 to 43 DEG C until the baking is completed. Through optimizing the tobacco leaf baking temperature control scheme, the tobacco baking quality can be improved, and the tobacco leaf baking cost can be reduced.

Owner:CHINA TOBACCO GUANGDONG IND

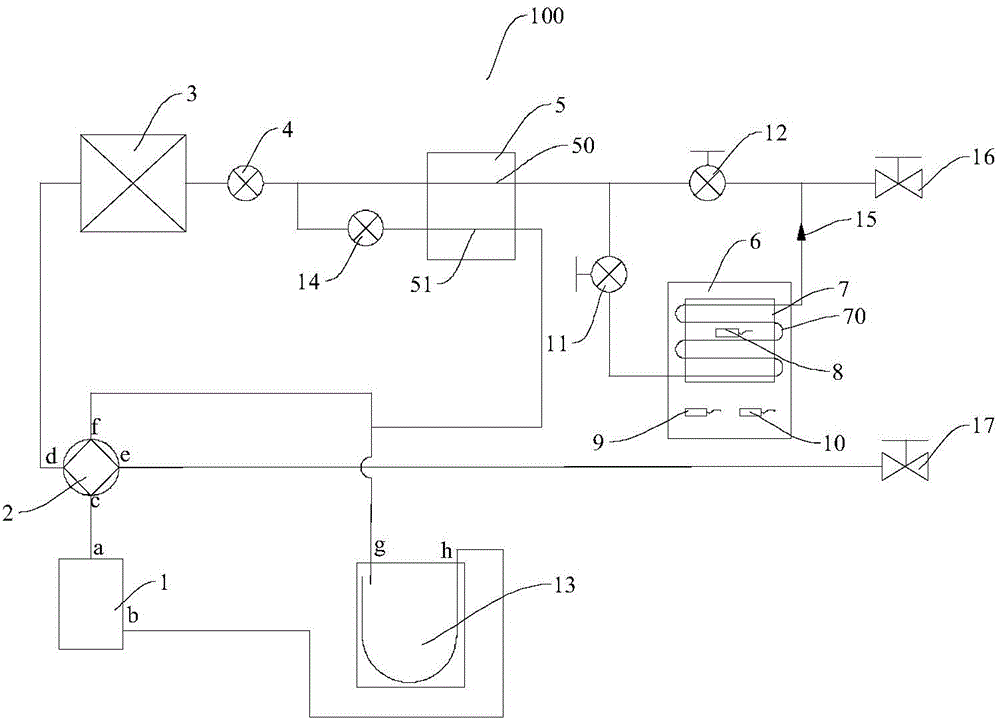

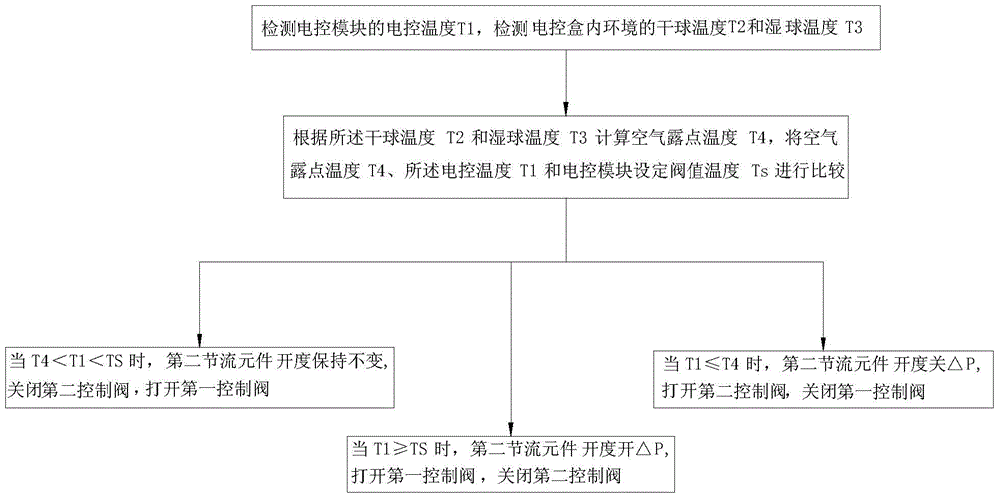

Air conditioner and cooling control method thereof

ActiveCN105091258AExtended service lifeAvoid short circuitSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringControl valves

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

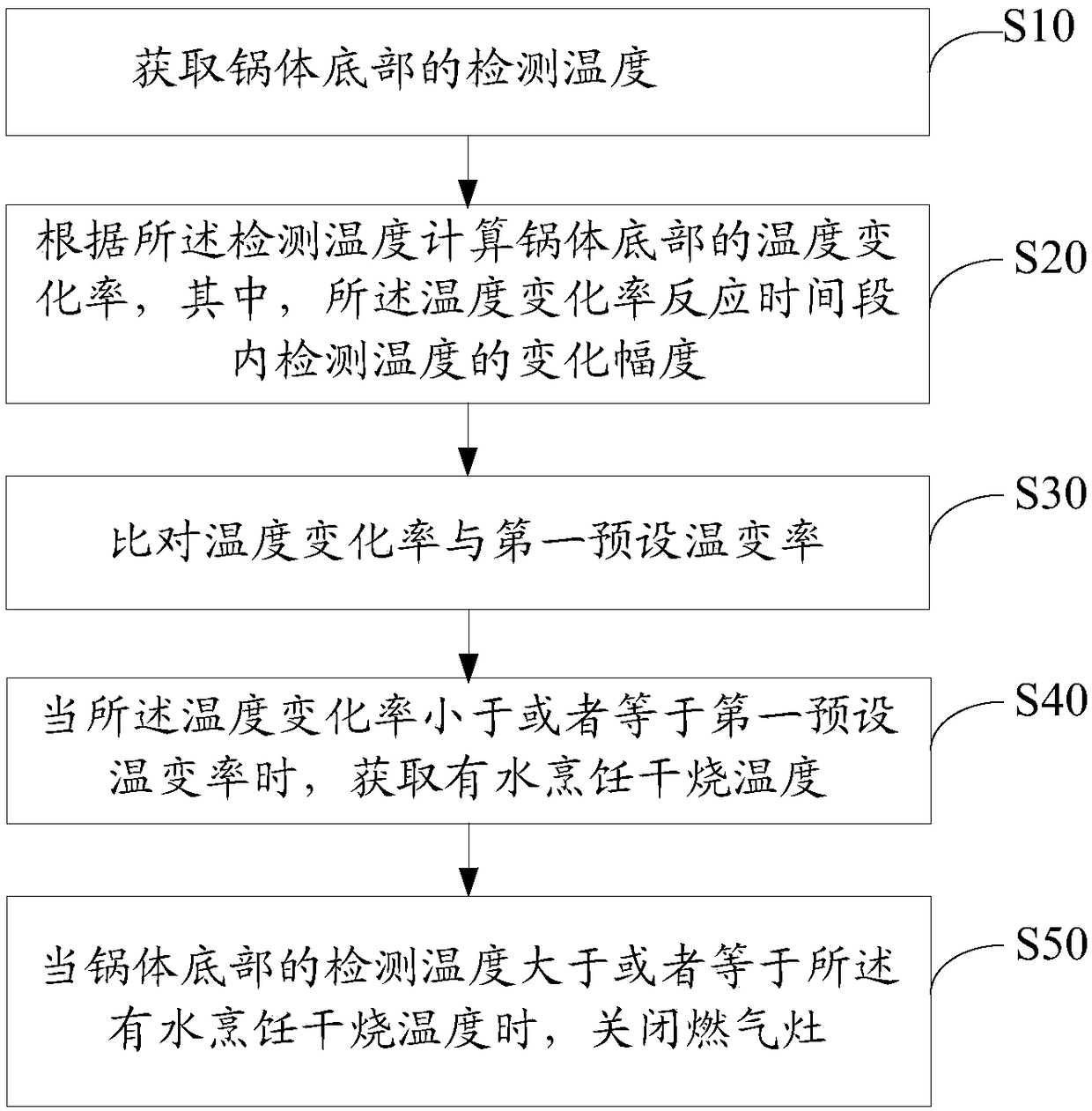

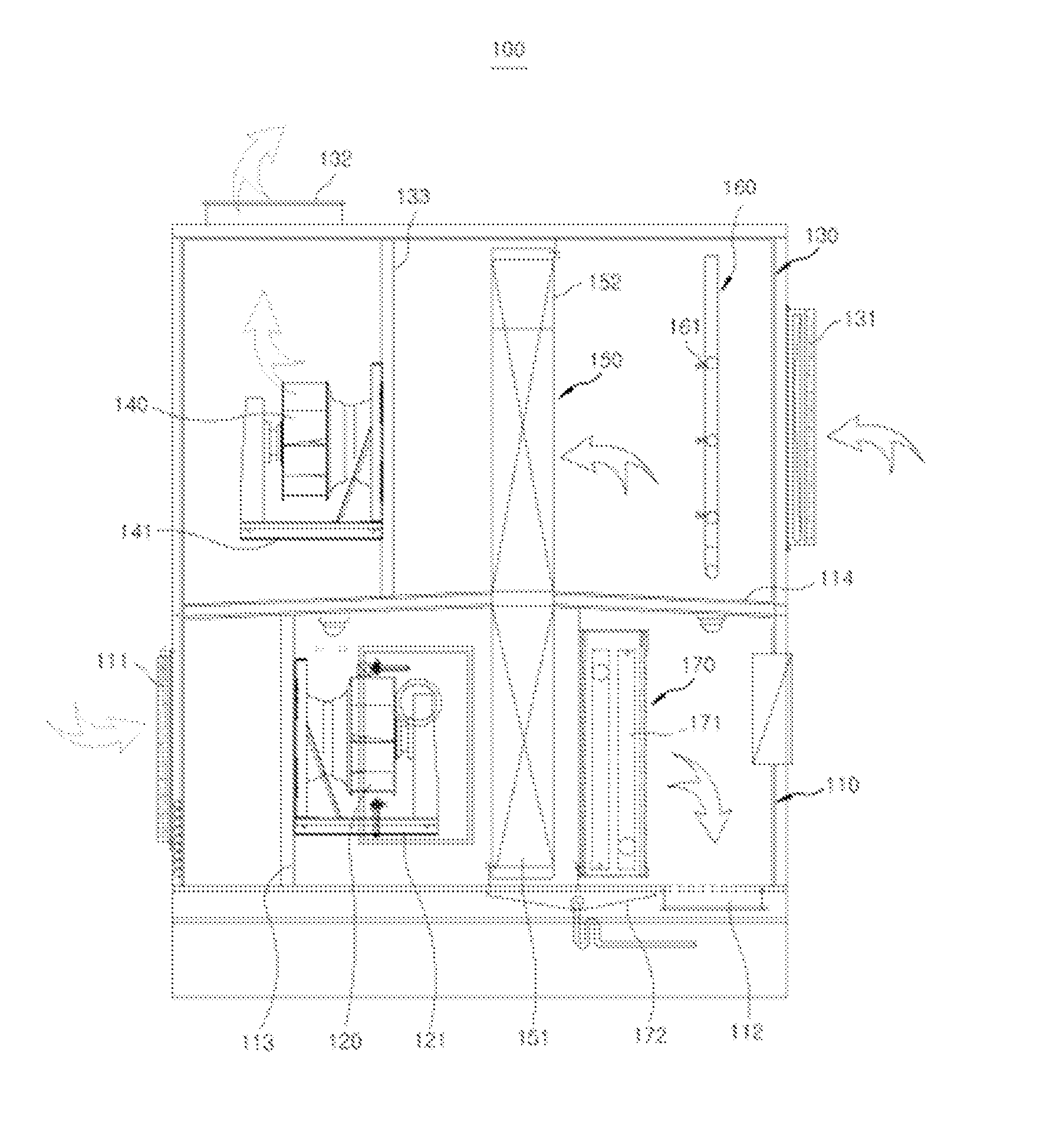

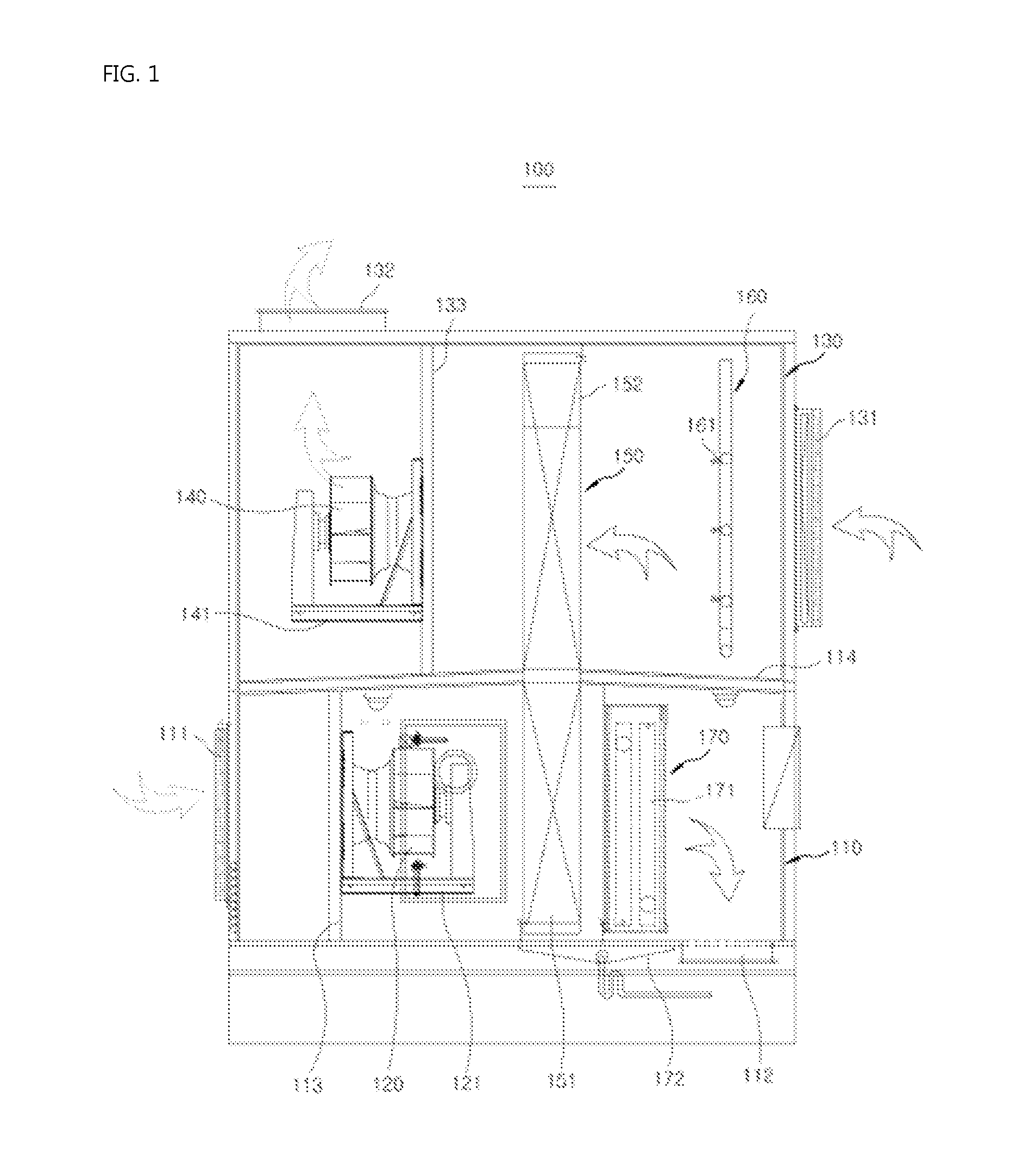

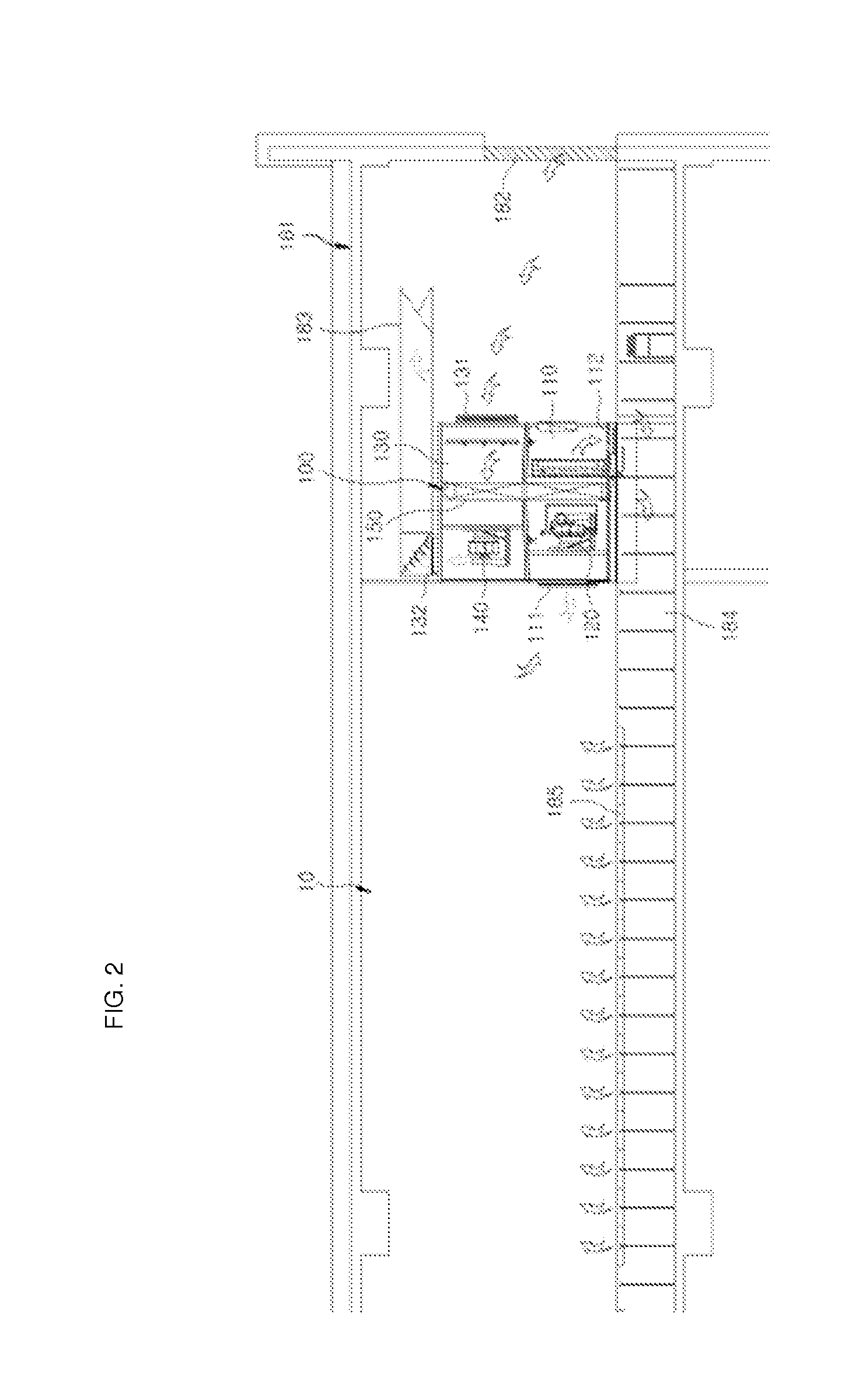

Gas stove and control method thereof

ActiveCN108332240AHigh Acquisition AccuracyHigh control precisionDomestic stoves or rangesLighting and heating apparatusGas cooking stoveGas stoves

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

Air conditioning system of data center using heat pipe and method for controlling thereof

InactiveUS20150034270A1Avoid lostOptimizationAir-treating devicesMechanical apparatusData centerEngineering

An air conditioning system of data center using heat pipe includes a cooling room that allows air within the data center to be drawn in by a first fan and circulated and fed back to the data center; a heat radiation room located separately from the cooling room; a heat pipe installed such that evaporator and condenser are located in the cooling room and heat radiation room, respectively; a sprayer installed in the heat radiation room and provided with a plurality of spray nozzles for spraying cooling fluid to the condenser; a cooling unit installed in the cooling room and cooling the air that passed the evaporator through heat exchange; dry bulb temperature measurement unit and wet bulb temperature measurement unit; and a control unit that receives the detection signal from the dry and wet bulb temperature measurement units and controls the sprayer and the cooling unit.

Owner:THERMOTEK

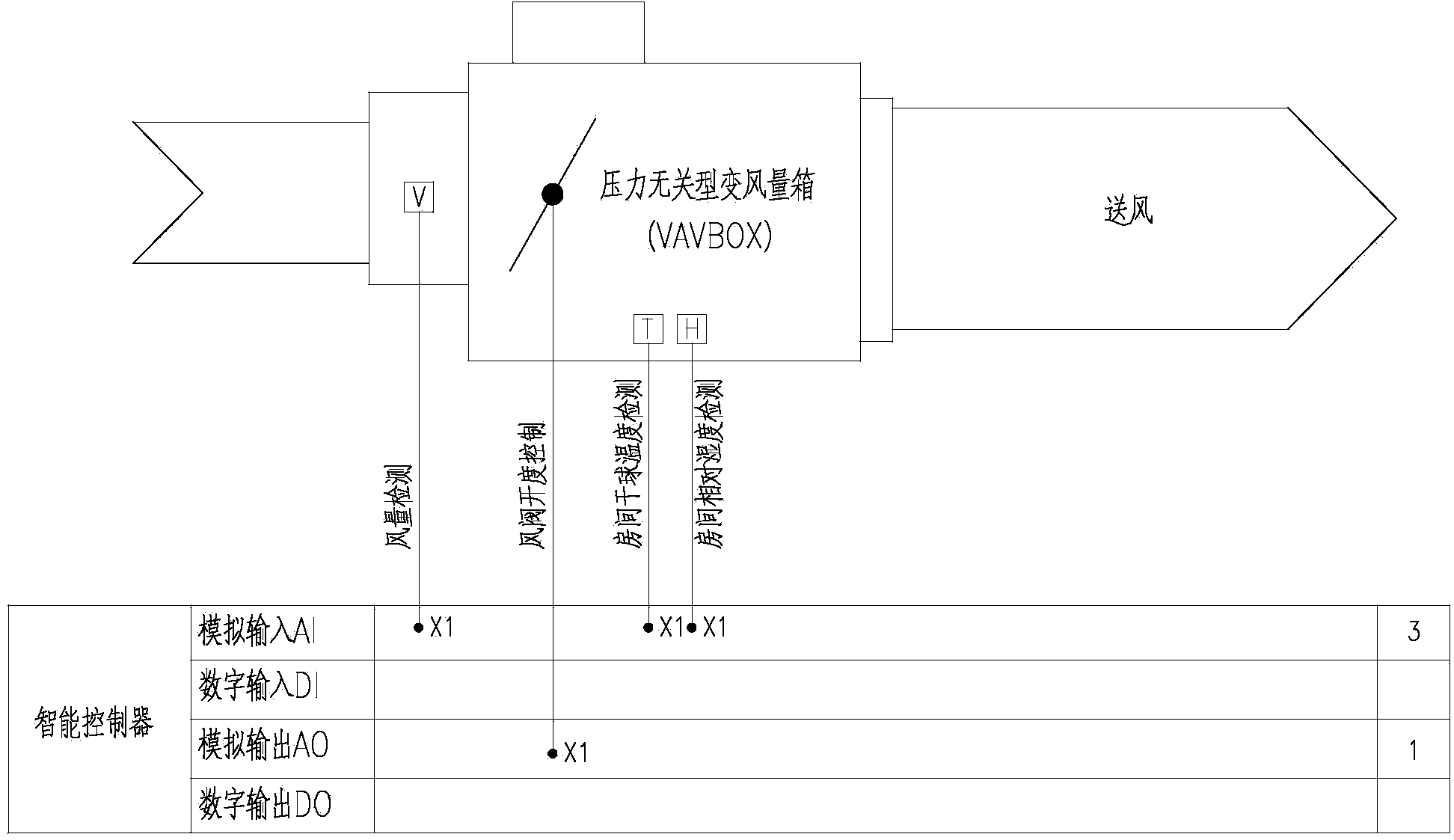

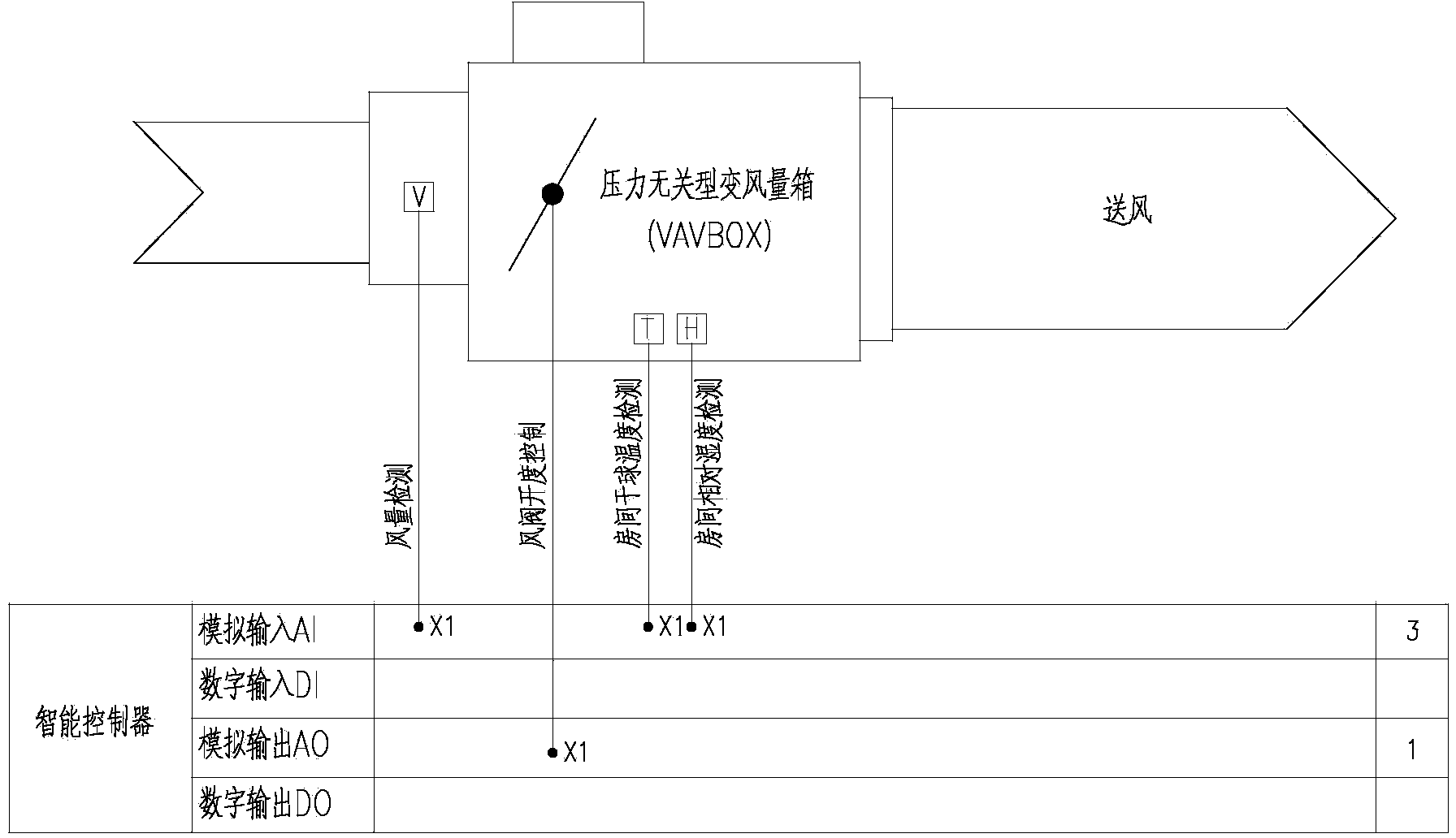

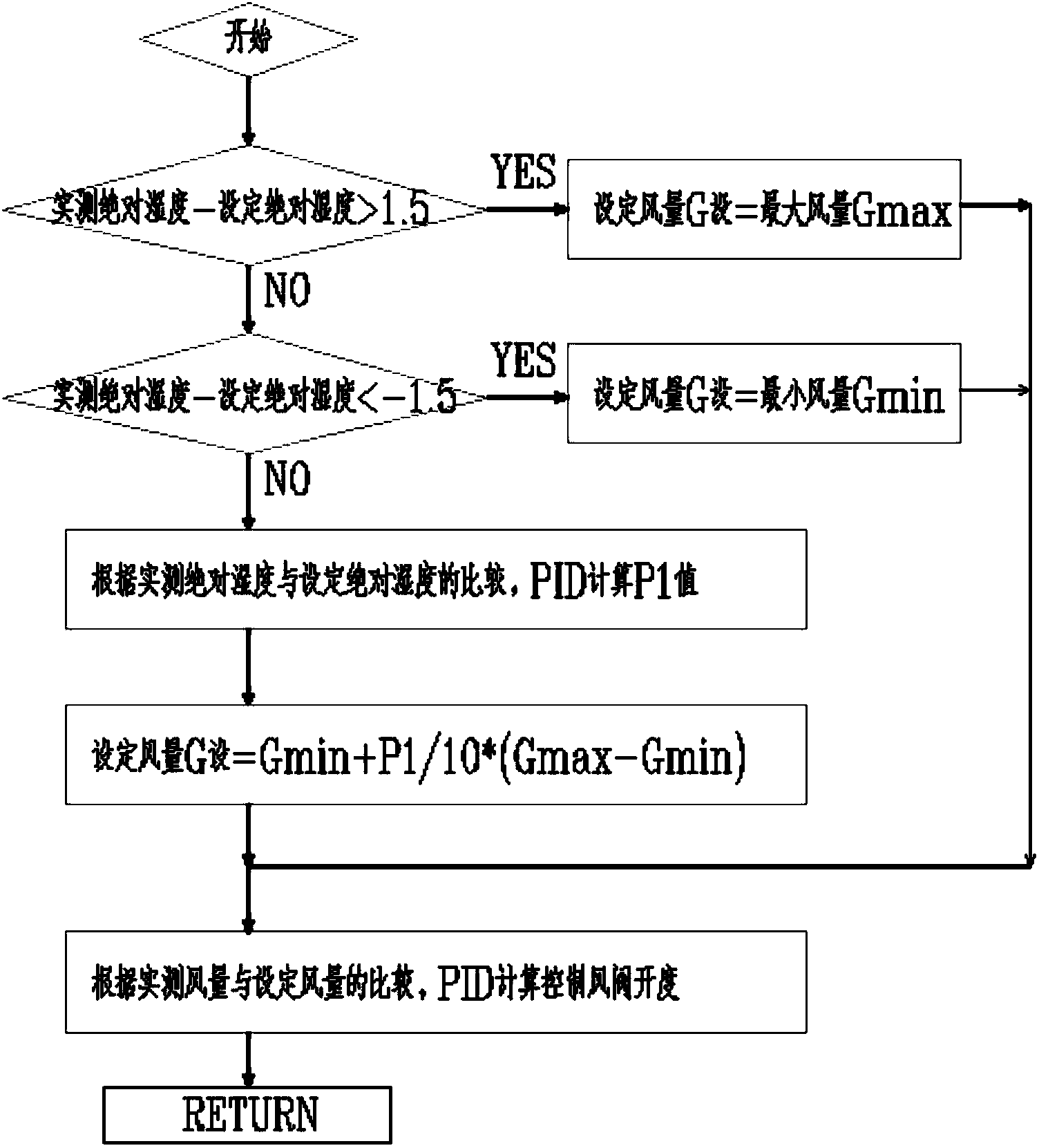

Fresh air variable air rate energy saving method and device based on absolute humidity control

ActiveCN103528144AAvoid the risk of condensationImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusAuto regulationAir volume

The invention relates to a fresh air variable air rate energy saving method and device based on absolute humidity control. The fresh air variable air rate energy saving method is characterized in that the fresh air variable air rate energy saving device based on the absolute humidity control is arranged at the tail end of the fresh air system of an air conditioning system, the opening degree of a valve is automatically controlled through the fresh air variable air rate energy saving device according to the change of indoor humidity, and the fact that the volume of fresh air supplied indoors meets indoor actual dynamic needs is guaranteed; the air volume is automatically adjusted according to the change of the moisture content, namely, the absolute humidity of a room, air output by a fresh air handling unit is dry air of a fixed state, and the relative humidity value of the room is guaranteed; the coupling relationship of relative humidity and dry-bulb temperature is relieved. The absolute humidity, an indoor environment parameter, is controlled, the indoor relative humidity can be precisely controlled, the coupling relationship of the relative humidity and the dry-bulb temperature is relieved well, the moisture condensation risk of a cold emission plate is avoided, meanwhile, control is stable and reliable, and the fresh air variable air rate energy saving method and device have good comfort and the good energy saving effect.

Owner:广州市设计院集团有限公司

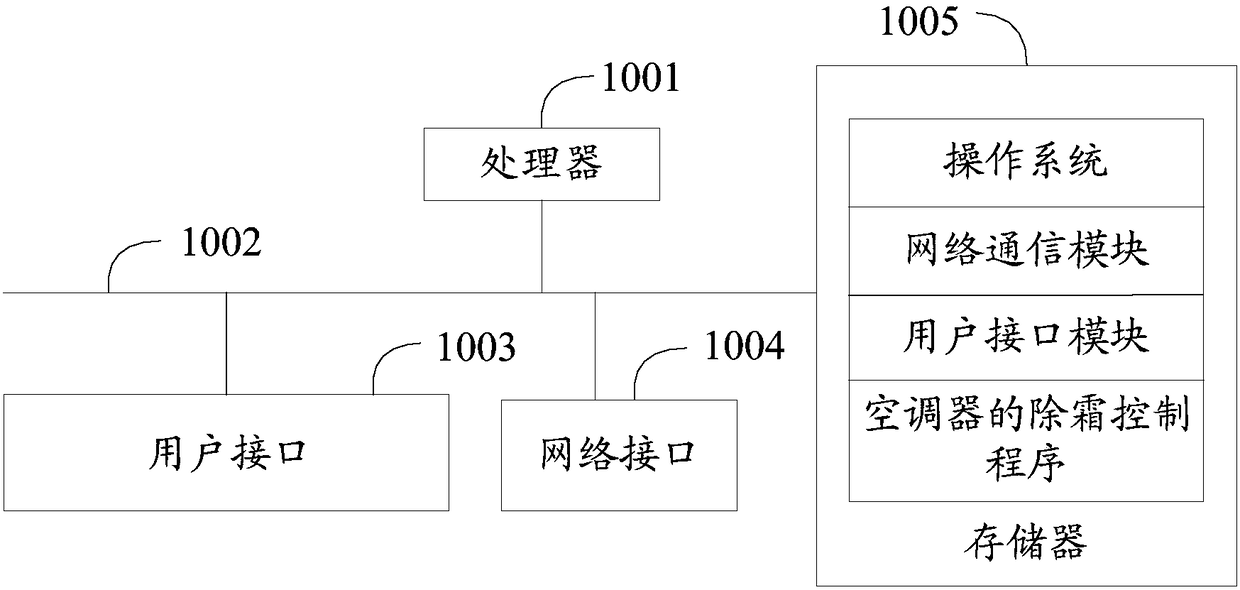

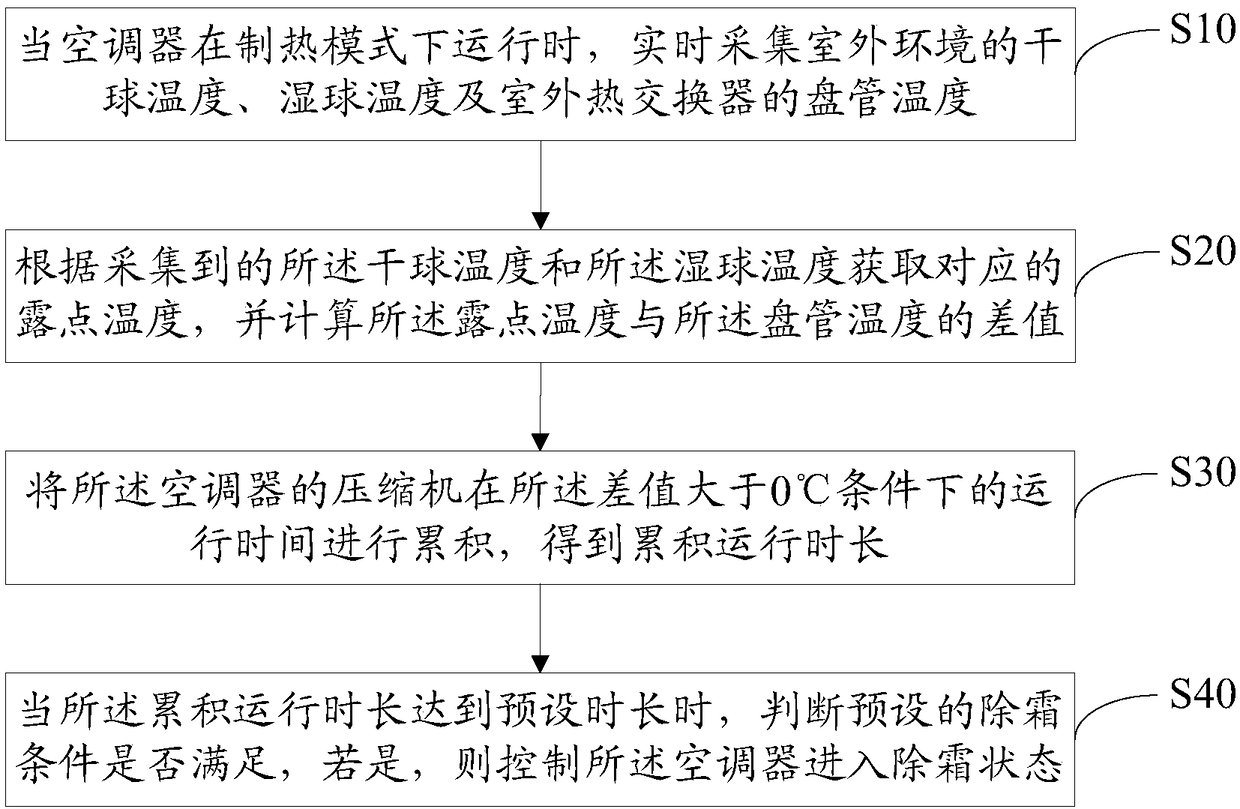

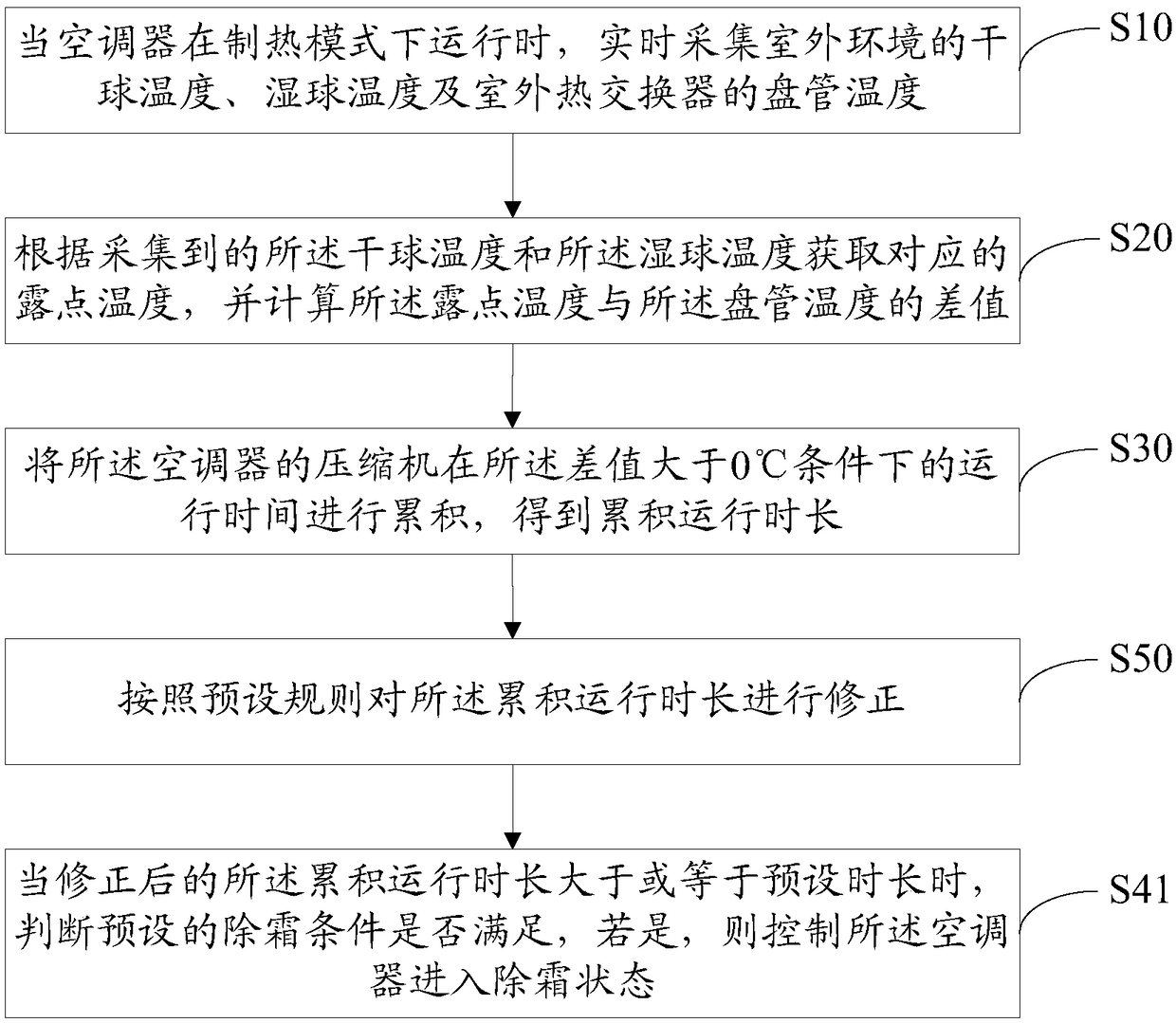

Defrosting control method for air conditioner, air conditioner and computer readable storage medium

ActiveCN108195027ASolve too frequent defrostingSolve the problem of defrostingMechanical apparatusSpace heating and ventilation safety systemsRunning timeWet-bulb temperature

The invention discloses a defrosting control method for an air conditioner. The method comprises the following steps that when the air conditioner runs in a heating mode, the dry bulb temperature andthe wet bulb temperature of an outdoor environment and the coil temperature of an outdoor heat exchanger are acquired in real time; the corresponding dew point temperature is obtained according to theacquired dry bulb temperature and the acquired wet bulb temperature, and the difference value between the dew point temperature and the coil temperature is calculated; the running time of a compressor of the air conditioner under the condition that the difference value is greater than 0 DEG C is accumulated, and the accumulated running time is obtained; and when the accumulated running time reaches the preset time, whether the preset defrosting condition is met or not is judged, if yes, the air conditioner is controlled to enter a defrosting state. The invention further discloses the air conditioner and a computer readable storage medium. The defrosting control method, the air conditioner and the computer readable storage medium can solve the technical problem of too frequent defrosting or untimely defrosting of the air conditioner due to a large judgment error of an existing air conditioner on the frosting degree of the outdoor heat exchanger.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

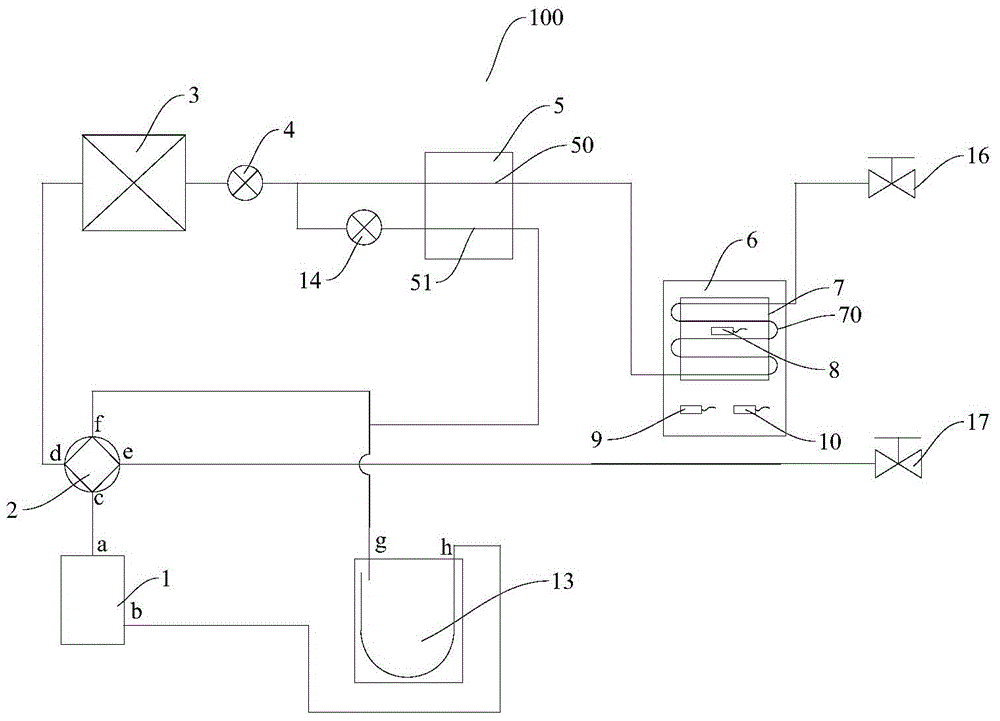

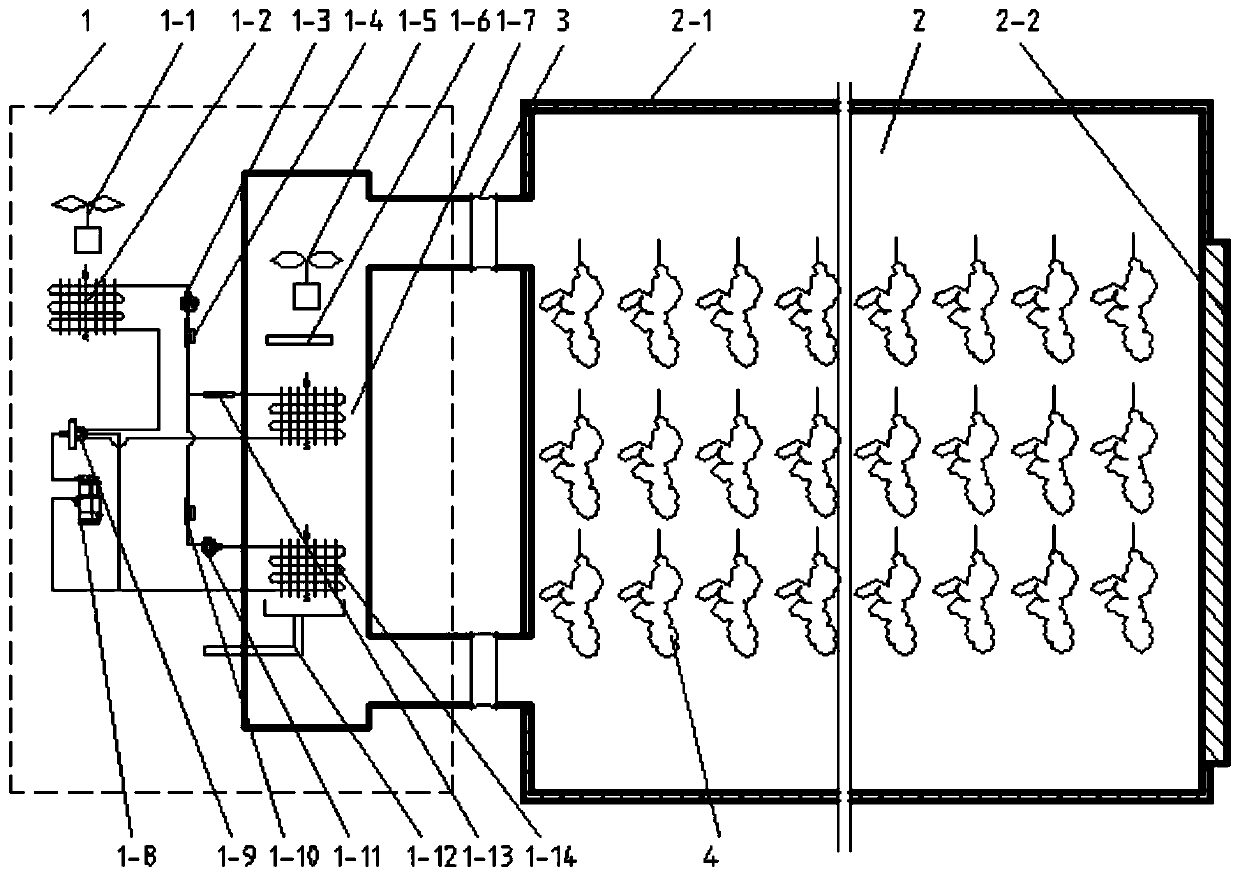

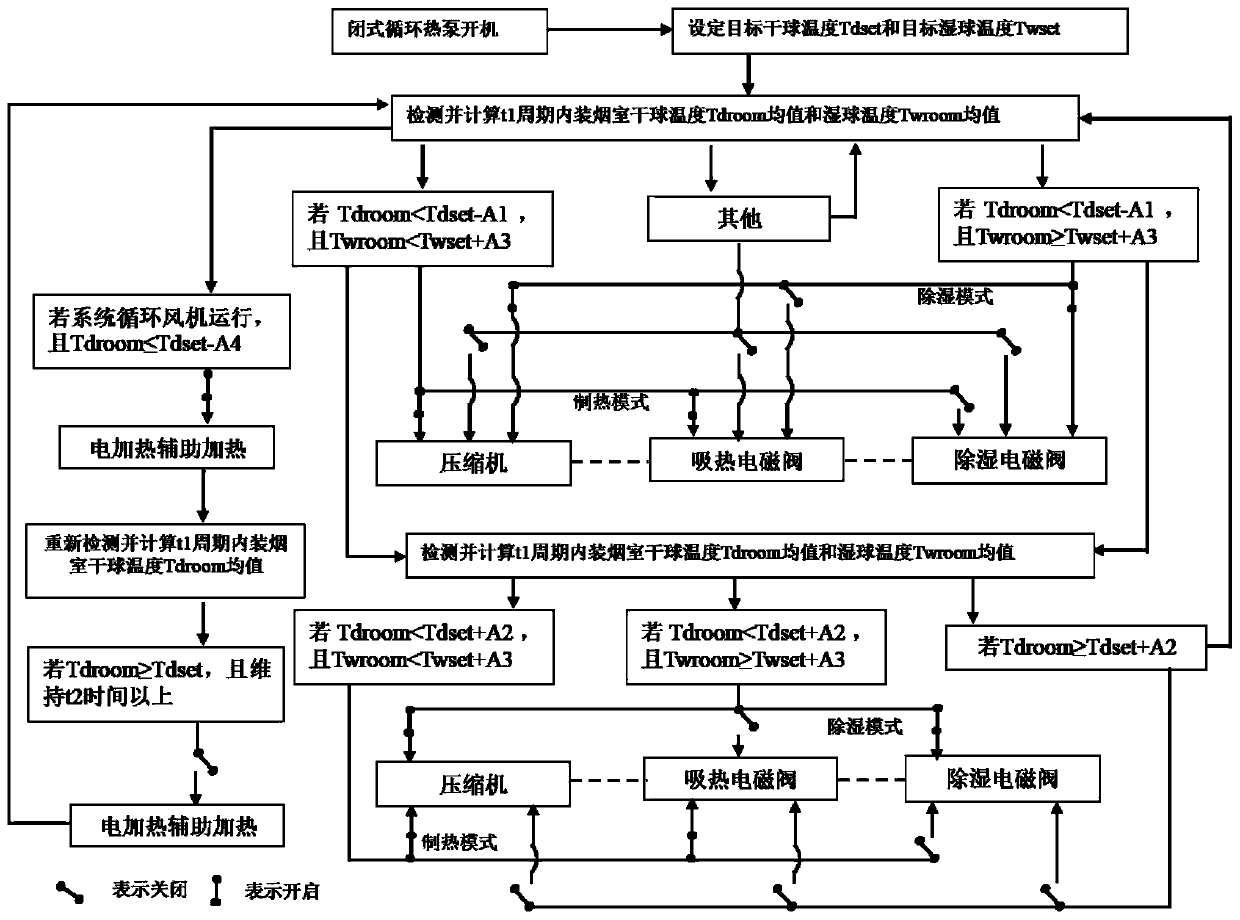

Intelligent temperature and humidity control method for closed circulation heat pump tobacco curing barn

ActiveCN110906698AImprove control effectDrying gas arrangementsDrying solid materialsThermodynamicsMedicine

The invention discloses an intelligent temperature and humidity control method for a closed circulation heat pump tobacco curing barn, which comprises the following steps of: (1) starting a closed circulation heat pump system, and setting a target dry bulb temperature Tdset and a target wet bulb temperature Twset, (2) detecting a dry bulb temperature and a wet bulb temperature in a tobacco loadingchamber, and comparing the dry bulb temperature and the wet bulb temperature with the target dry bulb temperature Tdset and the target wet bulb temperature Twset to realize starting and stopping of acompressor and switching control of heating and dehumidifying modes. In combination of control on auxiliary electric heating equipment, the compressor starting dry bulb temperature control amplitudedifference A1, the compressor stopping dry bulb temperature control amplitude difference A2, the compressor wet bulb temperature control amplitude difference A3 and the electric heating starting dry bulb temperature control amplitude difference A4 are creatively combined, and thus the compressor can be reasonably started and stopped and can be switched between the heating mode and the dehumidifying mode, the temperature and the humidity of the curing barn are ensured to be matched with the target temperature and the target humidity, the temperature and the humidity are both considered, the control effect is good, and high market application and popularization prospects are achieved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +3

Systems and methods for controlling local environment

InactiveUS6966364B1Avoid difficultyEasy to controlSpace heating and ventilationUsing liquid separation agentEngineeringHumidity ratio

The present invention provides systems and methods of controlling local environment. In one embodiment, incoming air enters a contactor such the Direct Contact Cooler-Condenser (DCCC) where the air contacts water distributed on the contact media. After passing through the DCCC, the air is saturated at a temperature equal or close to that of the water. Depending on the state of the incoming air, in the DCCC will be humidified or dehumidified to yield saturated air at the desired humidity ratio. In one embodiment, a blower draws air through the DCCC and blows into the heater. The heater heats the air to the desired dry-bulb temperature. Before exiting, the air may pass through a filter.

Owner:ASML HLDG NV

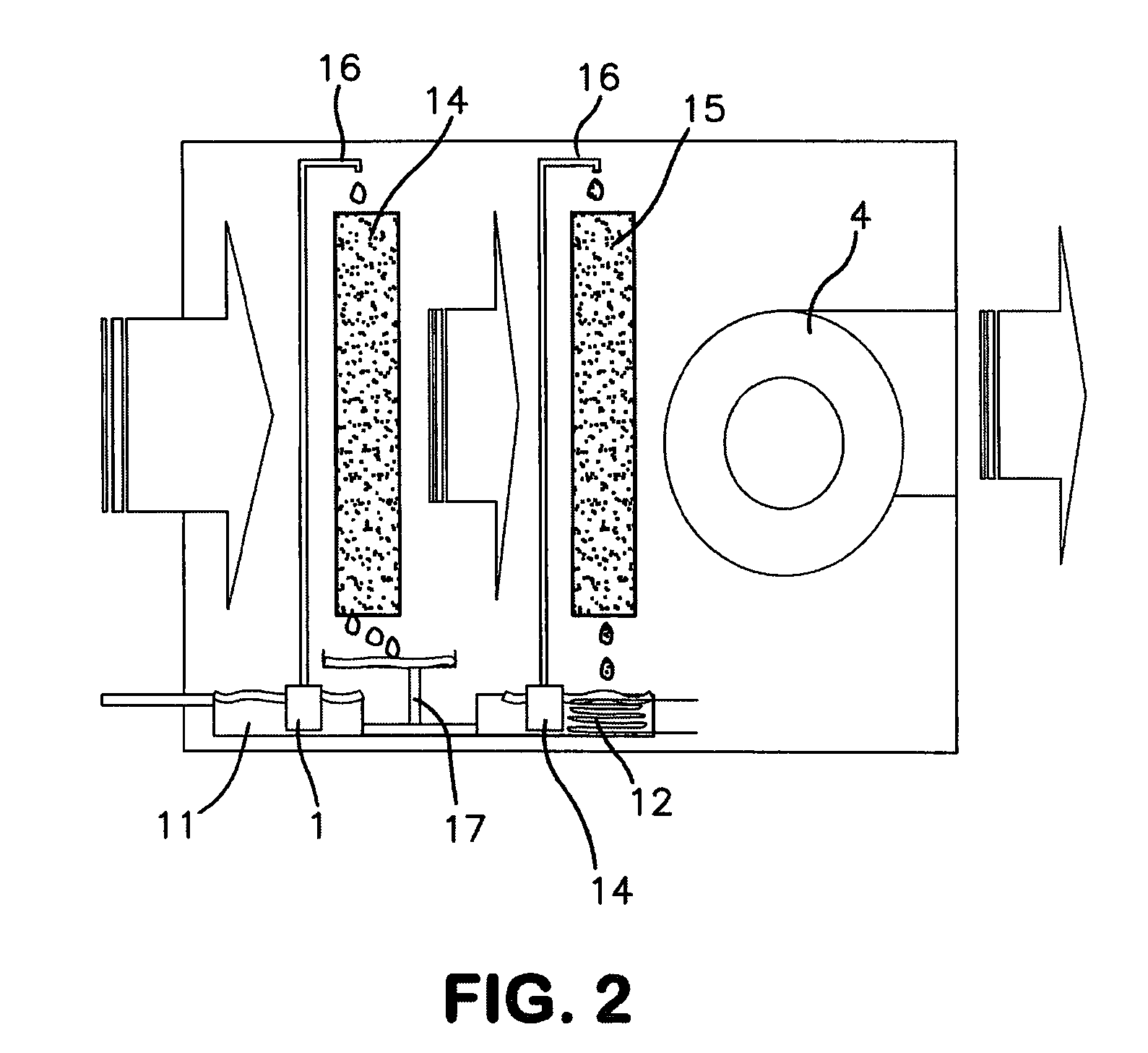

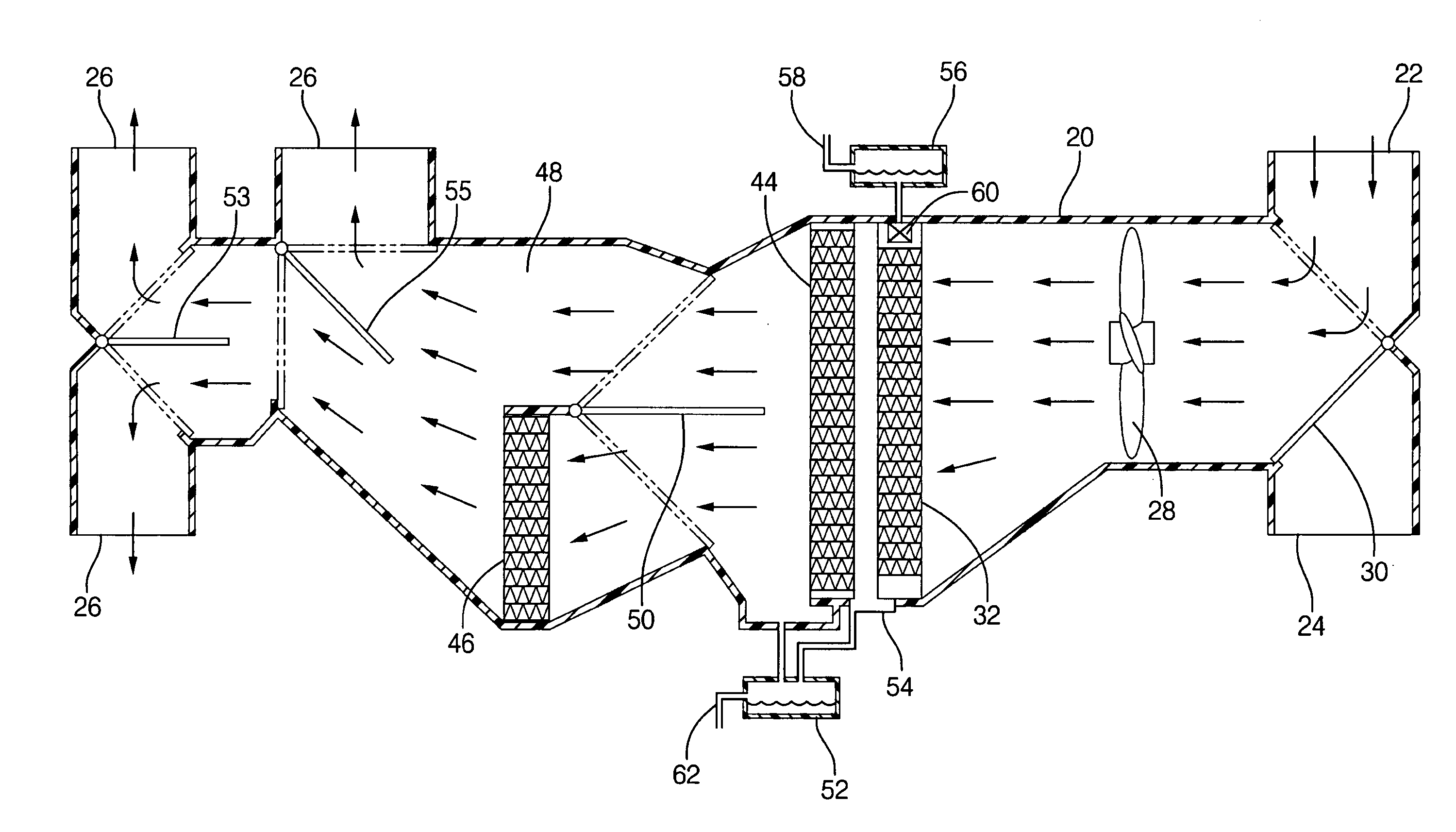

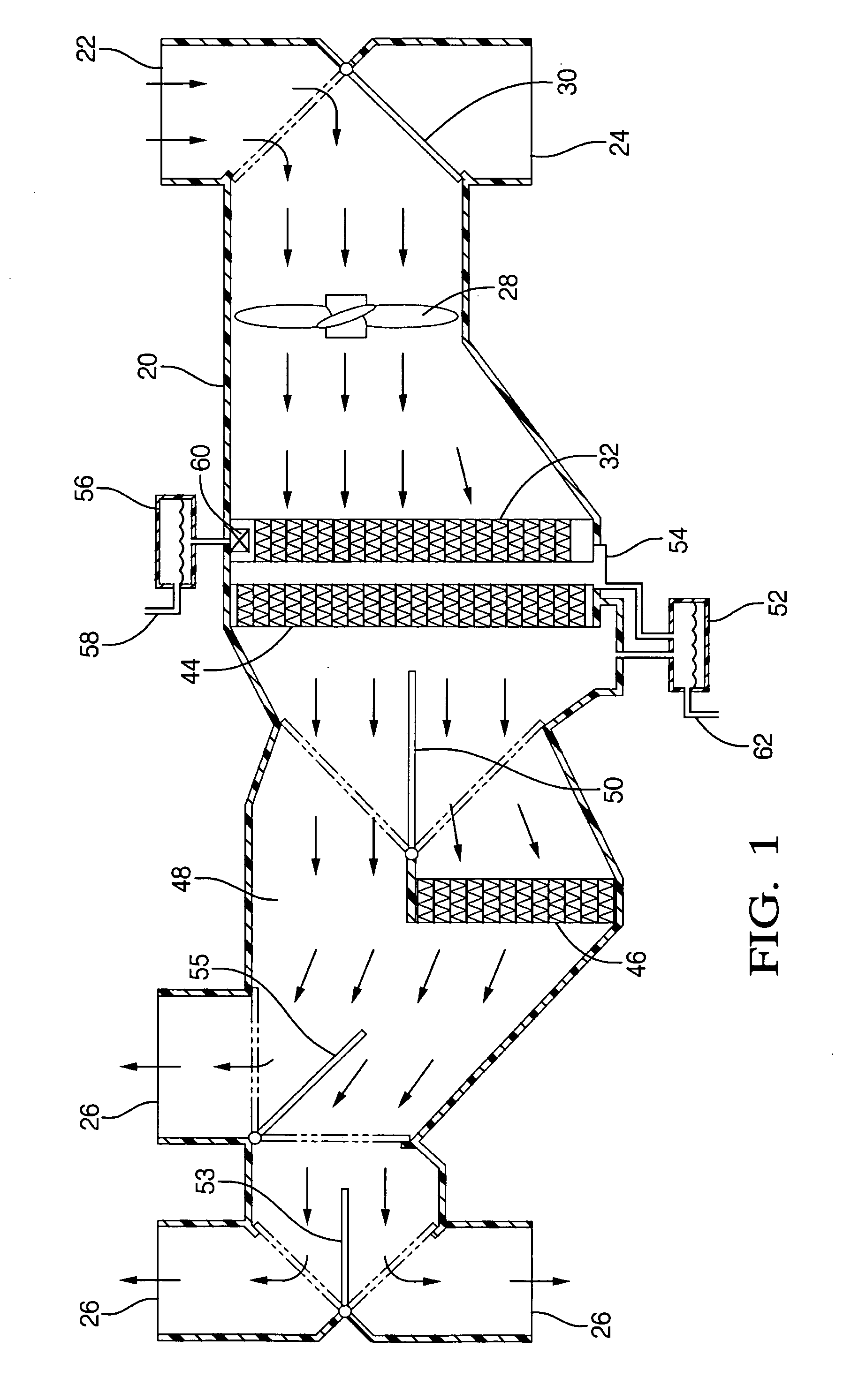

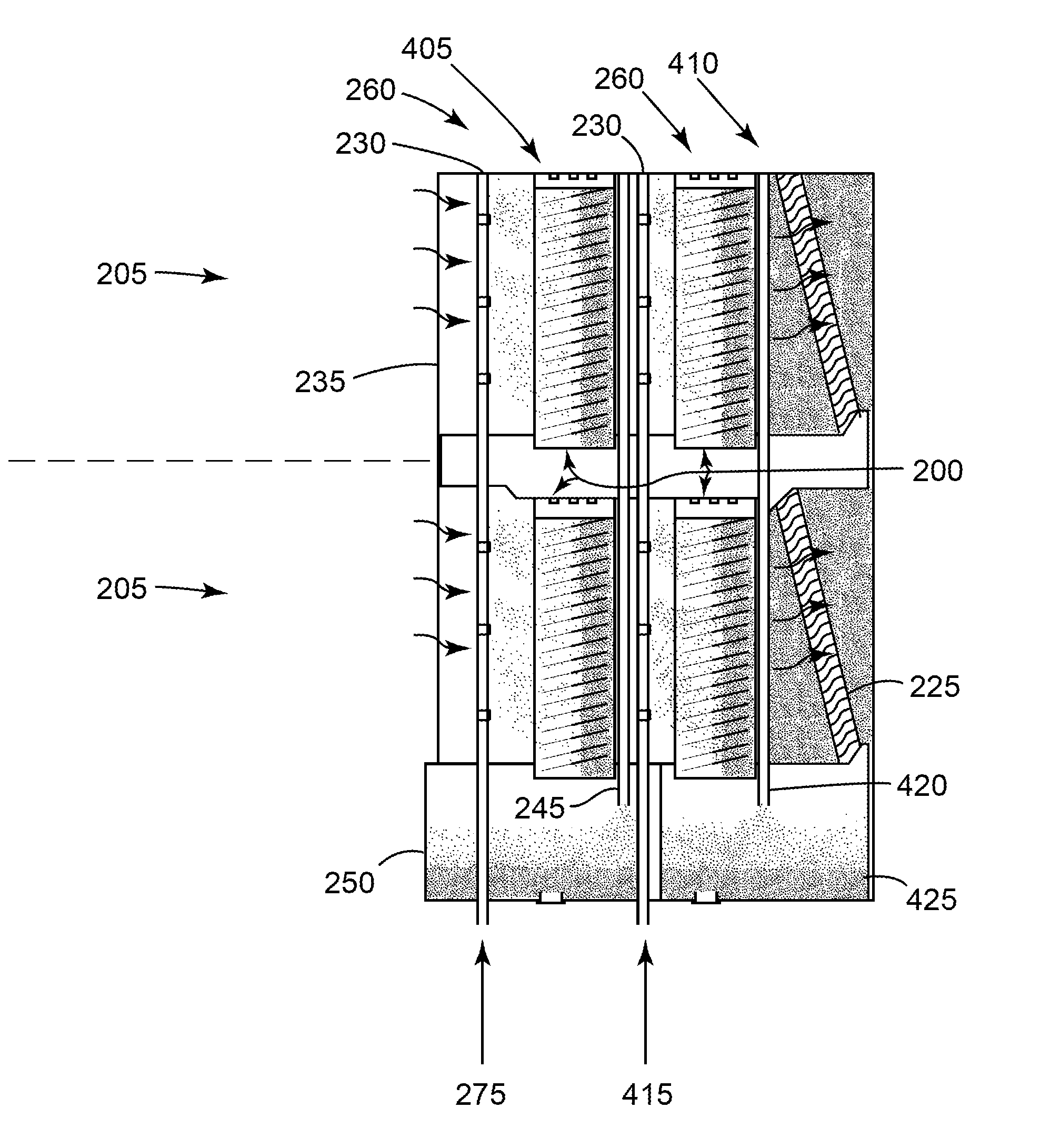

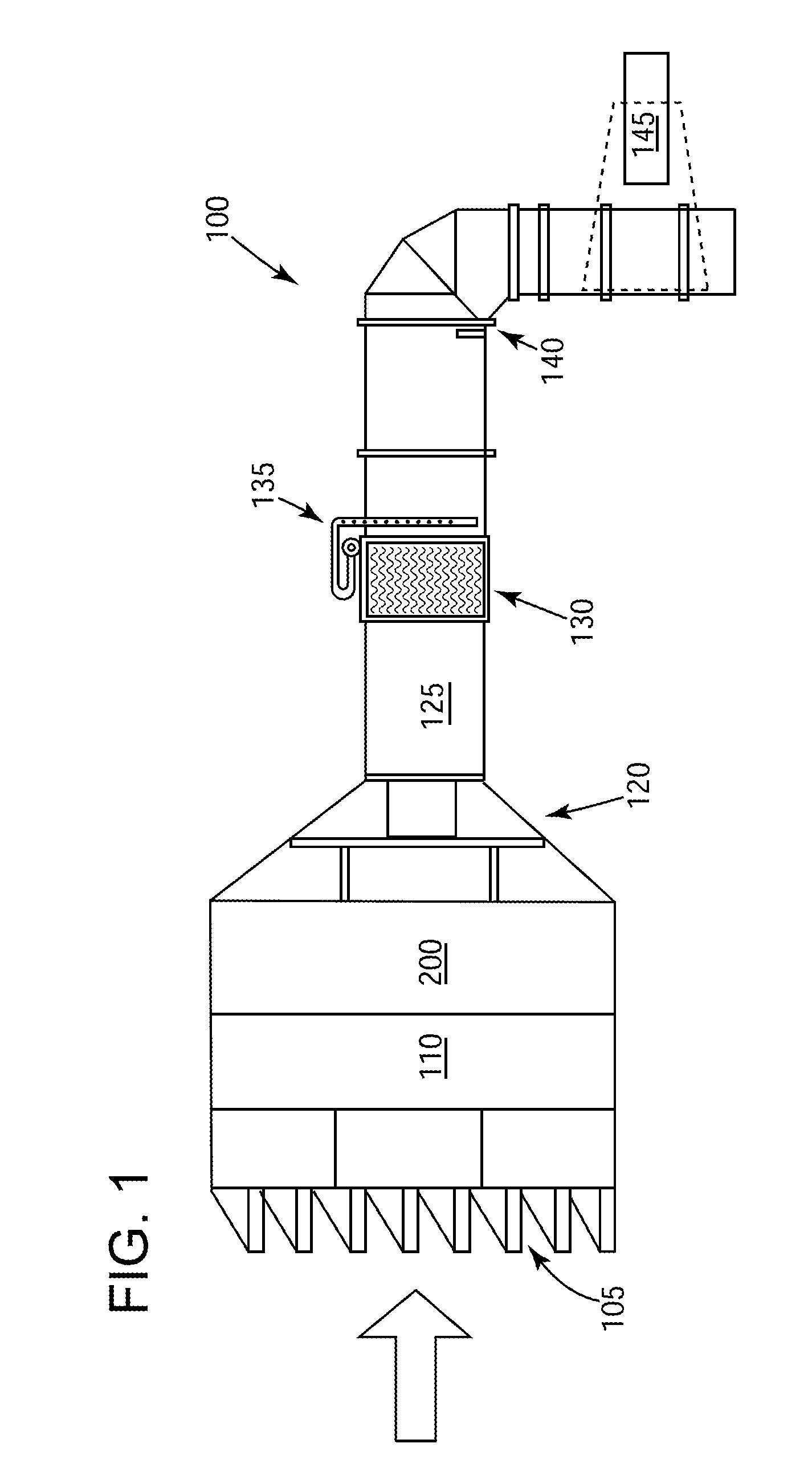

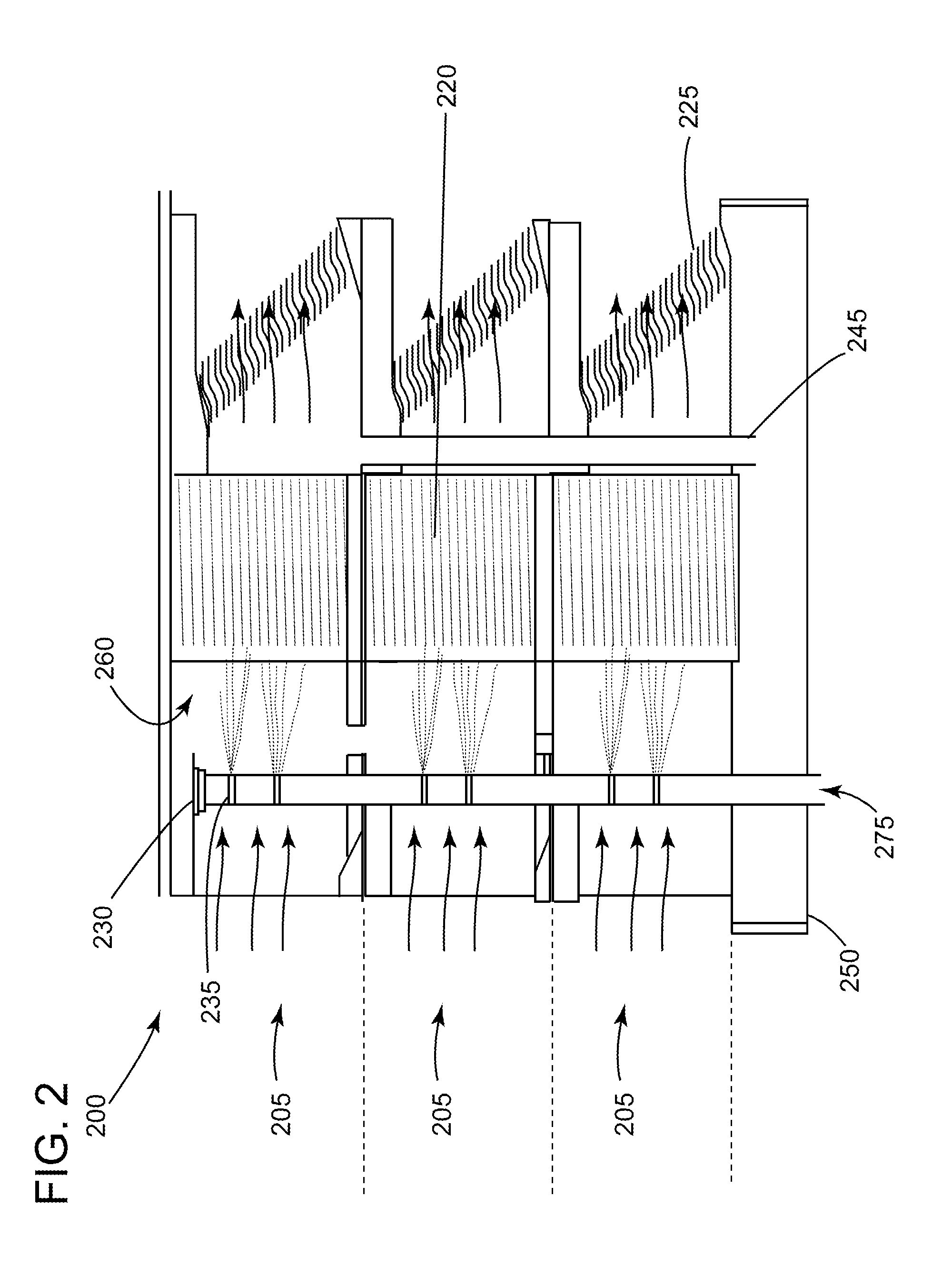

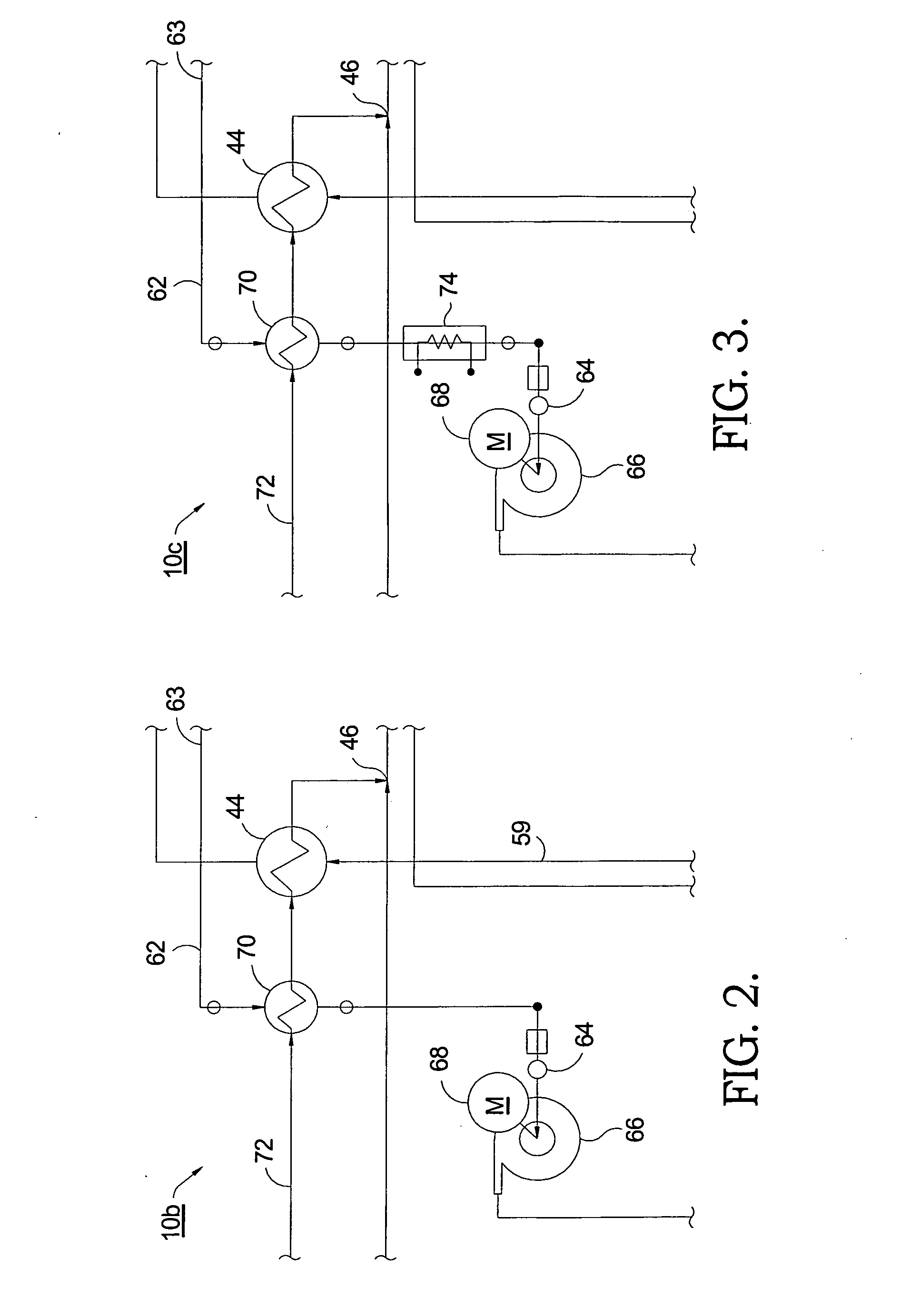

System for conditioning the airflow entering a turbomachine

ActiveUS20110042836A1Increase productionCombination devicesFlow mixersEngineeringVolumetric Mass Density

An embodiment of the present invention provides an air conditioning system (ACS) for conditioning the airstream entering an air-consuming machine, such as, but not limiting of, a gas turbine. Conditioning may be considered a process that adjusts at least one physical property of the airstream. The physical property may comprise: a wet-bulb temperature, a dry-bulb temperature, relative humidity, density, or the like. In an embodiment of the present invention, the major components of the ACS may be located in a single structure, which may be considered a module. Depending on the application of the ACS, multiple modules may be physically and / or operationally integrated on the air-consuming machine. An alternate embodiment of the ACS may comprise a module having multiples stages. Here, each stage may operate independently other stages. Furthermore, each stage may use a separate fluid from other stages.

Owner:GENERAL ELECTRIC CO

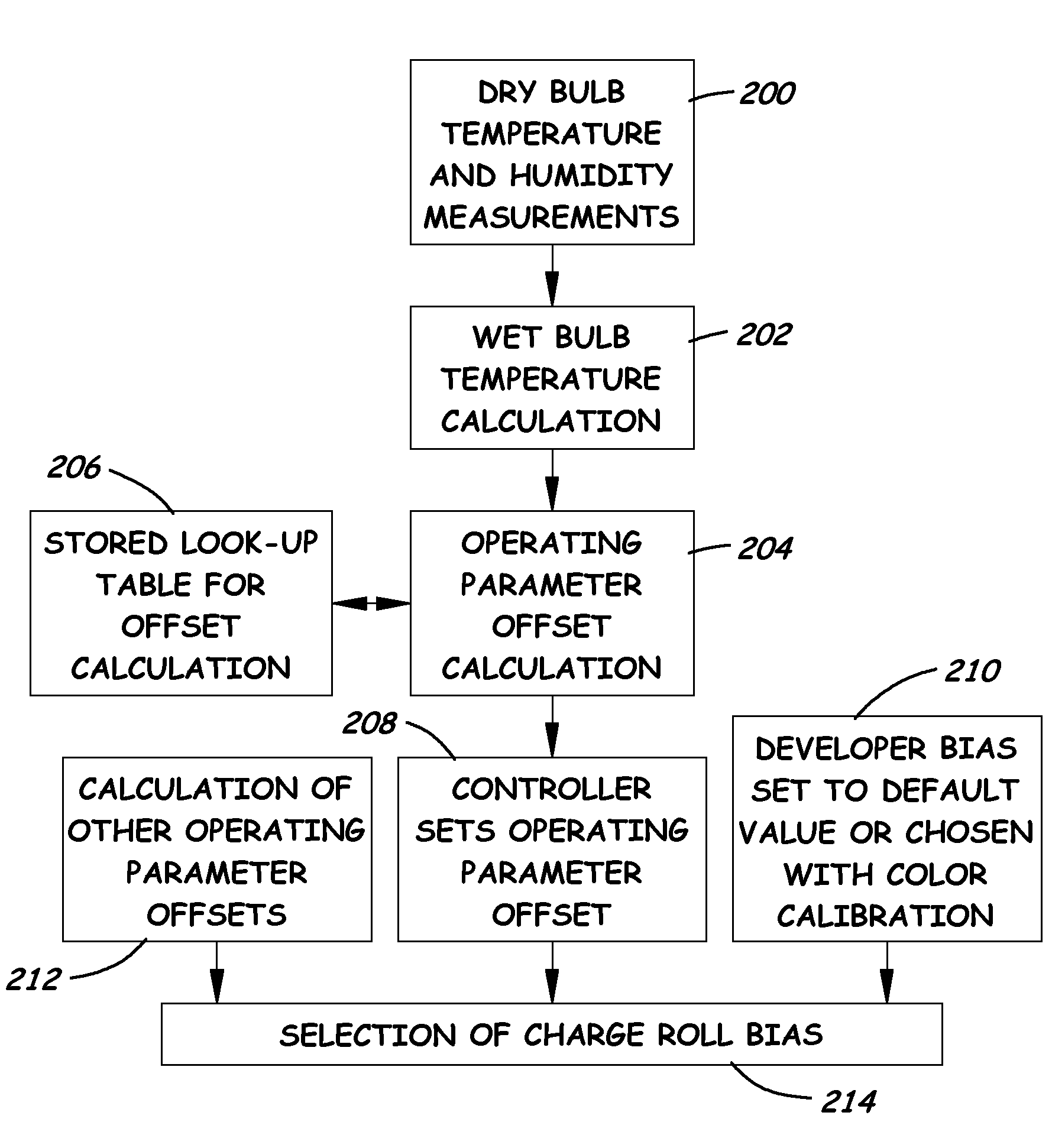

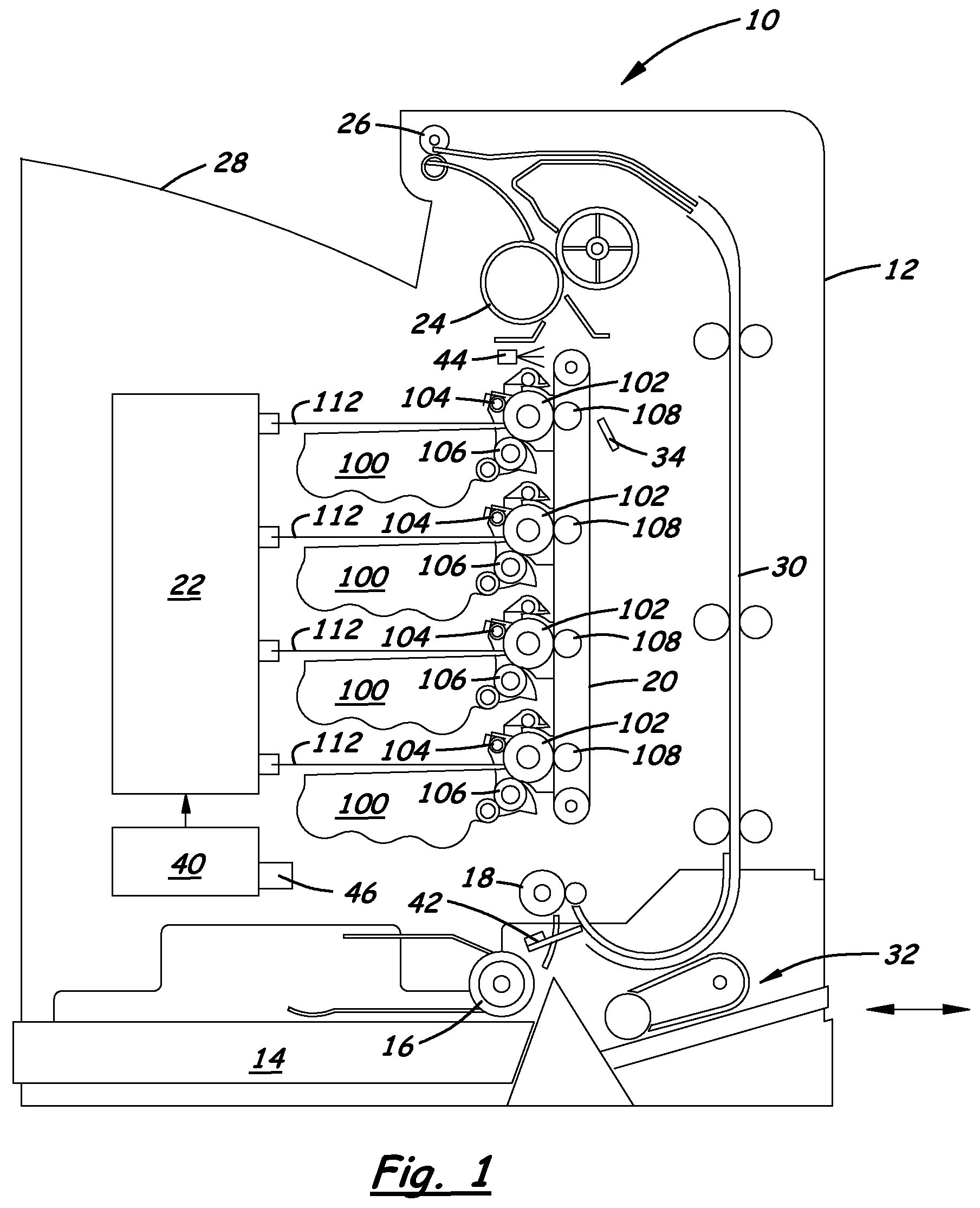

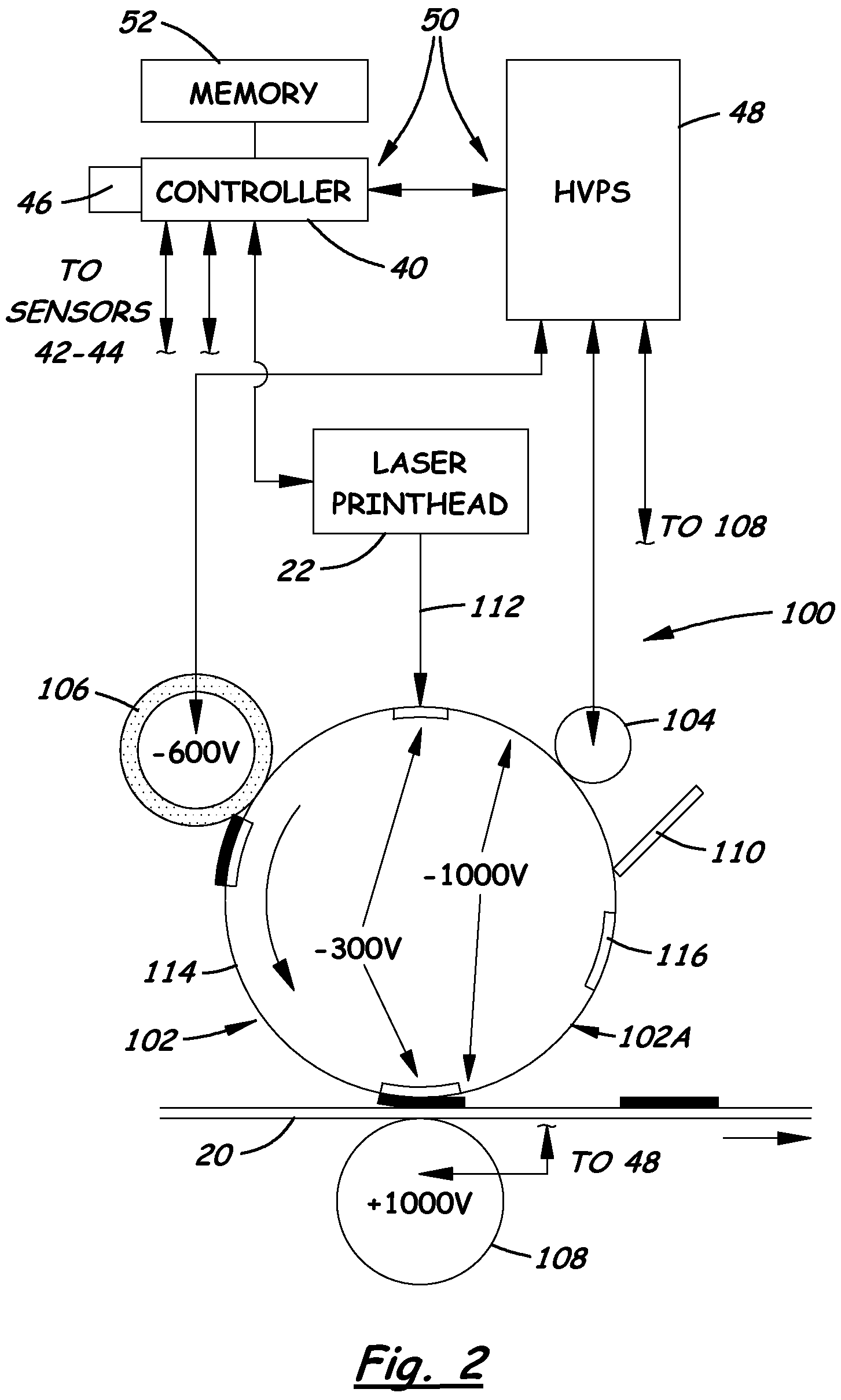

System and Method for Adjusting Selected Operating Parameter of Image Forming Device Based on Selected Environmental Conditions to Control White Vector

InactiveUS20100080585A1High voltageEasy to controlElectrographic process apparatusCorona dischargeLatent imageImage formation

A system for adjusting a selected operating parameter of an image forming device to control white vector based on selected environmental conditions includes an image forming station having a photoconductive surface with a latent image formed by discharged areas leaving non-discharged areas different from the discharged areas, a sensor mechanism for measuring selected environmental conditions of dry-bulb temperature and relative humidity, a control mechanism for reading the sensor mechanism to adjust the voltage bias of a charging unit by an offset applied to the charging unit based on a wet-bulb temperature value so as to minimize white vector without enabling onset of development of toner background on non-discharged areas, and a memory connected to and accessible by the control mechanism and storing a lookup table of a list of wet-bulb temperature values related to measured dry-bulb temperature and relative humidity values and correlated to a list of voltage bias offsets.

Owner:LEXMARK INT INC

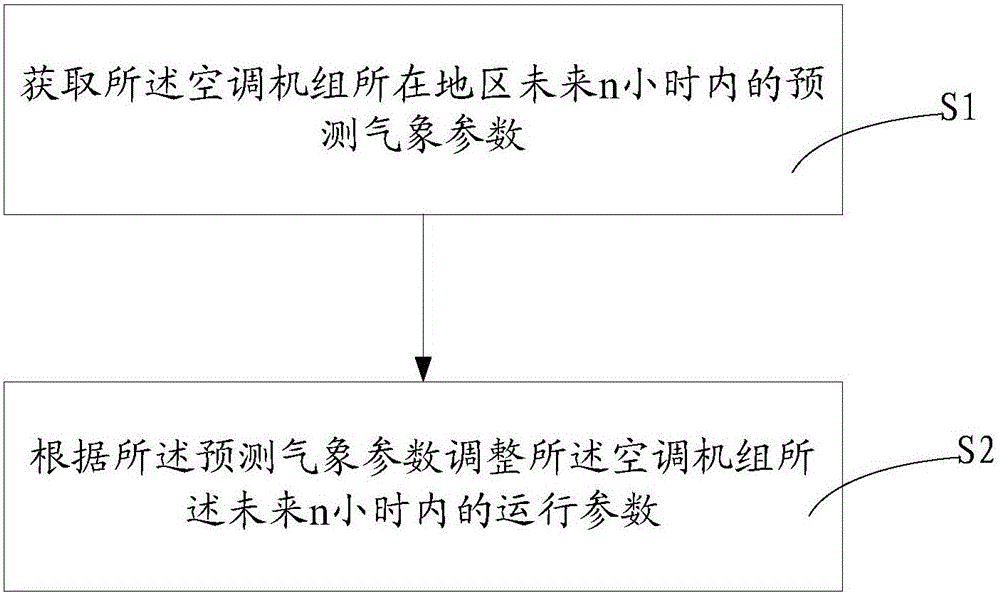

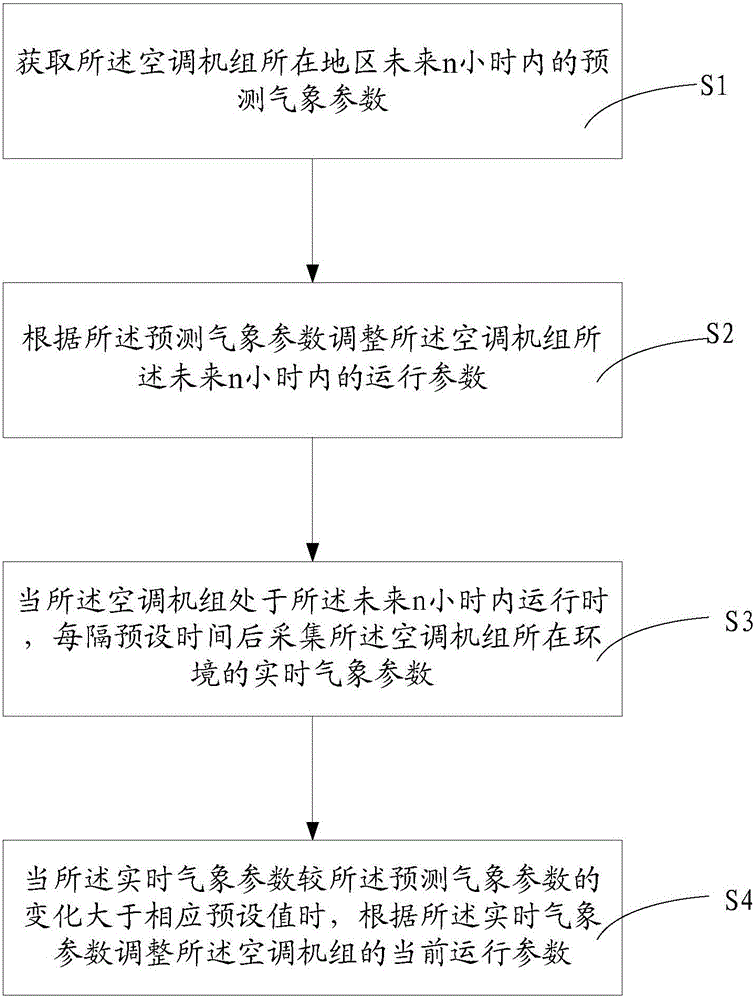

Control method and system for air conditioning unit and air conditioning unit

ActiveCN106091242AGood energy saving effectFlexible controlMechanical apparatusSpace heating and ventilation safety systemsControl systemFresh air

The invention discloses a control method and system for an air conditioning unit and the air conditioning unit. The control method includes the steps that predicted meteorological parameters within the next n hours of an area where the air conditioning unit is located are obtained, and the predicted meteorological parameters at least comprise one or more of the dry-bulb temperature, the wet-bulb temperature, the haze index, the wind scale, the sand storm level and the ambient temperature; and operation parameters of the air conditioning unit within the next n hours are adjusted according to the predicted meteorological parameters, the operation parameters at least comprise one or more of a defrosting parameter, a fan starting mode, fresh air starting and high / low pressure saturation temperature ranges, and n is larger than 0. According to the technical scheme provided by the method and system, the meteorological parameters within the next n hours are obtained, the operation parameters of the air conditioning unit within the next n hours are adjusted according to the meteorological parameters, control over the air conditioning unit is combined with weather conditions of the area where the air conditioning unit is located, and therefore the operation parameters of the air conditioning unit are flexibly controlled, and the energy saving performance of the air conditioning unit is improved.

Owner:GREE ELECTRIC APPLIANCES INC

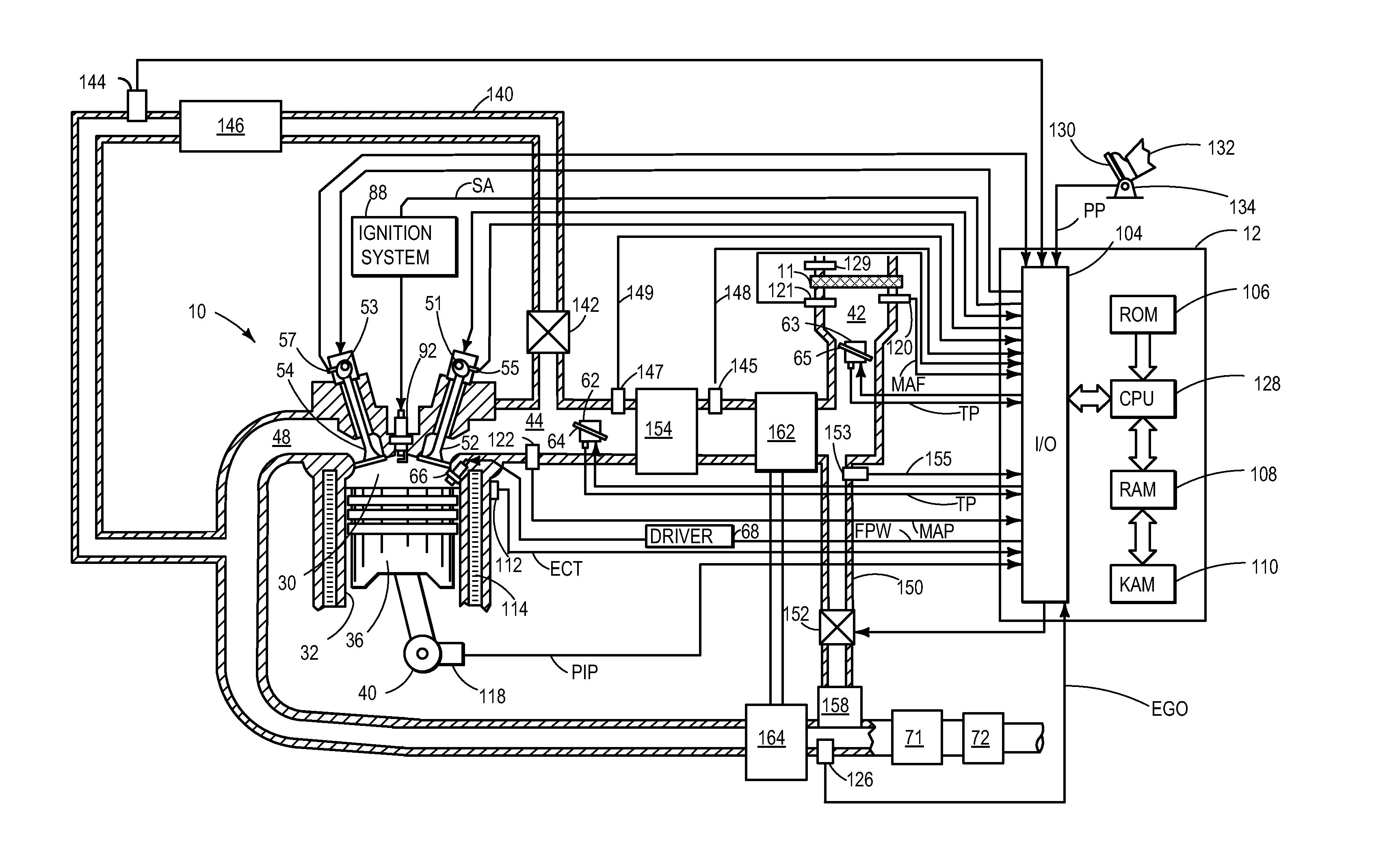

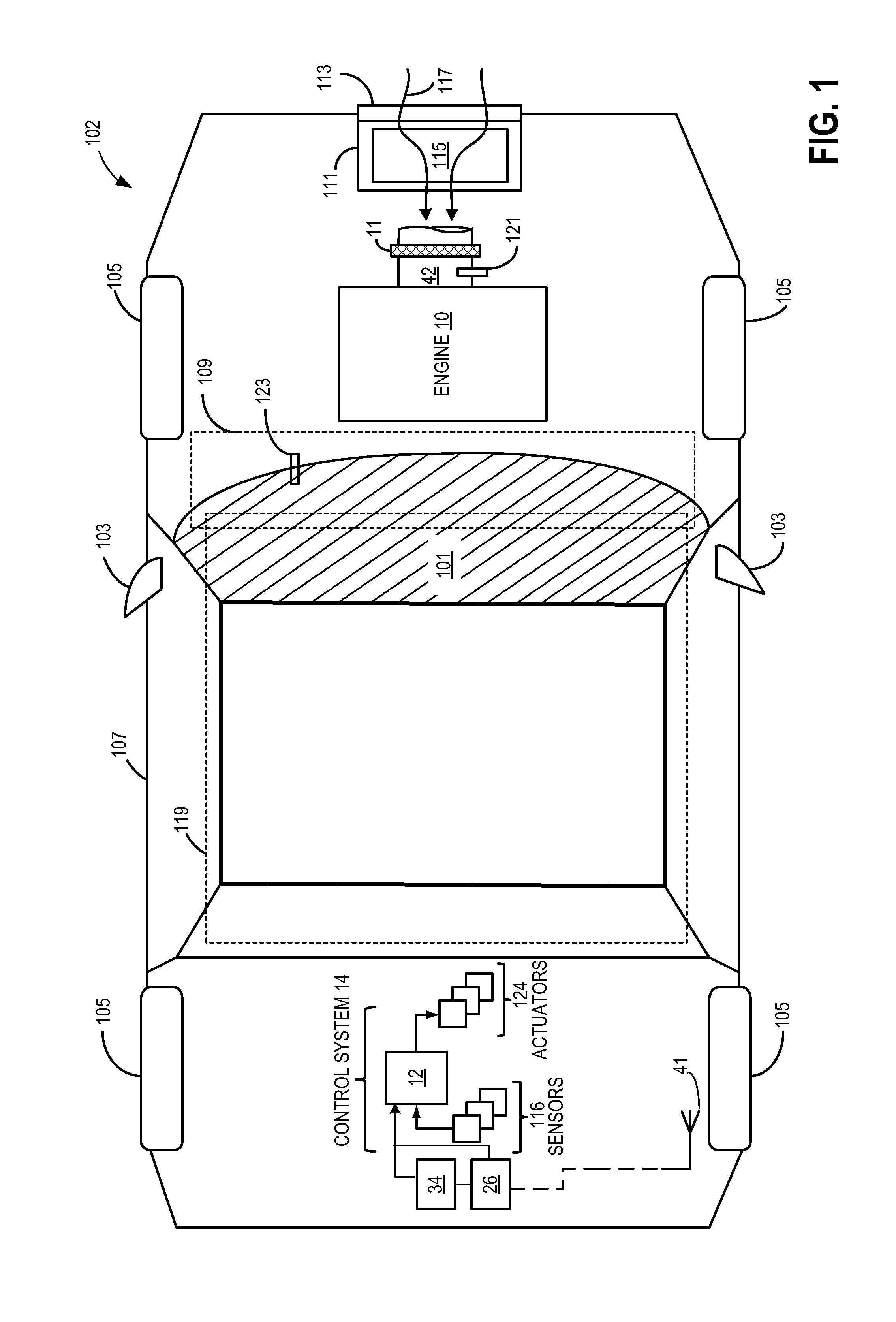

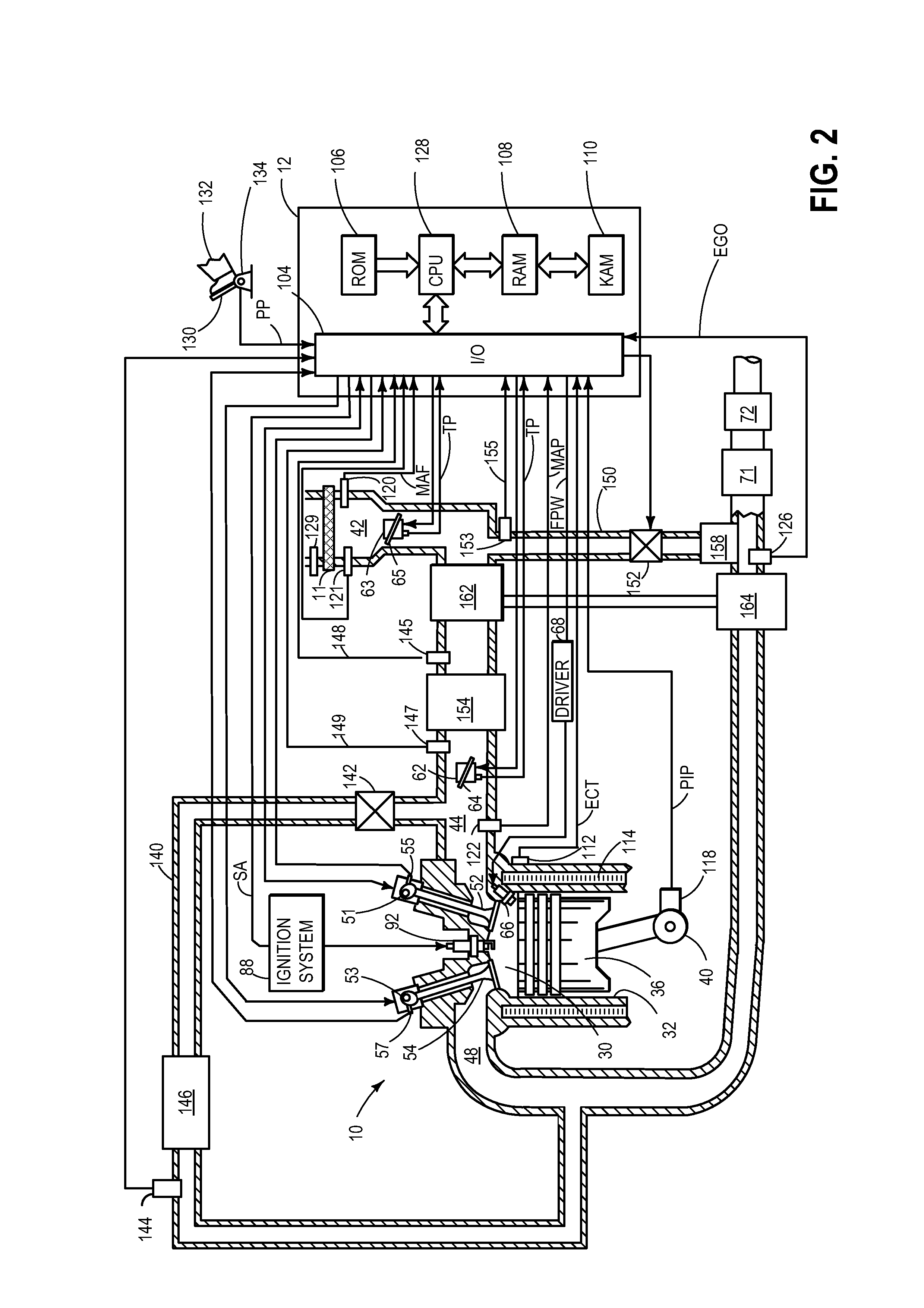

System and method for estimating ambient humidity

ActiveUS20150337745A1Improve engine performanceImprove fuel economyElectrical controlMachines/enginesAmbient humidityEngineering

Methods and systems are provided for estimating ambient humidity based on a wet bulb temperature and a dry bulb temperature during precipitation, and estimating ambient humidity based on the dry bulb temperature and not based on wet bulb temperature when precipitation is absent.

Owner:FORD GLOBAL TECH LLC

Anode tail gas recycle cooler and re-heater for a solid oxide fuel cell stack assembly

ActiveUS20060263657A1Maintain temperatureHydrogenFuel cell heat exchangeFuel cellsProcess engineering

An SOFC fuel cell stack system in accordance with the invention including a recycle flow leg for recycling a portion of the anode tail gas into the inlet of an associated hydrocarbon reformer supplying reformate to the stack. The recycle leg includes a controllable pump for varying the flow rate of tail gas. Preferably, a heat exchanger is provided in the leg ahead of the pump for cooling the tail gas via heat exchange with incoming cathode air. A low-wattage electrical reheater is also preferably included between the heat exchanger and the pump to maintain the temperature of tail gas entering the pump, during conditions of low tail gas flow, at a drybulb temperature above the dewpoint of the tail gas.

Owner:APTIV TECH LTD

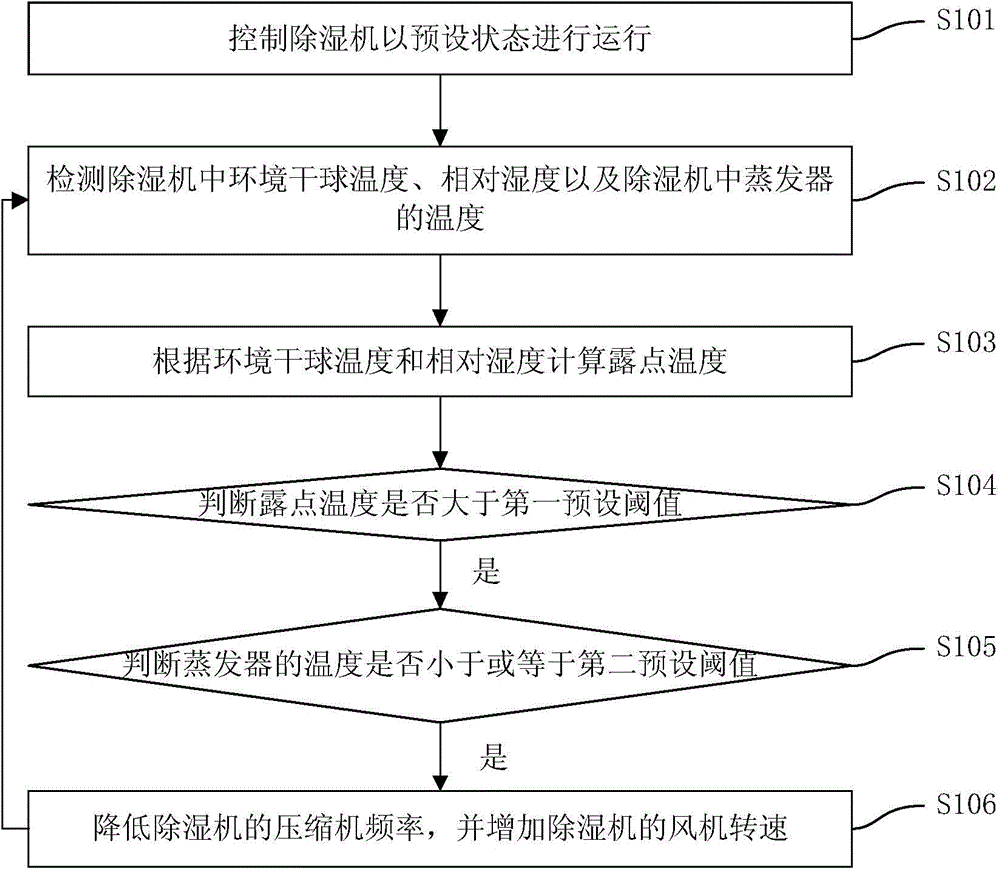

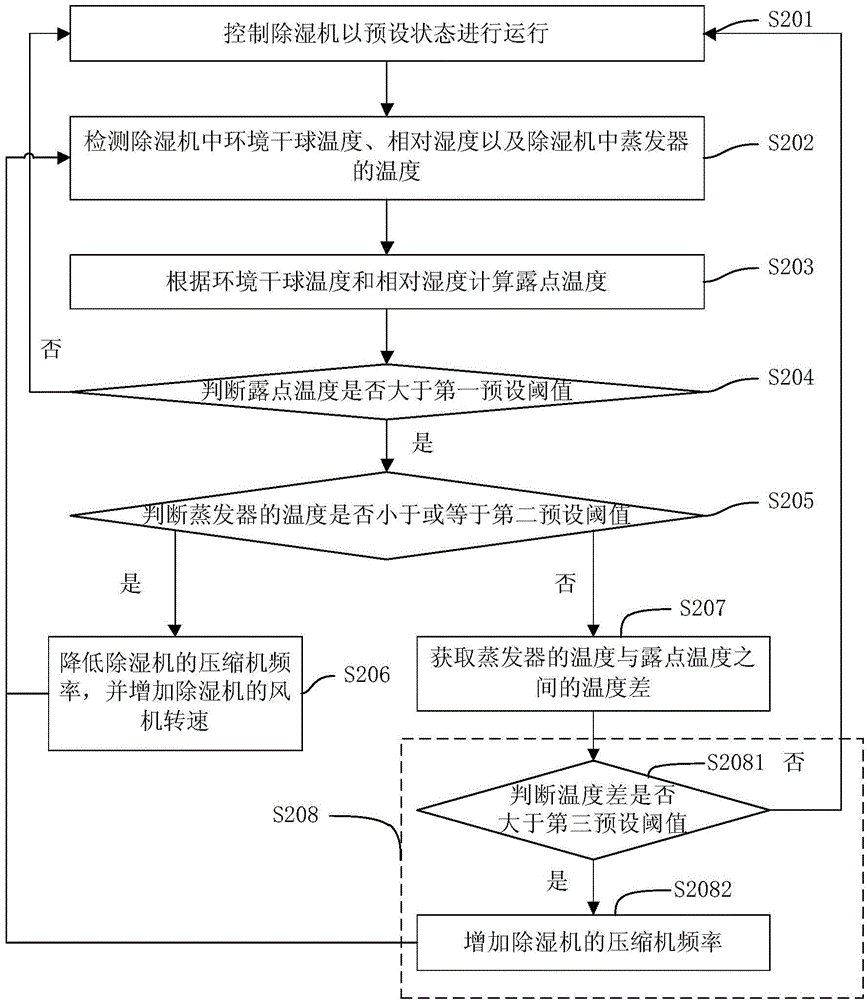

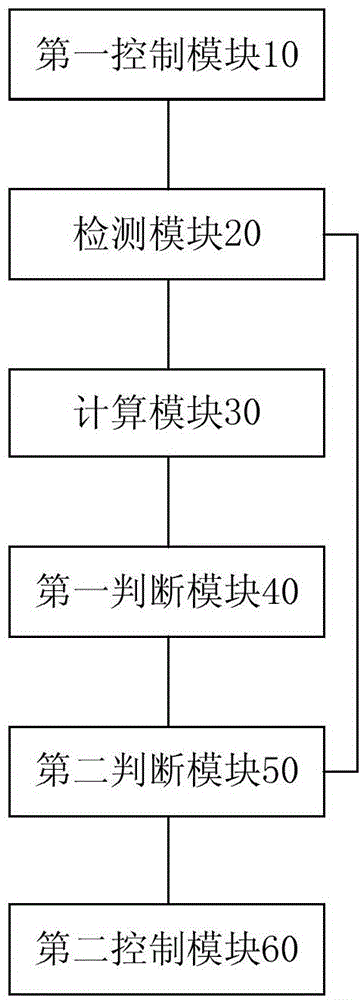

Variable frequency dehumidifier control method and device and dehumidifier

ActiveCN104879836AReduce compressor frequencyIncrease fan speedMechanical apparatusSpace heating and ventilation safety systemsEngineeringDry-bulb temperature

The invention discloses a variable frequency dehumidifier control method and device and a dehumidifier. The method includes: S1, controlling the dehumidifier to run in a preset state; S2, detecting environment dry-bulb temperature and relative humidity in the dehumidifier and temperature of an evaporator in the dehumidifier; S3, calculating dew-point temperature according to the environment dry-bulb temperature and relative humidity; S4, judging whether the dew-point temperature is higher than a first preset threshold or not; S5, if the dew-point temperature is higher than the first preset threshold, further judging whether the temperature of the evaporator is lower than or equal to a second preset threshold or not; S6, if the temperature of the evaporator is lower than or equal to the second preset threshold, lowering compressor frequency of the dehumidifier, increasing fan speed of the dehumidifier, and continuing to execute the step 2 after running for the preset time. By the method, the dehumidifier can delay frosting under the working condition that the dew-point temperature is higher than 0 DEG C, and dehumidification capacity under the working conditions is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

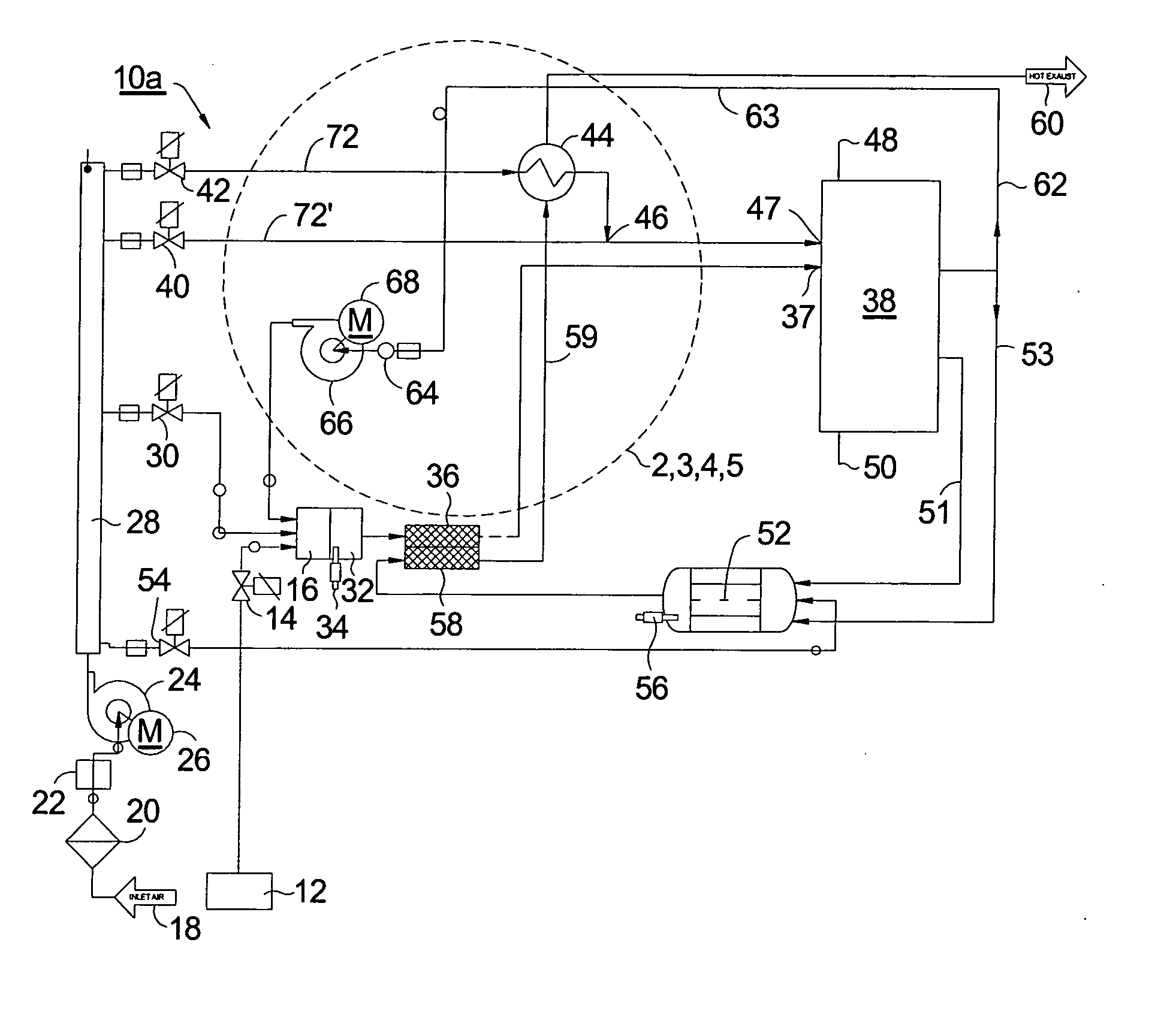

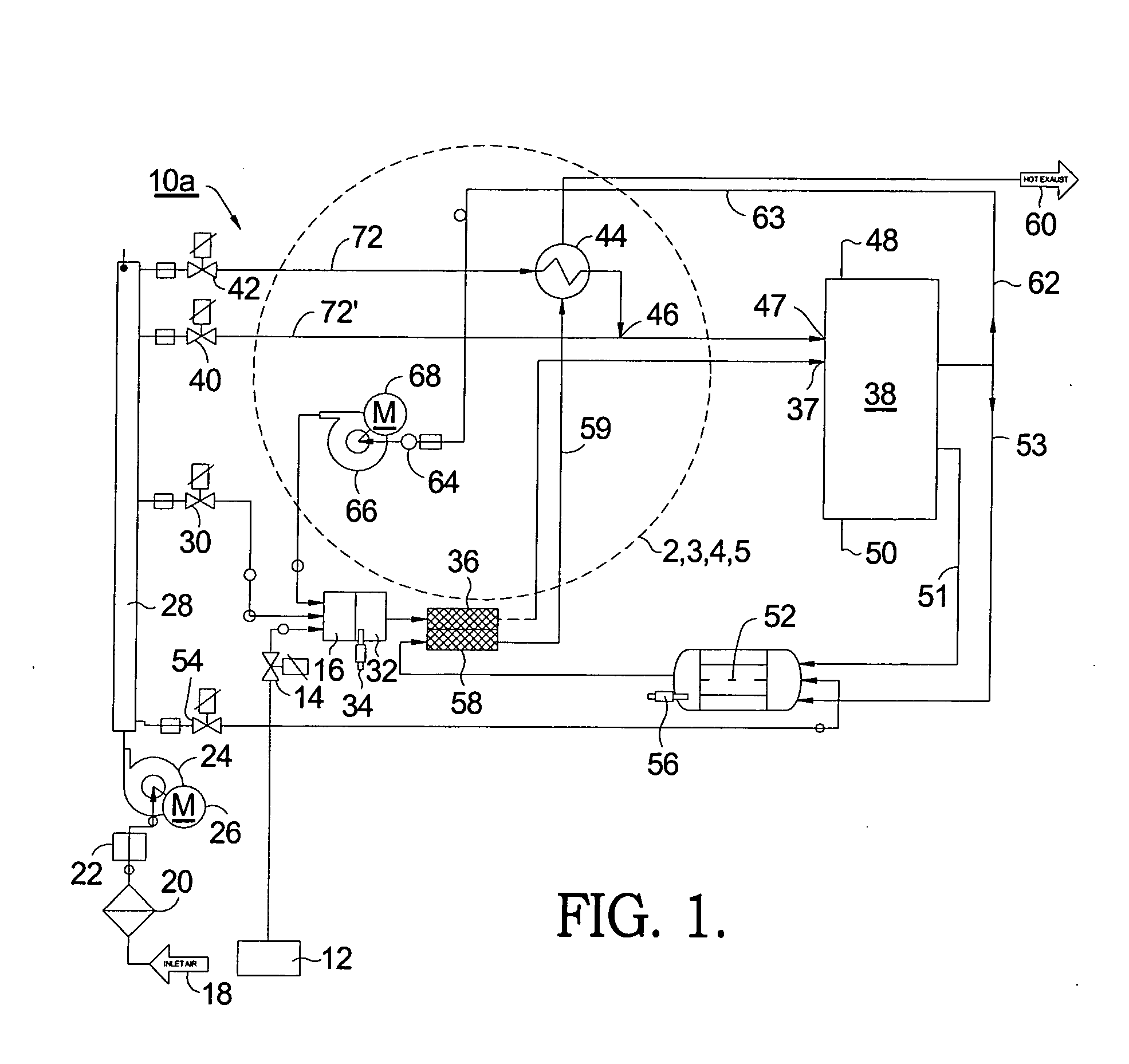

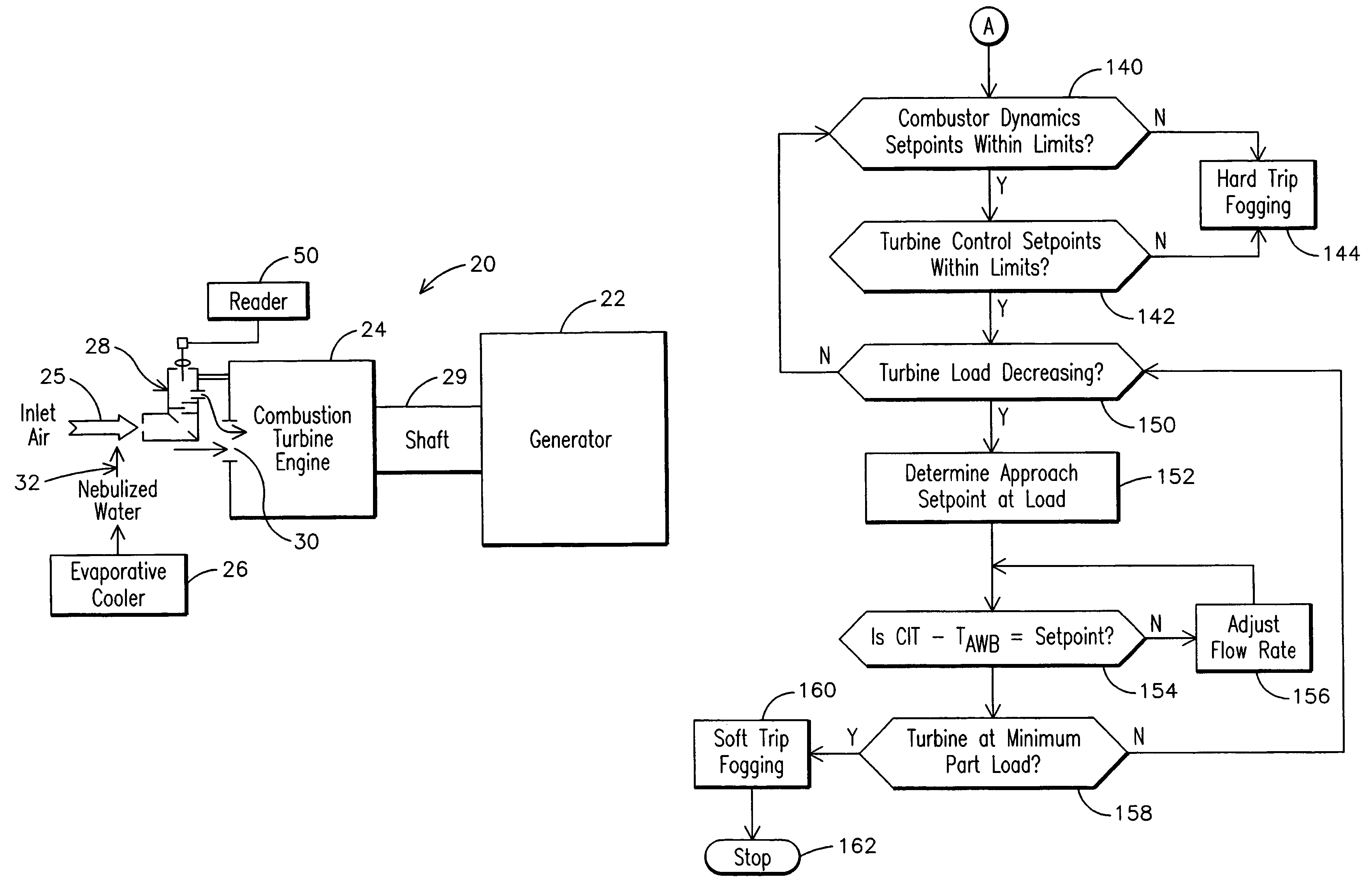

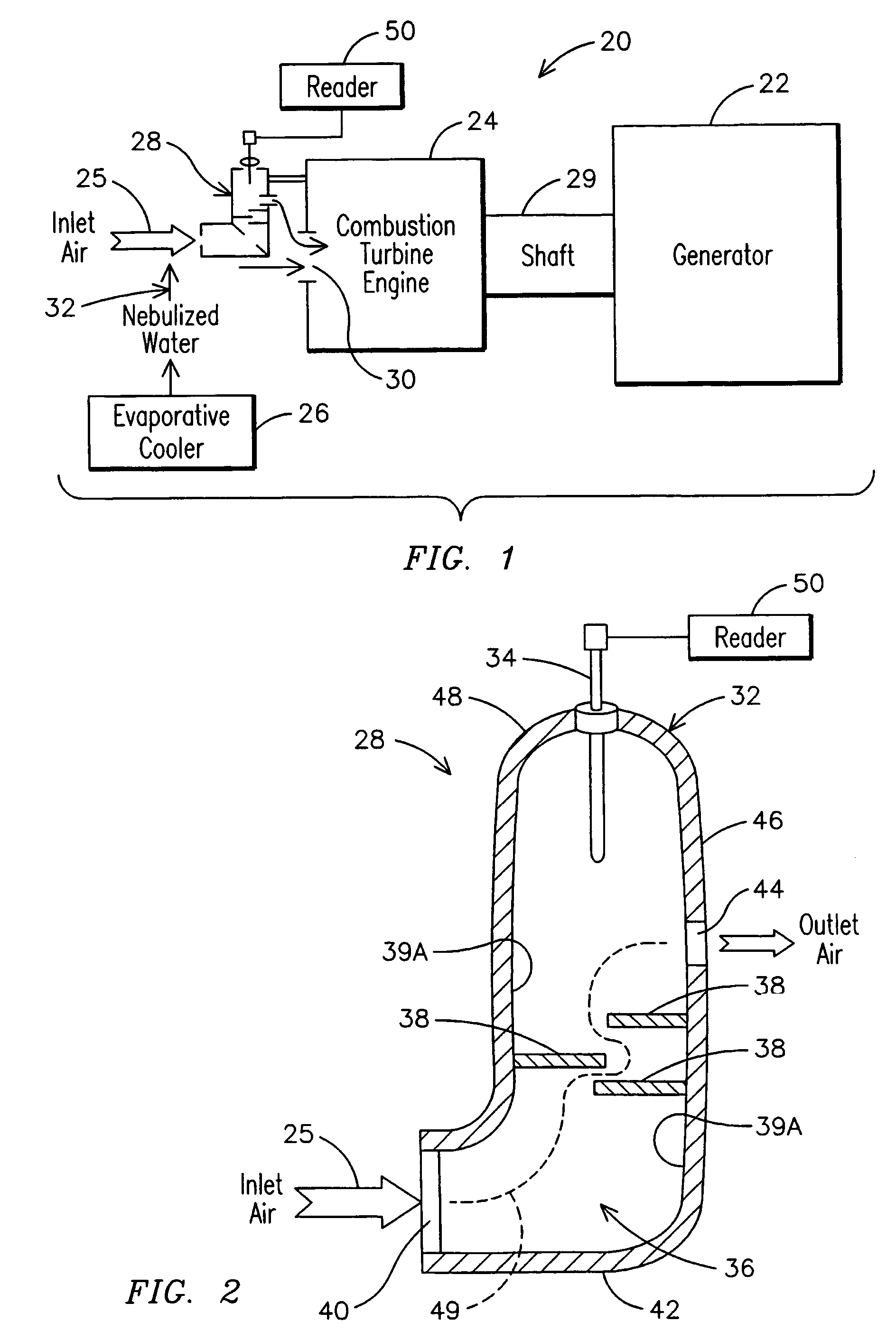

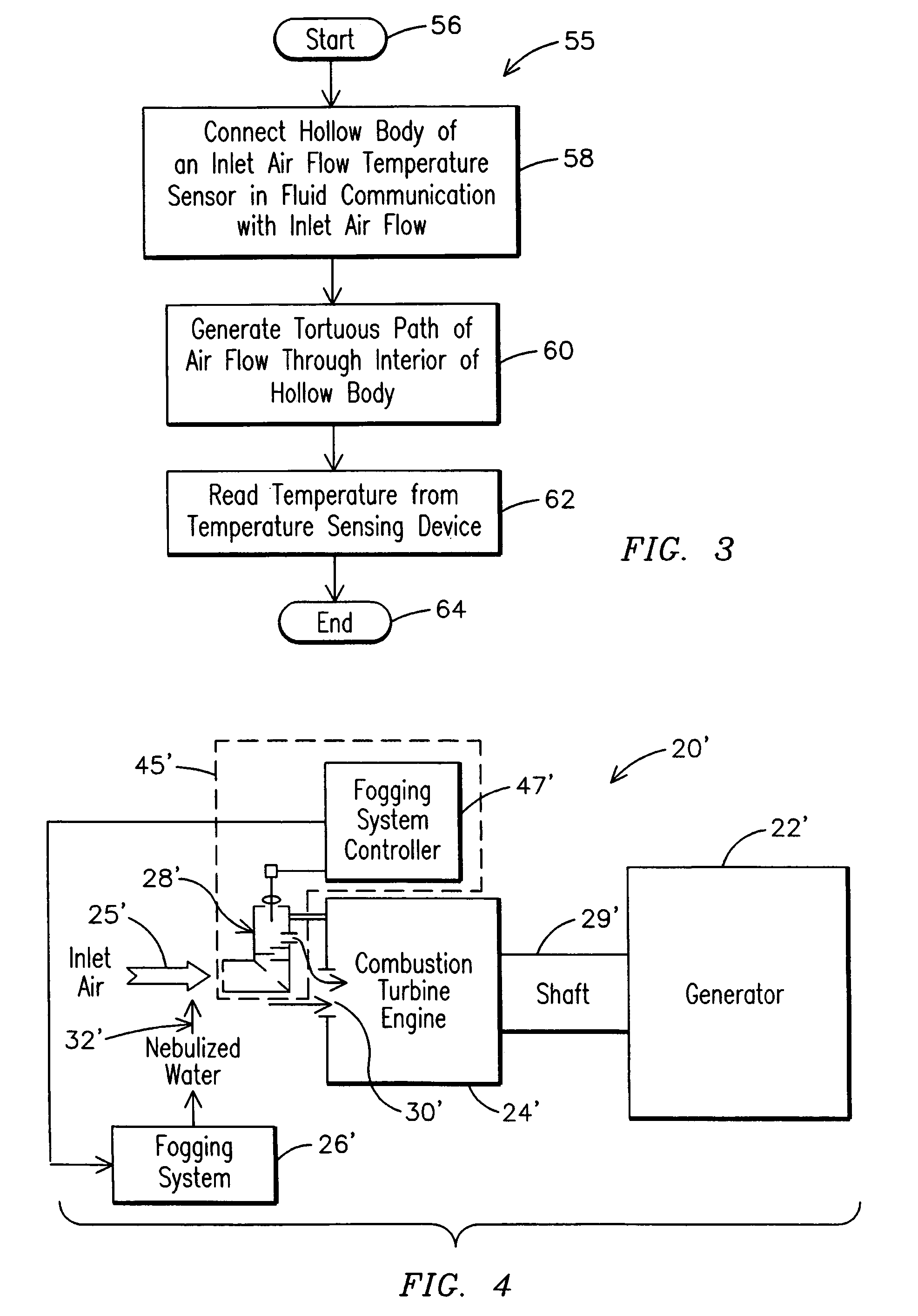

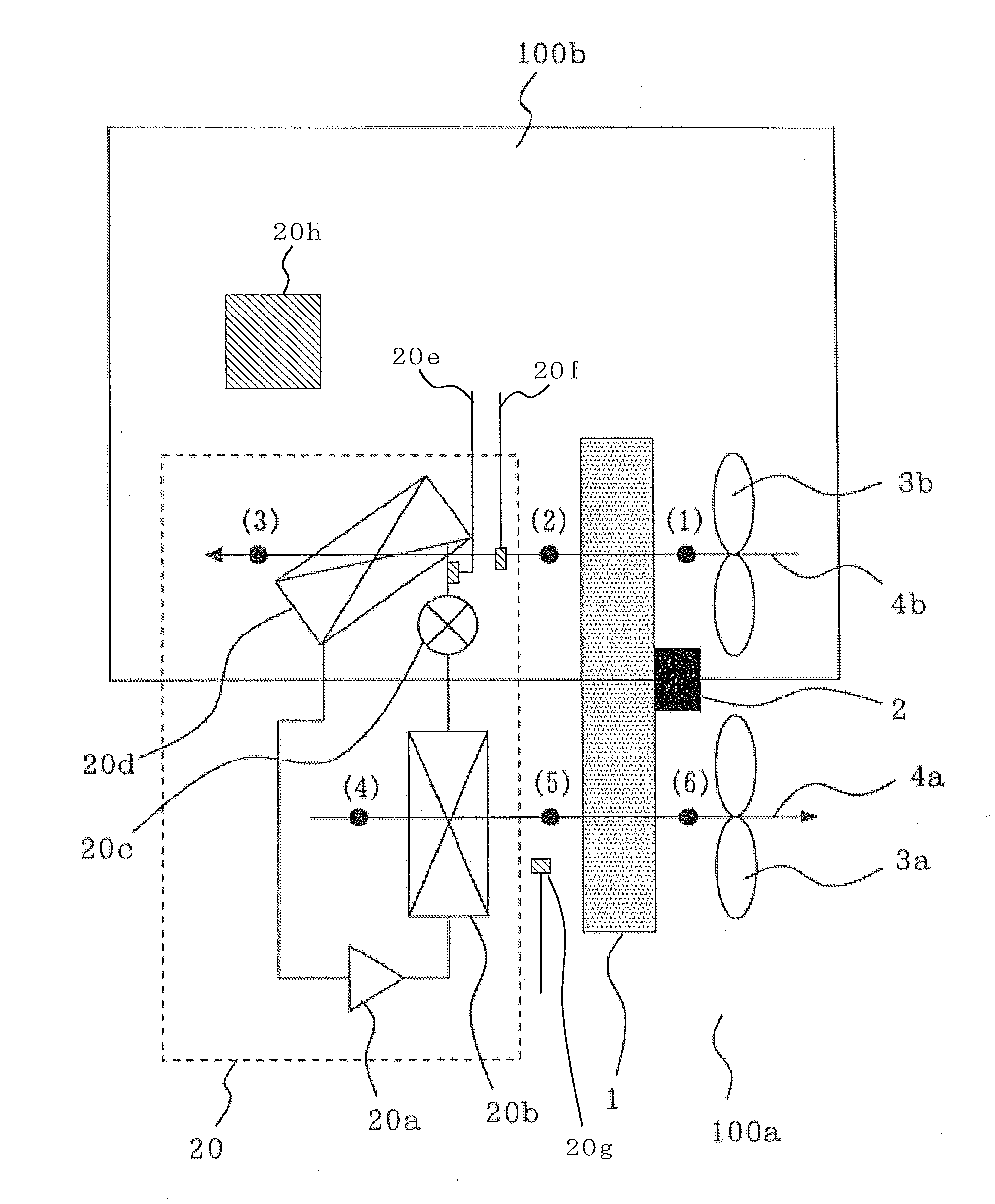

Inlet airflow cooling control for a power generating system

A power generating system (20) includes a generator (22) and a combustion turbine (24) for driving the generator (22). The combustion turbine (24) may have a combustion turbine air inlet (30) for receiving an inlet airflow (25). The power generating system (20) may include an evaporative water cooler (26) or fogging evaporative system (26′) for cooling inlet airflow (25), and an inlet airflow temperature sensor (28) proximate or within the combustion turbine air inlet (30). The inlet airflow temperature sensor (28) may sense a drybulb temperature of the inlet airflow (25) proximate the air inlet (30). A controller (47′) is provided for controlling the cooling of inlet airflow (25) across transient load conditions of the power generating system (20′). This control may be based upon the sensed drybulb temperature used to calculate an approach temperature with respect to the inlet airflow (25′) that is compared to an approach temperature setpoint based on load. The controller may adjust the flow rate of water of the fogging system (26′) to maintain the calculated approach temperature within limits of the setpoint.

Owner:SIEMENS ENERGY INC

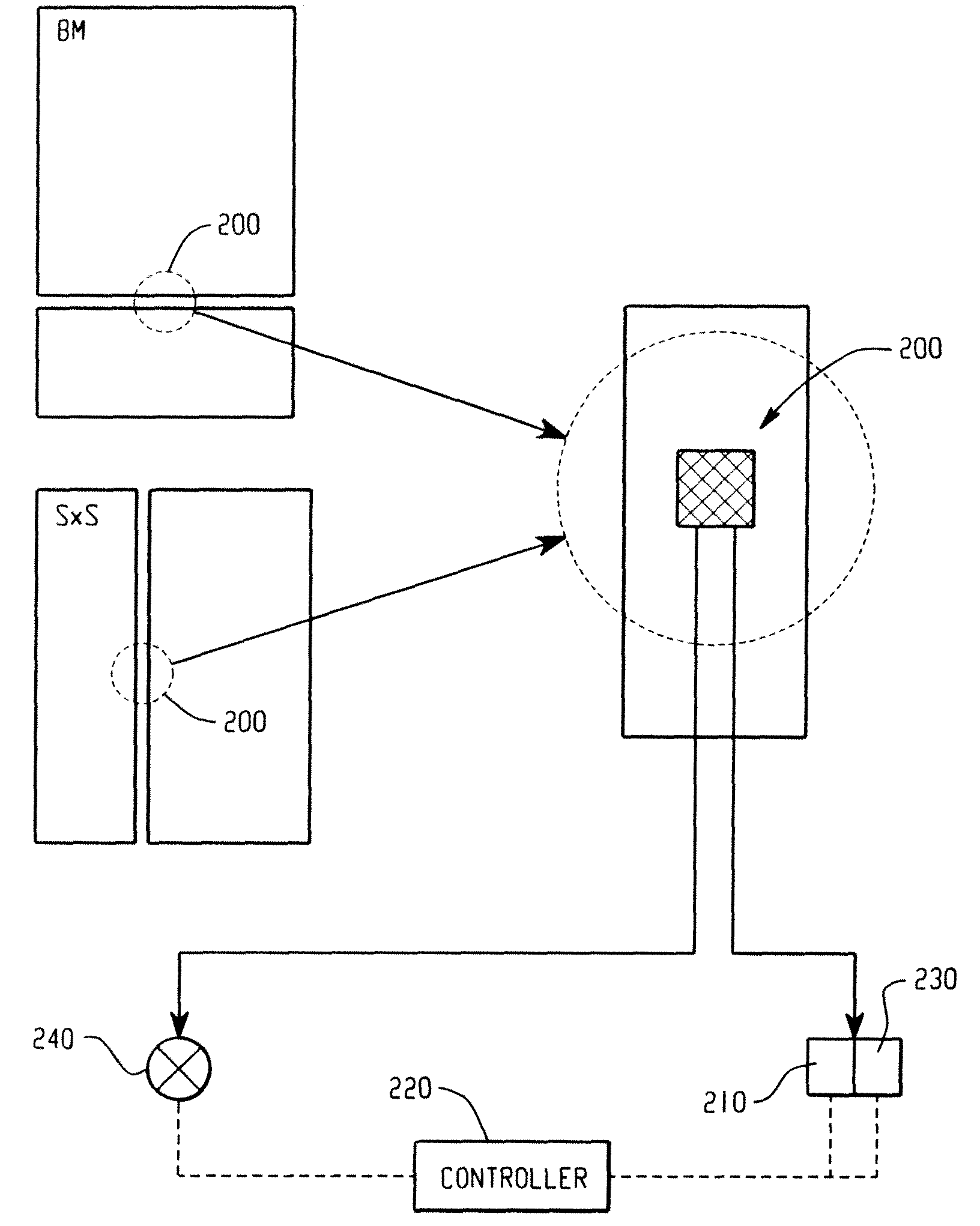

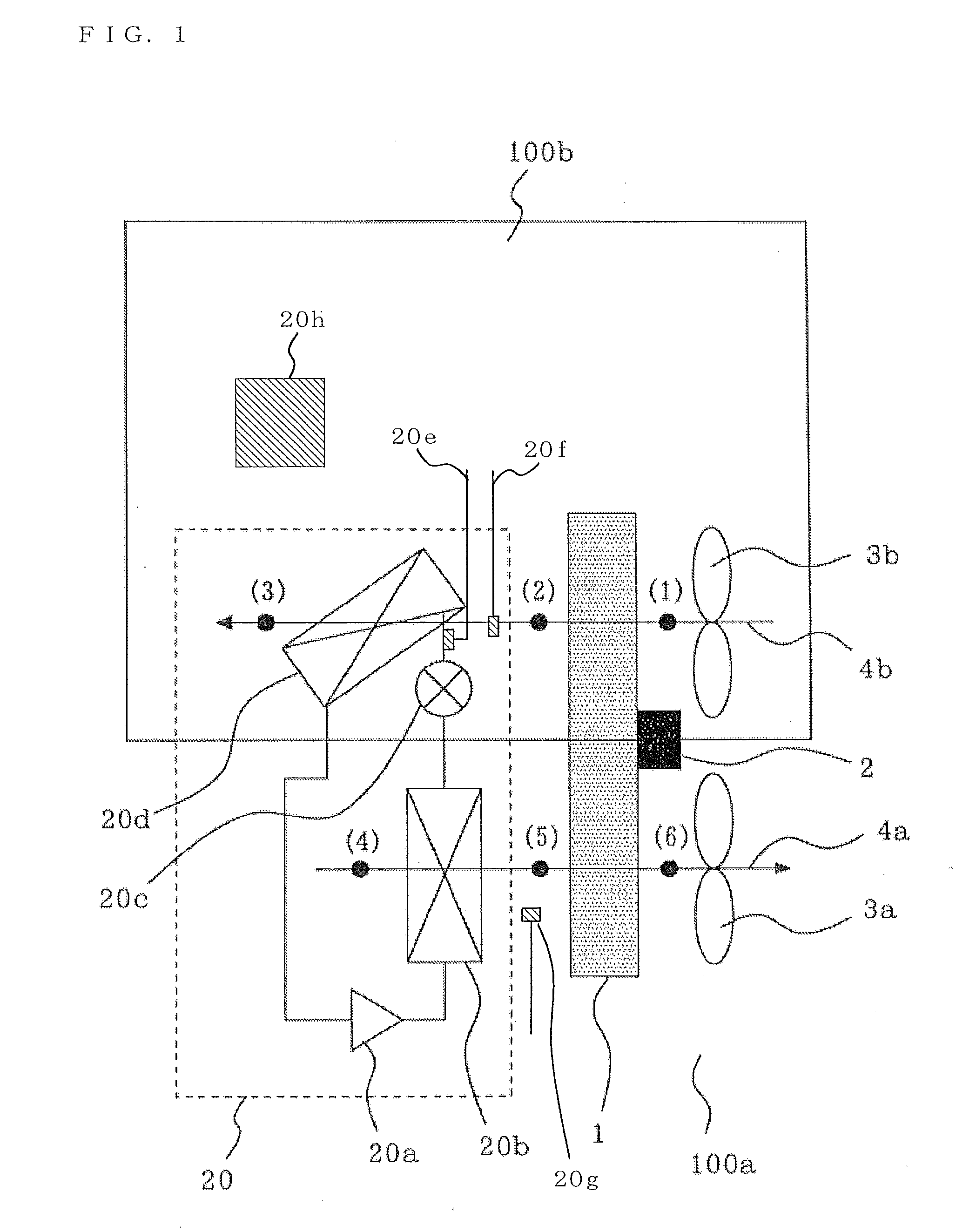

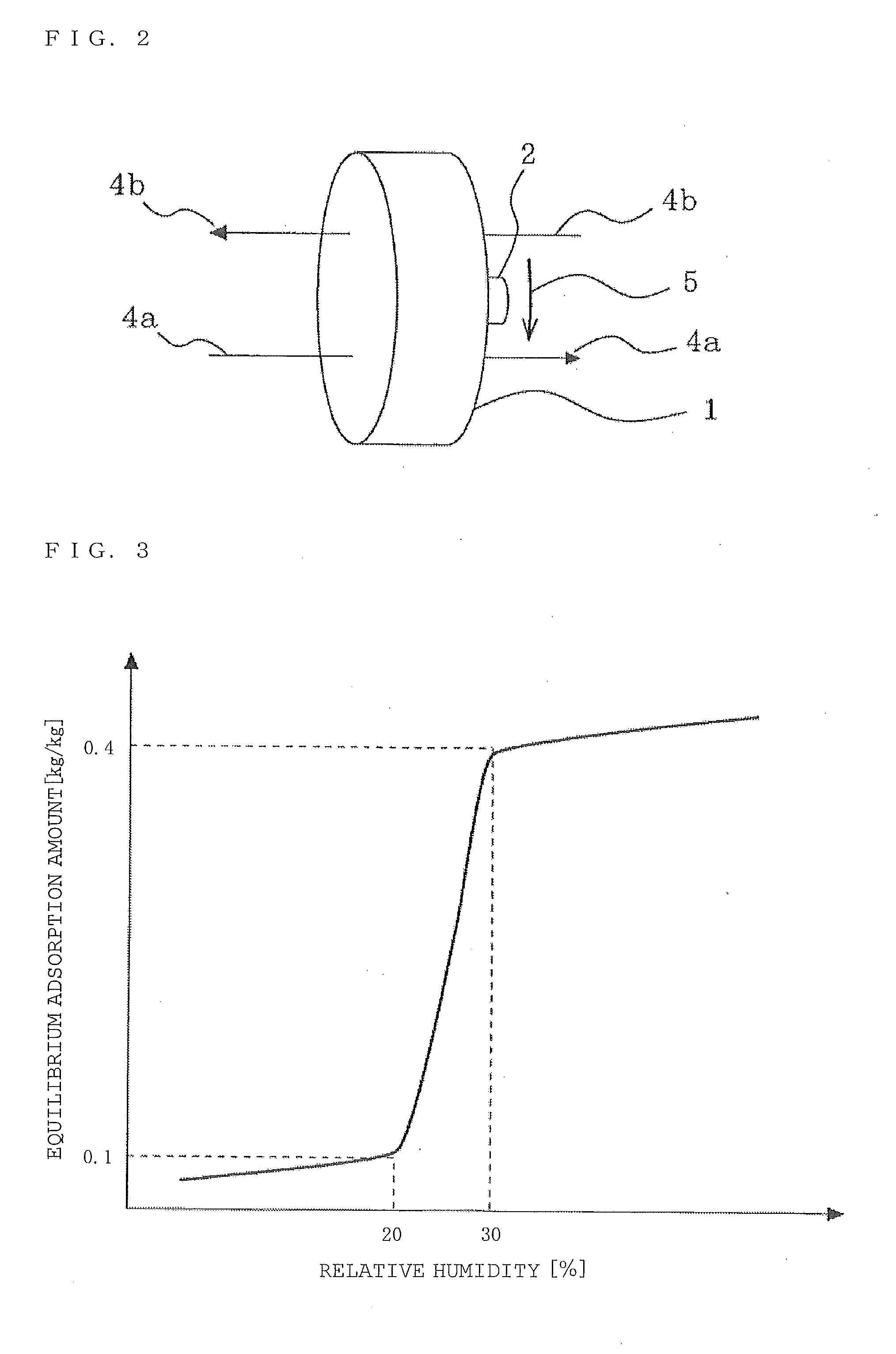

Refrigeration air conditioning system

ActiveUS20100000243A1Stable dehumidifying performanceCompression machines with non-reversible cycleRefrigeration safety arrangementFrostDesiccant

To obtain a refrigeration air conditioning system having a dehumidifying function by means of a moisture adsorption means, allowing the moisture adsorption means to be regenerated by use of discharged condensation heat or other discharged heat of a low temperature range in the refrigeration cycle, and exerting stable cooling performance even at a dry-bulb temperature of 0° C. or less.A desiccant rotor 1, being a moisture adsorption means, is made to hold an adsorbent having pore sizes of 5 μm or less, more preferably 20 nm or less, and furthermore preferably 1-1.4 nm in a space at a predetermined temperature range of a dry-bulb temperature of 0° C. or less. Forming of frost on an evaporator 20d is prevented by supplying the air dehumidified by the desiccant rotor 1 to the evaporator 20d disposed on the leeward side thereof in a freezing room as the desiccant rotor 1 is rotated, while the adsorbent having adsorbed moisture is made dried and made to recover its adsorbing ability by supplying the air dried by discharged heat from a condenser 20b disposed on the windward side thereof to the desiccant rotor 1 at the outside of the freezing room.

Owner:MITSUBISHI ELECTRIC CORP

Pine drying method

ActiveCN104511953AUniform moisture contentAvoid deformationWood treatment detailsDrying gas arrangementsWood machiningEngineering

The invention discloses a pine drying method, and belongs to the field of timber processing. The method comprises the following steps: selecting pine sheets with the thickness of 25-35mm and the water content of 40-45% before drying, putting the pine sheets in a kiln, stacking, using division bars between layers of the pine sheets, making a pine water content drying reference according to the dimension of the stack of the pine sheets, the flow velocity of a drying medium and the water content of the sheets, setting a wet and dry bulb temperature according to the water content drying standard, starting a system in the drying kiln to carry out automatic heating and steam injection to a preset required range, cooling the pine sheets, and discharging the cooled pine sheets from the kiln to obtain a finished product. The method allows the water content of the timber to be balanced in the drying process by adopting the pine drying reference and using automatic steam injection, prevents the deformation, cracking and bending of the sheets in the drying process, and realizes an optimal drying state through multi-time automatic steam injection, humidity elimination and adjustment.

Owner:柳州林道轻型木结构制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com