Patents

Literature

310results about How to "Fully formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Class II active center hydrogenation catalyst start-up vulcanization method

ActiveCN102311766AImprove catalytic performanceMoisturize thoroughlyHydrotreatment operations starting-upHydrocarbon oil crackingHydrogenVulcanization

The invention discloses a class II active center hydrogenation catalyst start-up vulcanization method, which comprises the following steps: (1) taking class II active center hydrogenation catalyst before vulcanization; (2) filling the class II active center hydrogenation catalyst before vulcanization into a reactor at normal temperature and pressure, introducing nitrogen to replace air in a reaction system, then replacing the nitrogen with hydrogen and carrying out gas seal; (3) continuing to adjust the temperature of a bed layer of the reactor, and introducing vulcanized oil to moisten the catalysts; (4) cycling the vulcanized oil in a closed mode in the reaction system, gradually injecting vulcanizers into the vulcanized oil, and raising the temperature continuously to complete vulcanization; and (5) adjusting the bed layer to the reaction temperature after vulcanization, and switching raw oil. The catalyst start-up vulcanization method disclosed by the invention is conductive to forming more class II hydrogenation active centers for the catalysts, and is conductive to improving the use performance of the catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

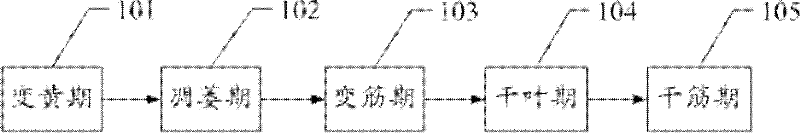

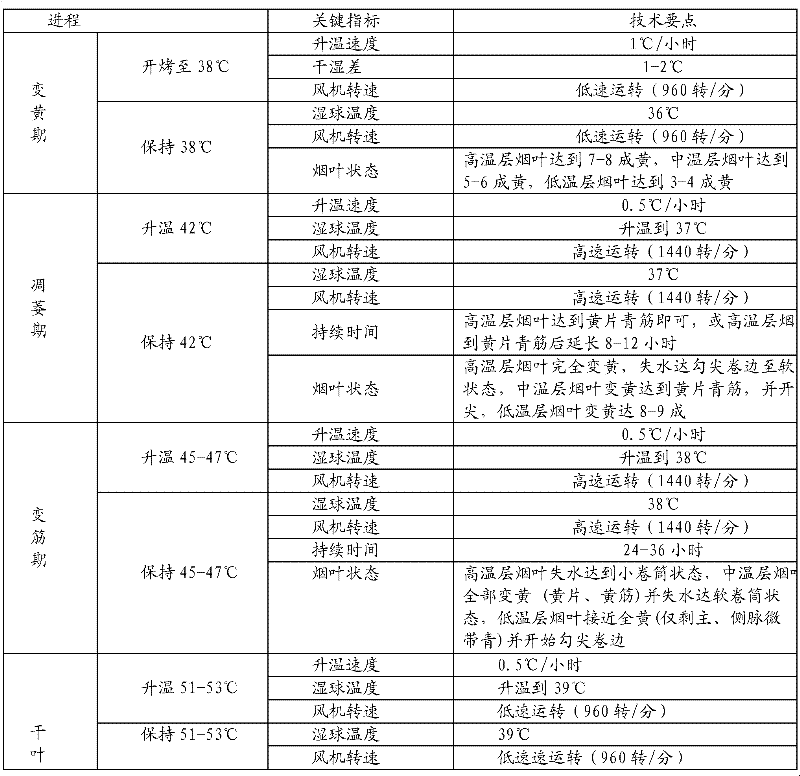

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

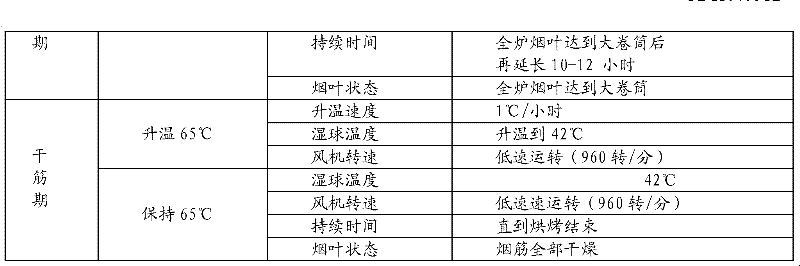

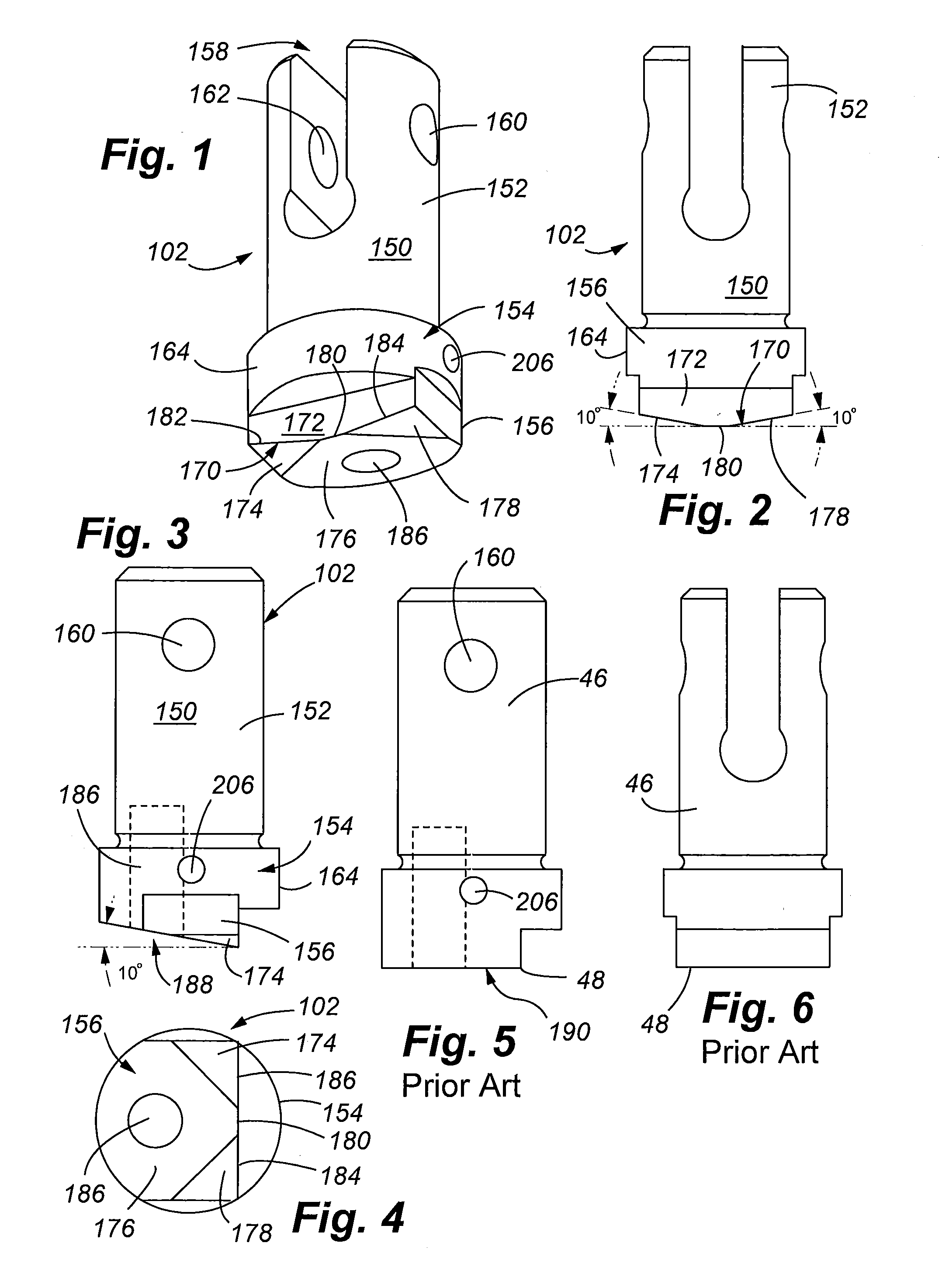

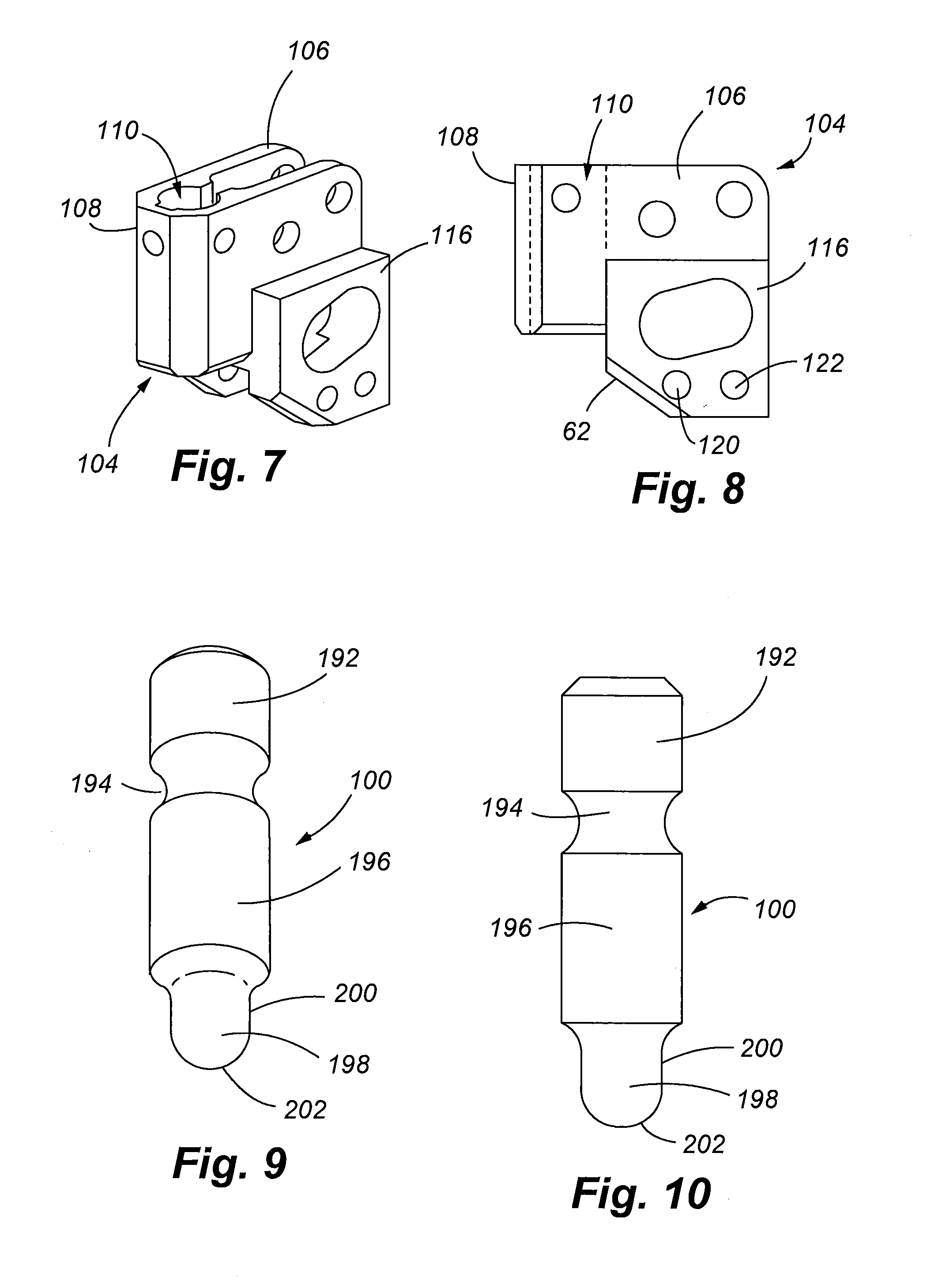

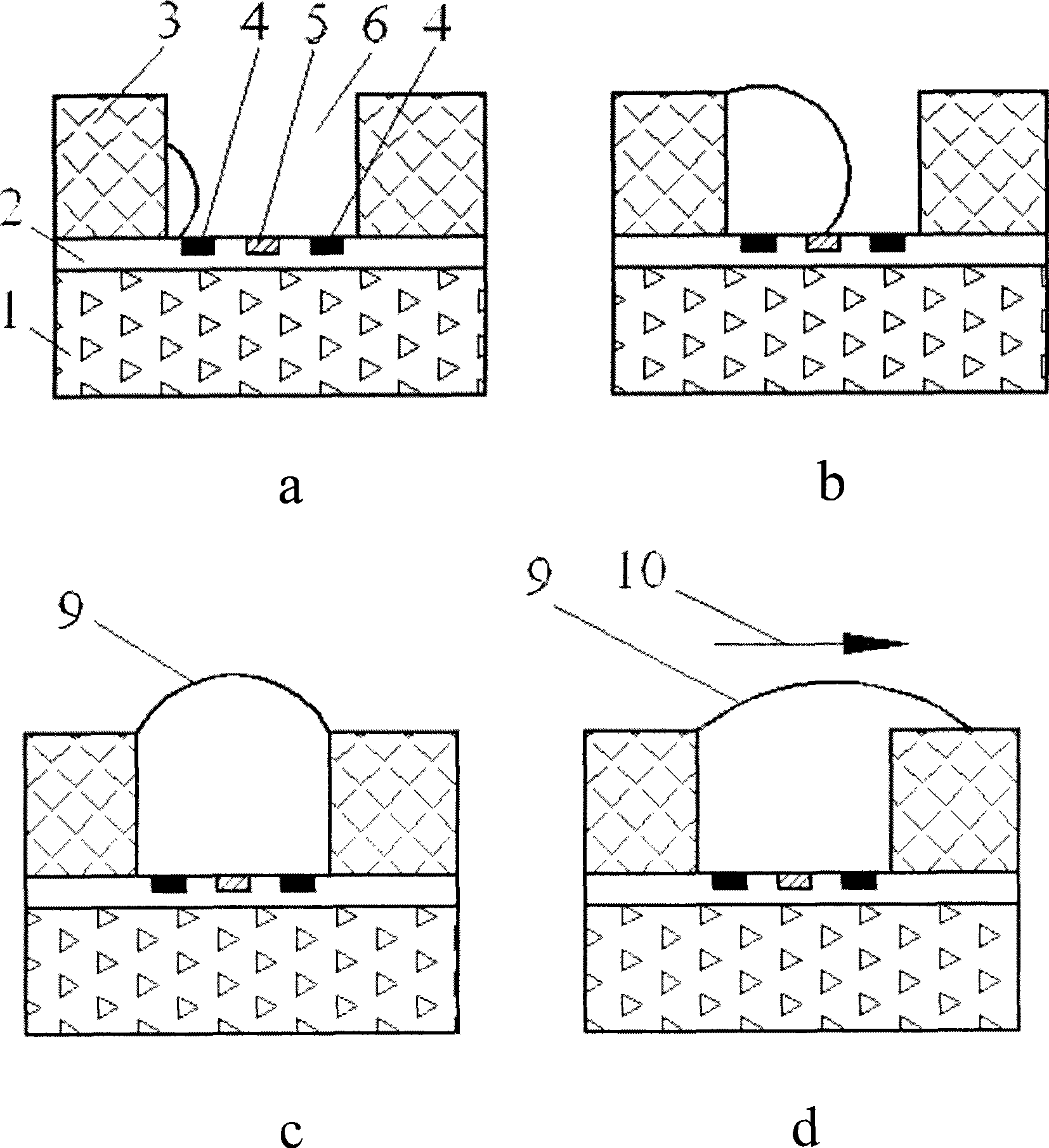

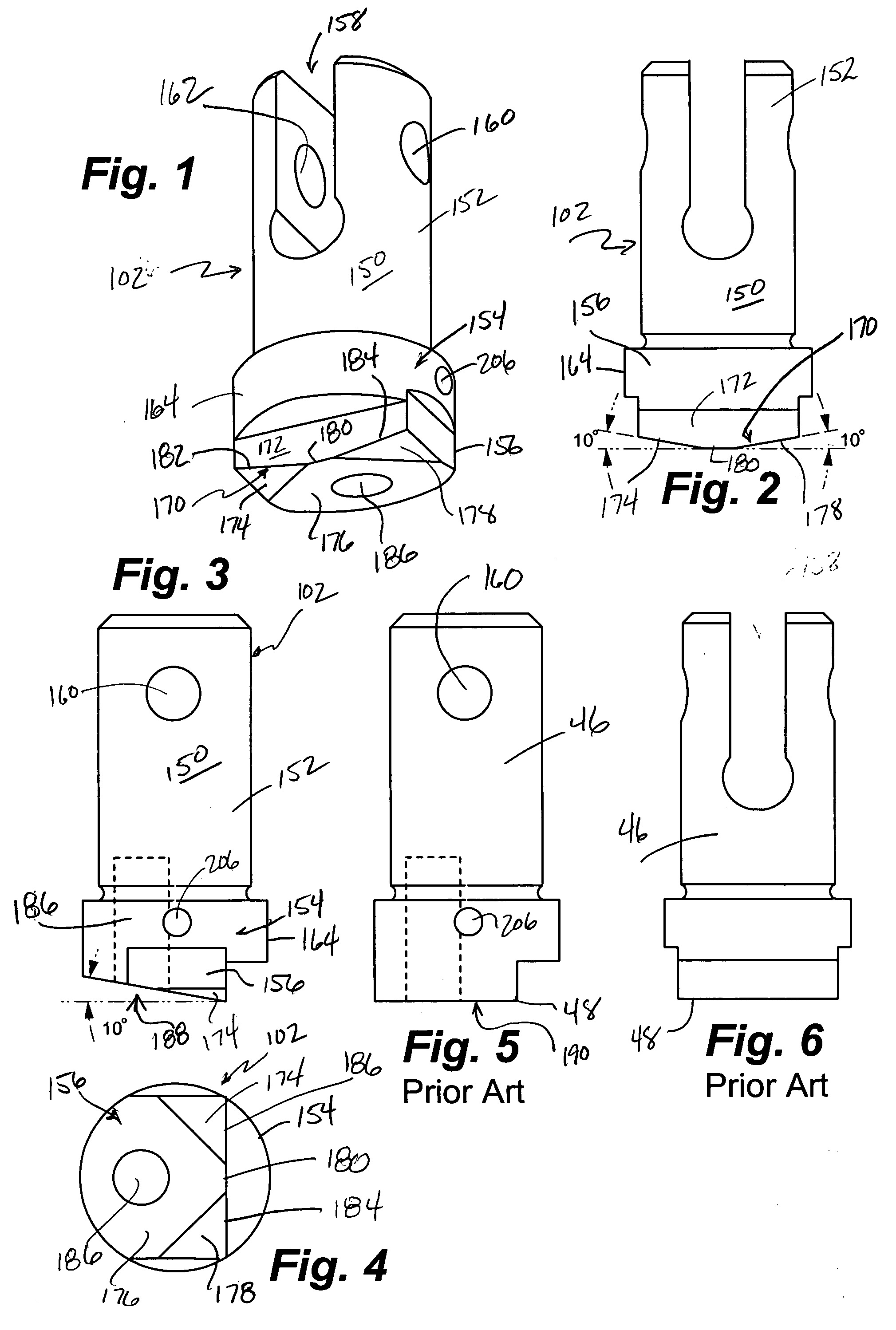

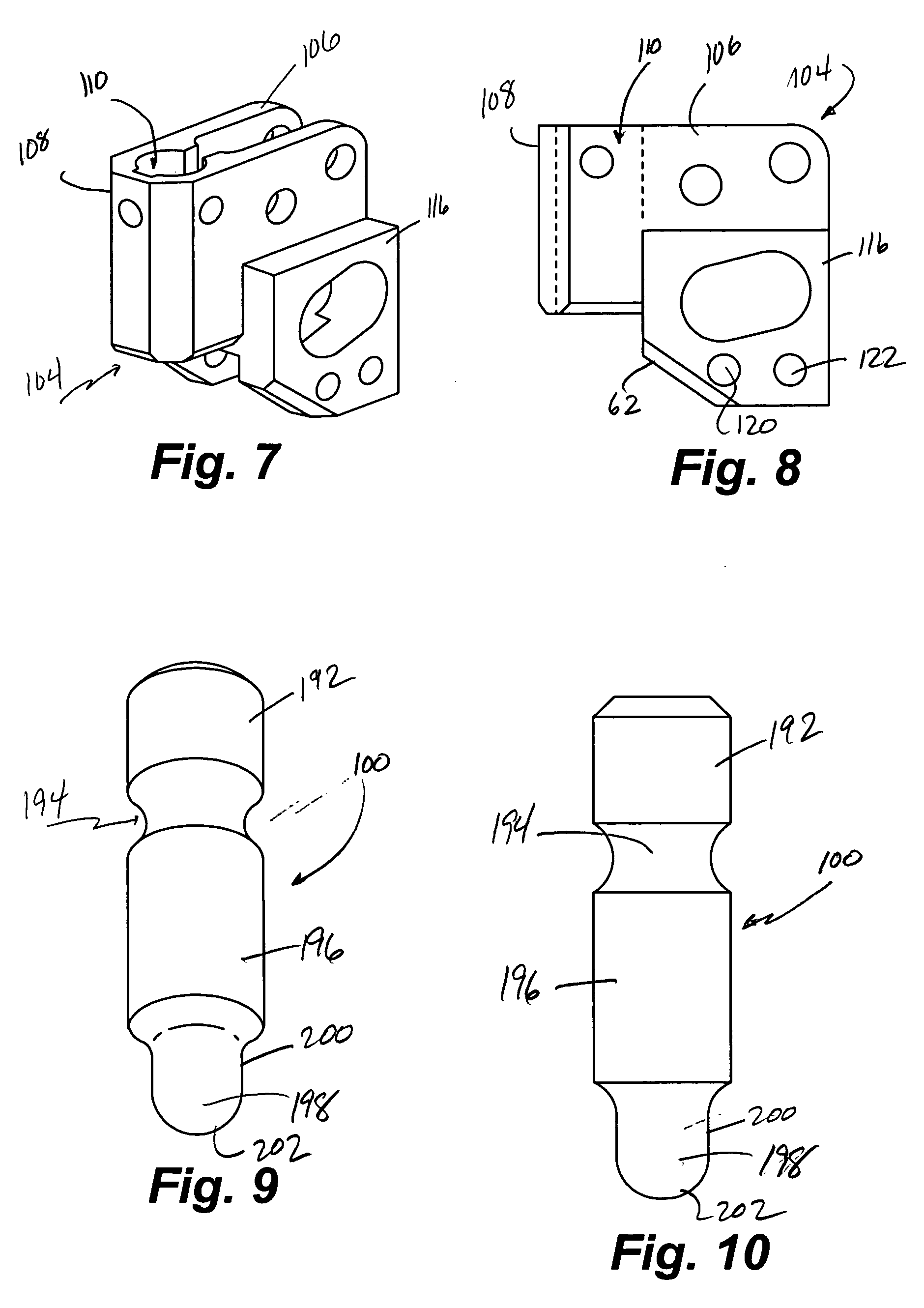

Method and apparatus for bundling objects

ActiveUS7650680B2Optimize formationReduce reboundFlexible elementsHose connectionsEngineeringMechanical engineering

An improved tool for locking a band clamp, and an improved lock for a band clamp is disclosed. The tool includes a knife body having a knife edge that progressively cuts the free end of the band over a period of time, rather than simultaneously cutting the entire band width. In one embodiment, this is accomplished with a knife edge that is non-linear. The tool further includes a punch with a rounded or hemispherical shaped leading tip that forms an improved locking dimple. The locking dimple forms an improved lock having side walls that are, at least in part, parallel with the walls of the surrounding aperture in the band. By varying the profile of the knife edge, the punch can more fully form an improved locking dimple.

Owner:BAND IT IDEX

Personalized bionic composite structure as well as preparation method of composite structure and method for drug screening by using composite structure

InactiveCN103756955AUseful for drug screeningFully formedMicrobiological testing/measurementVertebrate cellsCross-linkVascular tissue

The invention discloses a personalized bionic composite structure as well as a preparation method of the composite structure and a method for drug screening by using the composite structure, and relates to a bionic composite structure based on a composite multi-nozzle three-dimensional printing technology and a preparation method thereof. The bionic composite structure comprises a polymer shell, a branched vascular stent, a functional tissue area, a vascular tissue area and polymer isolating layers, wherein the functional tissue area is a hydrogel layer containing tissue cells; the vascular tissue area is a hydrogel layer containing vascular seed cells; the functional tissue area and the vascular tissue area are alternately arranged in space; the polymer isolating layers are alternately distributed in the functional tissue area and the vascular tissue area, and divide the functional tissue area and the vascular tissue area into a plurality of small regions; the branched vascular stent includes two parts, i.e., artery blood vessel and vein blood vessel. According to the invention, the tissue / organ bionic structure with the branched blood vessel is prepared through the composite multi-nozzle 3D printing technology; the hydrogel structures are not cross-linked or polymerized; in vivo vascularized tissue and blood vessel states are simulated to the greatest extent, thus providing a reference for vascularized organ and tissue.

Owner:TSINGHUA UNIV

Method for preparing paste soldering flux

ActiveCN102513734ADevelopedFully formedWelding/cutting media/materialsSoldering mediaOrganic acidRoom temperature

The invention provides a method for preparing a paste soldering flux. The soldering flux comprises the following raw materials: resin, a solvent, an amine activating agent, a thixotropic agent, an organic acid activating agent and a corrosion inhibitor. The preparation method comprises the following steps of: a) stirring the resin and the solvent, heating until the resin is dissolved completely, cooling, adding the amine activating agent, and stirring until the amine activating agent is dissolved completely; b) adding the thixotropic agent, and emulsifying and dispersing by using emulsification equipment at constant temperature, so that the thixotropic agent forms a thixotropic gel network structure; c) adding the organic acid activating agent, reacting with the amine activating agent to form a salt compound, and adding the corrosion inhibitor and stirring to dissolve the salt compound; and d) stirring and cooling slowly to room temperature to obtain the paste soldering flux. The prepared paste soldering flux is mainly applied to soldering paste formed by stirring and mixing the paste soldering flux and superfine solder powder under vacuum, and has high heat collapse resistance, and high viscosity stability in the processes of storage and printing to avoid the 'post-thickening' phenomenon.

Owner:厦门市及时雨焊料有限公司

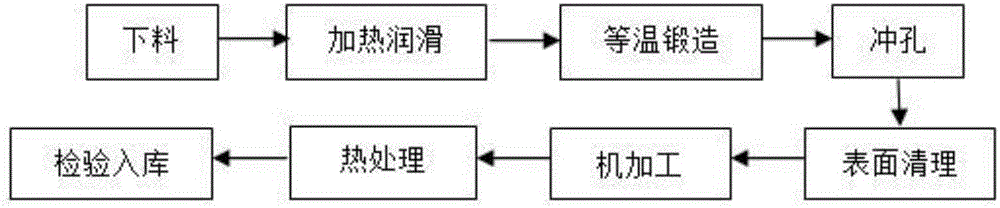

Titanium alloy with matched high strength and toughness and preparation process of titanium alloy

ActiveCN106591625AOptimizing plastic rheological propertiesHigh strengthHigh intensityTitanium alloy

The invention relates to a titanium alloy and the field of forming processes, in particular to titanium alloy with matched high strength and toughness and a preparation process of the titanium alloy. The alloy comprises the following components in percentages by weight: 5.5-6.5% of Al, 1.5-2.5% of Sn, 1.5-2.5% of Zr, 2.5-3.5% of Mo, 0.5-1.5% of Cr, 0.5-1.5% of V, 0.1-0.3% of Fe, 0.1-0.2% of O and the balance of Ti and inevitable impurities. The preparation process of the alloy comprises the following steps: step one, carrying out one-heating-number forging in a beta single-phase region at the temperature of 20-50 DEG C above an alloy phase transformation point, wherein forging deformation is about 40%-80%; step two, forging and forming in an alpha+ beta two-phase region at the temperature of 20-50 DEG C below the alloy phase transformation point, wherein the heating number of forging of the two-phase region is controlled to be 1-3, and the accumulative deformation does not exceed 20%; and step three, carrying out heat treatment in a temperature range of 500-600 DEG C. The titanium alloy can be used for manufacturing various types of products such as rods and wires, plates and forge pieces of high-strength and high-toughness titanium alloy, and is applied to the fields of aviation, aerospace, ships and warships and the like with requirements on structure weight reduction and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

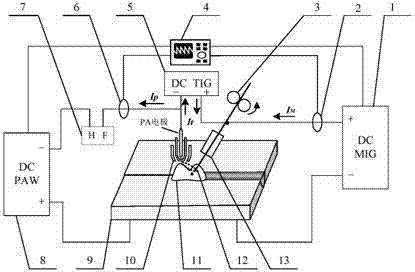

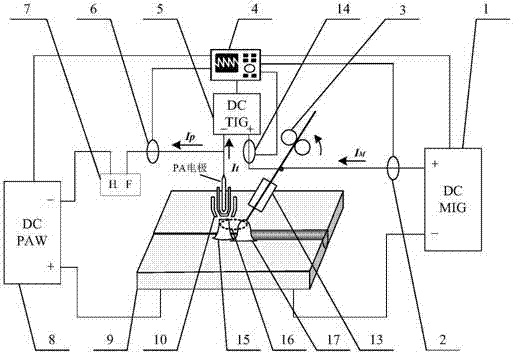

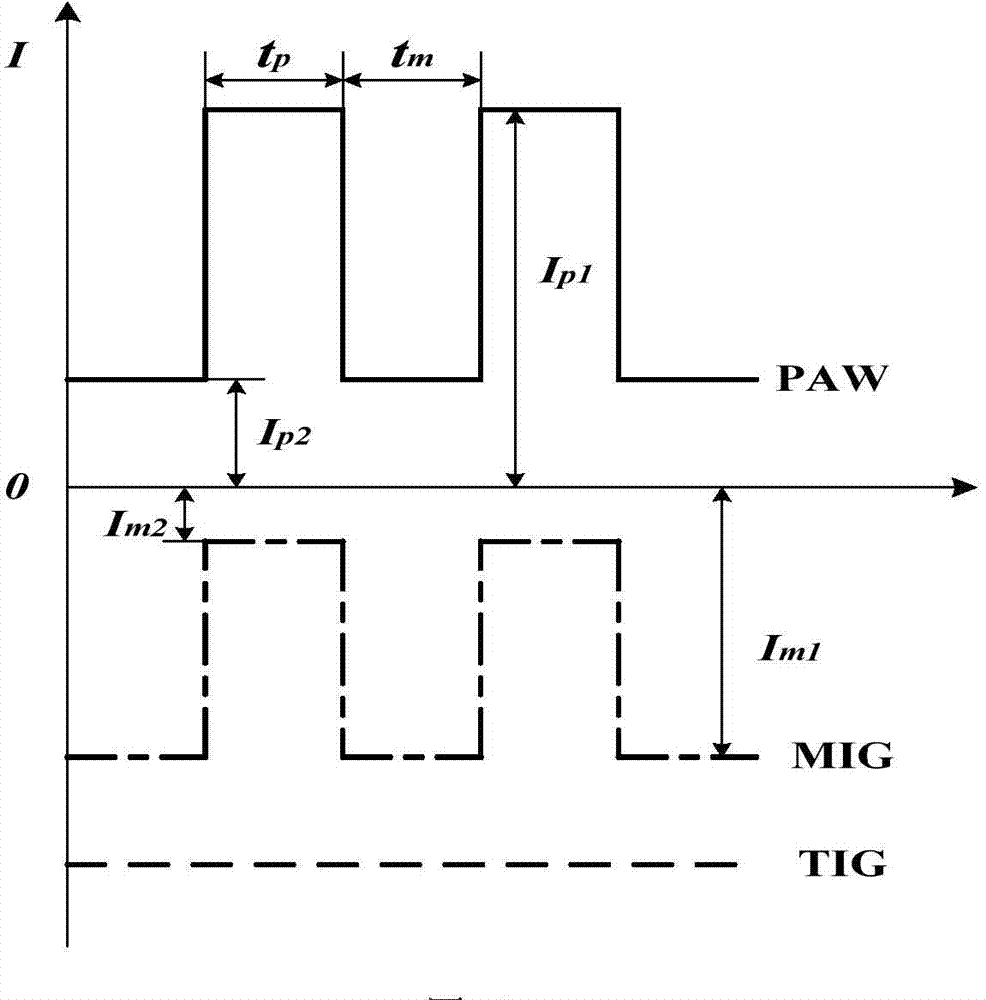

Plasma-melting electrode electric arc dynamic composite welding device and welding method thereof

ActiveCN104493368AHigh tensile strengthHigh elongationWelding apparatusPower flowWelding power supply

The invention provides a plasma-melting electrode electric arc dynamic composite welding device and a welding method thereof. A plasma arc welding gun is combined with a melting electrode electric arc welding gun to obtain a composite welding gun; the two electric arc welding guns are respectively connected with a negative pole of a direct-current pulsed plasma arc welding power supply and a positive pole of a direct-current pulsed melting electrode arc welding power supply and are also connected with a negative pole and a positive pole of an argon arc welding power supply (a TIG power supply); and a negative pole of the plasma arc welding power supply and a positive pole of the melting electrode arc welding power supply are connected with a workpiece. In order to prevent electromagnetic interference between a plasma arc and a melting electrode electric arc during welding, a pulsed coordination control method is used, namely, when melting electrode electric arc current waveform is a pulsed basic value pilot arc, the plasma arc is a pulse peak value, and welding is carried out; and when plasma arc current waveform is a pulse basic value, the melting electrode arc is pulse peak value welding current, and so forth. By the plasma-melting electrode electric arc dynamic composite welding device and the welding method thereof, the problems that electromagnetic interference between electric arcs is large, parameters are adjusted complexly, and electrodes are burnt down severely are solved.

Owner:HARBIN ENG UNIV

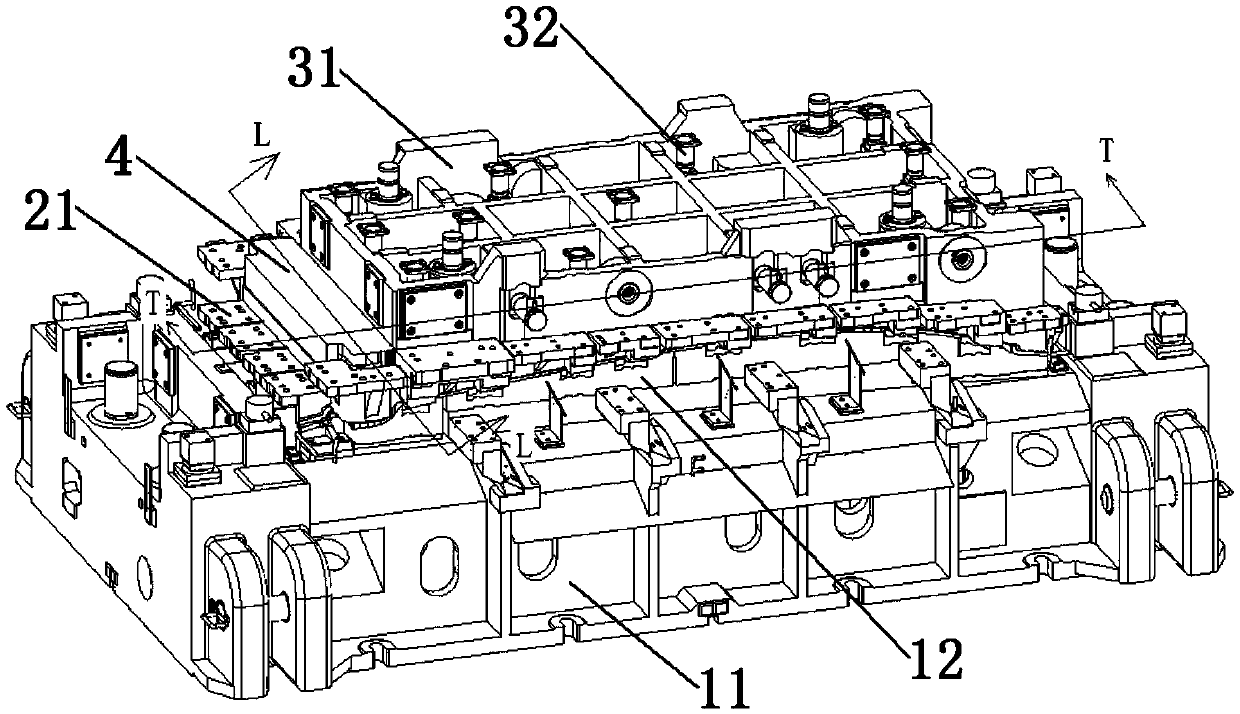

Stamping forming process and trimming and shaping composite mould for automobile roof cover

ActiveCN105499431ASolve the problems of poor fluidity and insufficient sheet metal formingSolve the problem of insufficient formingShaping toolsVehicle componentsEngineeringForming processes

The invention provides a stamping forming process for an automobile roof cover. The stamping forming process comprises a drawing forming procedure and a trimming and shaping procedure in sequence; in the drawing forming procedure, a positive R corner is formed at a connecting position of the top part and the tail part of the automobile roof cover; and in the trimming and shaping procedure, the positive R corner is shaped so as to enable the positive R corner to take the shape of a step with a negative R corner. The invention further provides a trimming and shaping composite mould. With the adoption of the stamping forming process and the trimming and shaping composite mould, the risk of cracking at the connecting position of the top part and the tail part of the automobile roof cover in the stamping forming process can be reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

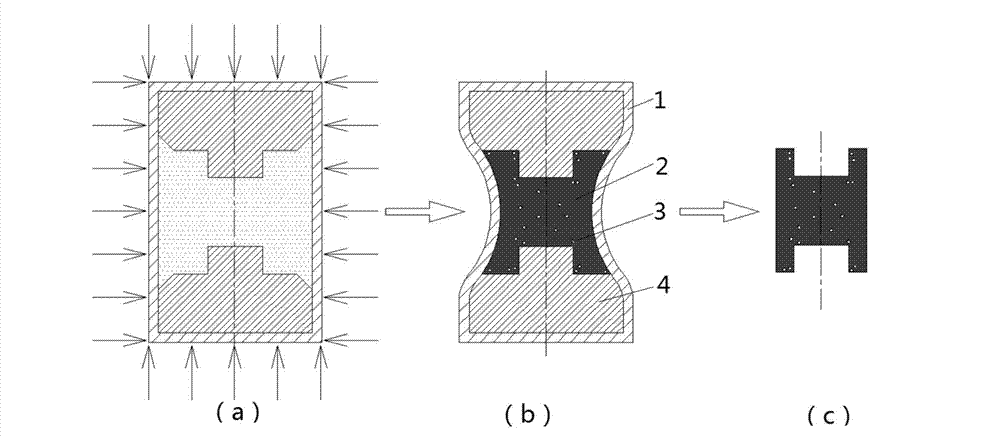

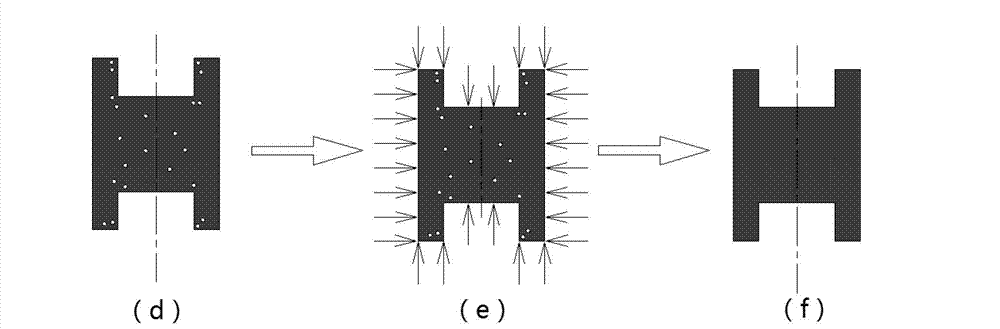

Hot isostatic pressing two-step forming method of high temperature alloy compact piece

The invention belongs to the field of advanced manufacturing, and particularly relates to a hot isostatic pressing two-step forming method of a high temperature alloy compact piece. The method includes two steps of hot isostatic pressing, according to a first step of hot isostatic pressing, a formation control mold is controlled to deform at a low temperature or pressure, part pressed blanks high in precision of shapes and sizes are obtained, wrapping sleeve limitation does not exist in a second forming step, the temperature and the pressure which are most suitable for formation material are adopted, both holes left in the first step are eliminated, compactness is improved, and the precision of the shapes and the sizes is guaranteed, and good organizational performance under the most suitable temperature and the most suitable pressure is obtained. Due to the fact that the temperature and the pressure in the first forming step are low, material choosing problem of complicated formation control molds is solved, material which is difficult to process and high in high temperature yield strength is not required to be chosen as a formation control type mold core, and manufacture cost of the mold is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

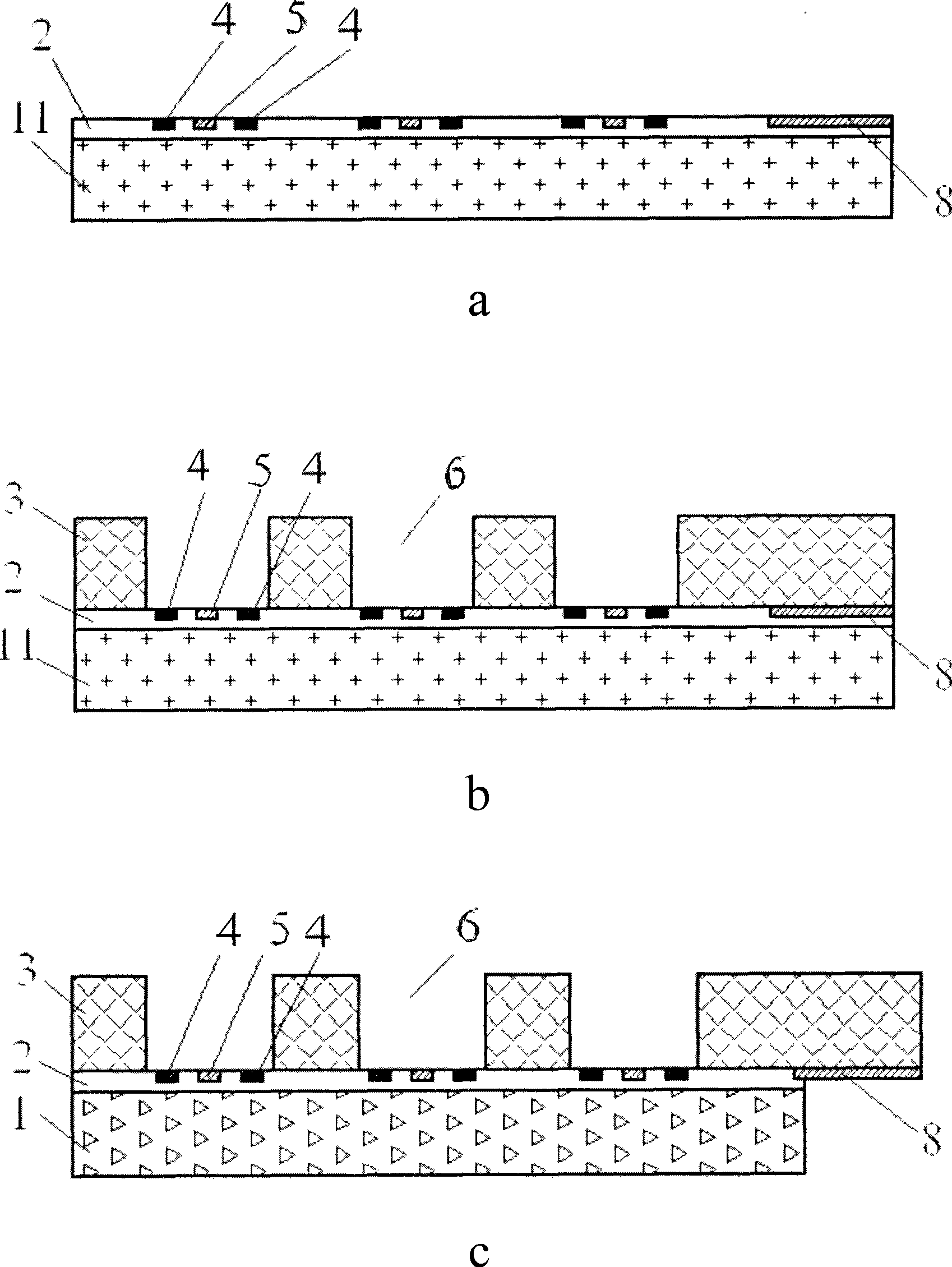

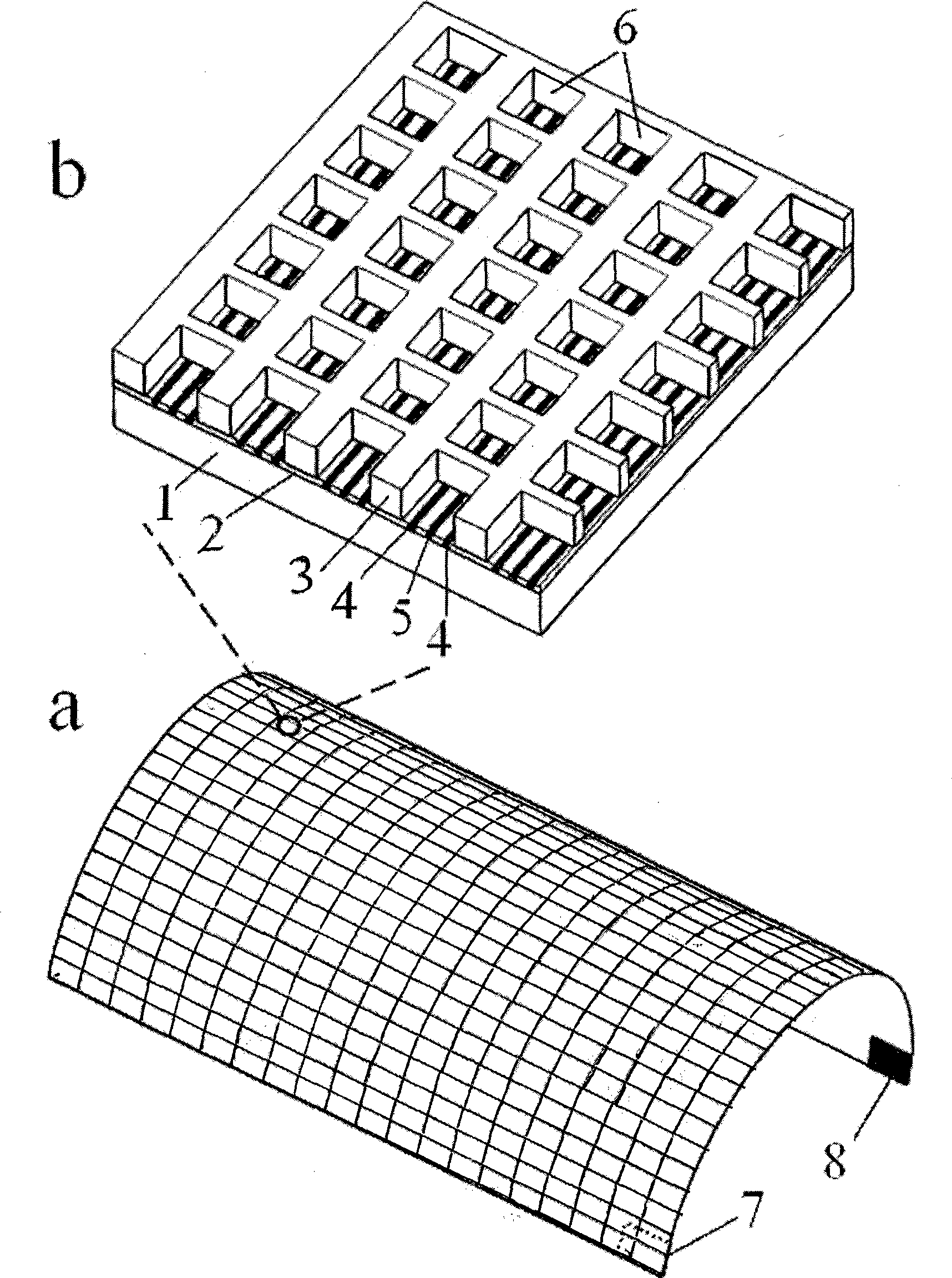

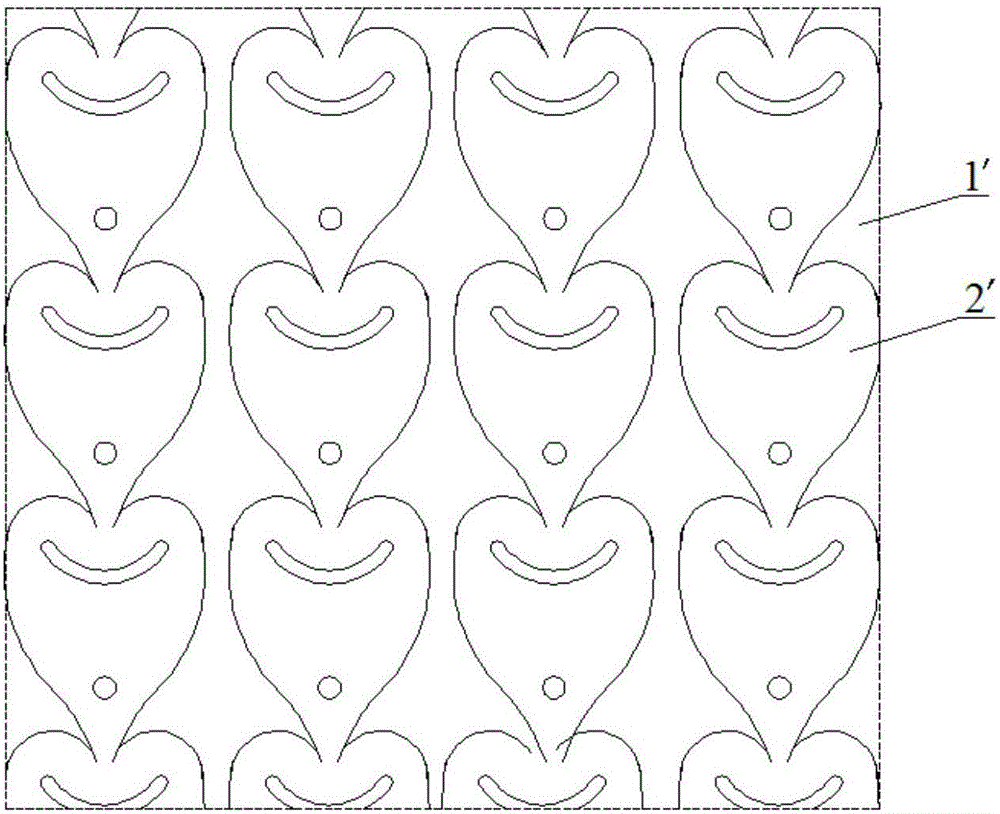

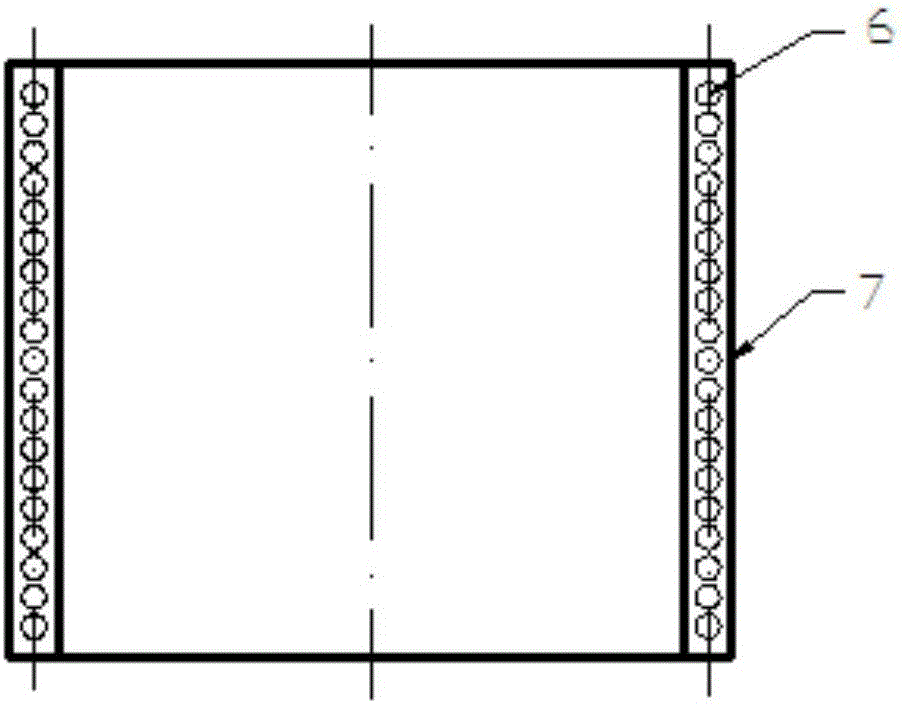

Flexible MEMS resistance reducing covering and method of manufacturing the same

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

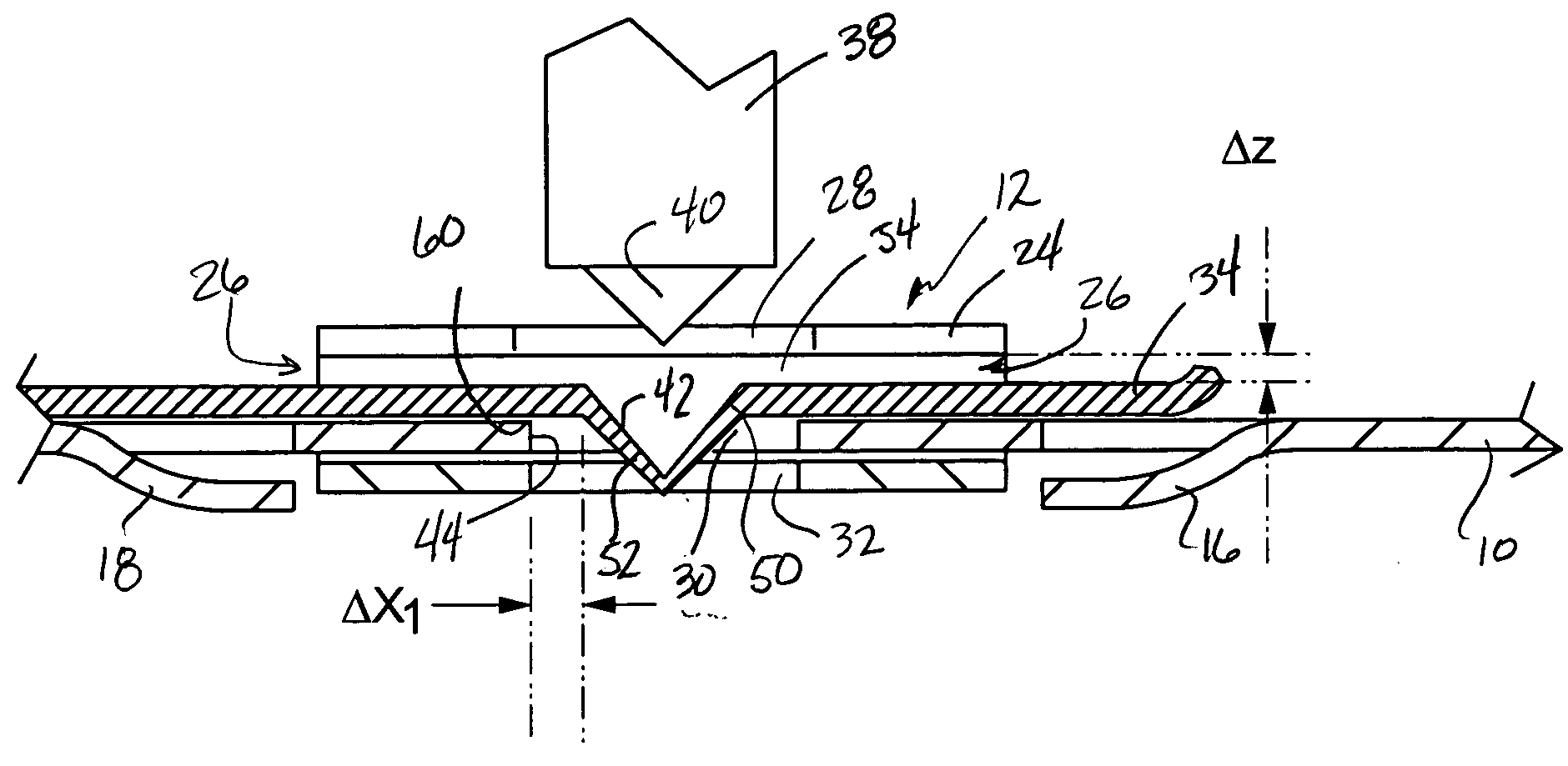

Method and apparatus for bundling objects

ActiveUS20070084022A1Optimize formationOptimize application of forceFlexible elementsHose connectionsEngineeringMechanical engineering

An improved tool for locking a band clamp, and an improved lock for a band clamp is disclosed. The tool includes a knife body having a knife edge that progressively cuts the free end of the band over a period of time, rather than simultaneously cutting the entire band width. In one embodiment, this is accomplished with a knife edge that is non-linear. The tool further includes a punch with a rounded or hemispherical shaped leading tip that forms an improved locking dimple. The locking dimple forms an improved lock having side walls that are, at least in part, parallel with the walls of the surrounding aperture in the band. By varying the profile of the knife edge, the punch can more fully form an improved locking dimple.

Owner:BAND IT IDEX

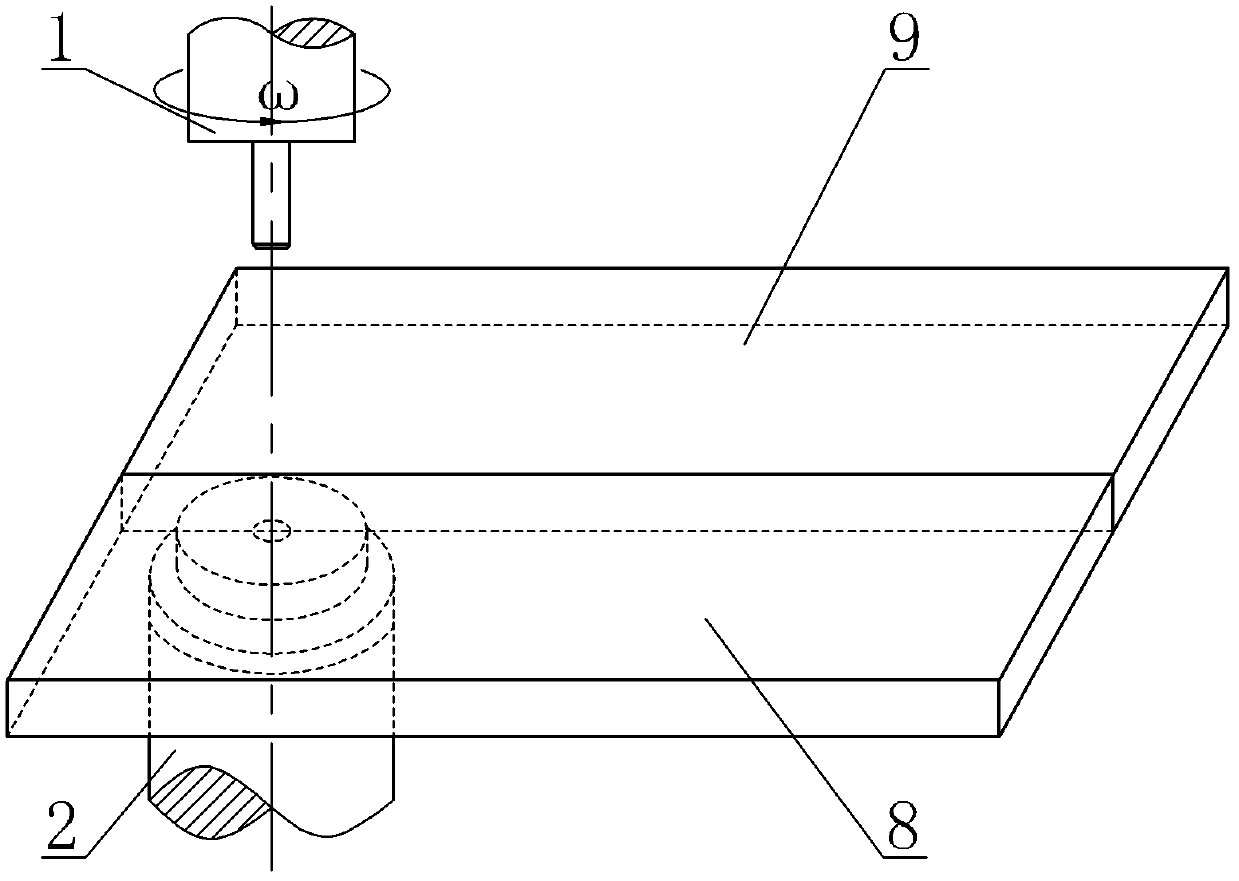

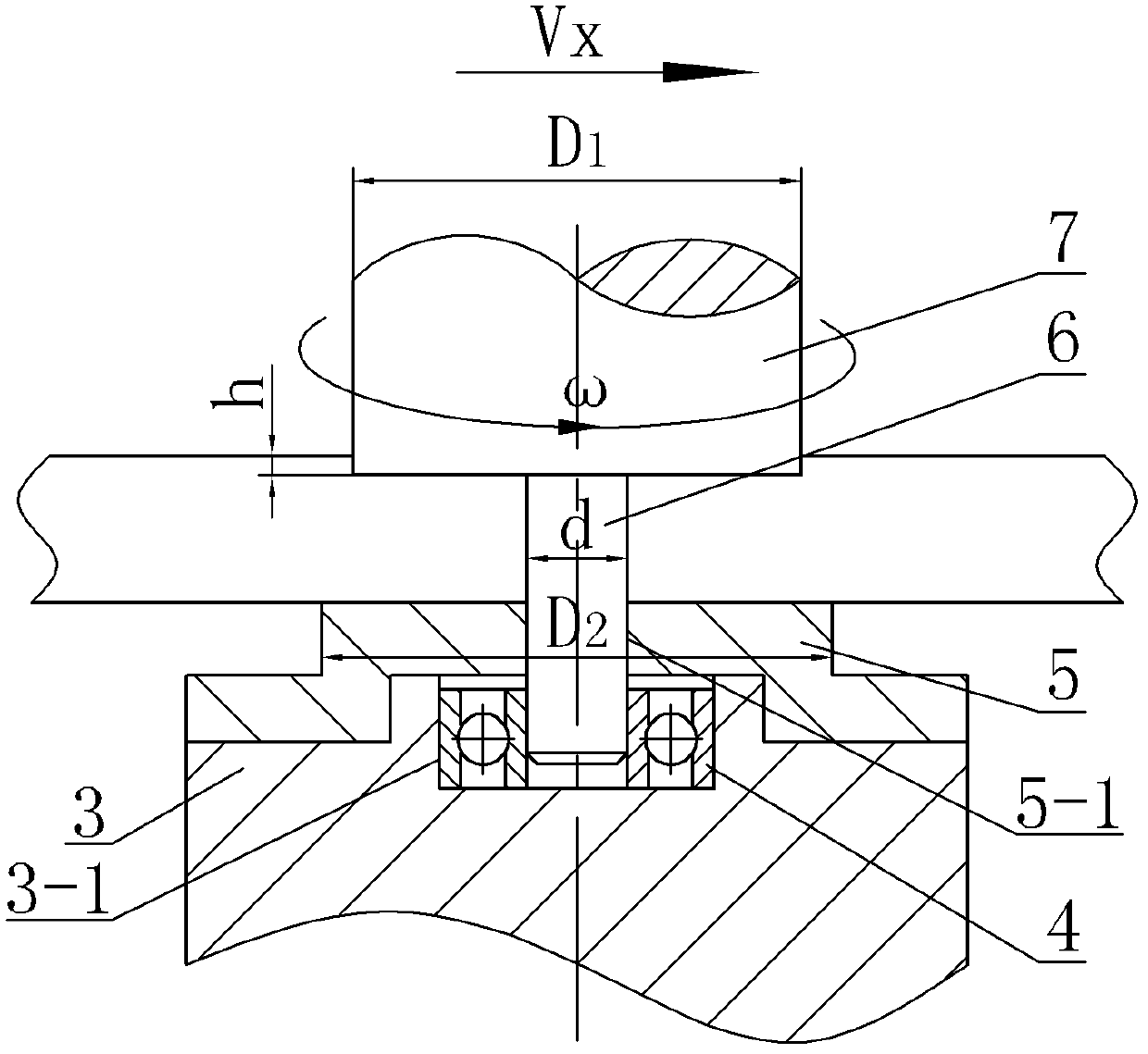

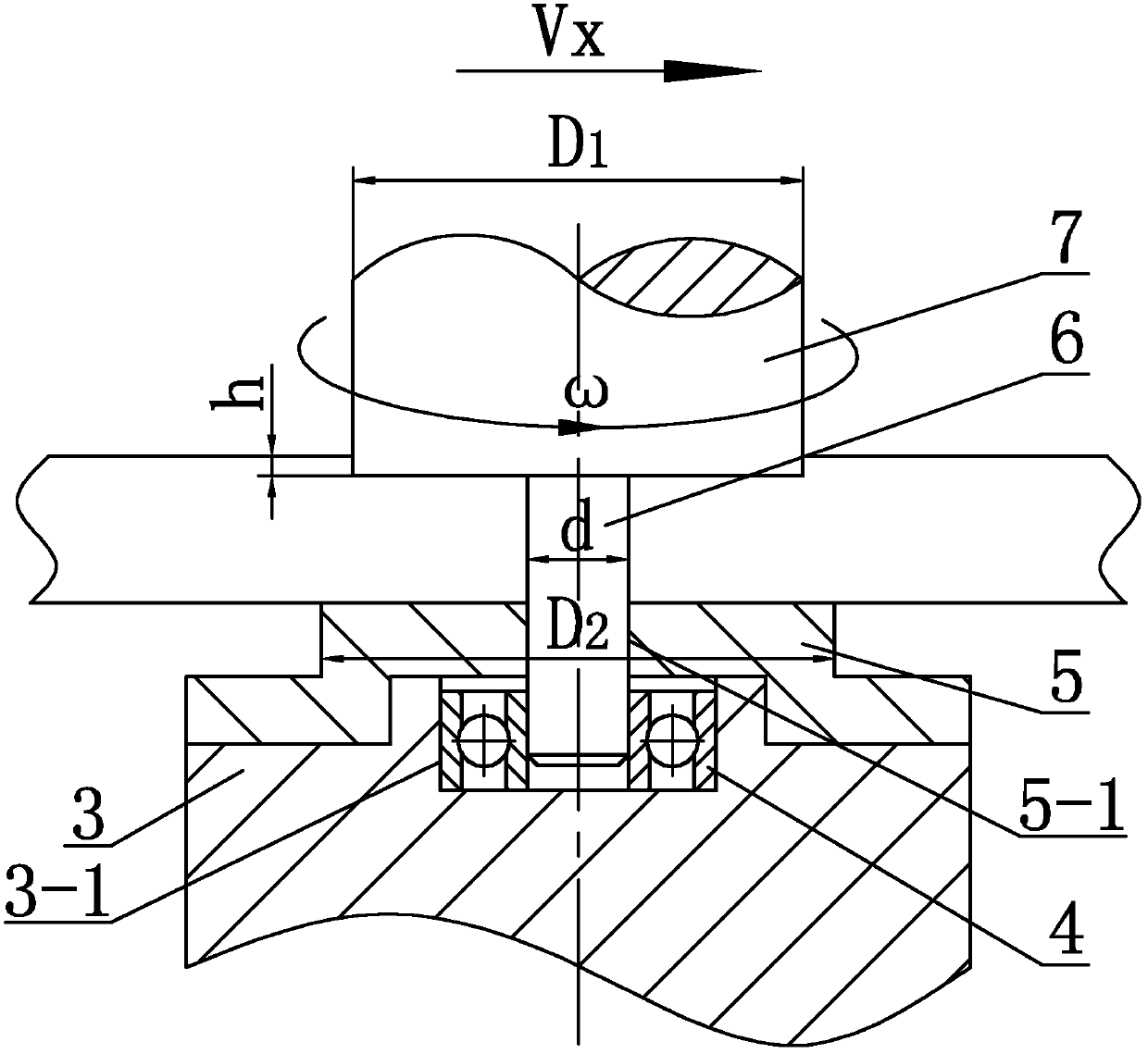

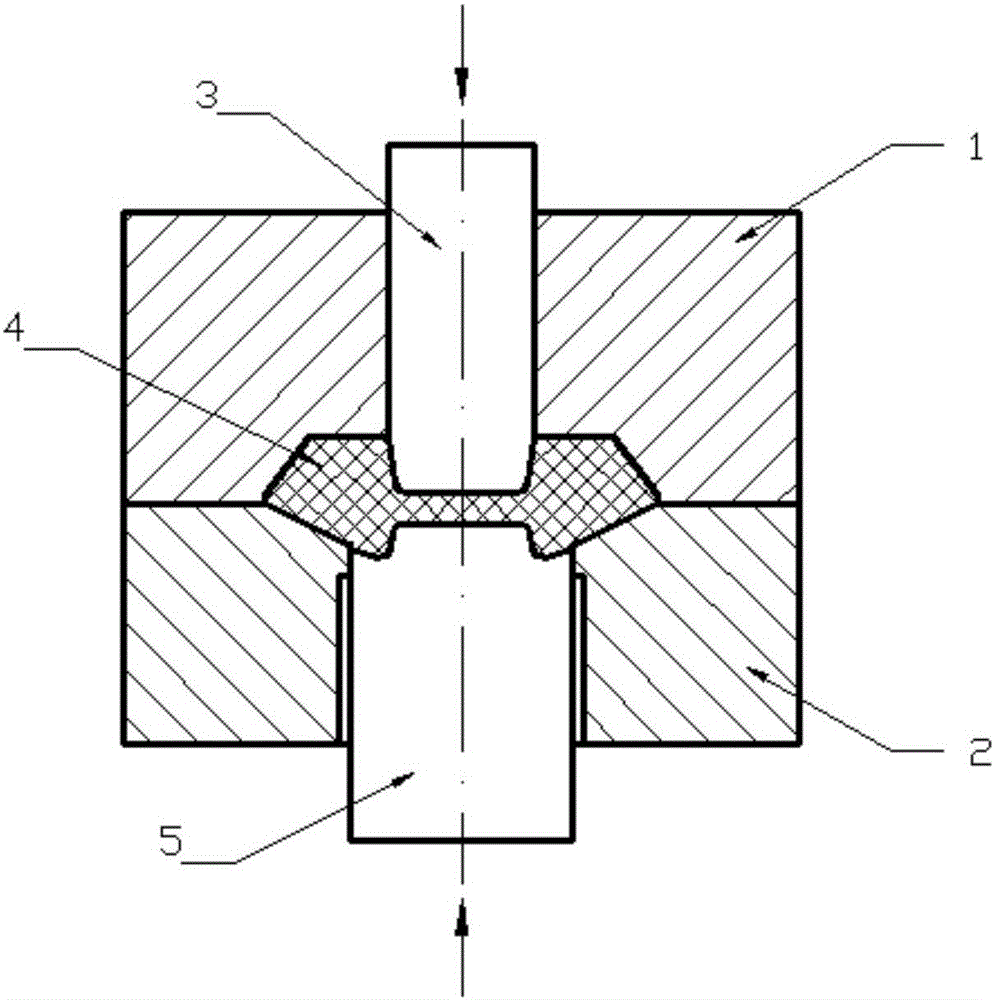

Self-sustaining friction stir welding stirring head with irrotational lower shaft shoulder and welding method of stirring head

InactiveCN102601515AAvoid rotating heatImprove carrying capacityNon-electric welding apparatusEngineeringMechanical property

The invention relates to a stirring head and a welding method, in particular to a self-sustaining friction stir welding stirring head with an irrotational lower shaft shoulder and a welding method of the stirring head, which solve the problems that welding heat input is increased as a lower shaft shoulder of an existing self-sustaining friction stir welding stirring head rotates to generate heat, weld formation is difficult, and the mechanical property of a welding joint is low. A circular groove is machined at the center of the upper end face of a support base, a radial positioning bearing is mounted in the circular groove, the lower shaft shoulder is fixedly mounted on the upper end face of the support base, a stirring pin is longitudinally machined on the lower shaft shoulder, and the lower portion of the stirring pin penetrates through the stirring pin and is mounted on the support base through the radial positioning bearing during welding. The welding method includes: firstly, determining the size of the stirring head; secondly, fixing workpieces to be welded; thirdly, positioning the stirring head before welding; fourthly, determining the rotation speed of the stirring head and the pressing depth of an upper shaft shoulder; and fifthly, determining welding speed and welding the first workpiece to be welded and the second workpiece to be welded. The stirring head and the welding method are used for friction stir welding.

Owner:HARBIN INST OF TECH

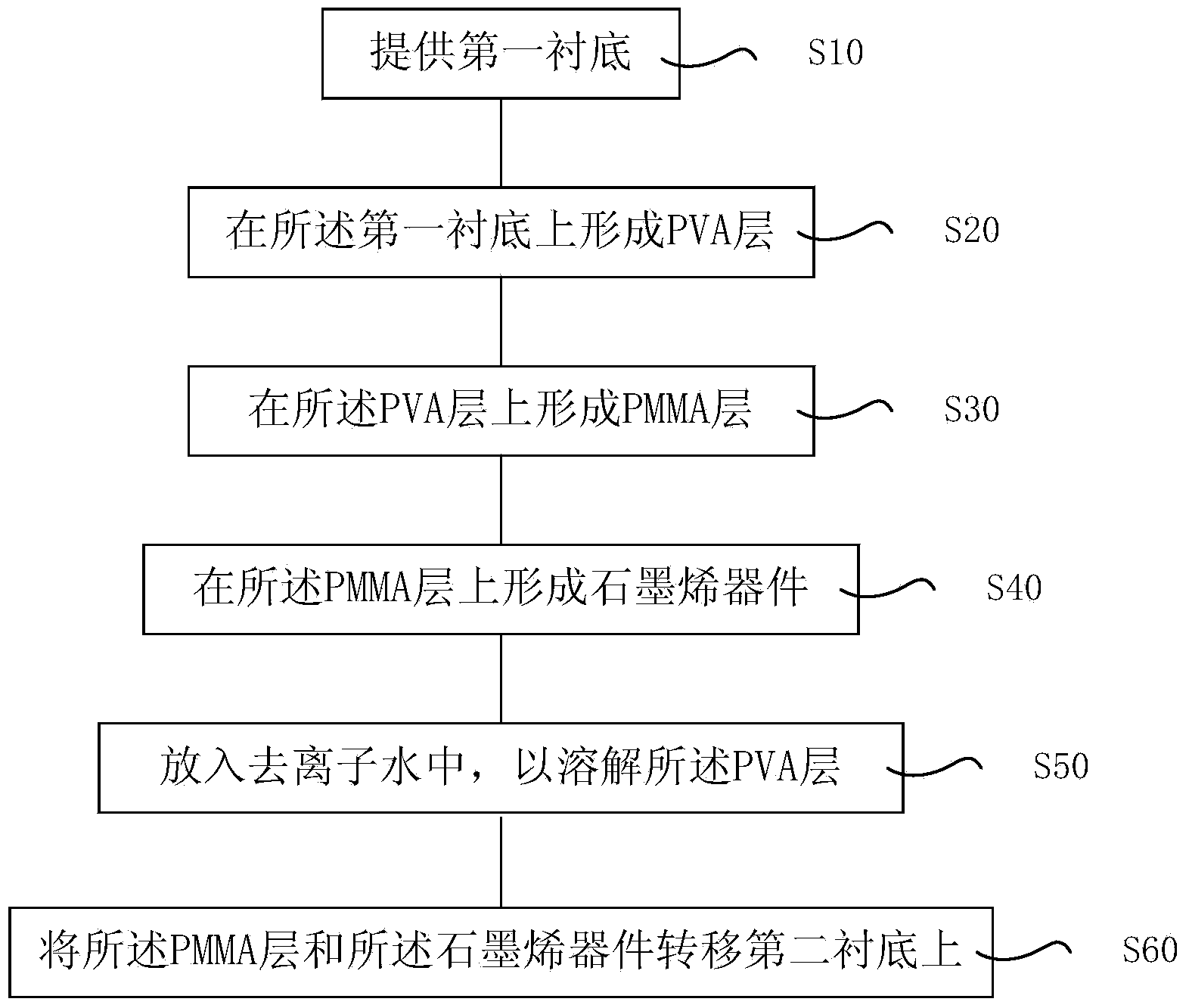

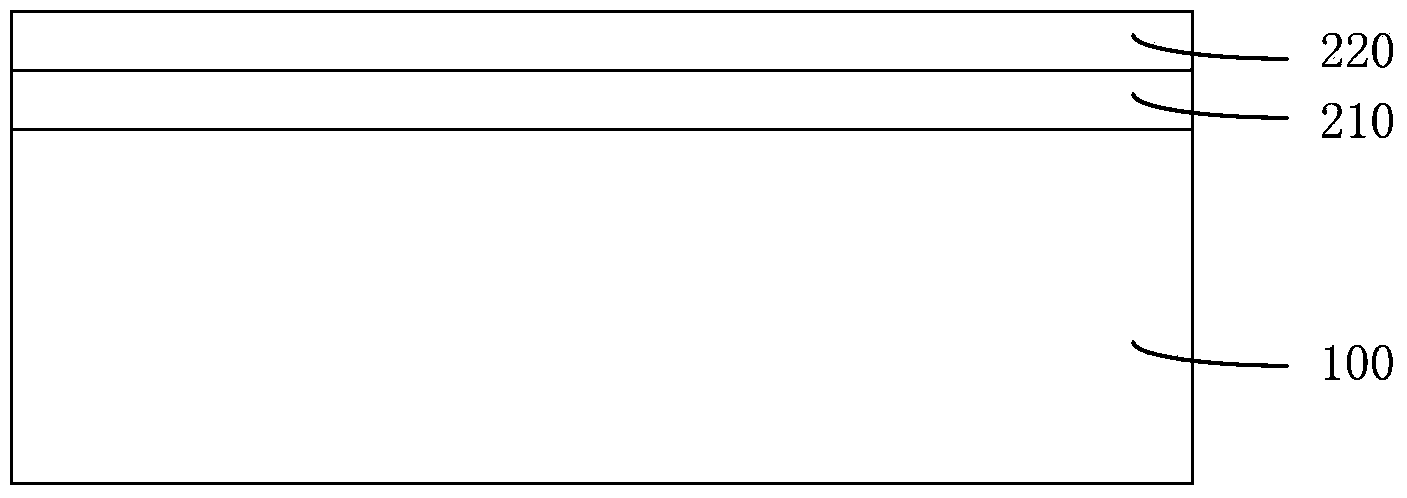

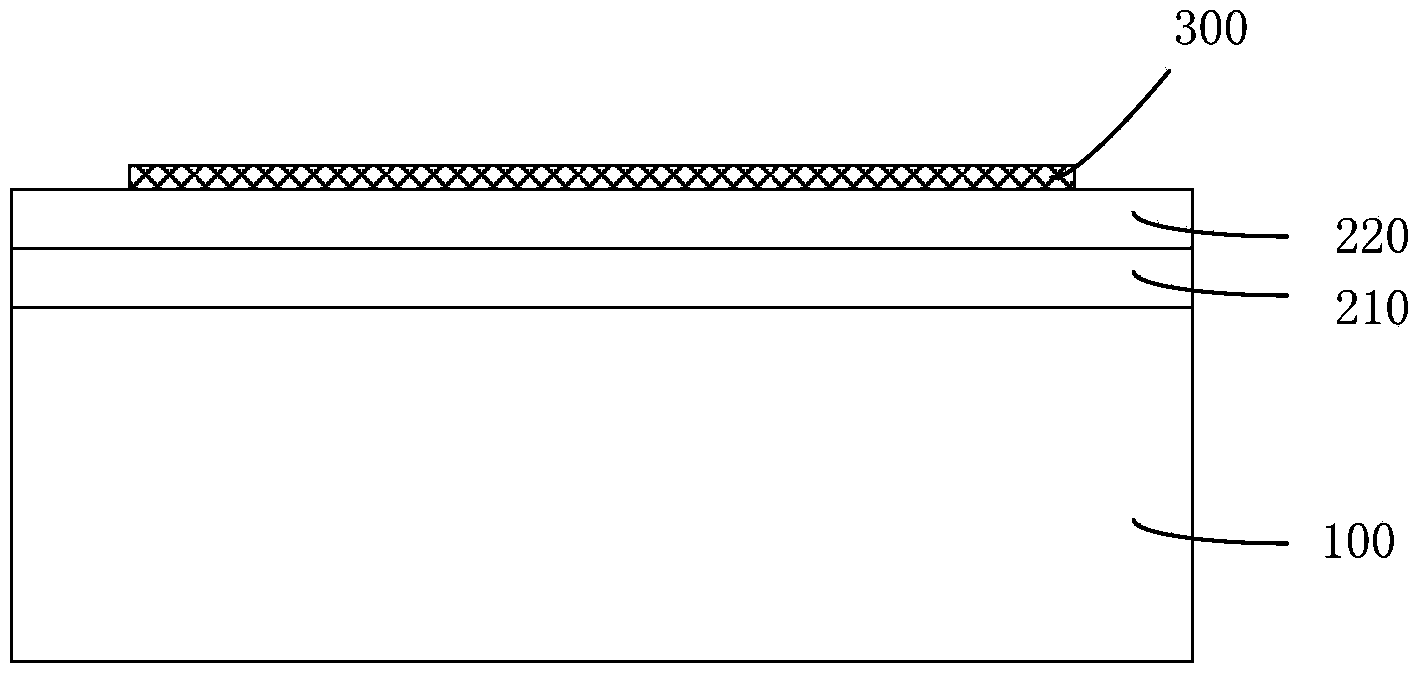

Manufacturing method of graphene device

ActiveCN103646855AFully formedEnsure complete formationSemiconductor/solid-state device manufacturingSemiconductor devicesPolyimide substratePolyvinyl alcohol

The invention provides a manufacturing method of a graphene device. The manufacturing method of the graphene device at least comprises providing a first substrate; forming a PVA (polyvinyl alcohol) layer; forming a PMMA (polymethyl methacrylate) layer on the PVA layer; forming the graphene device on the PMMA layer; putting the first substrate, the PVA layer, the PMMA layer and the graphene device into deionized water to dissolve the PVA layer and to separate the PMMA layer and the graphene device from the first substrate; transferring the PMMA layer and the graphene device to a second substrate. According to the manufacturing method of the graphene device, PMMA serves as the support layer and meanwhile PVA serves as the sacrificial layer; by removing the PVA, the graphene device formed on the PMMA layer and the PMMA layer can be separated from the first substrate simultaneously and then adhered to the second substrate (a polyimide substrate in the embodiment), therefore, the graphene device can be formed on the second substrate. The manufacturing method of the graphene device can widen the application range of the graphene device.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

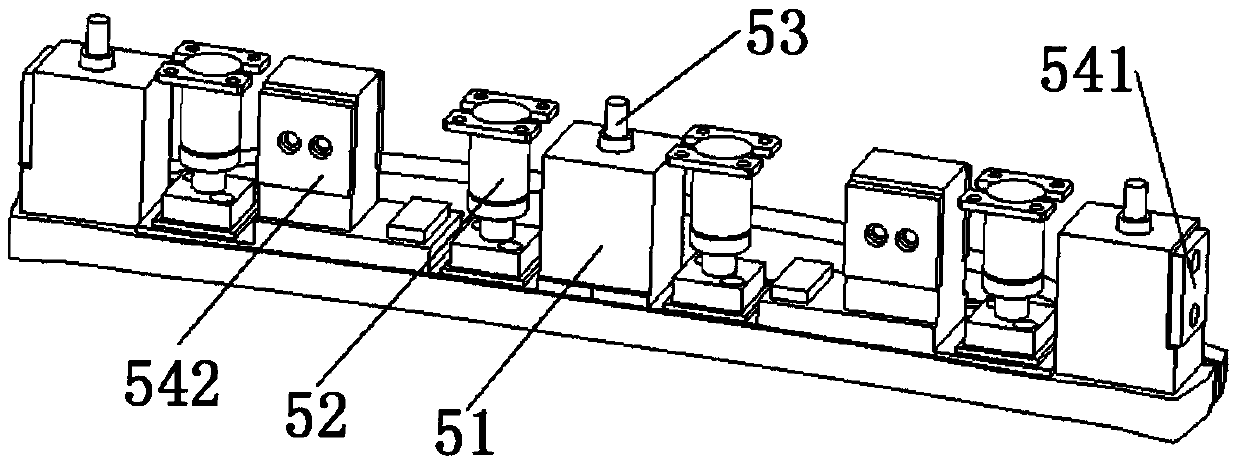

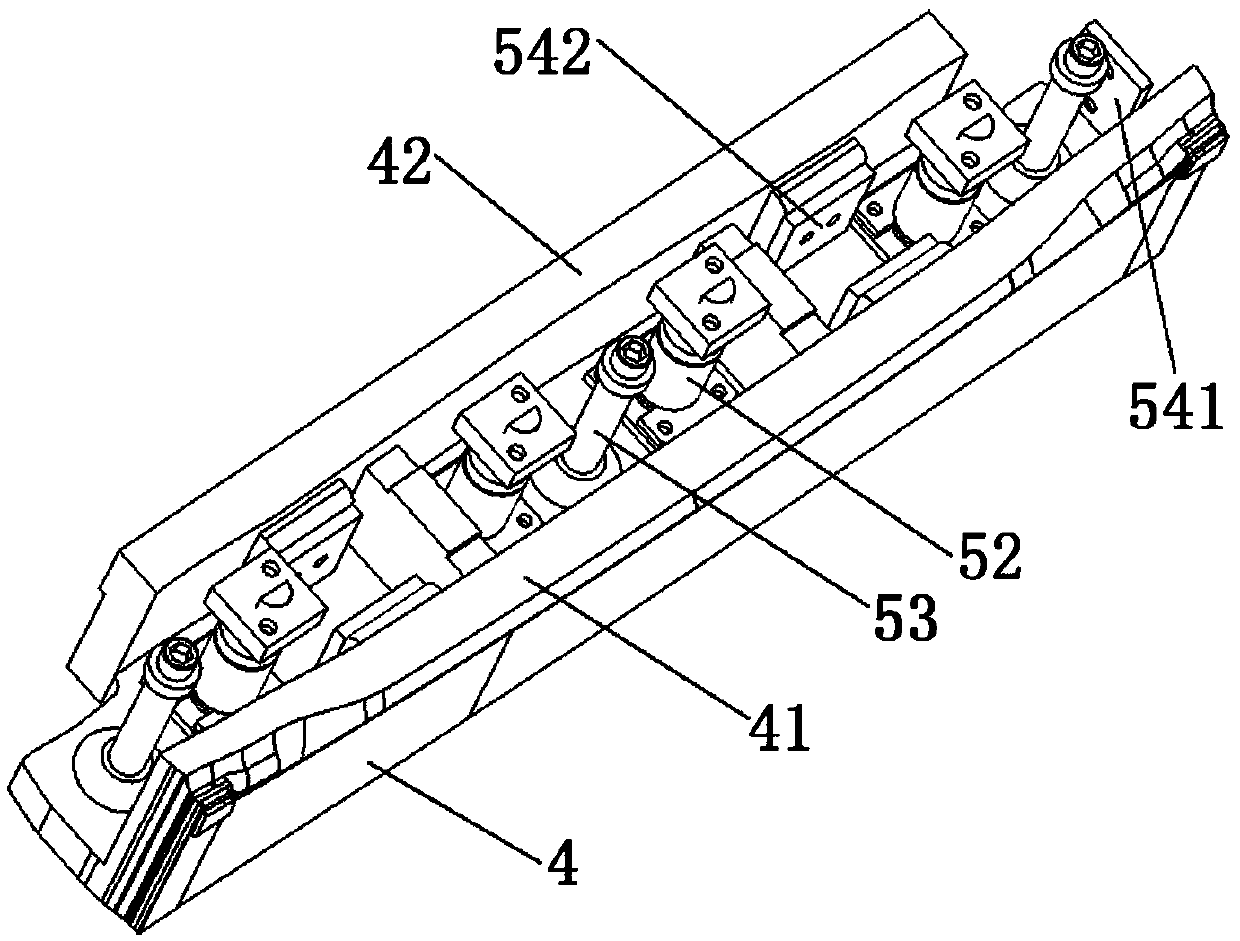

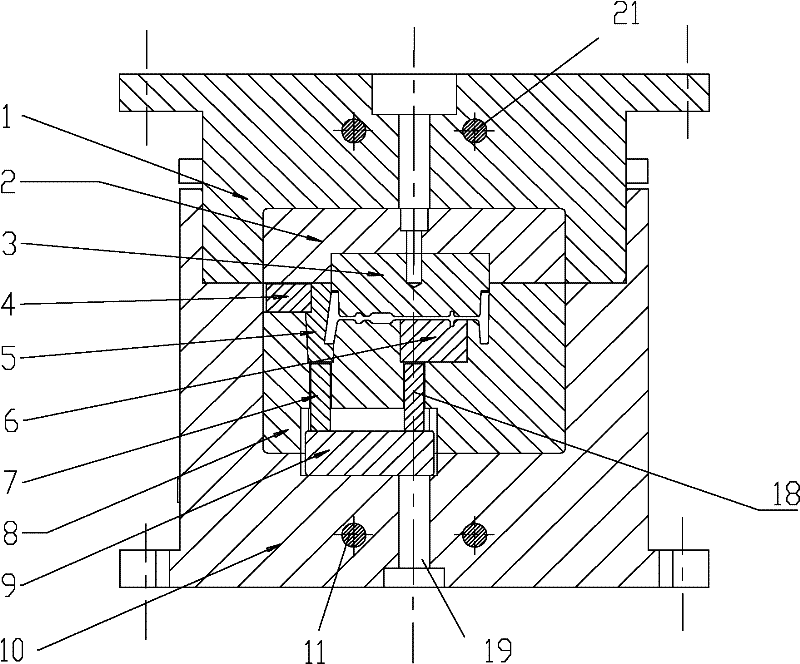

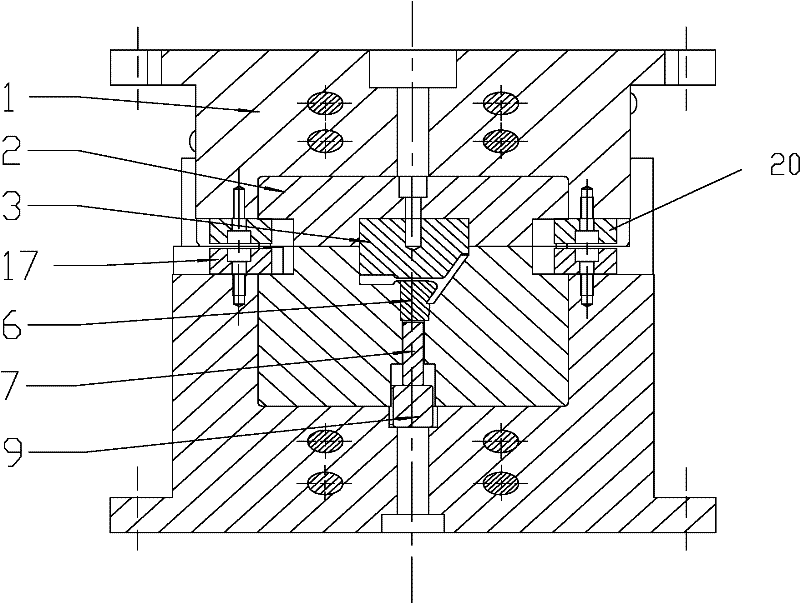

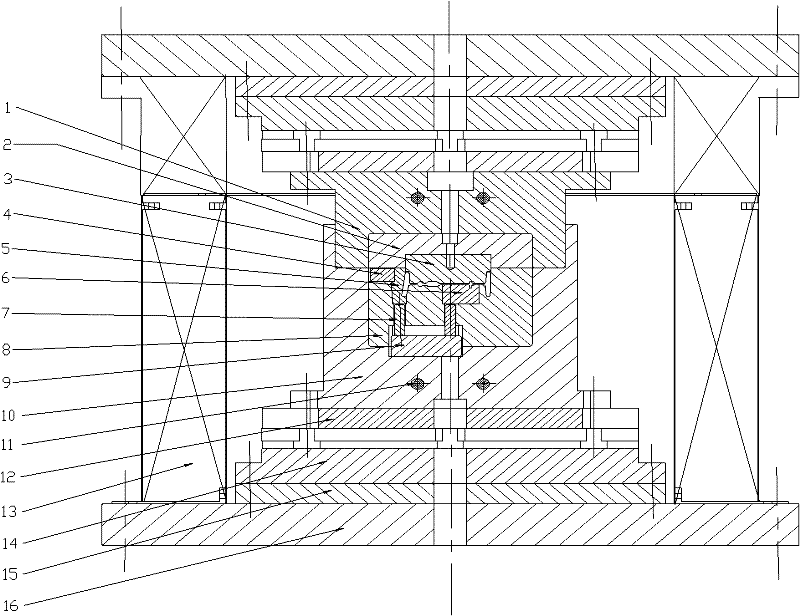

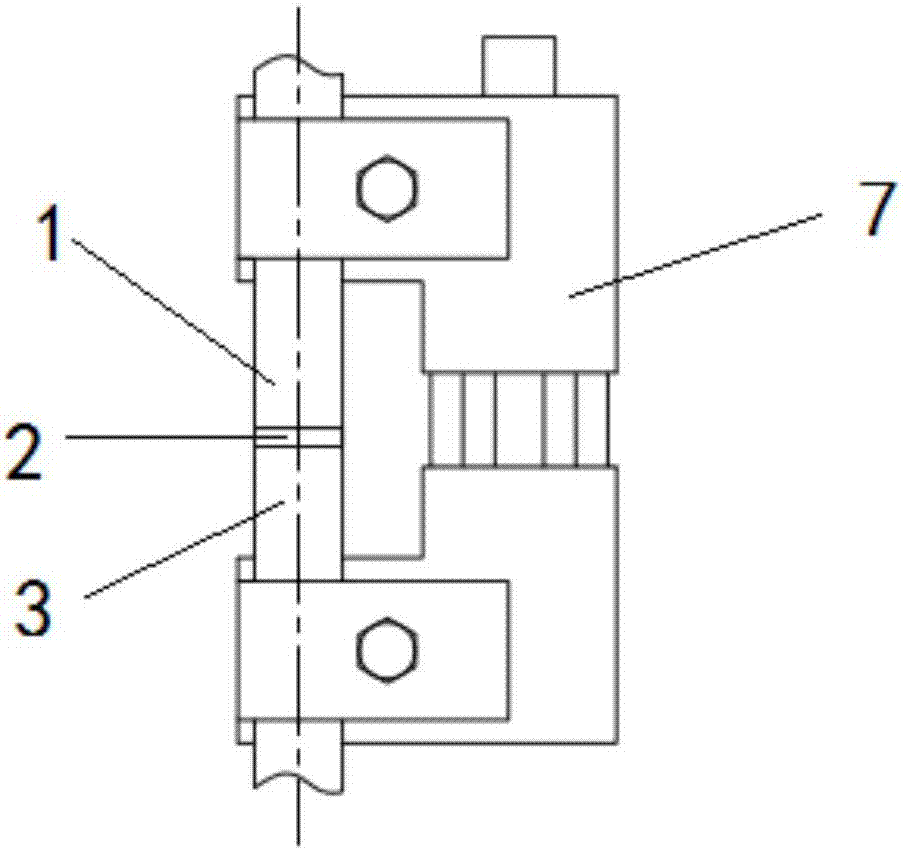

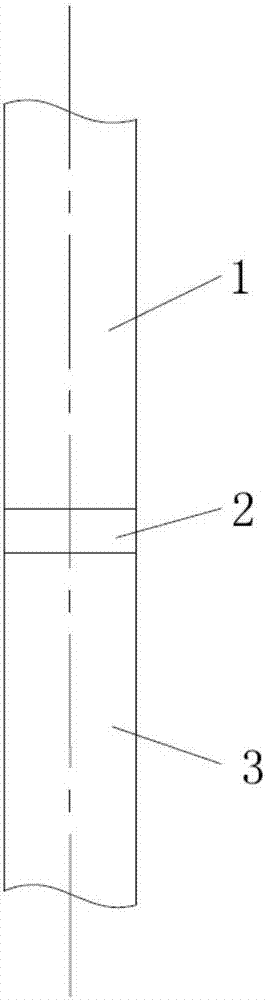

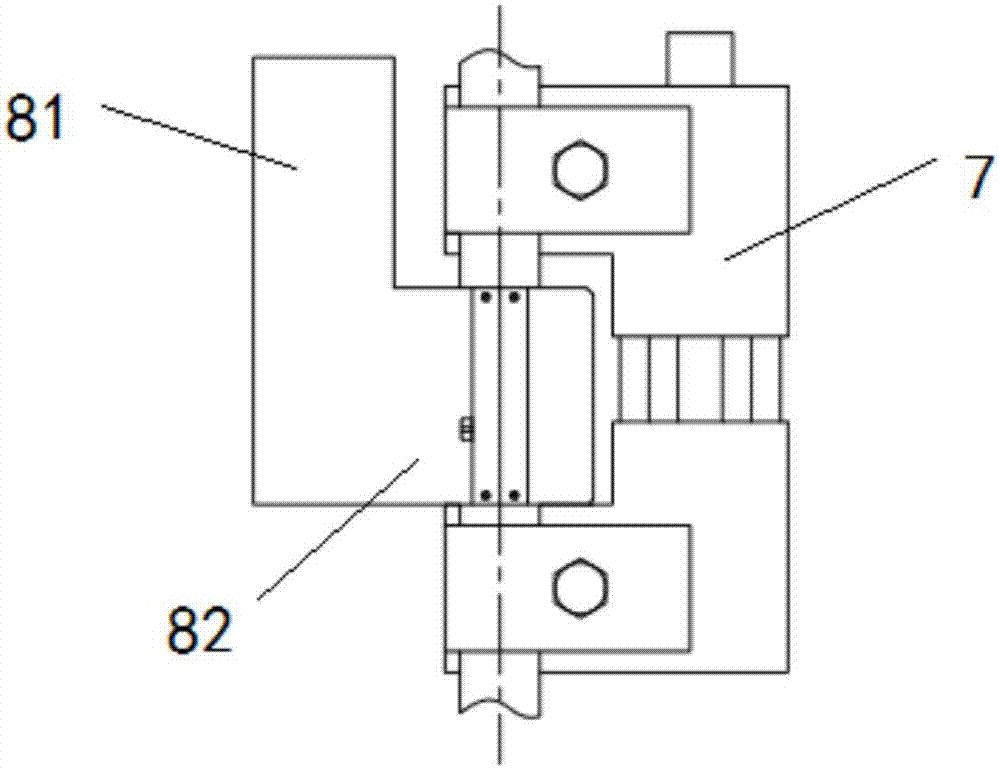

Precision isothermal forging combined die for complex aerospace die forged pieces

InactiveCN102179466AFully formedFull demouldingForging/hammering/pressing machinesEngineeringIsothermal forging

The invention discloses a precision isothermal forging combined die for complex aerospace die forged pieces, which comprises an upper die and a lower die, wherein the upper die comprises an upper die seat (1), an upper die inner sleeve (2) and an upper die insert block (3); and the lower die comprises a side surface insert block pressure plate (4), a side surface insert block (5), a bottom surface insert block (6), a first ejector rod (7), a second ejector rod (18), a lower die inner sleeve (8), an ejector rod tray (9) and a lower die seat (10). The upper die insert block (3) constitutes the die surface of the upper die; and the side surface insert block (5), the bottom surface insert block (6) and the lower die inner sleeve (8) constitute the die surface of the lower die together. The invention provides the combined die, which can realize complete filling, smooth streamline, no folding, easiness in die release and strong universality for aerospace type complex members, such as aerospace joint type parts.

Owner:CENT SOUTH UNIV

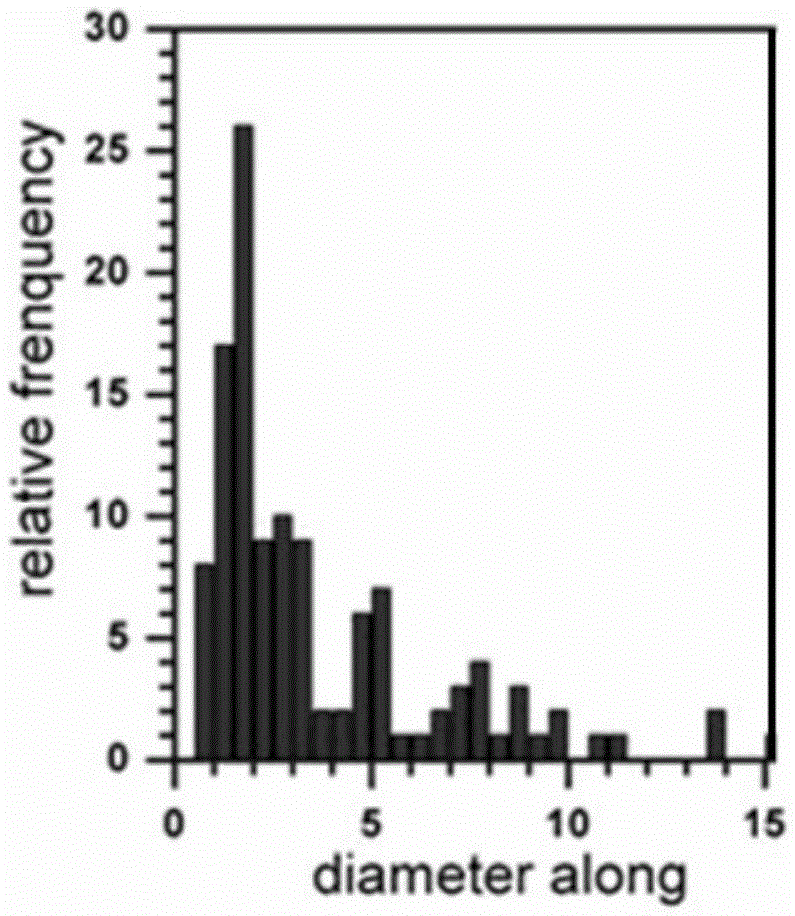

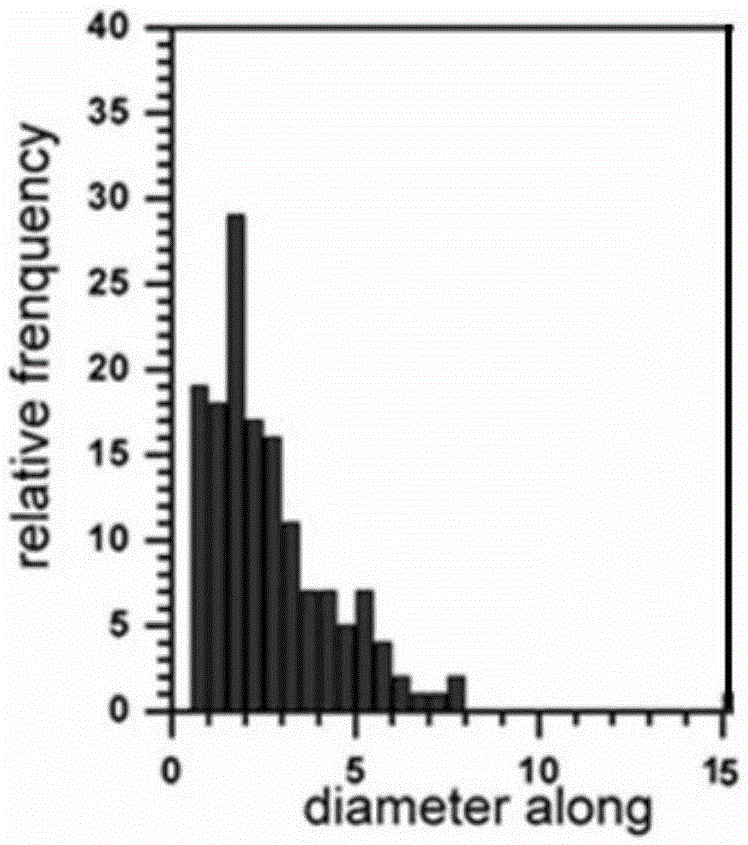

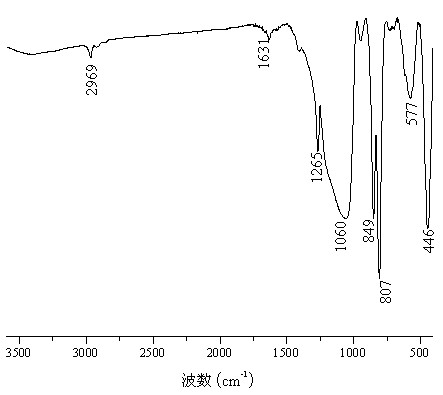

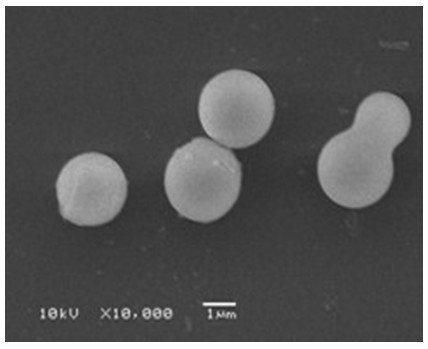

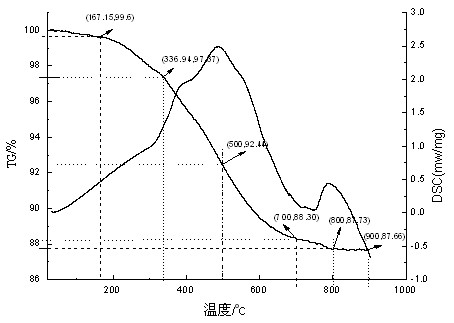

Synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant

The invention discloses a synthesizing method for organic silicon micro-balls with performances of super hydrophobicity and high temperature resistant, which relates to the synthesizing method of organic silicon. The synthesizing method for the organic silicon micro-balls comprises the following steps: firstly hydrolyzing n-silicate ester of which the structural formula is Si(ORn)4 (n is the number of carbon atom), and then forming a spherical pre-polymer after polycondensation; adding alkylchlorosilane of which the structural formula is Cl2Si(Rn)2 (n is the number of carbon atoms) or alkoxy silane of which the structural formula is (Rn)2Si(ORn)2 (n is the number of carbon atoms), so as to obtain the organic silicon micro-balls of which surfaces are fully provided with alkyls after copolycondensation. The obtained micro-balls have good dispersibility, and have characteristics of super hydrophobicity and high temperature resistant and the range of particle diameter is within 0.5-10 microns. The organic silicon micro-balls are simple in production technology, free form pollution during the production process and convenient for post-treatment technology, and can be widely applied to rubber, plastic and adhesive, so as to improve the temperature resistant performance of basis materials. The organic silicon micro-balls also can be applied to coating and self-prepared hydrophobic self-cleaned coating.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

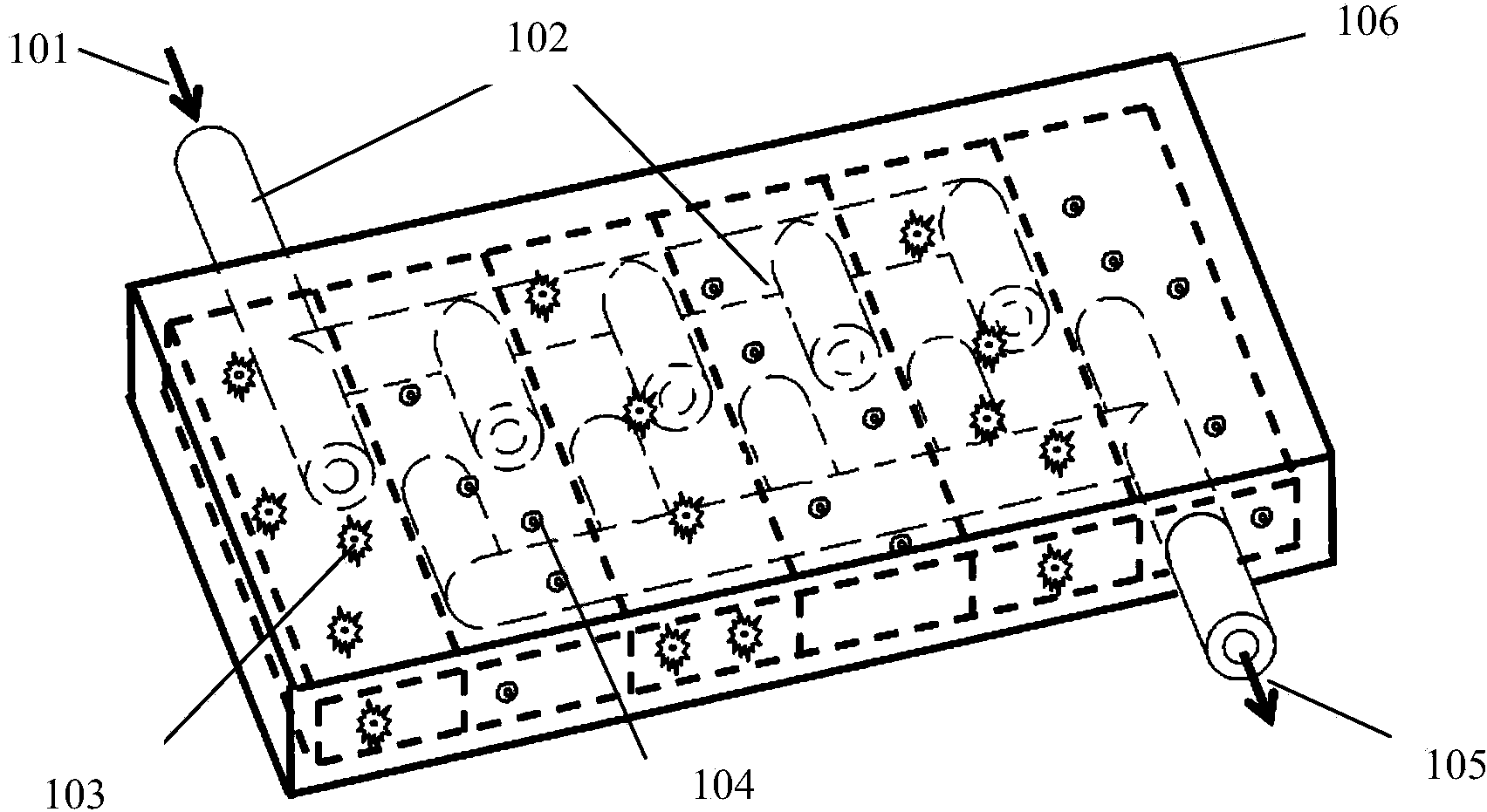

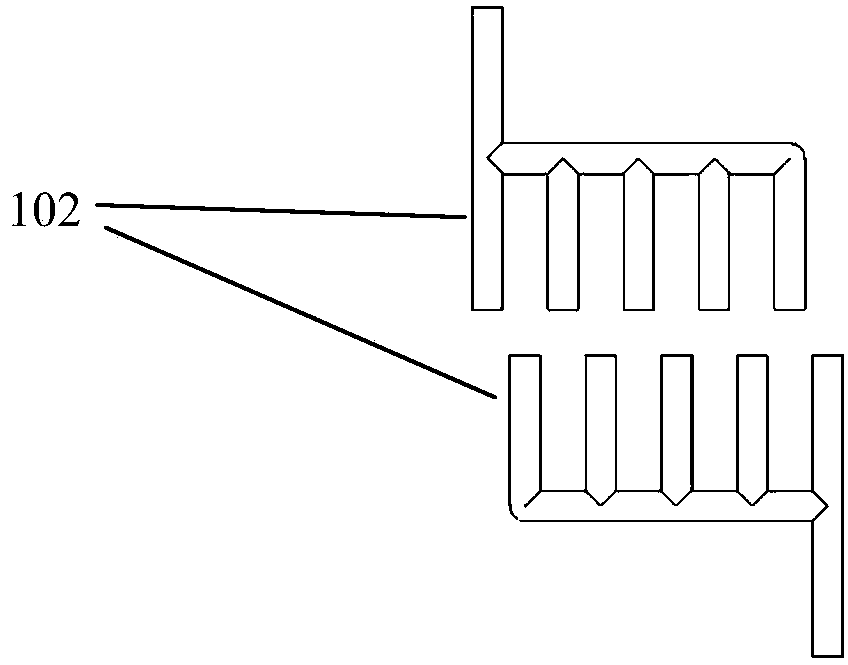

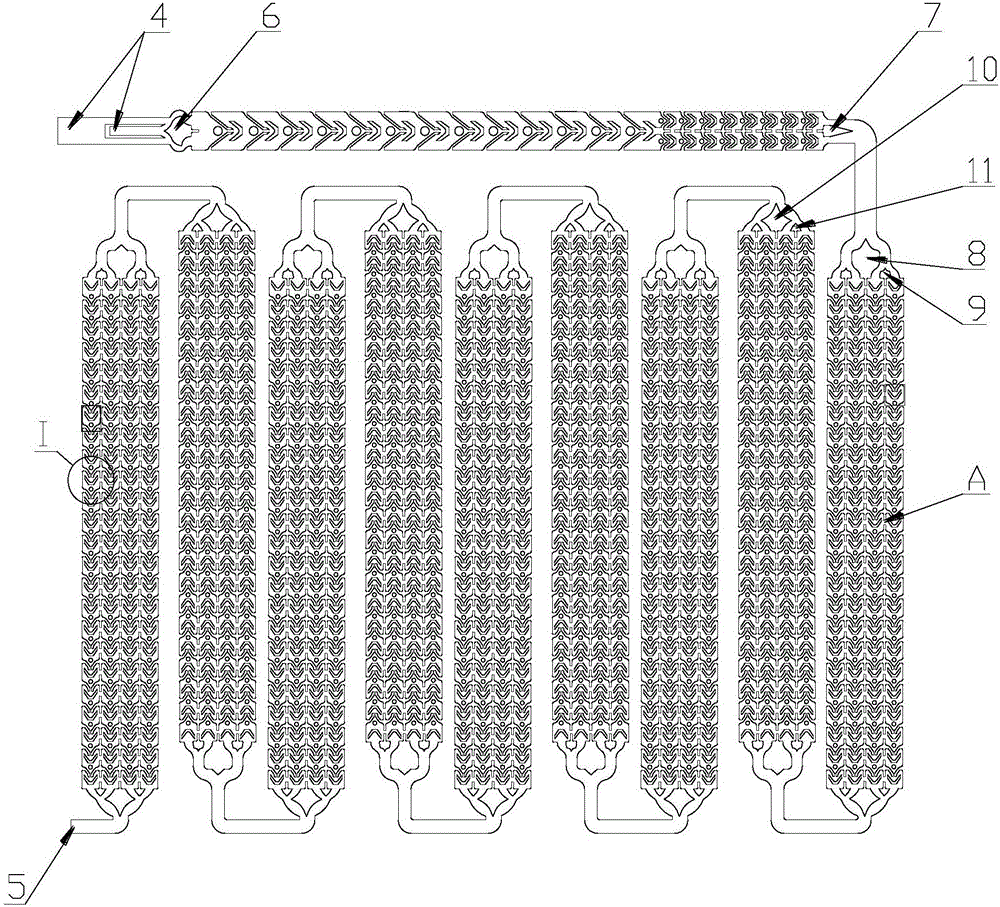

Micro-reactor

ActiveCN106423033AReduce areaKeep for a long timeChemical/physical/physico-chemical microreactorsChemical/physical/physico-chemical stationary reactorsMicroreactorEnergy consumption

The invention discloses a micro-reactor. The micro-reactor is provided with a reaction channel; the reaction channel is provided with a plurality of reaction cavities (12), and each reaction cavity (12) is internally provided with a diversion body (15) and a spoiler body (16); all the reaction cavities (12) are respectively in a rectangle; an outlet of each reaction cavity (12) comprises a V-shaped channel (17) and a linear channel (18), wherein the widths of the V-shaped channels (17) are reduced gradually, and the widths of the linear channels (18) are the same as one another; the widths a of the linear channels (18) are 0.002-6mm, and the ratios of distances b between the spoiler bodies (16) and two sides of the V-shaped channels (17) to the widths a of the linear channels (18) are equal to 0.93-2.2. The micro-reactor has a high specific surface area so as to augment and strengthen a reaction process, thus further increasing liquid holdup and handling capacity, effectively improving the conversion rate and yield of products and remarkably improving coefficient of heat conduction and heat exchange effect; furthermore, when a medium passes through a channel, the pressure drop is greatly reduced, so that the micro-reactor is beneficial to accurate control of reaction conditions and reduction of energy consumption.

Owner:SHANDONG HIMILE CHEM TECH

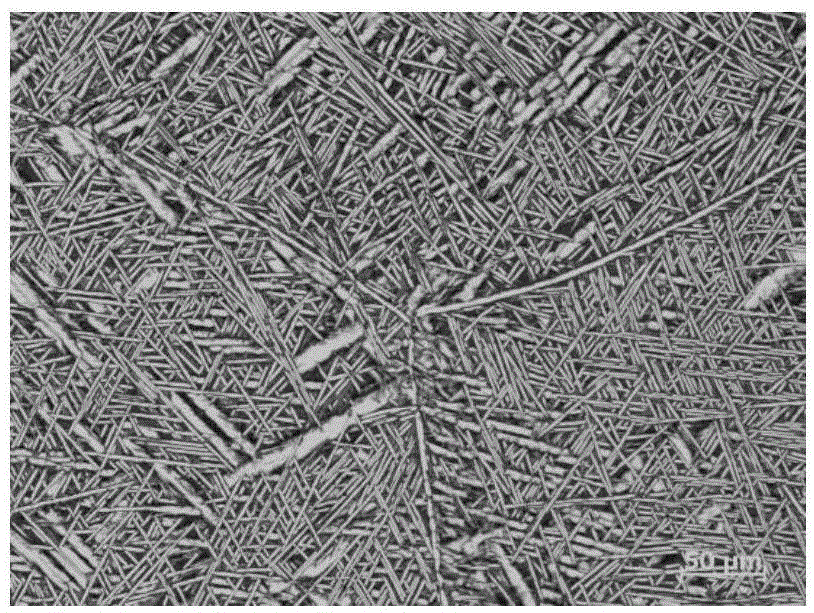

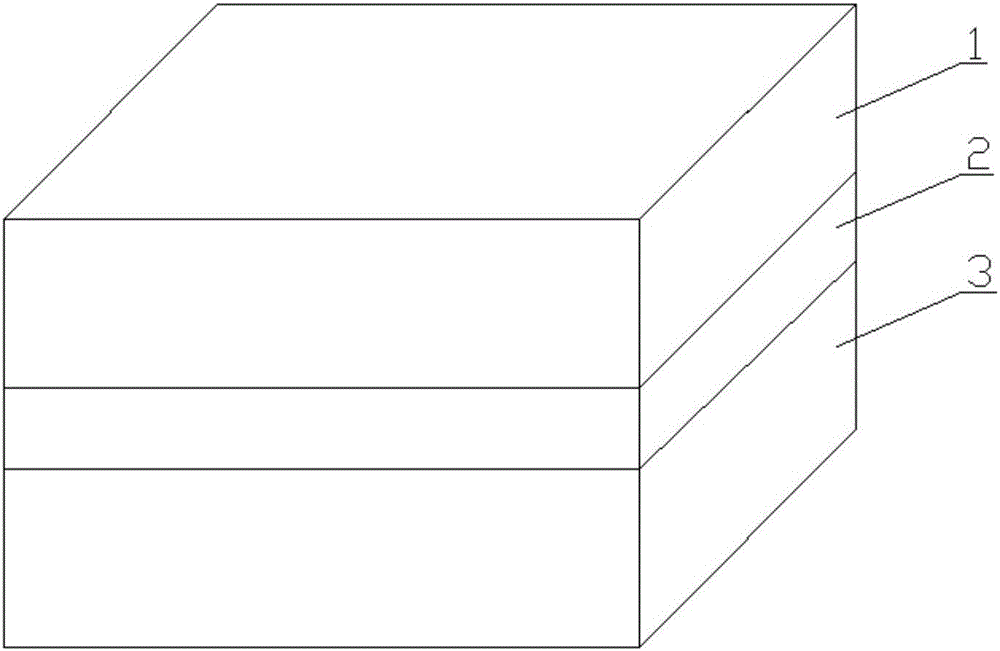

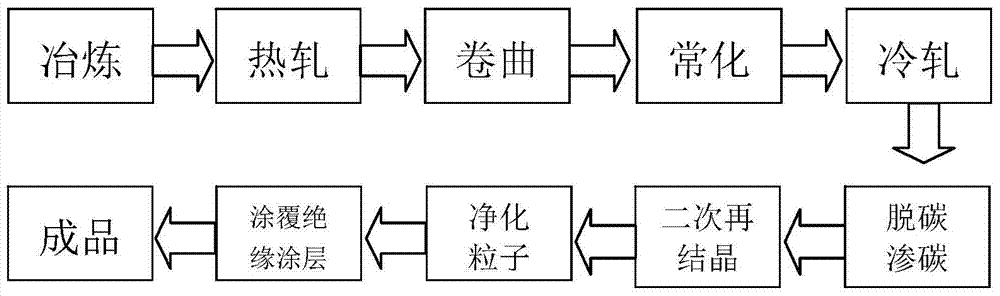

Thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet and production method thereof

The invention discloses a production technology of a thin-gauge, ultra-low iron loss, low-noise and high-magnetic induction oriented silicon steel sheet. The oriented silicon steel sheet comprises the following components in percentage by weight: 0.003-0.05 percent of C, 4.1-9 percent of Si, 0.05-0.5 percent of Mn, 0.02-0.06 percent of Al, 0.01-1 percent of Sn, 0.05-0.1 percent of Mo, 0.2-1 percent of Cu, 0.003-0.02 percent of N, 0.002-0.06 percent of P, 0.001-0.008 percent of S and the balance of iron and other inevitable impurities. The high-magnetic induction oriented silicon steel sheet which is produced through hot rolling, cold rolling and annealing processes and the like has the superior performances such as ultra-low iron loss, high flux density, low magnetostriction coefficient and small thickness, has the advantages of simple process, stable texture and capabilities of greatly saving the materials and saving the resources while guaranteeing that the capacity of a transformer is unchanged, and is the best candidate material for manufacturing high-grade power transmission and distribution transformer cores at present.

Owner:STATE GRID CORP OF CHINA +2

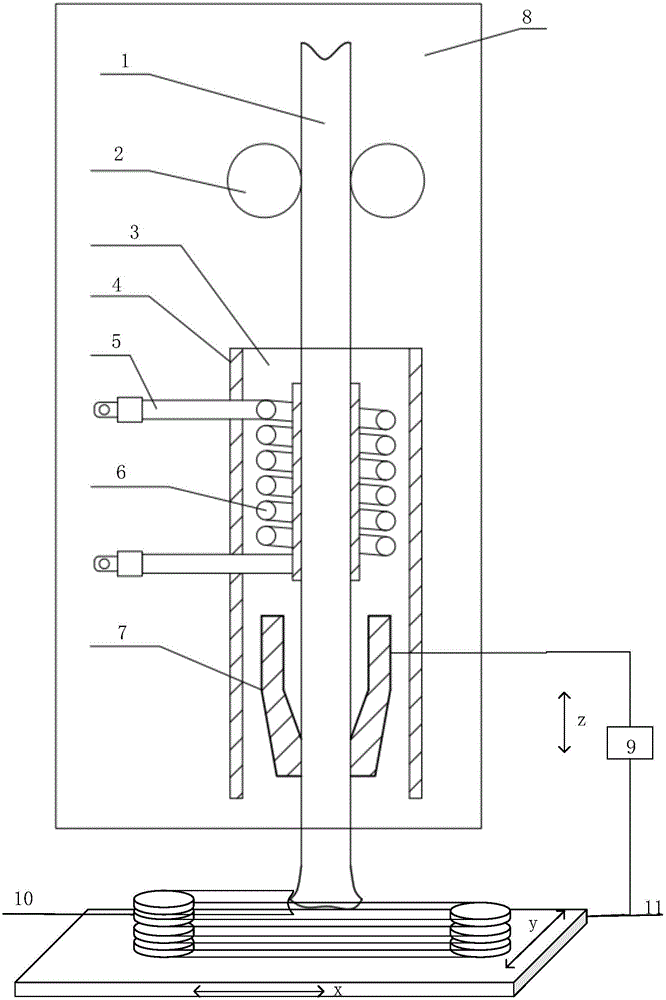

Method for forming metal wire through resistance and electromagnetic induction composite heating

ActiveCN106623939ALow investment costReduce maintenance costsAdditive manufacturing apparatusMagnetic tension forceElectrical resistance and conductance

The invention discloses a method for forming a metal wire through resistance and electromagnetic induction composite heating. A geometric model of a metal part is established through computer software, layered discretization is performed, and the movement track of the part is set and simulated; the metal wire is fed to an electromagnetic induction heating zone and a resistance heating zone at the constant speed by a pulsed wire feeding mechanism and is preheated to a certain temperature by an electromagnetic induction heating power supply, the wire with certain heat is continuously fed until the metal wire and a base material are short-circuited, resistance heat is produced at the part where the metal wire makes contact with the base material, and the metal wire melts to form melt under the effect of the resistance heat; the melt is stably transited to the base material under the effects of the gravity and the electromagnetic force and is solidified; and a three-dimensional movement system controls melting, transition and solidification of the metal wire according to the originally set movement track, and a formed workpiece of the metal part is completed gradually in a point-line-surface-body manner. With the technical scheme, the method has the characteristics that the cost is reduced, the efficiency is improved, the heat input to the base material is reduced, and deformation of the base material is reduced.

Owner:BEIJING UNIV OF TECH

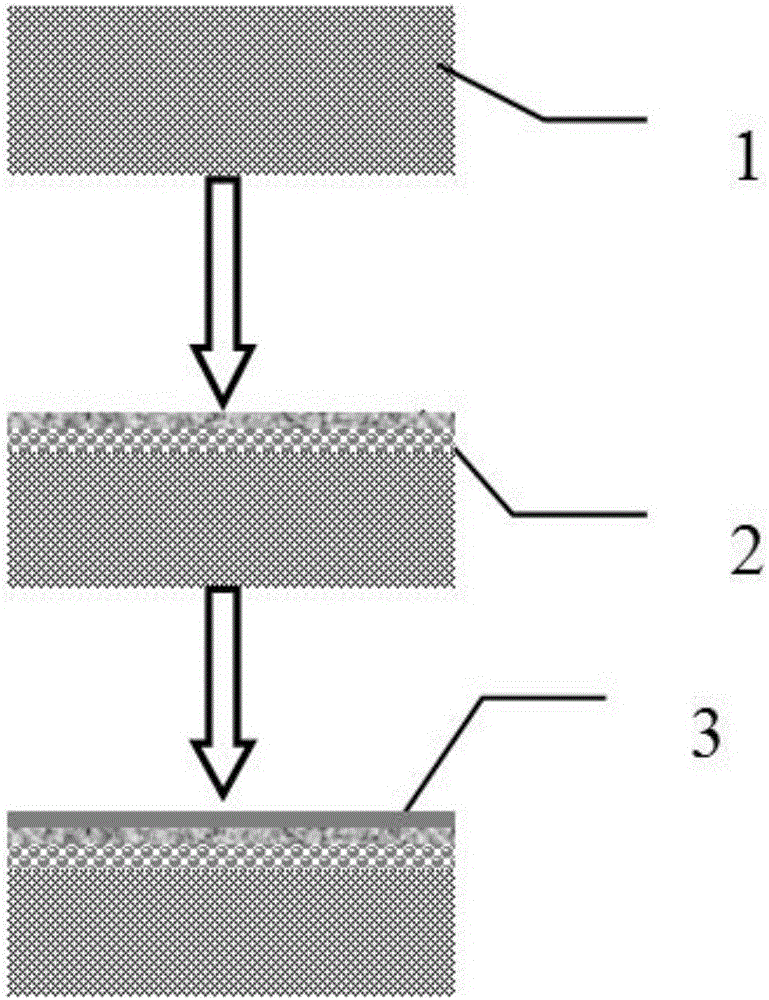

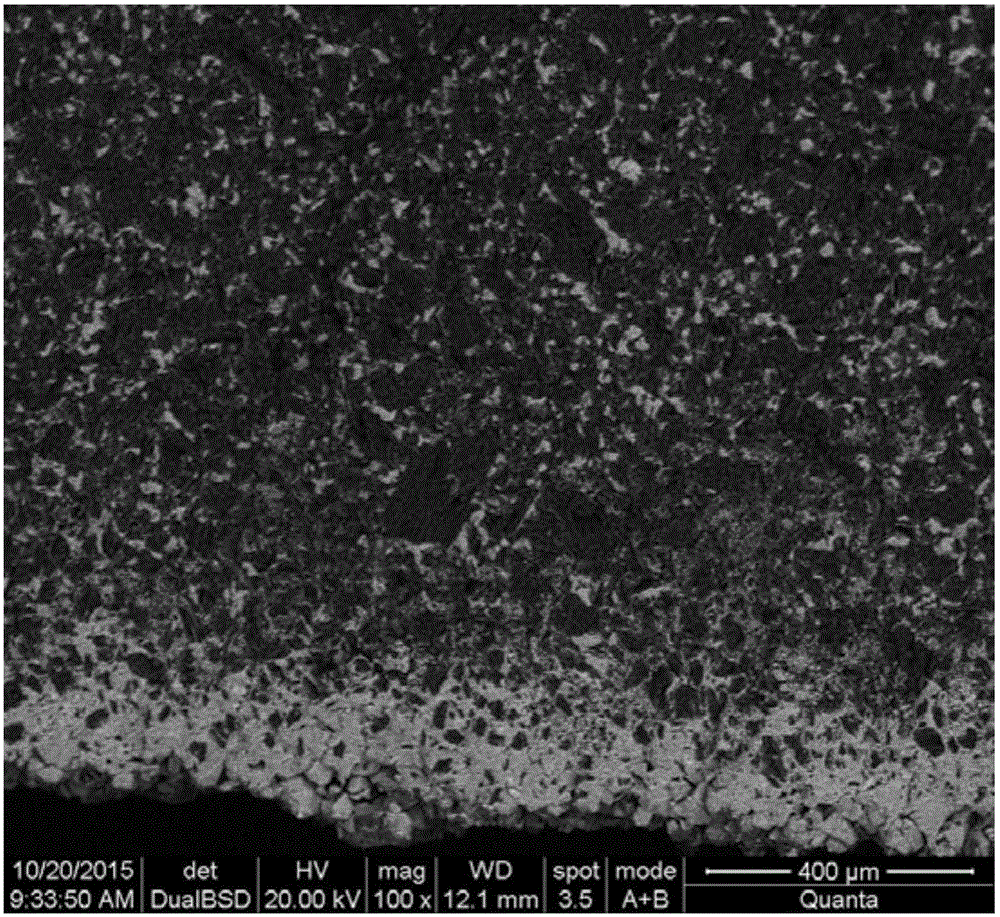

Graphite material with SiC coating and preparation method thereof

The invention discloses a graphite material with a SiC coating and a preparation method thereof. The graphite material comprises a graphite base and a SiC coating. The SiC coating comprises a primary SiC layer and a secondary SiC layer. The primary SiC layer permeates into the graphite base from the surface of the graphite base and is formed by an in-situ reaction of gaseous silicon and the graphite base. The secondary SiC layer is located on the primary SiC layer. The preparation method comprises 1, carrying out vapor silicon infiltration sintering on a graphite material to obtain a graphite material with the primary SiC layer and 2, carrying out vapor deposition of the secondary SiC layer. The graphite material with the SiC coating has the advantages that the SiC coating has good cohesiveness to the graphite material, has no thermal expansion coefficient mismatch, is compact and has high oxidation resistance. The preparation method effectively solves the problem of thermal expansion coefficient mismatch in preparation of the SiC coating on the surface of the graphite material directly through a CVD technology, and guarantees high bonding strength between the coating and graphite.

Owner:NAT UNIV OF DEFENSE TECH

Welding technology of bridge shell and spindle nose welding

InactiveCN100999036AReduce widthFully formedArc welding apparatusWelding/cutting media/materialsHeat-affected zoneNose

The present invention relates to a welding process of mixed gas protection welding (containing pulse) for welding rear-axle case and axle journal of large-tonnage drive axle. It includes welded joint forming procedure, welding procedure and collating procedure. It is characterized by that the welded joint for welding axle case and axle journal in welded joint forming procedure is an Y-shaped groove, the angle alpha of Y-shaped groove is 12.5 deg.-35 deg, the height of root face is 0 mm-2 mm, width of root face is 3-4 mm, on the closed back face end of Y-shaped groove a backing strip is added; in the welding procedure the described welding process is welding by layers, the welding line speed is 30-50 cm / min, welding voltage is 25V-40V, welding current is 280A-400A and gas flow rate is 15L / min-25L / min.

Owner:NANJING AUTOMOBILE GROUP CORP

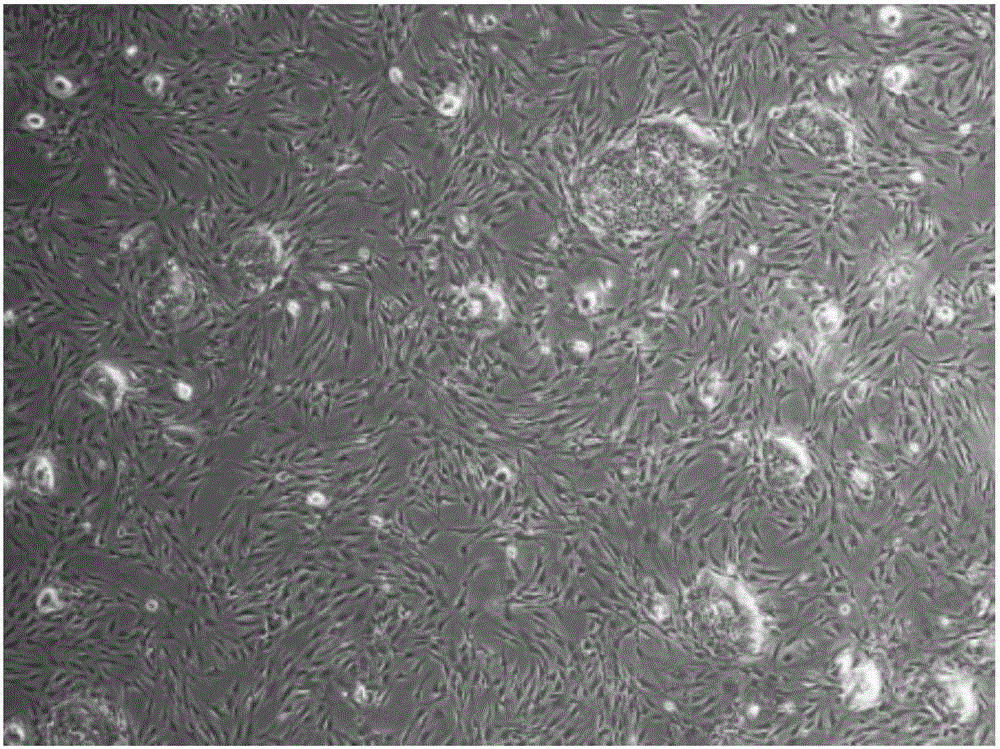

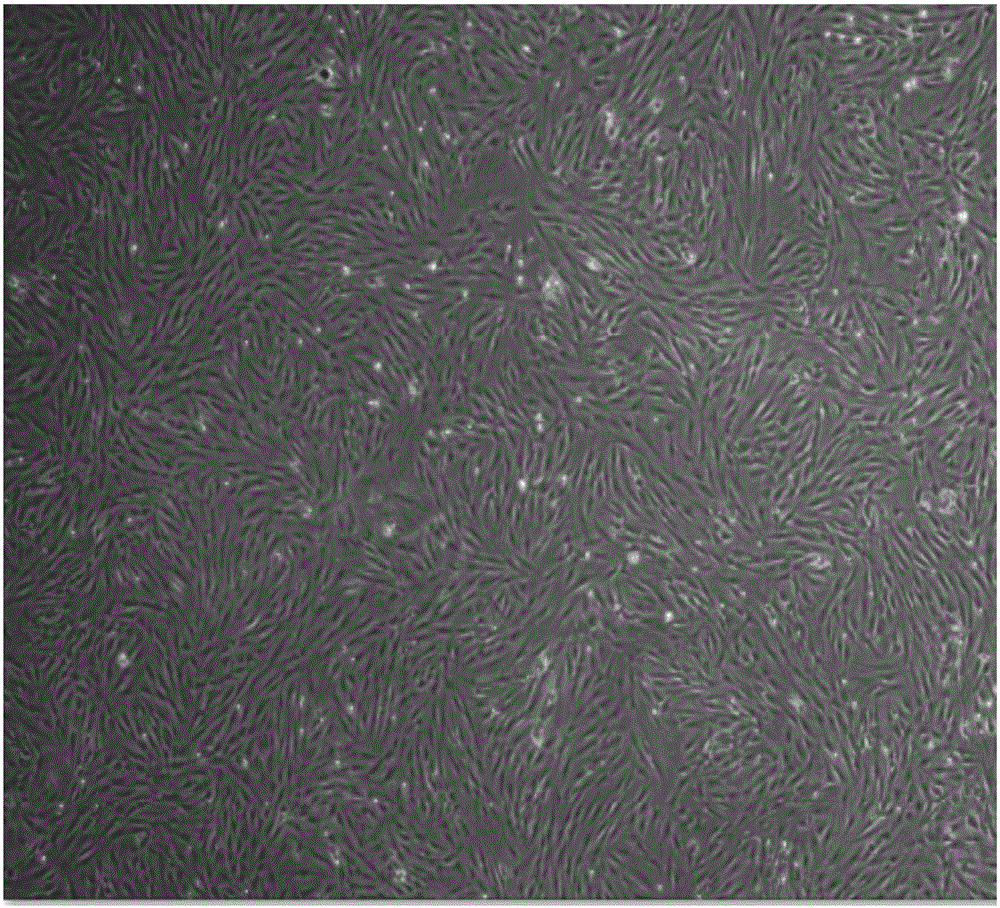

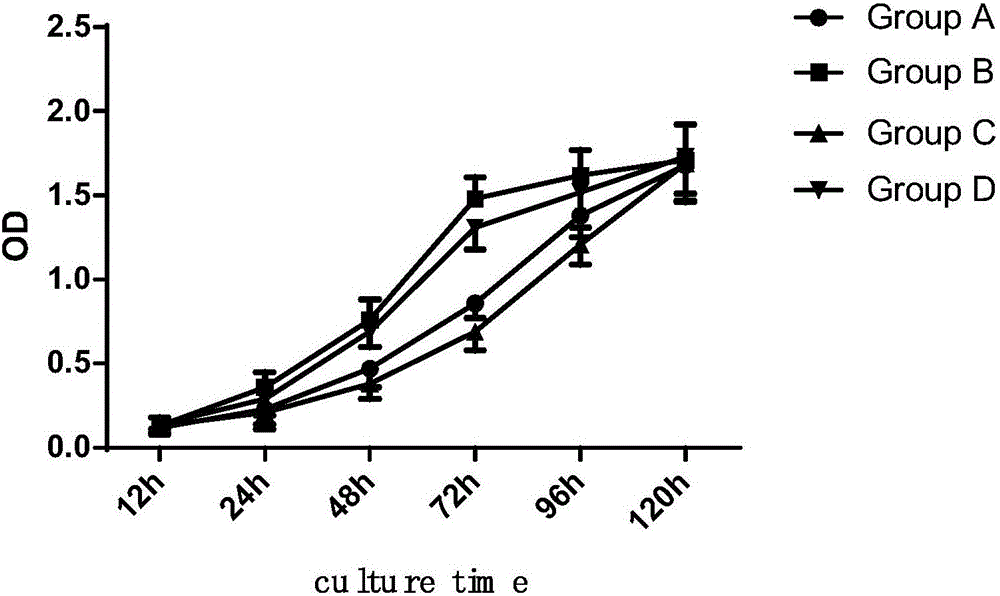

Method for culturing skin-origin fibroblasts

InactiveCN106399230AGuaranteed numberFully formedCell dissociation methodsArtificial cell constructsBasic fibroblast growth factorFibroblast

The invention relates to the technical field of cell isolated culture, in particular to an isolated culture method for culturing fibroblasts. The invention provides an isolated culture method for culturing skin-origin fibroblasts, comprising the steps of 1) acquiring fibroblasts from human skin tissues by means of two-step enzyme digestion; 2) culturing the fibroblasts by using DMEM and F12 media and adding epidermal growth factor EGF and / or bFGF (basic fibroblast growth factor), wherein a ratio of DMEM medium to F12 medium is 1:1. By using the DMEM / F12 (1:1) medium, it is possible to effectively promote the proliferation of fibroblasts, maintain original cell form of the fibroblasts and increase early collagen expression of the cells; EGF and bFGF are capable of promoting the proliferation of fibroblasts and increasing collagen secretion.

Owner:SHENZHEN POLYTECHNIC

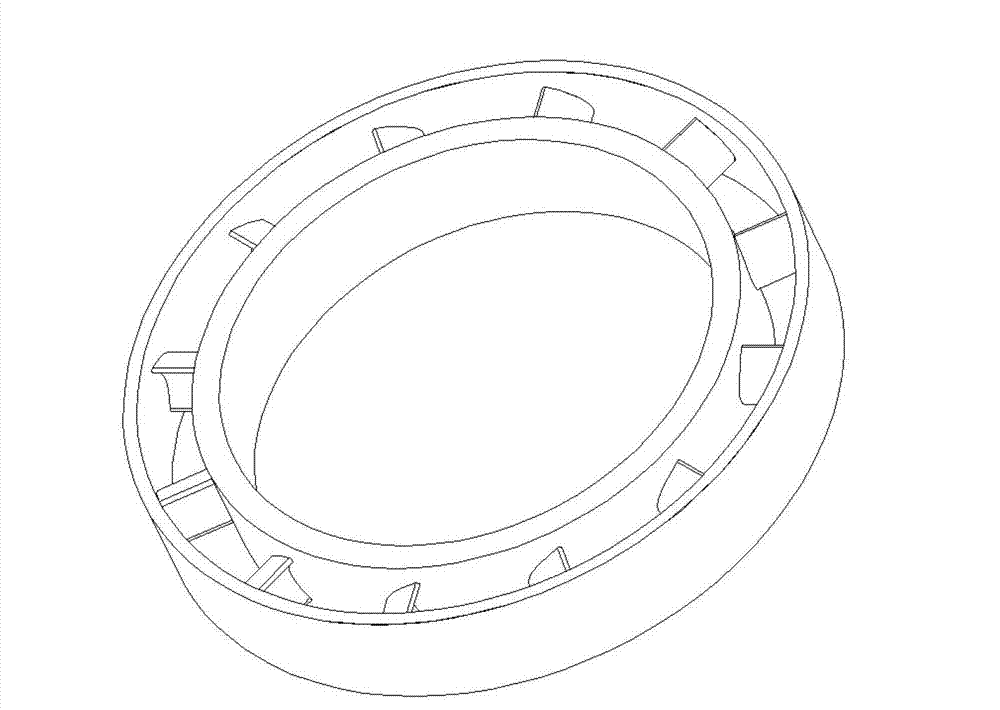

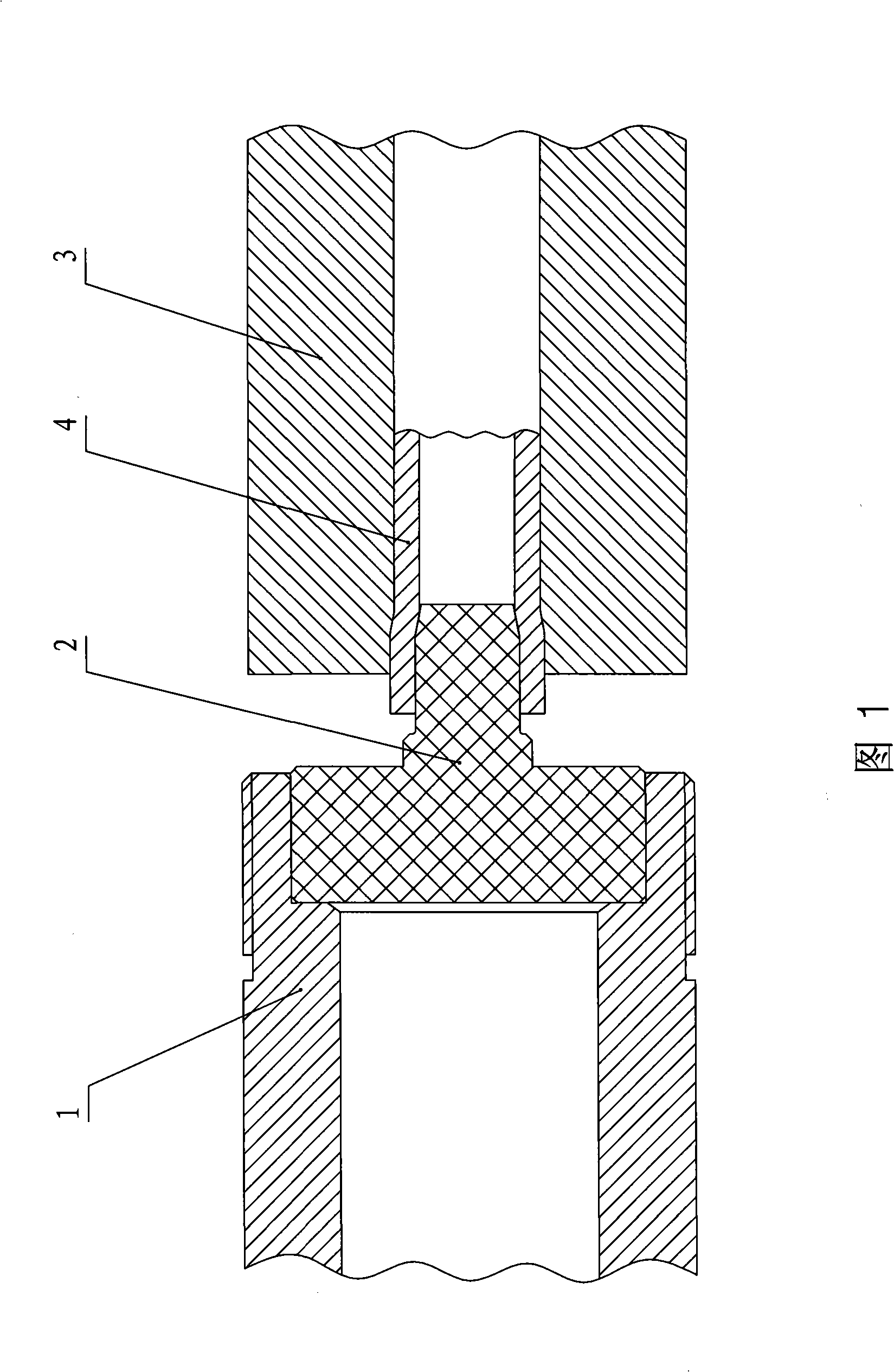

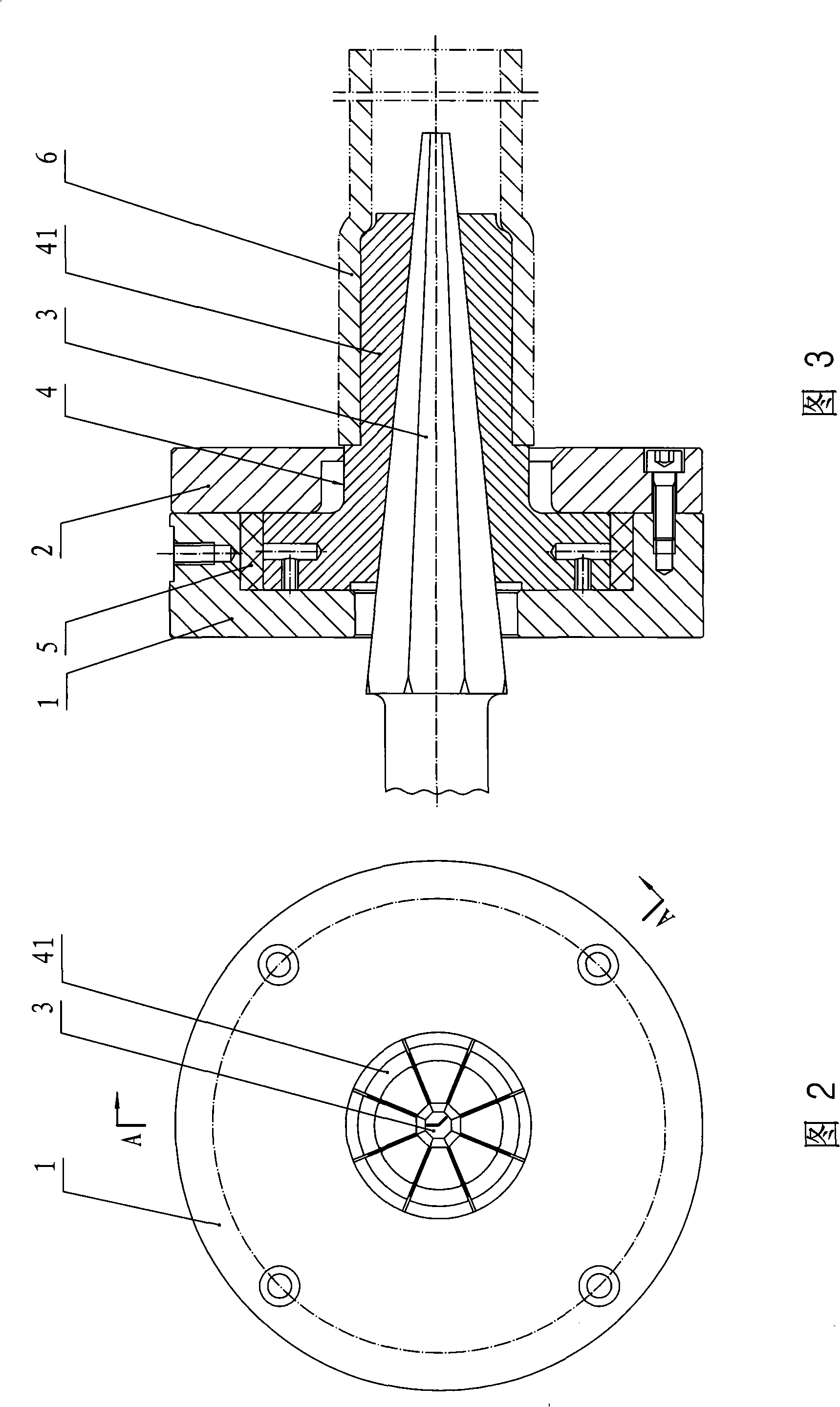

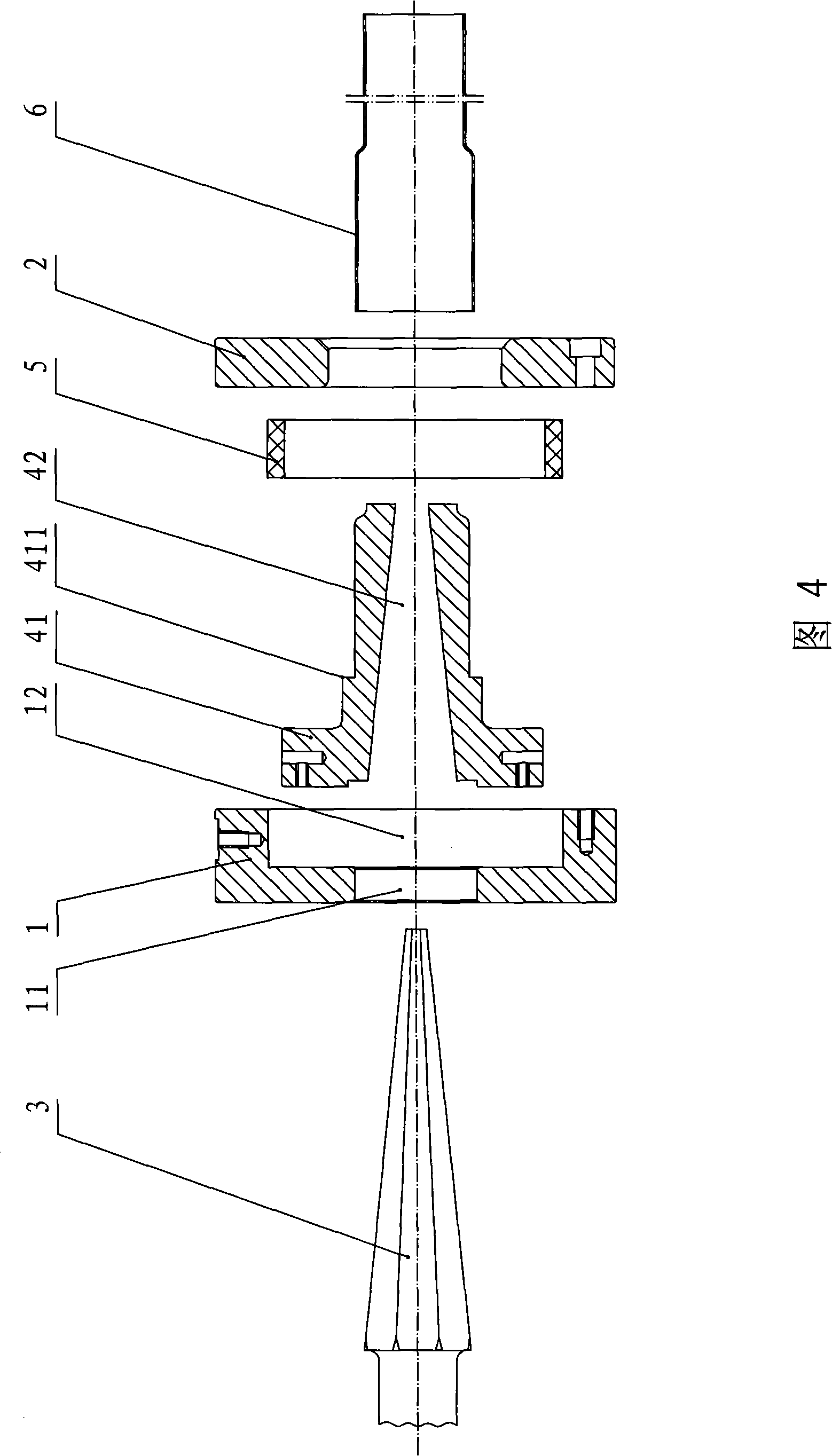

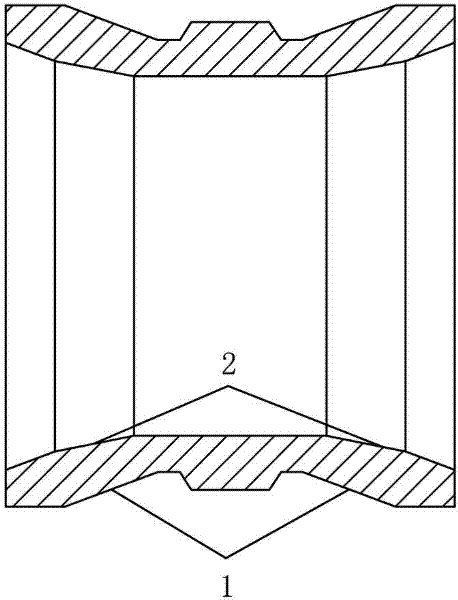

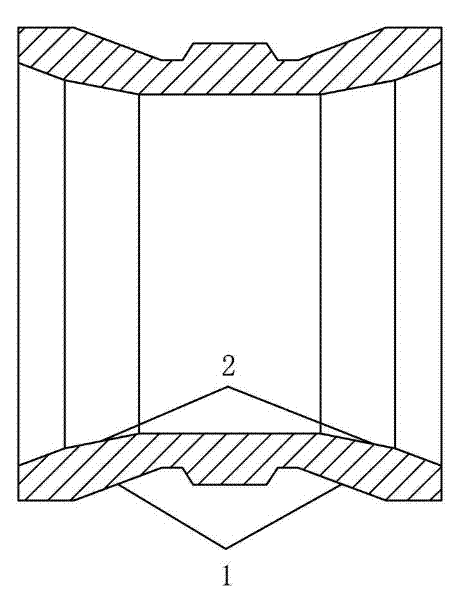

Pipe-expansion mold

The invention discloses a labor-saving, fast pipe-expansion die with high extensibility, which comprise a die holder and a pipe-expansion die; the die holder comprises a die holder body and a cover plate; a guide hole and a working hole which are mutually run-through are cut at two sides of the die holder body; the pipe-expension die comprises a pyramidal core shaft, an elastic washer and a pipe-expansion body which is composed of at least two combined pipe-expansion monomers of which the inner walls cooperate with the outer wall of the core shaft, and therefore a pyramidal hole formed in the pipe-expansion body coincides with the core shaft; the elastic washer is sheathed at the bottom of the pipe-expansion body and is clasped in the working hole by the cover plate; the core shaft runs through and is arranged in the guide hole and the pyramidal hole. The pipe-expansion die is mainly used in various pipe-end forming devices.

Owner:JIANGSU HEFENG MECHANICAL MAKING

Method for extracting tea oil by demulsification based on aqueous enzymatic method

InactiveCN104928012AFully formedIncrease the degree of emulsificationFatty-oils/fats productionWater bathsEnzymatic hydrolysis

The invention discloses a method for extracting tea oil by demulsification based on an aqueous enzymatic method. The method comprises the following steps: processing tea seed powder by microwaves for 60 to 120 seconds; adding distilled water at a material-liquid mass ratio of 1:4 to 1:8, pulping, and collecting upper-layer emulsified liquid; pulping the residual water phase and residues again, and collecting upper-layer emulsified liquid; combining the collected emulsified liquid; adding 0.5-6% of composite enzymatic hydrolysis liquid based on the total mass of the emulsified liquid, performing water bath enzymolysis, centrifuging, and taking upper-layer tea oil; adding an ethanol solution into the residual emulsified liquid, performing water bath treatment, centrifuging, and collecting upper-layer tea oil; combining the collected tea oil, an drying in vacuum. According to the method, the emulsified liquid is high in oil content, and the process is simple, novel and practical; the emulsified liquid is subjected to composite enzyme hydrolysis and ethanol demulsification, so that the enzymatic hydrolysis volume is greatly reduced, the enzyme consumption is greatly reduced, and the process is economic and efficient; microwaves, enzymatic hydrolysis and ethanol are adopted for assisting in oil extraction, so that natural active ingredients of the tea oil are better preserved, and the oil extraction process is safe and nutritive.

Owner:NANCHANG UNIV

Hole-reaming forming technology for internal and external specially-shaped surfaces

ActiveCN102172757AAvoid bendingFully formedForging/hammering/pressing machinesPunchingProcess design

The invention discloses a hole-reaming forming technology for internal and external specially-shaped surfaces, which belongs to the field of large-forging forging and forming technology. In the forming process disclosed by the invention, the shape of a symmetrical forging is designed as required, and special tooling equipment such as a swage block and a core saddle is designed according to the shape of the forging; and the forming process comprises the following steps: (I) forging design: designing the shape of a symmetrical forging; (II) tooling equipment design: designing a corresponding hole-reaming swage block according to the shape of the external shape surface of the forging, and designing a corresponding core saddle according to the shape of the internal shape surface of the forging; and (III) forging manufacturing: (1) blanking: blanking according to the weight requirement of the forging; (2) punching and reaming, and then forging by using a flat anvil and a mandril: according to the process design, forging blank material before hold-shrinking; and according to the characteristic of hole-shrinking deformation, before reaming, designing the forging into a structure the external shape surface of the forging has high end parts and a concave middle part; (3) hole-shrinking forging: forging a forged blank by using a normal mandril and a wide anvil, and then designing a hole-shinking forging process step; and (4) carrying out hole-reaming forming by using the swage block and the core saddle.

Owner:TONGYU HEAVY IND

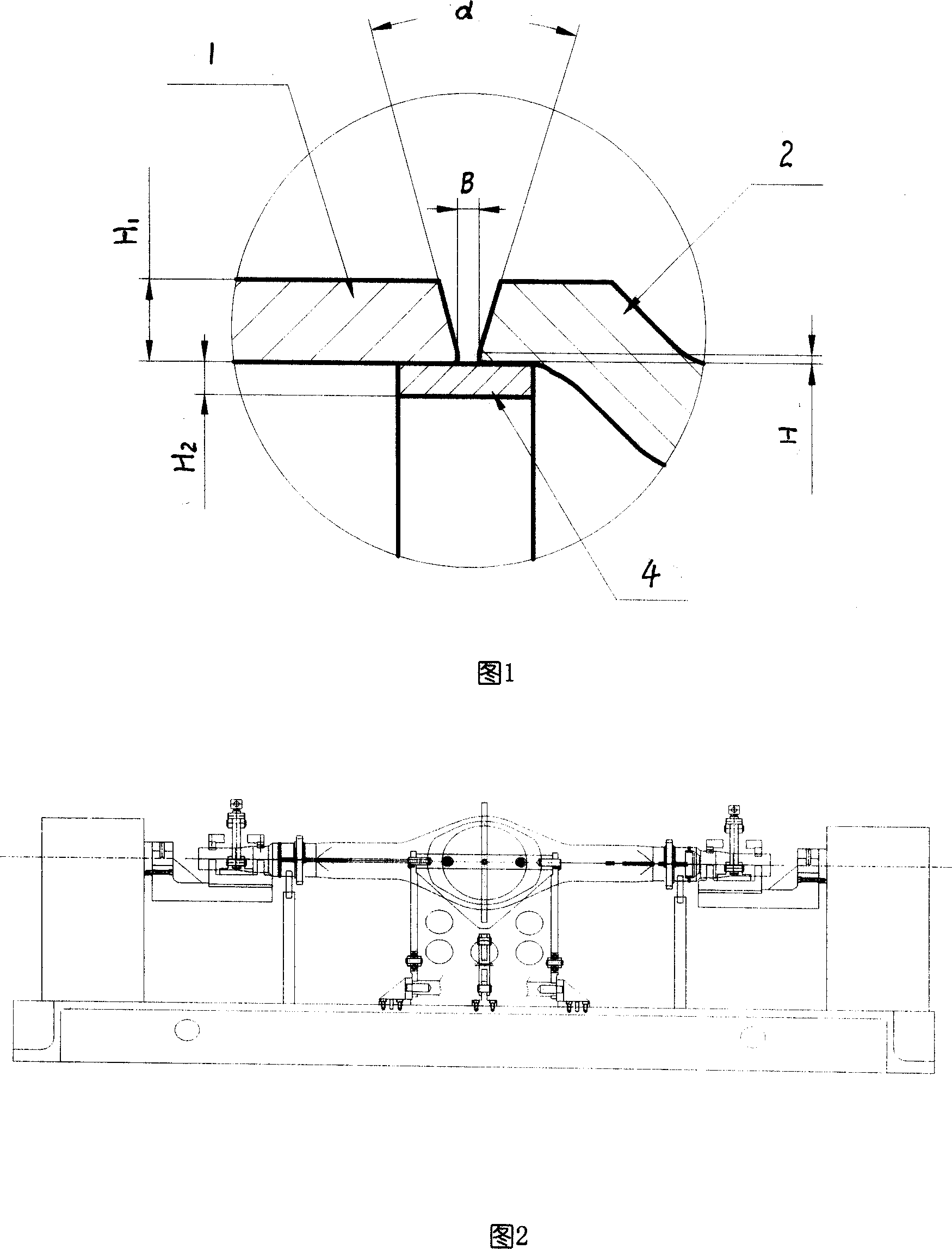

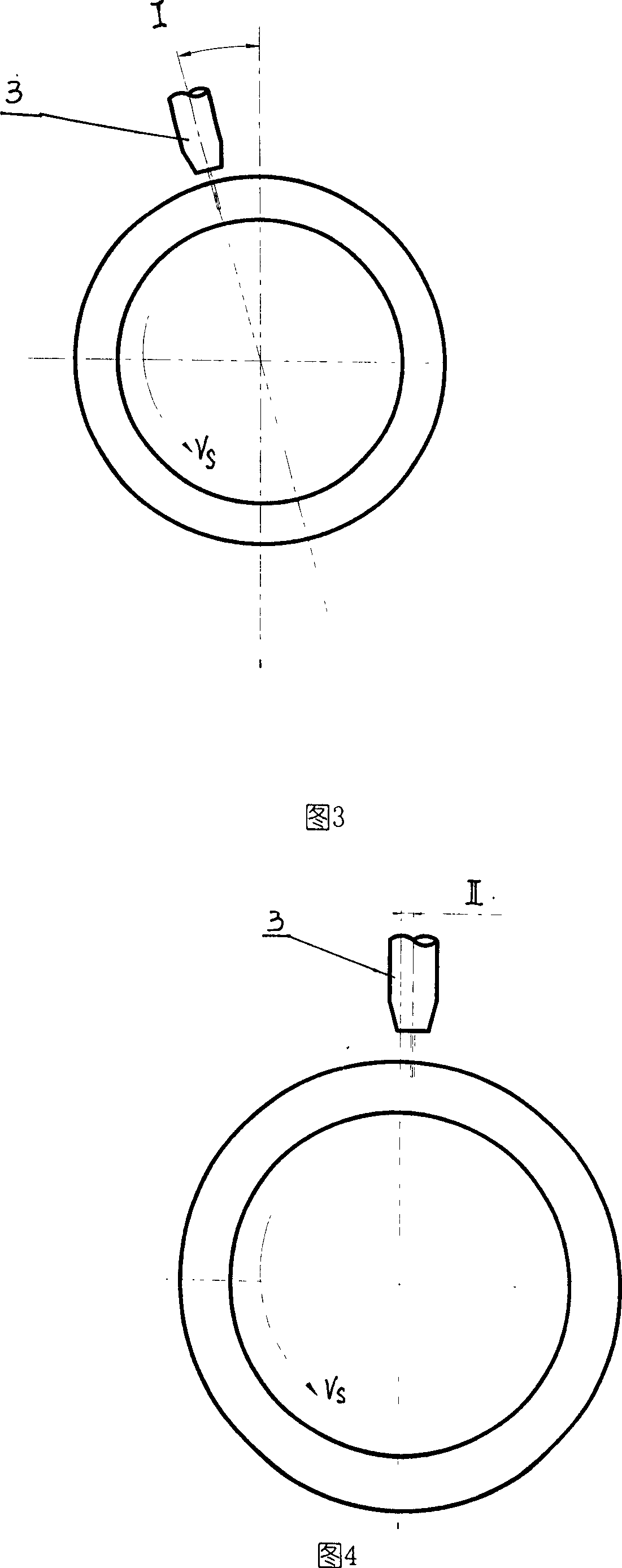

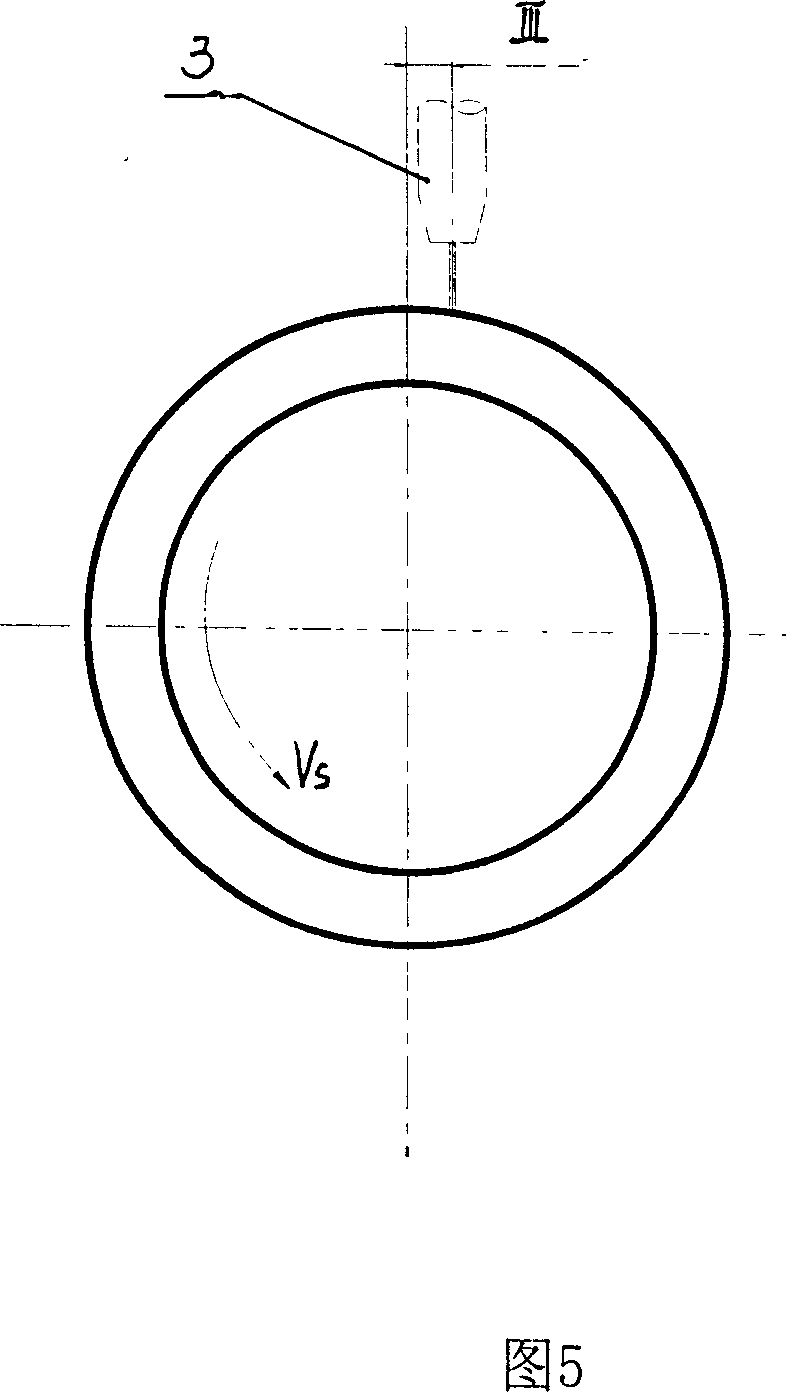

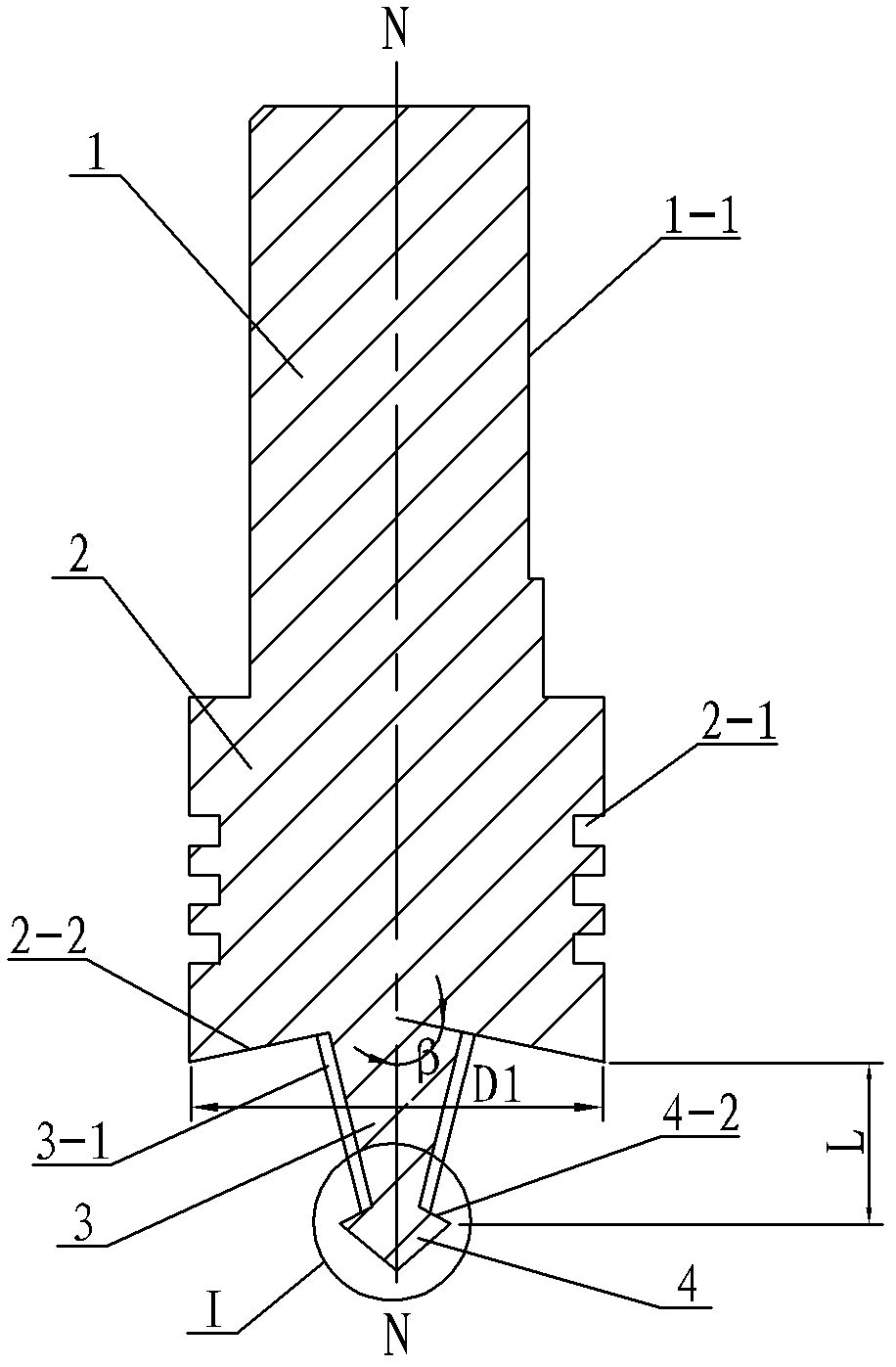

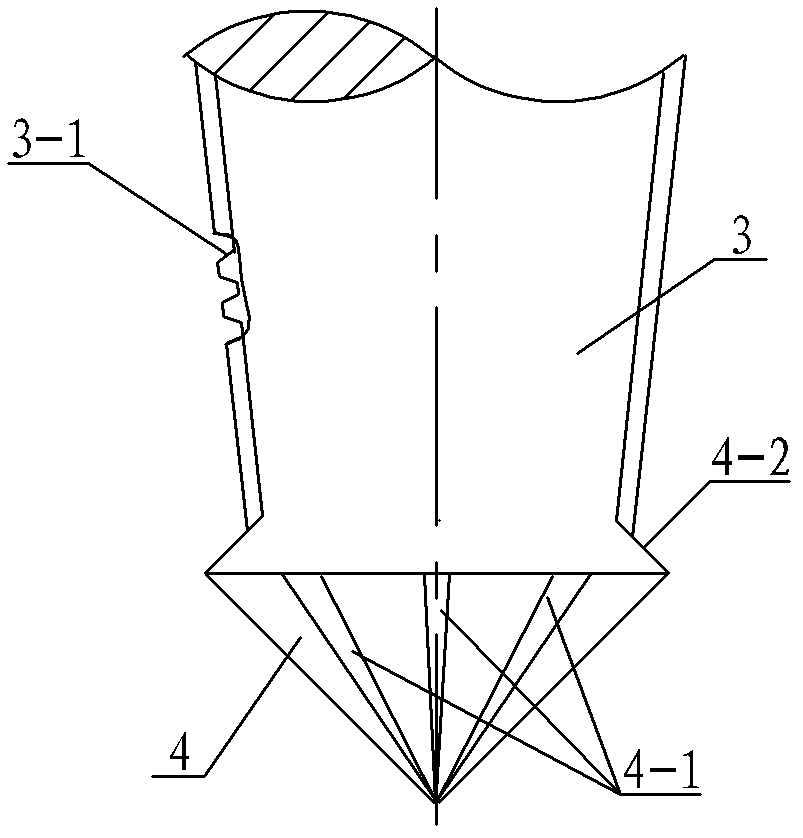

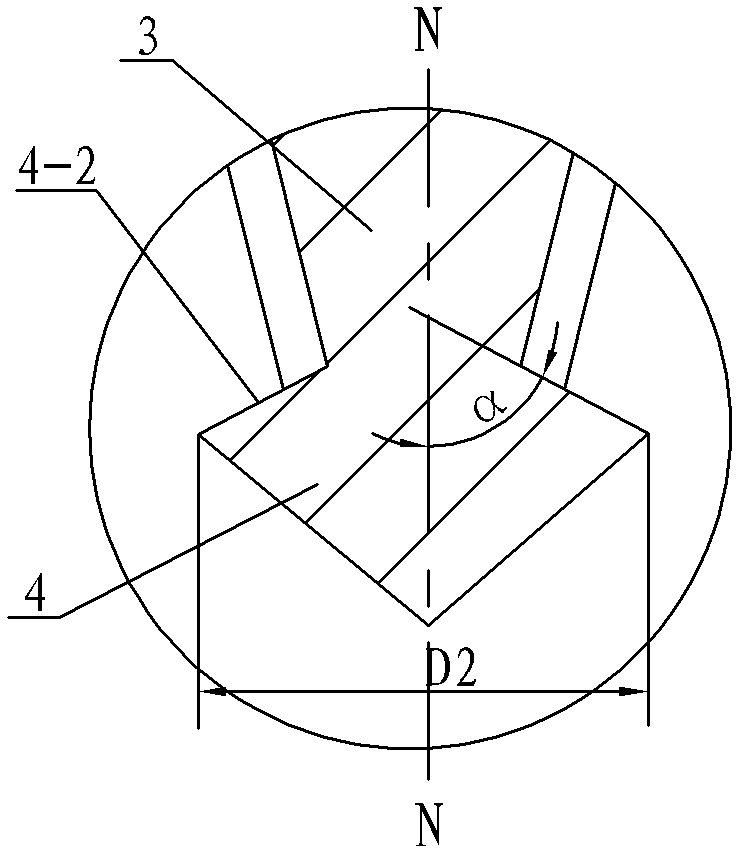

Soldering set for agitating friction welding with adjustable inclined angle and concave-top and convex-bottom type shaft shoulder and method thereof

ActiveCN102581475AImprove adaptabilityEasy to shapeNon-electric welding apparatusFriction weldingSoldering

The invention discloses a soldering set for agitating friction welding with an adjustable inclined angle and a concave-top and convex-bottom type shaft shoulder and a method thereof, relating to a soldering set for agitating friction welding and a method thereof. With the invention, the problems that a leading-in hole and a leading-out hole are required to be pre-fabricated in the conventional dual-shaft shoulder self-held agitating friction welding, and the thermal input amount in the agitating friction welding process is too large to cause decreased joint performance are solved. The soldering set comprises an upper cylinder, a lower cylinder, a main agitating needle, an auxiliary agitating needle which are orderly arranged from top to bottom and fabricated into one piece, the lower end face of the lower cylinder is a concave shaft shoulder face, and the upper end face of the auxiliary agitating needle is a convex shaft shoulder face. The method comprises the following steps of determining size of the auxiliary agitating needle; determining a lower included angle between the convex shaft shoulder face and the soldering set central axis; determining use length of an agitating body; determining an upper included angle between the concave shaft shoulder face and the soldering set central axis; adjusting the inclined angle of soldering set; and carrying out the agitating frictionwelding of a hollow unbraced structure. The invention is used for soldering the hollow unbraced structure.

Owner:安徽万宇机械设备科技有限公司

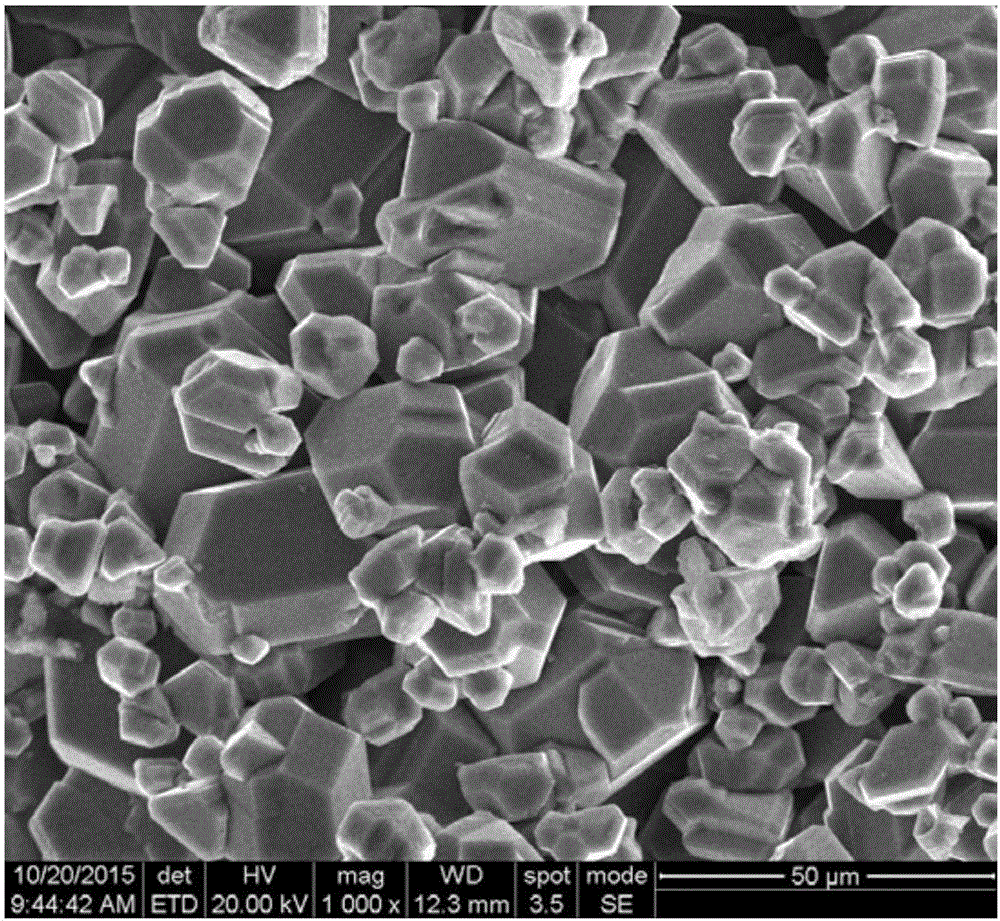

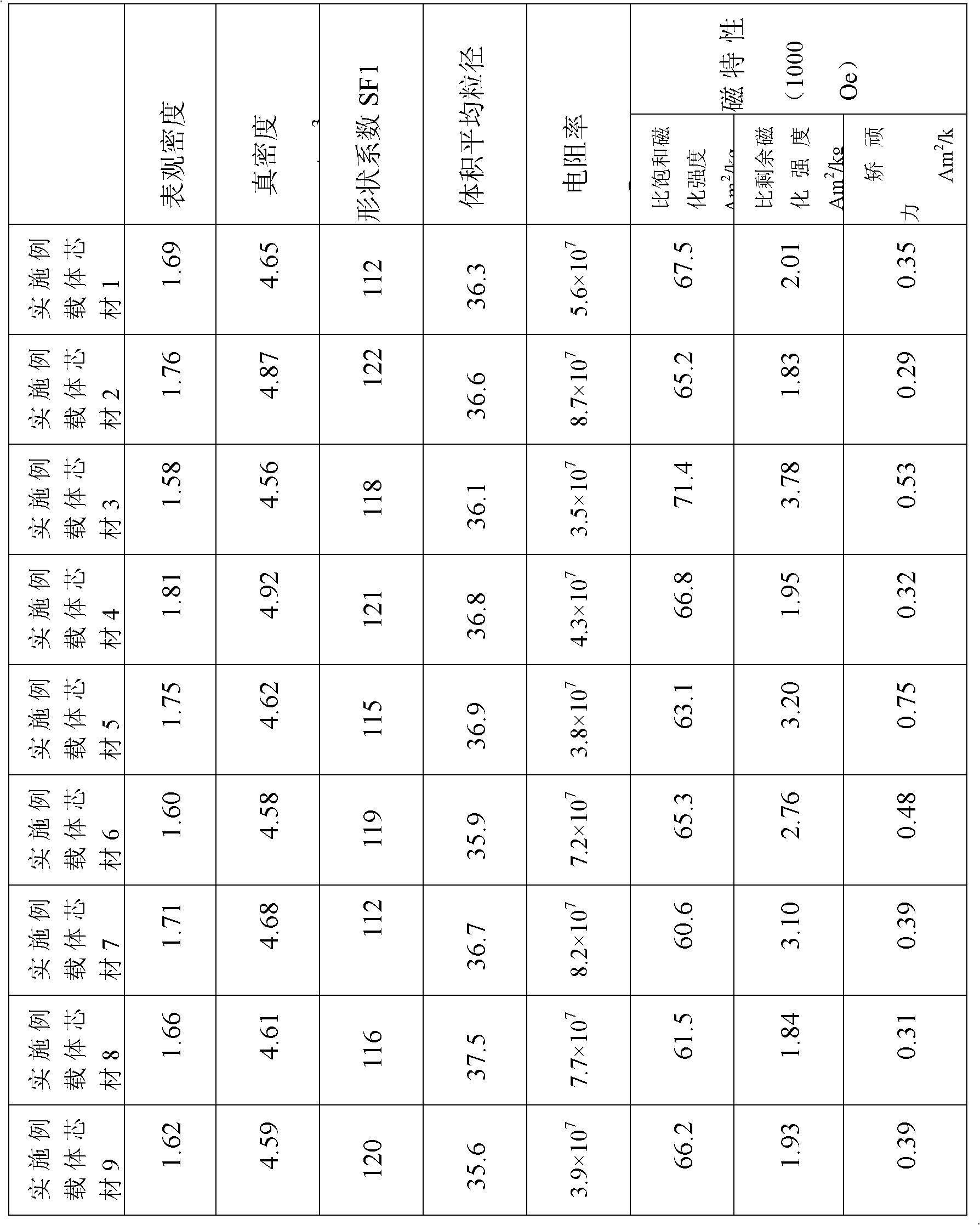

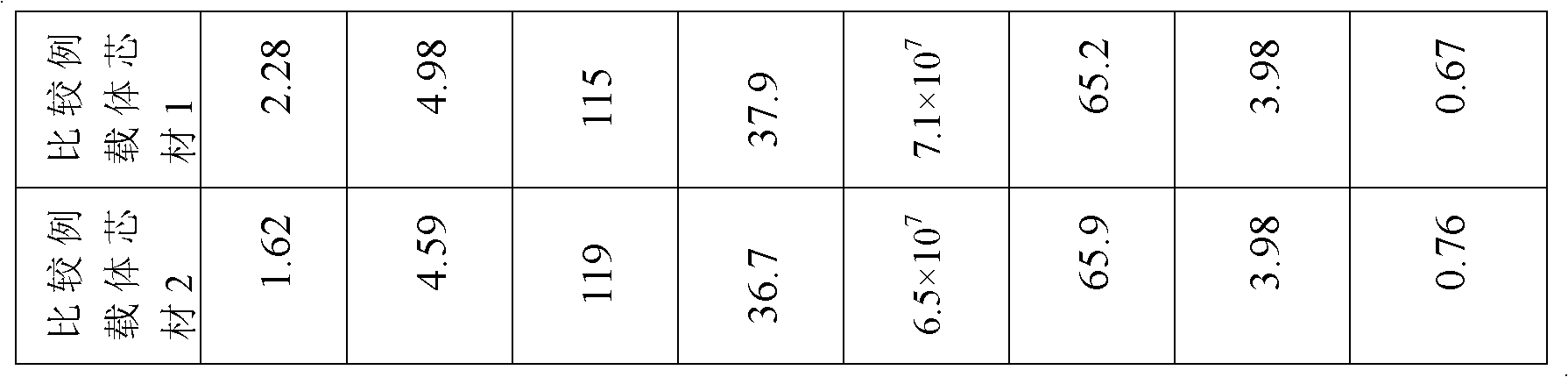

Low-density carrier core material for electrostatic image developer and preparation method thereof and carrier and application thereof

The invention relates to a low-density carrier core material for an electrostatic image developer and a preparation method thereof and a carrier and application thereof. Through the invention, the problems of low strength, high density, high energy consumption, low charged stability, complicated preparation technology and easy formation of development spots of the existing carrier core material for an electrostatic image developer are solved. The carrier core material provided by the invention is prepared from the mixture of a metal complex and a metal oxide by crushing, granulating, calcining and sintering, wherein the molar content of the metal complex is 70-80%; the metal complex at least comprises one metal element of iron, manganese and strontium; and the metal oxide at least comprises one metal element of iron, magnesium, manganese and strontium. The prepared carrier core material has the advantages of low density, good carrier durability, stable charged performance, long service life and good development effect.

Owner:HUBEI DINGLONG CO LTD

Automatic welding technology for butt joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes

ActiveCN107052517AGuaranteed performanceGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesButt weldingButt joint

The invention discloses an automatic welding technology for butt joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes. The automatic welding technology comprises the following steps that a heat-exchange tube I (1), a heat-exchange tube II (3), and a melting ring (2) are cleaned; the heat-exchange tube I (1), the heat-exchange tube II (3), and the melting ring (2) are assembled; welding equipment is installed and debugged; and parameters of the welding technology are set, and welding treatment is started. The automatic welding technology for butting joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes combines special heat-exchange tube specifications and special welding technology parameters and choose of tungsten electrode, and is applied to butt welding between heat-exchange tubes of small diameters and big thick walls, the welding process is stable and reliable, formation of a welding joint is even and artistic, the welding joint is well fused, the welding efficiency is high, all destructive tests and physical and chemical performance tests are conducted, and the result meets the requirement for welding quality of the dissimilar steel heat-exchange tubes in a high temperature gas cooled reactor steam generator.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Isothermal forging method of straight bevel gear

InactiveCN105921672AAvoid chillingPromote plastic flowMetal-working apparatusWheelsGear wheelBevel gear

The invention discloses an isothermal forging method of a straight bevel gear. A blank and a mold are heated to roughly consistent temperatures respectively, then the blank is placed into the mold and is subjected to forging molding in the mold at the relatively low strain rate, and the straight bevel gear is obtained through aftertreatment, wherein the relatively low strain rate is lower than 0.1 mm / s, and the mold adopts a closed mold forging structure. According to the method, firstly, the blank and the mold are heated to the equal temperature or basically equal temperatures, so that the chilling effect produced when the temperature of the mold is lower than that of the blank is avoided, and the plastic flow of the blank is improved; secondly, the mold adopts the closed mold forging structure, the blank bears three-dimensional compressive stress in the forging process, and thus molding of the blank is facilitated; thirdly, the strain rate is lower than 0.1 mm / s, accordingly, the deformation amount of the blank in unit time is small, deformation is sufficient, and molding of the blank is more facilitated.

Owner:SHANDONG UNIV +1

Multi-element nitralloy cored wire and application method thereof in reinforcing treatment technique of Q620D steel

The invention discloses a multi-element nitralloy cored wire and an application method thereof in a reinforcing treatment technique of Q620D steel and belongs to the technical field of alloy material application. A wire core of the multi-element nitralloy cored wire comprises 15.5-24.9% of N, 27-48% of V, 18-32% of Si, 0.3-4% of Nb, 0.05-3% of Mn, 0.3-4.5% of B, 0.8-7.0% of Ti, 0.1-5.0% of Cr, 0-1.4% of C, 0-0.10% of P, 0-0.10% of S, and the balance Fe and trace impurities. According to the multi-element nitralloy cored wire and the application method thereof in the reinforcing treatment technique of the Q620D steel, multi-element nitralloy with the most proper components is designed and selected; beneficial elements are added, so that N is transferred to V, B and Nb easily, the V, B and Nb and N are combined easily, and positive correlation functions are achieved for steel performance reinforcement; the requirements of a microalloying reinforcing technique of the Q620D steel are completely meet, and the reinforcing effect of the multi-element nitralloy cored wire is brought into full play.

Owner:马鞍山中科冶金材料科技有限公司

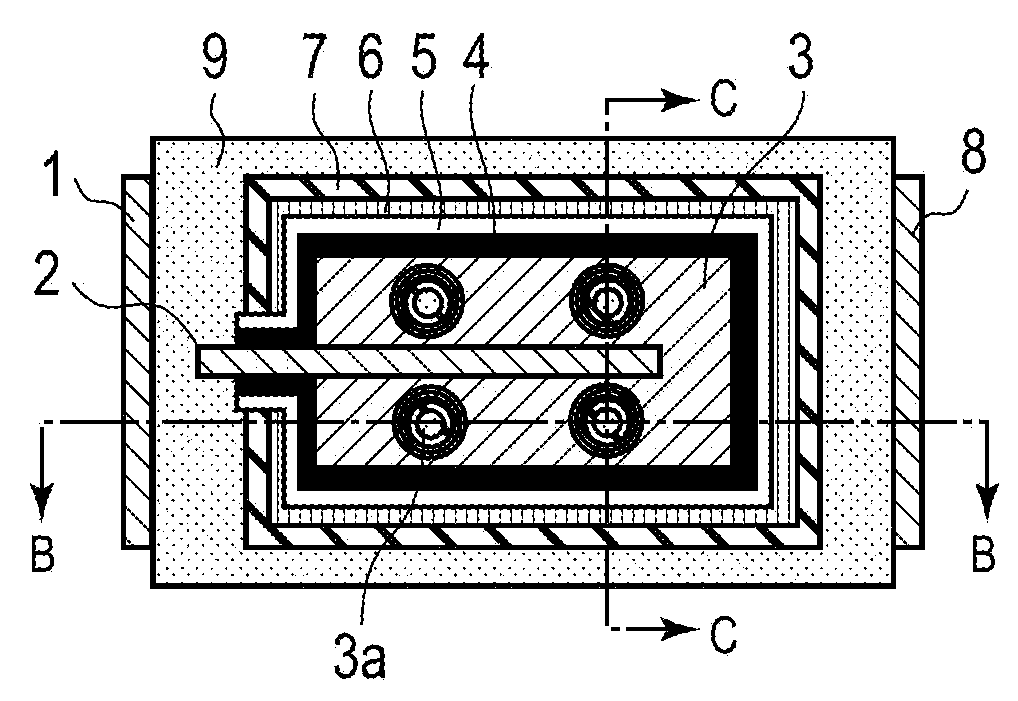

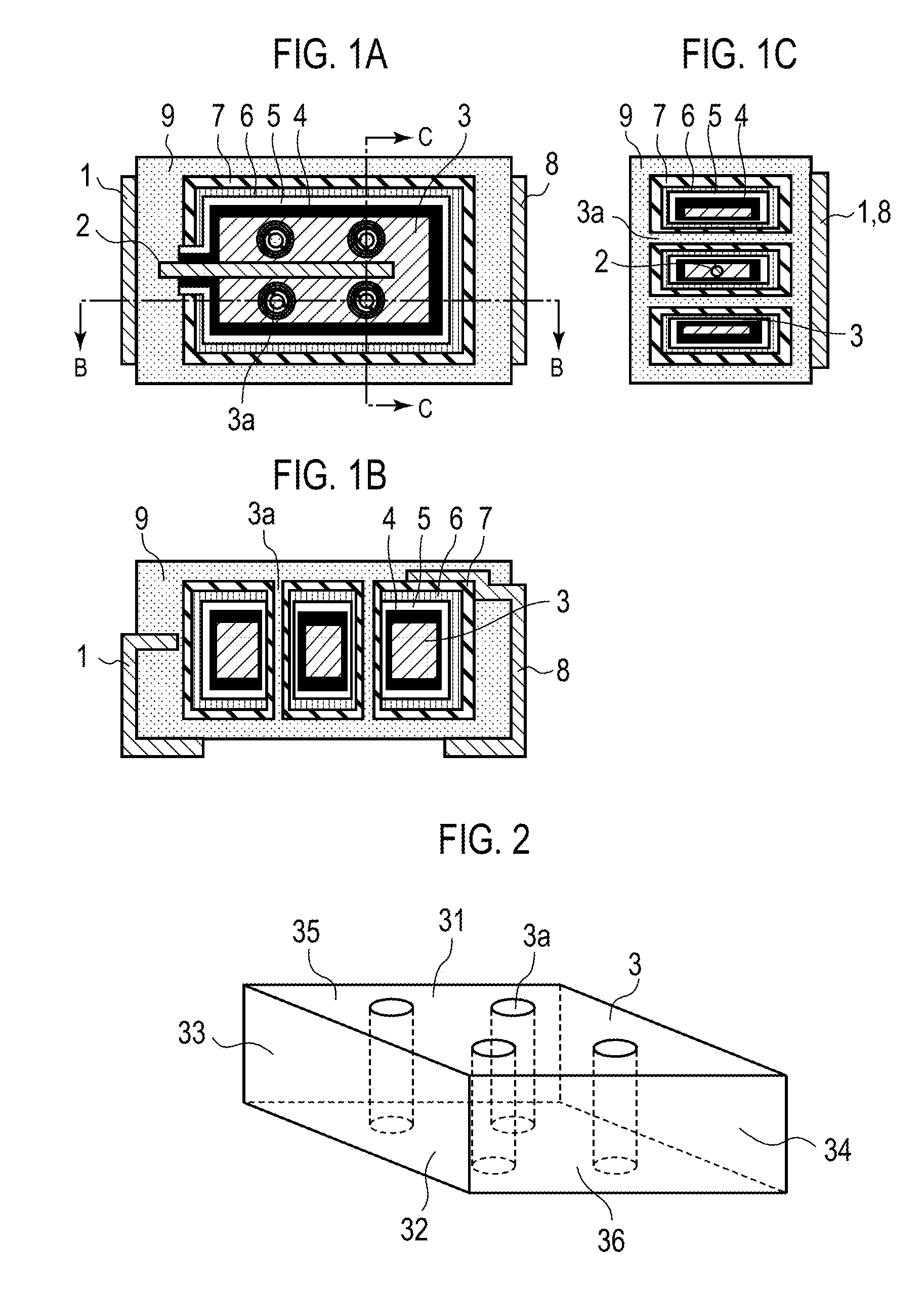

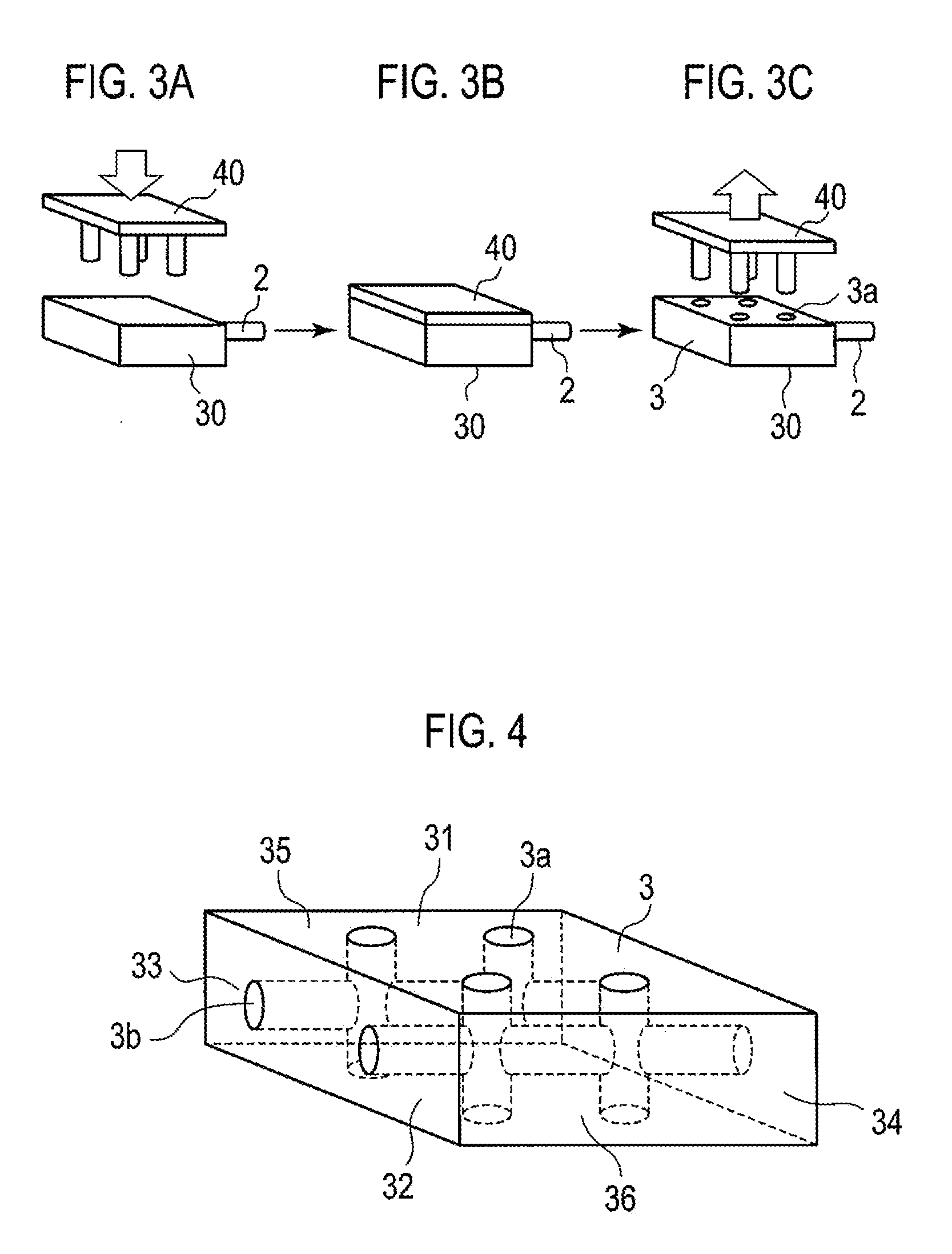

Solid electrolytic capacitor and method of manufacturing the same

InactiveUS20080266756A1Simple formatLarge capacitanceLiquid electrolytic capacitorsCapacitor electrolytes/absorbentsMetallurgyConductive polymer

Particles of a valve metal and a binder are mixed and kneaded together. The mixed-kneaded matter obtained thereby is molded, and a through-hole is formed in the molded body. An anode body is formed by sintering the molded body. A dielectric layer is formed on the surface of the anode body thus formed. Subsequently, an conducting polymer layer is formed on the dielectric layer.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com