Hot isostatic pressing two-step forming method of high temperature alloy compact piece

A hot isostatic pressing and superalloy technology, applied in the field of advanced manufacturing, can solve the problems of inability to guarantee the dimensional accuracy and shape accuracy of formed parts, low yield strength of mild steel at high temperature, and the performance of parts cannot meet the requirements. The effect of good tissue performance and high shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

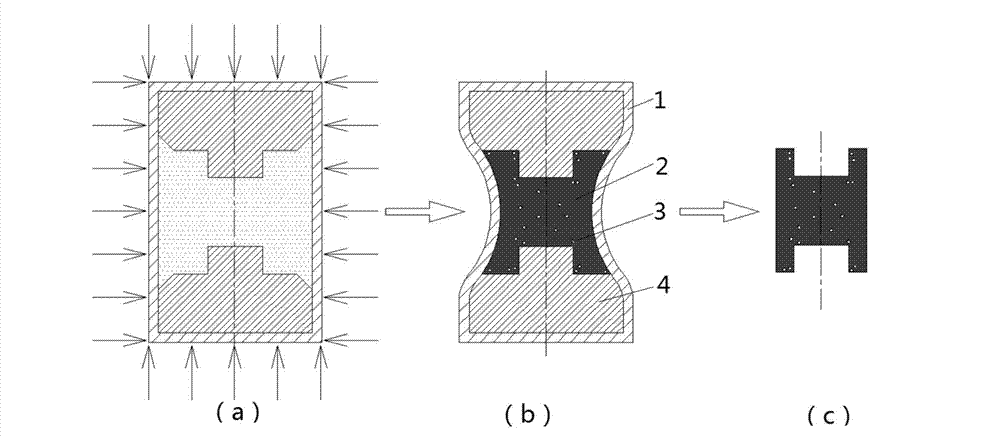

Method used

Image

Examples

example 1

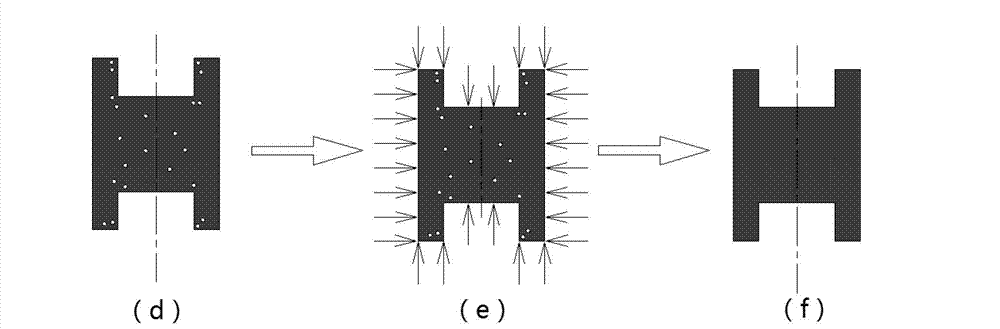

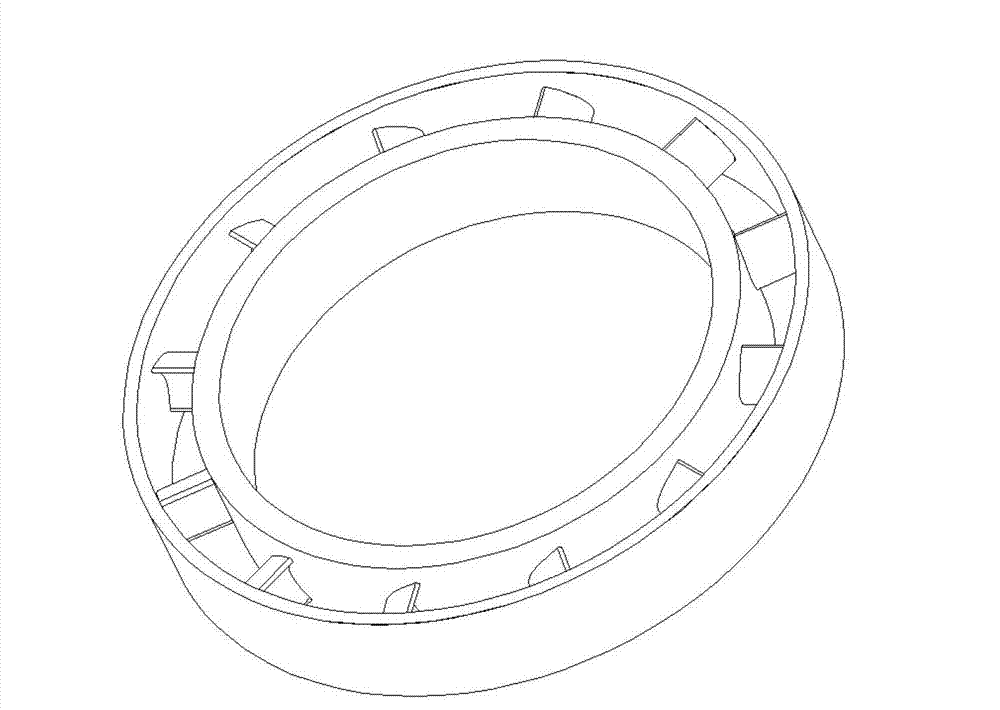

[0039] This is to utilize the present invention to manufacture titanium alloy (Ti6A14V, TC4) blisk ( image 3 ) instance:

[0040] The process parameters of conventional hot isostatic pressing of titanium alloy are: temperature 950°C, pressure 120MPa. Under this temperature and pressure, the structure and performance of the parts are excellent, and the density is high. However, under this high temperature and high pressure, the deformation of the shape-controlling mold is very large, and the shape accuracy and dimensional accuracy of the final parts are often low.

[0041] Against this background, the above-mentioned problems can be solved by using the present invention. Specific steps are as follows:

[0042] (1) According to the design of the hot isostatic pressing of the parts, No. 20 steel is selected as the material of the jacket, and the shape-controlled core ( Figure 4 ) is manufactured by machining;

[0043] (2) Weld the sheath, and weld the mold shape control part ...

example 2

[0056] This is to utilize the present invention to make nickel base alloy (Ni625) long straight rod ( Figure 6 ) instance:

[0057] The process parameters of conventional hot isostatic pressing of nickel-based alloys are: temperature 1050°C, pressure 120MPa. When forming a long straight rod under this process, the yield strength of the shape-controlling mold material is very low, the deformation is large, and the dimensional accuracy of the formed part cannot be guaranteed. Moreover, this long straight structure also has the problem of being difficult to fill and compact.

[0058] Against this background, the above-mentioned problems can be solved by using the present invention. Specific steps are as follows:

[0059] (1) According to the design of the hot isostatic pressing of the parts, No. 20 steel is selected as the material of the jacket;

[0060] (2) Weld the sheath, and weld the mold shape control part and the upper and lower end caps into a whole to assemble a clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com