Patents

Literature

159results about How to "Good processing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

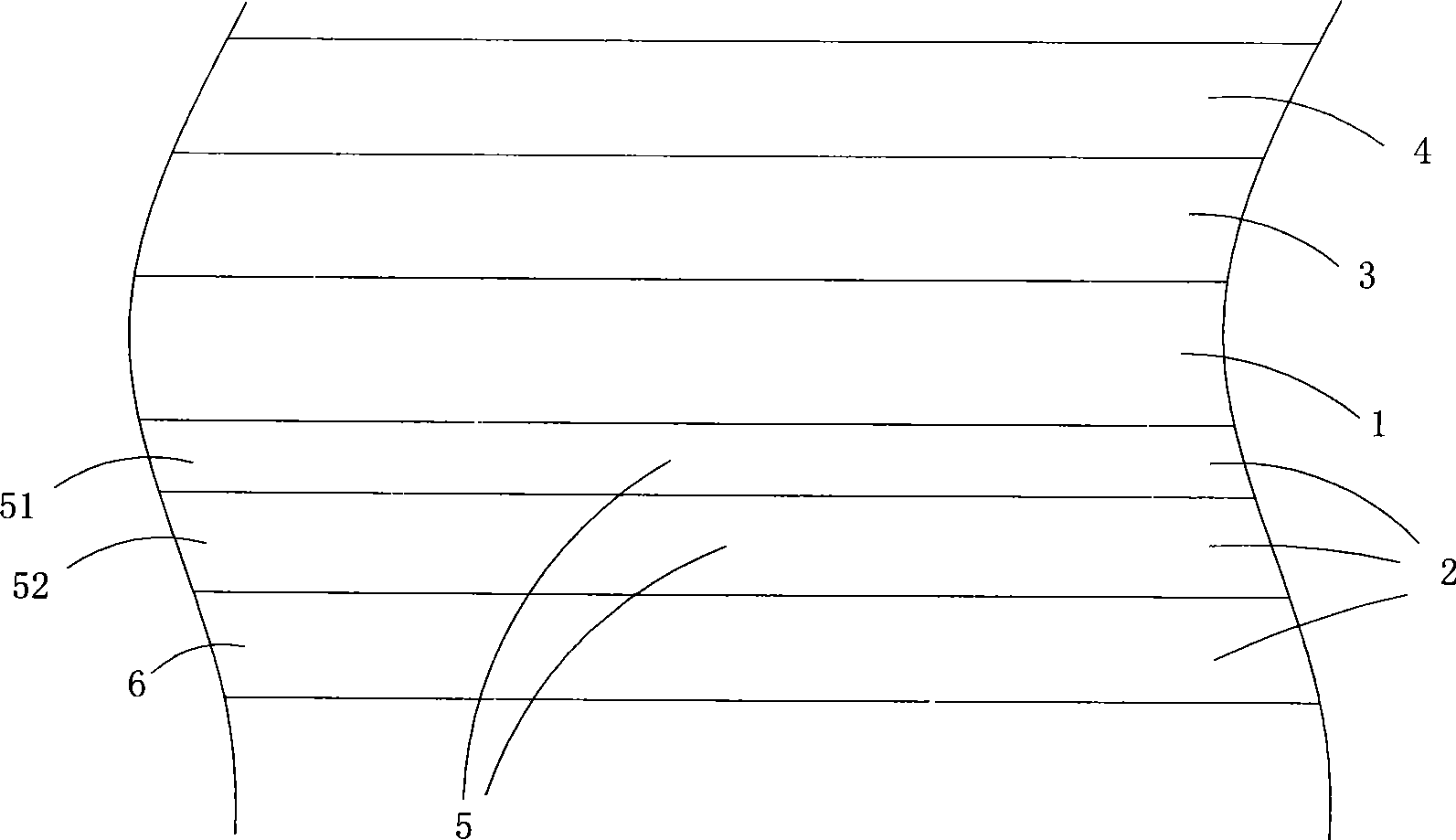

Fire-resistant ceramic silicone rubber, preparation method of fire-resistant ceramic silicone rubber and application in wires and cables

InactiveCN102850805AGood electrical insulationGood processing performanceRubber insulatorsSurface finishingSizing

The invention discloses a fire-resistant ceramic silicone rubber, a preparation method of the fire-resistant ceramic silicone rubber and application of the fire-resistant ceramic silicone rubber and in wires and cables. The rubber comprises 100 parts of methyl vinyl silicone rubber, 30-80 parts of carbon-white, 9- 40 parts of alumina, 1.5-8 parts of structure controlling agent, 3-5 parts of sintering additive, 0.25-1.5 parts of surface treating agent and 0.5-2 parts of crosslinking agent. The preparation method is as follows: covering rubber on and milling uniformly the methyl vinyl silicone rubber, feeding the carbon-white, the alumina, the surface treating agent, the structure controlling agent, the sintering additive and the crosslinking agent in turn, remlling the stand sizing material to recover plasticity, so as to obtain the fire-resistant ceramic silicone rubber provided by the invention. The fire-resistant ceramic silicone rubber provided by the invention has the characteristics of compact ceramic body, stable structure, stable fire-resistance property and good insulation property.

Owner:WUXI JIANGNAN CABLE

Sub-smooth type polyester film at least in single side and fabricating method

InactiveCN1660568AGood processing performanceReduce glossSynthetic resin layered productsChemistryPolyester

A bidirectionally stretched polyester film has at least three extruded layers. At least one surface layer is dull. Its preparing process is also disclosed. Its advantage is adjustable low lustre.

Owner:SHANGHAI ZIDONG FILM MATERIAL CO LTD

Preparation process and application of perfumery nano capsule dispersant liquid

InactiveCN100999697AGood processing performanceHas thermosetting propertiesEssential-oils/perfumesMicroballoon preparationPrepolymerFlavor

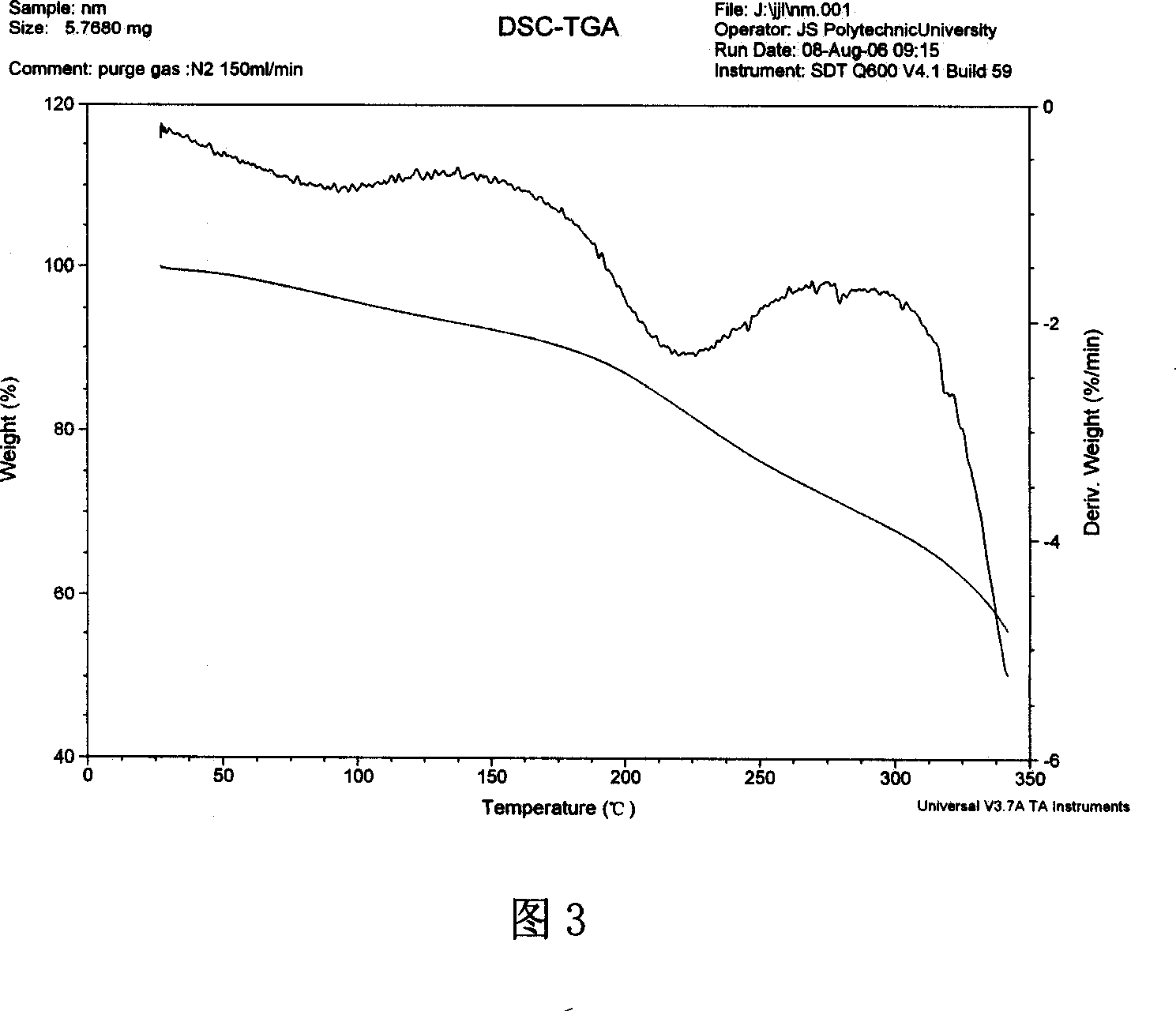

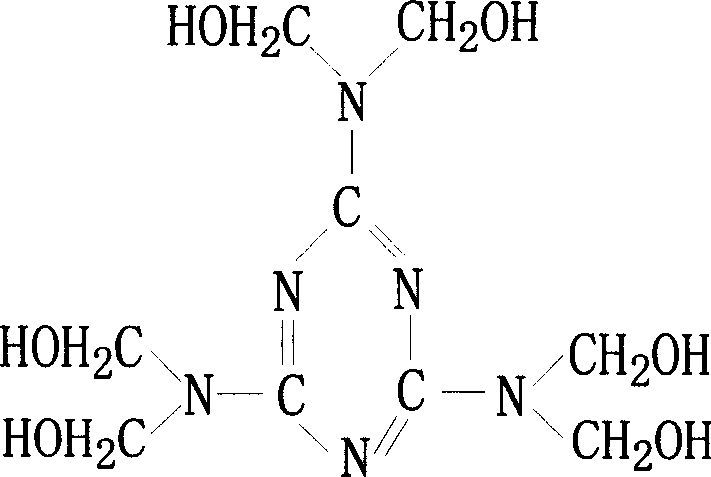

The present invention relates to fine chemical technology, and is especially preparation process and application of nanometer perfume capsule dispersing liquid. Etherified melamine resin prepolymer is used as the monomer for forming capsule wall material and is in-situ polymerized to prepare nanometer perfume capsule dispersing liquid. The said process can prepare capsule with concentrated particle size, average particle size of 140-180 nm, excellent dispersivity and excellent slow releasing property, and the capsule may be used in the scenting finishing of fabrics as well as ink, paint, printed matter, etc.

Owner:常州汉诺斯生物科技有限公司

Fully-biodegradable composition and preparation method thereof

The invention relates to a preparation method of a fully-biodegradable composition. The fully-biodegradable composition is prepared from the following components in parts by weight: 80-100 parts of polylactic acid, 0-20 parts of biodegradable polyester, 5-20 parts of flexibilizer, 0-20 parts of filler, 0.1-1 part of lubricant and 0.1-0.6 part of antioxidant. The preparation method of the fully-biodegradable composition comprises the following steps of: (1), drying polylactic acid, the biodegradable polyester and the filler; (2), weighing the components in parts by weight, adding the components to a high-speed mixer and mixing for 5 minutes to 10 minutes at high speed under normal temperature; and (3), adding the uniformly mixed materials to a double-screw extruder for melting, blending, extruding and pelletizing to obtain the needed fully-biodegradable composition. Compared with the prior art, the fully-biodegradable composition disclosed by the invention is not only good in processing performance, but also good in flexibility, and therefore, the prepared composition can be used for blow-molding and film-forming. Moreover, the adopted flexibilizer has a polylactic acid chain section, is good in compatibility with the polyactic acid substrate and capable of preventing the modifier from permeating.

Owner:WEIHAI LIANGAN ENVIRONMENTAL PROTECTION NEW MATERIAL TECH CO LTD

Sunshine polyvinyl butyral nanocomposite for blocking the sun's radiation and method for preparing the same

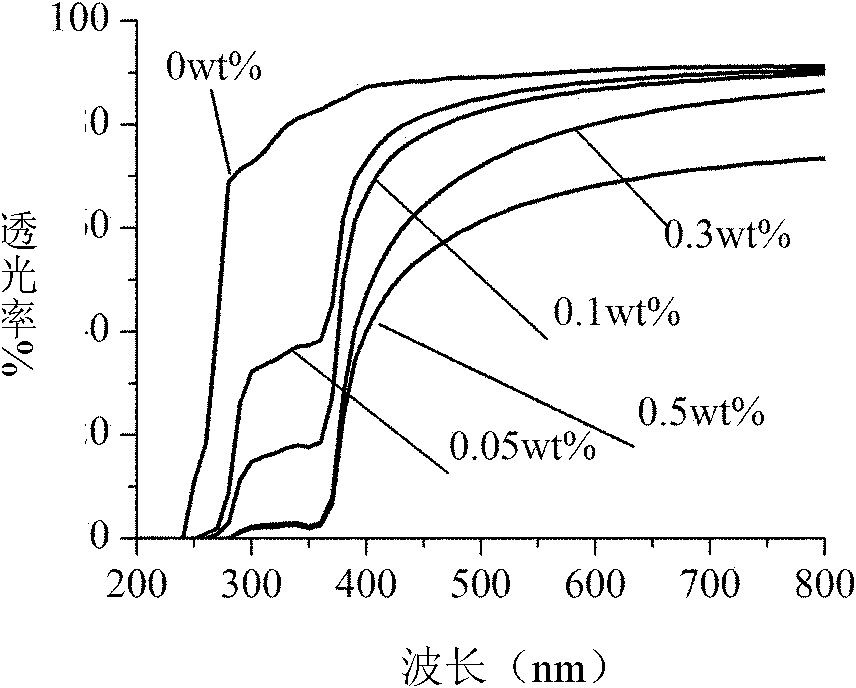

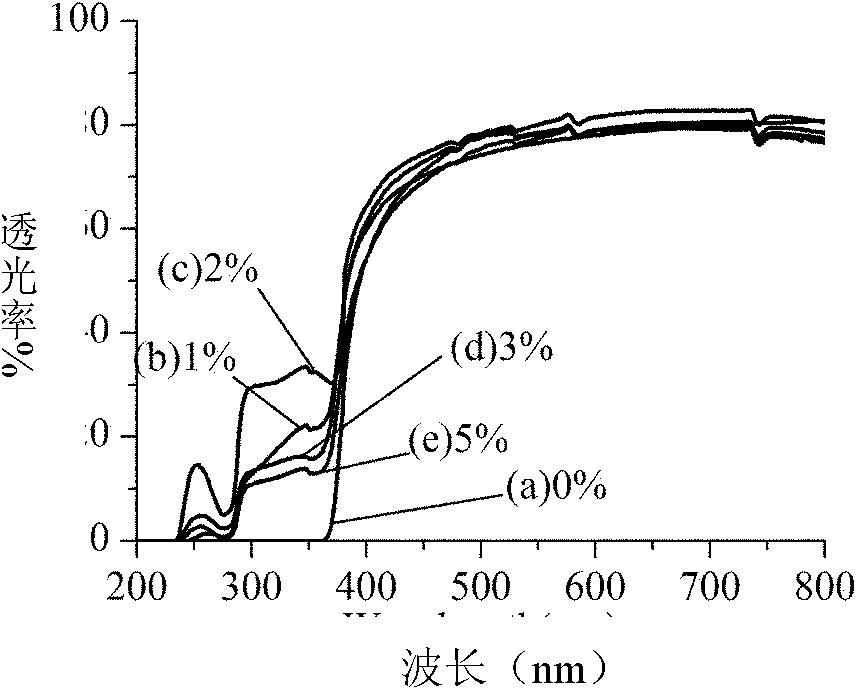

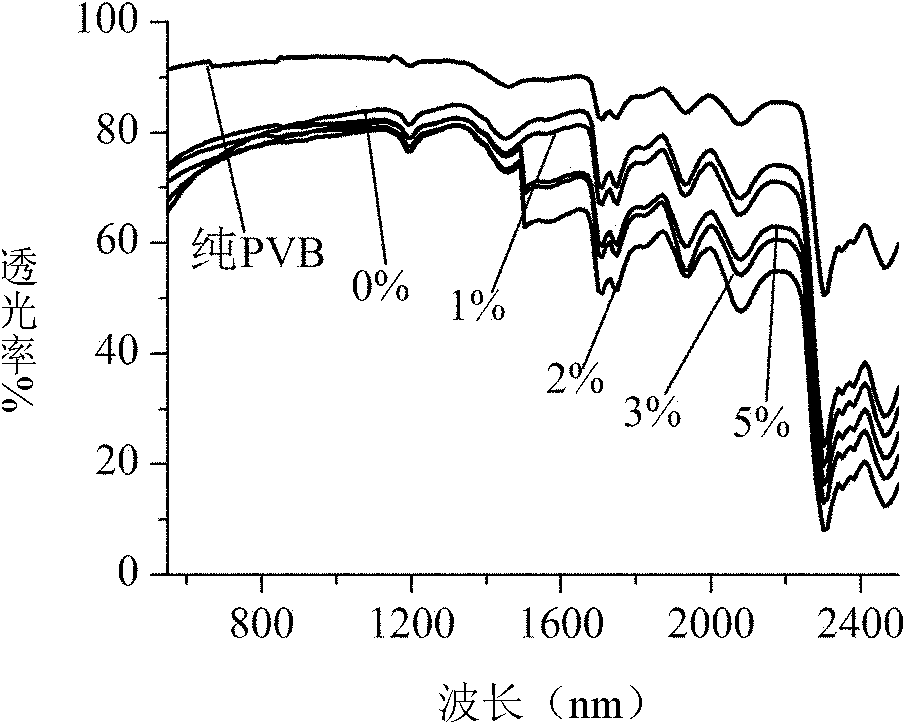

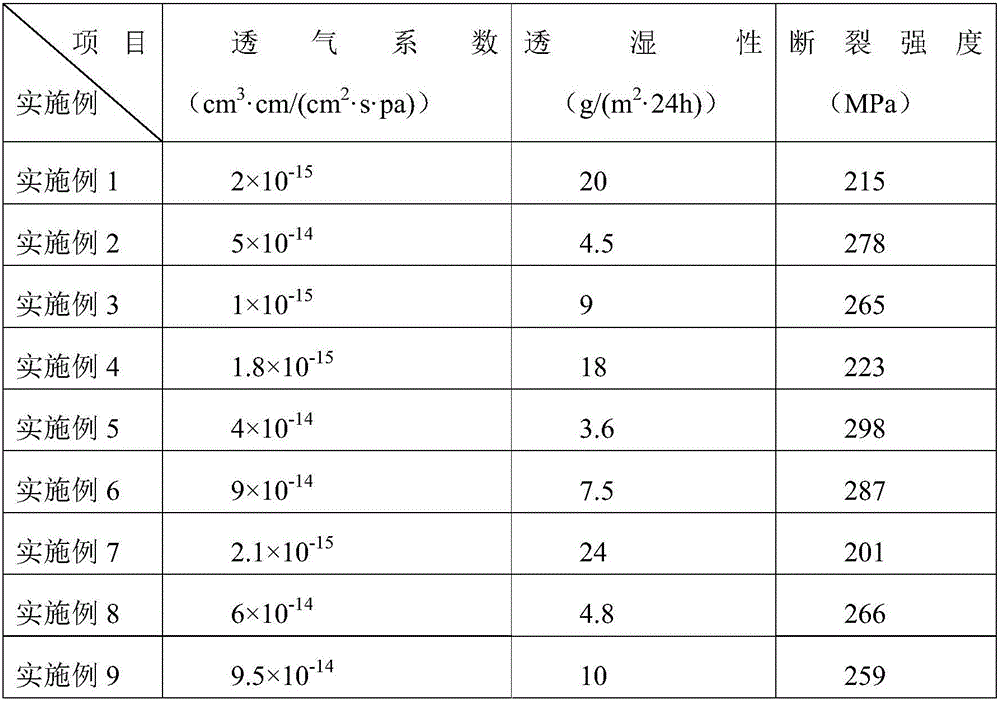

InactiveCN101983983AGood processing performanceHigh near-infrared rejection and visible light transmittancePolyvinyl butyralPlasticizer

The invention discloses a sunshine polyvinyl butyral nanocomposite for blocking the sun's radiation and method for preparing the same. Modified Al-doped nanometer zinc oxide, polyvinyl butyral, plasticizer and anti-oxidant are dispersed in the dispersant and poured into the mold to be compounded into the nanocomposite, wherein the weight ratio of Al-doped nanometer zinc oxide to polyvinyl butyral is (0.01-10):50. The nanocomposite compounded of AZO and PVB effectively has the advantages of good processing property, high ultraviolet and near-infrared rejection and visible light transmission, low cost, friendly environment and non toxicity, thus is widely applied in the fields of buildings, automobiles and aviation.

Owner:HUBEI UNIV

High-mechanical strength insulating heat-conducting plastic

InactiveCN101280108AImprove thermal conductivityGood processing performanceHeat-exchange elementsThermal insulationThermal conductivity

The invention relates to the technical field of thermal insulation plastics, particularly to a thermal insulating plastic with high mechanical strength, including 20-50% of plastic matrix, 10-70% of thermal conductive filler, 5-20% of long glass fiber, 0.5-5% of coupling agent, 0.5-5% of dispersant and 0.5-5% of lubricant. The plastic of the invention has high thermal conductivity, good processing performance, high mechanical strength, good anti-bending and anti-twisting performances, strong pressure-proof and aseismic abilities, and low costs.

Owner:东莞金富亮塑胶颜料有限公司 +1

Preparation of high-barrier nano modified PET composite material for packaging products

ActiveCN106349462AGood processing performanceEase of processing and recyclingPackage recyclingFlexible coversCvd grapheneIn situ polymerization

The invention relates to the technical field of materials, and particularly discloses preparation of a high-barrier nano modified PET composite material for packaging products. The preparation comprises the following steps: step (1) preparation of a modified nano material: treating 5 to 10 layers of graphene or white graphene by using a surfactant, thus obtaining modified nano material powder; step (2) preparing the nano modified PET composite material through an in-situ polymerization method or a melt blending method. According to the preparation of the high-barrier nano modified PET composite material, disclosed by the invention, the graphene, oxidized graphene or the white graphene has good gas isolation performance and high strength, and by adding a small amount (0.01 weight percent to 0.5 weight percent) of the graphene, the oxidized graphene or the white graphene, the barrier property of PET can be increased by a large margin, but other properties are not influenced; a prepared PET composite material product has good processing performance, and can be further prepared into single-layer-structure packaging bottles, and processing and recycling are more convenient.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

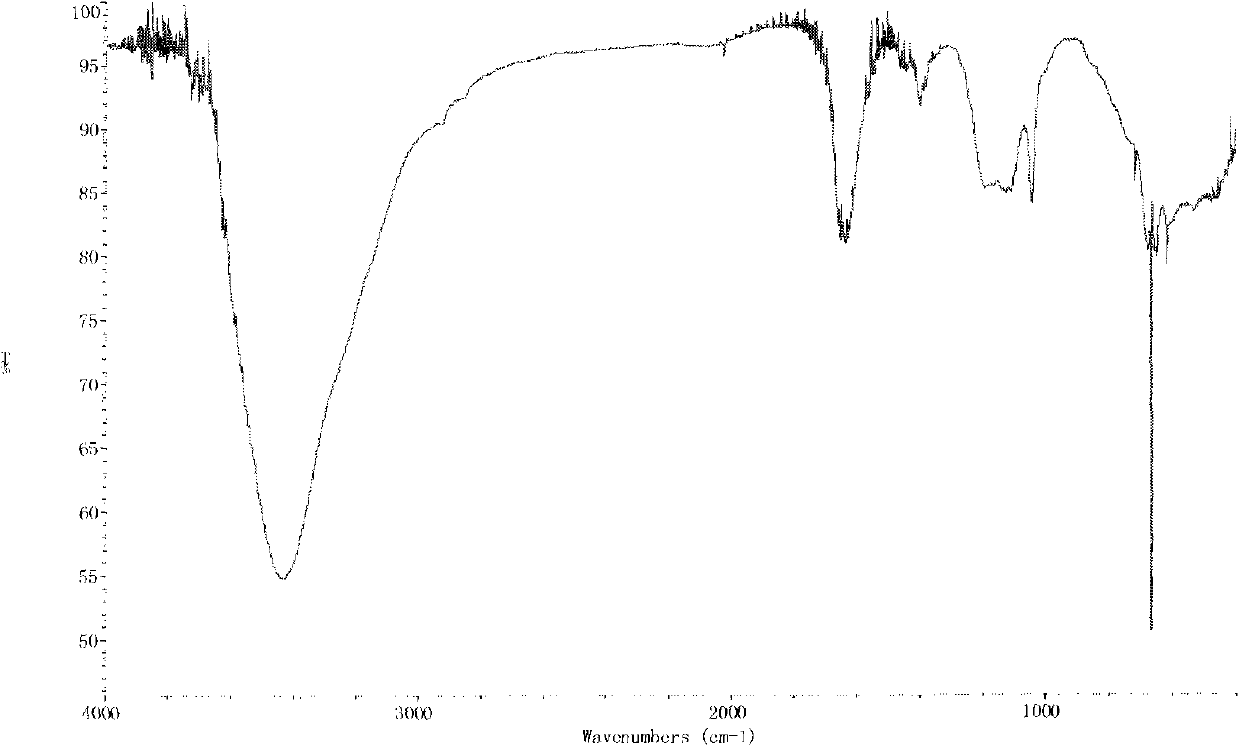

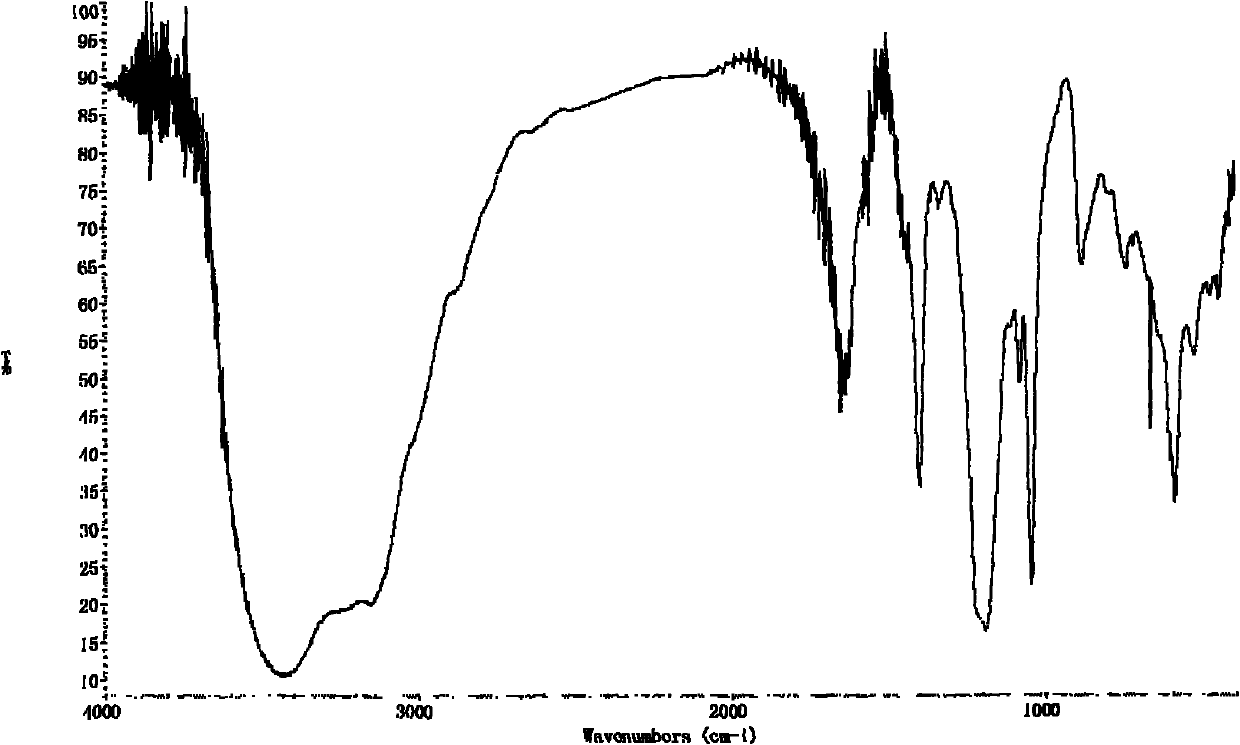

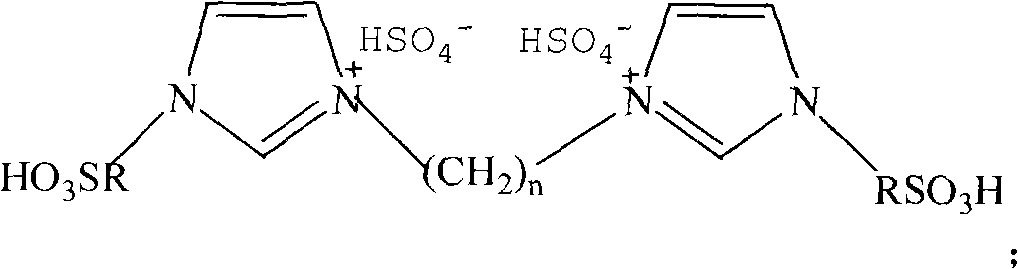

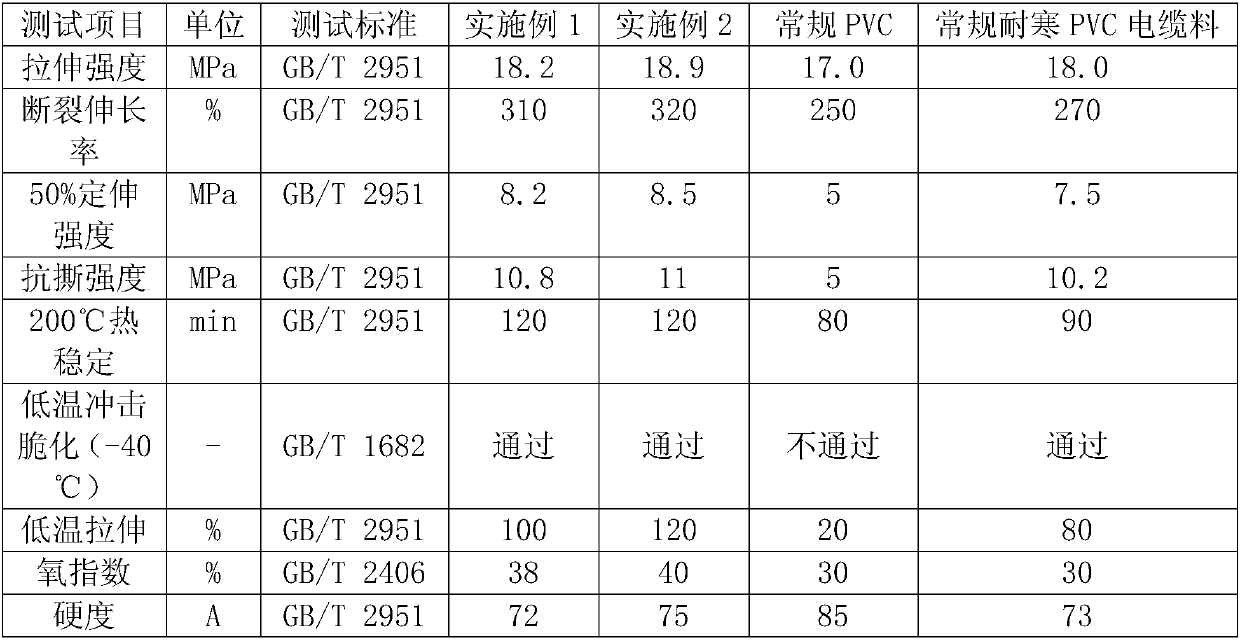

Sulfonic acid dual-core ion liquid catalyst and method using same for synthesizing polydiethylene glycol sebacate

InactiveCN102019202AGood processing performanceGood catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIonCatalysis

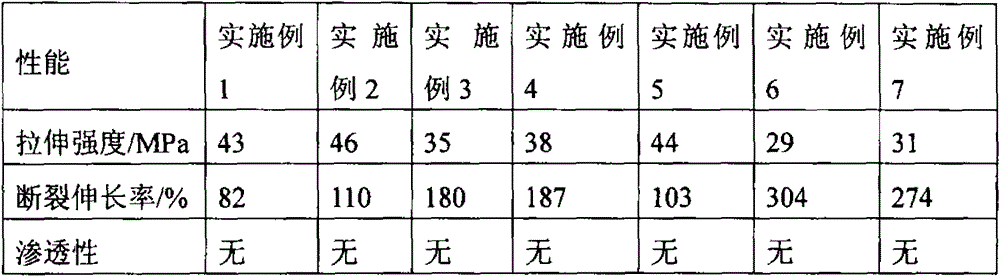

The invention relates to a sulfonic acid dual-core ion liquid catalyst and a method using the same for synthesizing polydiethylene glycol sebacate. The structure of the catalyst is shown in the specification, wherein R is CH2CH2CH2 or CH2CH2CH2CH2, and n is equal to 2-8. In the invention, sulfonic acid dual-core ion liquid catalyst is utilized to synthesize the polydiethylene glycol sebacate, therefore, the problems that in the prior art, PBS molecular weight is not high, the color phase is poor and the like are solved. By utilizing the catalyst, the molecular weight of the polydiethylene glycol sebacate obtained by catalytic catalysis is high, the viscosity-average molecular weight can reach 1.0*10<5>-1.5*10<5>, the breaking strength reaches 35-55MPa, and the breaking elongation is 200%-420%. In the invention, the viscosity-average molecular weight of the PBS is improved greatly; therefore, the application value of the catalyst is improved.

Owner:NANJING UNIV OF TECH

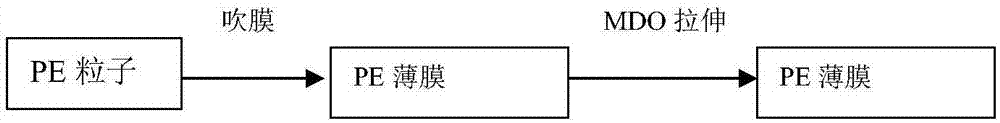

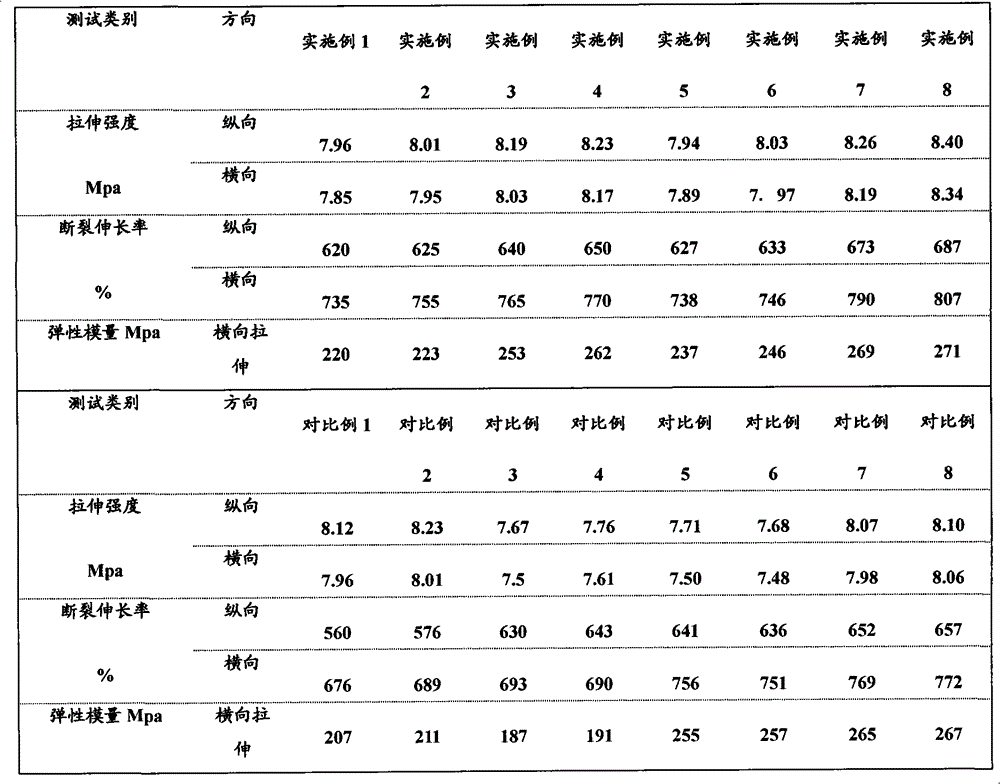

Uniaxially-tensioned high speed printing matt PE film and production technology thereof

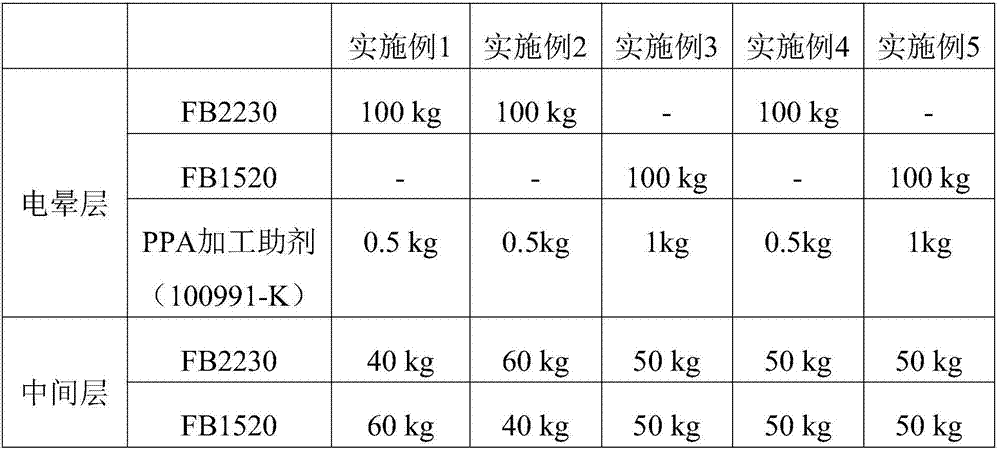

ActiveCN107351474AGood processing performanceGood resistance to stress crackingSynthetic resin layered productsDomestic containersEngineeringHigh stiffness

The invention discloses a uniaxially-tensioned high speed printing matt PE film and a production technology thereof. The matt PE film comprises a corona layer, a middle layer and a heat sealing layer, and the corona layer, the middle layer and the heat sealing layer respectively independently comprise blown film grade bimodal metallocene polyethylene. The uniaxially-tensioned high speed printing matt PE film has the advantages of guaranteeing of high haze, low crystallization point and high stiffness, and can meet the demands of high speed printing.

Owner:永新股份(黄山)包装有限公司

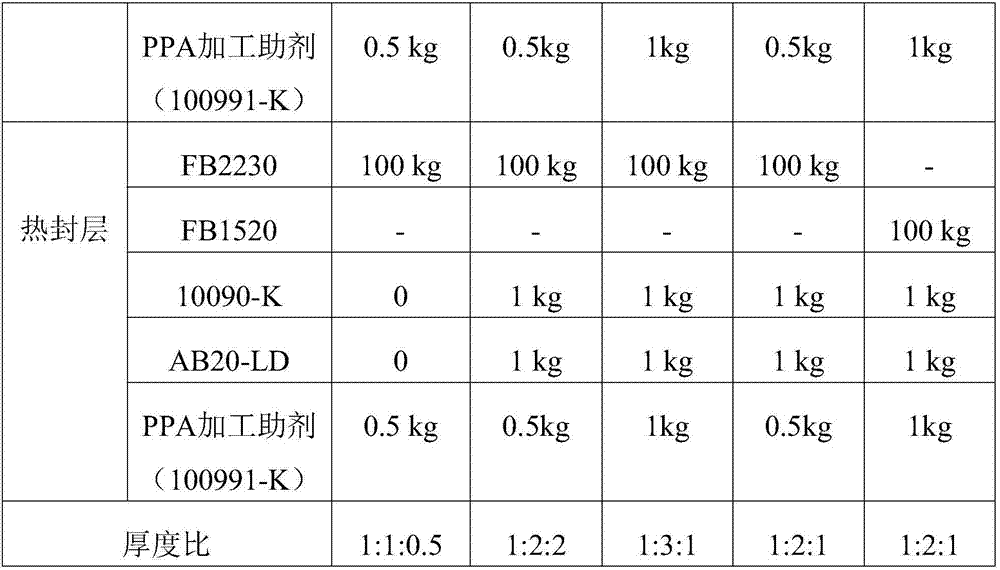

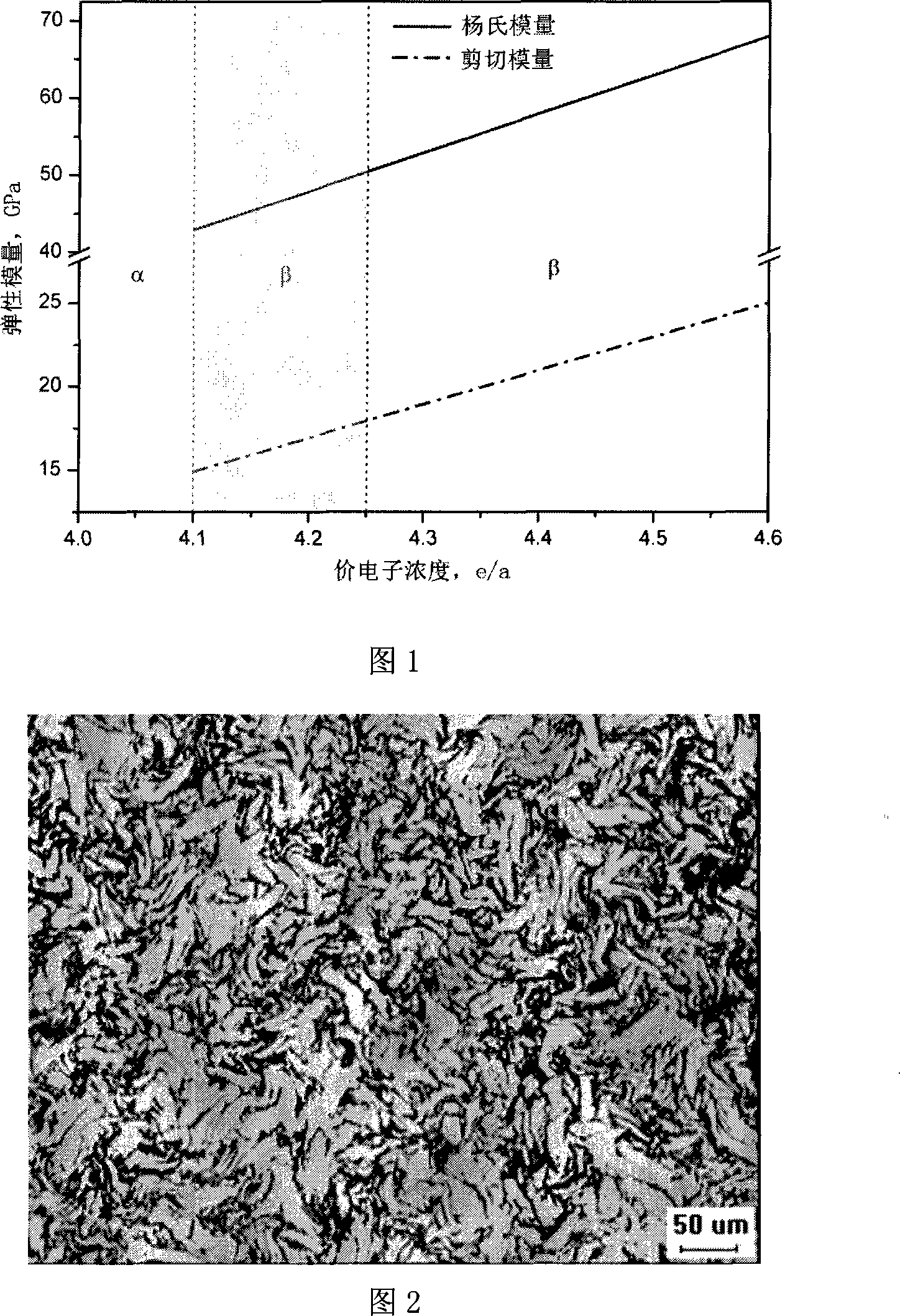

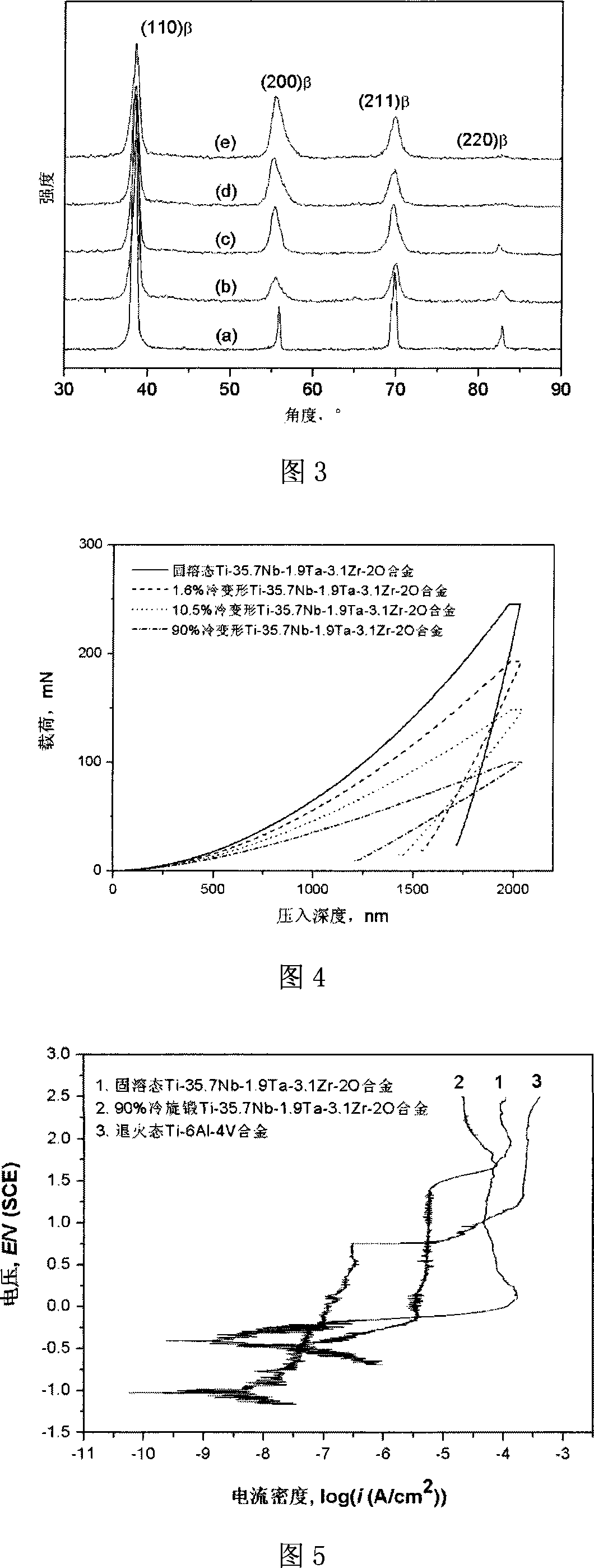

Metastable beta type Ti-Nb-Ta-Zr-O alloy and preparation method thereof

InactiveCN101215655AGood processing performanceLow work hardening rateProsthesisSingle phaseCorrosion

The invention relates to a metastable beta-type Ti- Nb-Ta-Zr-O alloy and a method for preparation, wherein the components of the alloy are that Nb is 35-38 percent by weight, Ta is 0-3 percent by weight, Zr is 2-4 percent by weight, O is 0.2-0.8 percent by weight, and the other content is Ti. The method comprises V1ing, the Ti- Nb-Ta-Zr-O alloy whose components are uniform is obtained through the vacuum consumable electrode arc furnace melting method. V2ing, Ti- Nb-Ta-Zr-O alloy ingots are done by heat processing treatment in the temperature range of 800-100 DEG C. V3ing, after being done by the solid solution quenching treatment, the Ti- Nb-Ta-Zr-O alloy which is treated in the temperature range of 1000-1200 DEG C is cooled, thereby obtaining a single-phase beta tissue. V4ing, solid solution state Ti- Nb-Ta-Zr-O alloy is done by cold processing treatment in room temperature, thereby obtaining various alloy bars and plates. The alloy of the invention has super elasticity, low modulus, high strength, no biological toxicity, corrosion resistance, excellent biocompatibility and easy processing forming, and the alloy is capable of being widely used on biological implantation materials and other medical devices.

Owner:SHANGHAI JIAO TONG UNIV

Maximum-thickness S355G10+N steel plate for ocean platform and production method of steel plate

The invention discloses a maximum-thickness S355G10+N steel plate for an ocean platform and a production method of the maximum-thickness S355G10+N steel plate. The production method of the maximum-thickness S355G10+N steel plate comprises smelting, casting, heating, rolling, cooling and heat treatment processes. The maximum-thickness S355G10+N steel plate comprises the following chemical ingredients in percentage by weight: 0.08-0.12% of C, 0.15-0.50% of Si, 1.40-1.65% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.040-0.060% of V, 0.020-0.030% of Nb, 0.020-0.050% of Al, less than or equal to 0.43% of Cea, less than or equal to 0.22% of Pcm and the balance of Fe and inevitable impurities. The maximum-thickness S355G10+N steel plate has the advantages that low-carbon and high-microalloying design thought is adopted in composition design, the problem of segregation of carbon and manganese is solved, and the requirements such as high strength, high impact toughness and wide cold bending performance are met; hardenability of the maximum-thickness S355G10+N steel plate is guaranteed under the low-carbon and low-equivalent carbon content conditions, and the maximum-thickness S355G10+N steel plate has good structure and overall performance and welding performance; and the maximum-thickness S355G10+N steel plate has good mechanical properties, welding performance and processability and can meet requirements of construction technological conditions of an ocean engineering equipment manufacturing plant.

Owner:WUYANG IRON & STEEL

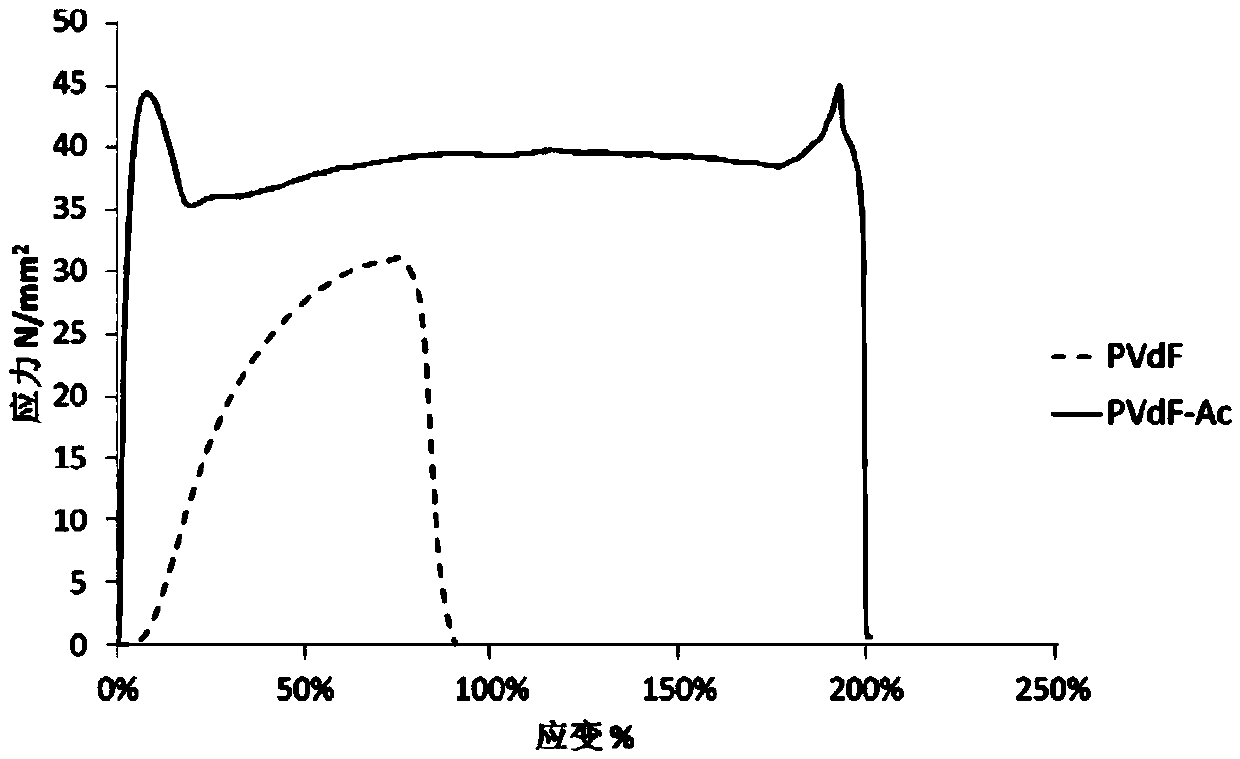

Adhesive and lithium ion battery with same

ActiveCN105514488AGood processing performanceImprove adhesionCell electrodesSecondary cellsElectrical batteryBattery energy

The invention relates to the field of lithium ion battery materials, and in particular relates to an adhesive and a lithium ion battery with the same. The adhesive is a polymer containing structure units shown as the formulas I, II, III and IV, and the number-average molecular mass of the adhesive is 0.5 million to 1.2 million. The invention also relates to the lithium ion battery, comprising a positive electrode piece, a negative electrode piece, a separator and electrolyte, wherein the positive electrode piece comprises the adhesive. With the adhesive, the flexibility of the positive electrode piece can be improved greatly, so that the problems of processing, battery performance and the like, caused by crisp electrode pieces, can be avoided, the compaction density can be enhanced, and the energy density of the battery can be further improved.

Owner:NINGDE AMPEREX TECH

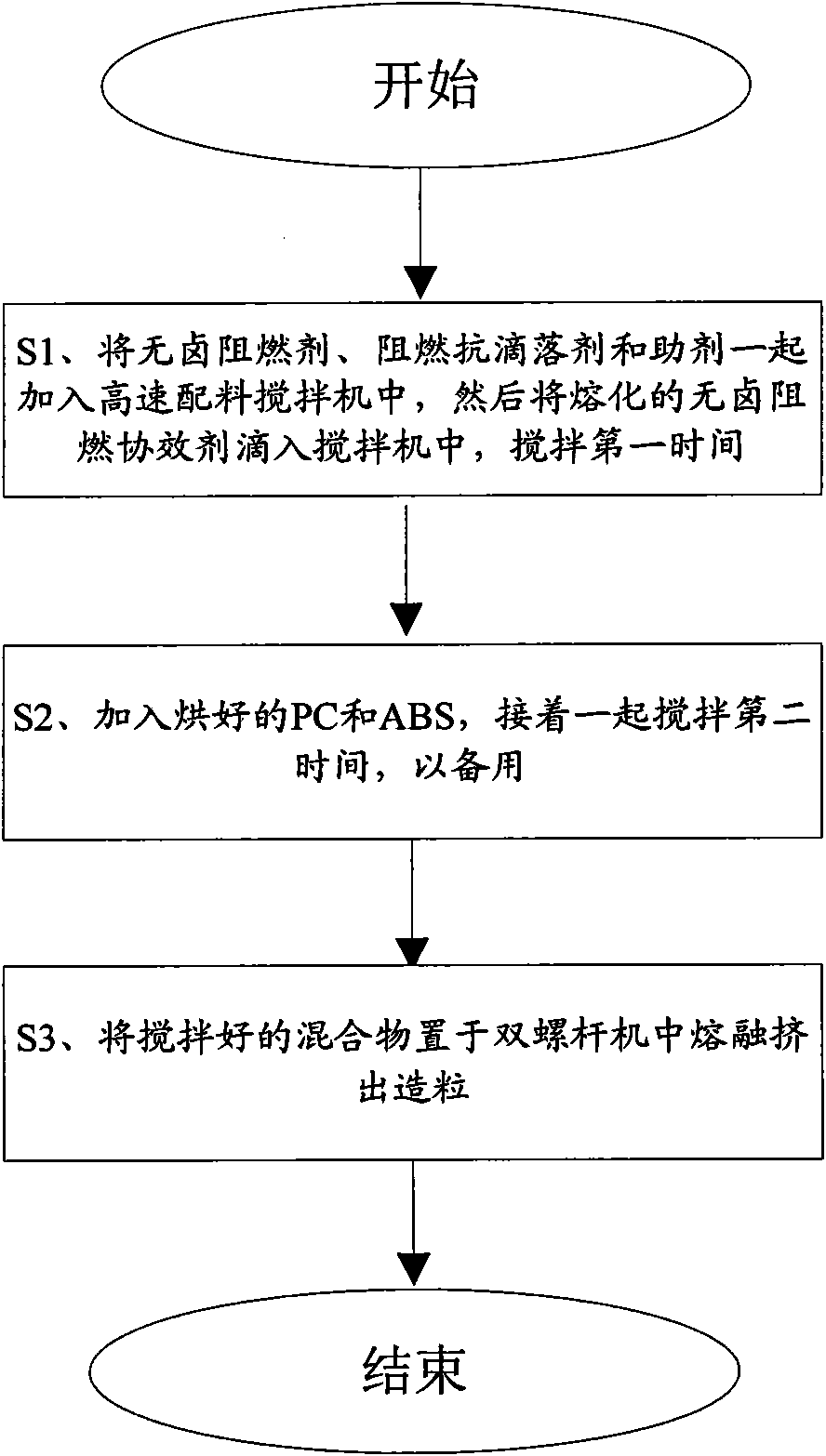

PC/ABS alloy and preparation method thereof

The invention relates to a PC / ABS alloy and a preparation method thereof.The method comprises the following steps: S1. adding non-halogen flame-retardant agent, inflaming retarding and anti-drippage agent into a high-speed burdening agitator, then dropwise adding melted non-halogen flame-retardant synergist into the agitator and agitating for a first time; S2. adding dried PC and ABS and agitating for a second time for standby use; S3. placing the agitated mixture in a double-screw machine for melt extrusion for pelleting.The prepared PC / ABS alloy comprises the following raw materials according to parts by weight: 60-68 parts of PC, 12-18 parts of ABS, 7-12 parts of non-halogen flame-retardant agent, 1-3 parts of non-halogen flame-retardant synergist, 0.1-1 part of inflaming retarding and anti-drippage agent and 6-20 parts of auxiliary.The PC / ABS alloy features good inflaming retarding effect and good comprehensive property and is halogen-free and environment-friendly; in addition, the alloy features fine suboptical effect and can be applied to components such as automobile upholsteries in need of suboptical effect and the like.

Owner:徐东

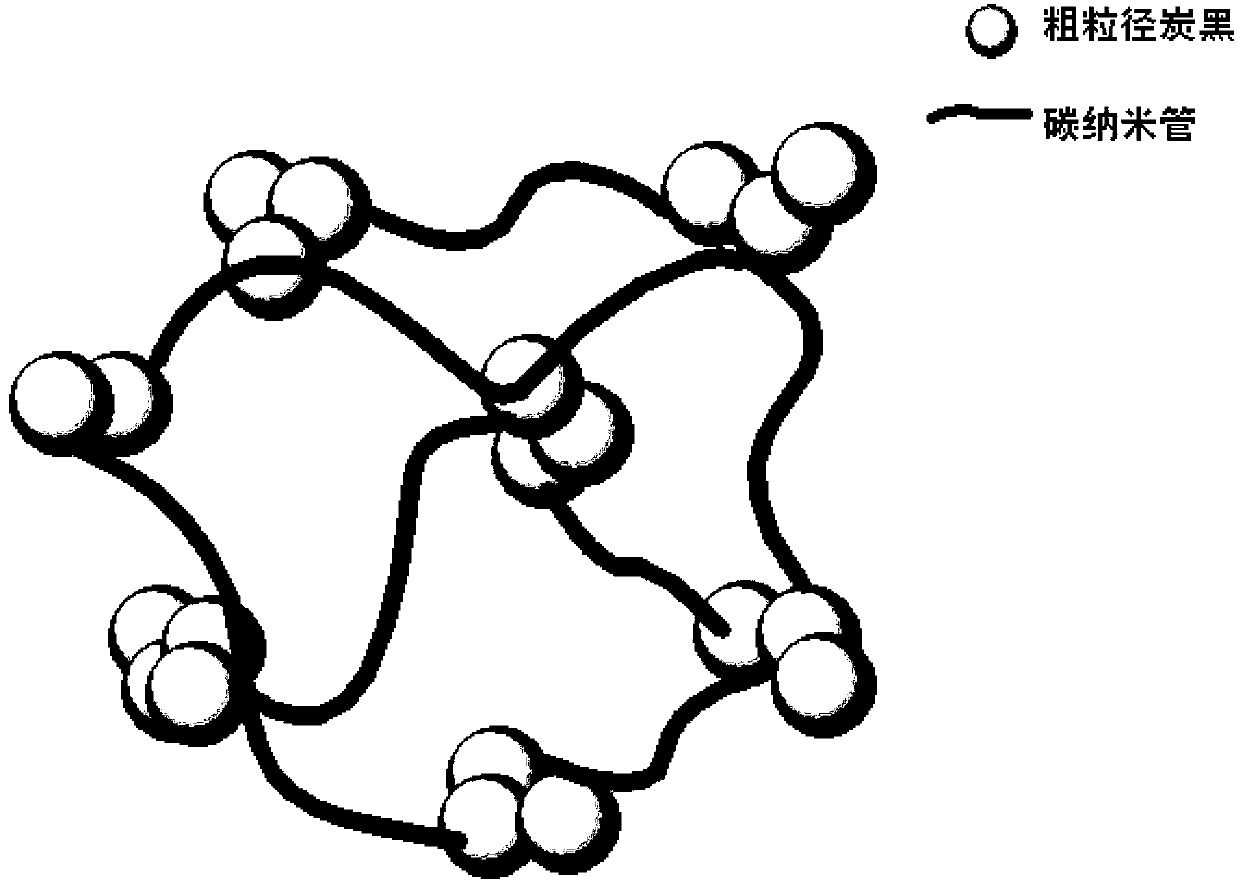

Shoulder wedge composite material and manufacturing method thereof

ActiveCN102898692AGood processing performanceImprove thermal conductivitySilane couplingThermal conductivity

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

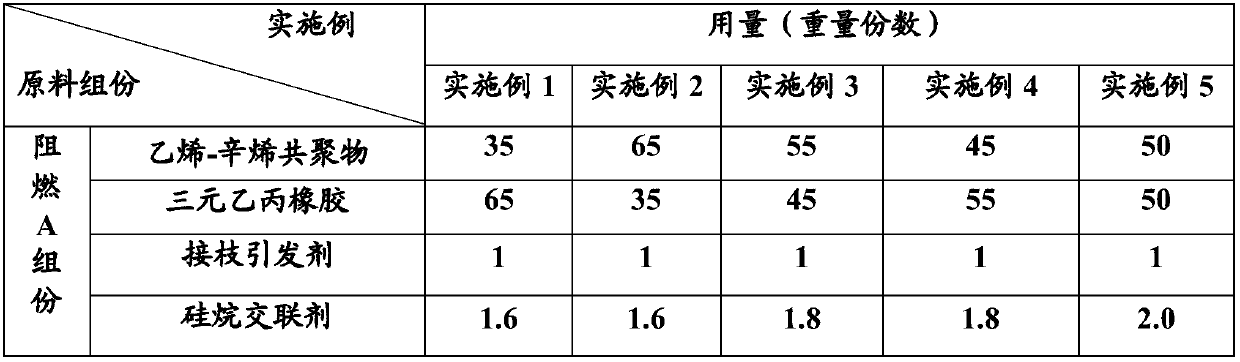

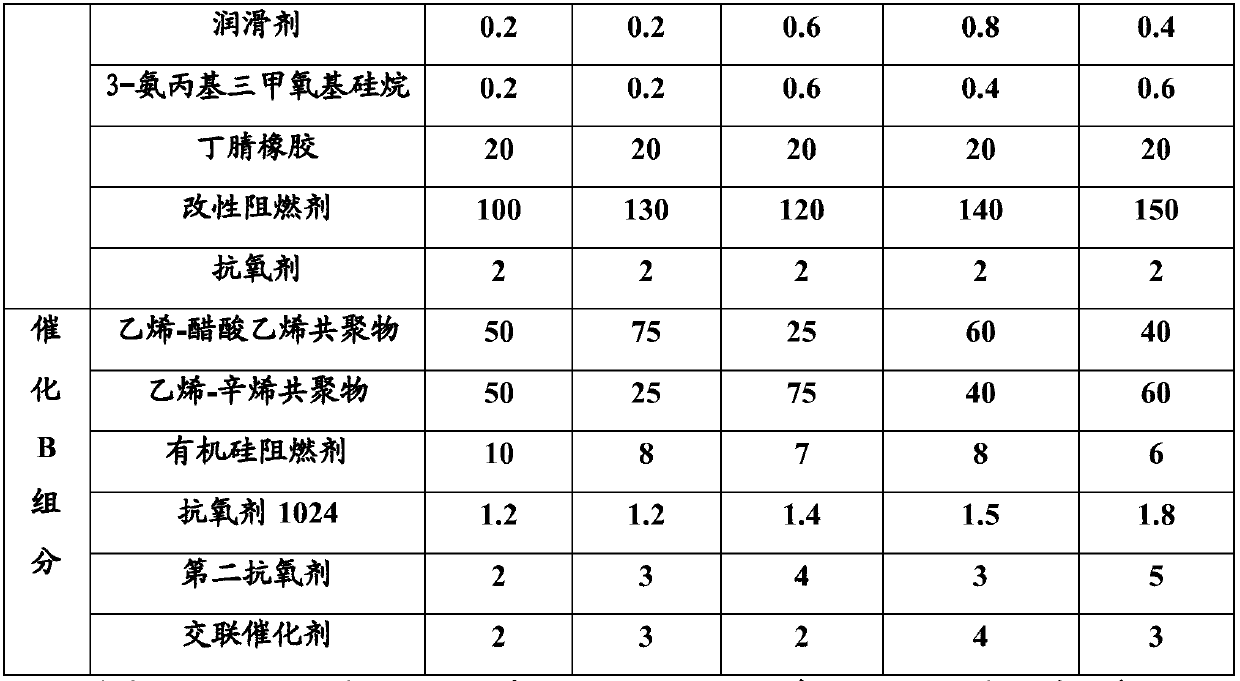

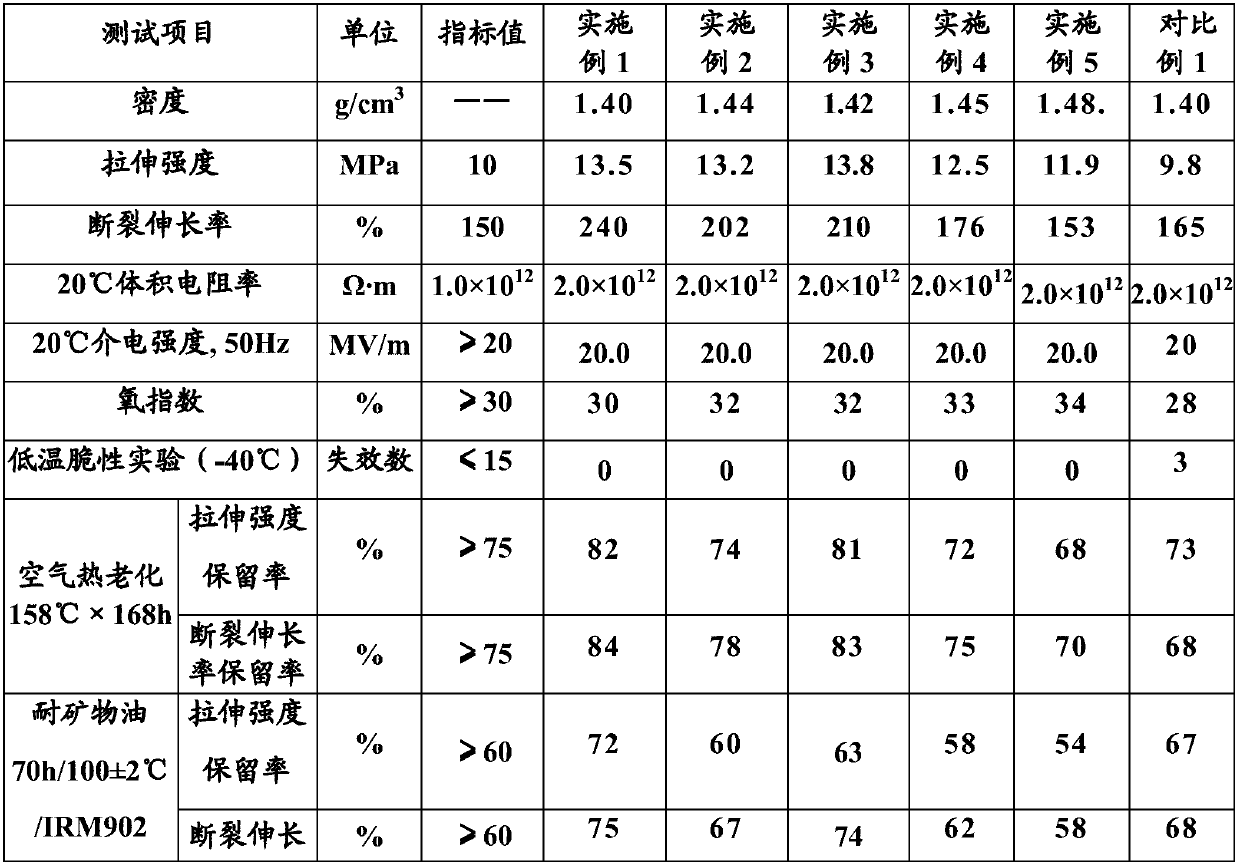

Silane self-crosslinking halogen-free low-smoke flame-retardant elastic material and preparation method thereof

ActiveCN102731917ASuperior elasticity and flame retardancyGood processing performanceInsulated cablesCable/conductor manufactureFlame resistanceSilanes

The invention relates to a silane self-crosslinking halogen-free low-smoke flame-retardant elastic material and a preparation method thereof. The elastic material comprises a flame-retardant component A and a catalysis component B with the weight proportion of 100:(4-6), wherein the flame-retardant component A comprises 30-70 parts of ethylene propylene diene monomer, 30-70 parts of ethylene-octylene copolymer, 15-25 parts of nitrile rubber, 1-6 parts of silane crosslinking agent, 0.3-1.5 parts of graft initiator, 0.1-5 parts of antioxygen, 0.2-2 parts of lubricant, 0.1-4 parts of 3-aminopropyl trimethoxy silane and 50-150 parts of modified flame retardant; and the catalysis component B comprises 100 parts of ethylene-vinyl acetate and / or ethylene-octylene copolymer, 3-50 parts of organosilicone flame retardant, 1-5 parts of first antioxygen, 1-10 parts of second antioxygen and 1-8 parts of crosslinking catalyst. The elastic material is a novel halogen-free low-smoke flame-retardant cable material, and has the advantages of excellent flame resistance and elasticity, low smoke, low toxicity, excellent processing performance and low cost.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

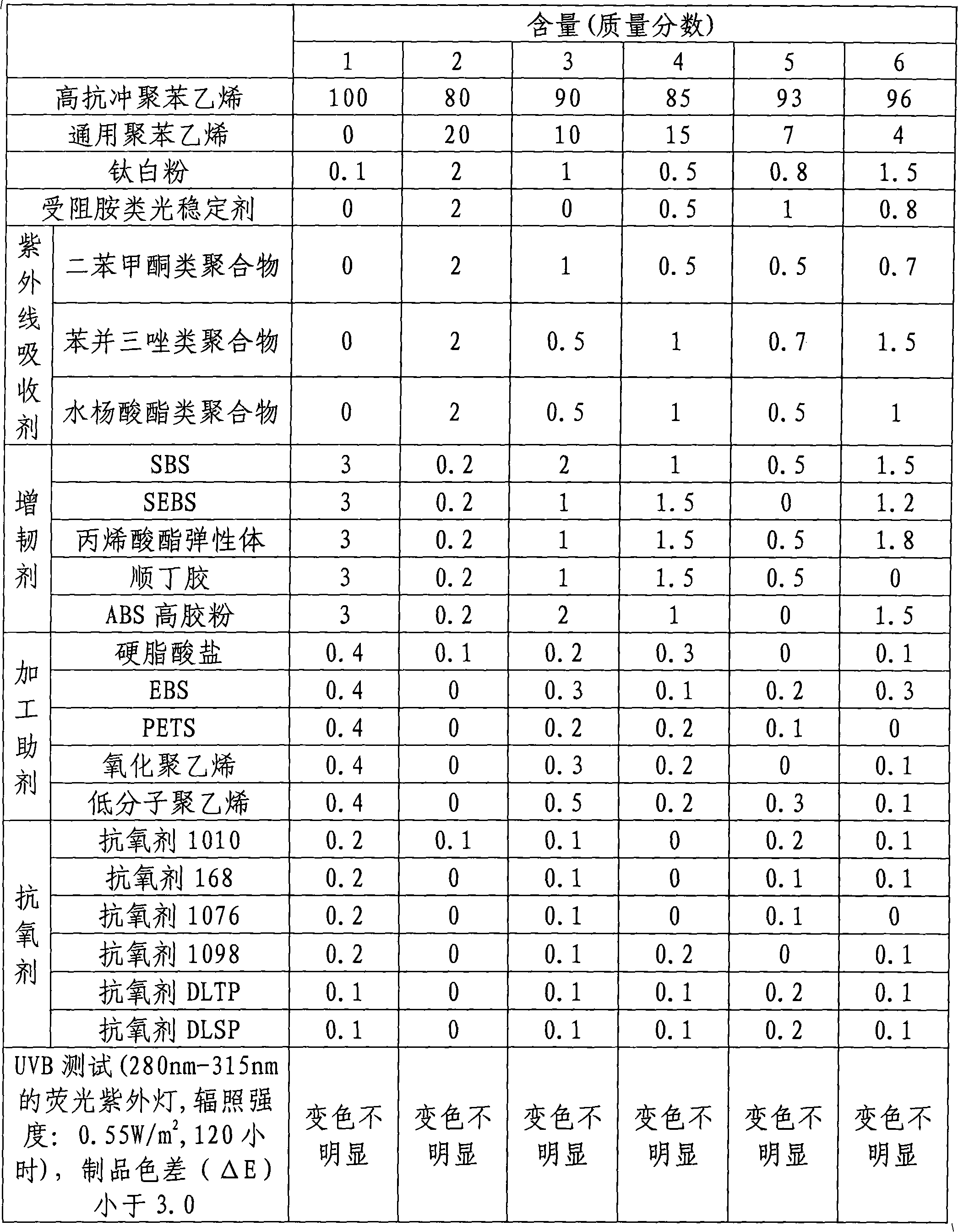

Weather-resistant high impact polystyrene material and preparation method thereof

The invention discloses a weather-resistant high impact polystyrene material, which is characterized by comprising high impact polystyrene resin, an anti-ultraviolet agent, a toughener, an antioxidant, and a processing aid, and comprising the following components in part by mass: 80 to 100 parts of high impact polystyrene resin, 0 to 20 parts of general purpose polystyrene, 0.1 to 10 parts of light stabilizer, 1 to 15 parts of toughener, 0.1 to 1 part of antioxidant and 0.1 to 2 parts of processing aid. The weather-resistant high impact polystyrene material has high weather resistance and stable performance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Semi-solid forming and casting technology of aluminum magnesium alloy pot

The invention discloses a semi-solid forming and casting technology of aluminum magnesium alloy pot. The semi-solid smelting of the casting technology adopts the rheological slurry temperature control smelting technology; metal tree crystal is broken up in rheological slurry temperature control smelting by electromagnetic mixing to form spherical crystal, the metal crystalline state as well as the metallic crystal nodularity of the aluminum magnesium alloy pot are improved, so that the aluminum magnesium alloy pot has high strength and high tenacity and is light in weight and firm compared with the traditional cast aluminum magnesium alloy pot; the smelting temperature of semi-solid slurry is low compared with the traditional casting, therefore, not only the energy consumption is greatly saved, but also the service life of casting dies is prolonged; and the aluminum magnesium alloy pot has no bubbles and needle holes on the surface, and the firm part has compact crystal and no casting defects. The technology realizes the semi-solid rheological extrusion forming of the aluminum magnesium alloy pot, and has high production efficiency, therefore, not only the quality of casts and the utilization ratio of materials are improved, but also the surface quality of the product is improved and the interior quality is equivalent to forging products; and the invention is suitable for scale production and has great popularization and application value.

Owner:李扬德

Cable sheath rubber

InactiveCN102250426AGood compression set properties and toughnessGood processing performanceInsulated cablesInsulated conductorsFlame resistanceMineral oil

The invention provides cable sheath rubber, which is characterized in that the raw material comprises 100 weight parts of chlorinated polyethylene, 2 to 6 weight parts of organic peroxide vulcanizing agent, 3 to 6 weight parts of sulfurization assisting agent, 0.5 to 1.5 weight parts of antiaging agent, 10 to 30 weight parts of fire retardant and 20 to 40 weight parts of reinforcing agent. The product has high fuel oil resistance, high mineral oil resistance, high resistance to low temperature after aging; the cable sheath rubber can be filled with more filler and has high compression deformation performance and toughness; and the smooth appearance of the rubber has high processing technical performance and high flame retarding performance.

Owner:上海南洋电缆有限公司

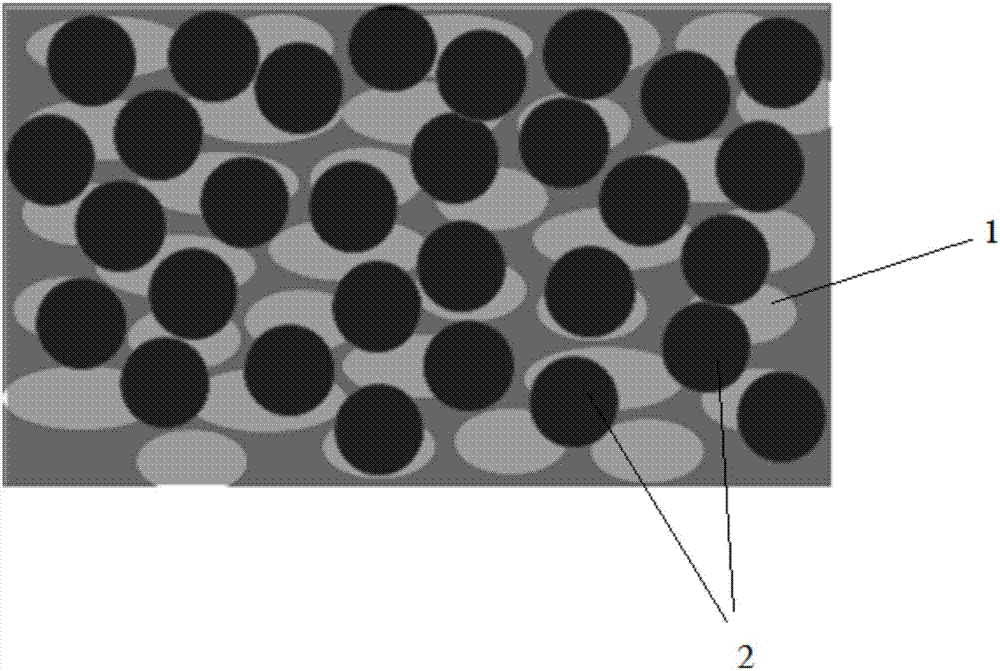

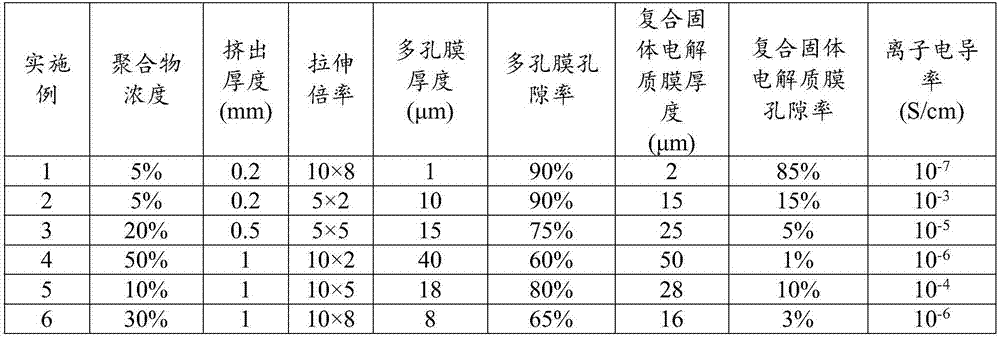

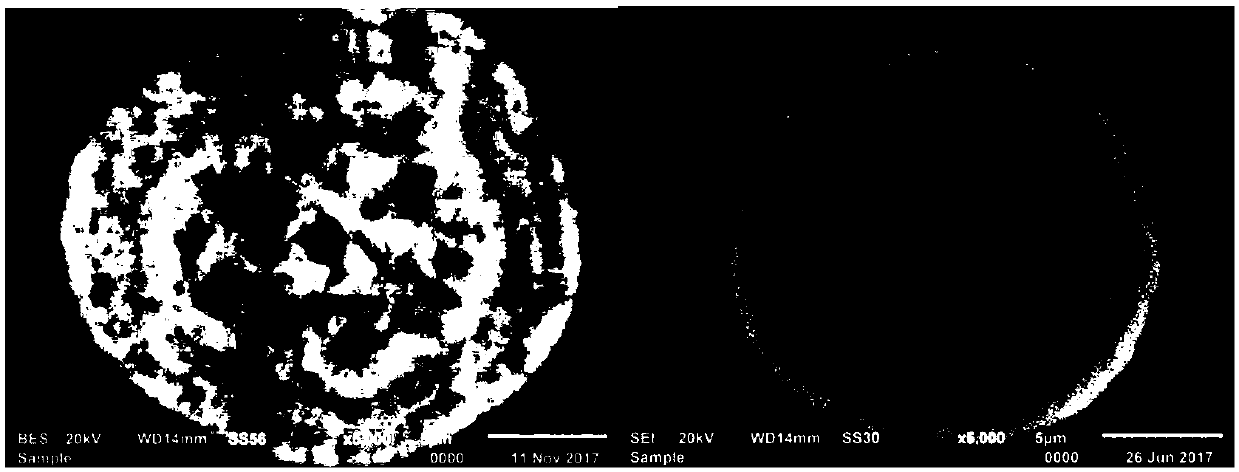

Solid electrolyte membrane, preparation method of solid electrolyte membrane, and lithium ion battery

InactiveCN107403954AImprove ionic conductivityGood processing performanceSolid electrolytesFinal product manufactureChemistryCorrosion

The invention discloses a solid electrolyte membrane, a preparation method of the solid electrolyte membrane, and a lithium ion battery. The solid electrolyte membrane is a material of a composite structure, wherein the material is formed by compounding lithium inorganic solid electrolyte and a polymer; a polymer with a continuous three-dimensional sponge network structure is filled with the lithium inorganic solid electrolyte; the primary particle size of the lithium inorganic solid electrolyte is 0.01-3 microns; the polymer has the continuous three-dimensional sponge network structure; the diameter of the polymer in the network structure is 0.002-0.5 micron; a weight ratio of the lithium inorganic solid electrolyte to the polymer is 70:30 to 95:5; the composite structure has pores; the size of each pore is 0.01-3 microns; a ratio of the pore volume to the volume of the whole composite material is 1-15%; the overall thickness of the composite material is 1-50 microns; and the tensile strength is higher than 10MPa. According to the solid electrolyte membrane disclosed by the invention, high ionic conductivity of the lithium inorganic solid electrolyte can be maintained, and excellent processability, mechanical property, corrosion resistance and oxidation resistance can be provided.

Owner:上海纳晓能源科技有限公司

Modified polyethylene and easy-to-uncover suppositorium packaging film

ActiveCN101463157AGood barrier propertiesGood processing performanceFlexible coversWrappersChemistrySuppository

The invention discloses modified polyethylene and an easy removing suppository packaging film. The raw materials of the modified polyethylene comprise according to the parts by weight: 100 parts of polyethylene and 5-40 parts of polybutene or modified polybutene. The easy removing suppository packaging film comprises a barrier layer and a heat-sealing layer. The barrier layer is an aluminum foil layer and a polyvinyl chloride layer. The barrier layer and a heat-sealing layer are compounded together by a gluing mode. The heat-sealing layer is composite layer structure and sequentially one to two-layer polyethylene layer and one-layer modified polyethylene layer along the direction far away the barrier layer. Raw materials used by the modified polyethylene layer are 100 parts of polyethylene, and 5-40 parts of polybutene or modified polybutene according to the parts by weight. The heat-sealing layer has good easy removing performance after lap piling and heat-sealing.

Owner:ZHEJIANG GOLDSTONE PACKING

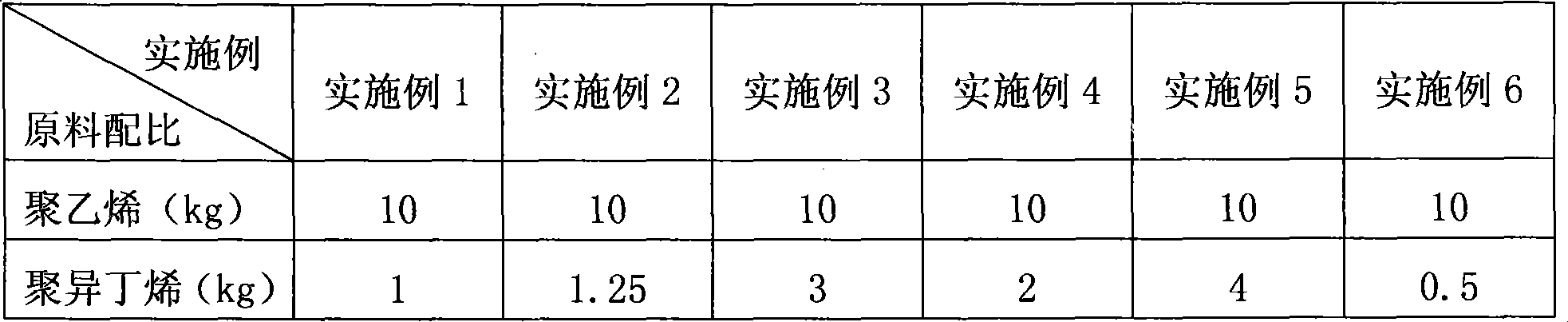

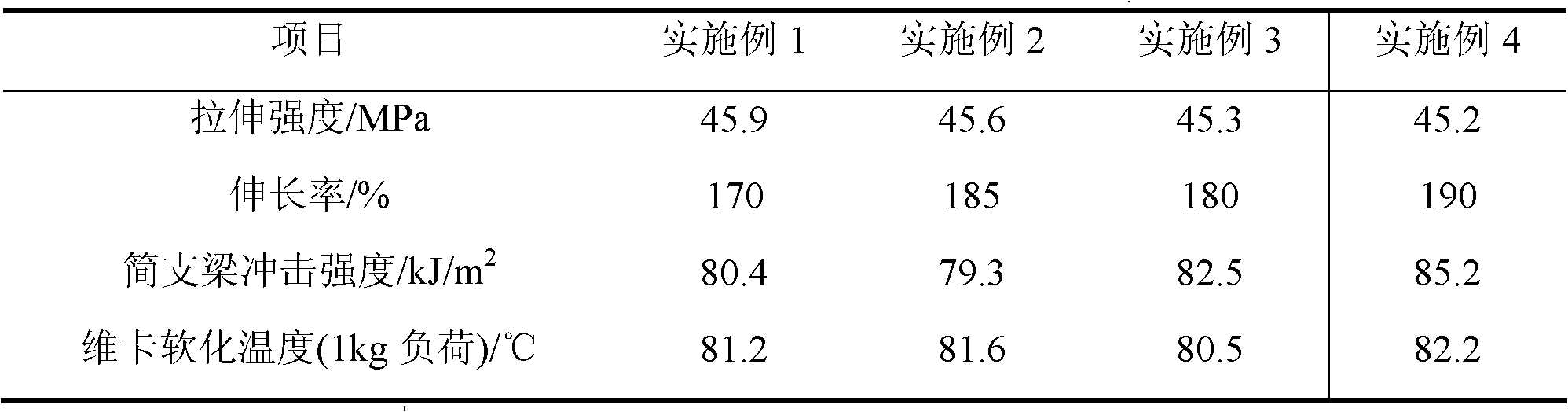

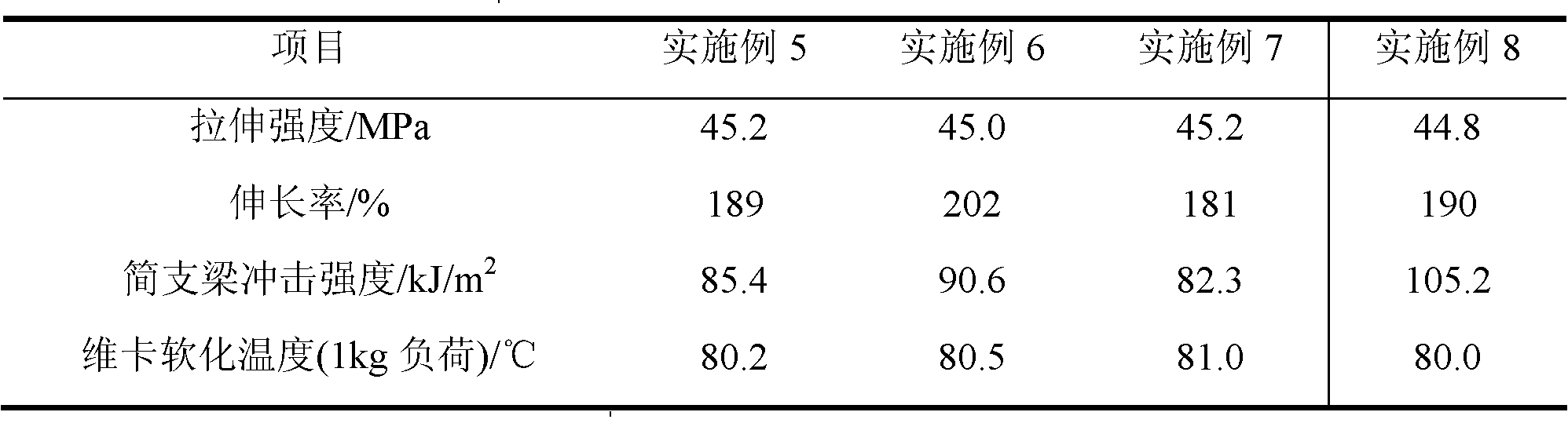

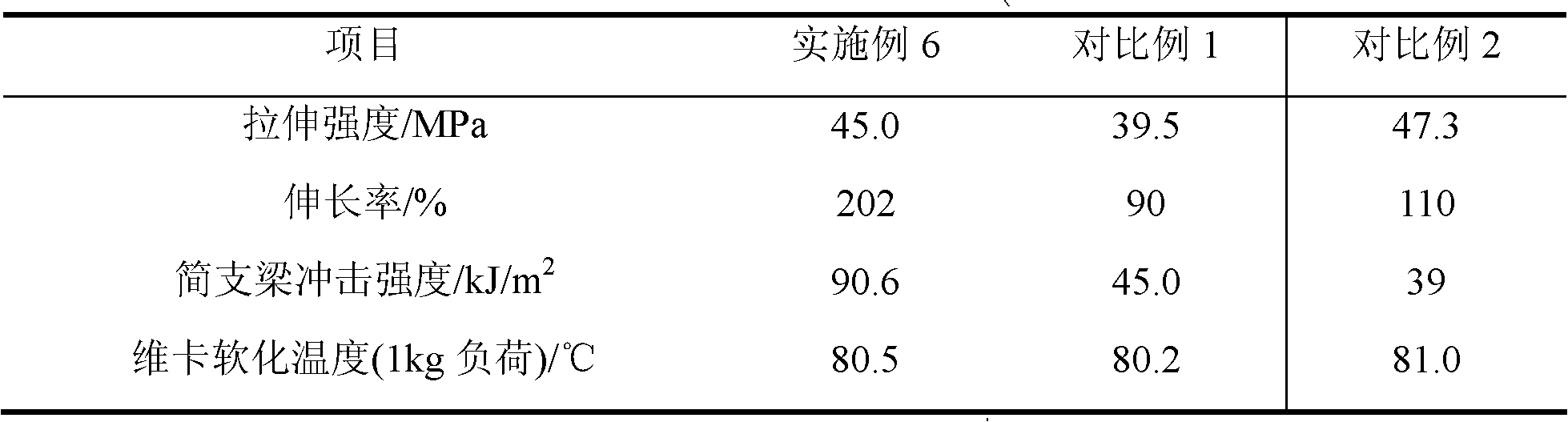

High-elongation high-shock resistance PVC tubular product composition and preparation method thereof

The invention discloses a high-elongation high-shock resistance PVC tubular product composition and a preparation method thereof, belonging to the technical field of plastic processing. The composition disclosed herein comprises 100 weight parts of PVC resin, 8-15 weight parts of IPN copolymer (ACM-M) of mild-chlorinated HDPE and acrylate, 0.8-3.0 weight parts of heat stabilizer, 1.8-3.5 weight parts of lubricant, 0-5 weight parts of filling agent, and 0-2 weight parts of coloring agent. According to the invention, the PVC tubular product produced by using the ACM-M modified high-elongation high-shock resistance PVC tubular product composition has an elongation being 202% and a simply-supported beam impact strength being 90.6kj / m<2>, has excellent shock resistance and high physical and mechanical properties, and the preparation method is simple, and the production cost is low.

Owner:CHINA PETROLEUM & CHEM CORP

Starch-based biodegradable combination as well as preparation method and application thereof

The invention provides a completely biodegradable combination which comprises the following components: a natural biopolymer occupying 5-70 percent of the total weight of the combination, a biodegradable polymer occupying 5-90 percent of the total weight of the combination, an interface reinforcing agent occupying 3-20 percent of the total weight of the combination, a plasticizer occupying 5-50 percent of the weight of starch and the balance of other processing additives acceptable to a plastic processing technology, wherein the natural biopolymer is the starch or modified starch, the biodegradable polymer is synthesized polyester, the interface reinforcing agent is thermoplastic hydroxylation polyester, and the compound plasticizer is compounded by glyceride of hydroxyl diacid and glycerol. The biodegradable combination has the advantages of higher starch content and good mechanical properties. The invention also provides a preparation method and application of the combination in preparing a plastic product.

Owner:ANHUI XUELANG BIOTECHNOLOGY CO LTD

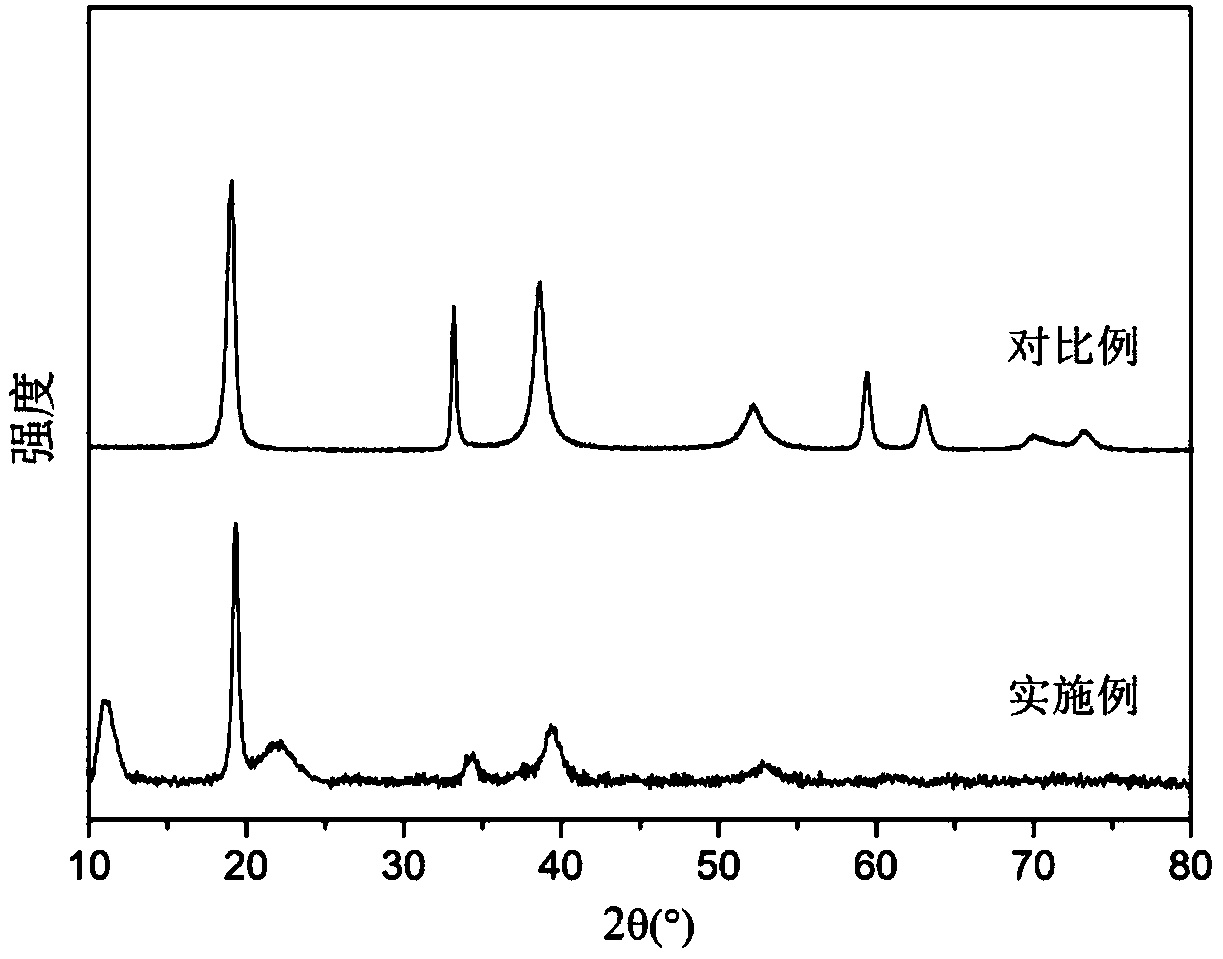

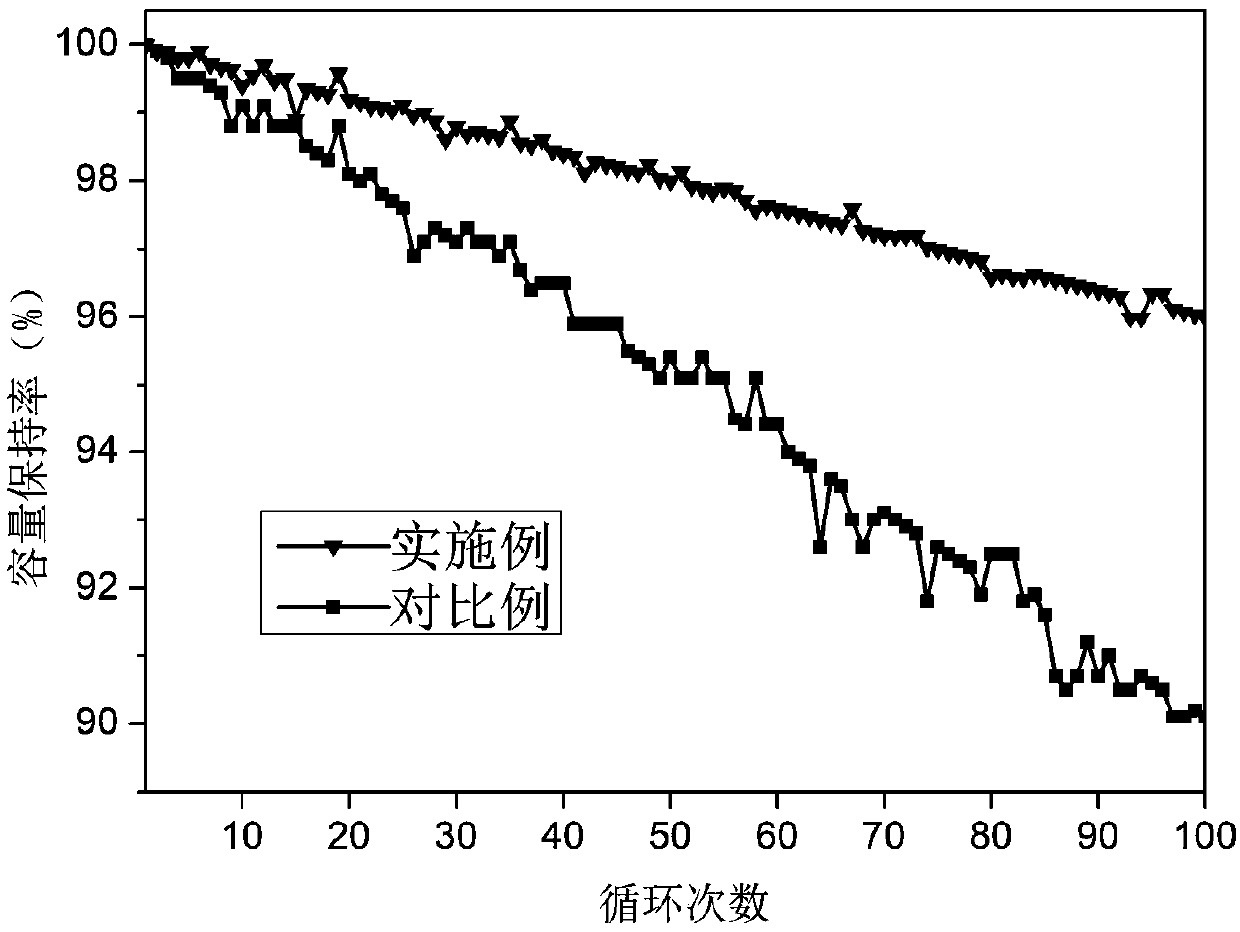

Method for preparing nickel-cobalt-manganese ternary cathode material

ActiveCN109671924AGood processing performanceLow residual lithiumCell electrodesSecondary cellsChemistryCarbon dioxide

A method for preparing a nickel-cobalt-manganese ternary cathode material comprises the steps of: injecting a mixed gas of carbon dioxide and oxygen in a reaction device, adding a nickel-cobalt-manganese mixed solution to control the pH of the reaction solution to be 9.5-10.5, and preparing a core of a nickel-cobalt-manganese ternary precursor at the temperature of 75-95 DEG C; regulating the reaction temperature to 45-65 DEG C, and regulating the pH of the reaction solution to 11.5-12.5 after crystallization; adding the nickel-cobalt-manganese mixed solution and a complexing agent solution tocontrol the pH of the reaction solution to be 11.5-12.5 and control the reaction temperature to be 45-65 DEG C, and preparing a housing of the nickel-cobalt-manganese ternary precursor; performing post-treatment of the product such as ageing to obtain a nickel-cobalt-manganese ternary precursor of a composite [alpha]-type and [beta]-type core-shell structure; and performing ball-milling mixing ofthe nickel-cobalt-manganese ternary precursor with lithium hydroxide to obtain a burn-in ternary cathode material through high-temperature sintering; and performing high-temperature sintering to obtain a nickel-cobalt-manganese ternary cathode material. The prepared cathode material is good in capacity, is high in capacity maintenance rate after multiple cycle and outstanding in electrochemical performance.

Owner:兰州金通储能动力新材料有限公司

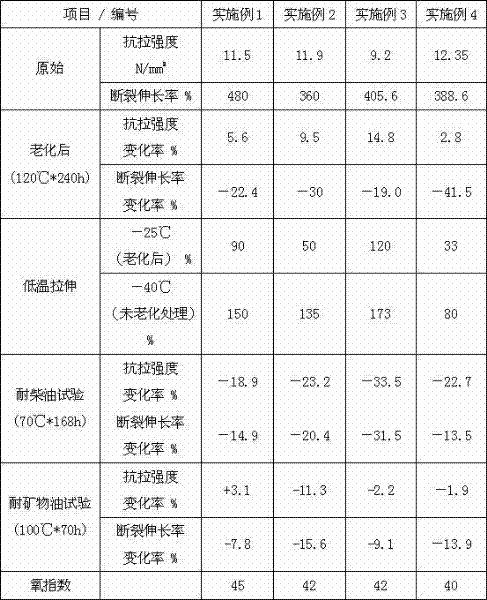

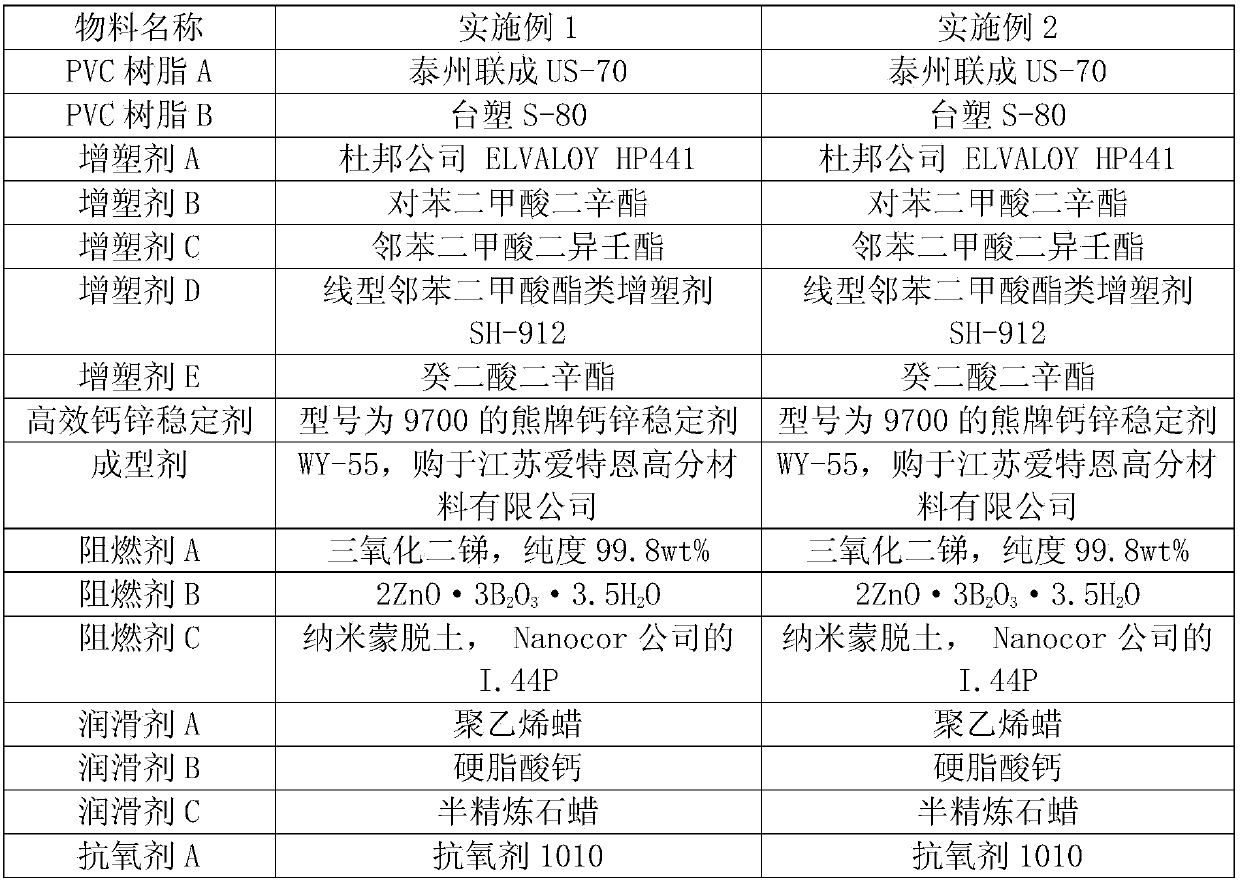

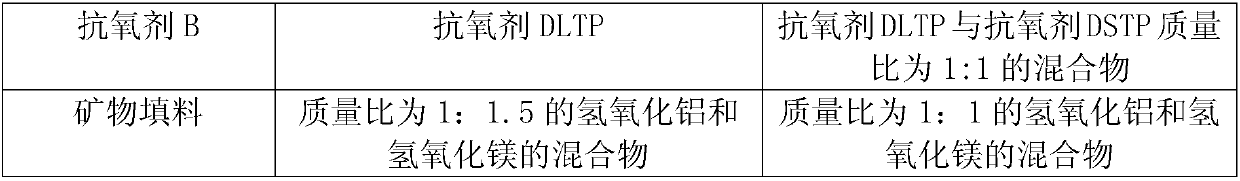

Cold-resisting (40 DEG C below zero) and high-flame retardant (OI is greater than or equal to 38) PVC (Polyvinyl Chloride) cable material and preparation method thereof

ActiveCN107857955AGood processing performanceGlue output is stablePlastic/resin/waxes insulatorsPlasticizerFire retardant

The invention discloses a cold-resisting (40 DEG C below zero) and high-flame retardant (OI is greater than or equal to 38) PVC (Polyvinyl Chloride) cable material and a preparation method thereof. The cold-resisting (40 DEG C below zero) and high-flame retardant (OI is greater than or equal to 38) PVC cable material is prepared from the following raw material components in parts by weight: 50 parts of polyvinyl chloride resin A, 50 parts of polyvinyl chloride resin B, 10 to 20 parts of plasticizer A, 10 to 30 parts of plasticizer B, 10 to 30 parts of plasticizer C, 20 to 30 parts of plasticizer D, 5 to 10 parts of plasticizer E, 1 to 3 parts of forming agent, 5 to 10 parts of flame retardant A, 5 to 10 parts of flame retardant B, 5 to 10 parts of flame retardant C, 0.2 to 0.8 part of lubricant A, 0.2 to 0.8 part of lubricant B, 0.2 to 0.8 part of lubricant C, 1 to 2 parts of antioxidant A, 1 to 2 parts of antioxidant B, 4 to 8 parts of high-efficiency calcium zinc stabilizer and 40 to70 parts of mineral filler. The cable material disclosed by the invention has the characteristics of cold resistance (40 DEG C below zero), excellent high-flame retardant property (OI is greater thanor equal to 38) and the like, and is suitable for being used in harsh environments with higher flame retardancy and external extreme cold.

Owner:JIANGSU SHANGSHANG CABLE GRP NEW MATERIAL CO LTD +1

Hydrolyzablecopolyester and preparation method and application thereof

InactiveCN109762143AGood water degradation performanceGood processing performancePolyesterChain segment

The invention discloses a hydrolyzablecopolyester. A molecular chain segment of the hydrolyzablecopolyester comprises a chain segment of a polyester difficult to hydrolyze and a chain segment of a hydrolyzable polyester body, and the hydrolyzablecopolyester is a random copolymer or a block copolymer composed of the chain segment of the polyester difficult to hydrolyze and the chain segment of thehydrolyzable polyester. The hydrolyzablecopolyester has good strength and toughness, meanwhile, is biodegradable, and can be degraded rapidly in the natural water environment. The invention further discloses a preparation method and application of the hydrolyzablecopolyester.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

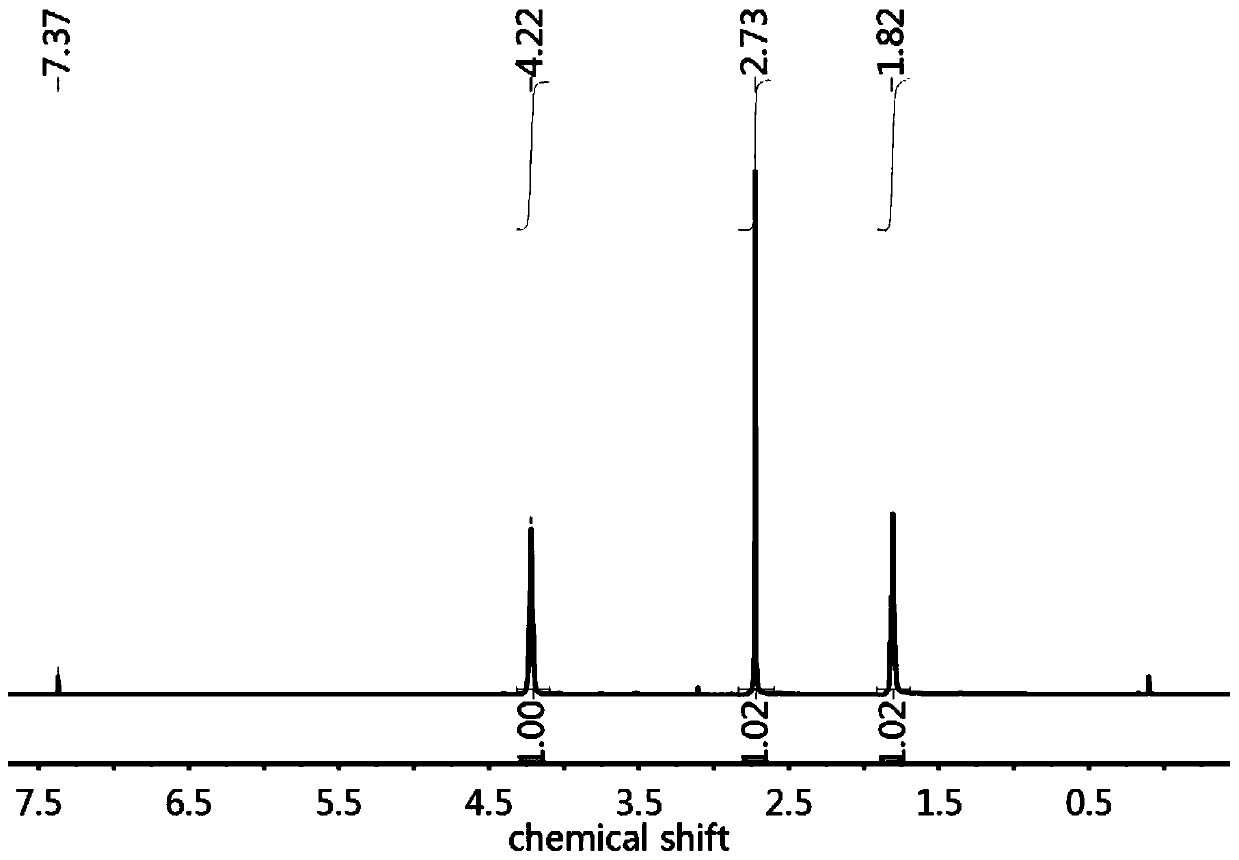

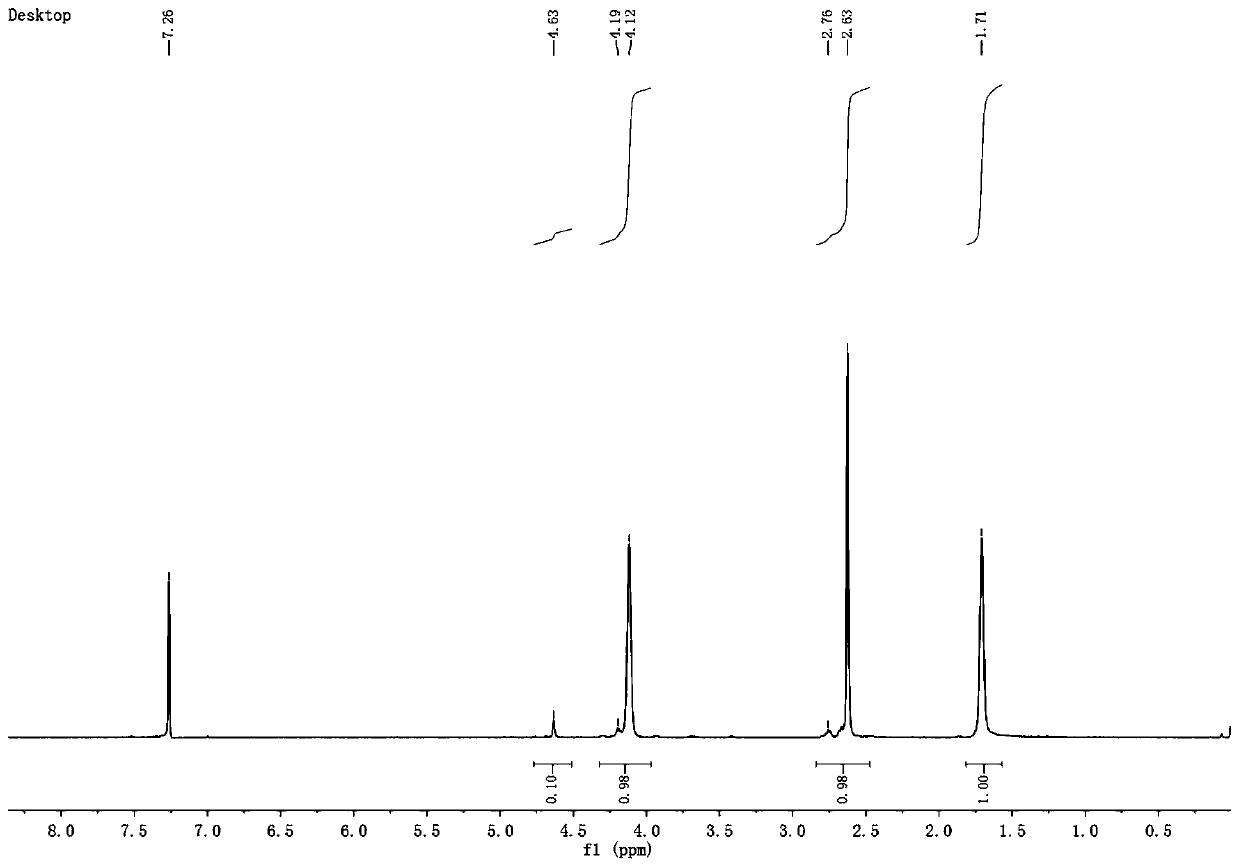

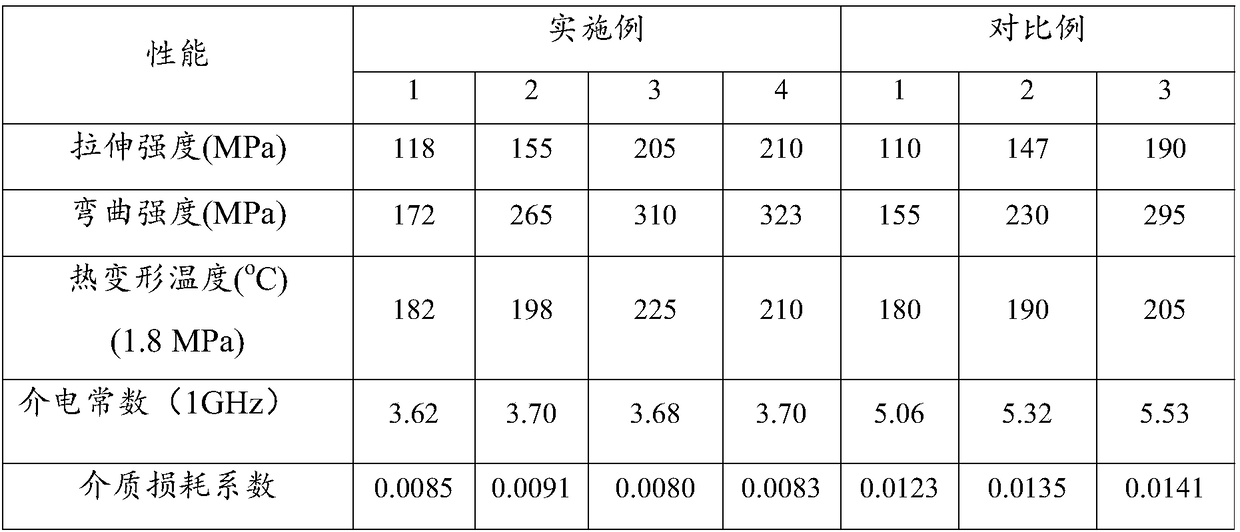

Glass fiber reinforced low dielectric nylon material and preparation method thereof

The invention provides a glass fiber reinforced low dielectric nylon material and a preparation method thereof. The glass fiber reinforced low dielectric nylon material is mainly prepared from the following raw materials of nylon resin, quartz glass fibers, a nucleating agent, a lubricant, a thermal oxygen stabilizer and the like. The prepared nylon material has the advantages of being excellent in mechanical performance and good in dielectric performance and heat resistance, having good processing performance and being further expanded in application in the field of electronic equipment.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

High-stiffness high-strength heat-sealing embossed film and preparation method thereof

ActiveCN102719200AGood processing performanceMaintain extrusion stabilityFlexible coversWrappersElastic modulusHigh stiffness

Owner:佛山新长盛塑料薄膜有限公司

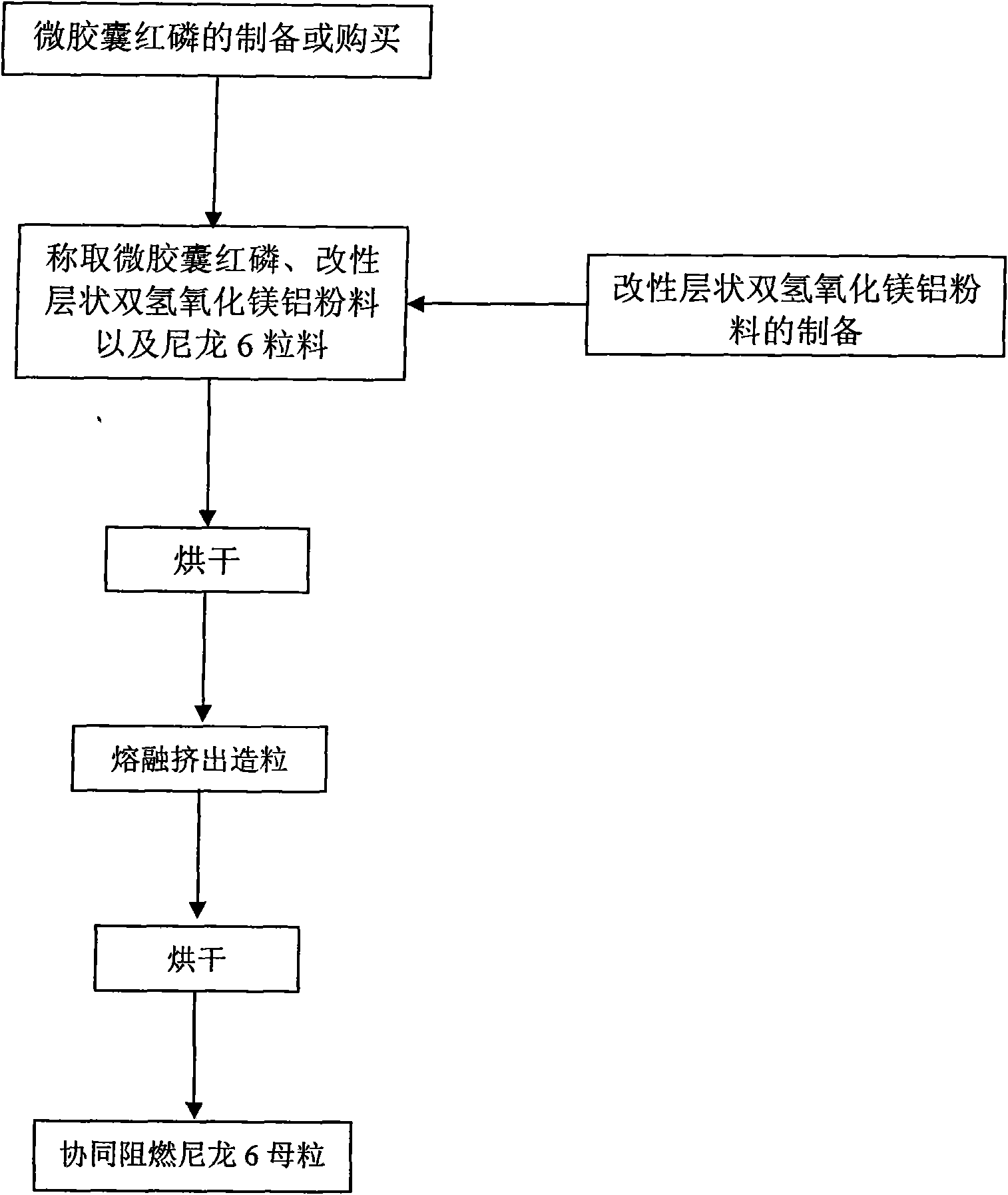

Method for preparing cooperative flame retardant nylon 6

The invention discloses a method for preparing cooperative flame retardant nylon 6, which comprises the following steps: adding a sodium hydroxide aqueous solution in an aluminum nitrate and magnesiumnitrate aqueous solution to react at room temperature; then adding a dissolved sodium stearate aqueous solution in the reaction system and then keeping the reaction; filtering, washing and drying theproduct to obtain modified lamellar magnesium aluminum bihydroxide powder; respectively weighing microcapsule red phosphorus, the modified lamellar magnesium aluminum bihydroxide powder and nylon 6 granules and drying; premixing the three dried materials; fusing, blending, extruding and granulating in a double-screw rod extruder; drying to obtain a cooperative flame retardant nylon 6 master granule. The invention uses ammonium persulphate as an initiating agent, and an ignition point of the prepared microcapsule red phosphorus exceeds 450DEG C; when the vertical combustion performance of a nylon 6 composite material reaches the V-0 level, and LOI reaches more than 28 percent, the consumption of flame retardant agents is less, and all used flame retardant agents are cheap halogen-free flame retardant agents, thereby reducing the cost.

Owner:NANJING UNIV OF SCI & TECH

Rubber and metal framework bonding method

The invention discloses a rubber and metal framework bonding method, which is characterized by comprising six steps including preparation of rubber, cleaning of a metal framework, drying of the metalframework, covering of primer, covering of surface glue and vulcanization. Through the above method, bonding strength between rubber and the metal framework can be remarkably enhanced, and it is ensured that rubber has good processability.

Owner:NINGBO TUOPU GROUP CO LTD

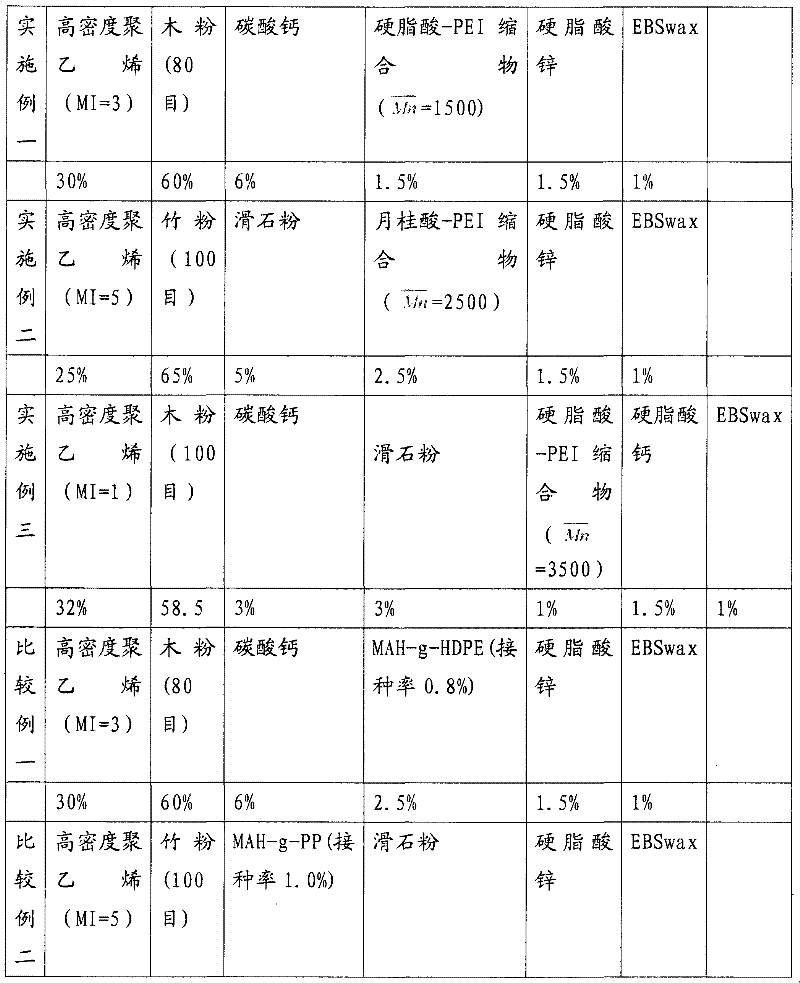

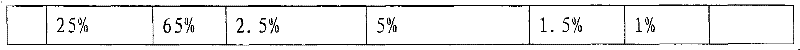

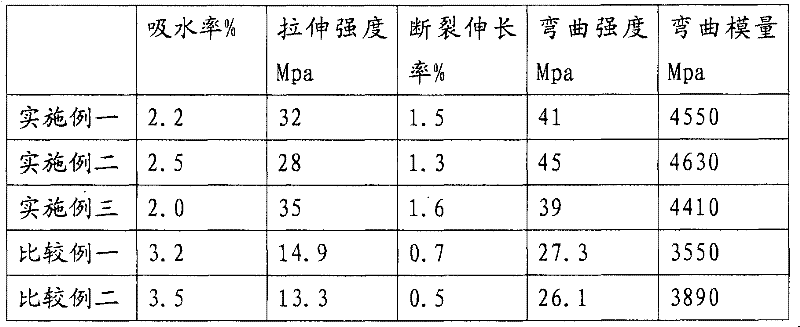

Natural fiber filled polyethylene composite material and preparation method thereof

InactiveCN102532661AGood processing performanceGood mechanical propertiesRevolutions per minuteEthylene imine

The invention provides a natural fiber filled polyethylene composite material and a preparation method thereof. The natural fiber filled polyethylene composite material comprises the following components by weight percent: 20-50% of high density polyethylene, 40-70% of natural fiber powder, 1-6% of fatty acid polyethylenimine condensation product, 1-15% of inorganic mineral filler and 1-6% of lubricating agent. The preparation method comprises the following steps: adding weighed natural fiber powder particles into a high-speed mixer, and stirring for 20-30 minutes at the speed of 2000r / min (revolutions per minute); adding other components in proportion, mutually mixing and stirring for 10-20 minutes, and then adding the mixture into a homodromous and parallel two-screw extruder; and pelleting to obtain the particles of the natural fiber filled polyethylene composite material. By using the preparation method, the defects that a common WPC (wood plastic composite) material is poor in mechanical property and poor in humidity resistance are solved.

Owner:广东省石油化工研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com