Fully-biodegradable composition and preparation method thereof

A technology of biodegradable polyester and composition, applied in the field of fully biodegradable composition and its preparation, can solve the problems of limited application and high cost of toughening agent, and achieve the effect of promoting application, low cost and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

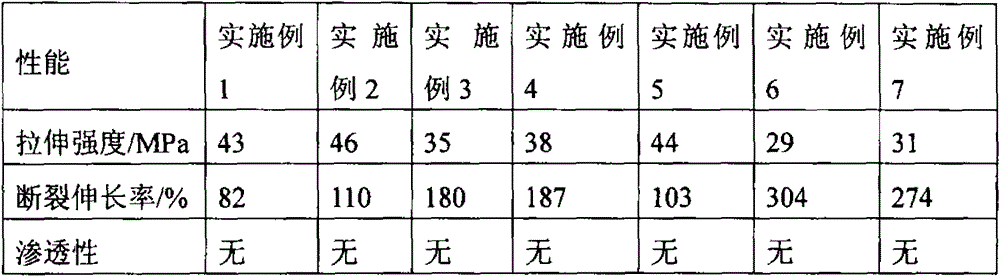

Examples

Embodiment 1

[0037] Put castor oil and L-lactic acid respectively in the polycondensation reactor, and vacuumize at 60°C for 2 hours to remove the moisture in the raw materials. Then castor oil and L-lactic acid are taken as 1: 1 according to the amount ratio of substances, and 0.1% stannous chloride dihydrate that accounts for the total mass of raw materials is used as a catalyst; The polycondensation reaction was carried out for 8 hours under the atmosphere, and then vacuumized, and the reaction was continued for 10 hours under vacuum. After the reaction, the number-average molecular weight of the obtained copolymer was 48000, which was the required toughening agent and was ready for use.

[0038] Polylactic acid PLA (provided by Nature Works, 4032D) and PBS (provided by Anqing Hexing Company, blown film grade) were dried in a blast oven at 60°C for 24 hours, and calcium carbonate (800 mesh) was dried in a blast oven at 105°C 10h.

[0039] Take 80 parts of PLA, 20 parts of PBS, 5 parts ...

Embodiment 2

[0042]Put the polycastor oil and D-lactic acid in the polycondensation reactor respectively, and vacuumize at 80°C for 1 hour to remove the moisture in the raw materials. Then take polycastor oil and D-lactic acid as 1: 300 according to the amount ratio of substance, and take 0.5% tin protochloride dihydrate that accounts for the total mass of raw materials as a catalyst; raw materials are added in the polycondensation reactor, and the system is first at 150 ° C, The polycondensation reaction was carried out for 4 hours under a nitrogen atmosphere, and then vacuumized, and the reaction was continued for 5 hours under vacuum. After the reaction, the number-average molecular weight of the obtained copolymer was 63,000, which was the required toughening agent and was ready for use.

[0043] PLA (provided by Nature Works, 2002D) and PBSA (provided by Anqing Hexing Company, blown film grade) were dried in a blast oven at 80°C for 6 hours, and talc powder (1250 mesh) was dried in a b...

Embodiment 3

[0047] Epoxy soybeans and DL-lactic acid were placed in polycondensation reactors respectively, and vacuumed at 70°C for 2 hours to remove moisture in the raw materials. Then take epoxidized soybean oil and DL-lactic acid as 1: 200 according to the amount ratio of substances, and take 0.2% stannous octoate that accounts for the total mass of raw materials as a catalyst; raw materials are added in the polycondensation reactor, and the system is first at 160 ° C under a nitrogen atmosphere The polycondensation reaction was carried out for 3 hours, and then vacuumized, and the reaction was continued for 6 hours under vacuum. After the reaction, the number average molecular weight of the obtained copolymer was 71000, which was the required toughening agent and was ready for use.

[0048] PLA (provided by Nature Works, 4032D) and PBAT (provided by BASF, blown film grade) were dried in a blast oven at 80°C for 10 h, and mica (2000 mesh) was dried in a blast oven at 110°C for 6 h.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com