Glass fiber reinforced low dielectric nylon material and preparation method thereof

A low-dielectric, glass fiber technology, used in the field of polymer modified materials, to achieve the effects of excellent processing performance, expanding the scope of use, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

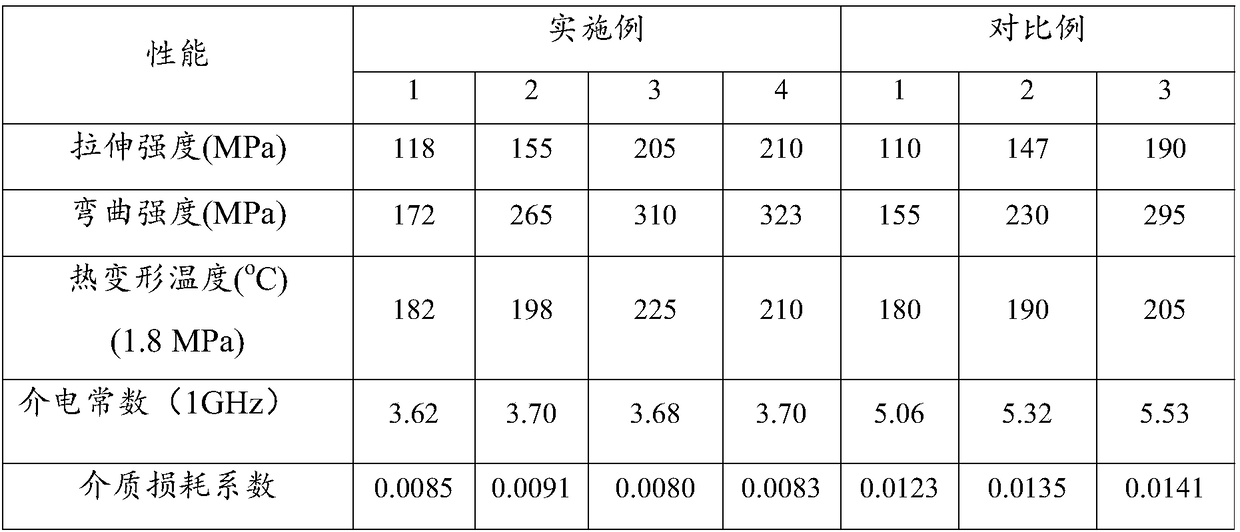

Examples

Embodiment 1

[0071] Weigh raw materials according to the following parts by weight: 60 parts of nylon 1010 resin, 20 parts of quartz glass fiber with a monofilament diameter of 10 μm treated by aminosilane coupling agent on the surface, 0.2 part of CaV102 nucleating agent, ultra-high molecular weight siloxane lubrication Agent 0.3 parts, Nylostab S-EED heat stabilizer 0.5 parts.

[0072] Put all the raw materials weighed above except quartz glass fiber into the high-speed mixer for 10 minutes, and then feed them into the twin-screw extruder from the main feeding port, and feed the quartz glass fiber into the extruder from the side feeder , extrusion granulation;

[0073] Wherein, the temperature of the twin-screw extruder is 240°C-280°C, and the screw speed is 280r / min.

Embodiment 2

[0075] Weigh raw materials according to the following parts by weight: 60 parts of nylon 1010 resin, 40 parts of quartz glass fiber with a monofilament diameter of 10 μm treated by aminosilane coupling agent on the surface, 0.2 part of CaV102 nucleating agent, ultra-high molecular weight siloxane lubrication Agent 0.3 parts, Nylostab S-EED heat stabilizer 0.5 parts.

[0076] Put all the raw materials weighed above except quartz glass fiber into the high-speed mixer for 10 minutes, and then feed them into the twin-screw extruder from the main feeding port, and feed the quartz glass fiber into the extruder from the side feeder , extrusion granulation;

[0077] Wherein, the temperature of the twin-screw extruder is 240°C-280°C, and the screw speed is 280r / min.

Embodiment 3

[0079] Weigh the raw materials according to the following parts by weight: 60 parts of nylon 1010 resin, 60 parts of quartz glass fiber with a monofilament diameter of 10 μm treated by aminosilane coupling agent on the surface, 0.2 part of CaV102 nucleating agent, ultra-high molecular weight siloxane Lubricant 0.3 parts, Nylostab S-EED heat stabilizer 0.5 parts. Put all the raw materials weighed above except quartz glass fiber into the high-speed mixer for 10 minutes, and then feed them into the twin-screw extruder from the main feeding port, and feed the quartz glass fiber into the extruder from the side feeder , extrusion granulation;

[0080] Wherein, the temperature of the twin-screw extruder is 240°C-280°C, and the screw speed is 280r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com