Hydrolyzablecopolyester and preparation method and application thereof

A technology of copolyester and polyester, applied in the field of degradable polymer materials, can solve the problems of difficult removal, high cost, and low molecular weight of the product, and achieve the effect of excellent processing performance and good water degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] Yet another embodiment of the present invention provides the preparation method of above-mentioned hydrolyzable copolyester, in one scheme, this preparation method comprises the steps:

[0069] Mixing the dibasic acid and dibasic alcohol used to form the chain segment of the difficult hydrolyzable polyester and the monomer of the easily hydrolyzable polyester, esterification and polycondensation in the presence of a catalyst to obtain the copolymerization ester, the copolymer at this time is a random copolymer.

[0070] It can be understood that the above-mentioned dibasic acid and dibasic alcohol forming the chain segment of the difficult hydrolyzable polyester can be exemplified as, when the difficultly hydrolyzable polyester is PBS, the dibasic acid forming PBS is 1,4- Succinic acid, the diol is 1,4-butanediol, and the content of 1,4-butanediol is 1-2 times the molar content of 1,4-butanedioic acid. At this time, the monomer of easily hydrolyzable polyester The mola...

Embodiment 1

[0095] A kind of preparation method of hydrolyzable copolyester, comprises the steps:

[0096] 10mol of 1,4-butanedioic acid, 15mol of 1,4-butanediol (excess), 1mol of glycolic acid, after esterification at 160-180°C for 2 hours, add catalyst tetrabutyl titanate 6.5g, high vacuum at 200-230°C Polycondensation 4h to obtain random copolyester PGBS1, its structural formula is as shown in the following formula:

[0097]

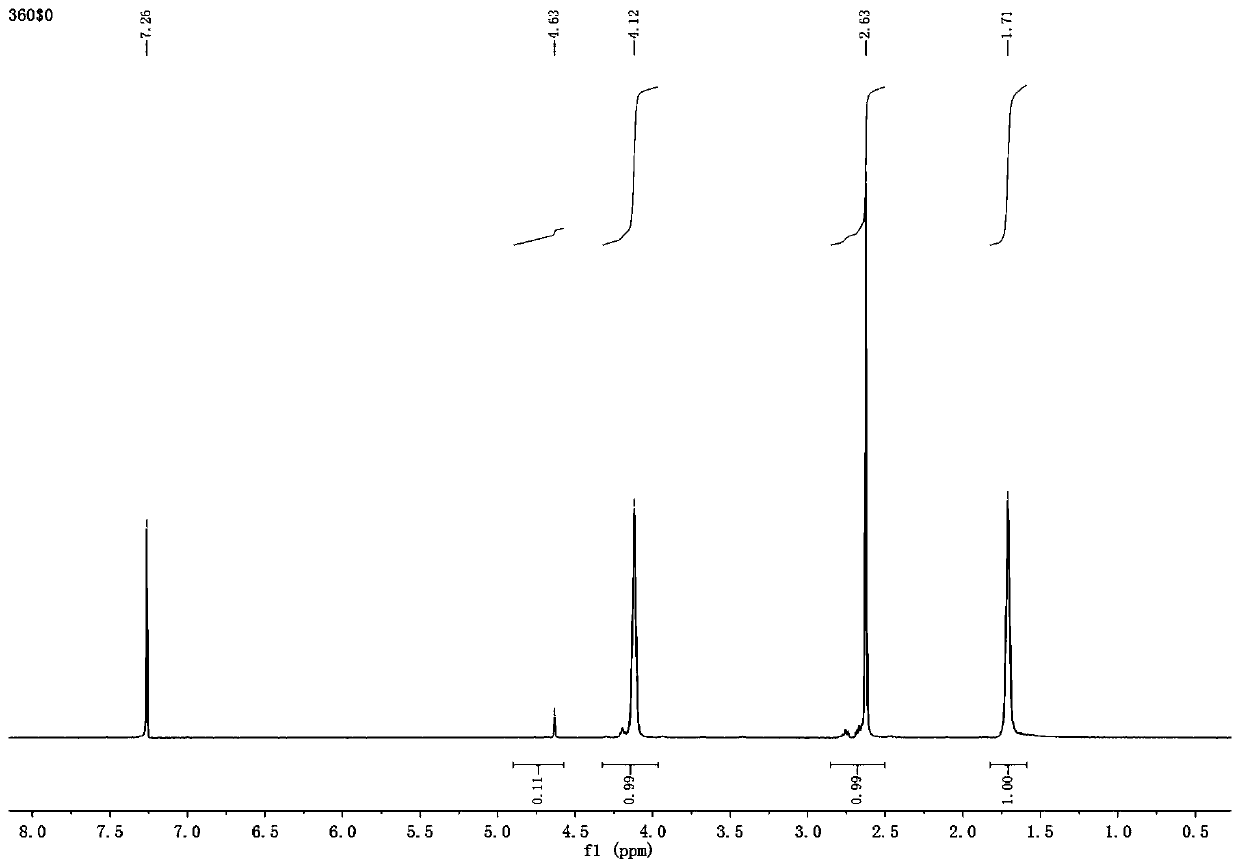

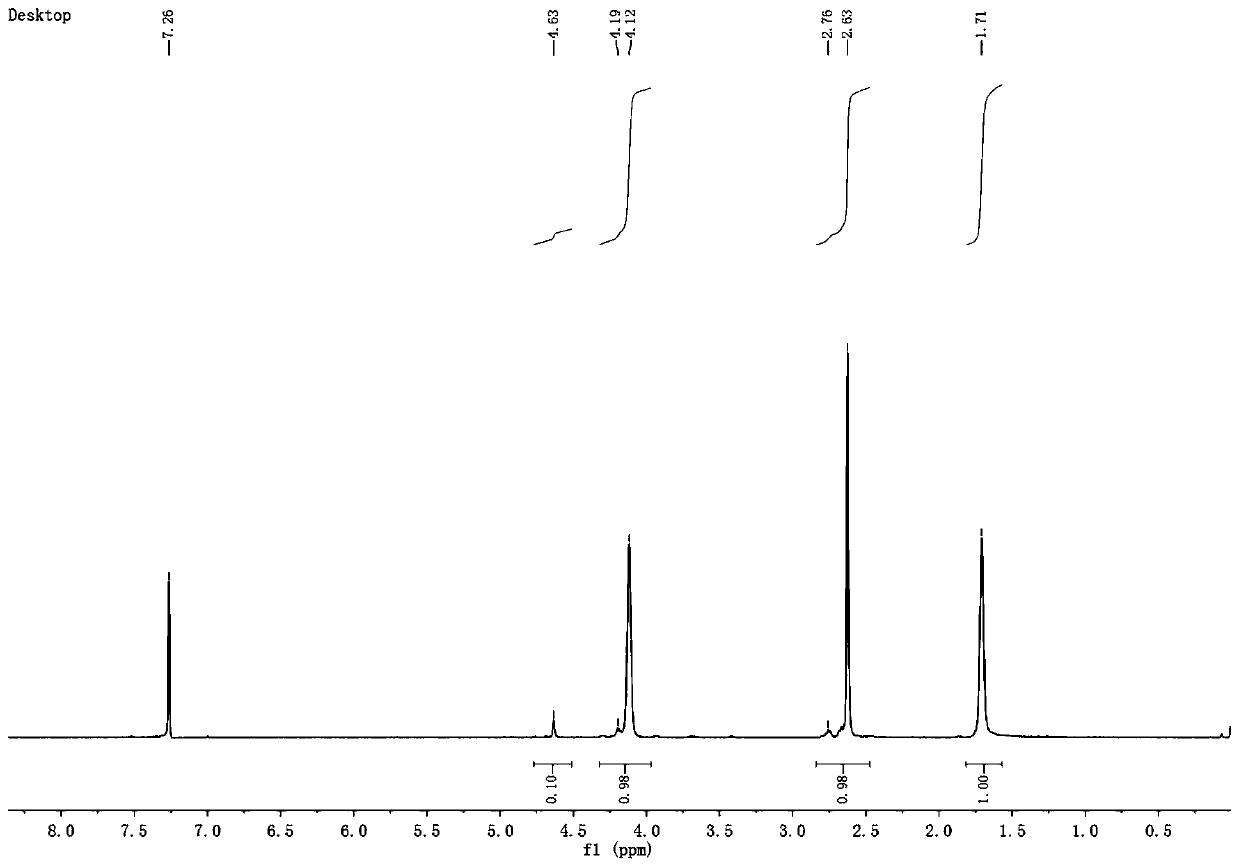

[0098] After determination, the M of the random copolyester n =49600, tensile strength 35MPa, elongation at break 120%, melting point 105°C, nuclear magnetic spectrum as figure 1 shown. It takes 4 months for the molecular weight to drop to 1 / 10 of the original in distilled water at 40°C. In natural seawater, it loses 70% of its weight in one year. The copolyester can be processed into disposable tableware such as knives, forks and spoons through injection molding or blister processing.

Embodiment 2

[0103] A kind of preparation method of hydrolyzable copolyester, comprises the steps:

[0104] 10mol of 1,4-butanedioic acid, 15mol of 1,4-butanediol (excess), 1mol of glycolide, after esterification at 160-180°C for 2h, add catalyst tetraisopropyl titanate 5.5g, stannous chloride 0.3g, high vacuum polycondensation at 200-230°C for 4.5h to obtain random copolyester PGBS2, whose structural formula is as follows:

[0105]

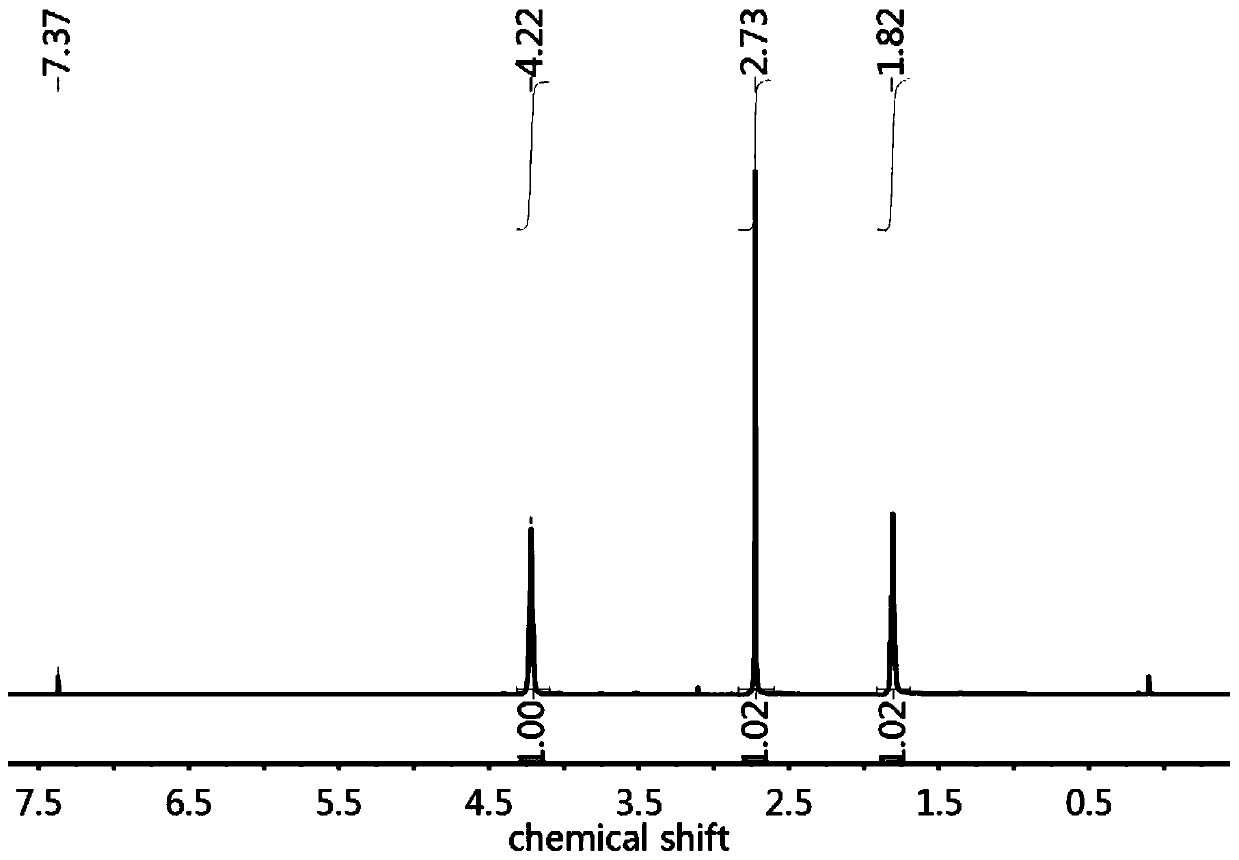

[0106] After determination, the M of the random copolyester n =50200, tensile strength 34MPa, elongation at break 130%, melting point 105°C. Its NMR spectrum is as image 3 As shown, it takes 4 months for the molecular weight to drop to 1 / 10 of the original in distilled water at 40°C. In natural seawater, it loses 70% of its weight in one year. The copolyester can be processed into various pipes by twin-screw extrusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com