Patents

Literature

2169 results about "Dibasic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dibasic acid is an acid that has two hydrogen ions to donate to a base in an acid-base reaction. Therefore, a dibasic molecule has two replaceable hydrogen atoms. Example: H₂SO₄.

Ester-terminated poly(ester-amide) in personal care products

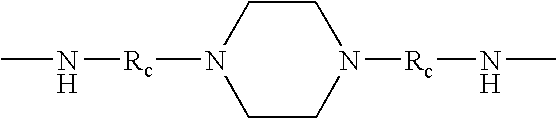

A resin composition is prepared by reacting components comprising dibasic acid, diamine, polyol and monoalcohol, wherein (a) at least 50 equivalent percent of the dibasic acid comprises polymerized fatty acid; (b) at least 50 equivalent percent of the diamine comprises ethylene diamine; (c) 10-60 equivalent percent of the total of the hydroxyl and amine equivalents provided by diamine, polyol and monoalcohol are provided by monoalcohol; and (d) no more than 50 equivalent percent of the total of the hydroxyl and amine equivalents provided by diamine, polyol and monoalcohol are provided by polyol. This resin composition may be formulated into, for example, personal care products, fragrance releasing products and candles.

Owner:CRODA INT PLC

Fluorinated polyesters with low surface energy and preparation method thereof

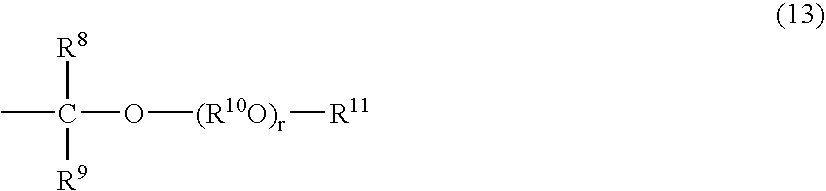

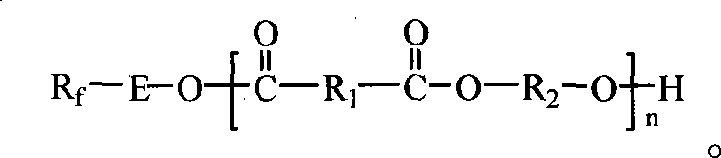

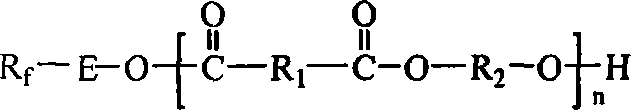

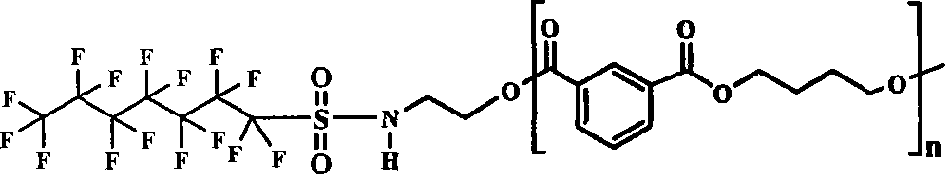

The present invention belongs to the field of mnacromolecule, relating to the fluorine-containing polyester of low surface energy and the preparation method of the fluorine-containing polyester. The polyester has the following chemical structure (1): wherein R f C is the straight chain of 2 - 21 C or the branch-chain pseudo-perfluoroalkyl; R1, R2 is the alkyl, aryl, or naphthenic base of the C1-C8; E is -(CH2) m-; formula (3) or formula (4); R' is H or the straight chain or the branch-chain alkyl under C4; m is an integer between 0 or 10. The polyester preparation method is that dibasic acid or the correspondent diester, dihydric alcohol and perfluoroalkane, which are 0.05 percent to 10 percent of the total material weight, are fused and polymerized under vacuum condition. The polyester preparation method at the pseudo-perfluoroalkyl sealed end is simple, and is of good drainage and oil dredging properties. The present invention can be widely used in antifouling coatings, and is of important development and application value.

Owner:DALIAN UNIV OF TECH

Nylon manufacturing method

The invention provides a nylon manufacturing method. The nylon manufacturing method comprises the following steps of 1, preparing a nylon salt aqueous solution from diamine and diacid, adjusting a pH value of the nylon salt aqueous solution to a specific value by diamine, and calculating a use amount ratio of the diamine to the diacid at the pH value equal to the specific value, and 2, adding the diamine to the diacid according to the calculated use amount ratio and carrying out a fusion polymerization process without a medium. The nylon manufacturing method reduces volatilization of the diamine in polymerization, saves a cost, reduces pollution, shortens a polymerization period, improves an equipment utilization rate, reduces polymerization energy consumption and can prepare green nylon suitable for a plurality of purposes.

Owner:CATHAY R&D CENT CO LTD +2

Nylon modified plastic

The invention discloses a nylon modified plastic which comprises the following raw materials in parts by weight: (1) 20-80 parts of nylon resin; and (2) one or more of 15-45 parts of reinforcer, 5-20 parts of toughener or 9-15 parts of compound flame retardant, wherein the nylon resin is prepared from pentamethylene diamine and aliphatic dibasic acid used as raw materials, and at least one of the pentamethylene diamine and the aliphatic dibasic acid is prepared through a biological method. The nylon modified particle prepared by the invention has excellent properties of reinforcing, toughening, flame retardance and the like, can be further used in the fields of automobile industry, electronic / electric apparatus industry, mechanical equipment and the like, and has wide industrial application prospects.

Owner:CATHAY R&D CENT CO LTD +1

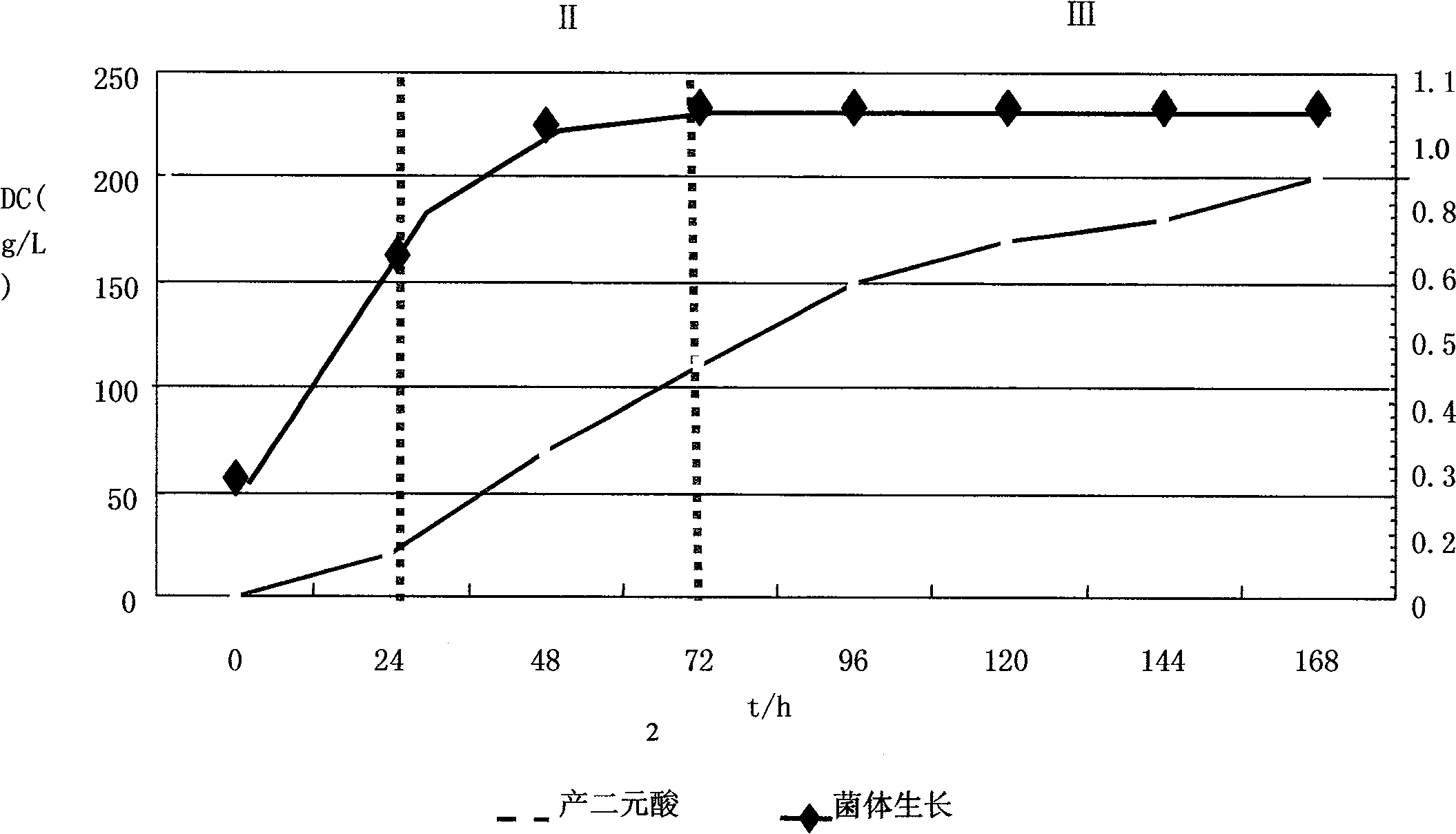

Long carbon-chain dibasic acid prepared from fatty acids or derivatives thereof and preparation method for the long carbon-chain dibasic acid

ActiveCN101121653AReduce dependencePromote the development of deep processingOrganic chemistryMicroorganism based processesAlkaneCarbon chain

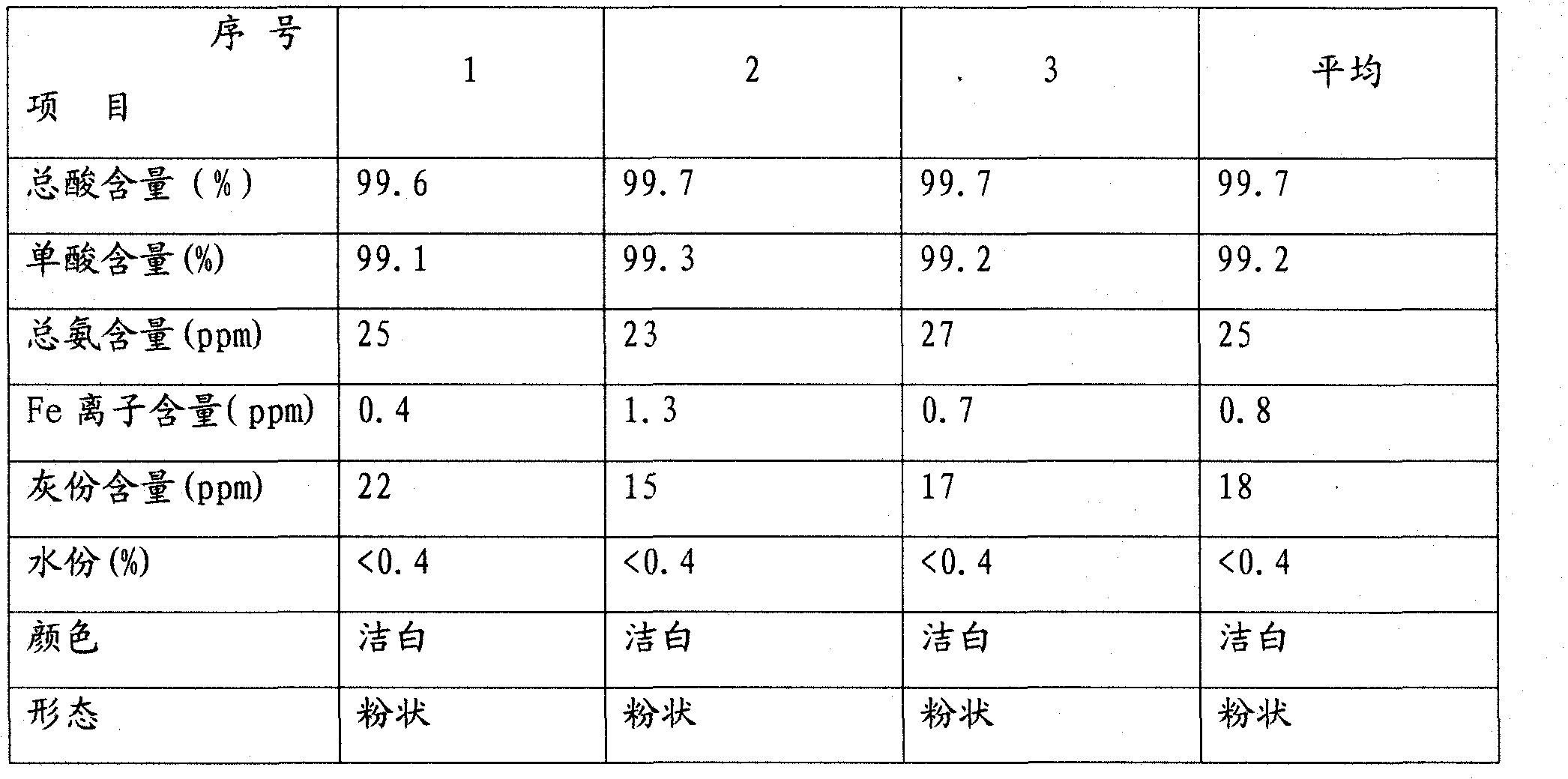

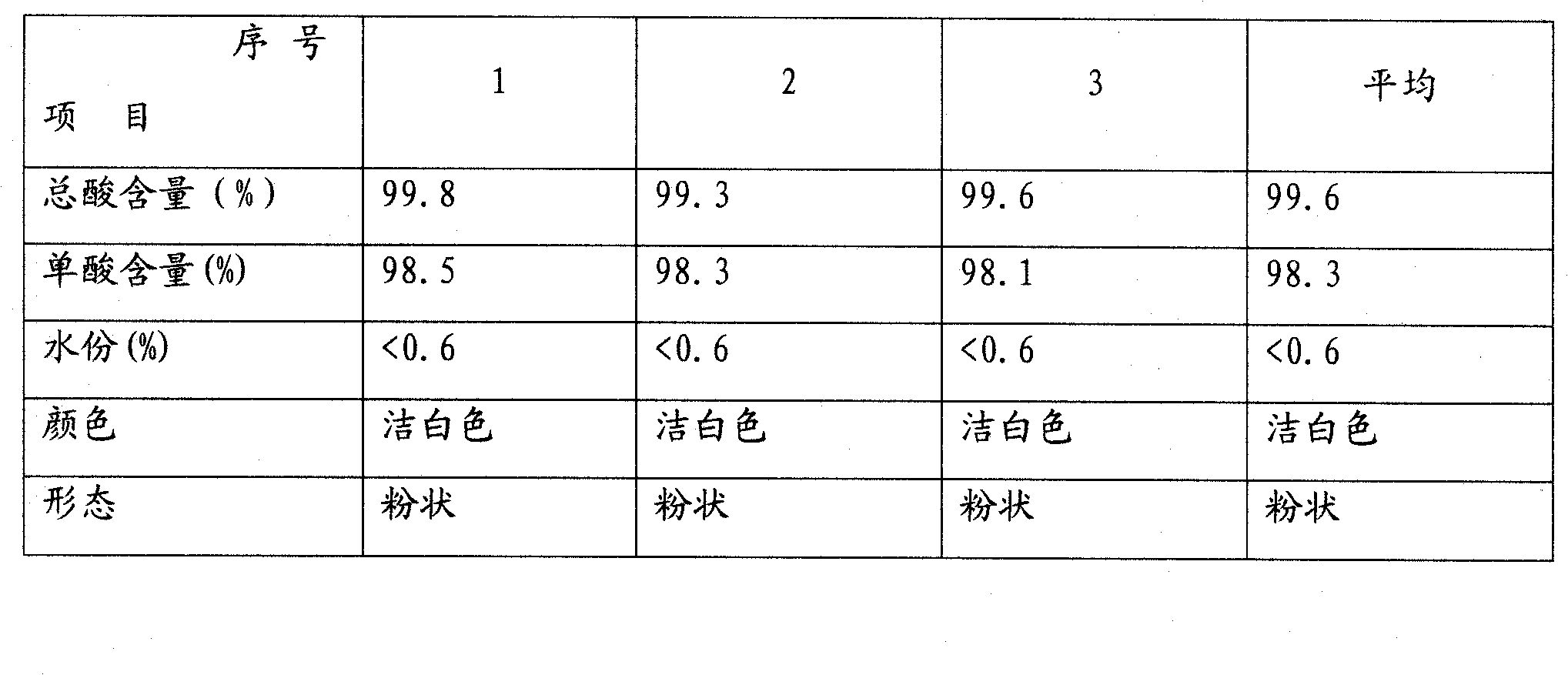

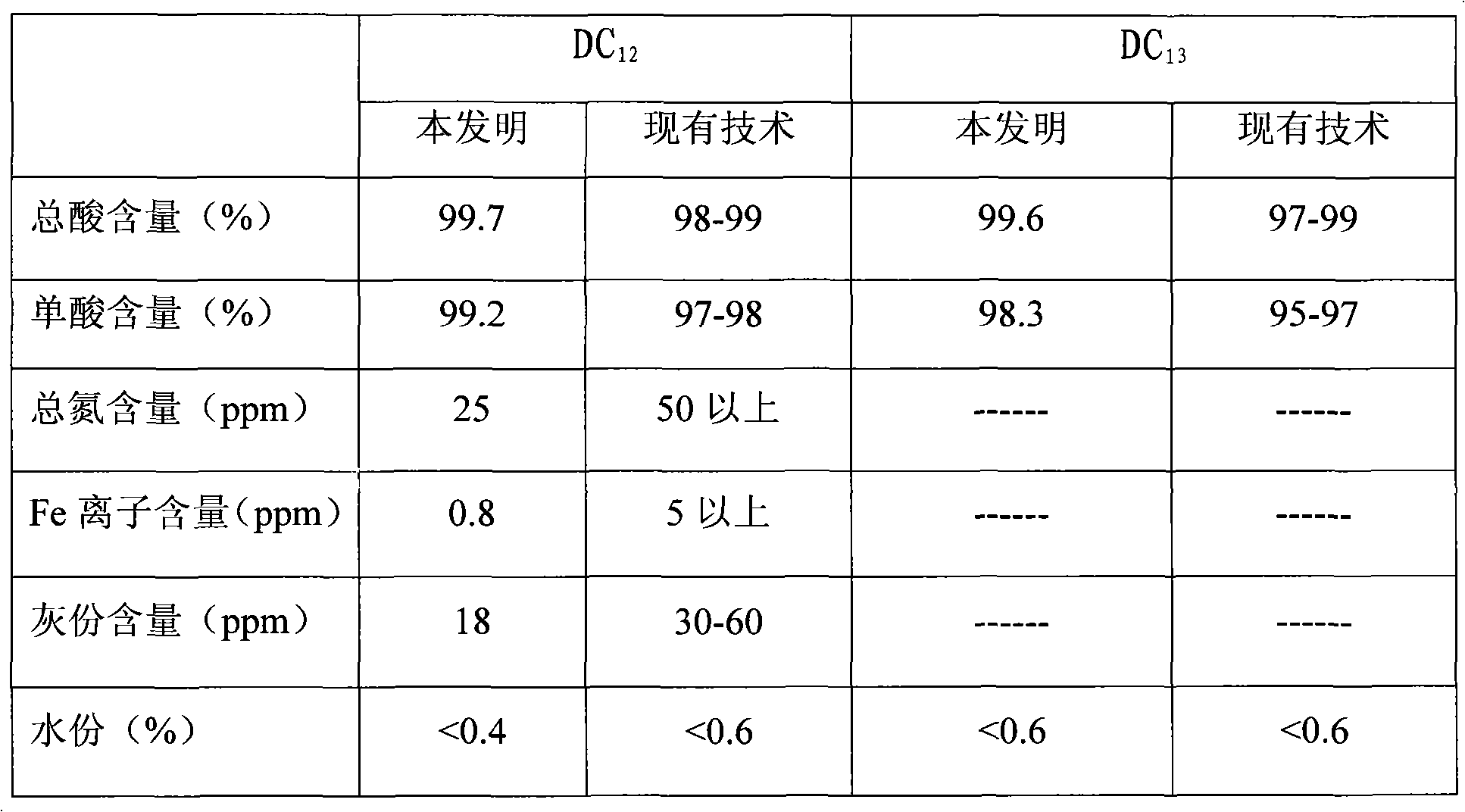

The invention discloses a biological preparation method of the long carbochain biatomic acid with the fatty acid or the ramification of the fatty acid as the starting material. The number of carbon atoms is between 9 and 20. The long carbochain biatomic acid with the total content of the biatomic acid no less than 95 percent and the content of the atomic acid no more than 0.5 percent is further refined; then the total content of the biatomic acid is no less than 98.5 percent and the content of the atomic acid is no more than 0.05 percent. The long carbochain biatomic acid can replace the current long carbochain biatomic acid produced in a chemical or biological method (with the alkanes as the raw material) to be used in each field. At the same time, the invention provides the preparation process of the long carbochain biatomic acid; the process begins from the fatty acid or the ramification of the fatty acid; first the bio-fermentation is used to produce the long carbochain biatomic acid; then after the special purification process, the required biatomic acid can be acquired.

Owner:CATHAY R&D CENT CO LTD

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

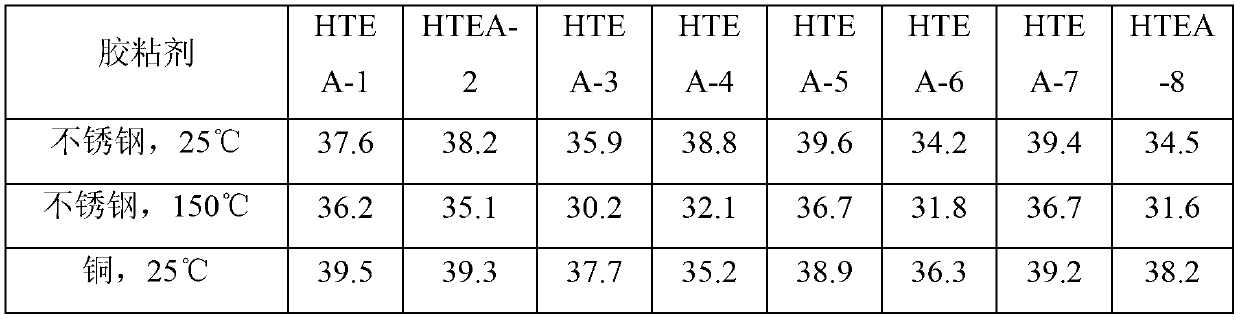

4,4'-bis(2,4-diamidophenoxy)biphenyl high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146331AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesTolueneDibasic acid

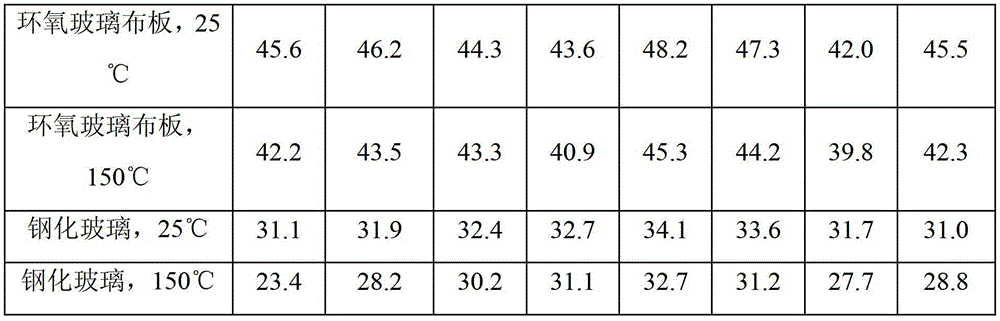

The invention relates to a 4,4'-bis[4-(2,4-diamidophenoxy)phenyl]biphenyl high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)biphenyl high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamidophenoxy)biphenyl and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)biphenyl and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

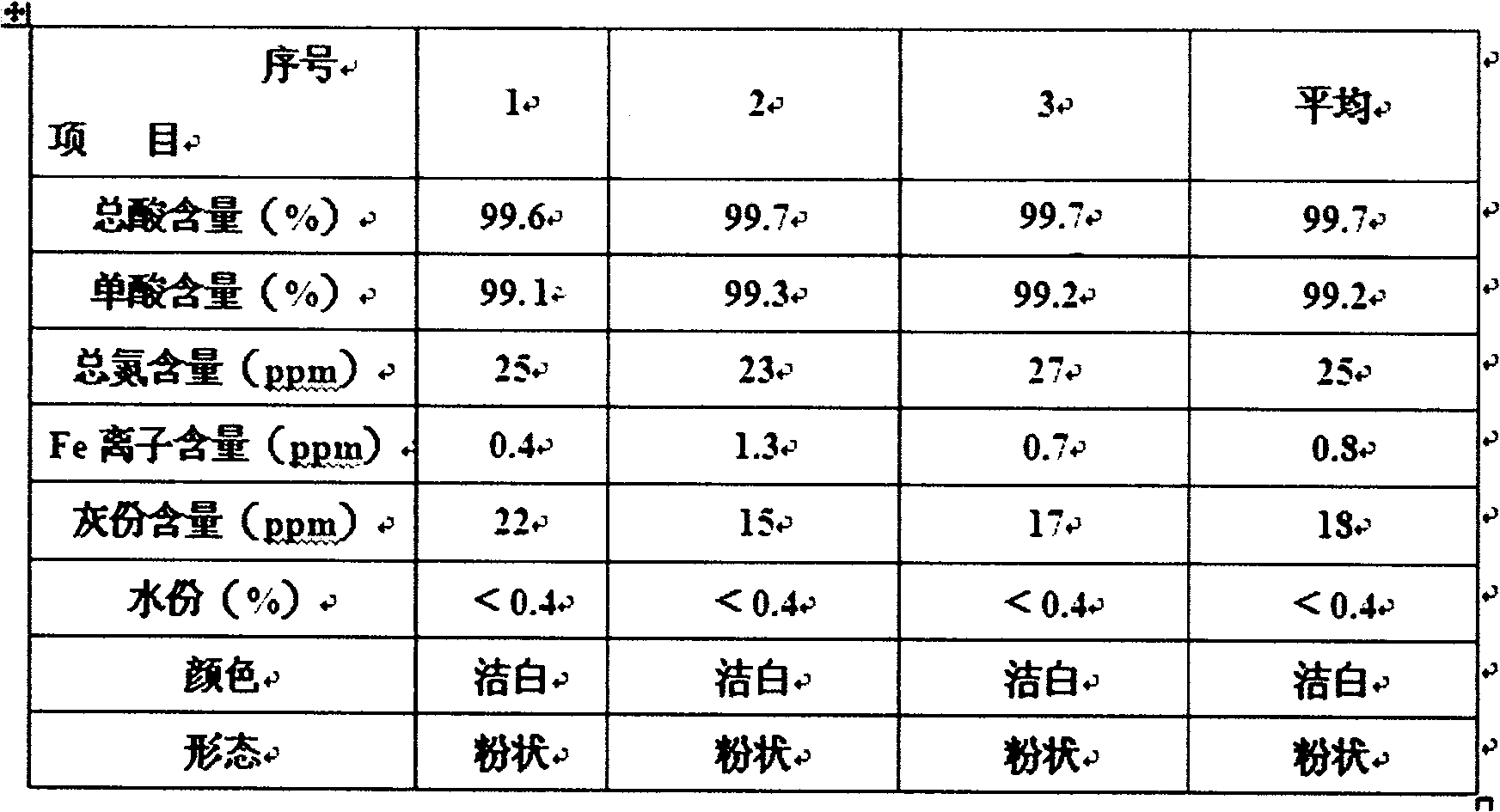

Refining technology for producing long carbon chain dicarboxylic acid by using biological fermentation process

ActiveCN101985416AHigh monoacid contentImprove thermal stabilityCarboxylic compound separation/purificationDielectricCarbon chain

The invention belongs to the technical field of preparing long carbon chain dicarboxylic acid by using a biological fermentation process, in particular relating to a refining technology for producing long carbon chain dicarboxylic acid by using a biological fermentation process. The technical scheme of the invention is the refining technology for producing long carbon chain dicarboxylic acid by using the biological fermentation process, which comprises the following steps: (1) decoloration and filtering; (2) primary crystallization and separation; (3) crystallization and separation of high-temperature water; and (4) drying. The obtained long carbon chain dicarboxylic acid product has the advantages of high single acid content, good photopermeability and high heat stability, can meet demands from different users, can be used for producing advanced spices, high-performance engineering plastics, high-temperature dielectric medium, advanced hot melt adhesive, cold-resistant plasticizer, advanced lubricating oil, advanced paint and coating and the like, and greatly broaden development space on down-stream products of the long carbon chain dicarboxylic acid.

Owner:CATHAY R&D CENT CO LTD

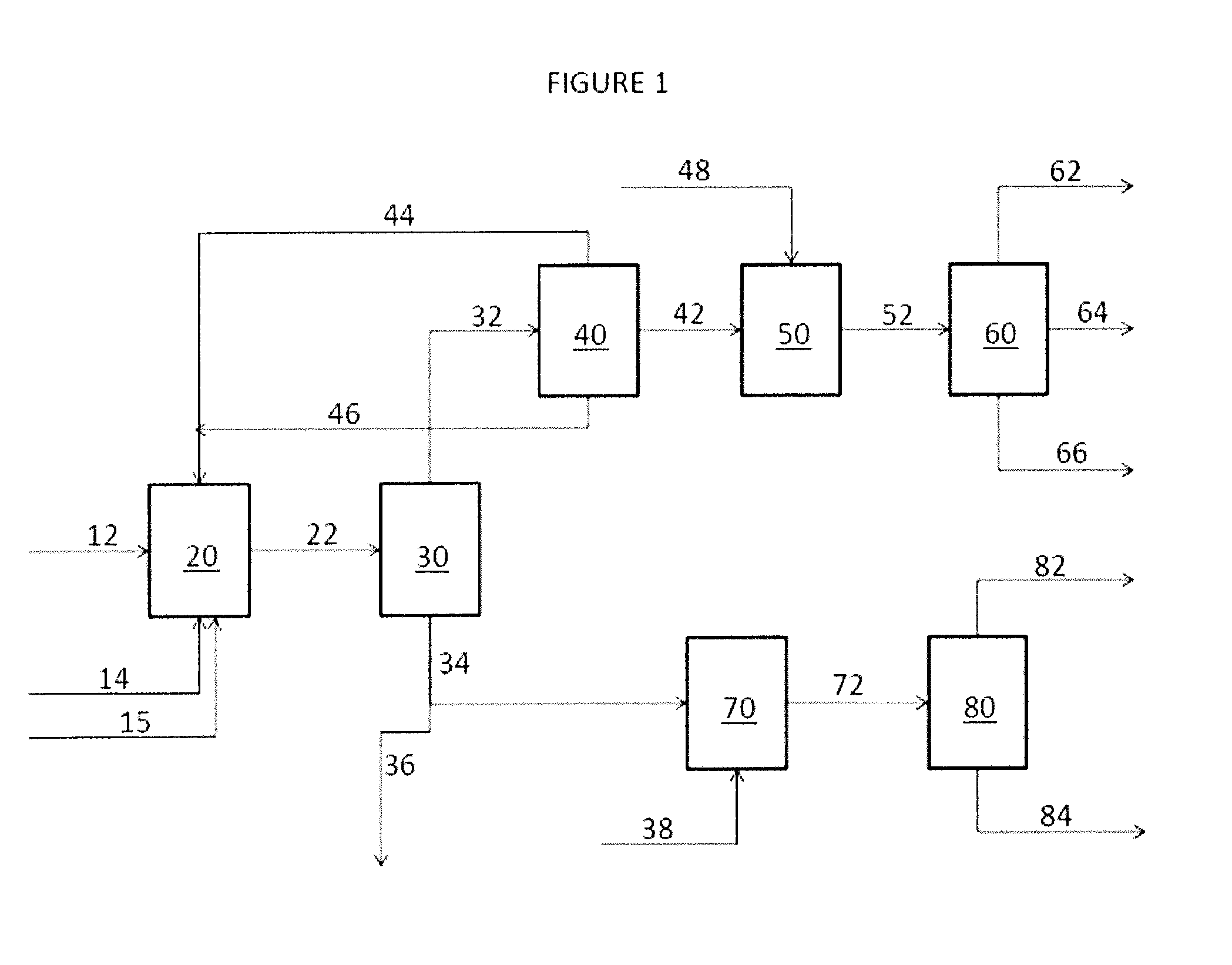

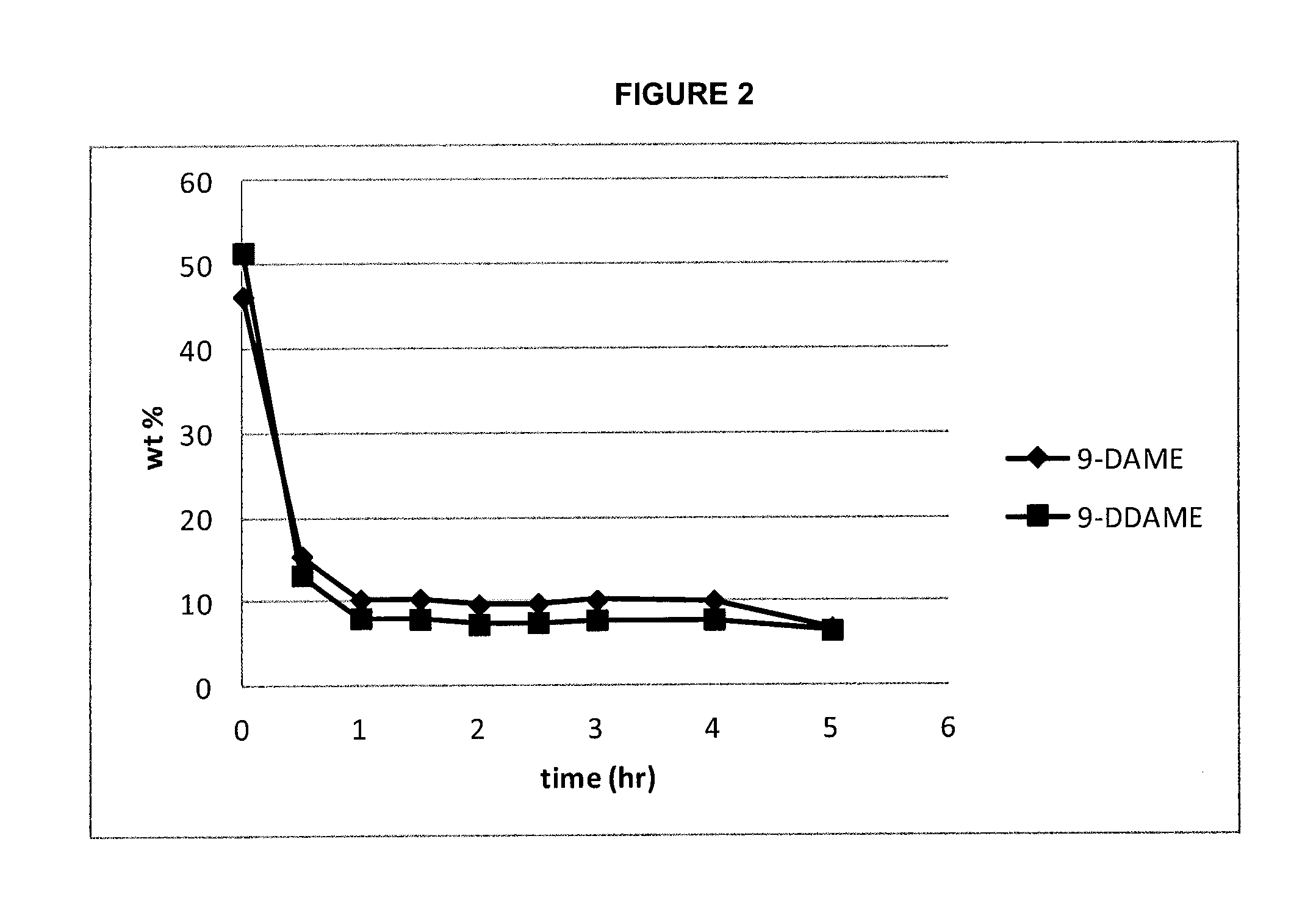

Methods of refining and producing dibasic esters and acids from natural oil feedstocks

Methods are provided for refining natural oil feedstocks and producing dibasic esters and / or dibasic acids. The methods comprise reacting a terminal olefin with an internal olefin in the presence of a metathesis catalyst to form a dibasic ester and / or dibasic acid. In certain embodiments, the olefin esters are formed by reacting the feedstock in the presence of a metathesis catalyst under conditions sufficient to form a metathesized product comprising olefins and esters, separating the olefins from the esters in the metathesized product, and transesterifying the esters in the presence of an alcohol to form a transesterified product having olefin esters.

Owner:WILMAR TRADING PTE LTD

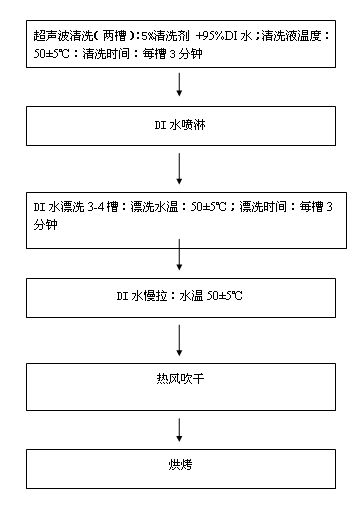

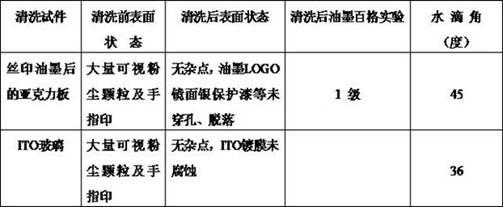

Cleaning agent for optical glass

ActiveCN102604751AEasy to cleanPromote wettingOrganic detergent compounding agentsNon-ionic surface-active compoundsOrganic baseCarbon chain

The invention discloses a cleaning agent for optical glass, which comprises the following components in weight percentage: 2-4% of long carbon chain dibasic acid; 6-10% of an anionic surfactant; 2-4% of an inorganic base; 2-6% of a nonionic surfactant; 2-4% of a special surfactant; 6-12% of a chelator; 10-20% of an organic base; and 40-70% of deionized water, wherein the long carbon chain dibasic acid is dicarboxylic acid with 21 carbon atoms, the anionic surfactant is dodecylbenzene sulfonic acid, the inorganic base is industrial NaOH, the nonionic surfactant is primary alcobol ethoxylate AEO9, the special surfactant is sodium POE nonylphenol ether sodiosulfosuccinate, the chelator is a mixture of Tetrasodium Ethylenediamine Tetraacetate and sodium gluconate, and the organic base is diethanol amine. The cleaning agent for optical glass provided by the invention has low corrosivity and good cleaning effect.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Refining method of carbon 11-18 long chain diacid

InactiveCN1410408AShort process routeLow costCarboxylic compound separation/purificationOrganic solventPetroleum

A process for refining (or purifying) C11-18 long-chain dibasic acid includes such steps as dissolving the said long-chain dibasic acid prepared by fermenting petroleum in organic solvent, filtering,cooling the filtrate, crystallizing and drying. Its advantages are high purity and output rate, and low cost.

Owner:ZIBO GUANGTONG CHEM

Epoxy asphalt material for express highway and bridge, and preparation method

ActiveCN1546571AHigh strengthImprove performanceIn situ pavingsBuilding insulationsAsphaltSuccinic anhydride

An epoxy asphalt material for express highway and bridge wherein the mass portion of the composition is, part A, asphalt 50-80 parts, aliphatic diacid or substituted carboxylic acid 10-25 parts, aliphatic acid anhydride 1-20 parts, polyisobutylene succinic anhydride 2-15 parts, epoxy resin 0-30 parts, epoxy resin hardening accelerating agent 0.1-1.0 part. Part B, epoxy resin, the mass ratio of part an and part B is 2-8:1. The invention also discloses the process for preparing the epoxy asphalt material.

Owner:JURONG NINGWU SCI & TECH DEV

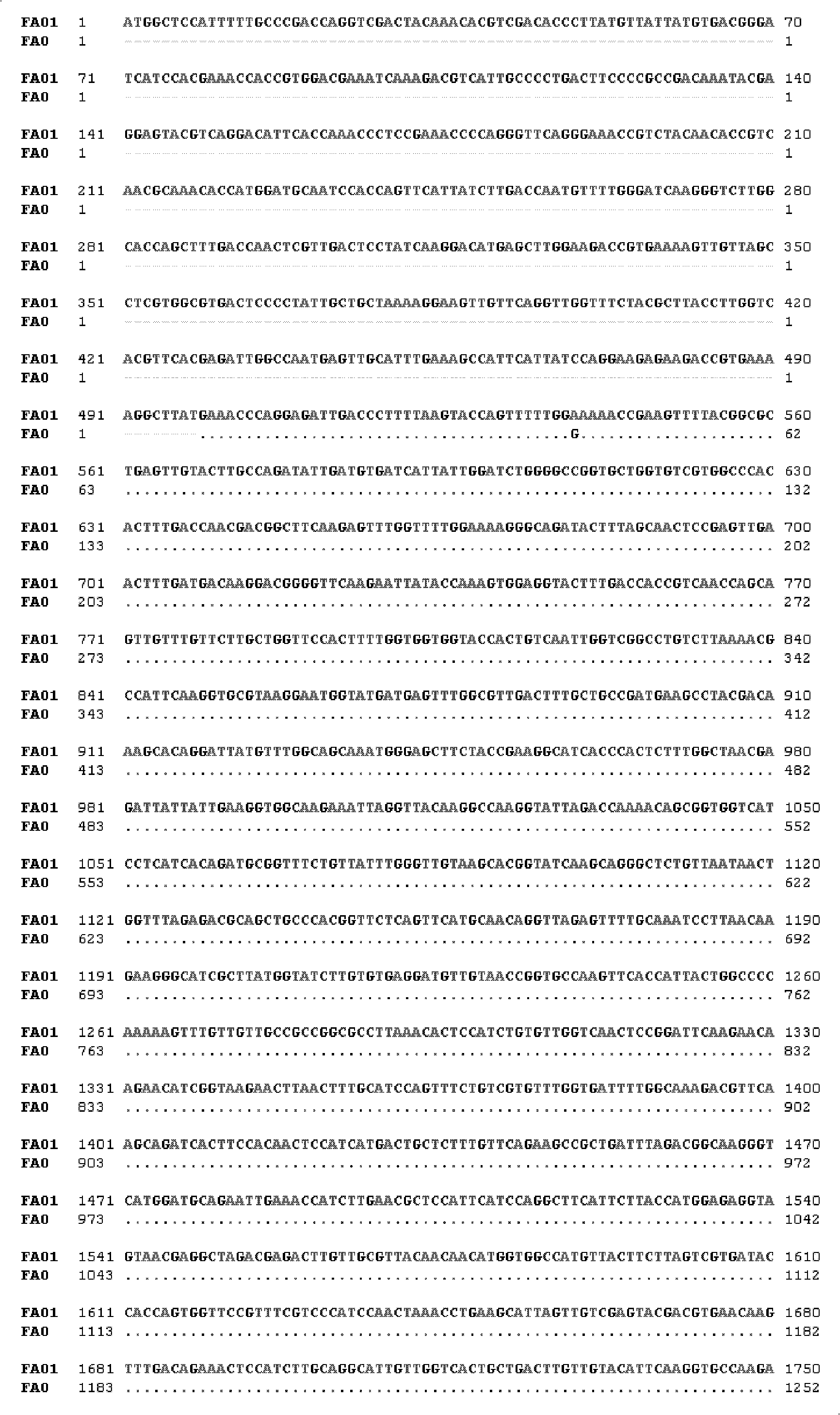

Strain producing long chain dibasic acid, and application thereof

ActiveCN102839133AImprove conversion abilityWide applicabilityFungiMicroorganism based processesAlkaneCandida tropicalis

The invention discloses a strain producing long chain dibasic acid, which is candida tropicalis CAT N145 with a collection number of CCTCC M 2011192. The invention also discloses an application of the strain and a method for producing dibasic acid by using the strain. The candida tropicalis CAT N145 provided by the invention has high conversion capacities upon n-alkanes, fatty acids, and fatty acid derivatives with different carbon chain lengths, and mixtures thereof. Miscellaneous acid content of the produced dibasic acid is low. The application range of the candida tropicalis CAT N145 is wide. With the strain and the application, the controlling over a fermentation process can be greatly simplified, and extraction and purification are easy. The strain has good market application prospect.

Owner:CATHAY R&D CENT CO LTD

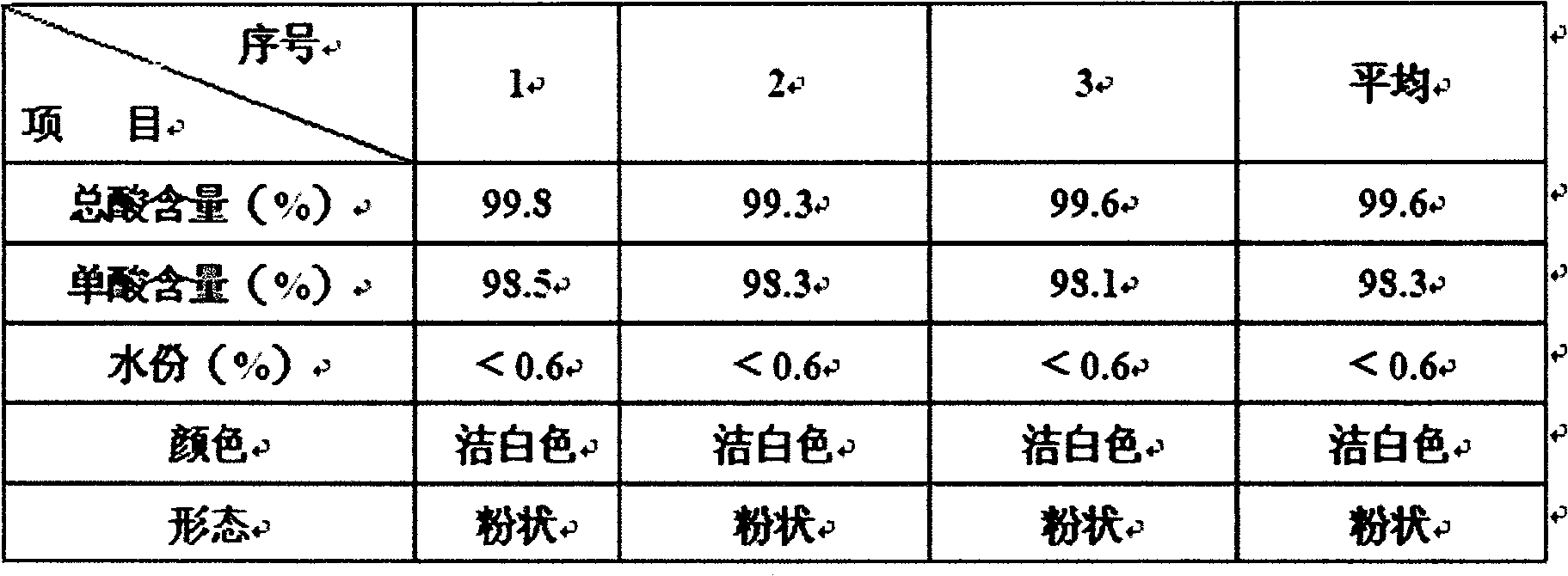

Preparation method of long carbon chain dibasic acid

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

Solvent-free polyurethane adhesive for compound film

ActiveCN101503611ANo pollution in the processImprove securityPolyureas/polyurethane adhesivesPolyesterComposite film

The invention discloses a solvent-free polyurethane adhesive for a composite film, which consists of an A component and a B component, wherein the A component is end-OH polyester polyol, and the B component is end NCO-polyurethane prepolymer; and the A component and the B component are mixed in the molar ratio of functional groups of NCO to OH being 1.2-1.9:1.0. The polyurethane adhesive for the composite film does not need to adopt solvent and has high safety. The adhesive shows low hydroscopic property as well as low hydrolysis and high shock strength due to introducing dimeric dibasic acid, and shows good adhesive property for some substrates which are particularly difficult to adhere and attach. The invention improves the adhesive strength of the composite film through the design of compositions and a molecular structure of the adhesive, the T peeling strength reaches more than 3.8N / 15mm after the plastic films are compounded for 3 to 5 days, and the T peeling strength between the plastic and an aluminum-plating film reaches more than 4.2N / 15mm.

Owner:黄山万丽美油墨科技有限公司

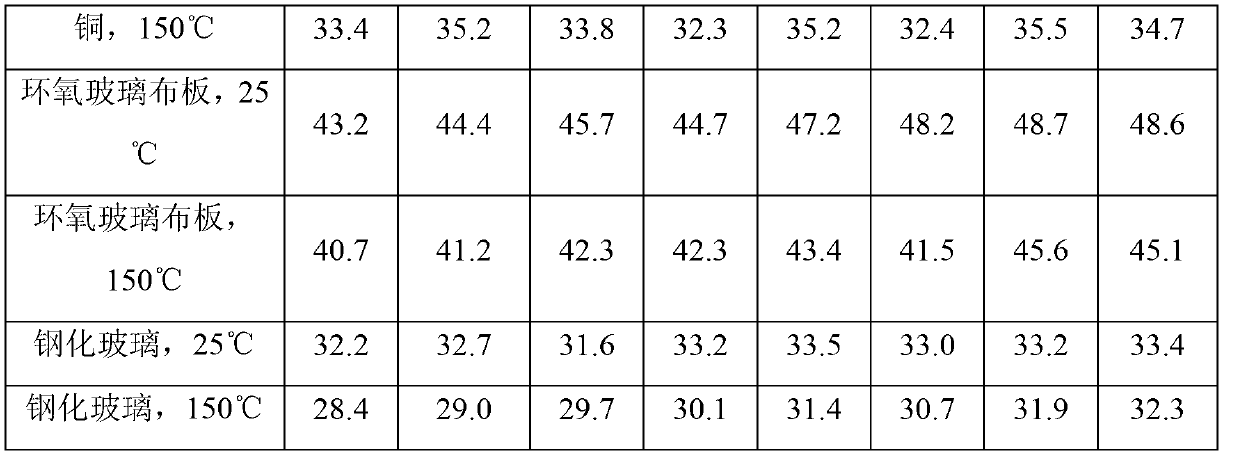

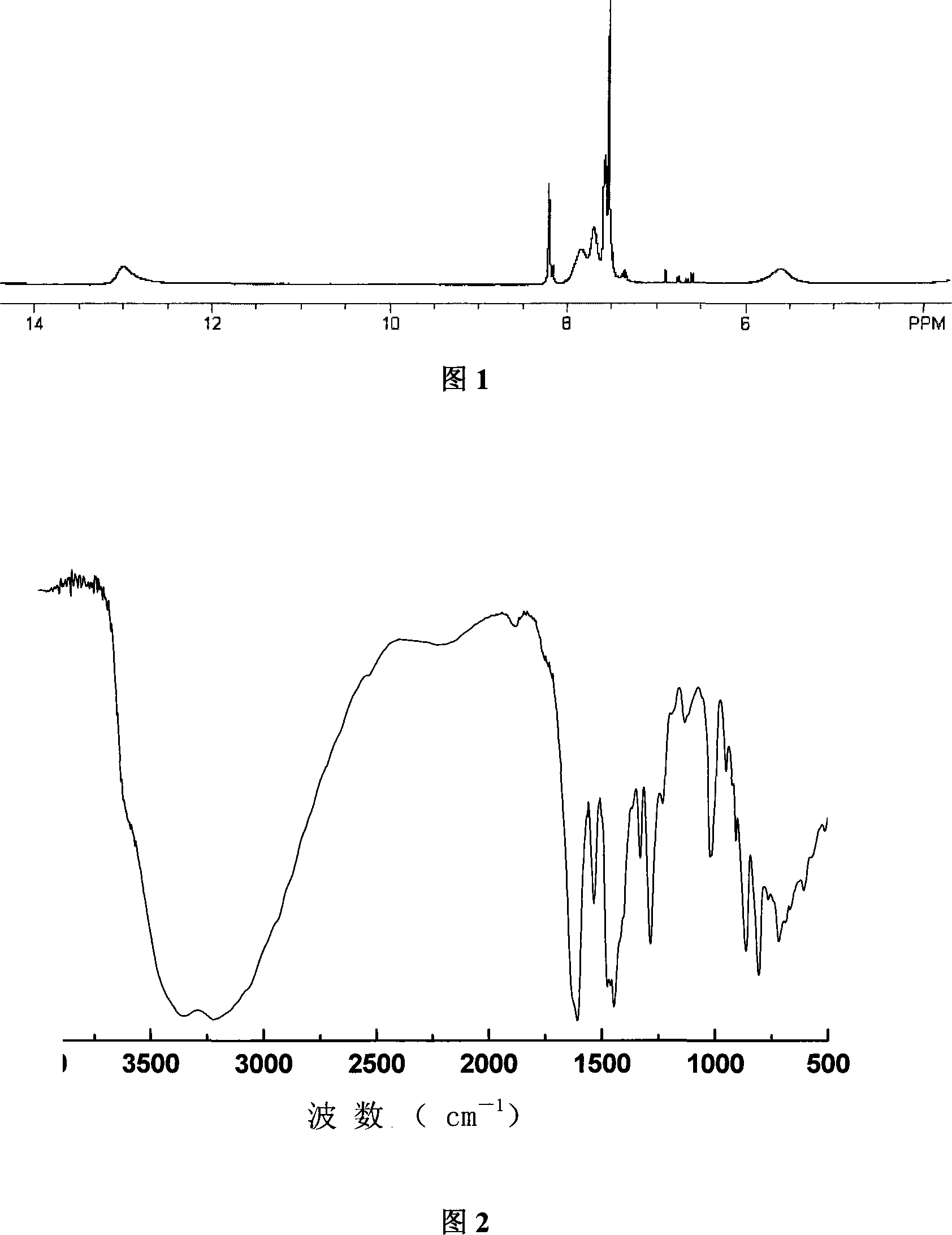

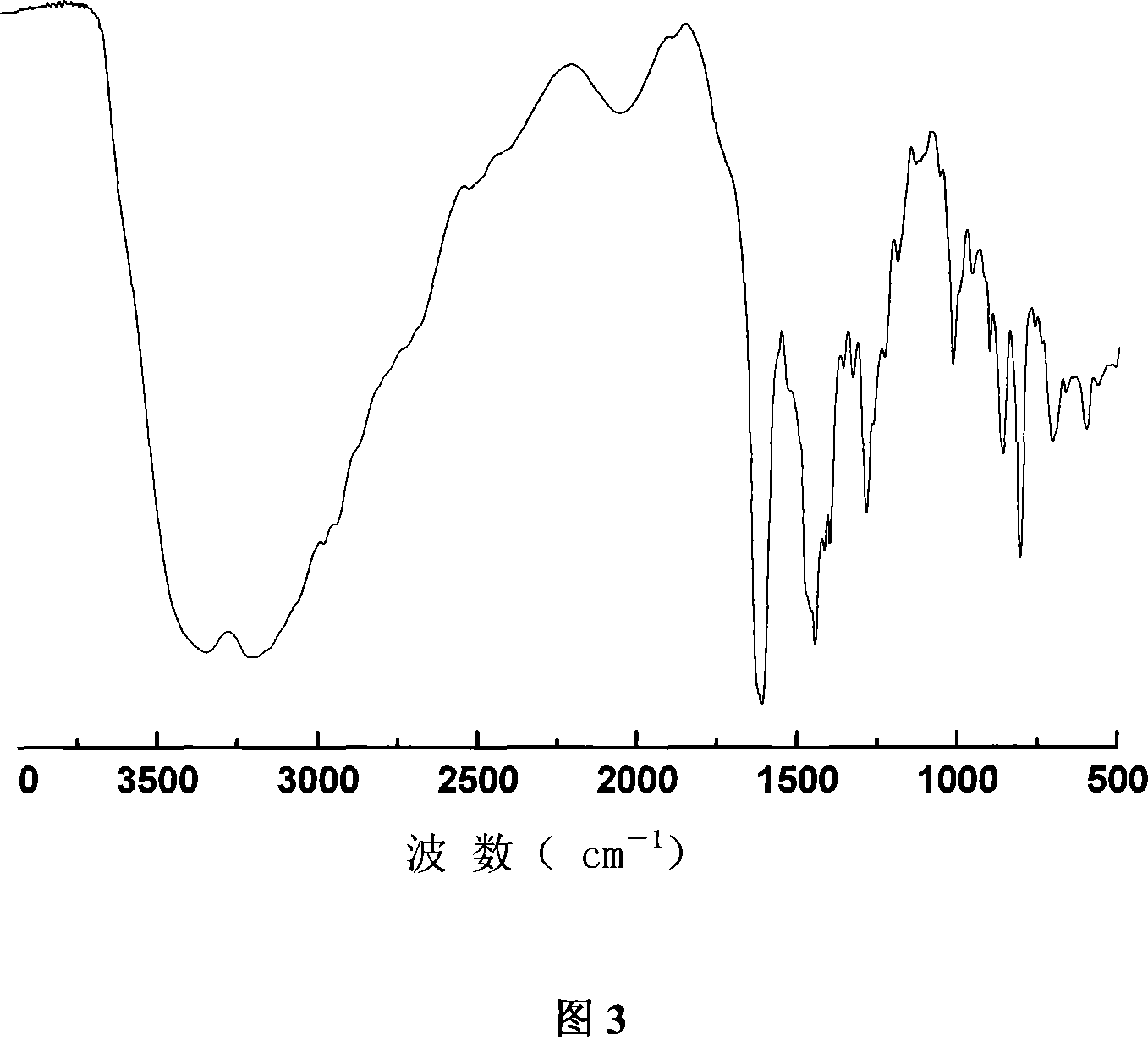

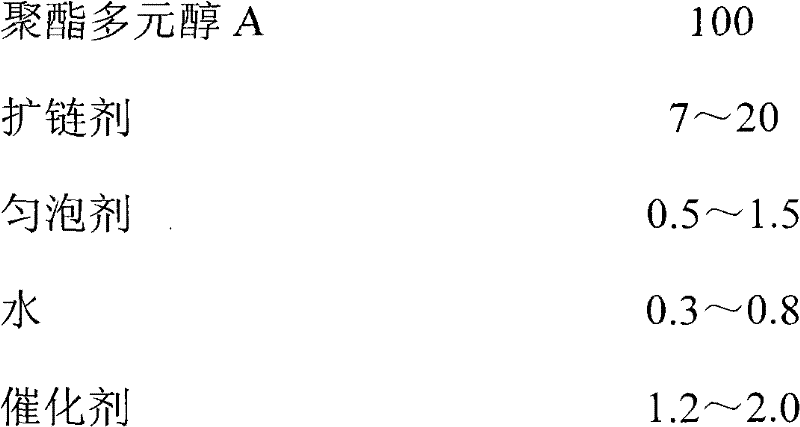

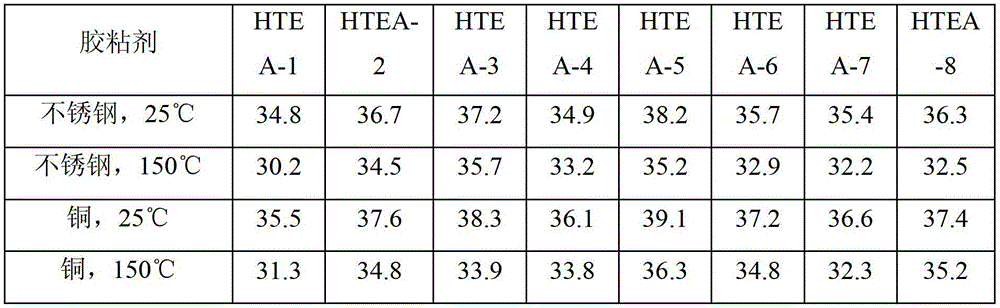

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103131369AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesOrganic solventRoom temperature

The invention relates to a 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive and a preparation method thereof. The 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone high-temperature-resistant epoxy adhesive is composed of a component A and a component B in a mass ratio of 1:(1-2), wherein the component A is a copolymer prepared by reacting 4,4'-bis(2,4-diamido phenoxy)diphenylsulphone and epoxy resin; and the component B is a homogeneous-phase transparent solution with the solid content of 15-30%, which is prepared by reacting 4,4'-bis(2,4-diamidophenoxy)diphenylsulphone and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and diphenylsulphone. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

Method for producing modified unsaturated polyester resins by low purity technical grade dicyclopentadiene

The present invention relates to a novel method of using industrial dicyclopentadiene of purity of 75 percent to 85 percent to prepare modified unsaturated polyester resin. In the preparation of the resin, the industrial dicyclopentadiene separated from the saturated or unsaturated dicarbonic acid or acidic anhydride and the distilled part of mixed C5 is used as the raw material. After hydrolysis and addition reaction, the diol or polyol of appropriate amount is added. The polymerization and dehydration reaction is done with the influence of acidic catalyst. When the mixture is condensed to the designated acid value, the inhibitor and cross-linking monomer of appropriate amount are added and then stirred to prepare the product. The present invention has the advantage that the cost of resin is lower than the common type unsaturated resin. At the same time, the air-drying performance, heat resistance, volumetric shrinkage rate and other performances are all superior to the common type unsaturated polyester resin. The product can be widely used in the fields of glass steel, mold, plastic clothing, sealing, and adhesive and so on.

Owner:泉州永悦新材料有限公司

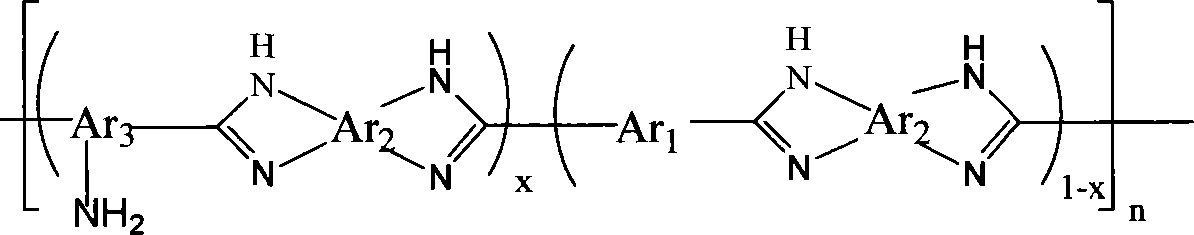

Production method for 2 or multi-halohydrocarbon crosslinked polybenzimidazole crosslinked membrane

The invention relates to a preparation method of a polybenzimidazole crosslinking membrane that is crosslinked with bihalohydrocarbon or polyhalohydrocarbon, which takes amino dibasic acid and aromatic tetraamine as monomer raw material and polyphosphoric acid as reaction medium and reaction is carried out for 5-30 hours at 150-220 DEG C under the nitrogen protection condition so as to obtain homopolymer containing amino polybenzimidazole, and takes the amino dibasic acid, nonaminonic dibasic acid and the aromatic tetraamine as the monomer raw materials to prepare copolymer containing amino polyphosphoric under the same conditions. The prepared homopolymer and the copolymer of the polybenzimidazole have good dissolvability in solvents of dimethyl sulphoxide, N, N-dimethylacetamide, phosphate, vitriol and methane-sulforic acid, etc. Both the structures of the homopolymer and the copolymer of the polybenzimidazole contain amino that can be used for crosslinking. The bihalohydrocarbon or the polyhalohydrocarbon is used as cross linking agent. The polybenzimidazole crosslinking membrane with good property can be prepared through crosslinking reaction of the amino contained in the polybenzimidazole and the bihalohydrocarbon or the polyhalohydrocarbon.

Owner:SHANGHAI JIAO TONG UNIV

Continuous production method for biodegradable aliphatic-aromatic copolyester

The invention discloses a continuous production method for biodegradable aliphatic-aromatic copolyester. The method comprises the following steps: respectively subjecting aromatic diacid and aliphatic dibasic acid to an esterification reaction with aliphatic dihydric alcohol so as to obtain two ester compounds; subjecting the two ester compounds to condensation polymerization so as to obtain biodegradable aliphatic-aromatic copolyester. According to the invention, aliphatic dibasic acid and aromatic diacid are respectively subjected to esterification, and since fat in the aliphatic dibasic acid has a low temperature, formation amount of tetrahydrofuran in the process of esterification is reduced; the chain extender isocyanate which has great toxicity is not used in the method, thereby reducing harm to environment and human bodies.

Owner:KINGFA SCI & TECH CO LTD +2

Preparation method of hydroxy fluorine-containing water-based acrylic resin-polyurethane hybrid

ActiveCN101845118AGood weather resistanceImprove low temperature impact resistanceCoatingsWater basedPolyester

The invention relates to a preparation method of hydroxy fluorine-containing water-based acrylic ester-polyurethane. The preparation process is as follows: (1) carrying out condensation polymerization on dihydric alcohol containing double bonds and binary acid at different proportions to synthesize unsaturated hydroxyl-terminated polyester; (2) taking unsaturated polyester as the talleta of polyurethane, adding a certain amount of dihydric alcohol chain extender so as to enable hydrophilic monomer, catalyst and diisocyanate to react, neutralizing and adding water for chain extension to prepare water-based polyurethane containing unsaturated double bonds; and (3) taking the macro-monomer of the water-based polyurethane as a surfactant, and utilizing acrylic ester- ethylene monomers, fluorine-containing acrylic ester monomers and hydroxyl acrylic ester monomers to synthesize the hydroxy fluorine-containing water-based acrylic resin-polyurethane hybrid by a nonsoap emulsion polymerization method. The invention can regulate the structure and performances of resin by regulating the use amount of fluorine monomers and hydroxyl monomers. The invention introduces hydroxyl into a water-based fluorine-containing acrylic ester polyurethane macromolecule chain so as to prepare room temperature-dried or baking-type thermoset water-based paint together with water-based polyisocyanates and water-based amino plastic, thus greatly improving the performance of the water-based paint; and the prepared paint can be used in various basal materials such as wooden wares, metal, plastics, concretes and the like.

Owner:广东天银实业有限公司 +1

Method for preparing solventless unsaturated polyester-imide wire coating enamel

InactiveCN101514276AHigh temperature resistantEnergy saving and environmental protectionPlastic/resin/waxes insulatorsCoatingsImideAcid value

The invention relates to a method for preparing solventless unsaturated polyester-imide wire coating enamel. The method comprises preparation of unsaturated polyester-imide and processing of paint mixing, wherein the unsaturated polyester-imide is prepared by the following steps: first step, adding polylol, dibasic acid or estolide into a reaction kettle according to a mol ratio of 1.05-1.5:1; stirring and heating the mixture to a temperature of between 160 and 170 DEG C; preserving the heat for 0.5 to 2 hours; and slowly heating the mixture to a temperature of between 200 and 205 DEG C until the acid value is no less than 50 mg KOH / g; and second step, cooling the mixture to a temperature of between 110 and 120 DEG C, adding trimellitic anhydride and diamine with the mol ratio of 2:1, and preserving the heat at a temperature of between 130 and 150 DEG C until the material is transparent; and after 1 hour of heat preservation, slowly heating the material to a temperature of between 200 and 205 DEG C until the acid value is no less than 30 mg KOG / g. Machine winding dipped by the solventless resin has the advantages of small volatilization loss, high filling rate, few times of paint dipping, short baking time, strong binding power, excellent performance of electrical appliance, environmental pollution reduction, and the like.

Owner:上海新天和树脂有限公司 +1

Aliphatic-aromatic copolyester, preparation method and application thereof

ActiveCN101717493AAvoid problems such as affecting performanceEvenly dispersedAdhesivesCarboxylic acid halidesMonomer

The invention provides aliphatic-aromatic copolyester, a preparation method and application thereof. Polymerization monomers comprise a compound selected from aliphatic dibasic acid, and naphthenic base dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound selected from aromatic dibasic acid or the ester, the anhydride and the acyl halide thereof, a compound simultaneously with two functional groups selected from an amino-group, a mercapto group or a hydroxy or a compound of a derivative of the amino-group, the mercapto group or the hydroxyl with an epoxy group and an azepine ring, a compound selected from unsaturated acid with at least one C-C, C-O, C-N or C-S double bond and C-C or C-N triple bond or the ester, the anhydride and the acyl halide thereof and a compound of unsaturated alcohol with at least one C-C double bond or a C-C triple bond or an epoxide thereof. The aliphatic-aromatic copolyester is prepared by carrying out esterification and polycondensation after mixing the polymerization monomers, polymerizing the double bonds and / or the triple bonds on the polymerization monomers under the action of an initiator and then carrying out a graftingand / or coupling reaction.

Owner:HANGZHOU XINFU TECH CO LTD

Polyol ester lubricants for hermetically sealed refrigerating compressors

InactiveUS6221272B1Good hygroscopicityPromote undesirable corrosionOrganic chemistryPlastic/resin/waxes insulatorsNonanoic acidWorking fluid

A high quality lubricant for hermetically sealed domestic air conditioner and refrigerator compressors, especially those using chlorine free hydrofluorocarbon refrigerant working fluids, is provided by mixed esters of hindered polyols, most desirably pentaerythritol, with a mixture of carboxylic acids including at least some isopentanoic acid along with either or both of iso-nonanoic acid and dibasic acids such as adipic.

Owner:COGNIS IP MANAGEMENT GMBH

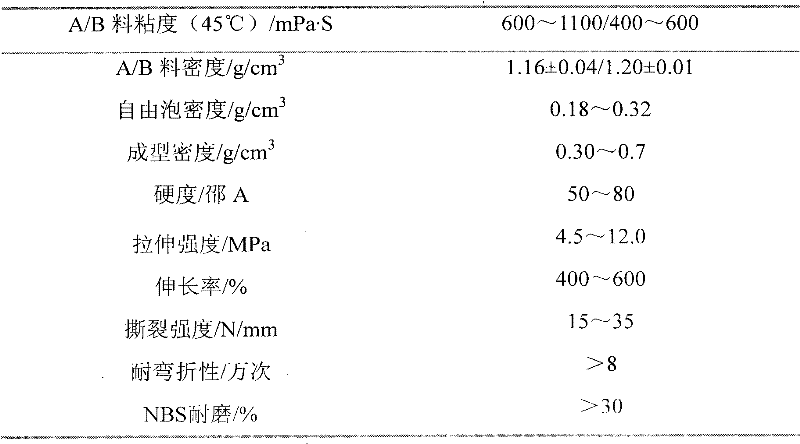

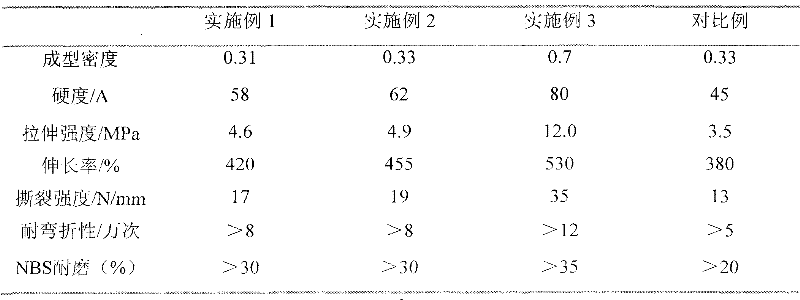

Microcellular polyurethane elastomer and preparation method thereof

The invention discloses a microcellular polyurethane elastomer and a preparation method thereof. The elastomer contains two components, i.e., a polyol component and a prepolymer component, wherein the polyol component comprises polyester polyol, a chain extender, a foam stabilizer, water, a catalyst and the like; and the prepolymer component comprises polyester polyol, isocyanate and the like. The polyester polyol in the polyol component is prepared from a mixture of aromatic dibasic acid and aliphatic diacid and a mixture of diethylene glycol and other dihydric alcohols by means of polycondensation reaction. Compared with common microcellular polyester-type elastomers, the prepared elastomer has higher hardness and mechanical properties as well as better abrasive and bending resistances, besides, the flowability of materials is good. The material can be used in the fields like soles, solid tires, buffer blocks and the like. The preparation method is simple and feasible.

Owner:LIMING RES INST OF CHEM IND

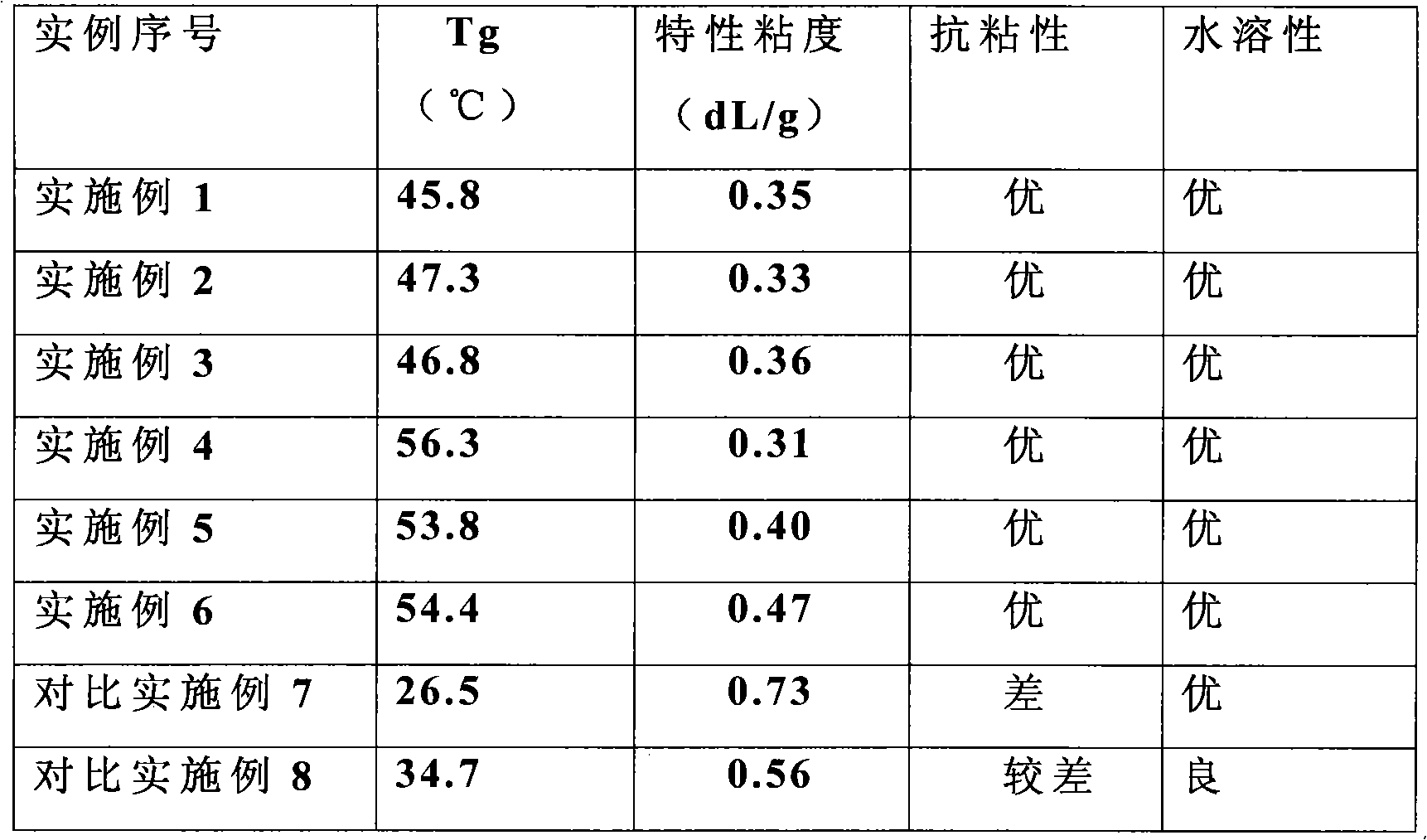

Method for preparing water-soluble sulfo-copolyester

The invention discloses a method for preparing water-soluble sulfo-copolyester used in textile slurry. The method comprises the following steps of: performing esterification reaction or transesterification on dibasic acid / ester at least containing isophthalic acid, sulfo-dibasic acid or ester and terephthalic acid and dibasic alcohol at least containing ethanediol to obtain polycondensation prepolymer; and performing polycondensation under reduced pressure to obtain a product, wherein the molar ratio of the dibasic acid to the dibasic alcohol is 1:1.3-1:1.8; the materials are put at one time; and the polycondensation prepolymer is obtained in one step. The method has the advantages of not using expensive polyethylene glycol materials, adopting a lower molar ratio of the dibasic acid to the dibasic alcohol, putting the materials at one time, reducing cost, along with simple process. The product has high water solubility and higher glass-transition temperature, is suitable for storage, and has good effect in slurry.

Owner:苏州瀚海化学有限公司

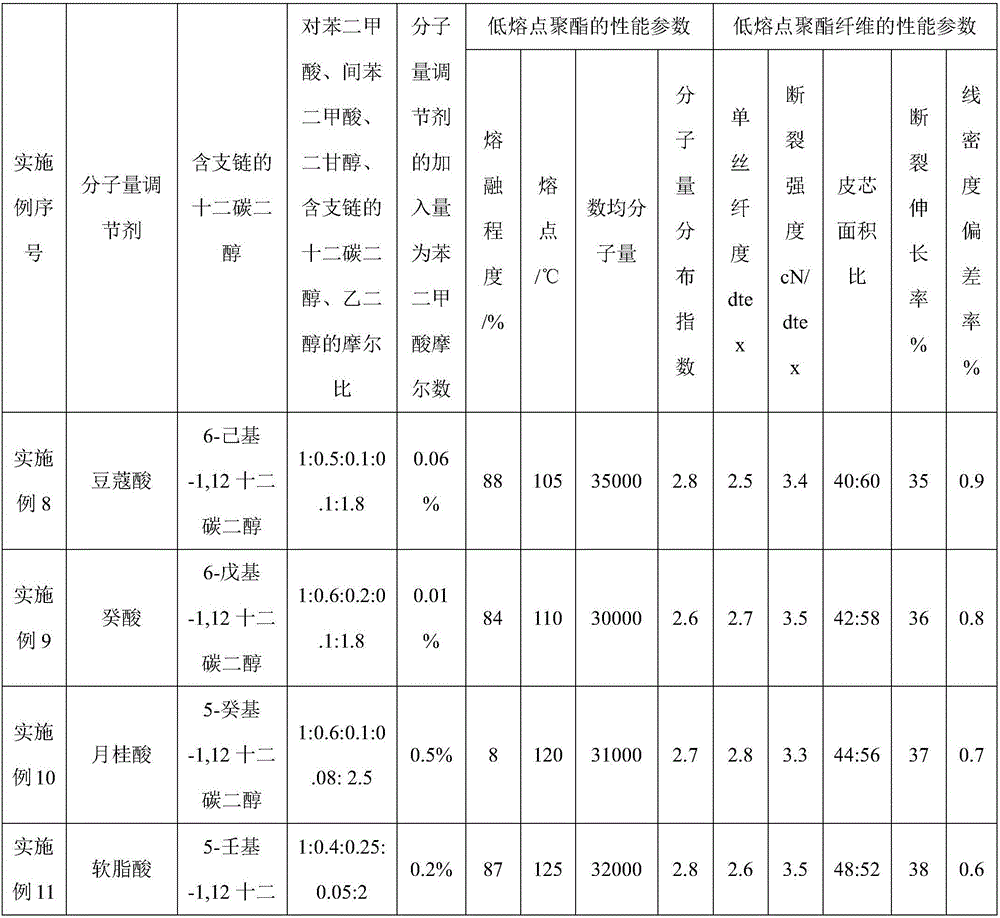

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

Method for making polyester for low-haze biaxial stretching polyester film

The invention discloses a method for preparing polyester for a low-haze biaxially oriented polyester film. The method takes dibasic acid and dihydric alcohol as the main materials to prepare low-haze biaxially oriented polyester film through direct esterification method by means of esterification and polycondensation. Agglomeration resistant agent and catalyzer are added during the esterification process and stabilizer is added during the polycondensation process; agglomeration resistant agent is steatite, calcium carbonate, barium sulfate or kaolinite. When taking the polyester prepared through the method of the invention to make films, no other agglomeration resistant agents are needed, the haze is more than 30%lower than normal like products and the agglomeration resistance is comparable with normal like products.

Owner:SINOPEC YIZHENG CHEM FIBER

Method for preparing biodegradable polyester from consumed polyester

The invention discloses a method for preparing biodegradable polyester from consumed polyester. The method comprises the following steps of: reacting the consumed polyester and divalent alcohol under the action of a catalyst at the temperature of between 190 and 250 DEG C to decompose the polyester to a corresponding oligomer by the alcohol; adding aliphatic dibasic acid or esterification derivative of the aliphatic dibasic acid and acid or alcohol of multifunctional groups into the oligomer, and performing esterification reaction at the temperature of between 180 and 240 DEG C to obtain corresponding esterification products; and performing condensation polymerization reaction on the esterification products to obtain biodegradable aliphatic-aromatic copolyester. By the method, the consumed and reclaimed polyester material can be directly converted into a biodegradable polyester material, and a virtuous circle channel is provided for reclamation and utilization of non-degradable polyester white pollutants; and the biodegradable polyester material has excellent mechanical and processing properties.

Owner:KINGFA SCI & TECH CO LTD +2

Refrigerating machine oil compositions

ActiveUS20070155635A1Maintaining thermal/oxidation stabilityLong operationBase-materialsAlcoholPolyol

The first refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one ester additive selected from esters of a monobasic fatty acid having 12 or more carbon atoms and a monohydric alcohol having 1-24 carbon atoms, and an ester of a chain-like dibasic acid and a monohydric alcohol. The second refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one oxygen-containing compound selected from the following (A1)-(A6). The third refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one oxygen-containing compound selected from the following (A1), (A2), (A4), (A7) and (A8). (A1) Alkylene oxide adduct of a polyhydric alcohol having 3-6 hydroxyl groups (A2) Polyalkylene glycol (A3) Trihydric alcohol having 3-20 carbon atoms apart from (A1) (A4) Dihydric alcohol having 2-20 carbon atoms apart from (A2) (A5) Hydrocarbyl ether of (A1)-(A4) (A6) Hydrocarbyl ester of (A1)-(A4) (A7) Hydrocarbyl ether of (A1), (A2) or (A4) (A7) Hydrocarbyl ester of (A1), (A2) or (A4)

Owner:NIPPON OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)