Patents

Literature

70 results about "Dibenzyl disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibenzyl disulfide is an organic disulfide that results from the formal oxidative dimerisation of benzyl thiol.It has a role as a metabolite. It is an organic disulfide and an organic aromatic compound.

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of nitrogen, sulfur and phosphorus heteroatom-doped carbon material

InactiveCN108313999AEasy to dopeUniversalCarbon preparation/purificationHigh concentrationCarbon nanotube

The invention discloses a preparation method of a nitrogen, sulfur and phosphorus heteroatom-doped carbon material, and belongs to the technical field of carbon materials. The method comprises the following steps: adopting a perfluorocarbon material or a fluorinated carbon nanotube as a carbon substrate, doping one or more of liquid sources containing nitrogen, sulfur and phosphorus heteroatoms into the carbon substrate at the temperature of 400 to 800 DEG C by adopting a pyrolysis deposition method, or mixing a solid source containing the nitrogen, sulfur and phosphorus heteroatoms with the carbon substrate and grinding, and calcining at the temperature of 400 to 800 DEG C to realize doping, so as to obtain the nitrogen, sulfur and phosphorus heteroatom-doped carbon material. The liquid source contains pyridine, thiophene, triphenylphosphine solution and the like, and the solid source contains sublimed sulfur, dibenzyl disulfide and the like. The method has the advantage of simple operation and high universality; high-concentration vacancy is generated by utilizing the fluorinated carbon nanotubes to remove fluorine at high temperature, and further high-efficiency doping of heteroatom can be realized.

Owner:SOUTH CHINA UNIV OF TECH

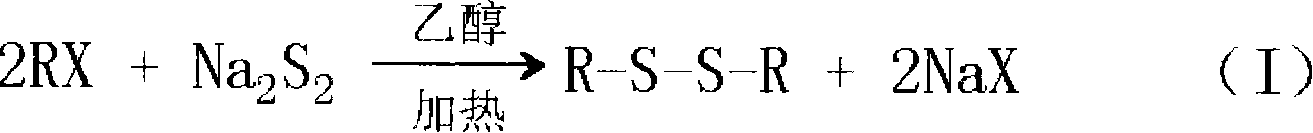

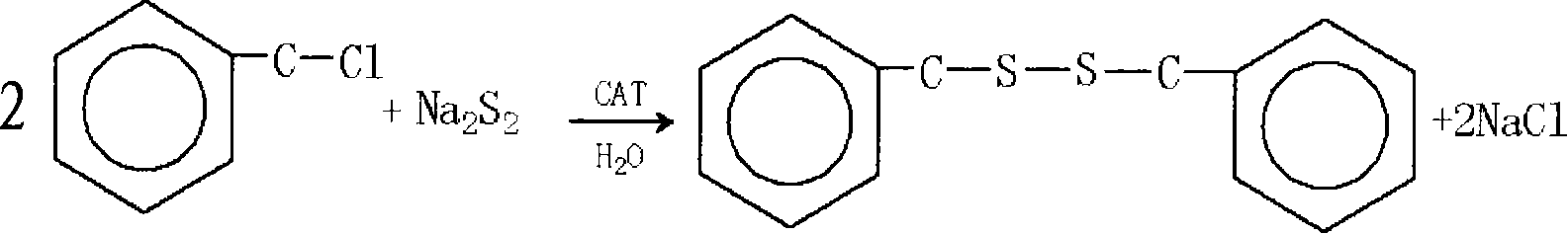

Method for preparing dibenzyl disulfide

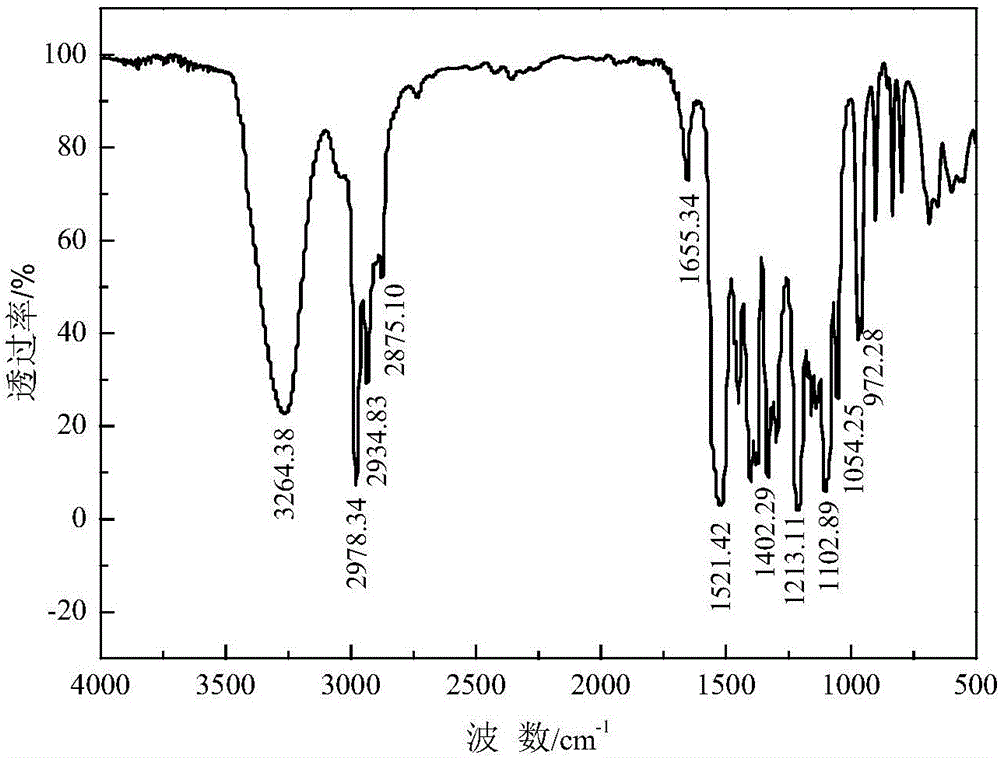

InactiveCN101607930AHigh yieldDelayed reaction timeHydropoly/poly sulfide preparationReaction temperatureBenzyl chloride

The invention relates to a method for preparing dibenzyl disulfide. The innovation points of the invention are that: water is taken as a reaction solvent; Na2S2, benzyl chloride and a catalyst are mixed and then react; the reaction temperature is between 30 and 50 DEG; the reaction time is between 10 and 40 minutes; the temperature of a reaction liquid is cooled to 20 DEG C after the reaction is finished; the pH value is adjusted to 7; and a separated organic phase is washed, dried and purified to obtain the dibenzyl disulfide. The method uses trioctylmethylammonium chloride as the catalyst to perform a catalytic reaction on the mixed Na2S2 and benzyl chloride, and has high yield of finished products which is improved by 15 to 20 percent compared with the prior synthetic method; and the method greatly reduces reaction time and reaction temperature, is easy to control reaction process, has few byproducts, and reduces the consumption of energy sources.

Owner:TIANJIN CHEM REAGENT RES INST

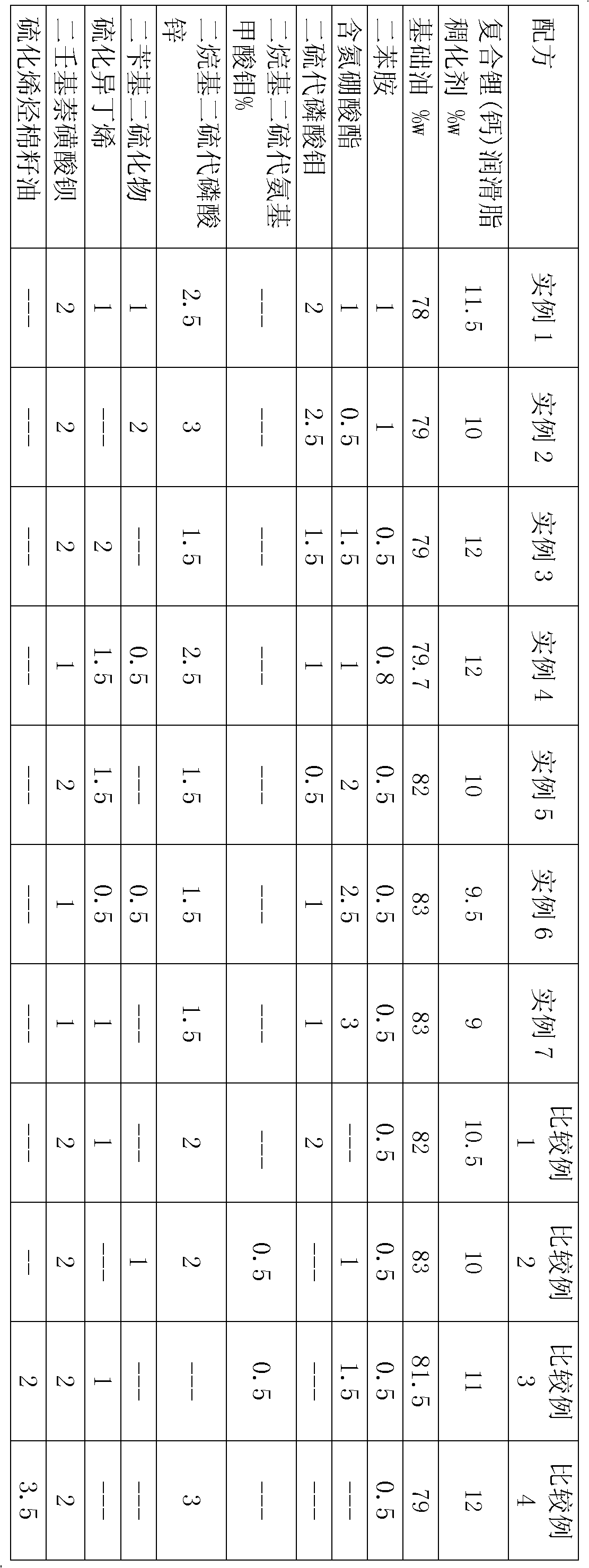

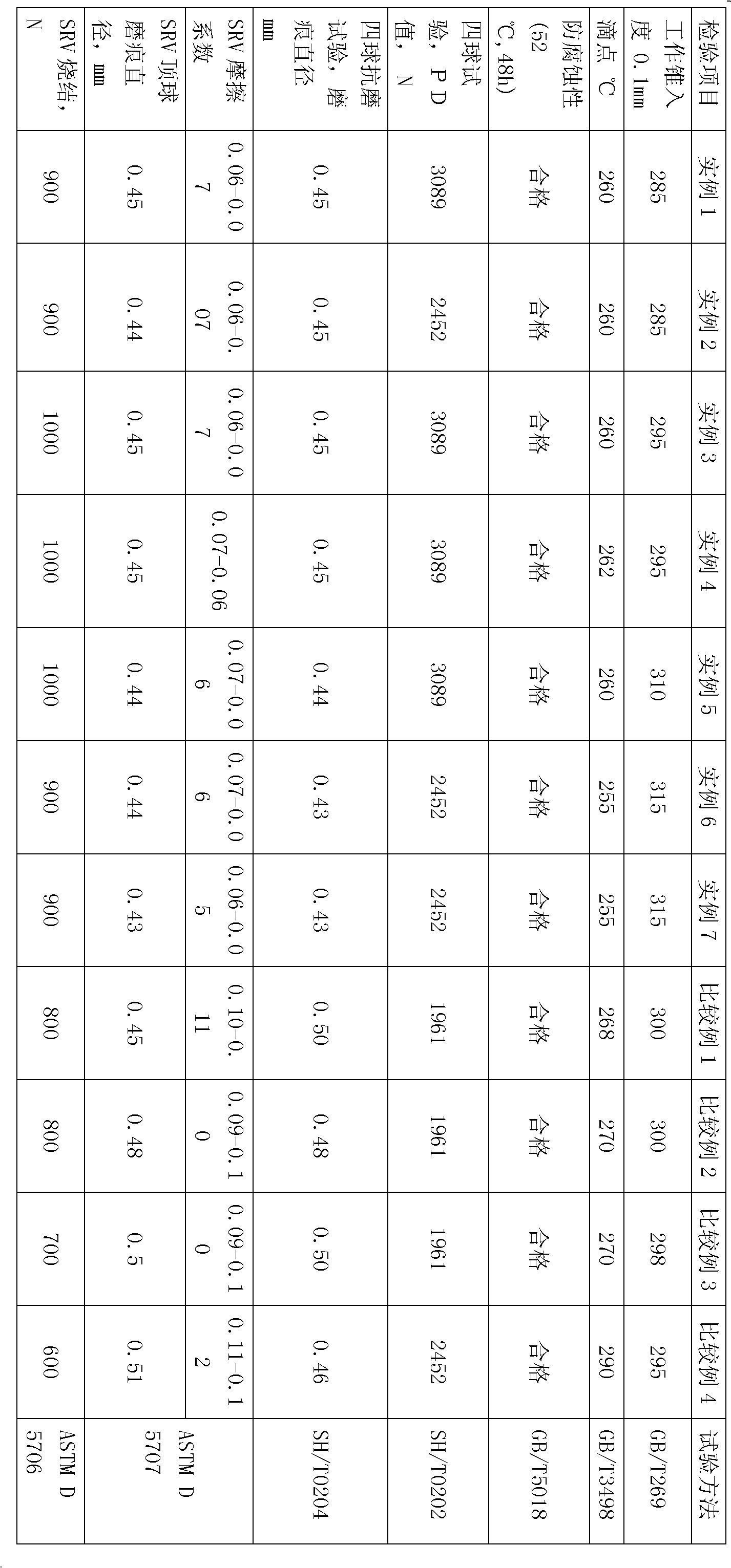

Lubricating grease used for three-pin type constant-velocity universal joint of vehicle

The invention discloses a lubricating grease composite used for a three-pin type constant-velocity universal joint of a vehicle transmission system. The lubricating grease comprises the following components based on 100 percent weight: (a) 78 to 83 percent of base oil, (b) 9 to 12 percent of composite lithium calcium soap thickener, (c) 0.5 to 2.0 percent of sulphide isobutene and / or an organic sulfide of dibenzyl disulfide, (d) 1.0 to 3.0 percent of zinc dialkyl dithiophosphates, (e) 0.5 to 2.5 percent of molybdenum dithio phosphate, (f) 0.5 to 3.0 percent of parathion-free nitrogen-containing boric acid ester, (g) 0.5 to 1.0 percent of amine or phenolic antioxygen, and (h) 1.0 to 2.0 percent of dinonyl naphthalene sulfonic acid barium antirusting agent. The composite has a low friction coefficient, low abrasion resistance and high extreme pressure property, can reduce or prevent noise, vibration and harshness (NVH), and is particularly suitable to be used for lubricating the three-pin type constant-velocity universal joint of a vehicle transmission shaft.

Owner:CHINA PETROLEUM & CHEM CORP

Method for producing thionocarbamate and dibenzyl disulfide

ActiveCN106380435ALower temperature conditionsSolve inseparableThiol preparationSulfide preparationBenzyl mercaptanFatty amine

The invention discloses a method for producing thionocarbamate and dibenzyl disulfide. The method comprises the following steps: carrying out an esterification reaction on alkyl xanthate and benzyl halide to obtain alkyl benzyl xanthate; carrying out an aminolysis reaction on the alkyl benzyl xanthate and fatty amine to obtain a thionocarbamate and benzyl mercaptan mixture; and carrying out an oxidation reaction on the thionocarbamate and benzyl mercaptan mixture and hydrogen peroxide, and carrying out liquid-solid separation to obtain a solid which is the dibenzyl disulfide product and a liquid, and allowing the liquid to stand for oil and water layering in order to obtain an oil phase which is the thionocarbamate product. The dibenzyl disulfide product and thionocarbamate product obtained through the method have high yield and high purity, and the method has the advantages of easiness in separation of the products in the preparation process, environmental protection, high atom economy property, low production cost, and easiness in realization of industrial production.

Owner:CENT SOUTH UNIV

Preparation method of adsorbent for removing dibenzyl disulfide in insulation oil

InactiveCN107638867AImprove oil qualityQuality improvementOther chemical processesLubricant compositionSorbentLanthanum

The invention provides a preparation method of an adsorbent for removing dibenzyl disulfide in insulation oil, and relates to the field of the preparation method of the adsorbent. The method aims at solving the technical problems that in the prior art, due to the corrosion of corrosive sulfur (the dibenzyl disulfide is the major corrosive sulfur) in the insulation oil on transformer winding copperwires, transformer faults frequently occur, and serious harm is caused on the power grid safety. The method comprises the following steps of 1, preparing a lanthanum modified molecular sieve; 2, preparing a copper carrying lanthanum modified molecular sieve; 3, compounding the copper carrying lanthanum modified molecular sieve by a nickel nitrate solution, and performing drying and roasting. Theadsorbent has a strong selectivity absorption effect on the dibenzyl disulfide in the insulation oil; the removal rate is high; the quality of the insulation oil is effectively improved. The preparedadsorbent is used for removing the corrosive sulfide in the product oil.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD ELECTRIC POWER RES INST +1

Lubricating oil additive

InactiveCN104403724AImprove the lubrication effectEasy to cleanAdditivesPhosphorous acidPhosphoric Acid Esters

The invention relates to a lubricating oil additive, which is prepared from the following raw materials by weight: 8-14 parts of sulfur phosphorus primary-secondary alkyl zinc salt, 3-10 parts of sulfurized isobutylene, 4-8 parts of glycerol acrylate, 3-7 parts of isooctyl phosphate, 2-7 parts of methyl silicone oil, 3-5 parts of calcium stearate, 6-8 parts of a butene adhesion agent, 3-9 parts of a dibenzyl disulfide, 1-5 parts of dibutyl phosphite, 4-7 parts of dodecylbenzene, 1-5 parts of diethanolamine, and 6-8 parts of carbon tetrachloride. The lubricating oil additive of the present invention has following beneficial effects of improvement of the lubricating effect and the washing effect of the lubricating oil, anti-oxidation and wide use.

Owner:QINGDAO TOPLINK INFORMATION TECH

Novel extreme-pressure (EP) gear oil

InactiveCN102041145AReduce frictionImprove energy savingLubricant compositionIndustrial equipmentOctanol

The invention discloses novel extreme-pressure (EP) gear oil, which comprises the following components in parts by weight: 30 to 45 parts of 100# mechanical oil, 40 to 50 parts of 38# cylinder oil, 0.1 to 1.0 part of BHT (butylated hydroxytoluene) antioxidant, 0.1 to 0.7 part of dibutyl phosphate, 1.0 to 2.0 parts of sulfur-phosphorous butyl octanol zinc salt, 0.2 to 0.8 part of alkenyl dibutyric acid, 0.2 to 0.9 part of demulsifying agent, 1.5 to 3.5 parts of dibenzyl disulphide, 10*10 to 6 parts of methyl silicone oil and 0.5 to 1.0 part of alkyl naphthalene. The EP gear oil has the advantages of the energy-conservation effect superior to the conventional product can be reached by fully reducing the friction; the EP gear oil has no toxin or harm to a human body and can reach the safety and environment protection requirements at high standards; the EP gear oil has good thermal oxidative stability and excellent rust protection and corrosion protection action; the service life of gears can be effectively prolonged; strong load or large load impact can be stood; the abrasion or the sintering of the gears can be prevented; and the EP gear oil is used for various industrial equipment working under the severe conditions of the heavy load or the impact load and high temperature.

Owner:薛淑芳

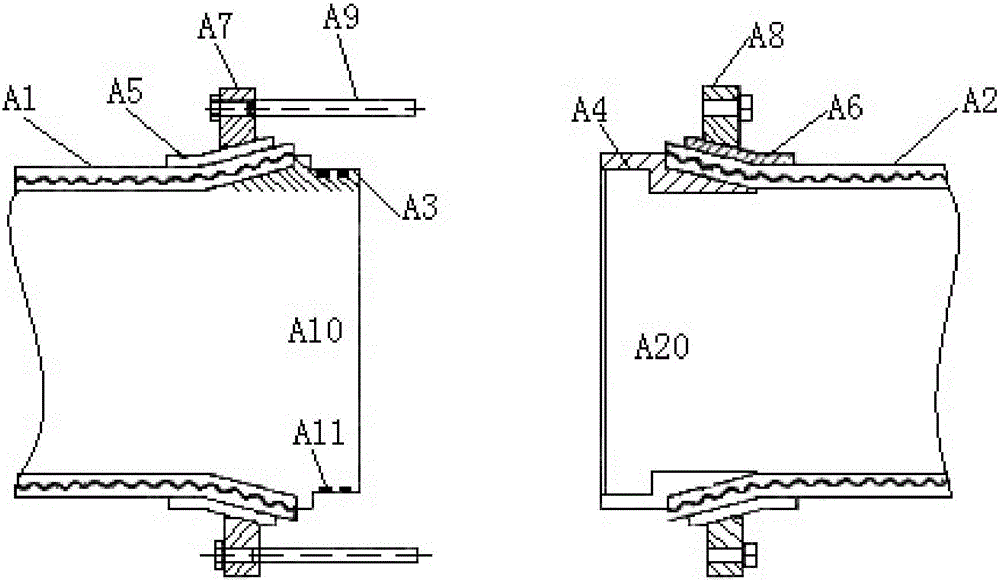

Acid-soluble pressure-bearing plugging agent for drilling fluid and preparation method

The invention relates to an acid-soluble pressure-bearing plugging agent for drilling fluid and a preparation method. The acid-soluble pressure-bearing plugging agent contains a friction material, a bridging material, a filler material, iron tailing sand, volcanic ash powder, woody activated carbon powder, nano calcium-zinc phosphate, paraffin, polyalcohol fatty acid ester, titanium white, red clay, alginic acid, dimethyl diallyl ammonium chloride, polyvinyl acetate, glyceryl monostearate, a glued stone cementing material, copper oxide, Dibenzyl disulfide, alpha-n-octyl-cyanoacrylate, sodium caseinate, steel slag, white carbon black, dolomite powder, manganese dioxide, diatomite, dibutyl phthalate, polyvinyl alcohol, tert-butylhydroquinone, phthalic anhydride and H2O. According to the acid-soluble pressure-bearing plugging agent for the drilling fluid and the preparation method, by using the preparation method, the defects in the prior art that on-site operating methods are tedious, operating requirements are strict, plugging performance is often poor due to invasion of surrounding solid-state particulate matters, a plugging framework is damaged, and a motor shaft or rotating shaft is subjected to expanding and contracting under the action of stress of the shaft during rotating due to infirm connection are avoided.

Owner:河南省遨太化工有限公司

Lubricant additive

The invention discloses a lubricant additive, and belongs to the technical field of lubricating oil. The lubricant additive comprises, by weight, 3 parts to 5 parts of N,N'-di-sec-butyl p-phenylenediamine, 4 parts to 6 parts of butylated hydroxytoluene, 2 parts to 5 parts of polyving akohol, 1 part to 2 parts of butane-like adhesives, 3 parts to 5 parts of sodium dodecyl benzene sulfonate, 1 part to 2 parts of magnesium silicate, 3 parts to 5 parts of fluorinated surfactants, 4 parts to 7 parts of dibenzyl disulphide, 1 part to 3 parts of dibutyl phosphite and 1 part of 3 parts of barium salt of phosphosulfurized polyisobutylene. According to the lubricant additive, the matching performance of the lubricant additive and lubricant base oil is high, the lubricant additive can rapidly permeate into a micro gap of any metal surface, the lubricant additive is combined with metal molecules to form a solid lubricating film, and the ultra-strong abrasion resistance and oxidation resistance are achieved.

Owner:广西超霸能源有限公司

Rustproof water-based lubricant and preparing method thereof

The invention provides rustproof water-based lubricant and a preparing method thereof, and relates to the field of lubricant preparation. The lubricant is mainly prepared from, by weight, 0.8-1.6 part of coconut diethanol amide, 0.5-3 parts of oleic acid, 2-4 parts of boric acid, 5-10 parts of stearic acid, 0.5-2 parts of phosphate extreme pressure agent, 1-5 parts of chlorcosane, 1-2 parts of sulfurized isobutylene, 2-4 parts of dibenzyl disulfide, 5-9 parts of trimethylolpropane, 3-7 parts of zinc dialkyl dithiophosphate, 3-5 parts of sodium dodecyl benzene sulfonate, 0.5-2 parts of glycerol, 0.3-0.9 part of polyamide resin, 1-4 parts of an antirust agent, 0.1-0.5 part of bactericide, 0.5-2 parts of defoamer and 25-35 parts of deionized water. The water-based lubricant has the effects of cooling, lubricating and cleaning and has excellent rustproof performance.

Owner:钟逸凡

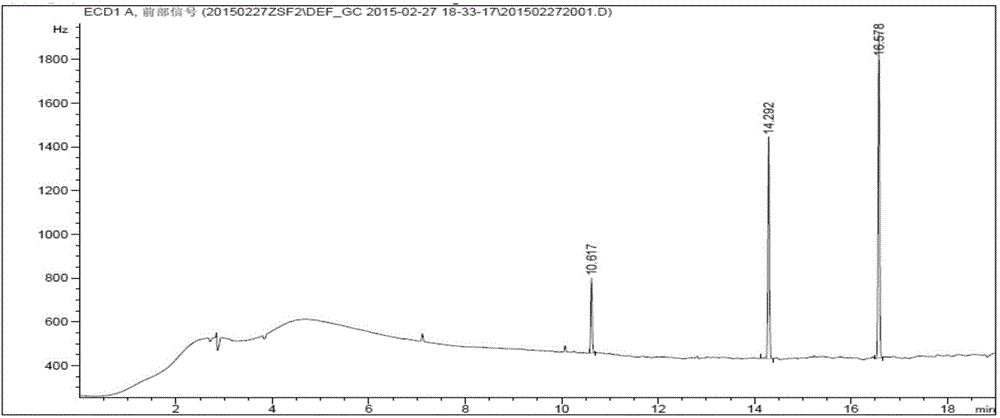

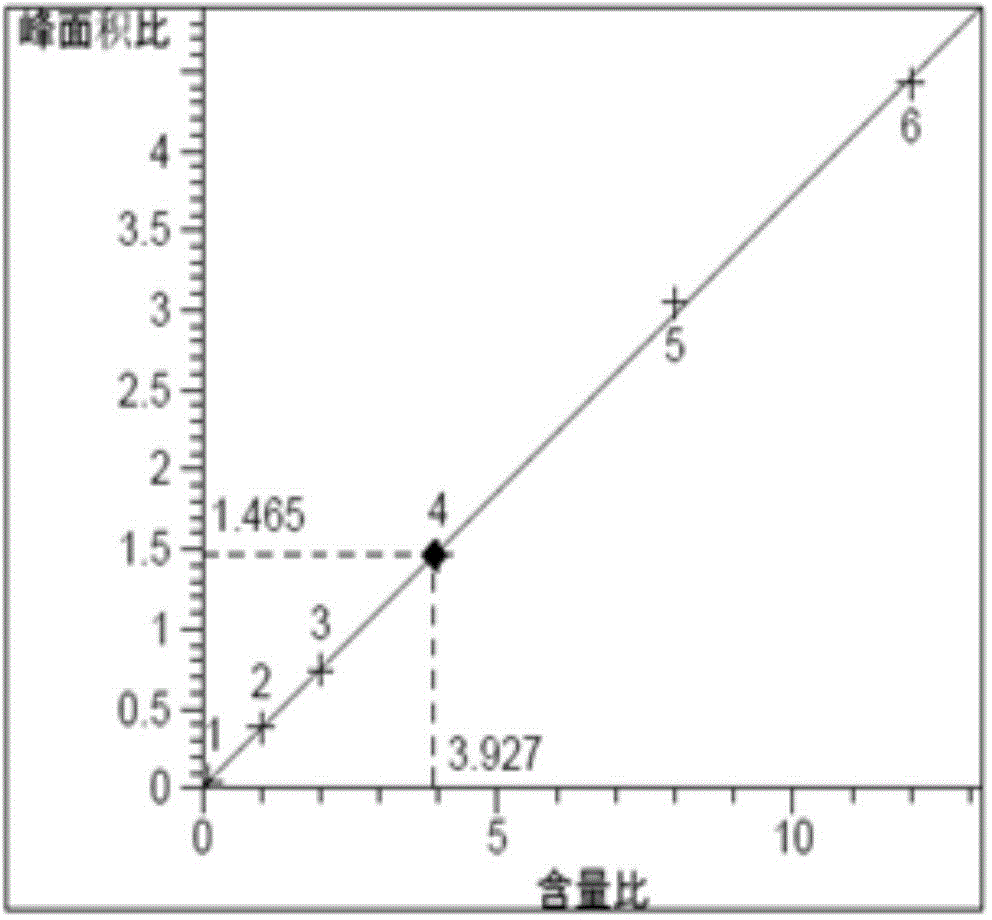

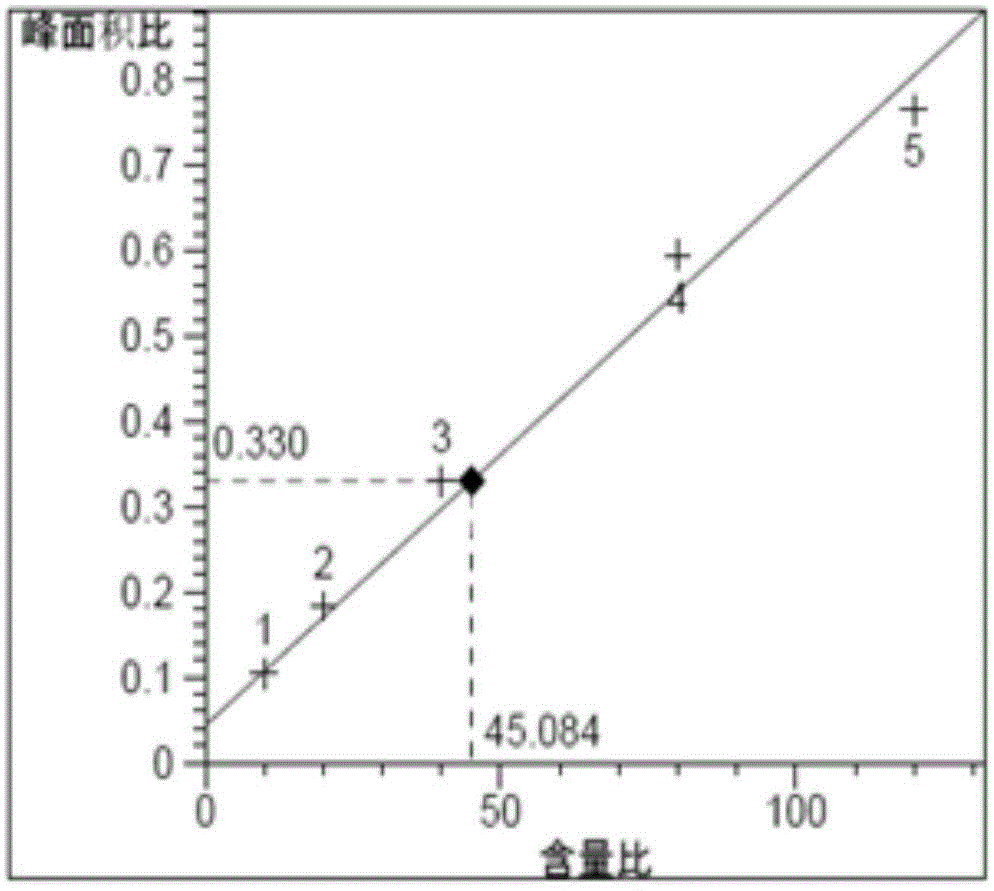

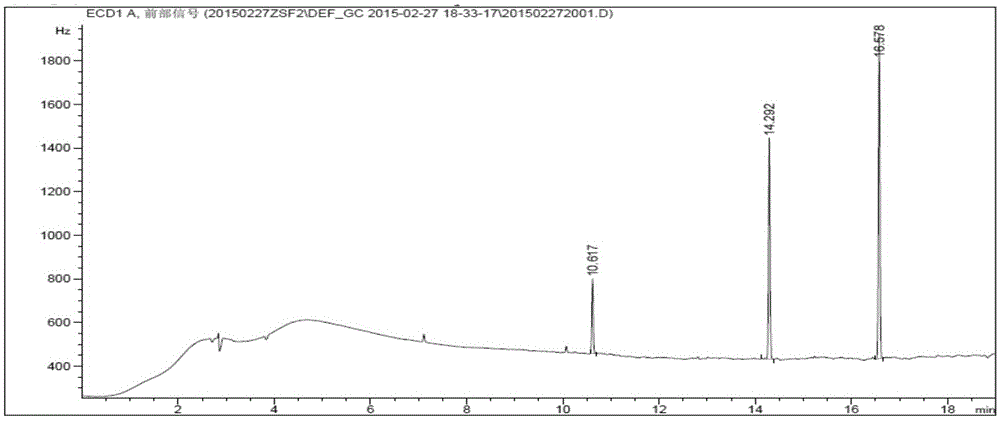

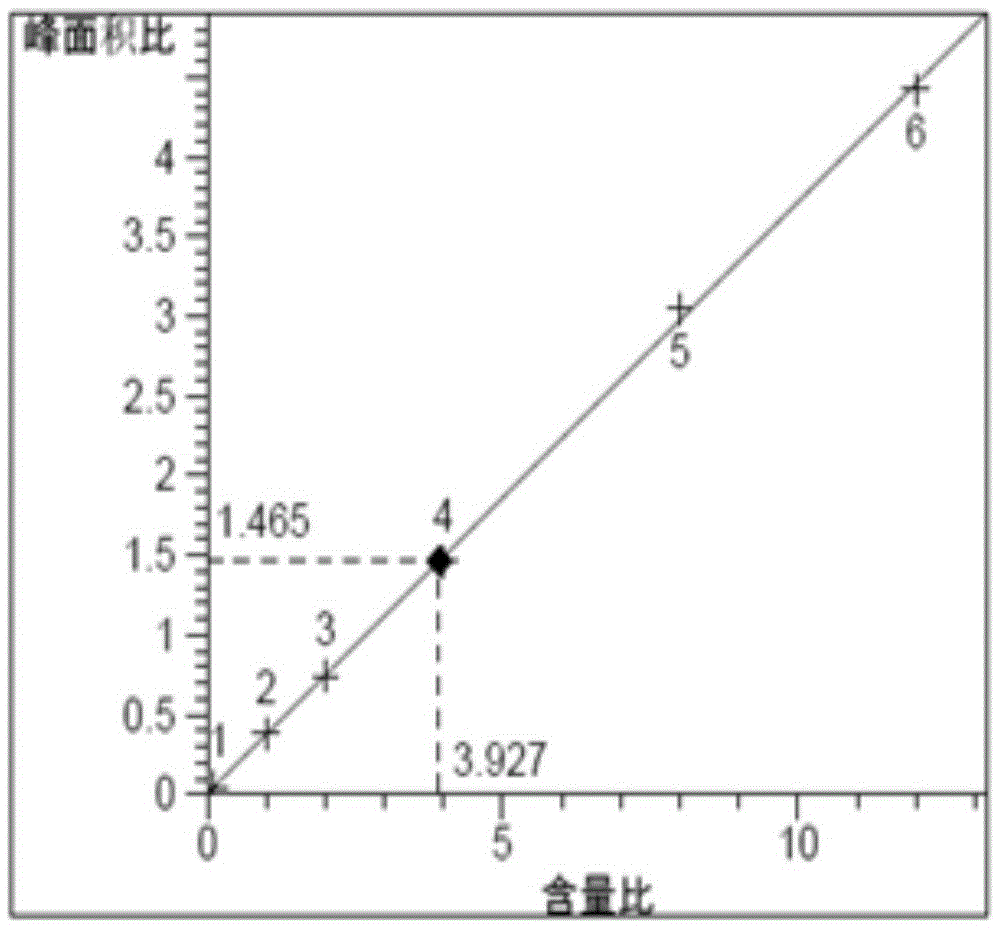

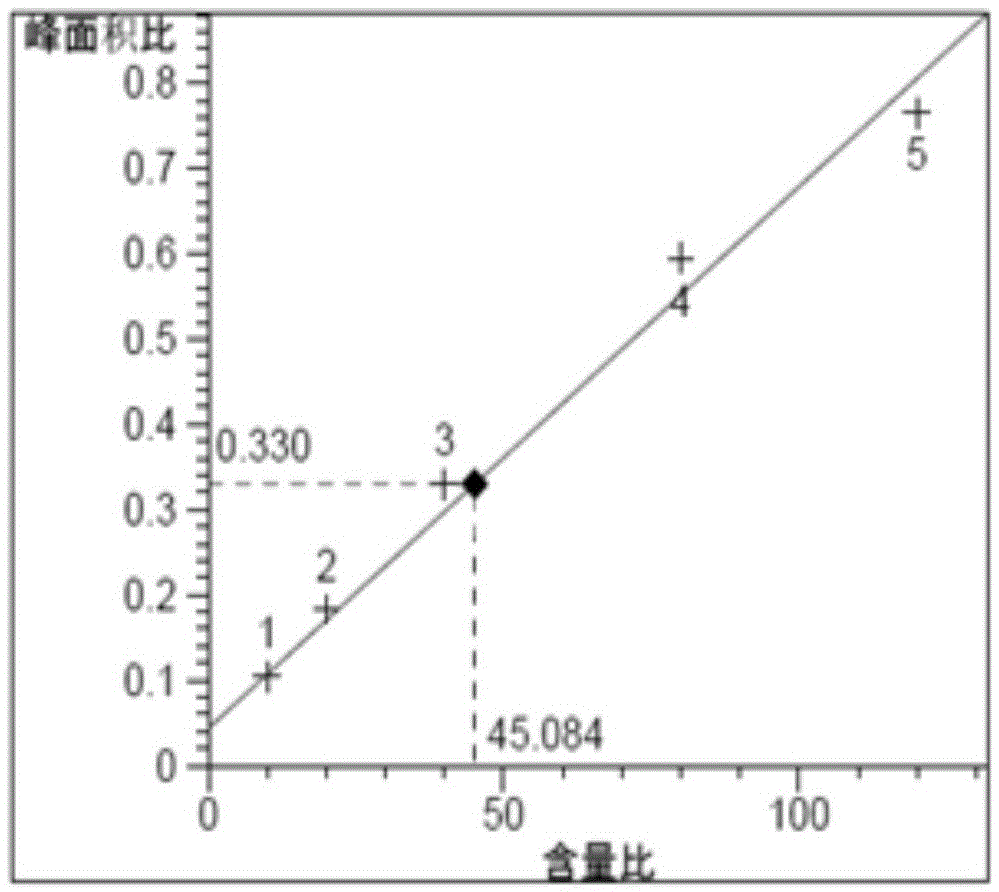

Detection method of dibenzyl disulfide and antioxidant in insulating oil

ActiveCN104807902AGood quantitative detection effectSave manpower and material resourcesComponent separationElectron capture detectorSulfur

The invention discloses a detection method of corrosive sulfur and an antioxidant in insulating oil. The detection method adopts gas chromatography detection, and comprises the following steps of (1) standard solution preparation, (2) sample pretreatment and (3) determination. The method for accurately and quantitatively determining dibenzyl disulfide (DBDS) in the insulating oil via a gas chromatography-electron capture detector (GC-ECD) is established, and the GC-ECD method has a good quantitative detection effect on 2,6-di-tert-butyl-4-methylphenol (T501) in the insulating oil. The method can simultaneously determine DBDS and T501 in the insulating oil via one sample injection.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Water soluble plastic packaging bag, and preparation method thereof

The invention provides a water soluble plastic packaging bag, and a preparation method thereof. The water soluble plastic packaging bag comprises, by weight, 10 to 40 parts of polyethylene, 10 to 30 parts of soybean starch, 5 to 20 parts of a plasticizer, 6 to 15 parts of zinc oxide, 1 to 5 parts of pine tar, 8 to 18 parts of allethrin, 5 to 10 parts of dibenzyl disulfide, 8 to 20 parts of salicylic acid, 3 to 8 parts of a surfactant, 5 to 12 parts of an antitack agent, 6 to 15 parts of polyoxyethylene ether, 2 to 10 parts of a pH conditioning agent, and 5 to 13 parts of an antiseptic. The water soluble plastic packaging bag is capable of dissolving in water completely; no harmful substance is generated; the water soluble plastic packaging bag is degradable, is friendly to the environment, is safe, and can be degraded in soil rapidly; the surrounding environment is not influenced; heat resistance is excellent; the water soluble plastic packaging bag is harmless for packaged products, is capable of prolonging product self life; heat stable time is 40min or longer at 180 DEG C; and damage is not easily caused.

Owner:安徽华猫软包装有限公司

Special lubricating grease for low-speed motor bearing and preparation method of special lubricating grease

ActiveCN104629882AExtended service lifeSmall starting loadLubricant compositionLow speedHydroxystearic Acid

The invention discloses special lubricating grease for a low-speed motor bearing and a preparation method of the special lubricating grease, belonging to the technical field of special lubricating grease for low-speed motor bearings. The technical scheme has the key points as follows: the special lubricating grease for the low-speed motor bearing is prepared from the following raw materials in parts by weight: 60 parts of dodecahydroxyl stearic acid, 40 parts of stearic acid, 38 parts of lithium hydrate, 3 parts of calcium hydroxide, 10 parts of azelaic acid, 10 parts of sebacic acid, 10 parts of benzyl disulfide T322 additives, 5 parts of T406 additives and 108 parts of base oil. The invention concretely discloses the preparation method of the special lubricating grease for the low-speed motor bearing. By using the special lubricating grease for the low-speed motor bearing, disclosed by the invention, the service life of the low-speed motor bearing is prolonged, meanwhile, the starting load of a low-speed motor is reduced, the low-speed motor can stably work for a long term, the production efficiency of an enterprise is increased, and the production cost of the enterprise is reduced.

Owner:XINXIANG HENGXING TECH CO LTD

Lubricant additive

InactiveCN105038909AImprove the lubrication effectImprove viscosity indexAdditivesPhosphoric Acid EstersPhosphorous acid

A lubricant additive is prepared from the following raw materials in parts by weight: 6-13 parts of N,N'-bis(1-methylpropyl)-1,4-phenylenediamine, 4-9 parts of sodium dodecyl benzene sulfonate, 7-8 parts of dibutyl phosphite, 4-6 parts of sulfurized isobutylene, 3-6 parts of sodium dodecyl benzene sulfonate, 7-9 parts of petroleum sulfonate, 4.2-5.6 parts of dibenzyl disulphide, 1.5-3.2 parts of dodecylbenzene, 4-6 parts of isooctyl phosphate ester, 1.3-3.6 parts of methyl silicone oil, 3-6.4 parts of sulfurized calcium alkyl phenolate, 1.4-3.5 parts of calcium petroleum sulfonate, 7-9 parts of amphi-di-iso-octyldiphenylamine and 6-12 parts of polyvinyl alcohol. The lubricant additive has the benefits that the viscosity index is greatly improved, the lubrication effect of the lubricant can be improved, and good abrasion resistance and oxidative resistance are achieved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

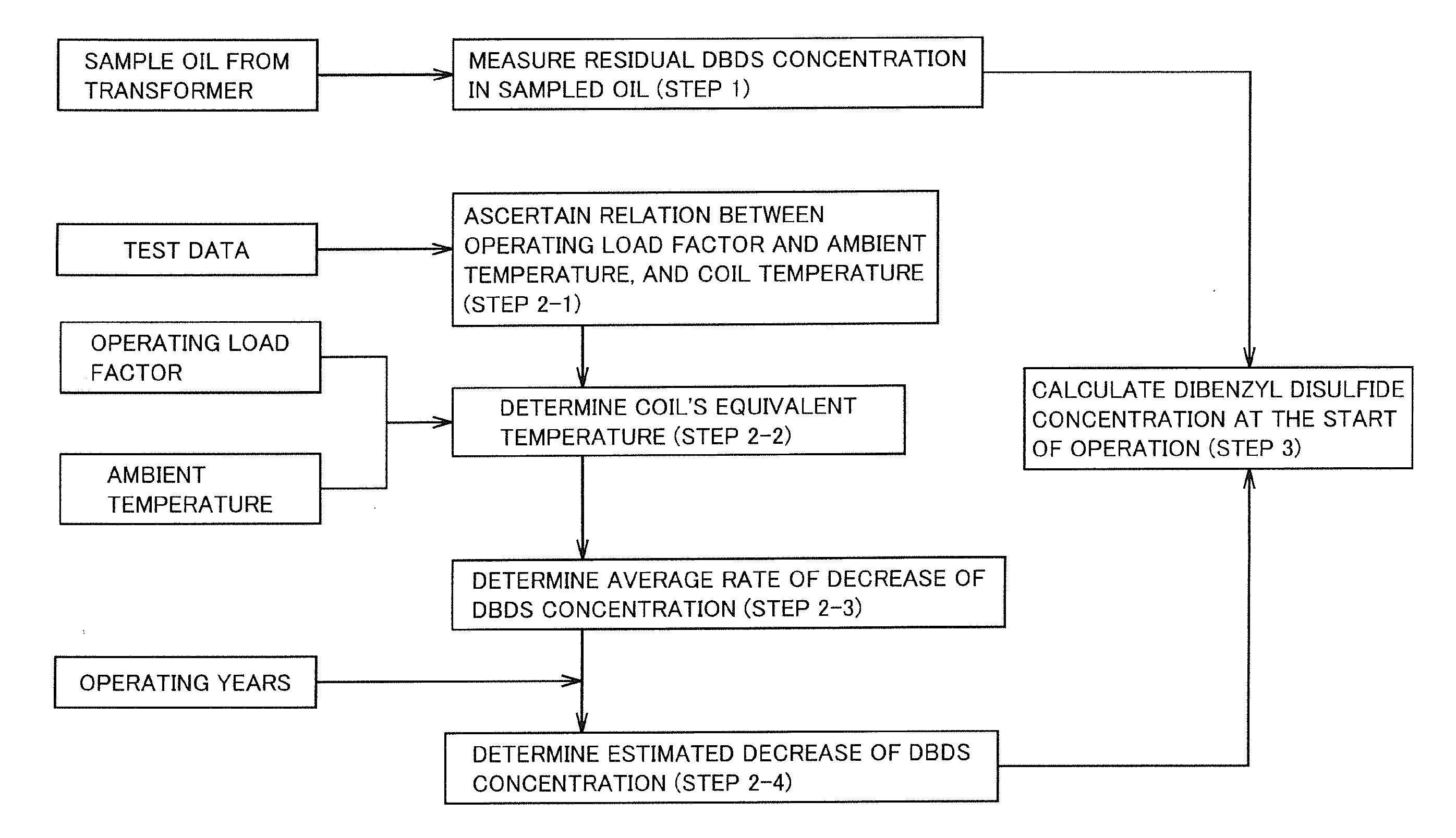

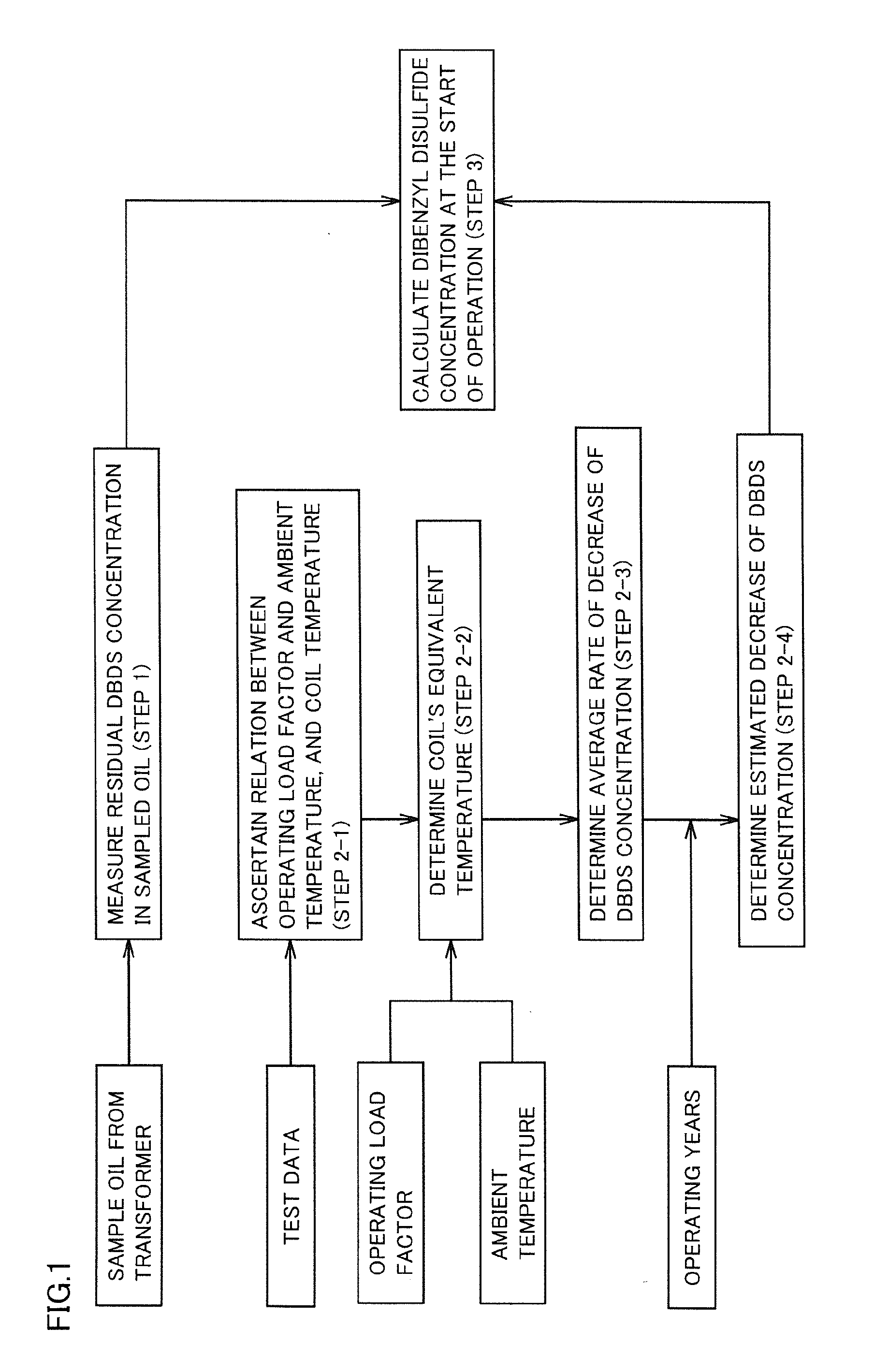

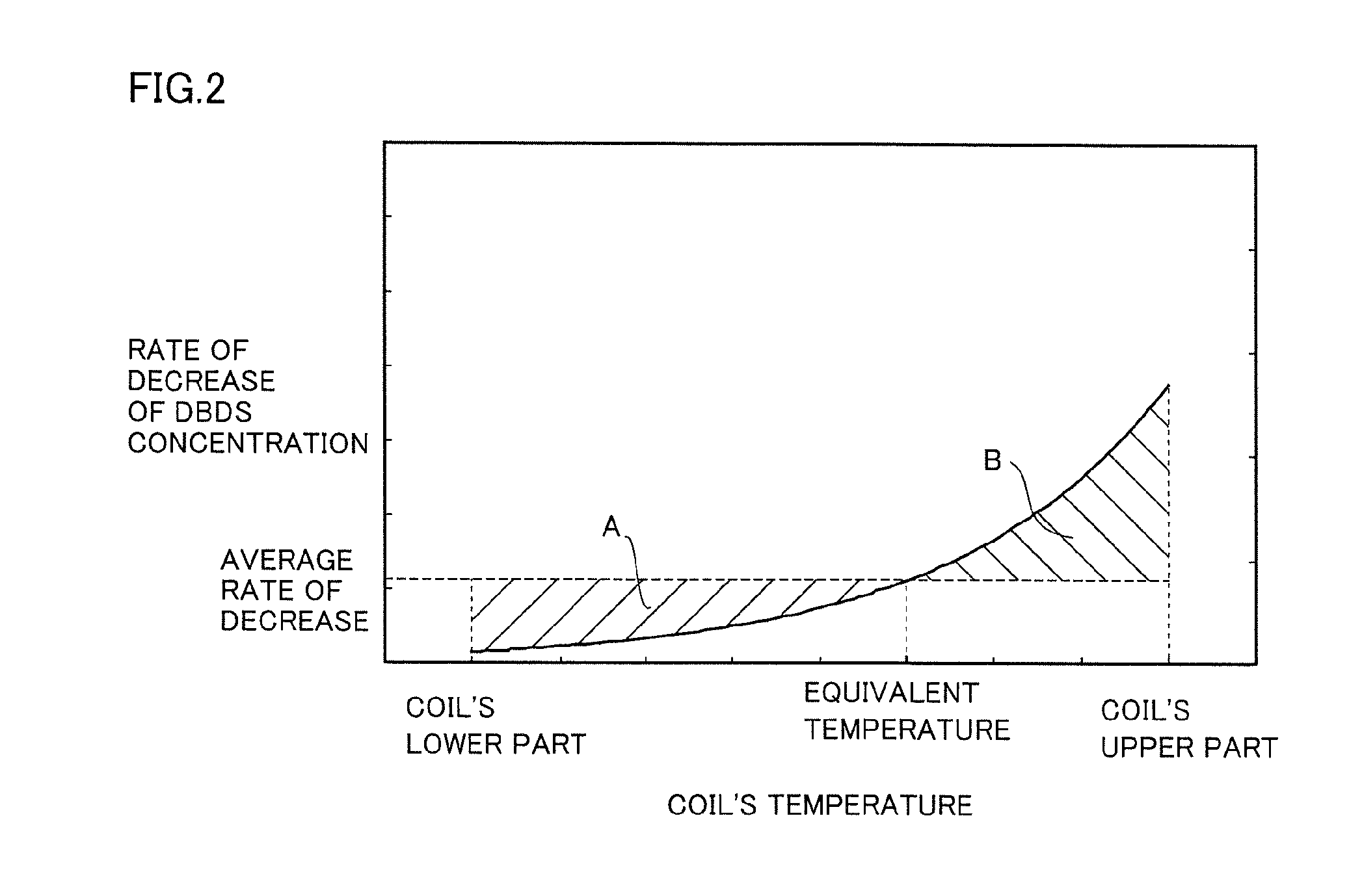

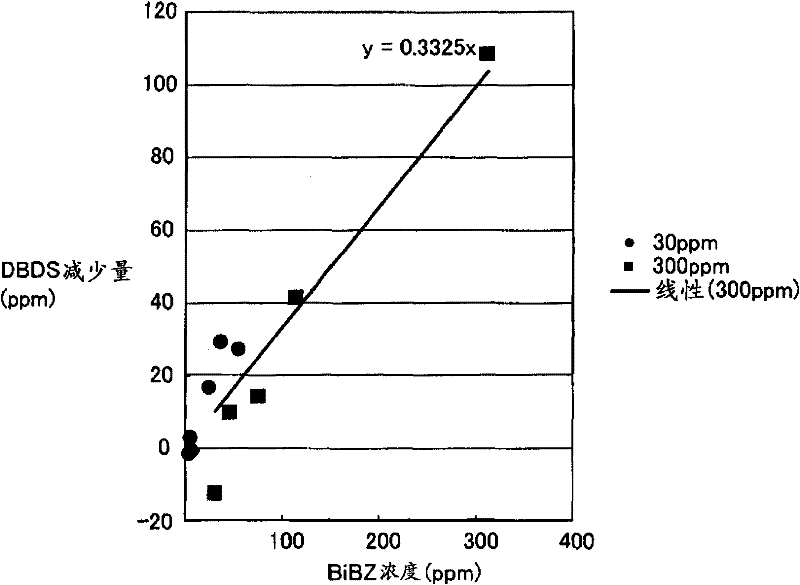

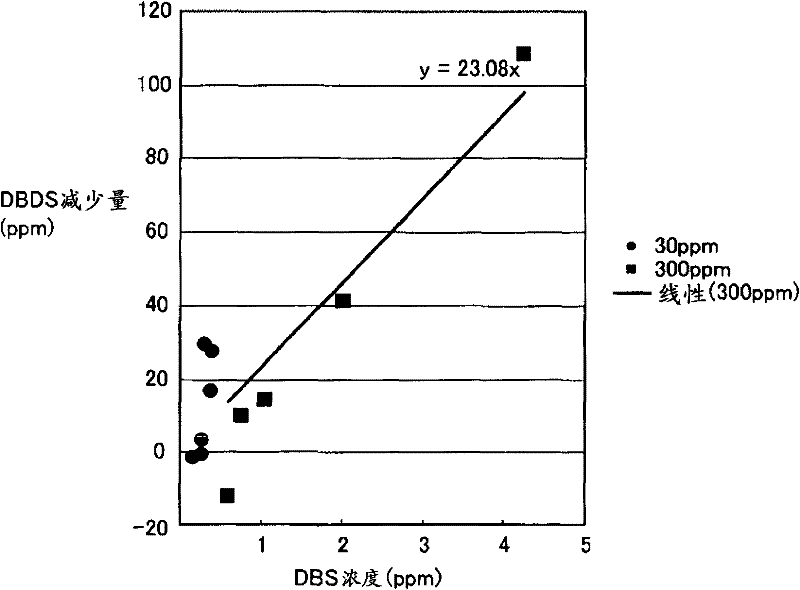

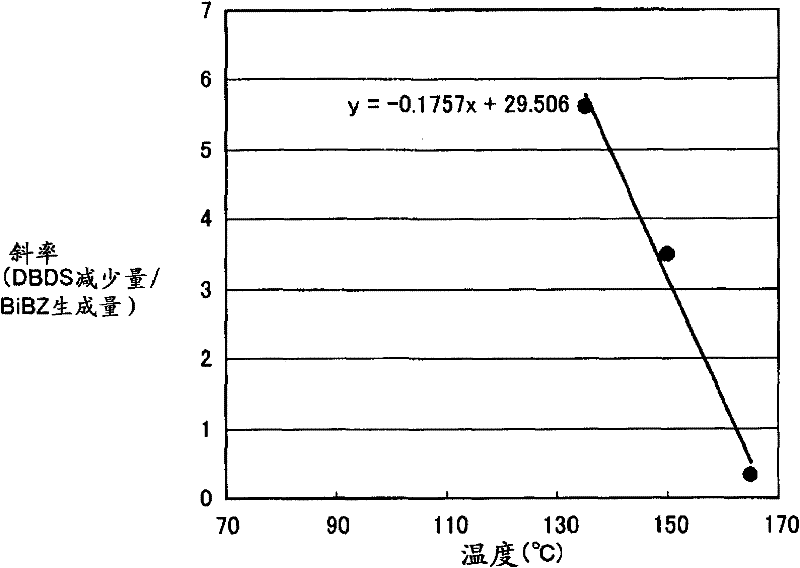

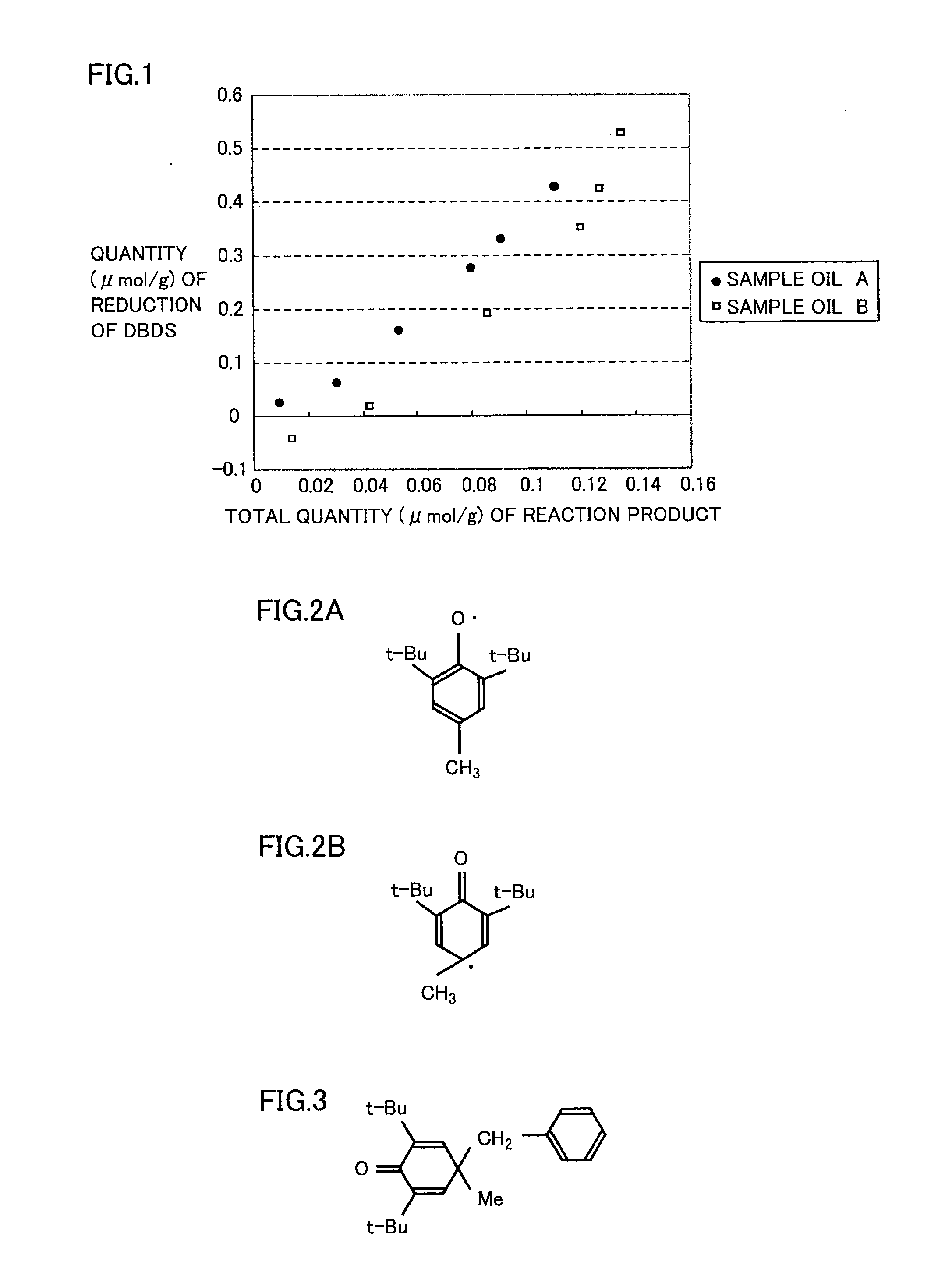

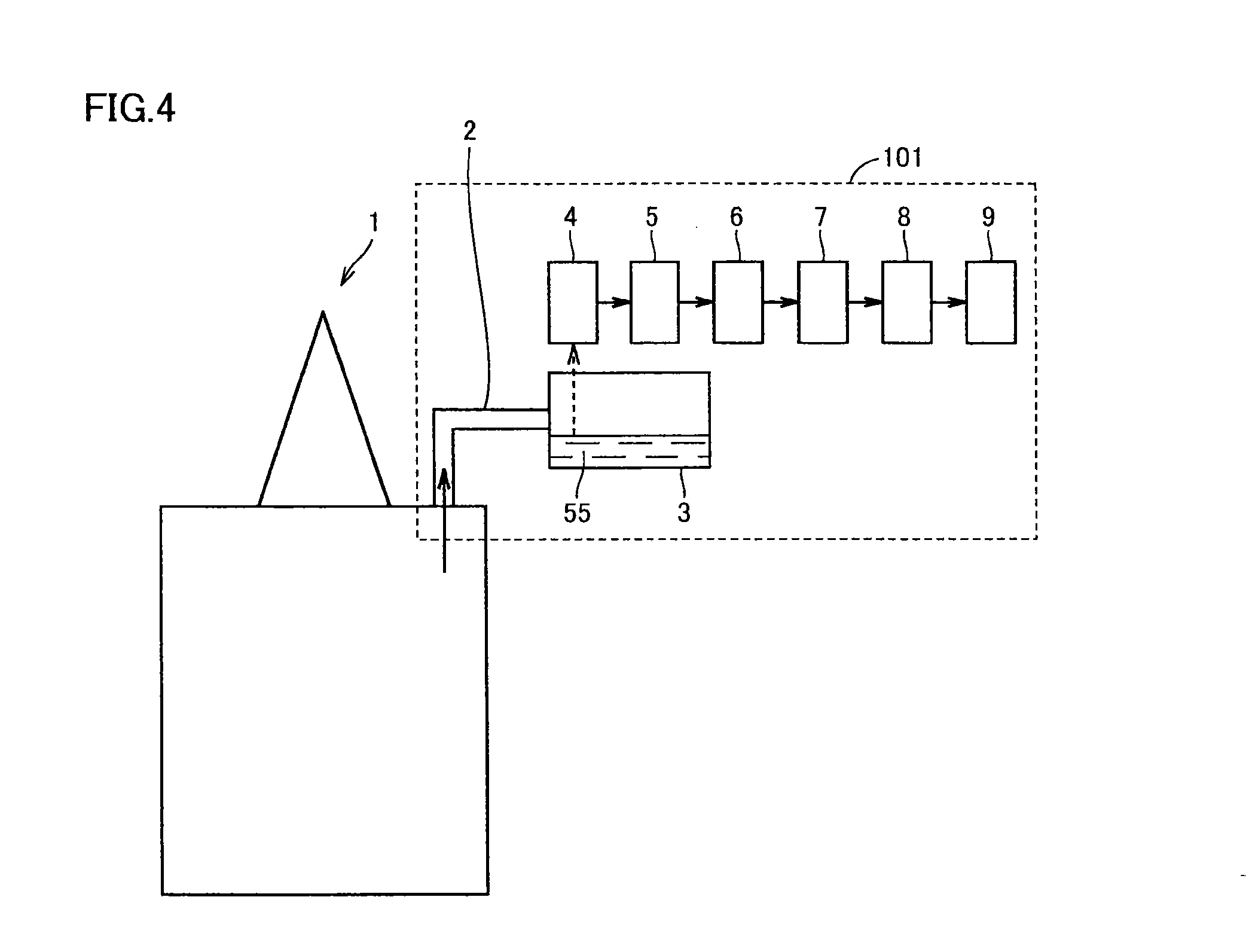

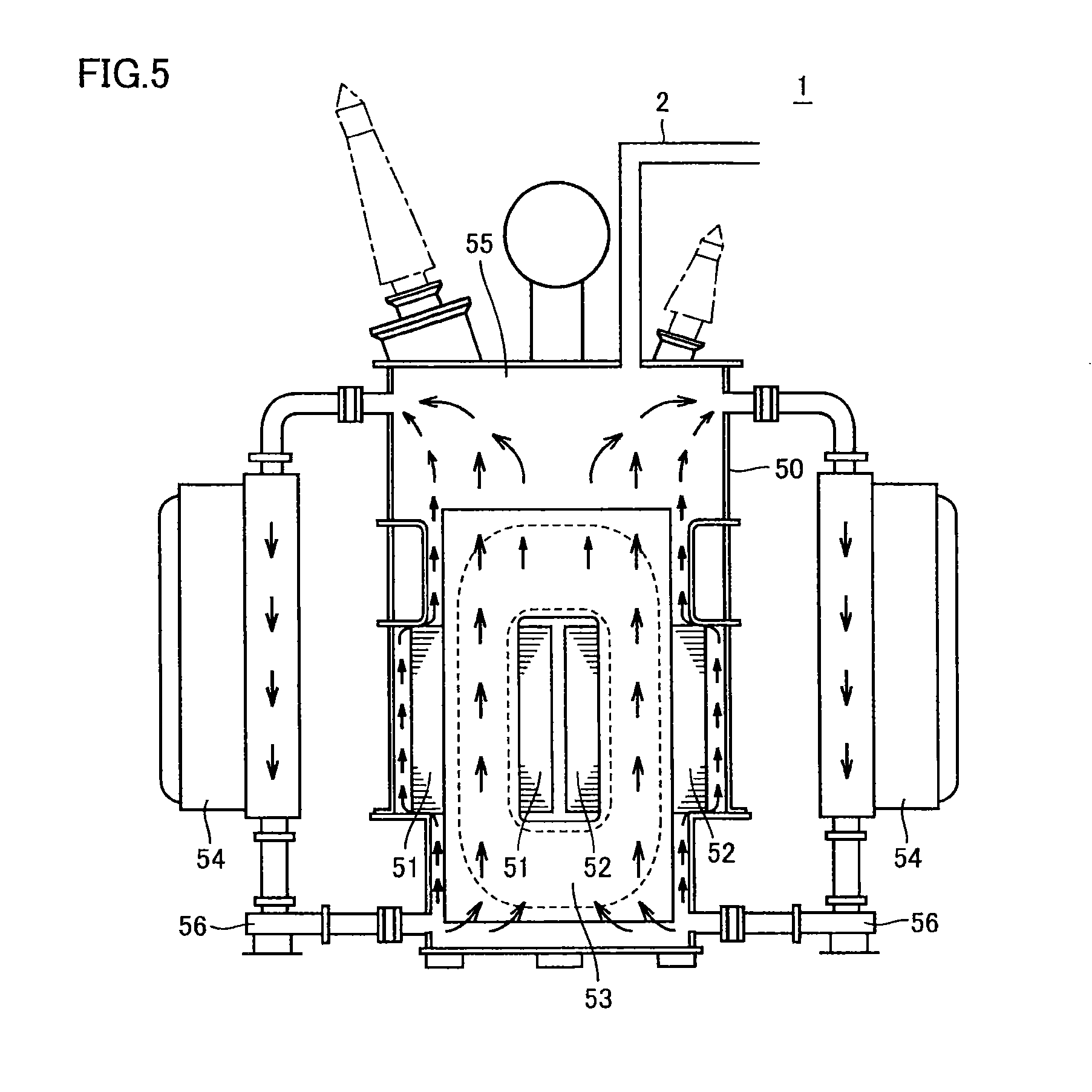

Method of predicting probability of abnormality occurrence in oil-filled electrical device

InactiveUS20120197559A1Electrical testingTransformers/inductances detailsEngineeringDibenzyl disulfide

The present invention is a method of predicting the probability of abnormality occurrence in an oil-filled electrical device, including the steps of: measuring a residual dibenzyl disulfide concentration in an insulating oil sampled from an oil-filled electrical device in operation; determining an estimated decrease of the residual dibenzyl disulfide concentration, relative to an initial dibenzyl disulfide concentration at the start of operation of the oil-filled electrical device; calculating the initial dibenzyl disulfide concentration from the residual dibenzyl disulfide concentration and the estimated decrease; and comparing the initial dibenzyl disulfide concentration with a specific management value.

Owner:MITSUBISHI ELECTRIC CORP

Lubricating oil for gearboxes and preparation method thereof

The invention discloses lubricating oil for gearboxes and a preparation method thereof. The lubricating oil for gearboxes is prepared by: adding antimony oxide, cerium oxide, neodymium oxide and lanthanum oxide into a grinder, grinding and mixing well, adding glycerin, and ultrasonically dispersing for 5-10 min to obtain mixture A; adding tetraethyl silicate and n-phenyliminodiacetic acid, and stirring to allow reaction at 90-100 DEG C for 30-40 min to obtain mixture B; mixing 5-amino-2-benzimidazolinone, dibenzyl disulfide, tricresyl phosphate, sorbitol and 2,6-di-tert-butyl-p-cresol, and stirring to allow reaction at 60-80 DEG C for 20-30 min to obtain mixture C; adding the mixture A, the mixture B and the mixture C into basic oil, performing intensive shear stirring at 180-200 DEG C for 0.5-1 h, continuously heating to 250-280 DEG C, and performing shear stirring for 1-2 h; cooling to 120-140 DEG C, continuously performing shear stirring for 2-3 h, and cooling to obtain the lubricating oil for gearboxes.

Owner:WUJIANG HUAWEI SPECIAL OIL

Extreme-pressure antiwear additive

The invention provides an extreme-pressure antiwear additive, relating to the technical field of antiwear additives. The extreme-pressure antiwear additive is composed of the following components in percentage by mass: 1-10% of silicon powder, 0.5-5% of magnesium oxide, 20-70% of aluminum powder, 0.5-5% of phosphate, 0.1-1% of nickel powder, 0.1-1% of dibenzyl disulfide, 1-5% of molybdenum naphthenate and 5-20% of molybdenum disulfide. The extreme-pressure antiwear additive can increase the surface hardness of the part to enhance the wear resistance, and can also repair the generated abrasion defect to prolong the service life of the friction part.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

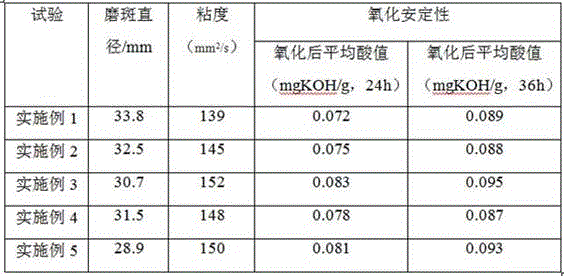

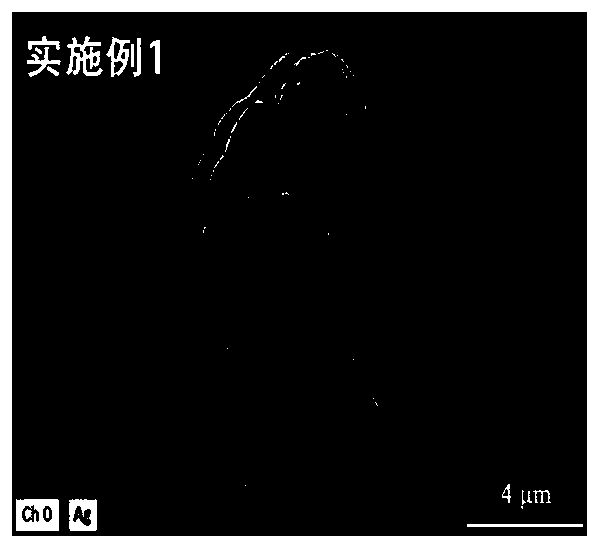

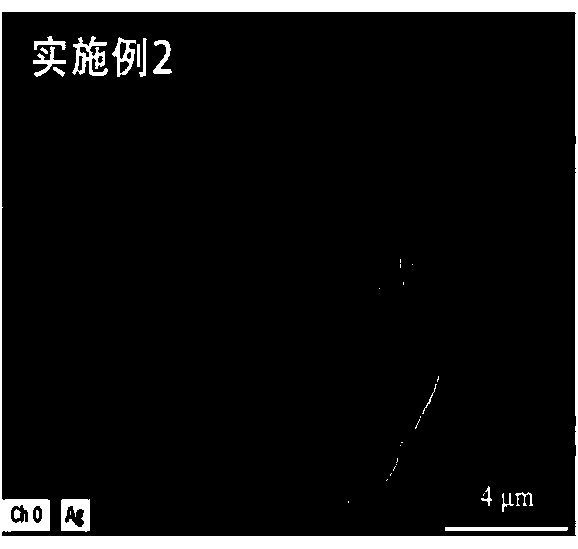

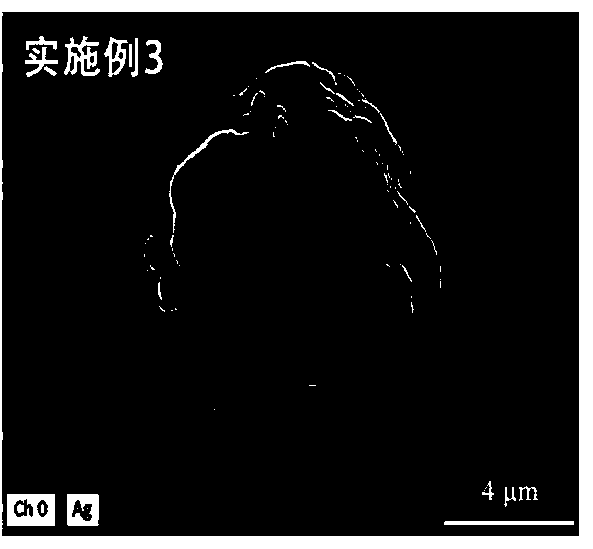

Adsorbent for normal-temperature removing of dibenzyl disulfide in transformer oil and method

ActiveCN110523370AImprove adsorption capacityImprove mixing uniformityOther chemical processesHydrocarbon oils refiningActivated carbonSorbent

The invention discloses an adsorbent for normal-temperature removing of dibenzyl disulfide in transformer oil and a method. The method comprises the steps that first, silver nitrate is dissolved intodeionized water, a porous carrier is added, and ultrasound treatment is conducted till carrier particles are evenly dispersed; second, raw materials prepared in the first step are placed into a planetary stirrer to be stirred, so that the raw materials are mixed evenly; third, slurry obtained in the second step is dried; and fourth, a dried sample is ground and then sieved through a sieve, and thus the adsorbent with uniform particles is obtained. The adsorption capacity of the prepared adsorbent to the dibenzyl disulfide at the normal temperature is higher than 50 mg / g, the removal rate is higher than 95%, and the performance of the adsorbent is much higher than that of traditional adsorption materials such as activated carbon and activated clay. The adsorbent is simple in preparation process, has the high efficiency of removing dibenzyl disulfide in the transformer oil and has potential application prospects in the field of transformer oil purification.

Owner:SOUTH CHINA UNIV OF TECH

Antiwear self-repairing lubricating oil additive and preparation method thereof

InactiveCN108329975AGood self-lubricating performanceGood anti-wear self-repair effectAdditivesChemical reactionAntioxidant

An antiwear self-repairing lubricating oil additive is composed of the following components in parts by mass: 10-22 parts of molybdenum diisooctyl dithiophosphate, 18-28 parts of triphenyl phosphate,15-20 parts of an antiwear agent and 10-30 parts of an antioxidant. With use of special antiwear agent components, the antiwear agent composed of sulfurized isobutylene, dibenzyl disulfide, di-n-butylphosphite, sodium metaborate, and a potassium metaborate material is added into lubricating oil, the lubricating oil is subjected to a chemical reaction with a metal surface, and a chemical reactionfilm is produced, so a lubricating effect is played, scratching of the metal surface is prevented, even fusion welding is prevented, the self lubricating performance of the lubricating oil is greatlyimproved, and the antiwear self-repairing effect is good. With special preparation of the multi-component antioxidant, the antiwear self-repairing lubricating oil additive has excellent anti-aging andanti-oxidation performance, is added into the lubricating oil, can highly delay the service life of the lubricating oil and improves the practical performance.

Owner:艾润工业介质(镇江)有限公司

High-performance lubricating oil additive

InactiveCN104974820AImprove viscosity coefficientImprove cooling effectAdditivesPhosphorous acidMeth-

A high-performance lubricating oil additive is composed of the following raw materials in parts by weight: 7 to 9 parts of di-tert-butyl-p-cresol, 8 to 11 parts of dibenzyl disulfide, 4 to 7 parts of polyisobutene barium salt, 5 to 8 parts of N,N-dimethyl formamide, 1.2 to 4 parts of glycerol acrylate, 6 to 10 parts of dibutyl phosphite, 9 to 12 parts of zinc dialkyl dithiophosphates-T206, 2 to 4 parts of methyl silicone oil, 7 to 11 parts of perfluorononyl ethyl benzene, 6 to 10 parts of amino thioester, 3 to 5 parts of phosphorous acid, 7 to 10 parts of zinc dialkyl dithiophosphates-T204, and 7 to 8.5 parts of dimethyl silicone oil. The provided lubricating oil additive has a high efficient comprehensive performance, is capable of improving the viscosity coefficient of lubricating oil, and improves the cooling and lubricating performances of lubricating oil at the same time.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Method for Predicting the Likelihood of Occurrence of Anomalies in Oil-Immersed Electrical Equipment

The present invention relates to a method for predicting the probability of abnormality occurrence in an oil-filled electrical apparatus, which comprises subjecting a sample of insulating oil withdrawn from a transformer in operation to compositional analysis, calculating the estimated concentration of dibenzyl disulfide in the insulating oil in its virgin state from the result of the analysis, and predicting the probability of abnormality occurrence in the oil-filled electrical apparatus on the basis of the level of the estimated concentration.

Owner:MITSUBISHI ELECTRIC CORP

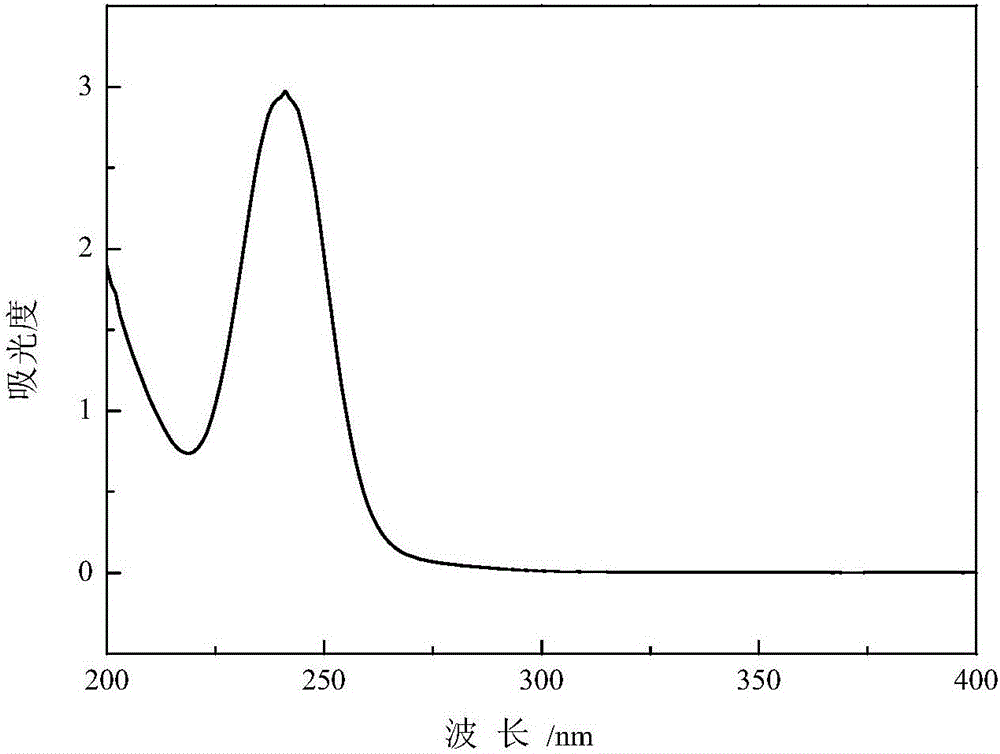

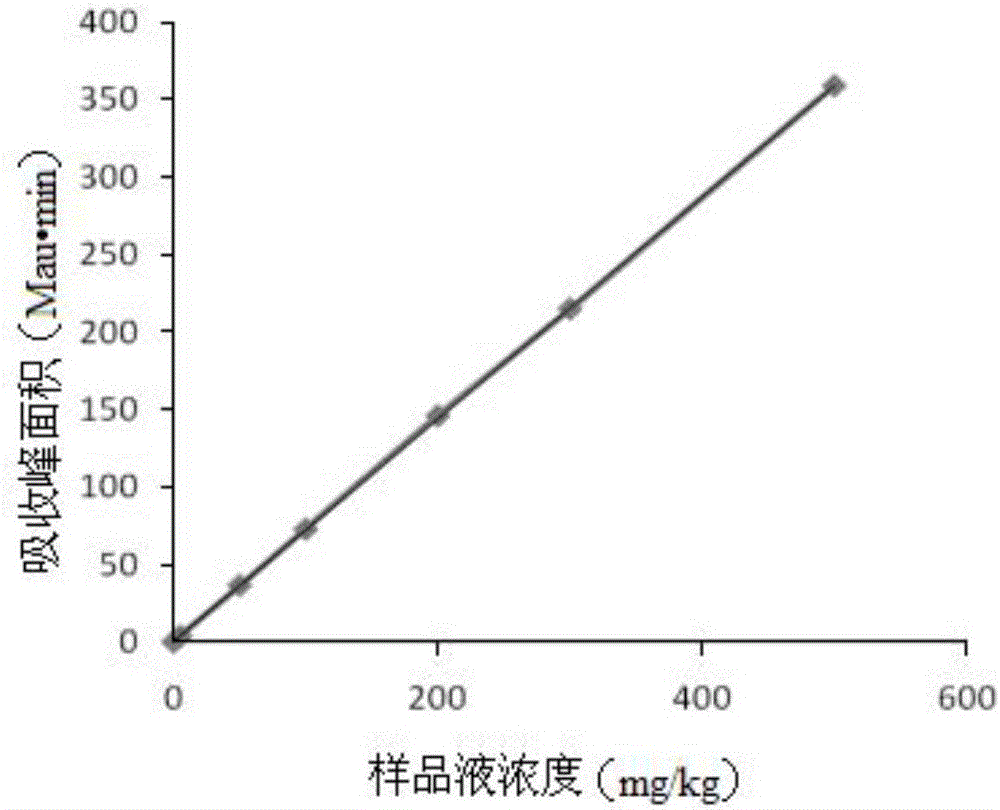

Reversed phase high performance liquid chromatography method for determining content of dibenzyl disulfide in insulating oil

InactiveCN105974042ALow priceGood repeatabilityComponent separationGas chromatography–mass spectrometryVapor phase chromatography

A reverse-phase high-performance liquid chromatography method for the determination of dibenzyl disulfide content in insulating oil. The invention relates to a method for measuring the content of dibenzyl disulfide in insulating oil. The purpose of the invention is to solve the problems of high cost and limited application of the existing gas chromatography-mass spectrometry method for determining the content of DBDS in insulating oil. Methods: 1. Preparation of stock solution; 2. Preparation of calibration solution; 3. Preparation of solid phase extraction adsorption column; 4. Preparation of sample solution; 5. Sample analysis; 6. Establishment of calibration curve; 7. Insulation to be tested Determination of dibenzyl disulfide content in oil. The method of the invention utilizes a relatively cheap liquid chromatograph to realize the determination of the dibenzyl disulfide content in the insulating oil, and the method is simple in operation, high in repeatability and accuracy, low in instrument equipment price, and easy to implement.

Owner:HEILONGJIANG ELECTRIC POWER RES INST +1

Diagnosis method and diagnosis apparatus for oil-filled electrical apparatus

InactiveUS20130034909A1Accurate assessmentNot at risk of errorTransformers/inductances coolingBiological testingCresolTert butyl phenol

Provided is a diagnosis method for an oil-filled electrical apparatus, which is for evaluating the degree of danger of copper sulfide being generated within the oil-filled electrical apparatus, comprising: a first step for detecting a specific compound contained within insulating oil inside the oil-filled electrical apparatus; a second step for evaluating the possibility of copper sulfide being generated inside the oil-filled electrical apparatus, on the basis of the result detected by the first step; and a third step for diagnosing the degree of danger of a malfunction occurring in the oil-filled electrical apparatus, on the basis of the evaluation result obtained in the second step. The specific compound contains dibenzyl disulfide and / or a reaction product of a radical resulting from dibenzyl disulfide, and di-tert-butyl-p-cresol and / or a reaction product of a radical resulting from di-tert-butyl-p-cresol, or, di-tert-butyl-phenol and / or a reaction product of a radical resulting from di-tert-butyl-phenol.

Owner:MITSUBISHI ELECTRIC CORP

Strong wear-resistance rubber sealing material for detector as well as preparation method of strong wear-resistance rubber sealing material

The invention provides a strong wear-resistance rubber sealing material for a detector as well as a preparation method of the strong wear-resistance rubber sealing material, and relates to the technical field of detector production. The rubber sealing material is prepared from the following raw materials in parts by weight: 40 to 50 parts of ethylene propylene diene monomer, 15 to 20 parts of isoprene rubber, 10 to 15 parts of acrylic ester rubber, 6 to 10 parts of tripolybutenone sulfide, 1 to 2 parts of neopentyl glycol dioleate sulfide, 0.8 to 1.2 parts of coupling agent, 5 to 7 parts of dibenzyl disulfide, 2 to 4 parts of sulfide terpene, 4 to 6 parts of hexachlorocyclopentadiene, 6 to 8 parts of potassium triborate, 2 to 4 parts of nickelous-nickelic oxide, 4 to 6 parts of calcium fluoride, 2 to 3 parts of silicon carbon fiber, 2 to 4 parts of vulcanizing agent and 2 to 4 parts of dispersing agent. According to the strong wear-resistance rubber sealing material for the detector aswell as the preparation method thereof, the defects in the prior art are overcome; the wear resistance and the cracking resistance of the rubber sealing material can be effectively improved; influence on the normal use of the detector caused by the fact that the rubber sealing material is worn, even is cracked under the action of an external force is avoided; and the rubber sealing material has excellent overall performance and high wear resistance and is suitable for popularizing.

Owner:ANHUI SHENGLONG ELECTRIC

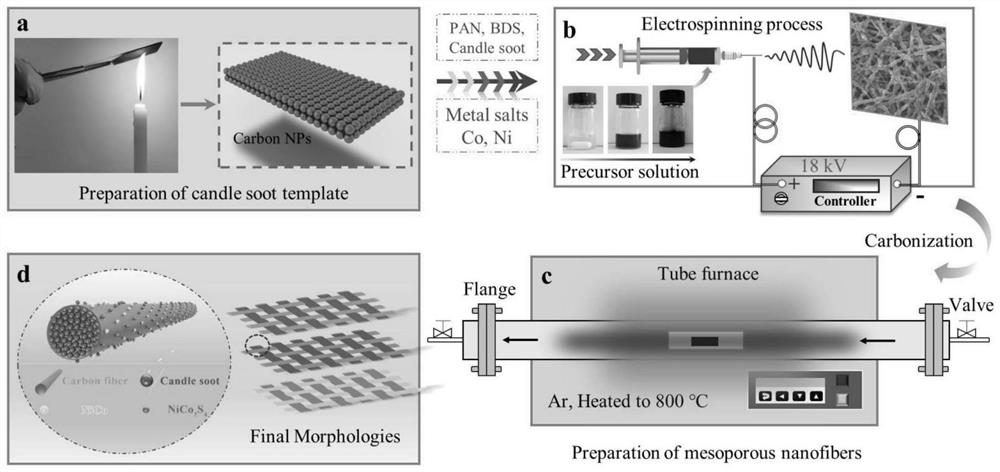

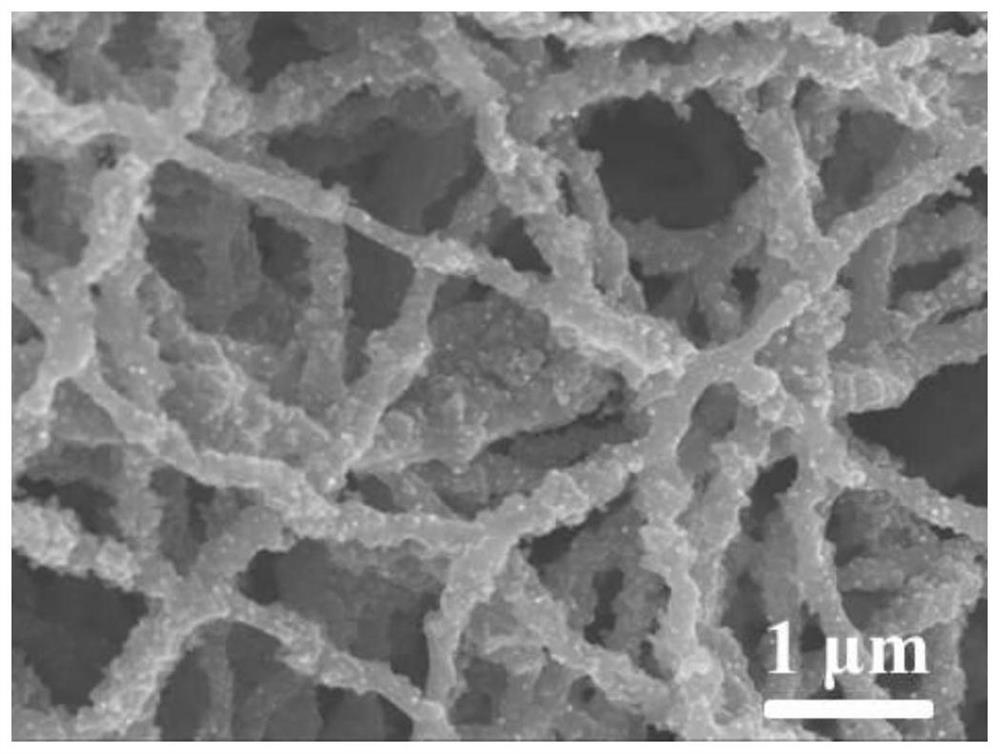

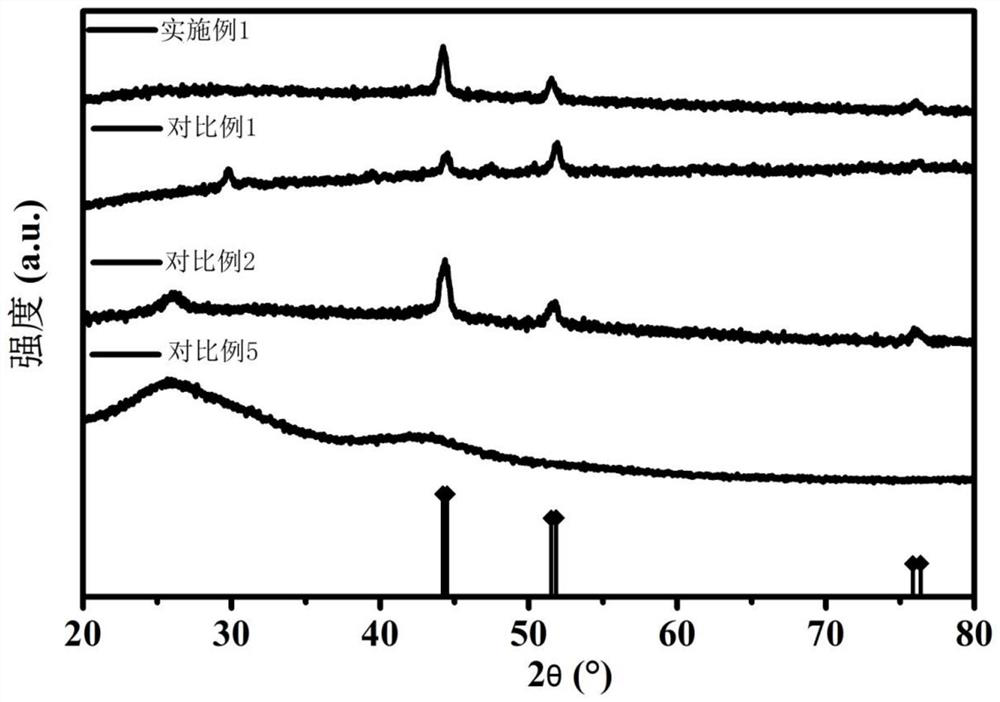

Preparation method and application of carbon nanofiber-based electrocatalyst

ActiveCN112599806AHas a rough surfaceLarge specific surface areaMaterial nanotechnologyCell electrodesFiberNickel salt

The invention provides a preparation method of a carbon nanofiber-based electrocatalyst. The preparation method comprises the following steps: dispersing candle ash in an organic solvent, adding a high-molecular polymer and dibenzyl disulfide, stirring, adding a cobalt salt and a nickel salt, and continuing stirring to obtain a precursor solution; carrying out electrostatic spinning on the precursor solution, collecting a fiber precursor, and drying; and carrying out air burning on the dried fiber precursor at 150-300 DEG C for 1-3 hours, and then carrying out high-temperature carbonization inan inert atmosphere to obtain the carbon nanofiber-based electrocatalyst. The carbon nanofiber-based electrocatalyst prepared by the method has excellent electrocatalytic performance and cycling stability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Determination method of dibenzyl disulfide and antioxidant in insulating oil

ActiveCN104807902BGood quantitative detection effectSave manpower and material resourcesComponent separationElectron capture detectorAntioxidant

The invention discloses a detection method of corrosive sulfur and an antioxidant in insulating oil. The detection method adopts gas chromatography detection, and comprises the following steps of (1) standard solution preparation, (2) sample pretreatment and (3) determination. The method for accurately and quantitatively determining dibenzyl disulfide (DBDS) in the insulating oil via a gas chromatography-electron capture detector (GC-ECD) is established, and the GC-ECD method has a good quantitative detection effect on 2,6-di-tert-butyl-4-methylphenol (T501) in the insulating oil. The method can simultaneously determine DBDS and T501 in the insulating oil via one sample injection.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Few-layer ReS2 nanosheet @ MoS2 quantum dot composite photocatalyst, and preparation method thereof

ActiveCN109954502AEfficient separationImprove conduction abilityCatalyst activation/preparationFreeze-dryingQuantum dot

The invention discloses a few-layer ReS2 nanosheet @ MoS2 quantum dot composite photocatalyst, and a preparation method thereof. The preparation method mainly comprises following steps: 1, ball milling is carried out to prepare ReS2; 2, ReS2 powder is dispersed in a solvent such as ethanl for ultrasonic peeling; 3, an obtained ultrasonic dispersed solution is subjected to centrifugalization, a product is collected, washed, and freeze-dried so as to obtain few-layer ReS2 nanosheet; 4, sodium molybdate dihydrate and dibenzyl disulfide are ultrasonically dispersed in deionized water and ethanol respectively, obtained two suspensions are introduced into an autoclave for hydrothermal treatment, and at last, an obtained corresponding product is subjected to centrifugalization to obtain MoS2QDs supernatant layer; and 5, the prepared MoS2QDs and the ReS2 nanosheet are subjected to second hydrothermal compounding so as to obtain the few-layer ReS2 nanosheet @ MoS2 quantum dot composite photocatalyst. The few-layer ReS2 nanosheet @ MoS2 quantum dot composite photocatalyst prepared through the preparation method is excellent in performance, simple in operation and high in application value.

Owner:ZHEJIANG UNIV

Strong-efficient wear-resistant cable sheath and preparation method thereof

The invention provides a strong-efficient wear-resistant cable sheath and a preparation method thereof, and relates to the technical field of the cable production. The cable sheath is prepared by the following raw materials in parts by weight: 40-50 parts of butadiene rubber, 15-20 parts of isoprene rubber, 10-15 parts of ethylene propylene rubber, 8-12 parts of vulcanized neopentyl glycol dioleate, 1-2 parts of a modifier, 6-8 parts of dibenzyl disulfide, 3-5 parts of 2,5-dimercaptothiazole, 5-7 parts of thiophosphate isobutylene, 2-4 parts of potassium metaborate, 4-6 parts of zinc thiocarbonate, 2-4 parts of iron sulfide, 3-5 parts of molybdenum nitride, 2-4 parts of a dispersant, and 2-4 parts of a vulcanizing agent. The strong-efficient wear-resistant cable sheath is capable of overcoming deficiency of the prior art, effectively improving a wear-resistant property of the cable sheath, preventing the cable from being damaged by trampling of people, and even causing an electric shock risk because an internal lead is exposed. The cable sheath is excellent in whole performance, high in safety, long in service life, and suitable for popularization.

Owner:ANHUI CABLE

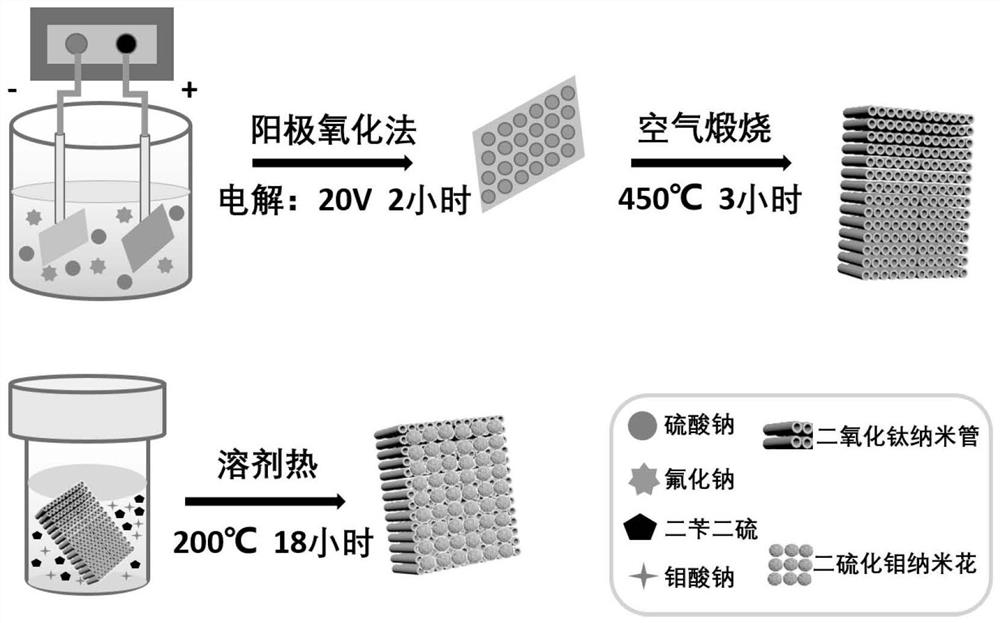

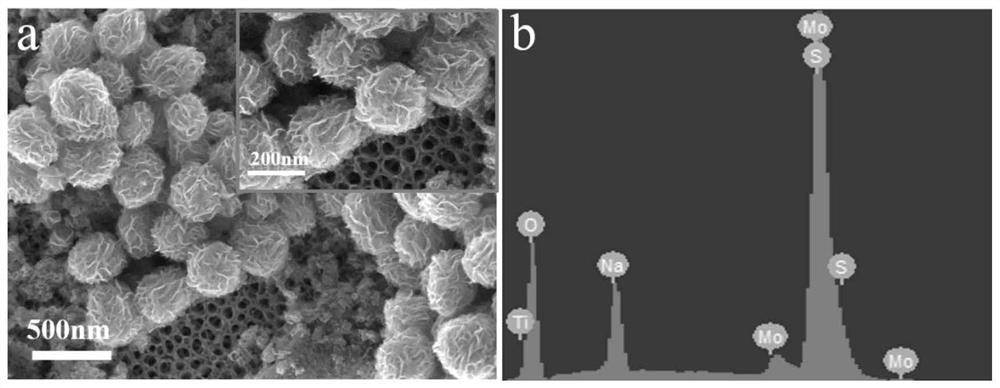

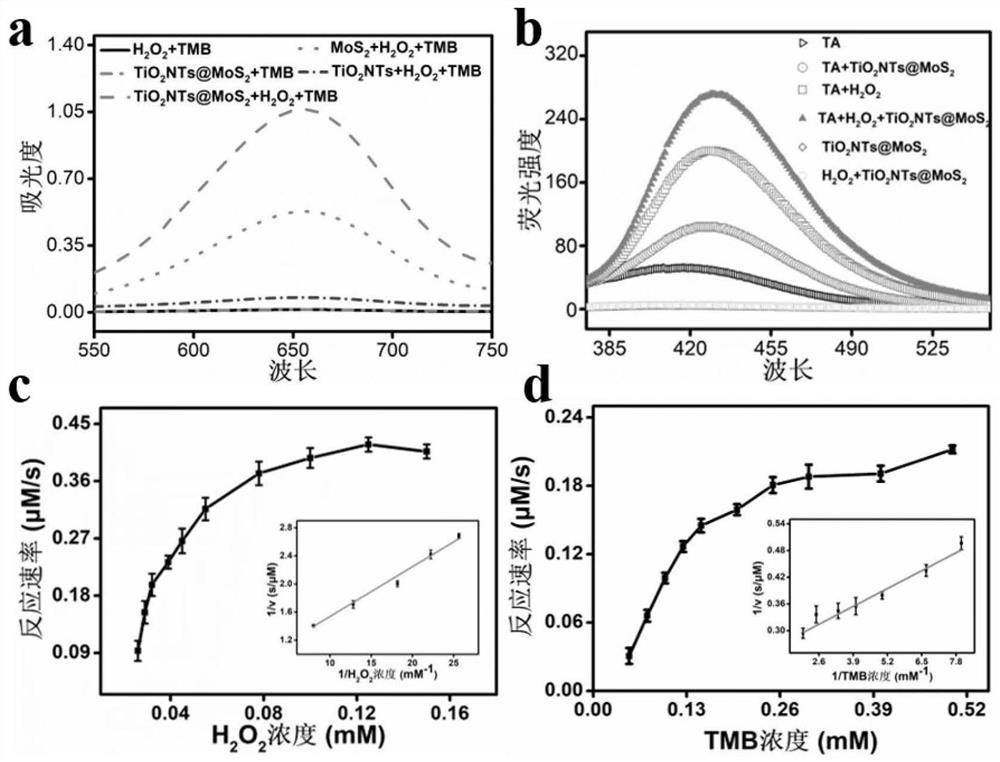

Titanium dioxide nanotube/molybdenum disulfide nanoflower compound as well as preparation method and application thereof

PendingCN113244393AEasy to makeAbundant raw materialsAntibacterial agentsPhotodynamic therapyTio2 nanotubePeroxidase

The invention belongs to the field of nano material preparation and antibiosis, and relates to a titanium dioxide nanotube / molybdenum disulfide nanoflower compound as well as a preparation method and application thereof. The titanium dioxide nanotube / molybdenum disulfide nanoflower compound is prepared by placing titanium dioxide nanotubes in an ethanol mixed solution containing dibenzyl disulfide and sodium molybdate and performing a solvothermal reaction. The molybdenum disulfide nanoflowers are loaded on the surfaces of the titanium dioxide nanotubes, the average size of the titanium dioxide nanotubes is 75 + / -5nm, and the average size of the molybdenum disulfide nanoflowers is 230 + / -20nm. The compound has visible light photocatalysis and peroxidase-like activity at the same time, so that the compound is applied to resisting bacteria and promoting wound healing based on the synergistic effect of the visible light photocatalysis and peroxidase-like activity. The compound is a nano biomimetic material, and the preparation method is ingenious in conception, simple in preparation process, green, environmentally-friendly, rich in raw material and low in cost. The antibacterial mode is novel, visible light is a main component of sunlight, and the visible light is fully utilized to perform photocatalysis to enhance the enzyme-like activity. The application environment and biocompatibility are good, and the market prospect is wide.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com