Patents

Literature

81results about How to "Improve viscosity index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

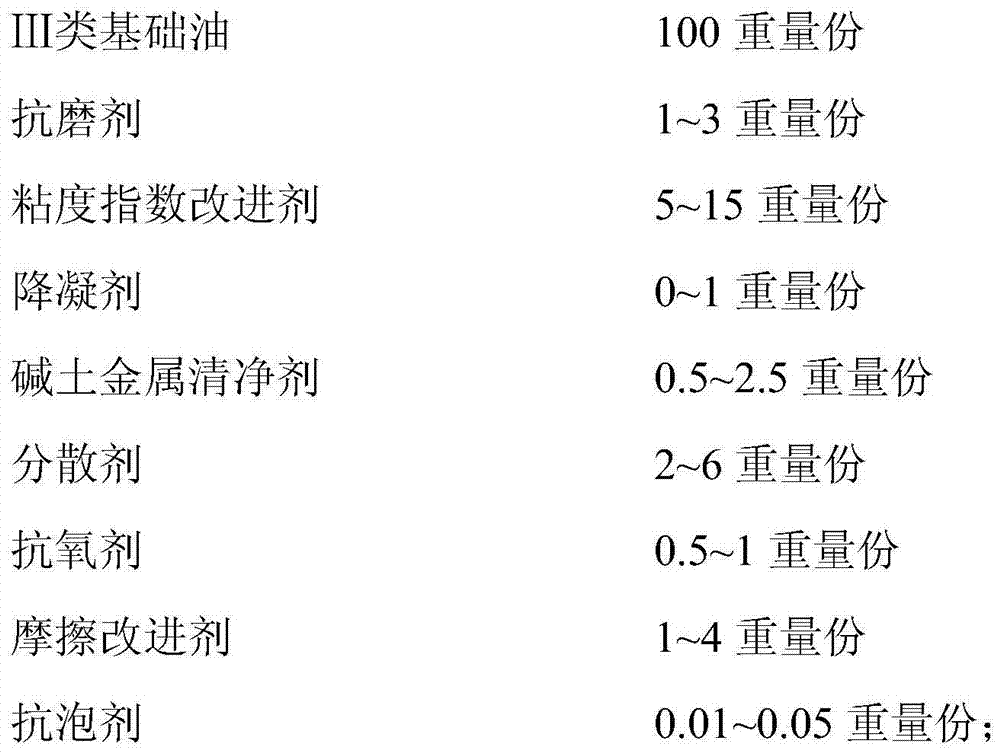

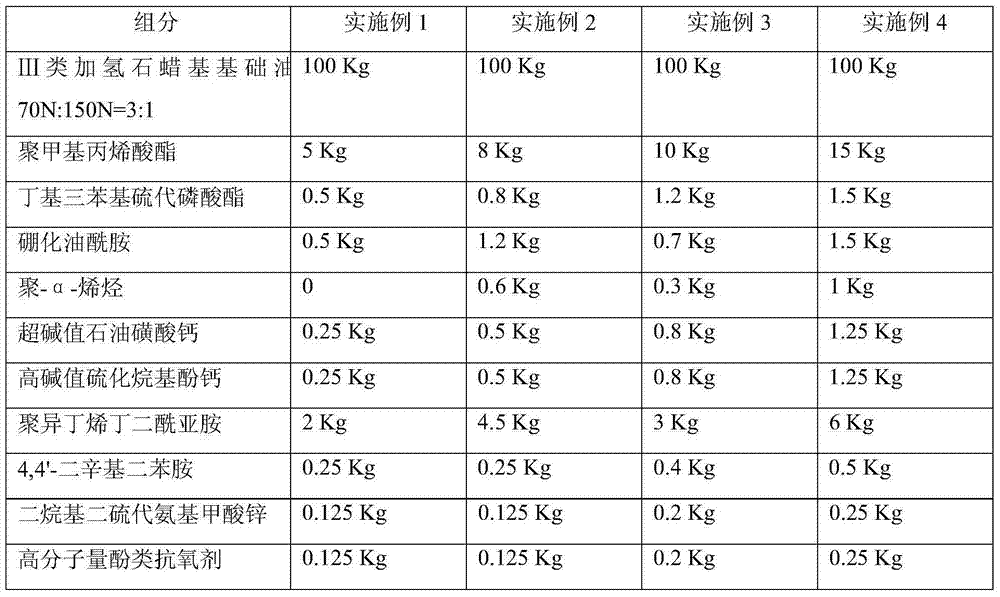

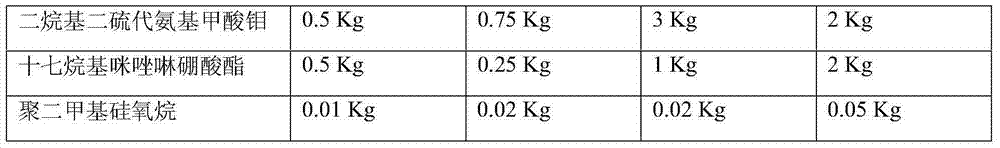

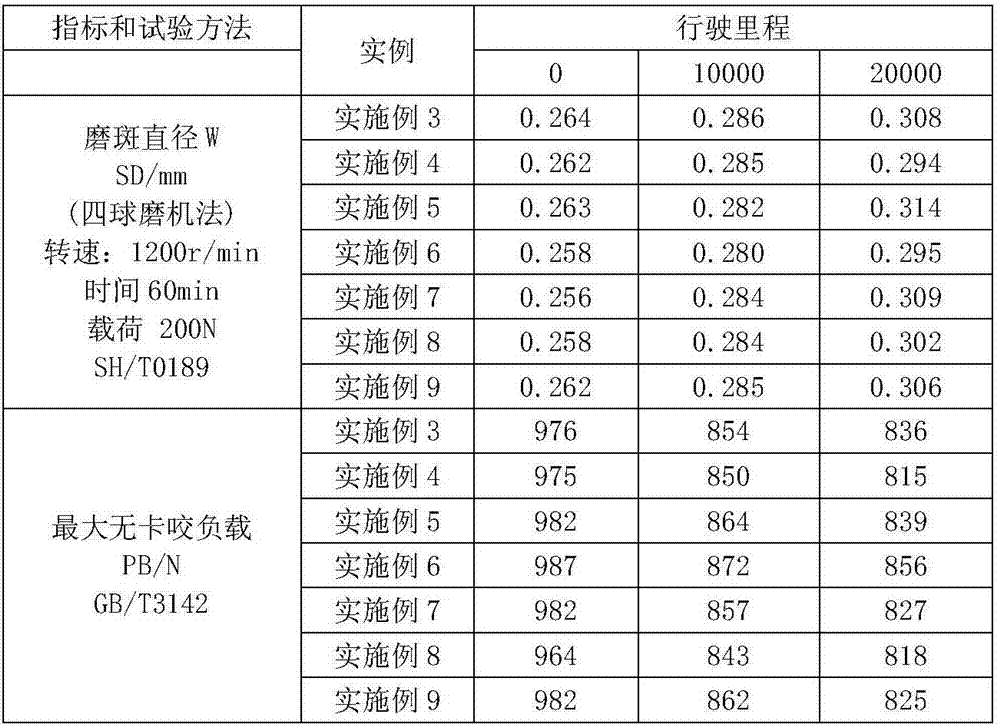

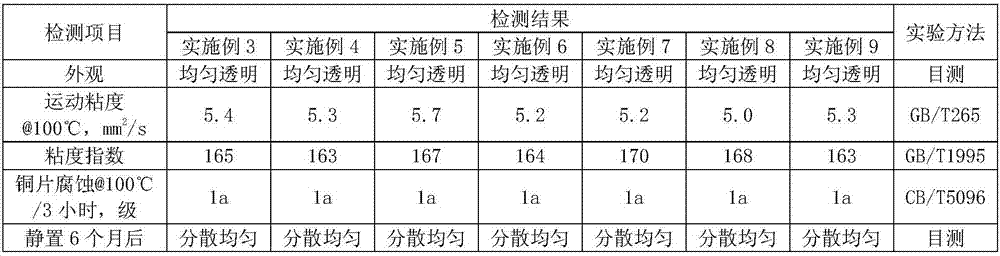

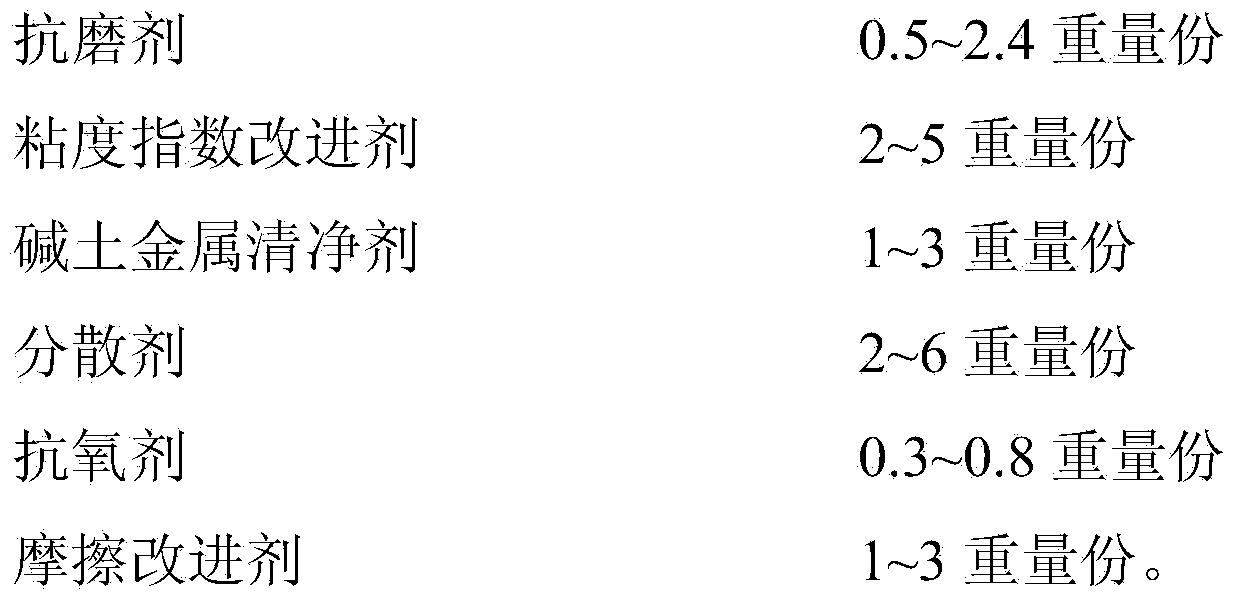

Automobile continuously variable transmission fluid and preparation method thereof

The invention discloses an automobile continuously variable transmission fluid and a preparation method thereof. The automobile continuously variable transmission fluid comprises the following components: 100 parts by weight of class III base oil, 1-3 parts by weight of antiwear agent, 5-15 parts by weight of viscosity index improver, 0-1 part by weight of pour point depressant, 0.5-2.5 parts by weight of alkaline earth clearing agent, 2-6 parts by weight of dispersant, 0.5-1 part by weight of antioxidant, 1-4 parts by weight of friction modifier and 0.01-0.05 part by weight of anti-foaming agent. According to the invention, the chosen additives are optimally combined together to obtain the CVTF, and the obtained CVTF has excellent comprehensive properties; the CVTF is excellent in viscosity index, oxidation stability, shear stability, wearing quality and cryogenic property, and more critically, large in torque, high in traction coefficient and high in transmission efficiency; and consequently, the use requirements of B-CVT and T-CVT can be met simultaneously.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

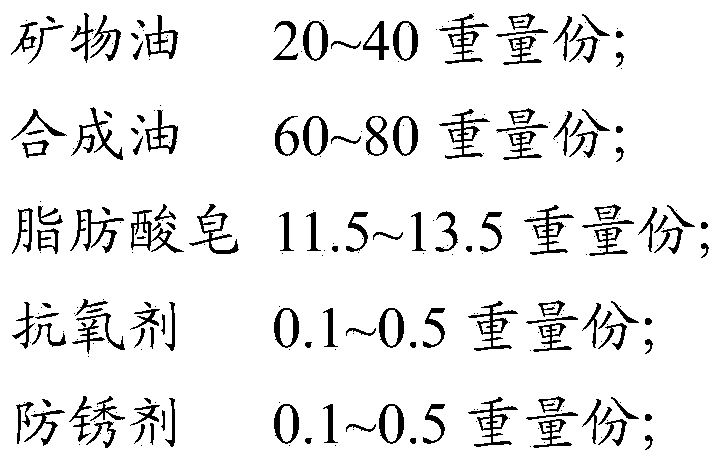

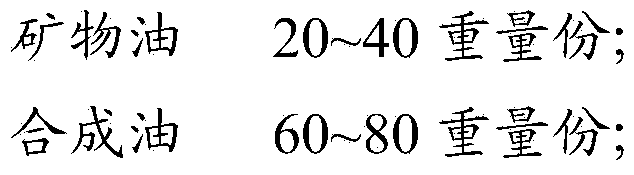

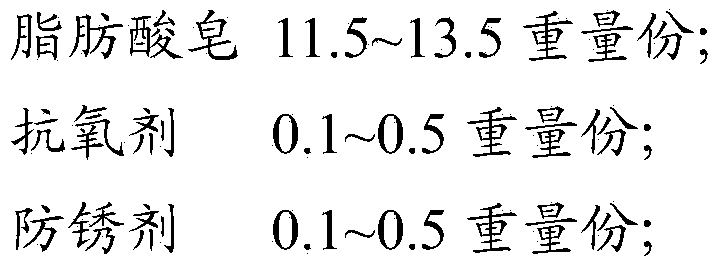

Low-temperature lubricating grease and preparation method thereof

ActiveCN103525510AHigh viscosity indexImprove viscosity indexLubricant compositionAntioxidantEvaporation

The invention provides low-temperature lubricating grease and a preparation method thereof. The low-temperature lubricating grease comprises mineral oil, synthesized oil, fatty acid soap, an antioxidant and an antirust agent. Compared with the prior art, the low-temperature lubricating grease is characterized in that semi-synthesized oil obtained by mixing III-type oil and ester oil and / or PAO (poly alpha olefin) oil is used as basic oil; the III-type oil has a high viscosity index and is high in high-temperature and low-temperature performance, oxidation stability, heat stability and evaporation performance; the ester oil and the PAO oil also have high viscosity indexes and are high in low-temperature performance; moreover, a mixture of lithium stearate and 12-hydroxy lithium stearate is used as a thickening agent for thickening the semi-synthesized oil, so that the low-temperature lubricating grease is high in low-temperature performance, and a used component can be normally lubricated under low temperature; the applicable temperature range is large; furthermore, the thickening agent is easy to synthesize.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating oil special for motorcycle engine and preparing method thereof

ActiveCN104031729AGood viscosity indexImprove anti-wear performanceLubricant compositionCorrosionMagnesium

The invention discloses a lubricating oil special for a motorcycle engine, and belongs to the technical field of lubricating oil. The lubricating oil is obtained through a reaction carried out on 80 parts to 90 parts of base oil, 2 parts to 5 parts of abrasion resistance agents, 5 parts to 10 parts of corrosion resistance agents, 2 parts to 5 parts of cleaning factors, 5 parts to 15 parts of antioxidant, 1 part to 3 parts of metal deactivator and 8 parts to 12 parts of viscosity modifier. The base oil is composed of 30 parts to 40 parts of PAO and 40 parts to 50 parts of naphthenic base oil. The cleaning factors are any one of metal-based sodium or metal-based calcium or metal-based magnesium. The invention further discloses a preparing method of the lubricating oil. According to the lubricating oil special for the motorcycle engine, the cost of the base oil is controlled, and the better viscosity index and the high abrasion resistance performance can be ensured at the same time; viscous black carbon mud particles wrapped on engine parts can be effectively removed through matched addition of auxiliaries, the service life of the engine is prolonged, the equipment maintenance cost is reduced, and the clean abrasion protection mode is provided for the motorcycle engine. The preparing method of the lubricating oil is simple in steps, environmentally friendly, and easy to implement.

Owner:镇江宝捷润滑油股份有限公司

Complex polyol esters with improved performance

InactiveUS20050049153A1Improve biodegradabilityImprove viscosity indexLiquid carbonaceous fuelsAdditivesPolymer sciencePolyol

A biodegradable lubricant composition containing a complex polyol ester having a polyfunctional alcohol residue and a saturated or unsaturated dicarboxylic acid residue having from about 9 to about 22 carbon atoms.

Owner:COGNIS IP MANAGEMENT GMBH

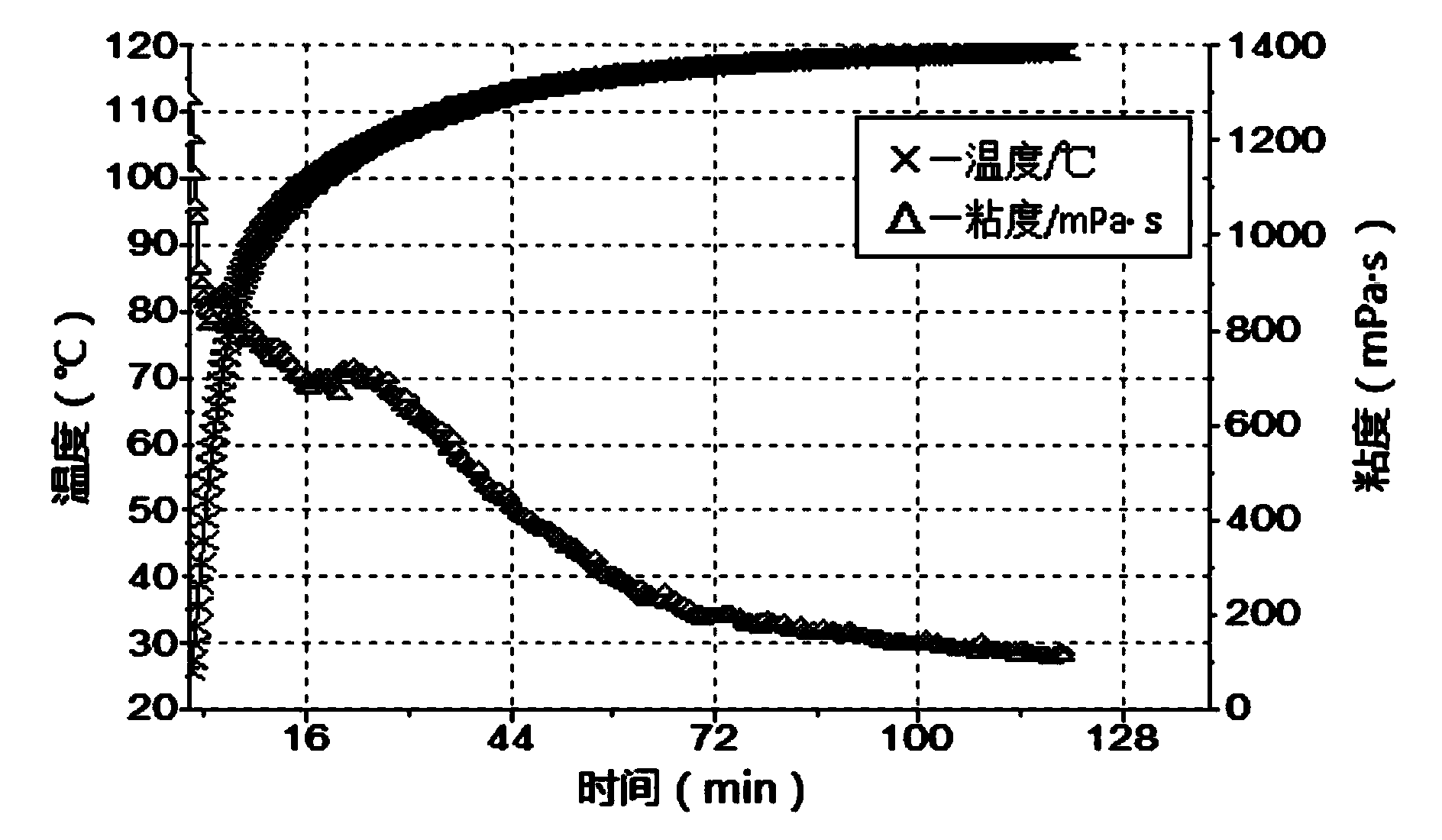

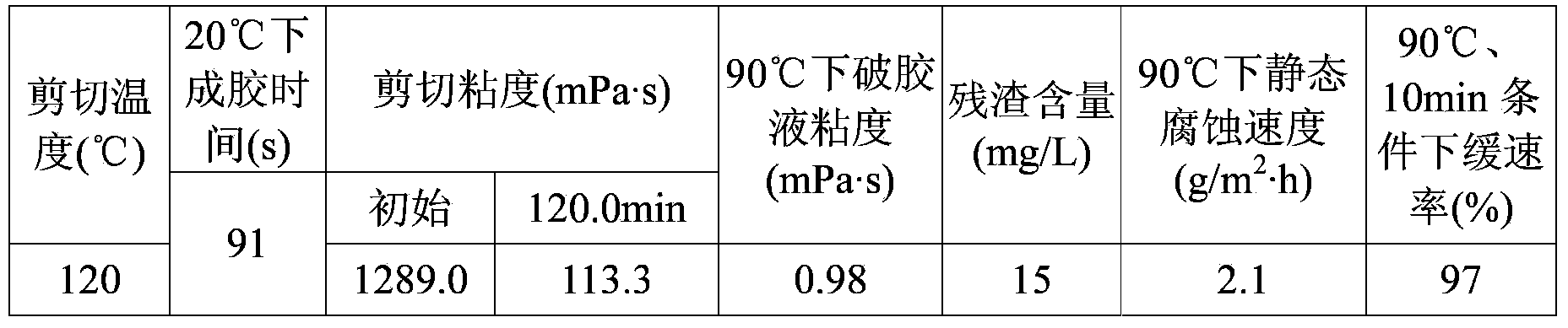

High-temperature-resistant ground cross-linked acid liquor and preparation method thereof

InactiveCN104073237AGood temperature resistance and shear resistanceLow toxicityDrilling compositionCross-linkAcid fracturing

The invention provides high-temperature-resistant ground cross-linked acid liquor. The acid liquor comprises the following components in percentage by mass: 15-28 weight percent of acid, 0.4-1.0 weight percent of polyacrylamide polymer, 0.1-0.5 weight percent of aldehyde cross-linking agent, 0.05-0.25 weight percent of phenol cross-linking agent, 0.05-0.02 weight percent of crosslinking promoter, 0.5-2.0 weight percent of corrosion inhibitor, 0.5-2.0 weight percent of ferric ion stabilizer, 0.01-0.1 weight percent of ammonium persulfate and the balance of water, wherein the acid is calculated based on pure substances. The invention also provides a method for preparing the high-temperature-resistant ground cross-linked acid liquor. Industrial raw materials which are low in toxicity and low in price are taken as cross-linking agents and cross-linking promoter, the toxicity of the cross-linking agents can be reduced, the process for preparing the high-temperature-resistant ground cross-linked acid liquor is simple, further synthesis is not needed, the field operability is high, the cost is effectively reduced, and application of acid fracturing is further widened.

Owner:PETROCHINA CO LTD

Engine oil composition for improving oil loss or engine oil combustion of German automobiles

The invention provides an engine oil composition for improving oil loss or engine oil combustion of German automobiles. The engine oil composition comprises 63 to 78 weight percent of dodecyl carbon poly alpha-olefin base oil, 2 to 15 weight percent of ester base oil, 0.1 to 0.3 weight percent of pour point depressant, 8 to 10 percent of viscosity index improver and 10 to 13 weight percent of synthetic oil composite additive. The engine oil composition provided by the invention has low Noah gram value and low consumption in use, is not easy to produce 'engine oil combustion', reduces the adding times of engine oil, and reduces the maintenance expense at the same time of bring convenience to a driver. Proved by experiments, the Noah gram value of the engine oil composition is less than 4; and when the engine oil composition is used for an Audi series automobile with serious 'engine oil combustion', the engine oil is kept above the middle line by examination with an engine oil scale after the automobile runs for 5,000 kilograms.

Owner:大庆劳特润滑油有限公司

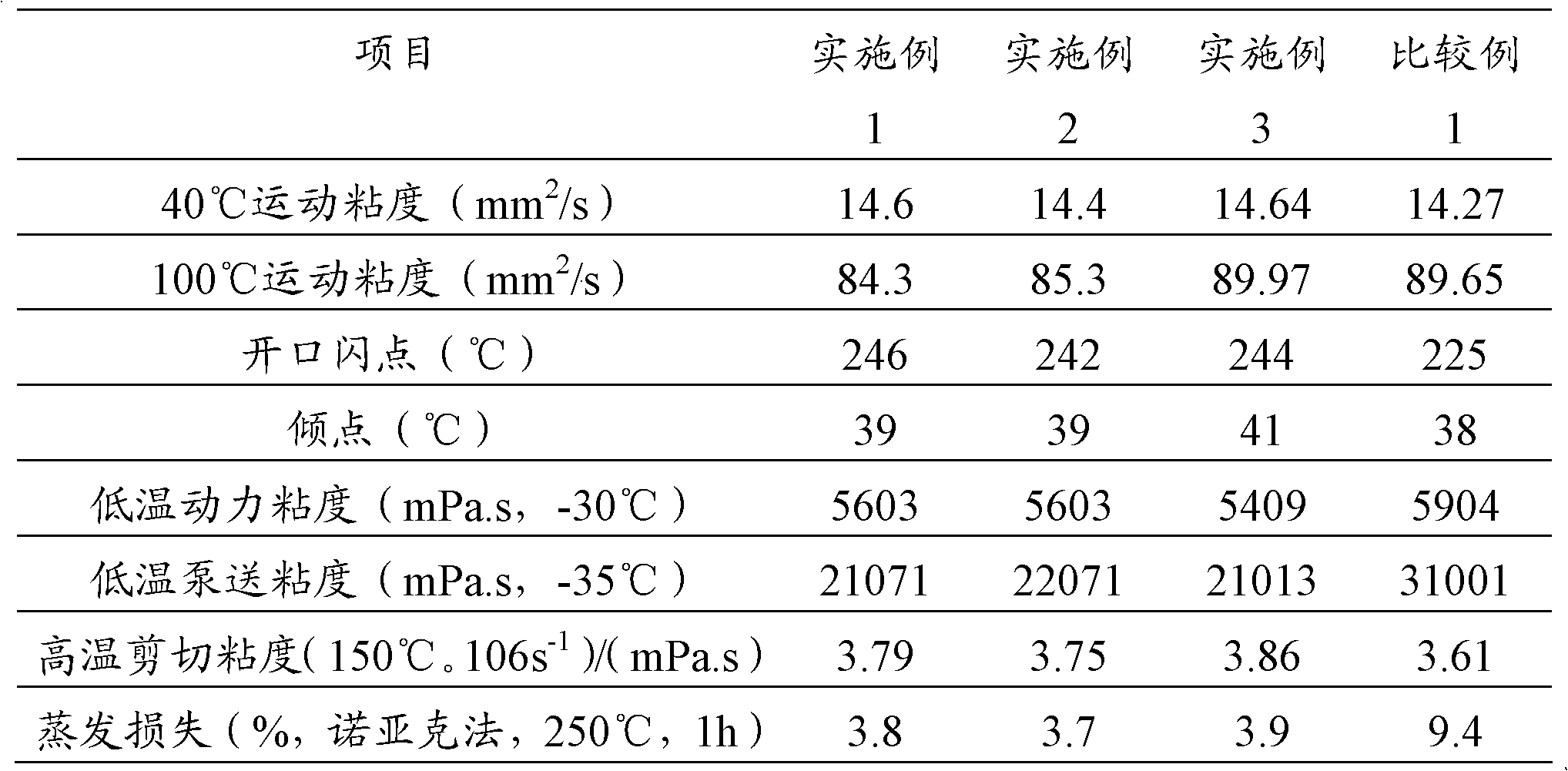

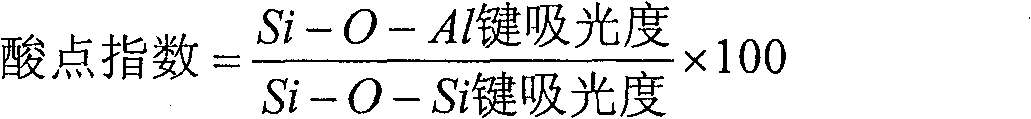

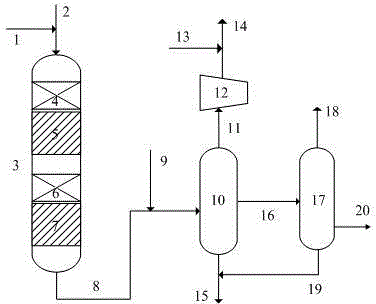

Hydroprocessing catalyst and preparation method of hydroprocessing catalyst and preparation method of lubricant base oil

ActiveCN102145296AHigh yieldExcellent cracking activityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsAbsorbanceSulfur

The invention provides a hydroprocessing catalyst and a preparation method of the hydroprocessing catalyst, and a preparation method of lubricant base oil. The hydroprocessing catalyst contains a silicon aluminum composite material carrier and active components loaded on the carrier, wherein the active components are Family VIII metallic elements, Family VIB metallic elements and phosphorus, an acid point index of the silicon aluminum composite material carrier is not lower than 80 and is the numerical value obtained by multiplying the ratio of Si-O-Al bond absorbance to Si-O-Si bond absorbance by 100, wherein the Si-O-Al bond absorbance refers to the high strength of the vibratory absorption peak of Si-O bond of Si-O-Al in an infrared absorption spectrum of the silicon aluminum compositematerial carrier, and the Si-O-Si bond absorbance refers to the high strength of the vibratory absorption peak of Si-O bond of Si-O-Si in the infrared absorption spectrum of the silicon aluminum composite material carrier. The hydroprocessing catalyst provided by the invention can obtain, at high yield, lubricant base oil having high viscosity index and low contents of sulfur, nitrogen and aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating oil

ActiveCN107338100AThe effect of reducing low temperature viscosityImprove viscosity indexLubricant compositionReducerBase oil

The invention relates to a lubricating oil. The lubricating oil comprises, by weight, 4-4.5 parts of a dispersant, 2-3 parts of a viscosity modifier, 0.5-0.8 part of an anti-wear agent, 0.2-0.3 part of a wear reducer, 0.05-0.1 part of a detergent, and base oil, and the total weight part is 100. The effect of the compatibility of all modification components is far better than the superposed effect of individual modification components in affection of the performances of the base oil, so the wear resistance and the dispersion performance of the lubricating oil are remarkably improved.

Owner:沈阳德远科技有限公司

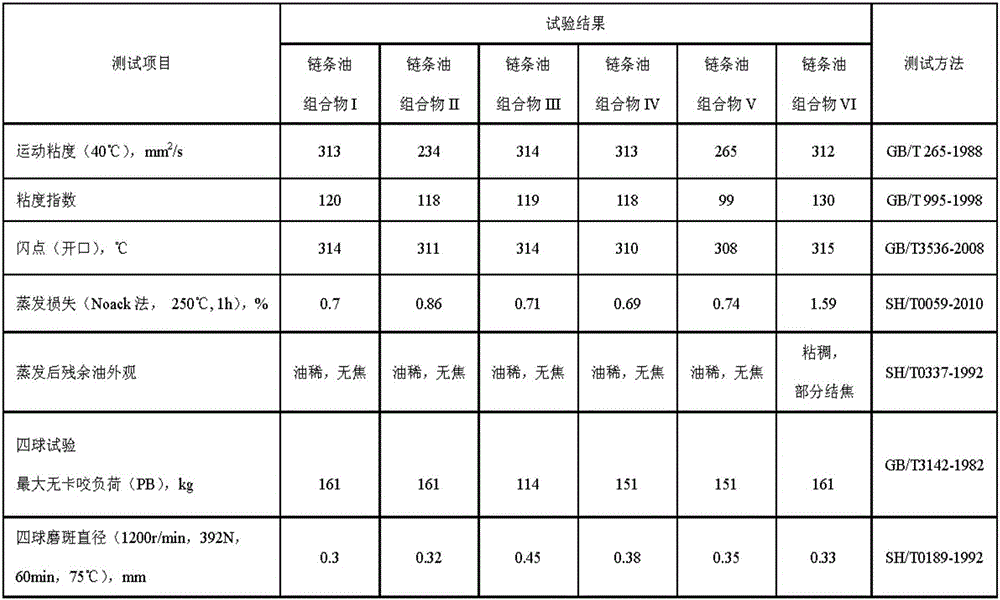

High-temperature chain oil composition and preparation method thereof

ActiveCN105838484AImprove high temperature performanceImprove wear resistanceAdditivesBase-materialsPentaerythritolPhosphate

The invention provides a high-temperature chain oil composition and a preparation method thereof. The high-temperature chain oil composition includes: (a) synthetic ester base oil; (b) alkoxy phosphate anti-wear reagent at extreme pressure; (c) oiliness agent; (d) viscosity index improver; (e) antioxygen; and (f) anticorrosive, wherein the (a) synthetic ester base oil is a mixture of dipentaerythritol ester and aromatic ester. The high-temperature chain oil composition is adapted to using at high temperature, has good high-temperature performance, has no carbon deposition residual working at high temperature for a long time, is without dripping, has good wear-resisting anti-attrition and corrosion resistant performances, and has low friction coefficient and small chain abrasion. Moreover, the high-temperature chain oil composition has low toxicity, is easy to decompose, and is environmentally friendly.

Owner:埃优诺特种新材料科技(山东)有限公司

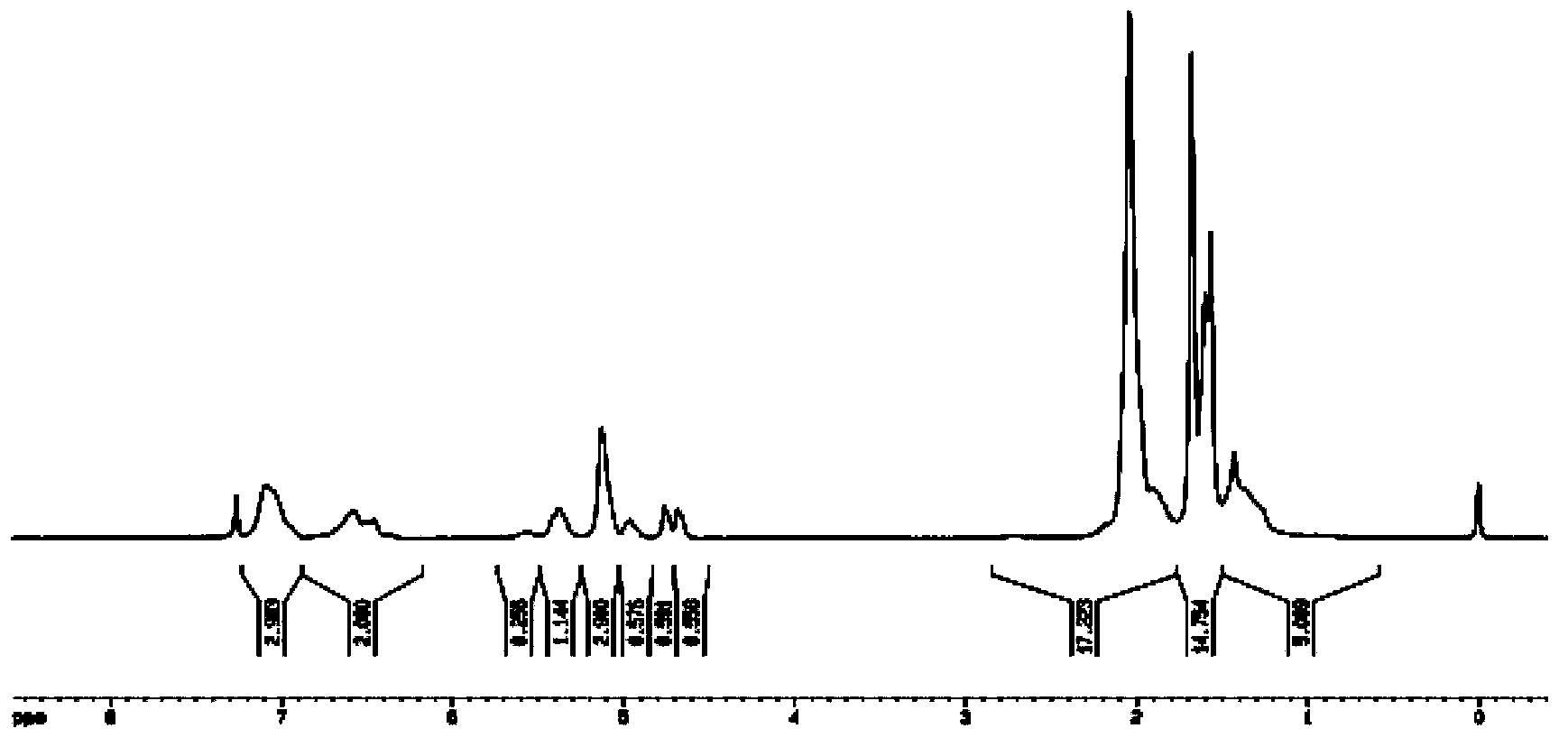

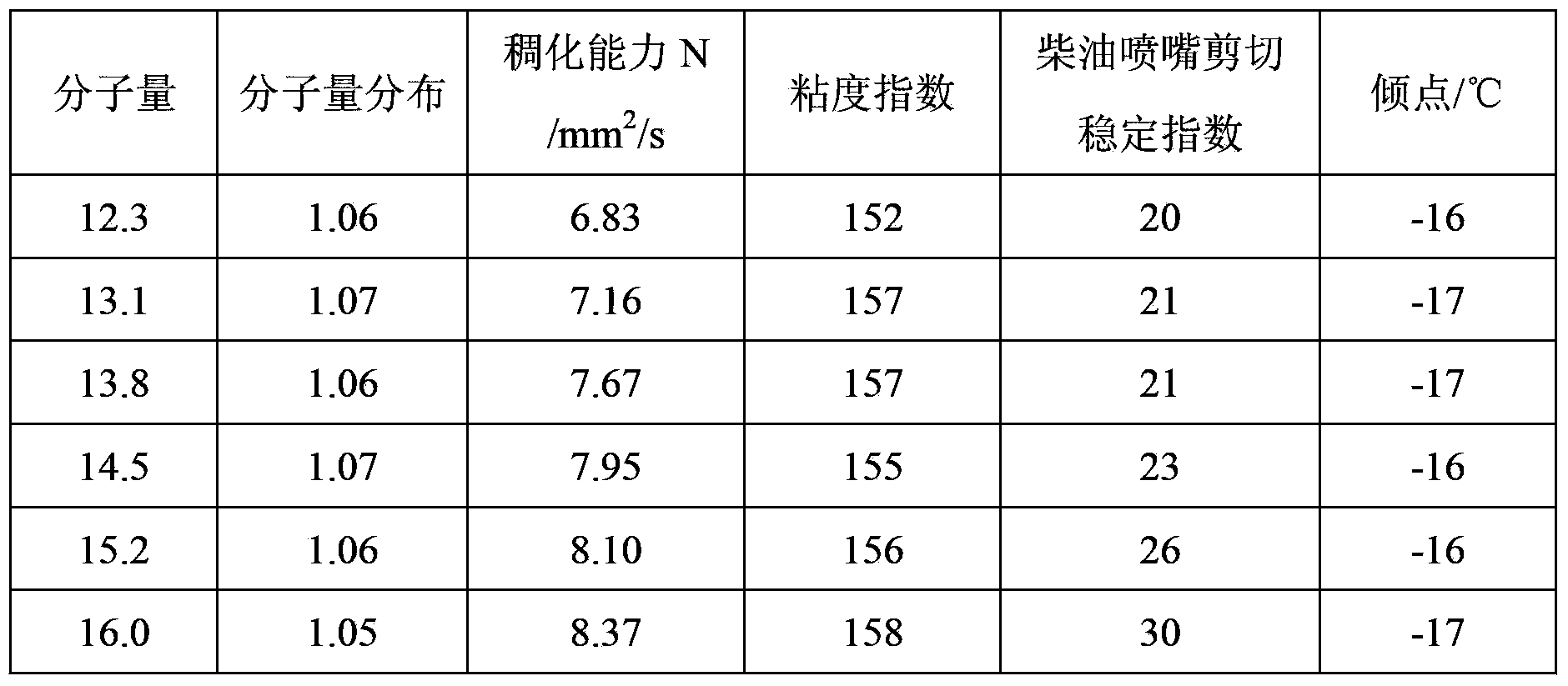

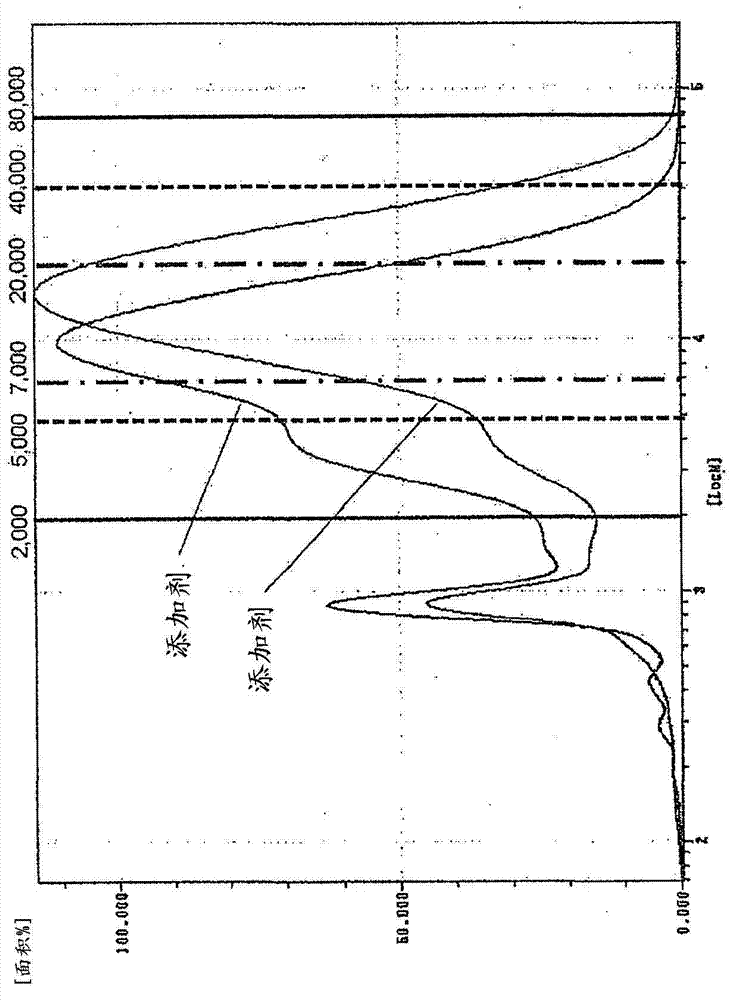

Lubricating-oil viscosity index improver and preparation method thereof

ActiveCN104342231AStrong thickening abilityGuaranteed mechanical propertiesAdditivesPolymer sciencePolystyrene

The invention discloses a lubricating-oil viscosity index improver and a preparation method thereof. The lubricating-oil viscosity index improver is obtained by performing hydrogenation modification on a polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer. The preparation method comprises, adding an adjusting agent into a polymerization reaction kettle with the temperature of 60-70 DEG C and the pressure of 0.1-0.5 MPa, and then successively adding an isoprene monomer, a butadiene monomer and a styrene monomer for polymerization reaction; and obtaining the polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer after the polymerization reaction is finished, and performing hydrogenation reaction on the obtained triblock copolymer, so as to obtain the lubricating-oil viscosity index improver. The preparation method is rapid and convenient in operation and simple in process, and the prepared hydrogenated polyisoprene-b-polybutadiene-b-polystyrene triblock copolymer is narrow in molecular weight distribution, complex in structure and good in chemical stability. Lubricating oil modified by the copolymer possesses the characteristics of strong thickening capability, high shearing stability, good oil-product oxidation stability and excellent low-temperature fluidity, and has wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP

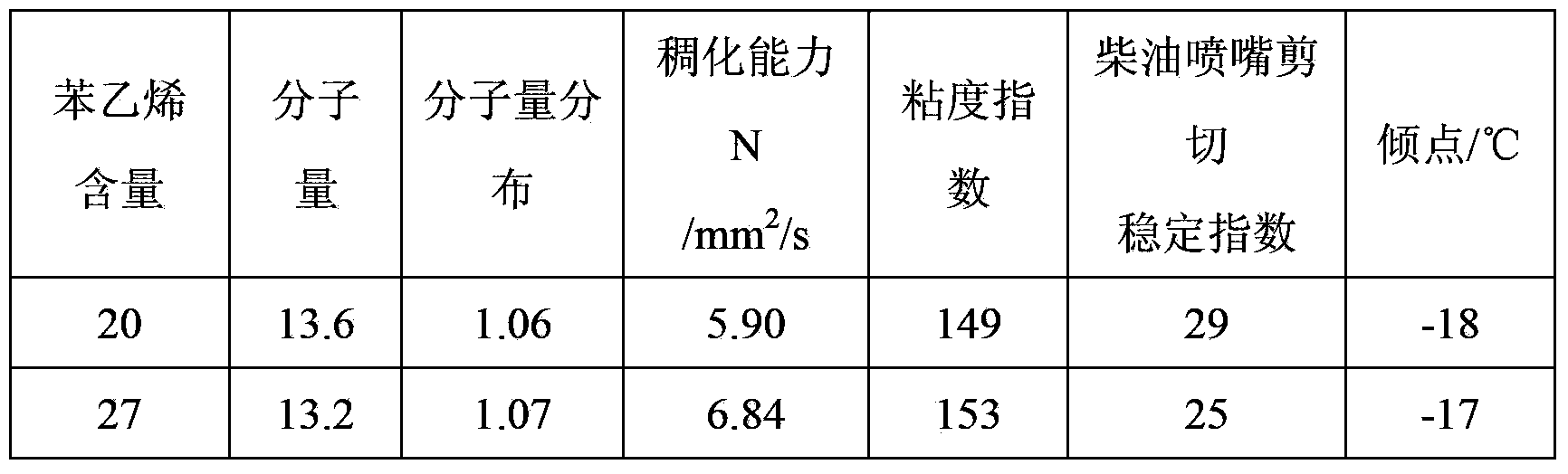

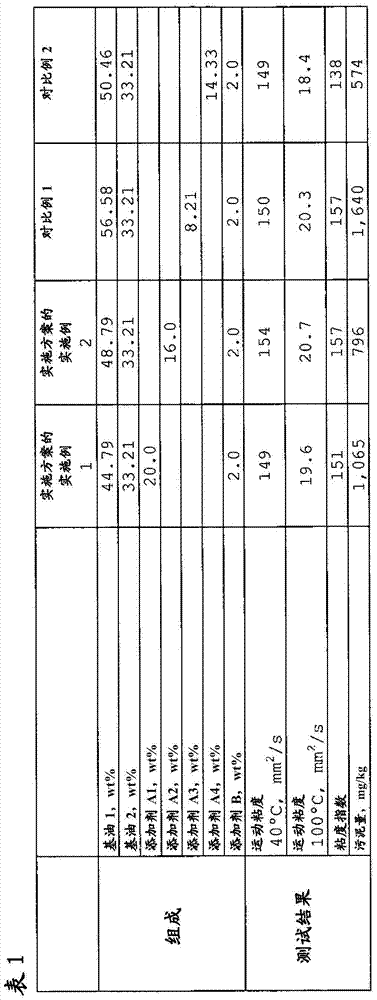

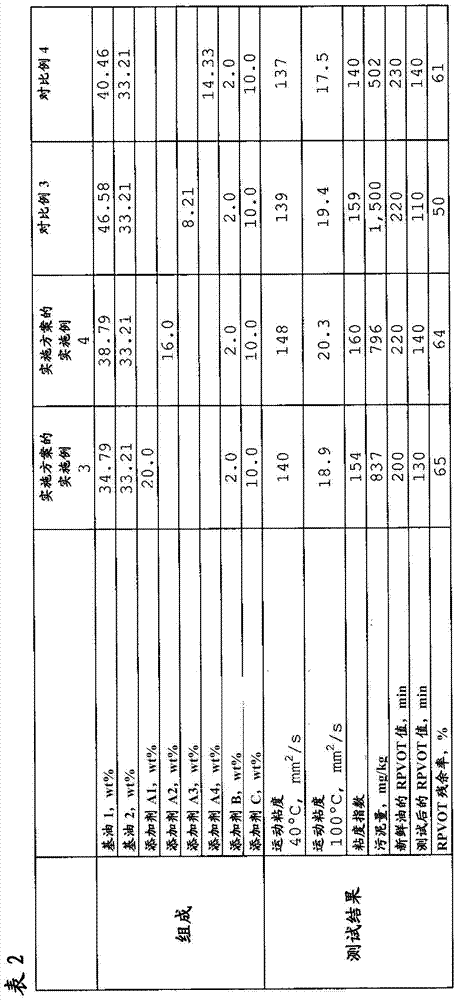

Full-synthetic continuously variable transmission (CVT) transmission fluid as well as preparation method and application thereof

InactiveCN103725385AImprove performanceImprove viscosity indexAdditivesAlkaline earth metalClearing Agent

The invention belongs to the technical field of automobile transmission and discloses full-synthetic continuously variable transmission (CVT) transmission fluid as well as a preparation method and application thereof. The transmission fluid comprises the following components in parts by weight: 100 parts of type IV base oil, 0-20 parts of type V base oil, 0.5-2.4 parts of an anti-wear agent, 2-5 parts of viscosity index improvers, 1-3 parts of an alkaline-earth metal clearing agent, 2-6 parts of a dispersing agent, 0.3-0.8 part of an antioxidant and 1-3 parts of a friction modifier. The full-synthetic continuously variable transmission transmission fluid has excellent comprehensive performance, has excellent viscosity index, oxidation stability, shear stability, wear resistance, low-temperature resistance and high transmission efficiency, and can simultaneously meet strict service requirements of various CVTs.

Owner:SOUTH CHINA UNIV OF TECH

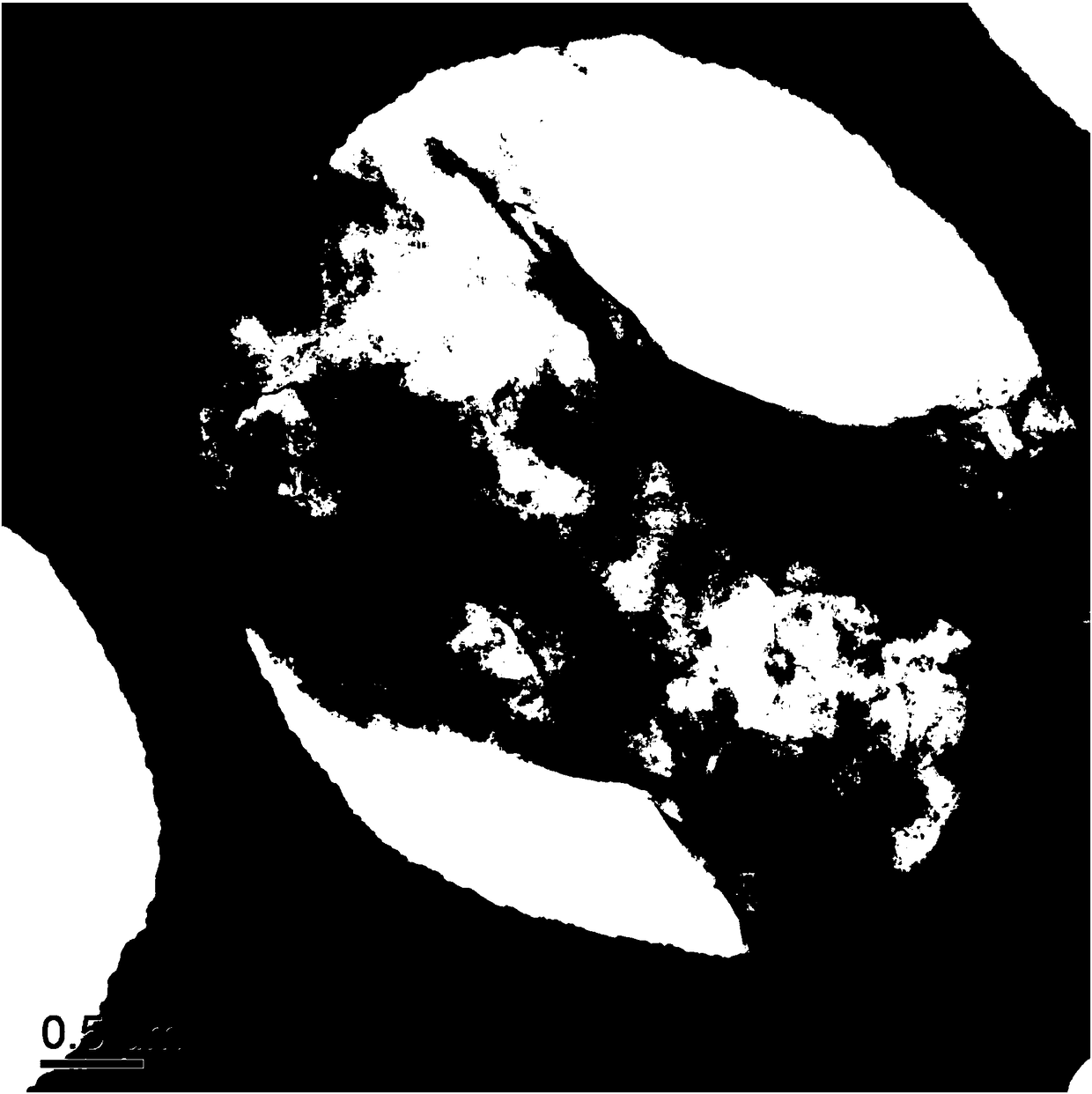

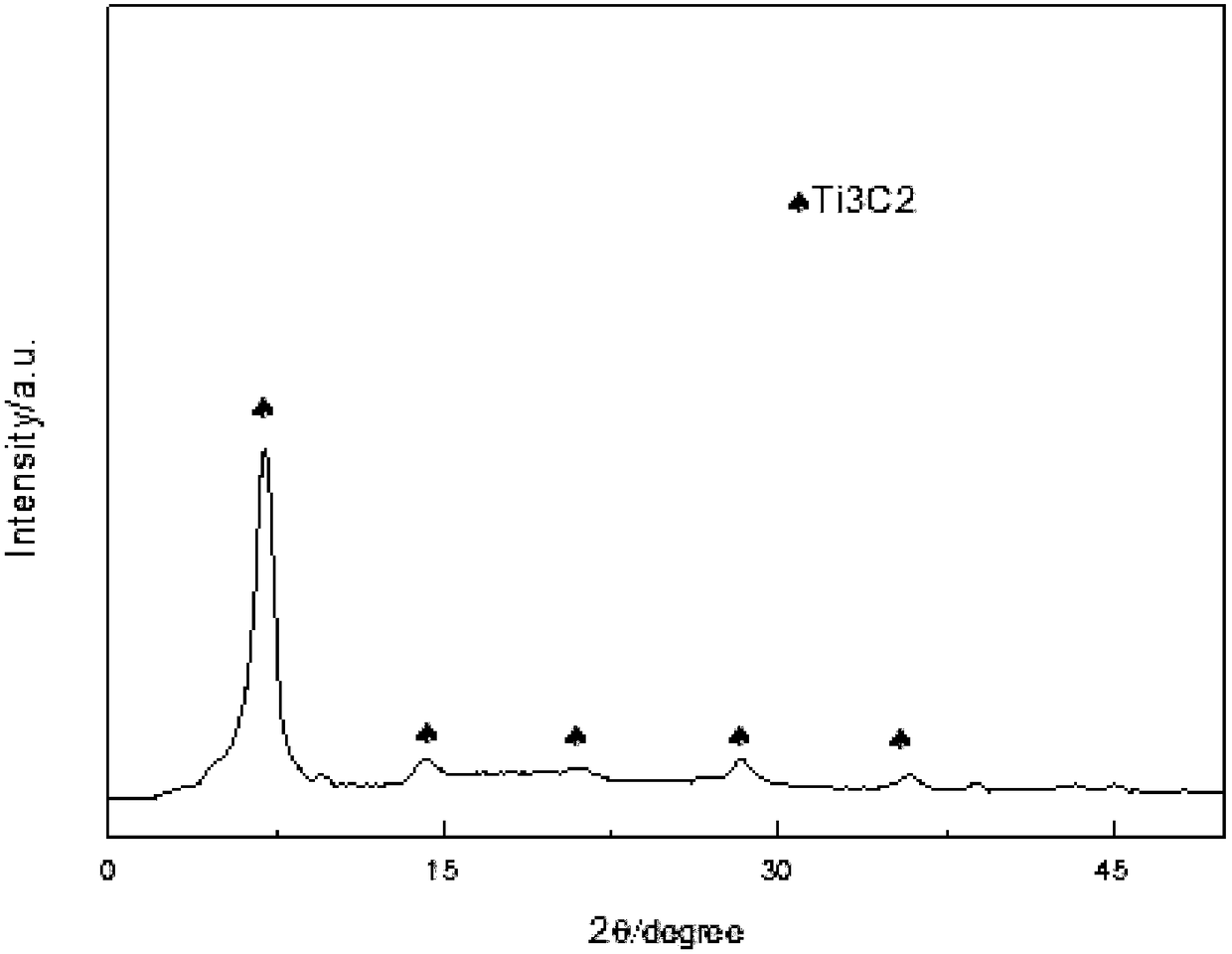

Preparation method of novel two-dimensional material reinforced polyethylene glycol lubricating oil

InactiveCN108384600AImprove mechanical propertiesImprove the lubrication effectAdditivesCorrosion reactionCombustion

The invention discloses a preparation method of novel two-dimensional material reinforced polyethylene glycol lubricating oil. The preparation method comprises the following steps: step I, adding Ti3AlC2 powder into an HF solution, performing the corrosion reaction, magnetically stirring for a plurality of time, then centrifugally washing, vacuum drying, and obtaining Ti3C2 powder; step II, mixingthe Ti3C3 powder in step I and an intercalating solvent, stirring, washing, drying, and obtaining the processed Ti3C2 powder; step III, dissolving the Ti3C2 powder processed in step II in the deionized water, ultrasonically processing, centrifuging, collecting supernatant, drying, and obtaining Ti3C2 two-dimensional nanosheets; and step IV, stirring and mixing the Ti3C2 two-dimensional nanosheetsobtained in the step III and polyethylene glycol, preparing different solutions of different concentrations, ultrasonically processing, and then performing the friction abrasion experiment. The preparation method has the advantages of excellent cooling performance, difficulty in combustion, low pollution, low cost and the like.

Owner:GUANGDONG UNIV OF TECH

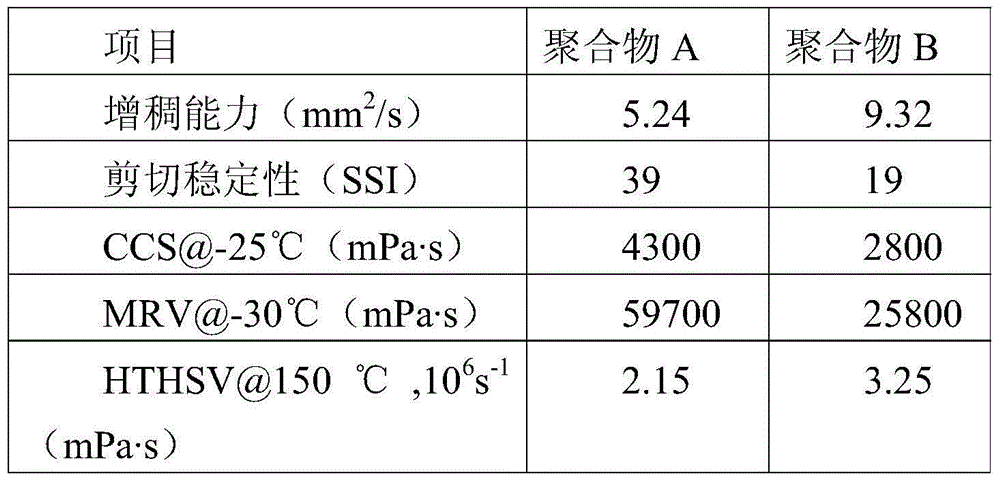

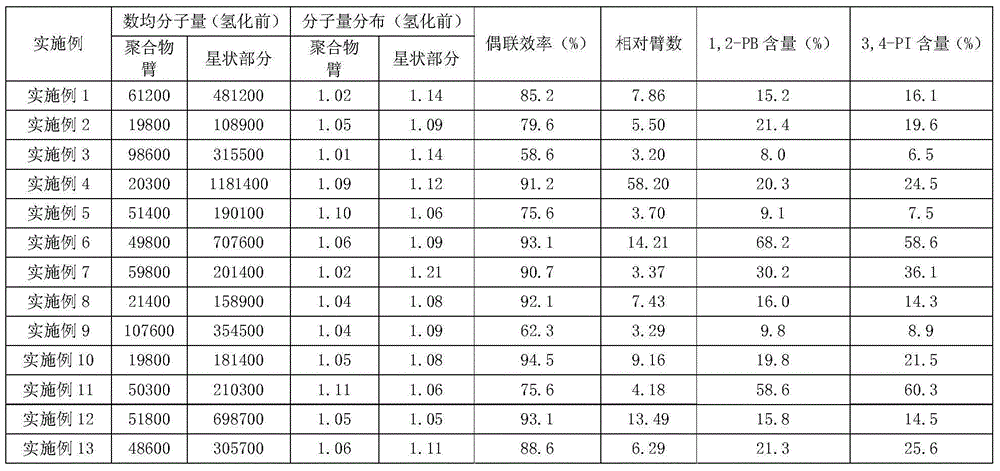

Star-shaped hydrogenated styrene diene copolymer and preparation method thereof

The invention relates to a star-shaped hydrogenated styrene diene copolymer which is used as a lubricating oil viscosity index improver. Each arm of the star-shaped hydrogenated styrene diene copolymer is a diblock copolymer including a block I being hydrogenated polyisoprene (EP) and a block II being and a block II being hydrogenated styrene-butadiene copolymer (SEB), and has a structural formula being (EP-SEB)n-C, wherein C is a core of a coupling agent, and n is the arm number of the copolymer and is no less than 3. The star-shaped hydrogenated styrene diene copolymer is finally prepared through polymerization, coupling, and hydrogenation. A novel copolymer is prepared through adjustment of numbers, ratio, and addition sequence of monomers in the arms of the copolymer and a microstructure. The copolymer is applied to a lubricating oil composition, and the thickening capacity, shear stability, low-temperature performance, and processing ability of lubricating oil are obviously improved. Meanwhile, the preparation method is simple and low in production cost.

Owner:PETROCHINA CO LTD

Lubricating oil composition

The object of this invention is to offer a lubricating oil composition which has superior extreme pressure properties (ability to prevent welding), which generates a small amount of sludge and which also has a high viscosity index. The invention provides a lubricating oil composition to which has been added a copolymer of specified olefins and alkyl methacrylates.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Lubricating oil for drive chains of locomotives and method for preparing same

InactiveCN105018192ASimple componentsImprove anti-wear performanceLubricant compositionEngineeringViscosity index

The present invention discloses lubricating oil for drive chains of locomotives and a method for preparing the same, and belongs to the technical field of lubricating oil. The lubricating oil consists of the following components in parts by weight: 30-50 parts of compound base oil, 10-20 parts of sulfide whale oil, 2-10 parts of graphene modified by sulfhydryl, 5-20 parts of polytetrafluoroethylene particles, 2-5 parts of 2,6-di-tertbutyl-4-methylphenol, 5-15 parts of zinc naphtenate, 1-3 parts of polyisobutylene, and 1-12 parts of monoethanolamine. The lubricating oil for drive chains of locomotives are simple in components, low in cost, better in viscosity index and high in wear resistance. The lubricating oil has a long service life. The steps of the method for preparing the lubricating oil are simple, environmentally friendly, and easy to implement.

Owner:赵兰

Lubricating oil special for motorbike

InactiveCN104371812AImprove protectionExtended service lifeBase-materialsButylated hydroxytolueneMooney viscosity

The invention relates to lubricating oil special for a motorbike. The lubricating oil comprises, by mass, 25-35 parts of base oil POA, 55-60 parts of naphthenic-base base oil, 0.4-0.6 parts of large-base-number synthesis calcium sulfonate which is an additive, 0.3-0.5 part of sulfur phosphorous butyl octyl group zinc salt which is an additive, 1.0-3.5 parts of sulfur ether phenol type antioxidant. 0.2-1.0 part of terpolymer of ethylene, propylene and non-conjugated dienes, 1-3 parts of metal deactivator, 5-10 parts of antioxidant, 1-10 parts of viscosity index improver, 0.06-1.2 parts of pour point depressant and 0.01-0.02 part of anti-foaming agent, wherein mooney viscosity of the terpolymer is 25-35, the metal deactivator is phosphide or sulfide, and the antioxidant is 2,3-butylated hydroxytoluene. Base oil cost is controlled while high viscosity index and high wear resistance can be guaranteed.

Owner:CHONGQING JIAZHOU LUBRICATING OIL

Automobile lubricating oil additive

InactiveCN104974821AImprove viscosity indexImprove the lubrication effectAdditivesPhosphoric Acid EstersOil additive

An automobile lubricating oil additive is composed of the following raw materials in parts by weight: 3 to 6 parts of phosphorodithioate, 2 to 4 parts of random polypropylene, 1.2 to 3 parts of oligomer of trimethyl hydrogen quinazoline, 4 to 6 parts of phenothiazine, 5 to 8 parts of phenyl-2-naphthylamine, 2 to 4 parts of methyl silicone oil, 3 to 5 parts of calcium oxide, 1 to 2 parts of succinate, 4 to 7 parts of mesembryanthemoidigenic acid, 3 to 6 parts of glycerin acrylate, 7 to 10 parts of lupeol palmitate, 5 to 8 parts of linolenic acid, 6 to 9 parts of coconut diethanolamide, 5 to 8 parts of inositol hexaphosphate, 2 to 4 parts of calcium chloride, 6 to 10 parts of polyacrylic acid, 4 to 7 parts of sodium dodecyl benzene sulfonate, 2 to 6 parts of tetrahydropalmatine, 3 to 5 parts of lupeol palmitate, 8 to 16 parts of benzyl alcohol, and 7 to 12 parts of sulfurized calcium alkyl phenate. The provided automobile lubricating oil additive has an improved viscosity index and a good lubricating performance, can effectively prevent lubricating oil from being oxidized or degraded, and prolongs the service life of lubricating oil.

Owner:QINGDAO YUXING INTELLIGENT TECH DEV CO LTD

Rust removing agent replacing hydrochloric acid to remove rust

ActiveCN109504975AGood water solubilityImprove hydrolytic stabilityChromium trioxideCompound organic

The invention provides a rust removing agent replacing hydrochloric acid to remove rust. The rust removing agent for removing the rust is prepared from the raw materials in parts by weight: 20-30 parts of composite organic acid, 5-10 parts of polymethylacrylic acid, 6-12 parts of chromium trioxide, 10-20 parts of a surface active agent, 3-6 parts of sodium gluconate, 1-3 parts of triethanolamine,1-3 parts of polyacrylamide, 1-2 parts of 1,4-butynediol, 0.01-0.1 part of sodium chloride, 0.5-2 parts of a functional additive and 70-90 parts of water; the pH value of the rust removing agent is about 6.0, and the density is 0.9-1.2 g / cm<3>; according to the rust removing agent, the hydrochloric acid is not used, that is, generation of acid mist is reduced from the source, matter which harms human body is not used in the rust removing agent, the environment cannot be polluted, and the rust removing agent is an environment-friendly rust removing agent; and the rust removing agent has a superior rust removing property, the rust removing time is short, meanwhile, the rust removing efficiency is high, the gloss on the surface of metal substrate effectively recovers, and the rust removing agent has good application prospects.

Owner:ZHUJI HUARUI CHEM FIBER FACTORY

Lubricant additive

InactiveCN105038909AImprove the lubrication effectImprove viscosity indexAdditivesPhosphoric Acid EstersPhosphorous acid

A lubricant additive is prepared from the following raw materials in parts by weight: 6-13 parts of N,N'-bis(1-methylpropyl)-1,4-phenylenediamine, 4-9 parts of sodium dodecyl benzene sulfonate, 7-8 parts of dibutyl phosphite, 4-6 parts of sulfurized isobutylene, 3-6 parts of sodium dodecyl benzene sulfonate, 7-9 parts of petroleum sulfonate, 4.2-5.6 parts of dibenzyl disulphide, 1.5-3.2 parts of dodecylbenzene, 4-6 parts of isooctyl phosphate ester, 1.3-3.6 parts of methyl silicone oil, 3-6.4 parts of sulfurized calcium alkyl phenolate, 1.4-3.5 parts of calcium petroleum sulfonate, 7-9 parts of amphi-di-iso-octyldiphenylamine and 6-12 parts of polyvinyl alcohol. The lubricant additive has the benefits that the viscosity index is greatly improved, the lubrication effect of the lubricant can be improved, and good abrasion resistance and oxidative resistance are achieved.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Lubricating oil base oil production method

ActiveCN104611044ALow aromatic contentReduce consumptionTreatment with hydrotreatment processesLubricant compositionFractionationWhite oil

The present invention discloses a lubricating oil base oil production method. According to the lubricating oil base oil production method of the present invention, a wax oil raw material and hydrogen gas are mixed and then sequentially pass through at least two hydrogenation reaction zones connected in series, wherein each hydrogenation reaction zone sequentially comprises a composite catalyst bed layer filled with a hydrodewaxing catalyst and a hydrocracking catalyst in a mixed manner and a hydrodewaxing catalyst bed layer according to the material flowing direction, and the reaction effluent obtained from the last hydrogenation reaction zone is subjected to separation and fractionation to obtain the lubricating oil base oil, the white oil and other products. With the method of the present invention, the temperature decrease during the hydrodewaxing process and the temperature increase during the hydrogenation process are subjected to reasonable combination utilization, such that the low freezing point lubricating oil base oil is produced while the viscosity index is increased, the hot spot temperature of the device is reduced, and the operation period is prolonged; and the cold hydrogen consumption or the heating furnace fuel gas loss is reduced, and the operating cost is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance lubricant additive

The invention discloses a high-performance lubricant additive. The lubricant additive comprises the following substances in parts by weight: 3-5 parts of sodium dodecyl benzene sulfonate, 5-10 parts of boronized polyisobutene succinimide, 1-3 parts of calcium chloride, 2-6 parts of sulfurized alkylphenol calcium, 4-6 parts of calcium oxide, 1-5 parts of zinc dialkyl dithiophosphate, 0.5-2.6 parts of petroleum sulfonate, 1-5 parts of sulfurized isobutylene, 10-20 parts of paraffin, 5-11 parts of polyacrylic acid, and 20-35 parts of dimethyl silicon oil. The high-performance lubricant additive has the beneficial effects of not only being convenient to use and low in manufacture cost, but also having good oxidation resistance and abrasion resistance, having moderate foam, being capable of effectively resisting corrosion and rust, and better improving viscosity index so as to improve the quality of the lubricant.

Owner:QINGDAO HUIERTONG TRADING

Safe, stable and high-performance wire enamel and preparation method thereof

InactiveCN107286841AImprove adhesionImprove insulation performanceFireproof paintsPolyurea/polyurethane coatingsLiquid viscosityLacquer

The invention discloses safe, stable and high-performance wire enamel. The wire enamel is prepared from the following raw materials in parts by weight: 25-35 parts of a mixed high molecular compound, 15-25 parts of composite resin, 8-14 parts of an insulating filler, 7-11 parts of a fire-retardant additive, 5-7 parts of a nano additive, 4-6 parts of a processing agent, 30-40 parts of a compound solvent, 3-5 parts of a coupling agent, 1-2 parts of m-cresol and p-cresol, 1-3 parts of epoxy acrylate, 1-2 parts of triethyl citrate, 1-2 parts of propyl gallate, 4-6 parts of glycerin and 2-4 parts of paraffin. The wire enamel has a relatively low water absorption rate and excellent mechanical and electrical properties, the temperature of the knee of a curve of medium loss is relatively high, the wire enamel can be directly used for coating an enamelled wire, the wire enamel is superior in the indexes of intermiscibility, precipitation and lacquer liquid viscosity, meanwhile, the costs of raw materials are relatively low, the preparation process is concise, the application method is quick and convenient, and the wire enamel has a relatively high practical value and an excellent application prospect.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

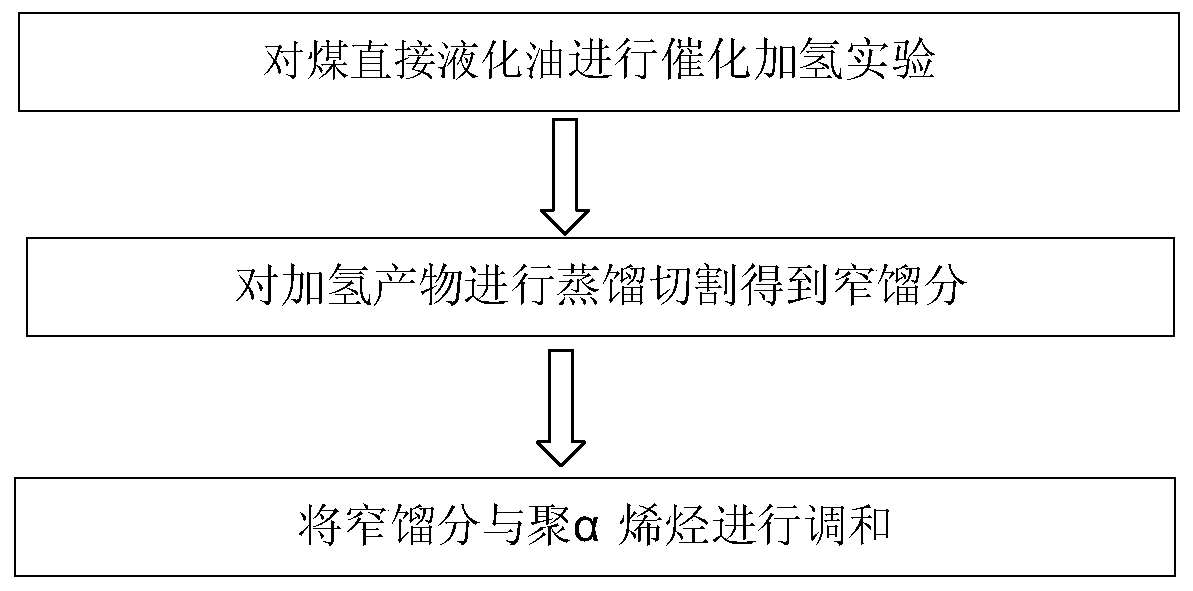

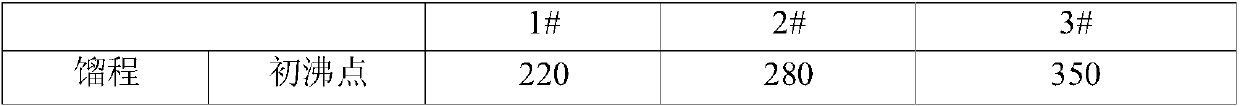

Coal directly liquefied oil composition and preparation method thereof

ActiveCN109825332AImprove physical and chemical propertiesImprove viscosity indexTreatment with hydrotreatment processesChemical compositionViscosity index

The invention provides a coal directly liquefied oil composition and a preparation method thereof. The preparation method comprises following steps: step one, catalytically hydrogenating coal directlyliquefied oil to obtain a hydrogenated oil product; step two, cutting the hydrogenated oil product by steam to obtain a plurality of narrow distillate oils; and step three, blending the narrow distillate oils with poly(alpha-olefin) to obtain the coal directly liquefied oil composition. The viscosity index, flash point, and low temperature properties of coal directly liquefied oil are improved effectively.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

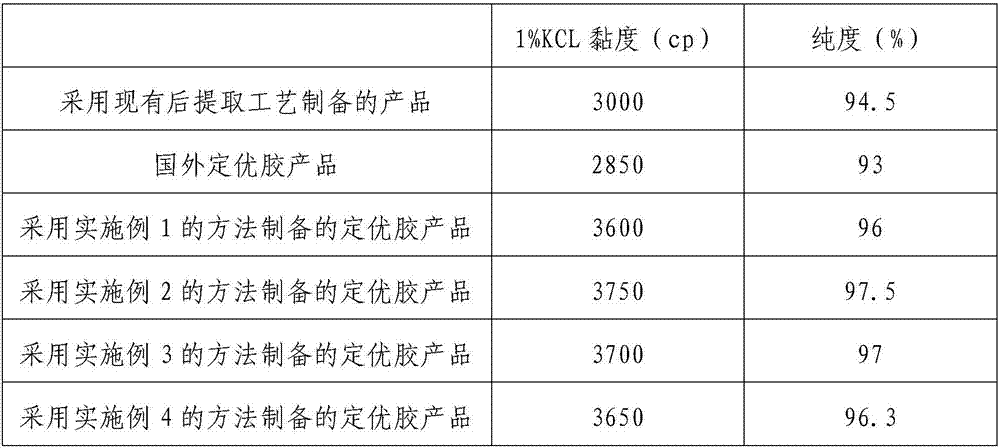

Method for extracting senplus from diutan gum fermenting liquid

The invention belongs to the extracting of fermenting products, in particular to a method for extracting diutan gum from a diutan gum fermenting liquid. The method comprises the following processing steps of pretreatment of fermenting liquid, primary extracting, primary centrifuging, secondary extracting, three times of diluting, and the like. The method has the advantages that the technical problems of low purity and viscosity of a diutan gum product prepared by the existing diutan gum post-extracting technology and the like are solved; compared with the existing product, the technology cycle is short, the control easy, the production cost is low, and the purity and viscosity of product are better.

Owner:张星昊

Rustproof bearing lubricant additive

InactiveCN105969486AExtended service lifeEffective anti-corrosion and anti-rustAdditivesGlycerolButylated hydroxytoluene

The invention discloses a rustproof bearing lubricant additive. The rustproof bearing lubricant additive is prepared from 2,6-butylated hydroxytoluene, trimethylolpropane, zinc stearate, sodium borate, sodium nitrate, lauryl sodium sulfate, triethanolamine, alkenyl dibutene, pentaerythritol, glycerol, triphenyl phosphorothioate, alkali zinc dialkyl dithiophosphate, para aminobenzoic acid, cocinic glycol amide, laurylene succinic acid, macromolecular polyisobutene oil solution, tricresyl phosphate, long-chain alkyl sodium sulfate, calcium dodecylbenzene sulfonate, dialkyl zinc dithiophosphate, sorbide oleate, castor oil potash soap and a rustproof agent. The rustproof bearing lubricant additive can effectively prevent corrosion and rust and improve viscosity index well, is excellent in hydrophily and lipophilicity, improves rustproof and lubricating effects and prolongs the service life of bearings.

Owner:ANHUI QIANSHAN BEARING MFG

Lubricating oil composition for integrated electric drive assembly speed reducer

InactiveCN111117747AReduced extreme pressure and wear resistanceImproved copper corrosion protectionLubricant compositionReduction driveGear wheel

The invention discloses a lubricating oil composition for an integrated electric drive assembly speed reducer. The lubricating oil composition comprises the following components in percentage by weight: 80%-90% of base oil, 4%-12% of a viscosity index improver, 5.5%-8% of a composite additive, 0.1%-0.5% of a reinforcing agent and 0.3%-0.5% of a pour point depressant. The product provided by the invention has relatively low viscosity, relatively high viscosity index, excellent high-temperature oxidation resistance, extreme-pressure wear resistance, shearing stability, copper corrosion protection and electrochemical characteristics; the lubricating oil provides excellent protection for gears and bearings, has good compatibility with sealing materials and motors, provides excellent protectionand power output efficiency for integrated electric drive assembly reducers, and is especially suitable for lubrication of integrated electric drive transmissions of pure electric buses.

Owner:LONGPAN LUBRICATION NEW MATERIAL TIANJIN CO LTD +1

Lubricant for machine tool bearings and preparation method of lubricant

The invention discloses a lubricant for machine tool bearings and a preparation method of the lubricant, and belongs to the technical field of lubricants. The lubricant comprises the following components by weight: 30 to 50 parts of compound base oil, 10 to 20 parts of paraffin, 2 to 10 parts of modified graphene, 5 to 10 parts of polytetrafluoroethylene particles, 2 to 5 parts of tri-m-tolyl phosphate, 5 to 15 parts of zinc naphthenate, 1 to 3 parts of polyisobutene, and 8 to 12 parts of monoethanol amine. The lubricant has the advantages that the components are simple; the cost is low; the viscosity index is relatively high; the wear resistance performance is high; the service life is long. The preparation method has the advantages that the steps are simple; the environment is protected; the implementation is easy.

Owner:赵兰

Stable weather-resistant high-insulating-property enamel wire coating and preparation method thereof

InactiveCN108587290AImprove securityImprove reliabilityInsulatorsPolyester coatingsLiquid viscosityOrganic solvent

The invention discloses a stable weather-resistant high-insulating-property enamel wire coating and a preparation method thereof. The coating includes, by weight, 40-50 parts of compound resin, 8-10 parts of a nano-modifying additive, 4-6 parts of organic glass powder, 3-5 parts of hydroxyapatite nano-particles, 9-13 parts of a processing aid, 6-8 parts of a silane coupling agent, 28-34 parts of organic solvent, 7-11 parts of a flame retardant, 4-6 parts of an ester additive, and 9-11 parts of auxiliary filler. The enamel wire coating is quick to dry, has great leveling property, is great in high temperature resistance, is acid and alkali resistant, has stable performance, is low in water absorption rate, and has excellent mechanical and insulation performances, is high in inflection pointtemperature on a dielectric loss curve, has excellent indices of dissolvability, precipitation and liquid viscosity, is low in raw material cost, has definite preparation process and convenient use method, and has great practical value and application prospect.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Low-temperature high-viscosity quick-frozen liquid composition and preparation and freezing methods thereof

InactiveCN109588472AFast freezing effectReduce ice crystal formationMeat/fish preservation by freezing/coolingChemistryWater soluble

The invention relates to the field of low-temperature refrigeration, in particular to a low-temperature high-viscosity quick-frozen liquid composition. The low-temperature high-viscosity quick-frozenliquid composition is prepared by uniformly mixing the following components in percent by mass: 10-15% of sodium chloride, 5-8% of sodium propionate, 10-15% of glycerol, 10-15% of glucose syrup, 10-15% of mixed sugar syrup, 3-10% of nanoscale water soluble mineral salt and the balance of distilled water. The quick-frozen liquid composition is suitable for freezing various substances, in particularaquatic products, meat and products thereof. The aquatic products, met and products are cooled quickly and cross the maximum ice crystal generation belt, so that the frozen substances have a high quality freezing effect.

Owner:深圳市福瑞者速冻科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com