Engine oil composition for improving oil loss or engine oil combustion of German automobiles

A technology of engine oil and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of increased maintenance cost, poor thermal stability, volatilization of carbon chain oil, etc. properties, and the effect of increasing the viscosity index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 76.7kg American Chevron Phillips company produced, model is the synthetic base oil of PAO5 and PAO7; 2kg Dow Corning Company produced, model is TMTC trimethylolpropane octanoic acid / capric acid complex ester base oil; 0.2kg 8.6 kg of SV261 viscosity index improver produced by Infineum and 12.5 kg of car synthetic oil of H953 produced by Afton Corporation of the United States Composite additives are blended to obtain an engine oil composition with a viscosity grade of SAE5W / 40.

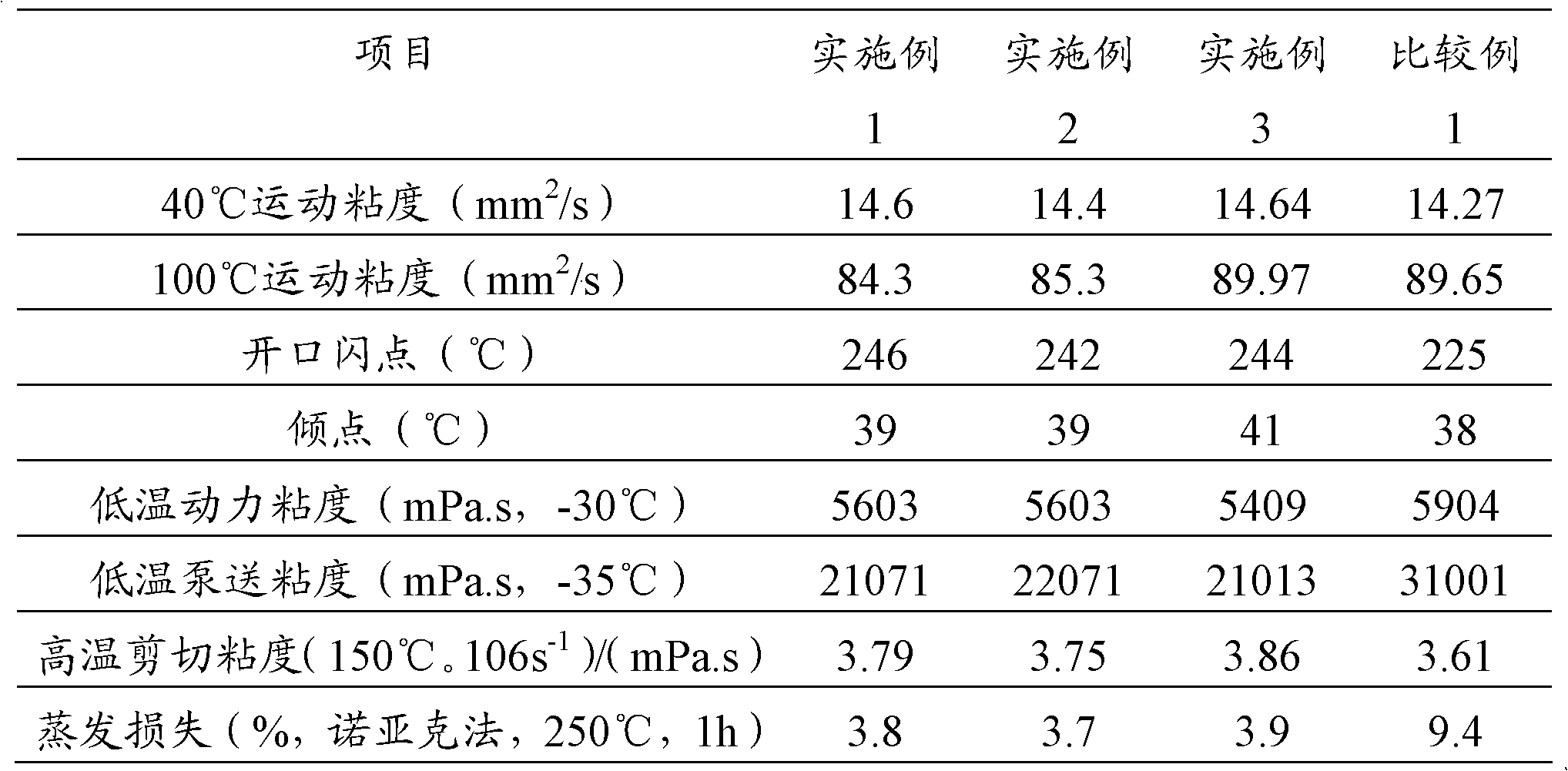

[0041] A performance test was performed on the engine oil composition, and the results are shown in Table 1. Table 1 shows the performance test results of the engine oil composition provided by the examples and comparative examples of the present invention.

Embodiment 2

[0043] 73.4kg of synthetic base oils produced by Chevron Phillips of the United States, whose models are PAO5 and PAO7; 5kg of Synesstic AN5 alkylnaphthyl ester base oils produced by ExxonMobil of the United States; 8.9kg of SV261 viscosity index improver produced by Infineum Co., Ltd. and 12.5kg of car synthetic oil produced by Afton Corporation of the United States with the brand name of H953. The additives are blended to obtain an engine oil composition with a viscosity grade of SAE5W / 40.

[0044] A performance test was performed on the engine oil composition, and the results are shown in Table 1. Table 1 shows the performance test results of the engine oil composition provided by the examples and comparative examples of the present invention.

Embodiment 3

[0046] 68.5kg of synthetic base oils produced by Chevron Phillips of the United States, models PAO5 and PAO7; 10kg of polyol ester base oils of PRI ECO 3000 produced by Shanghai Daopu; 0.3kg of Infineum produced, The brand is the fumarate lipid depressant of V385; the viscosity index improver of SV251 produced by 8.7kg Infineum Co., Ltd. and 12.5kg of Afton Company’s production, the car synthetic oil composite additive of the brand H953 is blended to obtain the viscosity Engine oil composition of grade SAE5W / 40.

[0047] A performance test was performed on the engine oil composition, and the results are shown in Table 1. Table 1 shows the performance test results of the engine oil composition provided by the examples and comparative examples of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com