Refining device for hemispherical lenses

A grinding device and fine grinding technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of large amount of wear, fast consumption of molds, inconvenient maintenance, etc., to prolong the service life, The effect of low mold loss and slow mold consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

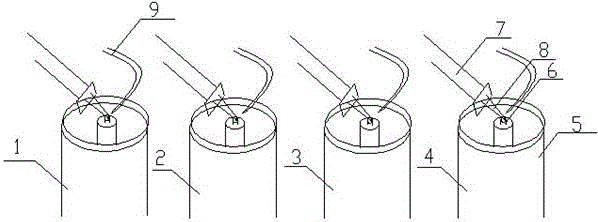

[0013] This embodiment provides a fine grinding device for hemispherical lenses, using four sets of fine grinding devices for grinding, which are respectively fine grinding device A1, fine grinding device B2, fine grinding device C3 and fine grinding device D4, the fine grinding device A1, fine grinding device The grinding device B2, the fine grinding device C3 and the fine grinding device D4 have the same structure, and are all composed of a column 5, a grinding block 6 and a lens grinding support 7. The grinding block 6 is installed on the column 5, and the lens grinding support 7 Installed next to the column 5, the bracket head 8 of the lens grinding bracket 7 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com