Patents

Literature

802results about How to "Not easy to change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

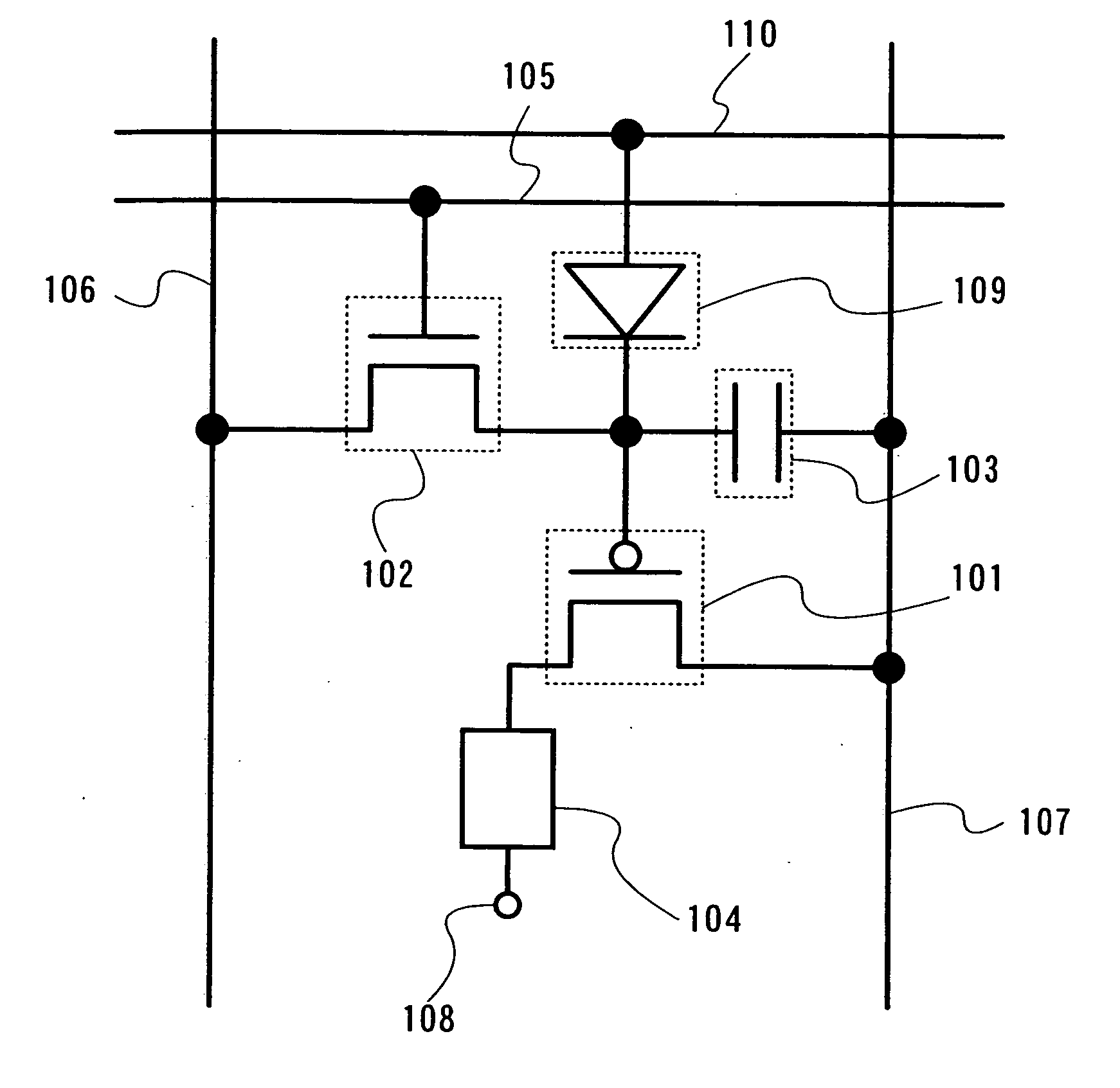

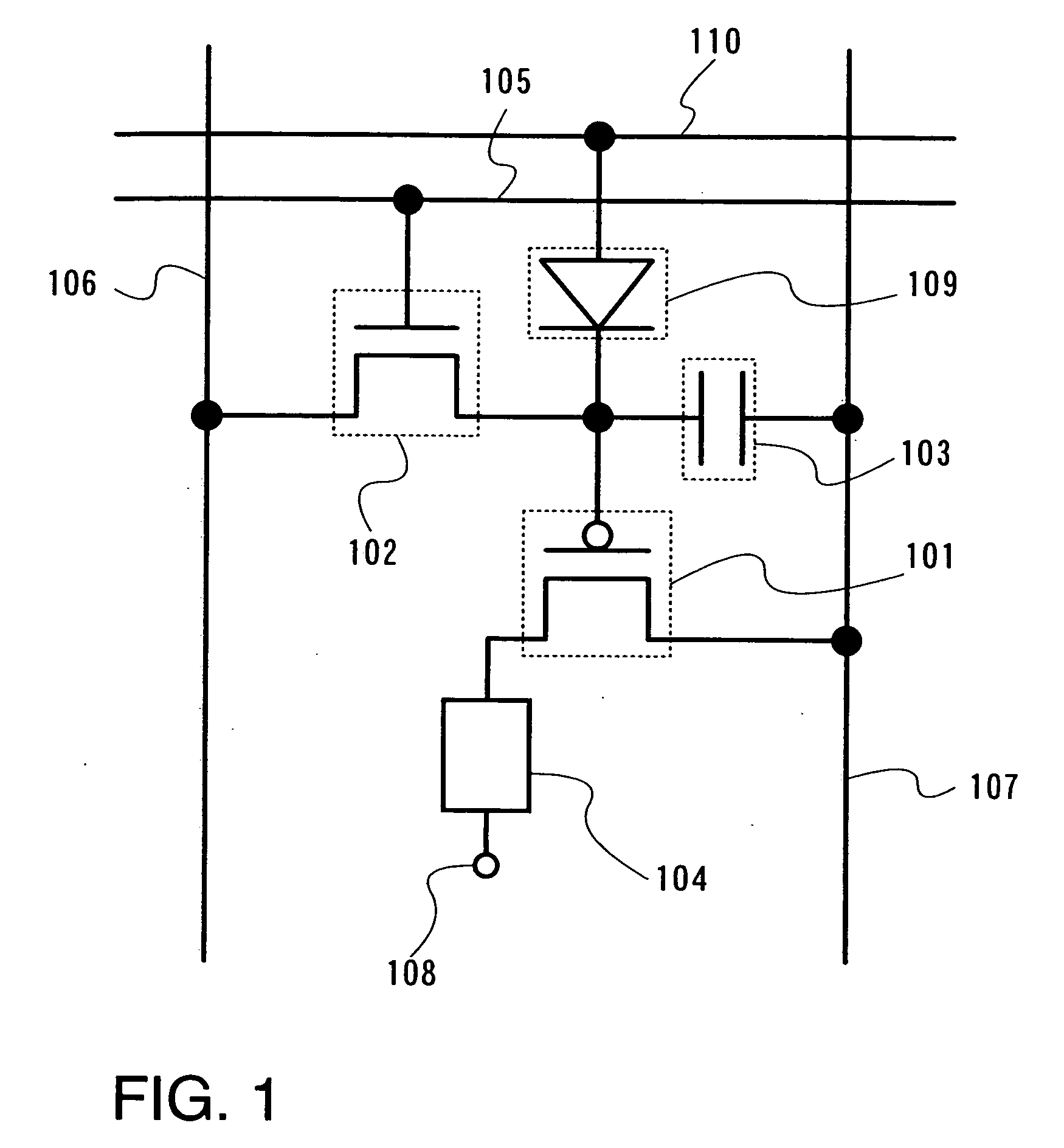

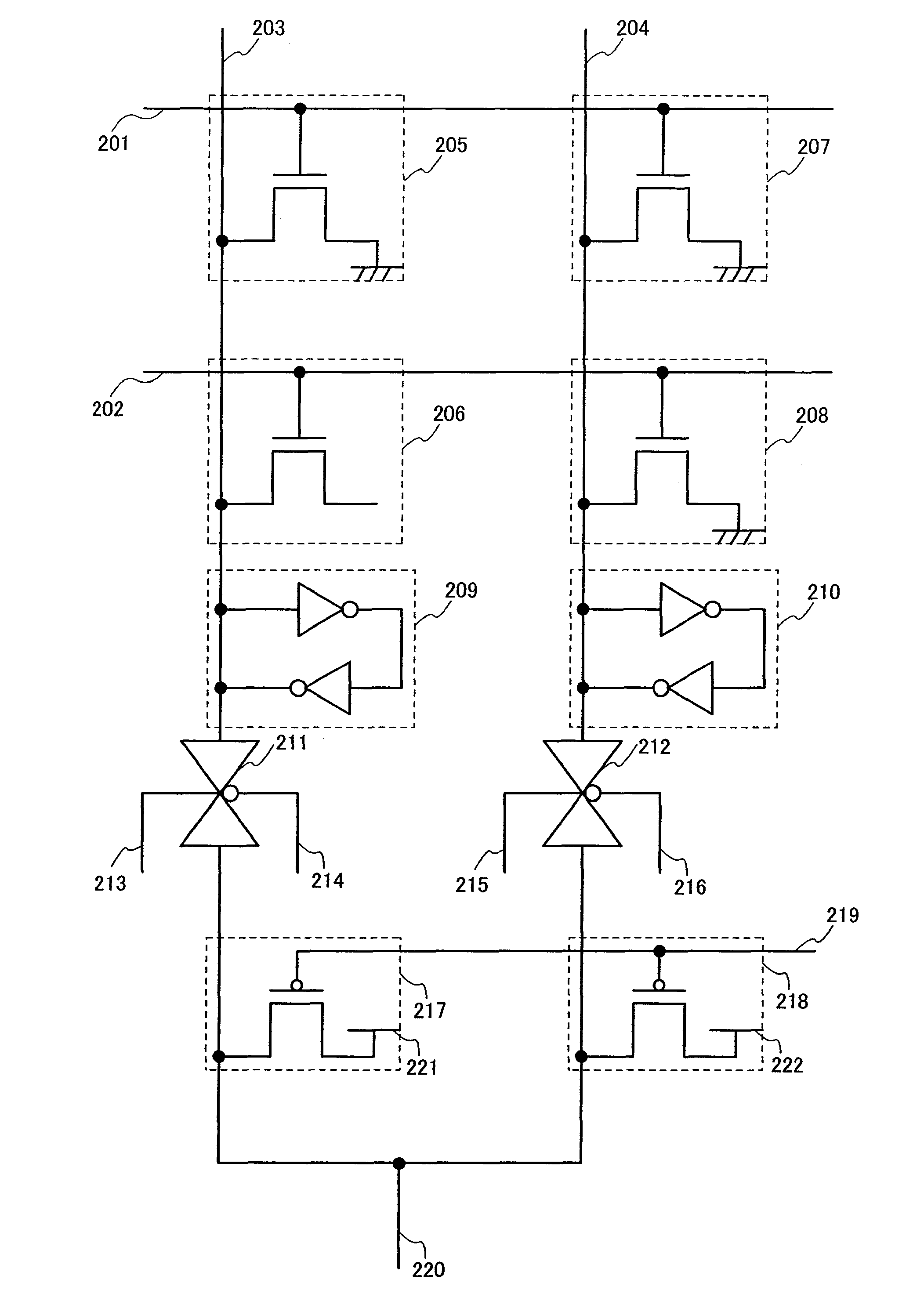

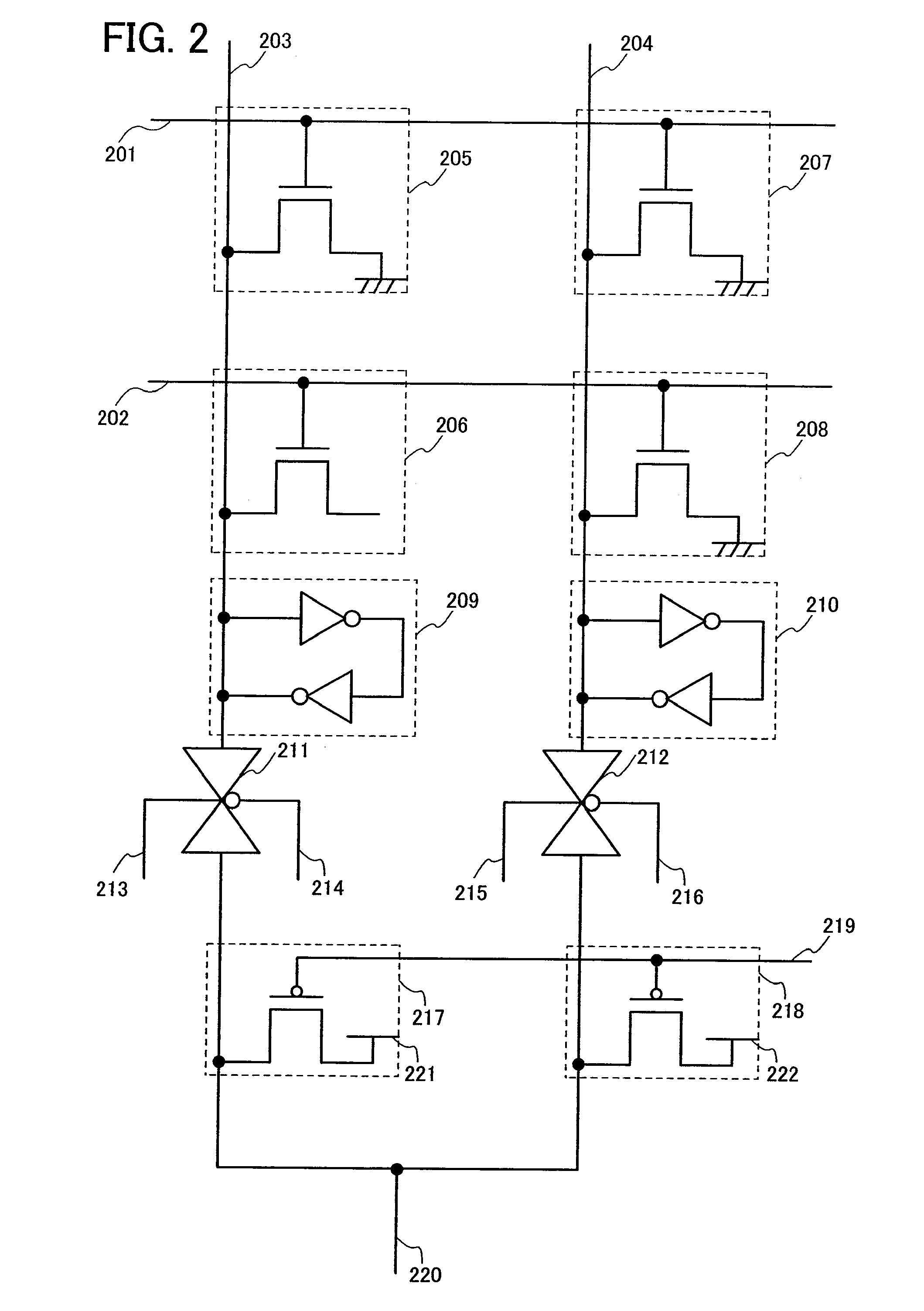

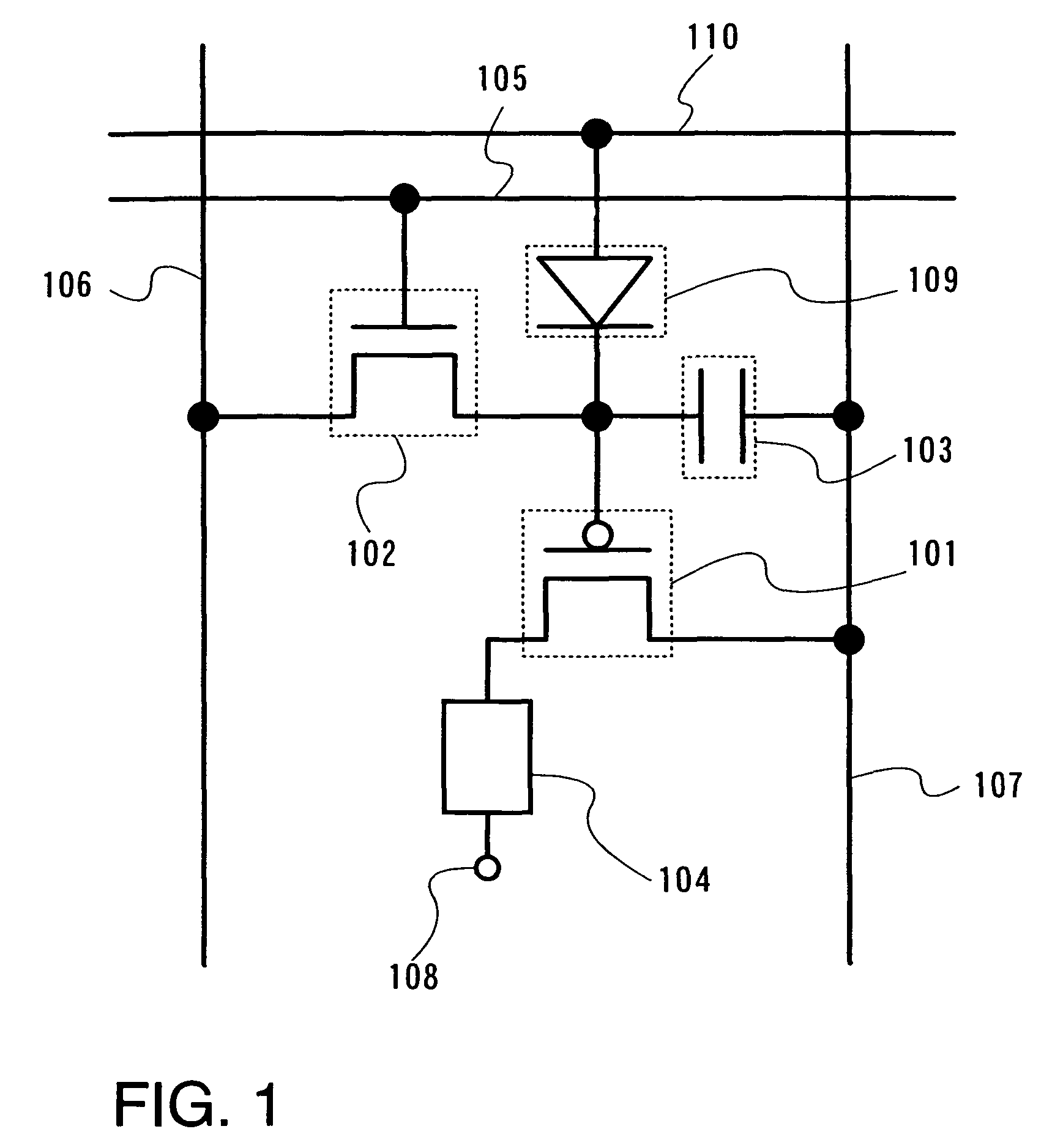

Semiconductor device and display device

InactiveUS20060238135A1Total current dropReduce trafficElectrical apparatusElectroluminescent light sourcesDevice materialScan line

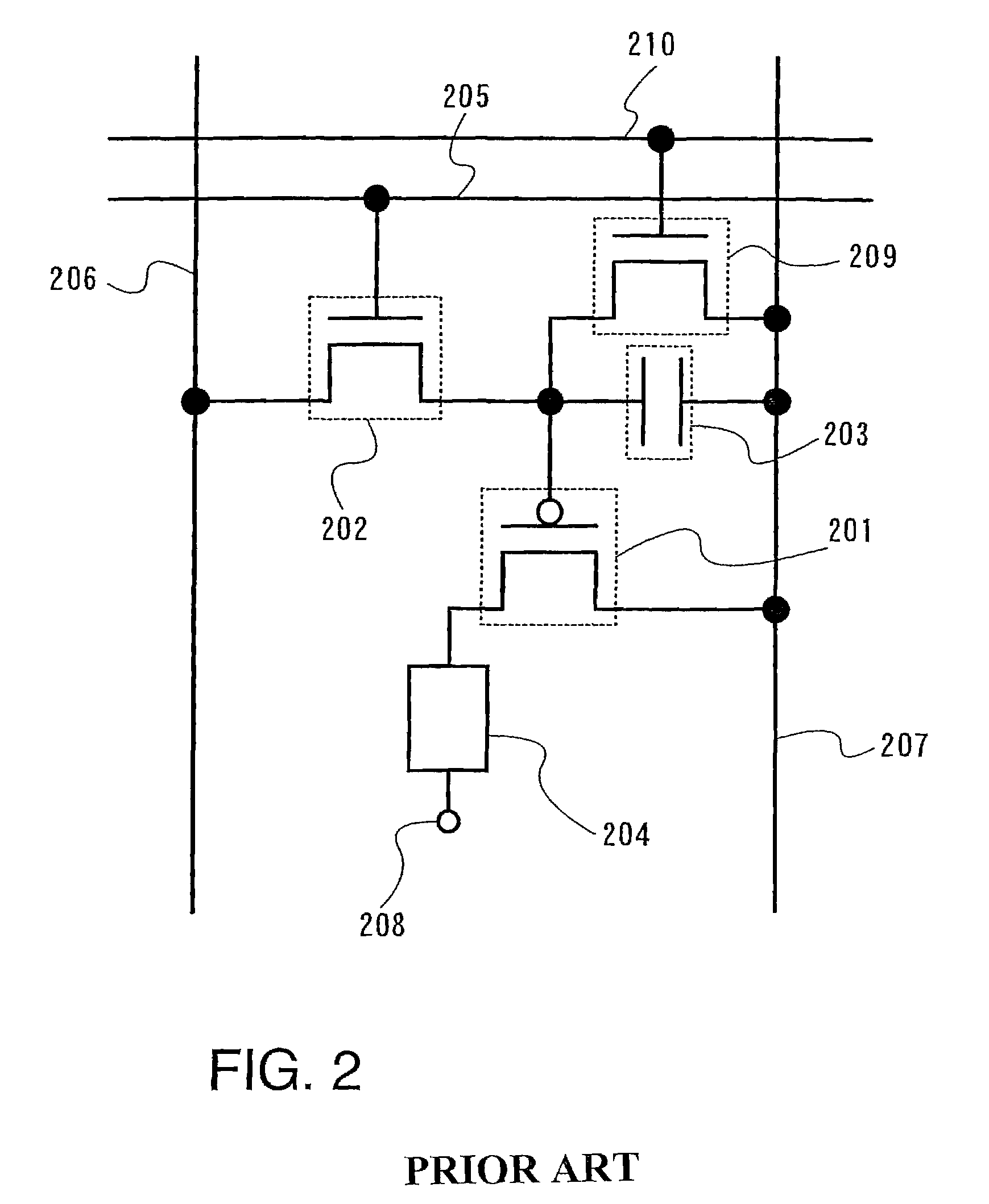

When a signal inputted to a pixel is erased by setting potentials of a gate terminal and a source terminal of a driving transistor to be equal, a current slightly flows through the driving transistor in some cases, which leads to occur a display defect. The invention provides a display device which improves the yield while suppressing the increase in manufacturing cost. When a potential of a scan line for erasure is raised, a potential of the gate terminal of the driving transistor is raised accordingly. For example, the scan line and the gate terminal of the driving transistor are connected through a rectifying element.

Owner:SEMICON ENERGY LAB CO LTD

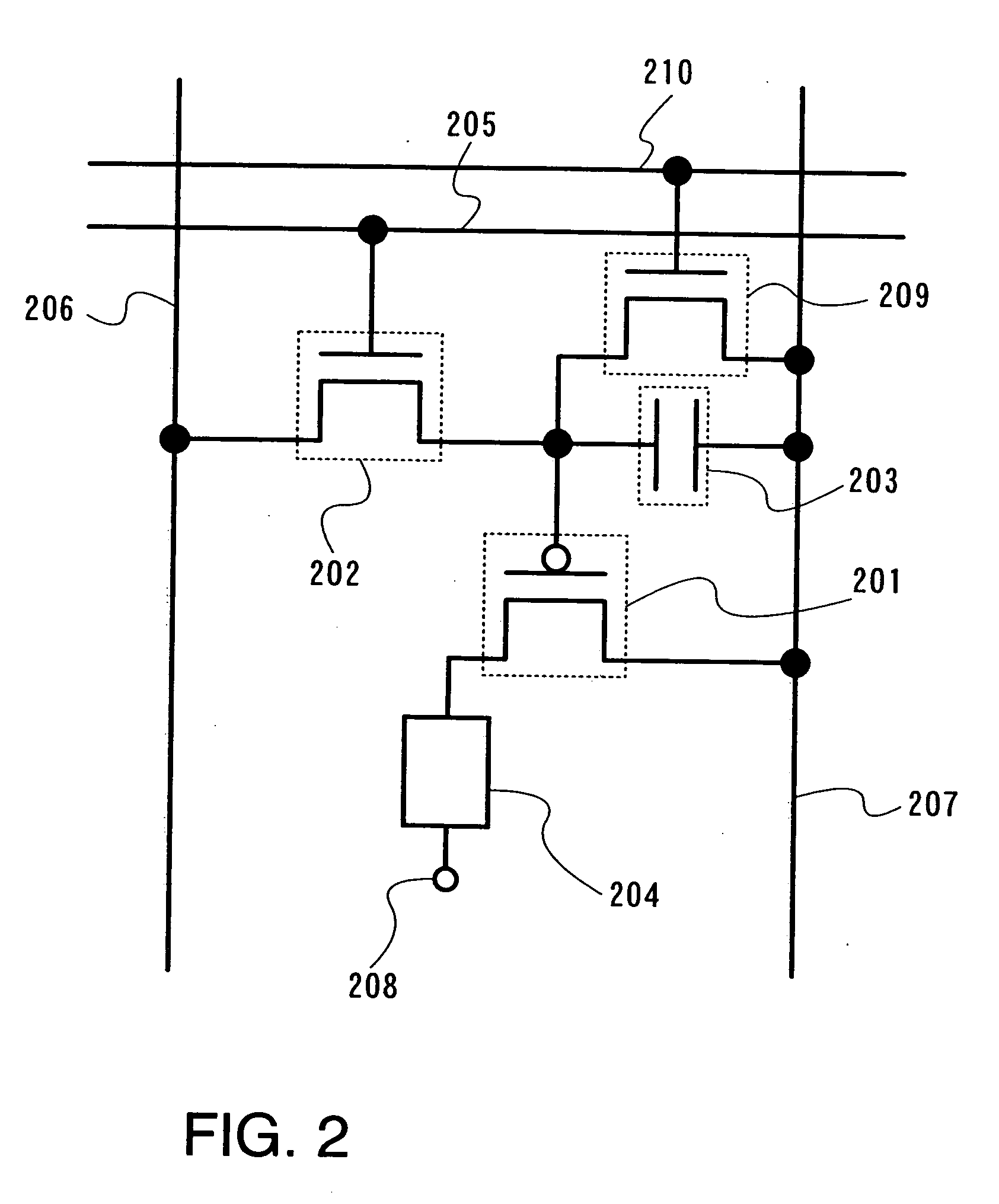

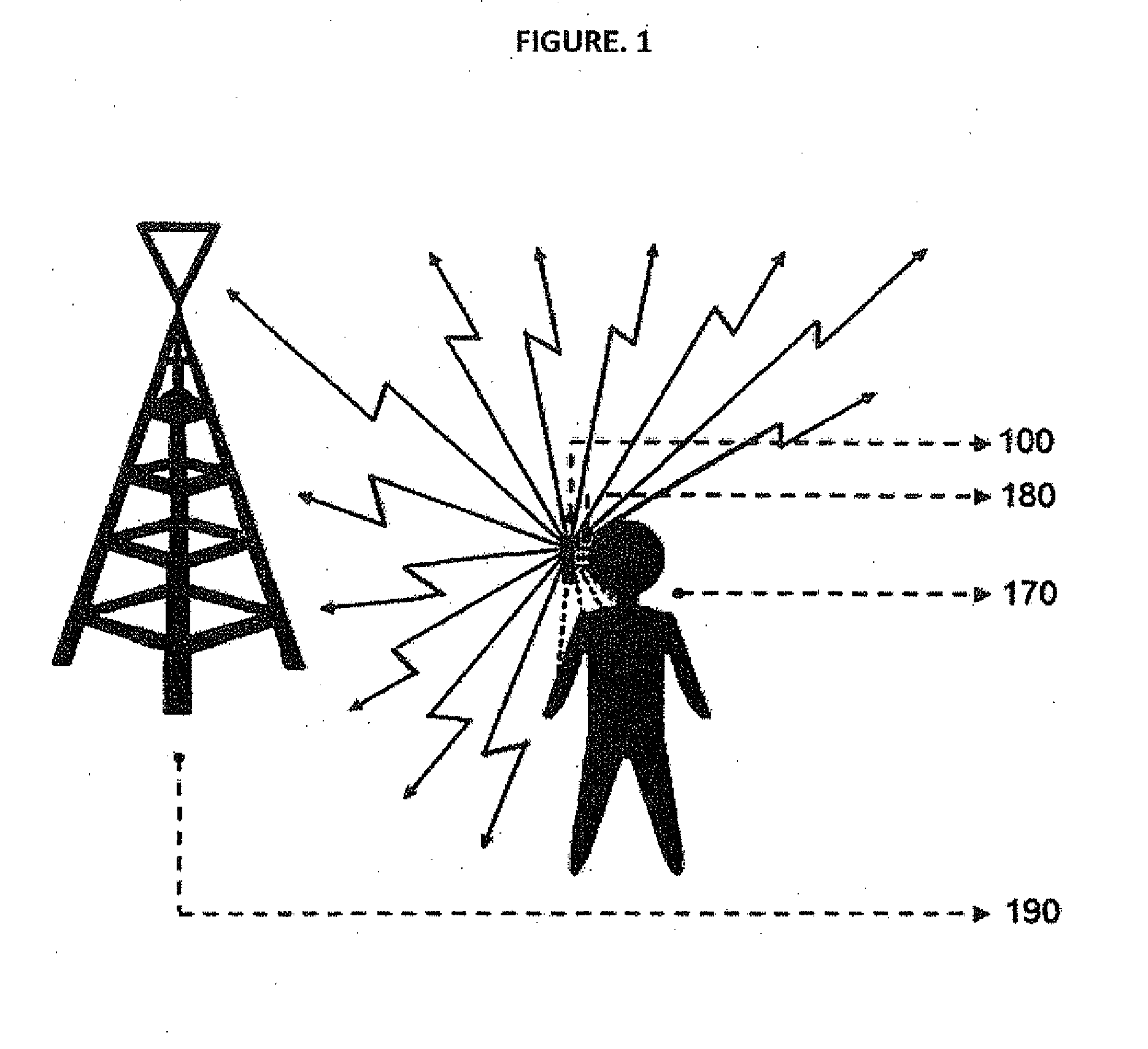

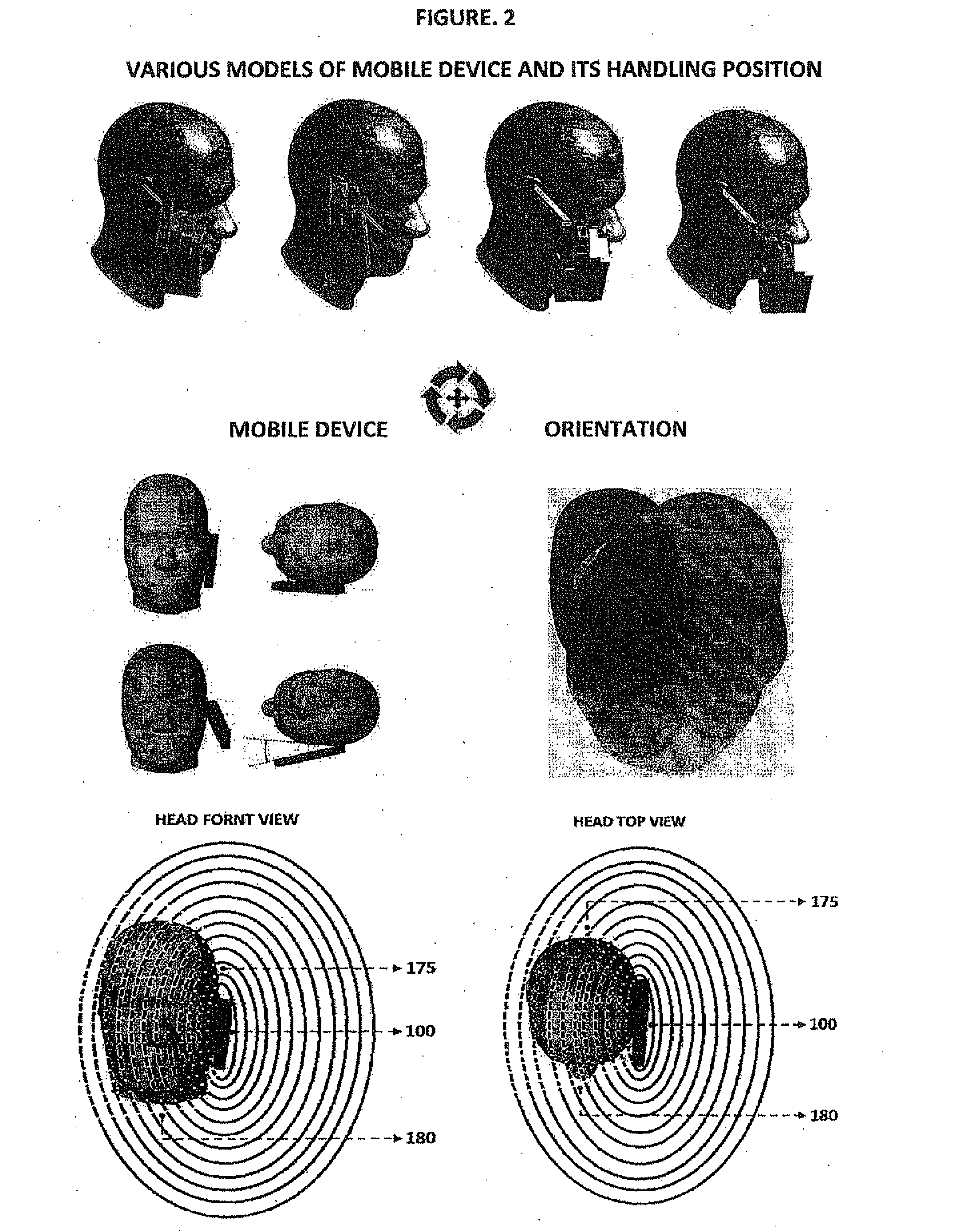

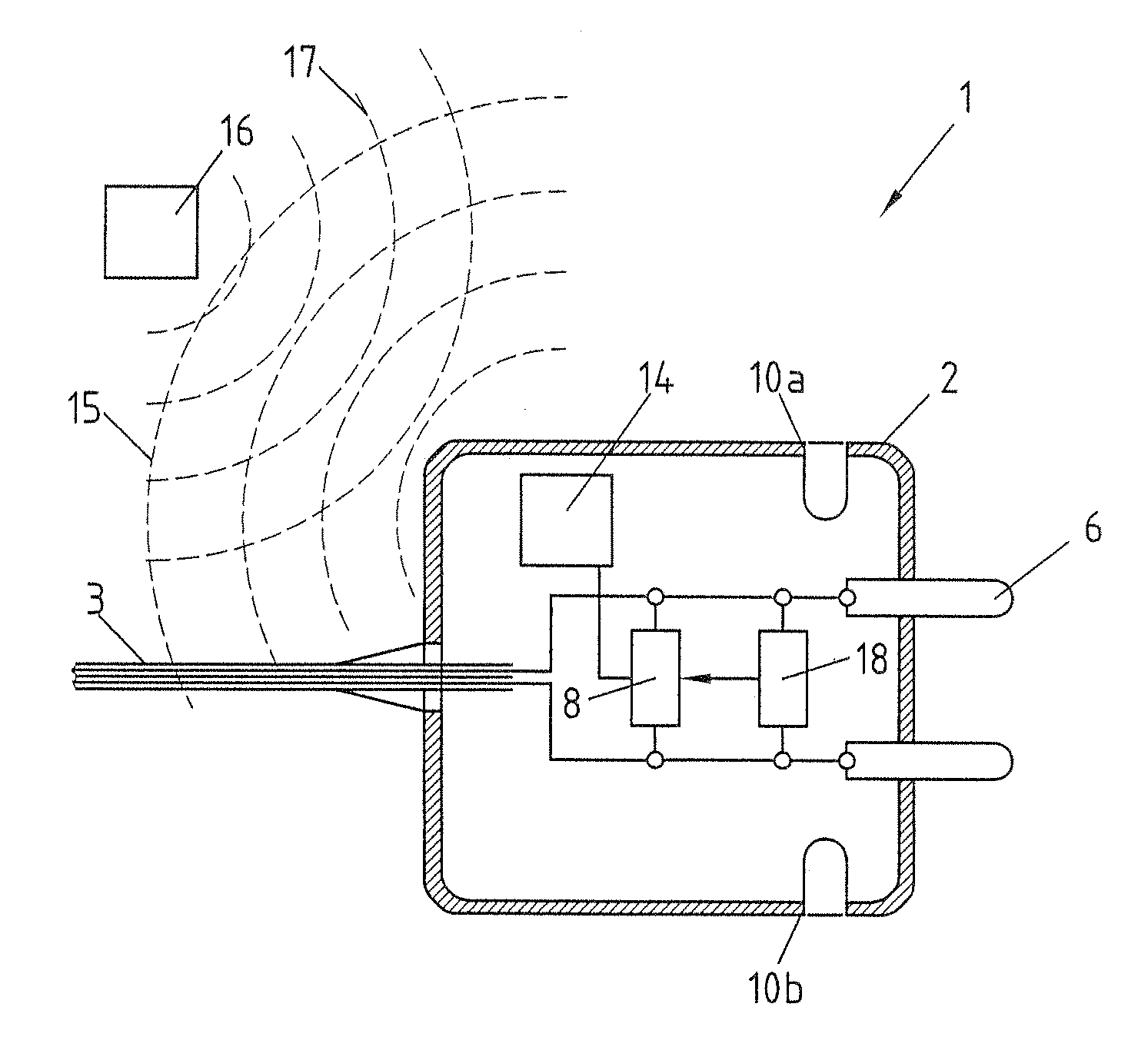

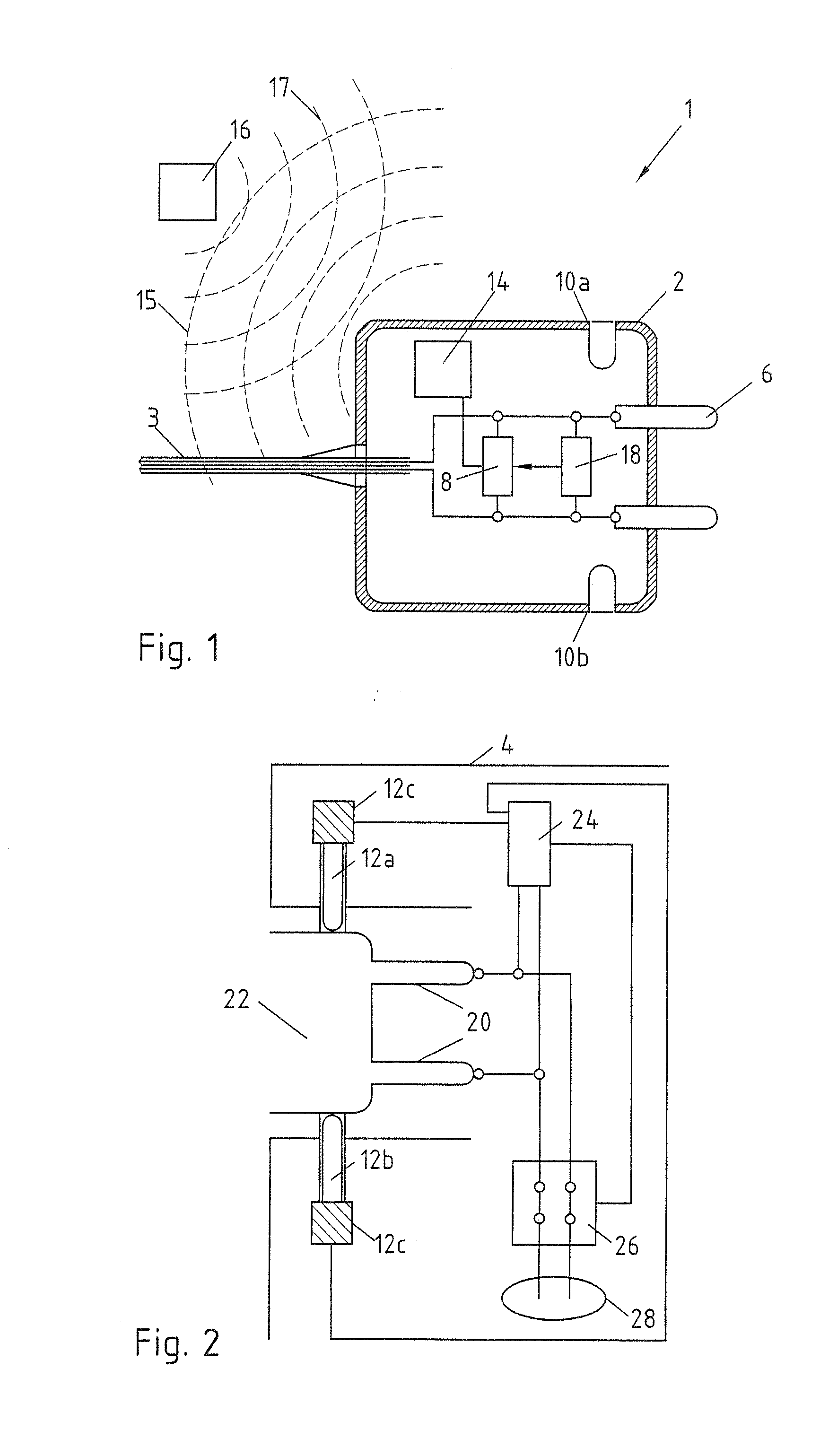

Smart Active Antenna Radiation Pattern Optimising System For Mobile Devices Achieved By Sensing Device Proximity Environment With Property, Position, Orientation, Signal Quality And Operating Modes

ActiveUS20140128032A1Save battery powerImprove signal qualityPower managementUnauthorised/fraudulent call preventionDistortionActive antenna

The smart dynamic radiation pattern optimising system is a design and technique to actively shape & optimise the radiation pattern of mobile device controlled by smart RF / Antenna system with signal processing algorithm that works by sensing the change in device proximity environment with nature or property, range, orientation, position, location, signal quality parameters and ambient intelligence to protect the user by controlling radiation exposure, enhance RF signal quality and to save battery power. Mobile devices are handled in different proximity environment which influence the antenna performance due to electromagnetic interaction based on environments properties that leads to detuning, radiation pattern distortion, impedance mismatch etc which in turn degrades the signal quality. Also change in device orientation according to usage leads to power loss due to polarization mismatch. So when the signal quality degrades the system will sense & compute in an adaptive closed loop manner to actively optimise the radiation pattern according to scenarios. The design consist of (a) a sensor system 220 to determine the change in proximity environment [close vicinity] with sensing its property, sensing multi-direction, dimension, layer, position & range of proximity environment with respect to device, sensing device (antenna) orientation, visual sensing, infrared or thermal vision, user recognition, user head & hand hold effect, location, usage scenarios & operating modes and accordingly generate the trigger signal 230; (b) a processing unit 150 for computing the interrupt control signal 140 according to the nature of trigger signal & existing signal quality parameters; (c) Smart active radiation pattern optimiser 120 that works based on control signal; (d) Antenna system 110 capable of achieving dynamic radiation pattern coupled with radiation pattern optimiser that actively shapes and controls the radiation pattern accordingly to protect the user and also restores radiation according to scenarios to optimise communication. Other aspects of the present invention are the same sensor system 220 is utilised to develop an application that guides the user locate & position the mobile device in living space to achieve optimised performance, protect the mobile device from theft and ambient intelligence to alert & interact with the user.

Owner:MUTHUKUMAR PRASAD

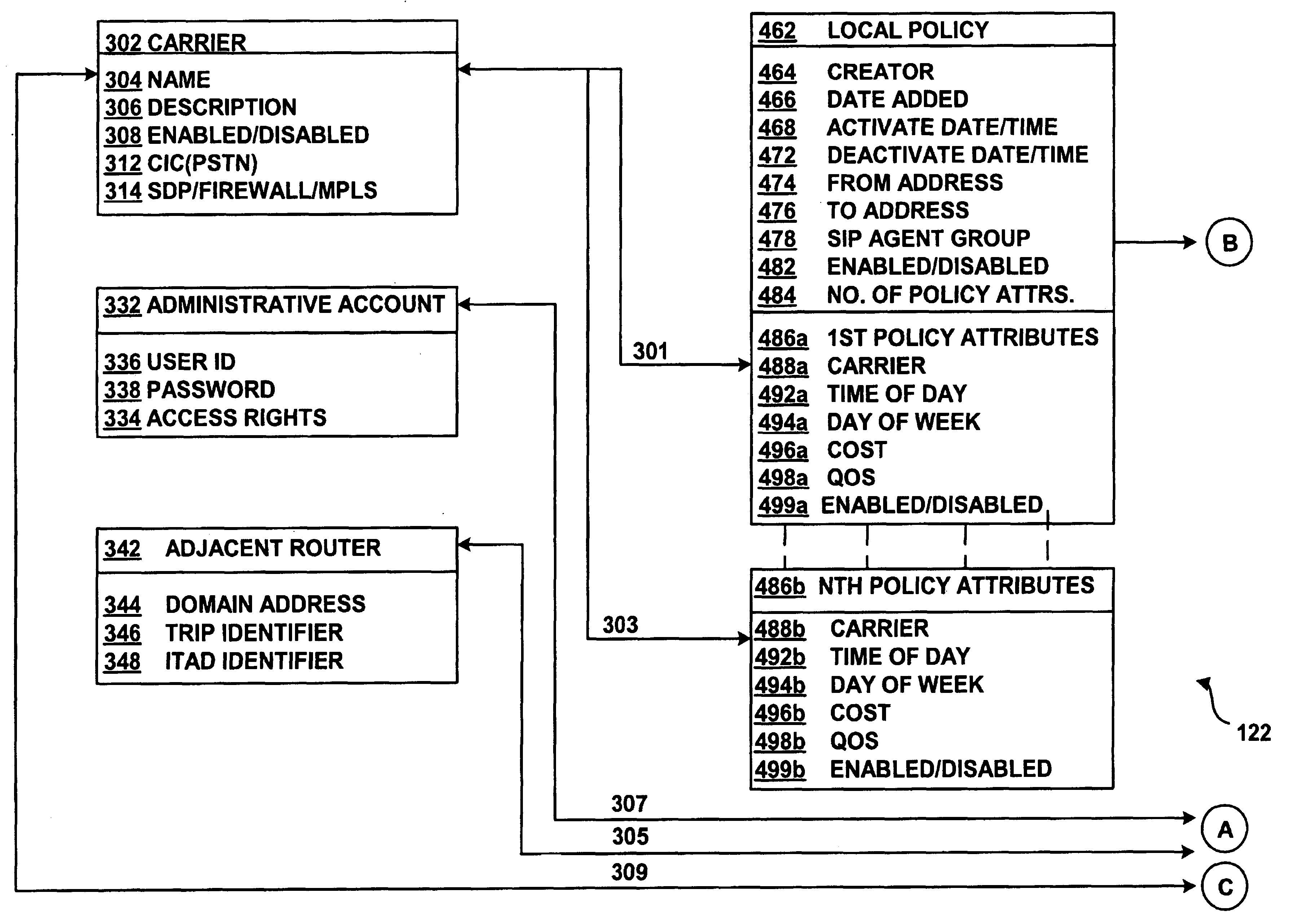

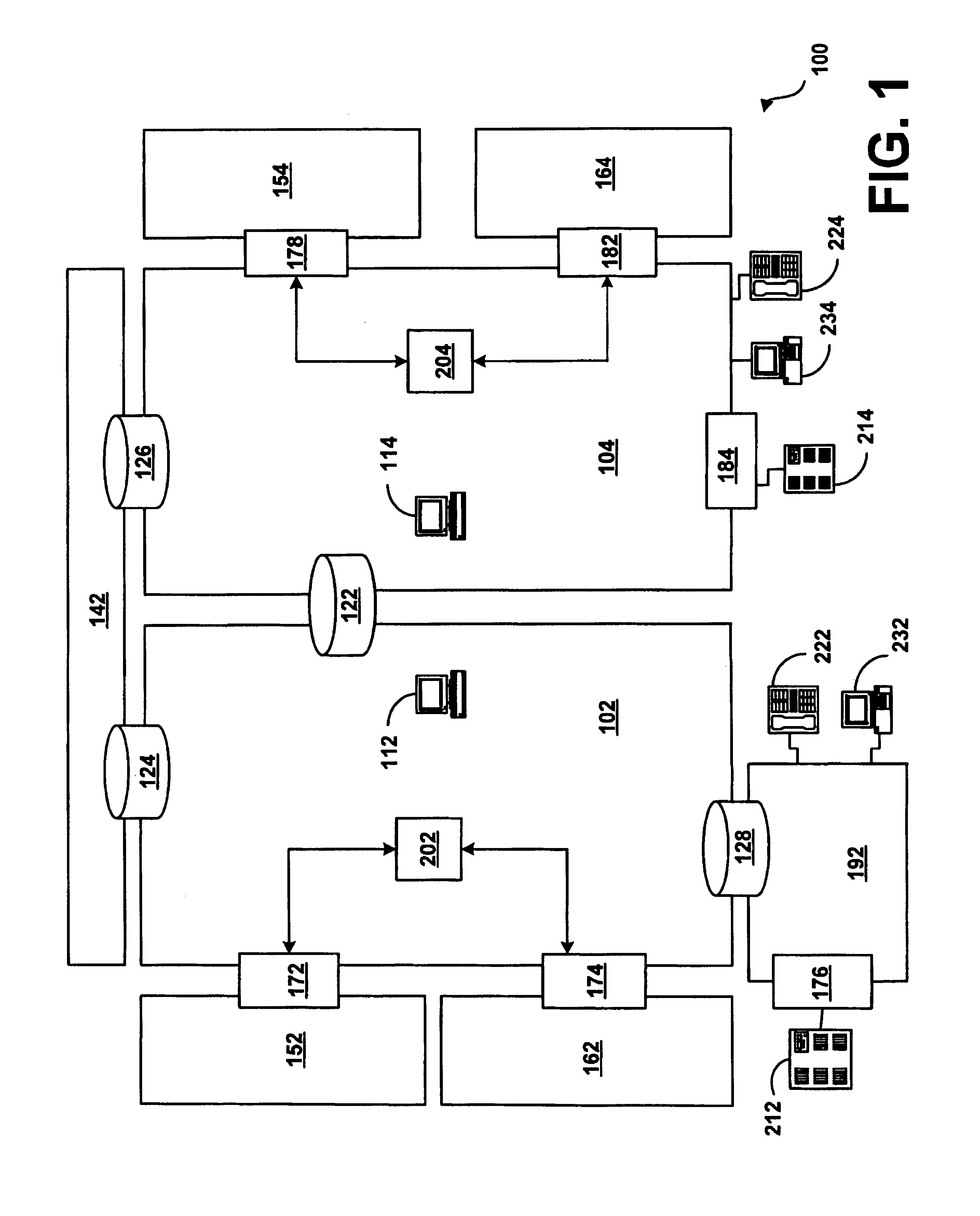

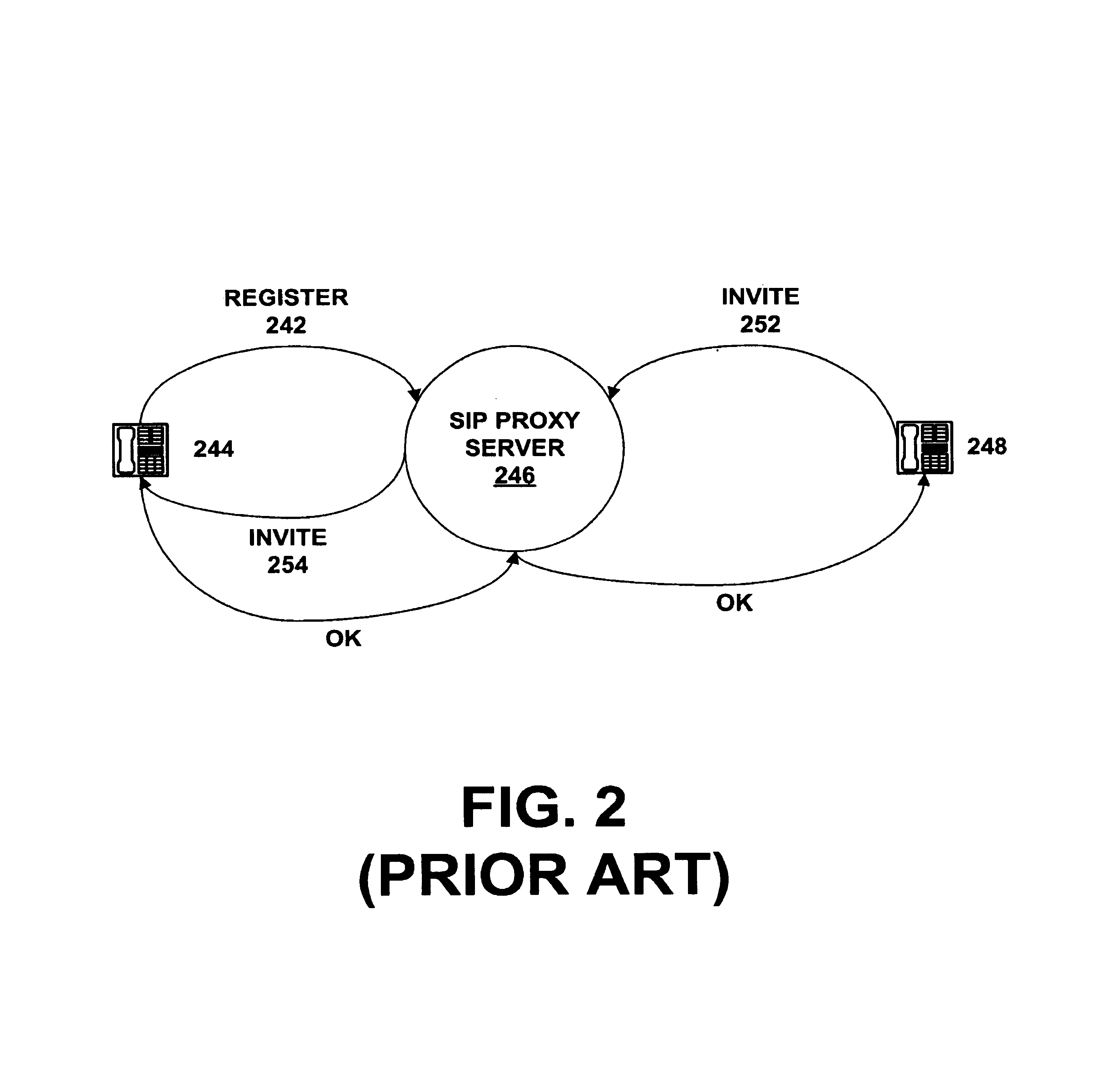

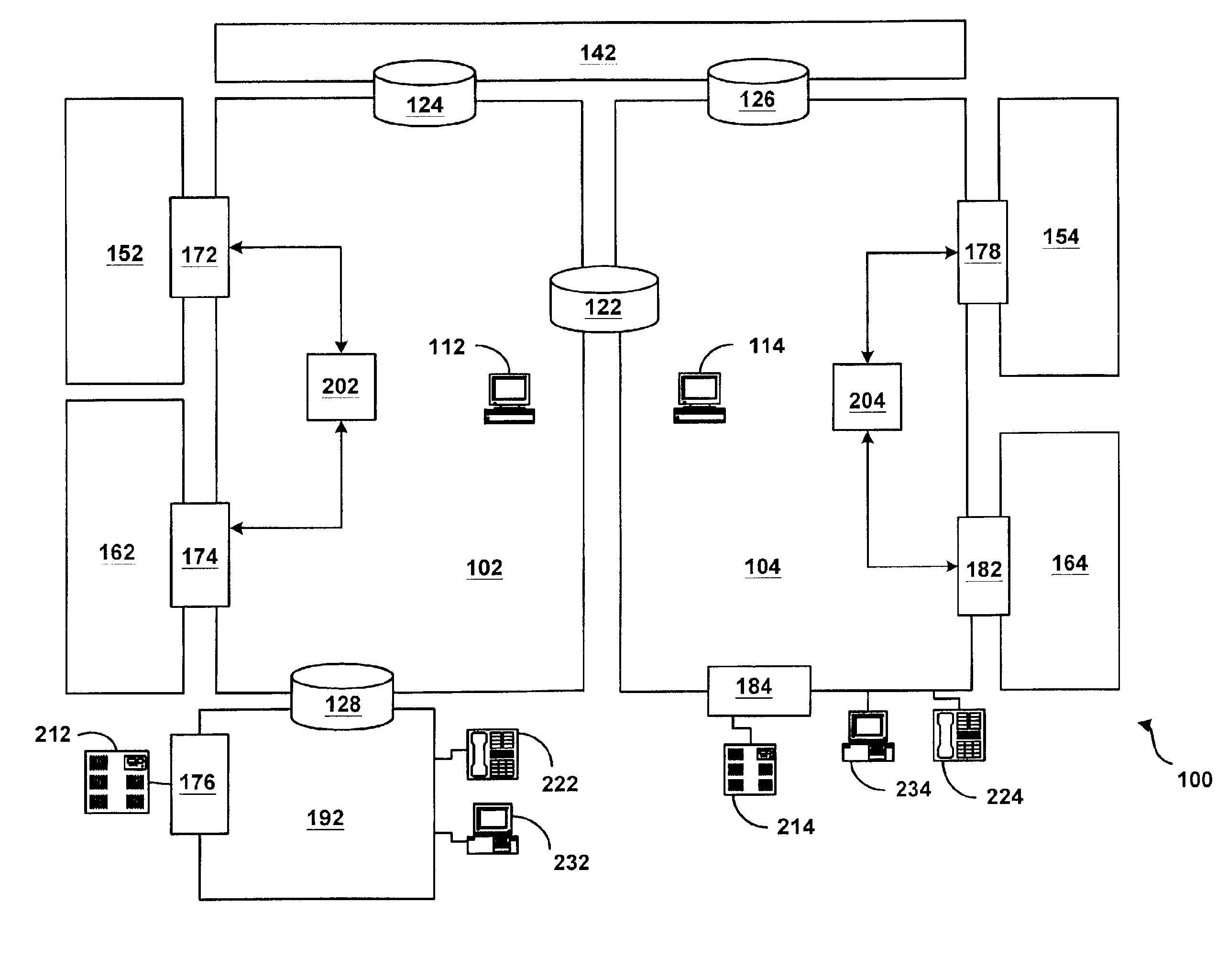

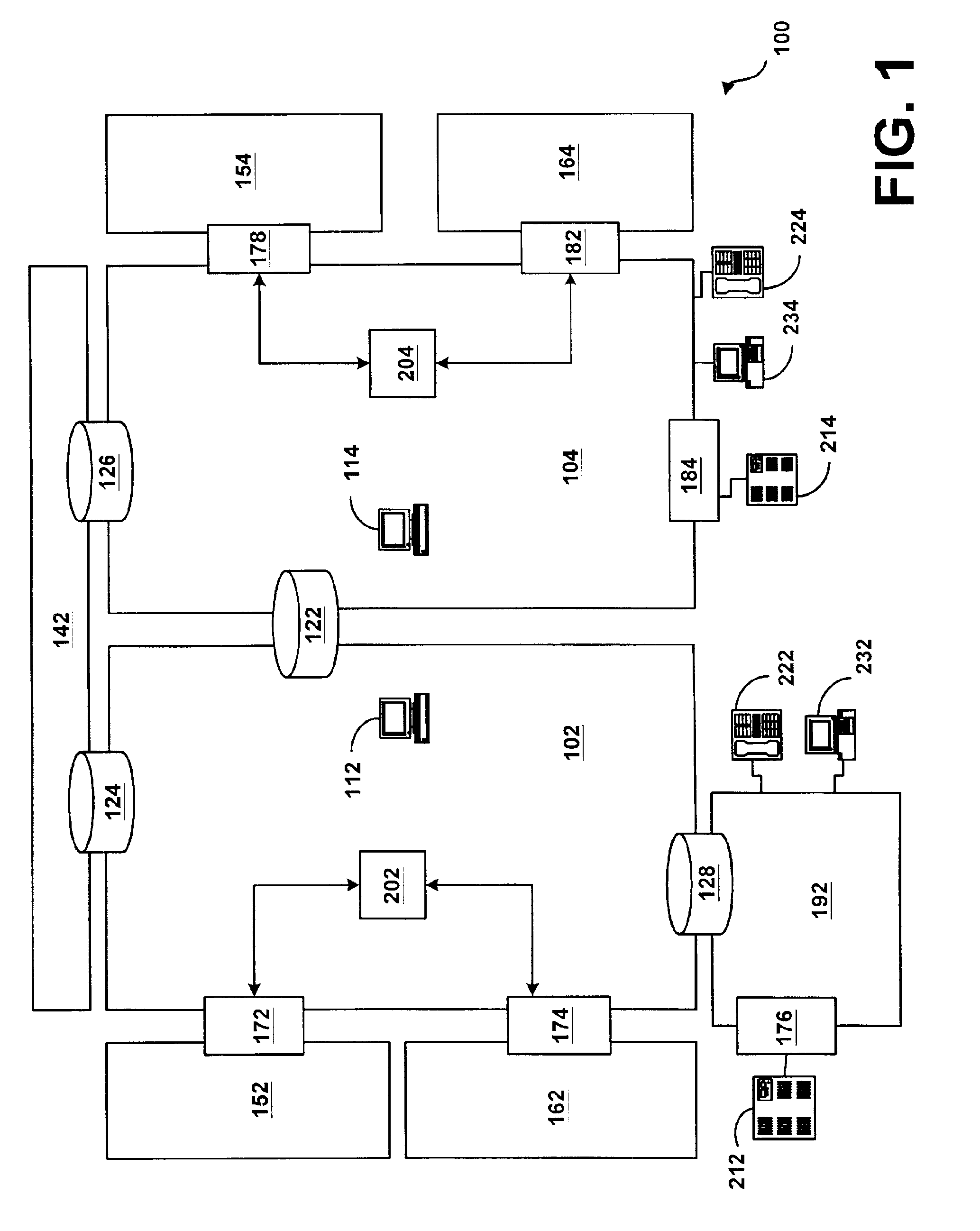

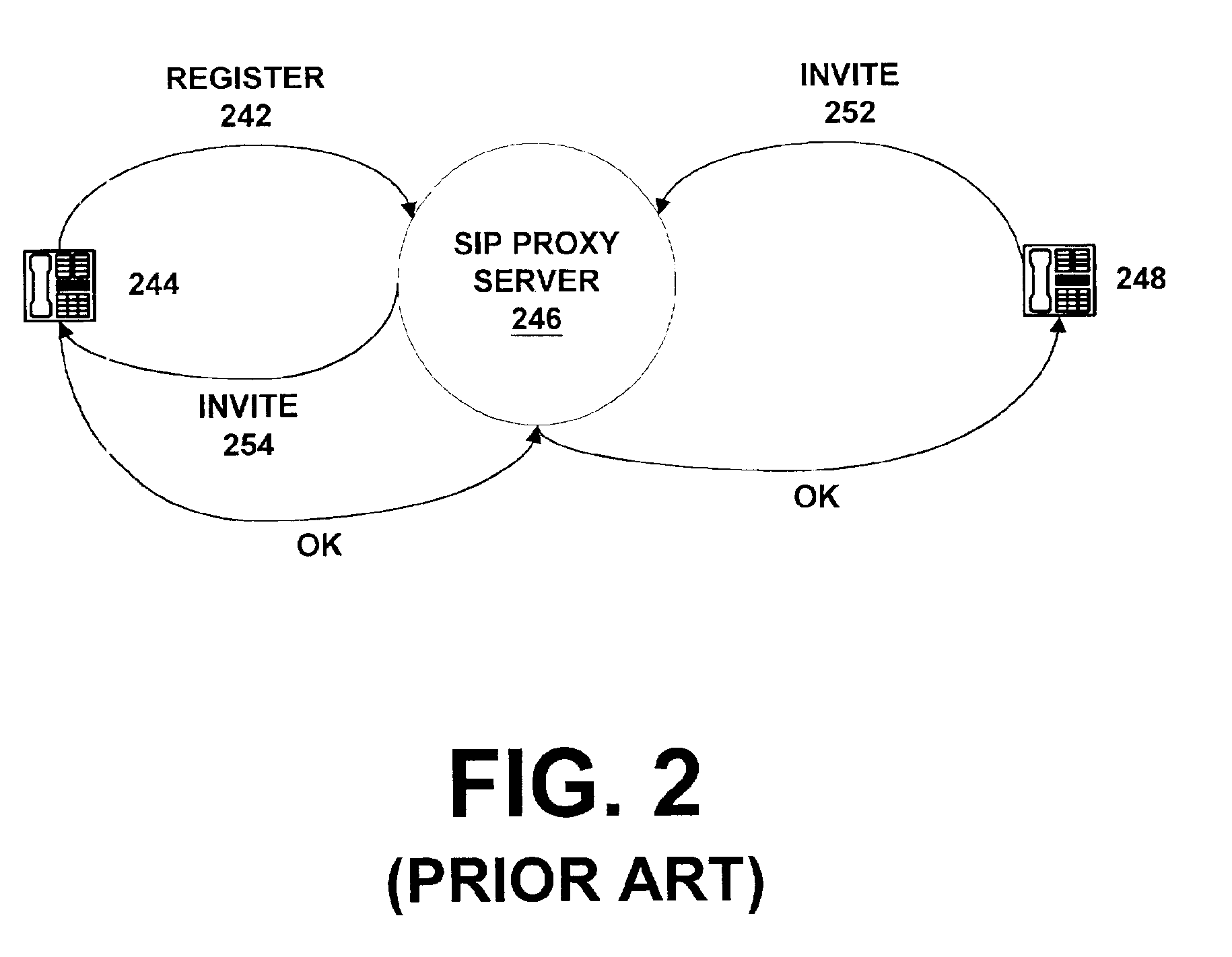

System and method for assisting in controlling real-time transport protocol flow through multiple networks via media flow routing

InactiveUS7028092B2Not easy to changeMultiplex system selection arrangementsInterconnection arrangementsTransceiverReal-time Transport Protocol

A system and method for assisting in controlling real-time transport protocol flow through multiple networks via media flow routing is disclosed. The system utilizes a first computer and a second computer connected to the first computer, via a group of associated computers, wherein each of the first computer, second computer, and group of associated computers comprise a transceiver, a memory, and a processor. The processor is configured by the memory to perform the functions of: performing an inbound screen on route information received from the first computer, to determine if the received route information should be discarded; if the route information is not discarded, comparing the received and screened route information to a local policy defined within the second computer; performing an outbound screen on the received and screened information prior to transmitting the received and screened route information to the first computer; and selecting a primary route from the received route information and local route information in accordance with the local policy, wherein the primary route is a path from the second computer to the first computer via the group of associated computers.

Owner:ACME PACKET +1

System and method for assisting in controlling real-time transport protocol flow through multiple networks via screening

ActiveUS7133923B2Not easy to changeMultiplex system selection arrangementsInterconnection arrangementsTransceiverReal-time Transport Protocol

A system for assisting in controlling real-time transport protocol flow through multiple networks via screening is disclosed. The system utilizes a transceiver, a memory having logic stored therein defining functions to be performed by the system, and a processor. The processor is configured by the memory to perform the functions of: determining if route information received by the transceiver is from an external source or an internal source; if the route information is from an external source, performing a first internal screen of the route information, wherein a destination address defined by the received route information is compared to a local destination address defined by the first internal screen; and if the route information is from an internal source, performing a second internal screen of the route information, wherein an origin address defined by the received route information is compared to a local origin address defined by the second internal screen.

Owner:PRIMARY NETWORKS +1

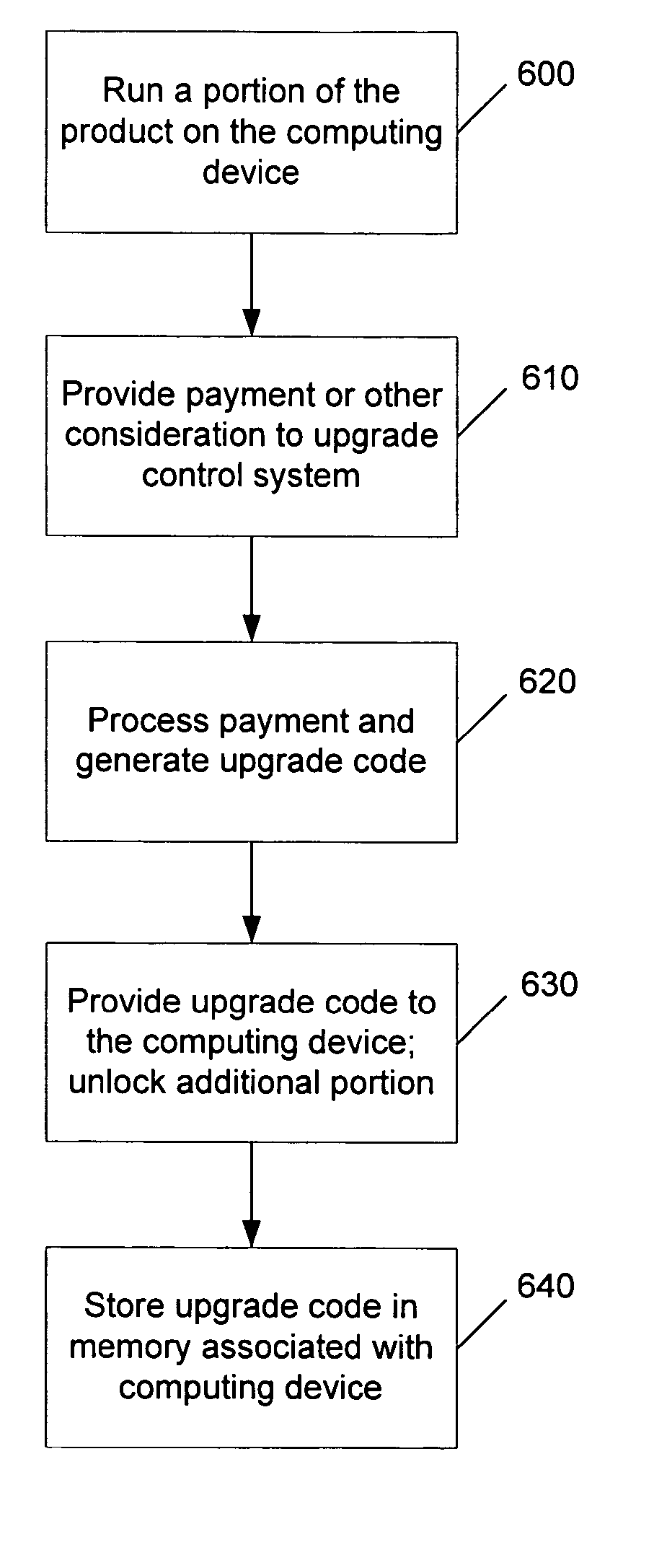

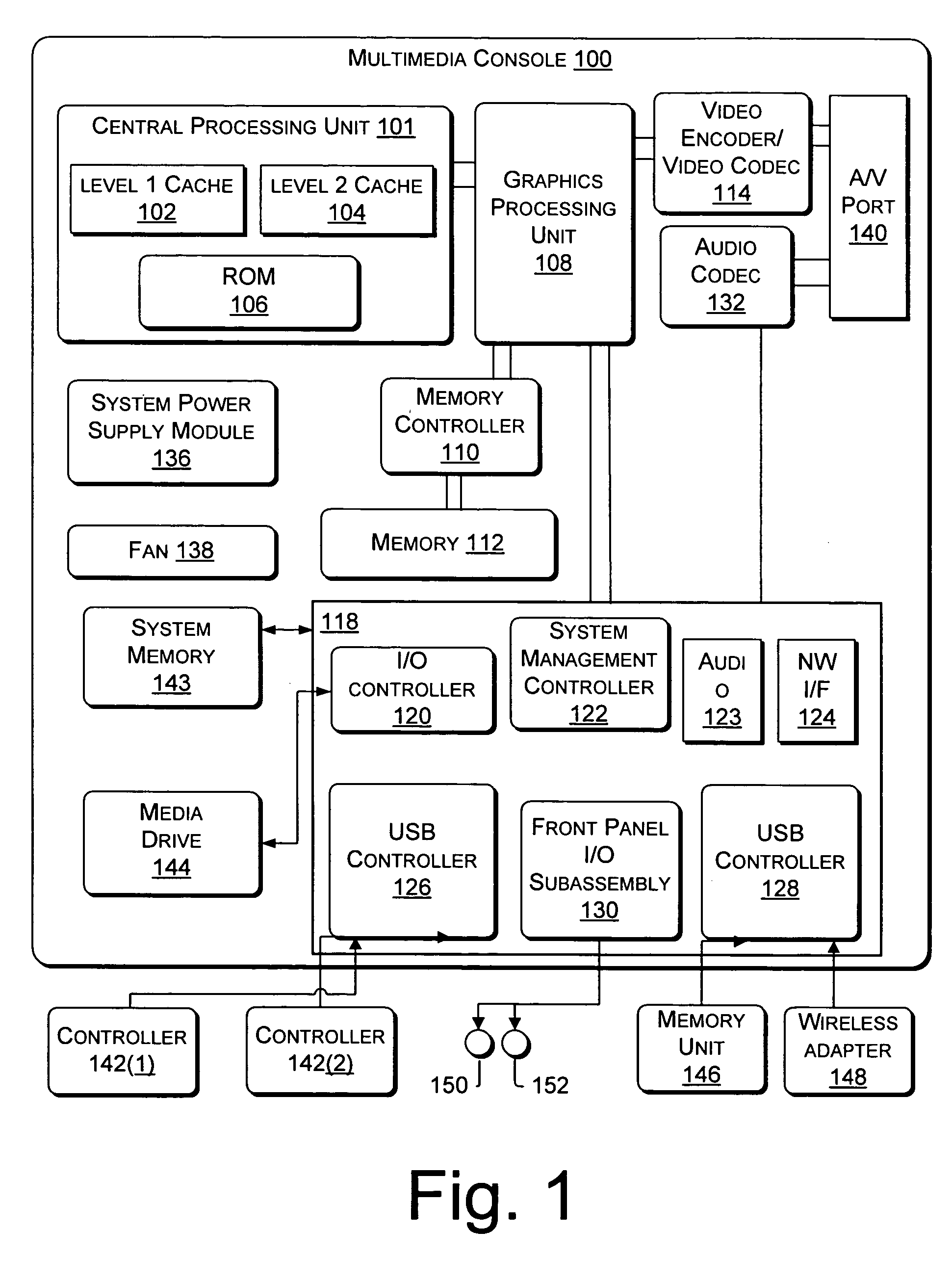

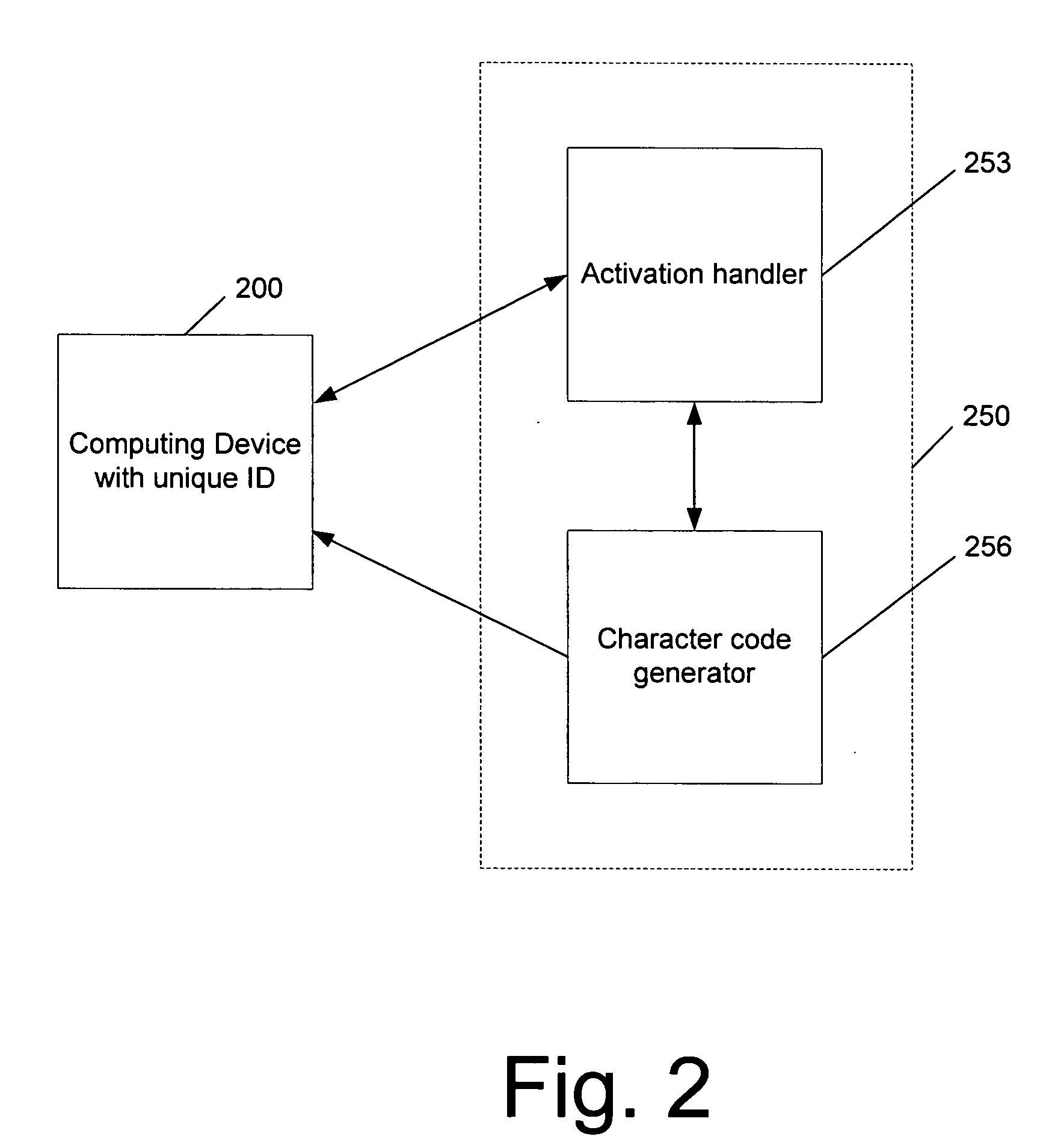

Licensing the use of a particular feature of software

InactiveUS20060048132A1Not easy to changeDigital data processing detailsUnauthorized memory use protectionWeb siteUnique identifier

Software is licensed for use on a particular computing device, such as a gaming console or a multimedia console. An unlocking code is provided from a distribution service to the computing device (either directly or via a user), which in turn, unlocks the appropriate software or portion of software for use with the associated computing device. The software may reside on a computer-readable medium, such as a CD-ROM or DVD disk, that is being used in conjunction with the computing device. The unlocking code may be provided directly to the user in private (e.g., via email or a mobile phone) or in public (e.g., published on a website). Portions of the software that may be unlocked include a particular level of a game or other features (such as additional characters or weapons), or a working or more advanced version of an application that was otherwise provided as a demo or older version. The unlocking code may be based on a unique identifier of the computing device and an identifier associated with the software seeking to be accessed. Thus, the code may only be used by the computing device having that unique identifier. This prevents unauthorized or unlicensed computing devices from using the software.

Owner:MICROSOFT TECH LICENSING LLC

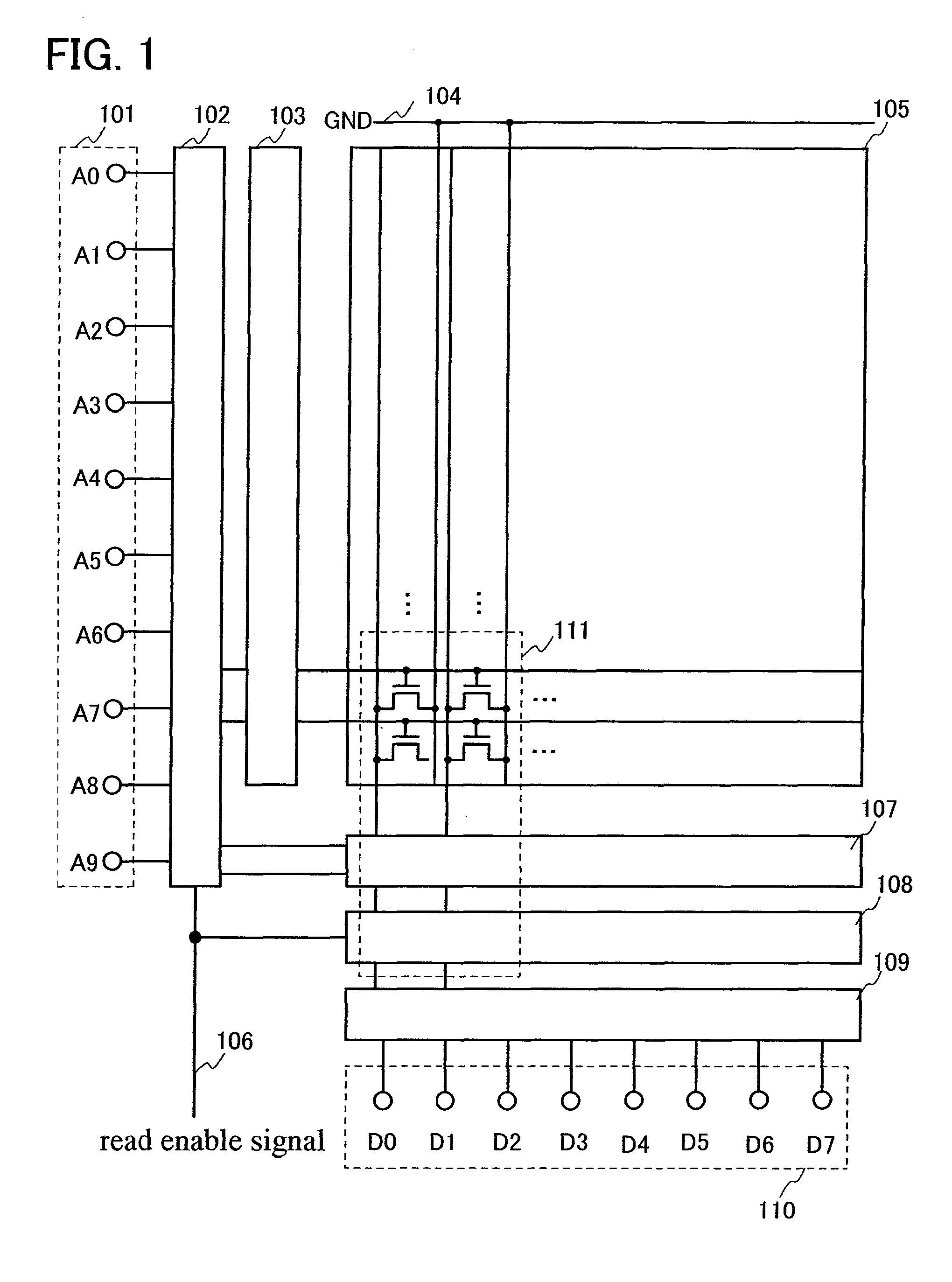

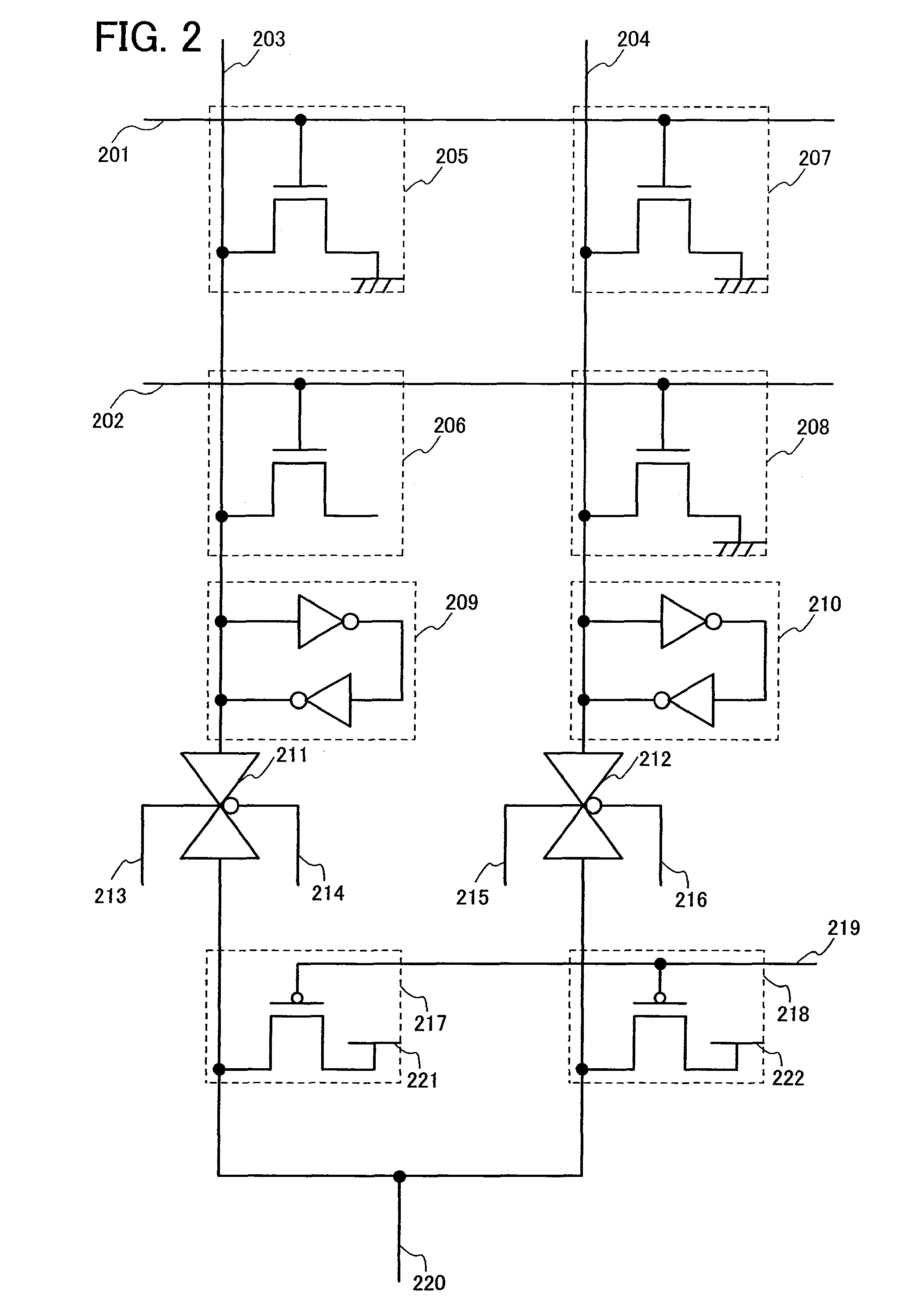

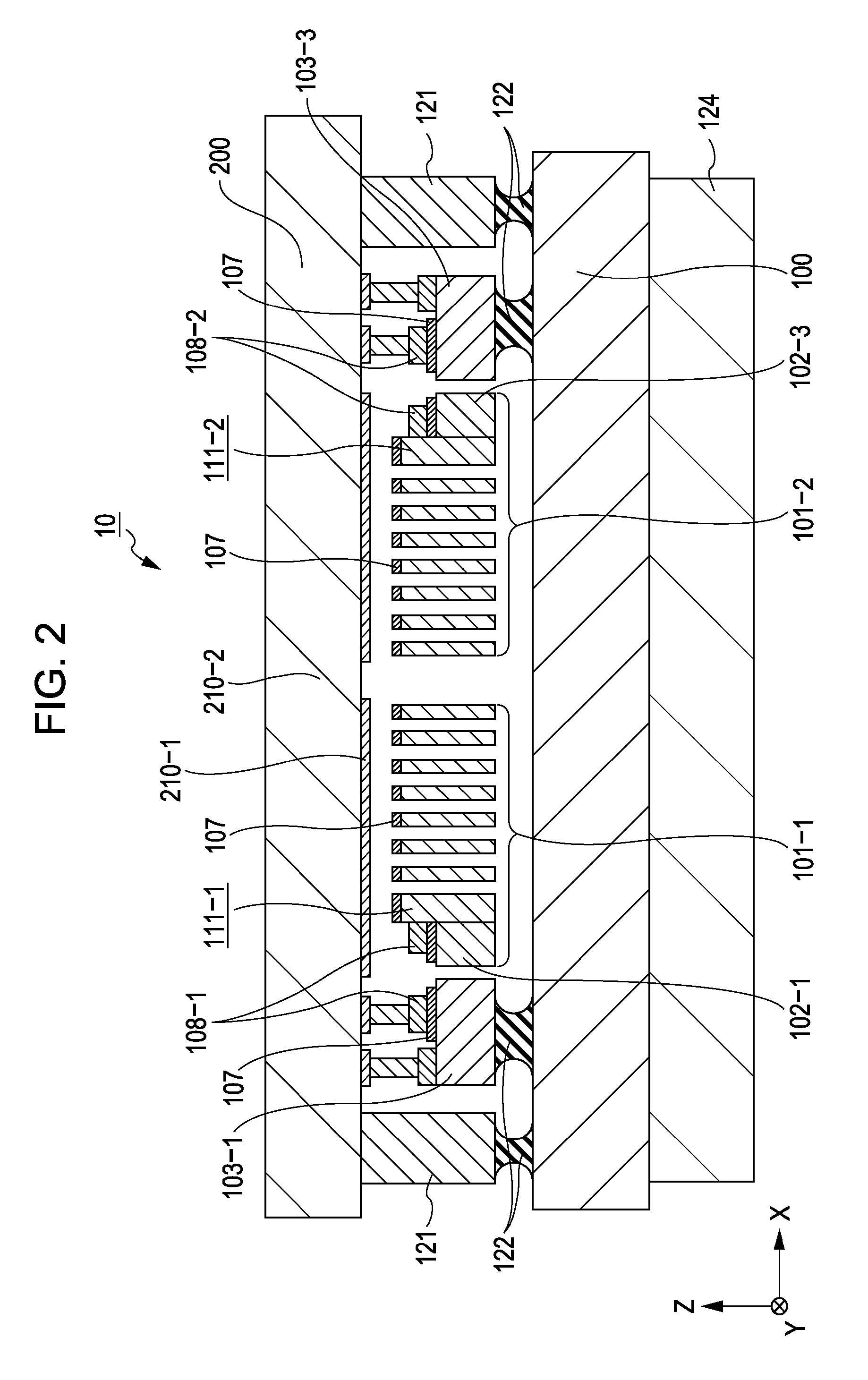

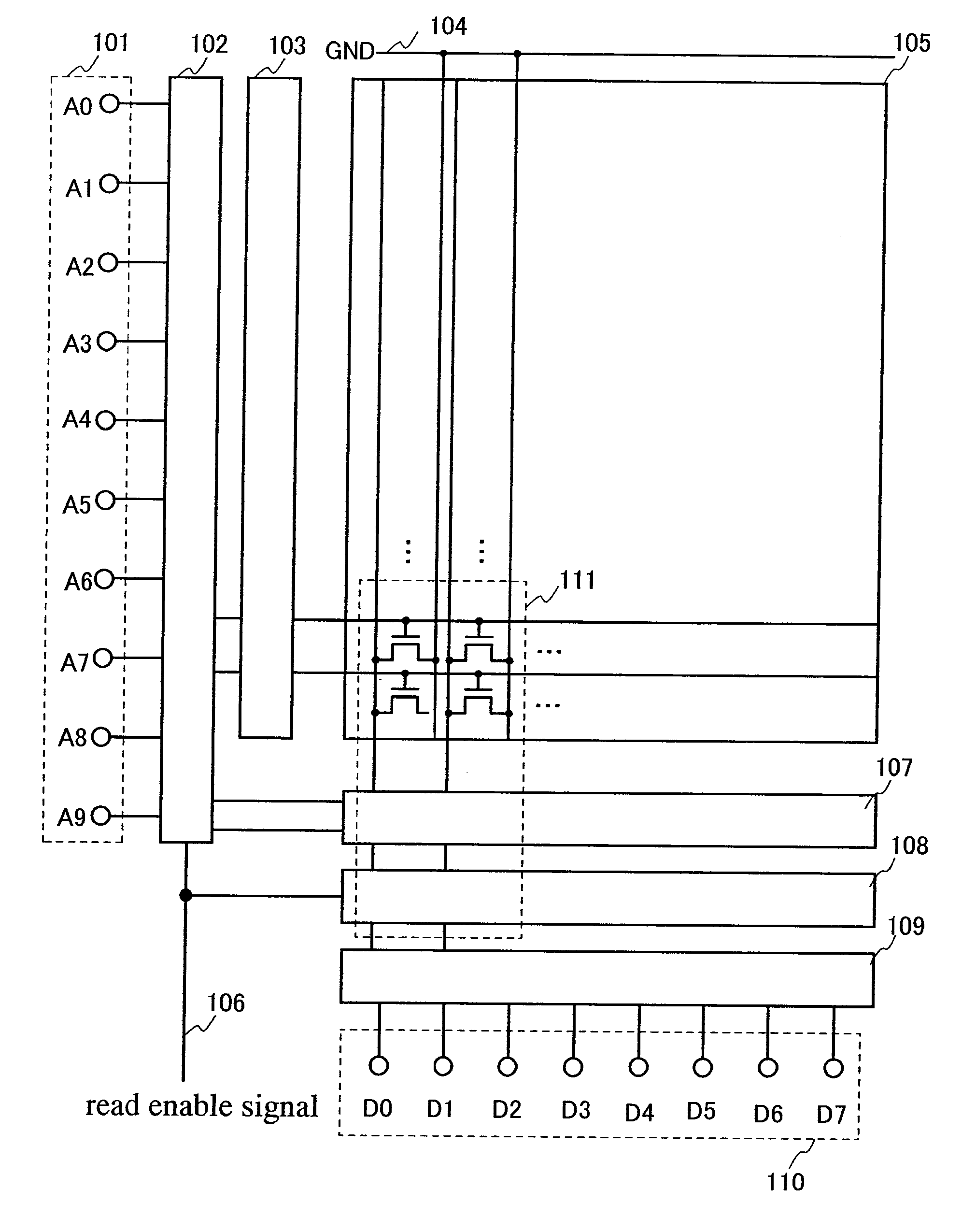

Semiconductor device and electronic device

InactiveUS7742351B2Increase valueAppropriate performanceSolid-state devicesSemiconductor/solid-state device manufacturingBit lineHemt circuits

In relation to reading of data in a memory, it is an object to provide a semiconductor device mounted with a low power consumption memory. A semiconductor device including a word line, a bit line, and a memory cell electrically connected to the word line and the bit line, further includes a precharge circuit for making the bit line have an electric potential for reading data stored in the memory cell. The precharge circuit is provided for each bit line and connected to the bit line. Further, the precharge circuit is capable of making each bit line have an electric potential for reading the data stored in the memory cell for each bit line.

Owner:SEMICON ENERGY LAB CO LTD

Catalyst with Cu being loaded for taking off waste gas containing HCN and its preparing method as well as application

InactiveCN1462652AGood dispersionGive full play to the catalytic advantagesDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTarMixed gas

A carried Cu catalyst for removing the HCN contained waste gas contains Cu and Al2O3 in Wt ratio of (2.96-5.92):100. Its preparing process includes adding Cu(NO3)2 solution to Al2O3 carrier, immersing, drying, calcining and H2 reducing. Its application method includes loading said catalyst into reaction furnace, heating to 150-300 deg.C, introducing the mixed gas containing HCN, NH3, tar and air to said reaction furnace, and catalytic combustion. Its advantages are simple operation etc.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

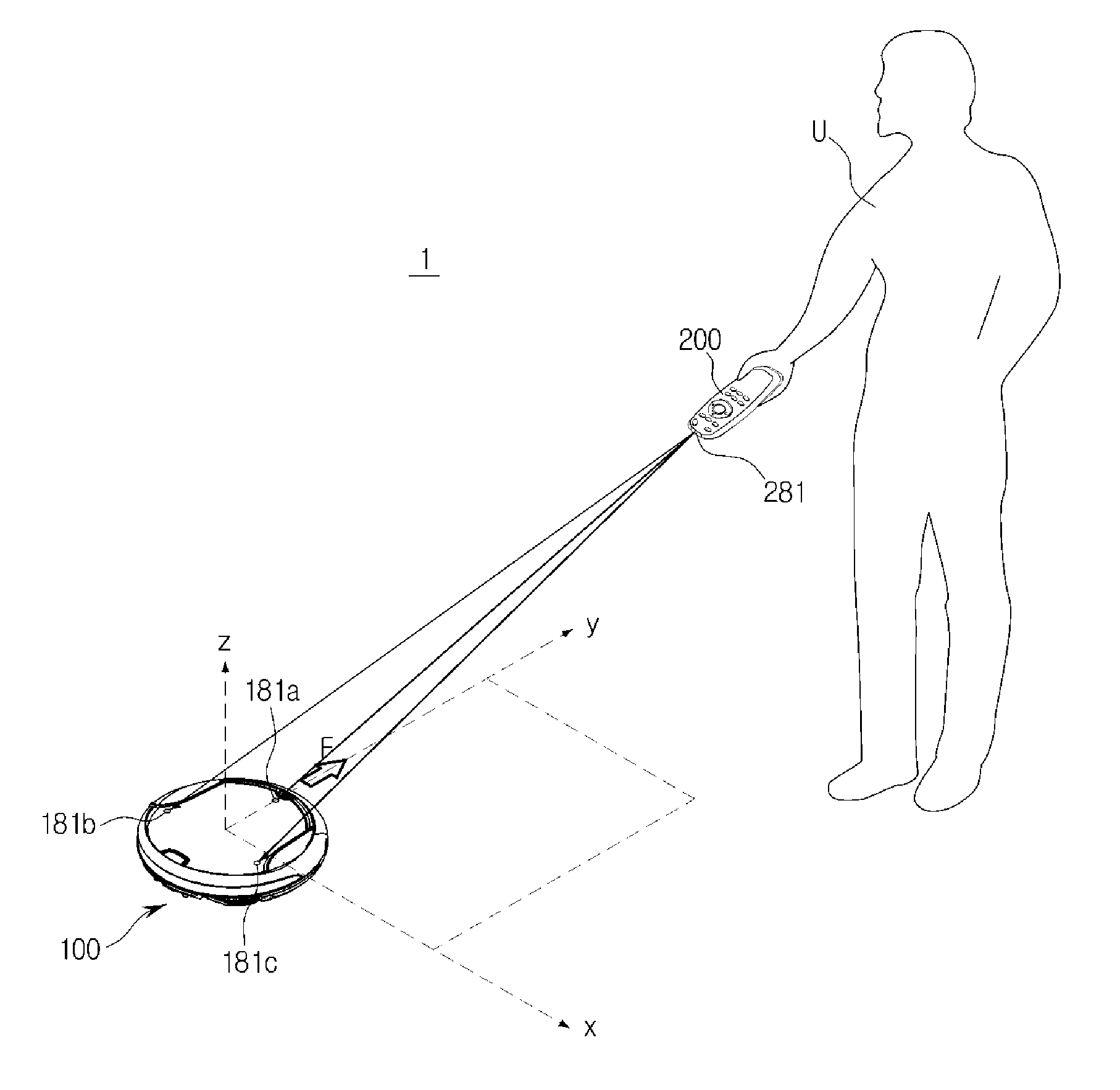

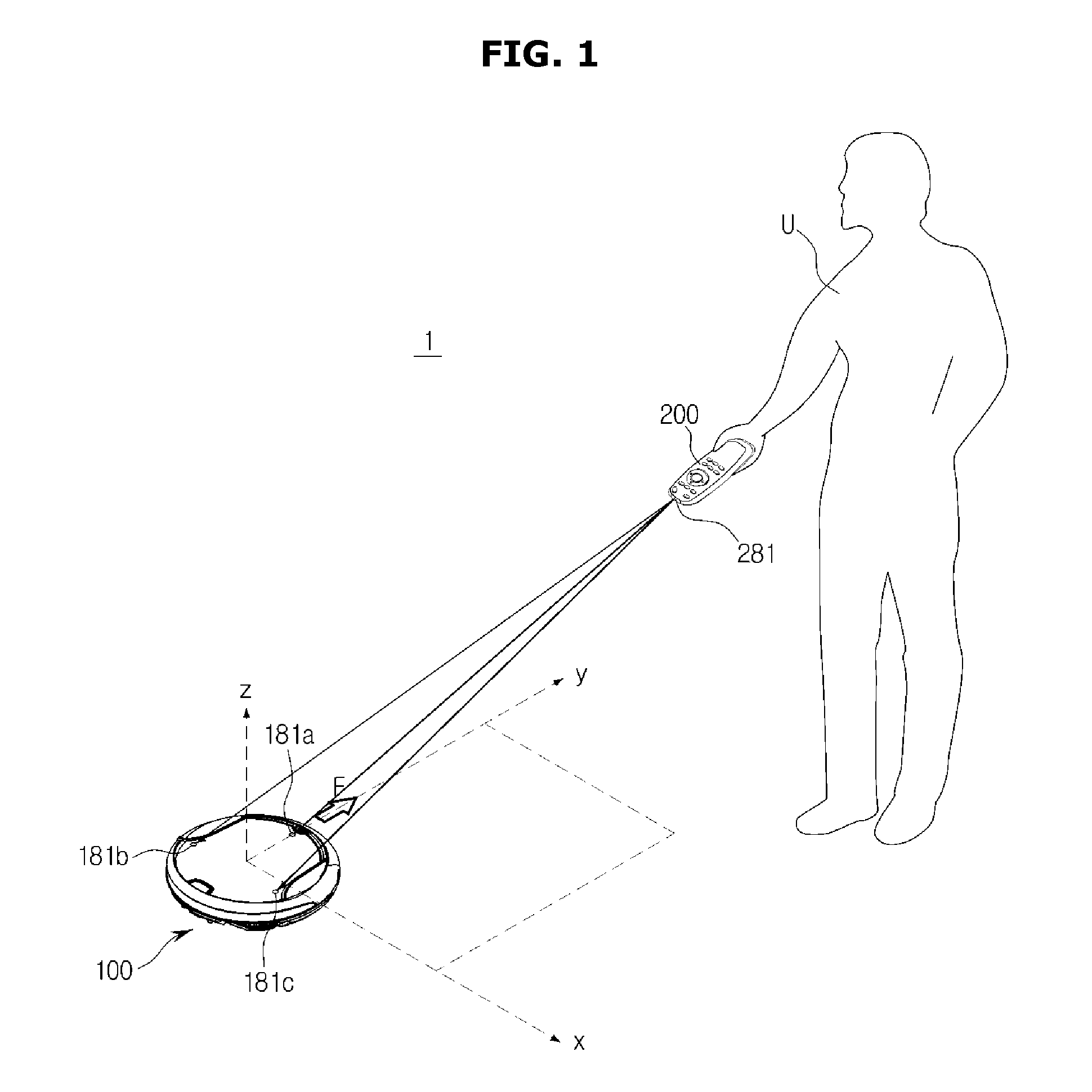

Cleaning robot

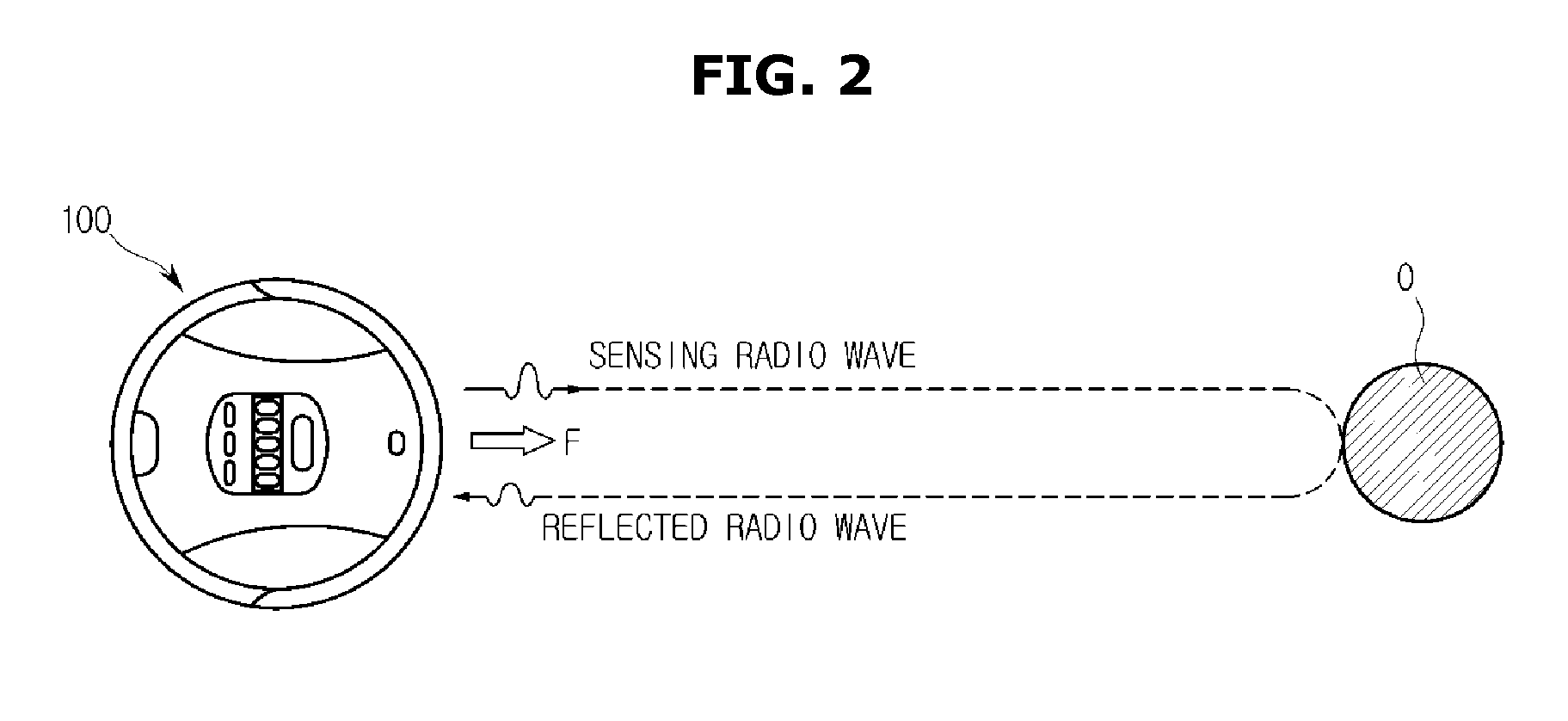

ActiveUS20160274580A1Not easy to changeAutomatic obstacle detectionTravelling automatic controlTime differenceEngineering

Provided is a cleaning robot including a main body; a driving unit configured to move the main body; a communication unit configured to establish wireless communication with a user terminal to which a manipulation command is input; and a controller configured to transmit a position detecting signal to the user terminal, and detect a position of the user terminal based on a time difference between the position detecting signal and a response signal transmitted from the user terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

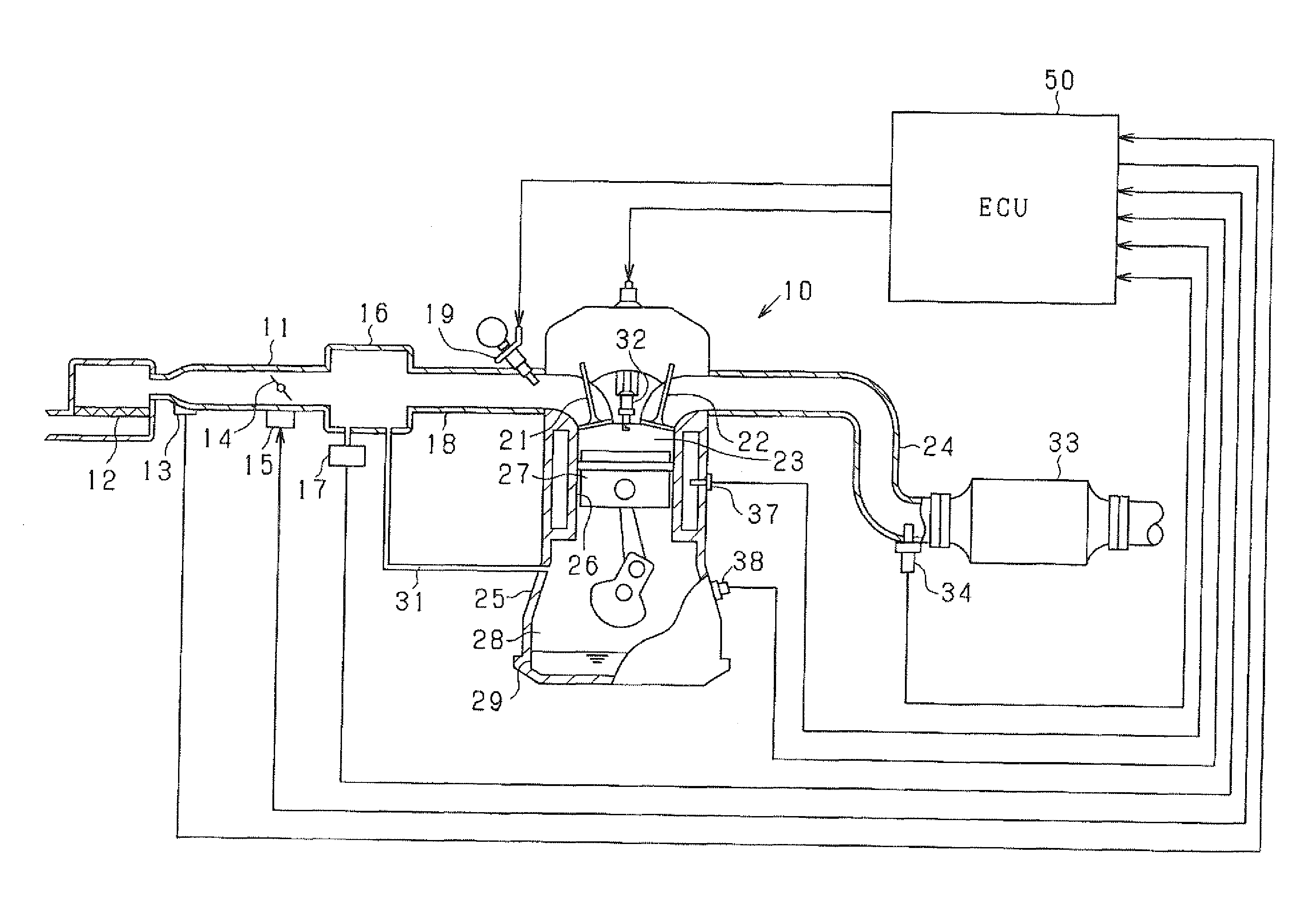

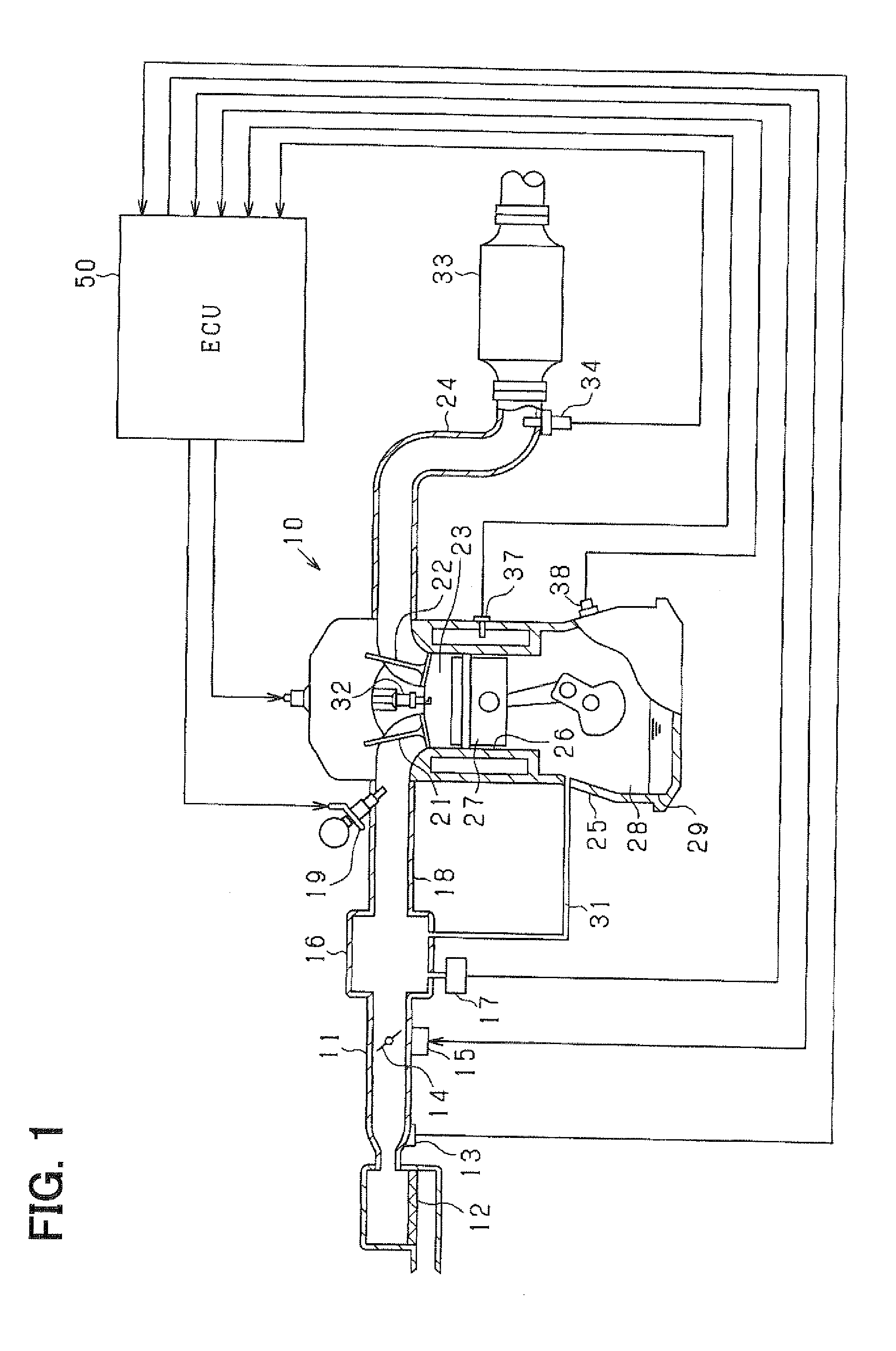

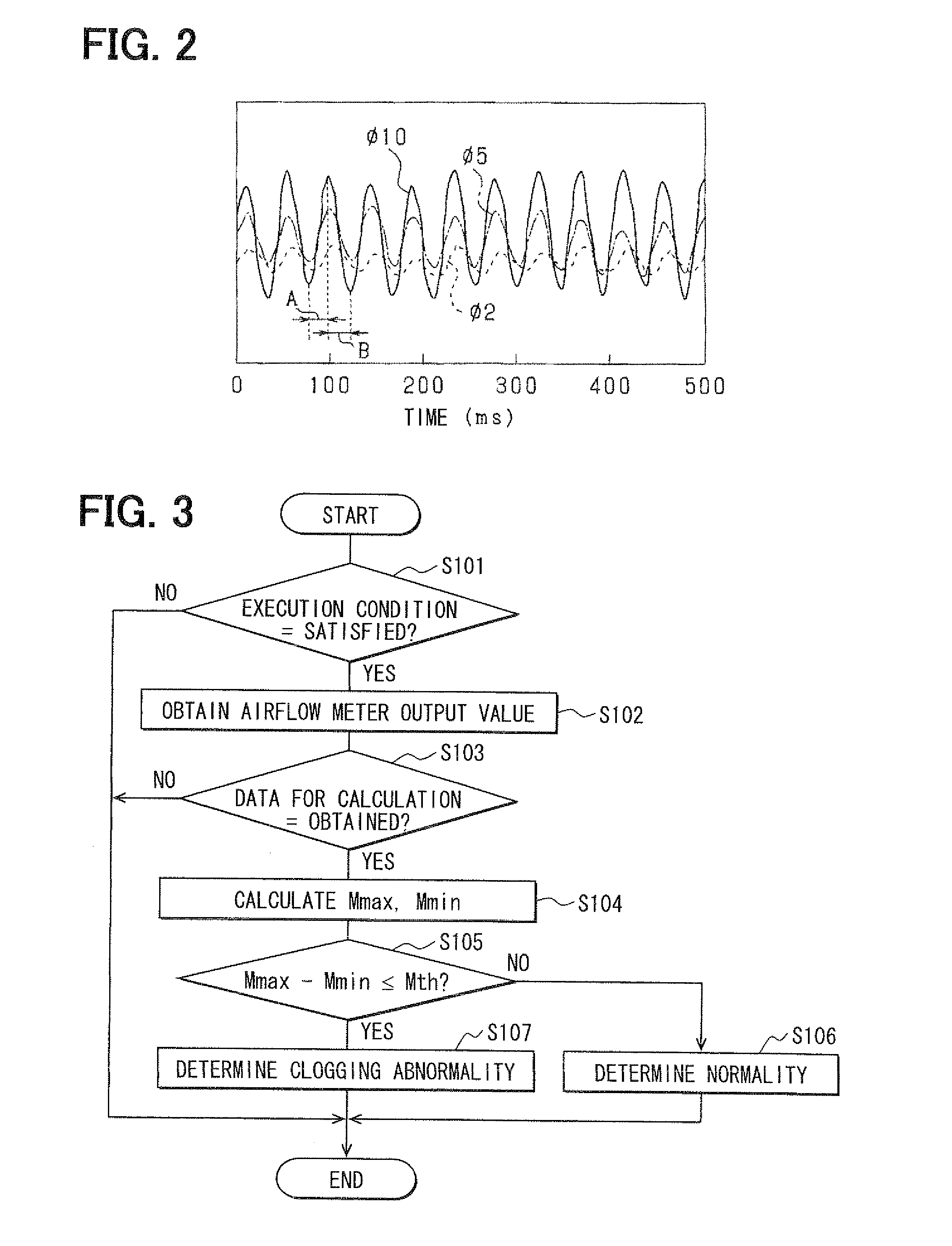

Abnormality diagnosis device of internal combustion engine

ActiveUS20110023852A1Improve responseImprove sensing accuracyAnalogue computers for vehiclesInternal-combustion engine testingExternal combustion engineEngineering

An engine has a PCV passage connected to an intake system for recirculating a blow-by gas to the intake system and an air flow meter provided upstream of a connection between the PCV passage and the intake system in the intake system for sensing an intake air flow rate. An electronic control unit (ECU) performing various types of control of the engine diagnoses a clogging abnormality of the PCV passage based on pulsation width of the intake air flow rate sensed with the air flow meter. A thermal type sensor having a heating section and a temperature sensing section provided on a semiconductor substrate is used as the air flow meter.

Owner:DENSO CORP

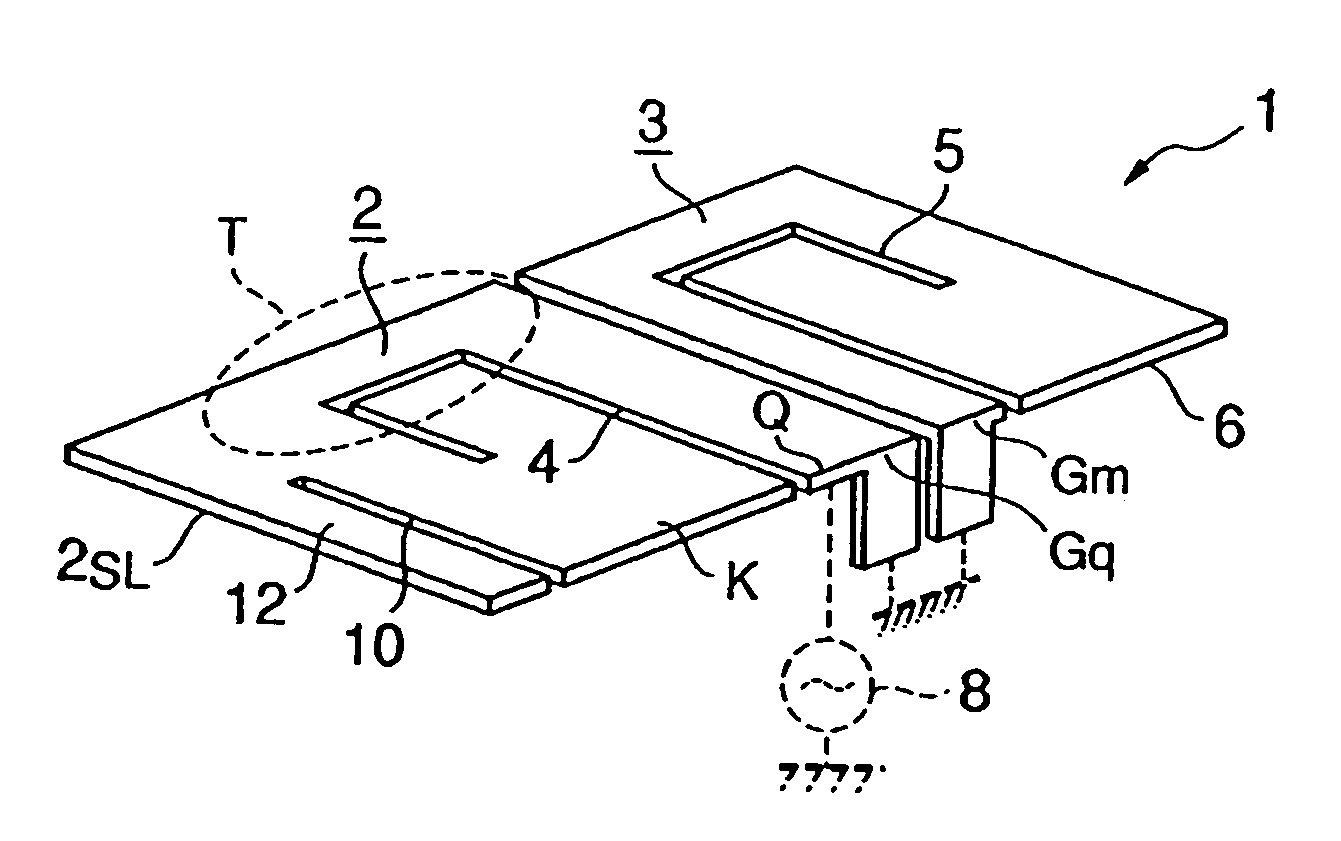

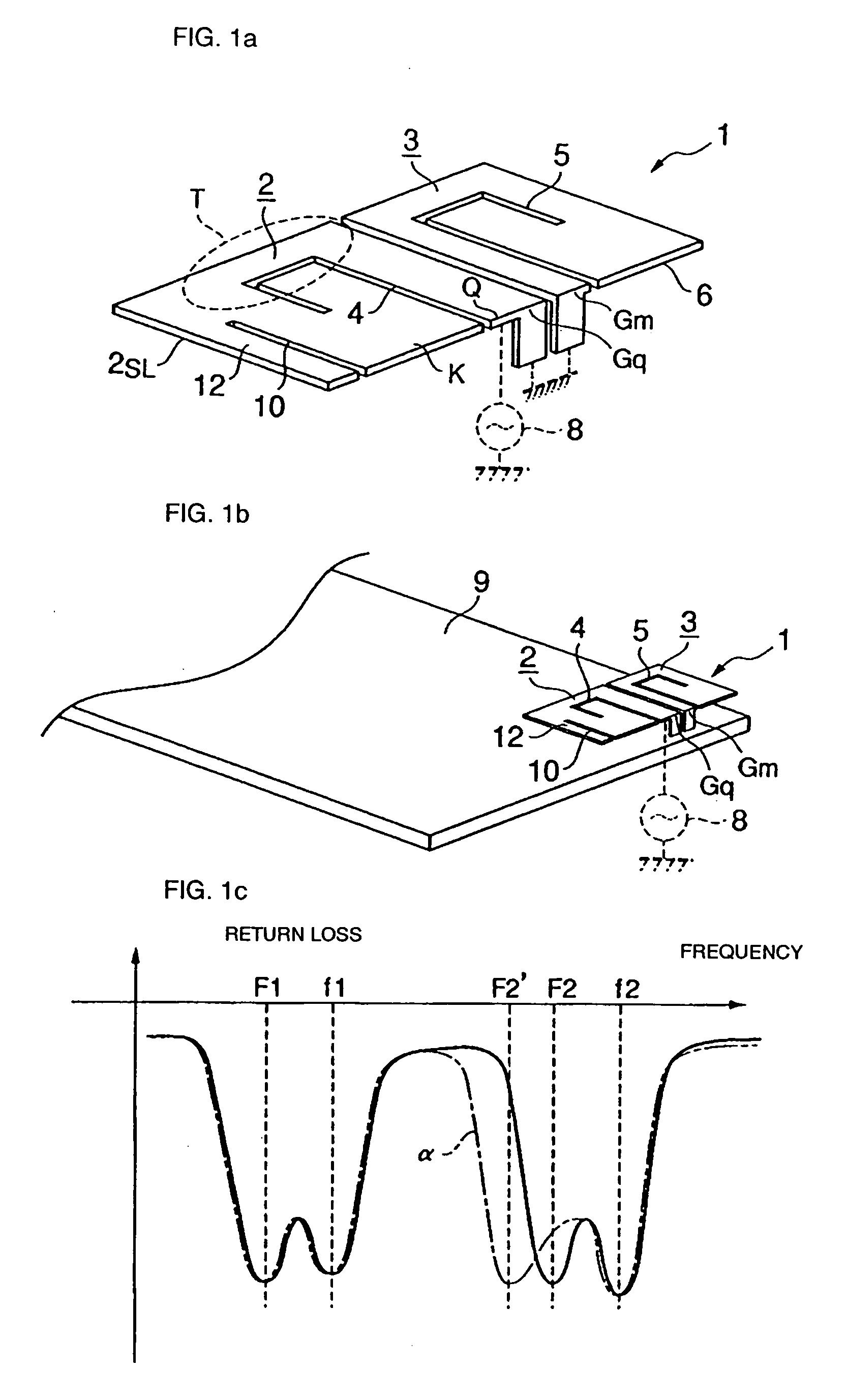

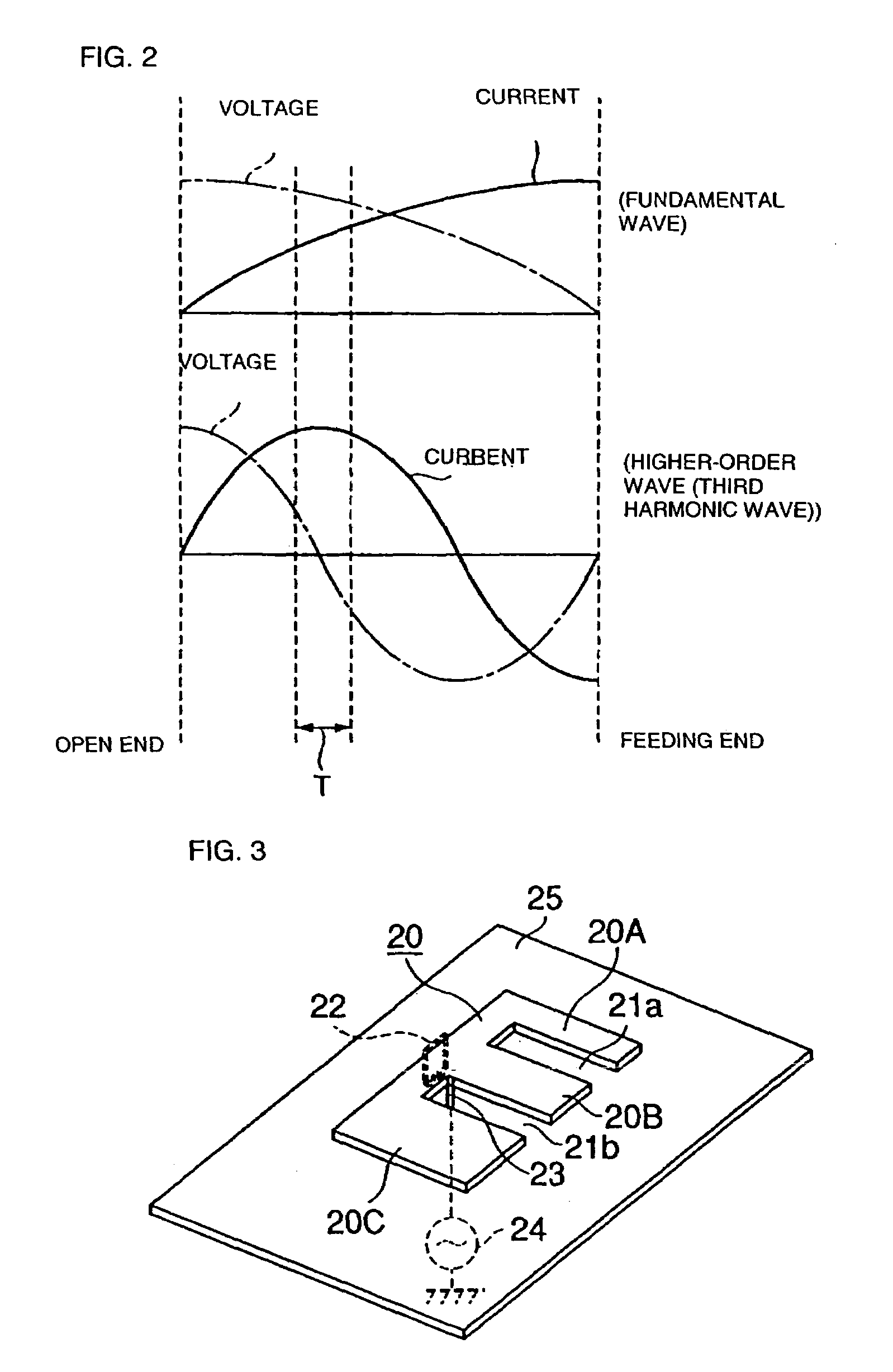

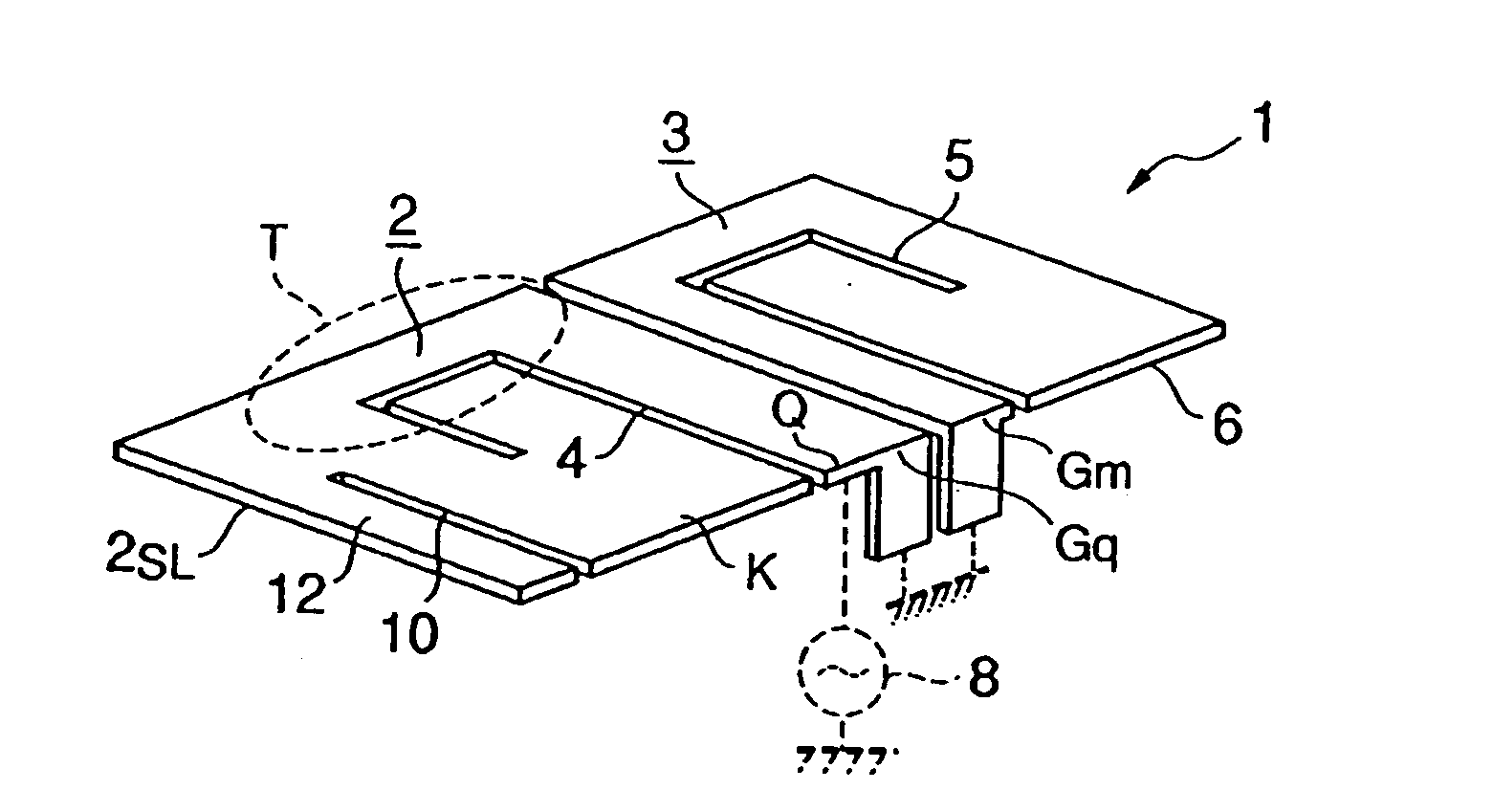

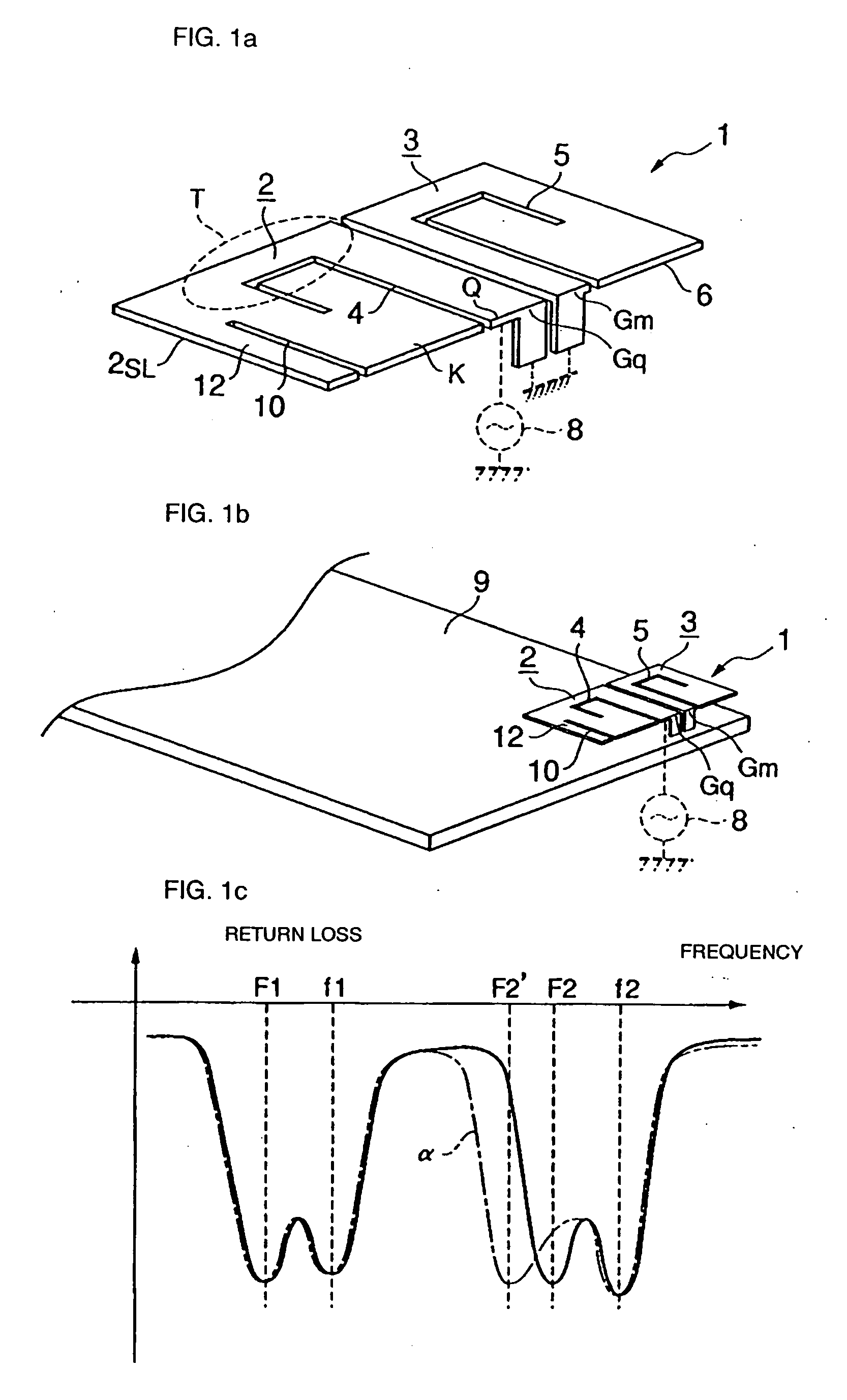

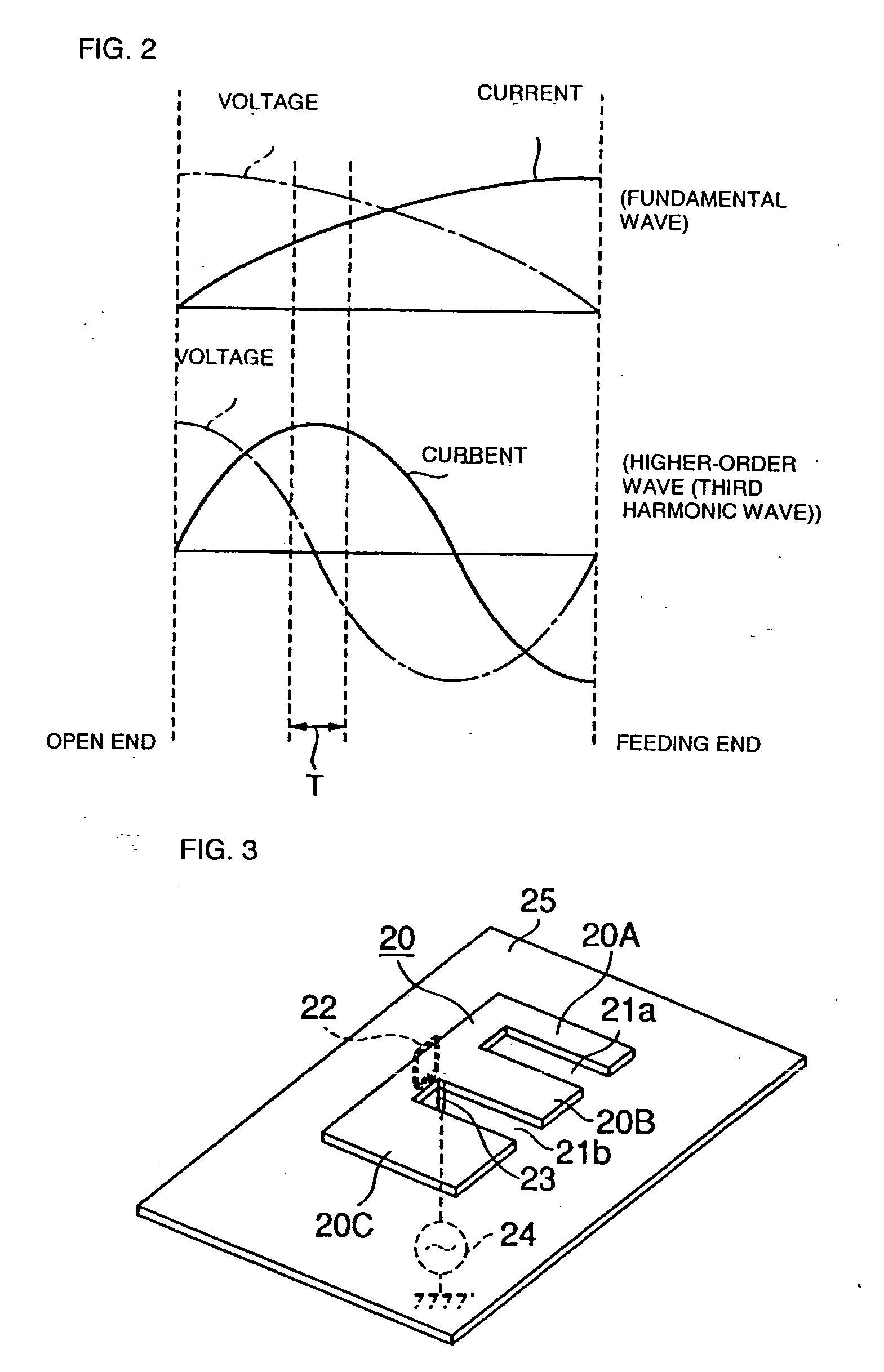

Antenna structure and communication apparatus including the same

InactiveUS7382319B2Easy to implementAvoiding reduction in an antenna gainSimultaneous aerial operationsAntenna supports/mountingsCapacitanceElectromagnetic coupling

In an antenna structure including a feeding radiation electrode and a non-feeding radiation electrode that are electromagnetically coupled to each other, due to formation of a main slit, the feeding radiation electrode includes a U-turn portion in the middle of a path circumventing the main slit from a feeding end to an open end. A sub-slit for forming an open stub that is connected to the U-turn portion and that provides the U-turn portion with electrostatic capacitance is formed in the feeding radiation electrode. By changing a value of the electrostatic capacitance to be provided by the open stub to the U-turn portion of the feeding radiation electrode, variable control of a higher-order resonant frequency F2 of the feeding radiation electrode 2 can be achieved while suppressing fluctuations in a resonant state (for example, a fundamental resonant frequency F1 and a Q-value) of a fundamental resonant frequency band of the feeding radiation electrode, in an electromagnetic coupling state between the feeding radiation electrode and the non-feeding radiation electrode, and in an impedance matching state.

Owner:MURATA MFG CO LTD

Prepn and application of catalyst for eliminating HCN-containing waste gas

InactiveCN1416950AGive full play to the catalytic advantagesLow costDispersed particle separationCatalyst activation/preparationTarProcess engineering

The catalyst for eliminating HCN-containing waste gas is prepared via dissolving H2PtCl6.6H2O in H2O, impregnating Al2O3 carrier in H2PtCl.6H2O solution, drying calcinating and reduction. When it is used, the catalyst is loaded in reactor furnace, the temperature in the furnace is raised to 250-450 deg.c mixed gas contg. HCN, NH3, tar and air is introduced into the reactor furnace to eliminate waste gas via catalytic burning. The present invention has the advantages of simple preparation process, low cost and simple operation.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

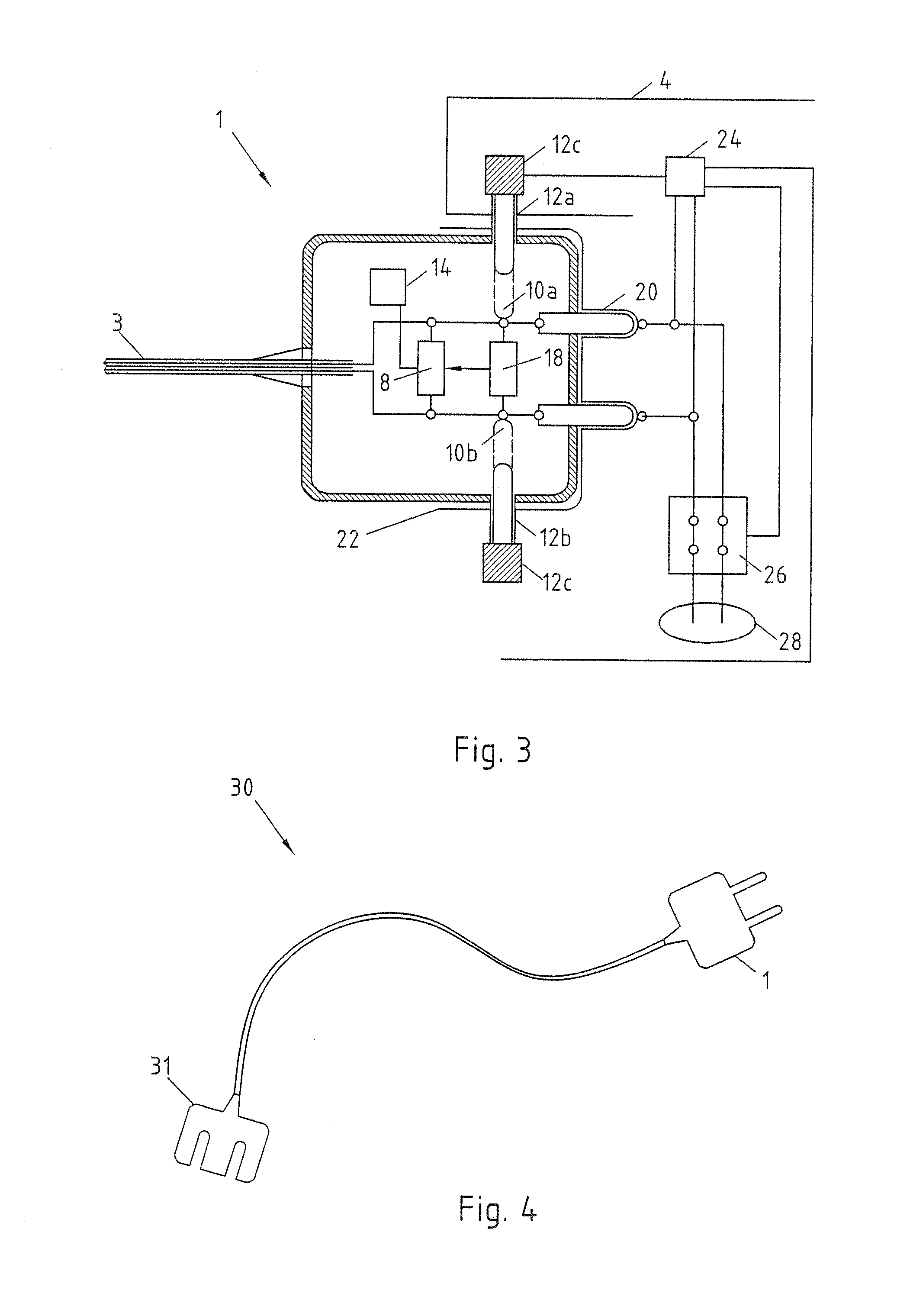

Charging cable plug for electric vehicles

InactiveUS20120135634A1Low costNot easy to changeElectrically conductive connectionsCharging stationsCharging stationElectrical contacts

Charging cable plug 1 for electric vehicles, with a housing 2 and electrical contacts 6, arranged in the housing 2, for connection to a charging station 4. For simple identification before a charging procedure, an identification means 8 is proposed, arranged in the housing 2 and communicating with the charging station 4 via the electrical contacts 6.

Owner:INNOGY SE

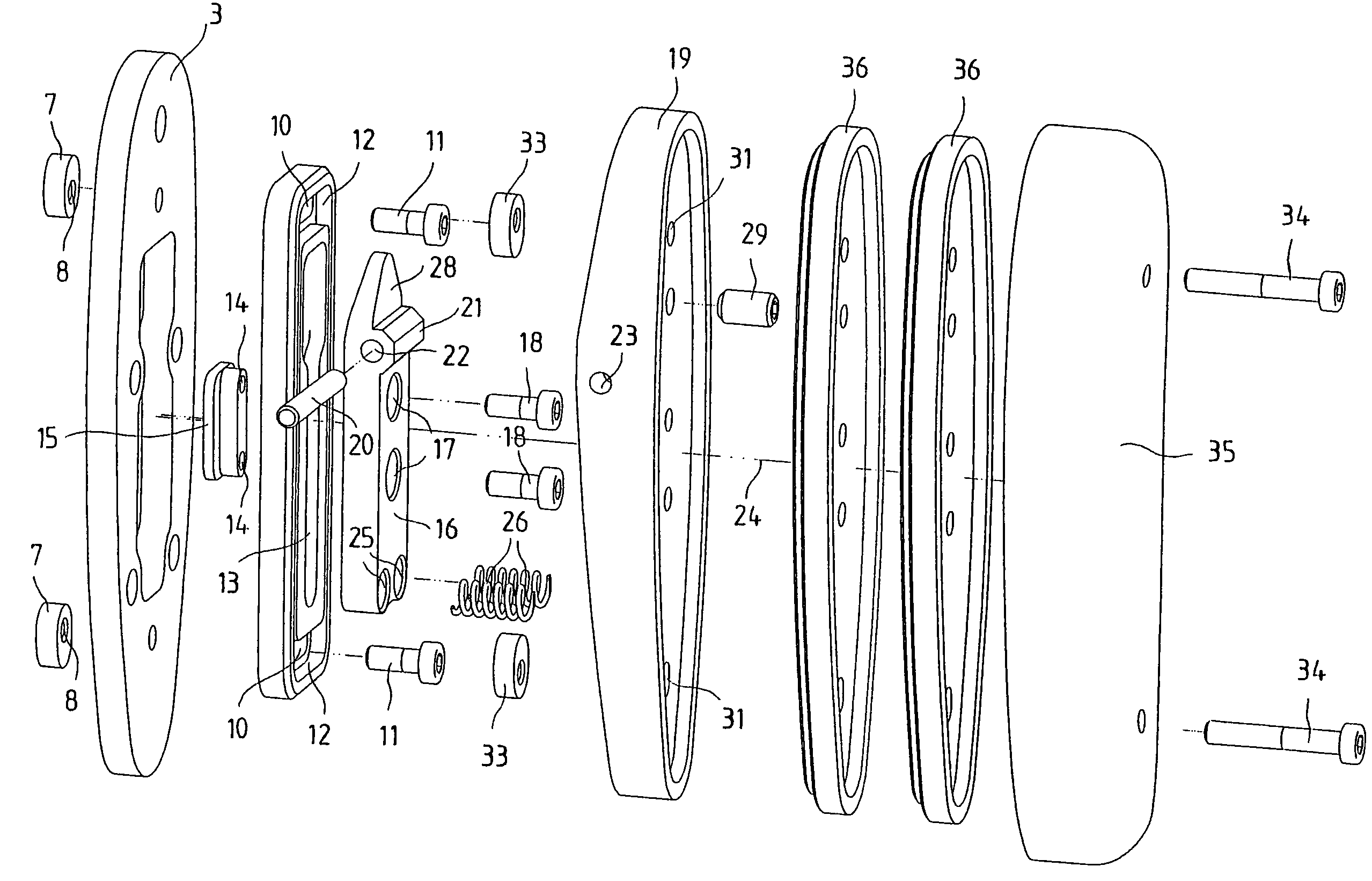

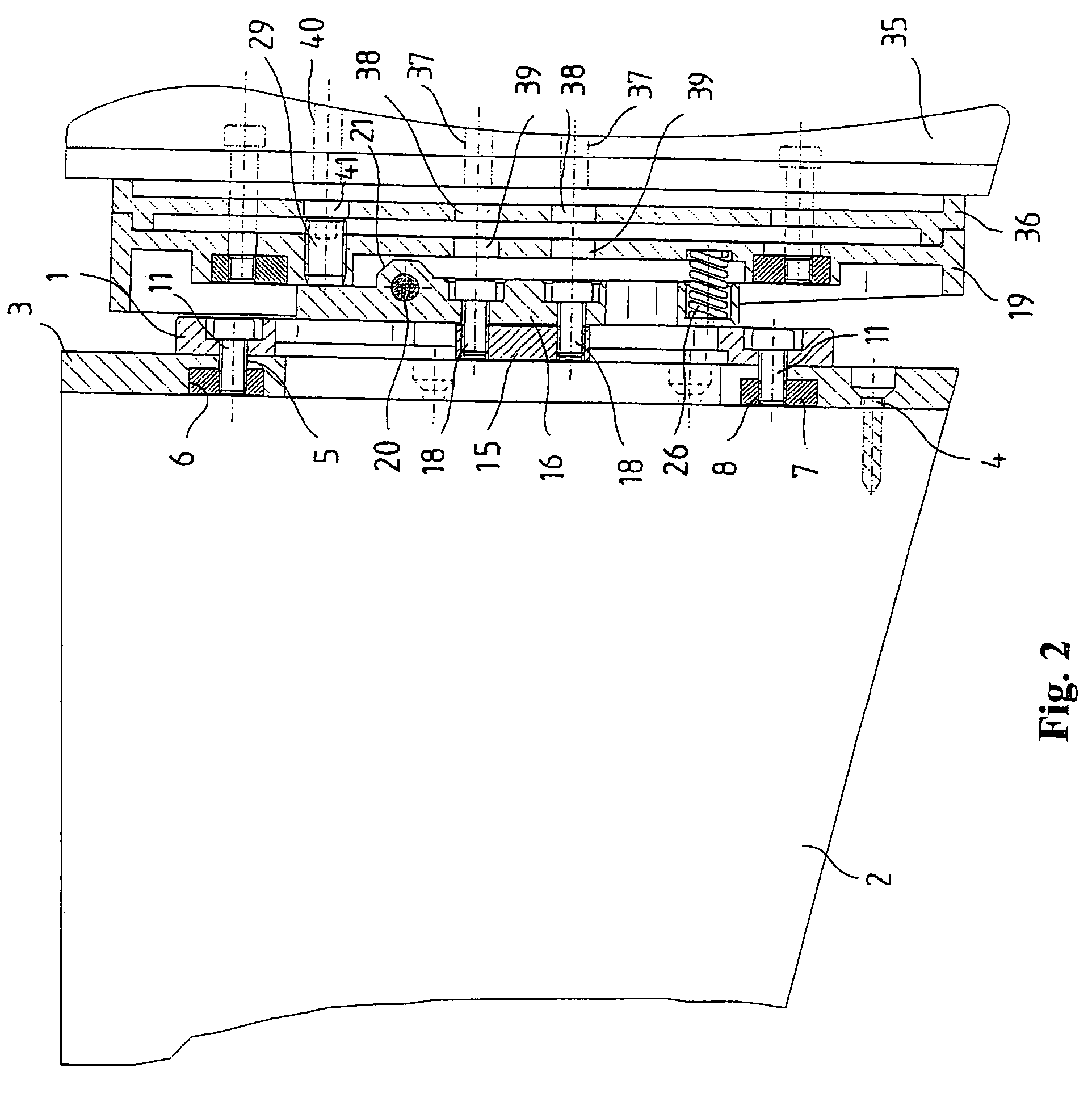

Adjustable recoil pad for a small arm

The invention concerns an adjustable recoil pad for a small arm, in particular, a rifle, with a base plate that can be adjustably affixed to a stock part of the small arm, a bottom plate which is adjustably mounted on the base plate, and at least one end part that can be affixed to the bottom plate. A simplified adjustment with a large number of adjustment possibilities is made possible in that the bottom plate is arranged so it can swivel about a transverse axis on a connecting piece, which is displaceably guided via guide elements on the base plate, and can be affixed in a desired position by at least one retaining screw.

Owner:BLASER FINANZHLDG

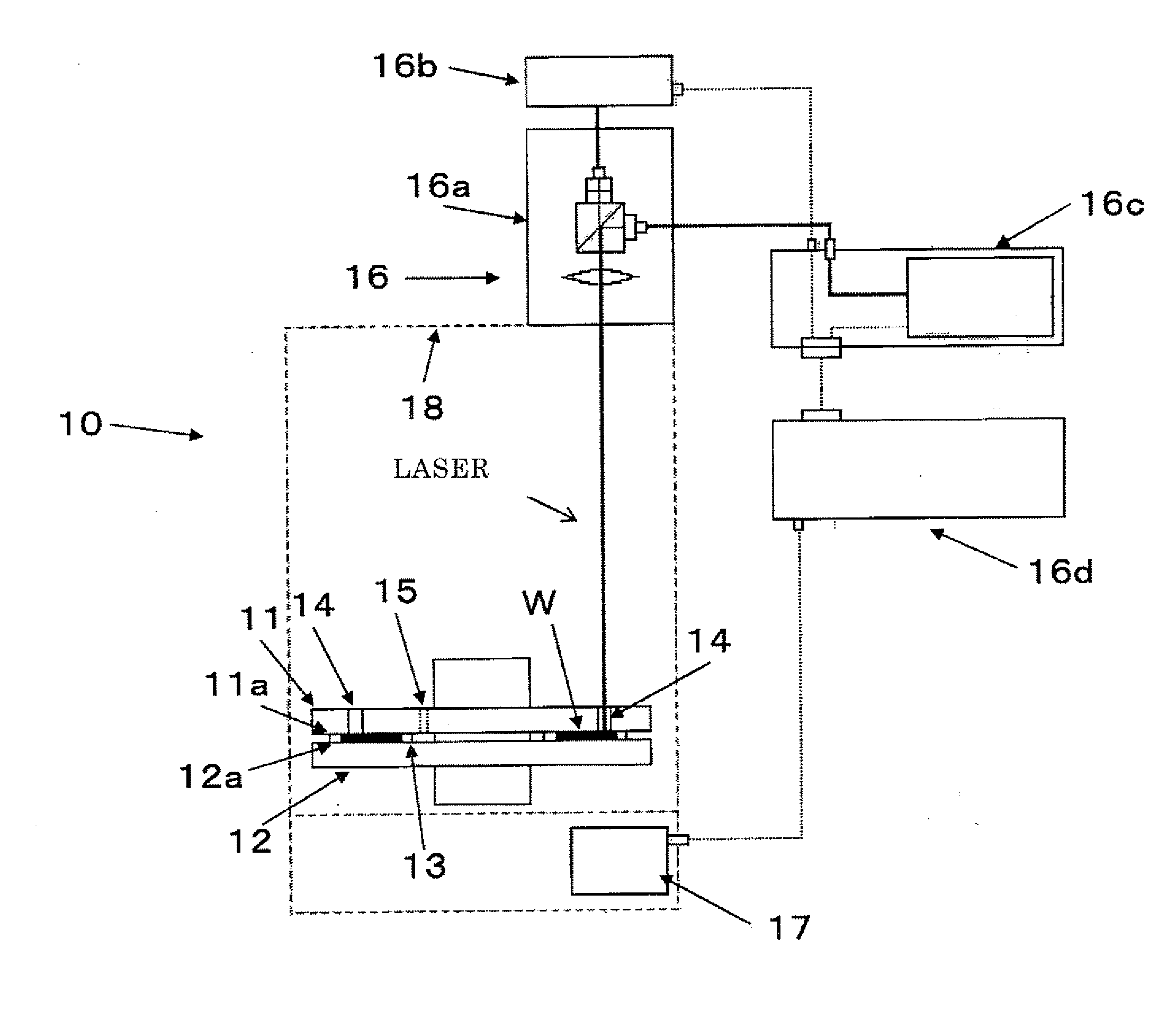

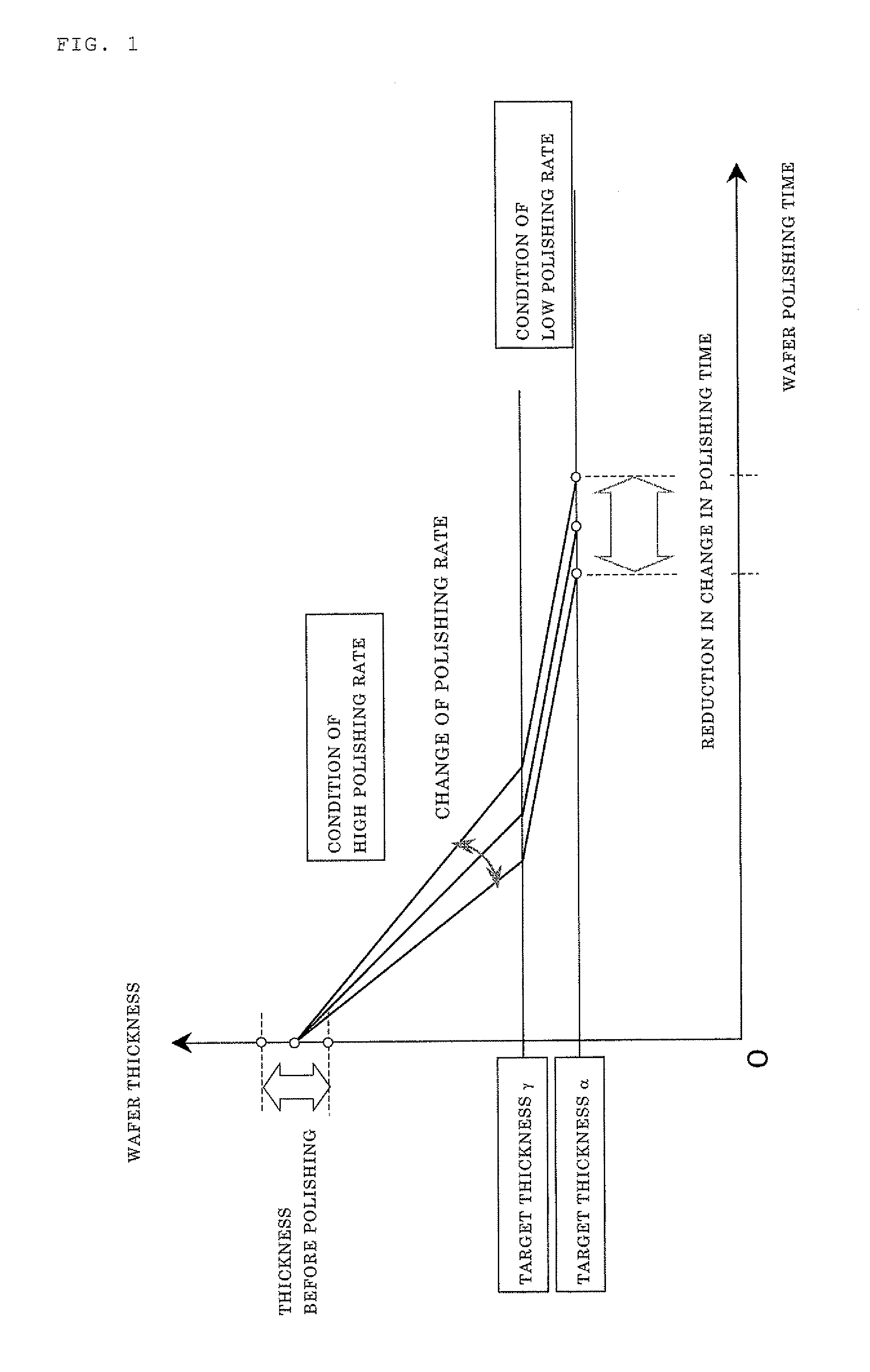

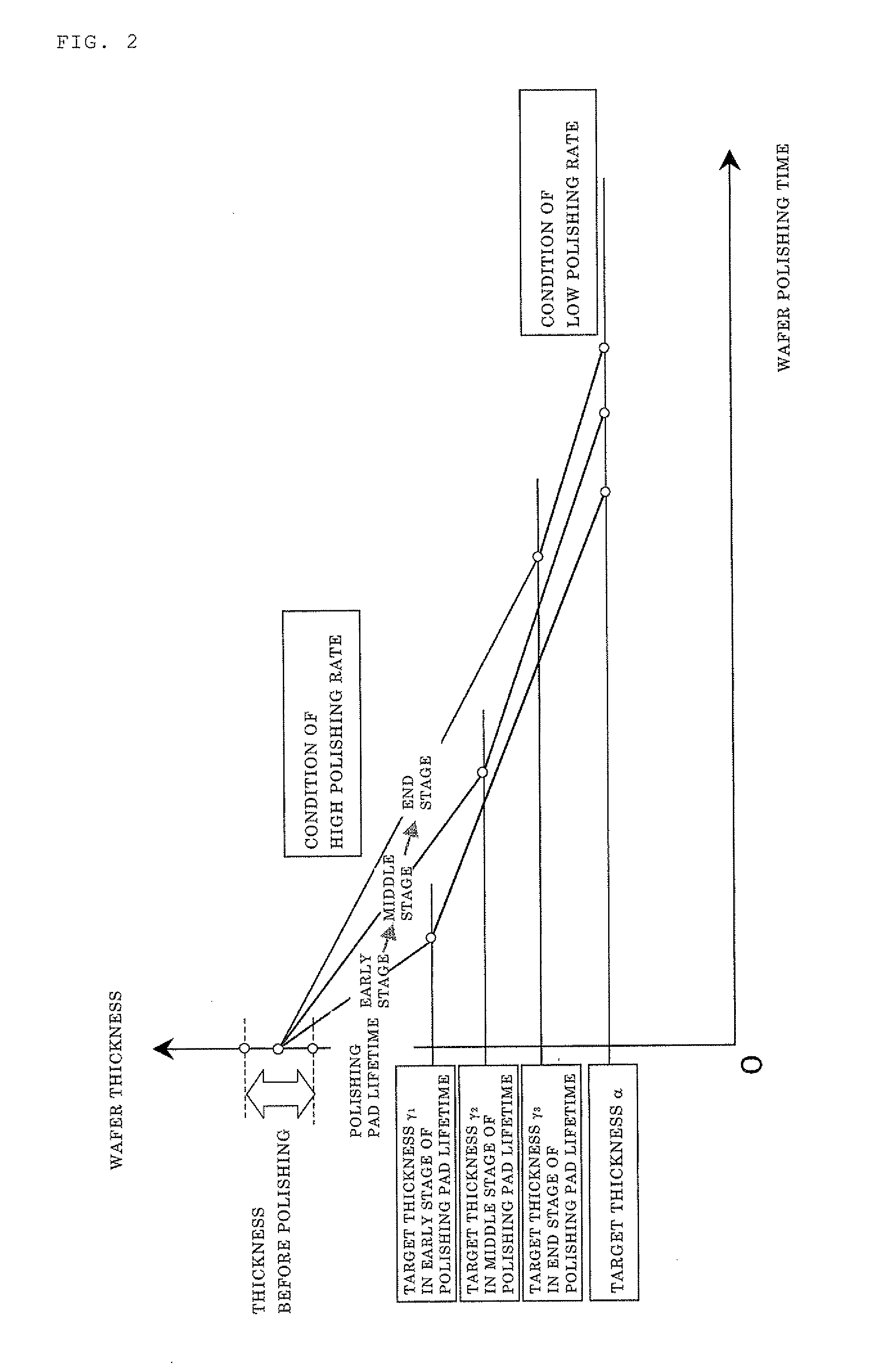

Wafer polishing method and double-side polishing apparatus

ActiveUS20110130073A1Easy to getImprove flatnessEdge grinding machinesSemiconductor/solid-state device testing/measurementWaferingPolishing

The present invention is a wafer polishing method including simultaneously polishing both surfaces of a wafer by pressing and rubbing the wafer, while holding the wafer with: a lower turn table having a flat polishing-upper-surface rotationally driven; an upper turn table having a flat polishing-lower-surface rotationally driven, the upper turn table being arranged with facing to the lower turn table; and a carrier having a wafer-holding hole for holding the wafer, wherein the polishing is performed while measuring a thickness of the wafer through a plurality of openings provided between a rotation center and an edge of the upper turn table or the lower turn table, and switching a polishing slurry with a polishing slurry having a different polishing rate during the polishing of the wafer. As a result, there is provided a wafer polishing method that can manufacture a wafer having a high flatness and a high smoothness at high productivity and high yield.

Owner:SHIN-ETSU HANDOTAI CO LTD

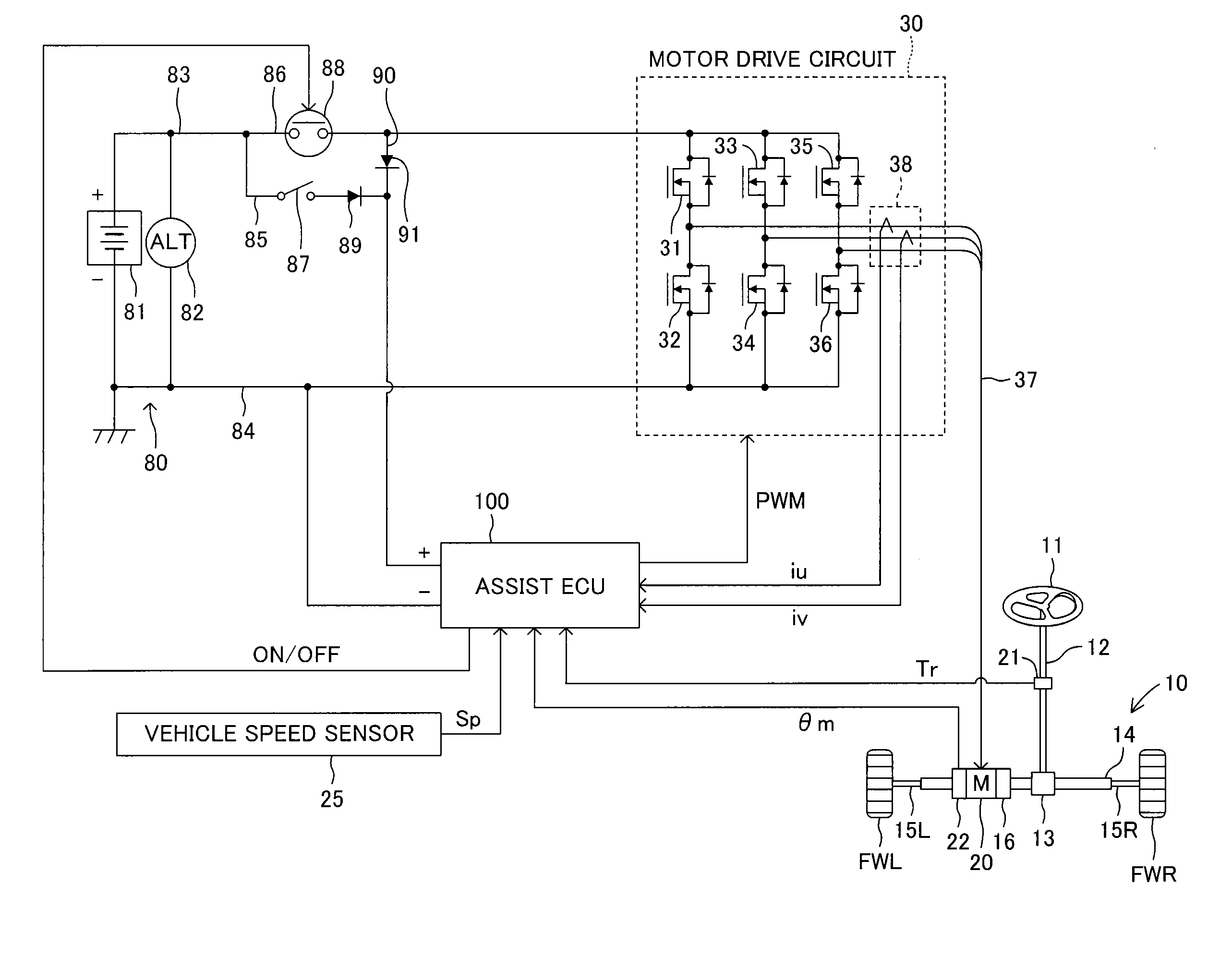

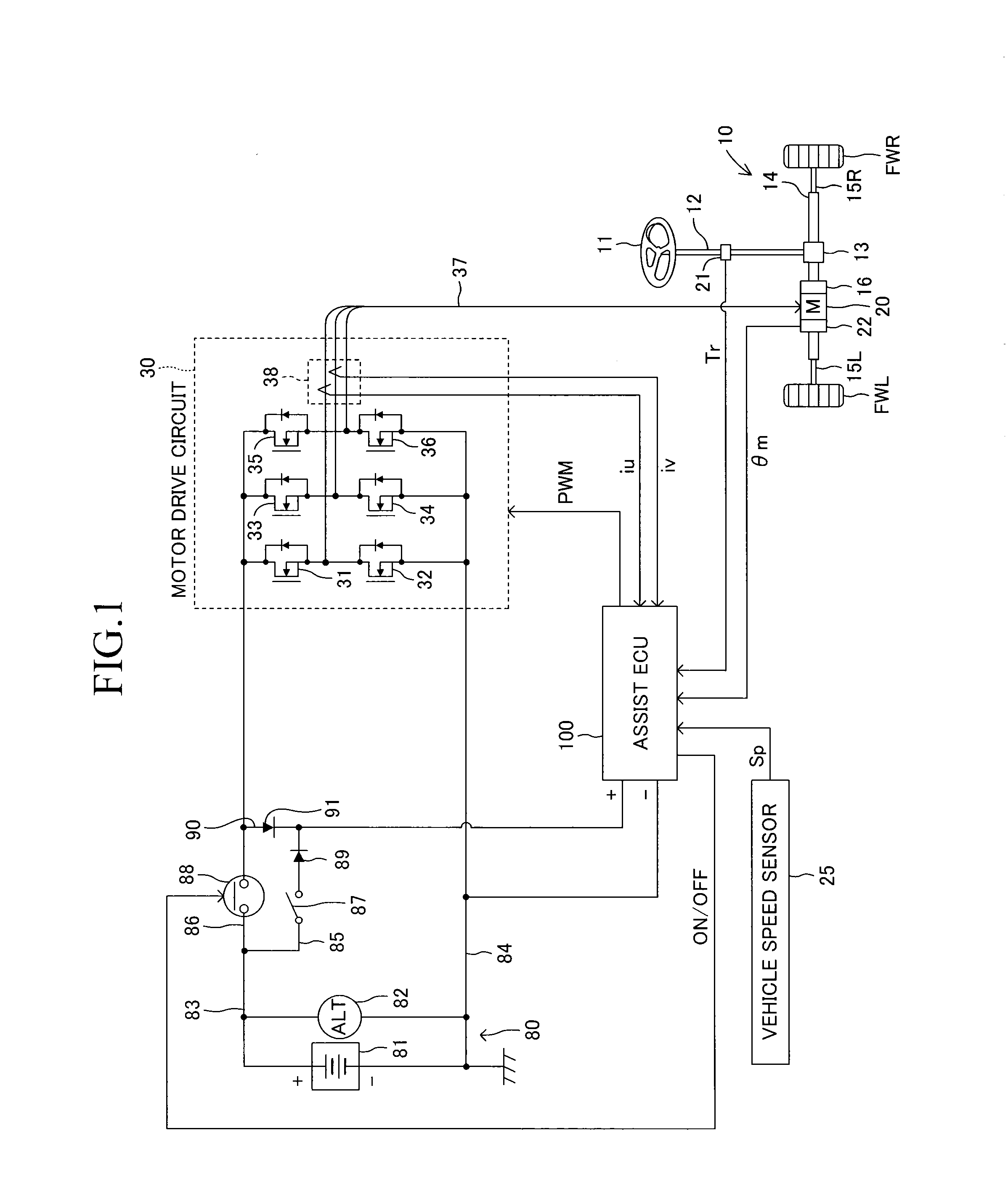

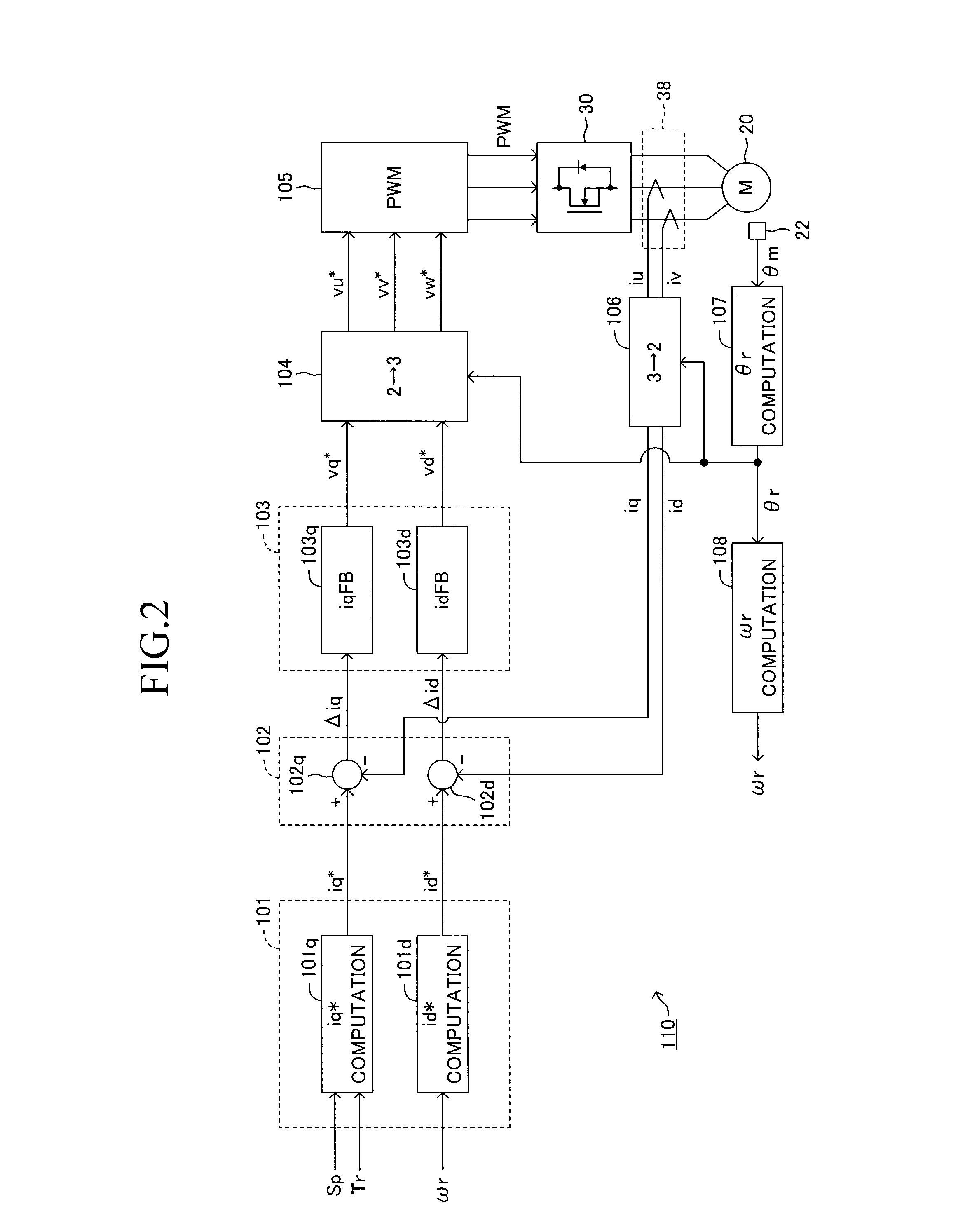

Electric power steering system

InactiveUS20130013154A1Improve performanceTorque can be increasedAC motor controlVector control systemsElectric power steeringDriver circuit

A feedforward control section computes, on the basis of a target current absolute value, a voltage limit value of a motor drive circuit, and a rotational speed ωr of a motor, a phase angle of a voltage vector which represents the output voltage of the motor drive circuit by a d-q coordinate system, the phase angle being a phase angle in relation to the d-axis of the d-q coordinate system. A feedback control section computes a phase angle based on a deviation between the target current absolute value and the actual current absolute value. A PWM control signal generation section outputs PWM control signals such that the motor drive circuit outputs a three-phase drive voltage whose electrical angle is advanced by a phase angle. Thus, in the case where a large reverse input is applied to a steering mechanism, the motor is caused to generate a large torque to thereby prevent the steering wheel from being rotated.

Owner:TOYOTA JIDOSHA KK

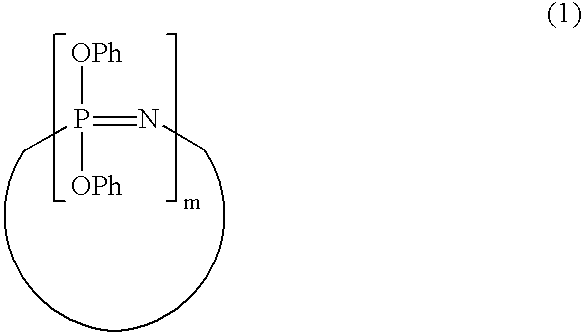

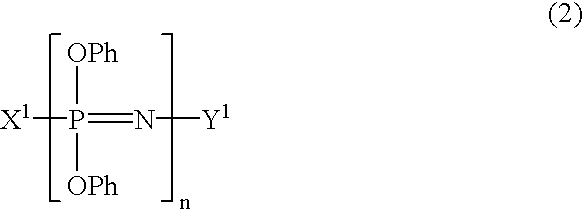

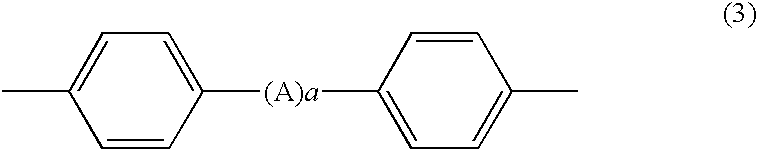

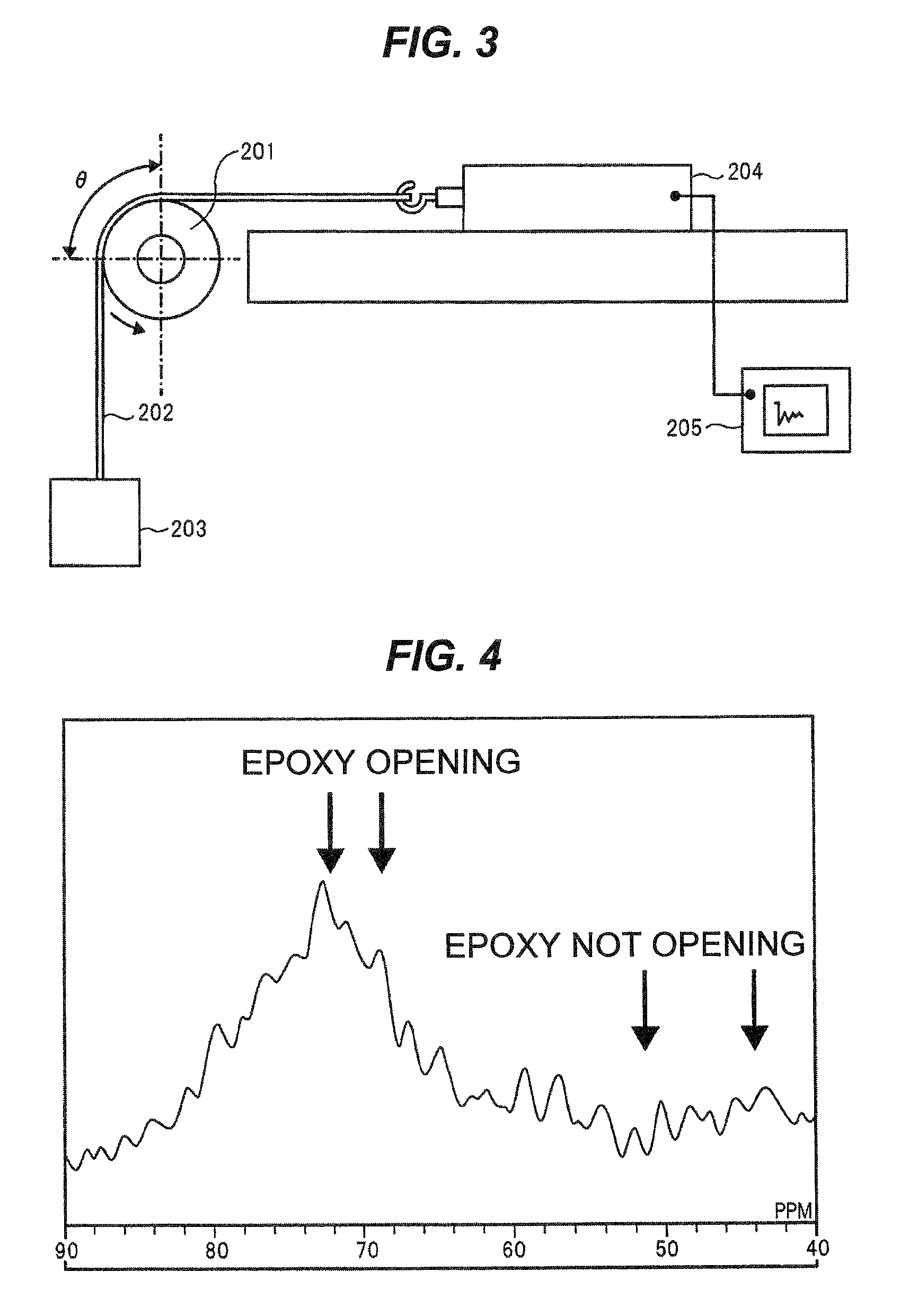

Process for producing phenoxyphosphazene compound, flame- retardant resin composition, and flame-retardant resin molding

InactiveUS20030040643A1Quality improvementIncrease resistanceGroup 5/15 element organic compoundsAlkanePolymer science

The phenoxyphosphazene compound of the present invention is prepared by treating a phenoxyphosphazene compound with (a) at least one adsorbent selected from activated carbon, silica gel, activated alumina, activated clay, synthetic zeolite and macromolecular adsorbents, (b) at least one reagent selected from metal hydrides, hydrazine, hypochlorites, thiosulfates, dialkyl sulfuric acids, ortho esters, diazoalkanes, lactones, alkanesultones, epoxy compounds and hydrogen peroxide or (c) both the adsorbent and reagent. Incorporation of the phenoxyphosphazene compound prepared by the process of the invention into a synthetic resin achives the following advantages: the synthetic resin can be prevented from discoloration; when the resultant resin composition is stored for a long time, the properties of the synthetic resin, such as heat resistance, weatherability, resistance to discoloration and chemical resistance are not deteriorated; and the resin composition gives a resin composition molded article excellent in properties such as flame retardancy, thermal stability, and moldability.

Owner:OTSUKA CHEM CO LTD

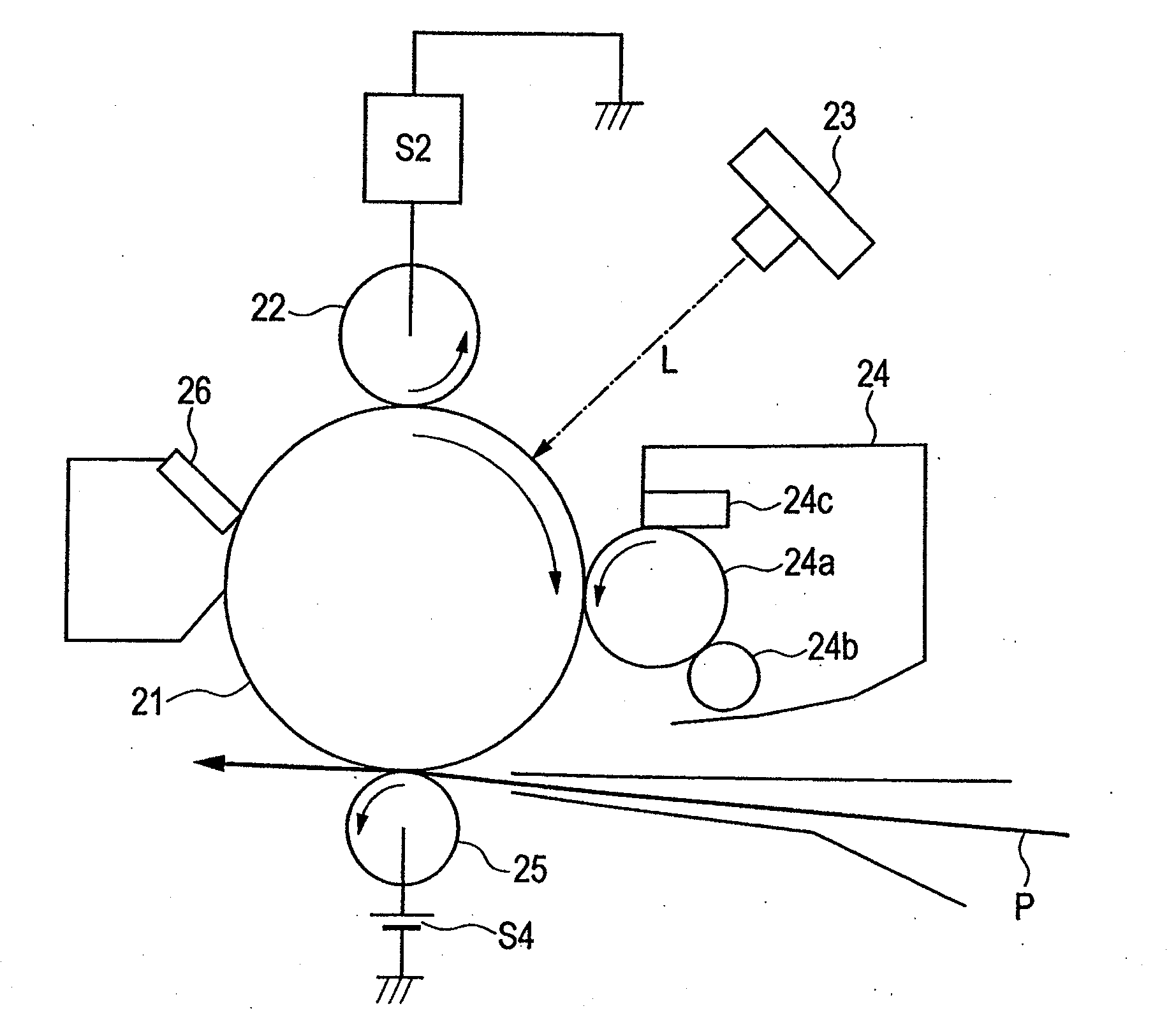

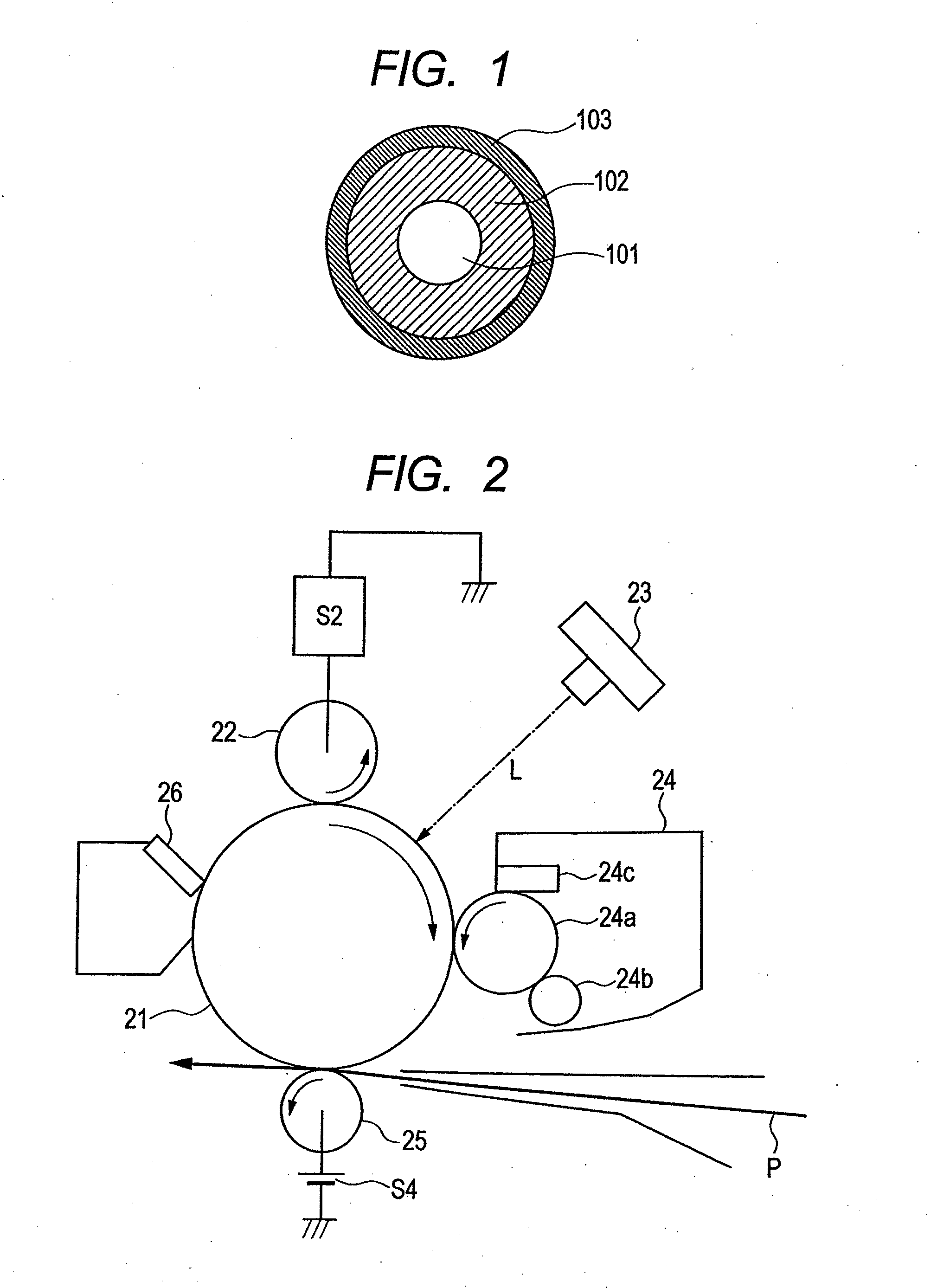

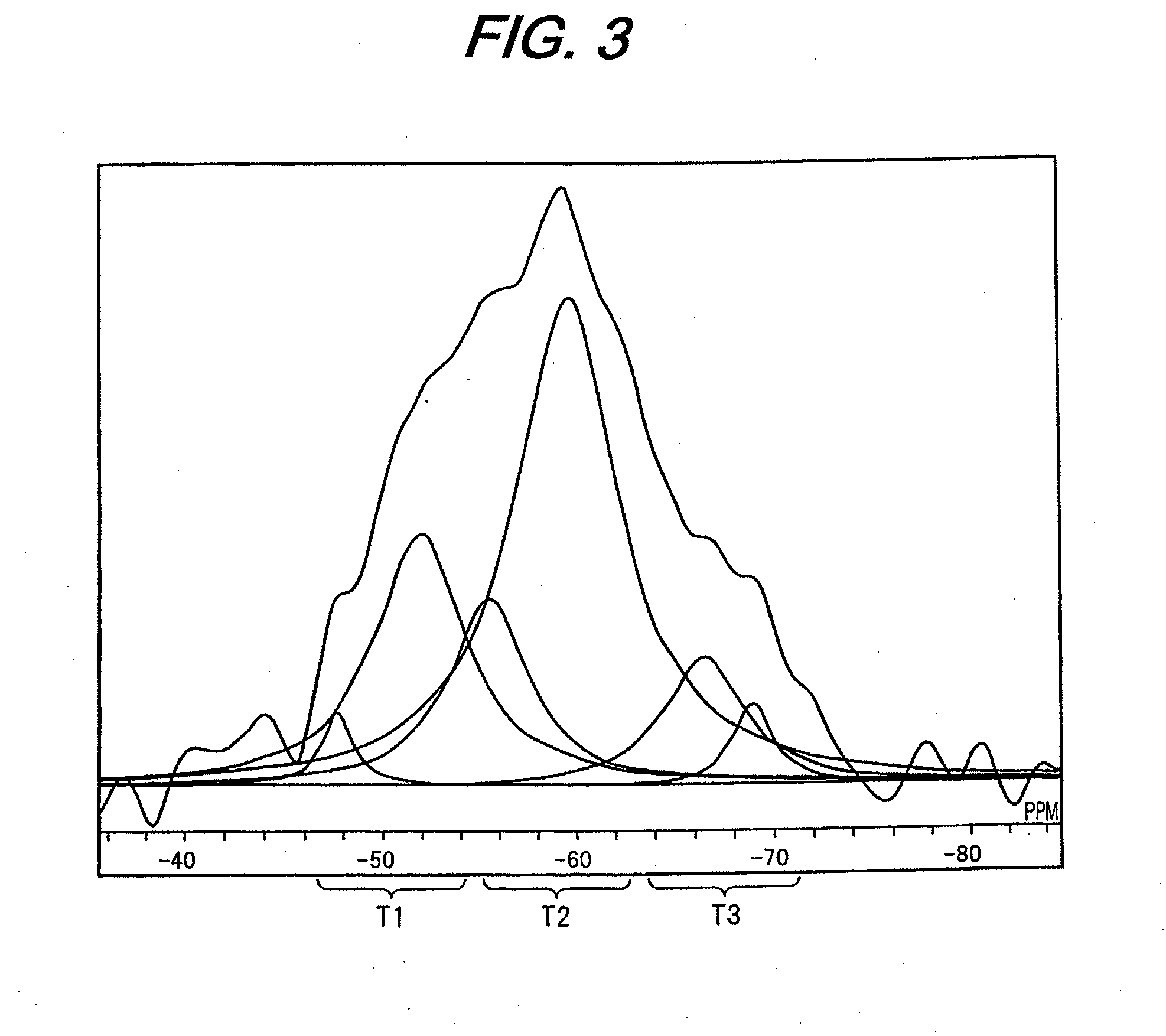

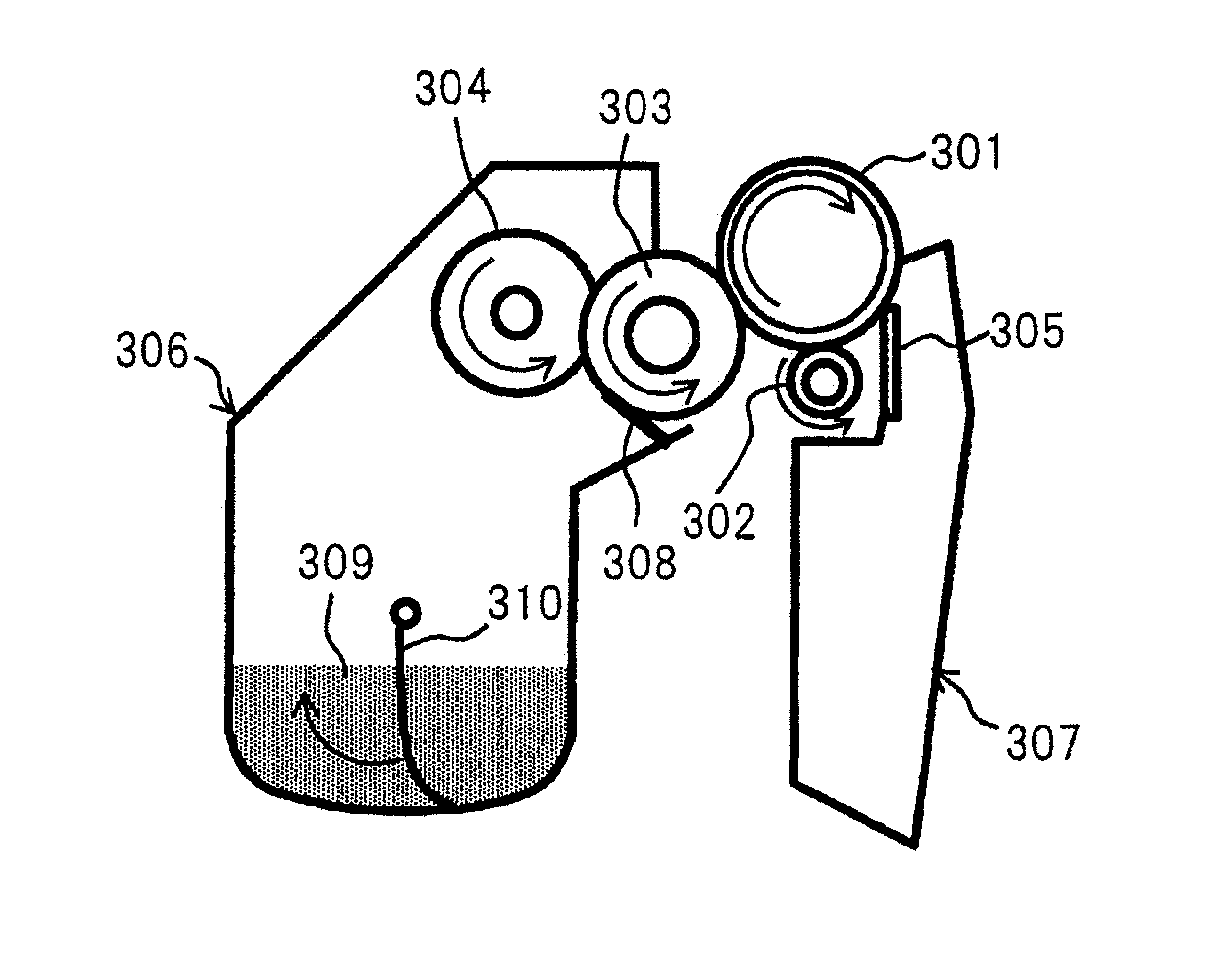

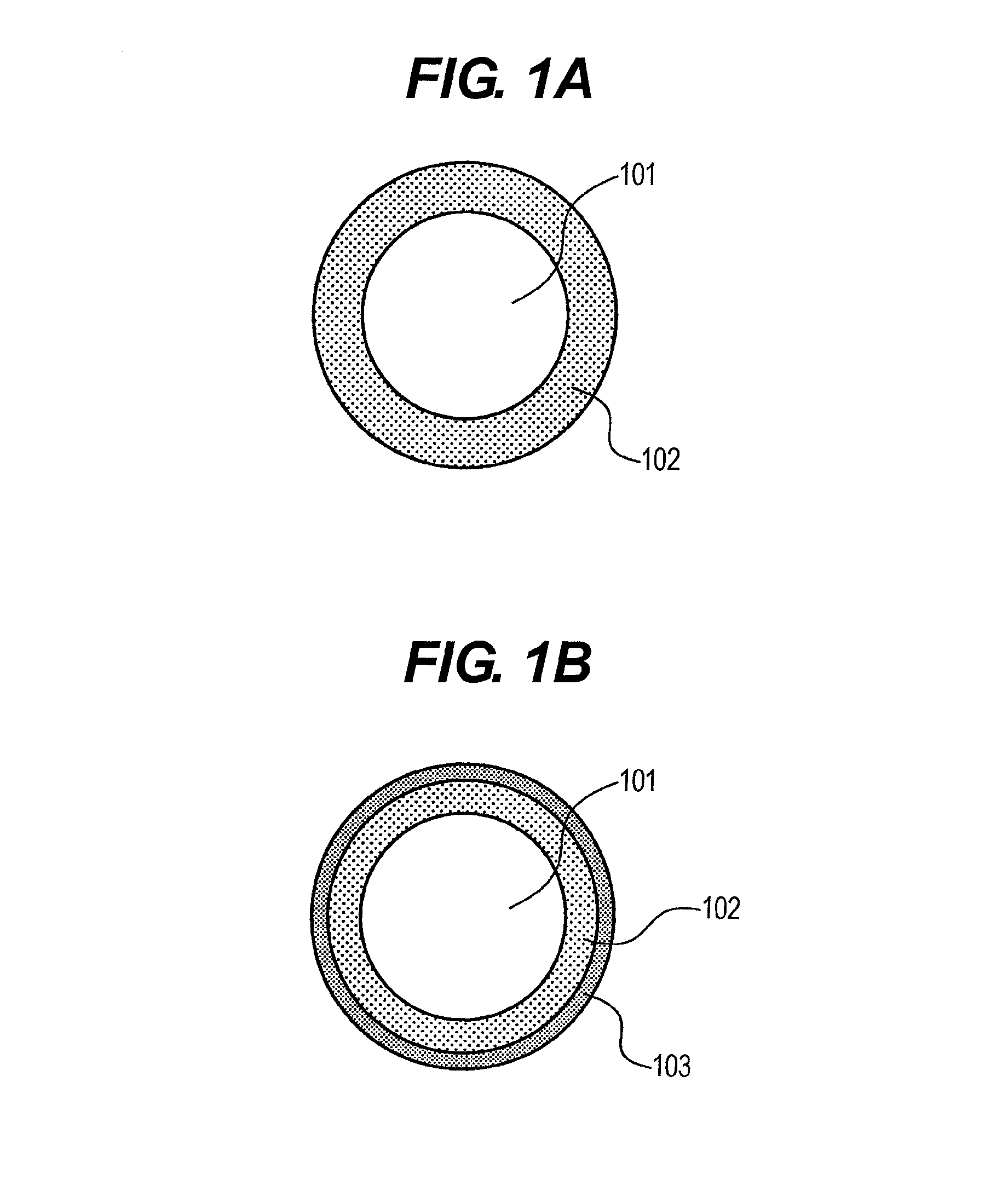

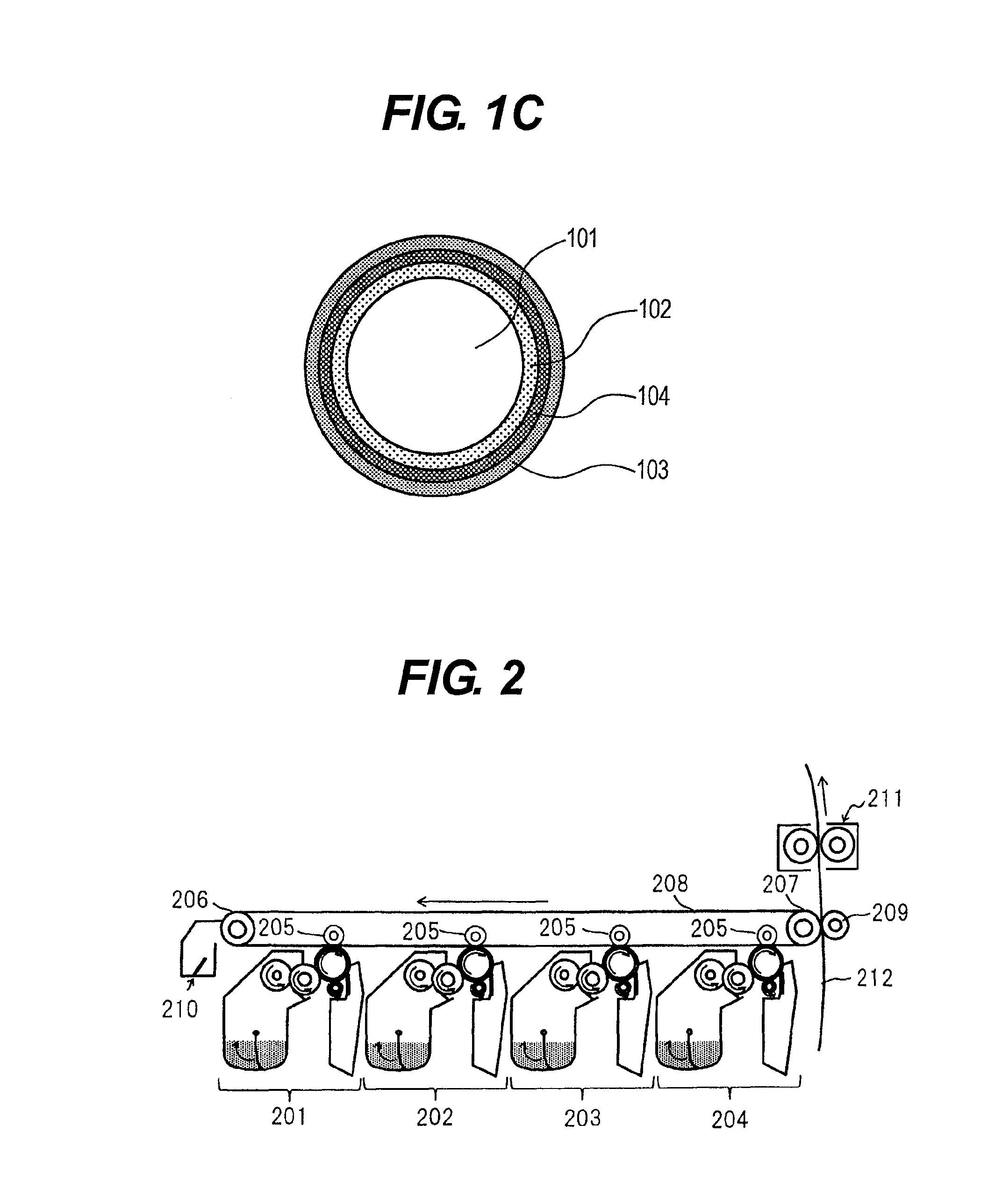

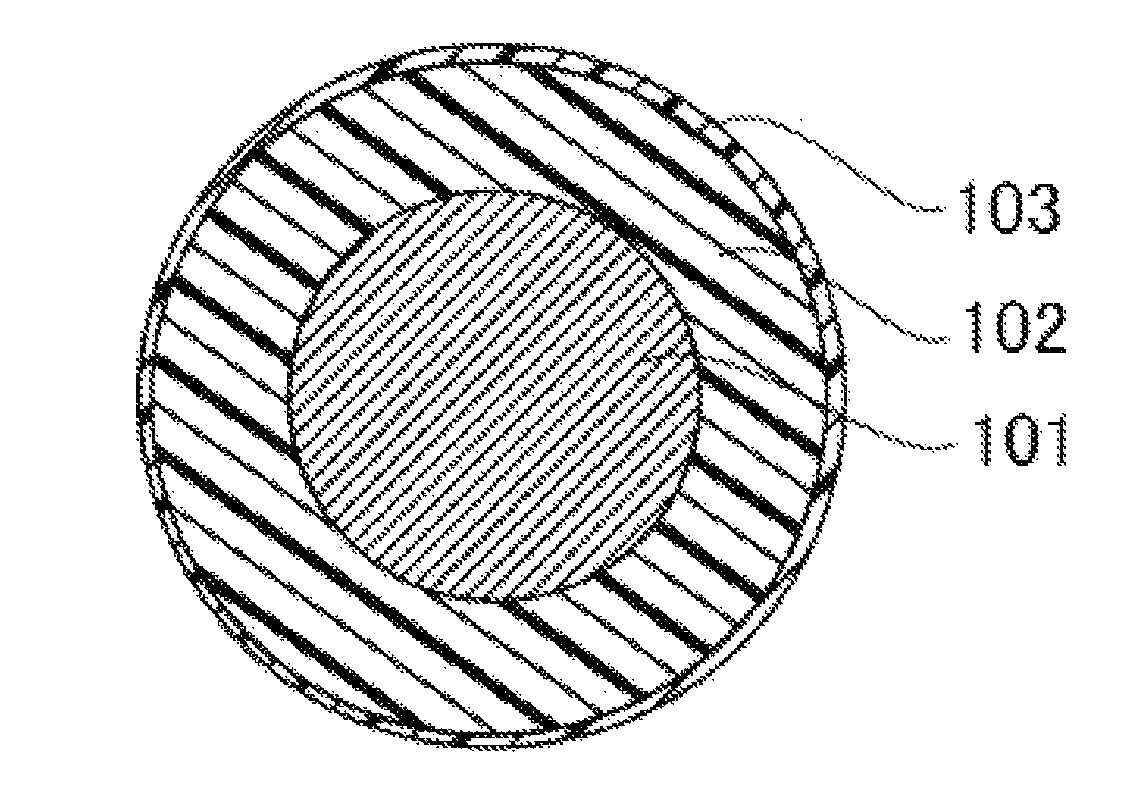

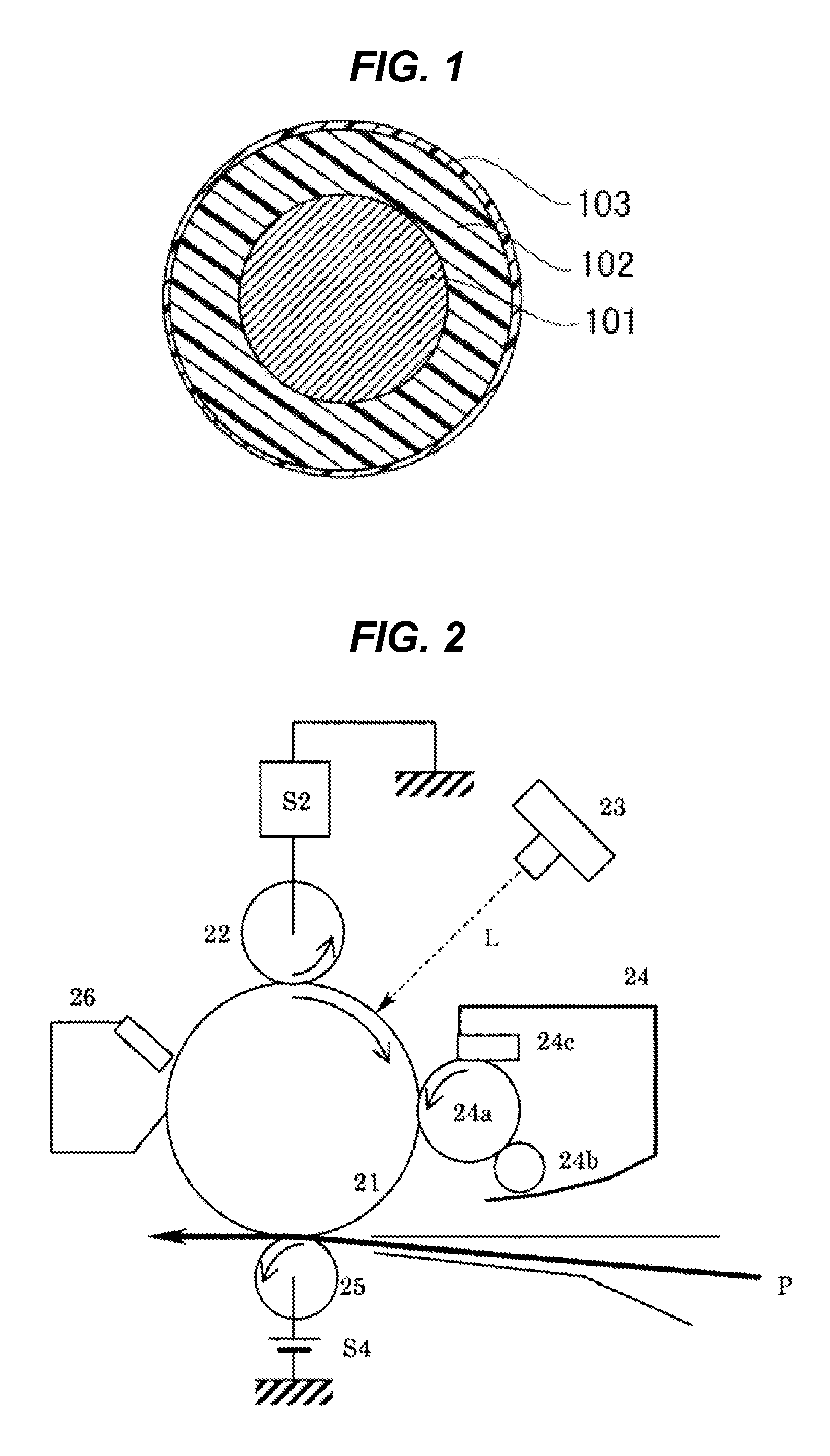

Charging member, process cartridge and electrophotographic apparatus

InactiveUS20130004206A1Improve charging effectNot easy to changeElectrographic process apparatusCorona dischargeSurface layerElectron

A charging member for electrophotographic apparatus is provided which has a superior charging performance for the electrophotographic photosensitive member and also can not easily change with time in charging performance. The charging member has a substrate, an elastic layer and a surface layer, which surface layer contains a high-molecular compound having an Si—O—Ti linkage in the molecular structure and a cyclic polysilane represented by the general formula (7) defined in the specification, and the high-molecular compound has a constituent unit represented by the general formula (1) and a constituent unit represented by the following formula (2) which are defined in the specification.

Owner:CANON KK

Electrically conducting member, process cartridge, and electrophotographic apparatus

ActiveUS8715830B2Image stabilizationNot easy to changeNon-insulated conductorsSynthetic resin layered productsEngineeringEpichlorohydrin

Owner:CANON KK

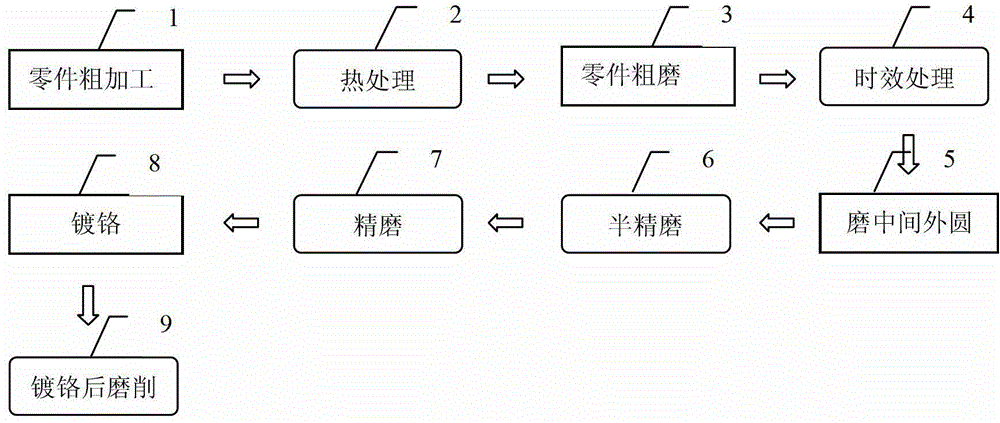

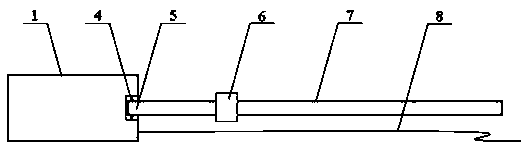

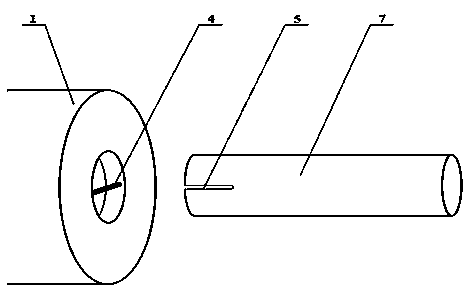

Technology treatment method of machining deformation of long and thin hole shaft type thin-wall part

InactiveCN103331651AImprove rigidityReduce unstable retained austeniteFurnace typesHeat treatment furnacesCold treatmentTempering

The invention provides a technology treatment method of machining deformation of a long and thin hole shaft type thin-wall part, and aims at providing a technology treatment method of the machining deformation, which is simple in flow, and high in machining precision and yield. The method adopts the following technical scheme that the method comprises the steps that the long and thin hole shaft type thin-wall part after mechanical rough machining and carburizing treatment is subjected to quenching heat treatment, subzero treatment and low temperature tempering treatment. During the quenching heat treatment, the quenching cooling time is 8-11S / mm; when a surface temperature of the part falls to 30-50 DEG C, the part is lifted up from oil; the surface temperature of the part rebounds in air after some time; and when the part is cooled to 30-50 DEG C again, residual oil is rinsed cleanly by hot water greater than or equal to 60 DEG C. During the subzero treatment, the part is transferred to a -70 DEG C to -80 DEG C refrigerator box to be refrigerated for 2-2.5h within 1h after quenching, and then subjected to air cooling for 60-90min till the part reaches a room temperature. During the low temperature tempering treatment, the part is subjected to heat preservation for 3-4h at 160-180 DEG C and the air cooling. The method solves the problem of the machining deformation of the long and thin hole shaft type thin-wall part due to heat treatment stress, grinding stress and the like, and the yield reaches 100%.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

MEMS sensor driving device, MEMS sensor driving method, and active sensor using MEMS

InactiveUS7451647B2Complicates a driving circuit for the MEMSNot easy to changeTelevision system detailsAcceleration measurement using interia forcesEngineeringMems sensors

Owner:SONY CORP

Semiconductor device and electronic device

InactiveUS20080002454A1Low power consumption memoryIncrease valueSolid-state devicesRead-only memoriesBit lineElectricity

In relation to reading of data in a memory, it is an object to provide a semiconductor device mounted with a low power consumption memory. A semiconductor device including a word line, a bit line, and a memory cell electrically connected to the word line and the bit line, further includes a precharge circuit for making the bit line have an electric potential for reading data stored in the memory cell. The precharge circuit is provided for each bit line and connected to the bit line. Further, the precharge circuit is capable of making each bit line have an electric potential for reading the data stored in the memory cell for each bit line.

Owner:SEMICON ENERGY LAB CO LTD

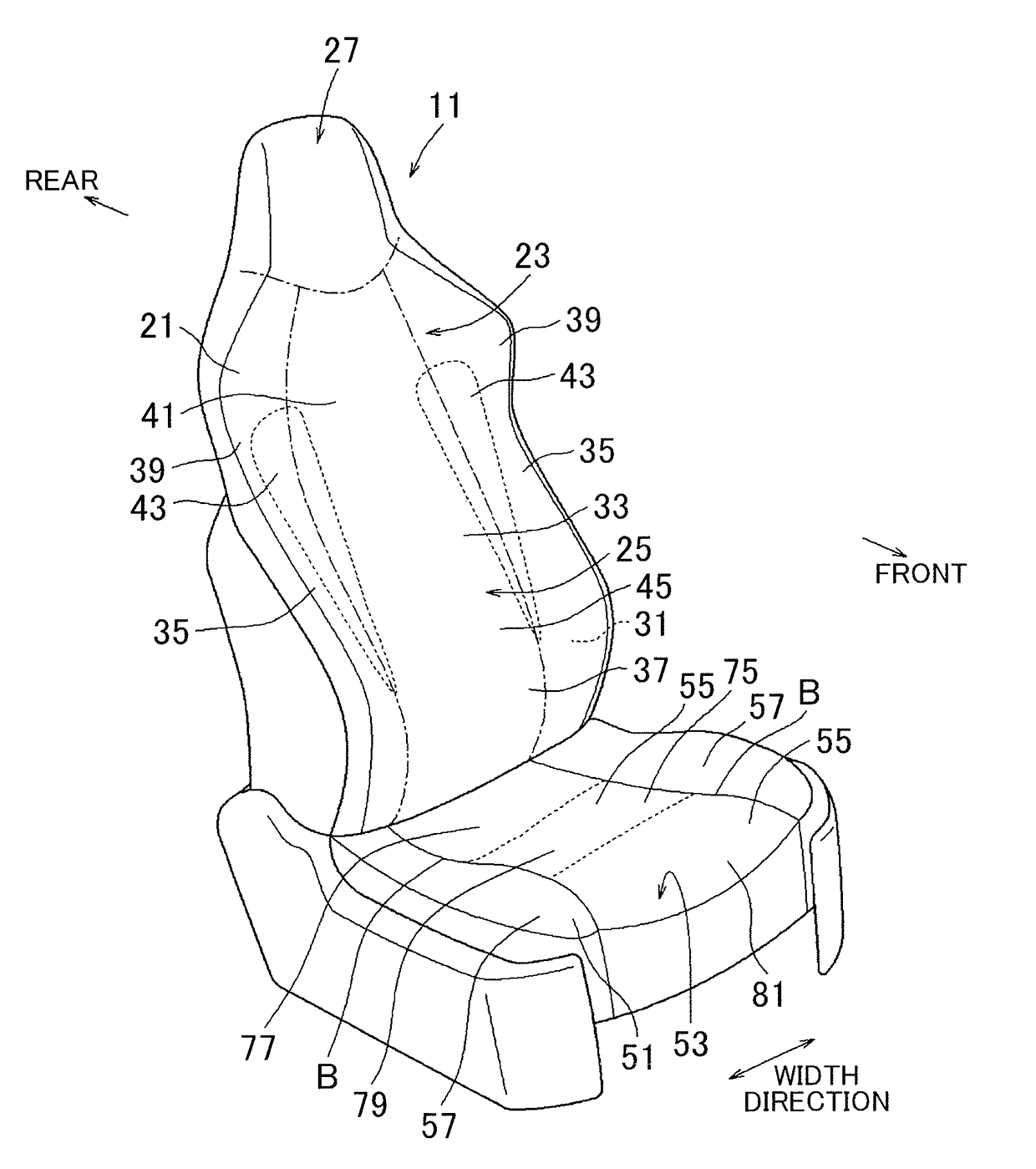

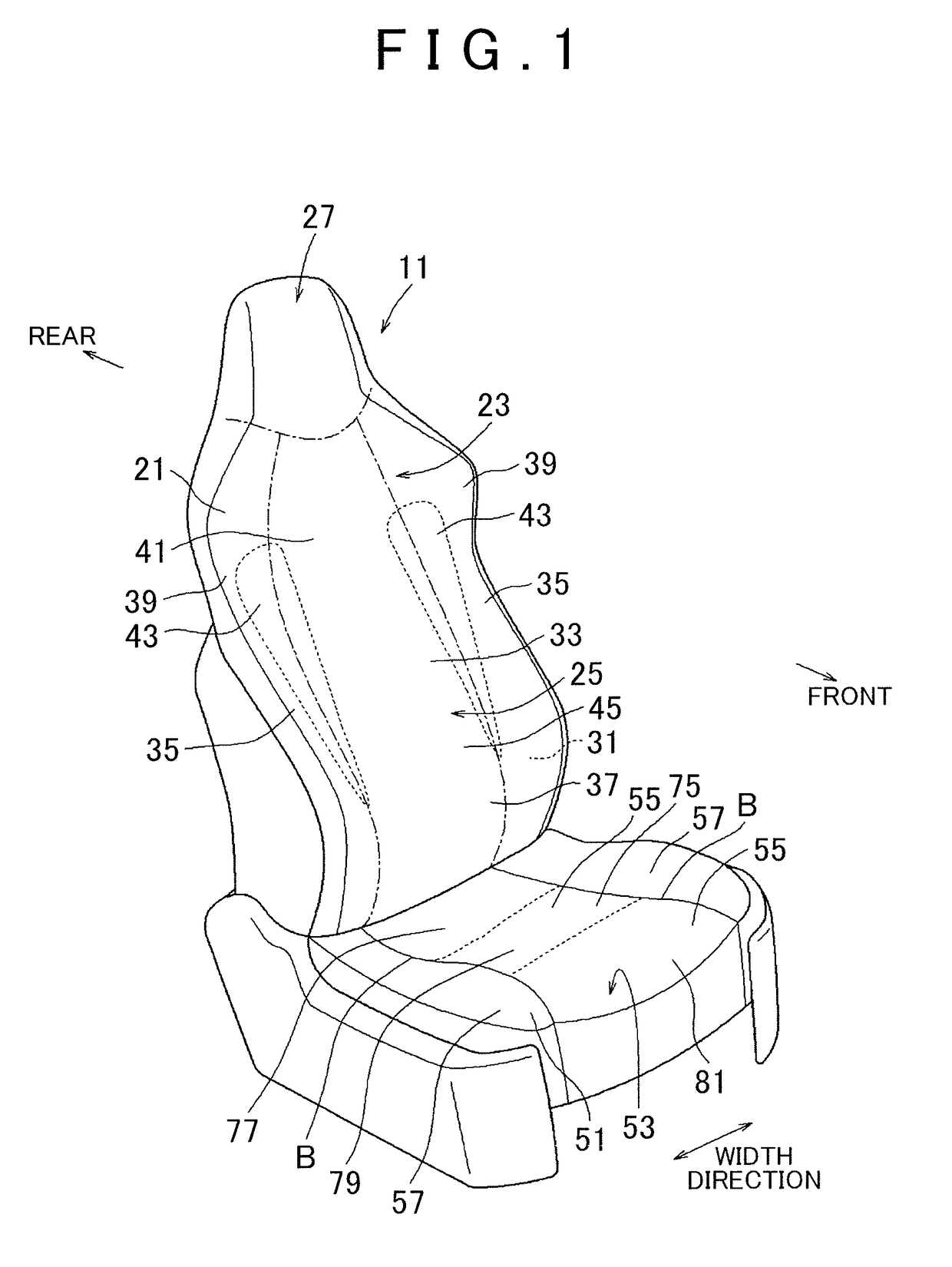

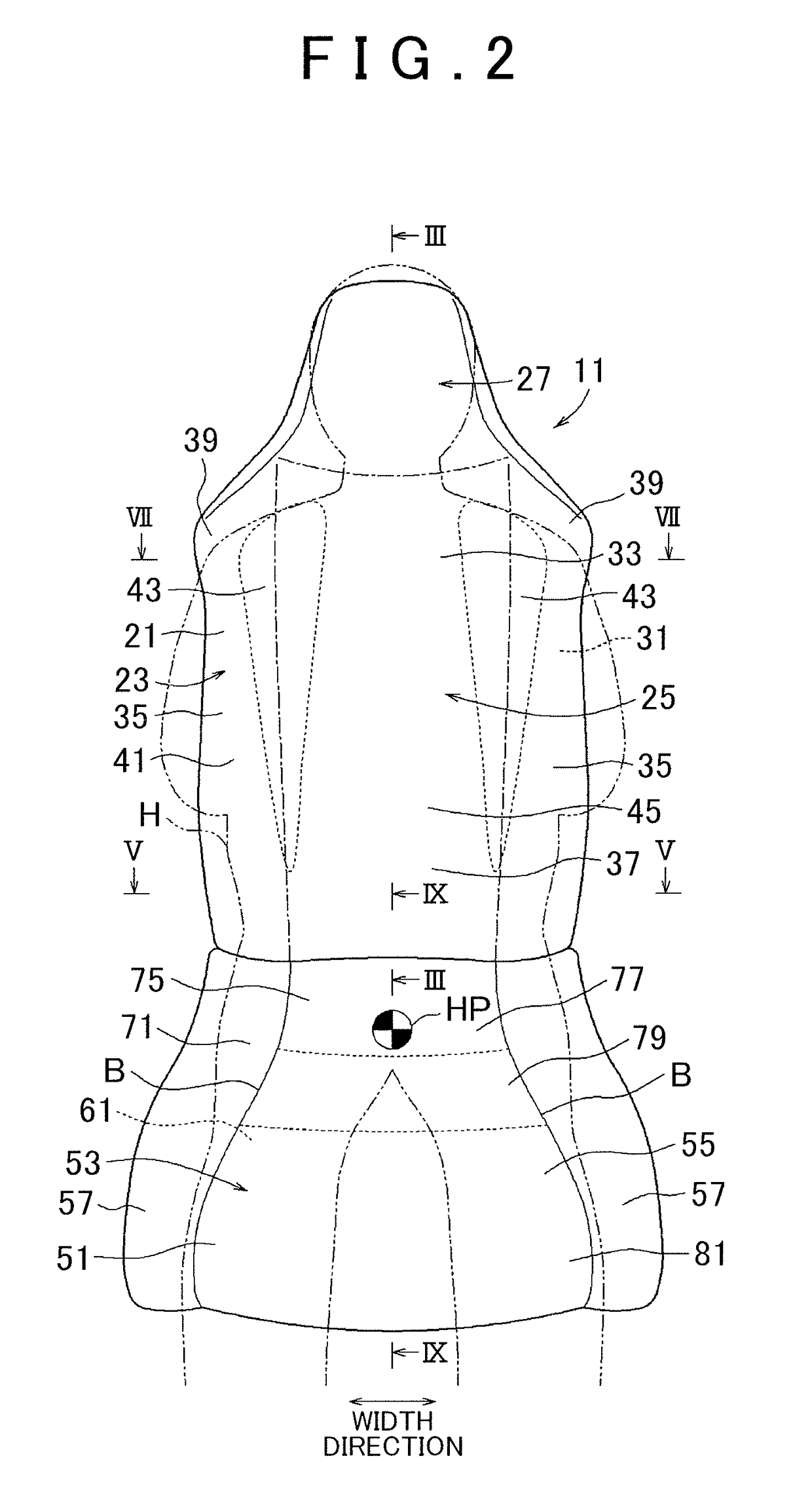

Vehicle seat

InactiveUS9637035B2Bending easiness of the skin partially differentHigh densitySeat coveringsBack restsBiomedical engineeringSupport surface

A vehicle seat includes: a seat pad that forms a supporting surface that supports a seated occupant; and a skin that is made of a knitted fabric or a woven fabric and covers the seat pad. The skin has a first region and a second region arranged adjacent to each other on the supporting surface, and the first region is lower in density and thinner than the second region.

Owner:TOYOTA BOSHOKU KK

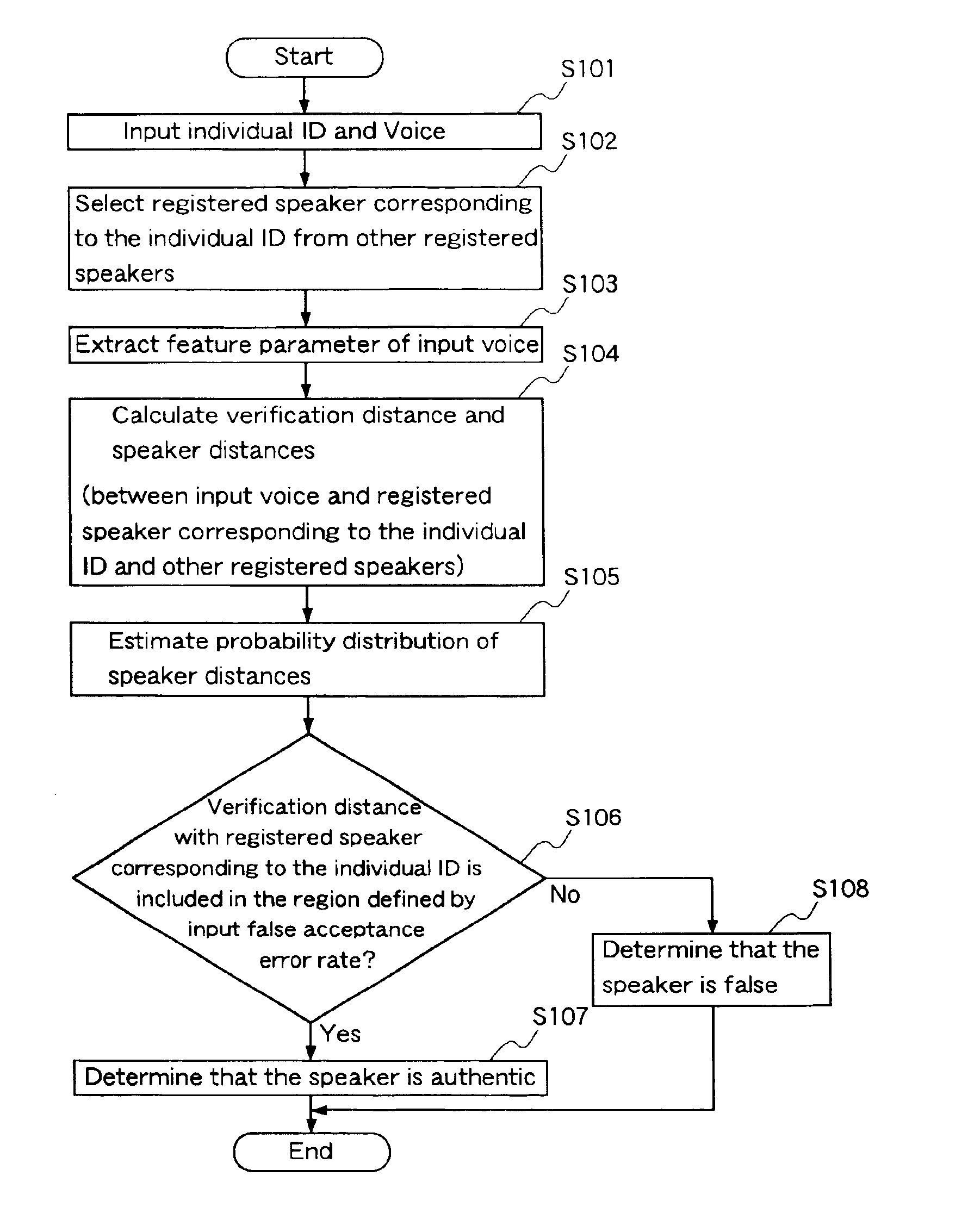

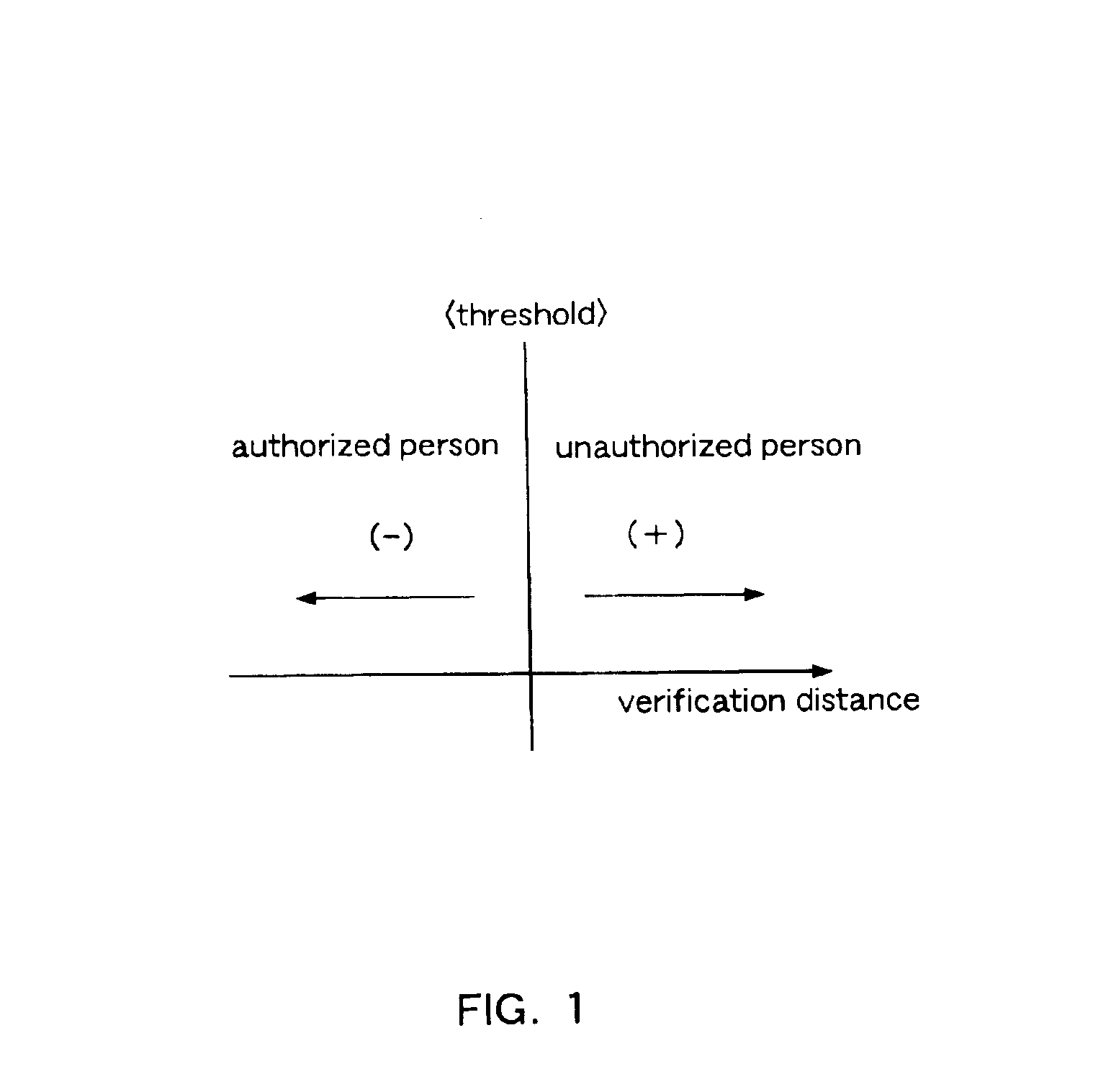

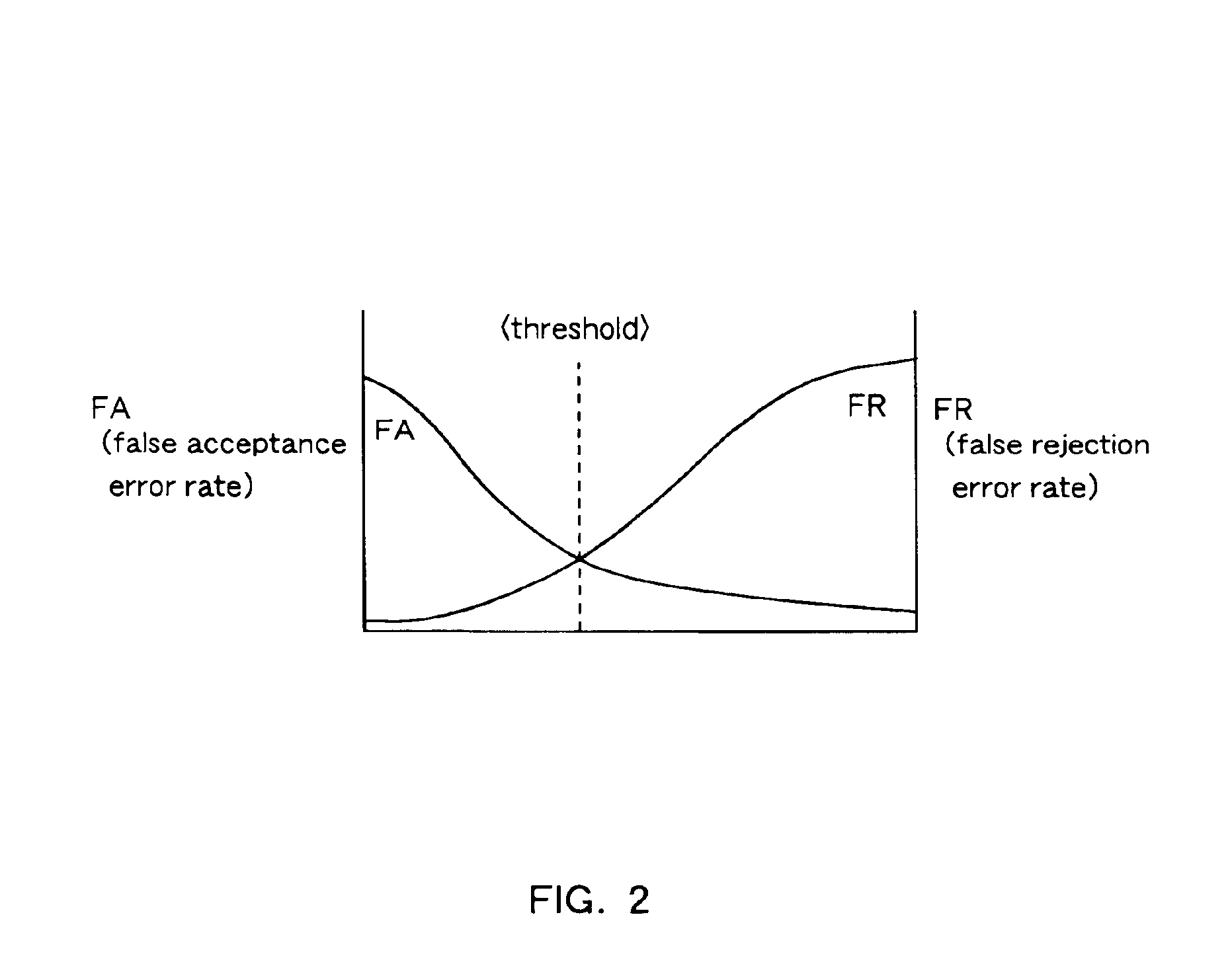

Speaker verification apparatus and method utilizing voice information of a registered speaker with extracted feature parameter and calculated verification distance to determine a match of an input voice with that of a registered speaker

InactiveUS6879968B1Improve accuracyMaintain accuracyDigital computer detailsBiological neural network modelsSpeaker verificationFeature parameter

A speaker verification apparatus and method input an identity claim, select voice information of a registered speaker corresponding to the input identity claim, input a voice of the speaker, analyze the input voice so as to extract a feature parameter, calculate a verification distance between a feature parameter of the input voice and that of the voice of the registered speaker and the speaker distances between a feature parameter of the input voice and those of the voices of other speakers; and determine whether or not the input voice matches that of the registered speaker. A false acceptance error rate, is input as a threshold, and a probability distribution of interspeaker distances is functions to determine that the input voice is the voice of the registered person specified by the identity claim.

Owner:CODEX TECH +1

Vegetable soilless culture nutrient solution and manufacturing method thereof

The invention discloses a vegetable soilless culture nutrient solution and a manufacturing method thereof. The invention is characterized in that every liter of water contains 5-7 mg / L potassium nitrate, 7-9 mg / L ammonium nitrate, 4-6 mg / L potassium dihydrogen phosphate, 2-4 mg / L ammonium dihydrogen phosphate, 0.5-0.7 mg / L disodium edetate, 0.2-0.4 mg / L magnesium sulfate, 0.04-0.07 mg / L iron chelate, 0.06-0.09 mg / L minor element and 2-4 mg / L boric acid. The rotten cottonseed hull contains abundant organic matters, and has certain actions of the slow-release controlled-release fertilizer. The formula is reasonable, and the pH value is approximate to neutrality. The vegetable soilless culture nutrient solution provides nutritive elements required by vegetable growth, and the ion concentration can not easily change. The vegetable soilless culture nutrient solution can effectively fix the plant root system, and has the advantages of simple production operation, low cost, high vegetable yield and good quality.

Owner:QINGDAO ZHONGTIAN XINDA BIOTECH R & D

Method for locating and installing deep soft rock geostatic stress testing device

InactiveCN103510951AEasy to solveEasy to calculateBorehole/well accessoriesRelative displacementMedial axis

The invention discloses a method for locating and installing a deep soft rock geostatic stress testing device. According to the method, a stress sensing column is manufactured, the stress sensing column is a cement concrete cylinder comprising two three-directional pressure boxes, and the center of each cubic pressure box is located on the medial axis of the cylinder; the front end of a push rod is connected with the stress sensing column, an angle testing device is installed, rotation angle and length of the stress sensing column are recorded when the push rod is pushed from a hole mouth to a tested point at the hole bottom, and accurate data necessary for stress resolving can be obtained. According to the method, no sharp protrusion exists at the front end or the side face of the stress sensing column, the hole wall will not collapse easily in the pushing process, relative positions of a pair of three-directional pressure sensors are fixed through the stress sensing column, the two three-directional pressure sensors will not move or rotate relatively in the pushing process, and the accuracy for calculating the geostatic stress of the tested point can be ensured.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

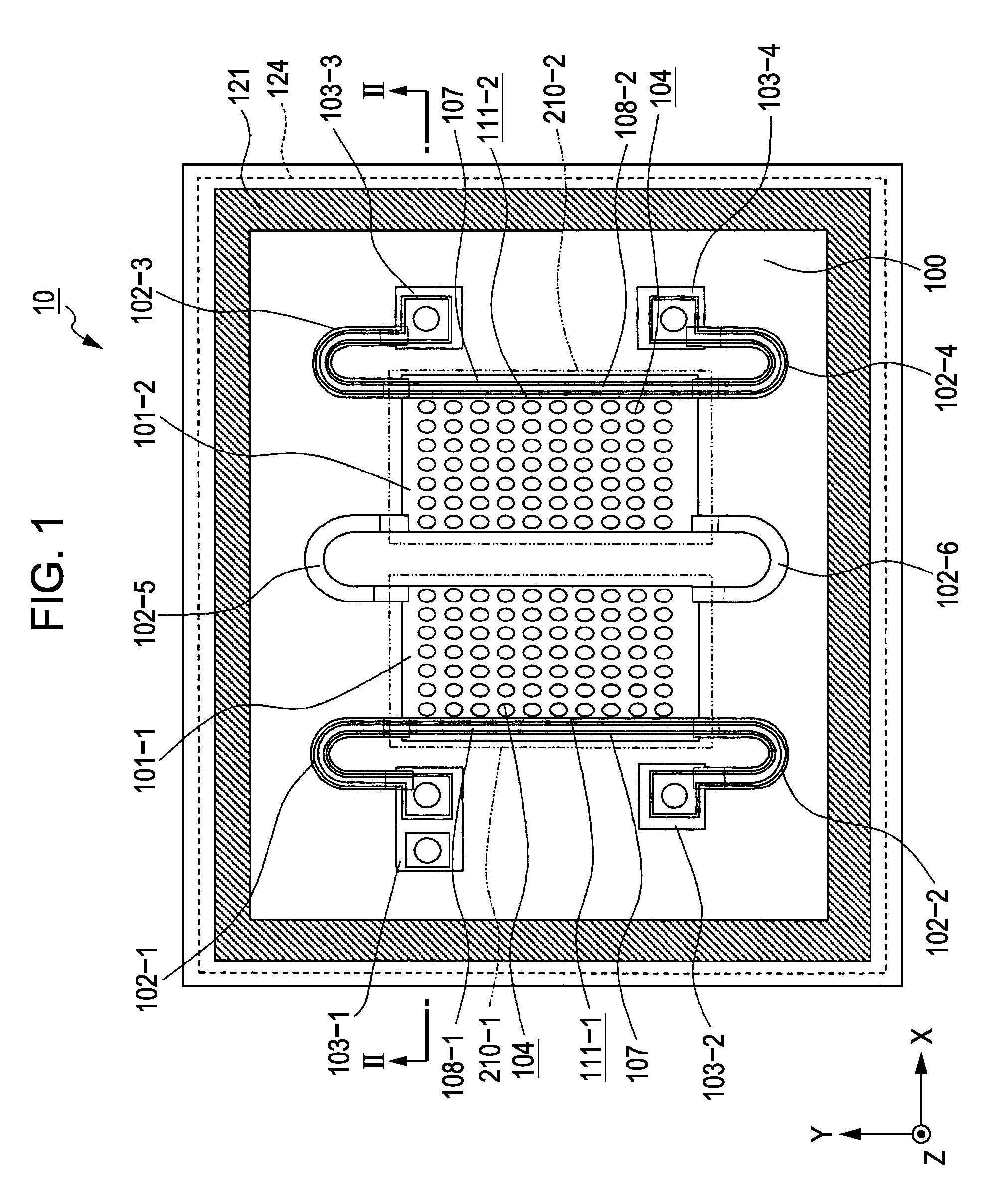

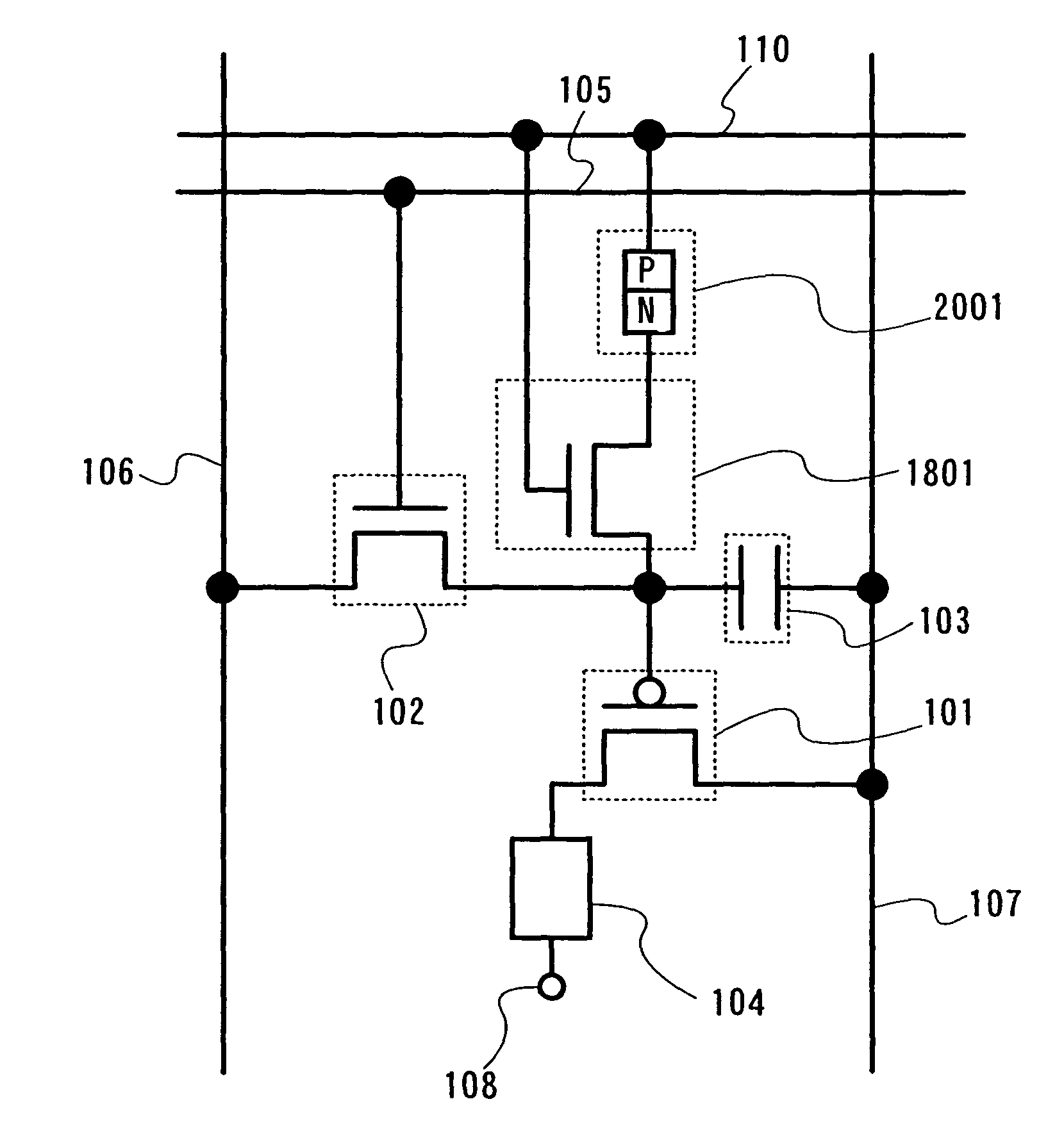

Semiconductor device comprising transistor having gate and drain connected through a current-voltage conversion element

InactiveUS8300031B2Suppression of manufacturing cost increaseIncrease productionElectrical apparatusElectroluminescent light sourcesScan lineDisplay device

When a signal inputted to a pixel is erased by setting potentials of a gate terminal and a source terminal of a driving transistor to be equal, a current slightly flows through the driving transistor in some cases, which leads to occur a display defect. The invention provides a display device which improves the yield while suppressing the increase in manufacturing cost. When a potential of a scan line for erasure is raised, a potential of the gate terminal of the driving transistor is raised accordingly. For example, the scan line and the gate terminal of the driving transistor are connected through a rectifying element.

Owner:SEMICON ENERGY LAB CO LTD

Charging member and method of producing the member, process cartridge, and electrophotographic image-forming apparatus

ActiveUS8503911B2Stable chargingImprove charging effectLayered productsElectrographic process apparatusSurface layerEngineering

Provided are the following charging member and a method of producing the charging member. The charging member has an improved charging ability and hence alleviates, in particular, a positive ghost. The charging member can maintain resistance to the adhesion of toner, a toner external additive, or the like over a long time period. The charging member for an electrophotographic apparatus comprises an electro-conductive support, an electro-conductive elastic layer, and a surface layer, wherein the surface layer comprises a polymer compound having an Si—O—Ti linkage in a molecular structure thereof, and the polymer compound has each of constitutional units represented by a formula (1), a formula (2), and a formula (3) defined in the description. The method is a method of producing the charging member.

Owner:CANON KK

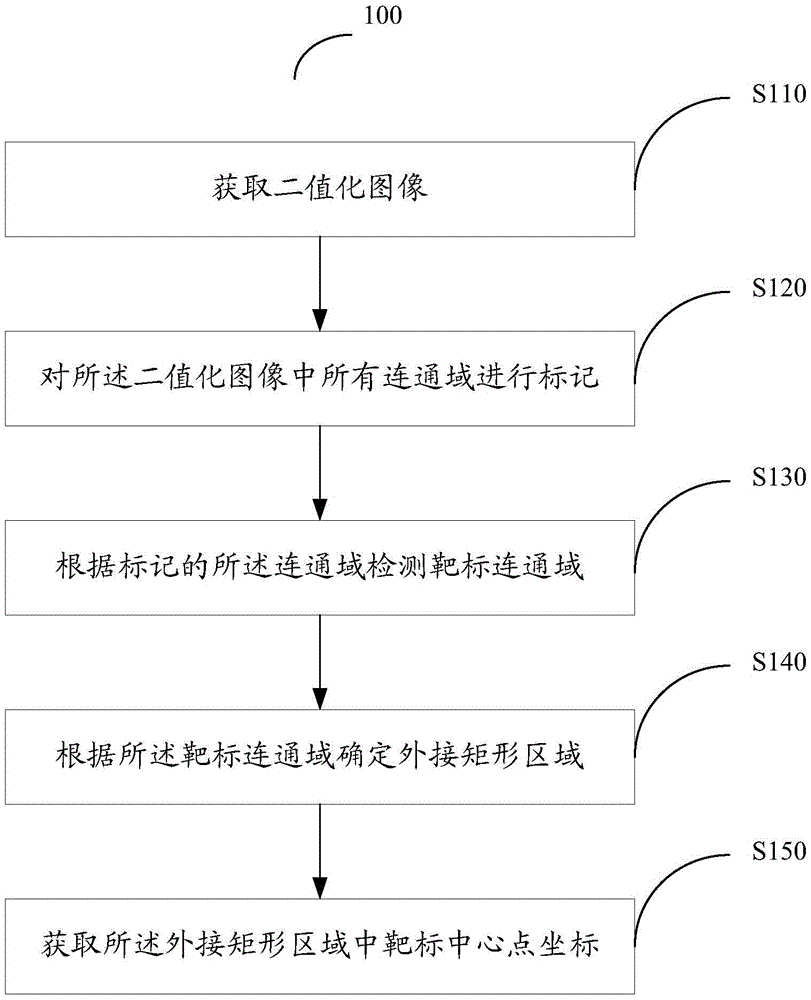

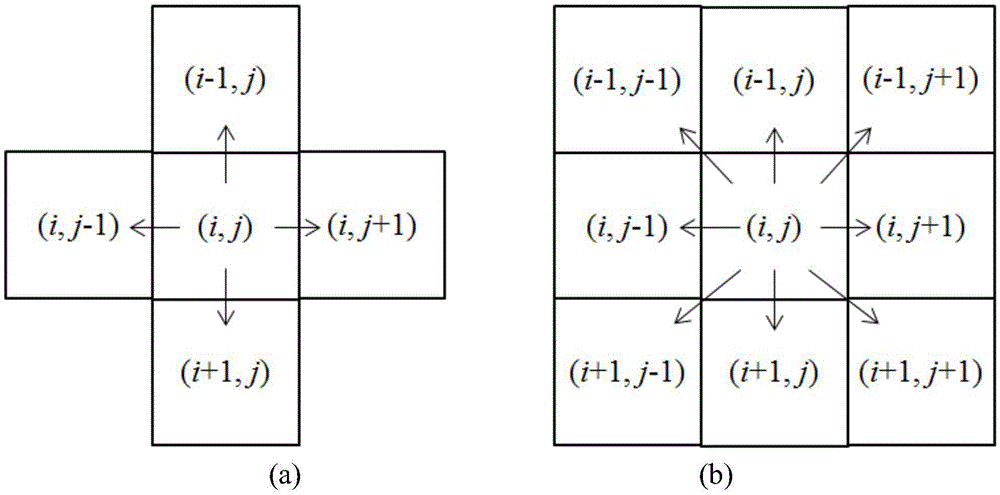

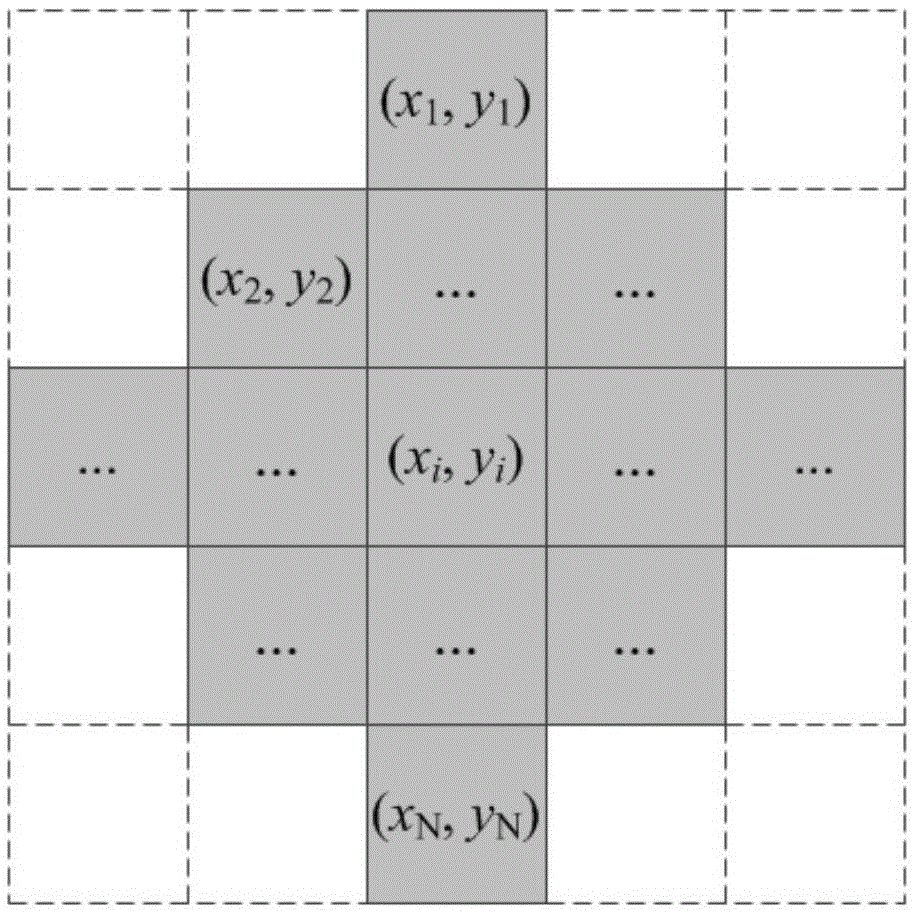

Rapid extraction method and system for target central point

InactiveCN105469084AImprove execution efficiencyNot easy to changeCharacter and pattern recognitionState of artComputer science

The invention provides a rapid extraction method and system for a target central point. All connecting areas in an obtained binary image are marked; a target connecting area is detected according to the marked connecting areas; an external rectangular area is determined based on the target connecting area; and thus a target central point coordinate in the external rectangular area is obtained. In the prior art, the multiplication and division operation load for the employed edge detection, Hessian matrix, Hough conversion, and fitting algorithms is heavy. However, according to the provided method, the most operation of the image binaryzation, connecting area marking and center of mass method belongs to the logic operation and adding and subtraction operation, so that the execution efficiency is high.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

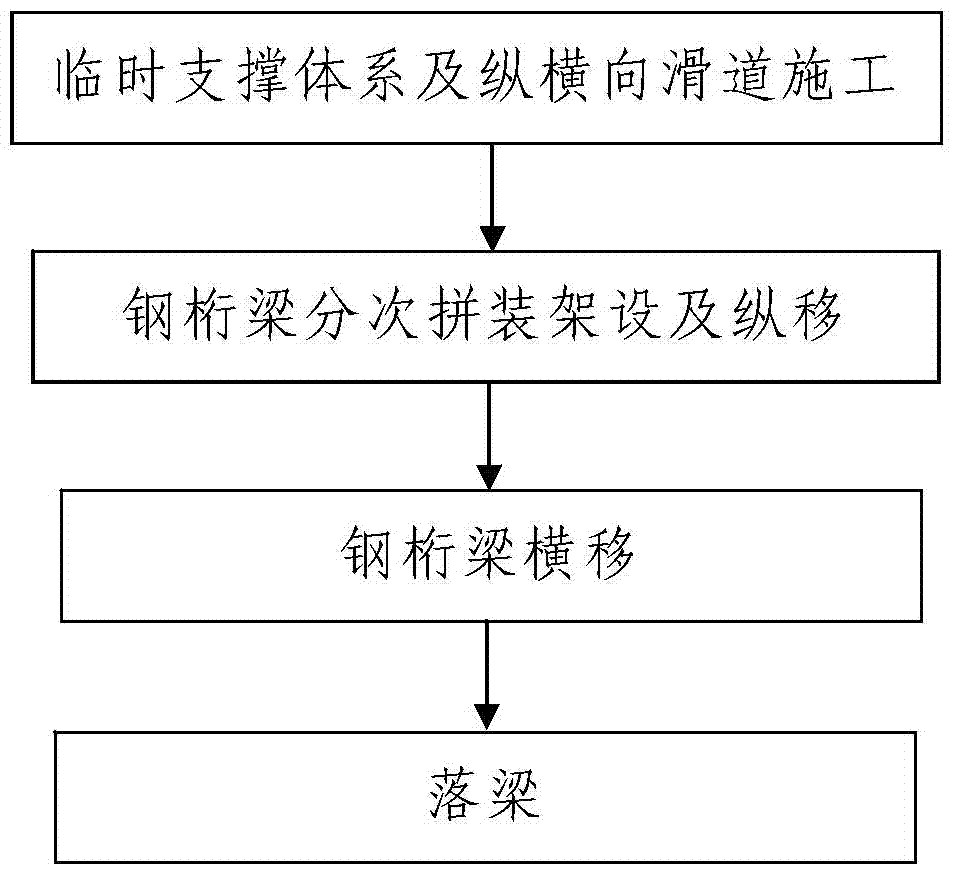

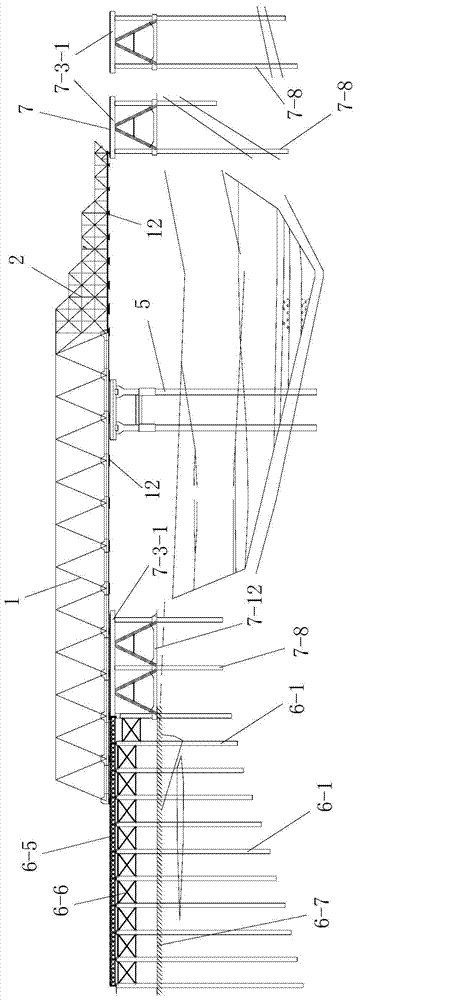

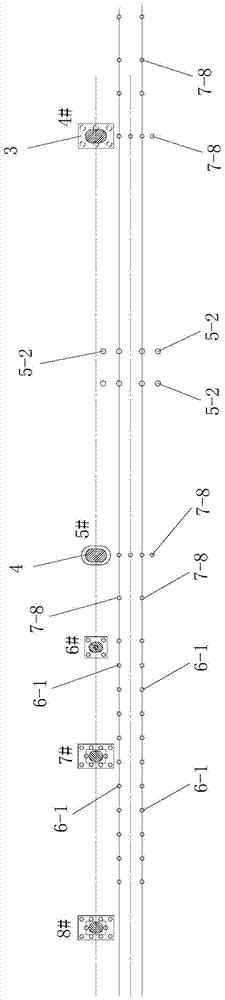

Steel truss girder assembling, erecting and construction process

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

Antenna structure and communication apparatus including the same

InactiveUS20070115177A1Easy to implementAvoiding reduction in an antenna gainSimultaneous aerial operationsAntenna supports/mountingsCapacitanceElectromagnetic coupling

In an antenna structure including a feeding radiation electrode and a non-feeding radiation electrode that are electromagnetically coupled to each other, due to formation of a main slit, the feeding radiation electrode includes a U-turn portion in the middle of a path circumventing the main slit from a feeding end to an open end. A sub-slit for forming an open stub that is connected to the U-turn portion and that provides the U-turn portion with electrostatic capacitance is formed in the feeding radiation electrode. By changing a value of the electrostatic capacitance to be provided by the open stub to the U-turn portion of the feeding radiation electrode, variable control of a higher-order resonant frequency F2 of the feeding radiation electrode 2 can be achieved while suppressing fluctuations in a resonant state (for example, a fundamental resonant frequency F1 and a Q-value) of a fundamental resonant frequency band of the feeding radiation electrode, in an electromagnetic coupling state between the feeding radiation electrode and the non-feeding radiation electrode, and in an impedance matching state.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com