Patents

Literature

39results about How to "The construction process steps are simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

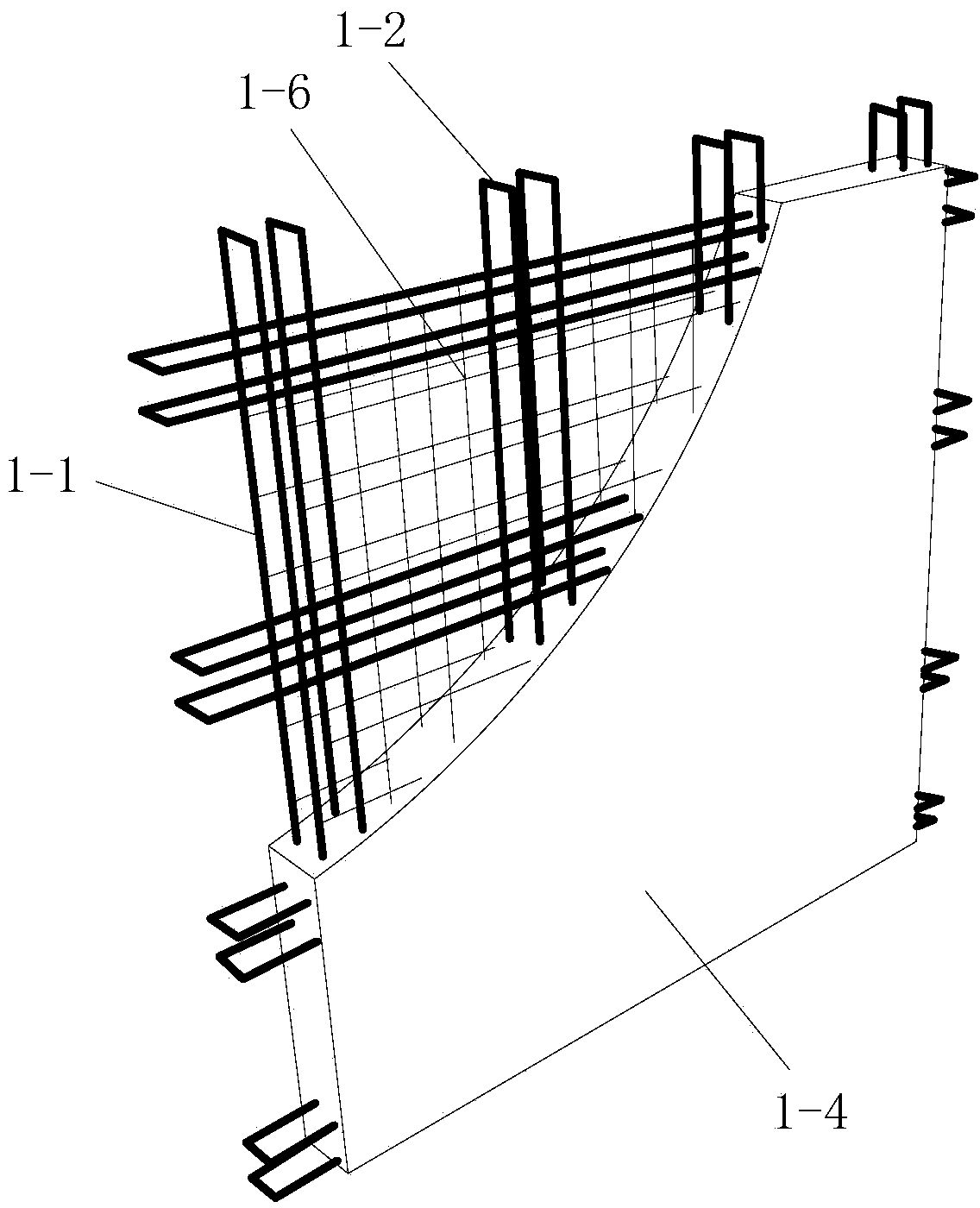

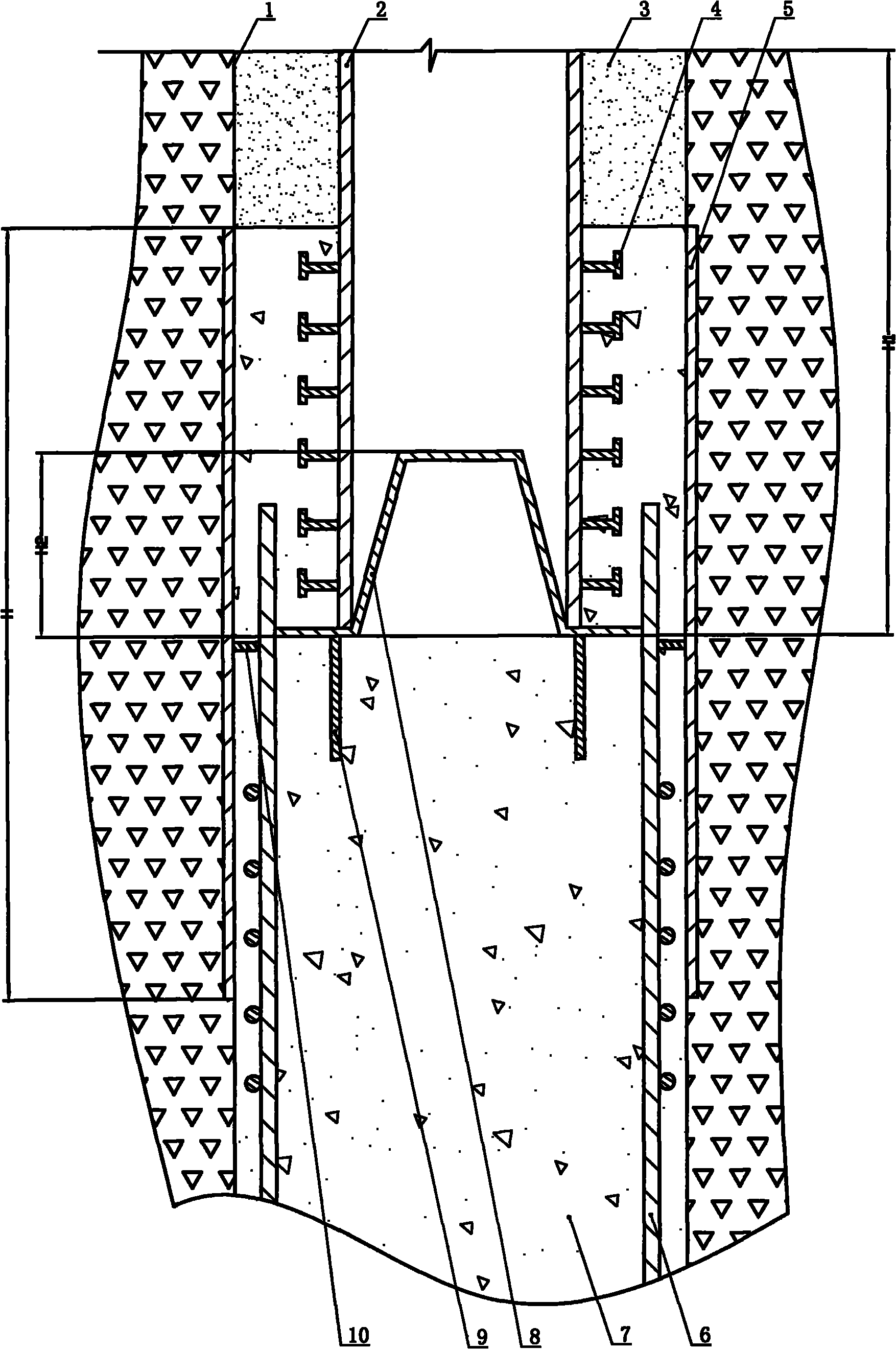

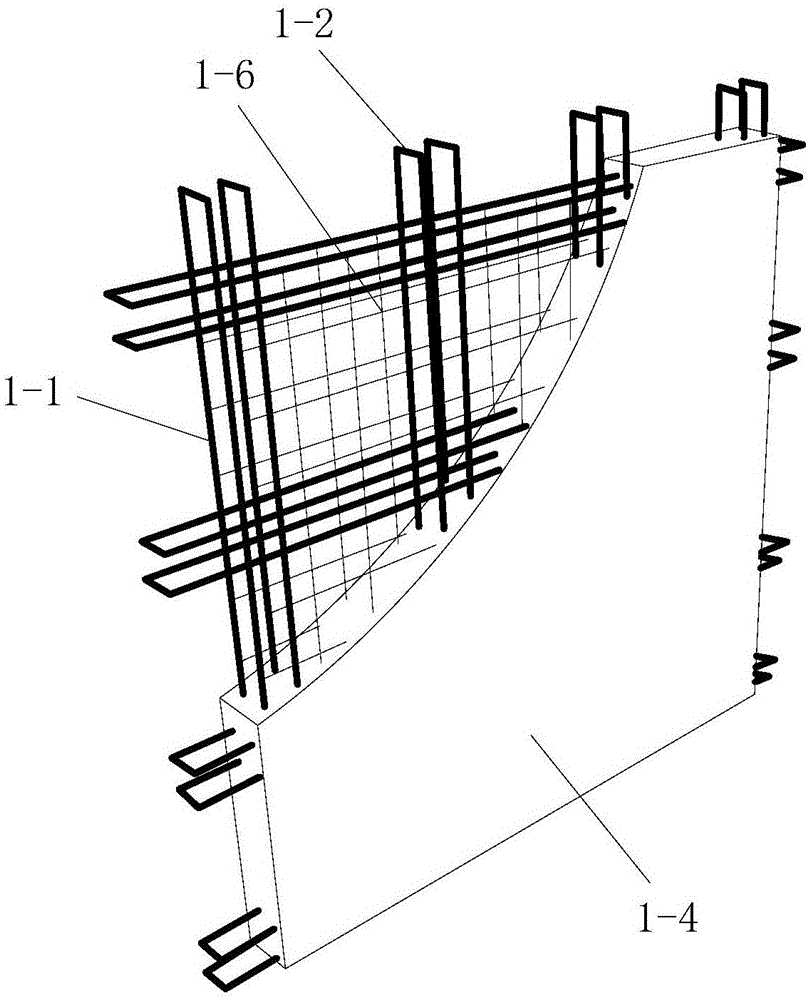

Assembled type gridding shearing wall structural system and construction technology of assembled type gridding shearing wall structural system

ActiveCN103924711ASimple structureLow input costWallsBuilding material handlingVertical edgeEngineering

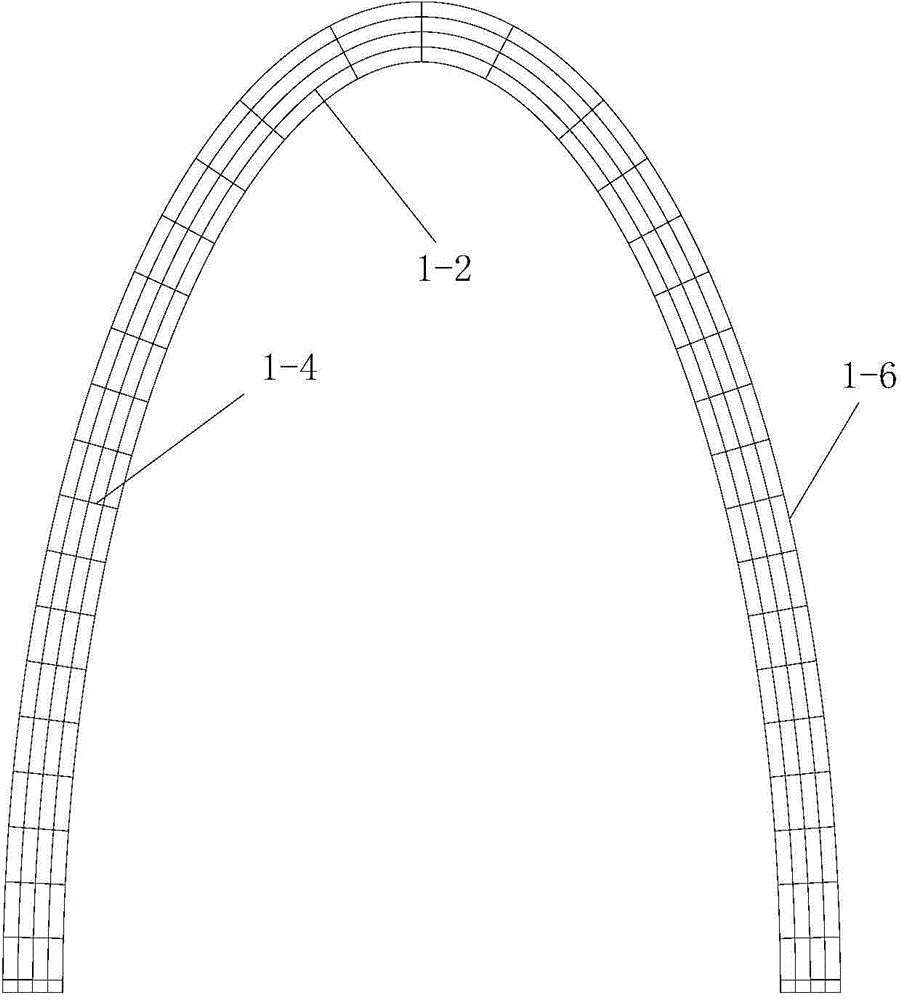

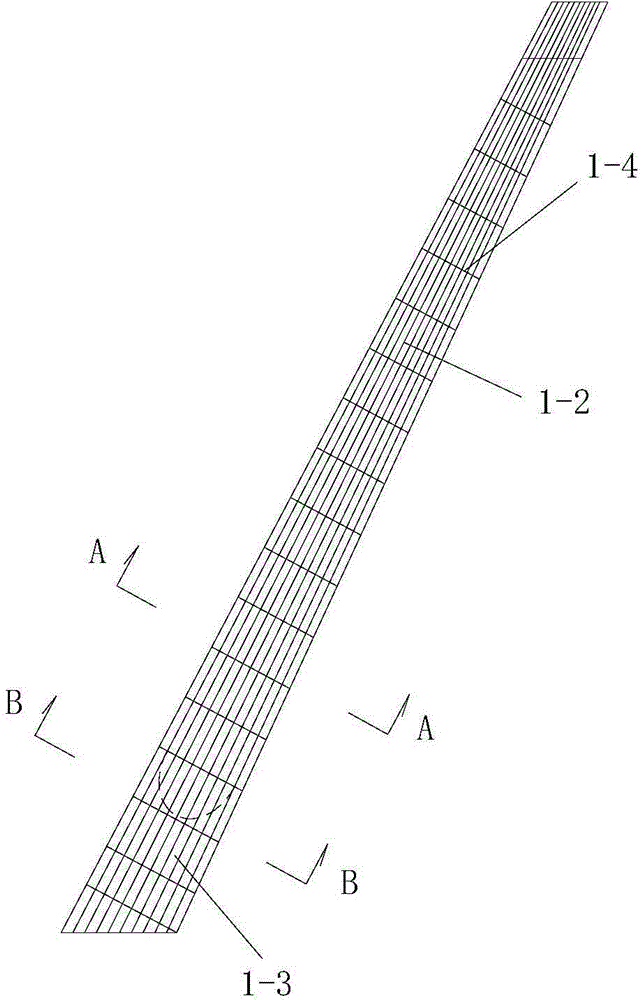

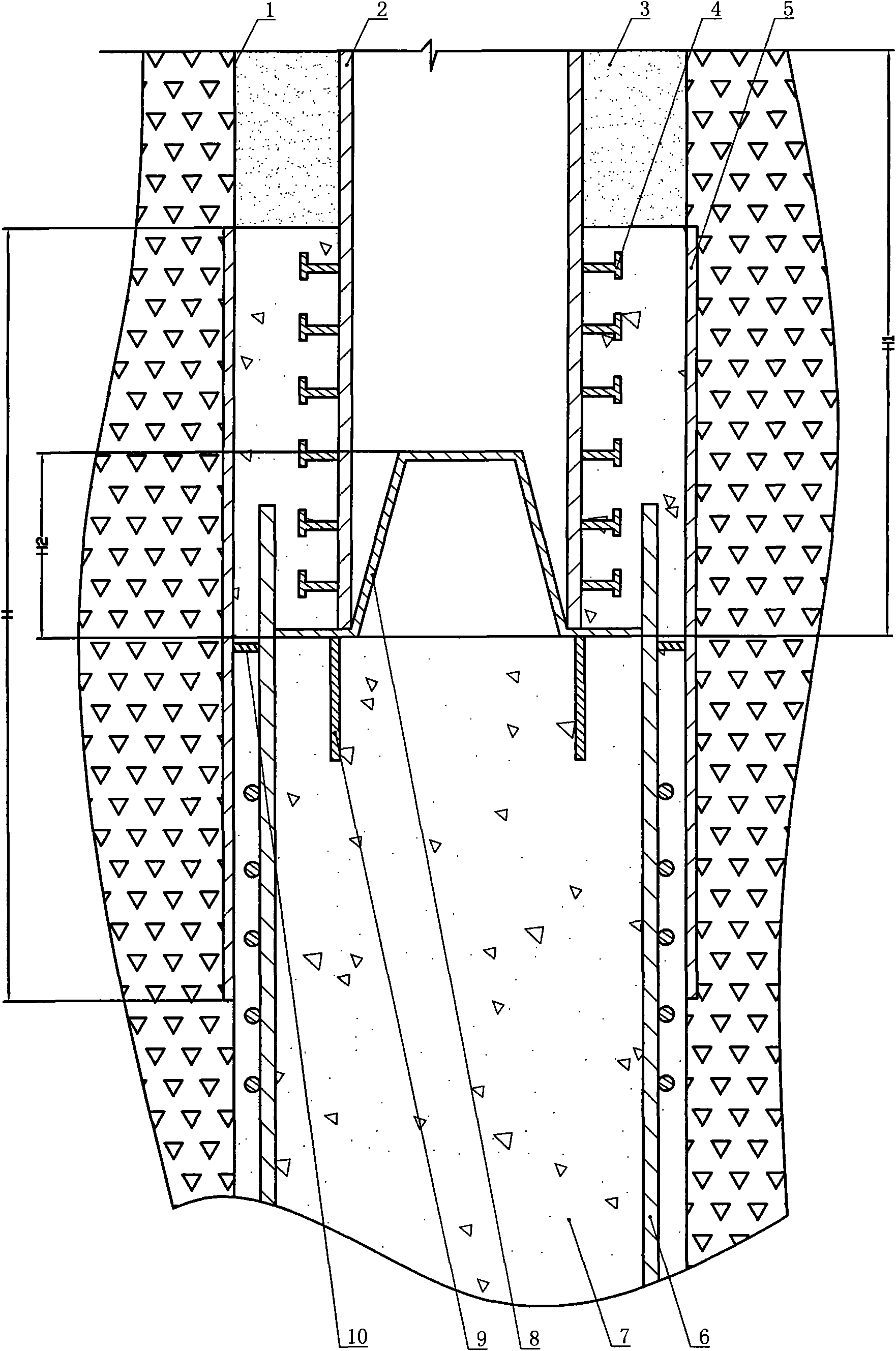

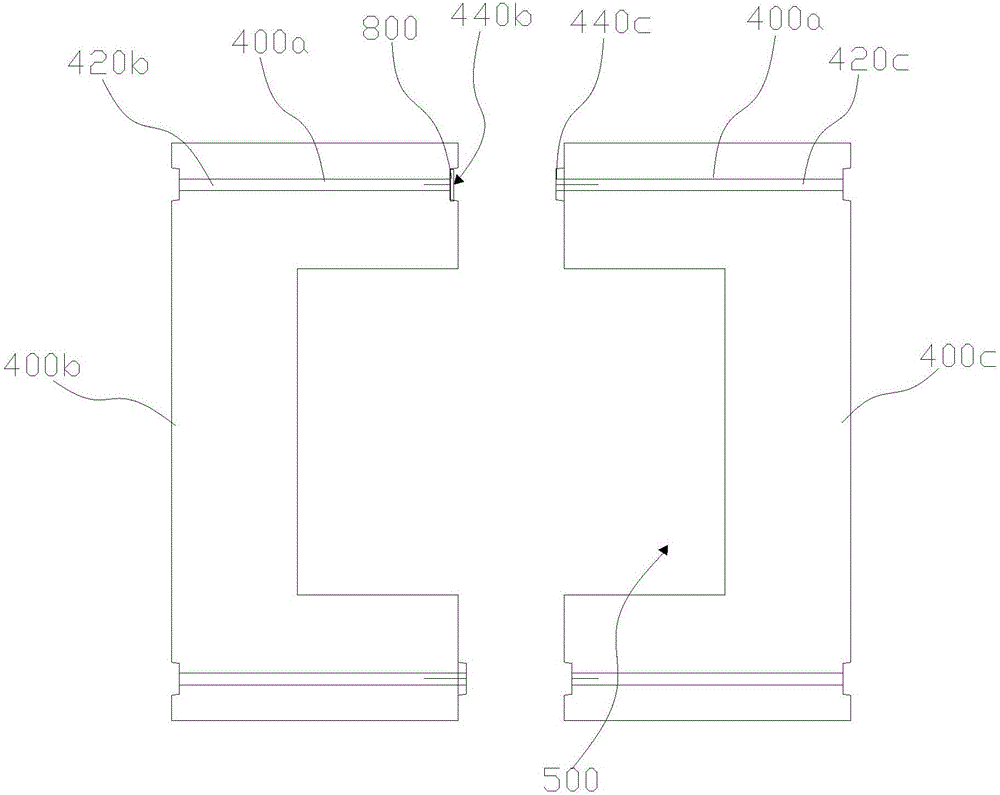

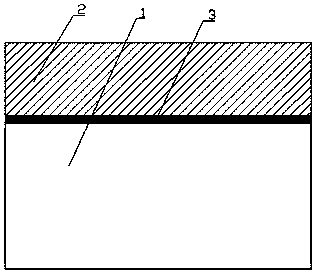

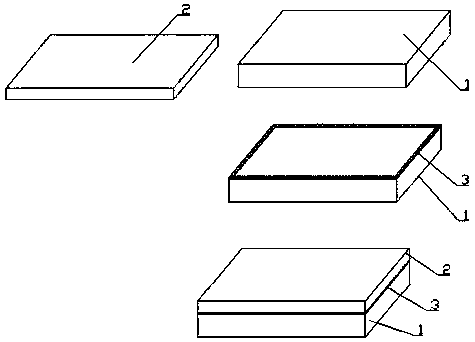

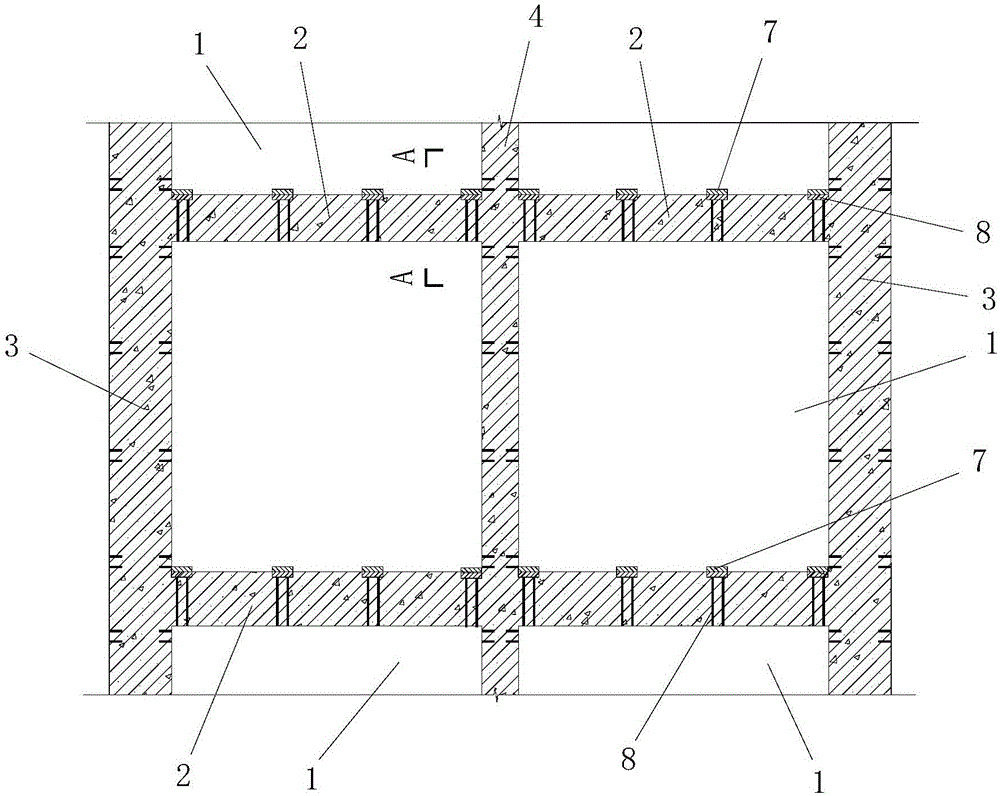

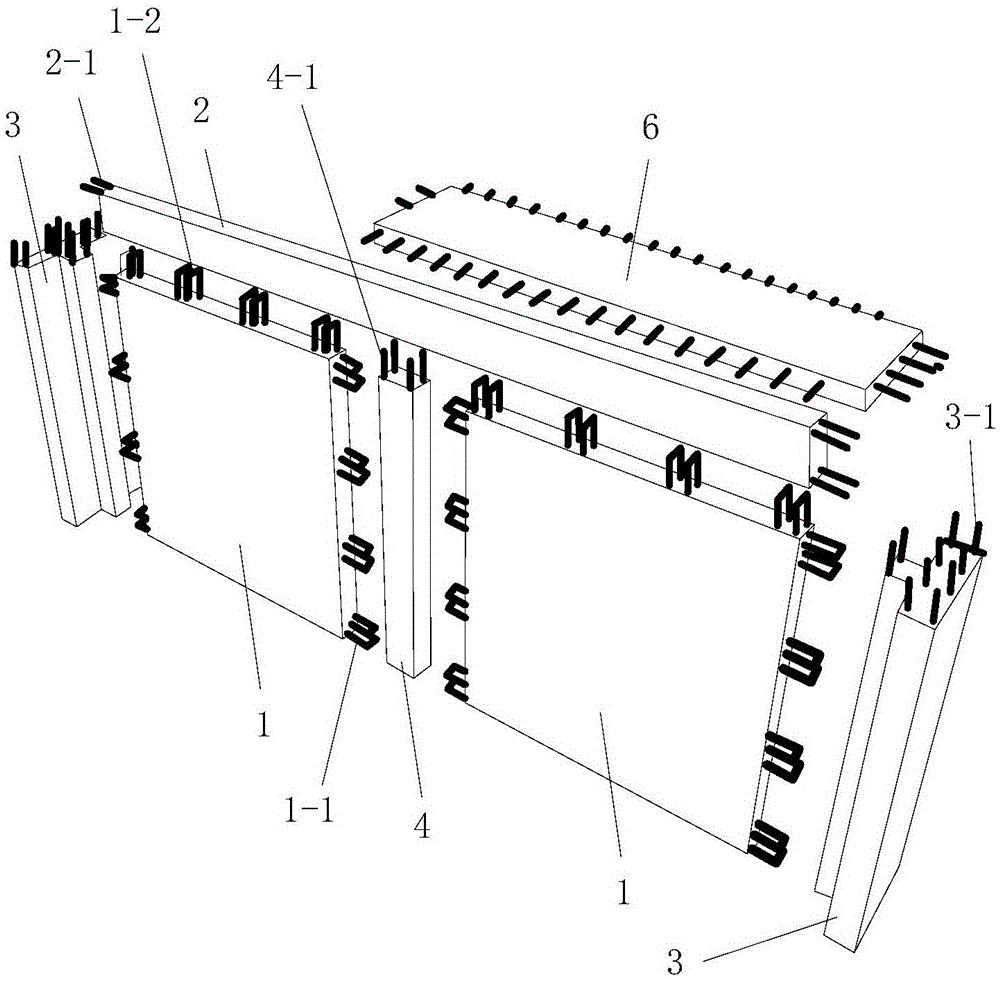

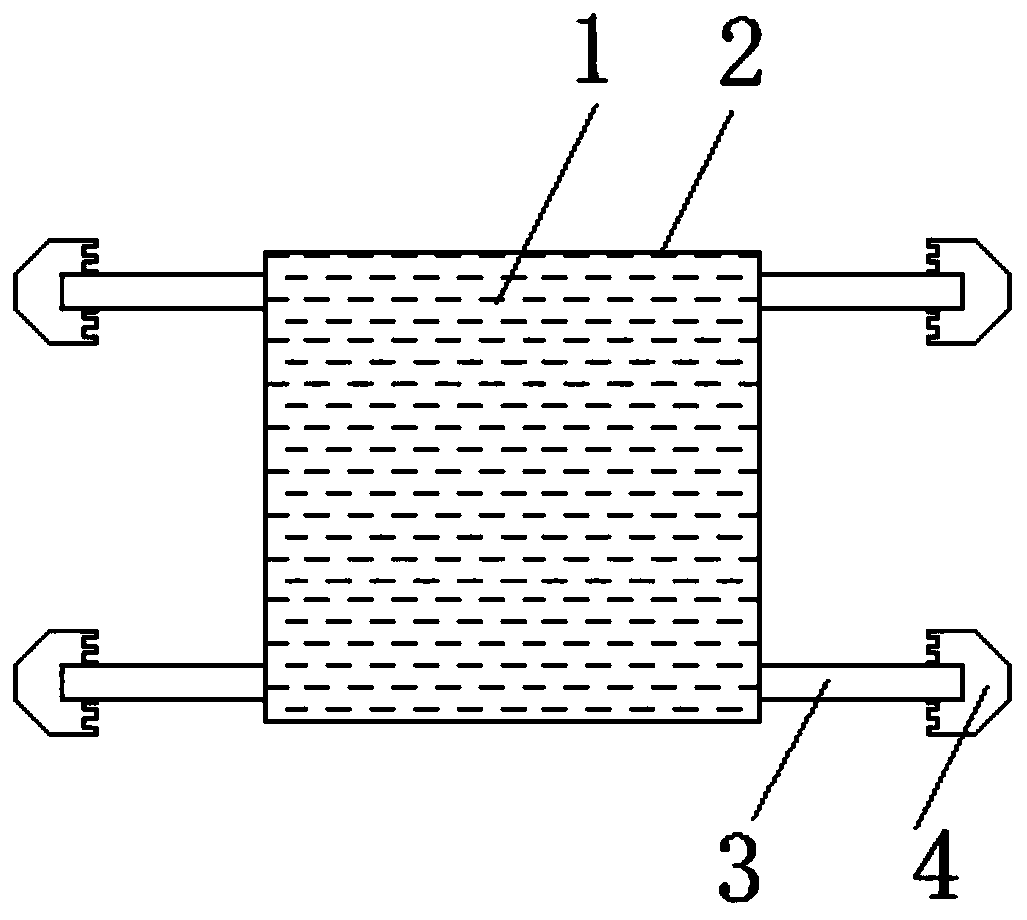

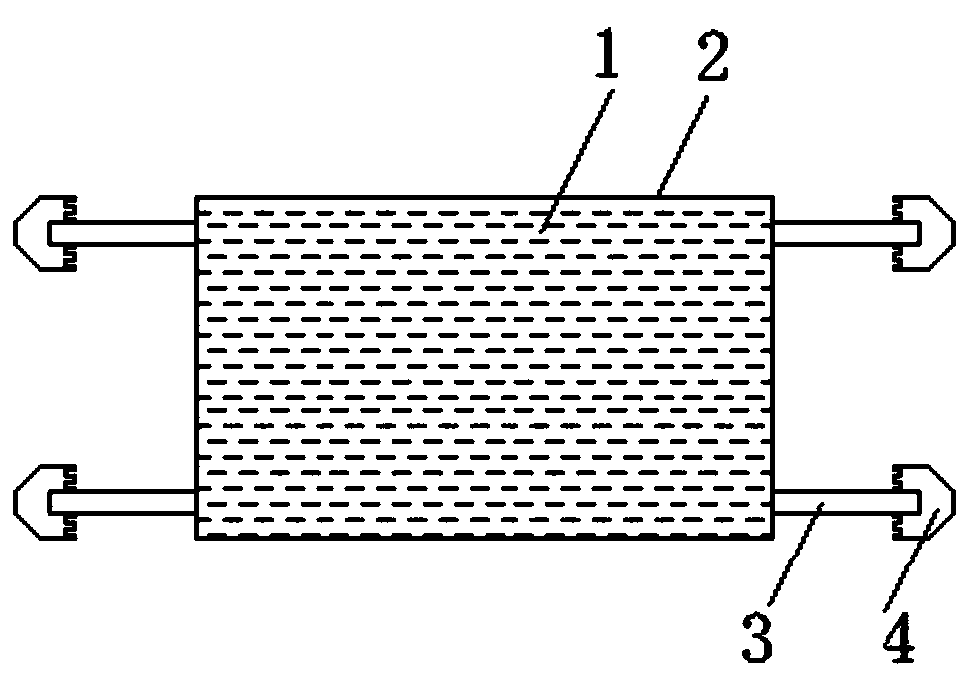

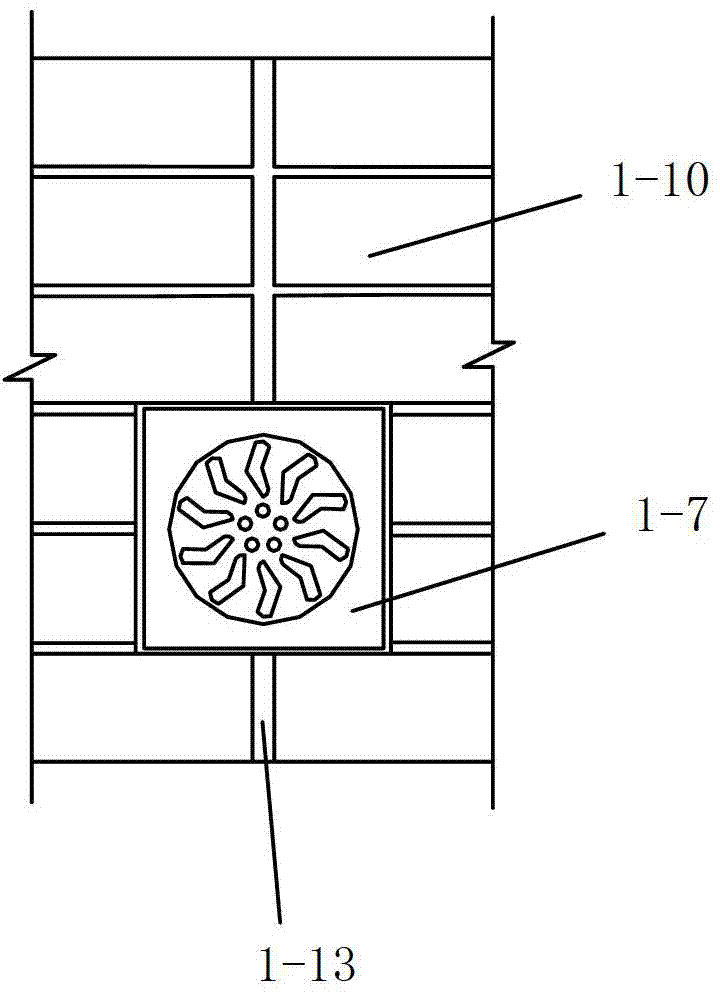

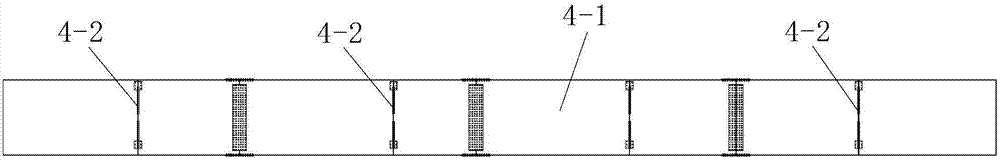

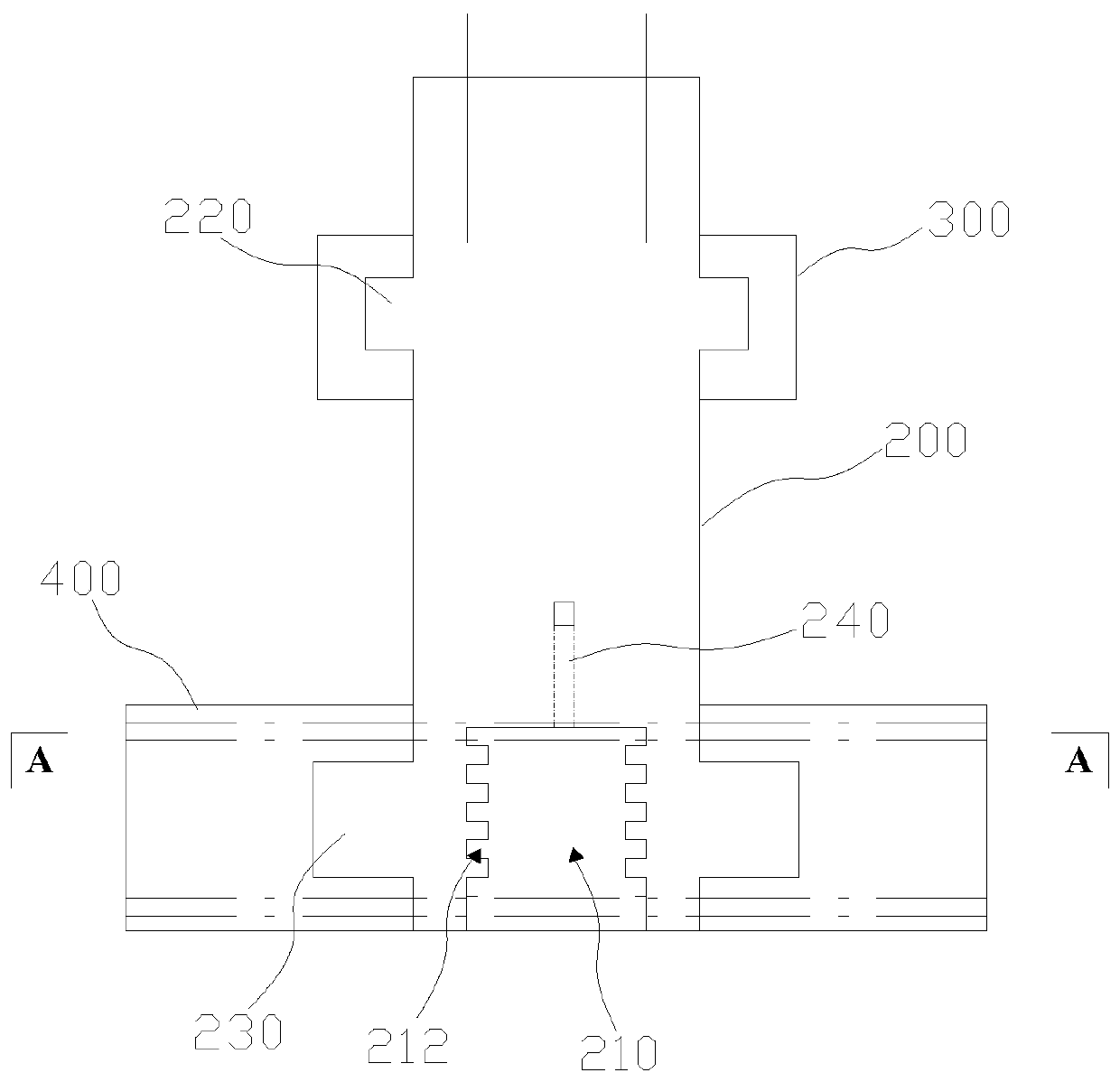

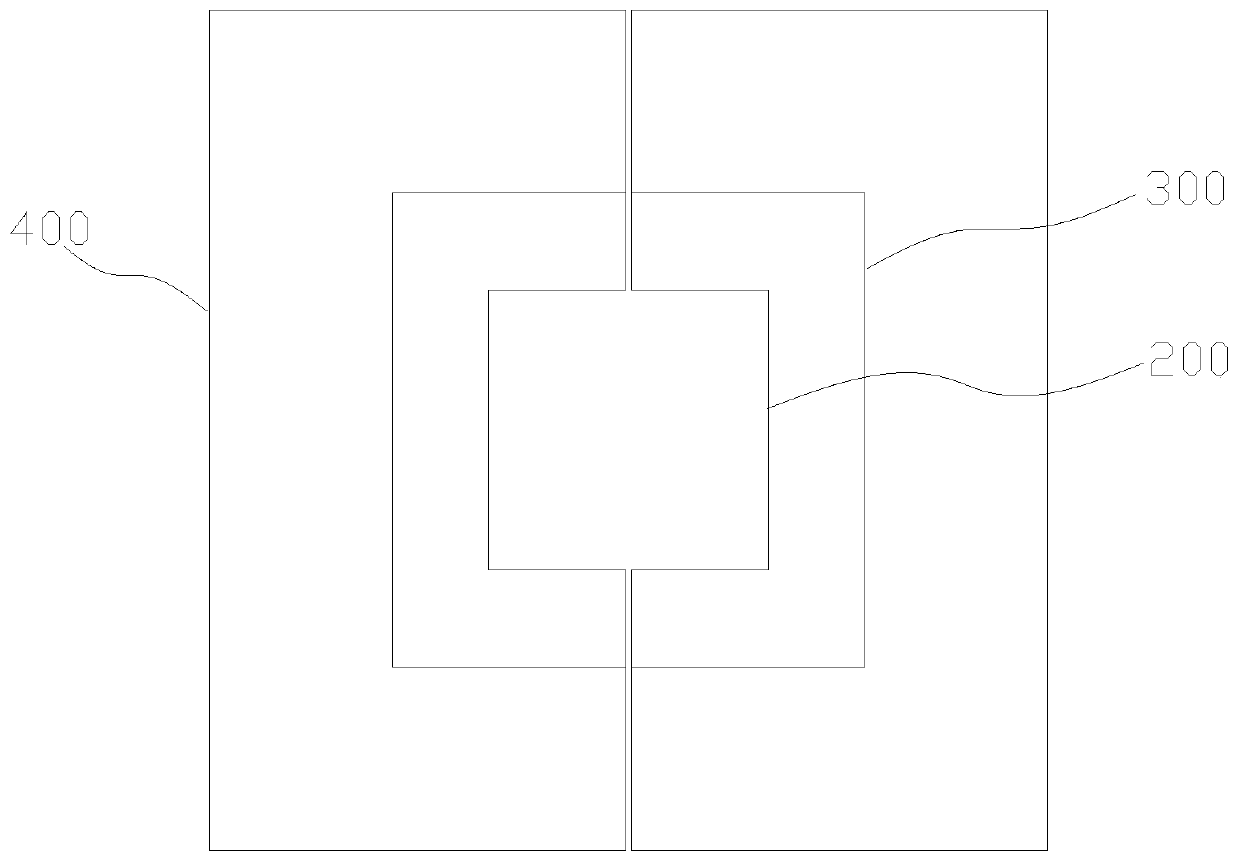

The invention discloses an assembled type gridding shearing wall structural system which comprises a plurality of shearing wallboards arranged from top to bottom. Each shearing wallboard comprises a shearing wall body, upper restraining hidden beams and two vertical edge restraining components, the shearing wall body is formed by a plurality of prefabricated gridding shearing wall main bodies in a spliced mode, every two adjacent prefabricated gridding shearing wall main bodies are connected through a connecting hidden column, and rectangular boxes on the internal framework of each prefabricated gridding shearing wall main body are respectively provided with a rectangular heat preservation board in an inlaid mode. A construction technology of the assembled type gridding shearing wall structural system includes the steps of (1) carrying out measuring and setting-out, (2) hoisting the prefabricated gridding shearing wall main bodies, (3) constructing the upper restraining hidden beams, the connecting hidden columns and the vertical edge restraining components, (4) constructing the shearing wallboard on the upper layer, and (5) repeating the steps till the construction process of the multiple shearing wallboards is completed. The assembled type gridding shearing wall structural system and the construction technology are reasonable in design, convenient to construct, low in investment cost and good in use effect, and multiple problems in traditional assembling of an integrated shearing wall structure can be effectively solved.

Owner:东莞市建安住宅工业有限公司

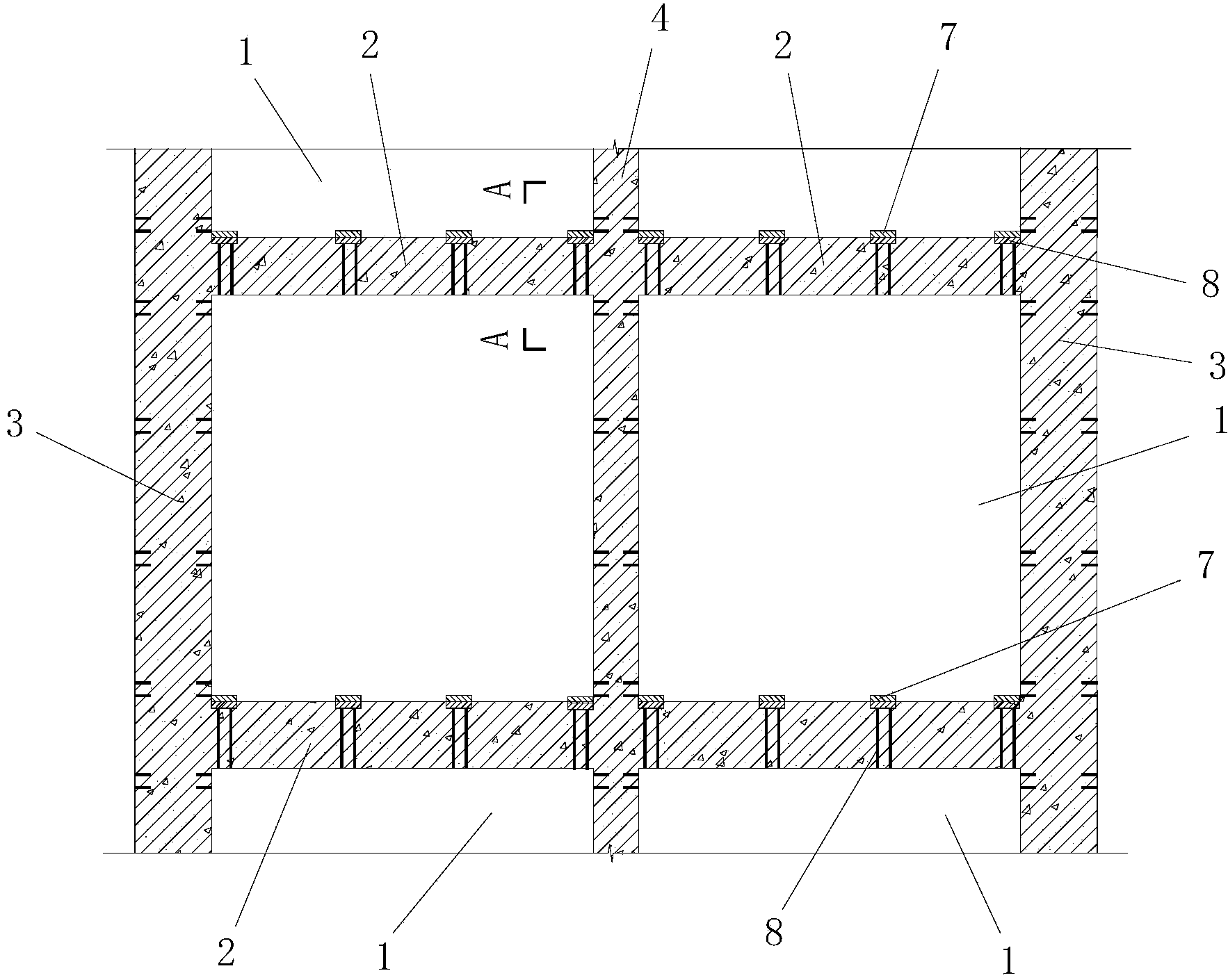

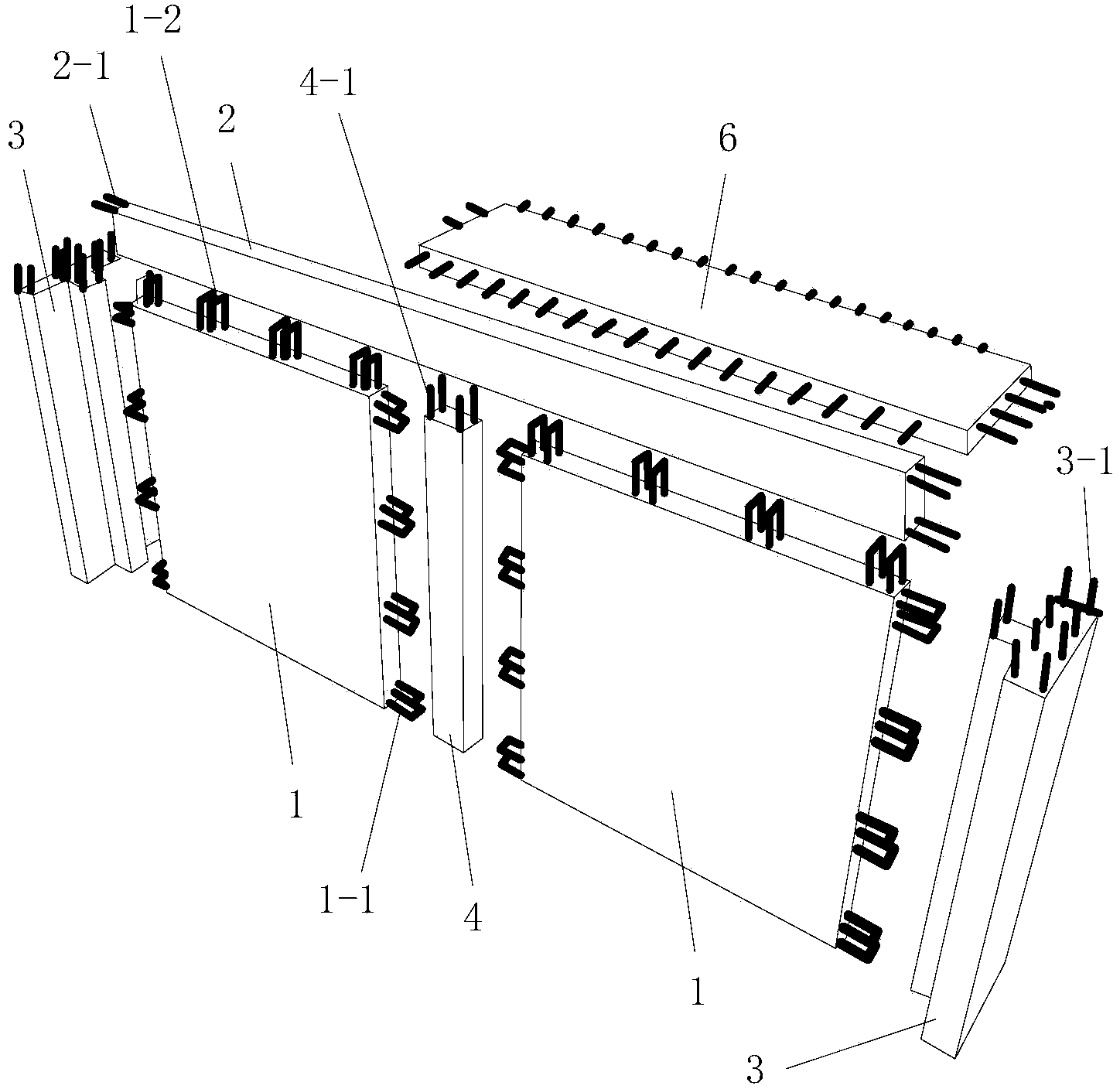

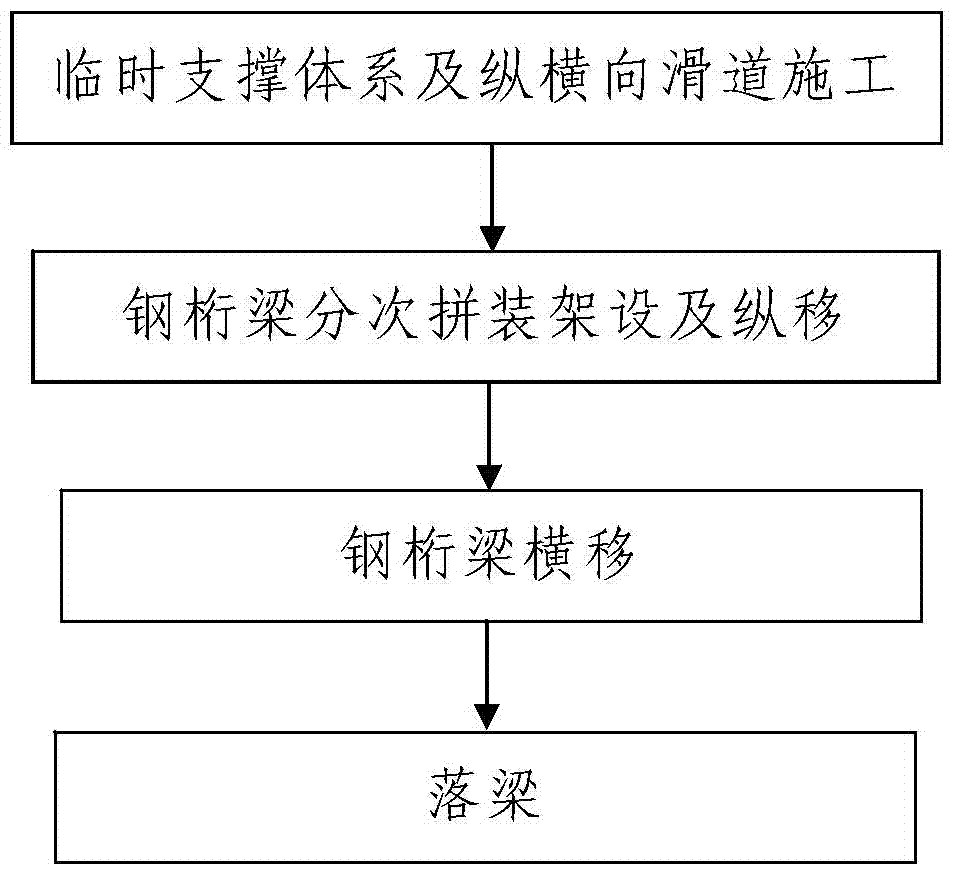

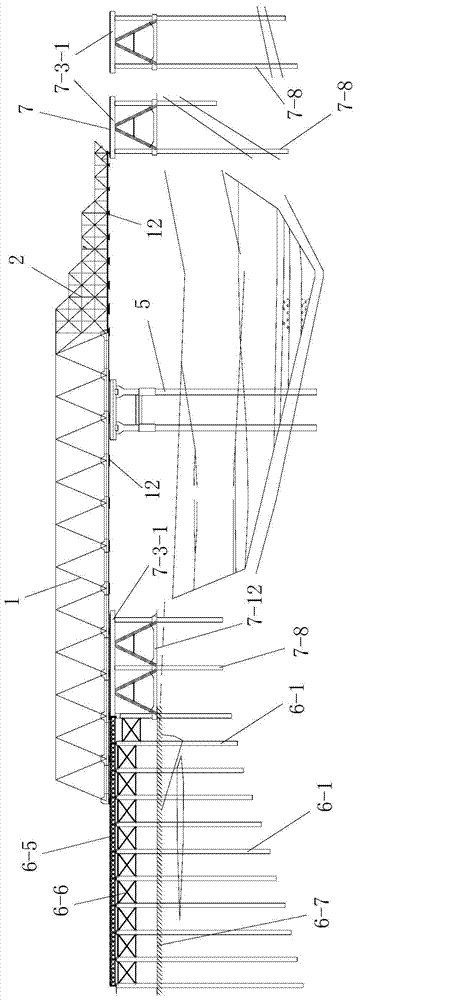

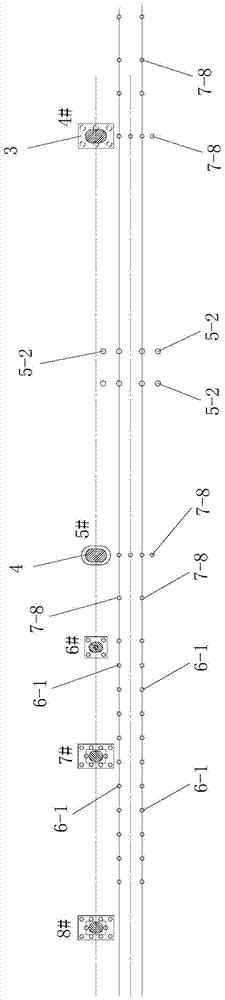

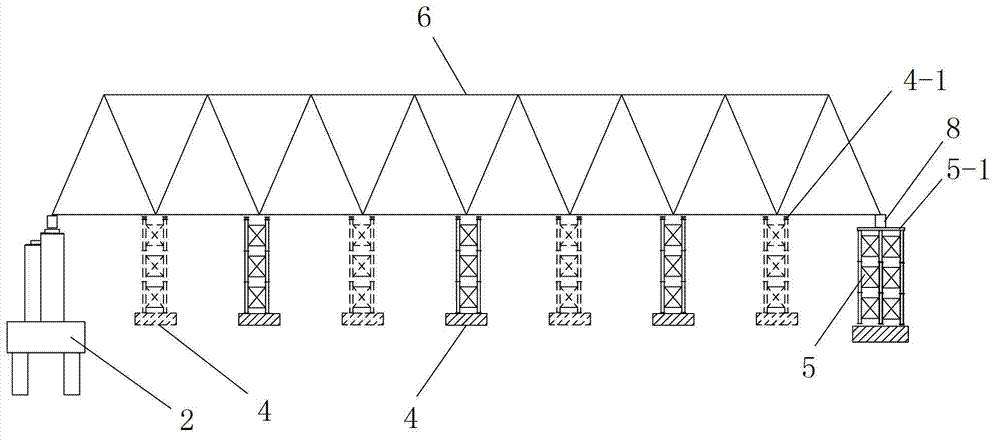

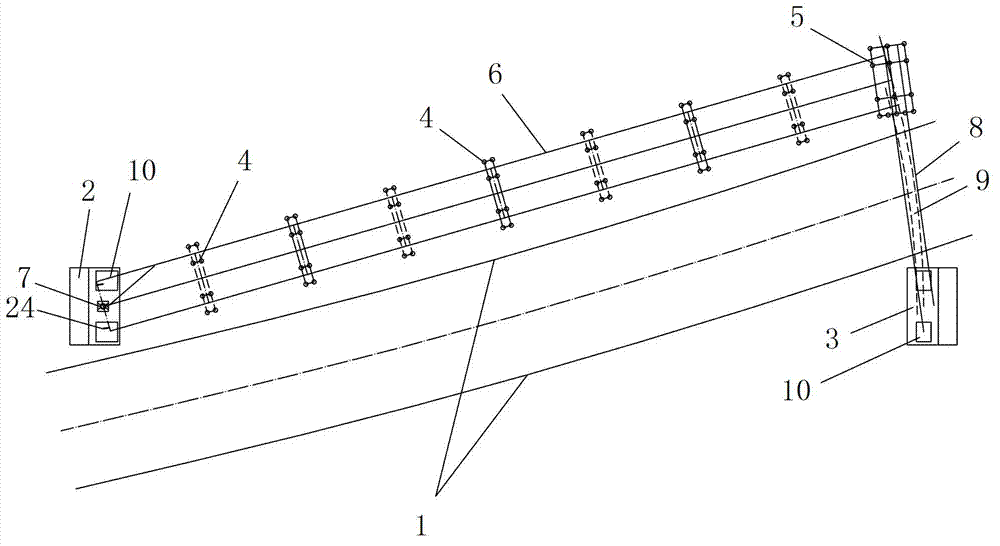

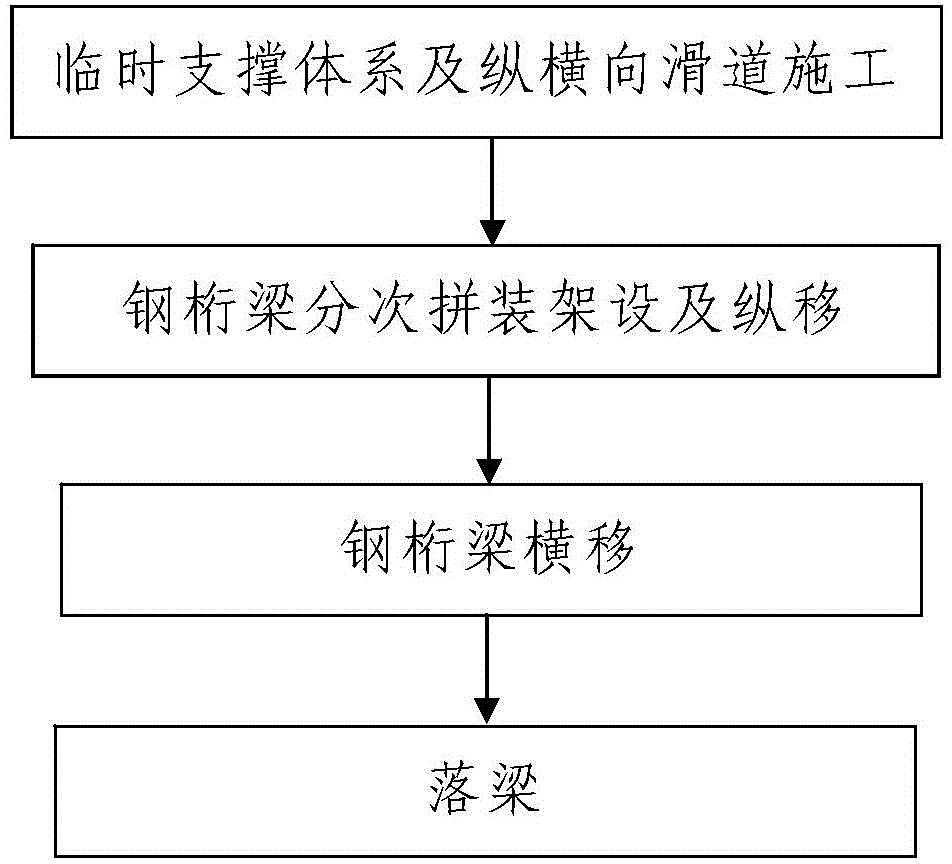

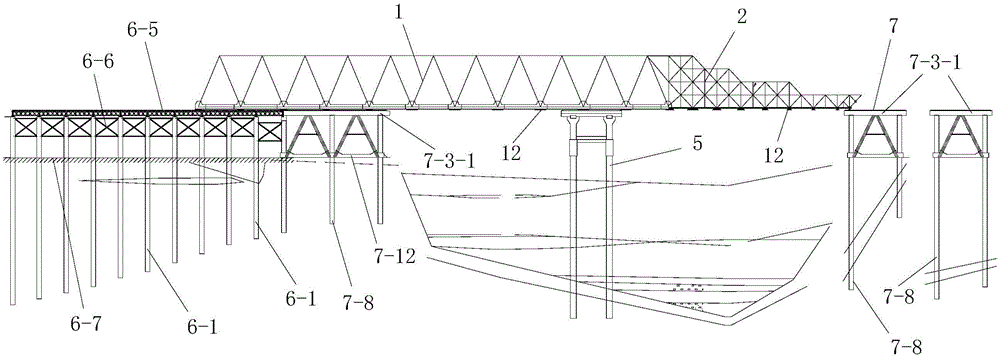

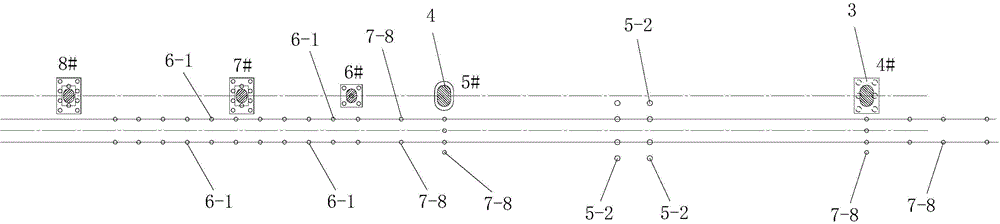

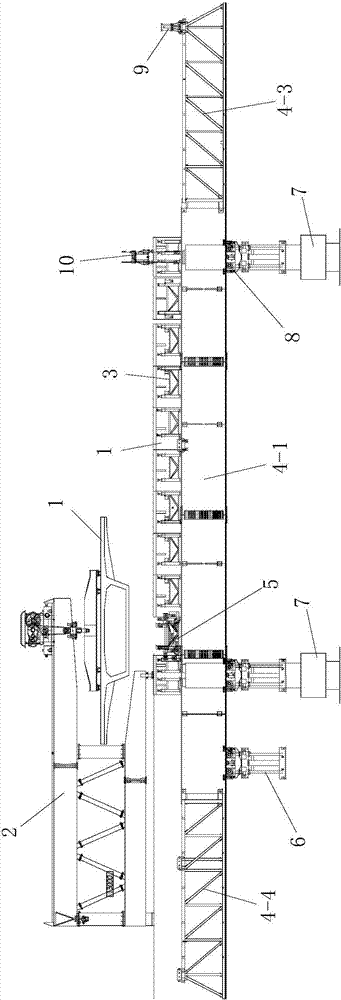

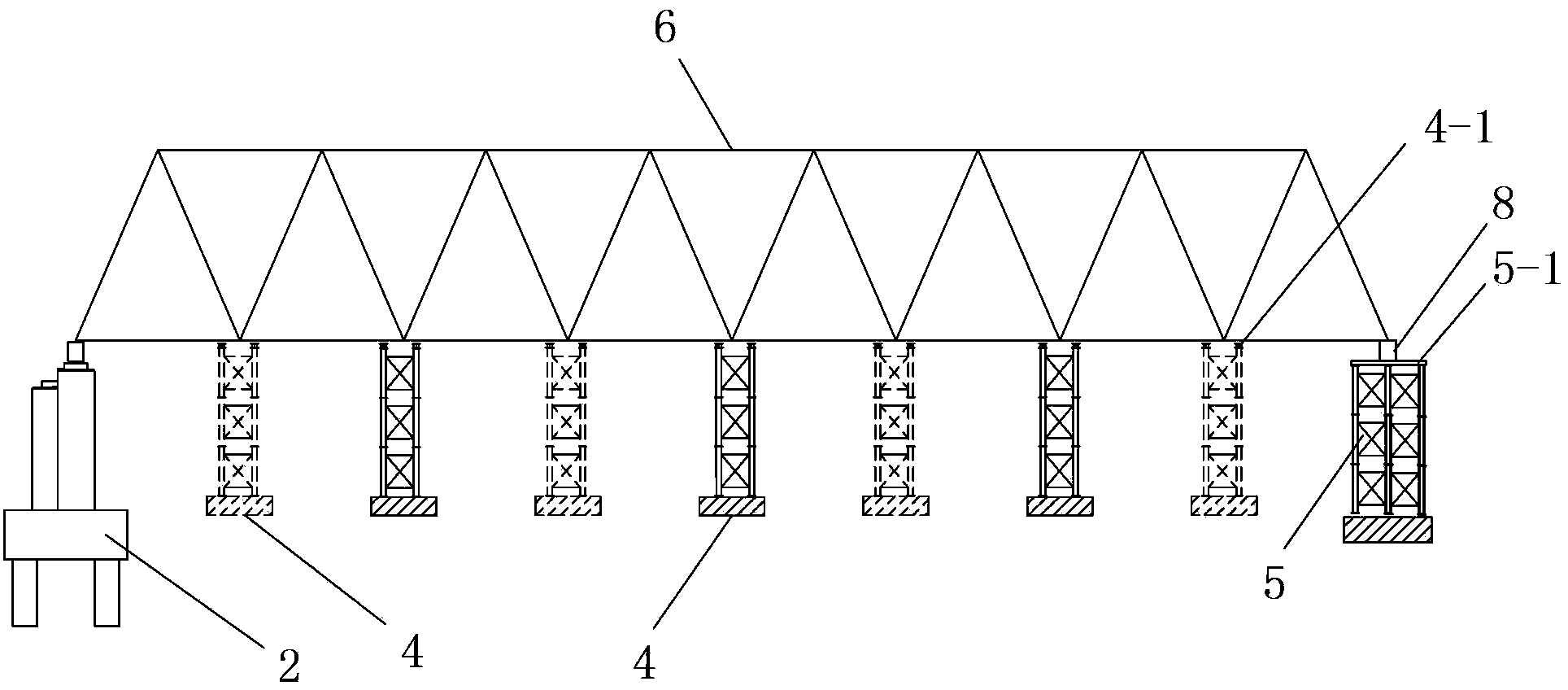

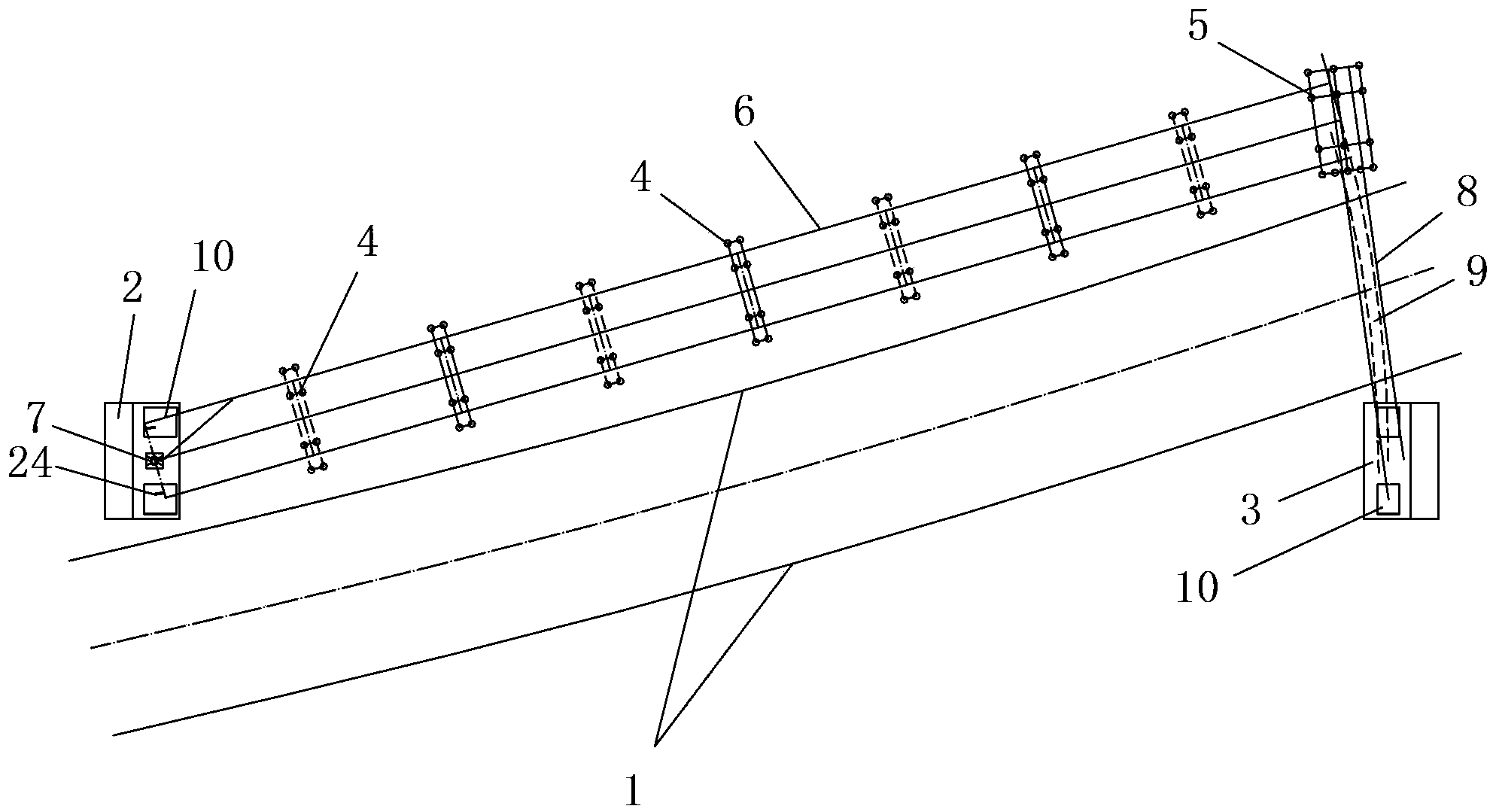

Steel truss girder assembling, erecting and construction process

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

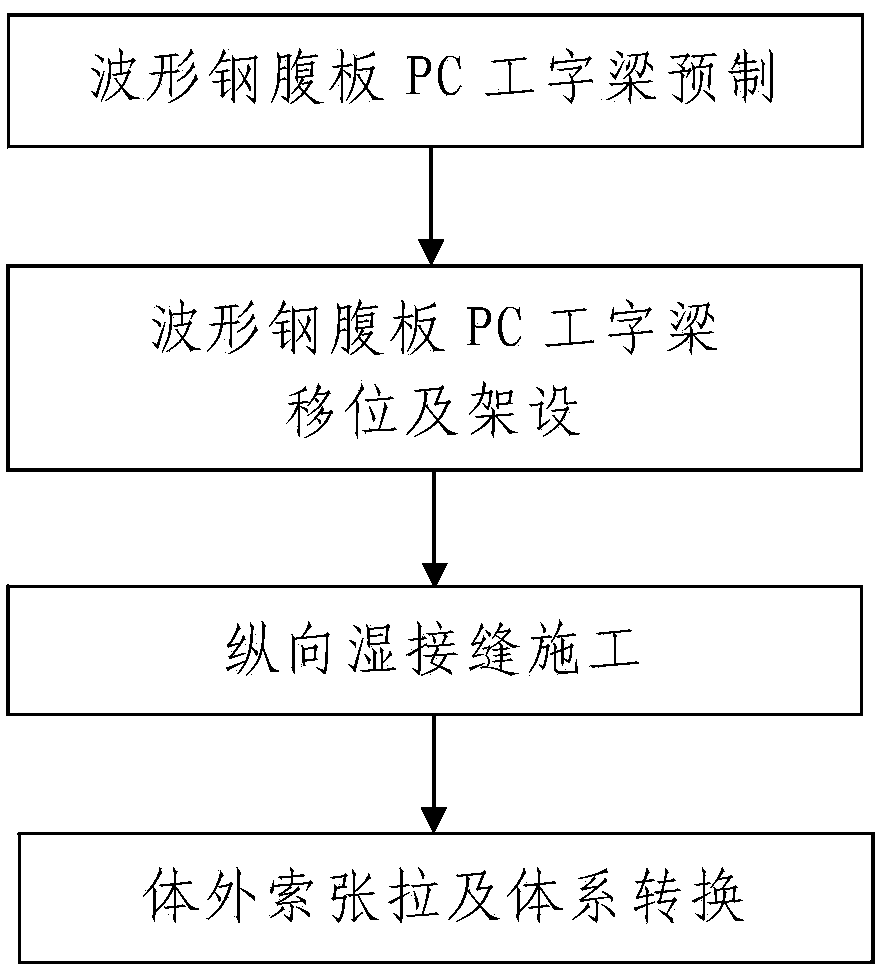

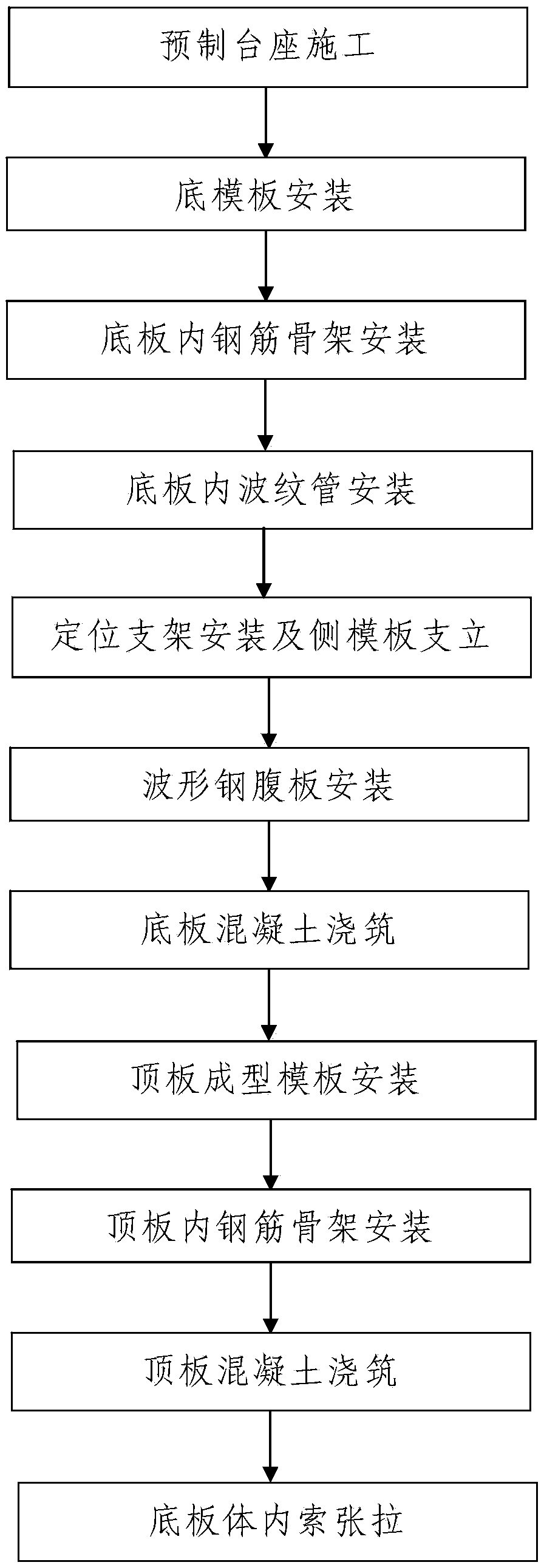

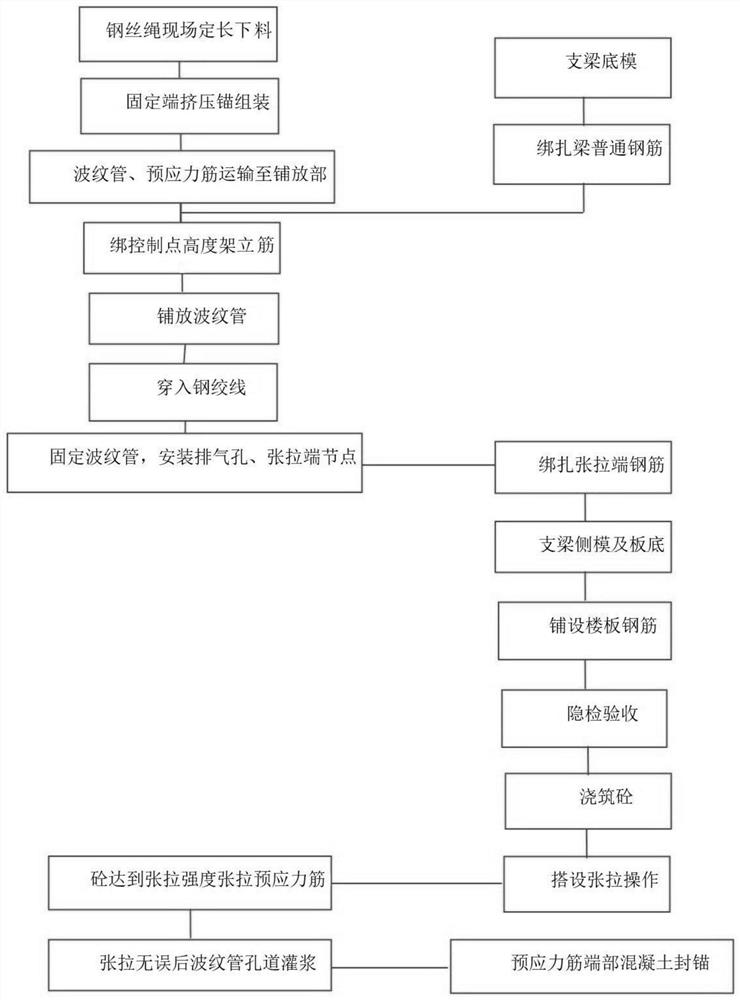

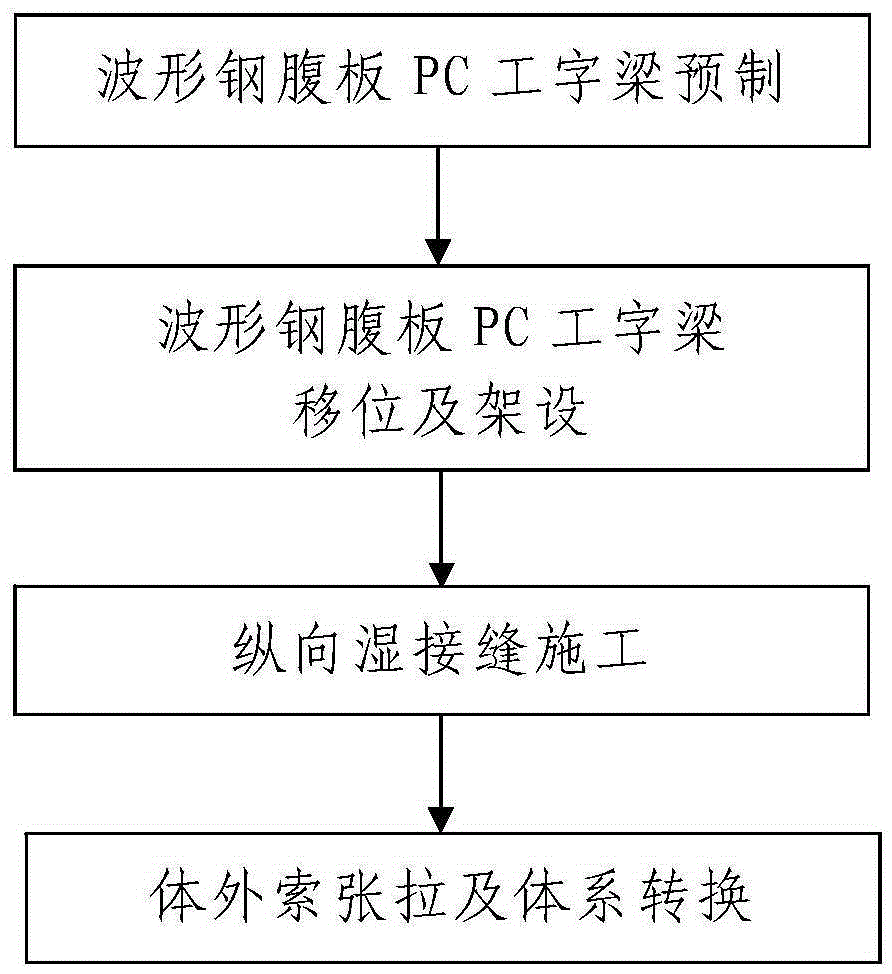

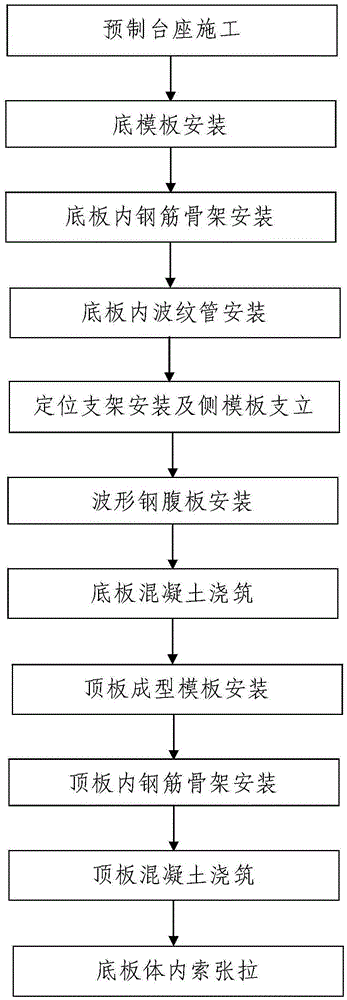

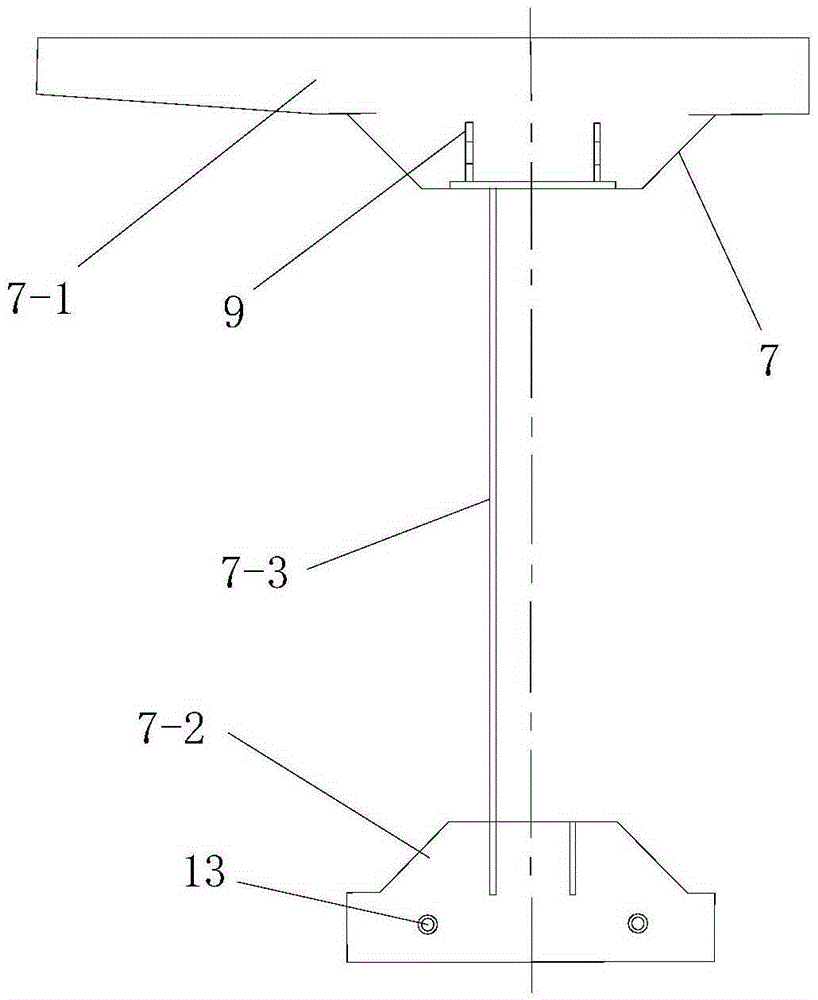

Construction technology for prefabricating a corrugated steel web PC I beam into combined box girder bridge

ActiveCN104195959ASimple structureEasy constructionBridge erection/assemblyBridge materialsEngineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

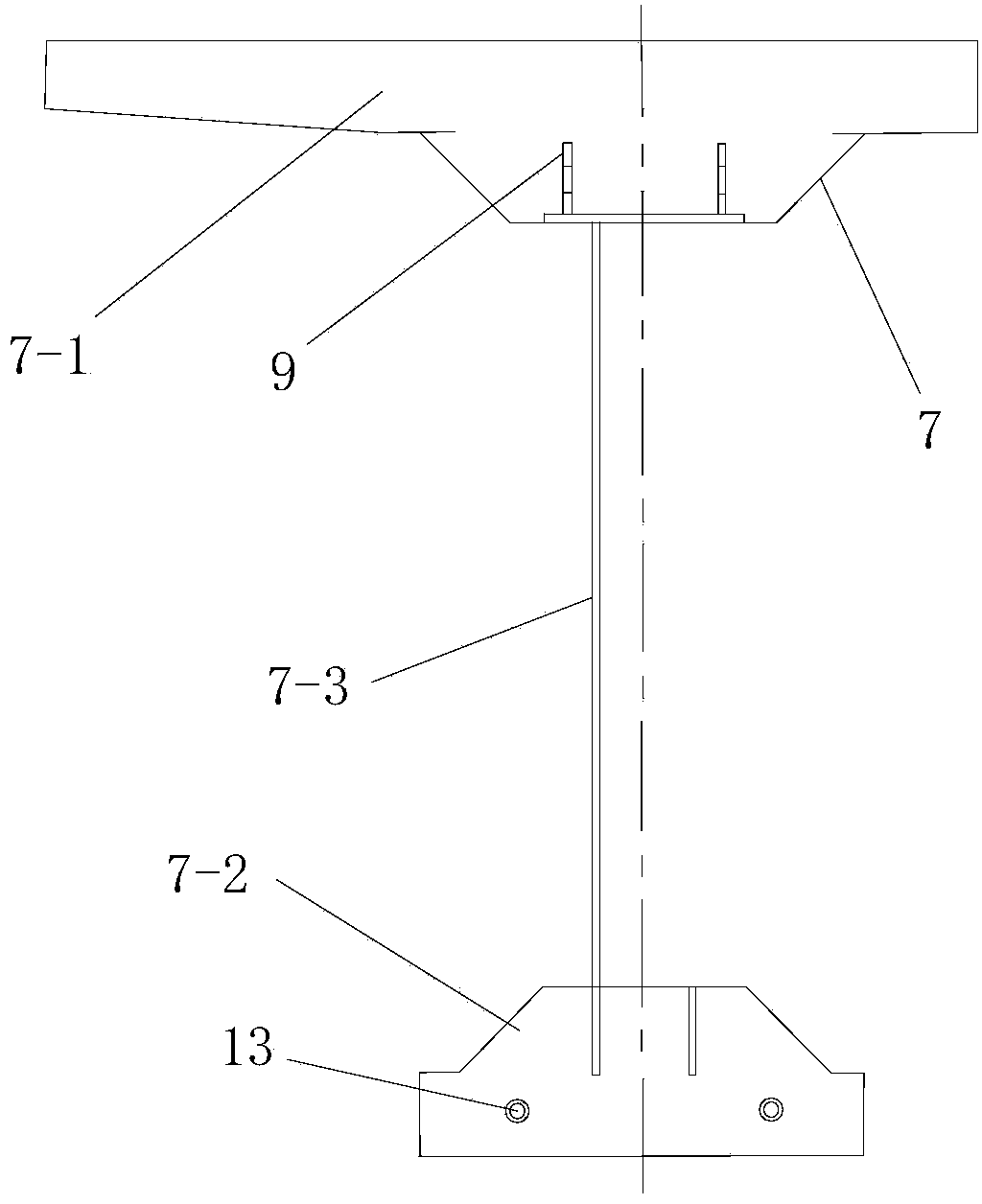

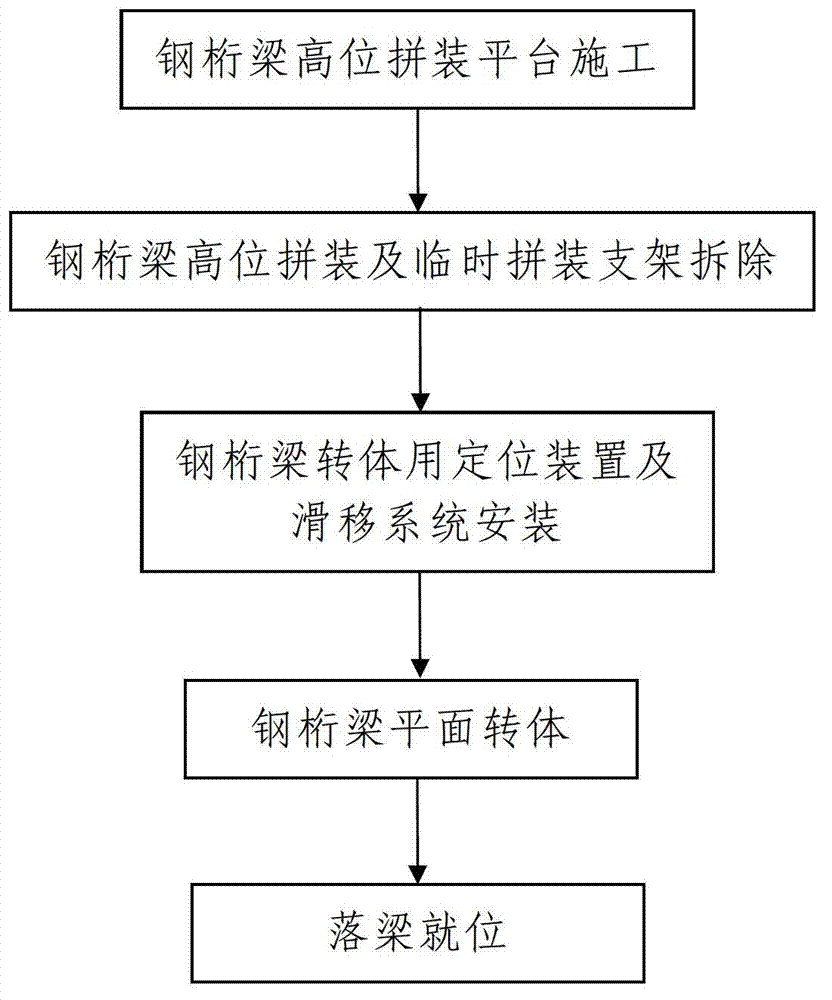

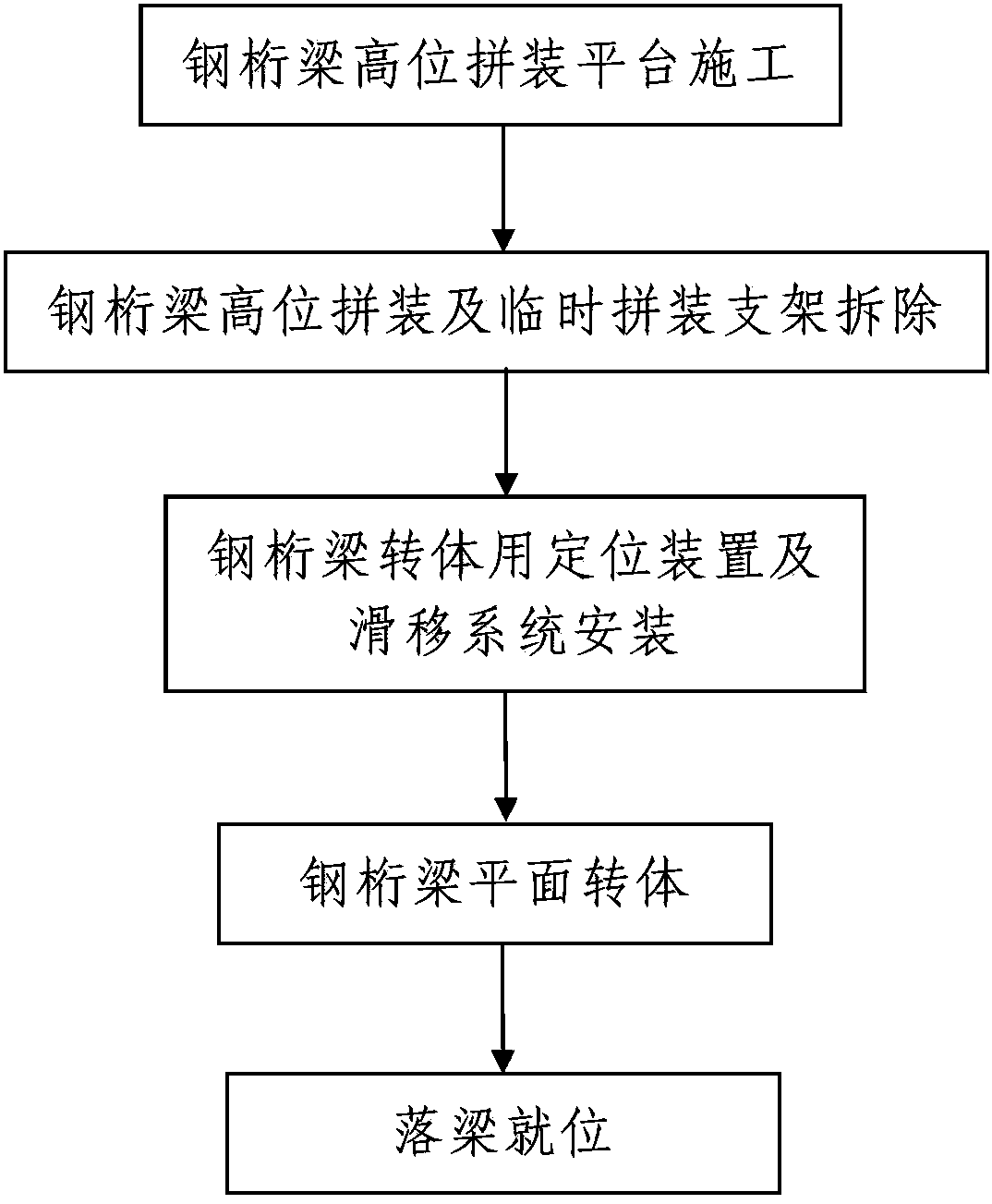

Plane rotation construction technique for steel truss girder for existing bridge spanning construction

The invention discloses a plane rotation construction technique for a steel truss girder for existing bridge spanning construction. A main girder of the constructed bridge is a steel truss girder spanning the existing bridge and obliquely crossing with the existing bridge; the technique comprises the following steps: firstly, constructing a high-altitude steel truss girder assembling platform which comprises a temporary buttress and a plurality of temporarily assembling brackets; secondly, assembling the steel truss girder at high altitude and removing the temporarily assembling brackets; thirdly, installing a steel truss girder rotation positioning device and a slippage system; before rotating the steel truss steel, firstly installing the steel truss girder rotation positioning device and the slippage system; fourthly, conducting plane rotation on the steel truss girder; and fifthly, dropping the girder in place. The construction technique is simple in steps, convenient to construct, fast to construct, safe and reliable in construction process and less in interference on the existing bridge, and can effectively solve the problems that the construction field is limited, the construction can not be normally conducted, the travelling interference on the existing bridge is large, the construction risk and hidden hazard are large and the like in construction with the existing in-situ falsework method and the dragging method.

Owner:NO 1 ENG LIMITED OF CR20G

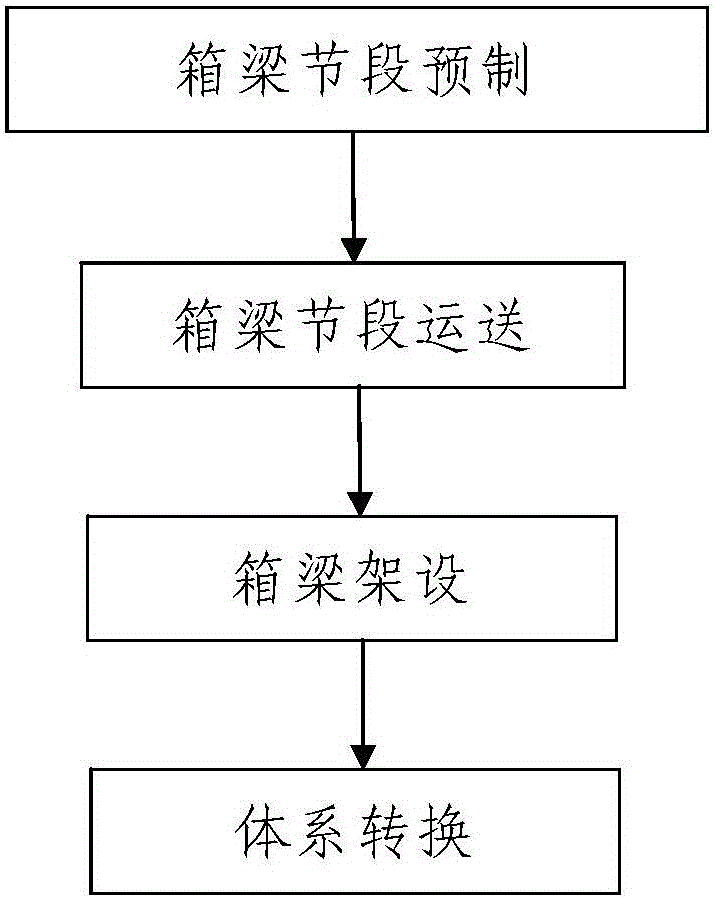

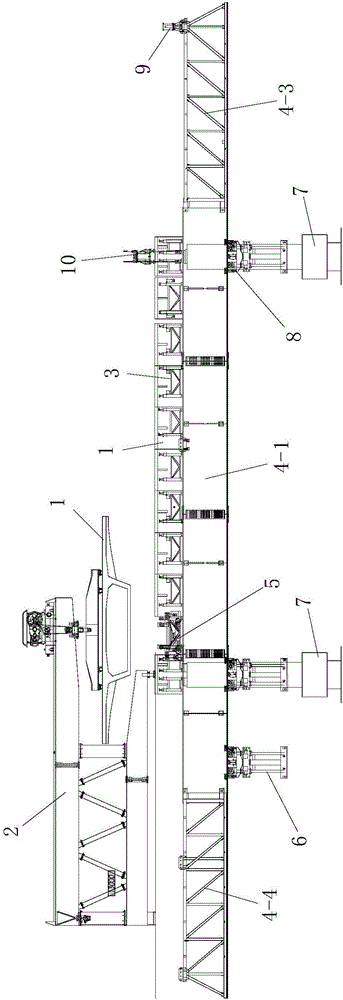

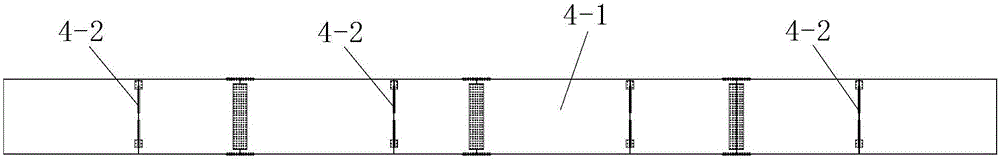

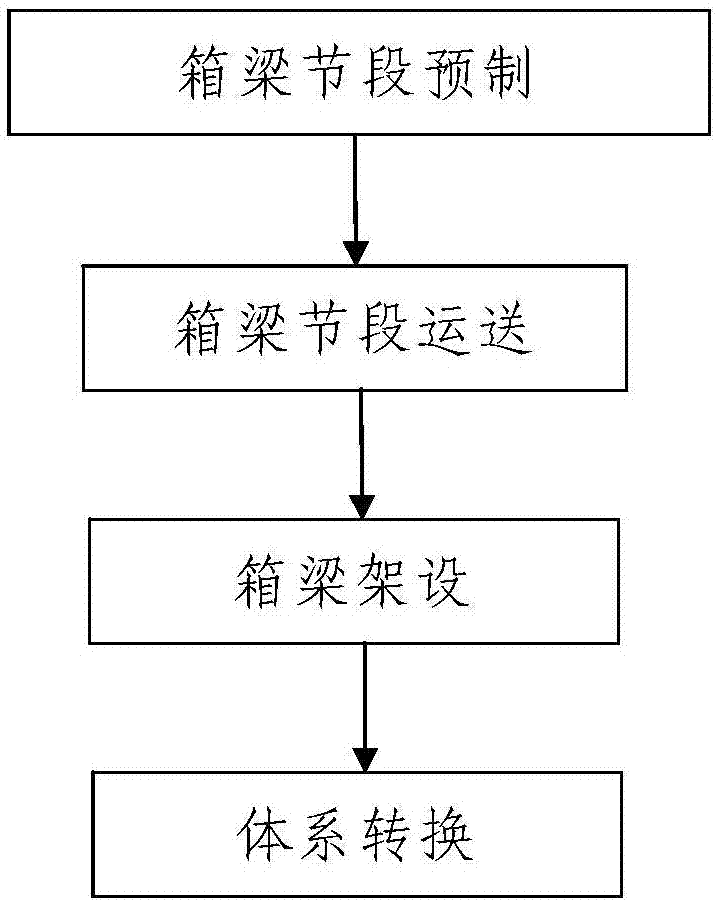

Segmental assembling box girder construction technology

ActiveCN105780660AThe construction process steps are simpleReasonable designBridge erection/assemblySupporting systemCantilever

The invention discloses a segmental assembling box girder construction technology. A constructed box girder is composed of multiple porous girders. Each porous girder is formed by assembling multiple box girder segments from back to front. When the constructed box girder is constructed, the process includes the following steps that firstly, the box girder segments are prefabricated, wherein all the box girder segments used for forming the constructed box girder are prefabricated in a prefabrication site in a concentrated manner; secondly, the box girder segments are transported, wherein all the box girder segments are transported to the erection position of the constructed box girder through a girder transport vehicle; thirdly, the box girder is erected, wherein the constructed box girder is erected and constructed through a descending bridge girder erection machine, and the descending bridge girder erection machine comprises a bottom horizontal supporting system, a main girder system, a longitudinal moving system, a cantilever crane, an assembling frame and an assembling vehicle; and fourthly, a system is converted, wherein the system is converted after the erection construction process is finished. By the adoption of the segmental assembling box girder construction technology, the technological step is simple, design is reasonable, construction is easy and convenient, a construction process is easy to control, a use effect is good, the segmental assembling box girder assembling process can be simply, conveniently and rapidly finished, and the construction quality is easy to guarantee.

Owner:CHINA RAILWAY FIRST GRP CO LTD

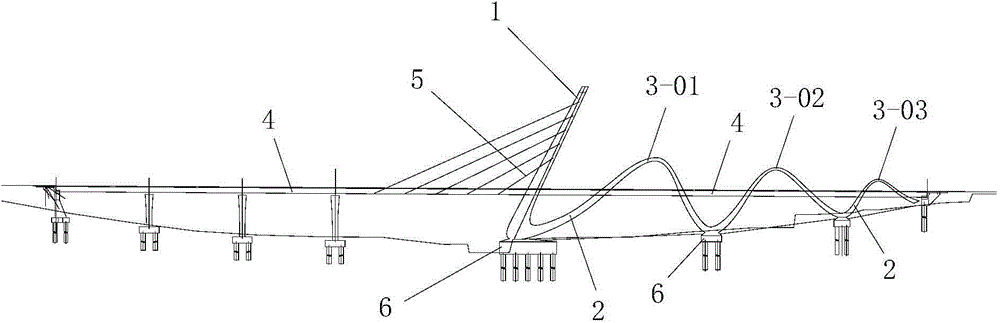

Ribbon-shaped single-tower cable-strayed-steel structure combined bridge and construction process thereof

ActiveCN104562913ASimple structureReasonable designCable-stayed bridgeBridge structural detailsCable stayedEngineering

The invention discloses a ribbon-shaped single-tower cable-strayed-steel structure combined bridge and a construction process thereof. The combined bridge comprises a lower supporting structure, a main beam, an arch-shaped main tower which is arranged on the main beam and gradually backwards inclined from bottom to top, and two ribbon-shaped supporting structures which are positioned at the rear side of the main tower; the two ribbon-shaped supporting structures are both integrally fixedly connected with the main beam; the two-ribbon-shaped supporting structures and the main beam are lengthways arranged along the bridge direction; a plurality of cable-strayed ropes are arranged between the main tower and the main beam; each ribbon-shaped supporting structure is divided into a lower ribbon-shaped supporting structure and an upper ribbon-shaped connecting structure through the main beam. The construction process of the combined bridge comprises the steps of 1, constructing the lower supporting structure; 2, constructing the lower ribbon-shaped supporting structure; 3, constructing the main beam; 4, constructing the main tower and the upper ribbon-shaped connecting structure. The combined bridge is reasonable in structural design, convenient to construct, outstanding in mechanical performance and a good in use effect; a non-back cable-stayed bridge and a continuous rigid structural bridge are effectively combined, and the advantages of the two bridges are brought into full play.

Owner:XIAN MUNICIPAL ENG DESIGN & RES INST +1

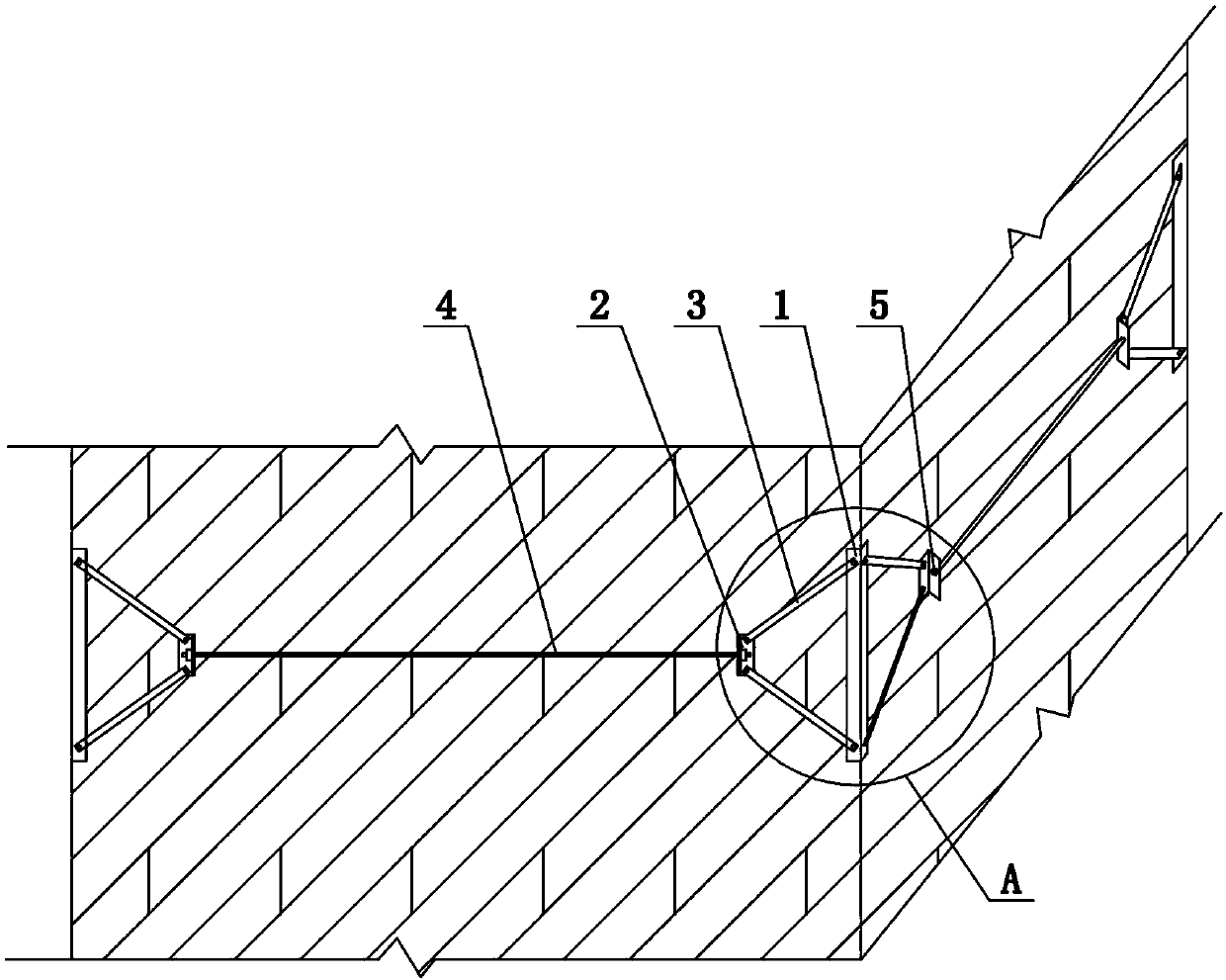

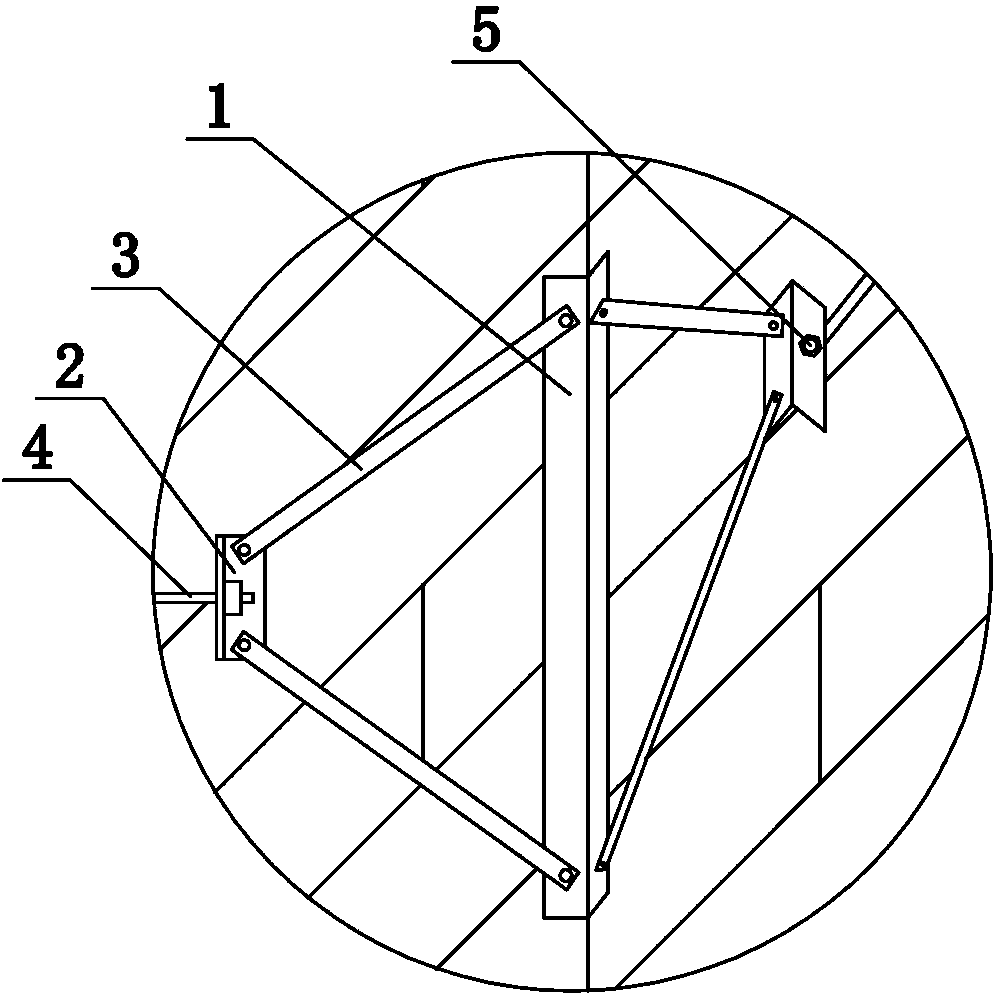

Angle hoop tie reinforcement system of traditional stone masonry house and construction technology

The invention relates to an angle hoop tie reinforcement system of a traditional stone masonry house and a construction technology. The system comprises long steel angles, the long steel angles are used for fixedly clamping outer wall corner angles of the stone masonry house, and one side of each short steel angle is connected with the corresponding long steel angle through diagonal tension plates. A connecting hole is formed in the middle of the other side of each short steel angle. Every two adjacent short steel angles are connected through tie bars penetrating through the connecting holes. The long steel angles, the short steel angles, the diagonal tension plates and the tie bars are mutually connected to form closed steel hoop structures. The steel hoop structures are hooped around the outer wall of the stone masonry house. The tie bars are prestressed steel bars. The steel angles are fixed to the corners of the wall of the stone masonry house, every two adjacent steel angles are connected through the steel tie bars, and prestress is exerted on the steel tie bars, so that the steel tie bars are matched with the steel angles to form the steel hoop structures. The steel hoops generate large constraint force on the corners of the wall, so that the stress condition of the original structure of the stone masonry house is changed, shear stress of connecting positions of longitudinal and transverse walls is reduced, and cracks at the connecting positions of the longitudinal and transverse walls and further expansion of cracks already generated are avoided.

Owner:ZHENGZHOU UNIV

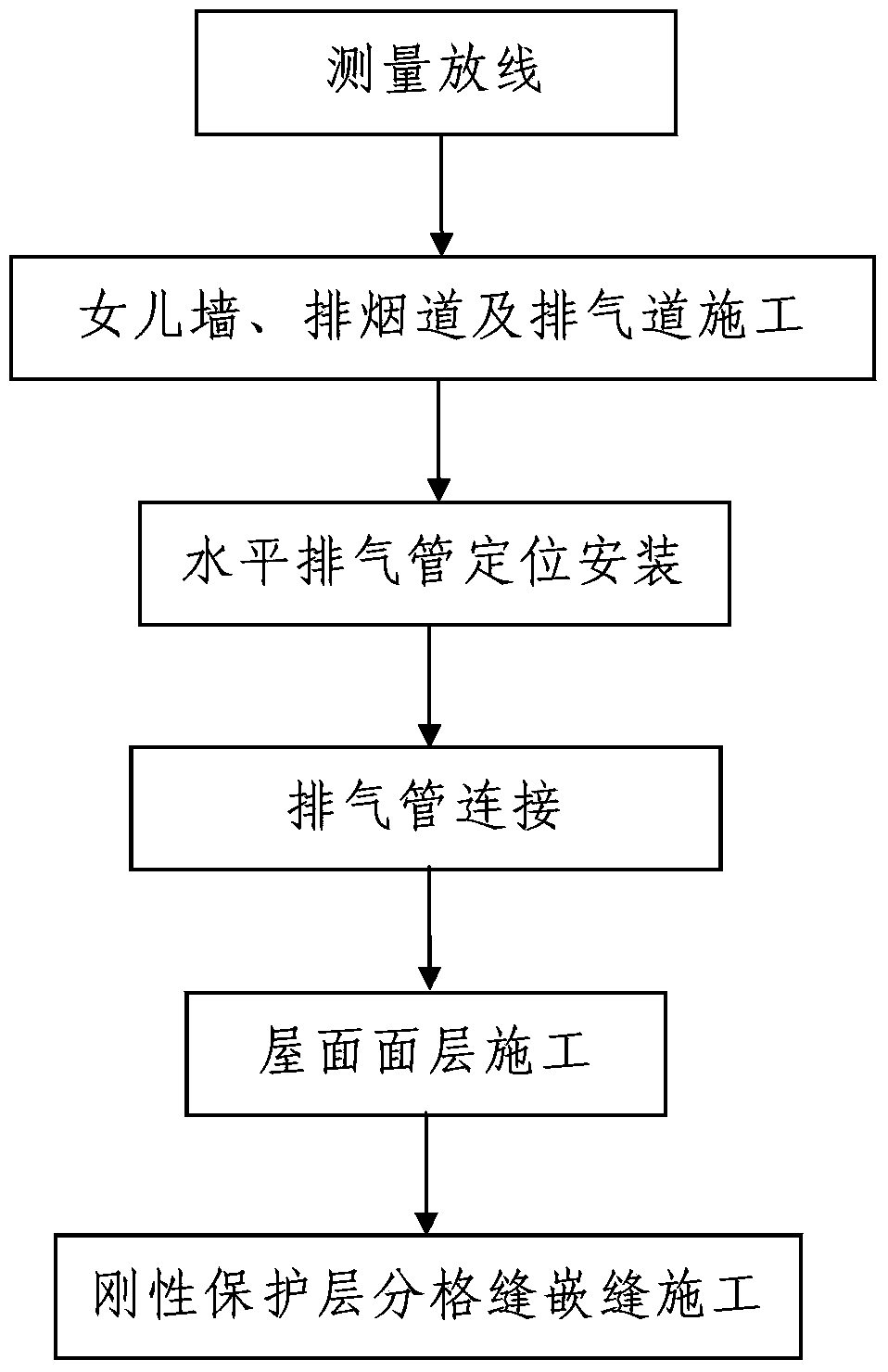

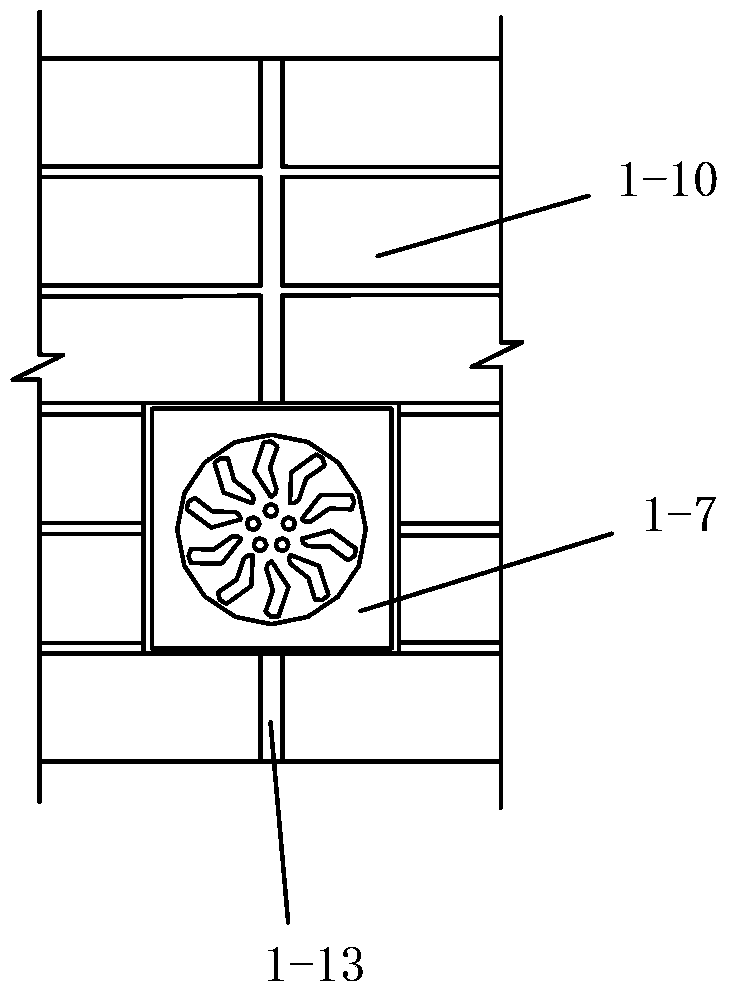

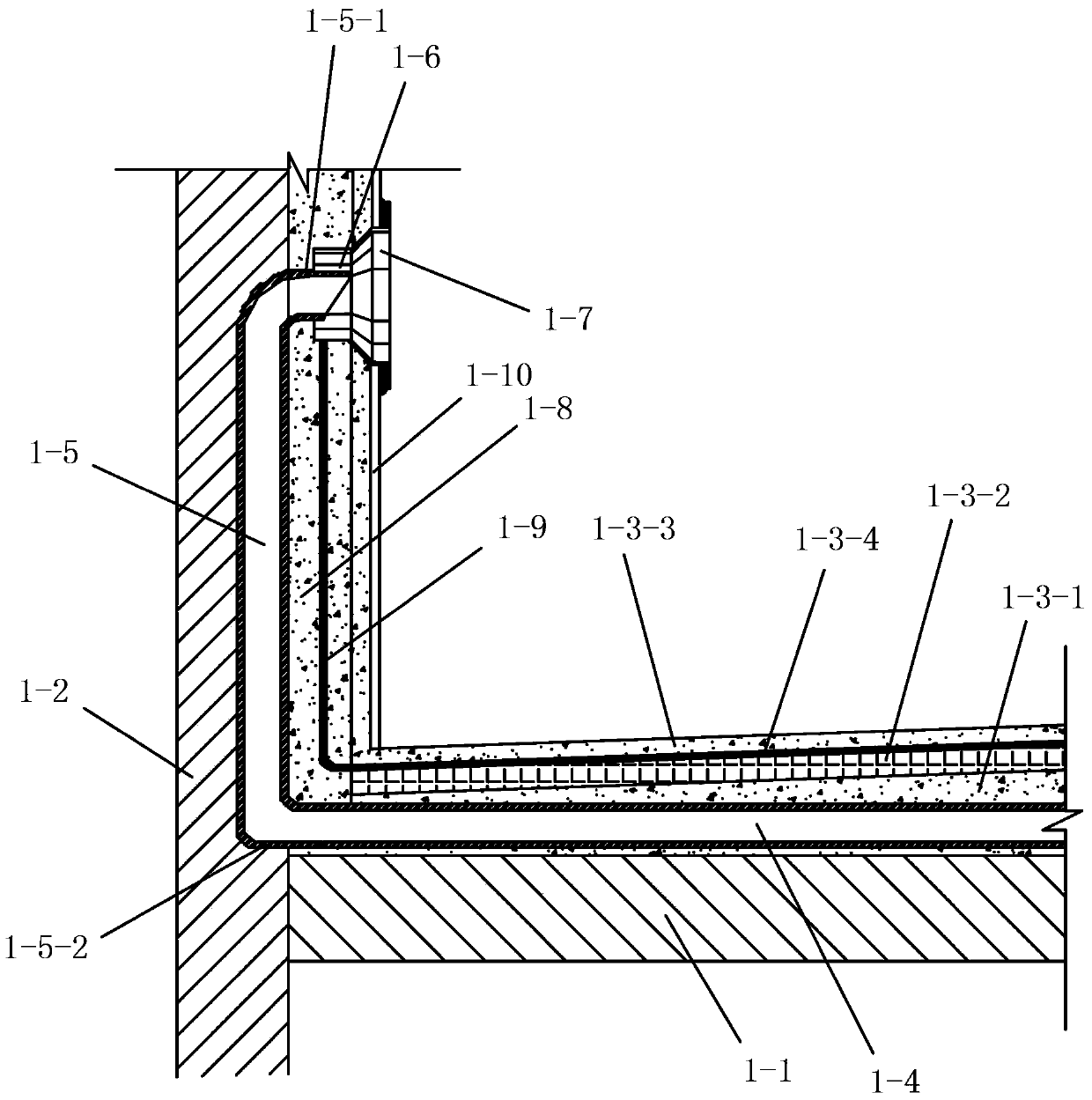

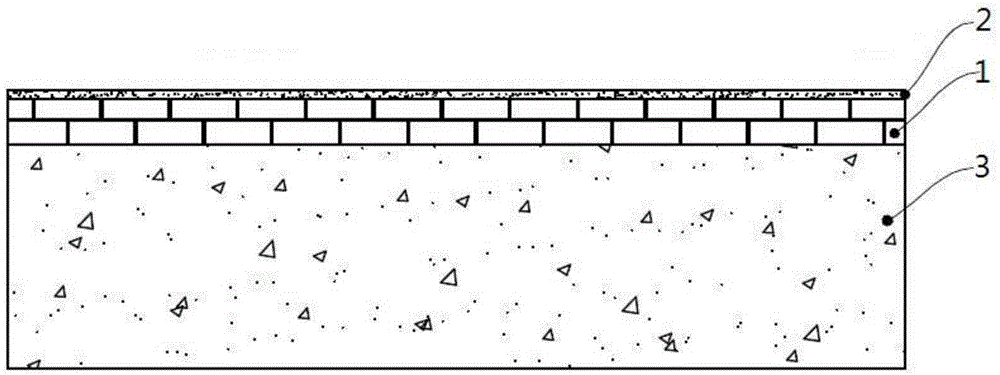

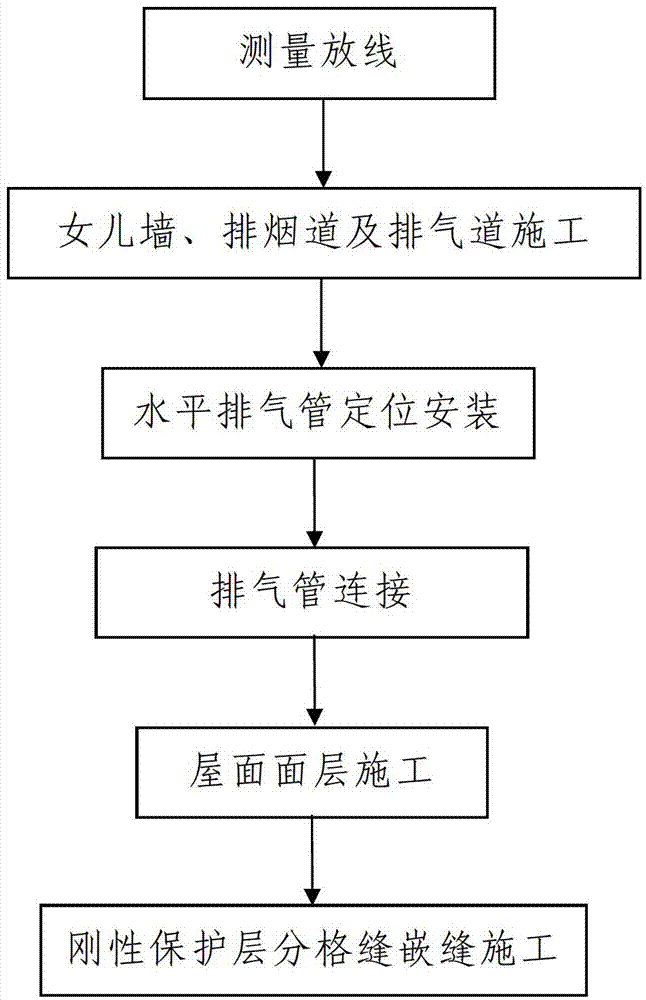

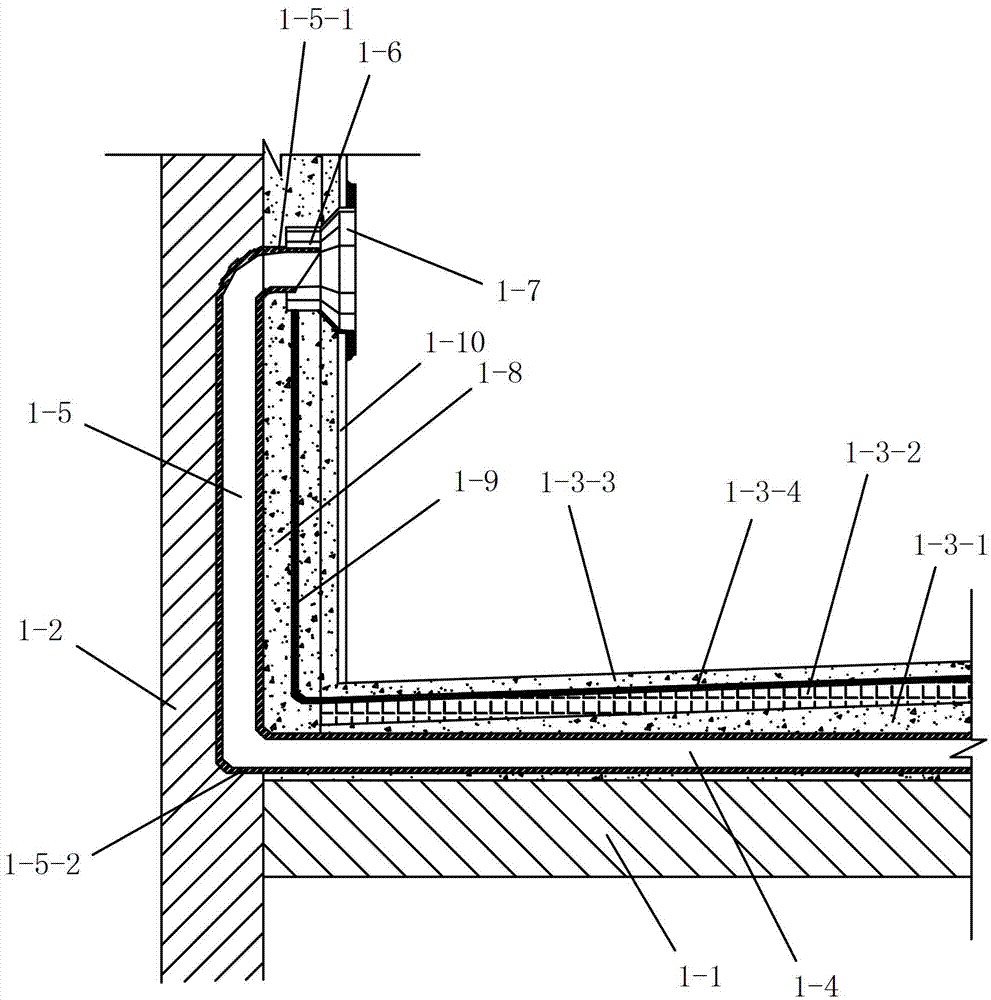

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

Construction method for inserting steel column in bored pile

InactiveCN102041806AReduce hoistingShorten construction timeBulkheads/pilesSteel columnsBuilding construction

The present invention relates to a construction method for inserting steel column in bored pile, comprising the following steps: (1) forming a pile hole of a bored pile; (2) hoisting a reinforcement cage; (3) pouring concretes; (4) hoisting a steel protection pipe; (5) cleaning the pile hole and placing a steel column bottom fixer; (6) hoisting a steel column, so as to complete the installation of the steel column; a top end of the hoisted reinforcement cage in the step (2) is coaxially and fixedly provided with a steel sleeve; the inner diameter of the steel sleeve is identical to the diameter of the pile hole; elevation at a top end of the steel sleeve is the same as the elevation at the top of the bored pile. The steps of construction technology of the present invention are simple; constructional time is shortened; working efficiency is improved; and constructional cost can be reduced effectively; and the present invention is a construction method for inserting steel column in bored pile with relatively high safety.

Owner:MCC TIANGONG GROUP

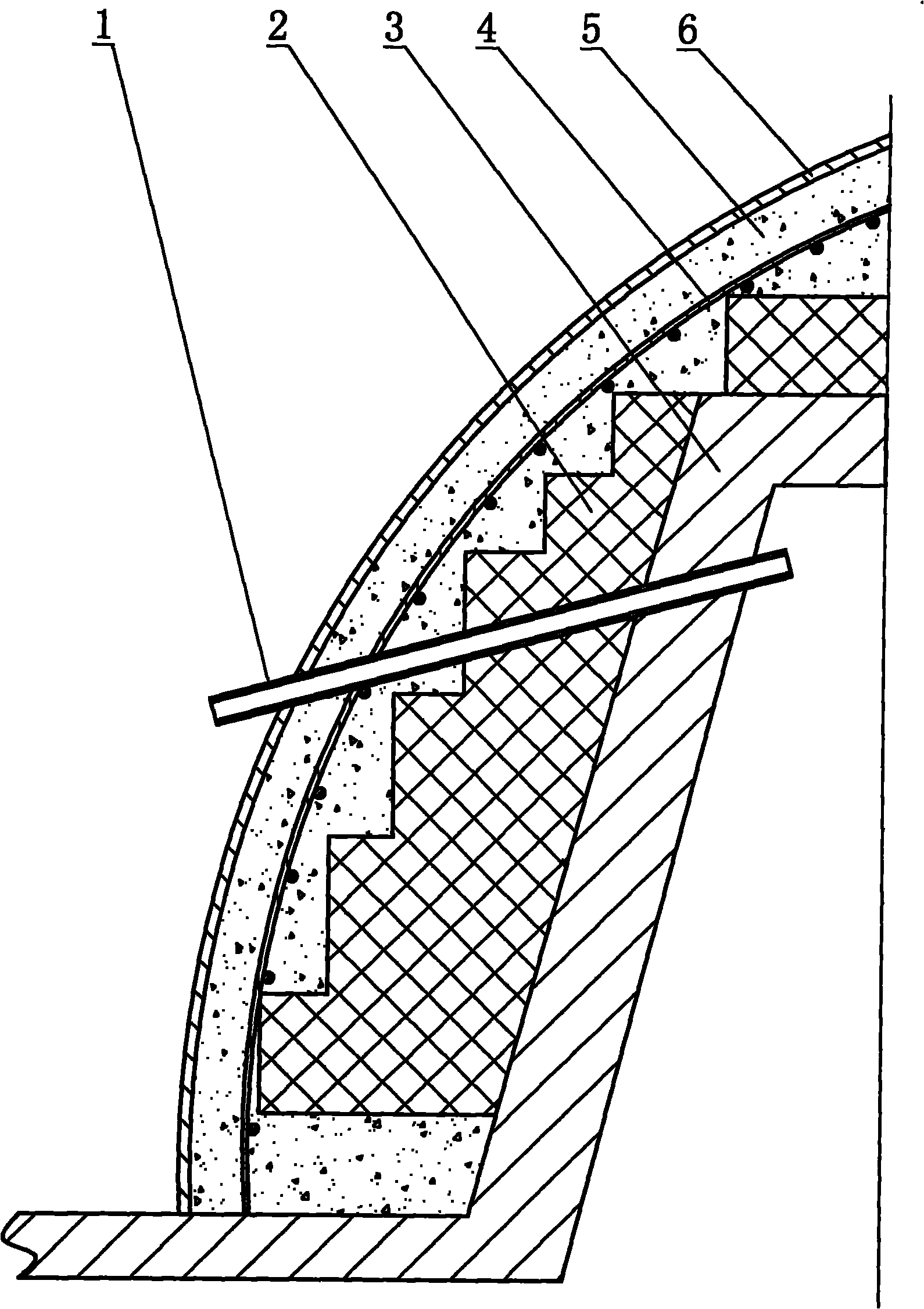

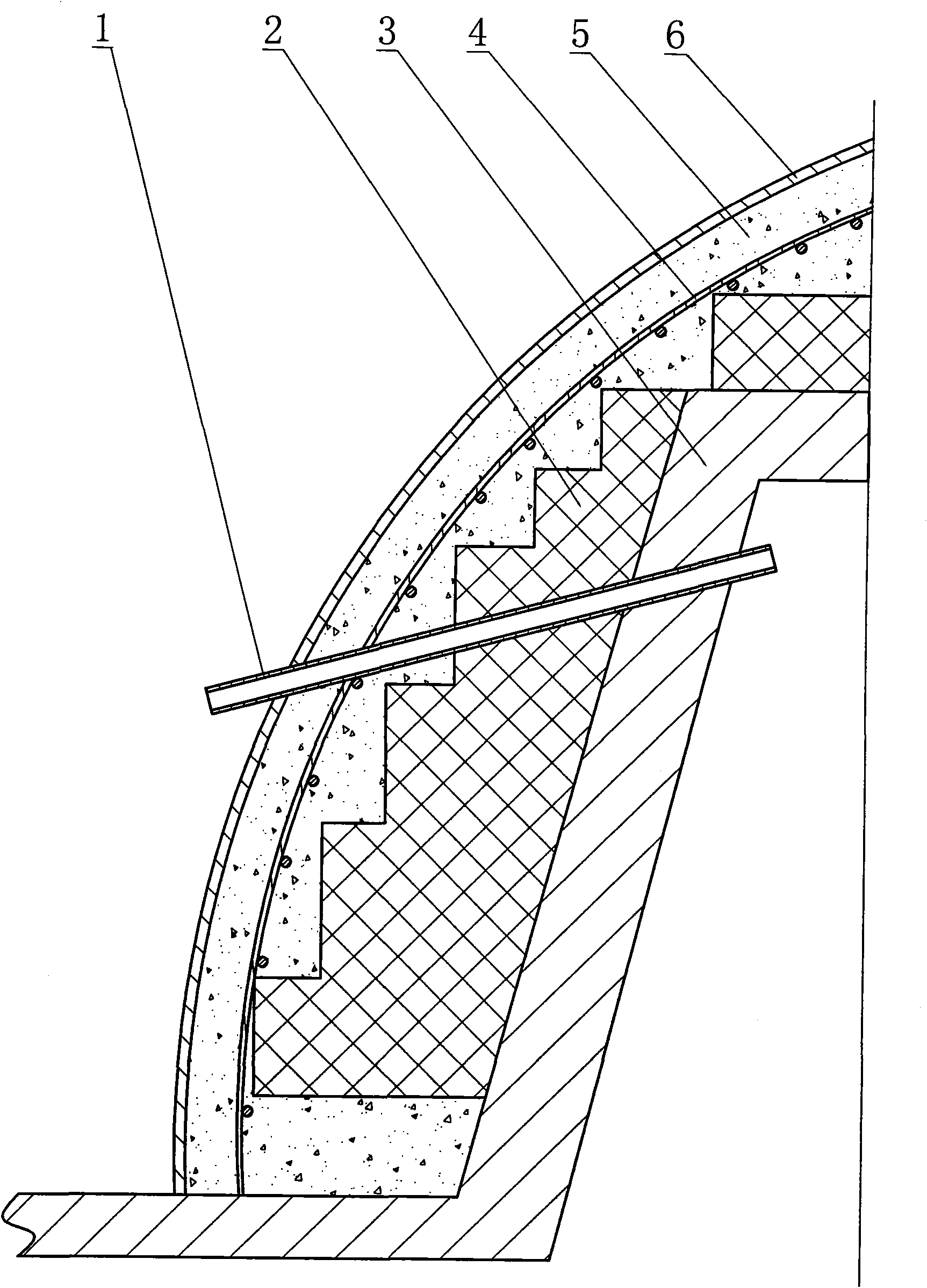

Construction method of hyperboloidal concrete structure of coal tower storage bunker incline wall

The invention relates to a construction method of a hyperboloidal concrete structure of a coal tower storage bunker incline wall, comprising the following steps of: (1) building a coal tower storage bunker incline beam; (2) building aerated concrete blocks from the top down in the form of steps by closely leaning the coal tower storage bunker incline beam, wherein a wind-powered coal vibration tube is embedded in the corresponding position in the building process; (3) binding reinforcing mat sheets at the outer sides of the step-typed aerated concrete blocks; (4) erecting frameworks in steps and casting concrete according to the step-typed aerated concrete blocks so as to form a hyperboloidal concrete structure; and (5) fixedly mounting a wearable slab on the external body of the hyperboloidal concrete structure, and then finishing the integral construction. The invention reduces the use load of the integral structure, has simple construction process steps, higher casting quality and precision of the concrete, effectively reduces the construction difficulty and the construction cost, and is a construction method of the hyperboloidal concrete structure of the coal tower storage bunker incline wall with higher innovation property.

Owner:MCC TIANGONG GROUP

Photocatalyst furniture and coating construction process thereof

The invention discloses photocatalyst furniture and a coating construction process thereof. A primer layer and a photocatalyst coating are sequentially arranged on the outer surface of the photocatalyst furniture from interior to exterior; the primer layer comprises polyether-modified silicone oil and a modified silane coupling agent, the mass ratio of the polyether-modified silicone oil to the modified silane coupling agent is 5:8, the thickness of the primer layer is 1-500 microns, and the thickness of the photocatalyst coating is 50-500 microns; the coating construction process of the photocatalyst furniture comprises the following steps: the surface of the furniture is cleaned; the surface of the furniture is coated with the primer layer by film formation equipment; the primer layer is dried; the surface of the primer layer is coated with the photocatalyst coating by the film formation equipment; the drying is carried out in a clean environment, and the photocatalyst coating curing is waited for being realized. The photocatalyst furniture can have the effects of purifying, bacteria resisting, deodorizing and fouling resisting on indoor air and is durable; the coating construction process is simple and easily understood in steps; a coated coating is firm and durable, and has low possibility of peeling off.

Owner:广东左凡智能家居科技有限公司

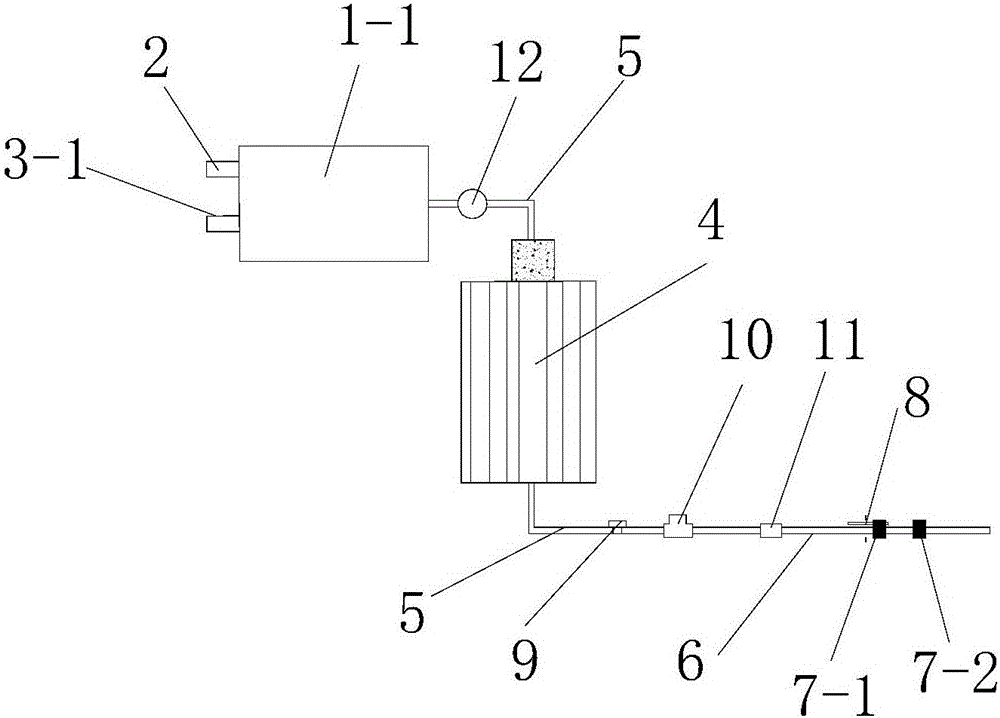

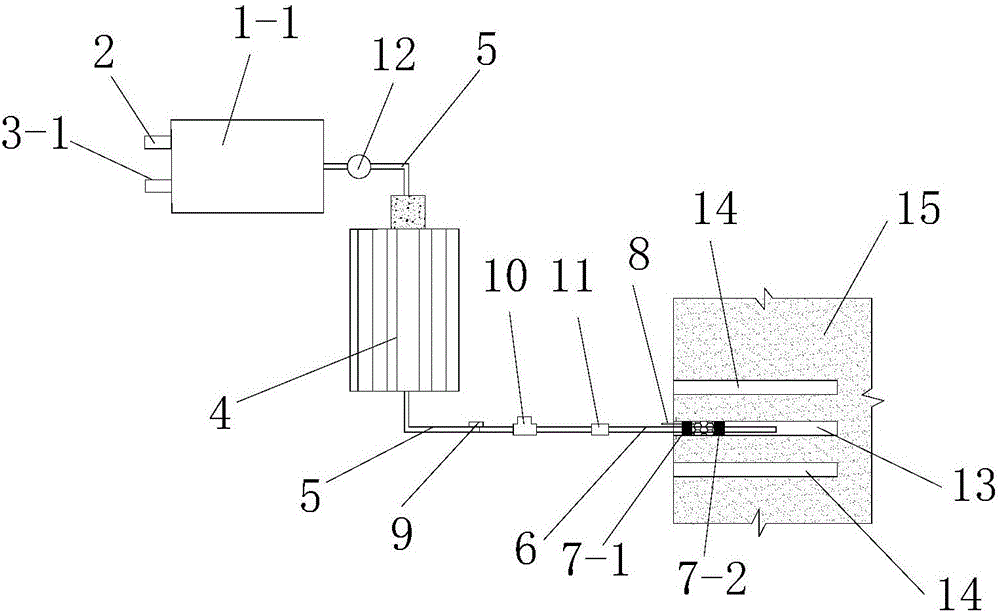

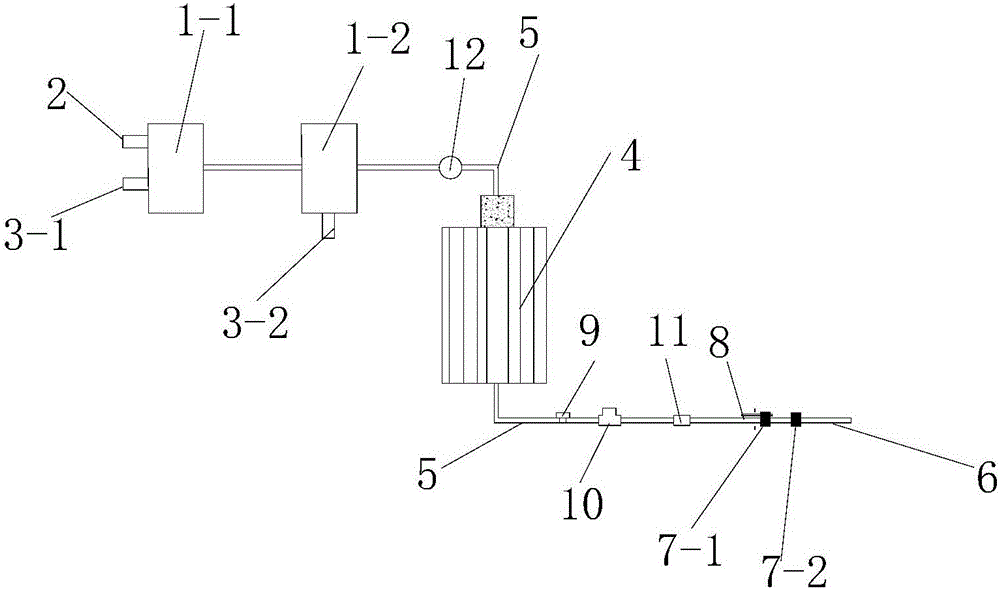

Active fracturing device for coal rock softening and coal rock fracturing construction process

The invention discloses an active fracturing device for coal rock softening and a coal rock fracturing construction process. The active fracturing device comprises a conveying mechanism and a fracturing mechanism communicated with the conveying mechanism, wherein the conveying mechanism comprises a pipeline and a supply unit, a power unit and an adjusting unit sequentially arranged on the pipeline, and the fracturing mechanism is arranged at the output end of the pipeline. The construction process comprises the steps of fracturing fluid preparation and drilling, pre-compression, hole sealing, fracturing and pressure relief. The active fracturing device is simple in structure and reasonable in design, a dustproof water fracturing fluid or supercritical CO2 active fracturing fluid serves as a fracturing fluid for a coal rock to be fractured, the input cost is low, a fracturing effect is good, fracturing energy can be continuously increased through gas-fluid two-phase circulating conversion of the fracturing fluid, a good fracturing effect is achieved, clay mineral expansion in the coal rock is effectively prevented, the damage of the fracturing fluid to a stratum is decreased, further the permeability of the coal rock to be fractured is further improved, and the construction process is easy to control.

Owner:库尔勒金川矿业有限公司 +1

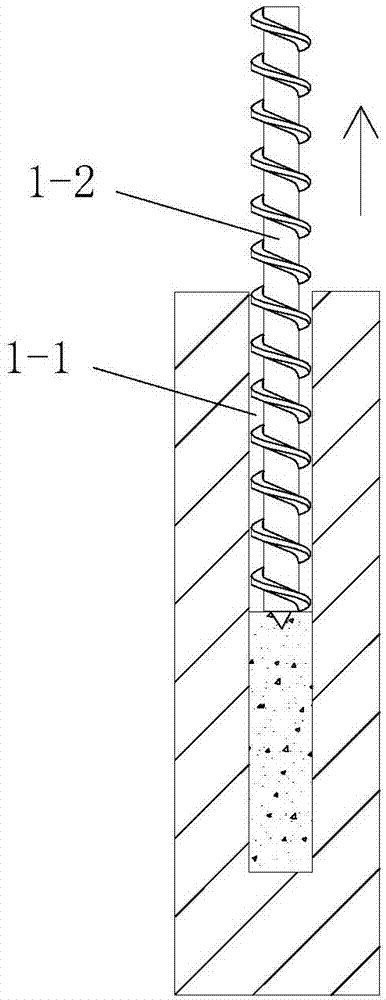

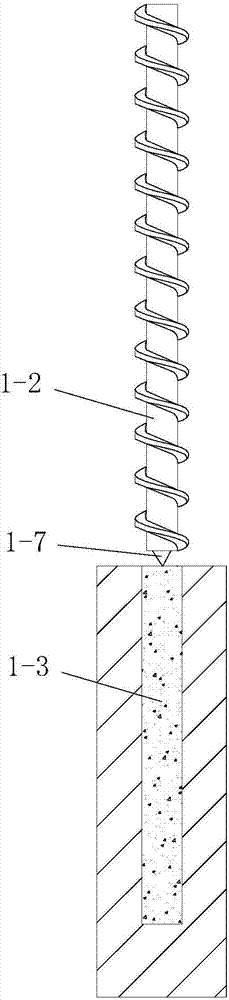

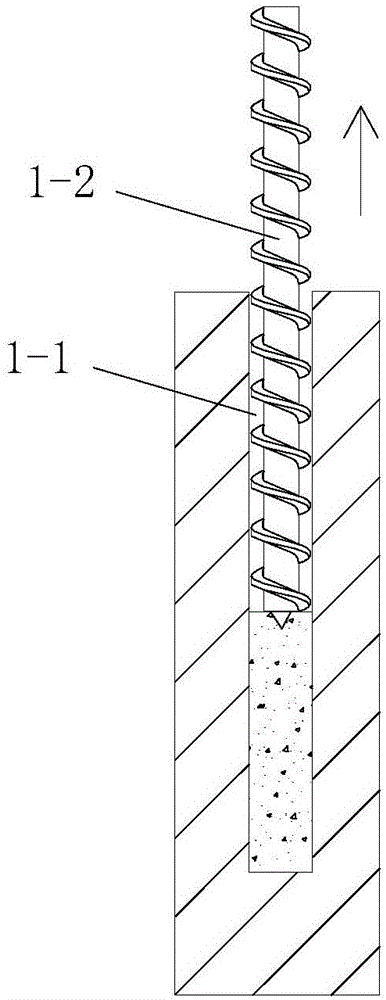

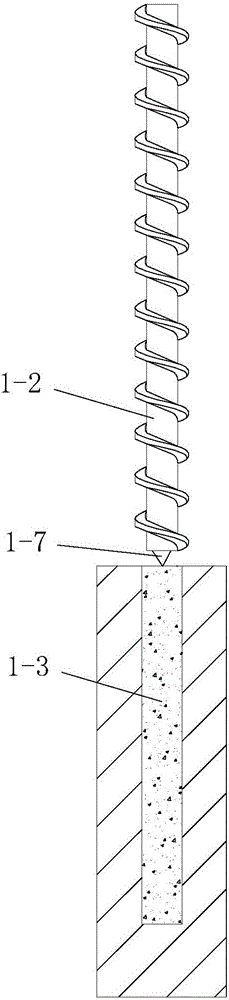

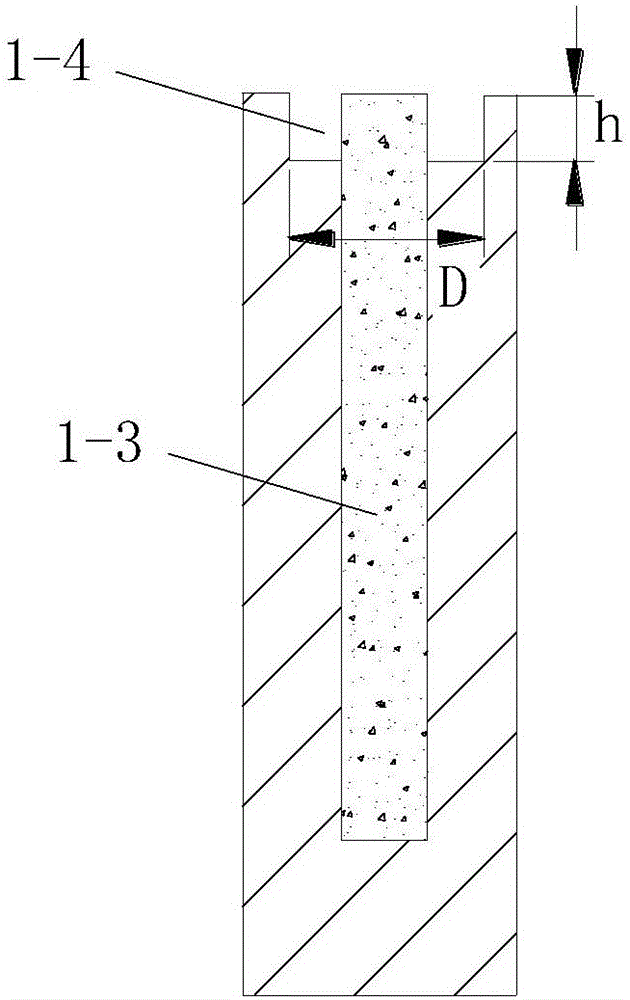

Forming device and forming construction process for reverse screw pile

The invention discloses a forming device and a construction process for reverse screw pile, wherein the forming device comprises a drill rod, a grouting equipment connected with external end of the drill rod and an integrated pipe cap forming device sleeved outside the upper part of the drill rod; the reverse screw pile comprises a pile body and pile ca, the outer wall of the pile body is provided with outer thread structure; the drill rod comprises a core rod and outer thread structure of rod body; the integrated pile cap forming device comprises a support, pile cap forming drill head, rotational drive device and lifting device, the pile cap forming drill head comprises a hollow sleeve and spiral blade; the forming construction process comprises steps of: 1, installing pile cap forming device; 2, drilling hole; 3, lifting and conducting synchronous pile body concrete grouting construction; 4, making the pile cap forming device drill to form clay model; 5, grouting construction of pile cap concrete; 6, forming of reverse screw pile. The forming device has reasonable design, simple construction and good effect, thus can finish construction process of pile body and pile cap of reverse screw pile easily and rapidly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

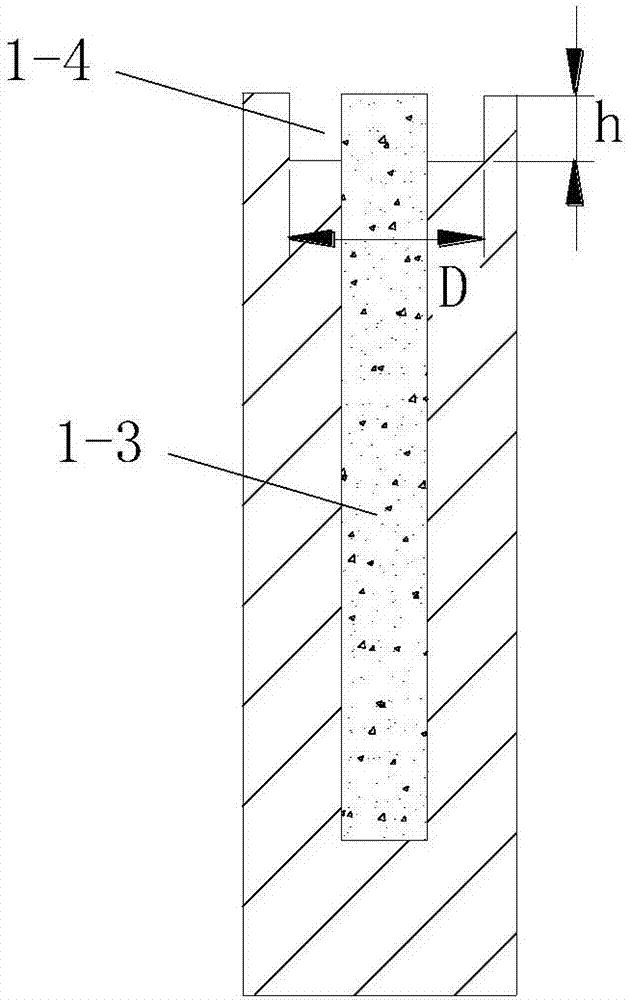

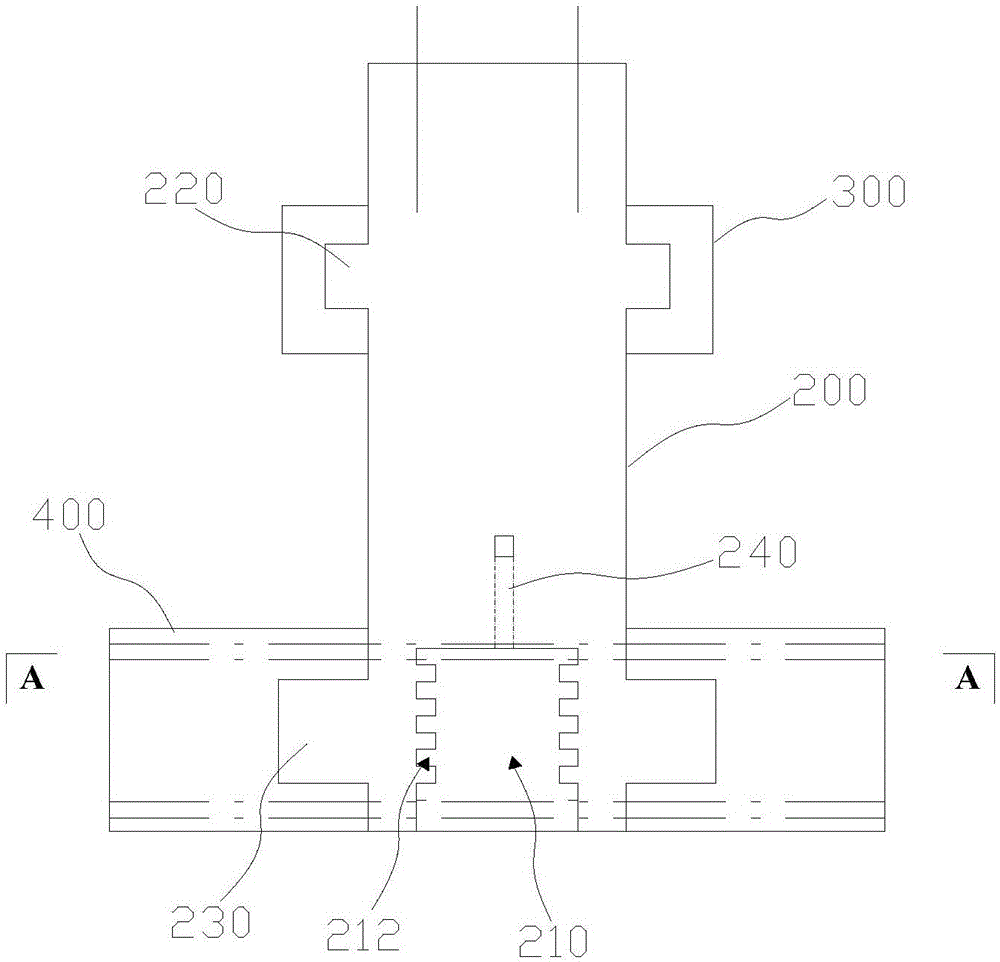

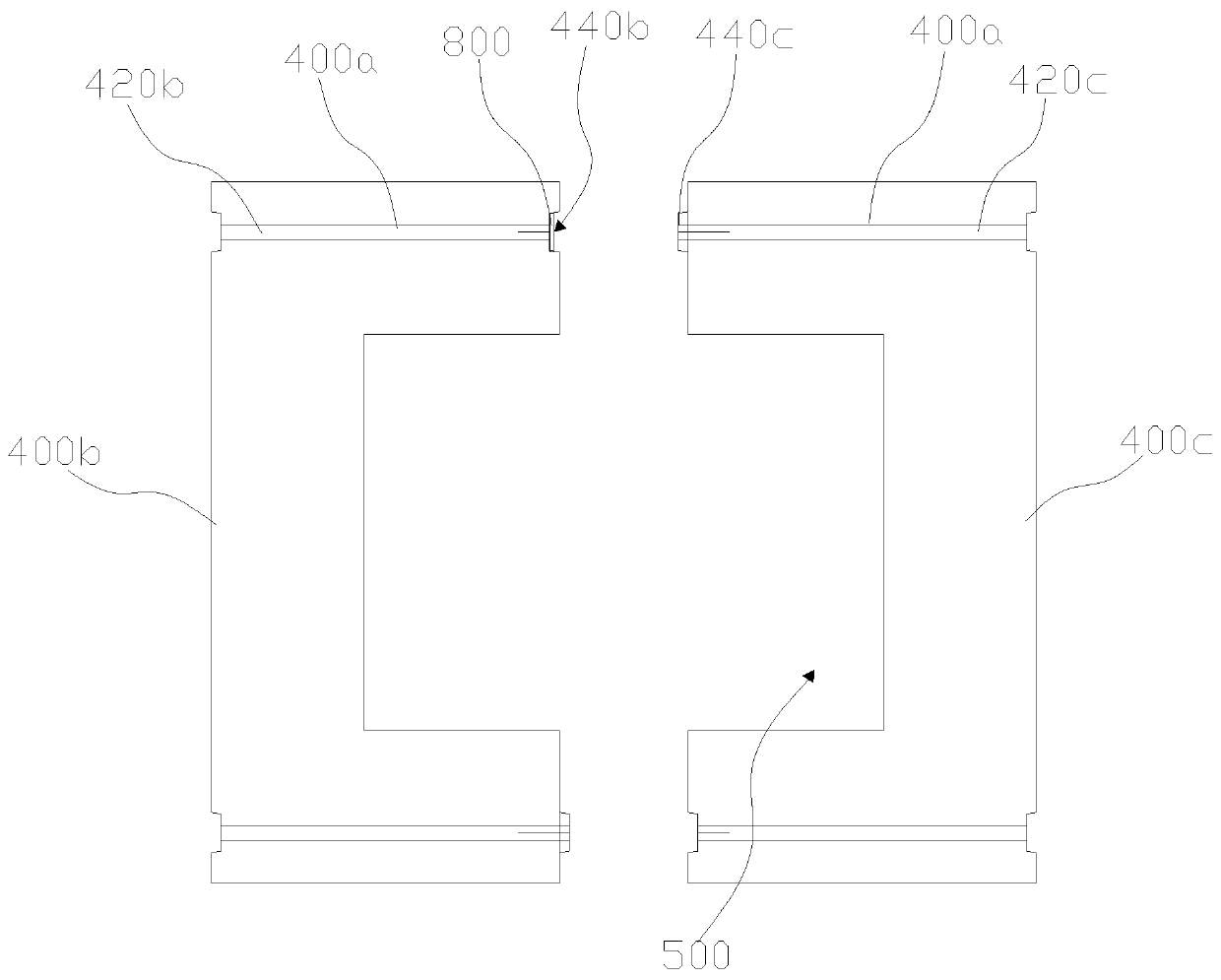

Prefabricated assembly type foundation structure and construction method thereof

ActiveCN106759441AThe construction process steps are simpleEnsure result strengthFoundation engineeringPull forceEngineering

The invention discloses a prefabricated assembly type foundation structure and a construction method of the prefabricated assembly type foundation structure. The structure comprises a pile foundation, a center column, a top fixing part and a bottom fixing part. The pile foundation is arranged in a foundation pit. The bottom of the center column is concaved inwards to form a containing groove. The pile foundation is embedded in the containing groove. The center column comprises a first assembly portion and a second assembly portion. The top fixing part is arranged on the first assembly portion in a sleeving mode. The bottom fixing part is arranged on the foundation pit in a pressed mode. The bottom fixing part is arranged on the second assembly portion in a sleeving mode. Accordingly, the foundation construction technological steps can be greatly simplified, the construction difficulty is effectively lowered, the structural strength of the foundation is ensured under large upward pulling force or downward pressure or under soft soil layer construction conditions, then, high using reliability is ensured, and meanwhile the environmental pollution problem caused by on-site construction can be avoided.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST

Tunnel inverted arch and inverted arch filling layer replacing steel-concrete composite structure and construction technology

PendingCN110219667ASimple structureReasonable designUnderground chambersDrainageConcrete compositesBuilding construction

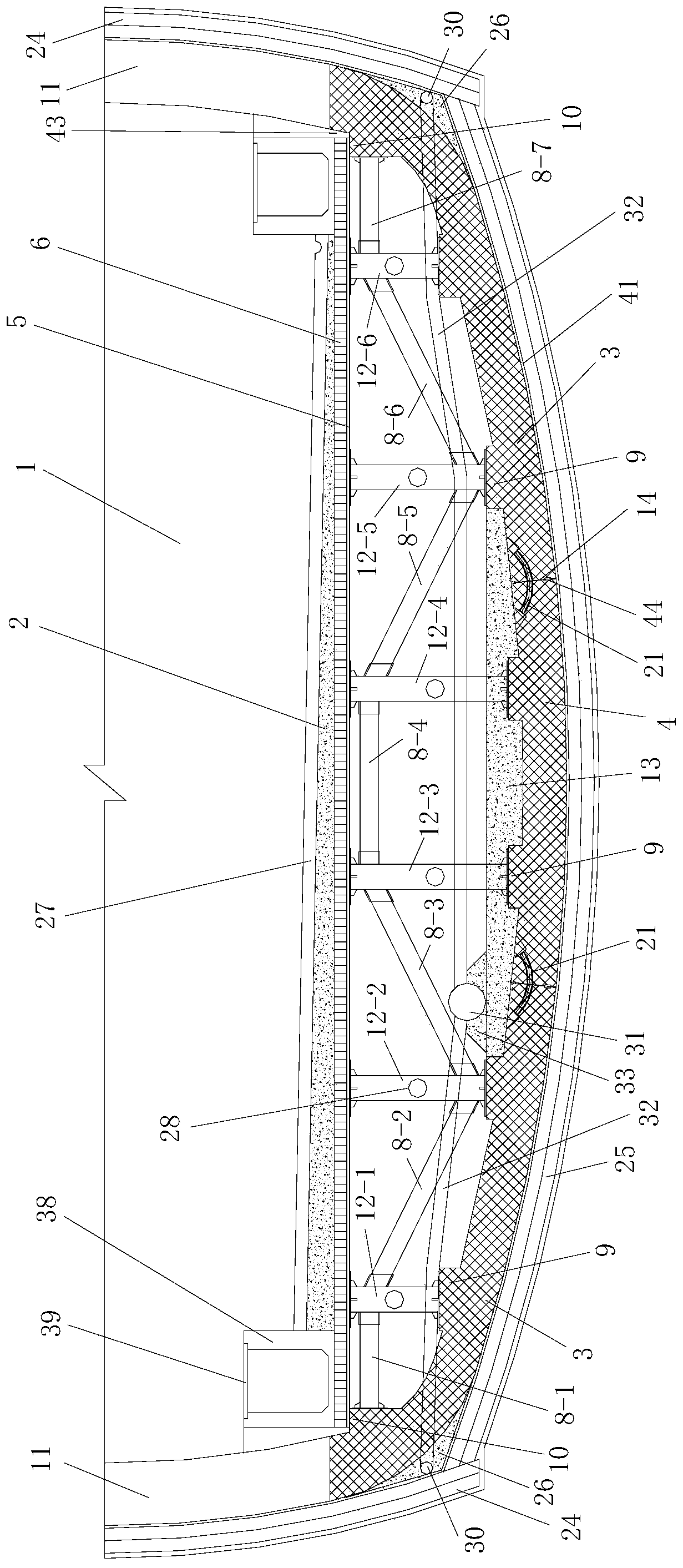

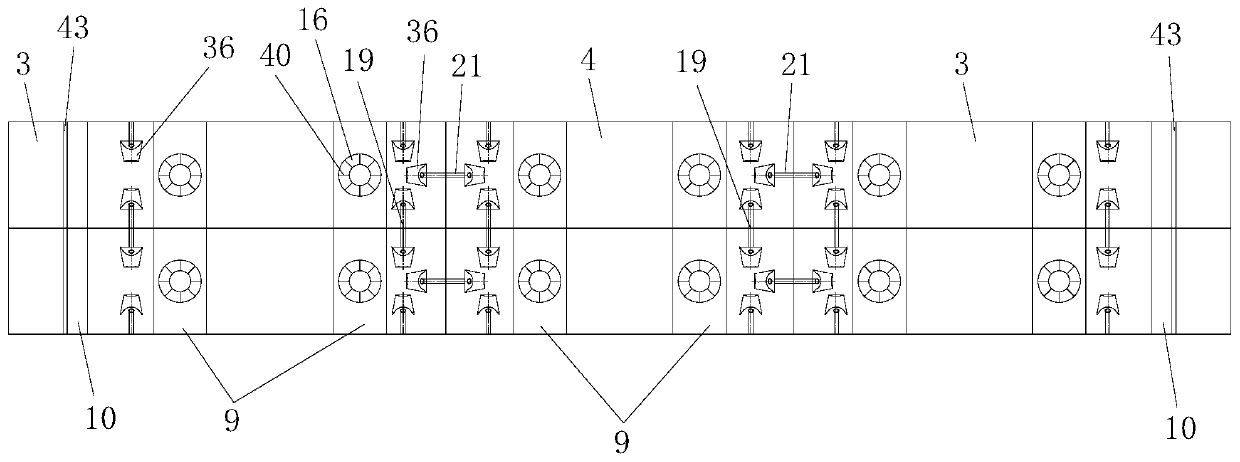

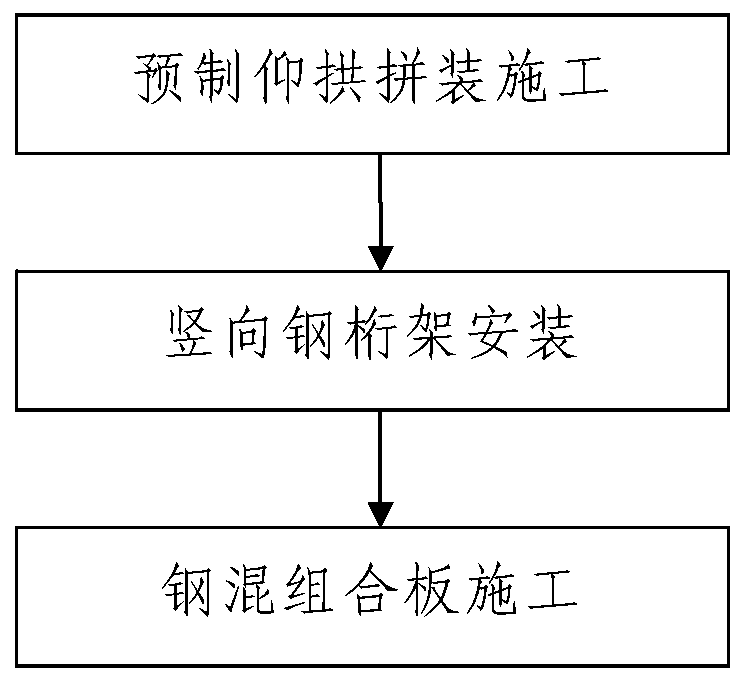

The invention discloses a tunnel inverted arch and inverted arch filling layer replacing steel-concrete composite structure and a construction technology. The tunnel inverted arch and inverted arch filling layer replacing steel-concrete composite structure is composed of a prefabricated inverted arch and a steel truss structure laid on the prefabricated inverted arch; the prefabricated inverted arch is formed by assembling a plurality of fabricated inverted arches from back to front, and the steel truss structure includes a plurality of vertical steel trusses and steel-concrete composite plates; and one vertical steel truss is arranged above the middle part of each fabricated inverted arch, and each steel-concrete composite plate includes horizontal steel plates and a cast-in-place concrete layer. The construction technology includes steps of first prefabricated inverted arch assembly construction and second steel truss structure construction. According to the tunnel inverted arch andinverted arch filling layer replacing steel-concrete composite structure and the construction technology, the structure design is reasonable, the construction technology is simple and convenient, andthe use effect is good; and a cast-in-place tunnel bottom lining is replaced by a fabricated inverted arch formed by connecting three inverted prefabricated parts, and the concrete-filled inverted arch filling layer is replaced by the steel truss structure, alignment and splicing are carried out on site, the tunnel inverted arch and tunnel filling construction process can be greatly simplified, the construction efficiency can be improved, and the construction quality can be ensured.

Owner:甘肃省交通规划勘察设计院股份有限公司

Processing technology of 2.5 D Ag glass

PendingCN108942423ASolve the problem of removing engraving marksSo as not to damageUltravioletProtective glasses

The invention belongs to the technical field of AG glass manufacturing, particularly relates to a processing technology of 2.5 D Ag glass. The processing technology comprises the following steps that(1) an AG glass substrate and protective glass are manufactured; (2) the AG glass substrate and the protective glass are cleaned and dried; (3) UV hydrolytic glue coats the periphery of the AG glass substrate; (4) the protective glass covers a UV hydrolysis glue layer, the AG glass with the protective layer is obtained; (5) the AG glass is placed on a laminating machine for pressing and bonding; (6) a ultraviolet lamp is used for illuminating, and curing of the UV hydrolytic glue is accelerated; (7) the AG glass is placed on a fine carving machine for processing according to the design, so that the 2.5 D AG glass with the protective layer is prepared; (8) the 2.5 D AG glass with the protective layer is put into a polishing machine for polishing treatment; (9) hydrolyzing is carried out toenable the protective glass to be separated from the AG glass substrate; and (10) the 2.5 D AG glass is taken out, and the glass is cleaned. The processing technology is simple in construction processand high in finished product qualification rate.

Owner:SICHUAN LANGMA NUMERICAL CONTROL EQUIP CO LTD

Construction Technology of Prefabricated Grid Shear Wall Structural System

ActiveCN103924711BSimple structureLow input costWallsBuilding material handlingVertical edgeStructural system

The invention discloses an assembled type gridding shearing wall structural system which comprises a plurality of shearing wallboards arranged from top to bottom. Each shearing wallboard comprises a shearing wall body, upper restraining hidden beams and two vertical edge restraining components, the shearing wall body is formed by a plurality of prefabricated gridding shearing wall main bodies in a spliced mode, every two adjacent prefabricated gridding shearing wall main bodies are connected through a connecting hidden column, and rectangular boxes on the internal framework of each prefabricated gridding shearing wall main body are respectively provided with a rectangular heat preservation board in an inlaid mode. A construction technology of the assembled type gridding shearing wall structural system includes the steps of (1) carrying out measuring and setting-out, (2) hoisting the prefabricated gridding shearing wall main bodies, (3) constructing the upper restraining hidden beams, the connecting hidden columns and the vertical edge restraining components, (4) constructing the shearing wallboard on the upper layer, and (5) repeating the steps till the construction process of the multiple shearing wallboards is completed. The assembled type gridding shearing wall structural system and the construction technology are reasonable in design, convenient to construct, low in investment cost and good in use effect, and multiple problems in traditional assembling of an integrated shearing wall structure can be effectively solved.

Owner:东莞市建安住宅工业有限公司

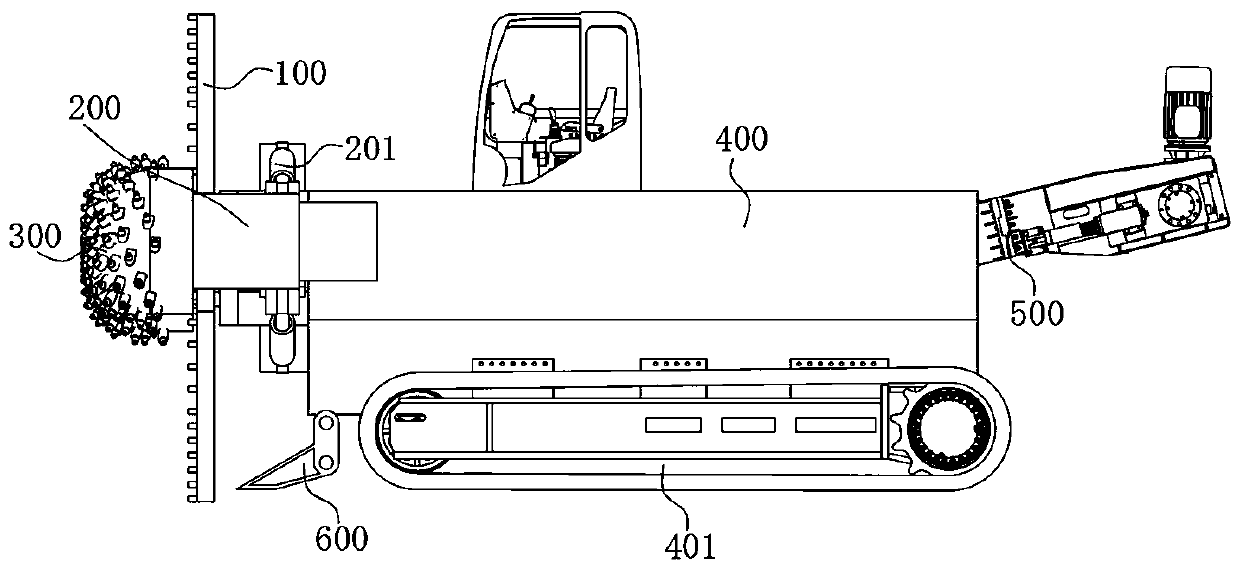

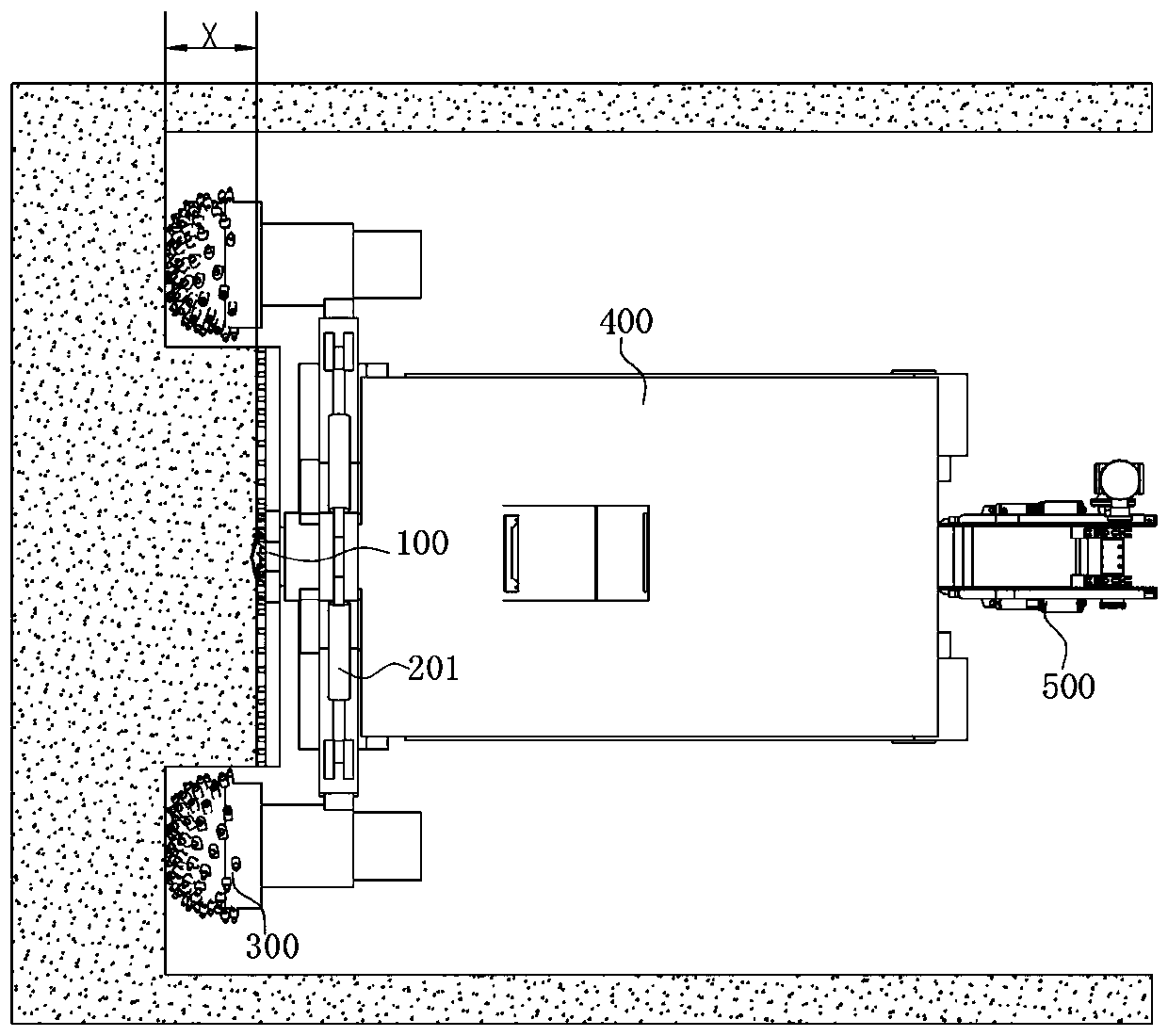

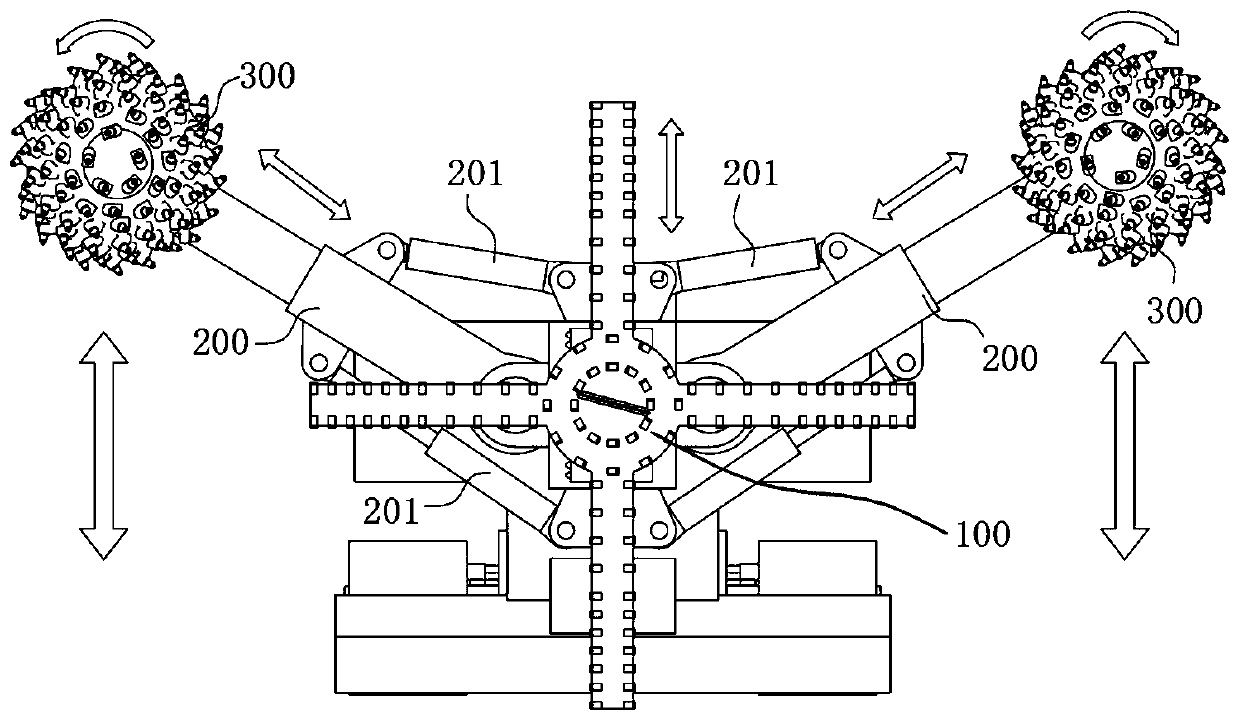

Cutting part, tunneling equipment and tunneling method

PendingCN110185465AReasonable structural designImprove cutting efficiencyTunnelsControl systemEngineering

The invention belongs to the technical field of tunneling construction equipment, and discloses a cutting part, tunneling equipment and further discloses a tunneling method. The cutting part is arranged in the front of a machine body of the tunneling equipment, and includes a middle part rotary tool holder, cutting arms arranged in the circumferential direction of the middle part rotary tool holder, a first driving part and a second driving part, and cutting power heads are arranged at the ends of the cutting arms; the first driving part drives the action of the middle part rotary tool holder;and the second driving part drives the actions of cutting arms and the cutting power heads. The tunneling equipment comprises the machine body, a cutting part body and a conveying system, a walking part is arranged on the lower part of the machine body, and a power system and a control system are arranged on the machine body, and the cutting part body is arranged at the front end of the machine body. According to the cutting part, the tunneling equipment and the tunneling method, the overall structure is reasonable in design; and by configuring the two cutting power heads and the large middlepart rotary tool holder, a new tunneling construction technology is realized, the cutting efficiency is high, and the requirements of operation under specific geological conditions can be met.

Owner:中铁工程装备集团隧道设备制造有限公司

Seabed scouring preventing bionic system and construction technology and application thereof

PendingCN110485365AThe construction process steps are simpleImprove work efficiencyPipe laying and repairCoastlines protectionOcean bottomEngineering

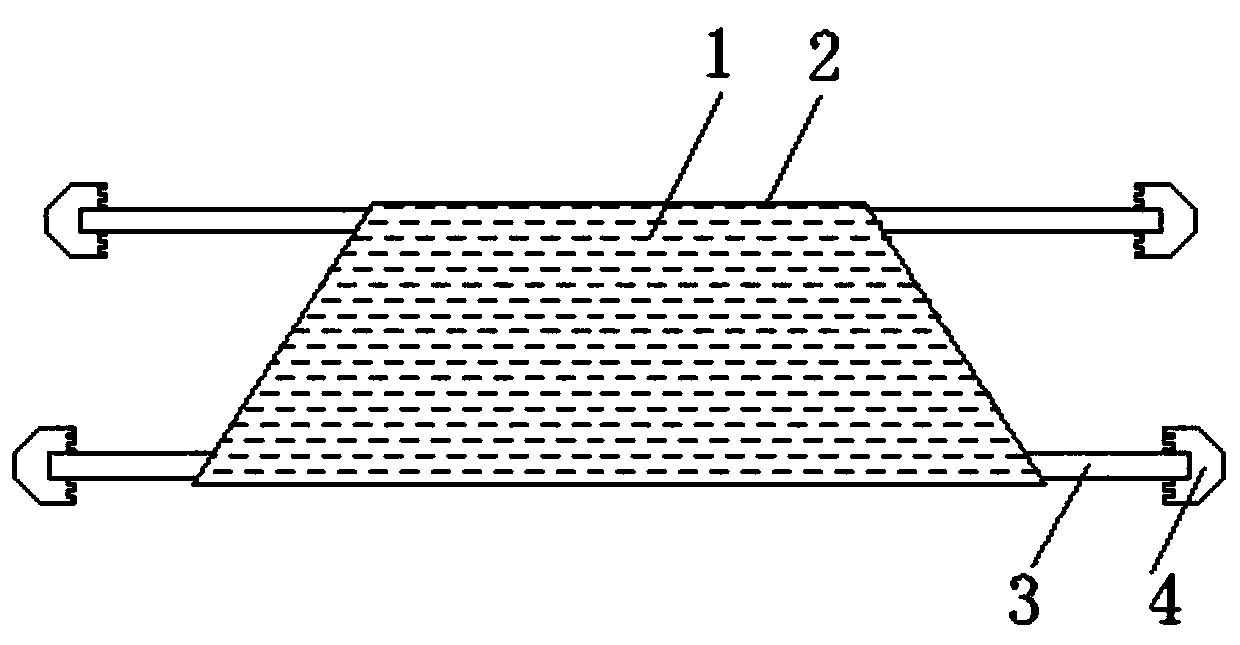

The invention discloses a seabed scouring preventing bionic system and a construction technology and application thereof. Bionic water plant leaves, an installing base pad, a plurality of anchor beltsand anchoring devices are included. The bionic water plant leaves are fixedly laid on the installing base pad, and the installing base pad is connected with the anchoring devices through the multipleanchor belts, wherein the anchoring devices are used for being fixed to a sand bag layer or seabed sediments. The bionic water plant leaves, the installing base pad, the multiple anchor belts and theanchoring devices are combined and connected into an integrated structure, during underwater pavement, the integrally-formed bionic water plant combined body is directly laid on the surface of a seabed suspension pipeline, the construction technology steps are greatly simplified, and the work efficiency is improved. The installing base pad is designed into a trapezoid or arc adapting to the appearance of the seabed suspension pipeline, seamless linkage of the installing base pad or seamless linkage with the seabed suspension pipeline can be directly achieved, connection is firmer, unfolding of bionic water plants forming a reel is not needed during underwater pavement, the pavement process is simplified, and the scouring preventing effect is improved.

Owner:宁夏宏海石油装备有限公司

Forming device and construction process for reverse screw pile

The invention discloses a forming device and a construction process for reverse screw pile, wherein the forming device comprises a drill rod, a grouting equipment connected with external end of the drill rod and an integrated pipe cap forming device sleeved outside the upper part of the drill rod; the reverse screw pile comprises a pile body and pile ca, the outer wall of the pile body is provided with outer thread structure; the drill rod comprises a core rod and outer thread structure of rod body; the integrated pile cap forming device comprises a support, pile cap forming drill head, rotational drive device and lifting device, the pile cap forming drill head comprises a hollow sleeve and spiral blade; the forming construction process comprises steps of: 1, installing pile cap forming device; 2, drilling hole; 3, lifting and conducting synchronous pile body concrete grouting construction; 4, making the pile cap forming device drill to form clay model; 5, grouting construction of pile cap concrete; 6, forming of reverse screw pile. The forming device has reasonable design, simple construction and good effect, thus can finish construction process of pile body and pile cap of reverse screw pile easily and rapidly.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

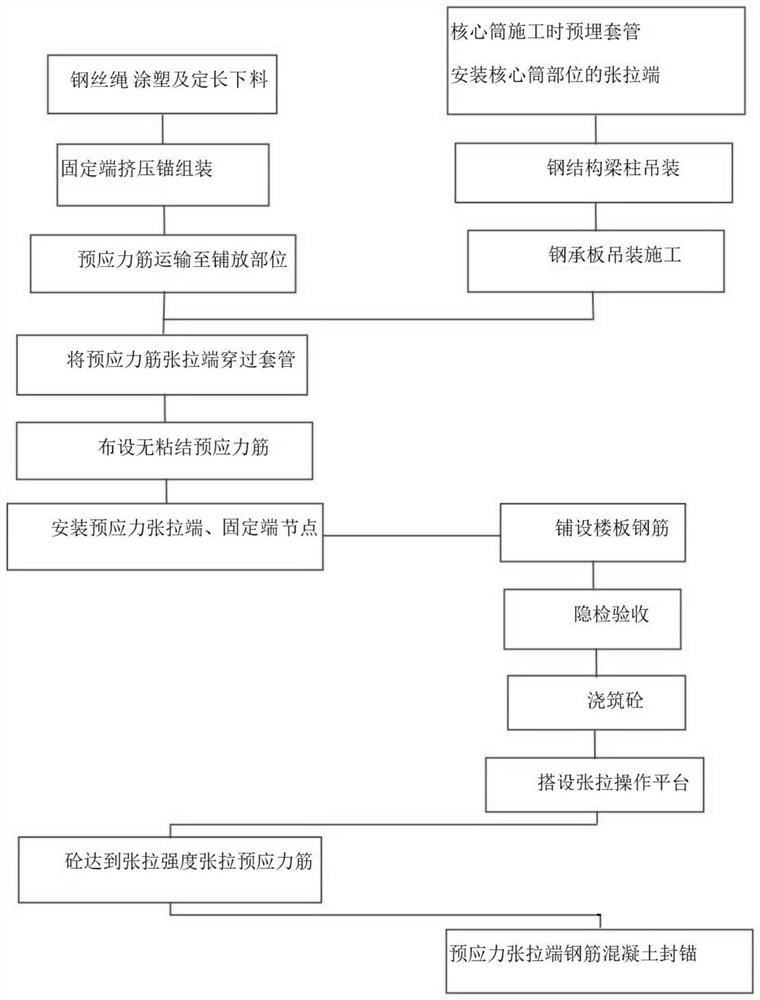

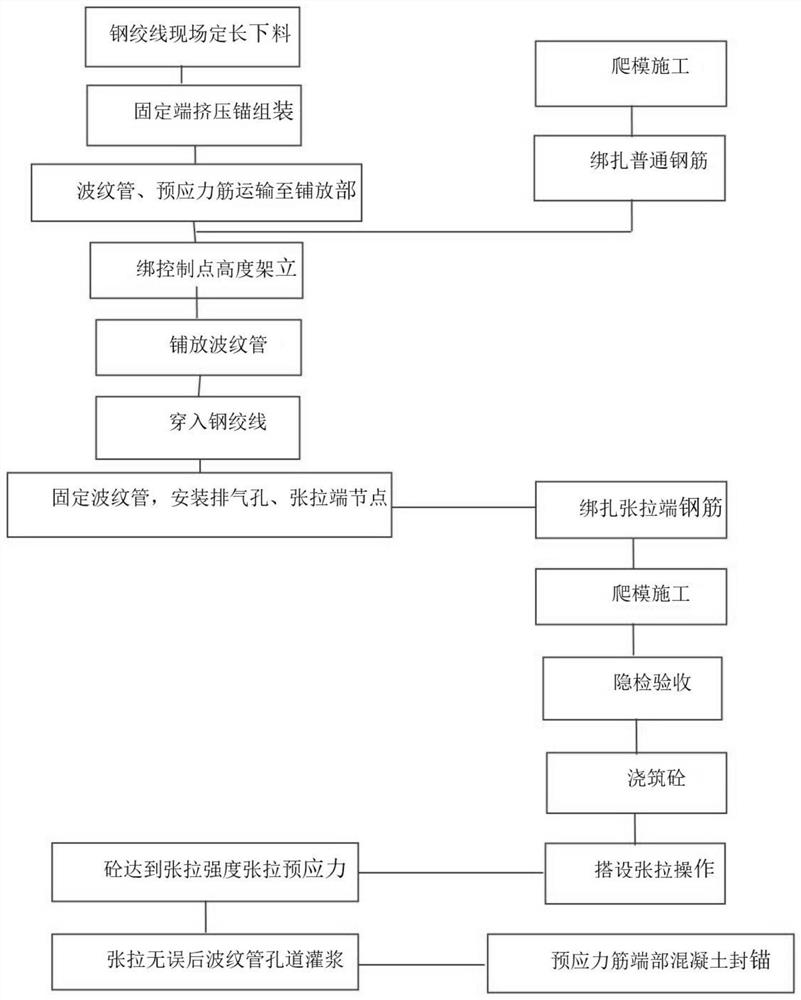

Prestressed construction process for building high-rise building structure

ActiveCN113550596AAvoid stress concentration problems in surrounding structuresEven by forceBuilding reinforcementsBuilding material handlingPre stressArchitectural engineering

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

Steel truss girder assembling, erecting and construction process

ActiveCN103614969BThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

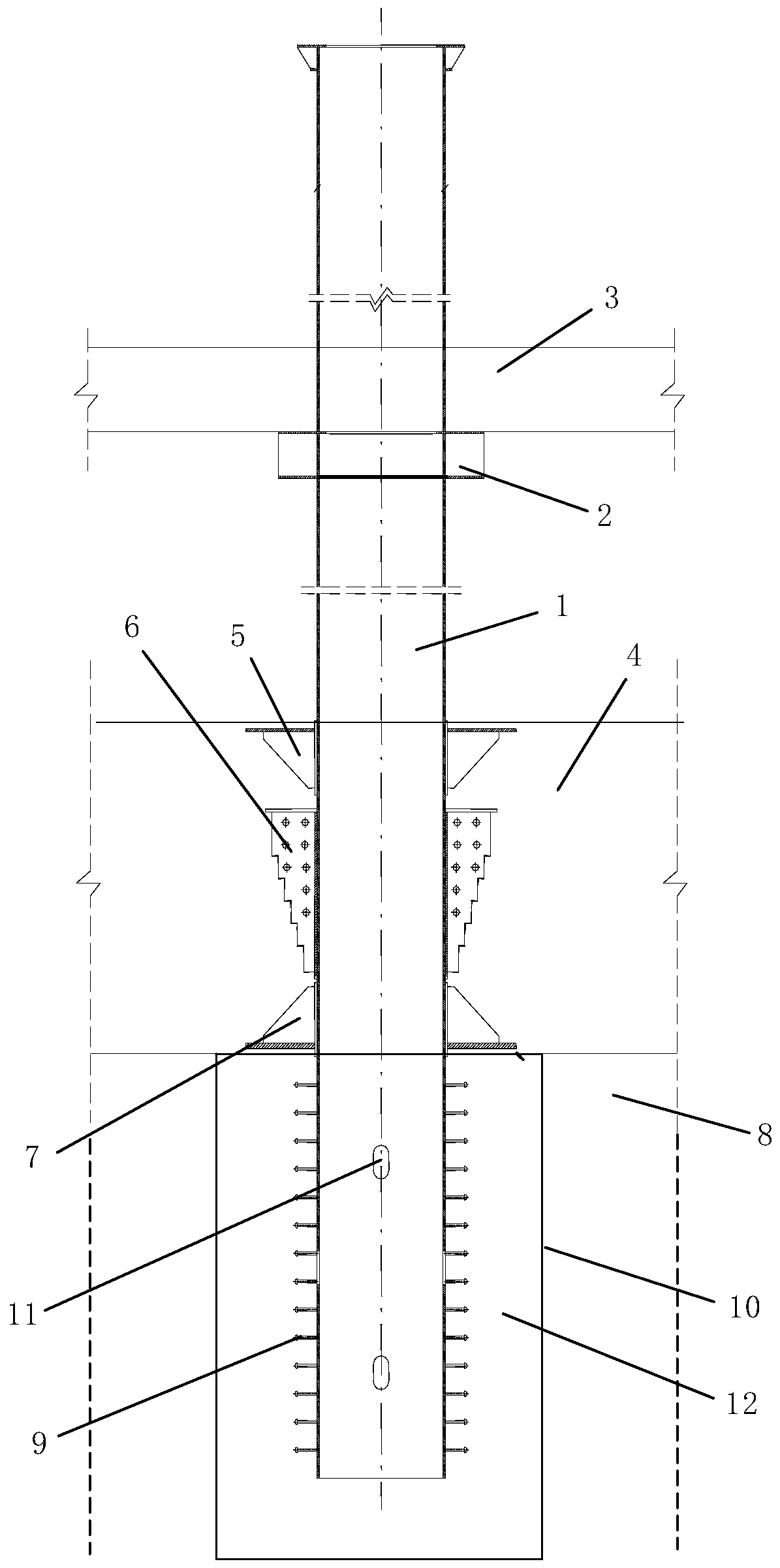

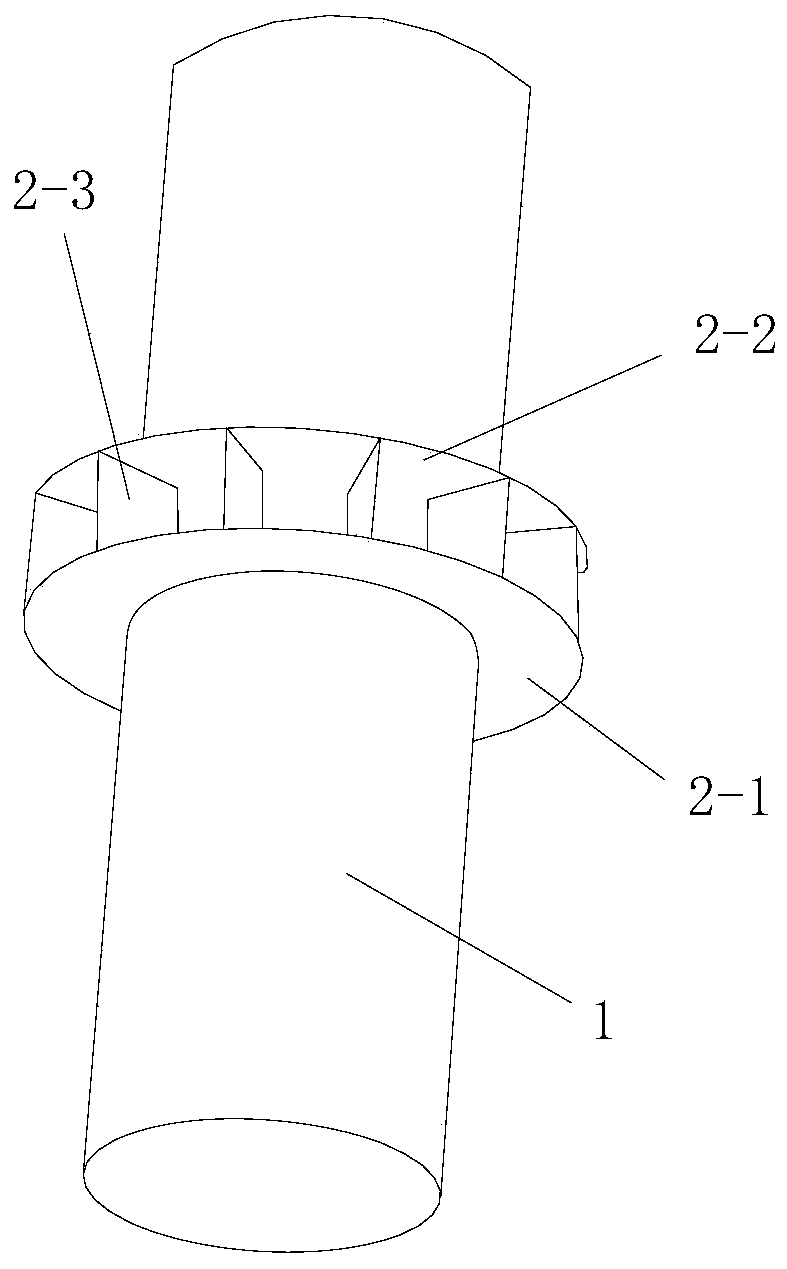

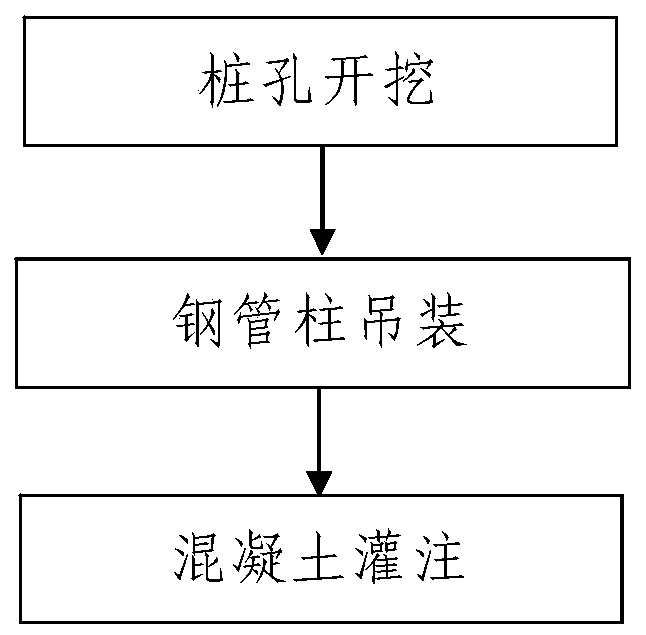

Steel pipe column for subway station and its construction technology

ActiveCN106320374BSimple structureEasy constructionArtificial islandsBuilding constructionsArchitectural engineeringSubway station

The invention discloses a steel pipe column for a subway station and a construction process of the steel pipe column. The steel pipe column comprises a steel pipe supporting column, a middle joint structure arranged on the middle portion of the steel pipe supporting column and a lower joint structure arranged on the lower portion of the steel pipe supporting column. The middle joint structure comprises a round tray coaxially arranged on the steel pipe supporting column in a sleeving manner; a middle plate beam is supported on the round tray which is located below the middle plate beam; and the round tray is installed on the steel pipe supporting column in a clamped manner, and the steel pipe supporting column penetrates the interior of the middle plate beam. The lower joint structure comprises an upper stiffening structure, a middle stiffening structure and a lower stiffening structure which are arranged from top to bottom; and the upper stiffening structure, the middle stiffening structure and the lower stiffening structure are all poured in a bottom plate. The construction process includes the first step of pile hole excavation, the second step of steel pipe column hoisting and the third step of concrete pouring. The steel pipe column for the subway station is reasonable in design, easy and convenient to construct and good in using effect, the construction process of the steel pipe column in the subway station can be easily, conveniently and fast completed, and the constructed and formed steel pipe column is excellent in mechanical property.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP

Building roof construction process

InactiveCN103362254BSimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

Owner:陕西建工集团有限公司 +1

A Construction Technology of Segmentally Assembled Box Girder

ActiveCN105780660BThe construction process steps are simpleReasonable designBridge erection/assemblySupporting systemEngineering

The invention discloses a construction technique for segmentally assembled box girders. The box girder to be constructed is a perforated girder, and each perforated girder is composed of a plurality of box girder segments assembled from the back to the front; As follows: 1. Prefabrication of box girder segments: Centrally prefabricate all box girder segments used to form the box girder to be constructed in the prefabrication yard; 2. Transport of box girder segments: transport all box girder segments to The erection position of the box girder under construction; 3. Box girder erection: use the descending bridge erecting machine to erect the constructed box girder. The descending bridge erecting machine includes the bottom horizontal support system, main girder system, longitudinal movement system, cantilever Cranes, assembly racks and assembly vehicles; 4. System conversion: system conversion will be carried out after the erection construction process is completed. The invention has the advantages of simple process steps, reasonable design, convenient construction, easy control of the construction process, good use effect, simple and rapid completion of the construction process of segmental assembled box girders, and easy guarantee of construction quality.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Prefabricated foundation structure and its construction method

ActiveCN106759441BThe construction process steps are simpleEnsure result strengthFoundation engineeringPull forceUltimate tensile strength

The invention discloses a prefabricated assembly type foundation structure and a construction method of the prefabricated assembly type foundation structure. The structure comprises a pile foundation, a center column, a top fixing part and a bottom fixing part. The pile foundation is arranged in a foundation pit. The bottom of the center column is concaved inwards to form a containing groove. The pile foundation is embedded in the containing groove. The center column comprises a first assembly portion and a second assembly portion. The top fixing part is arranged on the first assembly portion in a sleeving mode. The bottom fixing part is arranged on the foundation pit in a pressed mode. The bottom fixing part is arranged on the second assembly portion in a sleeving mode. Accordingly, the foundation construction technological steps can be greatly simplified, the construction difficulty is effectively lowered, the structural strength of the foundation is ensured under large upward pulling force or downward pressure or under soft soil layer construction conditions, then, high using reliability is ensured, and meanwhile the environmental pollution problem caused by on-site construction can be avoided.

Owner:GUANGZHOU ELECTRIC POWER DESIGN INST

Construction technology of prefabricated corrugated steel web pc I-beam to composite box girder bridge

ActiveCN104195959BSimple structureEasy constructionBridge erection/assemblyBridge materialsArchitectural engineeringRebar

The invention discloses a construction technology for prefabricating a corrugated steel web PC I beam into a combined box girder bridge. Each combined box girder segment in a combined box girder of the combined box girder bridge is formed by connecting two corrugated steel web PC I beams. The construction technology comprises the following steps: Step I, prefabricating the corrugated steel web PC I beams: pedestal prefabricating construction, installation of a soffit formwork, installation of a reinforcement cage in a bottom plate, installation of a corrugated pipe in the bottom plate, installation of a positioning bracket and erection of a side formwork, installation of a corrugated steel web, pouring of concrete on the bottom plate, installation of a top plate molding template, installation of the reinforcement cage in a top plate, pouring of concrete on the top plate, and stretch-drawing of a cable in the bottom plate; Step II, displacement and erection of the corrugated steel web PC I beams; Step III, lengthways wet joint construction; Step IV, stretch-drawing of a cable out of the bottom plate and system conversion. According to the invention, the processing steps are simple, the design is reasonable, the implementation is convenient, the construction period is short, the construction quality is high, pedestal prefabricating and the positioning bracket are combined to complete bridge prefabrication, and the construction quality of the combined box girder bridge can be effectively ensured.

Owner:中铁二十局集团第五工程有限公司

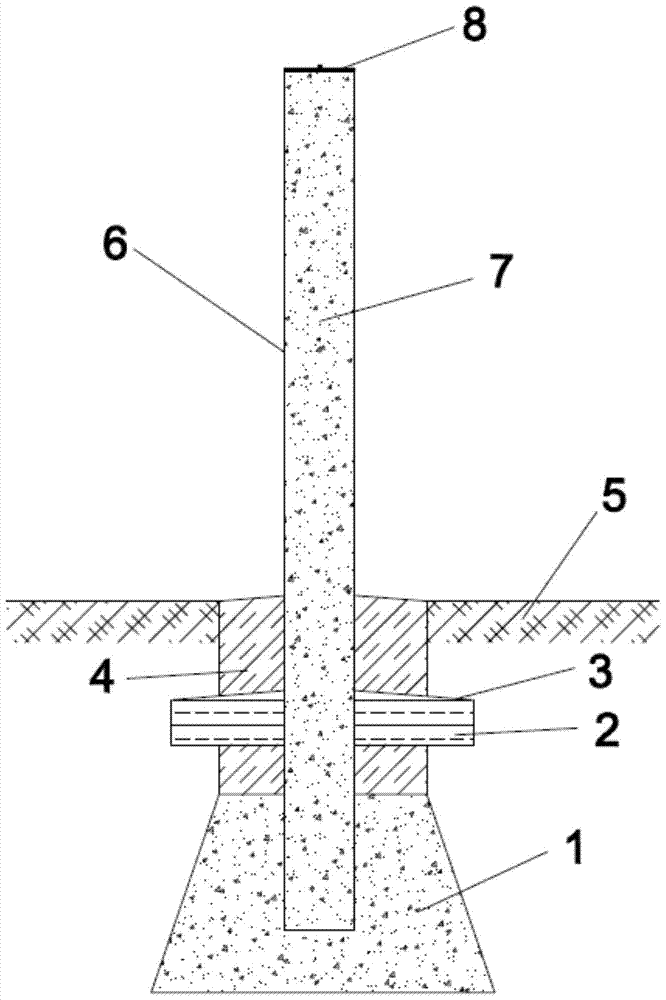

A gps monitoring pier and its construction technology for permafrost and expansive soil areas

InactiveCN105401589BGuaranteed StrengthGuaranteed stiffnessProtective foundationSoil scienceReinforced concrete

The invention provides a global position system (GPS) monitoring pier for frozen soil areas and swelling soil areas. The GPS monitoring pier comprises a pier foundation, a heat-preservation and water-resisting layer, a pier column and a GPS base for installing a static GPS. The pier foundation is buried under the surface of the earth, the pier column is vertically installed in the pier foundation, and the upper end of the pier column protrudes out of the surface of the earth; the heat-preservation and water-resisting layer is horizontally installed on the pier column, and the GPS base is installed at the top end of the pier column. The pier foundation is formed by pouring concrete. The pier column is a concrete molding plastic pipe filled with reinforced concrete internally. The invention further provides a construction process of the GPS monitoring pier. According to the GPS monitoring pier for the frozen soil areas and the swelling soil areas and the construction process thereof, the manufacturing process of a traditional GPS monitoring pier is simplified through the plastic pipe; the stability of the monitoring pier is ensured through burial depth, and the situation that freezing and thawing cycles and drying and watering cycles influence the monitoring pier is avoided; the pier foundation keeps in an environment of constant dry, wet and temperature by arranging the heat-preservation and water-resisting layer, and the influences of landforms and vegetation on the monitoring pier are decreased; the monitor precision and stability of the monitoring pier are high, and the device durability is good.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

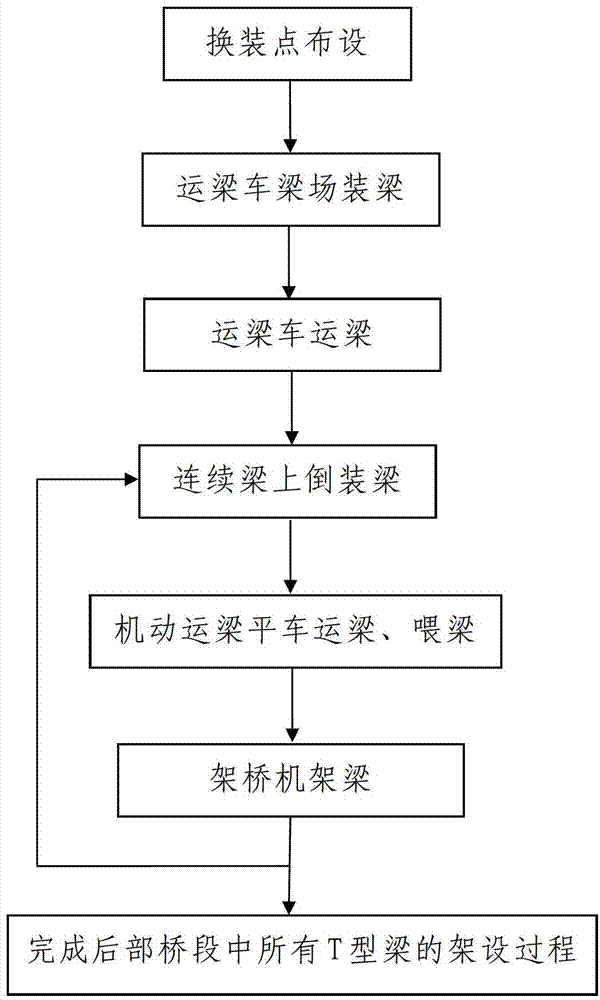

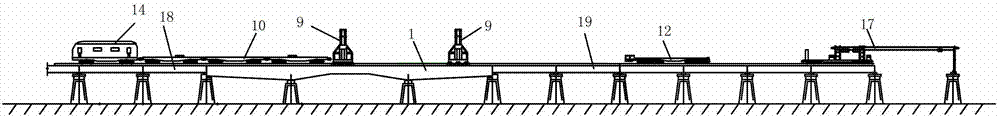

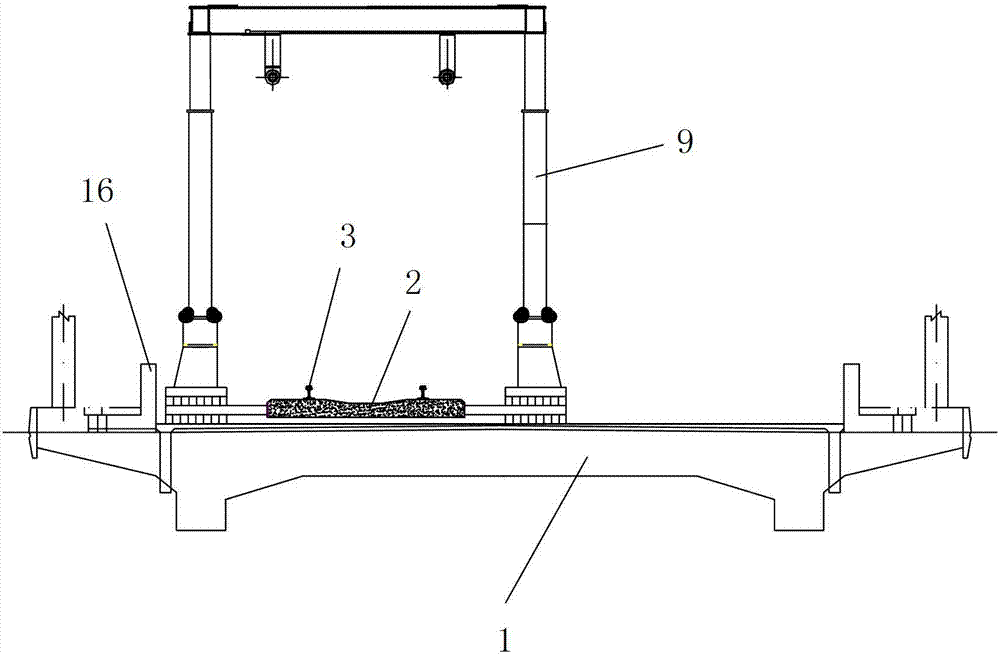

Railway T-beam erecting construction method based on continuous beam laying reloading points

ActiveCN102747693BThe construction process steps are simpleReasonable designBridge erection/assemblyT-beamContinuous beam

The invention discloses a railway T-beam erecting construction method based on continuous beam laying reloading points. A construction bridge comprises a front bridge section, a middle bridge section and a rear bridge section. The method comprises a first step of laying reloading points, and laying temporary reloading devices on the middle bridge section, a second step of loading beams on a beam transporting vehicle in a beam field; a third step of utilizing the beam transporting vehicle to transport the beams, and transporting T-beams to be erected to the reloading points; a fourth step of inversely loading the beams at the position of a continuous beam, and enabling the T-beams to be erected to be inversely loaded on a maneuvering beam-transporting flatcar; a fifth step of utilizing the maneuvering beam-transporting flatcar to transport the beams, and transporting the T-beams to be erected to be transported forwards to the position of a bridge erecting machine to feed the beams; a sixth step of utilizing the bridge erecting machine to erect the beams, and a seventh step of repeating the fourth step to the sixth step many times, and finishing the erecting process of all T-beams in the rear bridge section. The railway T-beam erecting construction method is simple in construction steps, simple and convenient to operate, low in input cost, quick in erecting speed and safe and reliable in the erecting process and can solve the problems that in an existing erecting method for inversely loading the T-beams at a bridgehead, the beam erecting progress is reduced, the working efficiency is low, the construction cost is high, and required construction devices and construction workers are too many, and the like.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Plane rotation construction technique for steel truss girder for existing bridge spanning construction

The invention discloses a plane rotation construction technique for a steel truss girder for existing bridge spanning construction. A main girder of the constructed bridge is a steel truss girder spanning the existing bridge and obliquely crossing with the existing bridge; the technique comprises the following steps: firstly, constructing a high-altitude steel truss girder assembling platform which comprises a temporary buttress and a plurality of temporarily assembling brackets; secondly, assembling the steel truss girder at high altitude and removing the temporarily assembling brackets; thirdly, installing a steel truss girder rotation positioning device and a slippage system; before rotating the steel truss steel, firstly installing the steel truss girder rotation positioning device and the slippage system; fourthly, conducting plane rotation on the steel truss girder; and fifthly, dropping the girder in place. The construction technique is simple in steps, convenient to construct, fast to construct, safe and reliable in construction process and less in interference on the existing bridge, and can effectively solve the problems that the construction field is limited, the construction can not be normally conducted, the travelling interference on the existing bridge is large, the construction risk and hidden hazard are large and the like in construction with the existing in-situ falsework method and the dragging method.

Owner:NO 1 ENG LIMITED OF CR20G

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com