Patents

Literature

186results about How to "Change stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

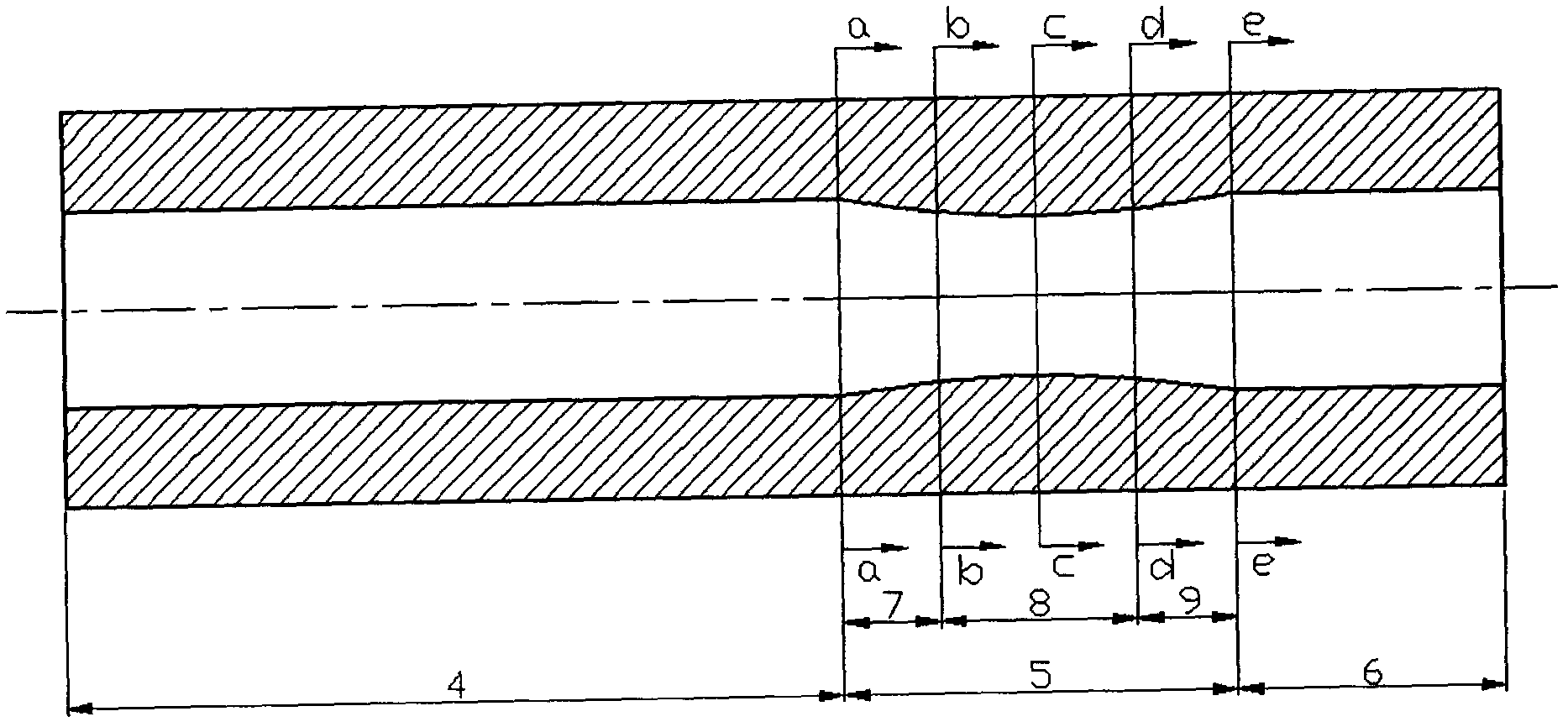

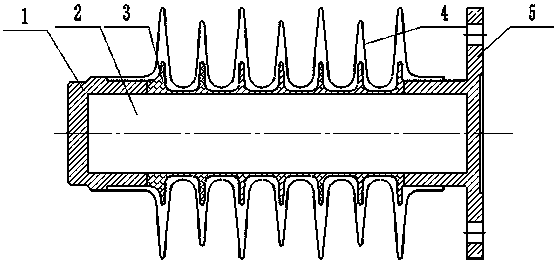

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

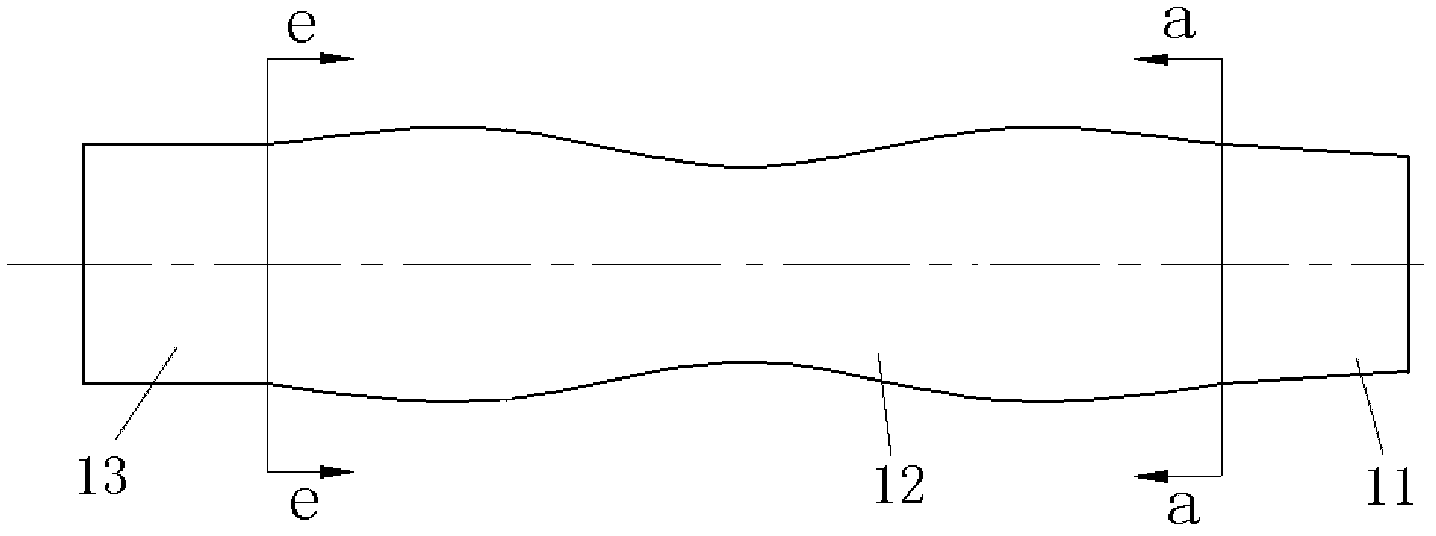

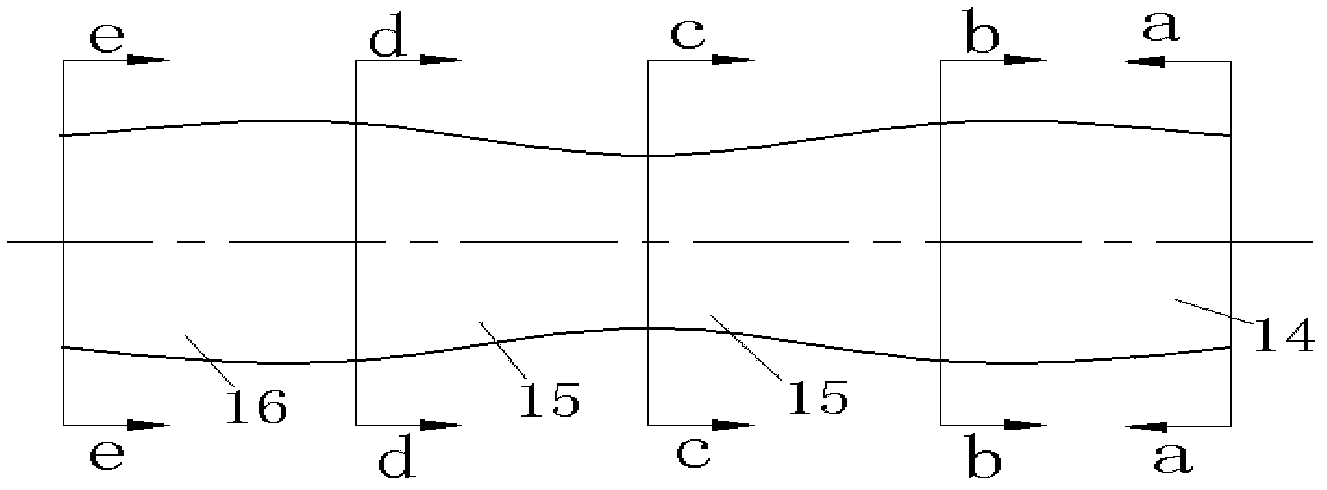

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing oxidic polyethylene wax microemulsion

InactiveCN101289540APrevent pinholesReduce the chance of needle breakageFibre treatmentPotassium hydroxidePotassium

The invention discloses a method for making oxidized polyethlene wax microemulsion. The method is characterized in that the heterogeneous 13-carbon fatty alcohol polyoxyethylene ether and a secondary alcohol ethoxy compound 15-S-9 are remixed, at the same time a small amount of additive of potassium hydrate and sodium hydrosulfite is added, at a high temperature and high pressure, the oxidized polyethlene wax is emulsified into microemulsion. The method can emulsify the oxidized polyethlene wax with high melting point and high hardness such as Hi-Wax 4202E and Hi-Wax 4051E of Mitsui company and AC-629 of Honeywell company into microemulsion; the product emulsion process does not adopt APEO surface active agent which is forbidden by REACH legislation; therefore, the product protects the environment; and the emulsion method of the oxidized polyethlene wax fills domestic blank, the product performance is up to the advanced world standard.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

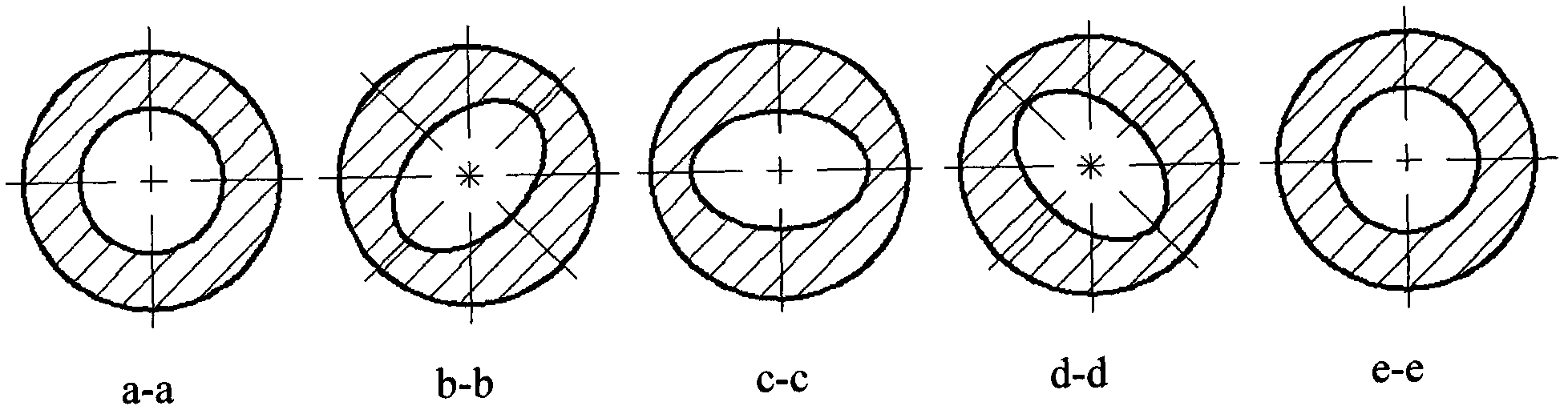

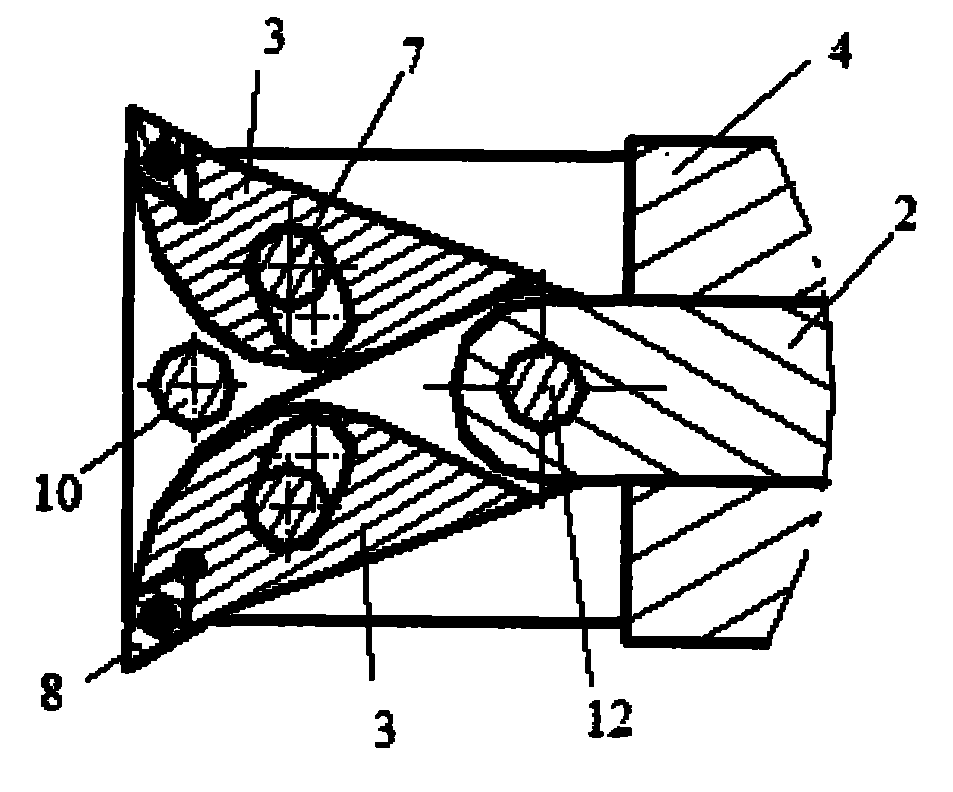

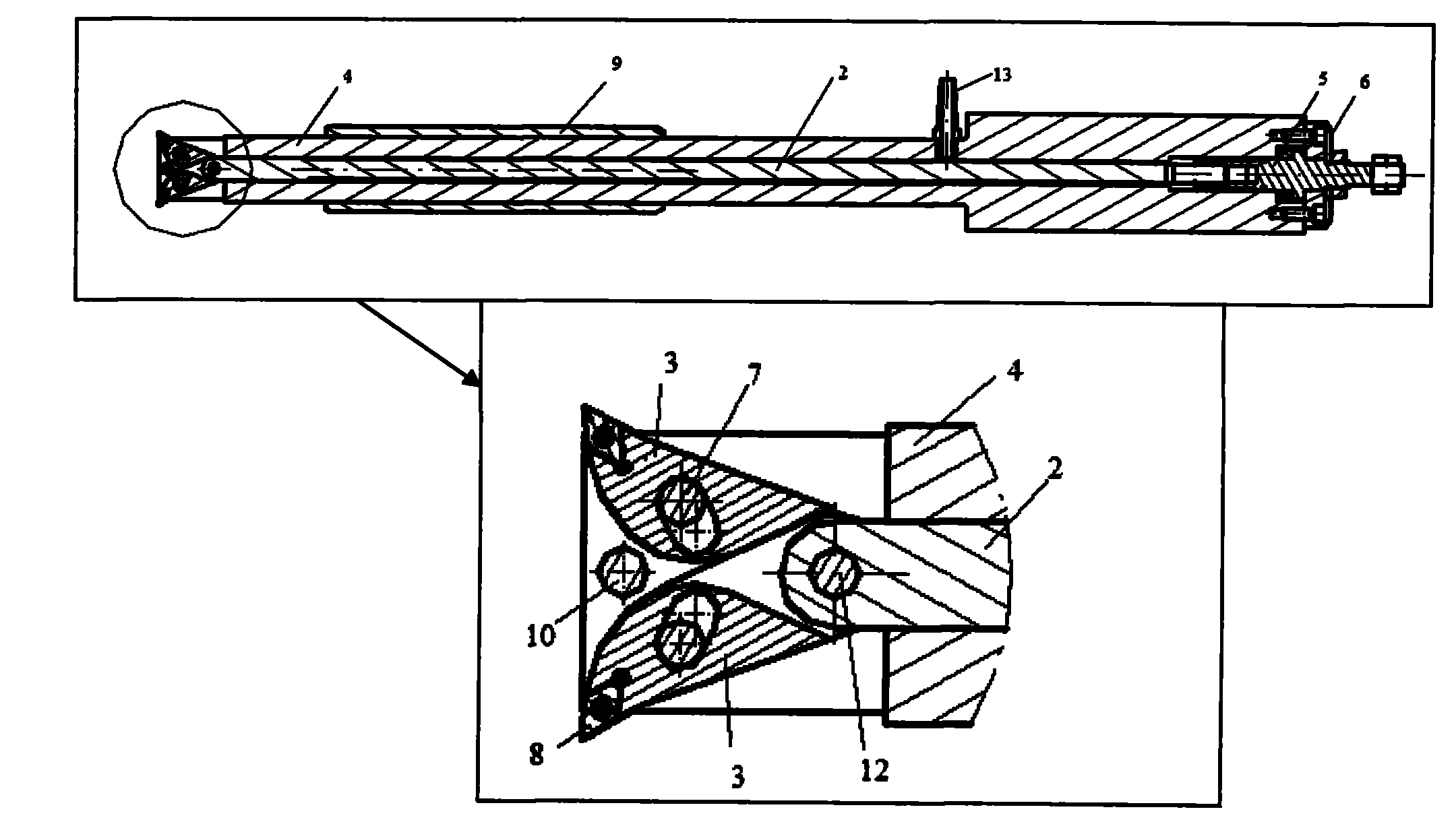

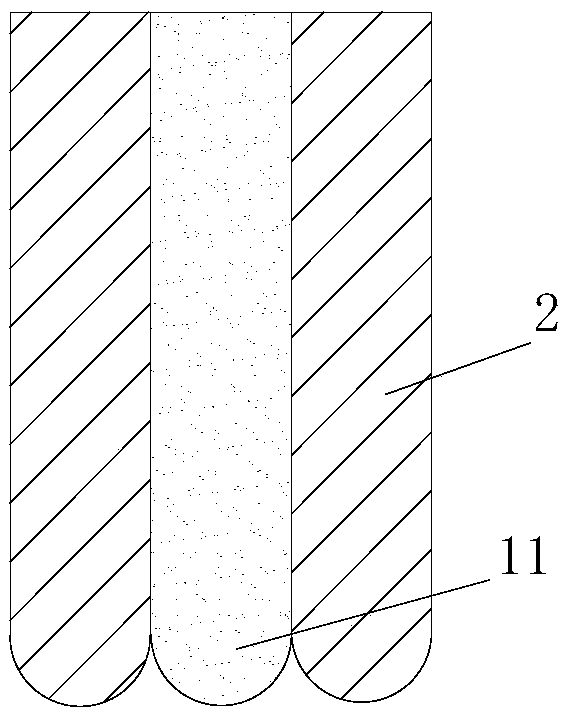

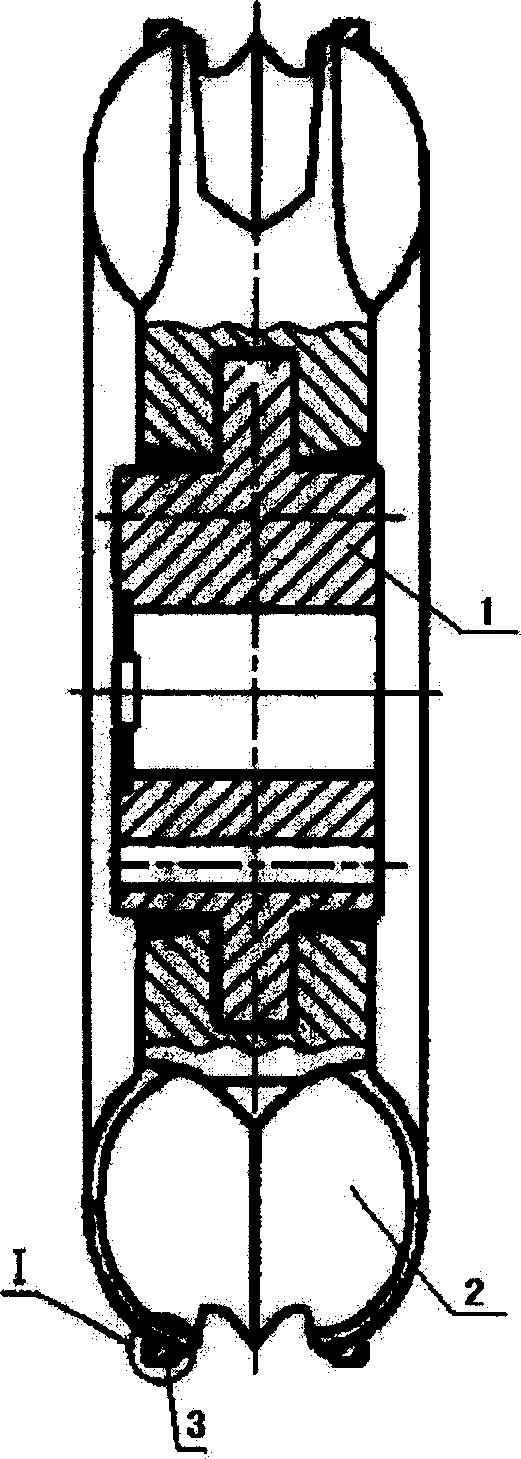

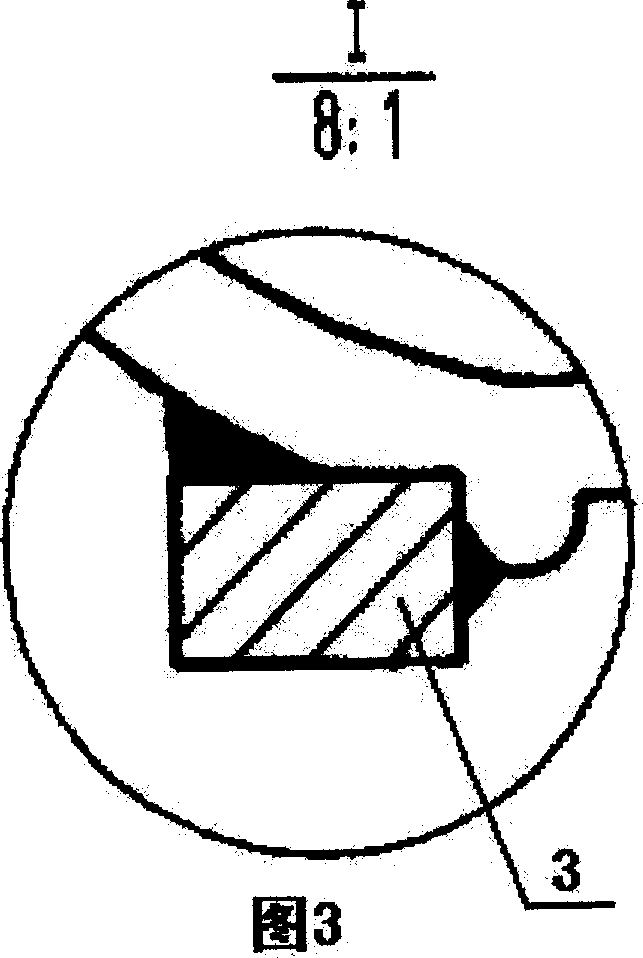

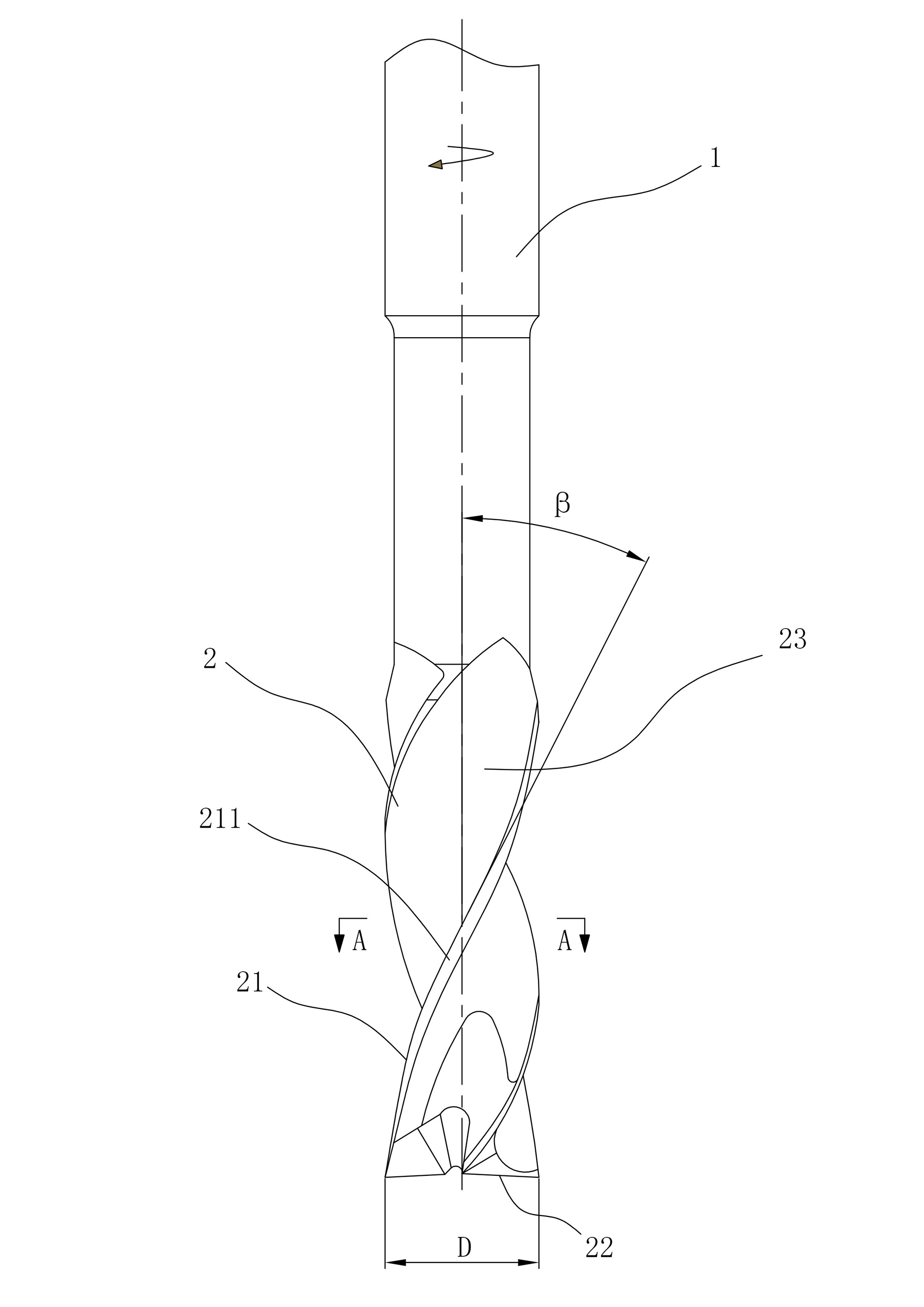

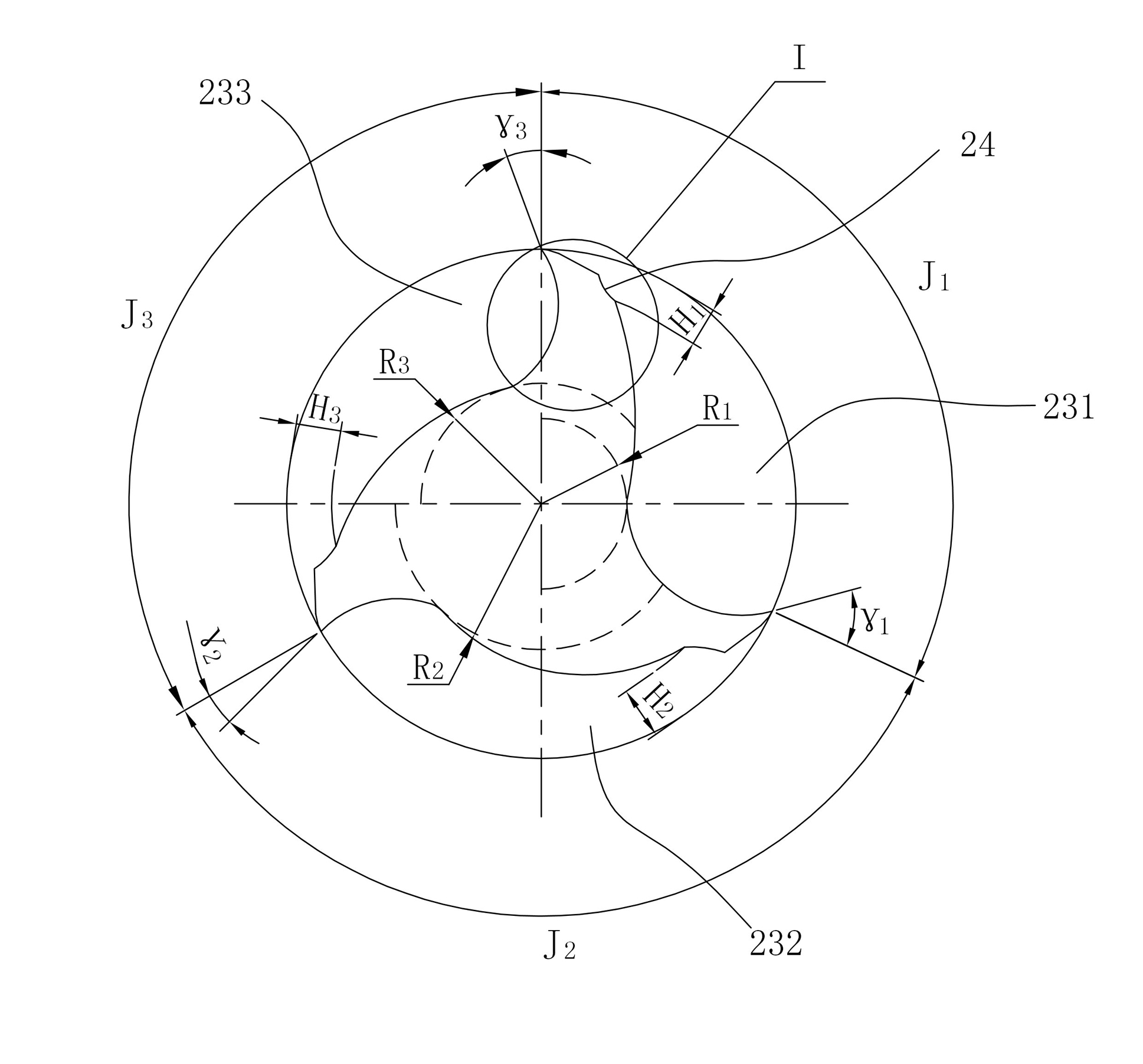

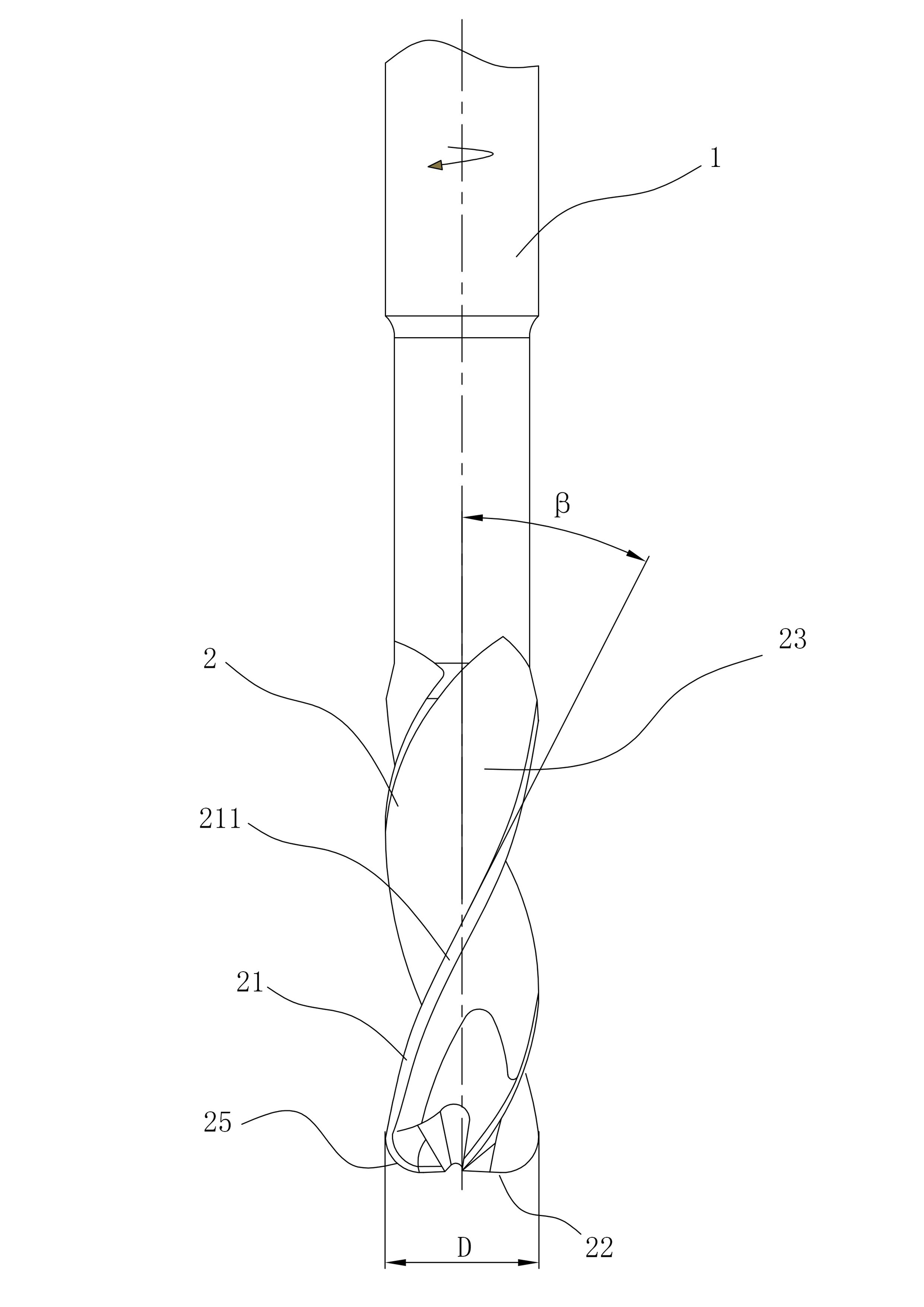

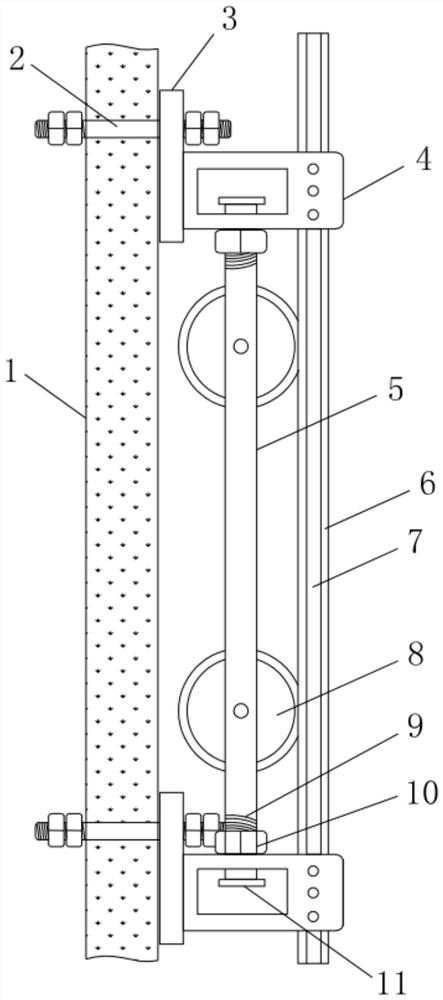

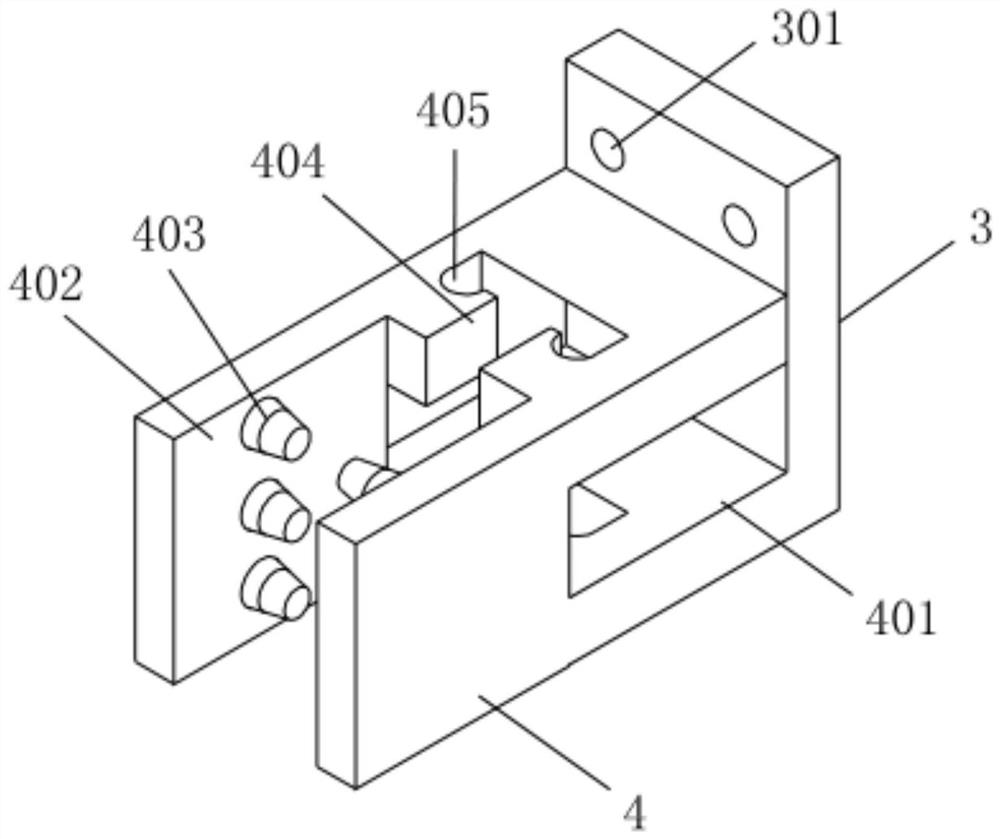

Telescopic double-edged deep-hole boring cutter

The invention provides a telescopic double-edged deep-hole boring cutter, aims to provide a deep-hole drilling boring cutter which has large length-diameter ratio, small self-excited vibration of a boring bar, reliable and stable feeding operation, no radial motion of a cutter arbor, and radial feeding of a cutting edge in a cutting process, and solves the problem that the deep-hole bottle cavity with large length-diameter ratio has large processing difficulty. The boring cutter comprises the boring bar which can extend to the deep-hole bottle cavity, wherein the central axis of the boring bar is provided with a through hole which runs through the central axis; a push rod (2) which is connected with a radial feeding device of the head of the boring bar is arranged in the through hole; the rear end of the push rod (2) is provided with a rotating handle; the rotating handle rotates a screw (5) and pushes the push rod (2) to do radial telescopic motion in the through hole of the boring bar; and the push rod (2) moves by way of pushing or pulling to drive the radial feeding device connected with the push rod and adjust the cutting edge of the double-edged boring cutter on a cutter block (3) to radically feed in the deep-hole bottle cavity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

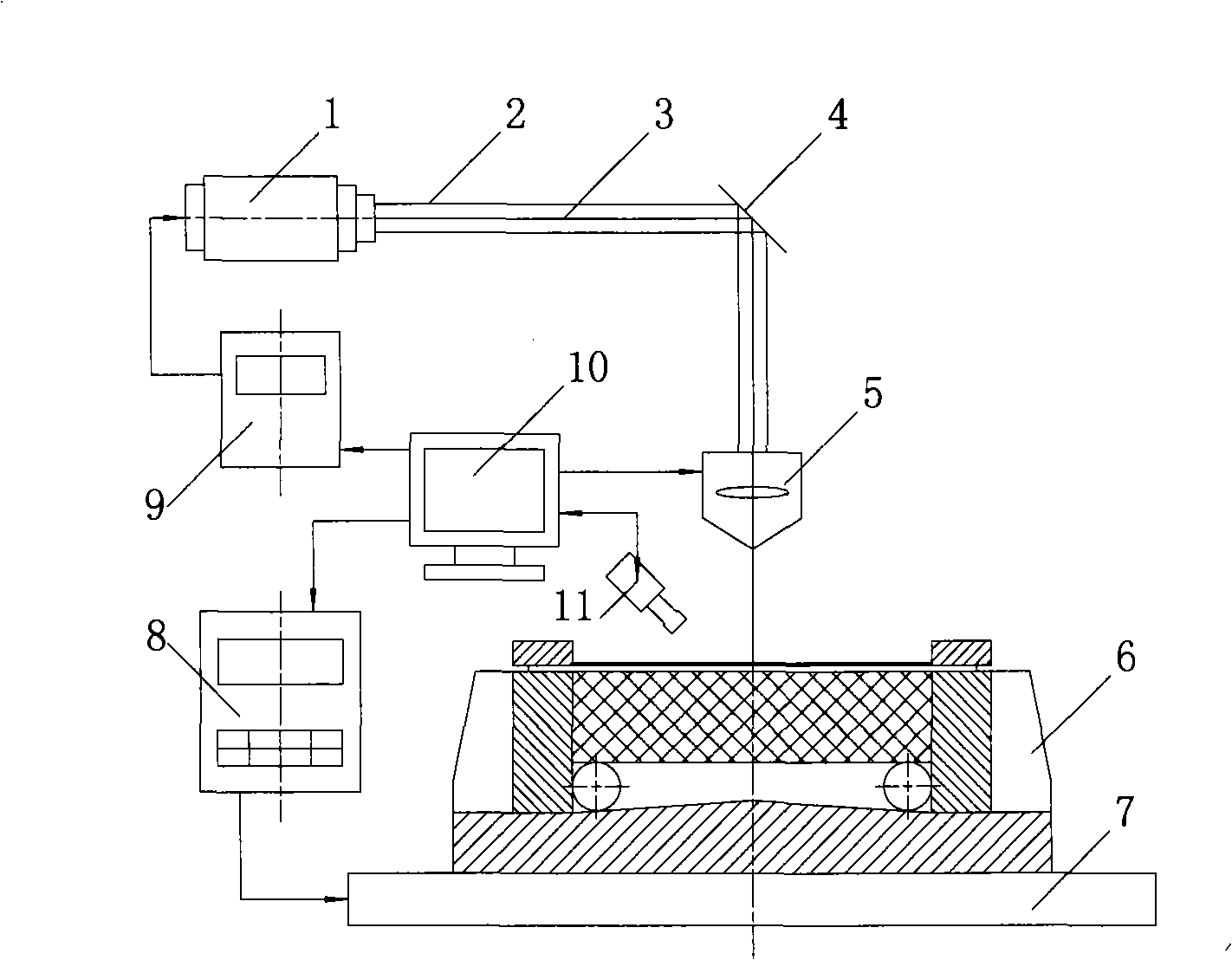

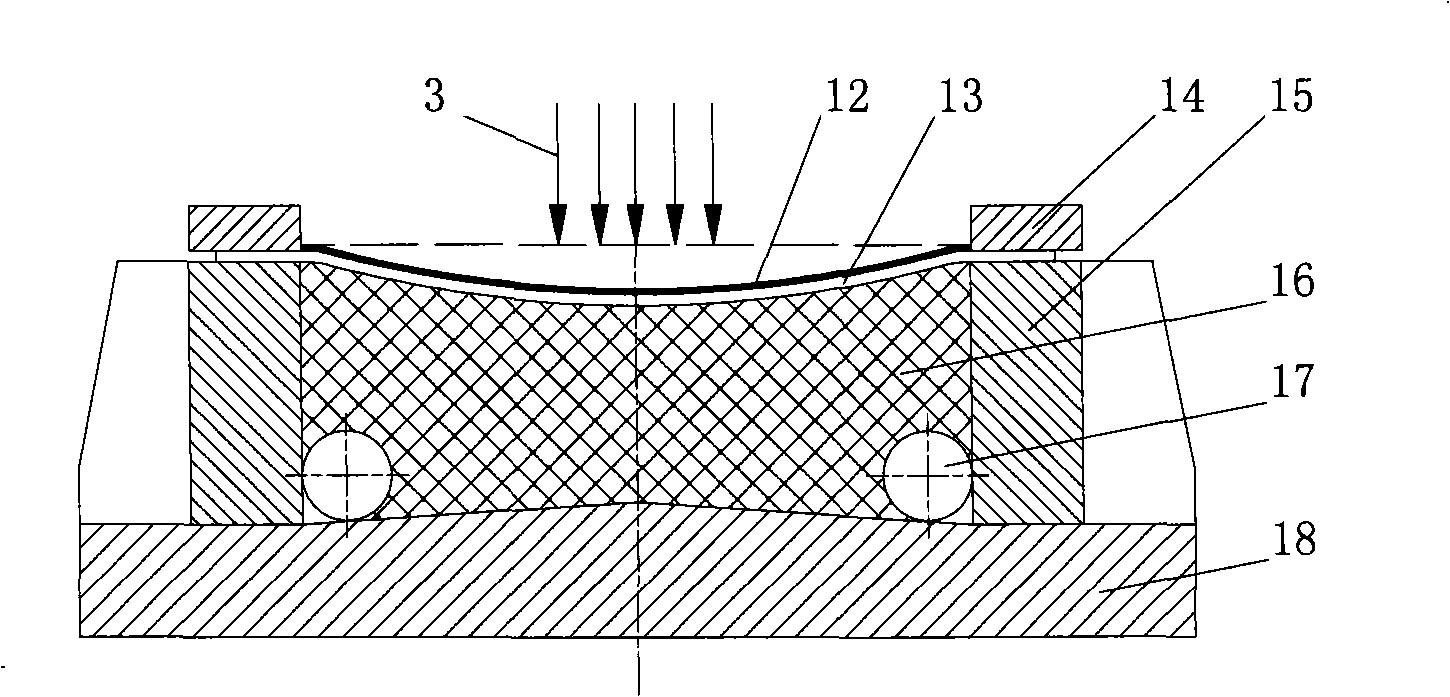

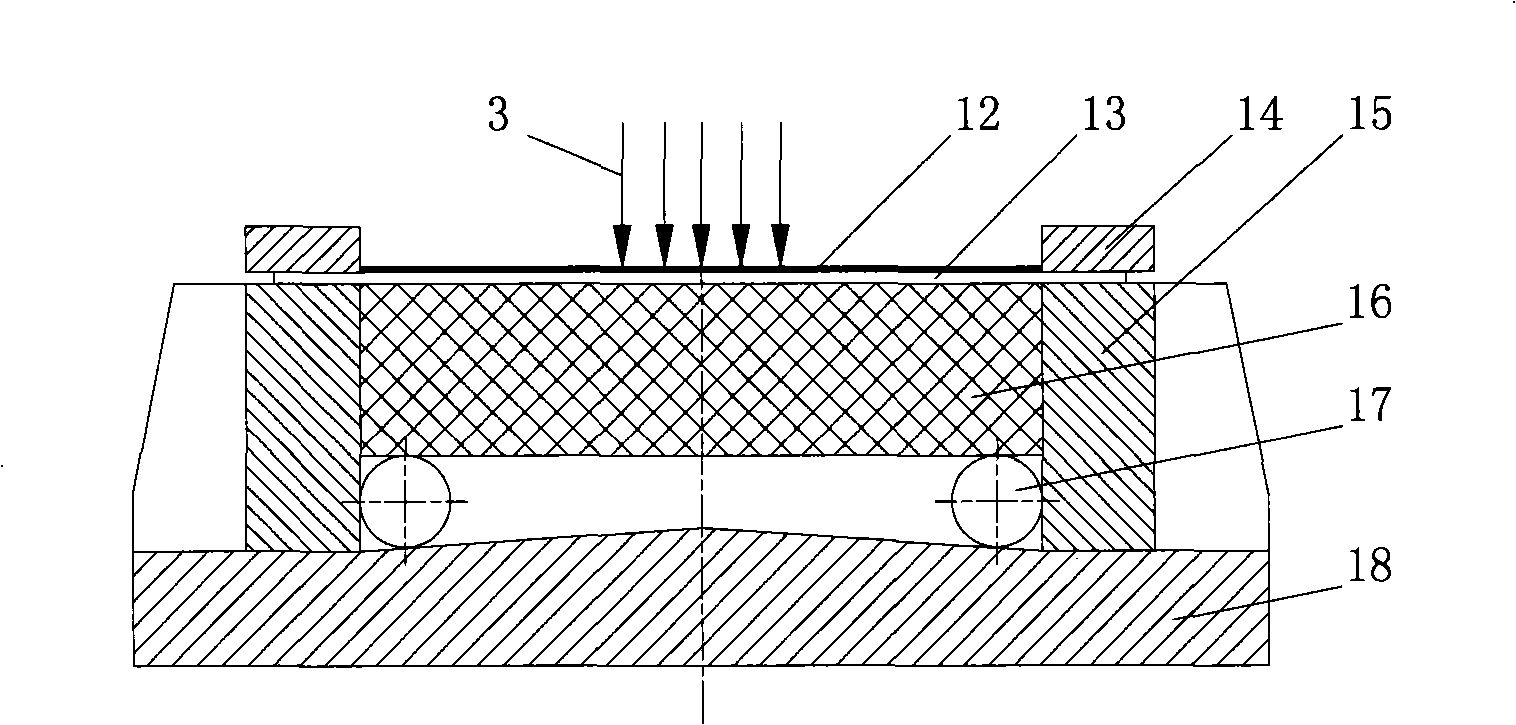

Method and device for laser shock forming on the basis of polyurethane rubber film

ActiveCN101524784APrecise large area impact formingPrecise and flexible levelingLaser beam welding apparatusShock waveStress conditions

The invention relates to a method and a device for laser shock forming on the basis of a polyurethane rubber film. The method is characterized in that shock waves induced by laser are used as a power source for forming; the polyurethane rubber film is used as a concave film for the laser shock forming; and the stress condition of a plate under the action of the shock waves is changed to achieve the shock forming of a complicated curved surface. The device comprises a laser generating device, a light guide system, a laser shock head, a polyurethane rubber film system and a control system and is also provided with a detection feedback system with a displacement measuring device. According to the requirement of the curved surface shape and forming rules of a plate, laser shock process parameters are optimized, the polyurethane rubber of proper hardness and thickness are selected, and the plate is deformed under the associative action of the shock waves and the polyurethane rubber. The device not only can achieve the complicated and precise forming of the plate, but also can carry out the flexible leveling of the plate, and also can be applied to the surface shock strengthening treatment of materials.

Owner:JIANGSU UNIV

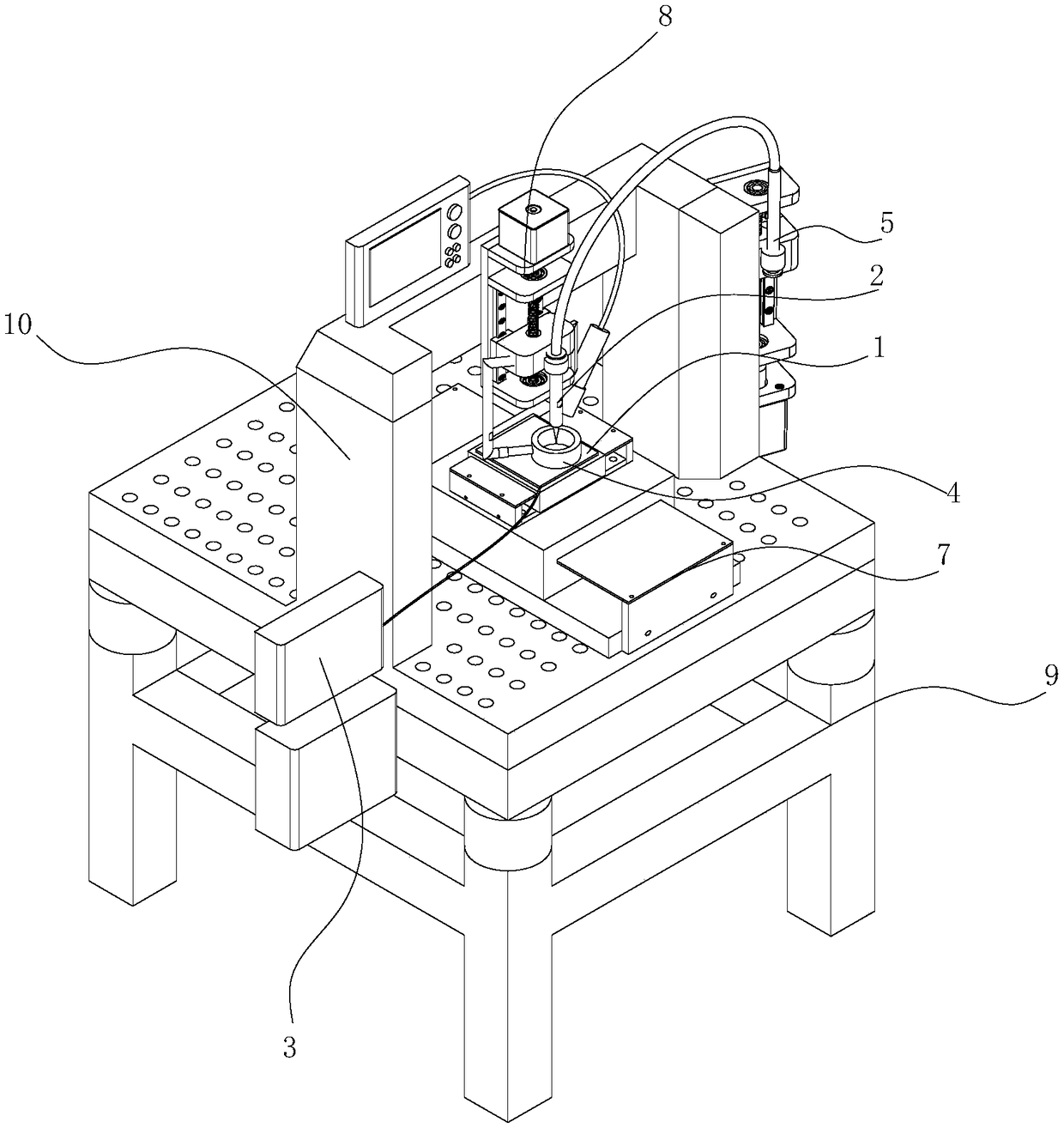

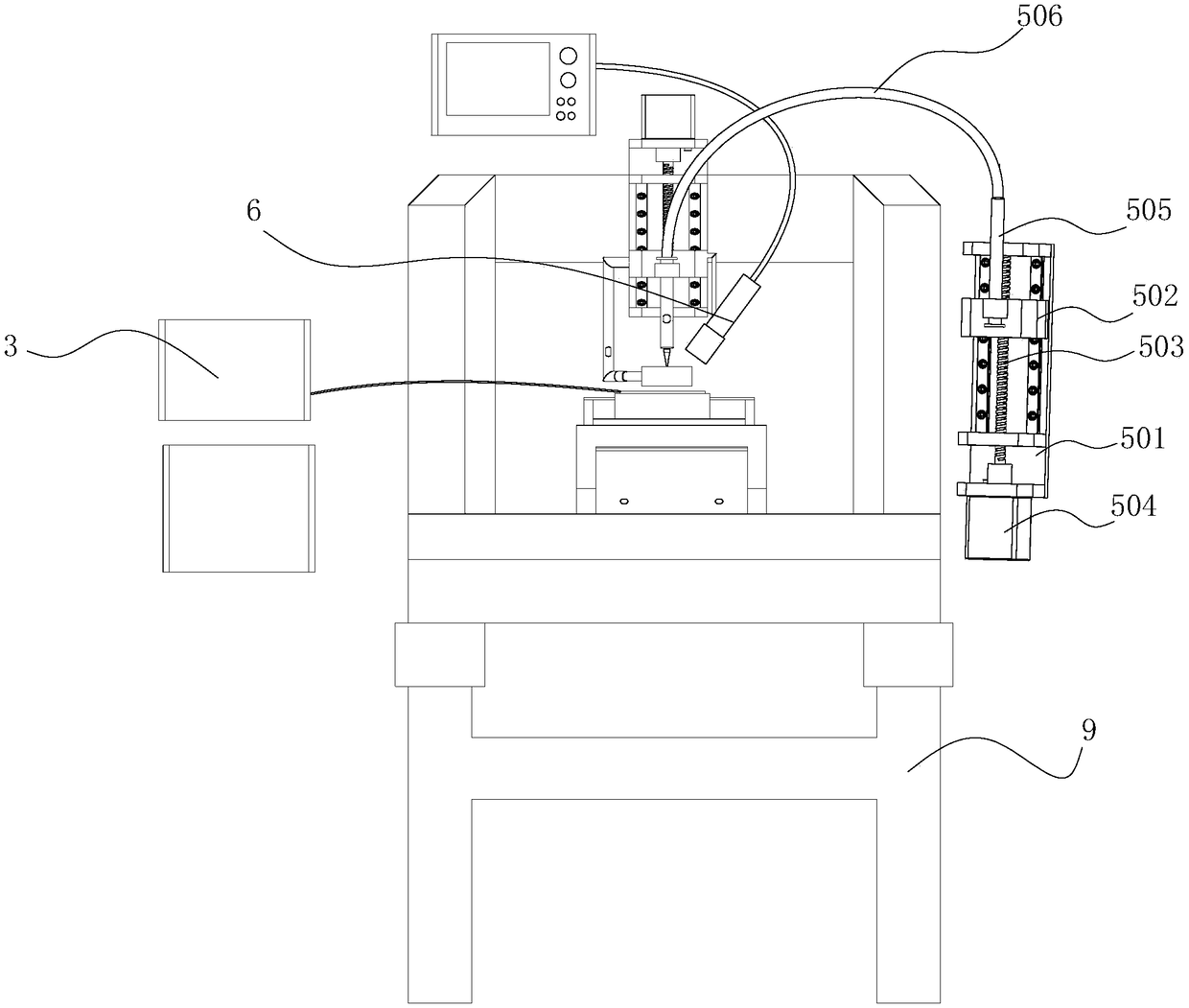

Nano-scale high-precision additive manufacturing equipment

PendingCN108748975AImprove printing accuracyChange stressManufacturing platforms/substratesAdditive manufacturing with liquidsHigh fluxSpray nozzle

The invention discloses nano-scale high-precision additive manufacturing equipment. The nano-scale high-precision additive manufacturing equipment comprises a printing platform and a printing nozzle,wherein a high-voltage pulse power supply is applied between the printing platform and a conductive nozzle of the printing nozzle; and a uniform-intensity magnetic field perpendicular to the printingplatform is further arranged between the printing platform and the printing spray head, and the distance between the printing platform and the printing nozzle meets the characteristic requirements. According to the nano-scale high-precision additive manufacturing equipment, nano-scale 2D and 3D additive manufacturing is achieved, high-voltage pulse electric fluid dynamic jetting, a nano-scale printing head and a constraint magnetic field are benefited, and the problem that high-precision nano-scale materials cannot be constructed in the prior art is solved, and particularly relates to the insufficiency and restrictions in the field of electronic circuit board printing, nano energy storage, solar cells and biomedicine, flexible electronic materials, high-flux preparation and the like.

Owner:CENT SOUTH UNIV

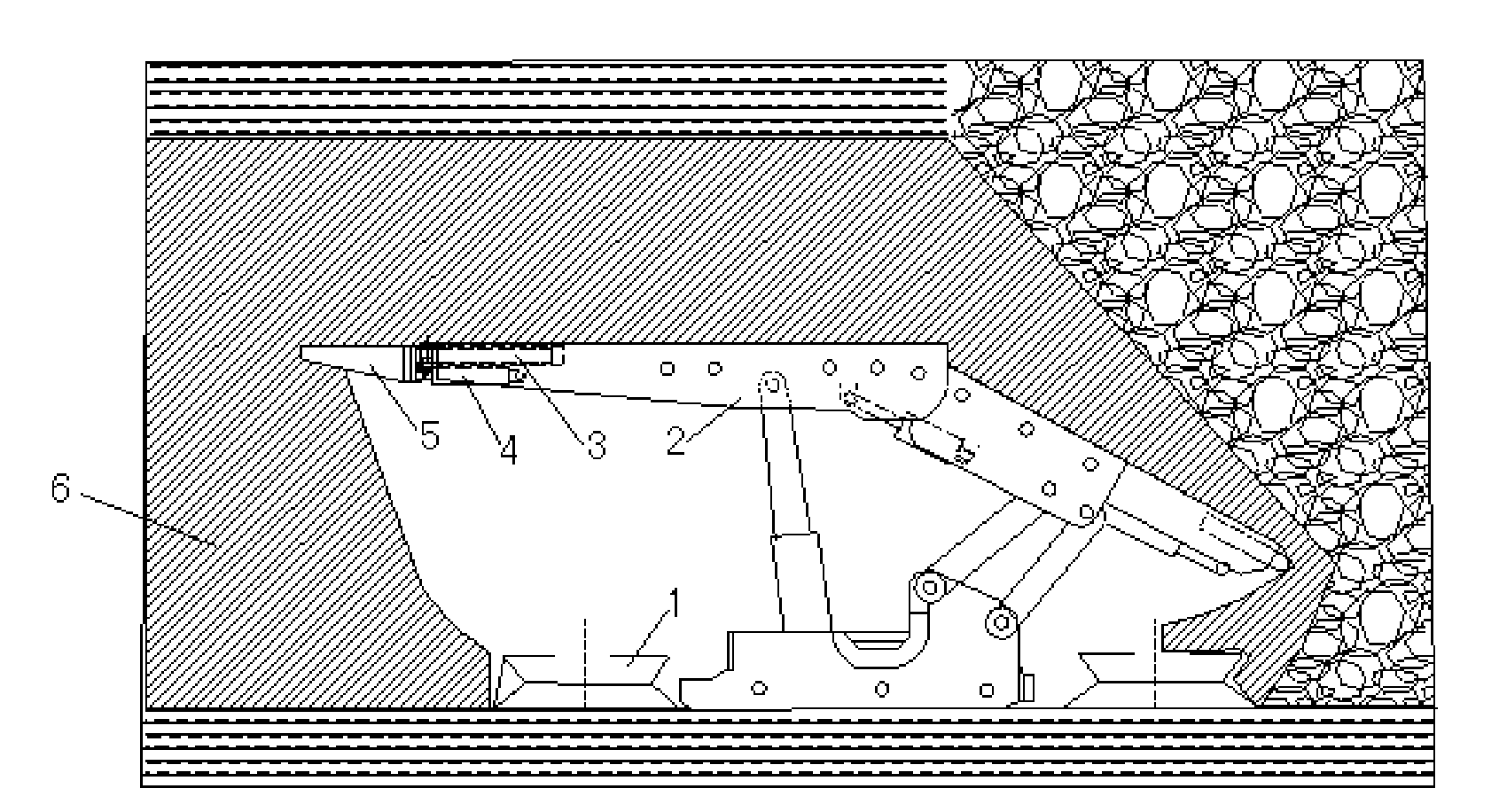

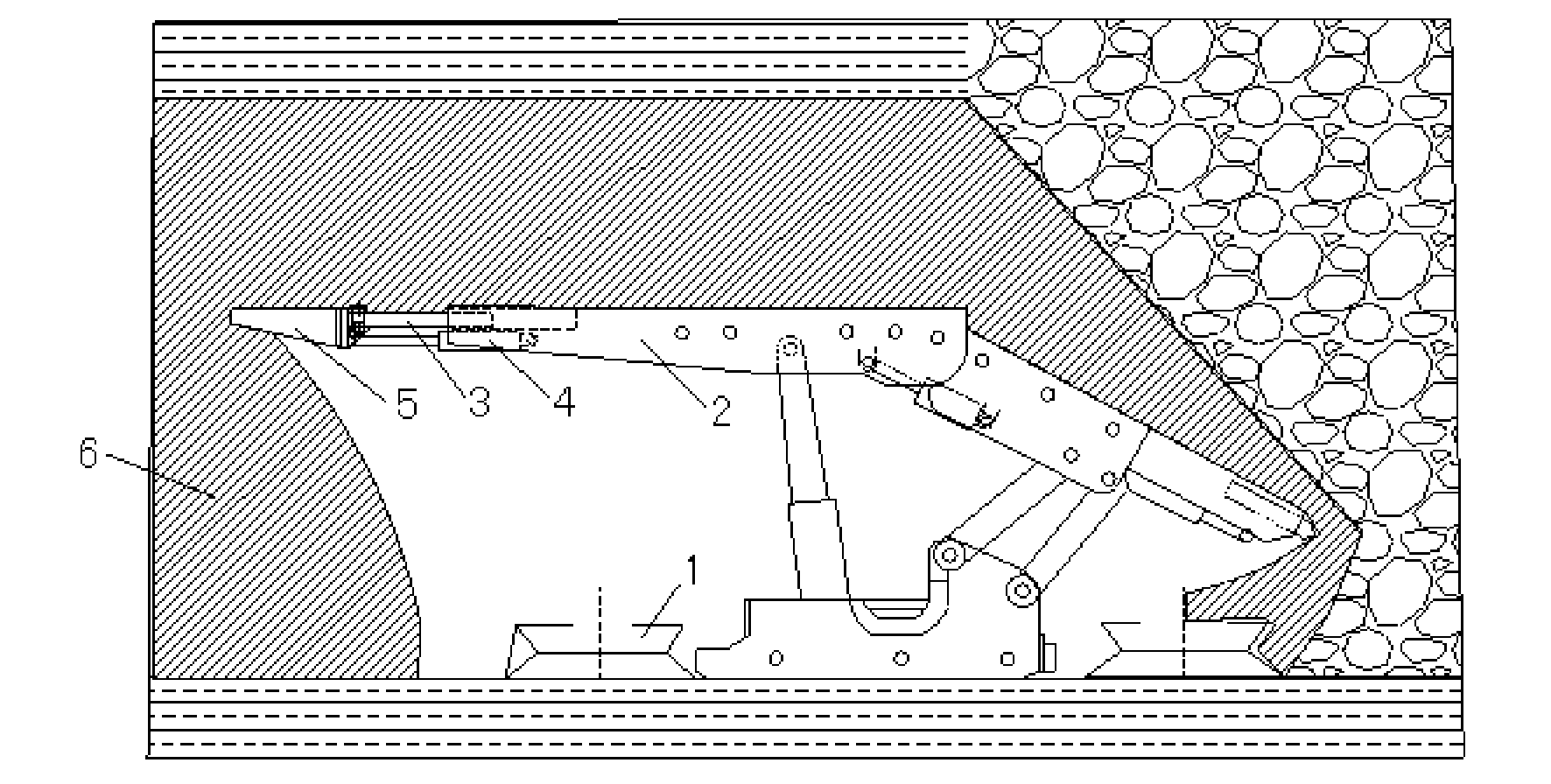

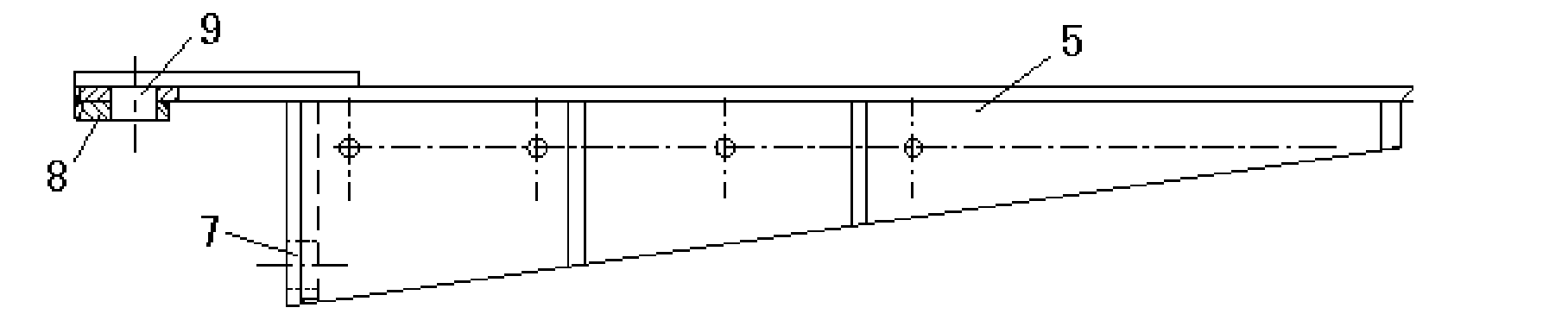

Coal mining method of lengthened front-beam fully-mechanized mining and fully-mechanized top coal carving of three-soft coal seam and equipment

ActiveCN101666230AChange stressImprove stress conditionUnderground miningSlitting machinesHydraulic cylinderEngineering

The invention discloses a coal mining method of a lengthened front-beam fully-mechanized mining and fully-mechanized top coal carving of a three-soft coal seam and an equipment. The invention is characterized in that the front end of the expansion front end of a fully-mechanized mining hydraulic bracket is provided with the lengthened front beam, a hydraulic cylinder of the expansion front beam isextended after a coal mining machine cuts coal; one part of the front end of the lengthened front beam extends into a coal wall so as to lead the lengthened front beam to support a top plate or top coal; then a scraping plate conveyor is gradually moved to be close to the coal wall behind the coal mining machine; then the hydraulic bracket is moved forward; at the time, the hydraulic cylinder ofthe expansion front beam is in retracted state again; and and top coal carving at the rear part is carried out at the place where the hydraulic bracket is moved. The invention can control the top coalor the top plate at the coal slide of the coal wall of fully-mechanized caving working face and the fully-mechanized mining working face of the three-soft unstable coal seam to lead the top coal or the top plate not to have the occurrence of leakage and roof fall and is characterized by moving the bracket fast, saving cost, having simple technique, being safer, saving working hour and having highproduction efficiency and the like.

Owner:耿学文

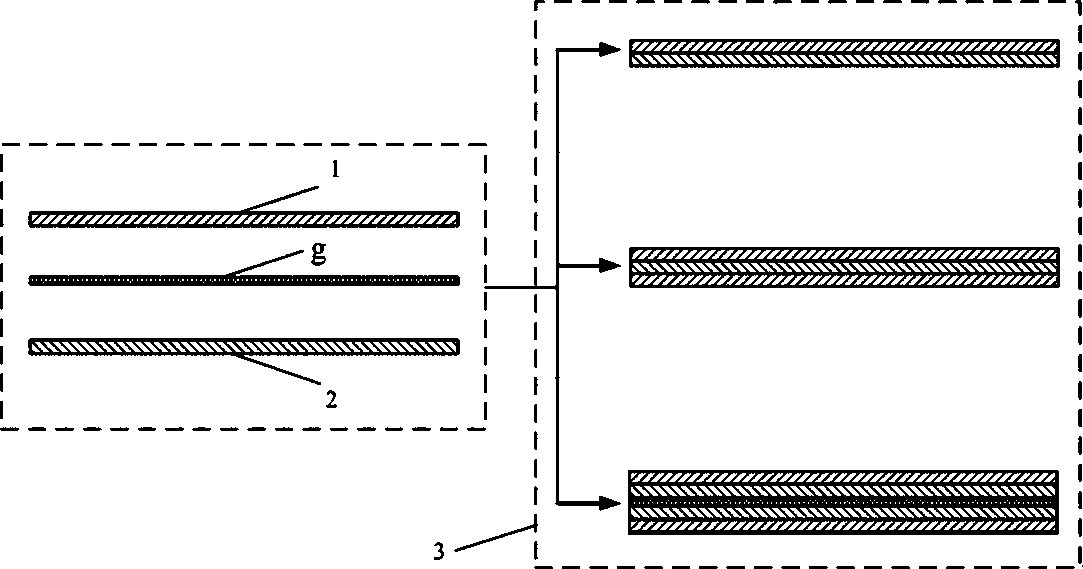

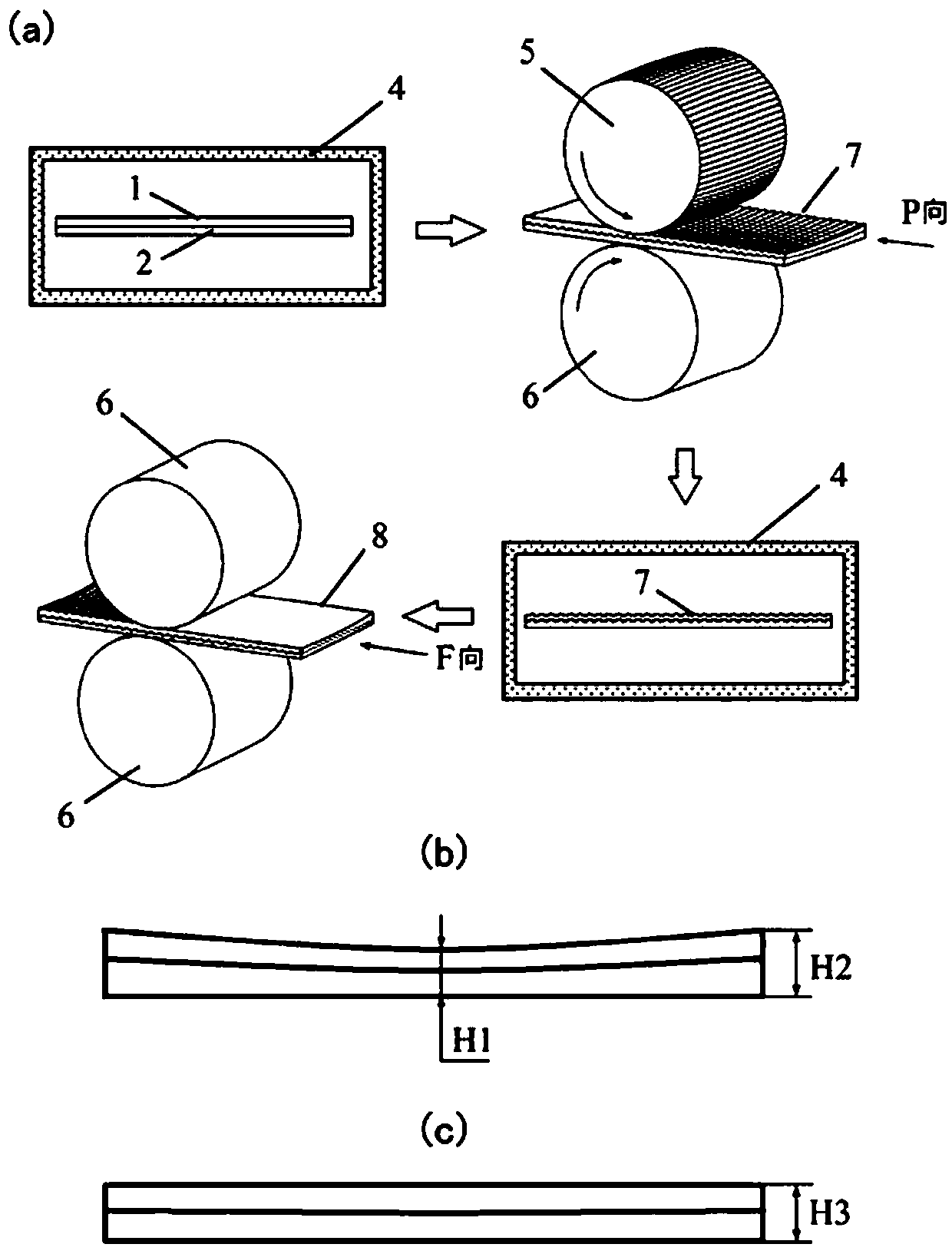

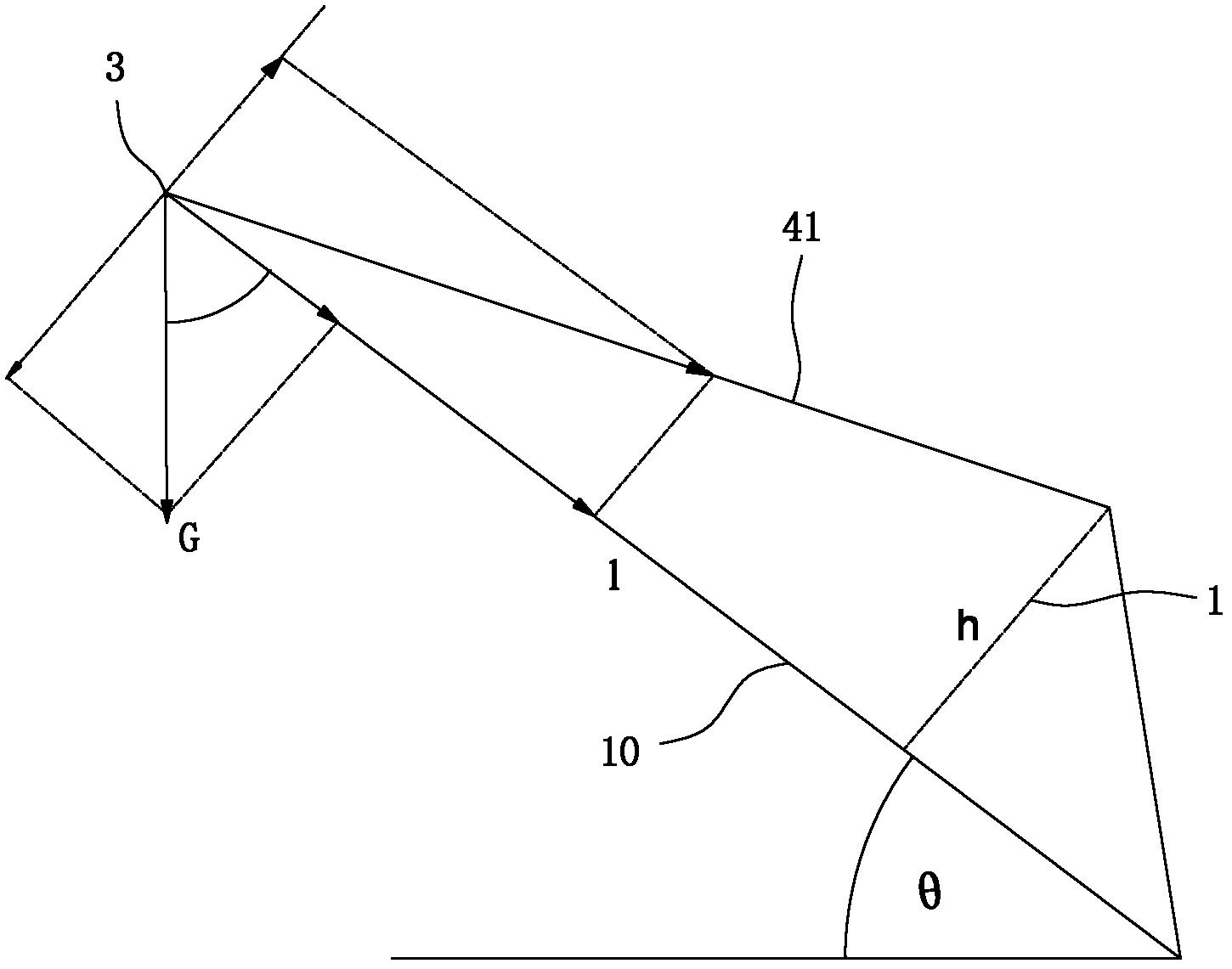

Method for rolling magnesium-aluminum layered laminated plate by drum-shaped corrugated roller

ActiveCN110722013AImprove bindingHigh bonding strengthMetal rolling arrangementsUltimate tensile strengthBonding strength

The invention relates to the field of processing of metal laminated plate belts, in particular to a method for rolling a magnesium-aluminum laminated plate by a drum-shaped corrugated roller. The method comprises the following steps of selecting a magnesium alloy plate with the same length and width as a clad plate and a pure aluminum or aluminum alloy plate as a base plate, cleaning the surface of the metal plate, buckling and assembling the ground surfaces of the base plate and the clad plate together, or buckling and stacking and assembling together. In the first pass, when the drum rolleris used for rolling the magnesium-aluminum laminated plate, a stress peak value can be formed on the lowest metal interface of the laminated plate, and the combination of the middle part of the laminated plate and the wave trough of the wave interface is promoted. In the second pass flattening process, a stress peak value is formed on the edge part of the laminated plate with poor bonding and themetal interface at the wave peak part during the first pass rolling of the plate, large plastic deformation is generated at the same time, and the bonding of the edge part of the laminated plate is promoted. According to the process, rolling is carried out twice in sequence, the bonding of the whole interface is promoted, and the bonding strength of the interface of the laminated plate is improved.

Owner:TAIYUAN UNIV OF TECH

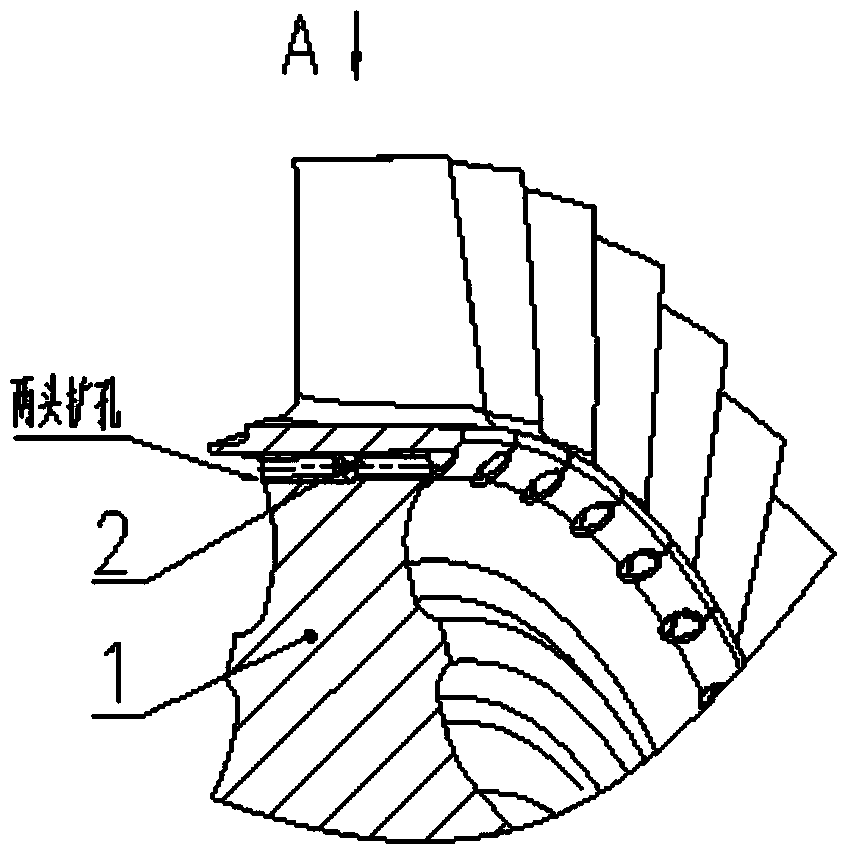

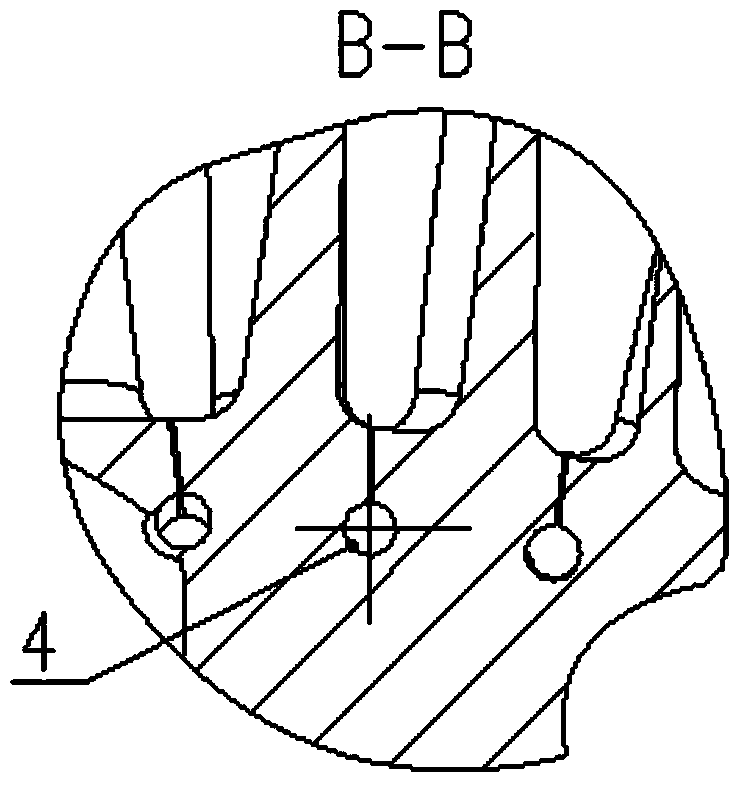

Adjustment structure and method for inherent frequencies of blades of overall blade disk of turbine

ActiveCN104314619AEasy to adjustFM effect is remarkableBlade accessoriesMachines/enginesAirflowEngineering

The invention belongs to the overall blade disk technology of turbines and relates to an adjustment structure and method for the inherent frequencies of blades of the overall blade disk of a turbine. Firstly, the initial inherent frequencies of the blades of the overall blade disk of the turbine are measured; then, according to the measured frequencies, the excitation frequency of periodic pulsation of airflow or the result of dynamic stress measurement is combined and the blade frequency needing to be adjusted is calculated, so that the inherent frequency of each stage of the blades can have safe resonance frequency margin; then, according to the blade frequency needing to be adjusted, the space between every two blades of the overall blade disk is slotted, and the radial depth of each slot is determined according to the requirements of adjusting the frequency; a stop hole is formed in each slot bottom, and a pin is mounted in each stop hole. The structure and the method effectively reduce the inherent frequencies of the blades and change the stiffness, modes of vibration and vibration stress distribution of the blades, and the blades do not resonate or the important mode of vibration of resonance of the blades is tuned out the range of working speed. The structure and the method are simple and easy to operate and significant in frequency modulation effect, are easy to control size precision, and can meet actual requirements.

Owner:AECC SICHUAN GAS TURBINE RES INST

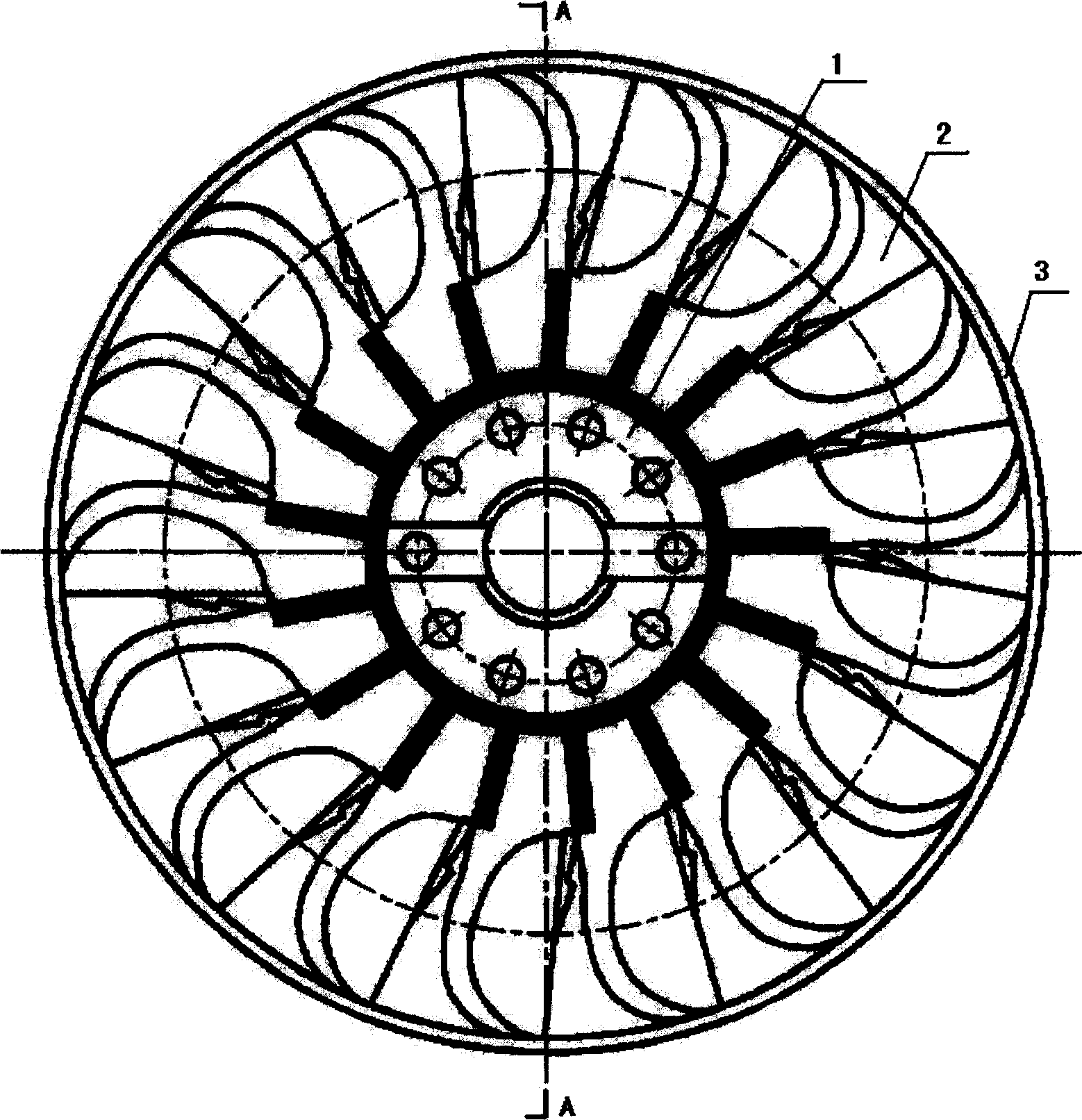

Impact type waterturbine wheel

InactiveCN1715640AReduce costsLow costFinal product manufactureHydro energy generationEngineeringStress concentration

The impact type water turbine wheel features that the wheel has at least one outer hoop to connect all the buckets successively and the circular hoop is set in the maximum position. The present invention has the advantage of changing the stress state of the buckets to avoid concentrated stress in the roots of the buckets leading to fatigue, crack and breaking while maintaining the basic structure and the production process of traditional impact turning wheel.

Owner:柳州市久源水轮机有限责任公司

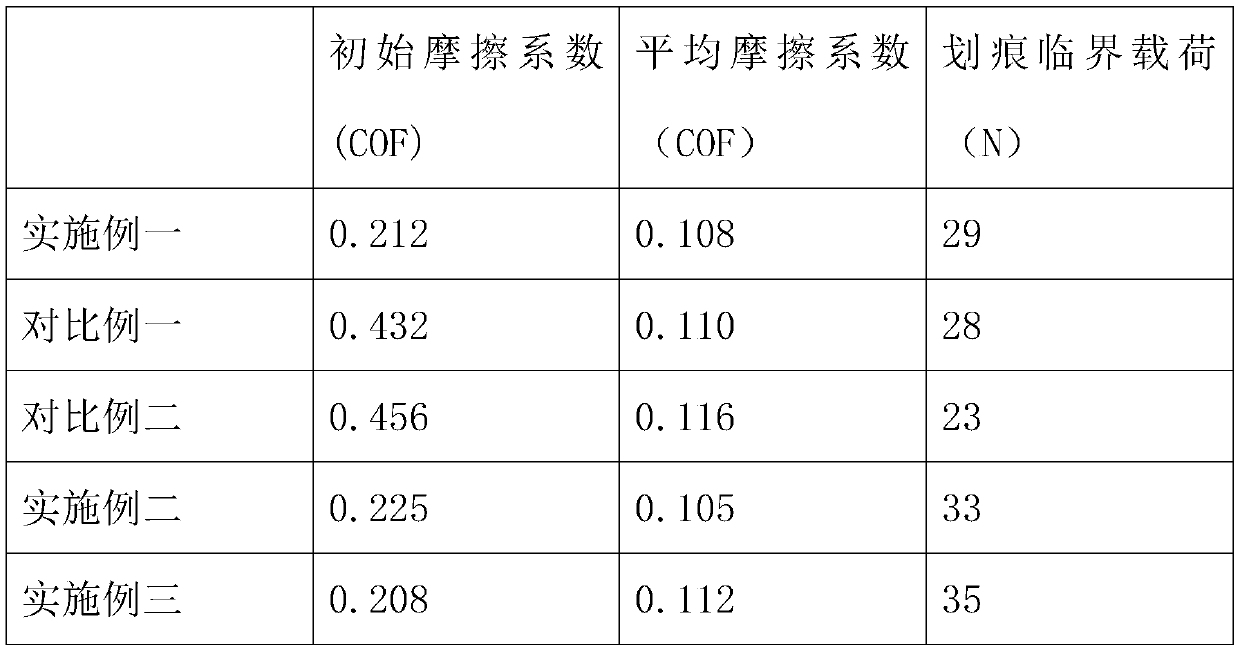

Composite diamond coating hard alloy cutter mold and preparation method thereof

ActiveCN109930129AAvoid it happening againImprove stress distributionChemical vapor deposition coatingMicro nanoEtching

The invention discloses a composite diamond coating hard alloy cutter mold and a preparation method thereof. The surface layer of the hard alloy cutter mold is provided with composite coatings composed of boron-doped or non-boron-doped micron-crystal diamonds and nanocrystalline diamonds which are alternately arranged, and a layer of diamond-like coating DLC is deposited on the surface of each composite diamond coating. The preparation method comprises the steps of oil removal and degreasing, chemical micro-etching, plasma activation, plasma enhanced gaseous boronizing, plasma cleaning, diamond slurry ultrasonic grinding, nano-scale and micron-diamond seed crystal planting, and vapor-phase deposition of the diamond composite coatings. According to the method, boron atoms enter diamond crystal lattices by doping boron in the diamond deposition process, the internal stress of the diamond coatings is adjusted, and the generation of a stress sudden change region is avoided, so that the situation that the stress of each layer is not matched is avoided fundamentally, the stress distribution inside the composite coatings is effectively improved, the integrity of the micro-nano composite coatings is further improved, the substrate-film binding force is improved, and the comprehensive mechanical property of the composite coatings is improved.

Owner:HU-NAN NEW FRONTIER SCI & TECH LTD

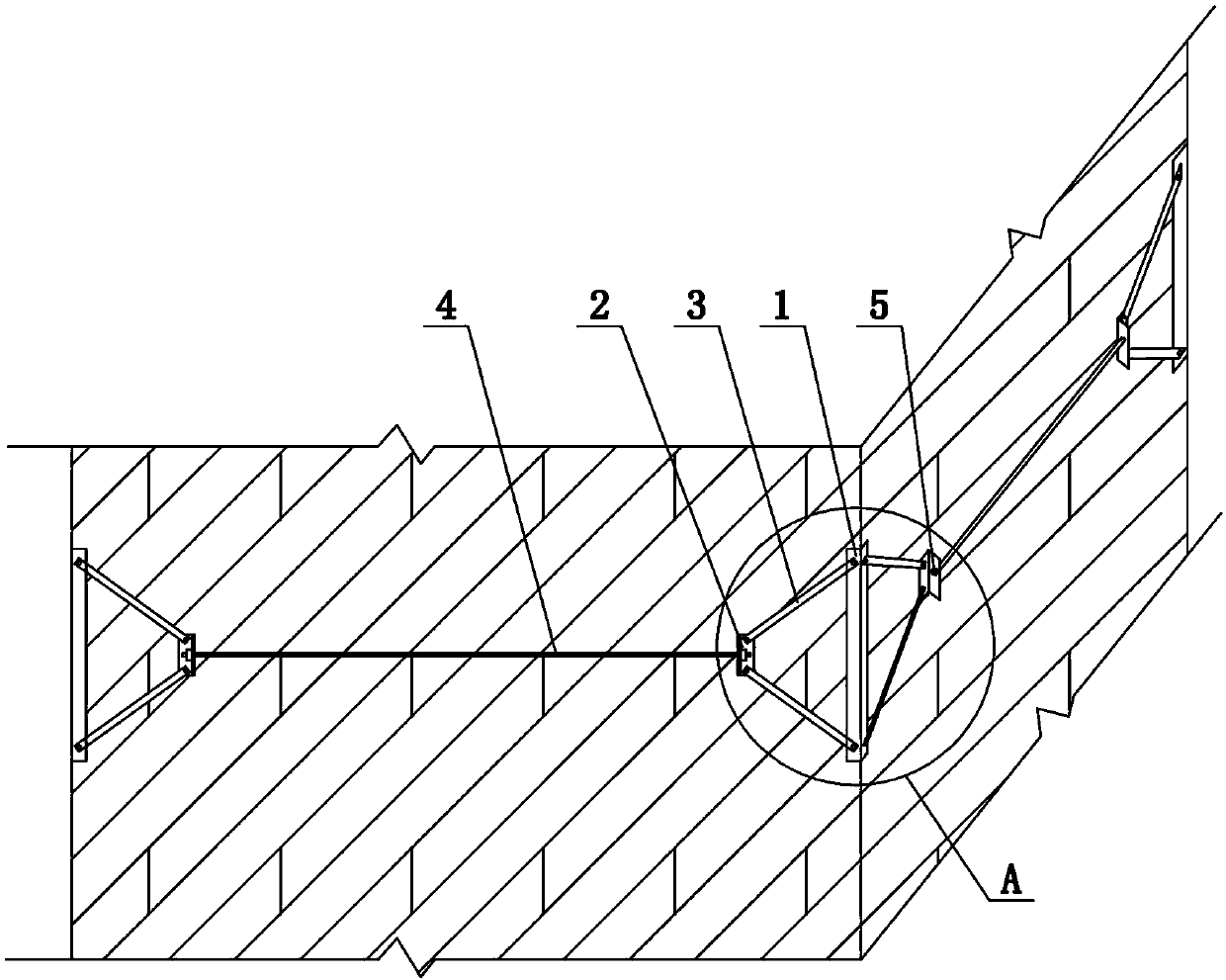

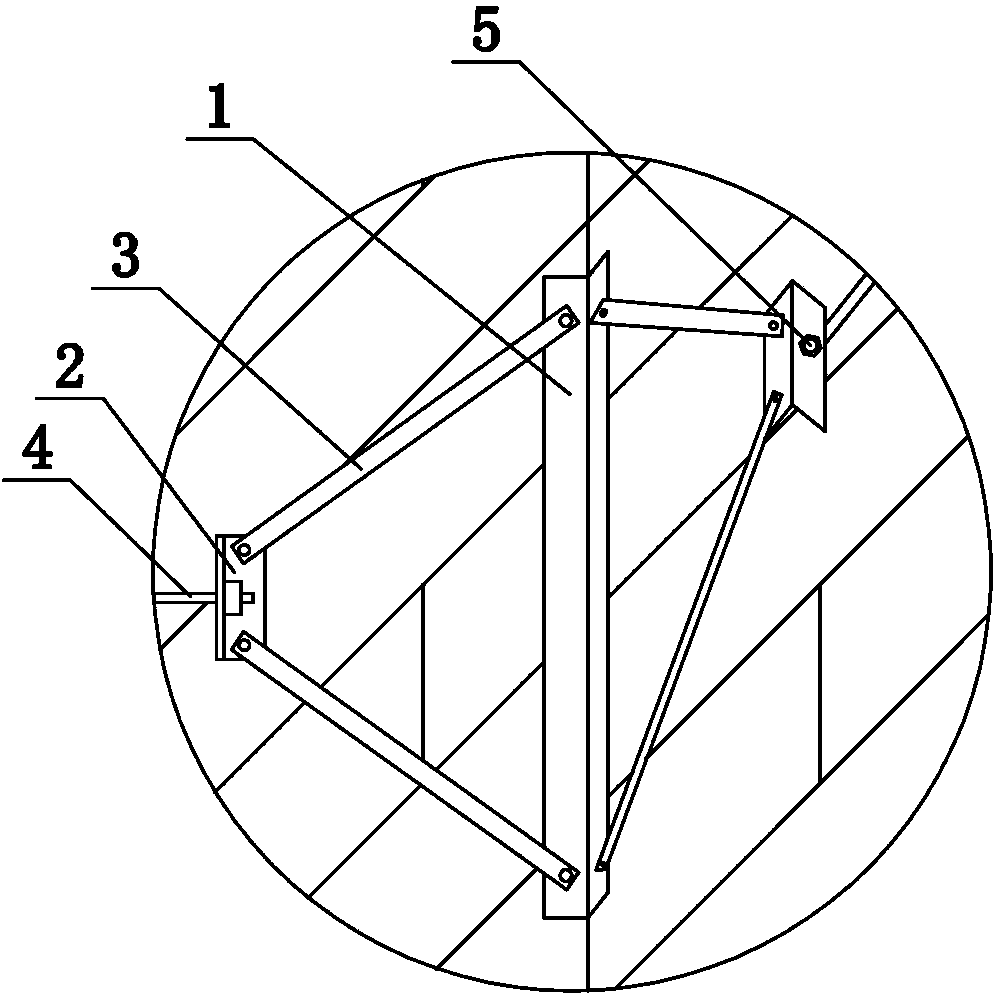

Angle hoop tie reinforcement system of traditional stone masonry house and construction technology

The invention relates to an angle hoop tie reinforcement system of a traditional stone masonry house and a construction technology. The system comprises long steel angles, the long steel angles are used for fixedly clamping outer wall corner angles of the stone masonry house, and one side of each short steel angle is connected with the corresponding long steel angle through diagonal tension plates. A connecting hole is formed in the middle of the other side of each short steel angle. Every two adjacent short steel angles are connected through tie bars penetrating through the connecting holes. The long steel angles, the short steel angles, the diagonal tension plates and the tie bars are mutually connected to form closed steel hoop structures. The steel hoop structures are hooped around the outer wall of the stone masonry house. The tie bars are prestressed steel bars. The steel angles are fixed to the corners of the wall of the stone masonry house, every two adjacent steel angles are connected through the steel tie bars, and prestress is exerted on the steel tie bars, so that the steel tie bars are matched with the steel angles to form the steel hoop structures. The steel hoops generate large constraint force on the corners of the wall, so that the stress condition of the original structure of the stone masonry house is changed, shear stress of connecting positions of longitudinal and transverse walls is reduced, and cracks at the connecting positions of the longitudinal and transverse walls and further expansion of cracks already generated are avoided.

Owner:ZHENGZHOU UNIV

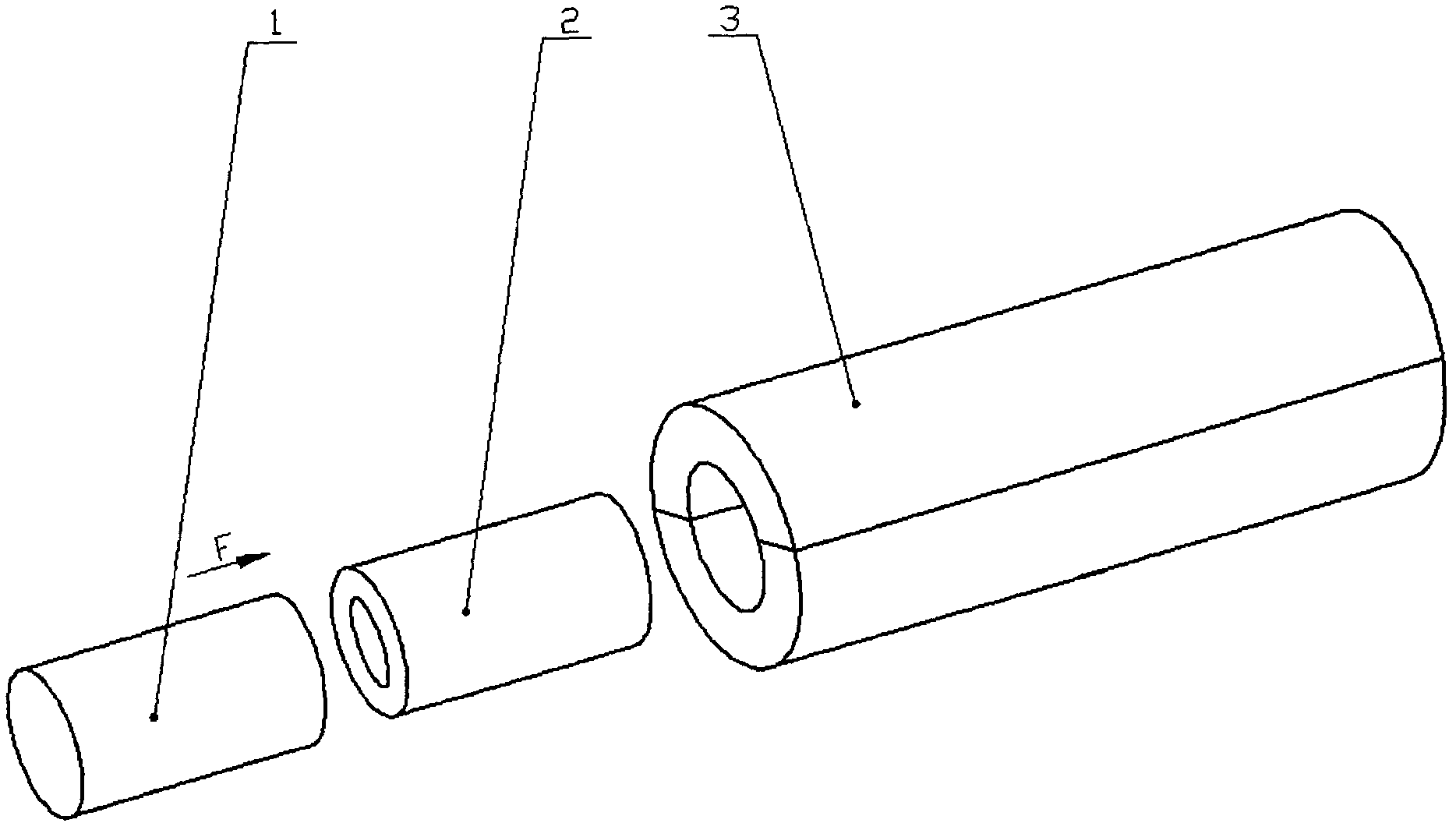

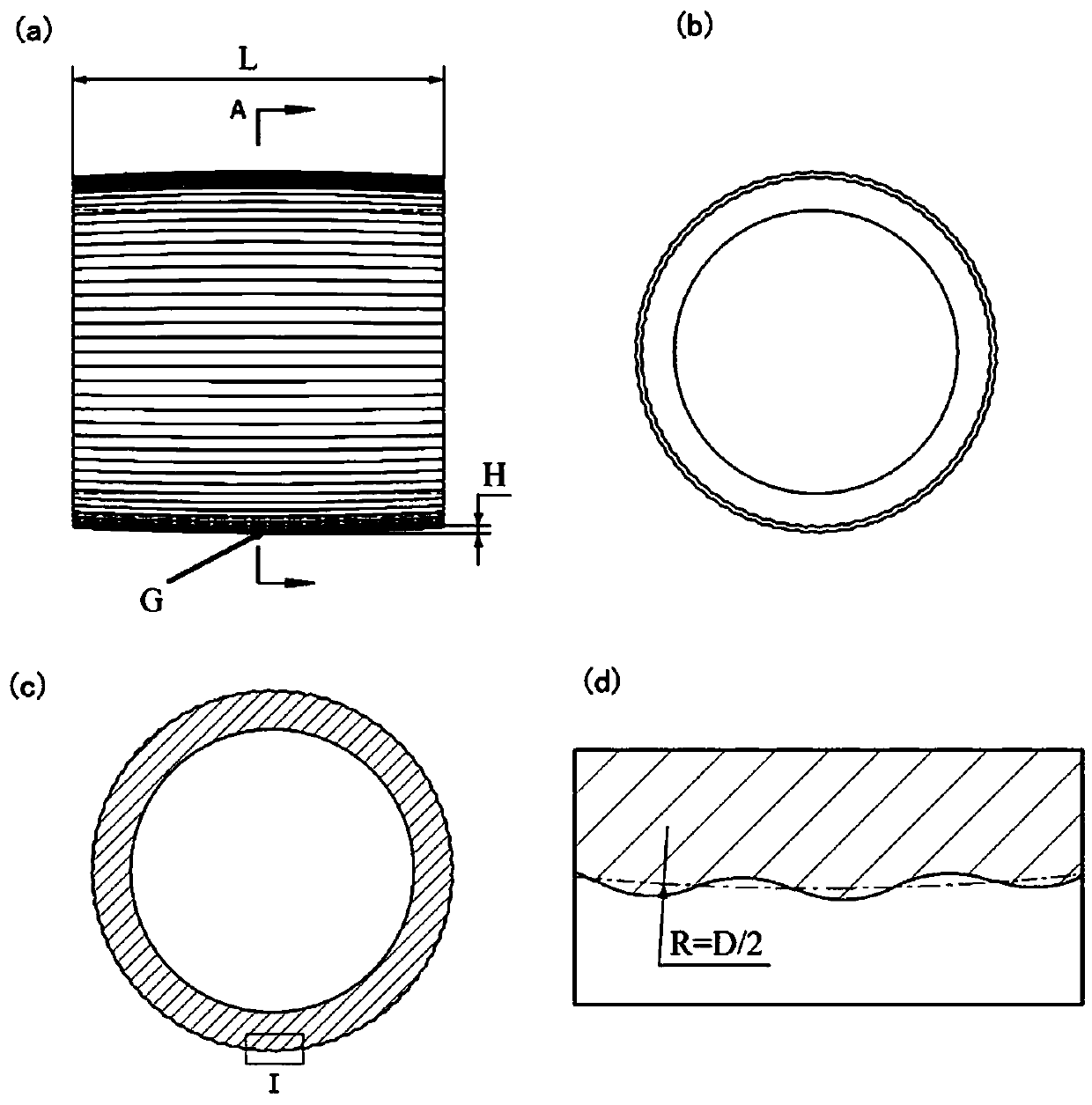

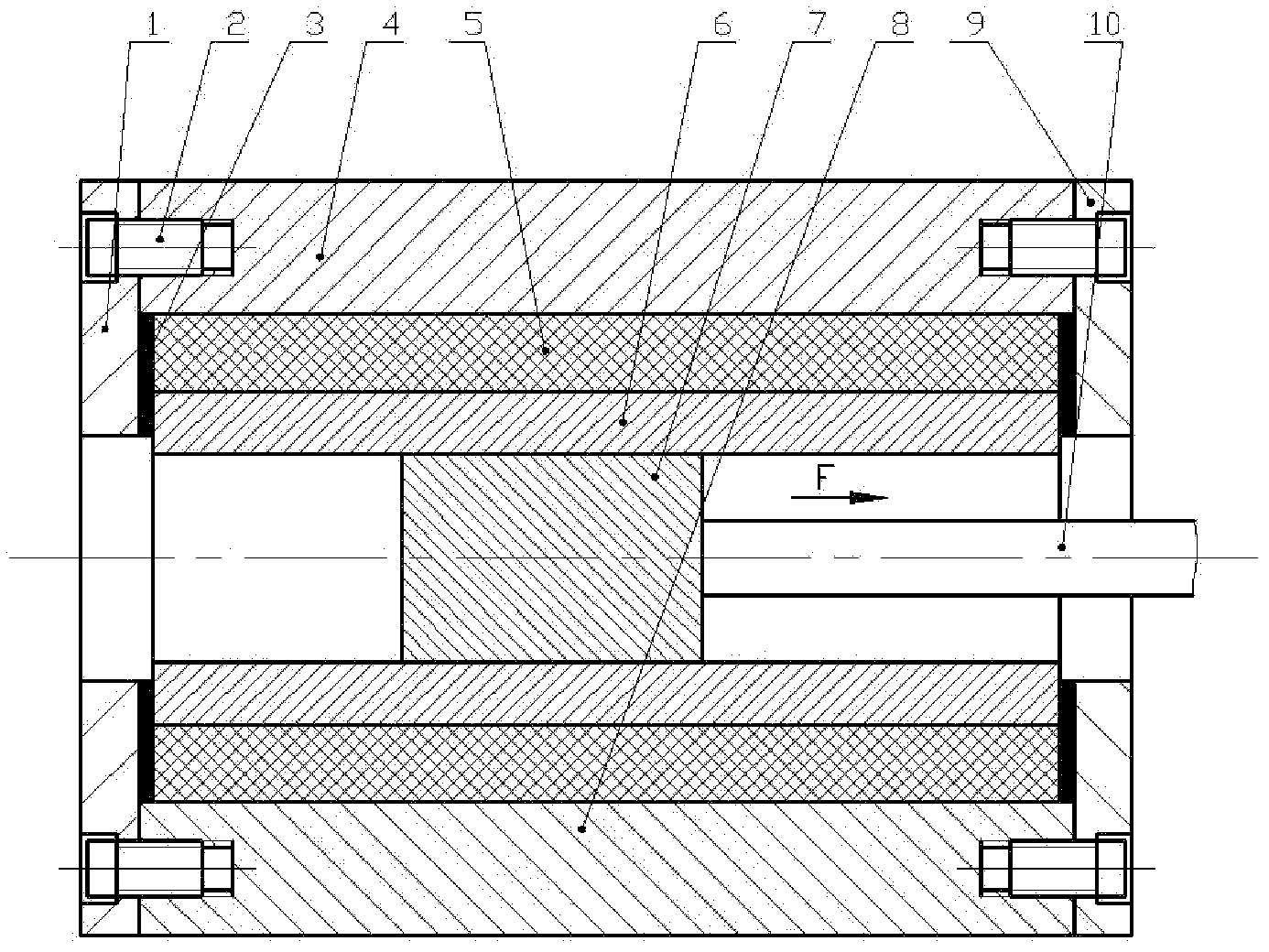

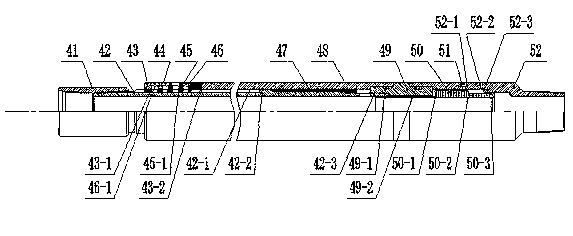

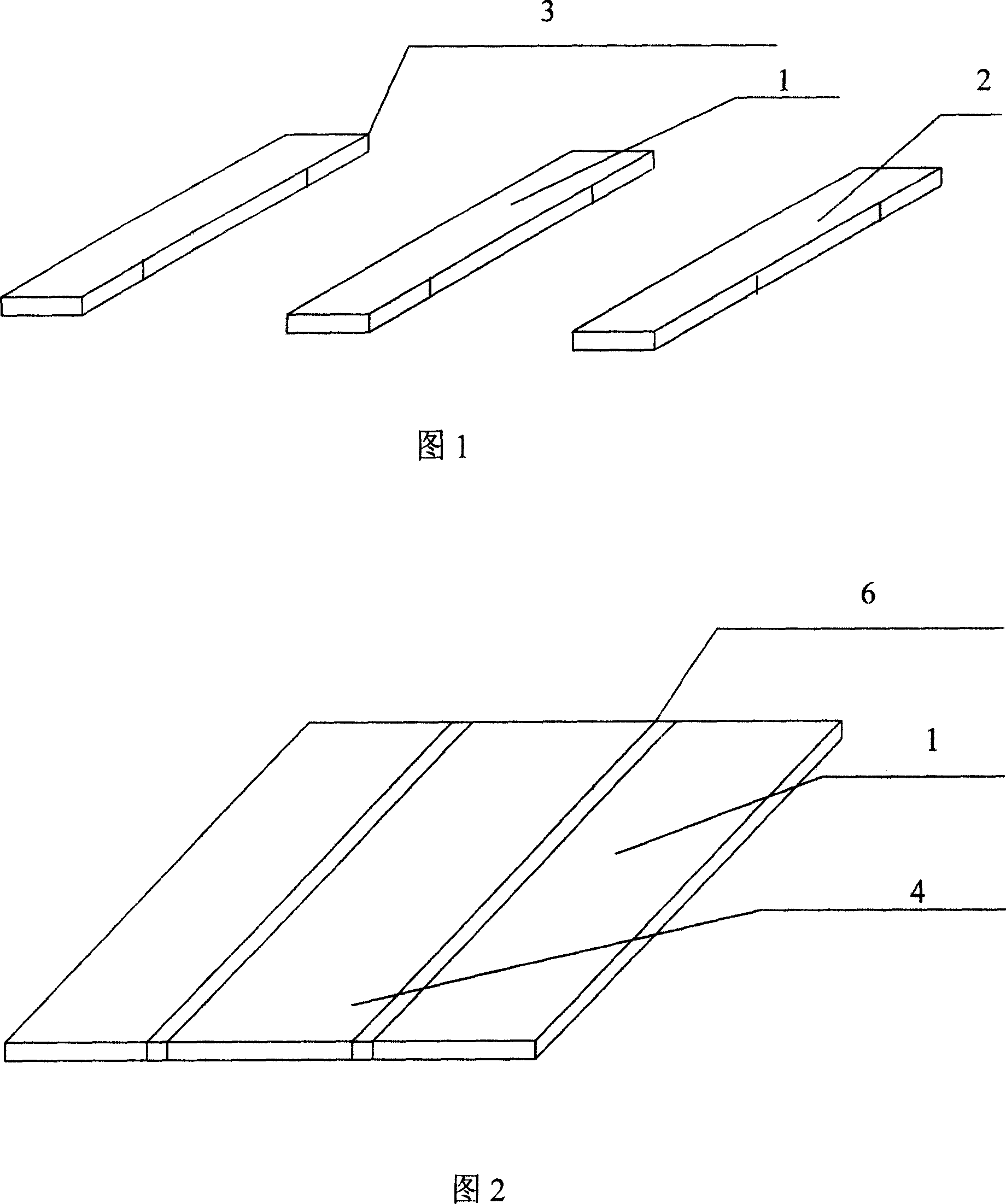

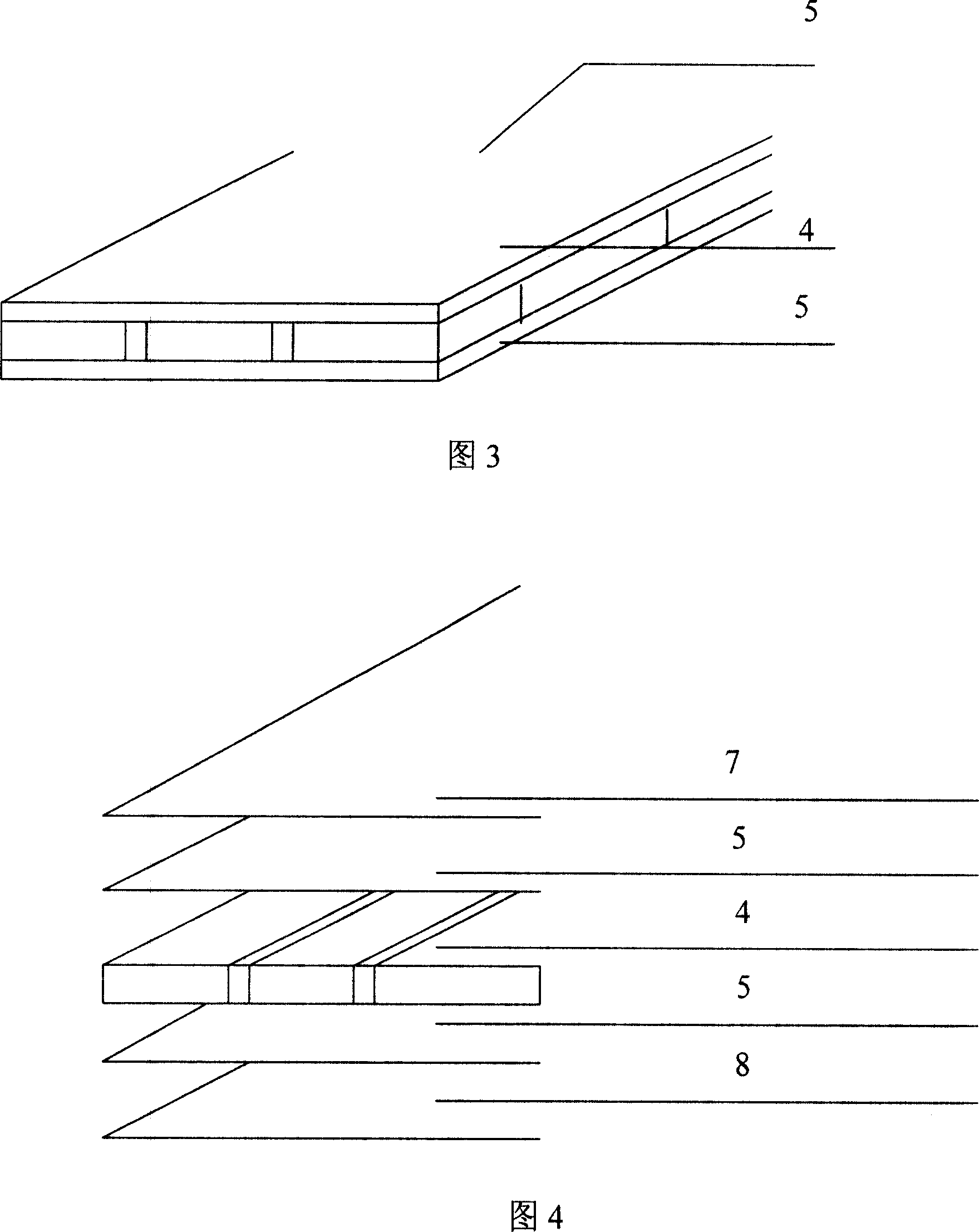

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Asymmetric dynamic balance vertical milling cutter

ActiveCN101920354AImprove machining accuracySatisfy the problem of unbalanced mass distributionMilling cuttersFluteMilling cutter

The invention discloses an asymmetric dynamic balance vertical milling cutter which comprises a cutter shank part and a cutting part, wherein the cutting part comprises more than two peripheral cutting edges and chip flutes, wherein each chip flute is arranged between every two adjacent cutting edges, the sizes of two adjacent chip flutes are different, and an unbalance quantity control step which enables the vertical milling cutter to satisfy the dynamic balance requirement is arranged at the tail of each chip flute. The asymmetric dynamic balance vertical milling cutter has the advantages of high metal removal rate and high processing accuracy and satisfies the requirement for dynamic balance.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

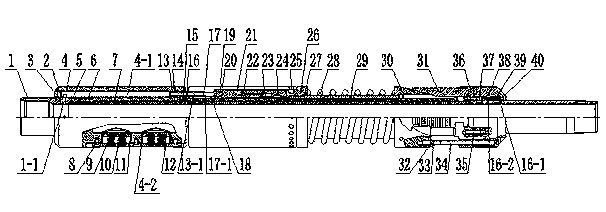

Insertion pipe type release separate-layer water injection string and operation process thereof

The invention relates to an oil field separate-layer water injection process and a matched tool, in particular to an insertion pipe type release separate-layer water injection string and an operation process thereof. The insertion pipe type release separate-layer water injection string is formed by a conventional separate injection tool string, an intubation tube connector and a string stabilizer; and the intubation tube connector and the string stabilizer are sequentially arranged at the upper part of the conventional separate injection tool string. According to the invention, by anchoring of a release and sealed water injection of an intubation tube, the force condition of the separate injection string is changed; a separated upper blank tubing is suspended at a wellhead; the separated separate injection tool string is anchored and suspended on the string stabilizer; the blank tubing at the upper part is in intubation tube seal fit with the string stabilizer and the separate injection tool string at the lower part without being in screwed connection with the string stabilizer and the separate injection tool string at the lower part; the hazard to a packer rubber sleeve at the lower part, which is caused by vermiculation of the string at the upper part when water injection pressure and temperature fluctuate, is fundamentally eliminated; the string stabilizer is released step by step; and the difficult problem that the release string cannot be pulled out is solved. The water injection tool is simply manufactured, is convenient to operate and has high universality.

Owner:李运柱

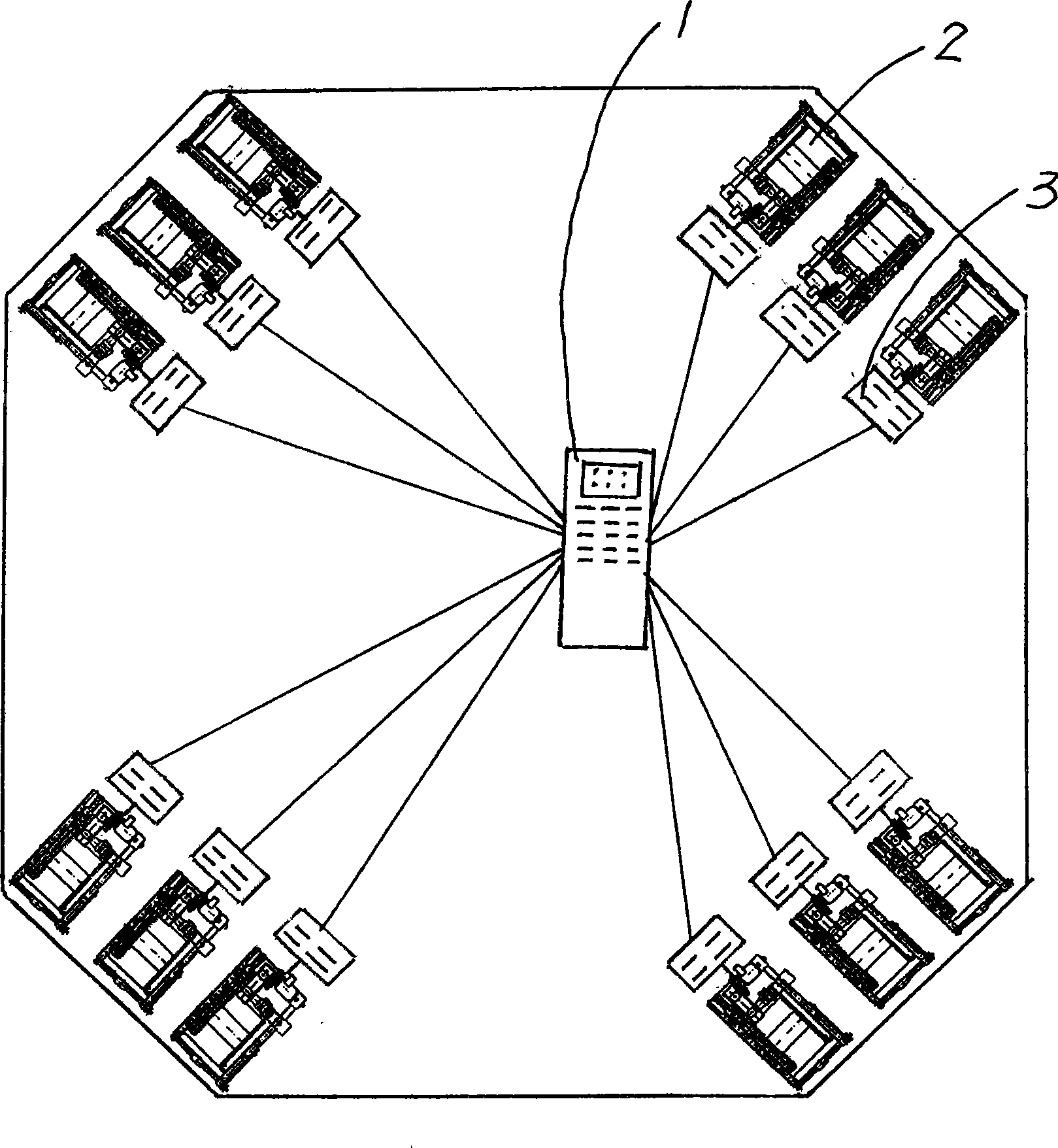

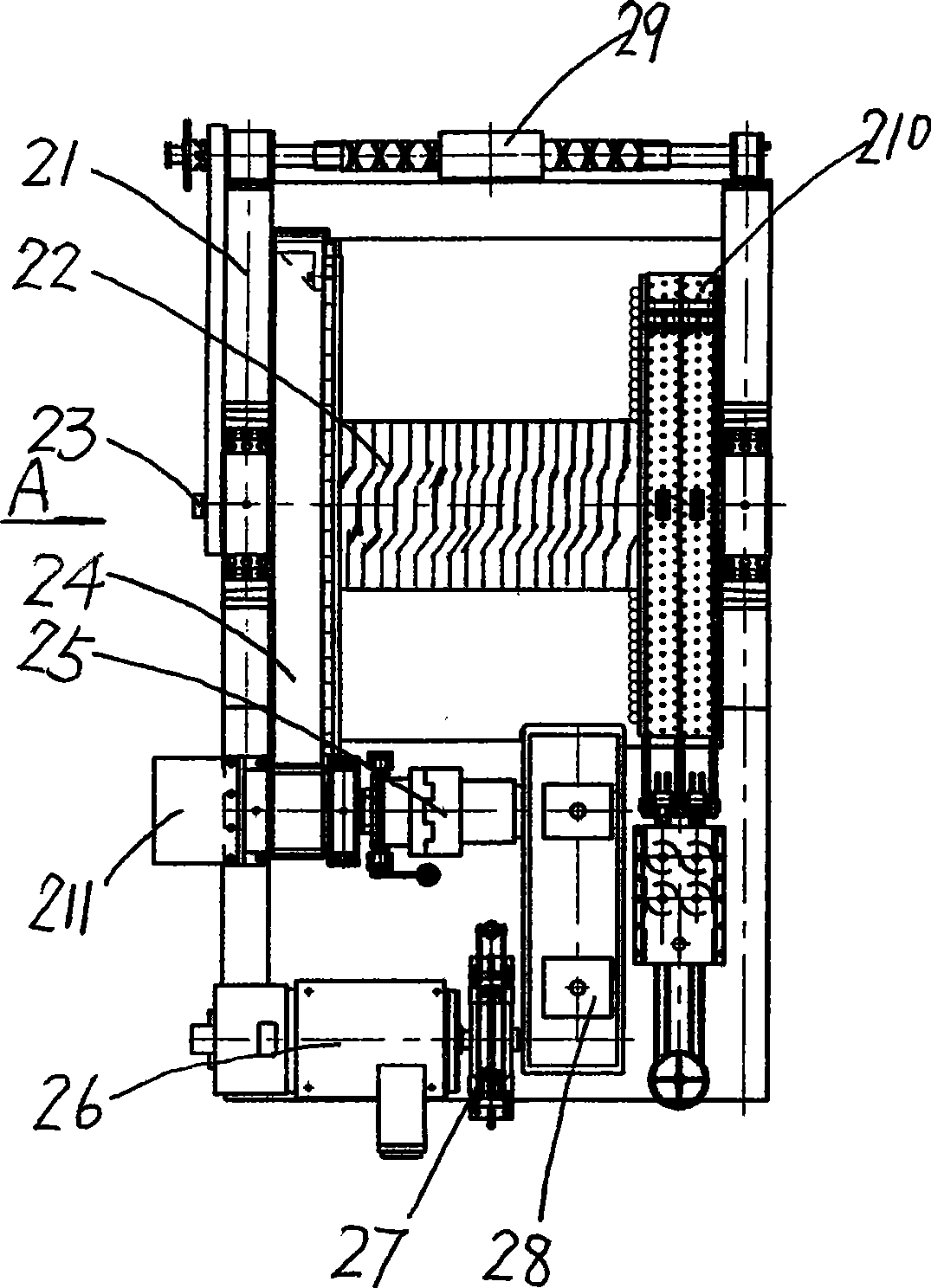

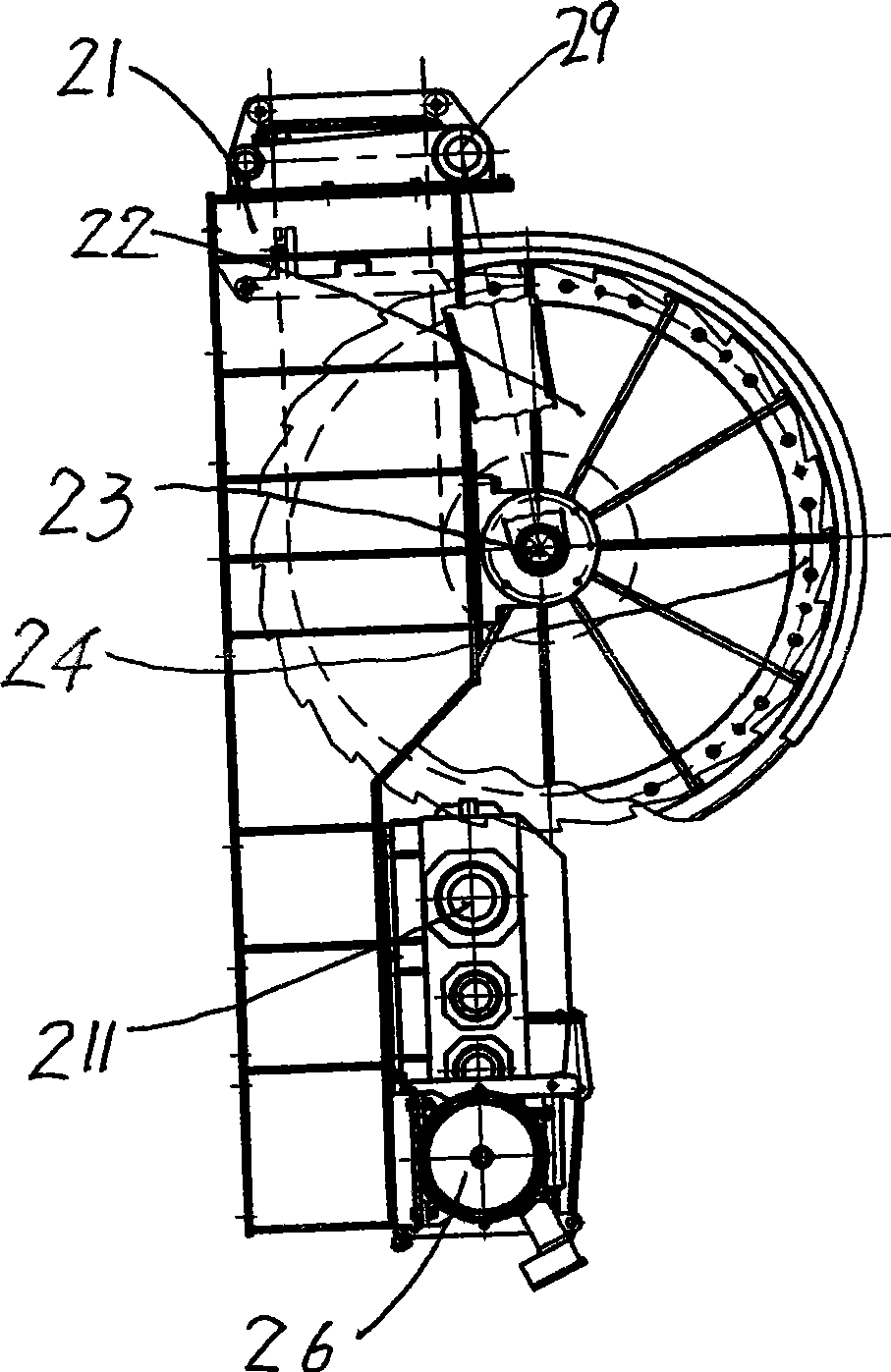

Mooring locating device for sea drill platform

ActiveCN101462581ASmall footprintChange stressAnchoring arrangementsElectrical resistance and conductanceStress conditions

The invention relates to a mooring and positioning device for an offshore drilling platform, which comprises a central controller, at least one mooring and positioning winch and a separating control device, wherein the central controller collectively controls working conditions of each mooring and positioning winch, the separating control device is respectively connected with the central controller and the each mooring and positioning winch, and the mooring and positioning winch is a water-cooled mooring winch with variable frequency resistance. Because a plurality of mooring and positioning winches are used for positioning, and a computer performs central control treatment, a cable of each mooring and positioning winch is in constant tension condition; because the mooring and positioning winch is designed into a multi-braking structural style, the diameter of a brake wheel is reduced, and space occupied by the winch on the platform is reduced; because a water cooled brake is provided, components are cooled in time, and service life of the components is prolonged; and because a wound roll is designed into a structure with a step rope guiding groove, stress condition of the cable is changed during winding, and abrasion of a wire cable is reduced.

Owner:NANTONG LIWEI MACHINERY

Motor rotor web crack welding repair method

ActiveCN103894702AAvoid Welding StressChange stressArc welding apparatusManufacturing stator/rotor bodiesPower flowRepair method

The invention discloses a motor rotor web crack welding repair method and solves the problems that a saw-toothed or crescent electrode is originally used to increase bath width and weld width, thermal stress is large and cracking occurs easily. A linear electrode manipulation method is adopted, a low-current small width welding method is adopted, arc ending is slow, a segment is re-welded to fill an end arc pit, the weld shape is changed, and cracking is avoided accordingly. A welding electrode A507 with higher tensile strength is used, a series of welding processes is taken, and the tensile strength of special equipment and special welds is met. The use of symmetric welding prevents excess welding stress effectively.

Owner:DATANG SHANDONG ELECTRIC POWER OVERHAUL & OPERATION

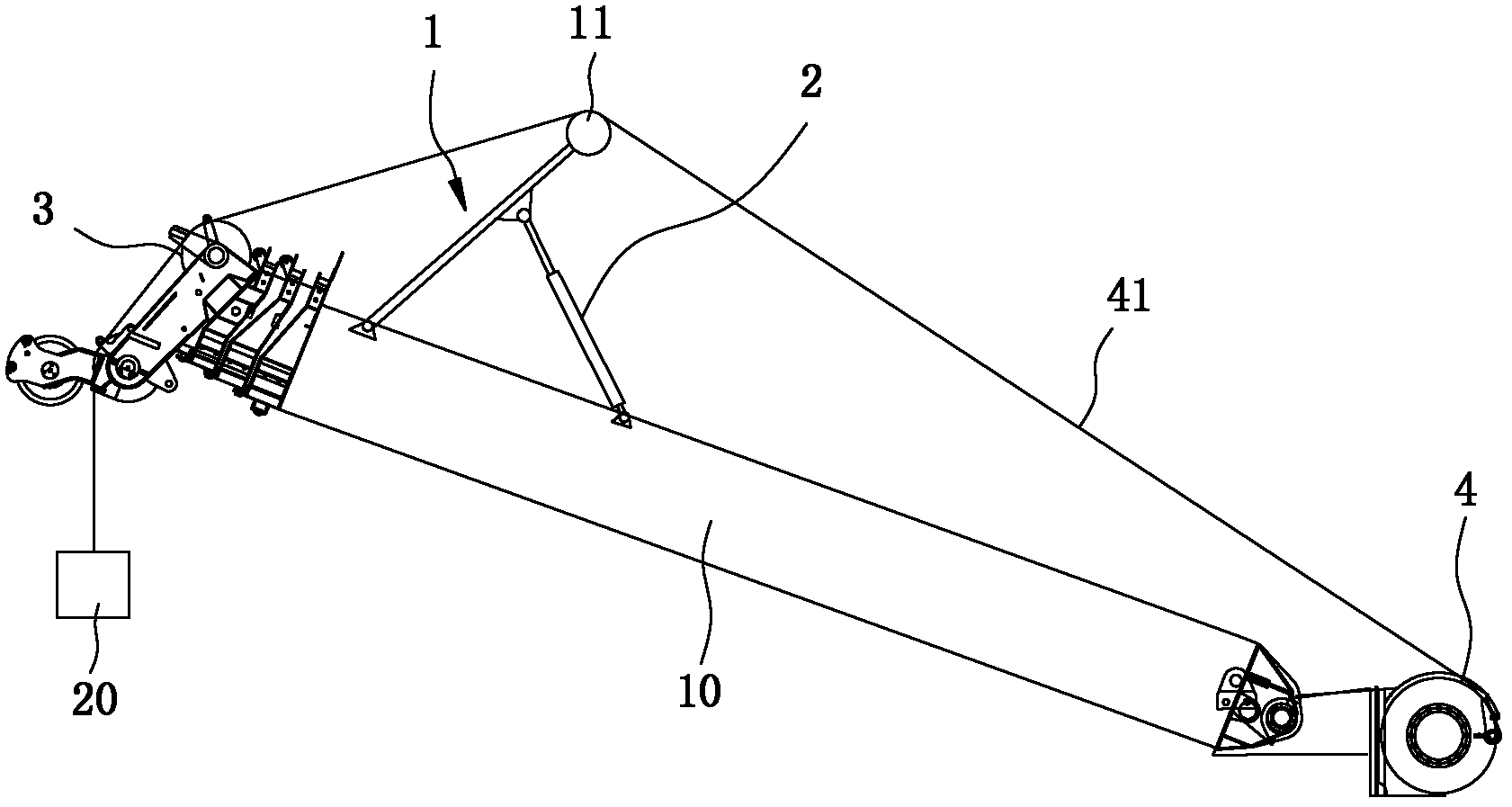

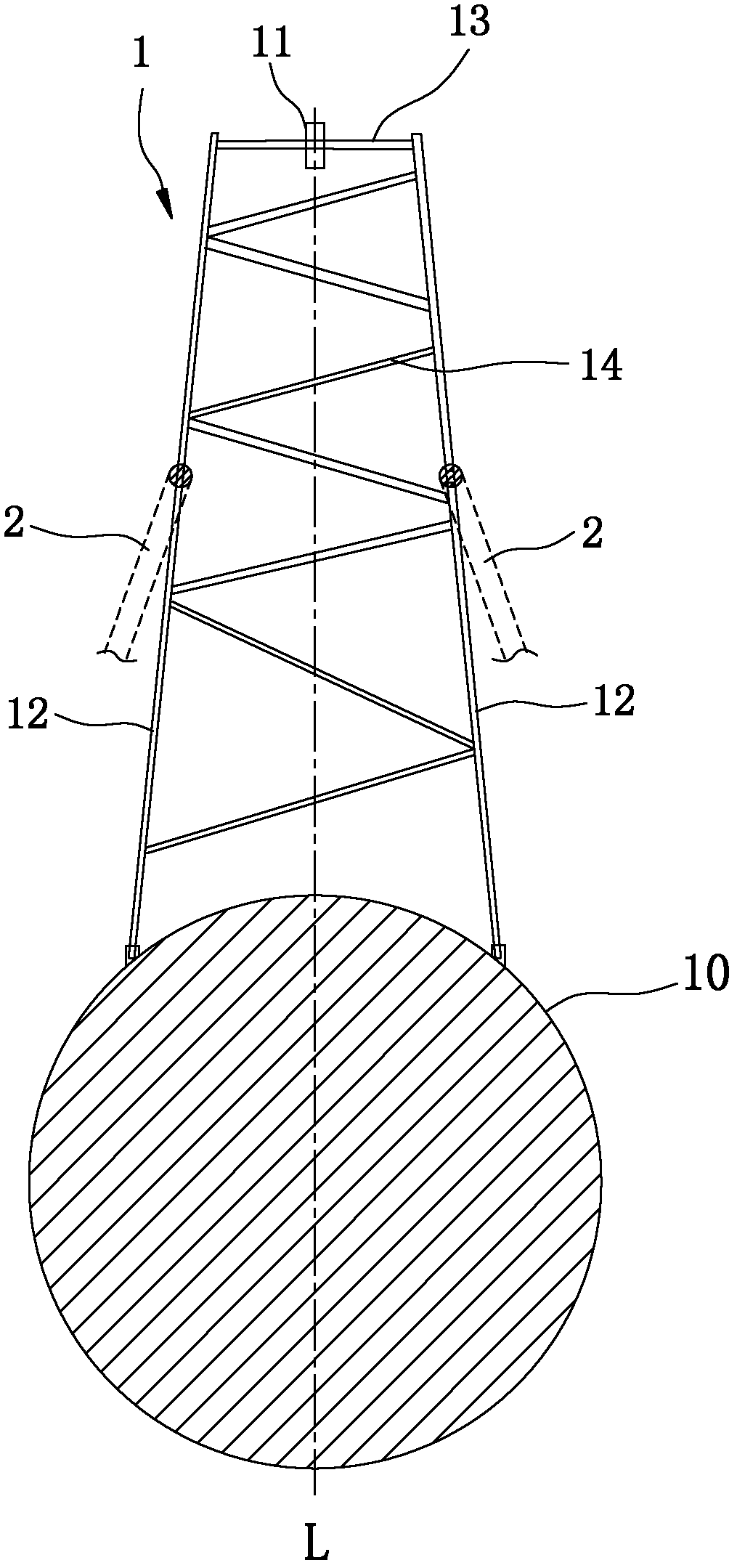

Super-lifting device for improving lifting performance of crane and crane

The invention discloses a super-lifting device for lifting the lifting performance of a crane and a crane. The super-lifting device comprises a support frame, a driving part, an arm head pulley and a winch, wherein the bottom end of the support frame is connected with the upper side of a crane boom, so that the support frame can swing within a vertical plane opposite to the crane boom, and a pulley part is arranged at the top end of the support frame; the driving part is connected to the support frame and is used for driving the support frame to swing on the crane boom; the arm head pulley is arranged at the arm head part of the crane boom; the winch extends along the crane boom through a steel wire rope extending out of the winch; the steel wire rope is connected with the pulley part and the arm head pulley in a winding manner in sequence to lift a heavy object; and the winch is used controlling the steel wire rope to stretch and contract, thereby realizing the lifting or the descending of the heavy object. The super-lifting device of the crane and the crane improve the stress condition of the crane boom with a simple structure, so that the lifting performance of the crane is improved.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Wood composite floor and production method therefor

ActiveCN101016799AChange stressSmall deformation coefficientWood working apparatusWood layered productsSolid woodBrick

A recombination solid wood floor with its production method relates to a recombination construction art within three-ply boards, wherein a middle board layer comprises rectangular wood bricks in direct processing art which are connected to be a base block board, and at least one side of the base block board is recombined with a -shaped wood board of different fiber orientation, while the base block board is recombined with at least two rectangular wood bricks via bars between the every two rectangular wood bricks. The method comprises processing the rectangular wood bricks to be a base layer of floor in direct processing art, making the rectangular wood bricks to be base block boards, and recombining the connected base block boards with the wood boards of different fiber orientation, thereby making the block board of floor to be -shaped. The method has advantages of simple structure, easy processing art, good quality, low cost, convenience assembling, and good using effect.

Owner:DER FUTURE SCI & TECH HLDG GRP CO LTD

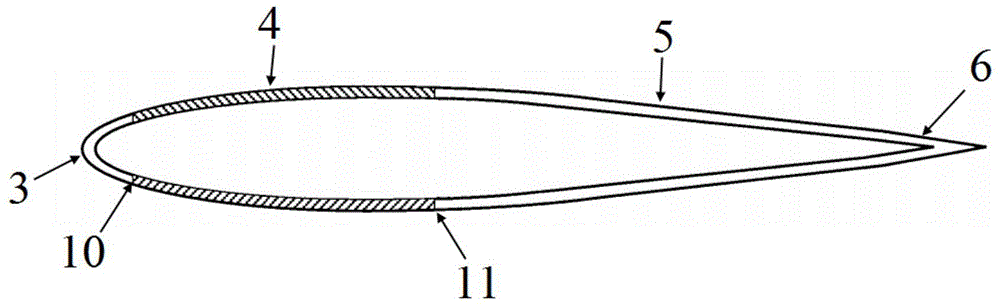

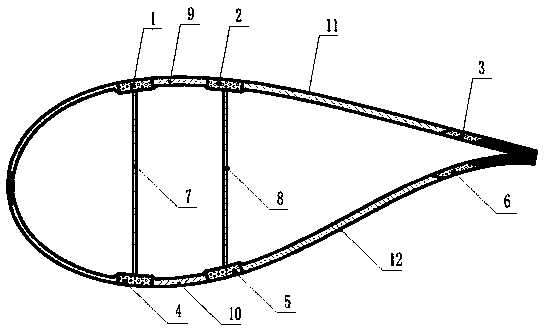

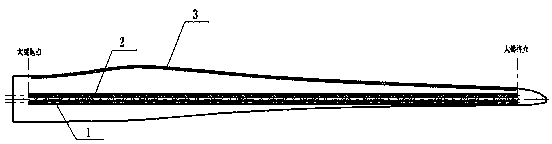

Piezoelectric composite material helicopter blade structure and control method thereof

InactiveCN104590558AImprove performanceExtended service lifeAircraft assemblyRotocraftElectricityEngineering

The invention discloses a piezoelectric composite material helicopter blade structure and a control method thereof. A piezoelectric composite material is embedded into a composite material lamination structure of a rotor blade. An analysis model is established and is capable of accurately describing the motion rule of the rotor blade based on a structure model, an aerodynamic force model, a piezoelectric composite material model and the like, and further accurately calculates the dynamics characteristics of the rotor blade. According to the control method, a controller is employed for controlling the rotor blade, a Kalman observer is employed for obtaining rotor blade data under the condition of white noise interference, and the rotor blade data is taken as input variable for controlling, and further by using the controller to control the input voltage of the piezoelectric composite material, the purpose of controlling blade dynamics response and deformation is finally realized. The provided model establishing method and the control method have relatively high versatility and accuracy, help to accurately obtain dynamics characteristics of the helicopter rotor blade, and are high in control efficiency.

Owner:HUNAN UNIV

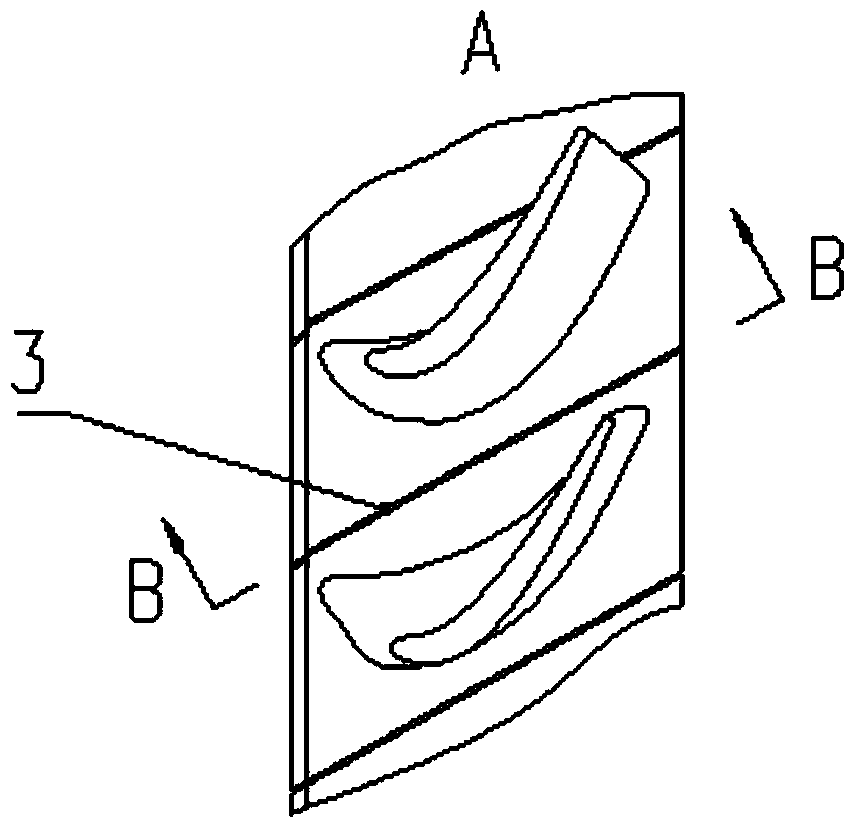

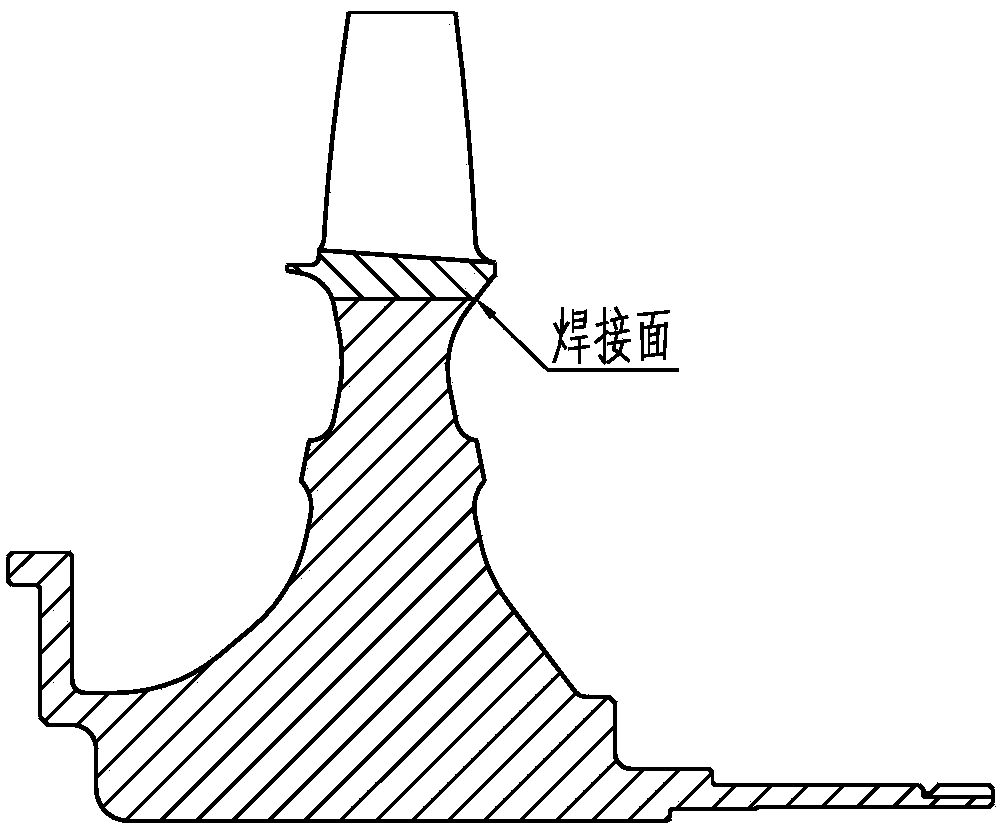

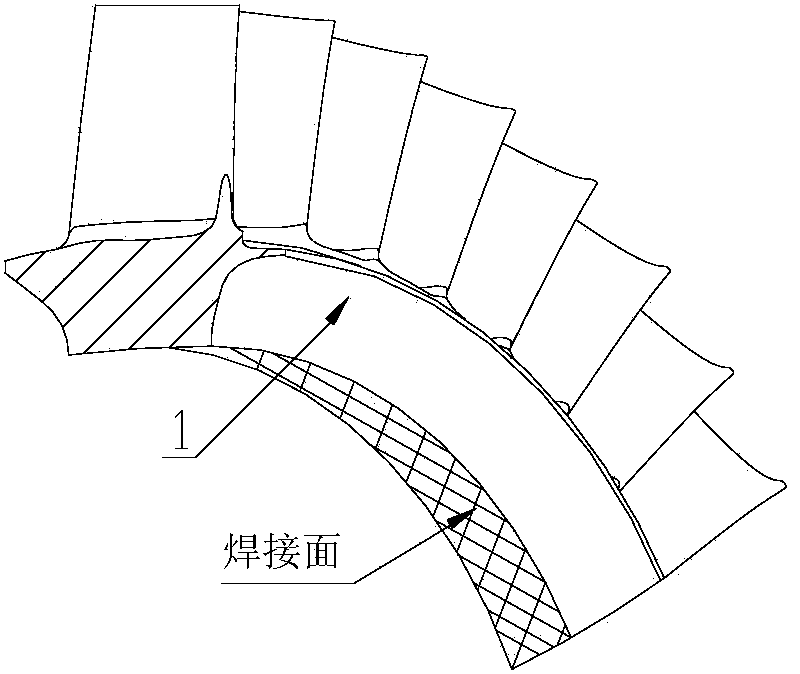

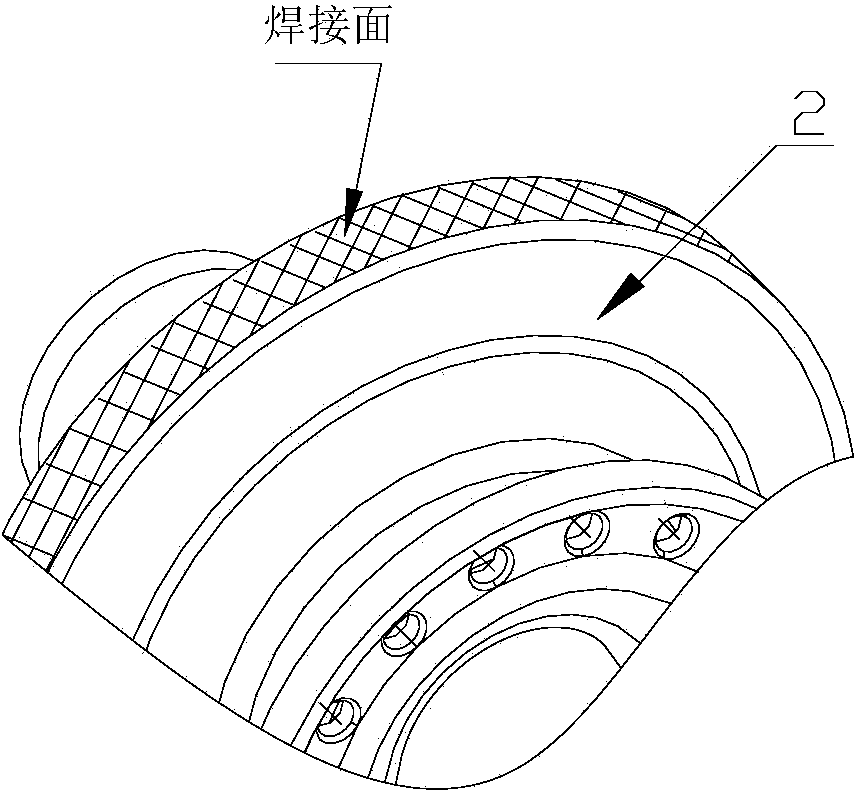

Anti-vibration type dual-alloy turbine blisk and manufacturing method thereof

InactiveCN104191184AHigh temperature durable creep performanceChange the stiffnessBlade accessoriesMachines/enginesTurbinePrecision casting

The invention belongs to turbine blisk technologies, and relates to an anti-vibration type dual-alloy turbine blisk and a manufacturing method thereof. The anti-vibration type dual-alloy turbine blisk is formed by welding a precision cast blade ring component and a sintered alloy blisk body in a diffusion mode through hot isostatic pressure, cut joints are formed between blade channels of the blisk, damping holes communicated with the cut joints are formed in the lower portion of the rim of the blisk, and friction dampers are arranged in the damping holes. The anti-vibration type dual-alloy turbine blisk is formed by welding the precision cast blade ring component and the sintered alloy blisk body in the diffusion mode through hot isostatic pressure, flexible selection and best usability matching of turbine disks and blades are achieved, meanwhile, the friction dampers are arranged on the blisk, the damping and vibration reducing effect is improved, the purposes of improving anti-fatigue ability of the blades and reducing vibration stress of the blades are achieved, and the anti-vibration type dual-alloy turbine blisk has great practical use value.

Owner:CHINA GAS TURBINE ESTAB

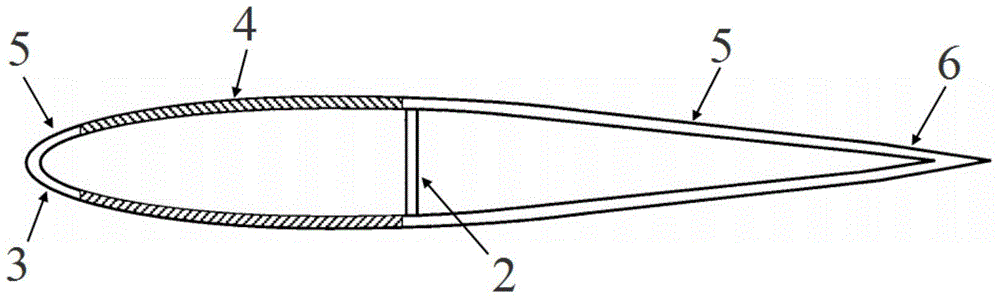

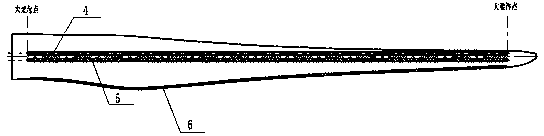

Multi-girder structure large size wind power blade and production method thereof

ActiveCN105508142AImprove the ability to resist buckling instabilityImprove structural rigidityEngine manufactureFinal product manufactureFiberCarbon fibers

The invention discloses a multi-girder structure large size wind power blade and a production method thereof. The multi-girder structure large size wind power blade is in a hollow layout structure, and comprises a blade envelope suction edge, a blade envelope pressure edge, main load-carrying construction girders and shearing-resistant web plates, wherein the blade envelope suction edge and the blade envelope pressure edge are combined to form a cavity structure of which the cross section is streamlined; a supporting structure formed by the main load-carrying construction girders and the shearing-resistant web plates is arranged in the cavity structure formed by the blade envelope suction edge and the blade envelope pressure edge; and the blade envelope suction edge and blade envelope pressure edge are in multisection combination structures, and are connected with the side surfaces of the main load-carrying construction girders through a plurality of edge sections respectively to form a blade envelope suction edge and blade envelope pressure edge integrated body. On the premise of ensuring the rigidity and strength of the blade, the resistance to buckling instability of the blade is improved; and by adopting a high-module carbon fiber spread layer, the weight of the blade can be reduced obviously, and loads, particularly a fatigue load, of the blade are reduced.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

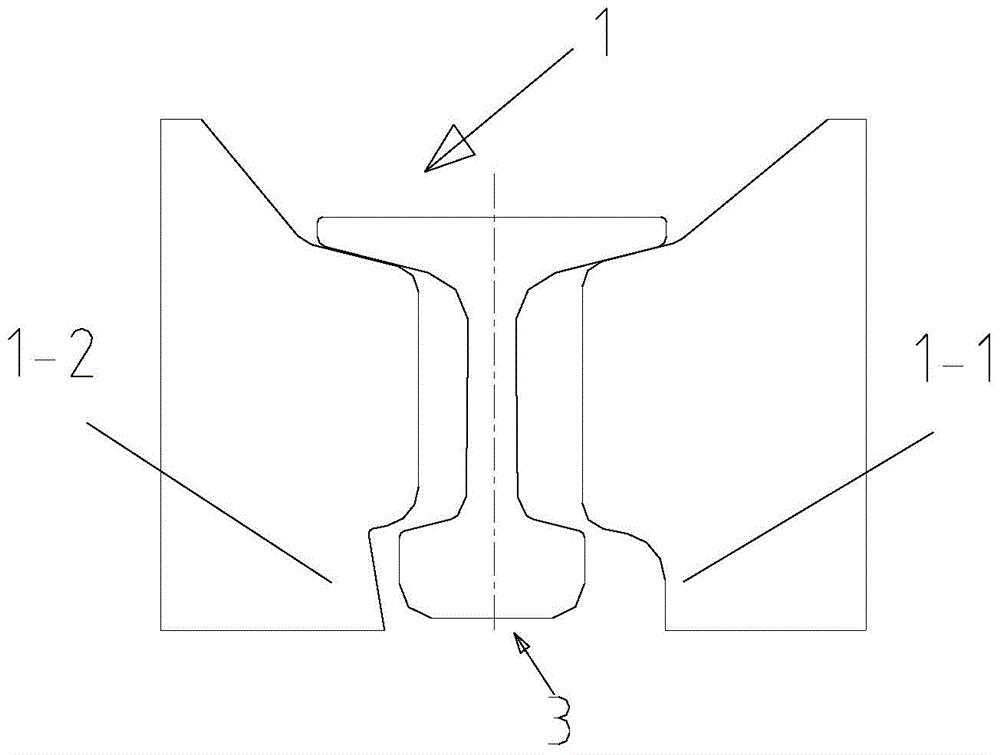

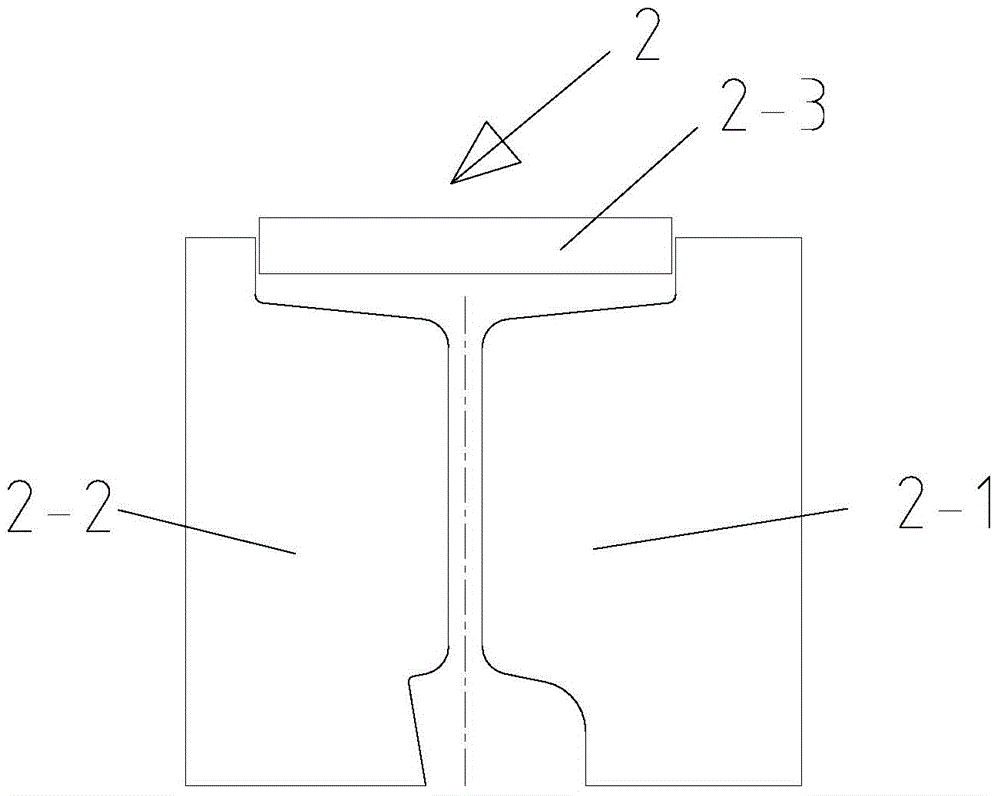

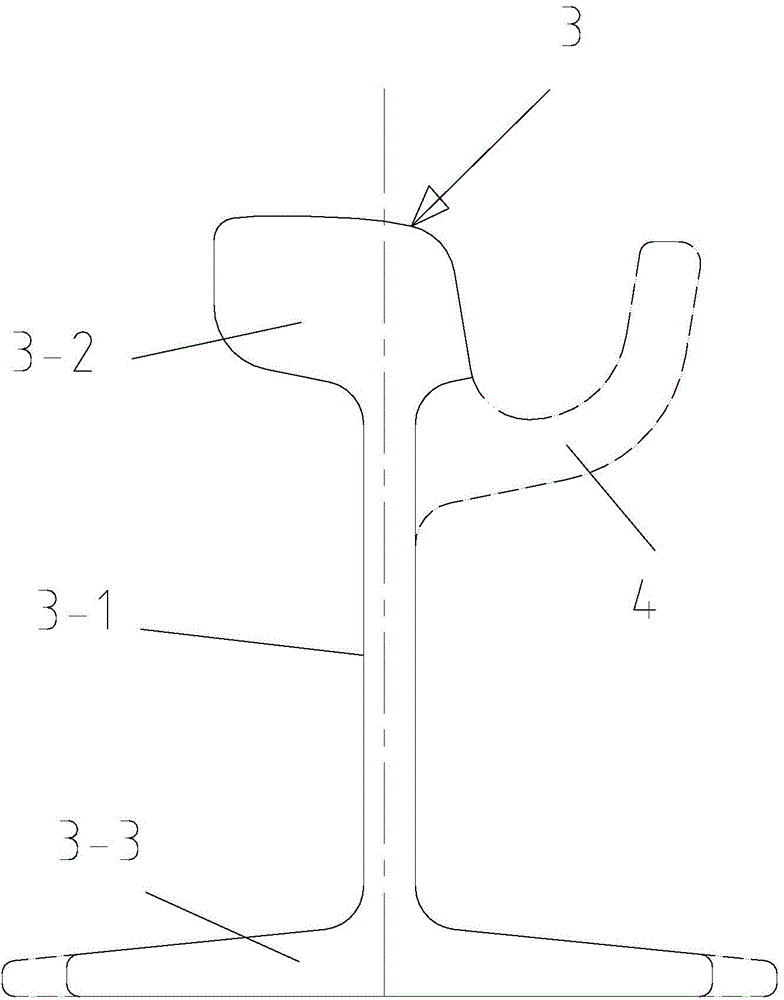

59R2 special-shaped rail and forming method thereof

ActiveCN104452486AImprove forging qualityEasy to processRailsForging/hammering/pressing machinesRoom temperatureEngineering

The invention provides a 59R2 special-shaped rail and a forming method thereof. The 59R2 special-shaped rail is composed of a raw material section, a profiling transition section and a forming section. The rail waist centerline of the forming section and the rail waist centerline of the raw material section have 20 mm offset, and the cross section of the forming section is an asymmetric cross section. The forming method of the 59R2 special-shaped rail includes the following steps of inductive heating or natural gas fuel heating before forging, preforging conducted through an asymmetric preforging die, finish forging conducted through an asymmetric finish forging die, normalizing heat treatment after forging, air cooling of a forged piece to a room temperature after forging and machining after forging, an asymmetric movable block combination die structure is adopted for the forging dies, the problems that according to an existing forming method, blank metal of a die is not prone to flow, the quality of a forged piece is low and process precision is poor are solved, and the forming method is suitable for high-precision, high-quality and high-efficiency production of the 59R2 special-shaped rail matched with 50kg / m-59R2 type steel rails.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

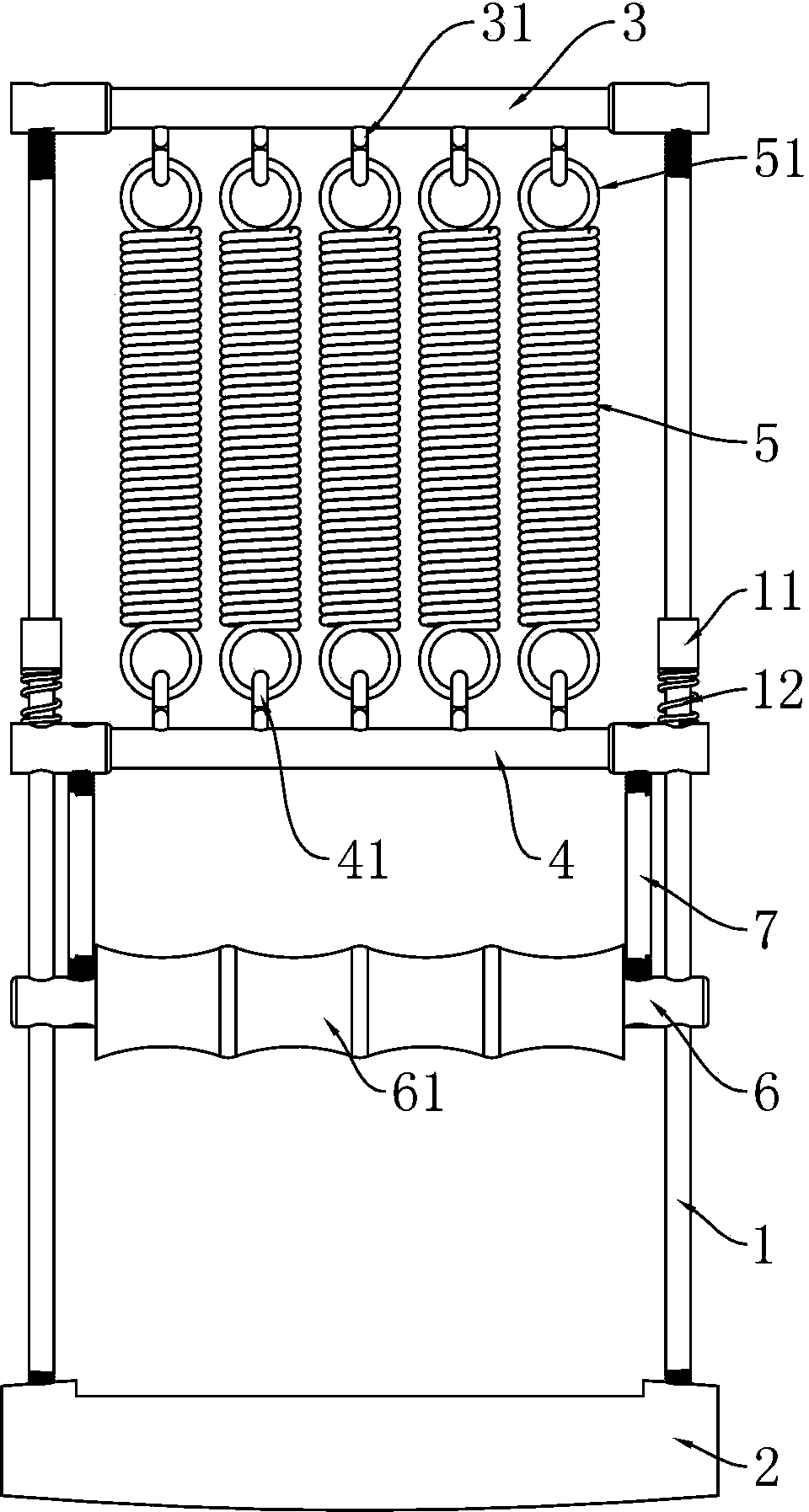

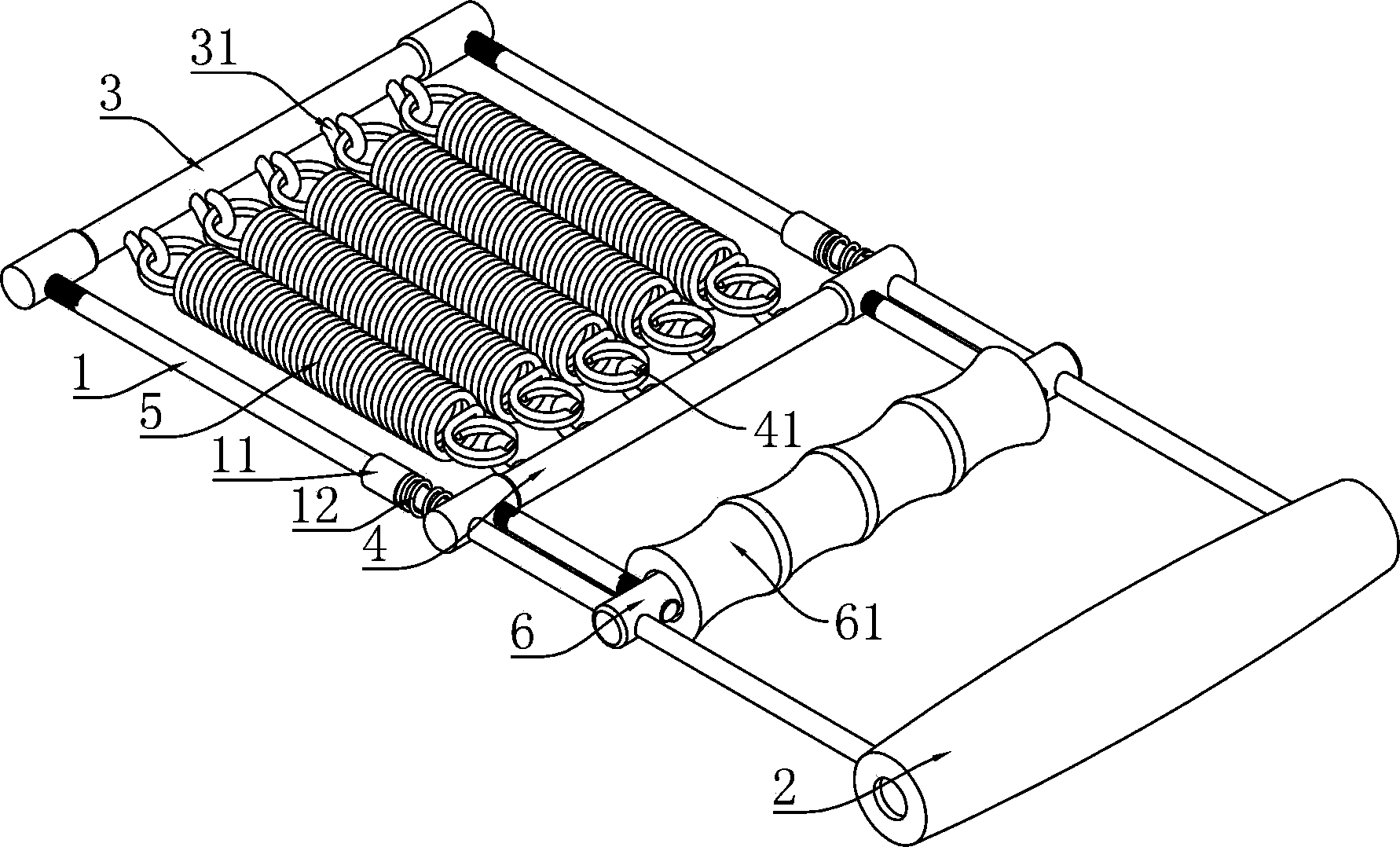

Wrist developer

InactiveCN103638647AExercise balanceEasy to replaceResilient force resistorsElastic componentFinger joint

The invention discloses a wrist developer. Fixing rods, movable rods, finger rods and holding handles are sequentially arranged on two mutually-parallel and equal-length long connecting rods, the fixing rods and the holding handles are fixedly connected with the long connecting rods, the movable rods and the finger rods are in sliding fit with the long connecting rods, the fixing rods are connected with the movable rods through elastic components, and the movable rods are connected with the finger rods through short connecting rods. According to the wrist developer, the finger rods and the holding handles serve as two handles of two wrist developers, the finger rods are parallel to the holding handles, the finger rods can be pulled by all the fingers except for the thumbs, and the aim of training the finger joints in a balanced mode is achieved. Compared with the prior art, the wrist developer is high in comfort performance and wide in application scope.

Owner:张文川

Method for producing color bamboo sheet

InactiveCN1616199ASolve single colorChange stressWood treatment detailsCork mechanical workingWood veneerCarbonization

The present invention relates to decorative material, and is especially the production process of surface decorating color bamboo sheet. Colored bamboo sheets are matched and pressed into bulk material, which is then turned, planed or sawed and dried to form color bamboo sheet. The colored bamboo sheet is produced with thin bamboo sheet and through high temperature steaming, bleaching, drying, and pressure coloring inside one pressure container, vapor carbonization coloring, soaking coloring or printing coloring. The present invention provides various kinds of colorful decorating bamboo sheets.

Owner:胡波

Wall-attaching support for building construction with falling-prevention mechanisms

The invention discloses a wall-attaching support for building construction with falling-prevention mechanisms. The wall-attaching support comprises a vertical plate, wherein supporting bodies are fixedly connected to one side of the lower portion of the vertical plate, and the two ends of a connecting rod are fixedly installed in T-shaped gaps of the supporting bodies through locking nuts respectively; a fixed shaft is fixedly inserted in a bearing inner ring of a supporting bearing, supporting teeth are fixedly connected to the circumference of the outer side of a rotary disc, and arc supporting openings are formed in the upper portions of the supporting teeth. Arc ratchet teeth are fixedly connected to the interiors of annular grooves, reversion-prevention ratchet pawls which are matchedwith the arc ratchet teeth are fixedly connected to the surfaces of one sides of sleeves, and reset springs further sleeve hexagonal prism supporting rods. The upper and lower wall-attaching supportsare connected together, then multiple sets of falling-prevention mechanisms are added at random positions between the upper and lower wall-attaching supports, thus the safety is improved, local stress of the wall-attaching supports is changed, local overload is lowered, and protection is achieved in an all-around way. In the meanwhile, connecting rods are easy to install and detach, the arrangement density of the wall-attaching supports can be lowered, and the cost is lowered.

Owner:厦门安科科技有限公司

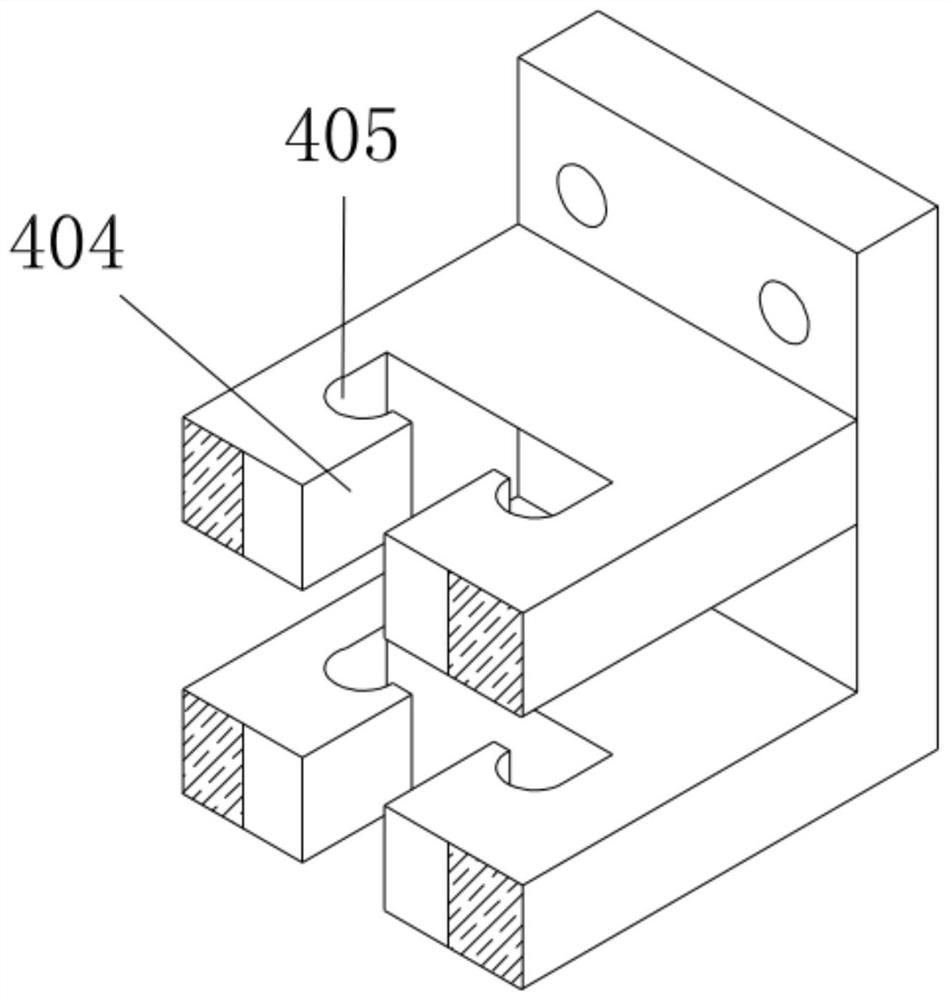

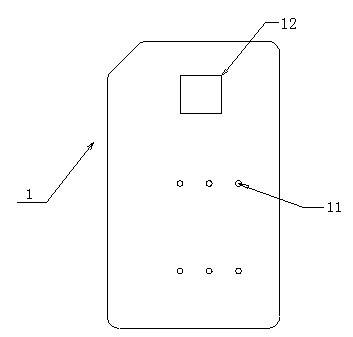

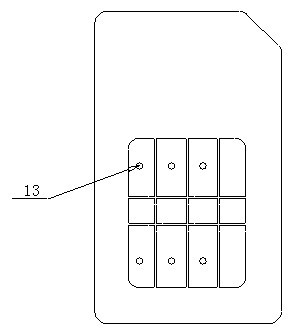

Method for encapsulating and manufacturing glue perfusion molded SIM (subscriber identity module) film card with flip naked chip

ActiveCN102169553AIncreasing the thicknessImprove consistencySolid-state devicesSemiconductor/solid-state device manufacturingBatch processingFlexible circuits

The invention relates to a method for encapsulating and manufacturing a glue perfusion molded SIM (subscriber identity module) film card with a flip naked chip, which comprises the following steps of: directly flipping a thinned naked chip with a metal bump on a flexible circuit board of an SIM film card, and in a loading region of the SIM film card, using the glue to encapsulate the loading region of the flip naked chip by using the glue perfusion method. The SIM film card is produced by flipping the naked chip with the metal bump and pouring the glue, the thickness of the SIM film card and the consistency of the appearance are improved; and meanwhile, the stress state of the film card is improved due to the integral encapsulation effect of the glue so that the quality of the SIM film card is more stable and the batch processing can be realized. The film card can be prevented from damaging due to the extrusion and bending stress in the use process, so that the SIM card can be connected with the film card without holing or grooving.

Owner:JCET GROUP CO LTD

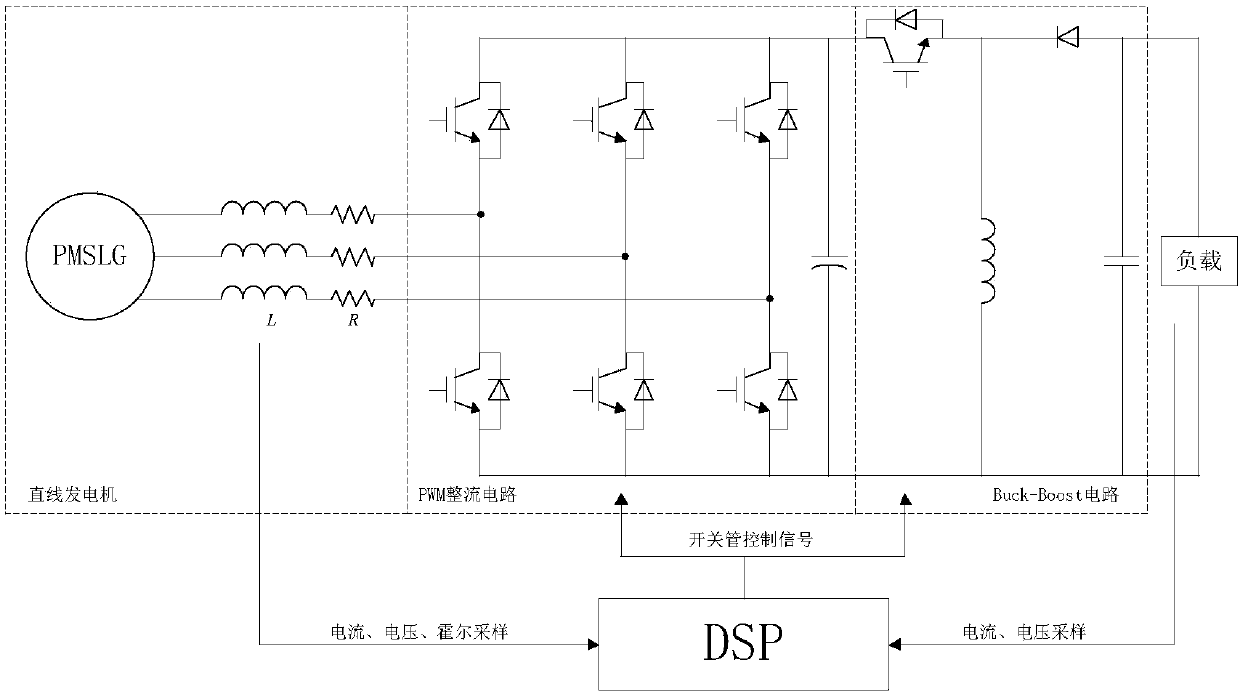

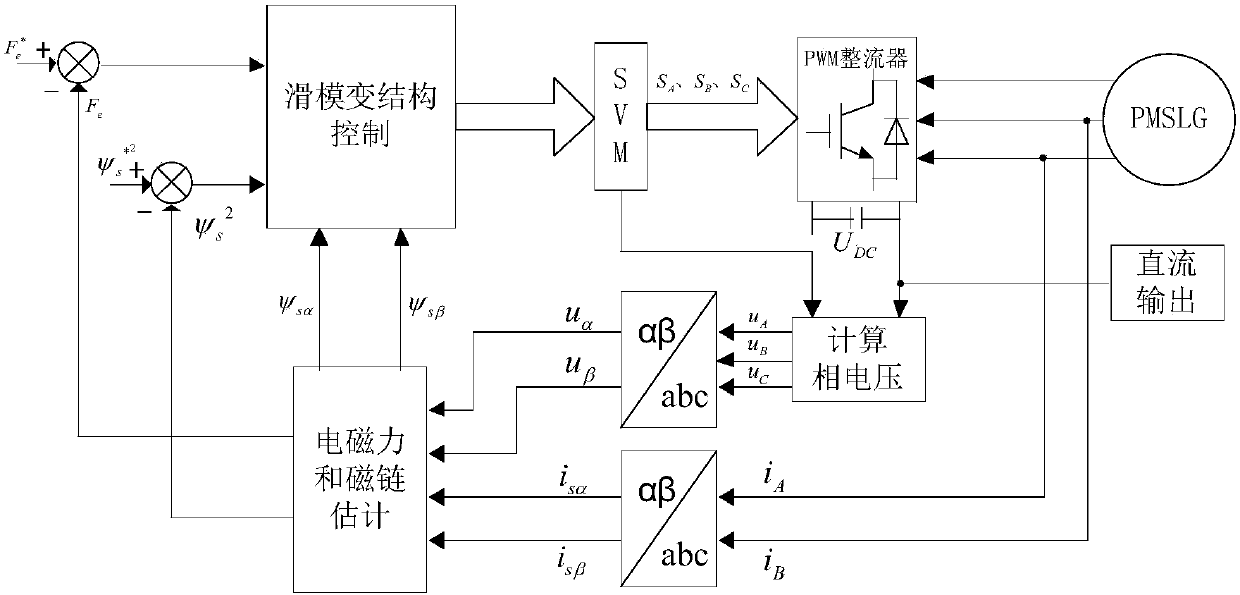

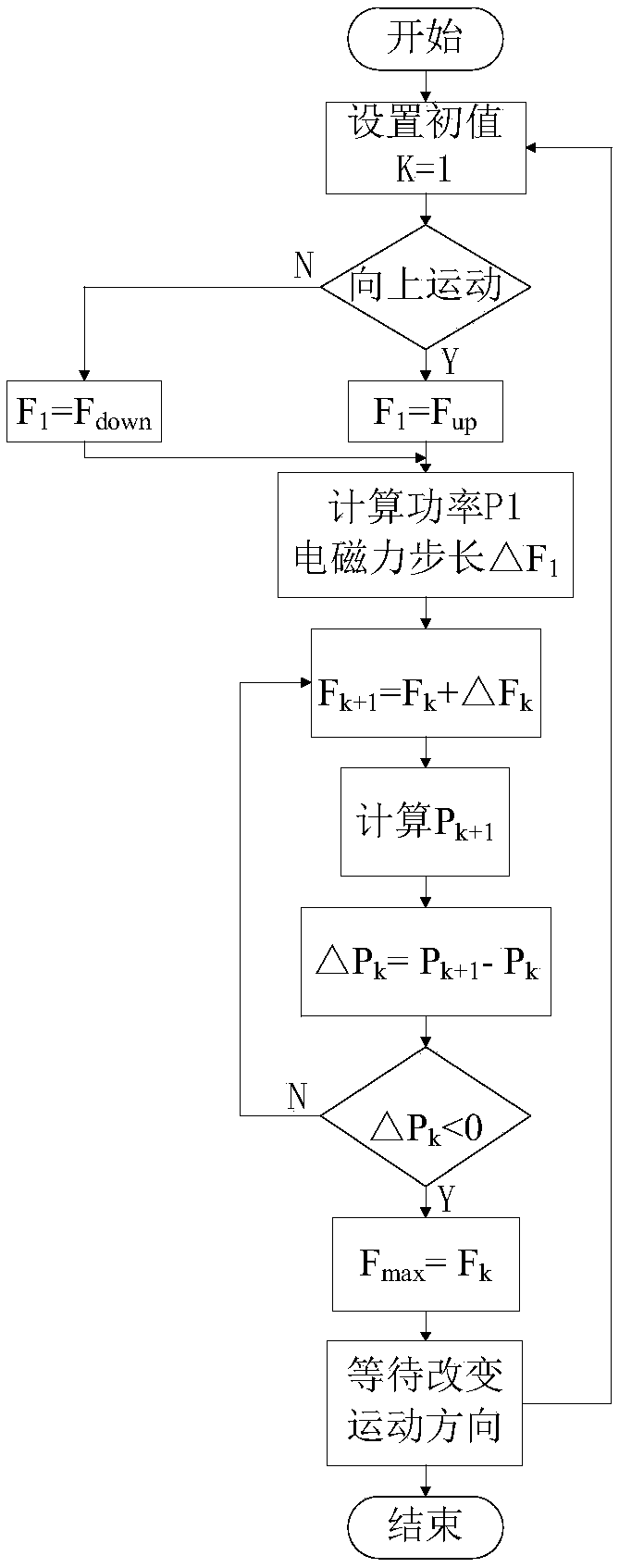

Direct-drive type wave power generation maximum power tracking algorithm and system

ActiveCN107918436AChange stressReal-time monitoring of running statusElectric variable regulationElectric generatorSea waves

The invention discloses a direct-drive type wave power generation maximum power tracking algorithm and system. The system includes a permanent magnet linear electric generator, a three-phase controllable rectifier, a Buck-Boost converter, a signal detection and conditioning circuit, and a DSP control circuit. The permanent magnet linear electric generator adopts improved direct thrust for control,and by adjusting the magnitude of magnetic force of the electric generator, the stress condition of the linear electric generator in sea waves can be changed. The optimal electromagnetism force is obtained by the fuzzy variable-step maximum power tracking algorithm, and thus maximum power tracking is achieved. In view of the extreme weather conditions, the motor rotor position is calculated by adopting linear hall, and the running state of the electric generator is monitored in real time. In the wave power generation system, the algorithm plays an important role in improving the power generation efficiency and increasing economic benefits.

Owner:SOUTHEAST UNIV

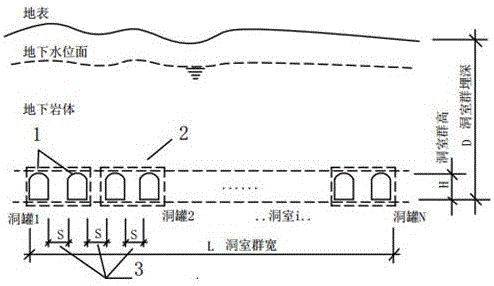

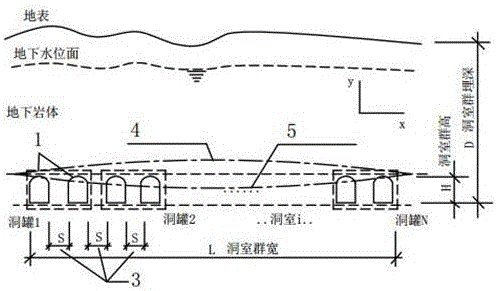

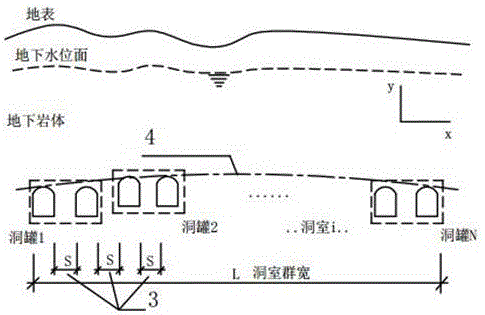

Optimization arrangement method for cavern groups of underground water sealed caverns

ActiveCN106649953AChange stressImprove stabilityGeometric CADSpecial data processing applicationsHorizontal axisEngineering

The invention discloses an optimization arrangement method for cavern groups of underground water sealed caverns. The method comprises the steps of performing calculation by using a spacing adjustment cyclic search algorithm through utilizing a mechanical action principle of an inherent natural "arch" in a rock-soil body of nature to obtain a vertical deformation curve of the top of each cavern group, and turning over the vertical deformation curve by an X axis as a horizontal axis to obtain a plurality of reasonable arched curves; selecting a corresponding optimal reasonable arched curve when a surrounding rock of each cavern group has a maximum stress and minimum deformation; and finally arranging the top of each cavern along the optimal reasonable arched curve to obtain optimal arrangement of the cavern groups. The cavern groups arranged in an arch shape are adopted, so that the overall stability of the surrounding rocks of the cavern groups is effectively improved; and the method is of positive technical and economic significances for reducing project investment and increasing cavern utilization rate, so that the method has a wide application prospect.

Owner:SINOPEC SHANGHAI ENG +1

Wind-resistant composite insulator and preparation process thereof

The invention discloses a wind-resistant composite insulator and a preparation process thereof. The insulator comprises a core rod, fittings arranged at the two ends of the core rod, and a plurality of epoxy resin frameworks which cover the outside the core rod, and are arranged along the axial direction and provided with bulges, silicon rubber umbrella skirts are arranged outside the epoxy resinframeworks, and the inclination angles of the upper surfaces of the silicon rubber umbrella skirts relative to the radial cross section of the core rod are the same as those of the lower surfaces of the silicon rubber umbrella skirts relative to the radial cross section of the core rod. The silicone rubber umbrella skirts are large umbrellas which are coaxial with a core rod and equal in diameter,or a small umbrella is arranged between every two adjacent large umbrellas; the small umbrellas are smaller than the large umbrellas in diameter. The core rod is composed of a glass fiber epoxy resindrawing rod. The epoxy resin is prepared from epoxy resin and a curing agent. Compared with the prior art, the defect that the root of the umbrella skirt is torn when encountering strong wind is overcome, the problem that the root of the umbrella skirt is torn can be effectively solved, and normal work of the insulator is guaranteed.

Owner:XIANGYANG GUOWANG COMPOSITE INSULATORS

High-zirconium alkali-resistant glass fiber surface-reinforced short-cut felt and production method thereof

The invention relates to high-zirconium alkali-resistant glass fiber surface-reinforced short-cut felt and a production method thereof, and belongs to the technical field of alkali-resistant glass fiber production. The method mainly solves the problems that existing medium-alkali and alkali-free glass fibers are poor in alkali resistance and cannot be applied to reinforced cement concrete. The felt is mainly characterized by comprising 55-64% of SiO2, 13.8-17.5% of ZrO2, 1.0-3.5% of TiO2, 4-7.0% of CaO, 11.0-13.5% of NaO2, 1.0-2.5% of K2O, 0-0.3% of Al2O3 and 0-0.2% of Fe2O3, and the felt is produced in the steps that high-zirconium alkali-resistant glass fiber filaments with the diameter of 7-9 micrometers are cut into filaments with the length of 50-75 mm, then the filaments are evenly distributed in multiple dimensions and then bonded through a powder adhesive or an emulsion adhesive, and then curing and drying are conducted. The method solves the problems that the alkali-resistant glass fibers are irregular in spray yarn distribution and poor in homogeneity, the durability can reach 60 years, and the half-life period is up to 100 years.

Owner:XIANGYANG HUIERJIE GLASSFIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com