Patents

Literature

530results about How to "Improve stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

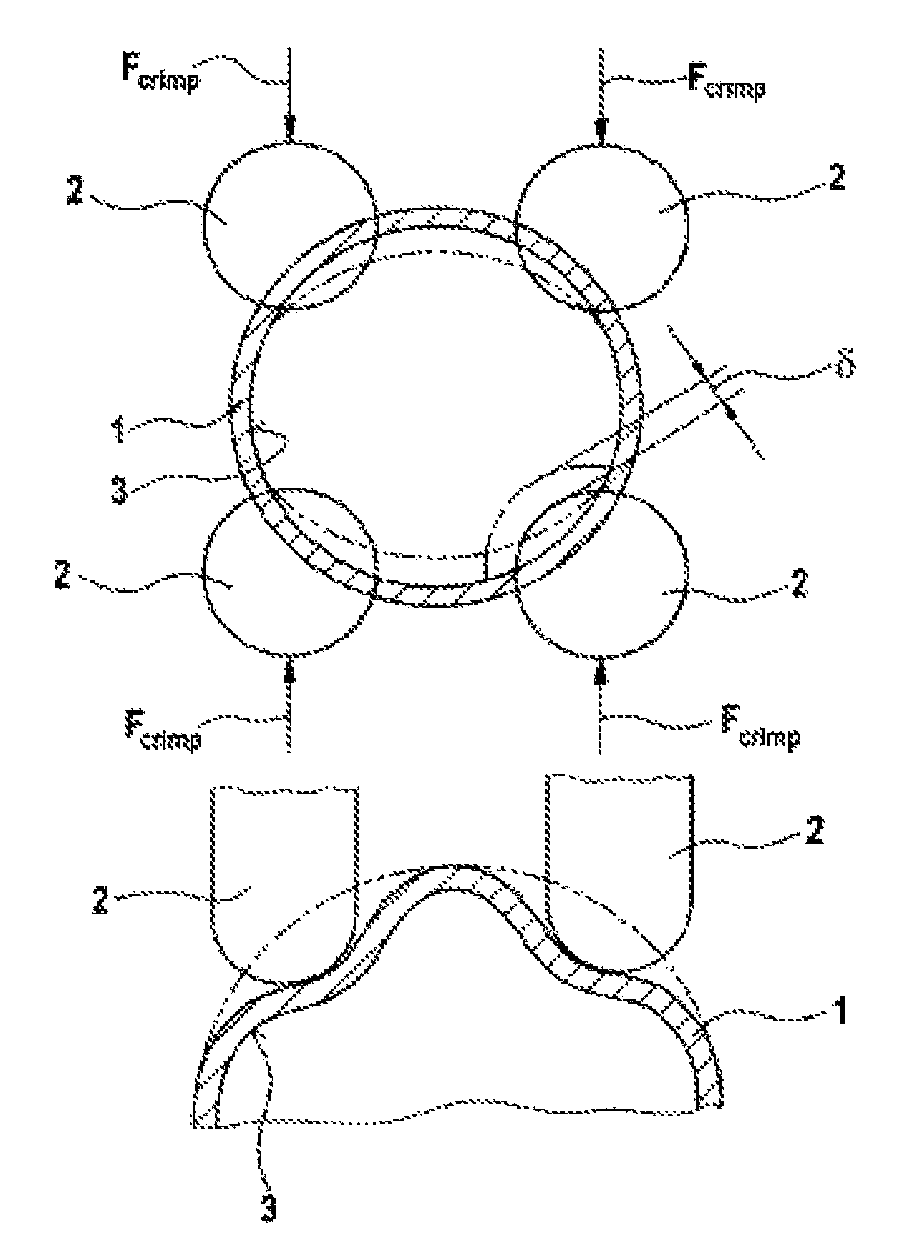

Hydraulic Fracturing Proppants

ActiveUS20110180259A1Increase contact areaImprove stress distributionFluid removalDrilling compositionStress distributionEmbedment

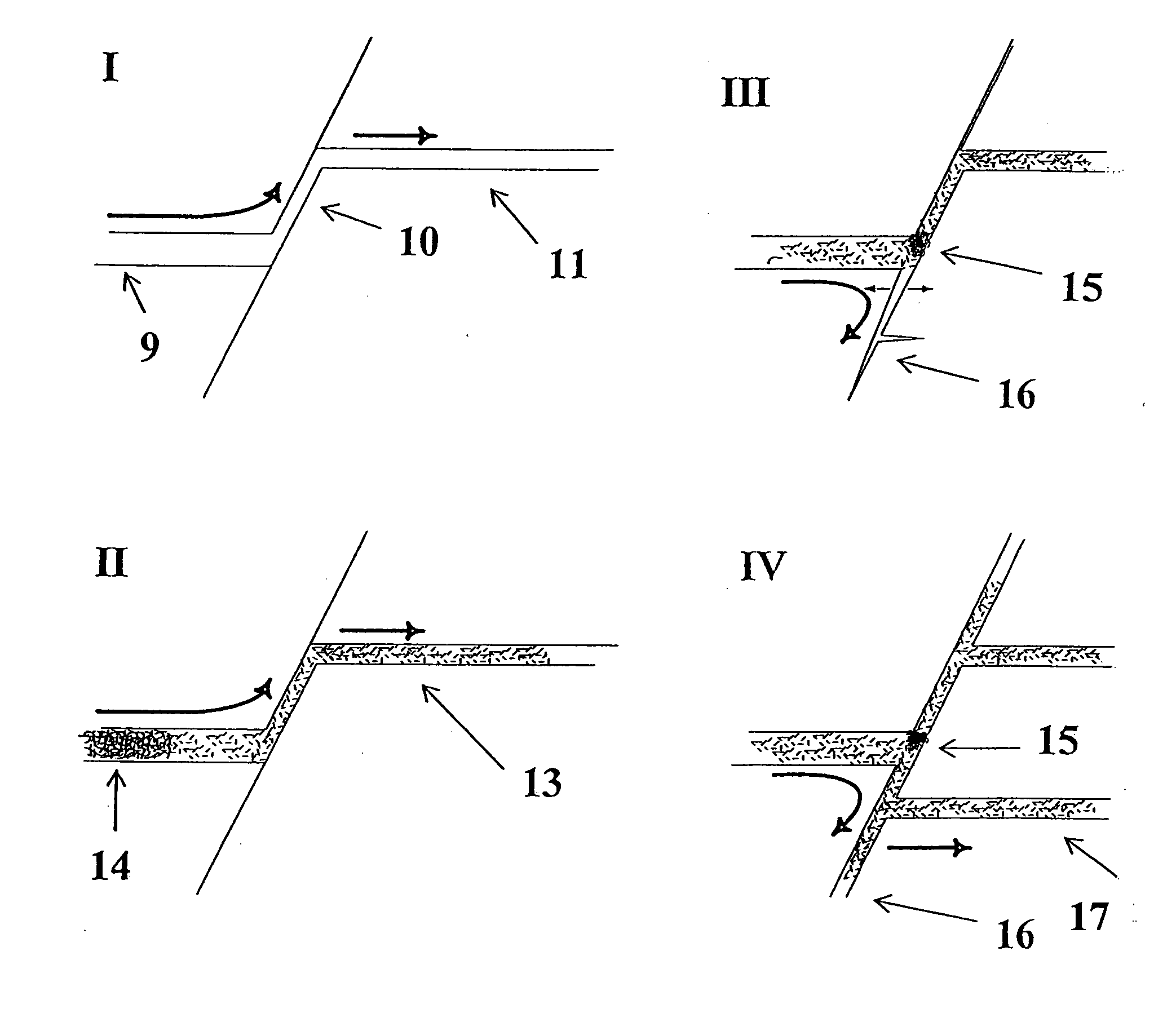

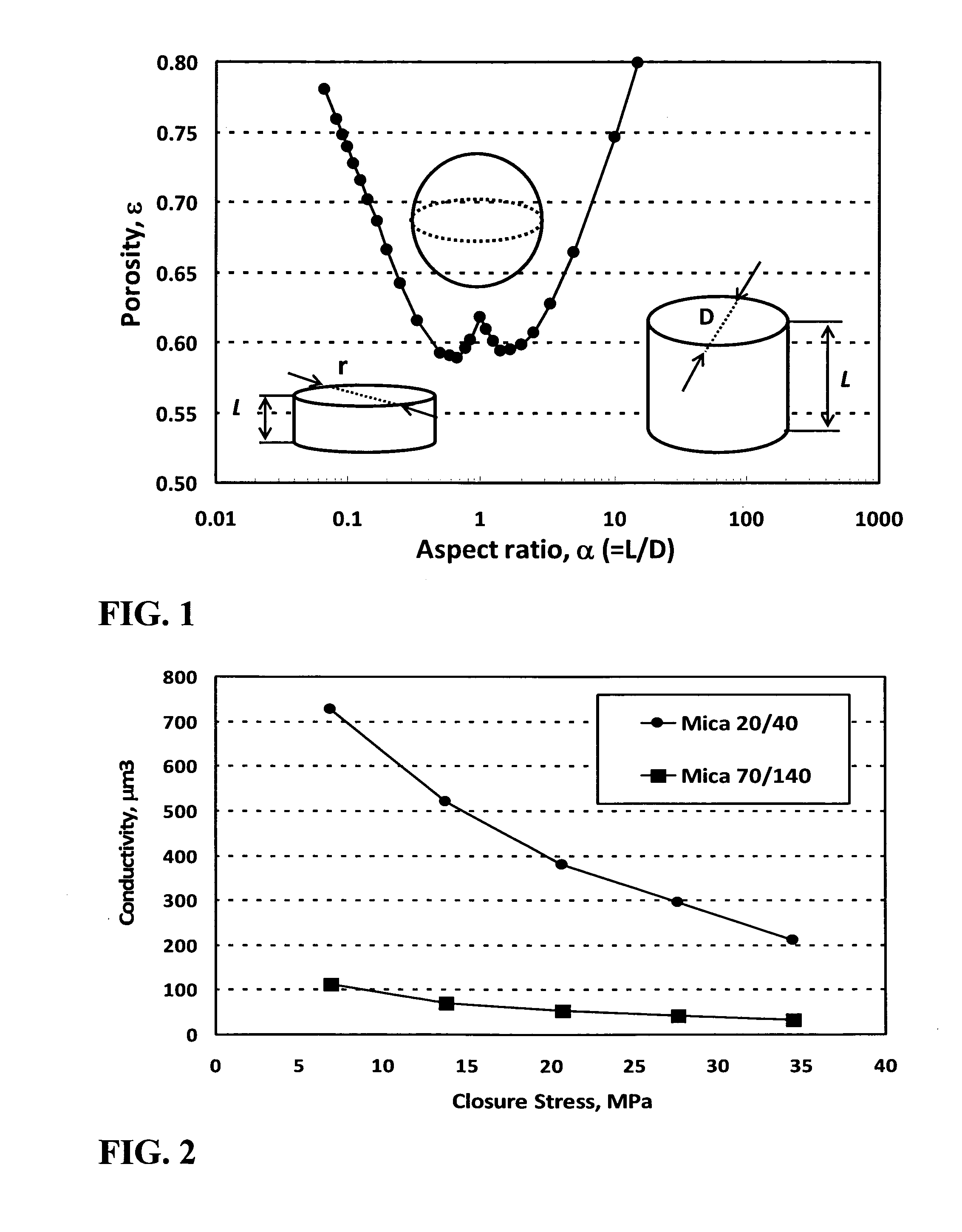

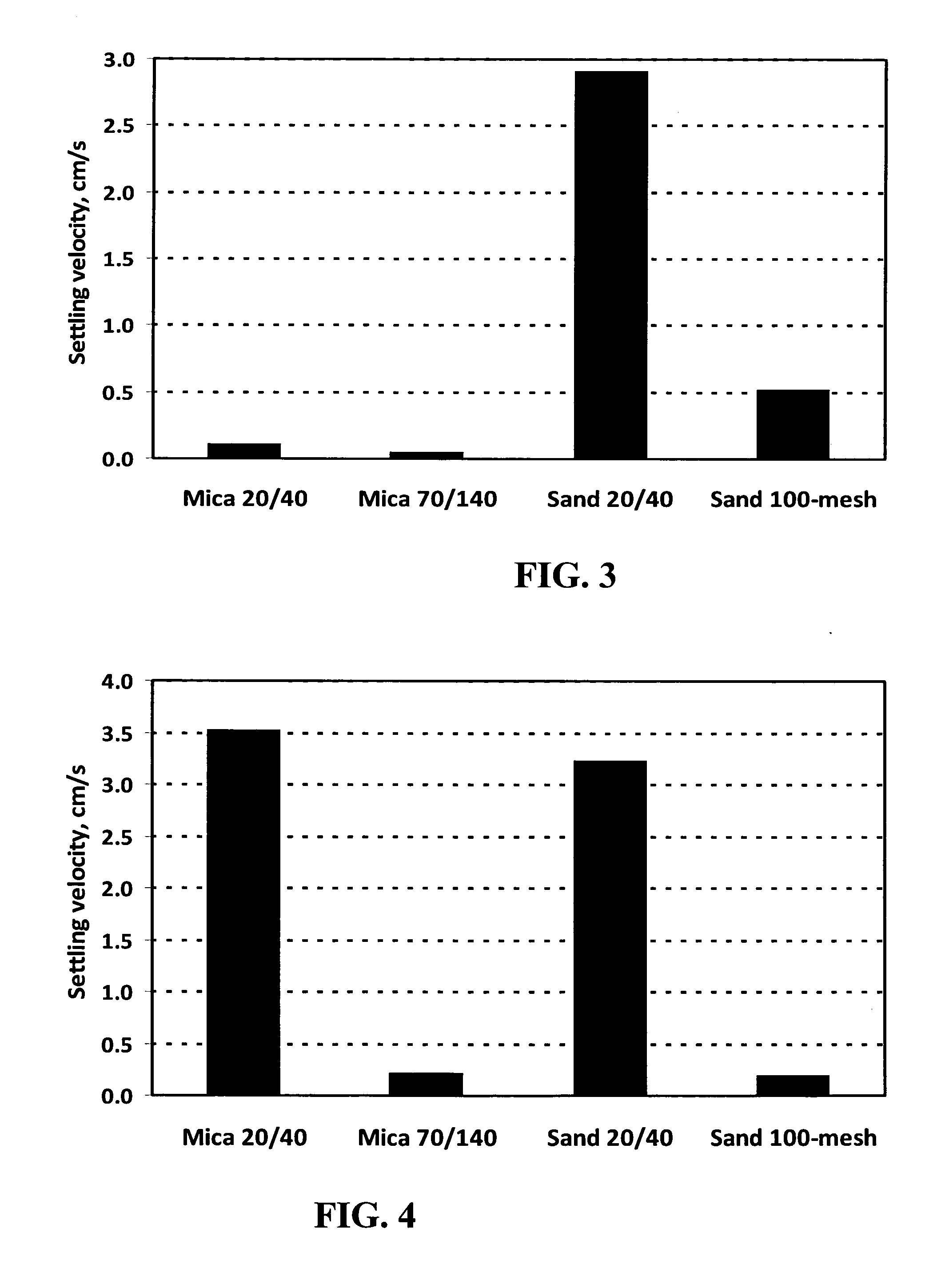

A method is given for treating a wellbore in a subterranean formation by hydraulic fracturing, slickwater fracturing, gravel packing, and the like, by using plate-like materials as some or all of the proppant or gravel. The plate-like materials are particularly useful in complex fracture systems, for example in shales. They may be used as from about 20 to about 100% of the proppant. Relative to conventional proppants, plate-like proppants demonstrate (a) enhanced crush resistance of the proppant due to better stress distribution among proppant particles, (b) diminished proppant embedment into formation fracture faces due to the greater contact surface area of proppant particles with the formation, (c) better proppant transport due to lower proppant settling rates, (d) deeper penetration into branched and fine fracture networks, and (e) enhanced proppant flowback control. Preferred plate-like proppants are layered rocks and minerals; most preferred is mica.

Owner:SCHLUMBERGER TECH CORP

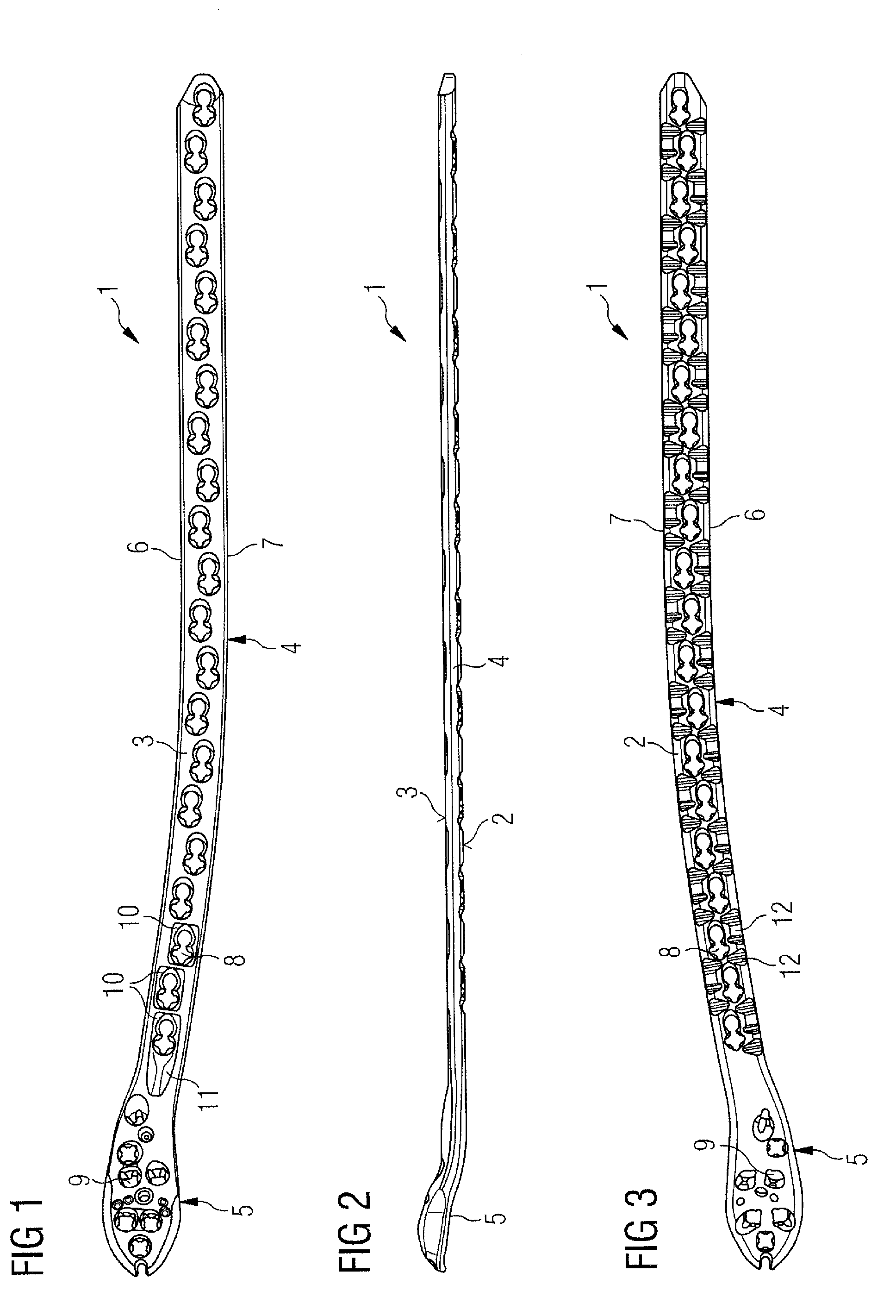

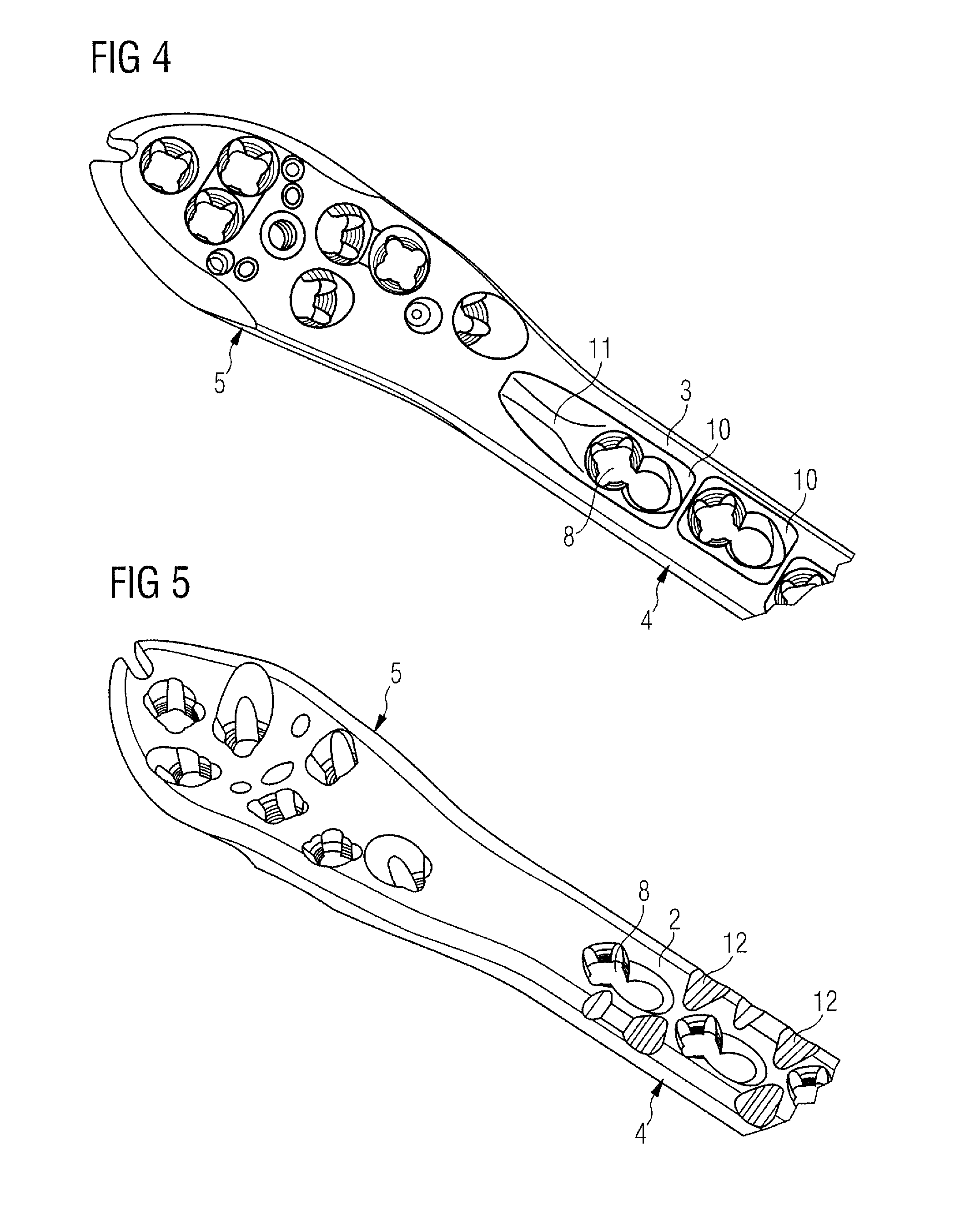

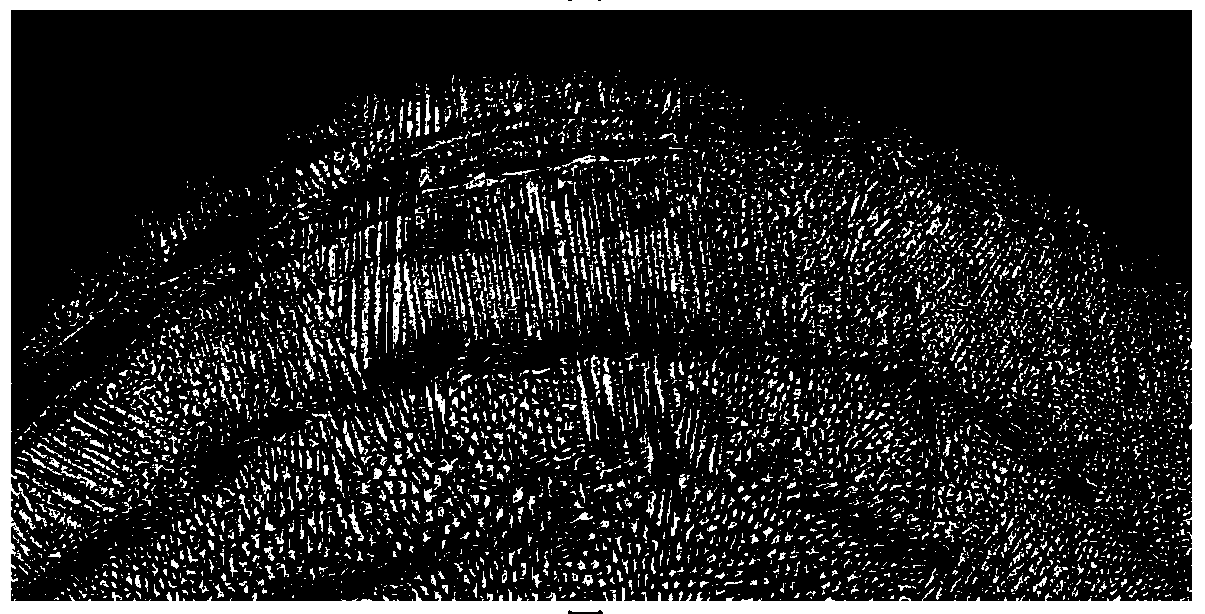

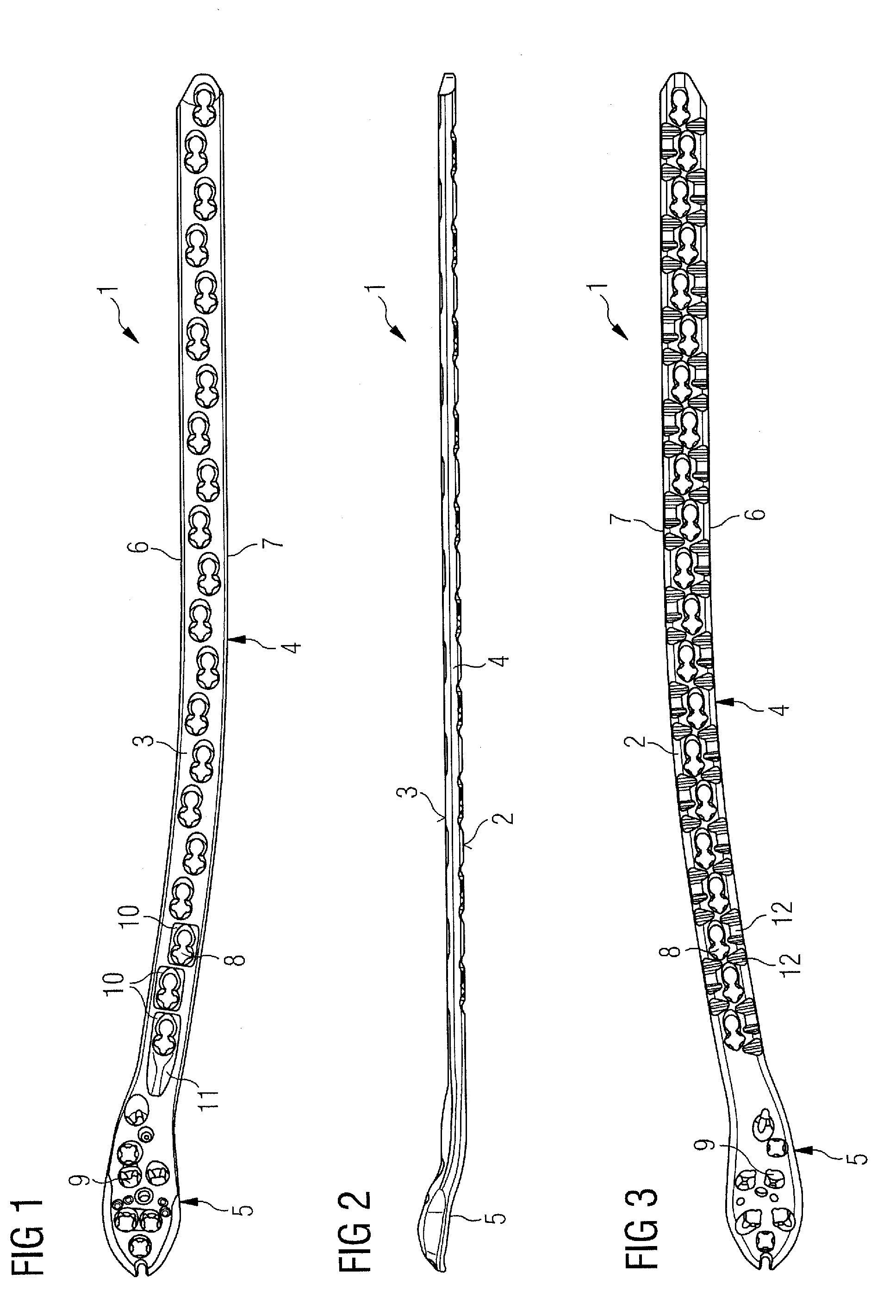

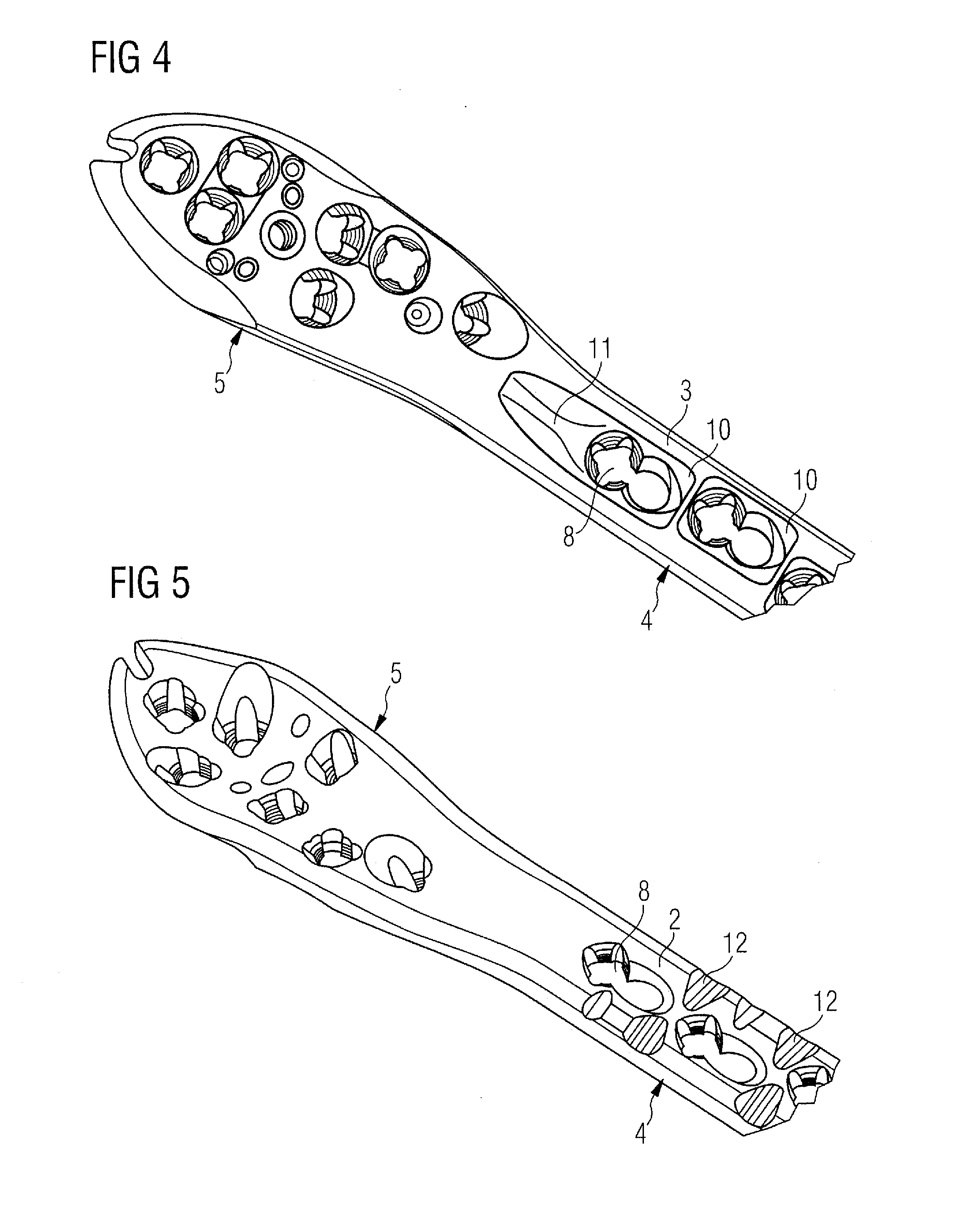

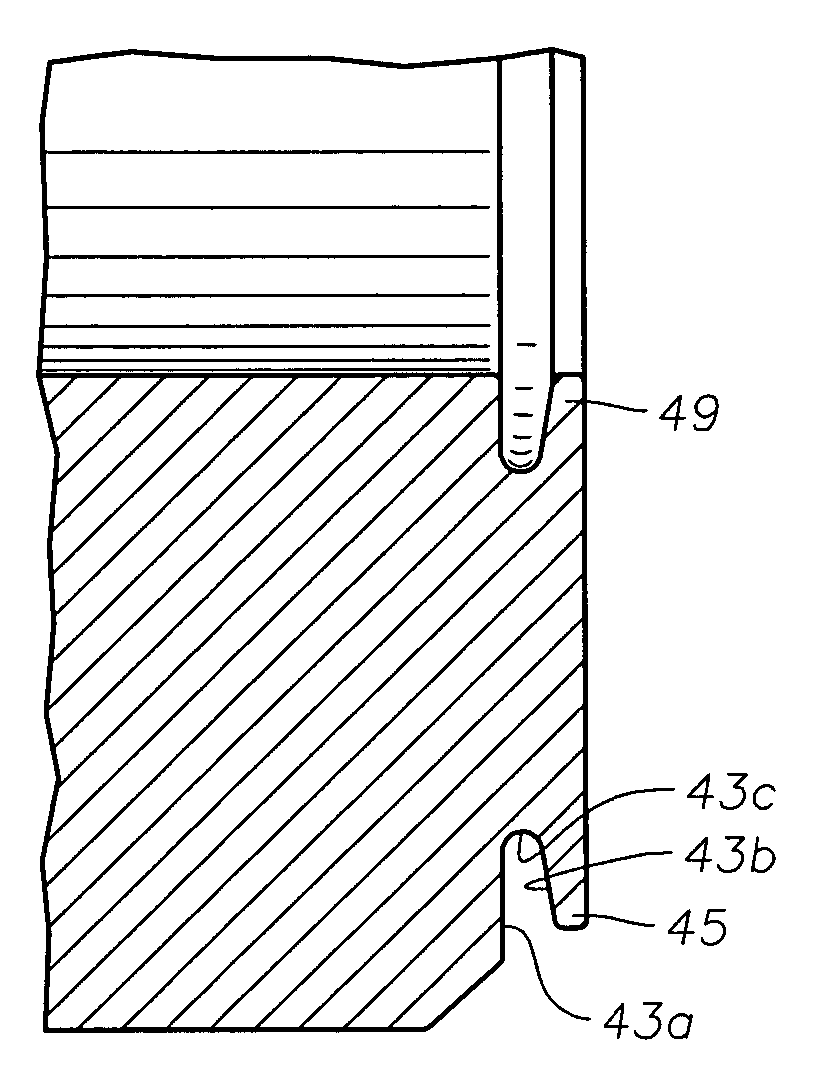

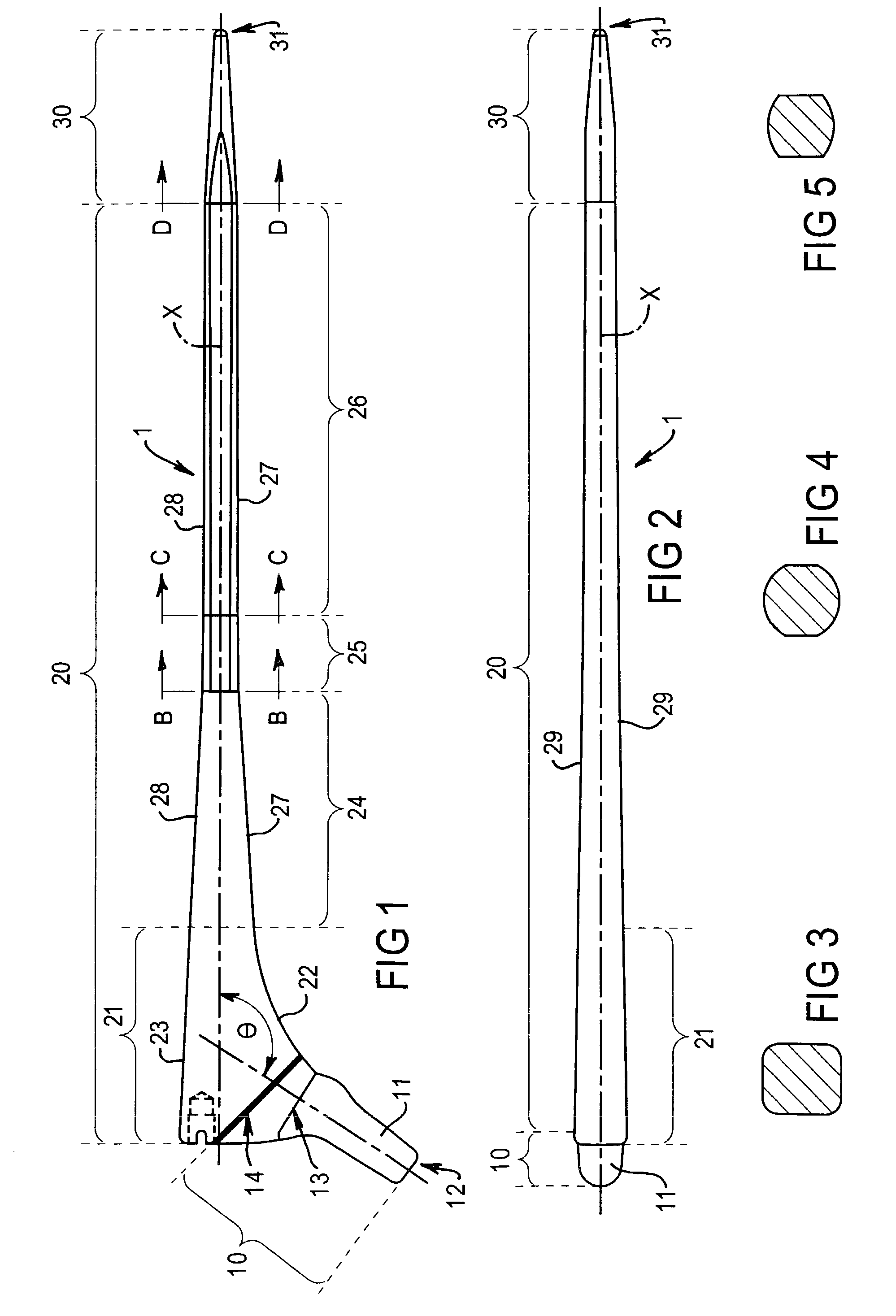

Bone plate

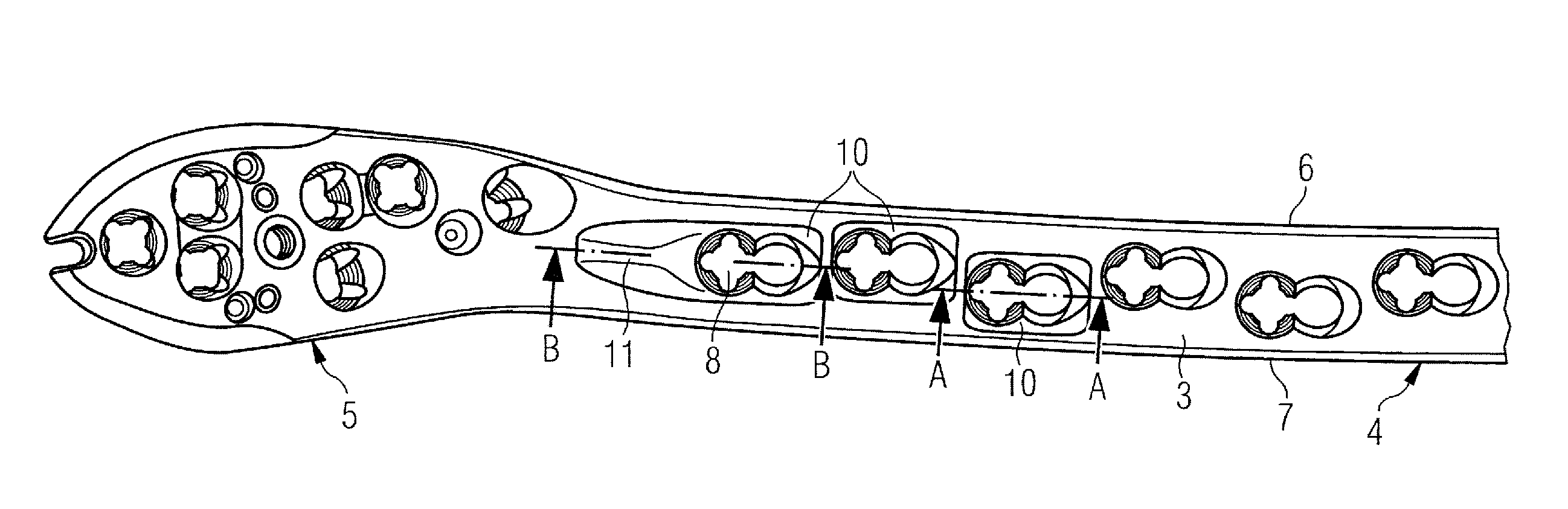

ActiveUS9545277B2Relieve pressureImprove stress distributionBone platesIliac screwBiomedical engineering

A bone plate having a first, bone-facing surface and an opposing second surface has an elongate shaft portion and a head portion that is shorter and wider in comparison thereto, with at least one through hole extending through the bone plate from the first surface to the second surface in the shaft portion. The through hole comprises a variable-angle portion with a hole axis configured to receive a threaded head of a locking screw therein at a desired angle within a permitted range of angulation relative to the hole axis. The second surface has at least one depression which extends therein along a portion of the second surface between the side wall and the through hole, the depression extending about a periphery of the through hole.

Owner:DEPUY SYNTHES PROD INC

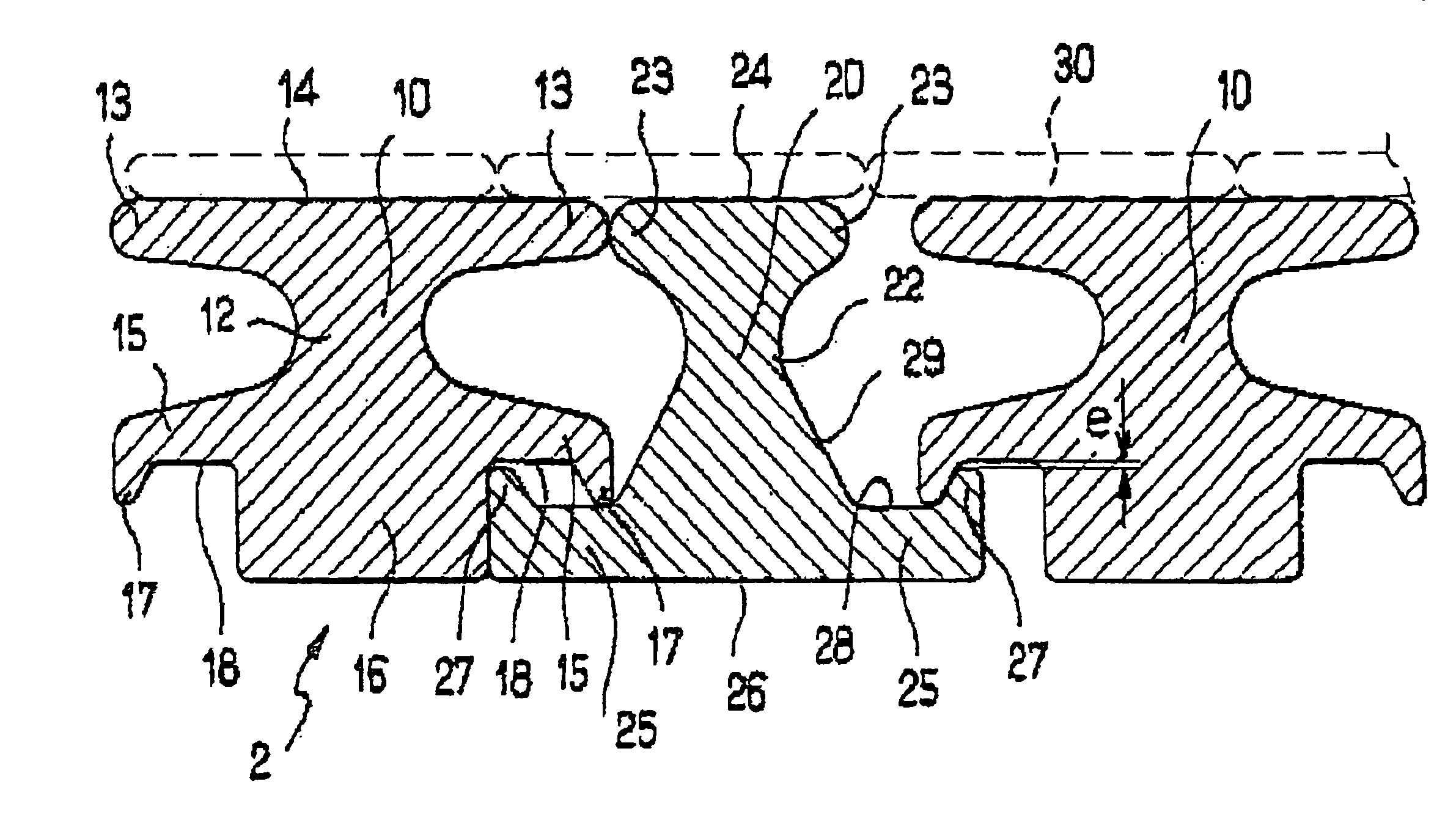

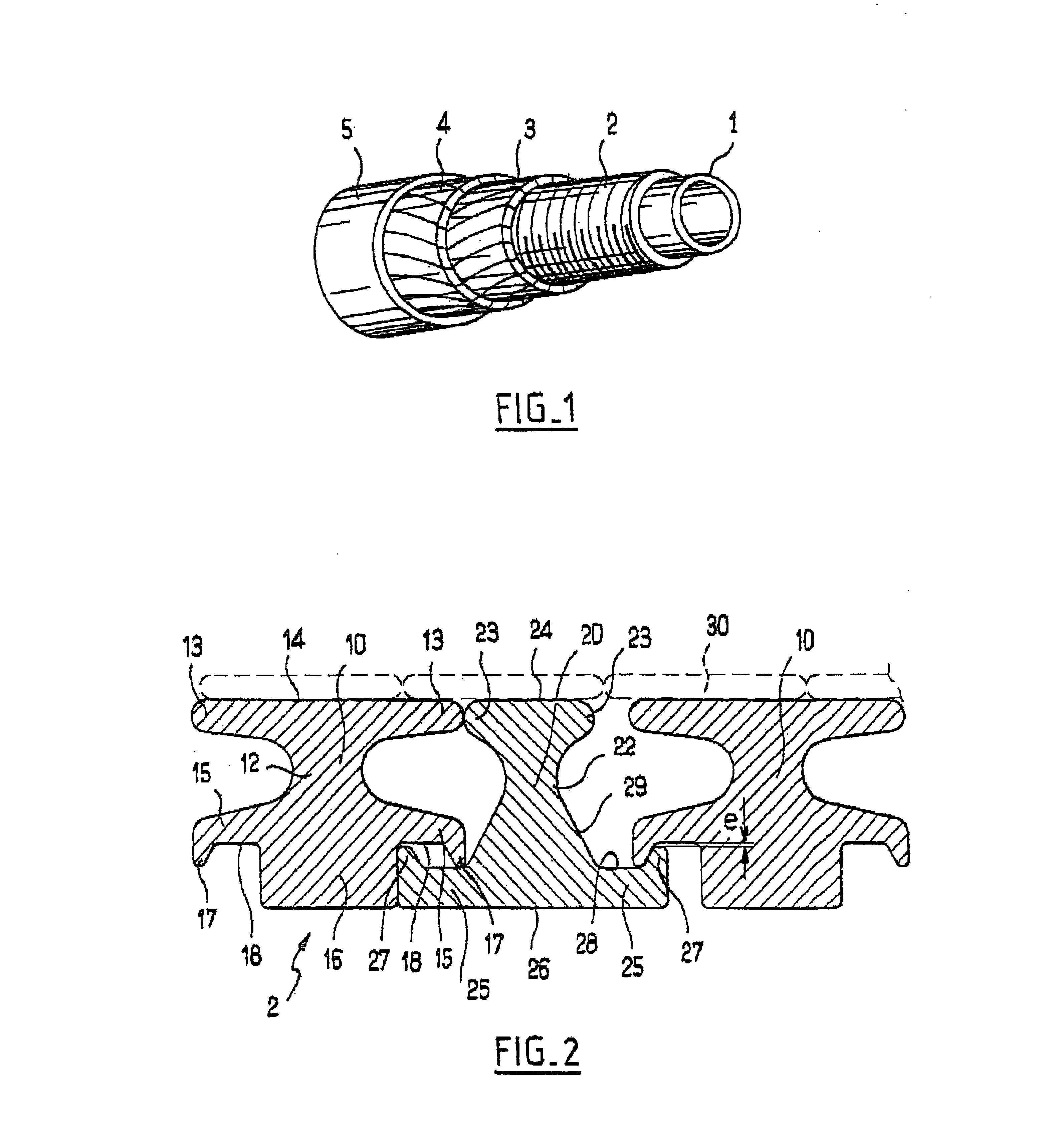

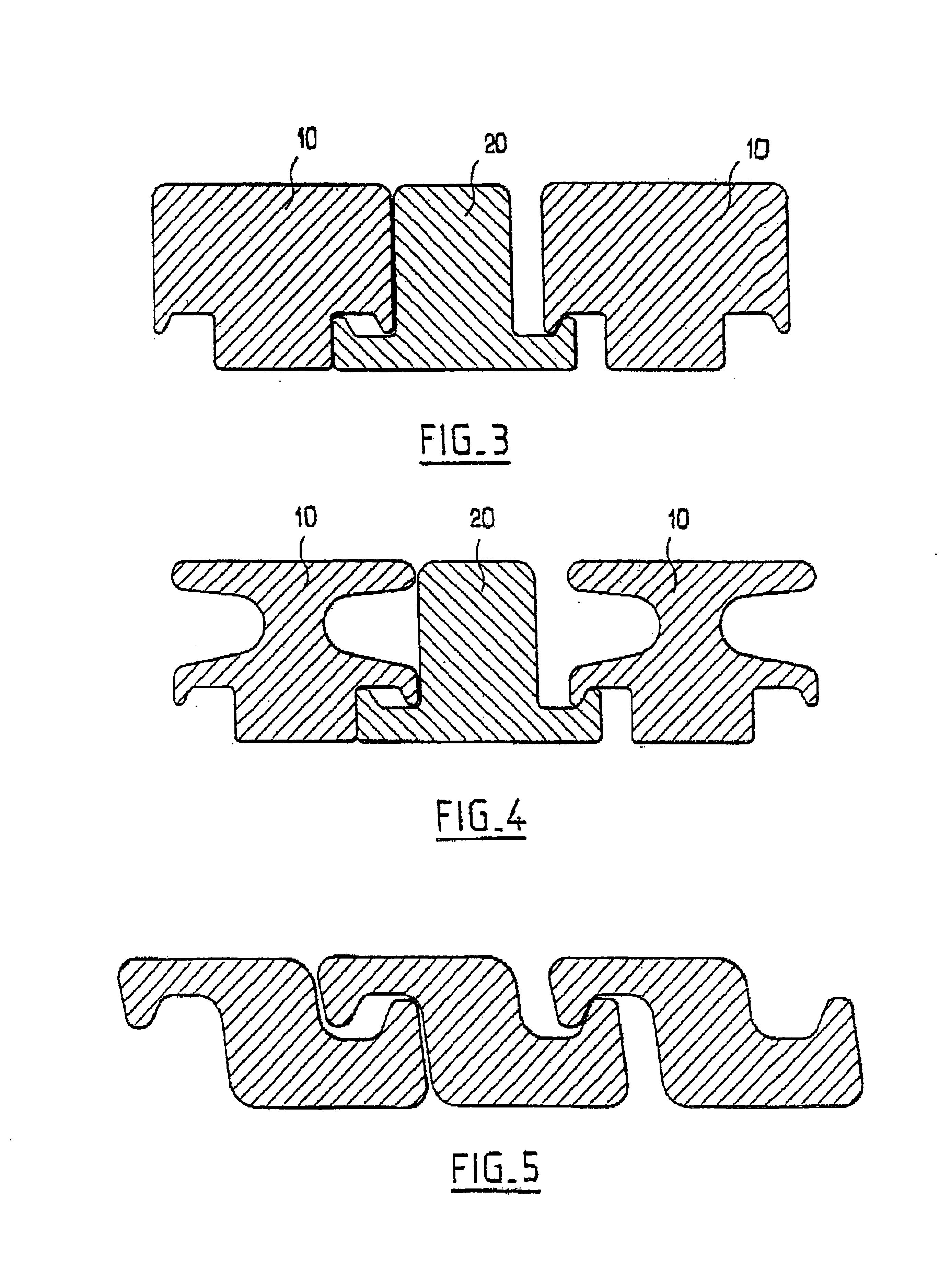

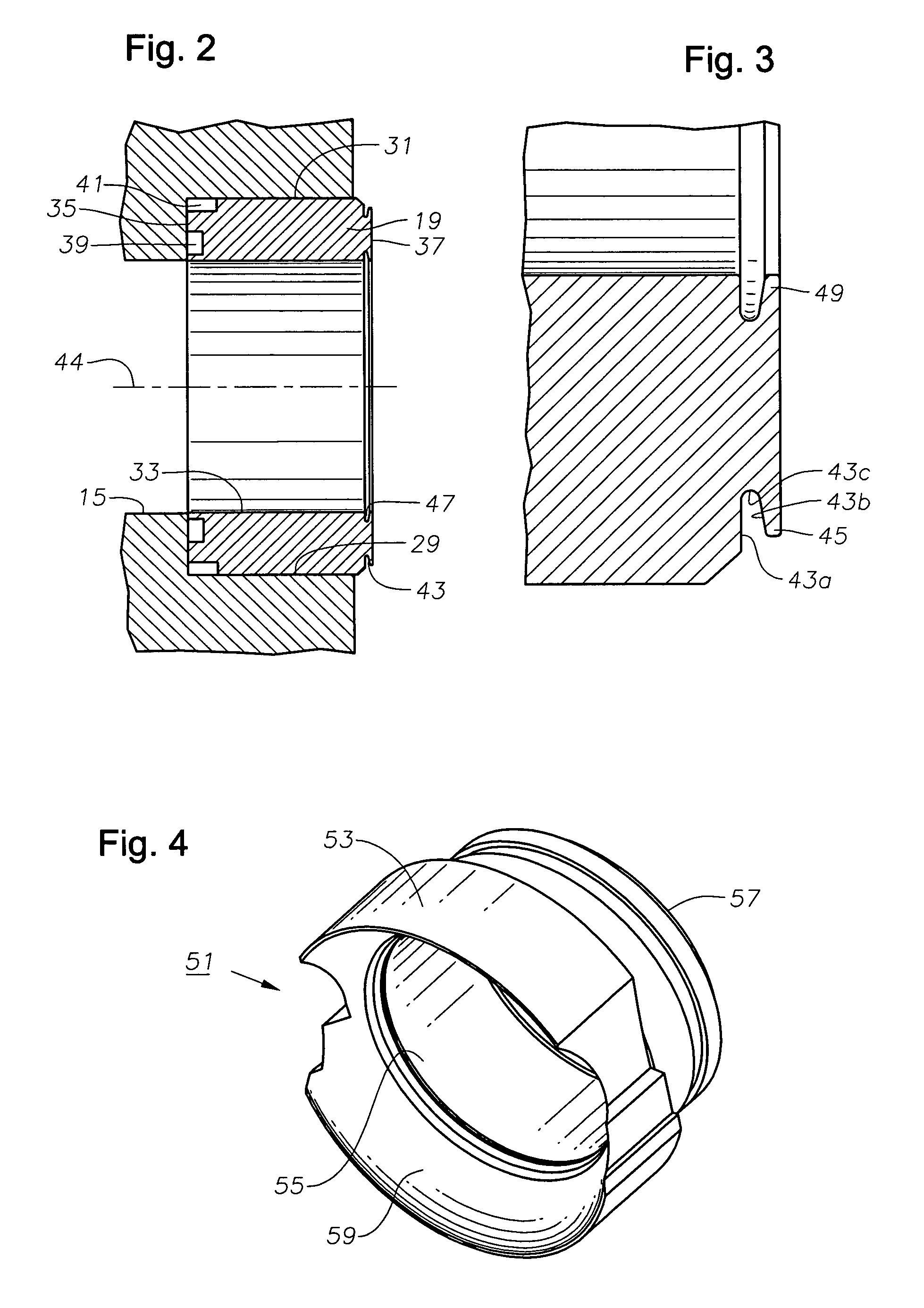

Flexible conduit with pressure vault interlocked from below

InactiveUS6889717B2Constant outside diameterImprove stress distributionFlexible pipesFiberEngineering

A flexible tubular pipe comprising at least, from the inside outwards, an internal sealing sheath made of a polymer material, a cylindrical pressure vault having an external face and having an internal face placed over the internal sheath. The vault is a winding, in a helix with a short pitch and with a gap between turns, of an interlocked metal profile wire. At least one ply of tensile armour layers is wound with a long pitch. An external protective sealing sheath is made of a polymer. The fastener wire has the same height as the profile wire and is fastened below the neutral fiber of the profile wire. The ratio of the cross section of the profile wire to the cross section of the fastening wire is between 1 and 2 and the ratio of the moment of inertia Iyy of the profile wire to the moment of inertia Iyy of the fastening wire is between 1 and 2.

Owner:TECH FRANCE SA

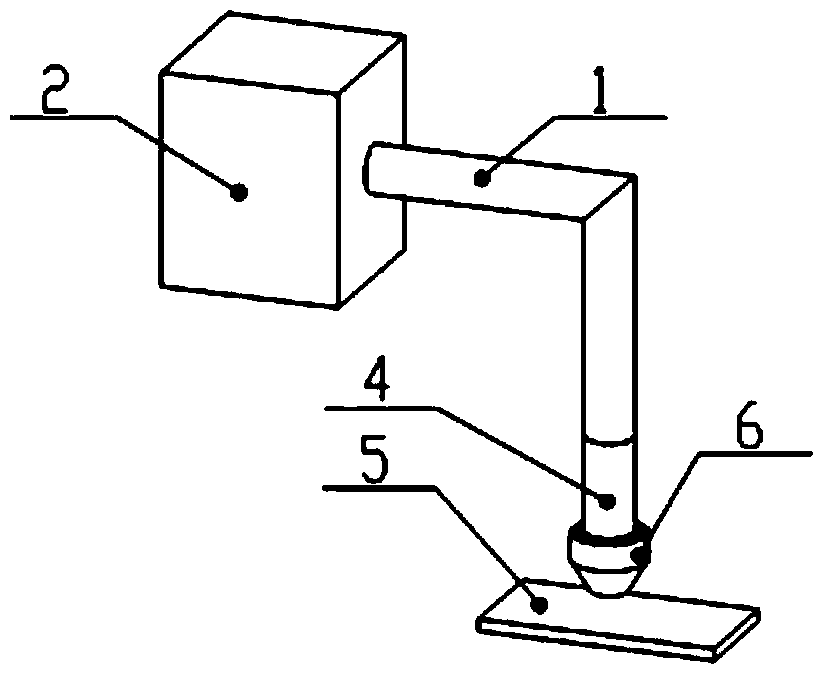

Method for eliminating residual stress in welding by ultrasonic peening and use thereof

InactiveCN102002581AImprove stress distributionSimple processProcess efficiency improvementAlternating currentPeening

The invention relates to a method for eliminating residual stress in welding by ultrasonic peening and use thereof. The method is implemented mainly by using an ultrasonic peening device which comprises an ultrasonic wave generator, an acoustic system and a machine frame, wherein the ultrasonic wave generator and the acoustic system are arranged on the machine frame; the acoustic system has an energy transducer; the ultrasonic wave generator converts 50Hz power frequency alternating current power in a grid into ultrasonic frequency 20kHz alternating current power for exciting the energy transducer of the acoustic system; and the energy transducer of the acoustic system converts electric energy into mechanical vibration at the same frequency and transmits the ultrasonic frequency mechanical vibration to a weld joint in a workpiece at the temperature of 400 to 800 DEG C, so that a deep enough plastic deformation is formed on the surface of the weld joint part. The method which adopts a simple process has high-efficiency, energy-saving and environmentally-friendly characteristics and other characteristics in the elimination of the residual stress generated in a repair and welding process of a cast steel piece such as a swing bolster and a side frame. In addition, the method improves the stress distribution and fatigue strength of the weld joint.

Owner:CRRC YANGTZE CO LTD

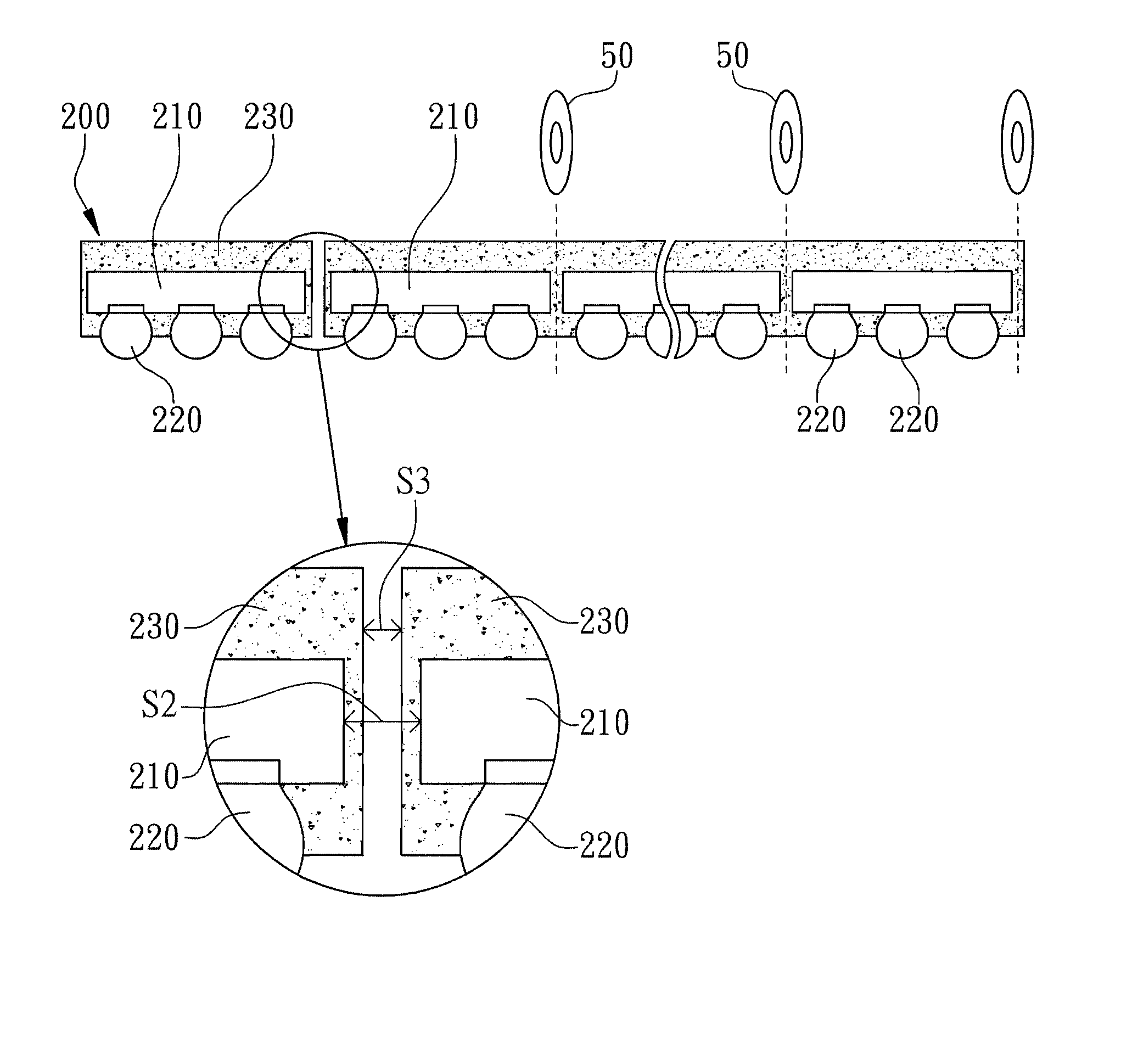

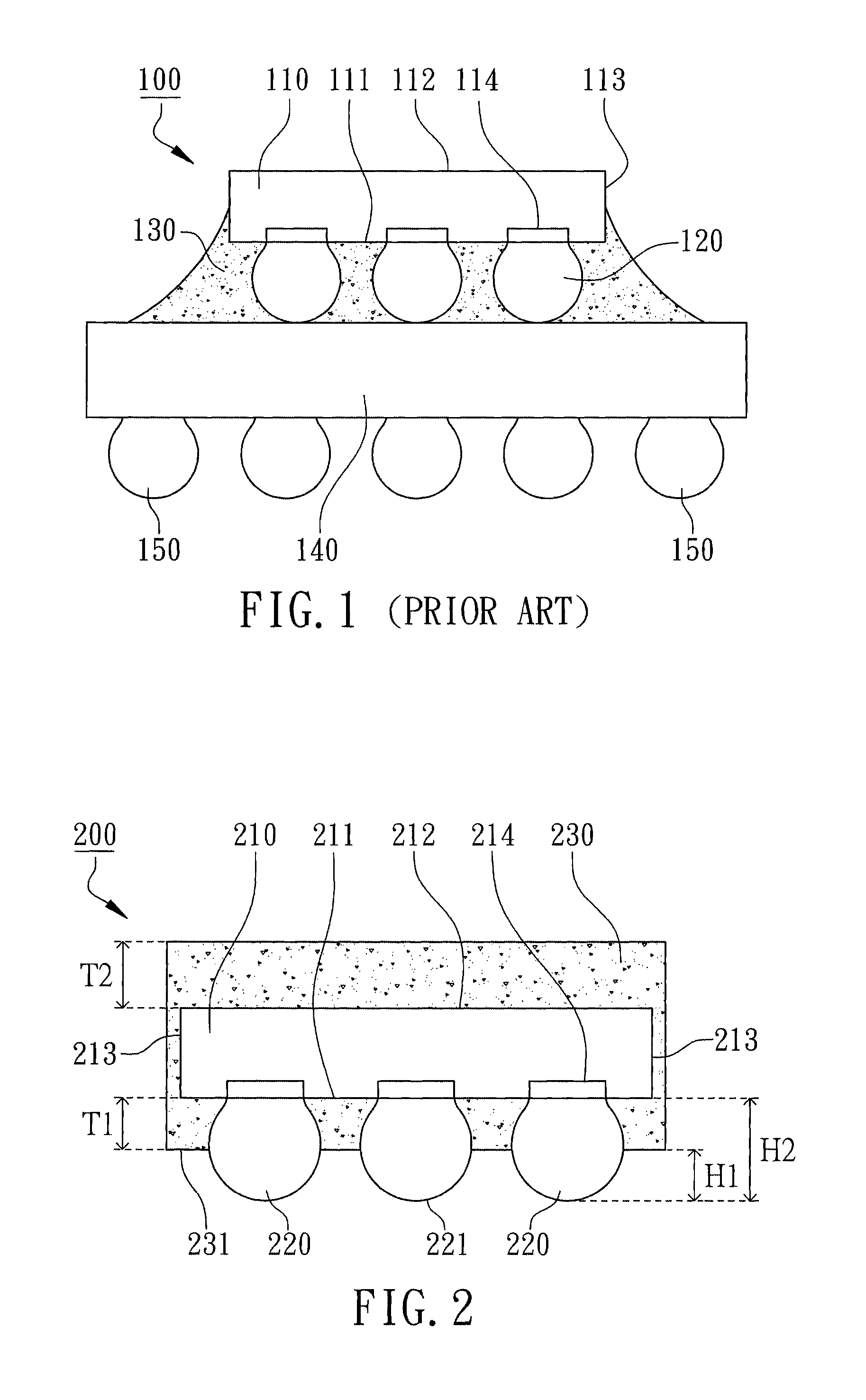

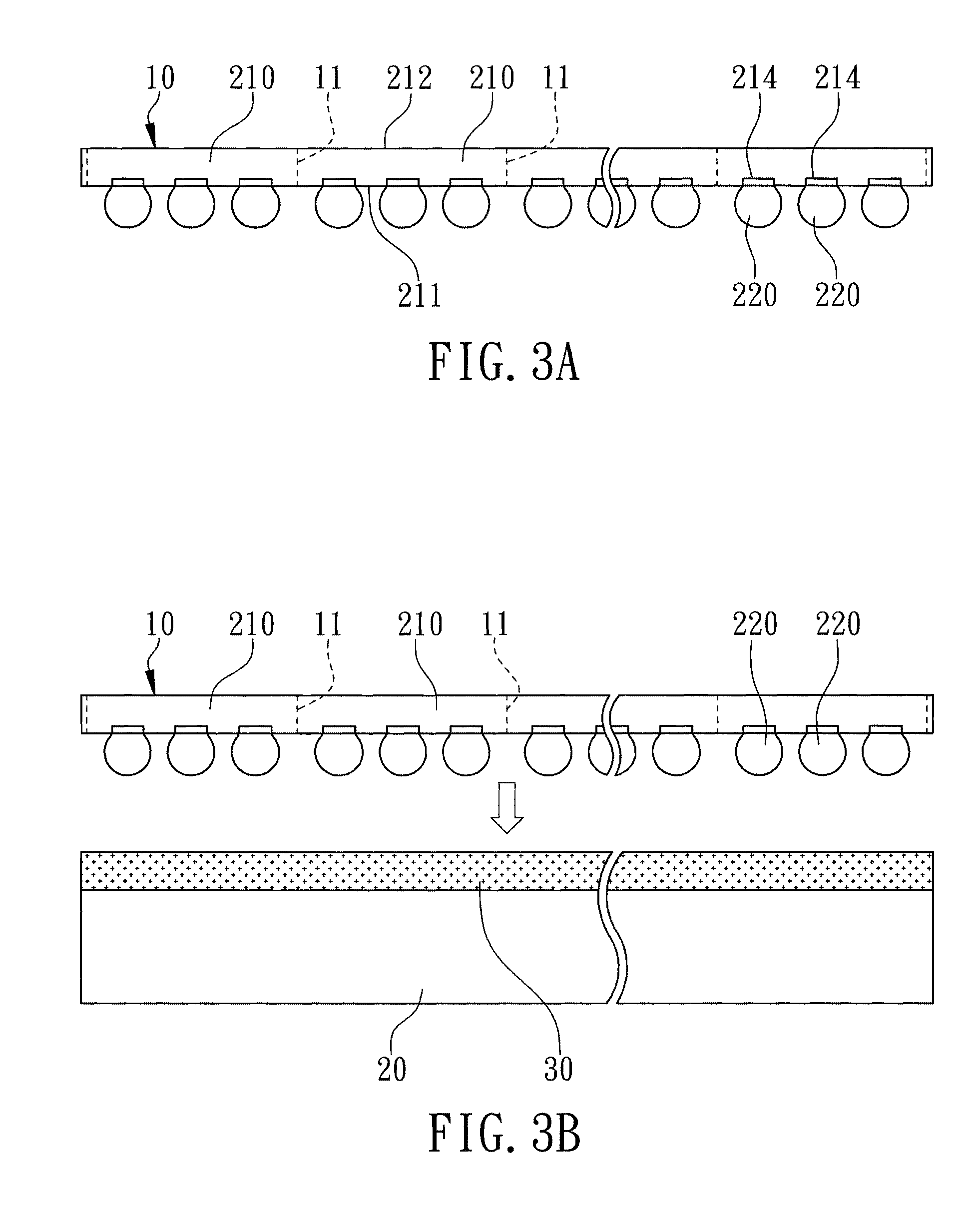

Method for fabricating wafer level chip scale packages

ActiveUS7776649B1Avoid wafer warpage issueAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringSealant

A method for fabricating a plurality of wafer level chip scale packages is revealed. A bumped wafer is laminated with a mold plate with a protection film placed thereon to partially embed the bumps of the wafer into the protection film and to form an underfill gap between the wafer and the protection film. By a first sawing step, the wafer fixed by the protection film is singulated into a plurality of chips having sides between the active surface and the back surface and also a filling gap is formed between the sides. Then, an encapsulant is formed on the protection film where the encapsulant fills the underfill gap through the filling gap to completely encapsulate the chips and the non-embedded portions of the bumps. By separating the encapsulant from the protection film and a second sawing step, the mold plate and the protection film are removed, and the encapsulant is singulated into a plurality of individual wafer level chip scale packages.

Owner:POWERTECH TECHNOLOGY

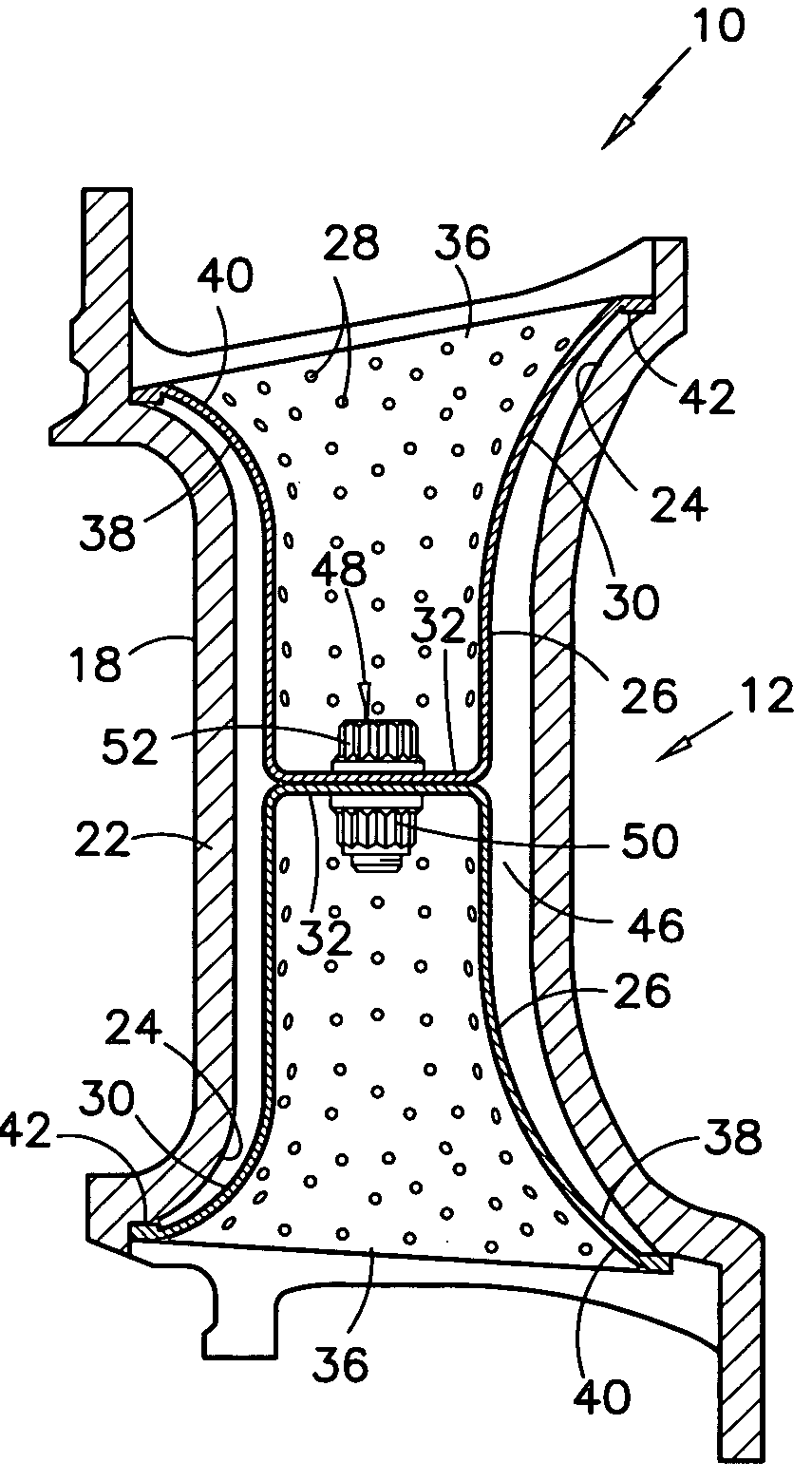

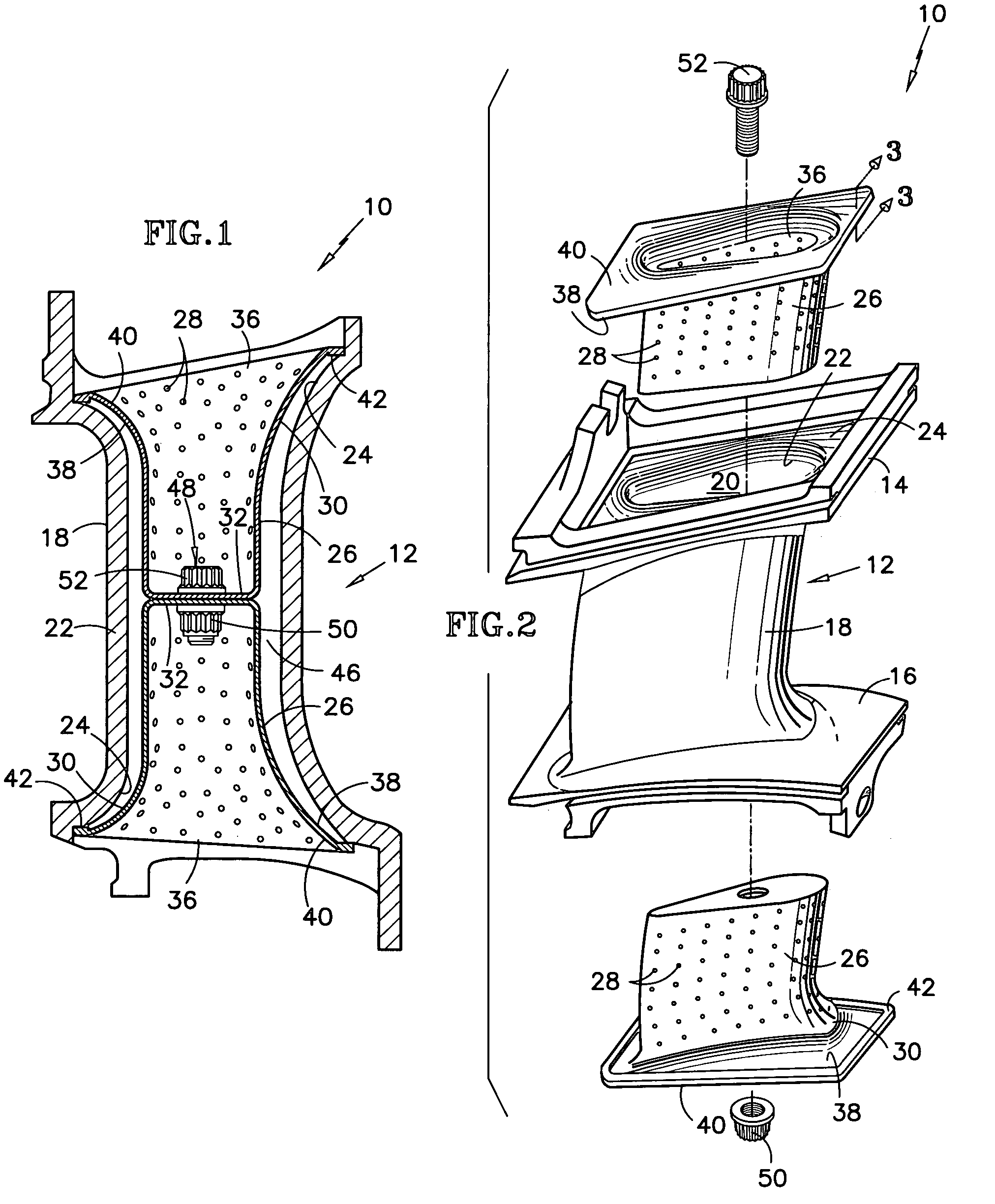

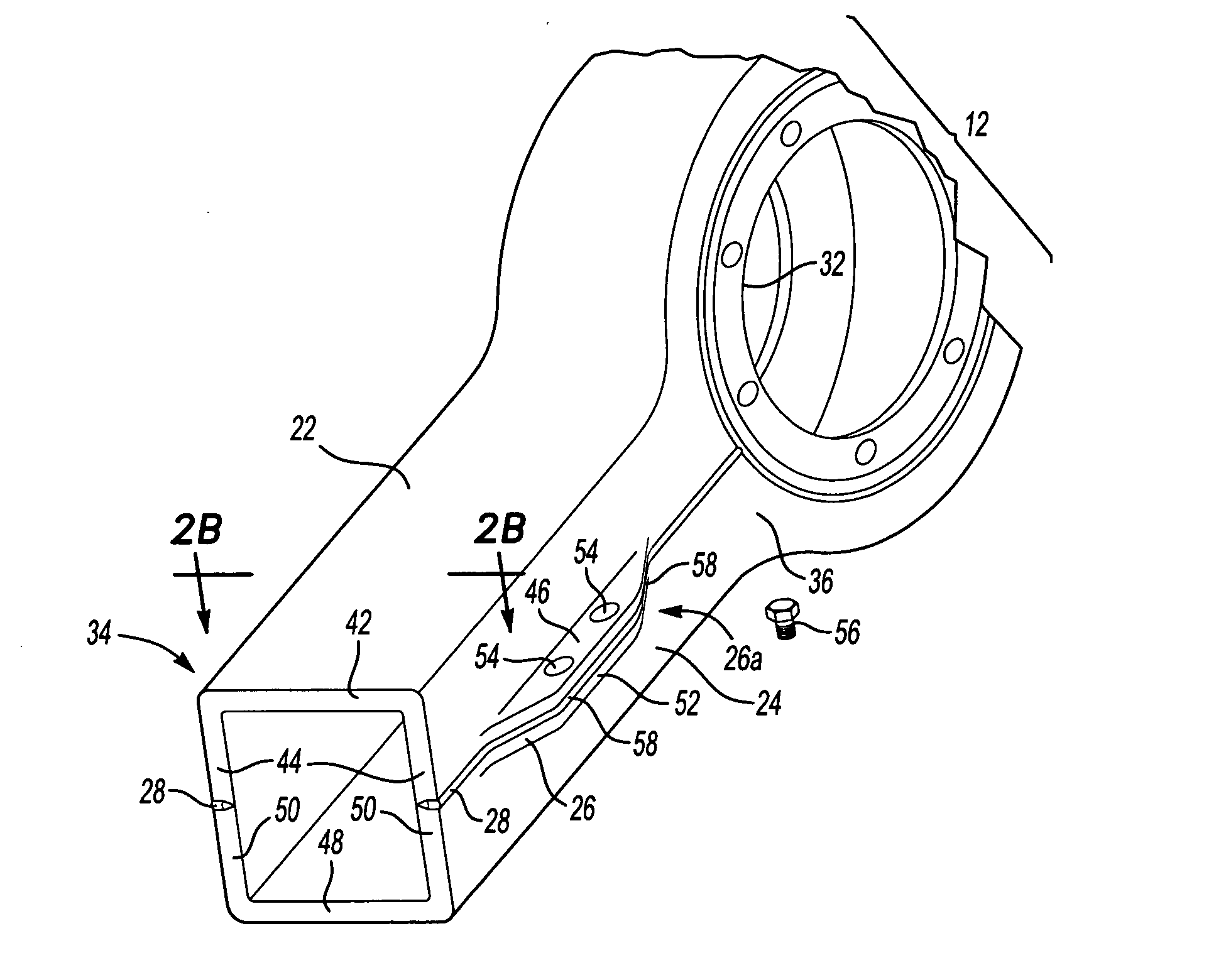

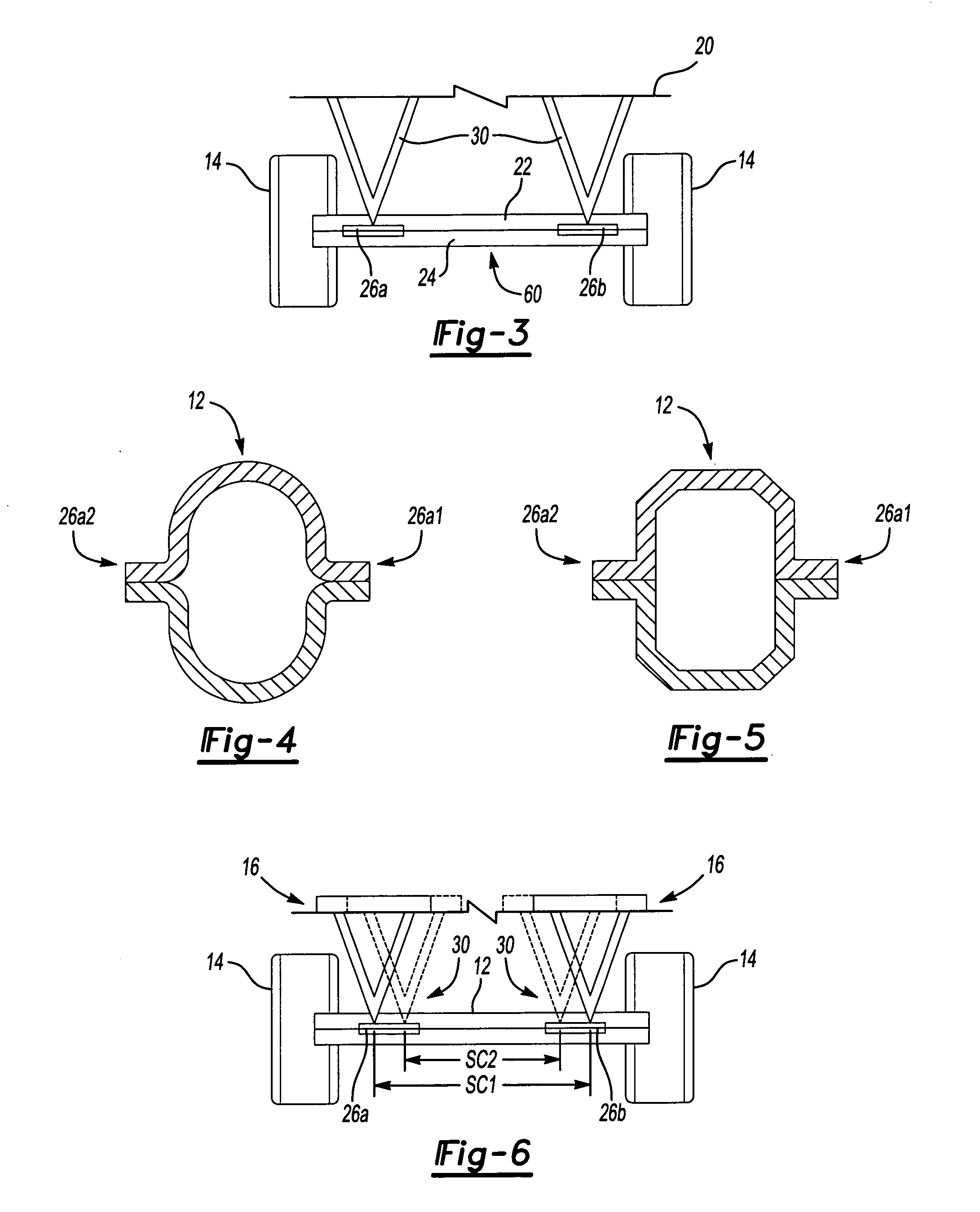

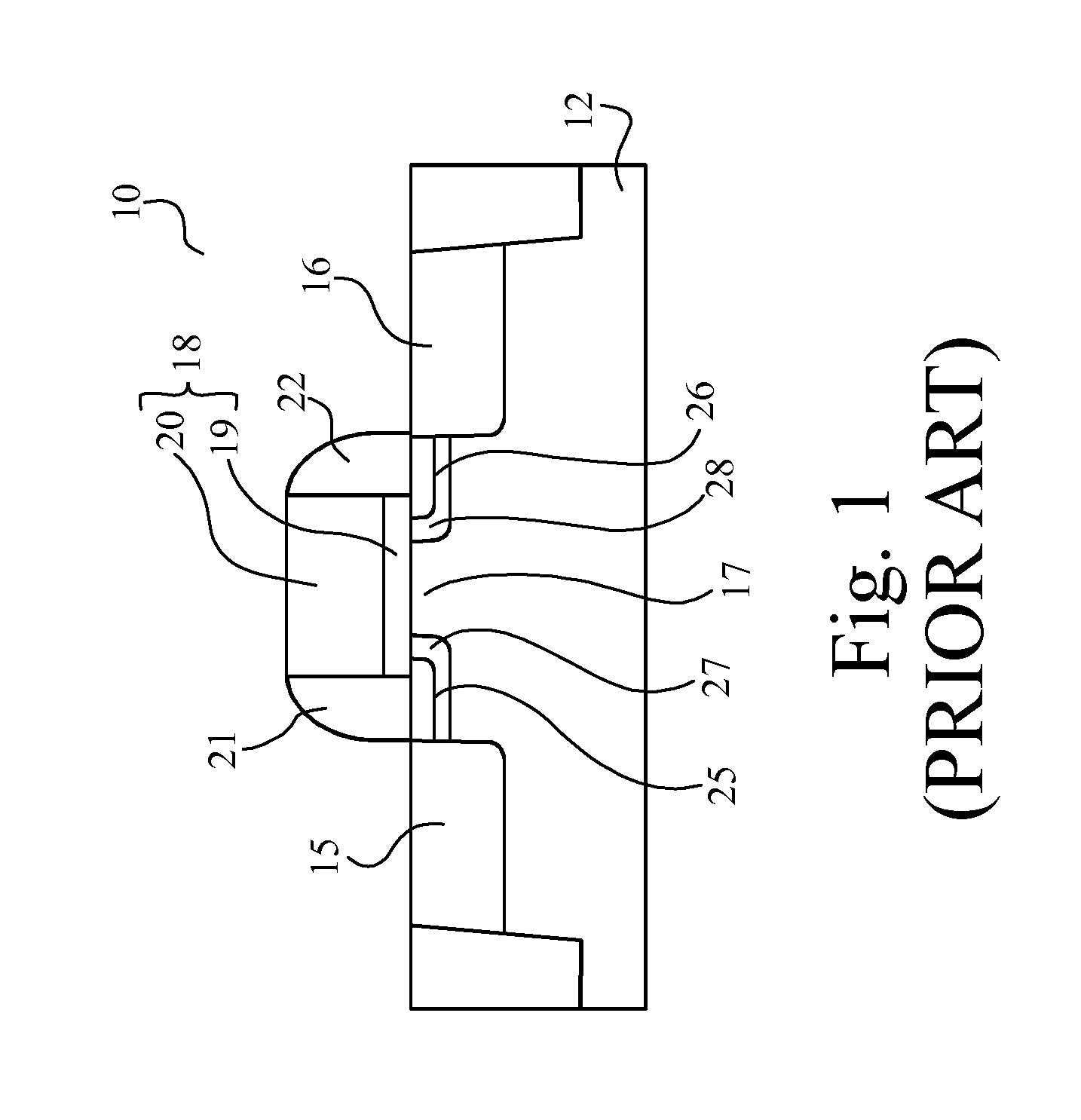

Temperature tolerant vane assembly

ActiveUS20060034679A1Improve stress distributionPropellersPump componentsDamage toleranceEngineering

A vane assembly 10 suitable for a turbine engine features a refractory vane 12 with an internal cavity 20 and a pair of flexible metallic baffles 26 extending into the cavity from spanwisely opposite ends of the vane. A rigid fastener 48, such as a nut and bolt assembly applies a tensile load to the baffles. The tensile load is reacted out as a compressive load applied to the vane. In another embodiment, the baffle is relatively rigid but the fastener is flexible. The compressive loading exerted on the vane counteracts the brittleness customarily exhibited by refractory materials and imparts damage tolerance to the vane. The arrangement also allows the use of a metal baffle that can be easily secured to the vane and dispenses with any need for a potentially troublesome seal between the baffles and the spanwise extremities of the vane.

Owner:RTX CORP

Method for preparing LED chip with separate crystal grain vertical structure

The invention presents a tube core shape design with high luminous efficiency, which comprises: epitaxial growing on island area LED chip with discrete grain; after laser peeling, packaging discrete chip into LED with vertical structure and high luminous efficiency. Wherein, the epitaxial growth improves crystal quality and internal quantum efficiency; the shape of island area increases LED light power; the island growth benefits to release stress, reduce stress on interface between GaN and sapphire substrate and the damage and spectral shift during peeling, thereby, it can obtain LED with high performance.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV

Bionic quadruped robot with energy storage effect

InactiveCN104149871AWalk fastLarge front and rear stridesAuxillary drivesVehiclesEngineeringEnergy storage

The invention belongs to the field of bionic robots and relates to a bionic quadruped robot with energy storage effect. The rigid spine of the existing bionic quadruped robot is modified. The bionic quadruped robot comprises a front trunk, a rear trunk, a spine, a left front leg unit, a right front leg unit, a left rear leg unit and a right rear leg unit. The front trunk and the rear trunk are connected with front and rear ends of the spine, respectively. The spine can drive the front trunk to rotate relative to the rear trunk. The left front leg unit, the right front leg unit, the left rear leg unit and the right rear left leg unit have same structures and are connected to left and right sides of the front and rear trunks, respectively. The spine is added between the front and rear trunks; the whole shape is more approximate to a true quadruped animal; when the robot walks, the front and rear trunks allow a larger step through the spine pitching up or down, and the robot can walk faster; less energy is lost when the robot touches the ground, motion stability is improved, and utilization rate of energy is increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Crepe facilitating composition

InactiveUS20070000630A1Improve stress distributionGood flexibilityMechanical working/deformationSpecial paperFiberWater insoluble

The invention relates to a crepe facilitating aqueous composition comprising at least one water-insoluble, non-surface active thermoplastic material having a softening or melting point within the range of from 40° C. to 100° C., and at least one water-soluble polymer, preferably a cationic water-soluble polymer. As the composition is comprised in a wet fibre web during creping thereof, a more uniform creping is obtained while the integrity of the web is preserved and dust formation is reduced, and a tissue product having improved properties is provided.

Owner:BIM KEMI

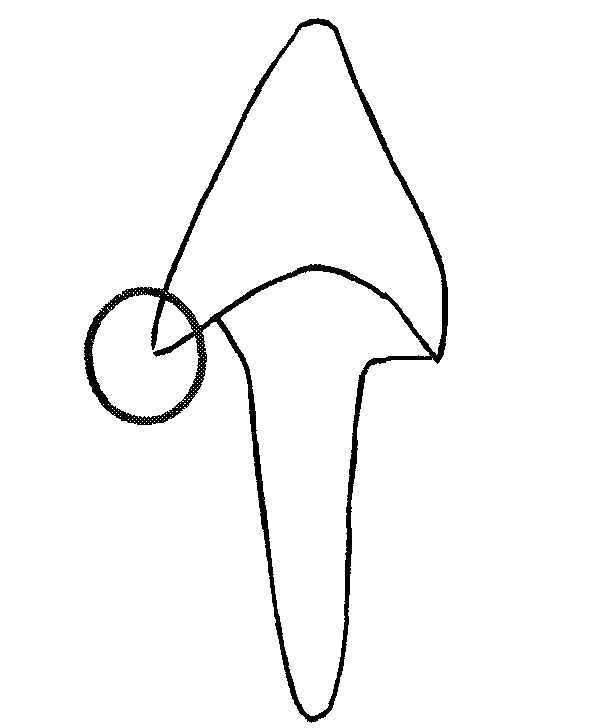

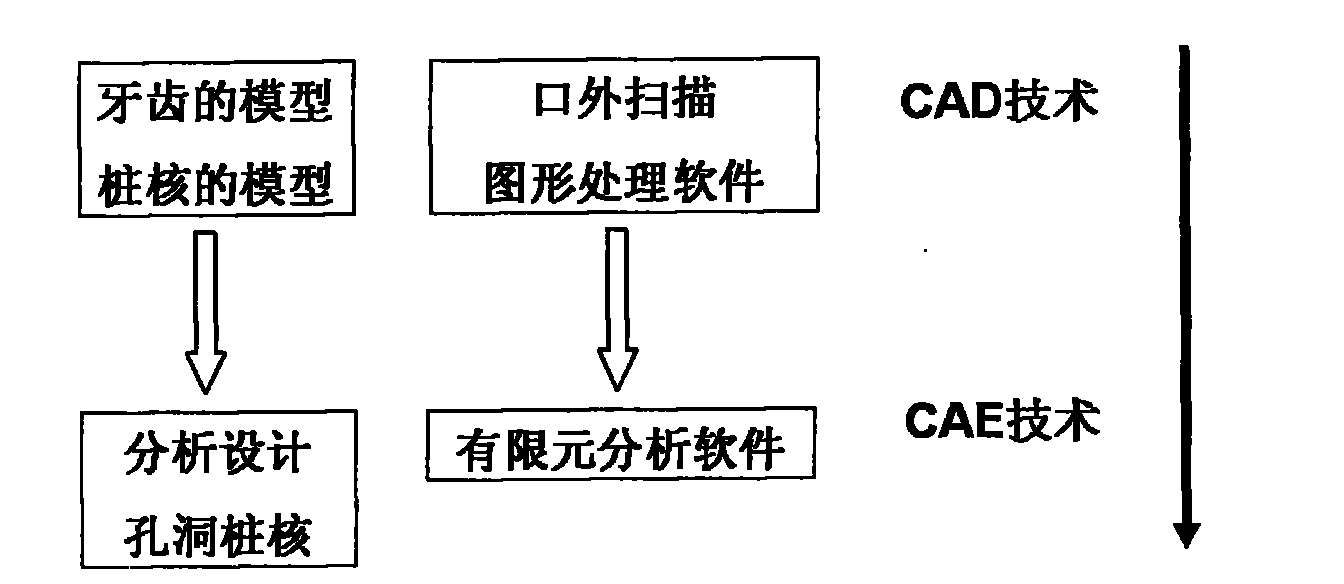

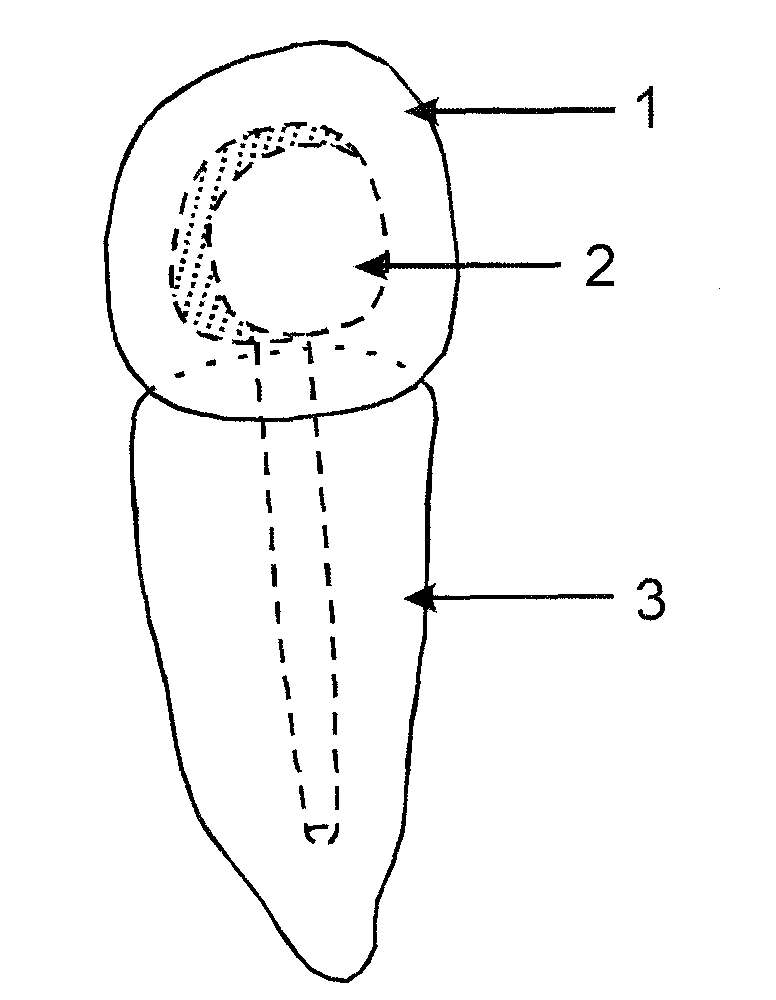

Integrated fiber post for dental restoration and preparation method thereof

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

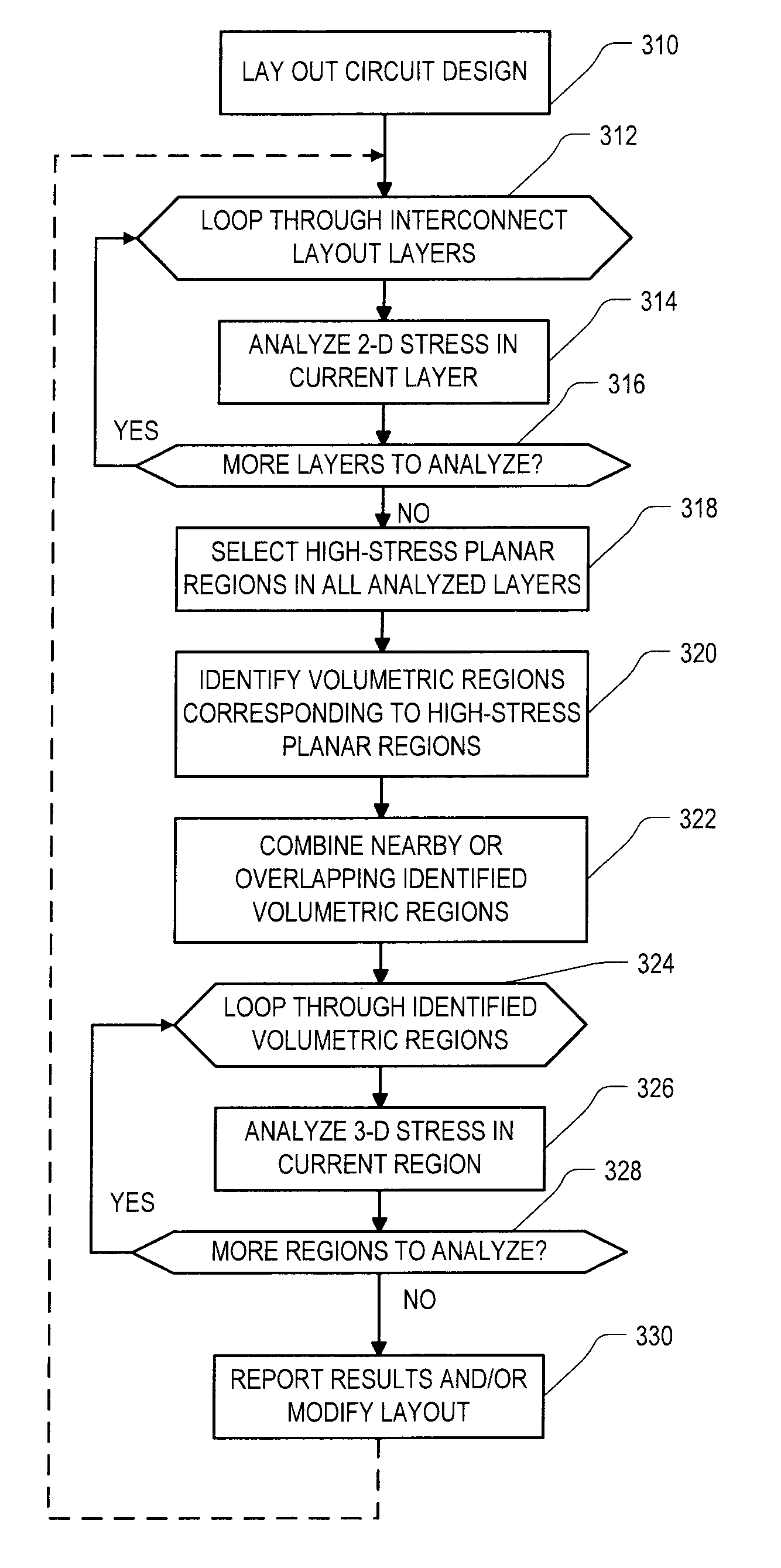

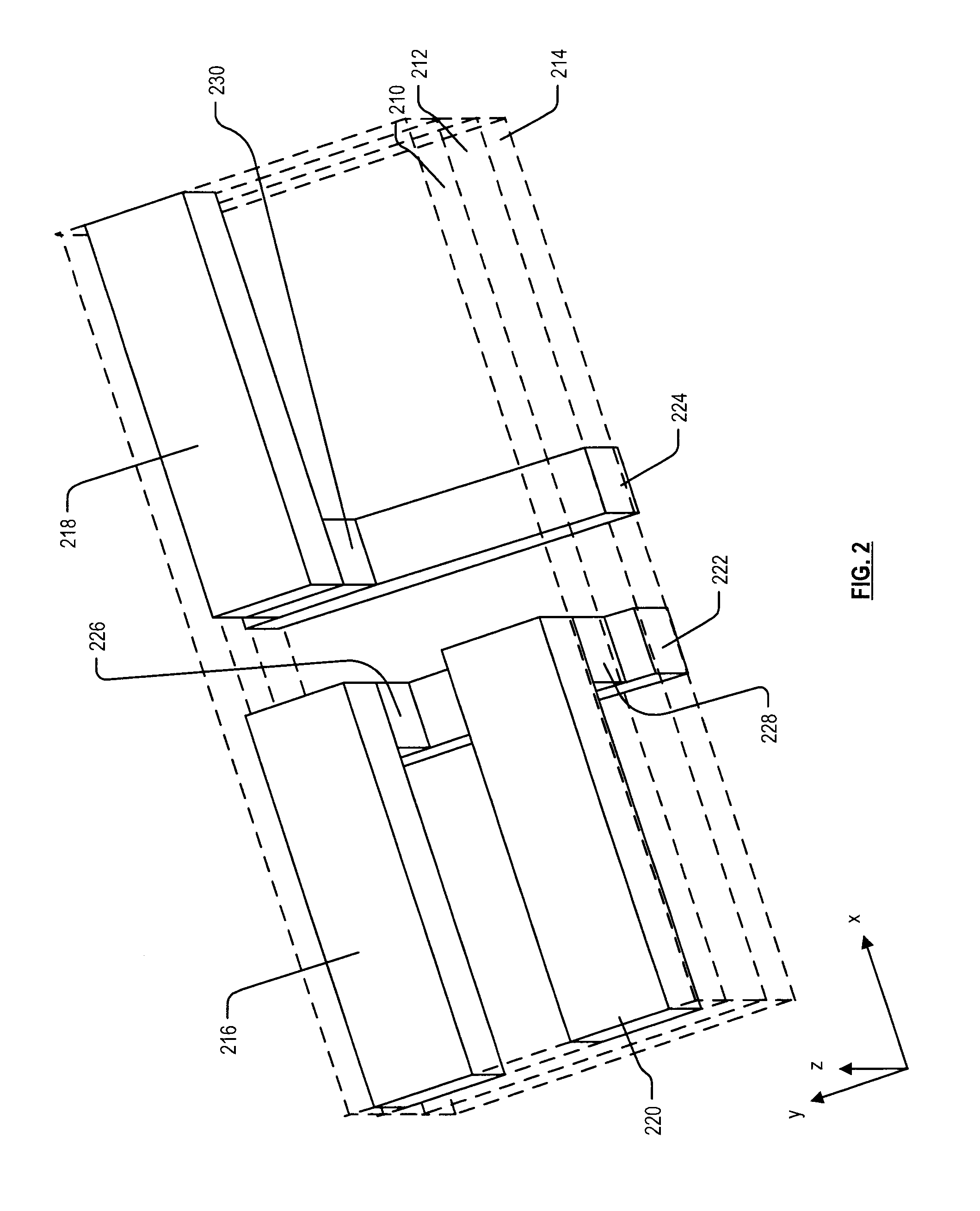

Method and apparatus for fast identification of high stress regions in integrated circuit structure

ActiveUS20080066023A1High stressReduction in size and numberDetecting faulty computer hardwareDesign optimisation/simulationComputational physicsIntegrated circuit

Roughly described, high-stress volumetric regions of an integrated circuit structure are predicted by first scanning one or more layout layers to identify planar regions of high 2-dimensional stress, and then performing the much more expensive 3-dimensional stress analysis only on volumetric regions corresponding to those planar regions that were found to have high 2-dimensional stress. A windowing method can be used for the 2-dimensional scan, optionally with an overlap region extending slightly into adjacent windows. Very narrow features arising at the edges of an analysis window can be relocated to the edge of the analysis window in order to avoid numerical artifacts.

Owner:SYNOPSYS INC

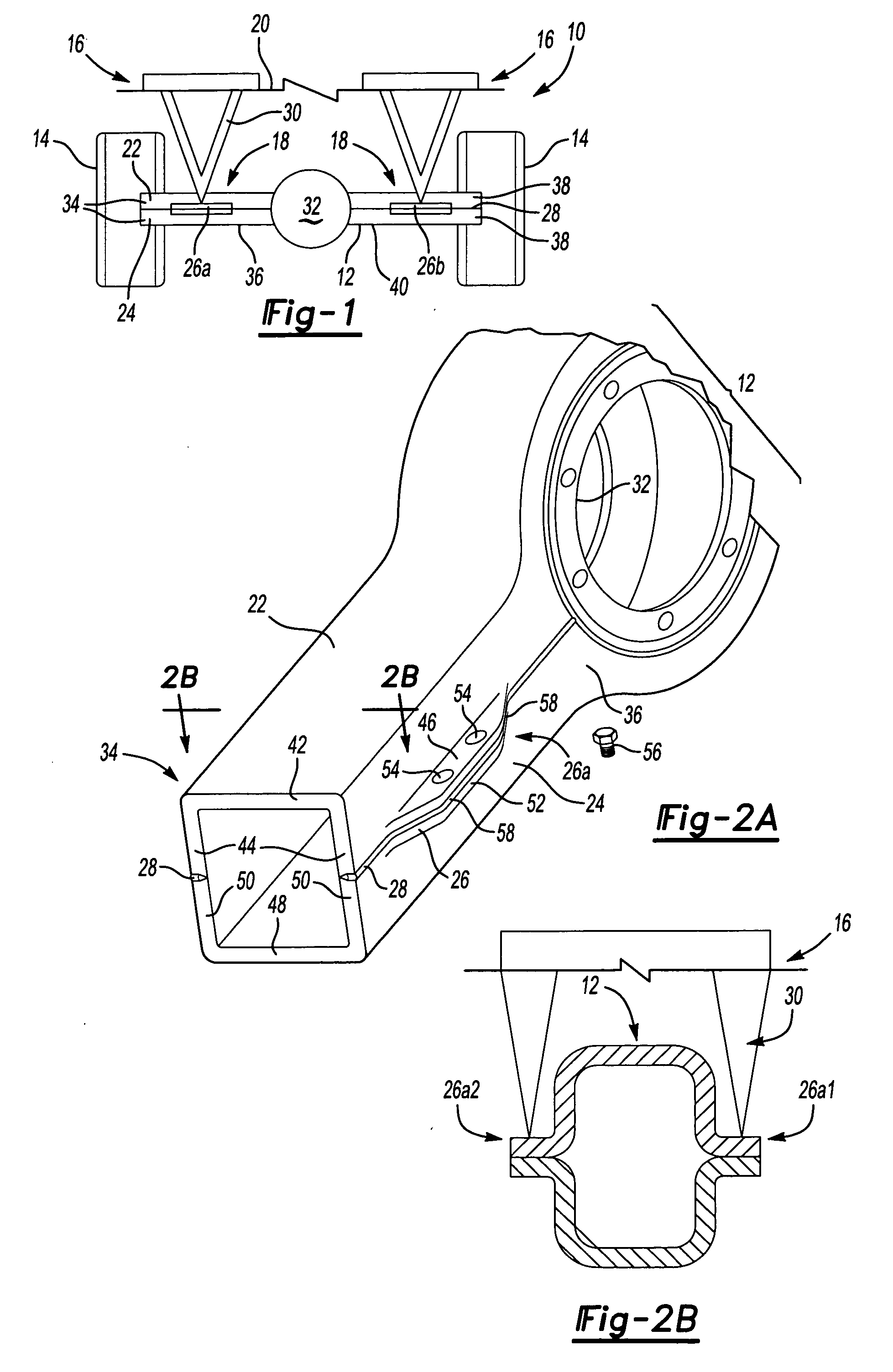

Axle housing with suspension flange

InactiveUS20050168057A1Improve stress distributionWall thickness can be minimizedWheel manufactureAxle unitsEngineeringSeam welding

A suspension mount includes a flange formed directly into an axle housing. The axle housing includes a pair of housing halves that are attached to each other along a seam weld. Each housing half includes at least one transversely extending flange. Prior to welding, the flanges from the upper and lower housing halves are aligned with each other to define the suspension mount. The suspension is then attached to the axle housing at the flanges with fasteners or by welding.

Owner:ARVINMERITOR TECH

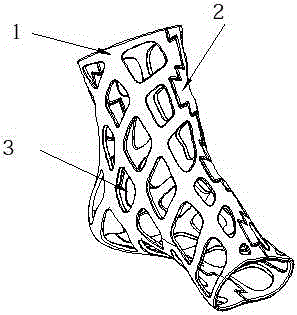

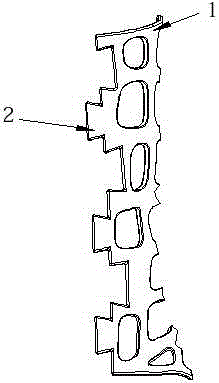

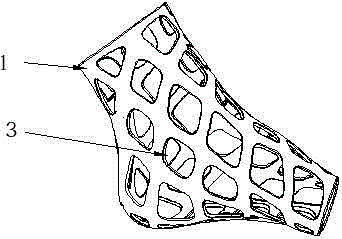

3D-printing-based customized external foot fixation protector

InactiveCN105250064AAchieve lightweightAchieve strengthAdditive manufacturing apparatusFractureAnkleItching

The invention discloses a 3D-printing-based customized external foot fixation protector. The 3D-printing-based customized external foot fixation protector comprises protectors at left and right portions, dual-dovetail-groove fasteners distributed on the edges of the protectors and air vents distributed in the surfaces of the protectors; the protector is realized through a 3D printing technology on the basis of CT data of a foot of a patient and is printed as left and right portions crossing an ankle, and the protectors at the left and right portions are fixed through the dual-dovetail-groove fasteners. The 3D-printing-based customized external foot fixation protector can be optimally customized aiming at different wounds of different patients, has the advantages of light weight, good air permeability, convenience in installation, simplicity in use and reliable fixation, facilitates the rehabilitation activities of the patient, prevents skin aging, itching and the like, and greatly improves the comfort of the patient during rehabilitation.

Owner:SHANGHAI UNIV

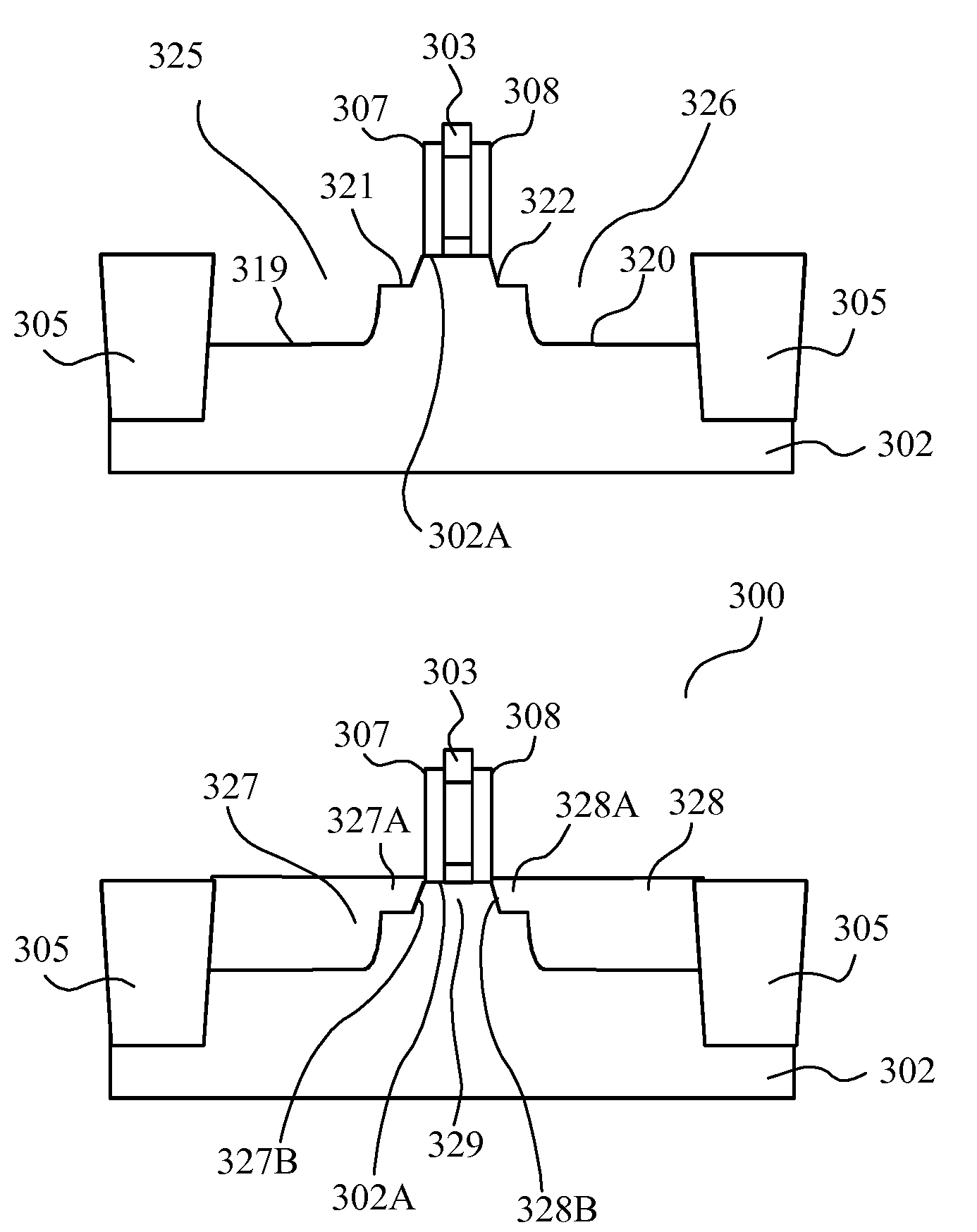

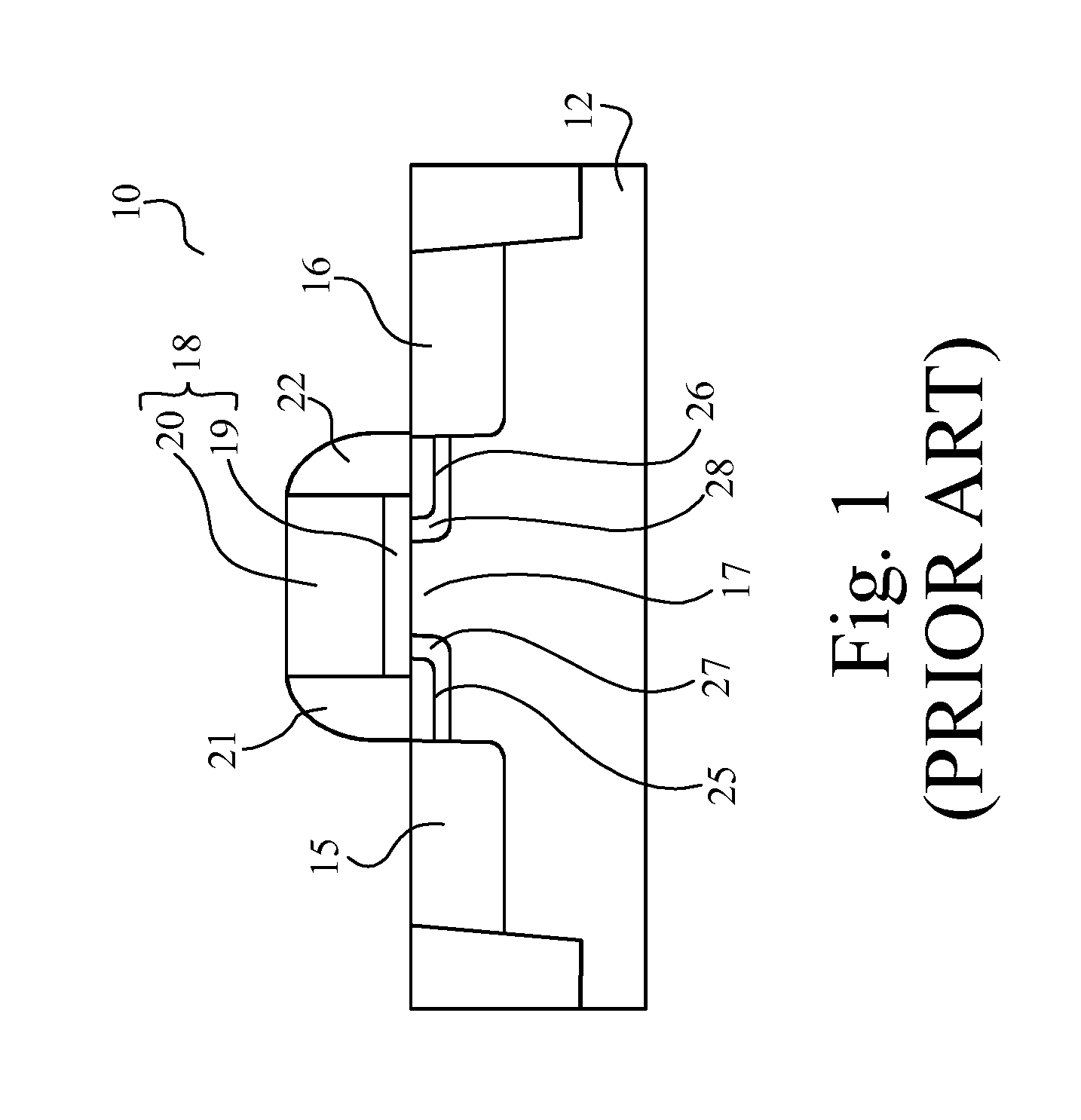

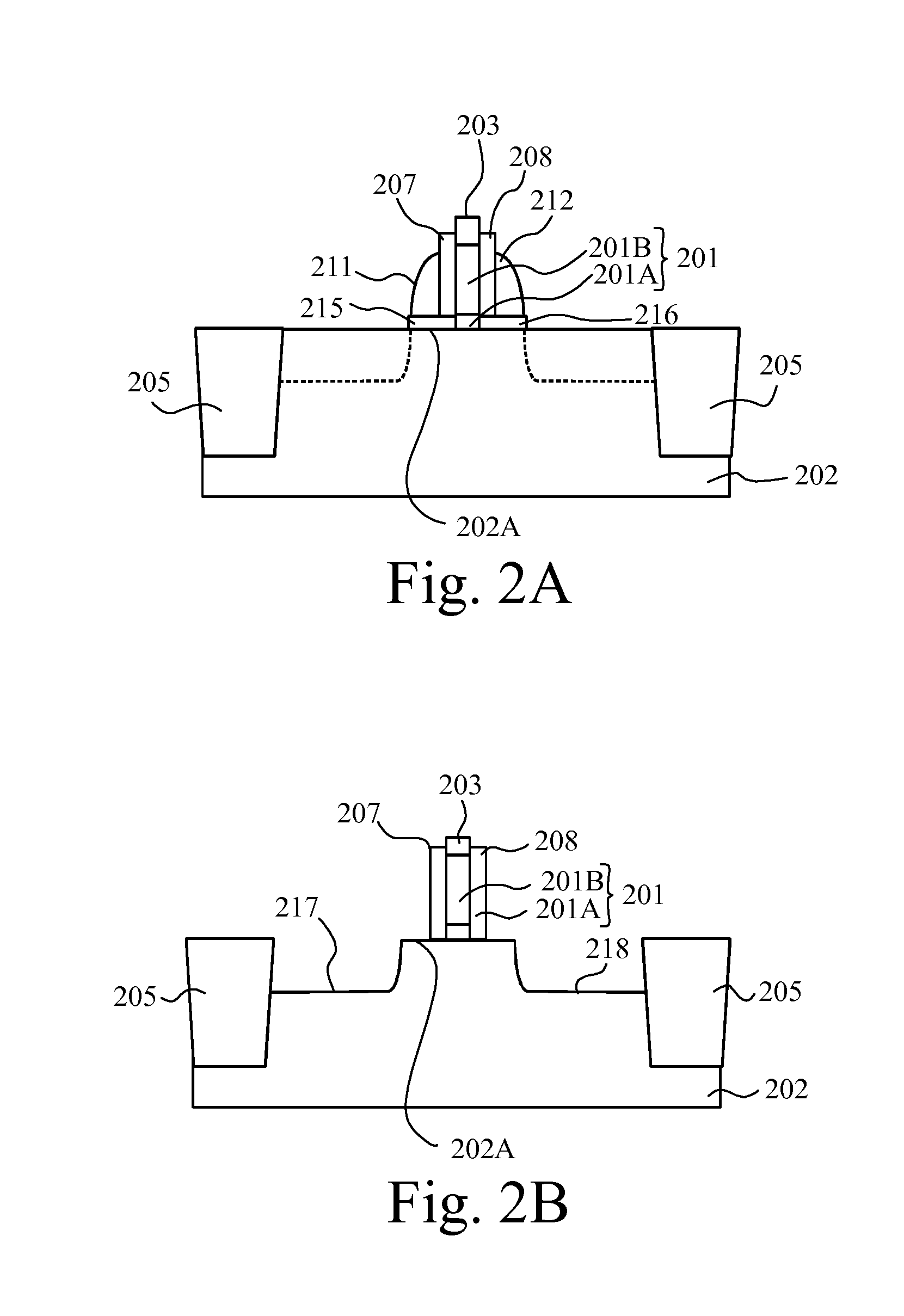

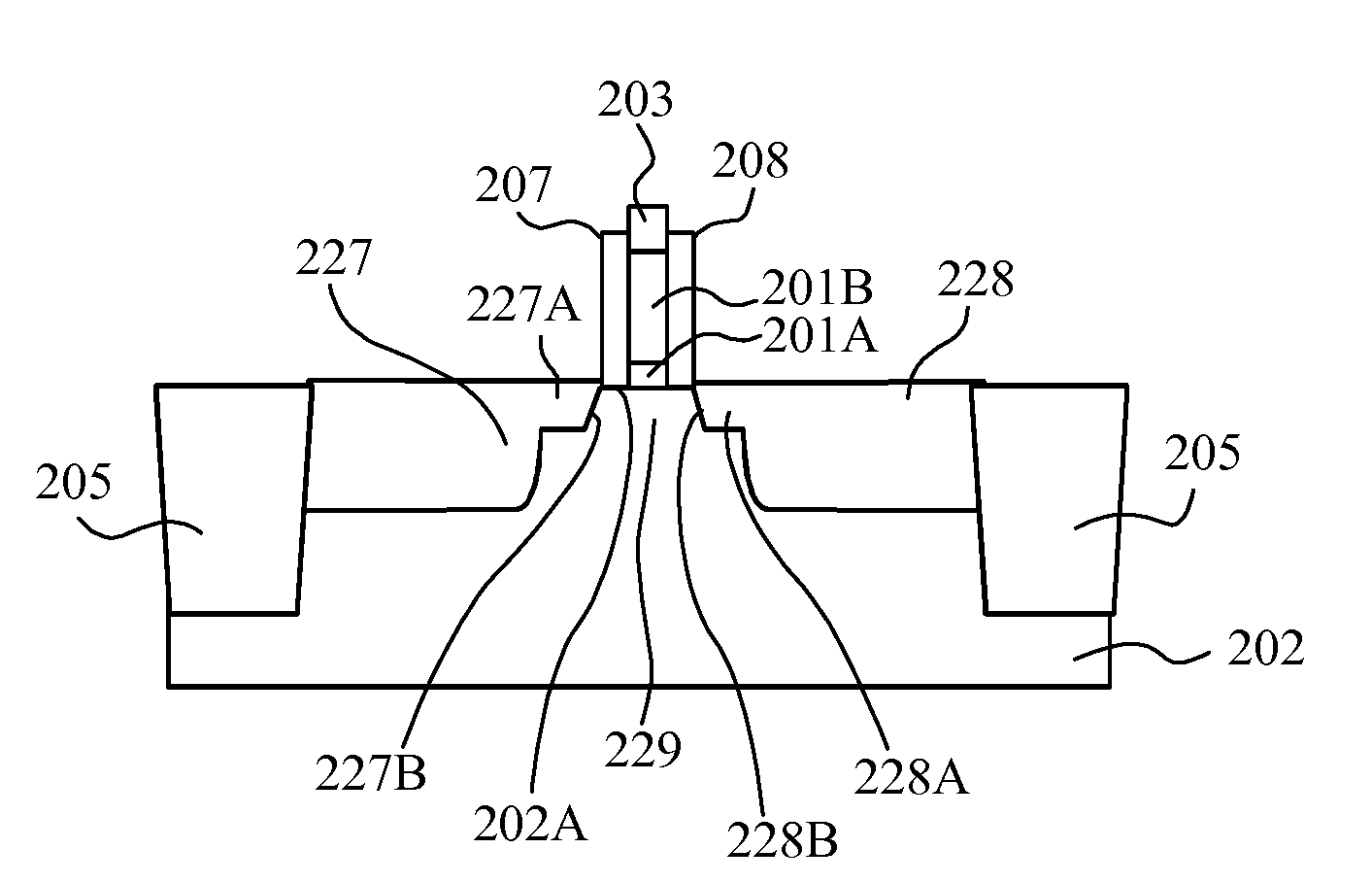

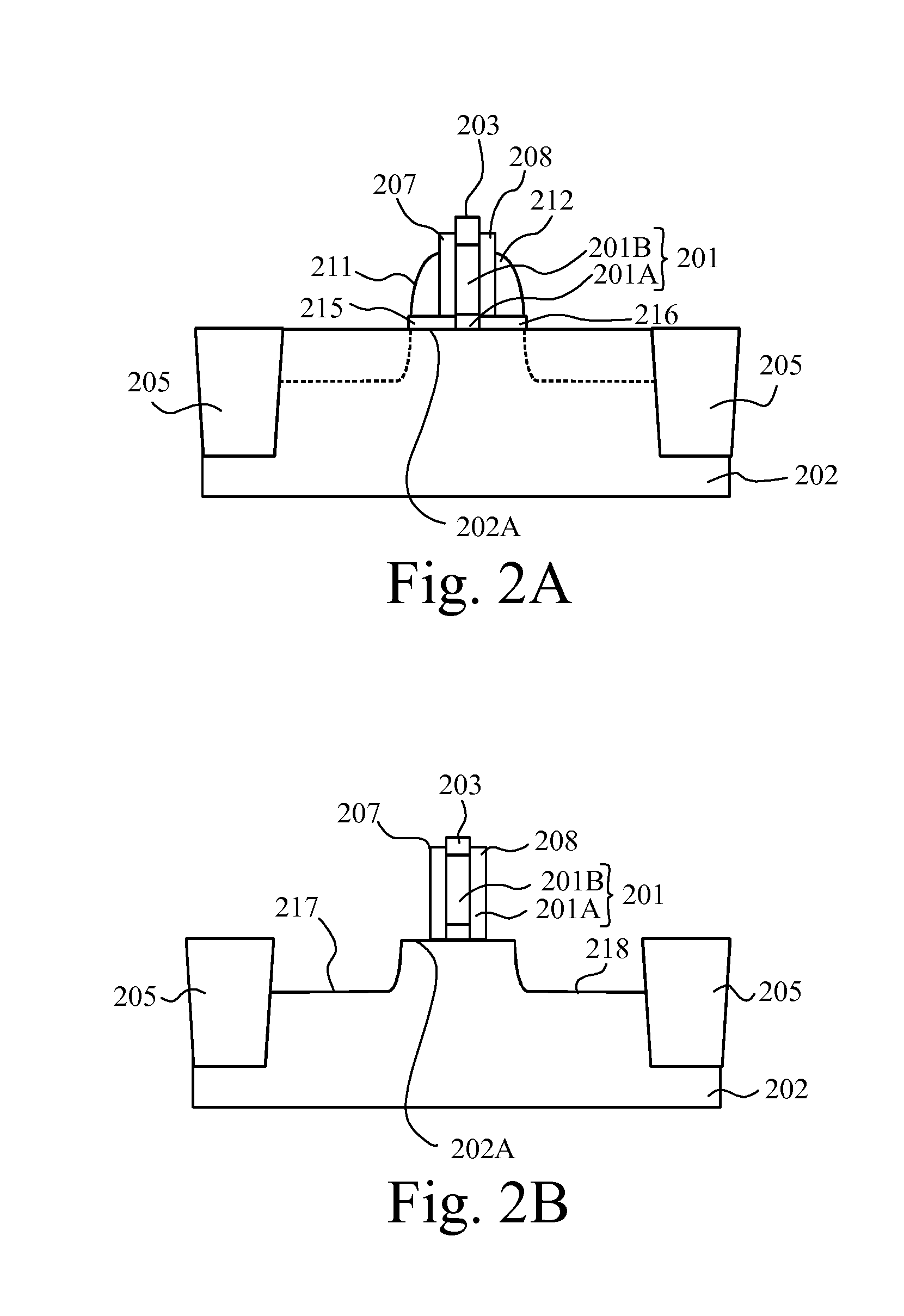

Method of fabricating a transistor structure

ActiveUS7413961B2High levelHigh strain levelTransistorSemiconductor/solid-state device manufacturingCMOSEngineering

The present invention relates to semiconductor integrated circuits. More particularly, but not exclusively, the invention relates to strained channel complimentary metal oxide semiconductor (CMOS) transistor structures and fabrication methods thereof. There is provided a method of forming a strained channel transistor structure on a substrate, comprising the steps of: forming a source stressor recess comprising a deep source recess and a source extension recess; forming a drain stressor recess comprising a deep drain recess and a drain extension recess; and subsequently forming a source stressor in said source stressor recess and a drain stressor in said drain stressor recess. The deep source / drain and source / drain extension stressors are formed by an uninterrupted etch process and an uninterrupted epitaxy process.

Owner:IBM CORP

Method of fabricating a transistor structure

ActiveUS20070269952A1High levelHigh strain levelTransistorSemiconductor/solid-state device manufacturingCMOSEngineering

The present invention relates to semiconductor integrated circuits. More particularly, but not exclusively, the invention relates to strained channel complimentary metal oxide semiconductor (CMOS) transistor structures and fabrication methods thereof. There is provided a method of forming a strained channel transistor structure on a substrate, comprising the steps of: forming a source stressor recess comprising a deep source recess and a source extension recess; forming a drain stressor recess comprising a deep drain recess and a drain extension recess; and subsequently forming a source stressor in said source stressor recess and a drain stressor in said drain stressor recess. The deep source / drain and source / drain extension stressors are formed by an uninterrupted etch process and an uninterrupted epitaxy process.

Owner:IBM CORP

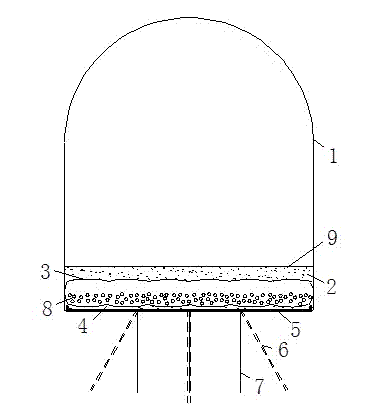

Strong resistance and strong evasion floor heave governing construction method of high-stress large-deformation soft rock drift

InactiveCN103206224AImprove stress distributionHigh pressureUnderground chambersTunnel liningReinforced concreteRebar

The invention discloses a strong resistance and strong evasion floor heave governing construction method of a high-stress large-deformation soft rock drift, belonging to the technical field of coal mine drift support. The strong resistance and strong evasion floor heave governing construction method is designed for solving the problems of large deformation and difficult support of the floor heaves of coal mine soft rock drifts. Certain depth is firstly dug downwards on a drift soleplate from a designed elevation, and then, a high strength deformed steel bar anchor rod, a grouting anchor rod, a steel beam and a concrete layer are used for supporting the drift soleplate to form a strong resistance supporting structure, a layer of aerated rubber air bags containing rubber granules is paved on the strong-resistance supporting structure, the air bags are used as strong evasion devices to release the pressure of the soleplate and buffer the deformation of the floor heave, and finally, a layer of reinforced concrete is poured on the rubber air bags to control the floor heave of the high-stress large-deformation soft rock drift. According to the invention, resistance is combined with evasion, the construction technique is simple, the construction speed is high, the repair rate low, the method is generally suitable for governing the floor heaves of various kinds of coal mine drifts and chambers, and the engineering practicability is strong.

Owner:SHANDONG UNIV OF SCI & TECH

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

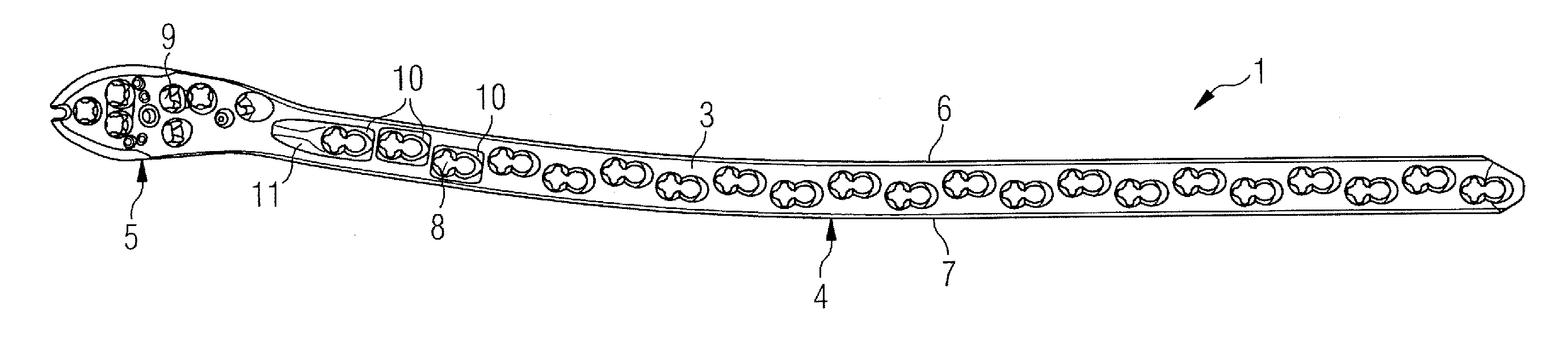

Static magnetic field-laser coaxial composite fusion covering method and device

ActiveCN103741138AWide range of applicationsFlexible regulationMetallic material coating processesSurface shapeElectromagnet

The invention relates to a static magnetic field-laser coaxial composite fusion covering method and a device and belongs to the technical field of laser processing. A static magnetic field is provided by an electromagnet, and the coaxial compositing of the magnetic field and a laser beam is realized through a device. When in magnetic field-laser coaxial fusion covering, the magnetic field generation device moves coaxially and synchronously with the laser beam, the coupling of the magnetic field and a laser-induced molten pool flow field can be completed, the laser fusion covering process is completed through a preset or coaxial powder delivery way, the flowing of the laser-induced molten pool can be inhibited, so that a purpose for controlling the solidification structure, improving the surface shape of the fuse covering layer, optimizing the distribution of the stress and reducing the splashing phenomenon in the fuse covering process can be realized. The coaxial synchronous motion of the magnetic field and the laser can be realized. The static magnetic field-laser coaxial composite fusion covering method and device have the characteristics of good capacity for controlling the fuse covering layer, wide application range, simplicity in structure, convenience in popularization and the like.

Owner:HANGZHOU BOHUA LASER TECH

Bone Plate

ActiveUS20150257802A1Reduce stress peaksImprove stress distributionSurgical instrument detailsBone platesIliac screwBiomedical engineering

A bone plate having a first, bone-facing surface and an opposing second surface has an elongate shaft portion and a head portion that is shorter and wider in comparison thereto, with at least one through hole extending through the bone plate from the first surface to the second surface in the shaft portion. The through hole comprises a variable-angle portion with a hole axis configured to receive a threaded head of a locking screw therein at a desired angle within a permitted range of angulation relative to the hole axis. The second surface has at least one depression which extends therein along a portion of the second surface between the side wall and the through hole, the depression extending about a periphery of the through hole.

Owner:DEPUY SYNTHES PROD INC

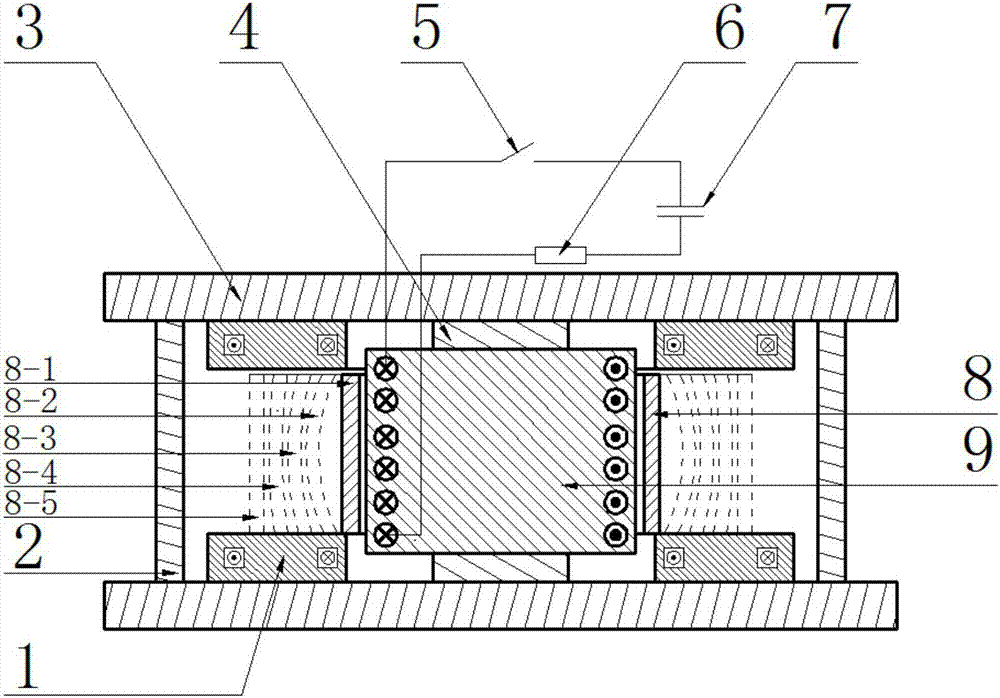

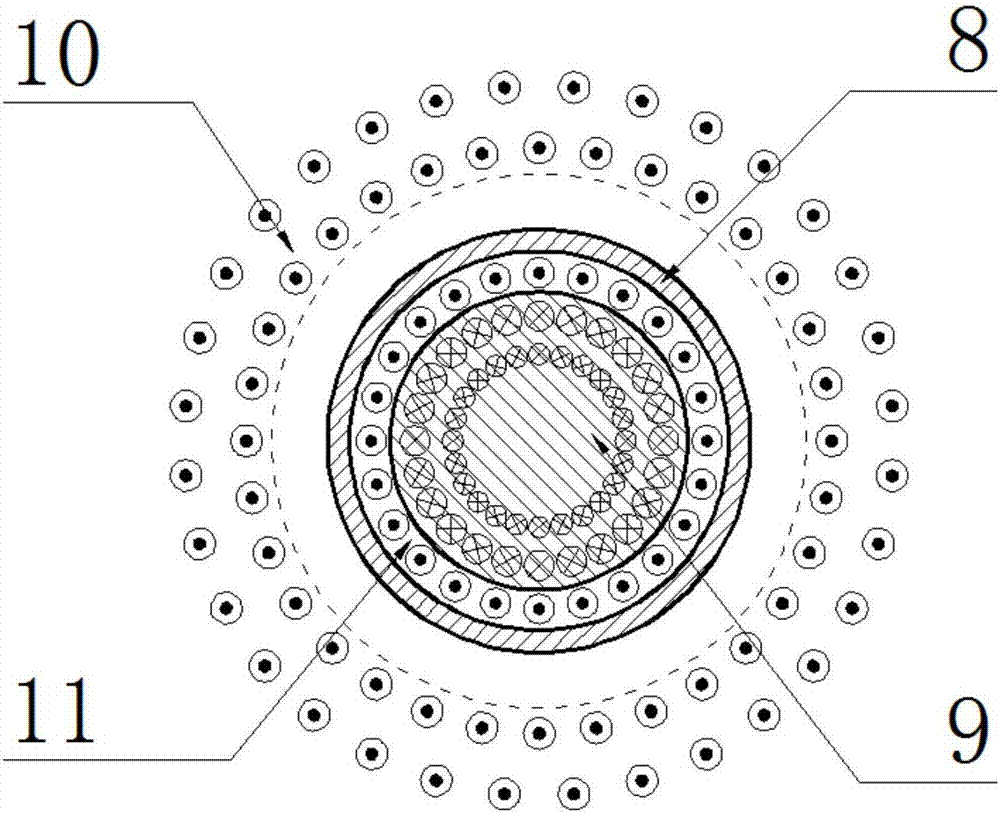

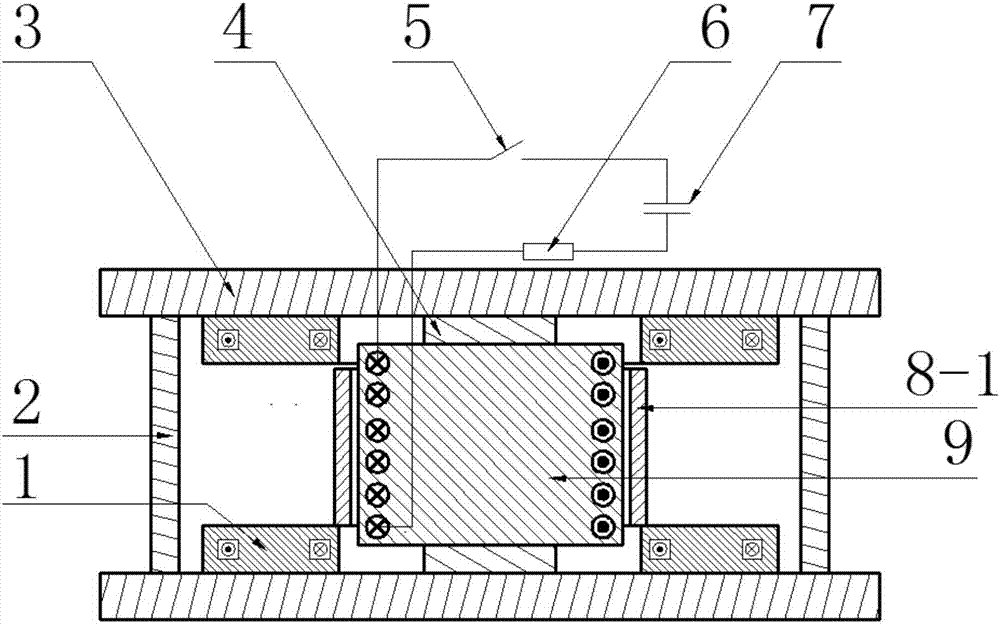

Electromagnetic moldless forming method and device of pipes based on background magnetic field

The invention discloses an electromagnetic moldless forming method and device of pipes based on a background magnetic field. The device comprises a Helmholtz coil system, a support rod, upper and lower support plates, a driving rod, a pulse discharge circuit and a forming coil. The background magnetic field is combined with a pulse magnetic field to realize uniform electromagnetic bulging of the pipes (such as aluminum alloy pipes). The nonuniform flowing of corresponding plastic deformation areas of the pipes deformed at high speed is stopped by a nonuniform resistance field formed by electromagnetic damping in the background magnetic field, so that the pipes generate no local thinning or spalling, and qualified expansion pipe fittings with uniform plastic flowing are obtained. The Helmholtz coil system can accurately control the input energy of the background magnetic field, so that the final forming shapes of the pipes are precisely controlled, such defects as high size fluctuation and weak process repeatability of expansion pieces in a traditional electromagnetic free expansion process are prevented, and the batching, the mechanization and the standardization of the process are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

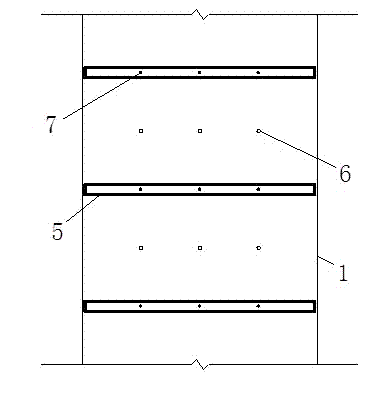

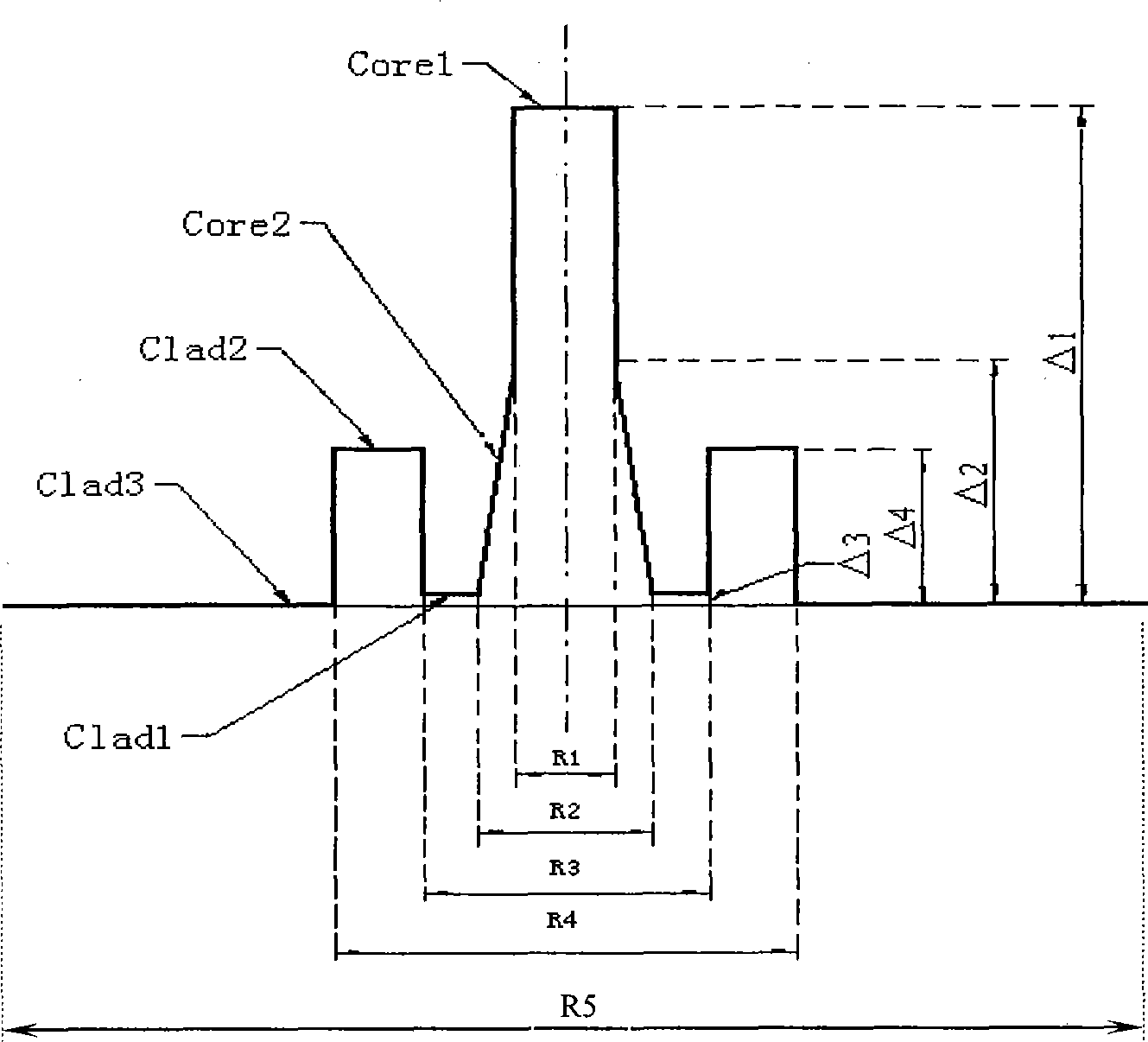

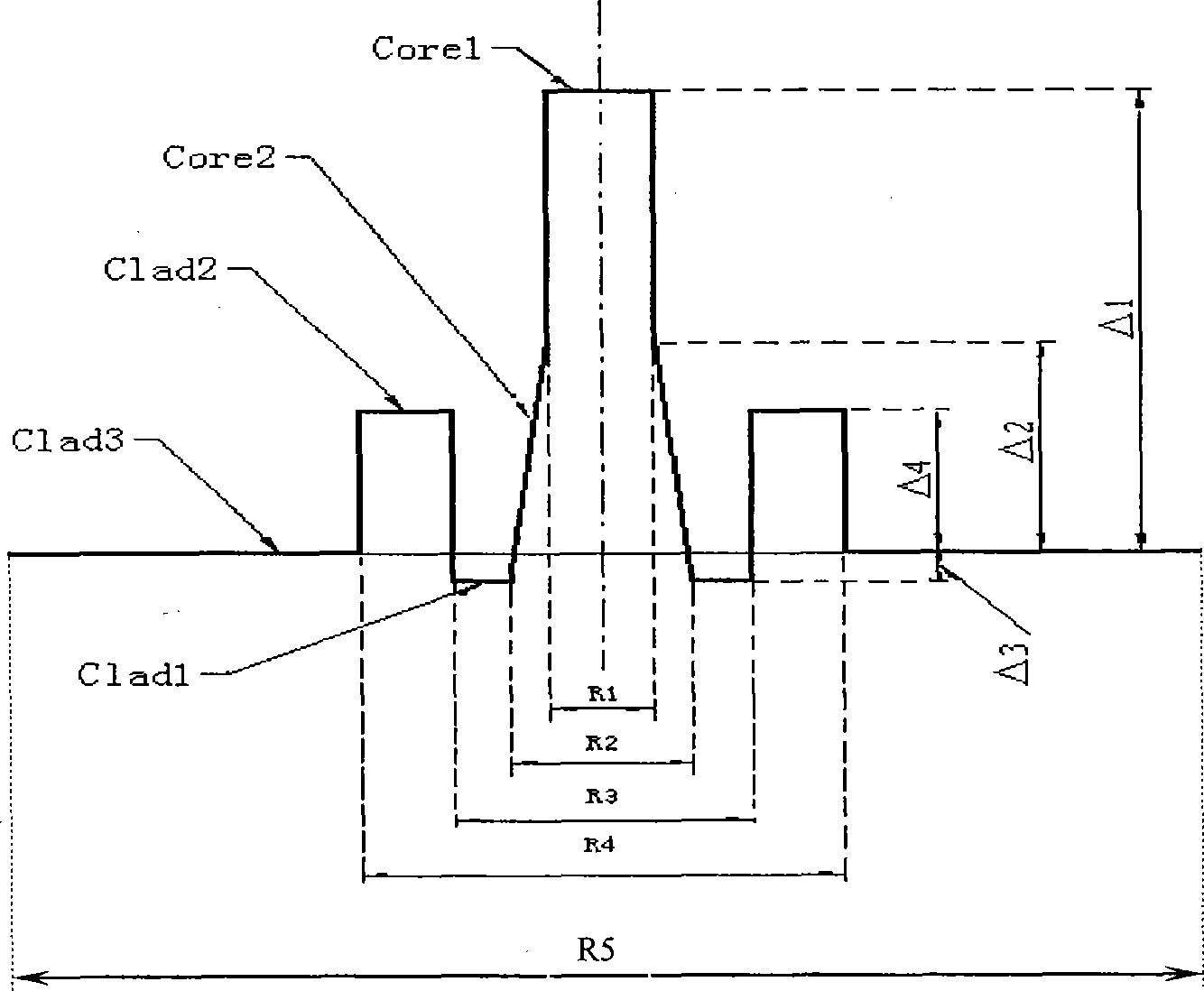

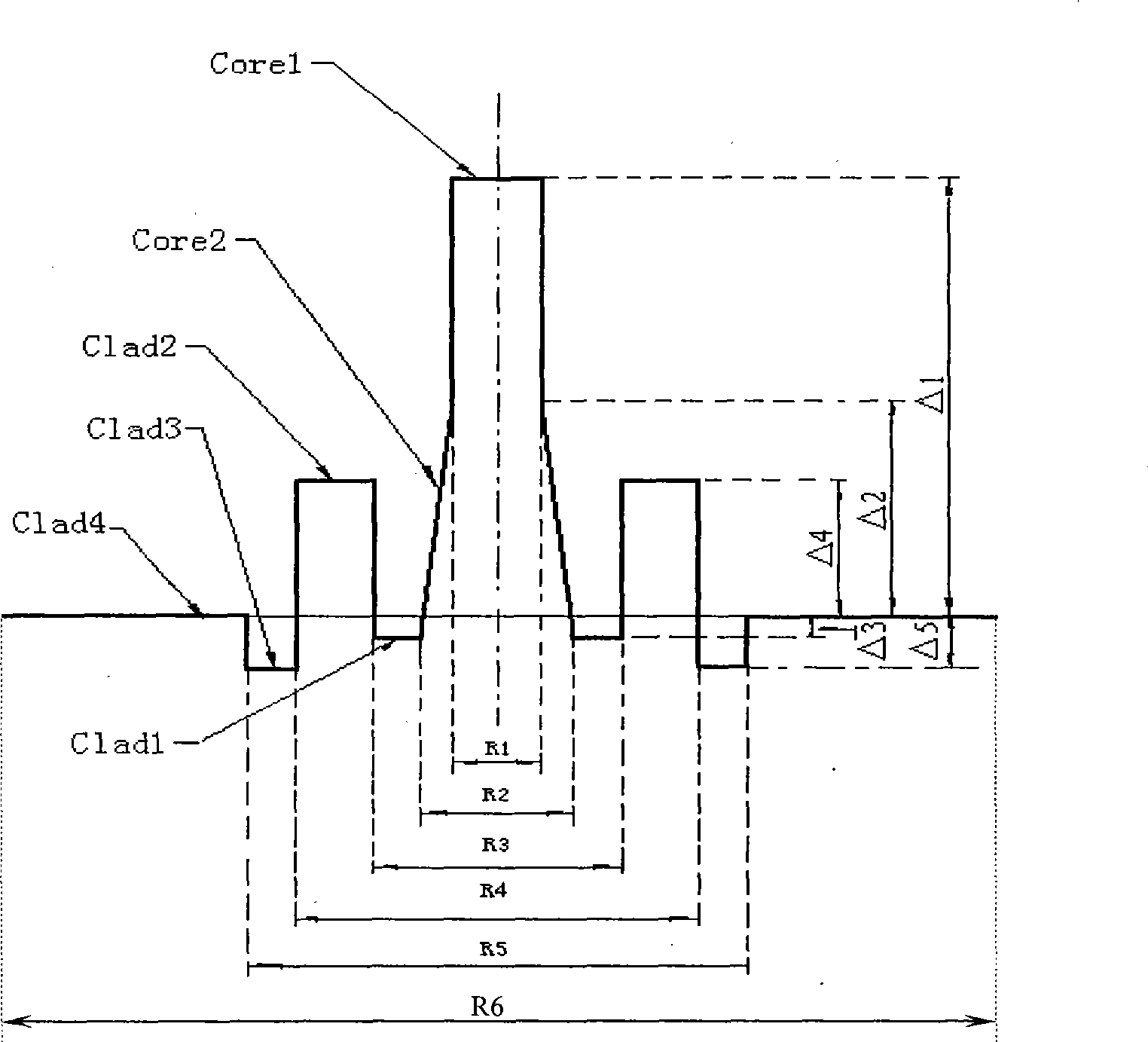

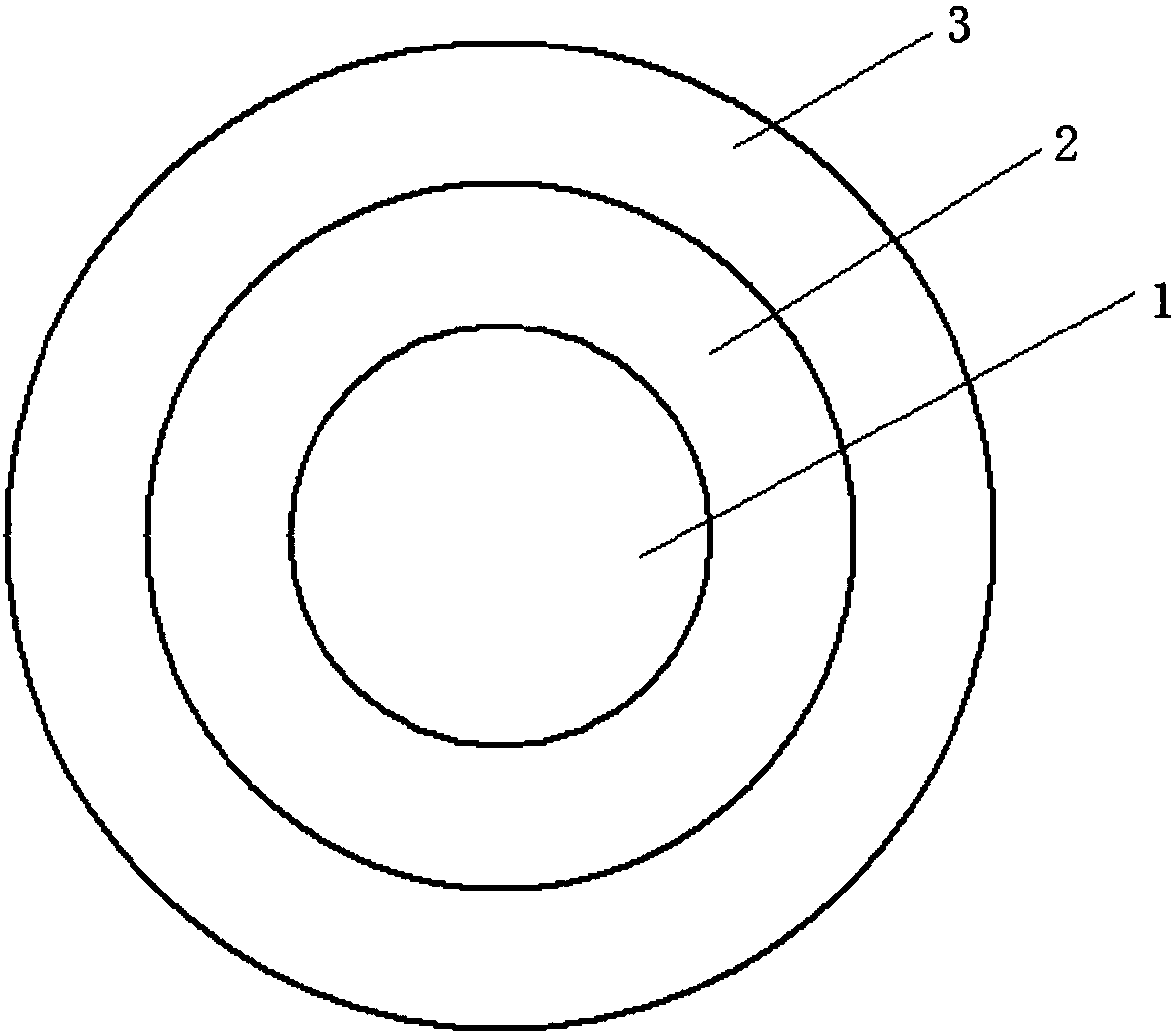

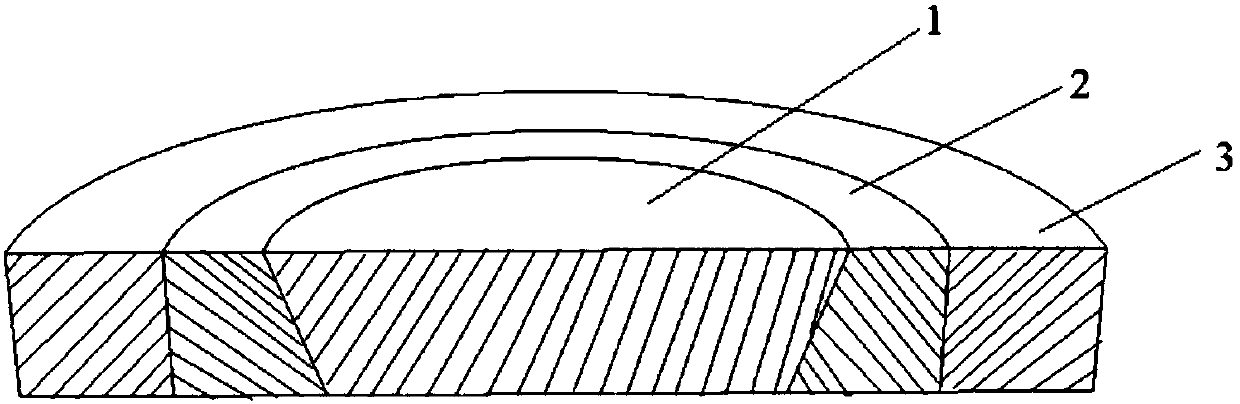

Improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution

ActiveCN101446663ASimple structureEasy to getOptical fibre with multilayer core/claddingOptical waveguide light guideColor effectPolarization mode dispersion

The invention provides an improved nonzero dispersion-shifted single-mode optical fiber with large mode field distribution, comprising an optical fiber core layer, and a cladding covered on the optical fiber core layer; wherein, the optical fiber core layer comprises an internal core layer and an external core layer enclosing the internal core, both of which have different refractive indexes; the refractive index of the external core layer is gradually distributed; the cladding comprises an internal cladding, a ring-core cladding and an external cladding which are sequentially arranged from interior to exterior and have different refractive indexes; the external cladding layer is a pure SiO2 glass layer; the refractive index distribution of the optical fiber core layer meets the formula that n1 is more than n2 which is more than nc; the refractive index distribution of the cladding meets the formula that n4 is more than n3 which is more than nc or n4 is more than nc which is more than n3. The improved nonzero dispersion-shifted single-mode optical fiber has low nonlinear color-effect characteristic (namely large effective area), optimum dispersion and low dispersion efficiency, effectively solves the nonlinearity problem and polarization mode dispersion problem of high-speed communication, reduces the dispersion management cost and has low fusing loss, thus being applicable to large-capacity high-speed long-distance transmission system.

Owner:HANGZHOU FUTONG COMM TECH CO LTD +1

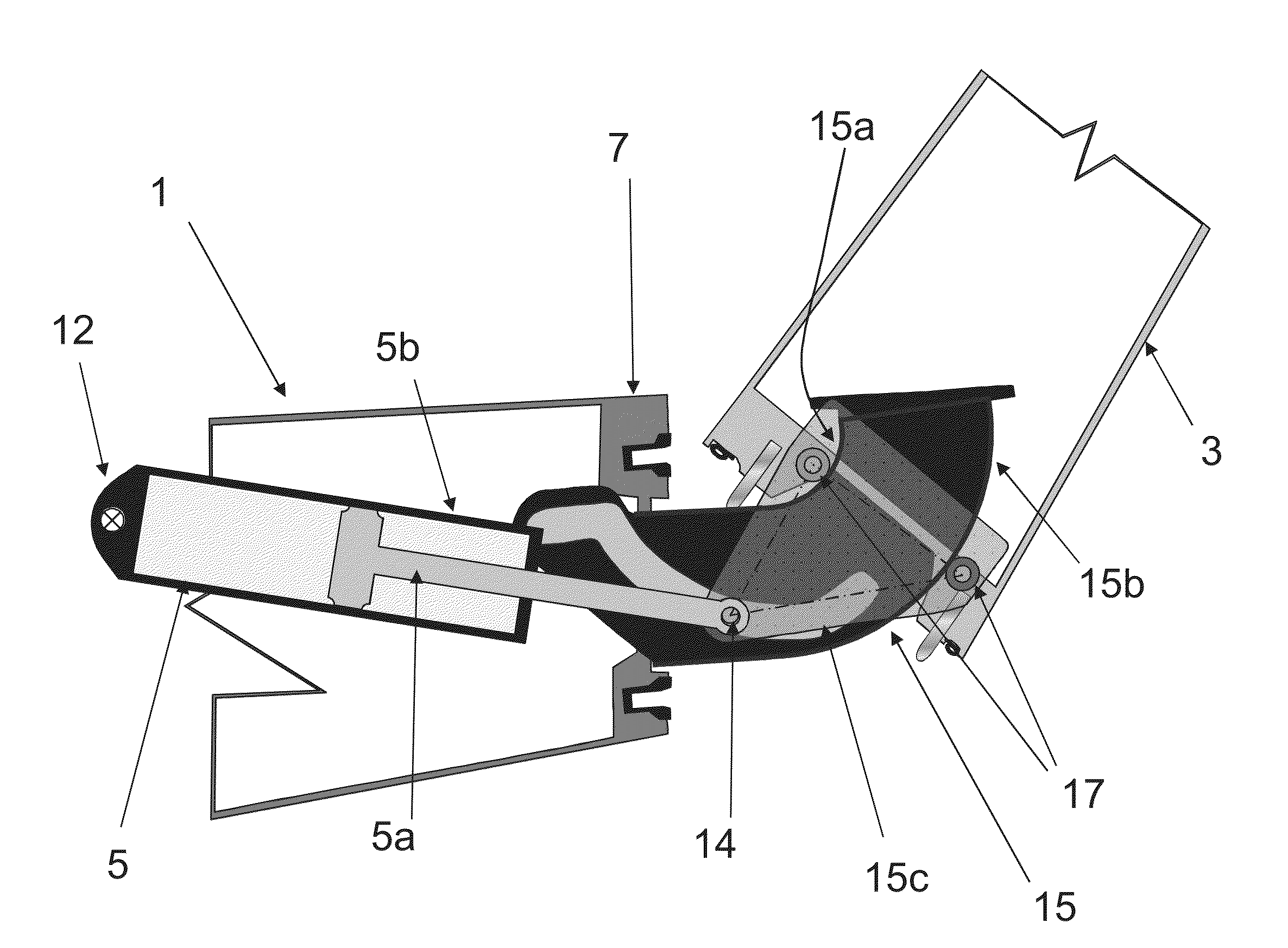

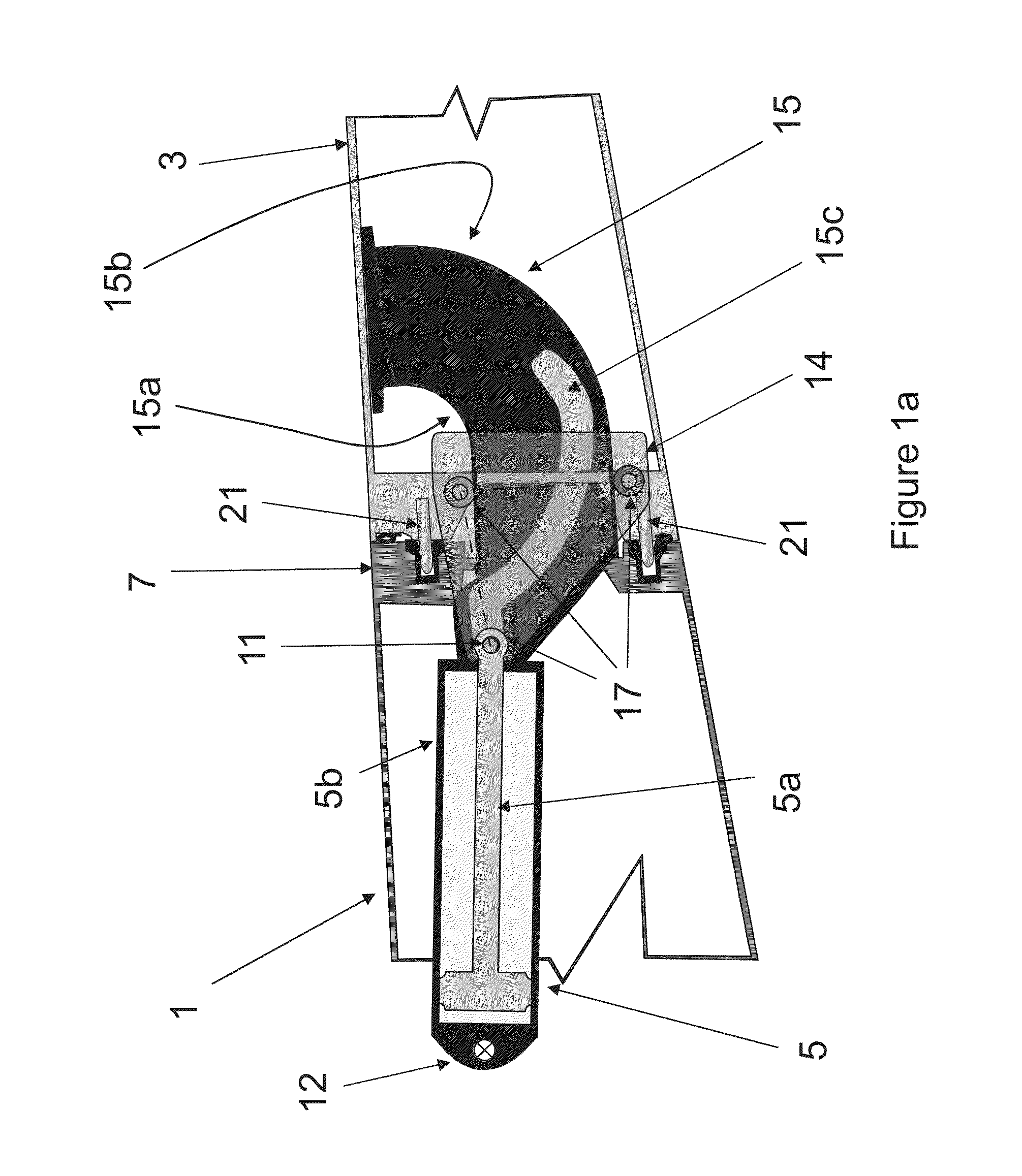

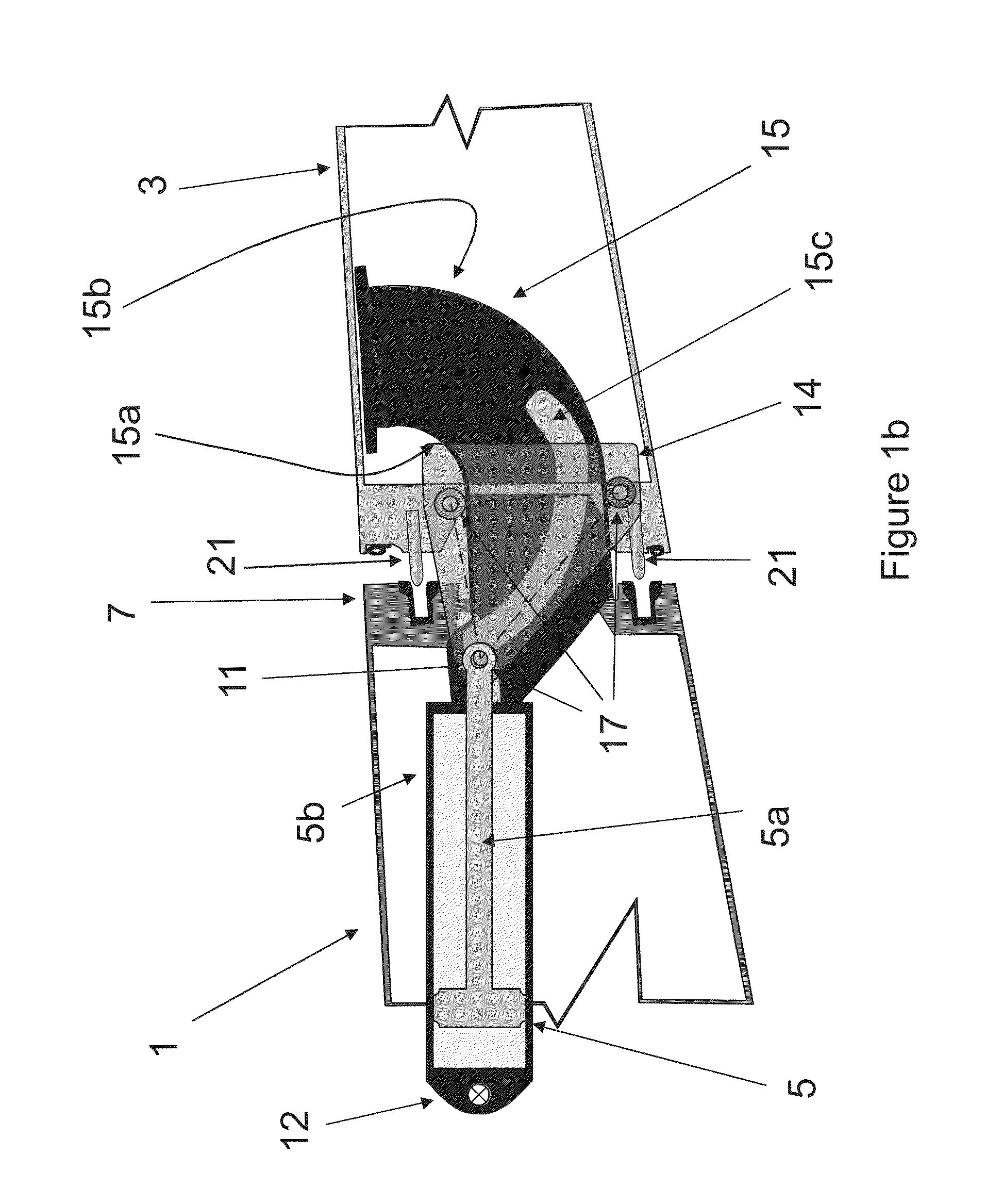

Arrangement for moving a wing tip device between a flight configuration and a ground configuration

InactiveUS20160251075A1Reduce spanEasy and convenientInfluencers by generating vorticesWing adjustmentsFlight vehicleWing configuration

An aircraft comprises a wing, a wing tip device at the tip of the wing and an actuator. The actuator is arranged to effect movement of the wing tip device between a flight configuration for use during flight and a ground configuration in which the wing tip device is moved away from the flight configuration such that the span of the aircraft is reduced. The aircraft comprises a carriage guide, such as a rail, fixed relative to the wing, and a carriage arranged to move along the carriage guide as the wing tip device moves between the flight and ground configurations. The wing tip device is fixed relative to the carriage such that the path of the wing tip device, during movement of the wing tip device, between the flight and the ground configurations, is defined by the shape of the carriage guide.

Owner:AIRBUS OPERATIONS LTD

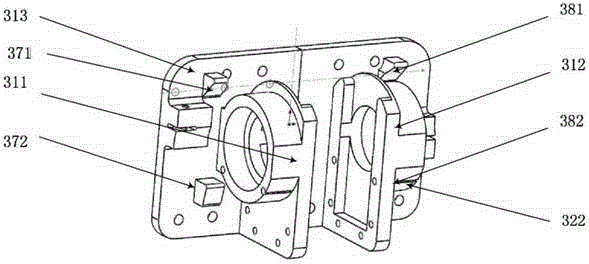

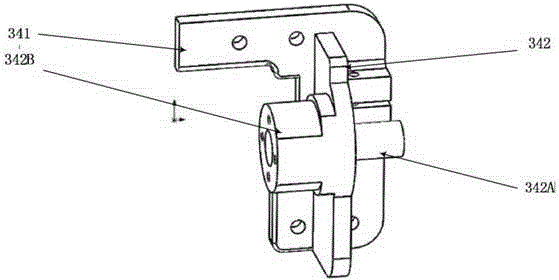

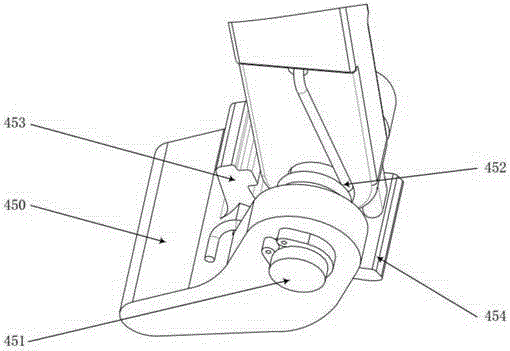

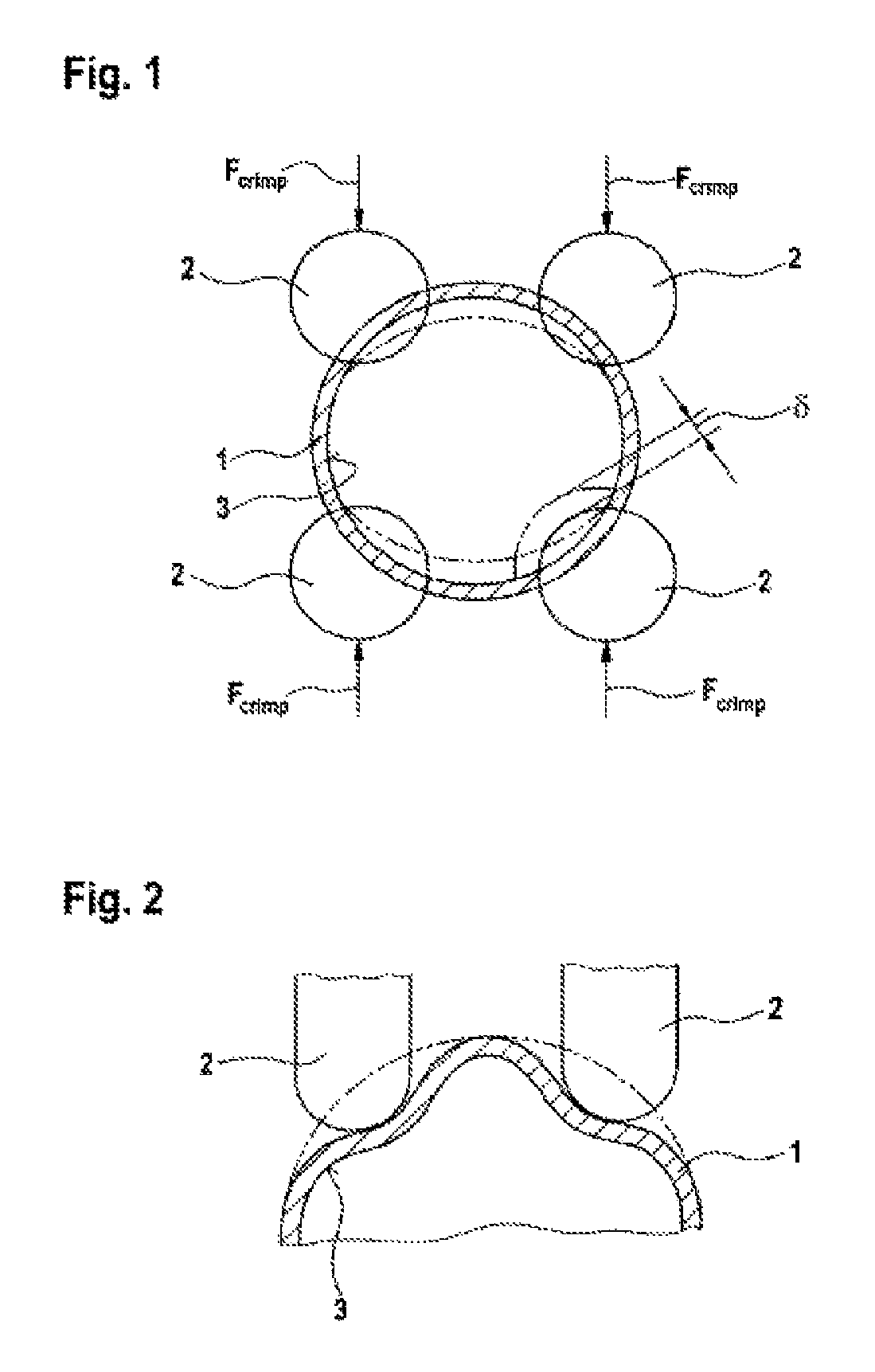

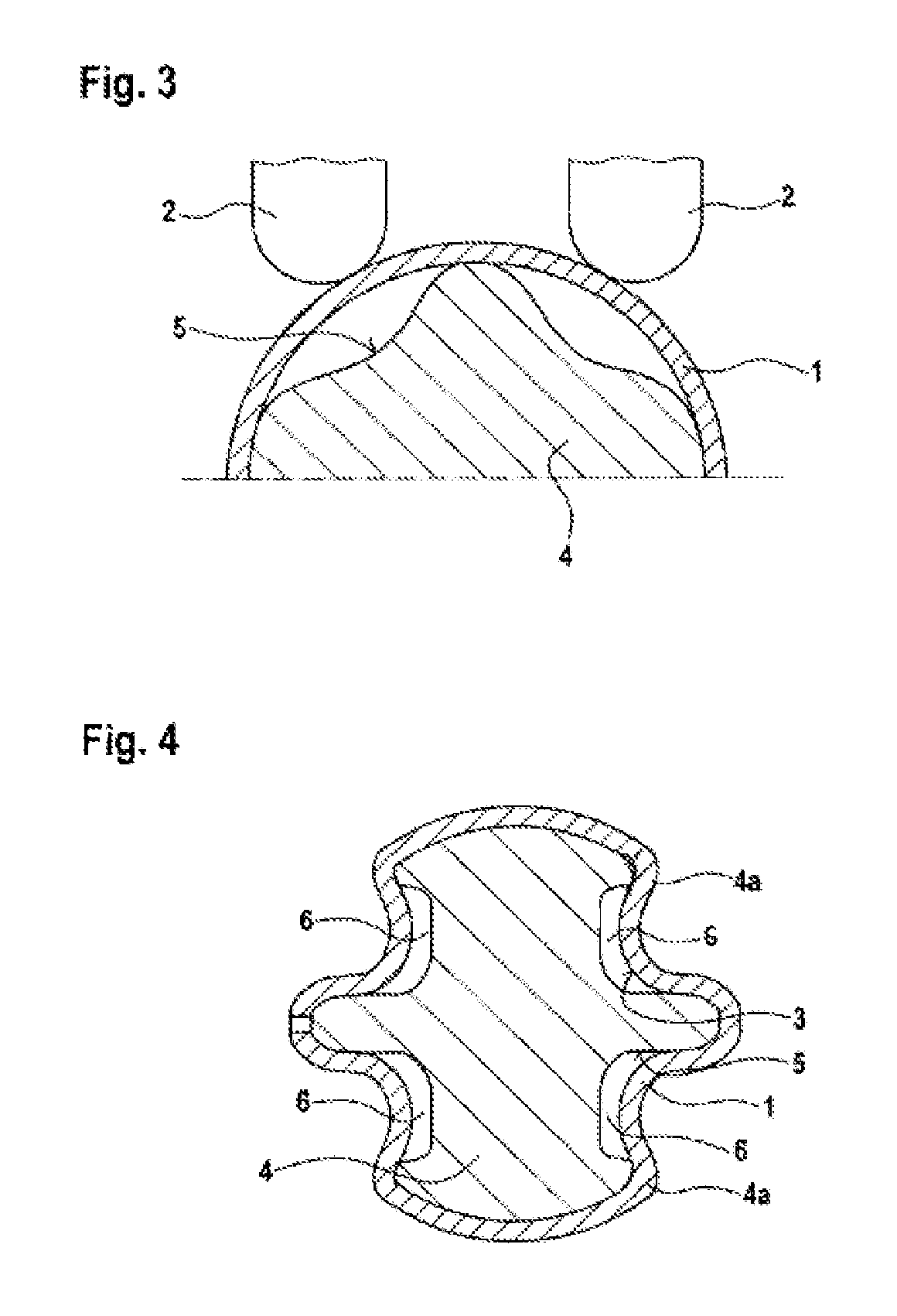

Windshield wiper apparatus

ActiveUS8863370B2Increase tolerance zoneGood dimensional stabilityRopes and cables for vehicles/pulleyMeasurement/indication equipmentsElectric machineryWindshield

The invention relates to a windscreen wiper apparatus for a motor vehicle, having a wiper motor and having at least one wiper bearing in which a wiper shaft is mounted, it being possible to drive said wiper shaft by means of the wiper motor in order to operate a wiper arm which is connected to the wiper shaft, wherein the wiper bearing has a bearing pin (4) for holding a tubular support (1), it being possible for said bearing pin to be fixed to the tubular support (1) by means of a crimp, characterized in that the bearing pin (4) has an outer contour (5) which is already formed, at least in a region of overlap with the crimp, so as to correspond to an inner contour (3) of the crimped tubular support (1), before the crimp is introduced, and also to a method for producing said windscreen wiper apparatus.

Owner:ROBERT BOSCH GMBH

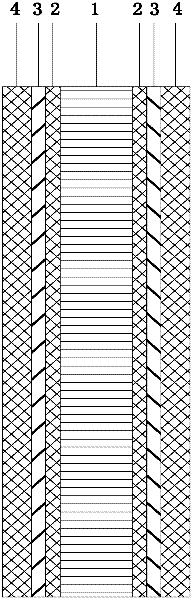

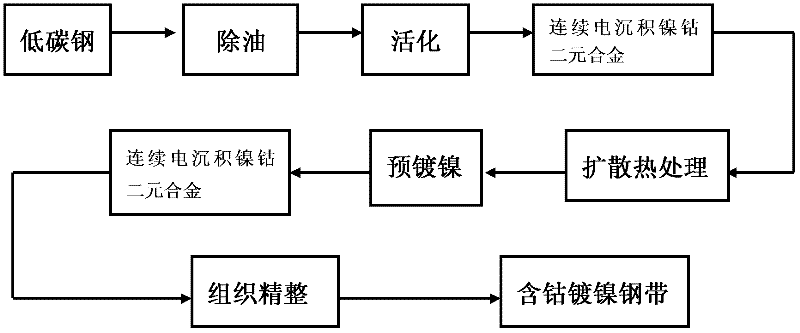

Cobalt-containing nickel plated steel strip serving as lithium battery shell material and preparation method thereof

InactiveCN102230200AImprove performanceTimely supplementCell component detailsElectrical batteryNitrogen

The invention discloses a cobalt-containing nickel plated steel strip serving as a lithium battery shell material and a preparation method thereof. The preparation method comprises the following procedures of: (1) pretreating a base material; (2) continuously electrodepositing a nickel-cobalt alloy plating layer on the pre-treated base material; (3) carrying out diffusion annealing treatment on the nickel-cobalt alloy plating layer under a protective atmosphere like high-purity nitrogen; (4) plating a nickel-cobalt alloy plating layer on the metal subjected to the diffusion annealing treatment again; and (5) rolling the plated nickel-cobalt alloy plating layer in a cold manner. The cobalt containing nickel plated steel strip disclosed by the invention is prepared by a special process of tightly combining the nickel-cobalt alloy plating layer and a low-carbon steel strip and then electroplating the nickel-cobalt alloy plating layer and the low-carbon steel strip, shows better corrosion resistance and can be used for shell materials of primary batteries, secondary batteries and lithium ion power cells such as 18650, 26650 and the like.

Owner:XIANGTAN UNIV

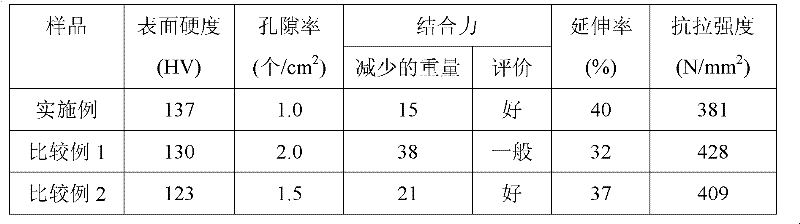

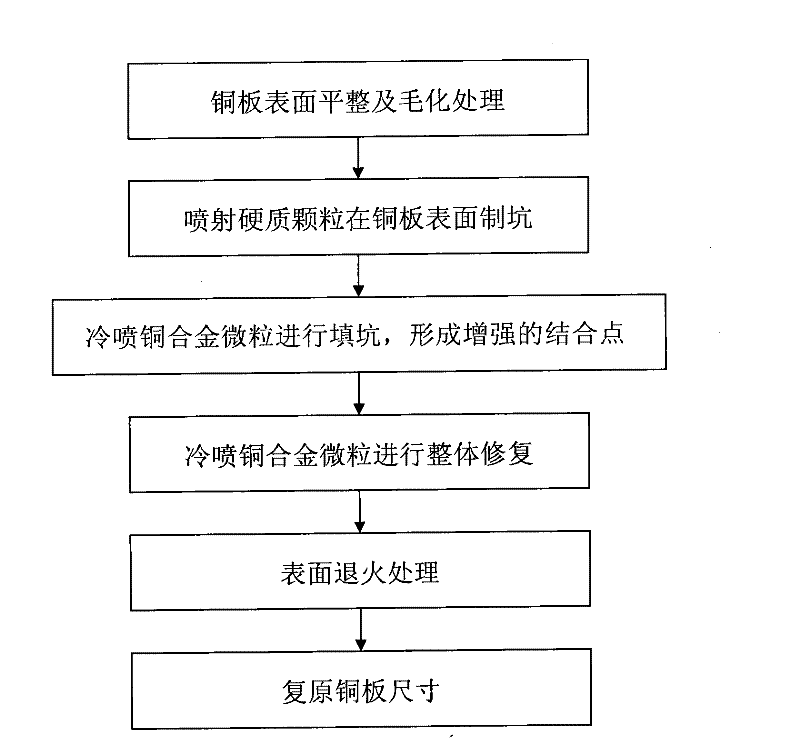

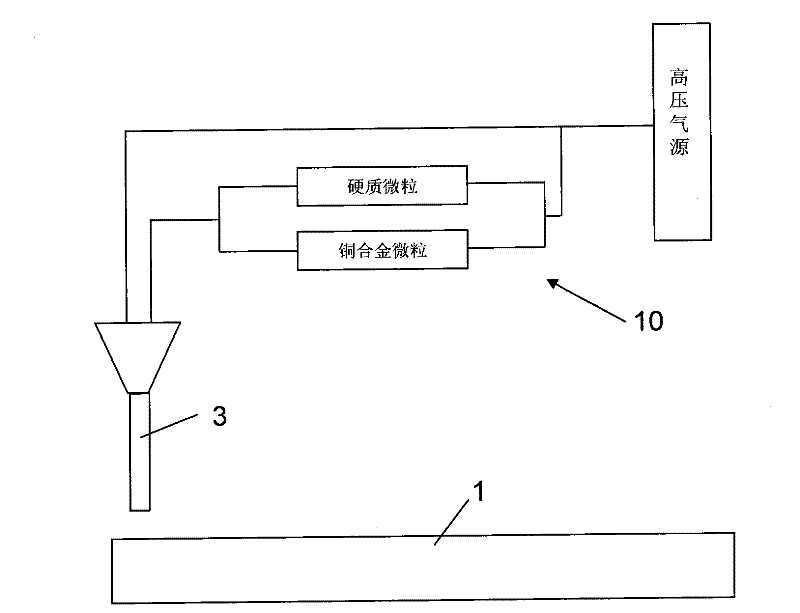

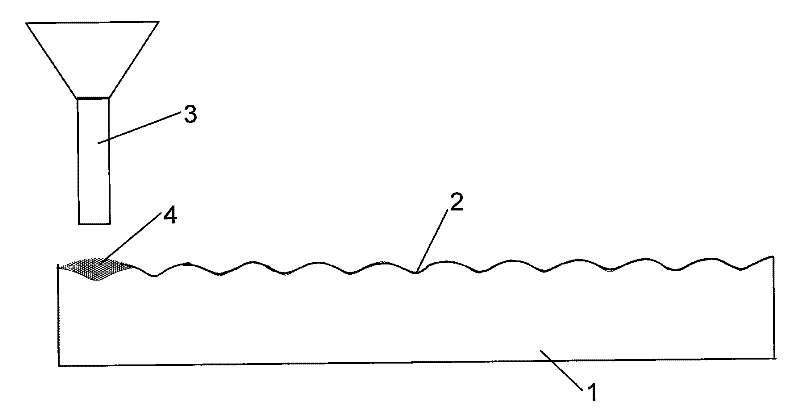

Cold spray repairing method for crystallizer copper plate

The invention discloses a cold spray repairing method for a crystallizer copper plate. The method mainly comprises the following steps: preparing textured appearance with natural streamline pits on the surface of a copper plate to be repaired by using supersonic hard particles so as to remarkably increase the surface area of the surface to be repaired of the crystallizer on the premise that the surface meets the cold spray repairing requirements; then filling the textured pits by using the cold air-powered spraying technology to form multiple reinforcing points with an increased combined areaand improving the stress distribution of an interface at the same time; and finally performing integral spray repairing on the surface of the copper plate, and performing annealing and size recovery.The method can increase the combined area and combination strength of the spray repairing layer and the copper plate surface, improve the heat conduction rate and alternating heat stress resistance of the copper plate repairing layer, thereby prolonging the service cycle of the copper plate.

Owner:BAOSHAN IRON & STEEL CO LTD

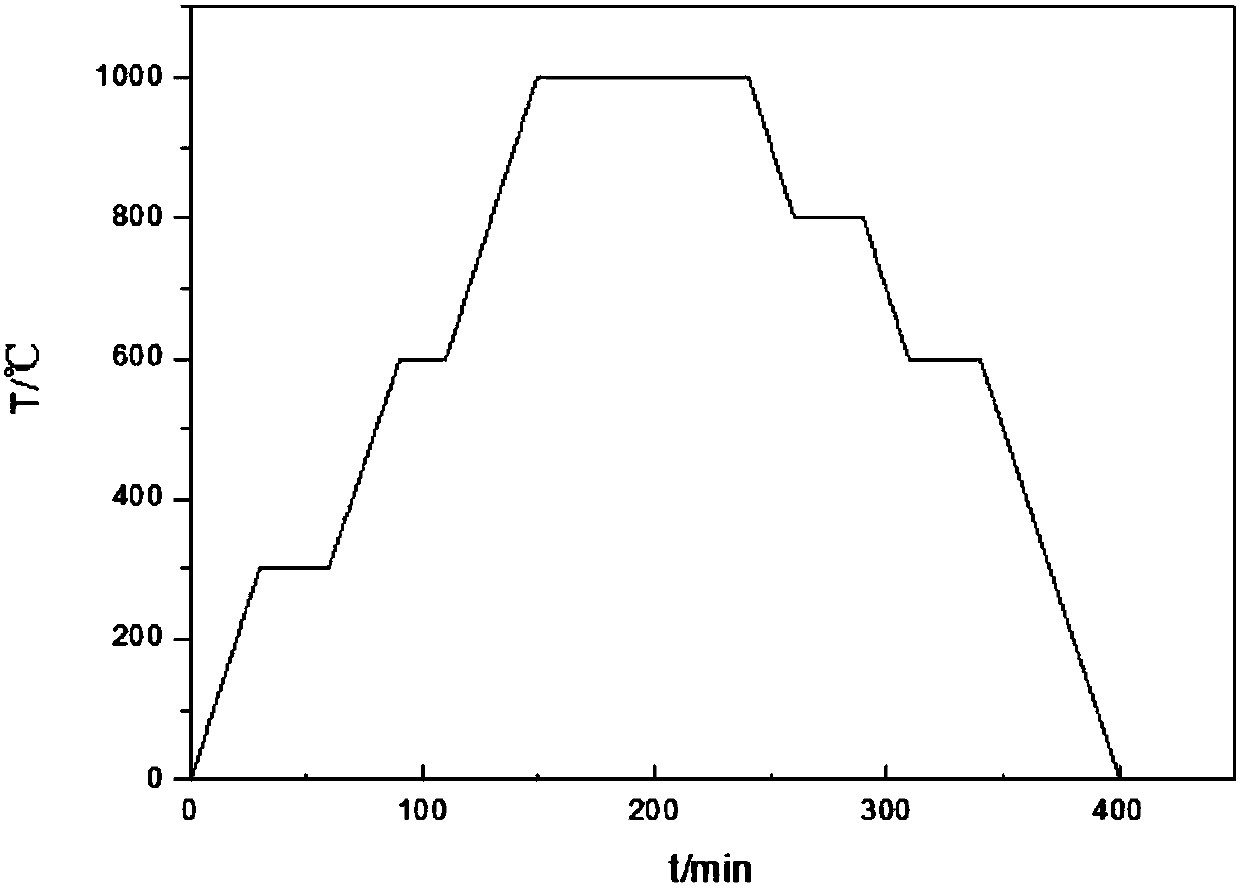

Diffusion connection method for high-temperature TiAl alloy annular piece and Ti2AlNb alloy annular piece

ActiveCN107745178AFirmly connectedControl distributionNon-electric welding apparatusPressure differenceIntermetallic

Disclosed is a diffusion connection method for a high-temperature TiAl alloy annular piece and a Ti2AlNb alloy annular piece. Pressure stress is provided through the expansion pressure difference of aclamp material and to-be-connected materials, and diffusion connection begins in the stepped temperature increasing process. Because the diffusion coefficient of a high-temperature TiAl disc edge islarger than the diffusion coefficient of a Ti2AlNb disc core, certain connecting pressure exists on a connecting interface in the stepped temperature decreasing process, and diffusion connection stillcontinues. In the process that the temperature is decreased to 800 DEG C, the connecting pressure existing in the heat preservation process is reduced gradually, and heat preservation treatment is conducted at the moment so that the excellent performance of a connector can be obtained easily. In the process that the temperature is decreased to the indoor temperature from 800 DEG C, the connectingpressure is increased gradually, heat preservation treatment is conducted at the temperature of 600 DEG C, and thus the excessively-large residual stress of the connector is avoided. Diffusion connection technical parameters are controlled simultaneously through a clamp, reliable connection of the dissimilar intermetallic compound annular pieces is achieved, and research and manufacturing foundations are provided for other complicated alloy annular pieces.

Owner:重庆两航金属材料有限公司

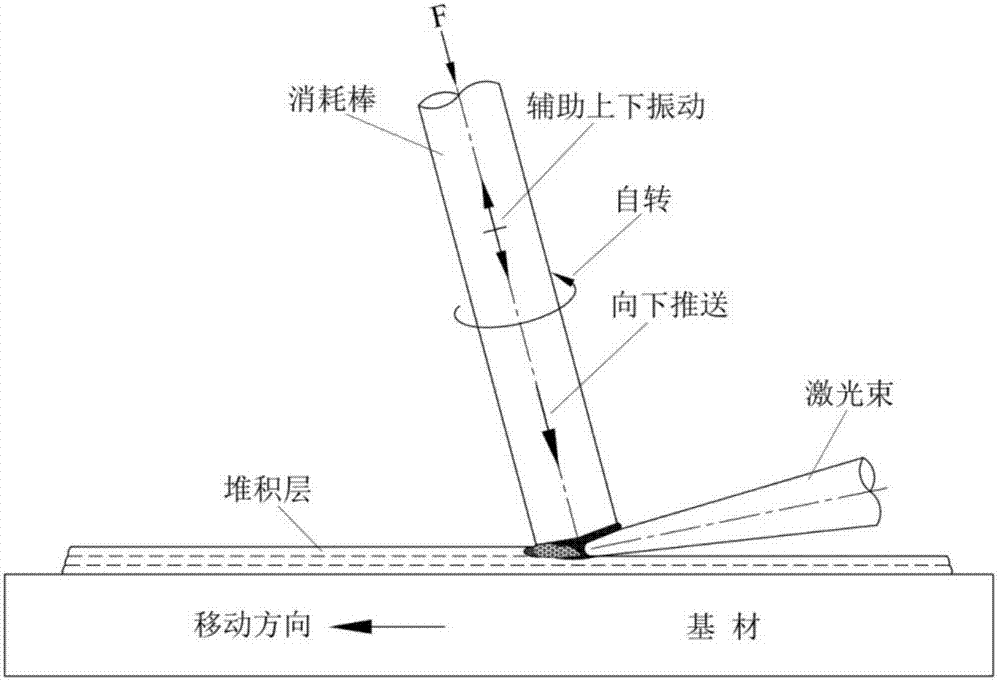

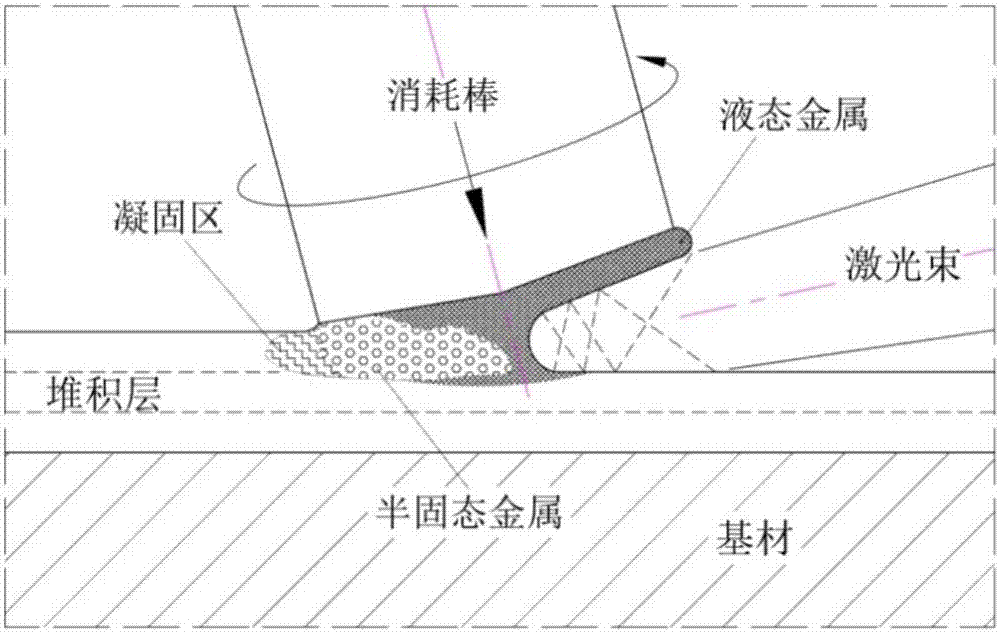

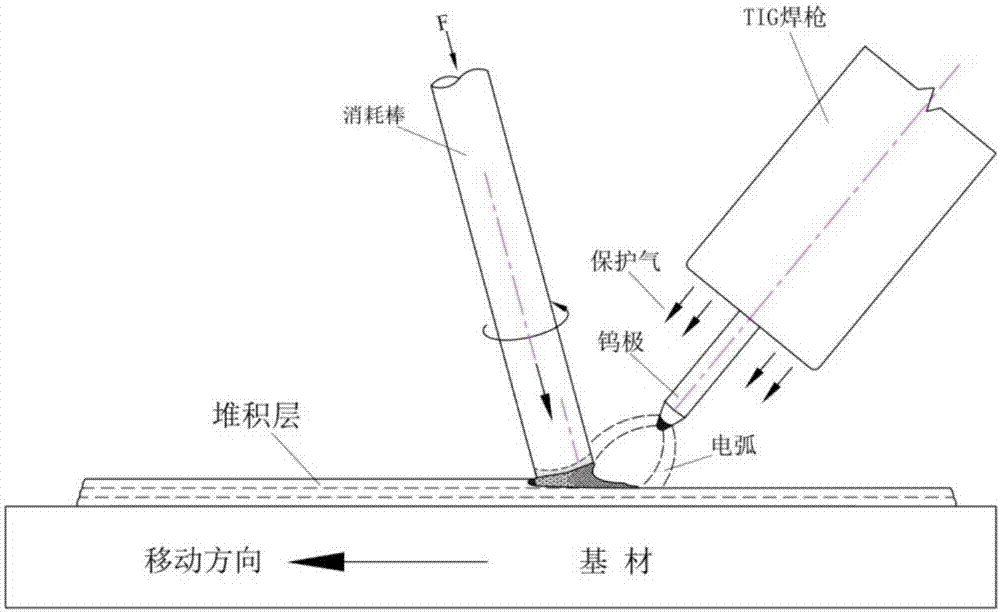

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

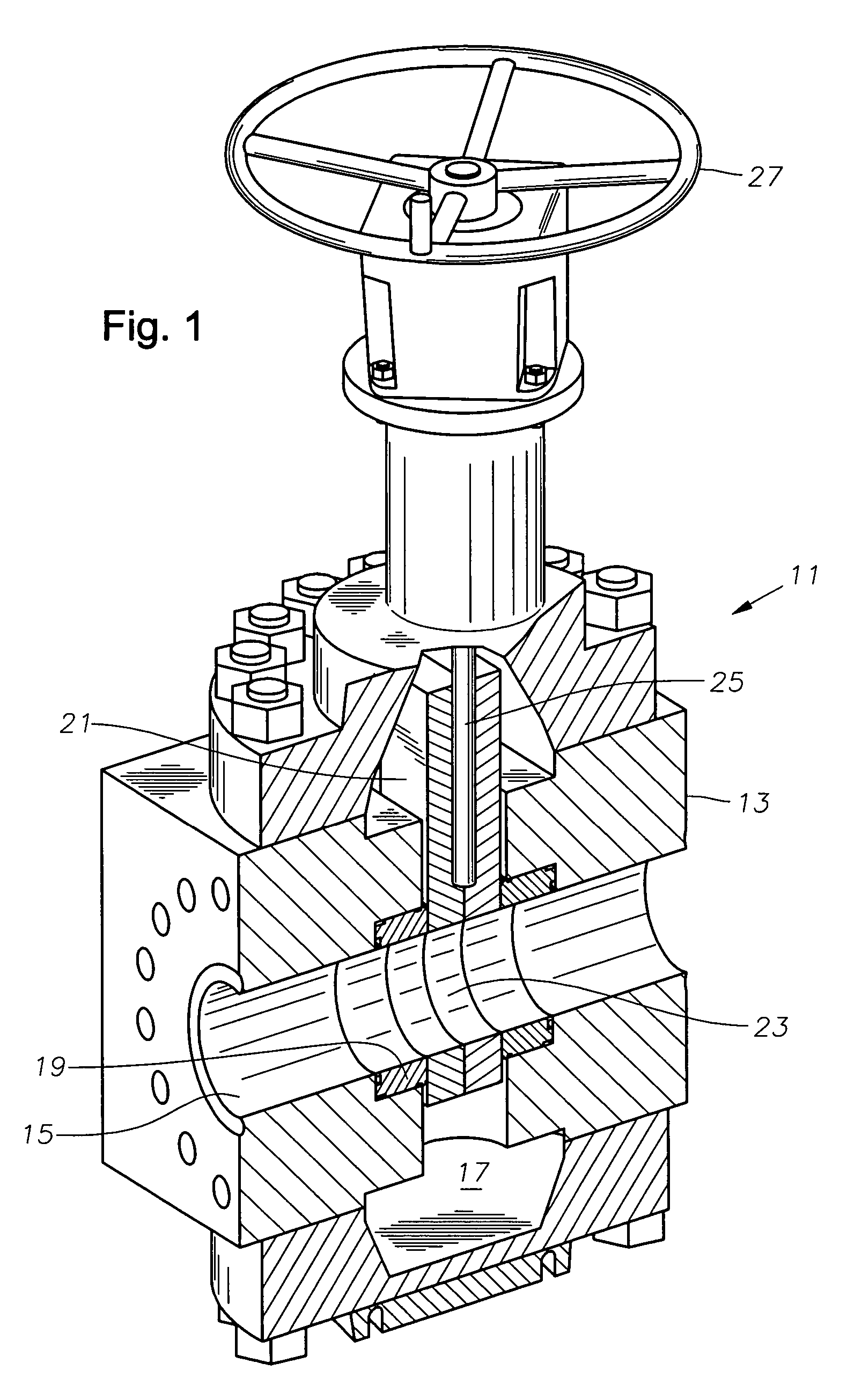

Valve seat edge relief profile

ActiveUS7325783B2Improve stress distributionReduce axial stiffnessPlug valvesCheck valvesStress reliefEngineering

A valve seat has an outer surface, a rearward end, a face and a forward end. A passage extends from the rearward end to the face. A valve element slidingly contacts the face. Stress relief flanges are located on the face in areas of high bearing stress. Each flange has a thickness that allows it to deflect slightly to reduce bearing stresses.

Owner:VETCO GRAY LLC

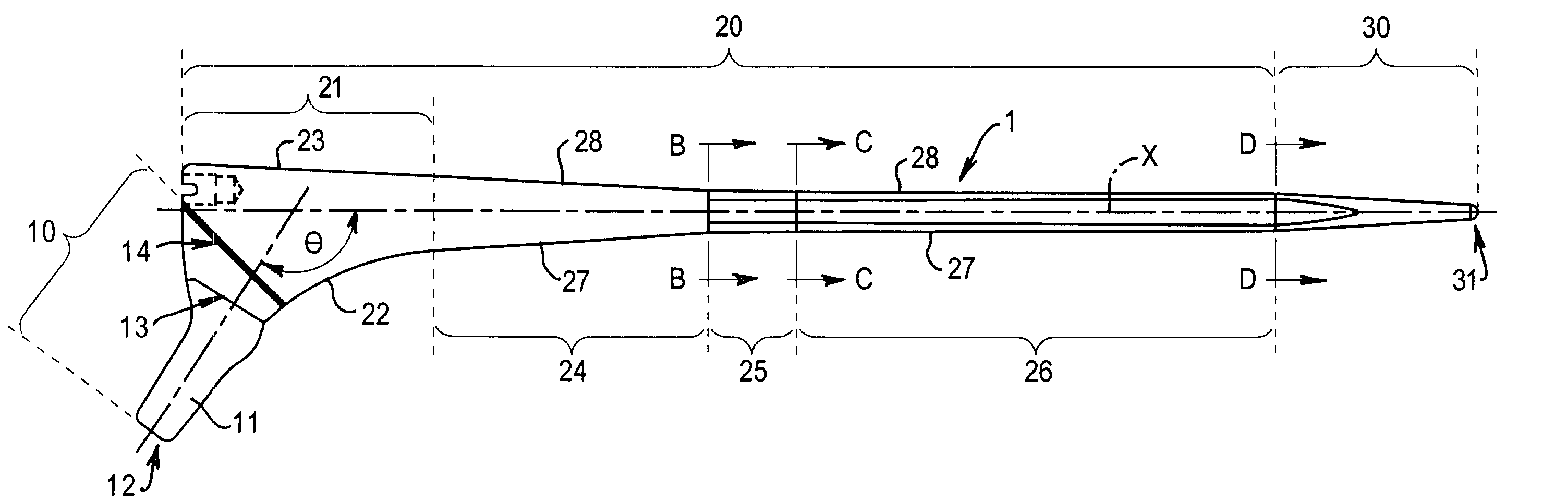

Prosthetic implant

InactiveUS6994731B2Improve stress distributionEnhance the fit of the implant within the boneBone implantJoint implantsSurgeryProximal neck

A highly polished femoral implant (1) has a proximal neck portion (10), a distal tip portion (30), and an elongate stem portion (20) that extends from the neck portion to the tip portion. The stem portion (20) has a proximal or metaphyseal end region (21) which adjoins the neck portion (10), the proximal / metaphyseal end region (21) having a profile in the medio-lateral plane defined by a curved or angled medial outer contour and a curved or straight lateral outer contour. The stem portion (20) of the implant has a first part (24) adjacent said send region (21) having a profile in the medio-lateral plane which tapers distally at a first angle of taper to a region intermediate the length of the stem portion, and a second part (25,26) distal of the first part (24) having a profile in the medio-lateral plan which tapers distally at a second angle of taper from the region intermediate the length of the stem portion.

Owner:HOWIE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com