Patents

Literature

798 results about "Magnesium Aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About Magnesium Aluminate. Magnesium Aluminate is a matrix material for high strength ceramics and in hardened glass, such as bulletproof glass. Aluminates are compounds with a negatively-charged alumina ion and a metallic oxide with various industrial applications such as water treatment and ceramics manufacturing.

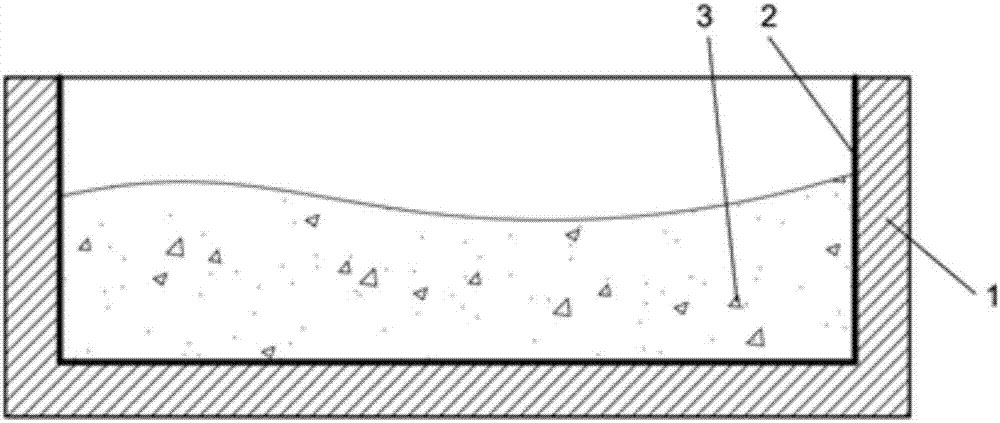

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

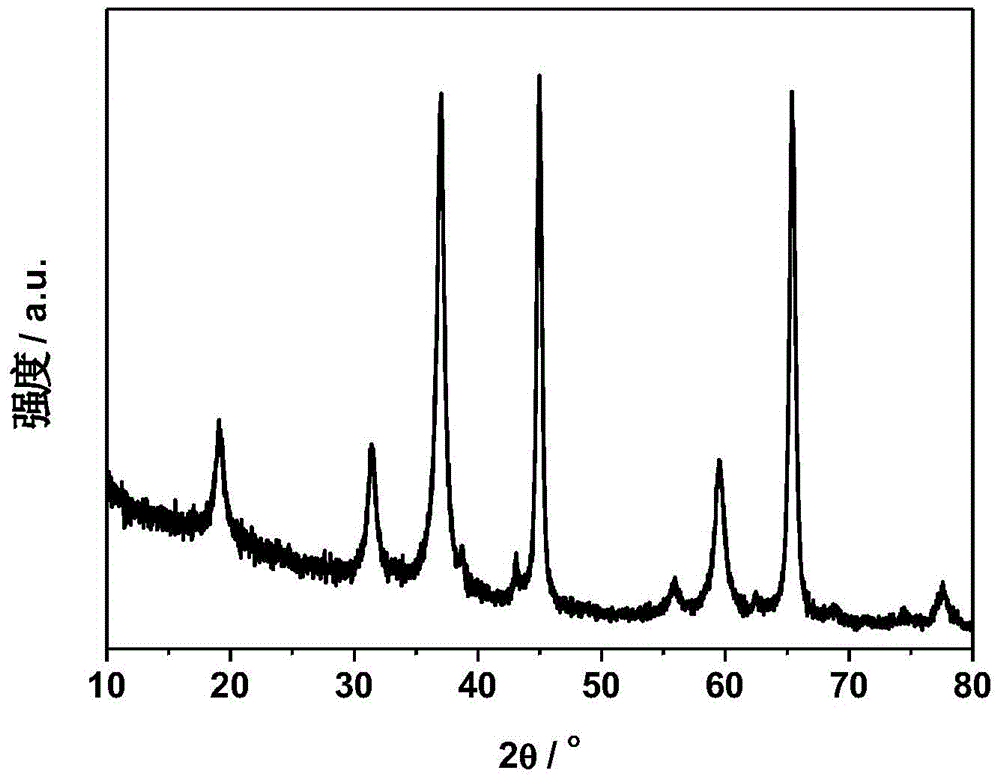

Method for preparing superfine mesoporous magnesium aluminate spinel

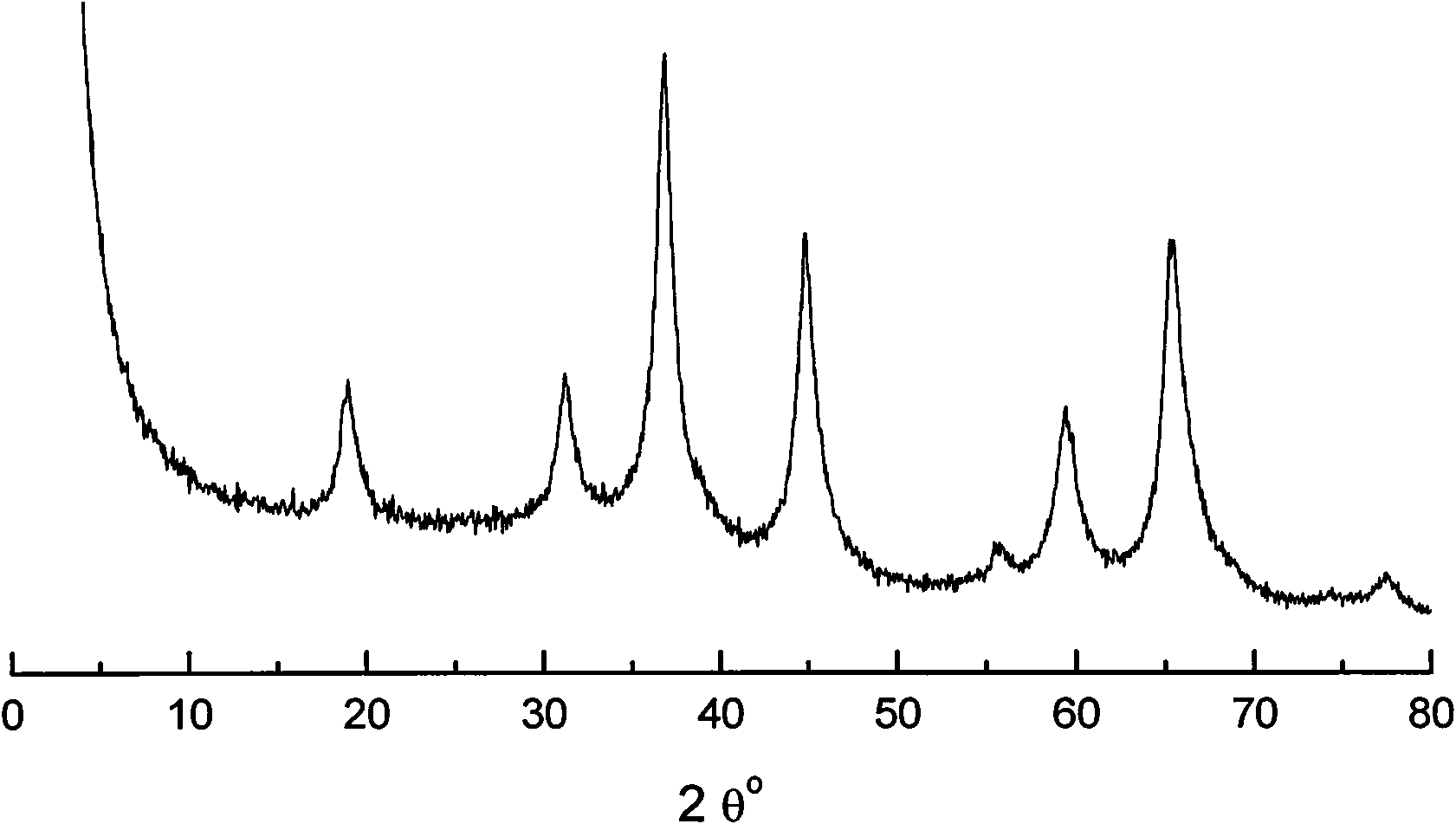

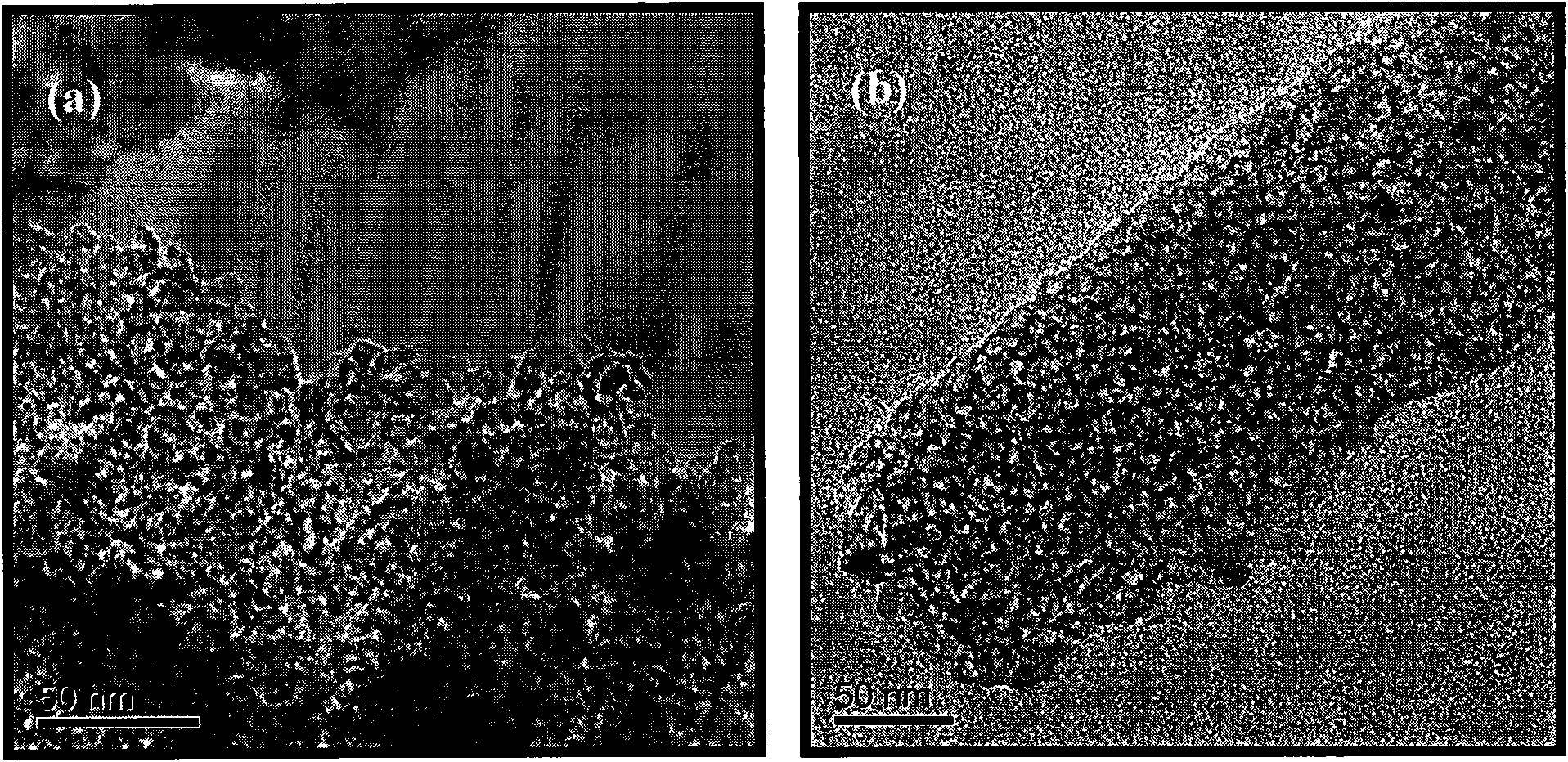

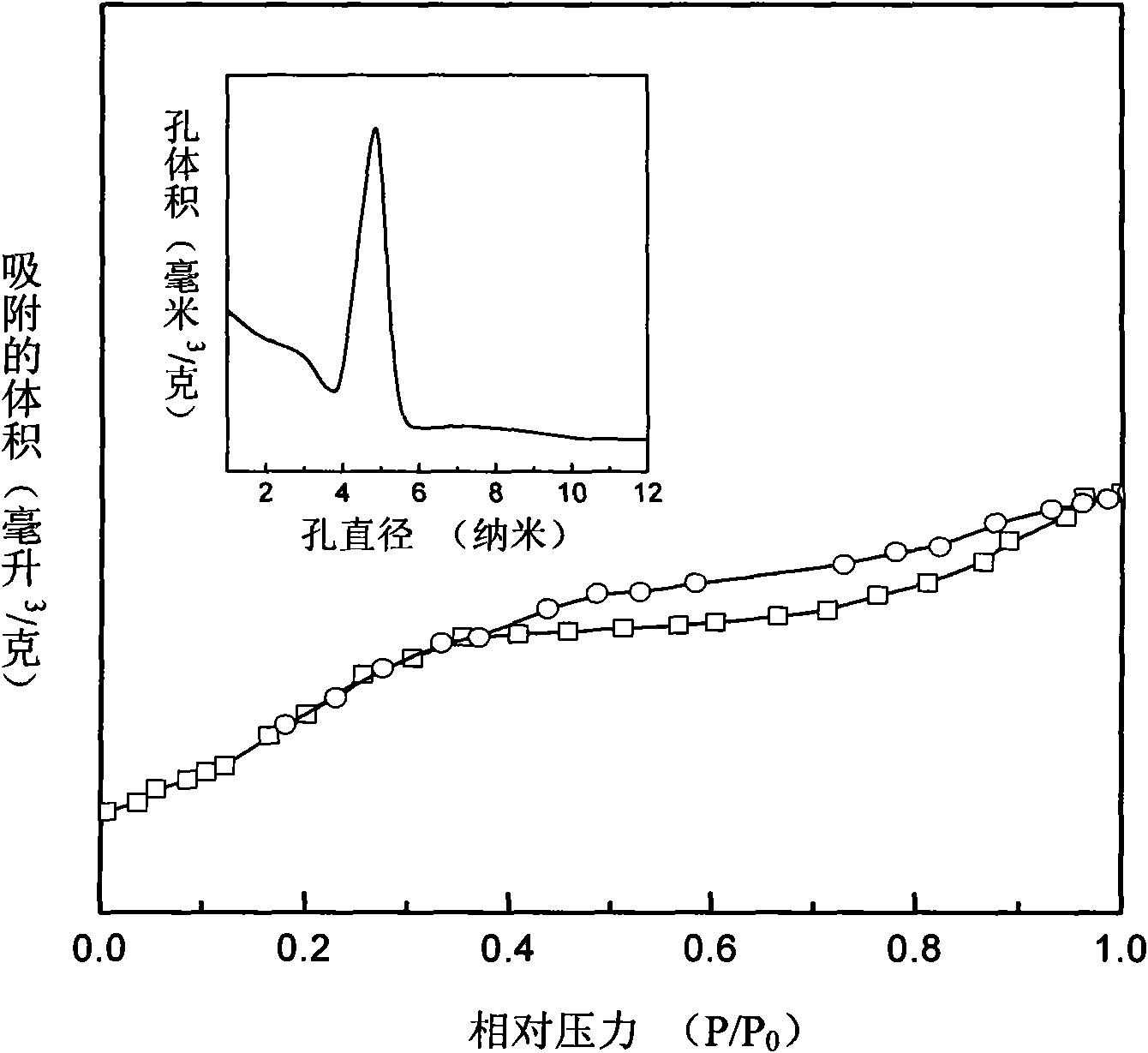

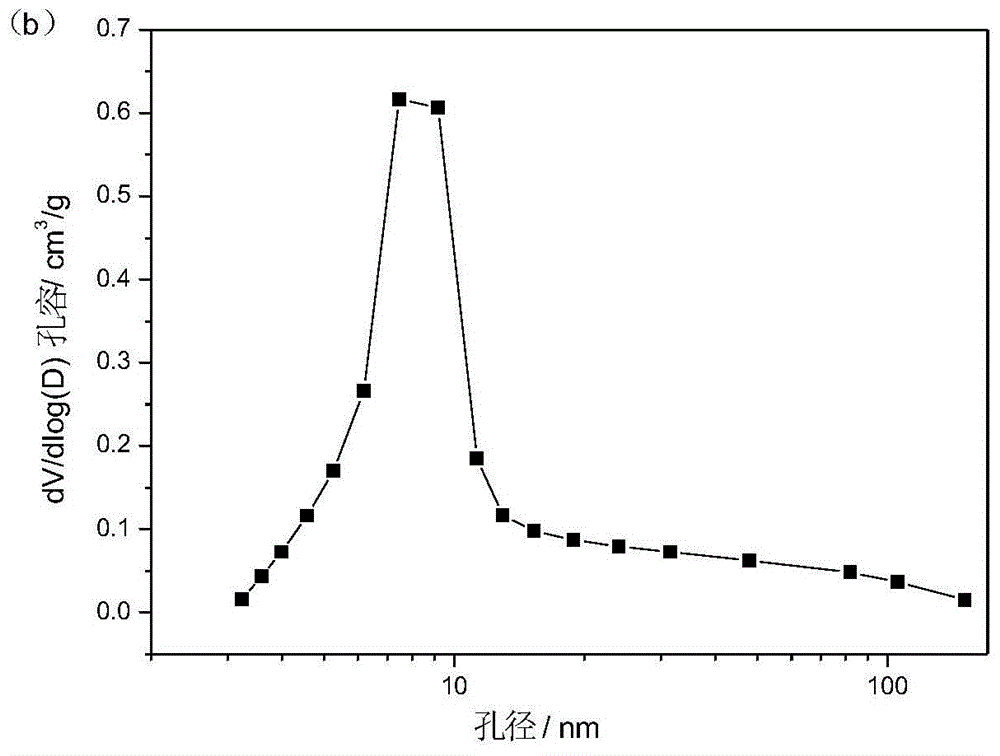

The invention discloses a method for preparing a superfine mesoporous magnesium aluminate spinel, which comprises the following steps: (1) adding an alkaline solution into a mixed solution of a soluble aluminum salt and a magnesium salt, and adding a surfactant into the mixture; (2) performing hydrothermal crystallization on the mixture after ageing at a temperature of between 120 and 180 DEG C for 4 to 72 hours; and (3) separating the mixture to obtain a solid product, and washing, filtering and drying the solid product to obtain magnesium aluminate spinel powder without baking or after baking at a temperature of between 500 and 700 DEG C for 4 to 6 hours. The particle size of the magnesium aluminate spinel prepared by the method is less than 100 nanometers, the specific surface area is between 200 and 400 m / gram, the pore volume is between 0.20 and 0.55 cm / gram, and the most probable pore diameter is between 3 and 6 nanometers.

Owner:NORTHWEST UNIV(CN)

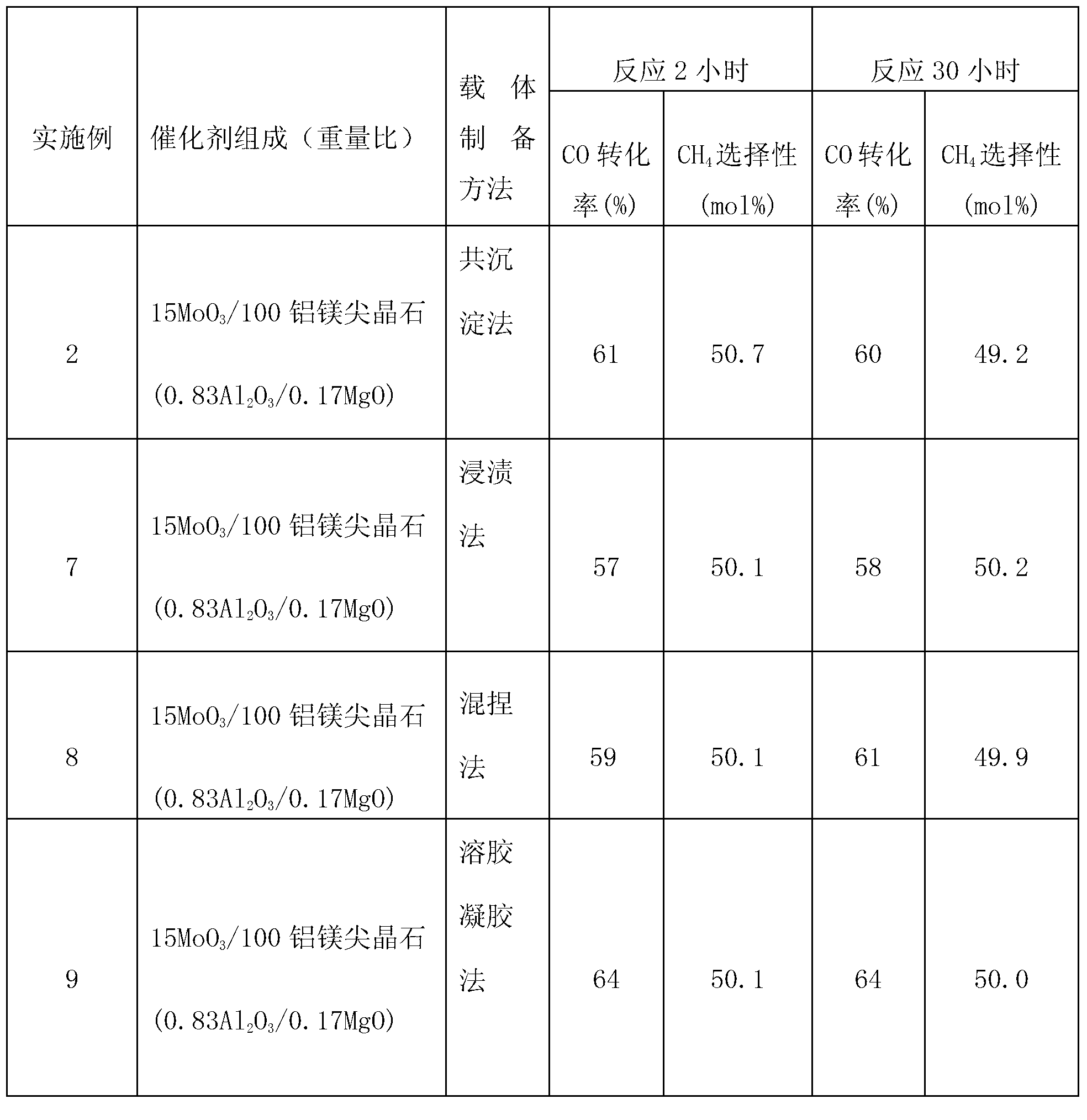

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

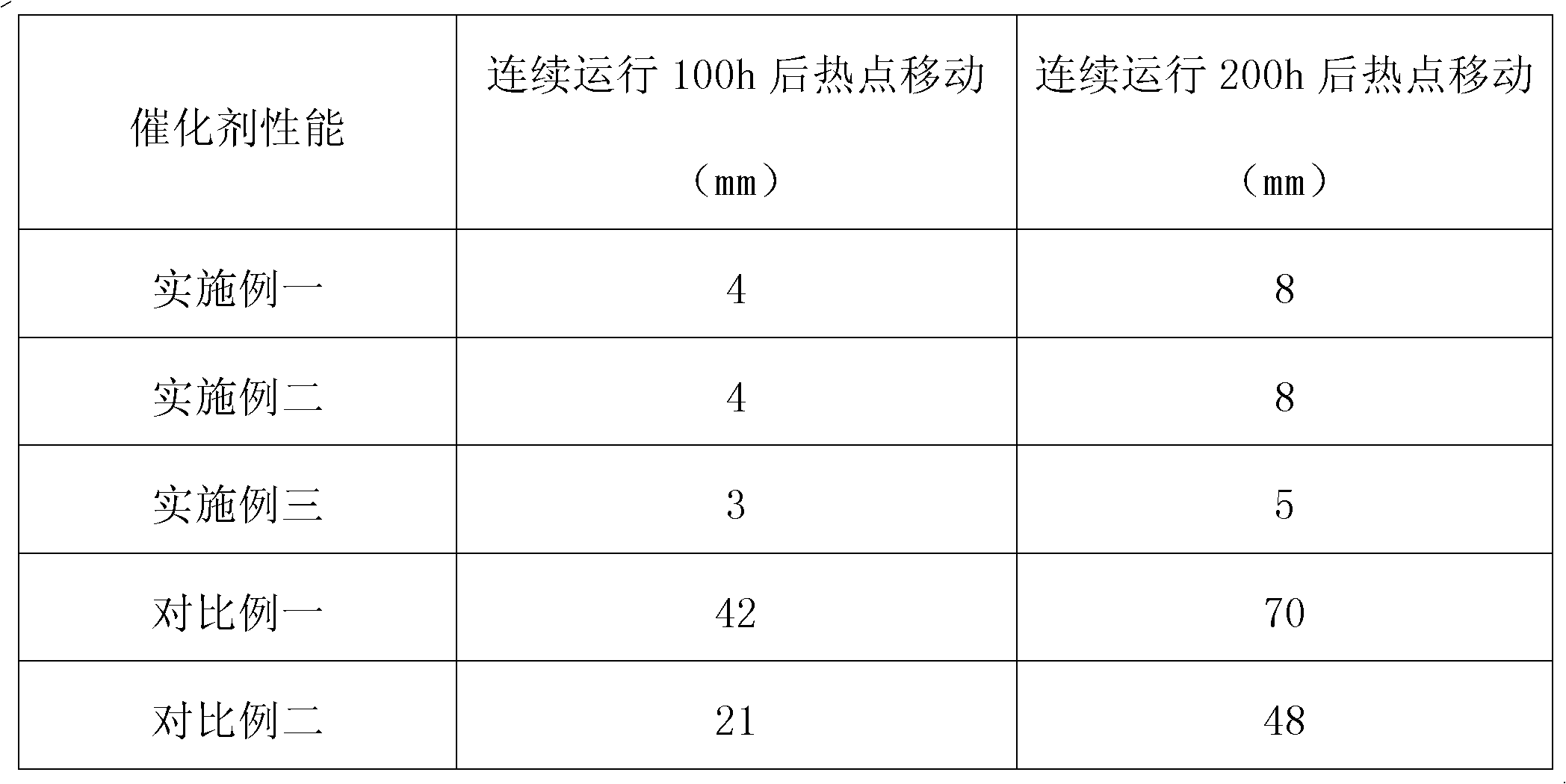

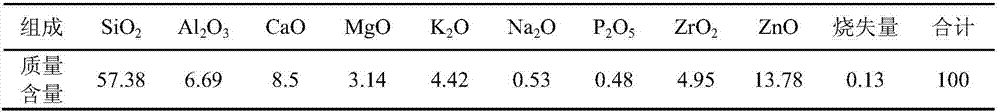

Catalyst for complete methanation of synthesis gas from coal and preparation method thereof

ActiveCN102139218AImprove stabilityHigh mechanical strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMagnesium AluminateChemistry

The invention discloses a catalyst for the complete methanation of synthesis gas from coal and a preparation method thereof. The catalyst is prepared by using NiO as an active component, one or two of rare earth metal oxides La2O3, CeO2 and Sm2O3 as a first assistant, one of alkali oxides CaO, BaO and SrO as a second assistant, and magnesium aluminate spinel formed by mixing Al2O3 with MgO as a carrier, and the obtained catalyst contains the ingredients in percent by mass as below: 20% to 70% of NiO, 15% to 50% of Al2O3, 6% to 30% of MgO, 5% to 20% of the rare earth metal oxide-type first assistant, 1% to 8% of the alkali oxide-type second assistant and 1% to 3% of graphite; the catalyst provided by the invention has the advantages of high catalytic activity, high mechanical strength, good thermal stability, strong carbon deposition resistance, strong resistance to toxicants in feed gas, excellent low temperature activity and low cost.

Owner:HUANENG CLEAN ENERGY RES INST

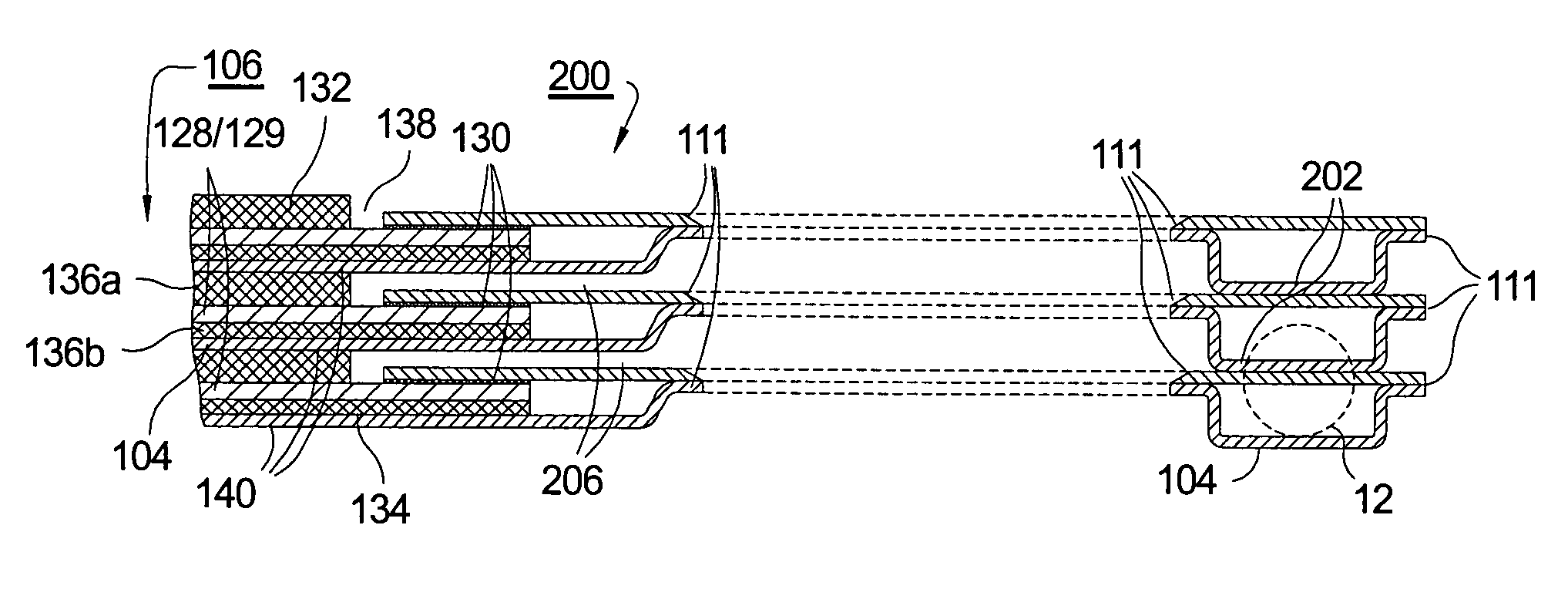

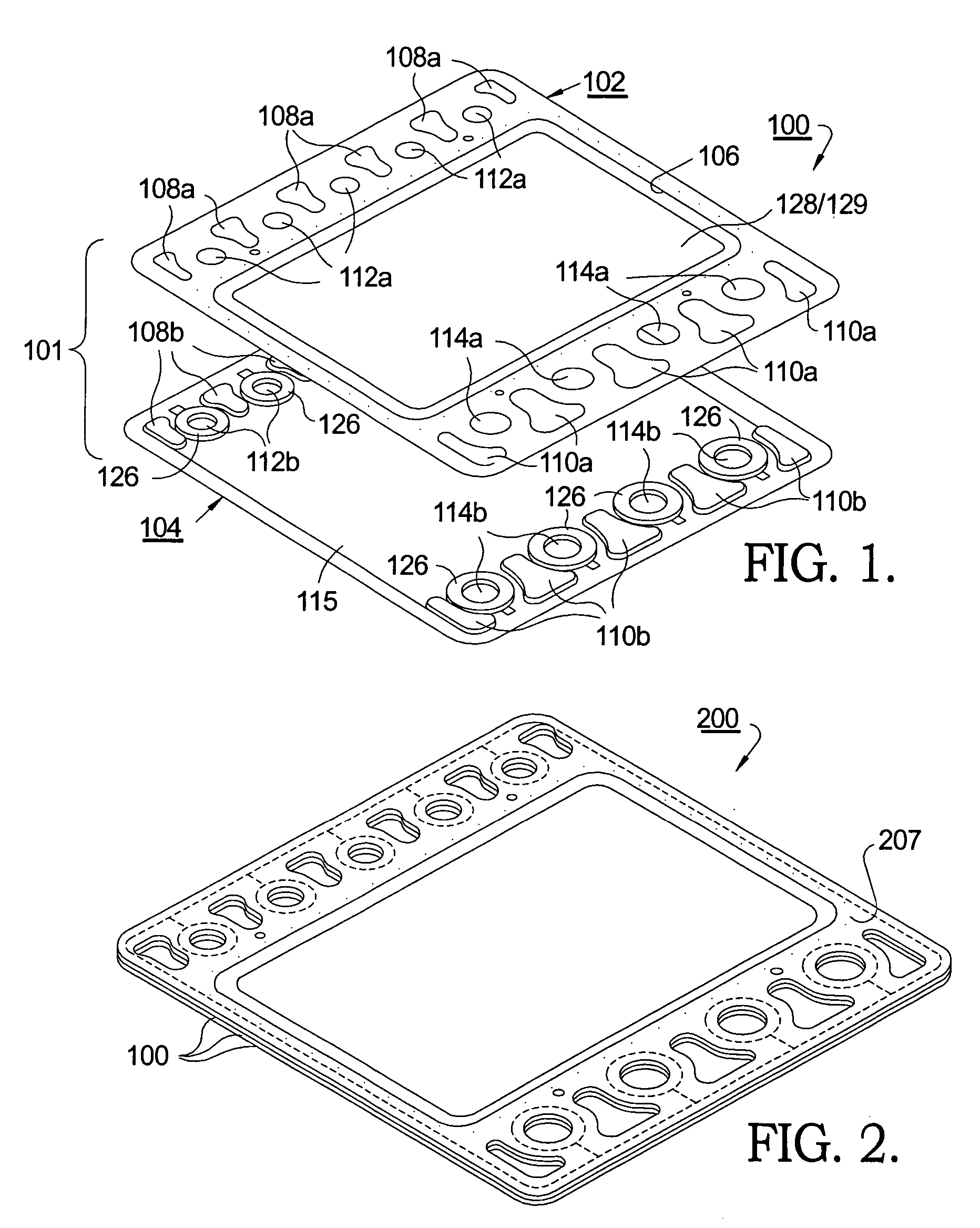

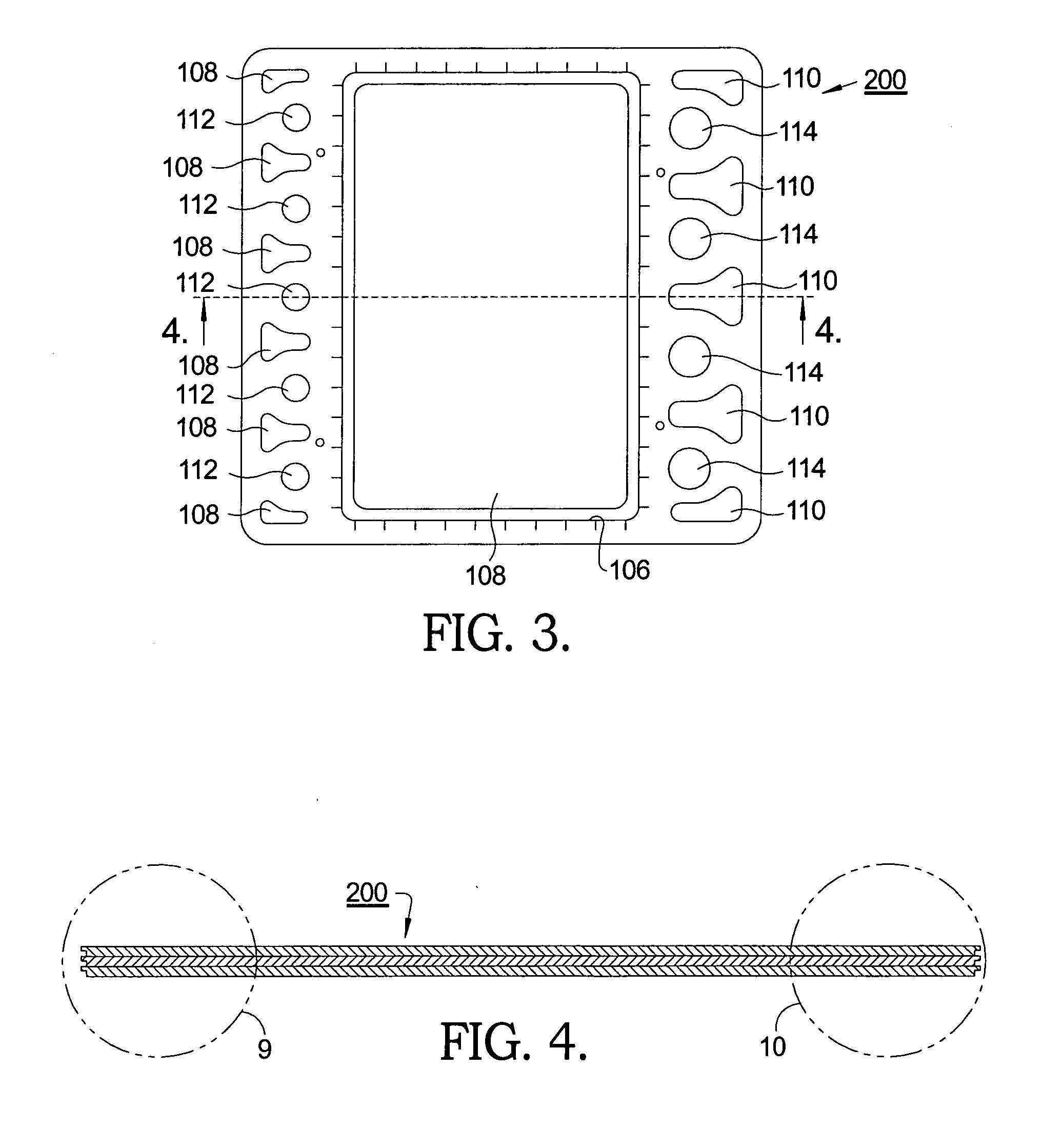

Ceramic coatings for insulating modular fuel cell cassettes in a solid-oxide fuel cell stack

ActiveUS20070134537A1Improve adhesionEngine sealsFuel cells groupingCeramic coatingSurface oxidation

In assembling an SOFC fuel cell stack from a plurality of cassettes, the mounting plate of one cassette is attached to, and insulated from, the separator plate of the next-adjacent cassette by a peripheral dielectric seal consisting of a ceramic coating and a metal braze. Materials suitable for the ceramic coating include yttrium stabilized zirconia (YSZ), zirconia toughened alumina, magnesium silicates such as the mineral forsterite, magnesium aluminates, magnesium aluminosilicates and lanthanum zirconate. The ceramic coating may be applied to the cassette's outer surface in known fashion as by physical vapor deposition, chemical vapor deposition, sputtering, and various methods of plasma spray. An underlayer of alumina may also be used to provide a redundant layer of electrical insulation.

Owner:BATTELLE MEMORIAL INST +1

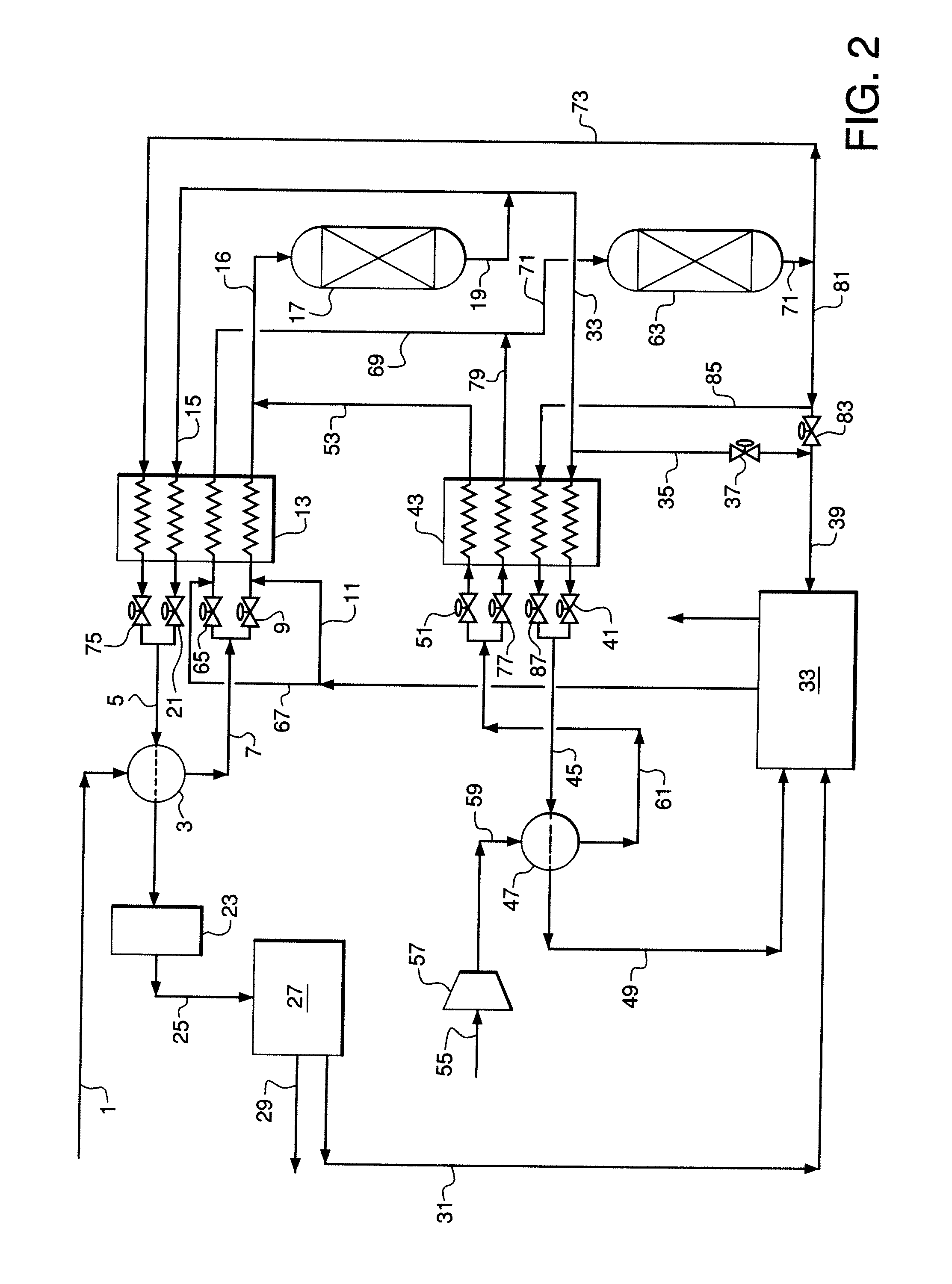

Process for treating H.sub.2 S containing streams

InactiveUS6030597AIncrease temperatureIncrease airflowOther chemical processesDispersed particle separationSorbentSulfur

This invention is directed to an improved process for conversion of H2S to sulfur, using MOST(Mobil Offgas Sulfur Treatment) catalyst or sorbent. The sorbent is typically a magnesium-aluminate spinet, with oxidation promoters such as ceria and vanadia. H.sub.2 S from the feed gas is used to regenerate sulfated sorbent, simultaneously producing elemental sulfur which is then condensed out. The improvement involves combusting part of the feed, converting some of the feed H.sub.2 S to SO.sub.2 prior to contacting the sulfated sorbent. Thus much of the stoichiometric oxygen required for conversion of H.sub.2 S to S is supplied in the form of SO.sub.2 by this pre-combustion step, instead of coming totally from the oxidized / sulfated solid sorbent. This can decrease the amount of sorbent required, as well as the frequency of regenerations, thus reducing process cost. The hot combustion gas also helps to heat the feed stream. One or more Claus reactors may optionally be added, to further increase sulfur recovery efficiency.

Owner:MOBIL OIL CORP

Light-weight corundum-spinel castable and preparation method thereof

The invention relates to a light-weight corundum-spinel castable and a preparation method thereof. The preparation method includes following steps: (A) employing 60-75 wt% of equal-diameter micro-porous corundum spheres as an aggregate, and employing 8-12 wt% of electric-fused white corundum fine powder, 2-8 wt% of electric-fused magnesite fine powder, 2-8 wt% of magnesium aluminate spinel fine powder, 6-12 wt% of [alpha]-Al2O3 micro powder, 0.5-2.5 wt% of chromium oxide powder and 3-7 wt% of an aluminum silicone gel powder as substrate materials, wherein the aggregate and the substrate materials form a raw material in total; (B) employing organic fibers accounting for 0.02-0.08 wt% of the raw material and a polycarboxylate water reducer accounting for 0.05-0.12 wt% of the raw material as additive materials, pre-mixing the substrate material with the additive materials and adding the aggregate with uniform mixing; (C) adding water accounting for 3-5 wt% of the raw material, stirring the mixture and performing cast moulding; and (D) maintaining the temperature at 110-200 DEG C for 12-48 h, roasting the moulded product at 800-1200 DEG C for 24-72 h to obtain the light-weight corundum-spinel castable. The light-weight corundum-spinel castable is low in apparent porosity, is low in volume density, is low in heat conductivity, is strong in anti-slag-erosion capability and is long in service life.

Owner:WUHAN UNIV OF SCI & TECH

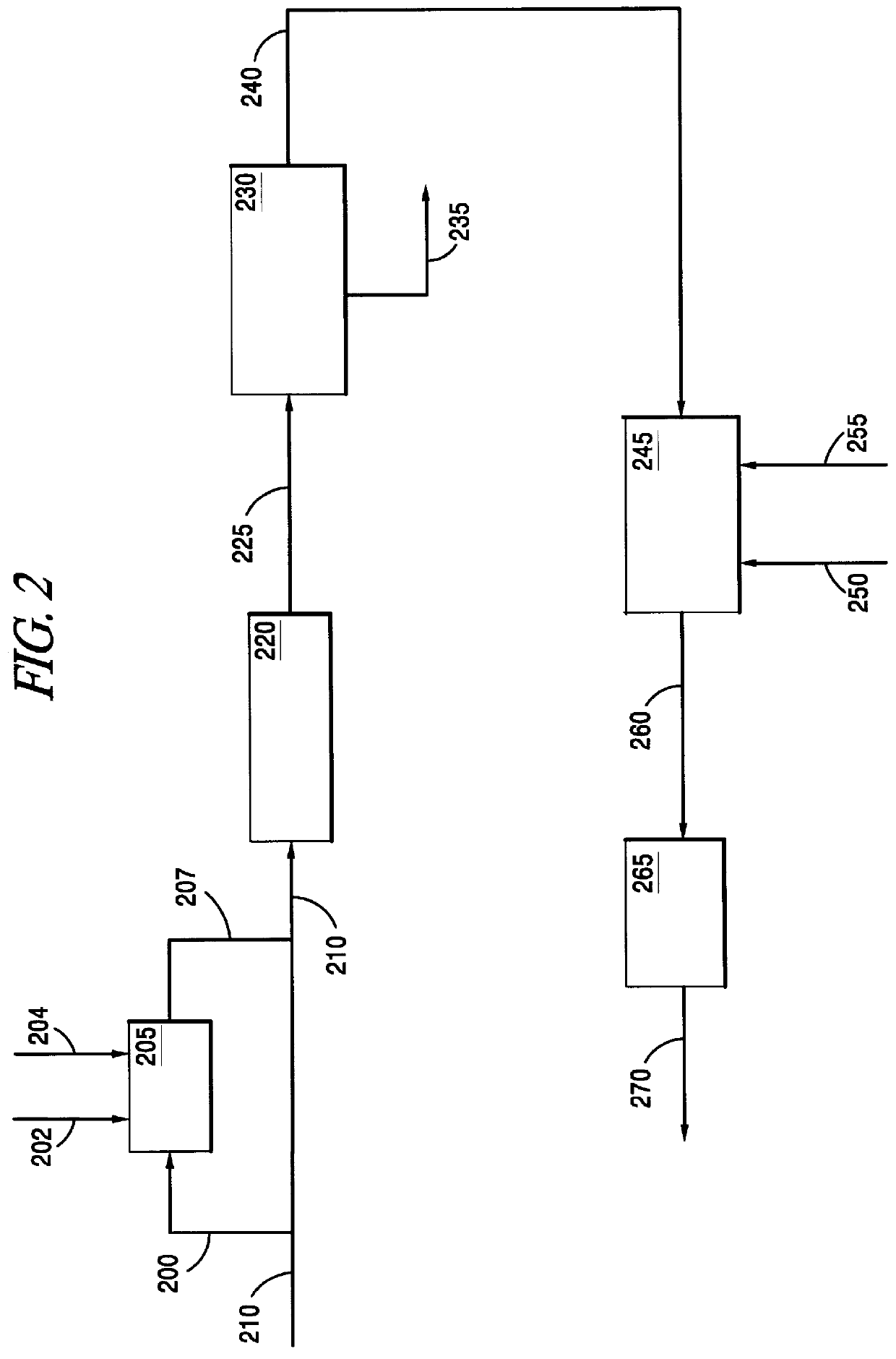

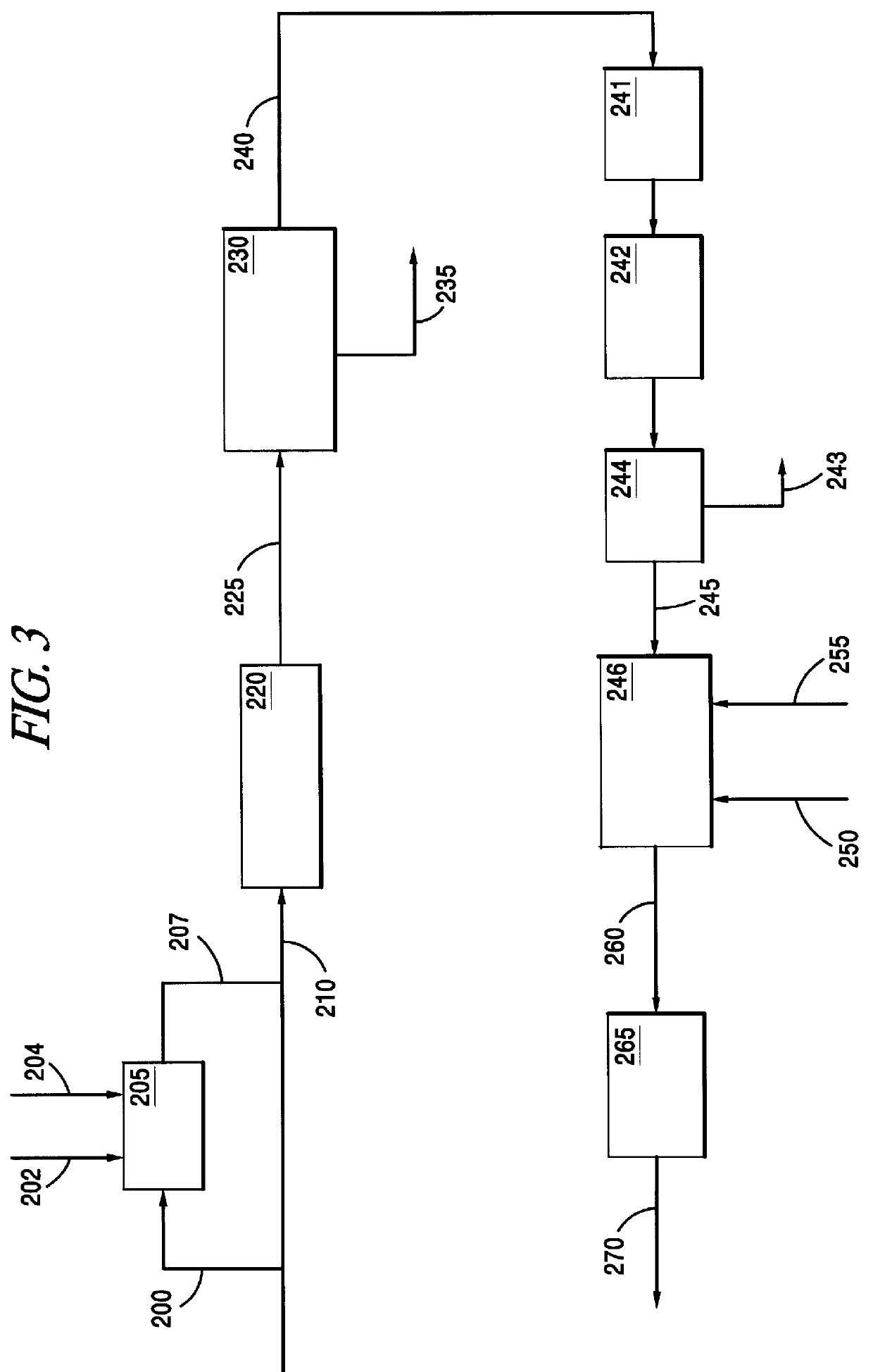

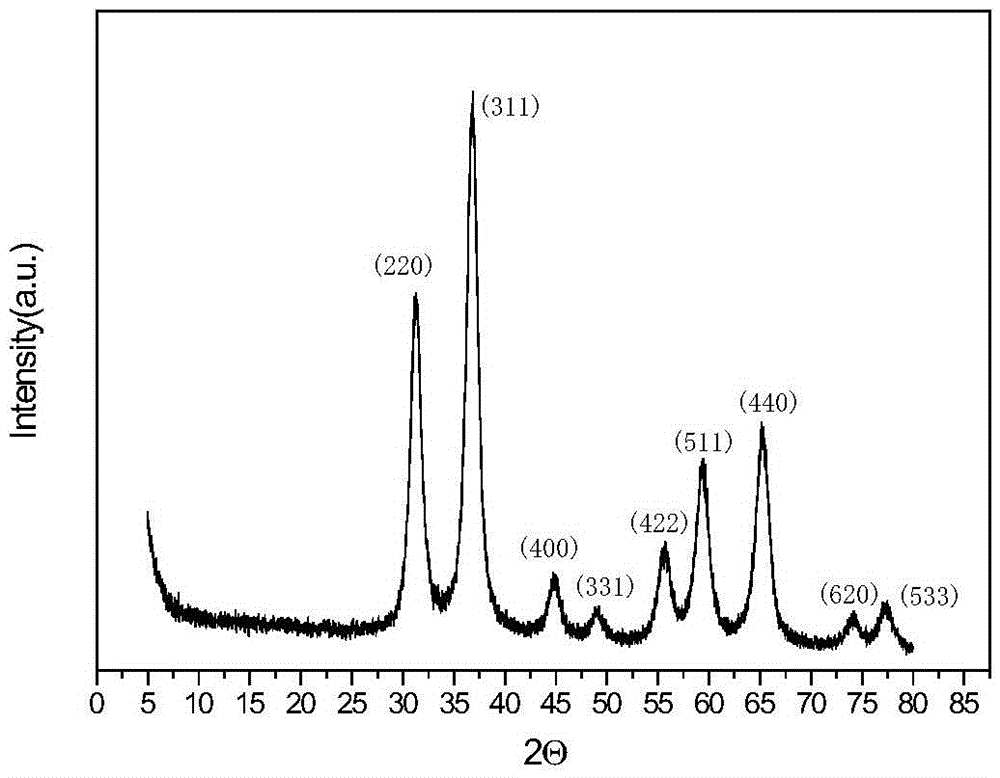

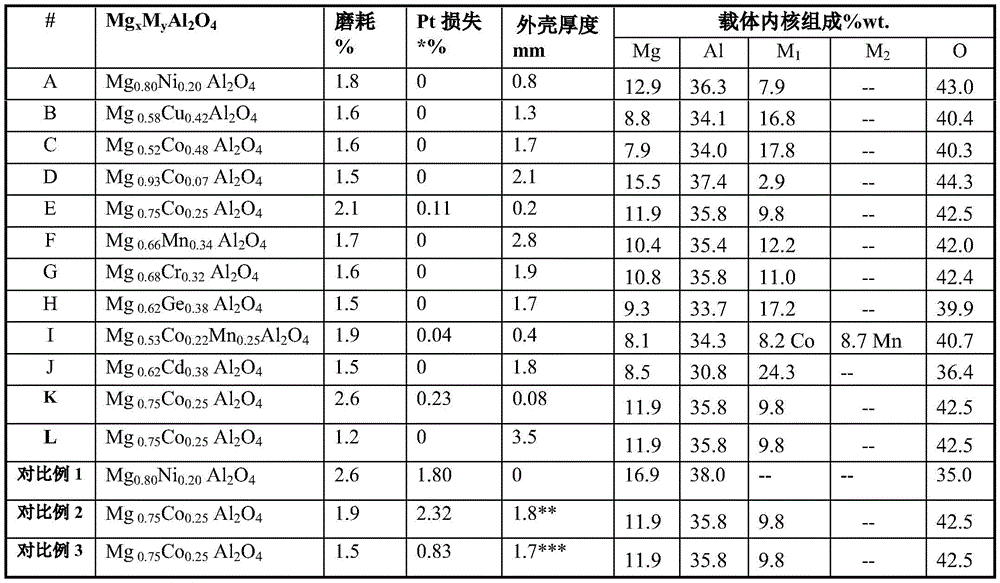

Carrier of catalyst for light alkane dehydrogenation preparation of light olefin and use thereof

ActiveCN106607100AImprove wear resistanceReduce catalysisCatalyst carriersHydrocarbonsAlkaneReaction temperature

The invention relates to a carrier of a platinum catalyst for light alkane dehydrogenation and a use thereof. The carrier mainly solves the problem that the existing catalyst has poor wear resistance and the precious metal is easy to lose along with the carrier wear during the use. A preparation method of the platinum catalyst comprises coating the surface of a magnesium aluminate carrier with alumina or pseudo-boehmite sol through a spraying or rolling method to obtain an alumina housing, carrying out drying and high temperature calcination to obtain a compound metal oxide carrier having the inert housing, loading platinum and tin components through an impregnation method through impregnation of a soluble salt aqueous solution of platinum, and carrying out drying, roasting and vapor treatment to obtain the platinum catalyst. Propane / isobutane as a raw material contacts with the catalyst and undergoes a reaction under conditions of a reaction temperature of 520 to 620 DEG C, reaction pressure of 0 to 0.4MPa, an alkane mass space velocity of 0.1 to 8.0h<-1> and a H2O / CnH2n+2 volume ratio of 1 to 18 to produce propylene / isobutene so that the problem is solved. The platinum catalyst carrier can be used in industrial preparation of a catalyst for light alkane dehydrogenation preparation of a light olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

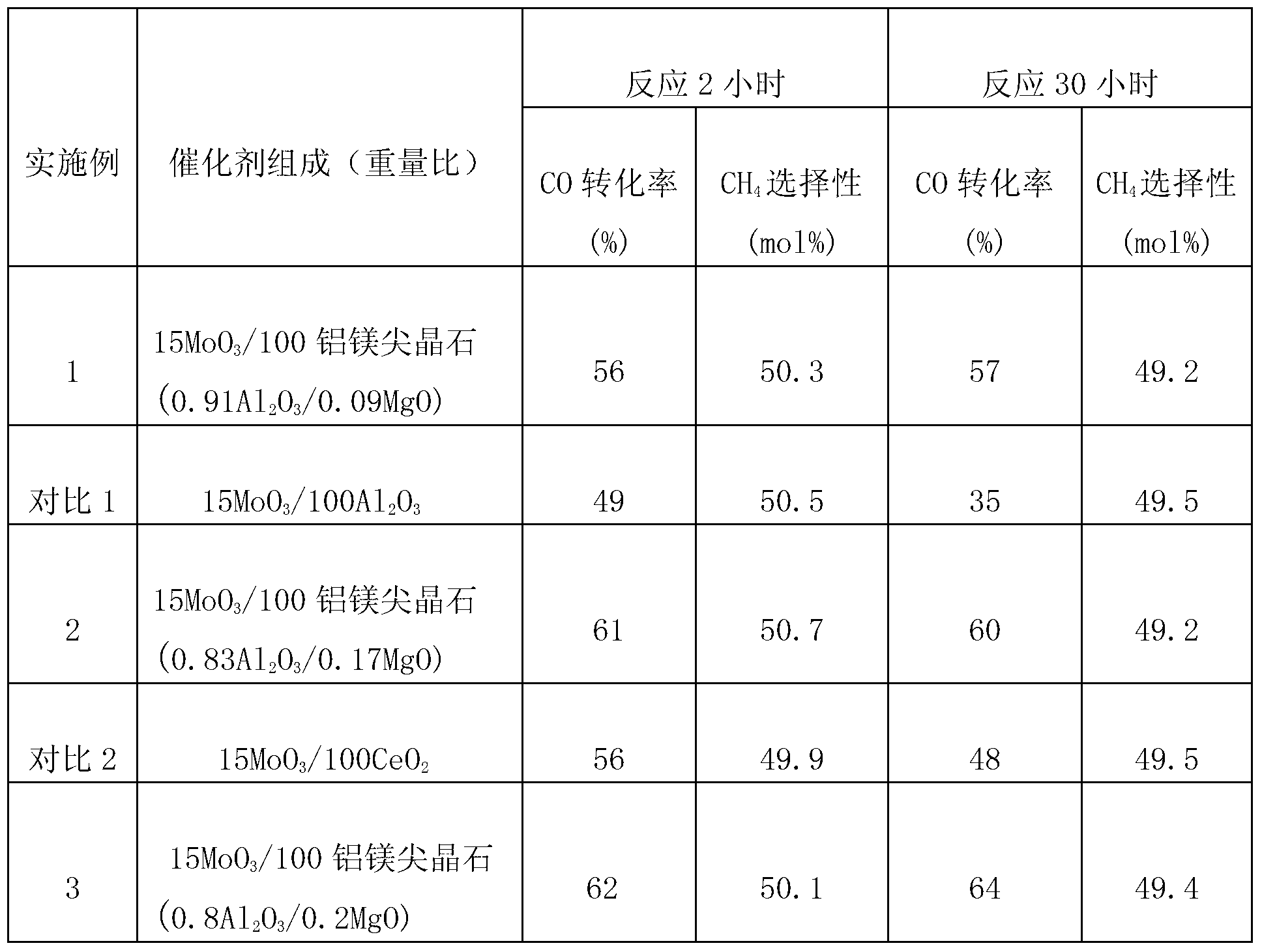

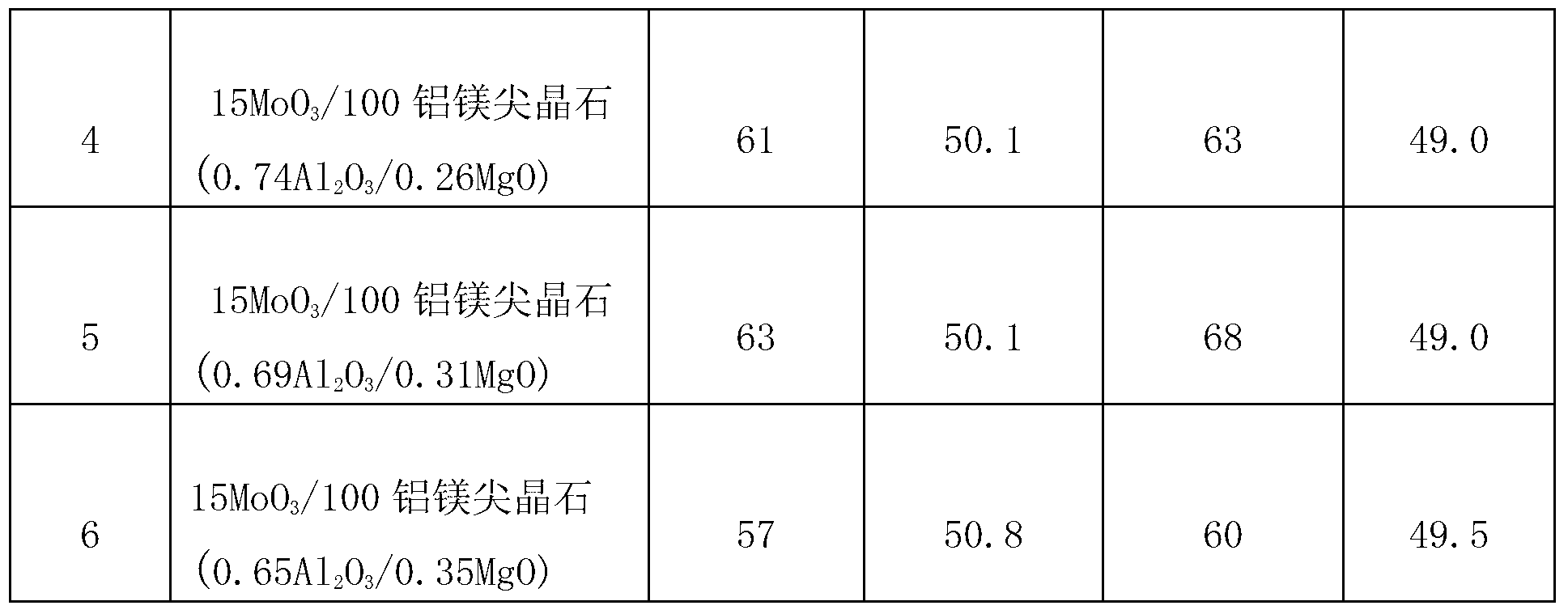

Sulfur-tolerant methanation catalyst and preparation method thereof

ActiveCN103495421ASolve pollutionHigh process complexity costMetal/metal-oxides/metal-hydroxide catalystsMethanationSulfur

The invention relates to a high-strength sulfur-tolerant methanation catalyst and a preparation method thereof. The catalyst uses magnesium aluminate spinel as a carrier and comprises the following active components: on the basis of the total amount of the catalyst, 0.2 to 20% of cobalt in terms of CoO and 1 to 30% of molybdenum in terms of MoO3, with the balance being an active auxiliary agent. The preparation method for the catalyst is a kneading or immersion method. According to the invention, production temperature for magnesium aluminate spinel is decreased, so production cost is reduced; generation of nitrogen oxide in the process of production is avoided, so the problem of environmental pollution is overcome. The catalyst prepared in the invention can be used at a pressure no more than 6.0 MPa and has high strength and strength stability.

Owner:刘博男

Lightweight periclase-magnesium aluminate spinel refractory material for rotary cement kiln and preparation method thereof

The invention relates to a lightweight periclase-magnesium aluminate spinel refractory material for a rotary cement kiln and a preparation method thereof. According to the scheme, the preparation method comprises the following steps of: uniformly dispersing 0.2 to 4wt% of magnesite micro powder and 0.2 to 4wt% of active alpha alumina micro powder into 5 to 8wt% of binding agent to obtain a modified binding agent; adding 50 to 70wt% of porous periclase-magnesium aluminate spinel ceramic particles to a vacuum agitating machine; vacuumizing to be below 2.5kPa; maintaining the constant pressure for 3 minutes; adding the modified biding agent to the vacuum agitating machine; agitating for 10 minutes; closing a vacuumizing system; then adding 10 to 25wt% of porous periclase-magnesium aluminate spinel ceramic fine powder, 4 to 20wt% of fine magnesia powder, and 1.5 to 4wt% of magnesium aluminate spinel fine powder to the vacuum agitating machine; uniformly agitating; mechanically pressing and modeling; drying; and maintaining the temperature of 1,500 to 1,650 DEG C for 2 to 10 hours. The lightweight periclase-magnesium aluminate spinel refractory material for the rotary cement kiln has the advantages of being low in heat conductivity, high in intensity, high in thermal shock resistance, high in kiln coating performance, and high in resistance to medium erosion.

Owner:WUHAN UNIV OF SCI & TECH

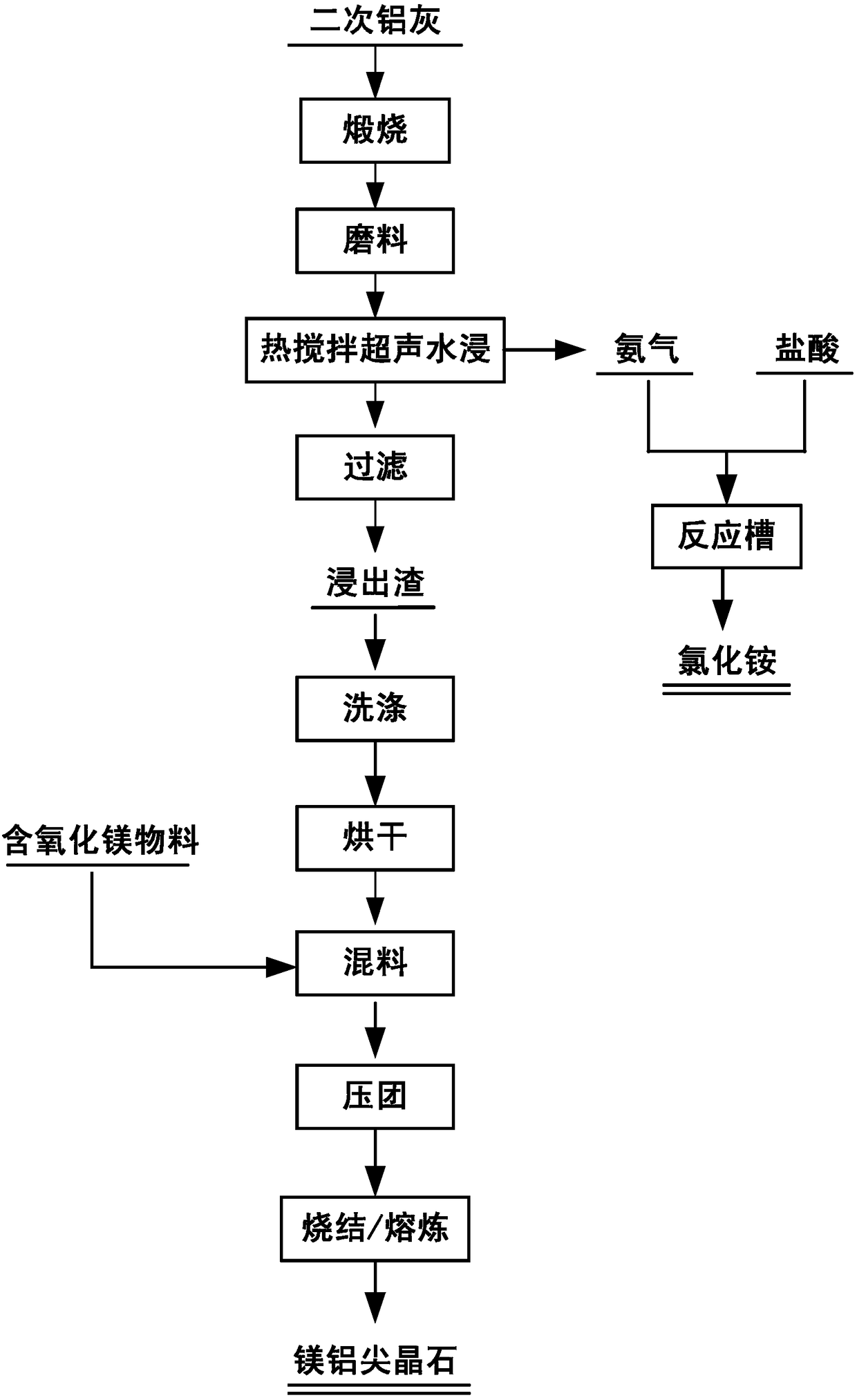

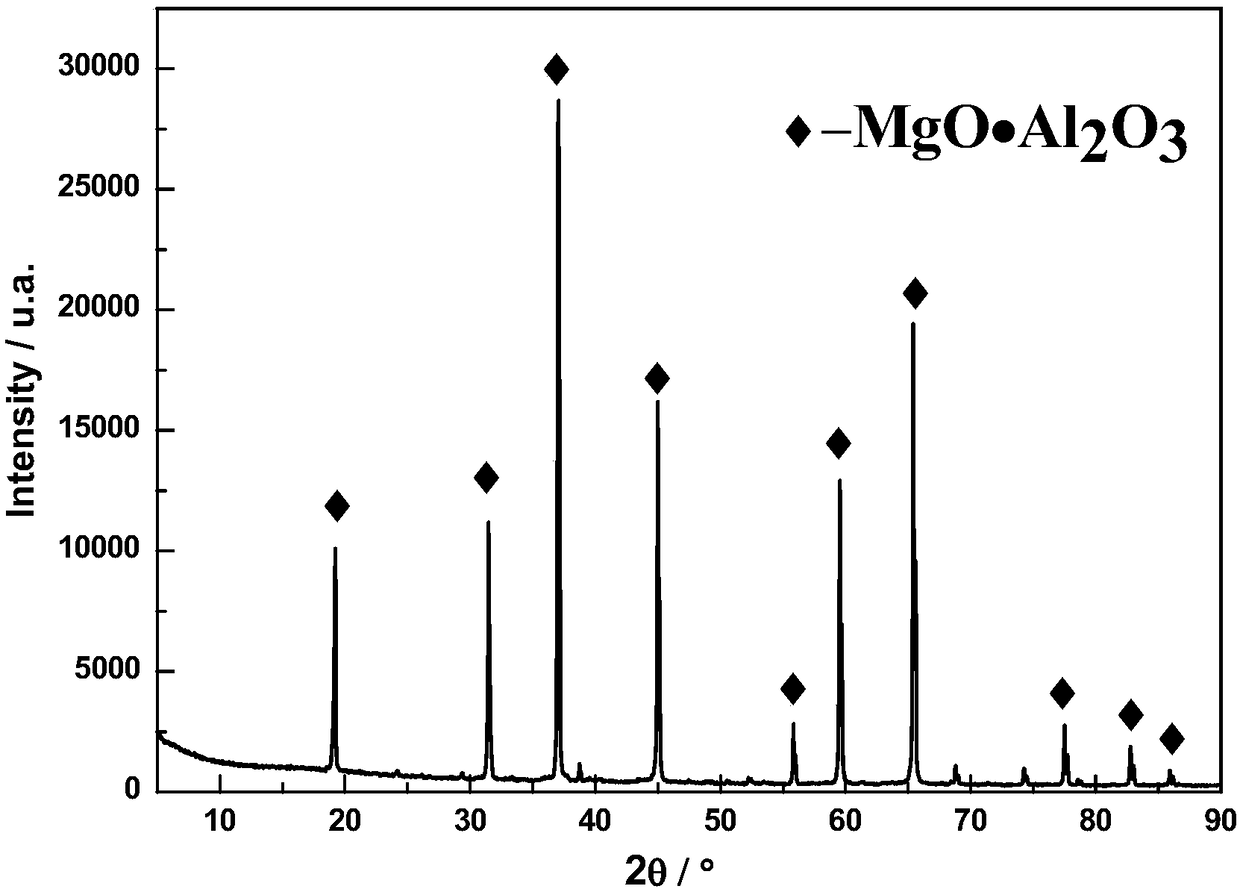

Method for preparing magnesium aluminate spinel by using secondary aluminum ash

ActiveCN108585826ARealize impurity removalQuick responseAmmonium chlorideElectric arc furnaceWater immersion

The invention discloses a method for preparing magnesium aluminate spinel by using secondary aluminum ash. The method comprises the following steps: (1) preparing the secondary aluminum ash as a raw material; (2) calcining for 1-3 h in 900-1200 DEG C, after cooling, ball-milling and preparing secondary aluminum ash fine powder; (3) adding the secondary aluminum ash fine powder to water, under theconditions of a temperature of 50-98 DEG C and stirring, and performing water leaching by applying an ultrasonic wave; feeding an ammonia gas generated by the water leaching to a reaction tank and generating ammonium chloride with hydrochloric acid; (4) filtering and separating a leaching residue, after washing and drying, mixing with a material containing magnesium oxide, and levigating; (5) pressing as pellets; and (6) sintering the pellets in a high temperature or smelting in an electric arc furnace so as to prepare the magnesium aluminate spinel. The method is rapid in reaction speed, andcapable of enabling nitrogen to be converted to the ammonia gas which is discharged and recycled, enabling soluble impurities to enter a liquid phase, and realizing the further impurity removal. The prepared magnesium aluminate spinel is high in purity, and less in impurity content.

Owner:NORTHEASTERN UNIV

High corrosion resistant integral stopper for continuous casting

The invention relates to the technical field of carbonaceous refractory materials, especially to a high corrosion resistant integral stopper for continuous casting. The stopper contains a stopper head and a stopper body, wherein the stopper body comprises the following components of: by weight, 15-25 parts of graphite, 20-70 parts of magnesium aluminate spinel, 0-30 parts of magnesia, 0-10 parts of alumina, 1-9 parts of an additive, and phenolic resin which accounts for 8-12% of the total weight of the above ingredients, wherein the additive contains one or more ingredients selected from metal silicon powder, metal aluminium powder and boron carbide. By the optimization of the material of the stopper body, porosity of the stopper body can be reduced, slag penetration resistance can be enhanced, erosion of alkaline slag to the stopper body of the integral stopper can be decreased, and service life of the stopper can be raised.

Owner:UNIV OF SCI & TECH LIAONING +1

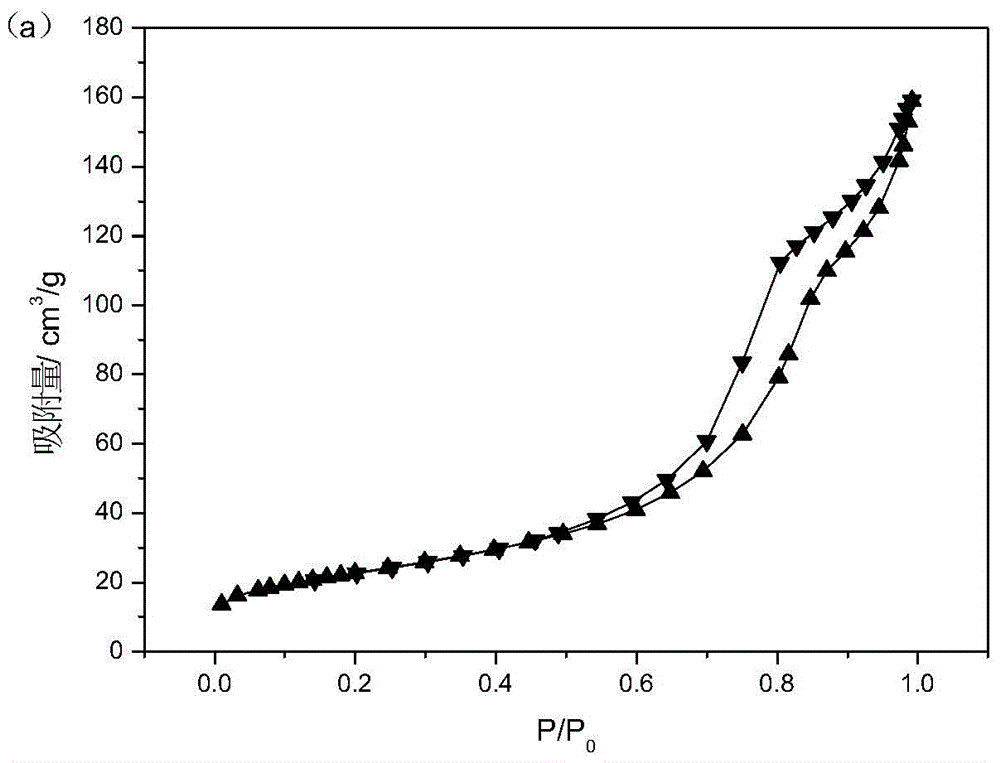

Preparation method of magnesium aluminate spinel for catalyst carrier

ActiveCN105642264AEasy to operateSynthesis temperature is lowMaterial nanotechnologyHydrocarbonsHigher alkanesPlatinum

The invention relates to a preparation method of magnesium aluminate spinel for a catalyst carrier; a sol-gel method is adopted for preparation, and the preparation method comprises the following steps: (1) under a condition of the temperature of 50-80 DEG C, mixing water and ethylene glycol together; (2) adding citric acid, a magnesium source and an aluminum source into the ethylene glycol aqueous solution with the molar ratio of citric acid (CA) to Mg to Al of 6 to (0.9-1) to (2-2.2); (3) heating the solution until the solution becomes a transparent red gel, and aging; and (4) at the temperature of 350-500 DEG C, roasting for 2-4 h, grinding, again roasting for 2-12 h at the temperature of 600-800 DEG C, and thus obtaining the magnesia alumina spinel carrier. The prepared magnesia alumina spinel product is mainly used for a carrier of a low-carbon alkane dehydrogenation reaction catalyst, is loaded with 0.01-0.5 wt.% of a platinum-family transition metal element, 0.01-1 wt.% of Sn, and has smaller size, higher specific surface, and suitable pore structure; and compared with a conventional dehydrogenation catalyst carrier, the carrier has the characteristics of high alkane conversion rate, good stability, and good monoolefine selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

Catalyst used for preparing isobutene through isobutane dehydrogenation and preparation method and application thereof

ActiveCN104525195AInhibition formationIncreased dispersionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalActive component

The invention provides a catalyst used for preparing isobutene through isobutane dehydrogenation and a preparation method and application of the catalyst. According to the catalyst, magnesium aluminate spinels serve as carriers, platinum nanoparticles serve as active components, tin serves as a first addition agent, and alkaline metal or alkaline-earth metal serves as a second addition agent; by weight of the magnesium aluminate spinel carriers, the capacity of the platinum nanoparticles is 0.2-0.6 wt%, the capacity of the first addition agent is 0.01-2 wt%, and the capacity of the second addition agent is 0.5-2 wt%. The invention further provides the preparation method of the catalyst and application of the catalyst in the field of preparing isobutene through isobutane dehydrogenation. The catalyst used for preparing the isobutene through isobutane dehydrogenation has high isobutane conversion rate and high isobutene selectivity; moreover the catalyst has good high-temperature stability; meanwhile the catalyst can inhibit deposited carbon from forming, and therefore side reactions can be effectively inhibited.

Owner:PETROCHINA CO LTD +1

Corundum spinel castable with micro-nano pore structure and preparation method of corundum spinel castable

The invention relates to a corundum spinel castable with a micro-nano pore structure and a preparation method of the corundum spinel castable. The technical scheme of the invention is as follows: the preparation method comprises the following steps of: dry-blending 45-82 percent by weight of tabular corundum particles and 1-15 percent by weight of magnesium aluminate spinel particles to obtain mixed aggregate, and dry-blending 1-10 percent by weight of magnesium aluminate spinel fine powder, 4-12 percent by weight of corundum fine powder, 5-15 percent by weight of Alpha-Al2O3 micropowder, 2-8 percent by weight of pure calcium aluminate cement and 0.1-0.5 percent by weight of SiO2 micropowder to obtain mixed powder; then adding a water reducing agent, water and foams which respectively account for 0.2-1.0 percent by weight, 3.5-4.5 percent by weight and 5-15 percent by weight of the aggregate and the powder to the mixed powder, and stirring to prepare mixed slurry; and pouring the mixed aggregate into the mixed slurry, stirring, moulding by casting, curing, demoulding, baking, heating to 1450-1760 DEG C and maintaining the temperature for 2-4 hours. The preparation method disclosed by the invention has the characteristics of simple process and easiness for construction and industrial production; and the prepared corundum spinel castable is high in comprehensive property, good in thermal shock resistance and long in service life.

Owner:WUHAN UNIV OF SCI & TECH

Flame-resistant corrosion-resistant coating

The invention discloses a flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating is an amorphous flame-resistant corrosion-resistant coating for protecting the surface of a liner of an industrial furnace. The flame-resistant corrosion-resistant coating is characterized in that fine powder of tabular corundum and magnesium aluminate spinel, calcined alpha-Al2O3 micro-powder, pure calcium aluminate cement as a curing agent, sodium hexametaphosphate as a sintering assistant, and a phosphoric acid or aluminum dihydrogen phosphate solution as a binder are blended into the flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating can resist corrosion produced by a high-concentration fluoride and a high-concentration hydrogen fluoride atmosphere, and has the advantages of high purity, good heat stability, application convenience, smooth and compact surface and relatively low cost. The flame-resistant corrosion-resistantcoating is suitable for the surface of a liner of a furnace with fluorides and a hydrogen fluoride atmosphere and also is suitable for the surface of a liner of a high-temperature and low-oxygen content furnace with a strong reduction atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

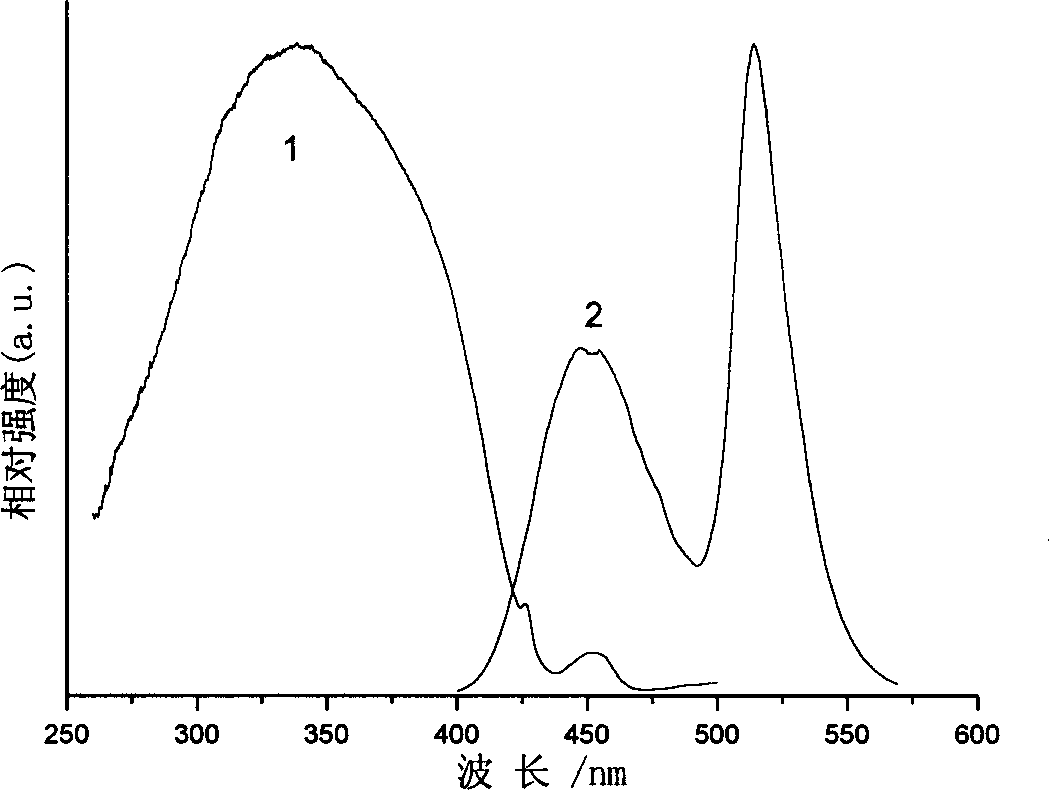

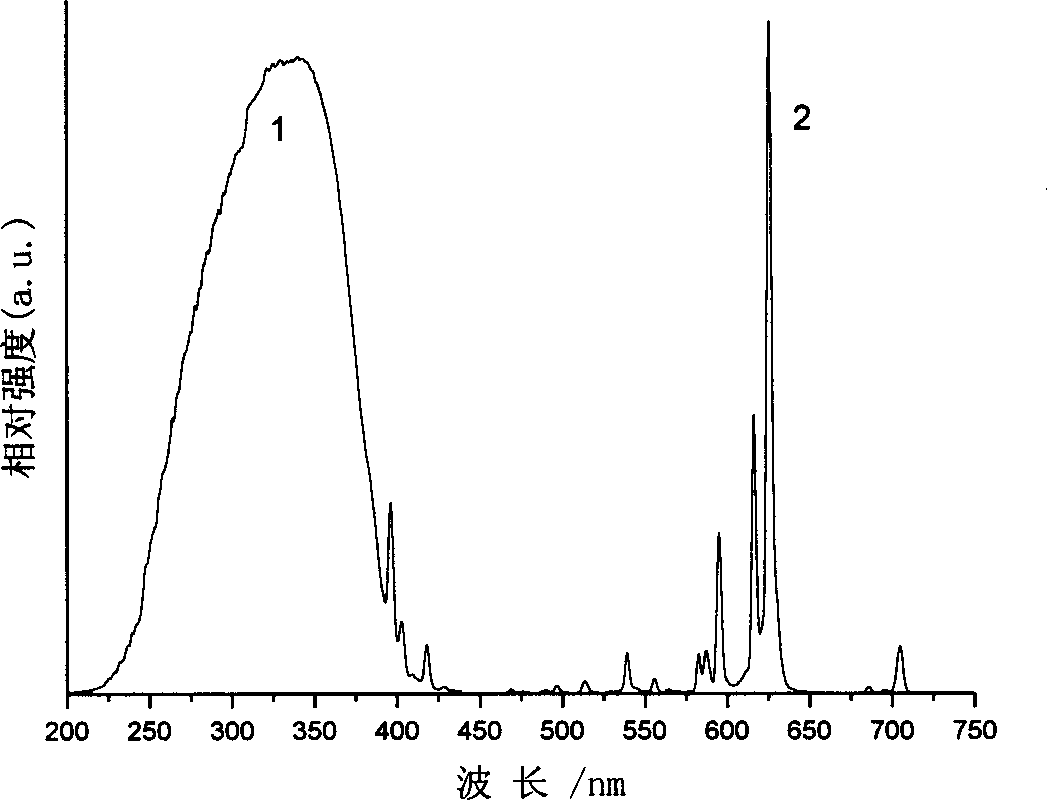

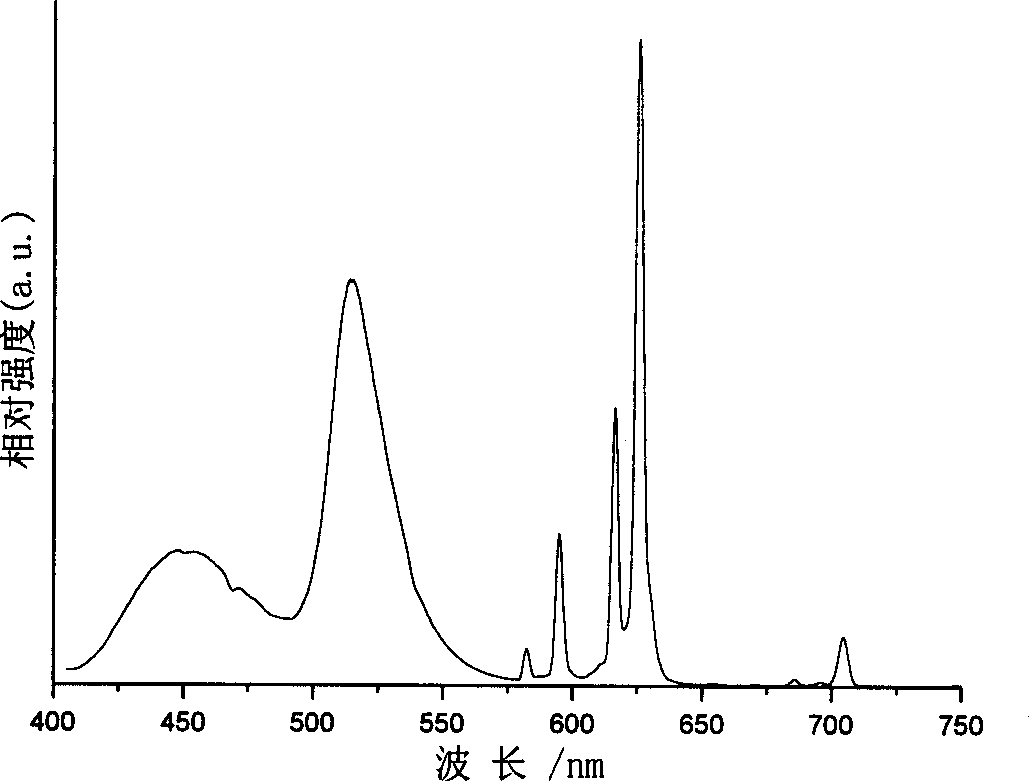

Violet light excitated bicomponent three basic colour fluorescent powder and its preparation method

A laser triggered two-element three-primary-color fluorescent powder contains the blue-green powder, which is the barium magnesium aluminate activated by 2-valence Mn and 2-valence Eu and has main emission peaks in blue and green regions, and the red powder, which is the yttrium thioxide activated by 3-valuence Eu and has main emission peak in red region through proportional mixing and high-temp solid-phase reaction.

Owner:PEKING UNIV

Sulphur resistant carbon monoxide transfer catalyst and preparation thereof

The invention discloses a sulfur resistant carbon monoxide shift catalyst and a preparation method thereof, relates to a carbon monoxide shift catalyst, and provides a sulfur resistant carbon monoxide shift catalyst which is applicable under wide operation conditions with high voltage and steam-gas ratio or low voltage and steam-gas ratio and a preparation method thereof. The active components consist of a Mo compound expressed in MoO3, Co compound expressed in CoO and K compound expressed in K2O, with magnesium aluminate spinel MgAl2O4 as the carrier. According to mol ratio 1:1 of light MgO and aluminum oxide, the light MgO and the porous, aqueous and amorphous aluminum oxide are put in a mix and pinch machine; the aqueous solution of nitrate acid is added in for mixing and pinching, to form a plastic body; the plastic body is extruded, shaped, dried and baked, to obtain the porous MgAl2O4 carrier is obtained. Hoevelite, cobalt salt, ammonium mloybdate and a complex stabilizer are dissolved by water, and the pH value of the solution is regulated by ammonia water; the measured MgAl2O4 carrier is soaked by the prepared mixed solution, and dried.

Owner:XIAMEN UNIV

A low-cost long-service-lifetime ceramic saggar and a preparing method thereof

The invention relates to a low-cost long-service-lifetime ceramic saggar and a preparing method thereof. The ceramic saggar is used for sintering powder of a lithium compound. Raw materials of a matrix of the ceramic saggar include, by weight, 20-25% of talcum, 15-20% of bauxitic rock, 5-35% of magnesium aluminate spinel having a size of 60-65 meshes, 15-45% of magnesium aluminate spinel having a size of 100-120 meshes, and 5-15% of cordierite. Some natural ore materials which are the talcum and the bauxitic rock are adopted as raw materials to prepare the ceramic saggar, and the cost is saved by 1 / 3 or above. The ceramic saggar prepared by the method can bear 50 times of thermal shock cycles without cracks, and has good thermal shock resistance. The ceramic saggar does not react with synthetic raw materials of lithium ion battery cathode materials at 1000 DEG C, and has good corrosion resistance. The service lifetime of the ceramic saggar can be 50 times or above.

Owner:WUHAN UNIV OF TECH

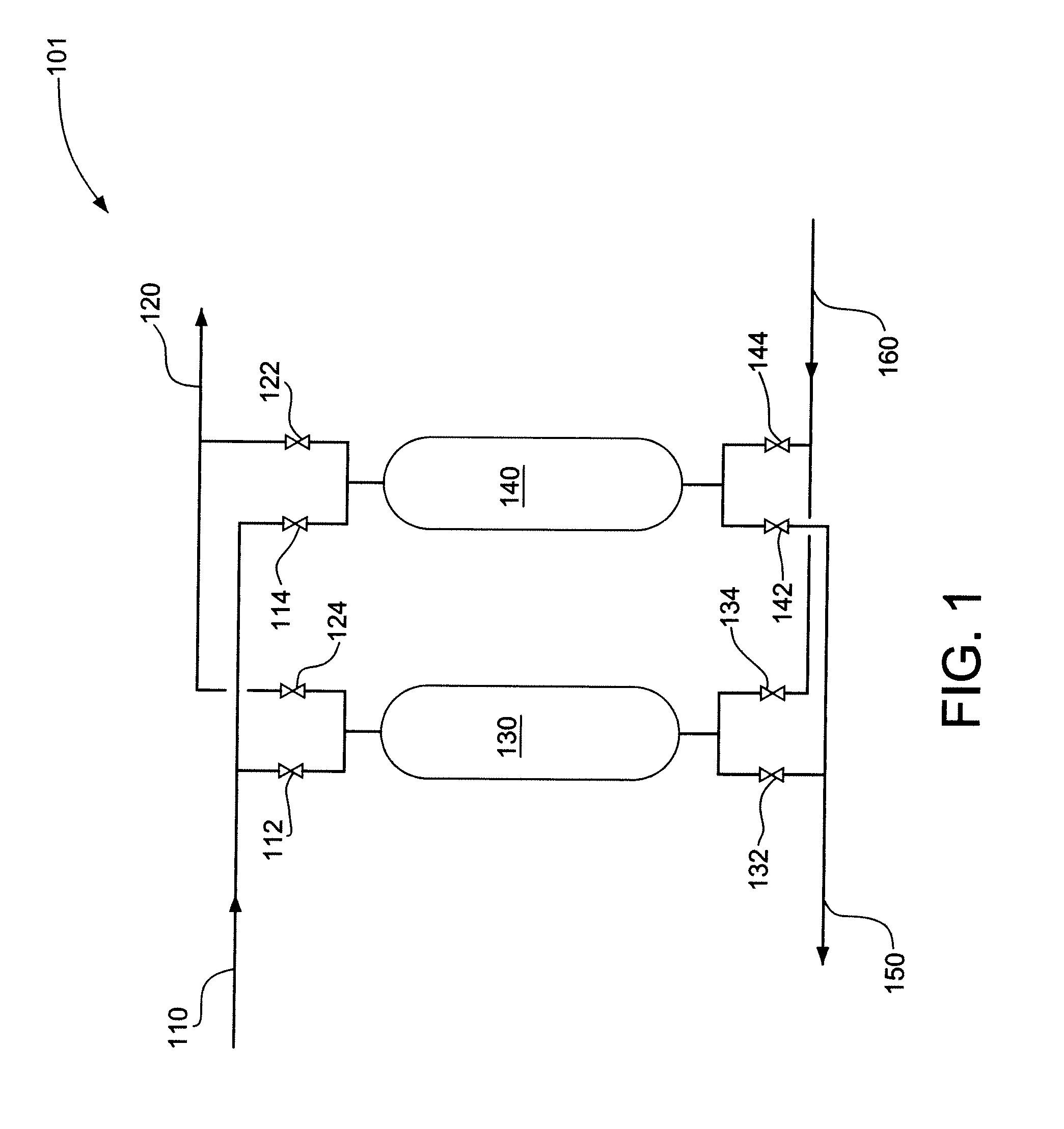

CO2-Sorptive Pellets and Uses Thereof

CO2 sorptive pellets and / or granules and their use for removing CO2 from CO2-containing gases and for producing hydrogen. CO2 sorptive pellets are suitable for use in fixed bed reactors and the like due to sufficient crush strength. CO2 sorptive granules are suitable for moving, ebullated, expanded and fluidized beds. The CO2 sorptive pellets and / or granules comprise calcium oxide and / or magnesium oxide and at least one binding agent such as calcium titanate, calcium aluminate, calcium zirconate, magnesium titanate, magnesium aluminate, and magnesium zirconate. A method for making the CO2-sorptive pellets is described. The CO2 sorptive pellets optionally comprise at Ni, Pd, Pt, and / or Rh.

Owner:AIR PROD & CHEM INC

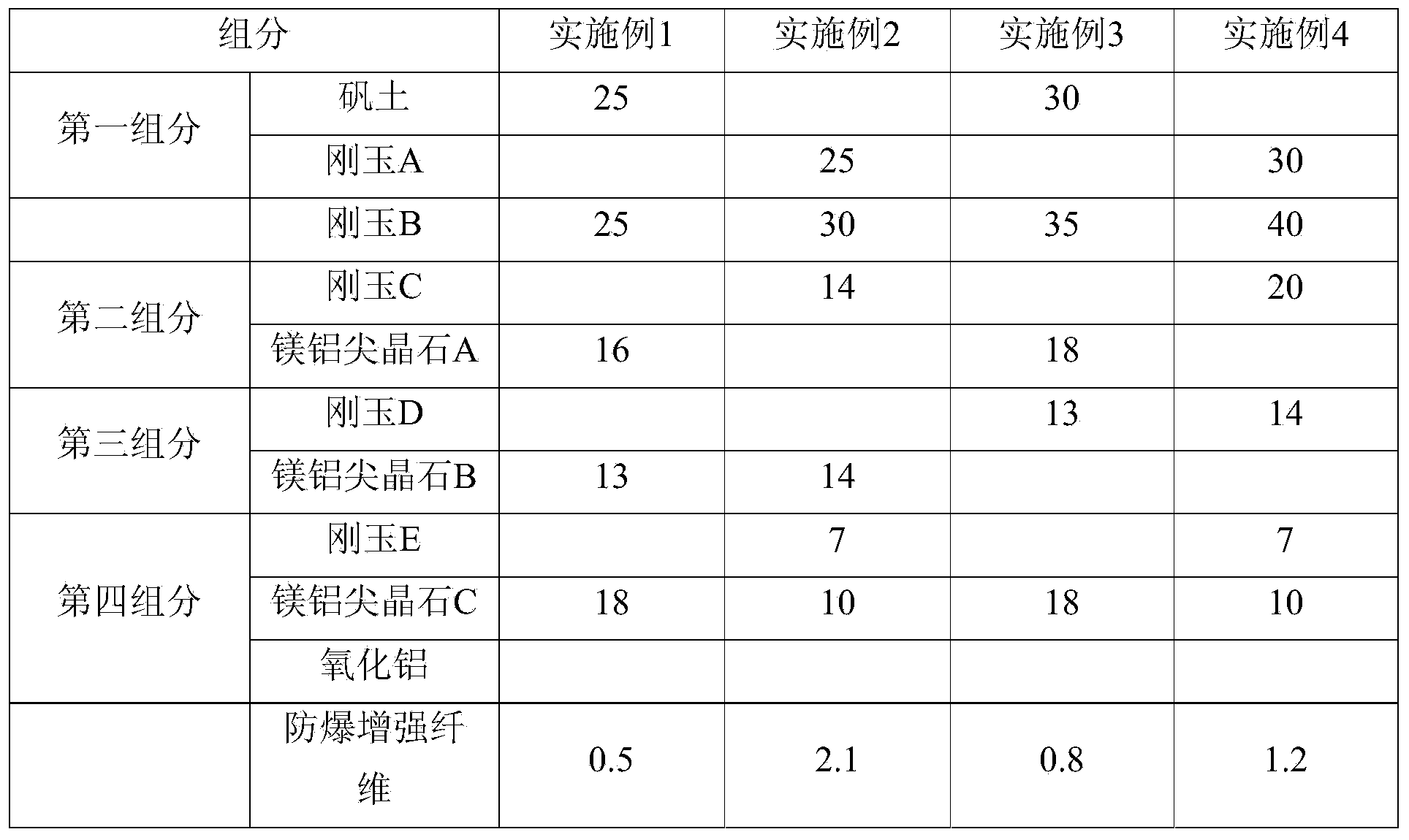

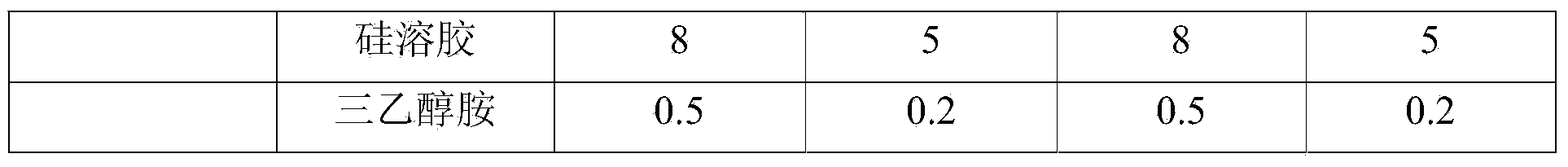

Magnesium aluminate spinel castable and method for producing prefabricated brick by using castable

The invention discloses a magnesium aluminate spinel castable and a method for producing a prefabricated brick by using the castable. The magnesium aluminate spinel castable comprises the following raw material components in parts by weight: 20-50 parts of a first component, 10-30 parts of corundum B, 10-25 parts of a second component, 5-15 parts of a third component, 5-20 parts of a fourth component, 0.1-3.5 parts of anti-explosion reinforced fibers, 4-12 parts of silica sol and 0.01-1.0 part of a curing agent. The prefabricated brick which is produced from the magnesium aluminate spinel castable by using the method has a good high-temperature resistance property, a high anti-erosion ability and a high thermal shock resistance stability property, and is short in production time, long in service life and good in heat preservation effect.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Light-weight corundum-magnesium aluminate spinel castable and preparation method thereof

The invention relates to a light-weight corundum-magnesium aluminate spinel castable and a preparation method thereof. The technical scheme of the invention is taking nano-aperture porous corundum-magnesium aluminate spinel ceramic particles with the partical sizes successively being 3-5mm, 1-2.5mm and 0.1-0.5mm as aggregates, taking nano-aperture porous corundum-magnesium aluminate spinel ceramic fine powder with the partical size being smaller than 0.074mm, magnesium aluminate spinel fine powder, corundum fine powder, magnesia fine powder and alpha-Al2O3 micro powder as matrixes and taking aluminate cement as a binding agent; the preparation method comprises the following steps: mixing the matrixes, the binding agent and sodium hexametaphosphate firstly, then adding the aggregates, uniformly mixing, then adding water, uniformly stirring, moulding by casting, carrying out maintenance, demoulding and drying, and keeping the temperature for 2-6h at the condition with the temperature being 1450-1600 DEG C to obtain the light-weight corundum-magnesium aluminate spinel castable. By adopting the light-weight corundum-magnesium aluminate spinel castable and the preparation method, the process is simple, and a prepared product has the average pore size in a nanoscale, is low in heat conductivity coefficient, good in medium erosion and penetrability resistance and high in thermal shock resistance, and is suitable for parts, including bottoms, walls and the like, of steel ladles.

Owner:WUHAN UNIV OF SCI & TECH

Magnesium aluminate spinel-supported sulphur-tolerant methanation catalyst

ActiveCN103191720AHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsChemical oxygen demandActive component

The invention discloses a magnesium aluminate spinel-supported sulphur-tolerant methanation catalyst. The magnesium aluminate spinel-supported sulphur-tolerant methanation catalyst comprises 0-20 parts (by weight) of catalyst auxiliary (M1) AOB (ammonia oxidizing bacteria), 5-90 parts (by weight) of catalyst active component (M2) COD (chemical oxygen demand), 5-90 parts (by weight) of support modifier (M3) EOF (electroosmotic flow), and 100 parts (by weight) of porous support-magnesium aluminate spinel, wherein M1 is Co, Ni, La and / or K; M2 is Mo, W and / or V; and M3 is Ce, Zr, Ti and / or Si.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

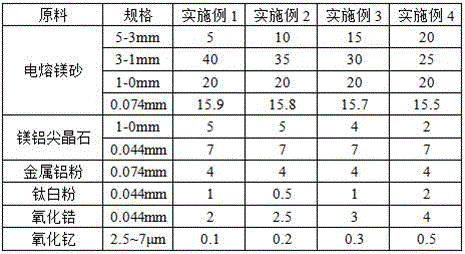

Slag-corrosion-resistant magnesite-spinel brick and preparation method thereof

The invention provides a slag-corrosion-resistant magnesite-spinel brick and a preparation method thereof and relates to a slag-corrosion-resistant magnesite-spinel brick. The slag-corrosion-resistant magnesite-spinel brick is prepared from, by mass, 61-81% of fused magnesite particles and fine powder, 0-8% of magnesium aluminate spinel particles, 3-10% of magnesium aluminate spinel fine powder, 2-8% of aluminum powder, 0.5-3% of titanium dioxide, 0.5-10% of zirconium oxide fine powder and 0.1-0.5% of yttrium oxide powder. The slag-corrosion-resistant magnesite-spinel brick is obtained through the steps of material preparation, premixing of materials, mixing of the materials and forming. Slag corrosion resistance, high-temperature oxidation resistance and compactness of the magnesite-spinel brick are improved, and accordingly the aim of prolonging the service life of the magnesite-spinel brick is achieved.

Owner:LUOYANG LIER REFRACTORY MATERIAL

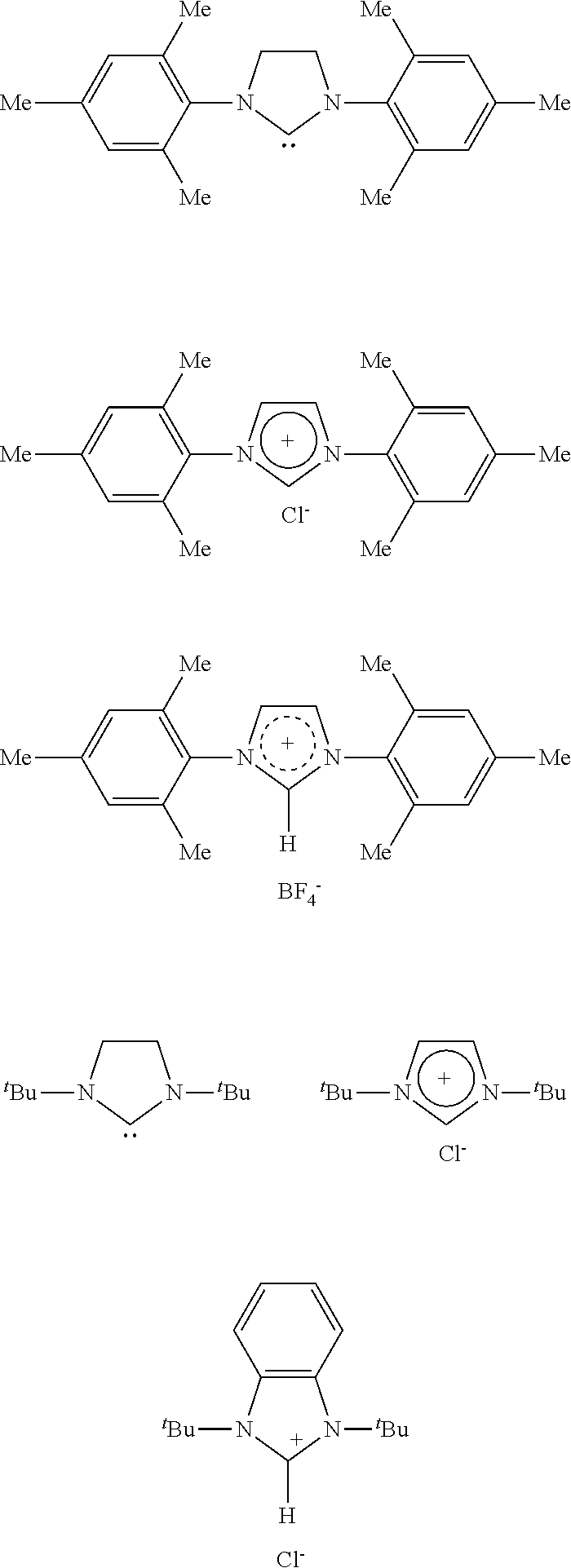

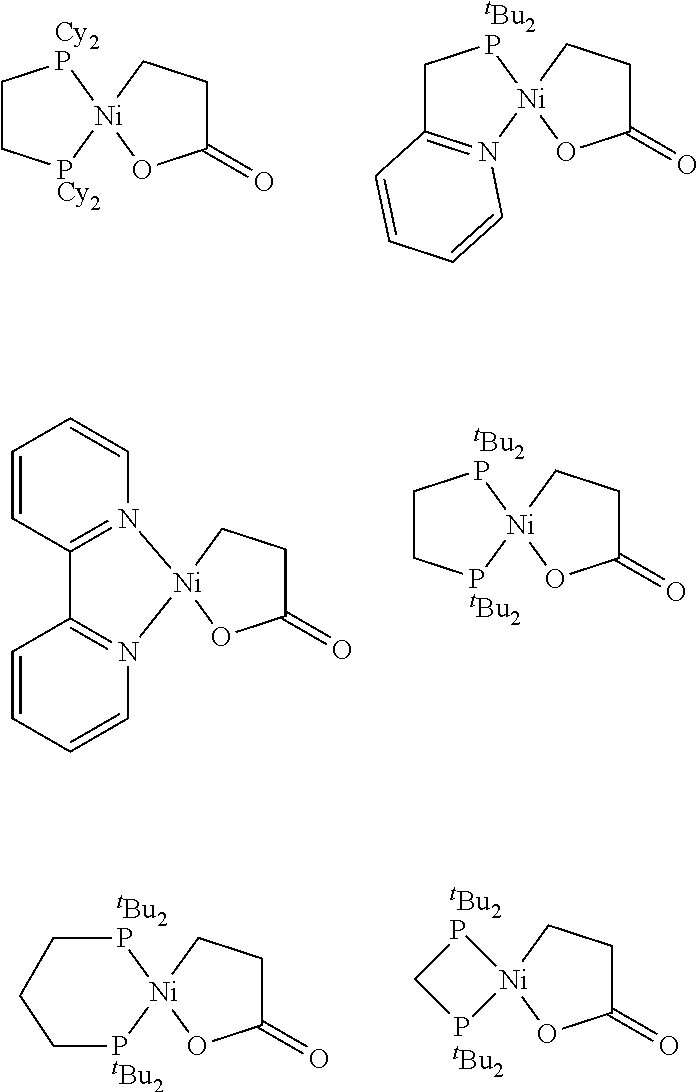

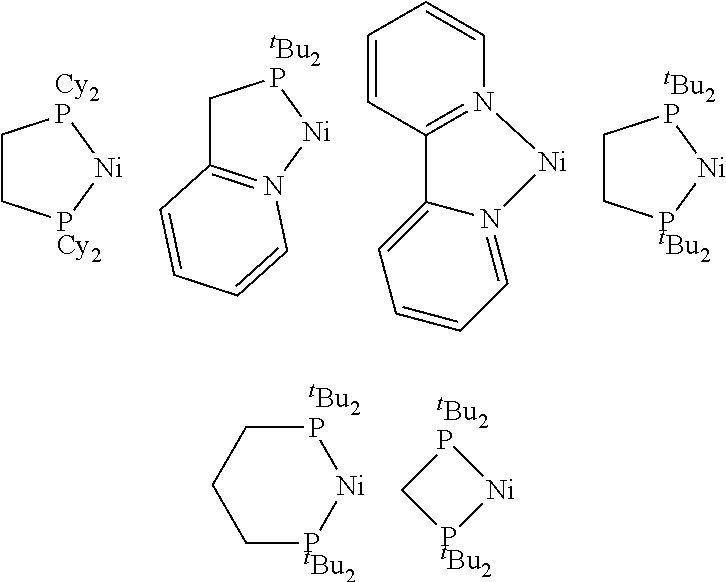

Methods for the production of α,β-unsaturated carboxylic acids and salts thereof

ActiveUS9416087B2Easy to separateProcedure is very challengingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMixed oxideSepiolite

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Zirconia ceramic material and preparation method thereof

The invention discloses a zirconia ceramic material and a preparation method thereof, belonging to the field of oral ceramic. The zirconia ceramic material is prepared from the following two raw materials: zirconia nanopowder containing 2-4 percent by mole of yttrium oxide and magnesium aluminate spinel nanopowder. When the thickness of the ceramic material is 1 mm, the light transmittance in a visible light range is over 25 percent and can reach 35 percent maximally, and the bending strength is over 970 MPa and can reach 1,100 MPa maximally. The zirconia ceramic material is obtained through a simple hot press sintering method, the ceramic material has better performance while the energy consumption is reduced, the process flow is simple, an obtained product is stable in quality, and the industrialization is easy.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

A composite electro-fusing refractory material and method for preparing the same

InactiveCN1844051AReduce pollutionReduce carbon contentChemical compositionElectrical energy consumption

The invention refers to a production method of electrocast refractories composite. The technical project is mixing 20-90 % aluminium ash and alumina or 10-80% magnesium-containing compound according to weight percent, pressing to compact, electric smelting in 1800-3000deg C, taking off after chilled, and then bruising, separating and the getted electrocast refractories composite is electro-melting corundum or electro-melting magnesium aluminate spinel compound. Thereinto: the percentage content of main component in chemical aluminium ash is Al2O3 10-70%, Al 10-40%, MgO 0.3-20%, SiO2 0.5-30%;Magnesium-containing compound is one or two kind of magnesium carbonate and magnesia. This invention using non-oxidized substance such as metal alumina, aluminium nitride and so on of aluminium ash as main reductor, fuse deacidizing oxidate such as SiO2,Fe2O3,TiO2 and so on in alumina or aluminium ash, so electrical energy consumption is low and environmental contamination is light; The prepared electro-melting corundum or magnesium aluminate spinel compoud has the character of low carbin containing.

Owner:WUHAN UNIV OF SCI & TECH

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

Sagger for mullite-cordierite lithium battery cathode material and preparation method thereof

InactiveCN110282964AImprove corrosion resistanceExtended service lifeCharge supportsCordieriteUltimate tensile strength

The invention relates to a sagger for a mullite-cordierite lithium battery cathode material and a preparation method thereof. According to the technical scheme, by weight, 30-35 of mullite particles, 20-25% of mullite fine powder, 30-35% of cordierite particles, 4-7% of dextrin and 5-7% of Guangxi white mud are mixed and stirred to obtain a mixture A; by weight, 30-35% of mullite fine powder, 30-35% of magnesium aluminate spinel fine powder and 35-36% of andalusite fine powder are stirred, dried and ground to obtain a mixture B; then, the mixture A is placed into a mold, the mixture B is uniformly sprayed on the surface of a pressure head, mechanical pressing is performed in the mode that a bowl opening faces downwards, drying is performed under the temperature of 1,300-1,400 DEG C, and the temperature is kept constant for 5-6 h to obtain the sagger for the mullite-cordierite lithium battery cathode material. The sagger is low in cost, simple in technology and high in yield; the prepared sagger for the mullite-cordierite lithium battery cathode material is high in volume density, high in compression strength, good in thermal shock resistance and good in corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com