Patents

Literature

71 results about "Higher alkanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Higher alkanes are alkanes having nine or more carbon atoms. Nonane is the lightest alkane to have a flash point above 25 °C, and is not classified as dangerously flammable. The term higher alkanes is sometimes used literally as "alkanes with a higher number of carbon atoms". One definition distinguishes the higher alkanes as the n-alkanes that are solid under natural conditions.

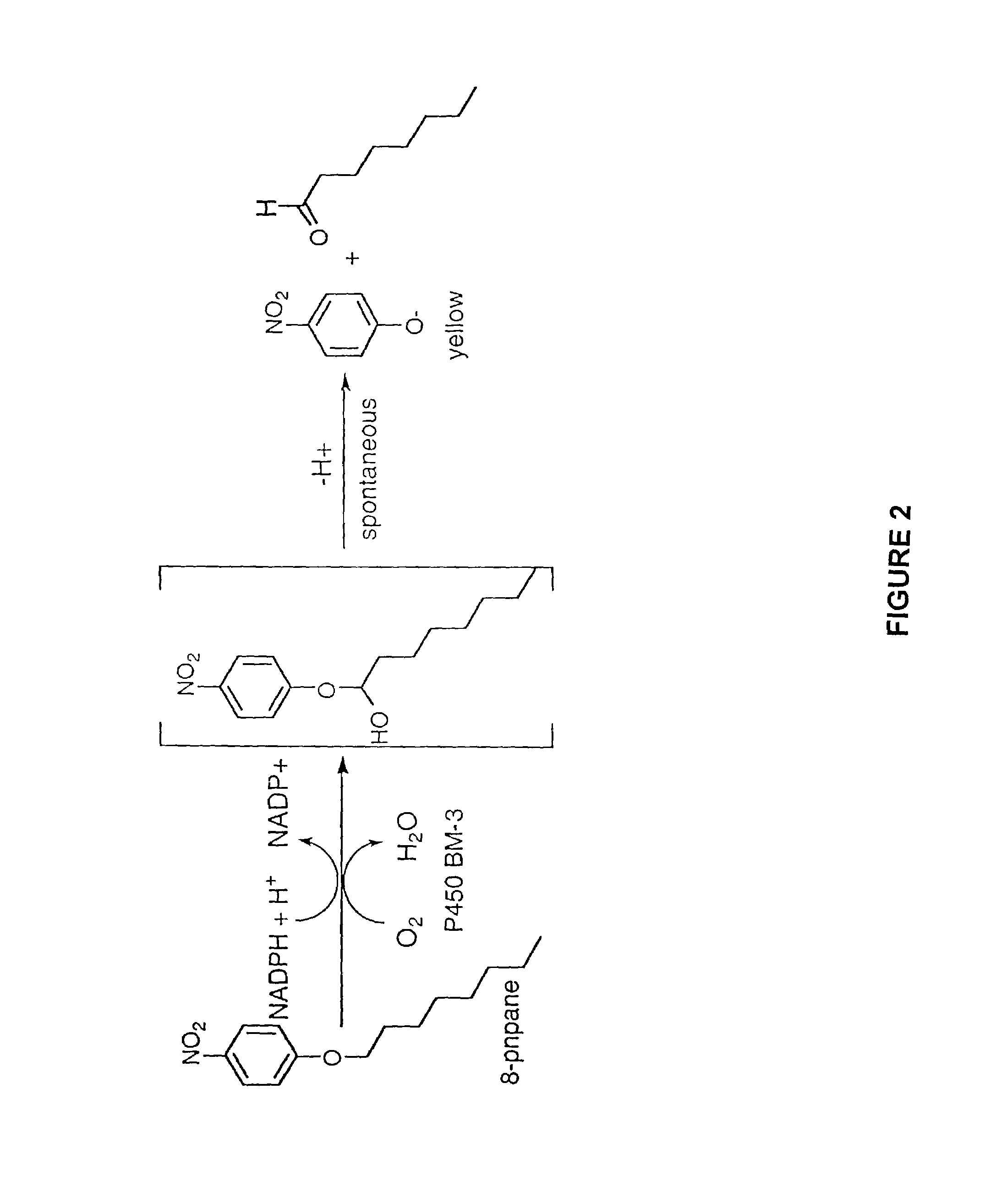

Cytochrome P450 oxygenases

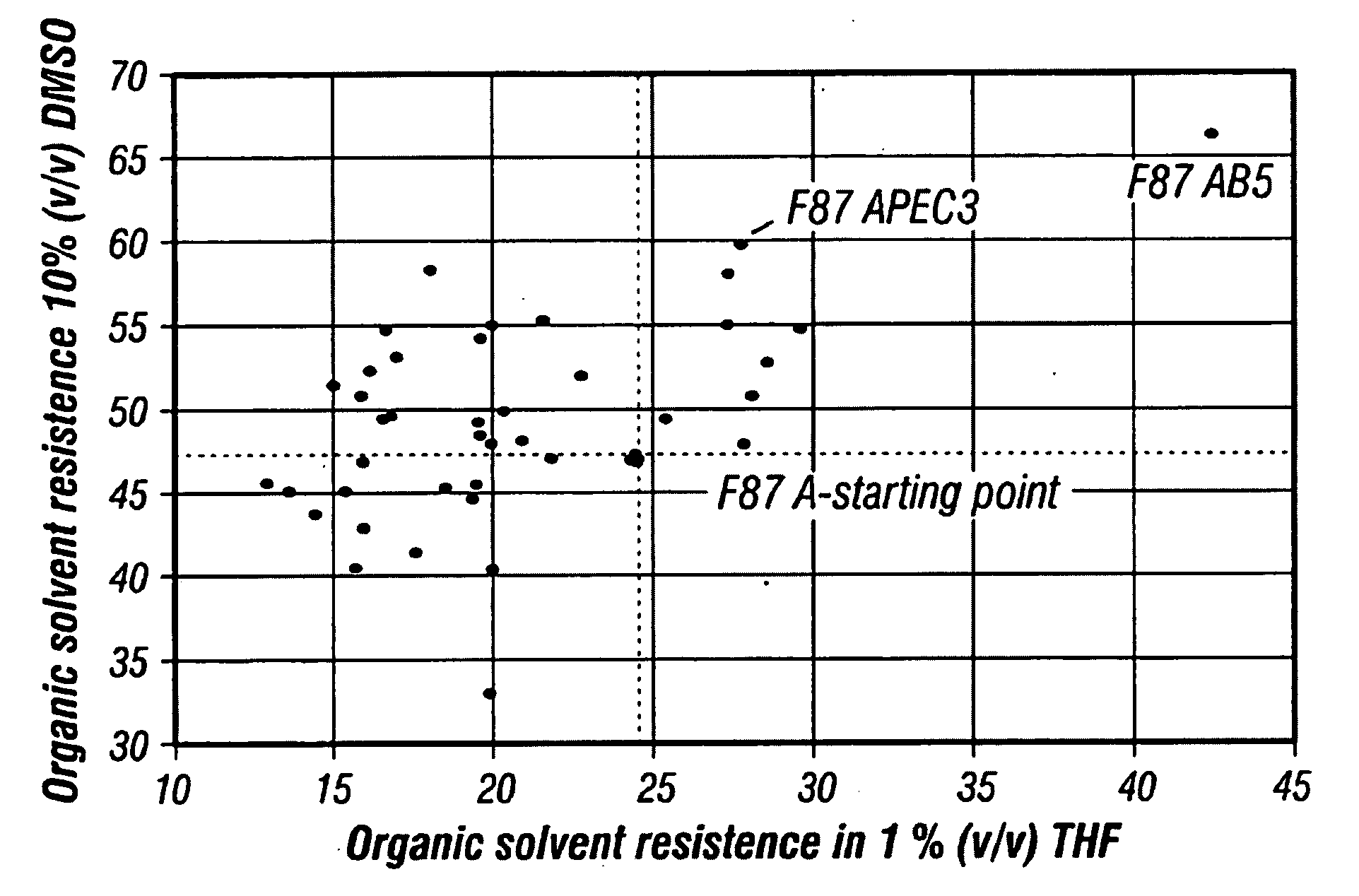

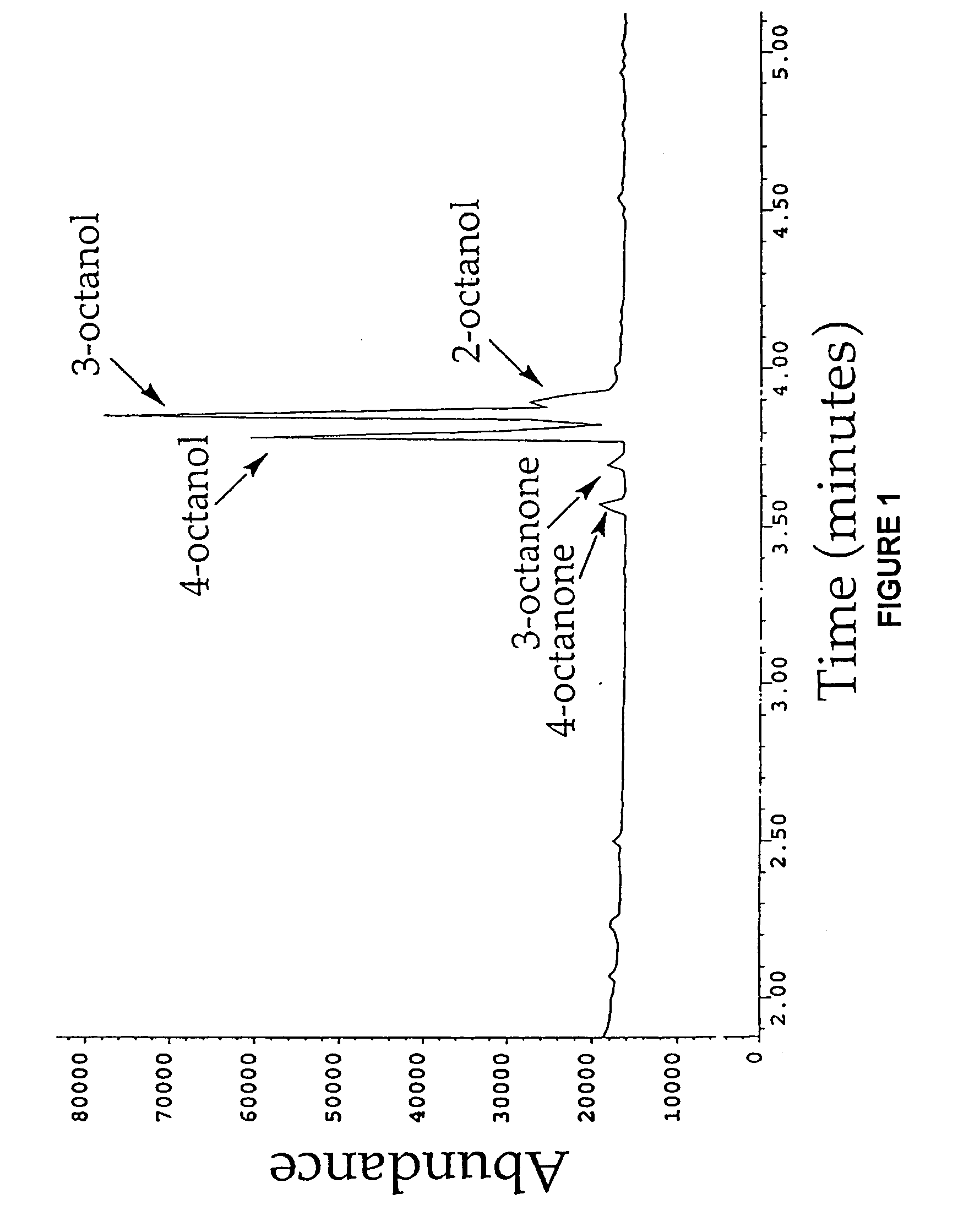

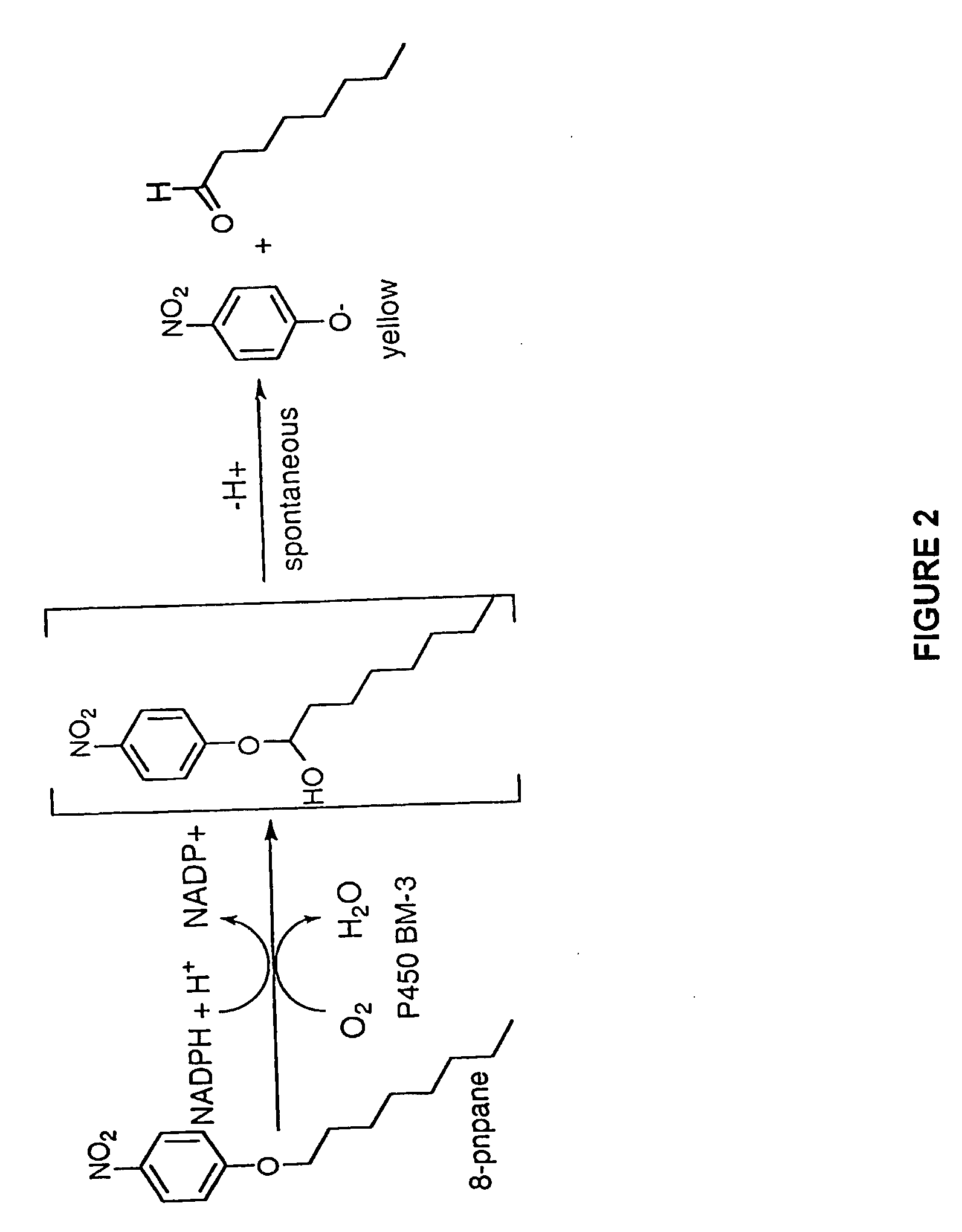

ActiveUS7226768B2High activityImprove stabilityBacteriaSugar derivativesCytochrome p450 enzymeAmino acid

Nucleic acids encoding cytochrome P450 variants are provided. The cytochrome P450 variants of have a higher alkane-oxidation capability, alkene-oxidation capability, and / or a higher organic-solvent resistance than the corresponding wild-type or parent cytochrome P450 enzyme. A preferred wild-type cytochrome P450 is cytochrome P450 BM-3. Preferred cytochrome P450 variants include those having an improved capability to hydroxylate alkanes and epoxidate alkenes comprising less than 8 carbons, and have amino acid substitutions corresponding to V78A, H236Q, and E252G of cytochrome P450 BM-3. Preferred cytochrome P450 variants also include those having an improved hydroxylation activity in solutions comprising co-solvents such as DMSO and THF, and have amino acid substitutions corresponding to T235A, R471A, E494K, and S1024E of cytochrome P450 BM-3.

Owner:NORO MOSELEY PARTNERS V +2

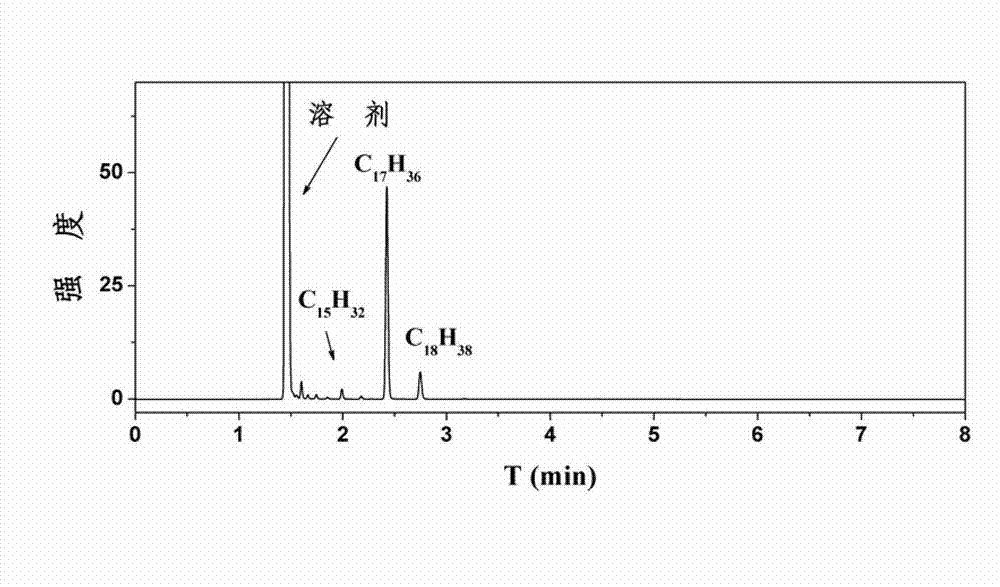

Method for preparing alkane fuel with high cetane number by catalyzing plant oil or long-chain fatty acid by Ru catalyst and application thereof

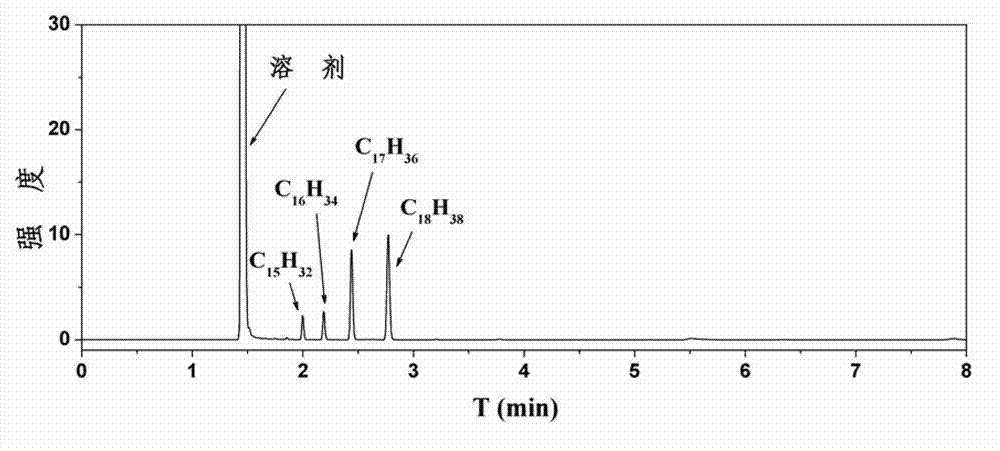

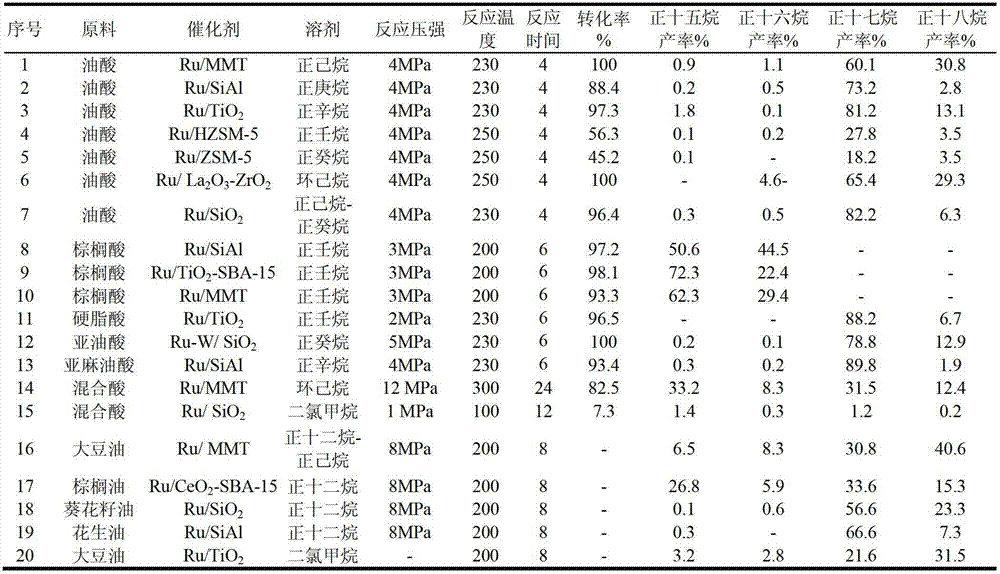

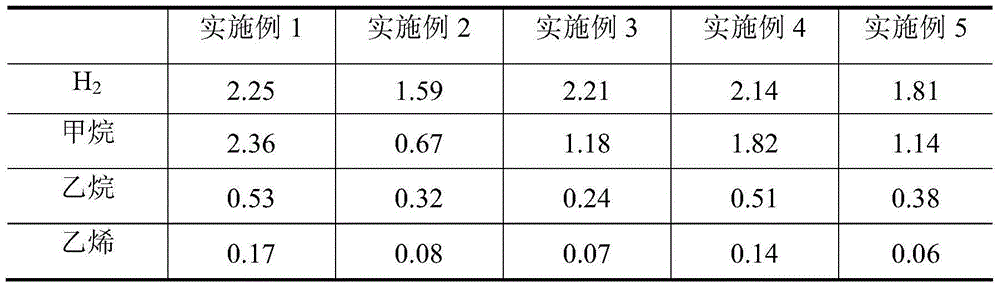

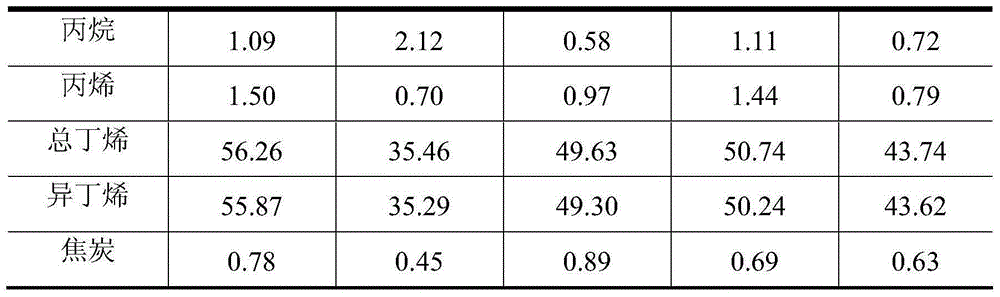

InactiveCN102876350AHigh yieldImprove conversion rateBiofuelsLiquid hydrocarbon mixture productionHigher alkanesLong chain fatty acid

The invention provides a method for preparing alkane fuel with a high cetane number by catalyzing plant oil or long-chain fatty acid by a Ru catalyst, which comprises the following steps: (1) mixing plant oil or long-chain fatty acid with a solvent in proportion; (2) adding a catalyst with the hydrogenation function into the mixed solution in step (1); (3) reacting in reducing atmosphere to obtain long-chain alkane with a main component of C15-C18. The method for catalyzing plant oil or long-chain fatty acid by a Ru catalyst provided by the invention has a high fatty acid conversion rate and a high alkane yield. In addition, the method of the invention is simple in process, convenient for operation, and mild in reaction condition; the whole reaction process is basically free of carbon deposition; the catalyst is cheap, easily available, and suitable for multi-time repeated use without activity reduction. The product of the invention can be used directly as diesel oil, and has important economic and social meaning for vehicle liquid fuel sustainable supply.

Owner:UNIV OF SCI & TECH OF CHINA

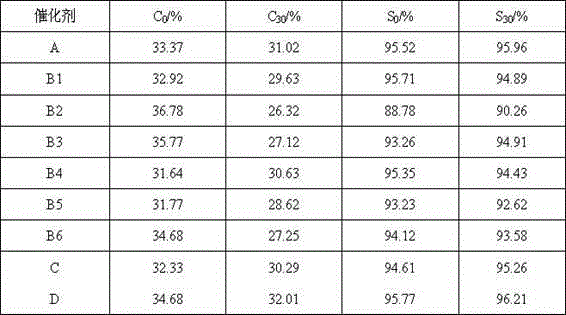

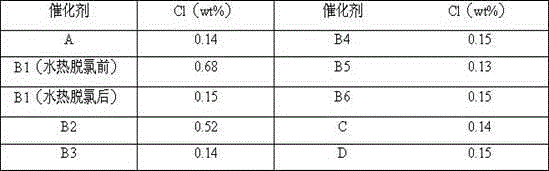

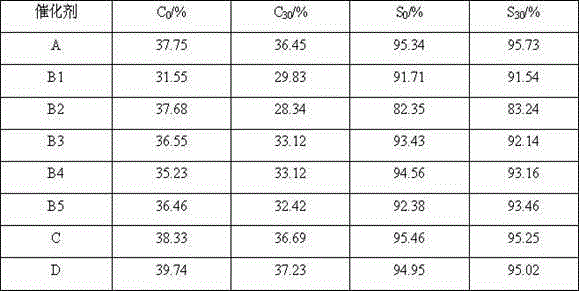

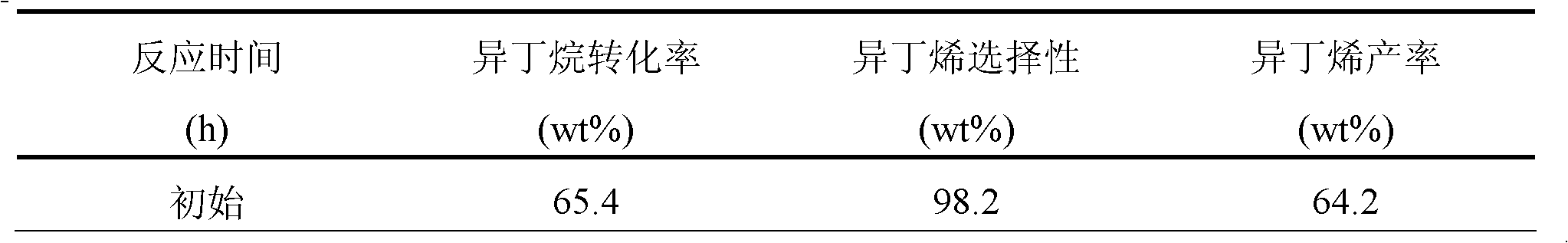

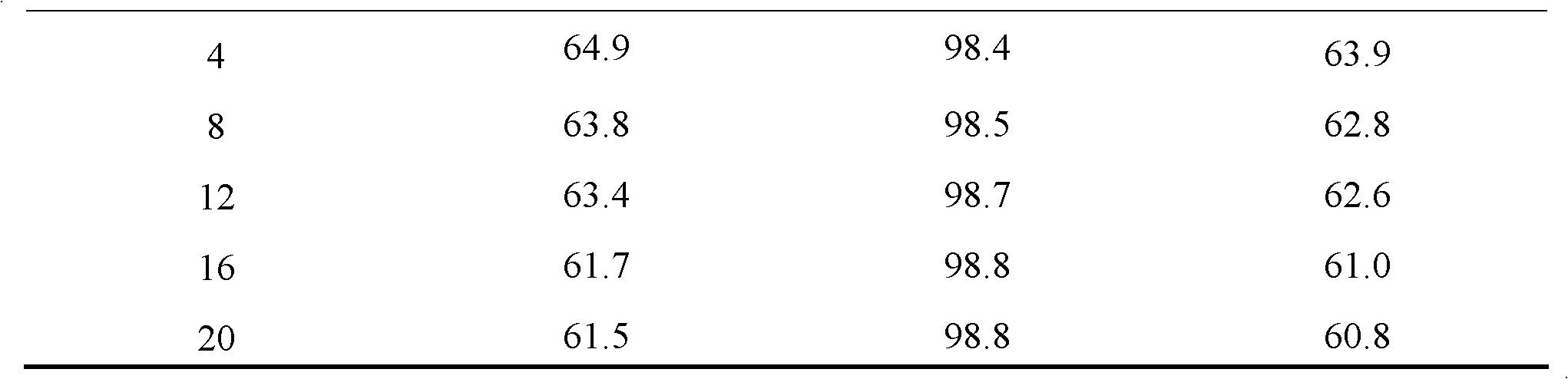

Catalyst used for alkane catalytic dehydrogenation and preparation method thereof

ActiveCN104607168AIncrease conversion rate per passHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsHigher alkanesPtru catalyst

A catalyst for alkane dehydrogenation comprises a component A and a component B, wherein the component A is an oxide selected from one or more of La, Fe, Zn, Cu, Co or Ce, and the content of the component A in the catalyst accounts for 0.5 to 50 wt%, preferably 10-30 wt%; the component B is a mixed oxide or a composite oxide selected from one or more of SiO2, Al2O3, ZrO2, Ga2O3 and MgO, and the content of the component B in the catalyst accounts for 50 to 99.5 wt%, preferably 70-90 wt%. The catalyst provided by the invention has high alkane single-pass conversion and high selectivity of olefin, after repeated regeneration, the reactivity is very stable, and the catalyst is used in a circulating fluidized bed reaction device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method of magnesium aluminate spinel for catalyst carrier

ActiveCN105642264AEasy to operateSynthesis temperature is lowMaterial nanotechnologyHydrocarbonsHigher alkanesPlatinum

The invention relates to a preparation method of magnesium aluminate spinel for a catalyst carrier; a sol-gel method is adopted for preparation, and the preparation method comprises the following steps: (1) under a condition of the temperature of 50-80 DEG C, mixing water and ethylene glycol together; (2) adding citric acid, a magnesium source and an aluminum source into the ethylene glycol aqueous solution with the molar ratio of citric acid (CA) to Mg to Al of 6 to (0.9-1) to (2-2.2); (3) heating the solution until the solution becomes a transparent red gel, and aging; and (4) at the temperature of 350-500 DEG C, roasting for 2-4 h, grinding, again roasting for 2-12 h at the temperature of 600-800 DEG C, and thus obtaining the magnesia alumina spinel carrier. The prepared magnesia alumina spinel product is mainly used for a carrier of a low-carbon alkane dehydrogenation reaction catalyst, is loaded with 0.01-0.5 wt.% of a platinum-family transition metal element, 0.01-1 wt.% of Sn, and has smaller size, higher specific surface, and suitable pore structure; and compared with a conventional dehydrogenation catalyst carrier, the carrier has the characteristics of high alkane conversion rate, good stability, and good monoolefine selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cytochrom P450 oxygenases

InactiveUS20080293928A1High activityImprove stabilityBacteriaSugar derivativesCytochrome p450 enzymeAmino acid

Owner:CALIFORNIA INST OF TECH

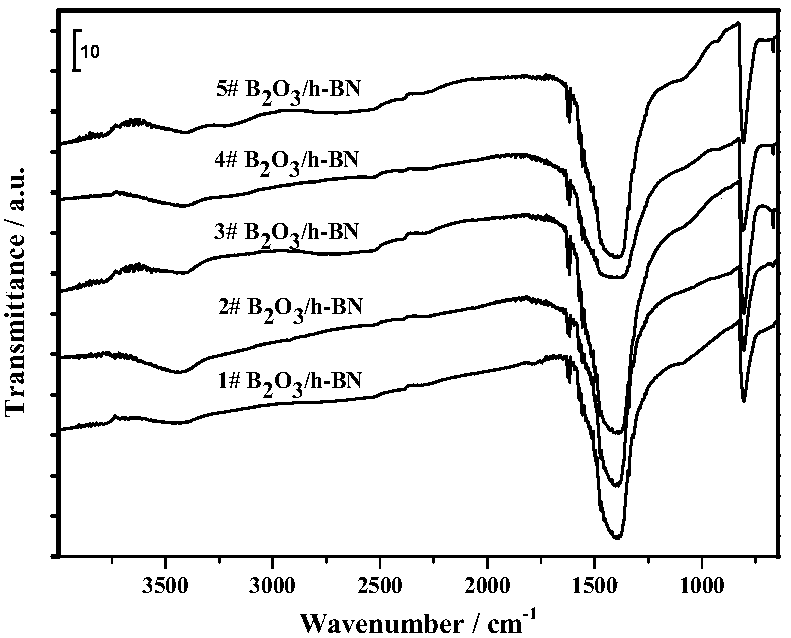

Preparation method of dehydrogenation catalyst

ActiveCN105582977ASimple manufacturing methodImprove stabilityMolecular sieve catalystsHydrocarbonsMolecular sievePotassium nitrate

The invention discloses a preparation method of a dehydrogenation catalyst. The preparation method comprises the following steps: (1) the ZSM-5 molecular sieve, aluminum oxide, sesbania powder and a dilute nitric acid solution are mixed, pulping, mixing and kneading, band extrusion, drying, and calcination are carried out, and the aluminum oxide carrier doped with ZSM-5 molecular sieve is obtained; wherein relative crystallinity of the ZSM-5 molecular sieve is 40-80%; (2) the carrier obtained in the step (1) is impregnated with an Sn-containing precursor, drying and calcination are carried out, and an Sn-loaded aluminum oxide carrier is obtained; (2) chloroplatinic acid, potassium nitrate and water are uniformly mixed, an impregnating solution is obtained, and the carrier obtained in the step (2) is impregnated with the impregnating solution; (4) programmed heating and drying, calcination, washing, drying and dehydration, and modification with a metal additive are carried out for the carrier which is treated by the impregnation in the step (3), and the dehydrogenation catalyst is obtained. The catalyst has the advantages of high alkane transformation efficiency, good alkene selectivity and good stability in the dehydrogenation reaction of light alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for production of triptane and triptene

Owner:RGT UNIV OF CALIFORNIA

Method for preparing low-carbon alkane dehydrogenation catalyst

ActiveCN105521813AExtend one-way operation cycleImprove stabilityMolecular sieve catalystsHydrocarbonsMolecular sieveHigher alkanes

The invention discloses a method for preparing a low-carbon alkane dehydrogenation catalyst. The method comprises the following steps: 1)mixing a ZSM-5 molecular sieve, alumina, sesbania powder and a dilute nitric acid solution, beating the materials, kneading the materials, extruding the materials, drying and performing calcination to obtain a ZSM-5 molecular sieve-doped alumina carrier; 2) impregnating the carrier by using a Sn-containing predecessor solution, drying the carrier and performing calcination on the carrier to obtain the Sn-containing carrier; 3) dropping ammoniacal liquor and adding the material into a ZnCl2 aqueous solution, preparing a Zn(NH3)4C12 solution, adding a platinum-containing compound to prepare an impregnation solution; and 4) performing impregnation on the Sn-containing carrier by using the impregnation solution in the step 4), drying the material, and performing calcination to obtain the low-carbon alkane dehydrogenation catalyst. The prepared low-carbon alkane dehydrogenation catalyst has high alkane conversion rate, alkene selectivity and good stability in a low carbon alkane dehydrogenation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method used for extracting cembrenediols from tobacco inflorescence

ActiveCN105001052AIncrease contentIncrease profitHydroxy compound separation/purificationNicotiana tabacumCembratriene

The invention relates to a method used for extracting cembrenediols from tobacco inflorescence. The method comprises following steps: 1, an organic solvent is adopted to extraction and condensation so as to obtain a tobacco flower surface glandular hair secreta crude extract; 2, the crude extract is subjected to solvent precipitation so as to remove higher alkanes, and pigments are removed with active carbon so as to obtain a tobacco diterpene extract product, wherein the tobacco diterpene extract product possesses broad-spectrum inhibition effect on plant pathogenic fungi, and especially excellent inhibition effect on apple rot; 3, the tobacco diterpene extract product is subjected to silica gel column chromatography successively so as to obtain two main diterpene compounds alpha-4,8,13-cembratriene-1,3-diol, and beta-4,8,13-cembratriene-1,3-diol with antitumor activity, neuroprotective agent activity, and bacteriostatic activity. Waste tobacco inflorescence is taken as the raw material, so that utilization of waste resources is realized; extraction step is simplified greatly, and cost is reduced; and product yield and purity are high.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD

Composition for preparing catalyst having hydrocracking effect, catalyst, applications of catalyst, and hydrocracking method

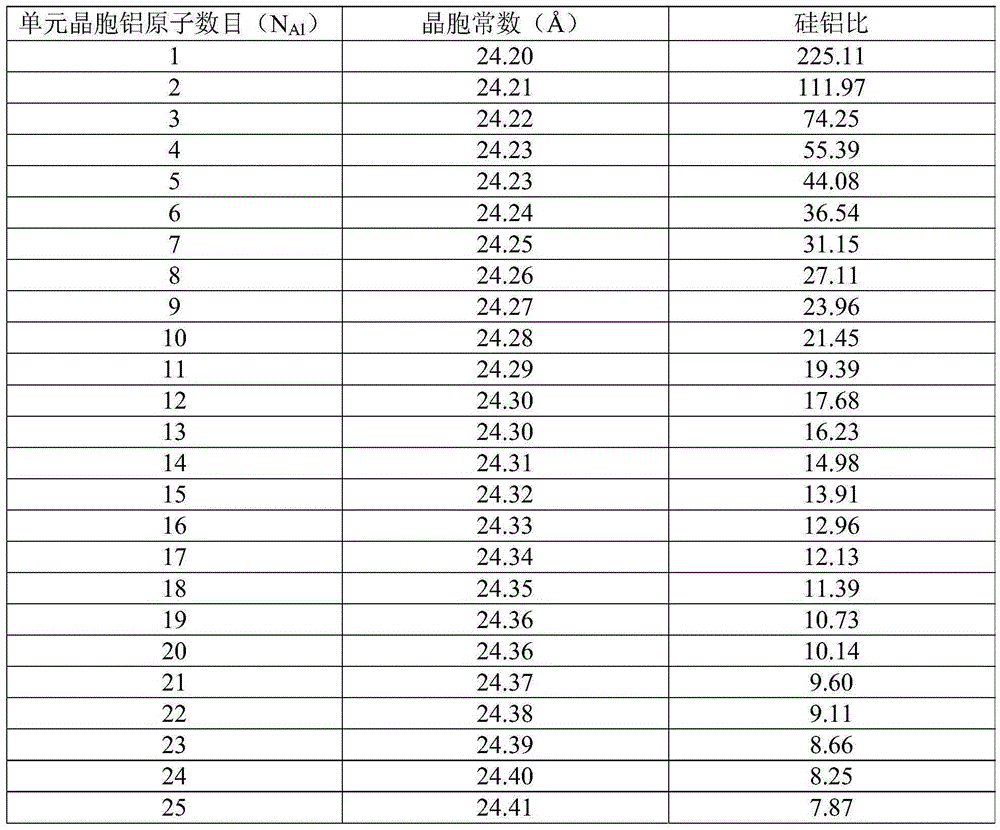

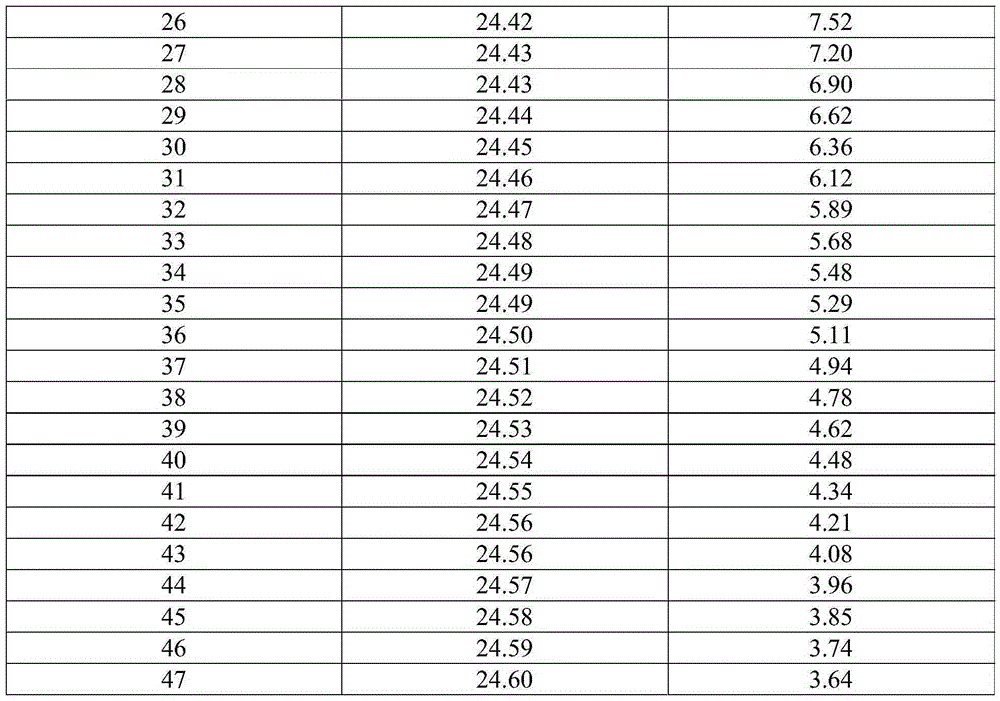

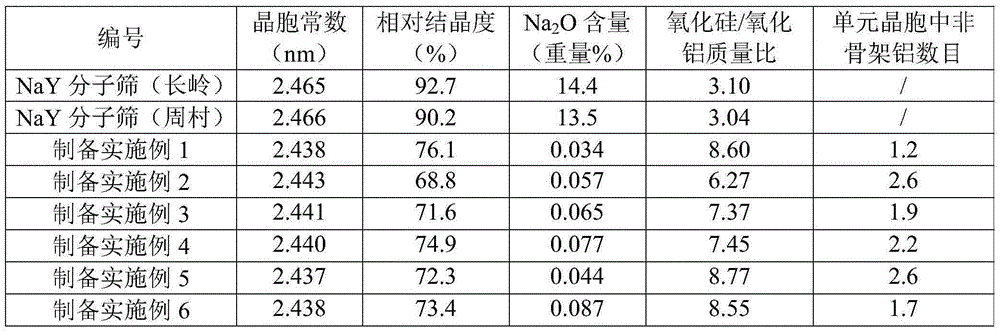

ActiveCN106622340AImprove balanceMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsHigher alkanesMolecular sieve

The present invention discloses a composition for preparing a catalyst having a hydrocracking effect, the catalyst prepared from the composition, and applications of the catalyst. The composition contains a carrier, a compound containing a group VIII metal element, a compound containing a group VIB metal and an organic additive, wherein the organic additive is selected from an organic acid and an organic amine, the carrier contains a dealuminzation Y-type molecular sieve and a heat-resistant inorganic oxide, the cell constant of the dealuminzation Y-type molecular sieve is 2.430-2.450 nm, the relative crystallinity is more than 65%, the secondary pore volume is 0.1-0.3 mL / g, the alkali metal element content is less than 0.2 wt% (calculated as the oxide), and the number of the non-skeleton aluminum in the unit cell is less than 3. The present invention further discloses a hydrocracking method using the catalyst. According to the present invention, the catalyst prepared from the composition has high catalyst activity and has high middle distillate selectivity, and the obtained tail oil has low BMCI value and high alkane content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low carbon alkane dehydrogenation olefin production catalyst and preparation method thereof

InactiveCN102989455AGood reaction selectivityHigh reactivityMolecular sieve catalystsHydrocarbonsDehydrogenationSilicon dioxide

The present invention provides a low carbon alkane dehydrogenation olefin production catalyst and a preparation method thereof. According to the catalyst, a carrier is loaded with 0.01-5% by mass of a platinum group transition metal element, 0.01-10% by mass of a gold element, 0.01-10% by mass of a Group VIA metal element, and 0.01-10% by mass of an alkali metal element; or 0.2-15% by mass of a halogen element and 0.01-3% by mass of a sulfur element are added to be adopted as a modification component; the Group VIA metal element, the platinum group transition metal element, the gold element, the alkali metal element, the halogen element and the sulfur element are sequentially and respectively impregnated onto a carrier such as silica, a molecular sieve, magnesium-aluminum spinel or alumina, and a steam treatment is performed after the Group VIA metal element, the platinum group transition metal element and the gold element are impregnated and loaded on the carrier, wherein the Group VIA metal element, the platinum group transition metal element, the gold element, the alkali metal element, the halogen element and the sulfur element are adopted as catalyst components; and the catalyst has characteristics of high alkane conversion rate, high monoene selectivity and good stability.

Owner:PETROCHINA CO LTD +1

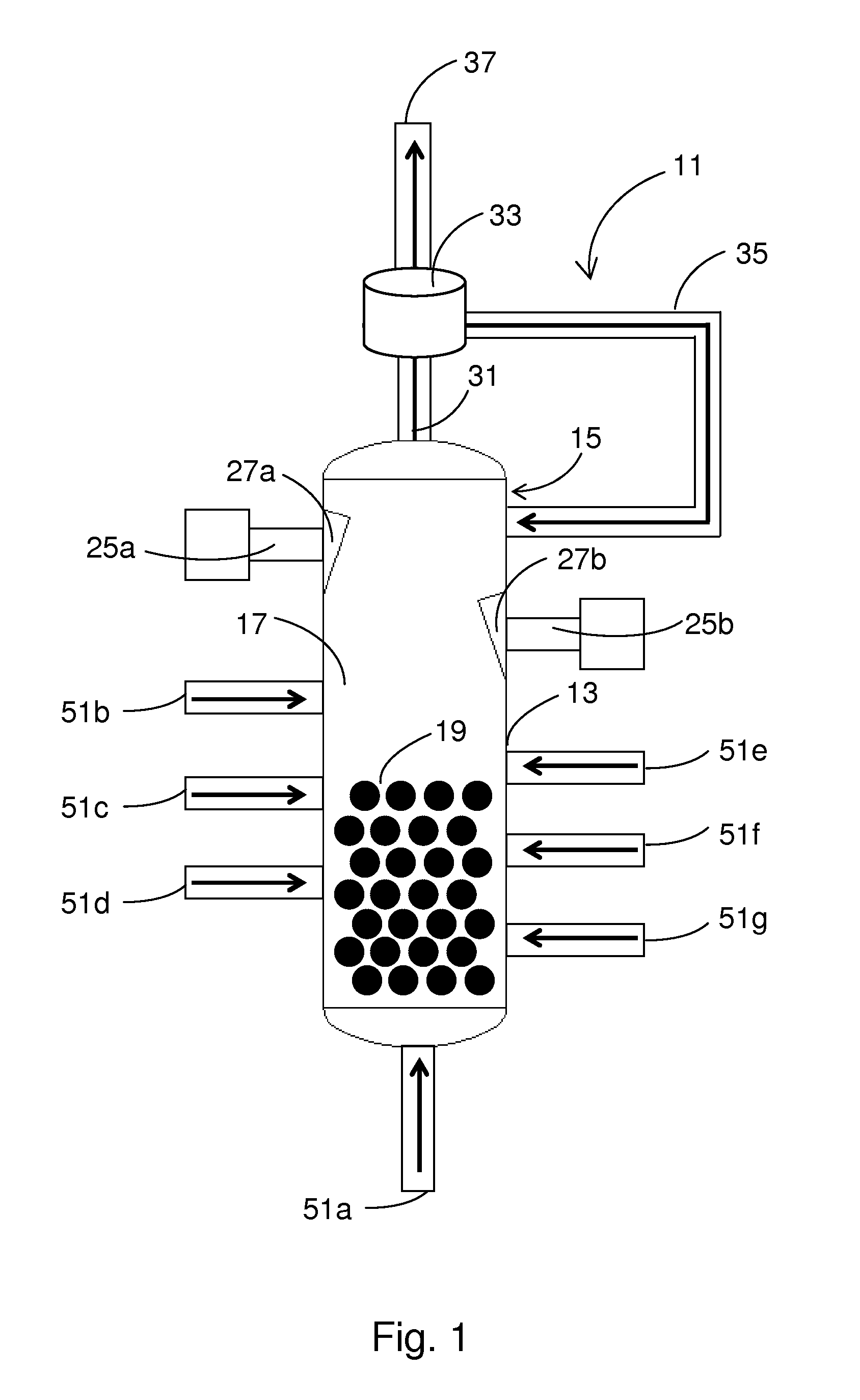

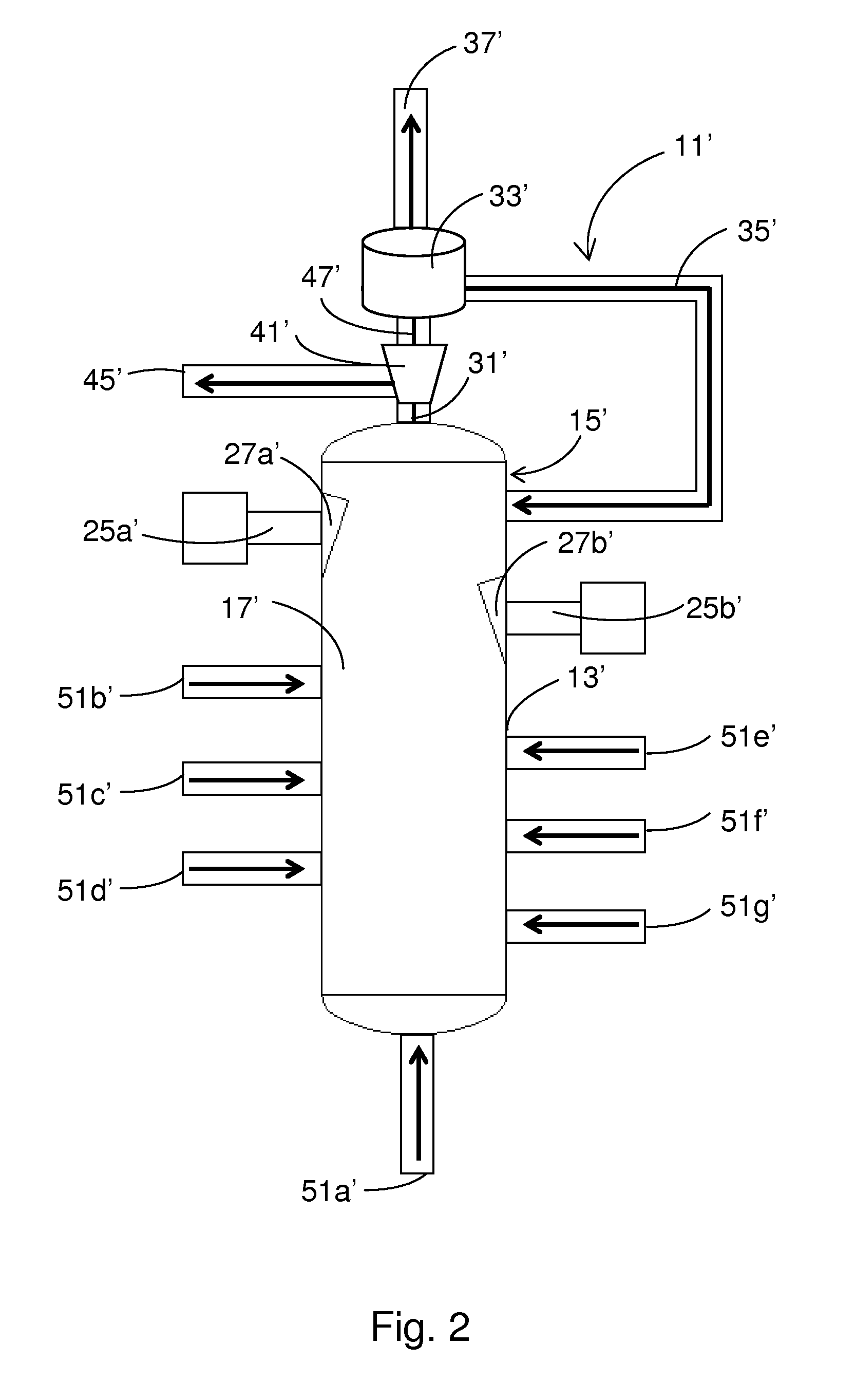

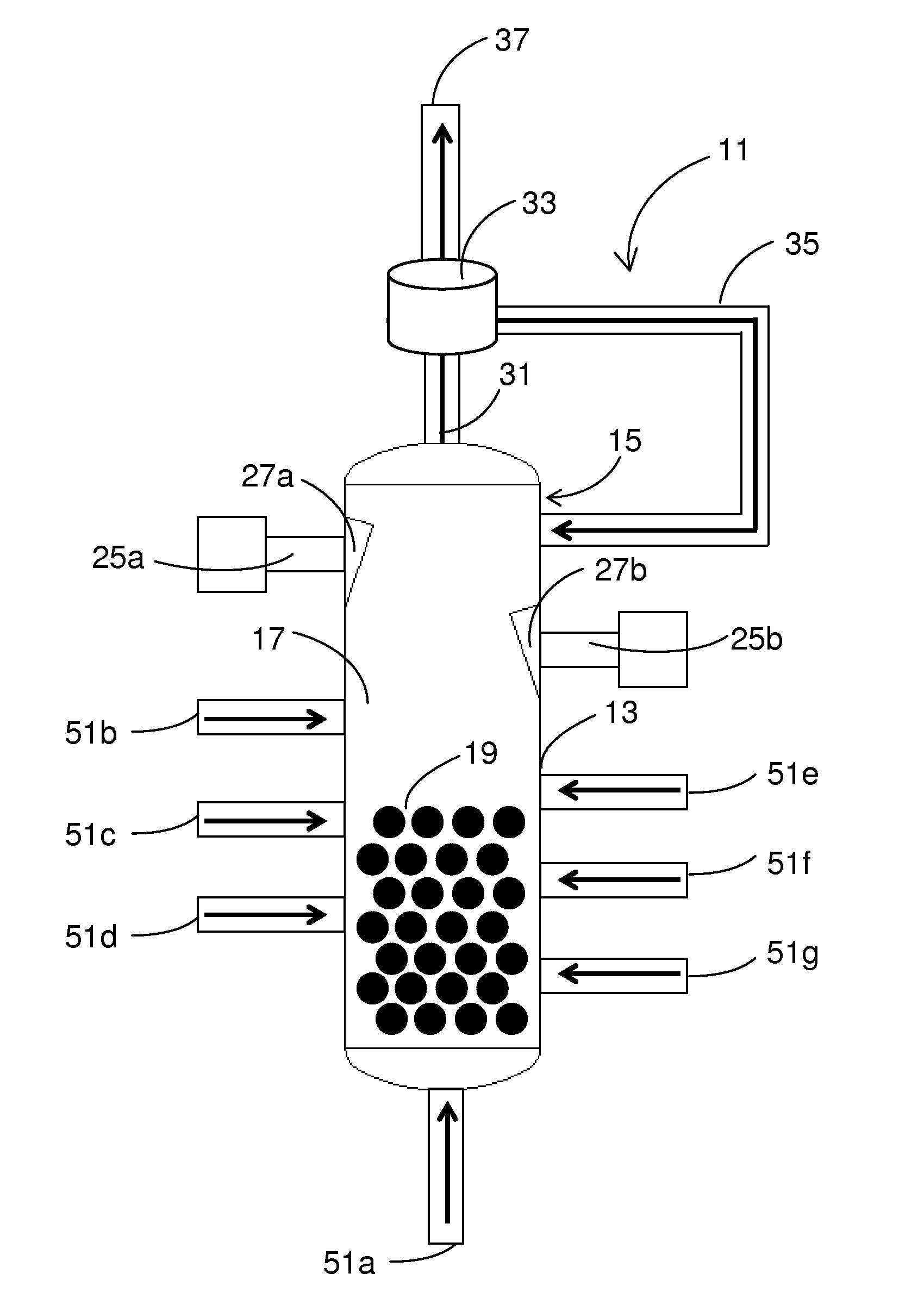

Process and apparatus for converting greenhouse gases into synthetic fuels

ActiveUS20130096213A1Improvement ingredientsHydrocarbon from carbon oxidesOrganic compound preparationHigher alkanesHydrogen

Embodiments of the present invention are directed to apparatus and methods for converting carbon dioxide and / or methane into higher alkanes and hydrogen gas in a single reaction chamber using a catalyst and microwave radiation.

Owner:ECOKAP TECH

Method for preparing easily-machined polyether type thermoplastic polyurethane elastomer

The invention discloses a method for preparing easily-machined polyether type thermoplastic polyurethane elastomer (TPU). The method comprises the following steps: 1) adding polyether polyhydric alcohol, an antioxidant and a catalyst into a reaction kettle for fusion, mixing and dehydration for later use; 2) respectively filling three components, namely, the polyether polyhydric alcohol, a dihydric alcohol chain extender and diisocyanate into a double-screw rod extruder for reaction through a high-precision gear pump; and 3) respectively adding solid higher alkane wax and higher fatty amine into the double-screw rod extruder by using a high-precision loss-in-weight in the middle of the double-screw rod extruder, fusing and mixing with polyurethane elastomer melt, and chopping under water to obtain easily-machined polyether type thermoplastic polyurethane elastomer grains. By adopting the method disclosed by the invention, the drying requirement is lowered (a dehumidification drying machine is not needed) when the easily-machined polyether type thermoplastic polyurethane elastomer is subjected to extrusion machining, and the surface smoothness degree of the product and the product extrusion stability are improved.

Owner:奥斯汀新材料(张家港)有限公司

VOC absorbent and processing method of VOC in air

InactiveCN106512658AImprove absorption rateEfficient purificationGas treatmentDispersed particle separationHigher alkanesProduct gas

The invention provides a VOC absorbent. The VOC absorbent is prepared from 3%-8% of Tween or Span, 20%-30% of a material A and the balance water. The material A is one of or a combination of triisopropylbenzene, biphenyl and high alkane. The invention further provides a processing method of VOC in the air. The method comprises the steps that the components are mixed to form microemulsion, the air containing VOC is introduced into the microemulsion in a concentrated mode and introduced out through an air outlet pipe, and outlet air is purified air which can be directly discharged into the interior. Accordingly, VOC in the air can be effectively removed, the method is simple, and use is convenient.

Owner:上海镁锶钡实业有限公司

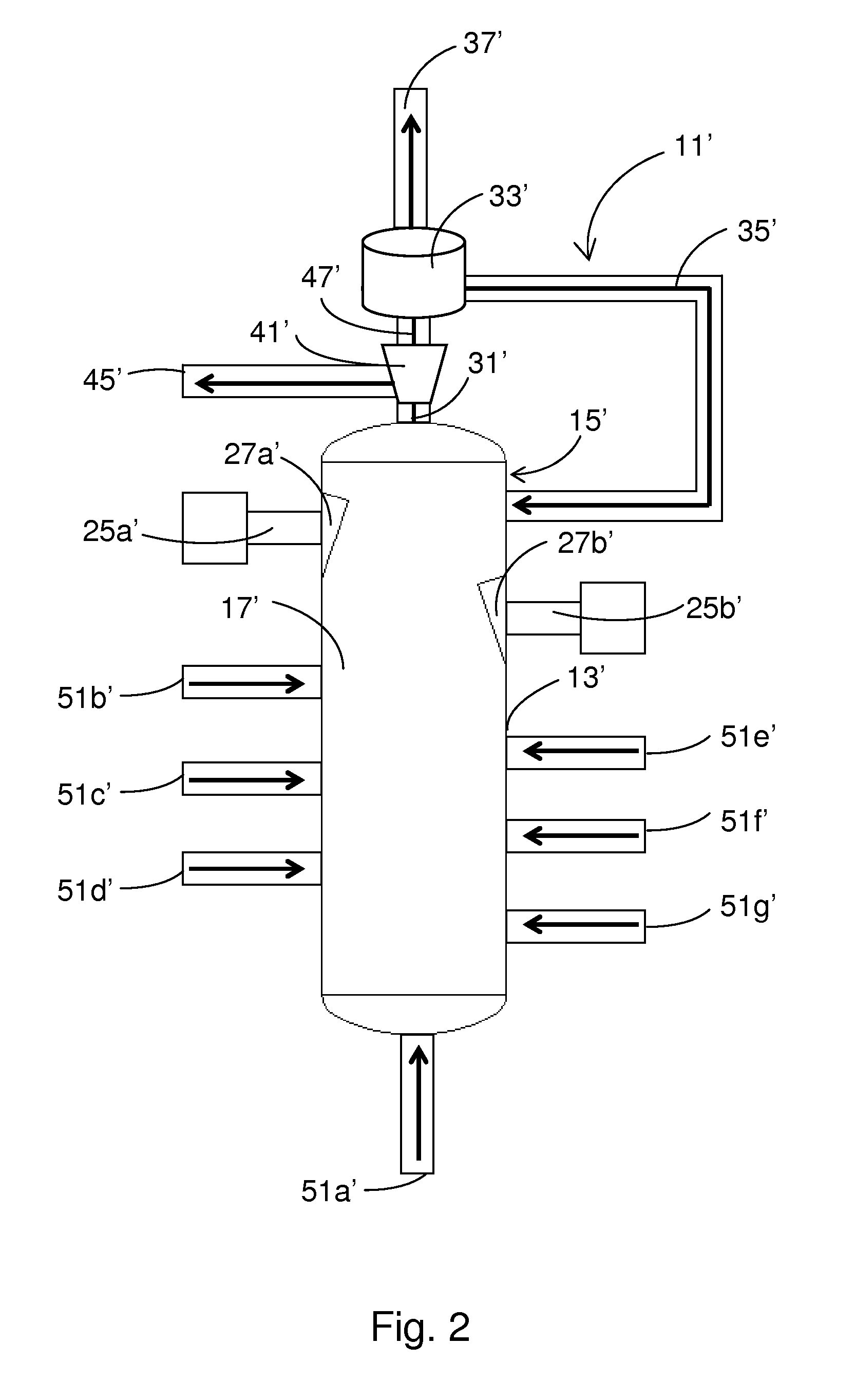

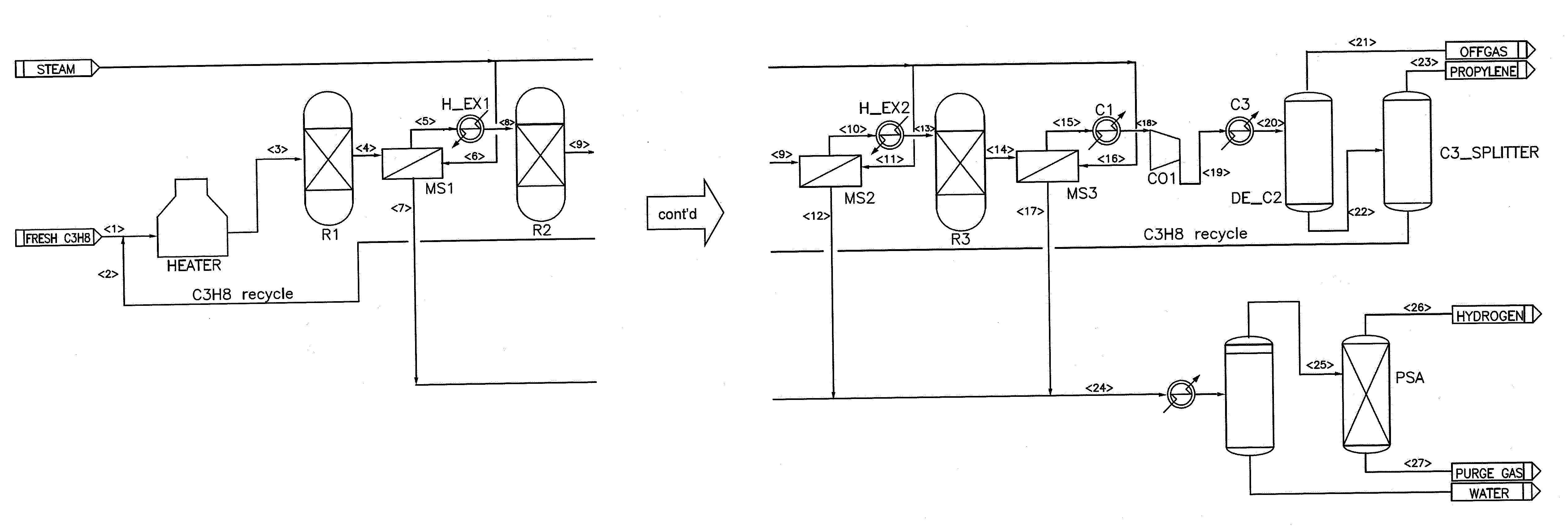

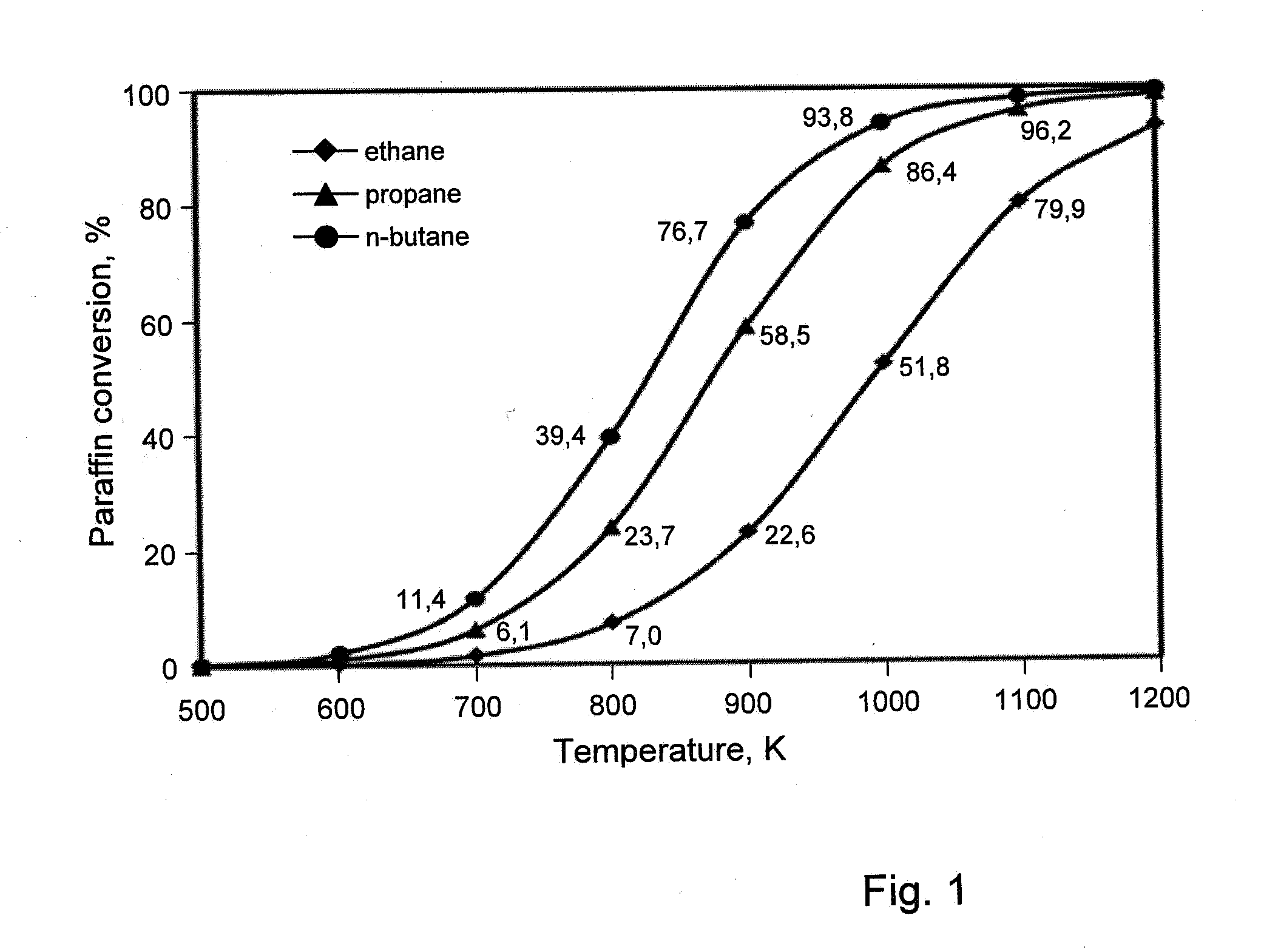

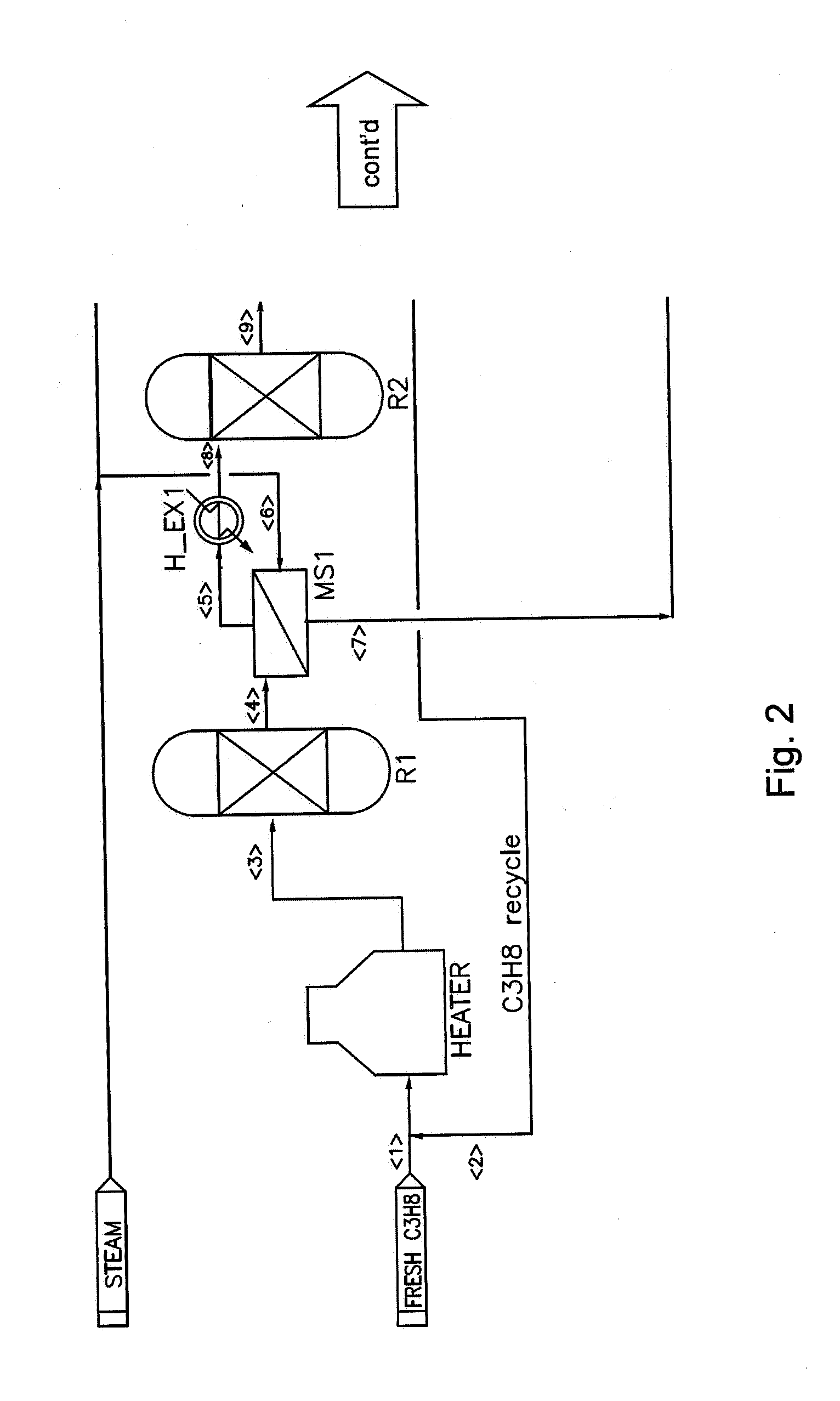

Method for olefins production

Disclosed is a process for the catalytic dehydrogenation of alkanes so as to form the corresponding olefins. The reaction mixture is subjected to membrane separation of hydrogen, in a separate unit. Preferably a plurality of alternating reaction and separation units is used. The process of the invention serves the purpose of reducing coke formation on the catalyst, and also of achieving a higher alkane conversion without a similar increase in coke formation. The process can also be used for the production of hydrogen.

Owner:STAMICARBON ACTING UNDER THE NAME OF MT INNOVATION CENT

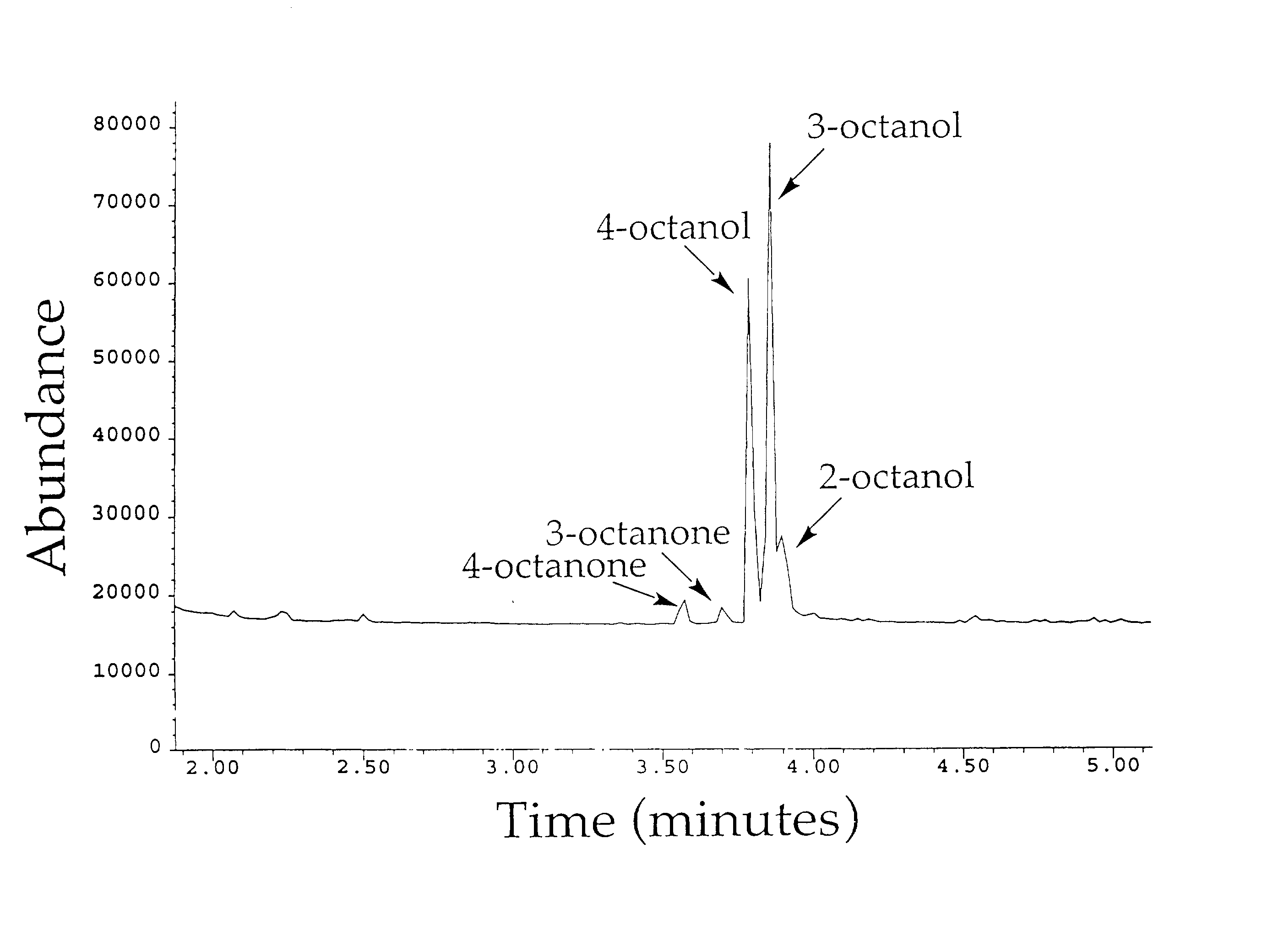

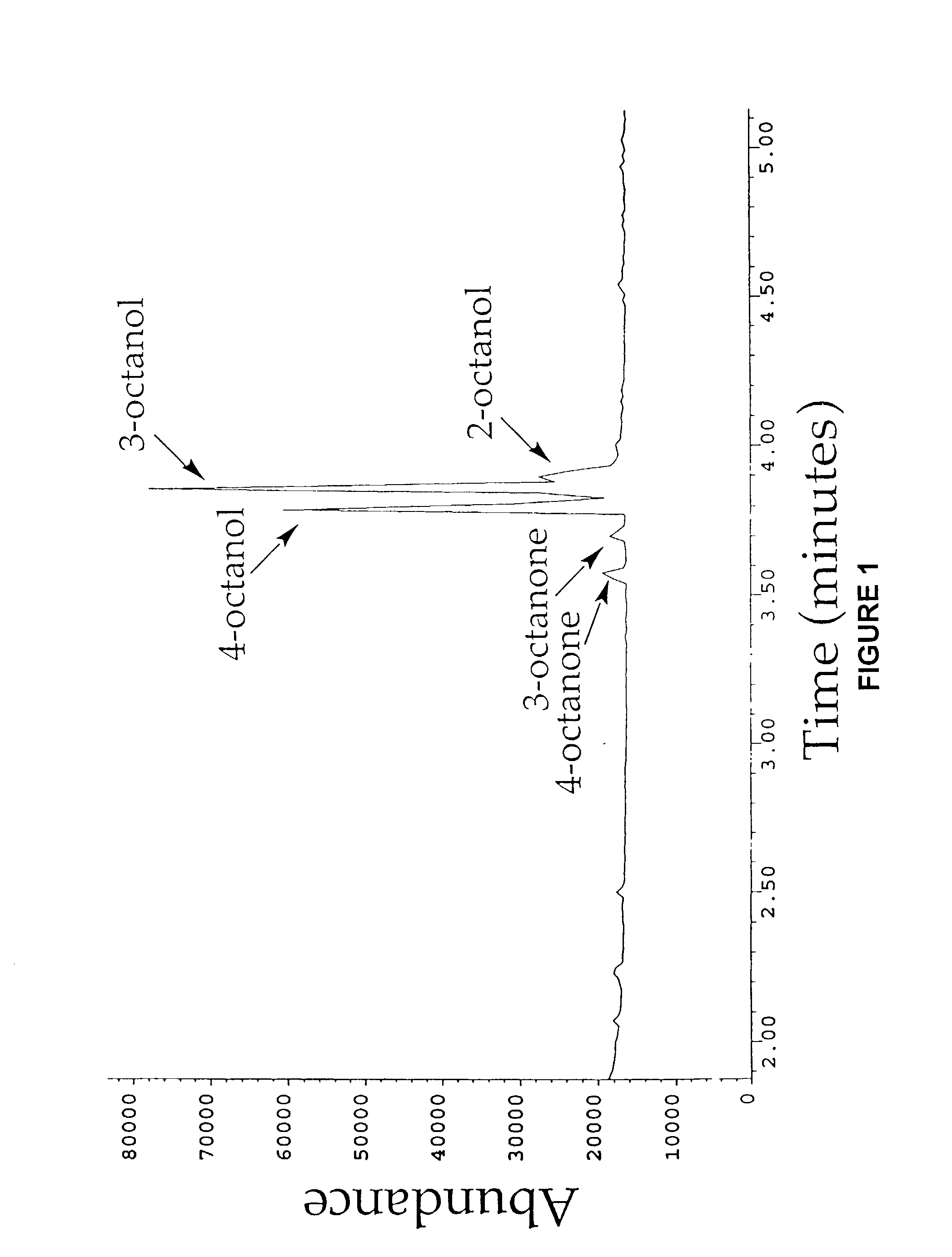

Process for preparation of a mixture of alcohols and ketones by liquid phase oxidation of higher alkanes

InactiveUS20060094905A1Preparation by oxidation reactionsOrganic compound preparationHigher alkanesDiketone

The present invention provides a process for the production of a mixture of alcohols and ketones by the liquid phase oxidation of higher alkanes using a catalyst system consisting of transition group metal such as palladium and support such as alumina, silica, carbon, preferably carbon in the presence of alkyl hydroperoxide as oxygen carrier, under stirring conditions at a temperature range of 10°-120° C. and at atmospheric pressure in a stirred glass reactor for a period of 1-30 h. The present invention produces a mixture of alcohols and ketones with high selectivity (preferably 60-90%) along with other byproducts such as diketones and acids.

Owner:COUNCIL OF SCI & IND RES

Dehydrogenation catalyst and preparation method thereof

ActiveCN106669792ANo hydrolysis reactionSimple and fast operationMolecular sieve catalystsMolecular sieve catalystHigher alkanesActive component

The invention discloses a dehydrogenation catalyst and a preparation method thereof. The catalyst adopts ZSM-5 molecular sieve doped alumina as a carrier, Pt as an active component and Sn and Na as assistants, and the catalyst comprises, by weight, 0.1-5% of Sn, 0.05-1% of Pt, 0.01-2% of Na, and the balance of the carrier; and the carrier comprises 20-50 wt% of ZSM-5 molecular sieve, wherein the relative crystallinity of the ZSM-5 molecular sieve is 40-80%. The preparation method comprises the following steps: 1, mixing the ZSM-5 molecular sieve, alumina, Sesbaria cannabina powder and a diluted nitric acid solution, beating the obtained mixture, kneading the beaten mixture, extruding the kneaded mixture to form strips, drying the strips, and roasting the dried strips to obtain the carrier; 2, loading the assistant Sn to the carrier; and 3, impregnating the carrier obtained in step 2 in an impregnating solution containing the active component, drying the impregnated carrier, and roasting the dried carrier to obtain the dehydration catalyst. The catalyst has high alkane conversion rate, high olefin selectivity and good stability in a low-carbon alkane dehydrogenation reaction.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEM +1

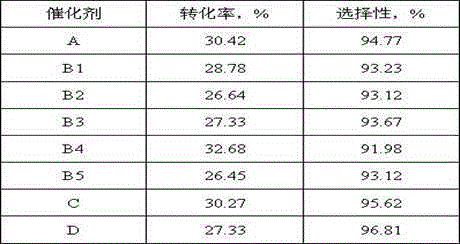

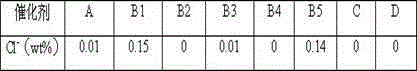

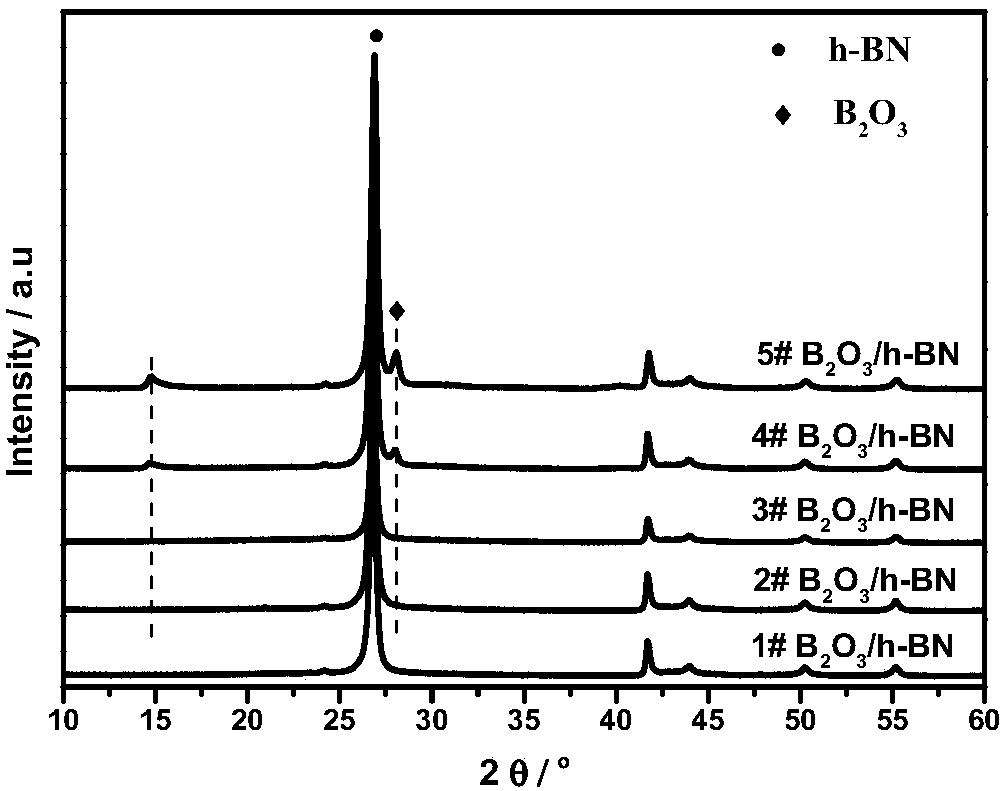

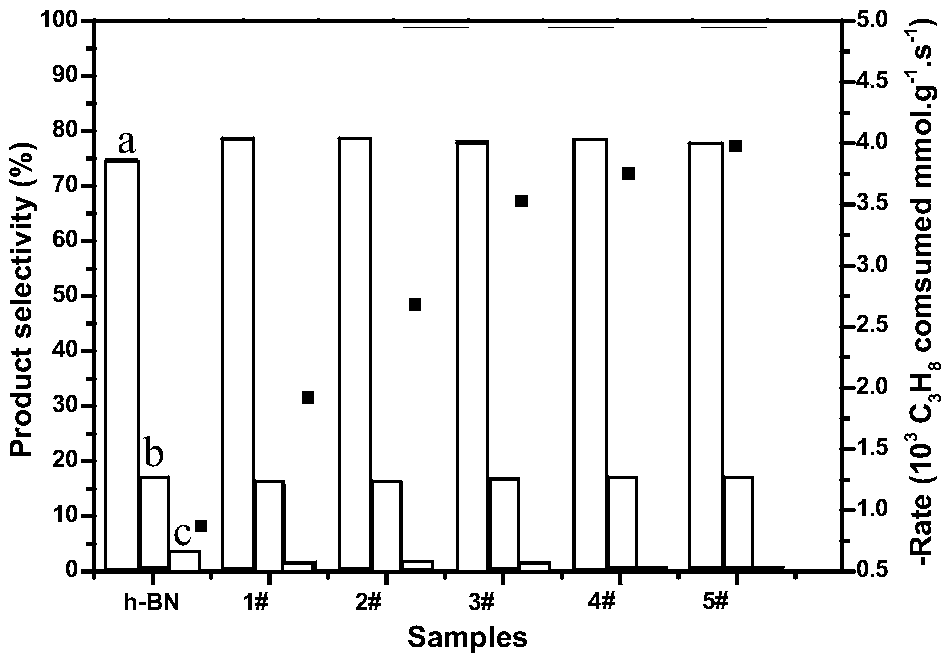

Preparation and application of boron modified boron nitride catalyst for oxidative dehydrogenation of low-carbon alkane

InactiveCN108043444AHigh selectivityImprove stabilityCatalystsHydrocarbon preparation catalystsEvaporationDehydrogenation

The invention relates to preparation and application of a boron modified boron nitride catalyst for oxidative dehydrogenation of low-carbon alkane and relates to catalysts. A boron source and boron nitride are mixed and dissolved in a solvent; after the solvent is volatilized, heat treatment is carried out to obtain a boron modified boron nitride material. The boron modified boron nitride catalystprepared by the invention is a non-metal catalyst without any metal and has high olefin selectivity and stability when being used for the oxidative dehydrogenation of the low-carbon alkane includingethane, propane and isobutane. Compared with the boron nitride, a relatively high alkane conversion ratio can be obtained under the condition that the olefin selectivity is ensured, and the yield of olefin is improved. According to the technical scheme for preparing the boron modified boron nitride catalyst, when the boron modified boron nitride material is prepared, a method for volatilizing thesolvent can be realized through selecting common manners including heating and stirring, natural volatilization, ultrasonic evaporation, rotary evaporation or spraying drying and the like.

Owner:XIAMEN UNIV

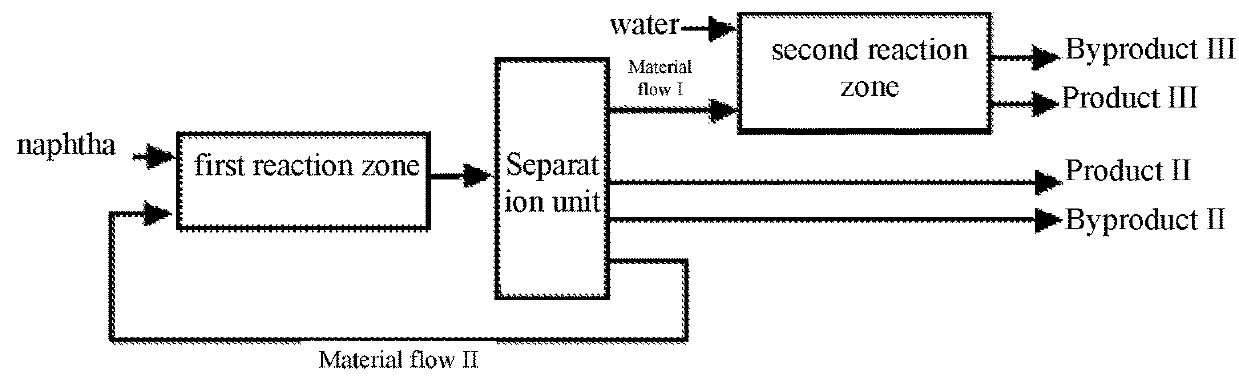

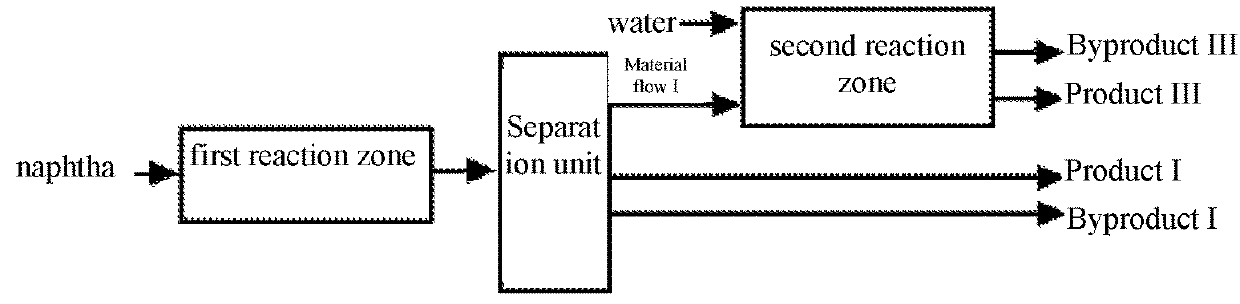

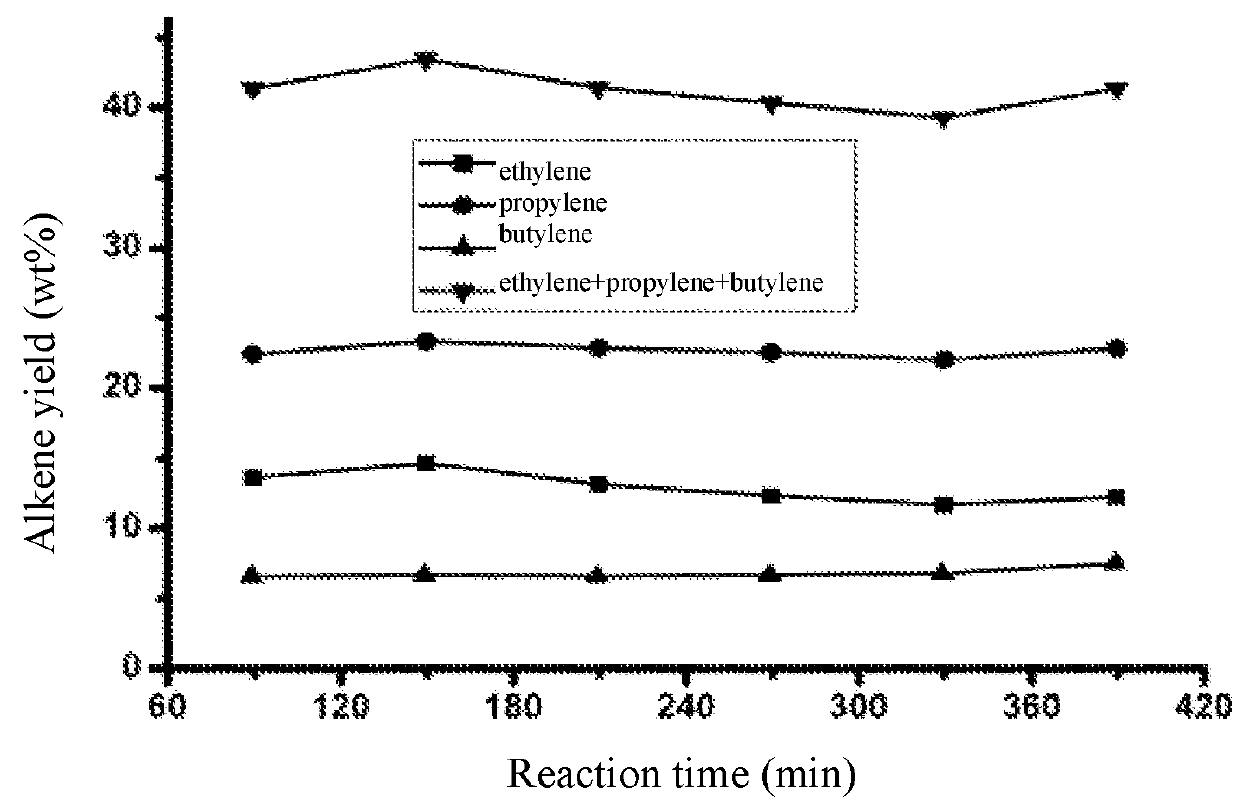

Process for converting naphtha

ActiveUS20180163147A1Low reaction temperatureHigh selectivityTreatment with plural serial cracking stages onlyCatalytic crackingHigher alkanesNaphtha

Disclosed is a process for converting naphtha. Lower olefin, light aromatic hydrocarbon, and gasoline with high octane number are produced through combining catalytic cracking of naphtha with steam cracking of lower alkane and catalytic cracking of higher alkane and higher olefin. The process increases the yield of product with high value and decreases the yield of product with low value significantly. At the same time, the power consumption is decreased as a whole since most reactants are converted in catalytic cracking at lower temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Process for Production of Triptane and Triptene

ActiveUS20090247803A1Hydrocarbon from oxygen organic compoundsHydrocarbonsHigher alkanesIsomerization

High octane C7 hydrocarbons, particularly 2,2,3-trimethylbutane (“triptane”) and 2,2,3-trimethyl-but-1-ene (“triptene”) (collectively “triptyls”) are produced by homologation of a feed comprising dimethyl ether and / or methanol and optionally including one or more aliphatic hydrocarbons in the presence of certain acidic zeolite catalysts. The process can be carried out at temperatures lower than those previously used for conversion of dimethyl ether and / or methanol to higher alkanes, including C7 alkanes, and results in selective production of triptane and / or triptene with relatively little isomerization to or production of other C7 alkanes.

Owner:RGT UNIV OF CALIFORNIA

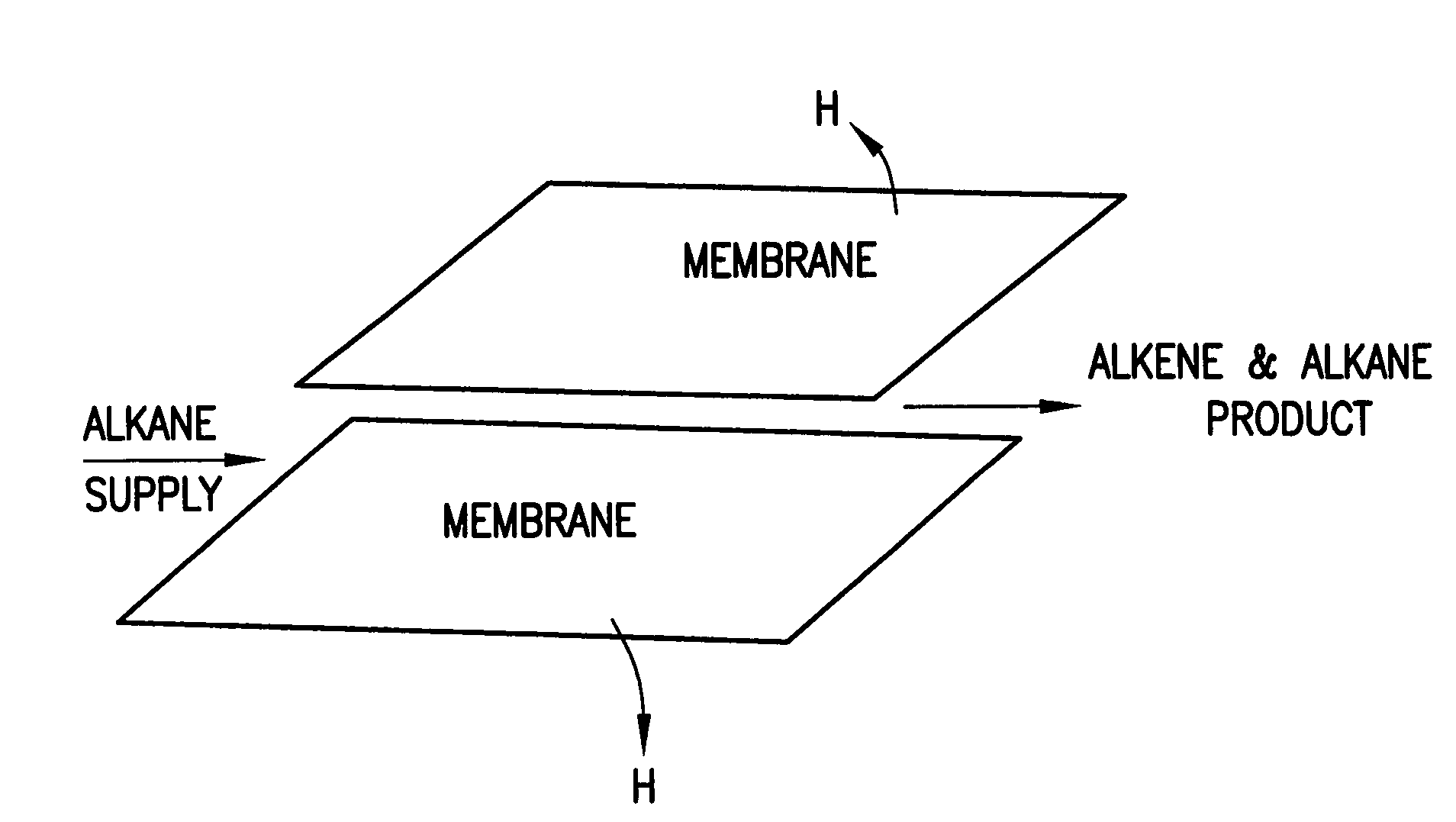

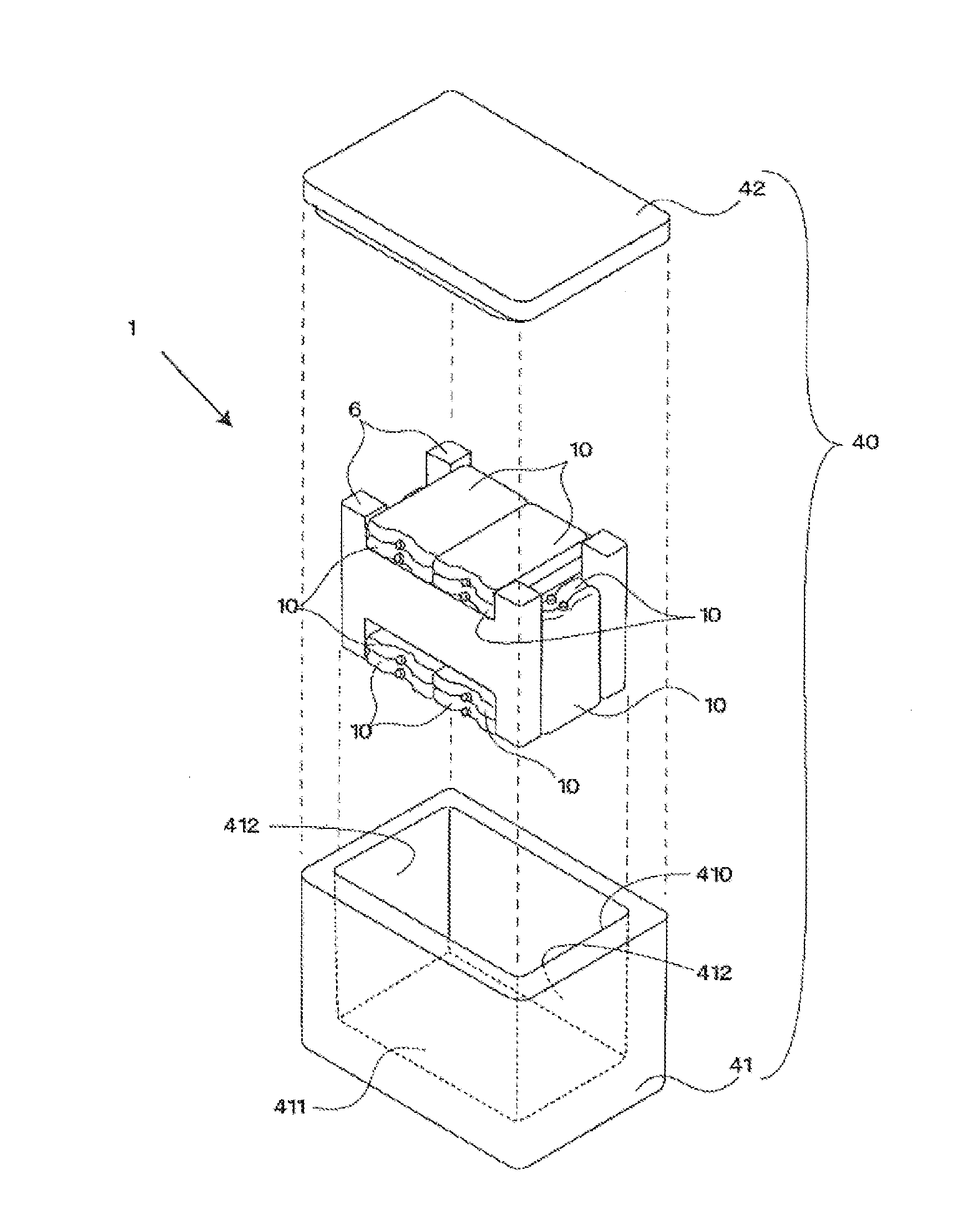

Polyolefin processes with constituent high conversion alkane dehydrogenation in membrane reactors

InactiveUS20070249884A1High feedstock conversion levelCost of productionSemi-permeable membranesMembranesPolyolefinDehydrogenation

Polymerization processes having as constituent parts high conversion membrane reactors, that provide a source of monomer, and subsequent polymerization of the monomer, without passing products of the conversion through an alkane / alkene splitter, are disclosed. Polymers of light alkene hydrocarbons, such as ethylene, propylene and alkenes consisting of up to 6 carbon atoms, are prepared from gaseous feedstreams consisting predominantly of volatile alkane compounds substantially free of dihydrogen and / or dioxygen. Equipment required for separation of alkene products from unreacted alkanes in conventional plants is eliminated because of the high alkane conversions provided in the membrane reactors. Particularly useful are flow reactors comprising dense membranes of multiphasic materials that provide independent, controllable, counter-current transport of hydrogen, electrons and oxygen.

Owner:INEOS USA LLC

Catalyst for converting methyl isobutyl ketone into 2-methylpentane and preparation method of catalyst

ActiveCN104028304AHigh activityEasy to inactivateOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsIon exchangeMetal-organic framework

The invention relates to a catalyst for converting methyl isobutyl ketone into 2-methylpentane and a preparation method of the catalyst. The catalyst is prepared from two parts, namely a sulfonic-acid-functional metal organic framework material MIL-101 (Al) and precious metal Pt, wherein the weight of the metal Pt is 0.5-5 weight percent in total weight percentage of the catalyst. The preparation method comprises the following steps: adding sodium fluoride into mixed liquor of aluminum nitrate nonahydrate, 2-sulfonic acid terephthalic acid monosodium salt and deionized water; after crystallization, using a hydrochloric acid solution for ion exchange; washing and drying to obtain the sulfonic-acid-functional metal organic framework material MIL-101 (Al); then dropwise adding a K2PtC16 solution to obtain a catalyst precursor, and reducing the catalyst precursor through hydrogen to obtain the catalyst. The catalyst has high catalytic activity and high alkane selectivity when being used for converting methyl isobutyl ketone into 2-methylpentane.

Owner:海宁市袁花镇工业投资有限公司

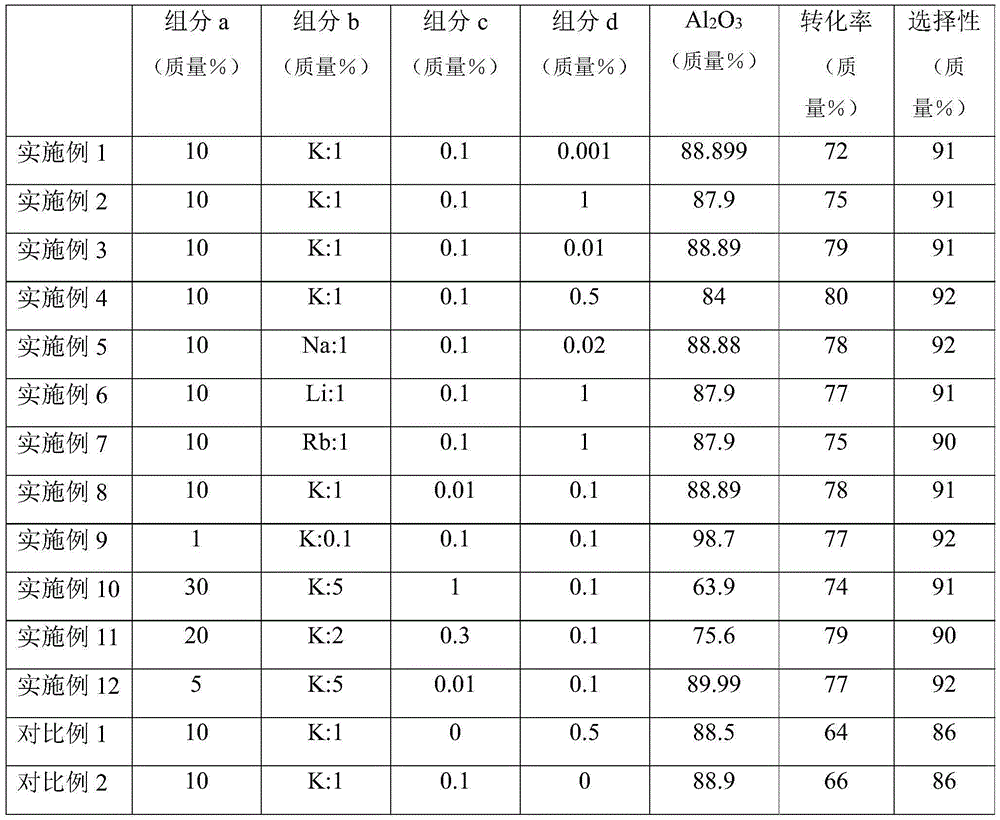

Catalyst applied to dehydrogenation of light alkane and preparation method thereof

InactiveCN105597766AImprove conversion rateHigh selectivityHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsHigher alkanesAlkaline earth metal

The invention relates to a catalyst applied to dehydrogenation of light alkane and a preparation method thereof. The catalyst is prepared from the following components in parts by weight: 1-30 parts of Cu element or oxides thereof, 0.1-5 parts of alkali metal oxides or alkaline earth metal oxides, 0.001-1 part of group VIII elements in the periodic table of elements or oxides thereof, 0.001-1 part of group IIIA elements in the periodic table of elements or oxides thereof, and 54-99 parts of Al2O3 or SiO2. Compared with the prior art, the catalyst has a higher alkane conversion rate which can be up to 60% at low reaction temperature, and high higher olefin selectivity, which is more than 90%, and achieves better technical effect.

Owner:贺东光 +4

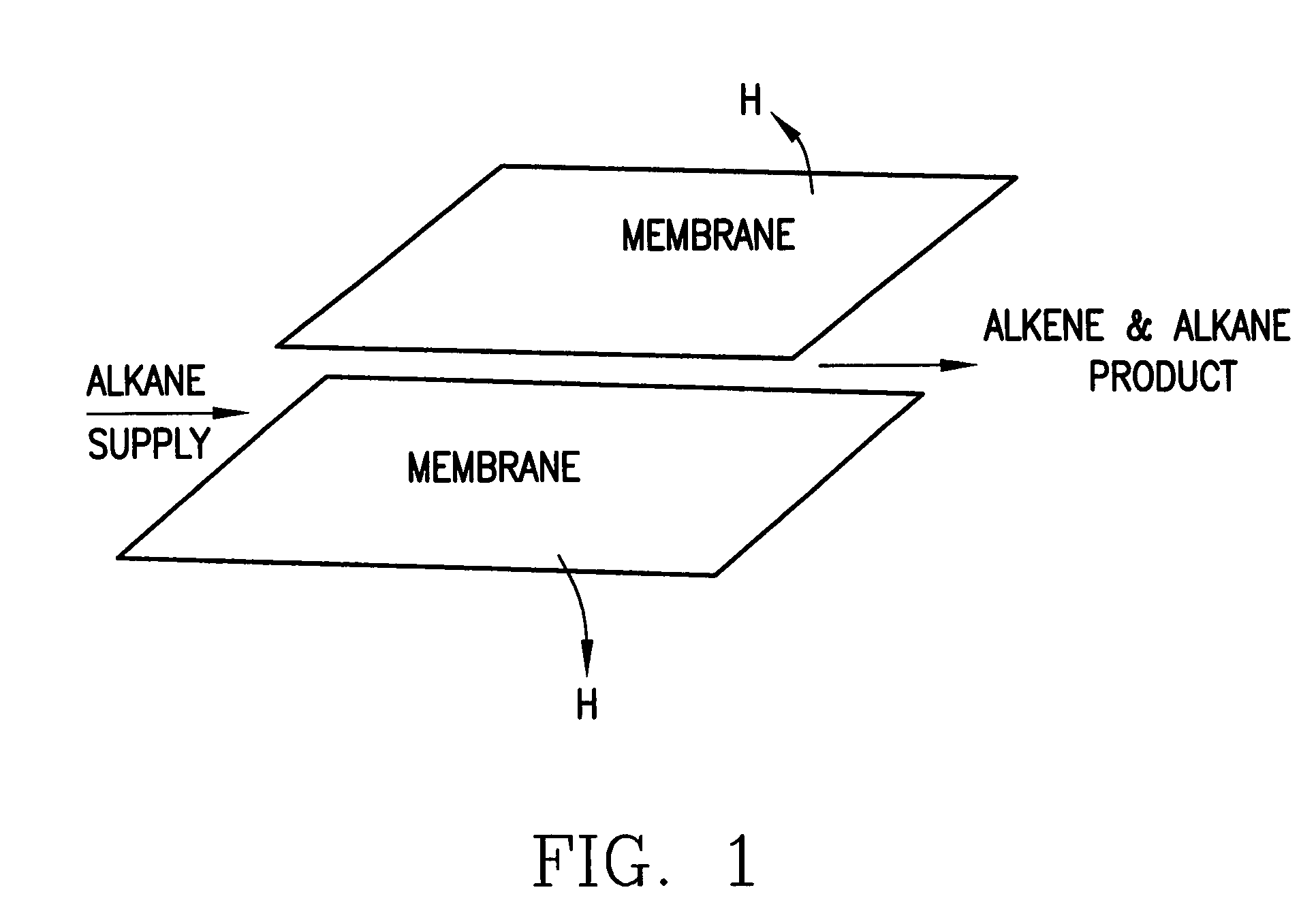

Hydrogen transport membranes for dehydrogenation reactions

InactiveUS7329791B2High yieldGood choiceCatalystsHydrocarbon preparation catalystsOxide ceramicHigher alkanes

A method of converting C2 and / or higher alkanes to olefins by contacting a feedstock containing C2 and / or higher alkanes with a first surface of a metal composite membrane of a sintered homogenous mixture of an Al oxide or stabilized or partially stabilized Zr oxide ceramic powder and a metal powder of one or more of Pd, Nb, V, Zr, Ta and / or alloys or mixtures thereof. The alkanes dehydrogenate to olefins by contact with the first surface with substantially only atomic hydrogen from the dehydrogenation of the alkanes passing through the metal composite membrane. Apparatus for effecting the conversion and separation is also disclosed.

Owner:UCHICAGO ARGONNE LLC

Method for preparing fuel oil with high alkane content by co-cracking non-edible grease and waste plastic

ActiveCN105038834AInhibition formationRealize complementary advantagesLiquid hydrocarbon mixture productionBio-feedstockOil and greaseMass ratio

Provided is a method for preparing fuel oil with high alkane content by co-cracking non-edible grease and waste plastic. The method comprises the steps that 1, the waste plastic is cut and broken into fragments of which the area is smaller than 100 cm<2>; 2, the waste plastic and the non-edible grease are mixed according to the mass ratio of 1:1-1:10; 3, the mixture is fed into a cracking reactor, air in the reactor is replace by nitrogen, heating is conducted, the heating rate is 5-300 DEG C / min, when the temperature of reactant is increased to 150 DEG C, a stirring device is started, heating is conducted continuously, the temperature of the cracking reaction is controlled to range from 350 DEG C to 600 DEG C, the reaction time is 2-90 min, and after gas-solid separation is conducted on a cracking reaction product, condensation is conducted on the gas, and the fuel oil with the high alkane content is obtained. By means of the method for preparing the fuel oil with the high alkane content by co-cracking the non-edible grease and the waste plastic, according to the problems that the plastic structure is compact and coking is serious in the cracking process, the swelling effect of the grease on the plastic and the characteristic that glycerin residues in the grease release free state hydrogen atoms under specific cracking conditions are fully utilized. The stable and high-quality liquid fuel oil of which the oil productivity is over 85% and the alkane content reaches up to 74% is obtained.

Owner:浙江加宝新能源科技有限公司

Hydrogen transport membranes for dehydrogenation reactions

InactiveUS20050222479A1High yieldGood choiceCatalystsHydrocarbon preparation catalystsOxide ceramicHigher alkanes

A method of converting C2 and / or higher alkanes to olefins by contacting a feedstock containing C2 and / or higher alkanes with a first surface of a metal composite membrane of a sintered homogenous mixture of an Al oxide or stabilized or partially stabilized Zr oxide ceramic powder and a metal powder of one or more of Pd, Nb, V, Zr, Ta and / or alloys or mixtures thereof. The alkanes dehydrogenate to olefins by contact with the first surface with substantially only atomic hydrogen from the dehydrogenation of the alkanes passing through the metal composite membrane. Apparatus for effecting the conversion and separation is also disclosed.

Owner:UCHICAGO ARGONNE LLC

Heat storage material composition, heat storage material and transport container

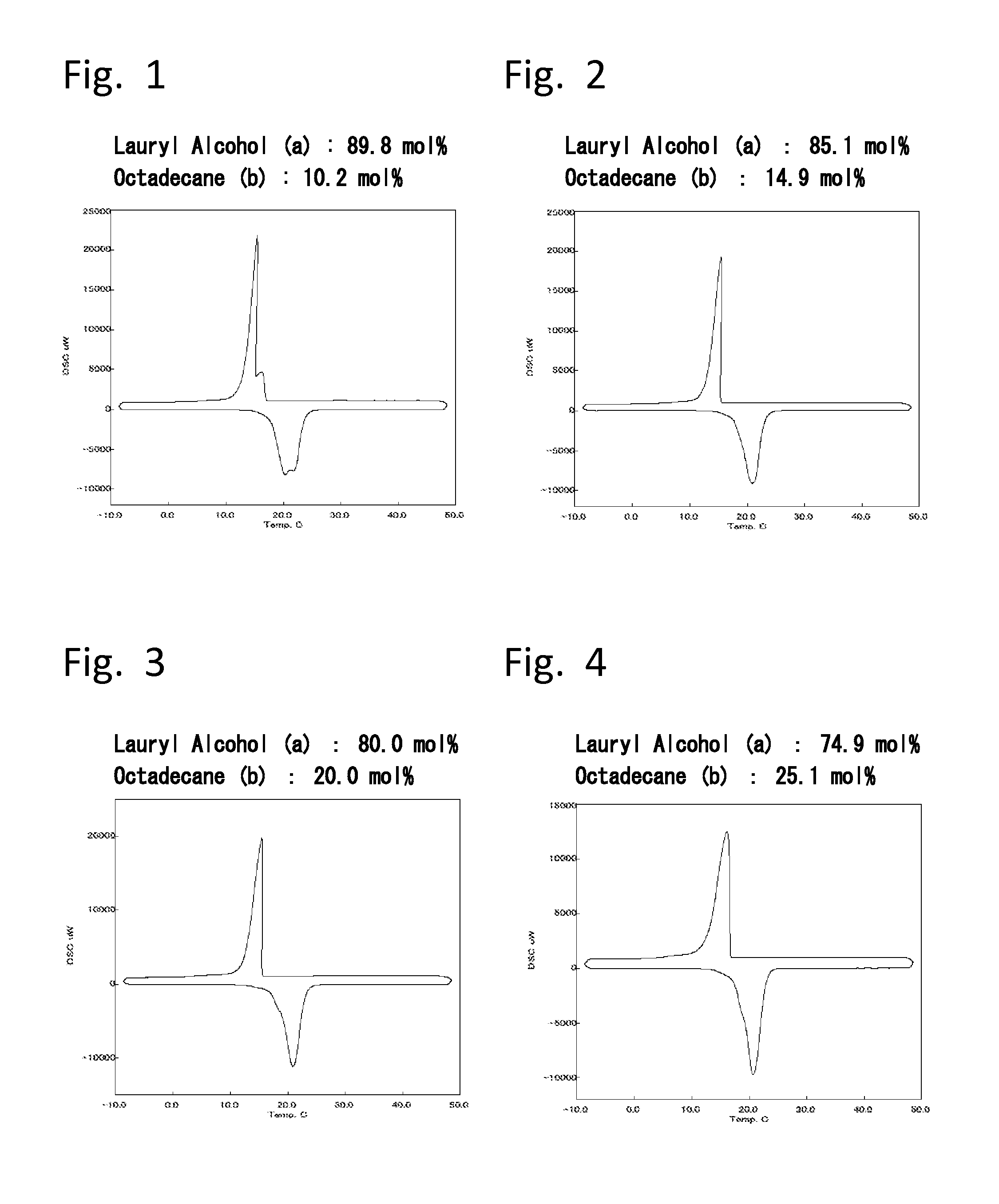

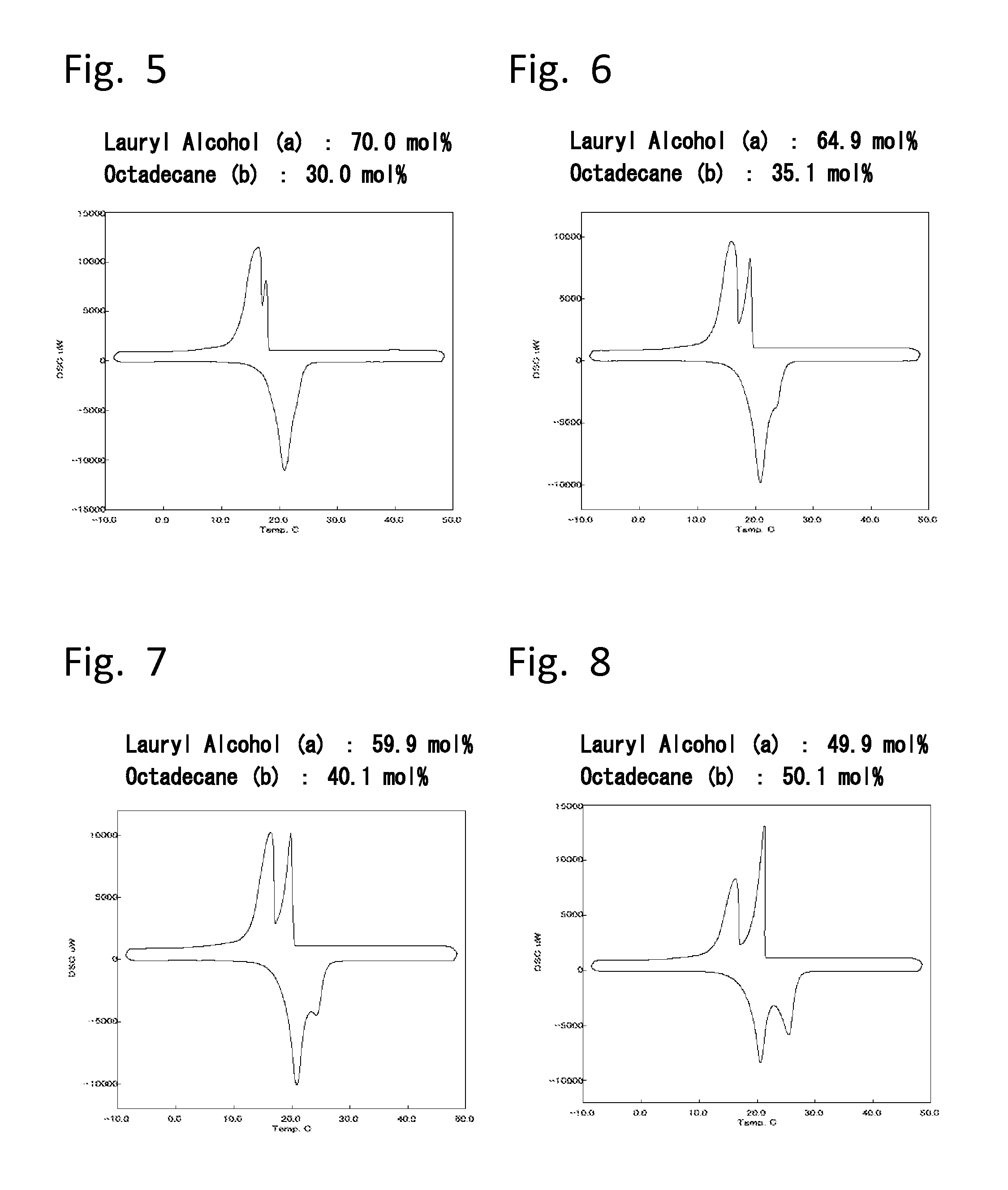

ActiveUS20150299549A1Reduce variationConstant melting temperatureDomestic cooling apparatusHeat storage plantsHigher alkanesCarbon number

A heat storage material composition having a melting temperature utilized for control of an optional management temperature, providing no variation in melting behavior and solidification behavior, and having a constant melting temperature. The heat storage material composition consists primarily of a mixture of a higher alkane having carbon number of 9 to 24 and a higher alcohol having carbon number of 6 to 20, and the mixture has a substantially single melting peak in DSC curve measured by a differential scanning calorimeter (DSC).

Owner:KANEKA CORP +1

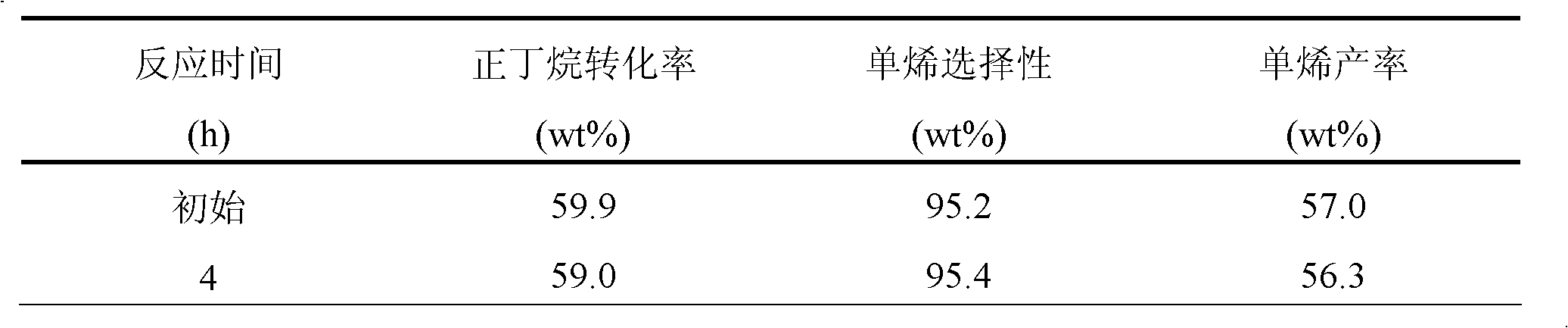

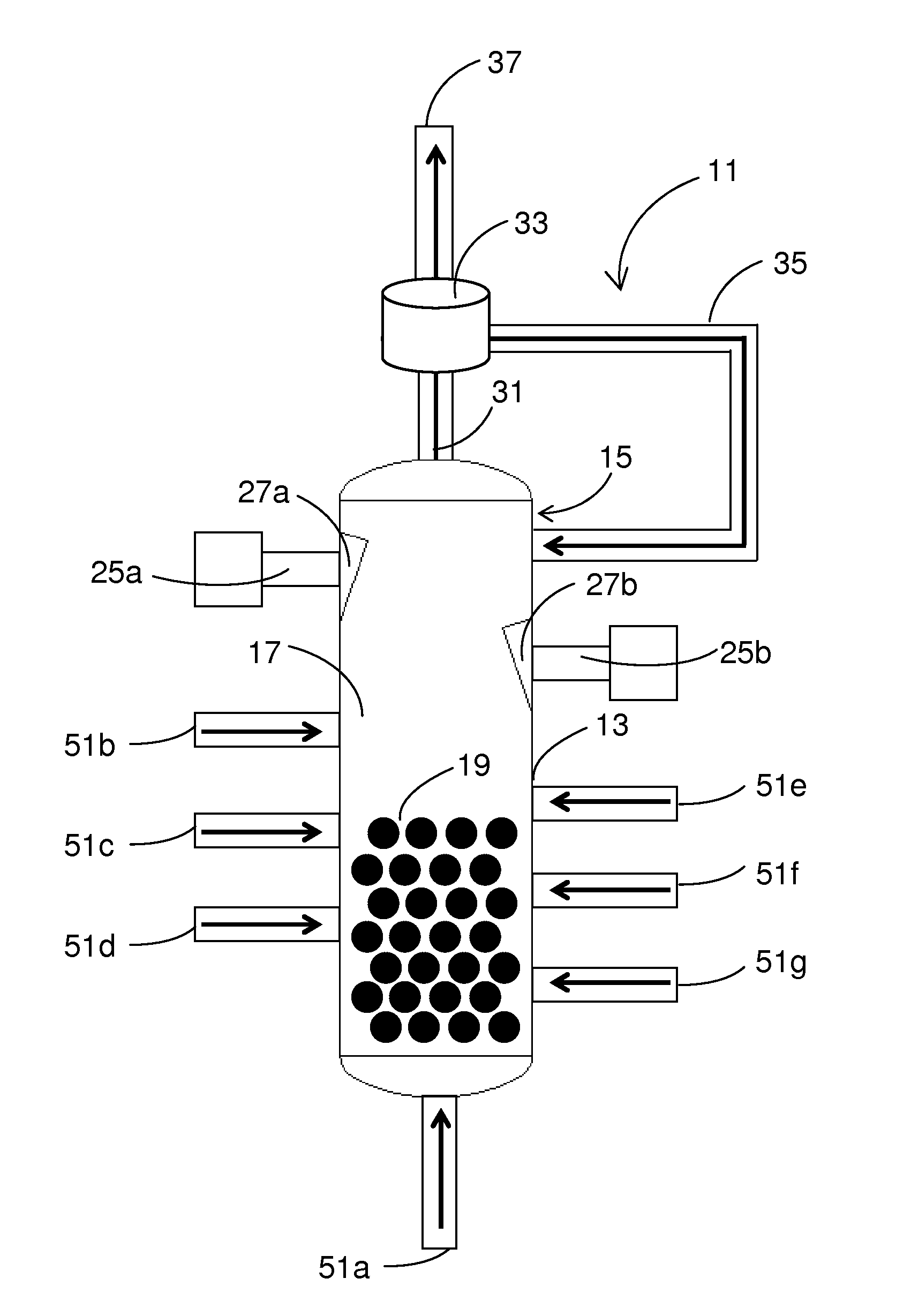

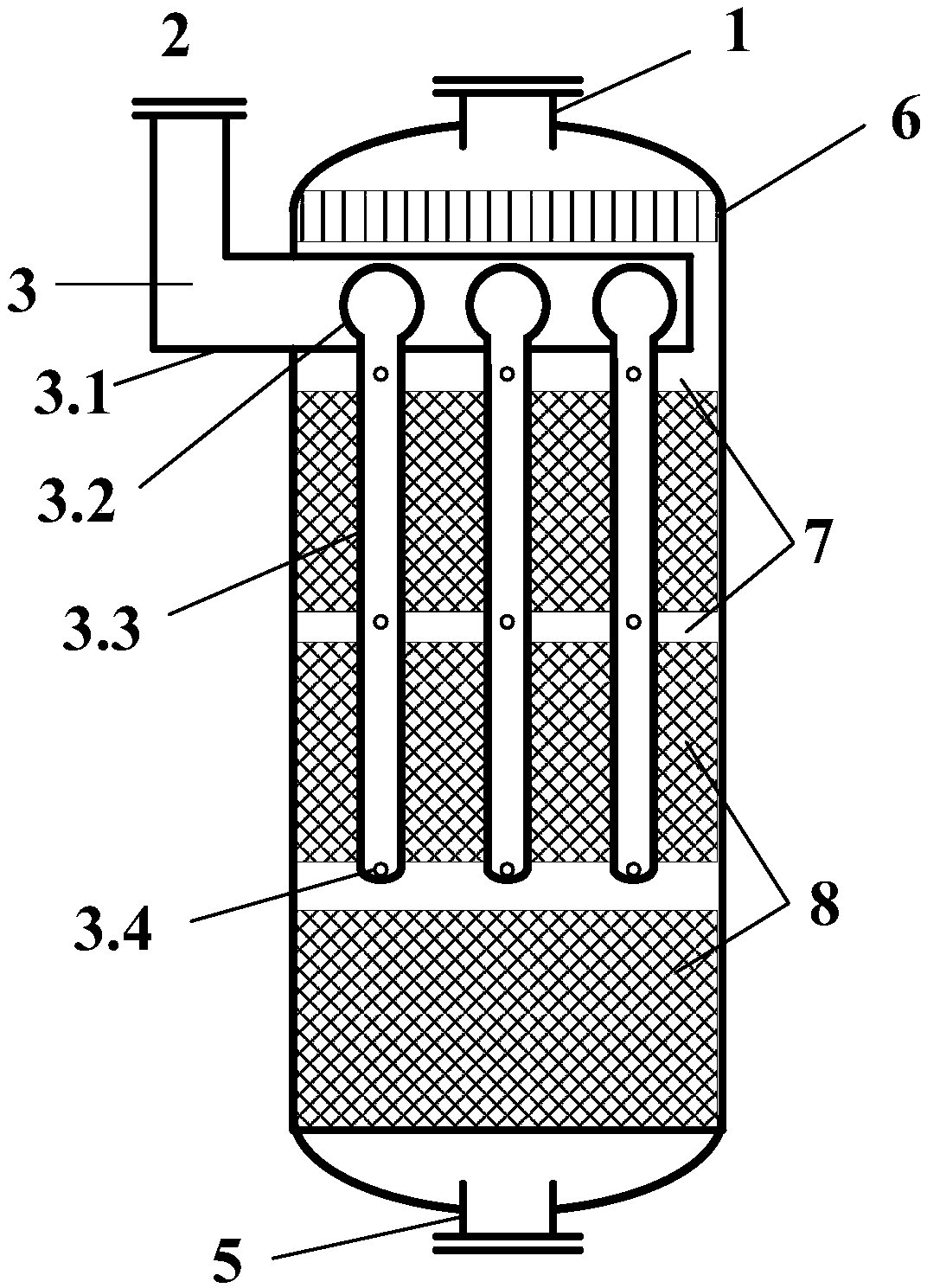

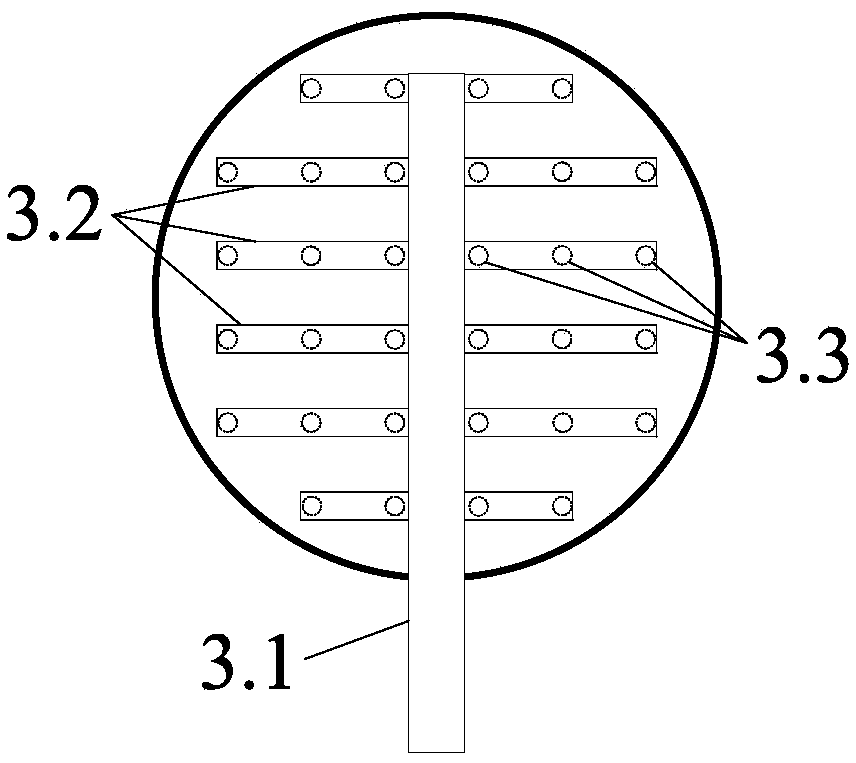

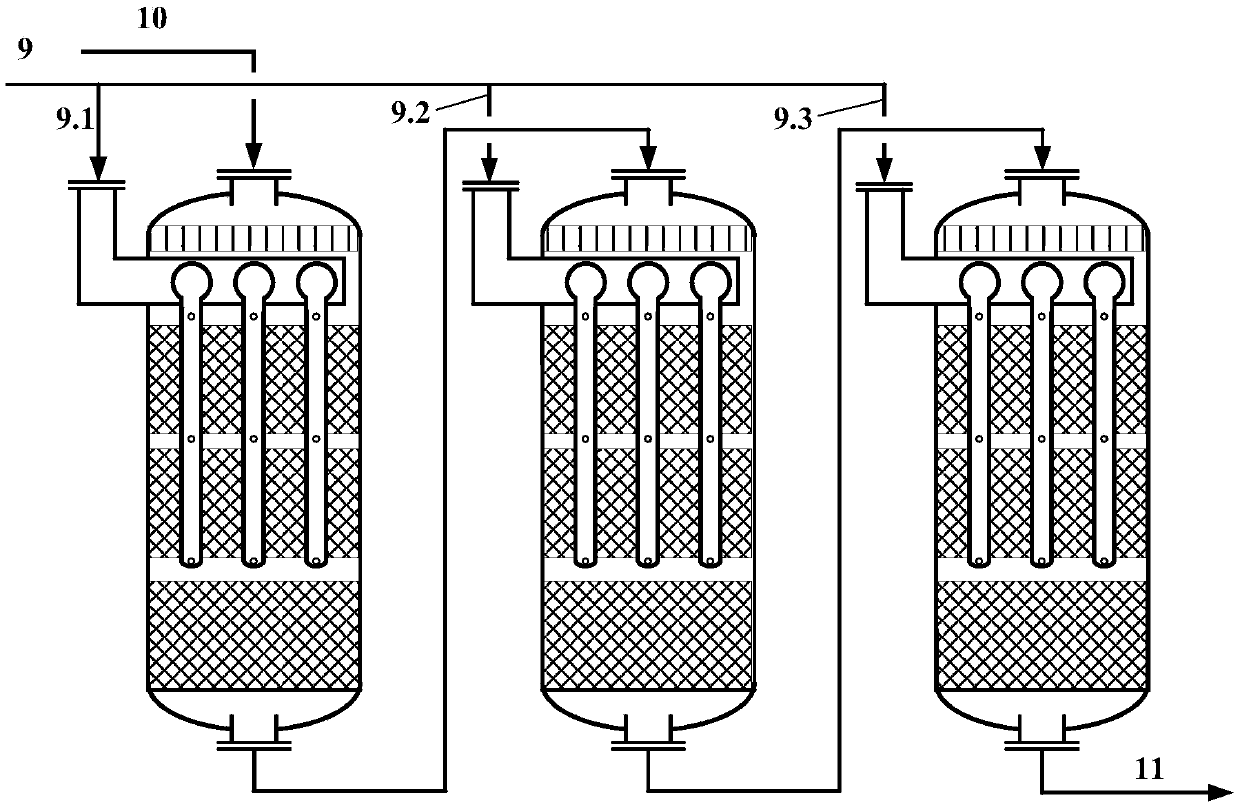

Liquid acid alkylation reactor and alkylation reaction method

ActiveCN110893335AGuaranteed high alkene ratioCompact structureLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical stationary reactorsHigher alkanesReaction zone

The invention relates to a liquid acid alkylation reactor and an alkylation reaction method. The reactor comprises a liquid acid inlet (1), a hydrocarbon inlet (2), a hydrocarbon feeding distributor (3), a mixed reaction zone and an acid hydrocarbon outlet (5), wherein the hydrocarbon inlet and the liquid acid inlet are positioned above the mixed reaction zone, the acid hydrocarbon outlet (5) is positioned below the mixed reaction zone, the hydrocarbon feeding distributor comprises a radial distribution part and an axial distribution part, the radial distribution part and the axial distribution part are communicated with each other, the pipeline extending directions of the radial distribution part and the axial distribution part are perpendicular to each other, the radial distribution partis arranged above the mixing reaction zone, the raw material inlet of the radial distribution part is communicated with the hydrocarbon inlet, the axial distribution part comprises a feeding verticalpipe (3.3), the top end of the feeding vertical pipe is communicated with the radial distribution part, the bottom end of the feeding vertical pipe is a free end, the bottom end of the feeding vertical pipe extends into the mixing reaction zone in the axial direction of the reactor, and a plurality of distribution holes (3.4) are formed in the pipe wall of the feeding vertical pipe at intervals in the axial direction. According to the alkylation reactor, in-situ multi-section feeding can be achieved so as to ensure high alkane-olefin ratio.

Owner:SINOPEC ENG +1

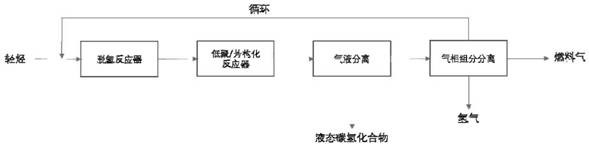

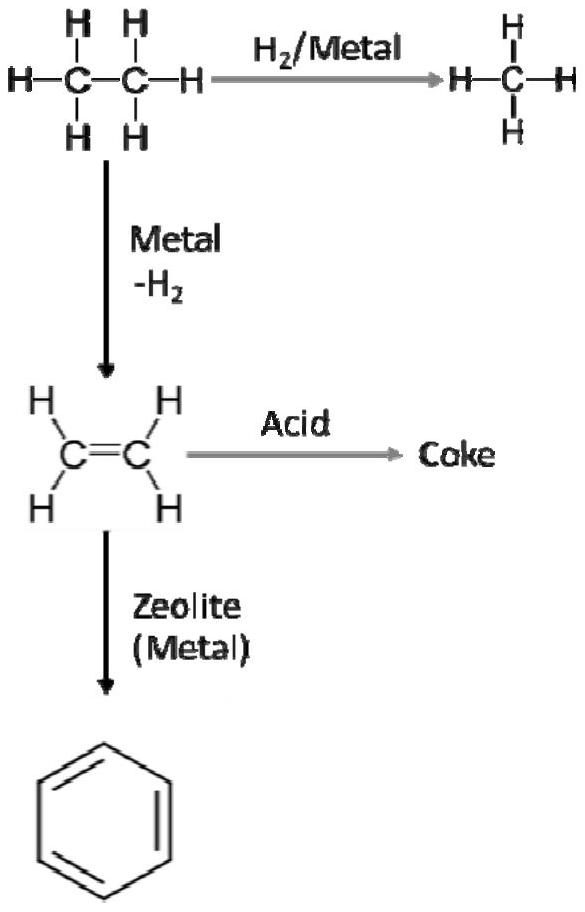

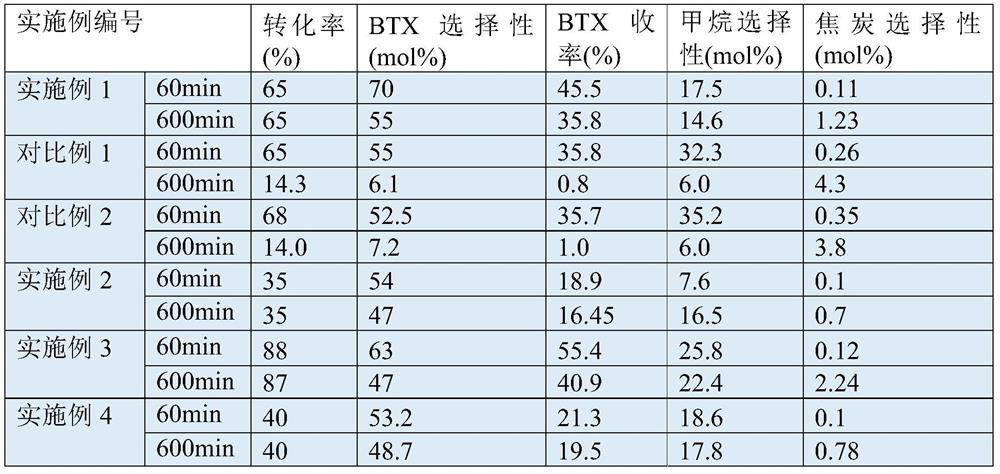

Method for producing aromatic hydrocarbon through light hydrocarbon dehydrogenation aromatization

ActiveCN112830858APromote regenerationLow selectivityHydrocarbonsChemical recyclingHigher alkanesPtru catalyst

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com