Dehydrogenation catalyst and preparation method thereof

A dehydrogenation catalyst and catalyst technology, applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of olefin selectivity reduction, catalyst deactivation, Pt sintering, etc., to reduce production costs, save energy consumption, and easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

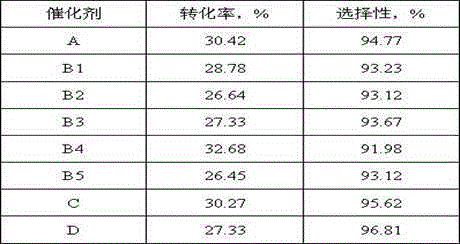

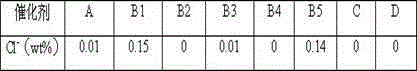

Examples

Embodiment 1

[0028] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 50% and a silicon-aluminum ratio of 100, mix them evenly with 350g of alumina and 25g of turnip powder, add 50g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The molded carrier was dried in the shade for 24 hours, then dried in an oven at 110° C. for 12 hours, and then baked in a muffle furnace at 600° C. for 6 hours. Then break the carrier to a length of 2-3 mm for later use.

[0029] Tin tetrachloride is formulated as an impregnating solution, impregnated with the above-mentioned carrier, then dried and roasted.

[0030] Impregnation of active components: Weigh 0.55 g of solid chloroplatinic acid and 0.28 g of sodium nitrite, dissolve them in 150 mL of deionized water, and stir thoroughly. After the solute is dissolved, heat the impregnating liquid to 100°C and boil, and stir at a speed of 60 rpm. After boiling for 15 minute...

Embodiment 2

[0045] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 70% and a silicon-aluminum ratio of 80, mix them evenly with 350g of alumina and 25g of turnip powder, add 50g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The molded carrier was dried in the shade for 24 hours, then dried in an oven at 110° C. for 12 hours, and then baked in a muffle furnace at 600° C. for 6 hours.

[0046] The tin oxalate is formulated as an impregnating solution, impregnated with the above-mentioned carrier, and then dried and roasted.

[0047] Preparation of impregnation solution: Weigh 0.27 g of solid chloroplatinic acid and 0.17 g of sodium nitrite, dissolve them in 180 mL of deionized water, and stir thoroughly. After the solute is dissolved, heat the impregnation solution to 105°C and boil, and stir at a speed of 60 rpm. After boiling for 18 minutes, cool the impregnation solution to room temperature. ...

Embodiment 3

[0052] Preparation of the carrier: Select 200g of ZSM-5 molecular sieve with a relative crystallinity of 60% and a silicon-aluminum ratio of 180, mix them evenly with 500g of alumina and 45g of turnip powder, add 70g of dilute nitric acid solution with a mass concentration of 10%, knead and extrude forming. The molded carrier was dried in the shade for 24 hours, then dried in an oven at 110° C. for 12 hours, and then baked in a muffle furnace at 600° C. for 6 hours.

[0053] Tin acetate is formulated as an impregnating solution, impregnated with the above-mentioned carrier, then dried and roasted.

[0054] Preparation of impregnation solution: Weigh 0.72g of solid chloroplatinic acid and 0.48g of sodium nitrite, dissolve them in 180mL of deionized water, and stir thoroughly. After the solute is dissolved, heat the impregnation solution to 105°C and boil, and stir at a speed of 60 rpm. After boiling for 18 minutes, cool the impregnation solution to room temperature.

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com