A kind of fully aromatic colorless transparent polyimide film and preparation method thereof

A technology of transparent polyimide and polyimide film, which is applied in the field of all-aromatic colorless and transparent polyimide film and its preparation, and can solve the problems of difficulty in obtaining uniform materials, unfavorable film forming performance, and molecular chain Problems such as fracture, to achieve the effect of retaining solubility and transparency, avoiding cross-linking reaction and darkening of color, and low order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under nitrogen protection and a reaction temperature of 20°C, first dissolve 4.28g of diamine 1,4-bis(2-trifluoromethyl-4-aminophenoxy)benzene (6FAPB) in 18g of N-methylpyrrolidine In the ketone, after the diamine is completely dissolved, add 3.1g 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA) and the remaining organic solvent, so that the solid content of the solution is 20%, After stirring and reacting for 24 hours, the resulting polyamic acid solution was added dropwise with 2.04 g of acetic anhydride and 2.02 g of triethylamine, and the reaction was continued for 8 hours at 30 ° C. Finally, the obtained solution was washed with excess distilled water, and the obtained product Put it in a vacuum oven at 100° C. and fully dry it to finally obtain 6.99 g of thermoplastic polyimide material with a yield of 94.7%. Finally, the polyimide film can be prepared by dissolving, coating and volatilizing the synthesized polyimide material.

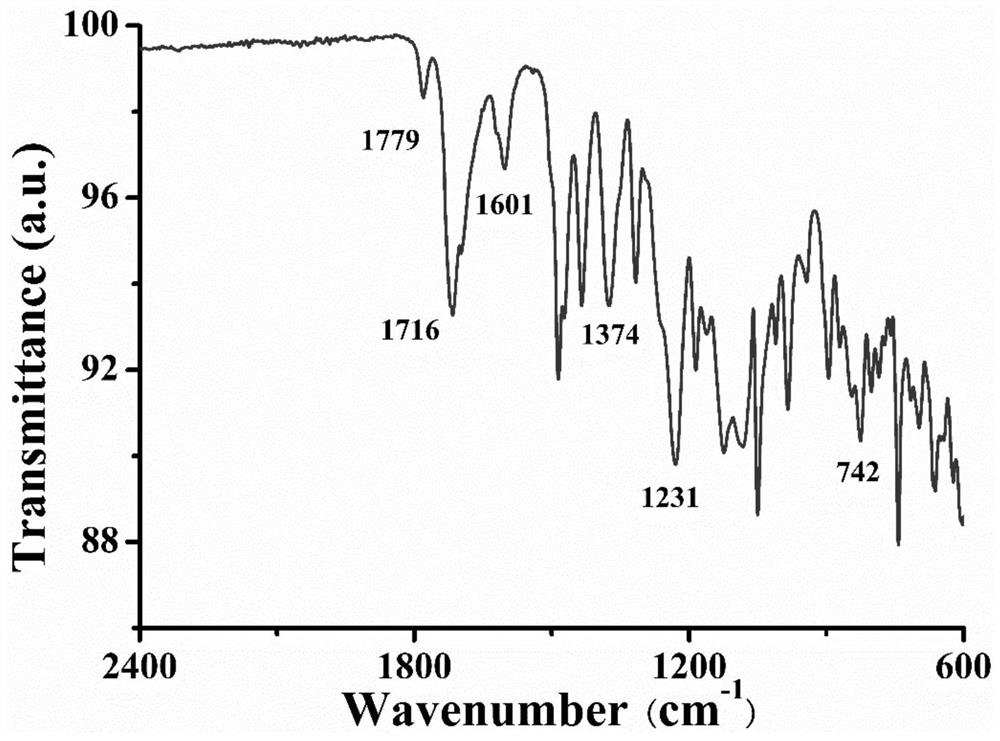

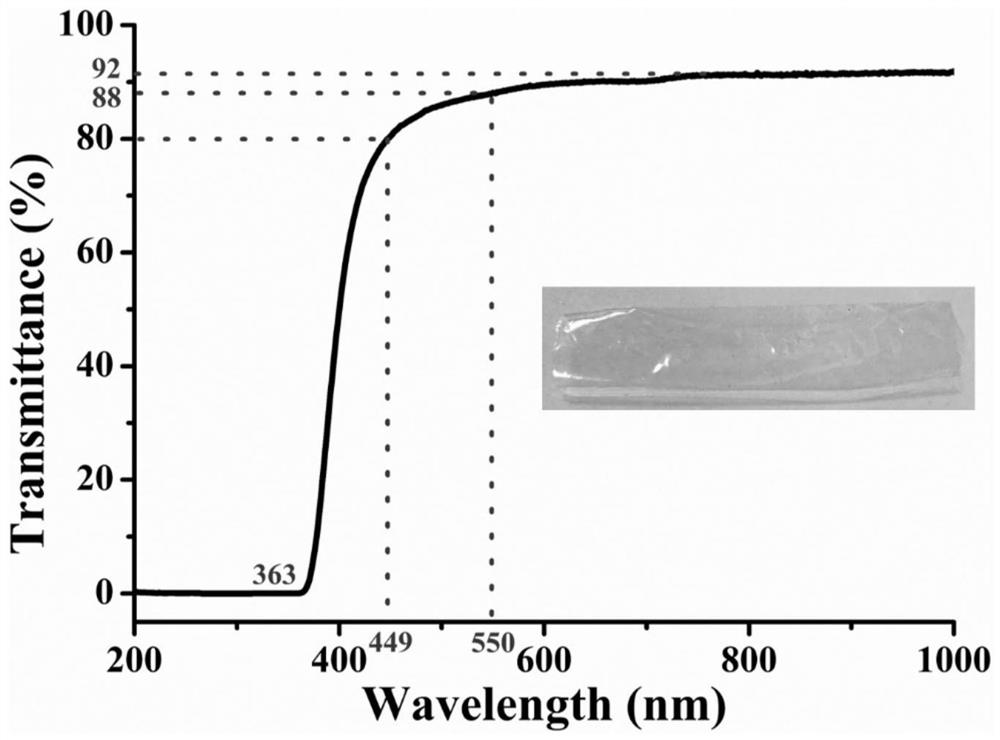

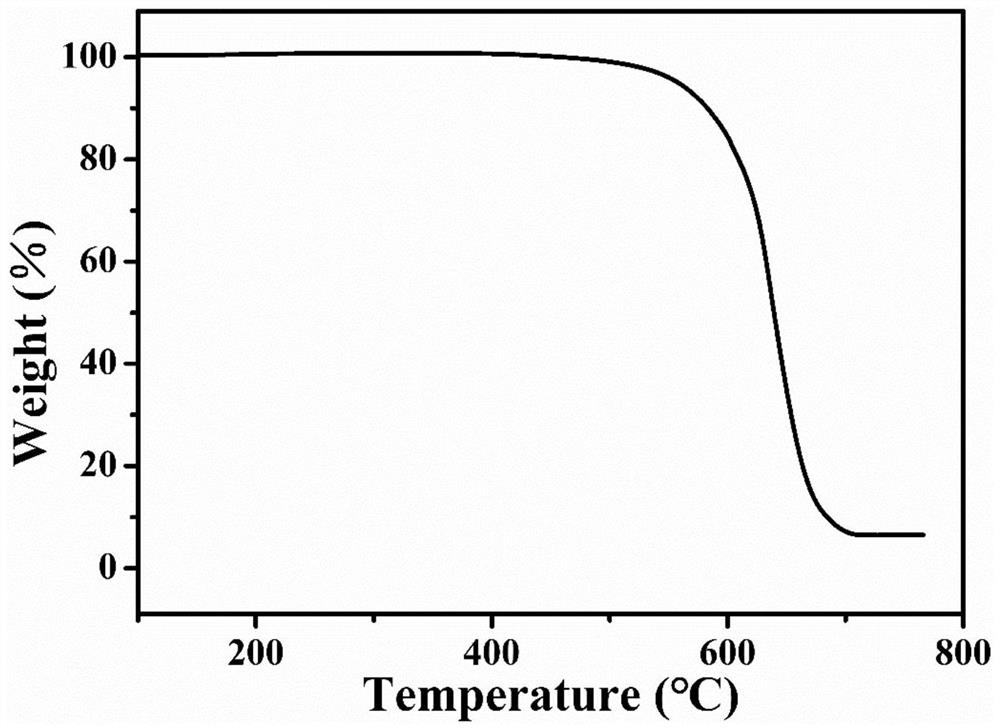

[0030] figure 1 Show...

Embodiment 2

[0035] Under nitrogen protection and a reaction temperature of 0°C, firstly, 4.28g of diamine 1,4-bis(2-trifluoromethyl-4-aminophenoxy)benzene (6FAPB) was dissolved in 18g of N-methylpyrrolidine In the ketone, after the diamine is completely dissolved, add 3.1g 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA) and the remaining organic solvent, so that the solid content of the solution is 20%, After stirring and reacting for 24 hours, the resulting polyamic acid solution was added dropwise with 3.06 g of acetic anhydride and 3.03 g of triethylamine, and the reaction was continued for 12 hours at 60°C. Finally, the obtained solution was washed with excess distilled water, and the obtained product Put it in a vacuum oven at 100° C. and fully dry it to finally obtain 7.02 g of thermoplastic polyimide material with a yield of 95.1%. Finally, the polyimide film can be prepared by dissolving, coating and volatilizing the synthesized polyimide material.

Embodiment 3

[0037] Under nitrogen protection and a reaction temperature of 0°C, first dissolve 4.28g of diamine 1,4-bis(2-trifluoromethyl-4-aminophenoxy)benzene (6FAPB) in 35g of N,N-dimethyl In acetamide (DMAc), after the diamine is completely dissolved, add 3.1g of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride (a-ODPA) and the remaining organic solvent, so that the solid content of the solution 10%, stirred and reacted for 48 hours to form a polyamic acid solution, then added 3.06 g of acetic anhydride and 3.03 g of triethylamine dropwise, continued the reaction for 12 hours at 30 ° C, and finally washed the obtained solution with excess distilled water, while The obtained product was fully dried in a vacuum oven at 100° C. to finally obtain 6.87 g of thermoplastic polyimide material with a yield of 93.1%. Finally, the polyimide film can be prepared by dissolving, coating and volatilizing the synthesized polyimide material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com