Method and apparatus for delivering cased glass stream

A glass flow and color register technology, applied in glass forming, glass forming, glass production, etc., can solve the problems of increasing production cost and increasing scrap rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

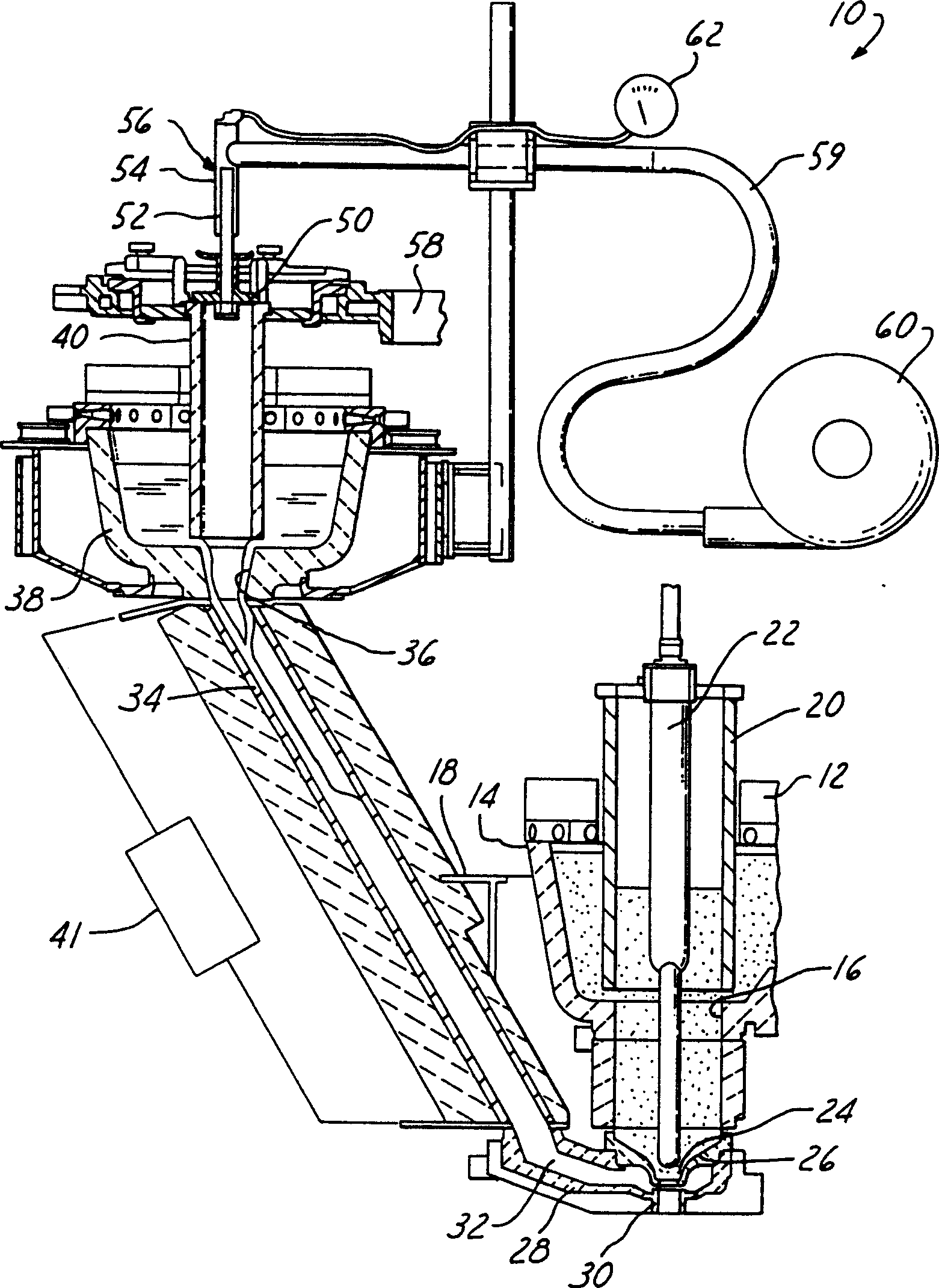

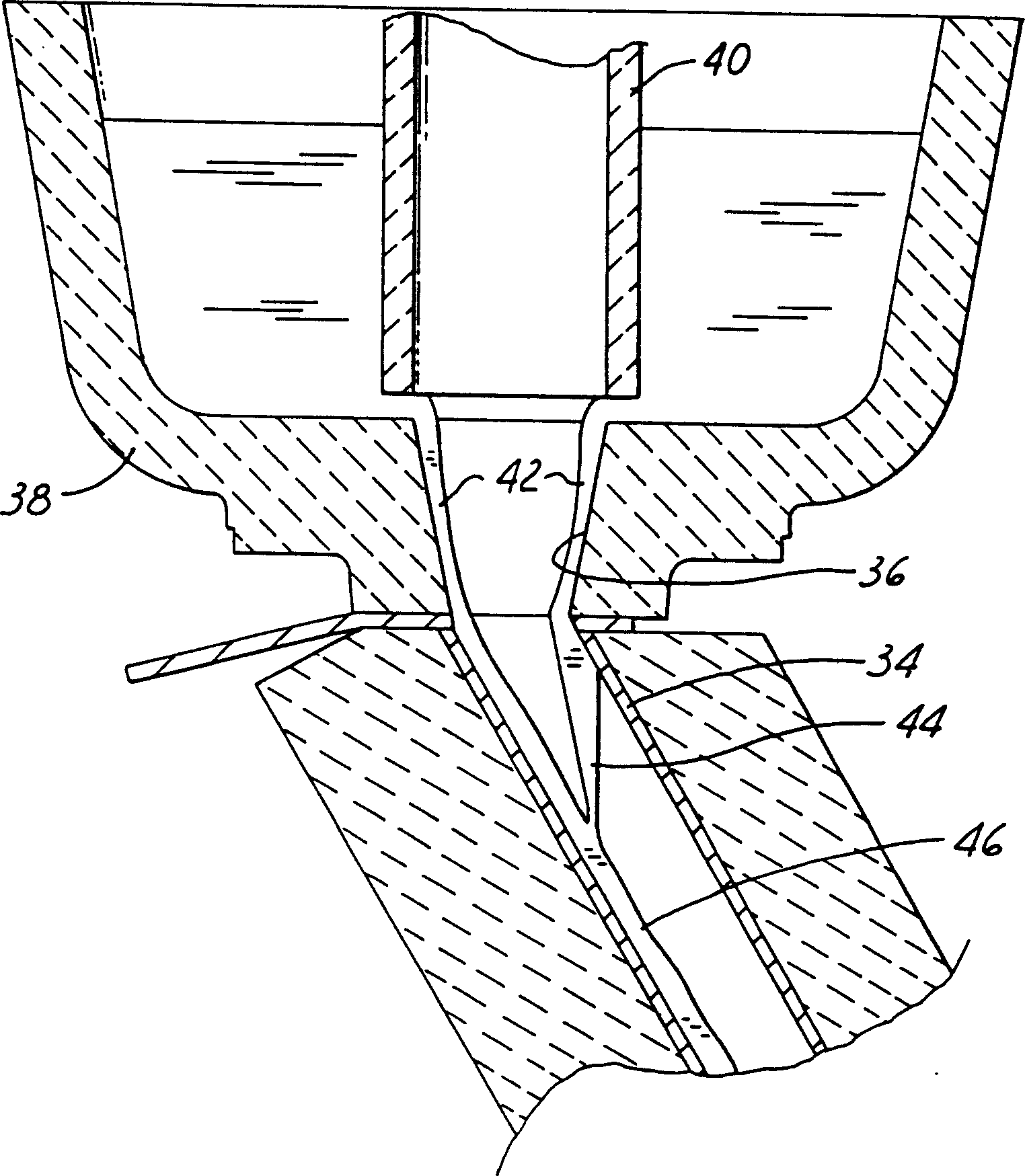

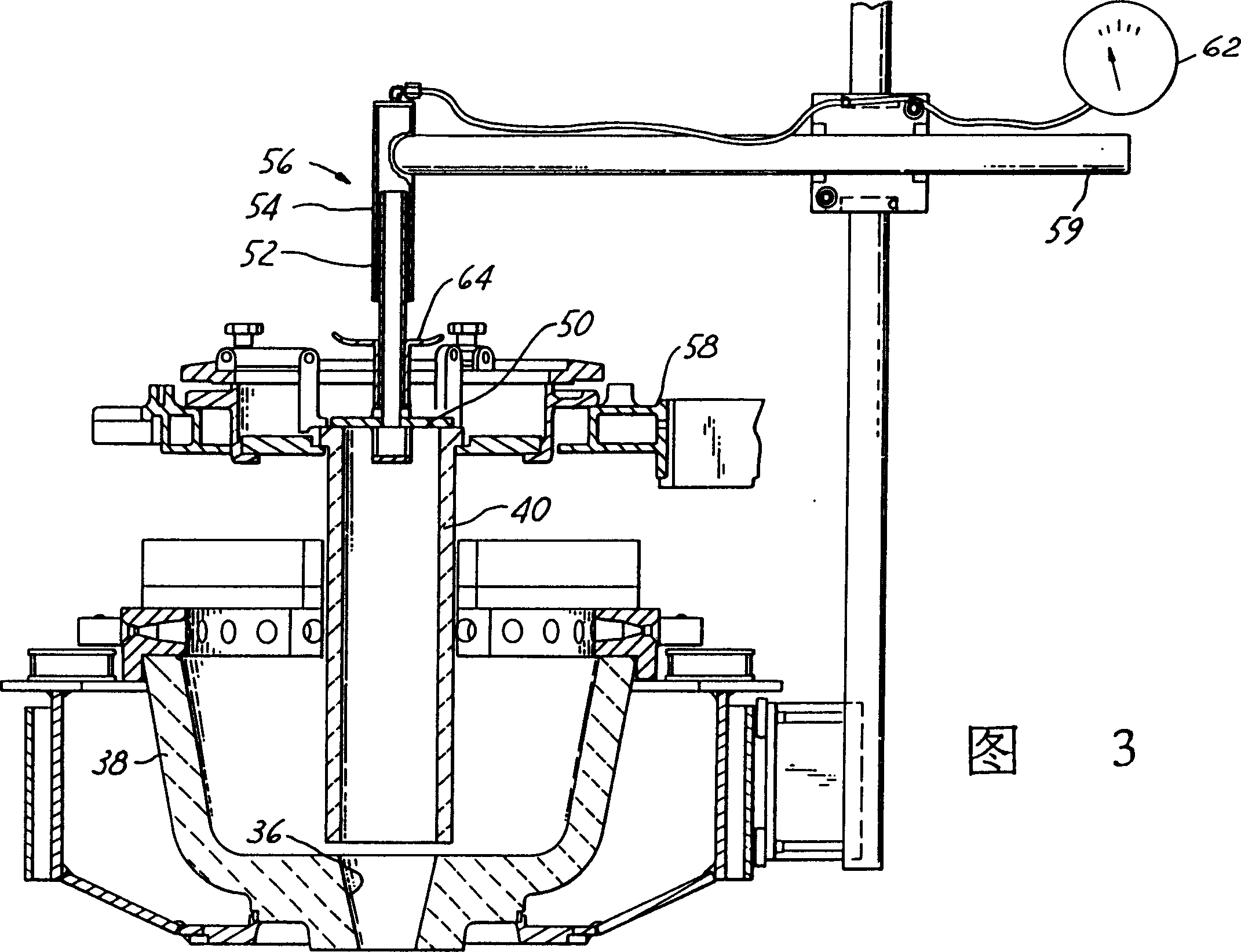

[0017] The drawing shows a system 10 for delivering a stream of cased glass. A first forehearth 12 delivers the core glass into a bowl or trough 14 which has an opening 16 at its lower end. The slot 14 is surrounded by a protective sheath 18, preferably constructed of a non-magnetic material such as stainless steel. Nozzle 20 and plunger 22 control the delivery of core glass from tank 14 through opening 16 to and through first hole 24 carried by upper annular ring 26 below tank 14 . The lower annular ring 28 carries one or more second holes 30 located below and aligned with the first holes 24 . Bore 30 is surrounded by an annular space 32 located between annular rings 26 , 28 . The annular chamber 32 is connected to the bore 30 by a lateral space or slot between the bores 24 , 30 . The annular chamber 32 is connected to the opening 36 located at the lower end of the cased glass tank 38 via the delivery pipe 34 . Tank 38 includes delivery control nozzle 40 which is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com