Method of friction welding

A friction welding and welding surface technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of reducing benefits and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

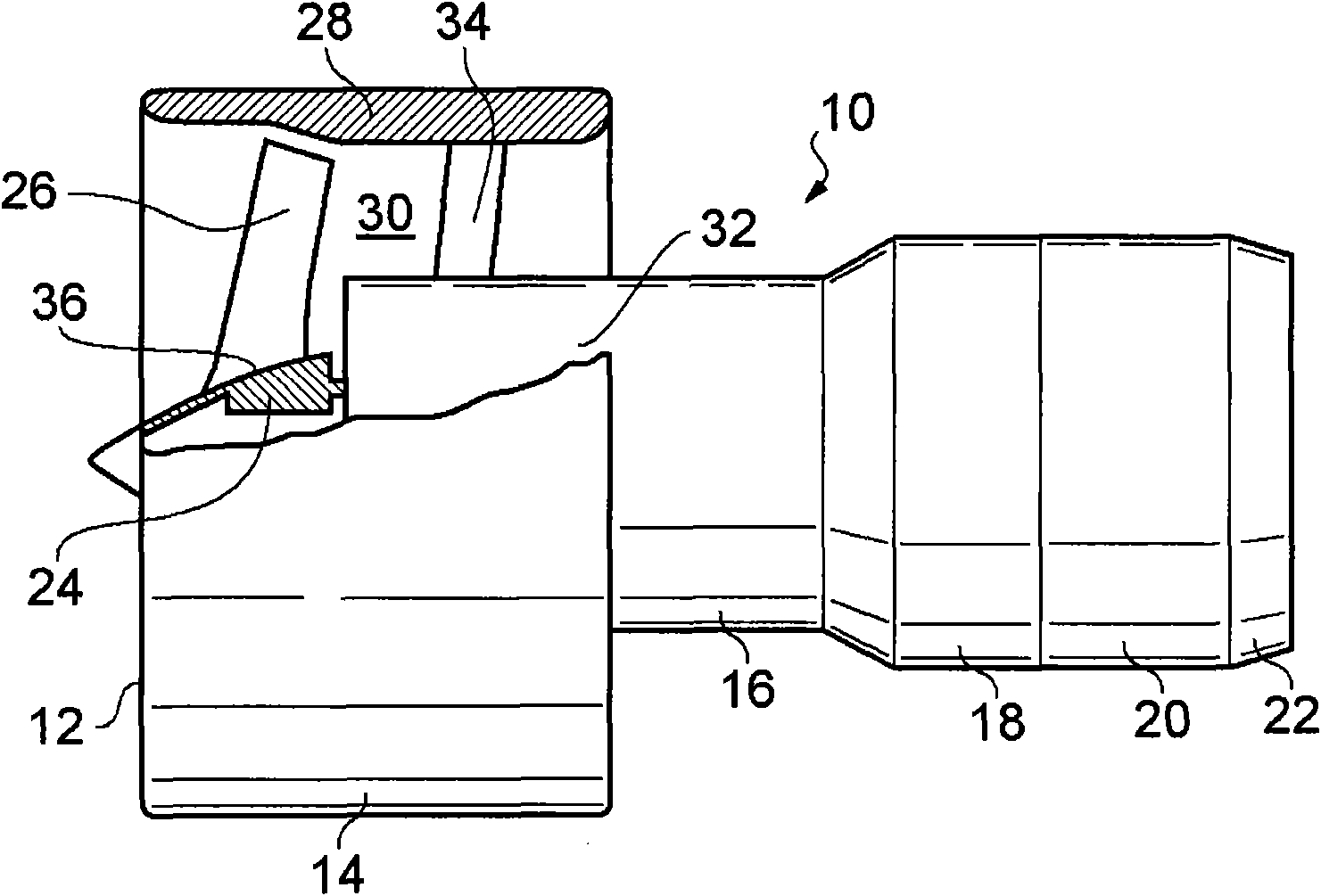

[0032] Such as figure 1 As shown, fan turbine gas turbine engine 10 includes, in flow order: inlet 12 , fan section 14 , compressor section 16 , combustion section 18 , turbine section 20 , and exhaust 22 . The fan section 14 includes a fan rotor 24 carrying a plurality of circumferentially spaced radially outwardly extending fan blades 26 . Fan section 14 also includes a fan case 28 arranged coaxially with and surrounding fan rotor 24 and fan blades 26 . The fan case 28 defines a fan duct 30 . The fan case 28 is secured to the core engine case 32 by a plurality of circumferentially spaced apart and radially extending fan outlet vanes 34 .

[0033] Compressor section 16 includes one or more compressors, such as an intermediate pressure compressor (not shown) and a high pressure compressor (not shown) or a high pressure compressor (not shown). Turbine section 20 includes one or more turbines, such as a high pressure turbine (not shown), an intermediate pressure turbine (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com