Patents

Literature

169results about "Feeder spouts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

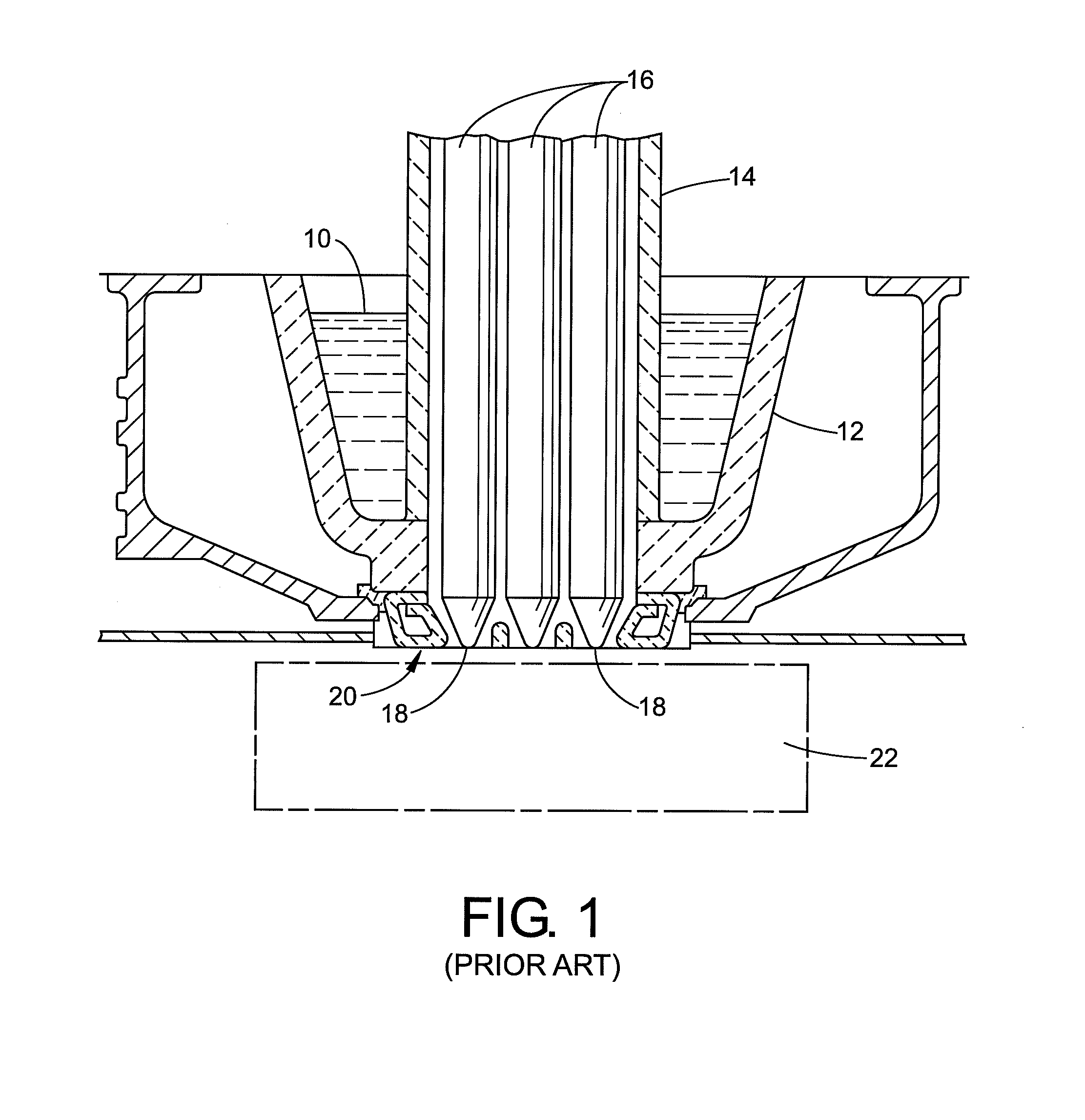

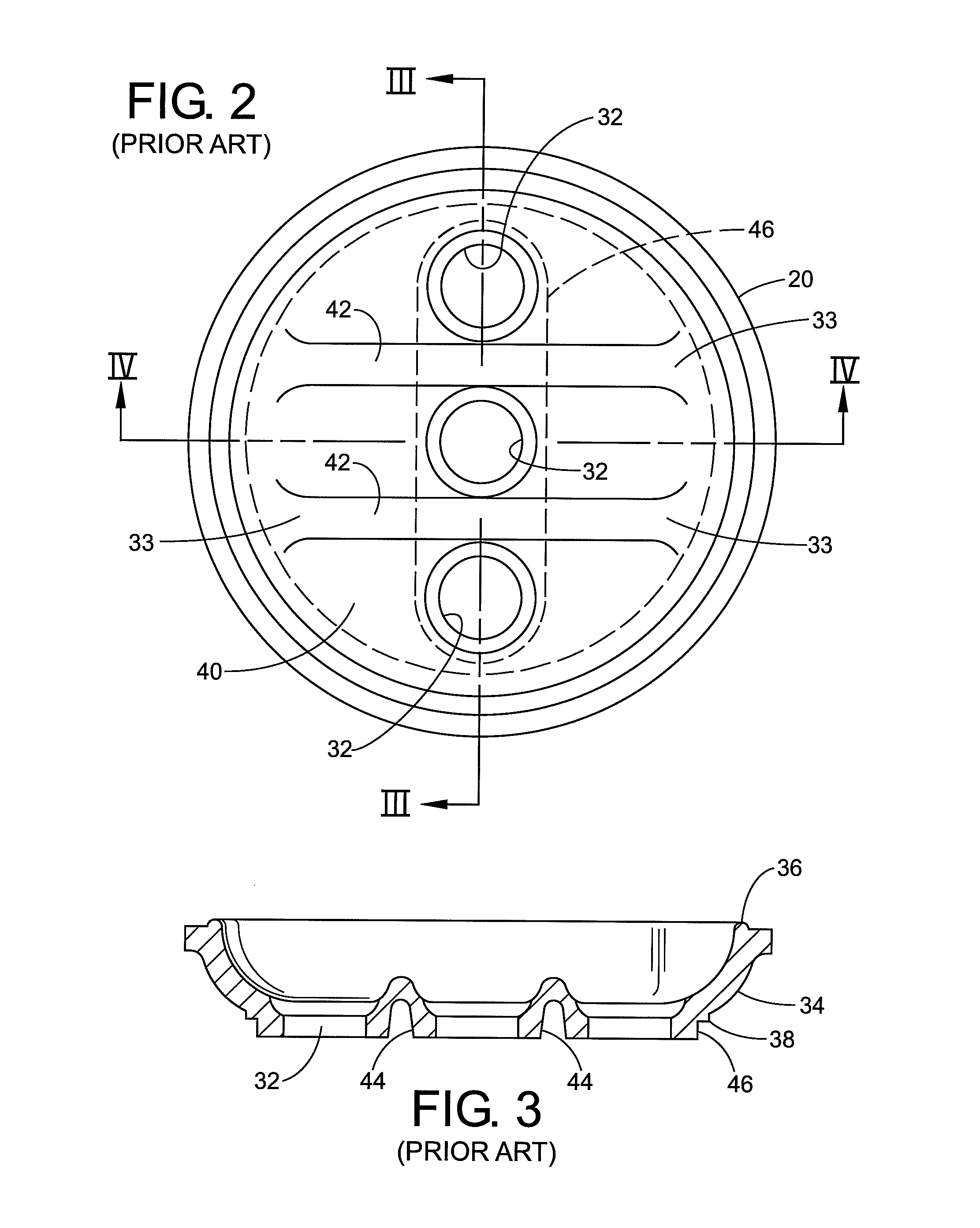

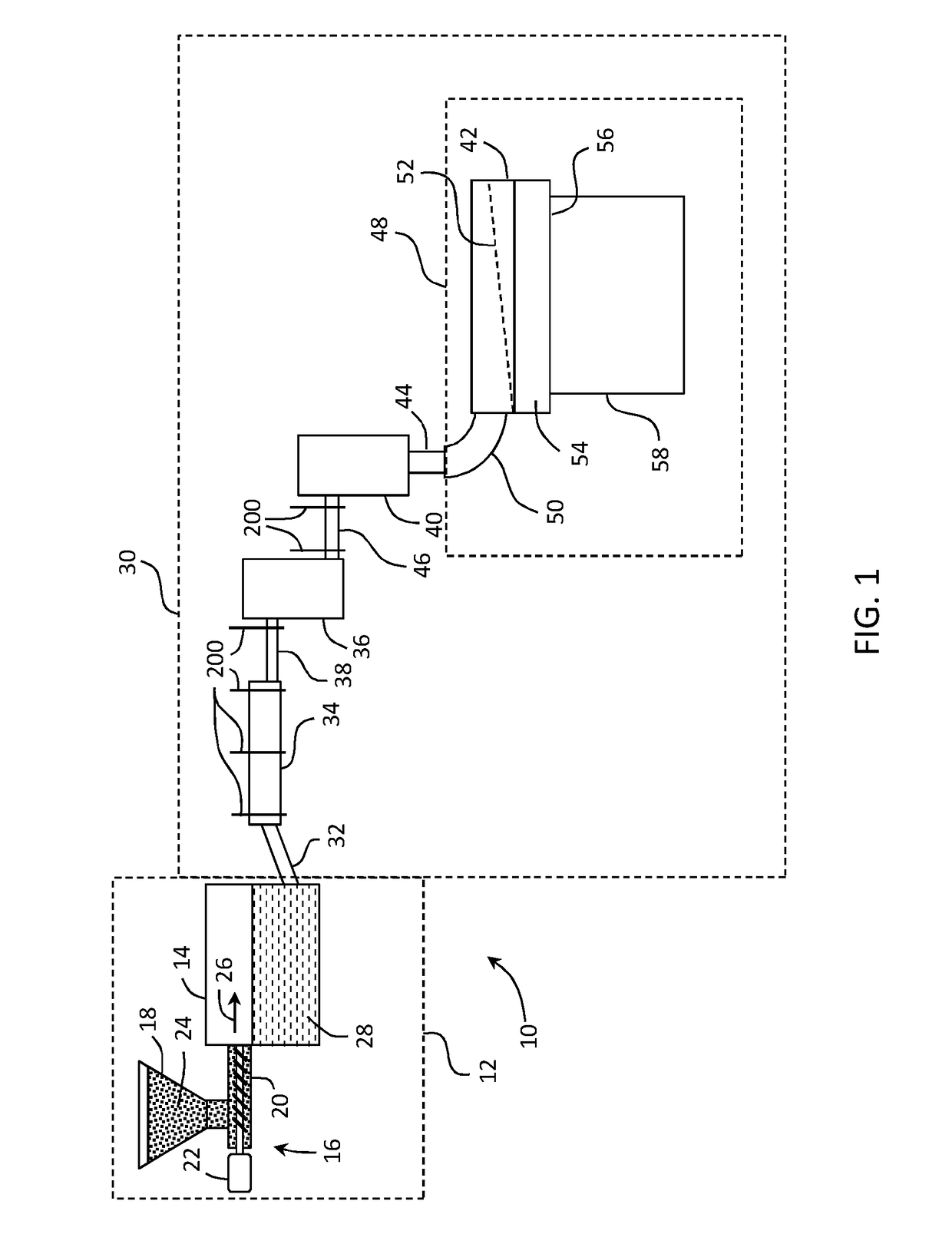

Oxygen-fired front end for glass forming operation

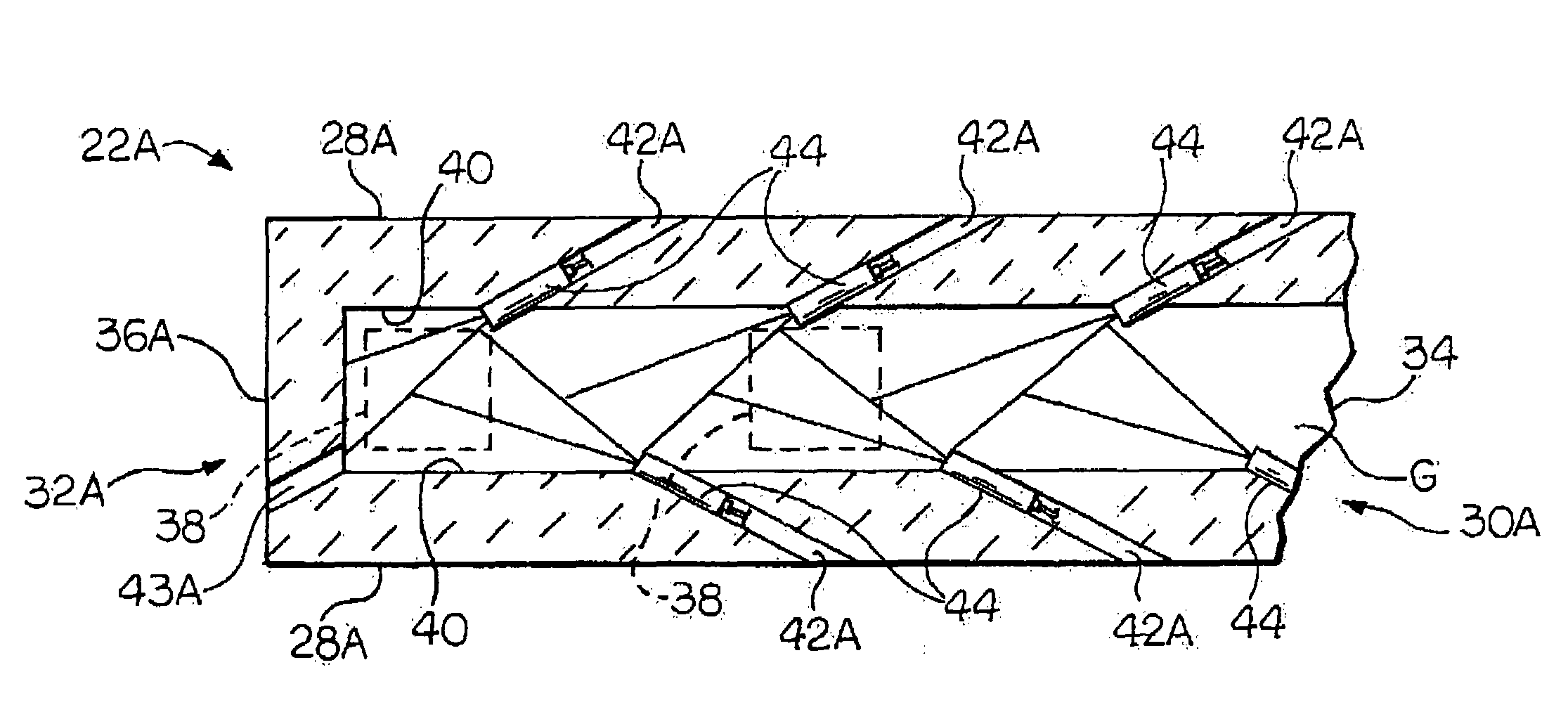

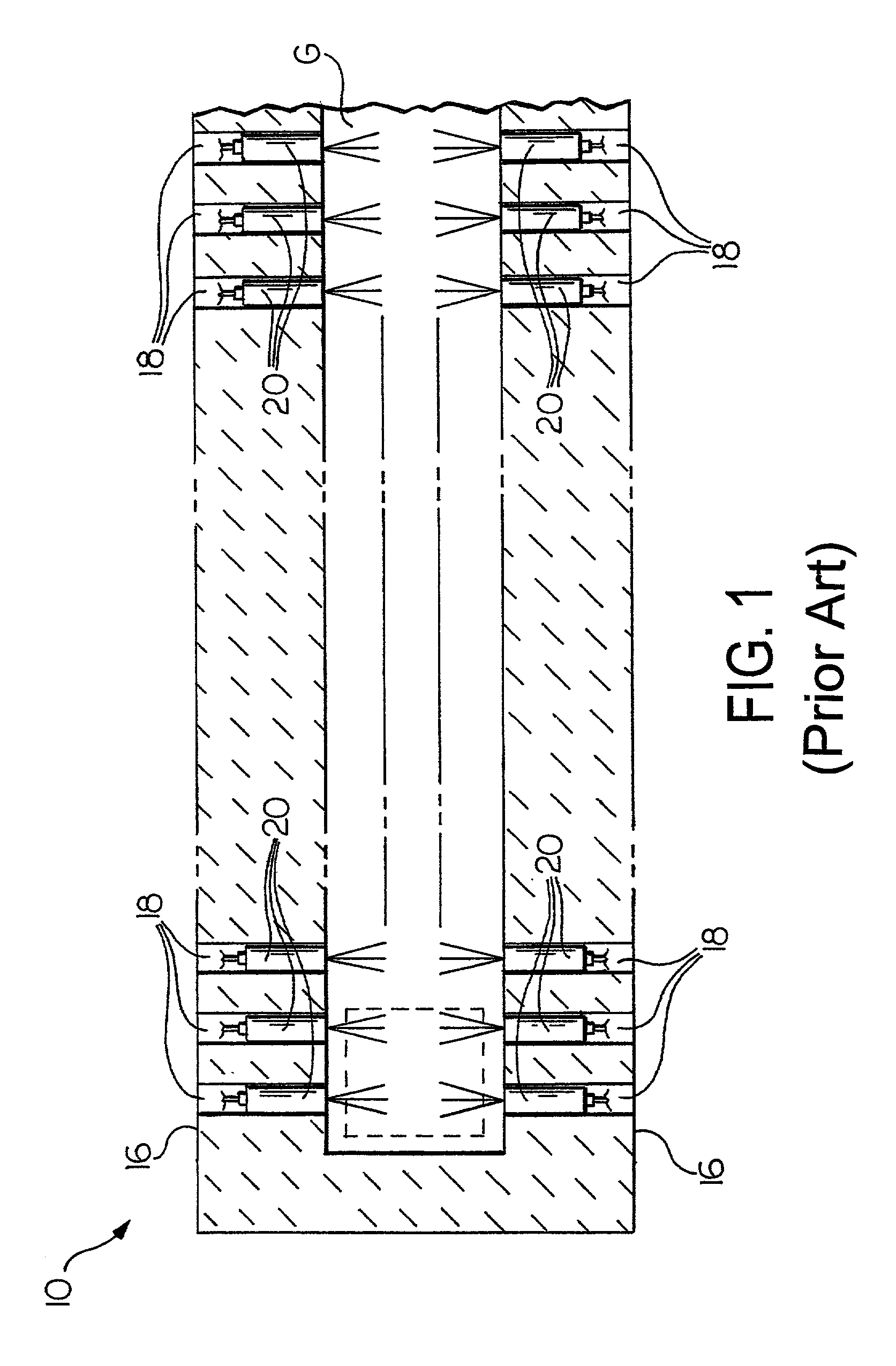

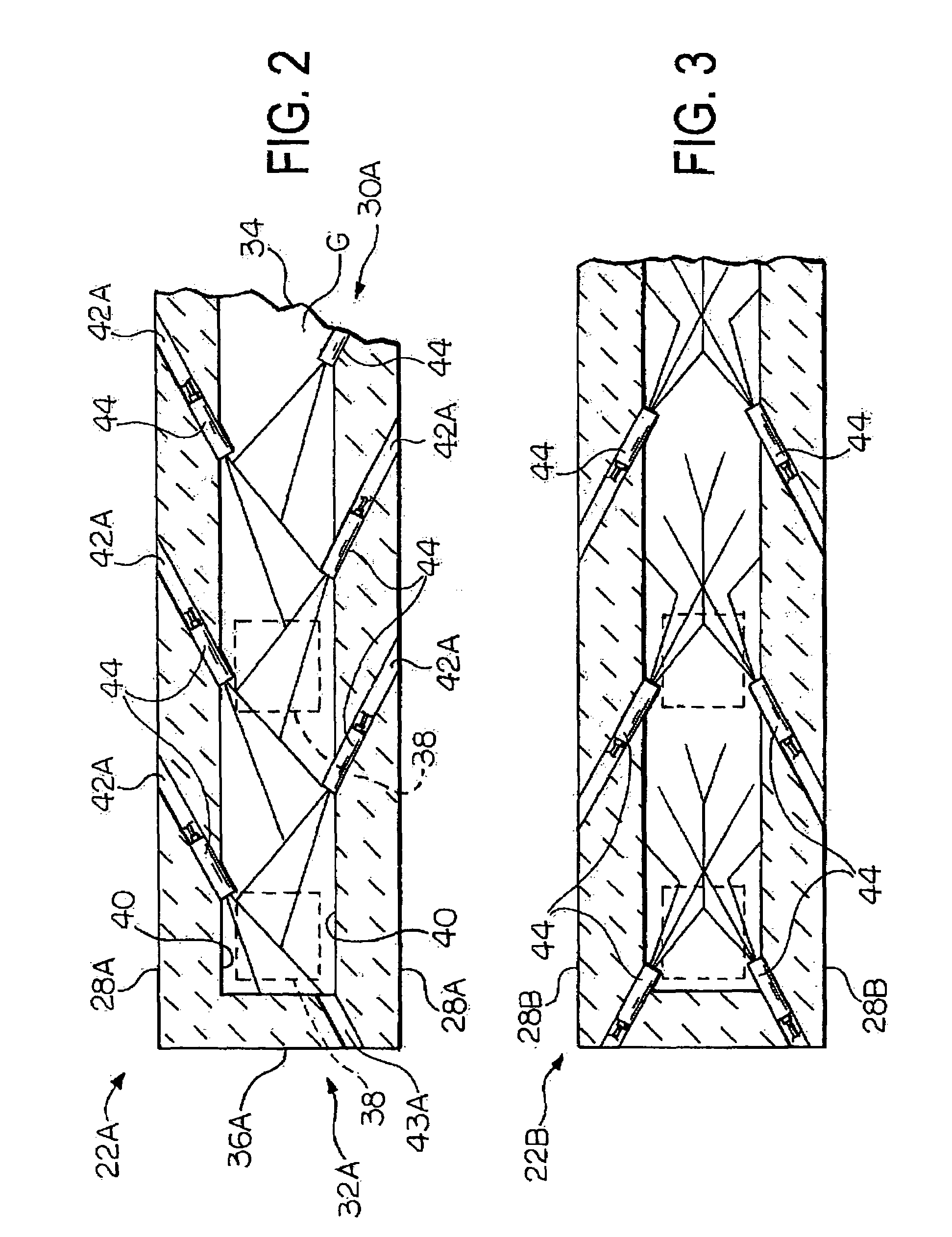

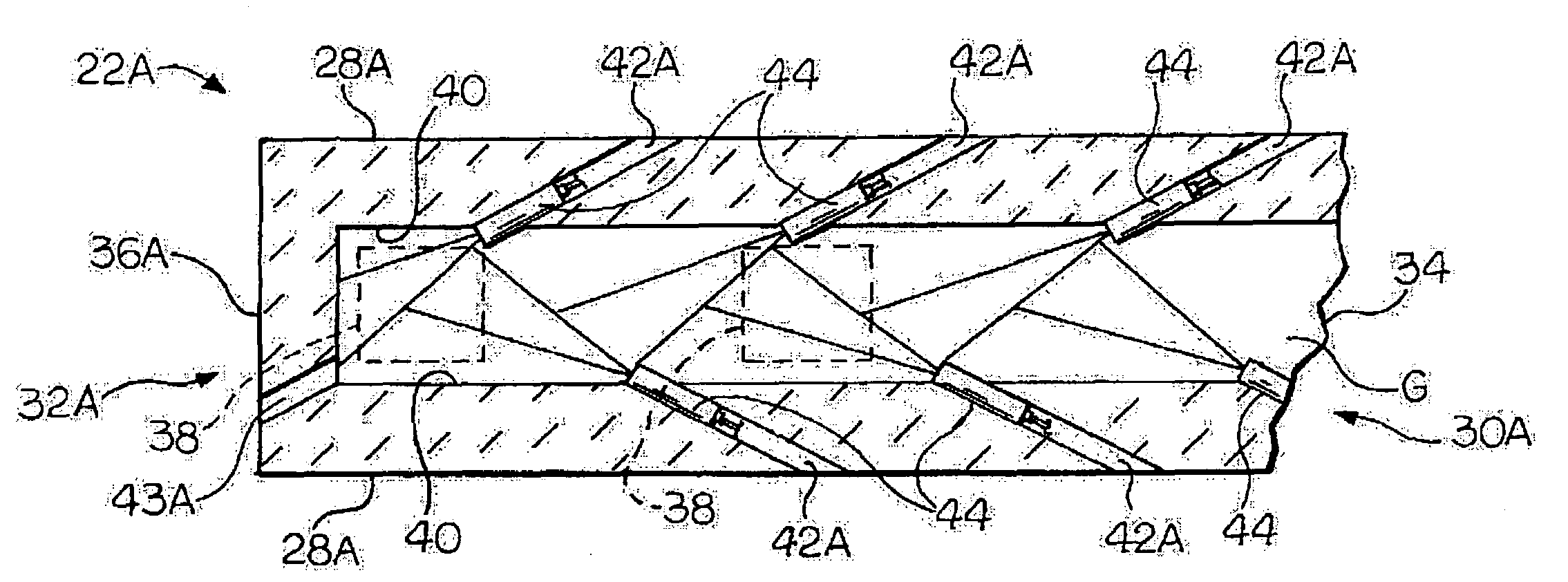

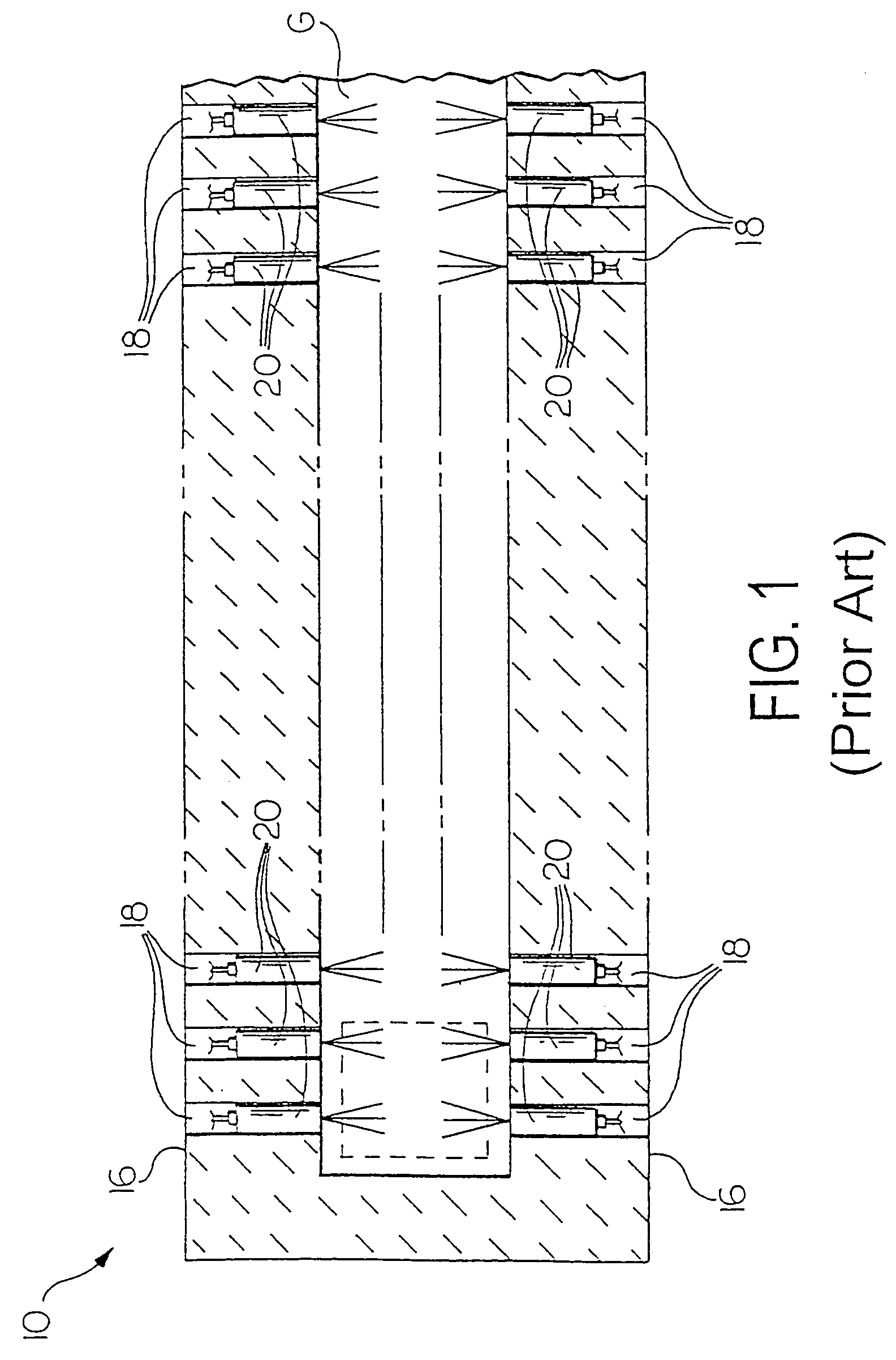

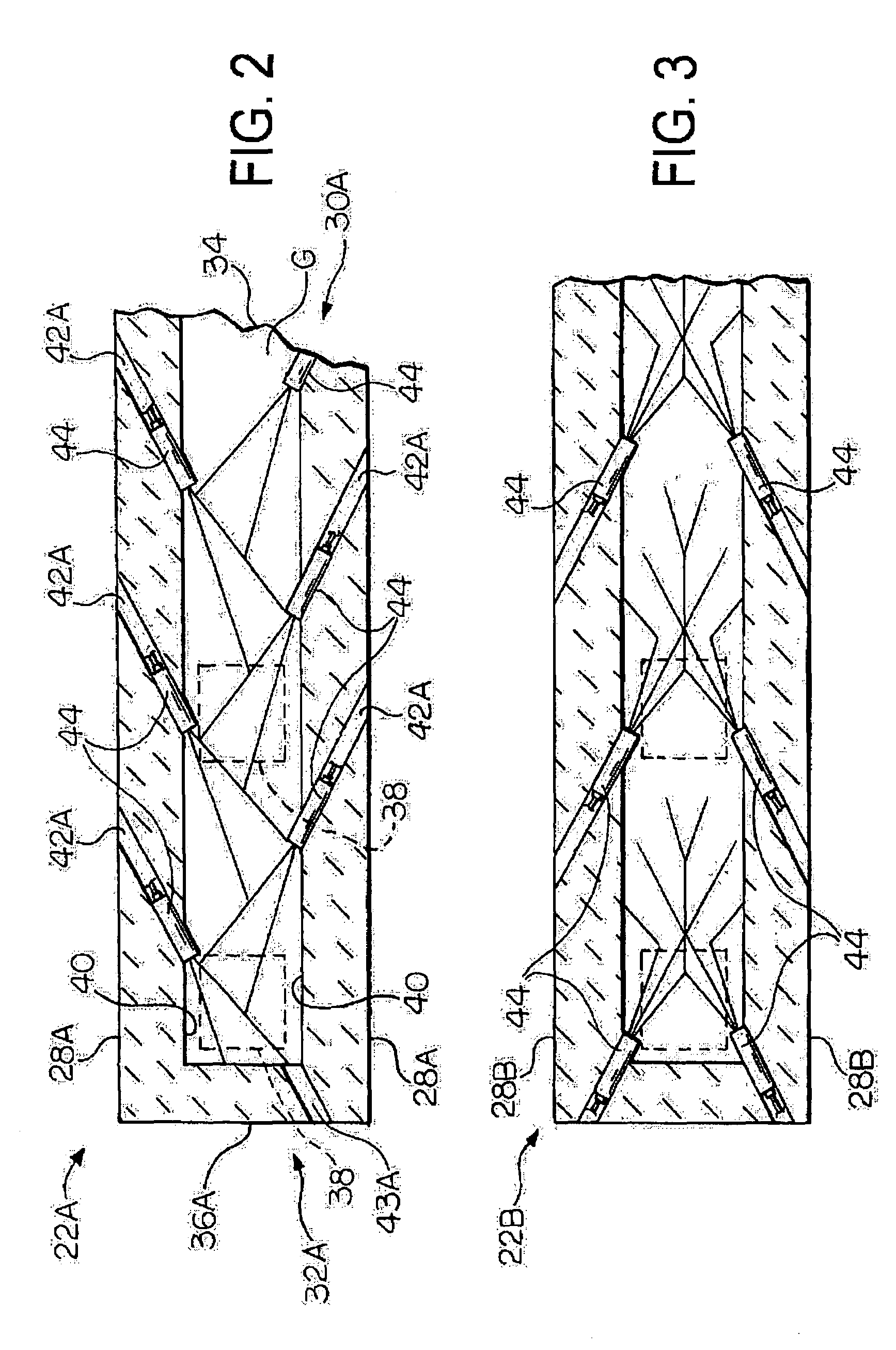

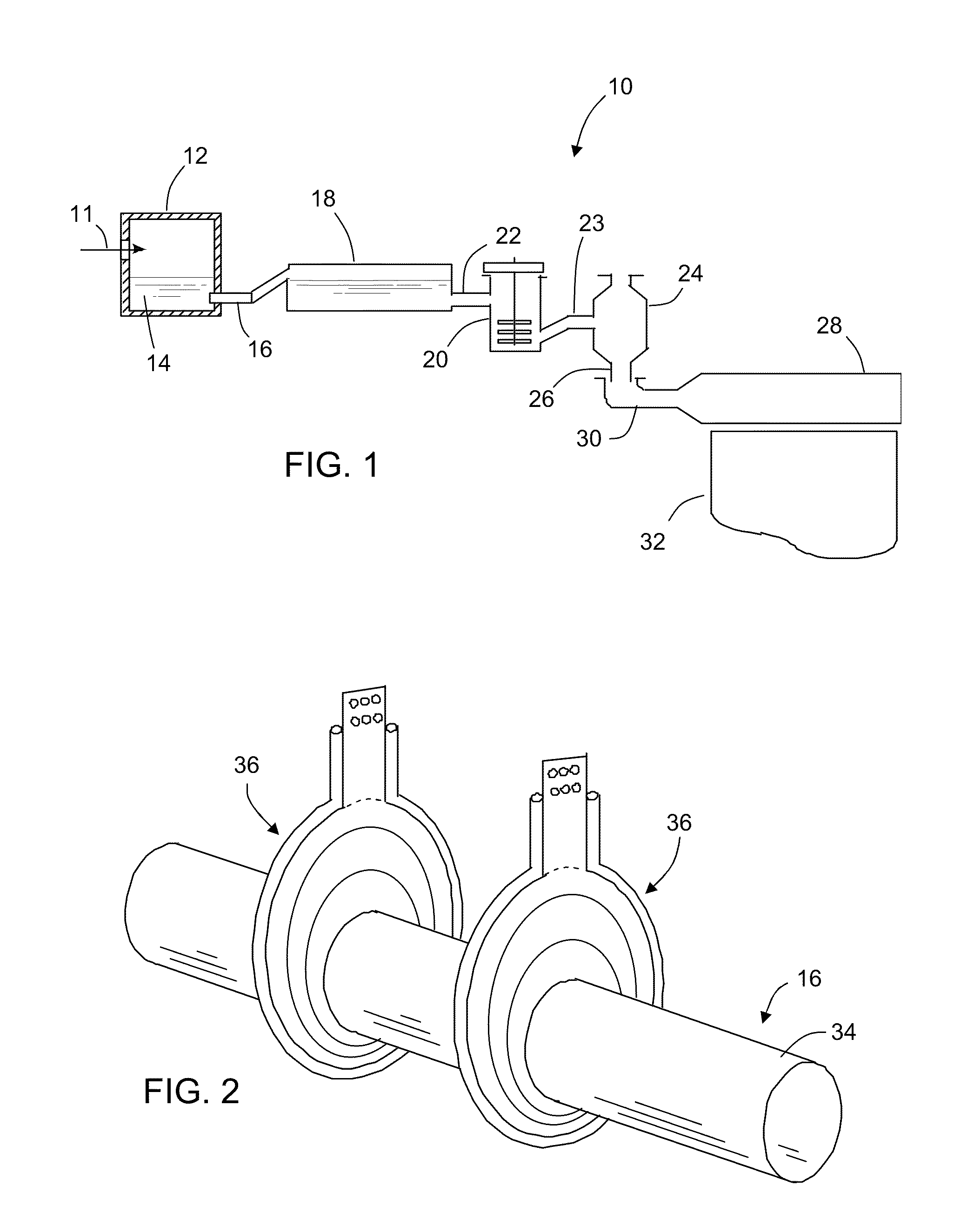

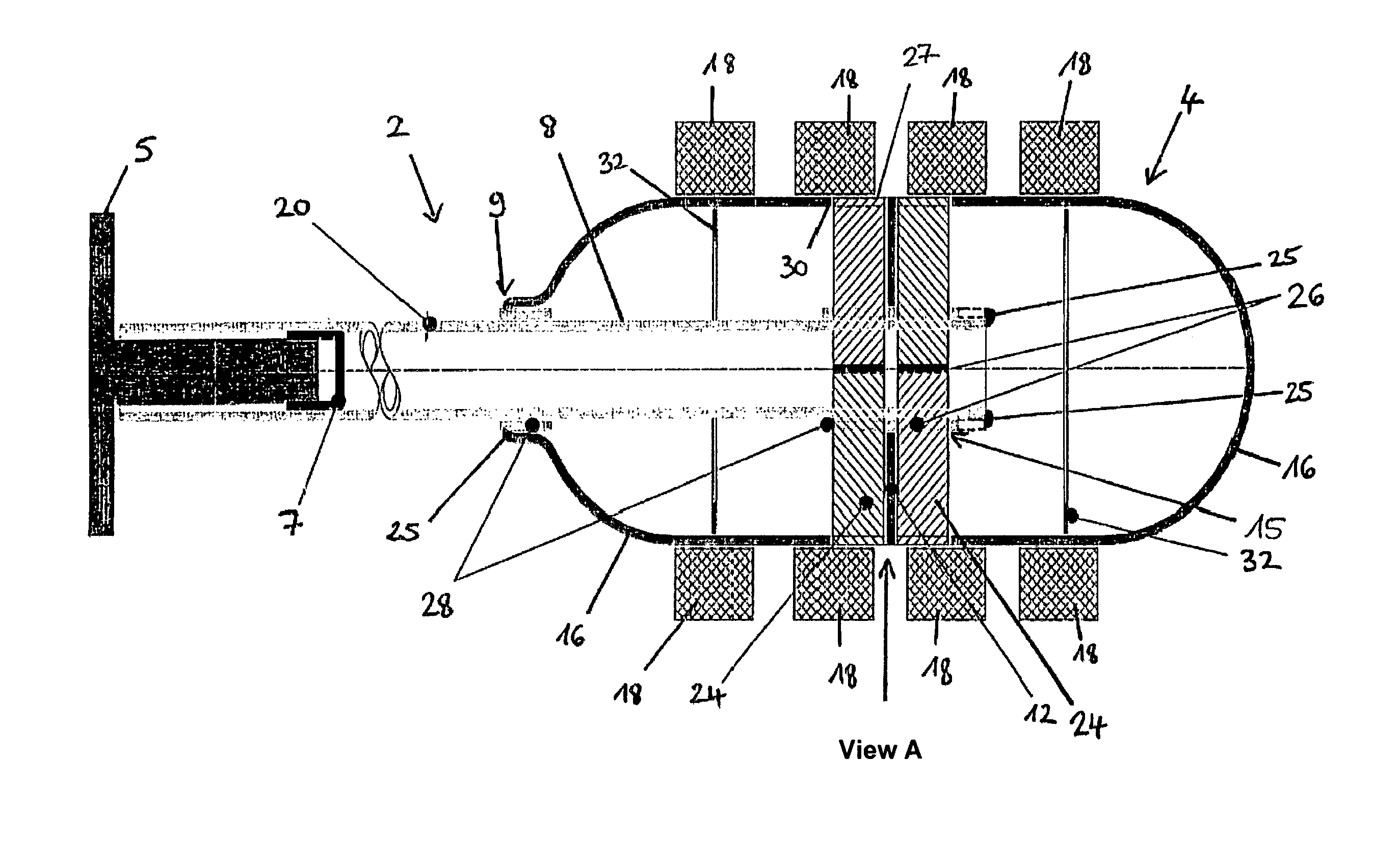

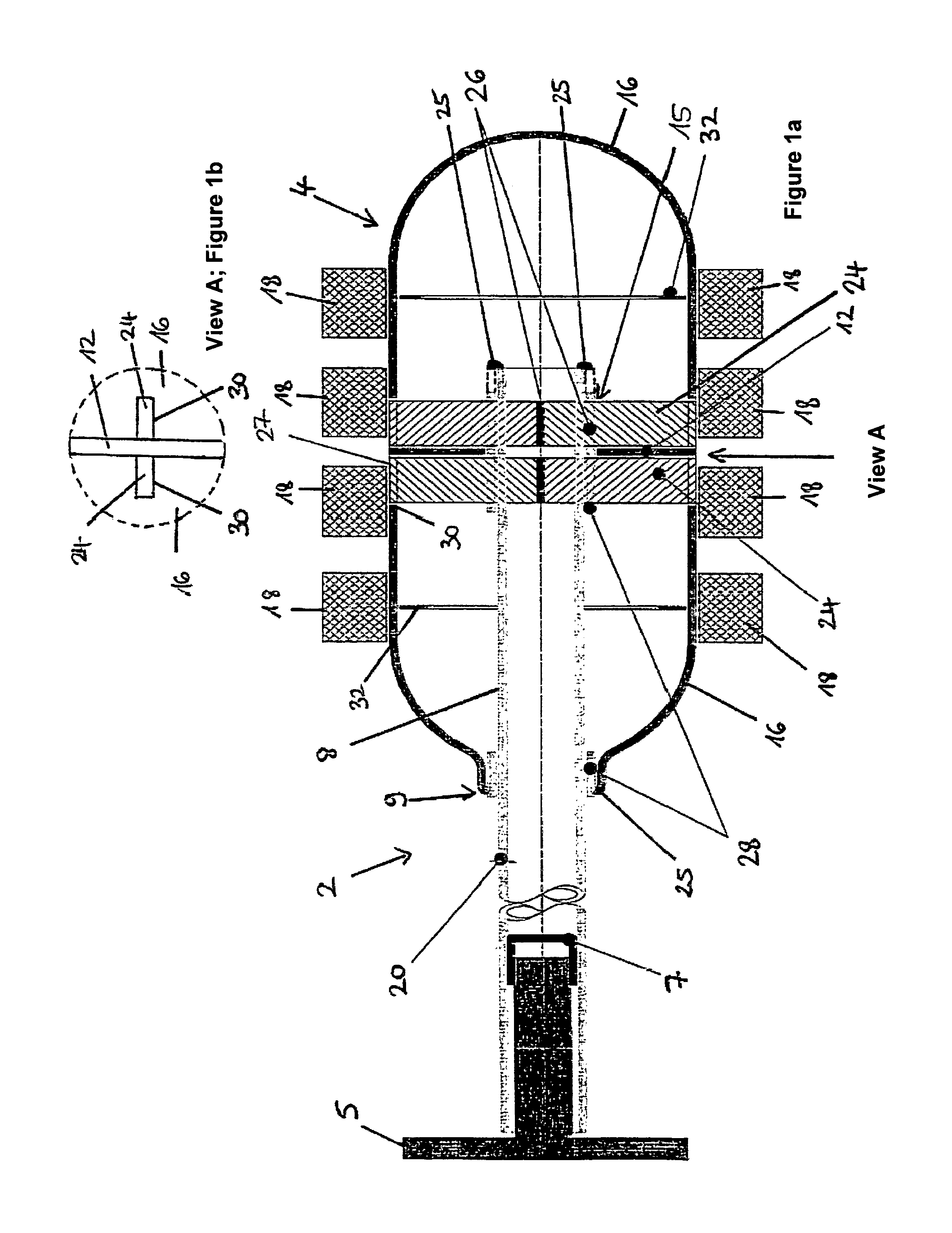

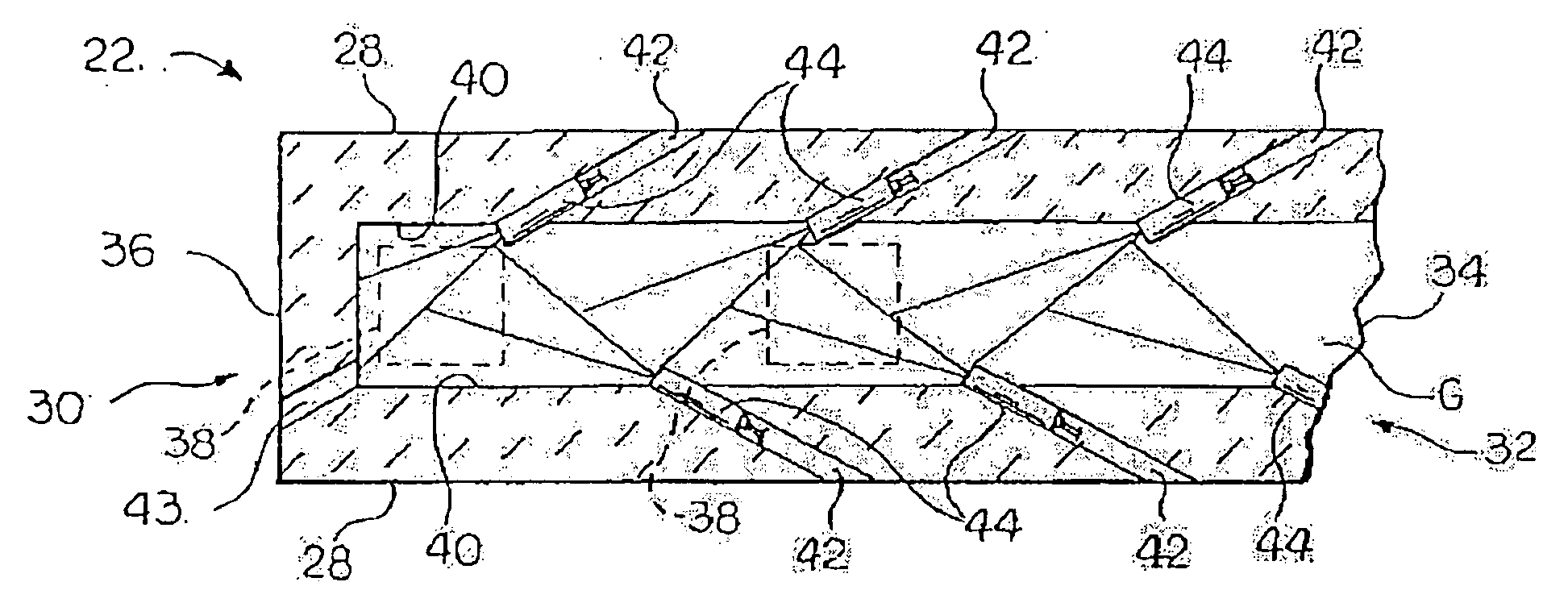

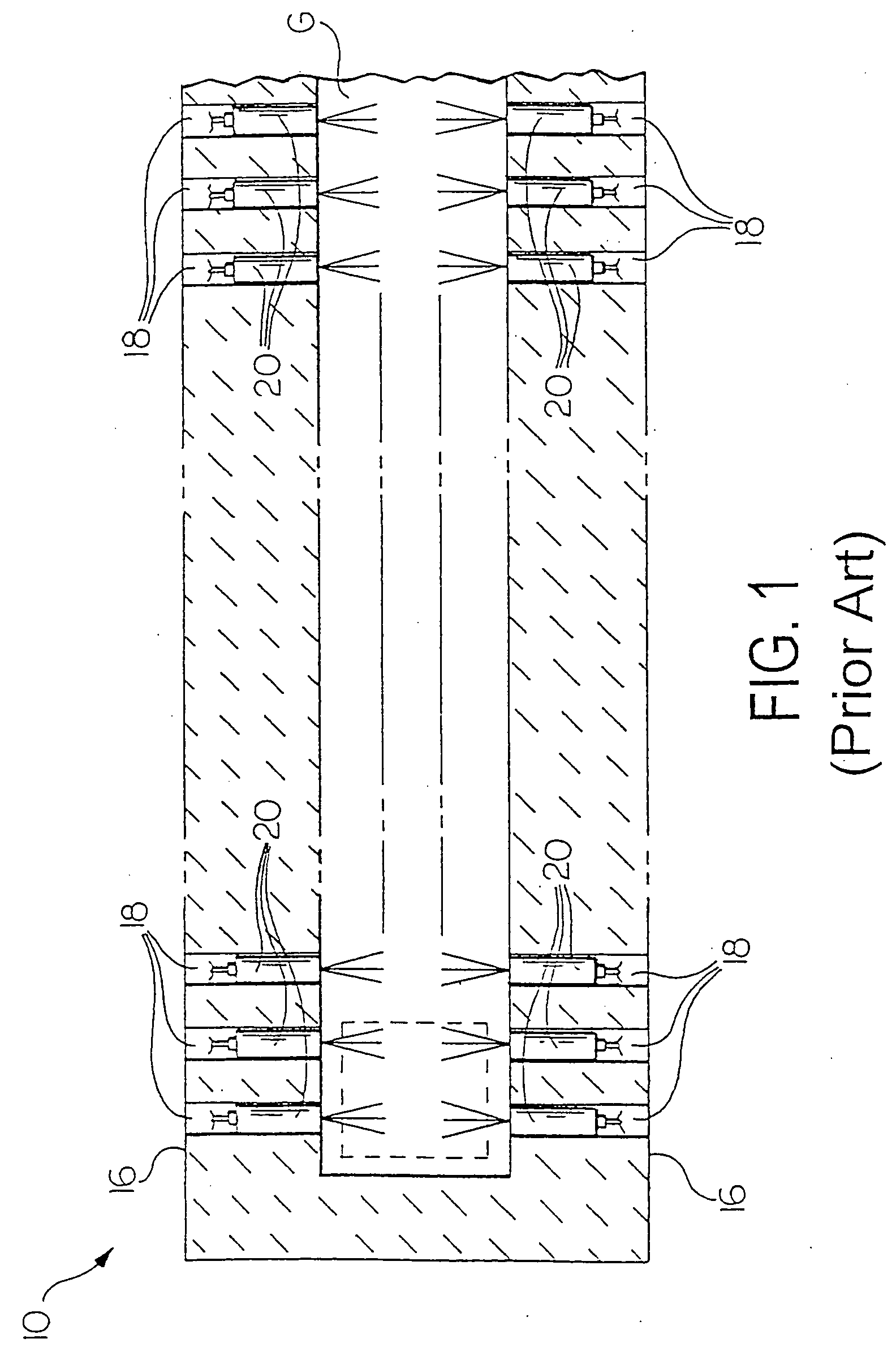

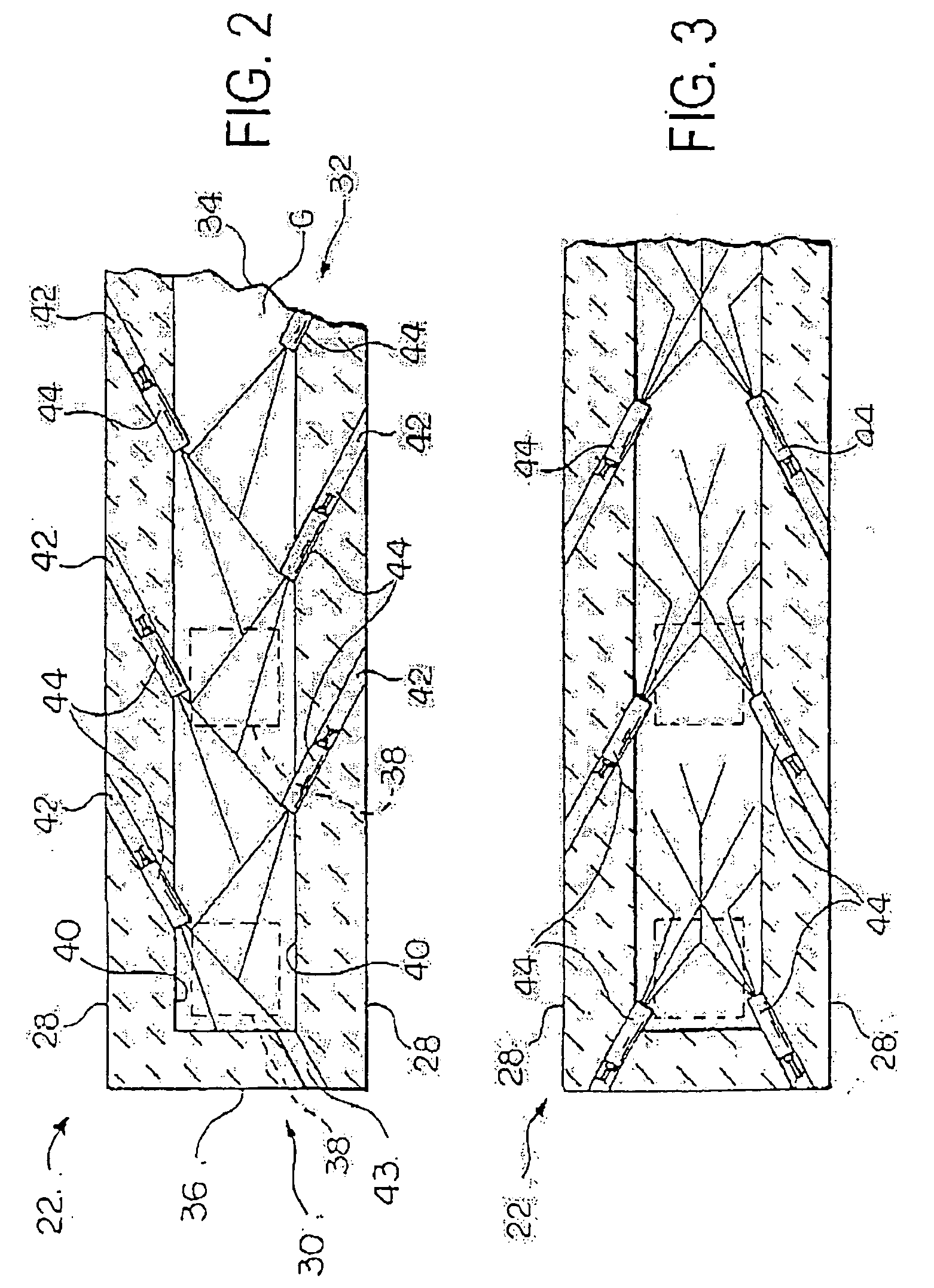

A front end for a glass forming operation comprises an open channel and at least one burner. The channel has at least one surface. The surface has at least one hole therein. The burner is oriented in the hole at an acute angle relative to the surface. In another embodiment of the invention, the channel has a top and a pair of sidewalls each having a surface. At least one hole is in at least one of the surfaces. The hole is at an acute angle relative to at least one surface. The burner is an oxygen-fired burner. In yet another embodiment of the invention, the top and sidewalls each have a super structure surface constructed of refractory material. The channel has an upstream end and a downstream end. At least one of the surfaces has a plurality of holes therein. The burners extend at an acute angle relative to at least one surface and in a plane extending between the upstream end and the downstream end and perpendicular to at least one surface. Oxygen-fired burners extend axially through corresponding holes.

Owner:OCV INTELLECTUAL CAPITAL LLC

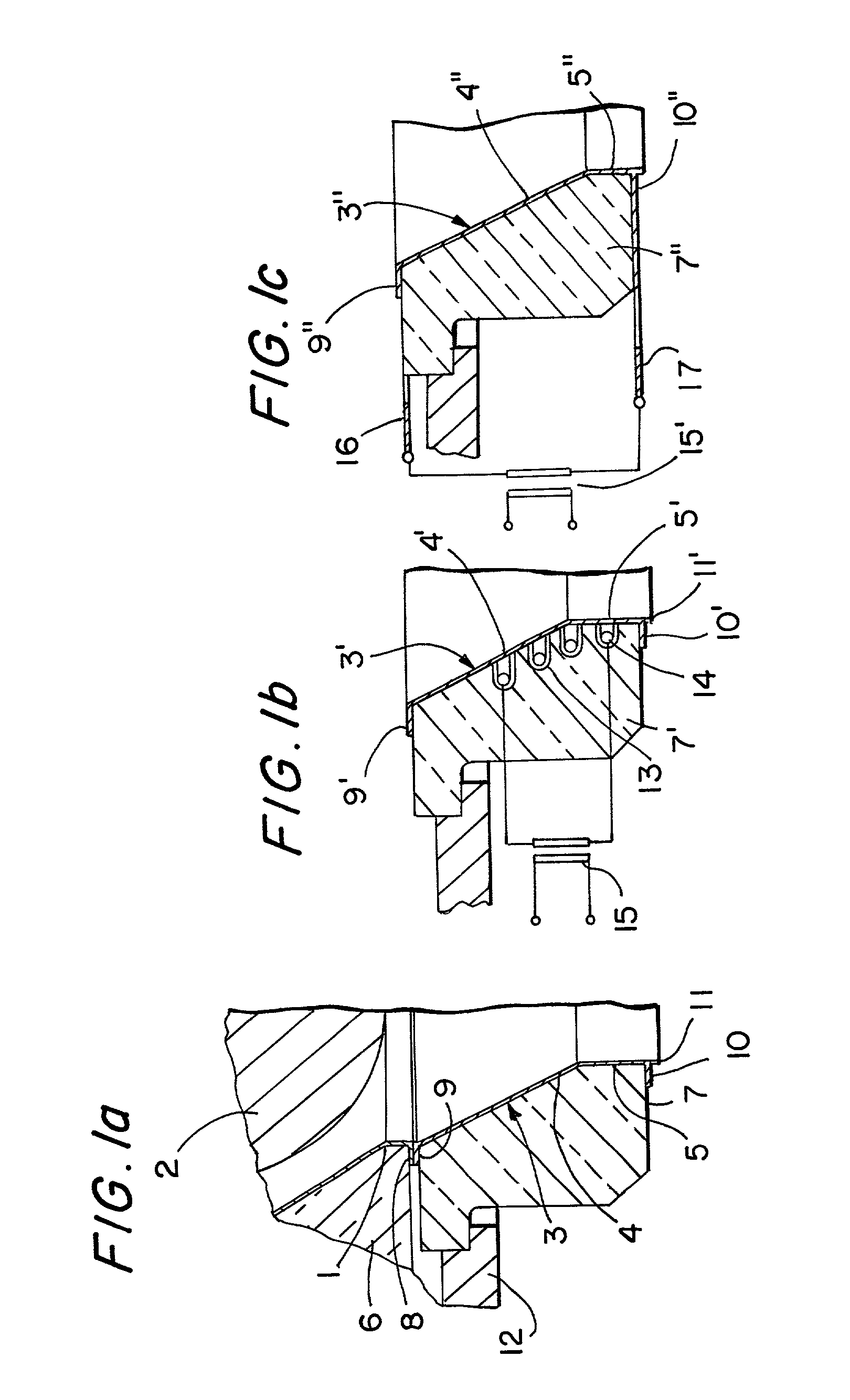

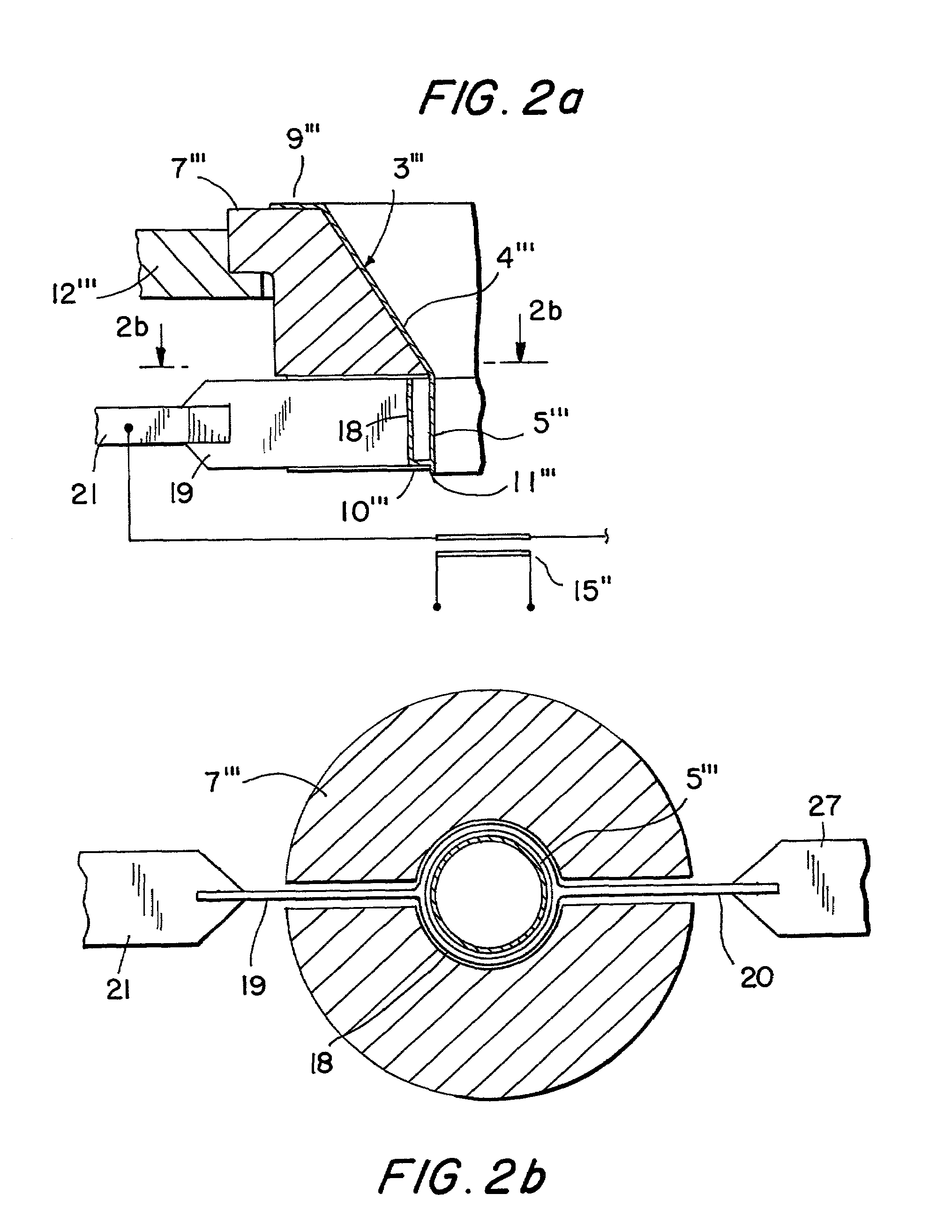

Low heat capacity gas oxy fired burner

A front end for a glass forming operation including an open channel and at least one burner. The channel surface has at least one burner port and a burner oriented in the burner port at an acute angle relative to the channel surface. The surface may be a top, side or end wall and the burner port is at an acute angle relative to the surface of the wall.

Owner:OCV INTELLECTUAL CAPITAL LLC

Glass packaging ensuring container integrity

ActiveUS20140120279A1Reducing and eliminating potentialCatastrophic failure is enhancedGlass blowing apparatusGlass/slag layered productsEngineeringCatastrophic failure

A strengthened glass container or vessel such as, but not limited to, vials for holding pharmaceutical products or vaccines in a hermetic and / or sterile state. The strengthened glass container undergoes a strengthening process that produces compression at the surface and tension within the container wall. The strengthening process is designed such that the tension within the wall is great enough to ensure catastrophic failure of the container, thus rendering the product unusable, should sterility be compromised by a through-wall crack. The tension is greater than a threshold central tension, above which catastrophic failure of the container is guaranteed, thus eliminating any potential for violation of pharmaceutical integrity.

Owner:CORNING INC

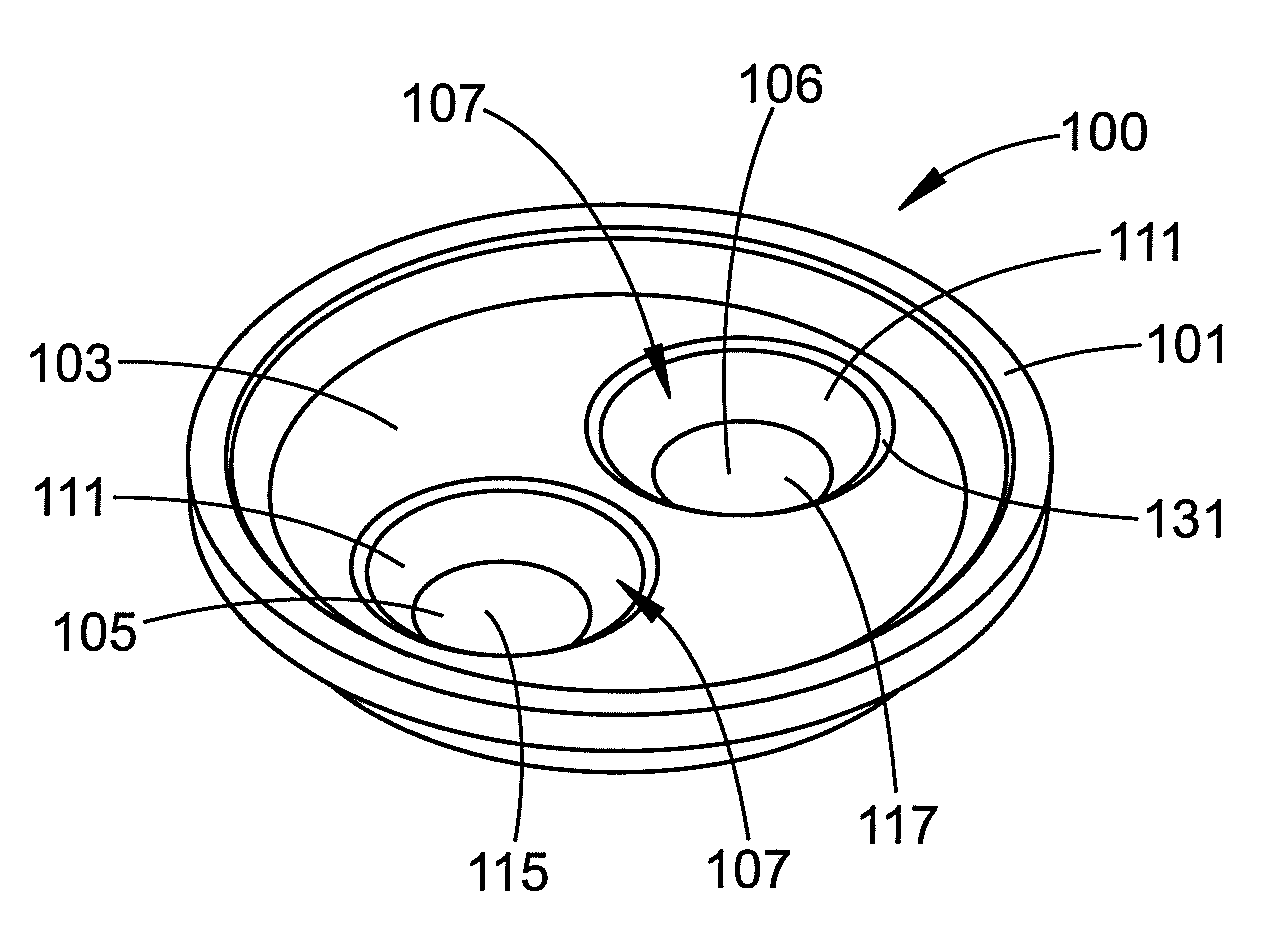

Glass forming apparatus

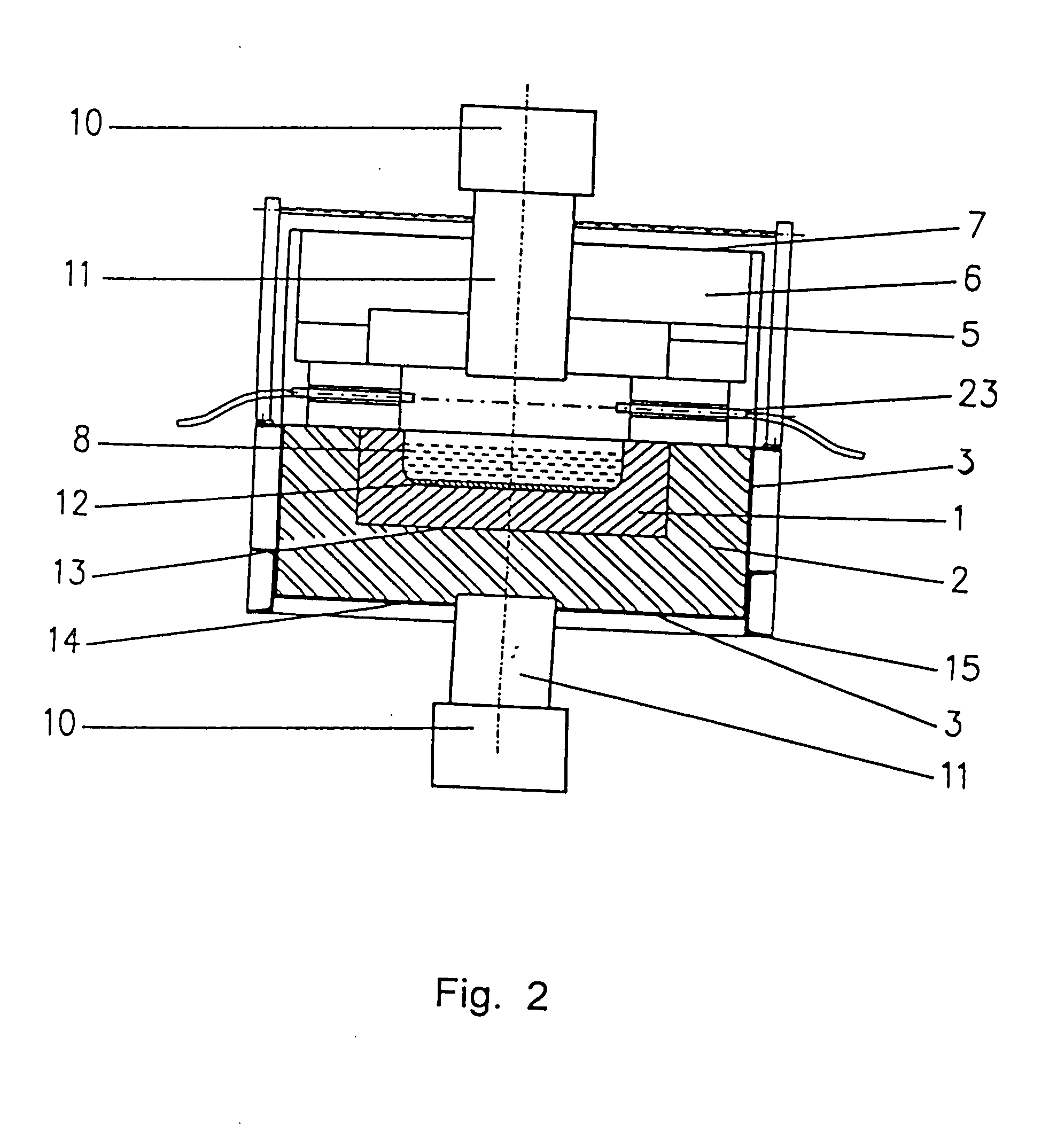

According to a first embodiment, a refractory orifice ring of a glass forming apparatus is provided. The orifice ring includes an annular side wall and a base wall. At least one discharge hole is formed in the base wall. The discharge hole includes a top opening and a bottom opening, wherein the top opening has a surface area greater than a surface area of the bottom opening.

Owner:PYROTECK INC

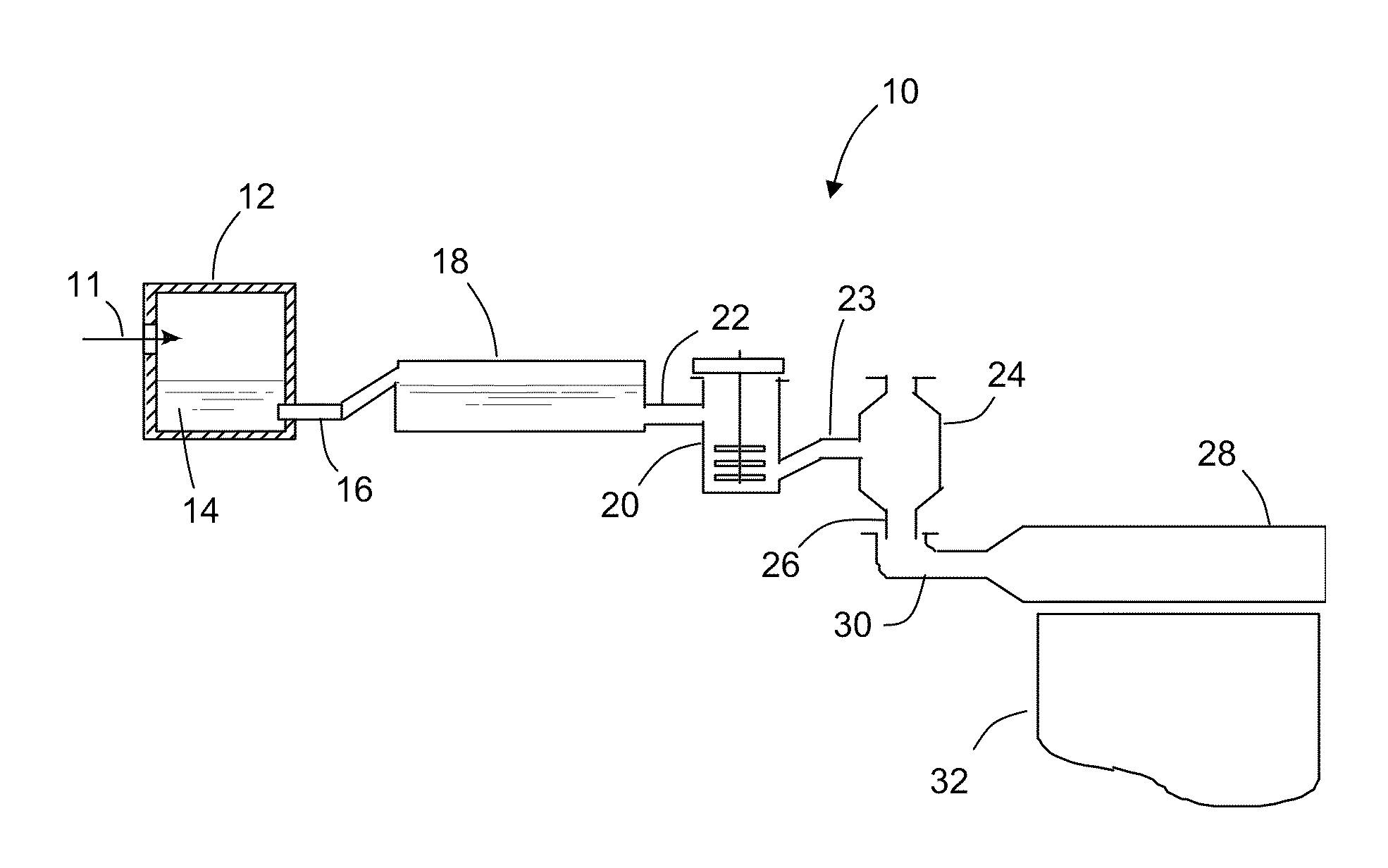

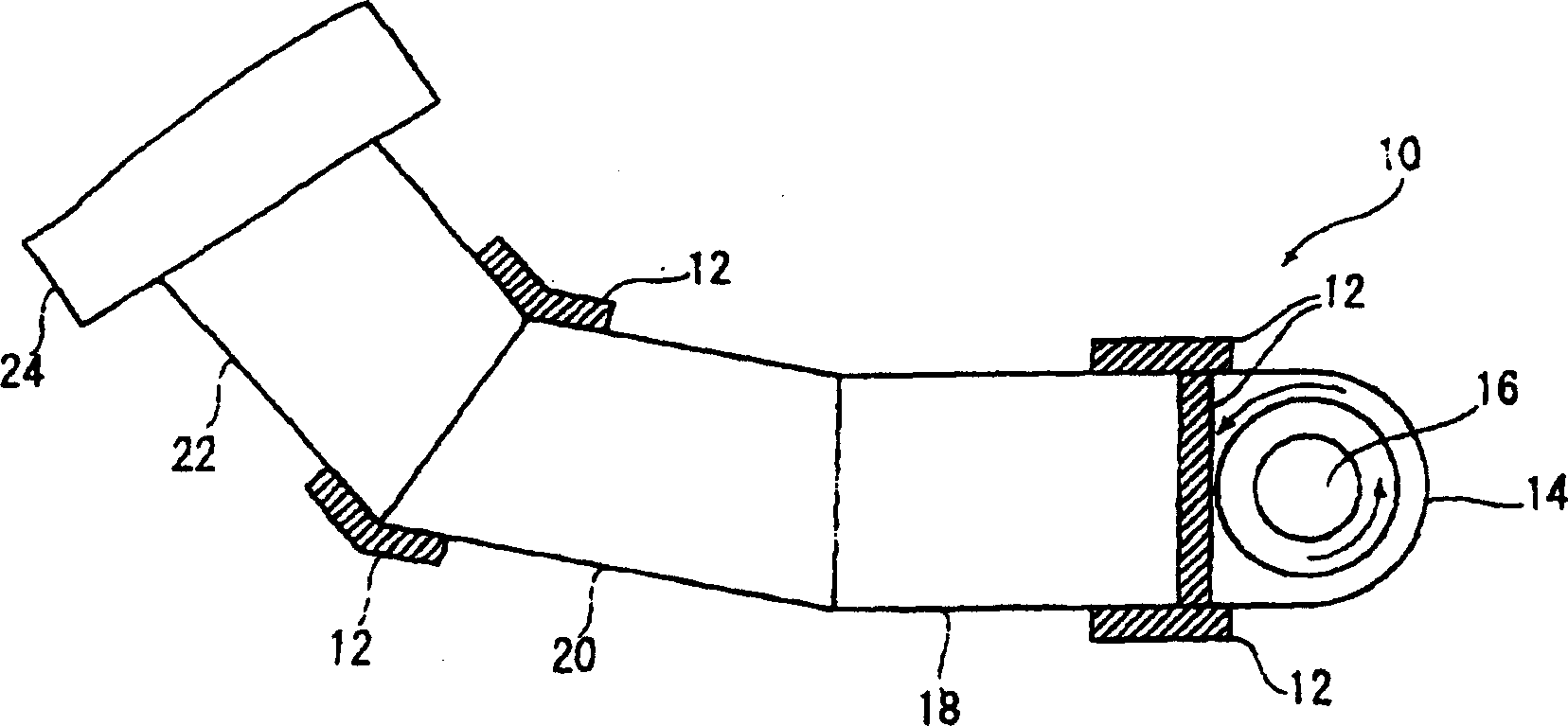

Device for glass melt delivery and method for using them

InactiveUS7013677B2Efficient heatingGlass furnace apparatusGlass forming apparatusMetallic materialsMetal

The present invention provides devices for glass melt devlivery and methods for using these devices. In these devices, a delivery nozzle comprising at least one platinum group metal material is directly heated by electricty. To facilitate heating, a cylindrical heating ring is mounted in ceramic base. The device's construction ensures a regulatable heating of the nozzle and the melted glass flux.

Owner:UMICORE AG & CO KG

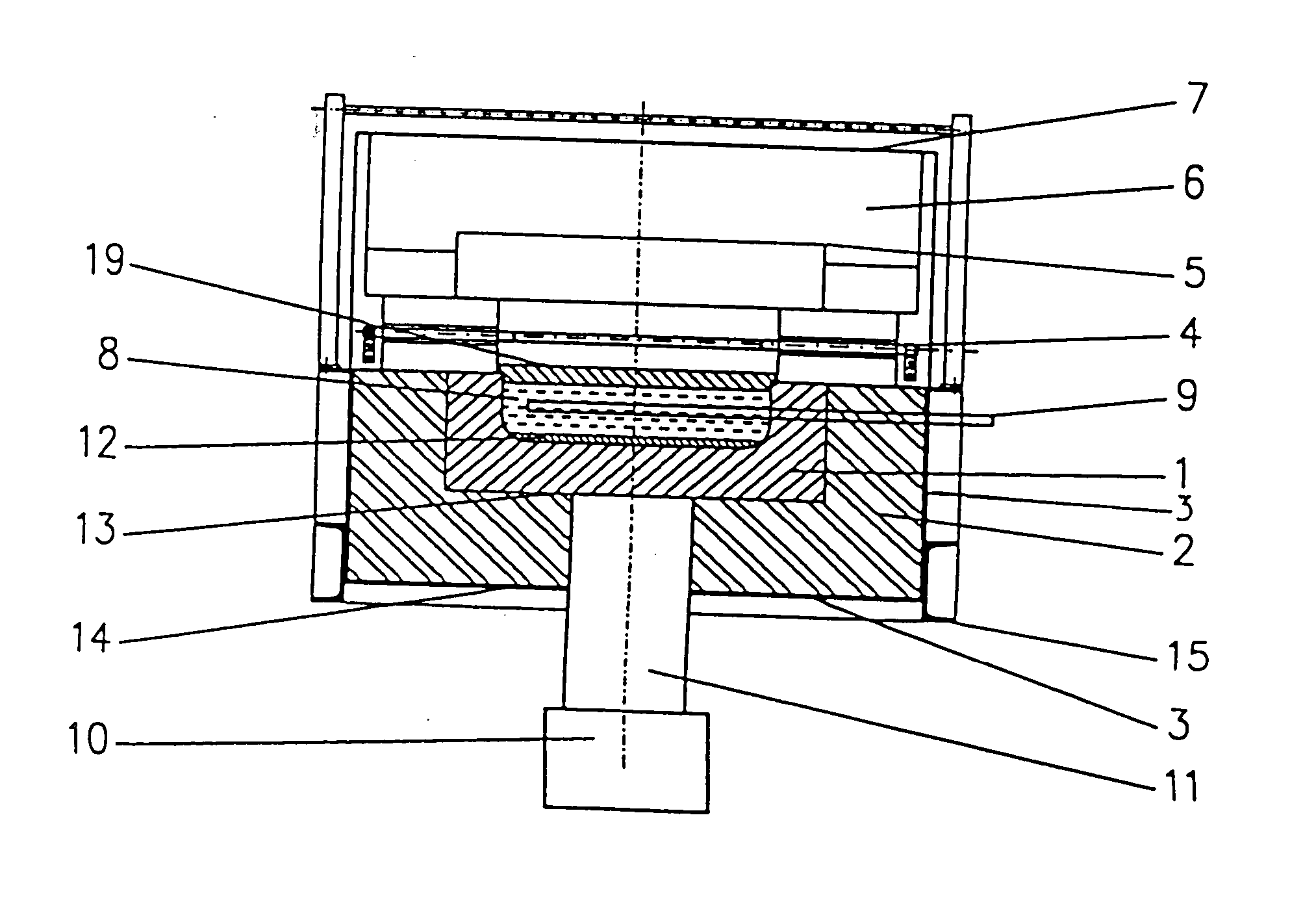

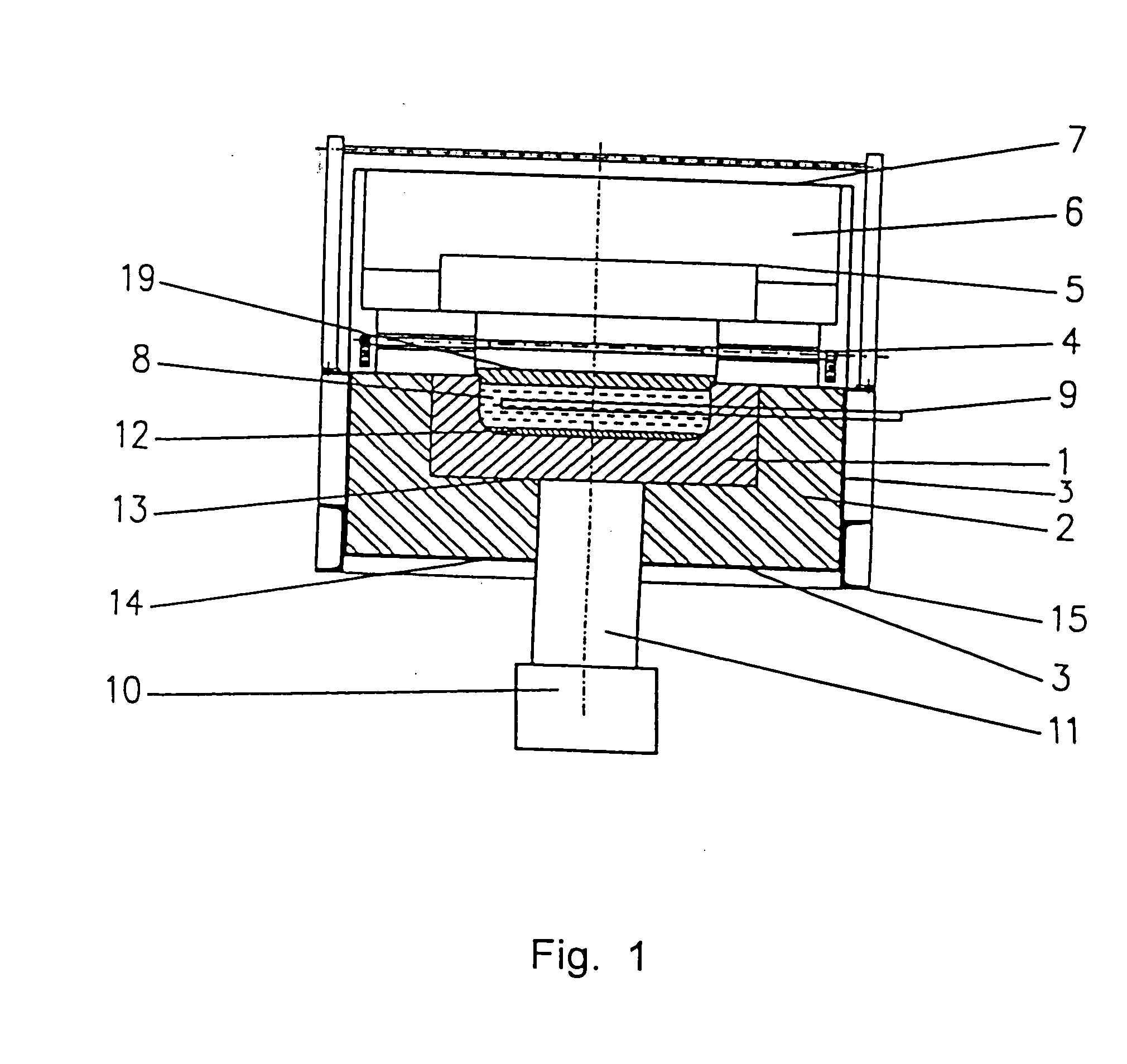

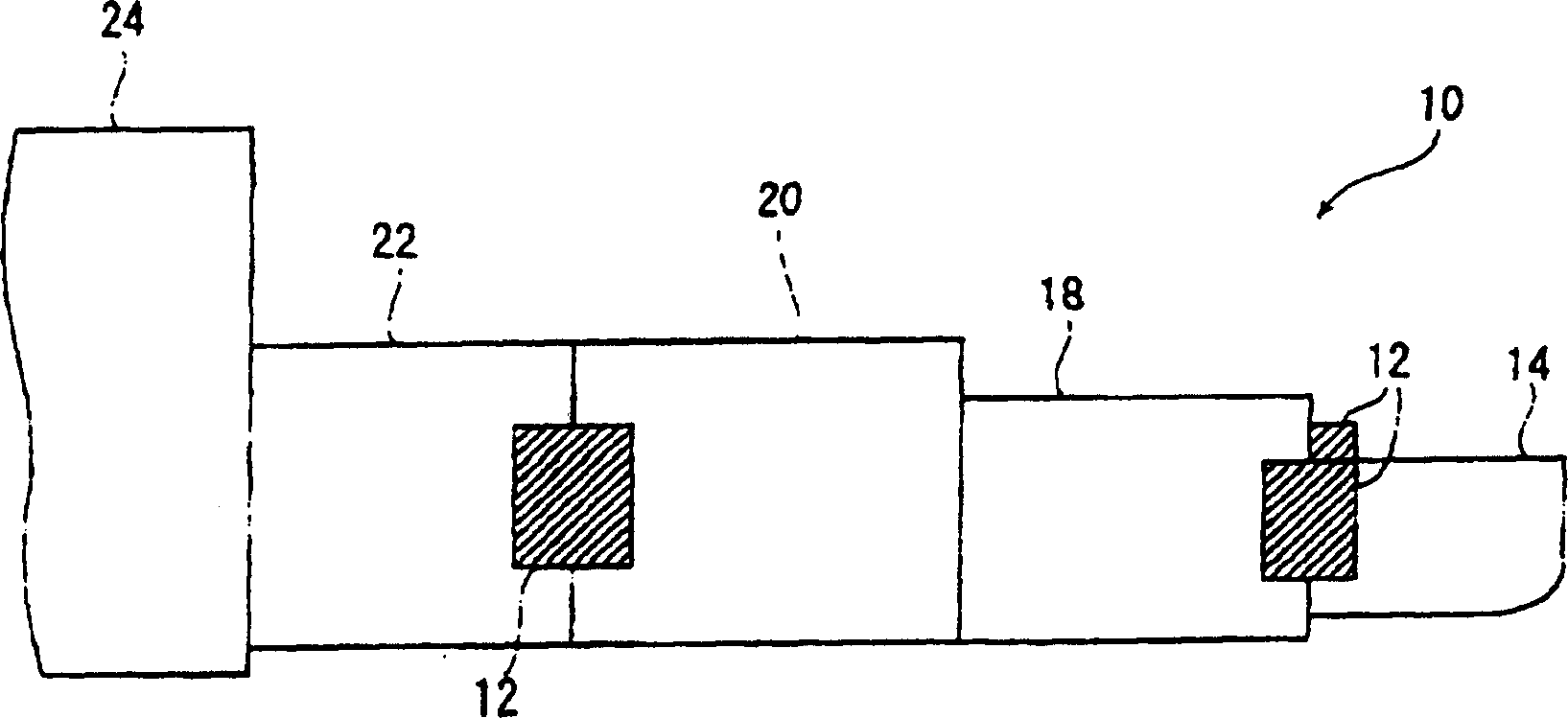

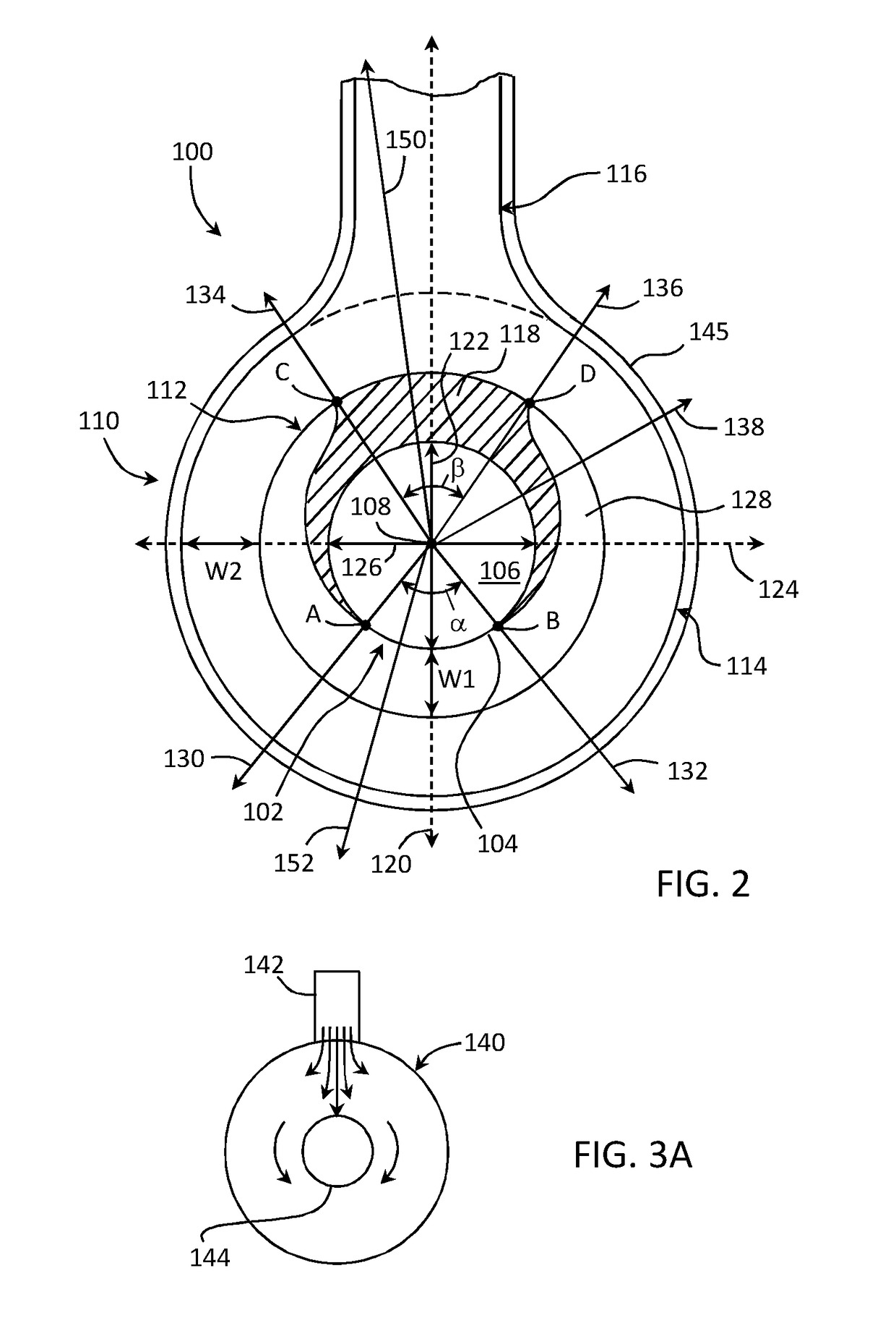

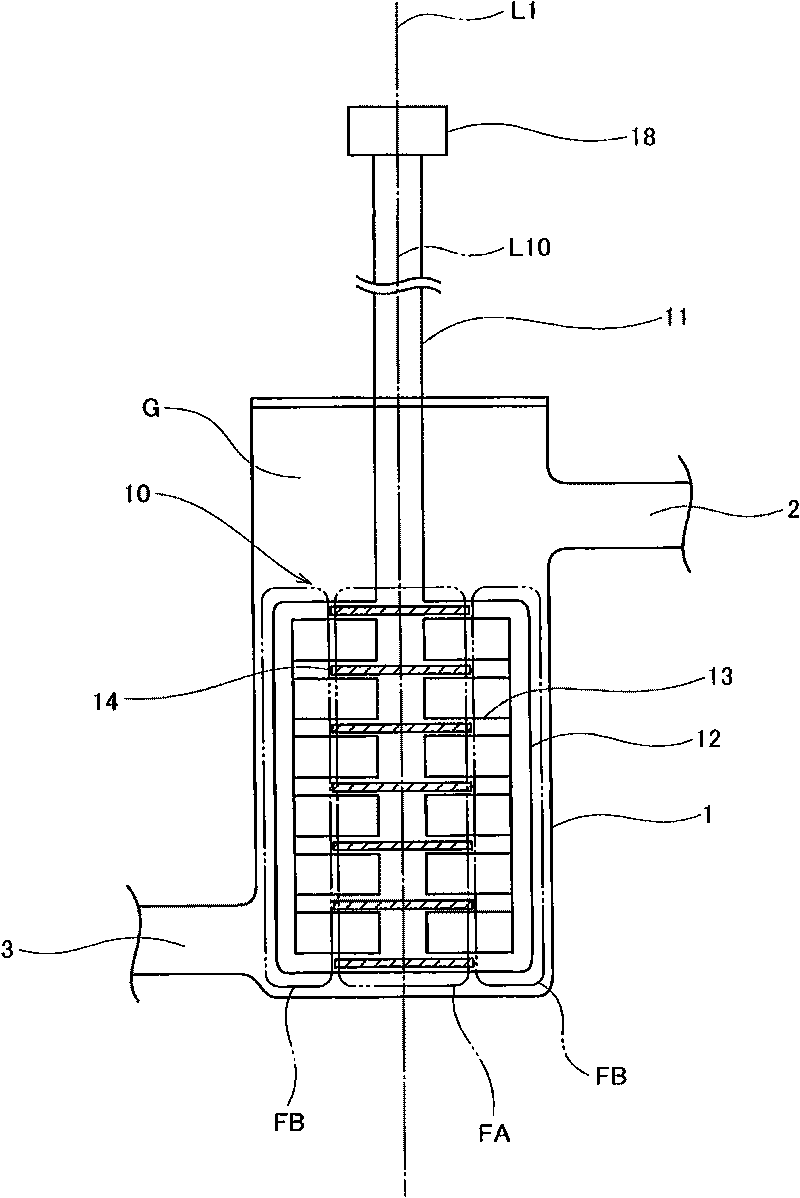

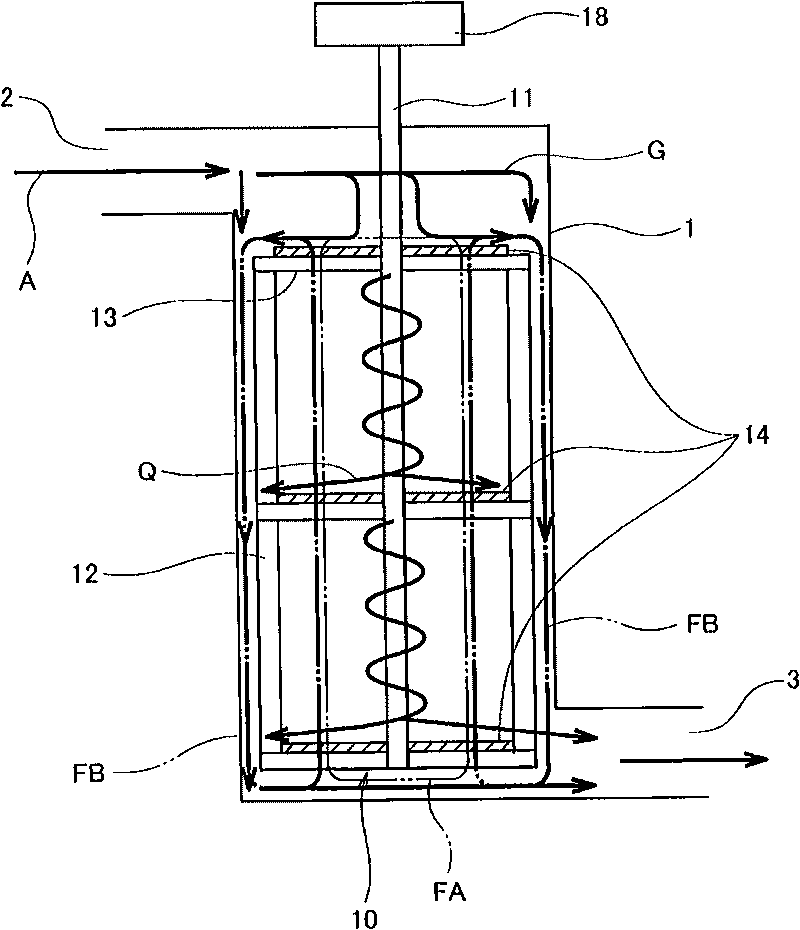

Apparatus for use in direct resistance heating of platinum-containing vessels

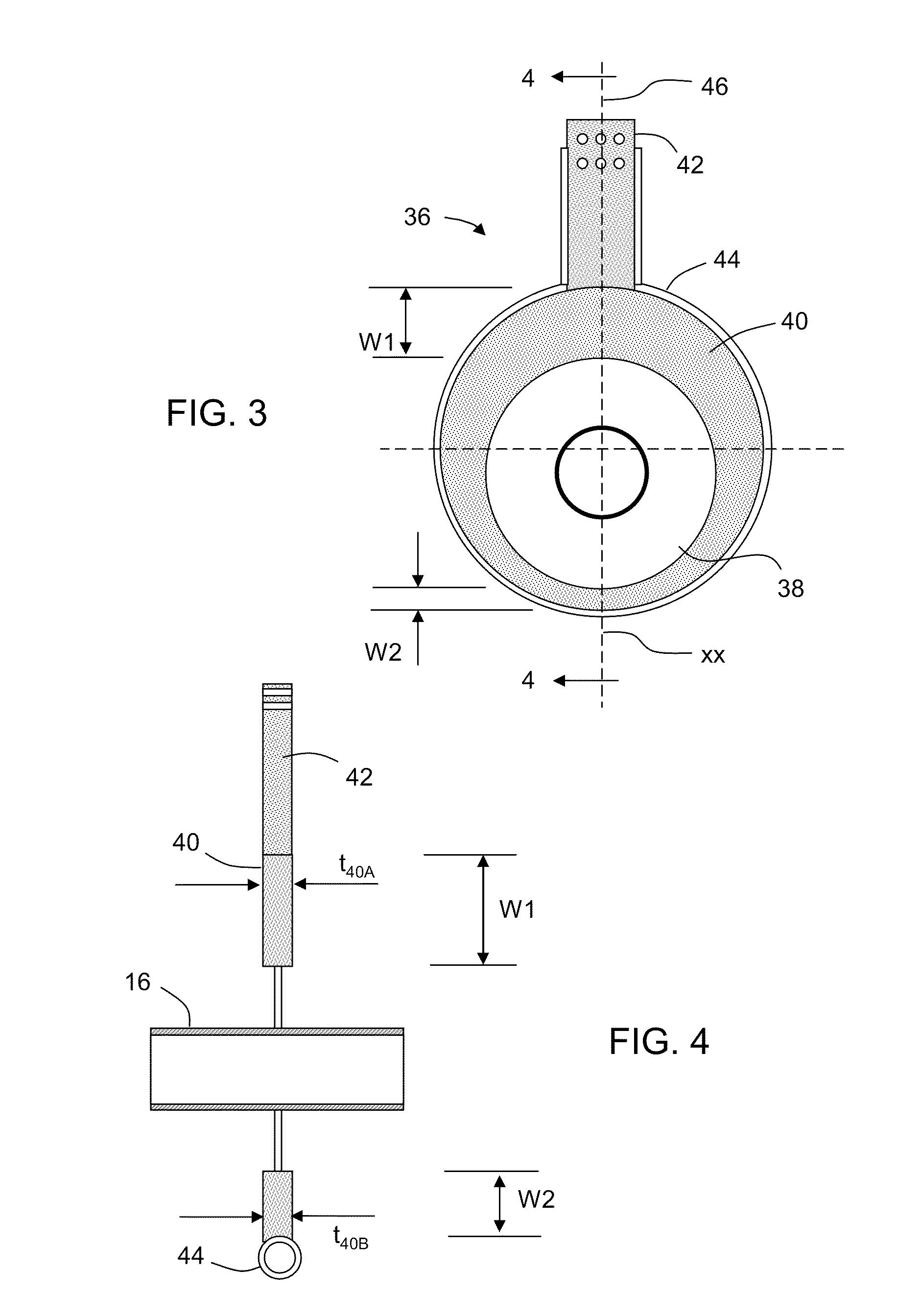

InactiveUS20110204039A1Improve uniformityEqually distributedForehearthsTank furnacesPlatinumElectrical resistance and conductance

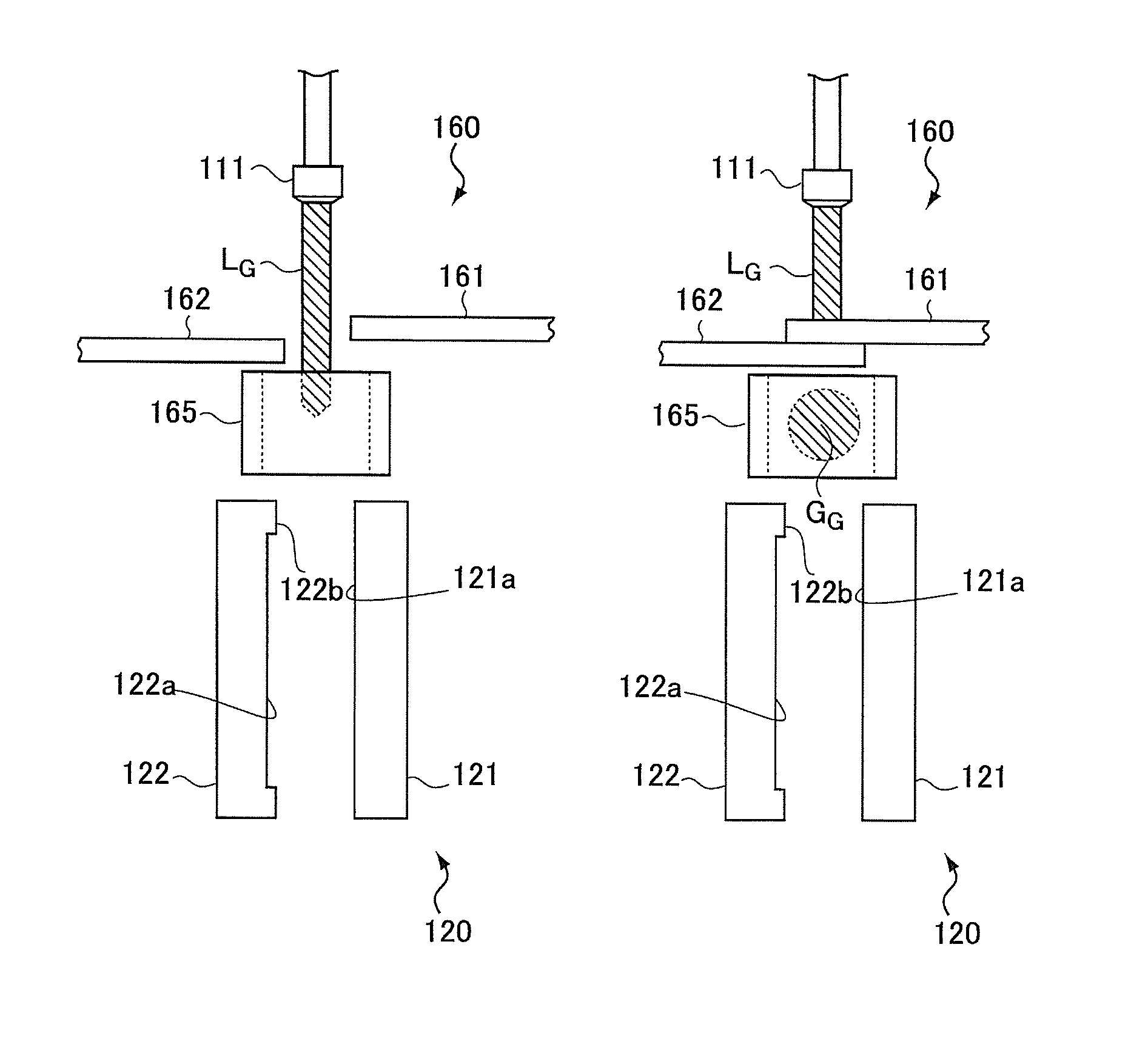

An apparatus for use in direct resistance heating of a molten glass-carrying vessel, such as a finer or connecting pipe, is provided. The apparatus comprises a flange comprises a plurality of electrically-conductive rings that include an inner ring joined to the vessel's exterior wall during use of the flange and an outer ring that receives electric current during use of the flange. The innermost ring comprises a high-temperature resistant metal preferably comprising at least 80% platinum, and the outermost ring preferably comprising at least 99.0% nickel. This combination of materials both increases the reliability of the flange and reduces its cost. Either one or both of the width or thickness of one or both of the inner or outer rings varies as a function of angular position relative to the vessel. The width and / or thickness of the inner and the outer rings with relation to each other produces a uniform current distribution in the flange and the vessel.

Owner:CORNING INC

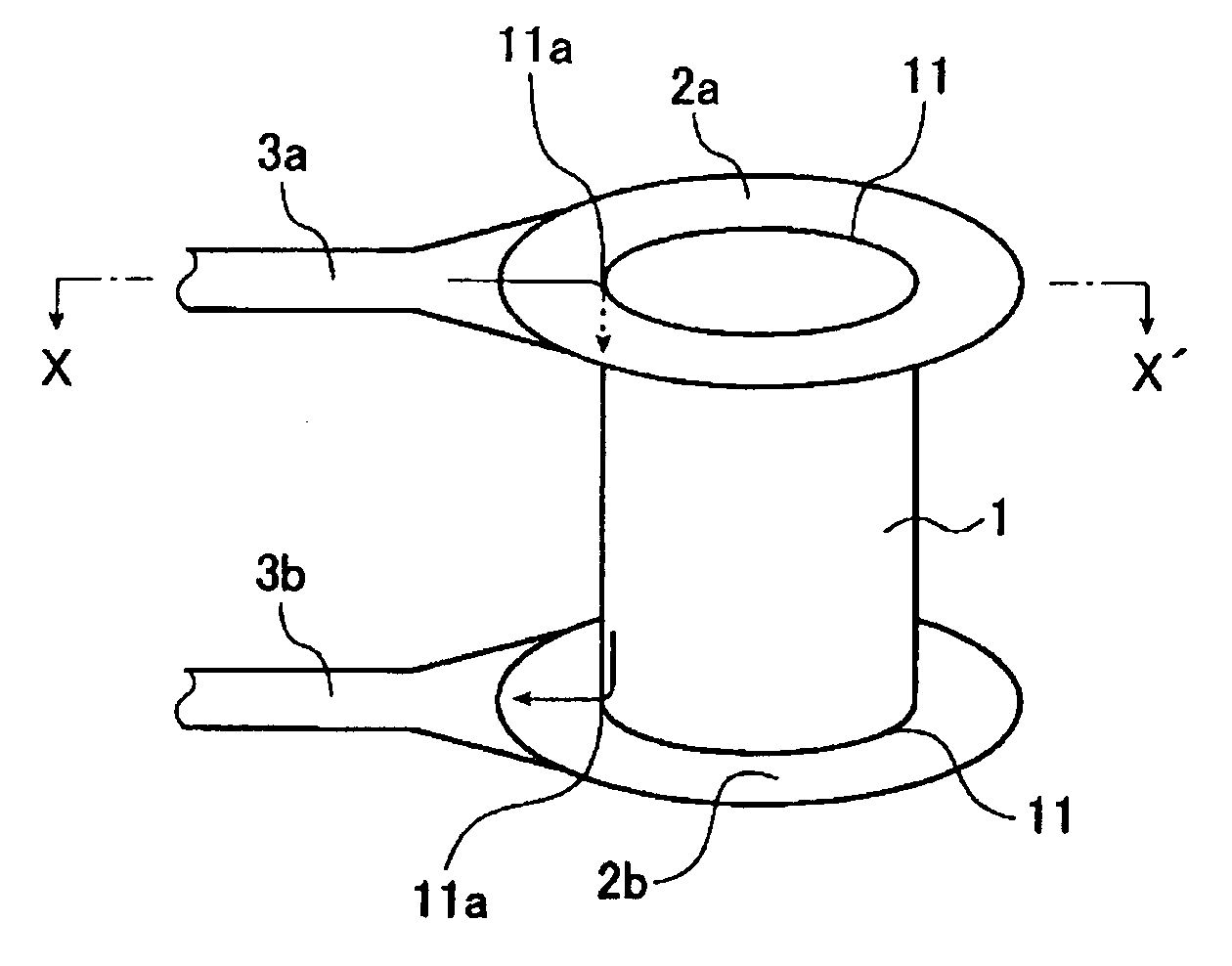

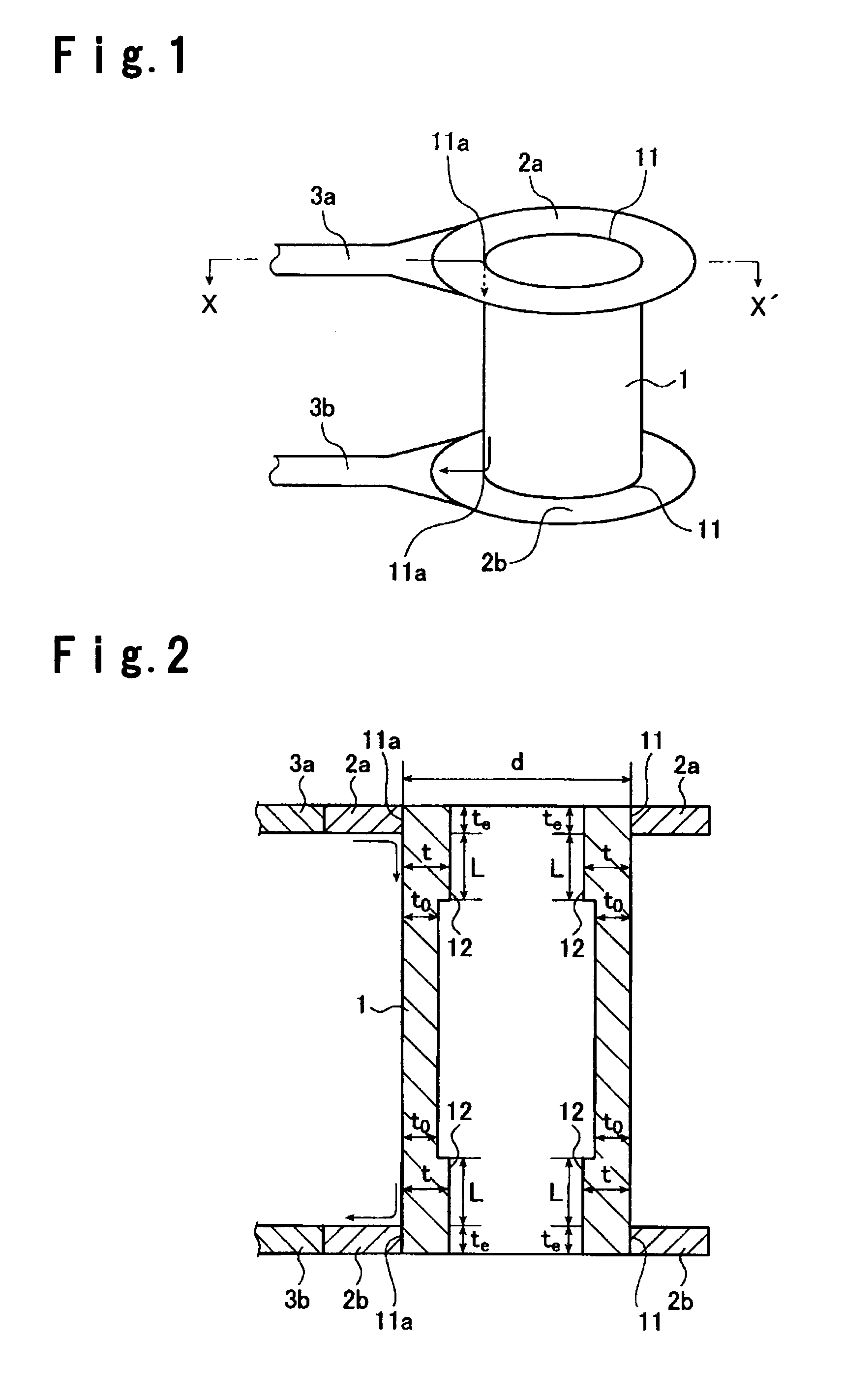

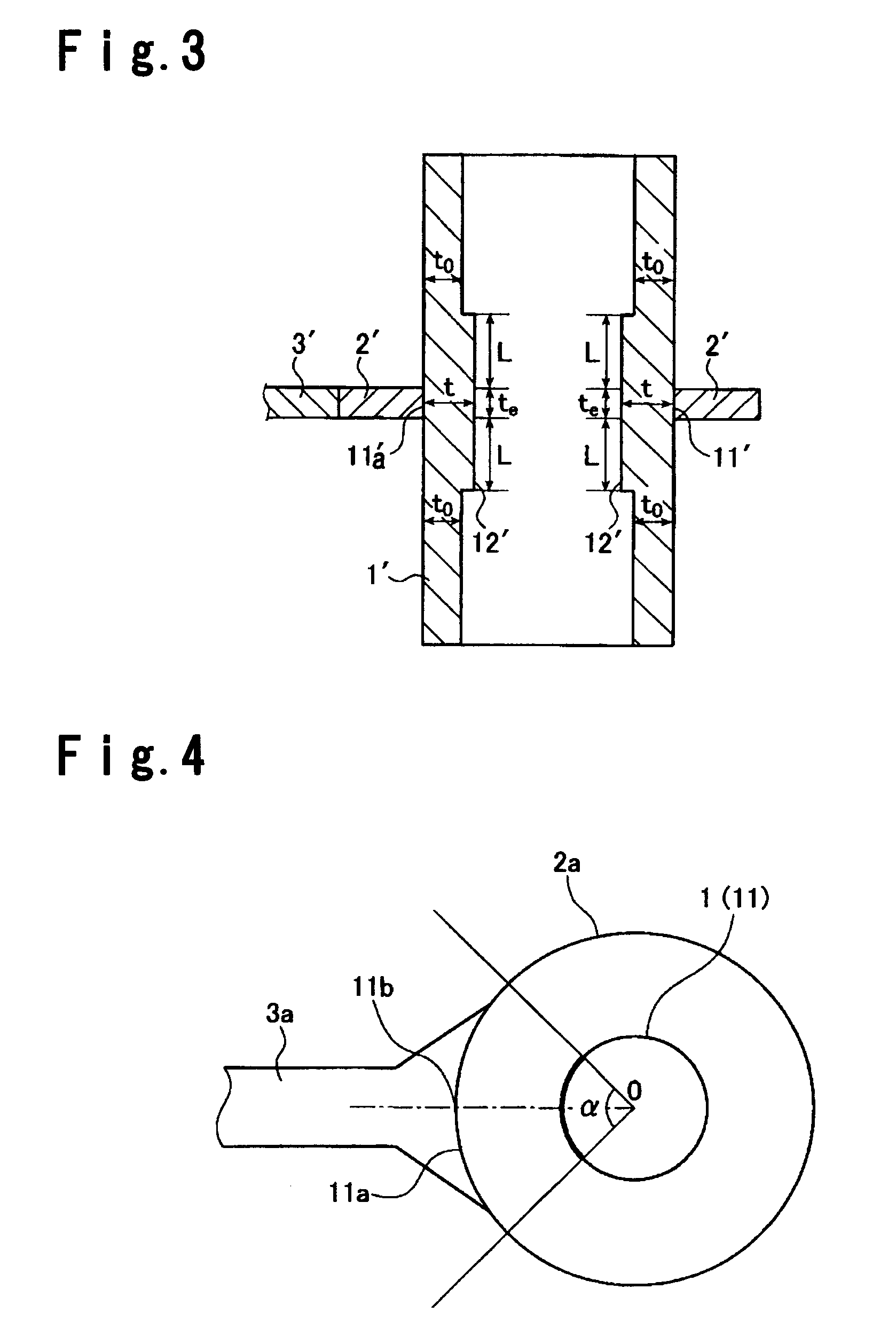

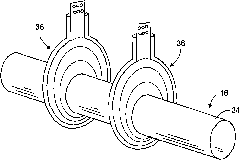

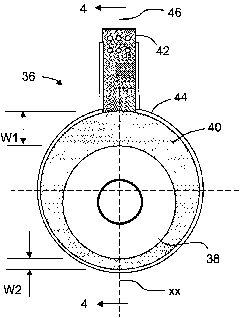

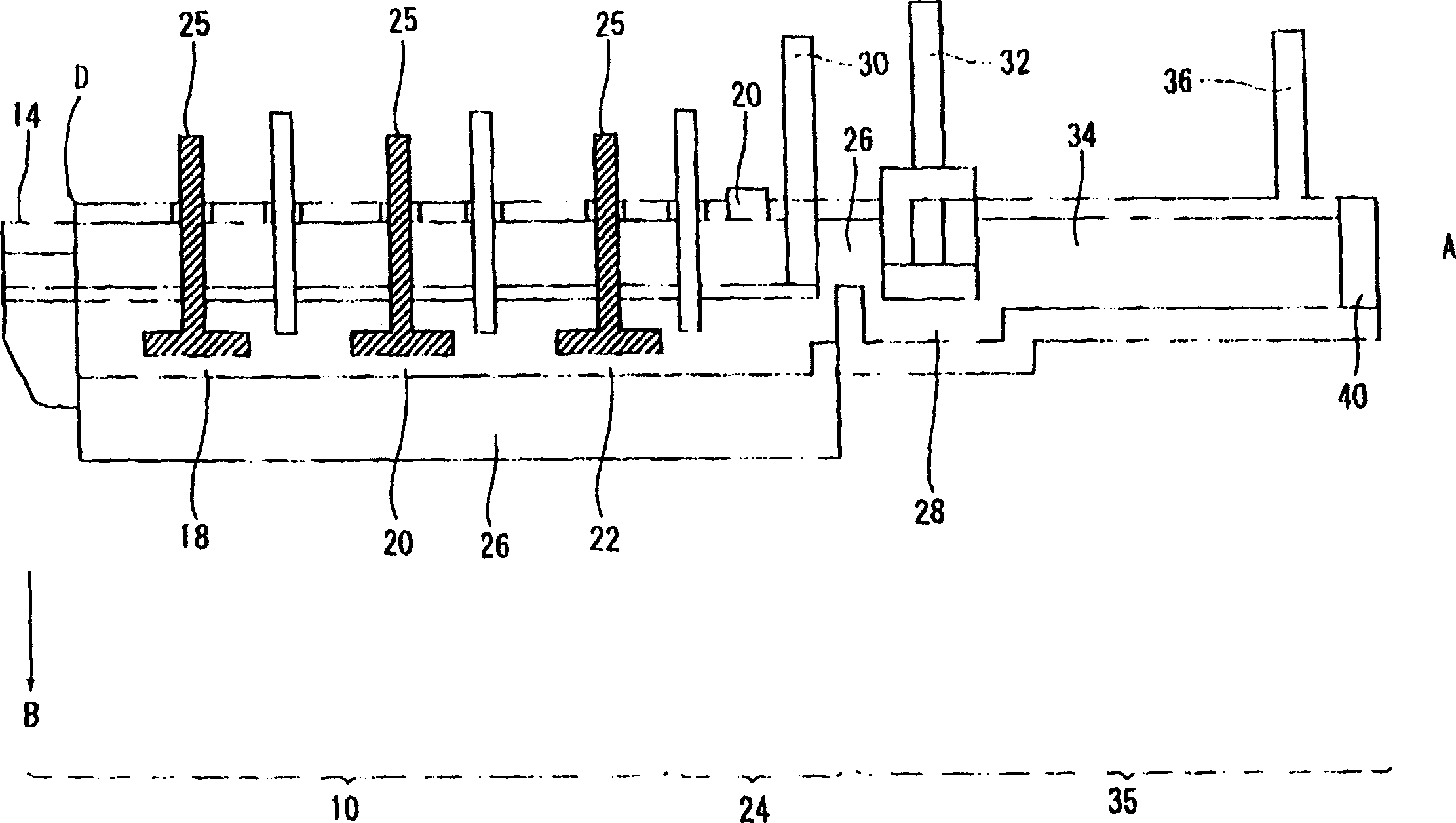

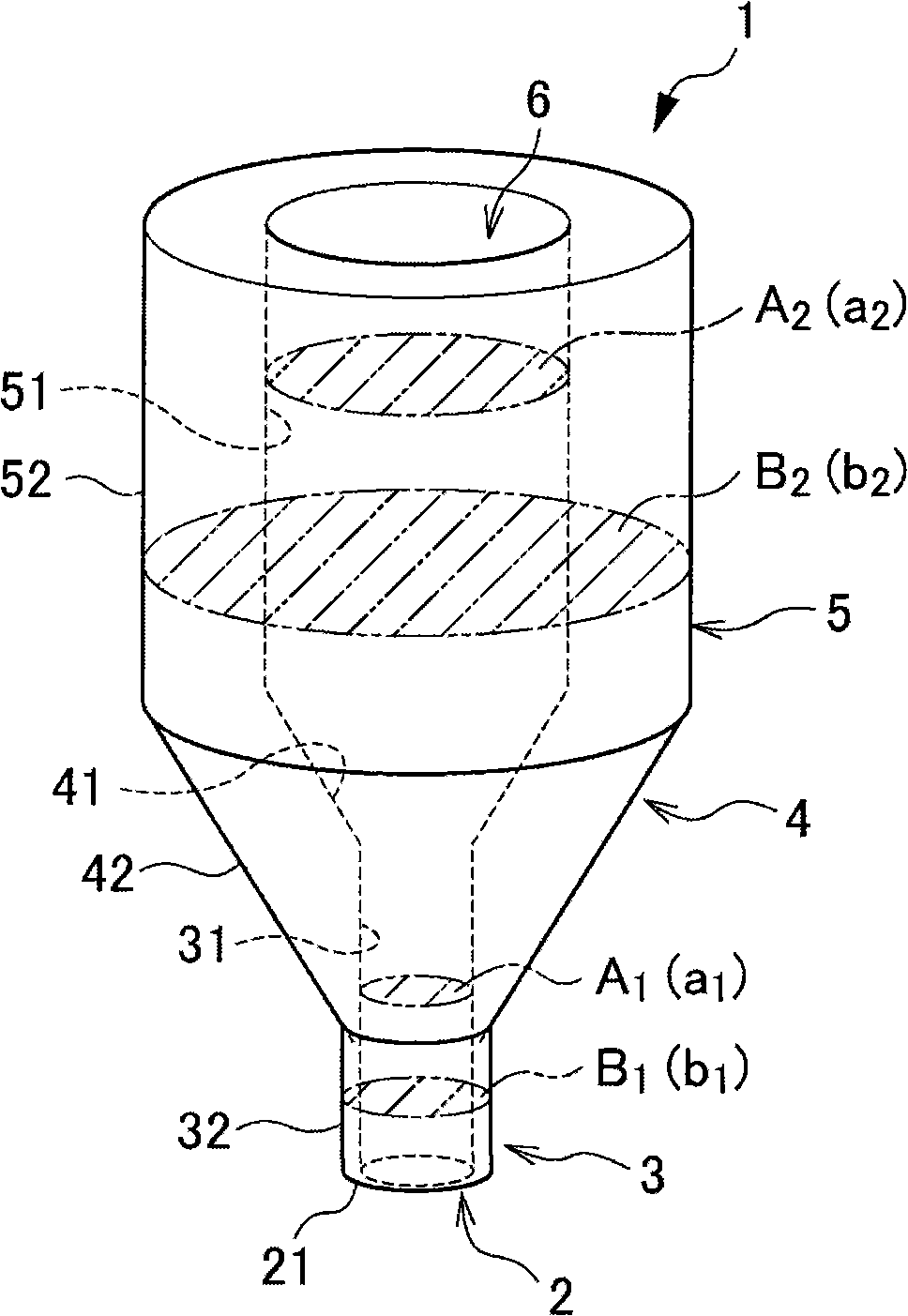

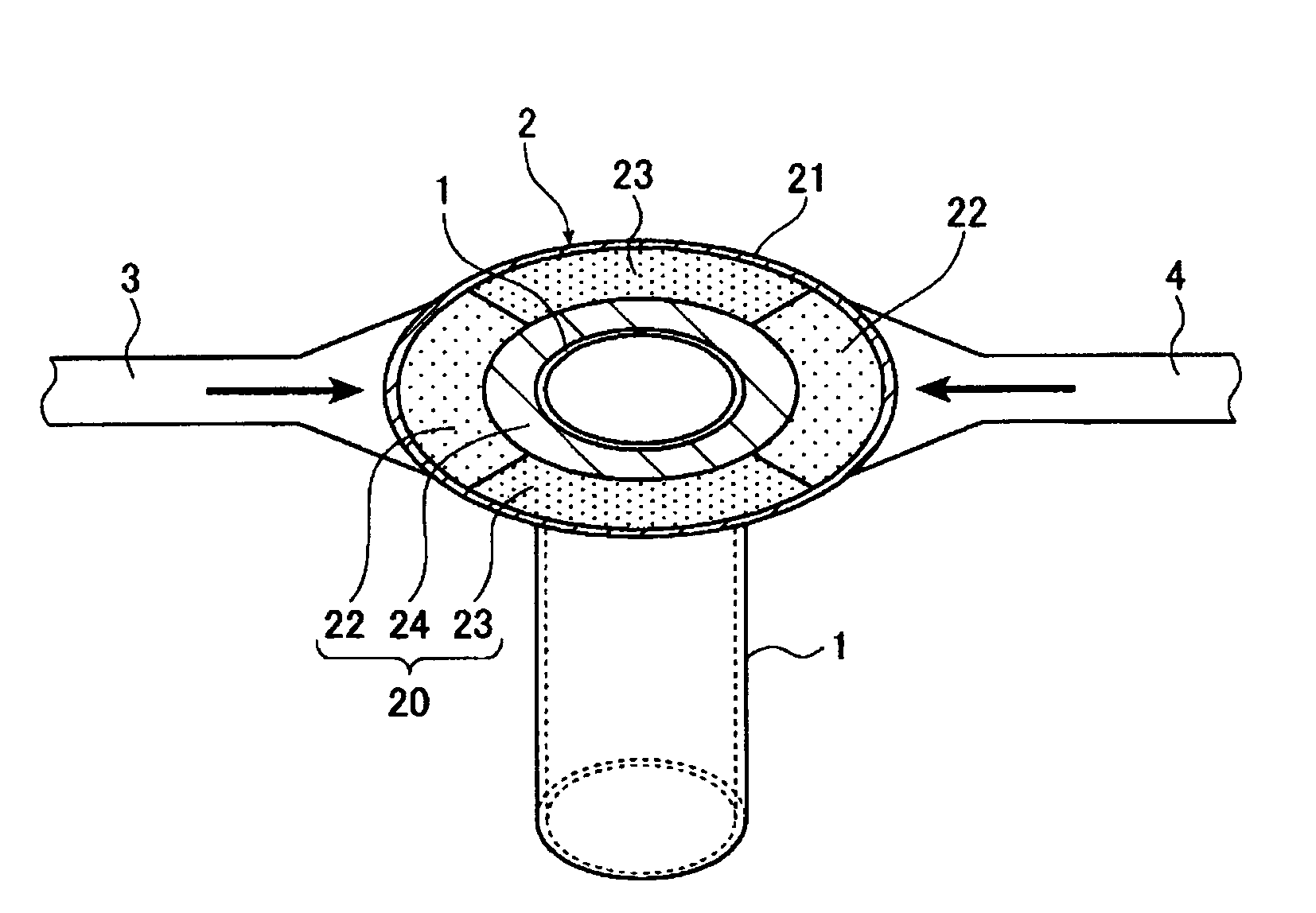

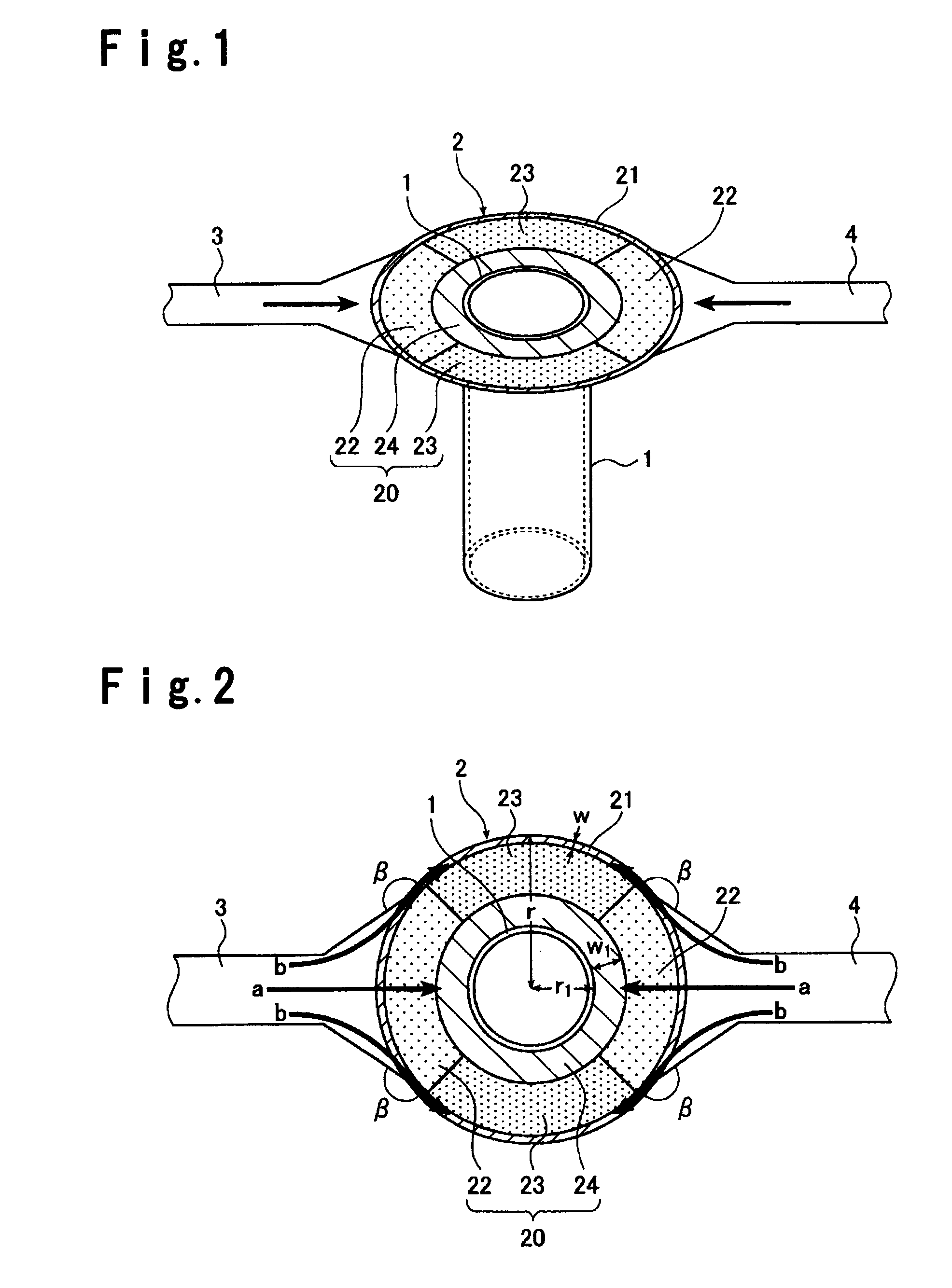

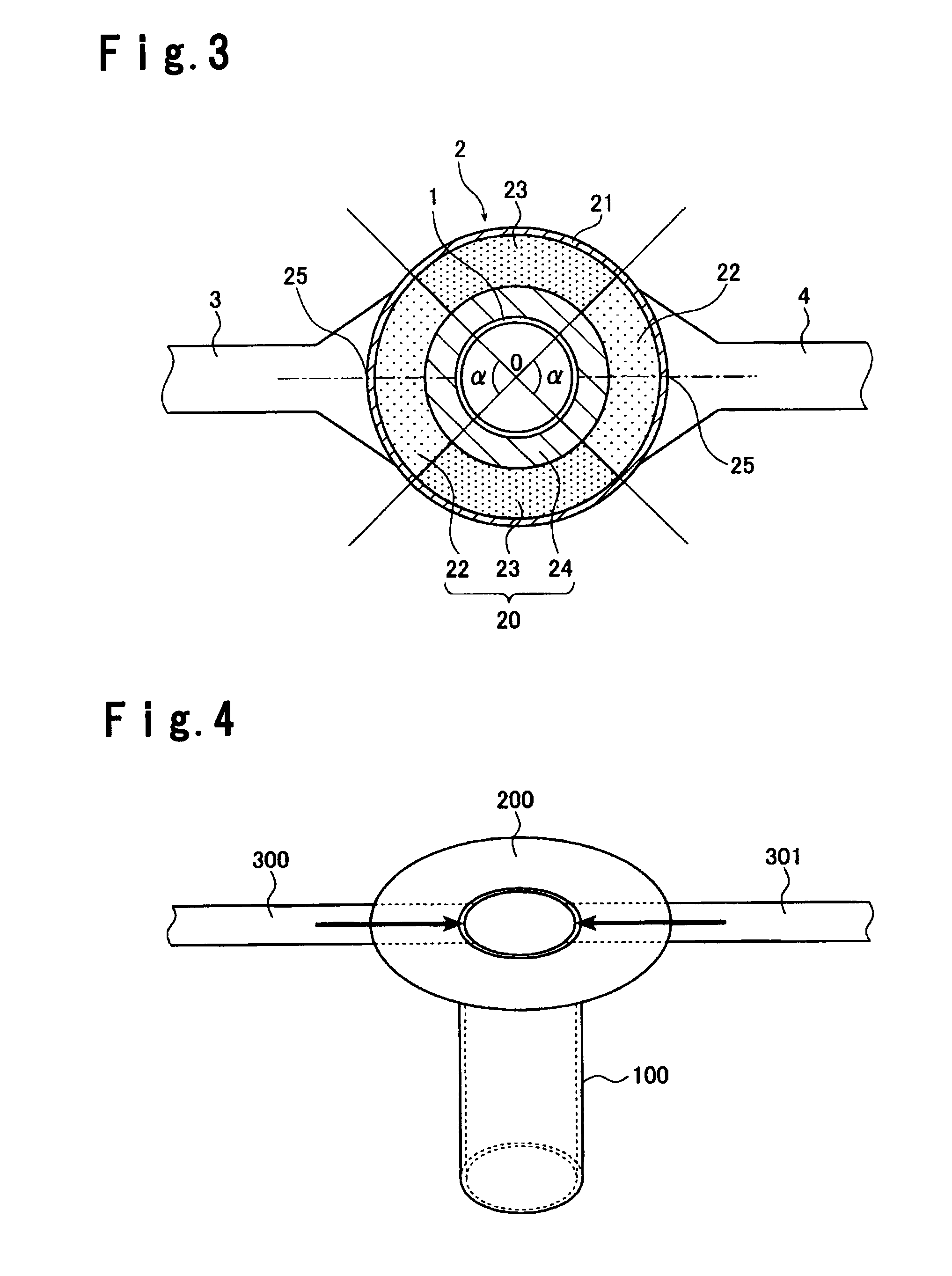

Glass manufacturing apparatus, a structural member thereof and method for heating the structural member by conduction heating

A hollow tubular body for molten glass in which local-overheating is reduced at the time of conduction heating. The hollow tubular body has a platinum or platinum alloy hollow tube, used for conduction heating, wherein a platinum or platinum alloy ring electrode is joined to the outer circumference of the hollow tube, a lead-out electrode is joined to an outer edge of the ring electrode, and a thick portion is provided in at least the joint portion closest to the lead-out electrode, of the ring electrode and in the vicinity thereof.

Owner:ASAHI GLASS CO LTD

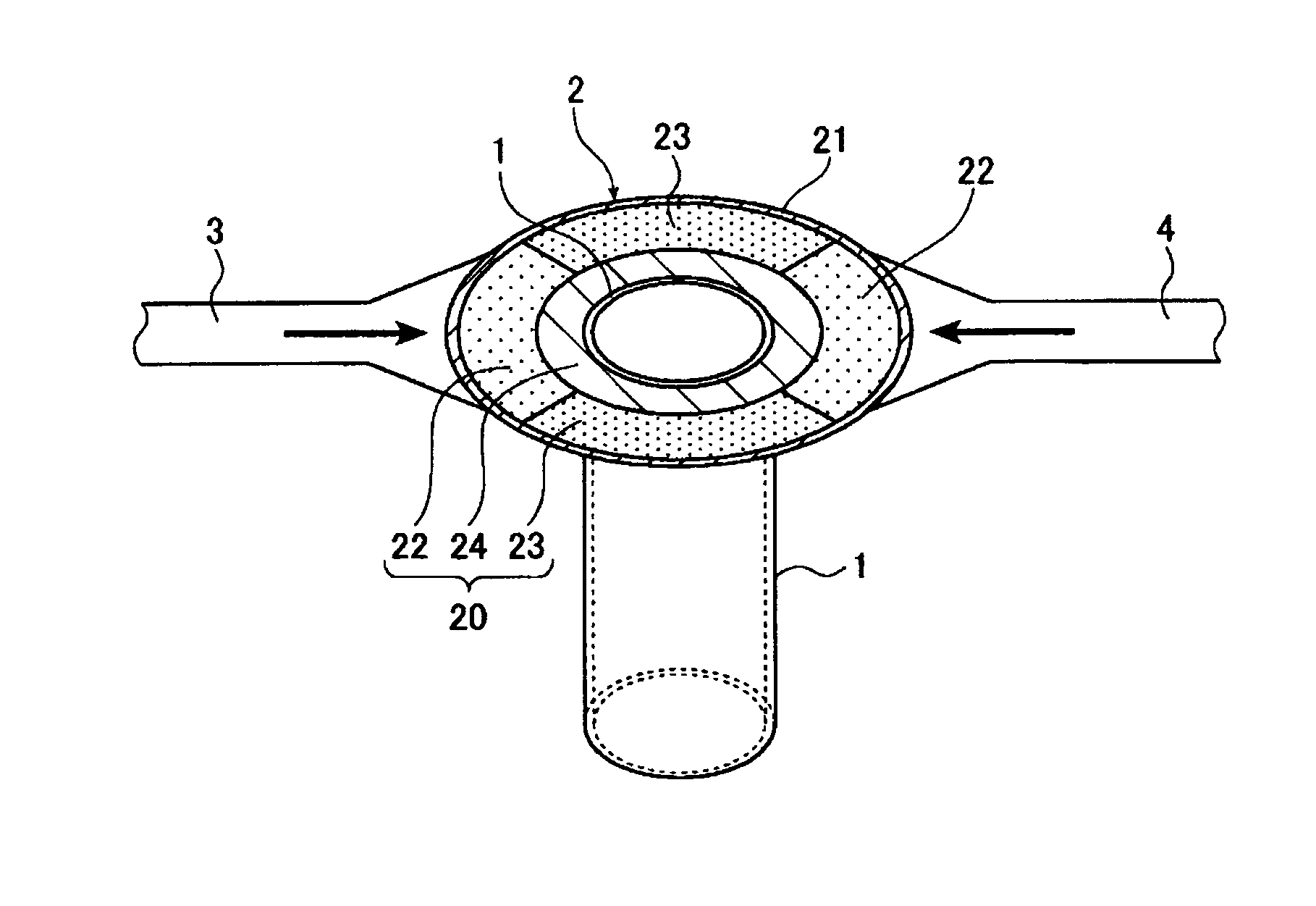

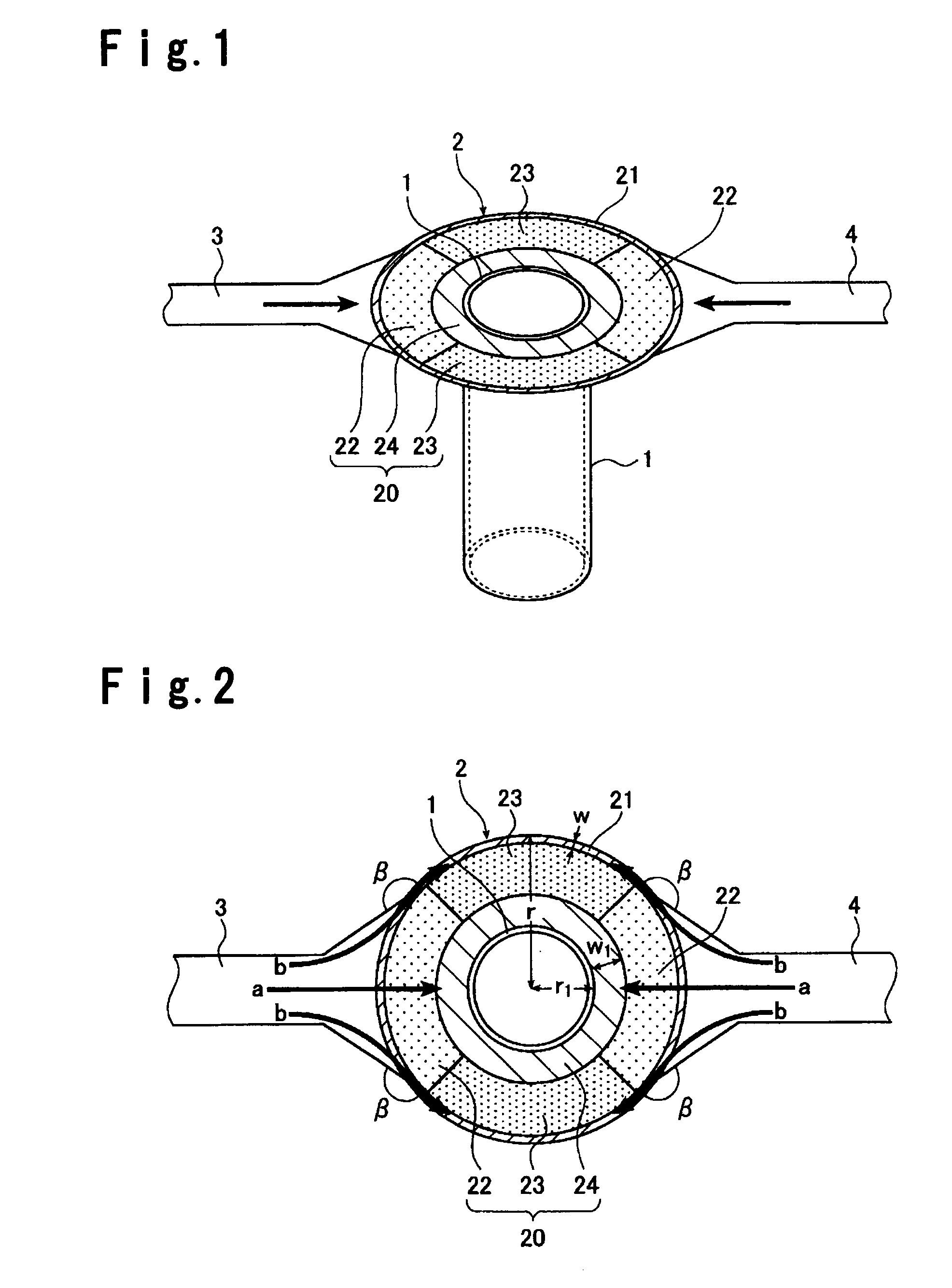

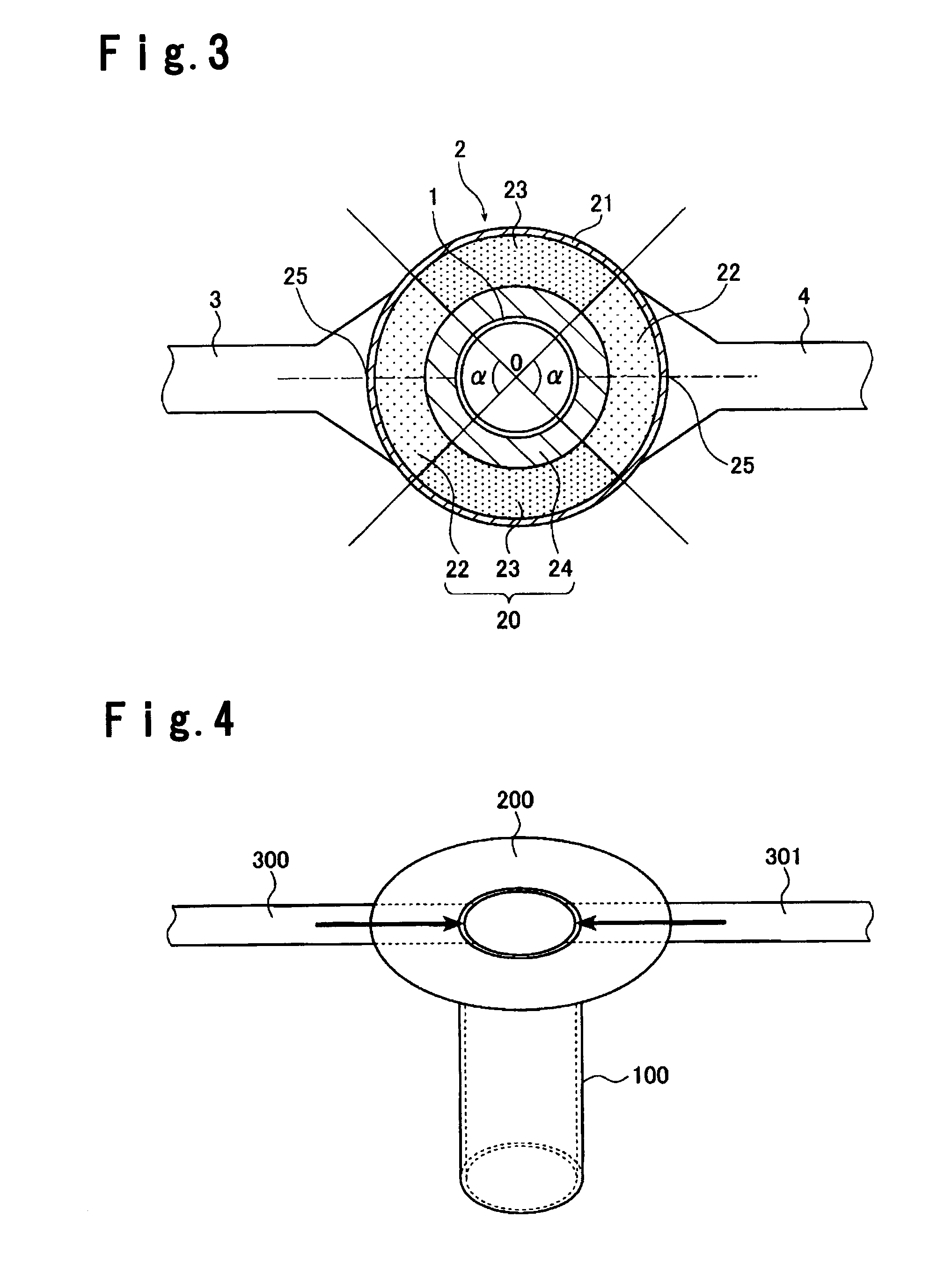

Glass manufacturing apparatus and a structural member thereof

ActiveUS20080087046A1Avoid conductionGlass drawing apparatusGlass transportation apparatusPlatinumMetallic materials

A hollow tubular body for molten glass by which local-overheating in the electrode for conduction heating is prevented. A hollow tubular body having a platinum or platinum alloy hollow tube, used for conduction heating is characterized in that a ring electrode is joined to the outer circumference of the hollow tube, at least one lead-out electrode is joined to an outer edge of the ring electrode, and the ring electrode comprises a core portion of electrode of platinum or platinum alloy and a thick portion of platinum or platinum alloy or of a metallic material other than platinum or platinum alloy, provided at an outer side of the core portion of electrode.

Owner:ASAHI GLASS CO LTD

Apparatus for use in the glass industry and method for processing molten glass

ActiveUS8434329B2Extended service lifeReduce stepsRotary stirring mixersGlass furnace apparatusMaterials scienceMolten glass

Apparatus, which is suitable for being surrounded by molten glass, the apparatus having a shank which has at least one at least partially seamless tube consisting of an oxide dispersion-strengthened PGM material, the shank having at least one thickened portion on which an actuating device is arranged.

Owner:UMICORE AG & CO KG

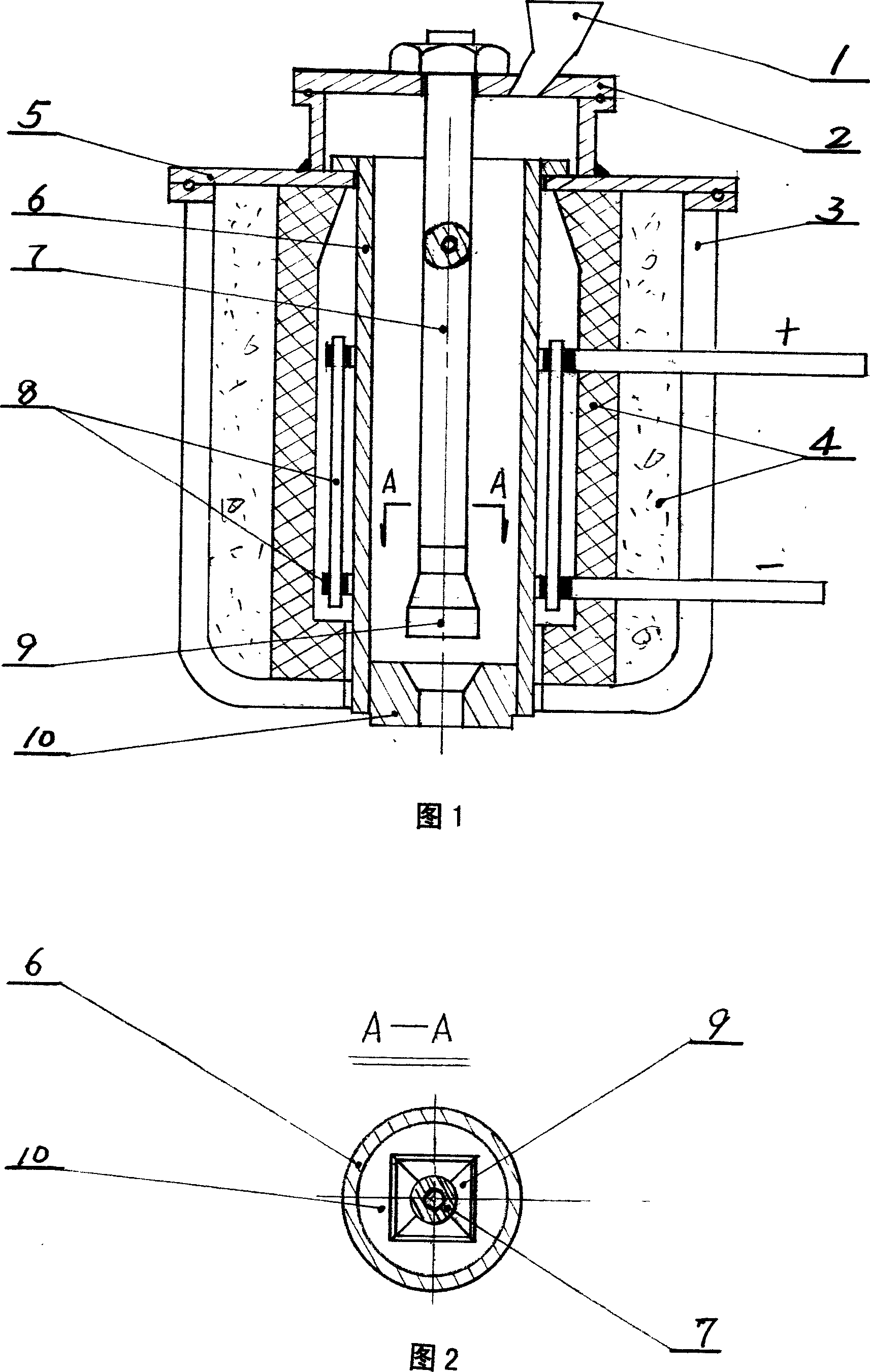

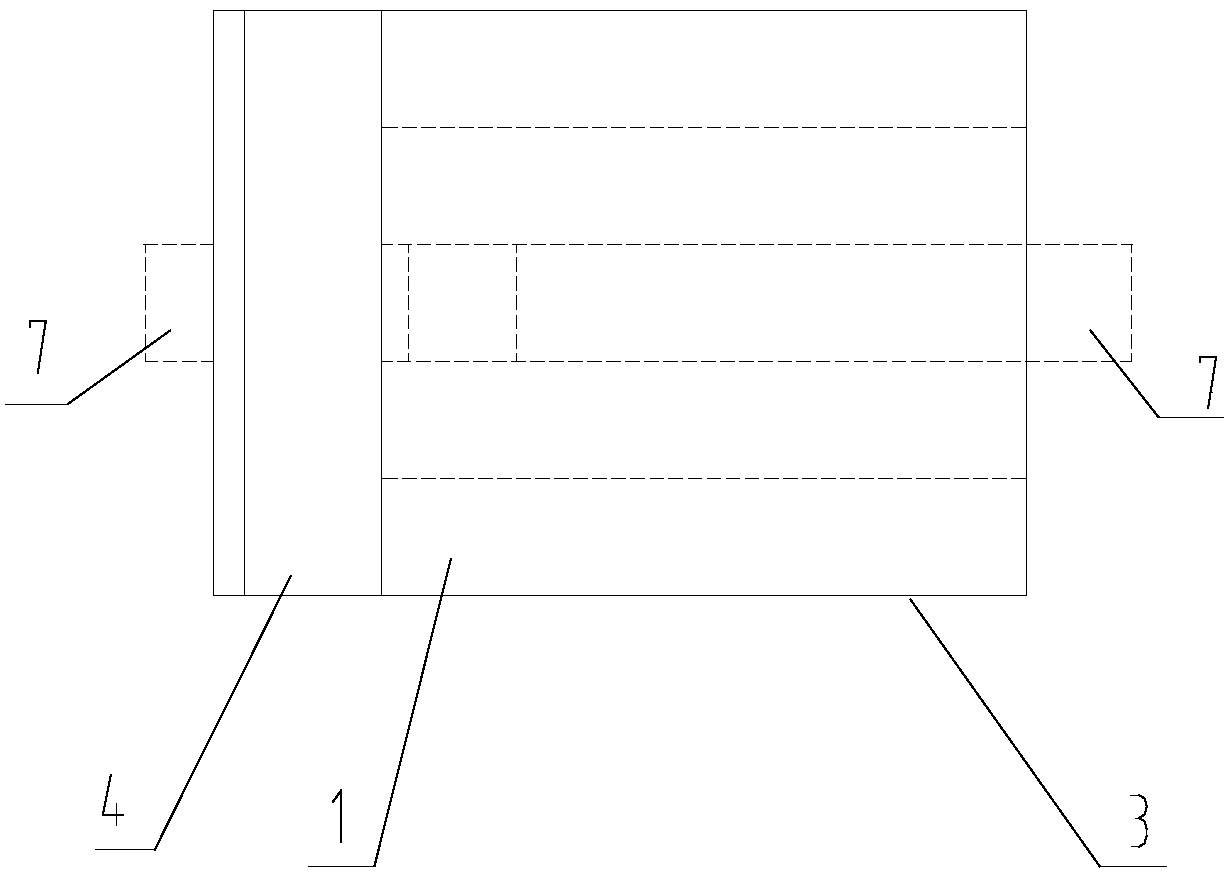

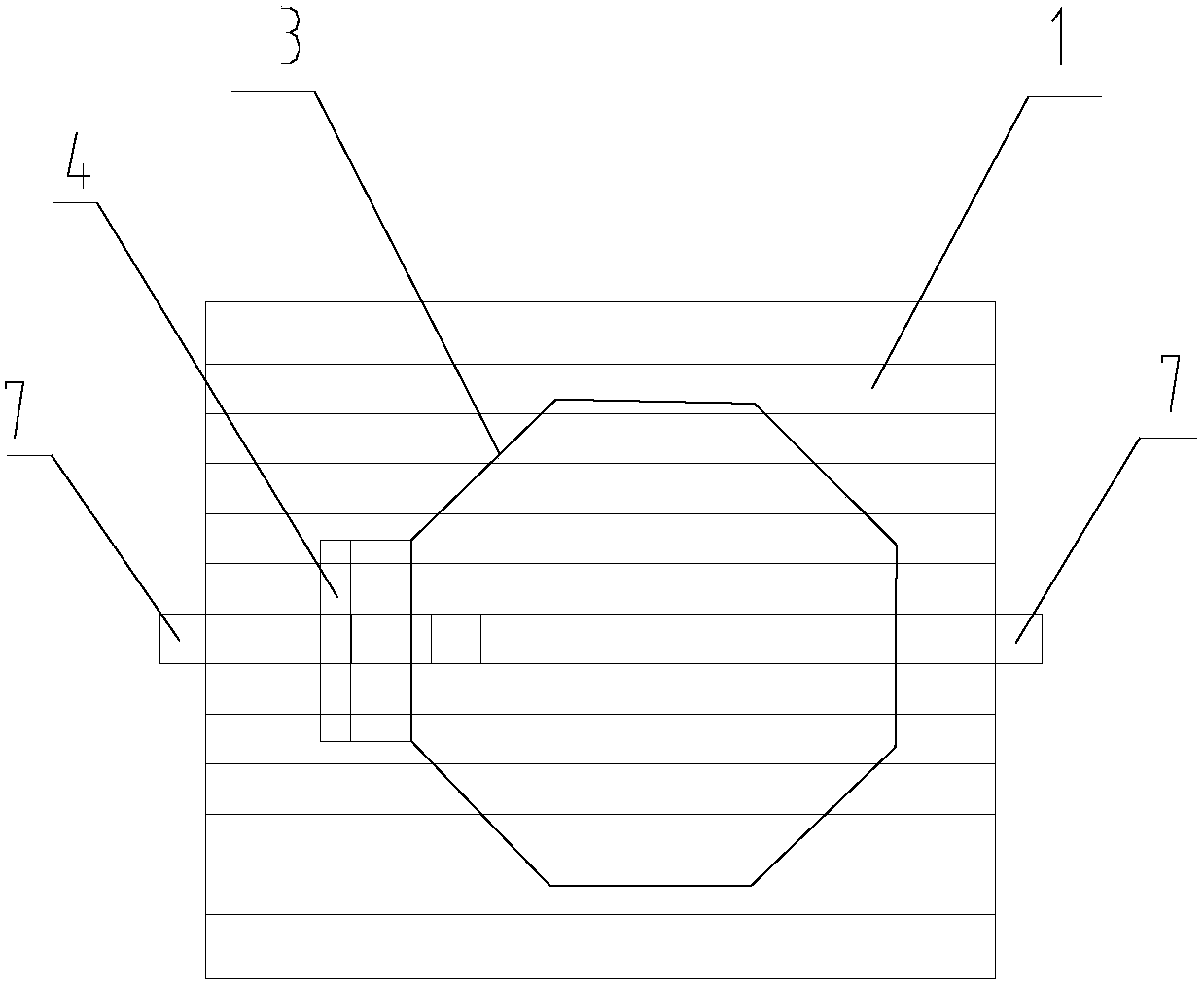

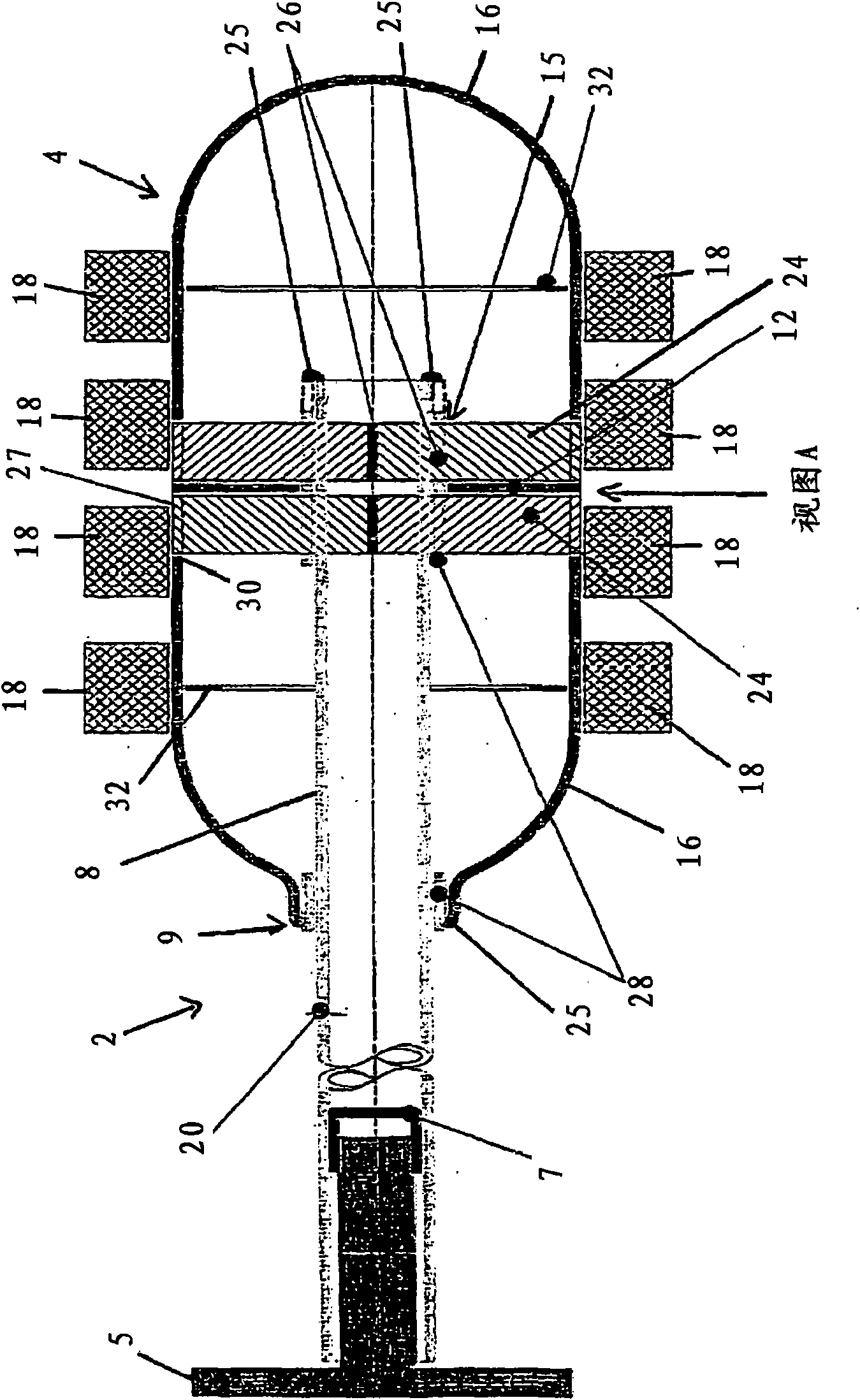

Continuous melting furnace and method for producing special-shaped quartz tube and quartz rod

The present invention is one kind of continuously smelting furnace and the method of producing specially shaped quartz tube and quartz rod therewith. The continuously smelting furnace includes furnace body, heater, heat insulating material, large furnace cover, small furnace cover, tungsten crucible, core bar, shaper and discharge stage. Both discharge stage and the shaper located over the discharge stage are circular, square, triangular or in other shapes for producing quartz tube and quartz rod in the corresponding shape. The present invention is superior in that specially shaped quartz tube and quartz rod may be produced by means of selecting shaper and discharge stage in corresponding shape and altering the location of shaper.

Owner:纪高仁

Low heat capacity gas oxy fired burner

A front end for a glass forming operation including an open channel and at least one burner. The channel surface has at least one burner port and a burner oriented in the burner port at an acute angle relative to the channel surface. The surface may be a top, side or end wall and the burner port is at an acute angle relative to the surface of the wall.

Owner:OCV INTELLECTUAL CAPITAL LLC

Apparatus for use in direct resistance heating of platinum-containing vessels

An apparatus for use in direct resistance heating of a molten glass-carrying vessel, such as a finer or connecting pipe, is provided. The apparatus comprises a flange comprises a plurality of electrically-conductive rings that include an inner ring joined to the vessel's exterior wall during use of the flange and an outer ring that receives electric current during use of the flange. The innermost ring comprises a high-temperature resistant metal preferably comprising at least 80% platinum, and the outermost ring preferably comprising at least 99.0% nickel. This combination of materials both increases the reliability of the flange and reduces its cost. Either one or both of the width or thickness of one or both of the inner or outer rings varies as a function of angular position relative to the vessel. The width and / or thickness of the inner and the outer rings with relation to each other produces a uniform current distribution in the flange and the vessel.

Owner:CORNING INC

Method and apparatus for homogenisation of melt

InactiveUS20050082282A1Low dielectric constantReduced effectivenessForehearthsGlass furnace apparatusAcousticsWaveguide

Microwave radiation of frequency 0.1 to 20 GHz, is applied to the melt of viscosity in the range 104 to 101 Pa.s. The outside surface of heated space, where an outlet of the waveguide of microwave radiation is located, can be cooled. The microwave radiation in the melt may be reflected by the reflective metallic elements in the melt back to the place of radiation entry into the melt and shielded from the surroundings by a shielding metallic element. An outlet is provided of at least one waveguide from the source of the microwave radiation, in any direction to the outside surface of the melt, into the space with the melt of a given viscosity. At least one waveguide is led, for example, to the outside surface of the bottom of the channel of the forehearth.

Owner:B H F ENG

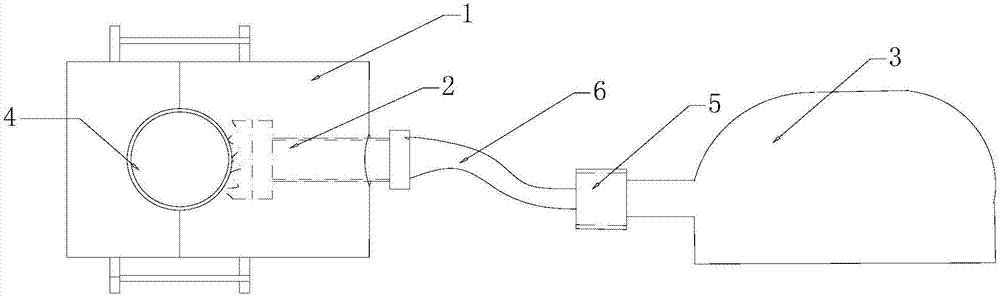

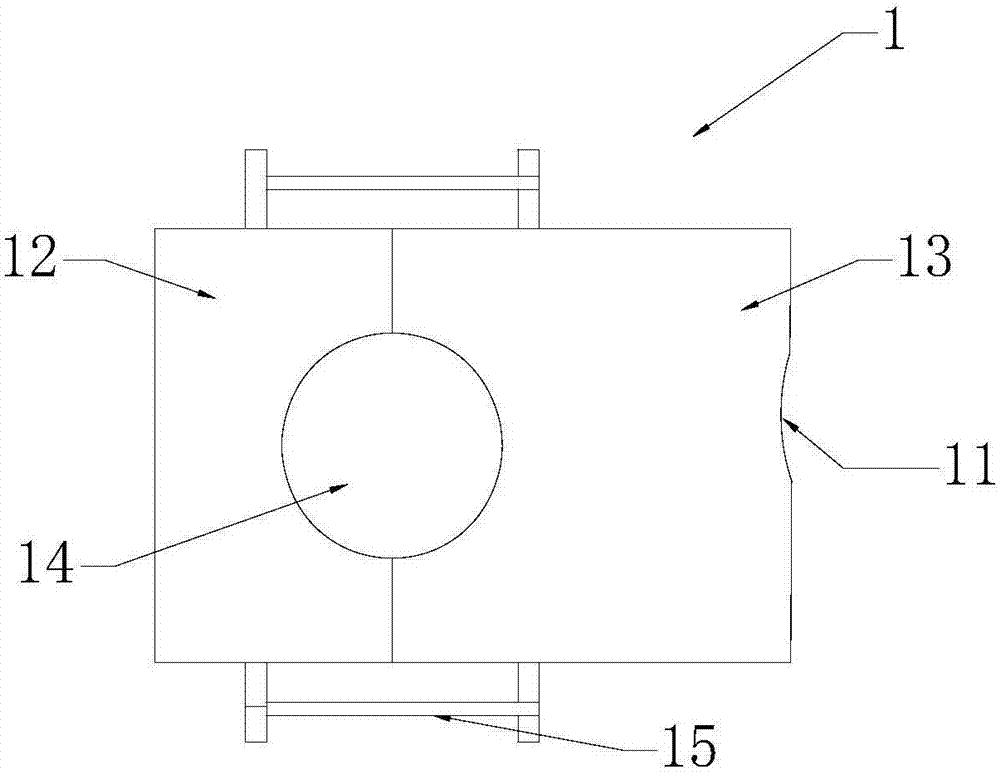

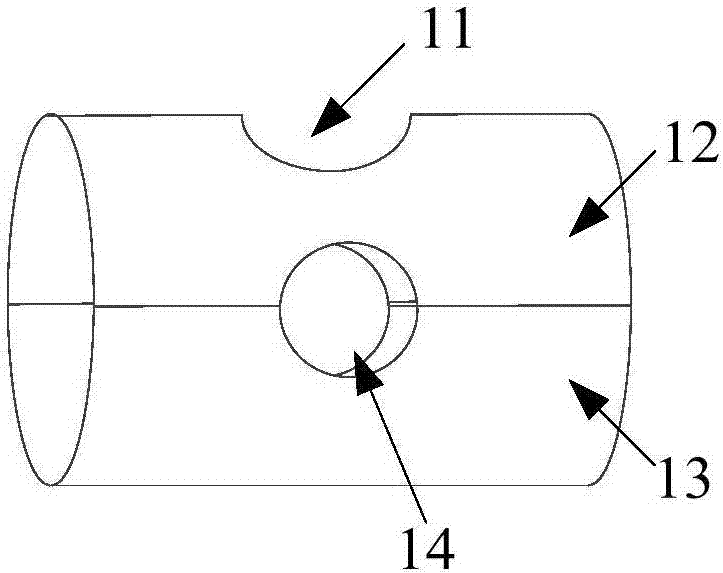

Microwave heating feeding passage and glass products manufacturing method using the feeding passage

The invention provides a microwave heating feeding passage and glass products manufacturing method using the feeding passage, wherein a microwave generation equipment is arranged on the material feeding passage, the microwave can heat the glass liquid with uniform and compatible glass liquid bulk temperature. The glass product preparing process employs a heating procedure for initiating the microwave generating apparatus and heating the glass liquid.

Owner:上海高雅玻璃有限公司

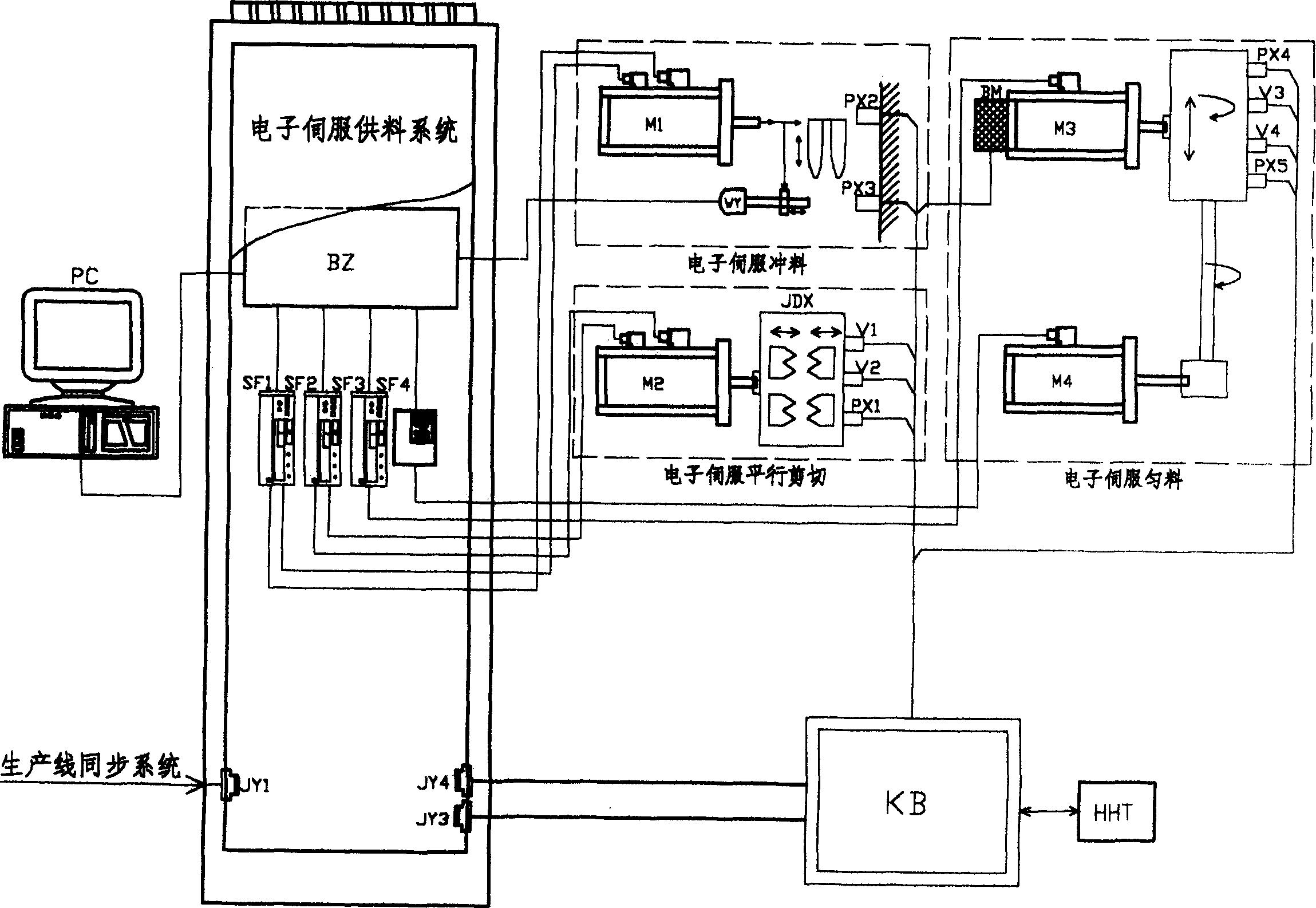

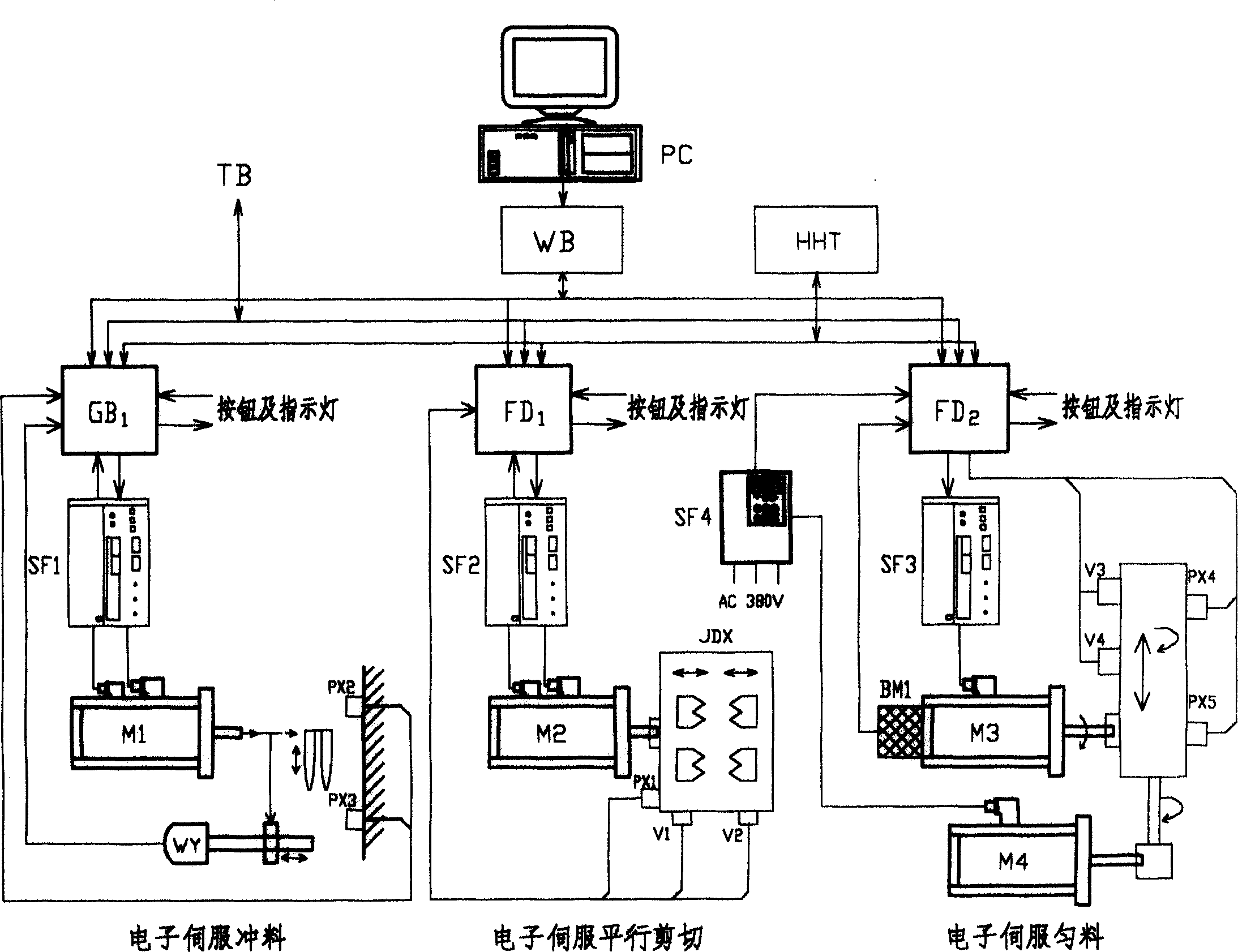

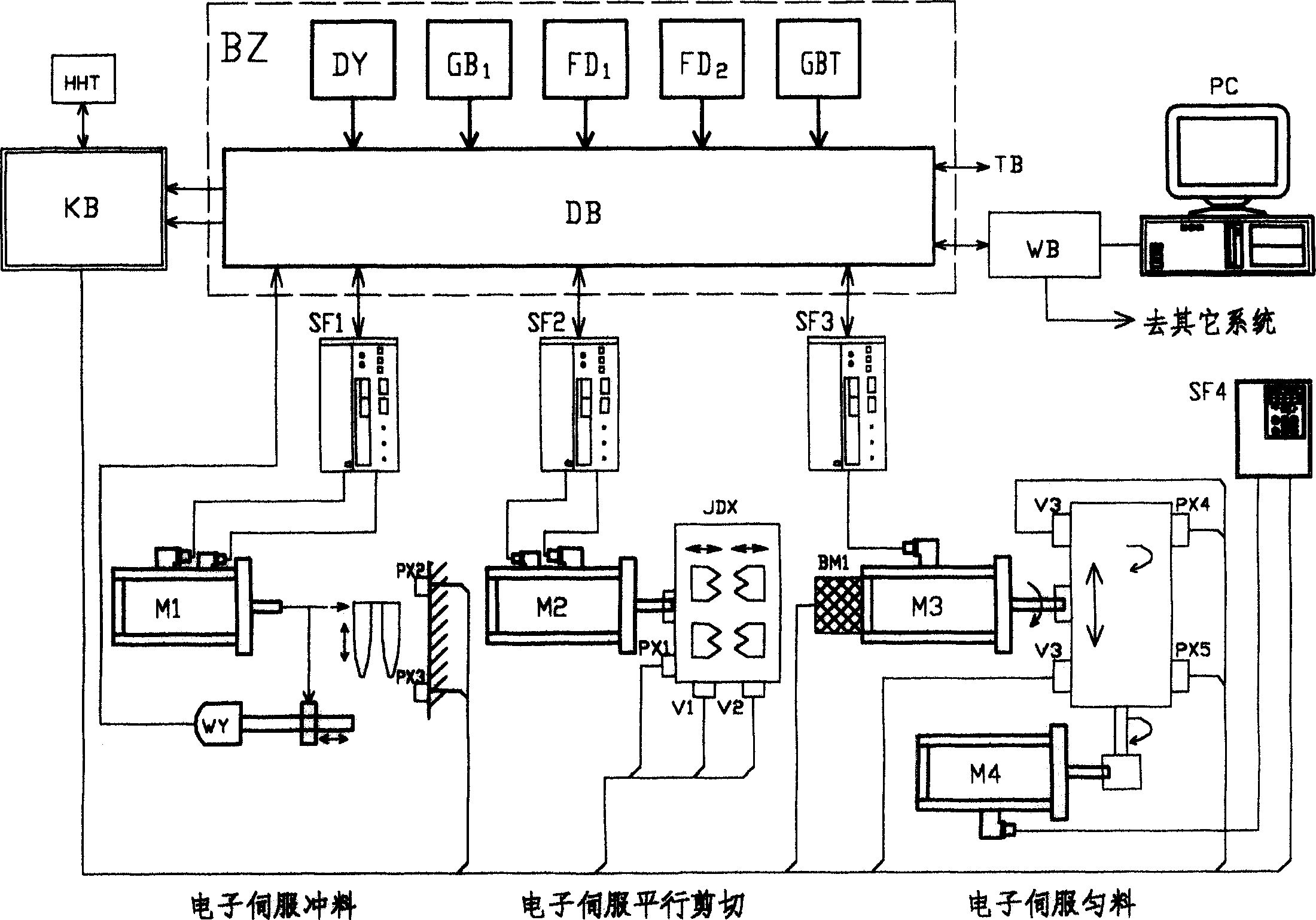

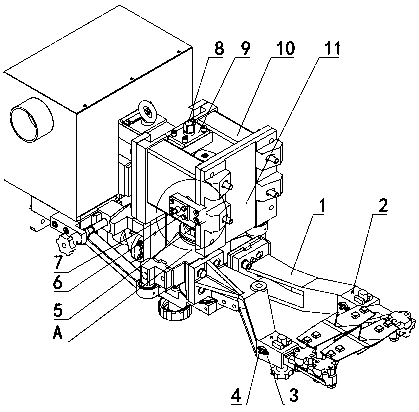

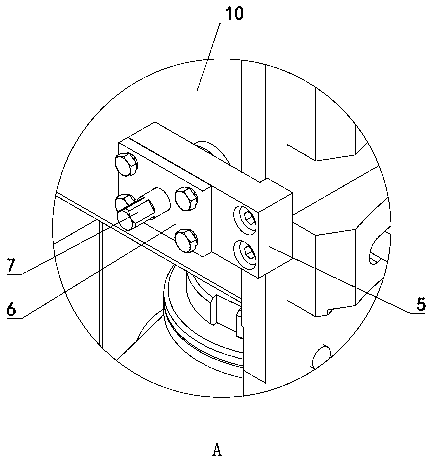

Electron servo feed system

An electronic servo feeding system is composed of an electronic servo punching unit, an electronic servo parallel shearing unit, and an electronic servo homogenizing system. Under the action of computer, the intelligent control is applied to the electronic feeding system. Its advantages are simple structure, correct and reliable operations, and high rate of qualified products.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

Leaking molding device and method for low-viscosity optical glass

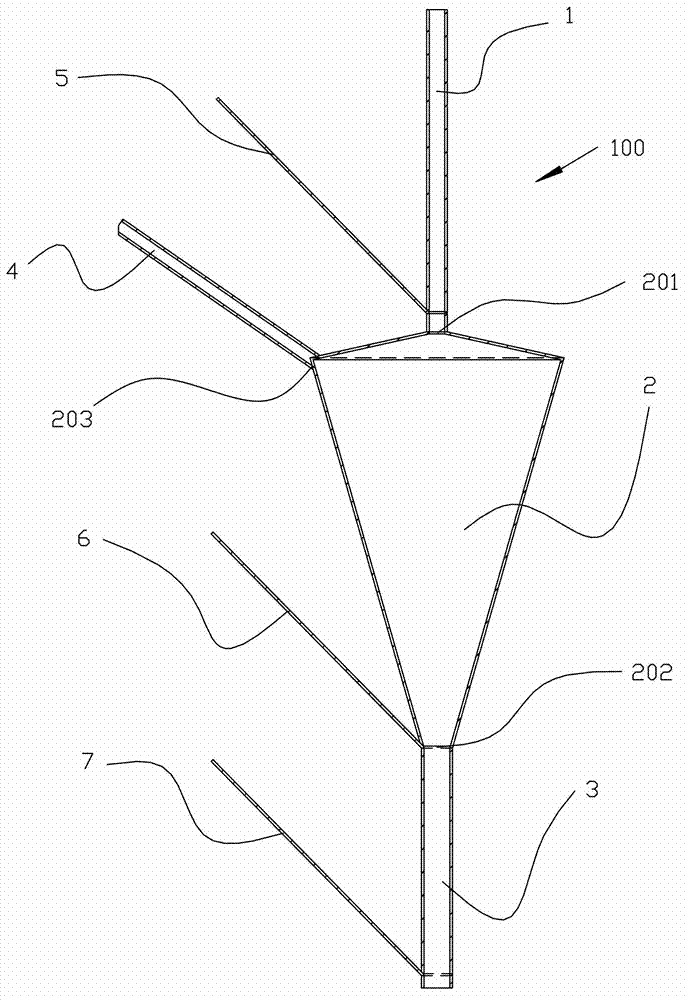

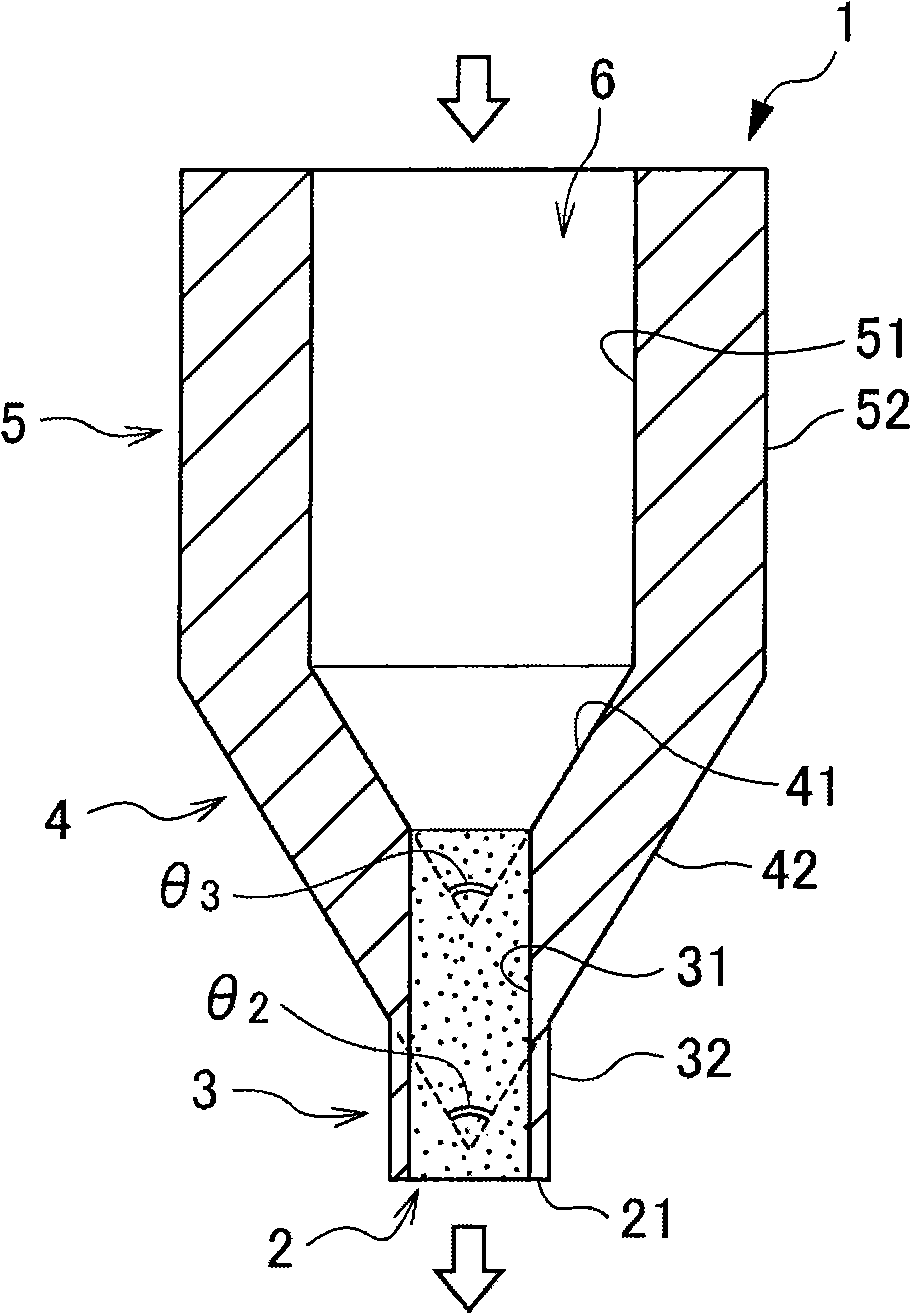

ActiveCN103193375AQuality improvementInhibit devitrificationGlass drawing apparatusFeeder spoutsControl systemEngineering

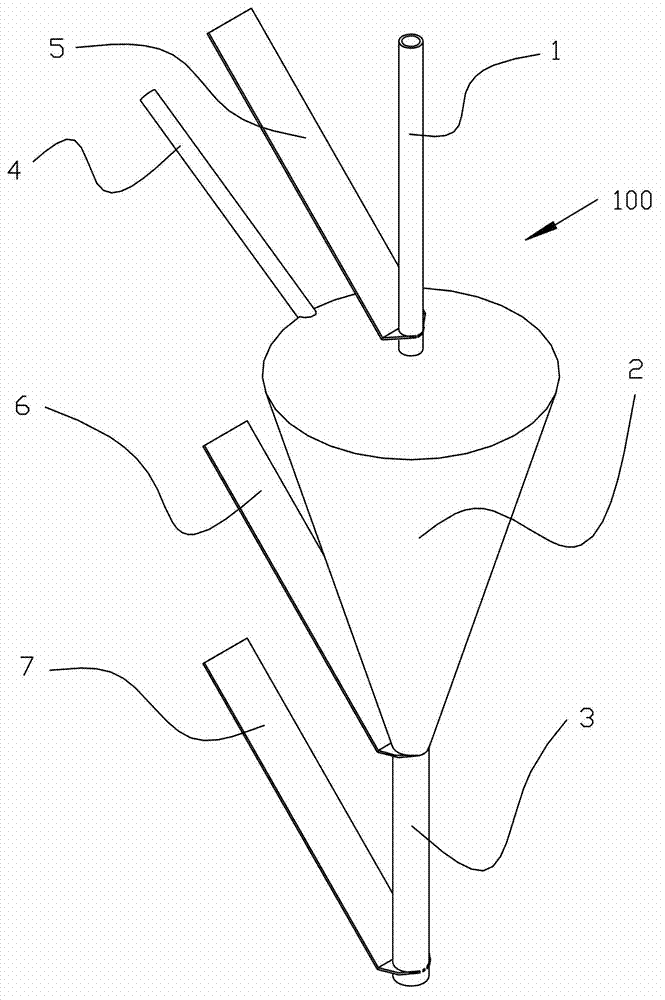

The invention provides a leaking molding device and method for low-viscosity optical glass. The leaking molding device (100) comprises a leaking pipe (1), a cooling buffer cavity (2) and a drawing molding pipe (3), wherein the wall of the side, close to the leaking pipe (1), of the cooling buffer cavity (2) is provided with a pressure adjusting hole (203); the pressure adjusting hole (203) is connected with one end of a pressure adjusting pipe (4); excepting a cavity inlet (201), a cavity outlet (202) and the pressure adjusting hole (203), the cooling buffer cavity (2) is of a sealed structure; and the on and off of the pressure adjusting pipe (4) are controlled by a control system; and when the pressure adjusting pipe (4) is in an on state, under the control of the control system, the pressure adjusting pipe (4) exhausts or aerates the cooling buffer cavity (2). The leaking molding method performs leaking molding on the low-viscosity optical glass by using the leaking molding device (100).

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

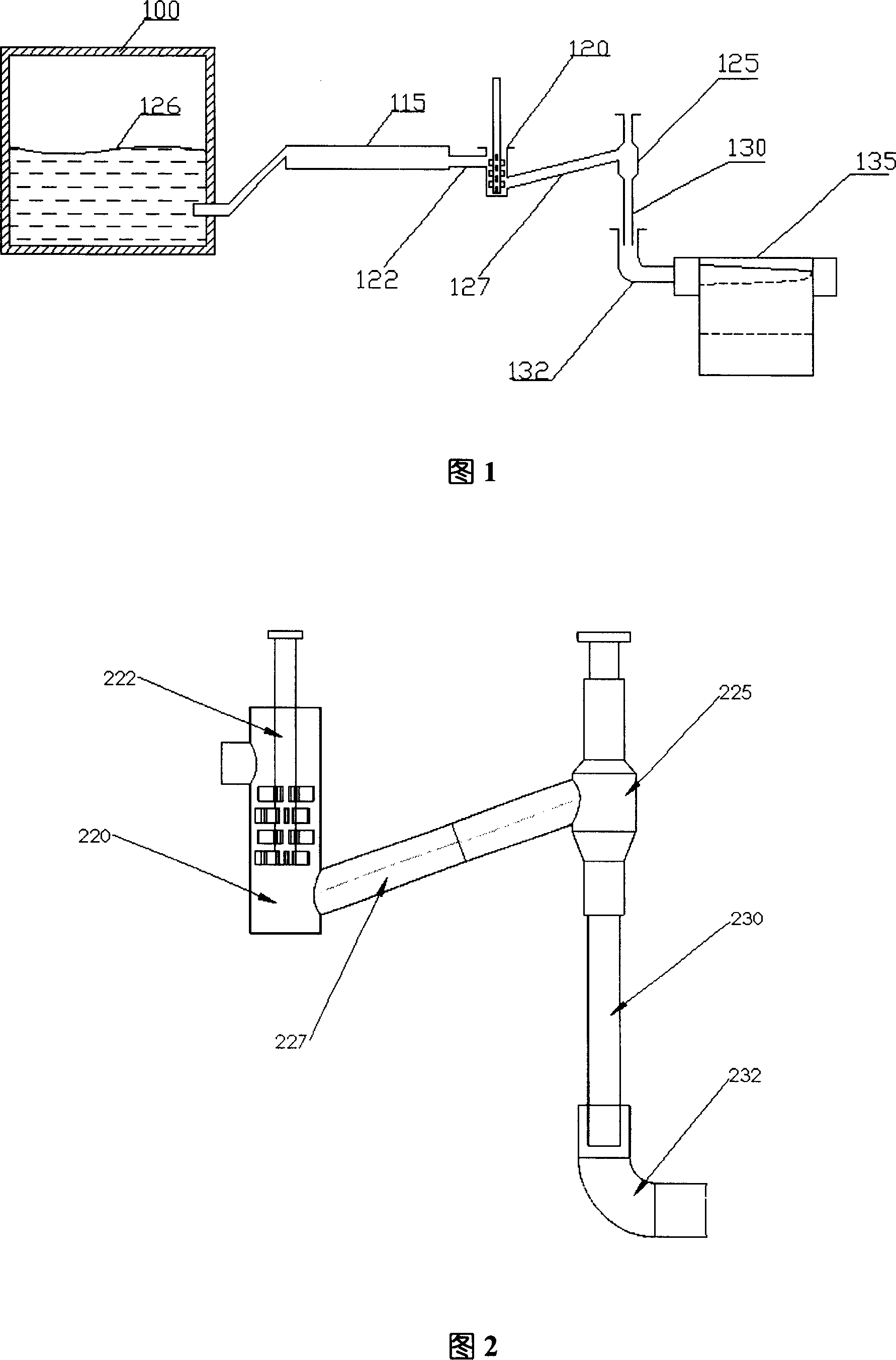

Glass material feeding method and device for controlling and regulating glass flow rate

InactiveCN1986465AReduce defectsStable temperatureFeeder spoutsGlass productionEngineeringGlass material

The present invention is glass material feeding method and device for controlling glass flow rate. The present invention controls glass flow rate through changing the rotation direction and / or rotation speed of the stirrer inside the stirring bath so as to control the liquid level inside the glass bowl and control the glass flow rate inside the falling pipe. The glass material feeding device is one capable of changing the energy the glass melt obtains from the stirrer when the stirrer changes its rotation direction and / or rotation speed. The present invention has convenient glass flow rate control.

Owner:HENAN ANCAI HI-TECH +1

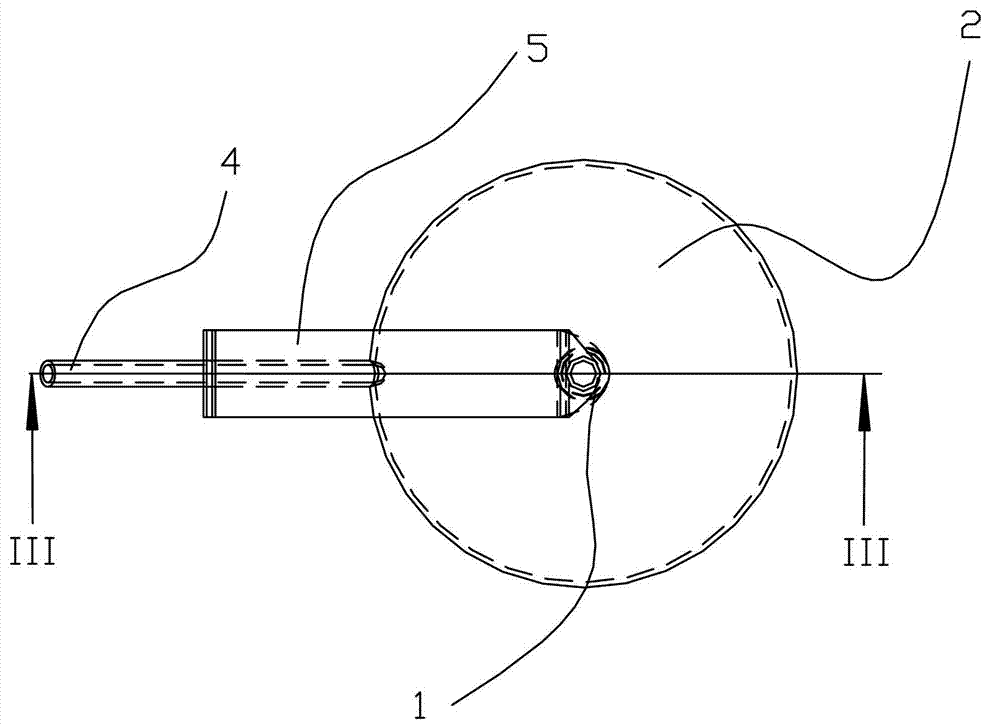

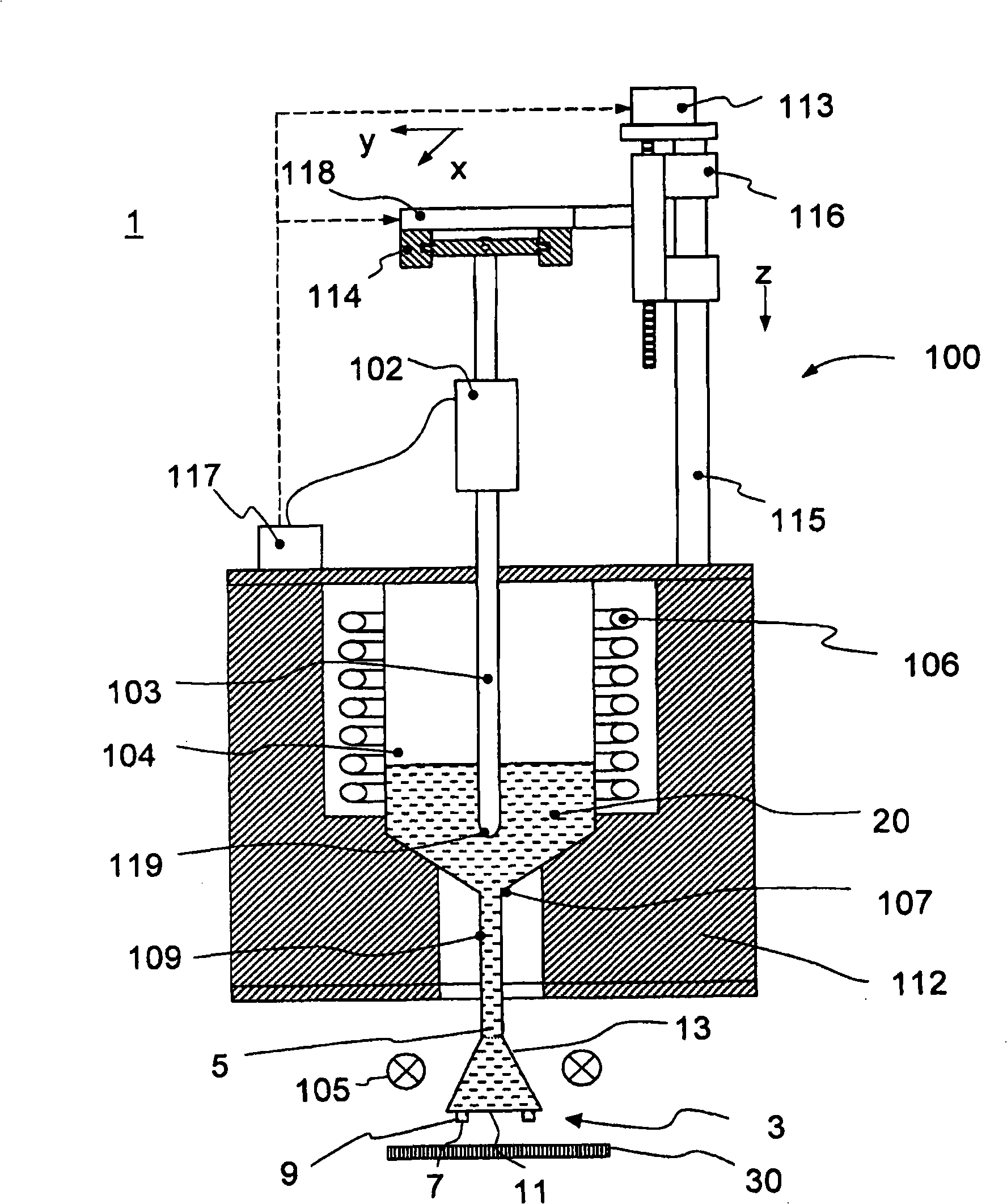

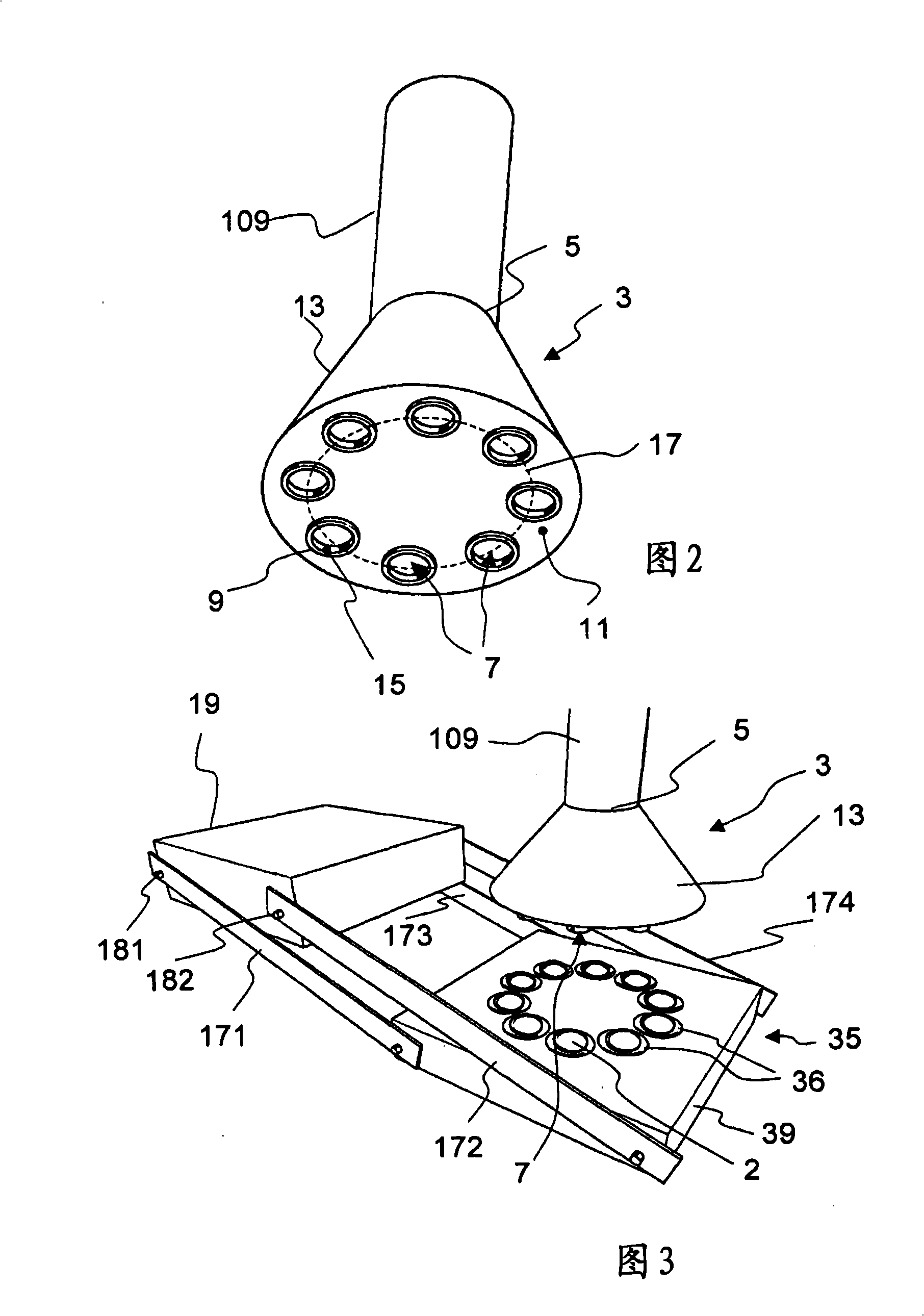

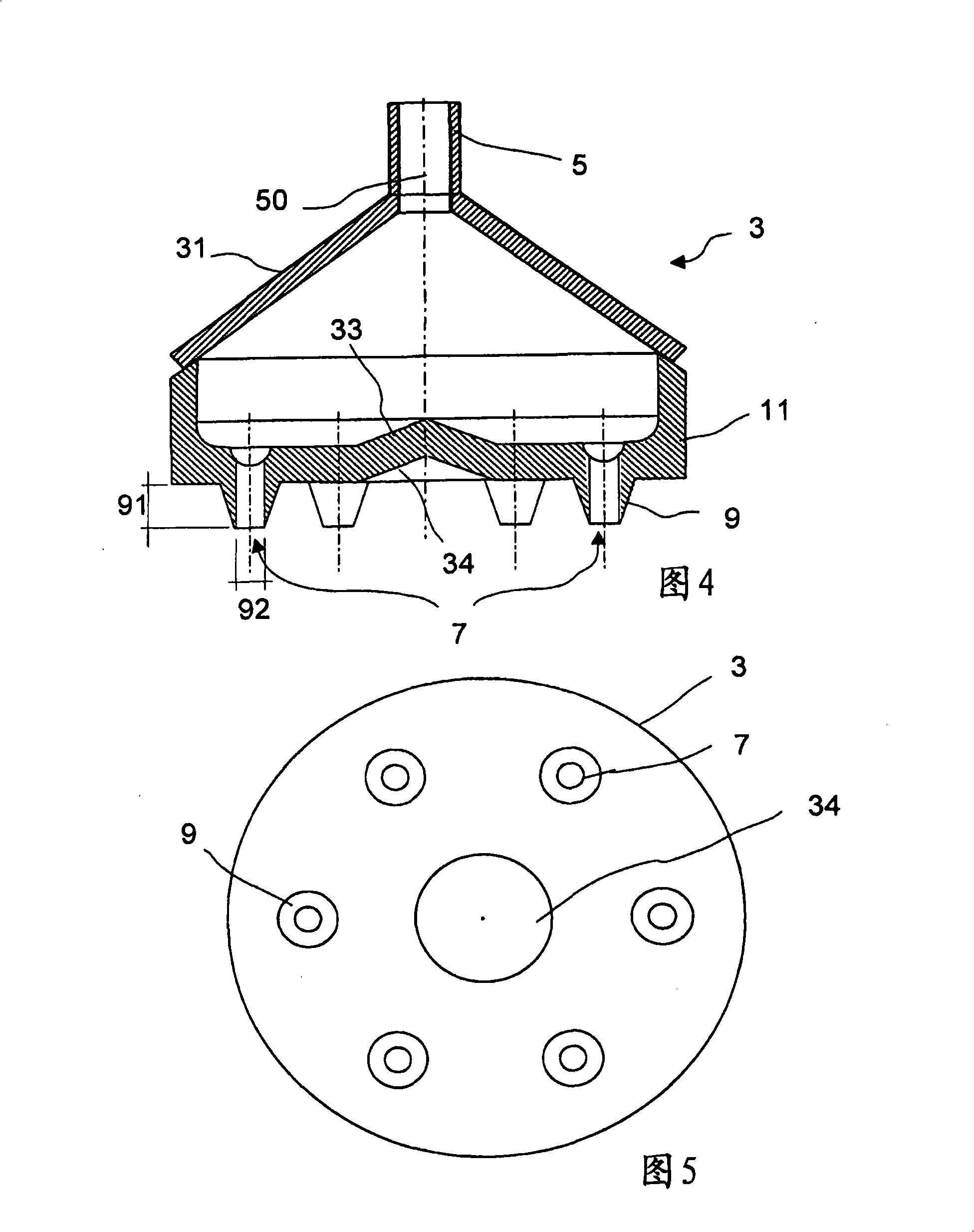

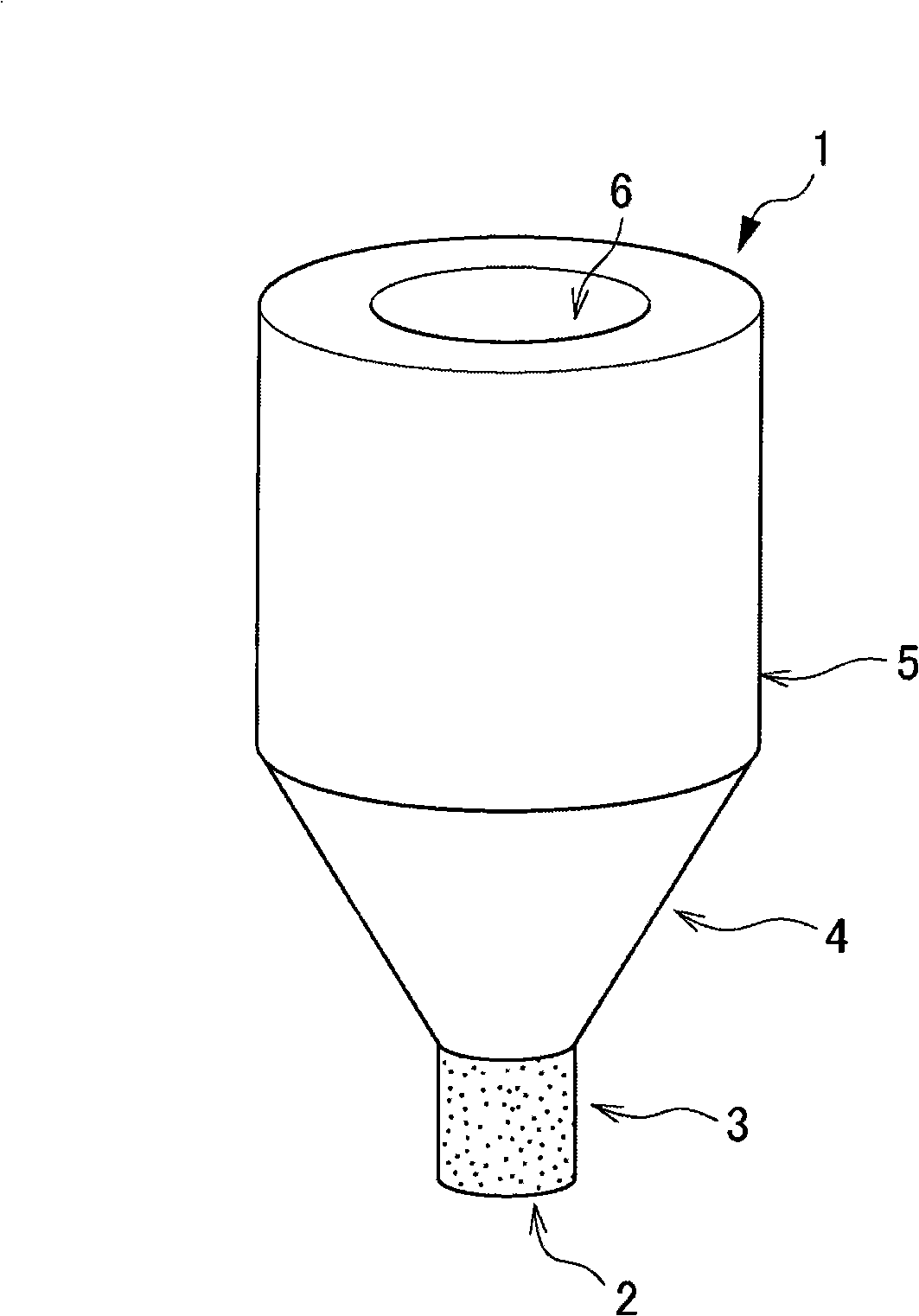

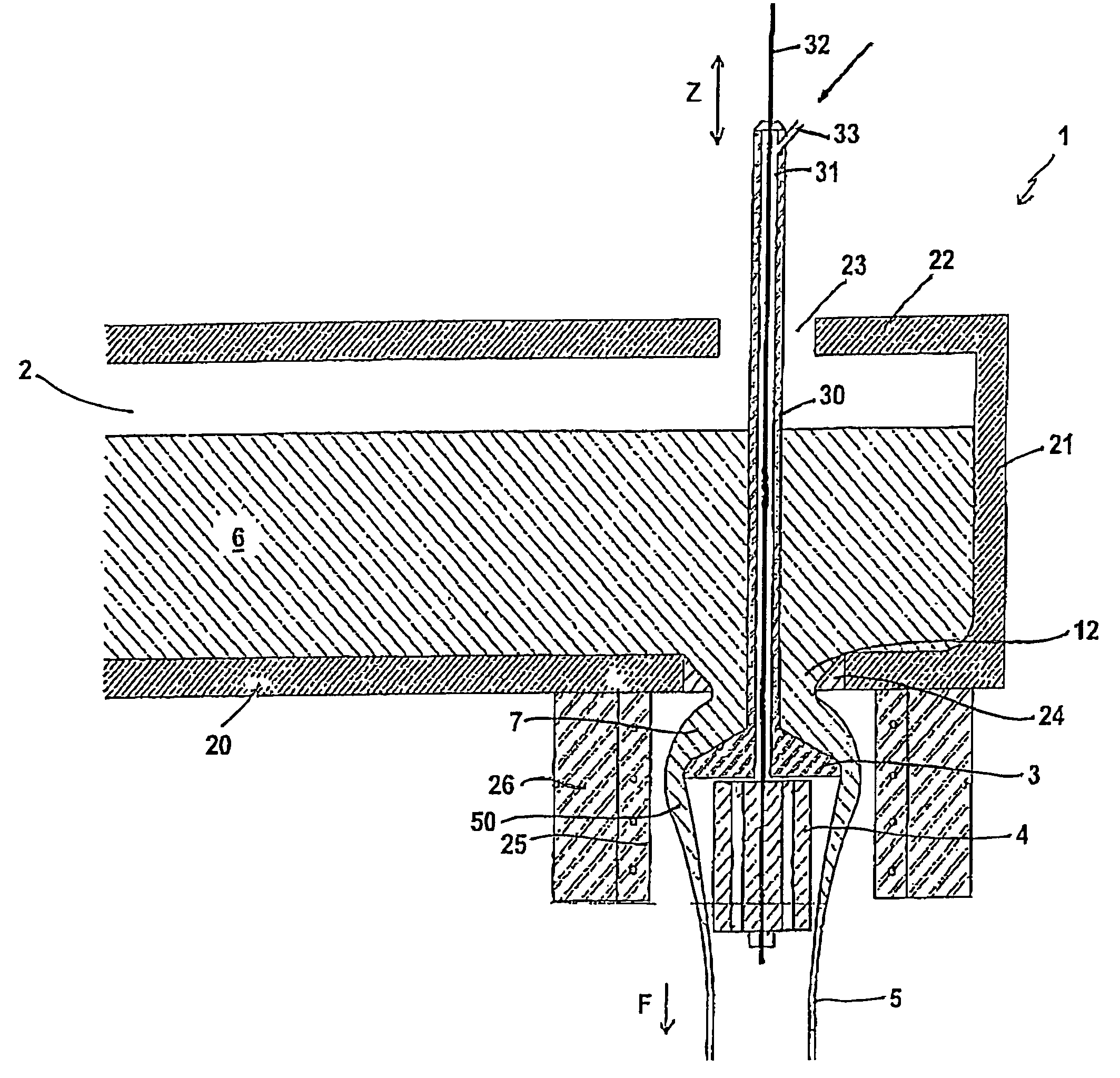

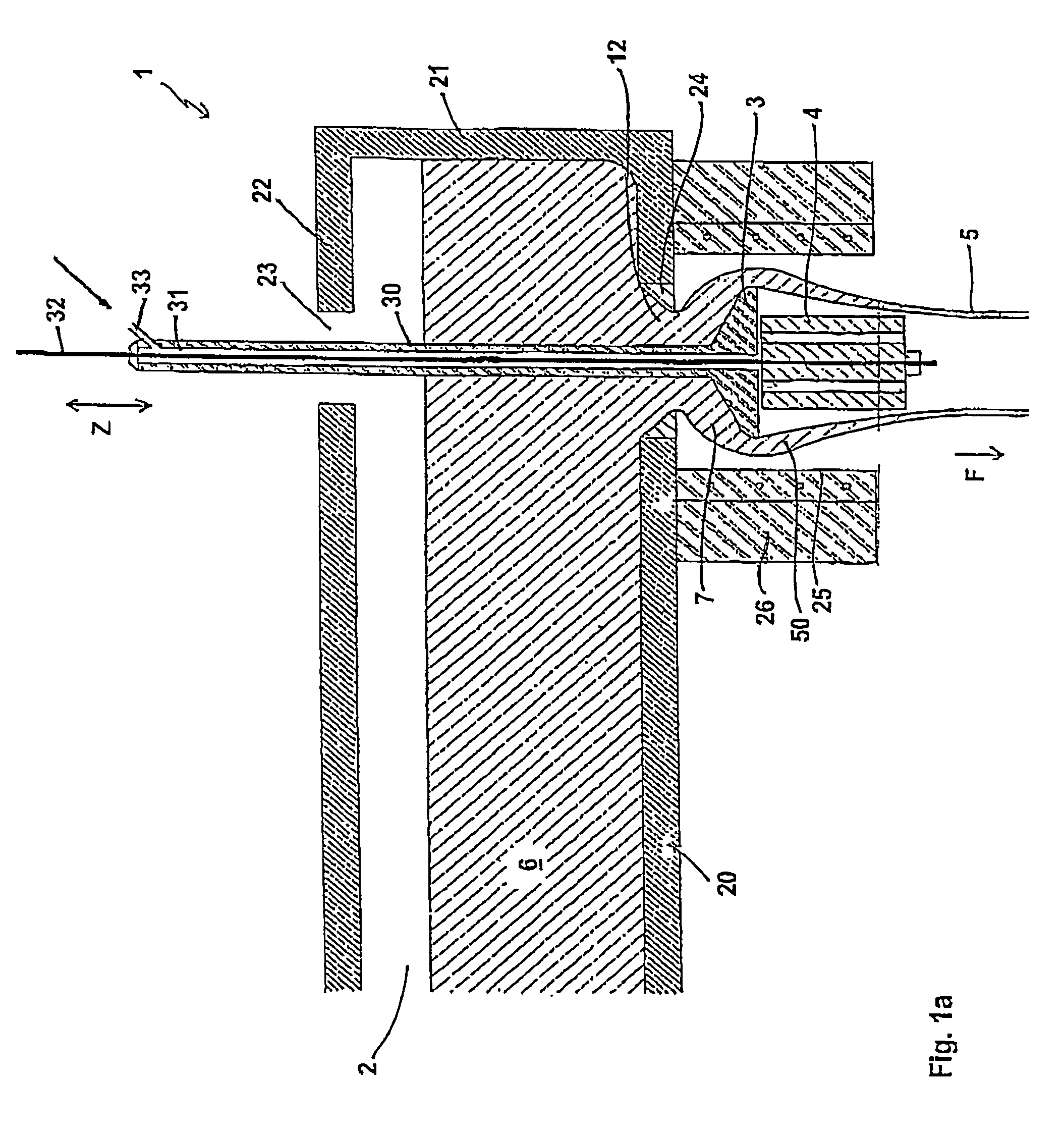

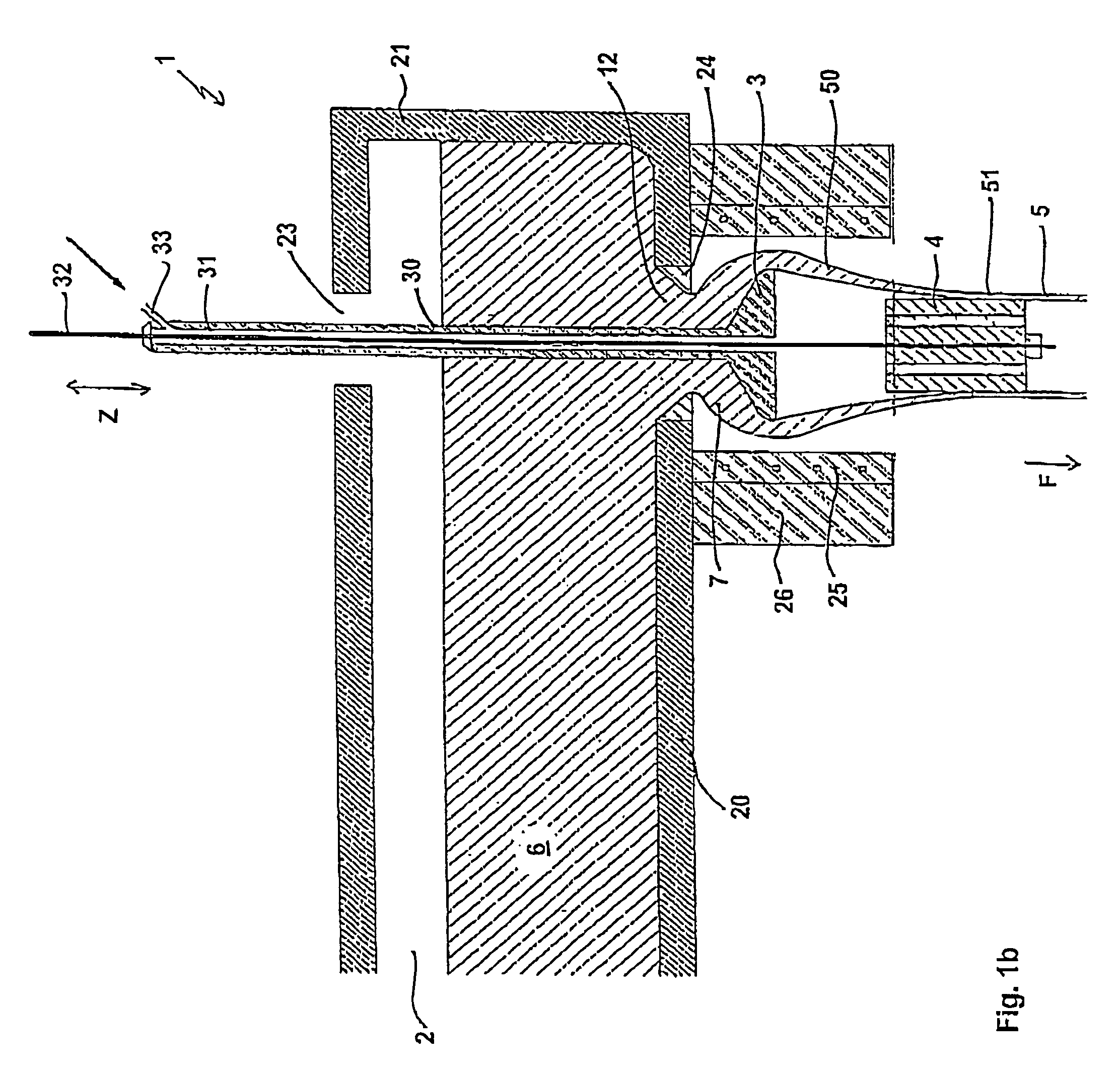

Method and device for accurately dividing a molten low-viscous glass into small portions

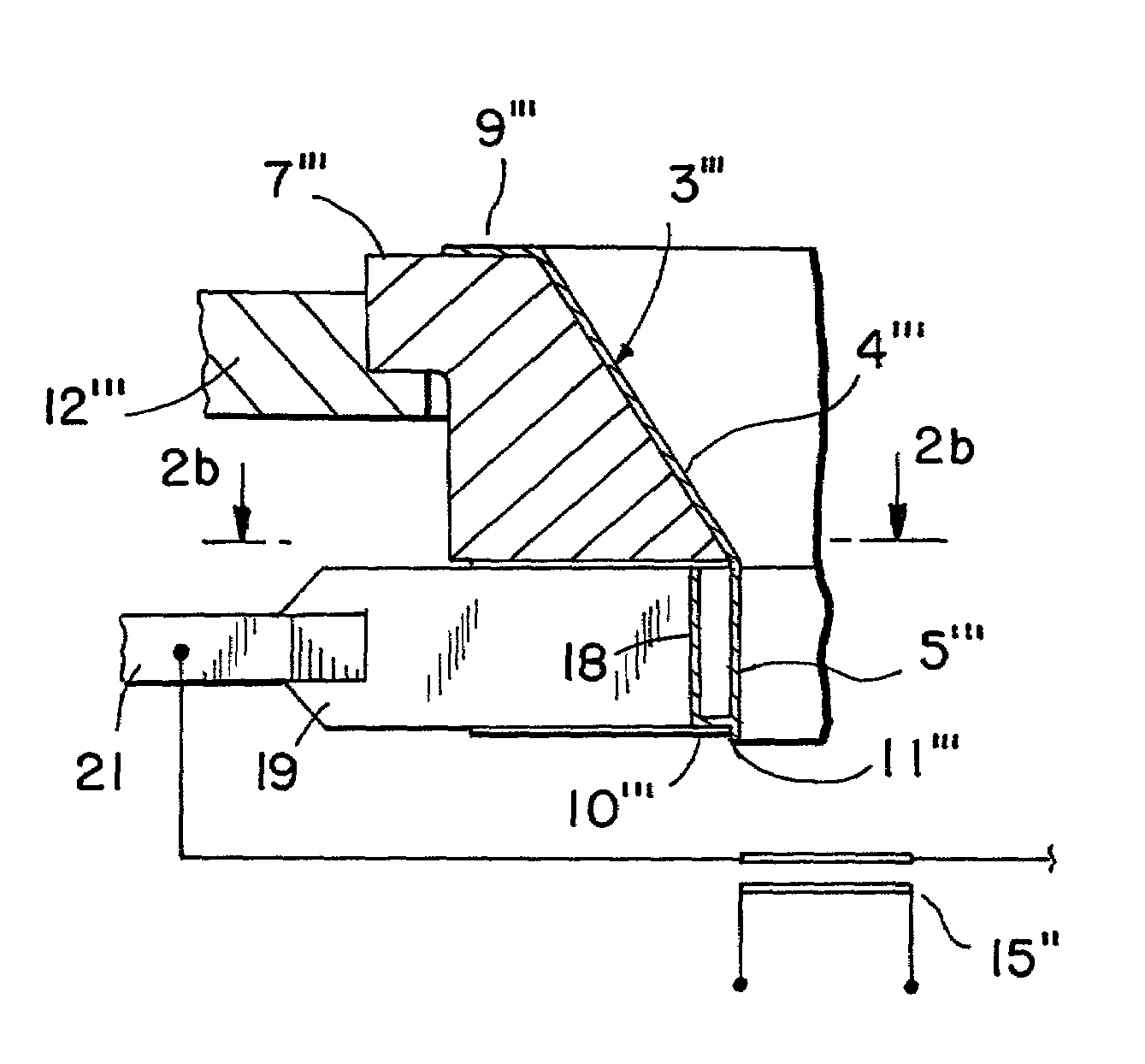

In order to portion glass melts and to increase the flow rate and transmission of optical melts, the inventive method for accurately portioning low-viscous glasses, whose viscosity is equal to 107.6 dPa.s with a temperature equal to or less than 670 DEG C, in particular glasses used for blank pressing or low-Tg glasses, is based on a continuous melting process consisting in repeatedly supplying the portions, whose weight ranges from 0.2 to 10 grams with a relative and / or absolute weight deviation less than 5 % with respect to the portion average weight, by means of a clocking needle feeder (100) which comprises a nozzle (3) provided with several outlets (7).

Owner:SCHOTT AG

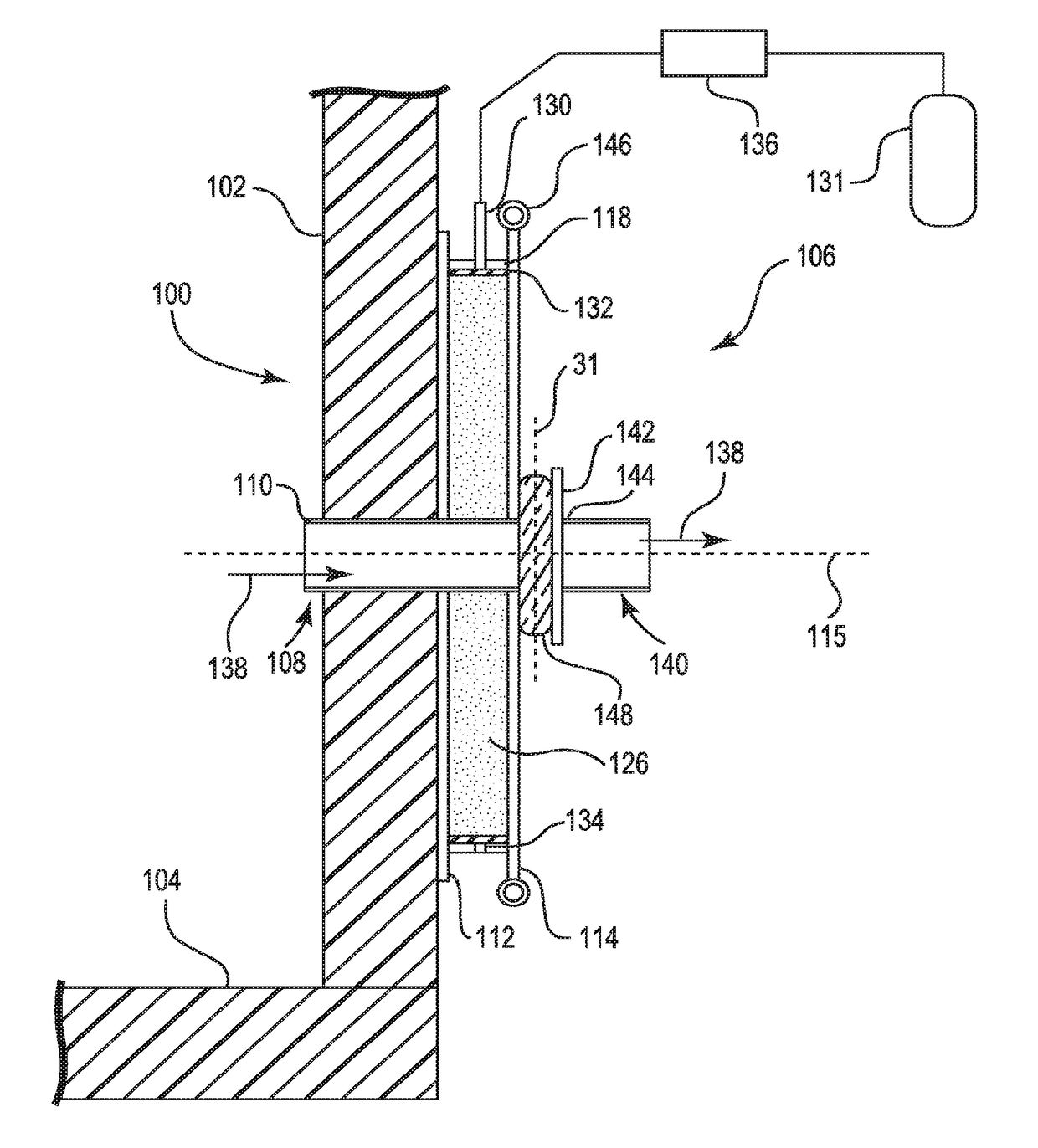

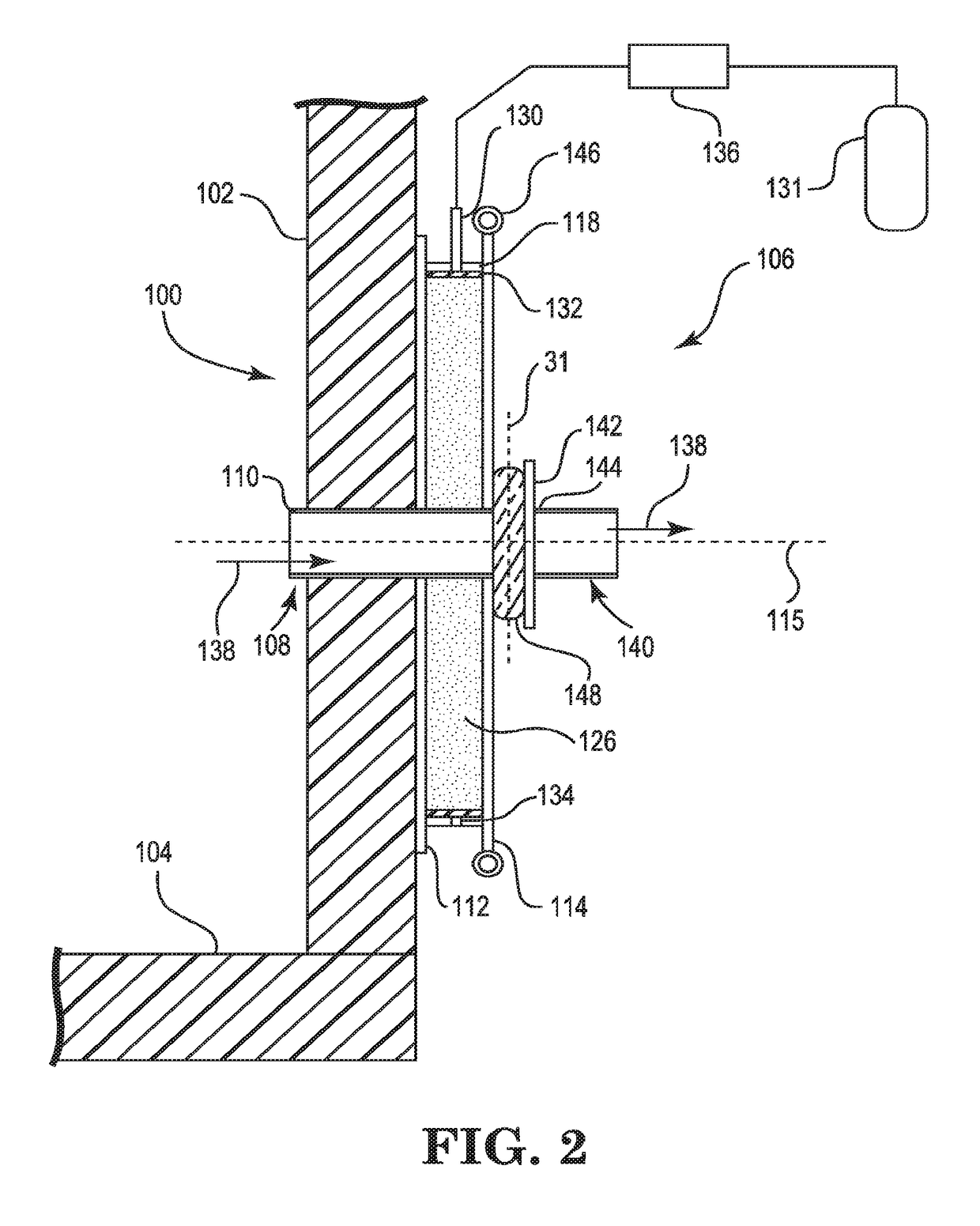

Apparatus and method for conditioning molten glass

Disclosed is an apparatus for conditioning molten glass. The apparatus includes a connecting tube assembly having a conduit for conveying the molten glass, the conduit (108) including at least two flanges (112, 114) and a sealing member (118) disposed between the at least two flanges (112, 114) around an outer peripheral region of the flanges, thereby forming an enclosed volume between an outer wall (110) of the conduit, the at least two flanges (112, 114) and the sealing member (118). An atmosphere within the volume may be controlled such that a predetermined partial pressure of hydrogen or a predetermined partial pressure of oxygen may be maintained within the volume. A current may be established between the at least two flanges to heat the conduit.

Owner:CORNING INC

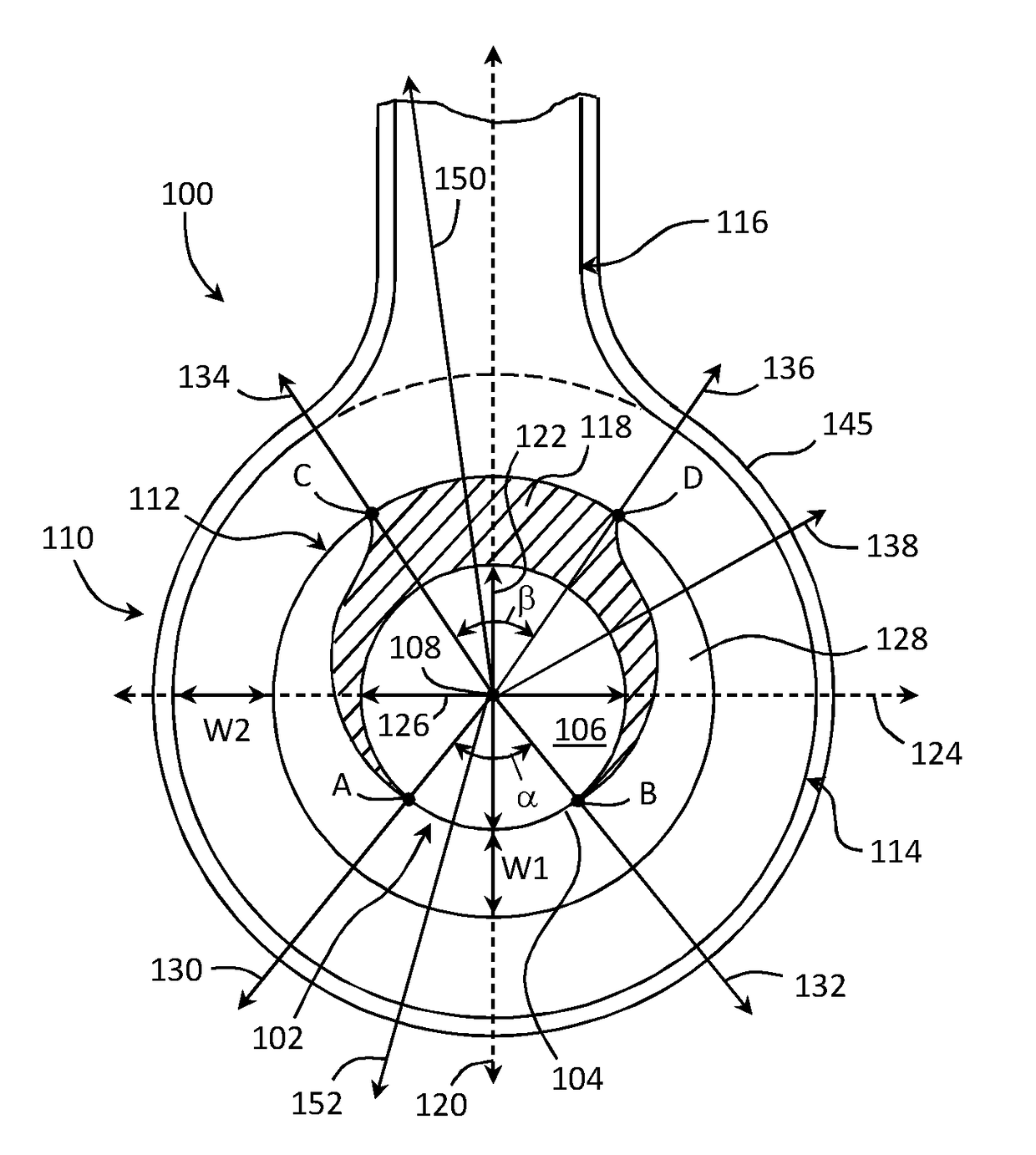

Apparatus and method for heating a metallic vessel

ActiveUS20180072602A1Reducing electric currentIncrease concentrationFurnace componentsForehearthsClosed loopEngineering

Disclosed is an apparatus and method of making molten glass. The apparatus includes a vessel for conveying the molten glass and at least one flange configured to supply an electric current to the vessel through the flange, the flange including a first ring extending completely around the vessel in a closed loop, the first ring comprising a first portion including a first thickness and a second portion including a second thickness different from the first thickness, wherein the first portion and the second portion overlap in a plane of the flange such that at least a portion of the first portion is positioned between at least a portion of the second portion and the vessel wall, and neither the first portion nor the second portion extends completely around the vessel. Also disclosed is a method of making glass using the disclosed flange.

Owner:CORNING INC

Melt material outlet nozzle

InactiveCN101293187ALess wetting riseEasy and complete removalGranulation by liquid drop formationFeeder spoutsMaterials scienceNozzle

The invention provides a smelt outflow nozzle that the melt has little wet rising on the nozzle when manufactures micro spherical particle or preformed materials, and the glass that has wet rising on the front end of the nozzle is easily to completely removed. The smelt outflow nozzle (1) outflows the smelt from the front end (2) and has a flow passage (6) of the smelt, comprising an inner surface (31) facing to the flow passage (6), an outer surface (32) covering the inner surface (31) and an end face (21) connected with the inner surface (31) and the outer surface (32) at the front end (2).The mean roughness (Ra) of center line of the outer surface (32) is less than or equal to 1.6 [mu]m.

Owner:OHARA

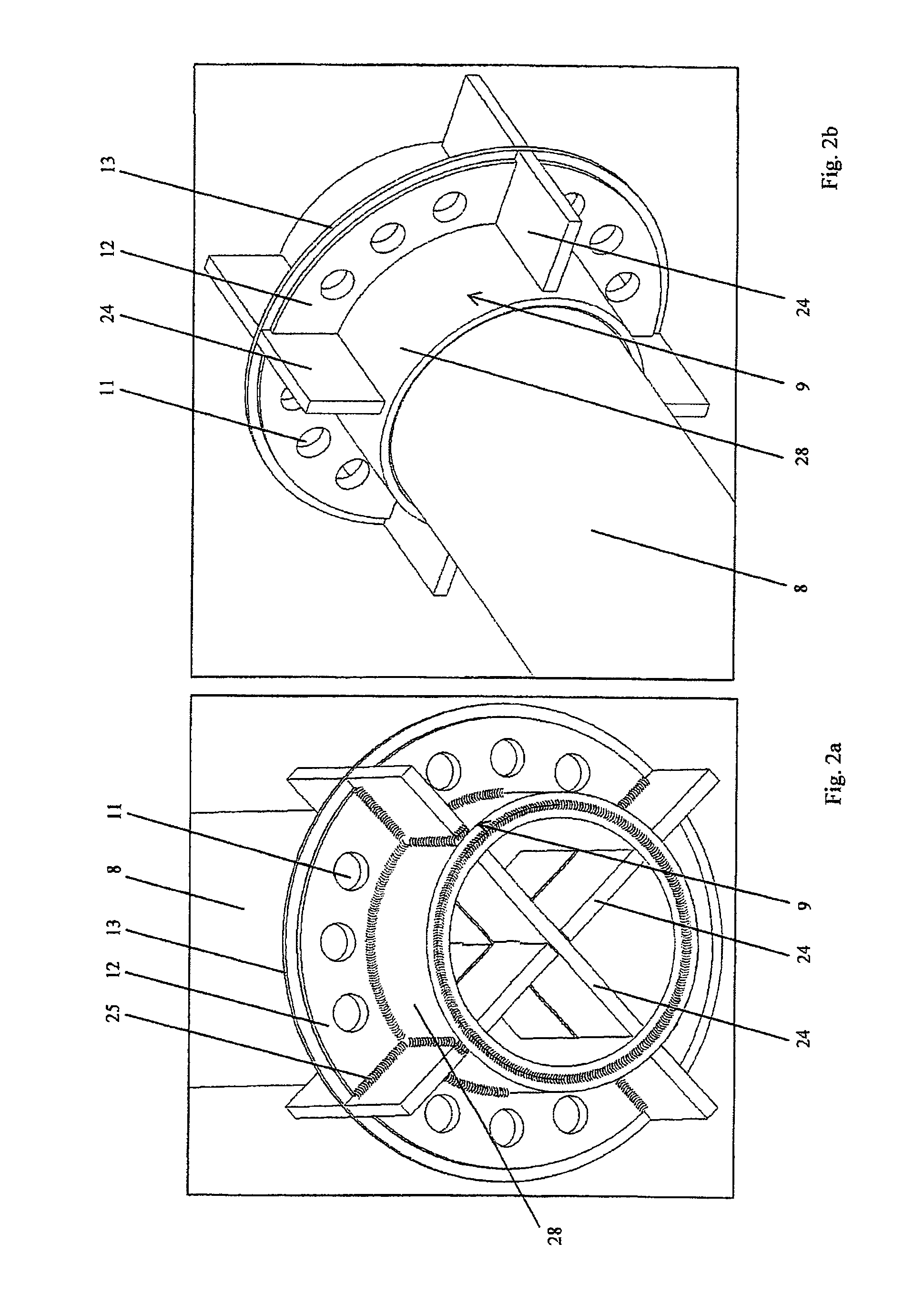

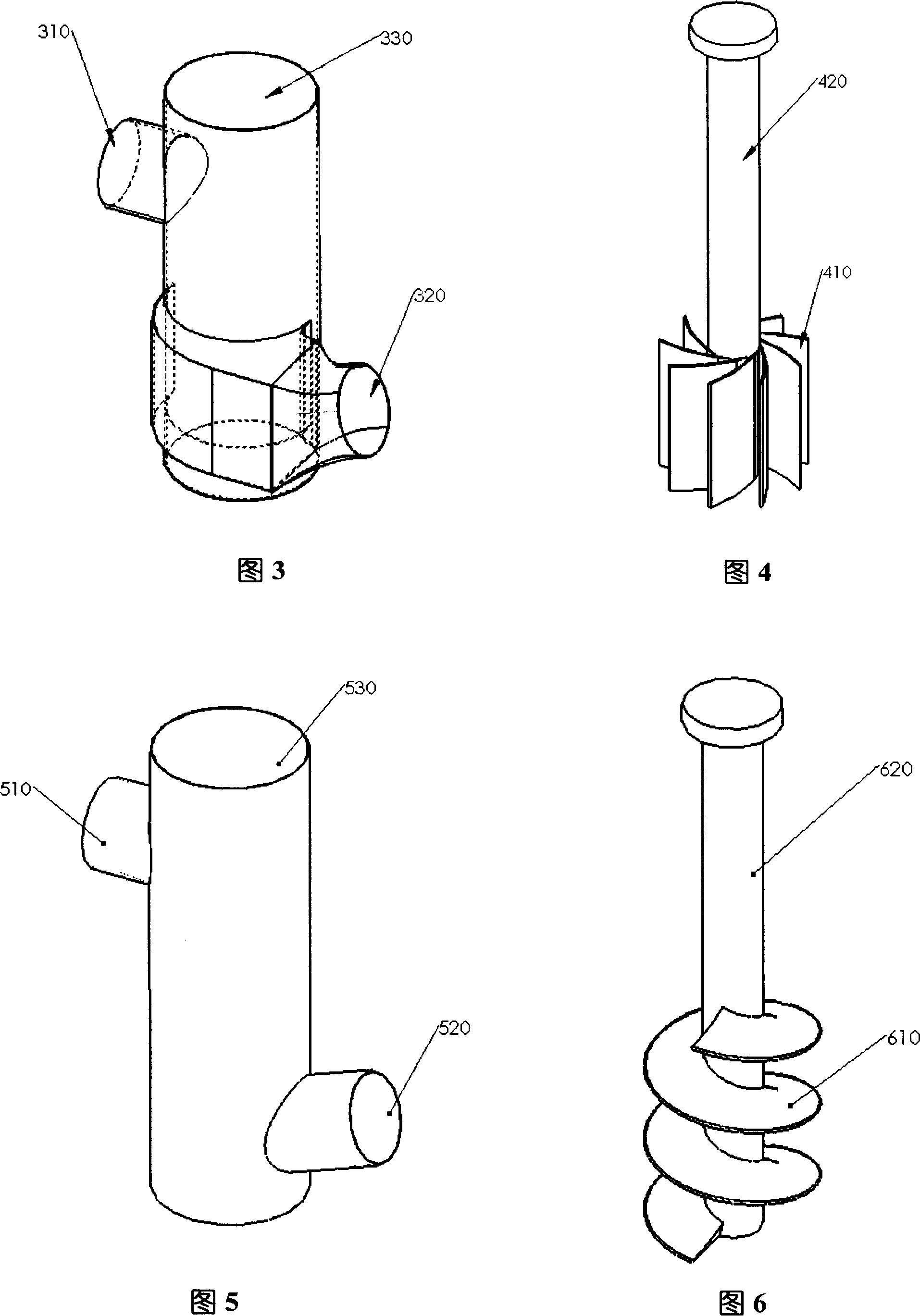

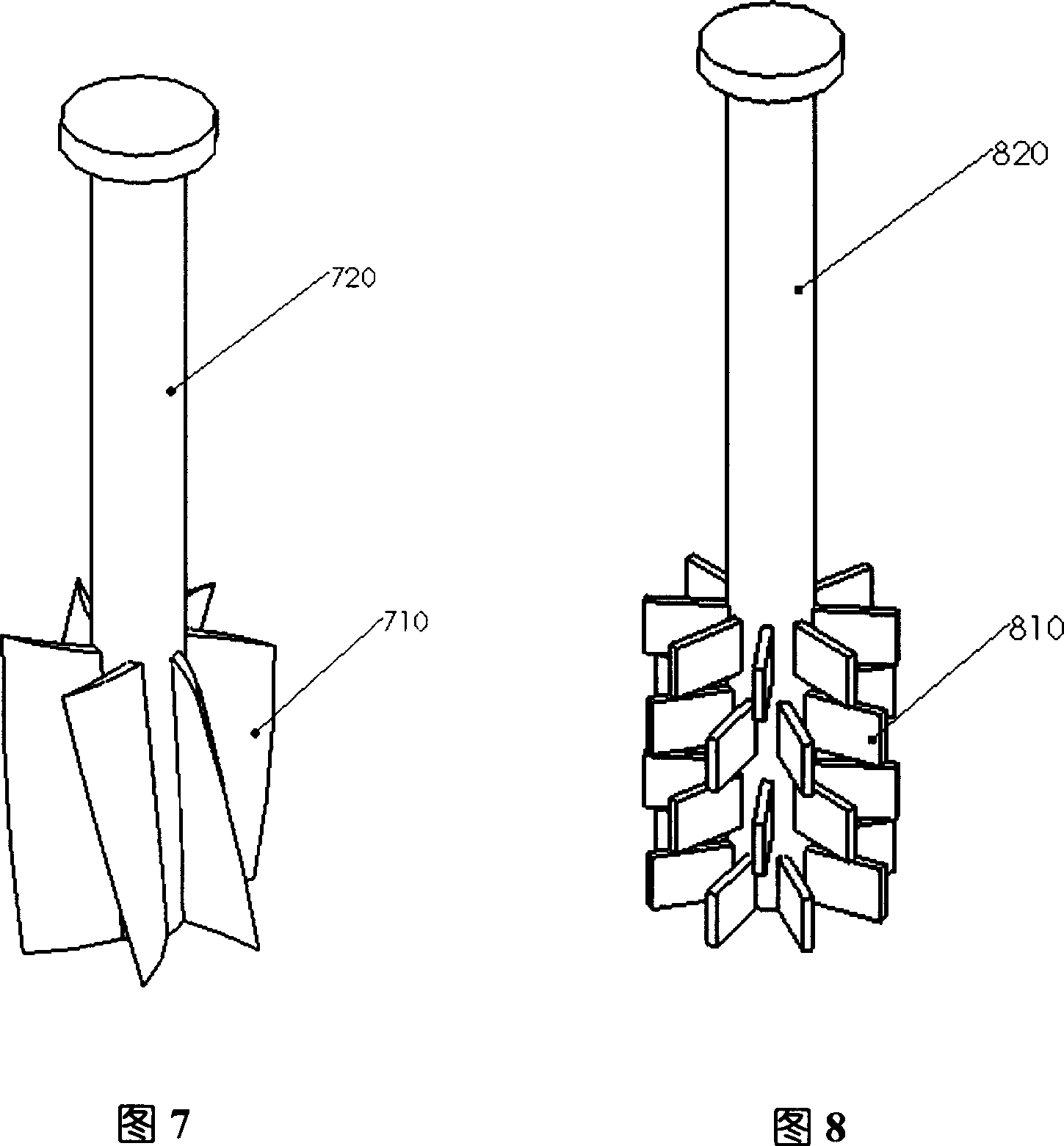

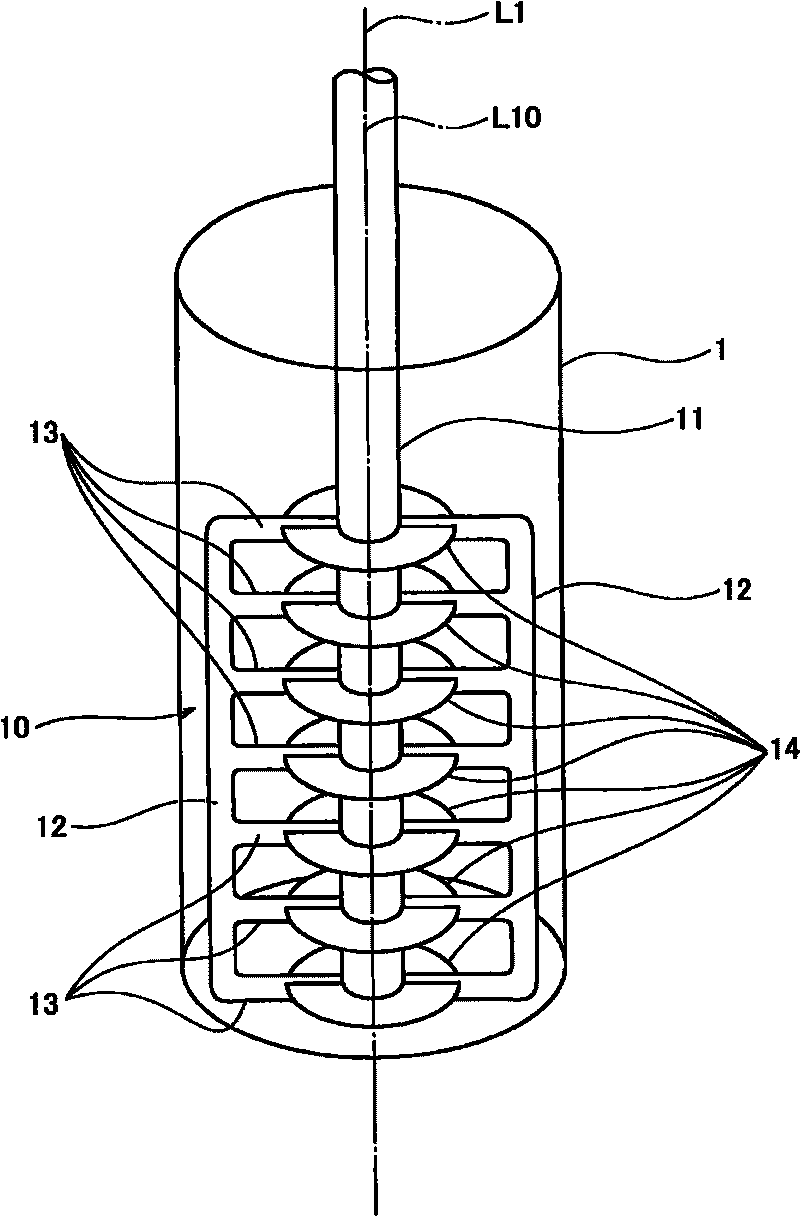

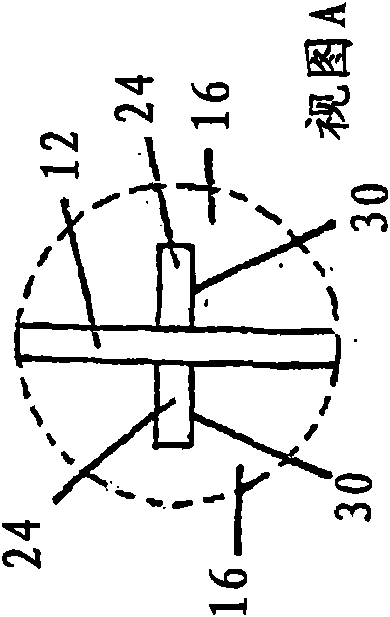

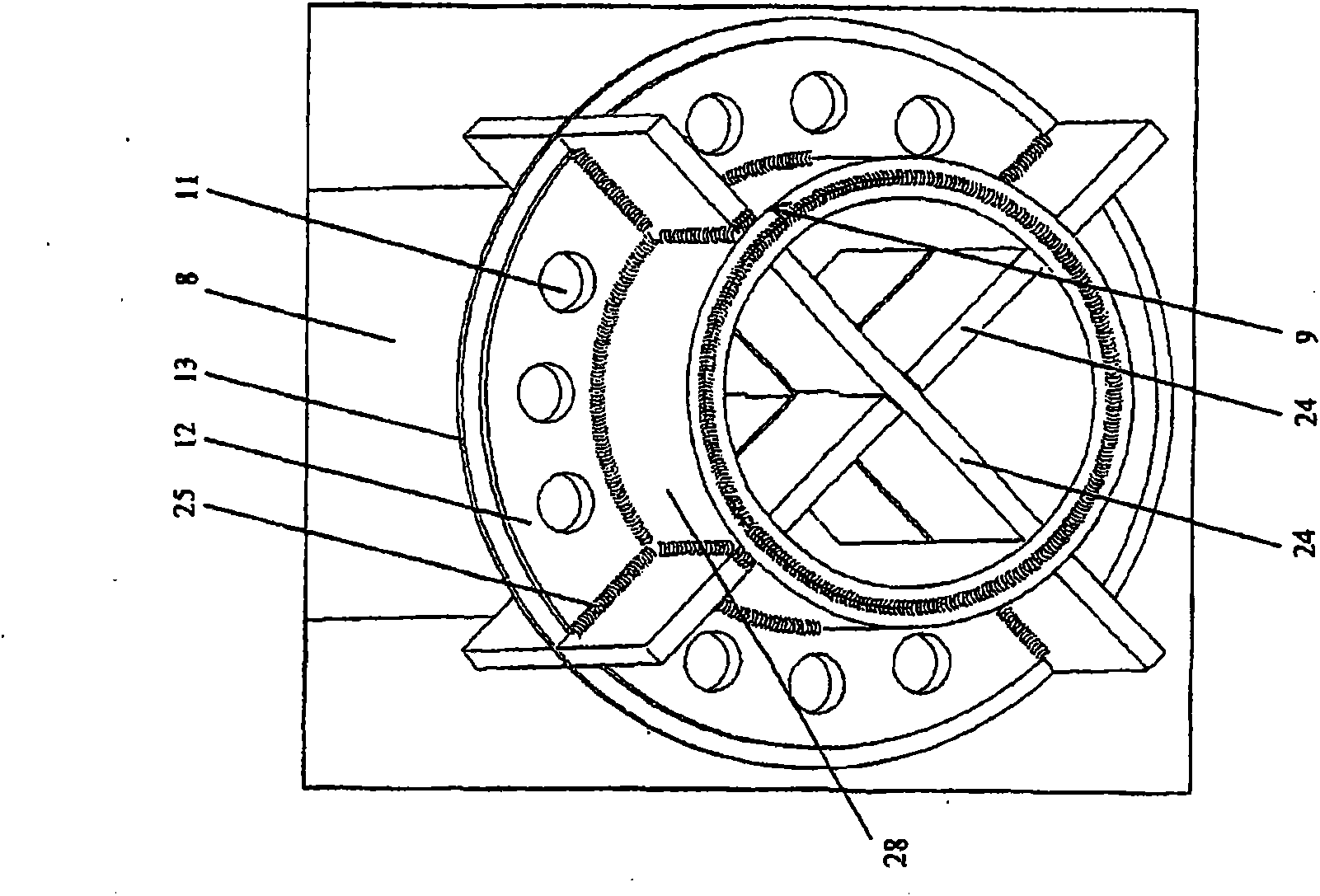

Stirring blade for molten glass and stirring device therefor

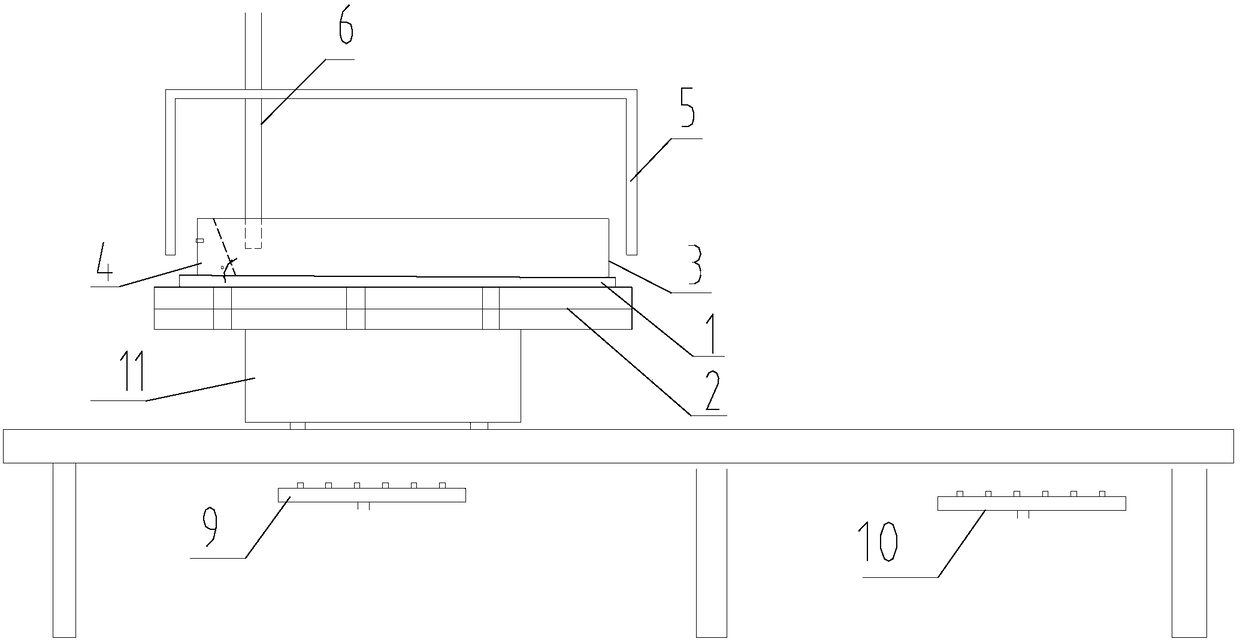

ActiveCN101723573AStir wellEliminate understirringGlass furnace apparatusFeeder spoutsIn planeMolten glass

The invention provides a stirring blade for molten glass and stirring device therefore, capable of completely stirring the molten glass including the center area in a groove to homogenize the molten glass without increasing rotation speed. The stirring blade comprises: a cross-bar first wing (12) extending along the vertical direction at the position far away from a rotation axle (L10) along the rotation radius direction and rotating adjacent to the inner wall of a stirring groove (1) to stirring the molten glass at the perimeter area of the stirring groove; a cross-bar second wing (13) extending along the rotation radius direction and rotating in the range from the center area of the stirring groove to the perimeter area to stir the molten glass in the range of from the center area to the perimeter area; a circular disk shaped third wing (14) at the inner circle side of the first wing and extending in plane shape along the direction orthogonal with the rotation axle and guiding the molten glass in the center area of the stirring groove to the perimeter area.

Owner:AVANSTRATE INC

Glass manufacturing apparatus and a structural member thereof

InactiveUS8019206B2Avoid conductionGlass drawing apparatusDielectric heating electrodesPlatinumMetallic materials

A hollow tubular body for molten glass by which local-overheating in the electrode for conduction heating is prevented.A hollow tubular body for molten glass by which local-overheating in the electrode for conduction heating is prevented. A hollow tubular body having a platinum or platinum alloy hollow tube, used for conduction heating is characterized in that a ring electrode is joined to the outer circumference of the hollow tube, at least one lead-out electrode is joined to an outer edge of the ring electrode, and the ring electrode comprises a core portion of electrode of platinum or platinum alloy and a thick portion of platinum or platinum alloy or of a metallic material other than platinum or platinum alloy, provided at an outer side of the core portion of electrode.

Owner:ASAHI GLASS CO LTD

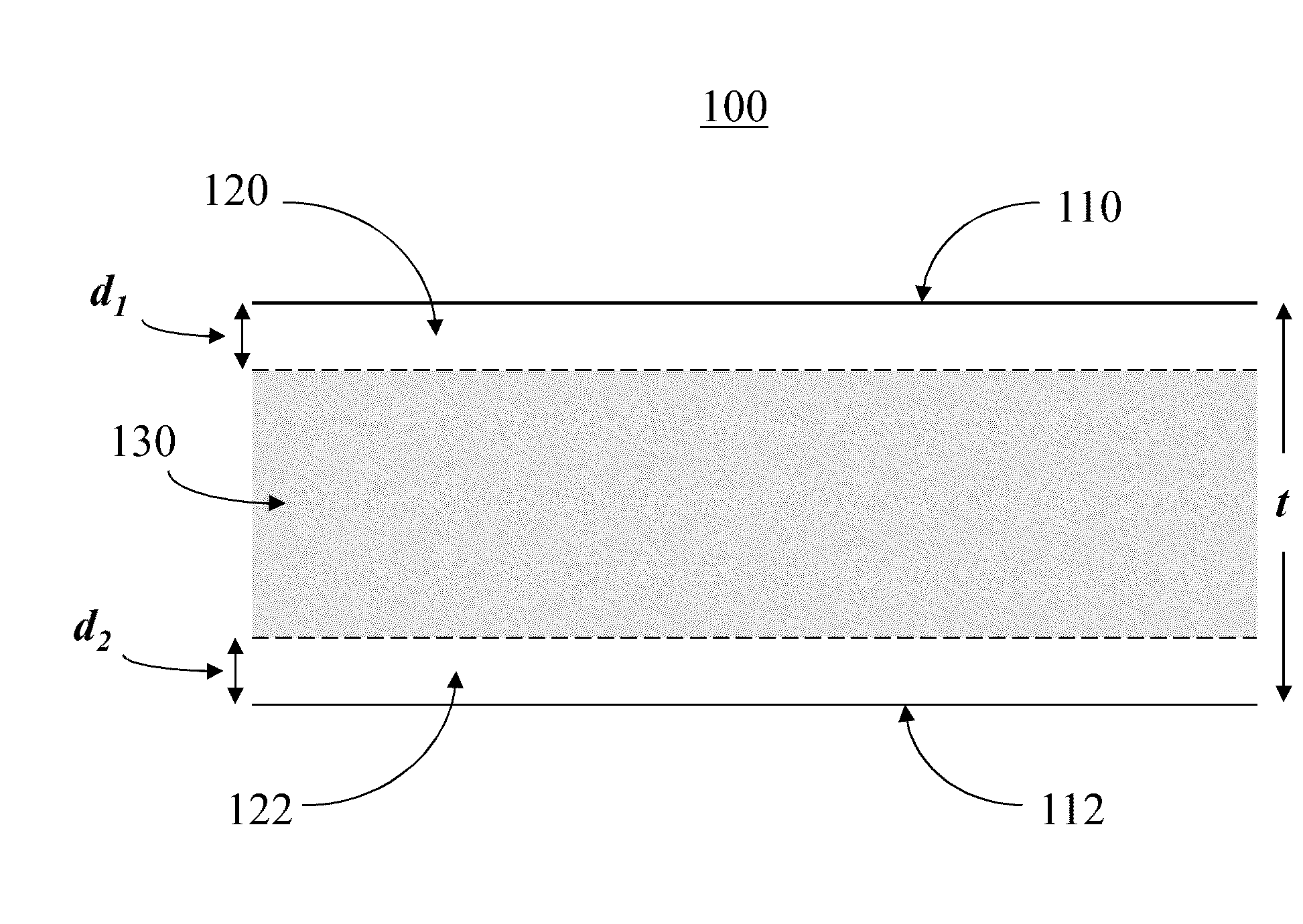

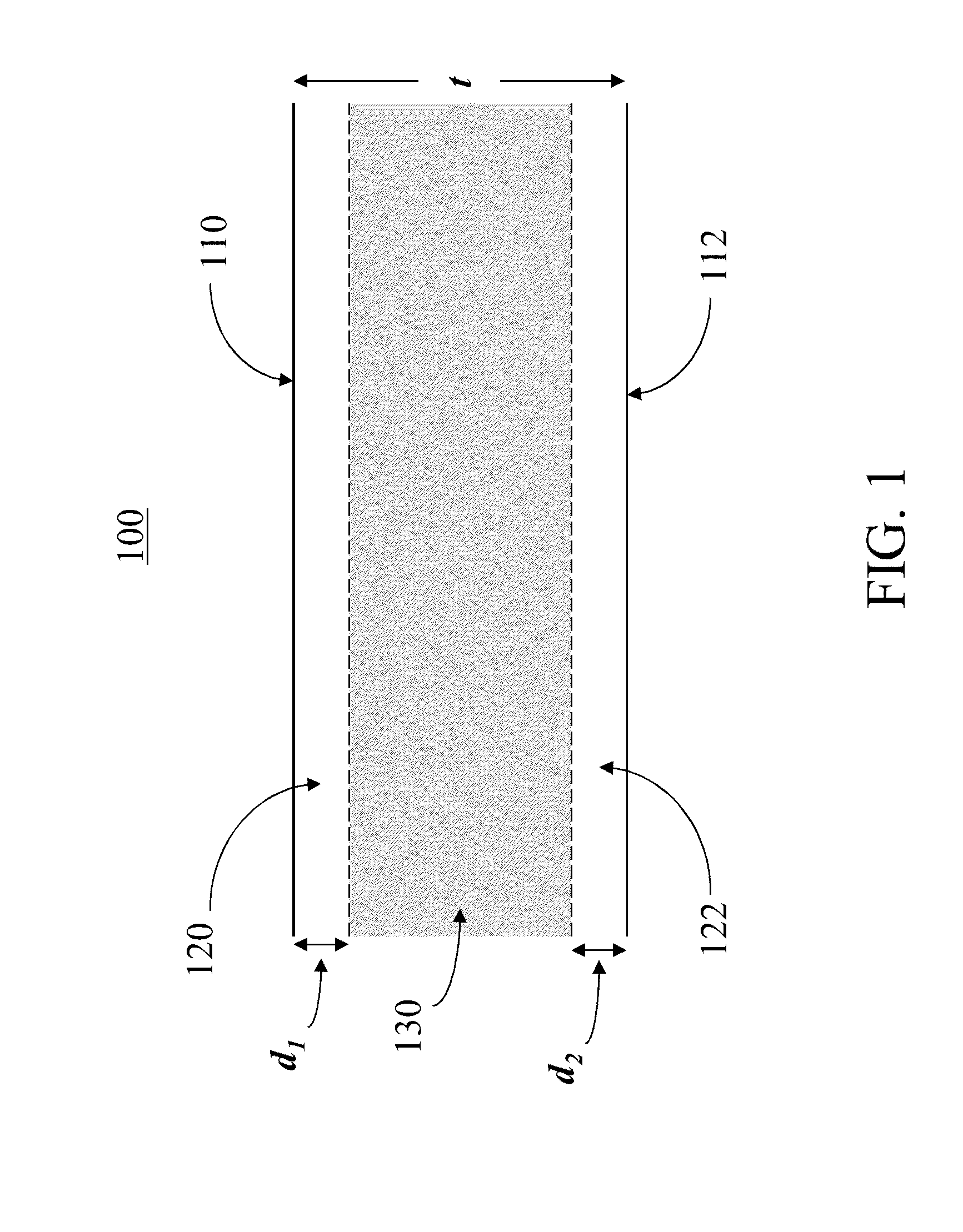

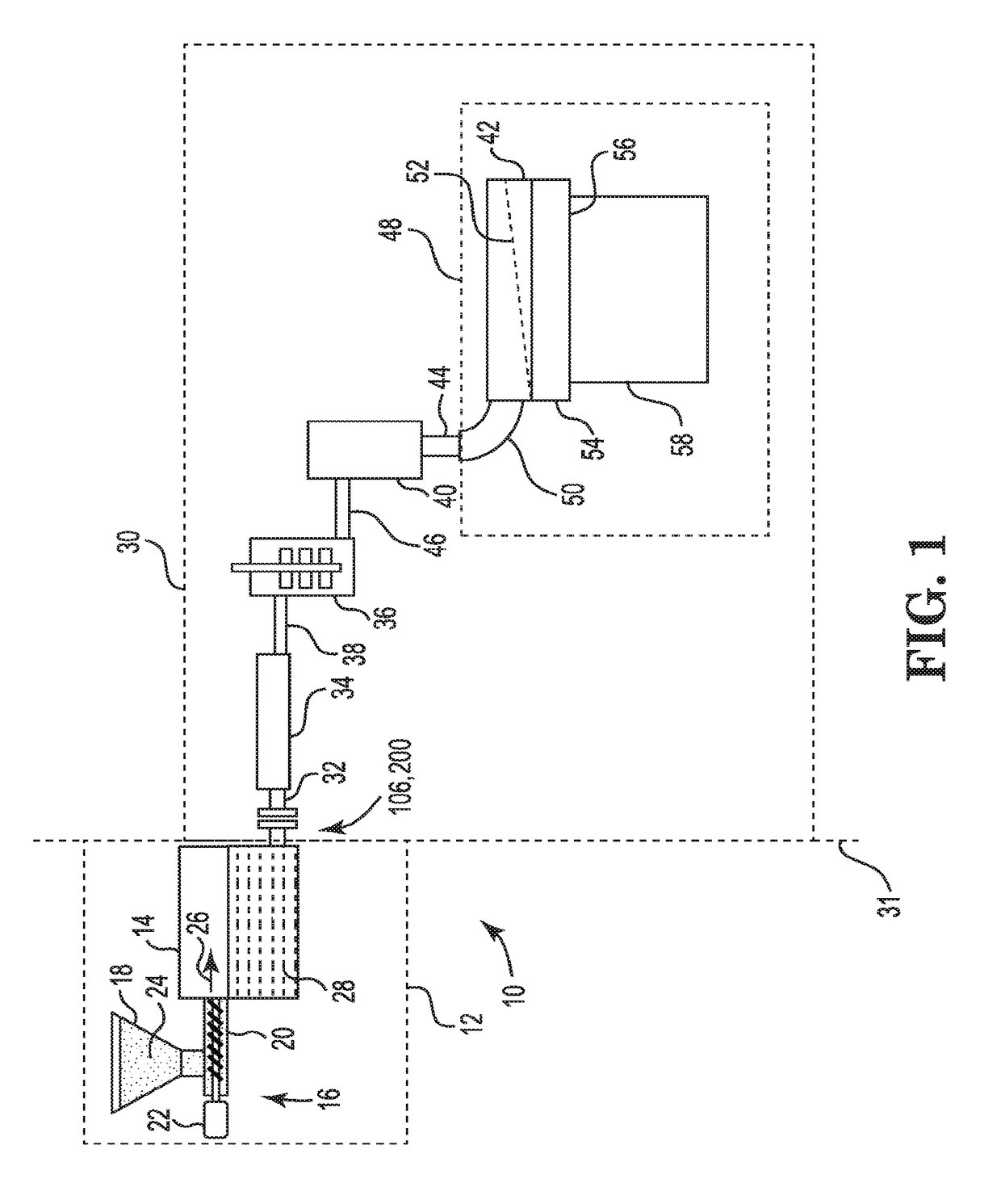

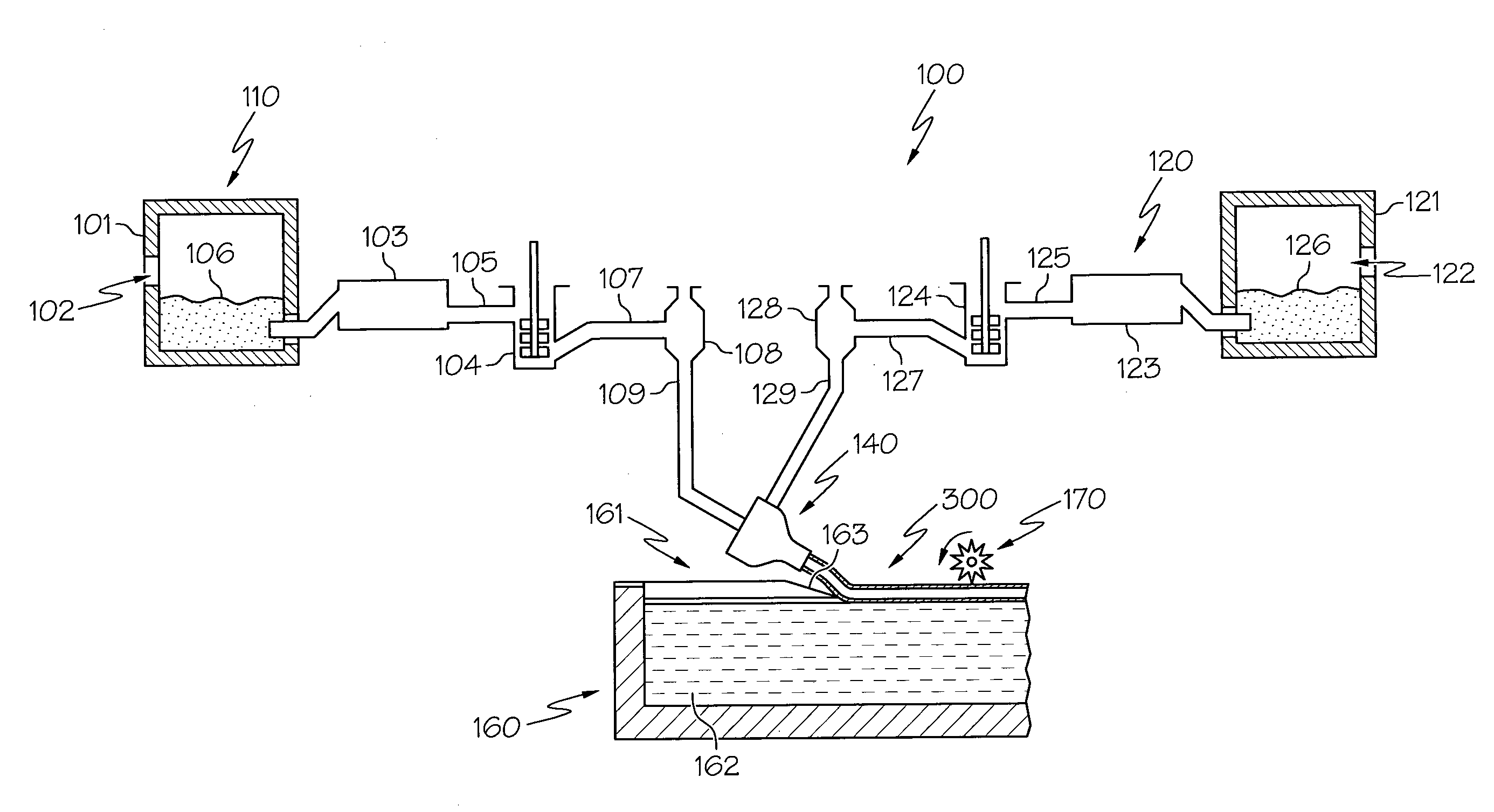

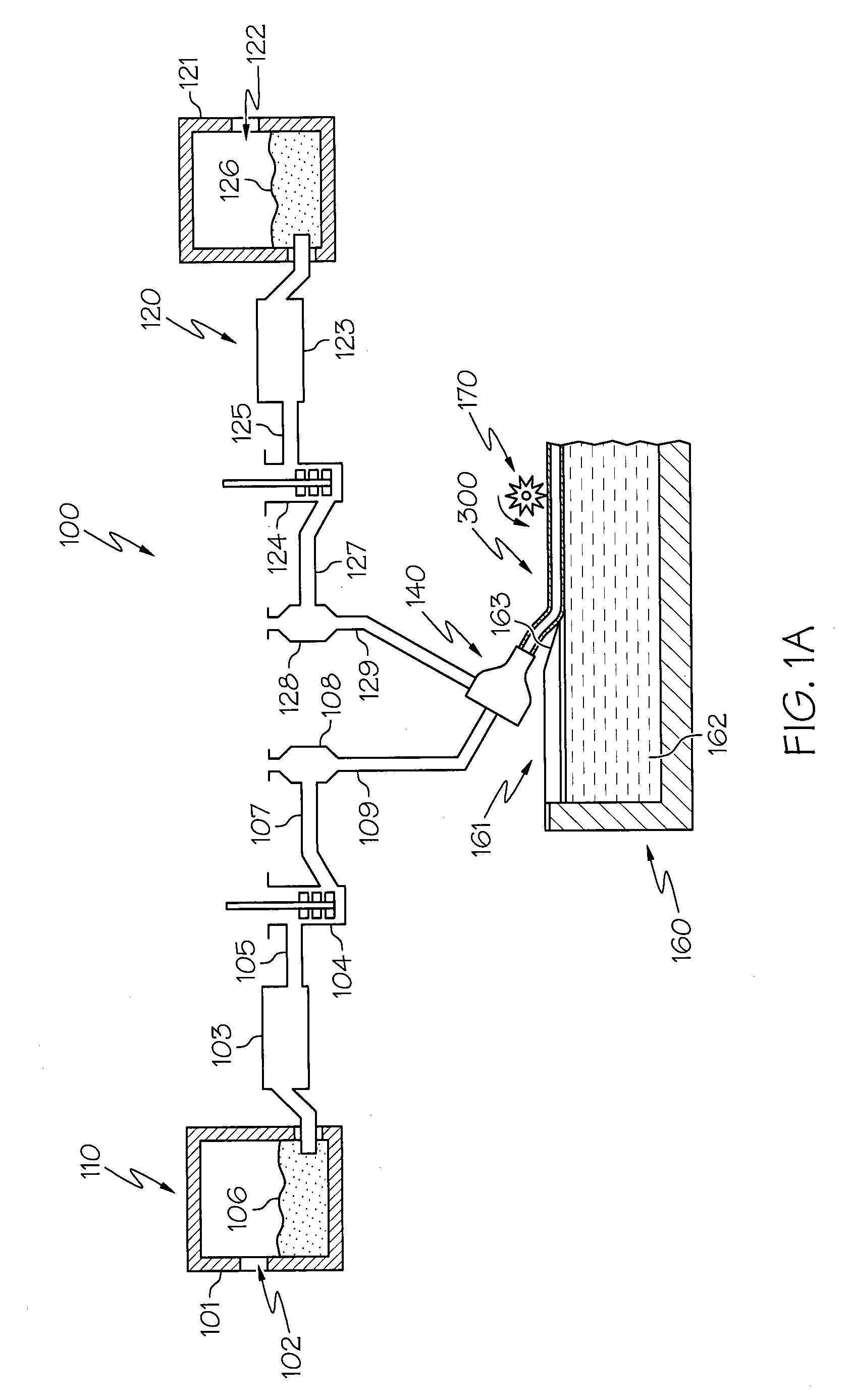

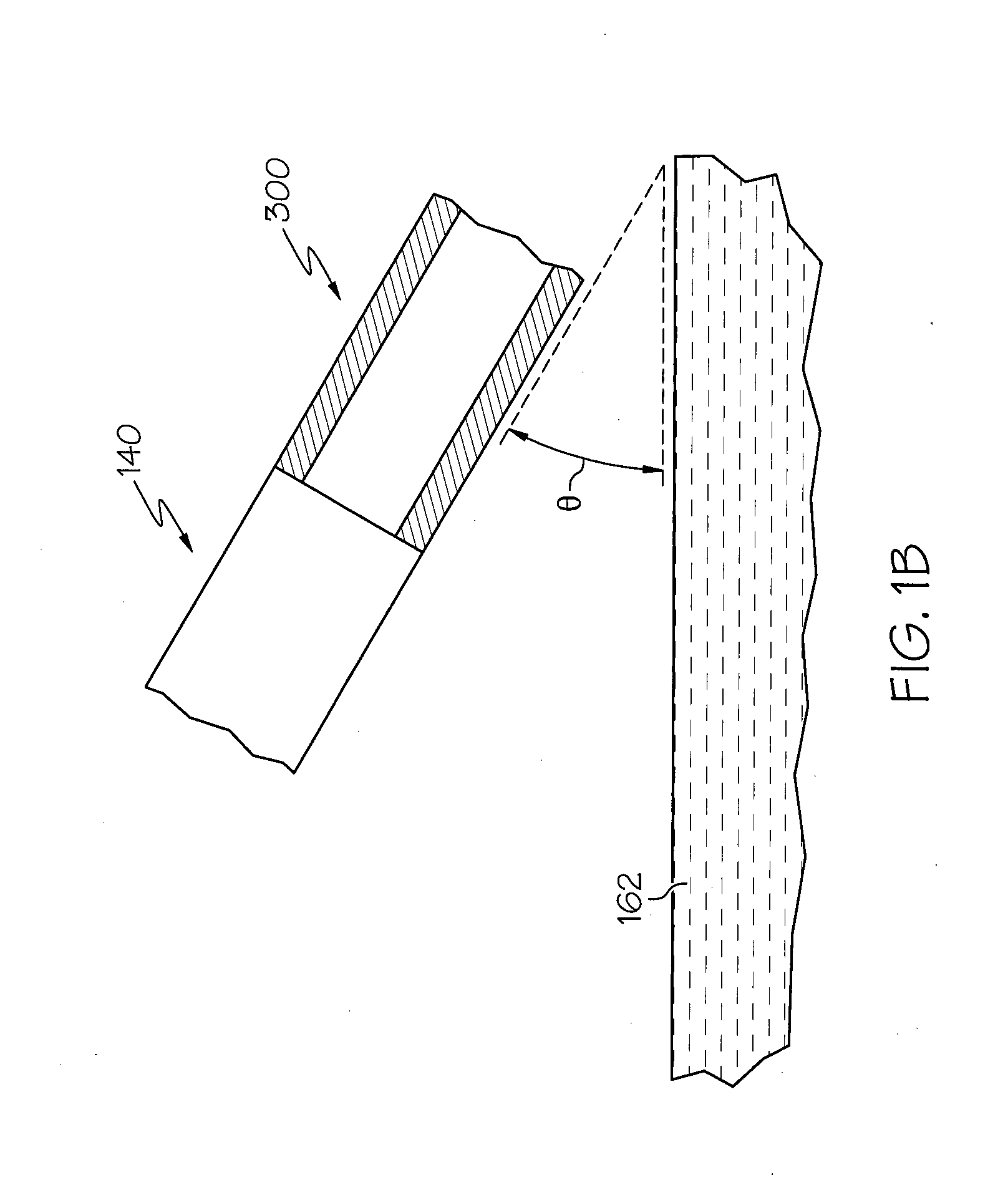

Methods and apparatuses for producing laminated glass sheets

ActiveUS20150191387A1Increase widthReduce thicknessGlass furnace apparatusGlass forming apparatusMolten metalLaminated glass

According to one embodiment, a method for forming a laminated glass sheet includes forming a multi-layer glass melt (300) from a molten core glass (106) and at least one molten cladding glass (126). The multi-layer glass melt (300) has a width Wm, a melt thickness Tm and a core to cladding thickness ratio TC:TCl. The multi-layer glass melt (300) is directed onto the surface of a molten metal bath (162) contained in a float tank (160). The width Wm of the multi-layer glass melt (300) is less than the width Wf of the float tank (160) prior to the multi-layer glass melt (300) entering the float tank (160). The multilayer glass melt (300) flows over the surface of the molten metal bath (162) such that the width Wm of the multi-layer glass melt (300) increases, the melt thickness Tm decreases, and the core to cladding thickness ratio TC:TCl remains constant as the multi-layer glass melt (300) solidifies into a laminated glass sheet. The invention also relates to the associated apparatus.

Owner:CORNING INC

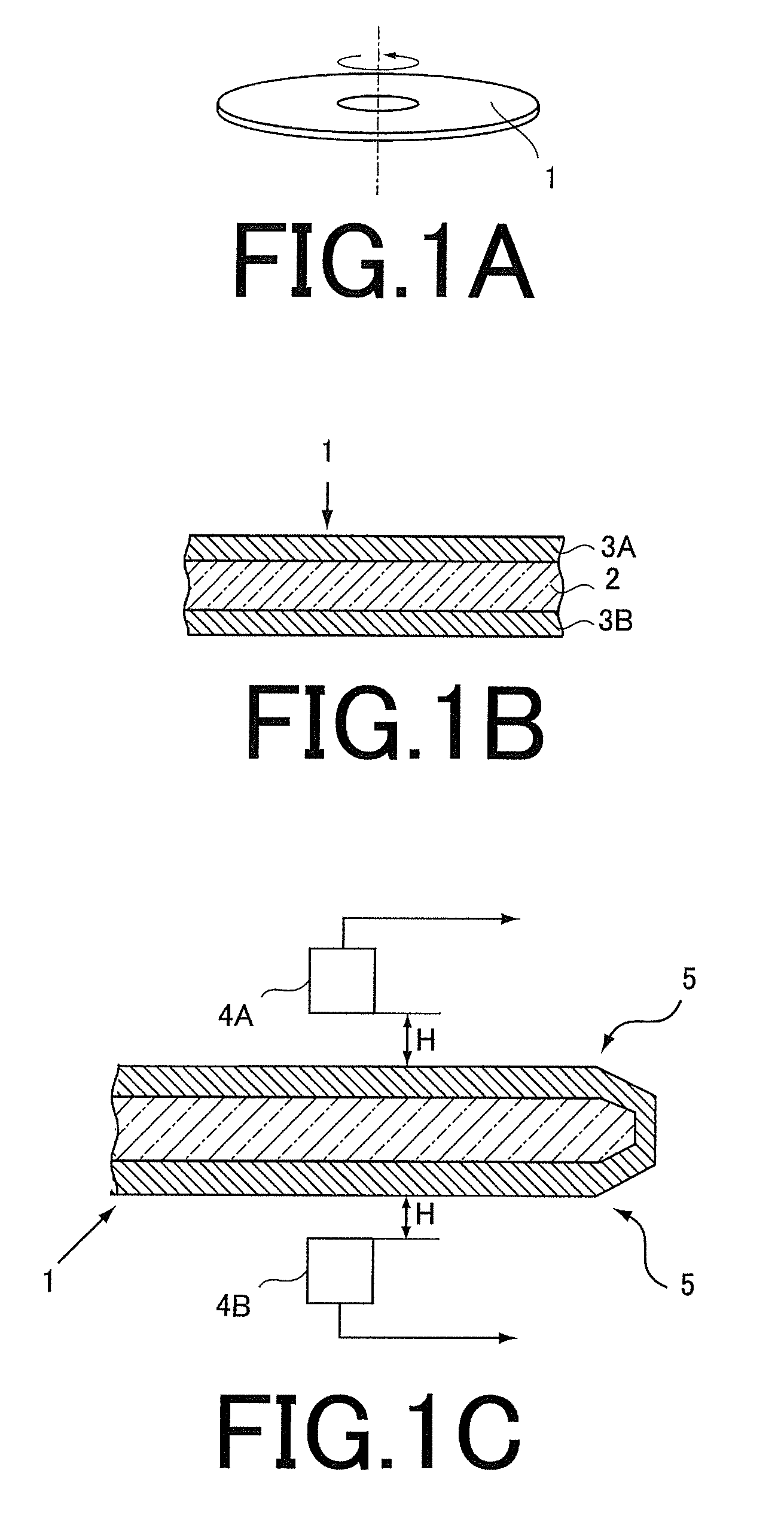

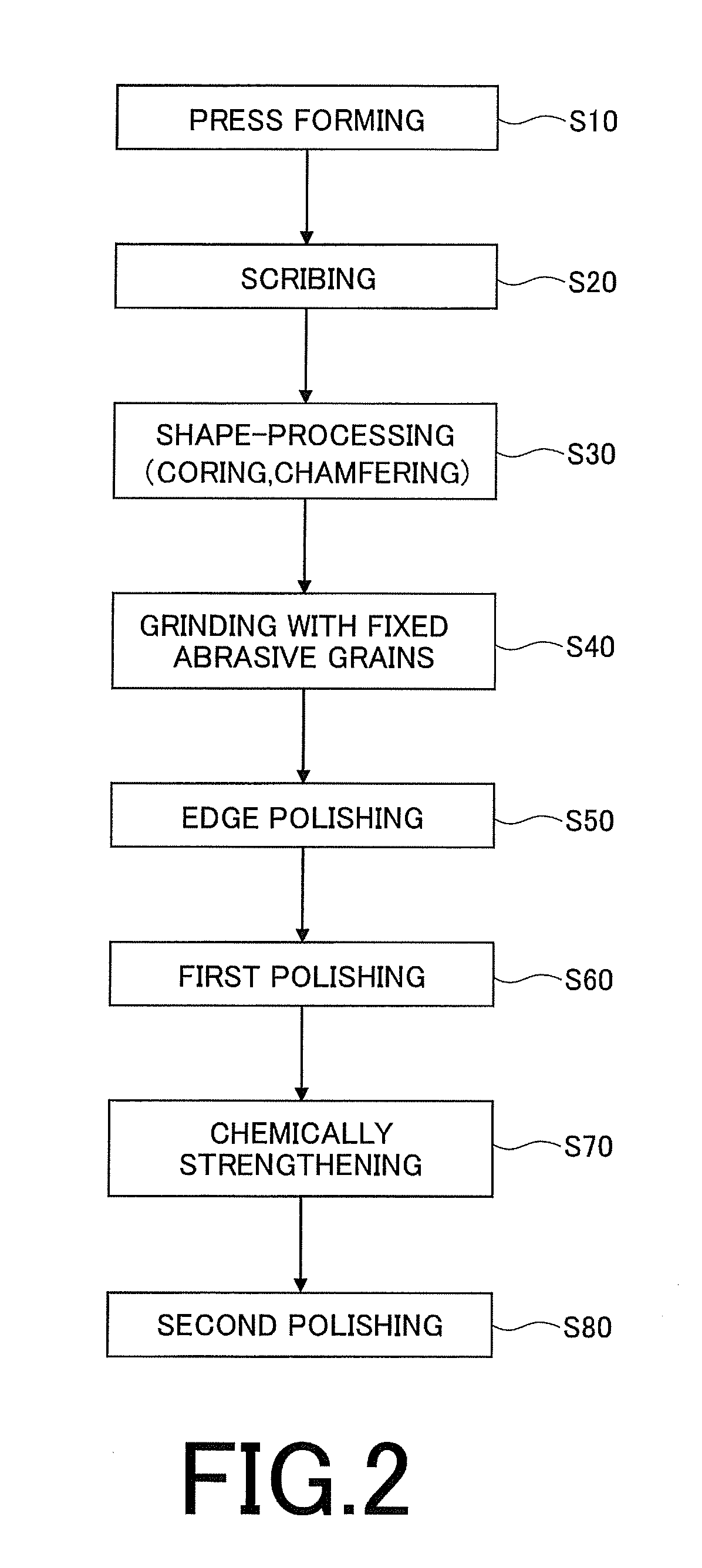

Manufacturing method of a glass blank for magnetic disk and manufacturing method of a glass substrate for magnetic disk

A manufacturing method of a glass blank for magnetic disk including a pair of principal surfaces, the method including: dropping process for dropping a lump of molten glass; pressing process for forming a sheet glass material by sandwiching simultaneously the lump from both sides of the dropping path of the lump with surfaces of the pair of dies facing together, and performing press forming to the lump; and temperature adjusting process for adjusting temperature of the lump before the pressing process such that viscosity variation of the lump is reduced with respect to positions over the entirety of the lump in the pressing process.

Owner:HOYA CORP

Method and apparatus for continuously manufacturing calibrated round or profiled glass tubes

ActiveUS7475567B2Easy to changeLess expensiveLayered productsGlass furnace apparatusBody positionsEngineering

Owner:SCHOTT AG

Device and system for cleaning separated crystal of stirring rod of platinum channel

The invention relates to a device and a system for cleaning separated crystal of a stirring rod of a platinum channel. The device comprises a steel brush (2) and a coating sleeve (1), wherein the coating sleeve (1) is coated at the periphery of a stirring rod (4); the steel brush (2) comprises a connecting rod (22) and a brush head (21), and the brush head (21) is positioned at the end part of the connecting rod (22); the coating sleeve (1) is provided with an opening (11) for the brush head (21) to enter to brush off the separated crystal which is attached to the stirring rod (4); the connecting rod (22) is of a hollow structure, so that air suction equipment (3) is capable of being communicated with fluid in the coating sleeve (1) through the connecting rod (22), thereby sucking the separated crystal brushed off by the brush head (21). The device and the system provided by the invention have the advantages that the falling amount of the separated crystal in the traditional stirring rod cleaning process is effectively reduced, so that the excitation amount of air bubbles is reduced, the discarding time of air bubbles is shortened, and the output loss is reduced.

Owner:ZHENGZHOU XUFEI OPTOELECTRONICS TECH +1

Optical glass edge drop material forming device and forming method

ActiveCN105948463BControlling long-standing technical problems of forming streaksImprove Optical UniformityFeeder spoutsDevitrificationLanthanide

Owner:CDGM GLASS LLC

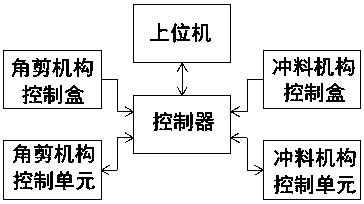

Glass bottle feeding machine control system and control method

ActiveCN107902872AAvoid frequent replacementRealize coordinated controlProgramme control in sequence/logic controllersFeeder spoutsKey pressingMachine control

The invention relates to a glass bottle feeding machine control system and a control method, and belongs to the field of glass bottle and pot equipment. The glass bottle feeding machine control systemcomprises an angle shearing mechanism and a punching mechanism, and is characterized by comprising an upper computer, a controller, an angle shearing mechanism control box, an angle shearing mechanism control unit, a punching mechanism control box and a punching mechanism control unit; the upper computer is in two-way connection with the controller; the angle shearing mechanism control box and the punching mechanism control box are connected with the input port of the controller; a plurality of keys for controlling the angle shearing mechanism are arranged in the angle shearing mechanism control box; a plurality of keys for controlling the punching mechanism are arranged in the punching mechanism control box; and the controller is in two-way connection with the angle shearing mechanism control unit and the punching mechanism control unit. Through the controller as well as the angle shearing mechanism and the punching mechanism controlled by the controller, the angle shearing mechanismand the punching mechanism can be subjected to coordinated control by the controller, and the angle shearing mechanism and the punching mechanism can work according to the respective working curve.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

Apparatus and method for processing molten glass

ActiveCN101657387AHigh breaking strengthReduce creepRotary stirring mixersGlass furnace apparatusMaterials scienceMolten glass

Owner:UMICORE AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com