Continuous melting furnace and method for producing special-shaped quartz tube and quartz rod

A technology of connecting melting furnace and quartz tube, applied in glass forming, glass furnace equipment, glass forming and other directions, can solve problems such as inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

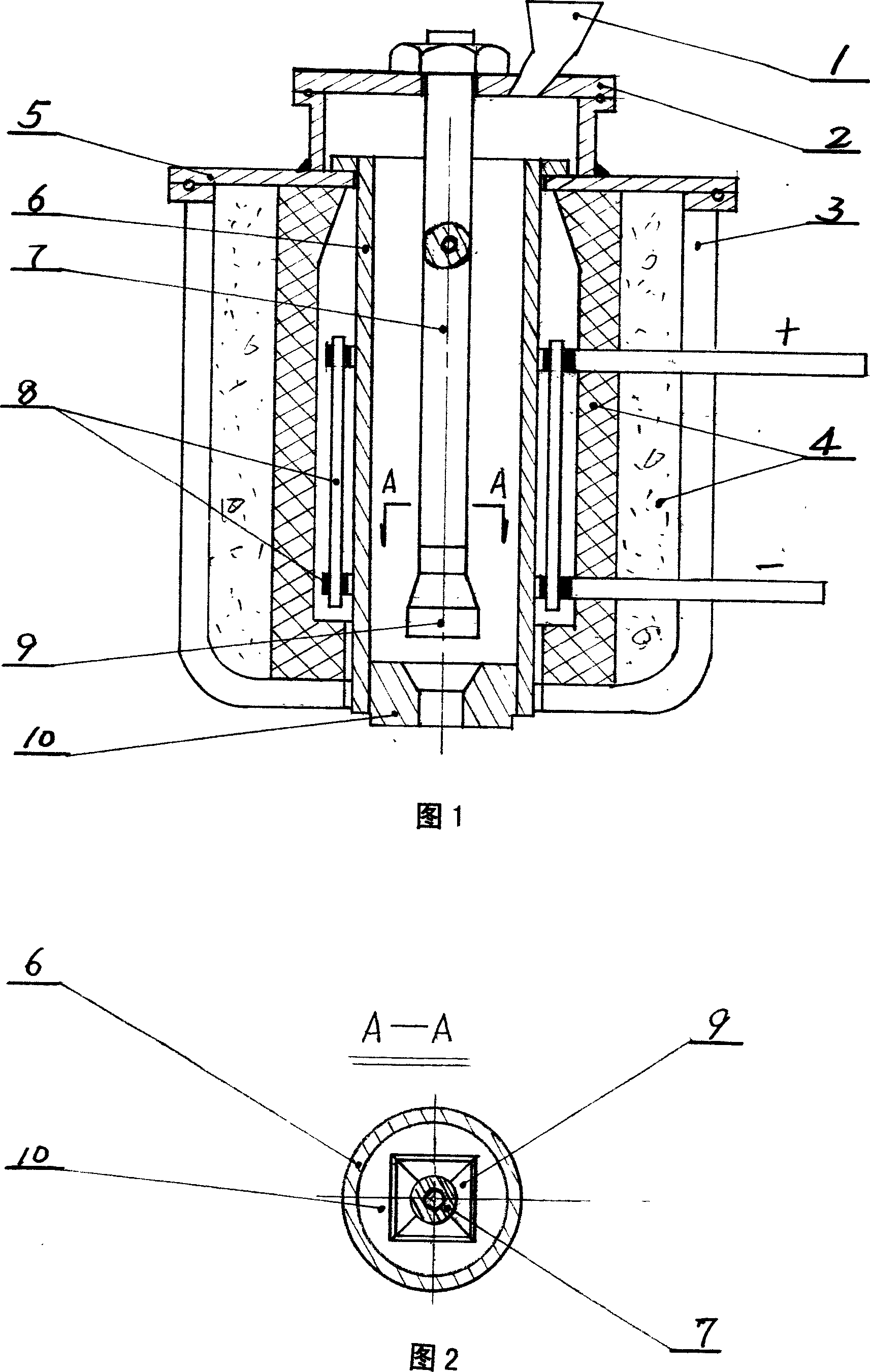

[0009] Referring to Figures 1 and 2, a furnace cover 5 is installed above the furnace body 3, and a discharge table 10 is installed at the bottom of the tungsten crucible 6. The discharge table has a discharge port, and the tungsten crucible is hung on the large furnace cover. The tungsten crucible The outer side of the tungsten crucible is a heater 8 and an insulating material 4. There is a small furnace cover 2 on the top of the tungsten crucible. There is a feeding port 1 on the small furnace cover. 9. The difference is that the shaper here is not only circular (referring to the cross section, the same below), but also square, rectangular, triangular, fan-shaped, oval and other shapes; the discharge table has circular, square, Discharge table with rectangular, triangular, fan-shaped, elliptical and other shapes; the shaper installed at the lower end of the core rod is located above the discharge table, and is 3mm or 5mm or 10mm or 15mm or 20mm higher than the upper edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com