Patents

Literature

3214 results about "Sapphire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminum oxide (α-Al₂O₃) with trace amounts of elements such as iron, titanium, chromium, copper, or magnesium. It is typically blue, but natural "fancy" sapphires also occur in yellow, purple, orange, and green colors; "parti sapphires" show two or more colors. The only color corundum stone that the term sapphire is not used for is red, which is called a ruby. Pink colored corundum may be either classified as ruby or sapphire depending on locale. Commonly, natural sapphires are cut and polished into gemstones and worn in jewelry. They also may be created synthetically in laboratories for industrial or decorative purposes in large crystal boules. Because of the remarkable hardness of sapphires – 9 on the Mohs scale (the third hardest mineral, after diamond at 10 and moissanite at 9.5) – sapphires are also used in some non-ornamental applications, such as infrared optical components, high-durability windows, wristwatch crystals and movement bearings, and very thin electronic wafers, which are used as the insulating substrates of special-purpose solid-state electronics such as integrated circuits and GaN-based blue LEDs.

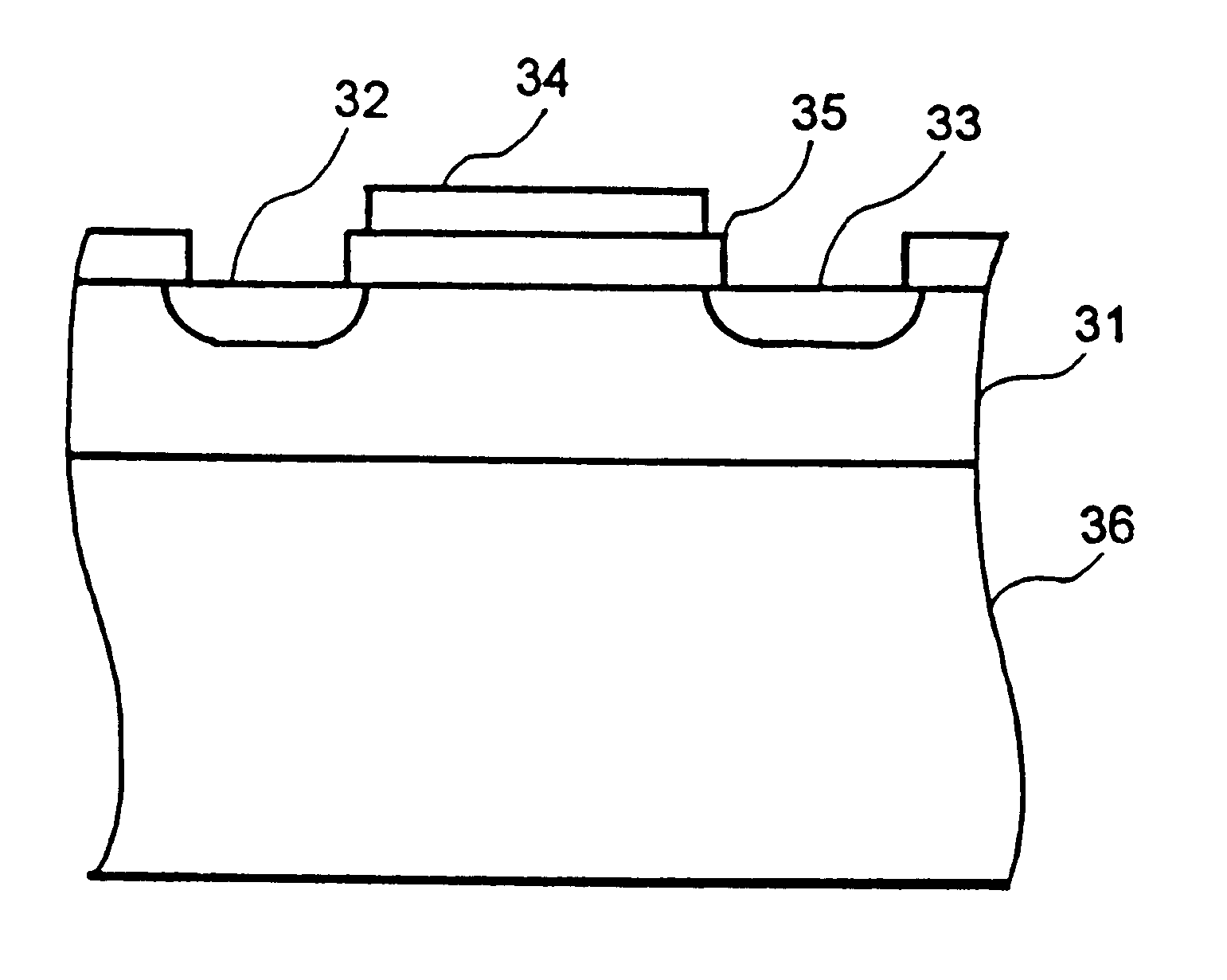

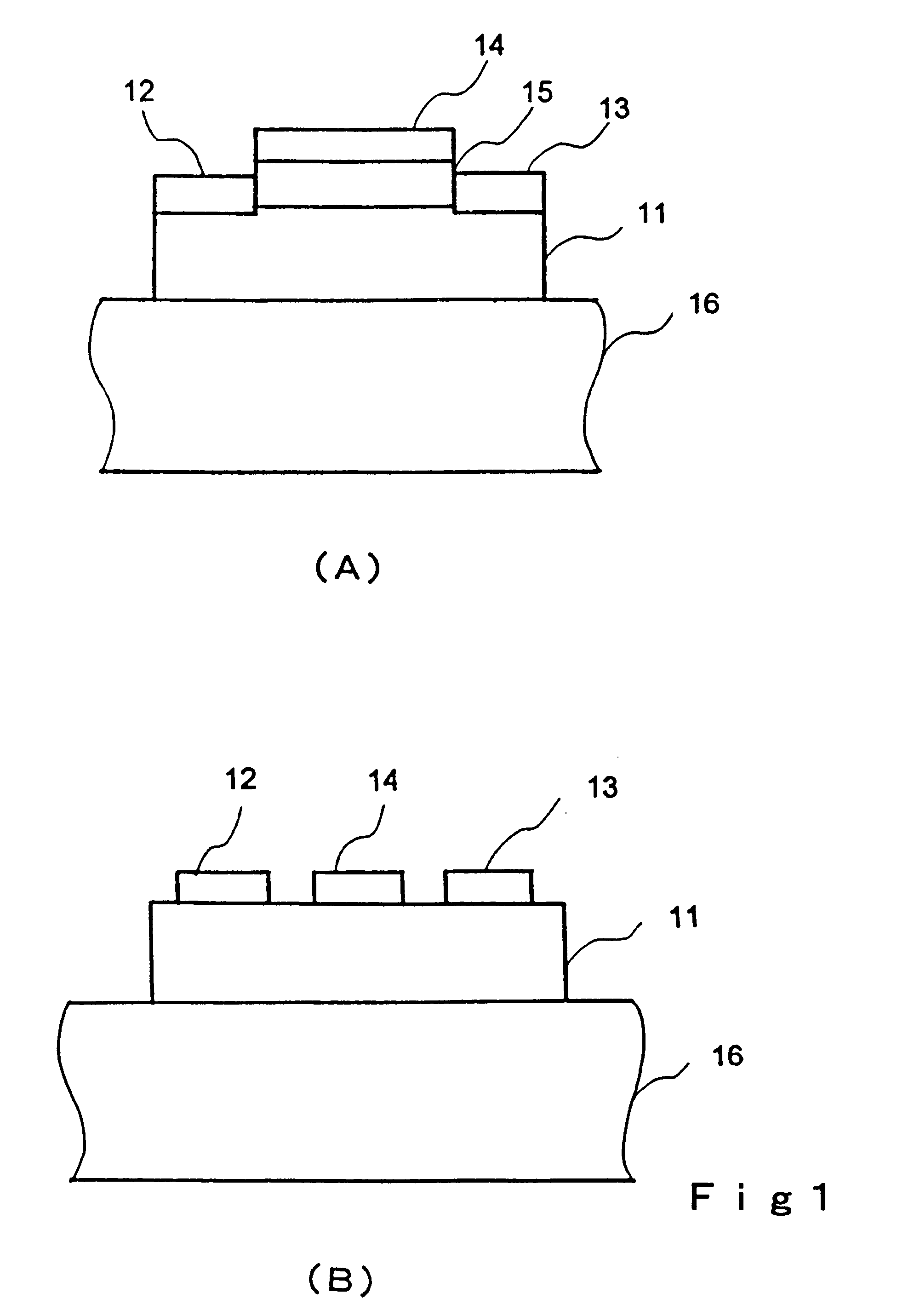

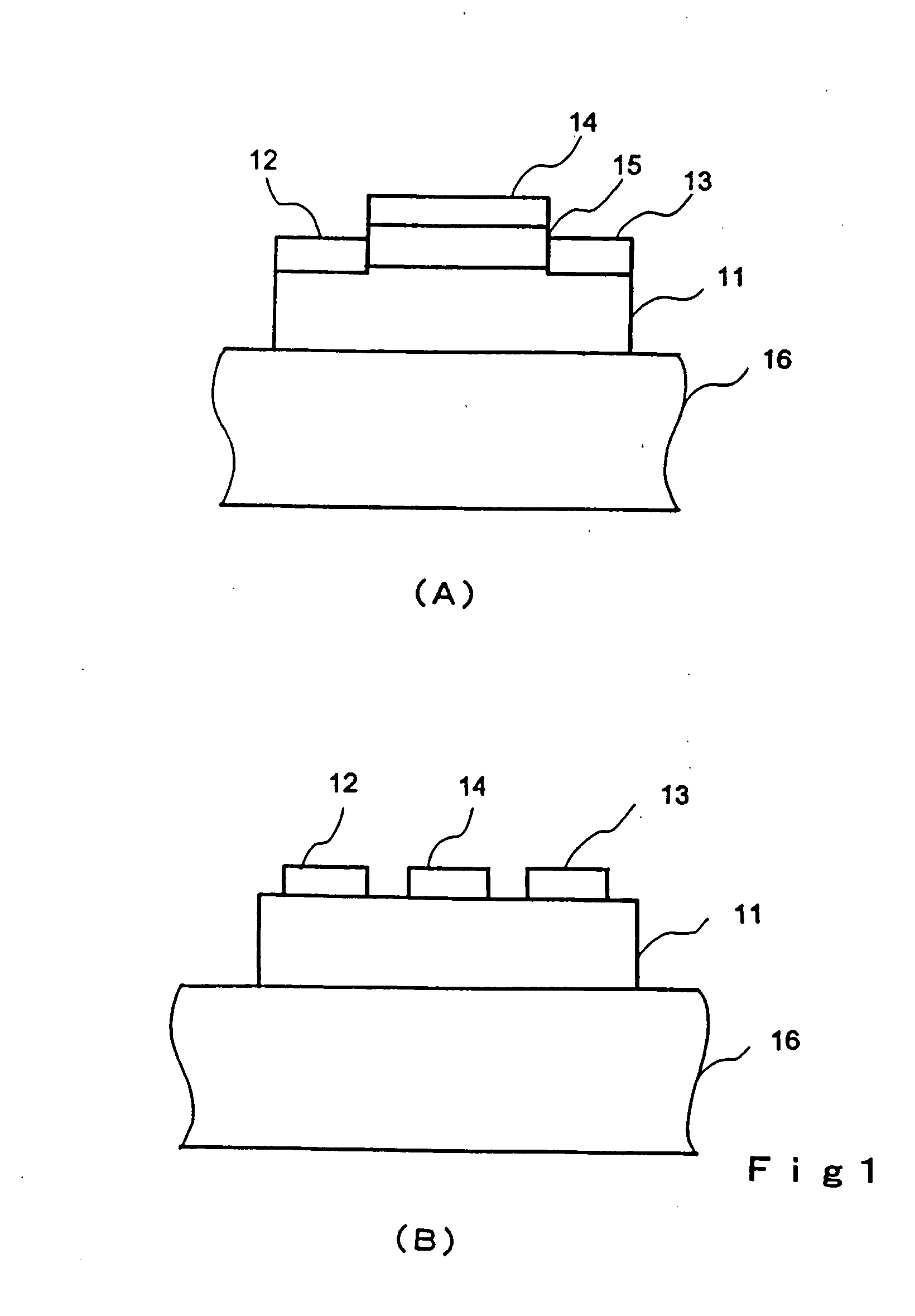

Transistor and semiconductor device

A transistor is provided, which is entirely and partially transparent by the use of a transparent channel layer made of zinc oxide or the like. A channel layer 11 formed of a transparent semiconductor such as zinc oxide ZnO. A transparent electrode is used for all of a source 12, a drain 13 and a gate 14, or a part of them. As the transparent electrode, a transparent conductive material such as conductive ZnO doped with, for example, group III elements is used. As a gate insulating layer 15, a transparent insulative material such as insulative ZnO doped with elements capable of taking a valence of one as a valence number or group V elements is used. If a substrate 16 must be transparent, for example, glass, sapphire, plastic or the like can be used as a transparent material.

Owner:JAPAN SCI & TECH CORP

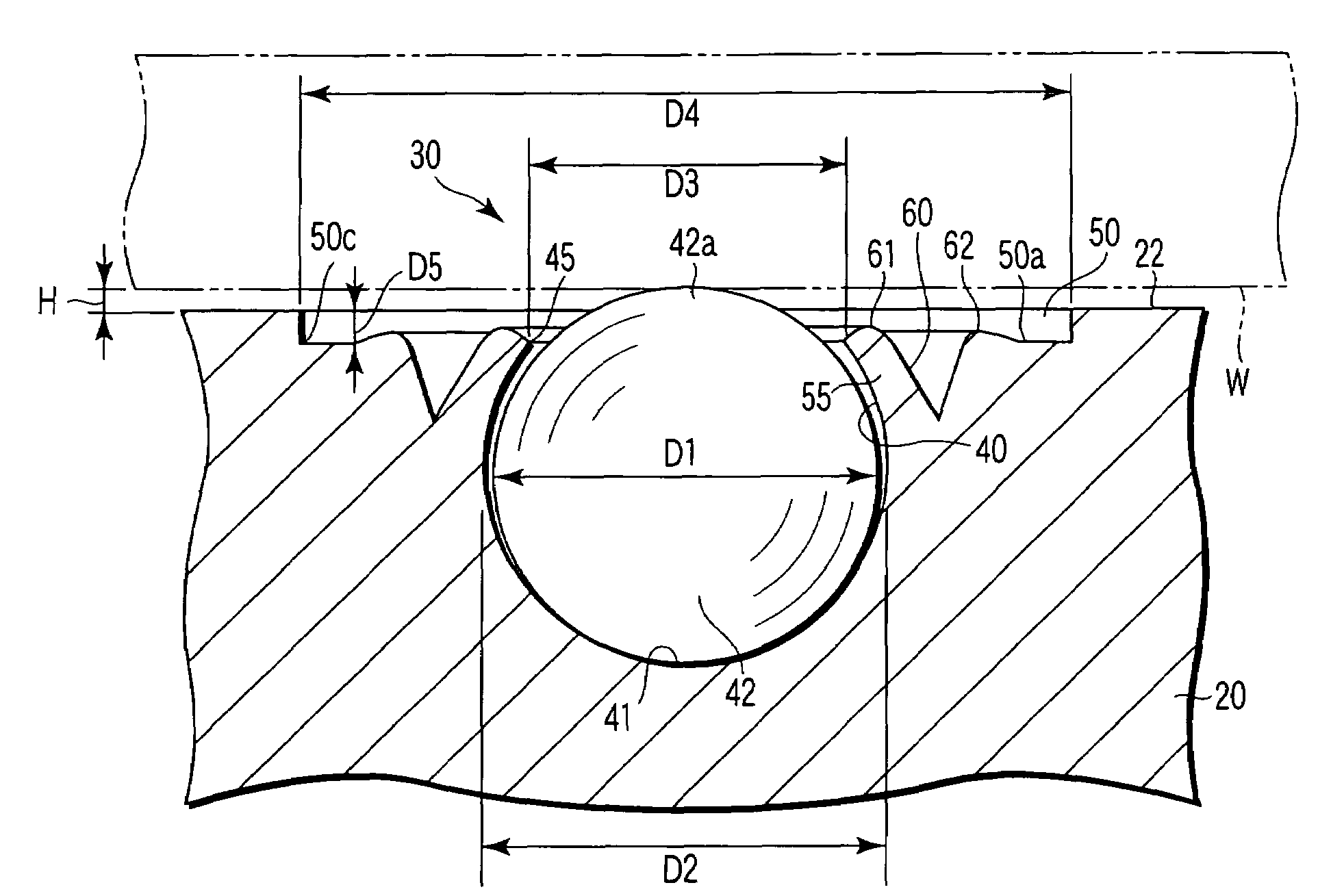

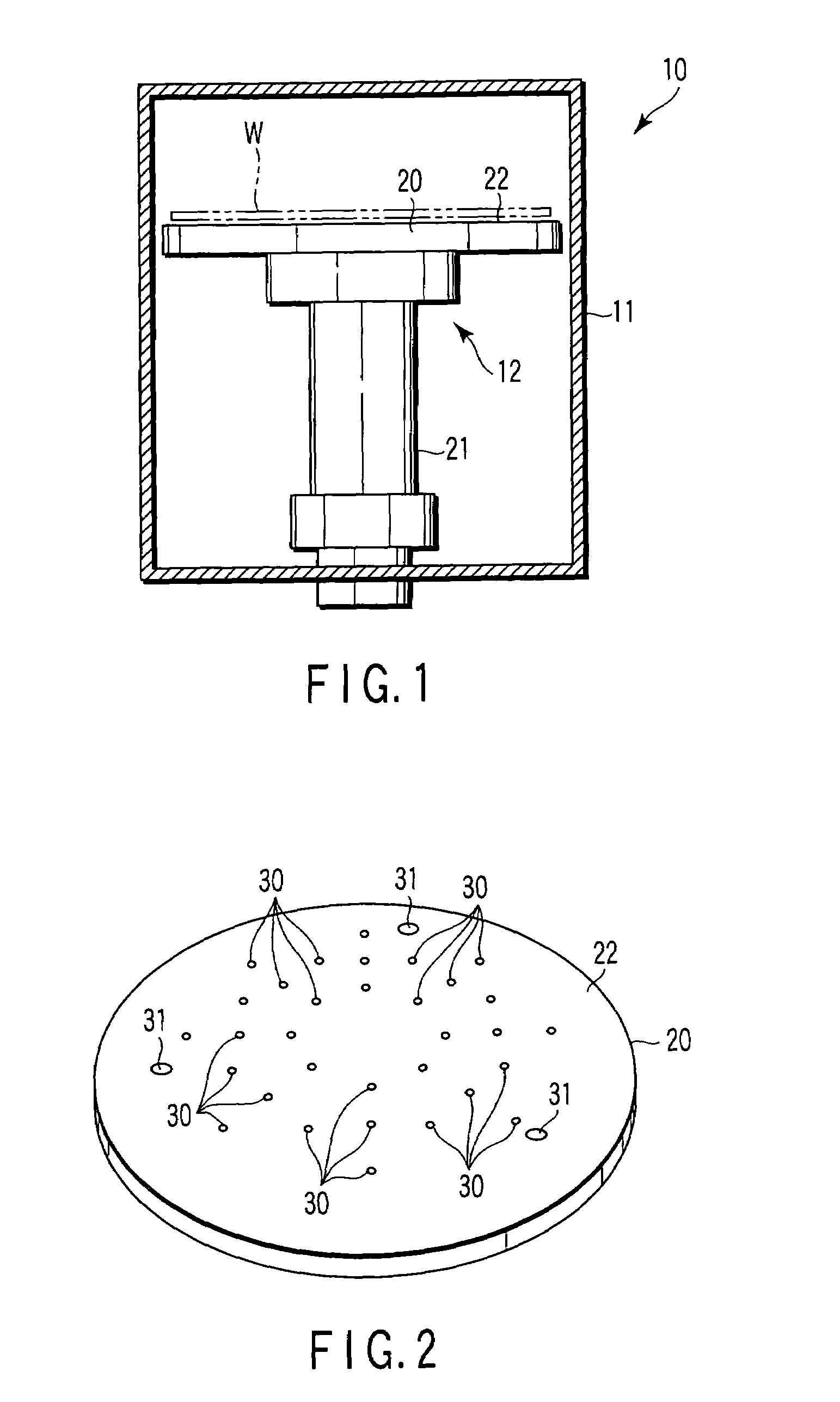

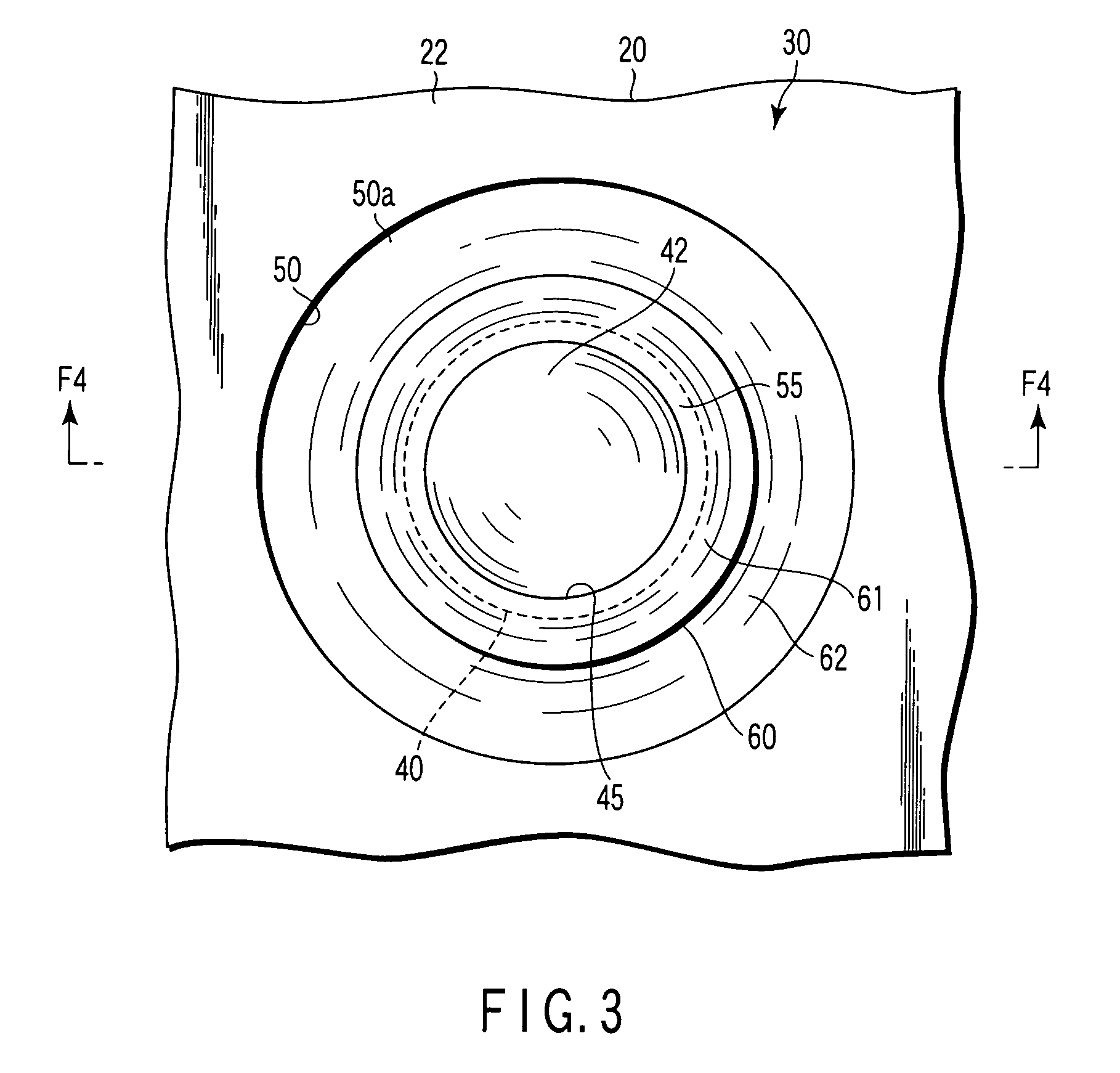

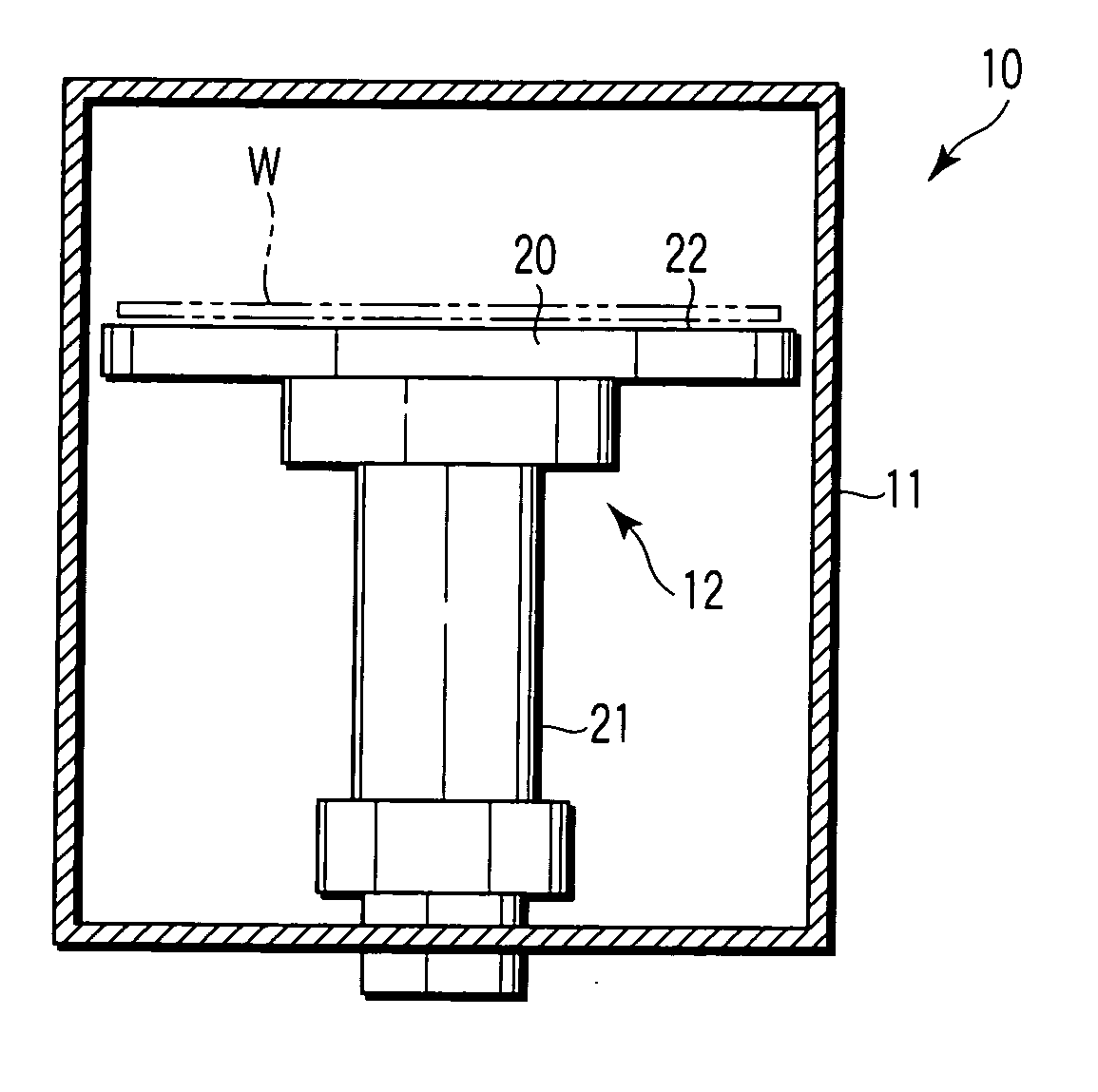

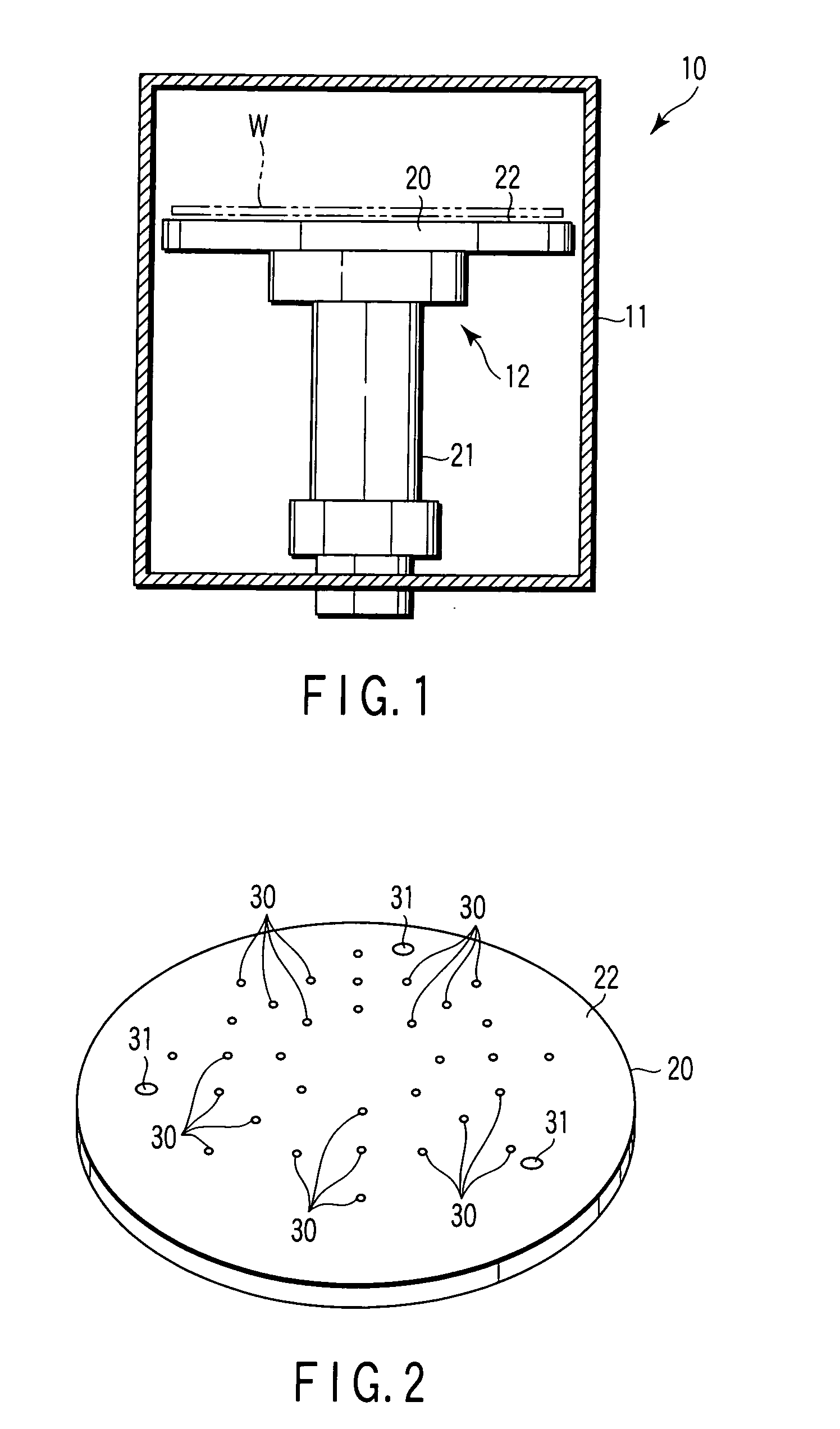

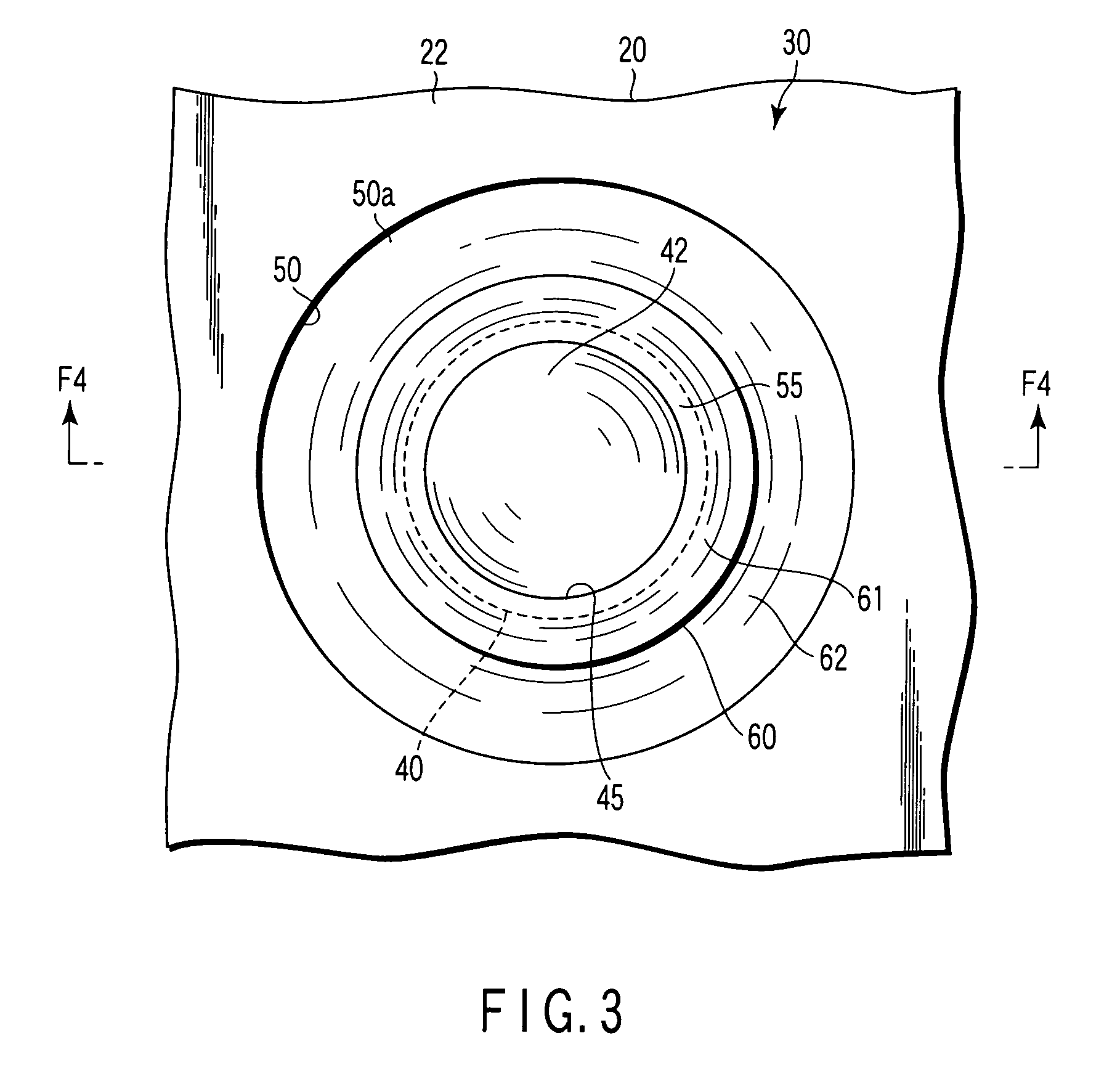

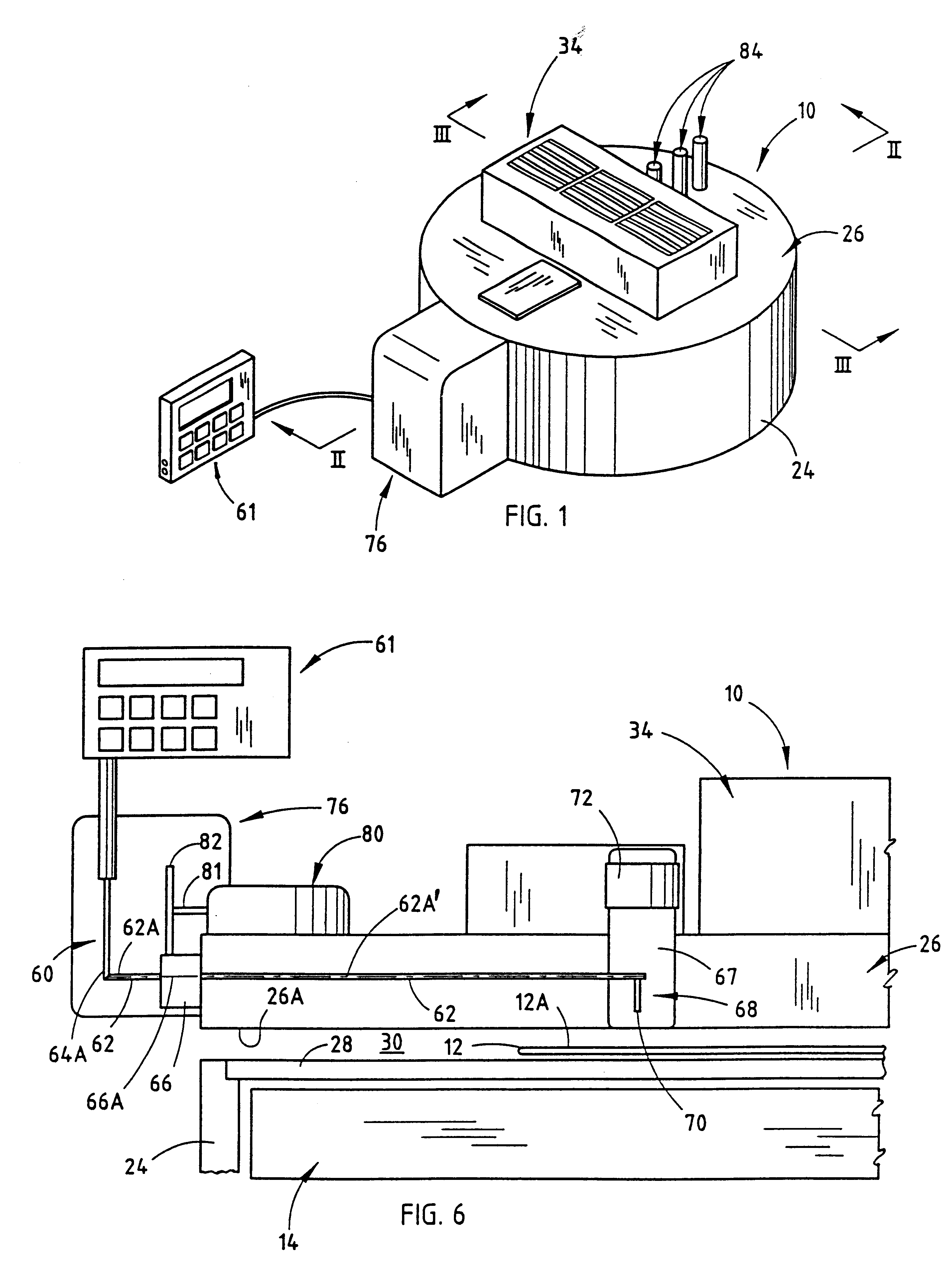

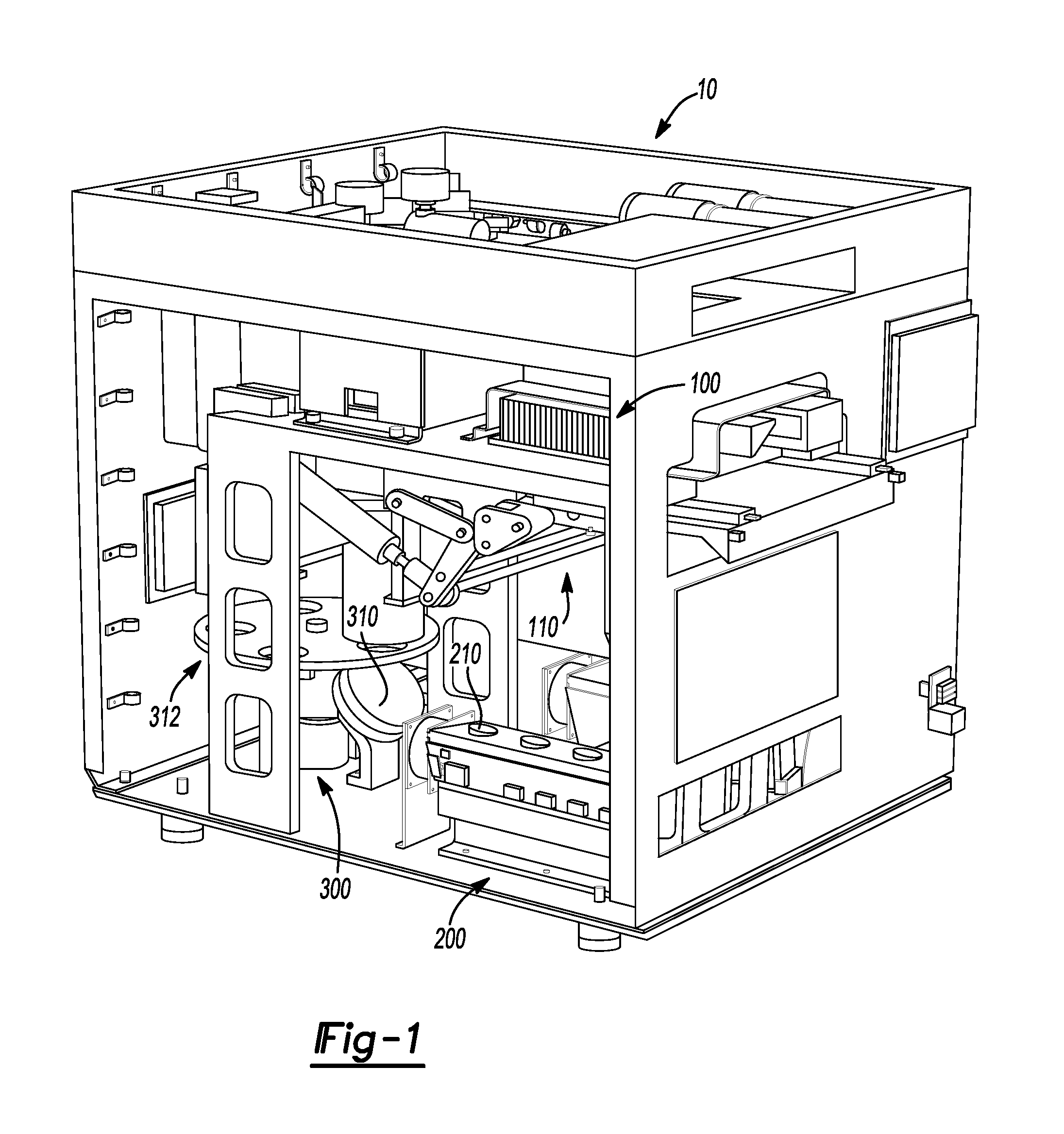

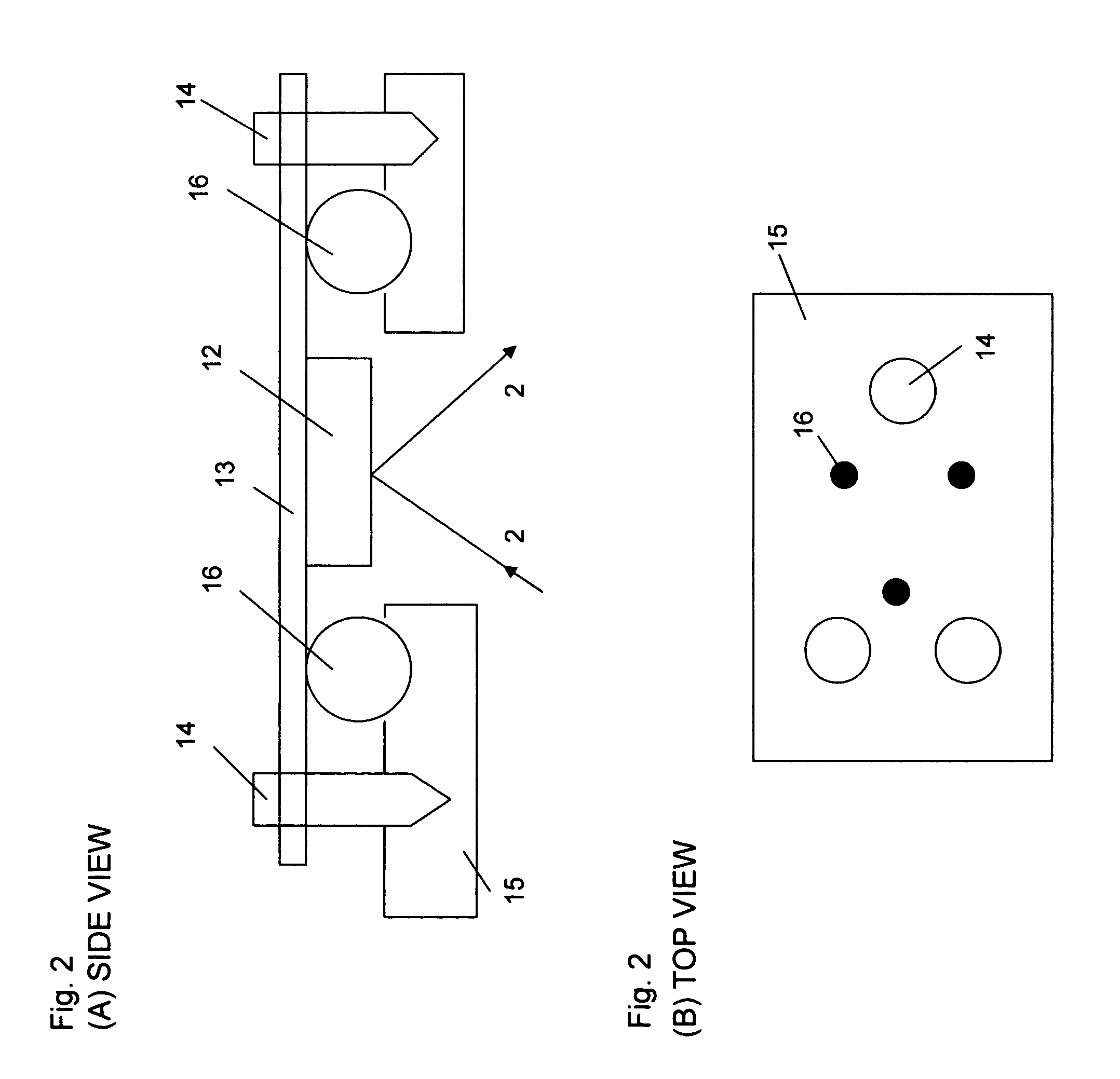

Substrate supporting apparatus

ActiveUS7503980B2Preventing slipping-off and breakageInhibit transferLiquid surface applicatorsLinear bearingsAlloyEngineering

A substrate supporting apparatus includes a plate member of an aluminum alloy having a flat upper surface, bottomed pits formed in the plate member, and spacer members held in the pits, individually. The spacer members are sapphire spheres. The diameter of each spacer member is a little smaller than that of each pit. The upper end of each spacer member projects from the upper surface of the plate member. A spot facing is formed in a region that includes the open edge portion of the pit. A bending portion which is obtained by plastically deforming the open edge portion of the pit toward the spacer member is formed on a bottom surface of the spot facing. A V-shaped groove is formed behind the bending portion.

Owner:NHK SPRING CO LTD

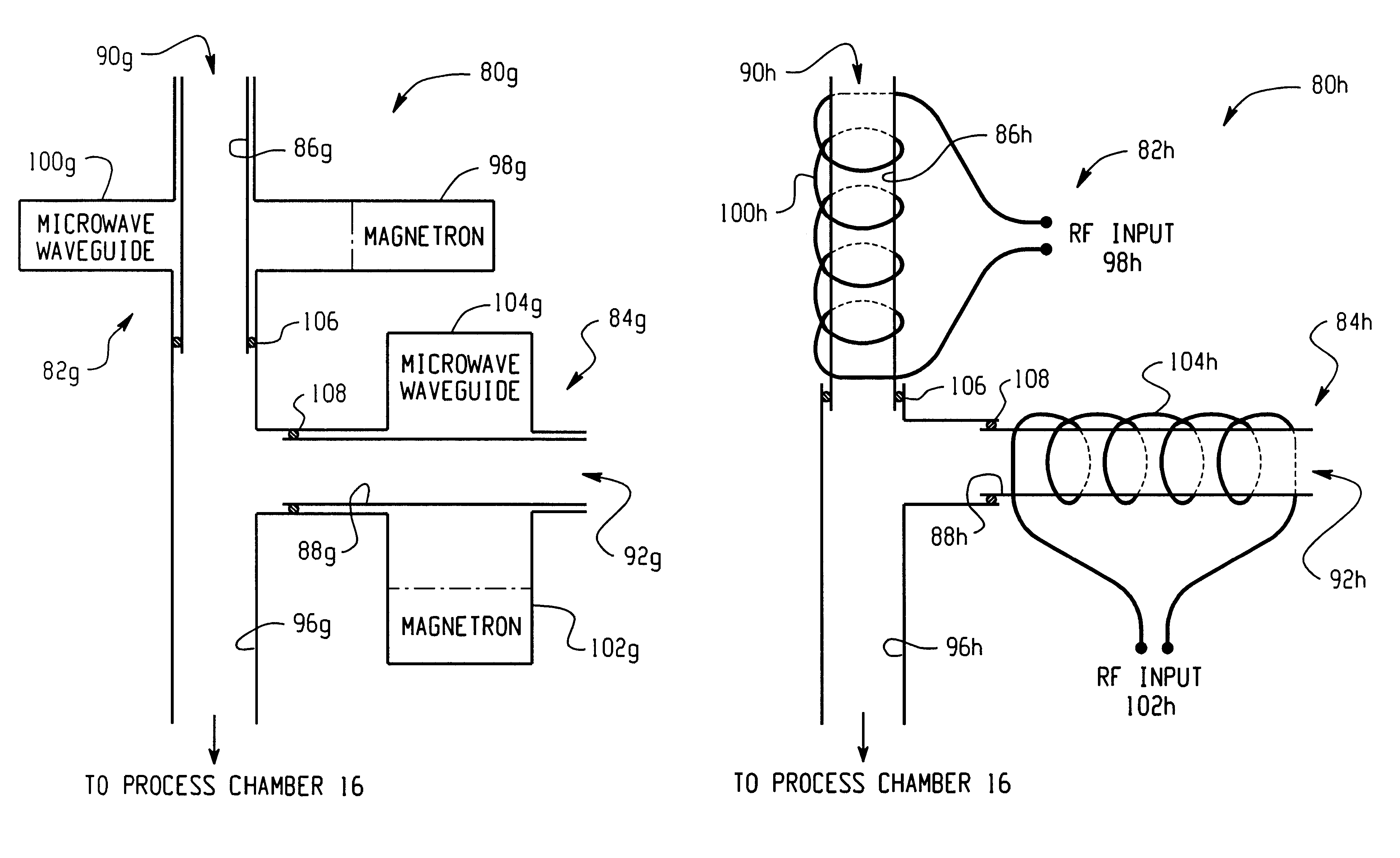

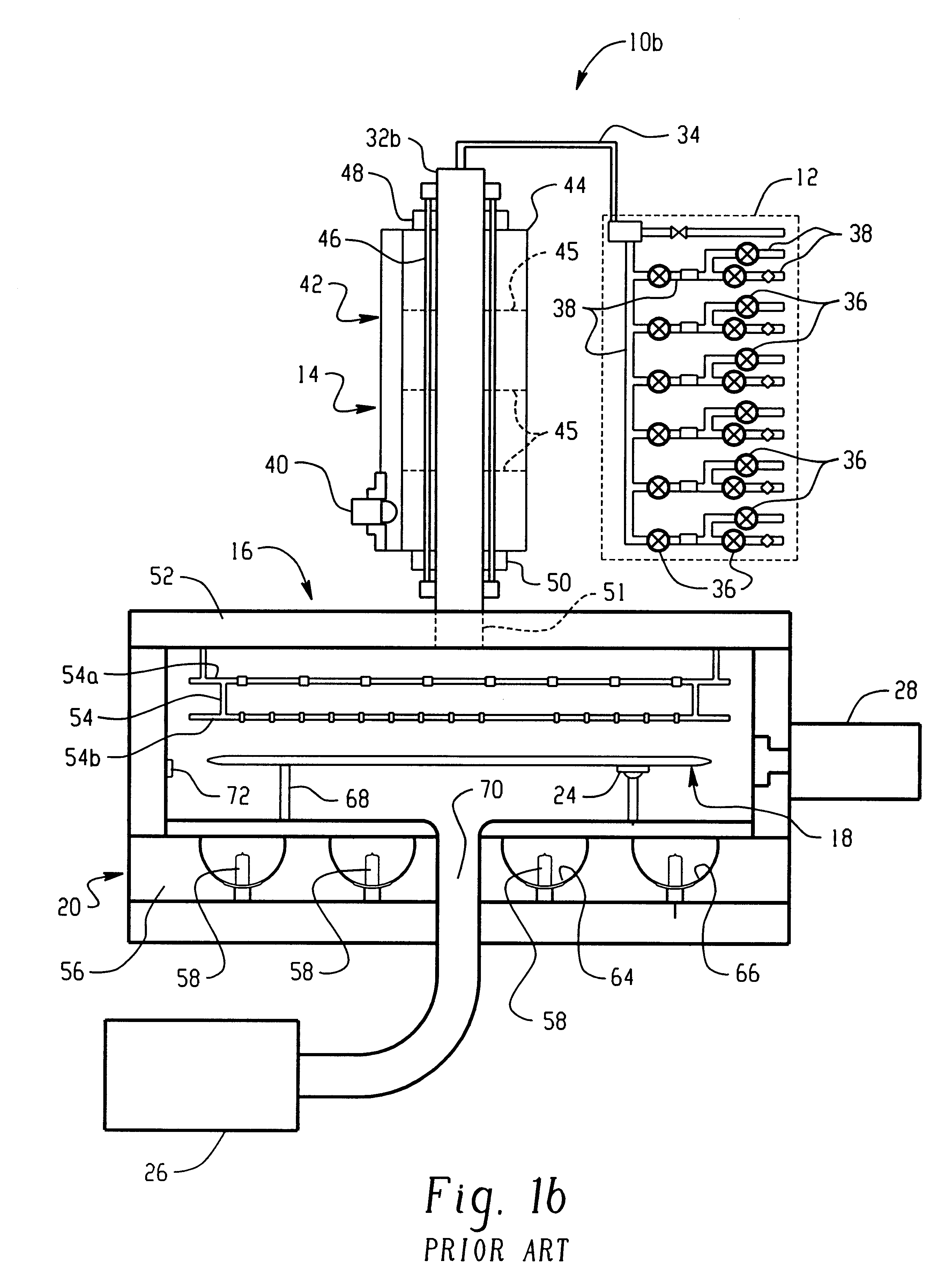

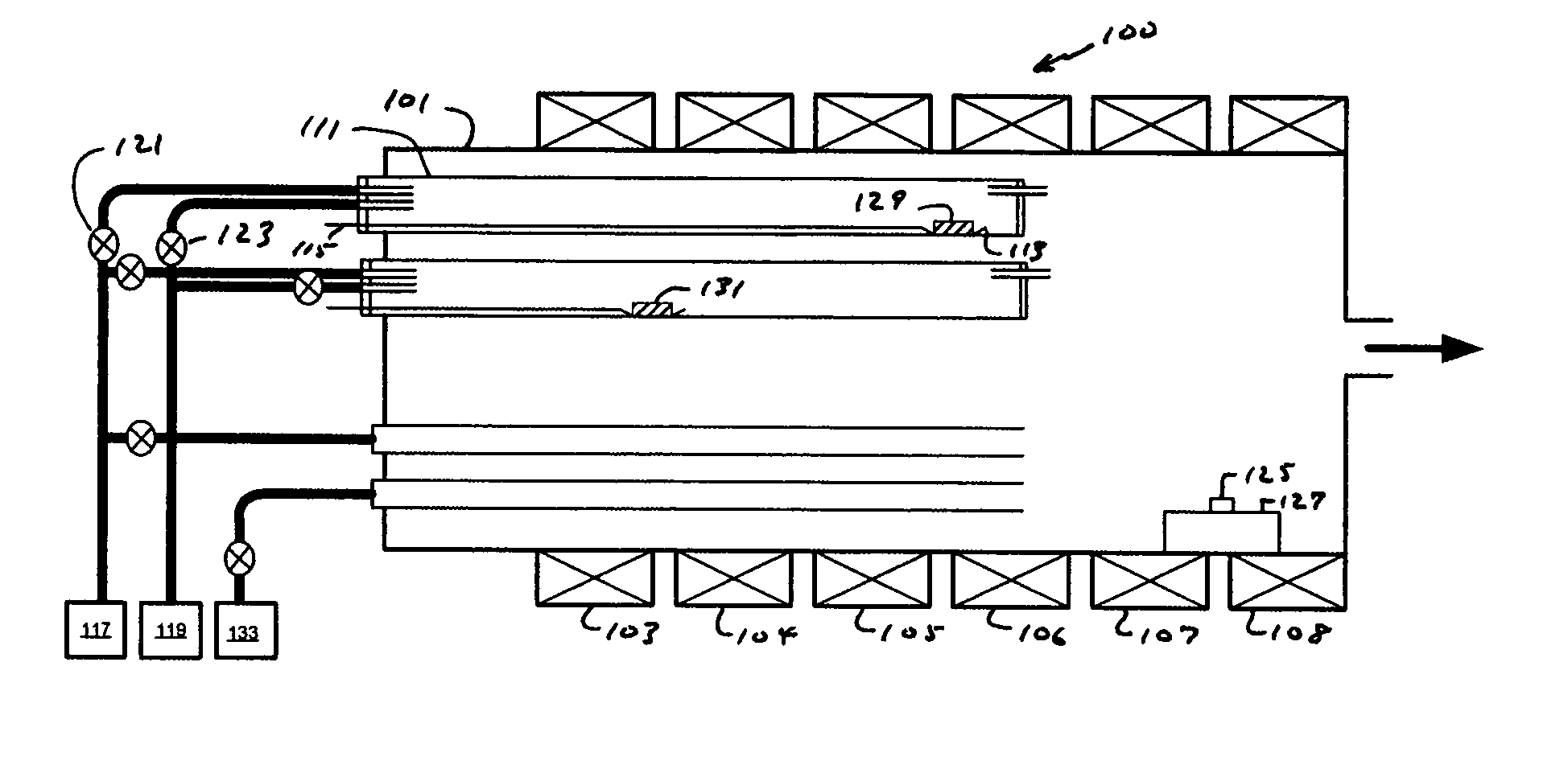

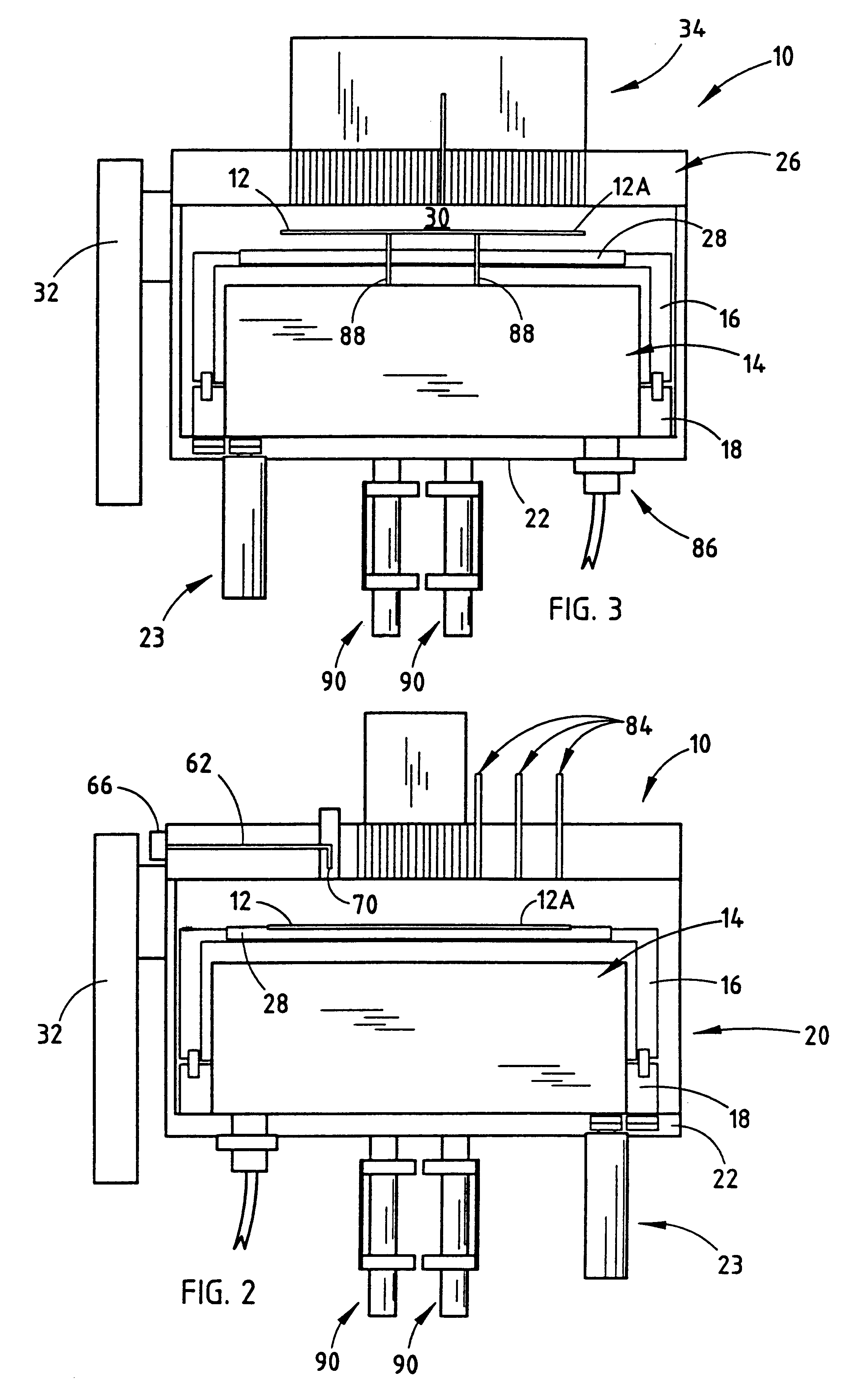

Dual plasma source for plasma process chamber

InactiveUS6225745B1Delayed recombinationSemiconductor/solid-state device manufacturingElectric arc lampsSingle crystalSapphire

A dual plasma source (80) is provided for a plasma processing system (10), comprising a first plasma source (82) and a second plasma source (84). The first plasma source (82) has a first plasma passageway (86) for transporting a first plasma therethrough toward a processing chamber (16), the first plasma passageway providing a first inlet (90) for accepting a first gas mixture to be energized by the first plasma source. The second plasma source (84) is connected to the first plasma source (82) and has a second plasma passageway (88) for transporting a second plasma therethrough toward the processing chamber (16), the second plasma passageway providing a second inlet (92) for accepting a second gas mixture to be energized by the second plasma source. The first plasma passageway (86) is constructed from a material that resists atomic oxygen recombination with the first plasma, and the second plasma passageway (88) is constructed from a material that resists etching by the second plasma. In a more limited embodiment, the first plasma passageway (86) is constructed from quartz (SiO.sub.2) and the second plasma passageway is (88) constructed from alumina (Al.sub.2 O.sub.3) or single crystal alumina (sapphire).

Owner:LAM RES CORP

Thin film coated process kits for semiconductor manufacturing tools

InactiveUS20110207332A1Convenient coatingElectric discharge tubesElectrostatic cleaningQuartzSilicon

A plasma processing apparatus used in semiconductor device manufacturing includes a process kit formed of insulating materials such as quartz and coated with a Y2O3 coating. The Y2O3 coating is a thin film formed using suitable CVD or PVD operations. The Y2O3 coating is resistant to degradation in fluorine etching chemistries commonly used to etch silicon in semiconductor manufacturing. The plasma processing apparatus may be used in etching, stripping and cleaning operations. Also provided in another embodiment is a plasma processing apparatus having a quartz process kit coated with a sapphire-like film.

Owner:TAIWAN SEMICON MFG CO LTD

Substrate supporting apparatus and manufacturing method therefor

ActiveUS20070157466A1Preventing slipping-offAvoid breakingLiquid surface applicatorsLinear bearingsEngineeringAlloy

A substrate supporting apparatus includes a plate member of an aluminum alloy having a flat upper surface, bottomed pits formed in the plate member, and spacer members held in the pits, individually. The spacer members are sapphire spheres. The diameter of each spacer member is a little smaller than that of each pit. The upper end of each spacer member projects from the upper surface of the plate member. A spot facing is formed in a region that includes the open edge portion of the pit. A bending portion which is obtained by plastically deforming the open edge portion of the pit toward the spacer member is formed on a bottom surface of the spot facing. A V-shaped groove is formed behind the bending portion.

Owner:NHK SPRING CO LTD

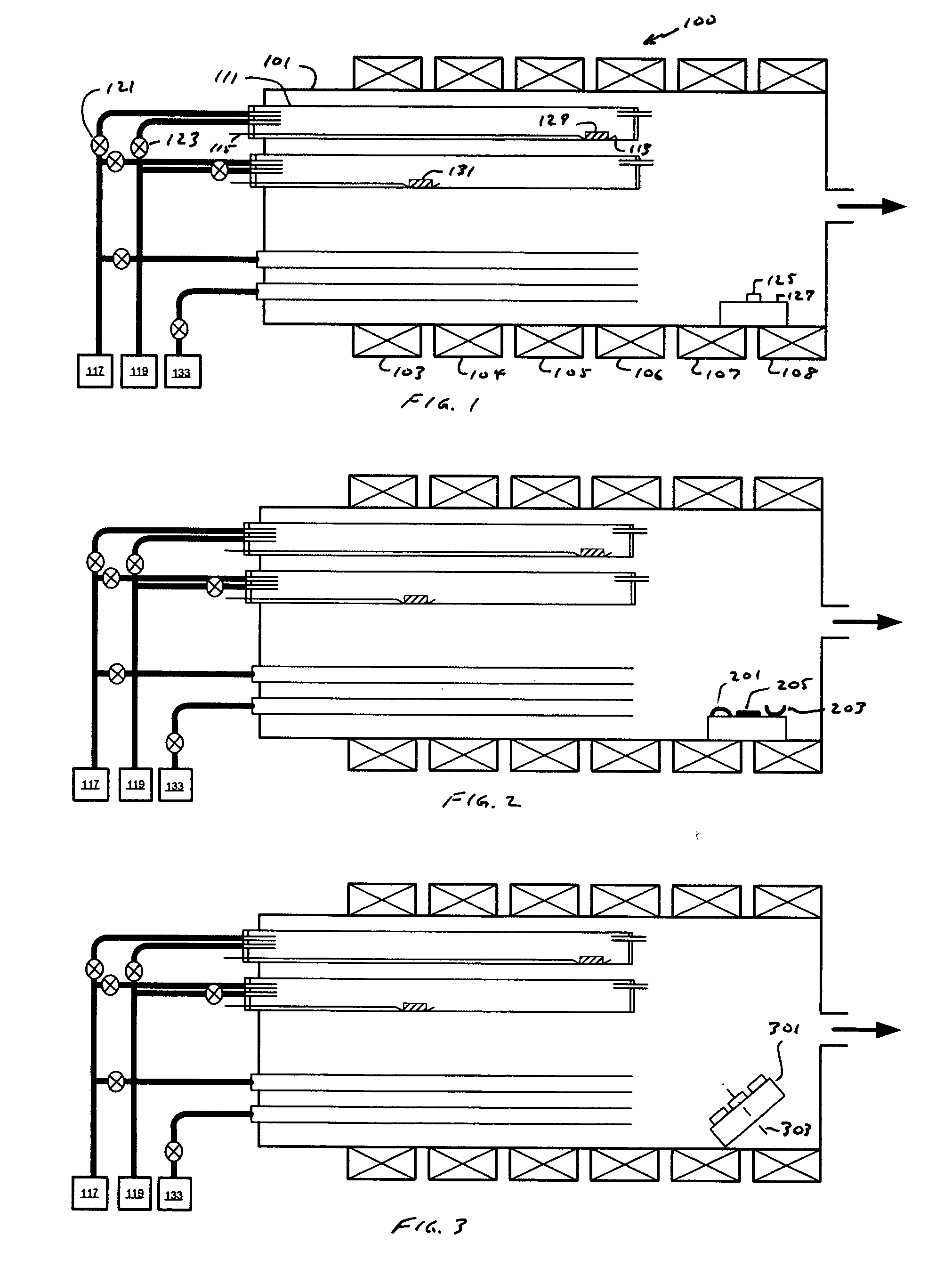

Method and apparatus for fabricating crack-free Group III nitride semiconductor materials

InactiveUS20050142391A1Polycrystalline material growthFrom chemically reactive gasesWaferingCrack free

A method and apparatus for growing low defect, optically transparent, colorless, crack-free, substantially flat, single crystal Group III nitride epitaxial layers with a thickness of at least 10 microns is provided. These layers can be grown on large area substrates comprised of Si, SiC, sapphire, GaN, AlN, GaAs, AlGaN and others. In one aspect, the crack-free Group III nitride layers are grown using a modified HVPE technique. If desired, the shape and the stress of Group III nitride layers can be controlled, thus allowing concave, convex and flat layers to be controllably grown. After the growth of the Group III nitride layer is complete, the substrate can be removed and the freestanding Group III nitride layer used as a seed for the growth of a boule of Group III nitride material. The boule can be sliced into individual wafers for use in the fabrication of a variety of semiconductor structures (e.g., HEMTs, LEDs, etc.).

Owner:FREIBERGER COMPOUND MATERIALS

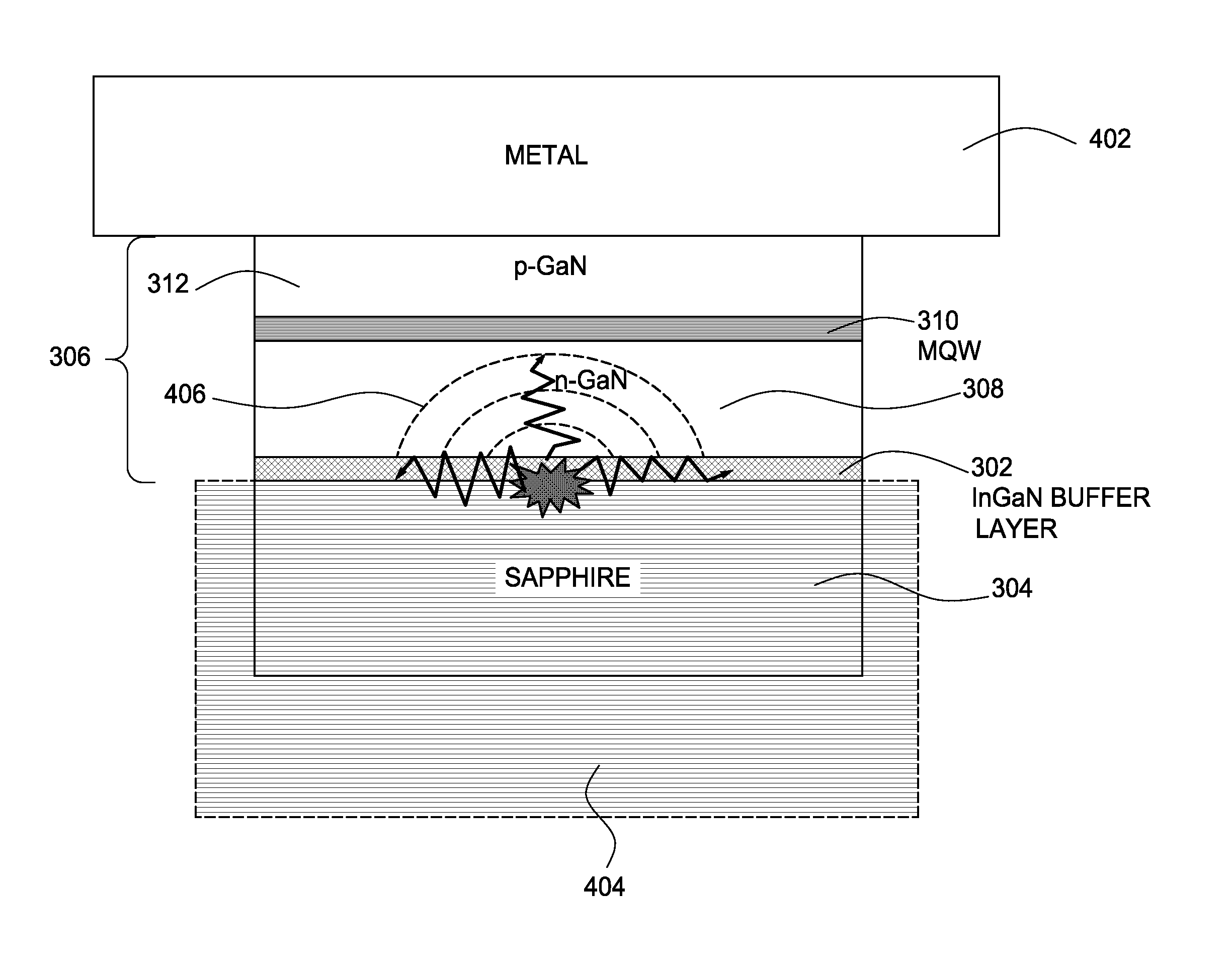

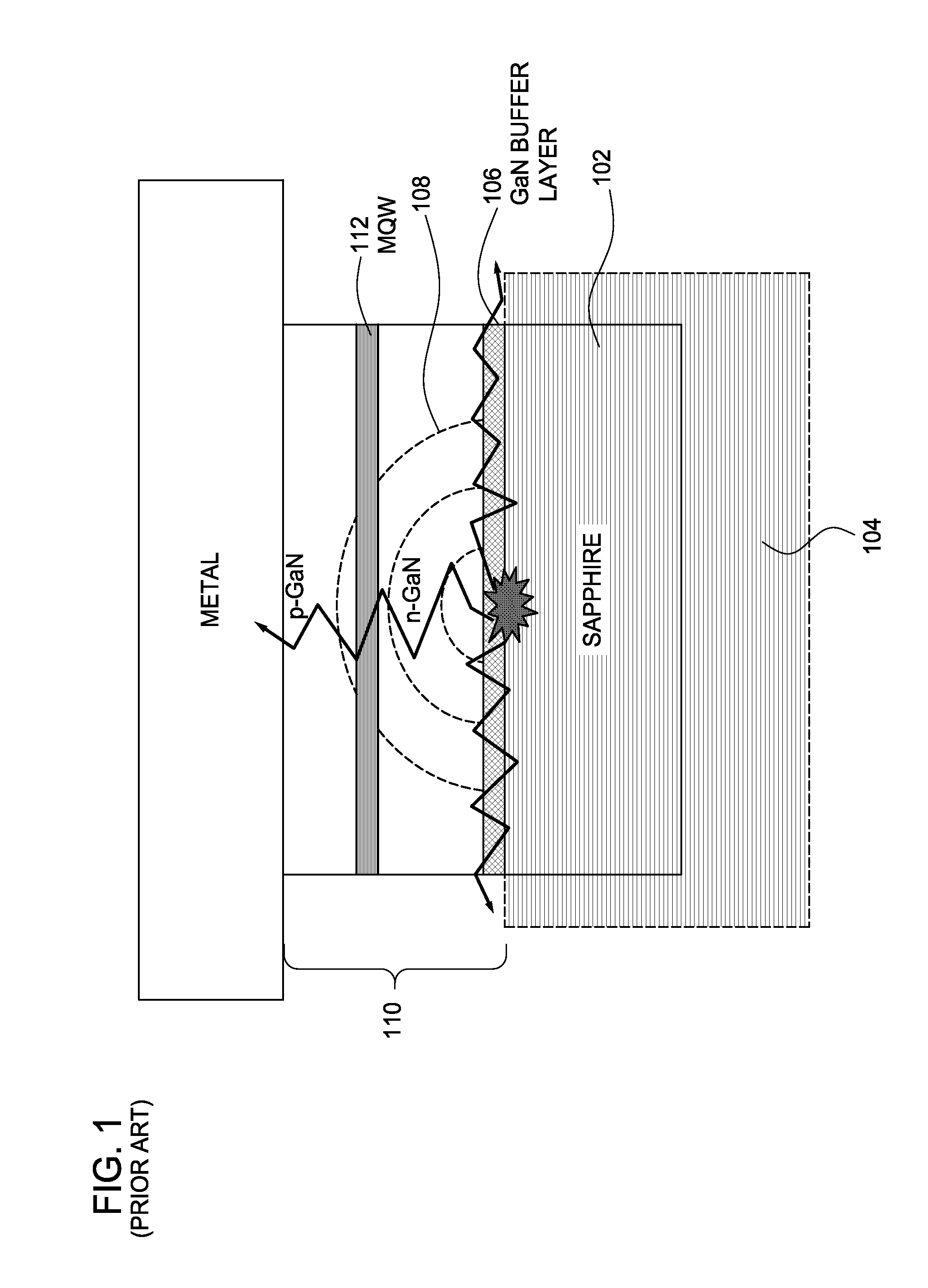

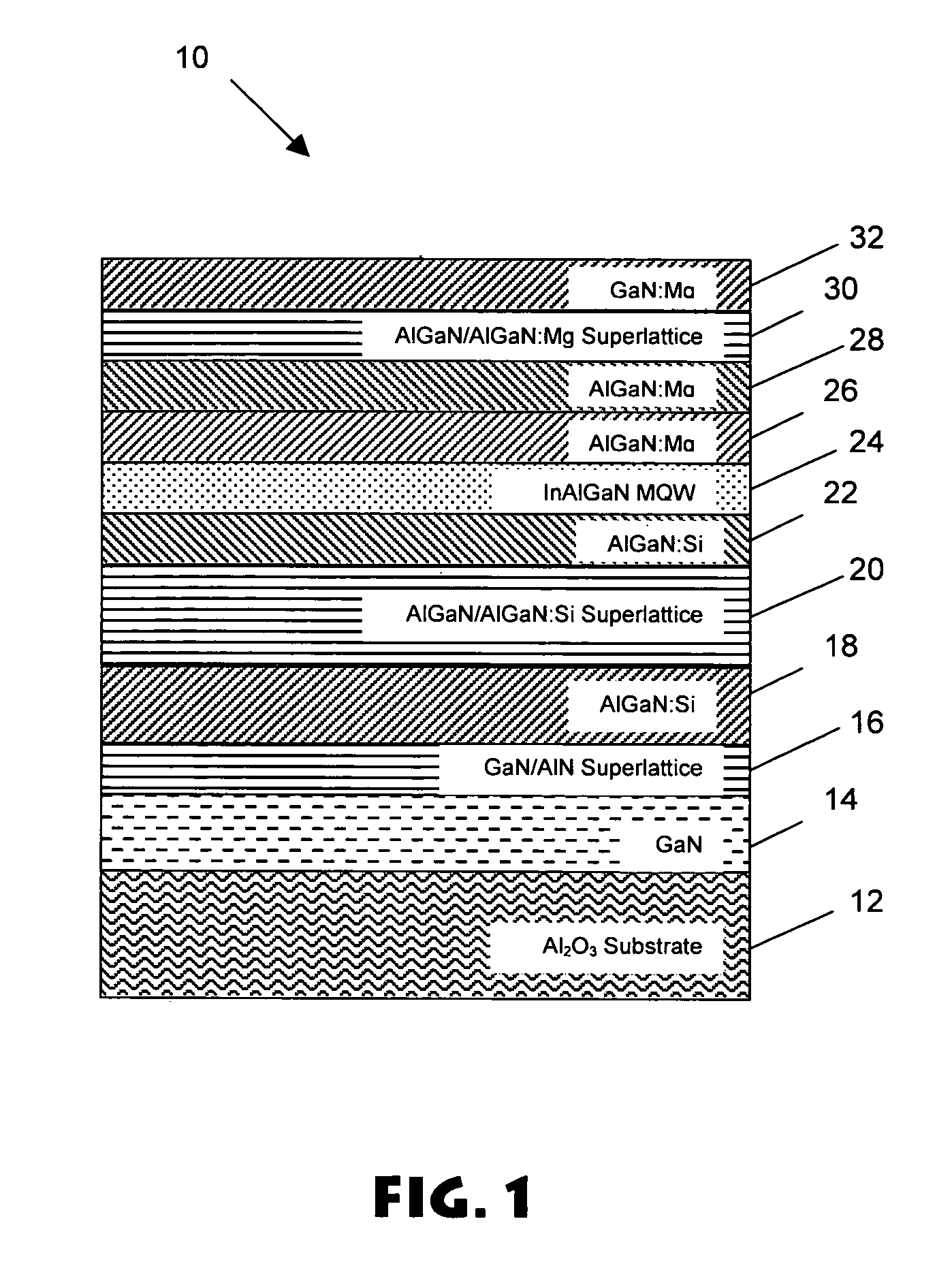

Method for producing group iii - group v vertical light-emitting diodes

ActiveUS20080099780A1Semiconductor/solid-state device manufacturingSemiconductor devicesInterface layerLight-emitting diode

A method of producing one or more vertical light-emitting diode (VLED) dies having a light-emitting diode (LED) stack comprising Group III-Group V combinations of elements (e.g., GaN, AlN, InN, AlGaN, InGaN, and InAlGaN) and a metal substrate is provided. The techniques include forming an InGaN or InAlGaN interface layer above a suitable growth-supporting substrate, such as sapphire or silicon carbide (SiC), and forming the LED stack above the interface layer. Such an interface layer may absorb a majority of the energy from a laser pulse used during laser lift-off of the growth-supporting substrate in an effort to prevent damage to the light emitting layers of the LED stack, which may result in improved brightness performance over VLED dies produced with conventional buffer layers.

Owner:SEMILEDS OPTOELECTRONICS CO LTD

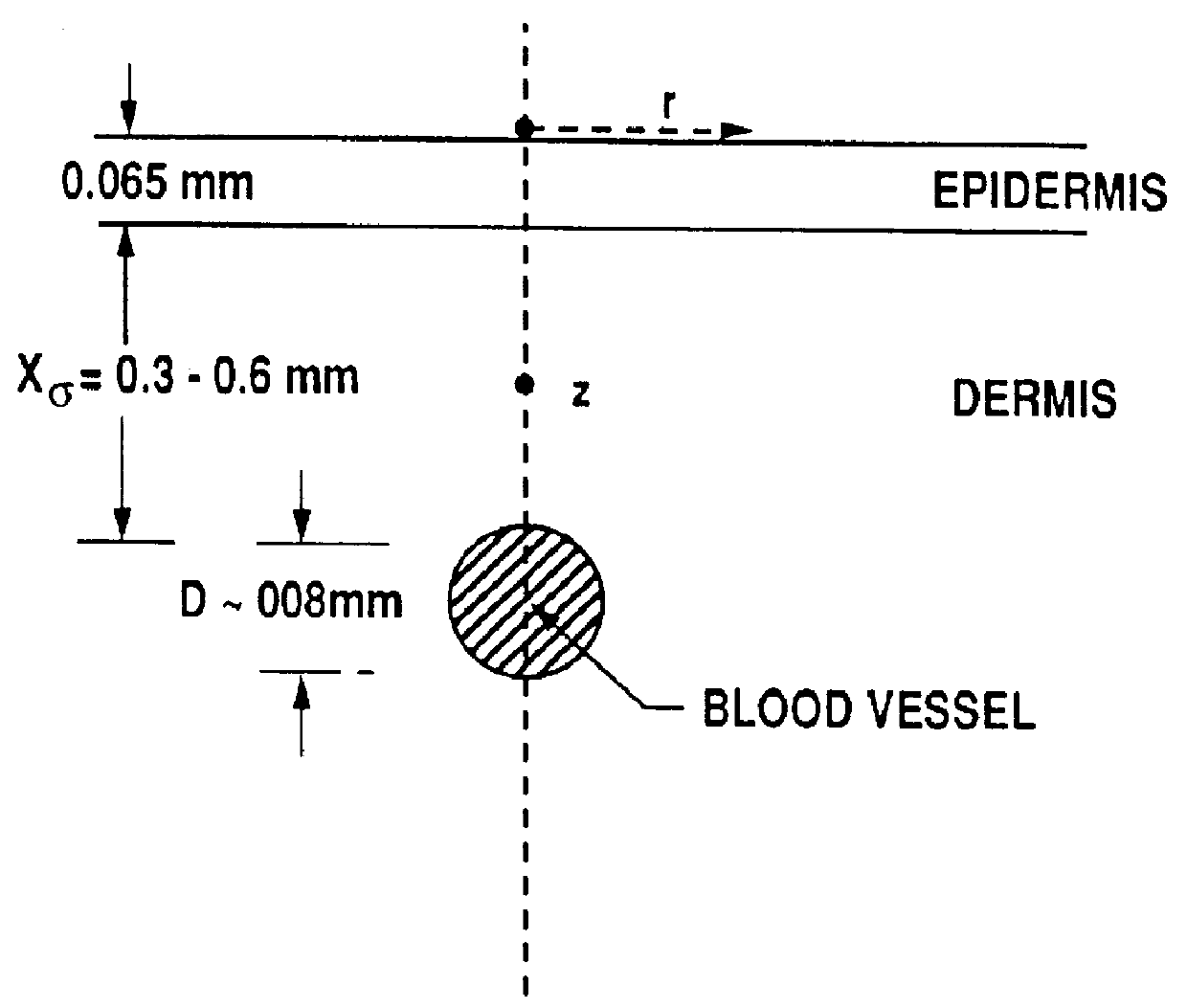

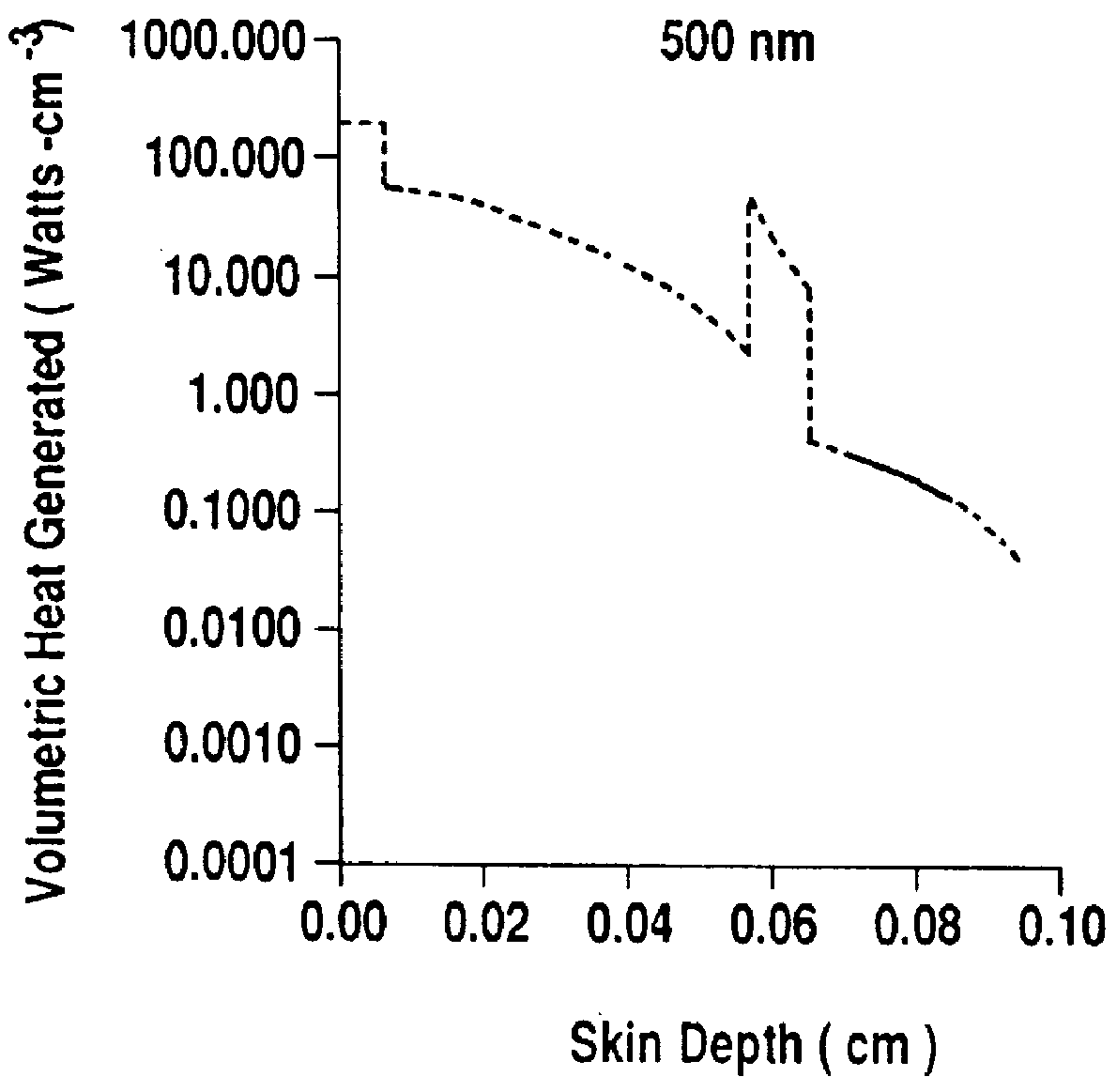

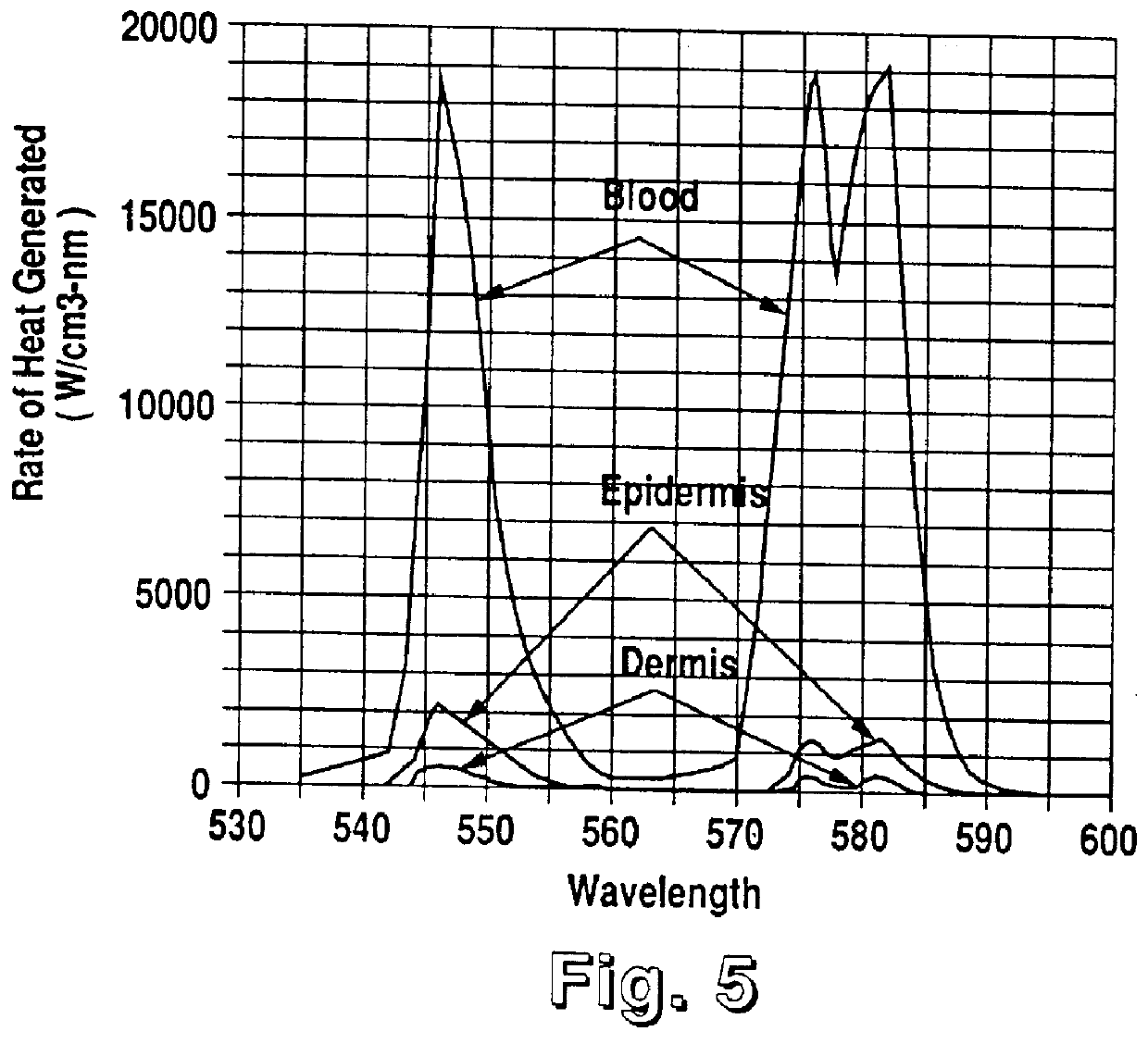

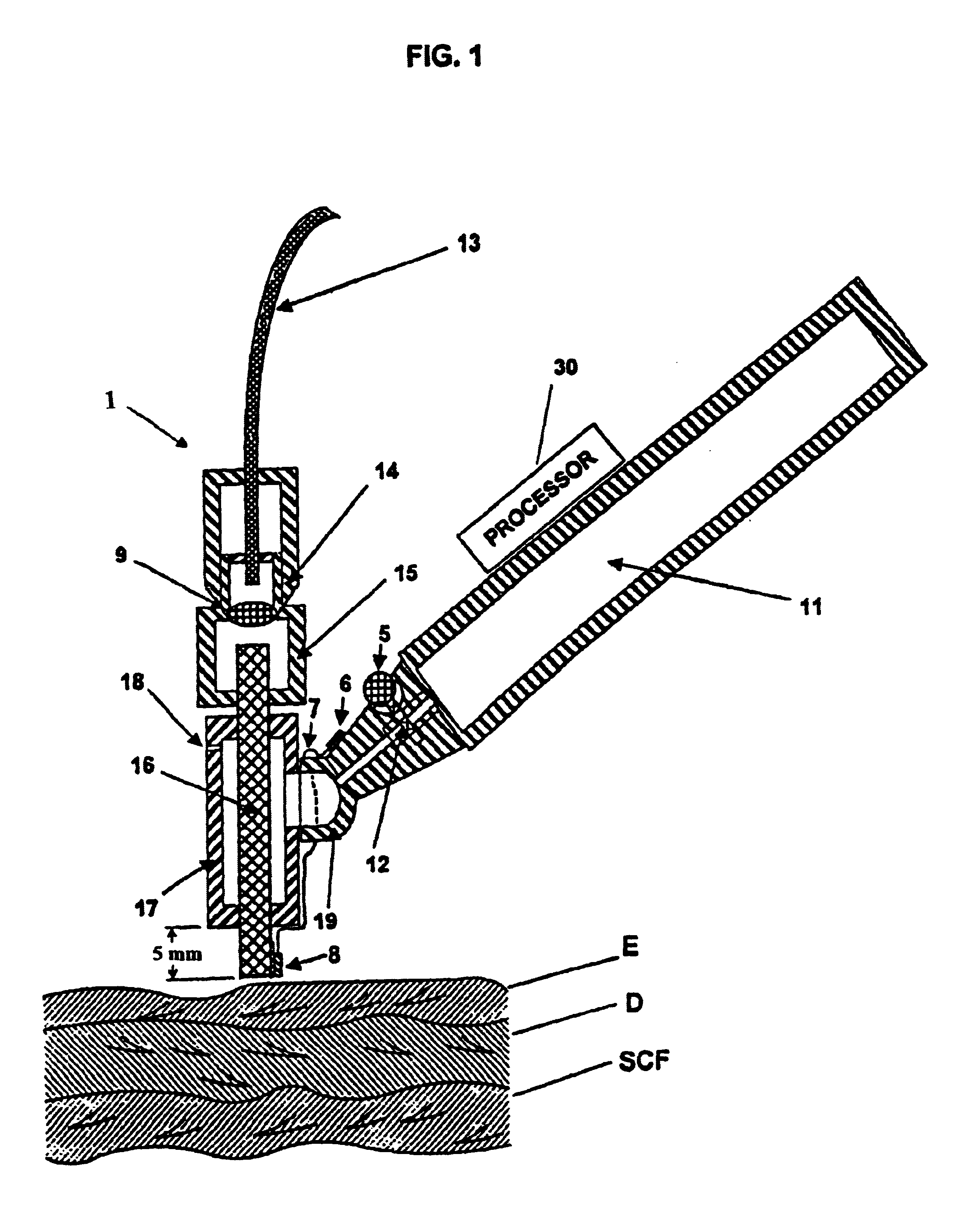

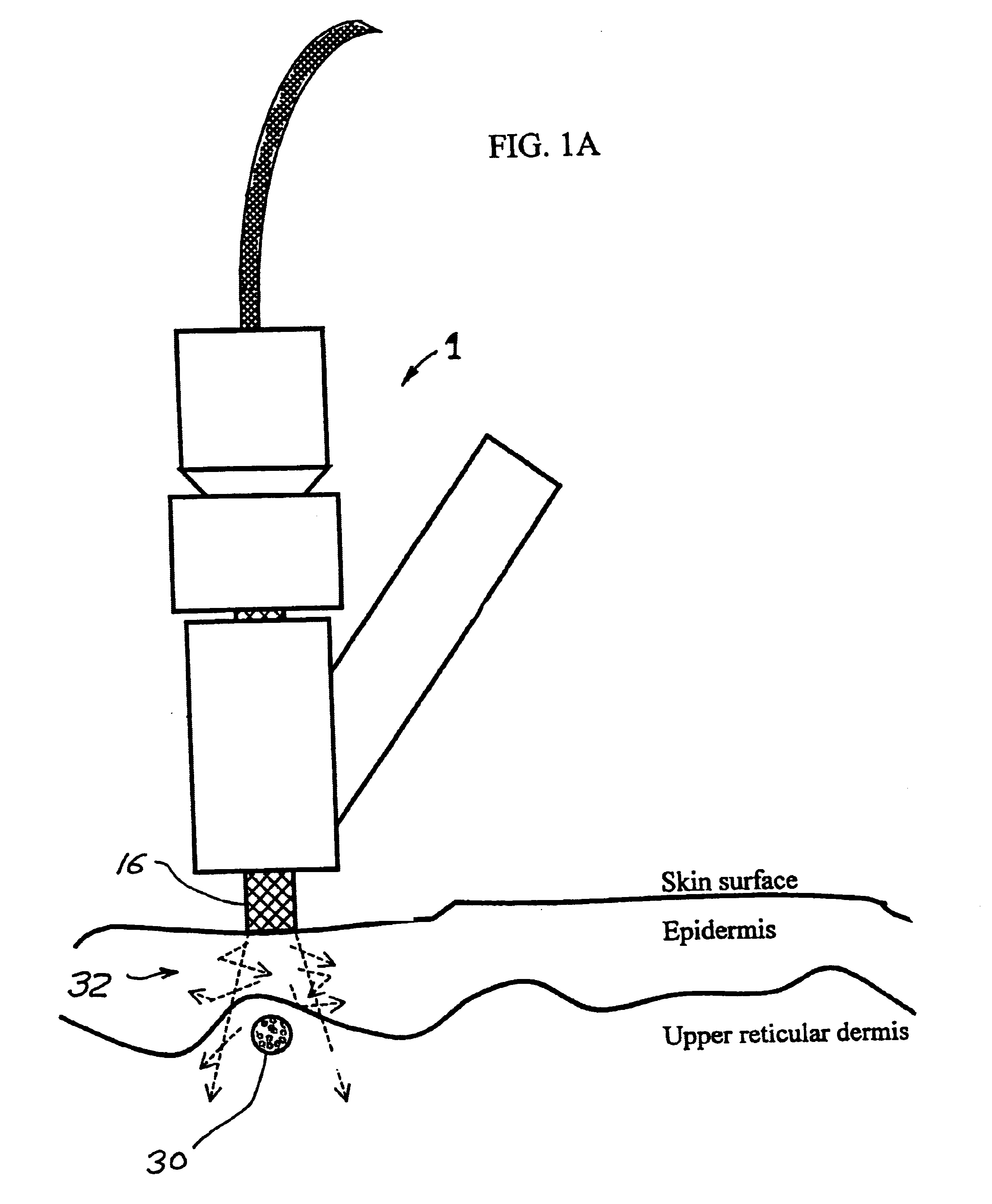

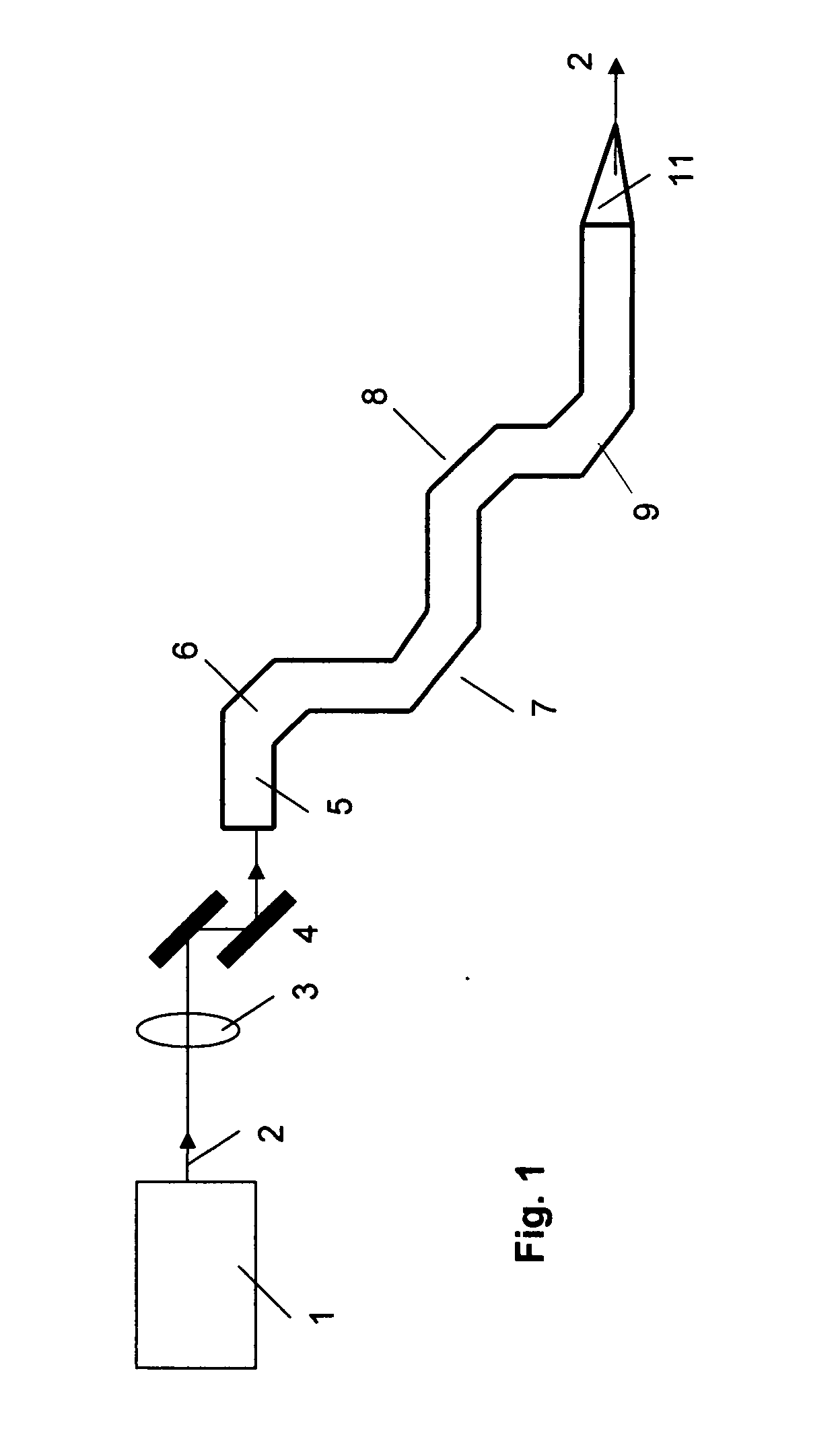

Optical system for treatment of vascular lesions

An improved optical system for treatment of disorders of the skin, especially vascular lesions, such as Port Wine Stains. The system irradiates the skin with radiation at a predetermined wavelength and cools the skin during a predetermined time interval in coordination with delivery of the radiation. The absorption of the radiation by the skin and the change in temperature of the skin is monitored by the system and the operation of the radiation delivery system is controlled to optimize treatment of the vascular lesion. The source of irradiation is an arc lamp and the cooling system delivers a cooling gas to a lens in contact with the skin. The cooling gas can be carbon dioxide, freon, or any other appropriate gas. The lens used has a high heat conductivity and may be formed of sapphire.

Owner:GHAFFARI SHAHRIAR

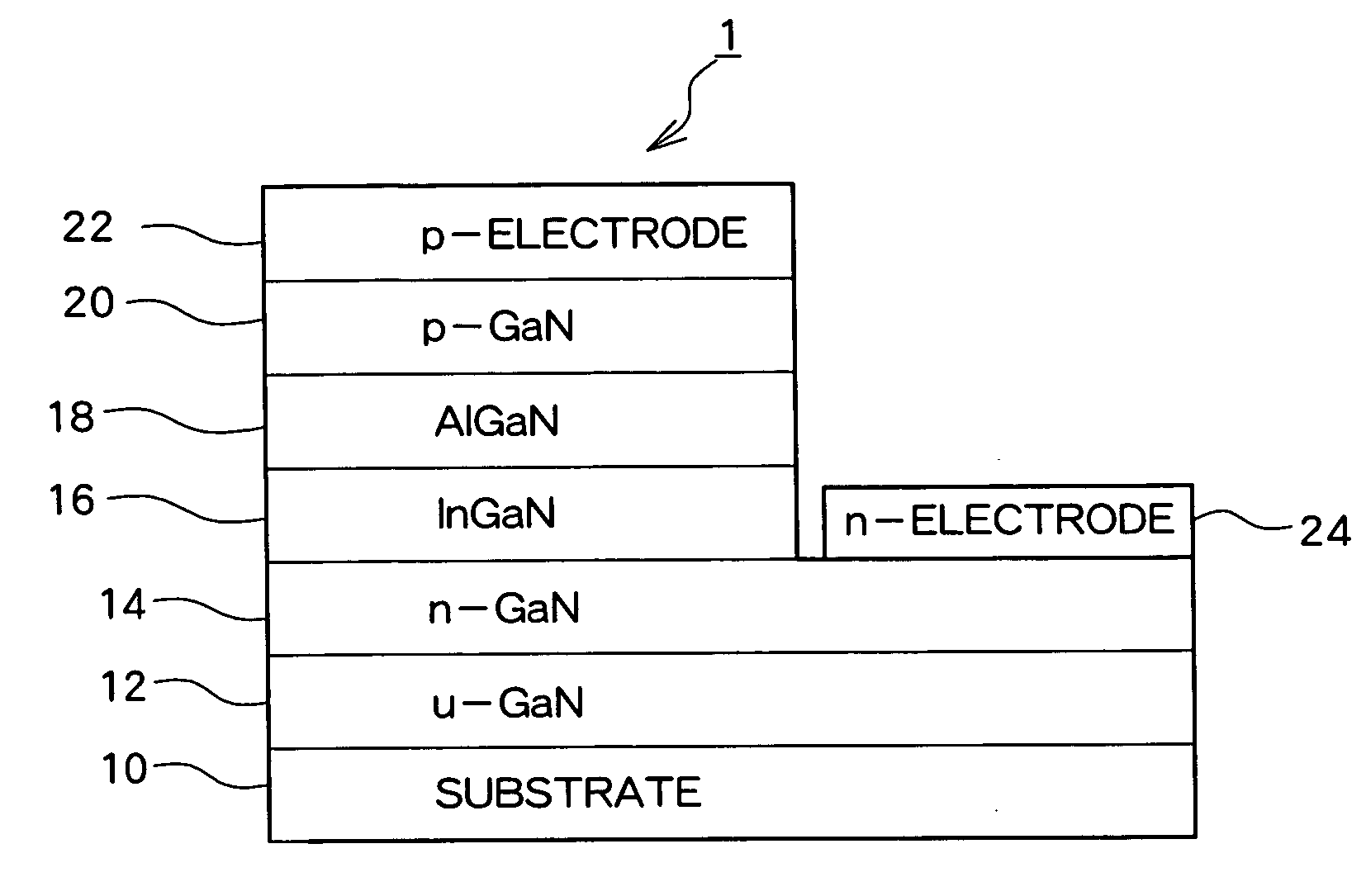

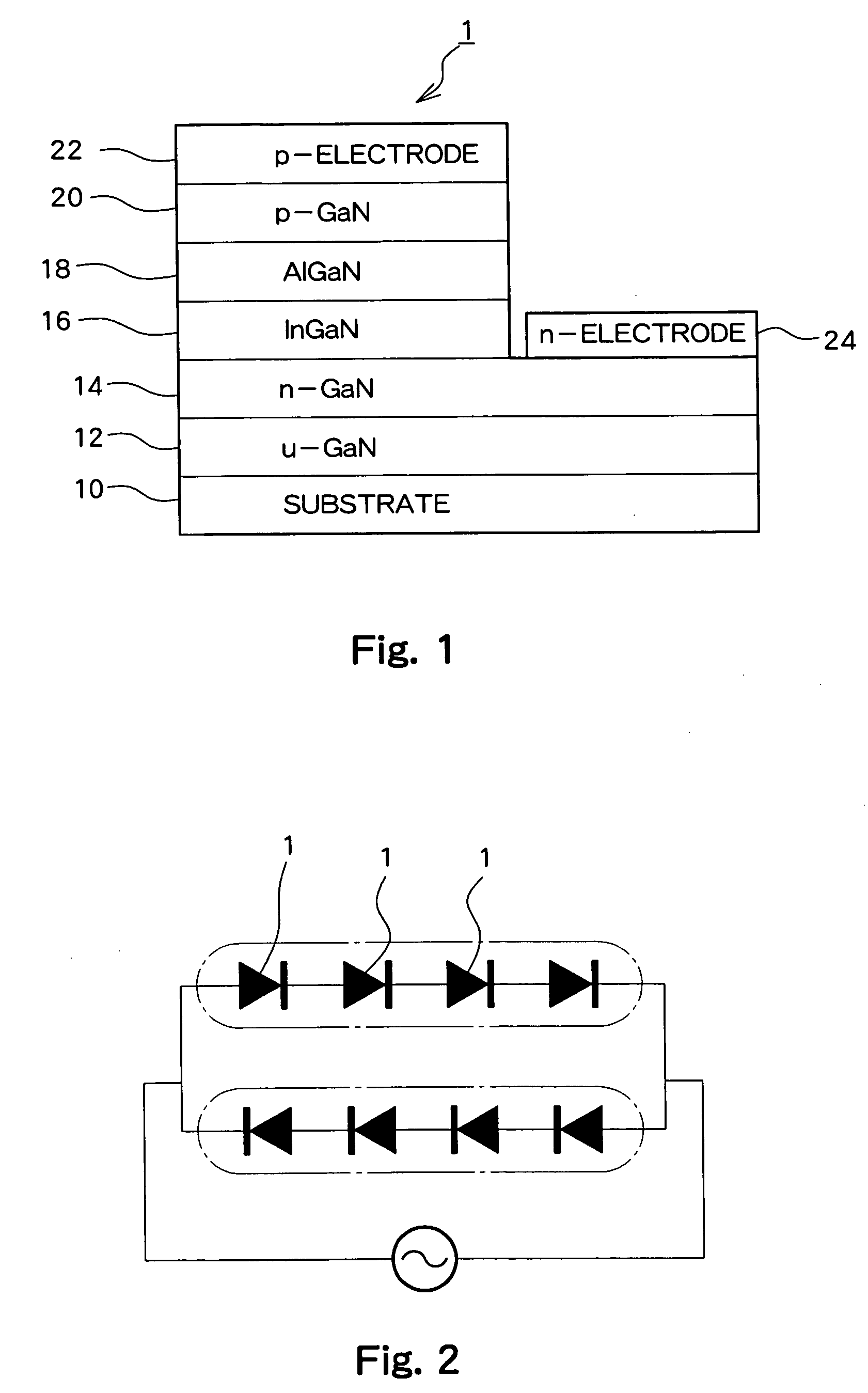

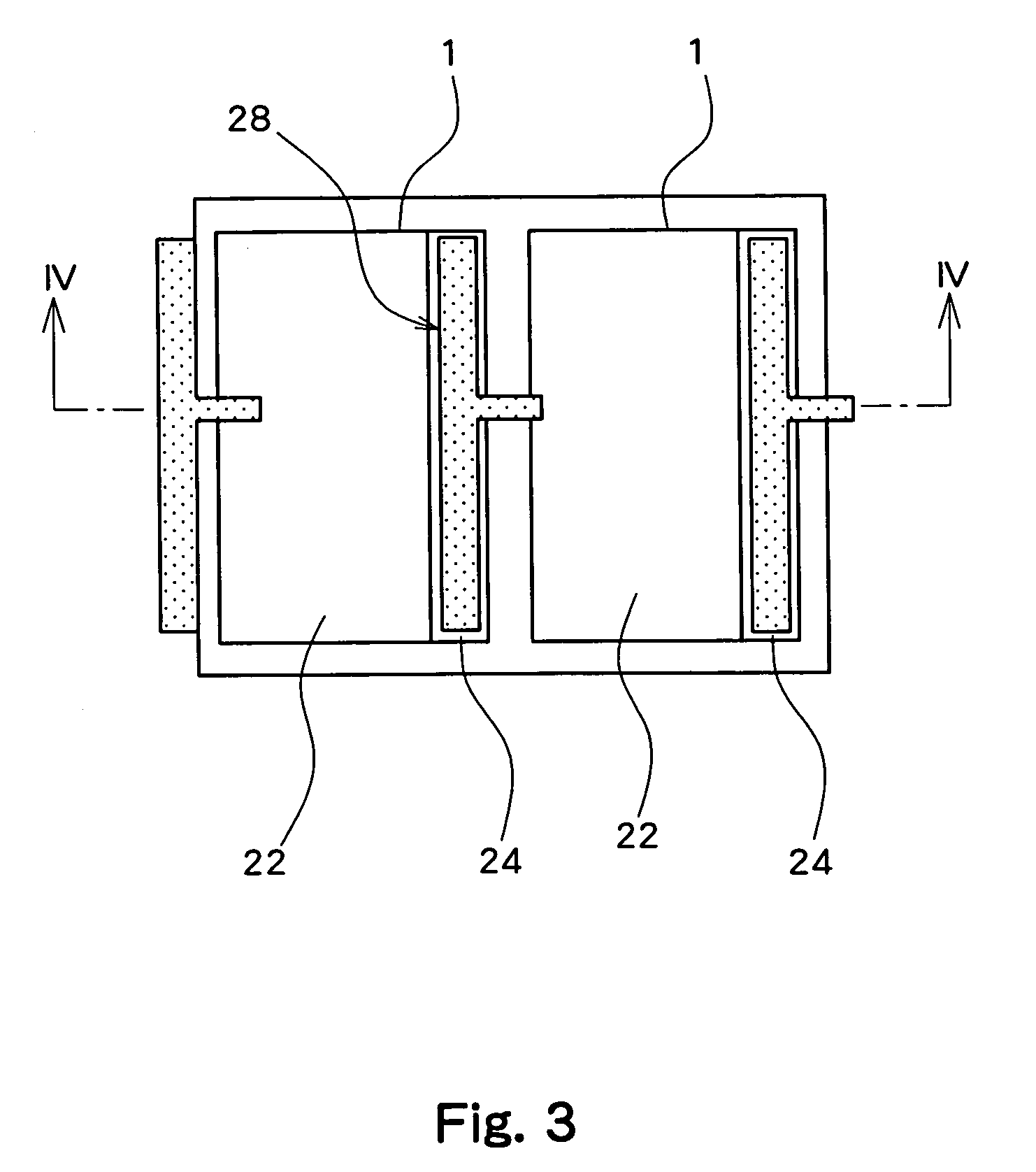

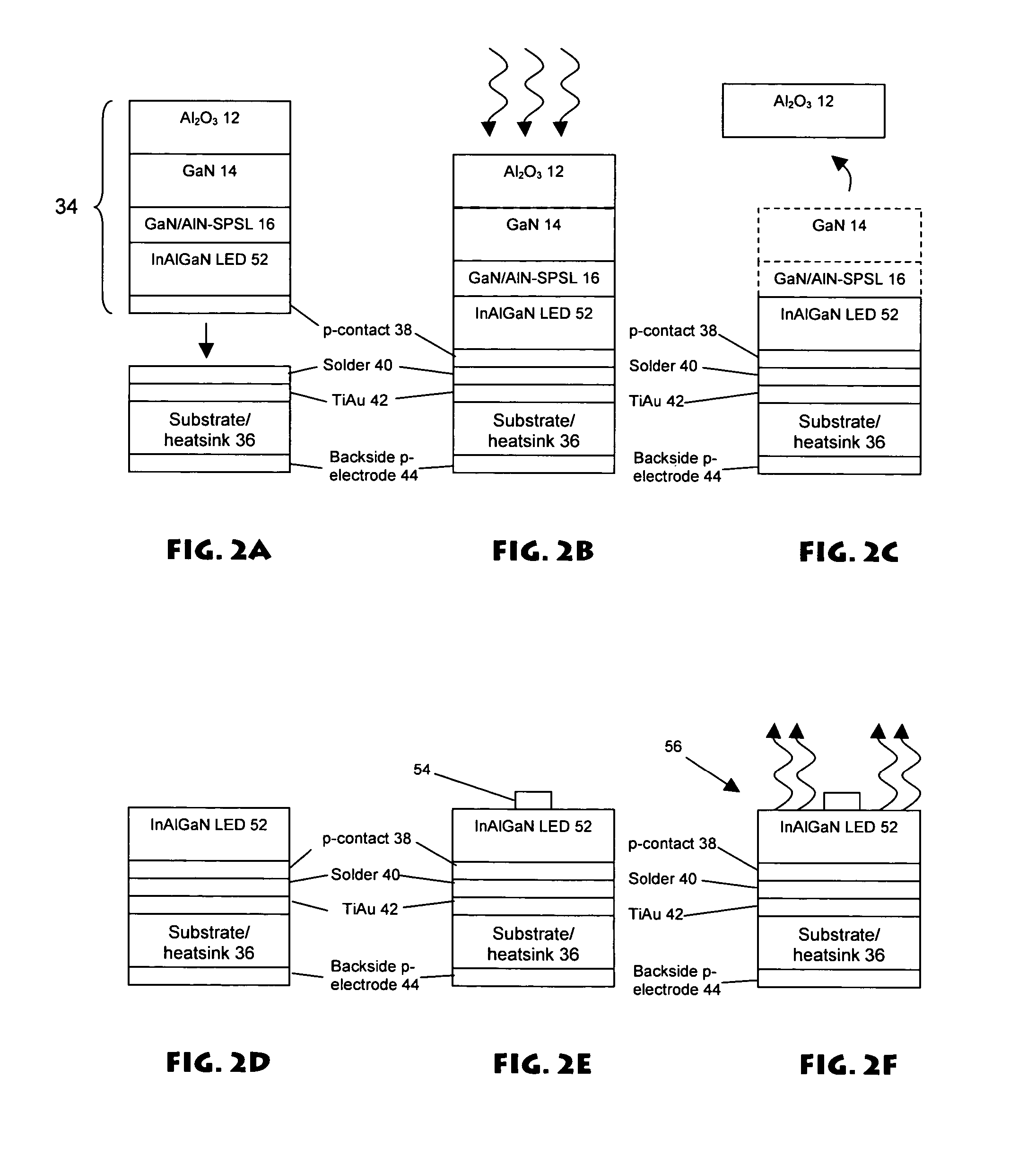

Light-emitting device having light-emitting elements

InactiveUS20050253151A1Increase the driving voltageEfficient use ofSolid-state devicesSemiconductor devicesDriving currentAir bridge

A light-emitting device operating on a high drive voltage and a small drive current. LEDs (1) are two-dimensionally formed on an insulating substrate (10) of e.g., sapphire monolithically and connected in series to form an LED array. Two such LED arrays are connected to electrodes (32) in inverse parallel. Air-bridge wiring (28) is formed between the LEDs (1) and between the LEDs (1) and electrodes (32). The LED arrays are arranged zigzag to form a plurality of LEDs (1) to produce a high drive voltage and a small drive current. Two LED arrays are connected in inverse parallel, and therefore an AC power supply can be used as the power supply.

Owner:SEOUL SEMICONDUCTOR

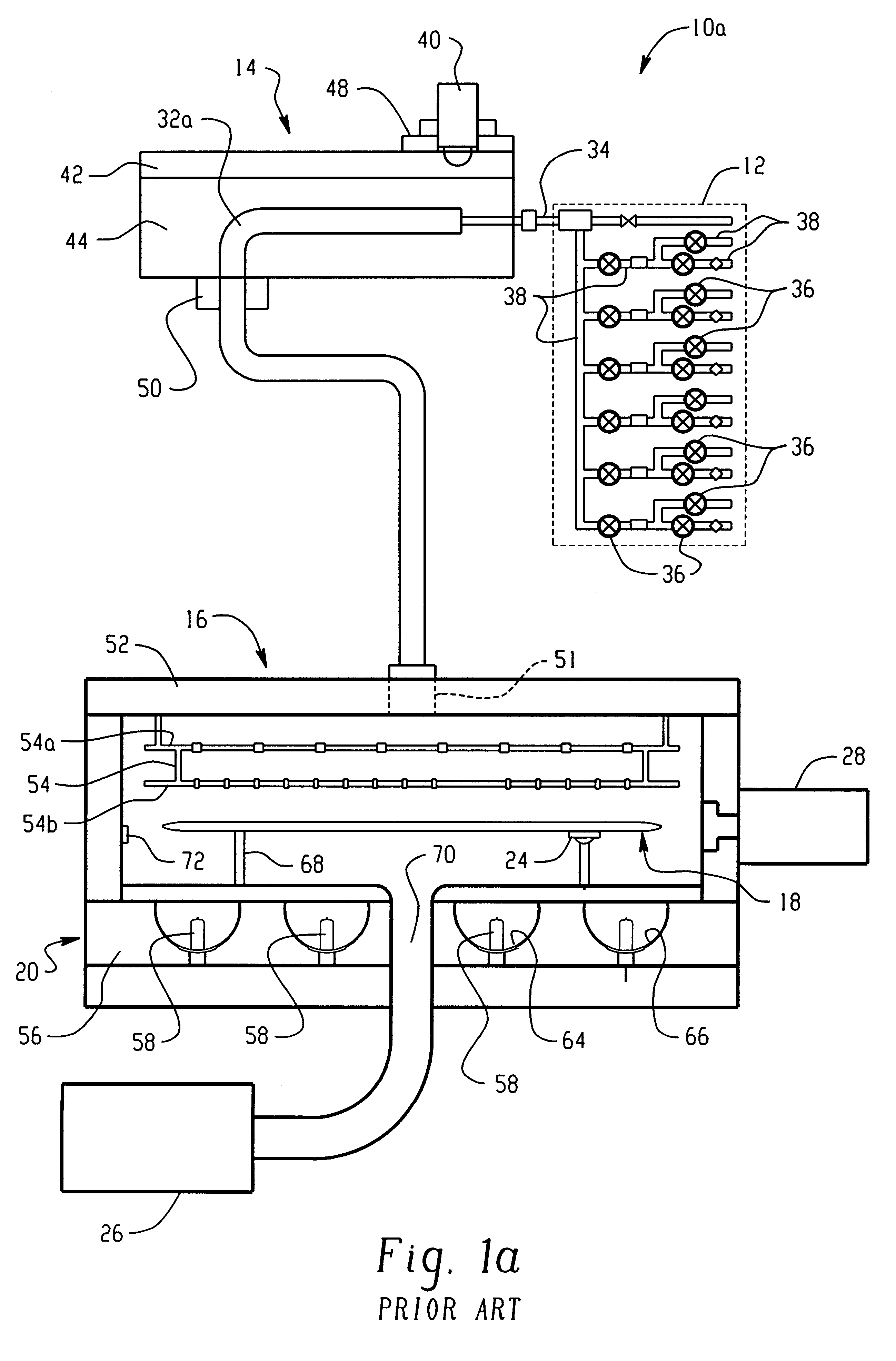

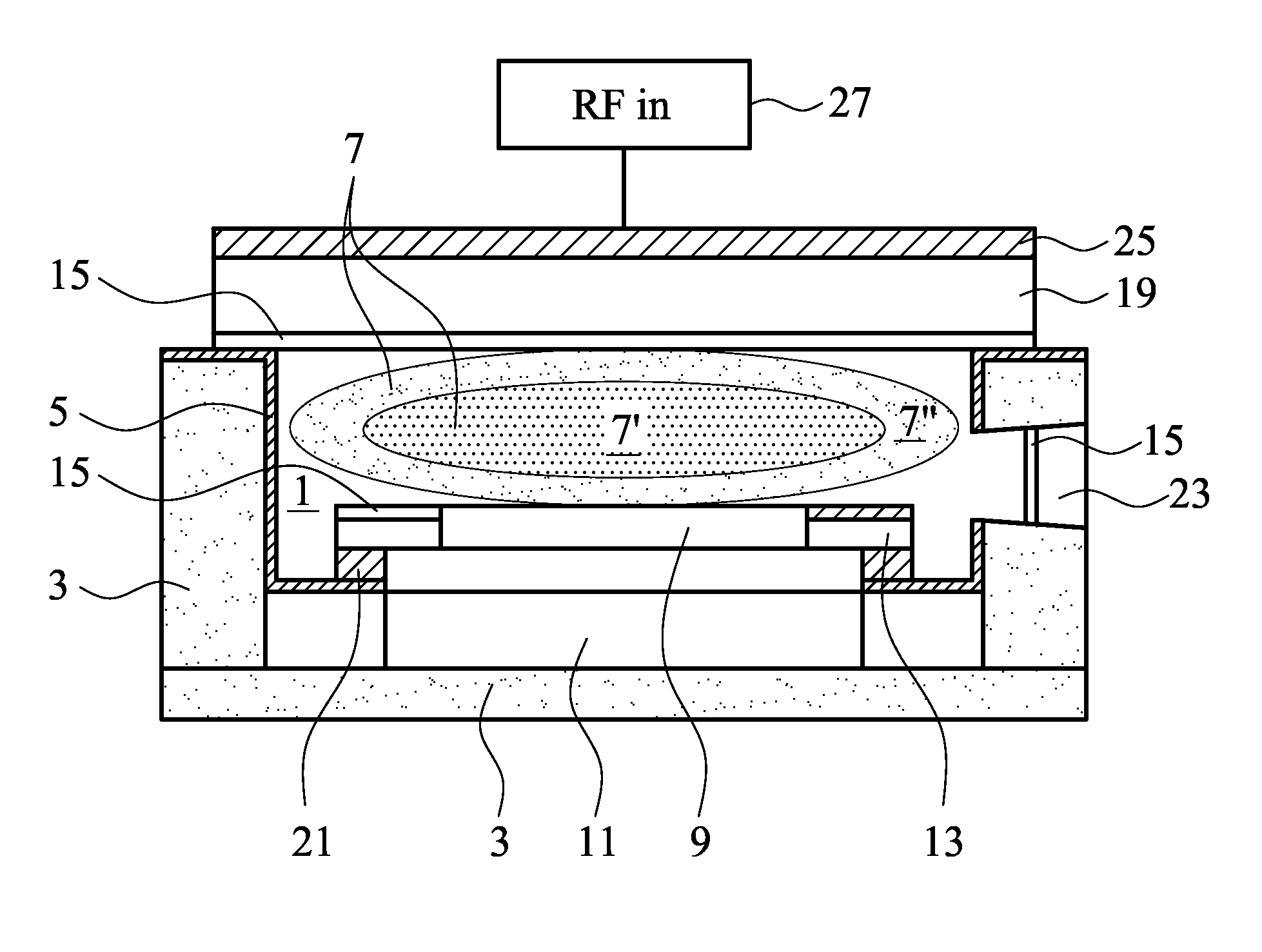

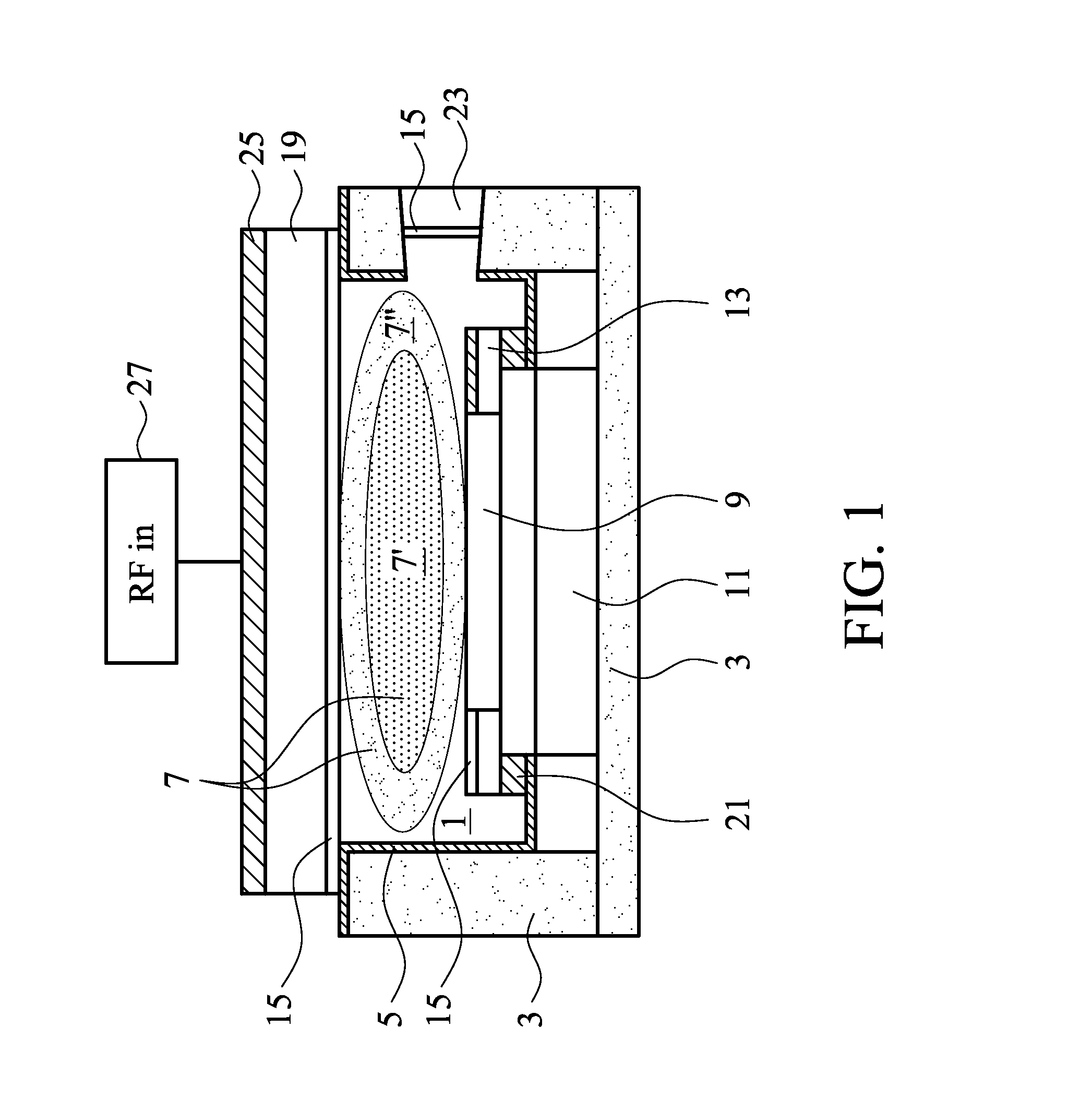

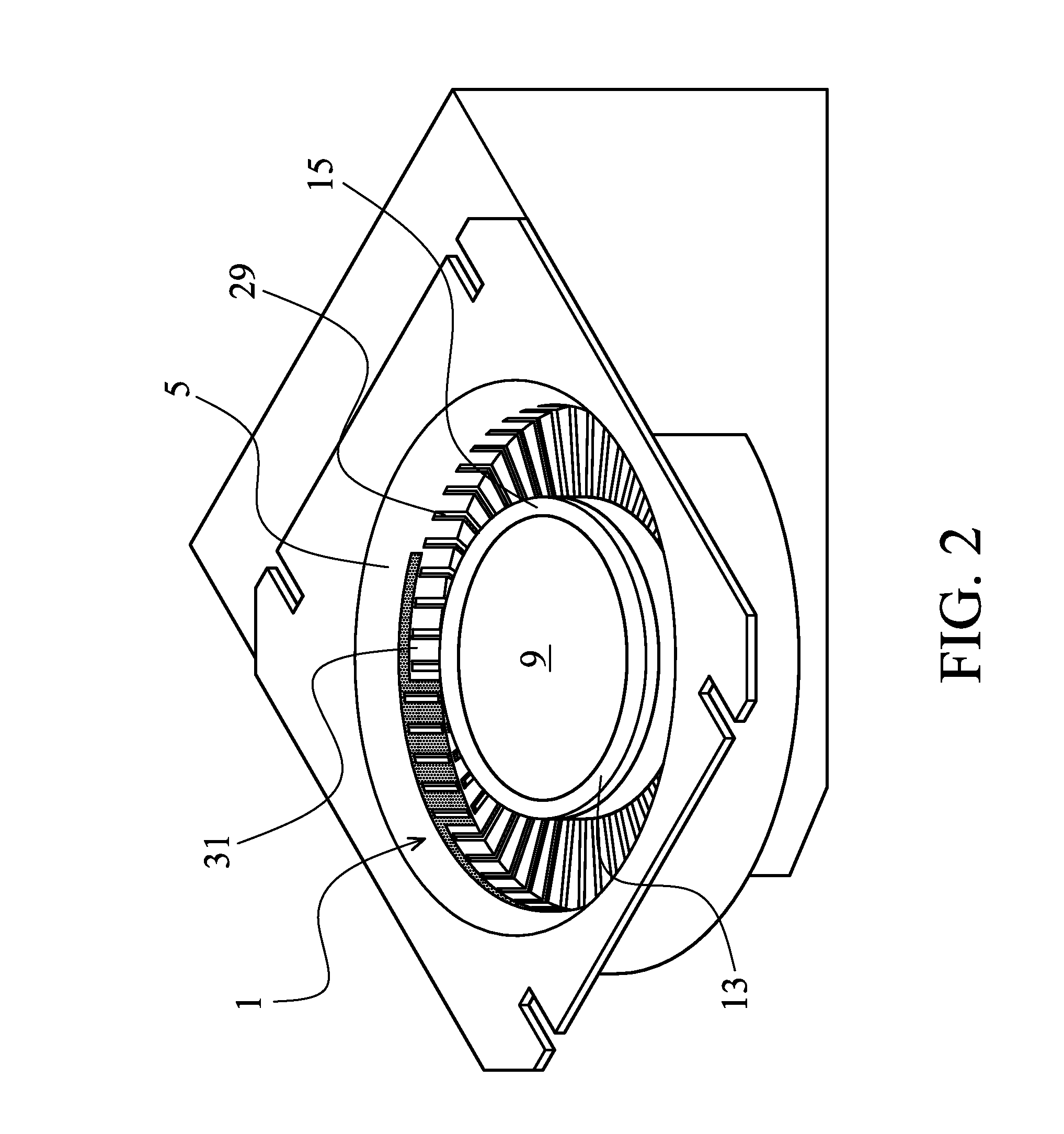

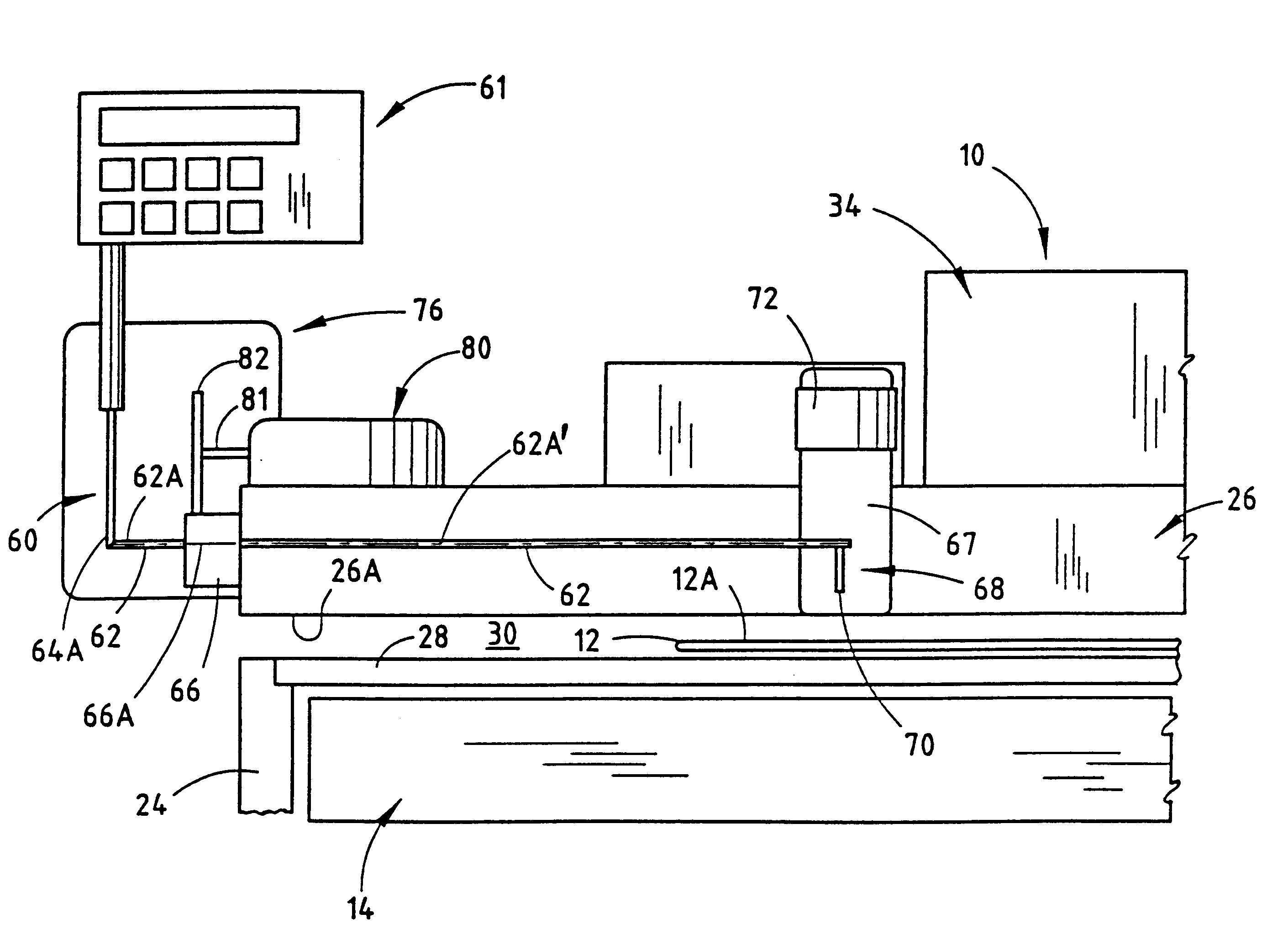

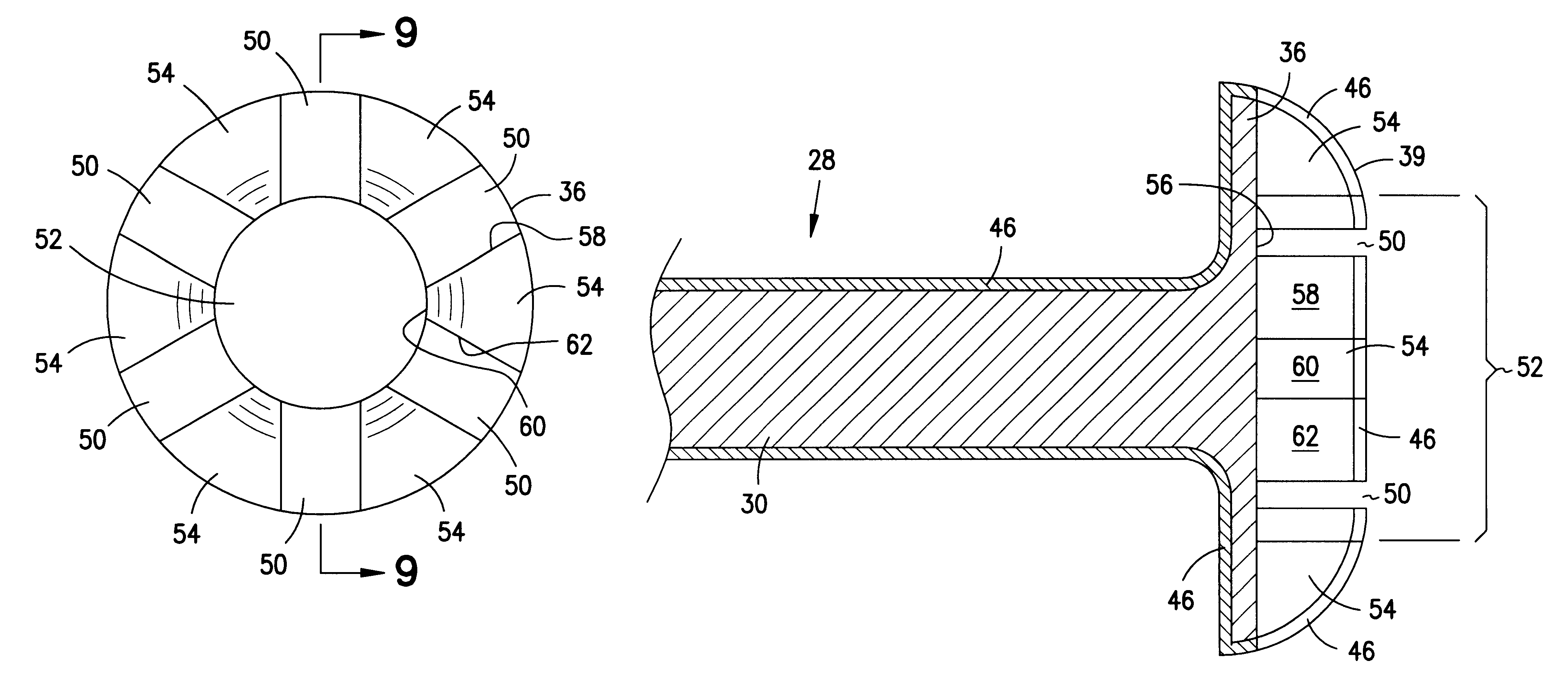

Reactor and method of processing a semiconductor substrate

InactiveUSRE37546E1Accurately determineEliminate needThermometer detailsRadiation pyrometryGas syringeEngineering

Owner:KOKUSAI SEMICON EQUIP CORP

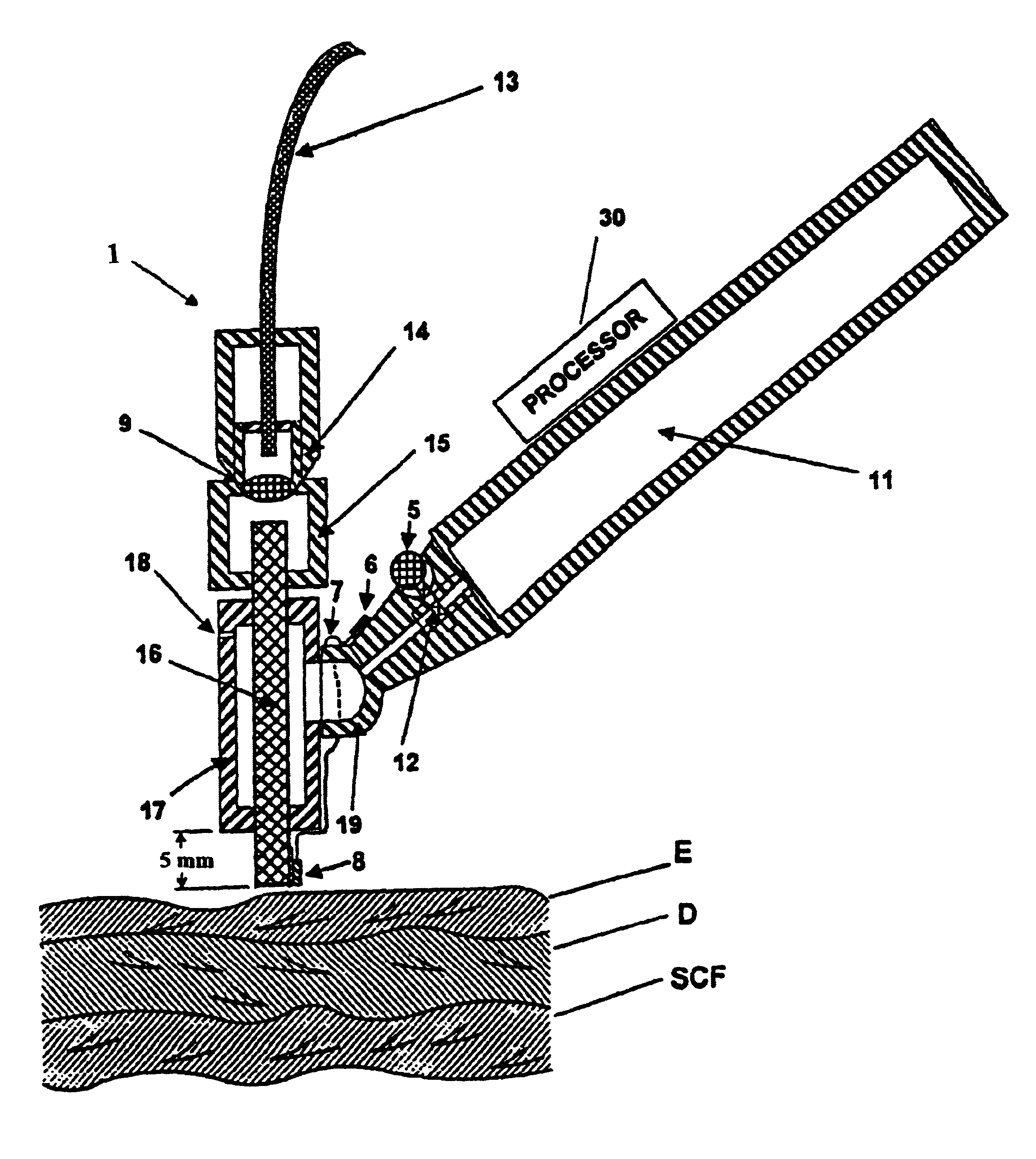

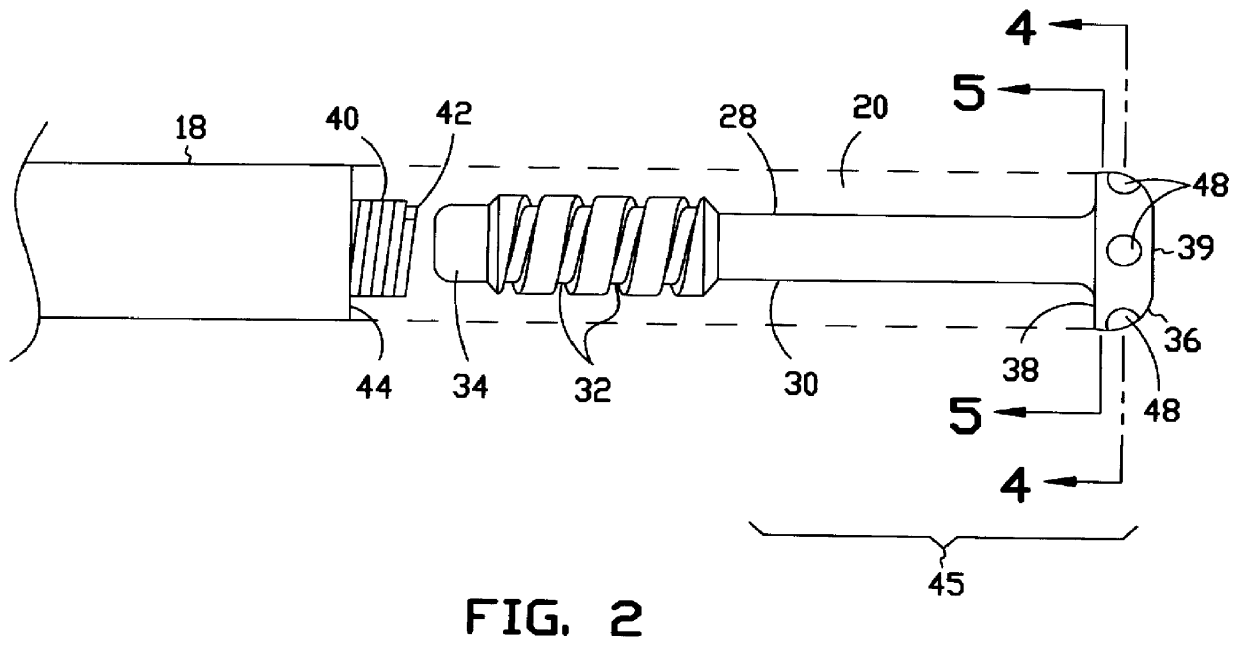

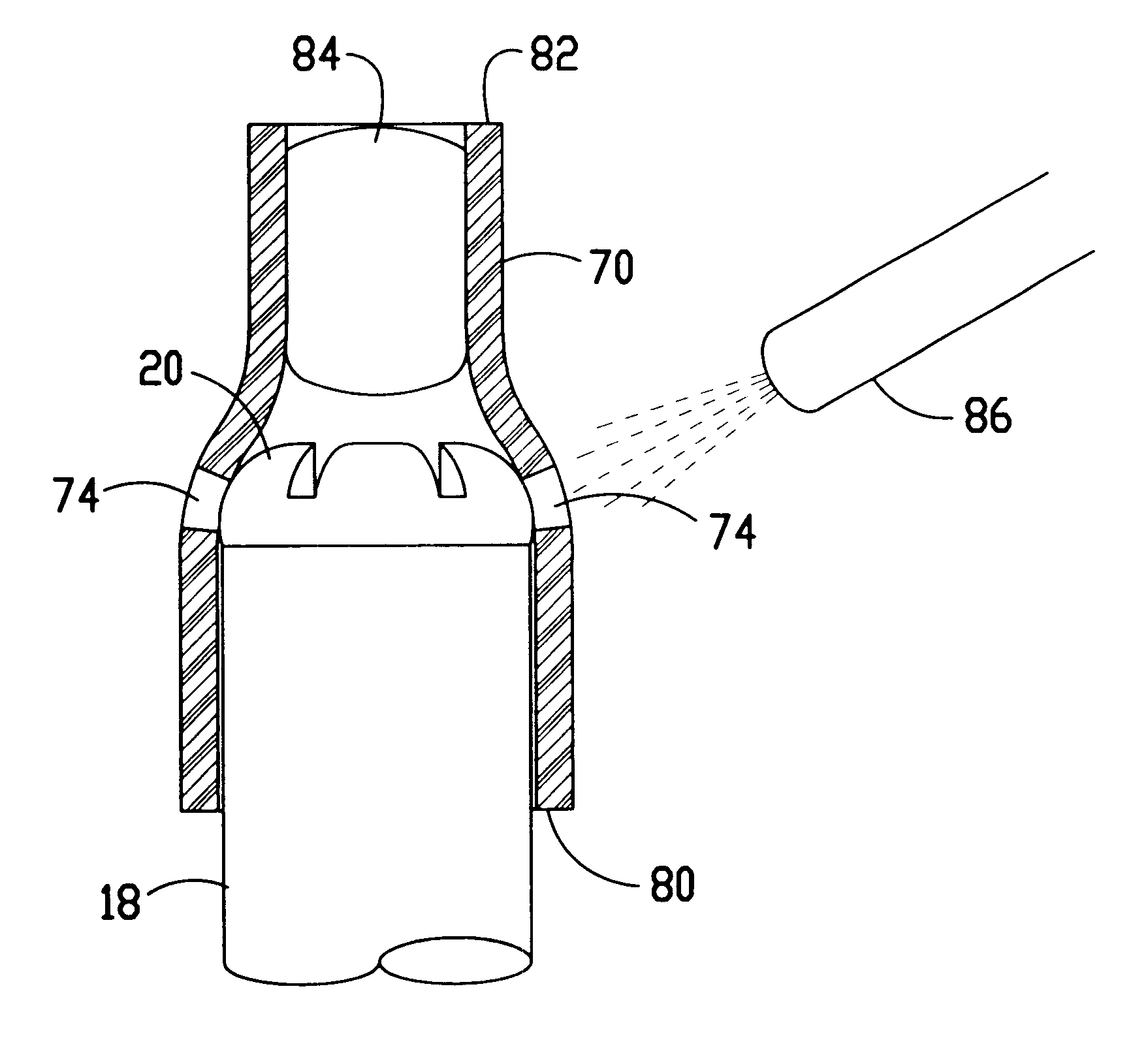

Tissue cooling rod for laser surgery

A laser treatment device and process with controlled cooling. The device contains a cooling element with high heat conduction properties, which is transparent to the laser beam. A surface of the cooling element is held in contact with the tissue being treated while at least one other surface of the cooling element is cooled by the evaporation of a cryogenic fluid. The cooling is coordinated with the application of the laser beam so as to control the temperatures of all affected layers of tissues. In a preferred embodiment useful for removal of wrinkles and spider veins, the cooling element is a sapphire plate. A cryogenic spray cools the top surface of the plate and the bottom surface of the plate is in contact with the skin. In preferred embodiments the wavelength of the laser beam is chosen so that absorption in targeted tissue is low enough so that substantial absorption occurs throughout the targeted tissue. In a preferred embodiment for treating large spider veins with diameters in the range of 1.5 mm, Applicants use an Er:Glass laser with a wavelength of 1.54 microns.< / PTEXT>

Owner:RELIANT TECH INC

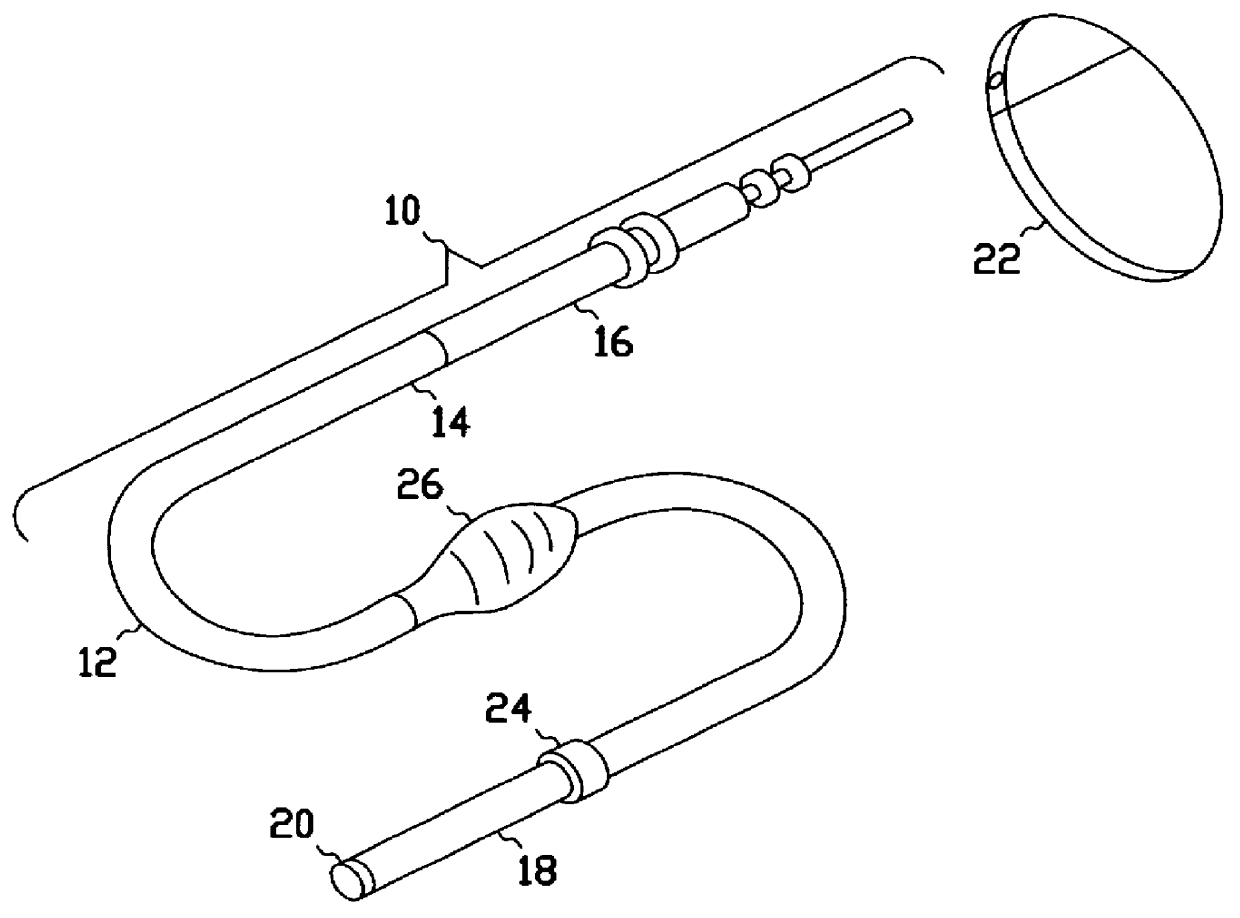

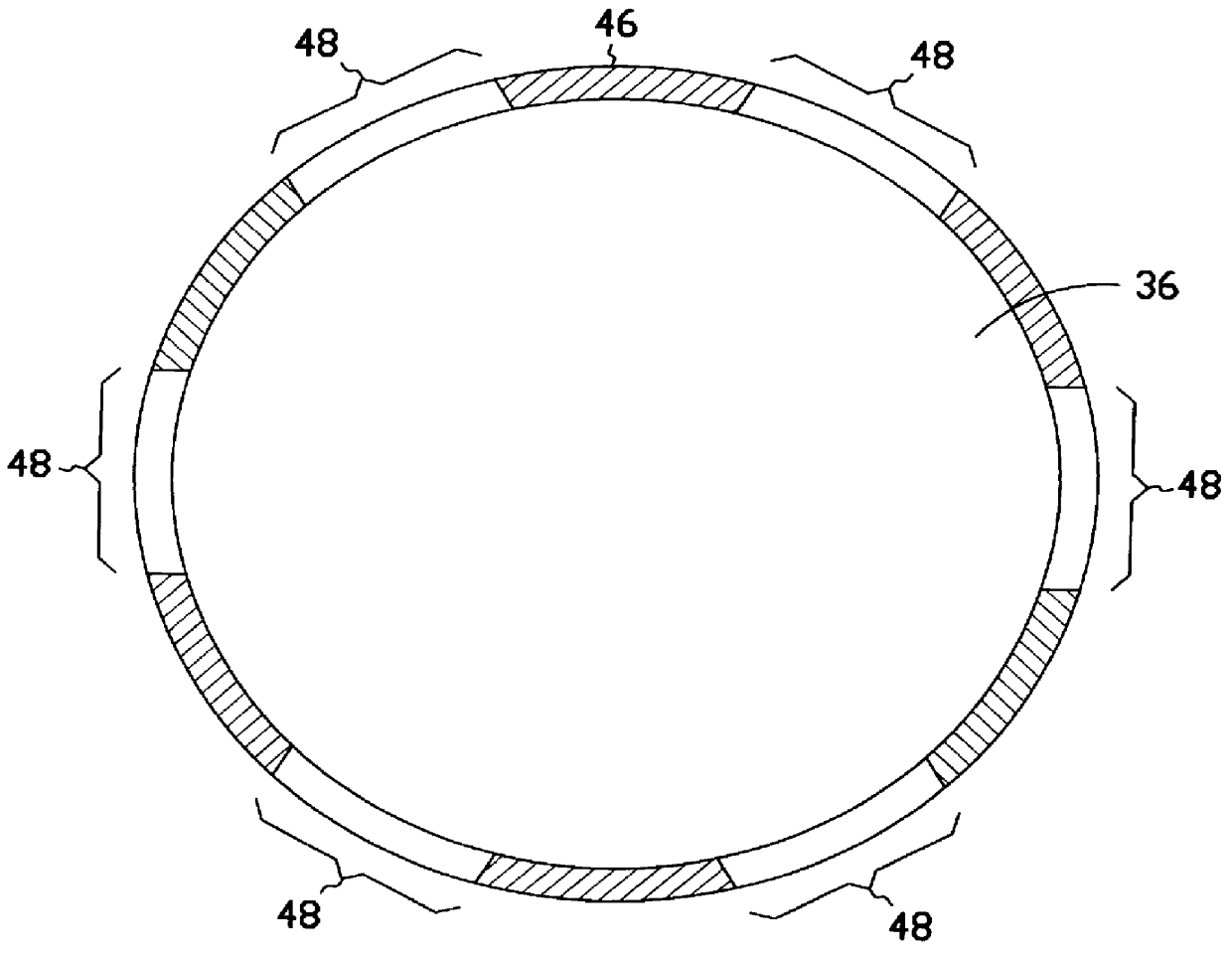

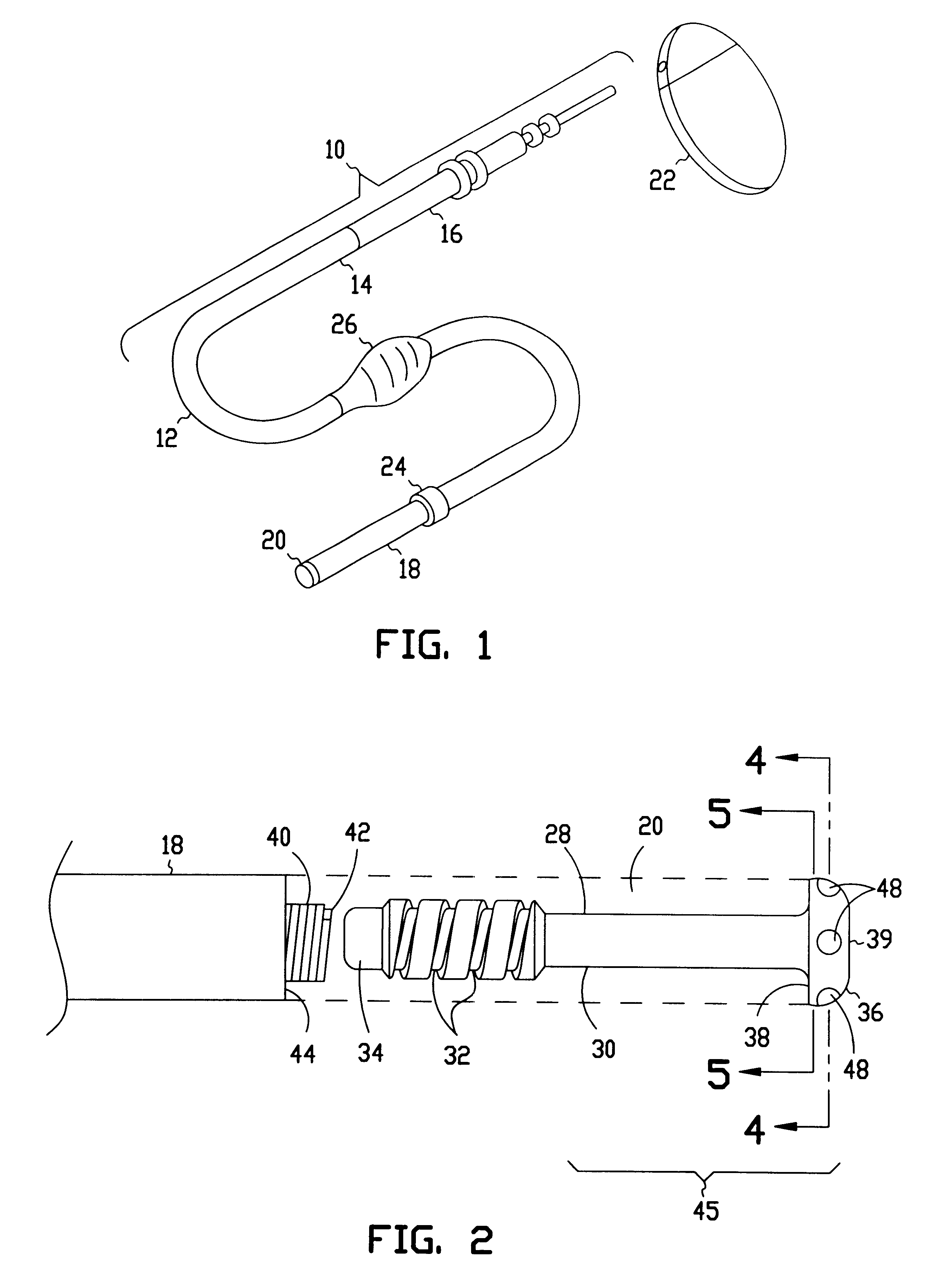

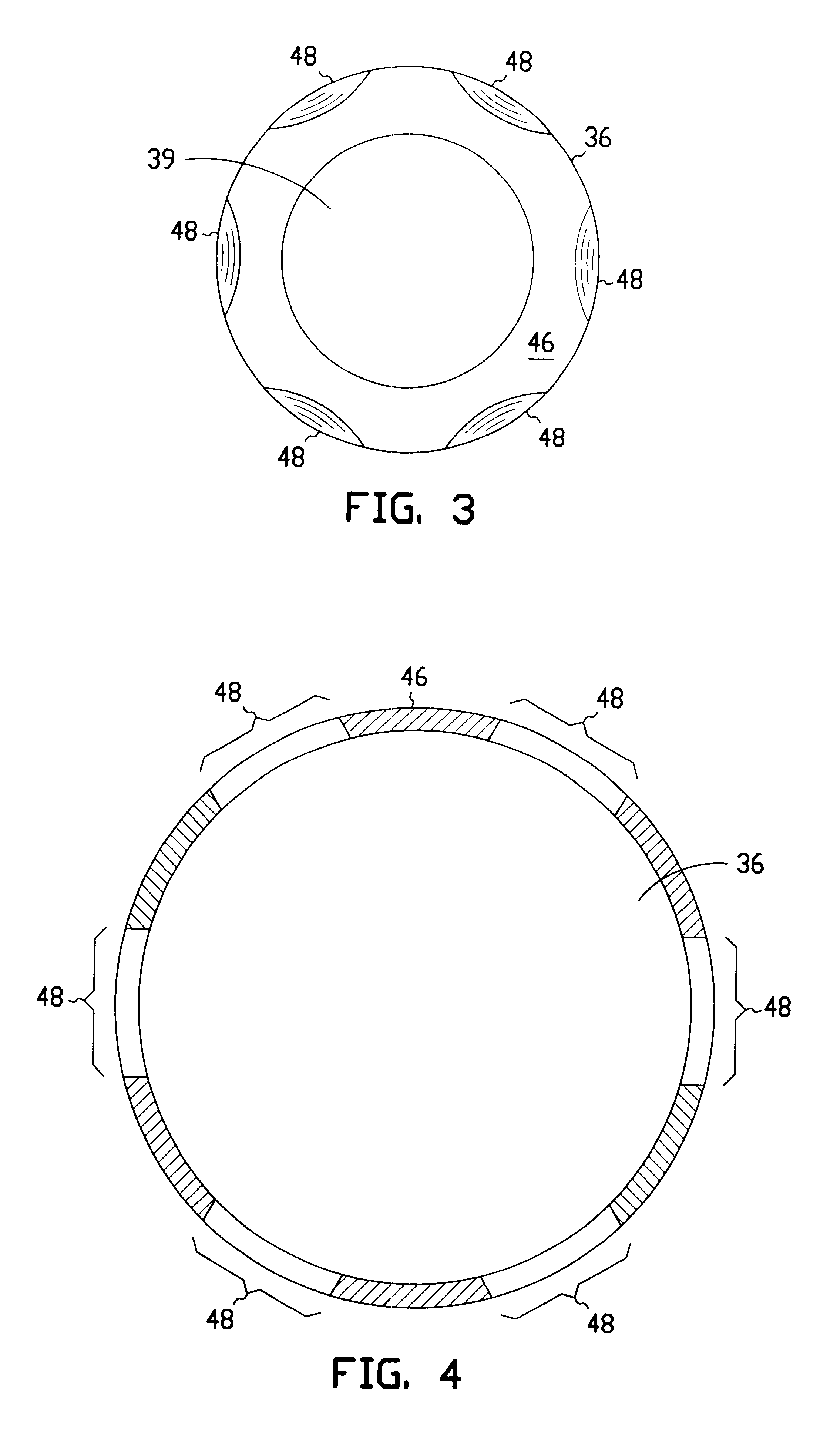

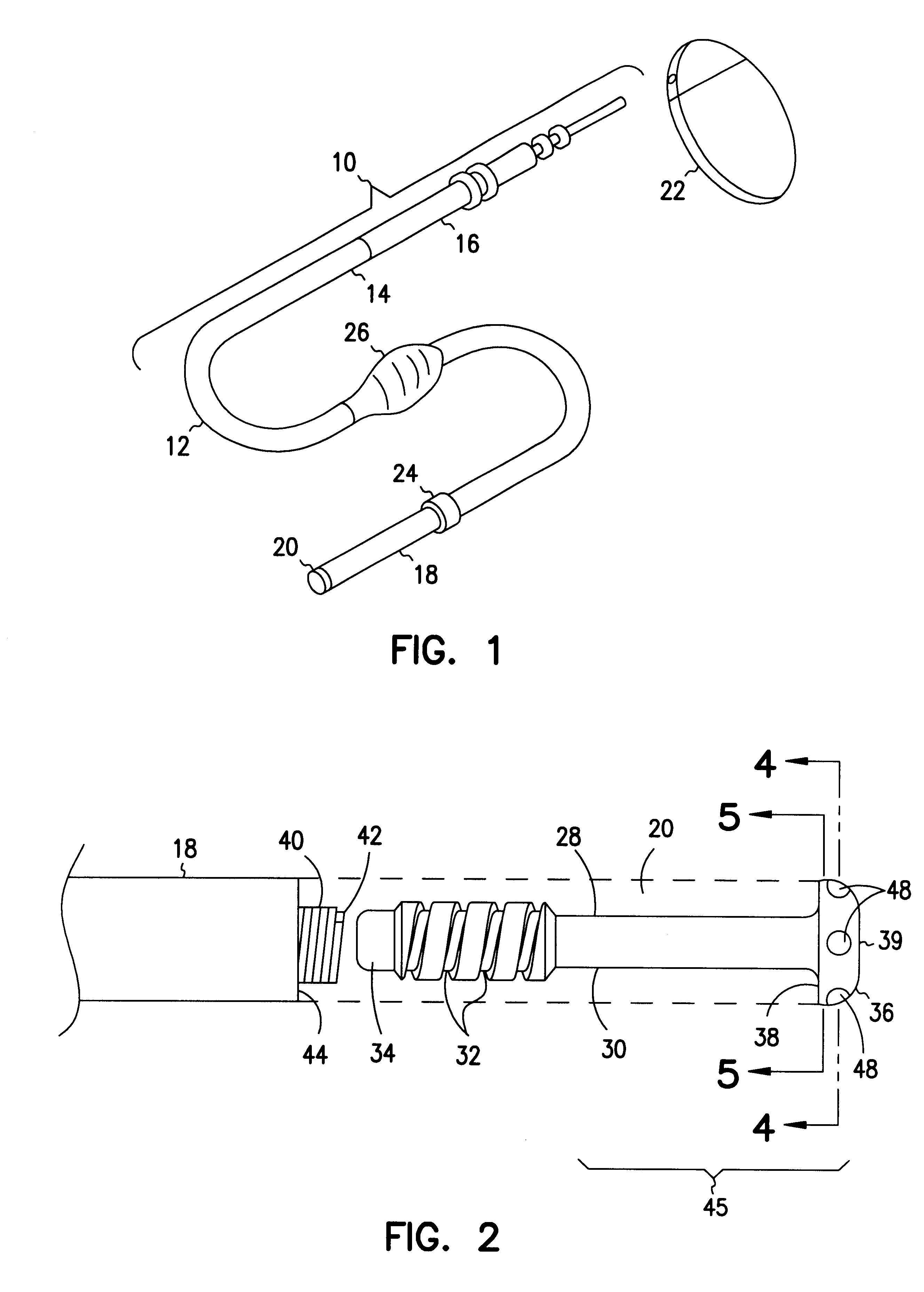

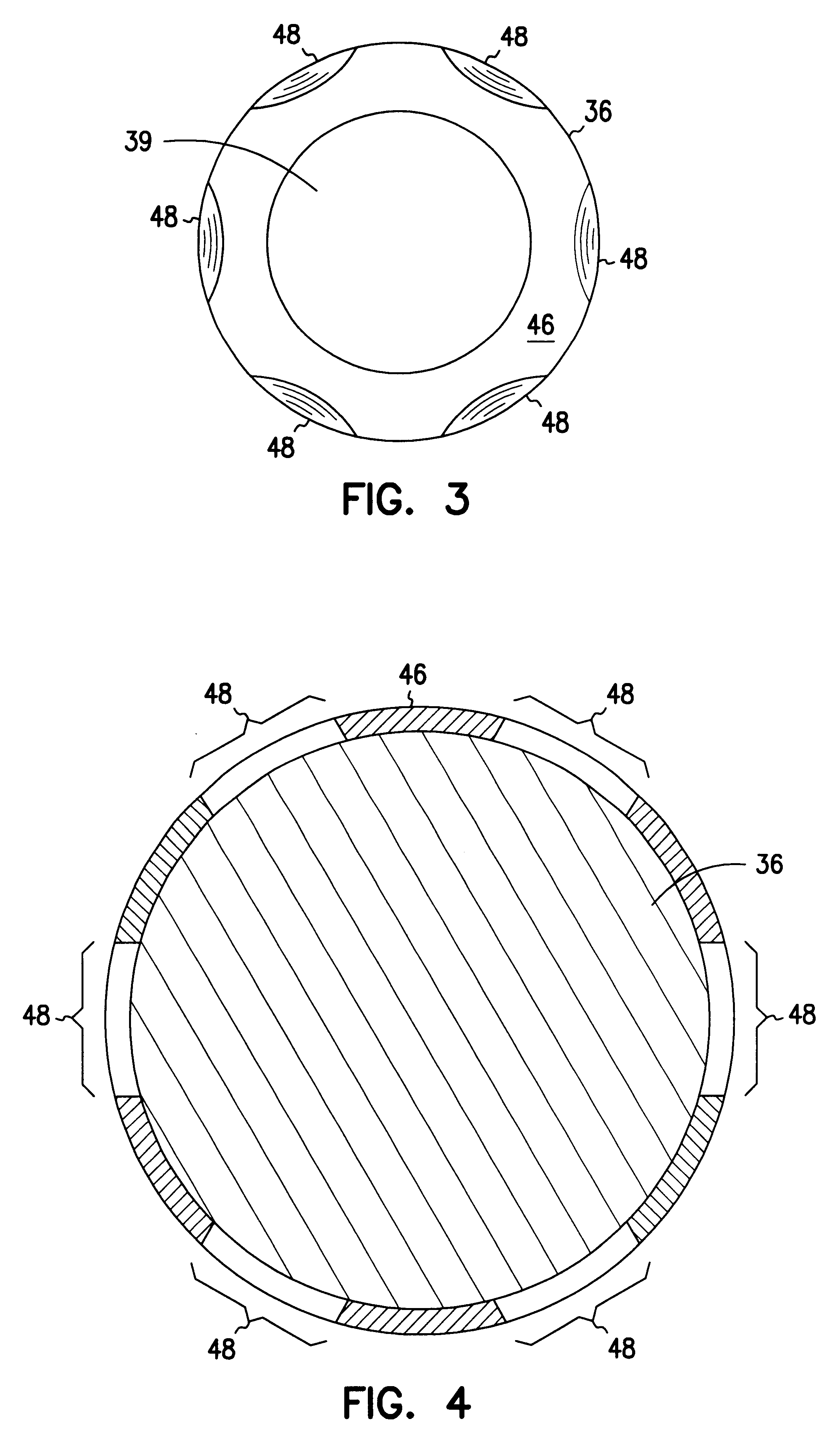

Method for making cardiac leads with zone insulated electrodes

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

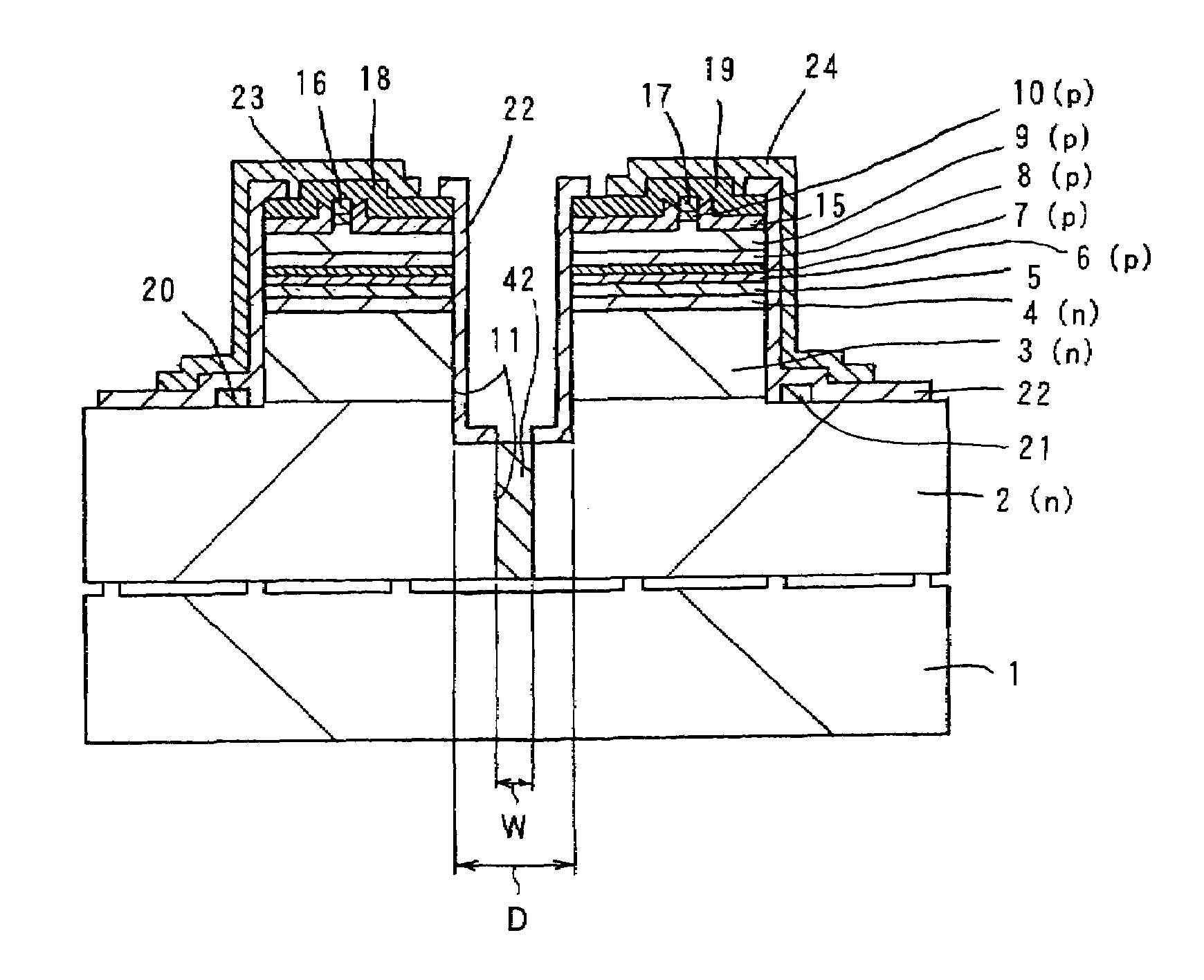

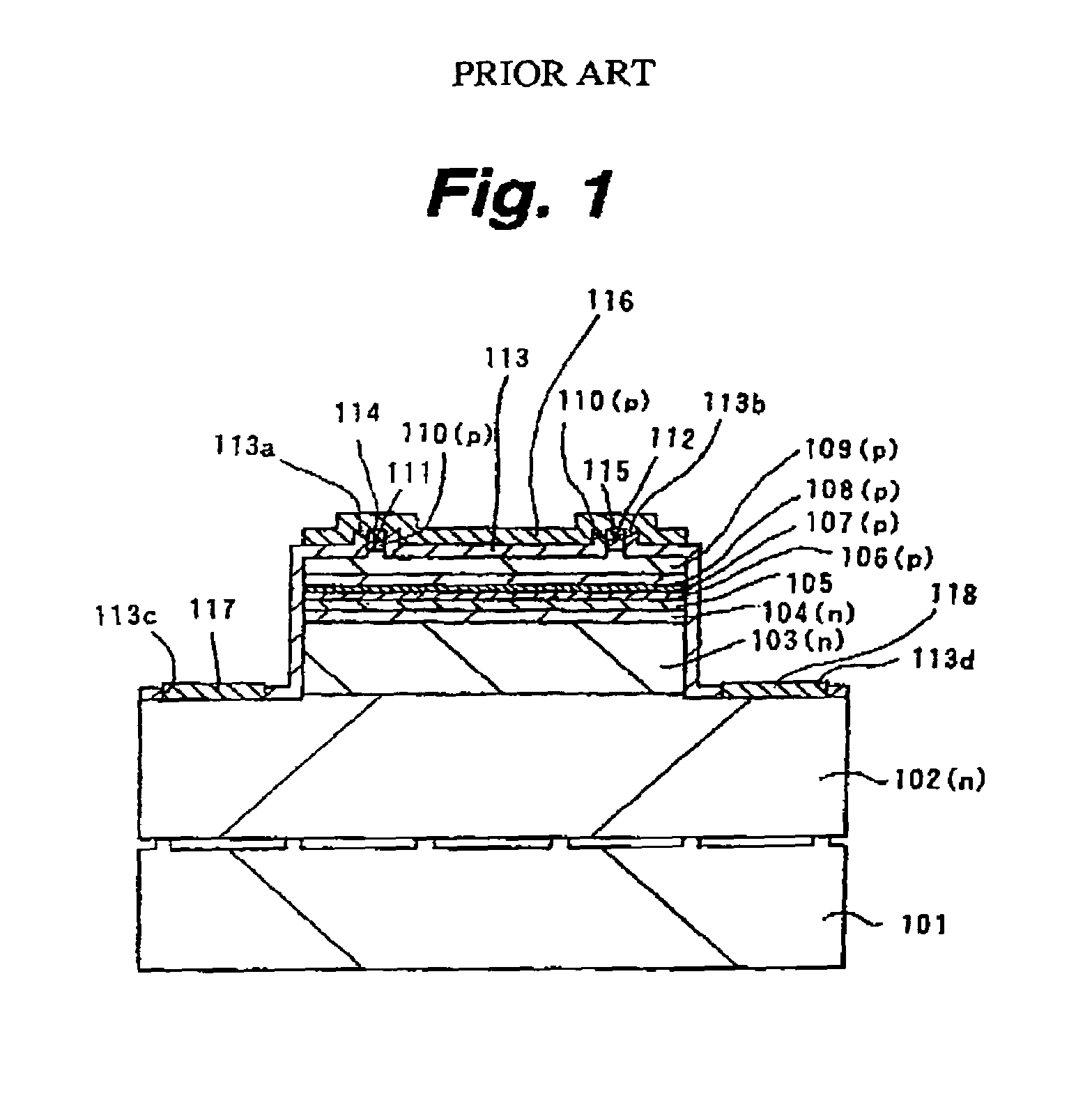

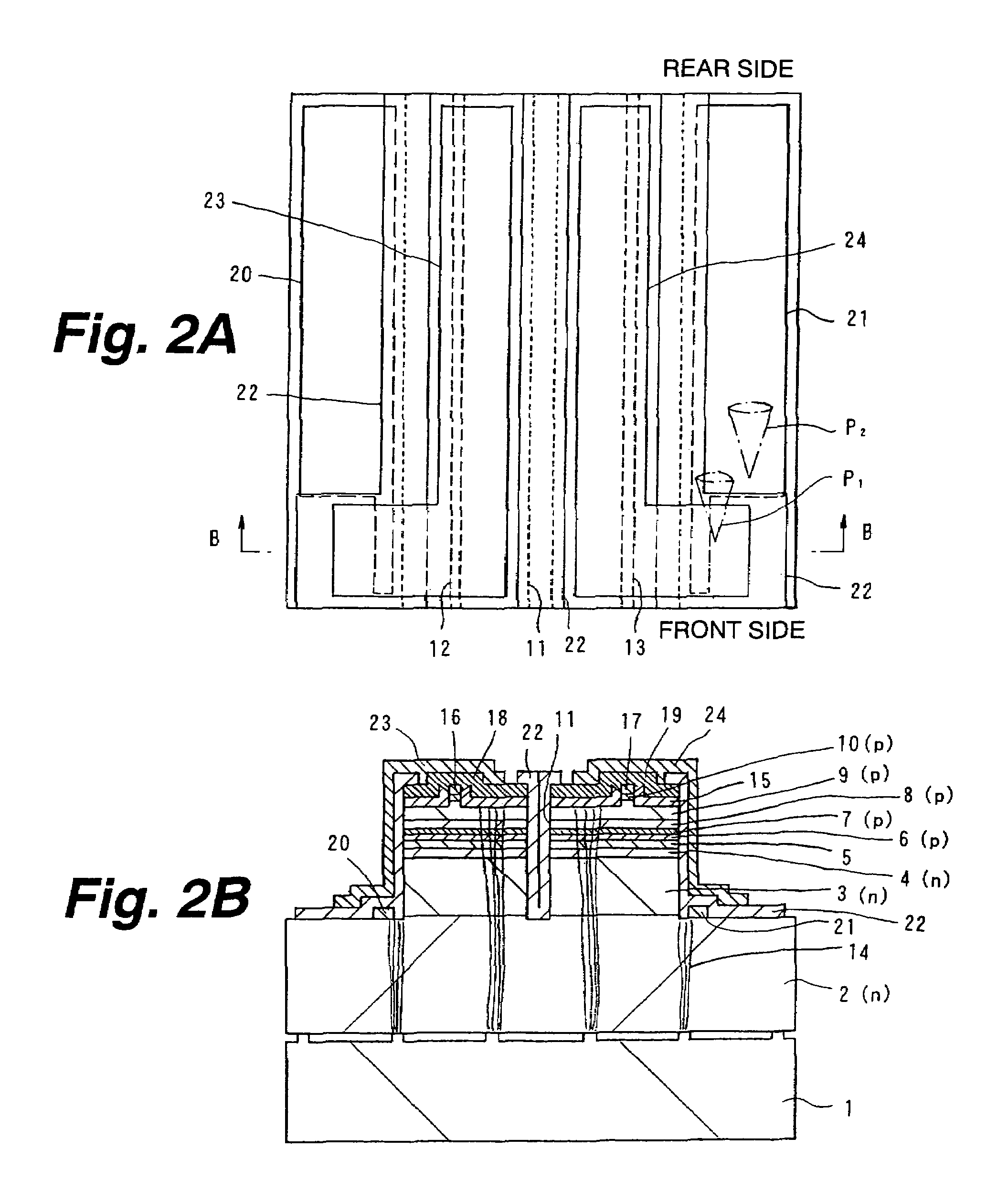

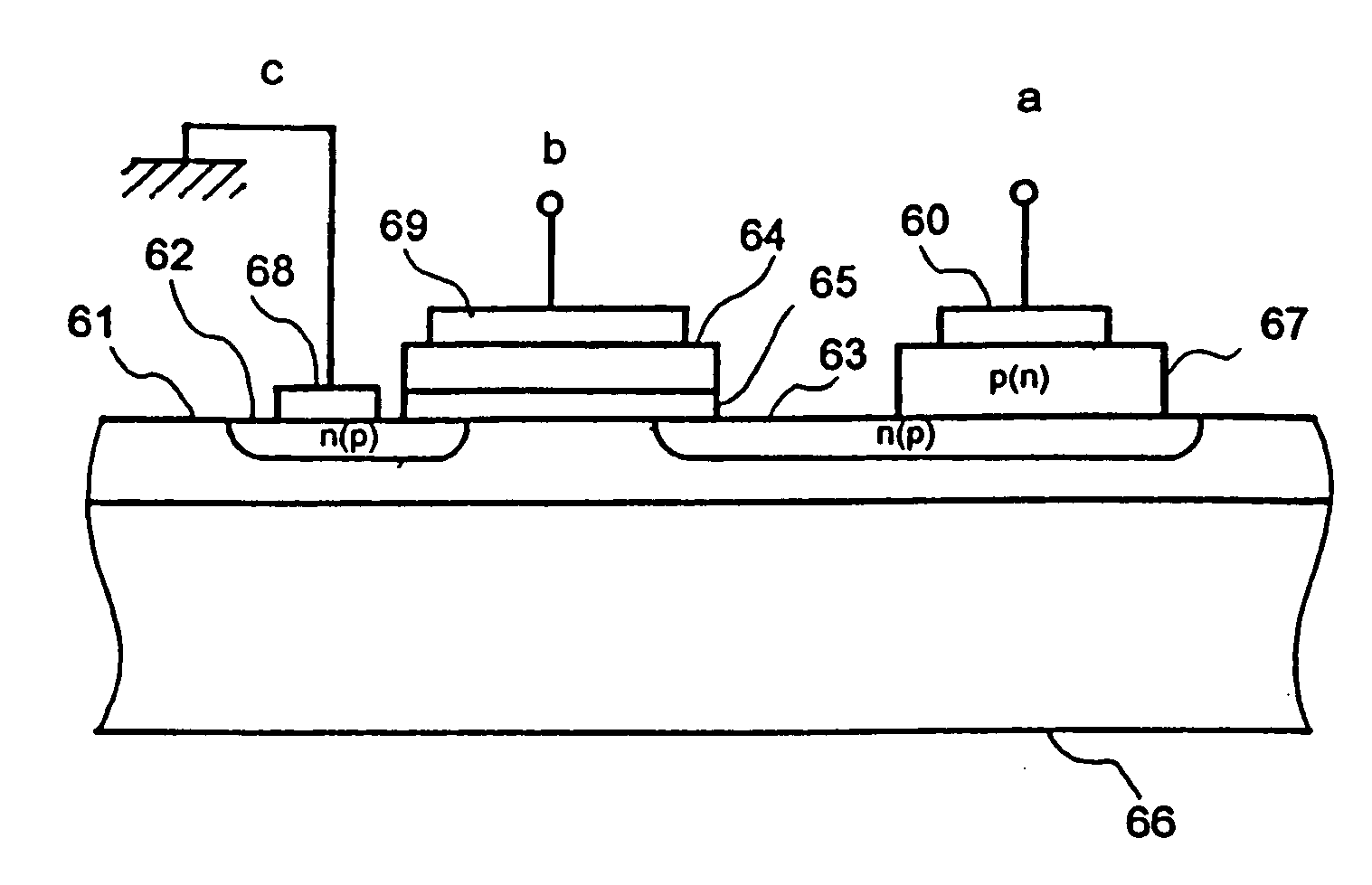

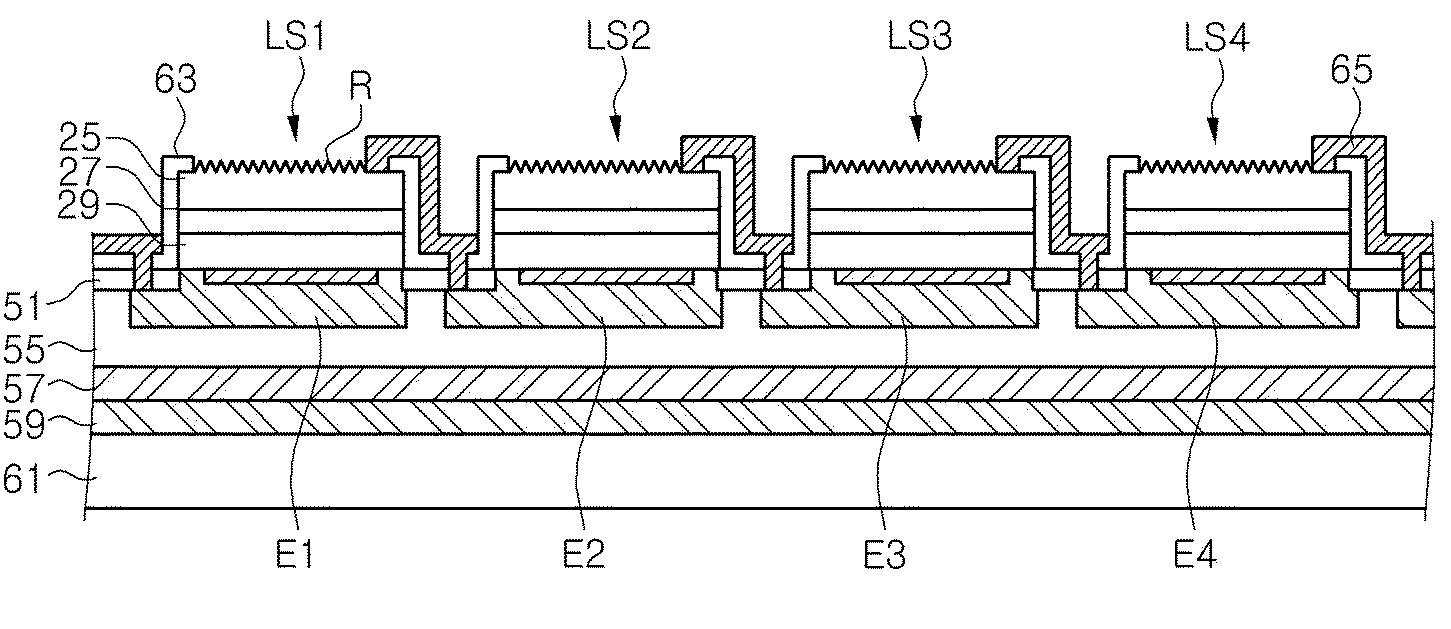

Multibeam semiconductor laser, semiconductor light-emitting device and semiconductor device

InactiveUS6995406B2Easy to checkReduce electrical and thermal cross talkOptical wave guidanceSemiconductor laser arrangementsLight emitting deviceNitride

In a multi-beam semiconductor laser including nitride III–V compound semiconductor layers stacked on one surface of a substrate of sapphire or other material to form laser structures, and including a plurality of anode electrodes and a plurality of cathode electrodes formed on the nitride III–V compound semiconductor layers, one of the anode electrodes is formed to bridge over one of the cathode electrodes via an insulating film, and another anode electrode is formed to bridge over another of the cathode electrodes via an insulating film.

Owner:SONY CORP

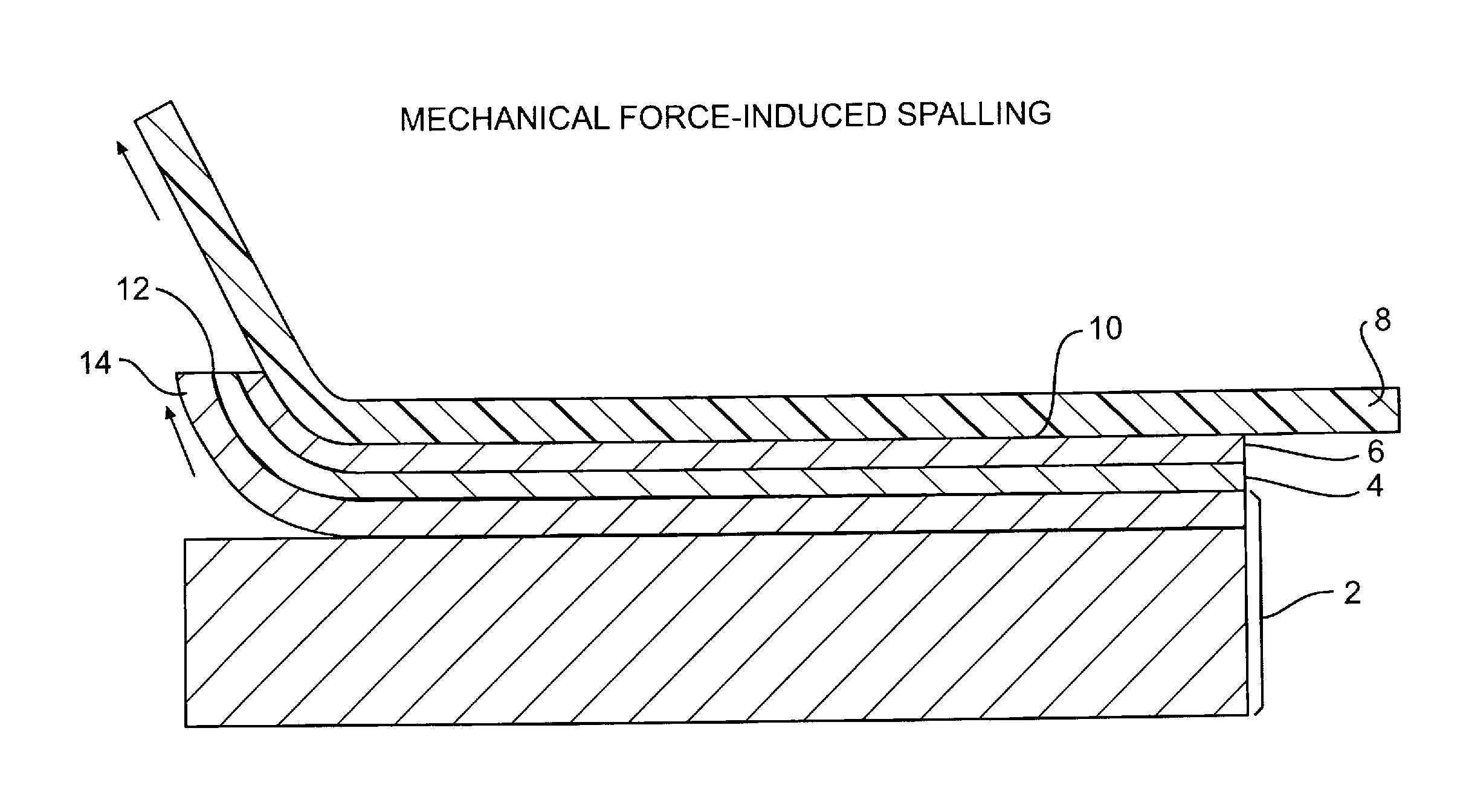

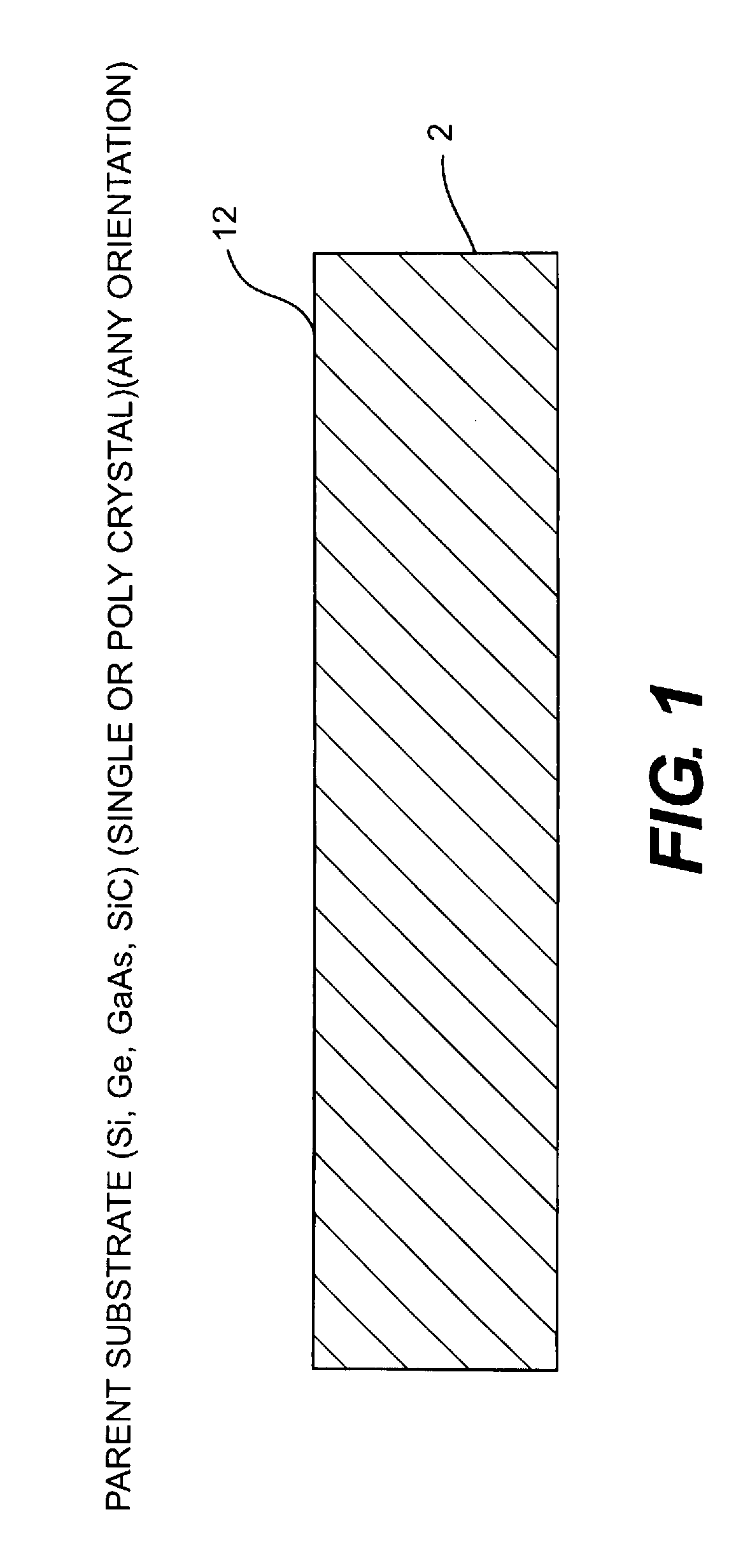

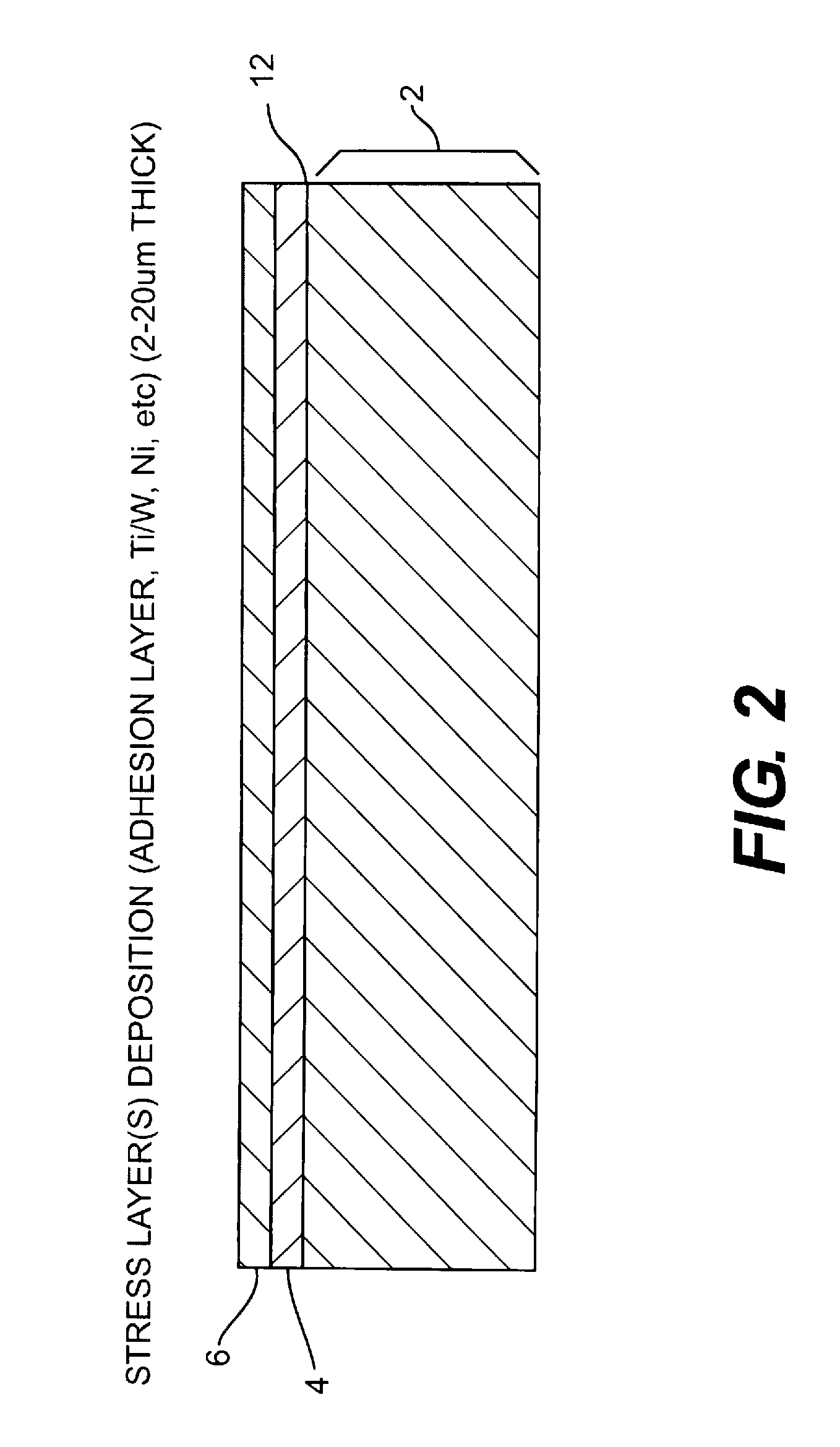

Thin substrate fabrication using stress-induced substrate spalling

ActiveUS20100311250A1Increase cost per Watt valueImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingStress inducedActive solar

A method for manufacturing a thin film direct bandgap semiconductor active solar cell device comprises providing a source substrate having a surface and disposing on the surface a stress layer having a stress layer surface area in contact with and bonded to the surface of the source substrate. Operatively associating a handle foil with the stress layer and applying force to the handle foil separates the stress layer from the source substrate, and leaves a portion of the source substrate on the stress layer surface substantially corresponding to the area in contact with the surface of the source substrate. The portion is less thick than the source layer. The stress layer thickness is below that which results in spontaneous spalling of the source substrate. The source substrate may comprise an inorganic single crystal or polycrystalline material such as Si, Ge, GaAs, SiC, sapphire, or GaN. In one embodiment the stress layer comprises a flexible material.

Owner:GLOBALFOUNDRIES US INC

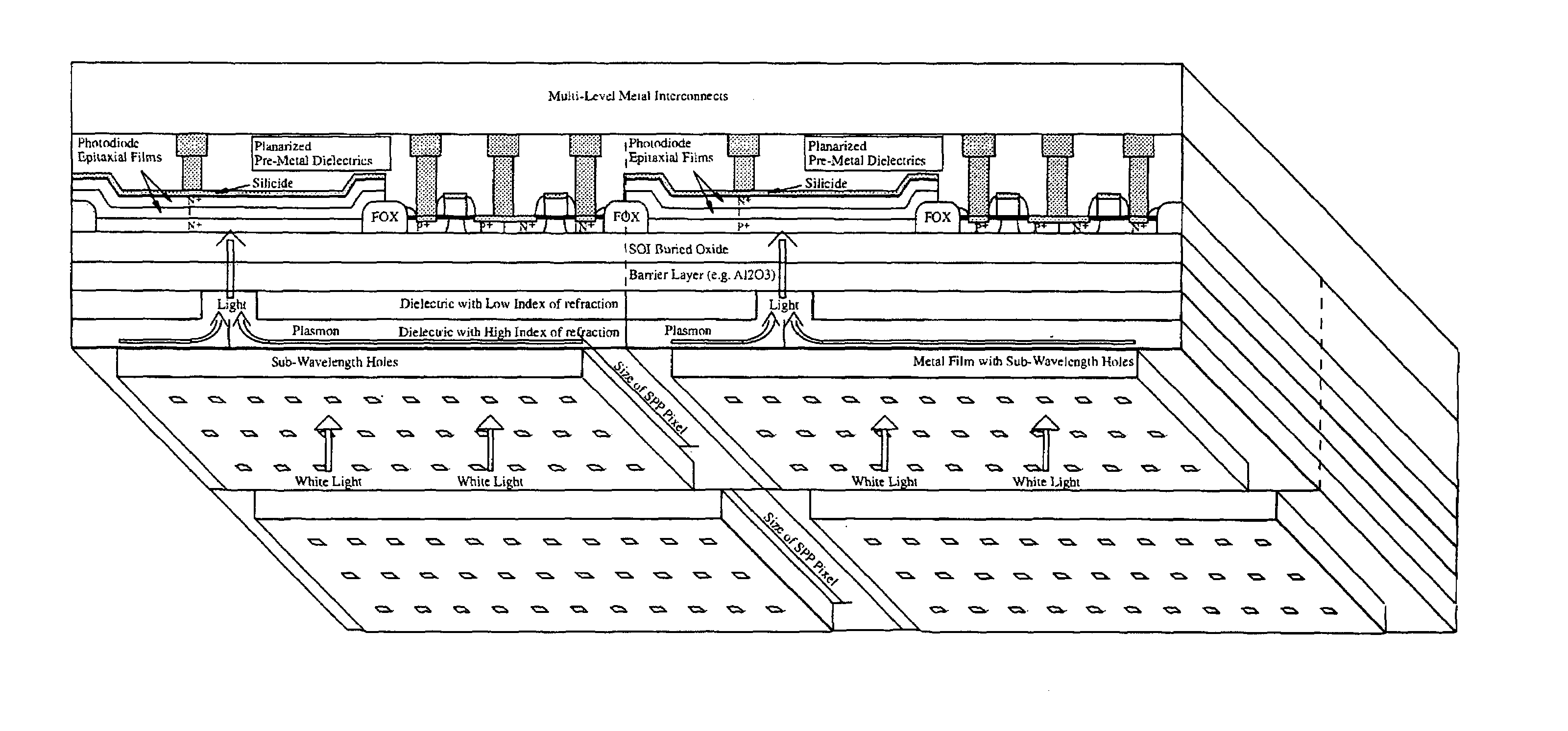

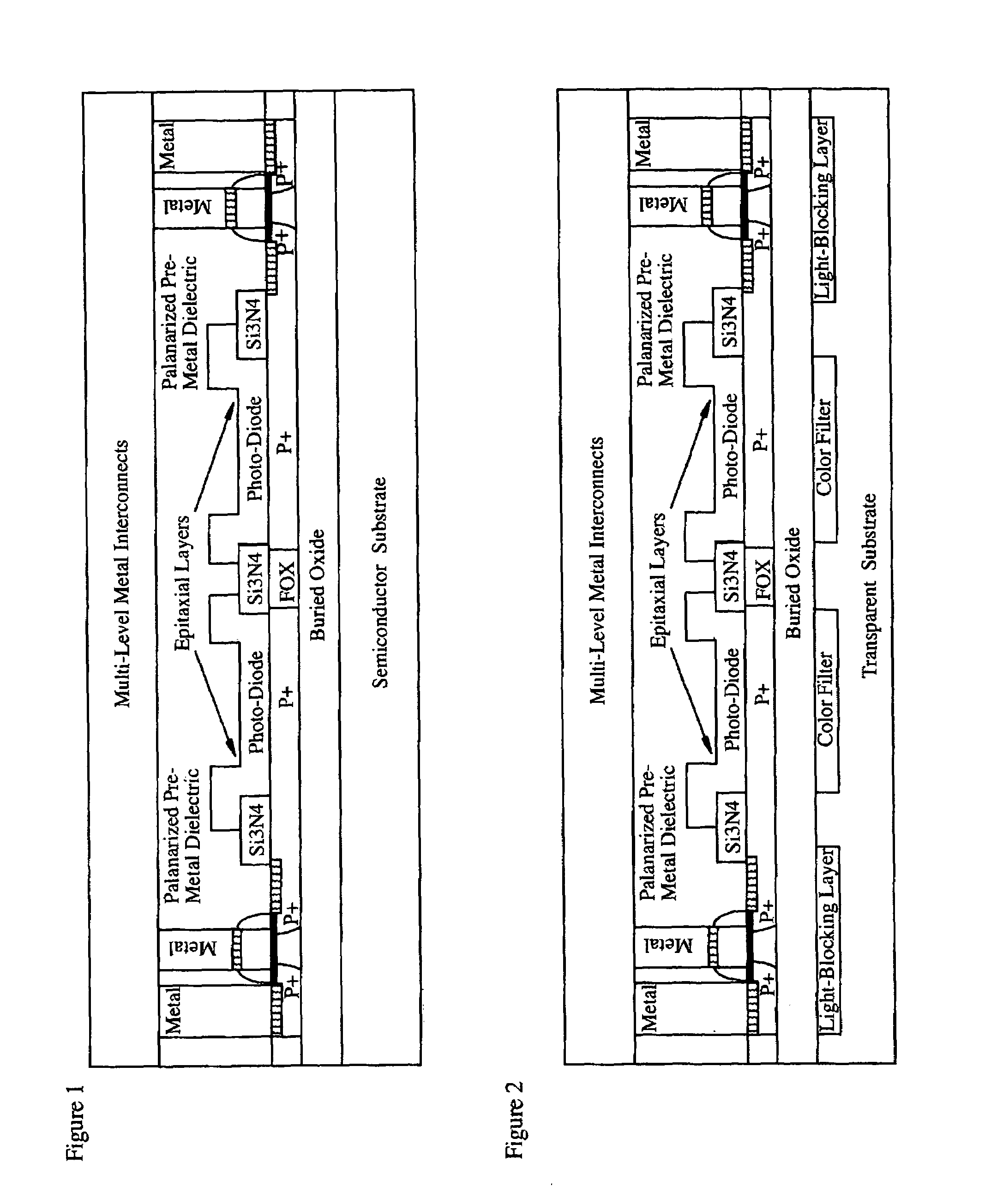

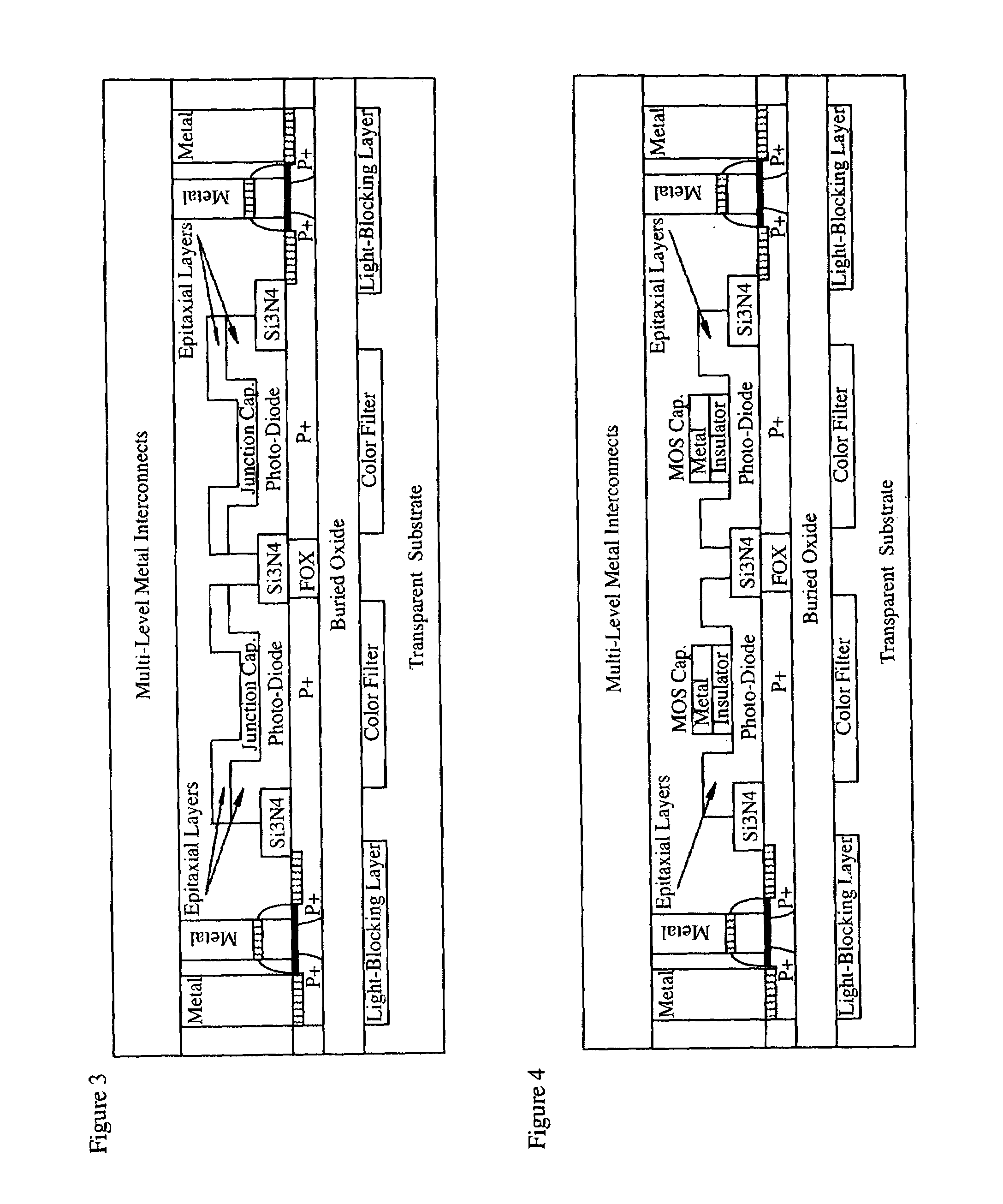

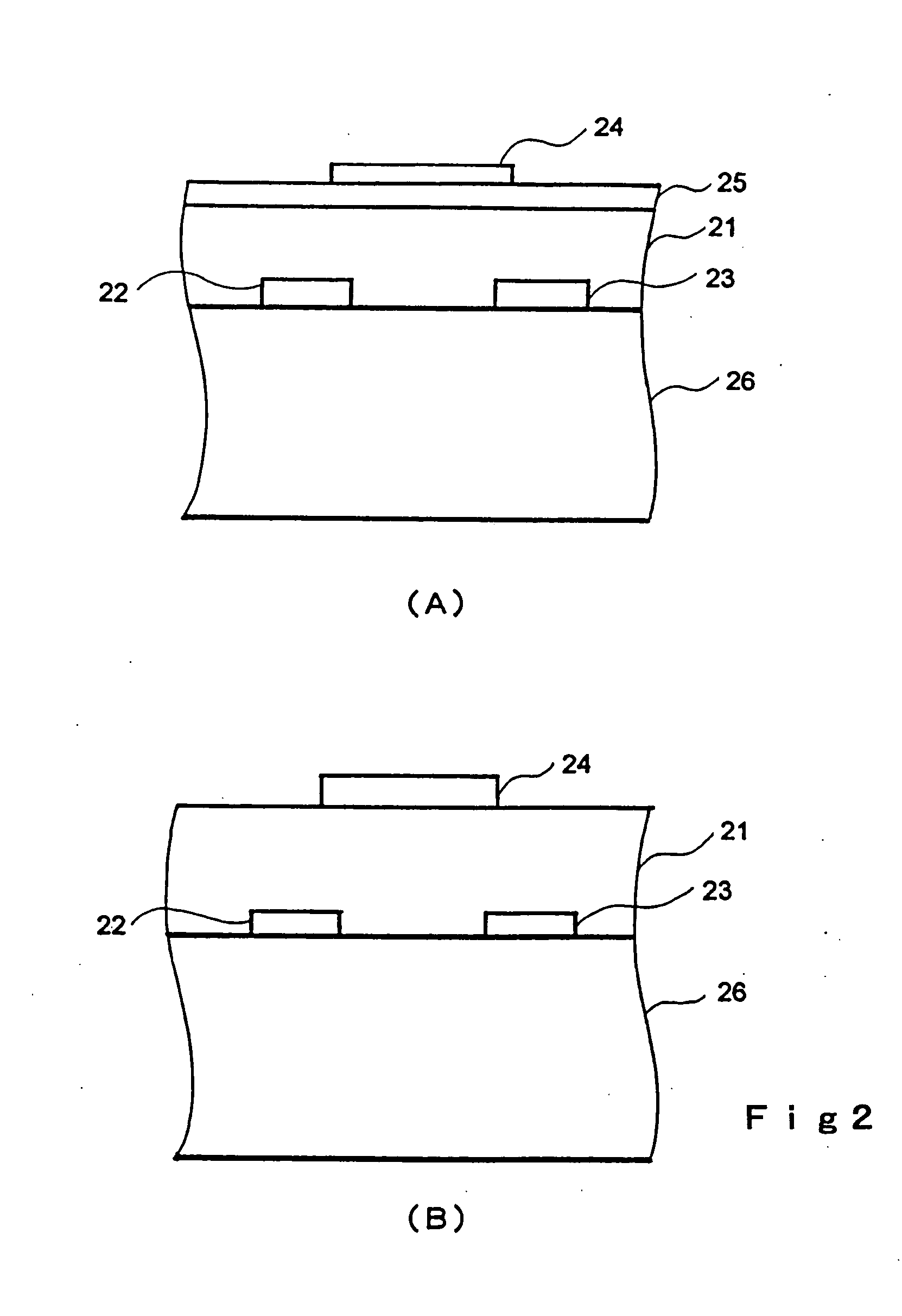

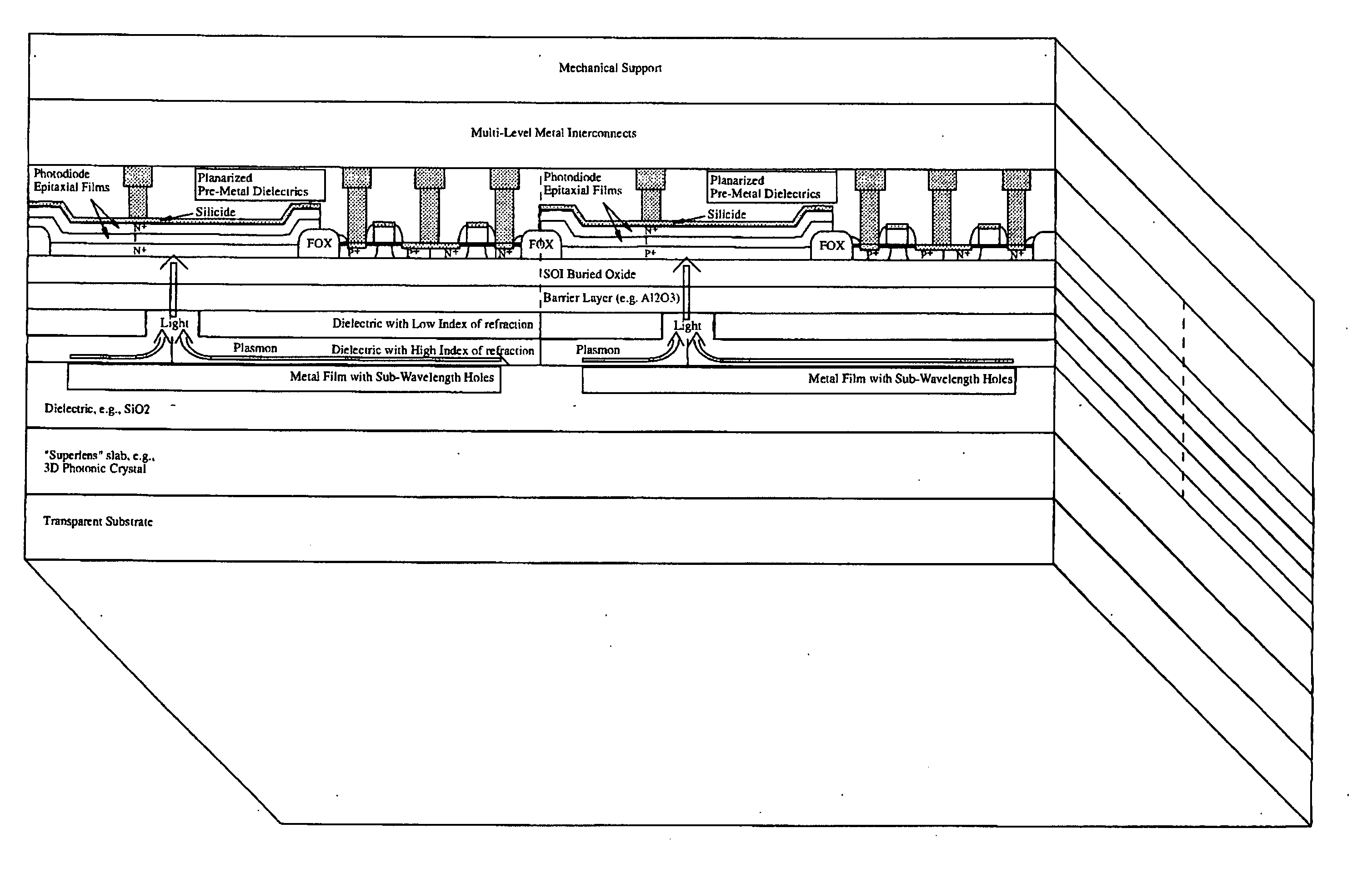

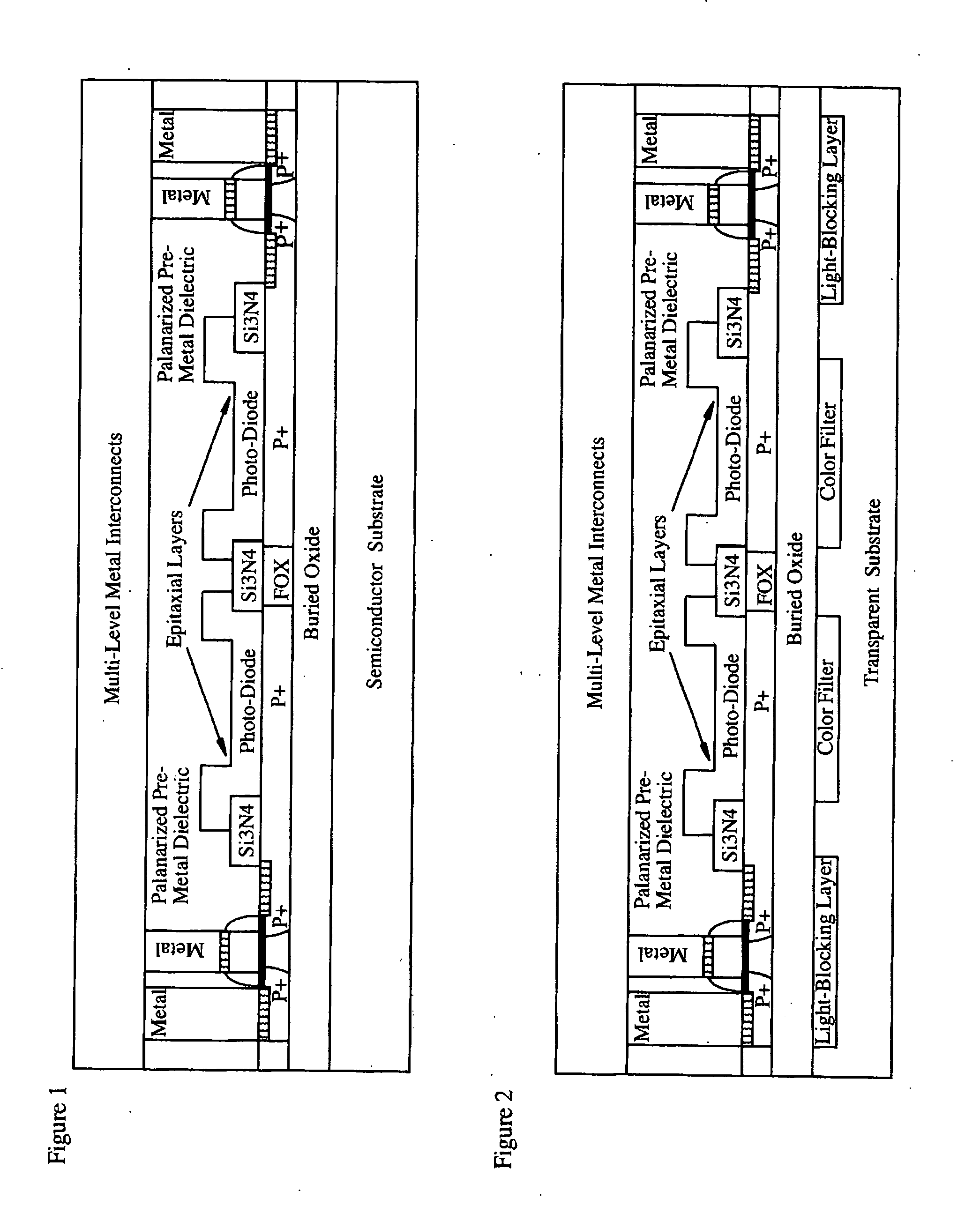

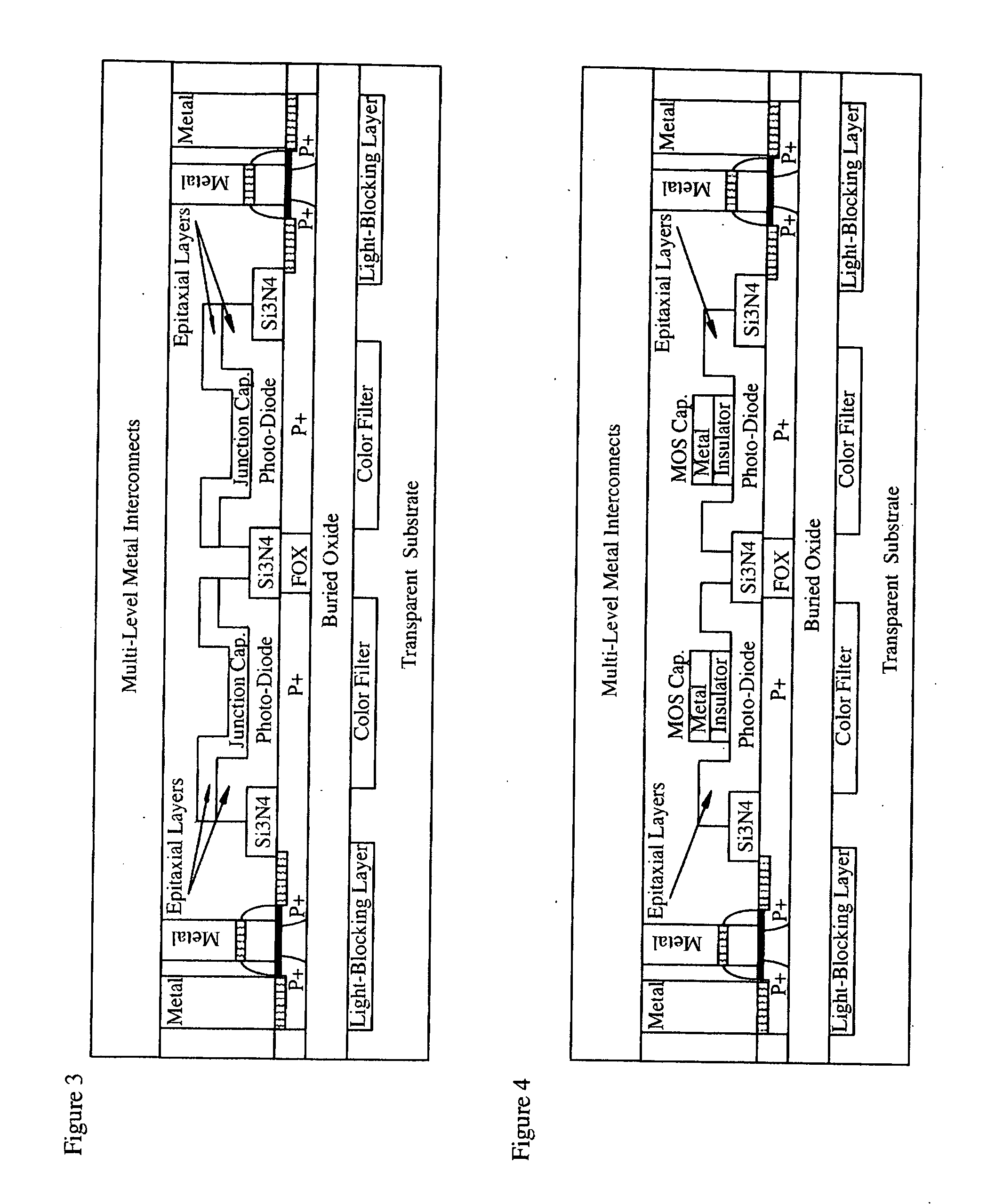

CMOS image sensor

Light sensing devices are monolithically integrates with CMOS devices on Thin-Film Silicon-On-insulator (TF-SOI) or Thin-Film Germanium-On-Insulator (TF-GeOI) substrates. Photo-diode active layers are epitaxially grown on the front-side of the substrate and after full processing of the front-side of the substrate, the substrate material is removed under the buried insulator (buried oxide). Monolithically integrated structures are then fabricated on the back of the buried oxide. The back-side is then bonded to a new substrate that is transparent to the wavelengths of interest. For example, quartz, sapphire, glass, or plastic, are suitable for the visible range. Back-side illumination of the sensor matrix is thereby allowed, with light traveling through the structures fabricated on the back of the substrate, opposite to the side on which CMOS is made.

Owner:QUANTUM SEMICON

Method for making cardiac leads with zone insulated electrodes

InactiveUS6526321B1Internal electrodesDiagnostic recording/measuringDiamond-like carbonBiomedical engineering

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

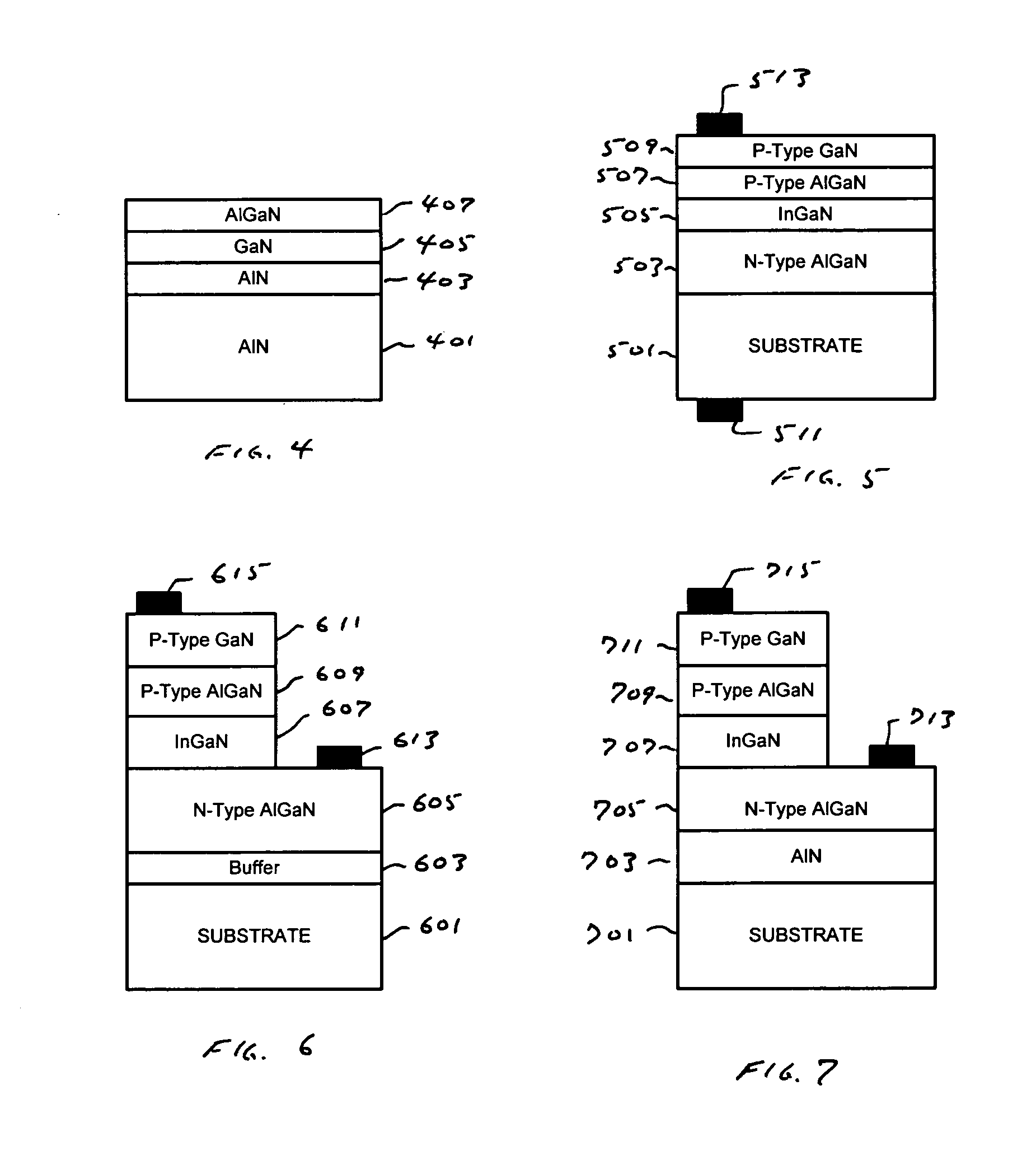

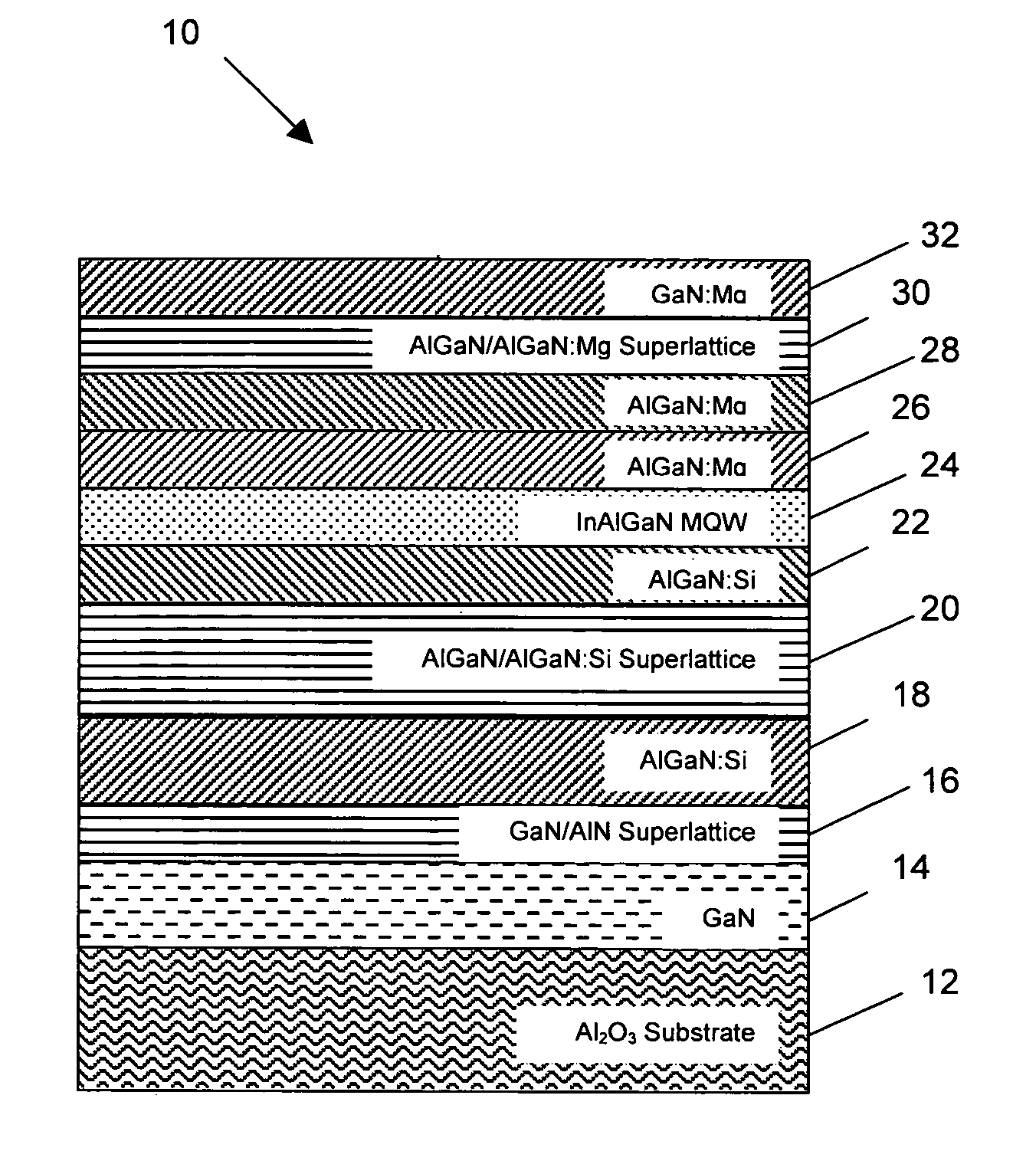

Superlattice strain relief layer for semiconductor devices

ActiveUS7547925B2High aluminum contentLow working voltageSolid-state devicesNanoopticsLength waveLight-emitting diode

A GaN / AlN superlattice is formed over a GaN / sapphire template structure, serving in part as a strain relief layer for growth of subsequent layers (e.g., deep UV light emitting diodes). The GaN / AlN superlattice mitigates the strain between a GaN / sapphire template and a multiple quantum well heterostructure active region, allowing the use of high Al mole fraction in the active region, and therefore emission in the deep UV wavelengths.

Owner:XEROX CORP

Transistor and semiconductor device

InactiveUS20050127380A1Increase brightnessIncrease ratingsTransistorLaser detailsDevice materialConductive materials

Owner:JAPAN SCI & TECH CORP

CMOS image sensor

Light sensing devices are monolithically integrates with CMOS devices on Thin-Film Silicon-On-insulator (TF-SOI) or Thin-Film Germanium-On-Insulator (TF-GeOI) substrates. Photodiode active layers are epitaxially grown on the front-side of the substrate and after full processing of the front-side of the substrate, the substrate material is removed under the buried insulator (buried oxide). Monolithically integrated structures are then fabricated on the back of the buried oxide. The back-side is then bonded to a new substrate that is transparent to the wavelengths of interest. For example, quartz, sapphire, glass, or plastic, are suitable for the visible range. Back-side illumination of the sensor matrix is thereby allowed, with light traveling through the structures fabricated on the back of the substrate, opposite to the side on which CMOS is made.

Owner:QUANTUM SEMICON

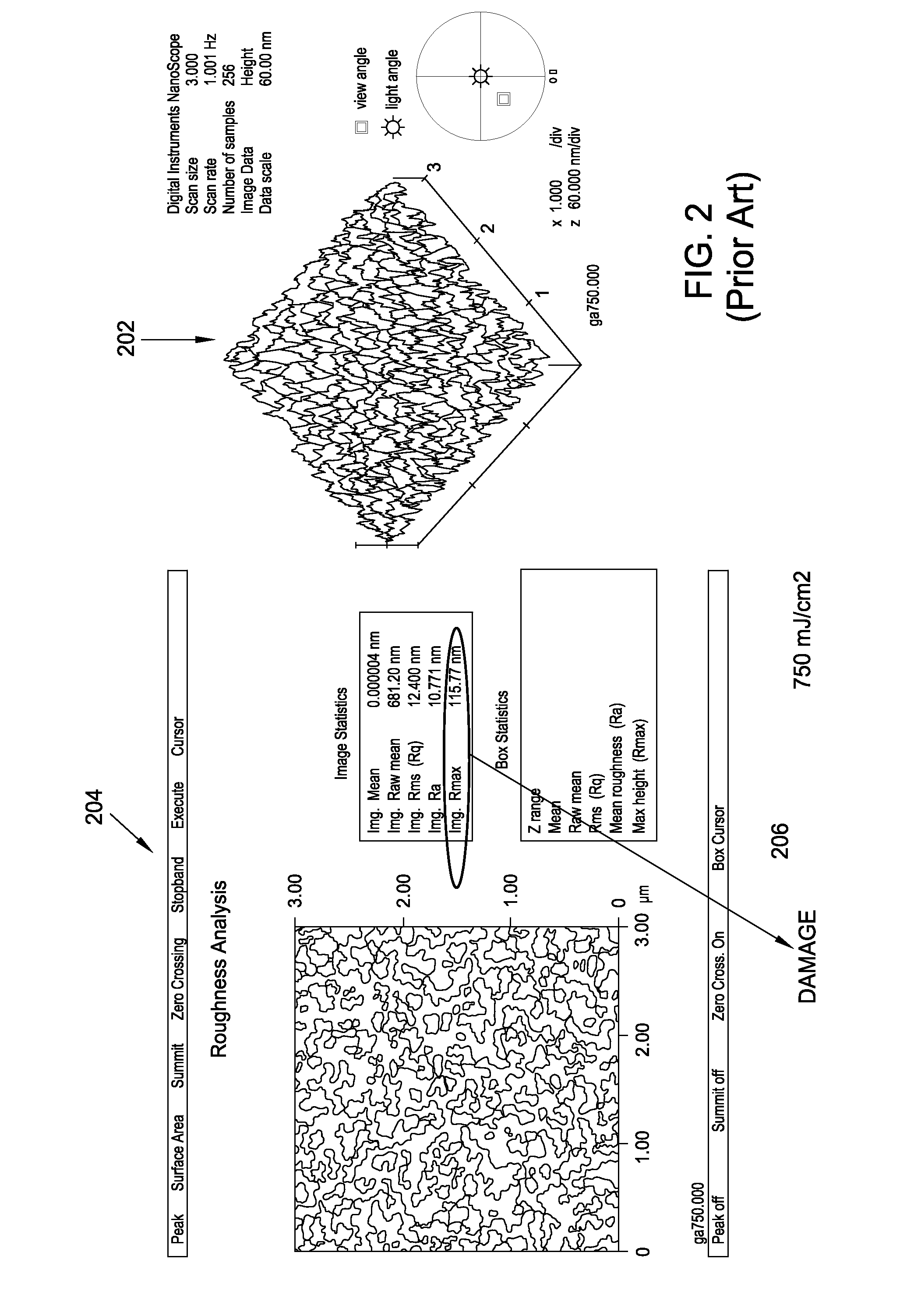

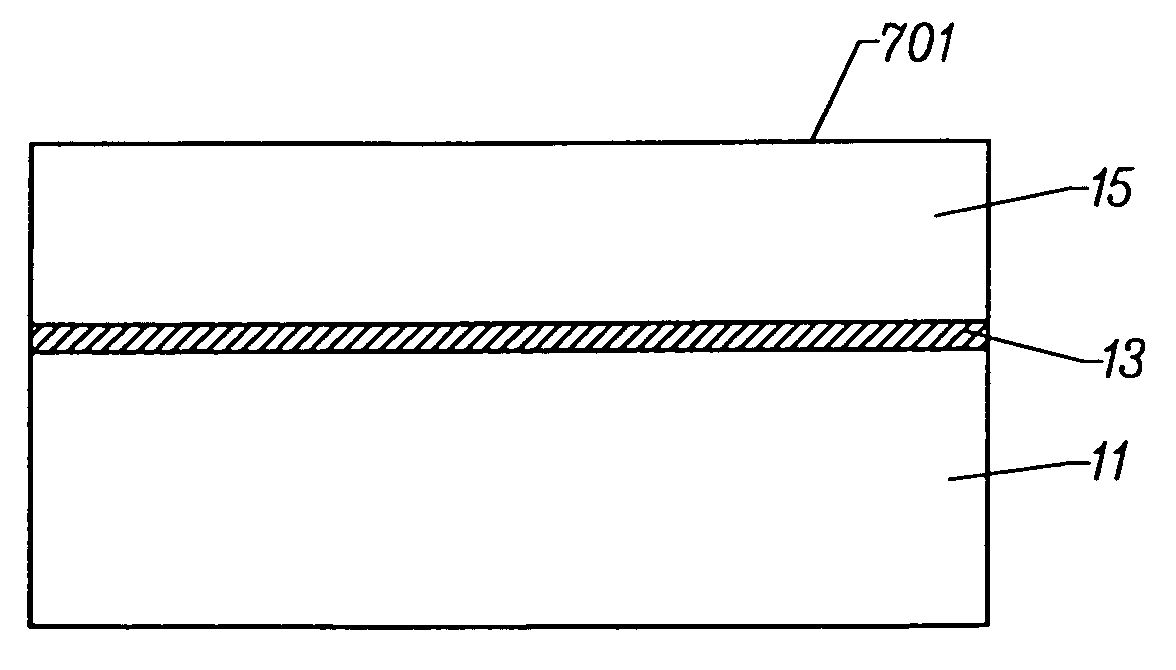

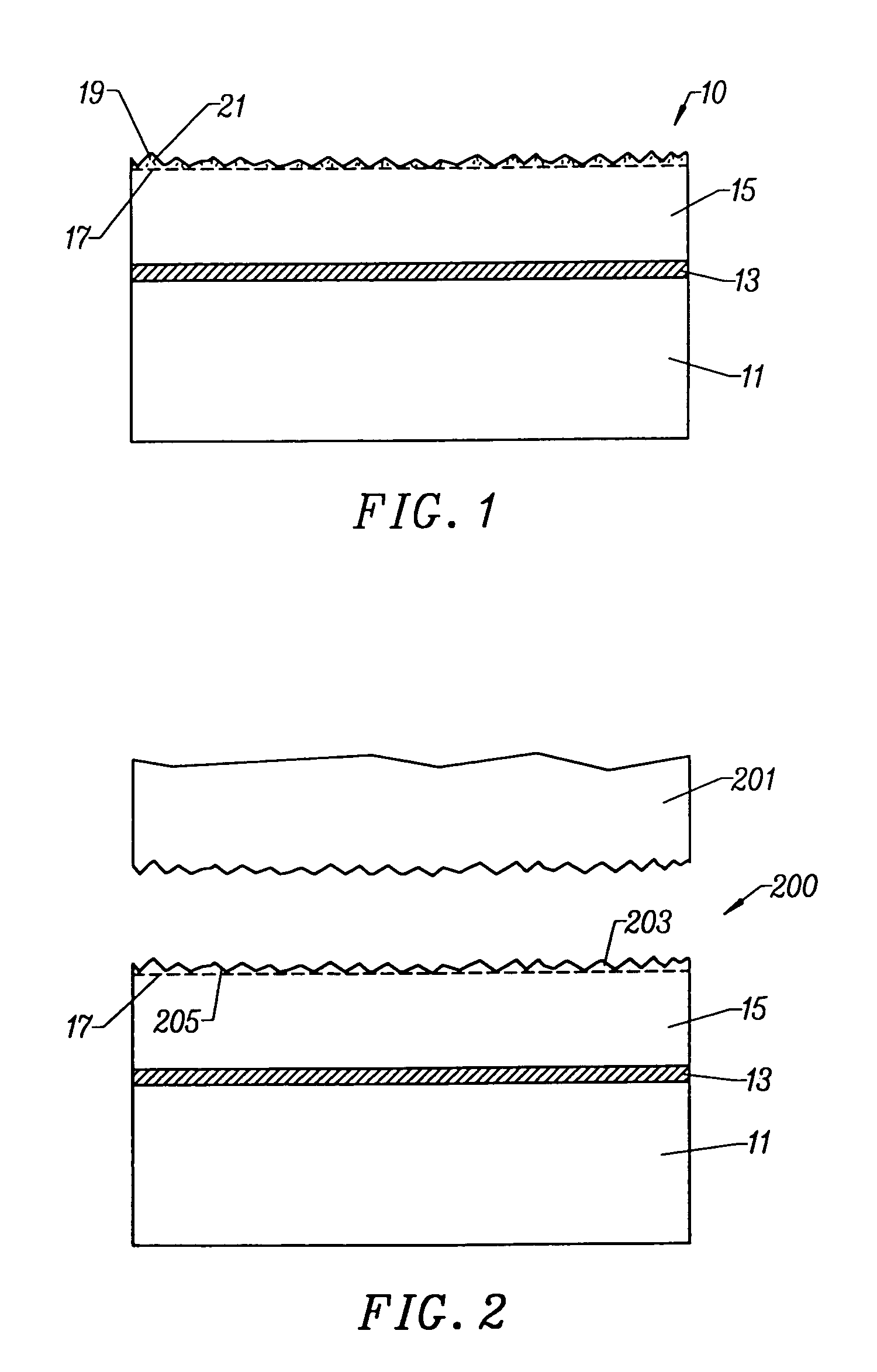

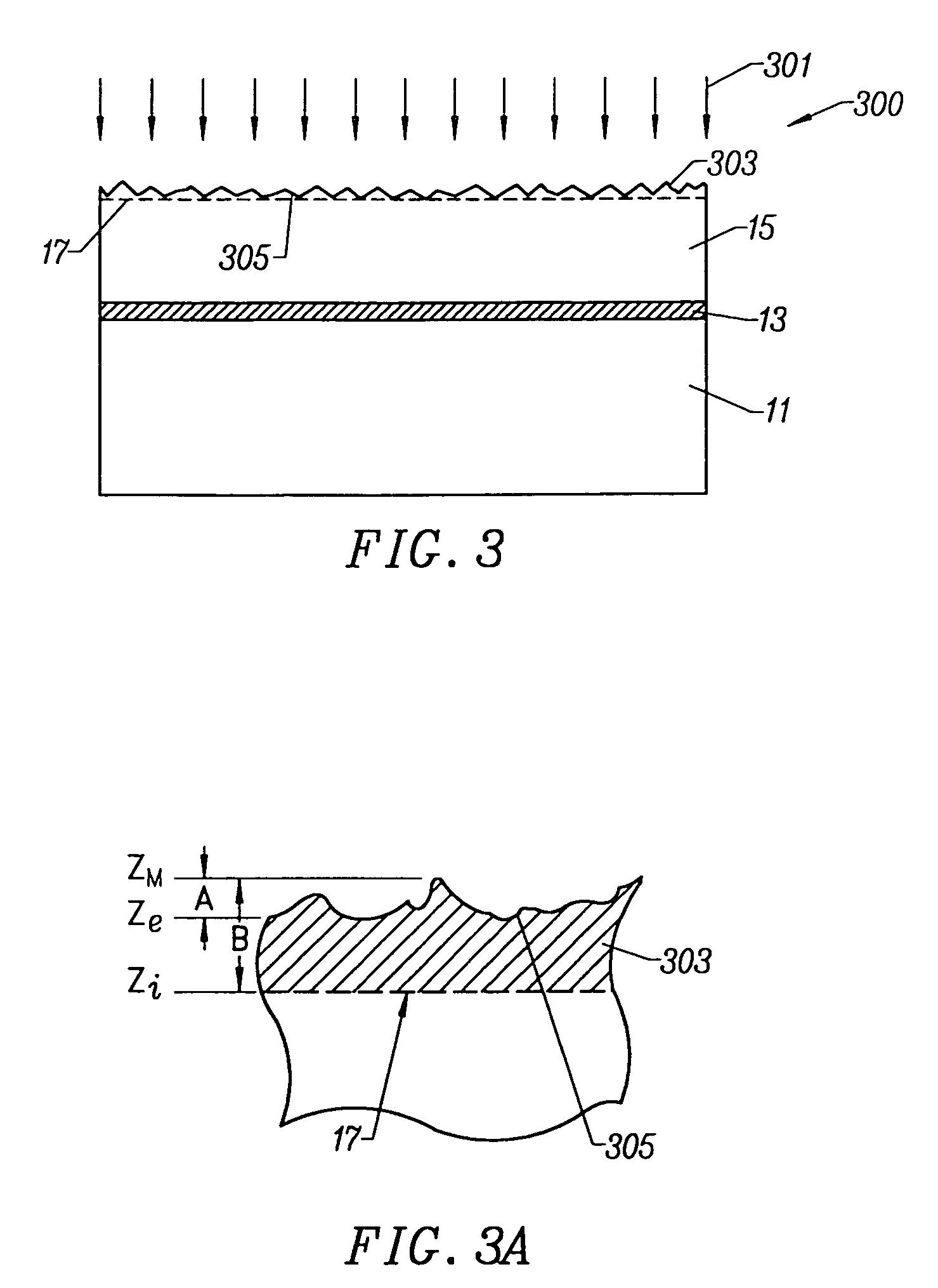

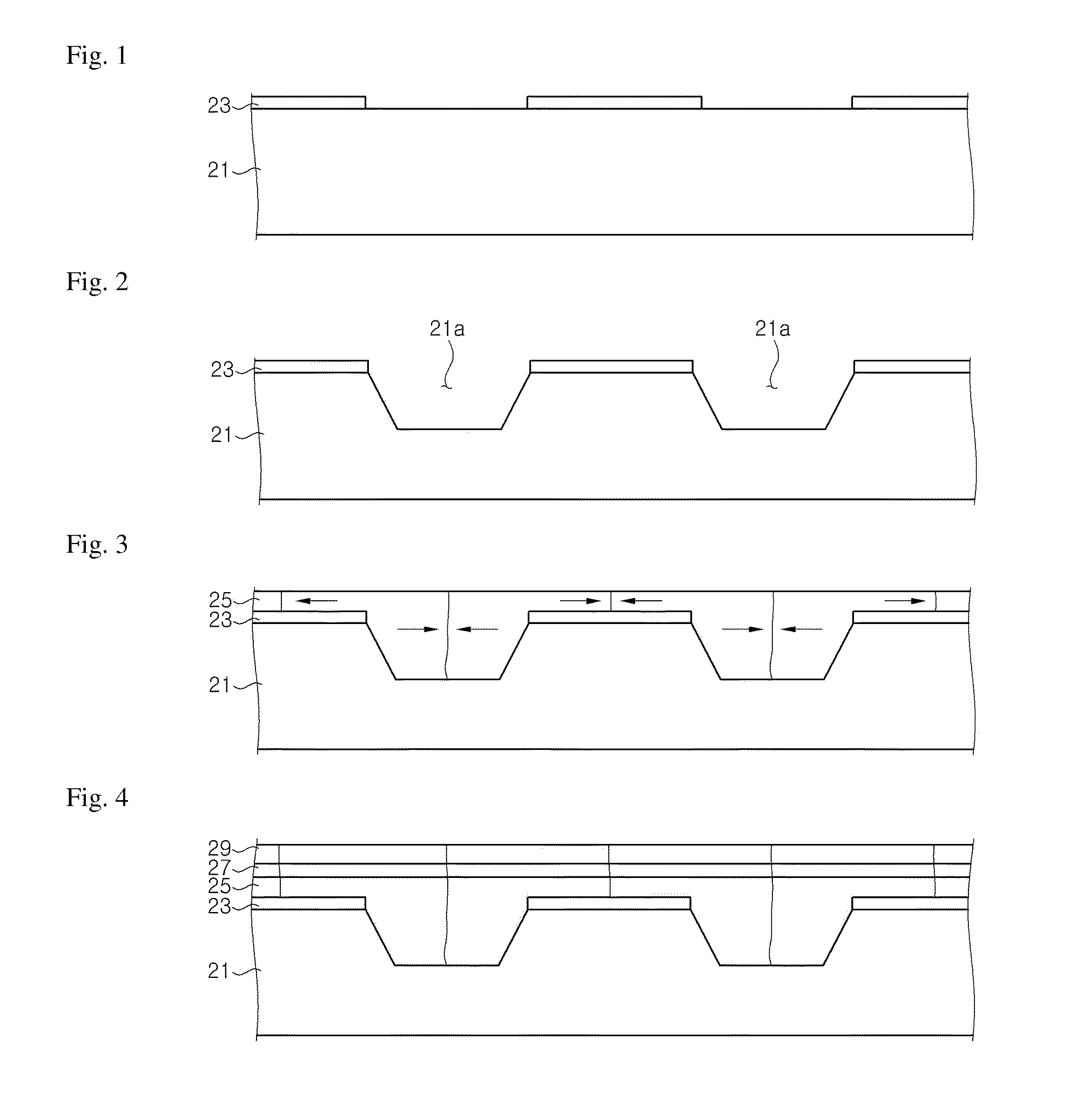

Treatment method of film quality for the manufacture of substrates

InactiveUS6969668B1Improve crystal structureReduce defectsDecorative surface effectsSemiconductor/solid-state device manufacturingSurface roughnessGallium nitride

A method of fabricating substrates, e.g., bulk wafers, silicon on insulator wafers, silicon on saphire, optoelectronic substrates. The method includes providing a substrate (e.g., silicon, gallium arsenide, gallium nitride, quartz). The substrate has a film characterized by a non-uniform surface, which includes a plurality of defects. At least some of the defects are of a size ranging from about 100 Angstroms and greater. The method also includes applying a combination of a deposition species for deposition of a deposition material and an etching species for etching etchable material. The combination of the deposition species and the etching species contact the non-uniform surface in a thermal setting to reduce a level of non-uniformity of the non-uniform surface by filling a portion of the defects to smooth the film of material. The smoothed film of material is substantially free from the defects and is characterized by a surface roughness of a predetermined value.

Owner:SILICON GENERAL CORPORATION

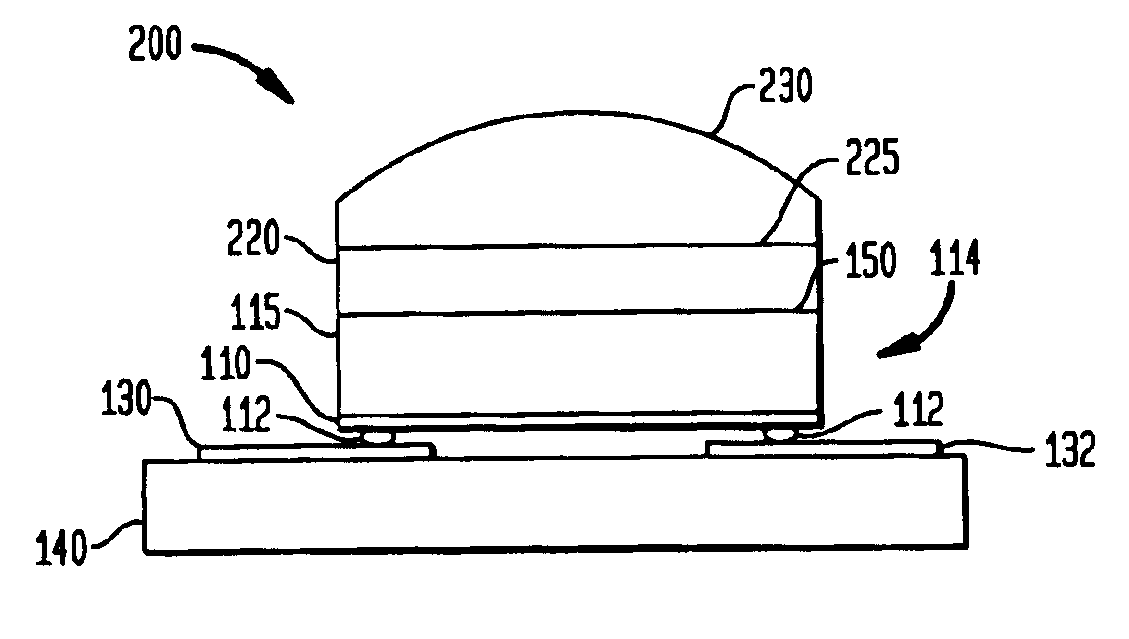

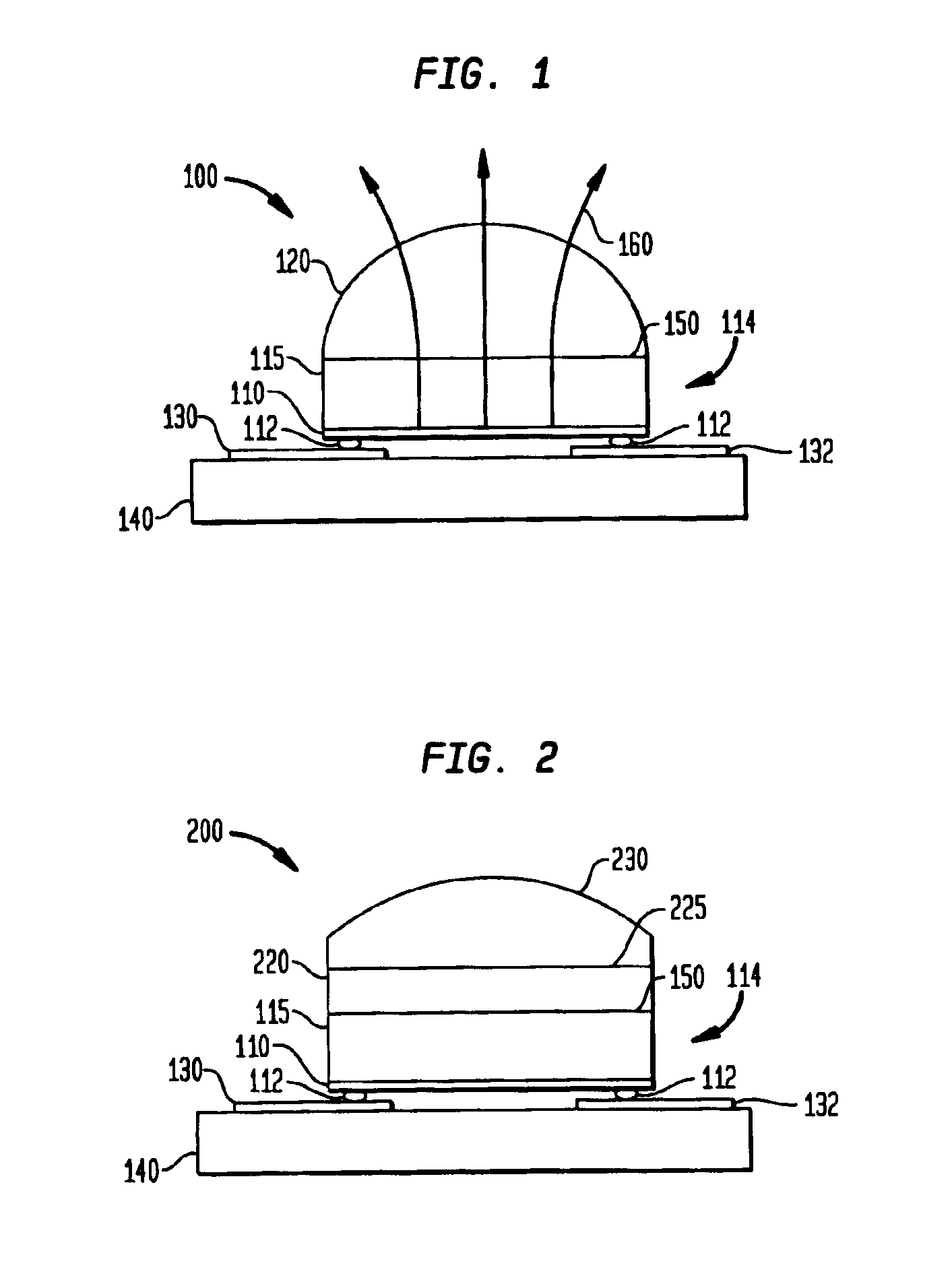

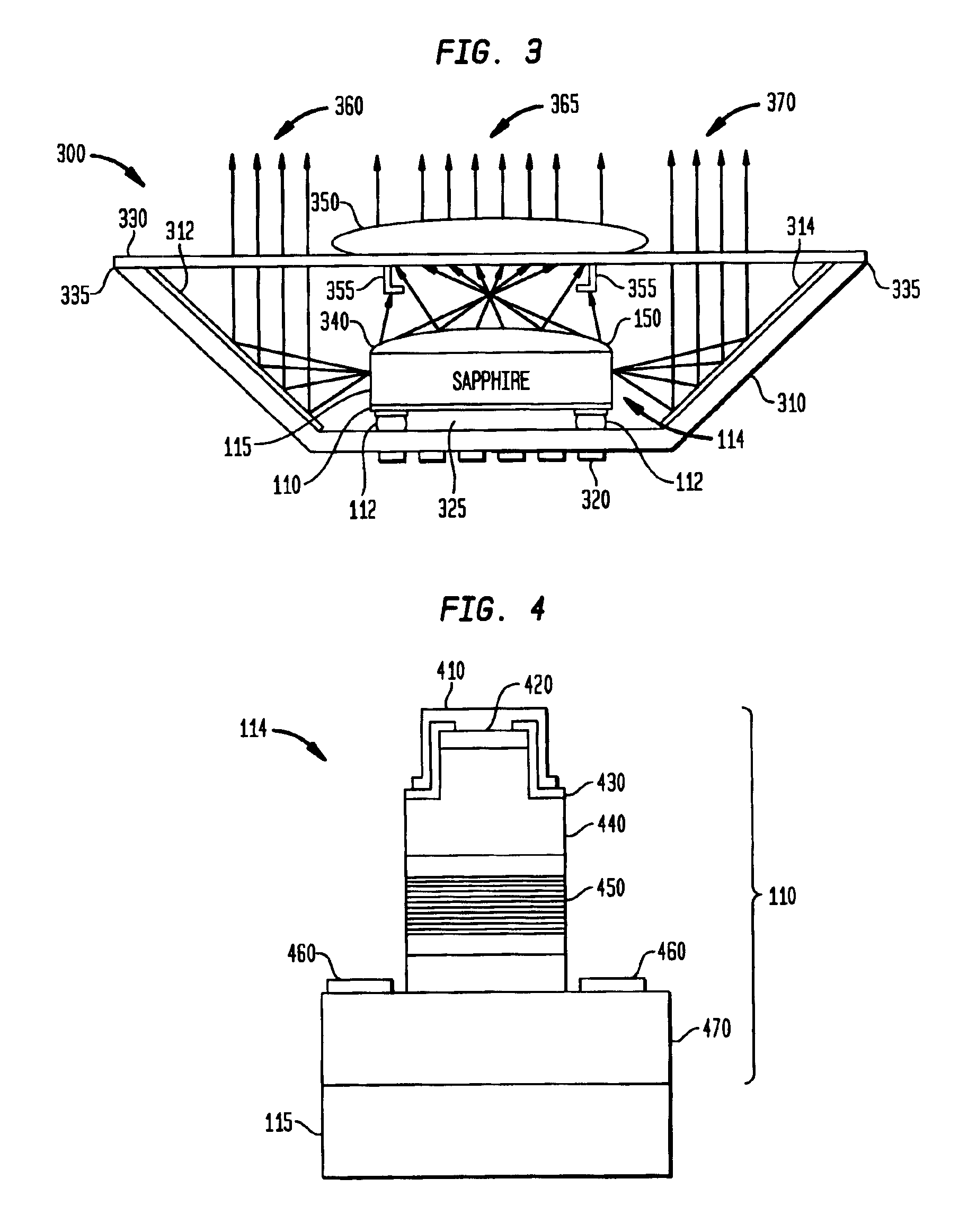

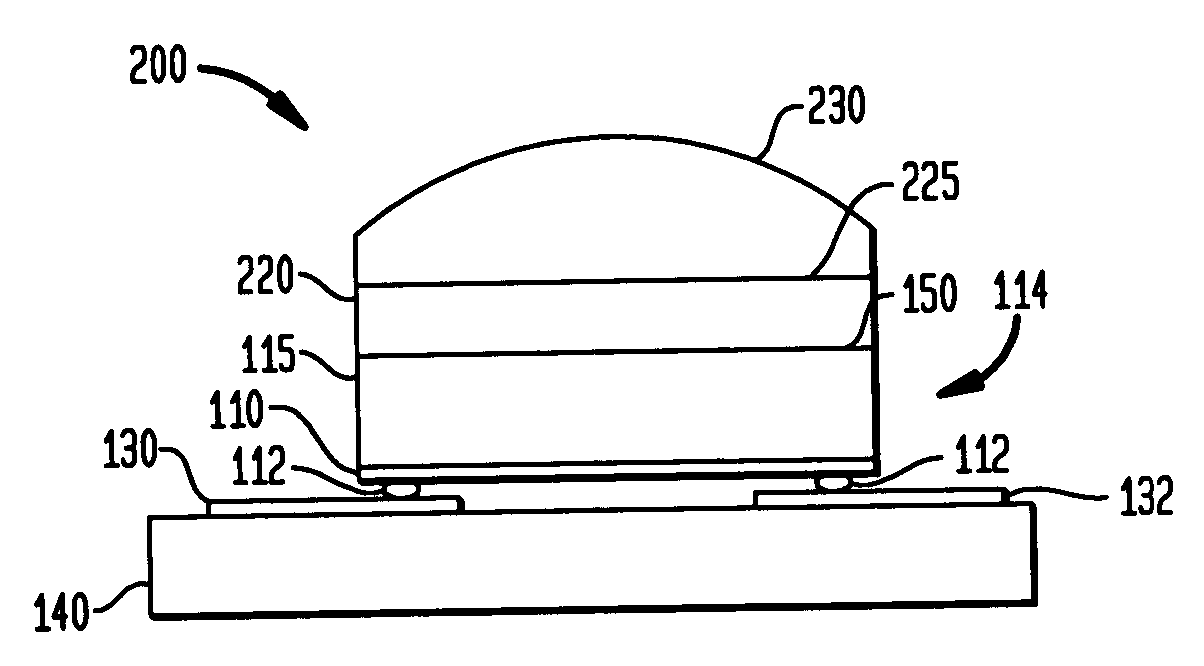

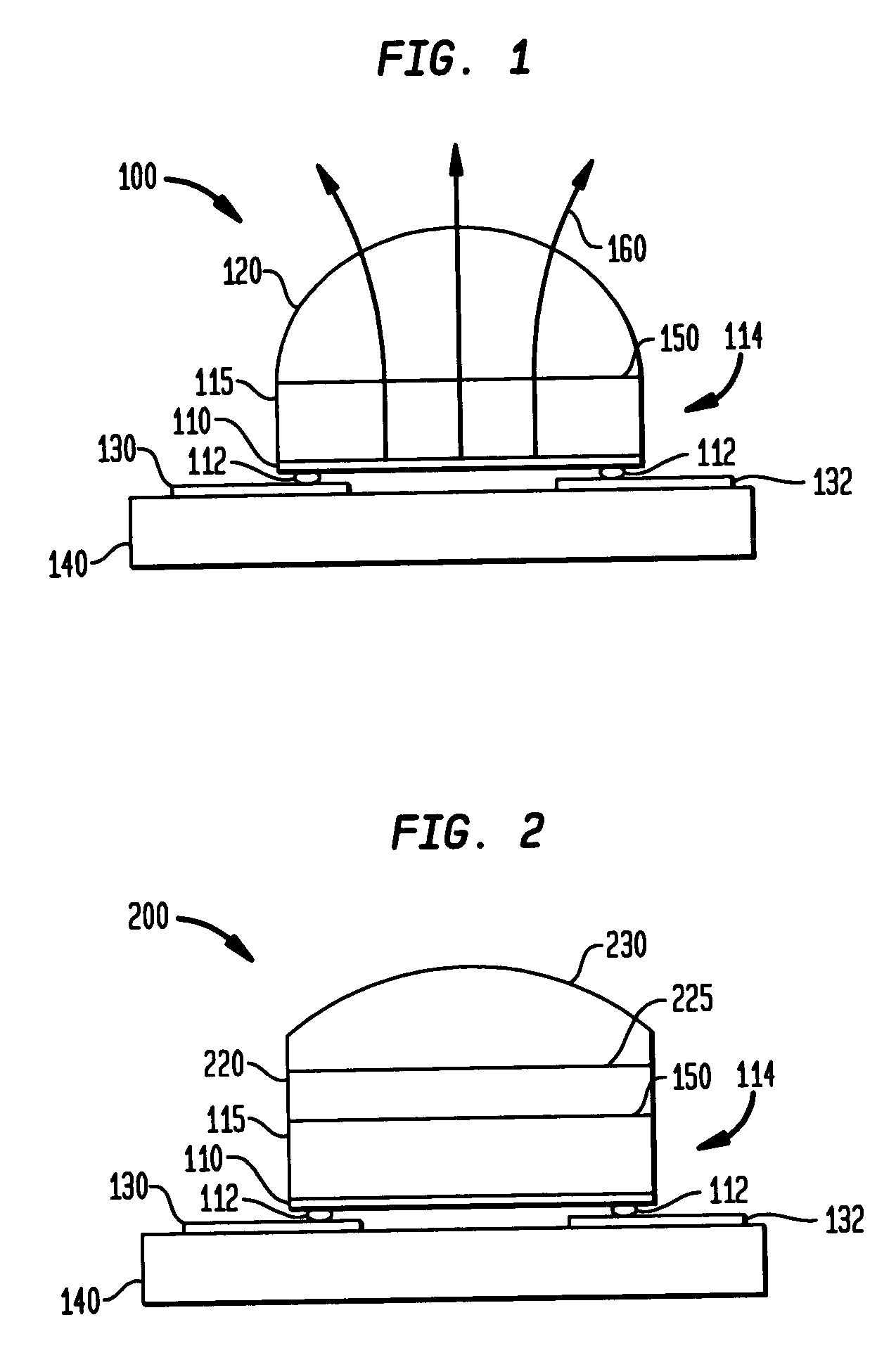

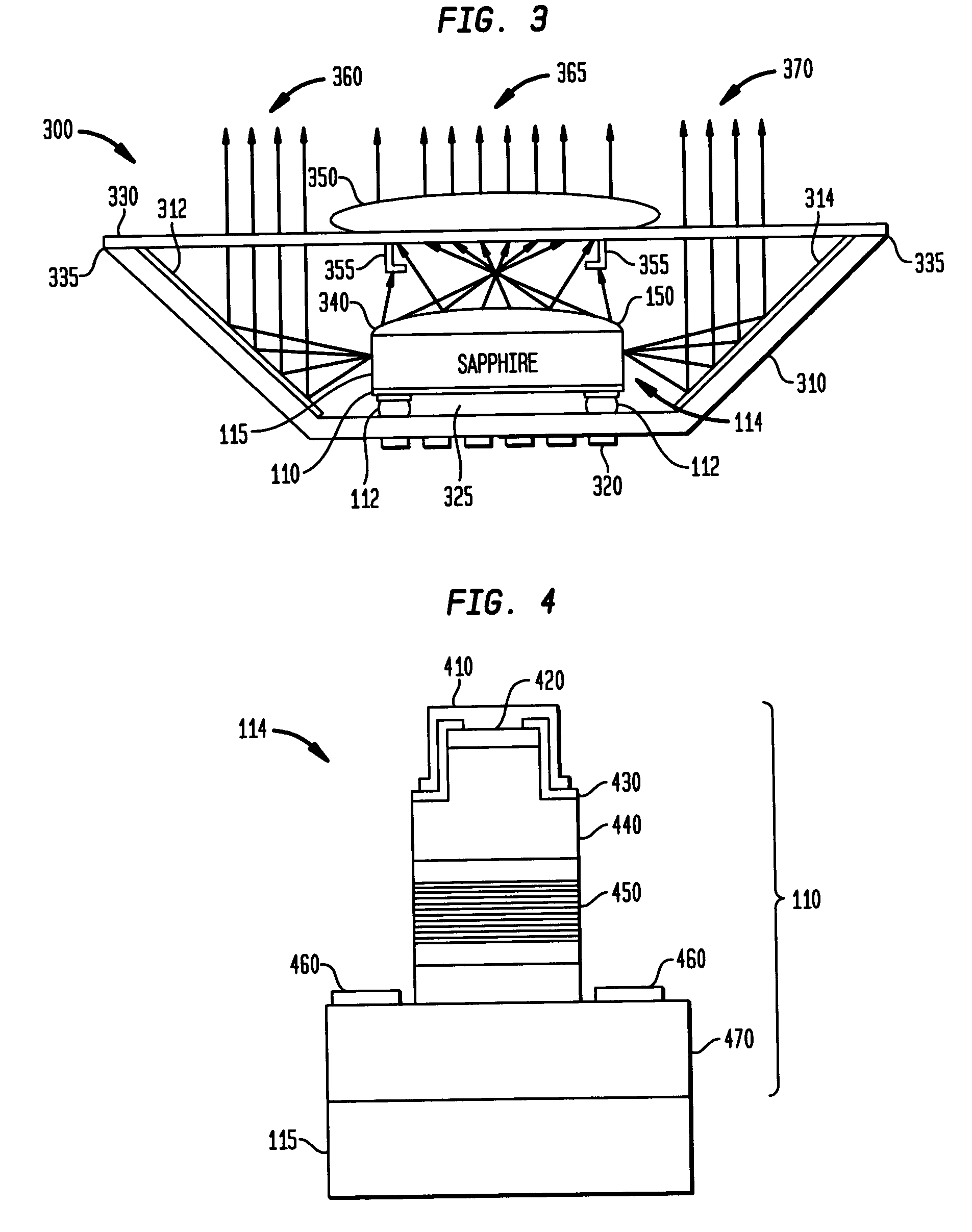

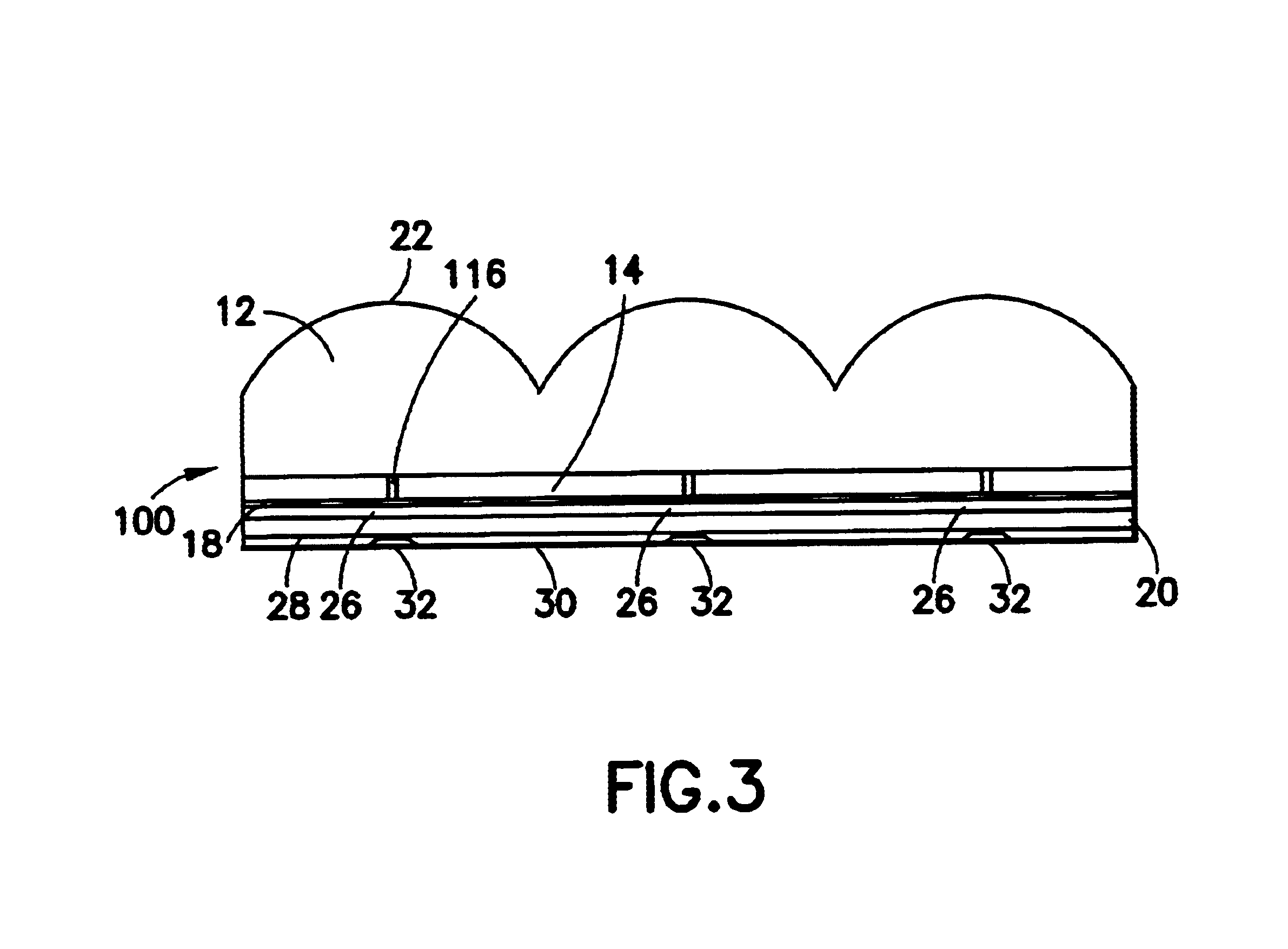

Light-emitting diode (LED) with amorphous fluoropolymer encapsulant and lens

InactiveUS6921929B2Discharge tube luminescnet screensCathode ray tubes/electron beam tubesUltravioletFluoropolymer

A lens and encapsulant made of an amorphous fluoropolymer for a light-emitting diode (LED) or diode laser, such as an ultraviolet (UV) LED (UVLED). A semiconductor diode die (114) is formed by growing a diode (110) on a substrate layer (115) such as sapphire. The diode die (114) is flipped so that it emits light (160, 365) through the face (150) of the layer (115). An amorphous fluoropolymer encapsulant encapsulates the emitting face of the diode die (114), and may be shaped as a lens to form an integral encapsulant / lens. Or, a lens (230, 340) of amorphous fluoropolymer may be joined to the encapsulant (220). Additional joined or separate lenses (350) may also be used. The encapsulant / lens is transmissive to UV light as well as infrared light. Encapsulating methods are also provided.

Owner:LOCKHEED MARTIN CORP

Light-emitting diode (LED) with amorphous fluoropolymer encapsulant and lens

A lens and encapsulant made of an amorphous fluoropolymer for a light-emitting diode (LED) or diode laser, such as an ultraviolet (UV) LED (UVLED). A semiconductor diode die (114) is formed by growing a diode (110) on a substrate layer (115) such as sapphire. The diode die (114) is flipped so that it emits light (160, 365) through the face (150) of the layer (115). An amorphous fluoropolymer encapsulant encapsulates the emitting face of the diode die (114), and may be shaped as a lens to form an integral encapsulant / lens. Or, a lens (230, 340) of amorphous fluoropolymer may be joined to the encapsulant (220). Additional joined or separate lenses (350) may also be used. The encapsulant / lens is transmissive to UV light as well as infrared light. Encapsulating methods are also provided.

Owner:LOCKHEED MARTIN CORP

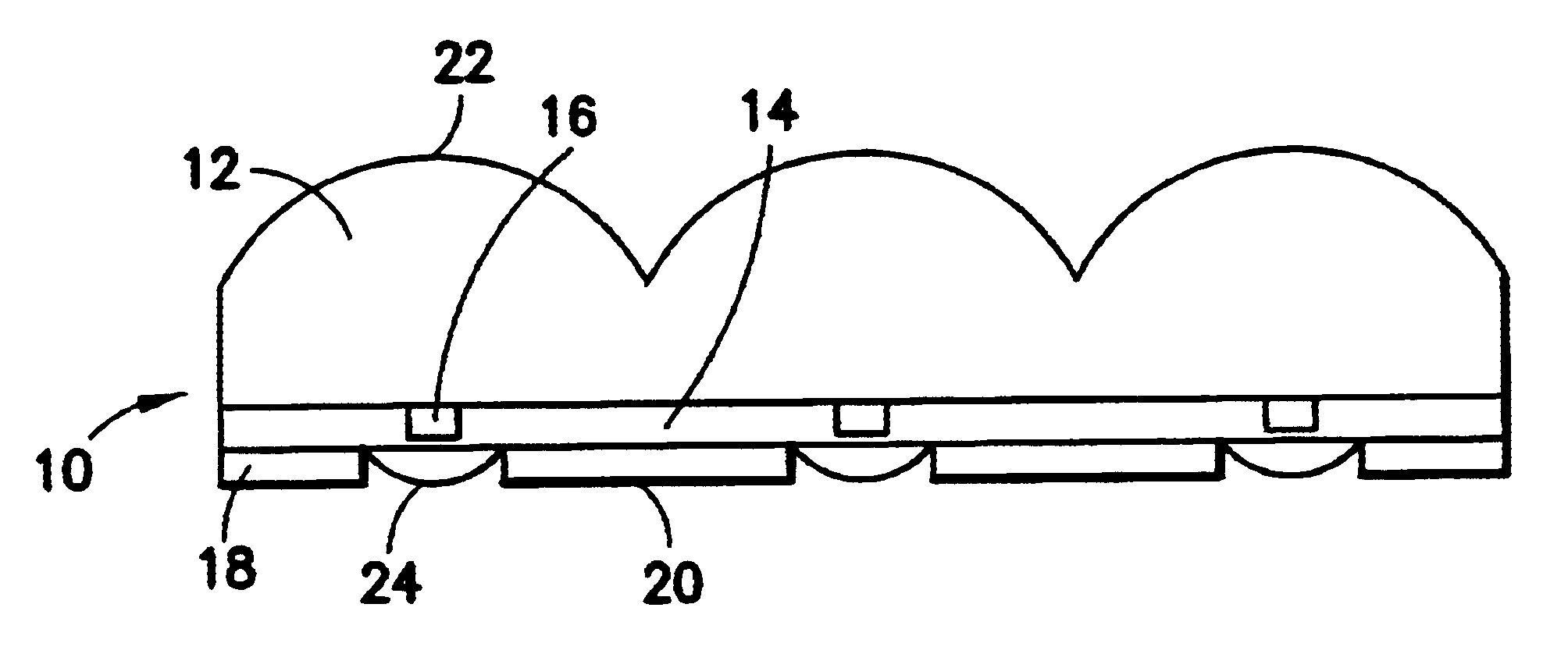

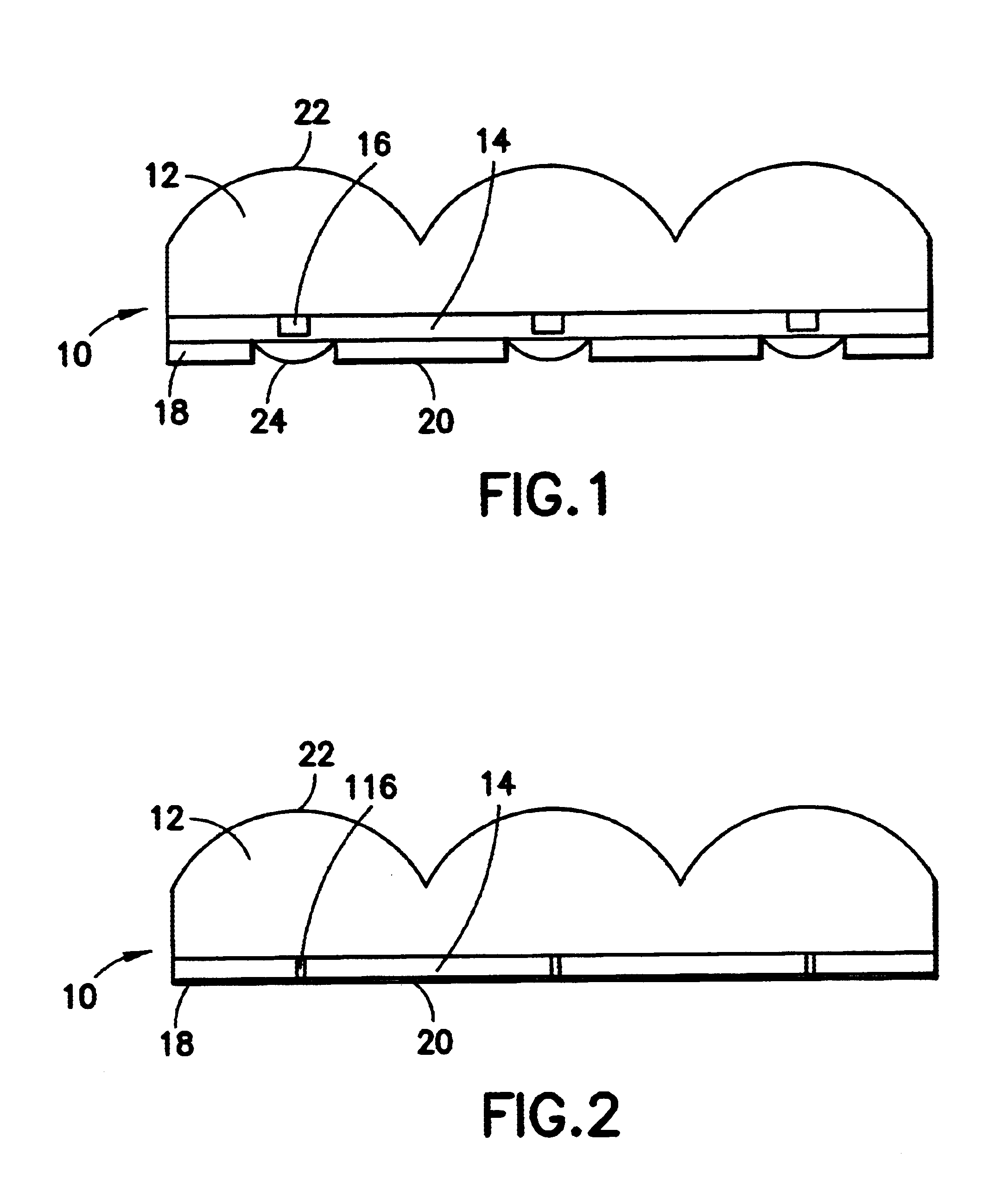

Image display generator for a head-up display

InactiveUS6661578B2Cosmonautic condition simulationsLaser using scattering effectsHead-up displayLight emitting device

An image display generator for use in a head-up display includes an array of light emitting devices such as LEDs or VCSELs formed on a semiconductor layer deposited on one surface of a glass like, e.g. Sapphire, sheet in which a plurality of lenses are formed on the opposite surface with each lens aligned with a respective one of the LEDs or VCSELs. A layer of transparent insulating material is disposed over the semiconductor layer and is coated with a reflecting material. Light emitted by the LEDs is directly incident onto respective over the lenses and is indirectly reflected onto the lenses by the reflecting material.

Owner:INNOVATIVE SOLUTIONS & SUPPORT

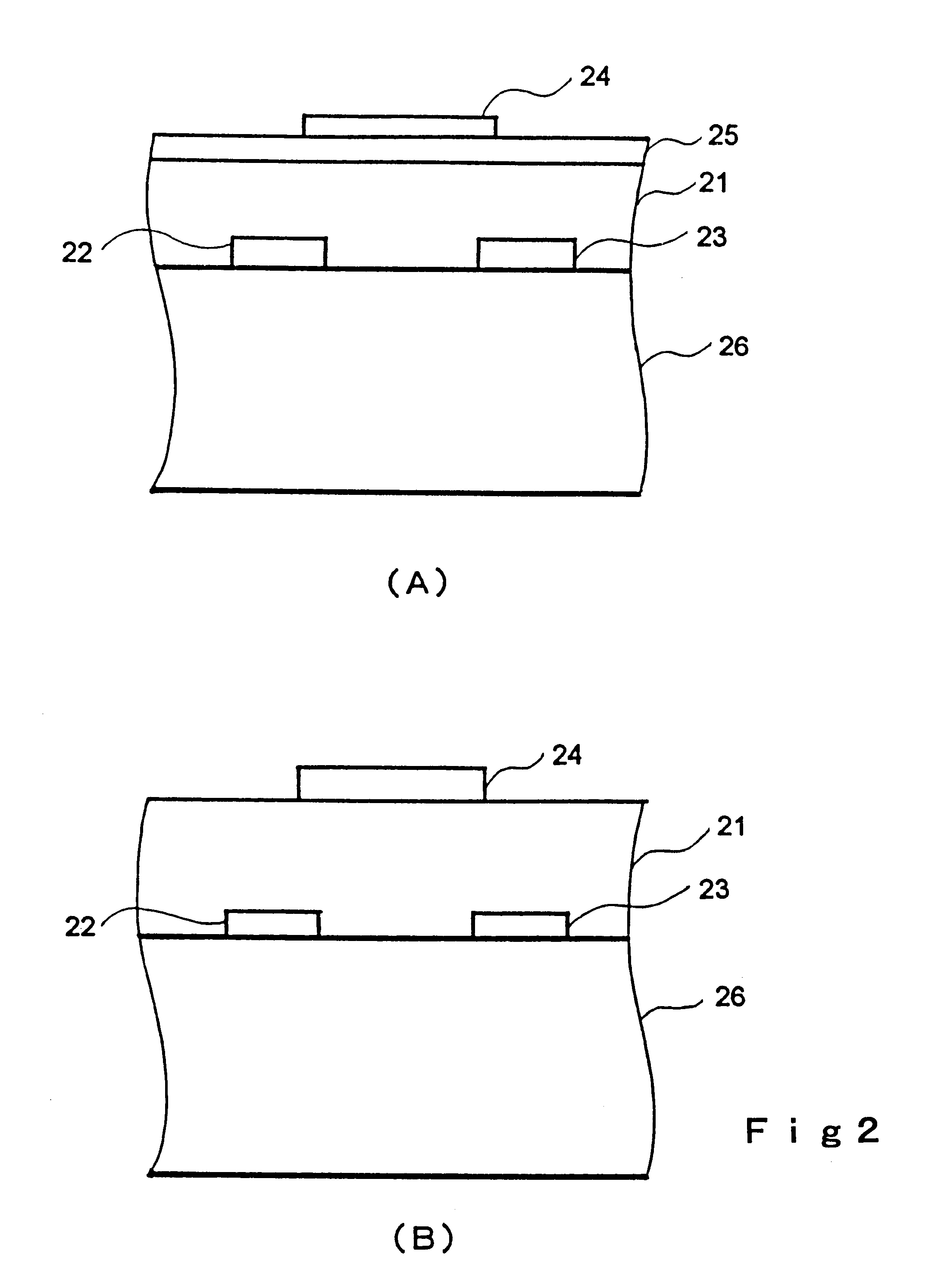

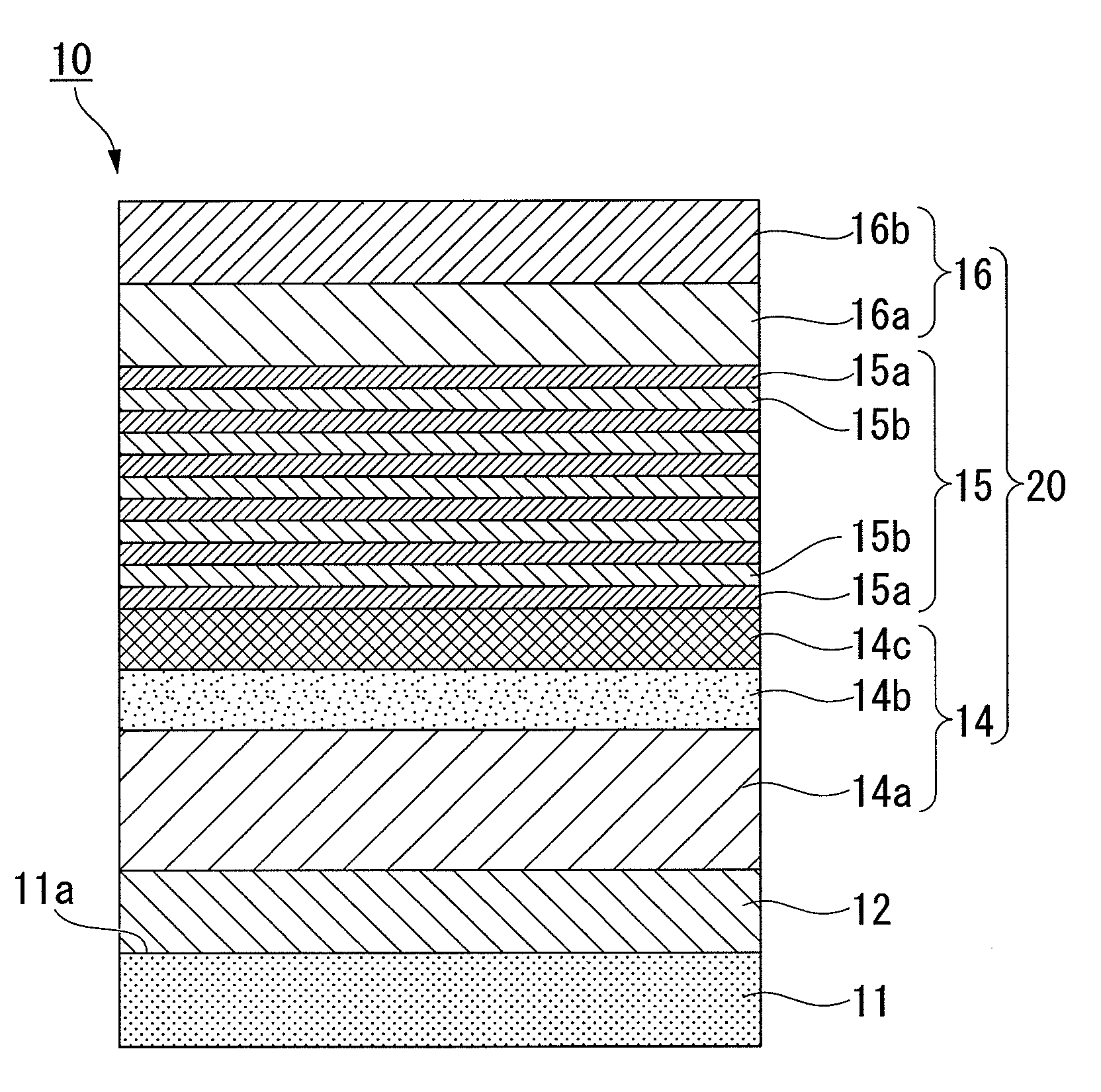

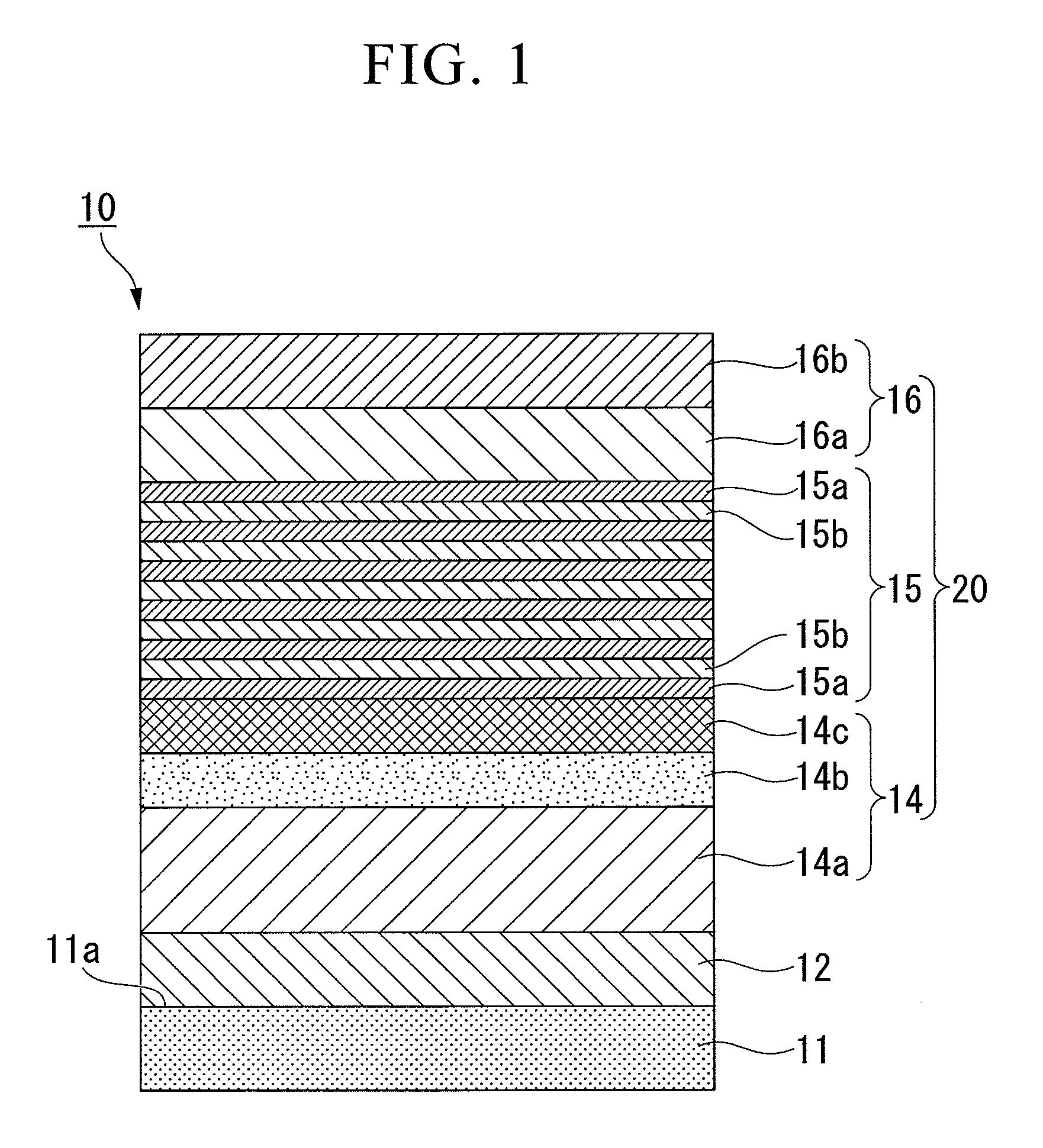

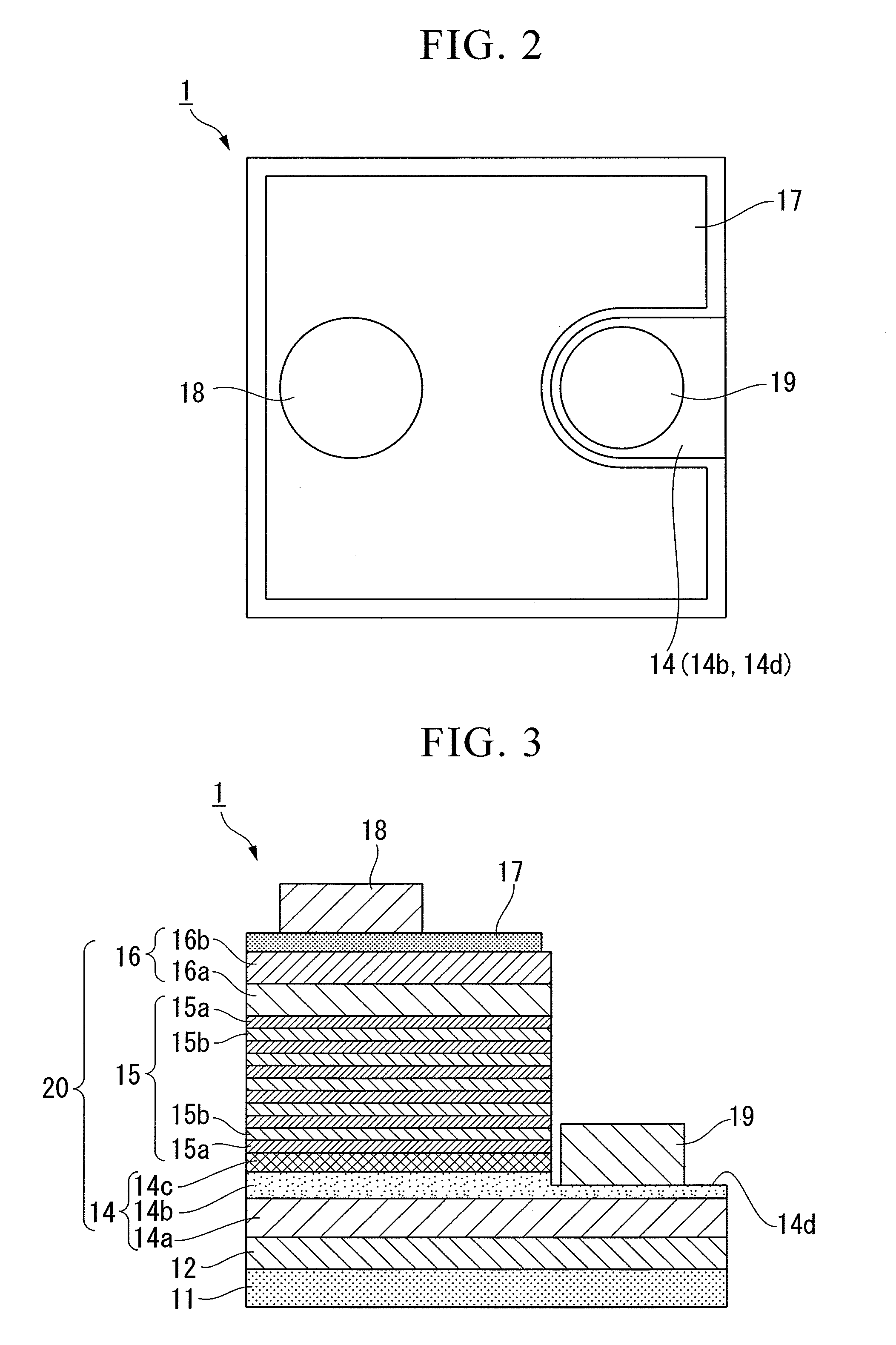

Group iii nitride semiconductor light-emitting device, method for manufacturing the same, and lamp

InactiveUS20100219445A1Improve luminous performanceHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingOxygenCrystallinity

A buffer layer 12 composed of at least a Group III nitride compound is laminated on a substrate 11 composed of sapphire, and an n-type semiconductor layer 14, a light-emitting layer 15, and a p-type semiconductor layer 16 are laminated in a sequential manner on the buffer layer 12. The buffer layer 12 is formed by means of a reactive sputtering method, the buffer layer 12 contains oxygen, and the oxygen concentration in the buffer layer 12 is 1 atomic percent or lower. There are provided a Group III nitride compound semiconductor light-emitting device that comprises the buffer layer formed on the substrate by means of the reactive sputtering method, enables formation of a Group III nitride semiconductor having favorable crystallinity thereon, and has a superior light emission property, and a manufacturing method thereof, and a lamp.

Owner:SHOWA DENKO KK

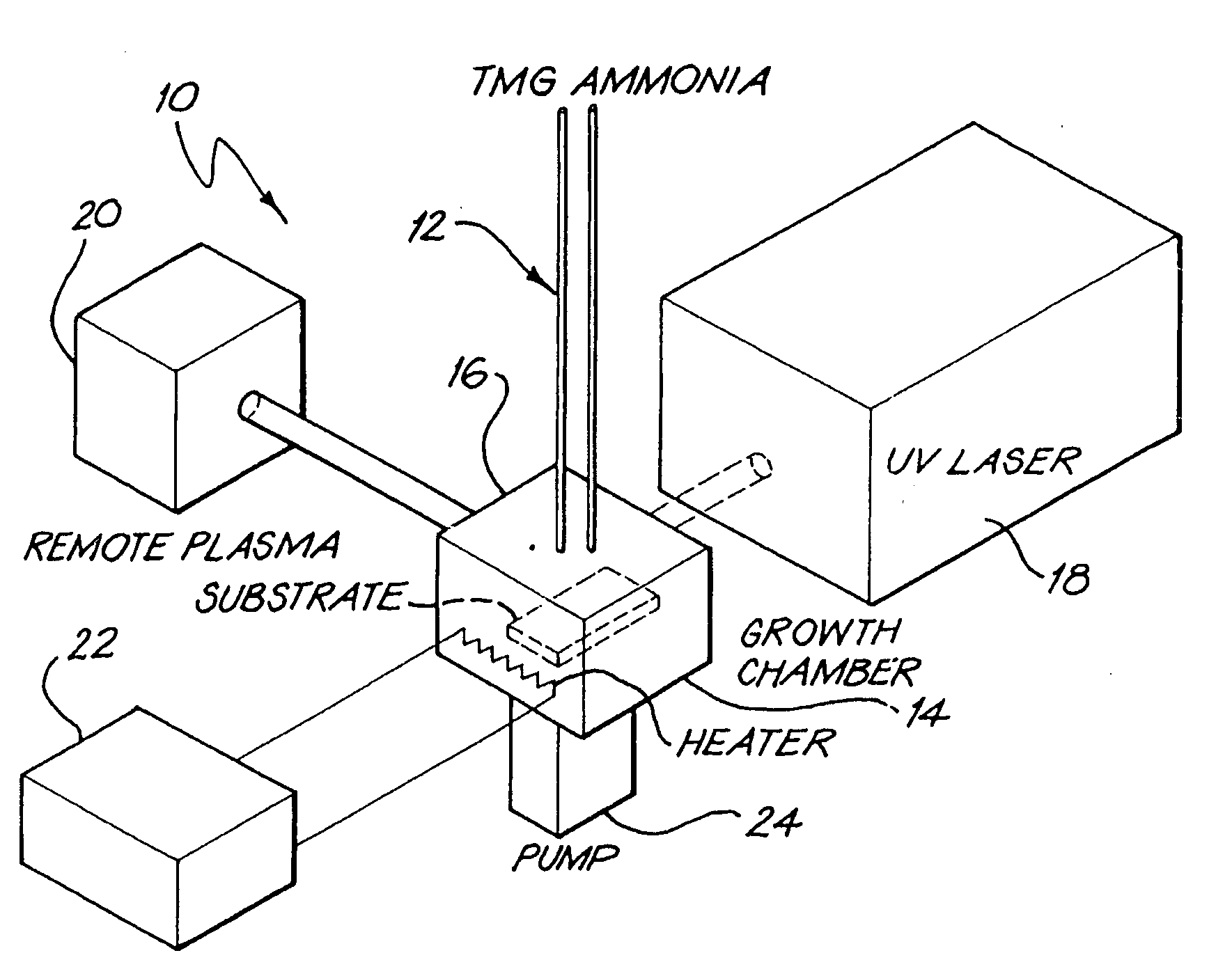

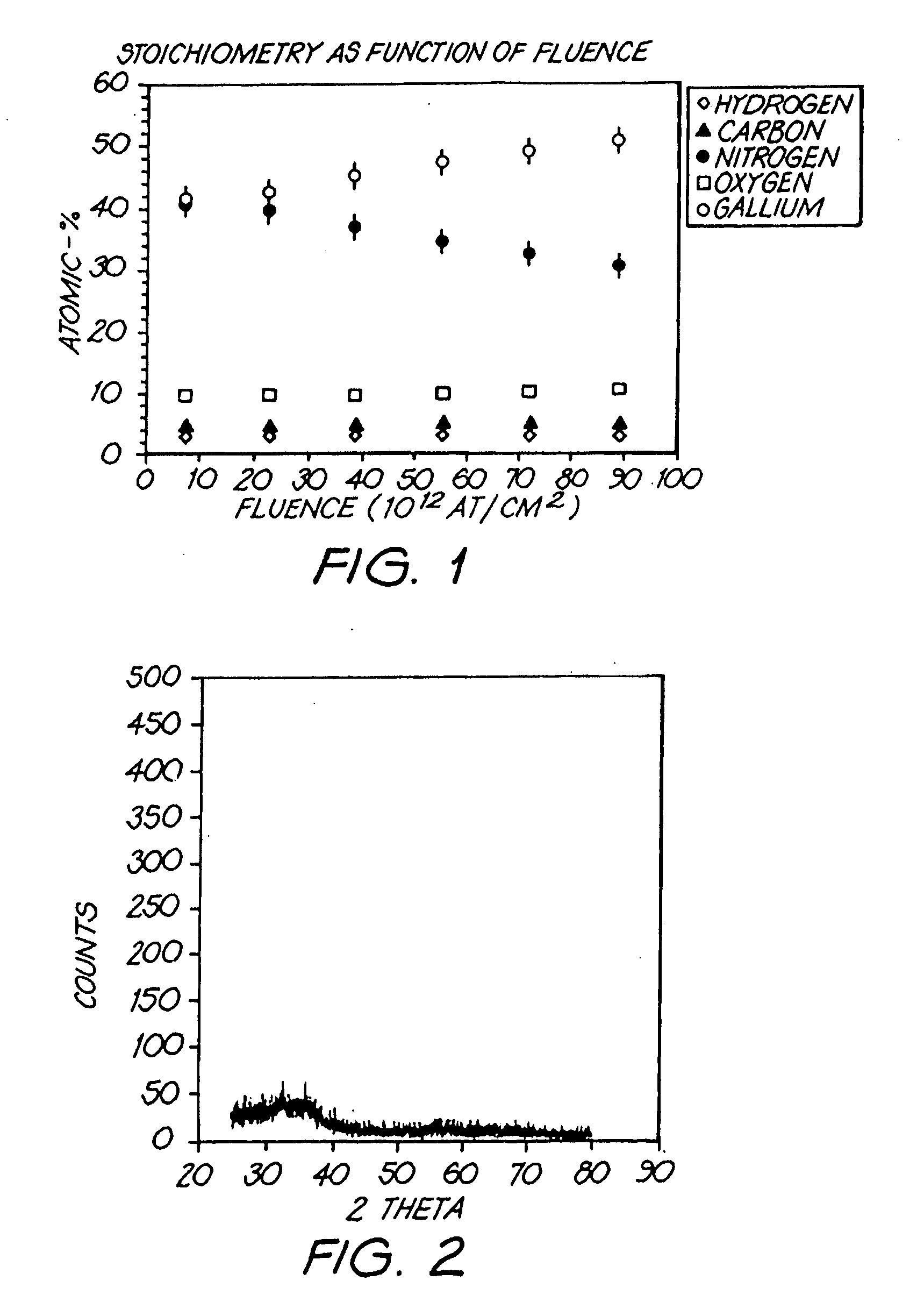

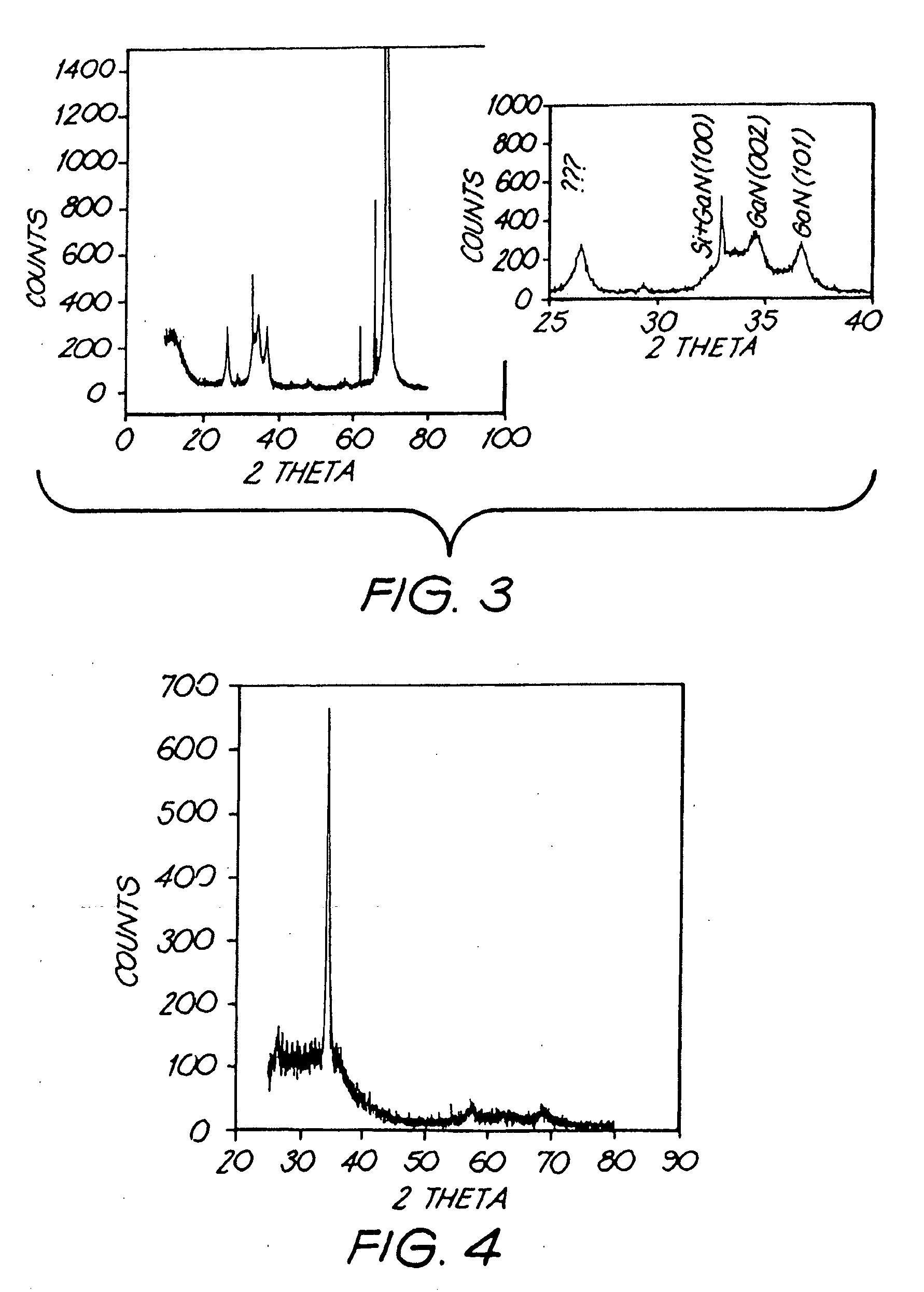

Process For Manufacturing A Gallium Rich Gallium Nitride Film

InactiveUS20080282978A1Improve conductivityLow resistivityPolycrystalline material growthAfter-treatment detailsGalliumGallium nitride

A process for the manufacture of a gallium rich gallium nitride film is described. The process comprises (a) preparing a reaction mixture containing a gallium species and a nitrogen species, the gallium species and the nitrogen species being selected such that, when they react with each other, gallium nitride is formed; and (b) growing the gallium rich gallium nitride film from the reaction mixture, by allowing the gallium species to react with the nitrogen species and to deposit gallium nitride on a substrate selected from the group consisting of silicon, glass, sapphire, quartz and crystalline materials having a lattice constant closely matched to gallium nitride, including zinc oxide, optionally with a zinc oxide buffer layer, at a temperature of from about 480° C. to about 900° C. and in the presence of a gaseous environment in which the partial pressure of oxygen is less than 10−4 Torr, wherein the ratio of gallium atoms to nitrogen atoms in the gallium rich gallium nitride film is from 1.01 to 1.20. The invention also provides the option of annealing the gallium rich gallium nitride film at a temperature of from about 20° C. to about 650° C. and for a time sufficient to decrease the resistivity of the film so that it becomes electrically conductive, for instance to a resistivity below 100 ohm.cm.

Owner:BUTCHER KENNETH SCOTT ALEXANDER +2

Heated cover methods and technology

A heating apparatus comprising a support base and a microplate having a first surface and an opposing second surface. The microplate is positioned adjacent the support base and comprises a plurality of wells formed in the first surface thereof. Each of the plurality of wells is sized to receive an assay therein. A sapphire crystalline transparent window is positioned adjacent the microplate opposing the support base. A heating device heats the transparent window in response to a control system.

Owner:APPL BIOSYSTEMS INC

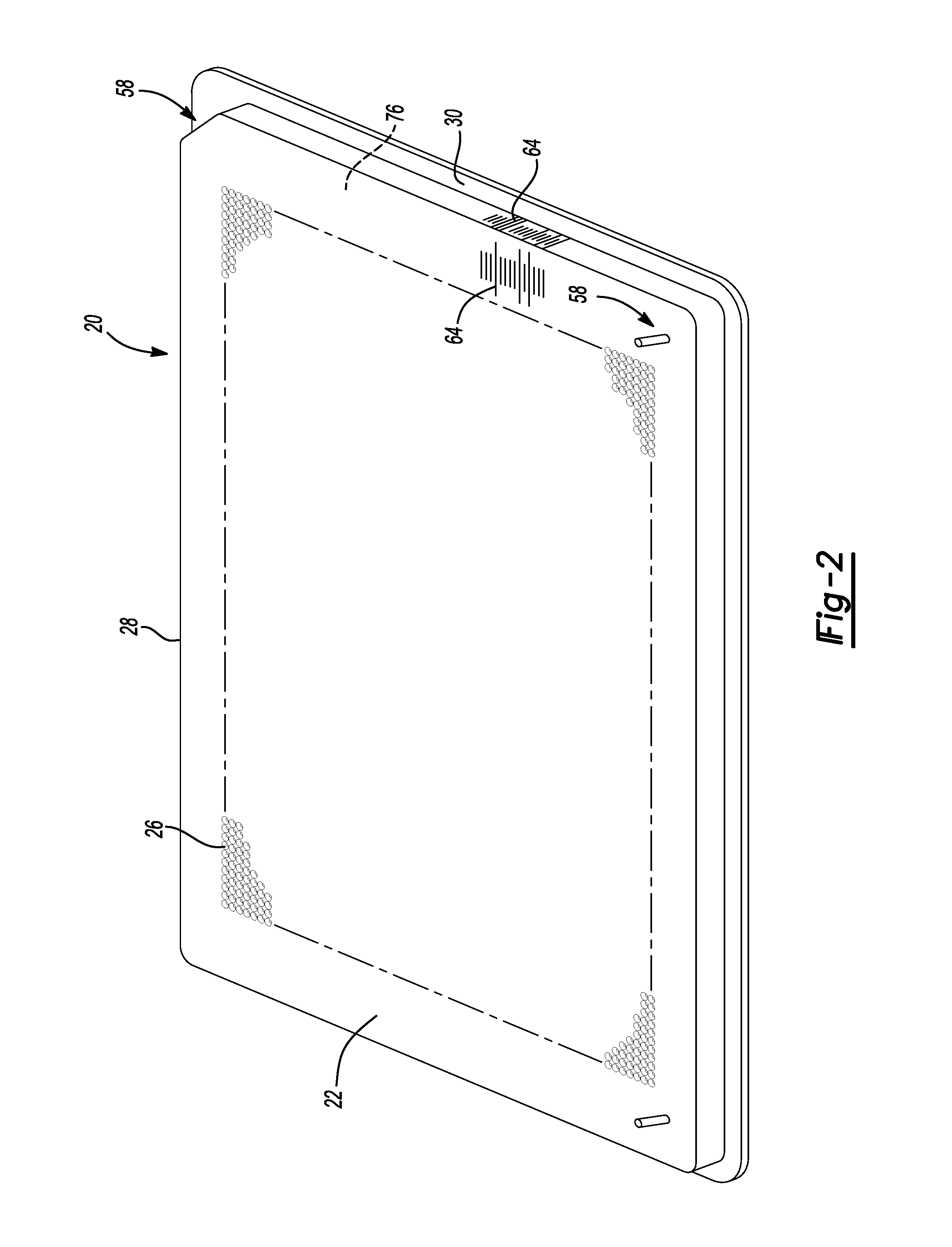

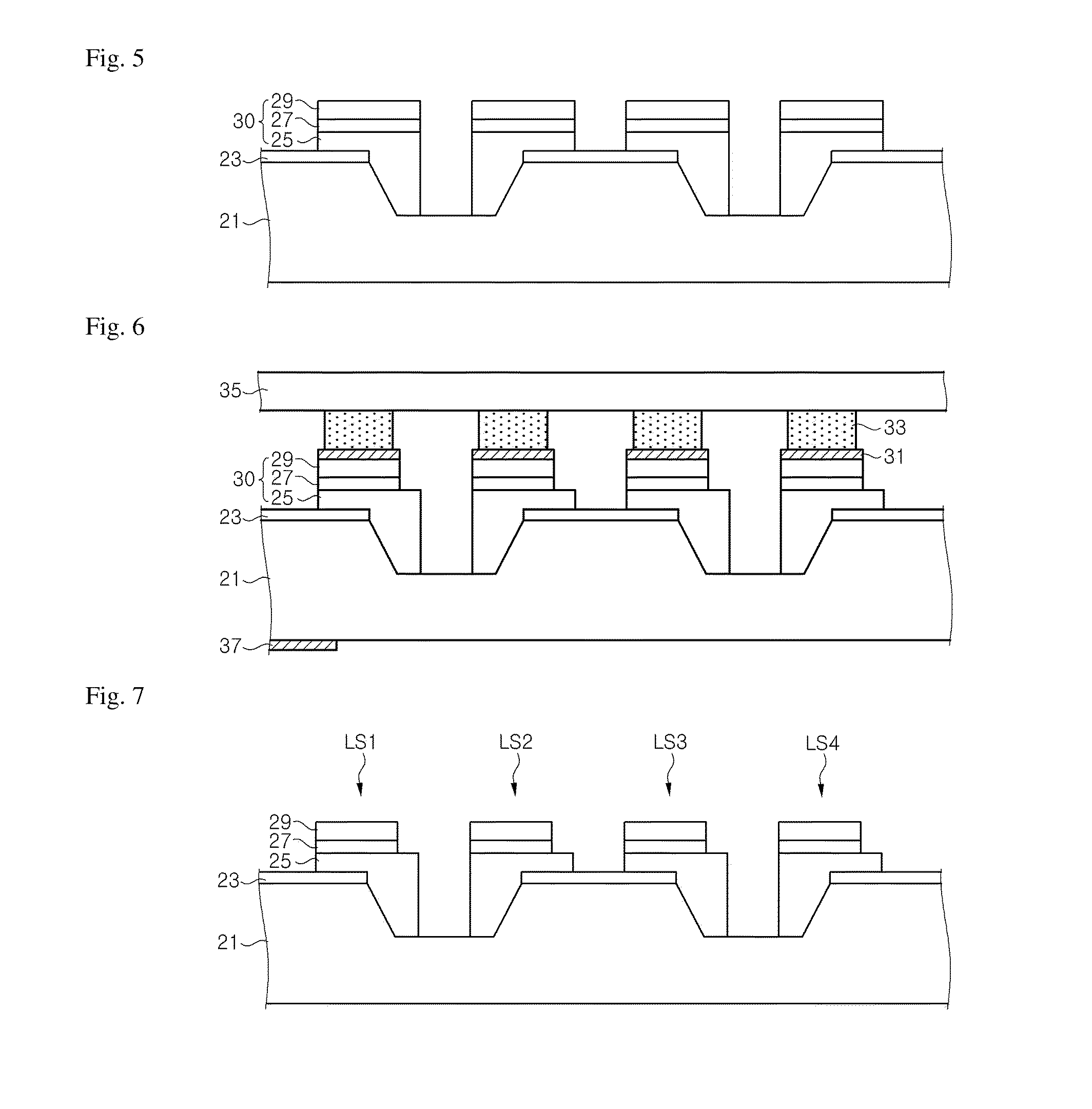

Light emitting device having plurality of non-polar light emitting cells and method of fabricating the same

ActiveUS20100163900A1High crystallinityReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceSapphire

Disclosed are a light emitting device having a plurality of non-polar light emitting cells and a method of fabricating the same. This method comprises preparing a first substrate of sapphire or silicon carbide having an upper surface with an r-plane, an a-plane or an m-plane. The first substrate has stripe-shaped anti-growth patterns on the upper surface thereof, and recess regions having sidewalls of a c-plane between the anti-growth patterns. Nitride semiconductor layers are grown on the substrate having the recess regions, and the nitride semiconductor layers are patterned to form the light emitting cells separated from one another. Accordingly, there is provided a light emitting device having non-polar light emitting cells with excellent crystal quality.

Owner:SEOUL VIOSYS CO LTD

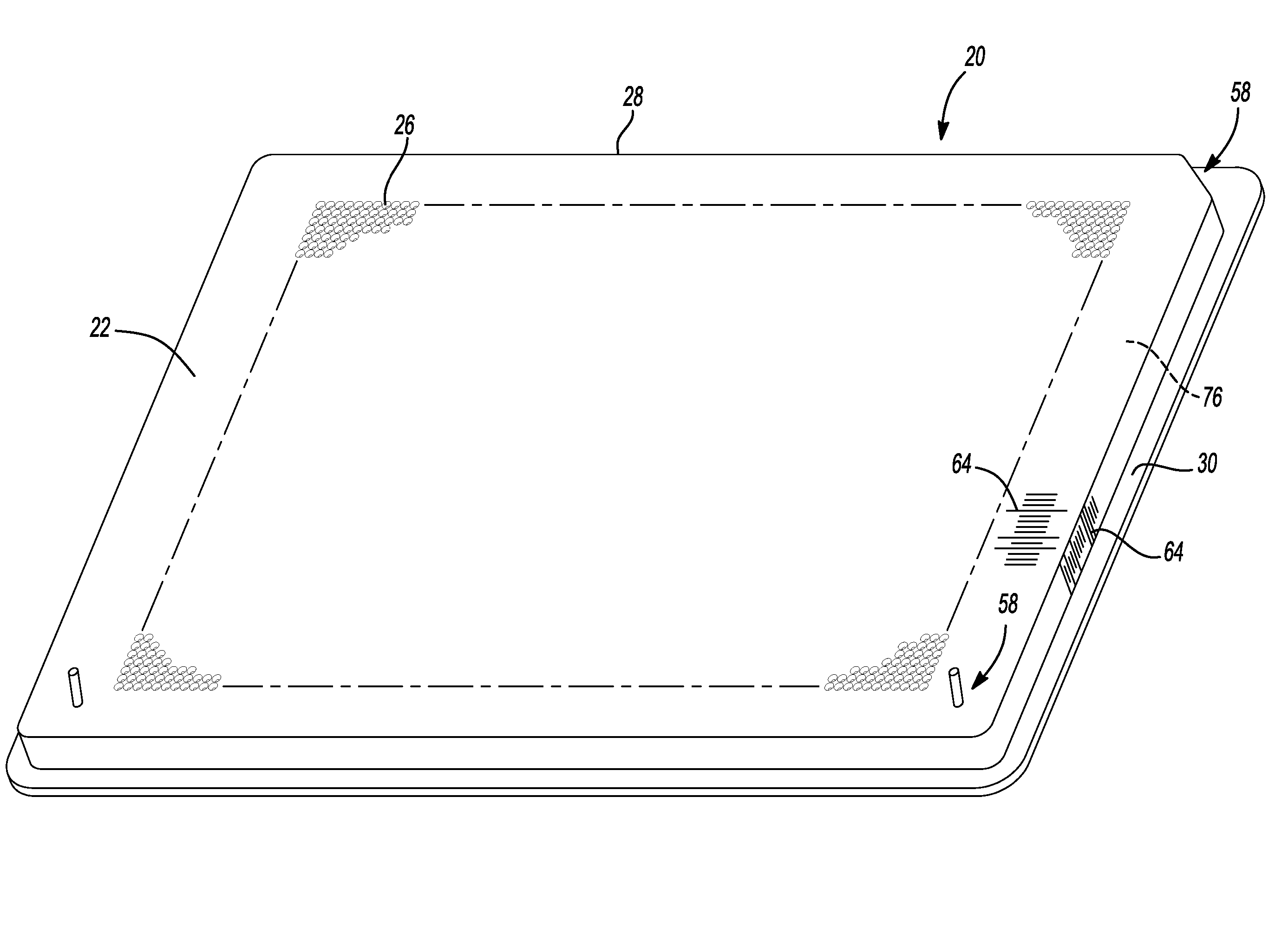

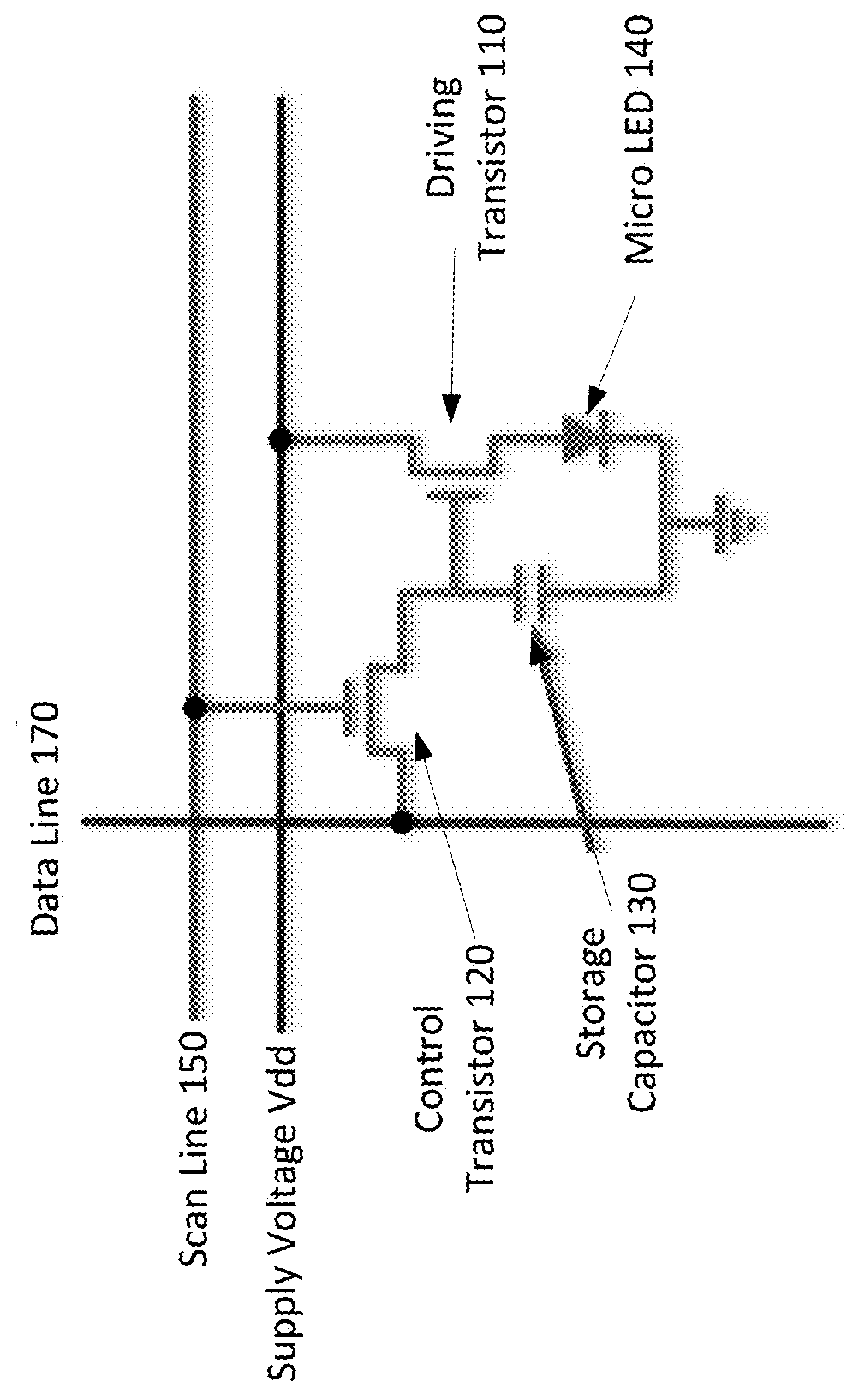

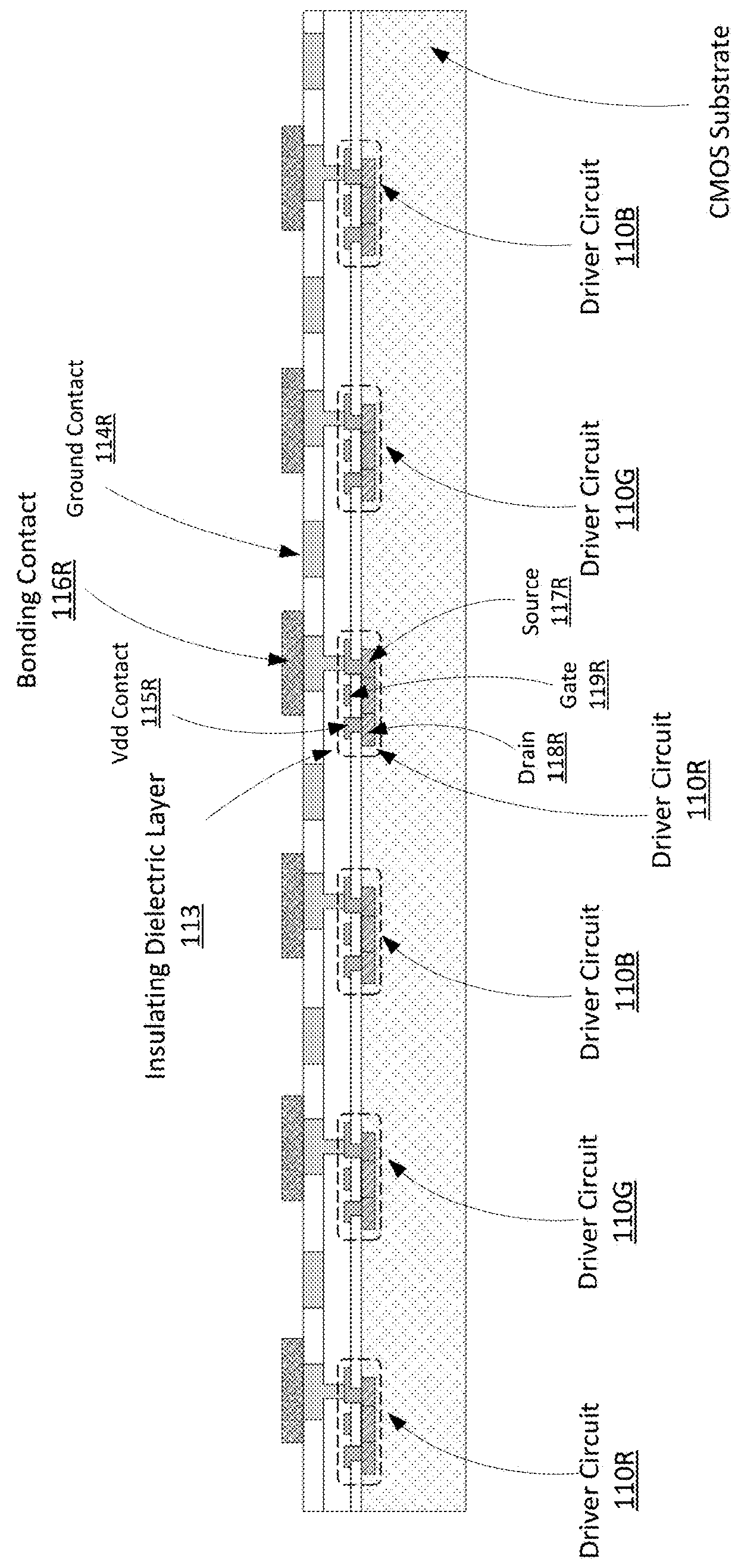

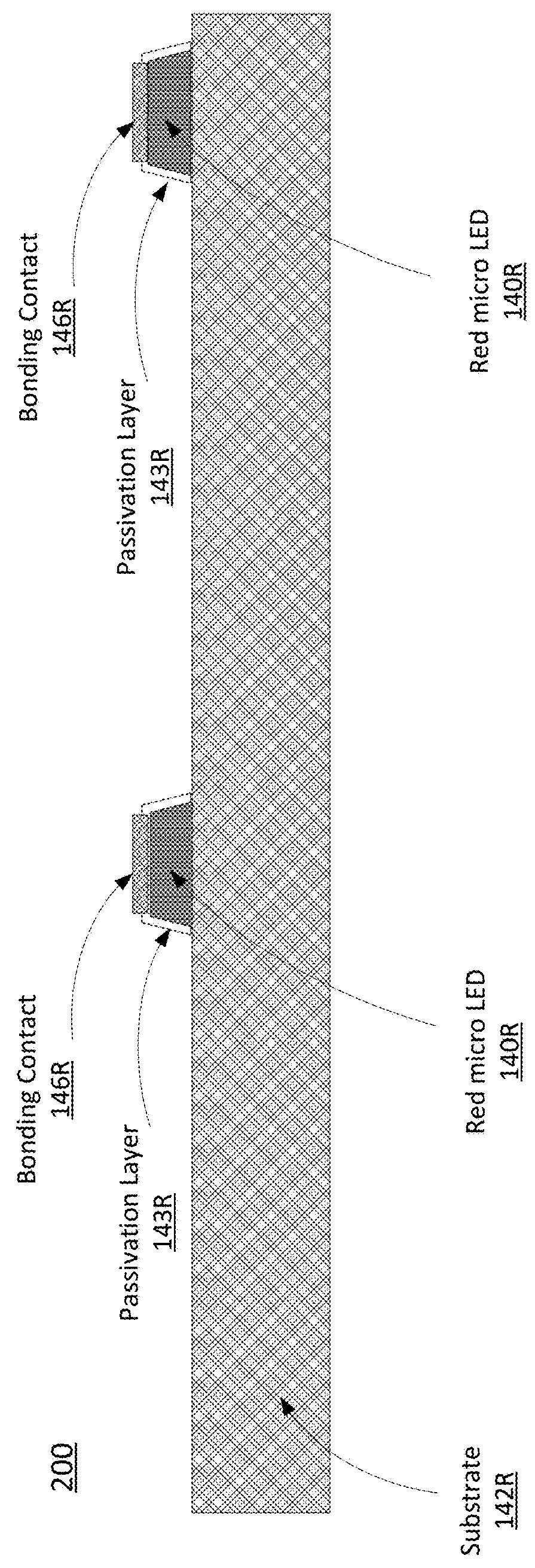

Mass Transfer Of Micro Structures Using Adhesives

ActiveUS20180166429A1Solid-state devicesSemiconductor/solid-state device manufacturingMicro structureLED display

Mass transfer of micro structures are effected from one substrate to another using adhesives. In the context of an integrated micro LED display, a micro LED array is fabricated on a native substrate and corresponding CMOS pixel drivers are fabricated on a separate substrate. The micro LED substrate (e.g., sapphire) and the CMOS substrate (e.g., silicon) may be incompatible. For example, they may have different thermal coefficients of expansion which make it difficult to bond the micro LEDs to the pixel driver circuitry. The micro LED array is transferred to an intermediate substrate (e.g., silicon) by use of an adhesive. This intermediate substrate may be used in a process of bonding the micro LED array to the array of pixel drivers. The intermediate substrate is separated from the micro LED array by releasing the adhesive.

Owner:JADE BIRD DISPLAY SHANG HAI LTD

Cardiac lead with zone insulated electrodes

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. The coating is composed of an electrically insulating material and covers a first portion of the exterior of the electrode member while leaving a preselected second portion thereof exposed. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

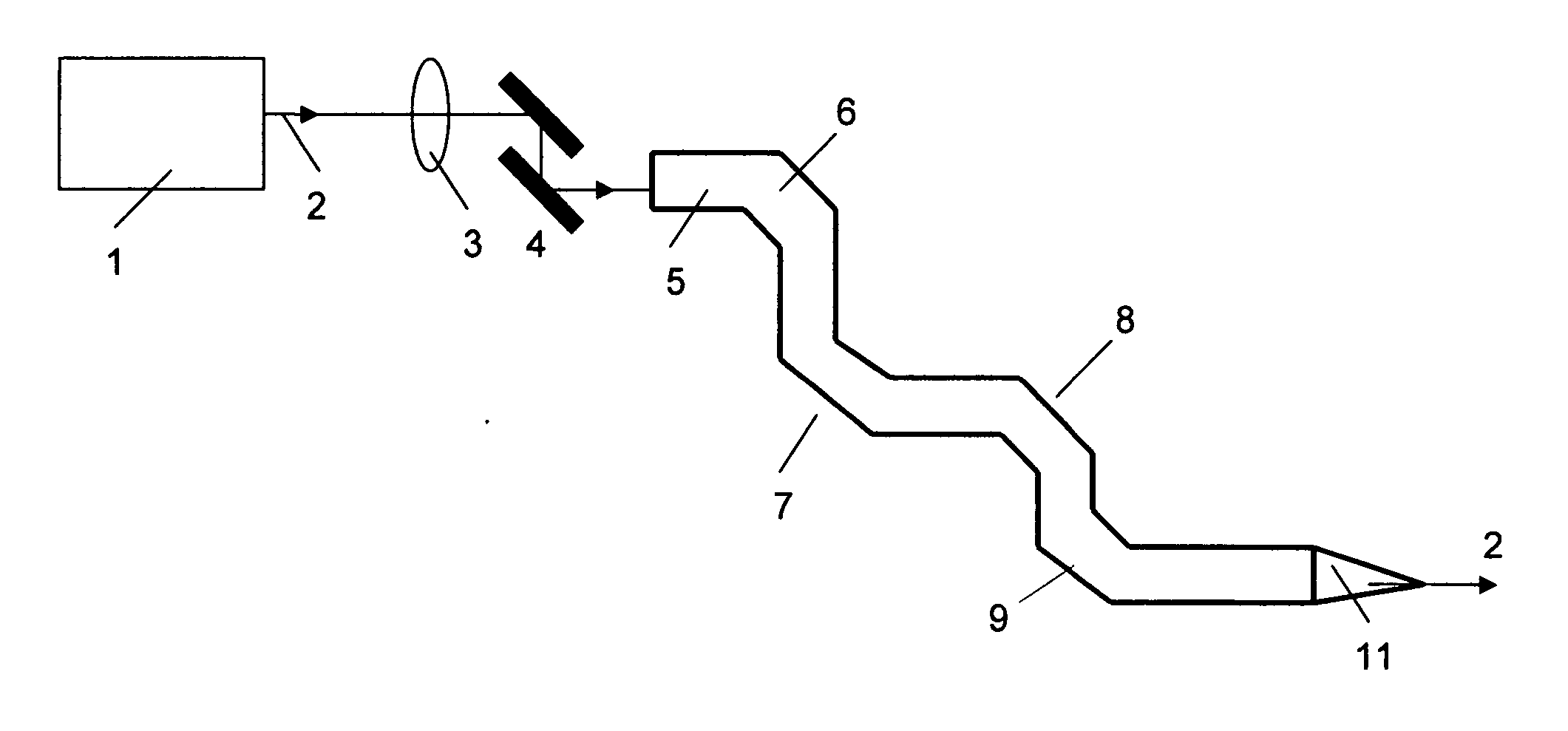

Treatment of eye disorders using articulated-arm coupled ultraviolet lasers

InactiveUS20060129141A1Increase flexibilityIncrease spacingLaser surgerySurgical instrument detailsIntra ocular pressureDisease

Surgical method and apparatus for presbyopia correction and glaucoma by laser removal a portion of the sclera and / or ciliary tissue are disclosed. The disclosed preferred embodiments of the system consists of a beam spot controller, an articulated arm and an attached end-piece. The basic laser beam includes UV laser having wavelength ranges of (0.19-0.36) microns, generated from UV excimer lasers of ArF, XeCl or solid state lasers of Nd:YLF, Nd:YAG, Ti:sapphire with harmonic generation using nonlinear crystals. Presbyopia is treated by ablation of the treated surface tissue in predetermined patterns outside the limbus to increase the accommodation of the eye. Glaucoma is treated by decreasing of intra ocular pressure of the laser surgery.

Owner:NEW VISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com