Process For Manufacturing A Gallium Rich Gallium Nitride Film

a gallium nitride and gallium rich technology, applied in the direction of crystal growth process, polycrystalline material growth, after-treatment details, etc., can solve the problems of reduced detection formation, limited cost effective application of present devices, and high cost of sapphire or silicon carbide substrates, etc., to achieve increased conductivity and/or crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

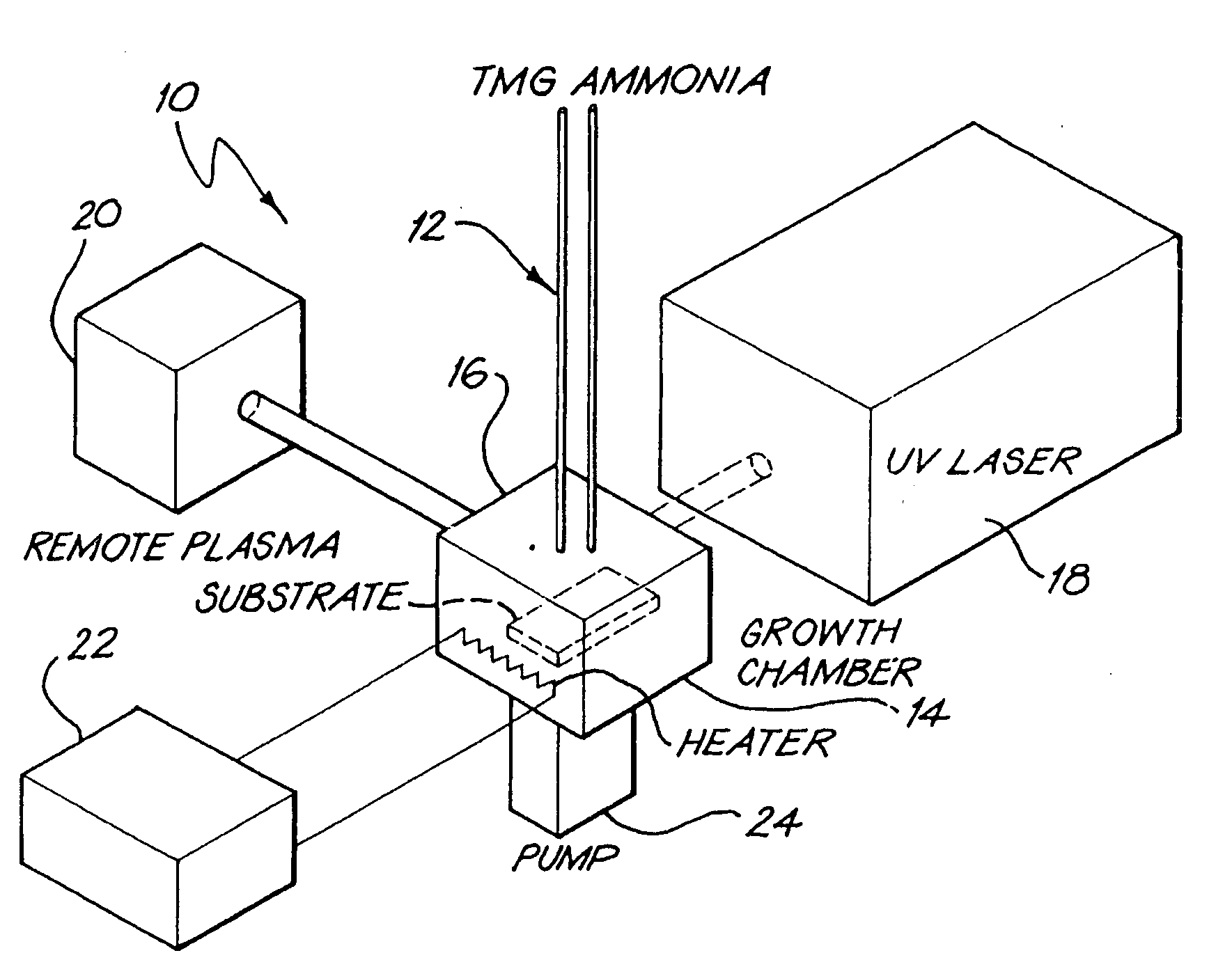

[0113]Fifteen films of gallium nitride (GaN) were grown at 540° C. on (1,0,0) silicon, using a remote plasma enhanced laser induced chemical vapour deposition (RPE-LICVD) technique. The quality of films grown using the aforementioned technique may be comparable to MBE grown material with unintentionally doped n-type material being produced with room temperature mobilities as high as 100-200 cm2 / V·s. [1].

[0114]A high vacuum system was used for the film growth, and the oxygen content of the films was moderated by controlling the background pressure prior to growth. From 1×10−4 Torr, to 2×10−6 Torr dependent on the condition of the chamber at the time of growth.

[0115]The samples were all grown under similar conditions-apart from the variation in the background vacuum level as mentioned before.

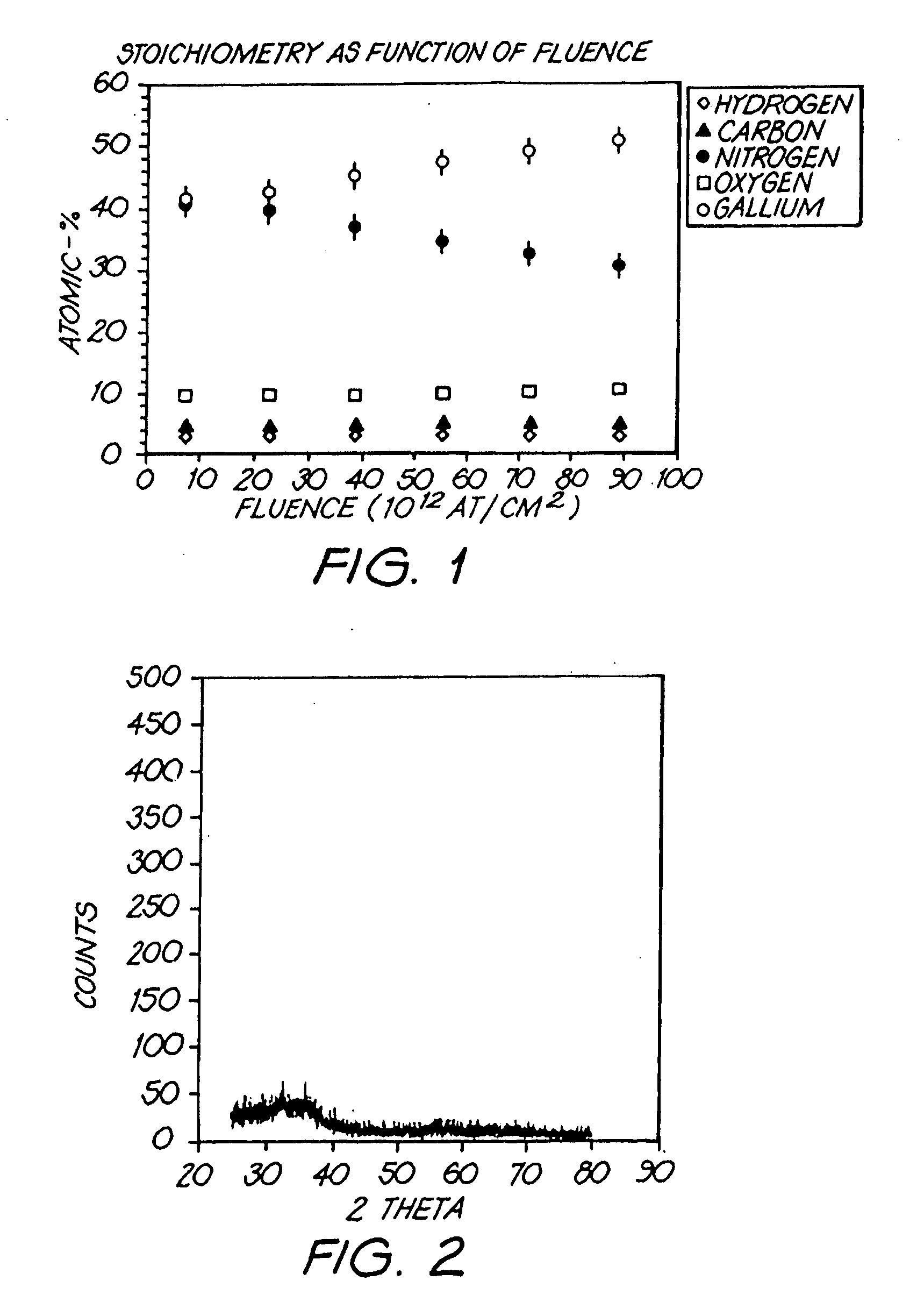

[0116]Of the fifteen films grown, three samples, which spanned the range of background vacuum levels used, were subjected to ERD analysis, as outlined below. These three samples were respectively ...

example 2

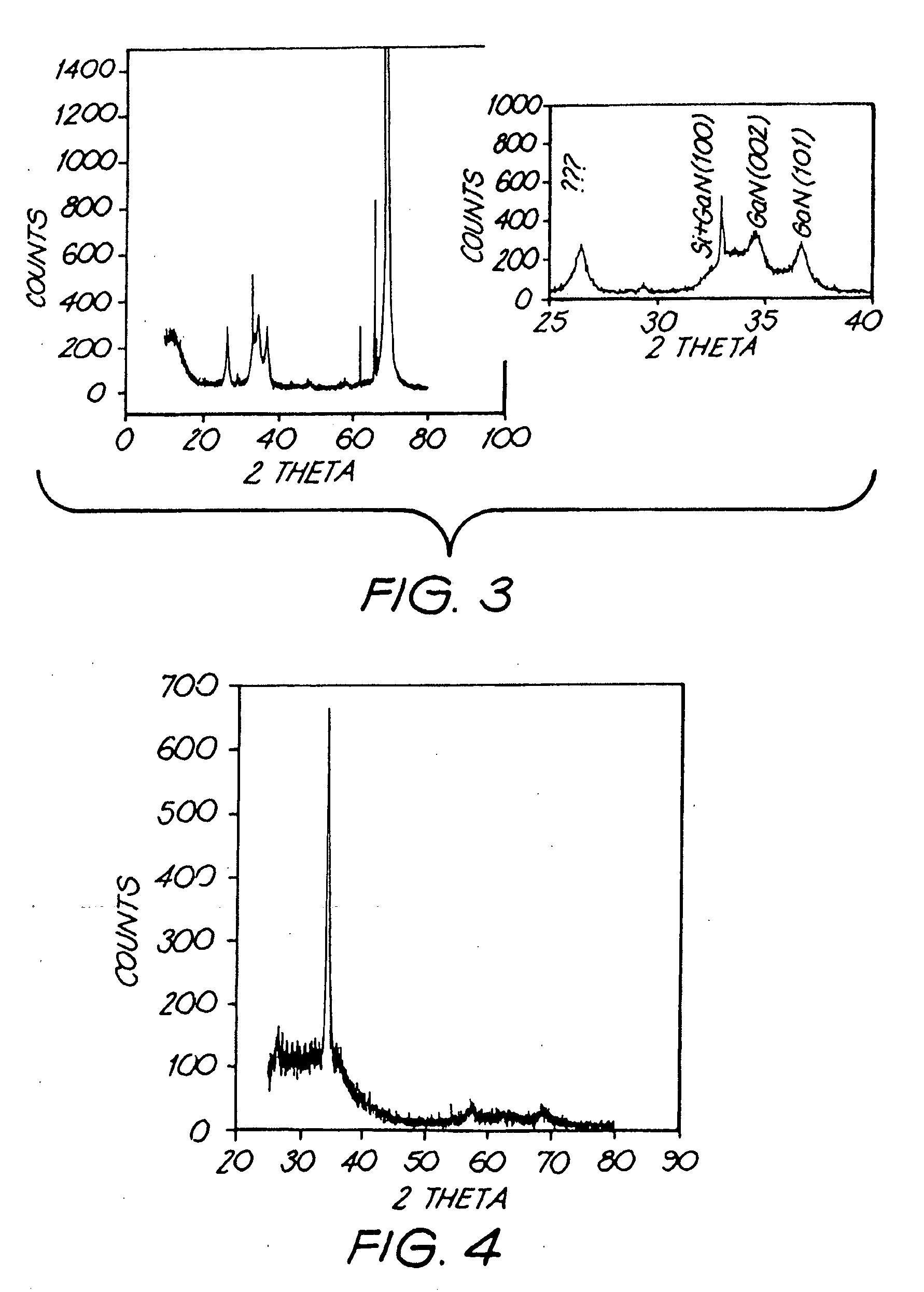

[0158]The attached pictures shows examples, by a number of different measurement techniques, of room temperature re-crystallization observed.

[0159]The pictures show a lot of small crystals, evidencing a polycrystalline nature shortly after growth, and a much less polycrystalline nature after two years.

example 3

Gallium Nitride Films Grown on Sapphire Substrates

[0160]Samples were grown on non-conducting sapphire substrates so that sample conductivity measurements could be made. The growth conductions used were the same as for the samples grown on silicon described in example 1 and 2 above.

[0161]Electrical measurements were made of the conductivity of samples of gallium nitride grown using the above technique. Some re-crystallization took place in a sample that was semi-insulating (resistivity more than 10,000 ohm-cm) shortly after growth and became much more conductive (86 ohm-cm) about two years later.

[0162]For the growth of this sample on sapphire, the above conditions produced gallium rich films under low oxygen conditions. A slightly yellow colouration was noted. This colouration was similar to that observed for gallium rich bulk grown gallium nitride [26].

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com