Patents

Literature

166 results about "Glass laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

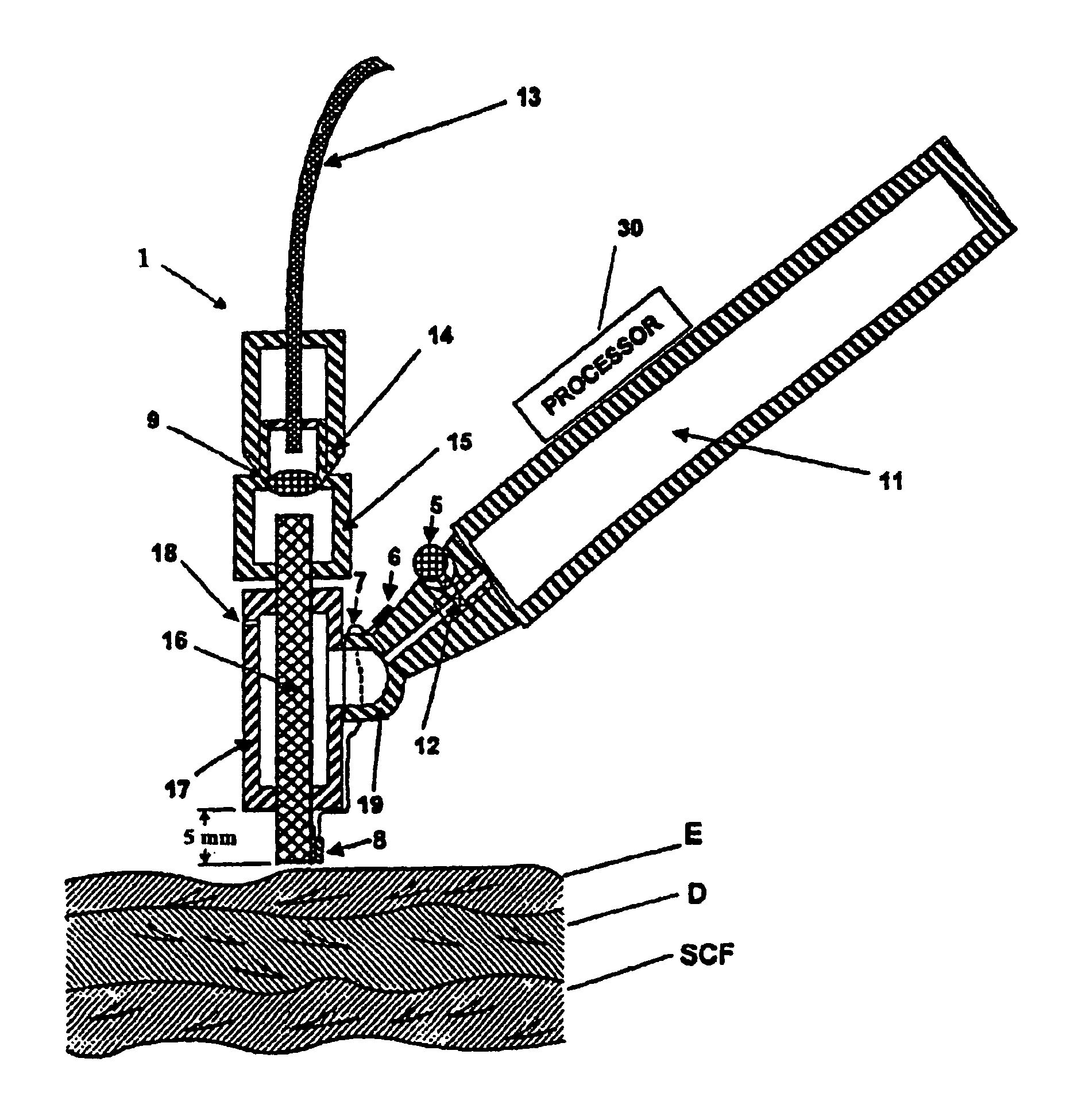

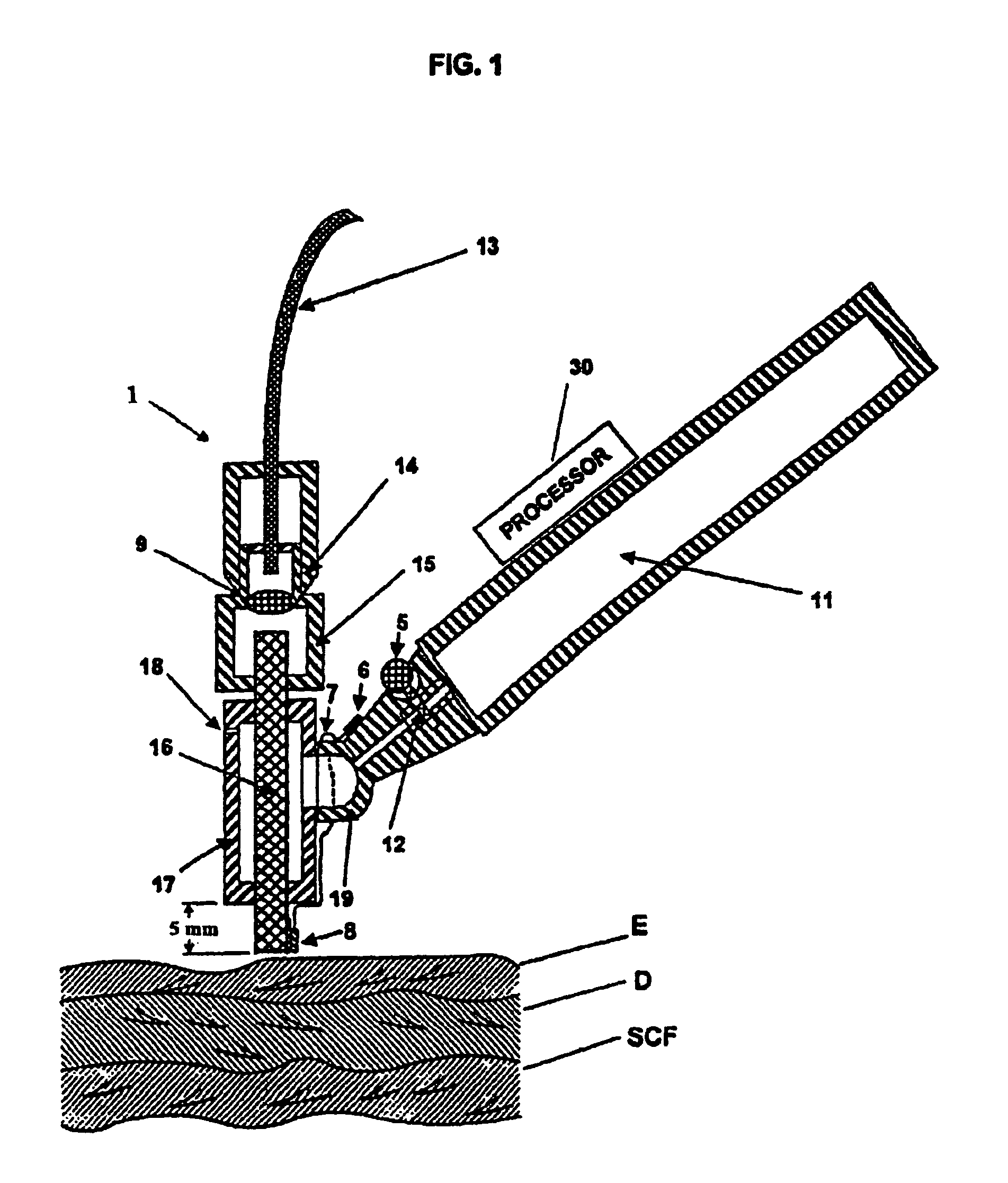

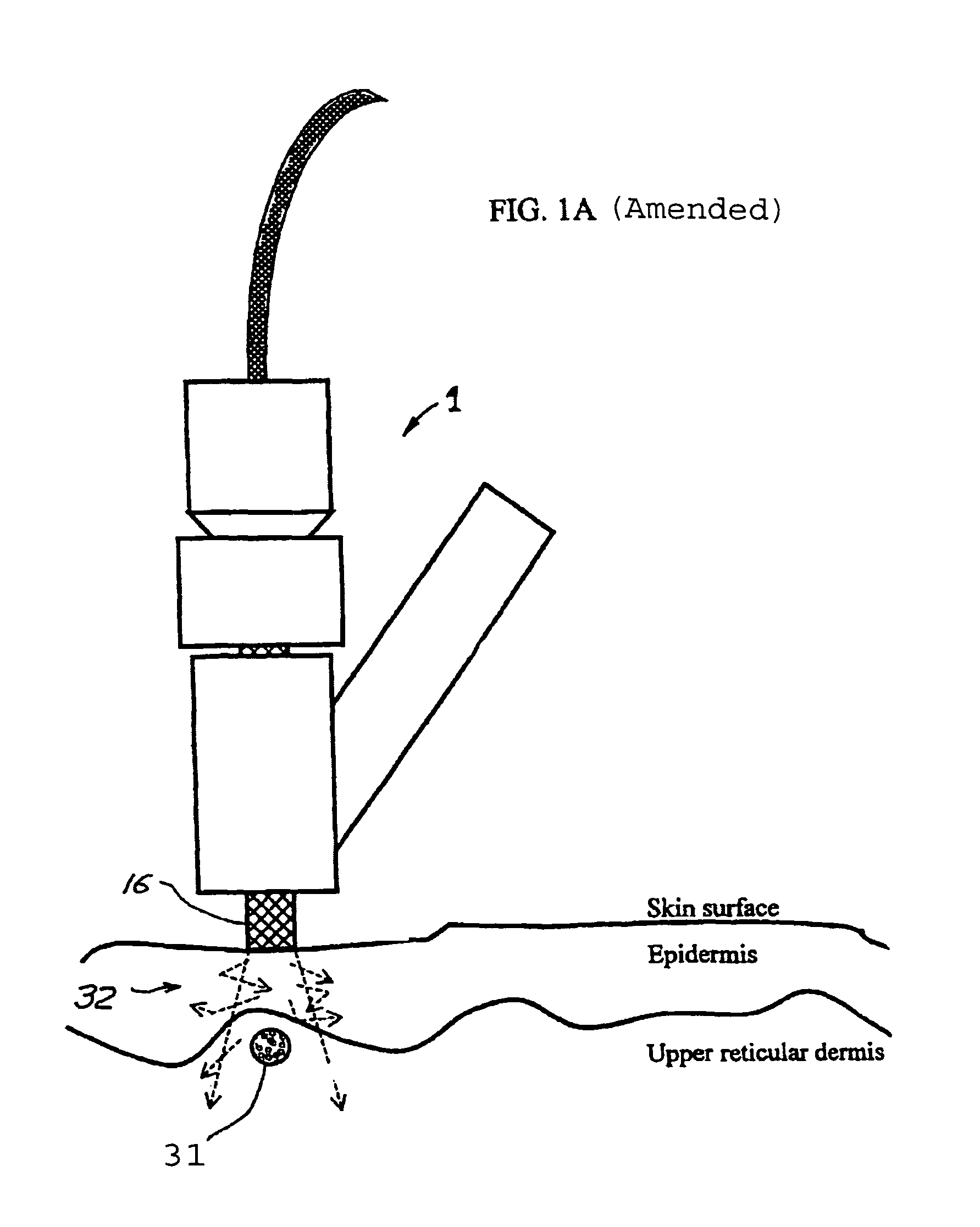

Tissue cooling rod for laser surgery

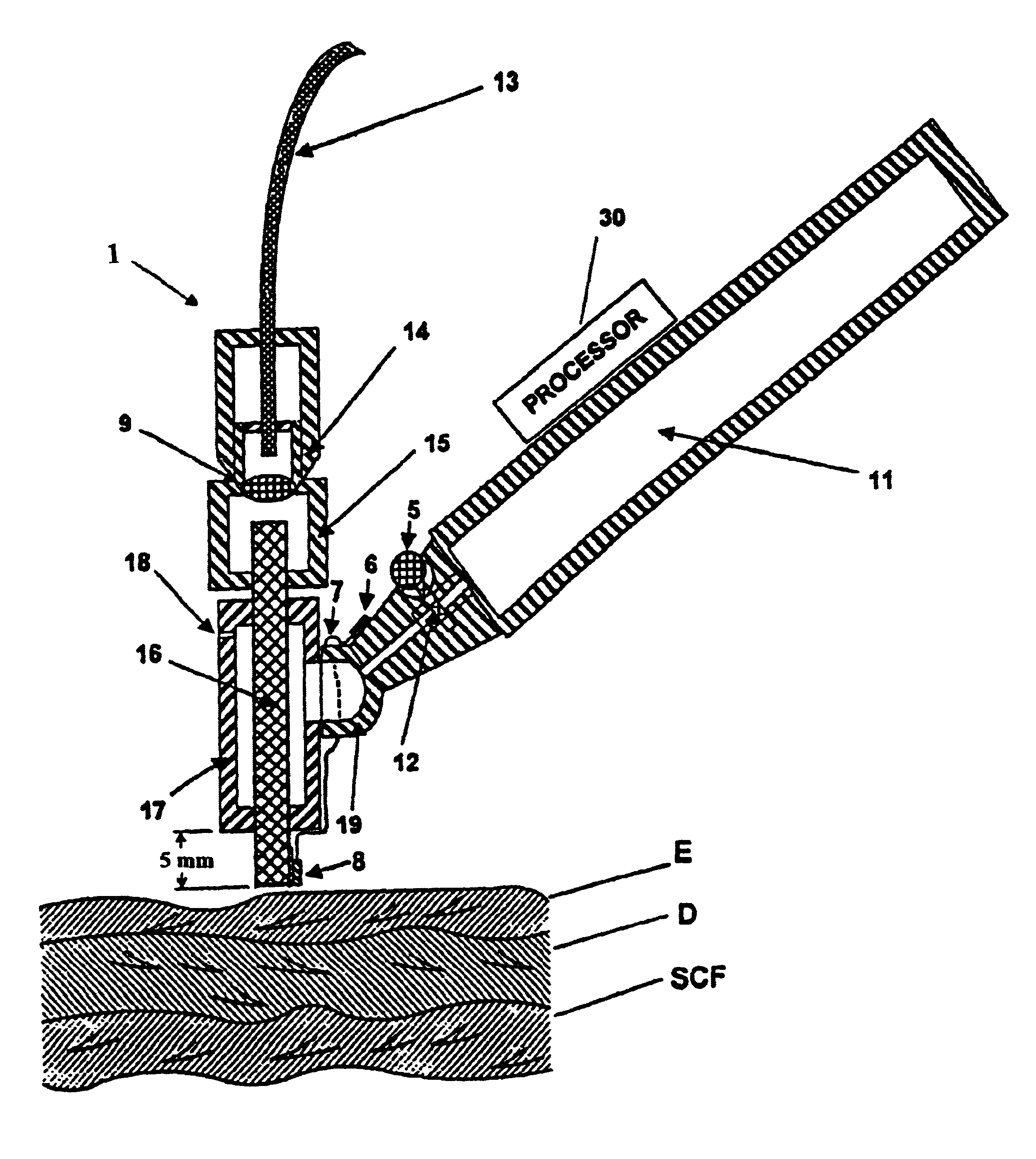

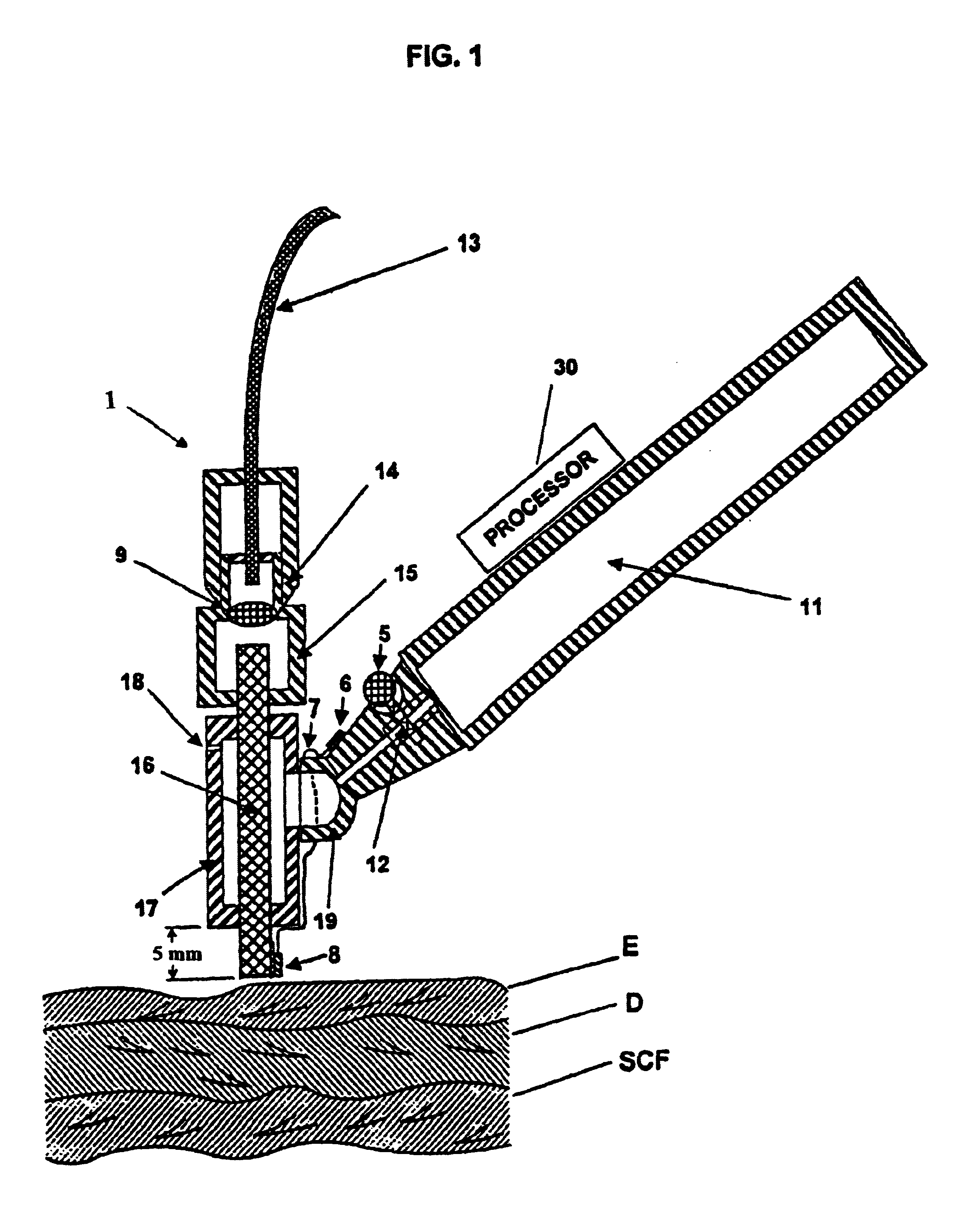

A laser treatment device and process with controlled cooling. The device contains a cooling element with high heat conduction properties, which is transparent to the laser beam. A surface of the cooling element is held in contact with the tissue being treated while at least one other surface of the cooling element is cooled by the evaporation of a cryogenic fluid. The cooling is coordinated with the application of the laser beam so as to control the temperatures of all affected layers of tissues. In a preferred embodiment useful for removal of wrinkles and spider veins, the cooling element is a sapphire plate. A cryogenic spray cools the top surface of the plate and the bottom surface of the plate is in contact with the skin. In preferred embodiments the wavelength of the laser beam is chosen so that absorption in targeted tissue is low enough so that substantial absorption occurs throughout the targeted tissue. In a preferred embodiment for treating large spider veins with diameters in the range of 1.5 mm, Applicants use an Er:Glass laser with a wavelength of 1.54 microns.< / PTEXT>

Owner:RELIANT TECH INC

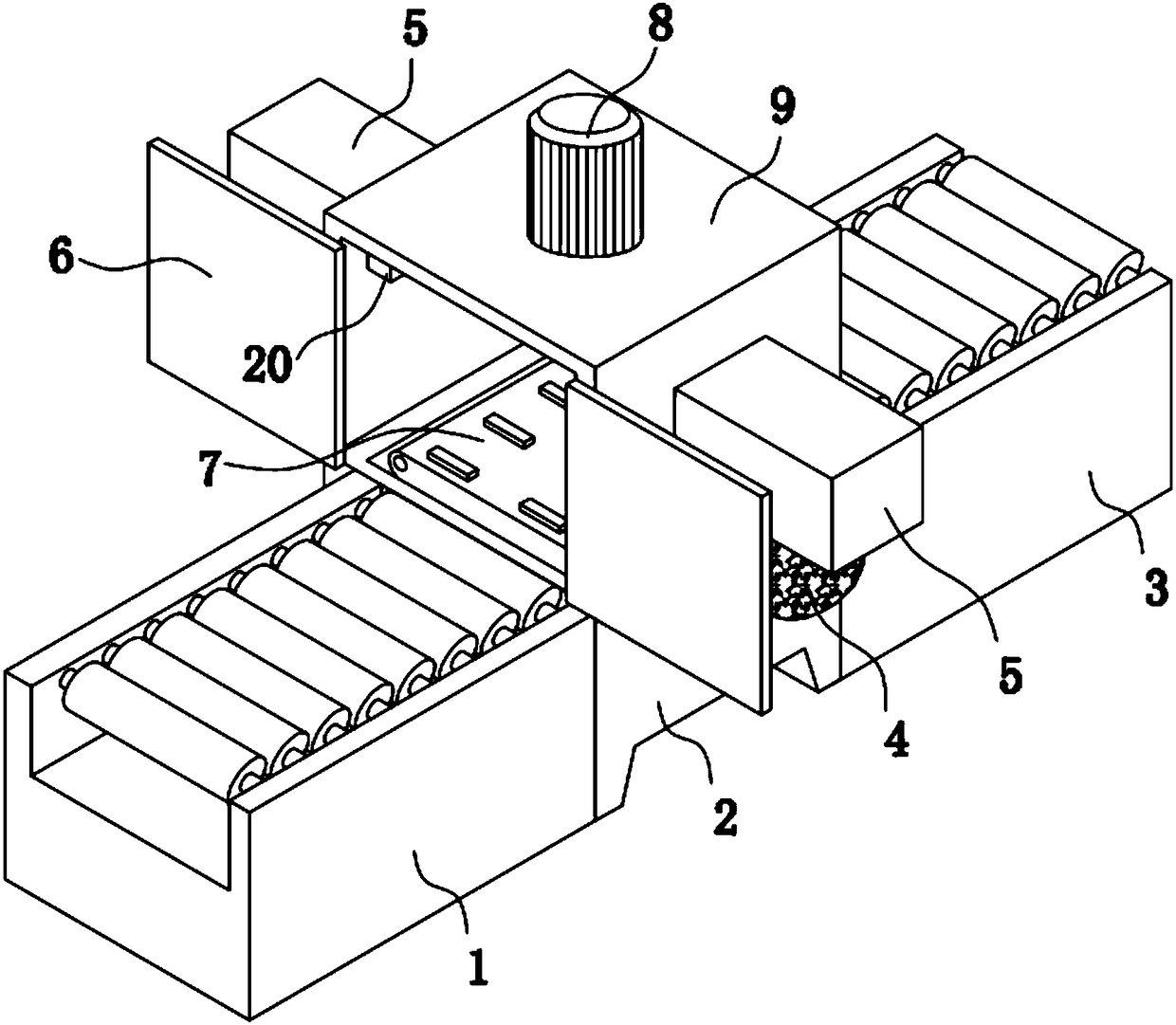

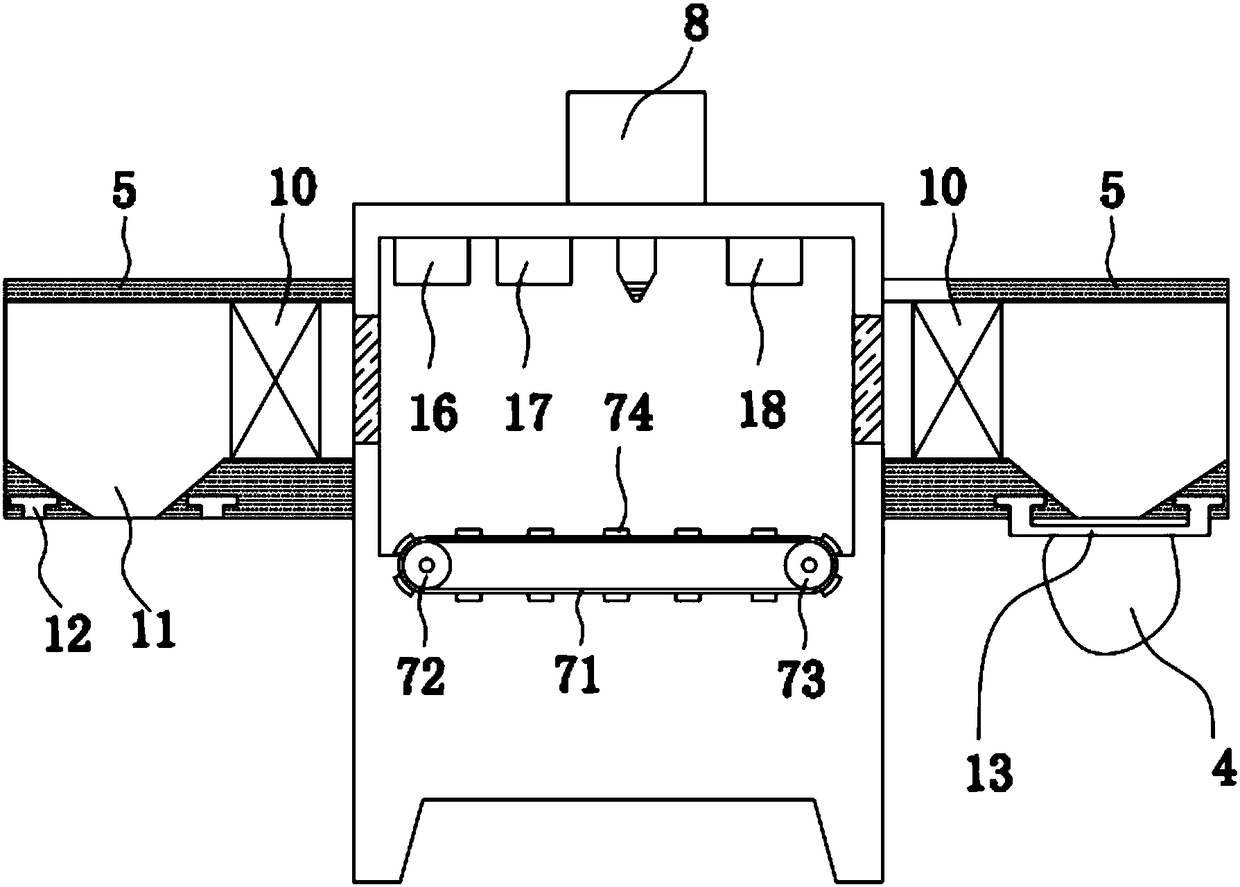

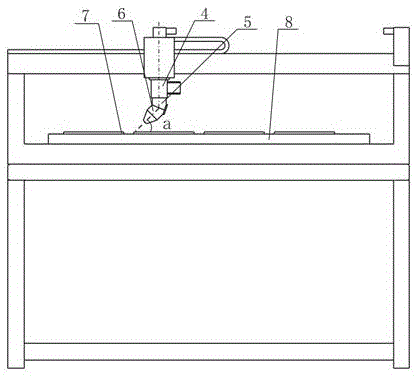

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

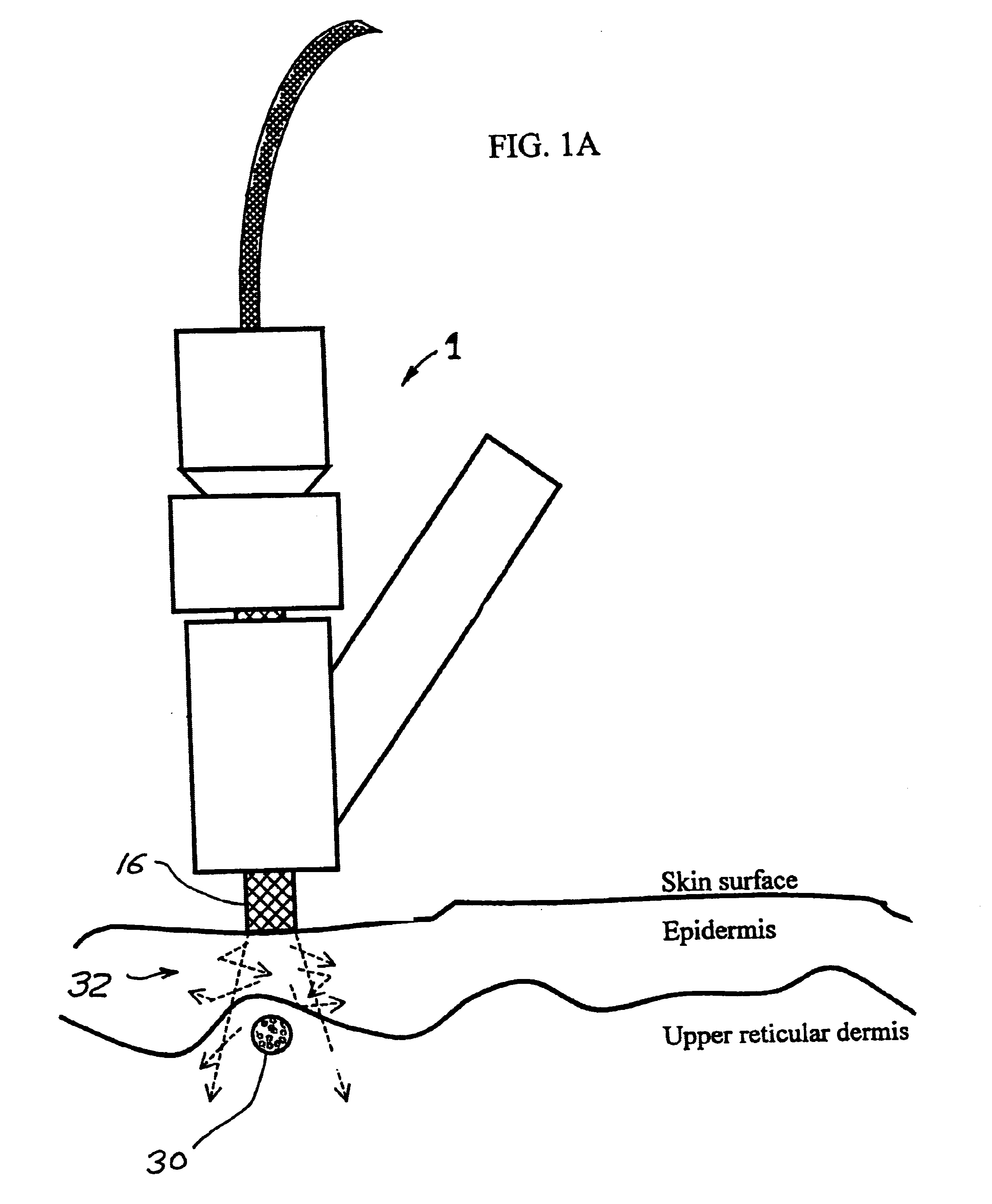

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

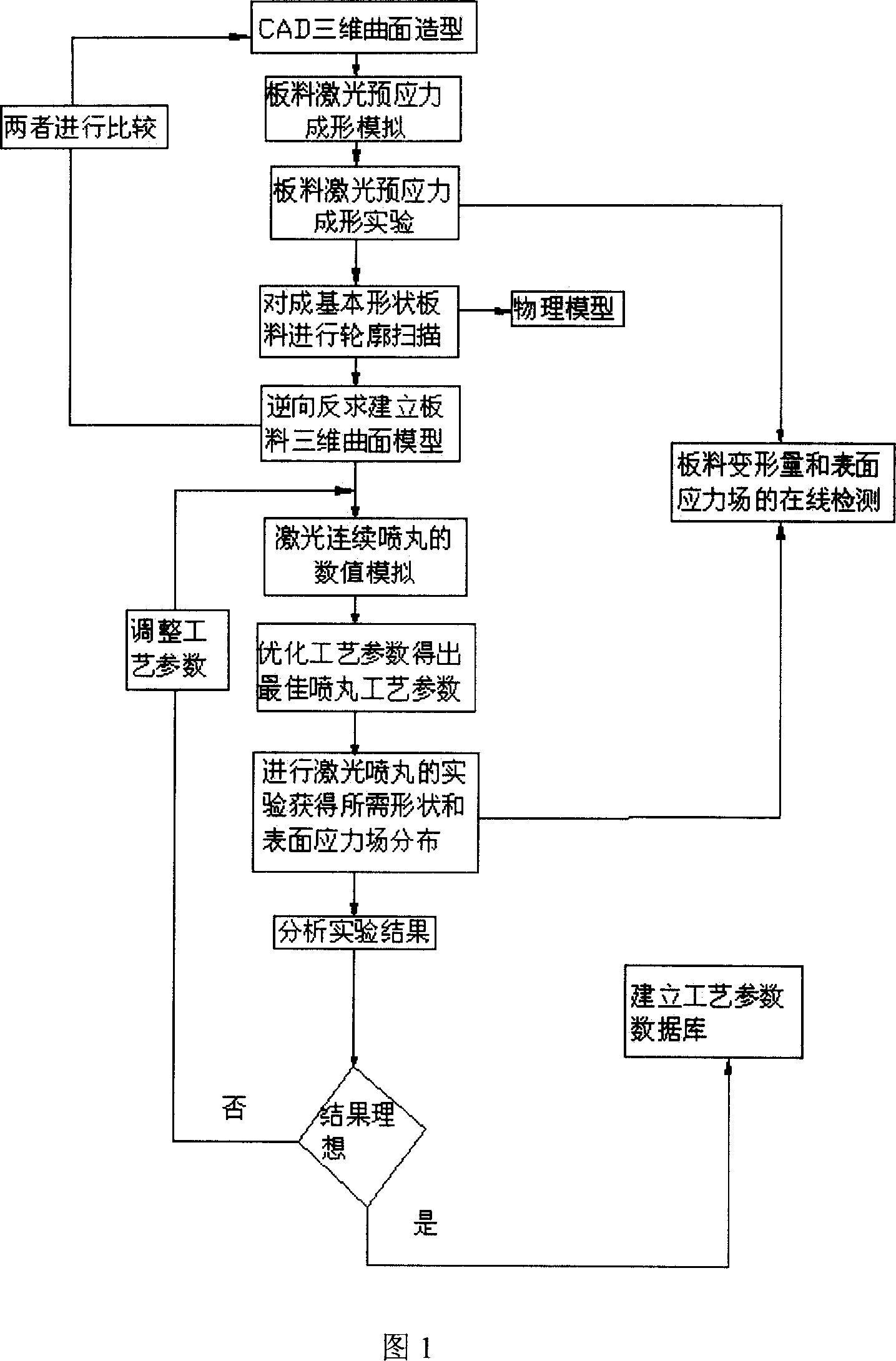

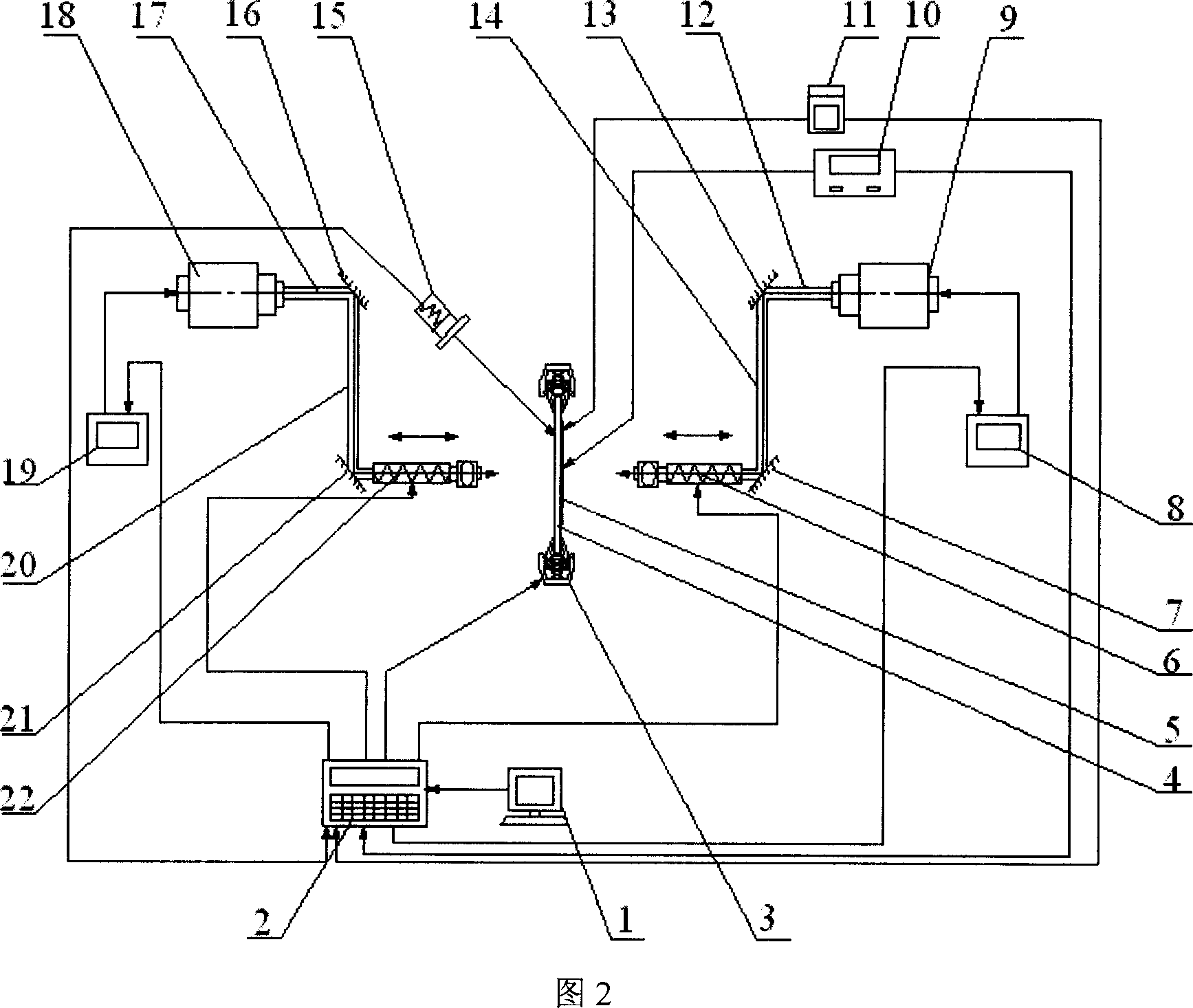

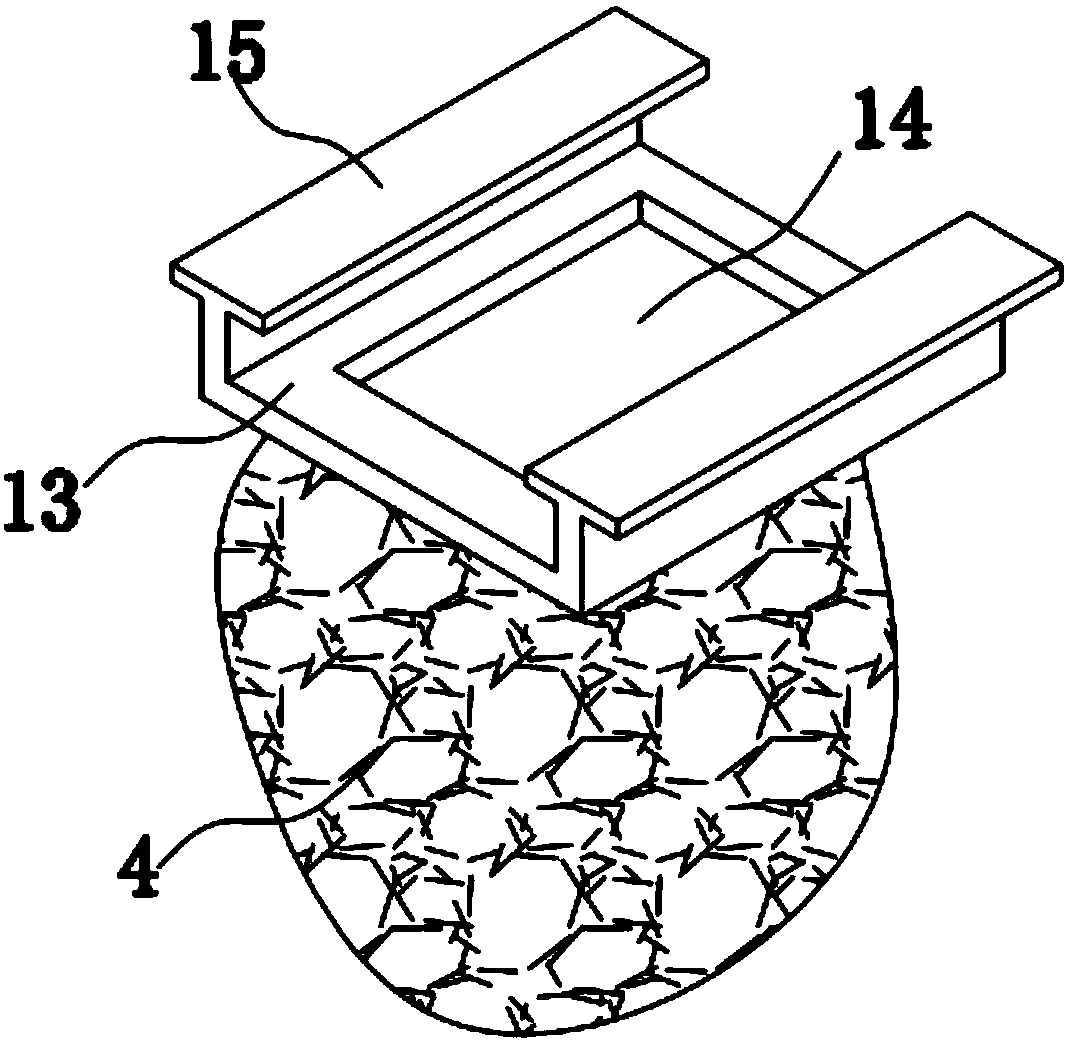

Method and apparatus of forming cut deal laser prestress composite shot blasting

InactiveCN101011777AImprove surface qualityImprove fatigue resistanceNumerical controlLaser beam welding apparatusSurface stressLaser light

A cut deal laser inherent stress composite peen forming features in the clipper using robot, using carbon dioxide to realize the basic formation, profile measuring feedback system controlling the deformation quantity, left stress meter measuring the surface stress of the board, optical scanning the pre formation, realizing board through model analog software, getting optimized process parameter instructing laser consecutive peen formation, using neodymium glass laser providing short pulse strong laser light, laser impact wave as the force source of precise forming, using the profile feedback device and on line measuring board surface stress left stress to control the deformation quantity to realize precision forming with complex shapes.

Owner:JIANGSU UNIV

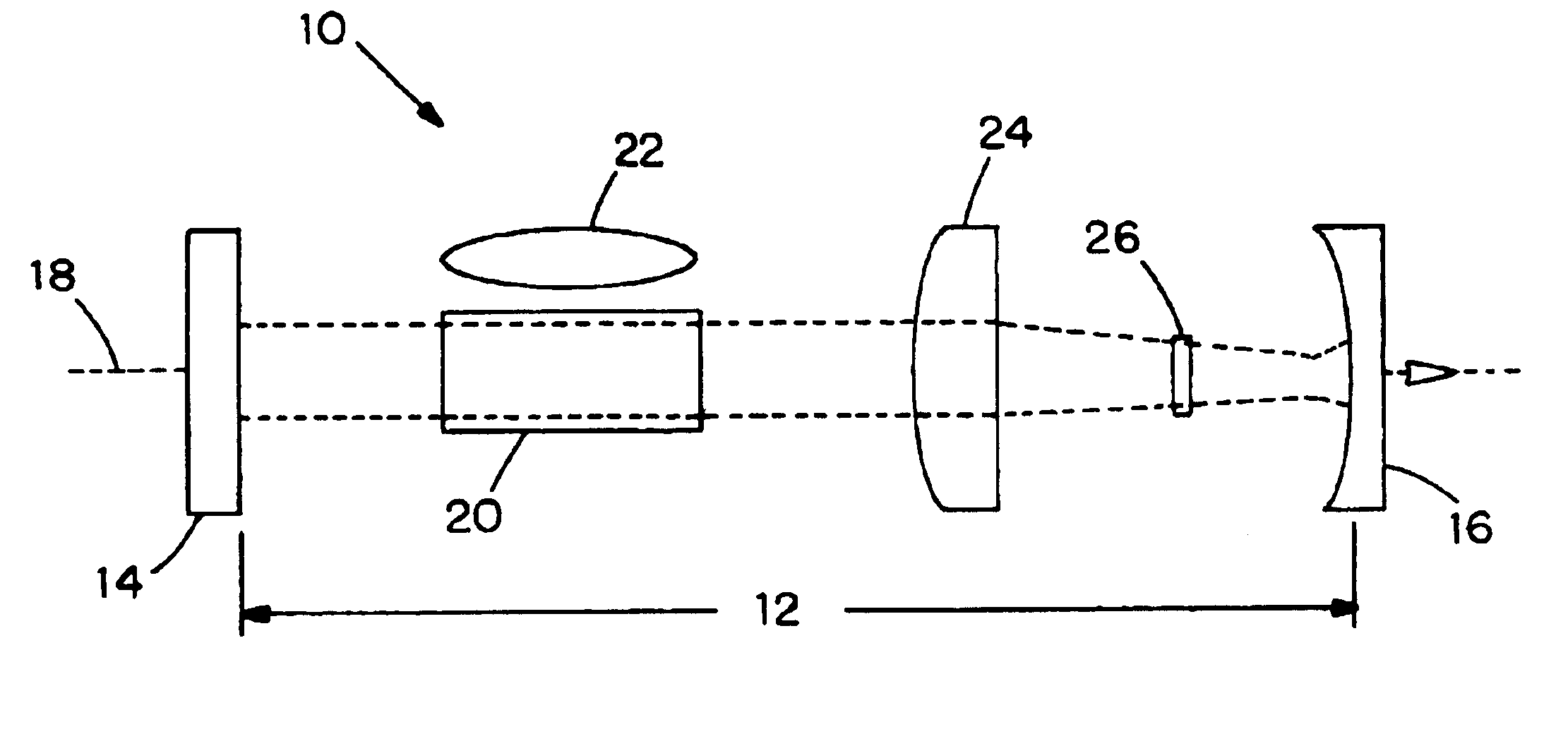

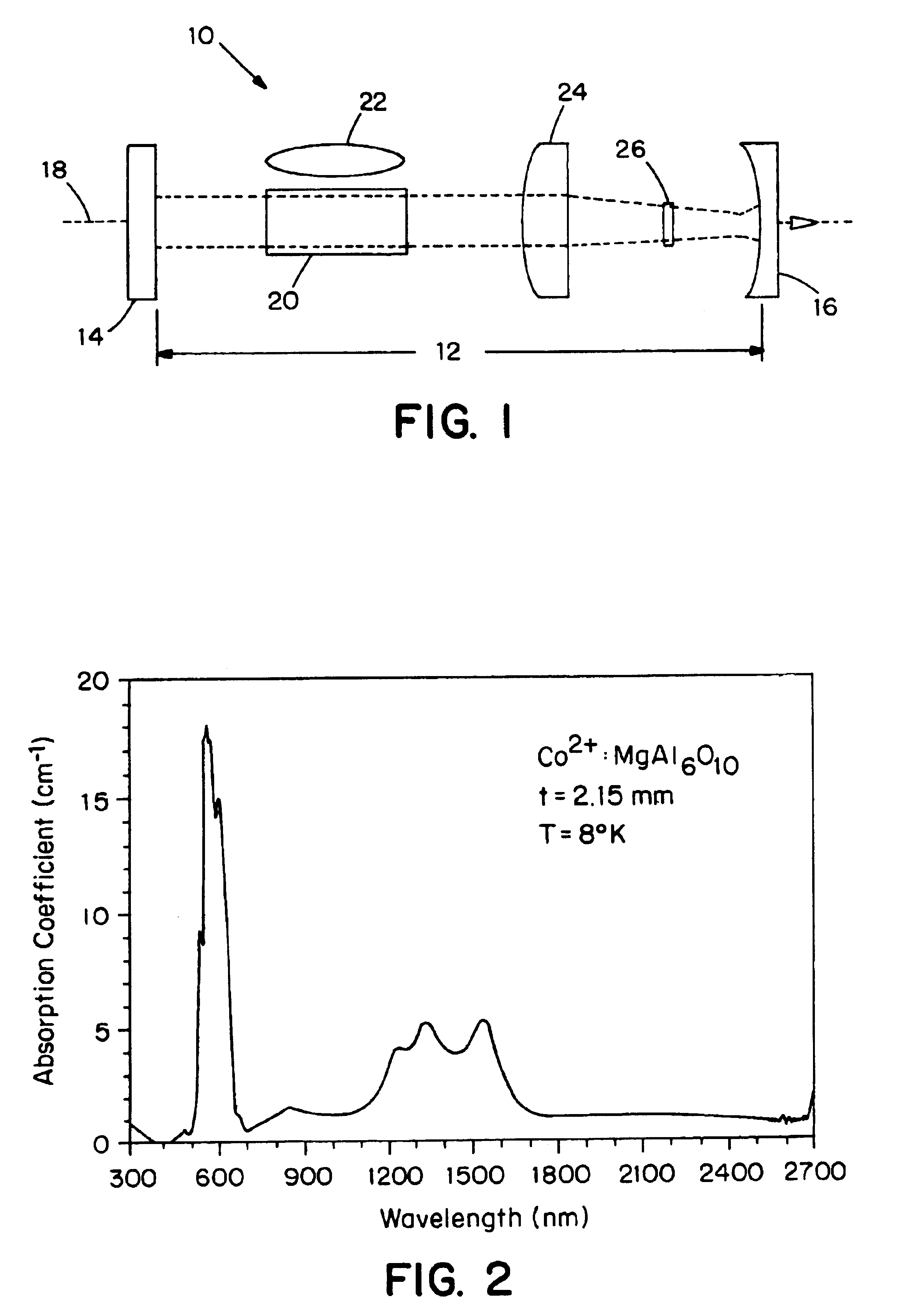

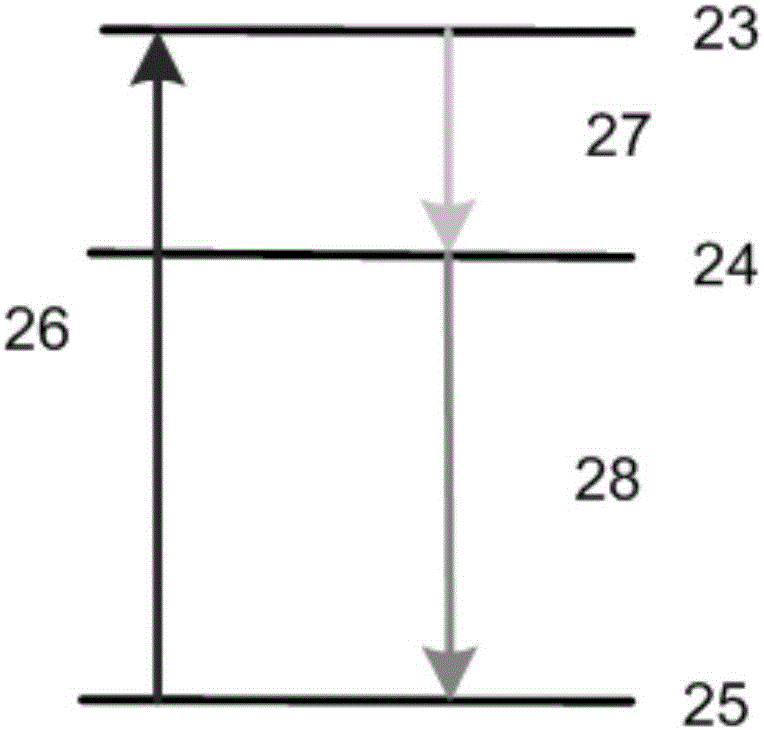

Cobalt-doped saturable absorber Q-switches and laser systems

InactiveUS6839362B2Improve efficiencyRaise the ratioOptical resonator shape and constructionActive medium materialOctahedronSingle crystal

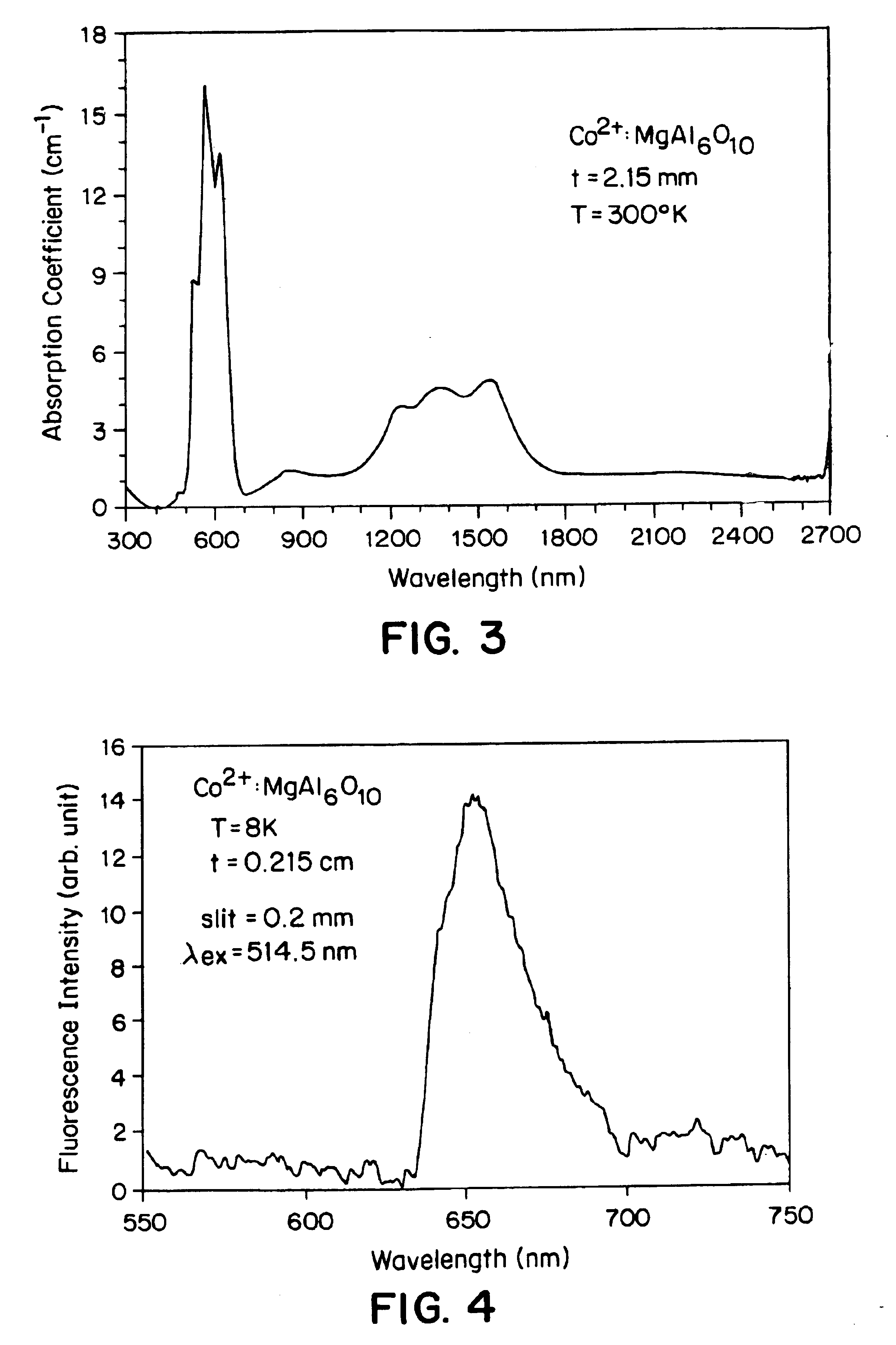

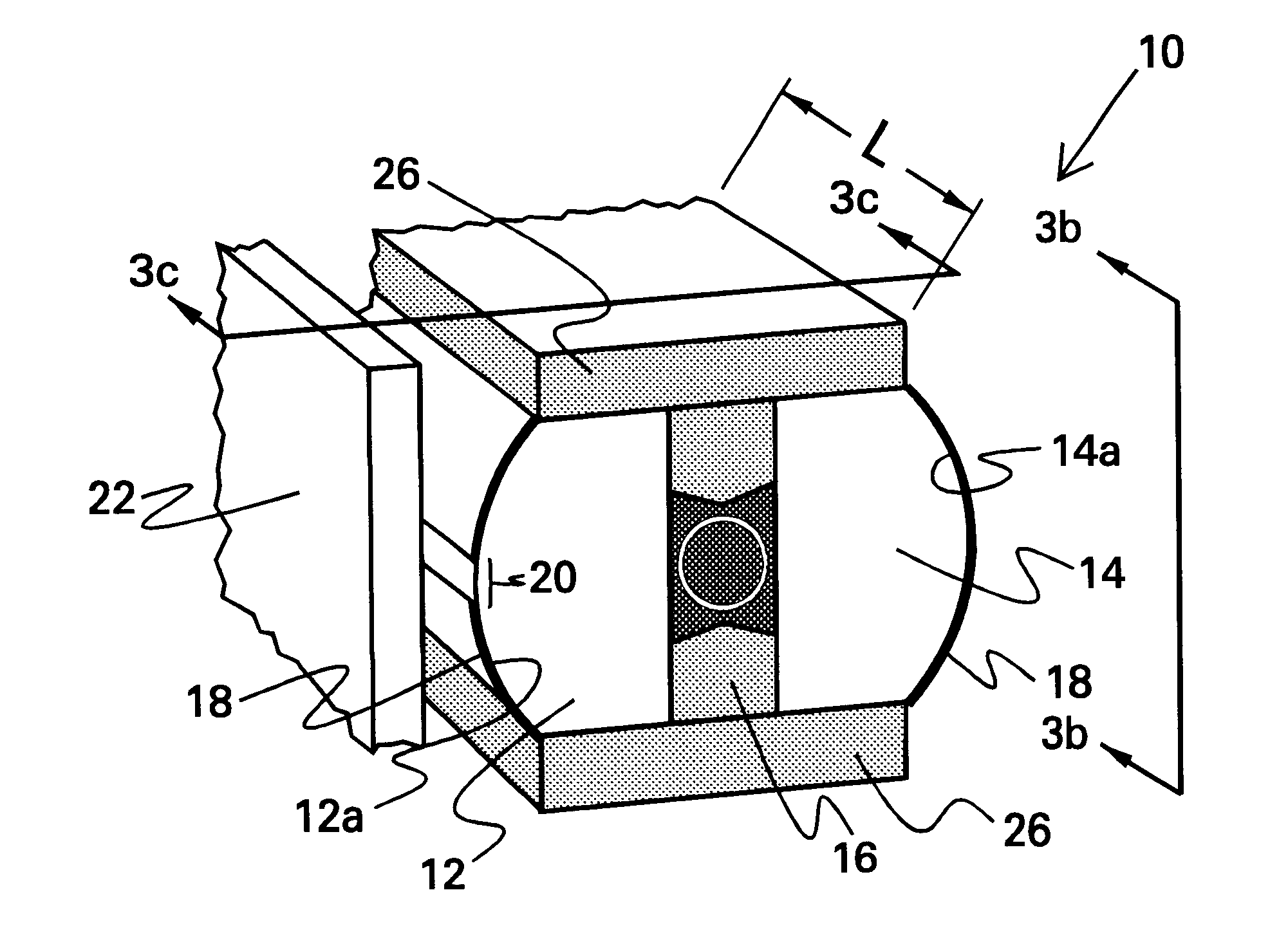

A saturable absorber Q-switch includes a monocrystalline lattice having the formula Mg1-xCoxAlyOz where x is greater than 0 and less than 1, y is greater than 2 and less than about 8, and z is between about 4 and 13. The lattice has tetrahedral and octahedral positions, and most of the magnesium and cobalt occupy tetrahedral positions. In one embodiment, the molar ratio of aluminum to the combined amount of magnesium and cobalt in the monocrystalline lattice can be controlled during growth of the monocrystalline lattice to thereby form a saturable absorber Q-switch that exhibits a 4T1 spectrum for the cobalt ion of at least about 1544 μm. In another embodiment, a laser system, such as an Er:Yr:glass laser system, includes a saturable absorber Q-switch that includes a monocrystalline lattice wherein the molar ratio of aluminum to the combined amounts of magnesium and cobalt exceeds 2:1, and preferably is about 6:1, and wherein essentially all of the magnesium and cobalt components of the monocrystalline occupy tetrahedral positions of the lattice.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

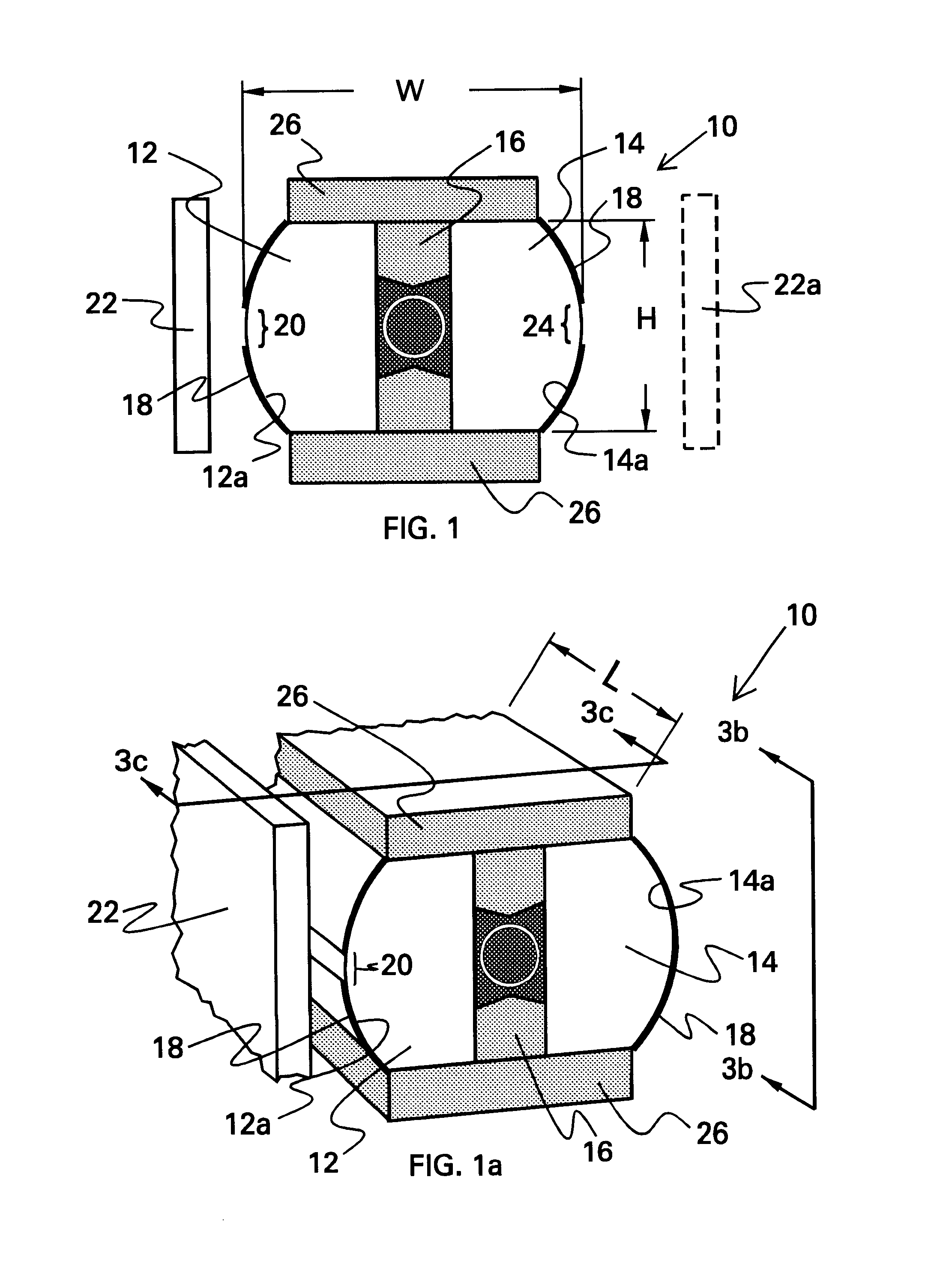

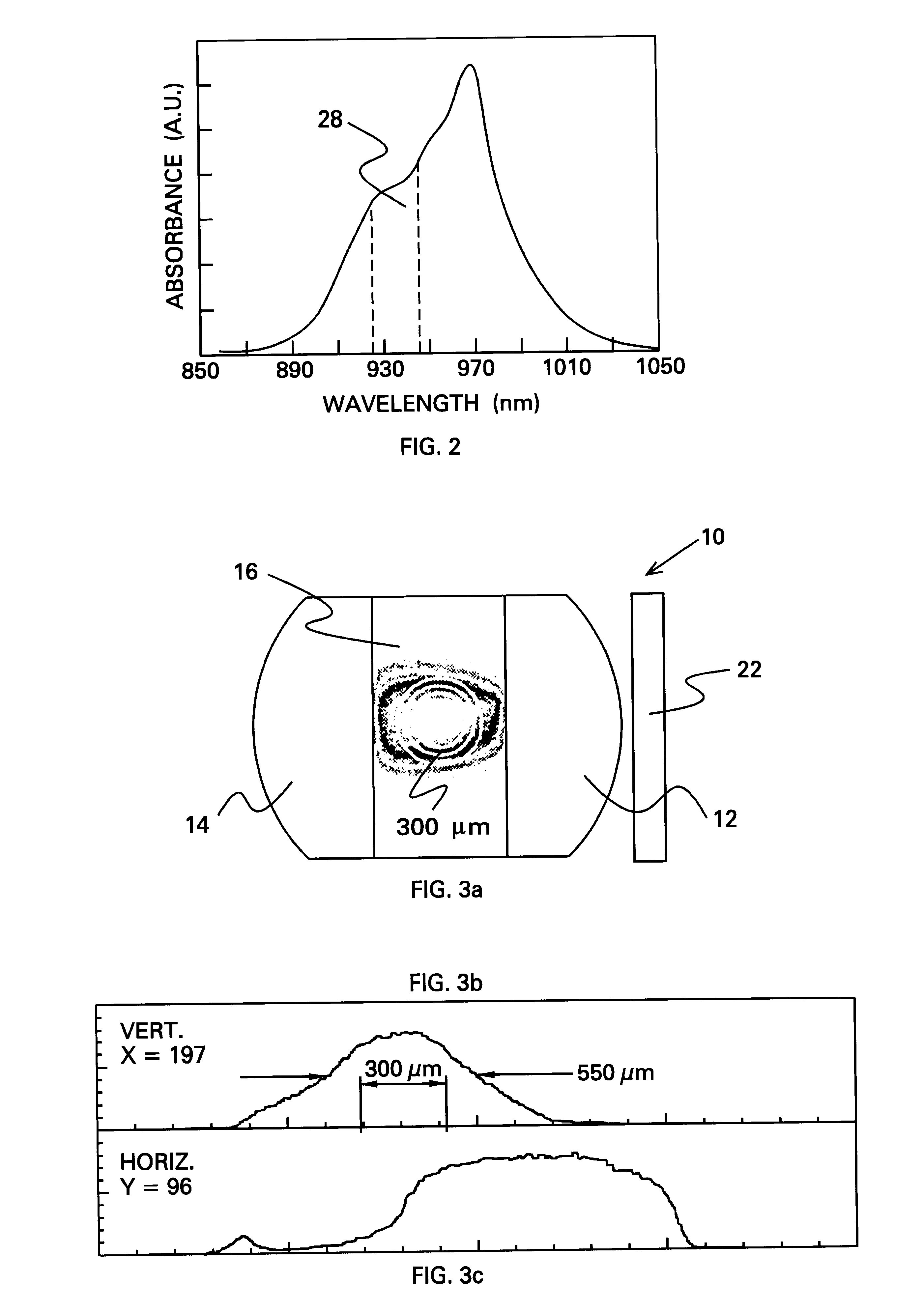

Integrating diode pump cavity for an Er, Yb:glass laser

A multi-pass, integrating diode pump cavity for an Er,Yb:glass laser is provided. The diode pump cavity comprises two end members of undoped glass sandwiching a center section of glass of the same composition as that of the two end members but doped with erbium and ytterbium ions. The two end members are each provided with a curved outer surface, which is coated with a reflective coating. At least one of the curved surfaces includes a slit through the reflective coating for transmission of pump laser light from a pump diode laser bar into the cavity. The diode pump cavity is small, compact, efficient, and eye-safe.

Owner:RAYTHEON CO

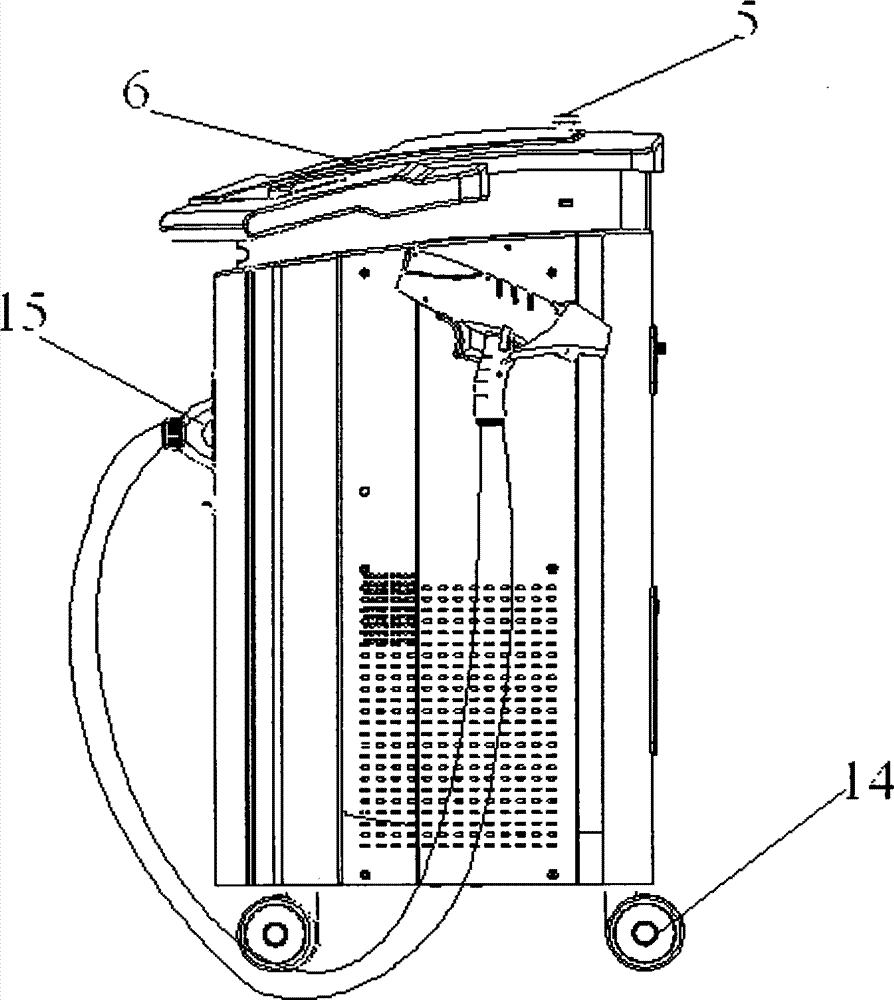

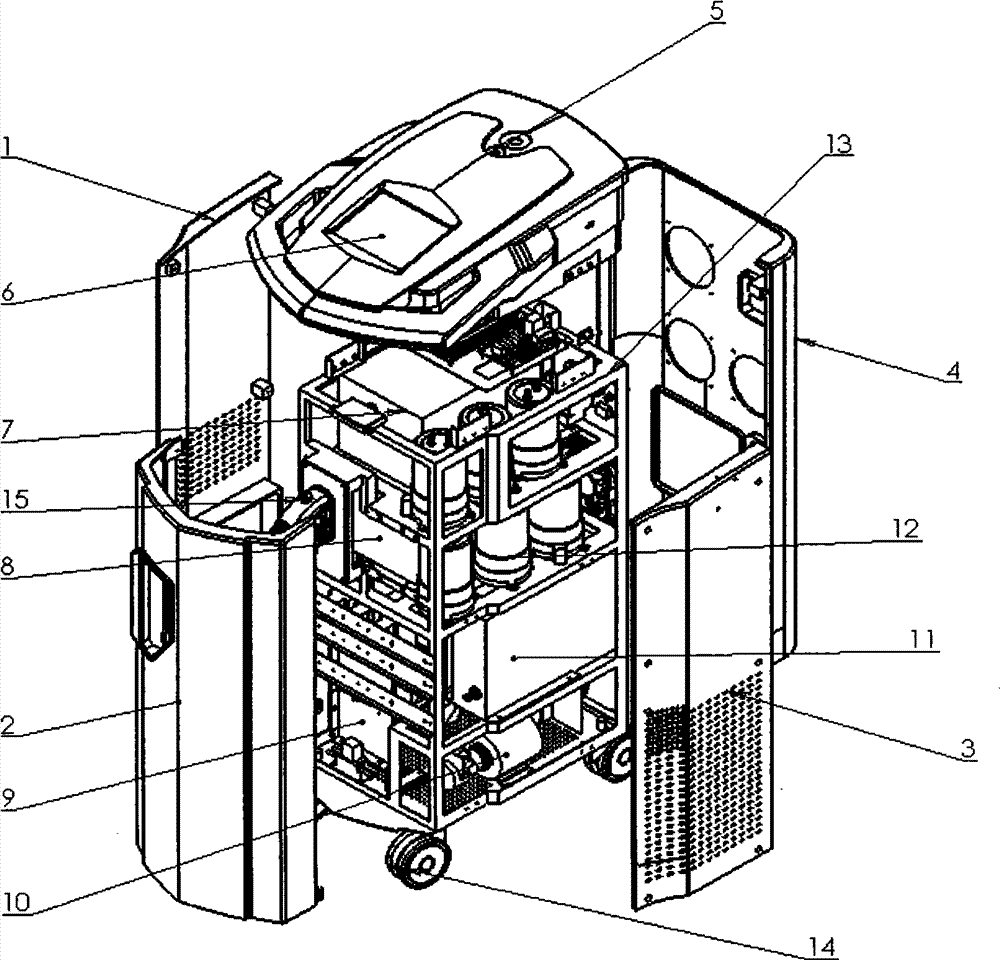

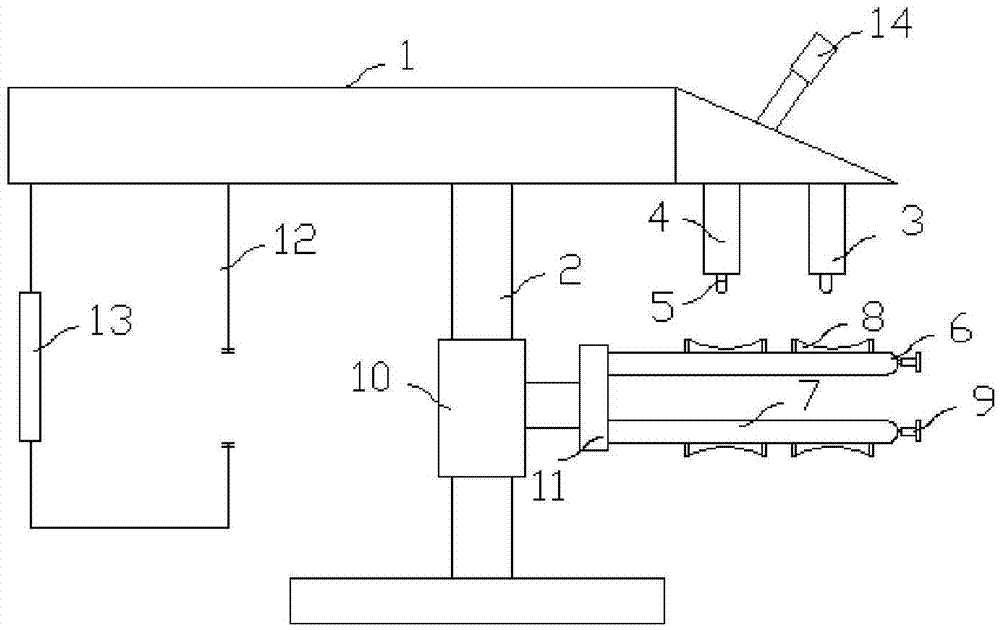

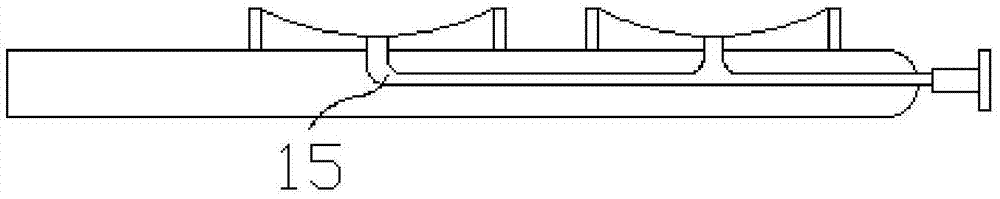

Multifunctional laser therapeutic instrument

InactiveCN104491989AImprove performanceEffective coolingSurgical instrument detailsRadiation therapyEr:YAG laserEngineering

The invention discloses a multifunctional laser therapeutic instrument, comprising a host, a cooling system, a power system, and a control system. The therapeutic instrument also comprises a treatment tool and a split housing. The treatment tool is installed on the host through a rapid hydroelectric integrated connector. The system has a function of control system automatic identification. The treatment tool comprises ER:GLASS laser, ER:YAG laser, long pulse ND:YAG laser, Q-switch ND:YAG laser, an IPL treatment head, an E light treatment head, a single-pole radio frequency treatment head and a bipolar radio frequency treatment head. The multifunctional laser therapeutic instrument is provided with eight kinds of lasers, and an identification pointer is disposed in the treatment tool to switch the lasers, realizing the therapeutic instrument has functions of eight therapeutic instruments, thereby reducing cost. Heat of the laser modules is effectively radiated by using air-cooling, built-in closed circulating water-cooling, and semiconductor refrigeration. The laser therapeutic instrument is more stable in performance, compact and small in structural design, convenient and efficient in operation and use. The laser therapeutic instrument is efficient, safe, and reliable, and reduces user use cost.

Owner:SHANGHAI APOLO MEDICAL TECH CO LTD

Method for annealing stress of prestressed glass laser

ActiveCN102992601APossess machinable propertiesSolve industry problems that are difficult to follow-up processingToughened glassUltimate tensile strength

The invention relates to a method for annealing stress of prestressed glass laser. According to the method, the rapid heating characteristic of laser on the prestressed glass (toughened glass and half-strengthened glass) is utilized to carry out rapid heating stress annealing treatment on the selective local area of the prestressed glass required to be subjected to subsequent processing, so that the local area has the processable characteristics, the overall using strength requirement of the prestressed glass is not substantiality influenced. The industry problem that the prestressed glass is difficultly subjected to subsequent processing is solved by the method.

Owner:张立国

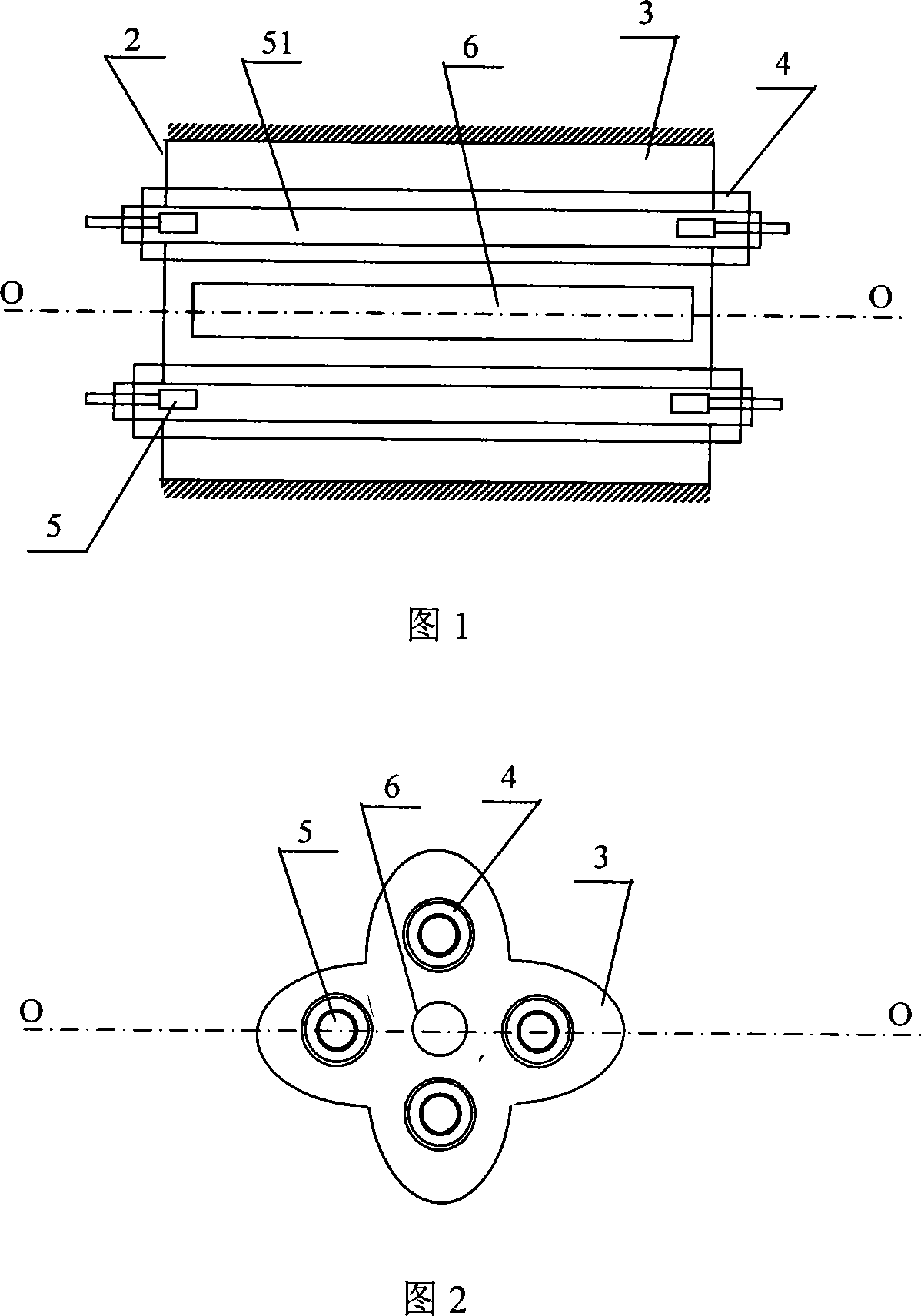

Heat capacity type neodymium glass bar-shaped laser

InactiveCN101202413AReduce volumeReduce weightOptical resonator shape and constructionActive medium shape and constructionClub shapedOptoelectronics

The invention discloses a neophane glass rod-shaped laser in heat capacity type, comprising a resonant cavity, an optical collector and rod-shaped neophane glass laser medium. The resonant cavity comprises a total reflective mirror and a half reflective mirror; the optical collector in club-shape consists of four semi-ellipse optical collecting cavities where xenon lamp is arranged to be parallel to the direction of the laser beam; a cooling pipe is sleeved outside the xenon lamp; the cooling pipe is internally provided with flowing cooling water; the pumping power density of the xenon lamp is less than or equal to 95J / cm<3>; the discharging pulse width of the xenon lamp is 1-2ms; the gain volume of the rod-shaped neophane glass laser medium is more than or equal to 1481cm<3> and the diameter thereof is more than or equal to 3.6cm; one end surface of the rod-shaped neophane glass laser medium is a bevel which has the inclination of 2 plus or minus 0.01 DEG. The invention has the advantages of ensuring laser output with high beam quality and effectively implementing high efficiency and high average power output by adopting the structure; and as the laser medium adopts the rod-shaped glass, the whole laser has small volume and light weight and no cooling is needed in the operation process of the laser.

Owner:NINGBO UNIV

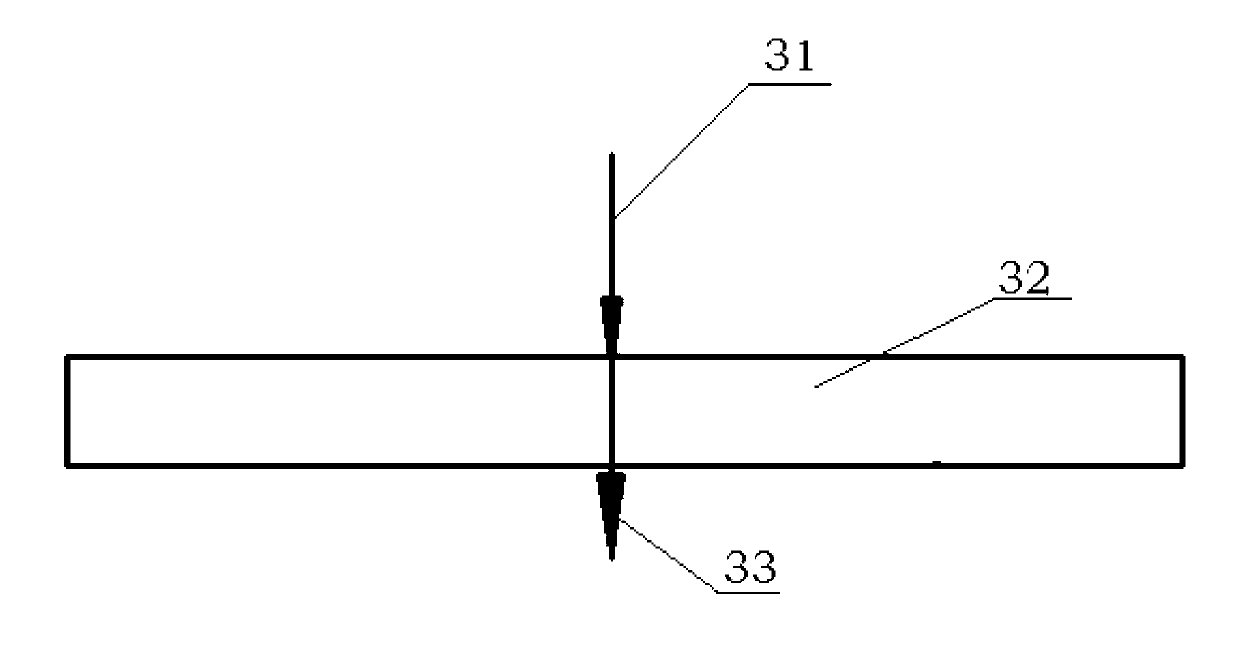

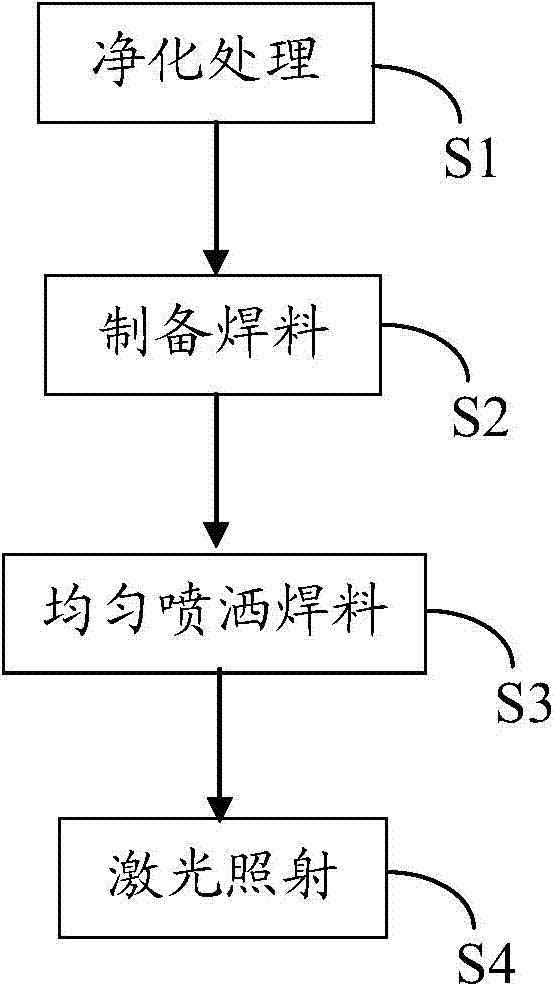

Sealing-in method for glass and kovar alloy and sealed body

The invention discloses a sealing-in method for glass and a kovar alloy and a sealed body. The sealing-in method comprises the following steps of S1, purifying the glass to be sealed and the kovar ally to be sealed; S2, providing glass powder and metal powder which have the particle sizes of 150-200 meshes, and mixing and grinding the powder to prepare a welding flux; S3, uniformly spraying the welding flux in the step S2 to the surrounding edge of the kovar ally to be sealed; and putting the glass to be sealed on the kovar alloy, wherein the glass and the kovar alloy are in tight contact; S4, irradiating the welding flux at an intersection of the glass to be sealed and the kovar alloy to be sealed through laser to obtain the sealing body formed by the glass and the kovar alloy. According to the sealing-in method for the glass and the kovar alloy, the welding flux is added to the intersection of the glass and the kovar alloy, and the intersection of the glass and the kovar alloy is straightly irradiated with laser, so that the problem of laser processing difficulty caused by high glass laser transmittance rate is solved, and the glass and the kovar alloy can be tightly connected and sealed.

Owner:SUZHOU UNIV

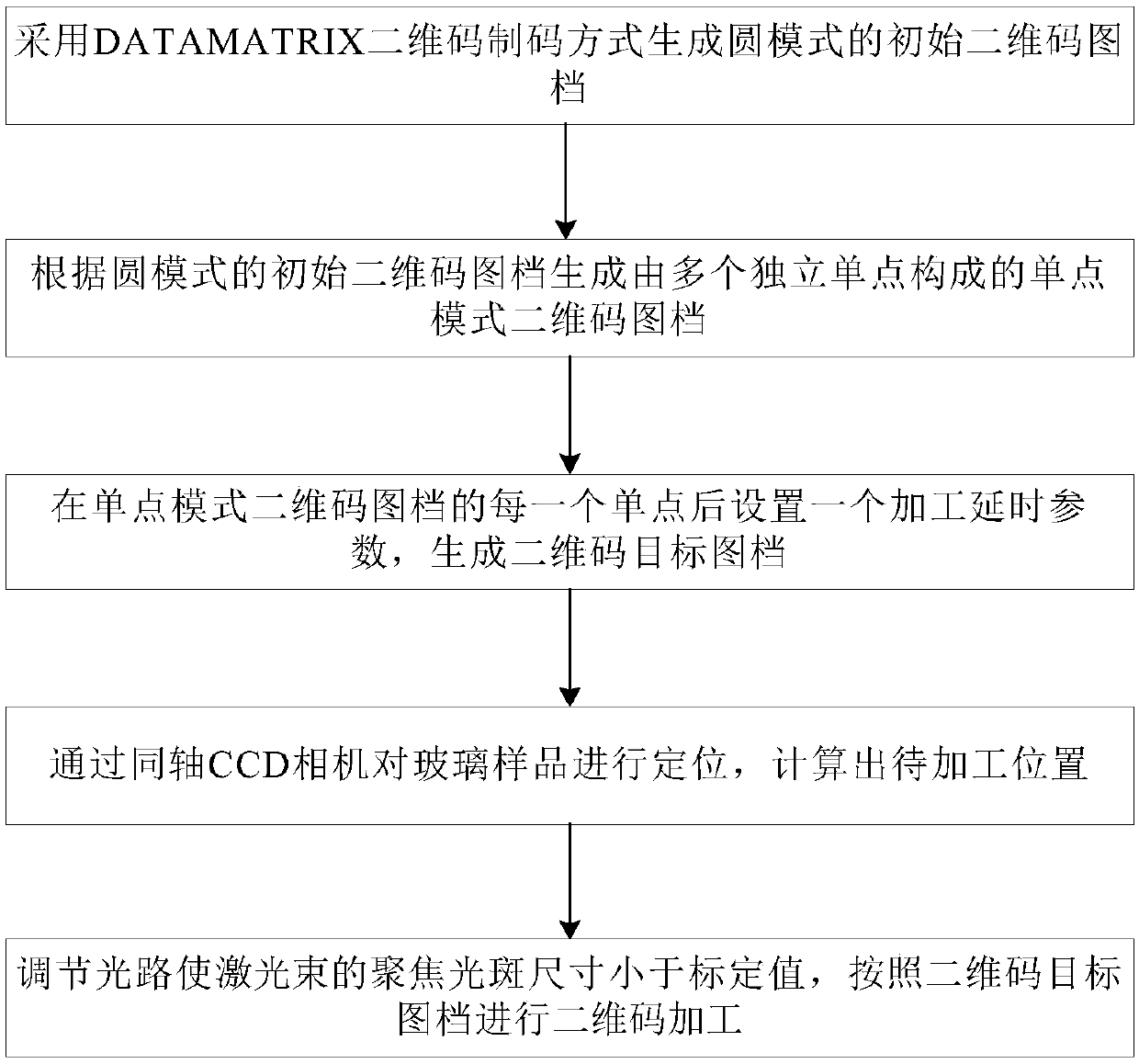

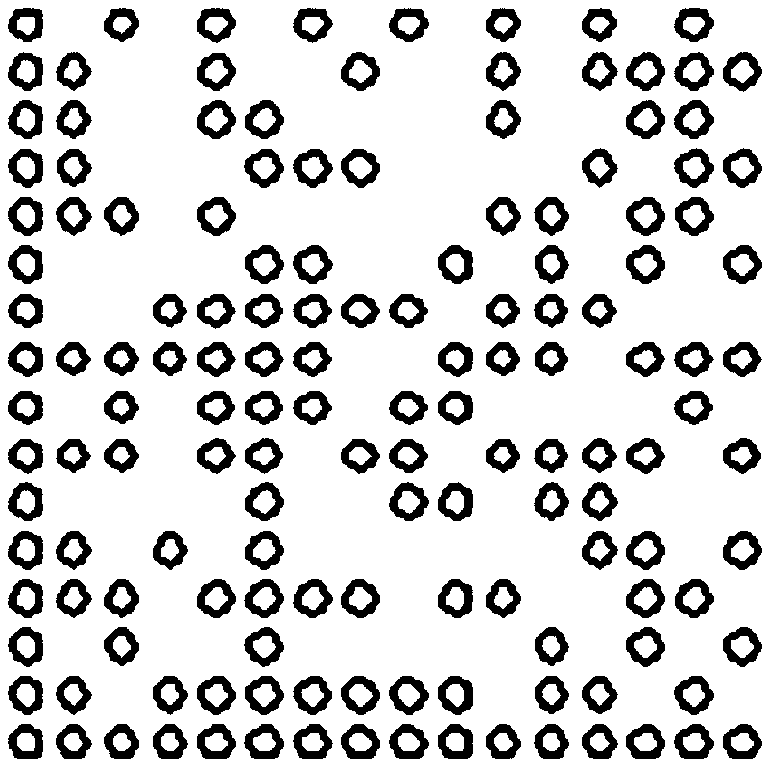

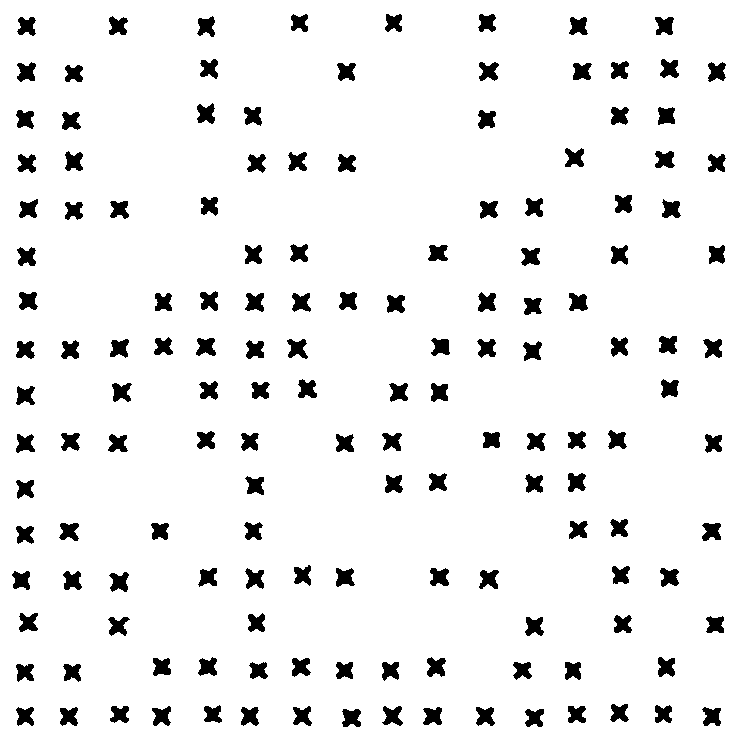

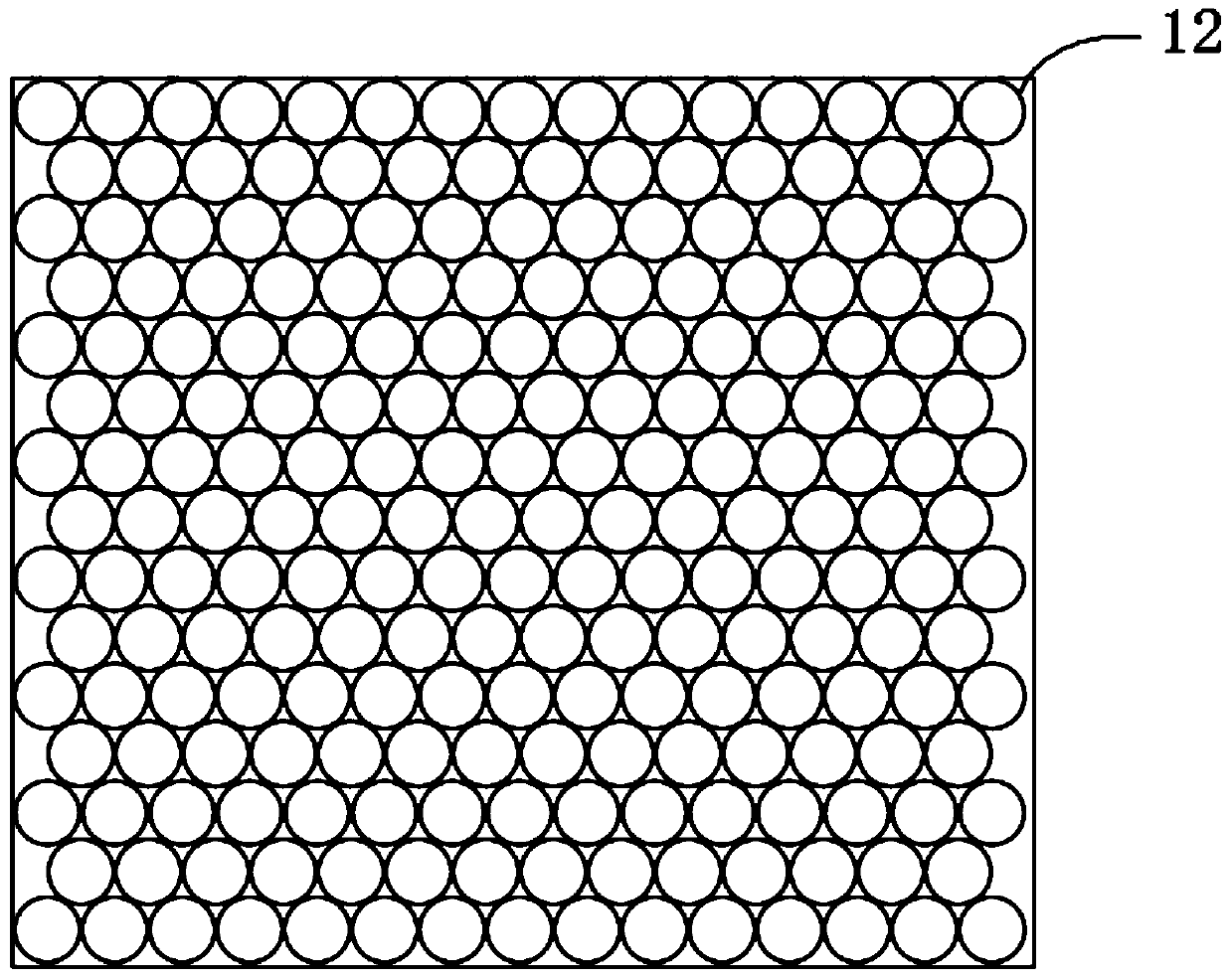

Method for engraving miniature two-dimensional code in glass laser

ActiveCN110626086ASufficient reaction timeAvoid smearingAblative recordingPicosecond laserLaser engraving

The invention relates to the technical field of laser engraving, in particular to a method for engraving a miniature two-dimensional code in glass laser. The method for engraving the miniature two-dimensional code in the glass laser comprises the following steps that a DATAMATRIX two-dimensional code encoding method is used for generating an initial two-dimensional code drawing file of a circle pattern; and a single-point mode two-dimensional code drawing file composed of a plurality of independent single points is generated according to the initial two-dimensional code drawing file of the circle pattern; processing delay parameters are arranged behind the each single point of the single-point mode two-dimensional code drawing file, and a target two-dimensional code drawing file is generated; a glass sample is located through a coaxial CCD camera, and the position to be processed is calculated; and an optical path is adjusted to enable the focused spot size of a laser beam to be smaller than a calibration value, a focus point of the laser beam is moved to the position to be processed inside the glass sample, and the two-dimensional code processing is carried out according to the target two-dimensional code drawing file. The tailing phenomenon caused by a galvanometer when the action time of a picosecond laser is extremely short is effectively prevented, and two-dimensional small-size engraving is enabled to be possible.

Owner:WUHAN HGLASER ENG CO LTD

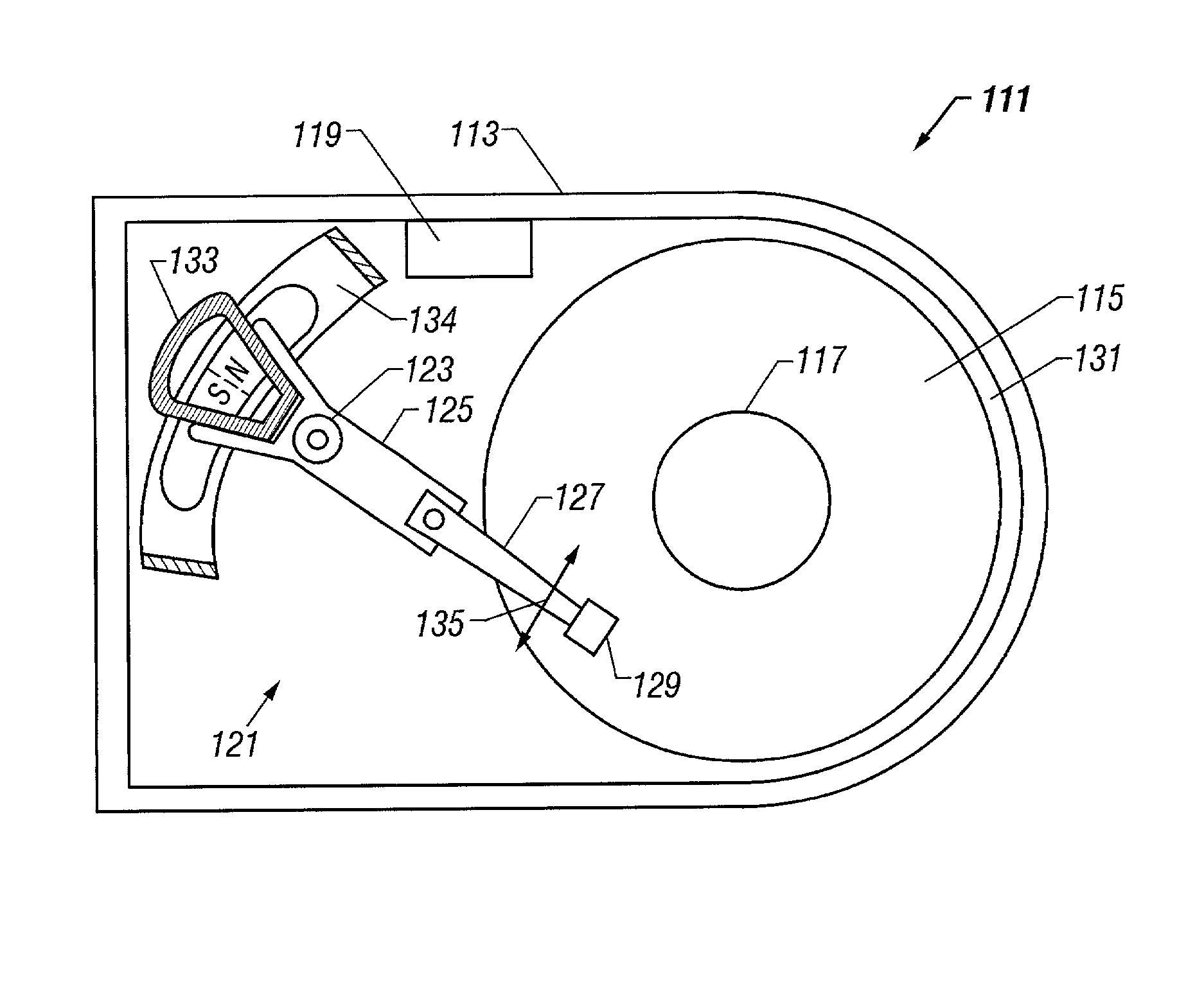

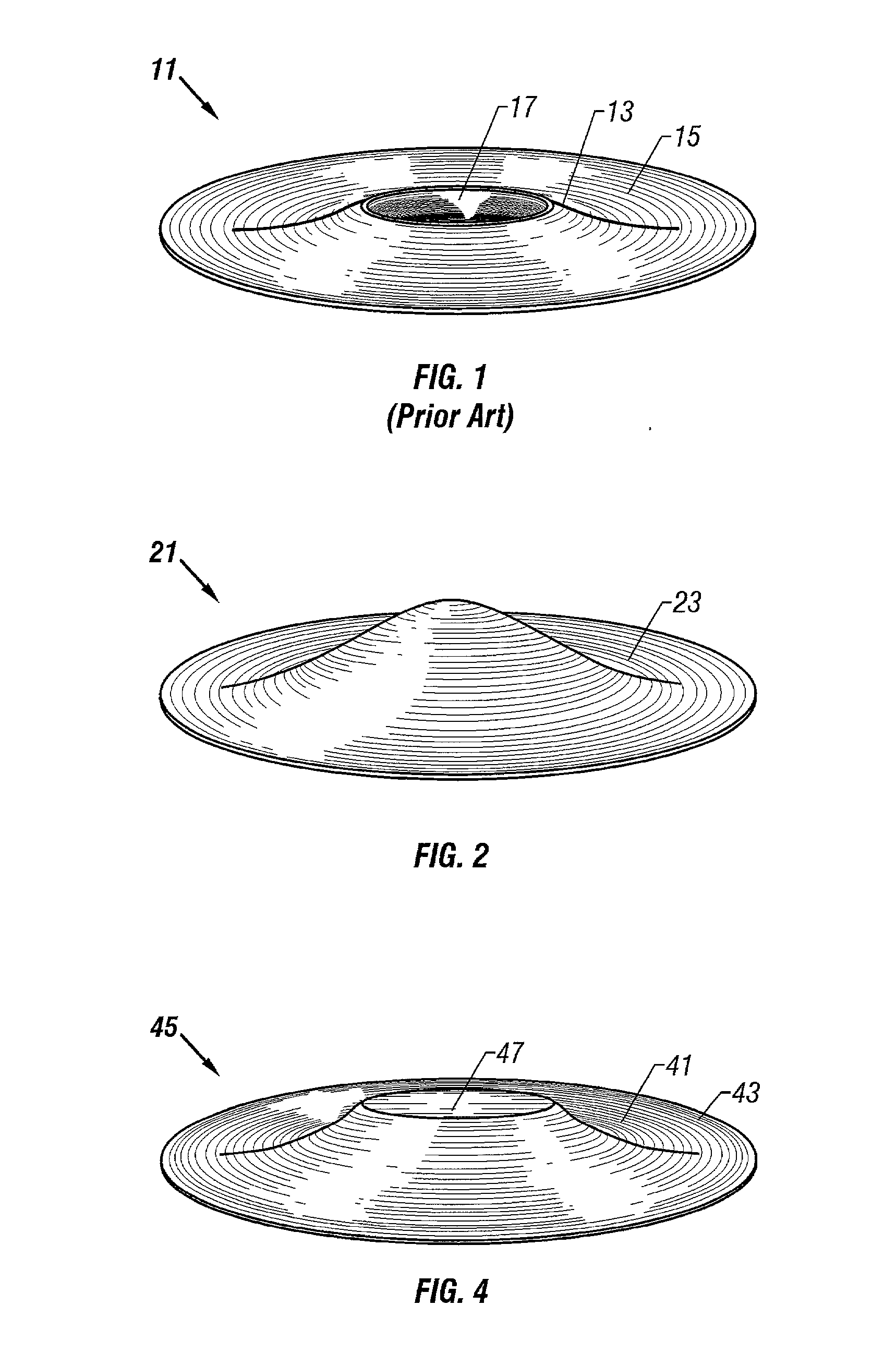

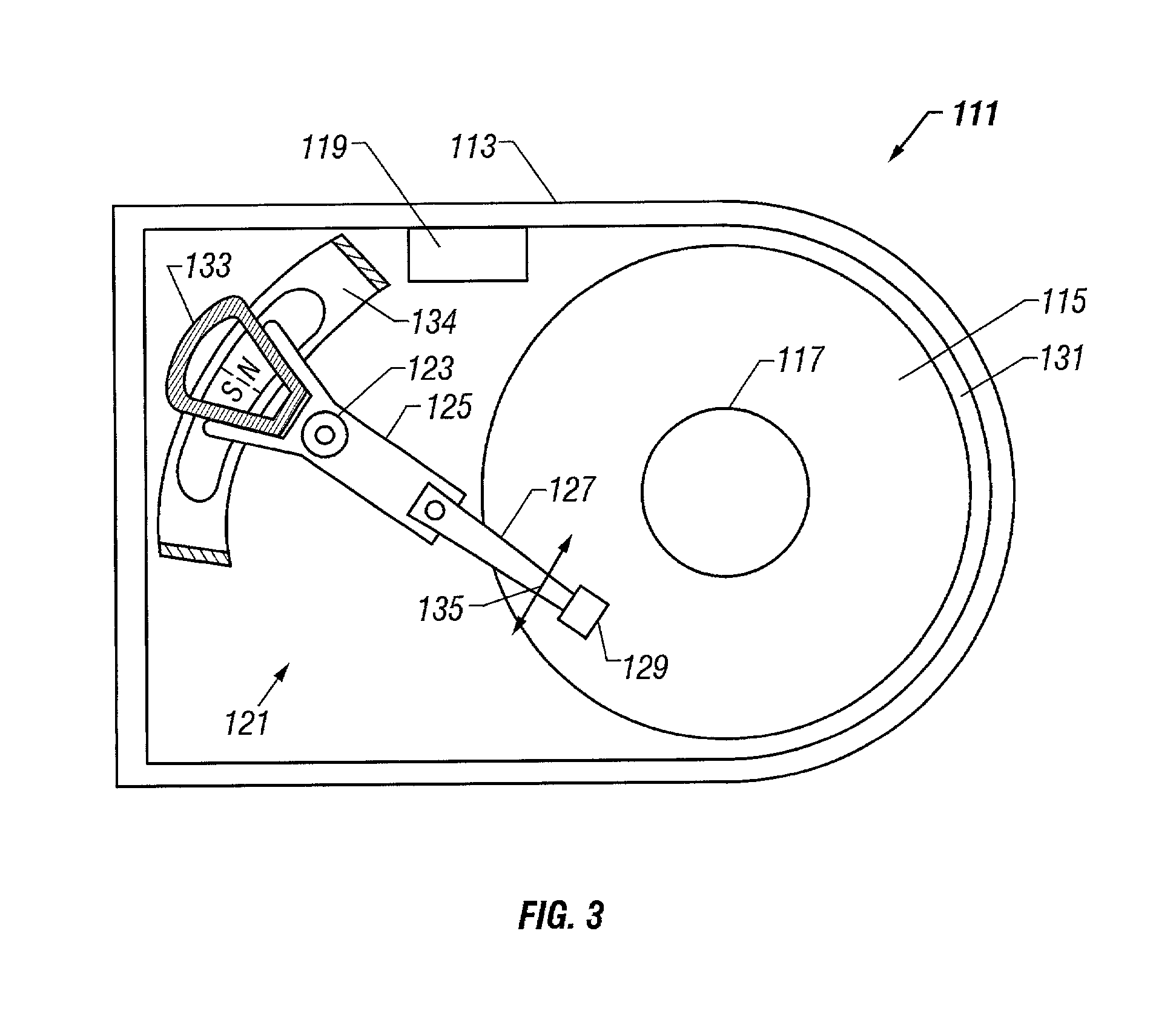

Disk drive laser melt bump disk for accurate glide calibration and certification processing

InactiveUS20030015018A1Using mechanical meansTesting/calibration of speed/acceleration/shock measurement devicesEngineeringManufacturing line

A bump disk for accurate glide calibration has a new type of glass laser melt bumps that give the same signal amplitudes as conventional AlMg laser melt bumps for the same bump height. The present invention provides a solution to switch the calibration bumps from AlMg to glass, and can be used in disk manufacturing lines to save 30% on the cost of hard disks from inaccurate glide certification processes. The solution is to trim or burnish away loose and / or high particles on production disks before the glide tests. This additional processing step causes the responses from the glass bumps to become very similar to those of the AlMg bumps, thereby enabling glass and AlMg disks to become materially compatible.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

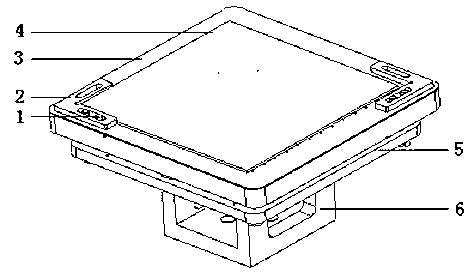

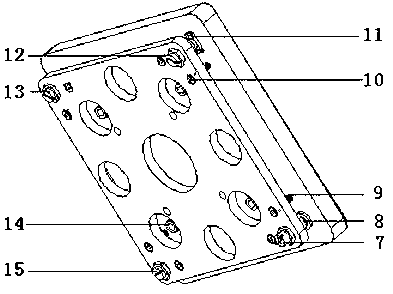

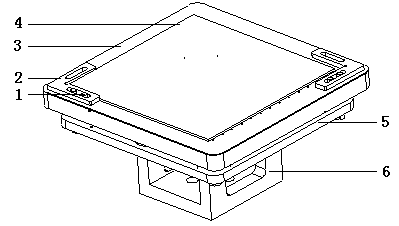

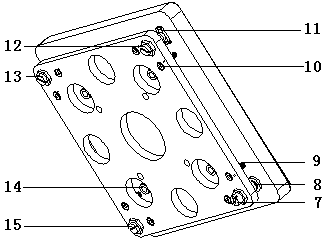

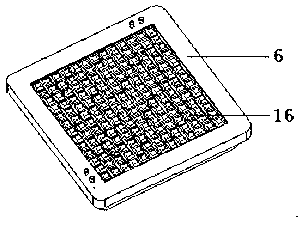

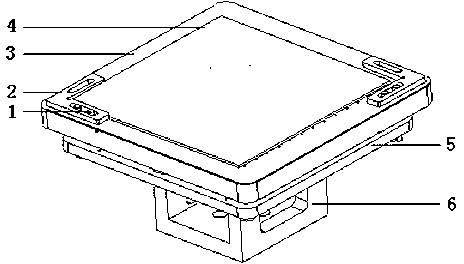

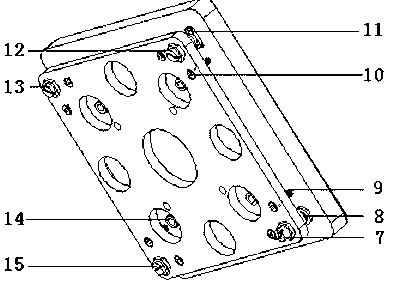

Multifunctional glass support platform

ActiveCN103214176AReduce processing costsFix random breaksGlass severing apparatusGlass fiberEngineering

The invention relates to a multifunctional glass support platform. The multifunctional glass support platform mainly solves the problem that the existing glass fixing platform easy causes thin-sheet glass ruleless cracking and inconvenient and inaccurate glass positioning, and is inconvenient for laser beam verticality adjustment. The multifunctional glass support platform comprises a glass adjustment module, a glass vacuum adsorption module and a glass fast and accurate positioning module. The glass adjustment module is a two-dimensional angle adjustment platform composed of double layers of flat plates comprising an upper flat plate and a lower flat plate. The two-dimensional angle adjustment platform comprises the upper flat plate and the lower flat plate. The surface of the upper flat plate is provided with vent holes. The glass vacuum adsorption module comprises a glass fiber plate covered on the upper flat plate, and an air suction device. The glass fiber plate opposite to the vent holes of the upper flat plate is provided with through holes. The glass fast and accurate positioning module comprises opposite angle locating pins and locating blocks arranged on the upper flat plate. The multifunctional glass support platform solves the above problem and can be used for a glass laser cutting processing industry.

Owner:KUNSHAN THETA MICRO

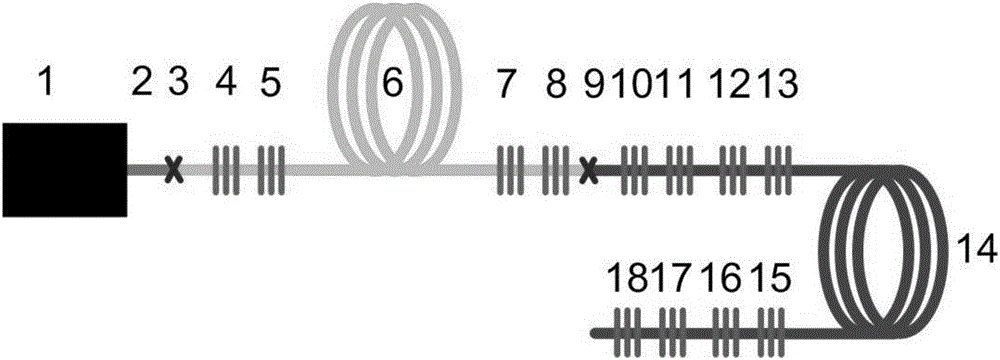

Intermediate infrared multi-band all-fiber soft glass laser and laser obtaining method

ActiveCN106374327AImprove scalabilityImprove portabilityActive medium materialActive medium shape and constructionInfraredMulti band

The invention provides an intermediate infrared multi-band all-fiber soft glass laser and a method for obtaining intermediate infrared multi-band fiber laser through the laser. The laser comprises a laser pumping source, laser pumping source tail fibers, a first fiber fusing point, a first fiber bragg grating, a second fiber bragg grating, first rare earth ion doped fibers, a third fiber bragg grating, a fourth fiber bragg grating, a second fiber fusing point, a fifth fiber bragg grating, a sixth fiber bragg grating, a seventh fiber bragg grating, an eighth fiber bragg grating, second rare earth ion doped fibers, an ninth fiber bragg grating, a tenth fiber bragg grating, an eleventh fiber bragg grating and a twelfth fiber bragg grating which are connected in sequence. According to the laser, a dual-band cascaded Ho<3+>-doped fluoride fiber laser pumped by a semiconductor laser is used as the pumping source; Pr<3+> and Tb<3+> co-doped sulfide fiber with annular composite core structures are used as gain medium; and a sulfide fiber bragg grating array is used as resonant cavity feedback and output coupling, so that simultaneous output of four-waveband fiber laser of 3.7[mu]m, 4.89[mu]m, 5.1[mu]m and 7.5[mu]m under the all-fiber structure can be realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

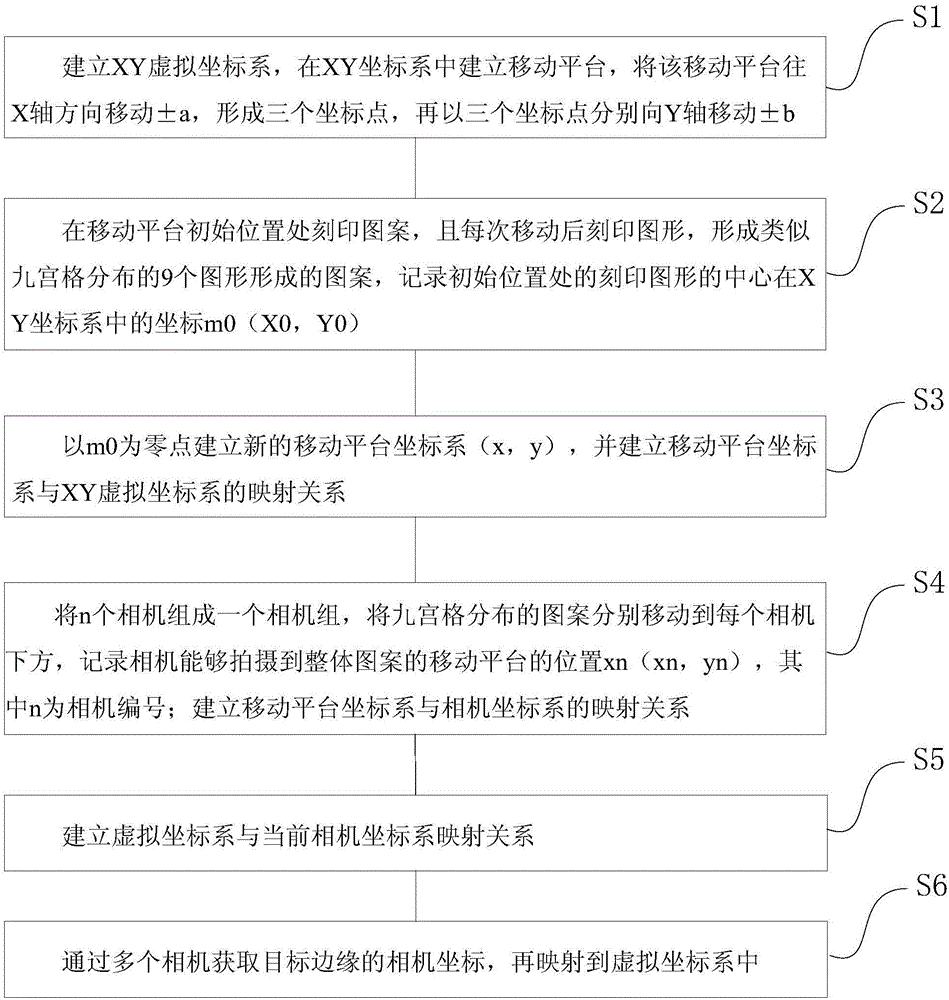

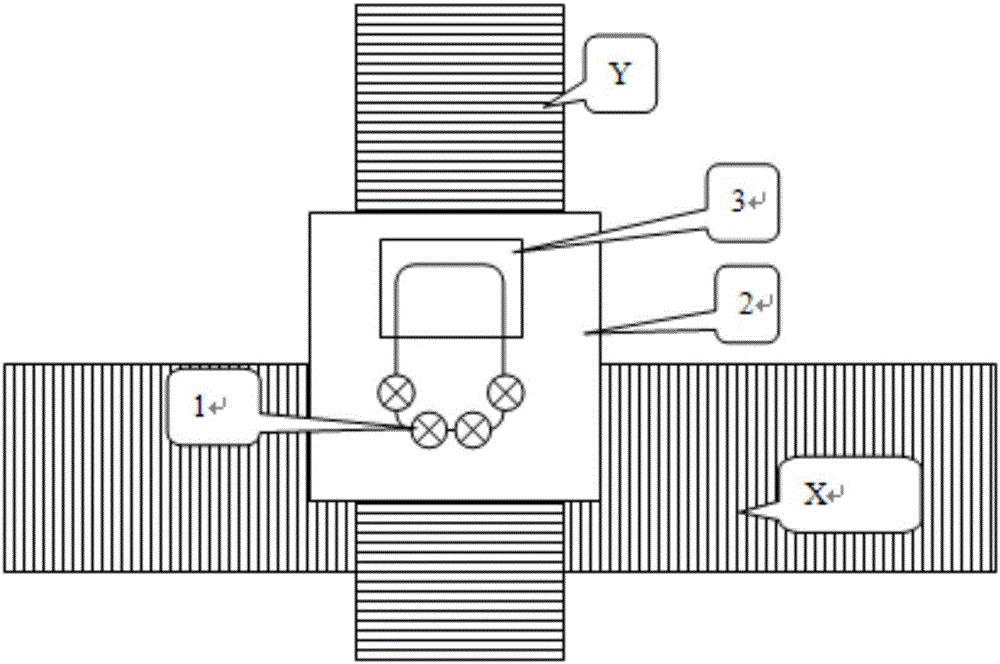

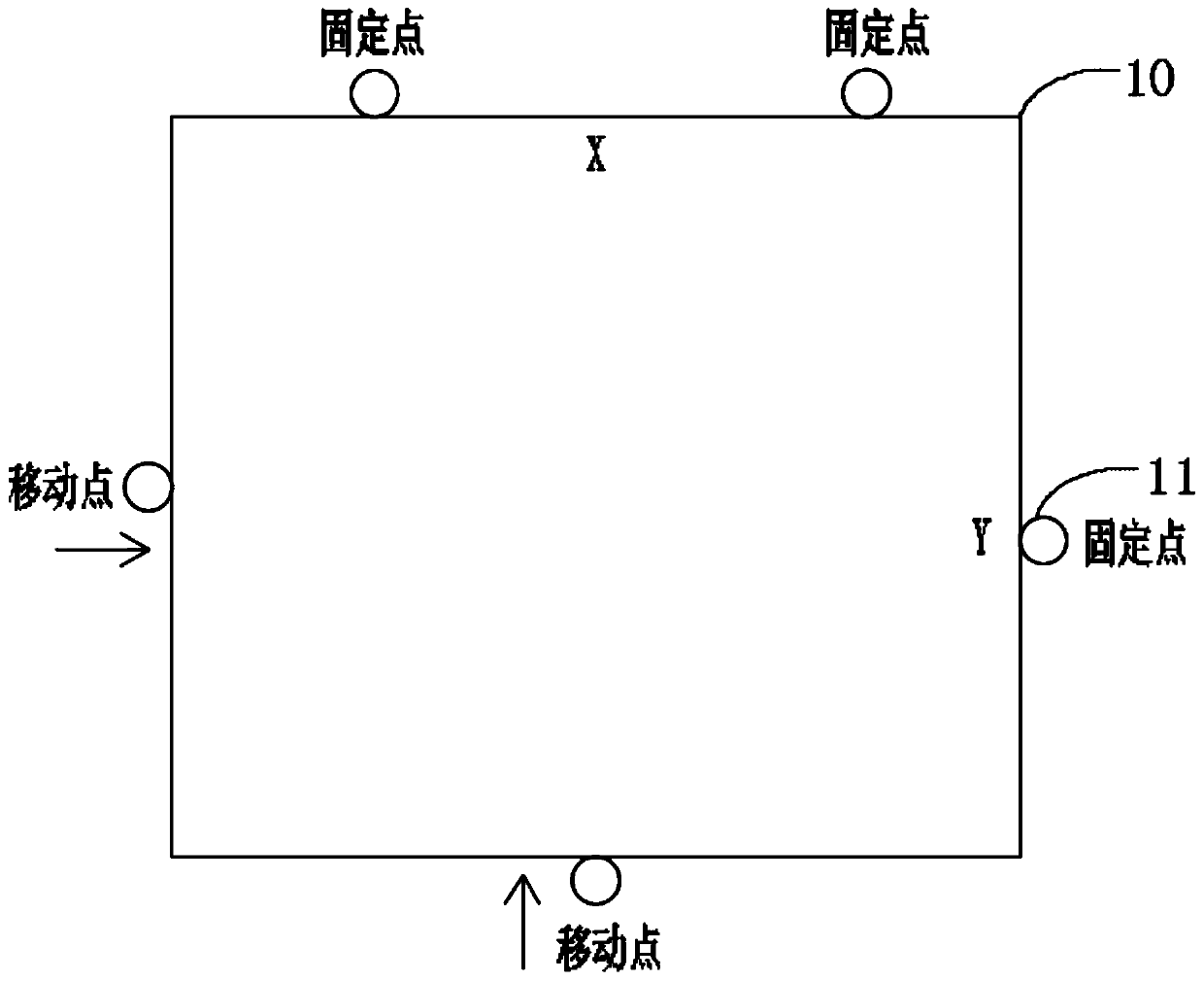

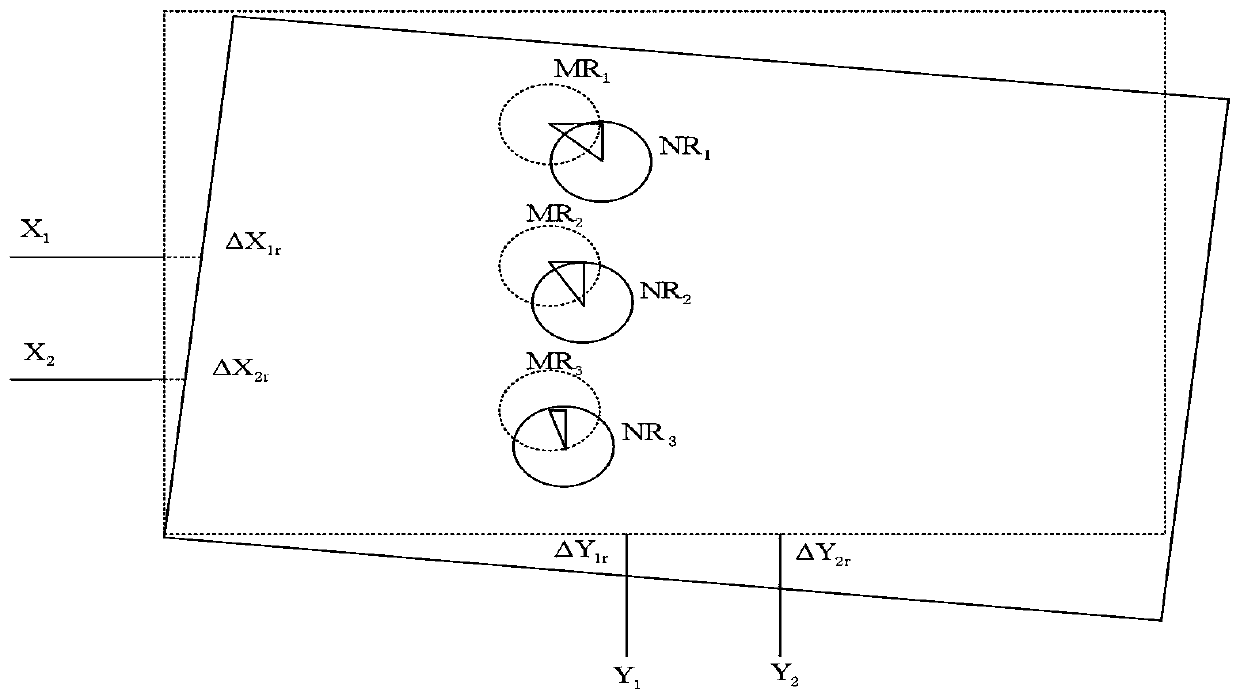

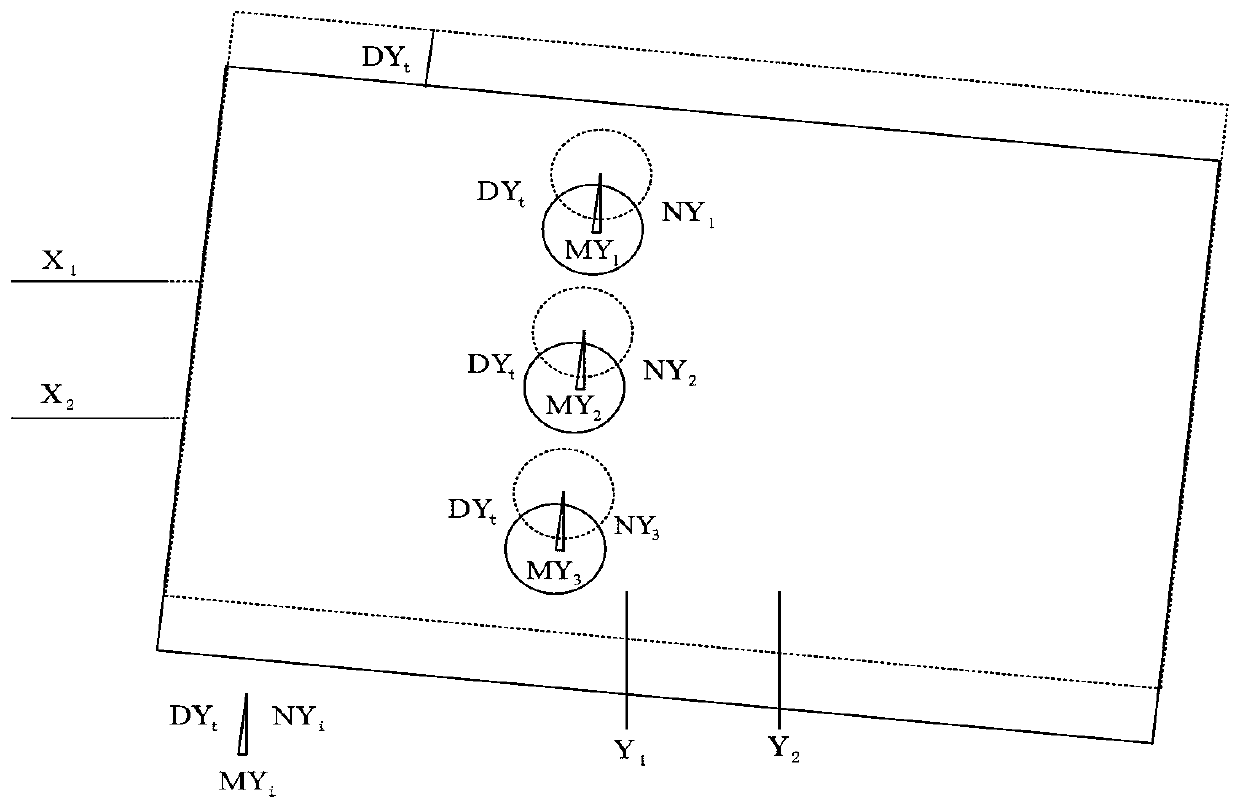

Multi-camera correcting and positioning method and glass laser cutting device

ActiveCN106363304AReduce computational difficultySimple designLaser beam welding apparatusGraphicsVirtual coordinate systems

The invention relates to a multi-camera correcting and positioning method and a glass laser cutting device. The multi-camera correcting and positioning method comprises the following steps that firstly, an XY virtual coordinate system is established, a mobile platform is moved to the middle position, and the mobile platform moves by plus a and minus a in the X-axis direction and moves by plus b and minus b in the Y-axis direction; secondly, the initial position of the mobile platform is marked with a pattern, pattern marking is conducted after movement every time, a pattern distributed like the speed dial is formed, and the coordinate m0 of the center of the pattern is recorded; thirdly, a new mobile platform coordinate system (x, y) with the m0 as the null point is established, and the mapping relationship between the mobile platform coordinate system and the XY virtual coordinate system is established; fourthly, the pattern is moved to the position under each camera, the positions, existing when the cameras can shoot the whole pattern, of the mobile platform are recorded, and the mapping relationship between the coordinate system (x, y) and a camera coordinate system is established; fifthly, the mapping relationship between the virtual coordinate system and the current camera coordinate system is established; and sixthly, the camera coordinates of the edge of a target are obtained through the multiple cameras, and the camera coordinates are mapped into the virtual coordinate system.

Owner:WUHAN HGLASER ENG CO LTD

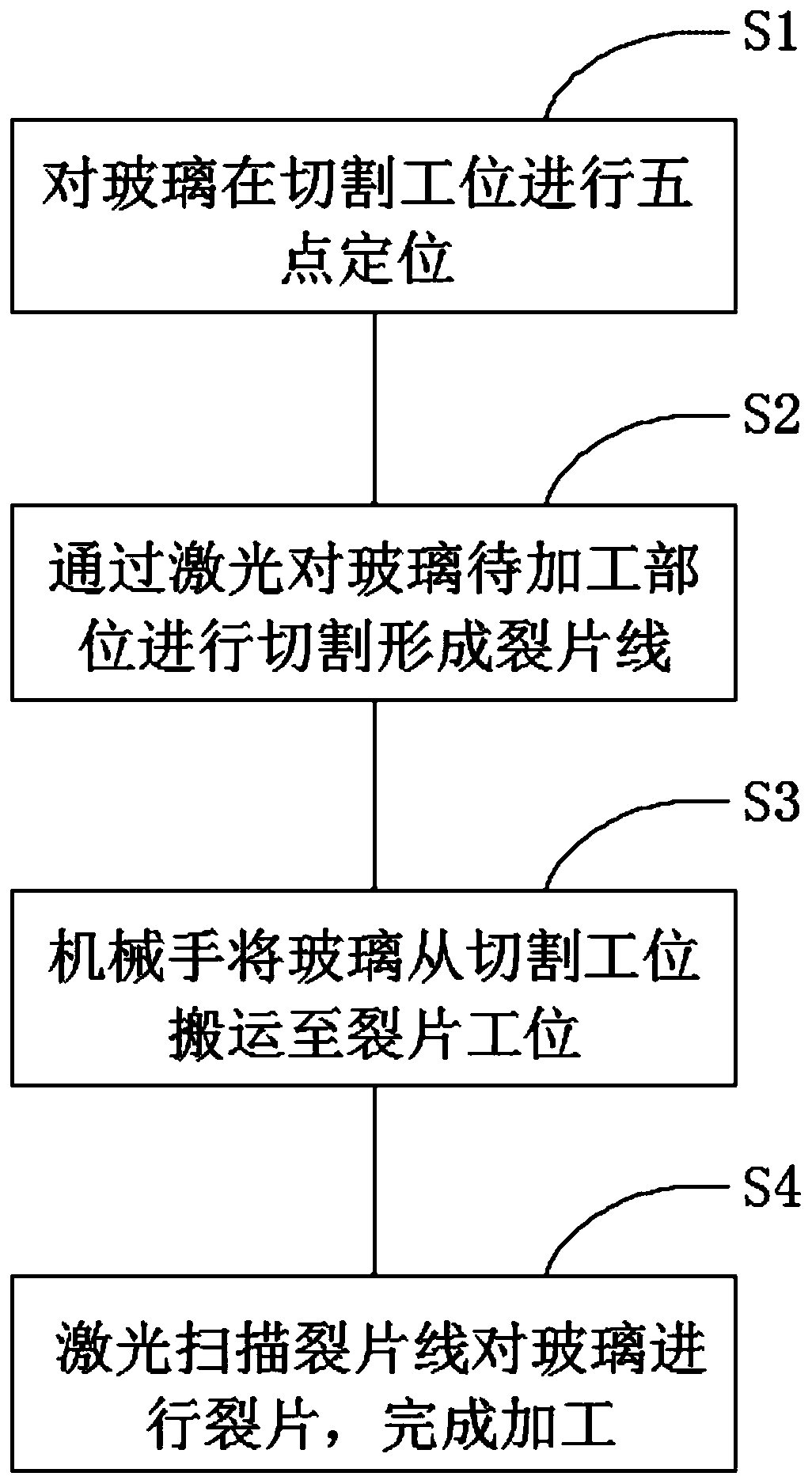

Glass cutting and splitting processing method and device

InactiveCN111393019AIncrease profitReduce labor costsGlass severing apparatusGlass productionLaser processingWatch glass

The invention relates to the technical field of laser processing, and discloses a glass cutting and splitting processing method and device, which are applied to watch glass laser cutting and splitting, and the method comprises the following steps: carrying out five-point positioning on watch cover glass at a cutting station; cutting and scribing the watch cover glass according to a set track to obtain a cutting line; using a transplanting manipulator for transplanting the watch cover glass from the cutting station to a splitting station; and generating laser thermal stress at the watch cover glass cutting line according to the set track so as to split the cut watch cover glass under the action of the laser thermal stress. According to the glass cutting and splitting machining method and device, watch cover glass cutting and splitting machining is integrated into circle cutting machining, only manual feeding and discharging are needed in the production process, the rest of cutting, splitting and carrying are all full-automatic machining, and the labor cost is reduced; compared with a traditional mode that a cutter wheel cuts square blocks and then CNC grinding is conducted to form circles, production efficiency is improved, machining processes are reduced, and the glass product utilization rate is increased.

Owner:深圳市青虹激光科技有限公司

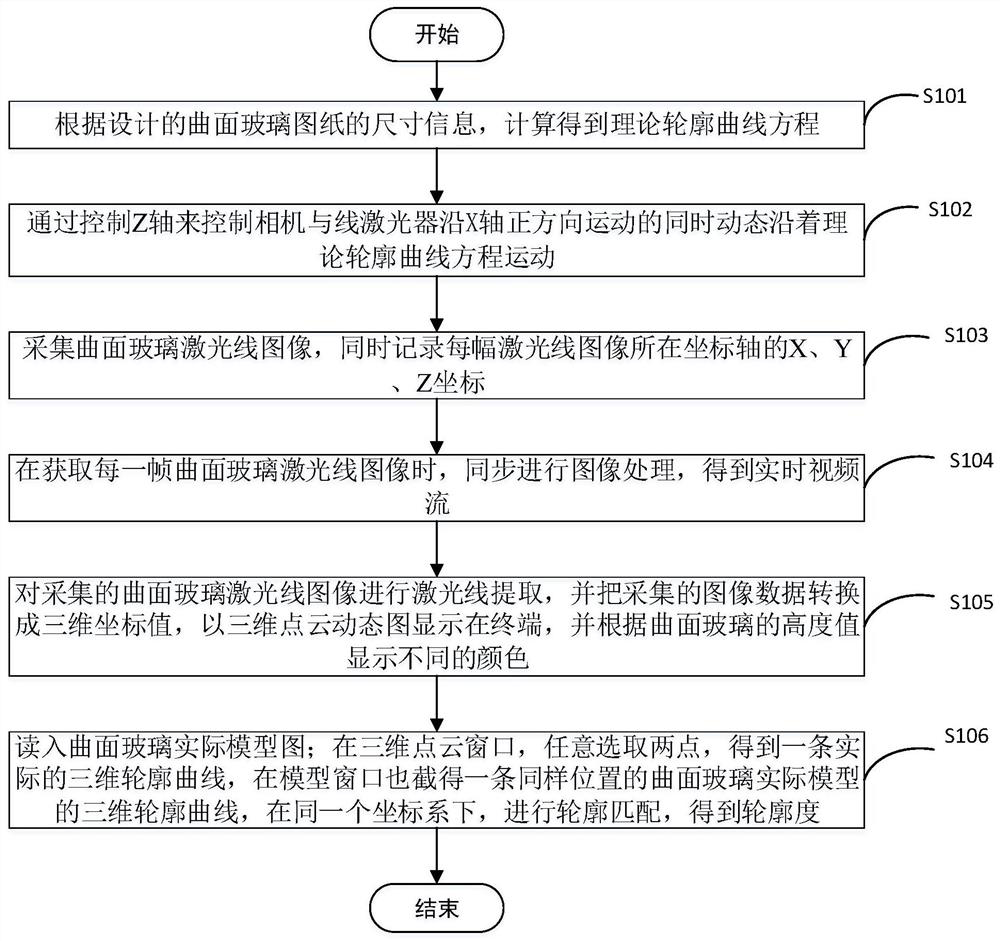

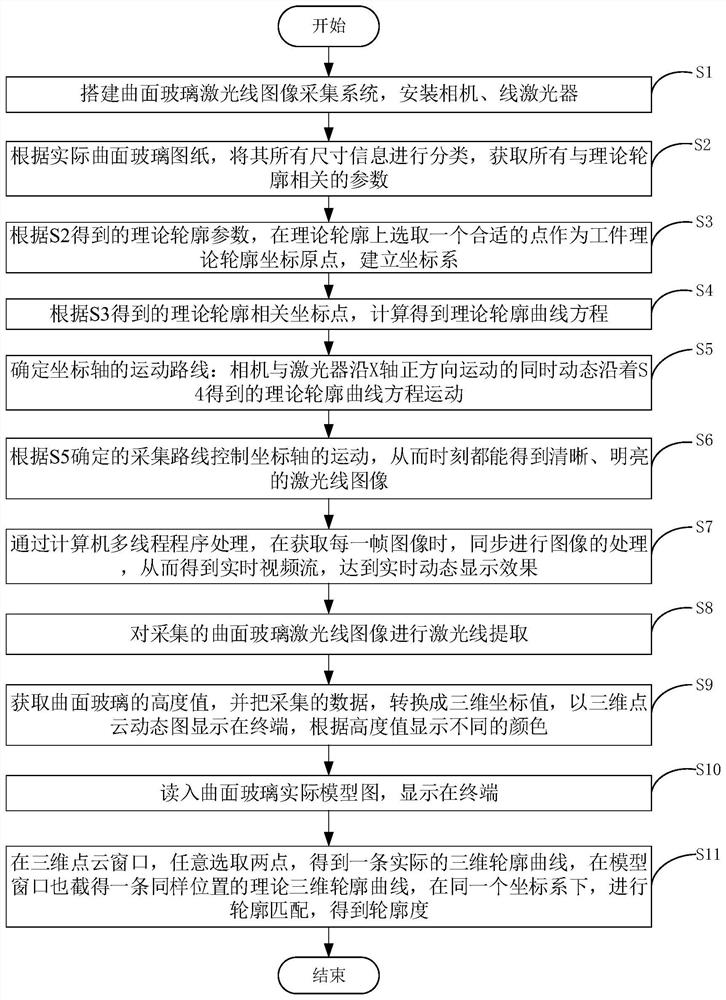

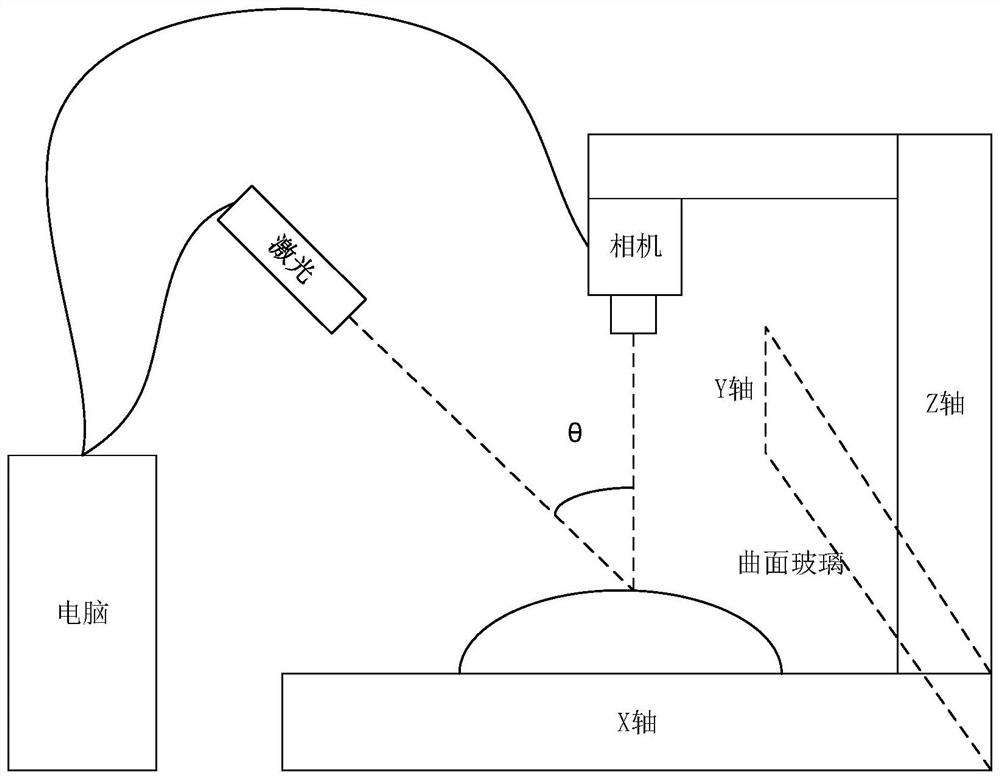

3D curved glass contour scanning detection method and system based on line structured light dynamic vision

ActiveCN112629441AOvercoming Depth of Field ProblemsClear processUsing optical meansContour matchingPoint cloud

The invention discloses a 3D curved glass contour scanning detection method based on line structured light dynamic vision. The method comprises the following steps of: calculating to obtain a theoretical contour curve equation according to the size information of a designed curved glass drawing; controlling a Z axis to control a camera and a line laser to move along the positive direction of an X axis and dynamically move along the theoretical contour curve equation at the same time; performing laser ray extraction on an acquired curved glass laser ray image, converting the acquired image data into three-dimensional coordinate values, displaying the three-dimensional coordinate values on a terminal in a three-dimensional point cloud dynamic graph, and displaying different colors according to the height value of curved glass; reading an actual model diagram of the curved glass; and randomly selecting two points in a three-dimensional point cloud window to obtain an actual three-dimensional contour curve, cutting out a three-dimensional contour curve of the actual model of the curved glass at the same position as the actual three-dimensional contour curve in a model window, and carrying out contour matching in the same coordinate system to obtain a contour degree.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

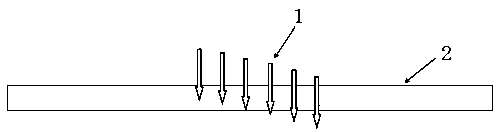

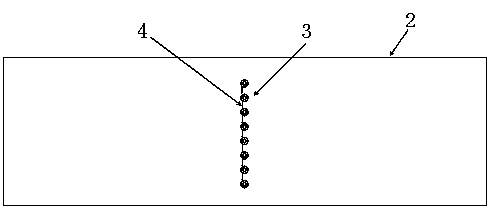

Laser processing method for glass

InactiveCN109592892AImprove yieldImprove efficiencyGlass severing apparatusGlass productionLaser processingCutting glass

Owner:WUHAN HGLASER ENG CO LTD

Glass laser hole machining device and machining method thereof

InactiveCN108406140AMeet needsHigh precisionLaser beam welding apparatusLaser processingMature technology

The invention discloses a glass laser hole machining device. The machining device comprises a controller, a first conveying platform, a second conveying platform, and a Y-direction CCD visual motion platform, wherein the first conveying platform and the second conveying platform are used for conveying glass, and the Y-direction CCD visual motion platform is perpendicular to the glass conveying direction; and a Y-direction transporting positioning device is arranged in the middle of the upper end of the Y-direction CCD visual motion platform, a protective box is arranged at the upper end of theY-direction CCD visual motion platform, the top of the inner cavity of the protective box is provided with a sensor connected with the controller and a positioning device for positioning the glass conveying position, and a laser machining device used for machining a glass hole is arranged at the top of the protective box. According to the machining device, two-dimensional large-stroke breadth machining is achieved by changing the conveying distance of a glass product and moving the one-dimensional movement of the Y-direction transporting positioning device, so that hole perforating in the full-breadth range of the large-breadth glass is achieved; and multiple simple single modules with mature technologies are creatively combined, so that a new problem is solved.

Owner:淮北辰威科技有限公司

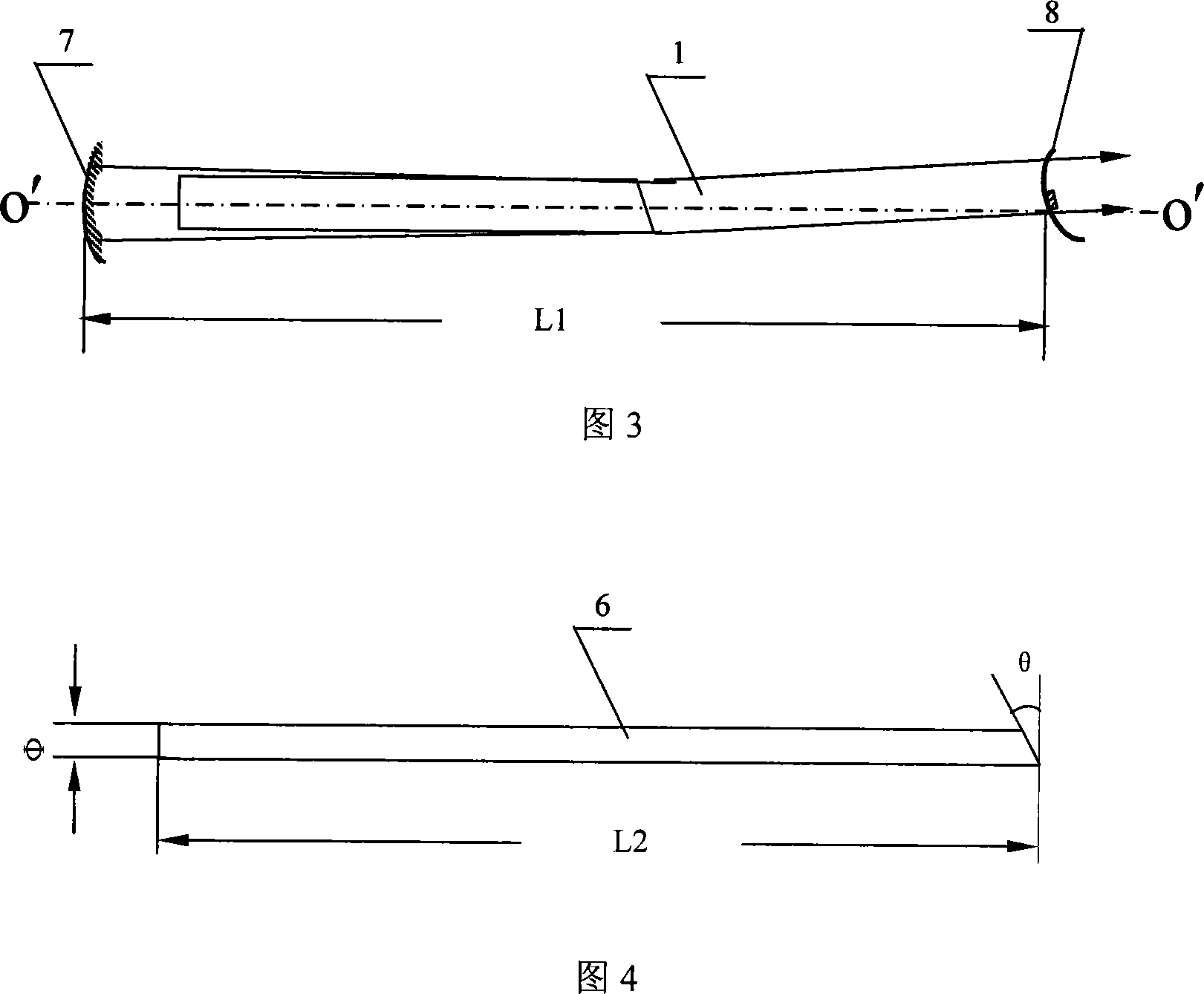

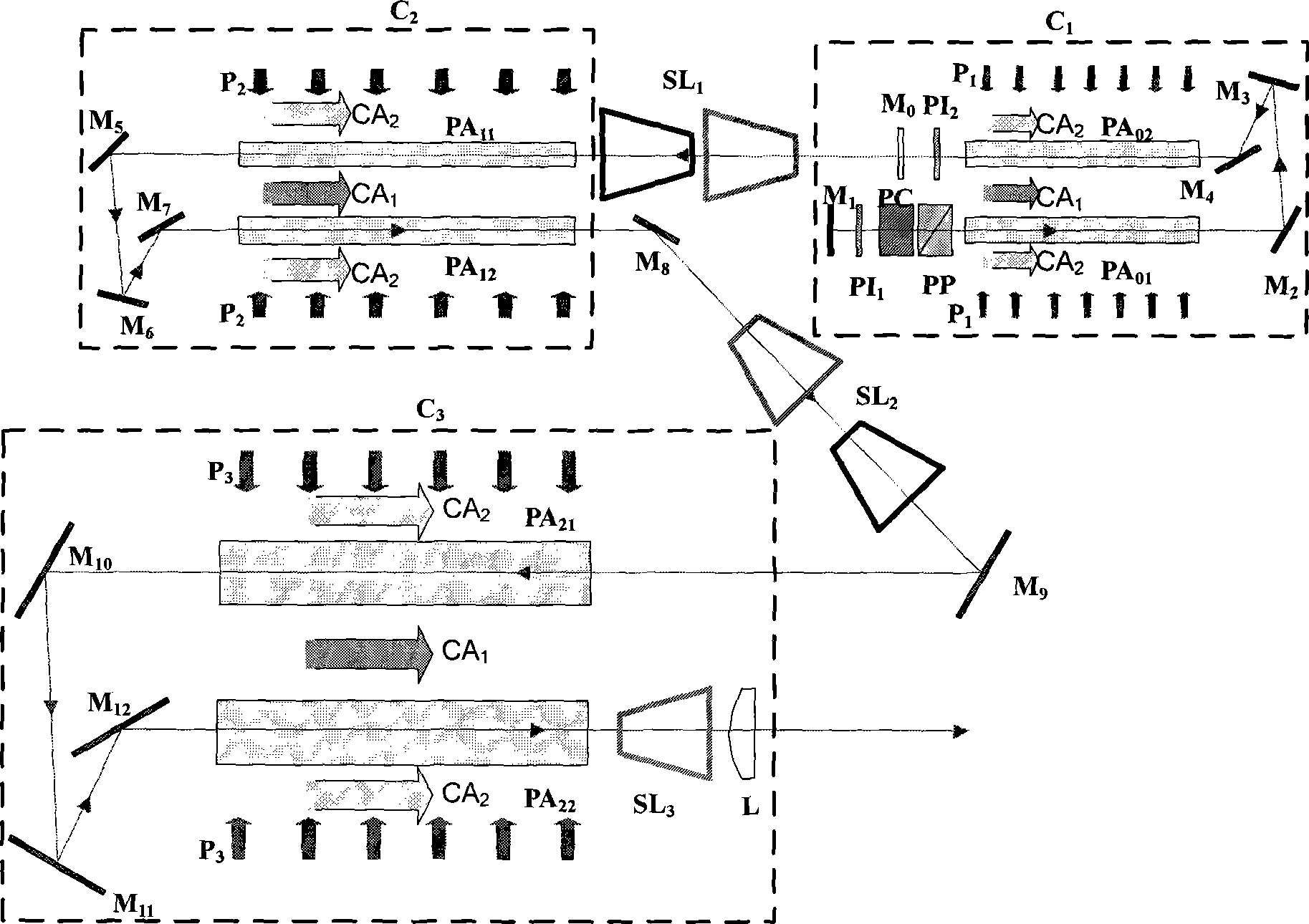

Novel high-power strip laser system

InactiveCN101399424APrevent thermal crackingImprove Optical UniformityExcitation process/apparatusOptical resonator shape and constructionHigh power lasersGlass laser

The invention relates to a novel high power slab laser system. The high power slab laser system comprises a laser cavity and an interstage beam expanding compensation lens; the laser cavity is composed of a laser oscillator C1, a preamplifier C2 and a main amplifier C3, two neodymium glass laser medium slabs which are parallel with each other and have the same size, material and property are respectively put into an embraced ceramic diffuse reflection cavity composed of the laser oscillator, the preamplifier and the main amplifier, both pumping and cooling use a mirror symmetry mode, and a laser beam goes into the other neodymium glass slab through three refractions; and an interstage beam expanding compensation lens is arranged among the laser oscillator, the preamplifier and the main amplifier. The high power slab laser system has the advantages of improving the output laser beam quality, obtaining high power laser beam, having long service life of a xenon lamp and improving the beam quality of the laser beam.

Owner:JIANGSU UNIV

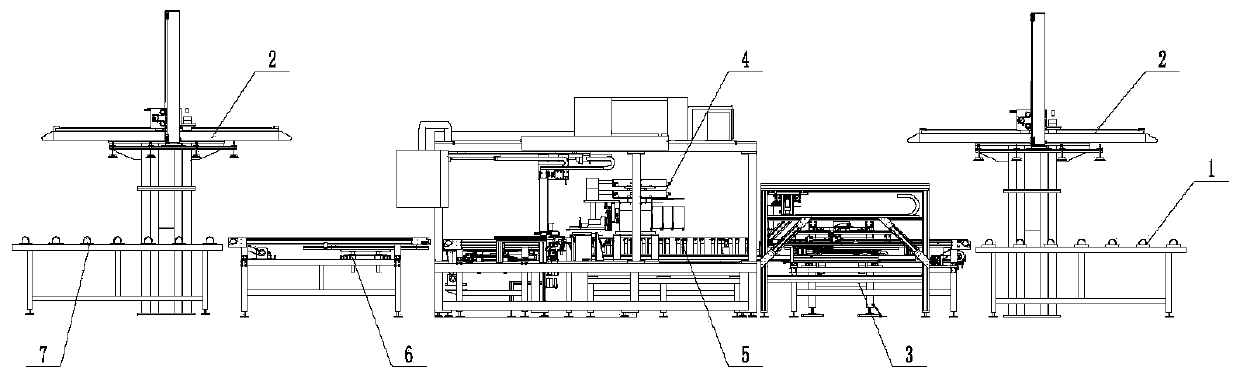

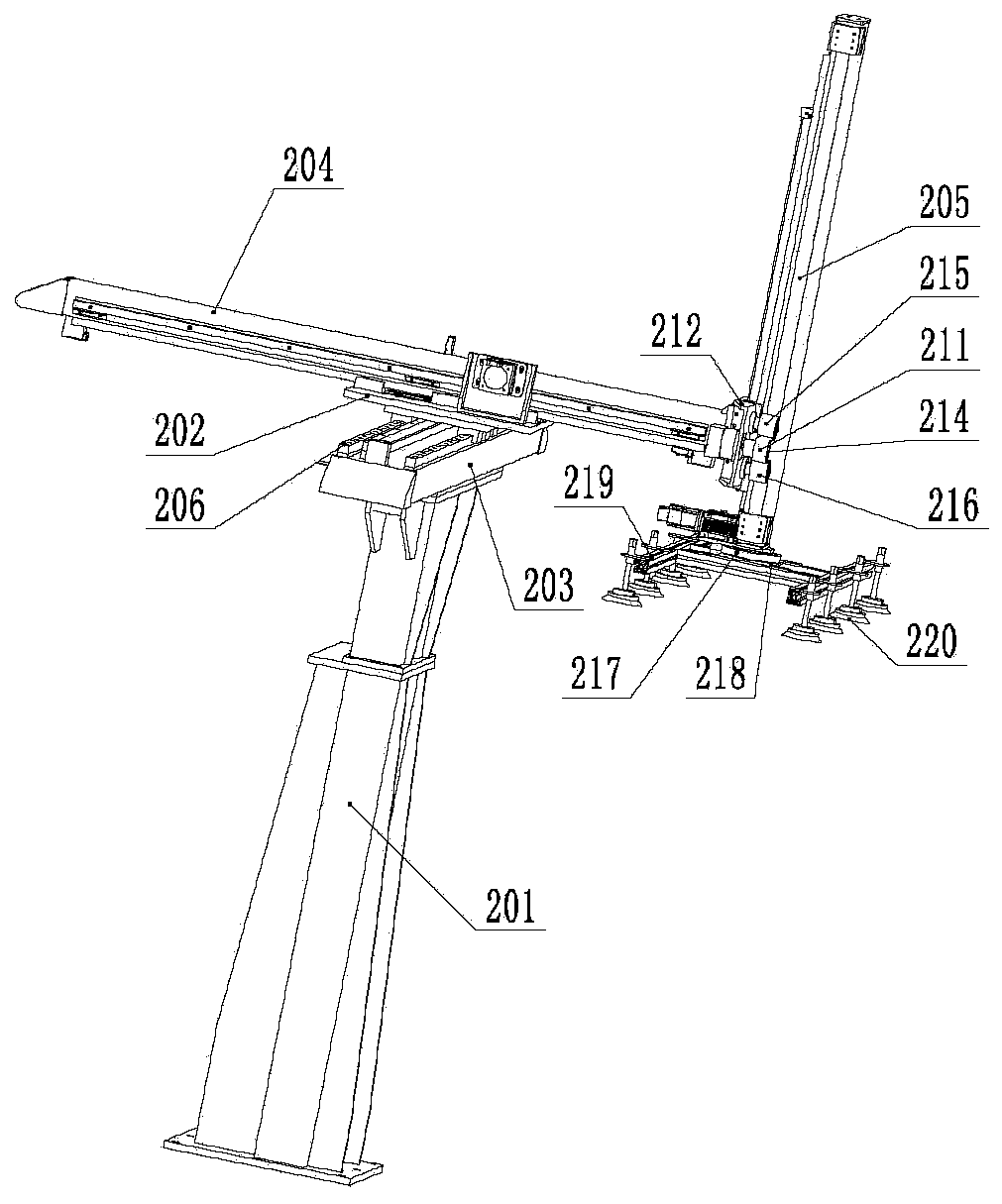

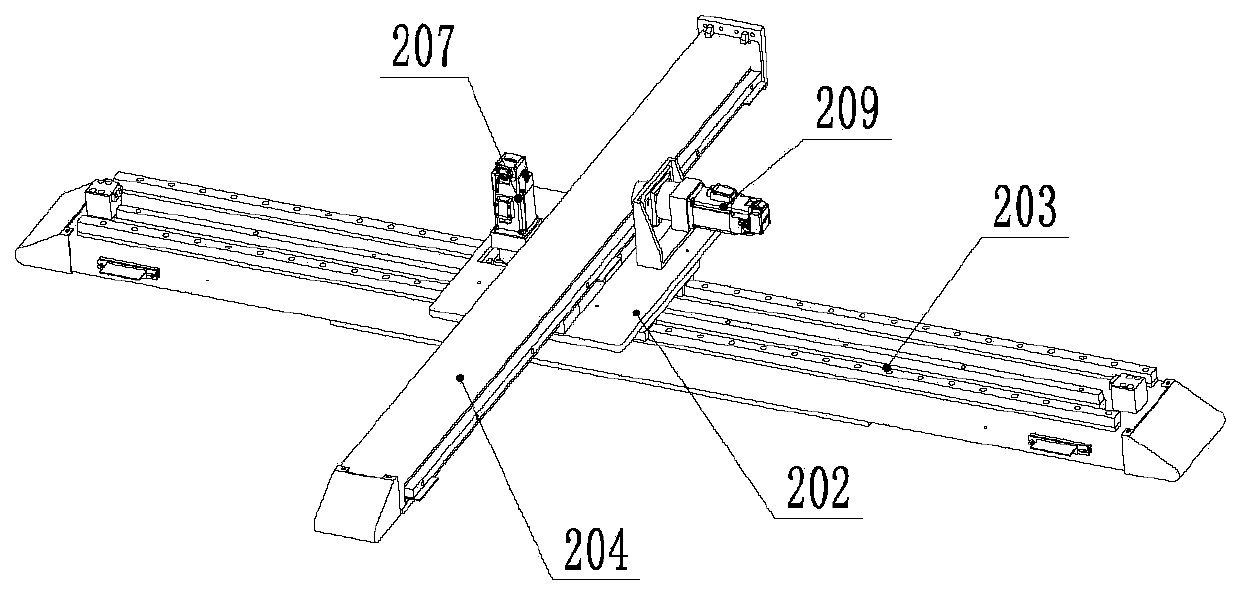

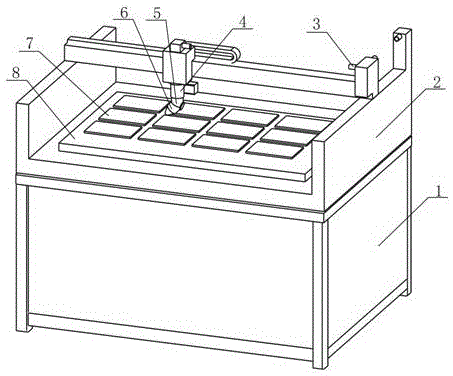

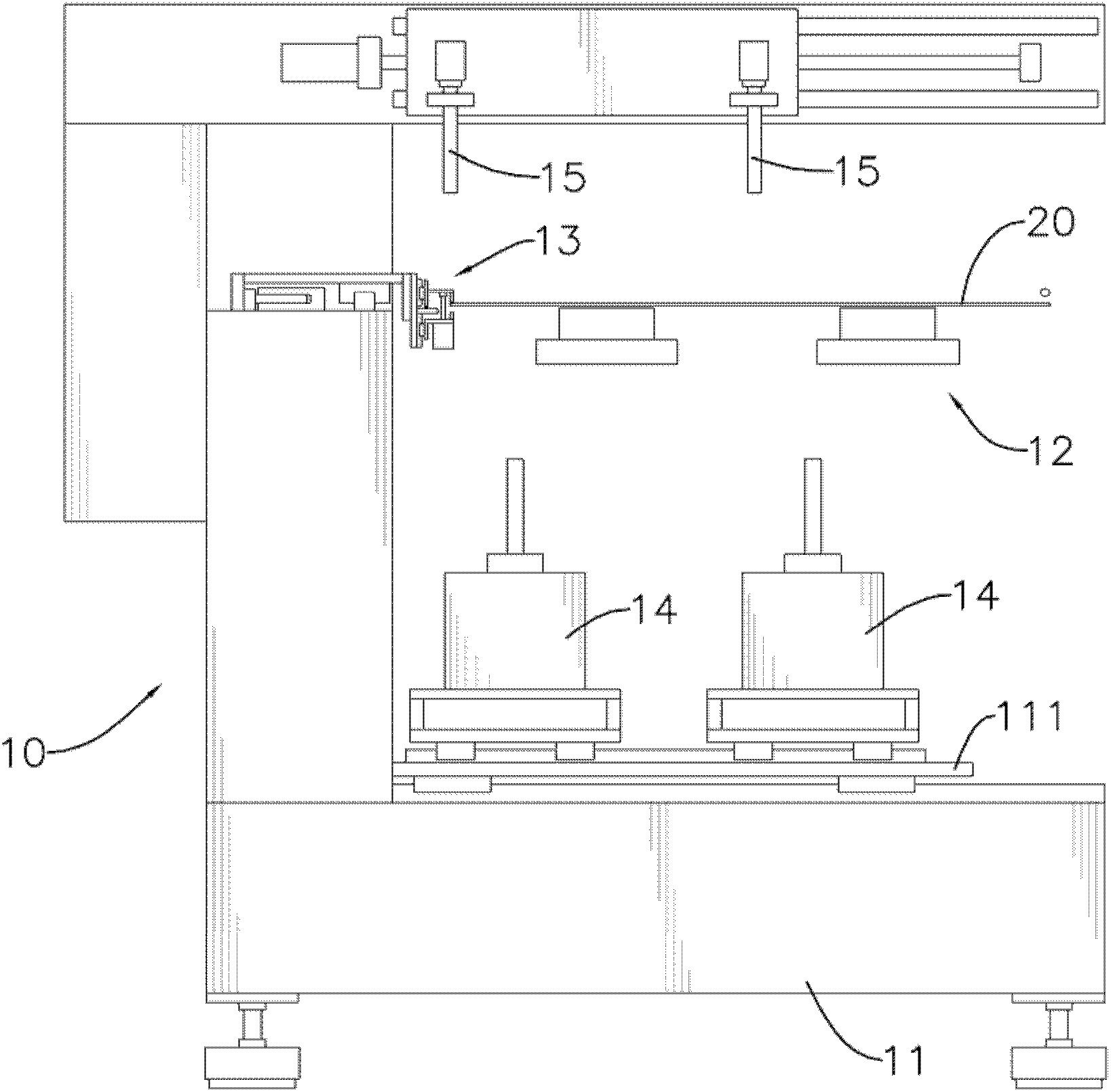

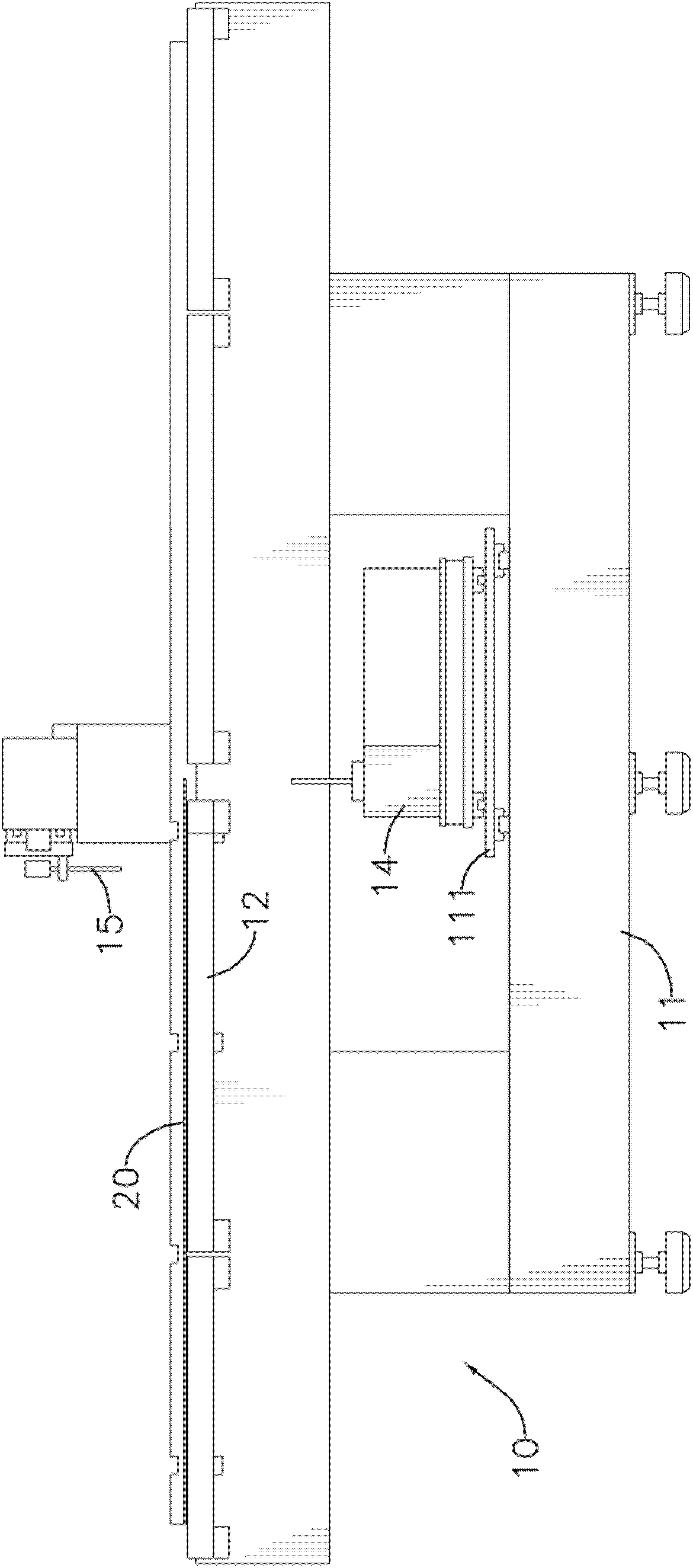

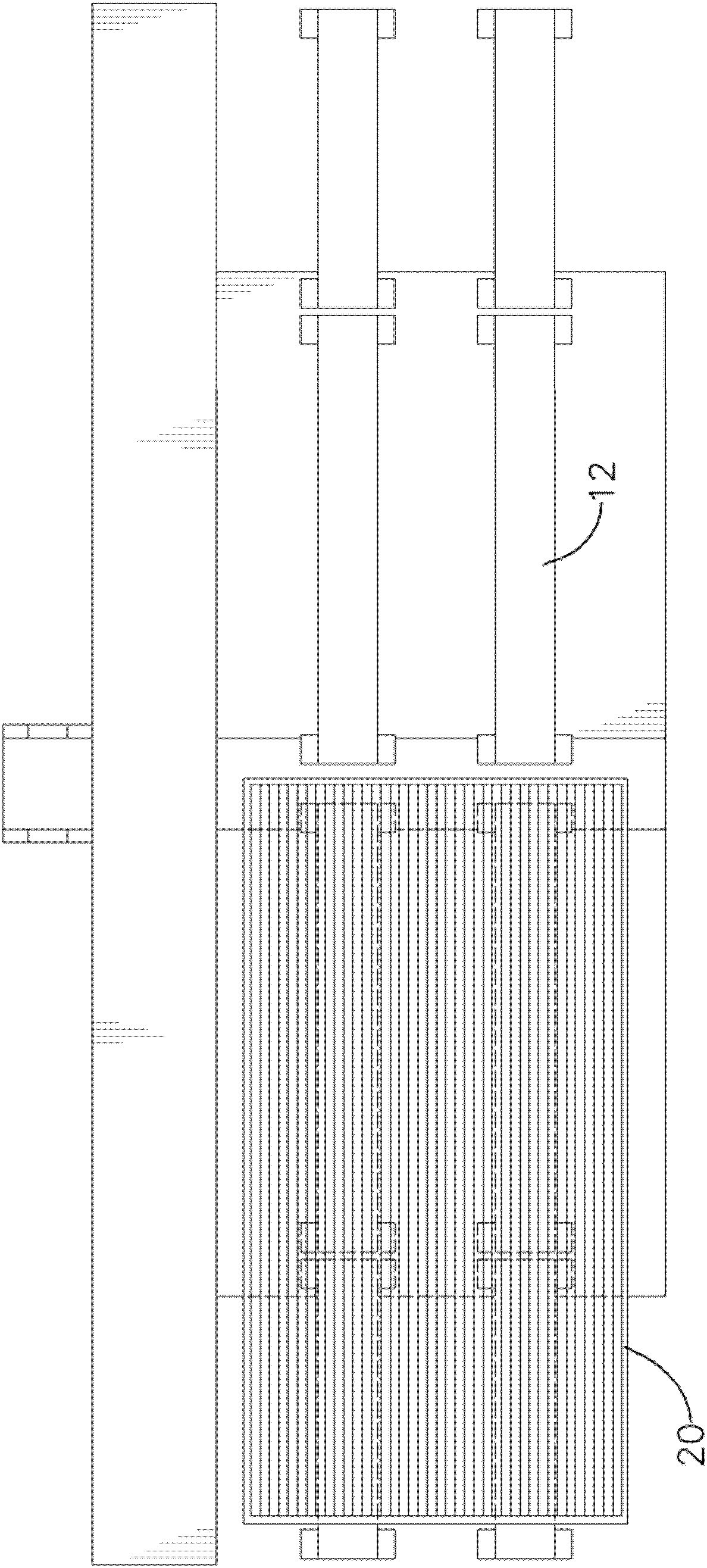

Glass laser cutting equipment

PendingCN111116031ARealize the four-way reformAchieve lengthGlass severing apparatusGlass productionLaser cuttingMechanical engineering

The invention discloses glass laser cutting equipment, and relates to the technical field of glass processing; the glass laser cutting equipment is additionally provided with linear module conveying on the basis of original belt conveying, the linear module conveying precision is high, and the hole site processing precision is effectively improved. And meanwhile, the glass laser cutting equipmentis provided with a transverse alignment measuring assembly and a longitudinal alignment measuring assembly, so that four-direction alignment and length and width measurement of glass are realized, theglass positioning accuracy is improved, and the hole site machining precision is further improved.

Owner:ZHEJIANG HUA GONG GLORY INTELLIGENT EQUIP TECH CO LTD

Adjustment method of multifunctional glass support platform

ActiveCN103214178AReduce processing costsFix random breaksGlass severing apparatusGlass fiberEngineering

The invention relates to an adjustment method of a multifunctional glass support platform. The adjustment method solves the problem that by the prior art, the glass fixing platform easy causes thin-sheet glass ruleless cracking and inconvenient and inaccurate glass positioning, and is inconvenient for laser beam verticality adjustment. The multifunctional glass support platform comprises a glass adjustment module, a glass vacuum adsorption module and a glass fast and accurate positioning module. The glass adjustment module is a two-dimensional angle adjustment platform composed of double layers of flat plates comprising an upper flat plate and a lower flat plate. The two-dimensional angle adjustment platform comprises the upper flat plate and the lower flat plate and the surface of the upper flat plate is provided with vent holes. The glass vacuum adsorption module comprises a glass fiber plate covered on the upper flat plate, and an air suction device. The glass fiber plate opposite to the vent holes of the upper flat plate is provided with through holes. The glass fast and accurate positioning module comprises opposite angle locating pins and locating blocks arranged on the upper flat plate. The adjustment method solves the above problem and can be used for a glass laser cutting processing industry.

Owner:KUNSHAN THETA MICRO

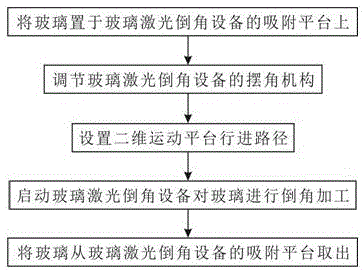

Laser chamfering method and equipment for glass

InactiveCN106552996ANo cracking phenomenonImprove yield rateLaser beam welding apparatusOptoelectronicsMachining process

The invention provides a laser chamfering method and equipment for glass. The laser chamfering method for glass comprises the following steps of: (1) putting the glass on an adsorption platform of the laser chamfering equipment for glass; (2) adjusting a tilt angle mechanism, wherein the included angle between the axis of a laser beam output by a focusing mechanism of the laser chamfering equipment for glass and the glass is equal to the degree to be cut and chamfered; (3) arranging a two-dimensional movement platform advancing path on operating software of the laser chamfering equipment for glass according to a chamfered edge path of the to-be-machined glass; (4) chamfering the glass; and (5) taking out the glass from the adsorption platform of the laser chamfering equipment for glass. According to the laser chamfering equipment for glass, a rotating mechanism and the tile angle mechanism are mounted between an optical path system and the focusing mechanism. According to the laser chamfering method and equipment for the glass provided by the invention, in a process of machining the glass, no dust will be generated, cracks at the edge of the glass are avoided, the product yield is high, and no cooling liquids are required in the machining process for cooling.

Owner:WUHAN GSTAR TECH CO LTD

Tissue cooling rod for laser surgery

A laser treatment device and process with controlled cooling. The device contains a cooling element with high heat conduction properties, which is transparent to the laser beam. A surface of the cooling element is held in contact with the tissue being treated while at least one other surface of the cooling element is cooled by the evaporation of a cryogenic fluid. The cooling is coordinated with the application of the laser beam so as to control the temperatures of all affected layers of tissues. In a preferred embodiment useful for removal of wrinkles and spider veins, the cooling element is a sapphire plate. A cryogenic spray cools the top surface of the plate and the bottom surface of the plate is in contact with the skin. In preferred embodiments the wavelength of the laser beam is chosen so that absorption in targeted tissue is low enough so that substantial absorption occurs throughout the targeted tissue. In a preferred embodiment for treating large spider veins with diameters in the range of 1.5 mm, Applicants use an Er:Glass laser with a wavelength of 1.54 microns.

Owner:RELIANT TECH INC

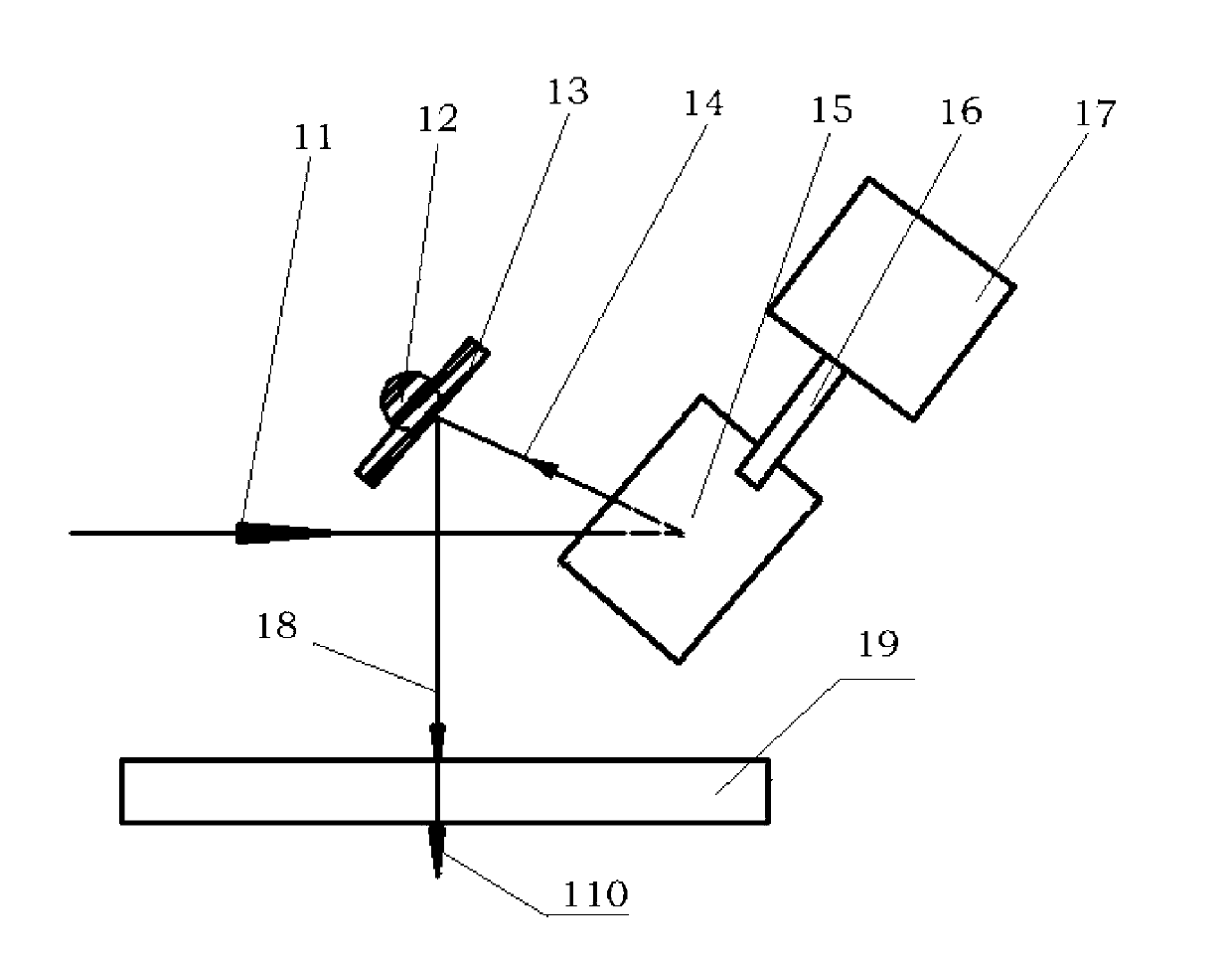

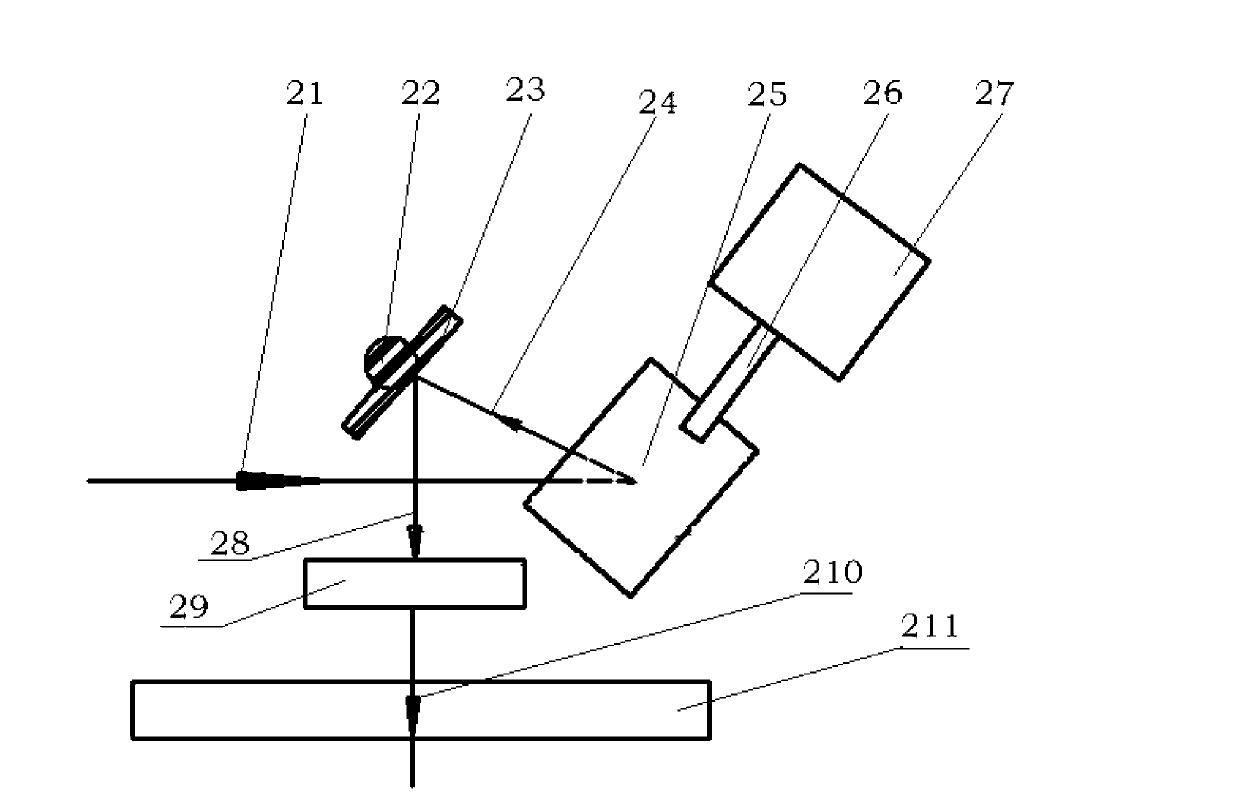

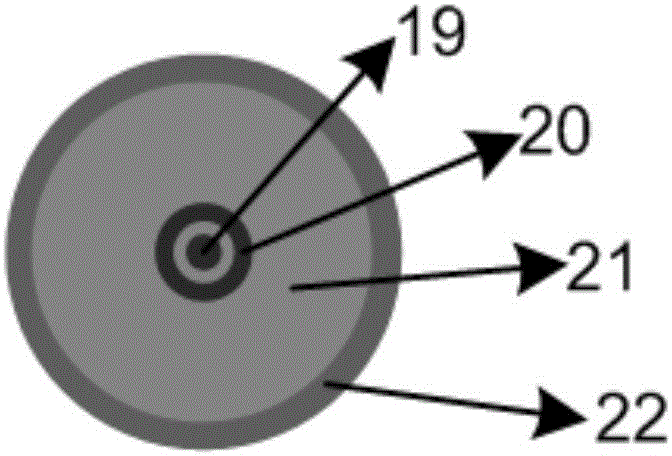

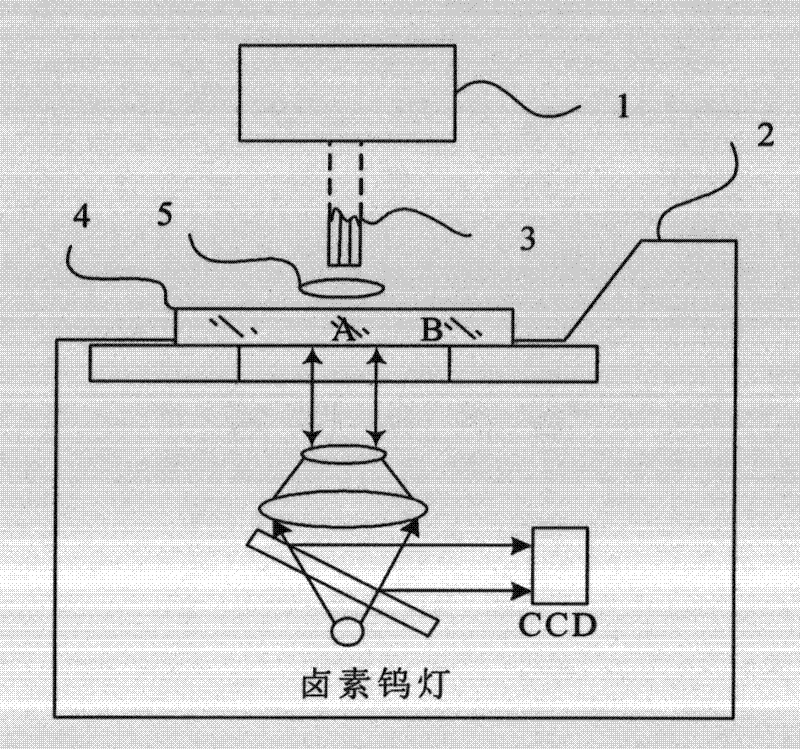

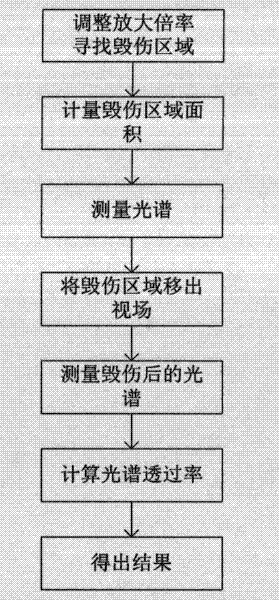

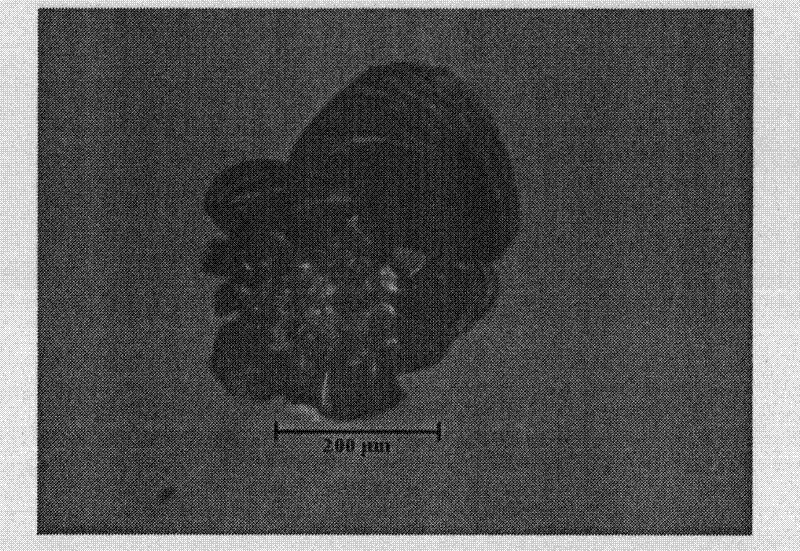

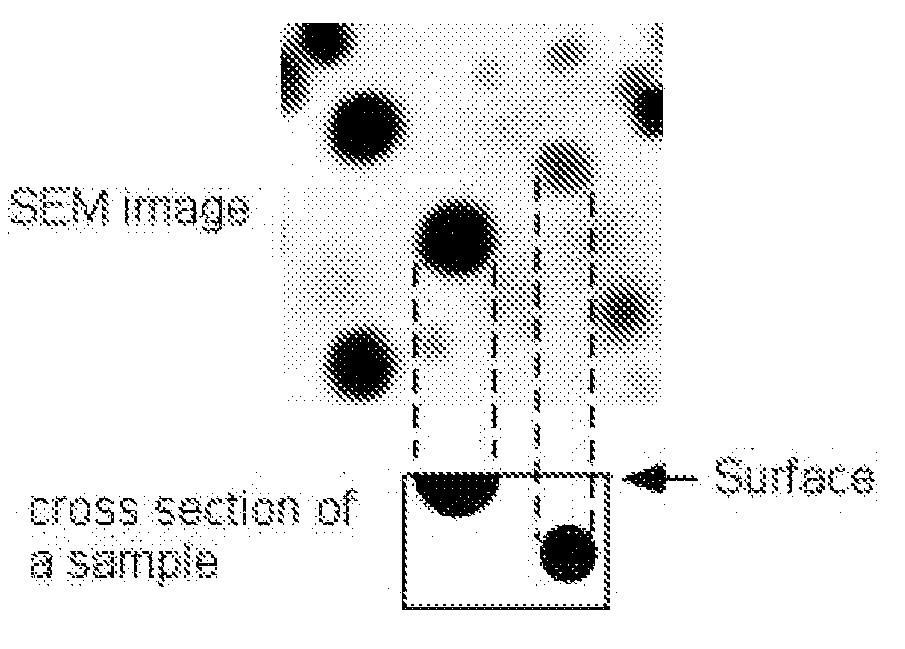

Micro-area optical damage test method and device

InactiveCN102269716AOvercome the problem of large errorsTransmissivity measurementsZone sizeGlass laser

The invention belongs to the field of optical testing, and relates to a method and a device for measuring the optical transmittance of a micro-area, especially in the aspect of detecting the micro-area damage caused by laser light to glass. Optical glass is an essential component in the laser application process. Its transmittance indicates the strength of the laser transmission ability and is an important basis for judging the degree of laser damage. As lasers are increasingly used in medical, military, scientific research, industrial processing and other fields, the measurement of optical glass transmittance becomes extremely important. Since the diameter of the damaged area of optical glass is generally small, it is difficult to accurately measure its transmittance by traditional spectrophotometry. This paper proposes a method and device for measuring the damaged area by combining a microscope and a fiber optic spectrometer, as shown in Figure 1. While quantitatively analyzing the size of the region, the transmission spectrum before and after the damage of the region is measured, and the spectral transmittance is calculated. This technology overcomes the problem of large errors in the measurement of micro-area damage by traditional methods, and provides a new idea and method for testing the transmittance or reflectance of micro-units.

Owner:CHANGCHUN UNIV OF SCI & TECH

Glass fixing method for multifunctional glass support platform

ActiveCN103214177AReduce processing costsFix random breaksGlass severing apparatusGlass laserEngineering

The invention relates to a glass fixing method for a multifunctional glass support platform. The glass fixing method mainly solves the problem that by the prior art, the glass fixing platform easy causes thin-sheet glass ruleless cracking and inconvenient and inaccurate glass positioning, and is inconvenient for laser beam verticality adjustment. The multifunctional glass support platform comprises a glass adjustment module, a glass vacuum adsorption module and a glass fast and accurate positioning module. The glass adjustment module is a two-dimensional angle adjustment platform composed of double layers of flat plates comprising an upper flat plate and a lower flat plate. The two-dimensional angle adjustment platform comprises the upper flat plate and the lower flat plate and the surface of the upper flat plate is provided with vent holes. The glass vacuum adsorption module comprises a glass fiber plate covered on the upper flat plate, and an air suction device. The glass fiber plate opposite to the vent holes of the upper flat plate is provided with through holes. The glass fast and accurate positioning module comprises opposite angle locating pins and locating blocks arranged on the upper flat plate. The glass fixing method solves the above problem and can be used for a glass laser cutting processing industry.

Owner:KUNSHAN THETA MICRO

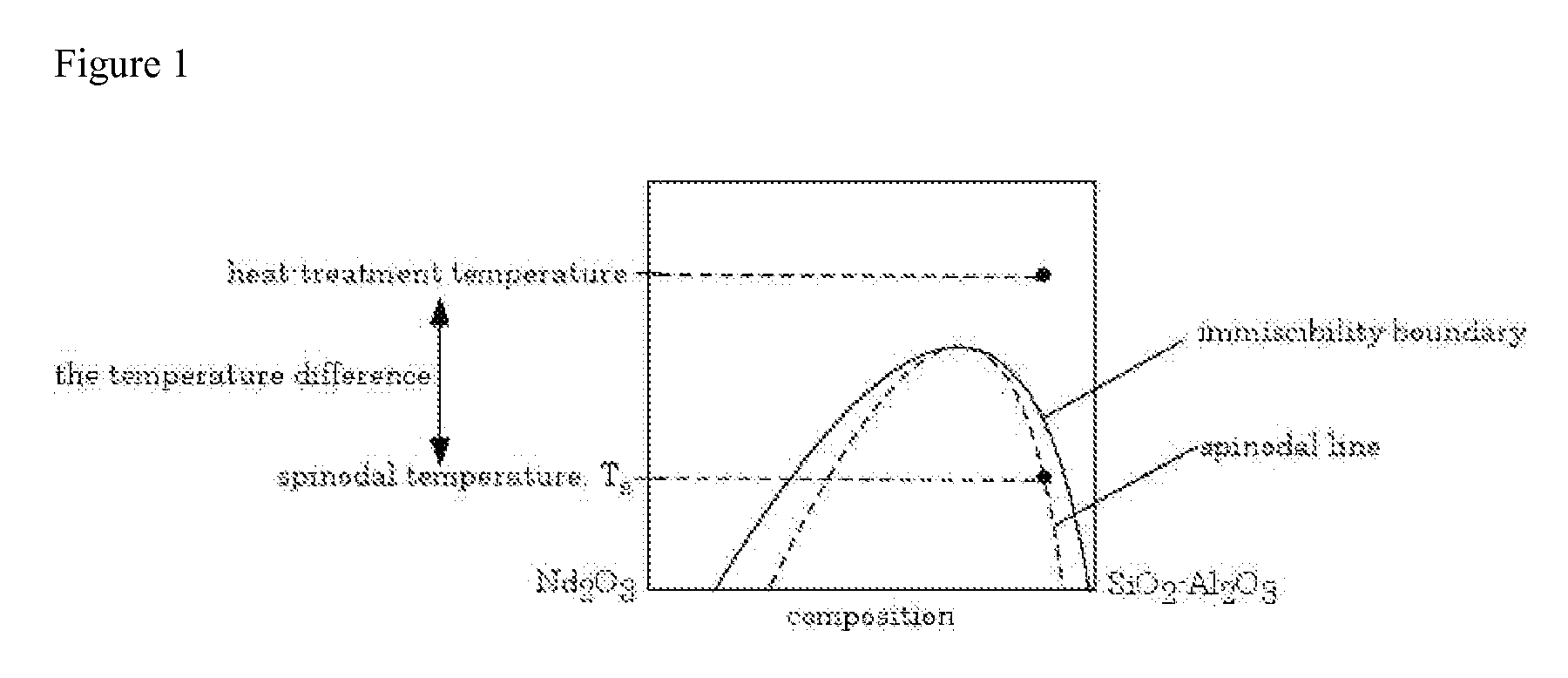

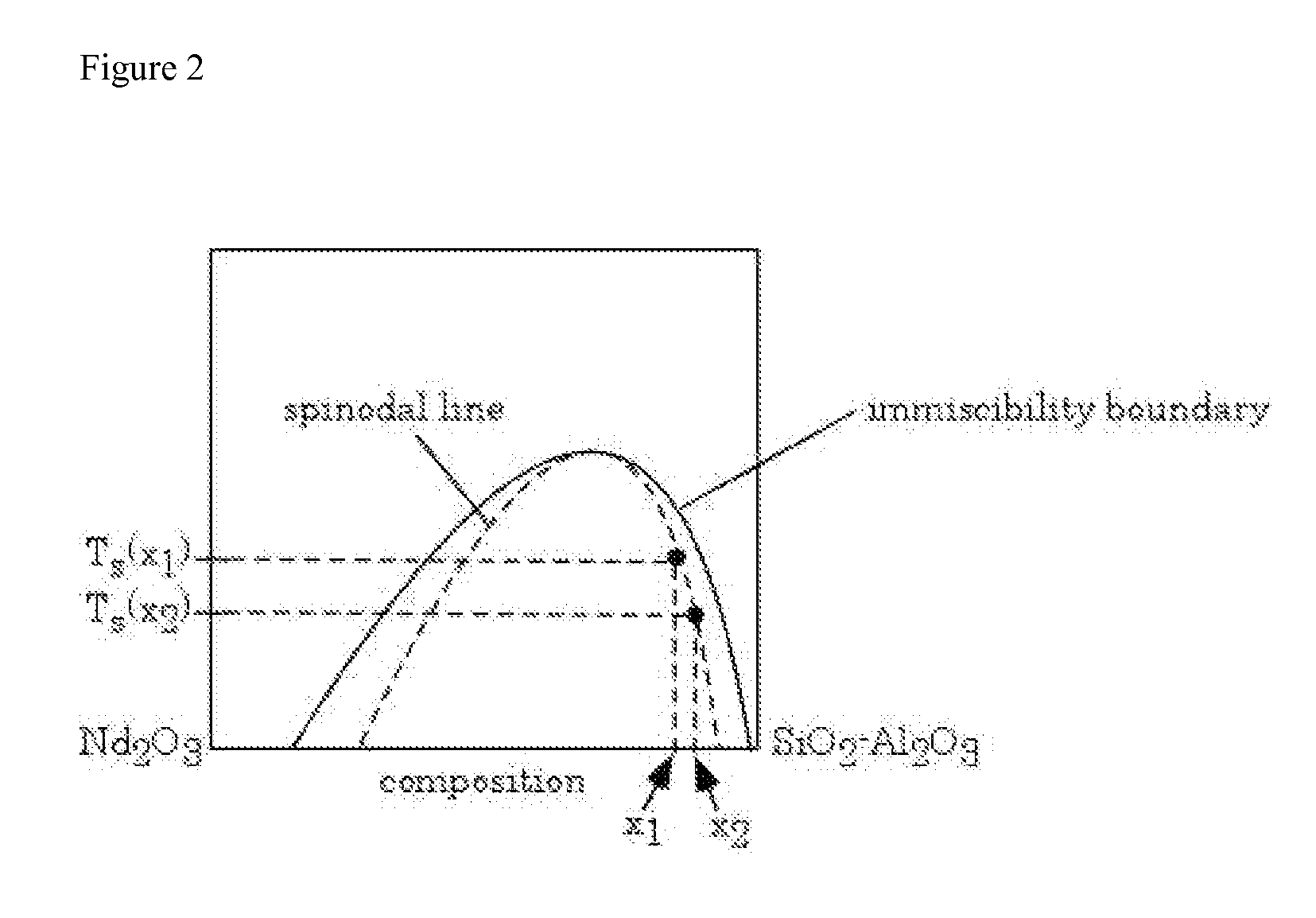

Process for making rare earth containing glass

InactiveUS20100323204A1Reduce concentration quenchingReduce solubilityGlass drawing apparatusGlass forming apparatusRare-earth elementSpinodal

The invention relates to a process for making a SiO2—RExOy—Al2O3 glass comprising preparing a glass according to a conventional process wherein the conventional process comprises a step of heat treating a mixture of SiO2, RExOy, and Al2O3 at a temperature greater than the spinodal temperature for 0.1 to 10 hours wherein RExOy is a rare earth oxide and RE is a rare earth element chosen from Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and combinations thereof. The invention also relates to glasses prepared by the process and glass lasers, optical amplifiers and laminated glass that comprise the glass prepared by the process.

Owner:SEKISUI CHEM CO LTD +1

Precise solar energy glass laser scribing method

InactiveCN102756212AInstant adjustment of line slopeImprove parallelismFinal product manufactureLaser beam welding apparatusLaser scribingEngineering

Disclosed is a precise solar energy glass laser scribing method, comprising a straight line image-taking action and a laser scribing action, The straight line image-taking action respectively takes images of two straight lines scribed in the film layer of previous manufacturing process upon the substrate, thus to obtain two-point coordinate of each straight line and master the line slope of each straight line as well as the distance between lines. Then, the laser scribing action carries out image taking over the film layer of the following manufacturing process upon the substrate, and timely adjusts the line slope of the straight line scribed by the laser scribing apparatus in the following manufacturing process, thereby realizing the objective of raising the depth of parallelism between every two straight lines.

Owner:HORNG TERNG AUTOMATION

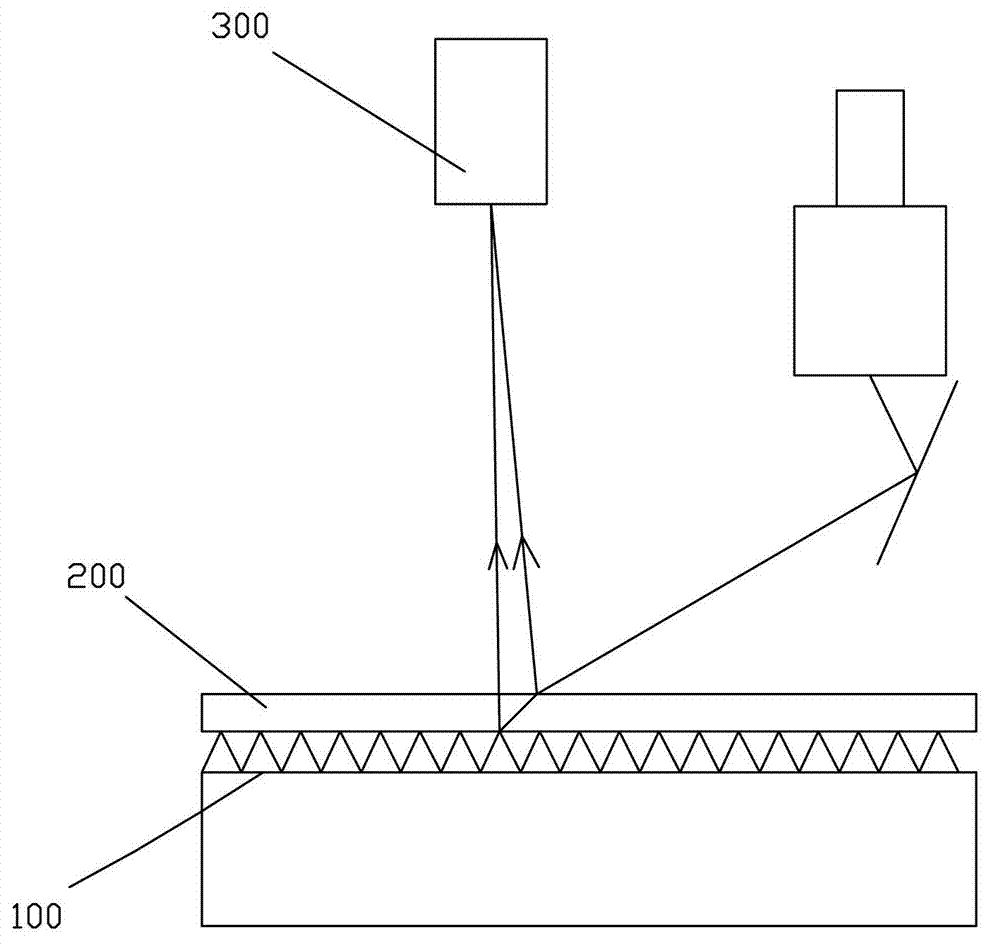

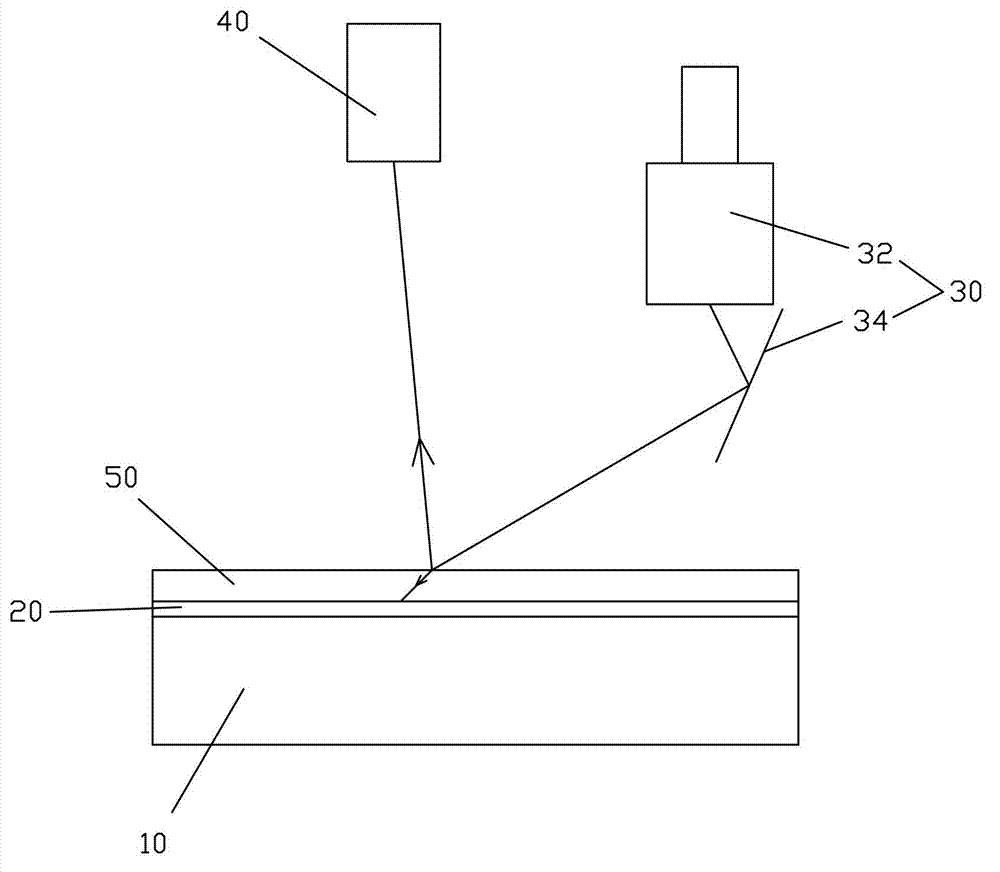

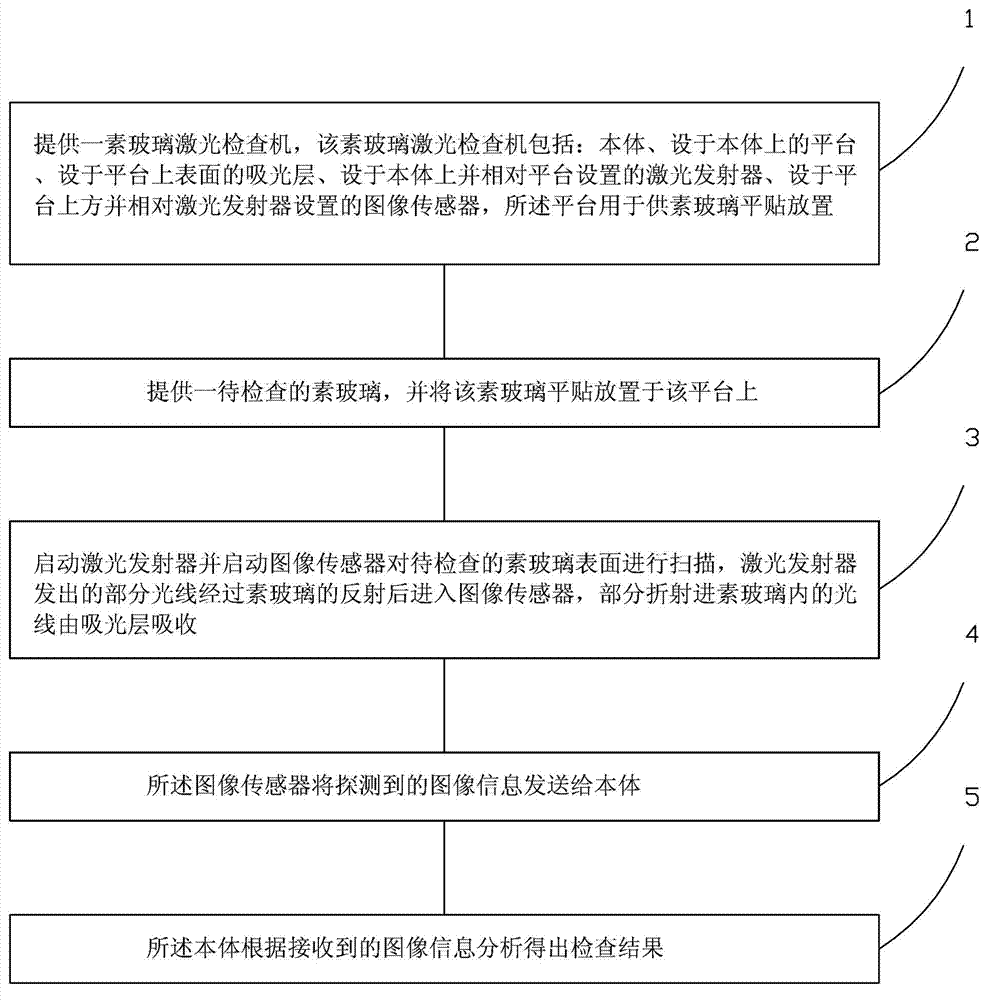

Laser inspection machine for mother glass and mother glass inspection method

ActiveCN103076343AAvoid false detectionEasy to operateOptically investigating flaws/contaminationLight reflexLaser transmitter

The invention provides a laser inspection machine for mother glass and a mother glass inspection method. The inspection machine comprises a main body, a platform arranged on the main body, a light absorbing layer arranged on the upper surface of the platform, a laser transmitter which is arranged on the main body and opposite to the platform, and an image sensor which is arranged above the platform and opposite to the laser transmitter, wherein the platform is used for flatly pasting mother glass. As flat-pasting platform is used for holding the mother glass, and the light absorbing layer is arranged on the platform, false detection of the image sensor due to light reflex caused by dirty back side of the mother glass is avoided, whether the product is abnormal can be accurately judged to avoid false rework or rejection of the product, the production efficiency and the qualification rate are both improved, the manhour is reduced and the manufacturing cost is lowered; and the mother glass inspection method is simple to operate, can well prevent false rework or rejection caused by false detection of the product, improves the production efficiency and the qualification rate, reduces the manhour and lowers the manufacturing cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

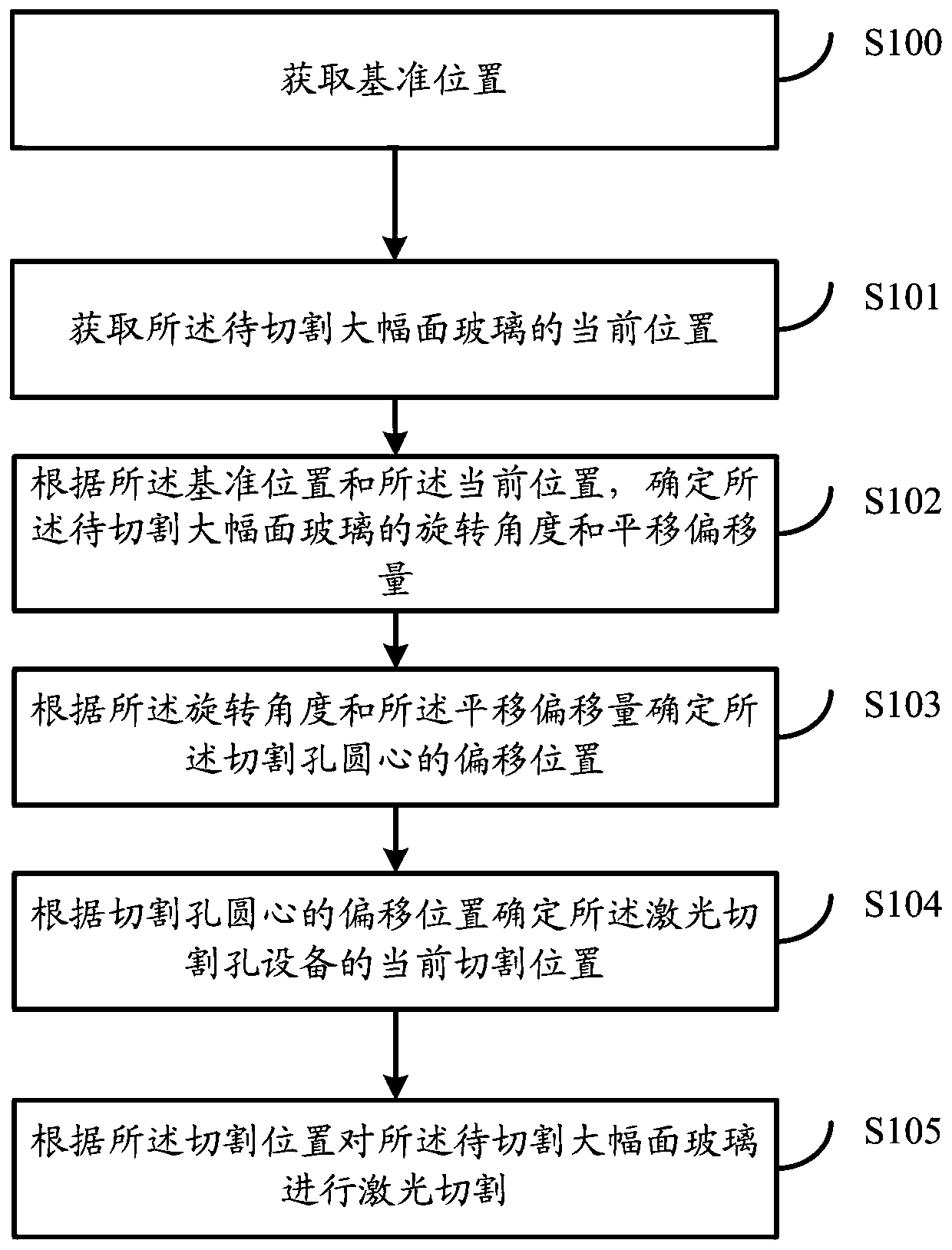

Large-format glass laser cutting hole positioning method and system

ActiveCN110340553AHigh precisionAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingMachining

The invention discloses a large-format glass laser cutting hole positioning method and system. The method comprises the following steps that a reference position is acquired; a current position of a to-be-cut large-format glass is acquired; according to the reference position and the current position, a rotation angle and a translation offset of the to-be-cut large-format glass are determined; anoffset position of a circle center of a cutting hole is determined according to the rotation angle and the translation offset; a current cutting position of laser cutting hole equipment is determinedaccording to the offset position of the circle center of the cutting hole; and laser cutting is carried out on the to-be-cut large-format glass according to the cutting position. According to the large-format glass laser cutting hole positioning method and system, the offset of the large-format glass conveyed to an accurate machining station can be accurately obtained, the precision of the large-format glass laser cutting hole positioning is improved, and damage to glass is prevented.

Owner:ZHEJIANG HUA GONG GLORY INTELLIGENT EQUIP TECH CO LTD

Glass laser-drilling machine capable of quick cooling

InactiveCN105436716AReduce damage rateRapid coolingLaser beam welding apparatusArchitectural engineeringDrilling machines

The invention discloses a glass laser-drilling machine capable of quick cooling. According to the glass laser-drilling machine, a fixing frame is fixedly arranged at the bottom of a connecting arm, and a first laser welding head and a second laser welding head are arranged at the bottom of one end of the connecting arm in parallel; collecting lenses are respectively arranged at the bottom ends of the first laser welding head and the second laser welding head; a first fixing arm and a second fixing arm are arranged at the bottoms of the first laser welding head and the second laser welding head in parallel, and two sucking discs are arranged on the surface of each of the first fixing arm and the second fixing arm; one ends of the first fixing arm and the second fixing arm are both connected to the surface of a rotary table, the other end of the rotary table is fixed on the surface of a rotating shaft sleeve, and the rotating shaft sleeve is mounted on the cylinder surface of the fixing frame in a sleeving manner. According to the glass laser-drilling machine, glass is tightly adsorbed through the sucking discs on the fixing arms and is drilled through two laser welding heads, the traditional drilling way is changed, and the defects of the mechanical drilling way in the traditional glass processing process are overcome.

Owner:CHONGQING JIAWEITE ENERGY SAVING GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com