Laser inspection machine for mother glass and mother glass inspection method

An inspection method, plain glass technology, applied in the direction of optical testing flaws/defects, material analysis through optical means, measuring devices, etc., can solve the problems of reducing production efficiency and yield, increasing man-hours and costs, and rework, etc., to improve Production efficiency and good product rate, reduction of man-hours, and reduction of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

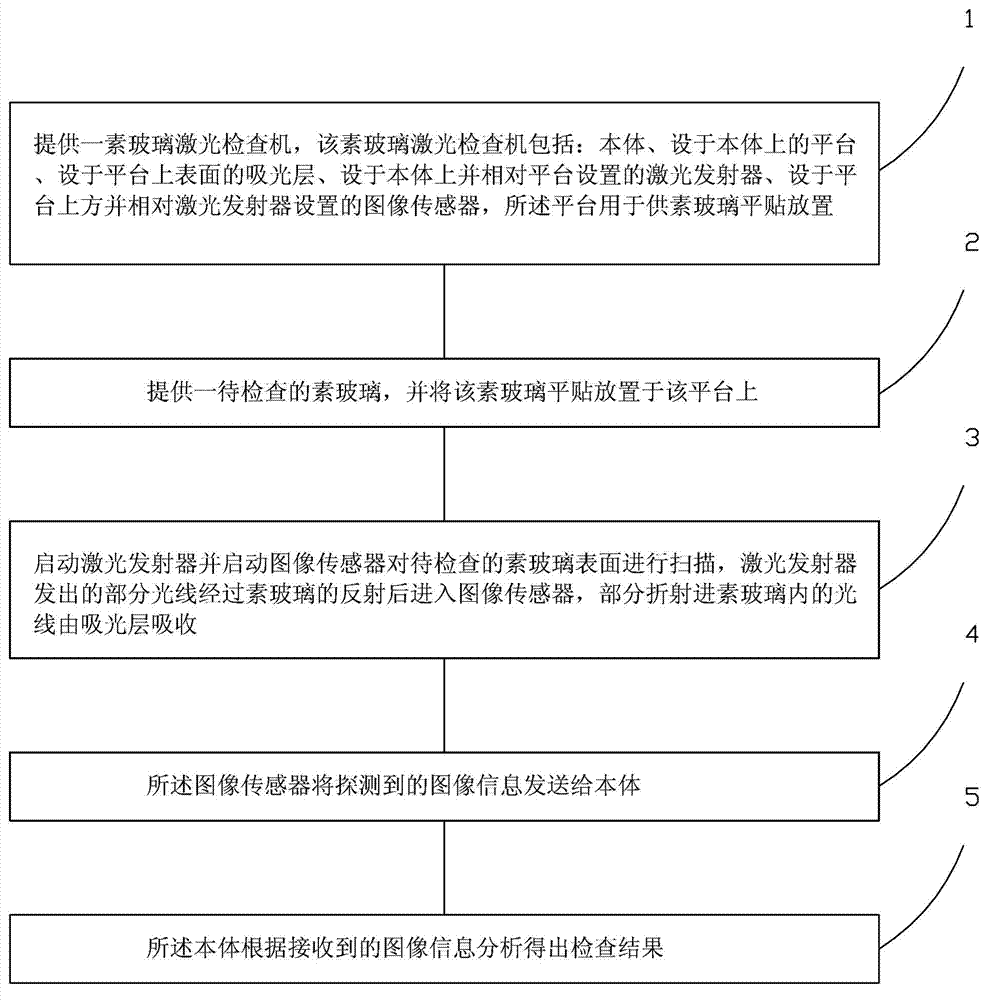

[0029] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

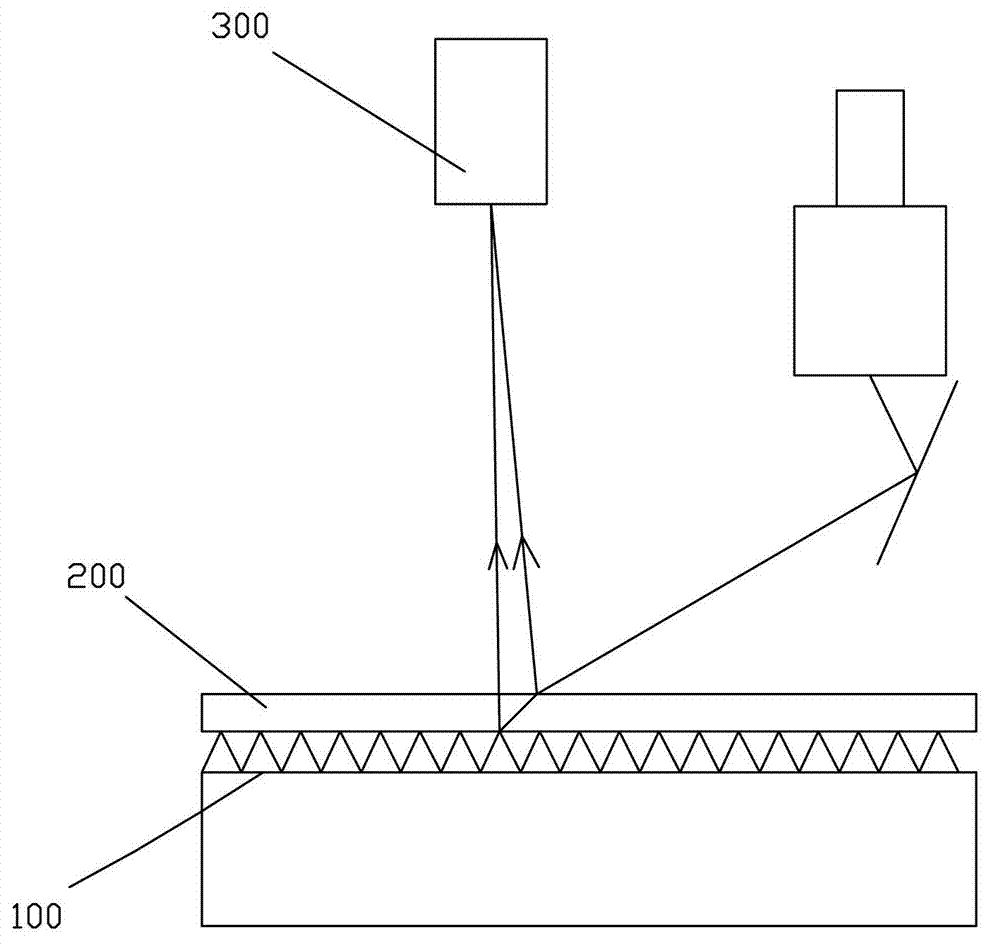

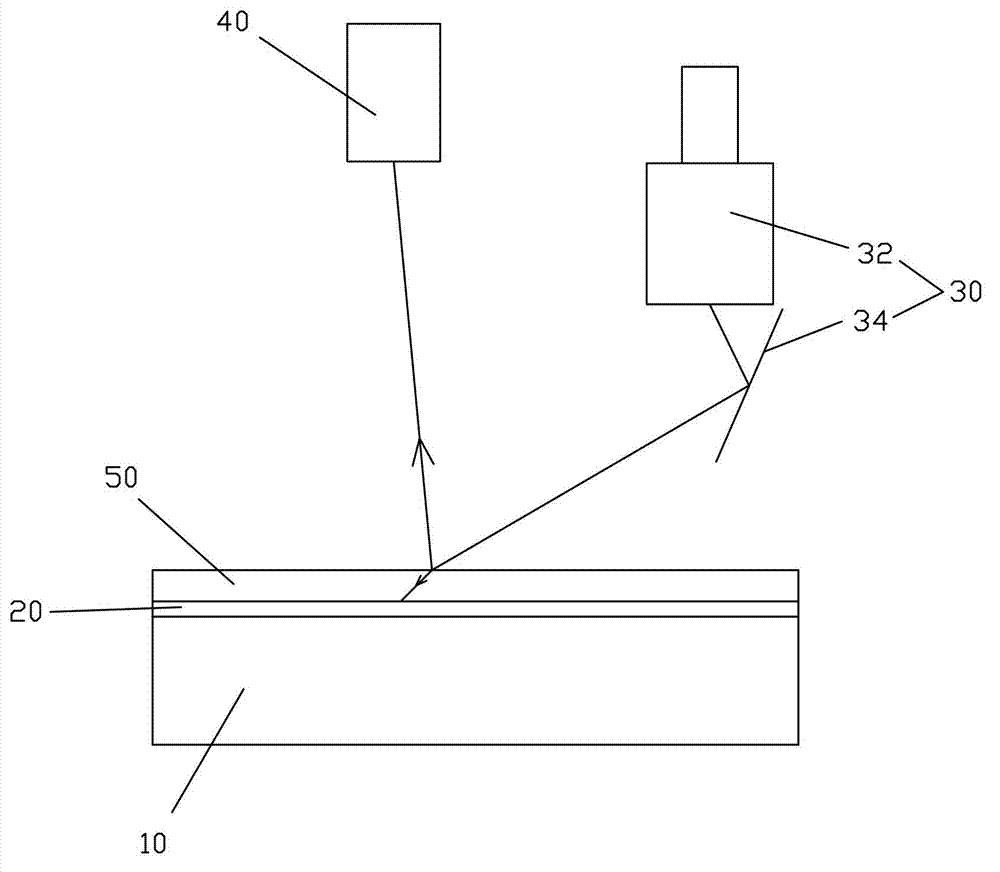

[0030] see figure 1 , the present invention provides a plain glass laser inspection machine, which includes: a body (not shown), a platform 10 disposed on the body, a light-absorbing layer 20 disposed on the upper surface of the platform 10, disposed on the body and opposite to the platform 10 The laser emitter 30 and the image sensor (CCD) 40 are arranged above the platform 10 and opposite to the laser emitter 30, and the platform 10 is used for laying the plain glass 50 flat. The main body has the usual functions of the existing plain glass laser inspection machine. After the plain glass 50 to be inspected is placed on the platform 10, the laser emitter 30 emits laser light, and the main body starts the image sensor 40 to inspect the plain g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com