Honeycomb paper core defect detection method based on machine vision

A technology of honeycomb paper core and defect detection, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems affecting the ability of honeycomb paperboard to withstand collision, irregular cavity structure, manual defect detection errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

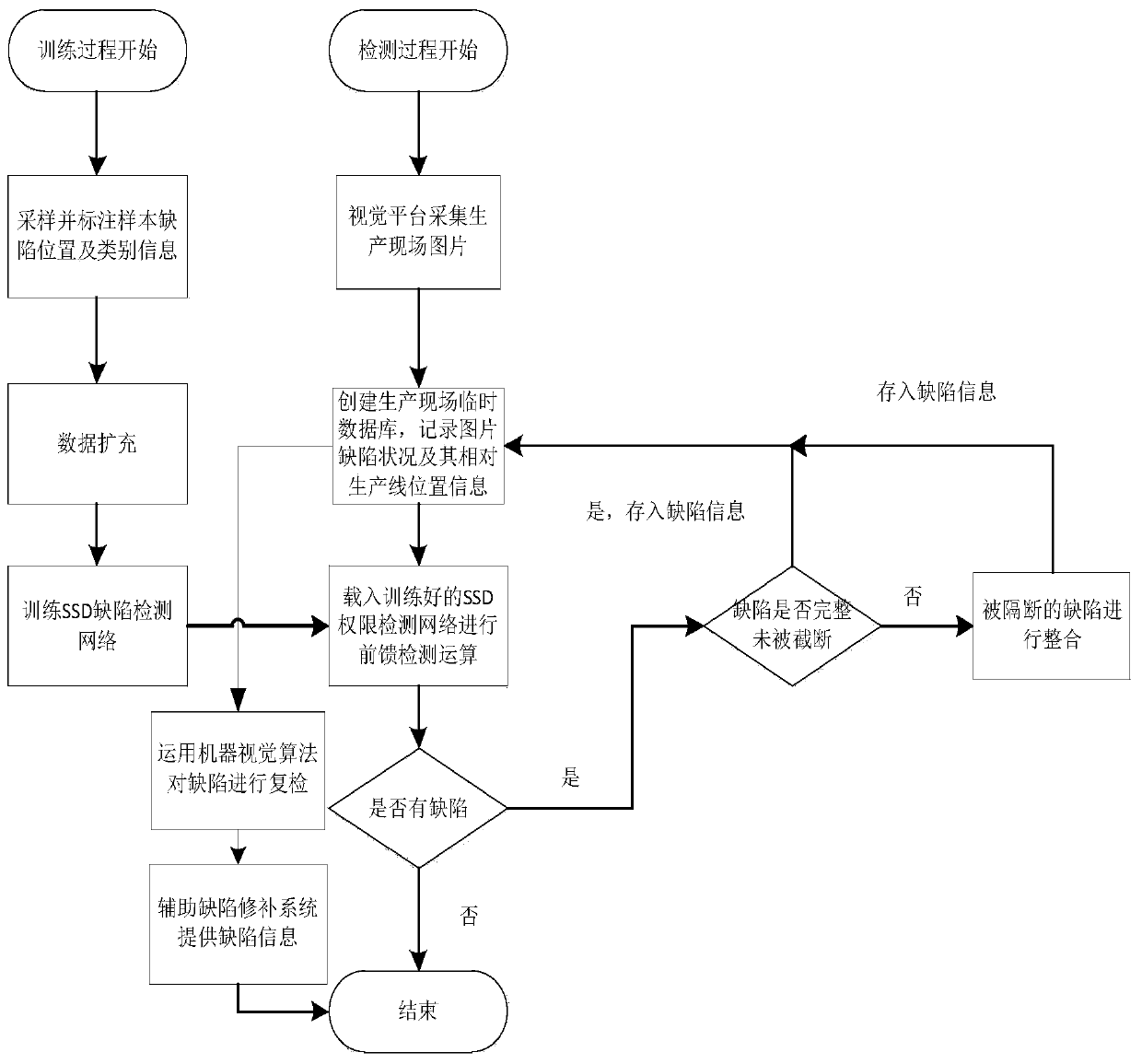

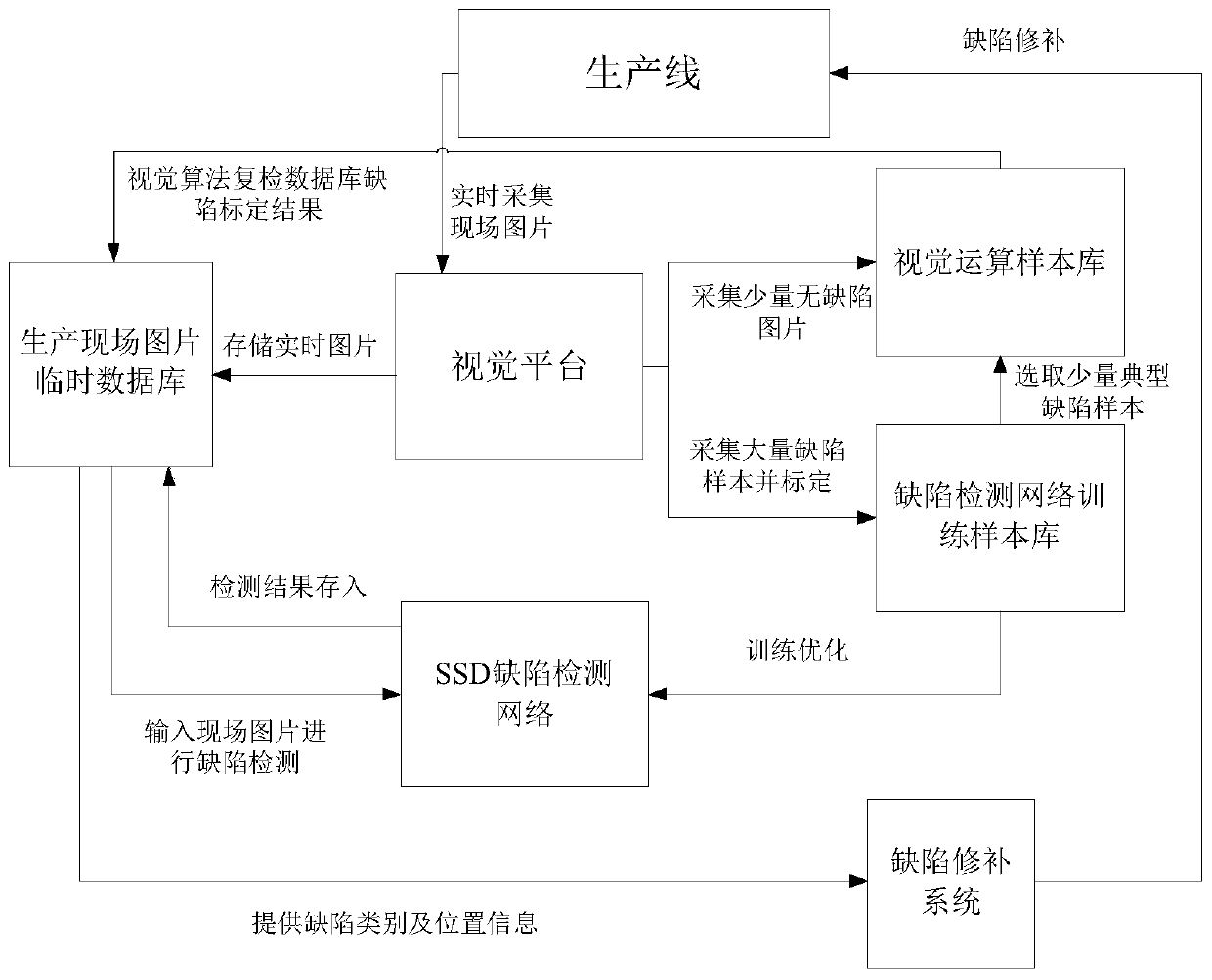

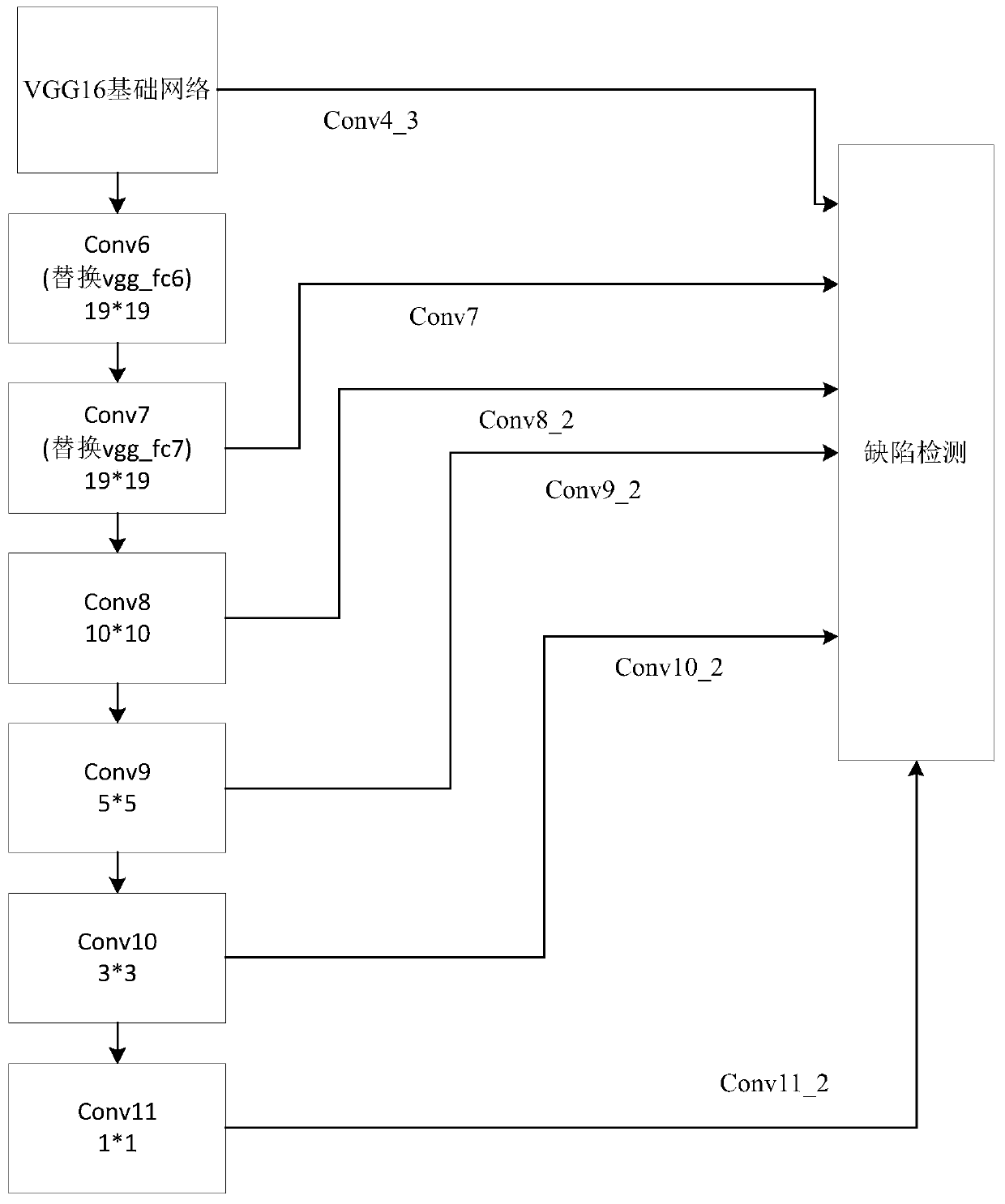

Method used

Image

Examples

Embodiment Construction

[0038] 1. Mobilize the production equipment at the honeycomb paper core industrial production site to produce a large number of honeycomb paper core samples, build a visual platform at the industrial site, fix the camera, and give a certain amount of constant lighting, set the collection size to a long strip image, The width of the picture is 2400, the height is 300, adjust the height so that the width direction of the camera just captures the overall width of the production line, that is, captures the entire width information of the tape entrance position, and the height of the picture is 300, which is used as the production line for subsequent analysis. The unit of measure for pacing. Carry out equidistant segmentation (divided into 8 blocks) for the collected long strip pictures, that is, generate a set of [300,300] images, manually check whether there are defects in the pictures, if there are defects, use labelImg to mark the defect position, and calibrate Good pictures ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com