Patents

Literature

6970 results about "Paperboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paperboard is a thick paper-based material. While there is no rigid differentiation between paper and paperboard, paperboard is generally thicker (usually over 0.30 mm, 0.012 in, or 12 points) than paper and has certain superior attributes such as foldability and rigidity. According to ISO standards, paperboard is a paper with a grammage above 250 g/m², but there are exceptions. Paperboard can be single- or multi-ply.

Bulk enhanced paperboard and shaped products made therefrom

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. / 3000 square feet and at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch respectively, has a GM Taber stiffness of at least about 0.00716 w2.63 grams-centimeter / fiber mat density1.63 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch, and a GM tensile stiffness of at least about 1890+24.2 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Hollow sphere organic pigment for paper or paper coatings

InactiveUS6139961ATrend downHigh molecular weightSynthetic resin layered productsCellulosic plastic layered productsVitrificationPaperboard

A hollow sphere organic pigment in which a core containing a void is encapsulated by a first shell polymer having a glass transition temperature greater than 50 DEG C., the first shell having polymerized thereon a second shell polymer having a glass transition temperature of -15 DEG C. to -50 DEG C. is provided. Also provided is a paper or paperboard coating composition containing the hollow sphere organic pigment, a method for improving the strength and opacity of a paper or paperboard coating by using the coating composition dried, a coated paper or paperboard bearing the dried coating composition, and a method for improving the strength and opacity of paper or paperboard by incorporating a particular hollow sphere organic pigment into the formed wet sheet.

Owner:ROHM & HAAS CO

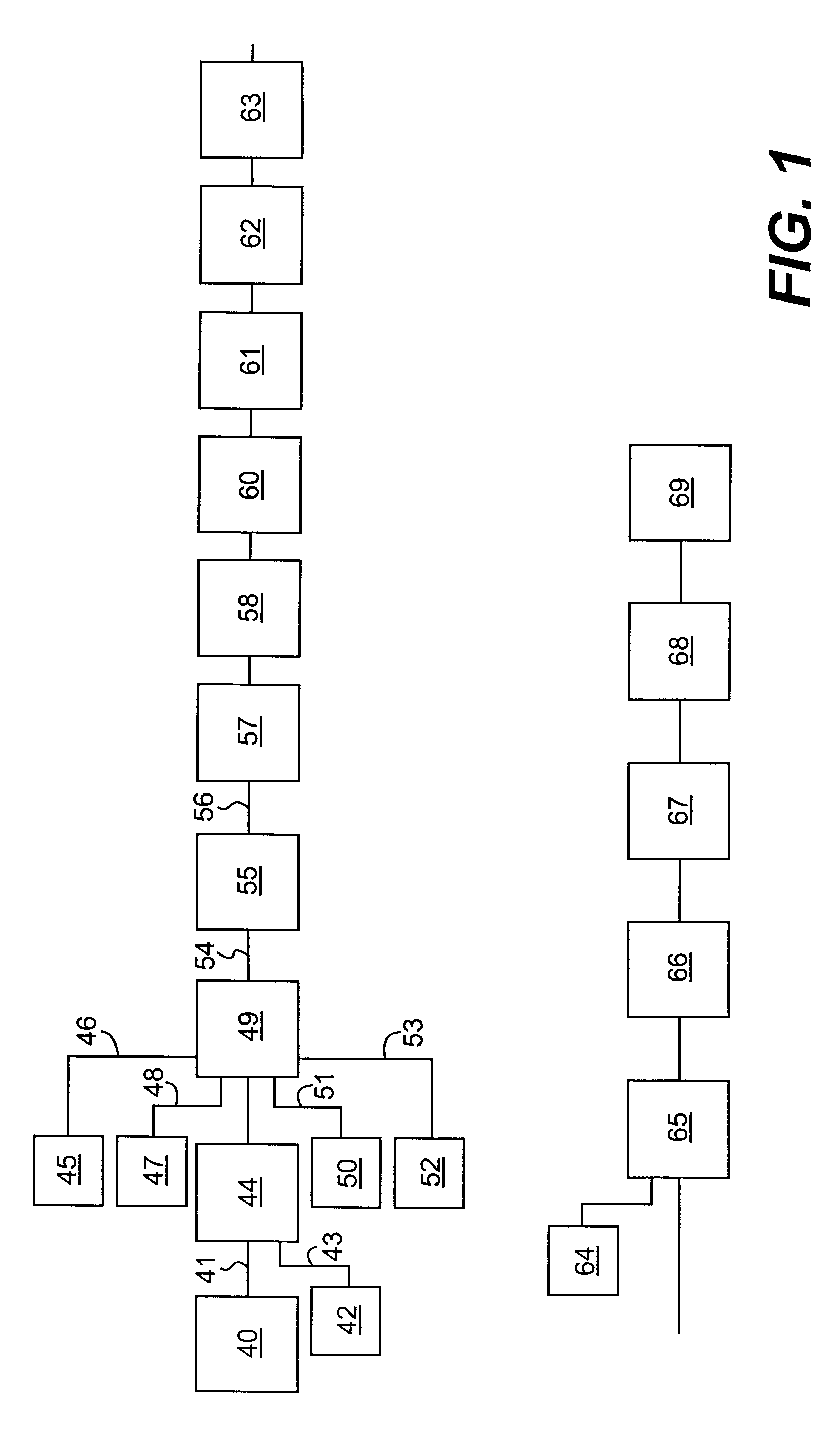

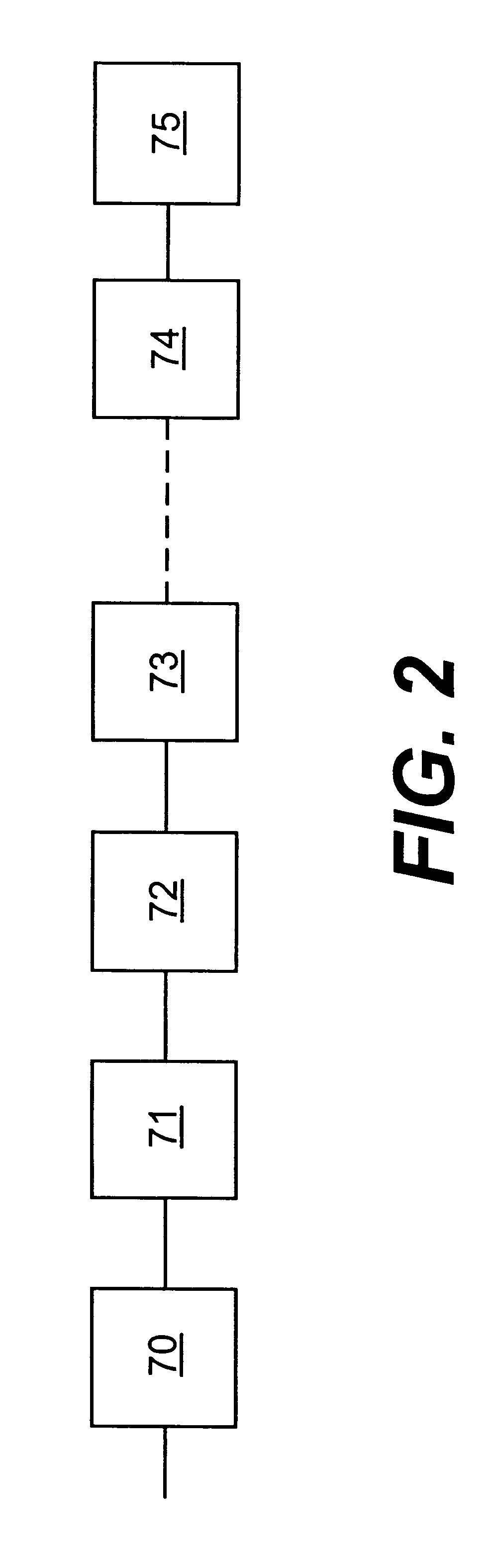

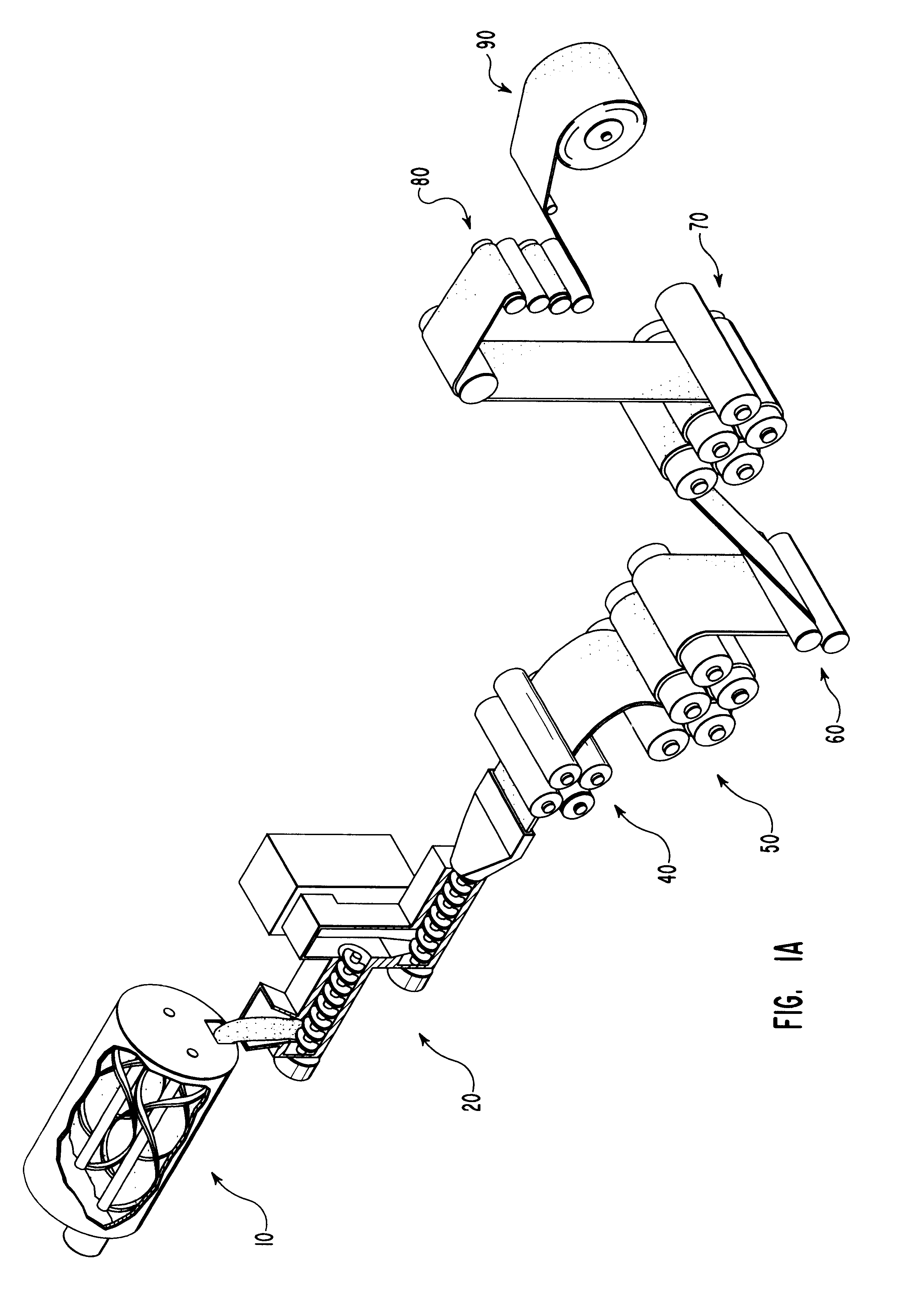

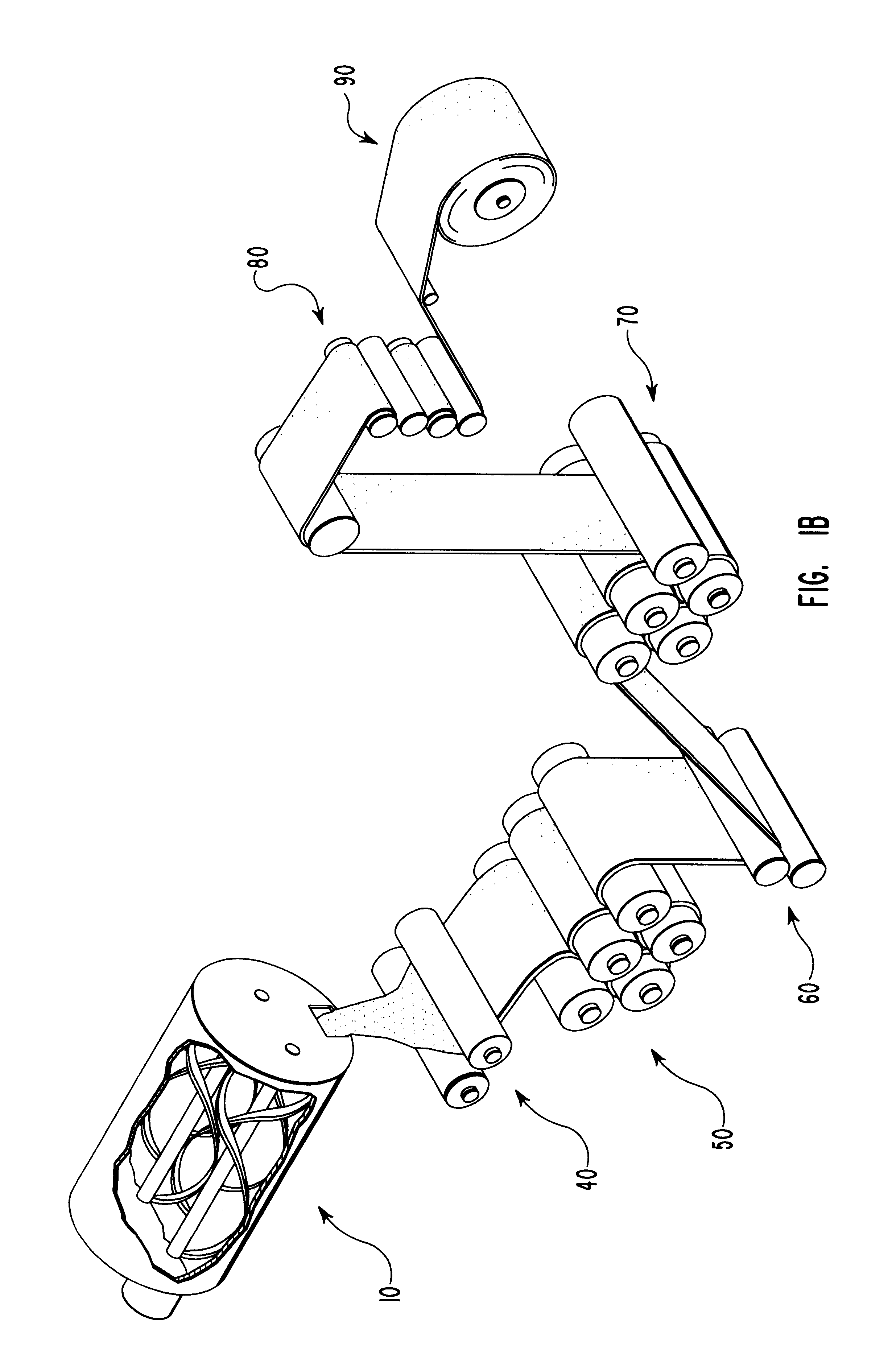

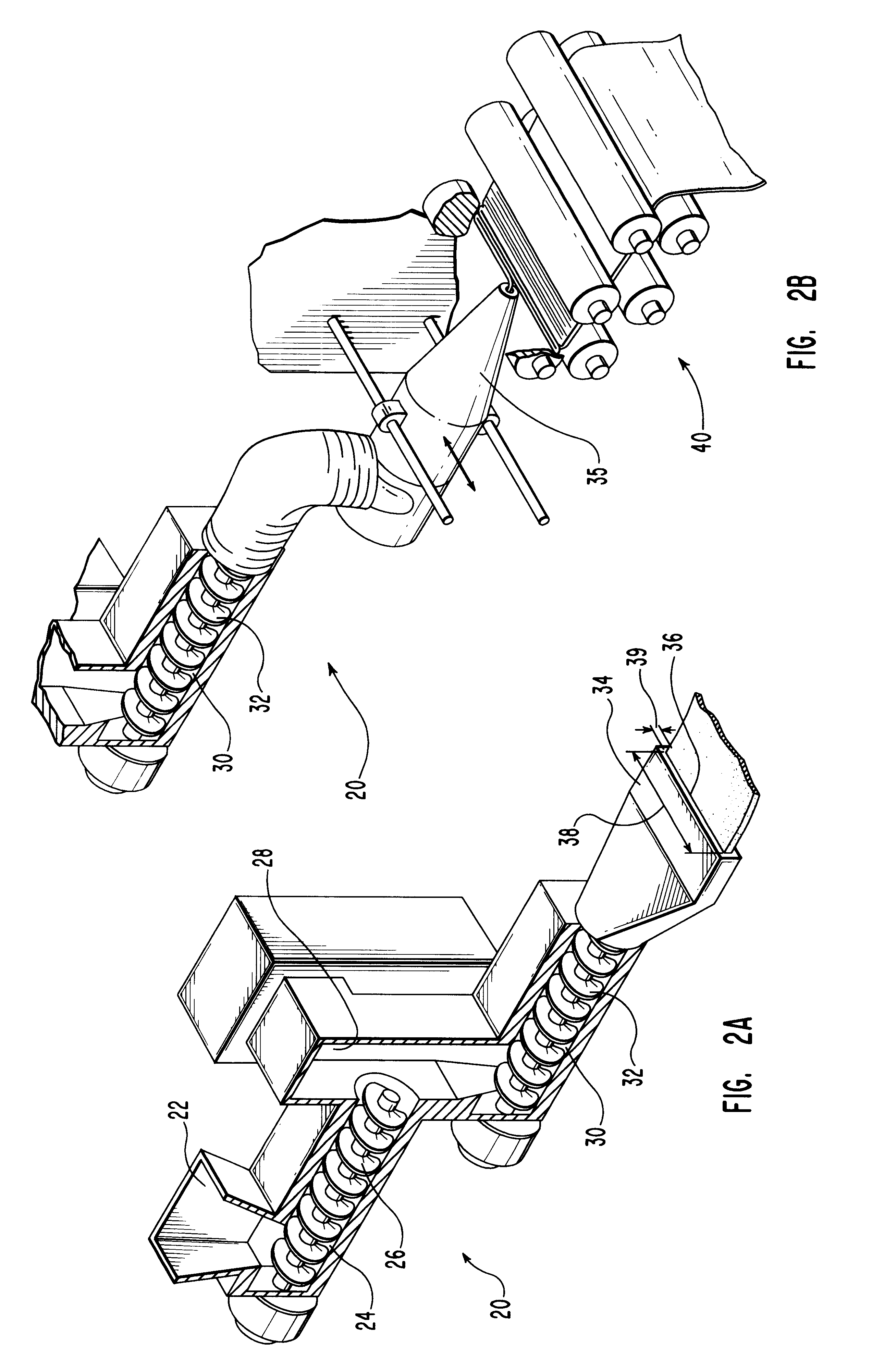

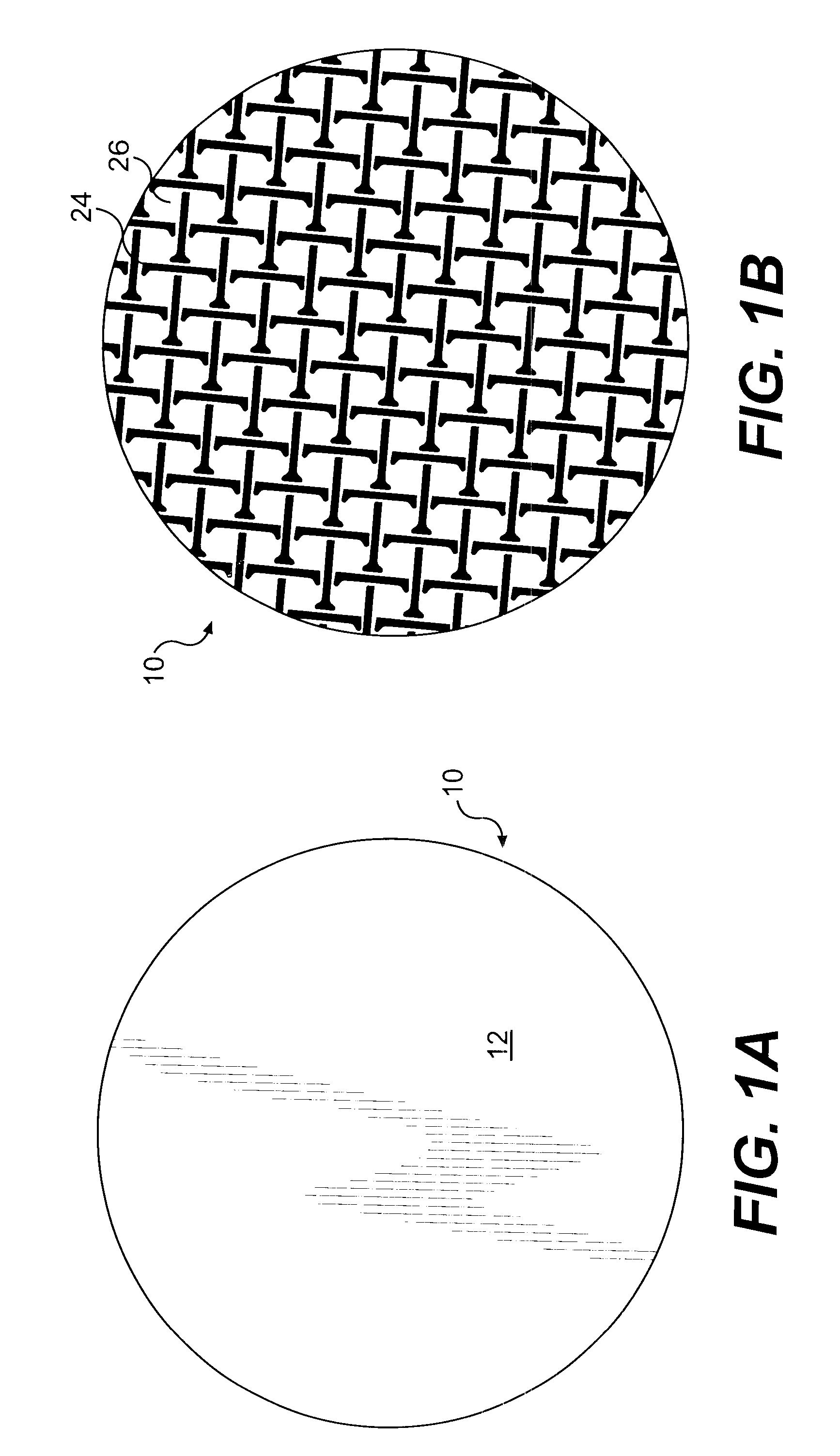

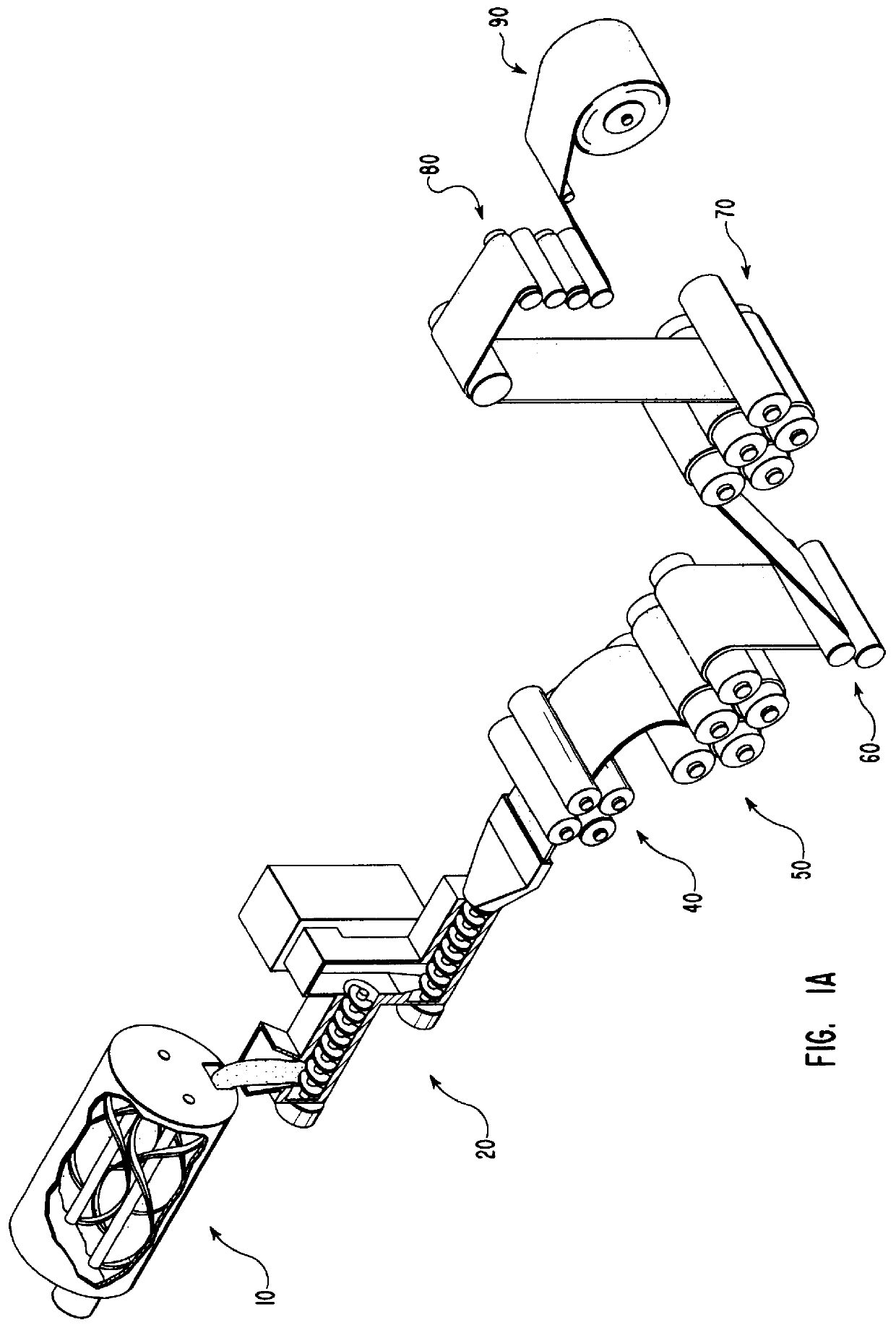

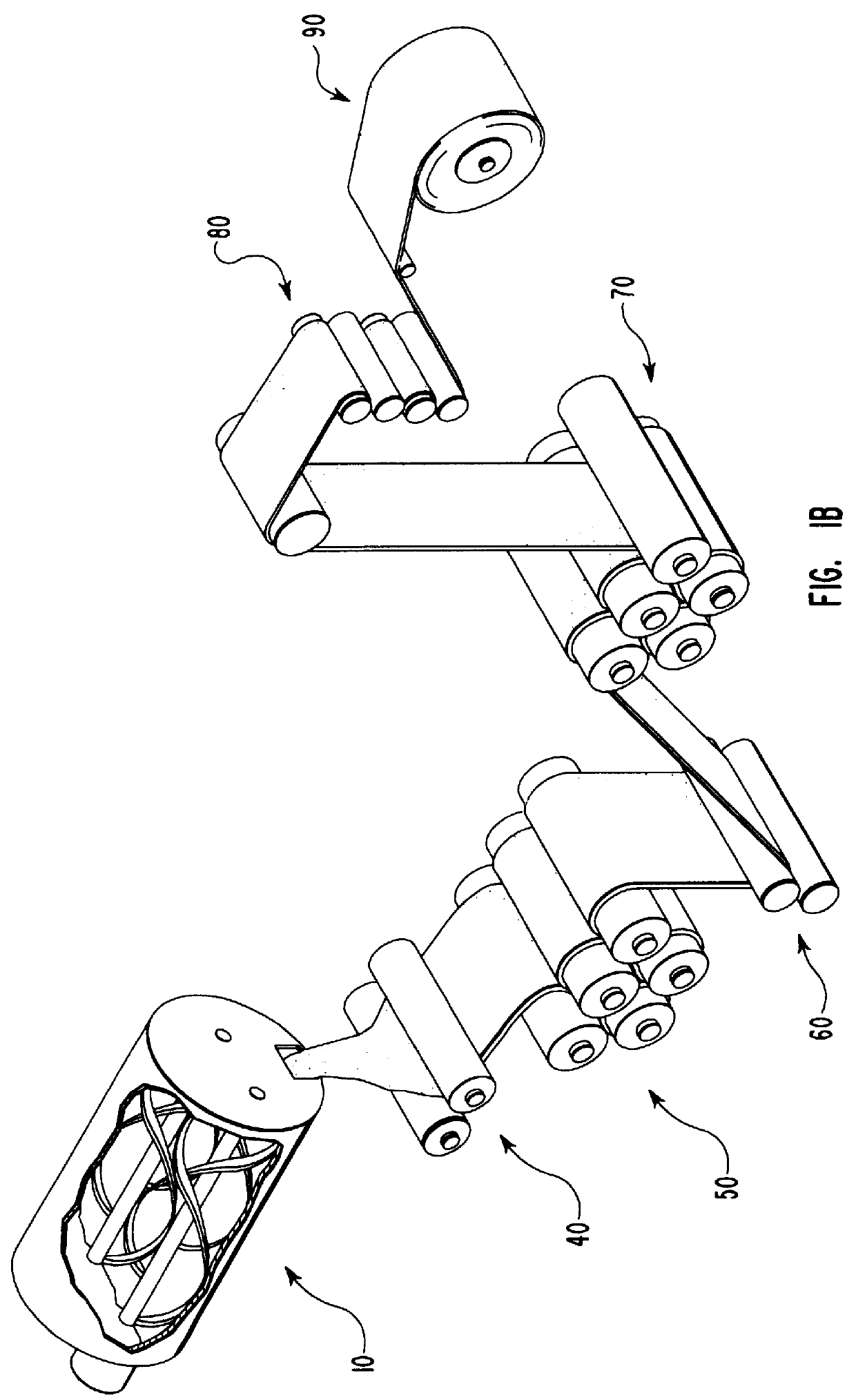

Compositions and methods for manufacturing starch-based compositions

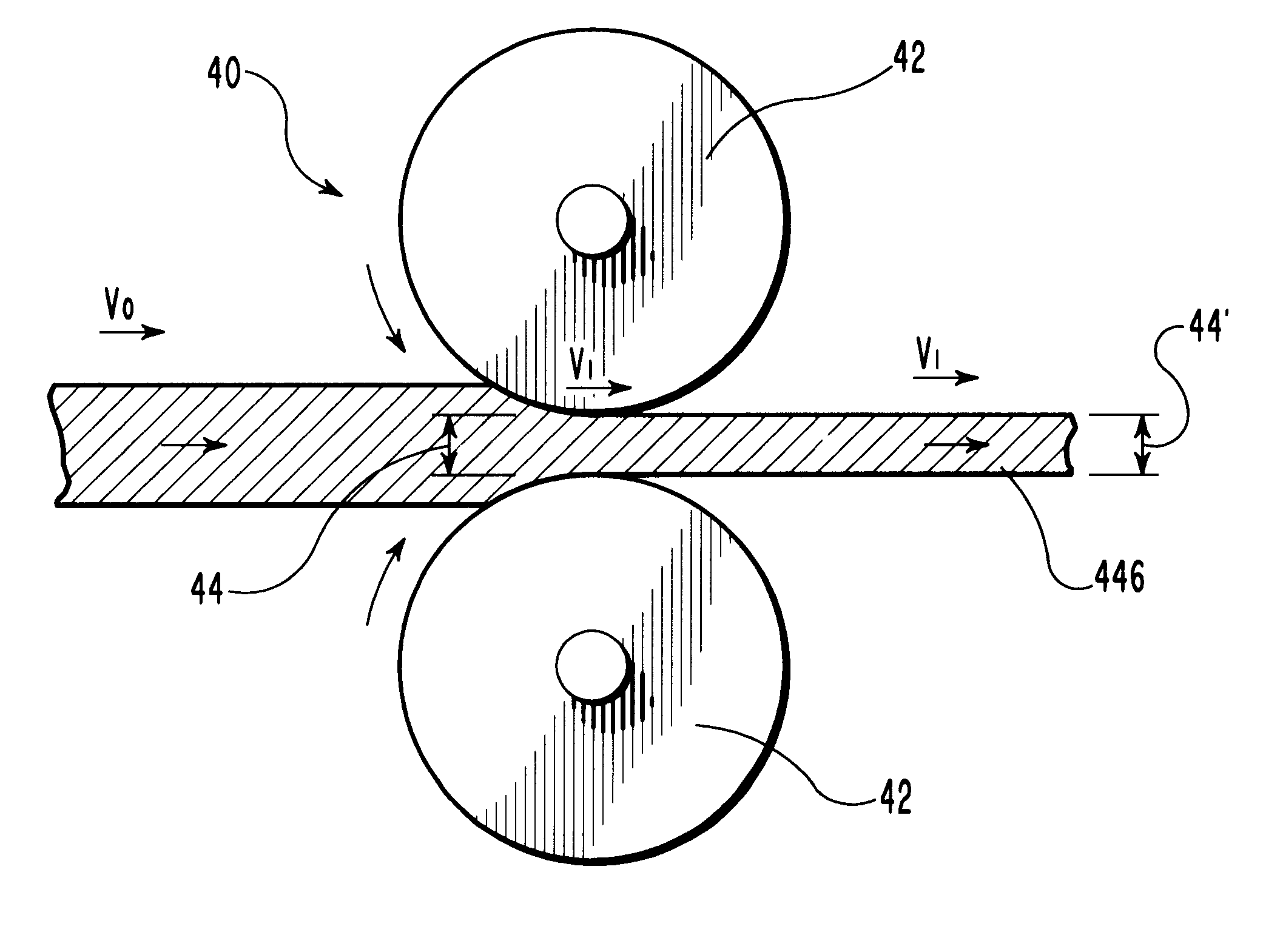

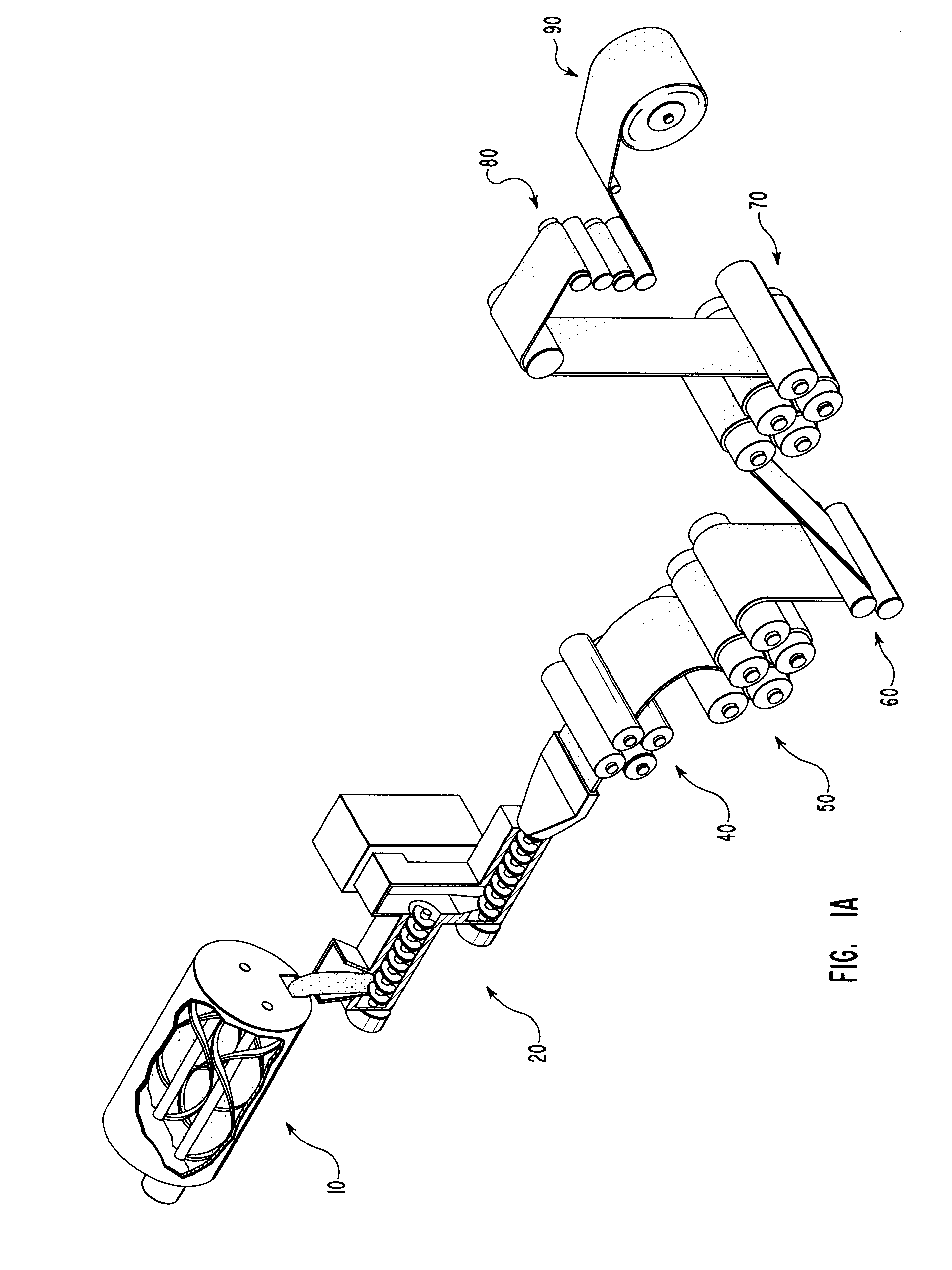

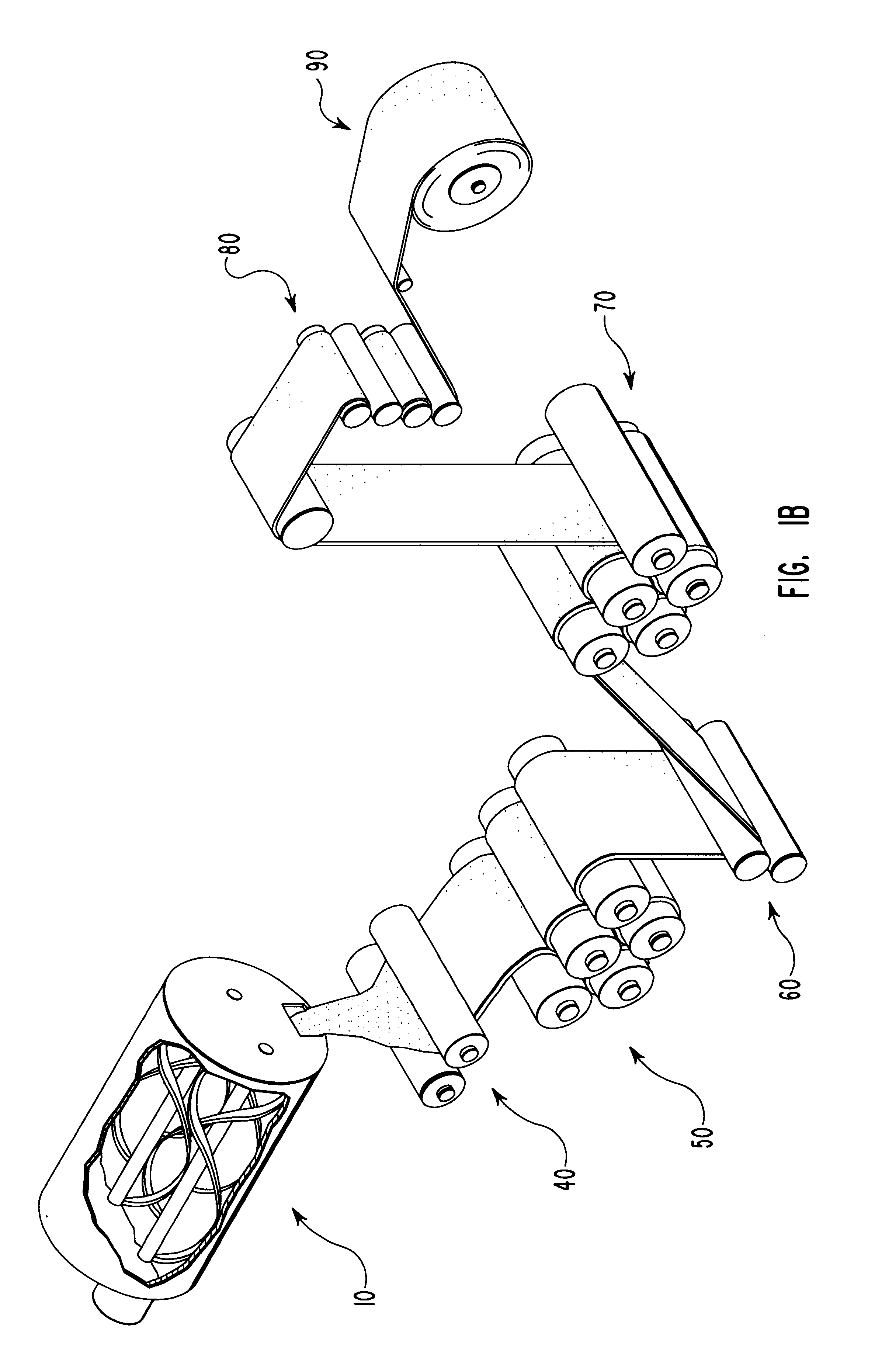

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

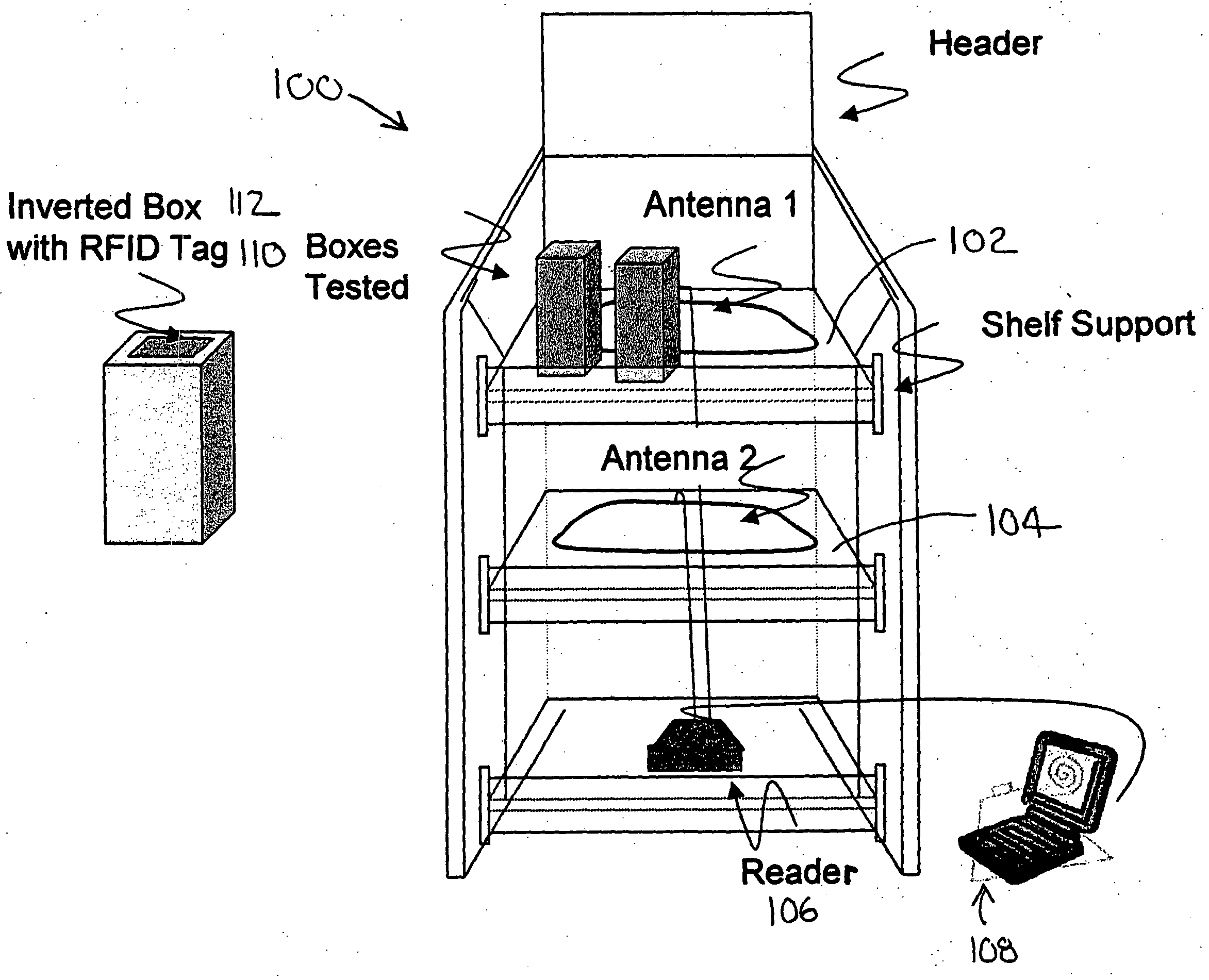

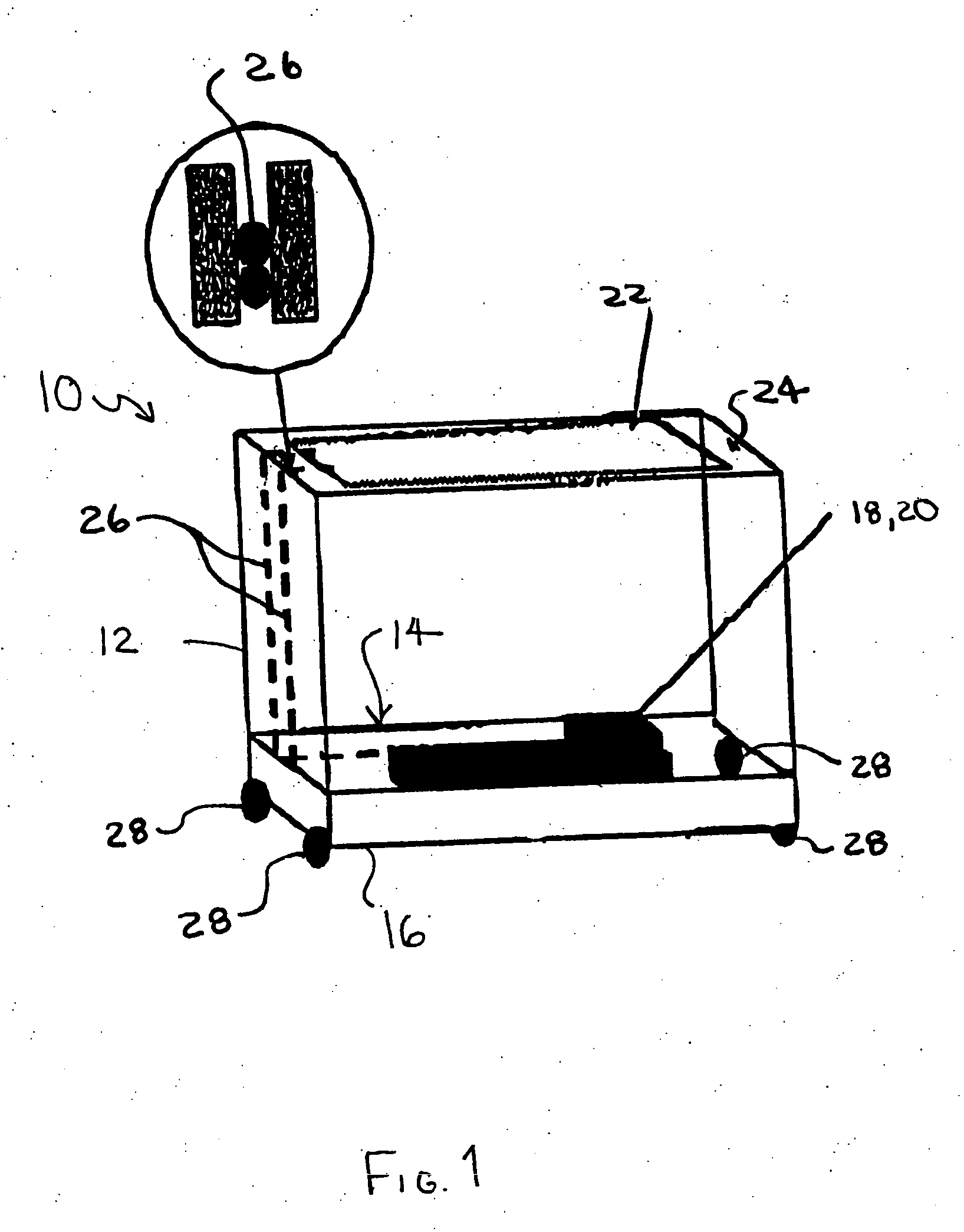

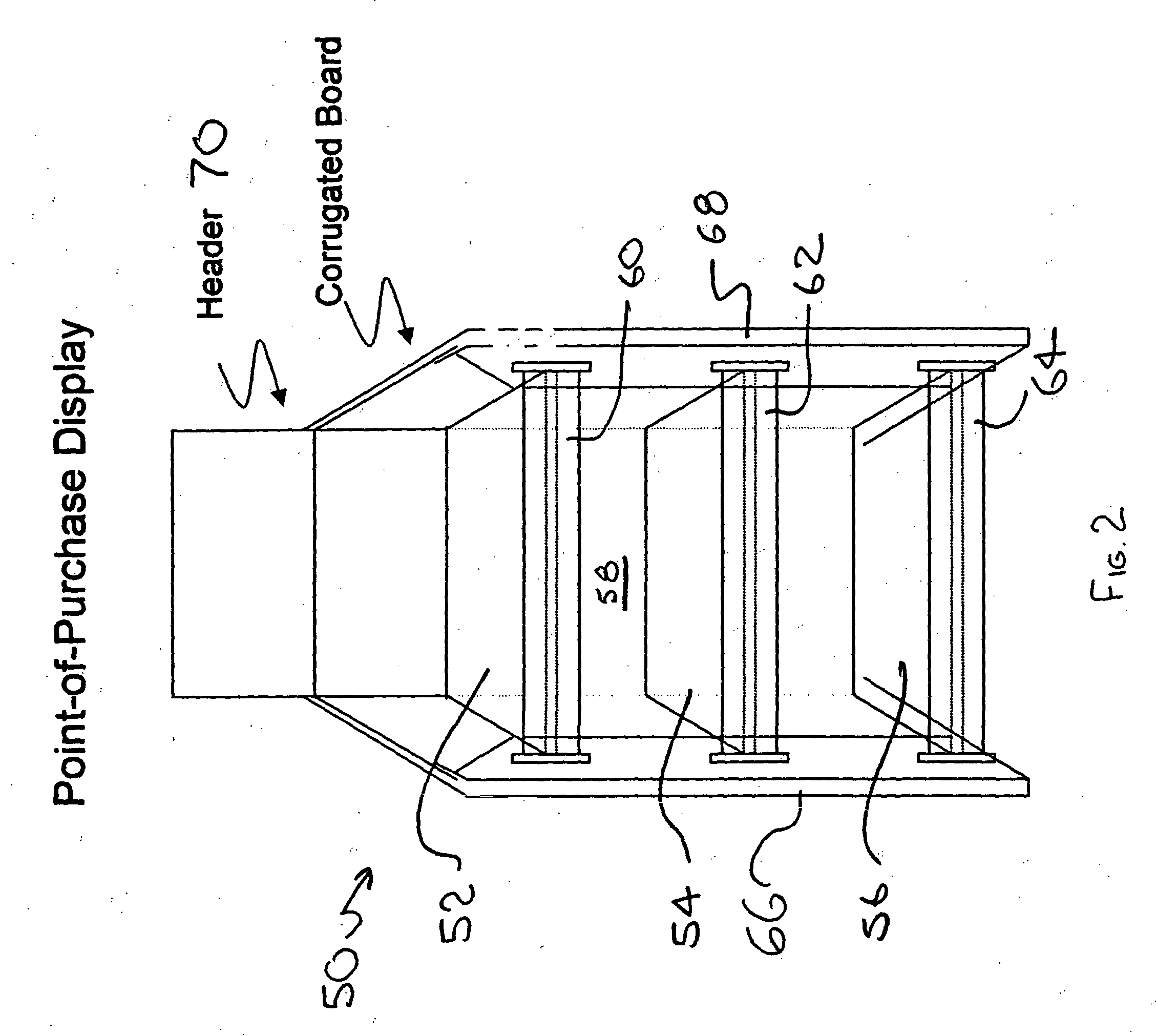

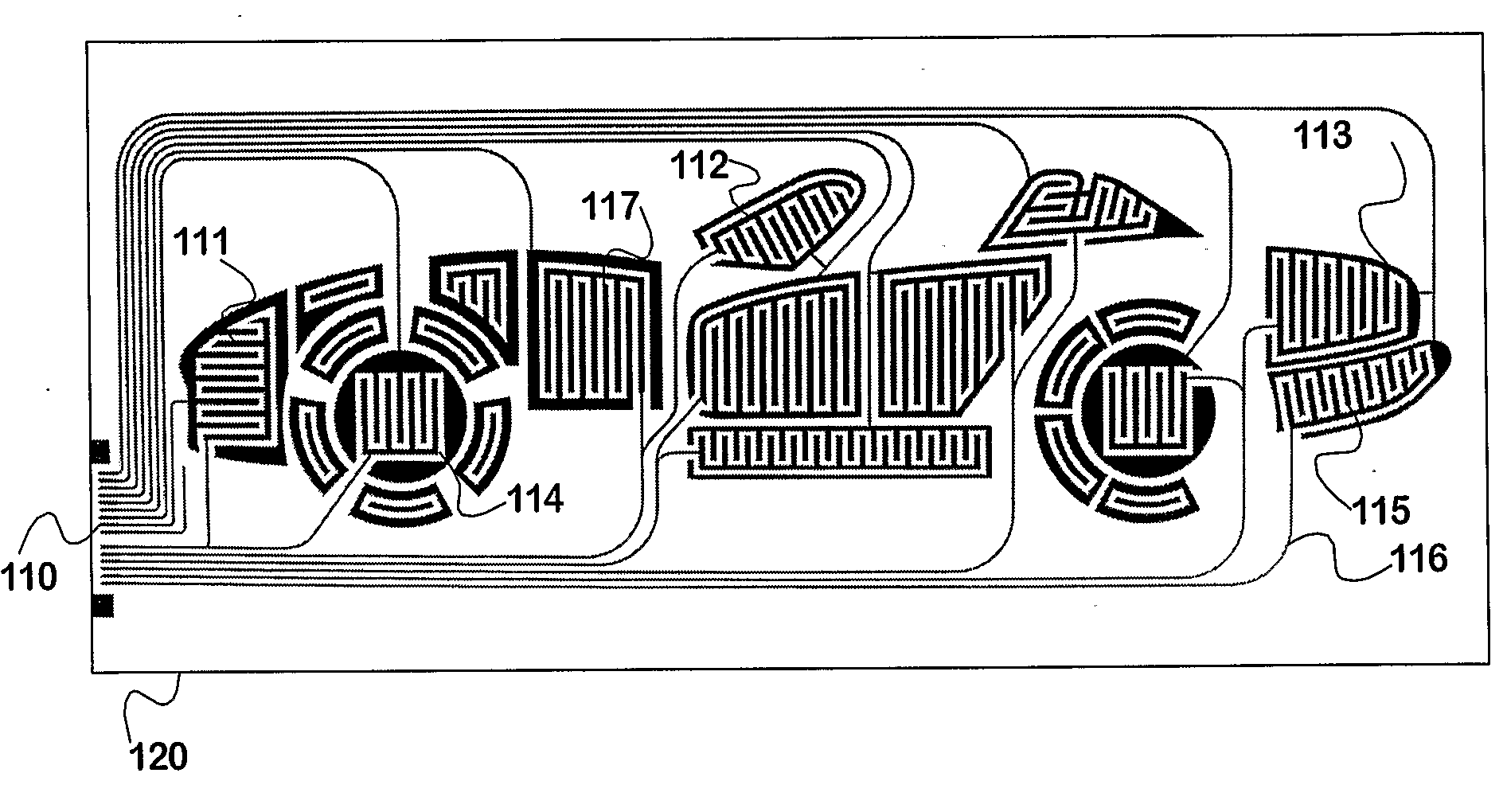

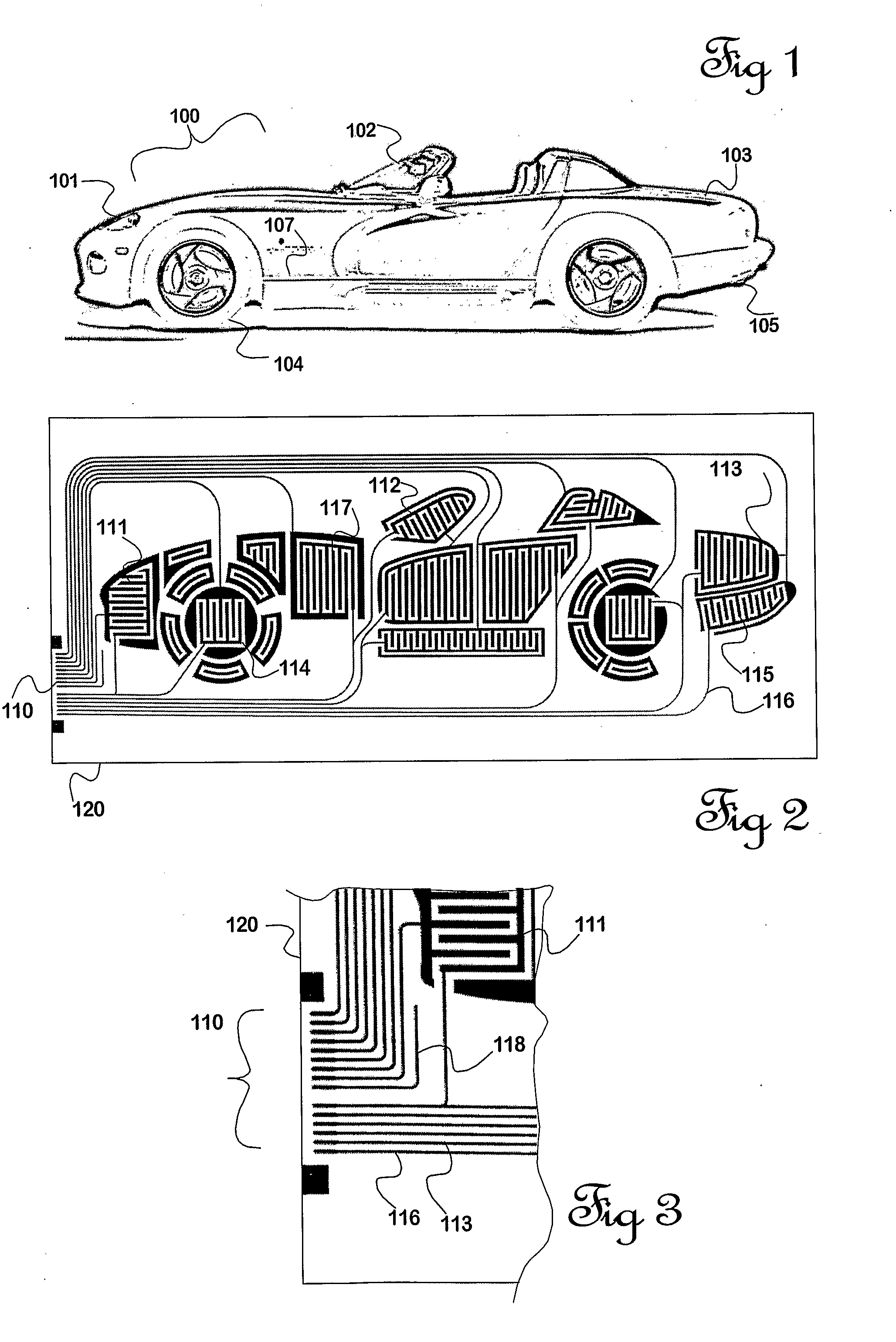

Point-of-purchase display with RFID inventory control

InactiveUS20050040934A1Promote sportsElectric signal transmission systemsHand manipulated computer devicesTransceiverDisplay device

A point-of-purchase (“POP”) display employing RFID (Radio Frequency IDentification) technology for inventory control is provided. The POP is preferably fabricated from paper, paperboard and / or corrugated paperboard material, and incorporates one or more shelves and / or cover layers. An RF antenna structure is applied to the surfaces of, or built into, the one or more shelves and / or cover layers. Suitable RF transmitter / receiver circuitry may also be built into the POP, or the POP may simply have suitable connections built in, to permit such transceiver apparatus to be plugged into the POP. The transceiver circuitry is connected in any suitable manner to an inventory control computer, such as the retail store's computer. Each article that is to be displayed in the POP is provided with an RFID tag. Removal of an article from the POP, results in a signal being transmitted to the inventory control computer, corresponding to the removal of the article from the POP, and corresponding adjustment of the inventory records in the inventory control computer.

Owner:WESTROCK SHARED SERVICES LLC

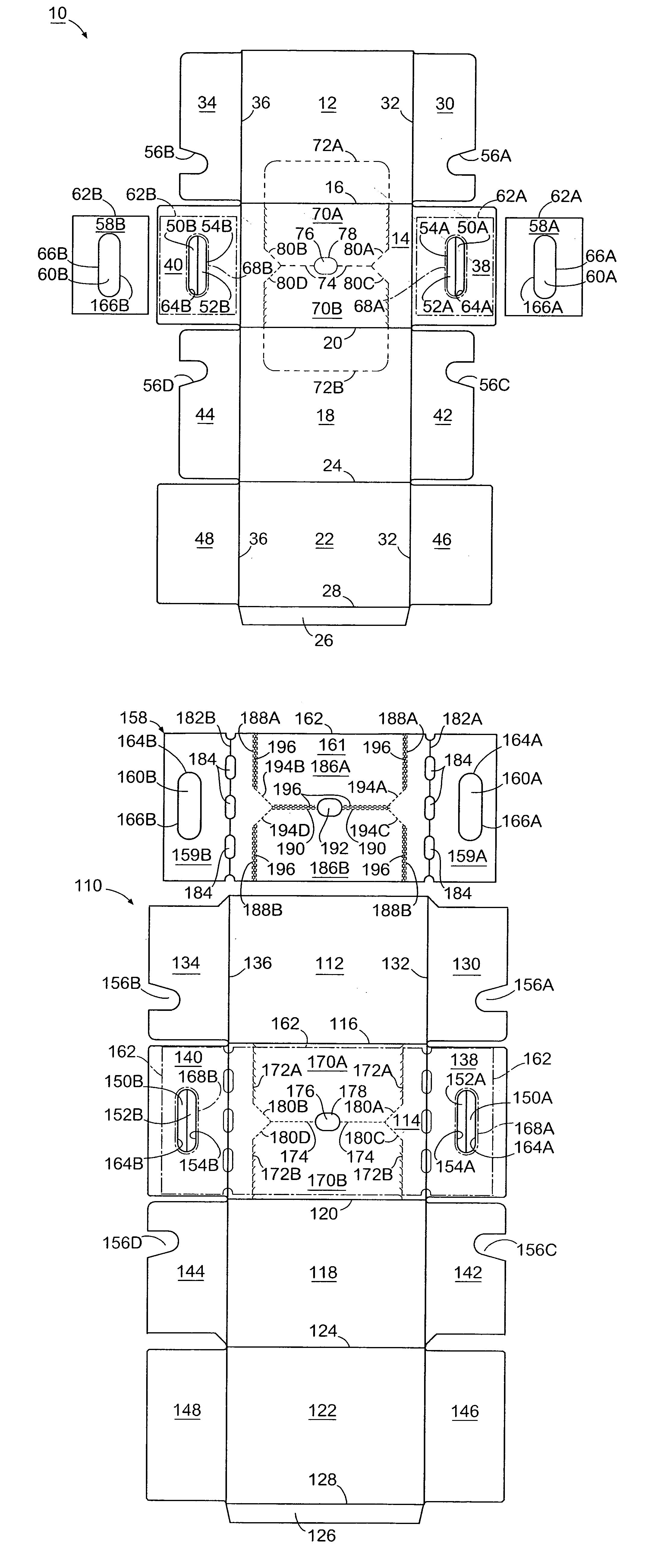

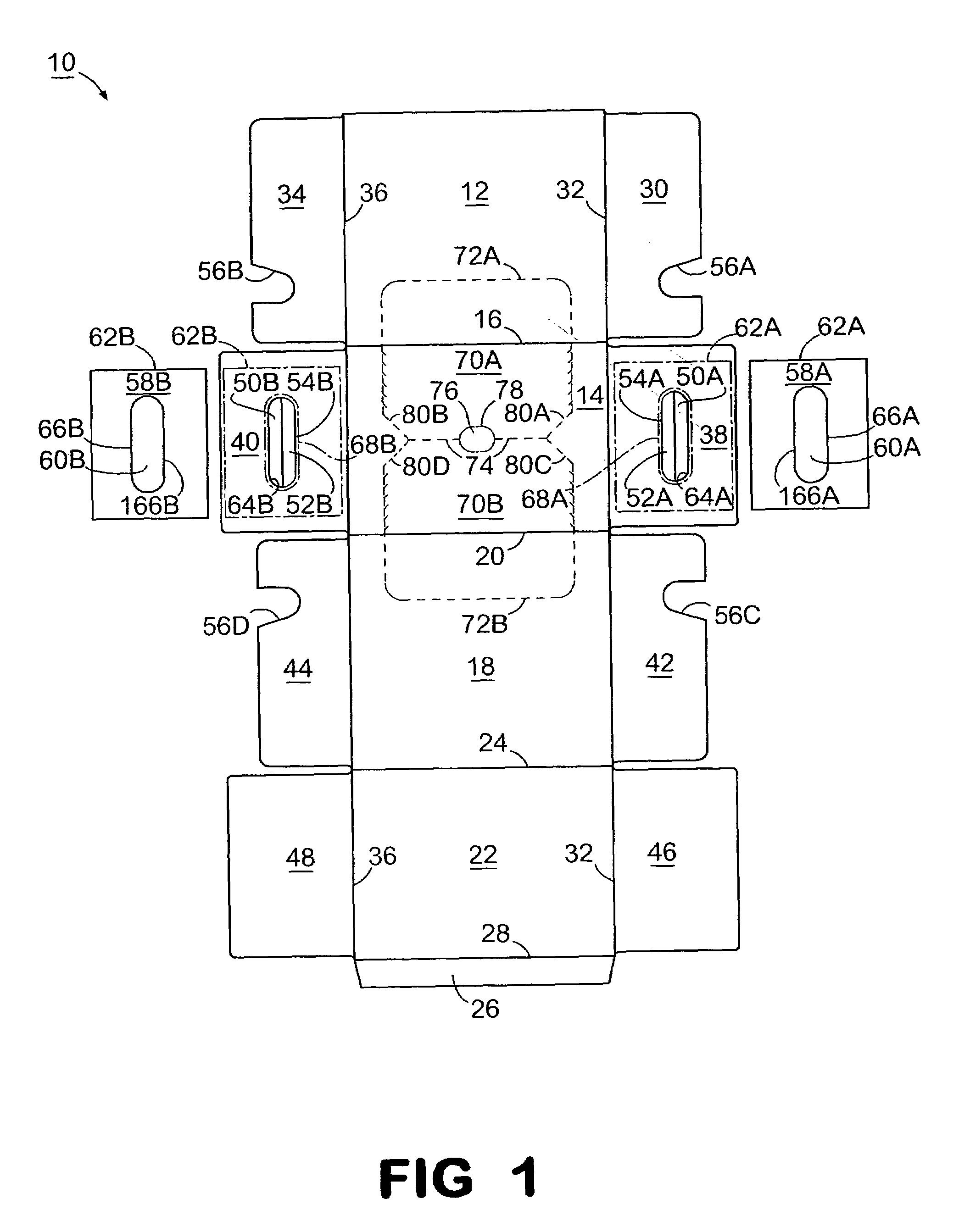

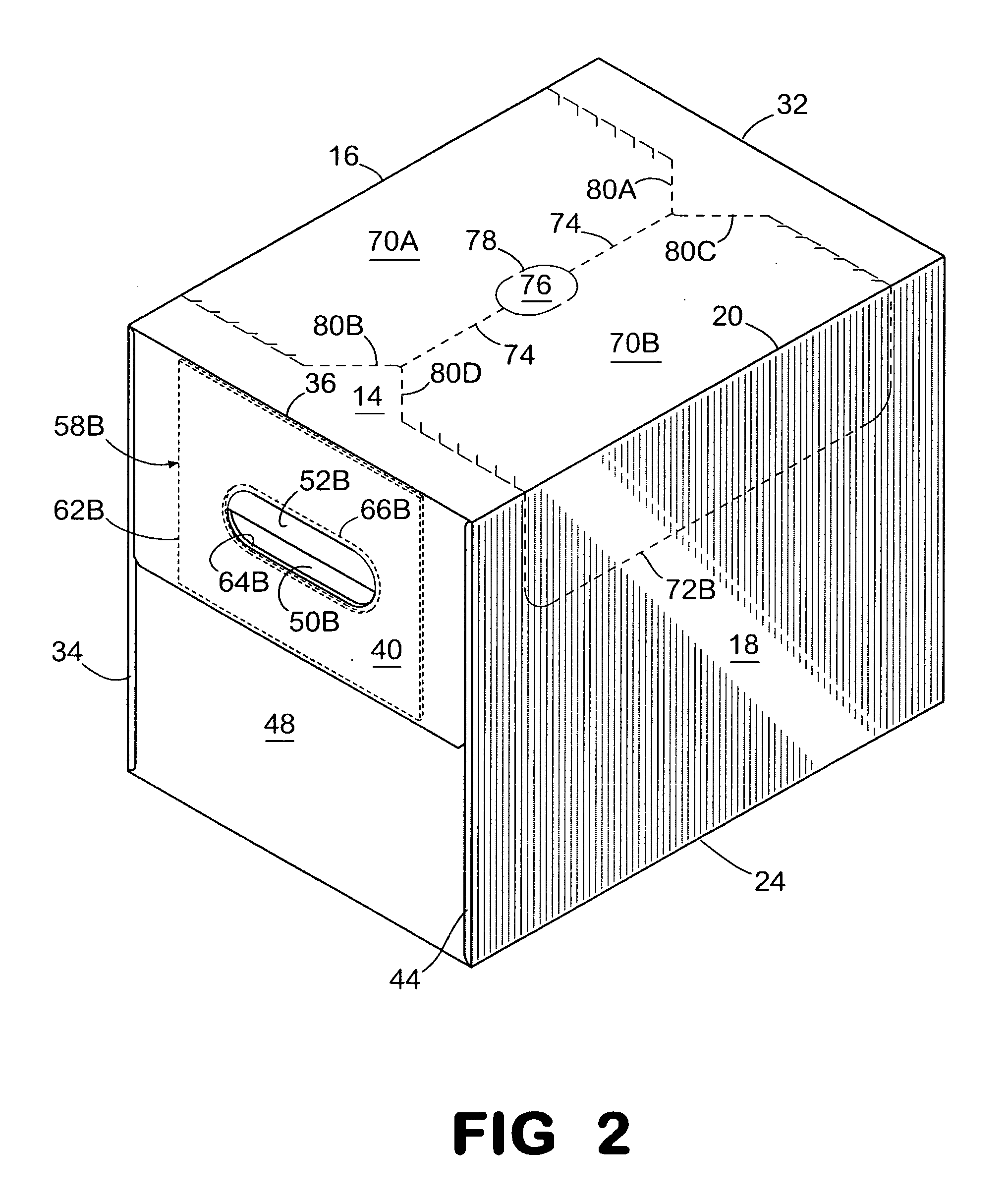

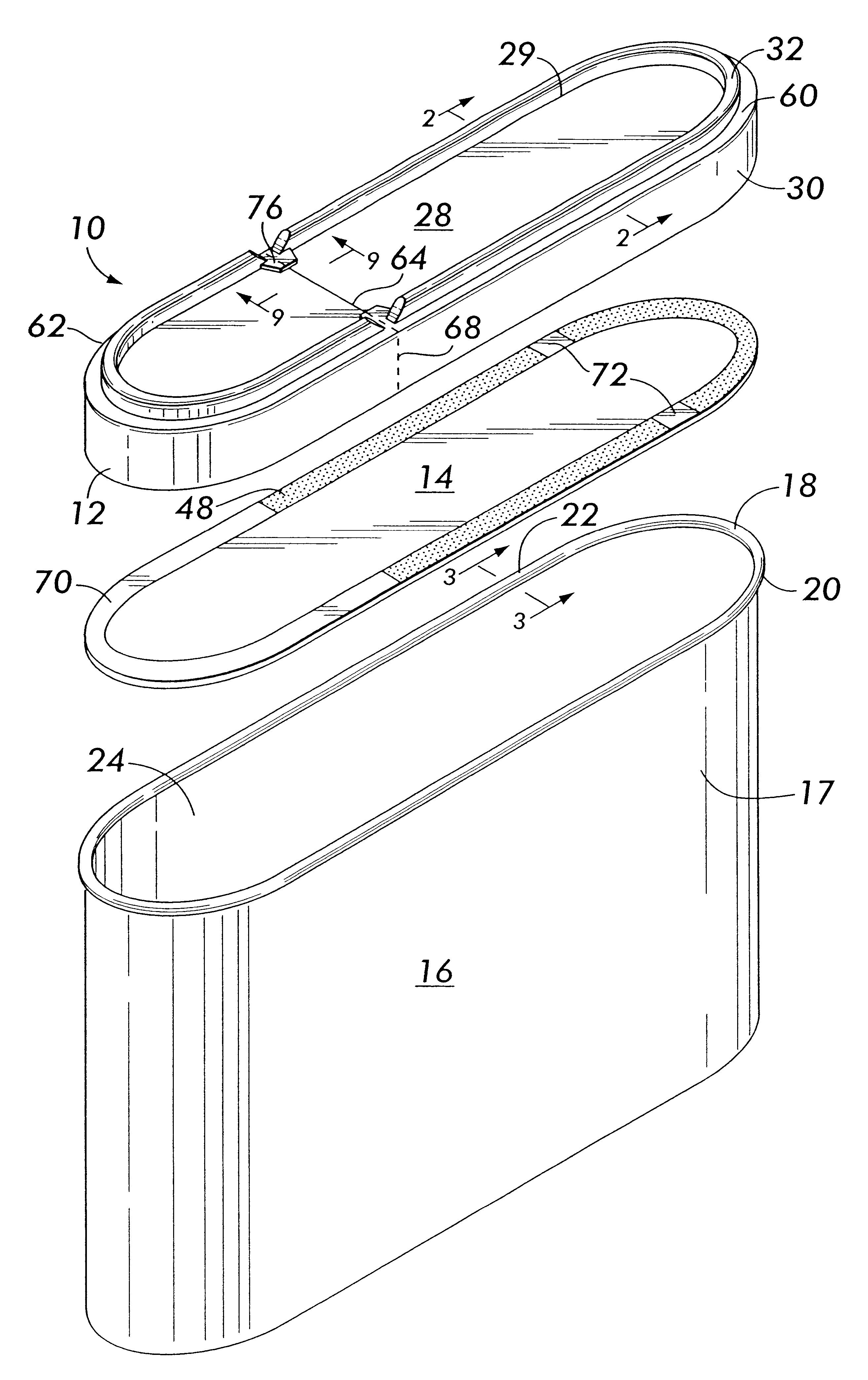

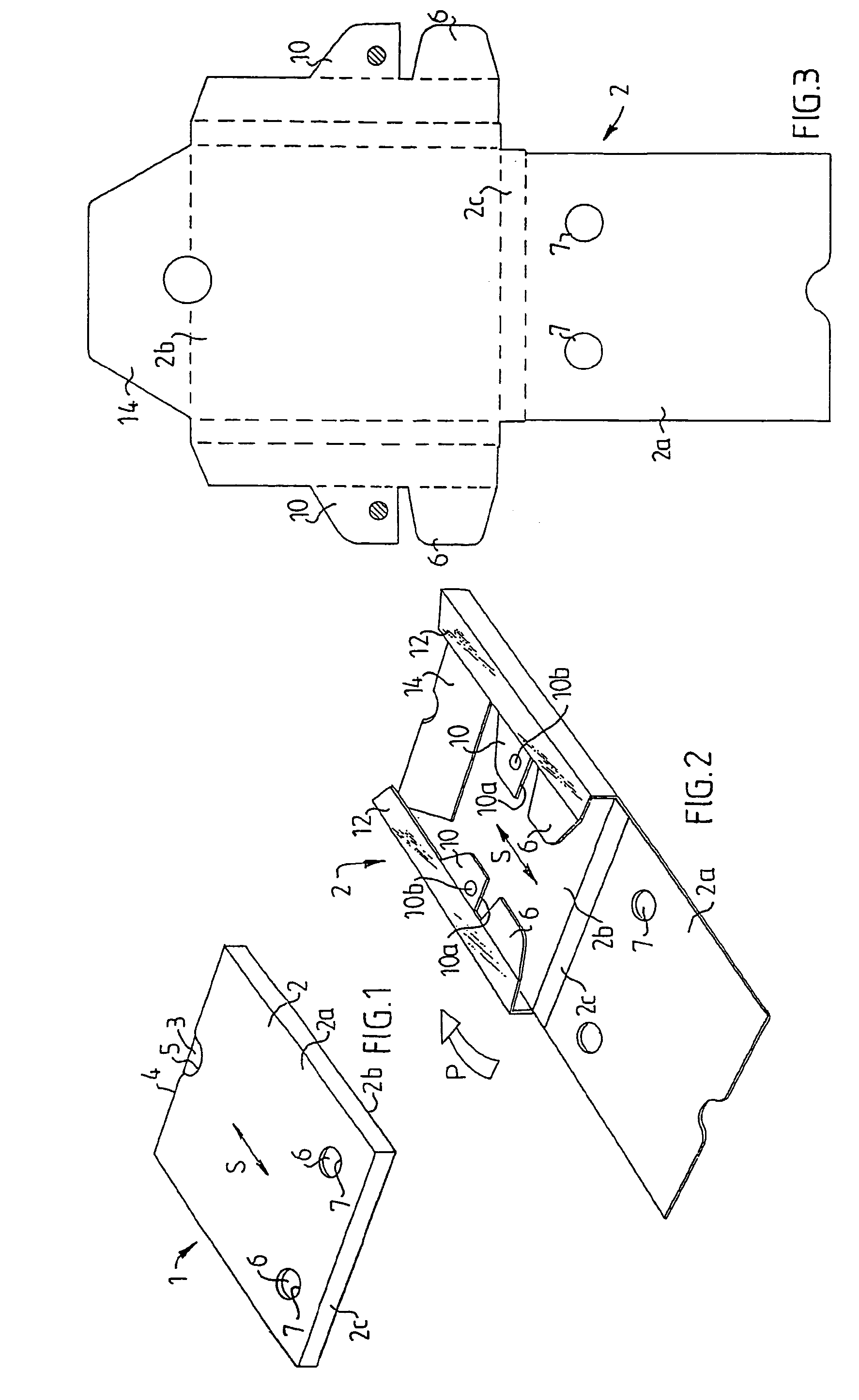

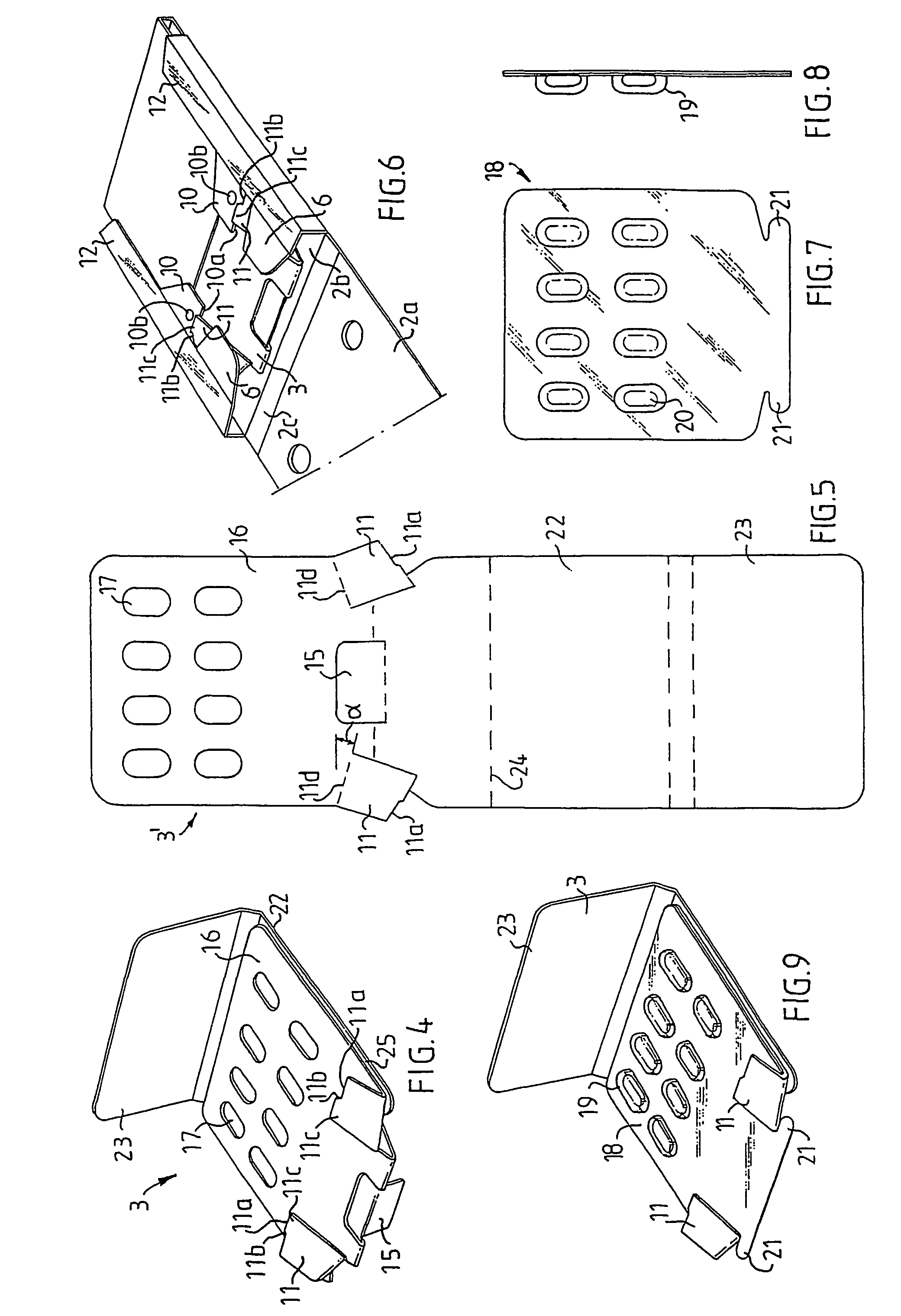

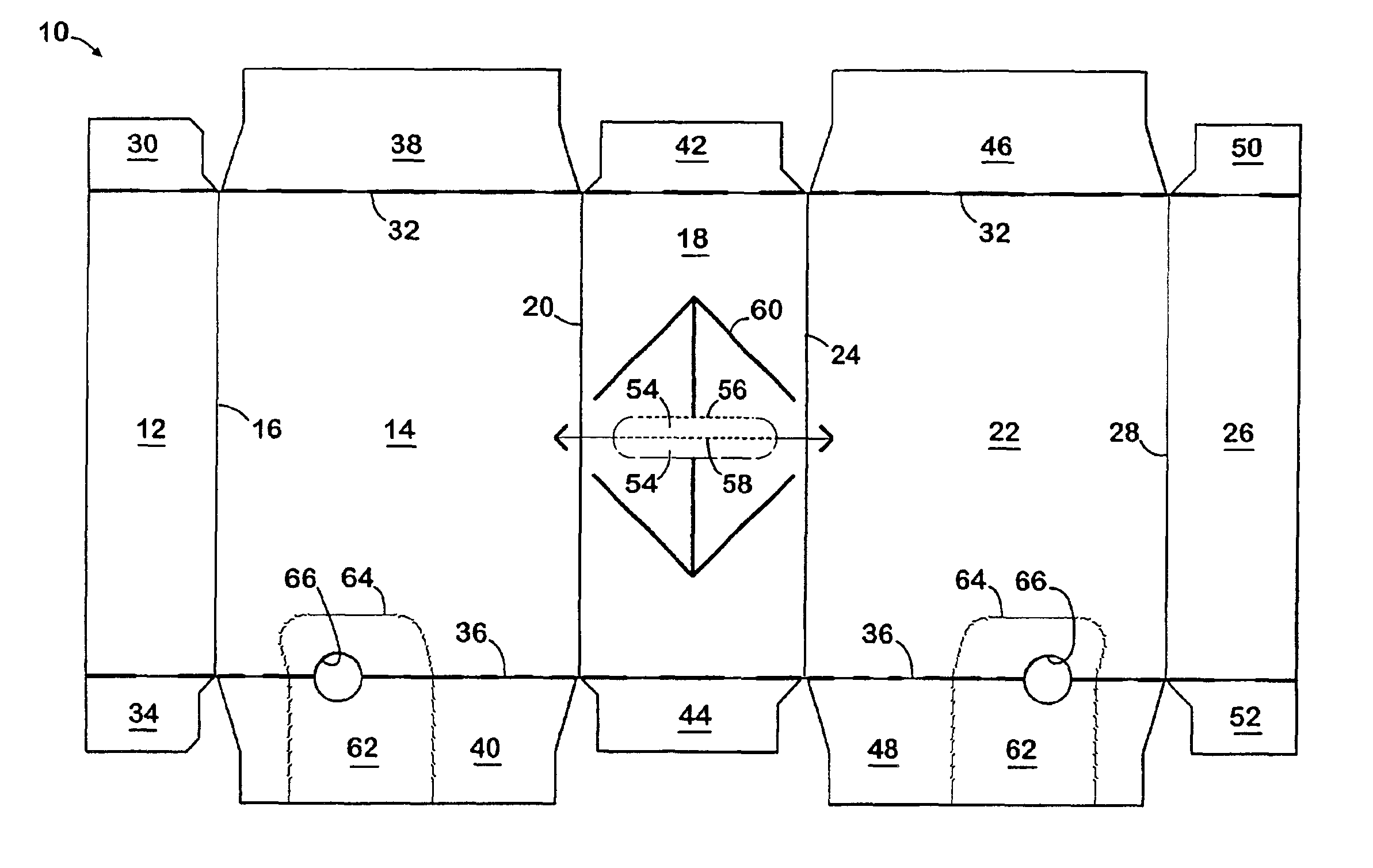

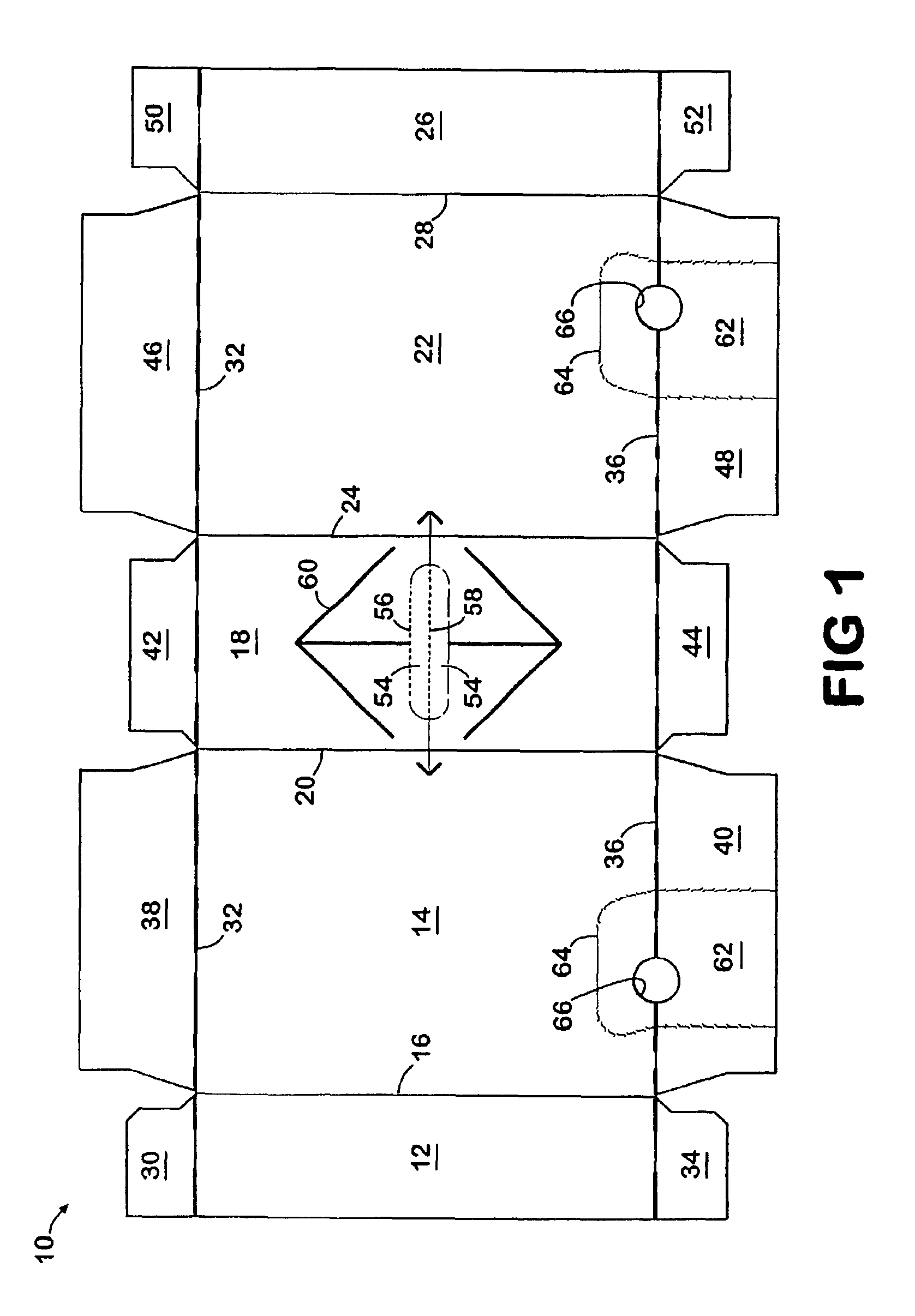

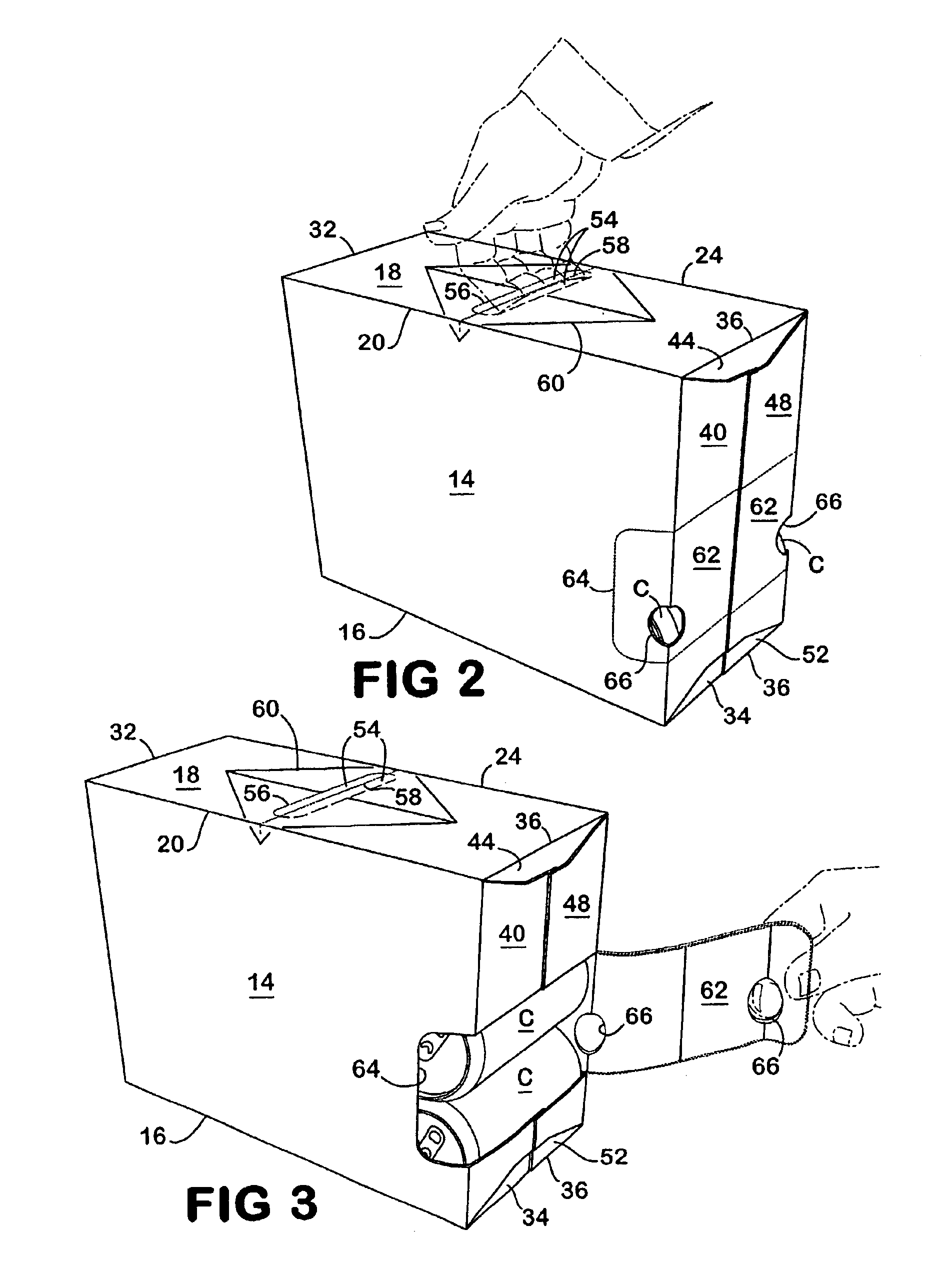

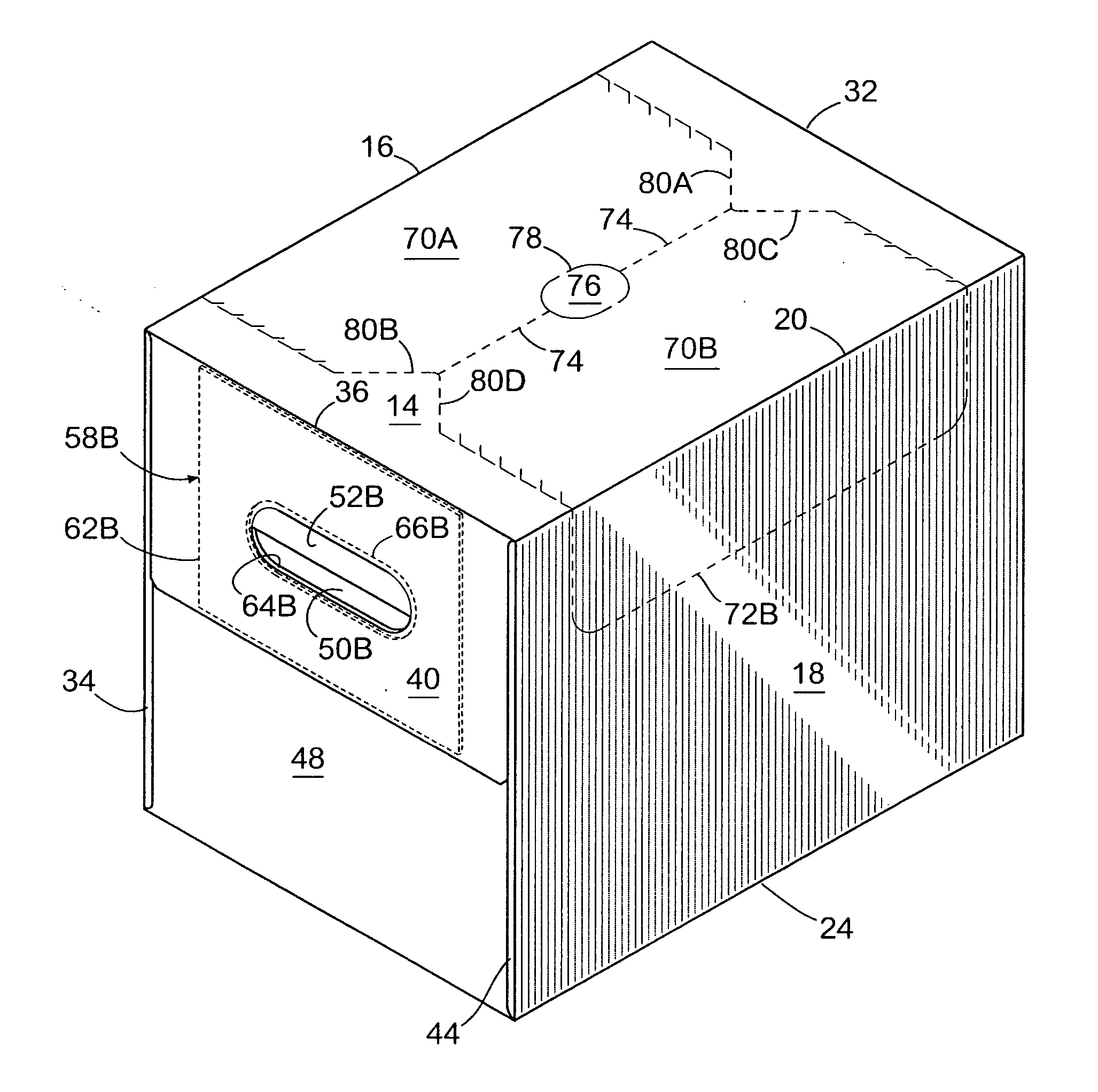

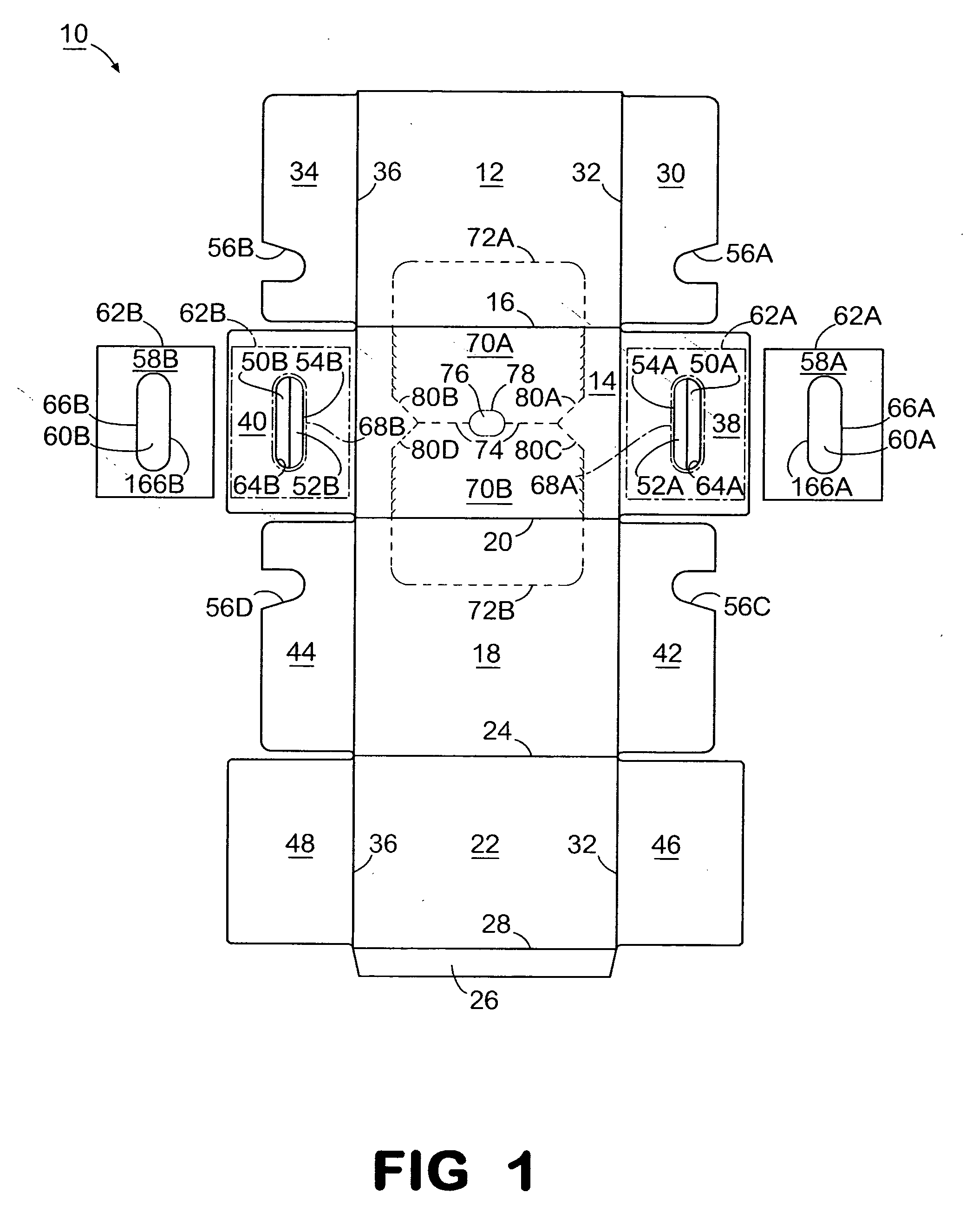

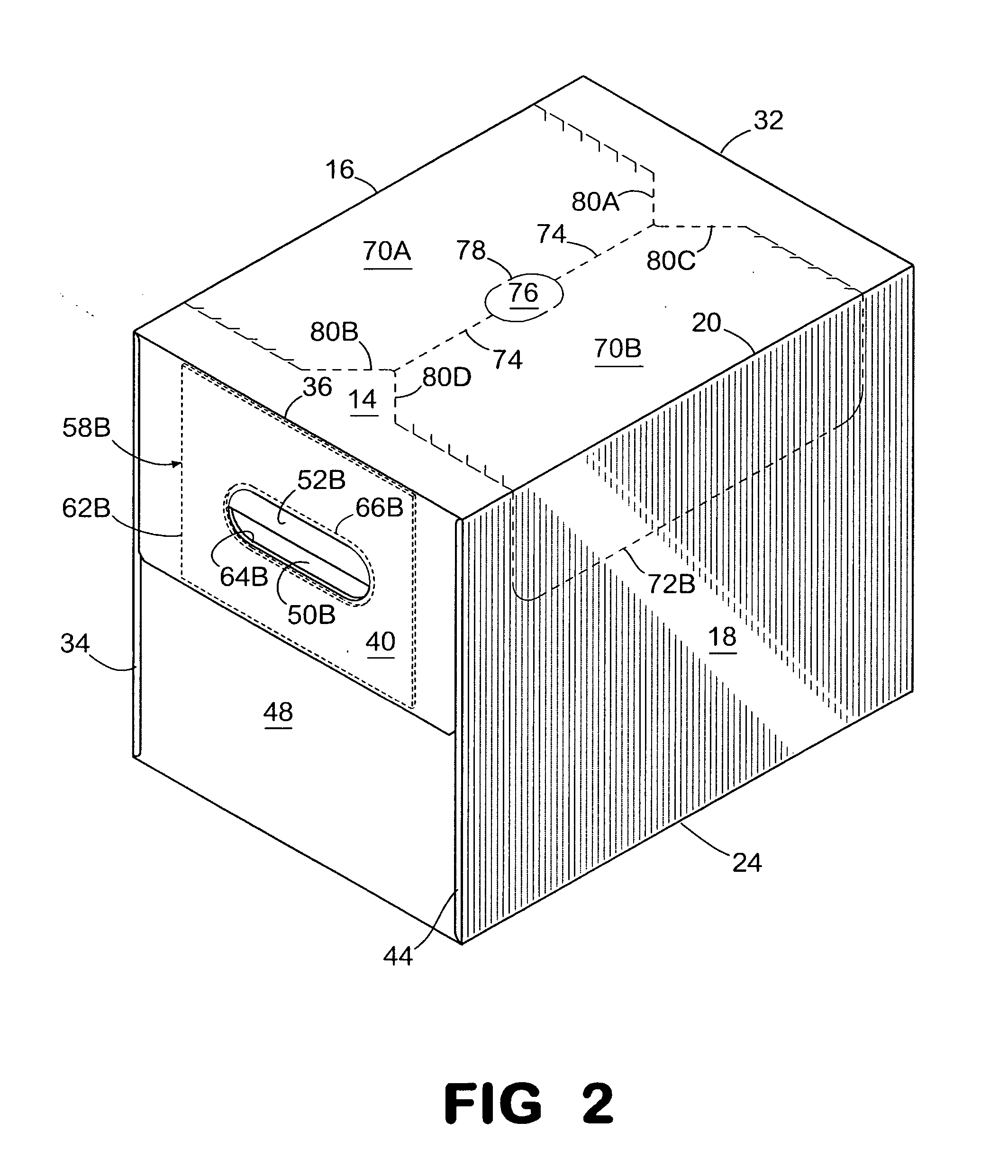

Handle and top handle reinforcement for a paperboard carton

A fully enclosed carton for carrying heavy loads with a reinforcement insert for the handle apertures located in the top end flaps of the carton. The paperboard reinforcing insert may be extended as a bridge across the top panel of the carton to prevent tearing of the handle apertures in the top end flaps and also tearing in the top panel of the carton when carrying a heavy load. The carton may have one or more dispensers in the top panel which may extend into an adjoining side panel. Multiple tear lines may be formed for the dispenser flap in the insert that extends across the top panel to permit easy access to the containers, such as bottles, in the carton.The paperboard reinforcing insert may have a larger aperture than the handle aperture in each top end flap to adjust for any imprecision in the alignment of the paperboard insert in forming the carton sleeve from the paperboard blank. When the paperboard insert extends across the top panel and one or more dispensers are formed in the top panel, multiple tear lines may be used to form the flaps in the insert to compensate for any imprecision in the insertion of the insert that extends across the top panel into the carton sleeve when it is being formed.

Owner:GRAPHIC PACKAGING INT

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS6919111B2Quality improvementImprove insulation performanceNon-fibrous pulp additionWrappersPaperboardEngineering

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. per 3000 square feet and, at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inches, has a GM Taber stiffness of at least about 0.00246 w2.63 grams-centimeter / fiber mat density1.63, and a GM tensile stiffness of at least about 615+13.18 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Sheets having a starch-based binding matrix

Compositions and methods for manufacturing sheets having a starch-bound matrix, optionally reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, a cellulosic ether, optionally fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the cellulosic ether to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and cellulosic ether form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

Compositions used in manufacturing articles having an inorganically filled organic polymer matrix

InactiveUS6090195AReadily and inexpensively mass producedHigh strengthClosure lidsWrappersFiberPolymer science

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more aggregate materials, fibers, and optional admixtures in the correct proportions in order to form an article which has the desired performance criteria. The inorganically filled mixtures are molded to fashion a portion of the mixture into a form stable shape for the desired article. Once the article has obtained form stability, such as by heating to remove water by evaporation, the article is removed from the mold and allowed to harden to gain strength. The articles may have properties substantially similar to articles presently made from traditional materials like paper, paperboard, polystyrene, plastic, or metal. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

Compositions and methods for manufacturing starch-based sheets

Compositions and methods for manufacturing sheets having a starch-bound matrix reinforced with fibers and optionally including an inorganic mineral filler. Suitable mixtures for forming the sheets are prepared by mixing together water, unmodified and ungelatinized starch granules, an auxiliary water-dispersible organic polymer, fibers, and optionally an inorganic mineral filler in the correct proportions to form a sheet having desired properties. The mixtures are formed into sheets by passing them between one or more sets of heated rollers to form green sheets. The heated rollers cause the auxiliary polymer to form a skin on the outer surfaces of the sheet that prevents the starch granules from causing the sheet to adhere to the rollers upon gelation of the starch. The green sheets are passed between heated rollers to gelatinize the starch granules, and then to dry the sheet by removing a substantial portion of the water by evaporation. The starch and auxiliary polymer form the binding matrix of the sheets with the fibers and optional inorganic filler dispersed throughout the binding matrix. The starch-bound sheets can be cut, rolled, pressed, scored, perforated, folded, and glued to fashion articles from the sheets much like paper or paperboard. The sheets are particularly useful in the mass production of containers, such as food and beverage containers.

Owner:E KHASHOGGI INDS

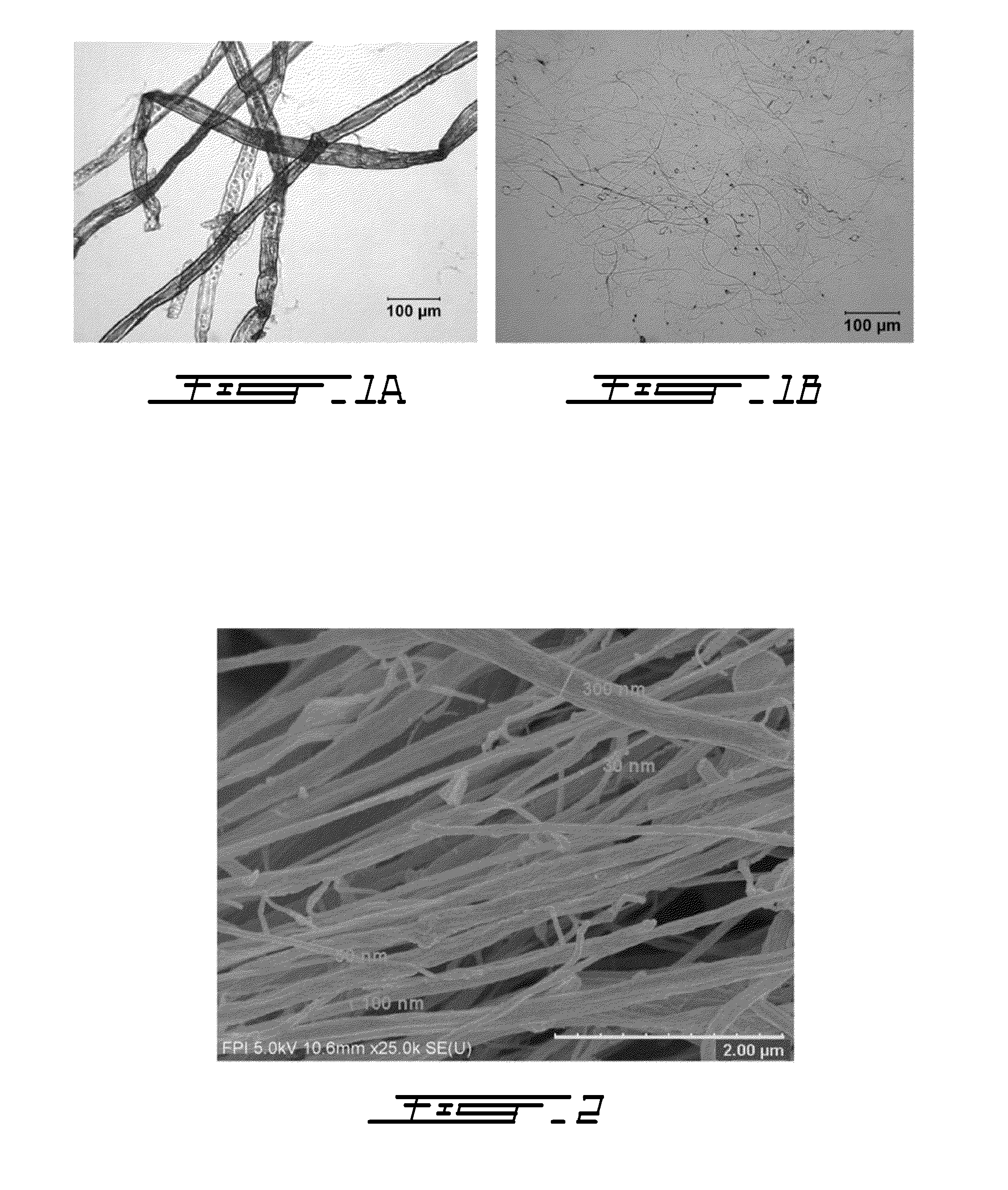

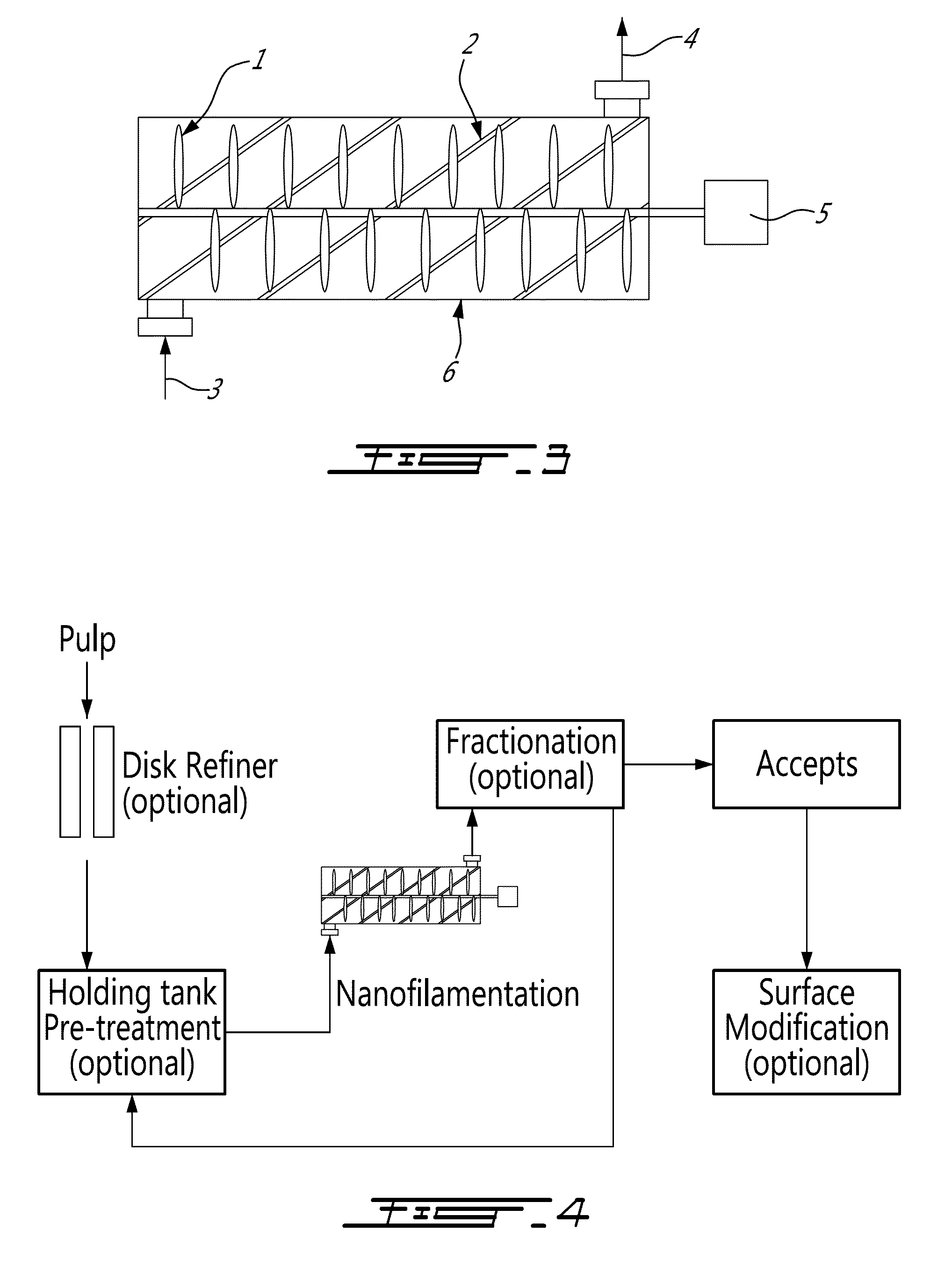

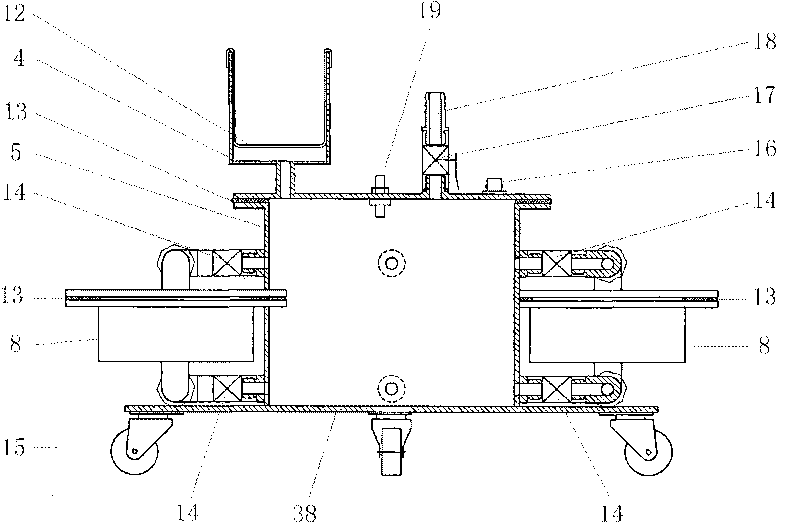

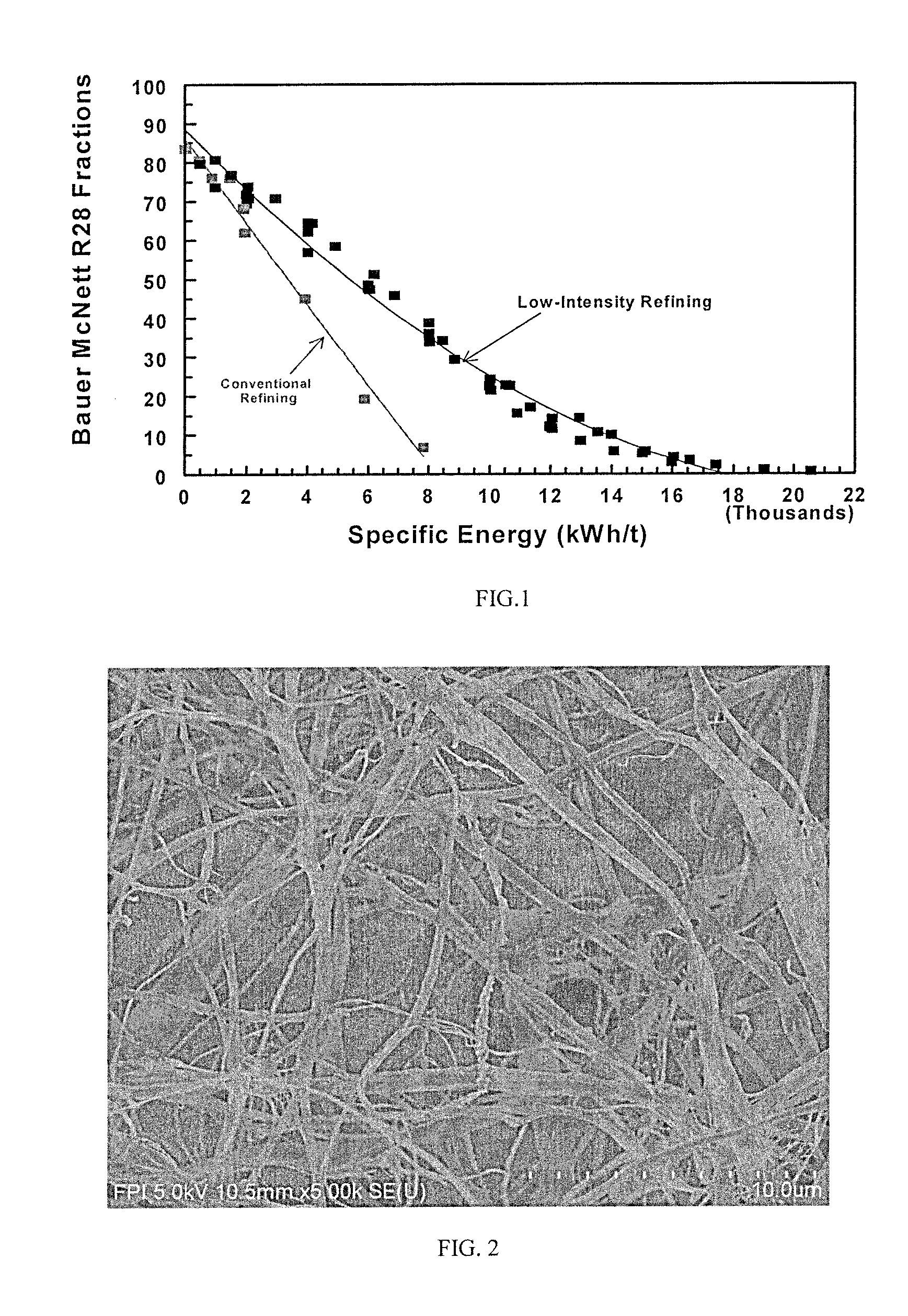

Cellulose nanofilaments and method to produce same

ActiveUS20110277947A1Improve strength propertiesMaterial nanotechnologyNatural cellulose pulp/paperPolymer sciencePaperboard

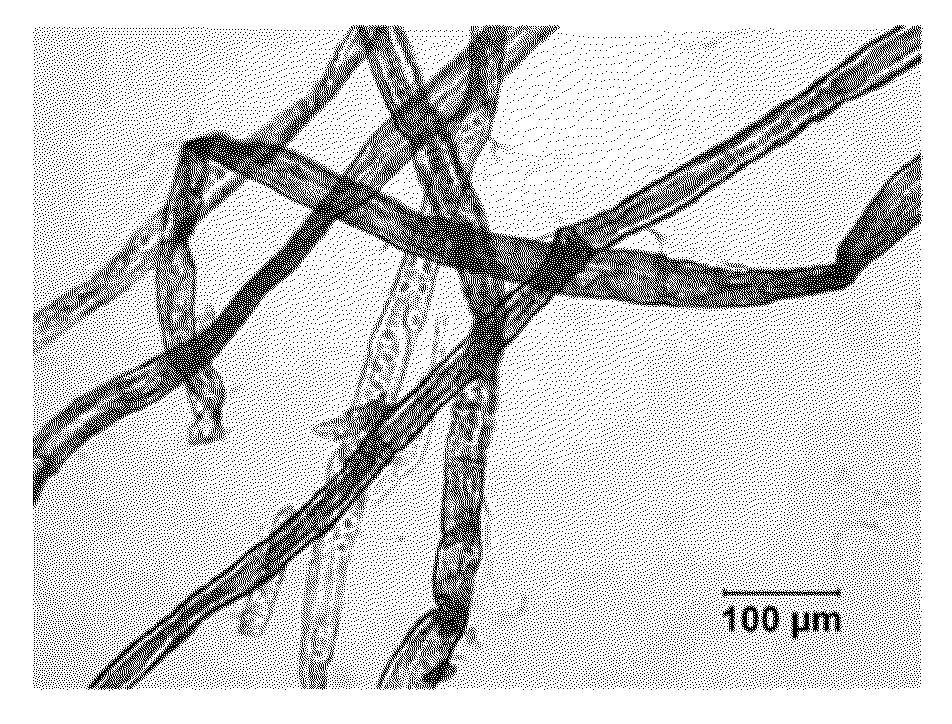

Cellulose nanofilaments from cellulose fibers, a method and a device to produce them are disclosed. The nanofilaments are fine filaments with widths in the sub-micron range and lengths up to a couple of millimeters. These nanofilaments are made from natural fibers from wood and other plants. The surface of the nanofilaments can be modified to carry anionic, cationic, polar, hydrophobic or other functional groups. Addition of these nanofilaments to papermaking furnishes substantially improves the wet-web strength and dry sheet strength much better than existing natural and synthetic polymers. The cellulose nanofilaments produced by the present invention are excellent additives for reinforcement of paper and paperboard products and composite materials, and can be used to produce superabsorbent materials.

Owner:FPINNOVATIONS INC

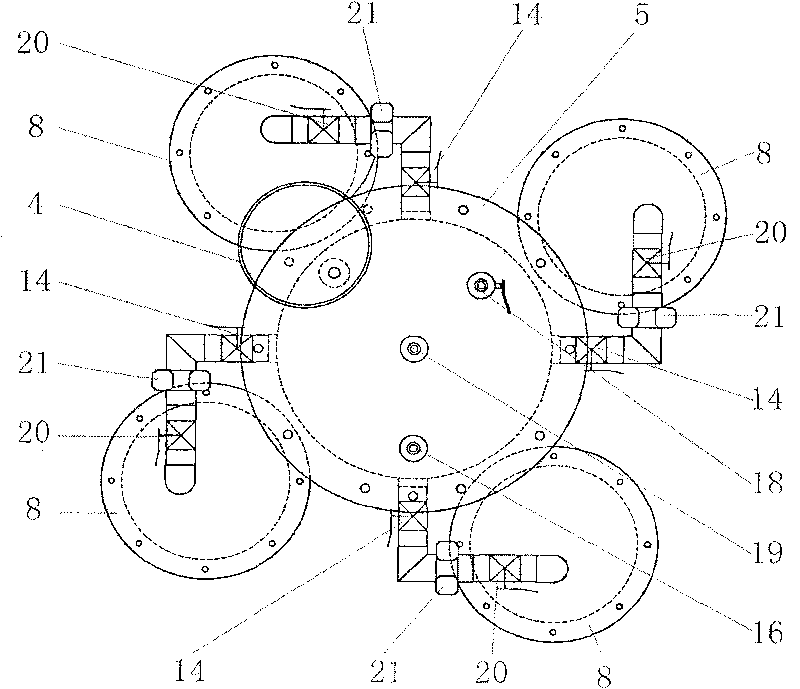

Experimental device and experimental method for transformer oilpaper insulating thermal ageing

InactiveCN101713721AWeighing by removing componentWeather/light/corrosion resistanceThermal ageingElectricity

Owner:XI AN JIAOTONG UNIV

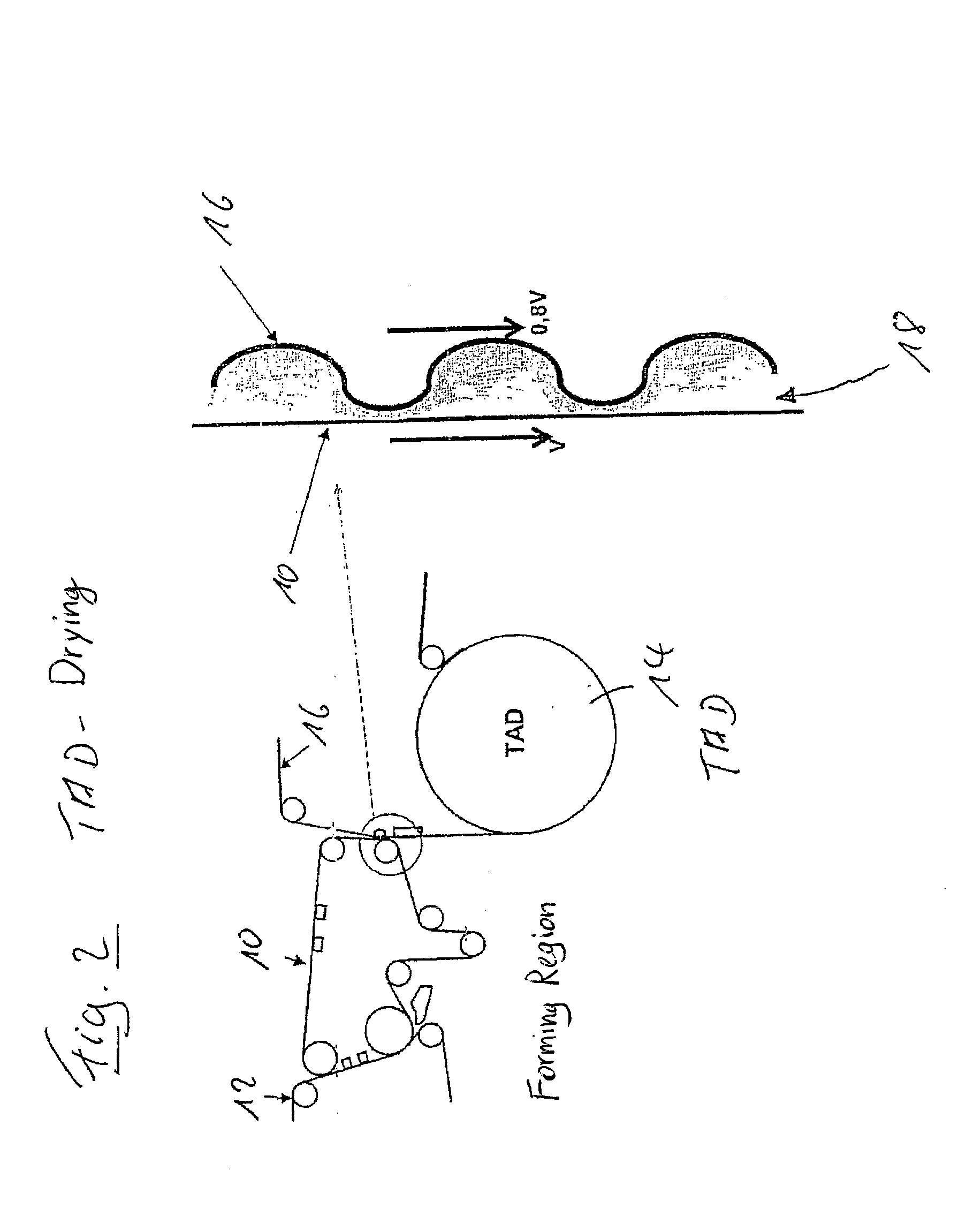

Paper or paperboard substrate, a process for production of the substrate and a package formed of the substrate

The present invention relates to a paper or paperboard substrate having barrier properties which substrate comprises a first fiber based layer, a second layer comprising microfibrillated cellulose and a third layer comprising a polymer. The invention further relates to a process for the production of said substrate and a package formed of said substrate.

Owner:STORA ENSO OYJ

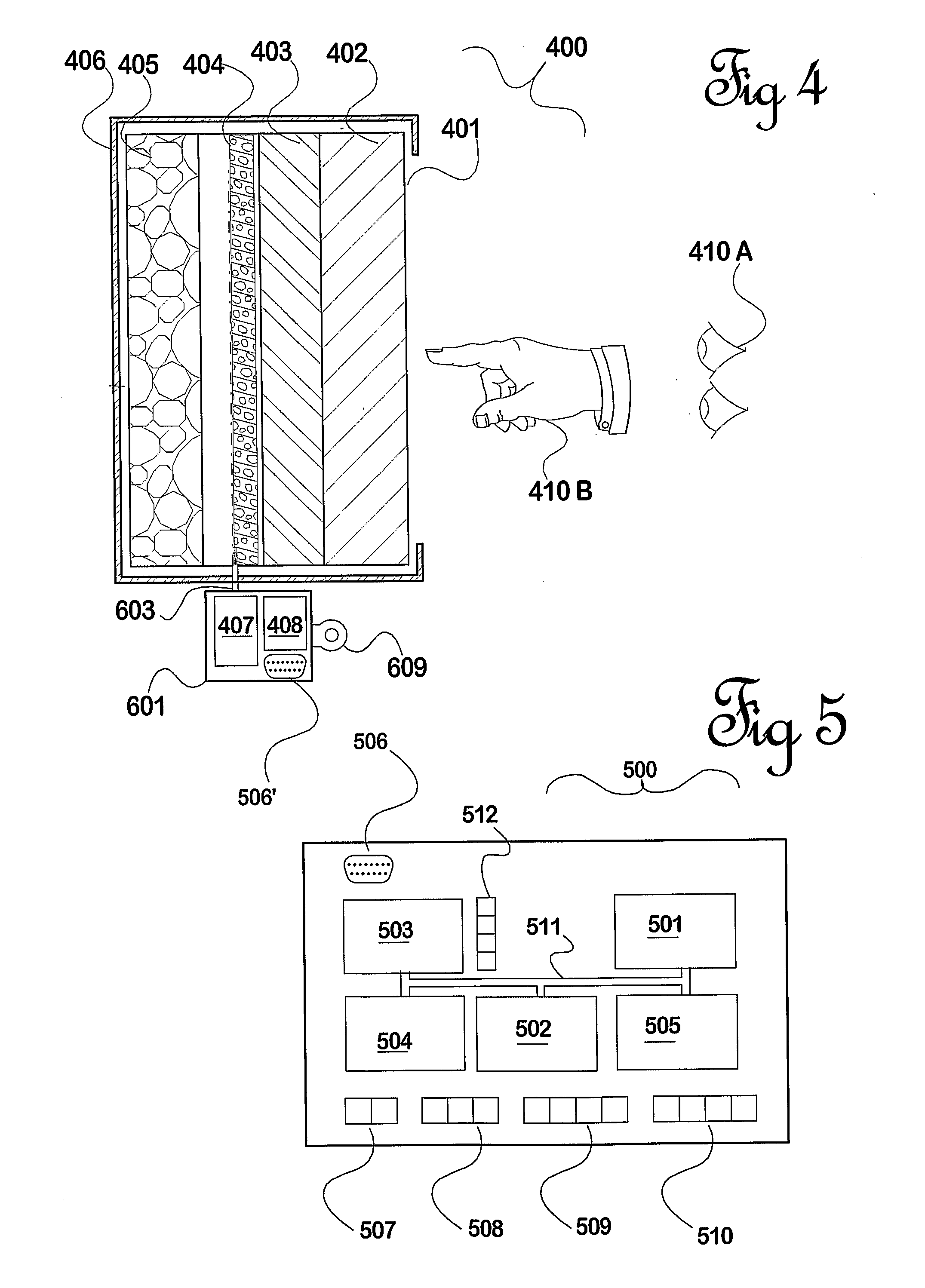

Apparatus and Method for Proximity-Responsive Display Materials

InactiveUS20080238706A1Easy to replaceEasy to modifyElectric/electromagnetic visible signallingElectronic switchingProximity sensorComputer graphics (images)

Apparatus and a method for causing a printed display (poster, placard or promotional flier) to become interactive when a person points to part of the display. Behind the display a customised layout of capacitative proximity sensors printed with conductive inks on to a low-cost disposable, replaceable substrate (paper, plastic, cardboard) in alignment with visually significant features of the display is connected to proximity-sensing circuitry. Audio-visual or multimedia responses using pre-recorded or synthesised information are reproduced in event of a selection.

Owner:KENWRIGHT DAVID NORRIS

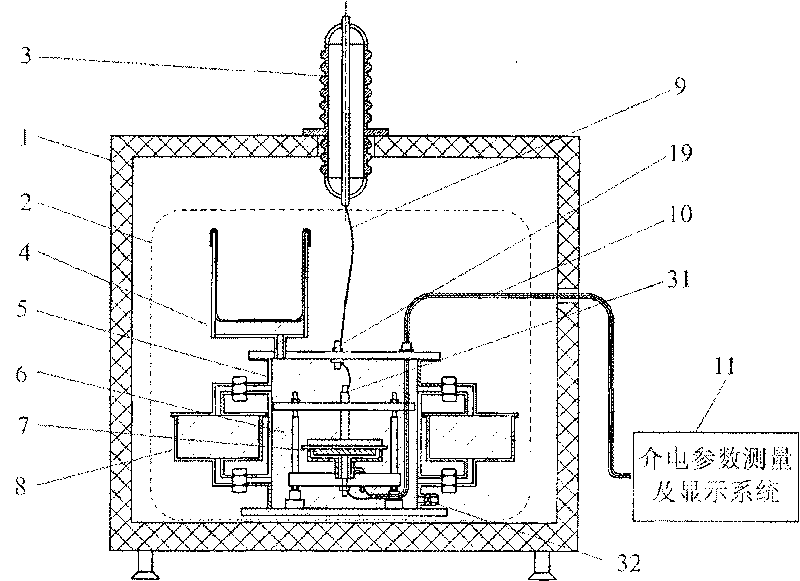

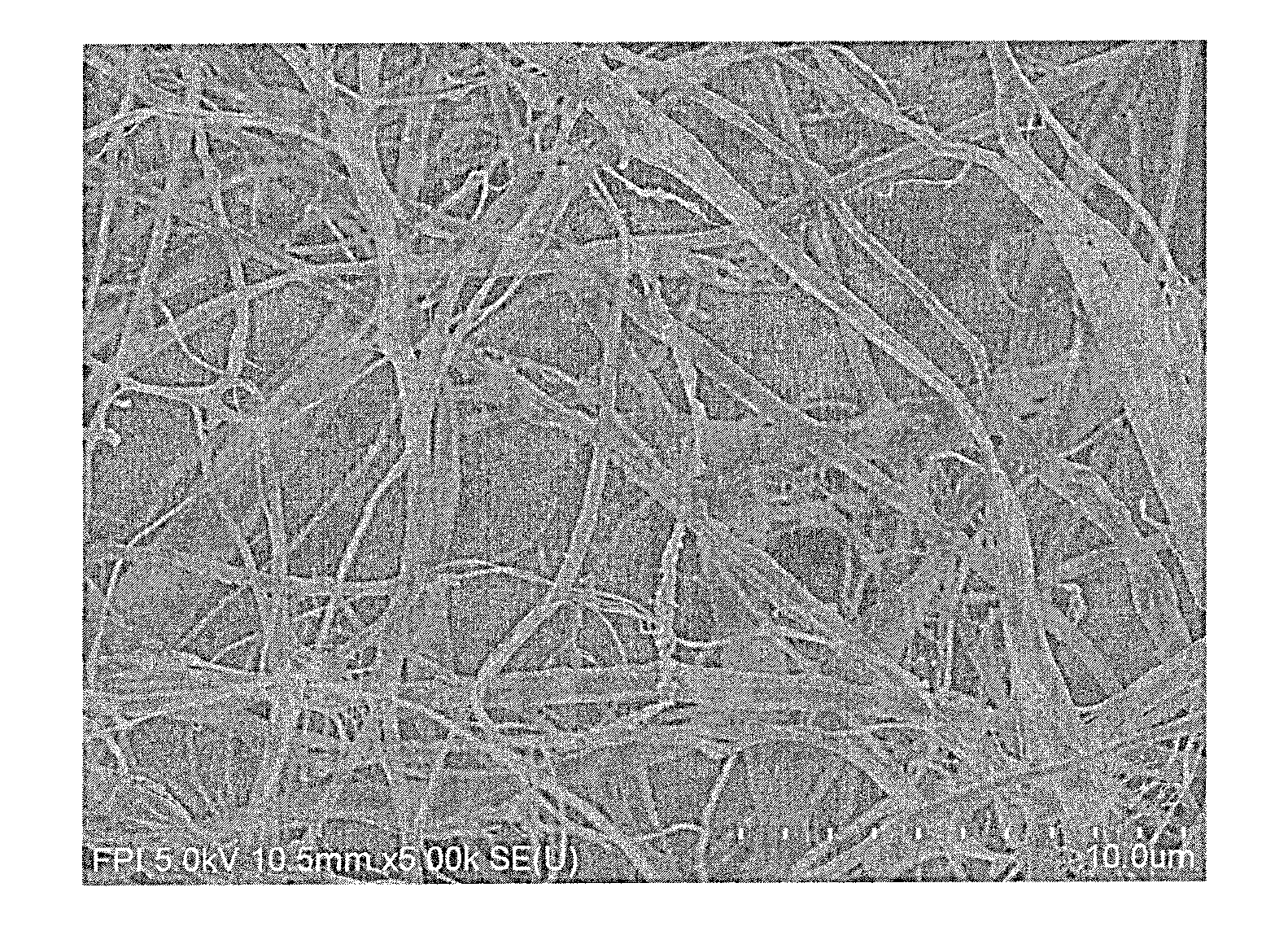

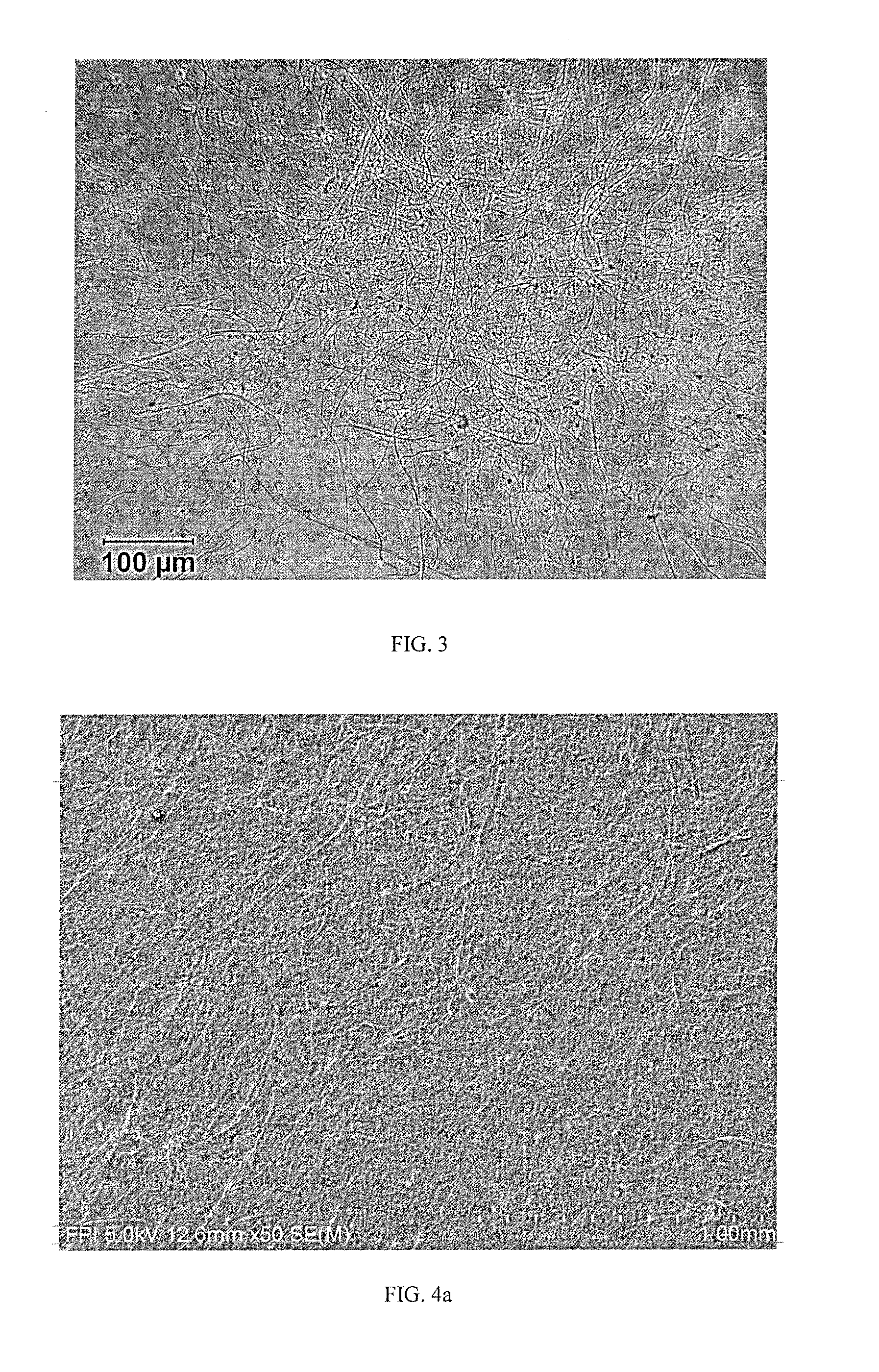

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

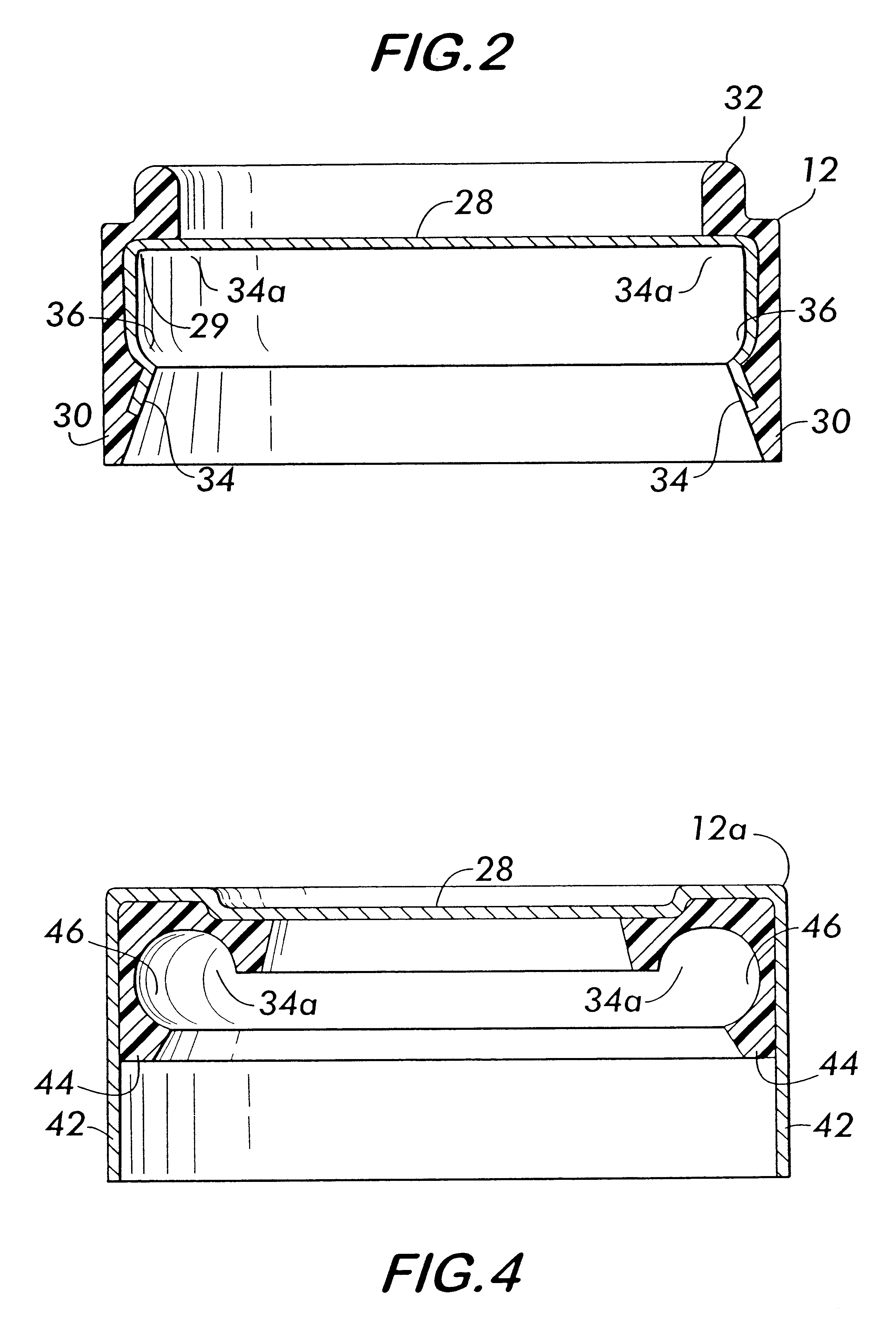

Stackable hinged container lid having detents

A lid and a container using the lid are disclosed, the lid having a central panel of paperboard with a resilient plastic skirt joined about its perimeter. A metal foil membrane having heat activated adhesive layers is attached to the lid and the rim of the container by inductive heating. Detents project from an inside surface of the skirt and cooperate with the rim on the container to hold the lid in an open position. A stacking lip extends from the skirt and interfits within an identical lid to allow the lids to be stacked for shipment. A hinge extends transversely across the central panel and divides the lid into movable and fixed portions. Weakened regions on the skirt separate when the lid is opened and provide evidence of potential tampering.

Owner:DOUBLE H PLASTICS

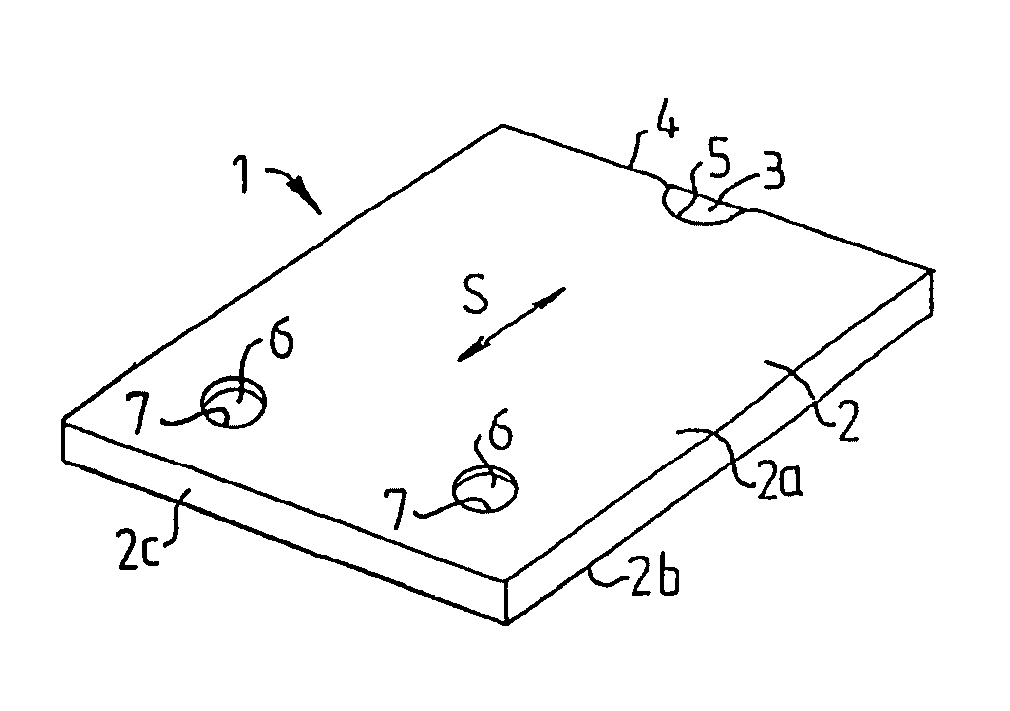

Child resistant package with slidable tray section

InactiveUS7090079B2Reliable lockingEasy to manufactureSmall article dispensingPharmaceutical containersCardboardEngineering

A package made of cardboard, includes a sleeve and an insert, the sleeve being provided with at least one catch tab located on the inside of the sleeve and provided with at least one projection, so that the catch tab forms an angle with the upper wall of the sleeve. At least one locking tab is provided on the insert, which is arranged so as to be at least in part inserted between the catch tab and the upper wall. At least one operating tab is provided, in addition to which the sleeve is provided with at least one cutout next to the operating tab, the operating tab being arranged so as to be pressed by a user against the locking tab, movement of the insert in the sliding direction (S) towards the opening being made possible.

Owner:STORA ENSO AB

Oxygen-scavenging filled polymer blend for food packaging applications

InactiveUS6037022AOxygen transmission propertyLow oxygenDomestic containersThin material handlingPaperboardFood packaging

The specification discloses a polymer blend especially well-suited for coating paperboard substrates used in food packaging, particularly acidic or acid-generating foods such as fruit and vegetable juices. The blend contains an acid-activatable oxygen scavenger dispersed in a film-forming synthetic polymer such as an EVOH copolymer. When placed as a film or layer on the side of the substrate inside the container in contact with the food the blend is effective to reduce the oxygen in the container over time to a very low concentration, replacing the same with carbon dioxide, for an excellent preservative effect.

Owner:INT PAPER CO

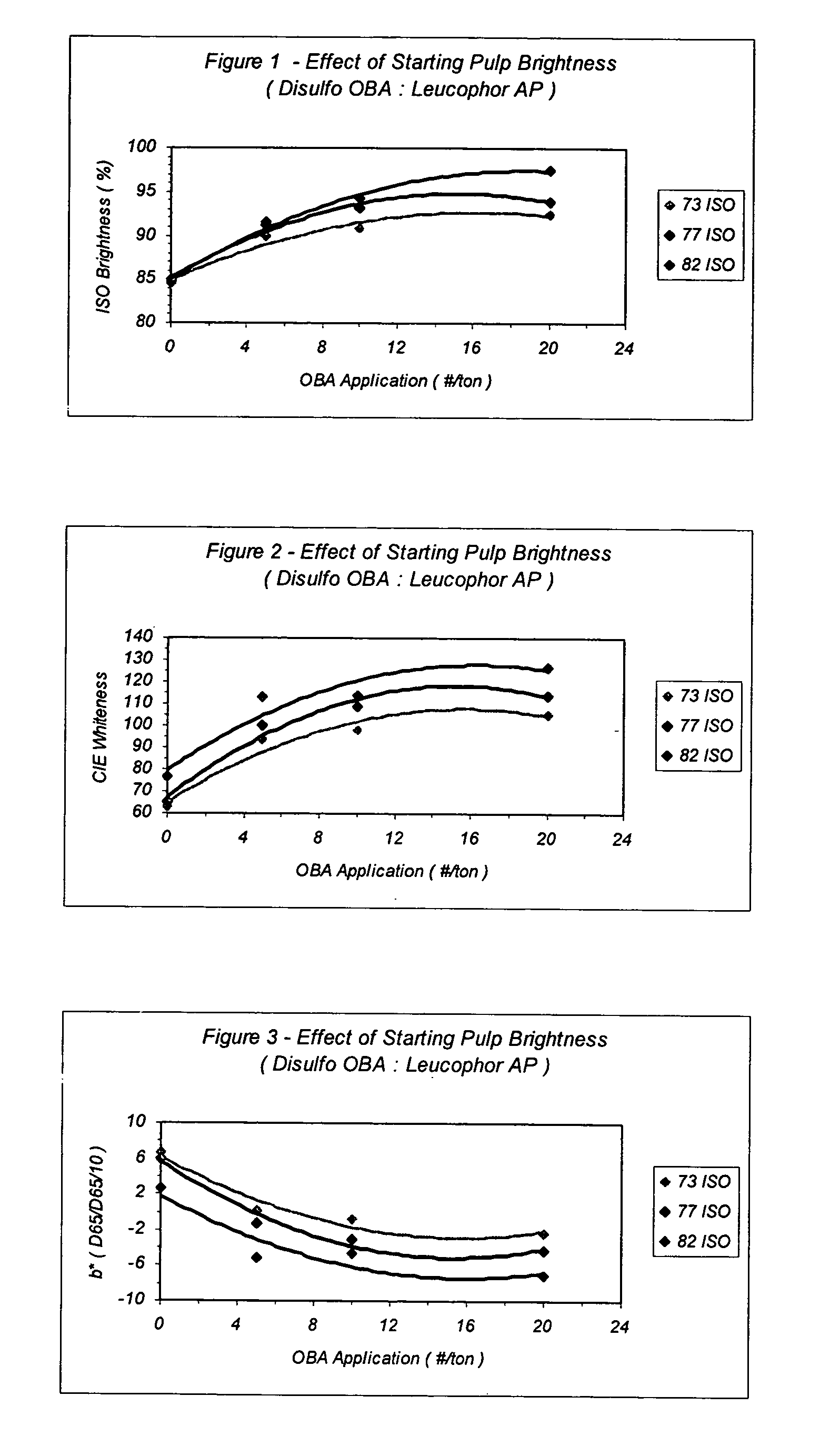

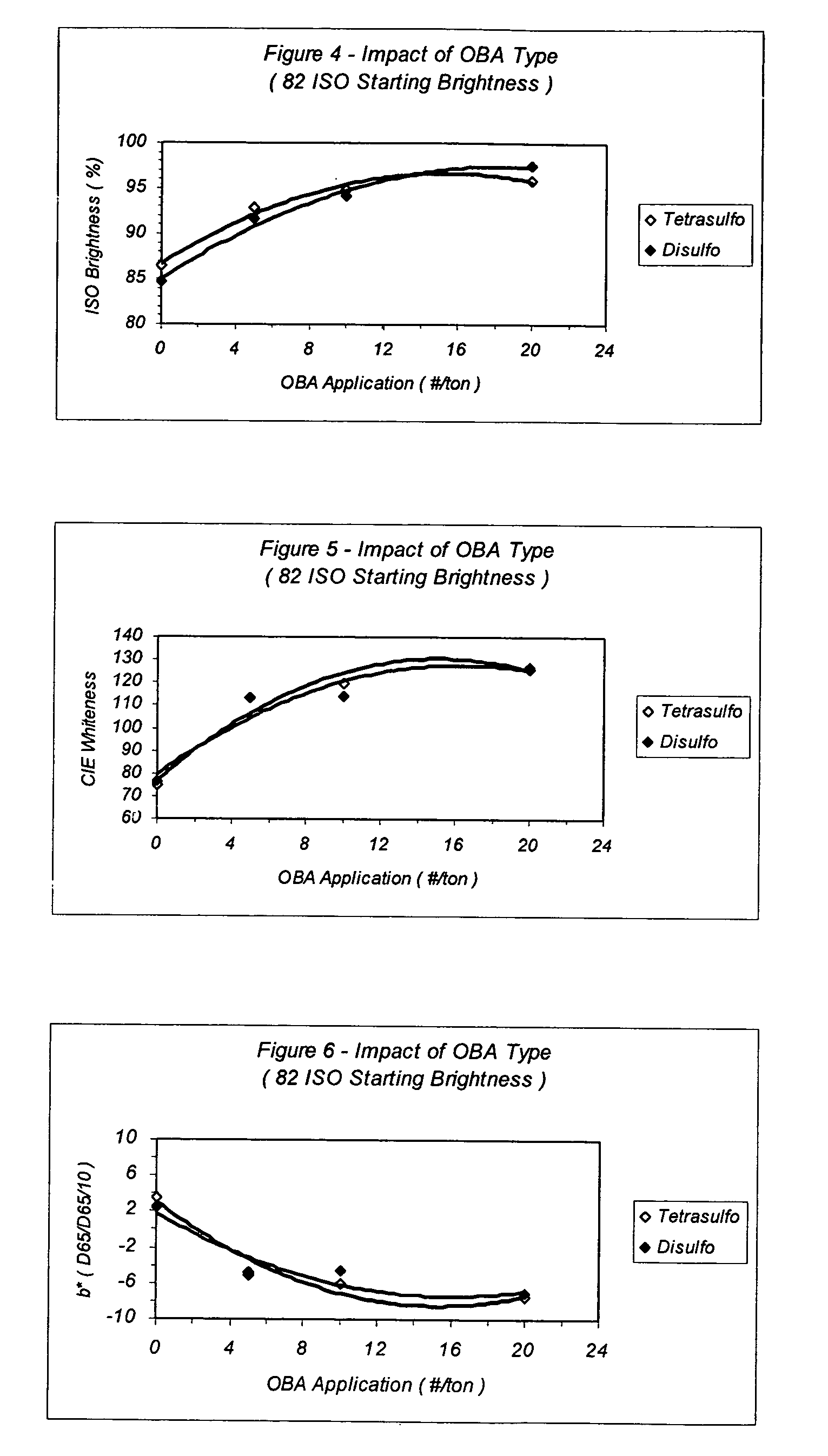

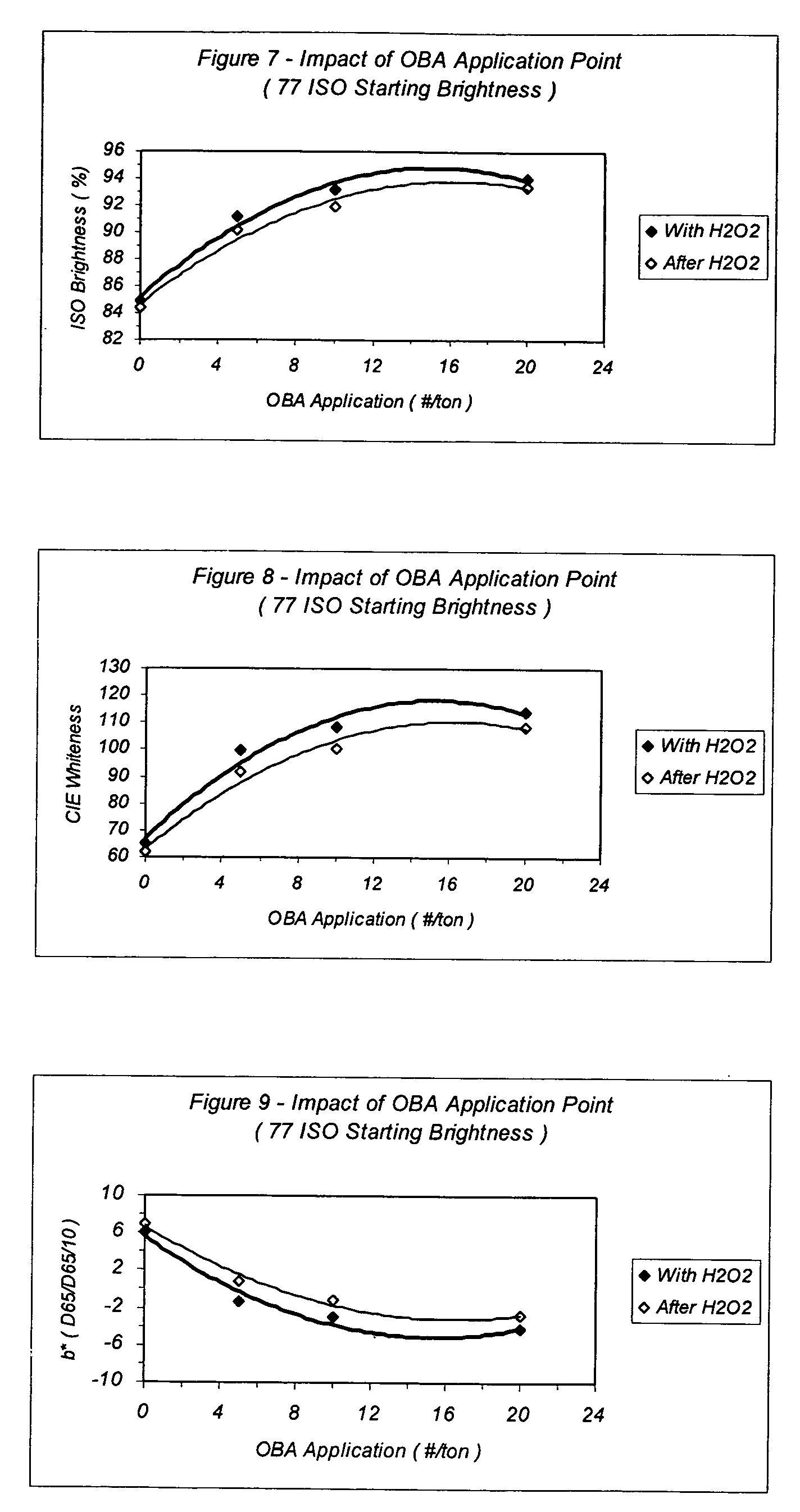

Process for manufacturing pulp, paper and paperboard products

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

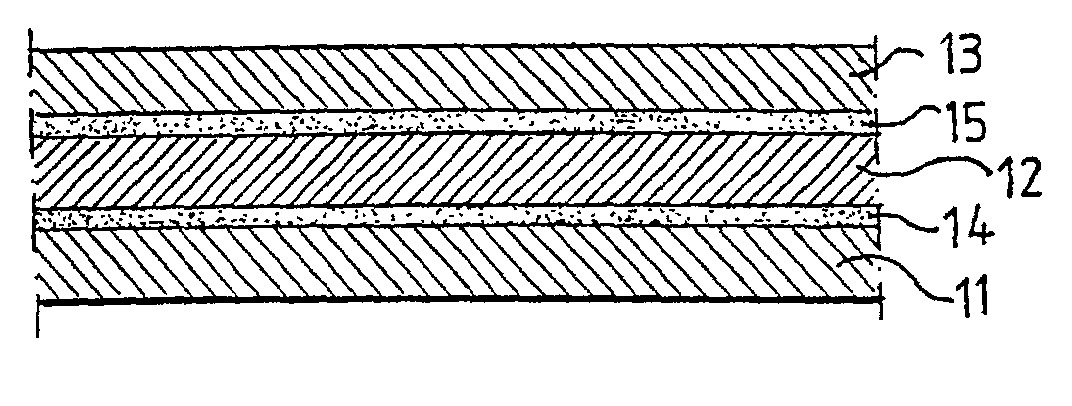

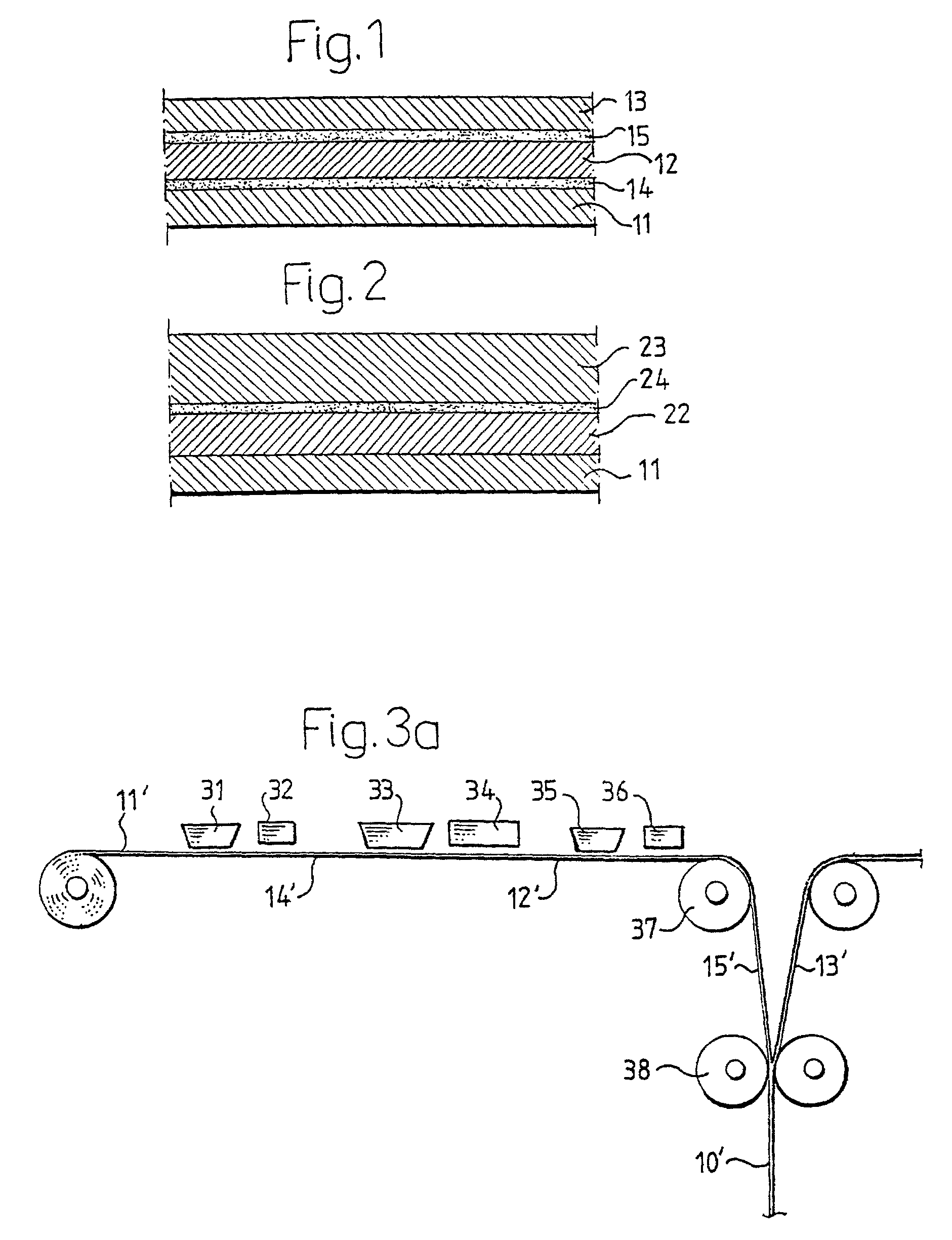

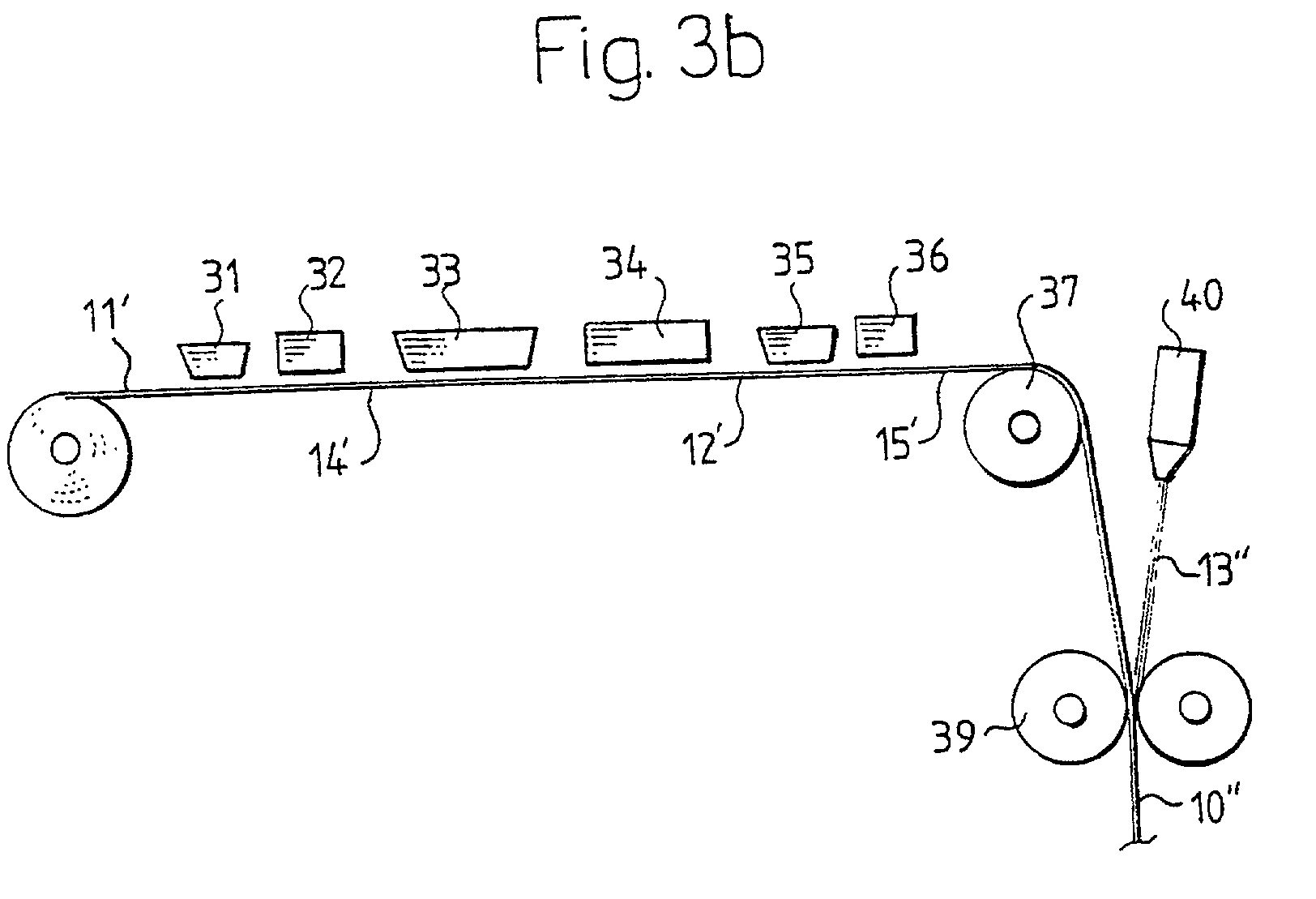

Biodegradable packaging laminate, a method of producing the packaging laminate, and packaging containers produced from the packaging laminate

InactiveUS20020127358A1Improve adhesionExcellent gas barrier performanceAdhesive processesLiquid surface applicatorsLactideBiopolymer

Packaging laminate for packages for liquid foods having excellent liquid and oxygen gas barrier properties in which all included layers are biodegradable. The packaging laminate includes at least one liquidtight layer (11, 13) of homo or copolymers of monomers selected from a group consisting of lactic acid, glycol acid, lactide, glycolide, hydroxy butyric acid, hydroxy valeric acid, hydroxy caproic acid, valerolactone, butyrolactone and caprolactone, as well as an oxygen gas barrier layer (12) of ethylene vinyl alcohol, polyvinyl alcohol, starch or starch derivatives. The oxygen gas barrier layer is preferably applied by a dispersion coating process. The layers may be laminated directly to one another or indirectly by means of interjacent adhesive layers. The packaging laminate may also include a core layer of, for example, paper or paperboard, or a biopolymer. The invention also realises a method of producing the biodegradable packaging laminate according to the invention.

Owner:TETRA LAVAL HLDG & FINANCE SA

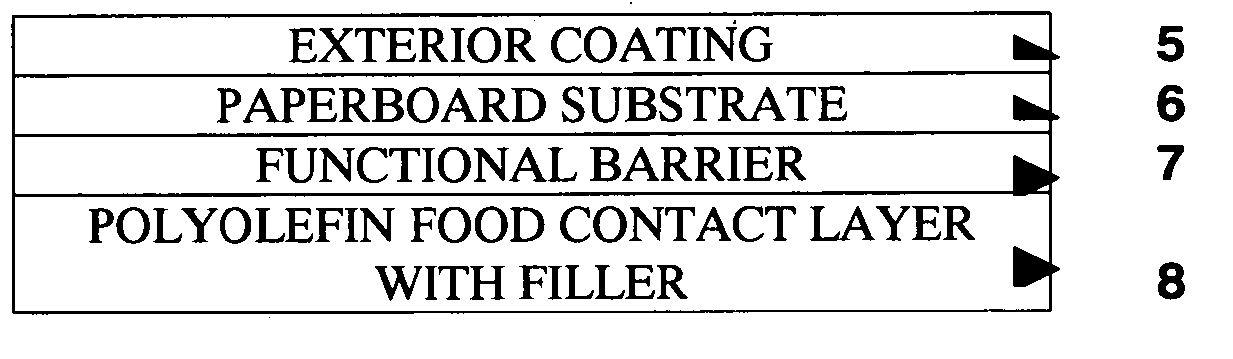

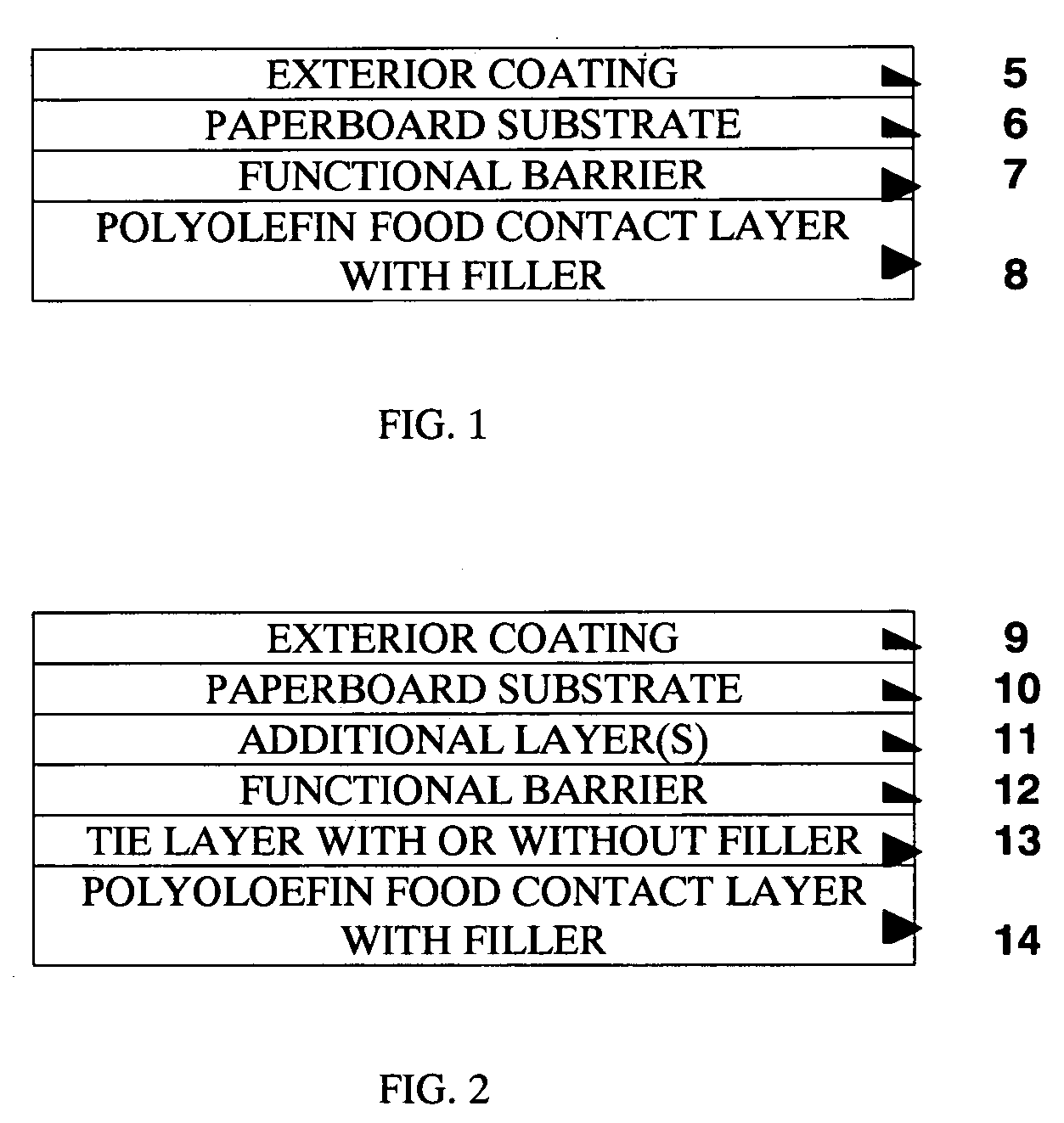

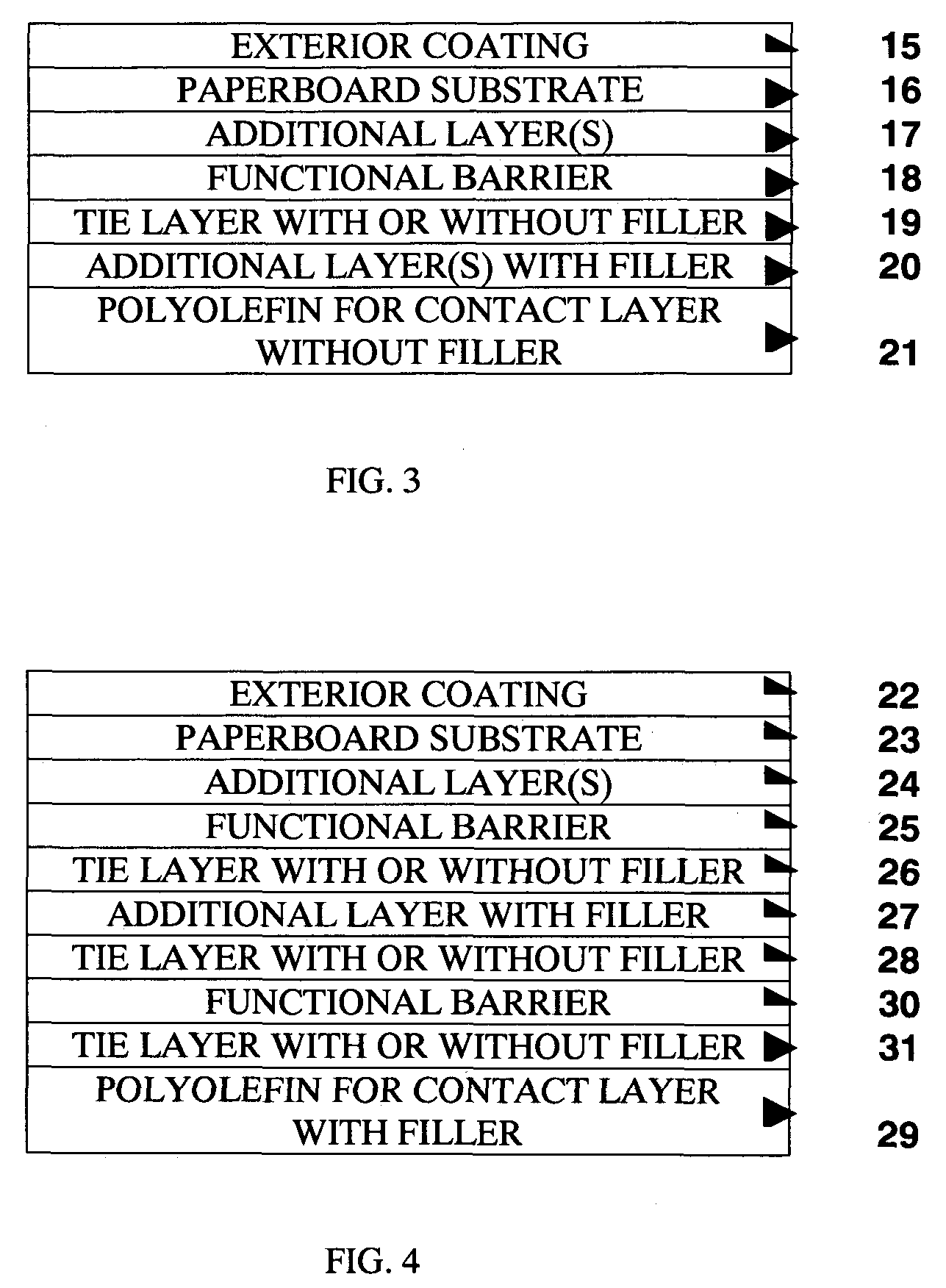

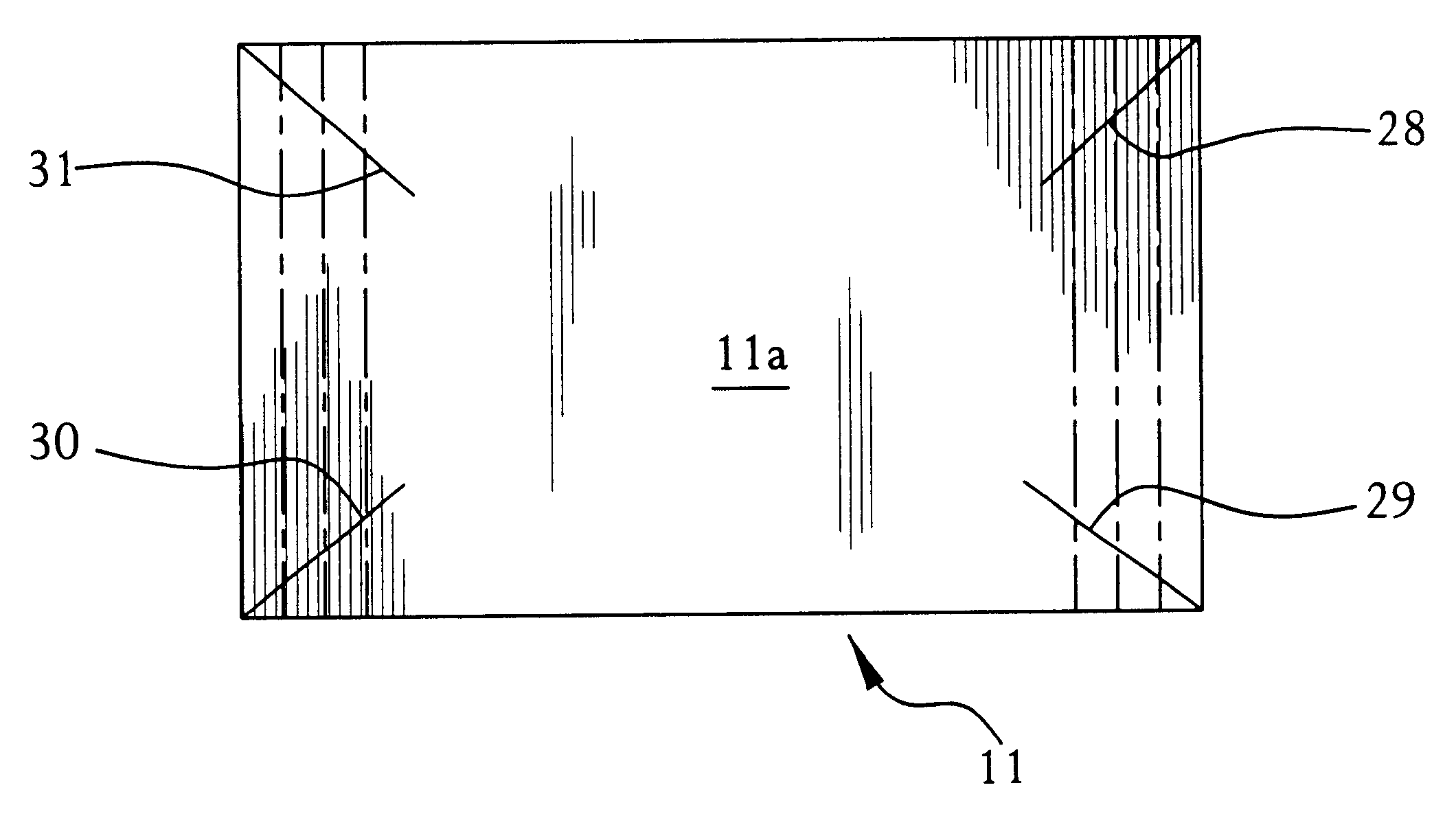

Paperboard laminate for food packaging applications

A laminate structure having improved resistance to the migration of essential oils, aromas and flavors and improved oxygen barrier characteristics for beverage packaging comprising an exterior coating of polyethylene applied onto the outer surface of paperboard substrate, a barrier layer of aluminum foil, EVOH, polyamide or PET applied directly or indirectly onto the paperboard and tie and other sublayers which may or may not contain inorganic filler applied intermediate the barrier layer and the innermost food contact layer which may or may not contain filler. The containers or cartons prepared from the laminate structures are characterized by minimized scalping and preserved product quality.

Owner:INT PAPER CO

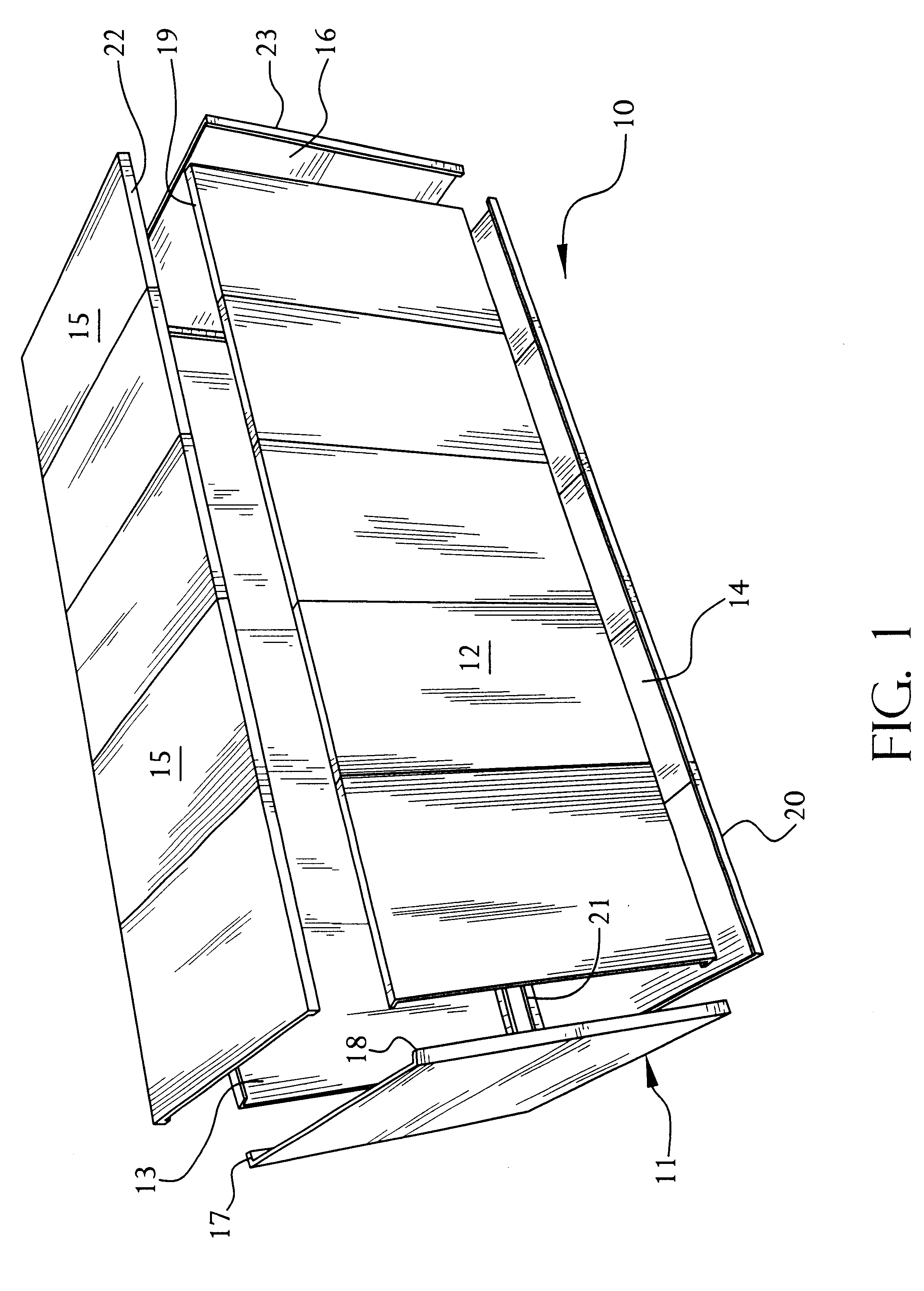

Liner for container

InactiveUS6308850B1Simple to fitReduce cleaningLarge containersContainer/bottle contructionPaperboardEngineering

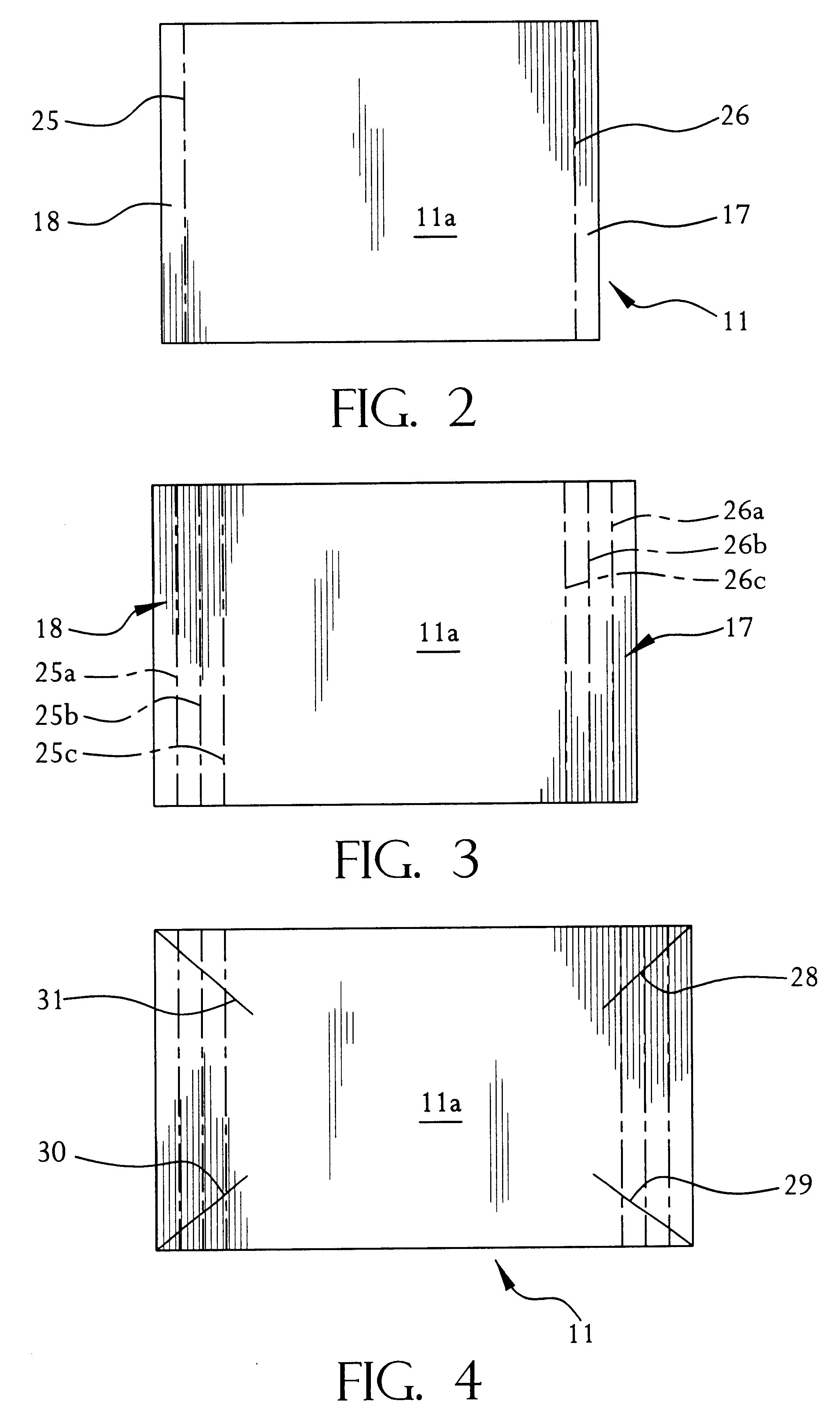

A liner for a container, such as a shipping container, including an end panel (11), a first side wall panel (12), a second side wall panel (13), a floor panel (14), a roofpanel (15) and a second end panel (16), the end panel (11) including flaps (17), (18), end panel (12) including top flap (19) and a lower flap (not shown) the side wall panel (13) including similar top and lower flaps to side wall panel (12), the floor panel (14) including a first flap (20) and a second flap (21), the roof panel (15) including flap (22) and another flap (not shown) on the edge opposed to the edge carrying flap (22), the second end panel (16) including flap (23) and another flap (not shown) on the opposed edge to that carrying flap (23), the panels (11 to 16) being formed from double faced corrugated paperboard. At least panel (11), and preferably panels (13 to 16), can have multiple fold or score lines (25a to c and 26a to c) to enable folding at selected lines to fit different containers. Diagonal slots (31) can be provided at each corner to accommodate protuberances in the corners of the container.

Owner:VISY R & D PTY LTD

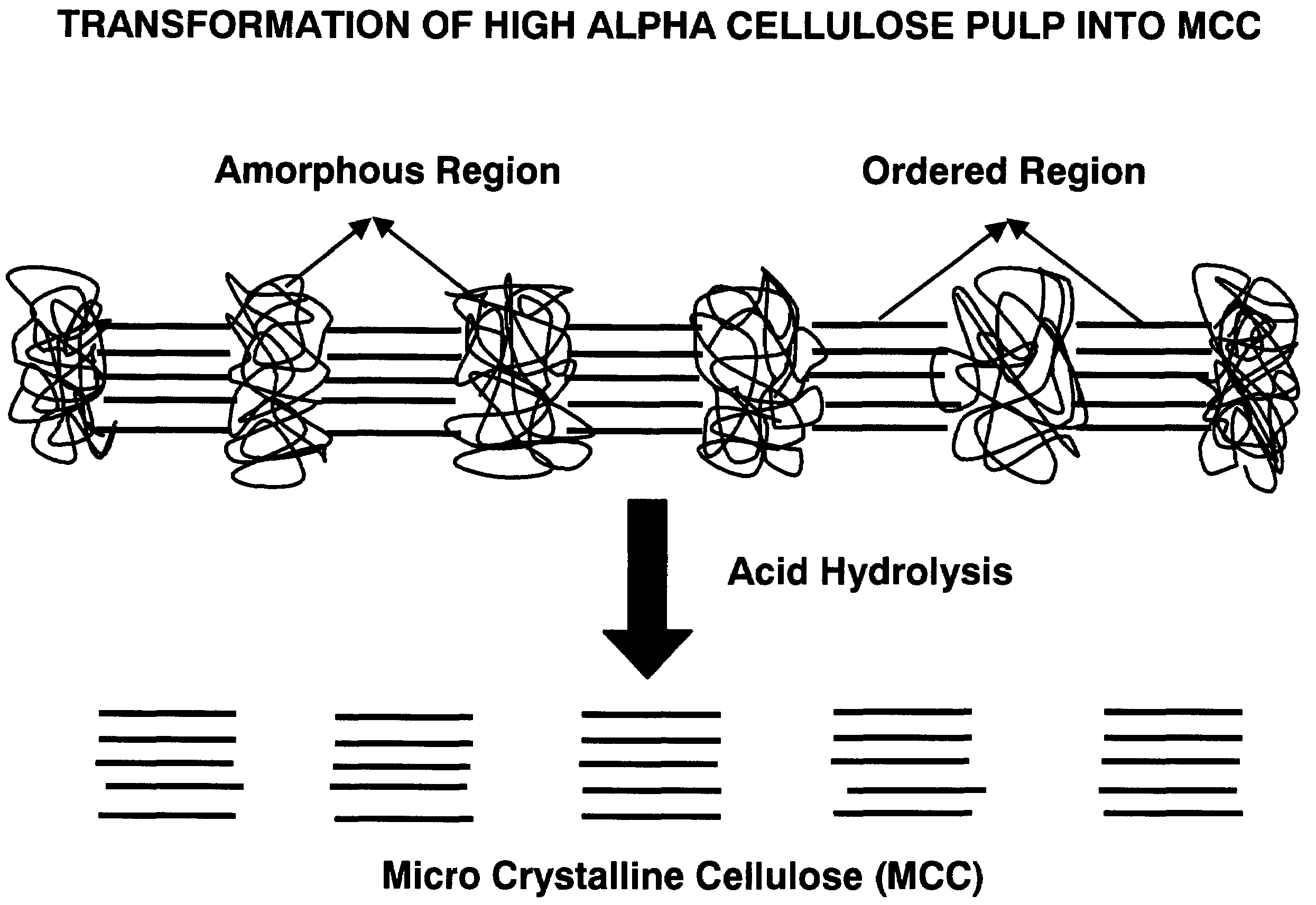

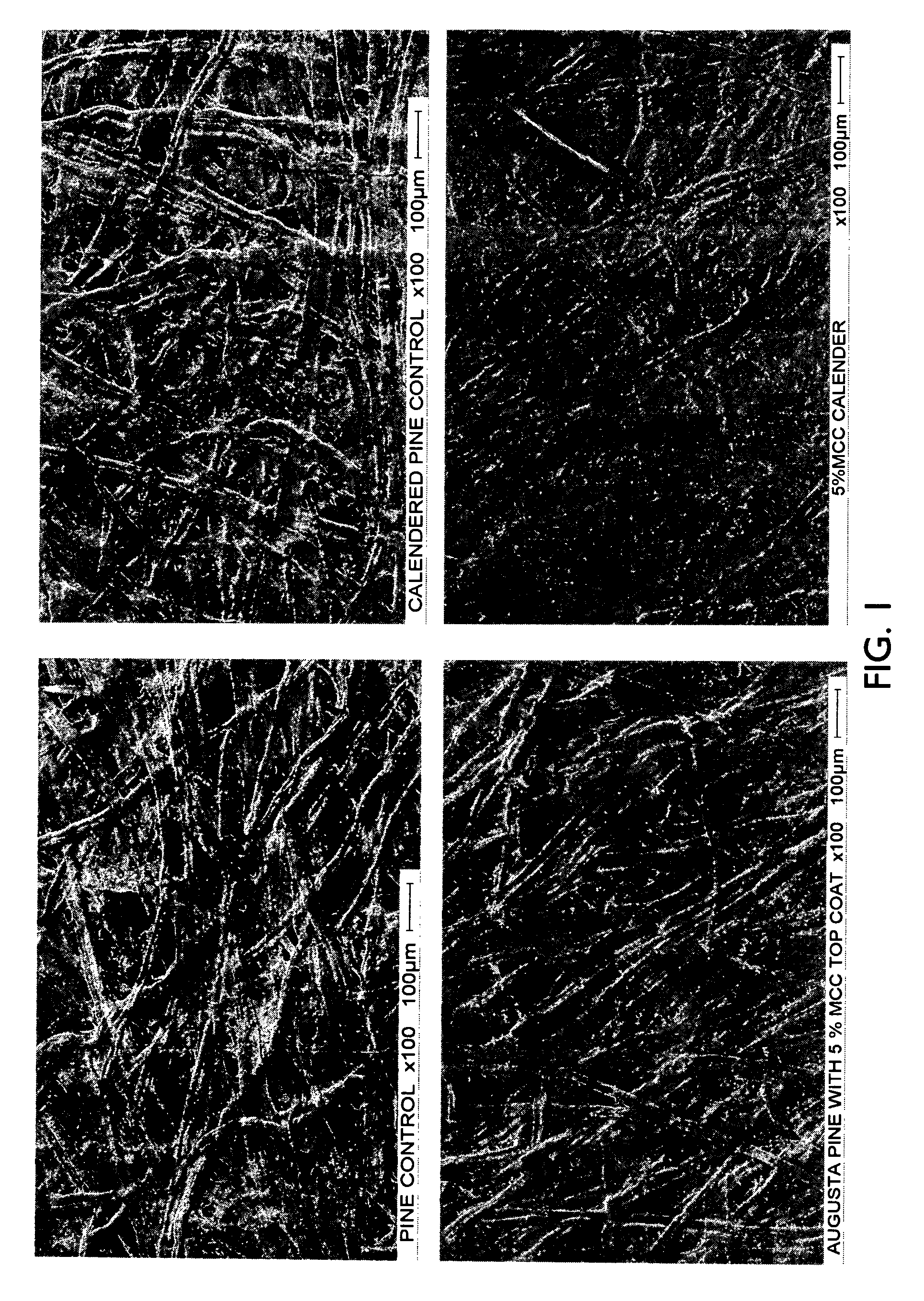

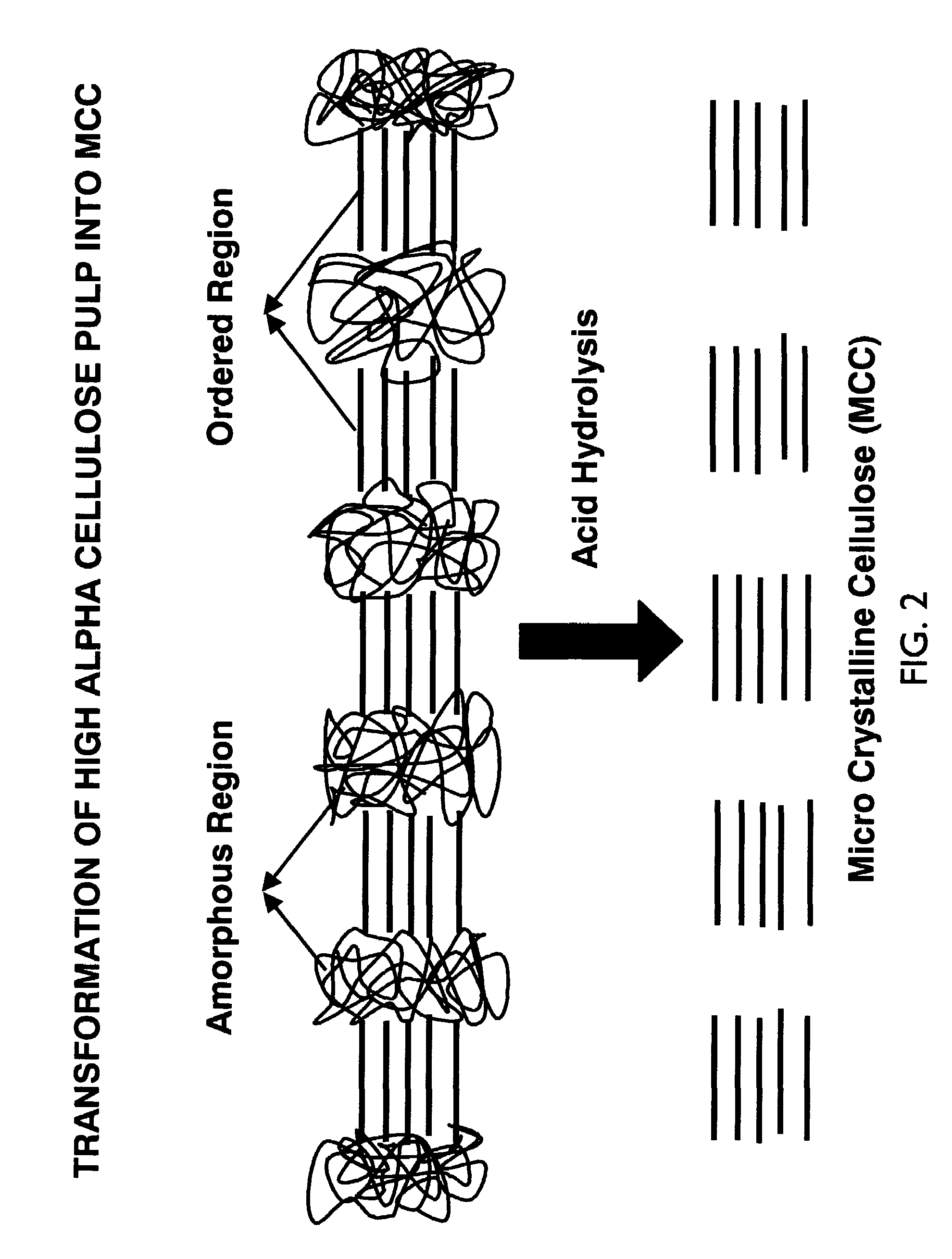

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS7037405B2High binding capacityImprove abilitiesNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Paper or paperboard product and a process for production of a paper or paperboard product

InactiveUS20130180680A1Improve retentionGood strength performancePulp properties modificationSpecial paperCellulosePaperboard

The present invention relates to a paper or paperboard product comprising a furnish wherein said furnish comprises a cationic polymer in an amount of above 1.5% by weight, an anionic polymer and microfibrillated cellulose. The invention further relates to a process for the production of said product.

Owner:STORA ENSO OYJ

Paperboard carton with a new type of dispenser

A carton for carrying a plurality of cans in at least three rows having a dispenser flap that is easily removed from the end of the carton to expose a dispenser which has a bottom of a sufficient height from the bottom panel to prevent containers in the bottom row from rolling out, but less than the diameter of a container in the bottom row. The top of the dispenser is at a height from the bottom panel that is equal to diameter of a can contained in the carton plus the distance that is substantially less than the diameter of a can, such height being sufficient to prevent any container in the middle row from automatically rolling out of the dispenser when opened, but allowing a person to grasp and pull out the container in the middle row that is adjacent to the dispenser.

Owner:GRAPHIC PACKAGING INT

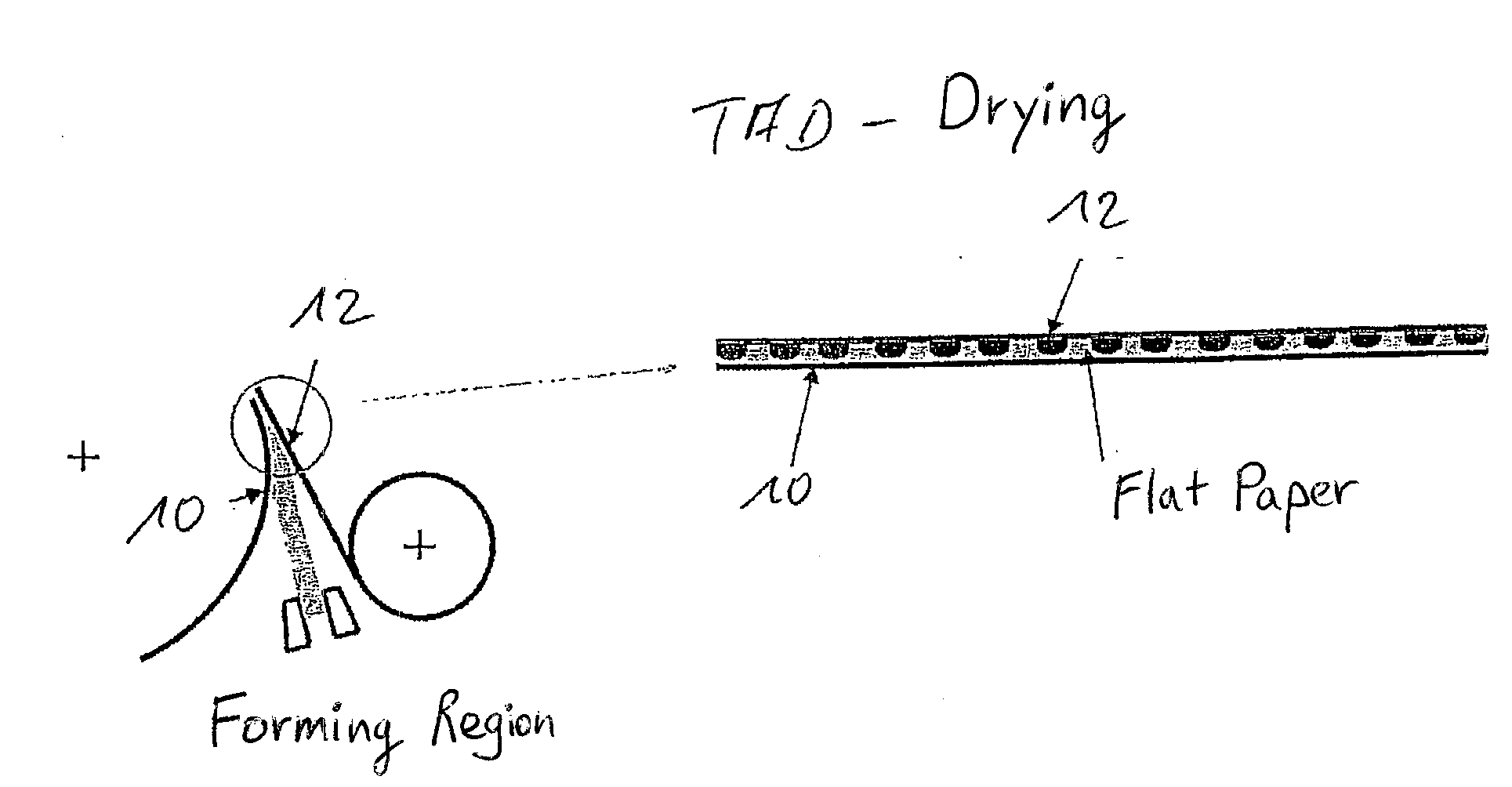

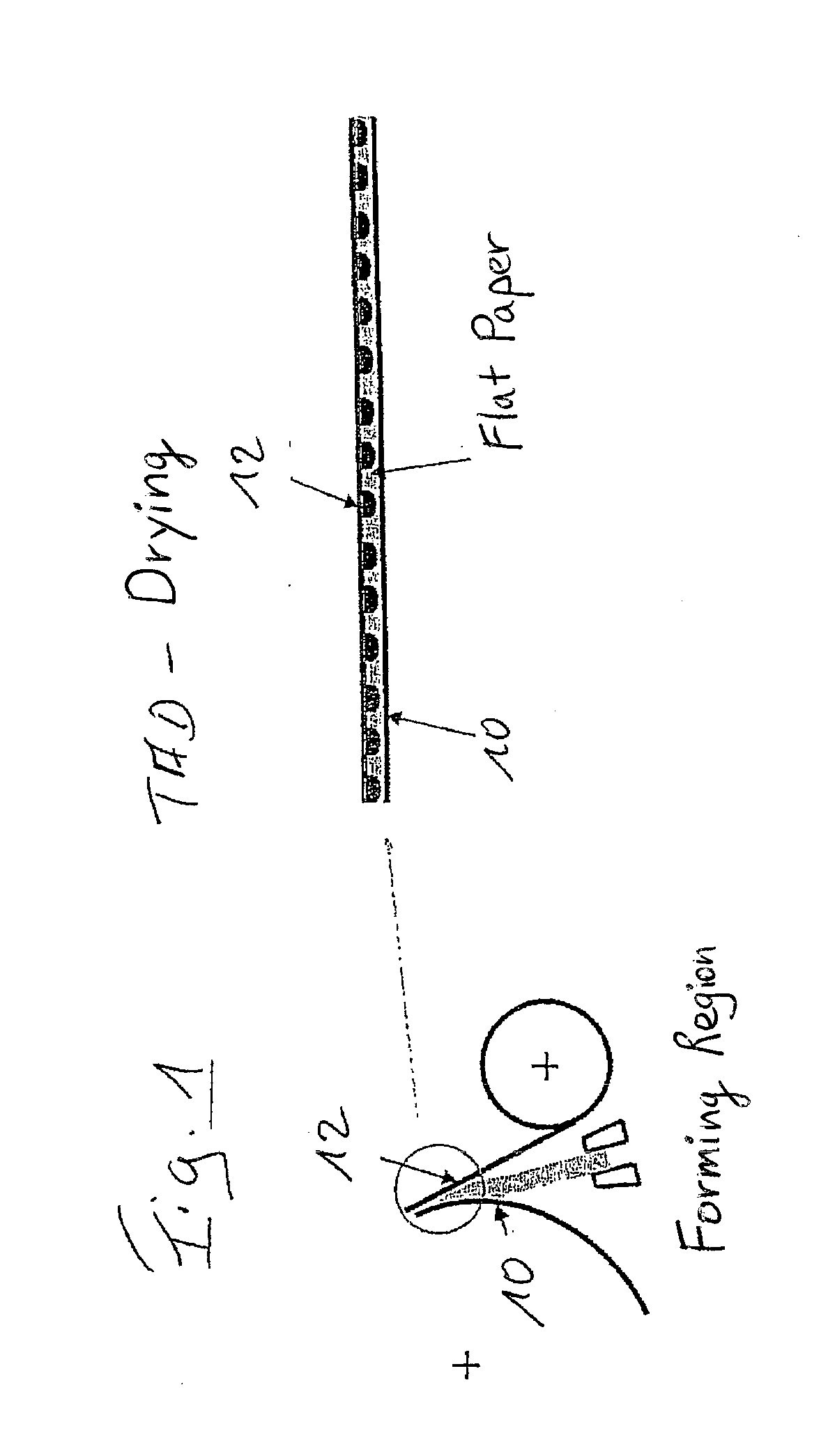

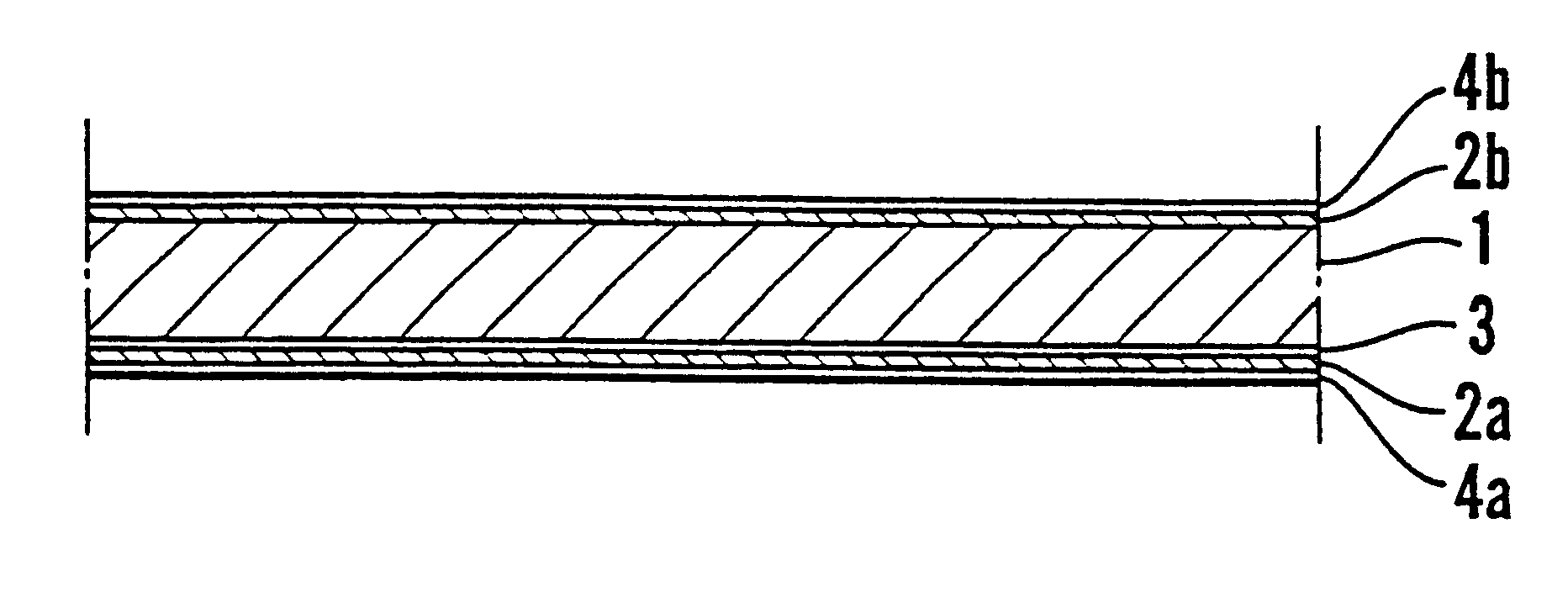

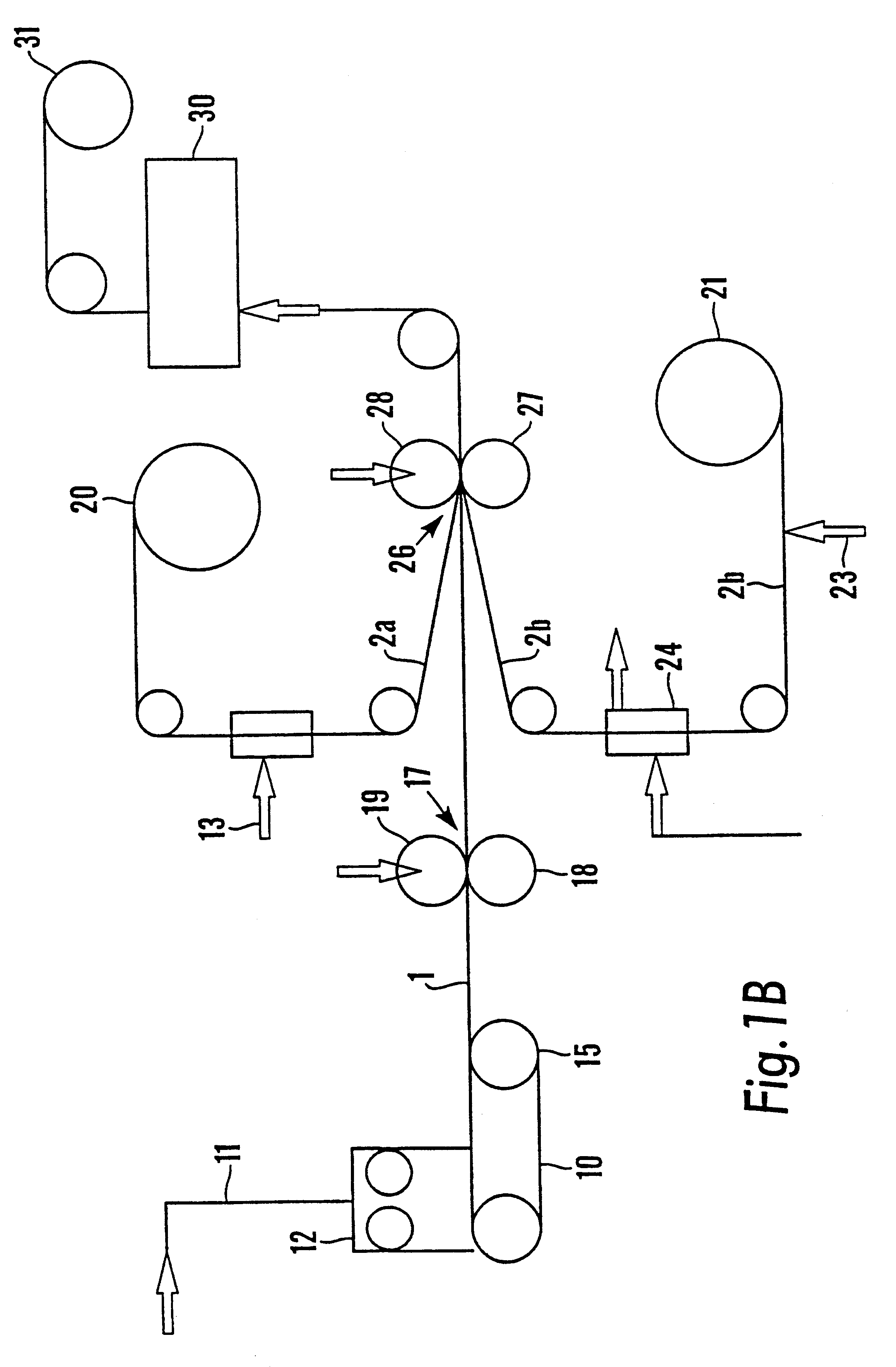

Machine for producing a fibrous web

InactiveUS20080149292A1Reduce absorptionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

A machine for producing a fibrous web, in particular a paper web, paperboard web or tissue web, includes a former on which the fibrous web is formed on a structured belt and is dewatered between said structured belt and a forming belt, and a drying apparatus for the further dewatering of the fibrous web, through which the fibrous web is guided together with the structured belt and in which hot air flows through the permeable structured belt and the fibrous web. The forming fabric is formed by a printed forming fabric or a DSP fabric with zonally different permeability.

Owner:VOITH PATENT GMBH

Paper or paperboard laminate and method to produce such a laminate

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

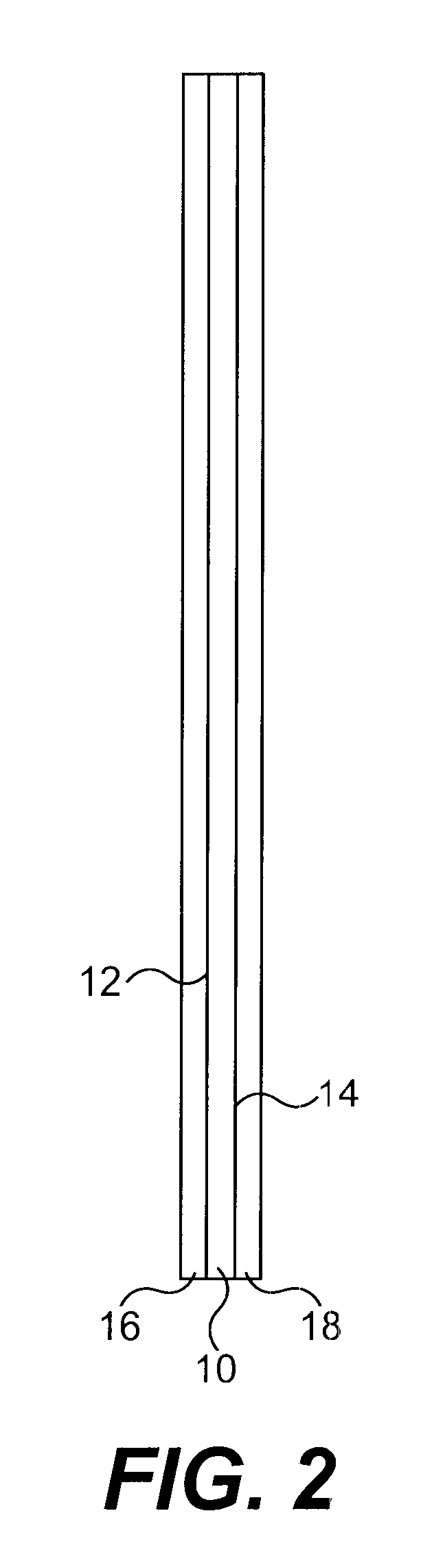

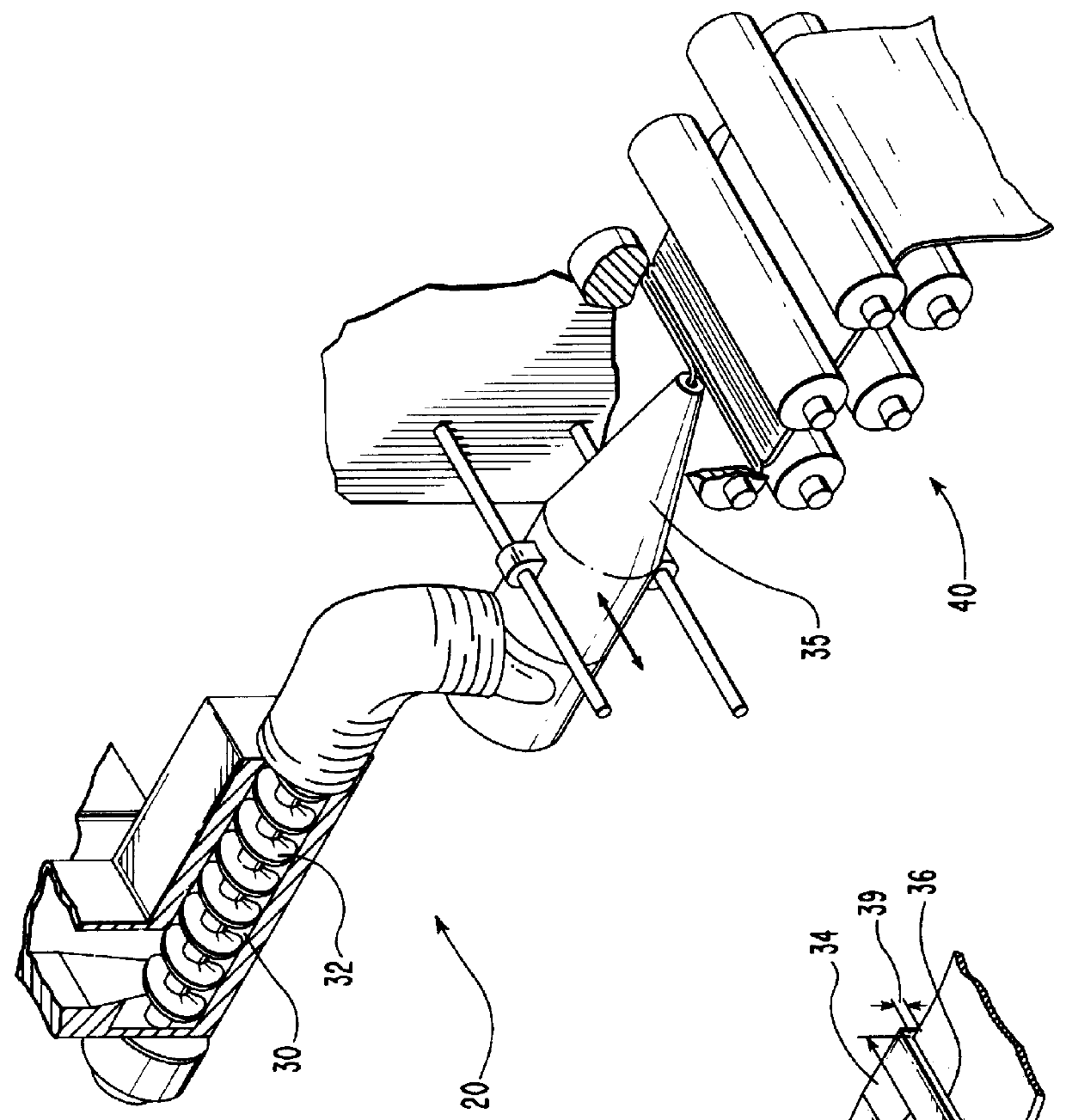

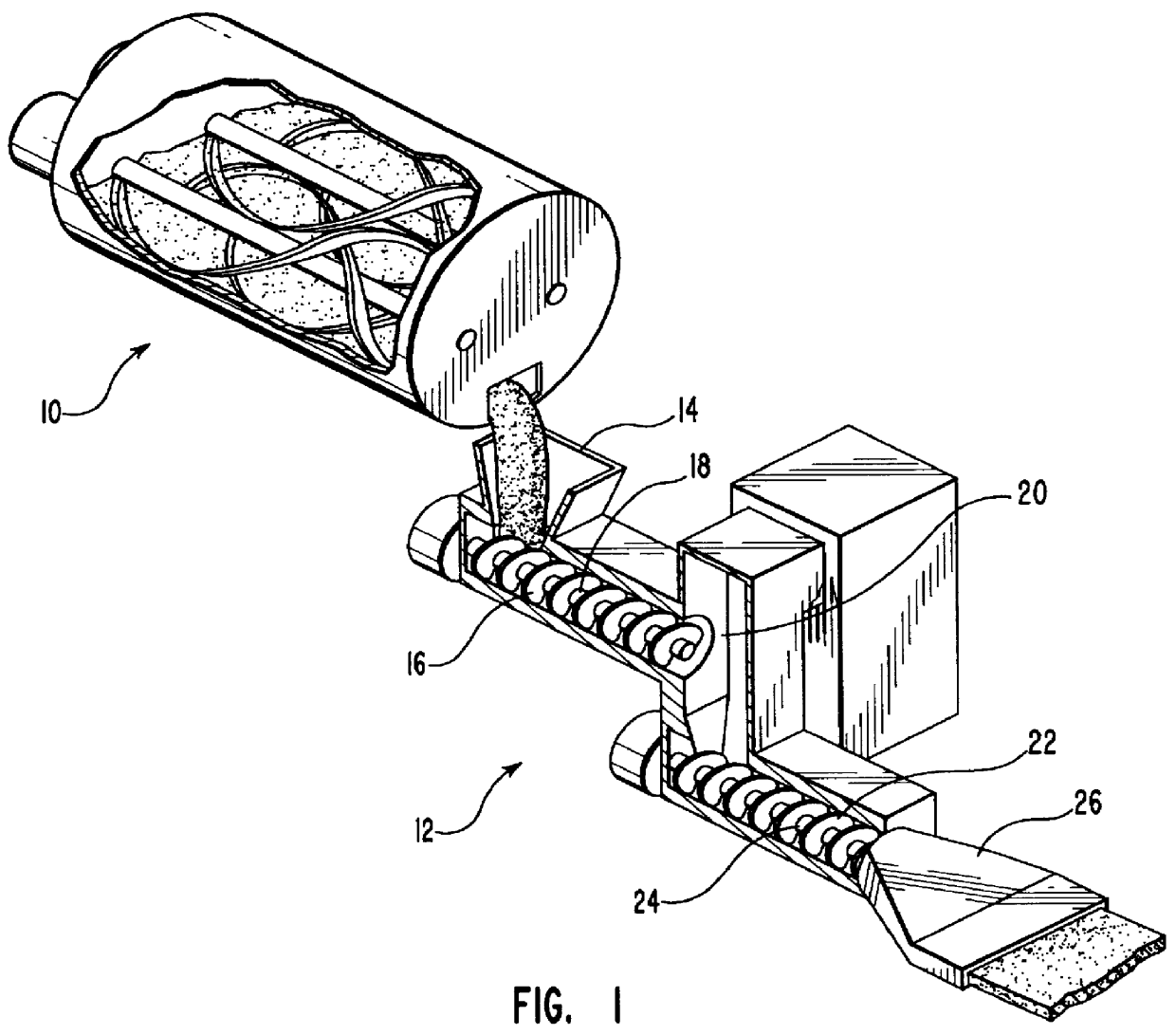

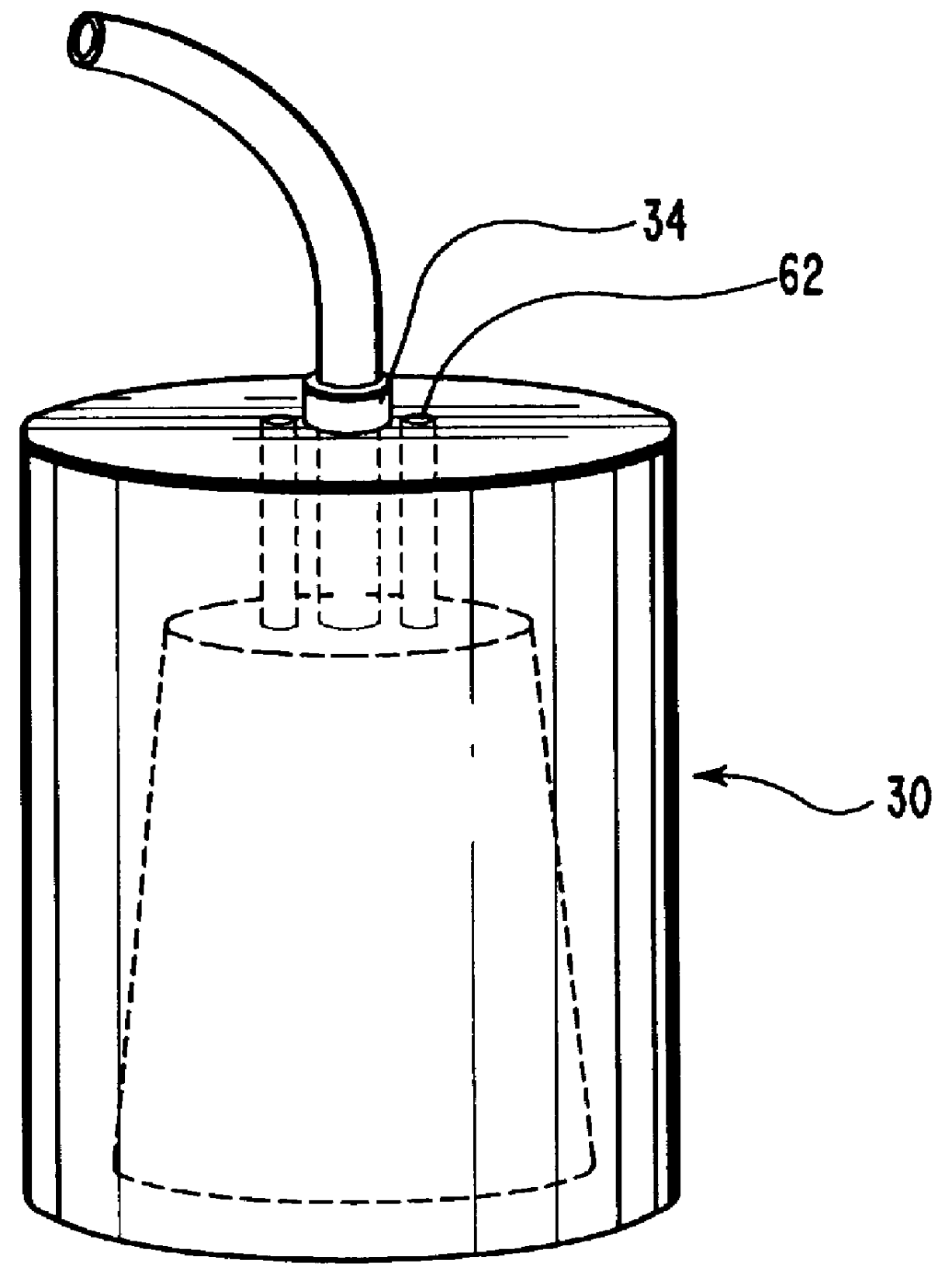

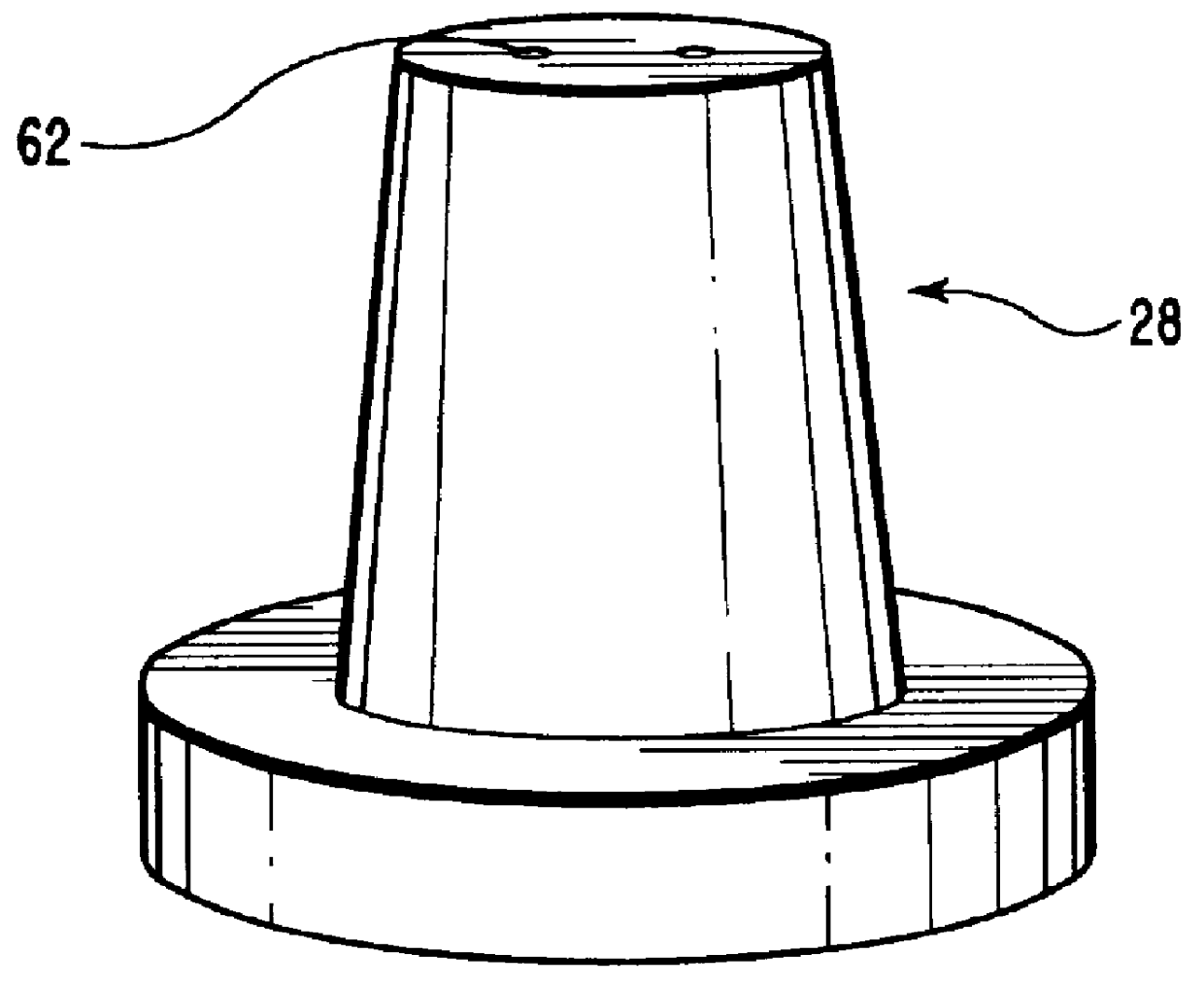

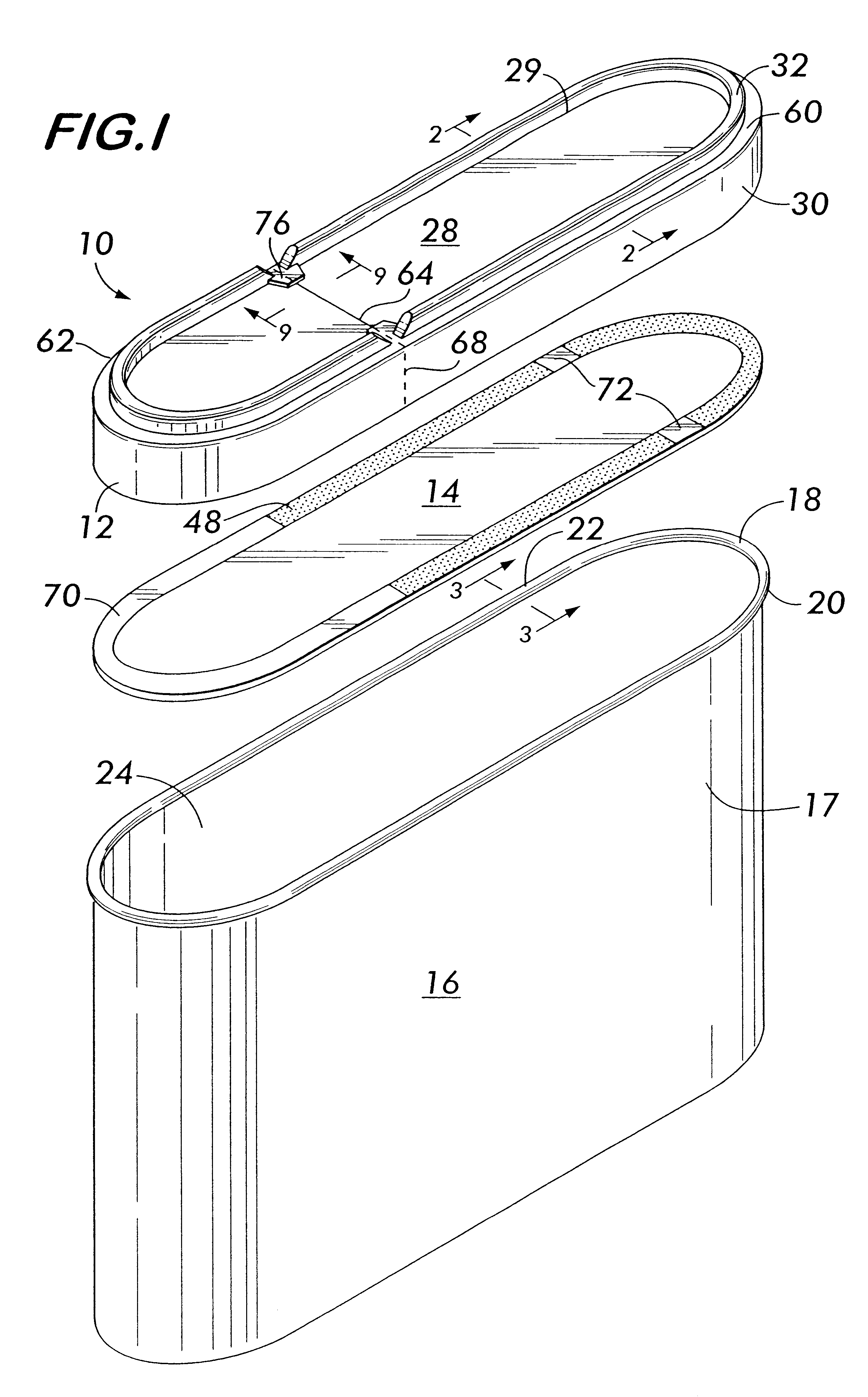

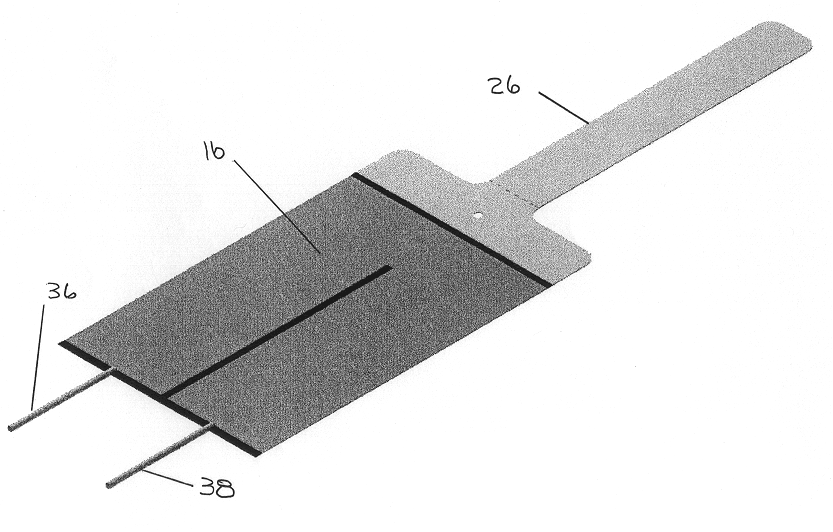

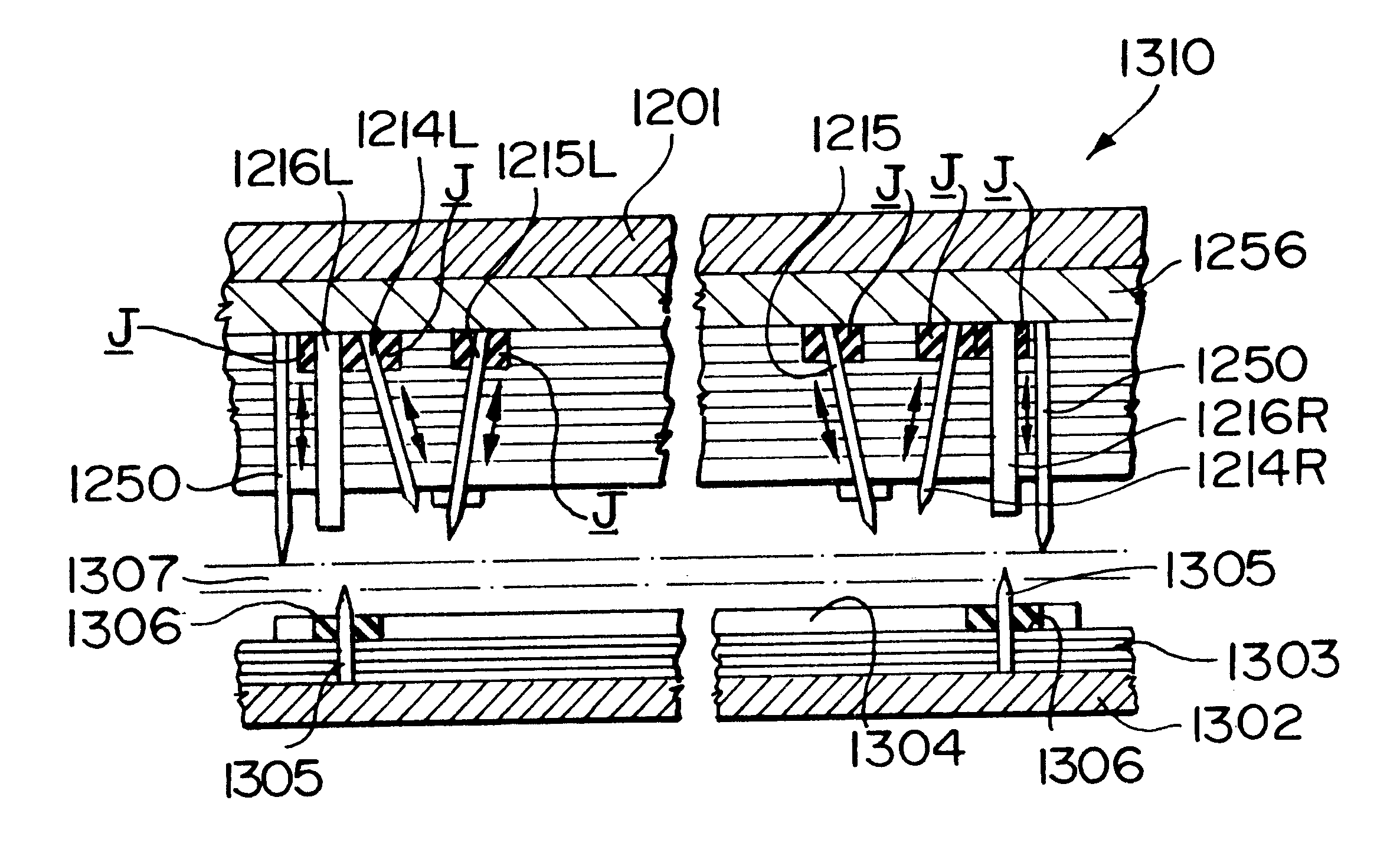

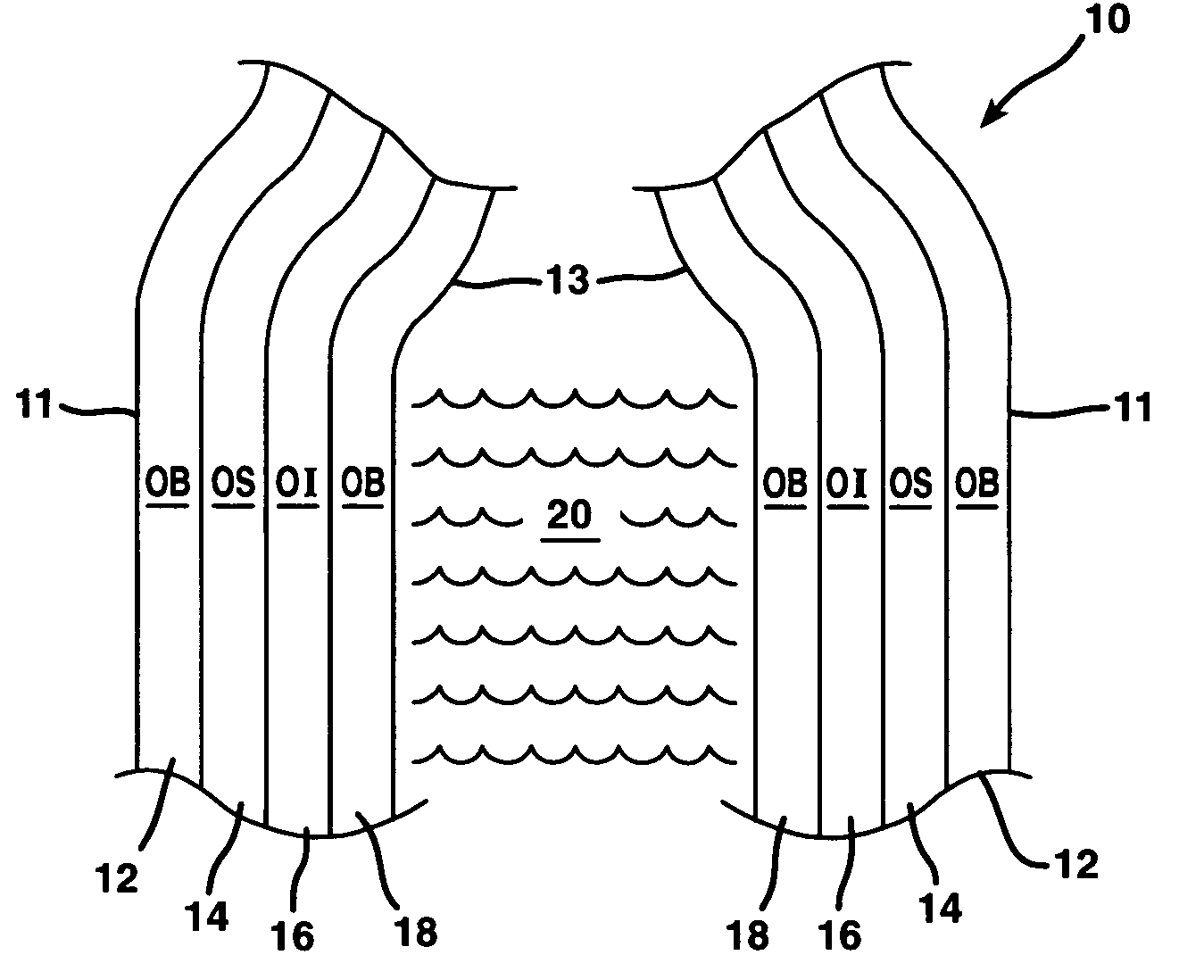

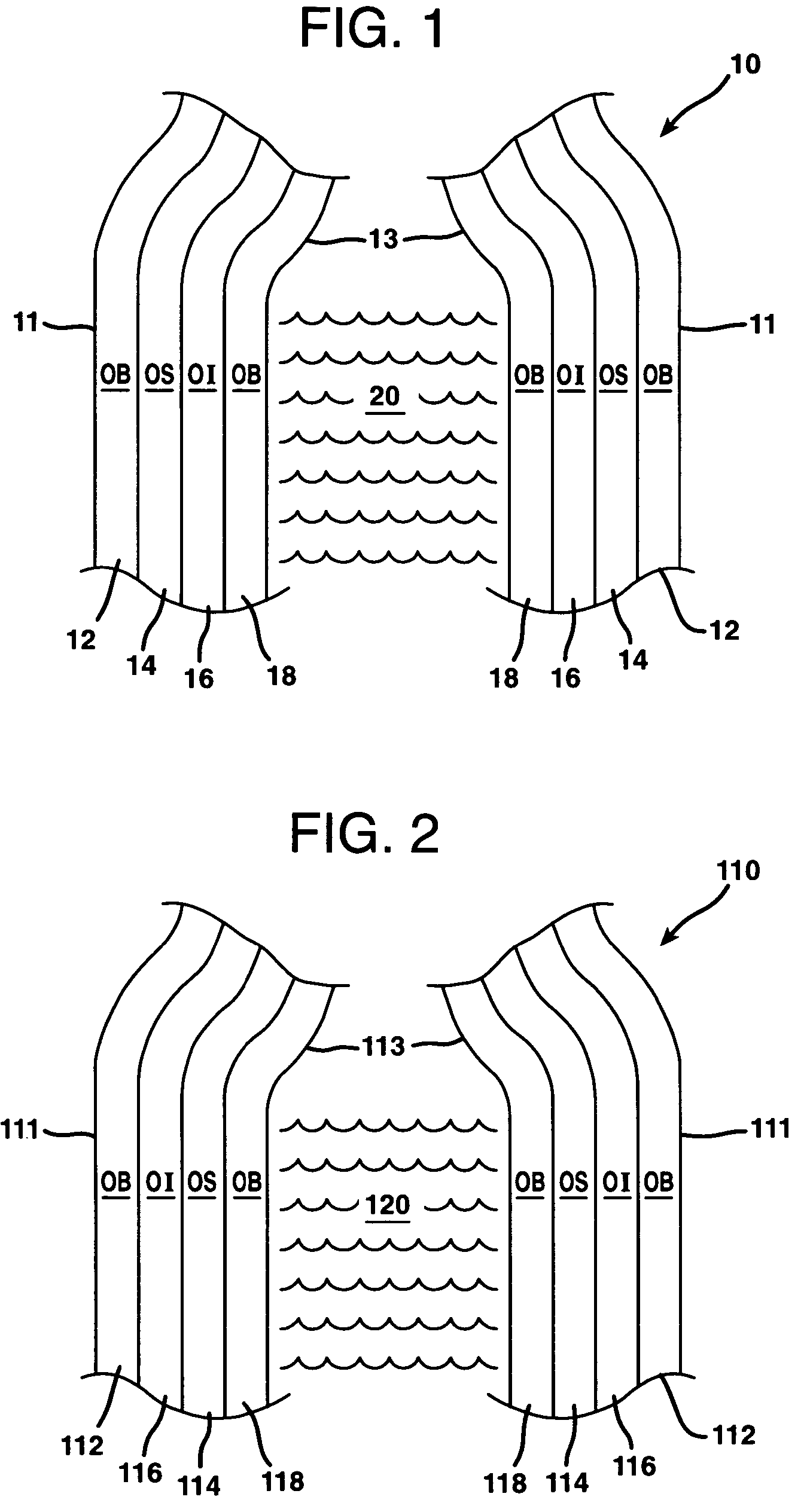

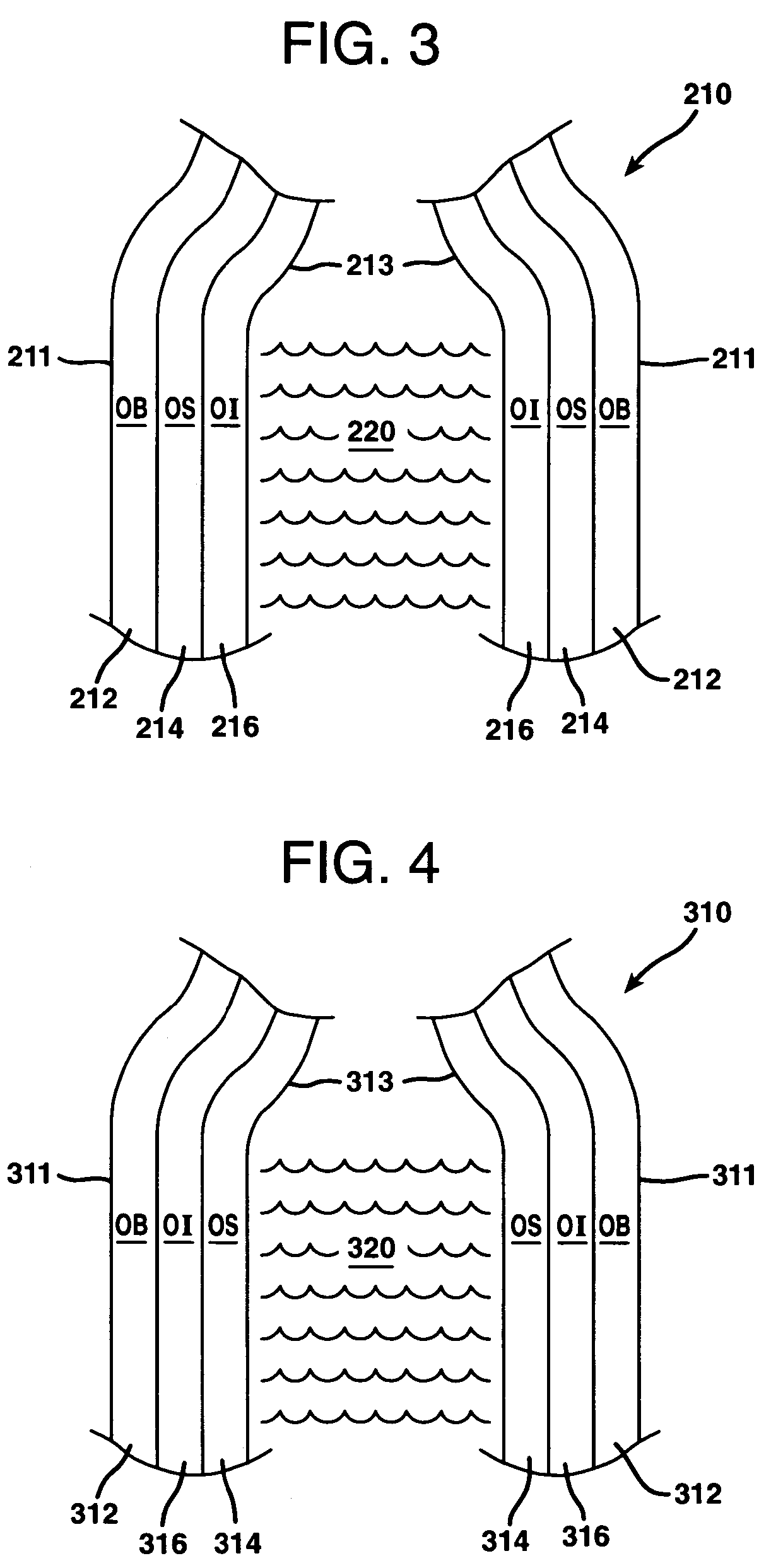

Convection blood warming system with disposable flattened tube envelope incorporating paperboard "needle" for inserting envelope between heating plates and employing active and passive insulation of outlet flow path to provide normothermic fluid at zero to 600 milliliters per minute

InactiveUS6608968B2Closer spacingEconomical and simpleWater heating stoves/rangesMedical devicesBlood warmersDistal portion

A thin, flat paperboard inserter or "needle" which is longer than the blood warmer heating plates is attached to the edge of the flattened tube envelope to enter the very narrow gap between the heating plates. The inserter is fed between the heating plates and advanced to emerge from the other end of the blood warmer where it is grasped and used to pull the envelope into operational position. A high air flow hydrophobic vent with check valve to prevent reverse flow is incorporated into the drip chamber to allow automatic priming and venting of air bubbles. A conductively heated and externally insulated drip chamber holder and a patient intravenous line that is passively insulated by a small annular air space extruded as part of the tube preserve heat in the warmed fluid, improving low flow rate performance. A reusable external heater may optionally be applied to the distal portion of the patient line to provide normothermic fluid to the patient down to essentially zero flow rate.

Owner:BAKKE ALLAN P

Handle and top handle reinforcement for a paperboard carton

A fully enclosed carton for carrying heavy loads with a reinforcement insert for the handle apertures located in the top end flaps of the carton. The paperboard reinforcing insert may be extended as a bridge across the top panel of the carton to prevent tearing of the handle apertures in the top end flaps and also tearing in the top panel of the carton when carrying a heavy load. The carton may have one or more dispensers in the top panel which may extend into an adjoining side panel. Multiple tear lines may be formed for the dispenser flap in the insert that extends across the top panel to permit easy access to the containers, such as bottles, in the carton. The paperboard reinforcing insert may have a larger aperture than the handle aperture in each top end flap to adjust for any imprecision in the alignment of the paperboard insert in forming the carton sleeve from the paperboard blank. When the paperboard insert extends across the top panel and one or more dispensers are formed in the top panel, multiple tear lines may be used to form the flaps in the insert to compensate for any imprecision in the insertion of the insert that extends across the top panel into the carton sleeve when it is being formed.

Owner:GRAPHIC PACKAGING INT

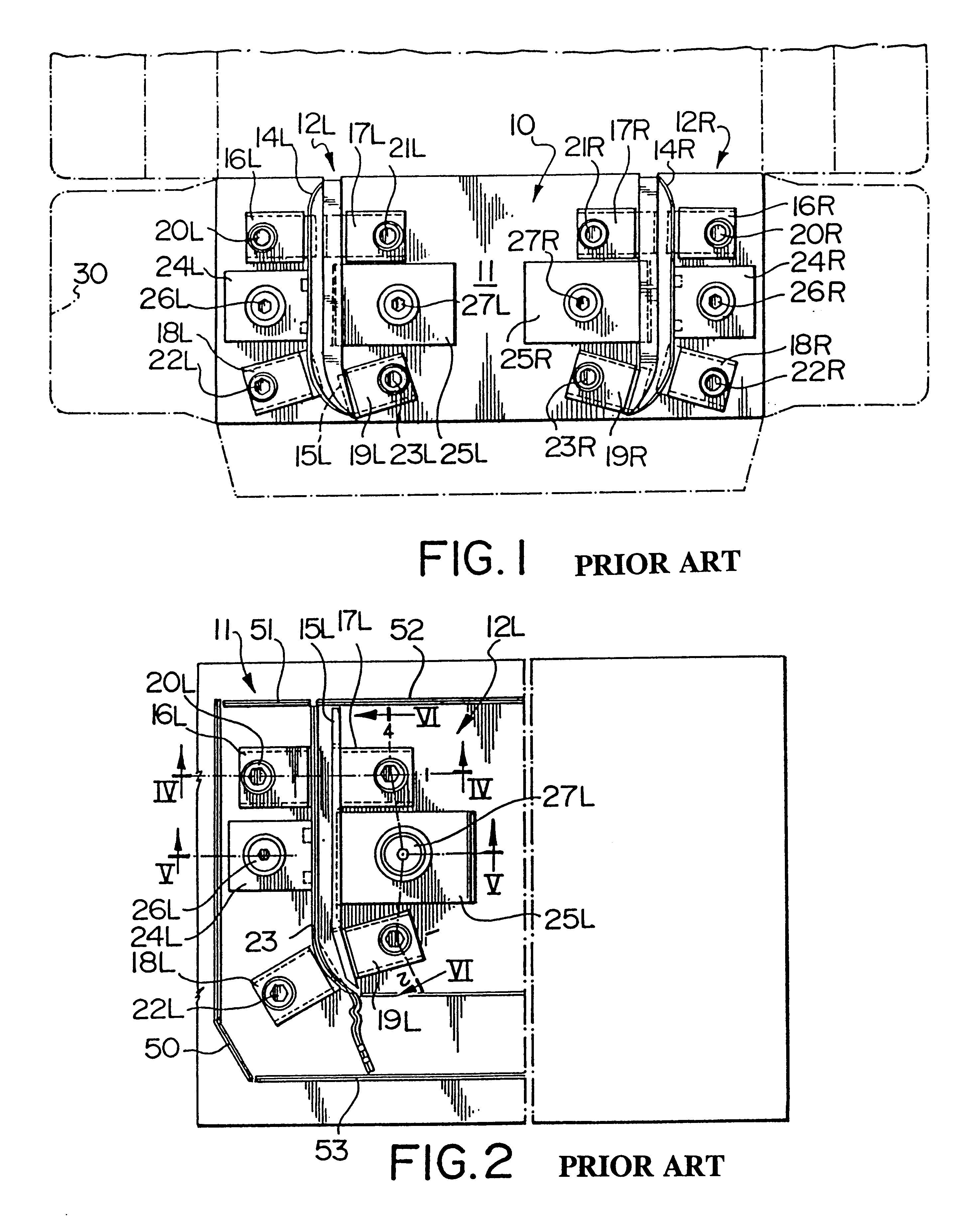

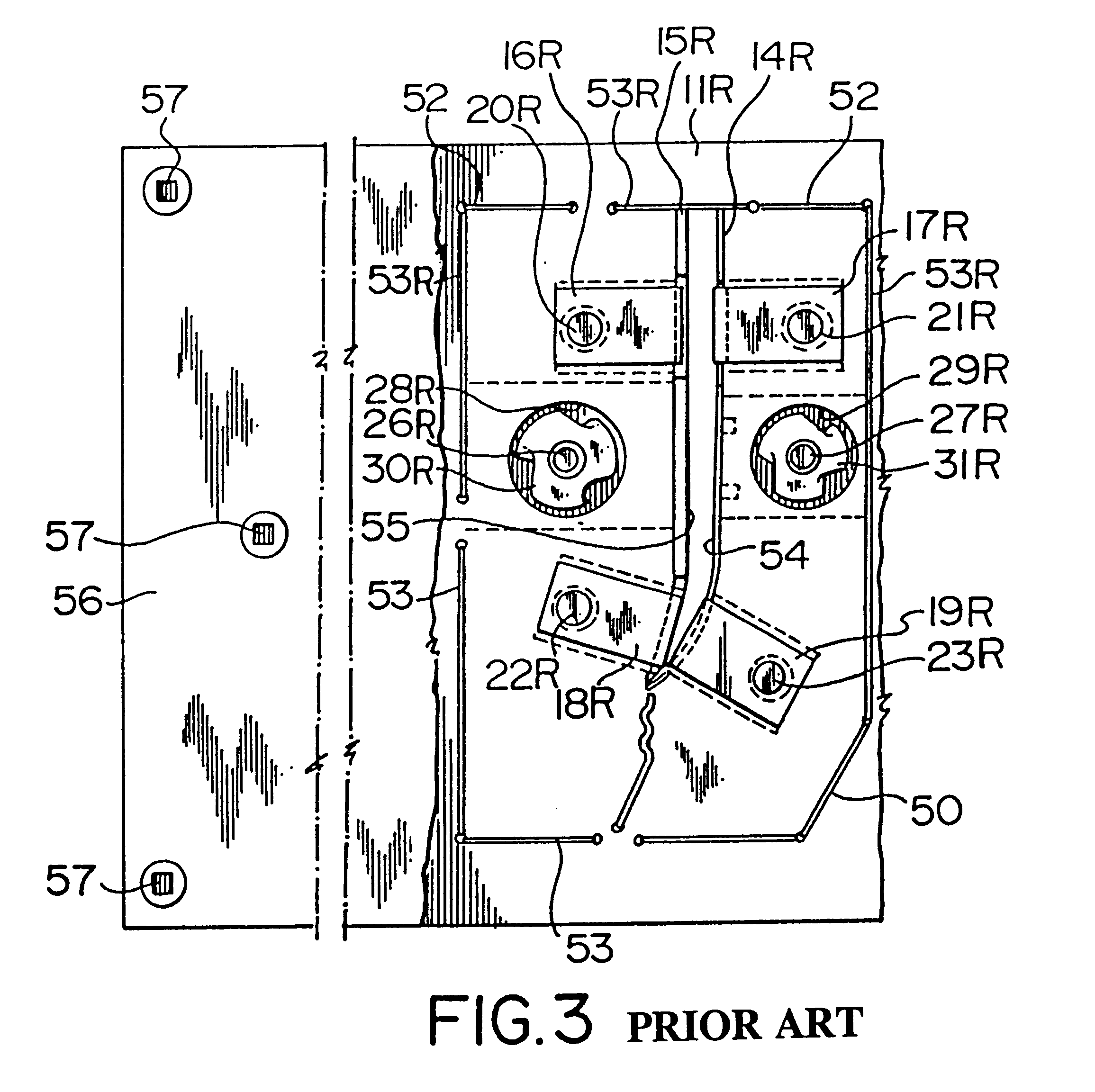

Cutting, scoring and perforating die set and method

InactiveUS6203482B1Accurate startMechanical working/deformationBox making operationsCartonPaperboard

An apparatus for substantially-simultaneously die cutting cardboard sheets for forming folded cardboard cartons and an openable and closable tab. The improvement resides in a die set comprising a plurality of cutting knives projecting from a base, the cutting knives being fixed into a preselected pattern of grooves within the base. The die set may further include at least one transversely-spaced-apart pair of a die blade and a perforating knife mounted in the base, in which either or both of the die blade or the perforating knife is "jackably mounted" for selective manual raising or lowering. The die set may alternatively further include at least one transversely-spaced-apart pair of a die blade and an anvil mounted in the base, in which either or both of the die blade or the anvil is "jackably mounted" for selective manual raising or lowering. In either case, the base is secured to a back-up plate. Either die set is used in a double platen die cutting apparatus in which the die set is mounted on the upper platen and in which the lower platen is movable towards the upper platen. The perforating knife may still further alternatively be mounted on the lower platen. In all cases, the die blade and the perforating knife converge to a common focal or starting point when the platens are urged towards one another with the cardboard therebetween, to provide for a common starting point for the operable and closable tab.

Owner:SANDFORD PETER NMI

Oxygen detection system for a rigid container

The present invention relates to the non-invasive use of a luminescent compound to detect and measure concentrations of oxygen dissolved in a rigid container, especially a bottle, a tray, a carton, a lidstock associated with a tray, a stand up pouch, or a paperboard container. The measurement is made independent of the oxygen concentration of the surrounding atmosphere. The invention is especially useful as a quality assurance check to verify oxygen scavenger activation during the assembly of bottled products, and modified atmosphere and vacuum packages. The method according to the invention is faster and less wasteful than previous methods that rely on measuring oxygen concentration within the headspace of an assembled package.

Owner:CRYOVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com