Patents

Literature

411results about How to "Improve strength properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

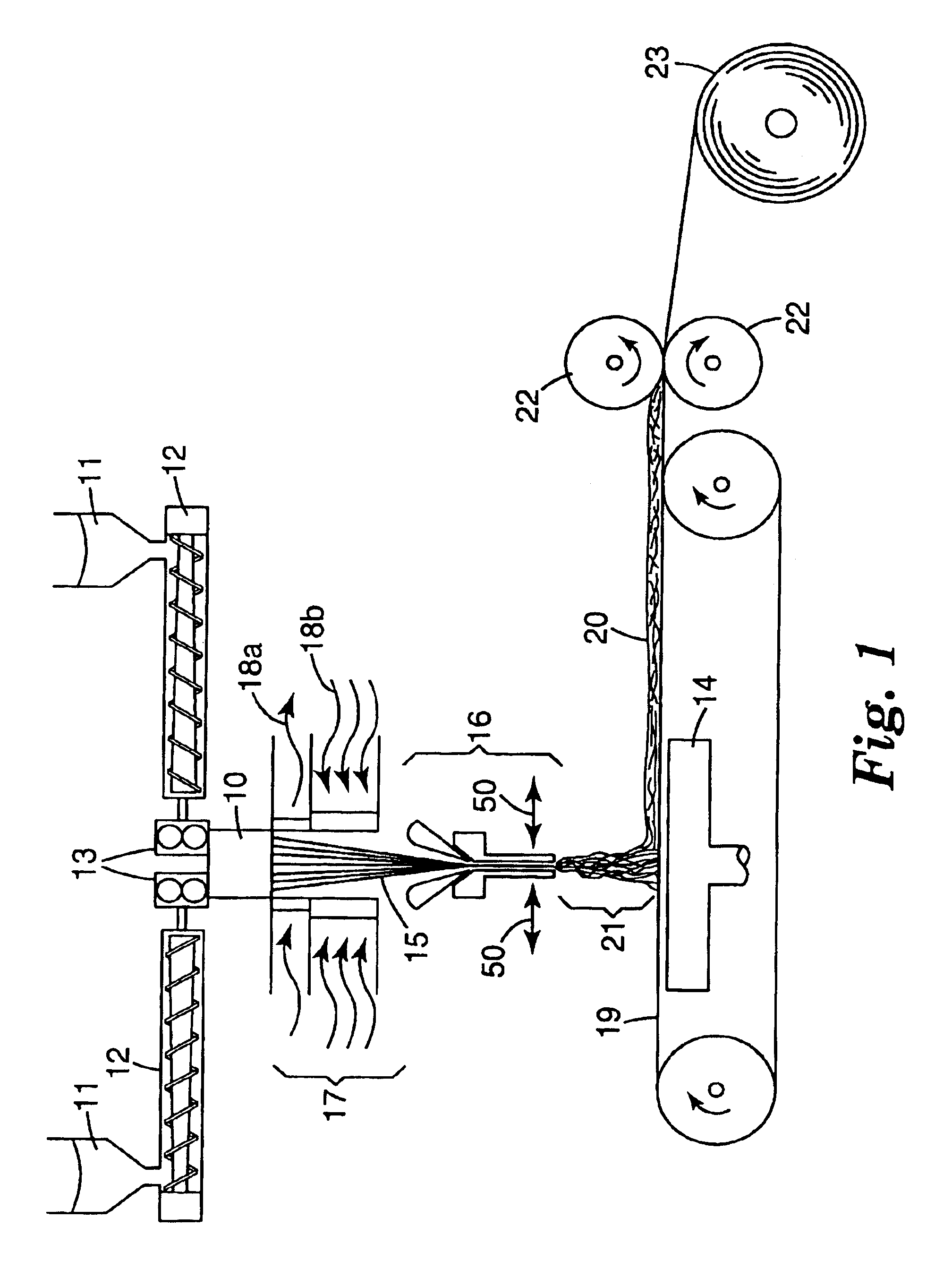

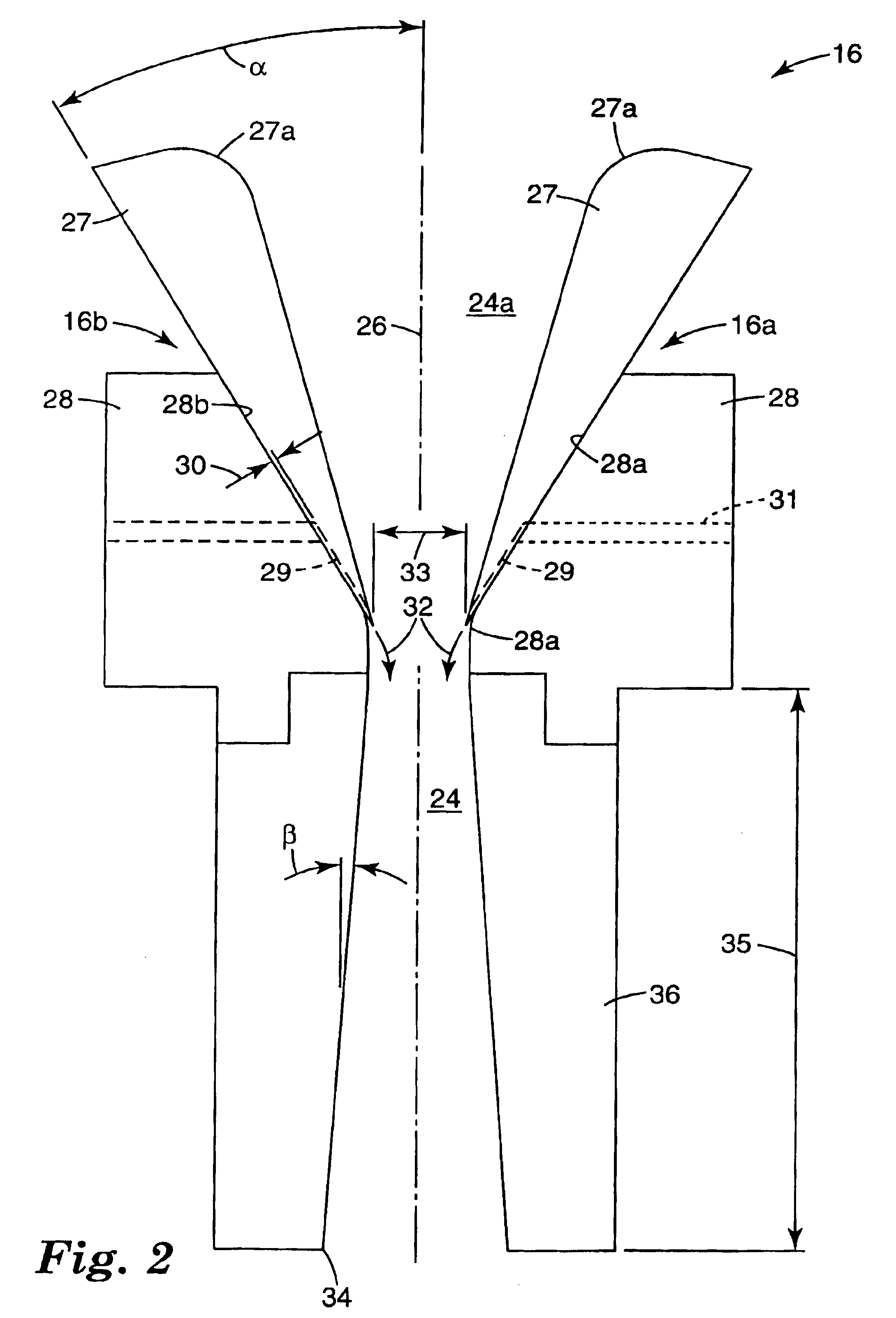

Bondable, oriented, nonwoven fibrous webs and methods for making them

InactiveUS6916752B2Improve adhesionImprove strength propertiesDecorative surface effectsDuplicating/marking methodsFiberEngineering

Nonwoven fibrous webs comprise fibers of uniform diameter that vary in morphology along their length. The variation provides longitudinal segments that exhibit distinctive softening characteristics during a bonding operation. Some segments soften under the conditions of the bonding operation and bond to other fibers of the web, and other segments are passive during the bonding operation. Webs as described can be formed by a method that comprises a) extruding filaments of fiber-forming material; b) directing the filaments through a processing chamber in which the filaments are subjected to longitudinal stress; c) subjecting the filaments to turbulent flow conditions after they exit the processing chamber; and d) collecting the processed filaments; the temperature of the filaments being controlled so that at least some of the filaments solidify while in the turbulent field.

Owner:3M INNOVATIVE PROPERTIES CO

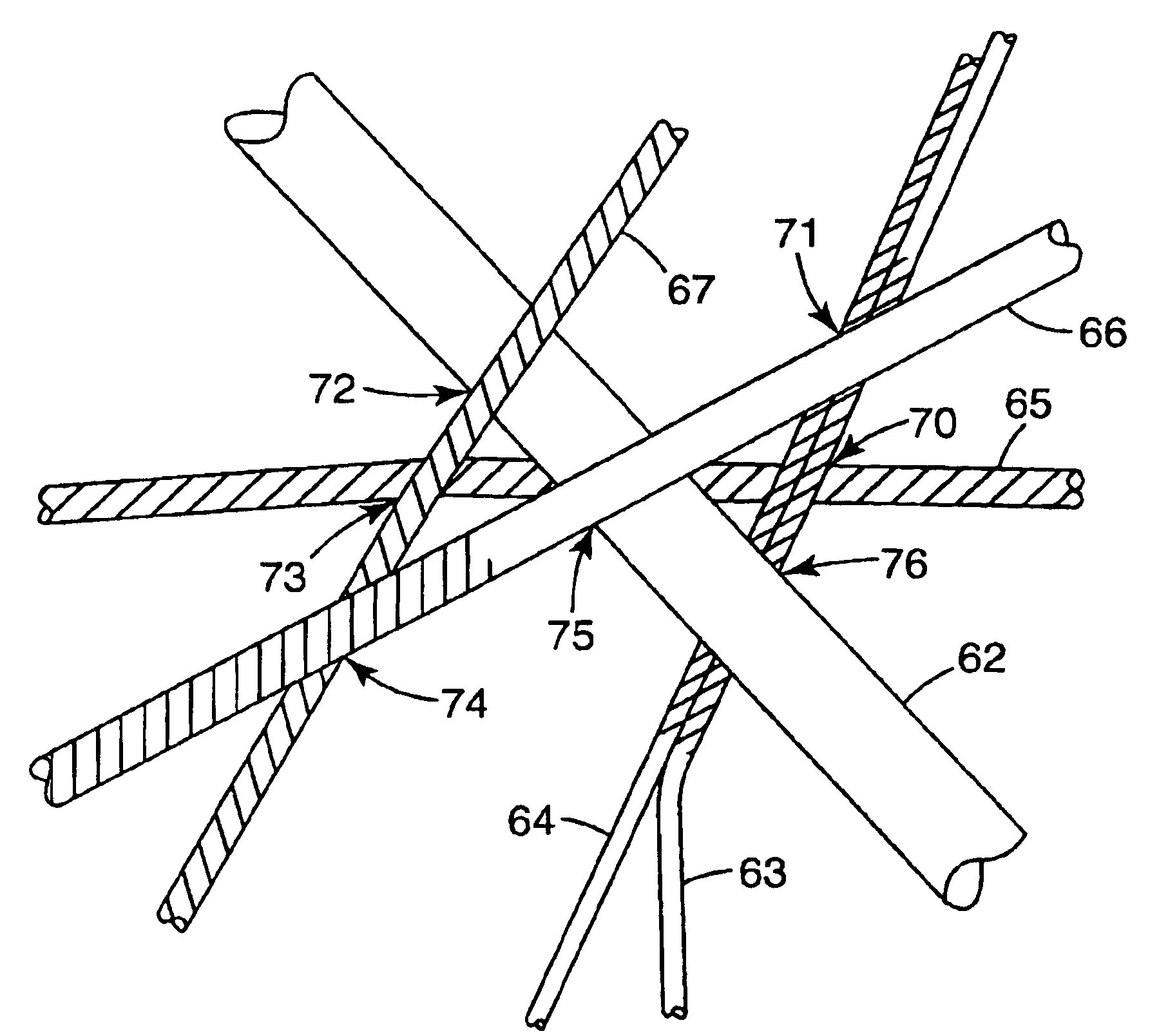

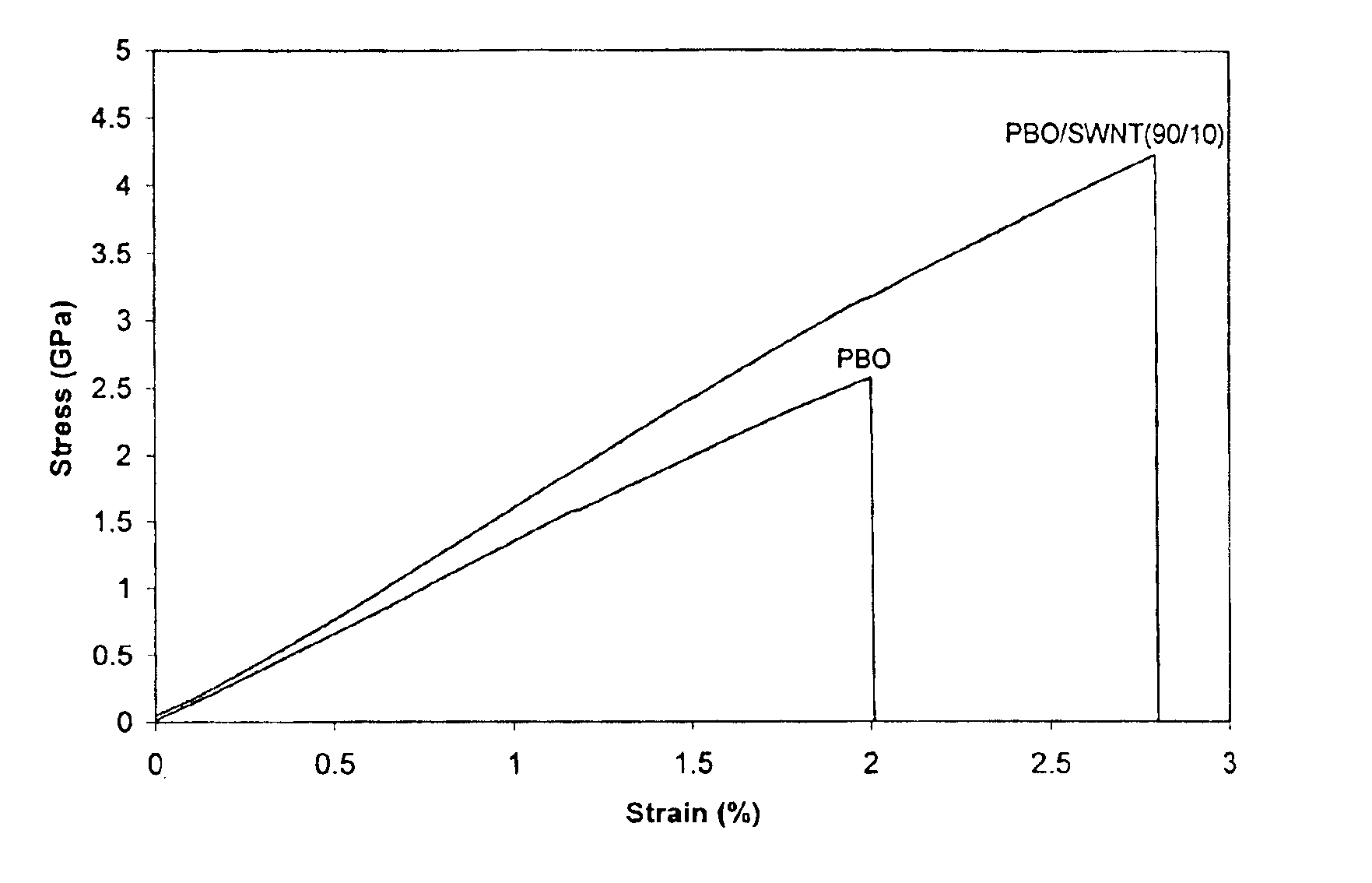

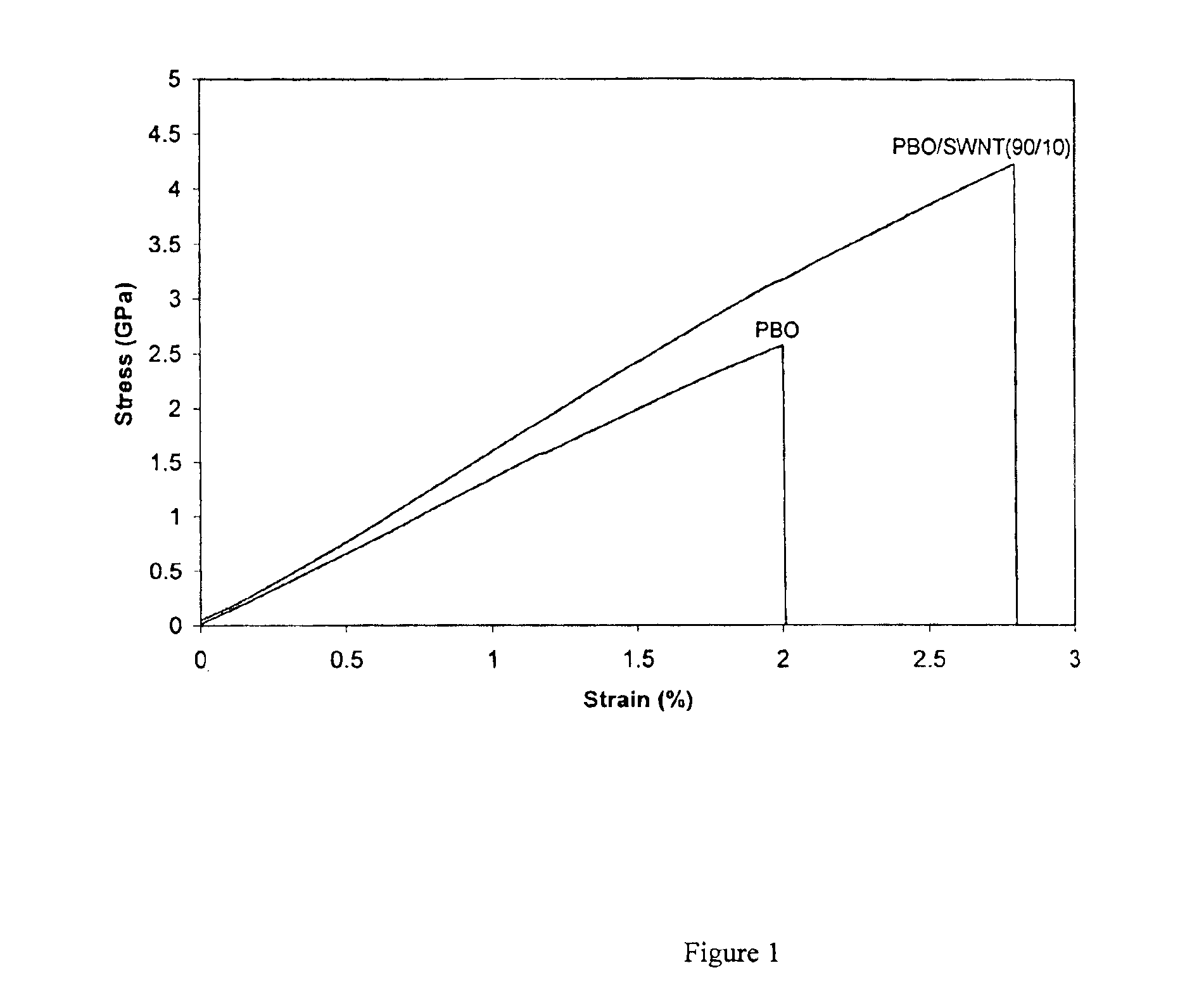

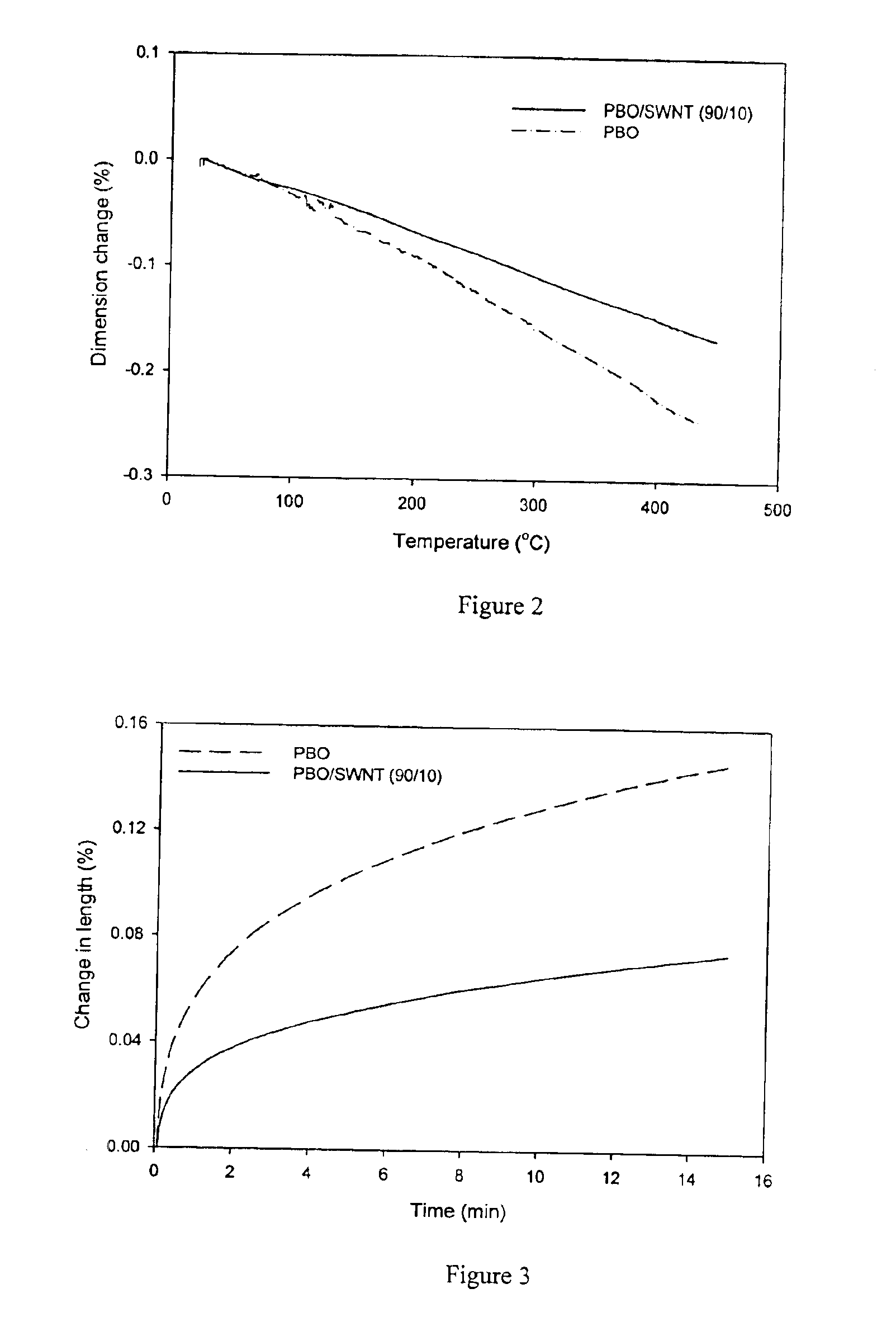

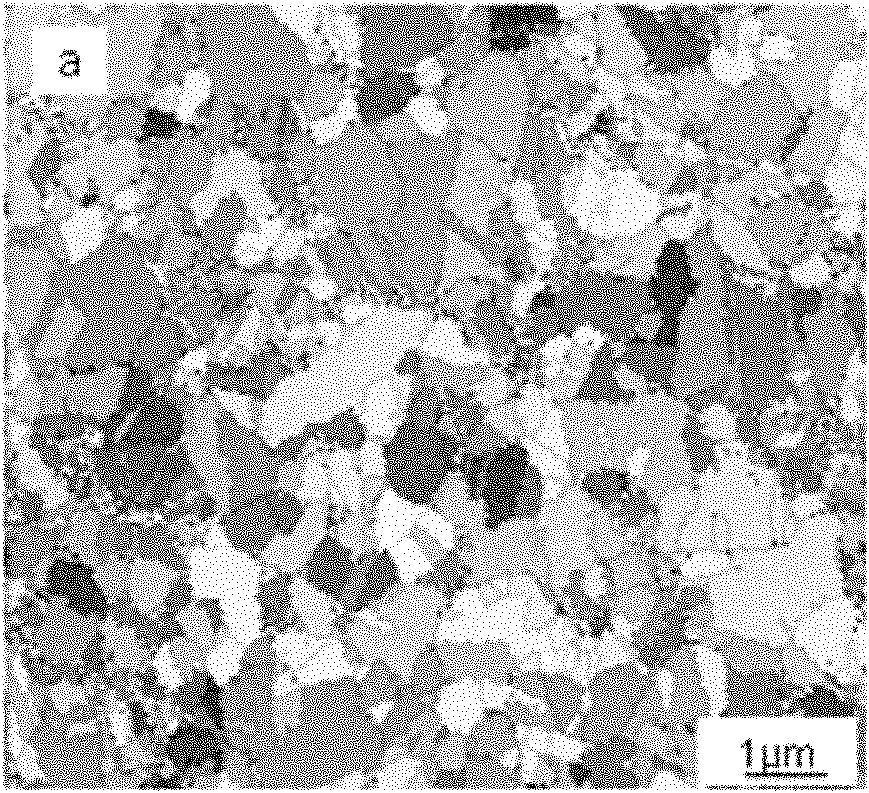

Compositions comprising rigid-rod polymers and carbon nanotubes and process for making the same

InactiveUS6900264B2High modulusHigh stiffnessMaterial nanotechnologySpecial tyresFiberLiquid crystalline

The present invention relates to compositions comprising rigid-rod polymers and carbon nanotubes. The compositions comprise dispersed carbon nanotubes aligned with rigid-rod polymers. The alignment of the nanotubes and polymers can be liquid crystalline. The rigid-rod polymers of this invention include, but are not limited to, polymers and copolymers comprising benzobisazole, pyridobisimidazole and benzamidazobenzo-phenanthroline repeat units. Dispersion of carbon nanotubes is achieved by in-situ polymerization in the presence of the carbon nanotubes, which may be either single-wall or multi-wall or a combination of both. The polymer compositions comprising carbon nanotubes may be spun into fibers or formed into films. The strength of the resulting fibers of the present invention is significantly greater than that of fibers without carbon nanotubes.

Owner:GEORGIA TECH RES CORP

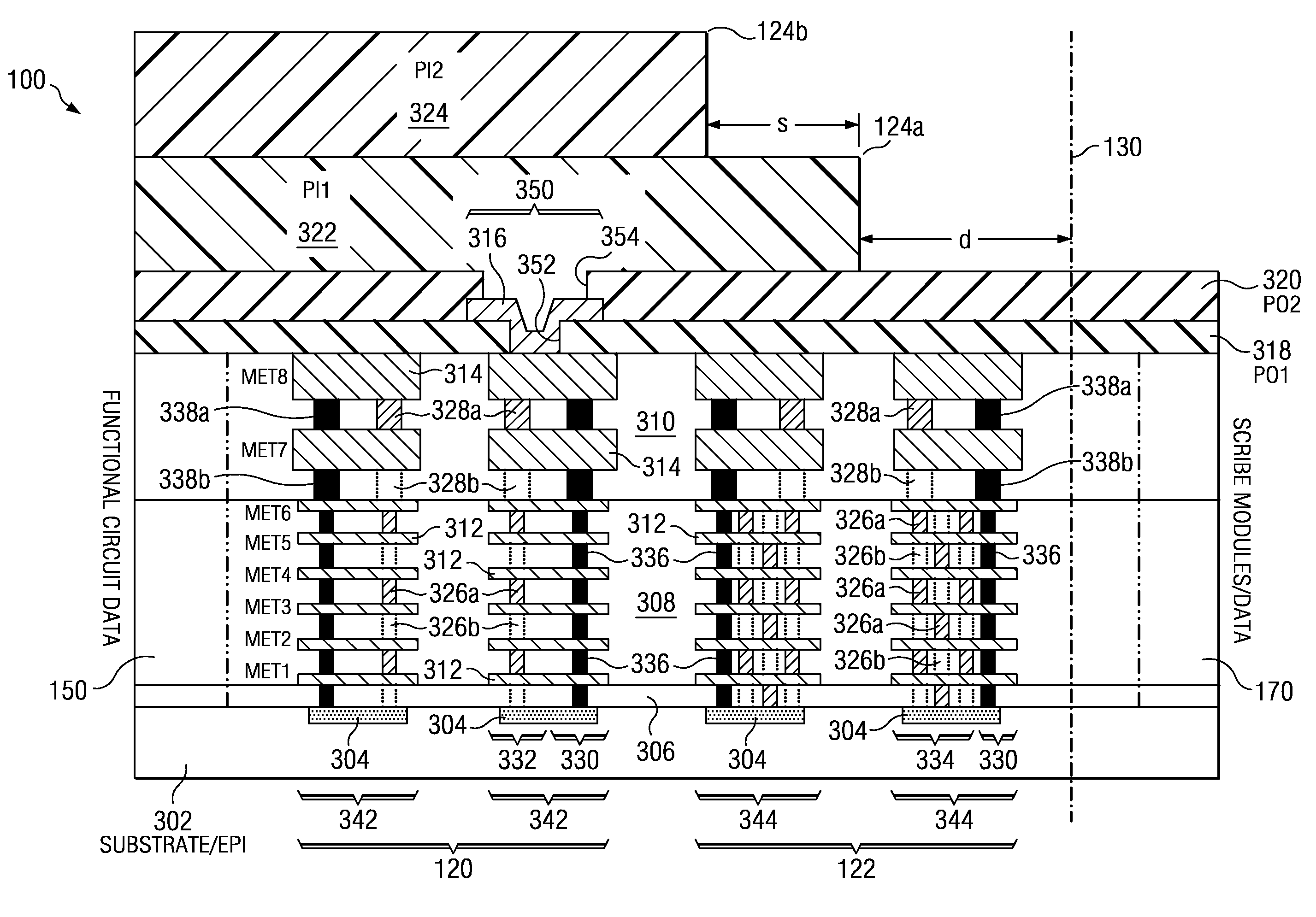

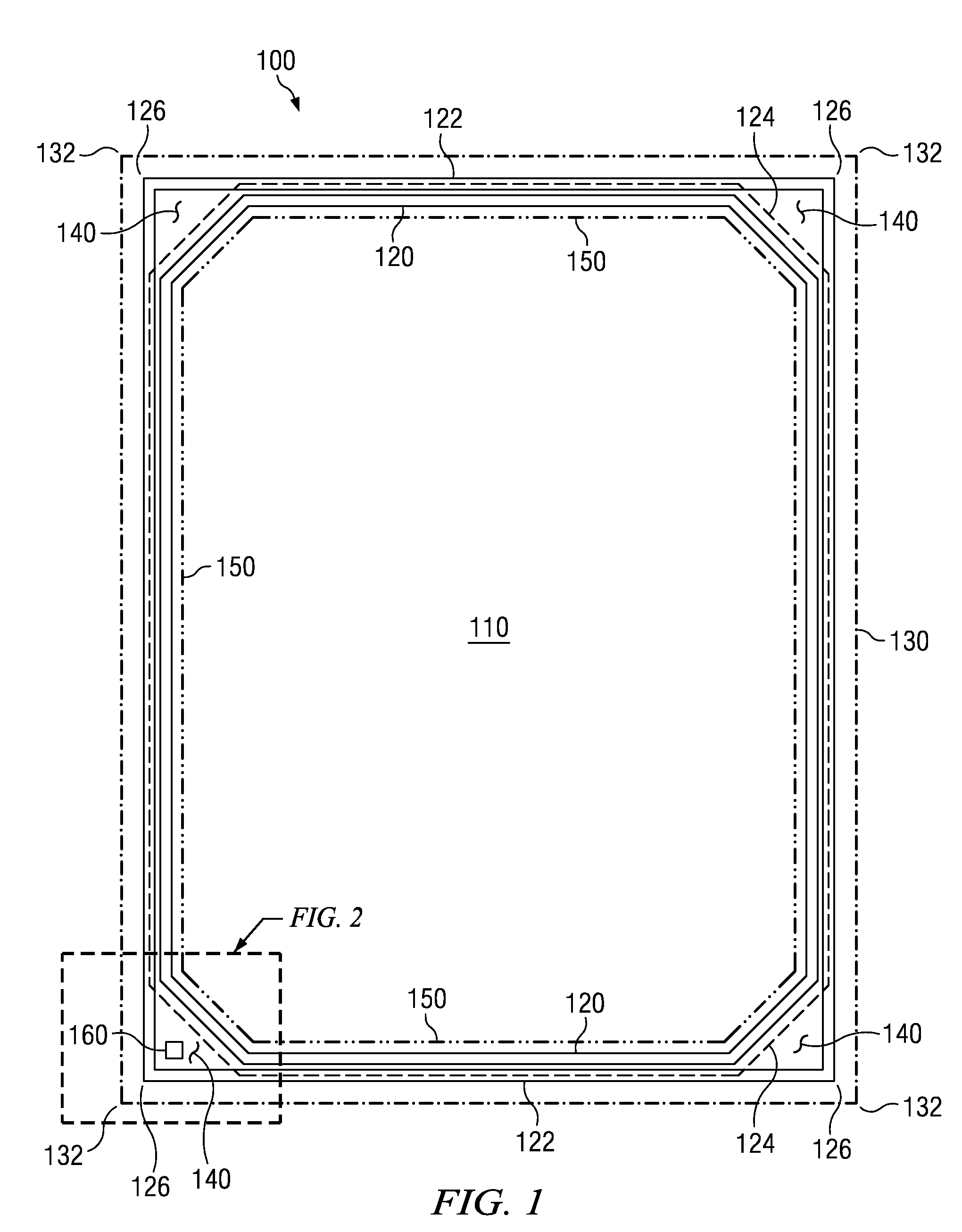

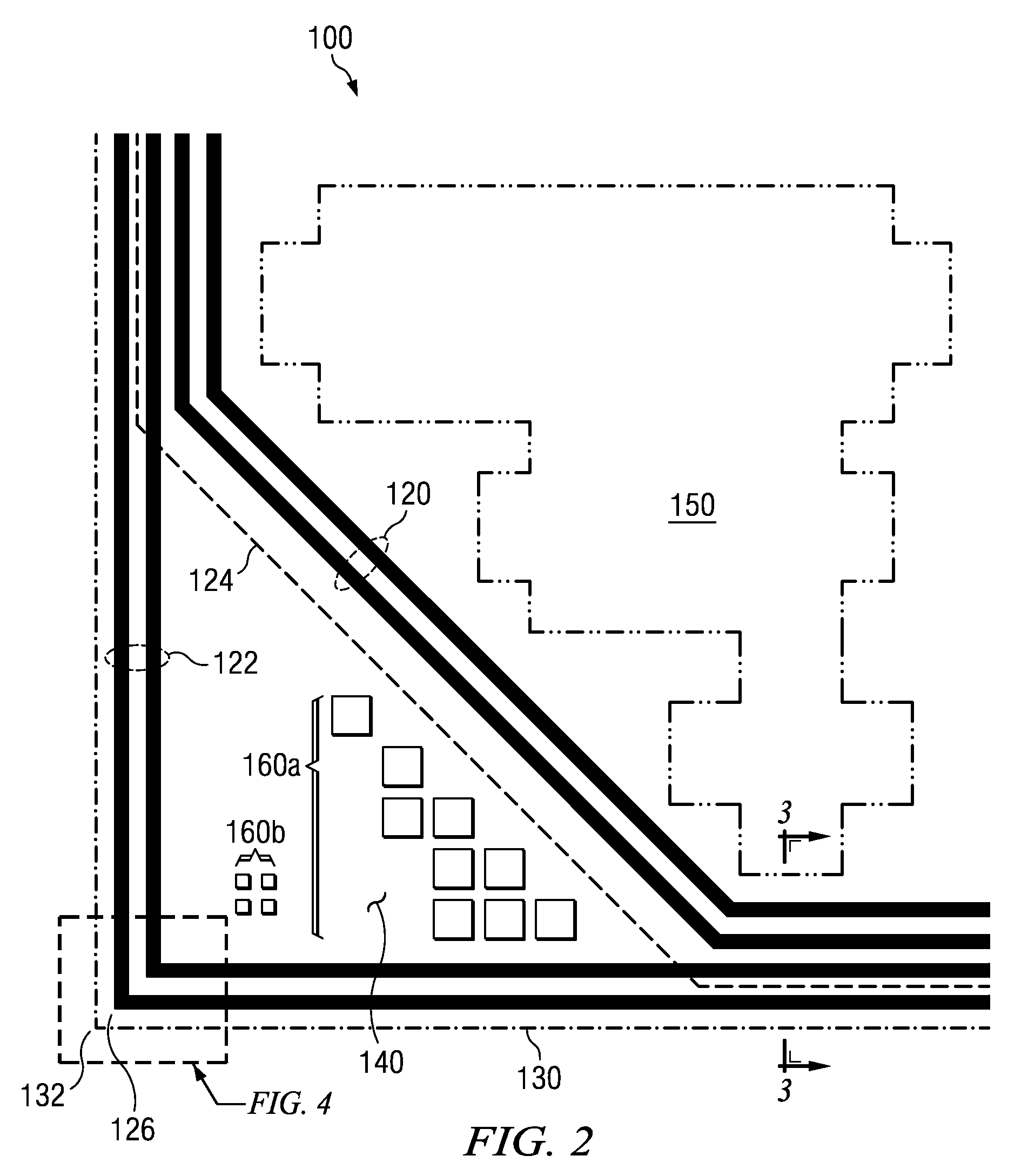

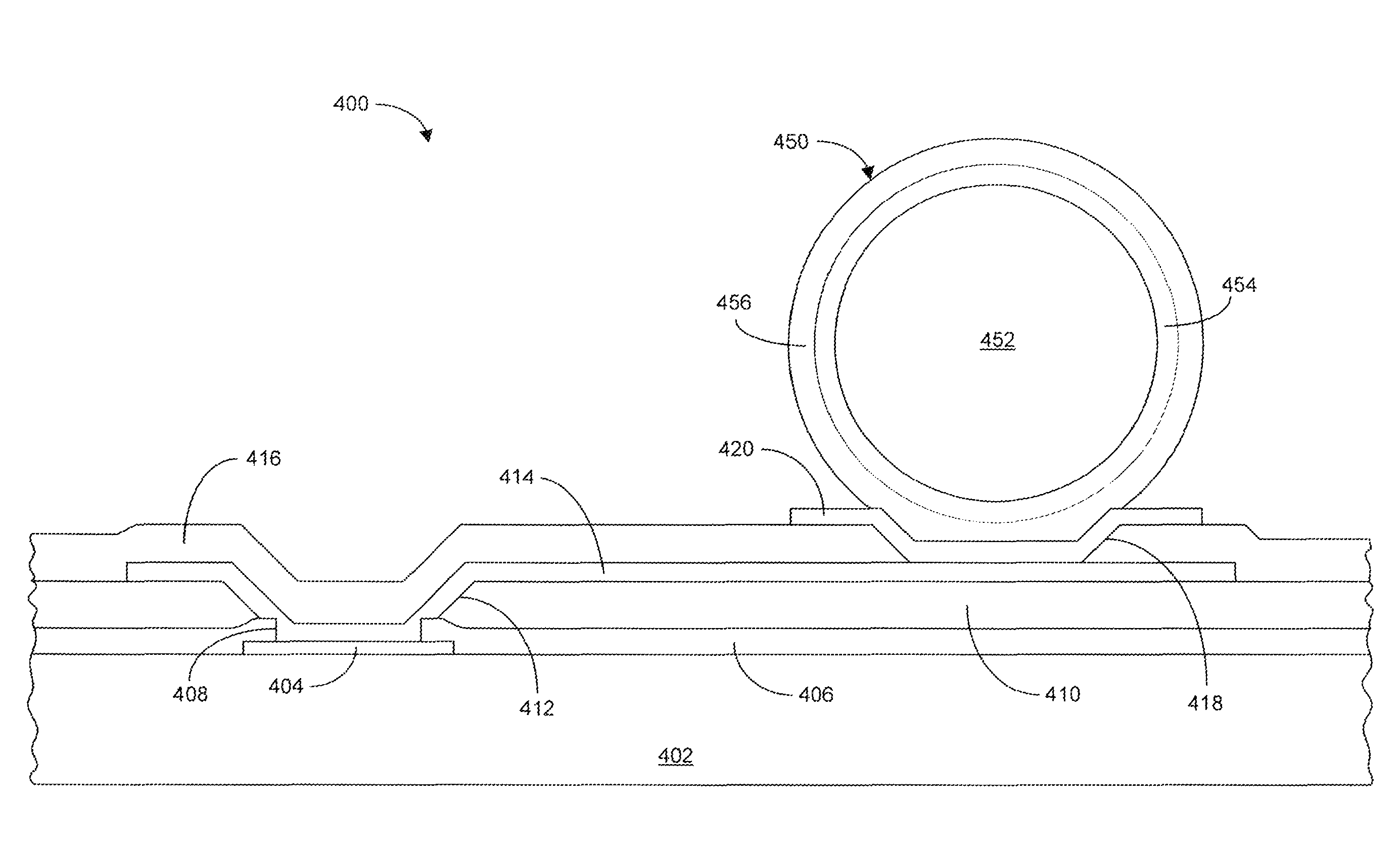

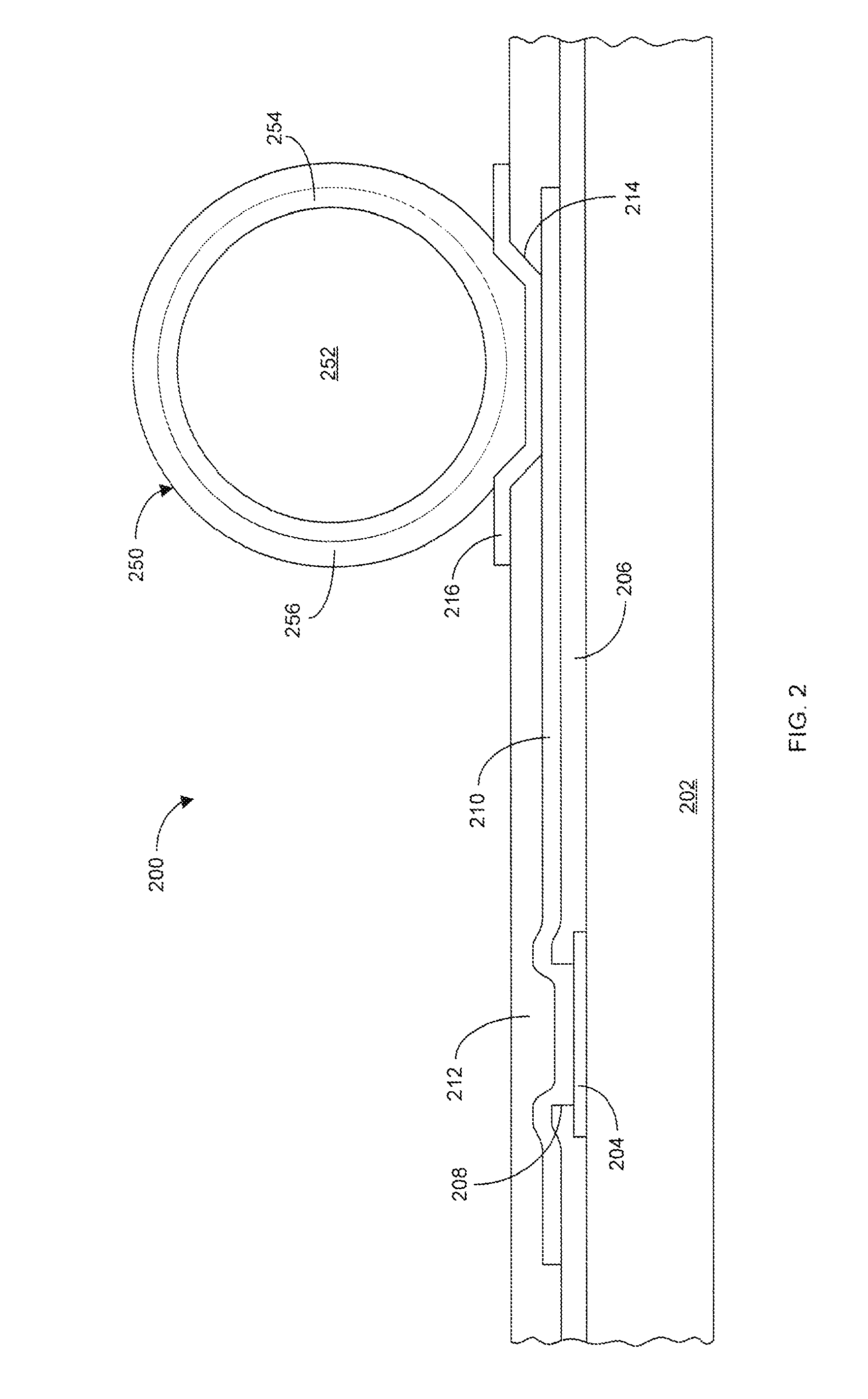

Environmental die seal enhancement for wafer level chip scale packages

ActiveUS20100078769A1Improve barrier propertiesImprove strength propertiesSemiconductor/solid-state device detailsSolid-state devicesMoisture penetrationEngineering

In a semiconductor device for use in a wafer level chip scale package (WLCSP) and a method for fabrication, an inner scribe seal is formed around a functional circuit area that does not extend all the way into the corners of the rectangular die, and an outer scribe seal follows the perimeter of the die and into the corners, with the outer scribe seal having a continuous barrier wall towards the die edges so that moisture penetration in dielectric layers of the die is minimized, and cracks and delamination are stopped near the die edges. Limiting the extent of the insulating layer or layers in the WLCSP to cover the functional circuit area also reduces the stresses caused by these layers near the die corners. Other features further enhance the strength and barrier properties of the scribe seals and the layers near the die corners, terminate cracks and delamination at various levels within the dielectric stack of the die and the die protective overcoat, and prevent damage during the WLCSP assembly process.

Owner:TEXAS INSTR INC

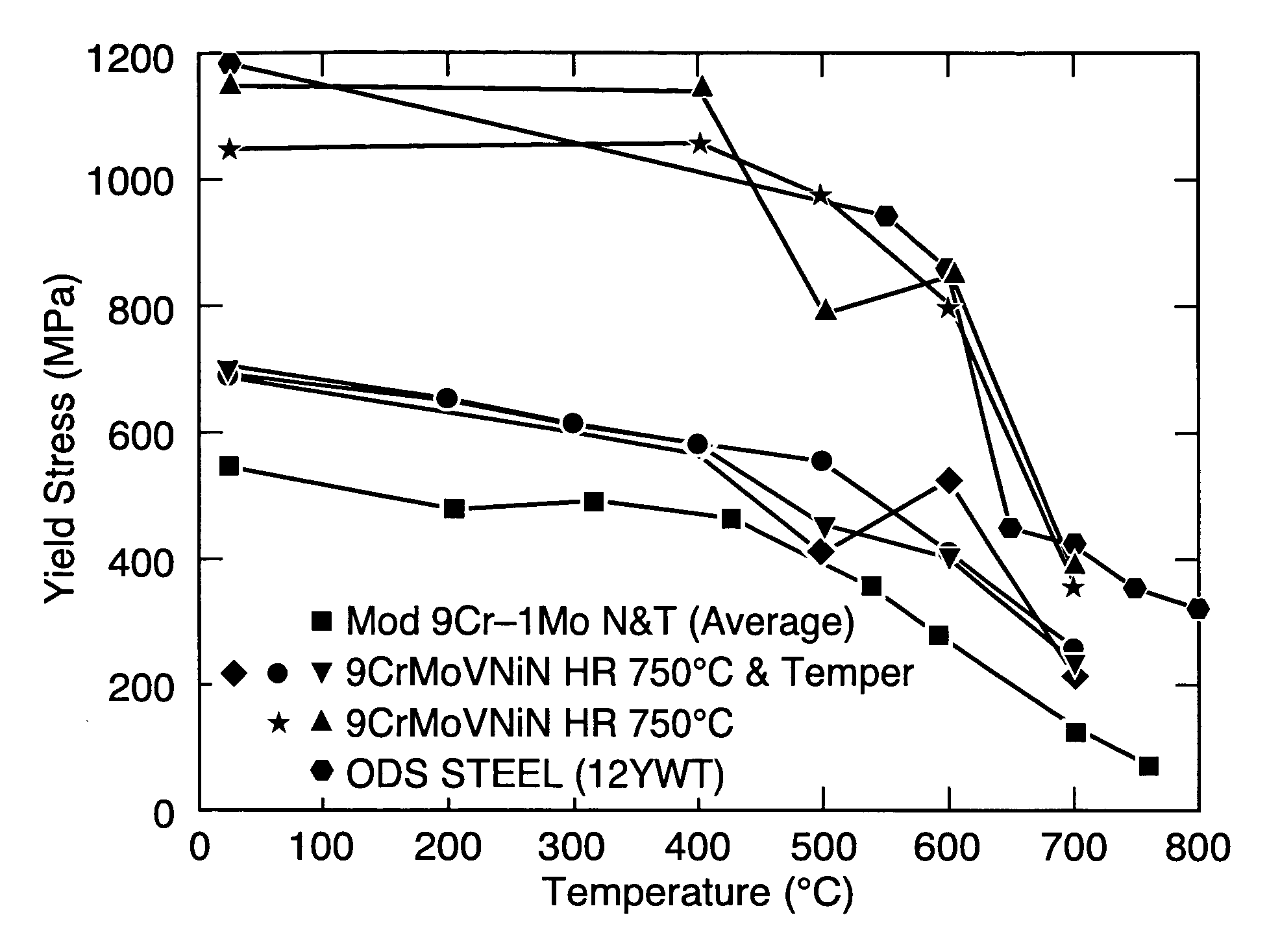

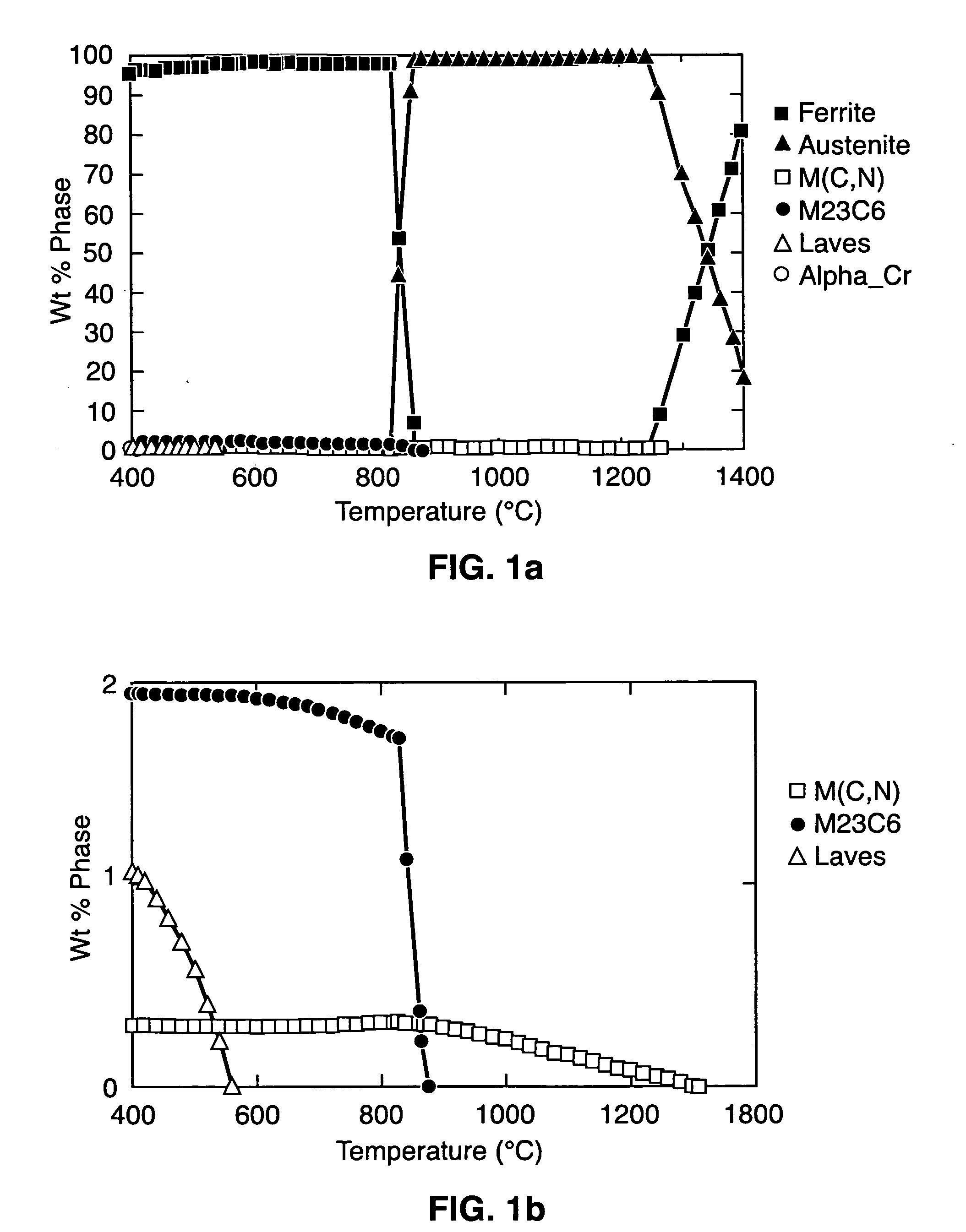

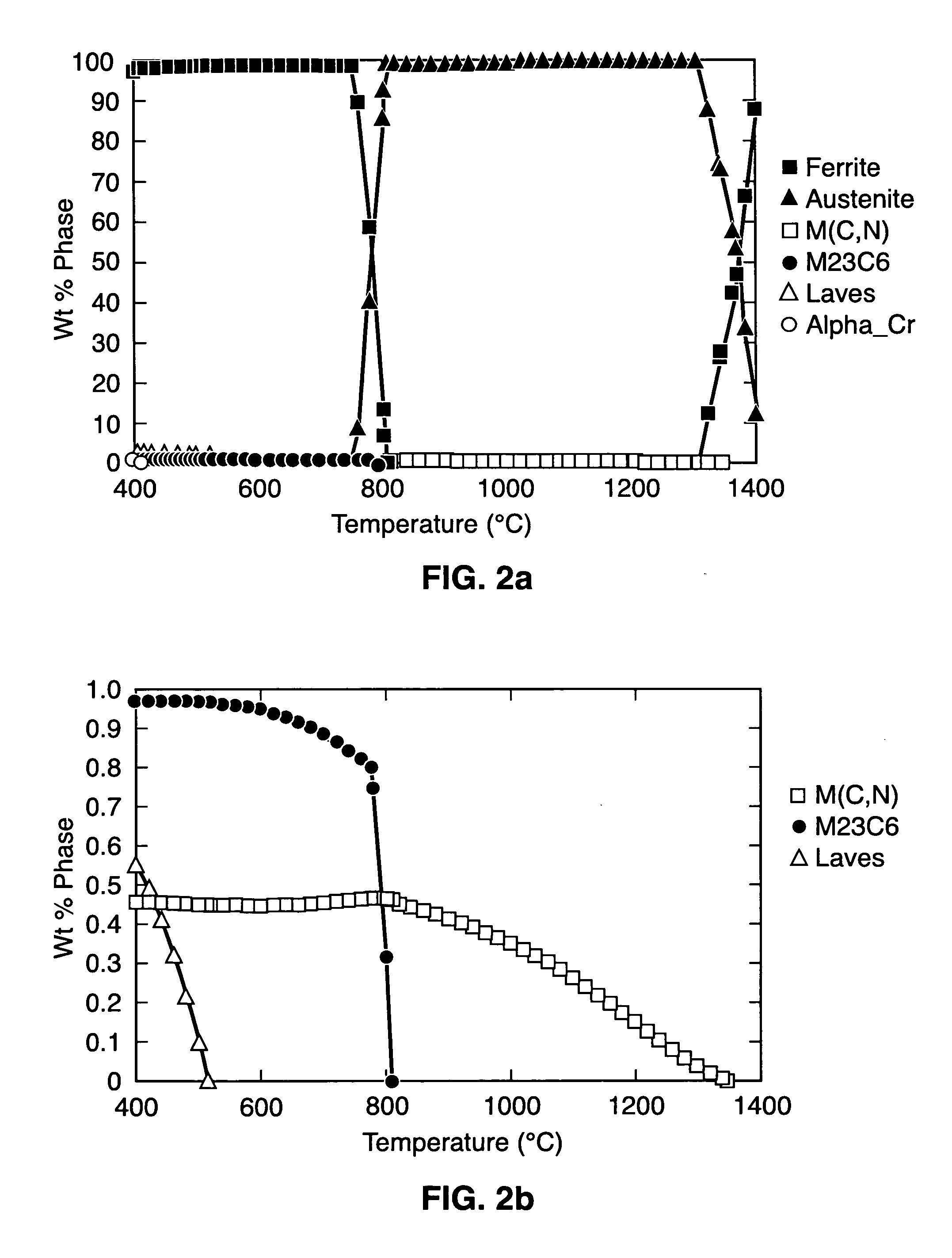

Nano-scale nitride-particle-strengthened high-temperature wrought ferritic and martensitic steels

InactiveUS20060060270A1Improved elevated-temperature strength propertyImprove strength propertiesFurnace typesHeat treatment furnacesHot workingNitride

A method of making a steel composition includes the steps of: a. providing a steel composition that includes up to 15% Cr, up to 3% Mo, up to 4% W, 0.05-1% V, up to 2% Si, up to 3% Mn, up to 10% Co, up to 3% Cu, up to 5% Ni, up to 0.3% C, 0.02-0.3% N, balance iron, wherein the percentages are by total weight of the composition; b. austenitizing the composition at a temperature in the range of 1000° C. to 1400° C.; c. cooling the composition of steel to a selected hot-working temperature in the range 500° C. to 1000° C.; d. hot-working the composition at the selected hot-working temperature; e. annealing the composition for a time period of up to 10 hours at a temperature in the range of 500° C. to 1000° C.; and f. cooling the composition to ambient temperature to transform the steel composition to martensite, bainite, ferrite, or a combination of those microstructures.

Owner:UT BATTELLE LLC

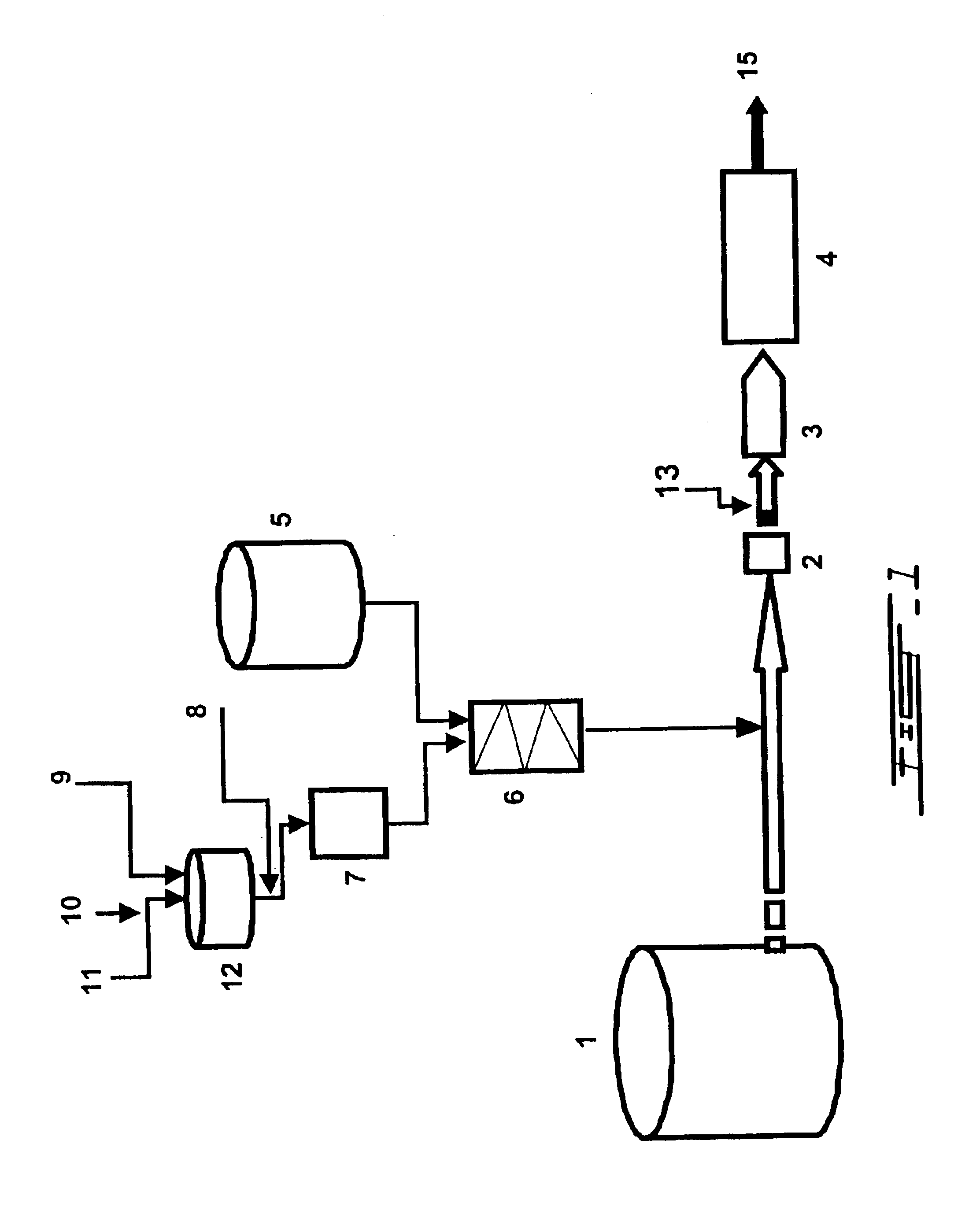

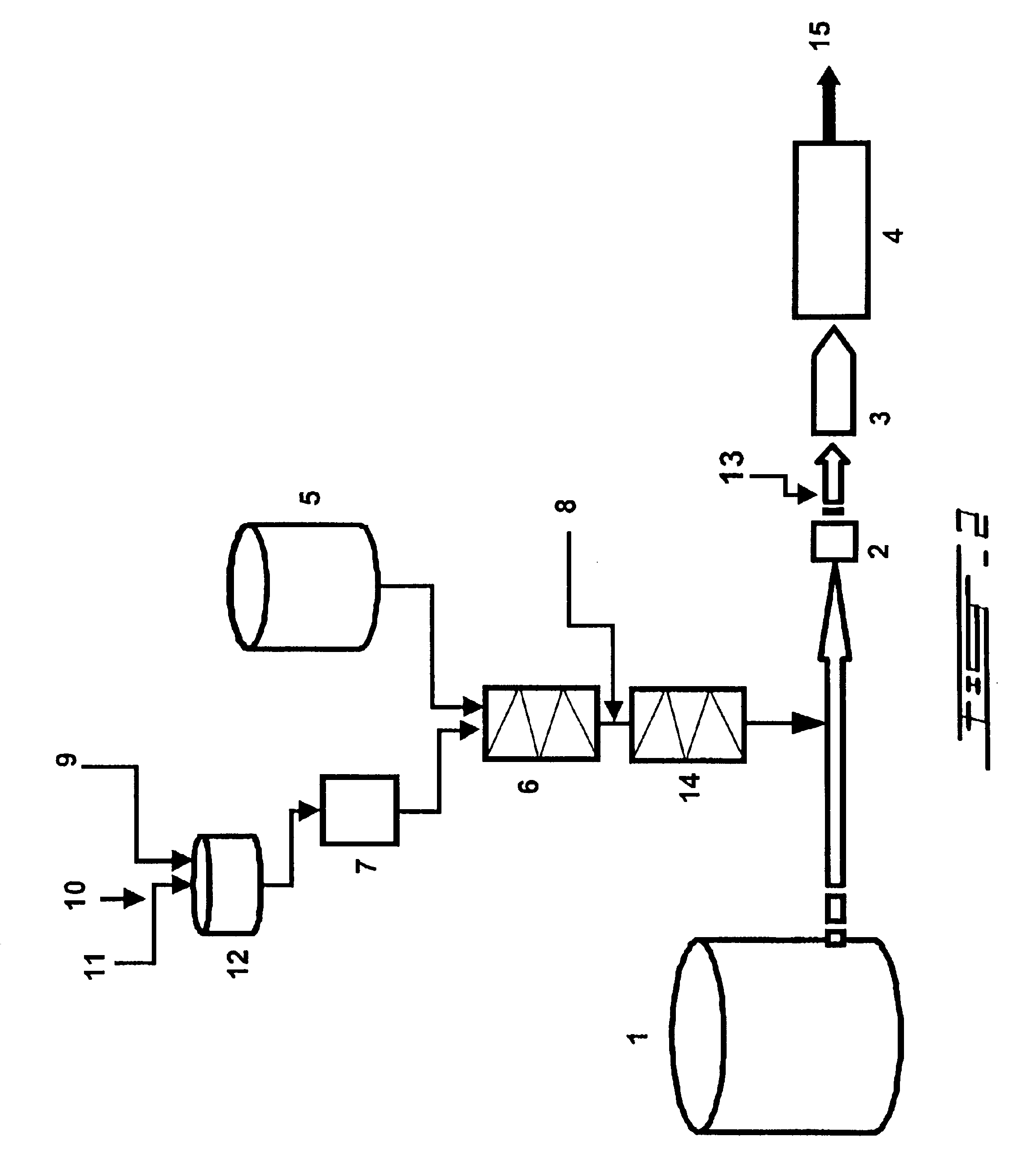

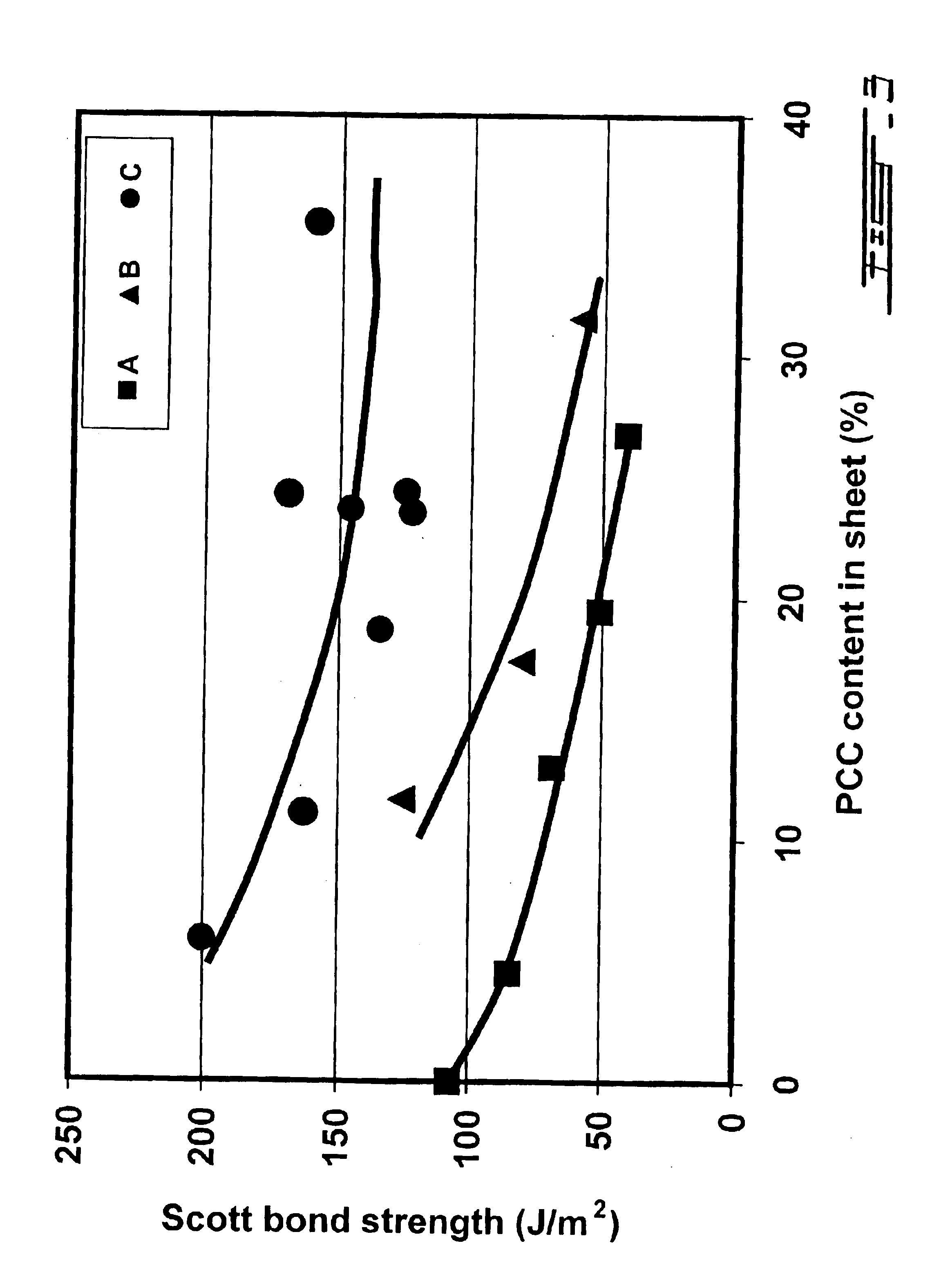

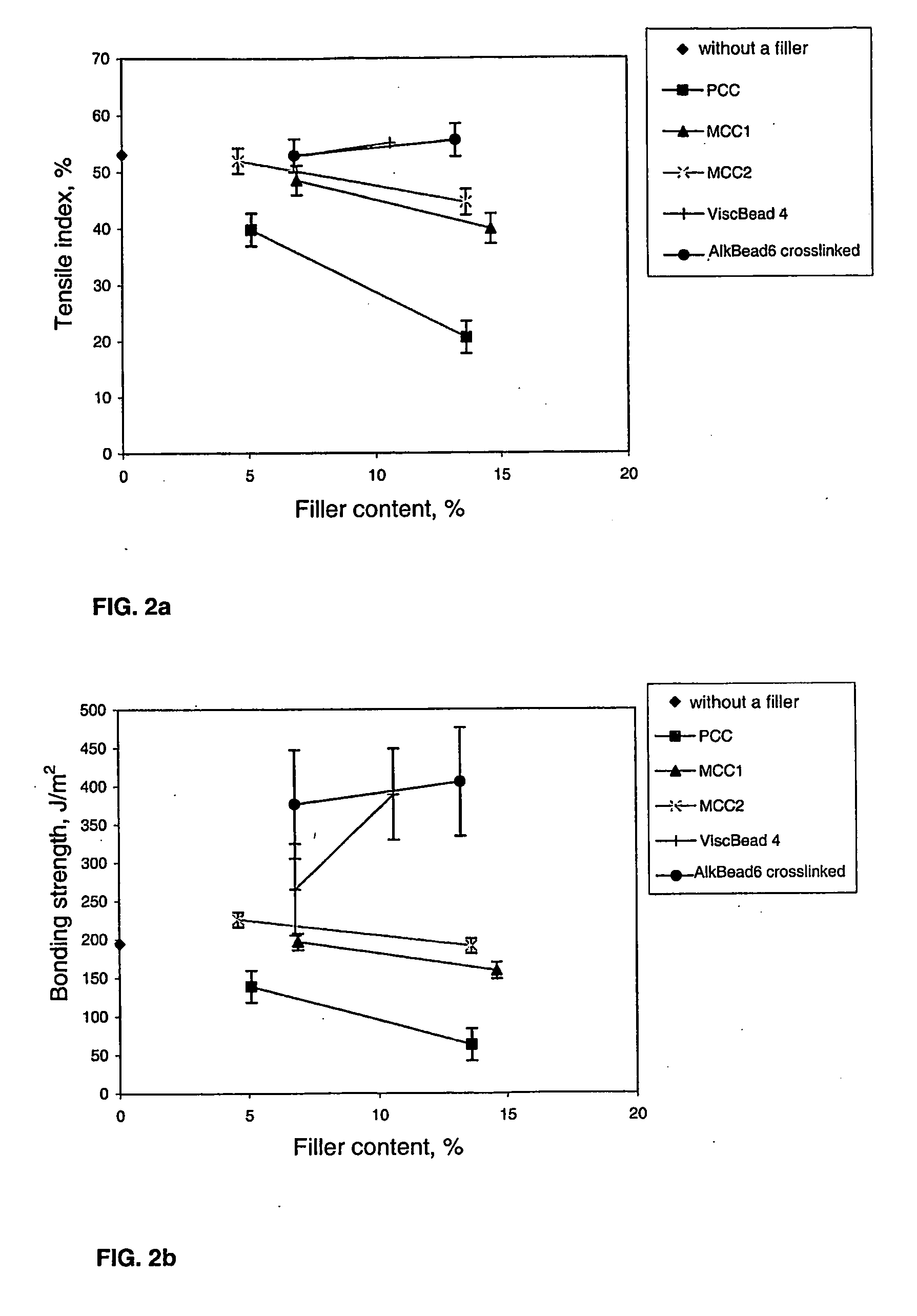

Swollen starch-latex compositions for use in papermaking

InactiveUS7074845B2High retention rateEasy to drainPigmenting treatmentNatural cellulose pulp/paperPaperboardPapermaking

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

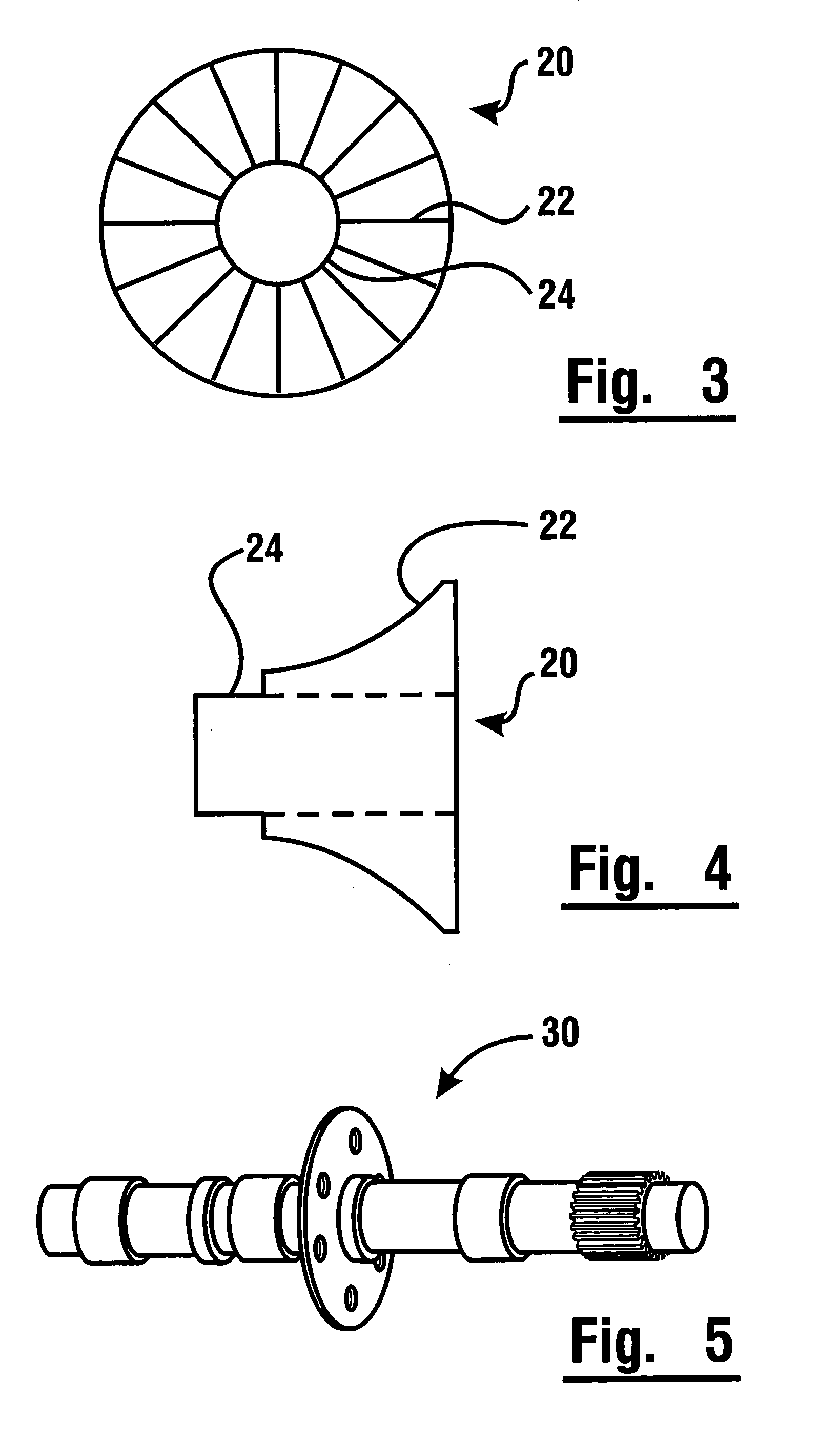

Nickel base superalloy turbine disk

InactiveUS6974508B1Favorable microstructuresImprove mechanical propertiesPropellersPump componentsImpellerRefractory

A low solvus, high refractory alloy having unusually versatile processing mechanical property capabilities for advanced disks and rotors in gas turbine engines. The nickel base superalloy has a composition consisting essentially of, in weight percent, 3.0–4.0 Al, 0.02–0.04 B, 0.02–0.05 C, 12.0–14.0 Cr, 19.0–22.0 Co, 2.0–3.5 Mo, greater than 1.0 to 2.1 Nb, 1.3 to 2.1 Ta, 3.0–4.0 Ti, 4.1 to 5.0 W, 0.03–0.06 Zr, and balance essentially Ni aid incidental impurities. The superalloy combines ease of processing with high temperature capabilities to be suitable for use in various turbine engine disk, impeller, and shaft applications. The Co and Cr levels of the superalloy can provide low solvus temperature for high processing versatility. The W, Mo, Ta, and Nb refractory element levels of the superalloy can provide sustained strength, creep, and dwell crack growth resistance at high temperatures.

Owner:NASA

Carbon Nanotube-Fiber Reinforced Cement And Concrete

InactiveUS20080134942A1Improve strength propertiesMeasurable strength enhancementCeramicwareReinforced concretePlasticizer

Carbon nanotubes (CNTs) are combined with cement, aggregate and plasticizers to form composites with increased strength. CNT reinforced concretes comprising cement, plasticizer, aggregate, and nanotubes, hydrated with water are disclosed. A mixture of CNTs, cement, and plasticizer can be prepared for later admixture with aggregates and water to form composites having improved strength characteristics. A method for increasing the strength of concrete comprising the steps of admixing CNTs and plasticizer's with cement, aggregate, and water for hydration is also disclosed.

Owner:BRENNER MATTHEW +2

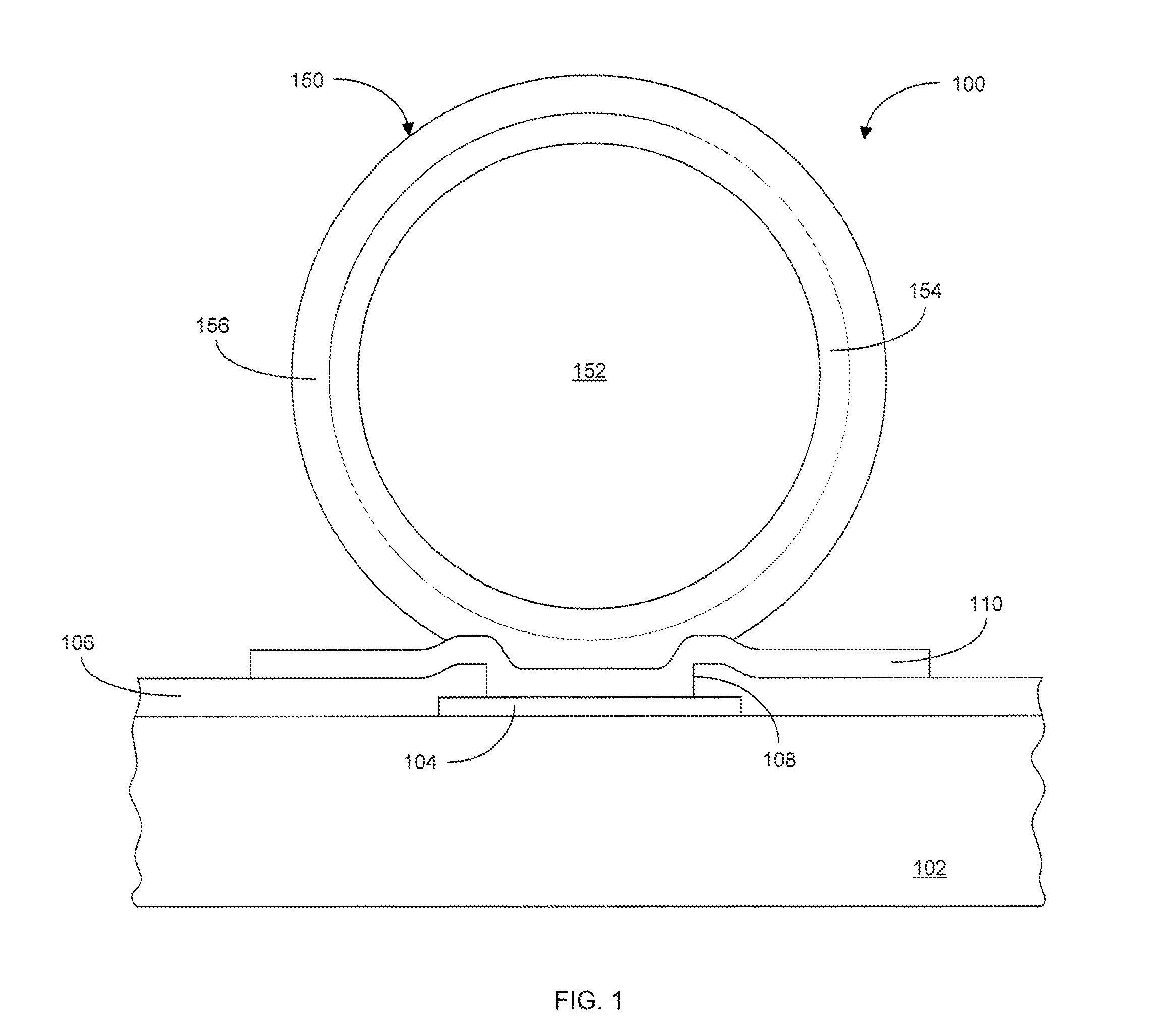

Wafer level package integrated circuit incorporating solder balls containing an organic plastic-core

ActiveUS8035226B1Increase resistanceHigh elongationSemiconductor/solid-state device detailsSolid-state devicesHigh resistanceElectrical resistance and conductance

An integrated circuit including solder balls containing an elastic or resilient material core, a hard or rigid shell substantially enclosing the core, and an electrical contact layer substantially enclosing the shell. The elastic or resilient core serves as a stress buffer layer in a wafer level package (WLP) integrated circuit. The elastic or resilient material core may include an organic plastic material, such as a Divinilbenzene cross-linked co-polymer of relatively high resistance. This material has a relatively good elongation property so that it can effectively absorb forces exerted upon the integrated circuit by, for example, the flexing of a printed circuit board (PCB) or other structure to which the integrated circuit is attached. The hard or rigid shell serves to contain the elastic or resilient core and may include copper. The electrical contact layer serve to provide a good adhesive electrical contact to an under bump metallization (UBM) layer, may include a lead free, Tin-Gold (SnAg) material.

Owner:MAXIM INTEGRATED PROD INC

Heat-resistant aluminum-alloy conductor material for cables and manufacture method thereof

InactiveCN101948971AImprove creep resistanceHigh tensile strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare-earth elementElectrical conductor

The invention relates to a heat-resistant aluminum-alloy conductor material for cables and a manufacture method thereof. The aluminum-alloy conductor material is prepared from the following components in percentage by weight: 0.3-1.0 percent of Fe, 0.01-0.3 percent of Cu, 0.01-0.3 percent of Mg, 0.01-0.3 percent of one, two or three of Mg, Ca, Mo and Sb and 0.05-0.8 percent of one or more rear-earth elements of Sc, Y and Er, not larger than 0.1 percent of Si, not larger than 0.15 percent of other impurities and the balance of Al. The aluminum-alloy conductor material has excellent conductivity, tensile performance, flexible performance and excellent heat resistance, can be used as insulated cable cores of wires and cables and is particularly suitable for overhead insulated conductor wire cores.

Owner:绩溪欣意圣厚源电缆有限公司

Binder compositions for making fiberglass products

ActiveUS20120064323A1Improve methodImprove strength propertiesCosmetic preparationsLiquid surface applicatorsGlass fiberCopolymer

Fiberglass mats, binder compositions, and methods for making the same are provided. The fiberglass mat can include a plurality of glass fibers and an at least partially cured binder composition. The binder composition, prior to at least partial curing, can include a first copolymer modified by reaction with one or more base compounds. The first copolymer can include one or more unsaturated carboxylic acids, one or more unsaturated carboxylic anhydrides, or a combination thereof, and one or more vinyl aromatic derived units. The first copolymer can have a weight average molecular weight (Mw) of about 500 to about 200,000. The first copolymer can be present in an amount ranging from about 60 wt % to about 95 wt %, based on a combined weight of the first copolymer and the one or more base compounds.

Owner:GEORGIA PACIFIC CHEM LLC

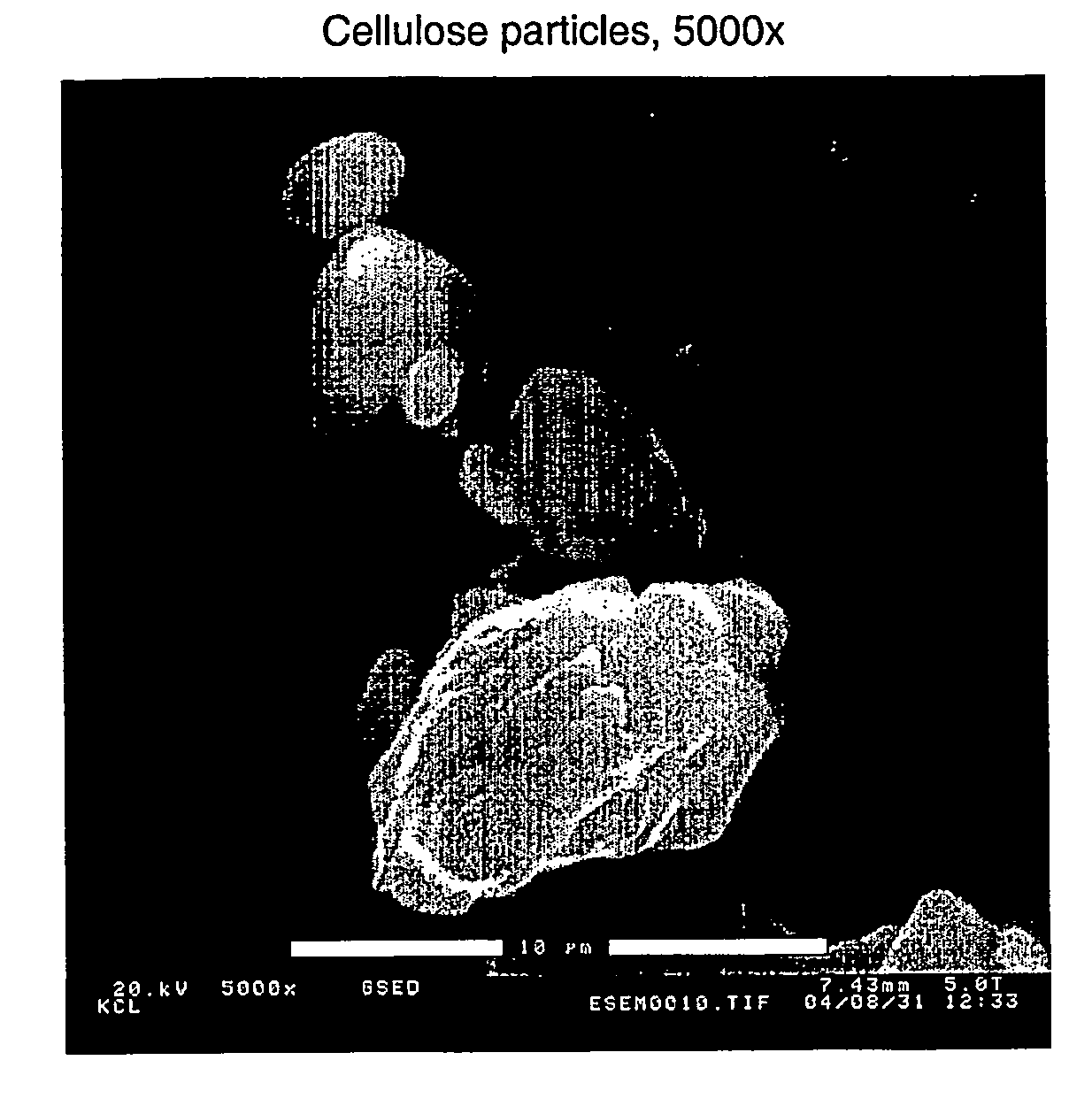

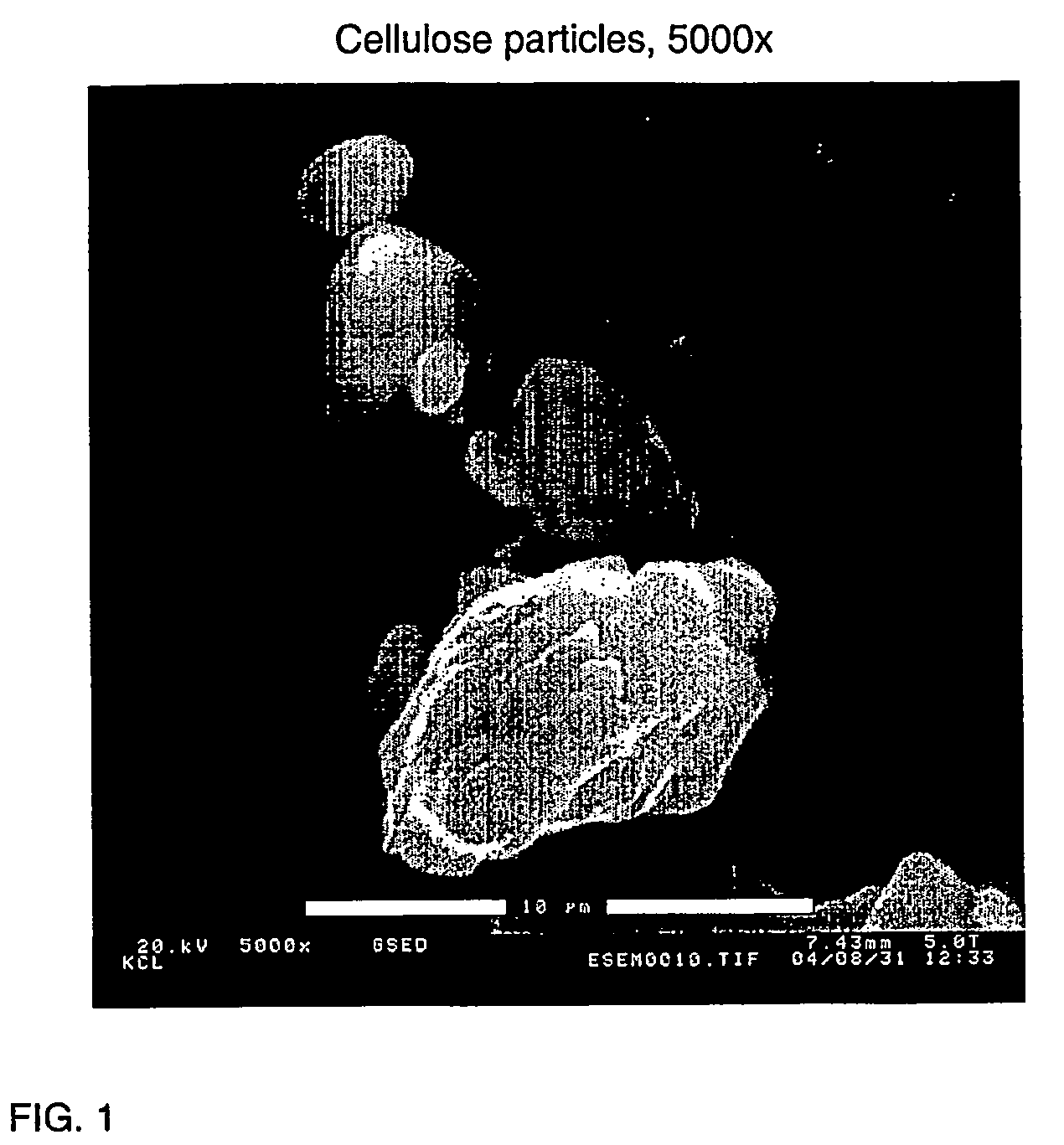

Method for Dissolving Cellulose and for Producing Cellulose Particles

InactiveUS20090014902A1Improve strength propertiesNon-fibrous pulp additionPaper coatingCardboardPigment

The invention relates to a method for dissolving cellulose e.g. for the production of regenerated cellulose products such as films, fibres, particles and the like. In said method, the cellulose material is dissolved using an enzymatic treatment, followed by a base treatment. The invention is also directed to a method for producing cellulose particles wherein cellulose dissolved as described above is sprayed or mixed into a regenerating solution for precipitating cellulose particles. Moreover, the invention relates to the use of said cellulose particles produced with this method as a filler and / or coating pigment of paper and board. The invention is also directed to methods for producing and coating paper and board.

Owner:SAPPI NETHERLANDS SERVICES

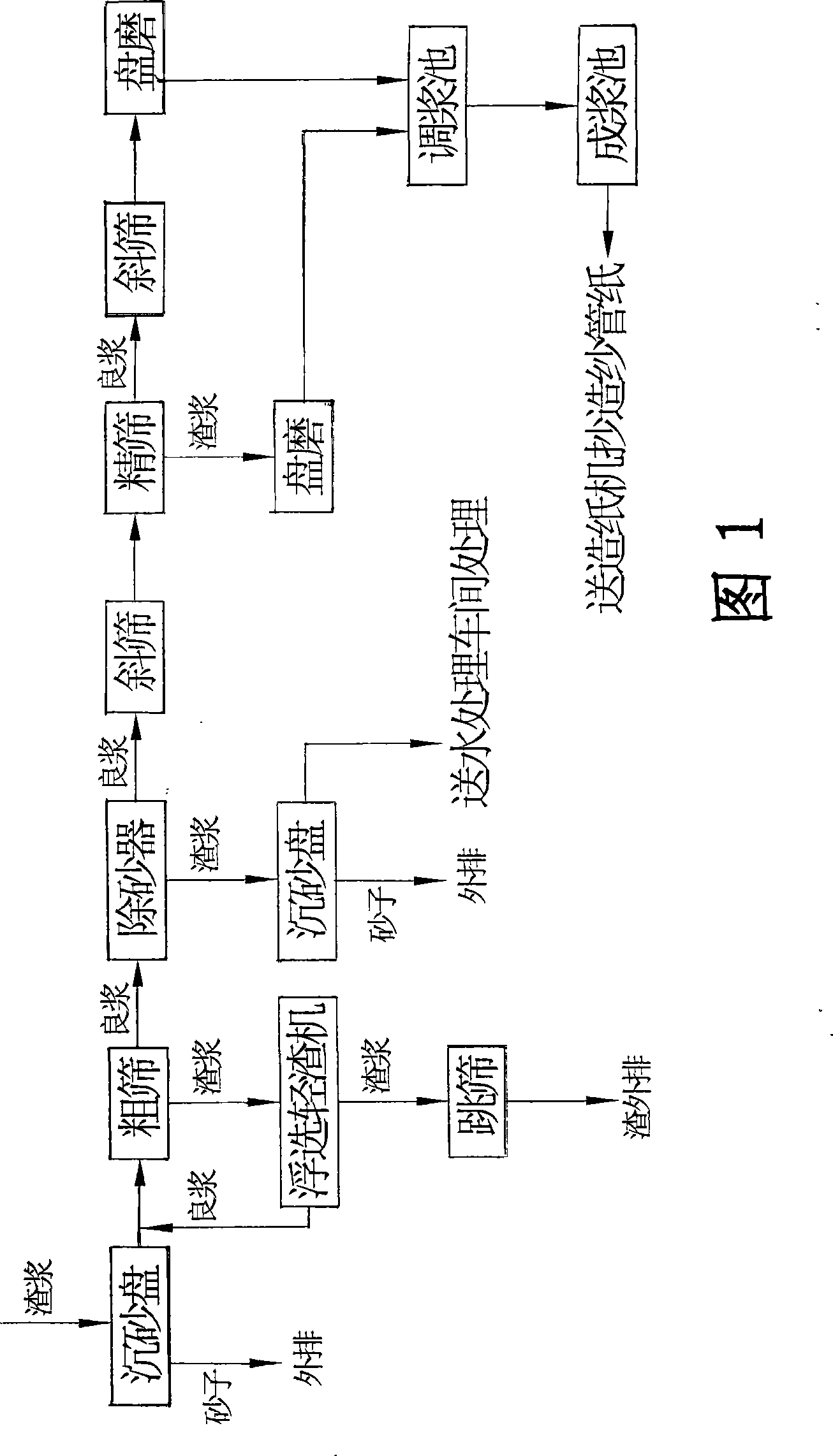

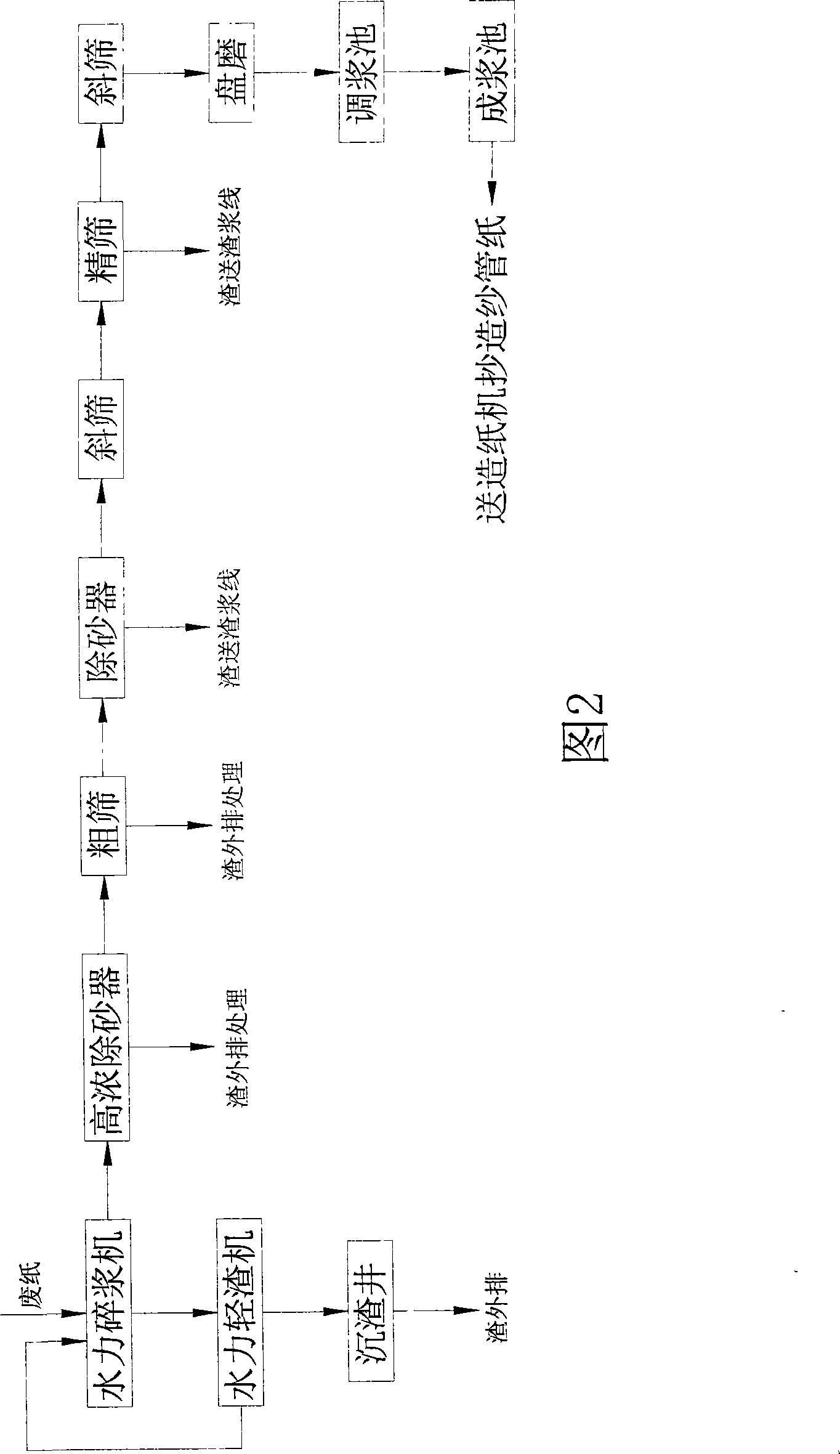

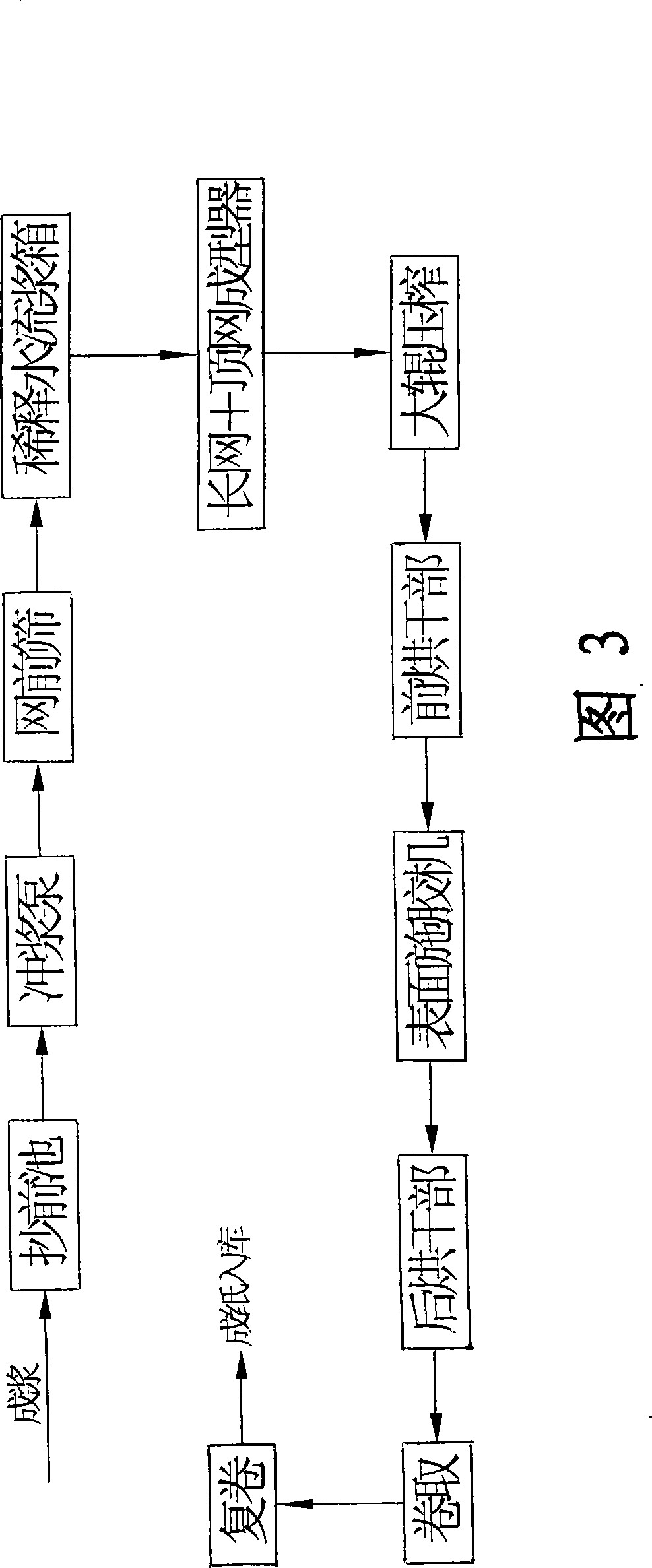

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

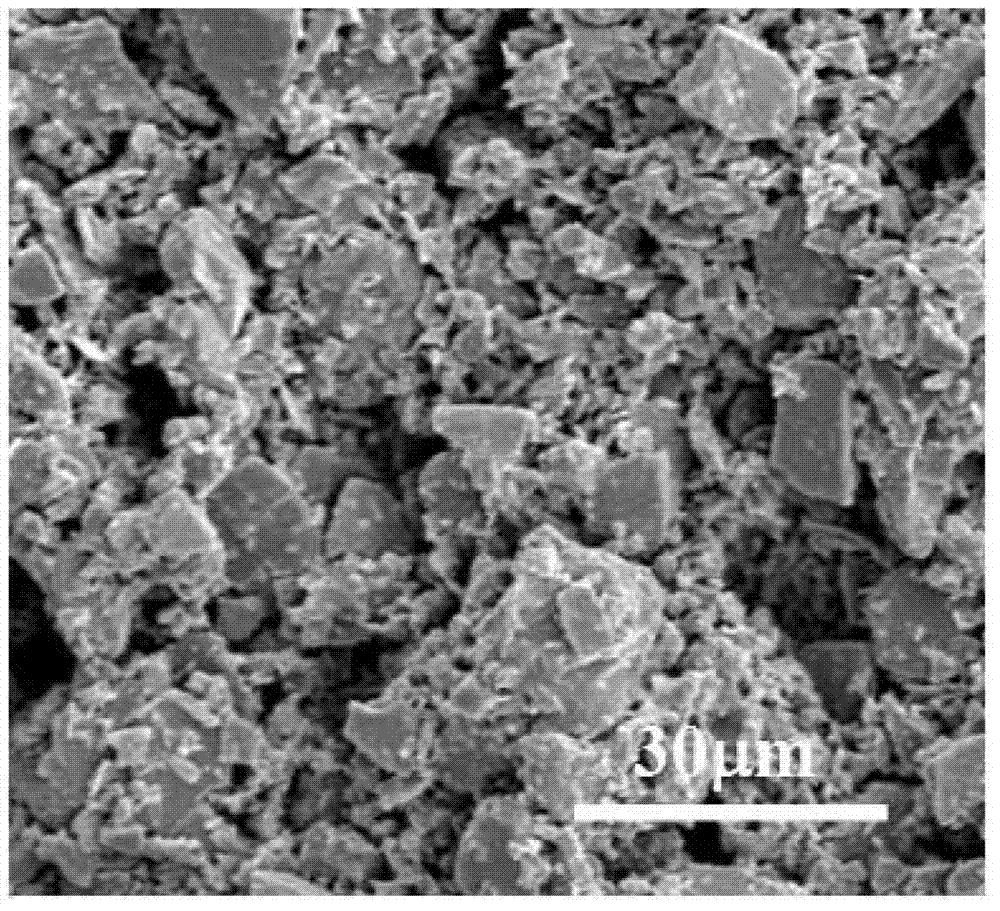

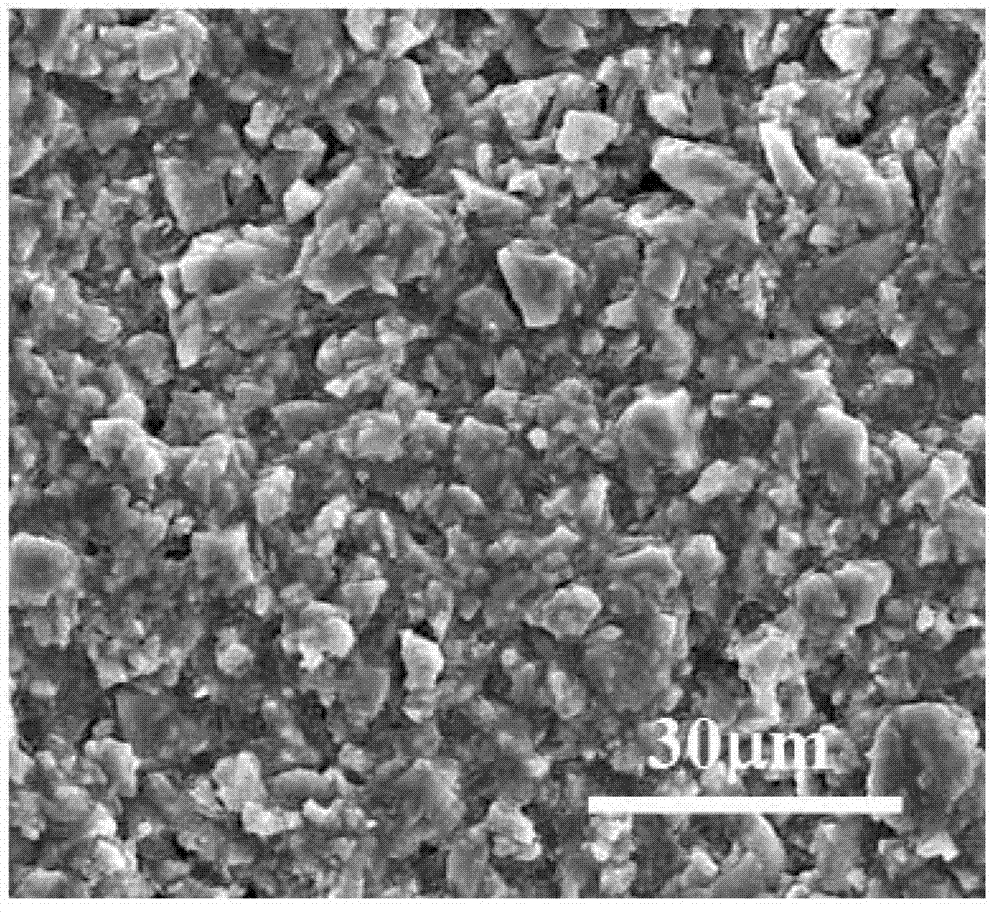

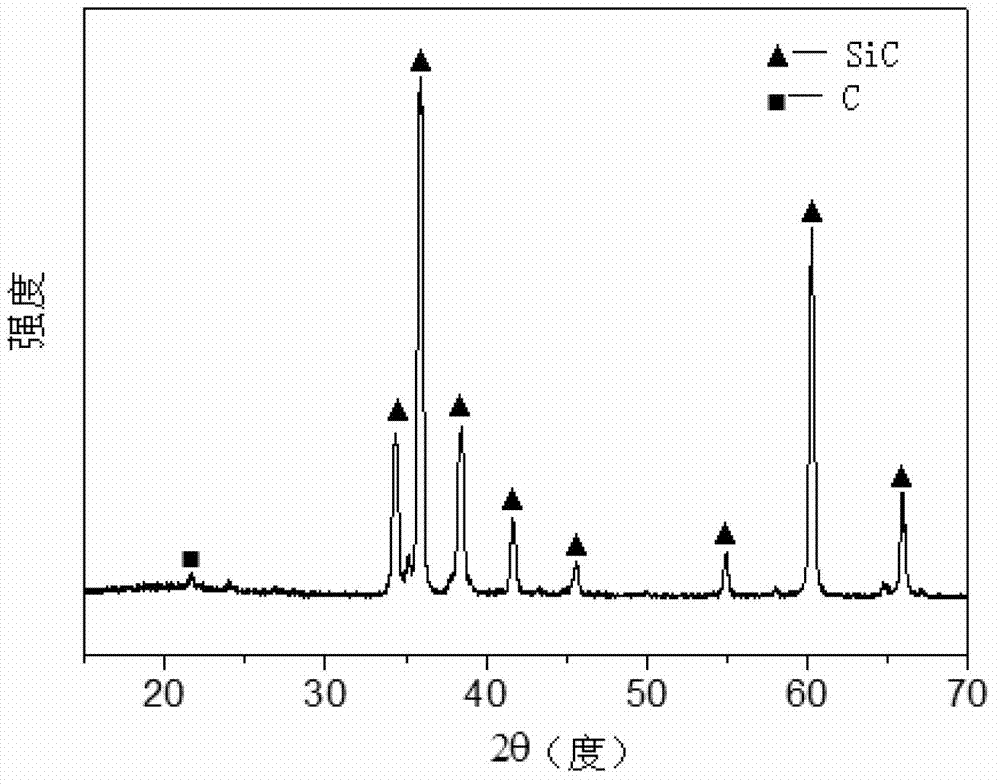

Method for preparing porous silicon carbide ceramic

ActiveCN102807391AImprove strength propertiesLow costCeramicwareSilica fumeMechanical properties of carbon nanotubes

The invention discloses a method for preparing porous silicon carbide ceramic, and relates to a method for preparing silicon carbide ceramic. The invention aims to solve the technical problems of low mechanical properties and low porosity of porous silicon carbide ceramic prepared through the existing method. The method comprises the following steps of 1, preparing pulp; 2, preparing a porous ceramic green body; 3, preparing a prefabricated body; 4, preparing carbon gel; 5, preparing a composite material of silicon carbide and the carbon gel; 6, preparing a composite material of porous silicon carbide and carbon aerogel; and 7, putting the composite material of the porous silicon carbide and the carbon aerogel and monatomic silicon powder into a sintering furnace to be sintered to obtain the porous silicon carbide ceramic. The porosity of the opening of the porous silicon carbide is 30-83 percent, the aperture size is 0.3-100m, and pore spaces can be uniformly distributed or directionally arranged. Through a three-point bending test, the bending strength of the finally prepared porous silicon carbide ceramic material with the porosity of 47.8 percent achieves 164.62 MPa.

Owner:HARBIN INST OF TECH

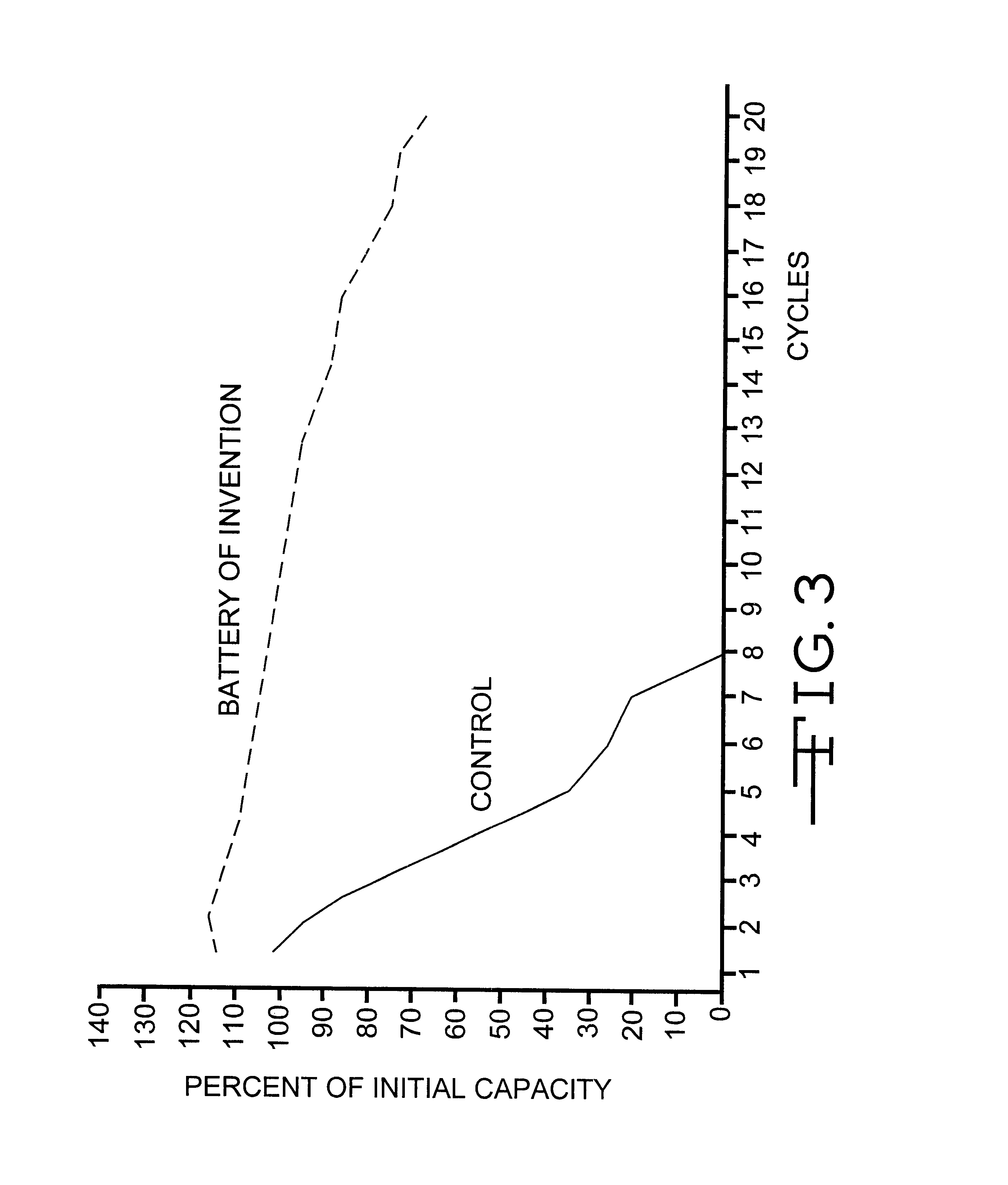

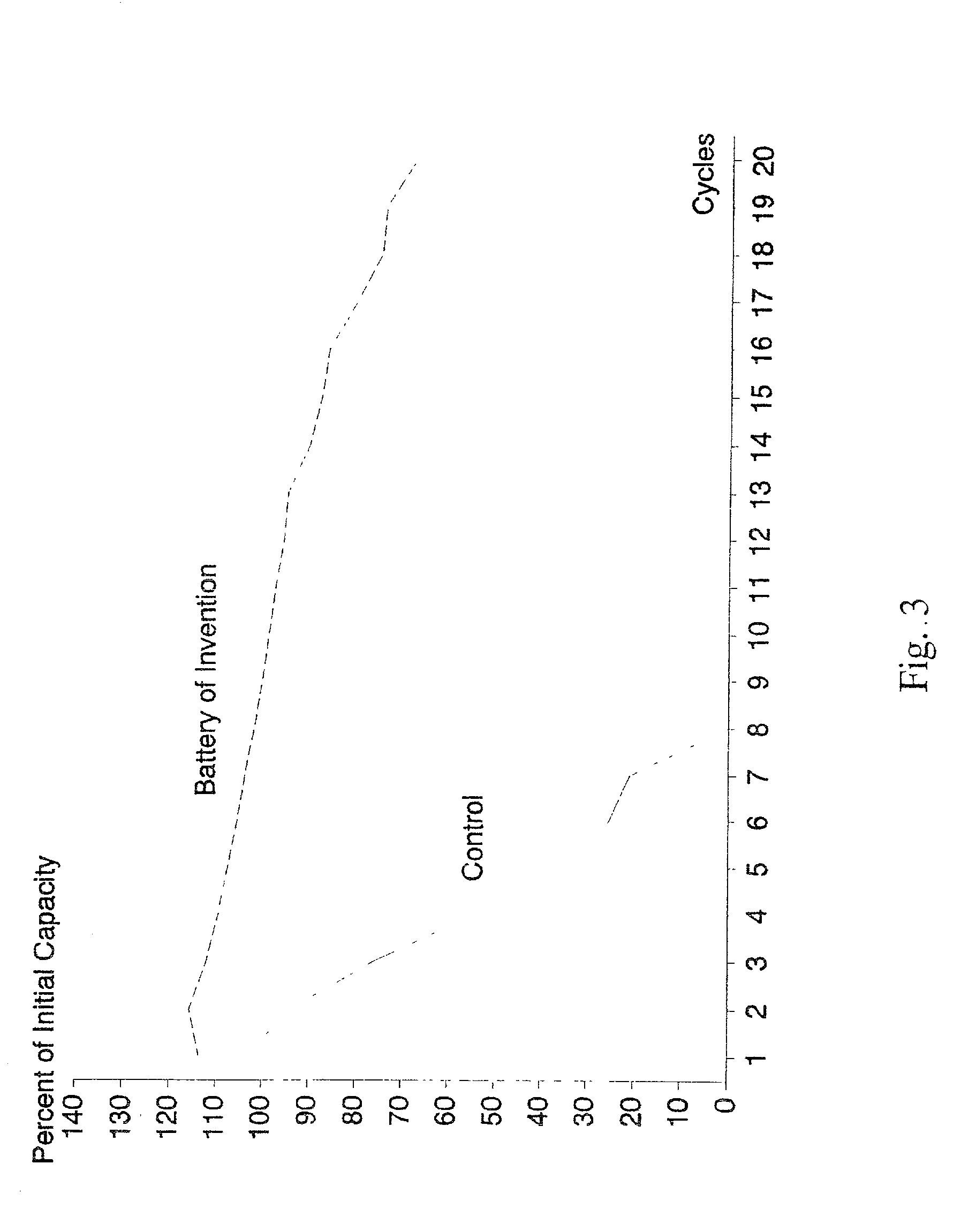

Glass fiber separators for lead-acid batteries

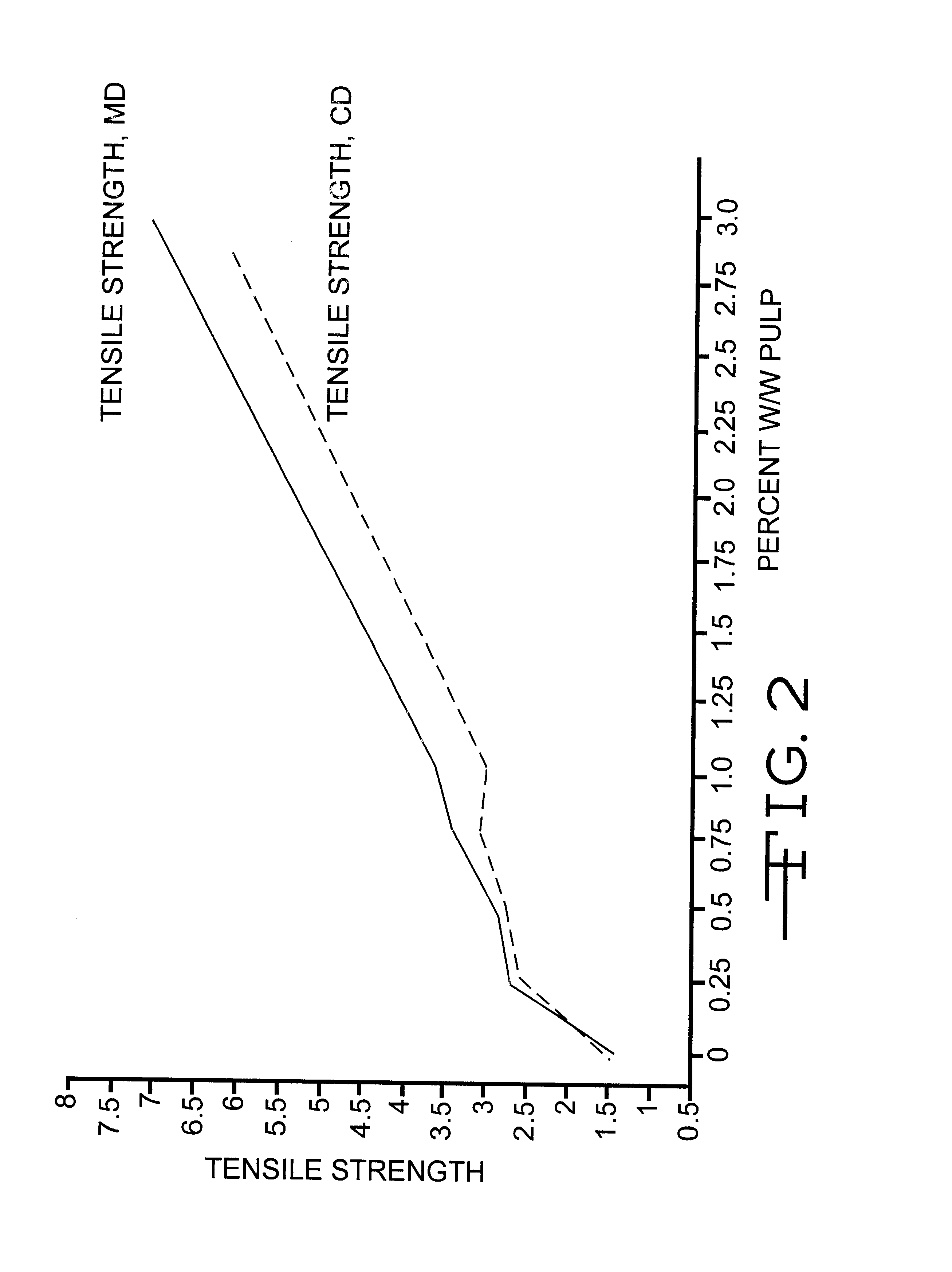

InactiveUS6495286B2Improve strength propertiesImprove the immunityLead-acid accumulatorsCell component detailsCelluloseGlass fiber

A glass fiber separator material is disclosed. The separator is composed of a mass of intermeshed glass fibers substantially all of which have a fiber diameter not greater than about 20 mum, and at least 5 percent w / w of which have a fiber diameter less than 1 mum, and, distributed through the glass fibers, and from 0.2 percent w / w to 20 percent w / w of cellulose fibrils. The fibrils are from a slurry having a Canadian freeness sufficiently low that the separator material has a tensile strength greater than an otherwise identical separator where glass fibers having an average diameter greater than 1 mum replace the cellulose fibrils.

Owner:HOLLINGSWORTH VOSE

Solid supported comb-branched copolymers as an additive for gypsum compositions

InactiveUS6869988B2Significant commercial advantageImprove strength propertiesSolid waste managementGypsumCopolymer

A gypsum composition suitable for use in the manufacture of gypsum products is provided. The gypsum composition includes gypsum, water, and a solid dispersant comprising a supported acrylic / polyether comb-branched copolymer. A method of making a gypsum composition is also provided. The method includes mixing together, in any combination, gypsum, water, and a solid dispersant comprising a supported acrylic / polyether comb-branched copolymer.

Owner:COATEX SA

Urethane polymer compositions

ActiveUS20030232956A1Increasing ultimate cohesive strengthImprove responseAdhesive processesPolyureas/polyurethane adhesivesPolymer sciencePolyol

Owner:ROHM & HAAS CO

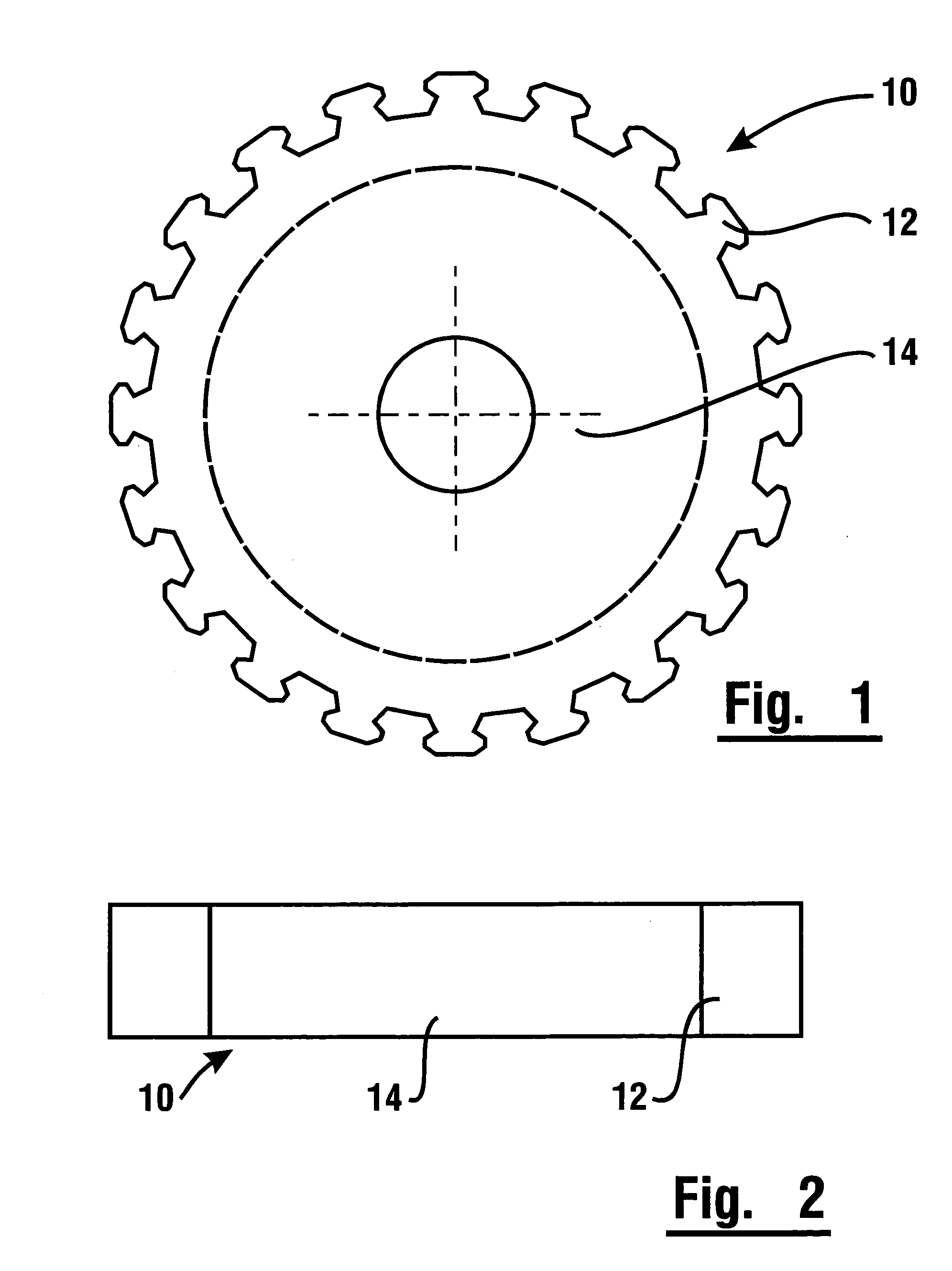

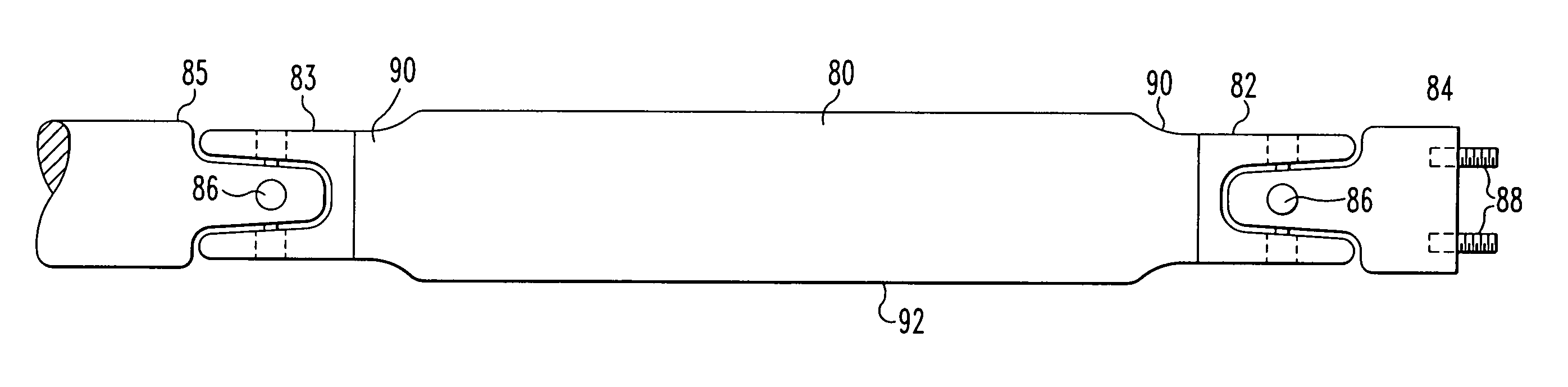

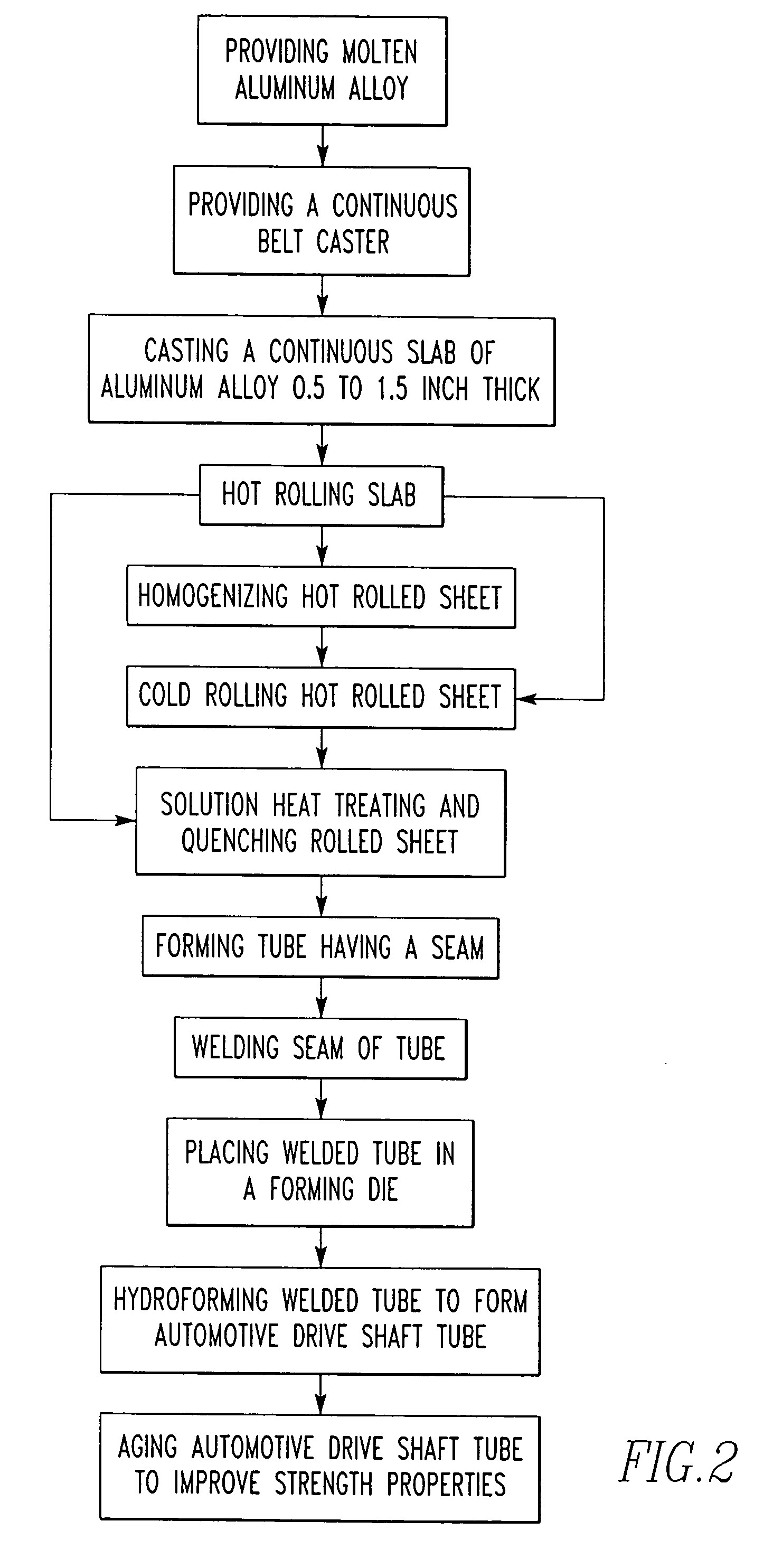

Aluminum automotive drive shaft

InactiveUS6959476B2Improve strength propertiesMetal rolling stand detailsShaftsDrive shaftSeam welding

A method for producing aluminum drive shafts from molten aluminum alloy using a continuous caster to cast the alloy into a slab. The method comprises providing a molten aluminum alloy consisting essentially of 0.2 to 0.8 wt. % Si, 0.05 to 0.4 wt. % Cu, 0.45 to 1.2 wt. % Mg, 0.04 to 0.35 wt. % Cr, 0.7 wt. % max. Fe, 0.15 wt. % max. Mn, 0.25 wt. % max. Zn, 0.15 wt. % max. Ti, the remainder aluminum, incidental elements and impurities and providing a continuous caster such as a belt caster for continuously casting the molten aluminum alloy. The molten aluminum alloy is cast into a slab which is rolled into a sheet product. After solution heat treatment, the sheet product is formed into a tube having a seam which is welded to provide a seam welded tube. The seam welded tube is placed in a forming die and hydroformed to form the drive shaft.

Owner:COMMONWEALTH INDS

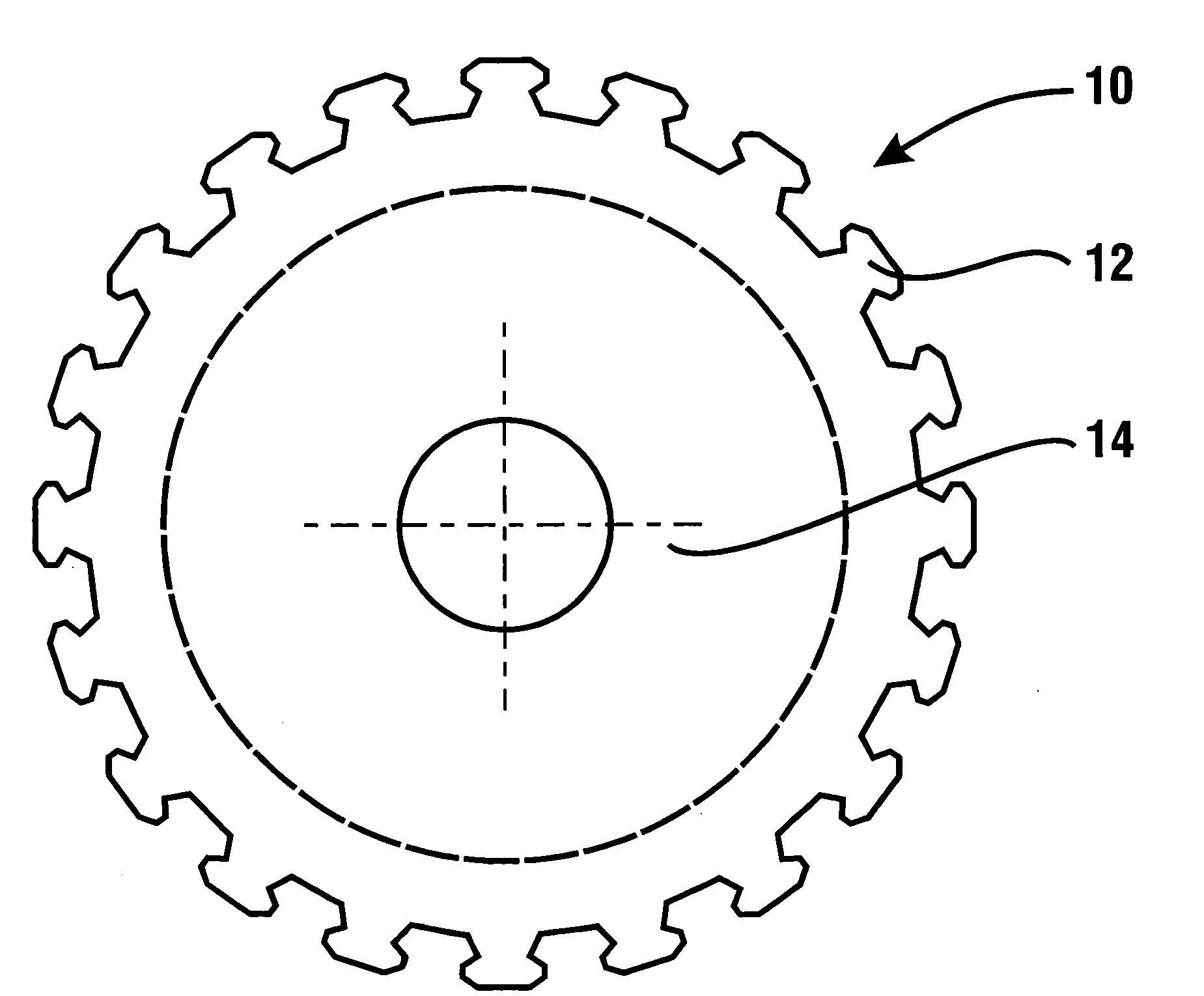

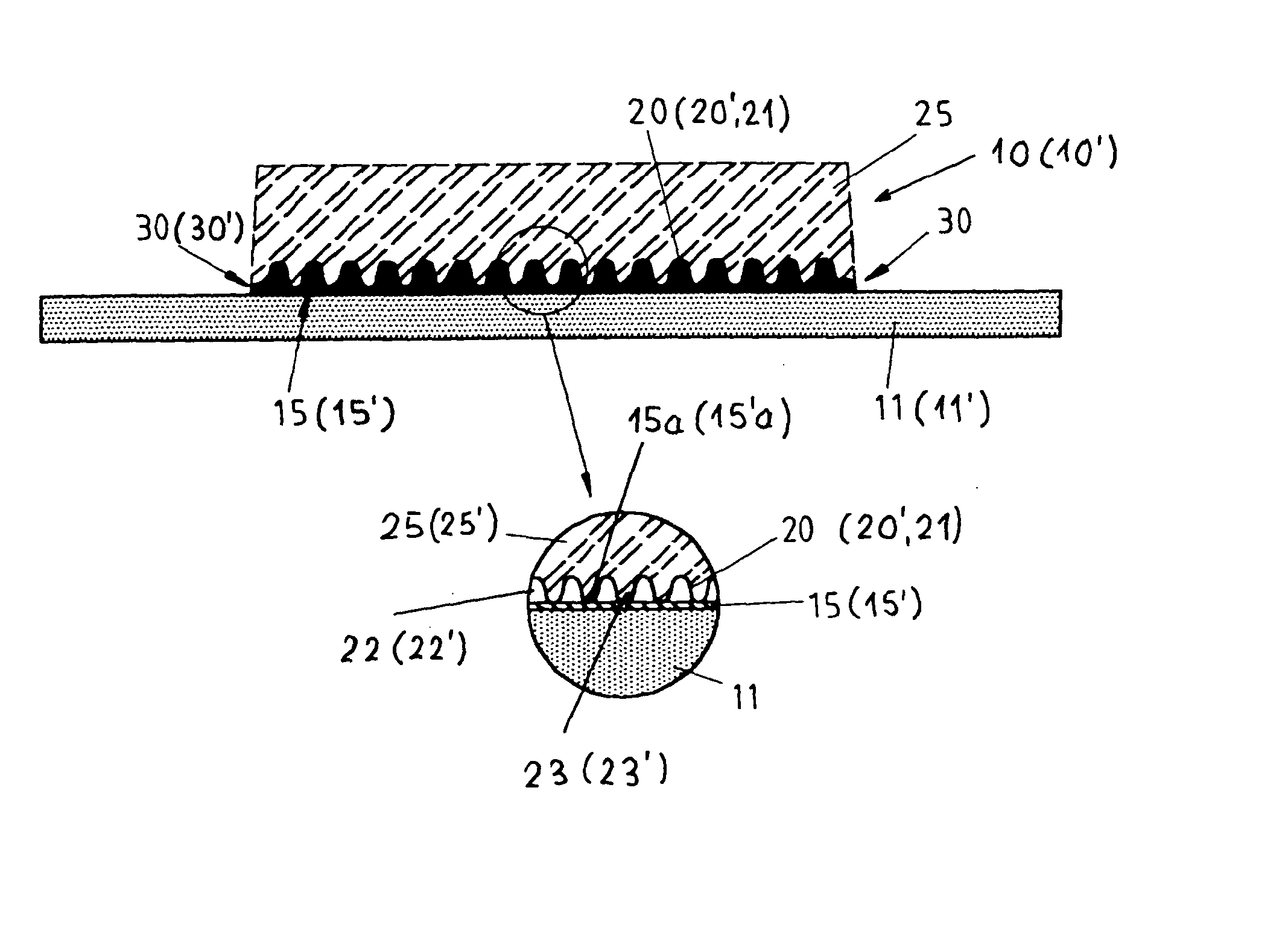

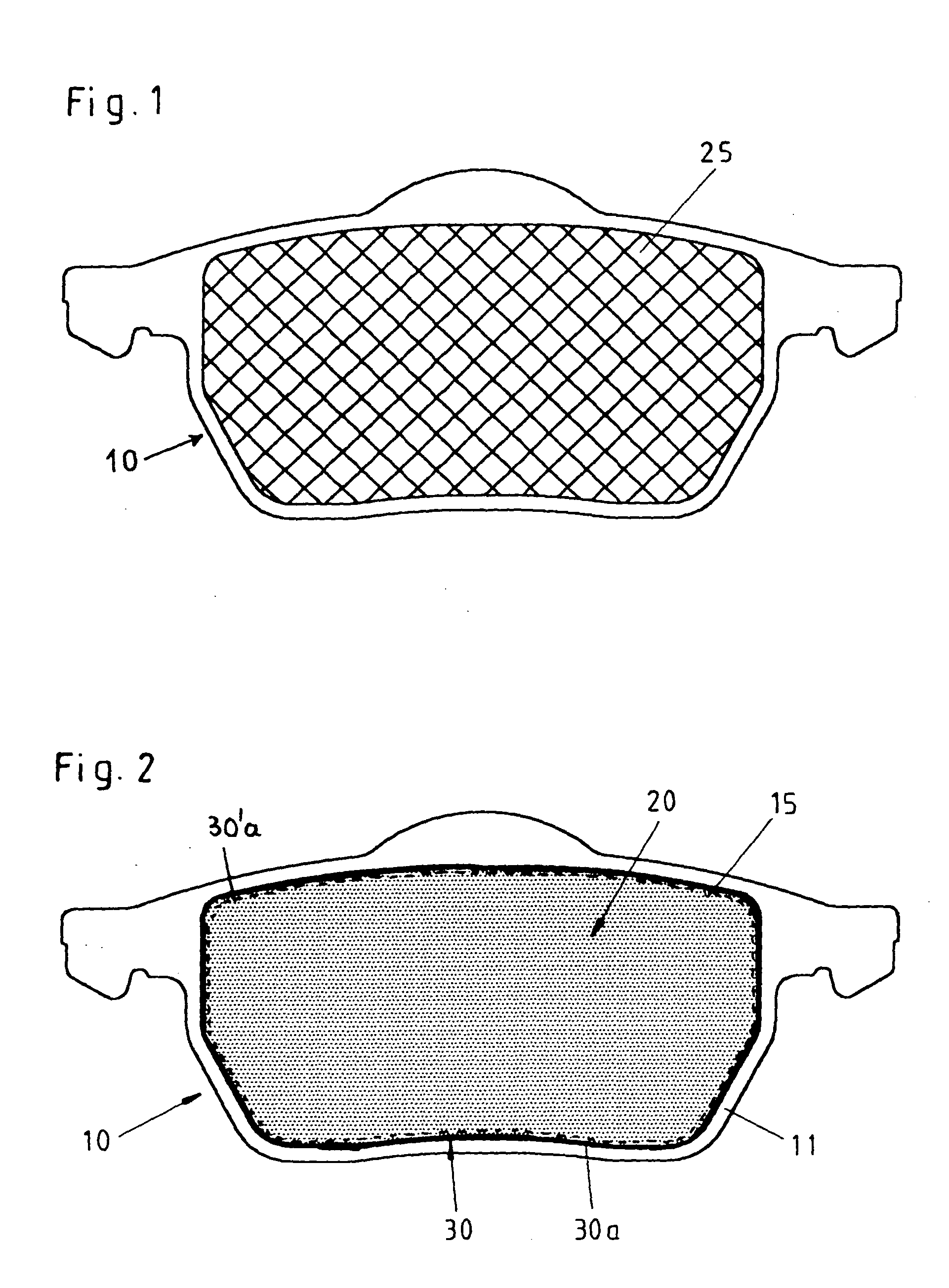

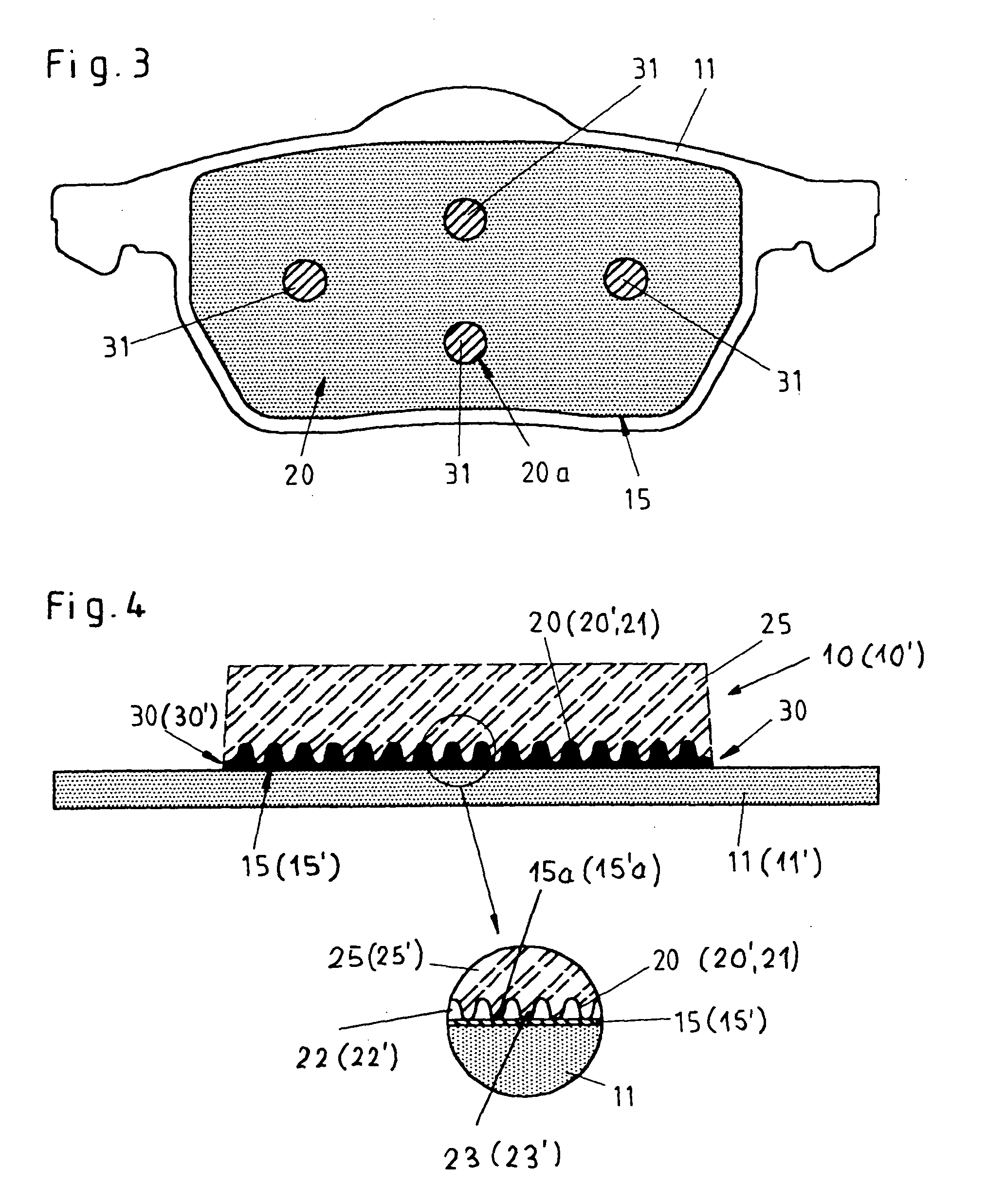

Lining, in particular friction lining for disc brakes

InactiveUS20040099493A1Improve strength propertiesMaintain propertiesNoise/vibration controlFriction liningSynthetic materialsMetal sheet

The lining or functional body (10) consists a carrier (11) in form of a ground plate, for example a carrier plate or a carrier sheet, of a thin-walled rough ground carrier (15; 15') made of a metal sheet or of another appropriate material placed on the carrier (11; 11'), of a rough ground (20') made of a support base (20; 20'; 21) sintered on the surface (15a; 15'a) of the rough ground carrier (15; 15') which is turned away from the lining carrier (11; 11'), this support base being made of single moulded bodies (22') with undercuts, recesses or the like which are positively and frictionally connected with the rough ground carrier (15; 15'), and of a functional block (25; 25') fixed on the rough ground carrier (15; 15') with the rough ground (20'), this functional block being made of a friction material, a synthetic material, in particular of such a synthetic material which is not appropriate to be glued together or to be applied in another manner, for example of a polymer or teflon, whereby the rough ground carrier (15; 15') is fixed on the lining carrier (11; 11') by means of a welded, riveted or glued joint (30; 30') or other connecting procedures, such as engraving.

Owner:HONEYWELL BREMSBELAG GMBH

Rare-earth aluminum alloy lead wire

InactiveCN102360583AImprove electrical performanceImprove wear resistancePower cablesMetal/alloy conductorsRare-earth elementHeat resistance

The invention provides a rare-earth aluminum alloy lead wire. The aluminum alloy material comprises 0.01-1 wt% of Fe, 0.01-1 wt% of Cu, 0.01-1 wt% of B, 0.01-0.5 wt% of Si; 0.01-0.1 wt% of Mg, 0.01-0.1 wt% of Zn, 0.01-1 wt% of rare-earth element and the balance of aluminum and inevitably impurities, wherein the rare-earth element is one or more than one of Sc, Y, La, Ce, Pr and Nd. The rare-earthaluminum alloy lead wire has good electrical property, wear-resisting property, heat resisting property and corrosion resistance.

Owner:欣意(通辽)特种电缆有限公司

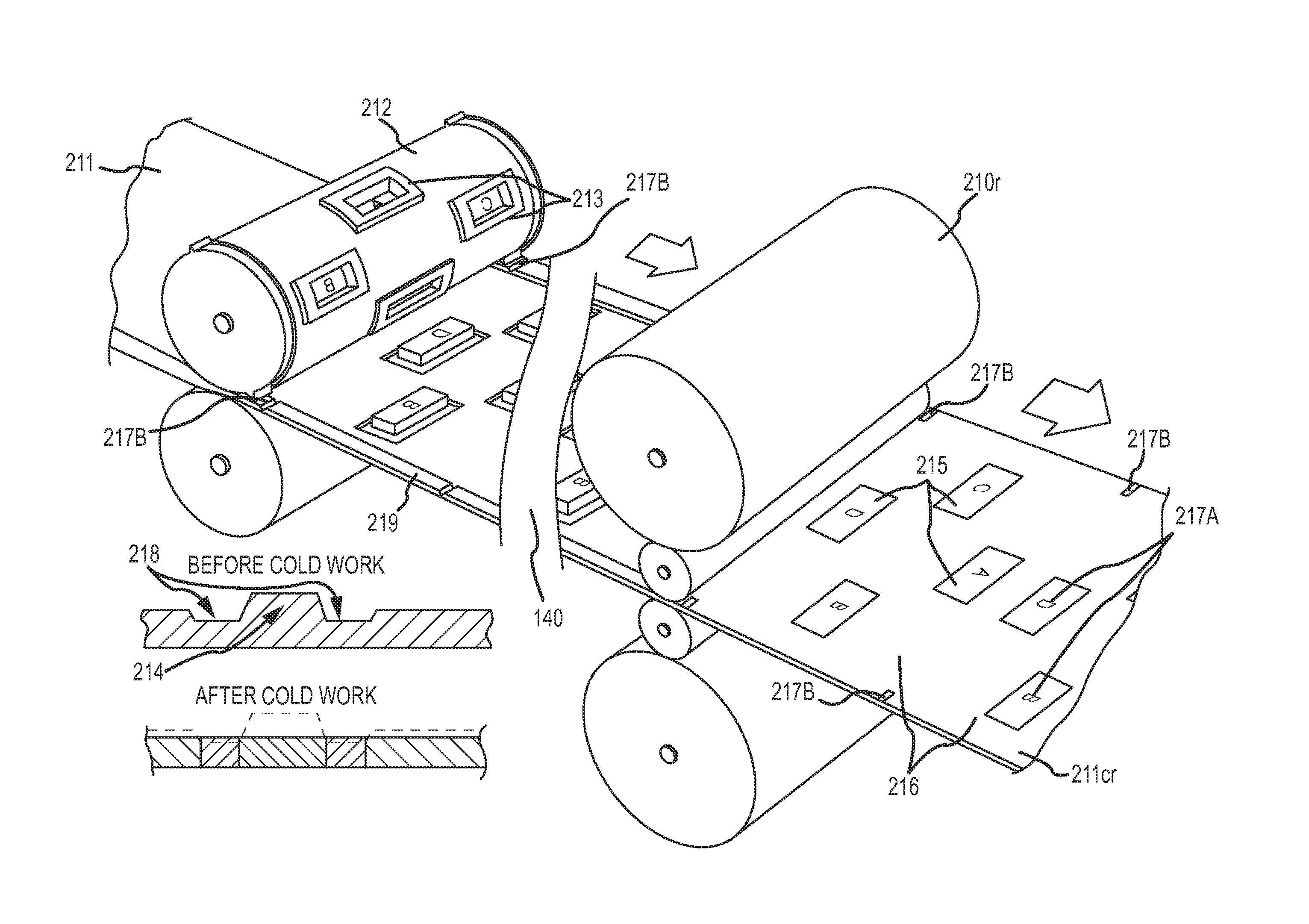

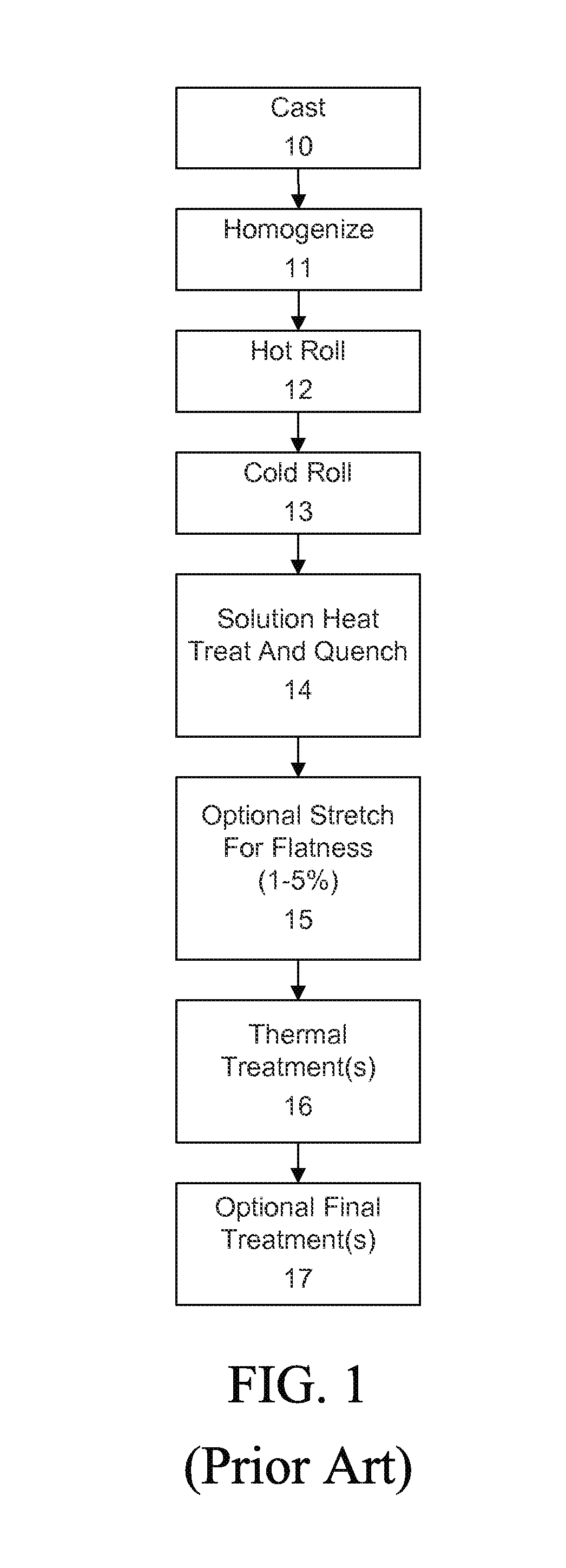

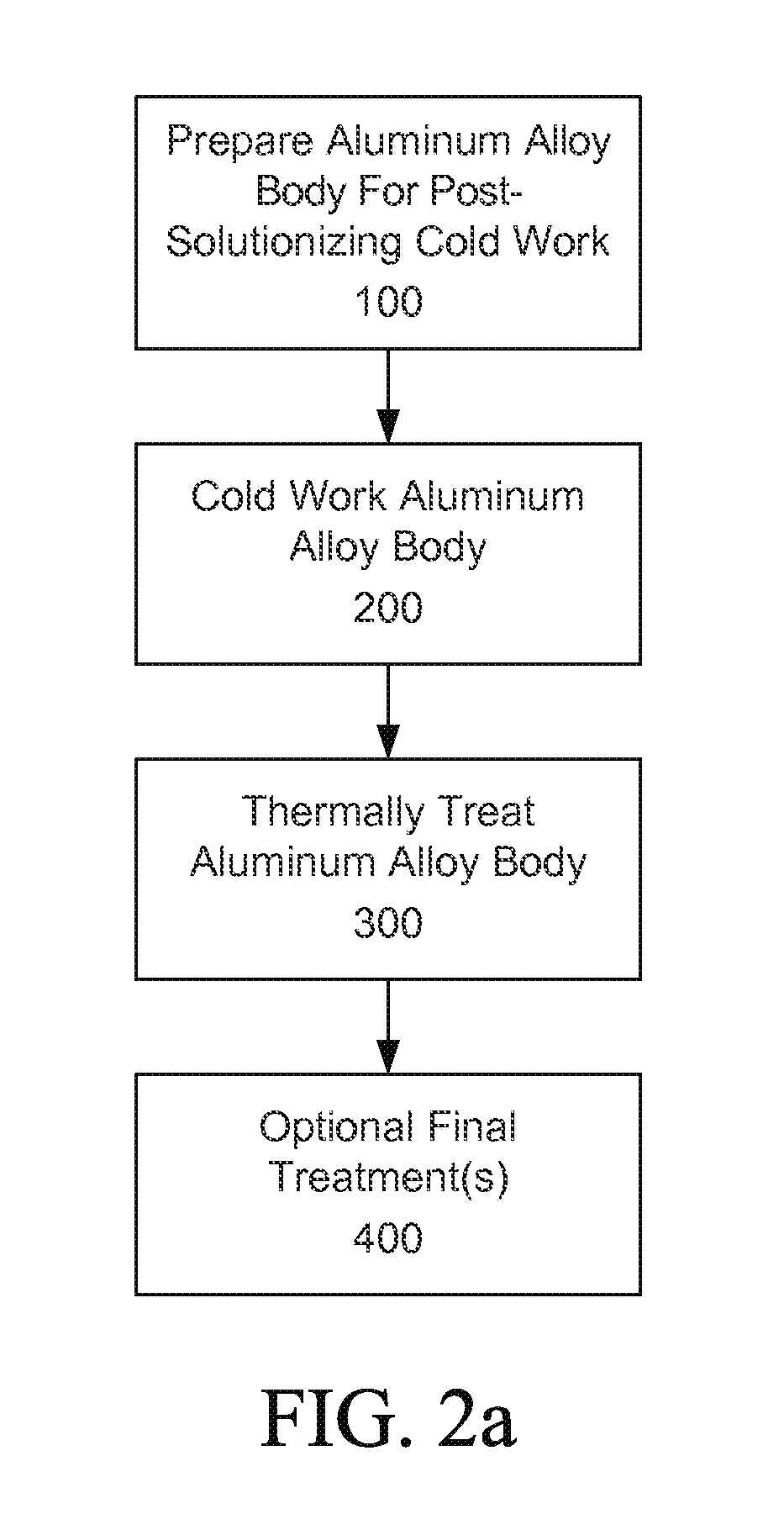

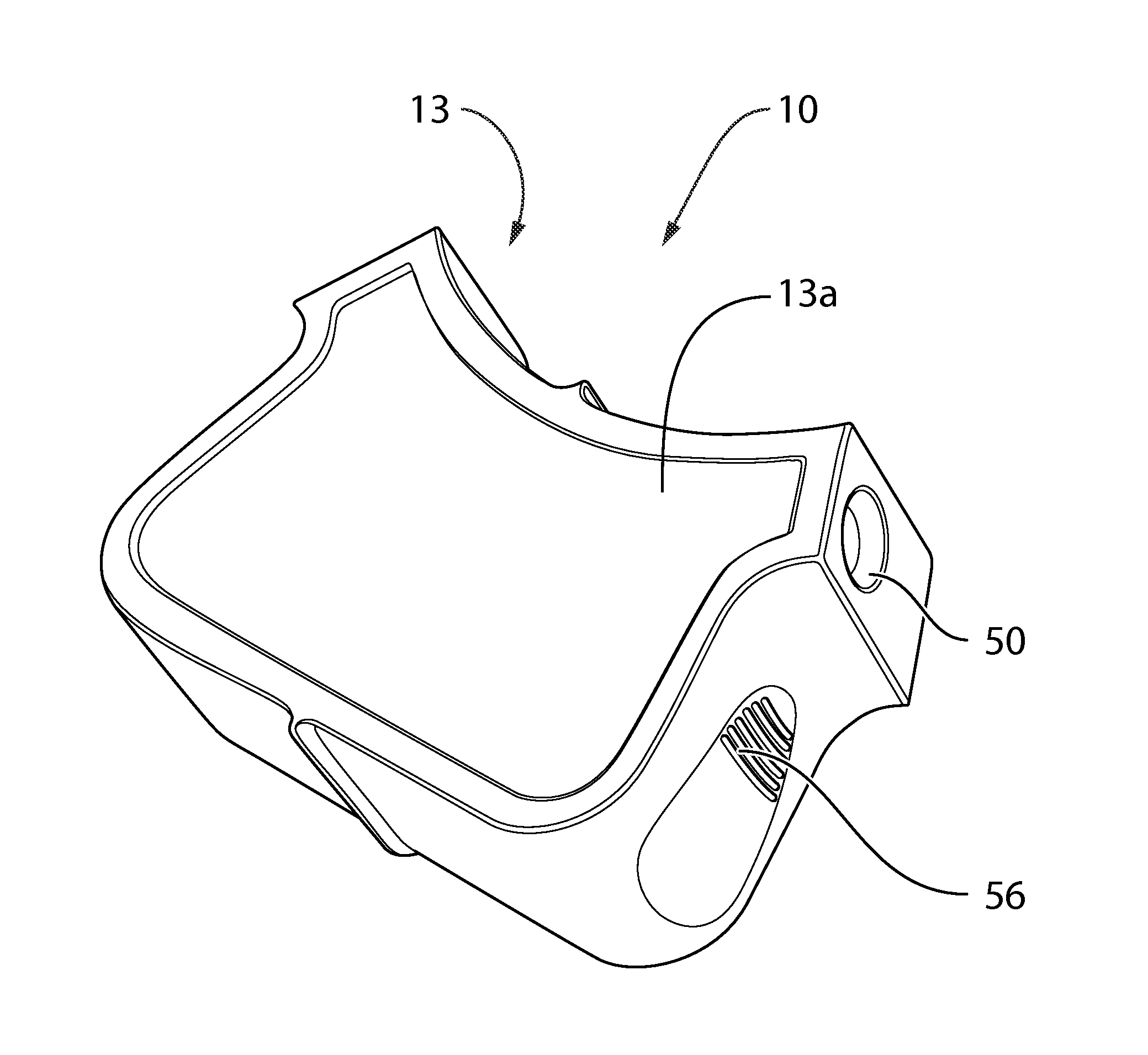

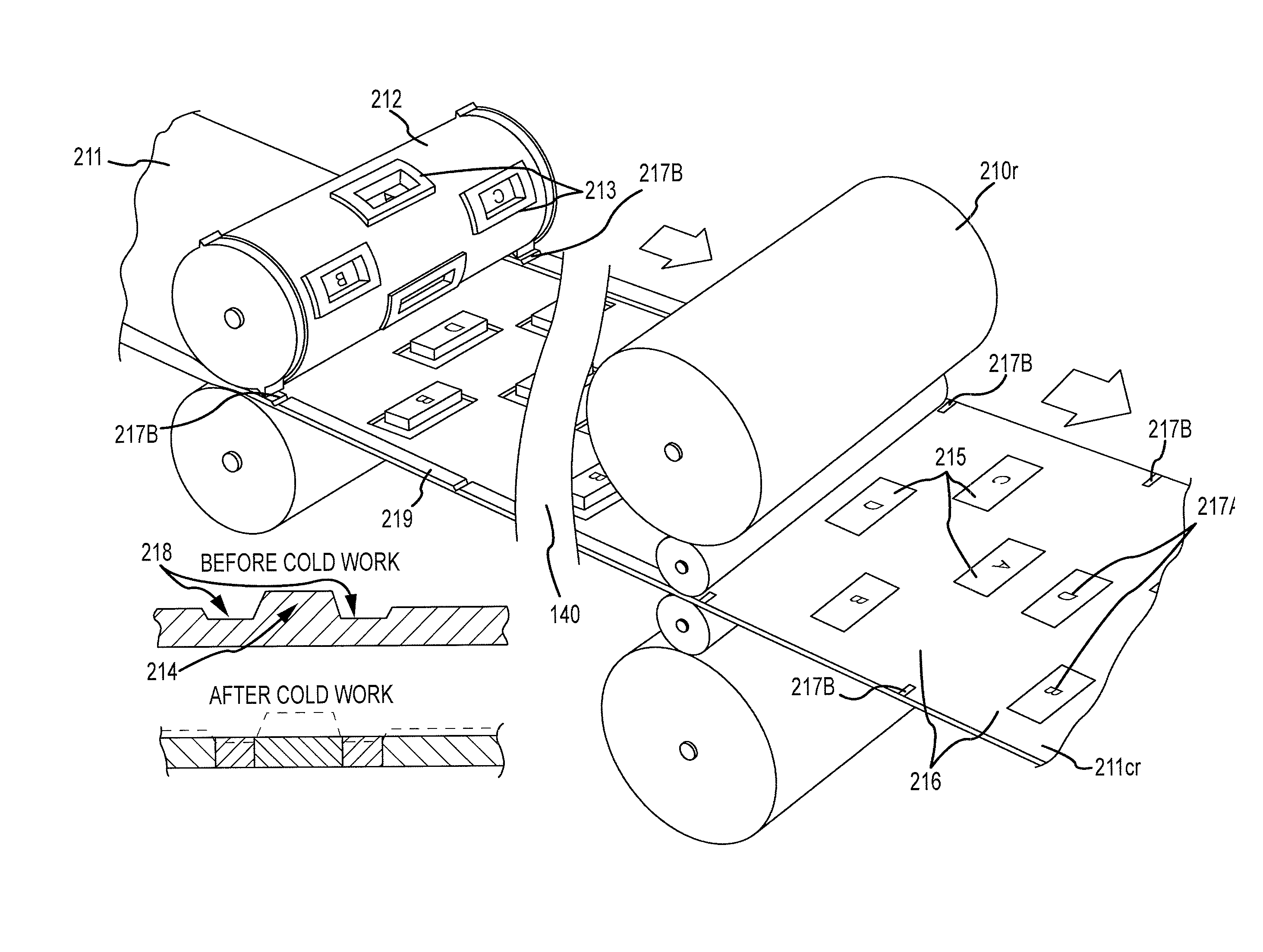

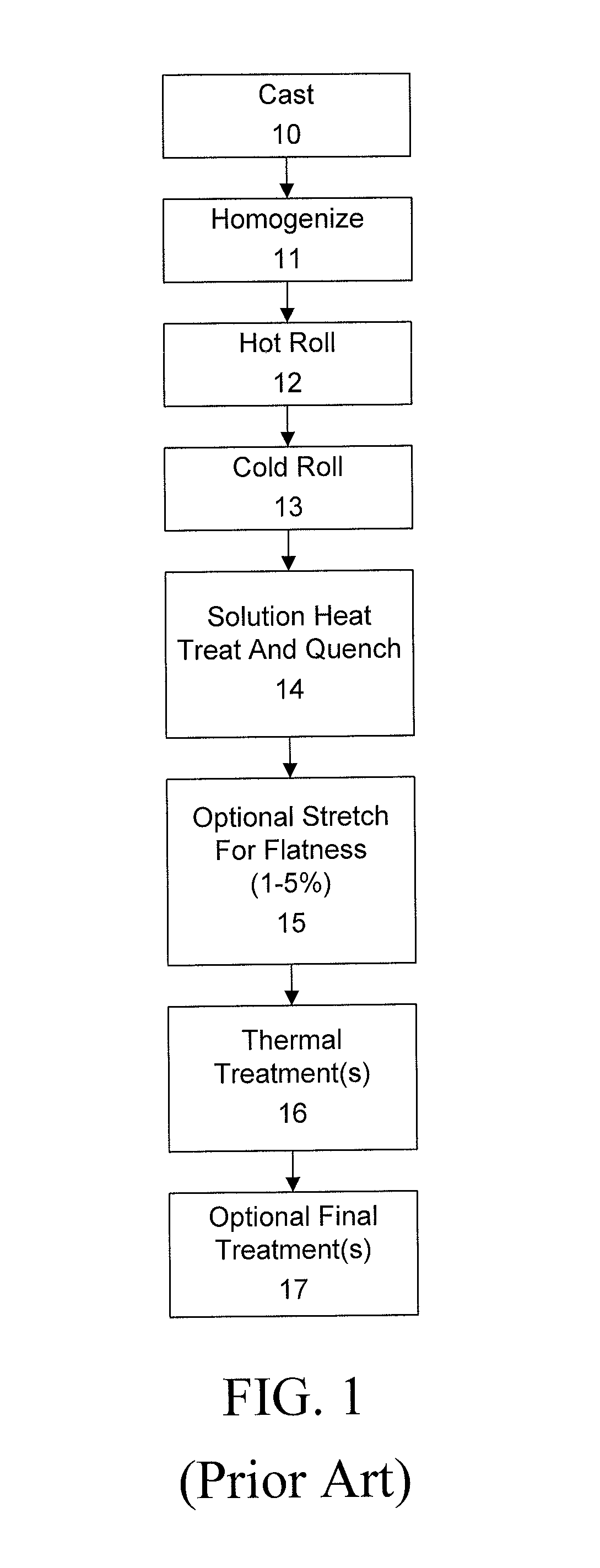

6xxx aluminum alloys, and methods for producing the same

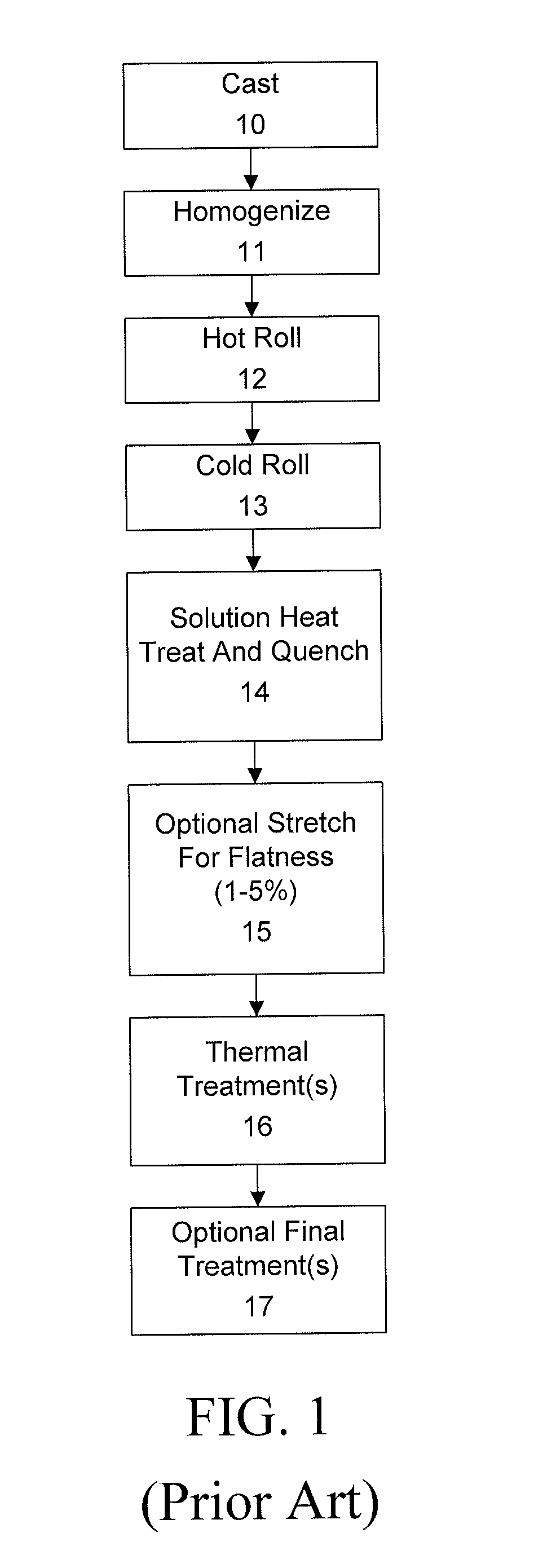

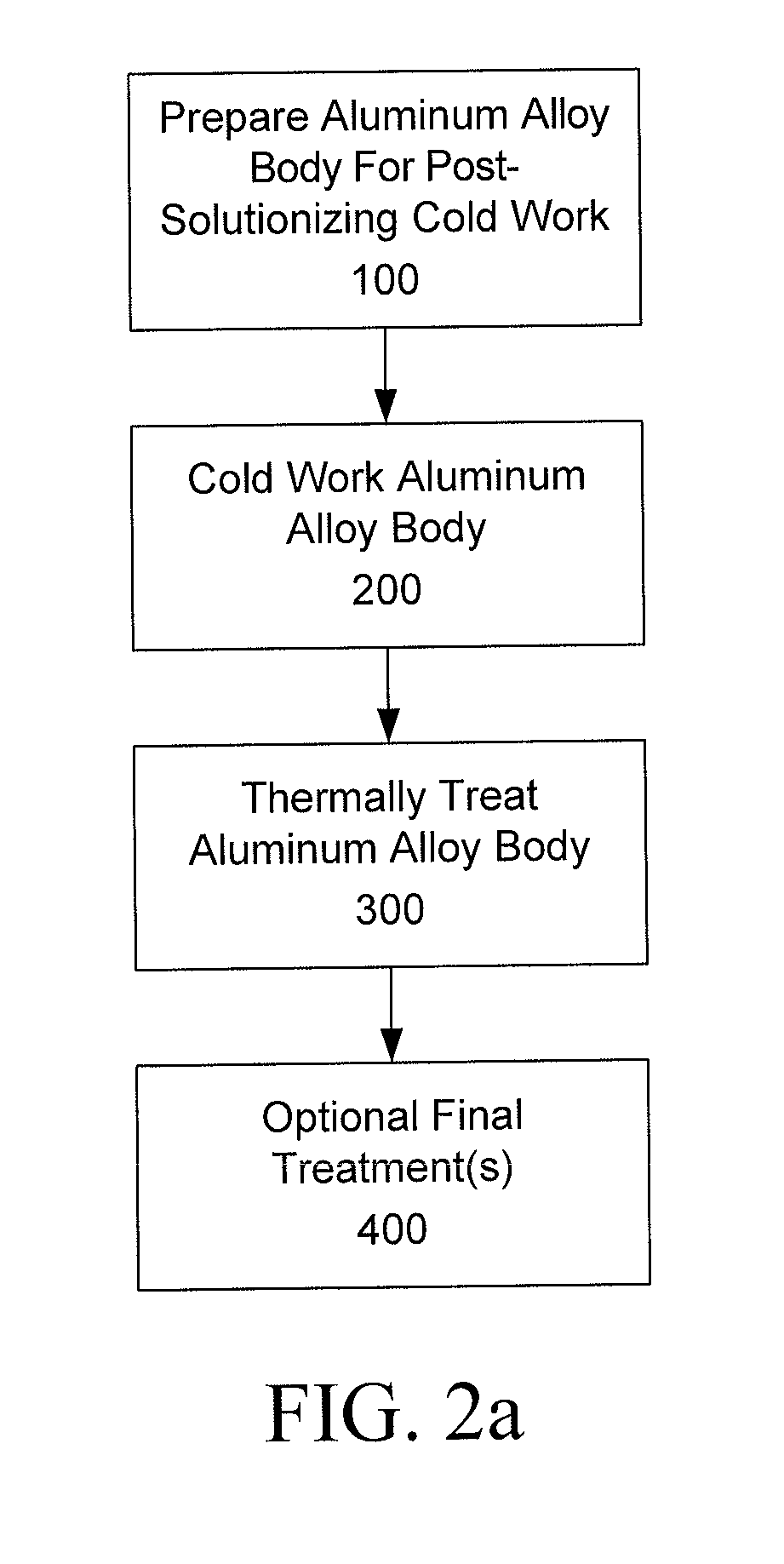

InactiveUS20140366998A1Minimize changesAvoid unevennessSuperstructuresUltimate tensile strengthHeat treated

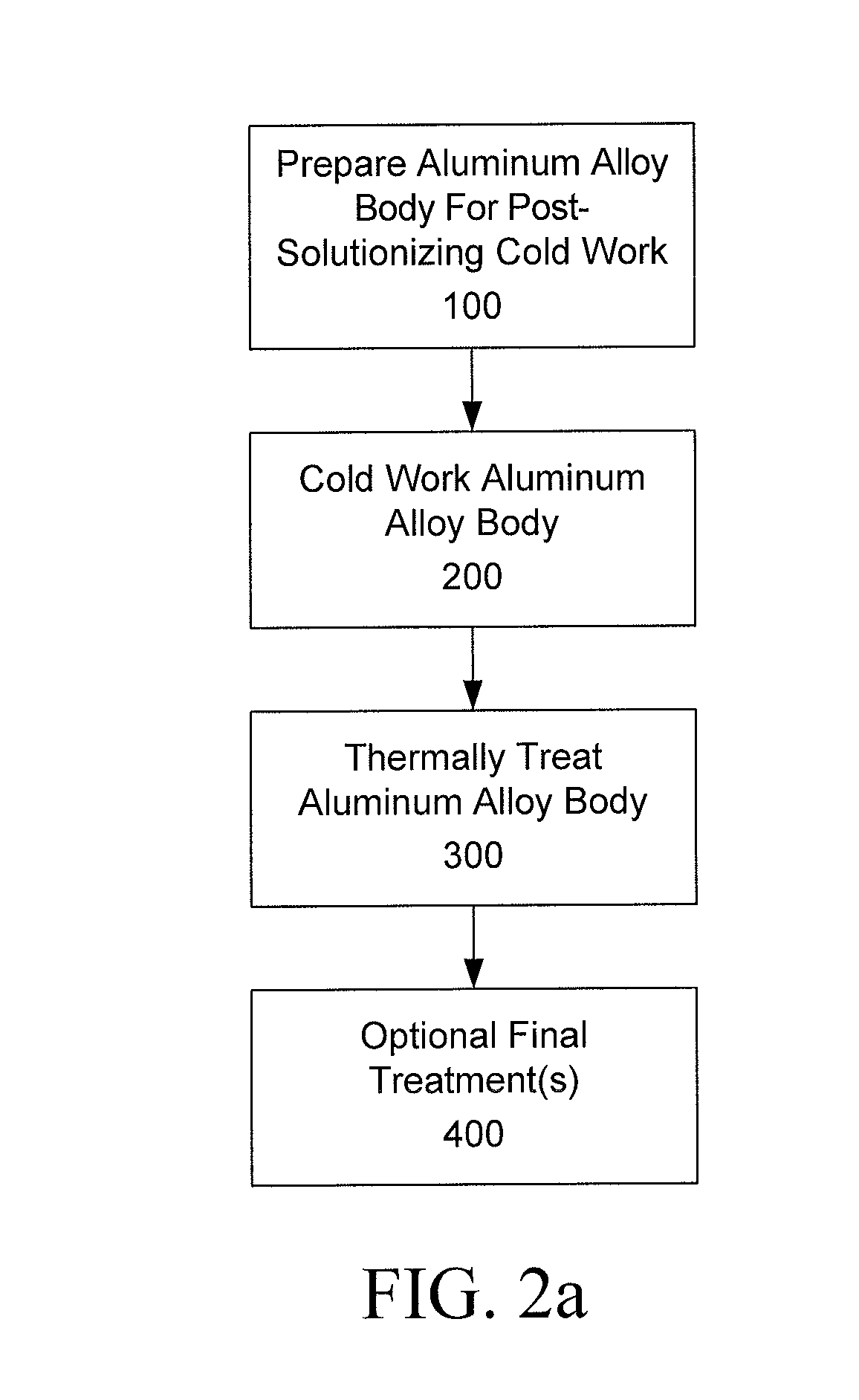

New 6xxx aluminum alloy bodies and methods of producing the same are disclosed. The new 6xxx aluminum alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new 6xxx aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

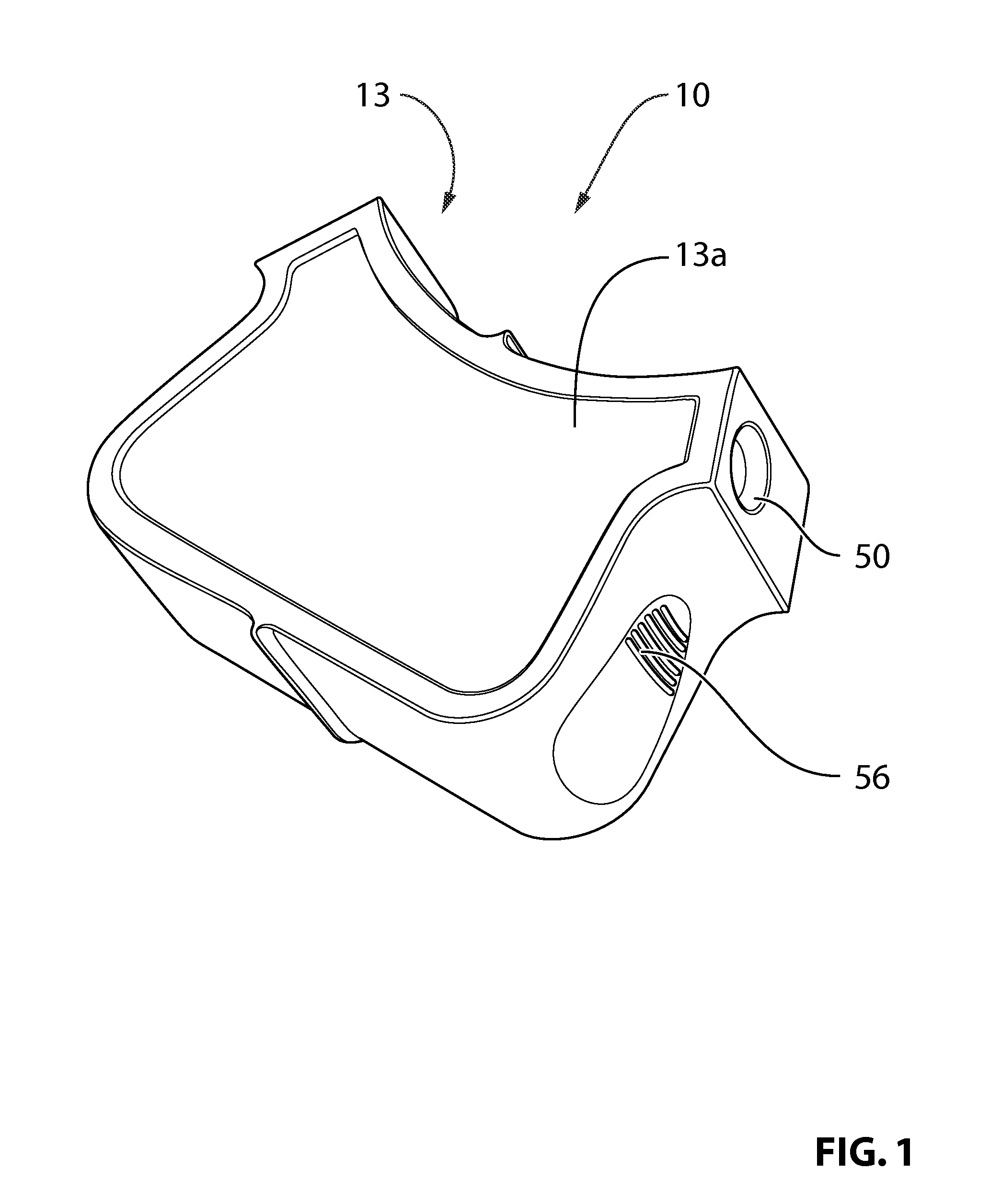

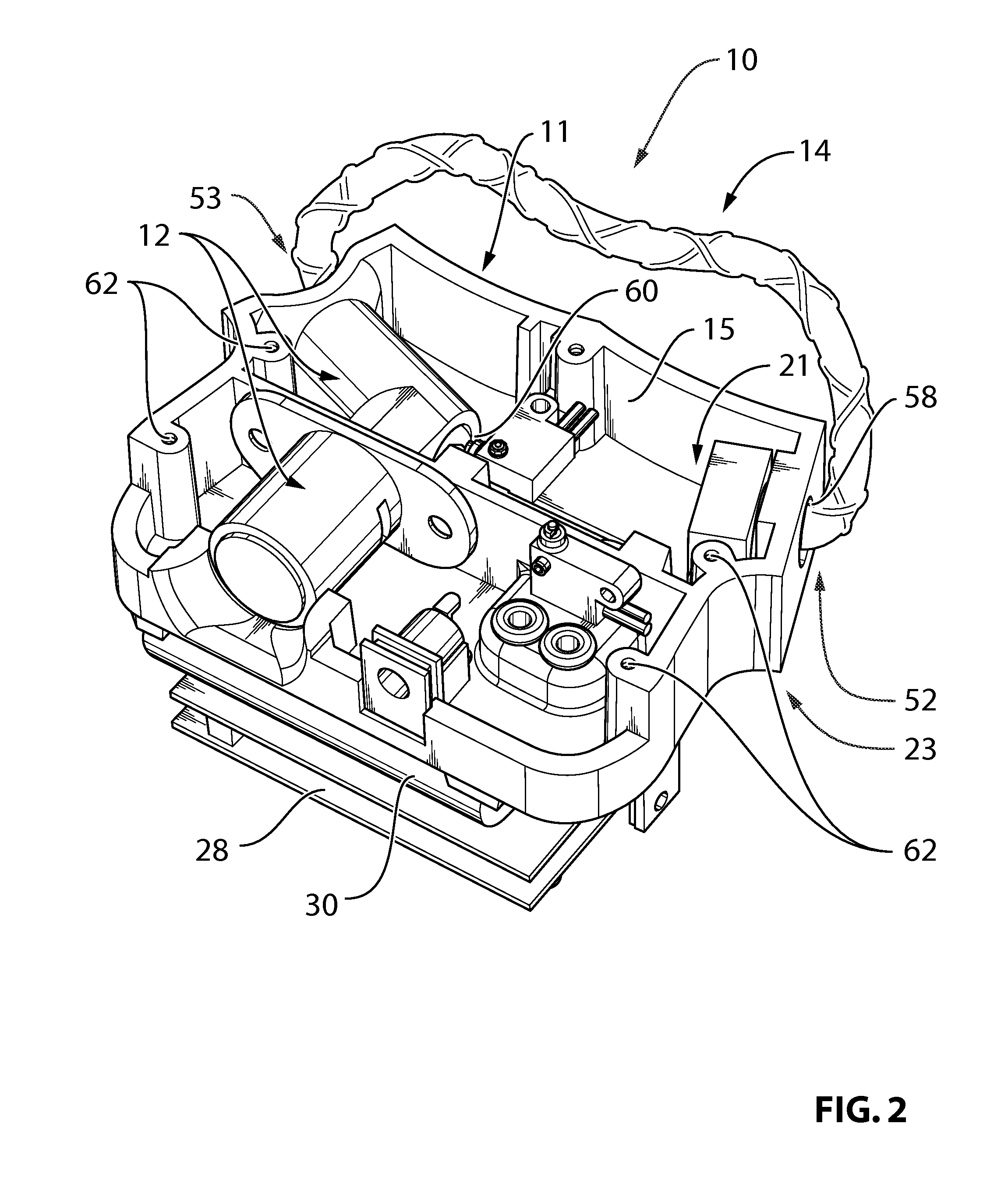

Electronic locking device for securing goods

InactiveUS20140007628A1Improve strength propertiesLocks for portable objectsPadlocksLocking mechanismClosed loop

The present document describes an electronic locking device for securing goods comprising: a locking mechanism; an electrically conductive link used for forming a closed loop to the locking mechanism for securing the goods and for forming a closed electrical circuit; and a mobile communication device connected to the closed electrical circuit and being in communication with at least one of a plurality of access points of an external network, the external network sending an advisory message upon tampering with at least one of the closed electrical circuit, the mobile communication device and the locking mechanism.

Owner:ENTREPRISES MOBILOCK

7xxx aluminum alloys, and methods for producing the same

InactiveUS20150020930A1Minimize changesAvoid unevennessSuperstructuresAlloyUltimate tensile strength

New 7xxx aluminum alloy bodies and methods of producing the same are disclosed. The new 7xxx aluminum alloy bodies may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new 7xxx aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

Wrought aluminium AA7000-series alloy product and method of producing said product

A wrought aluminium AA7000-series alloy product, including (in wt %): Zn 7.5 to 14.0, Mg 1.0 to 5.0, Cu<0.28, Fe<0.30, Si<0.25, and one or more members selected from the group of: Zr<0.30, Ti<0.30, Hf<0.30, Mn<0.80, Cr<0.40, V<0.40, and Sc<0.70, remainder: incidental elements and impurities, each <0.05, total <0.15, and balance aluminium. The product having reduced hot crack sensitivity, and improved strength and toughness properties, and when in artificially aged condition having a hardness of more than 180 HB.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

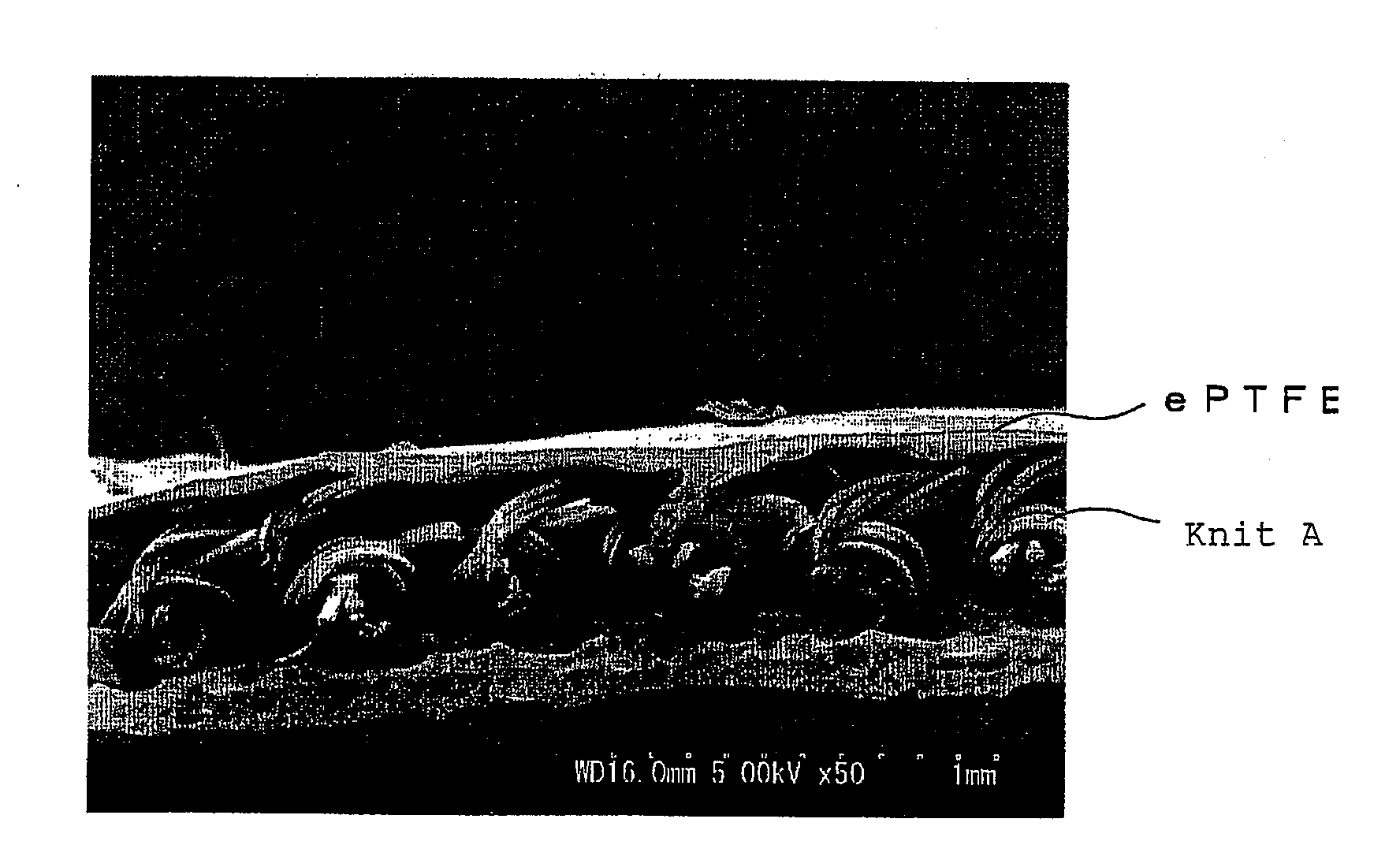

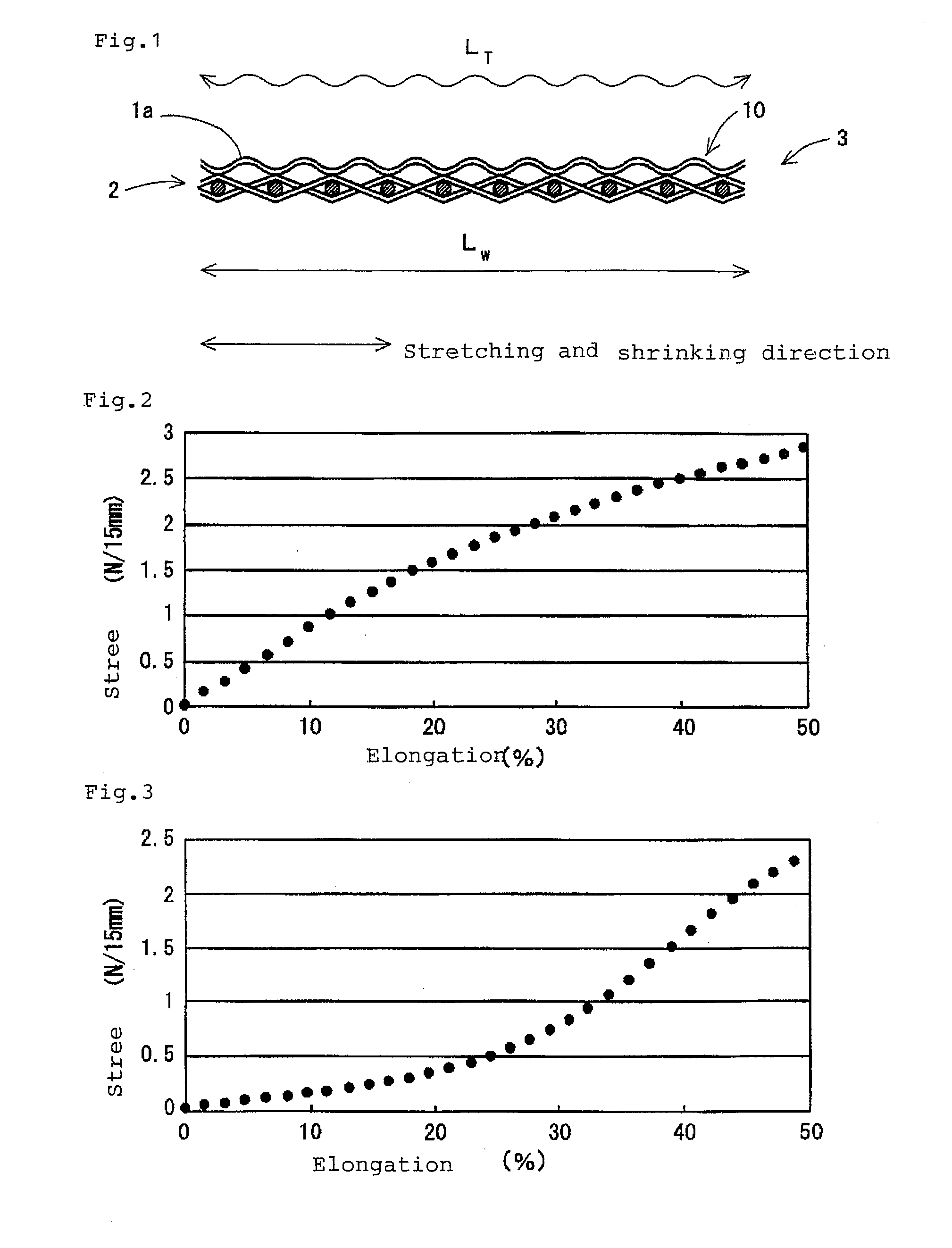

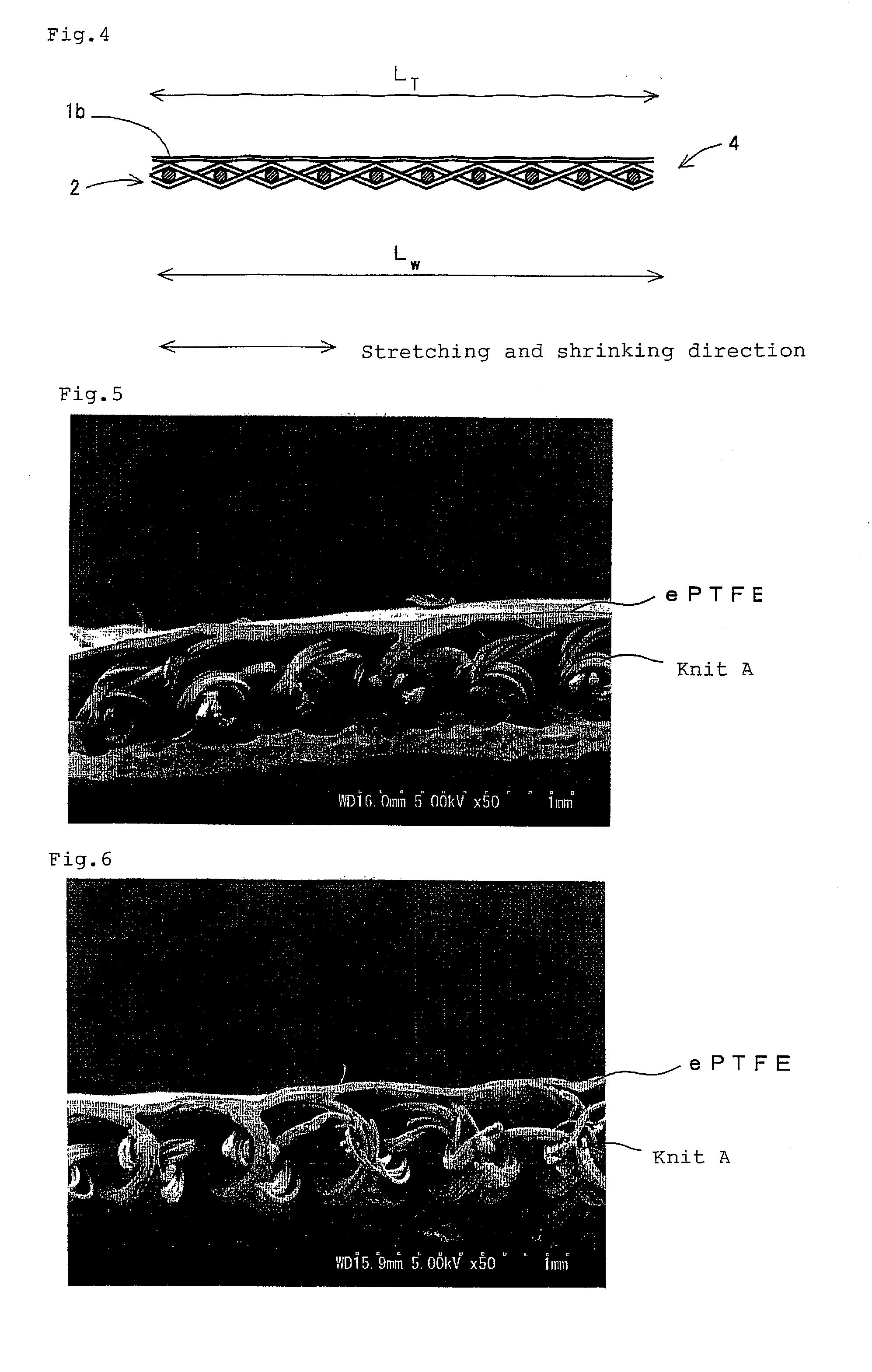

Stretch Composite Fabric and Expanded Porous Polytetrafluoroethylene Film

InactiveUS20090227165A1Improve strength propertiesImprove propertiesWarp knittingCircular knitting machinesMaterials sciencePTFE - Polytetrafluoroethylene

A stretch composite fabric comprises a sintered expanded porous polytetrafluoroethylene film and a stretch cloth laminated to each other while maintaining a flat state. The stretch composite fabric has a tensile stress at 10% elongation, as measured in at least one direction, of 1.8 N / 15 mm or less. When a 5 cm-width test piece of the stretch composite fabric is stretched in a length direction under a load of 300 g and then released from the stress, an elongation recovery R of the stretch composite fabric, which is given by the following equation, is preferably 70% or more. R=(L2−L3) / (L2−L1)×100 (In the equation, L1, L2, and L3 represent the lengths of the composite fabric before the load is applied, when the load is applied, and after the load is removed, respectively.)

Owner:JAPAN GORE TEX INC

Glass fiber separators for batteries and method for making such separators

InactiveUS20020142226A1Increased strength propertyImprove cut through resistanceCell component detailsGastight accumulatorsAverage diameterCellulose

A glass fiber Separator material is disclosed. The separator is composed of a mass of intermeshed glass fibers substantially all of which have a fiber diameter not greater than about 20 mum, and at least 5 percent w / w of which have a fiber diameter less than 1 mum, and, distributed through the glass fibers, and from 0.2 percent w / w to 20 percent w / w of cellulose fibrils. The fibrils are from a slurry having a Canadian freeness sufficiently low that the separator material has a tensile strength greater than an otherwise identical separator where glass fibers having an average diameter greater than 1 mum replace the cellulose fibrils.

Owner:HOLLINGSWORTH VOSE

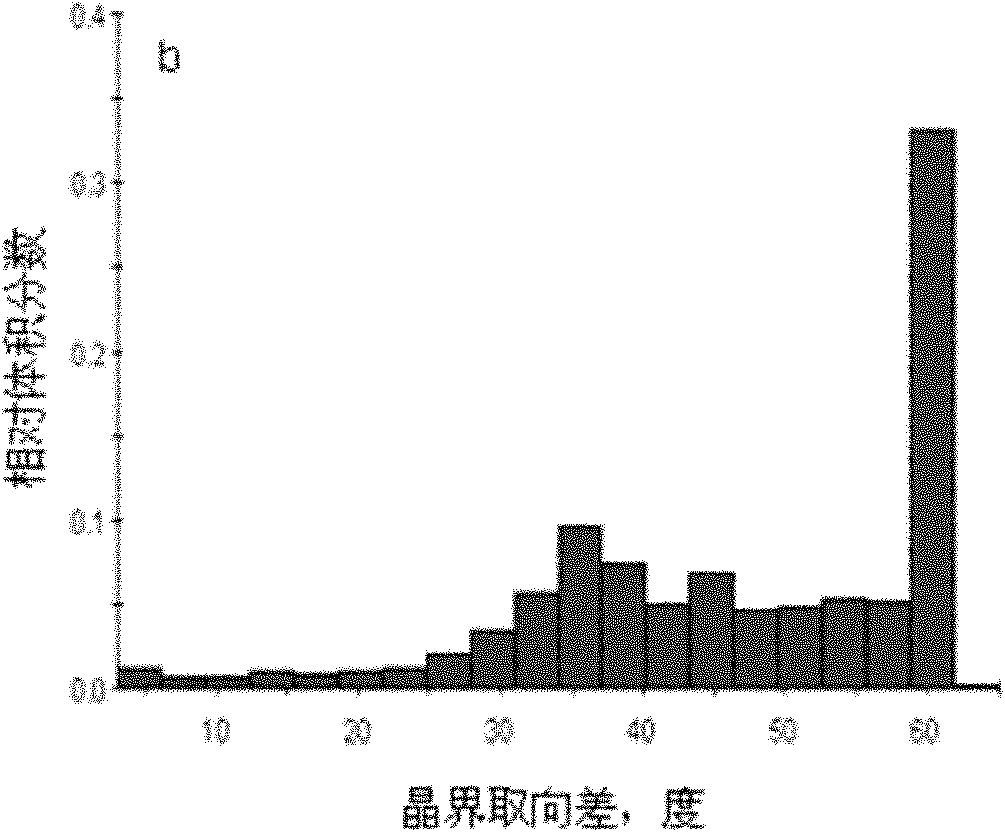

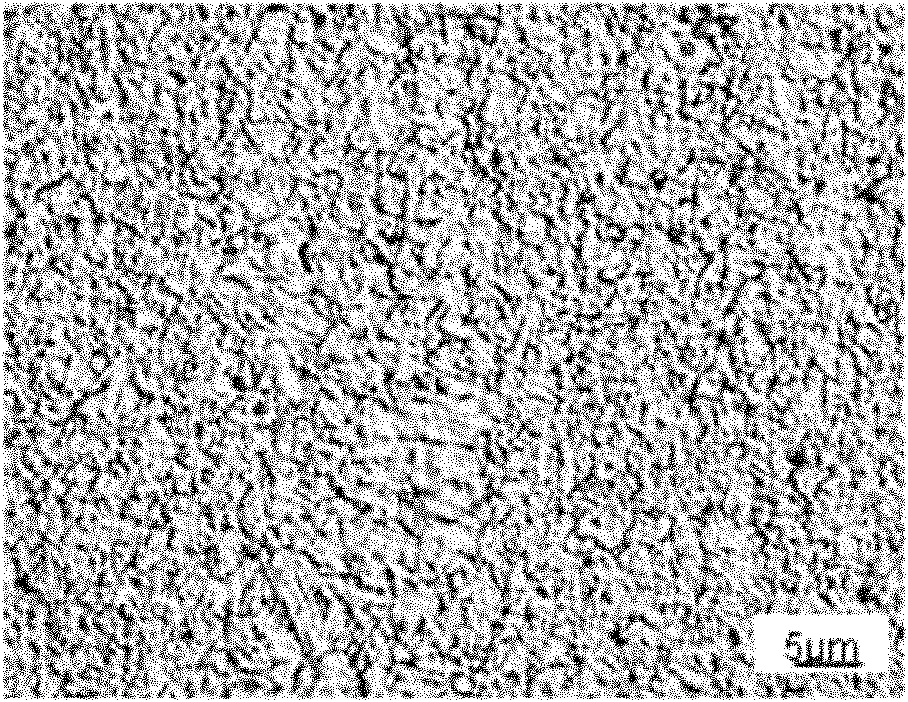

Method for preparing ultra-fine crystal grain high-strength high-toughness copper alloy strip

The invention discloses a method for preparing an ultra-fine crystal grain high-strength high-toughness copper alloy strip. The method comprises the following steps of: performing hot-rolling with the distortion of 40 to 70 percent after performing high-temperature annealing on a copper alloy cast ingot to obtain a plate blank; performing cold-rolling with the distortion of 30 to 60 percent; performing intermediate annealing after the cold-rolling; after soaking the plate blank in liquid nitrogen for 5 to 30 minutes, taking the plate blank out and performing the cold rolling immediately; performing cryogenic treatment and the cold-rolling repeatedly after performing the cold-rolling; after accumulated strain capacity reaches 40 to 90 percent, performing low-temperature annealing to obtain the ultra-fine crystal grain high-strength high-toughness copper alloy strip with the average size of about 0.8 mu m, wherein the tensile strength of the copper alloy strip is 650 to 880 MPa and the elongation rate is 10 to 30 percent. The method has a simple production process and low processing cost, and can implement cold-deformation and annealing after the cryogenic treatment on a copper alloy on conventional production equipment; crystal grains are thinned by generated deformation twin and annealing twin, simultaneously both the strength and the tensility of the copper alloy are improved; therefore, the method has a very good industrial application prospect.

Owner:CENT SOUTH UNIV

Heat treatable aluminum alloys having magnesium and zinc and methods for producing the same

New magnesium-zinc aluminum alloy bodies and methods of producing the same are disclosed. The new magnesium-zinc aluminum alloy bodies generally include 3.0-6.0 wt. % magnesium and 2.5-5.0 wt. % zinc, where at least one of the magnesium and the zinc is the predominate alloying element of the aluminum alloy bodies other than aluminum, and wherein (wt. % Mg) / (wt. % Zn) is from 0.6 to 2.40, and may be produced by preparing the aluminum alloy body for post-solutionizing cold work, cold working by at least 25%, and then thermally treating. The new magnesium-zinc aluminum alloy bodies may realize improved strength and other properties.

Owner:ARCONIC INC

Wrought aluminium AA7000-series alloy product and method of producing said product

A wrought aluminium AA7000-series alloy product, including (in wt %): Zn 7.5 to 14.0, Mg 1.0 to 5.0, Cu<0.28, Fe<0.6, Si<0.5, and one or more members selected from the group of: Zr<0.30, Ti<0.30, Hf<0.30, Mn<0.80, Cr<0.40, V<0.40, and Sc<0.70, remainder: incidental elements and impurities, each <0.05, total <0.15, and balance aluminium. The product has reduced hot crack sensitivity, and improved strength and toughness properties, and has a hardness of more than 180 HB in artificially aged condition.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

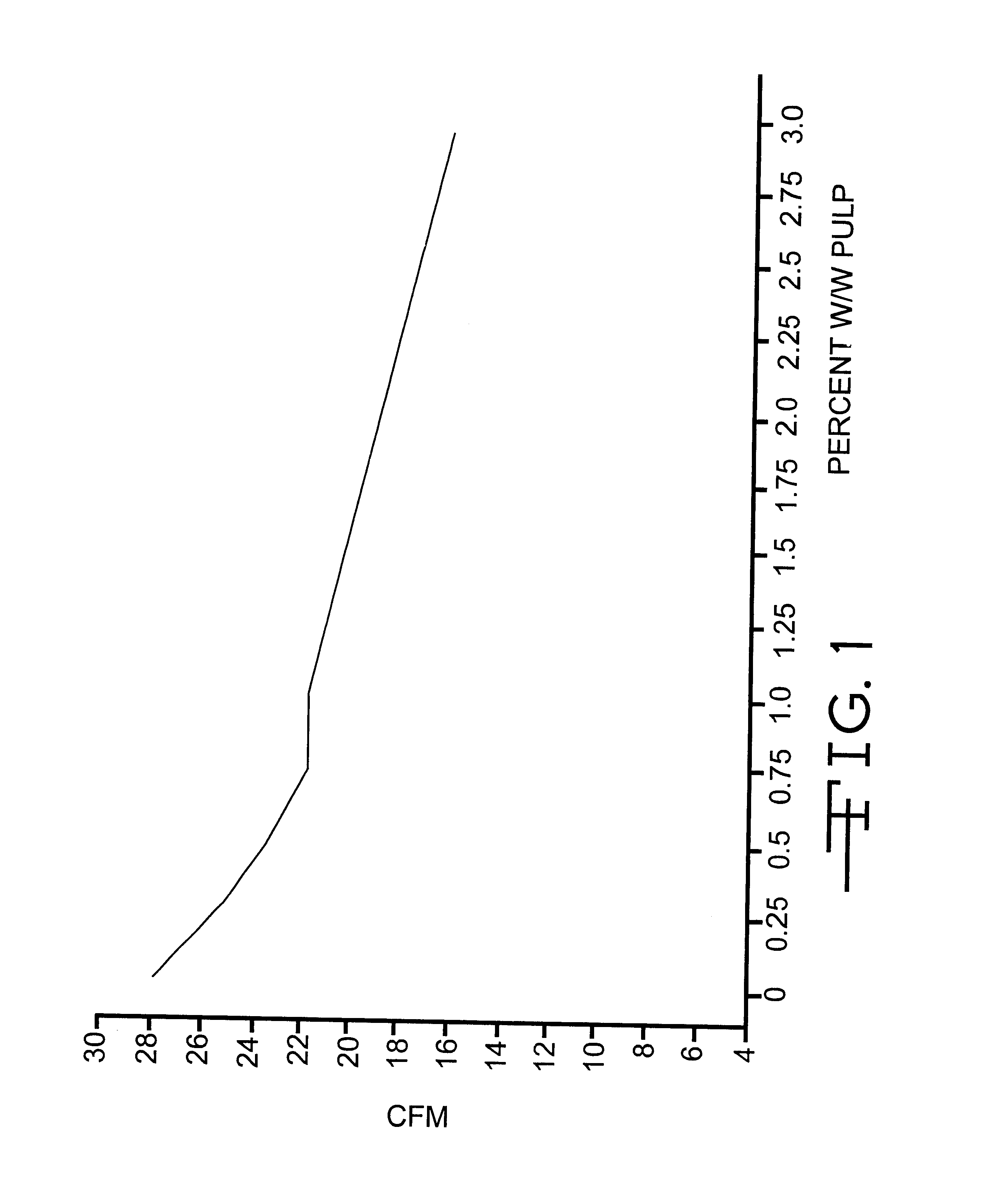

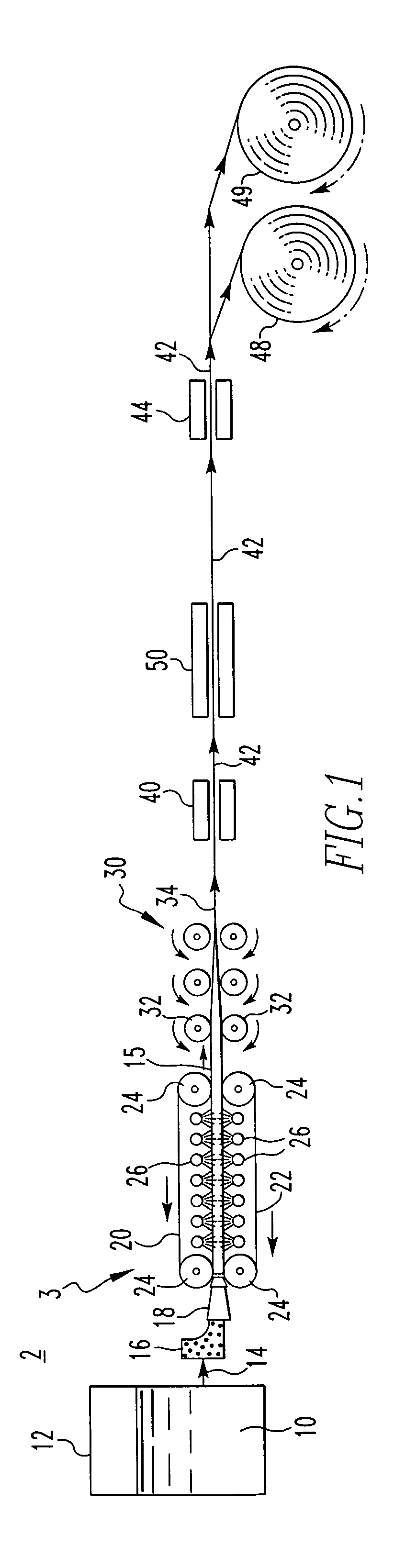

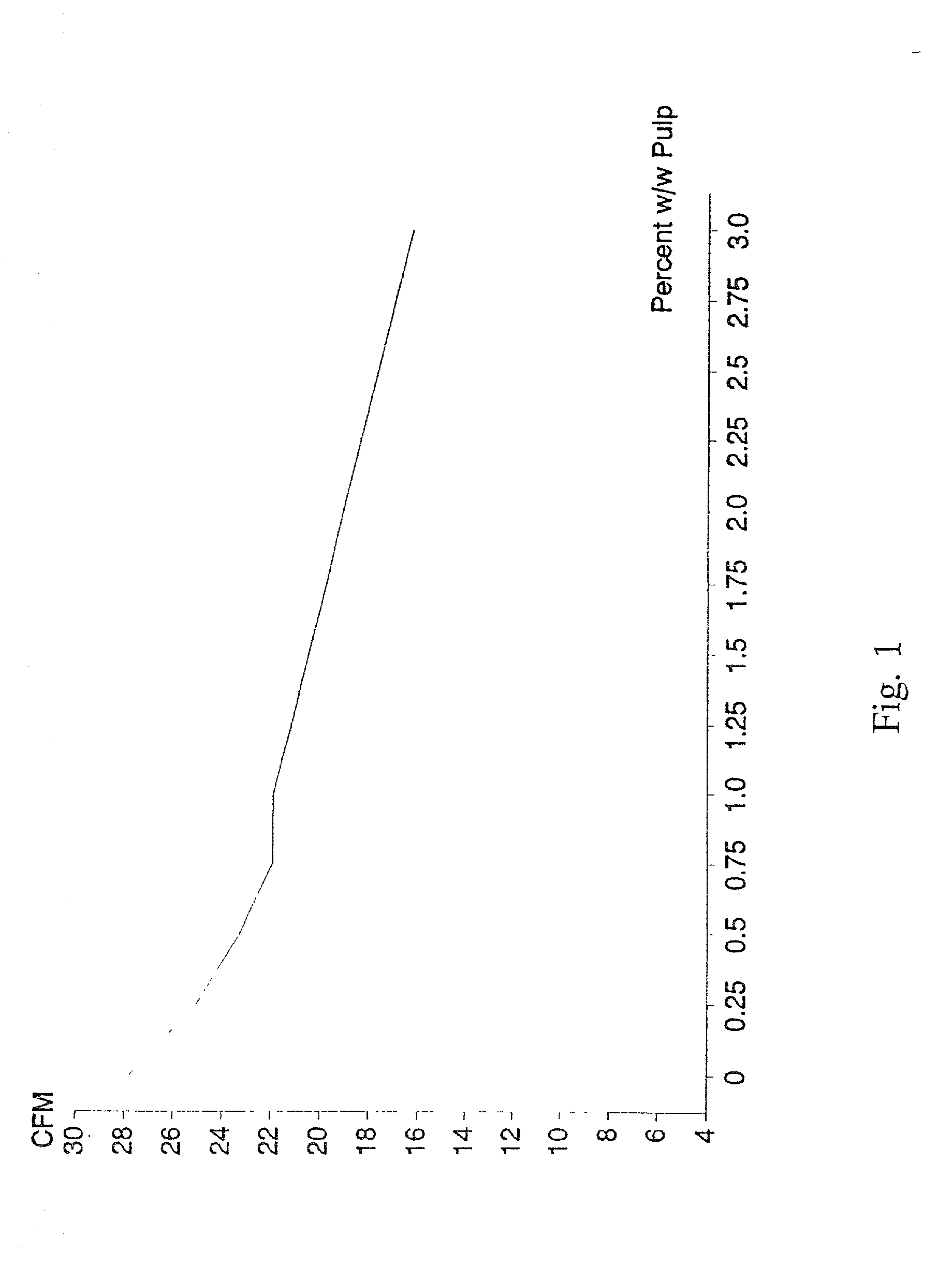

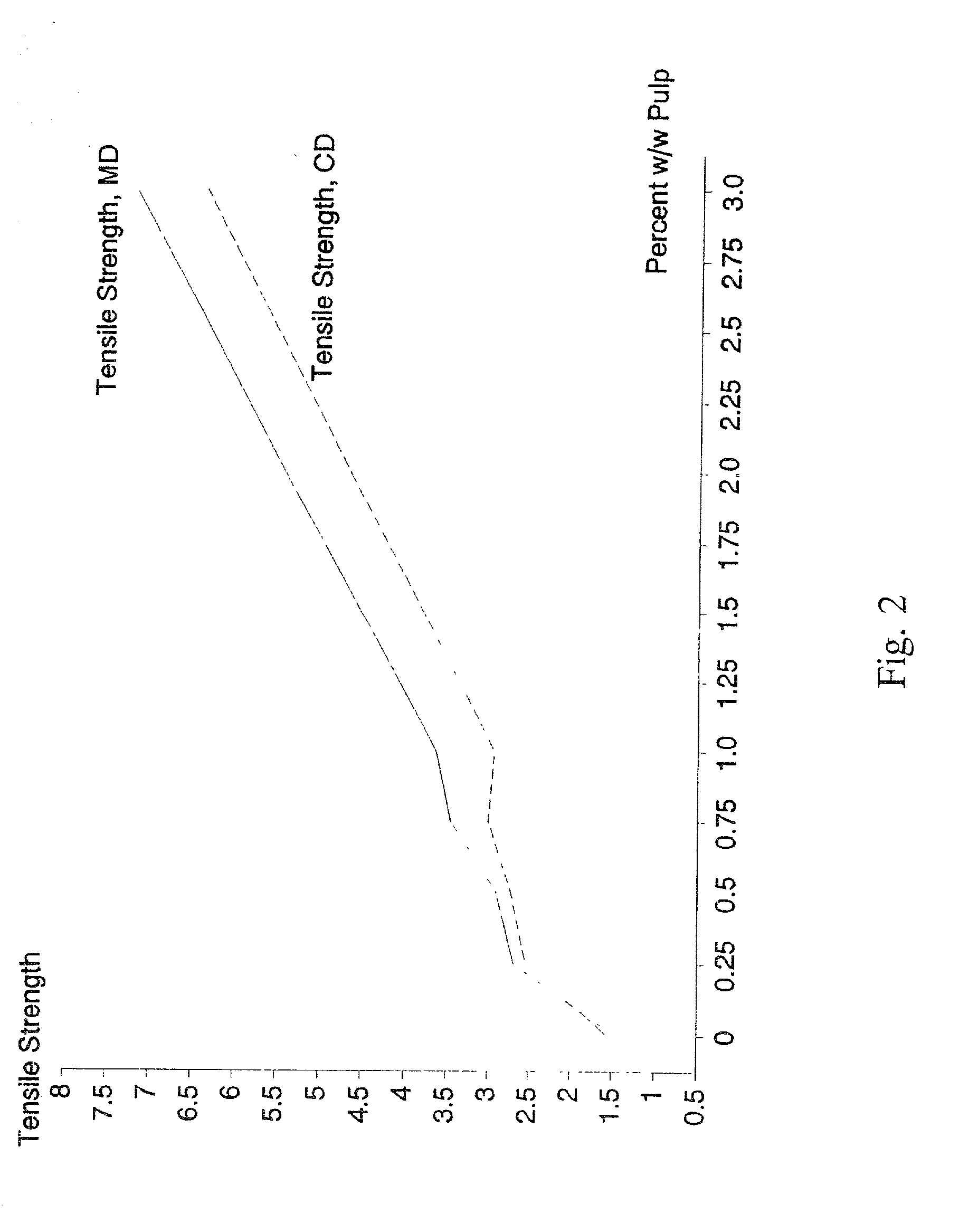

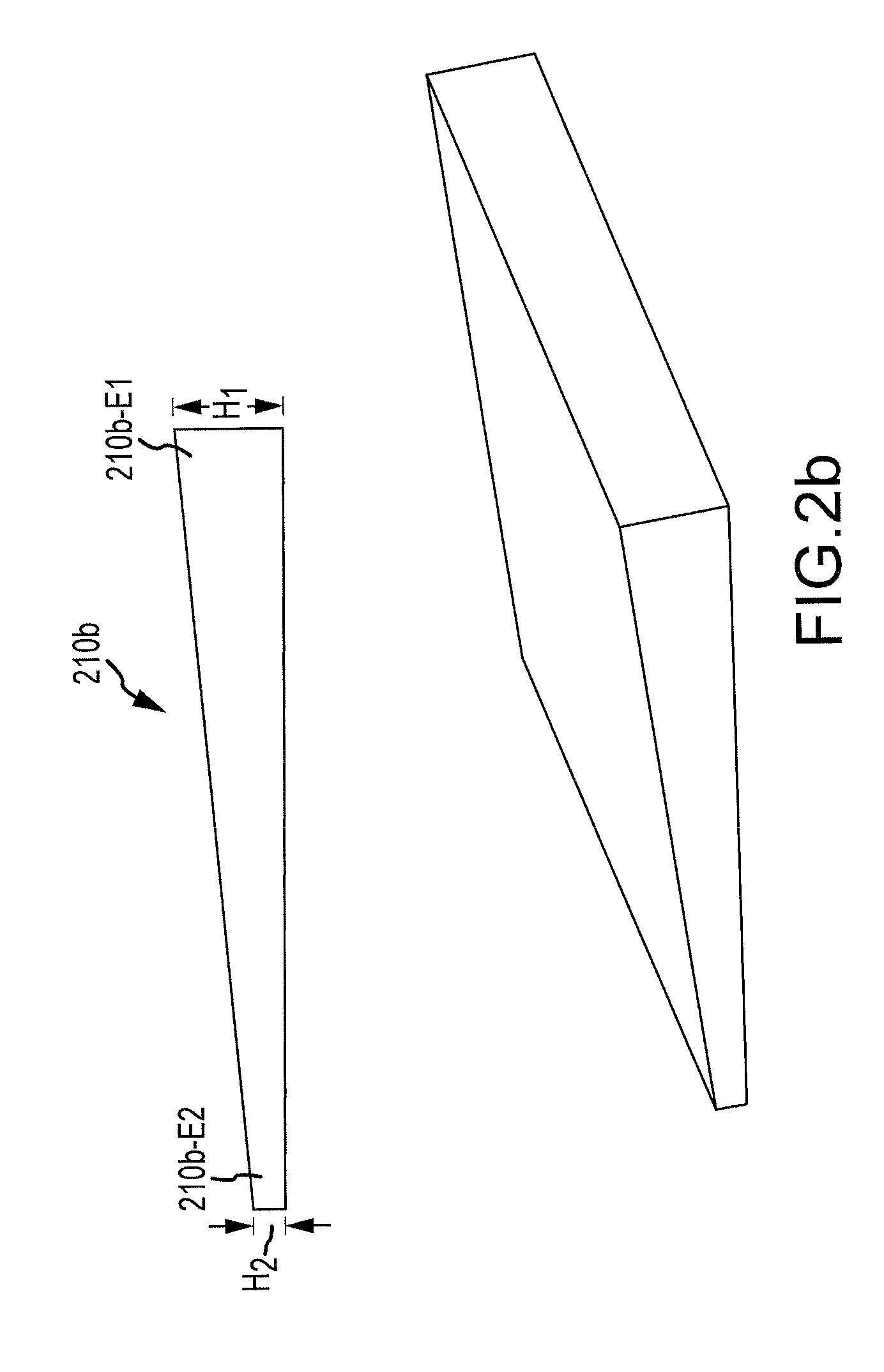

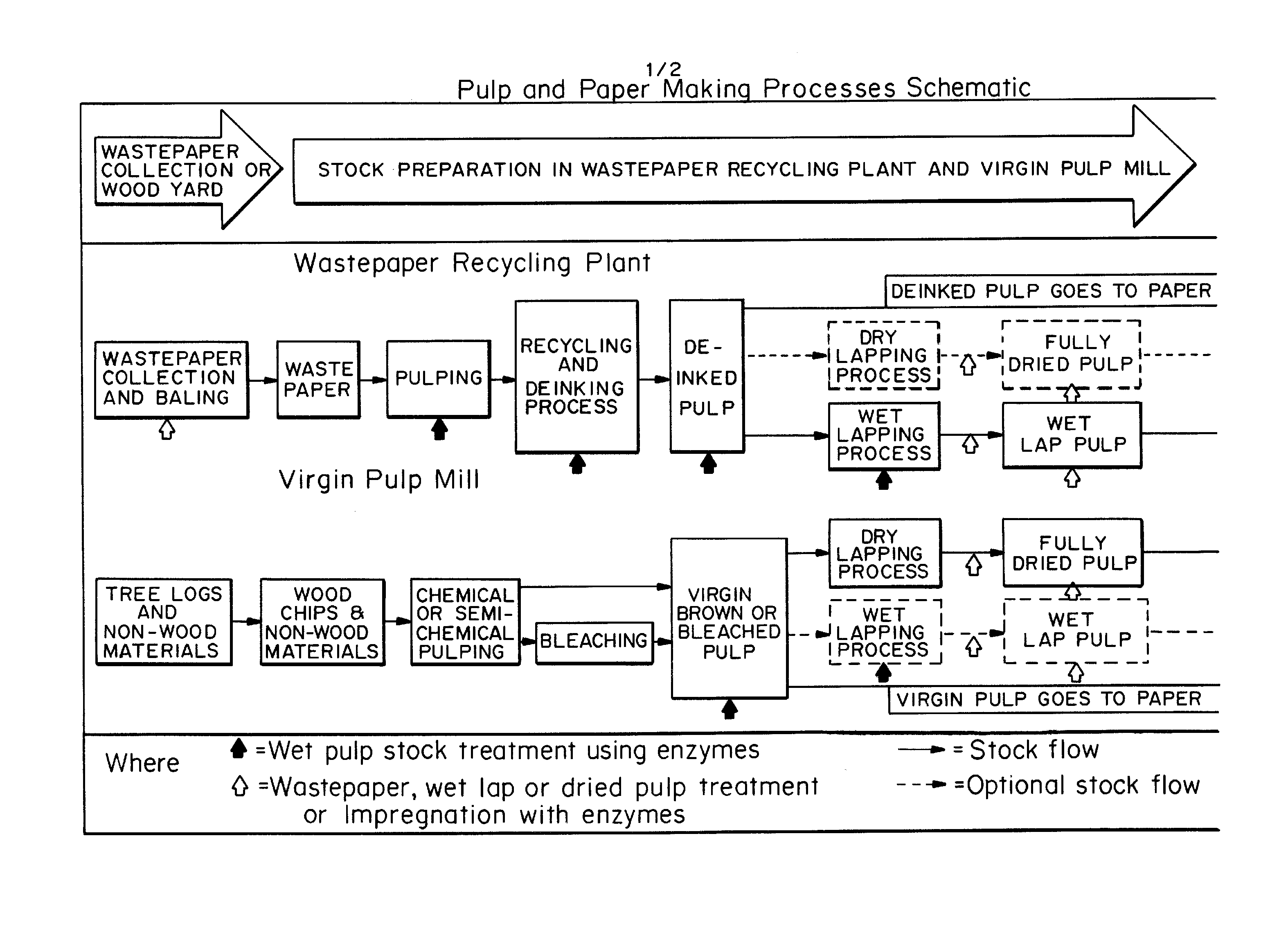

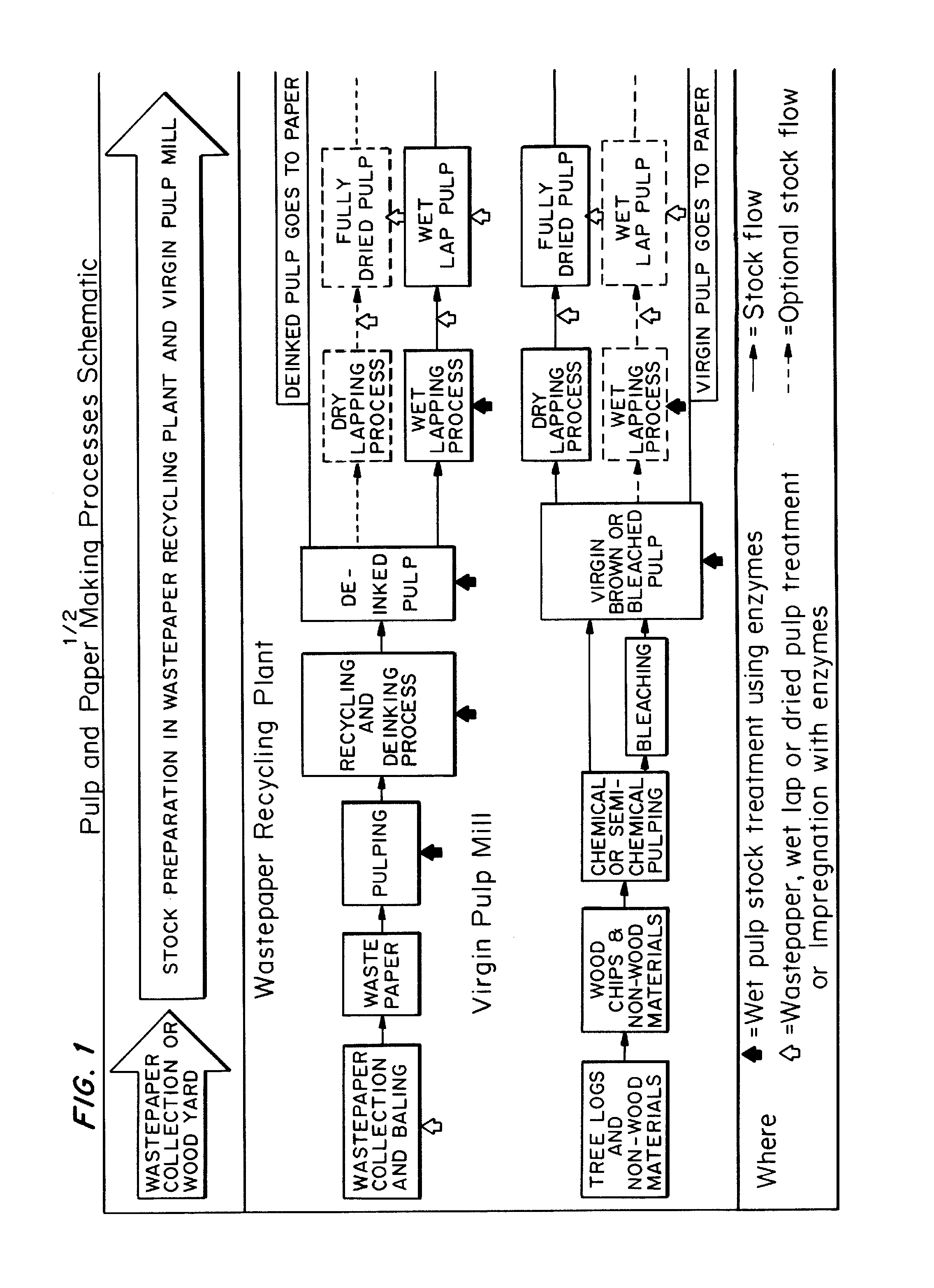

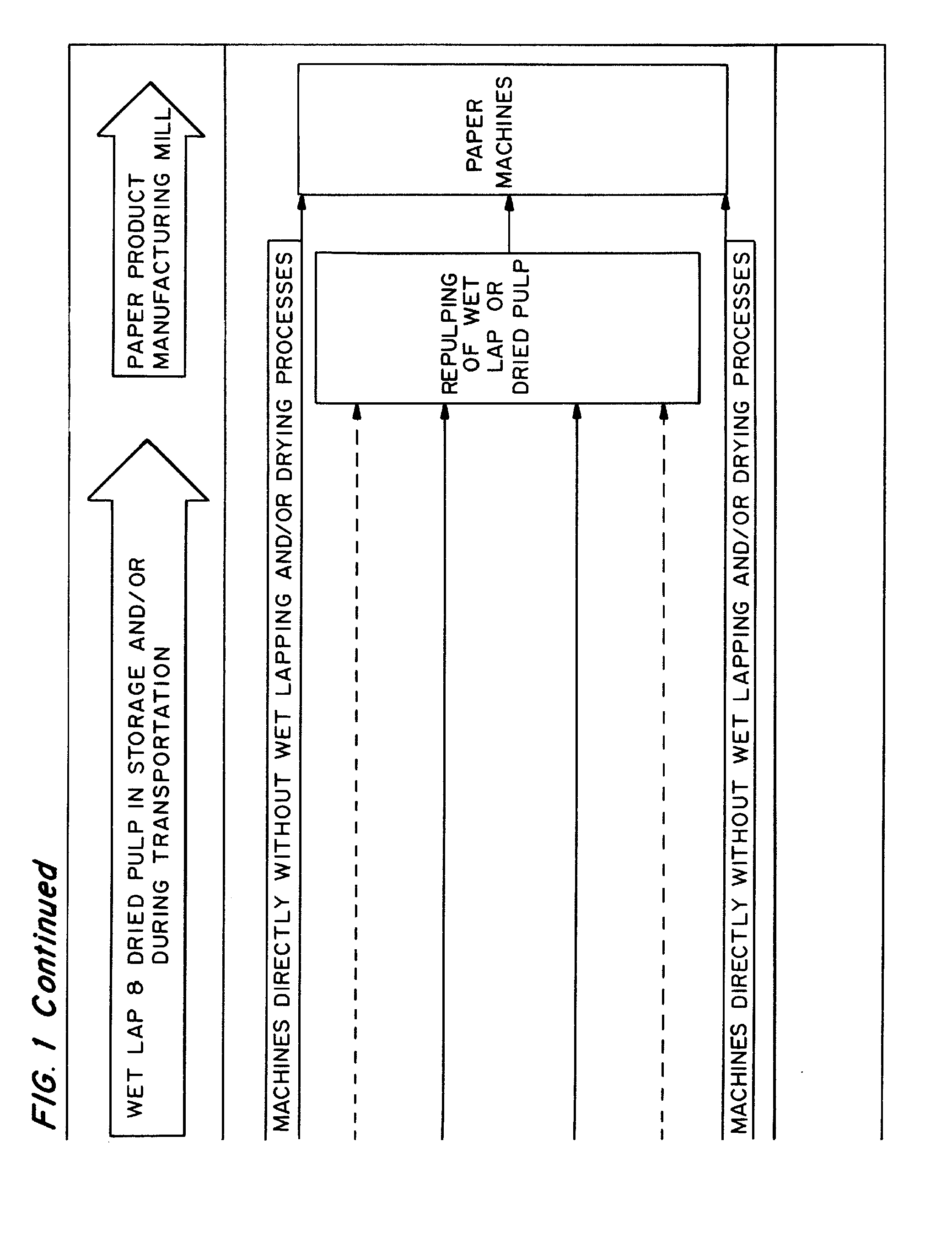

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20130146239A1Increasing pulp drainageImprove strength propertiesMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Methods for reducing the effects of wetlapping, drying, and hornification of pulp fibers and consequently increasing the pulp drainage and strength properties in the final product (i.e., paper) are provided. The method which has been developed creates a “value-added” product by the wastepaper supplier or at the pulp and / or deinking (recycled paper) mill—a wastepaper load / bale, wet pulp stock or wet lap, or dried pulp treated with or impregnated with enzymes that enhance the quality of the pulp or paper product when it is repulped and processed at the paper mill.

Owner:ENZYMATIC DEINKING TECH LLC

Use of precipitated carbonate in the manufacture of a fibre product

InactiveUS20140069302A1Good strength performanceImprove strength propertiesCalcium/strontium/barium carbonatesPigmenting treatmentCardboardFiber

The present invention relates to a filler or a filler mixture containing carbonate, as well as to a process for manufacturing the same by precipitating the filler directly into the pulp or, as a separate process without the presence of fibres, particularly from the wire water of the paper or board manufacture. The invention also relates to a fibre product containing this filler, such as a paper or board product, or a plastic, rubber, concrete or paint product.

Owner:NORDKALK AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com