Method for preparing porous silicon carbide ceramic

A technology of porous silicon carbide and silicon carbide powder, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of low mechanical properties and low porosity of porous silicon carbide ceramics, achieve low thermal expansion coefficient, improve strength performance, and good The effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

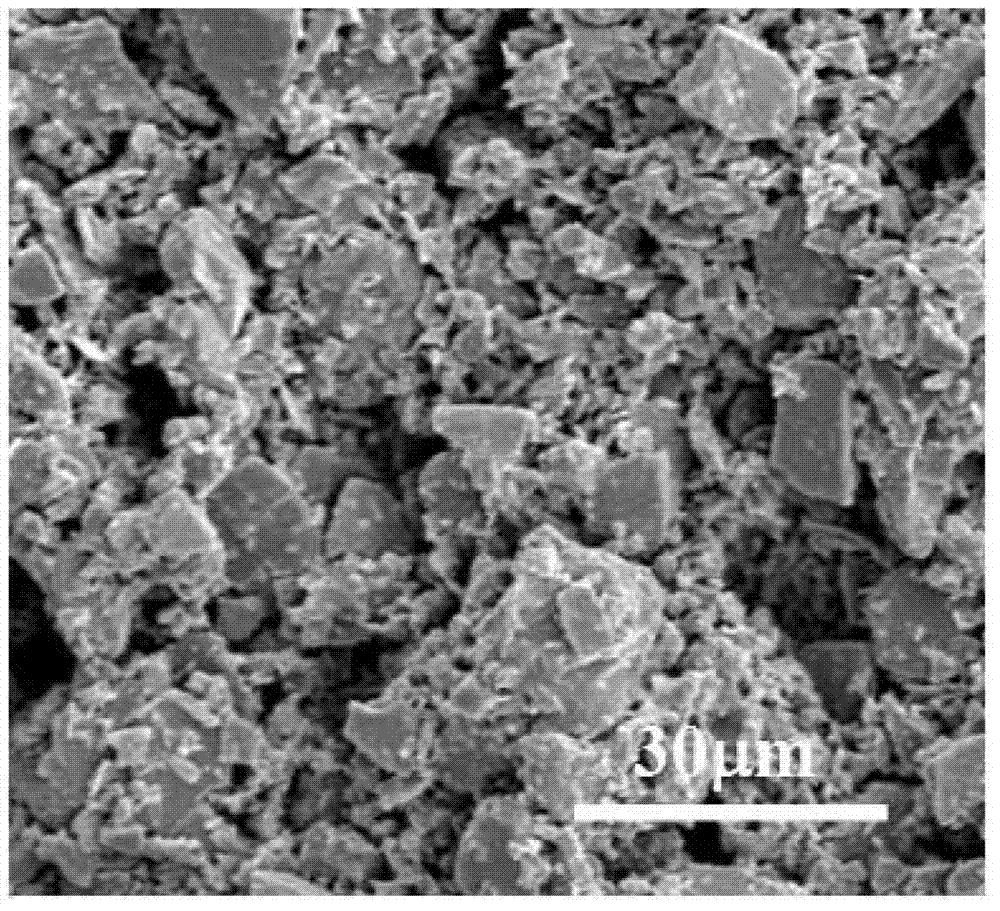

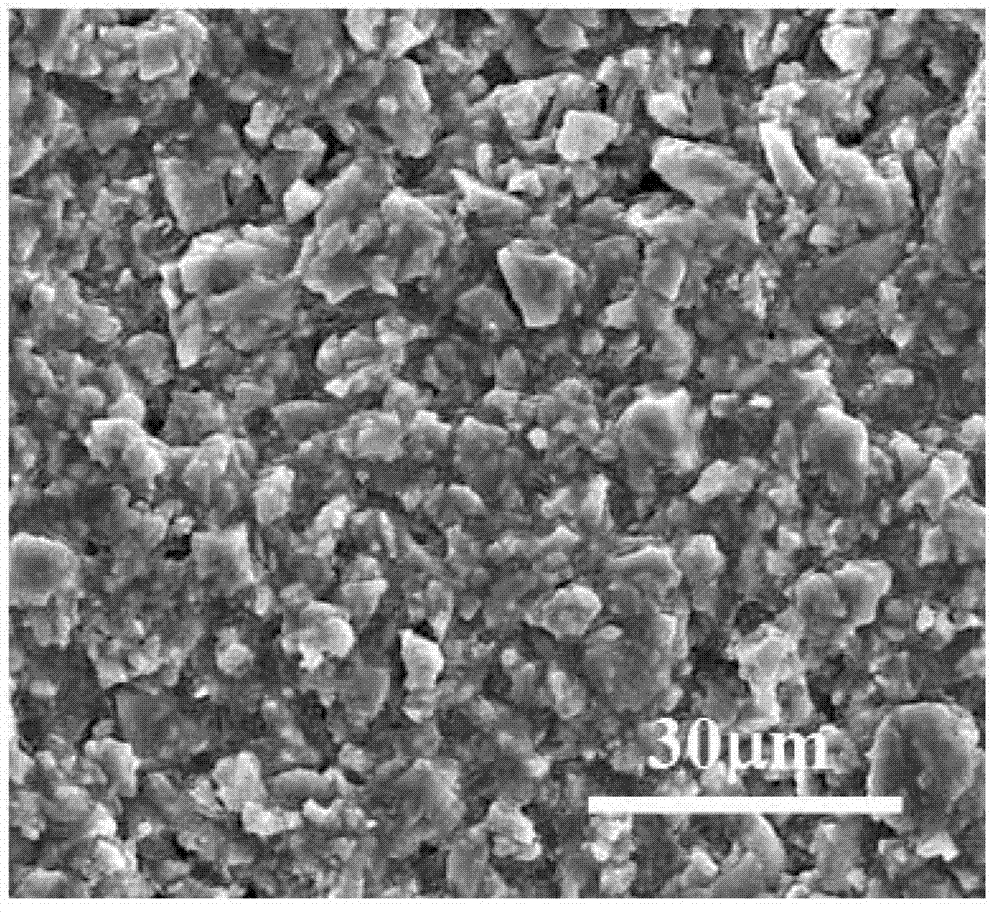

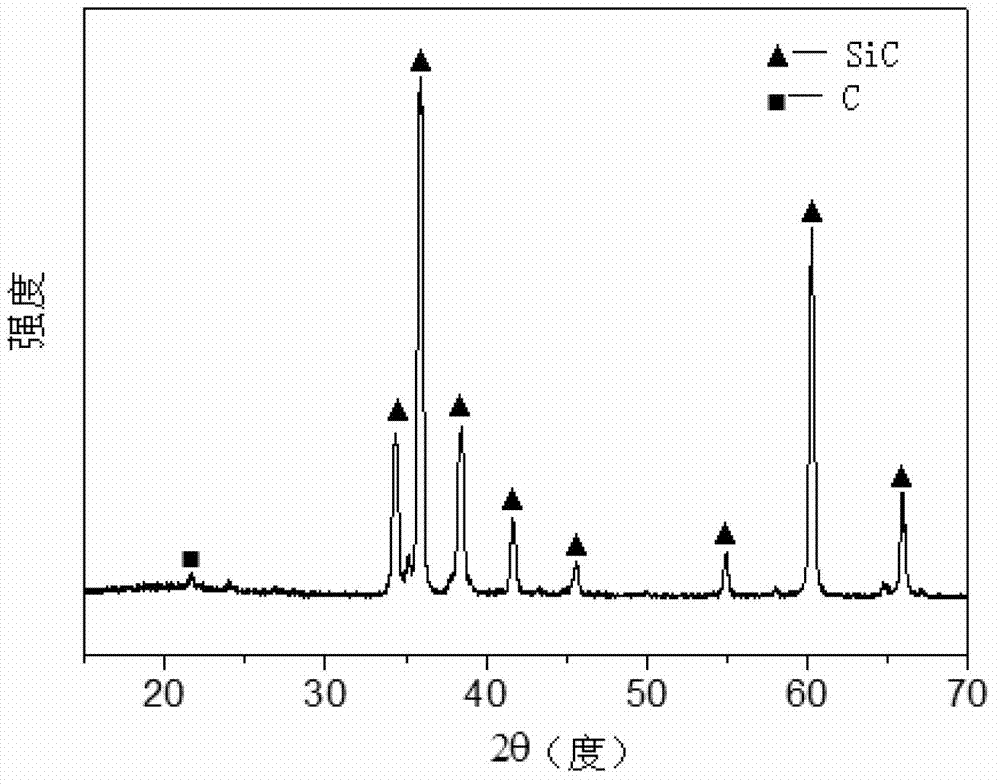

[0033] Embodiment 1: The preparation method of porous silicon carbide ceramics in this embodiment is carried out according to the following method:

[0034] 1. Mix 5-60 parts by mass of raw materials with 40-95 parts by mass of deionized water, then add dispersant, binder and defoamer, and then add silicon carbide balls for ball milling for 24 hours (the mass ratio of balls to materials is 3: 1), obtain slurry;

[0035] The raw material is silicon carbide powder or a mixture of silicon carbide powder and sintering aid, and the mass fraction of the sintering aid in the mixture of silicon carbide powder and sintering aid is 1 to 10%, wherein the silicon carbide powder The mass ratio of silicon carbide powder to dispersant is 1:0.001-0.03, the mass ratio of silicon carbide powder to binder is 1:0.005-0.03, and the mass ratio of silicon carbide powder to defoamer is 1:0.001-0.01;

[0036] The sintering aid described in step 1 is Al 2 o 3 , Y 2 o 3 and BaAl 2Si 2 o 8 one or...

specific Embodiment approach 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of the sintering aid in the mixture of silicon carbide powder and sintering aid in step 1 is 5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the mass ratio of silicon carbide powder and dispersant in Step 1 is 1:0.02. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com