Patents

Literature

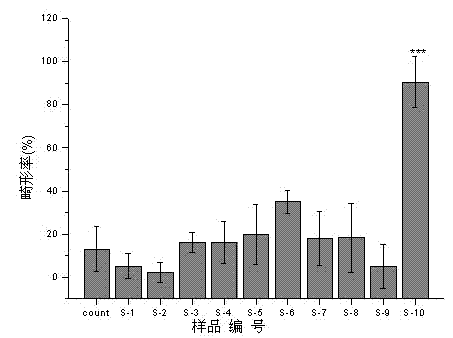

413results about How to "Good strength performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collagen device and method of preparing the same

InactiveUS20050283256A1Minimize presenceEasy to operateSurgeryTissue regenerationMeningesUltimate tensile strength

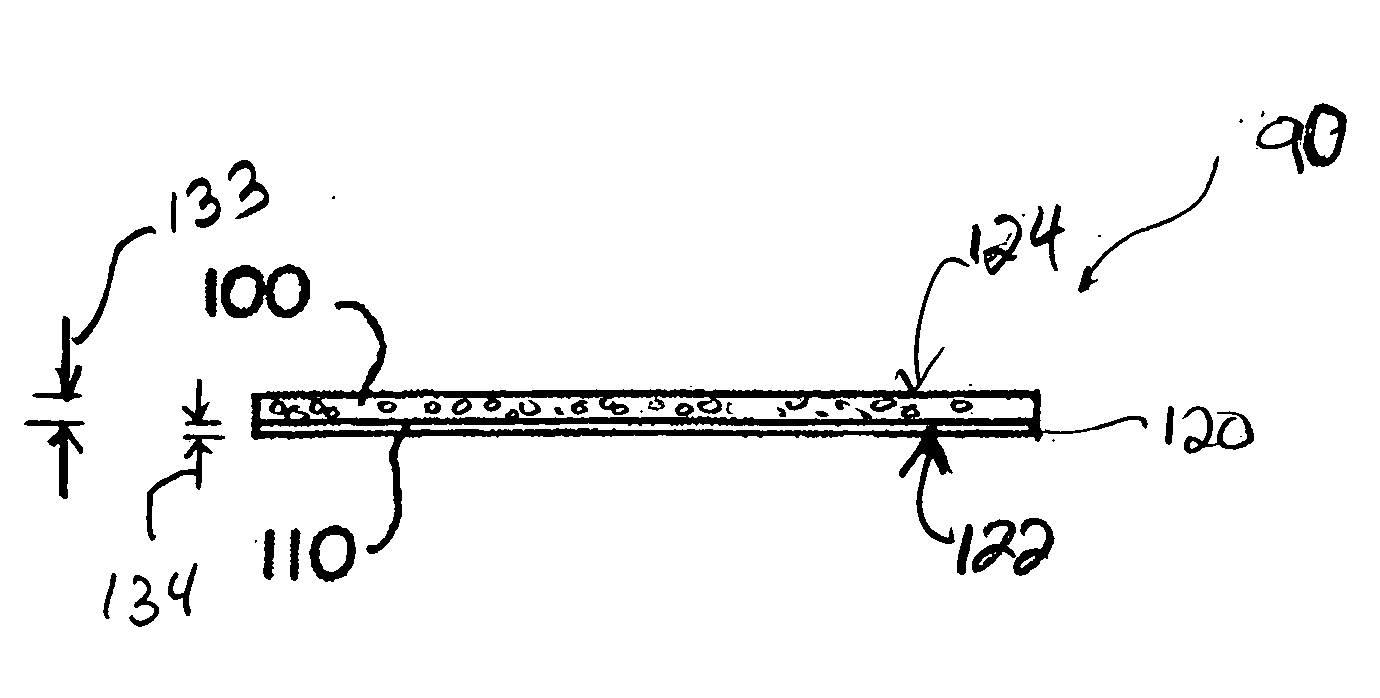

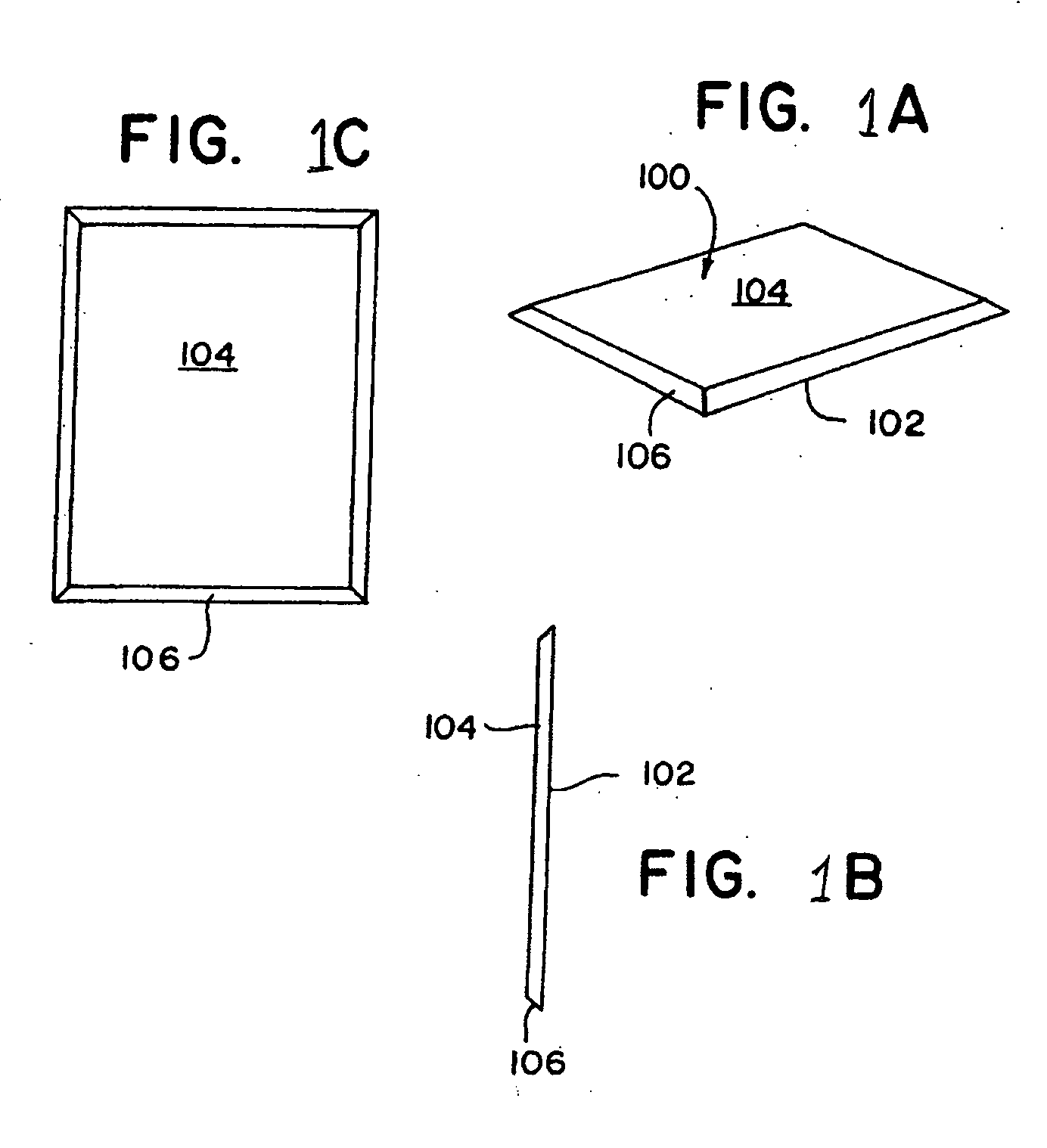

A laminated, bioimplantable dural graft product is configured for use as both an onlay graft and a suturable graft. The dural graft product is sufficiently pliable so as to sufficiently conform to a curvature of a tissue surface to which it is applied, such as the curved surface of a meningeal membrane. The use of the graft product can have improved properties, including suture retention strength and fluid impermeability. To use the dural graft product as an implant to replace, reinforce or strengthen bodily tissue, or to act as an adhesion barrier, the dural graft is placed in contact with bodily tissue and conforms to the curvature of the bodily tissue. Sutures can be used to maintain the contact between the dural graft and the bodily tissue.

Owner:CODMAN & SHURTLEFF INC

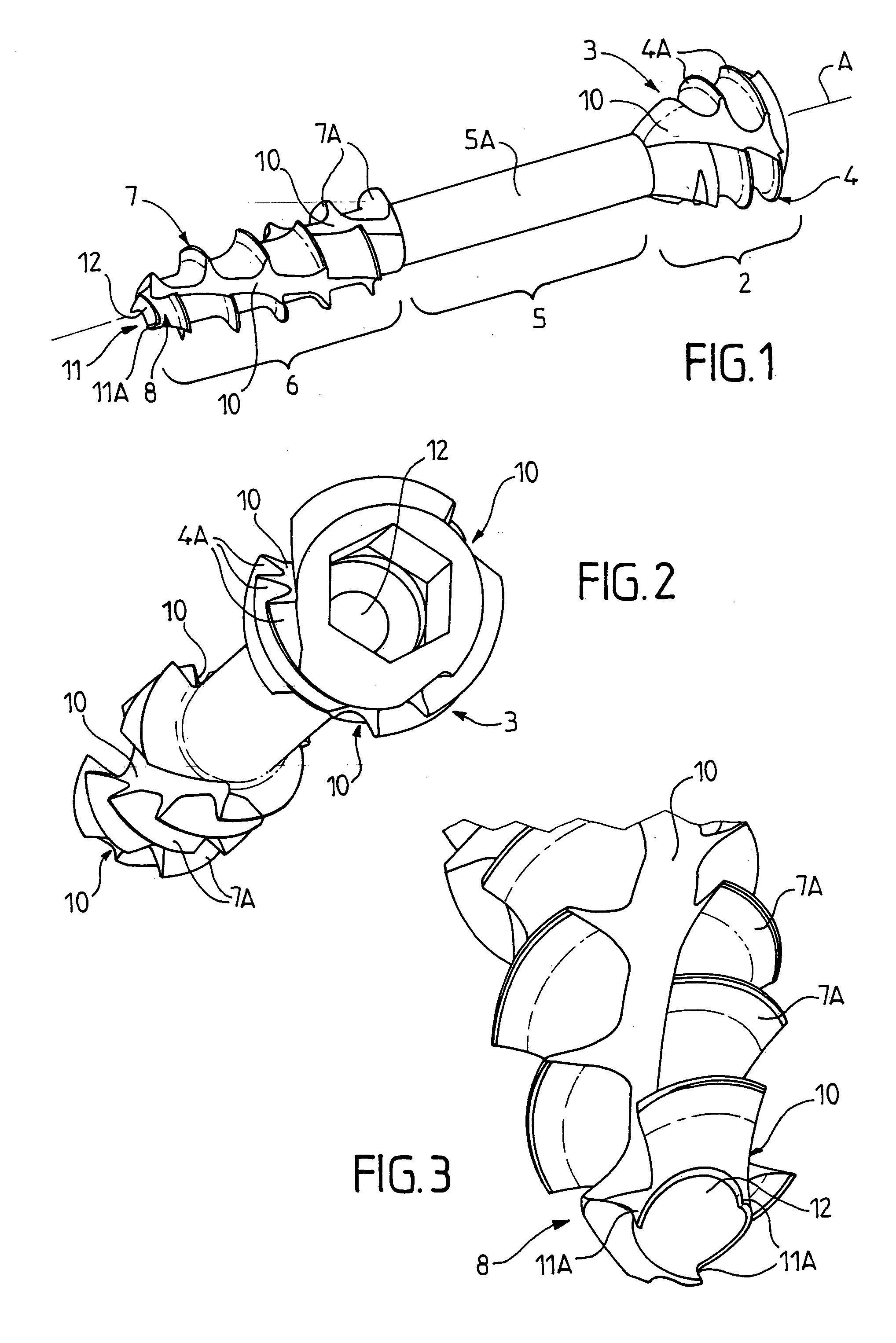

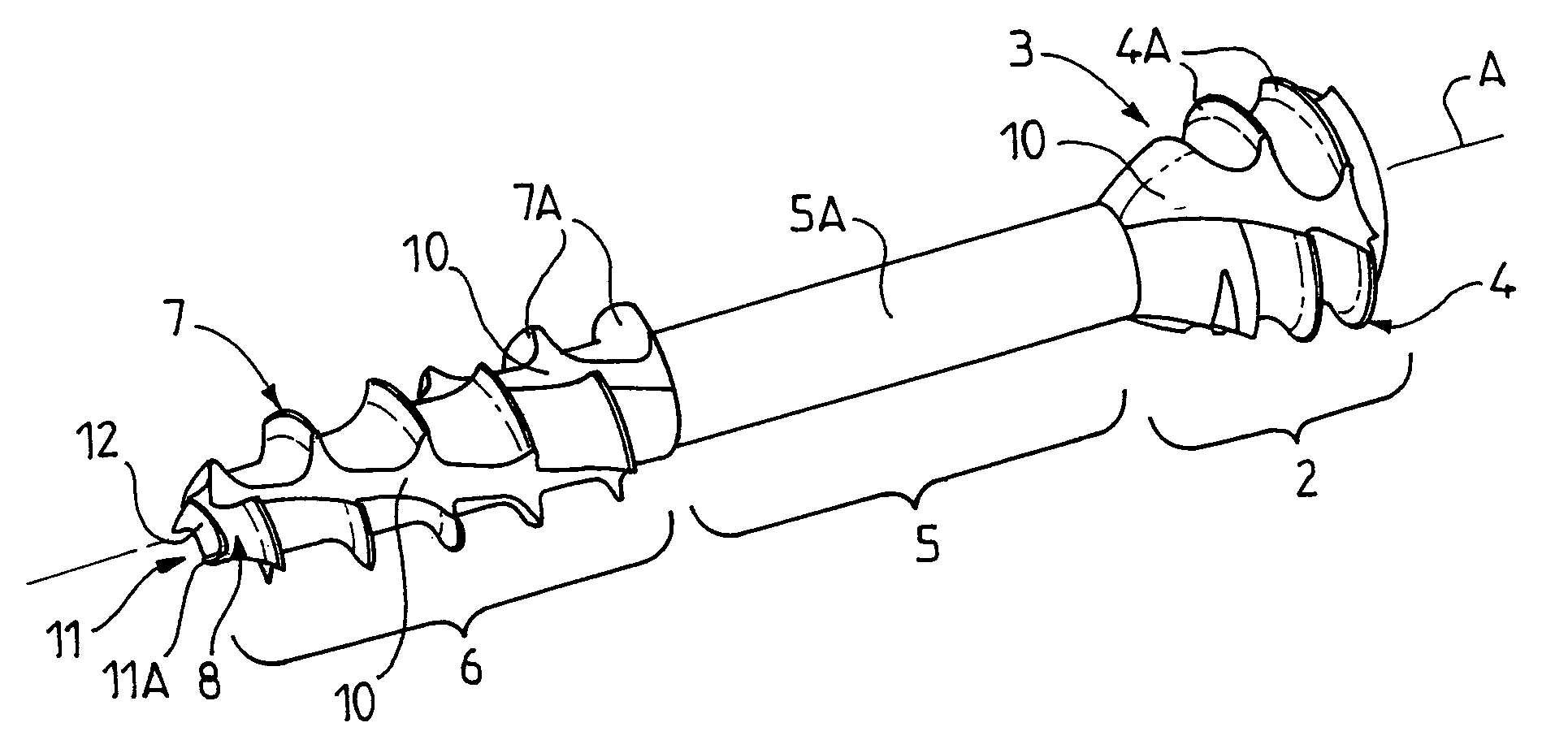

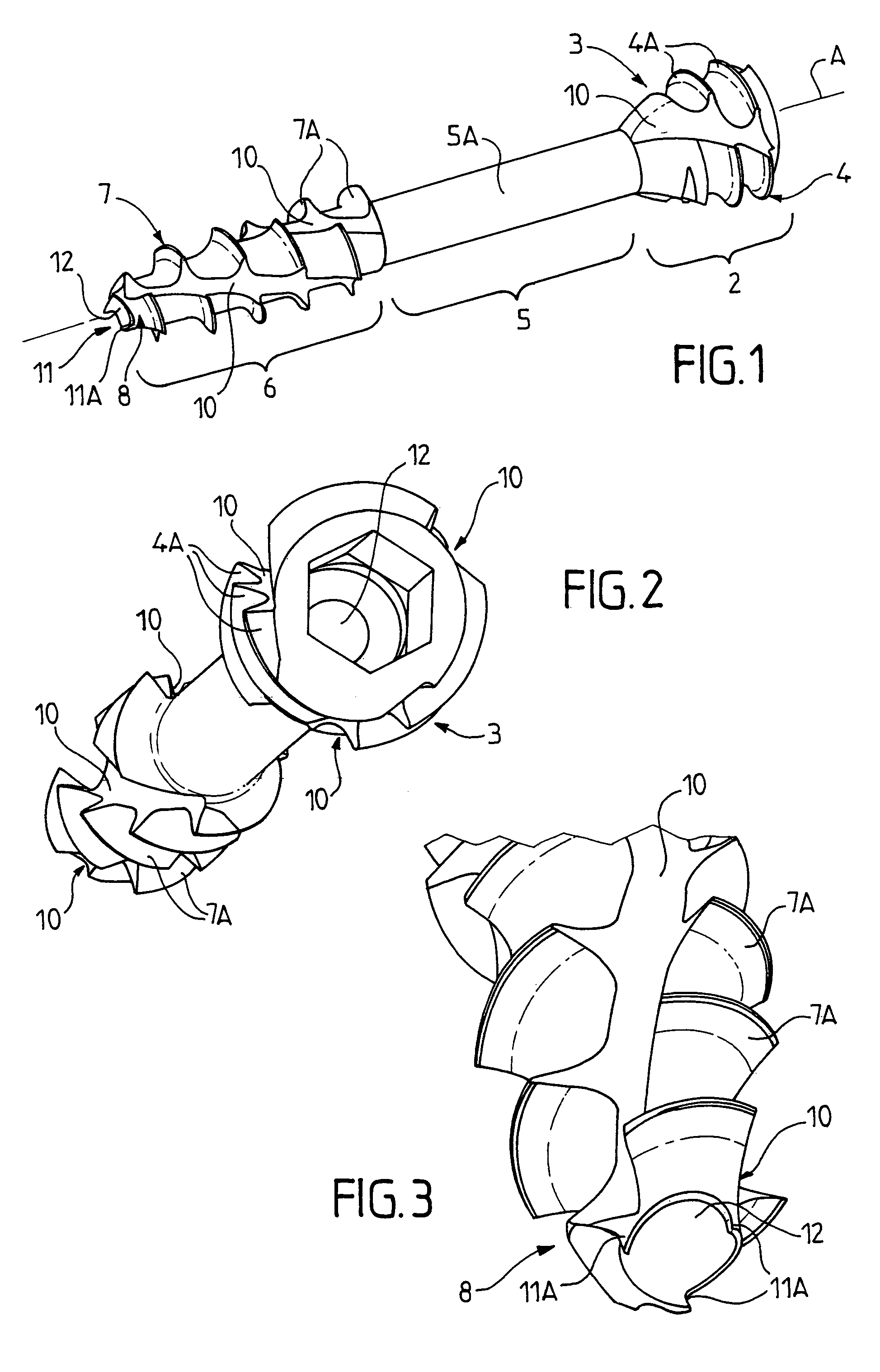

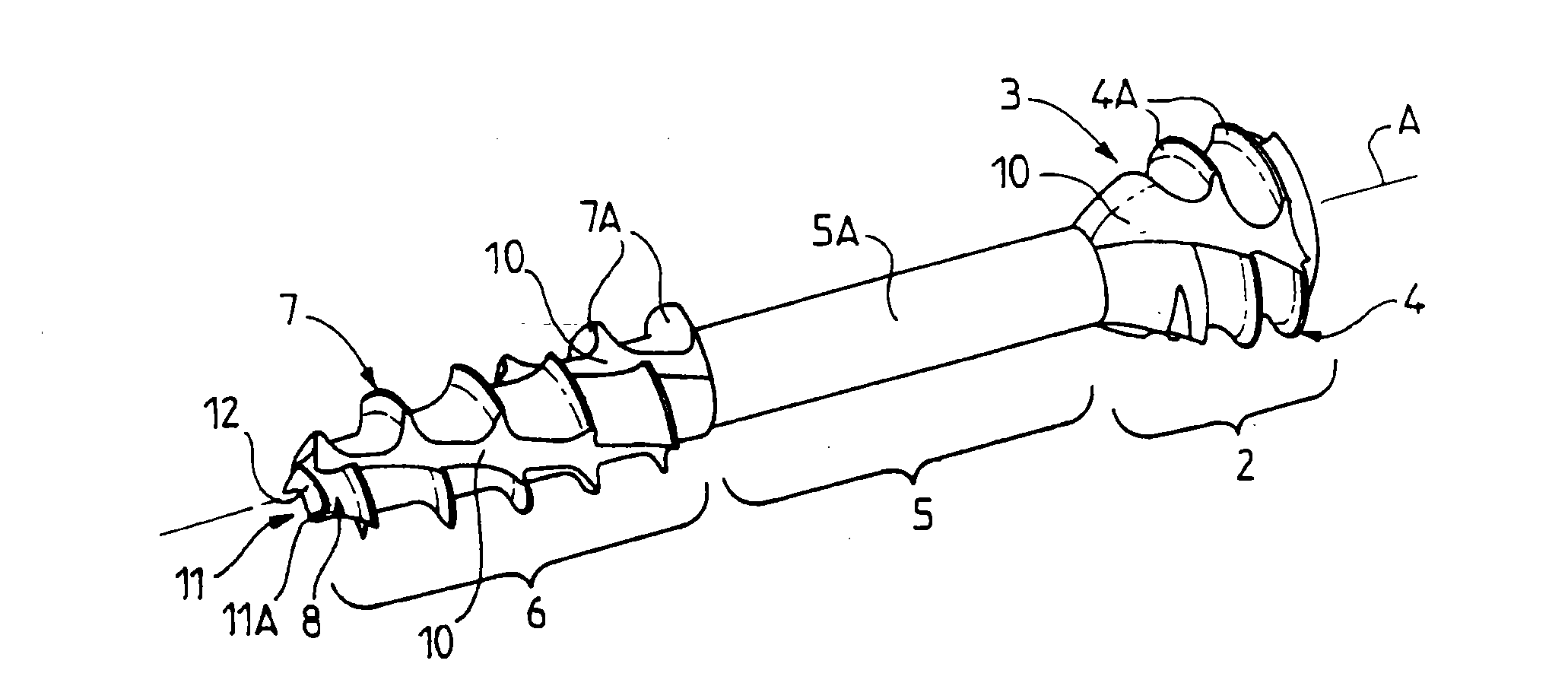

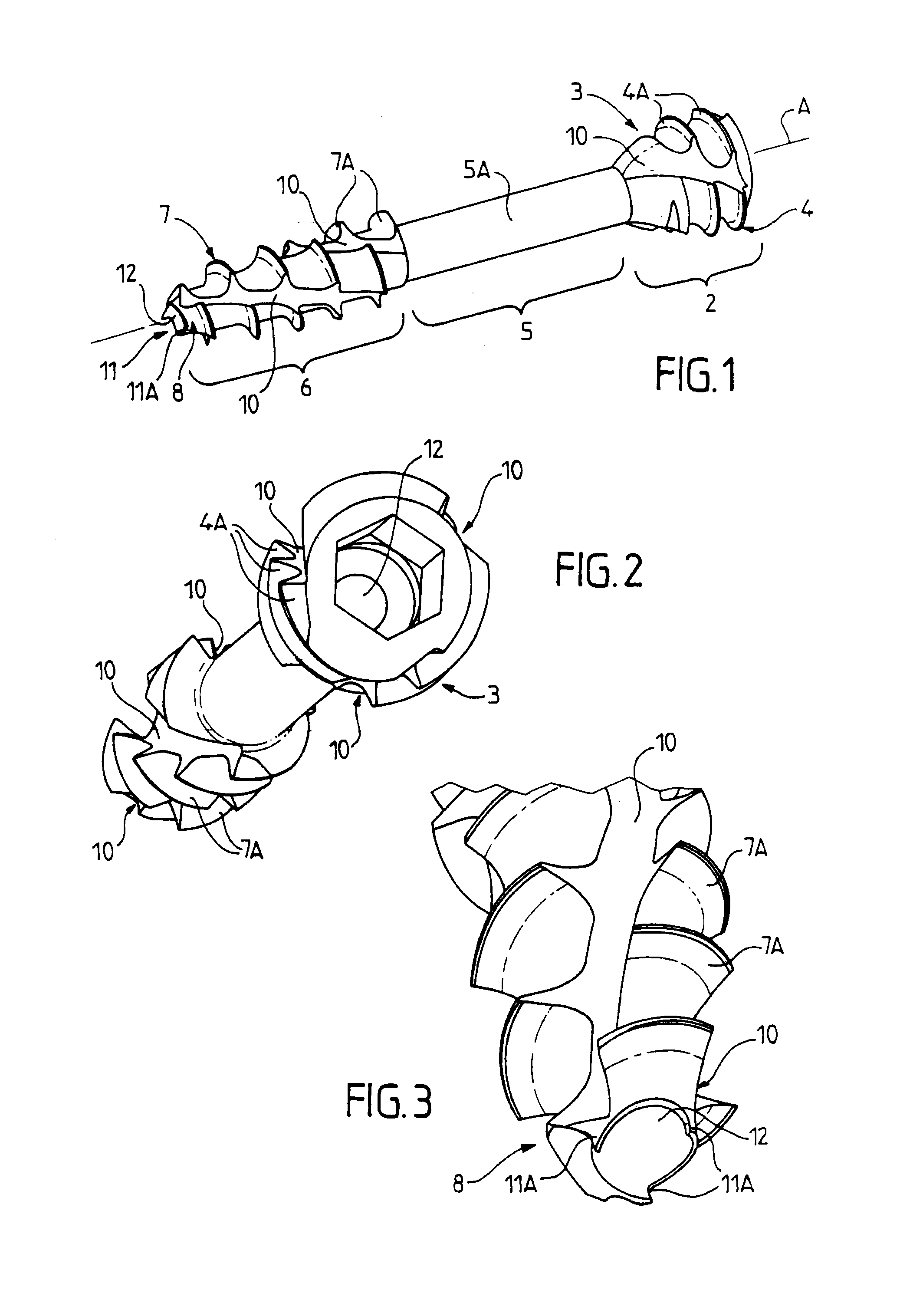

Self-boring and self-tapping screw for osteosynthesis and compression

ActiveUS20040068261A1Easy to installControl is possibleSuture equipmentsJoint implantsDistal portionBiomedical engineering

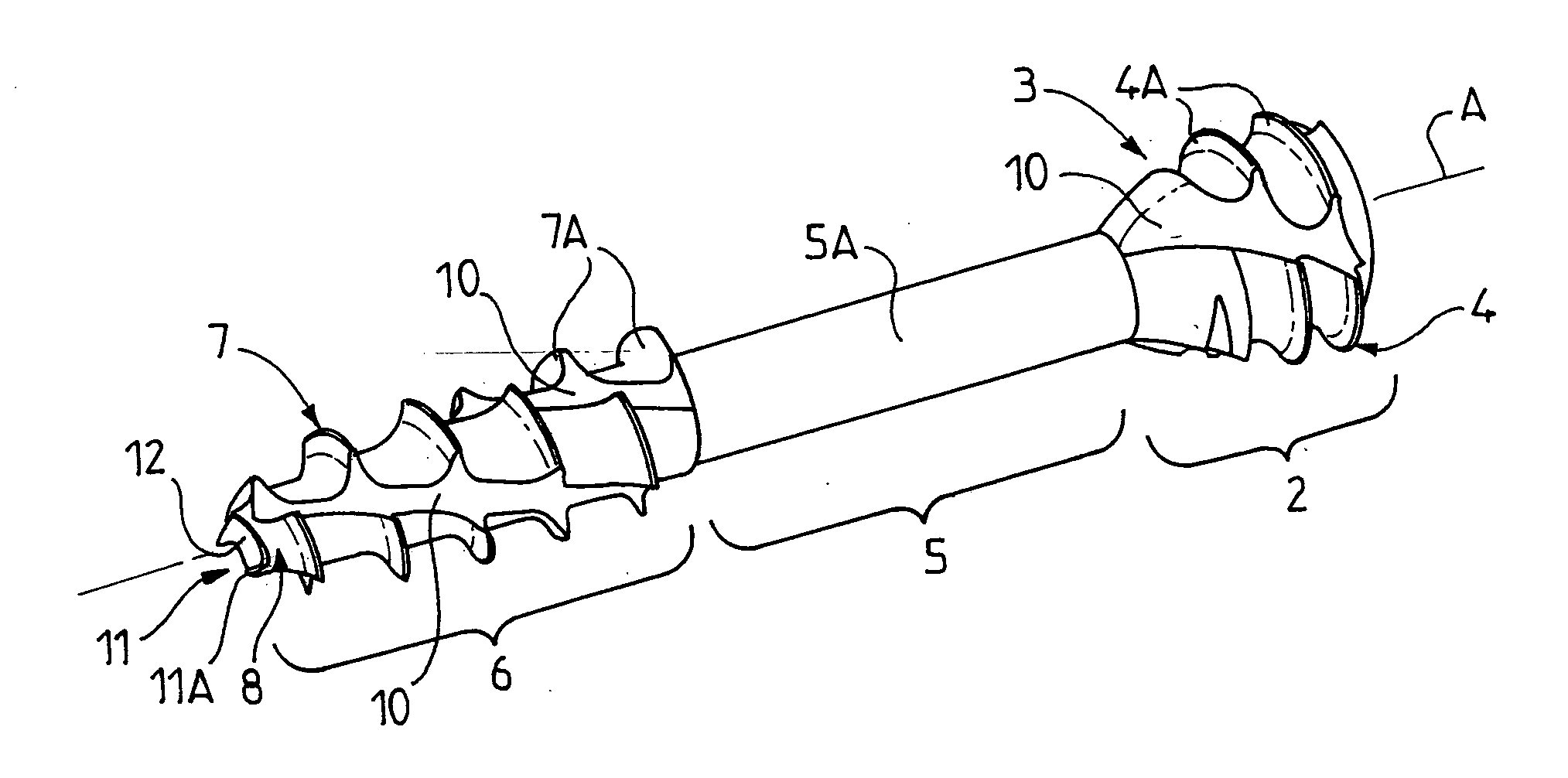

The invention provides an osteosynthesis and compression screw that is self-boring and self-tapping for the purpose of coaptation of small bone fragments. The screw comprises: a proximal portion formed by a screw head provided with an outside thread; an intermediate portion having no thread; and a distal portion provided with an outside thread. Wherein: each of the screw head and the distal portion includes at least one groove, firstly extending over the entire axial length of its thread, and secondly being formed through each thread in such a manner to form tapping means; and the terminal zone of the distal portion is provided with preparation means for preparing a housing in the bone fragments for receiving the intermediate and distal portions of the screw.

Owner:SMITH & NEPHEW INC

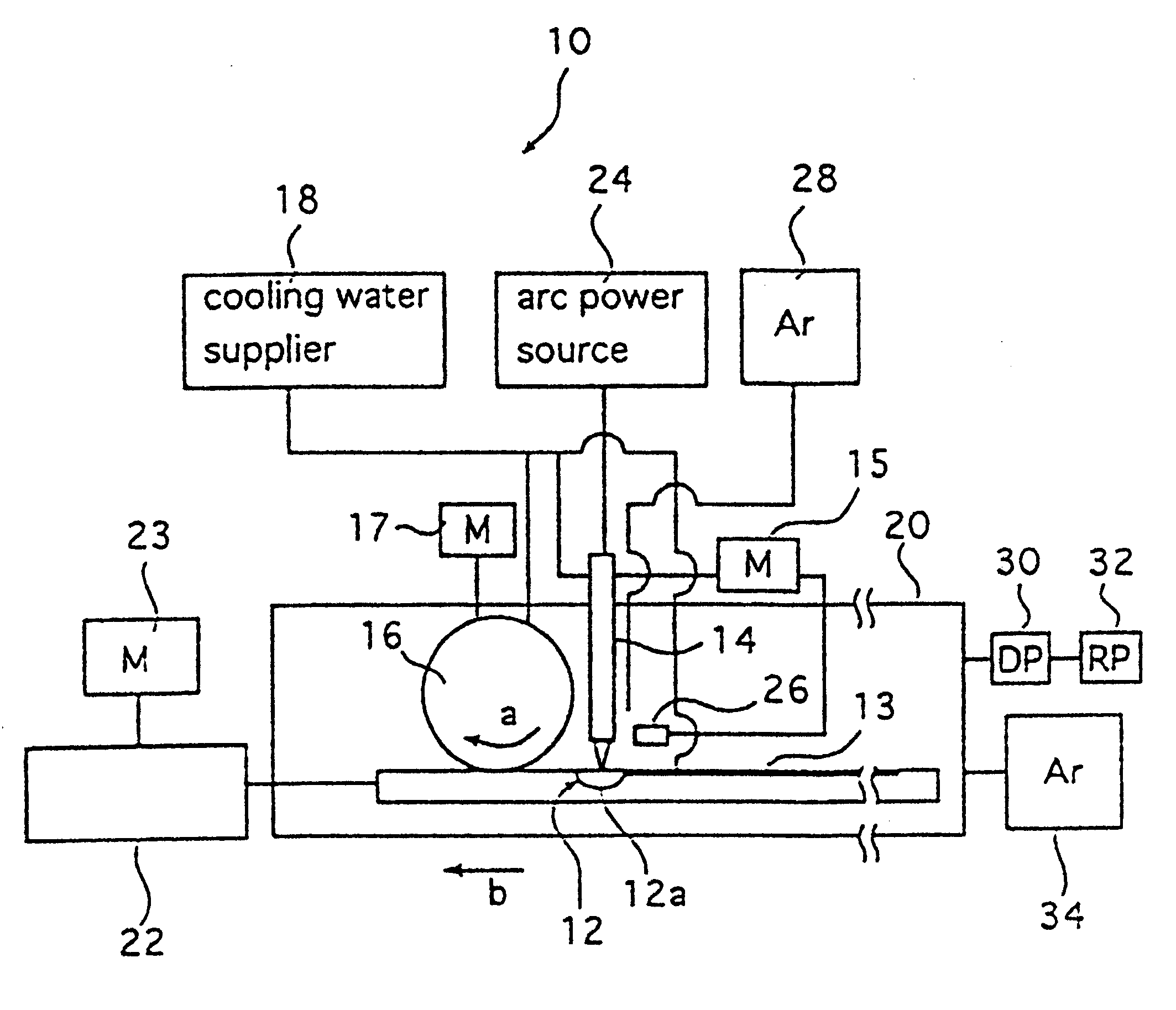

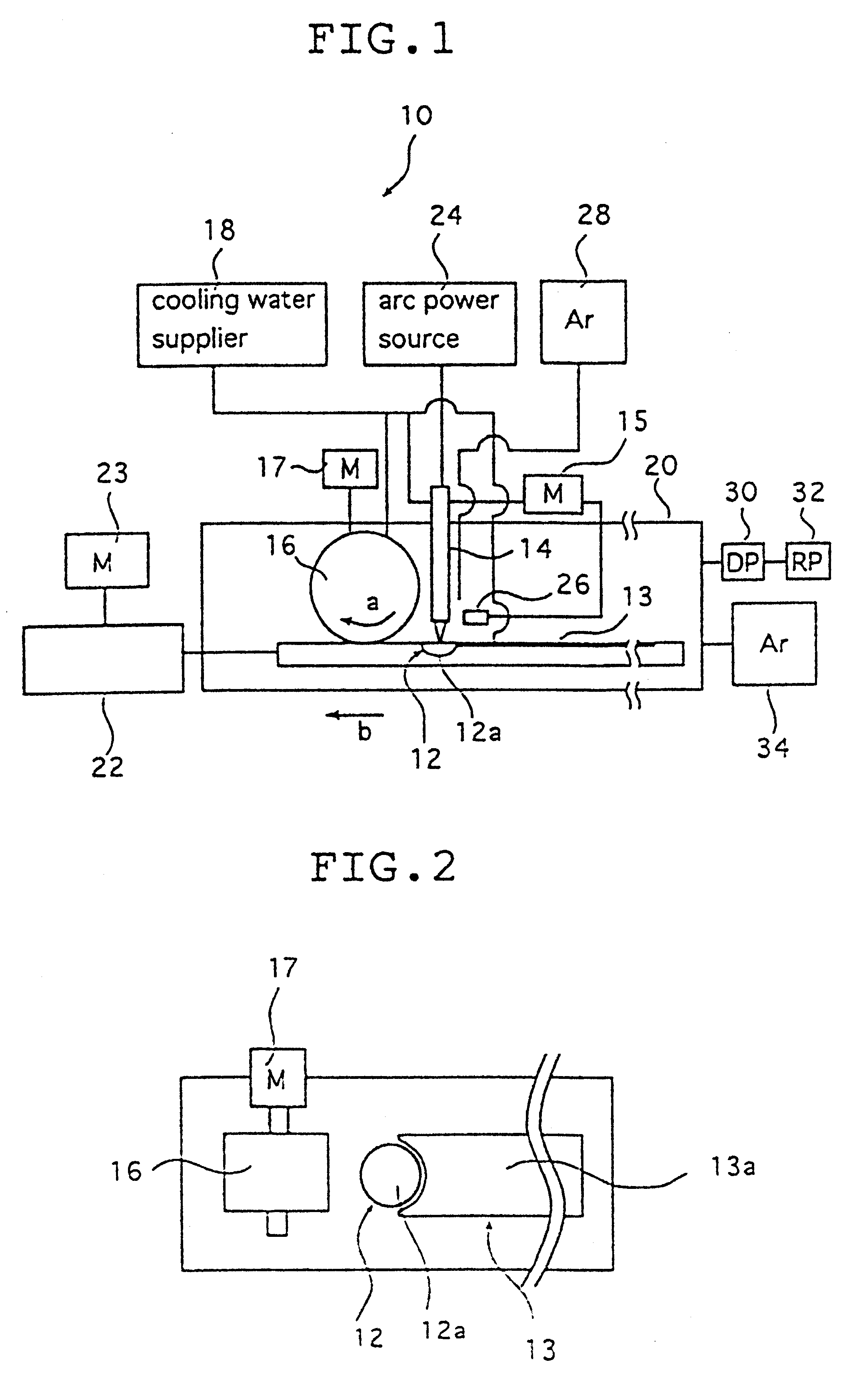

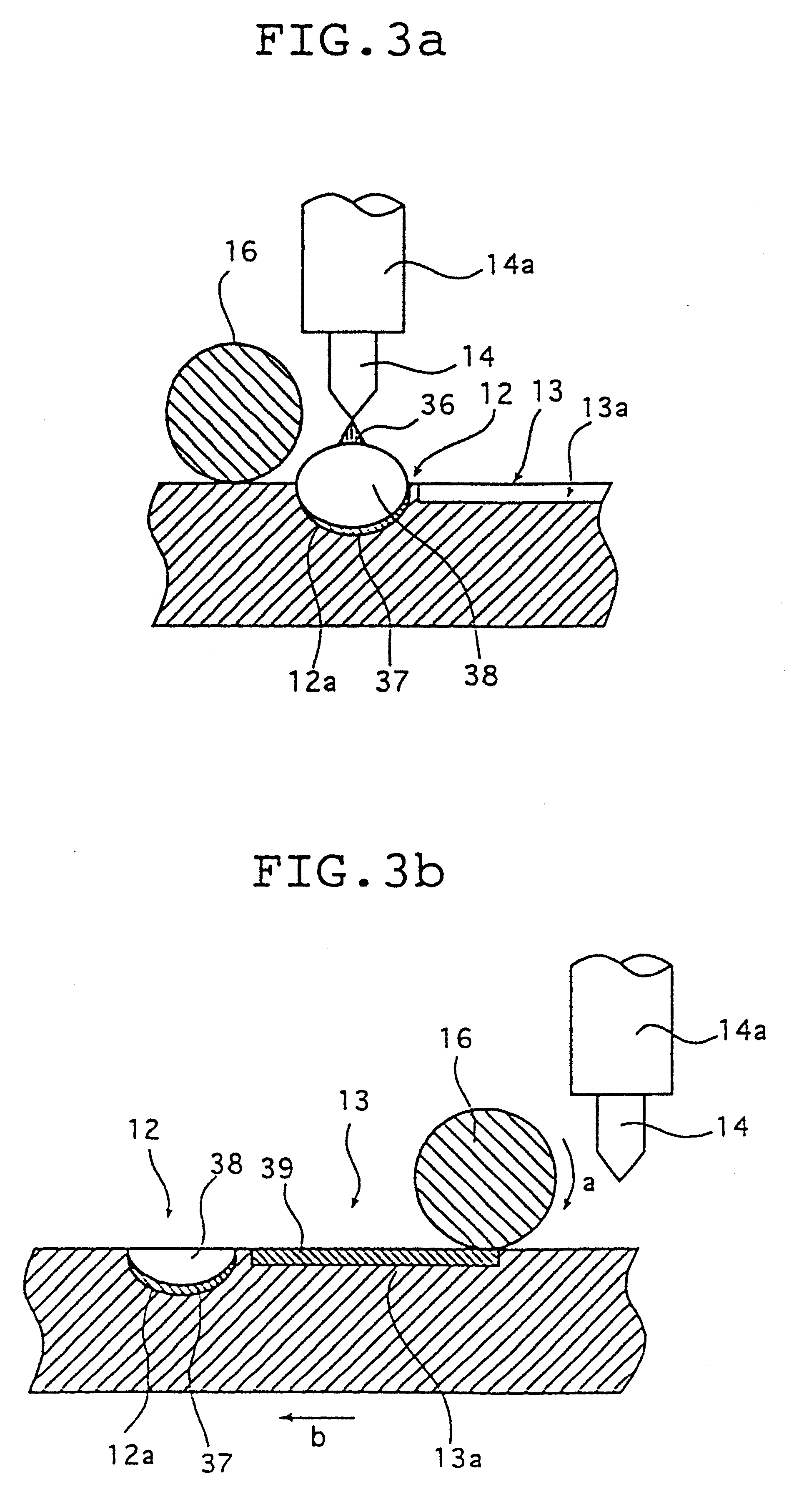

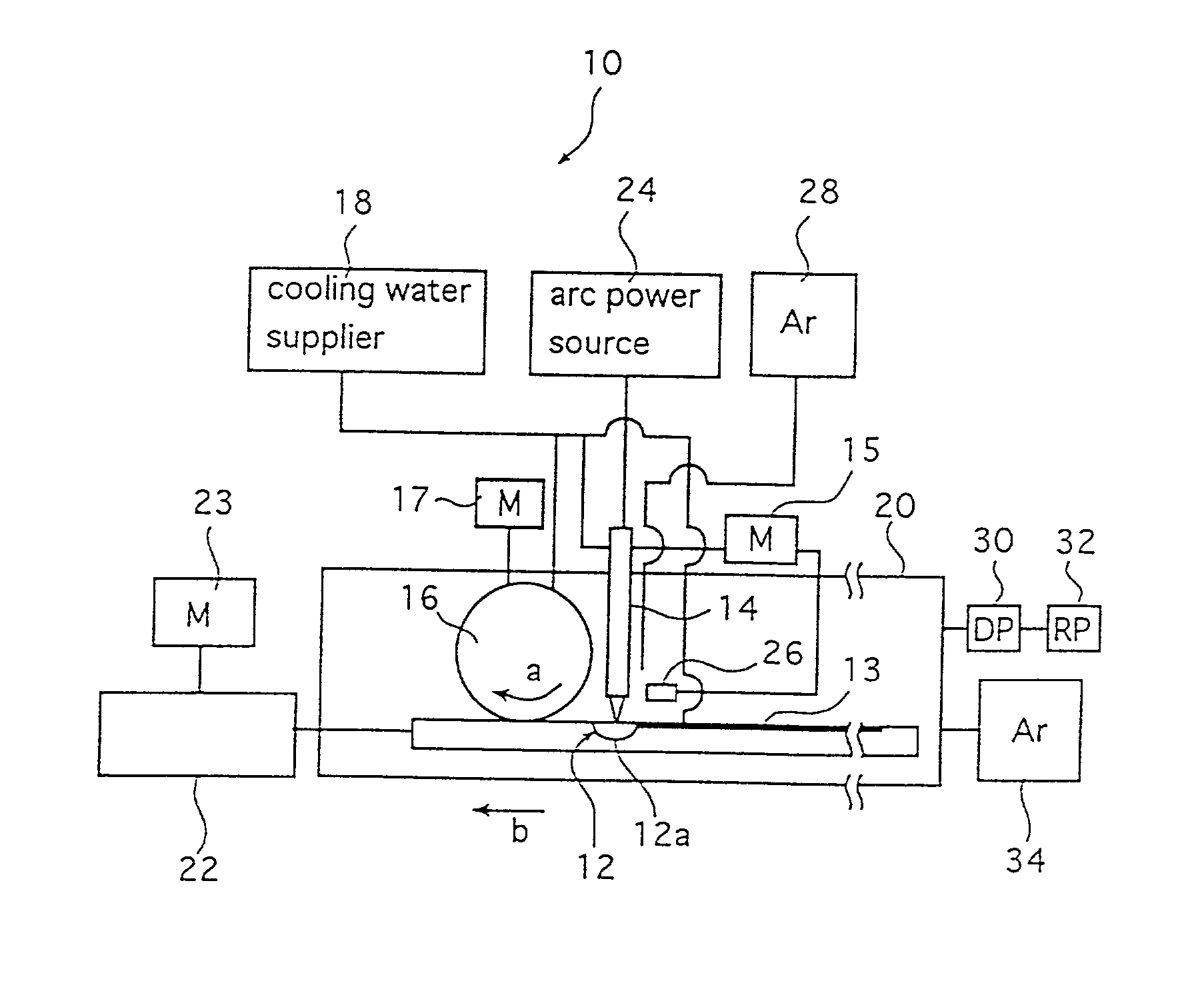

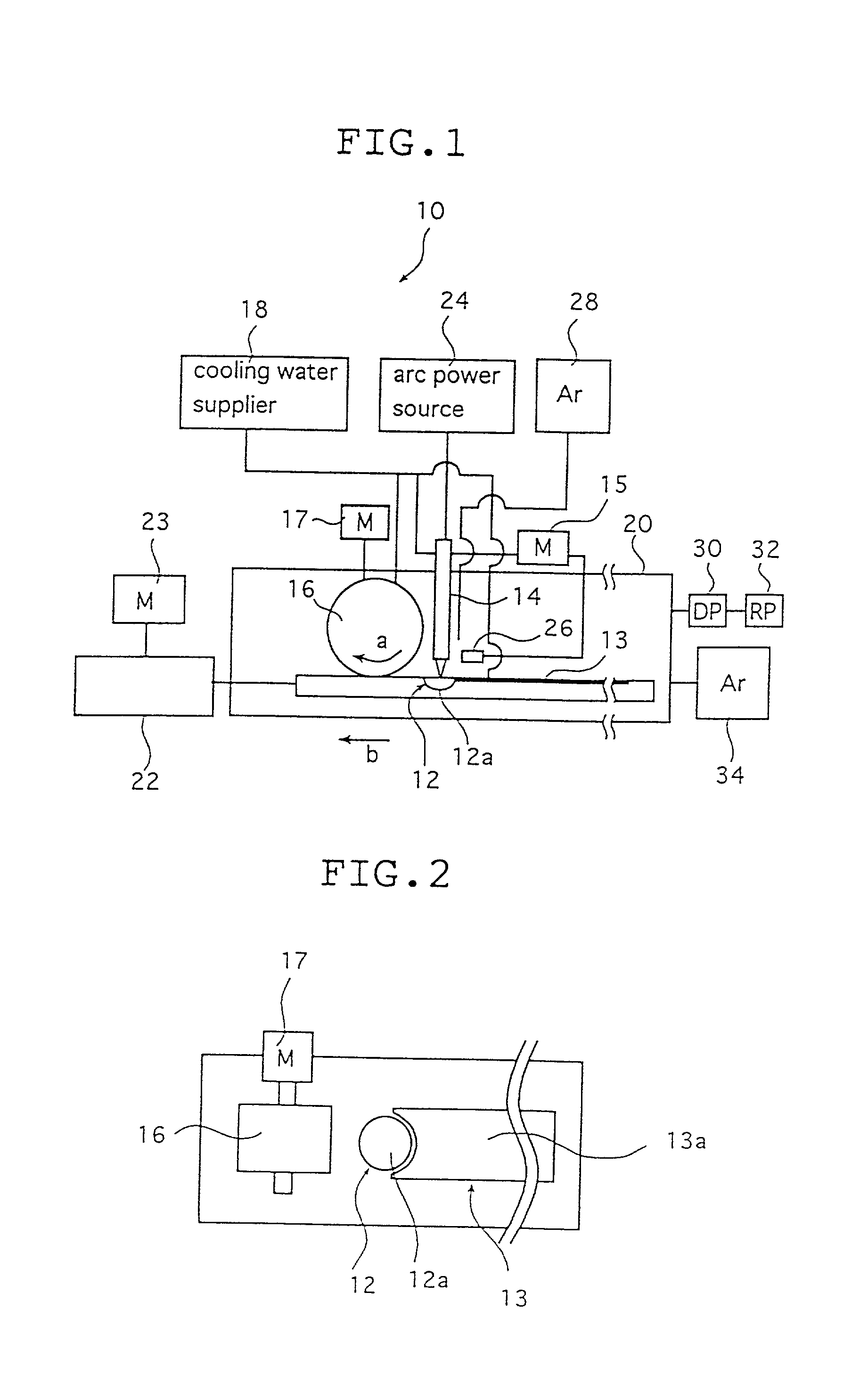

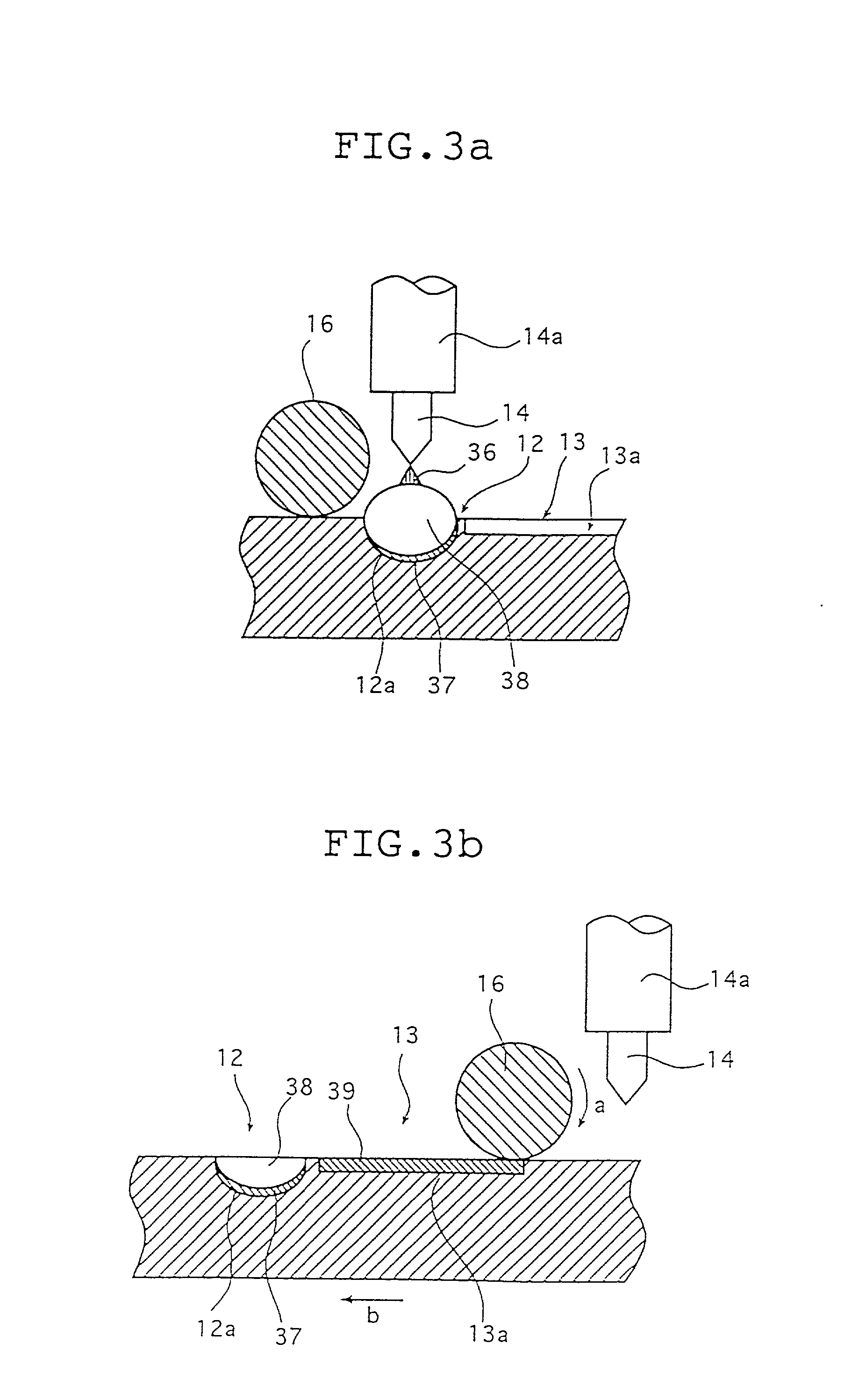

Process and apparatus for producing metallic glass

InactiveUS6427753B1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyHearth

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

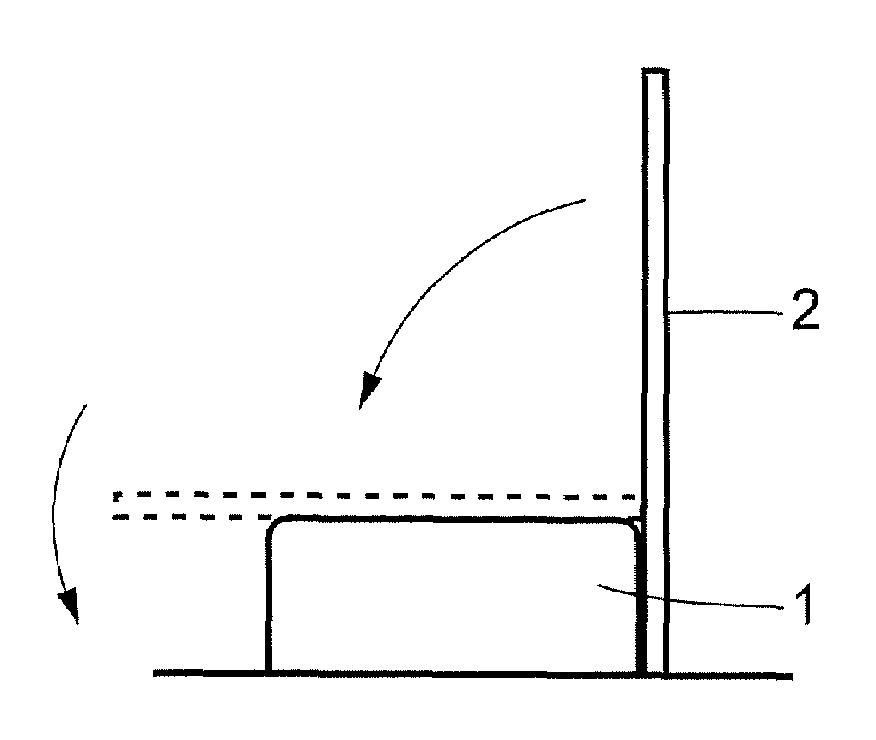

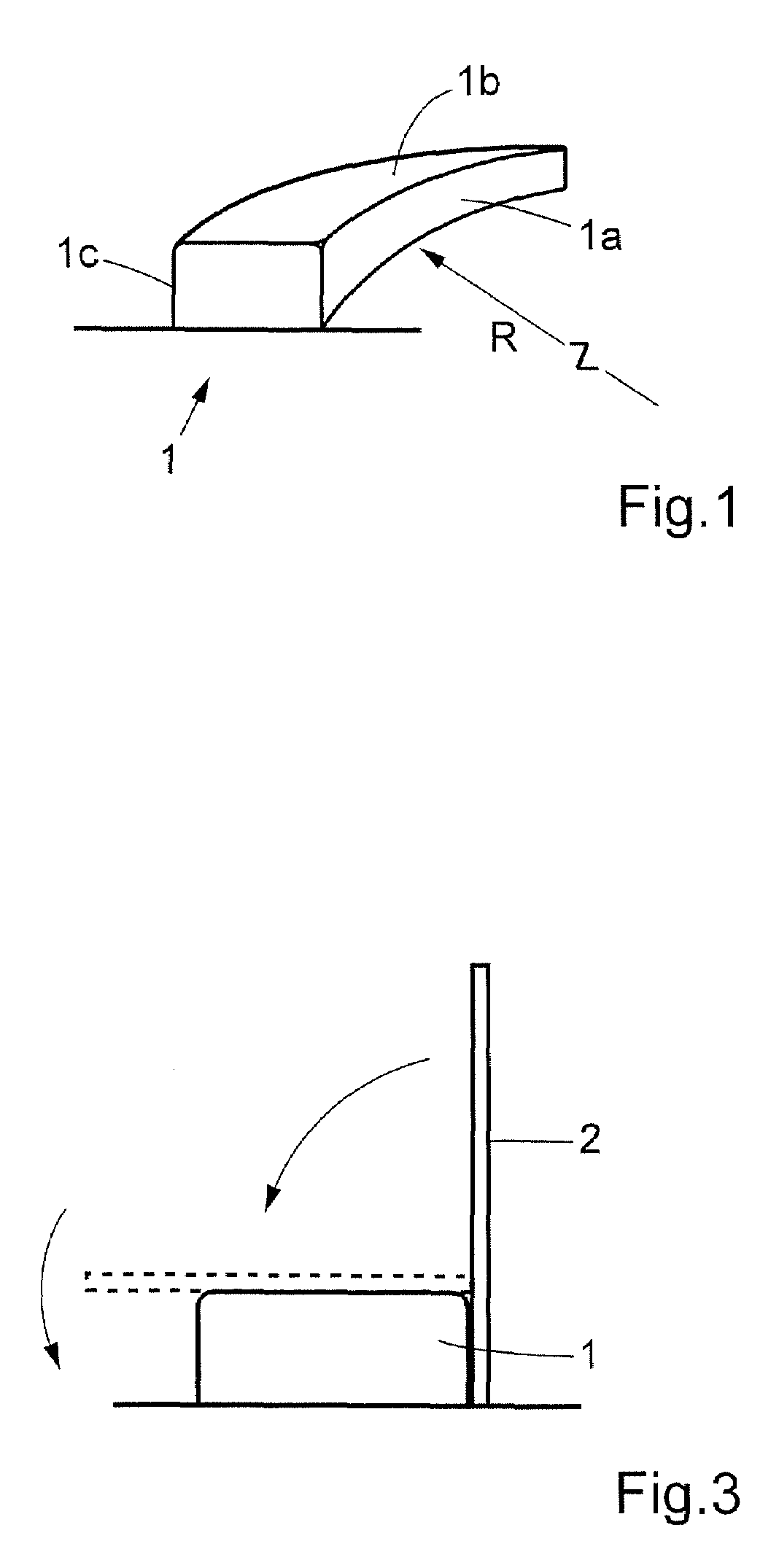

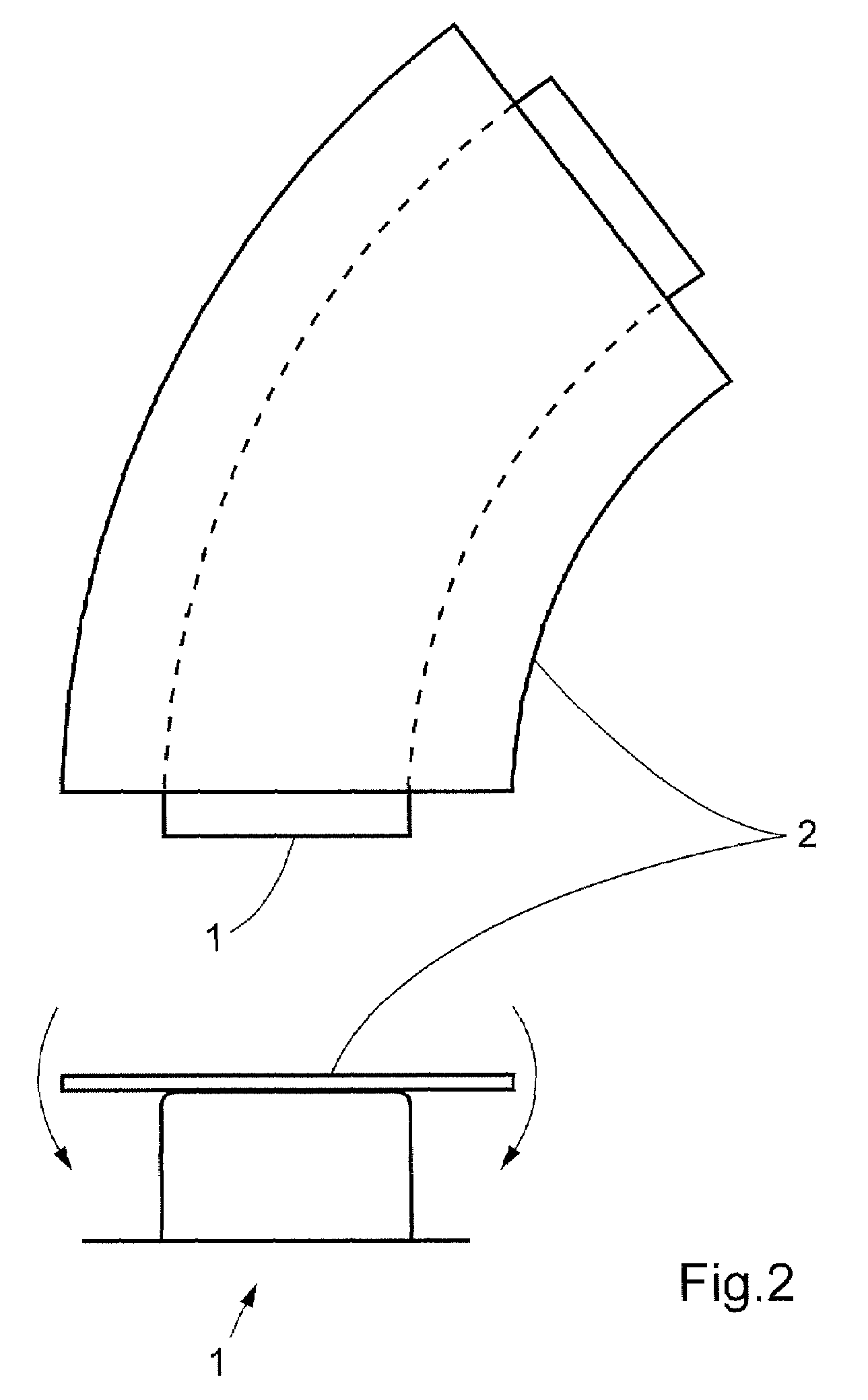

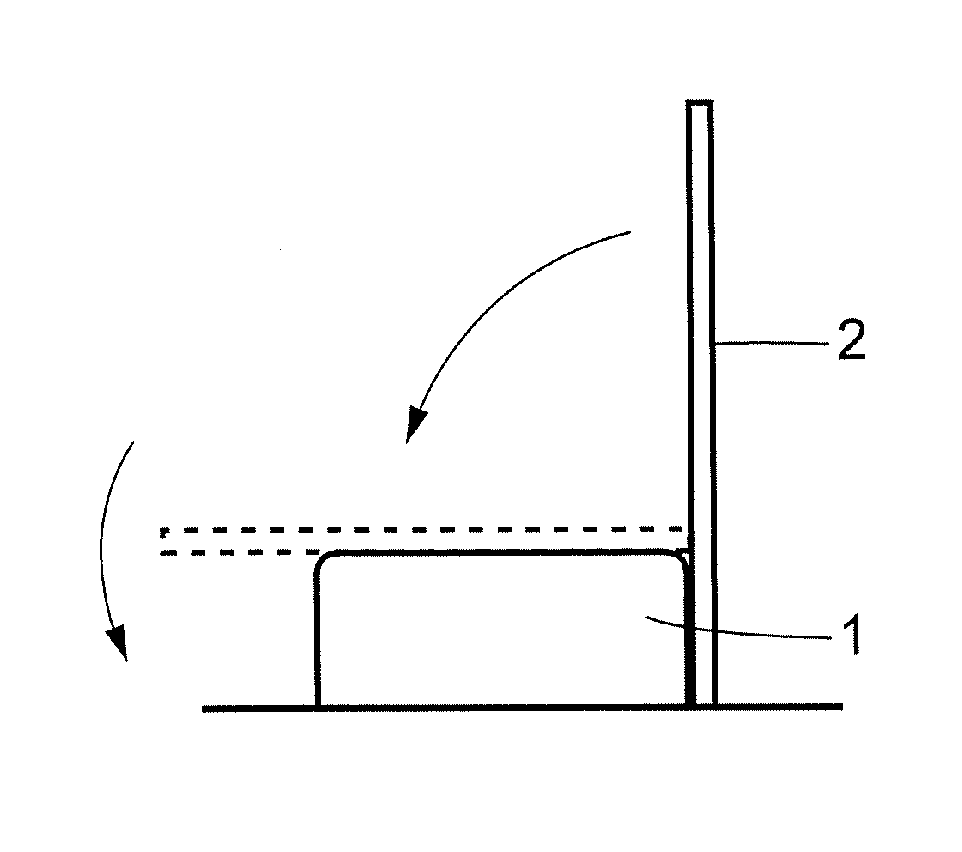

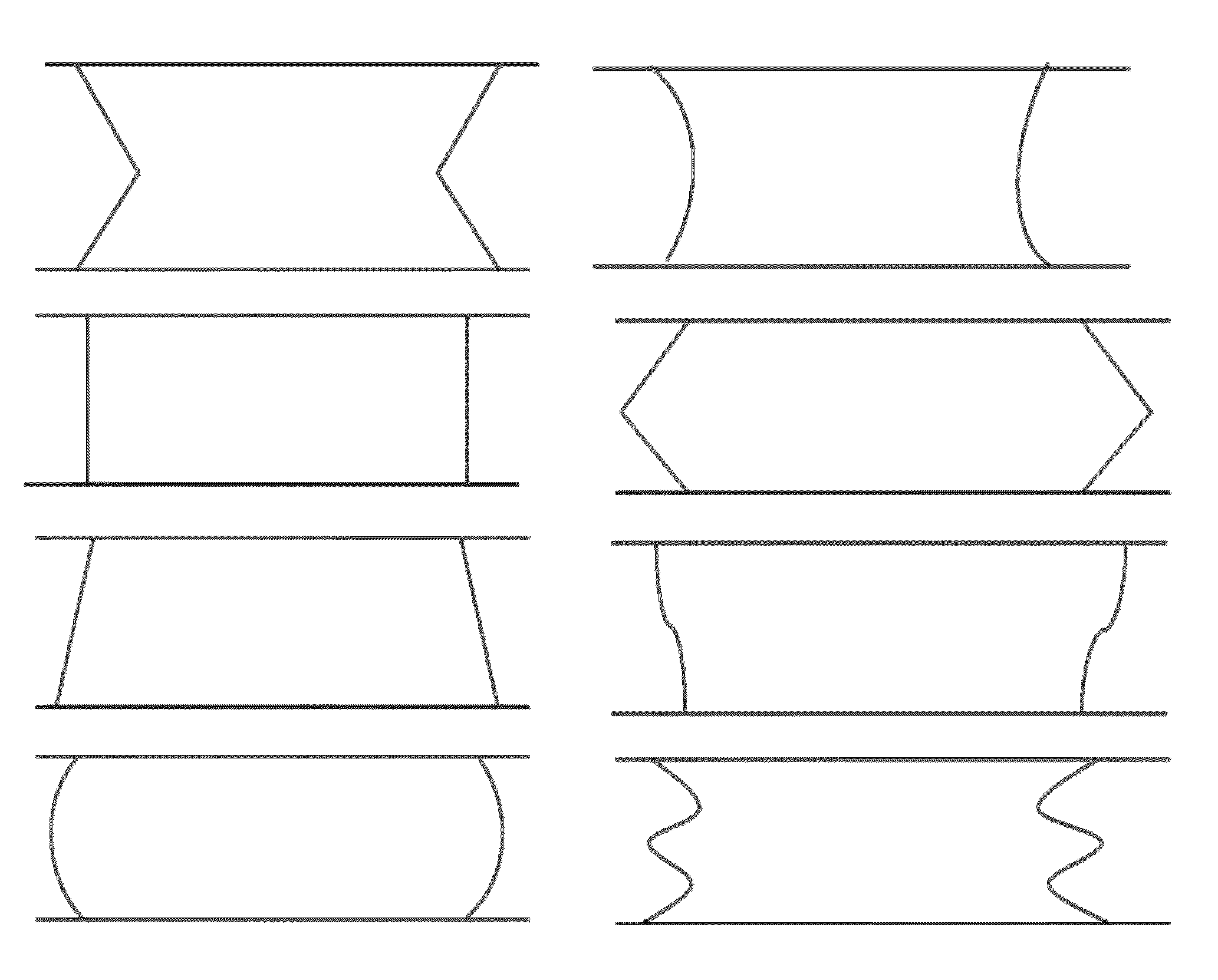

Method for fabricating a curved beam from composite material

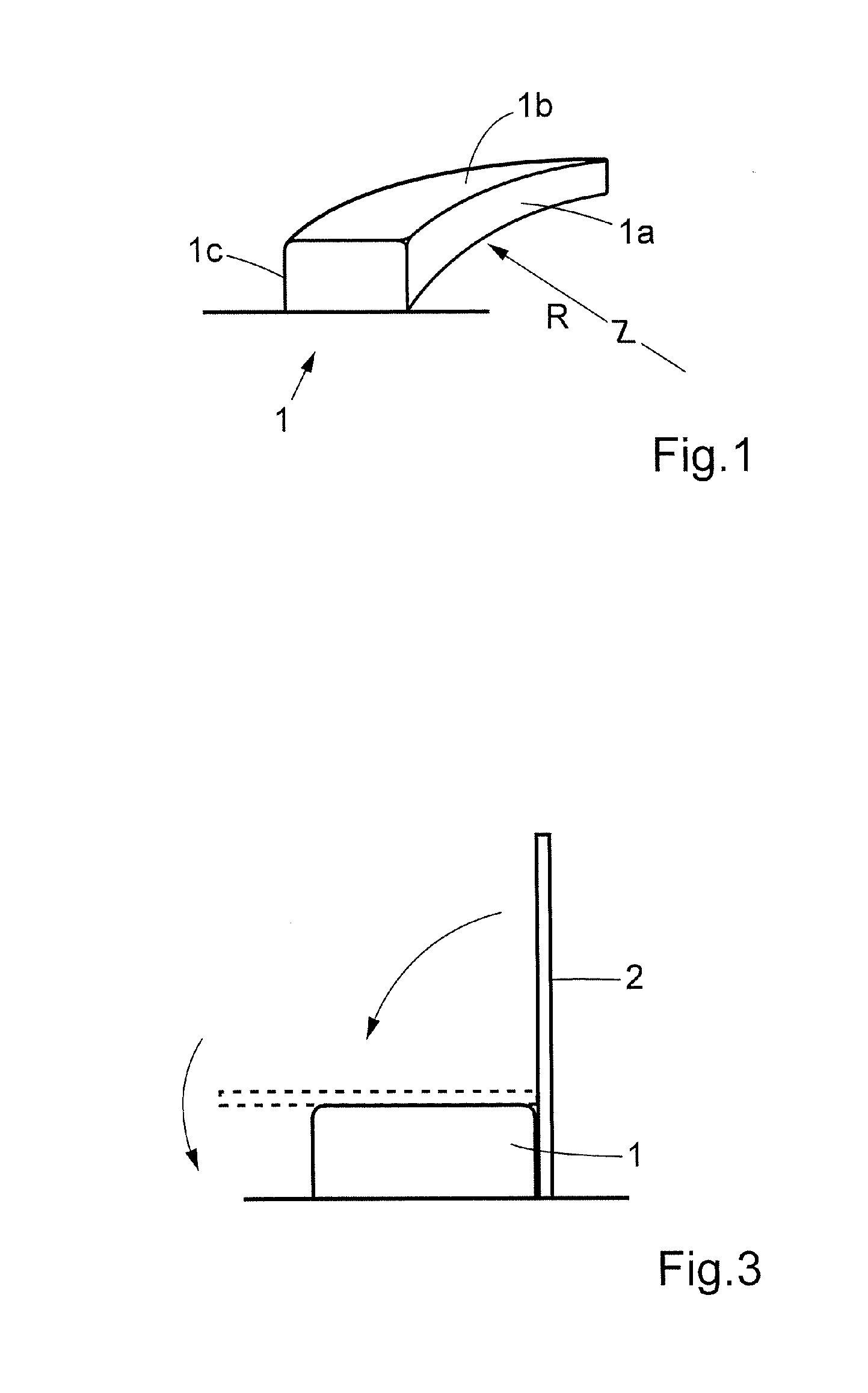

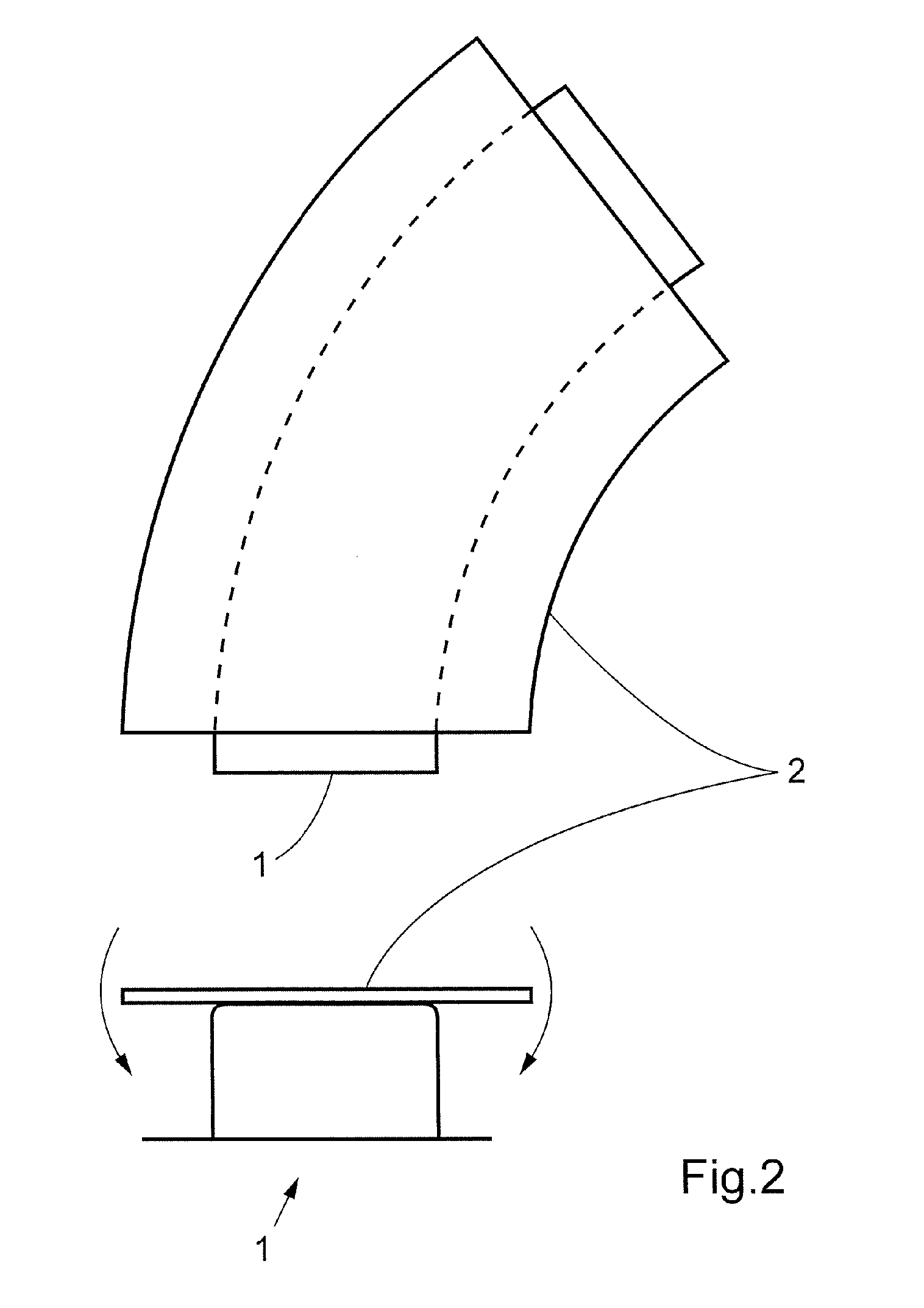

InactiveUS7670525B2Avoid huge wasteGood strength performanceMouldsWood working apparatusComposite laminatesEngineering

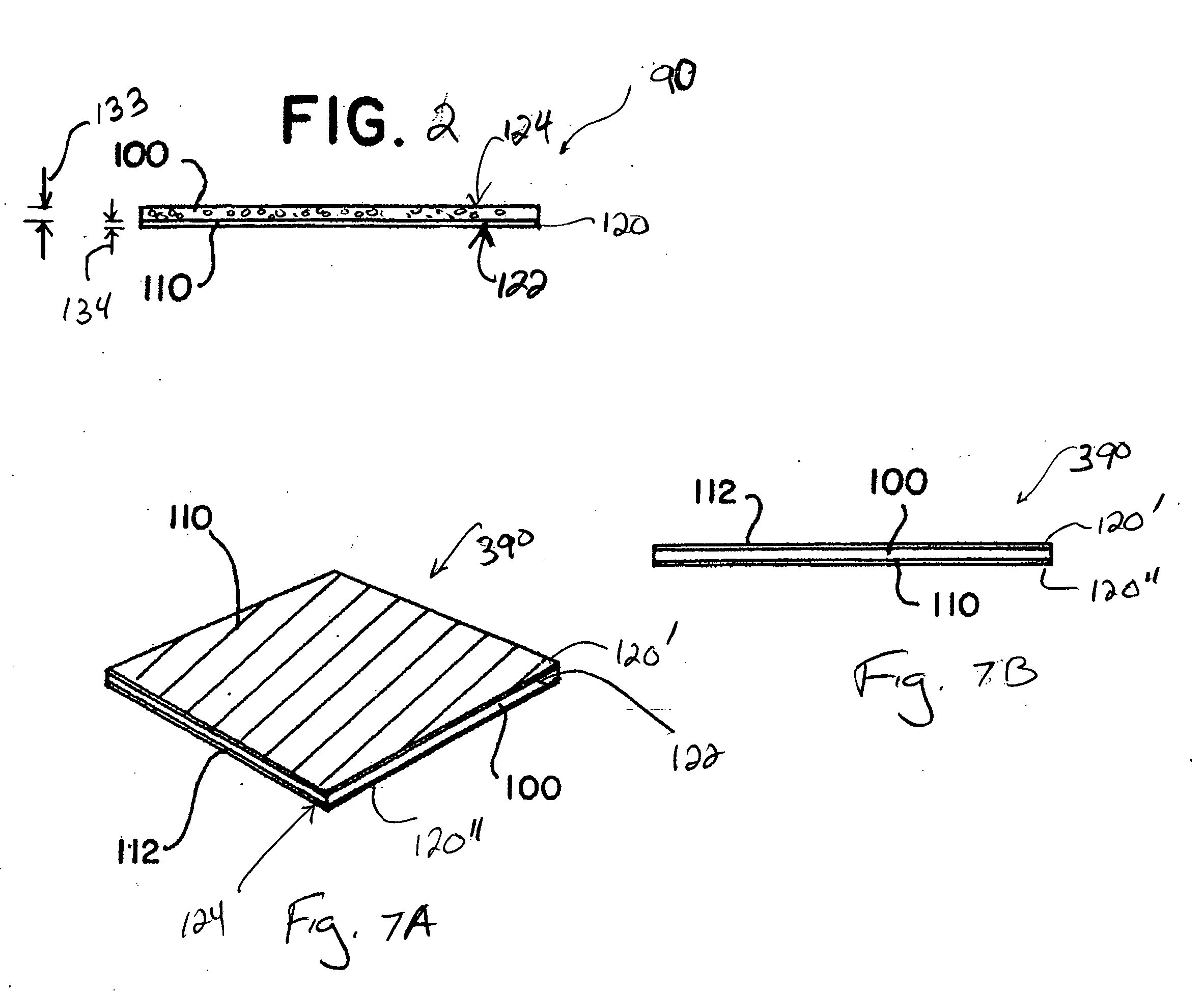

A method for fabricating a curved beam from fiber composite material. A flat fiber composite laminate including a plurality of layers and at least two different fiber directions is formed. The fiber composite laminate is disposed in contact with a male tool includes a first flange, a second flange and an intermediate web. The male tool is curved in its longitudinal direction with a radius of curvature in such a way that the first flange has a shorter longitudinal extent than the second flange. The fiber composite laminate is brought into contact with and secured to the first flange of the male tool. The male tool and the fiber composite laminate are then rotated relative to one another so that the fiber composite laminate is brought into contact with the intermediate web of the male tool in a first rotational movement, and brought into contact with the second flange of the male tool in a second rotational movement. The fiber composite laminate hardens on the male tool, and the finished beam is separated from the tool. Also a beam of fiber composite material fabricated according to the method.

Owner:SAAB AB

Method For Fabricating A Curved Beam From Composite Material

InactiveUS20060216480A1Avoid huge wasteGood strength performanceMouldsLayered productsComposite laminatesEngineering

This invention concerns a method for fabricating a curved beam from fiber composite material. A flat fiber composite laminate (2) comprising a plurality of layers and at least two different fiber directions is formed. The fiber composite laminate (2) is disposed in contact with a male tool (1) comprised of a first flange (1a), a second flange (1c) and an intermediate web (1b), which male tool (1) is curved in its longitudinal direction with a radius of curvature R in such a way that the first flange (1a) has a shorter longitudinal extent than the second flange (1c). The fiber composite laminate (2) is brought into contact with and secured to the first flange (1a) of the male tool (1). The male tool (1) and the fiber composite laminate (2) are then rotated relative to one another so that the fiber composite laminate (2) is brought into contact with the intermediate web (1b) of the male tool (1) in a first rotational movement, and brought into contact with the second flange (1c) of the male tool (1) in a second rotational movement. The fiber composite laminate (2) hardens on the male tool (1), and the finished beam is separated from the tool (1). The invention also relates to a beam of fiber composite material fabricated according to the method.

Owner:SAAB AB

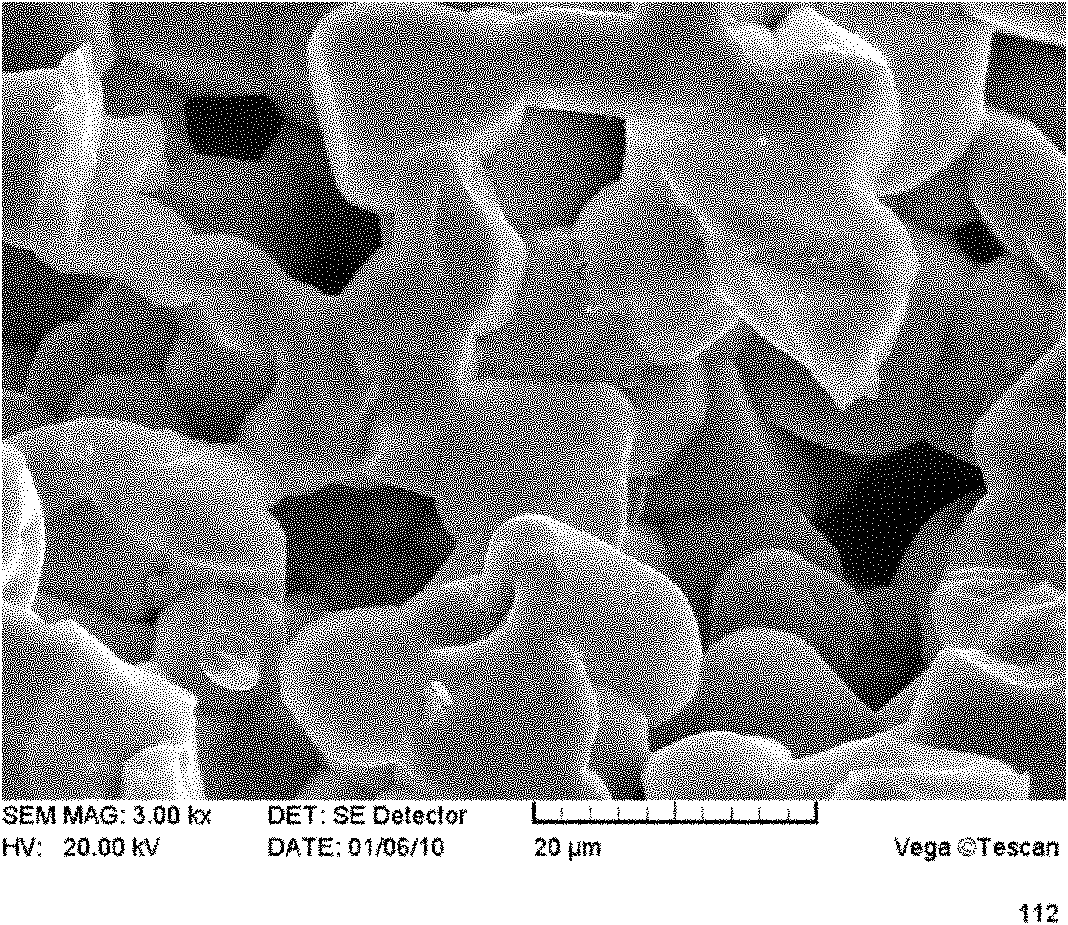

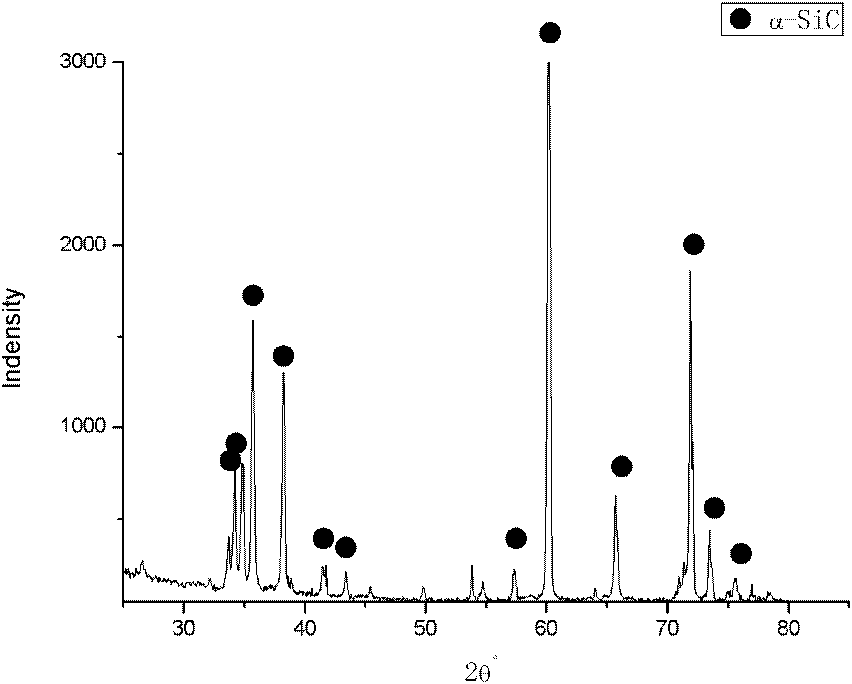

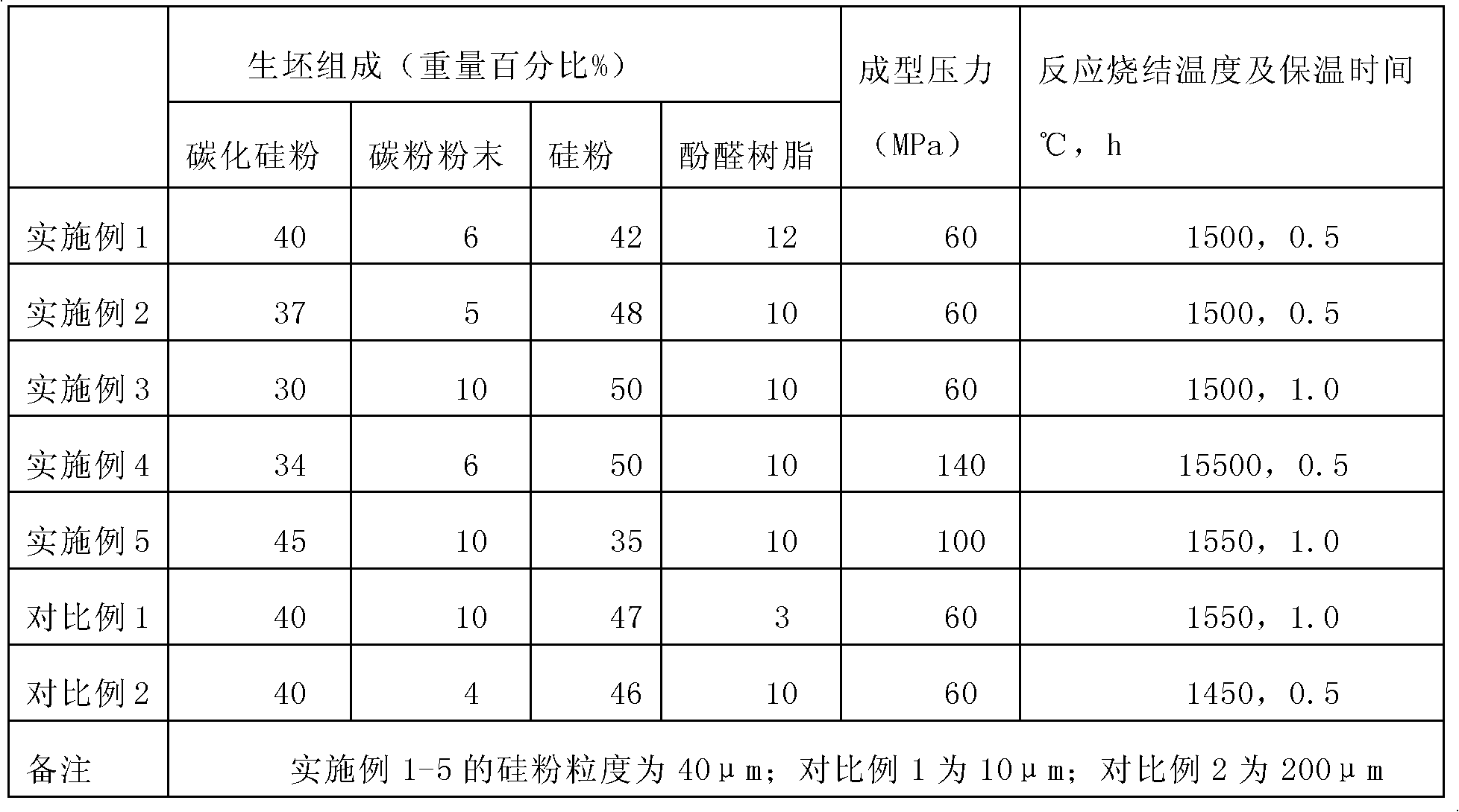

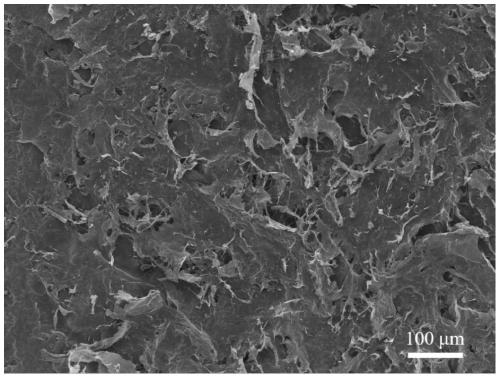

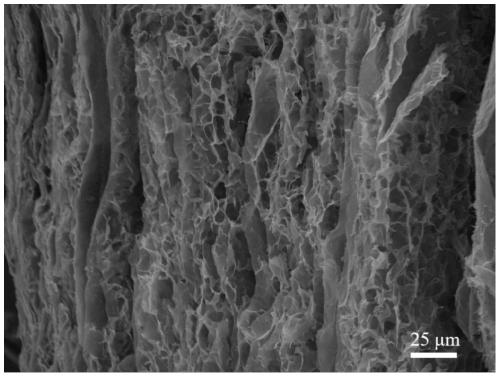

Silicon carbide porous ceramic and preparation method thereof

The invention discloses silicon carbide porous ceramic and a preparation method thereof. The silicon carbide porous ceramic is characterized by comprising the following components in percentage by weight: 30 to 45 percent of silicon carbide powder, 5 to 10 percent of carbon powder, 35 to 50 percent of silicon powder and 3 to 12 percent of adhesive phenol resin. The method comprises the following steps of: ball-milling the silicon carbide powder, the carbon powder and the silicon powder and wet-mixing to obtain mixed powder; adding the adhesive phenol resin for granulation; performing compression molding; drying a molded green body and then placing into an air furnace to remove adhesives; sintering the green body according to a reaction sintering process after the adhesives are removed; and recrystallizing a product obtained by the reaction sintering at the high temperature of over 2,000 DEG C and removing silicon to obtain a single-phase porous silicon carbide material. The porous silicon carbide material prepared by the invention has the characteristics of controllable porosity, high strength, high corrosion resistance and high thermal stability, can be widely used as a filteringmaterial in high temperature atmospheres and corrosive atmospheres and a carrier material for a chemical reaction and can be used for high-temperature heat insulation.

Owner:XI AN JIAOTONG UNIV

Self-boring and self-tapping screw for osteosynthesis and compression

ActiveUS7708738B2Easy to installGood strength performanceSuture equipmentsLigamentsDistal portionIliac screw

The invention provides an osteosynthesis and compression screw that is self-boring and self-tapping for the purpose of coaptation of small bone fragments. The screw comprises:a proximal portion formed by a screw head provided with an outside thread;an intermediate portion having no thread; anda distal portion provided with an outside thread.Wherein:each of the screw head and the distal portion includes at least one groove, firstly extending over the entire axial length of its thread, and secondly being formed through each thread in such a manner to form tapping means; andthe terminal zone of the distal portion is provided with preparation means for preparing a housing in the bone fragments for receiving the intermediate and distal portions of the screw.

Owner:SMITH & NEPHEW INC

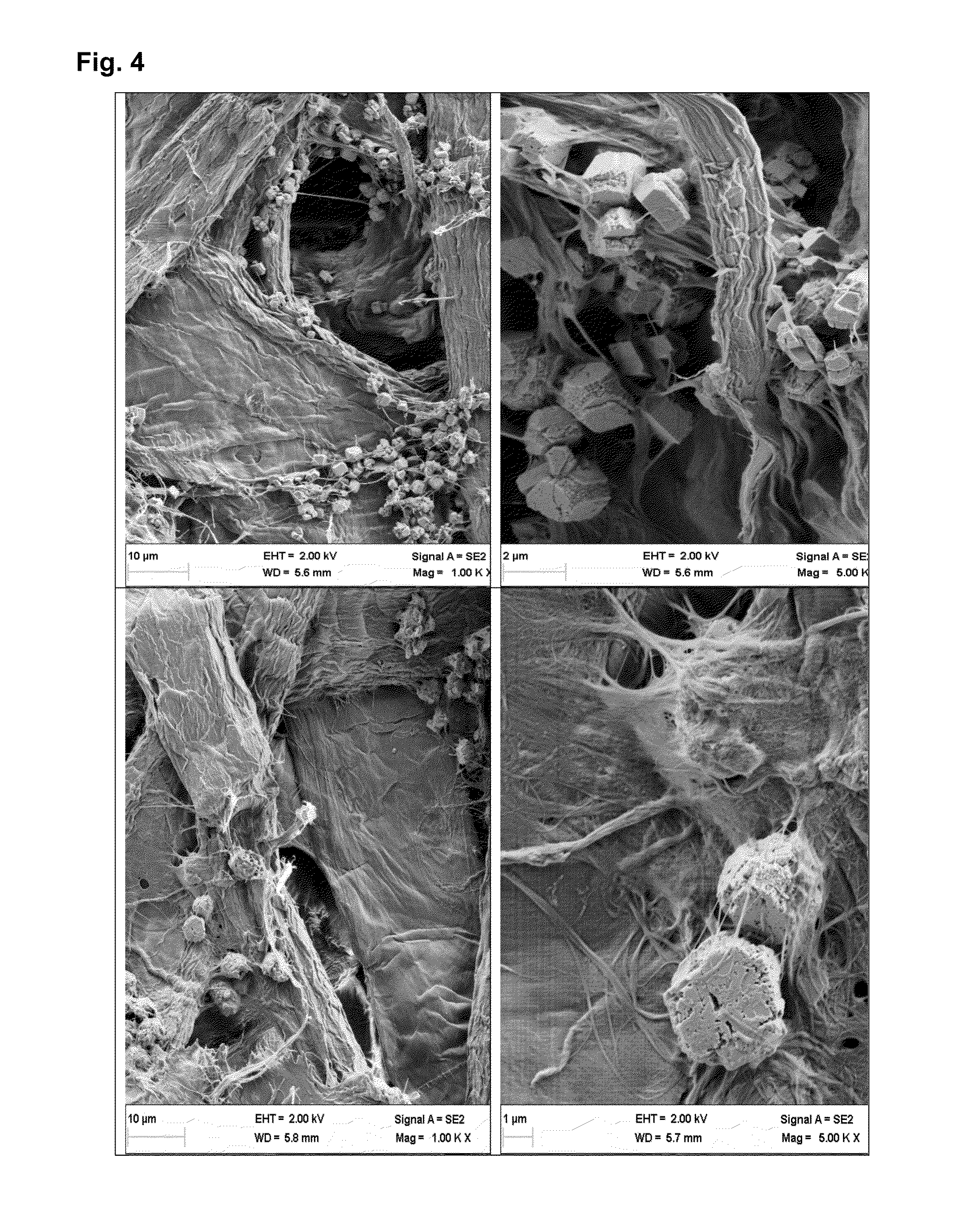

Micro staple fiber nonwoven fabric and leather-like article in sheet form, and method for their production

InactiveUS20060234587A1Good strength performanceQuality improvementSynthetic resin layered productsAbsorbent padsApparent densityPolymer science

To provide a nonwoven fabric containing ultra-fine fibers suitable as a leather-like sheet, and also a leather-like sheet with an excellent compactness. A nonwoven fabric containing ultra-fine fibers, characterized in that it contains staple fibers with a fiber fineness of 0.0001 to 0.5 decitex and a fiber length of 10 cm or less, and has a weight per unit area of 100 to 550 g / m2, an apparent density of 0.280 to 0.700 g / cm3, a tensile strength of 70 N / cm or more, and a tear strength of 3 to 50 N.

Owner:TORAY IND INC

Process and apparatus for producing metallic glass

InactiveUS20020100573A1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyAlloy

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

Technology for processing high strength large hexagon-headed bolt used for steel structure

InactiveCN101934466AImprove heating uniformityFast heatingBoltsFurnace typesHigh intensityElectrical current

The invention provides a technology for processing high strength large hexagon-headed bolt used for steel structure. The invention relates to a technology for processing high strength connecting piece. High frequency induction current hot forging and cold extruding are adopted, so as to produce a bolt. The invention is on the basis of patent application with patent application number of 200810020090.5, high frequency induction heating is adopted in hot forging, frequency thereof is controlled to be 20000-50000Hz, and the advantages of high frequency induction heating that speed is fast and heating is uniform are utilized, so that work piece surface can obtain uniform tissue and properties from center part to the surface, heating uniformity of work piece is improved, better crystal phase structure can be obtained, and high strength bolt with better property can be obtained.

Owner:扬州狮鹤高强度螺栓有限公司

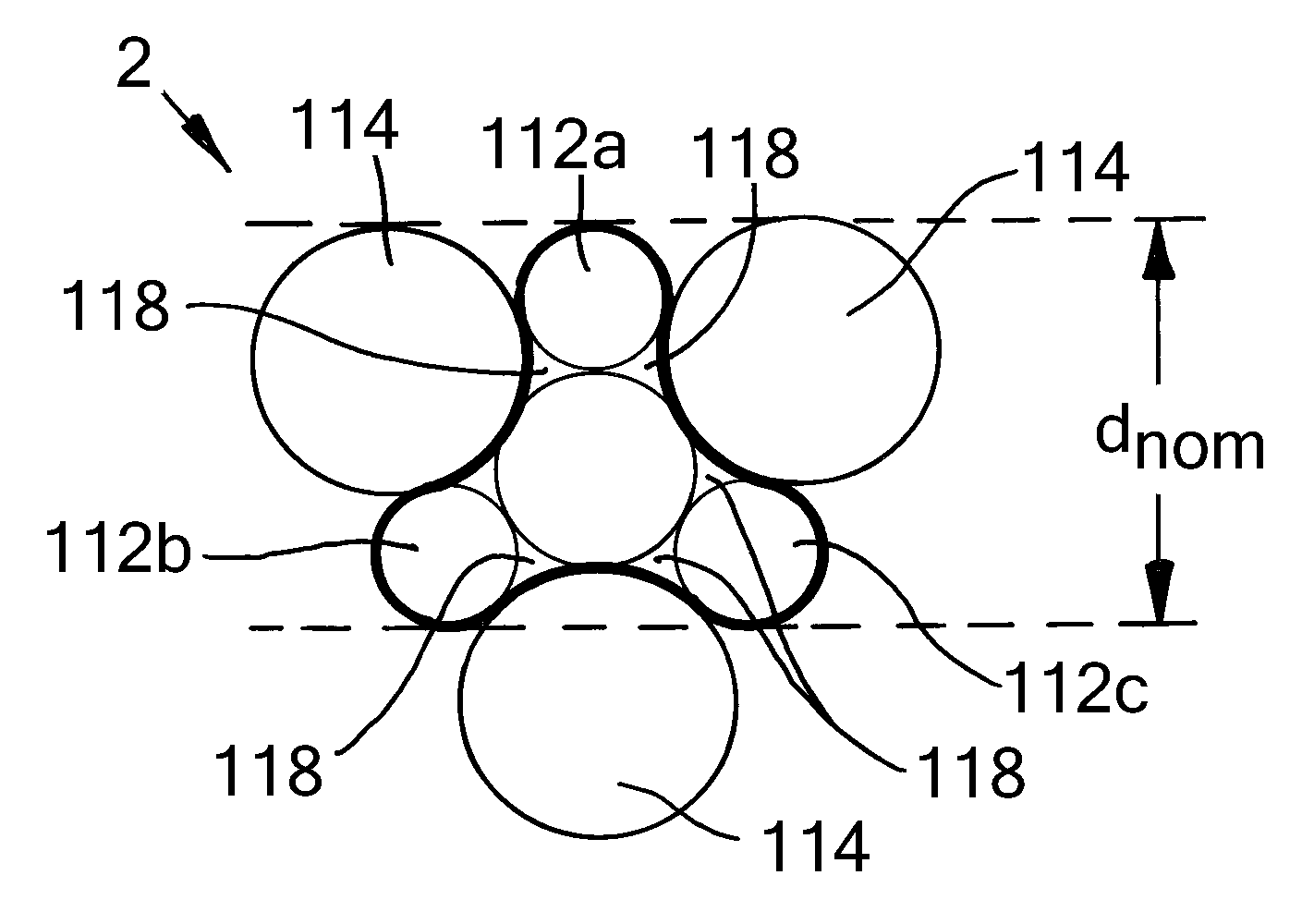

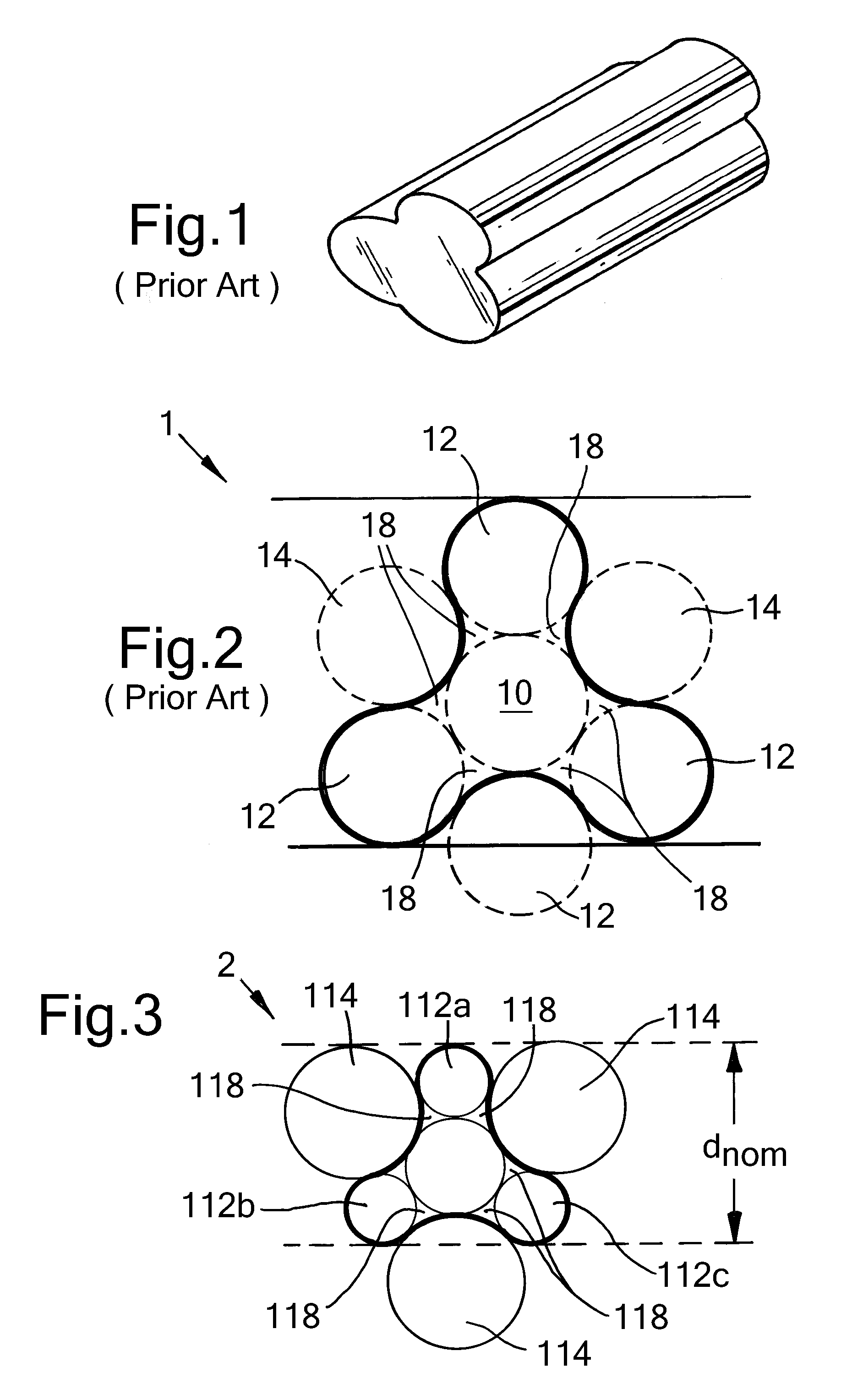

Catalyst, catalyst precursor, and catalyst carrier

InactiveUS20080262115A1Good strength performanceFast and relatively inexpensive and suitable manufacturingLiquid hydrocarbon mixture productionGlass/slag layered productsMechanical engineeringCatalyst support

A catalyst, catalyst precursor, or catalyst carrier formed as an elongated shaped particle having a cross section comprising three protrusions each extending from and attached to a central position. The central position is aligned along the longitudinal axis of the particle. The cross-section of the particle occupies the space encompassed by the outer edges of six outer circles around a central circle, each of the six outer circles contacting two neighbouring outer circles, the particle occupying three alternating outer circles equidistant to the central circle and the six interstitial regions, the particle not occupying the three remaining outer circles which are between the alternating occupied outer circles. The ratio of the diameter of the central circle to the diameter of the outer occupied circle is more than 1, and the ratio of the diameter of the outer unoccupied circle to the diameter of the outer occupied circle is more than 1. The ratio of the diameter of the outer unoccupied circle to the diameter of the outer occupied circle is more than the ratio of the diameter of the central circle to the diameter of the outer occupied circle.

Owner:SHELL OIL CO

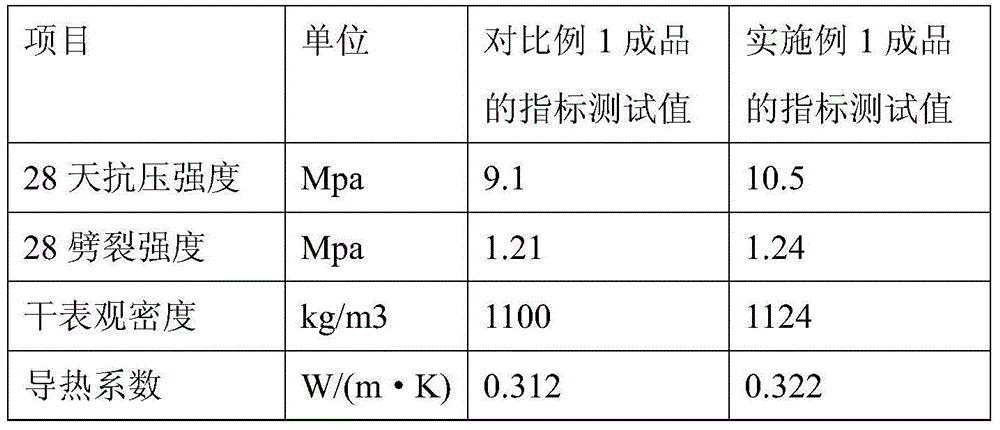

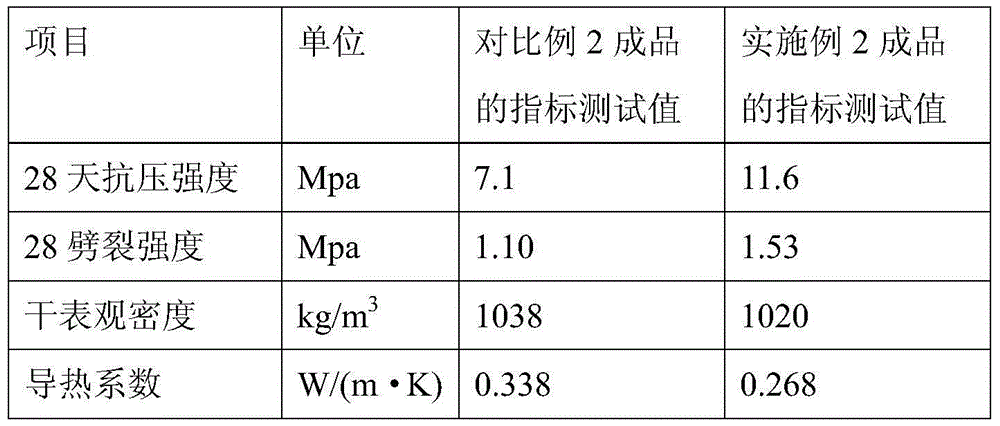

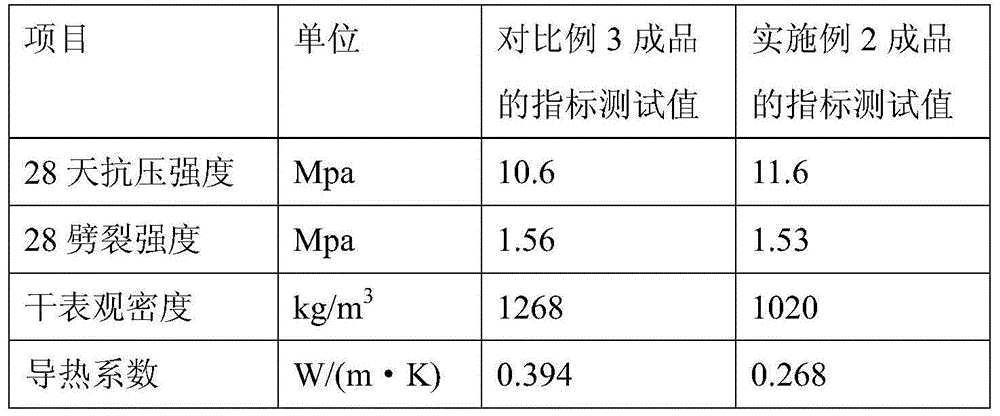

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

Method for producing wood plastic composite material using plant straw and waste plastic and material thereof

InactiveCN101417459ASimple processing technologyDo not reproduceFlat articlesDomestic articlesFiberPolyester

The invention relates to a method for manufacturing wood plastic composite material by using plant straw and waste plastics and materials thereof. Polyester and plant wood fiber materials such as sawdust, bamboo powder, rice hull, straw, and the like, are mixed according to certain ratios, a tailor-made additive is added, and after the processes of high temperature, extrusion, molding, and the like, the composite building profile is manufactured. The wood plastic material can replace wood, plastics, and the like, and is mainly used in the industries of packaging, building materials, furniture, logistics, and the like. The invention has simple processing technology, and the product has good processing properties and strength property, good water proof and corrosion resistant property and adjustability, the materials have wide sources and applications, especially the plant straw and waste plastics which contain waste mulch film and are recovered under the northern planting pattern of mulch film can be used for production, thus using the waste and restraining the current pollution of the mulch film planting to the lands effectively.

Owner:石河子市森力新材料科技有限公司

Circumferential stiffeners for composite fancases

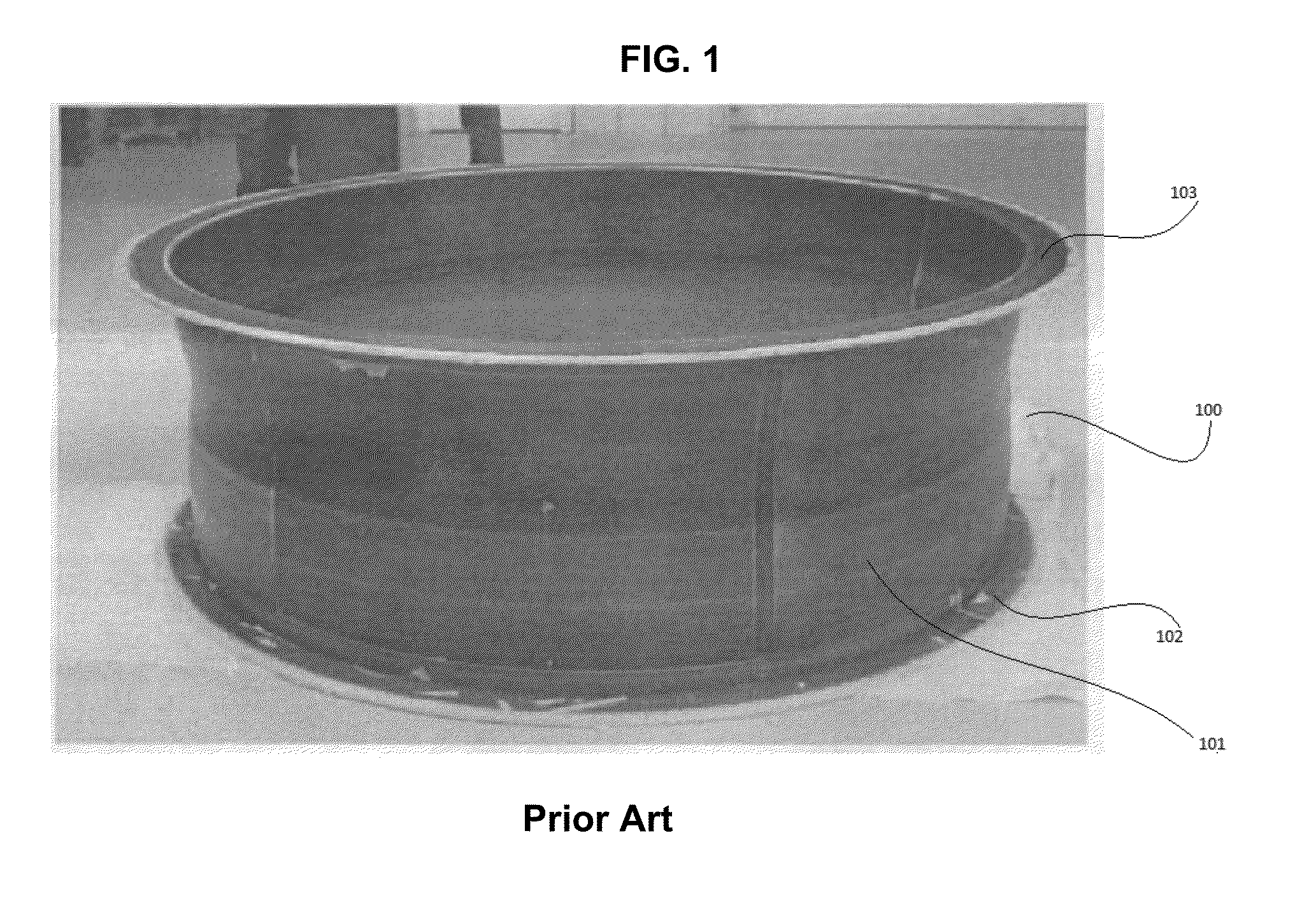

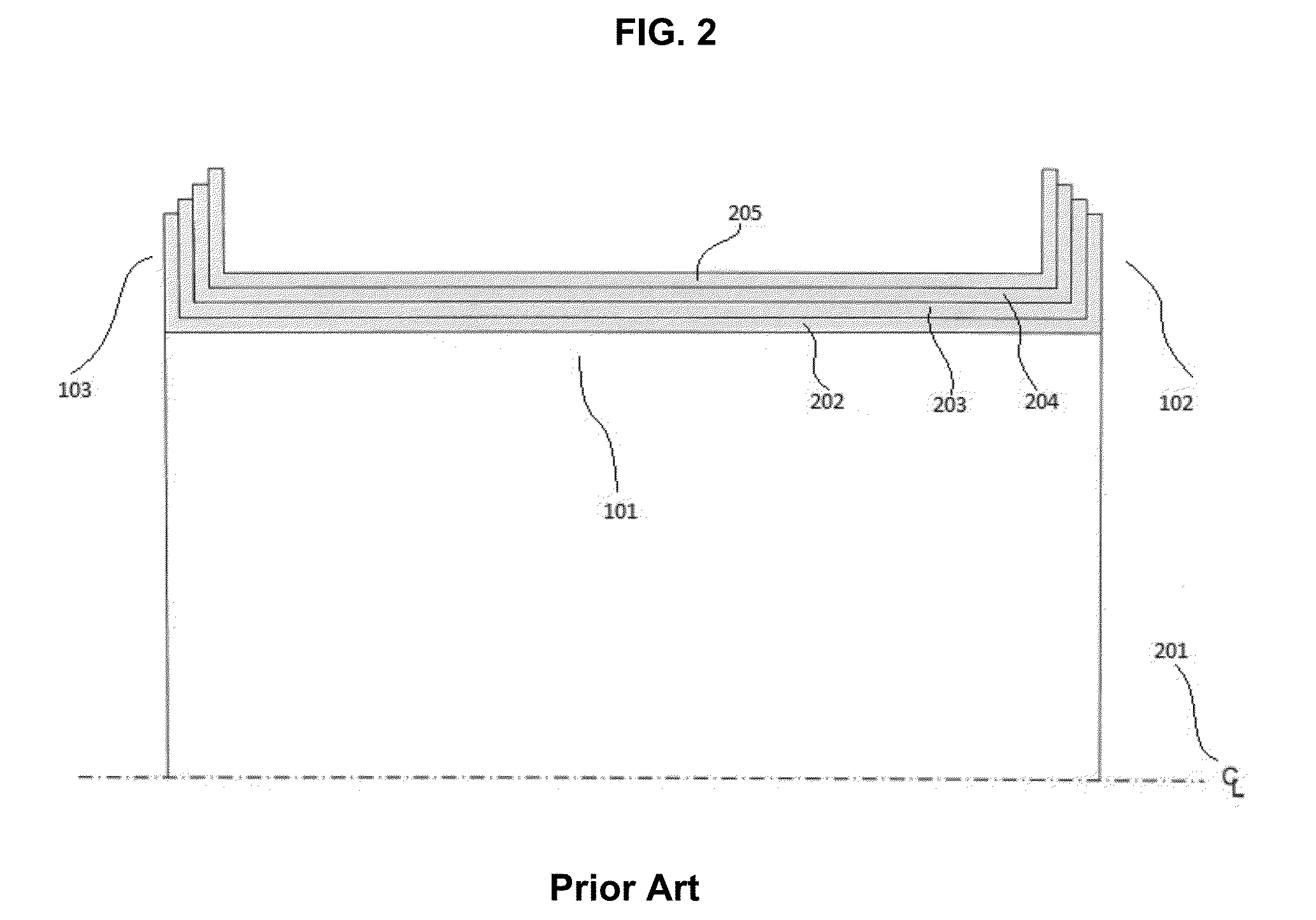

ActiveUS20140113088A1Improve dynamic performanceGood strength performanceCeramic layered productsPreformed elementsEngineeringBiomedical engineering

Woven preforms, for example those used for jet aircraft engine fancases, may need additional stiffeners to improve the strength and / or dynamic performance of the preform assembly, as well as to serve as attachment points. The present invention describes several improved woven preforms that include circumferential or axial stiffeners, as well as methods of manufacturing the same. One embodiment includes circumferential stiffeners added to a woven preform. Another embodiment includes sub-preforms with integral flanges that combine to make integral stiffeners. A further embodiment includes an intermediate stiffener wrapped onto a base sub-preform wrap, wherein the intermediate stiffener wrap incorporates intermediate stiffeners. Another embodiment incorporates bifurcations in one or more layers of an outermost wrap of a multi-layer fabric composite that forms a preform, wherein the bifurcated outer wrap is folded to form stiffeners that may be oriented circumferentially or axially.

Owner:ALBANY ENGINEERED COMPOSITES

Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

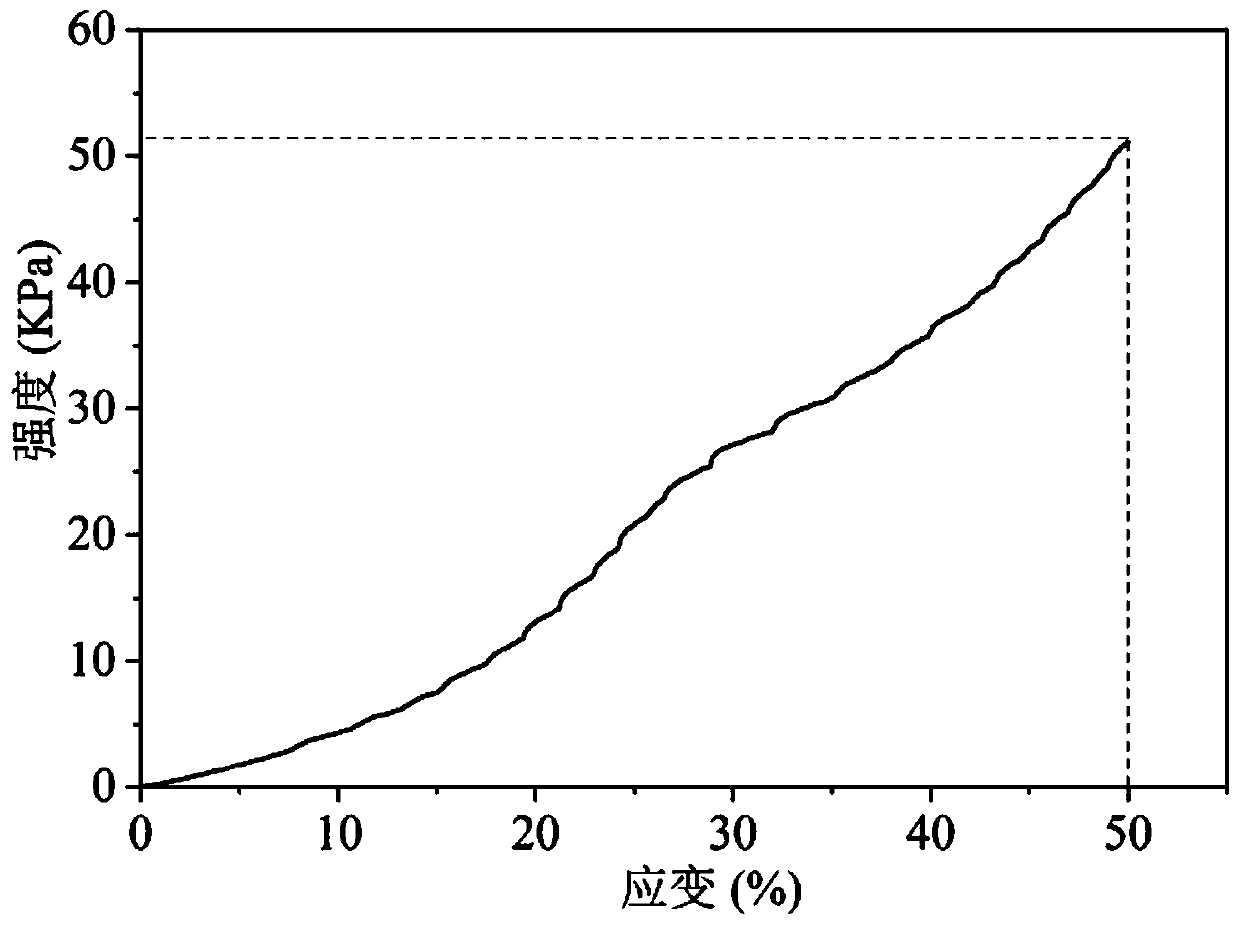

ActiveCN111040238ALarge aspect ratioImprove temperature resistanceForce measurementElectrically conductiveFibrous composites

The invention discloses aramid nanofiber / MXene composite conductive aerogel and a preparation method thereof. By using aramid nanofibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using MXene with excellent conductivity, good chemical stability and a unique two-dimensional nano-film structure as a conductive and fillingcoating material, the aramid nanofiber / MXene composite conductive aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing an MXene dispersion liquid, preparing an aramid nanofiber / MXene composite dispersion liquid, preparing a gelatinous aramidnanofiber / MXene composite material and the like, thereby obtaining the aramid nanofiber / MXene composite conductive aerogel. The preparation process is simple and easy to implement, and the obtained aramid nanofiber / MXene composite conductive aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

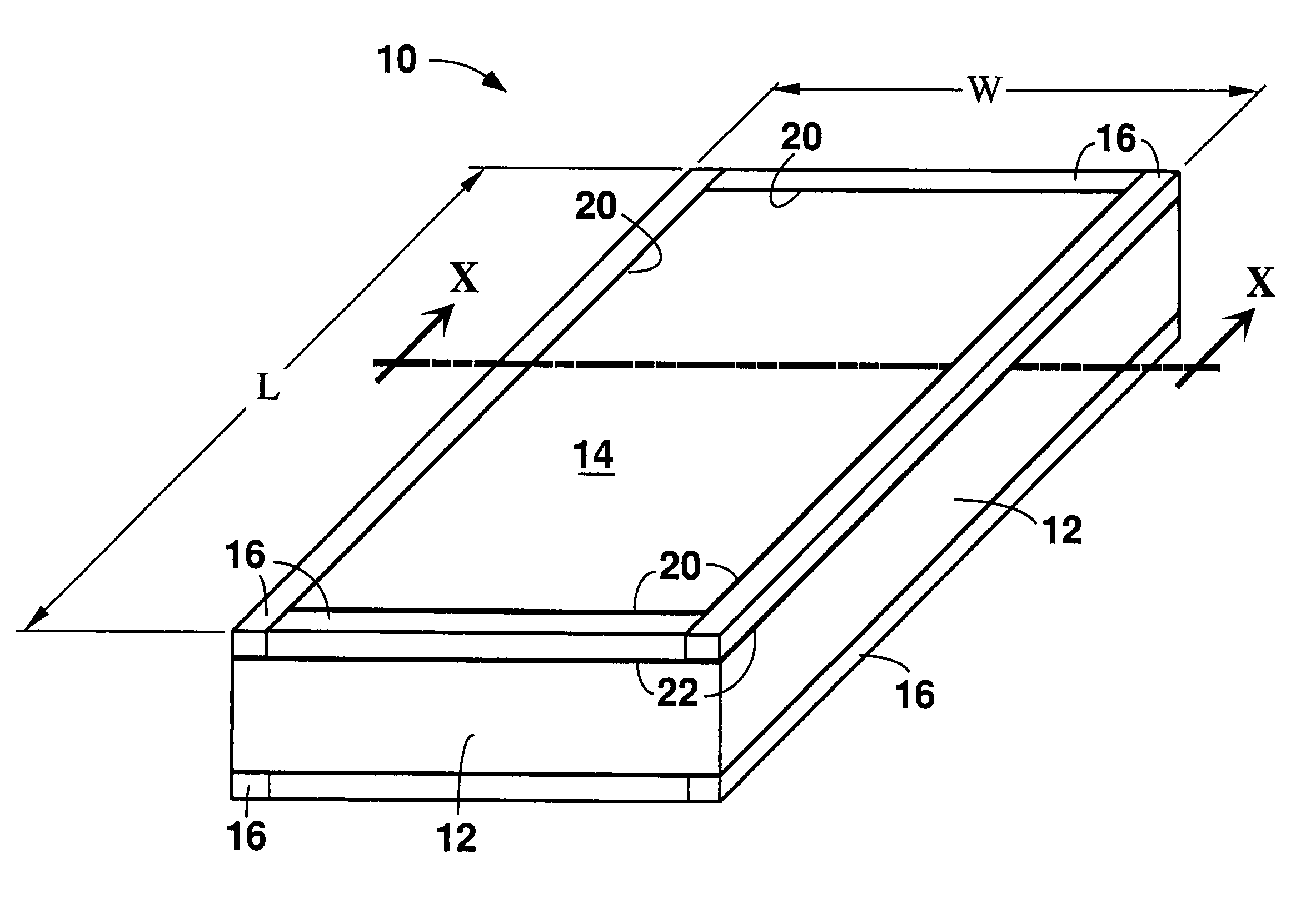

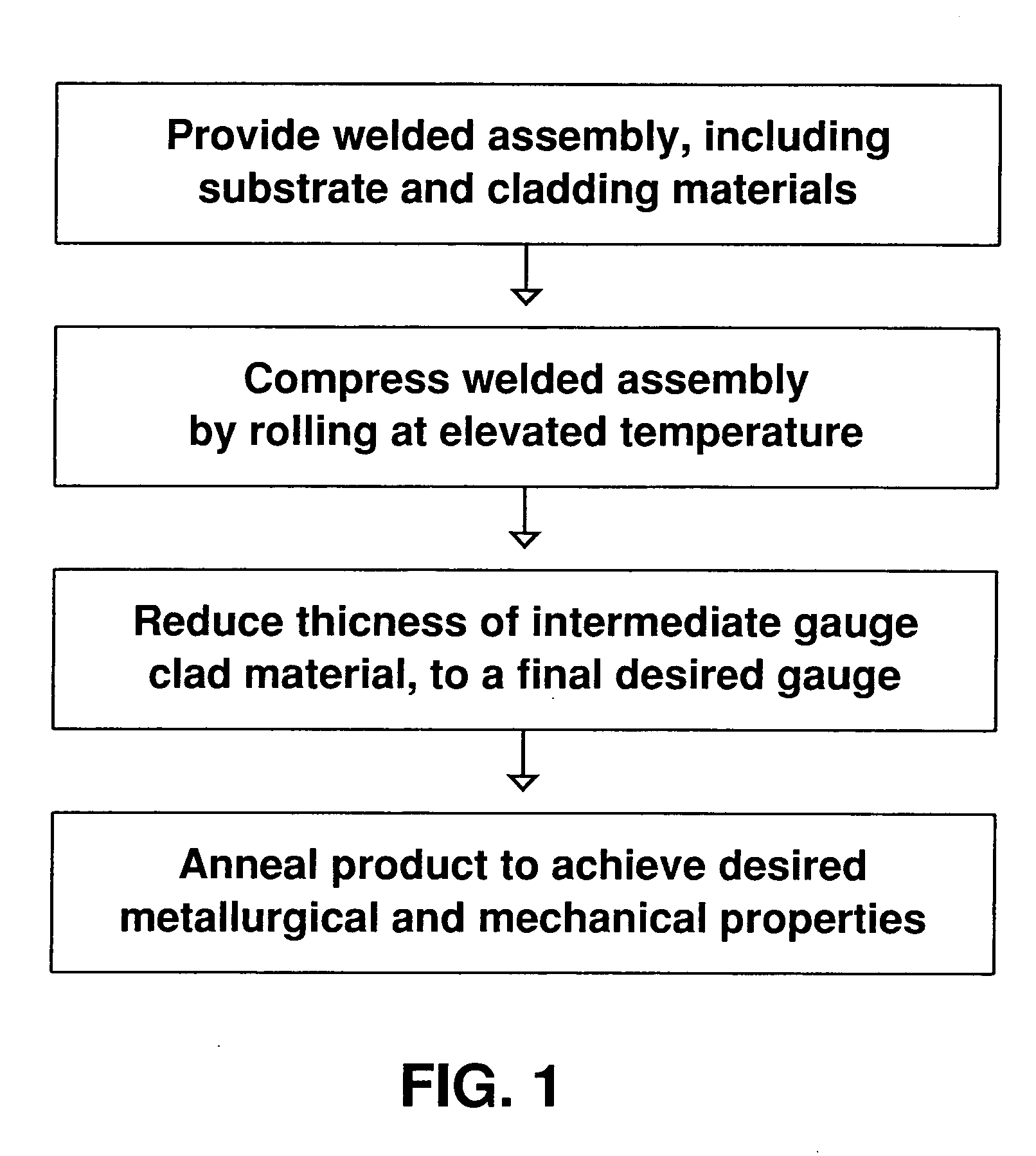

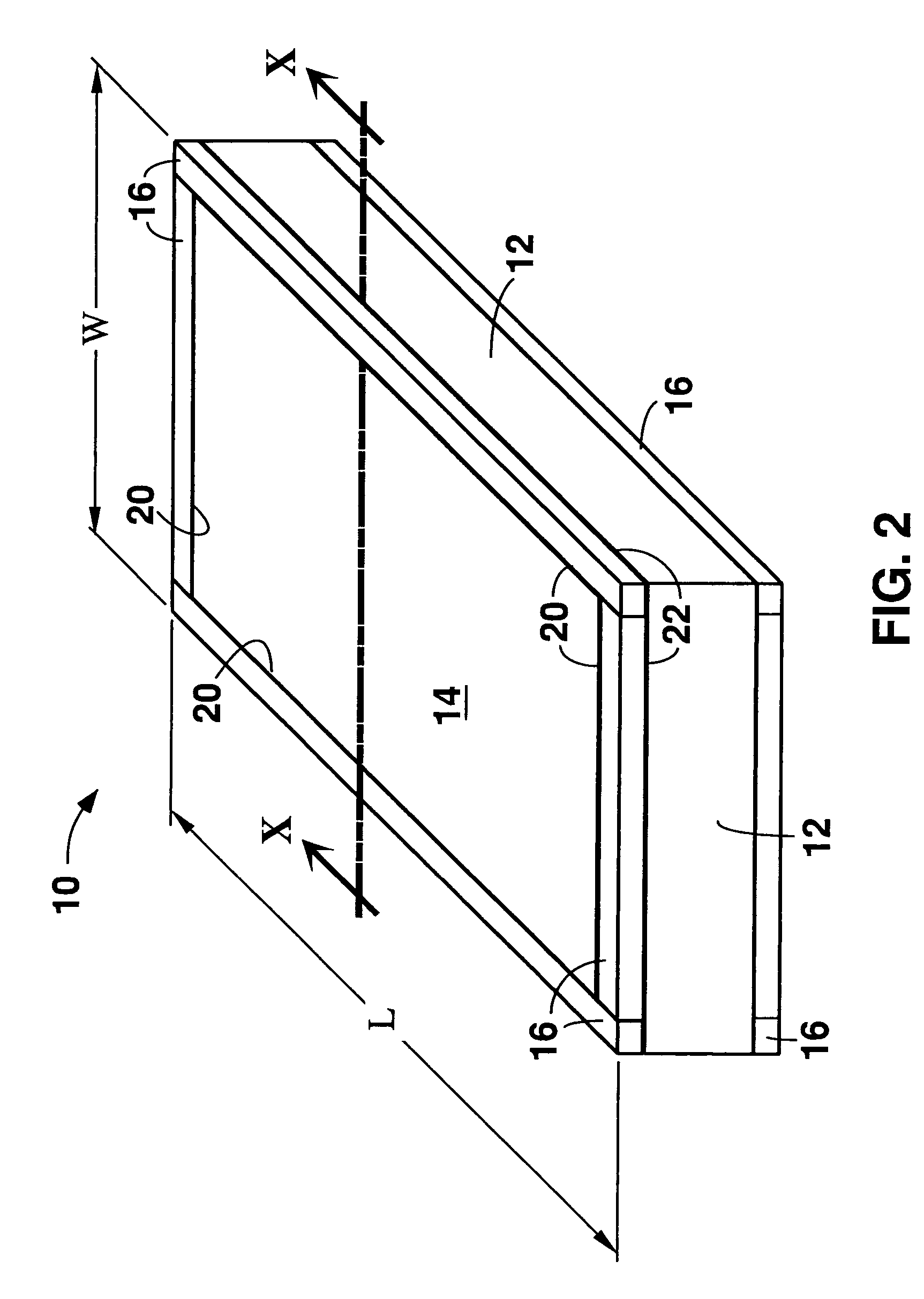

Clad alloy substrates and method for making same

InactiveUS20050273994A1Good strength performanceImprove corrosion resistancePig casting plantsExtrusion containersAlloy substrateNickel alloy

A method for producing a single-clad or multiple-clad product includes providing a welded assembly comprising a cladding material disposed on a substrate material. Both the substrate material and the cladding material are individually selected alloys. At least a first edge of the cladding material of the welded assembly does not extend to a first edge of the substrate material and thereby provides a margin between the first edges. A material that is an alloy having hot strength greater than the cladding material is within the margin and adjacent the first edge of the cladding material. The welded assembly is hot rolled to provide a hot rolled band, and the material within the margin inhibits the cladding material from spreading beyond the edge of the substrate material during the hot rolling. In certain embodiments of the methods, the substrate material is stainless steel and the cladding material is nickel or a nickel alloy.

Owner:ATI PROPERTIES

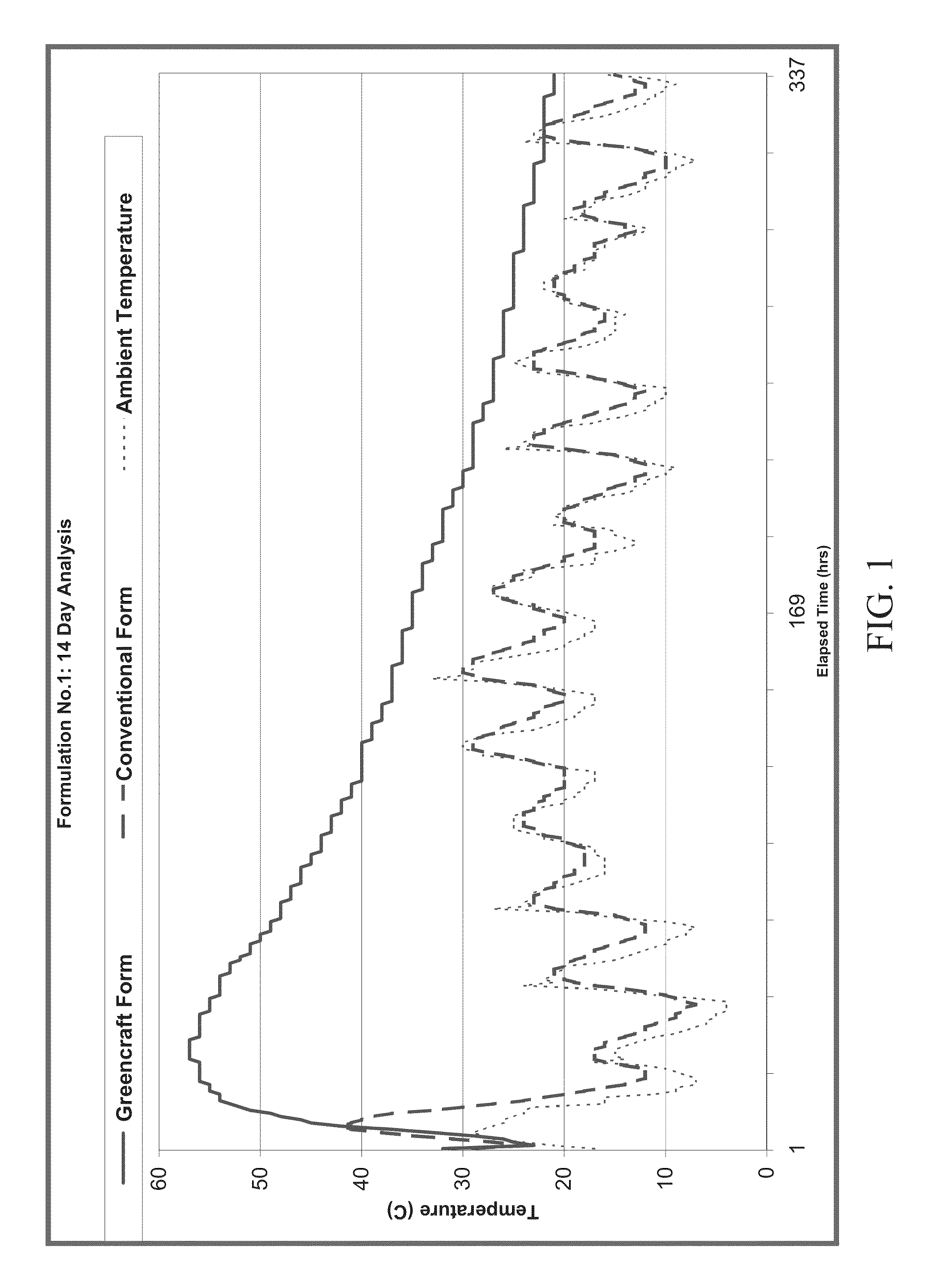

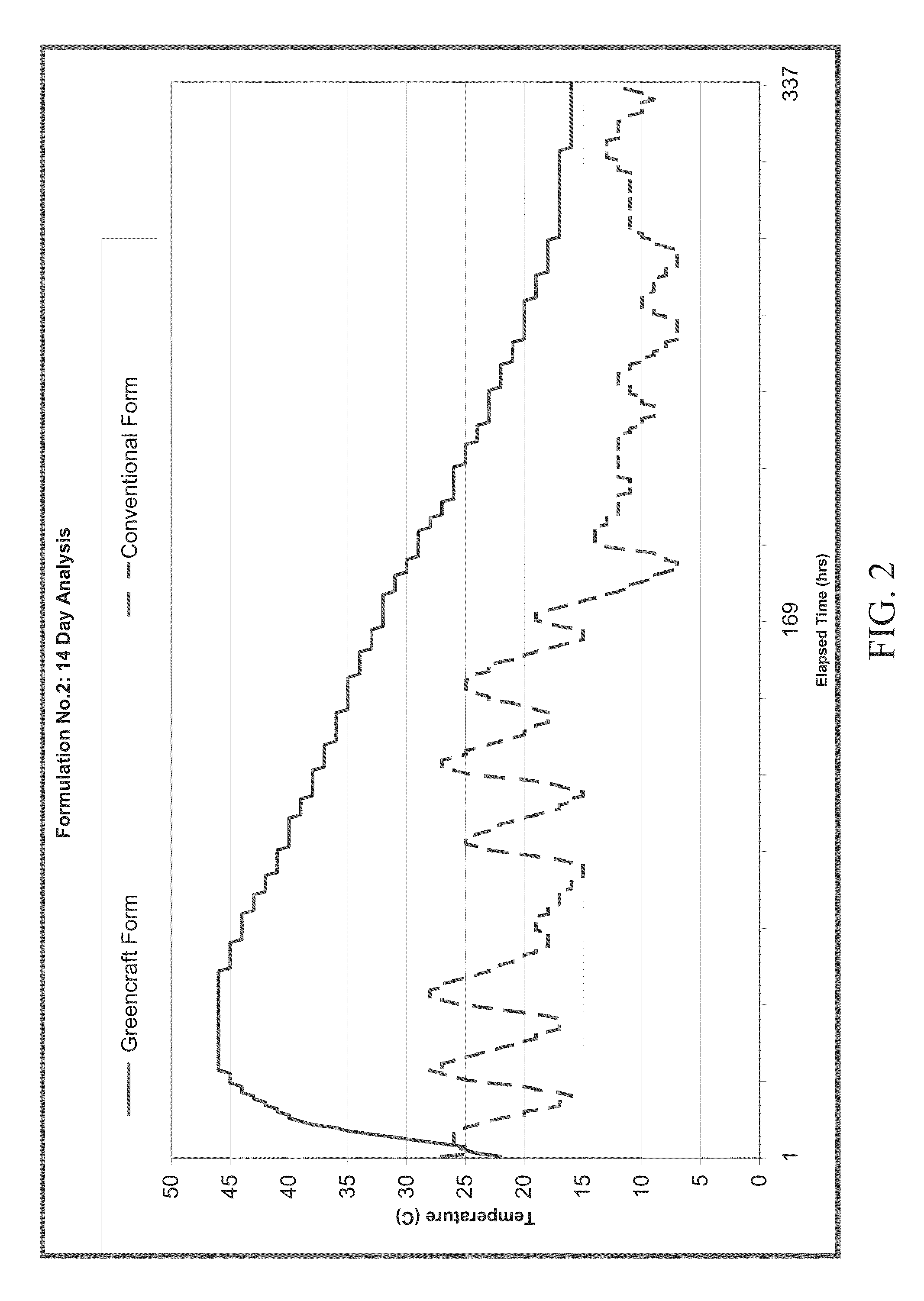

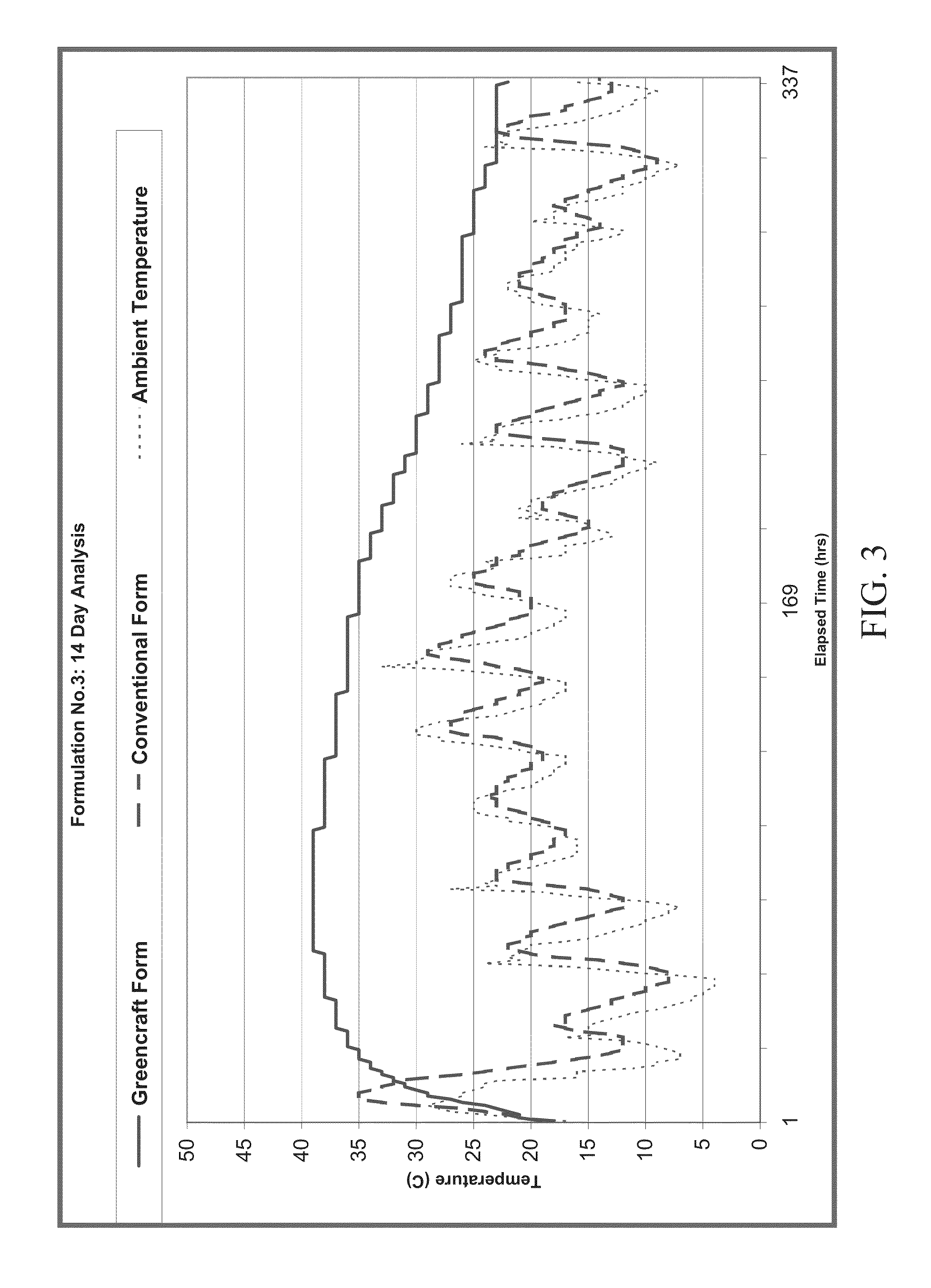

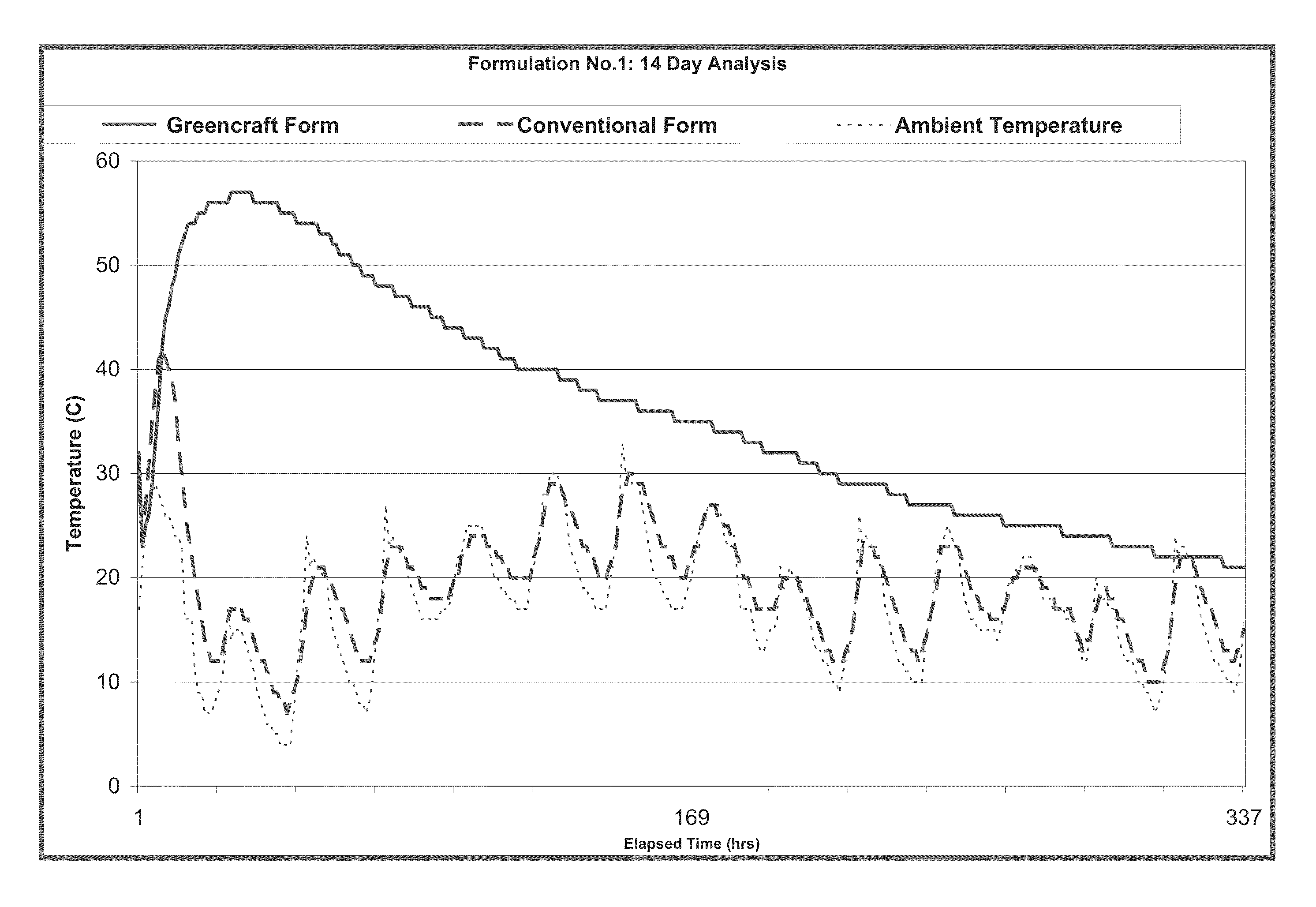

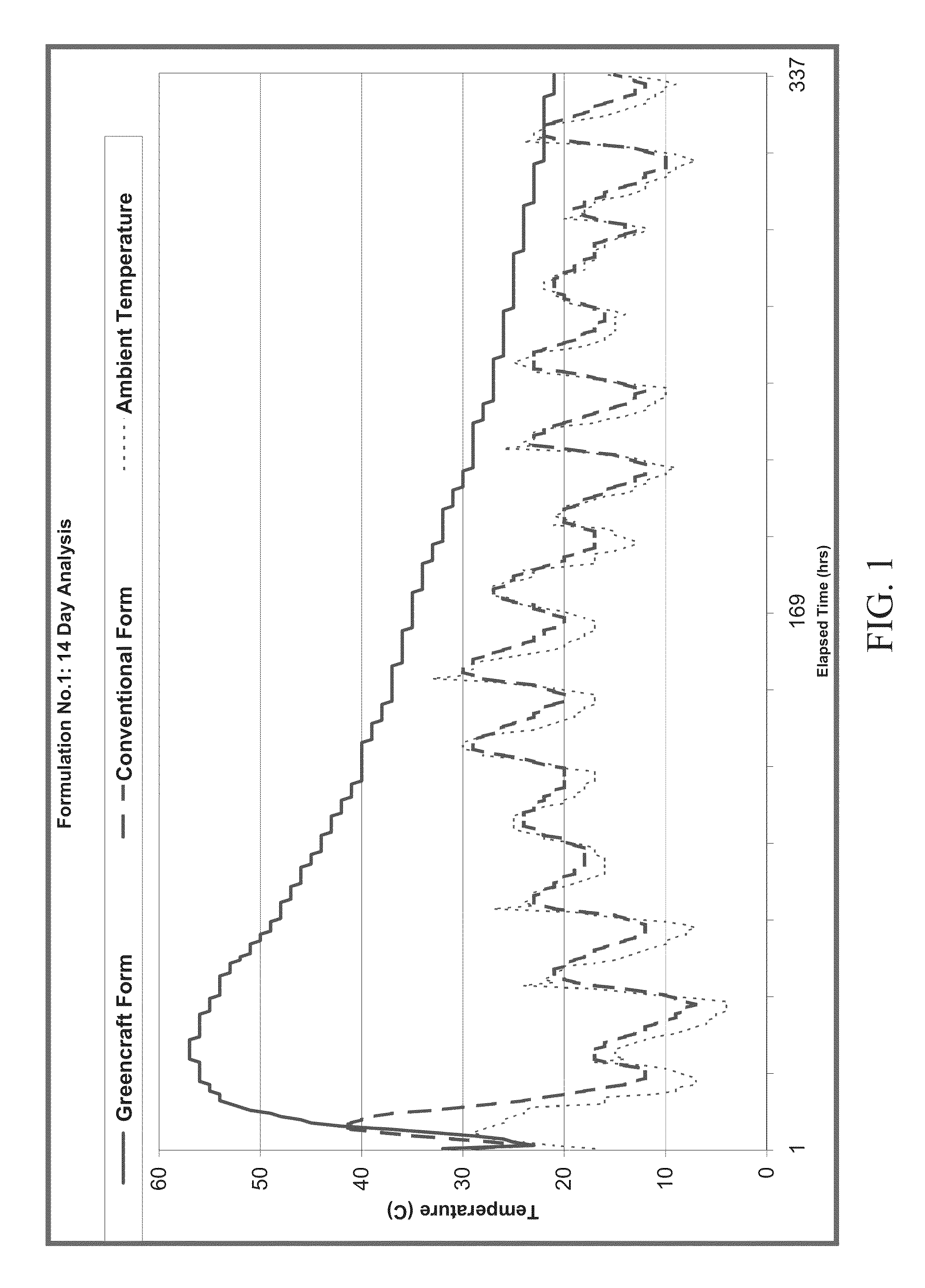

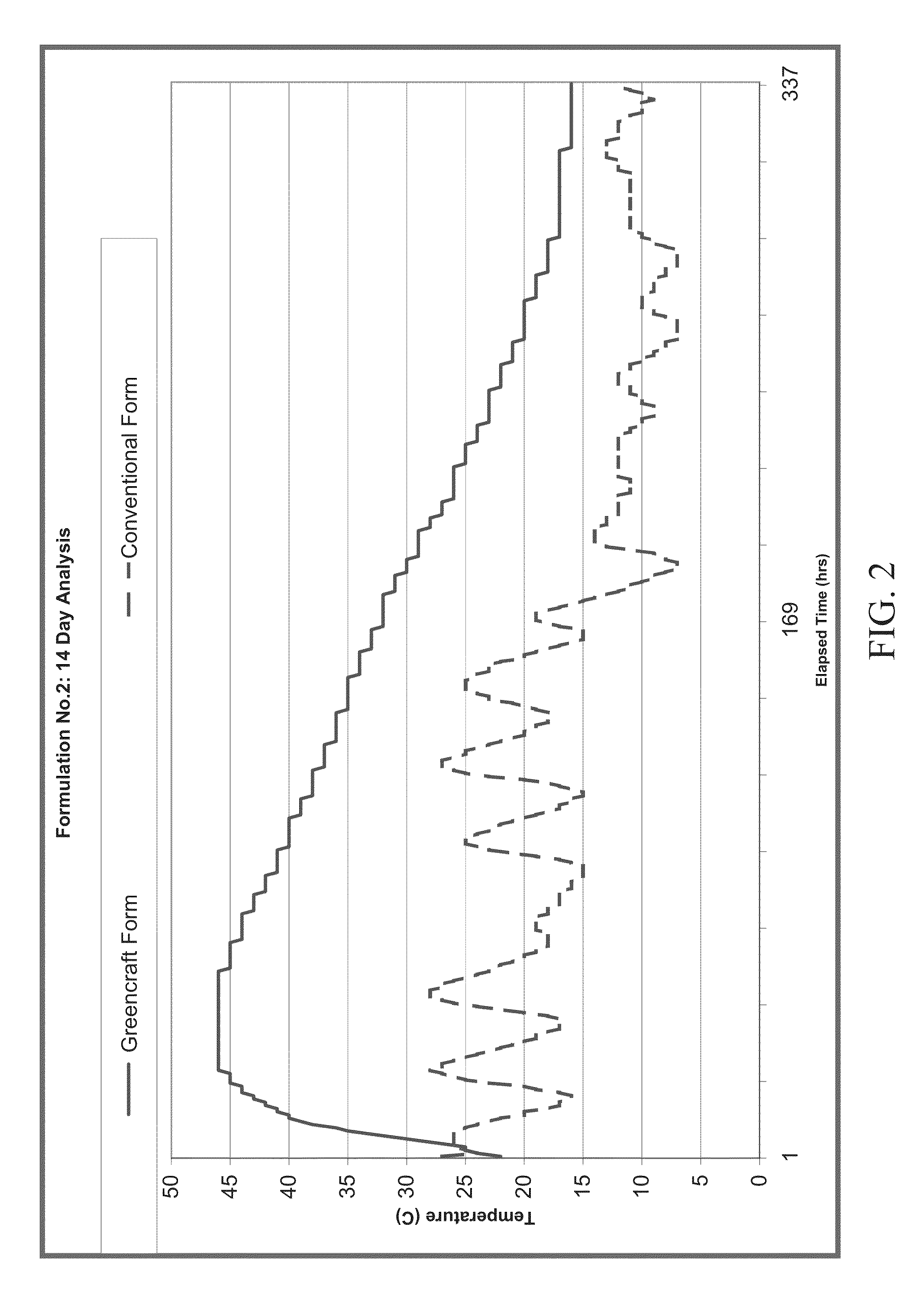

Concrete mix composition, mortar mix composition and method of making and curing concrete or mortar and concrete or mortar objects and structures

ActiveUS20130119576A1Easy to useLess concrete shrinkageSolid waste managementCeramic shaping apparatusSlagPortland cement

The invention comprises a method of making a cement-based object or structure having a compressive strength greater than about 1,000 psi. The method comprises placing a cement-based material in an insulated concrete form, wherein the insulated concrete form has an R-value of at least 1.5, wherein the cement-based material comprises approximately 10% to approximately 80% by weight portland cement, and at least one of approximately 10% to approximately 90% by weight slag cement and approximately 5% to approximately 80% by weight fly ash. The invention also comprises a method of making a cement-based object or structure. The invention further comprises objects or structures made by the foregoing methods.

Owner:CIUPERCA ROMEO ILARIAN

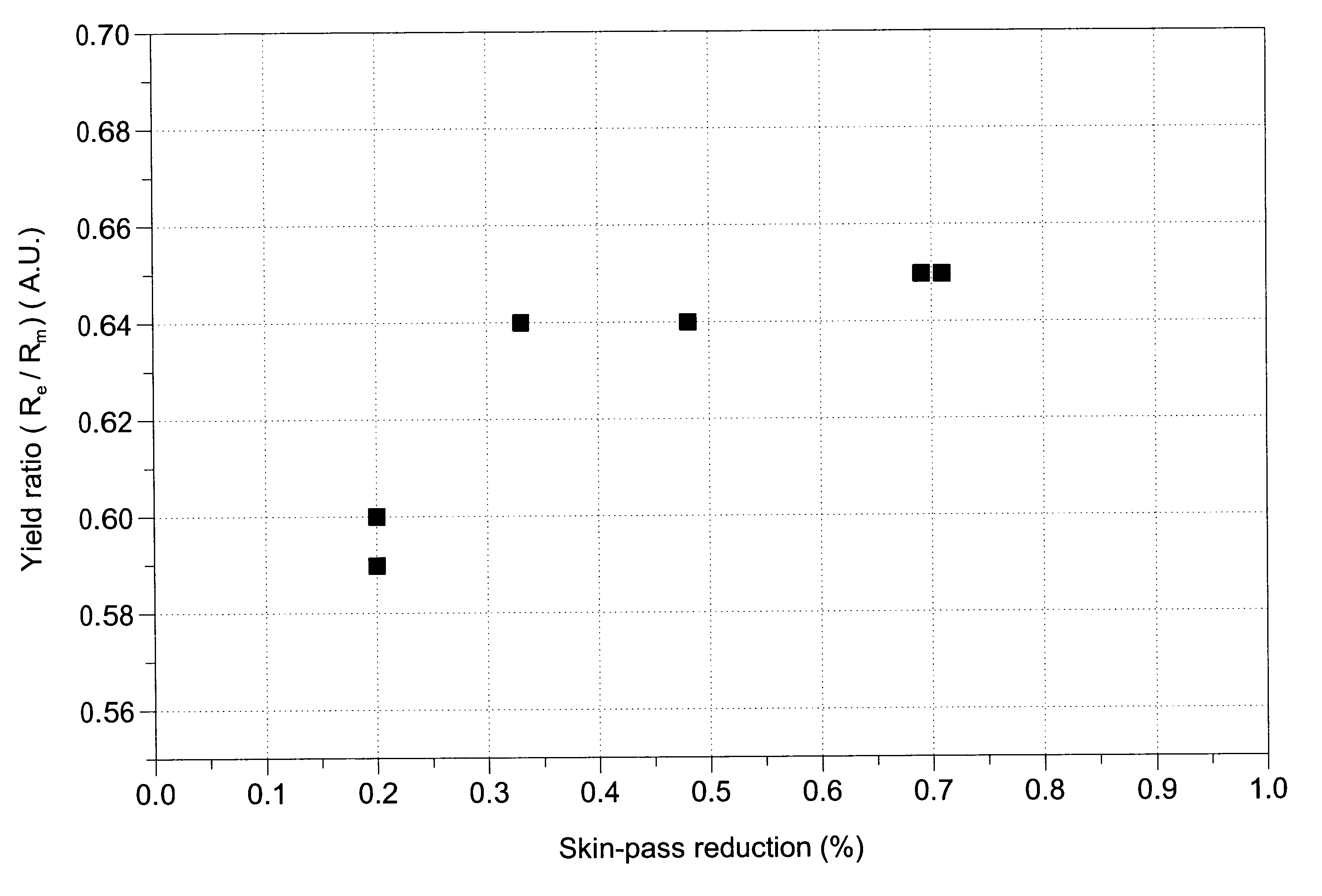

Method of production of cold-rolled metal coated steel products, and the products obtained, having a low yield ratio

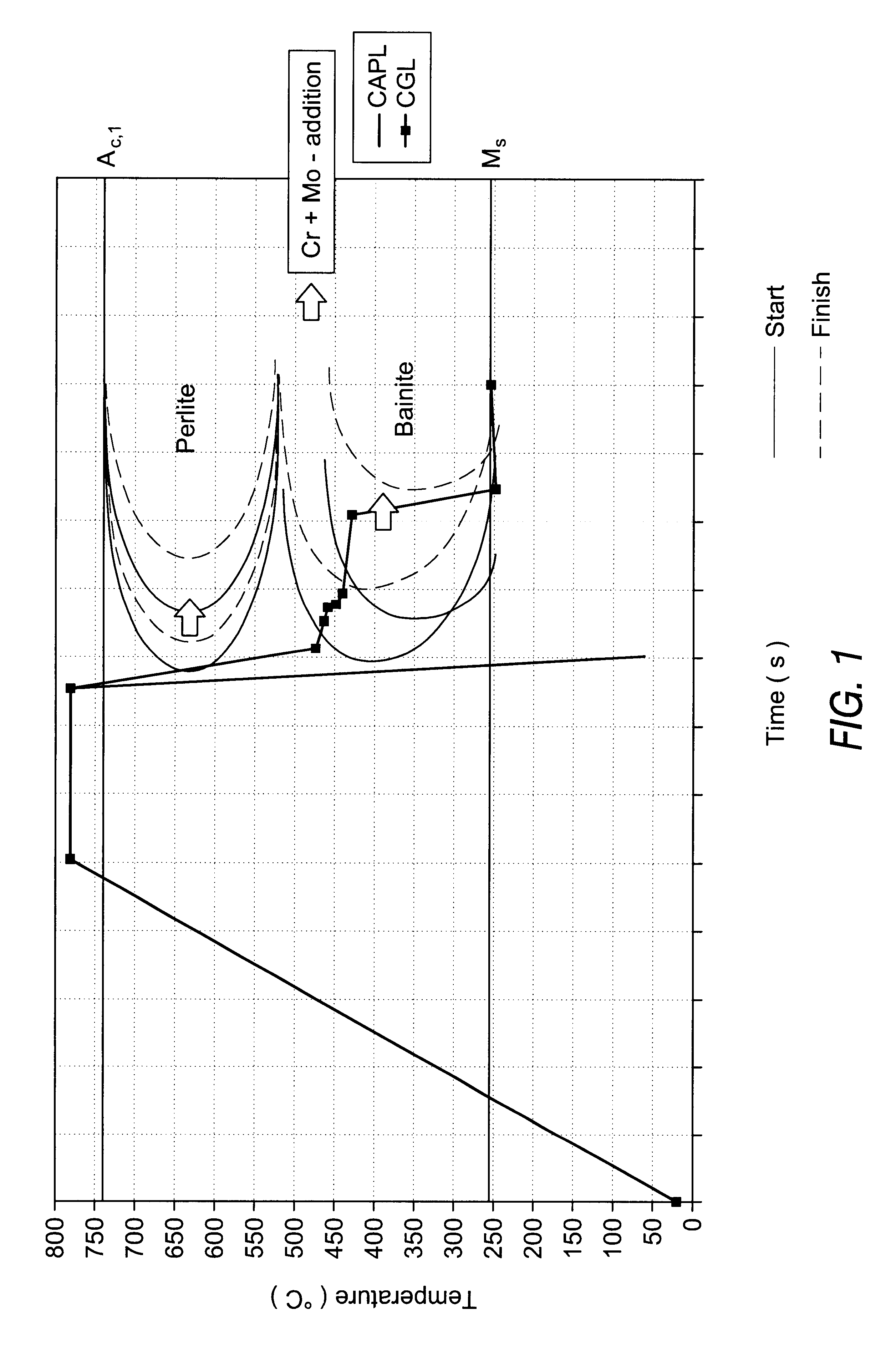

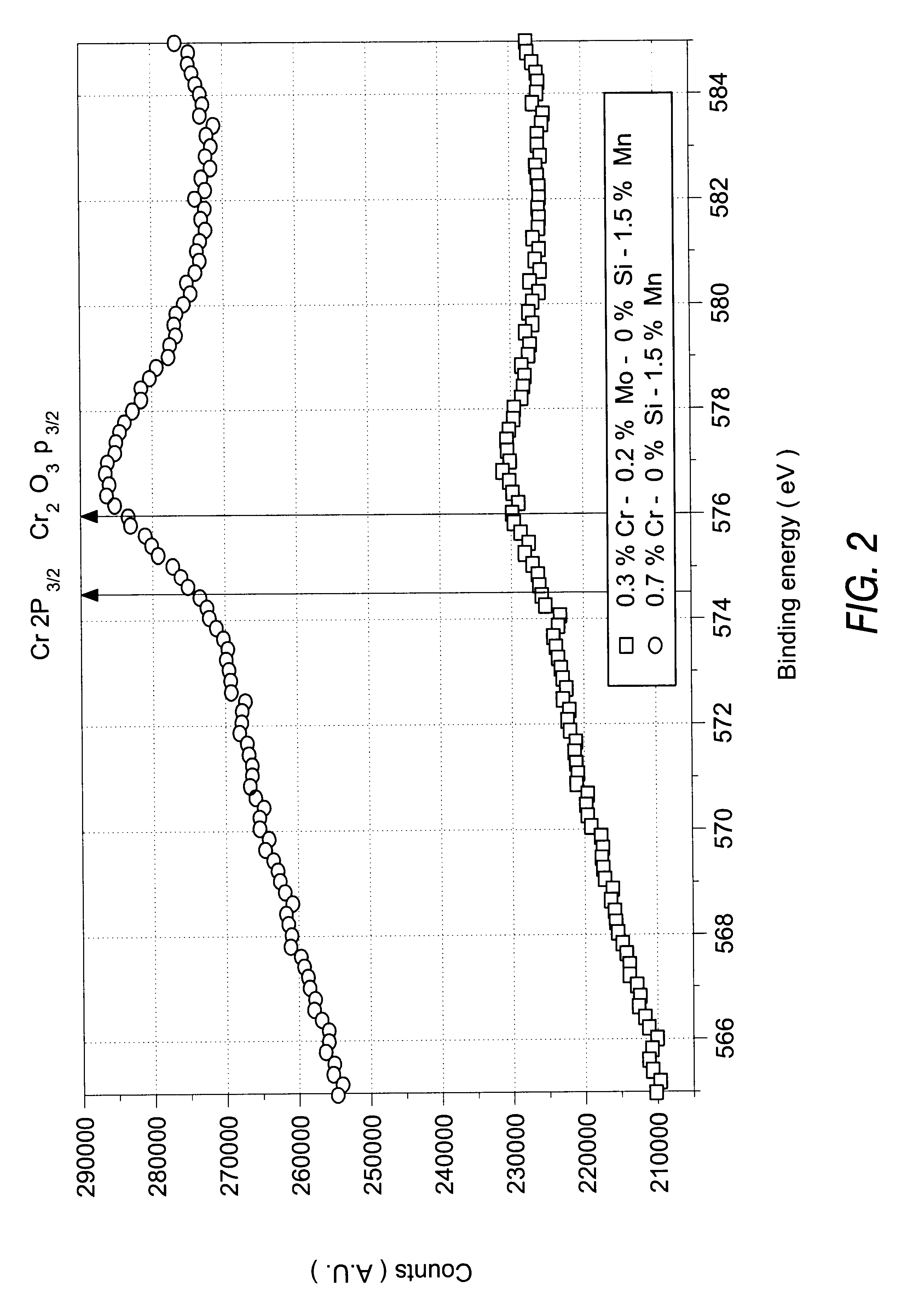

InactiveUS6641931B2High strengthGood molding effectHot-dipping/immersion processesFurnace typesManganeseYield ratio

The present invention aims to produce a cold rolled metal coated multi-phase steel, characterized by a tensile strength of at least 500 MPa, a yield ratio (Re / Rm) lower than 0.65 in skinned conditions, lower than 0.60 in unskinned conditions, and with good metal coating adhesion behavior. In the case of the aluminized steel according to the invention, the steel also has superior resistance to temperature corrosion up to 900° C. and excellent mechanical properties at this high temperature. The hot metal coated steel product having a steel composition with a manganese content lower than 1.5%, chrome content between 0.2 and 0.5%, molybdenum content between 0.1 and 0.25%, and a relation between the chrome and molybdenum content as follows Cr+2 Mo higher than or equal to 0.7%, undergoes a thermal treatment in the hot dip metal coating line defined by a soaking temperature between Ac1 and Ac3, a primary cooling speed higher than 25° C. / sec and a secondary cooling speed higher than 4° C. / sec.

Owner:SIDMAR

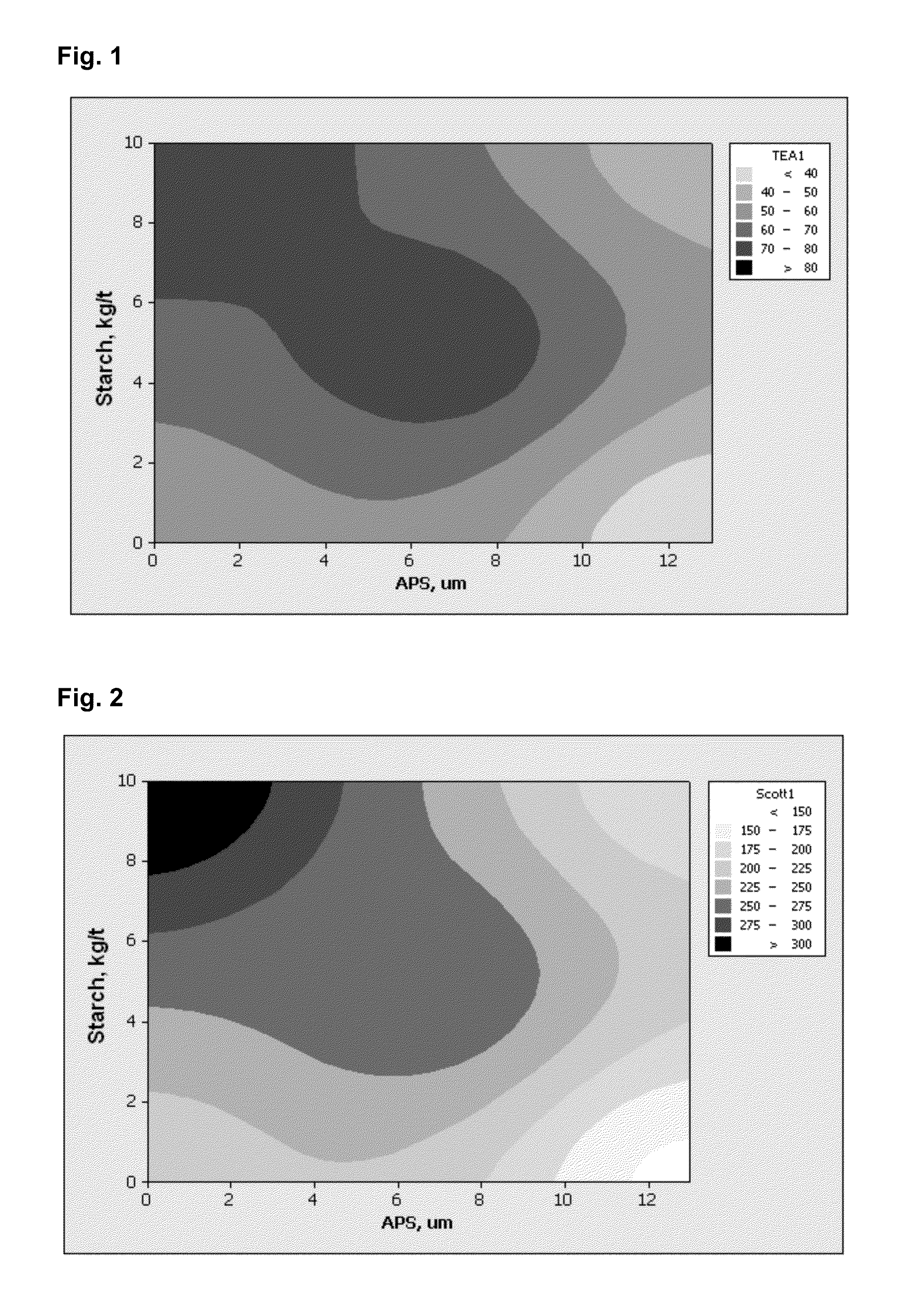

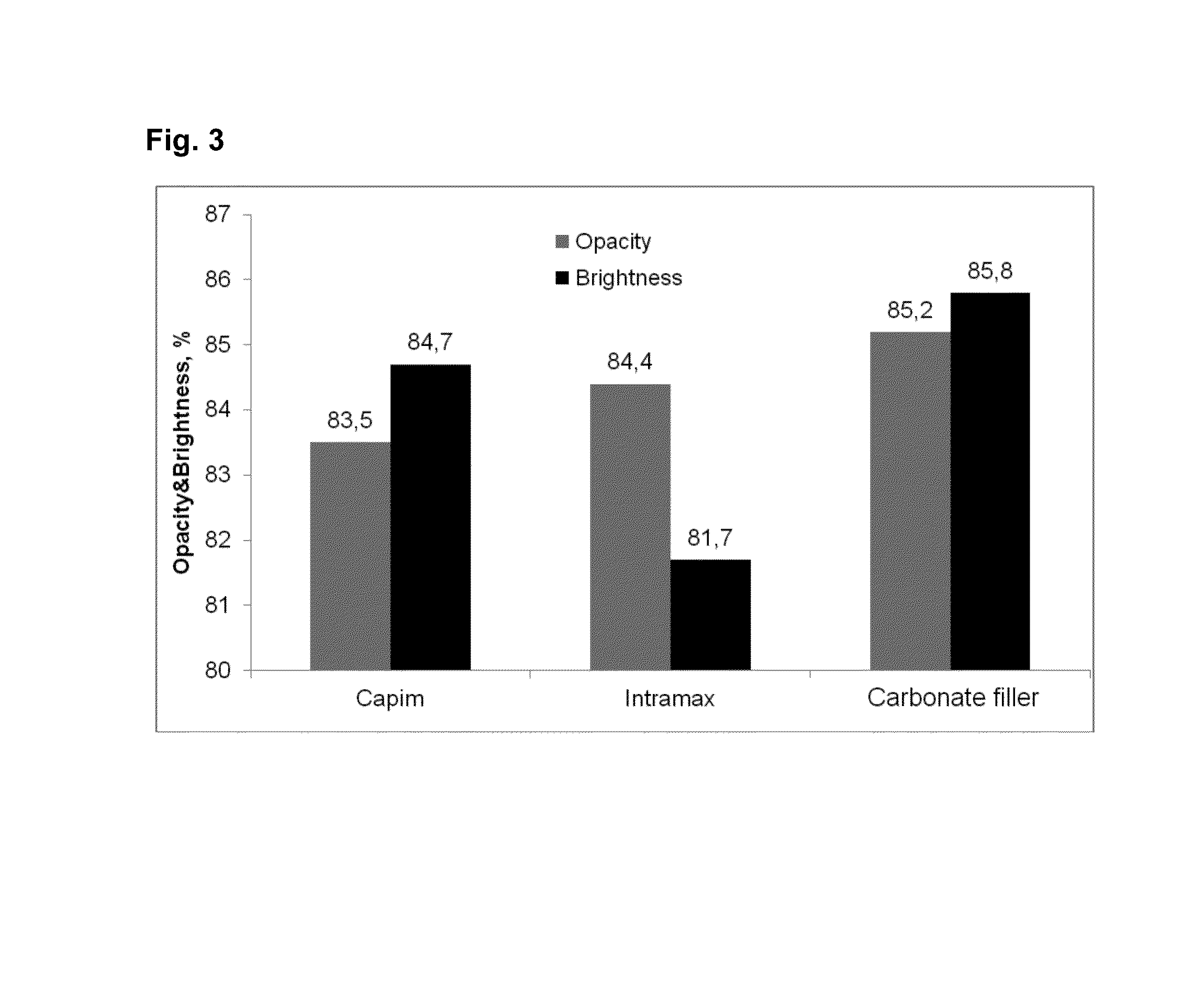

Use of precipitated carbonate in the manufacture of a fibre product

InactiveUS20140069302A1Good strength performanceImprove strength propertiesCalcium/strontium/barium carbonatesPigmenting treatmentCardboardFiber

The present invention relates to a filler or a filler mixture containing carbonate, as well as to a process for manufacturing the same by precipitating the filler directly into the pulp or, as a separate process without the presence of fibres, particularly from the wire water of the paper or board manufacture. The invention also relates to a fibre product containing this filler, such as a paper or board product, or a plastic, rubber, concrete or paint product.

Owner:NORDKALK AB

Polyester waterproof ventilated membrane, three-layer compound material, preparation method and application thereof

ActiveCN101717561AExcellent waterproof, breathable and moisture permeable functionGood strength performanceSynthetic resin layered productsRoof covering insulationsChemistryCushion

The invention relates to a polyester micro-porous film having waterproof ventilating and drenching functions, a three-layer compound material, a preparation method and the application thereof. The blend of polyethylene glycol terephthalate, polyethylene terephthalates, Valox and low-melting polyester is the base of polymer. Inorganic filler and processing agent are added in order to prepare polyester micro-porous film having waterproof ventilating and drenching functions. Based on the softening point difference among the low-melting polyester in the polymer base of the micro-porous film and the PET, PTT and PBT, the high intensity three-layer compound material having waterproof, ventilating and drenching functions is prepared by hot-pressing the inner and outer layers of polyester non-woven fabrics, with a polyester micro-porous film in the middle layer. The compound material of the invention can be used as a waterproof ventilating and drenching cushion ply on a slope roof and also can be used as a waterproof drenching cushion ply on the inner side of the hanging type decoration materials on the outer wall of building.

Owner:宁波曦昀高分子新材料有限公司

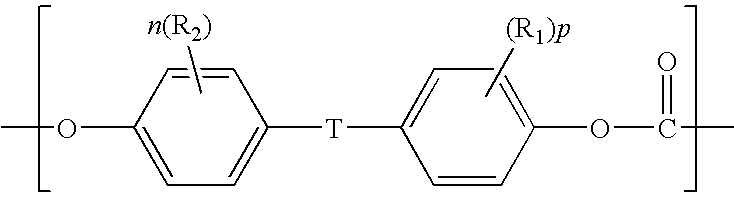

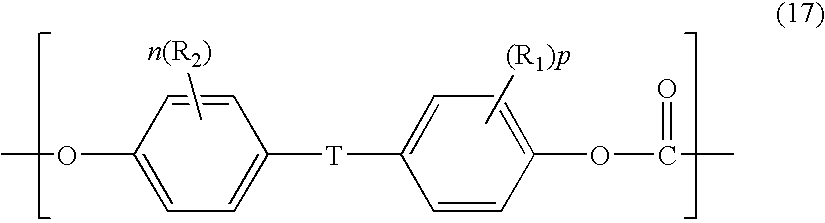

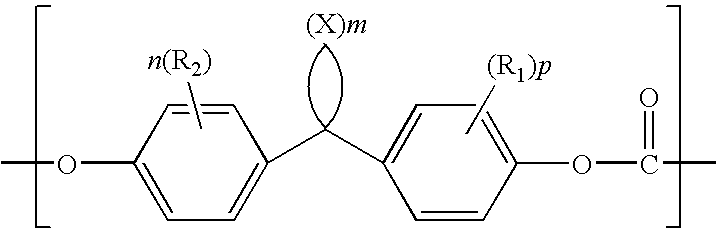

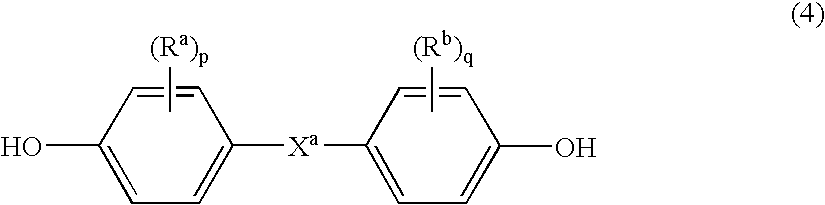

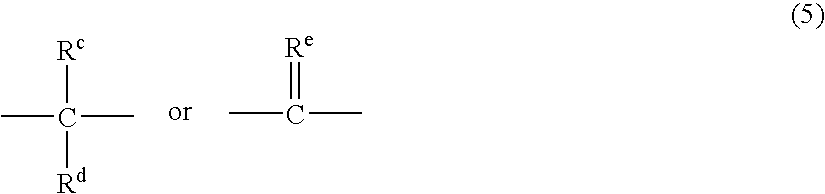

Flame retardant and scratch resistant thermoplastic polycarbonate compositions

A flame retardant thermoplastic composition comprising in combination a polycarbonate homopolymer or copolymer comprising repeat carbonate units having the following structure:wherein R1 and R2 are independently at each occurrence a C1-C4 alkyl, n and p are each an integer having a value of 1 to 4, and T is selected from the group consisting of C5-C10 cycloalkanes attached to the aryl groups at one or two carbons, C1-C5 alkyl groups, C6-C13 aryl groups, and C7-C12 aryl alkyl groups; an impact modifier, wherein the impact modifier comprises wherein the impact modifier comprises a rubber modified thermoplastic resin comprising a discontinuous elastomeric phase dispersed in a rigid thermoplastic phase, and wherein the impact modifier has a specific mean particle size and Q value; and a flame retardant. The compositions have excellent scratch resistance as well as an improved balance of physical properties such as impact strength and spiral flow, while at the same time maintaining their good flame performance.

Owner:SHPP GLOBAL TECH BV

Preparation method for bottom mud brick

InactiveCN102826818ALow biological toxicityHigh strengthSolid waste managementCeramicwareCompression moldingBrick

The invention discloses a preparation method for a bottom mud brick. Riverway bottom mud serves as a raw material, the riverway bottom mud, plant straws, waste glass powder and a binding agent are mixed in proportion, and the preparation method comprises the following steps that: steel slag is added for evenly mixing; a moisture content is adjusted to be 20-40%, even stirring and beating homogenizing are carried out, and a brick making die is used for pressing and compression molding; the moisture content is adjusted to be 1-5% in a dried mode; and the bottom mud brick is made through high-temperature calcination of a muffle furnace. The bottom mud brick prepared by the method is high in strength, good in water permeability, multiple in hole, less in energy dissipation, less in heavy metal dissolution and low in biotoxicity. The preparation method utilizes bottom mud of heavy-polluted riverways, therefore, solidification of heavy metals in polluted bottom mud is achieved, damage of the bottom mud to environment is reduced, and simultaneously, resource recycling of the bottom mud is achieved.

Owner:EAST CHINA NORMAL UNIV

Non-steamed brick and preparation method thereof

ActiveCN102336550AAchieving zero emissionsGood mechanical propertiesSolid waste managementCeramic shaping apparatusBrickAdhesive

The invention discloses a non-steamed brick and a preparation method thereof. The non-steamed brick comprises the following components in percentage by weight: 60 to 85 percent of iron tailings, 5 to 18 percent of river sand, 8 to 20 percent of cement, and 0.5 to 3 percent of admixture, wherein the admixture is one or more of high-strength adhesive, water reducing agent and waterproof agent. The preparation method comprises the steps of proportioning, mixing, pressure molding and natural curing. Proved by practice, the non-steamed brick has simple component, low cost and excellent comprehensive performance; and the preparation method is mild in conditions and easy in operation.

Owner:武钢资源集团有限公司 +1

Self-boring and self-tapping screw for osteosynthesis and compression

InactiveUS20100174323A1Easy to installGood strength performanceSuture equipmentsLigamentsBone tissueDistal portion

The invention provides an osteosynthesis and compression screw that is self-boring and self-tapping for the purpose of coaptation of small bone fragments. The screw comprises:a proximal portion formed by a screw head provided with an outside thread;an intermediate portion having no thread; anda distal portion provided with an outside thread.Wherein:each of the screw head and the distal portion includes at least one groove, firstly extending over the entire axial length of its thread, and secondly being formed through each thread in such a manner to form tapping means; andthe terminal zone of the distal portion is provided with preparation means for preparing a housing in the bone fragments for receiving the intermediate and distal portions of the screw.

Owner:NEWDEAL

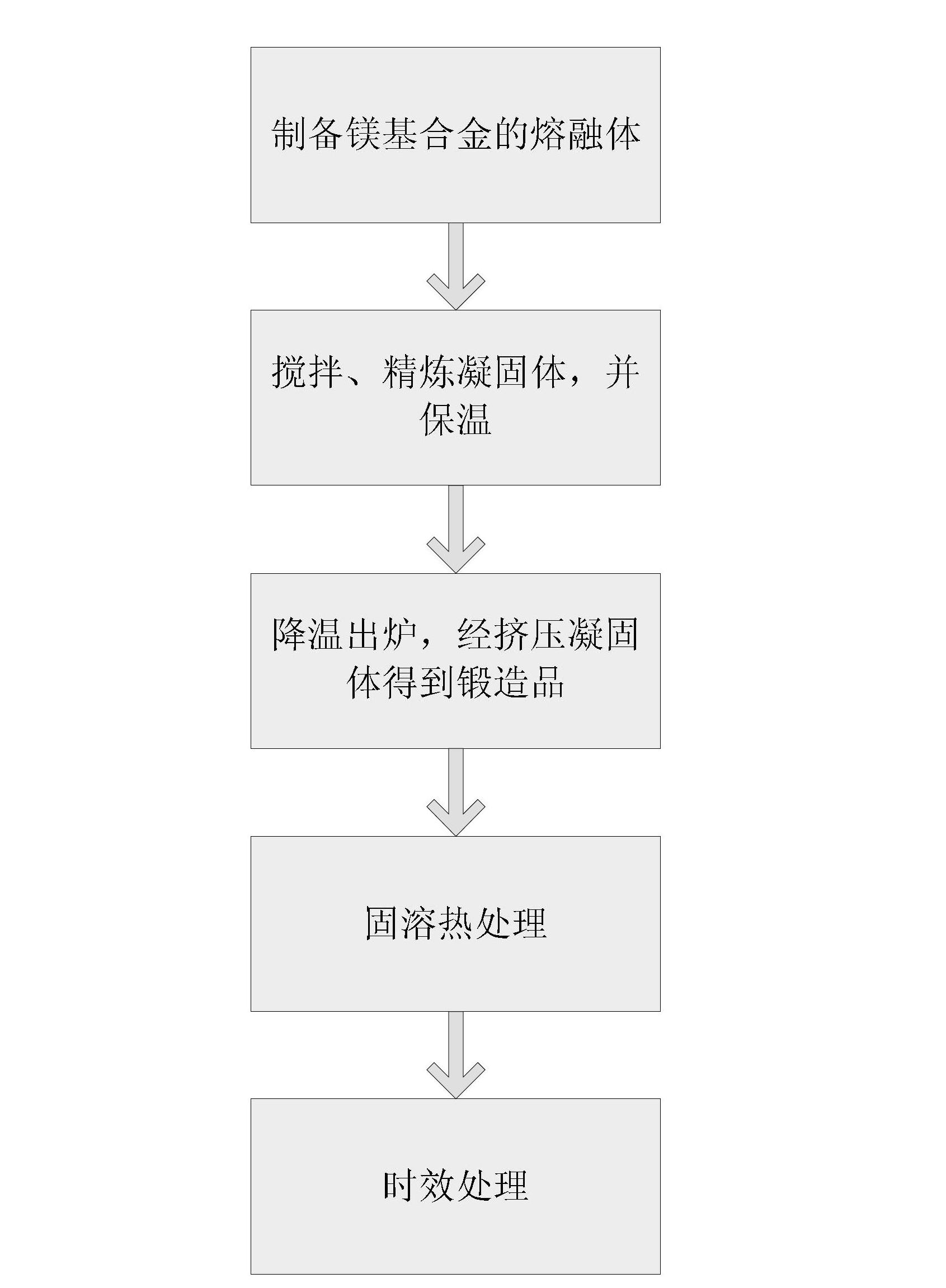

Al-Zn-Mg alloy and preparation method thereof

The invention relates to an Al-Zn-Mg alloy, which comprises the following components: 1-3wt% of Zn, 3-9wt% of Al, 0.5-0.9wt% of Ti, 0.07-0.14wt% of Zr, 0.02-0.11wt% of Re and the balance of iron and inevitable impurities. The alloy can also comprise Y, Mn, Sr and Nb. The strength of the Al-Zn-Mg alloy provided by the invention is improved by adding Zn, Al, Ti, Zr and Re into Mg base, and the goodstrength effect is realized by adding the components of different proportions; and in the preparation method, the Al-Zn-Mg alloy precipitate is hardened by three steps of ageing treatment, so that the hardness of the obtained Al-Zn-Mg alloy is very high.

Owner:DONGGUAN WENYU IND

Concrete mix composition, mortar mix composition and method of making and curing concrete or mortar and concrete or mortar objects and structures

ActiveUS8545749B2Good strength performanceReducing CO<subSolid waste managementCeramic shaping apparatusSlagPortland cement

The invention comprises a method of making a cement-based object or structure having a compressive strength greater than about 1,000 psi. The method comprises placing a cement-based material in an insulated concrete form, wherein the insulated concrete form has an R-value of at least 1.5, wherein the cement-based material comprises approximately 10% to approximately 80% by weight portland cement, and at least one of approximately 10% to approximately 90% by weight slag cement and approximately 5% to approximately 80% by weight fly ash. The invention also comprises a method of making a cement-based object or structure. The invention further comprises objects or structures made by the foregoing methods.

Owner:CIUPERCA ROMEO ILARIAN

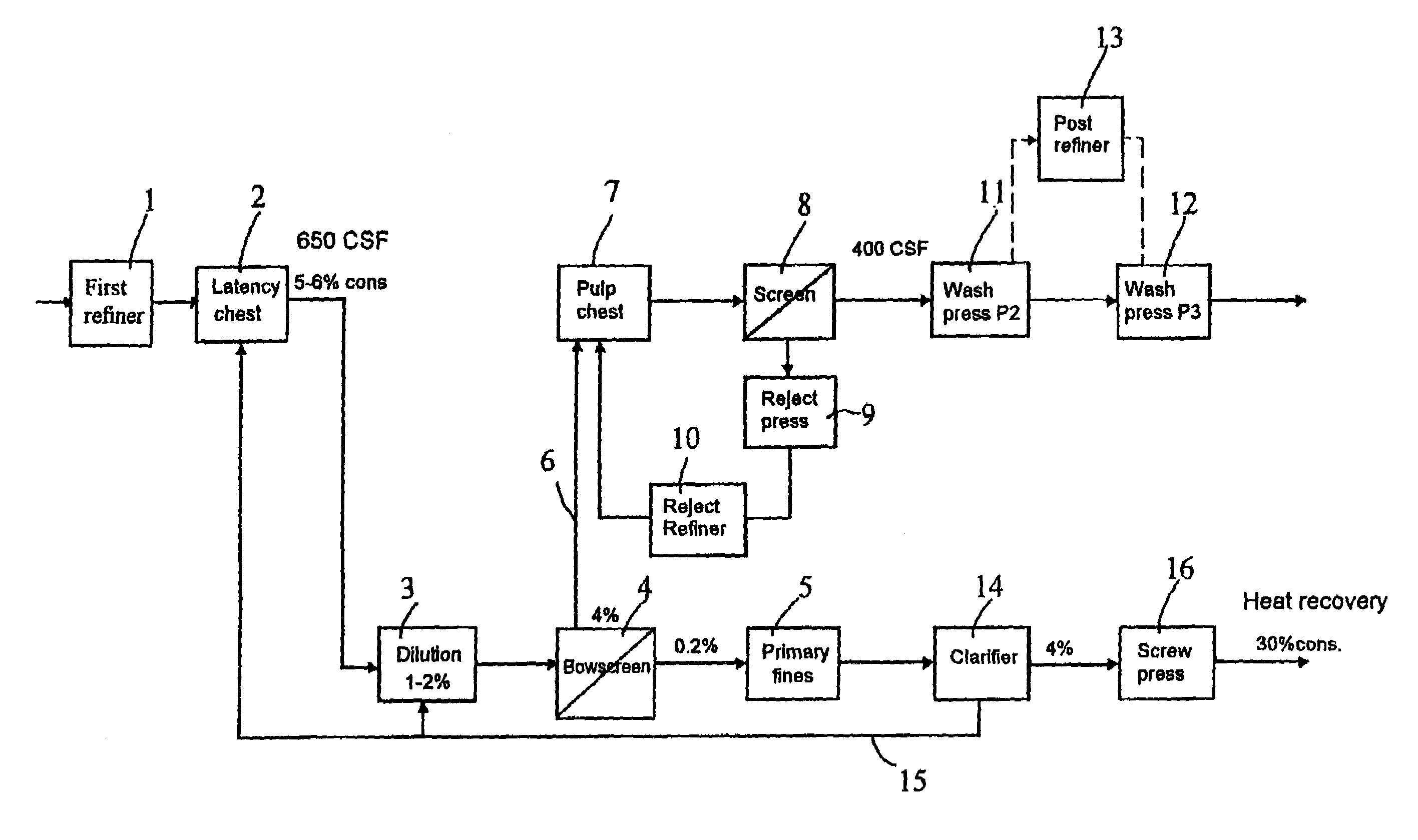

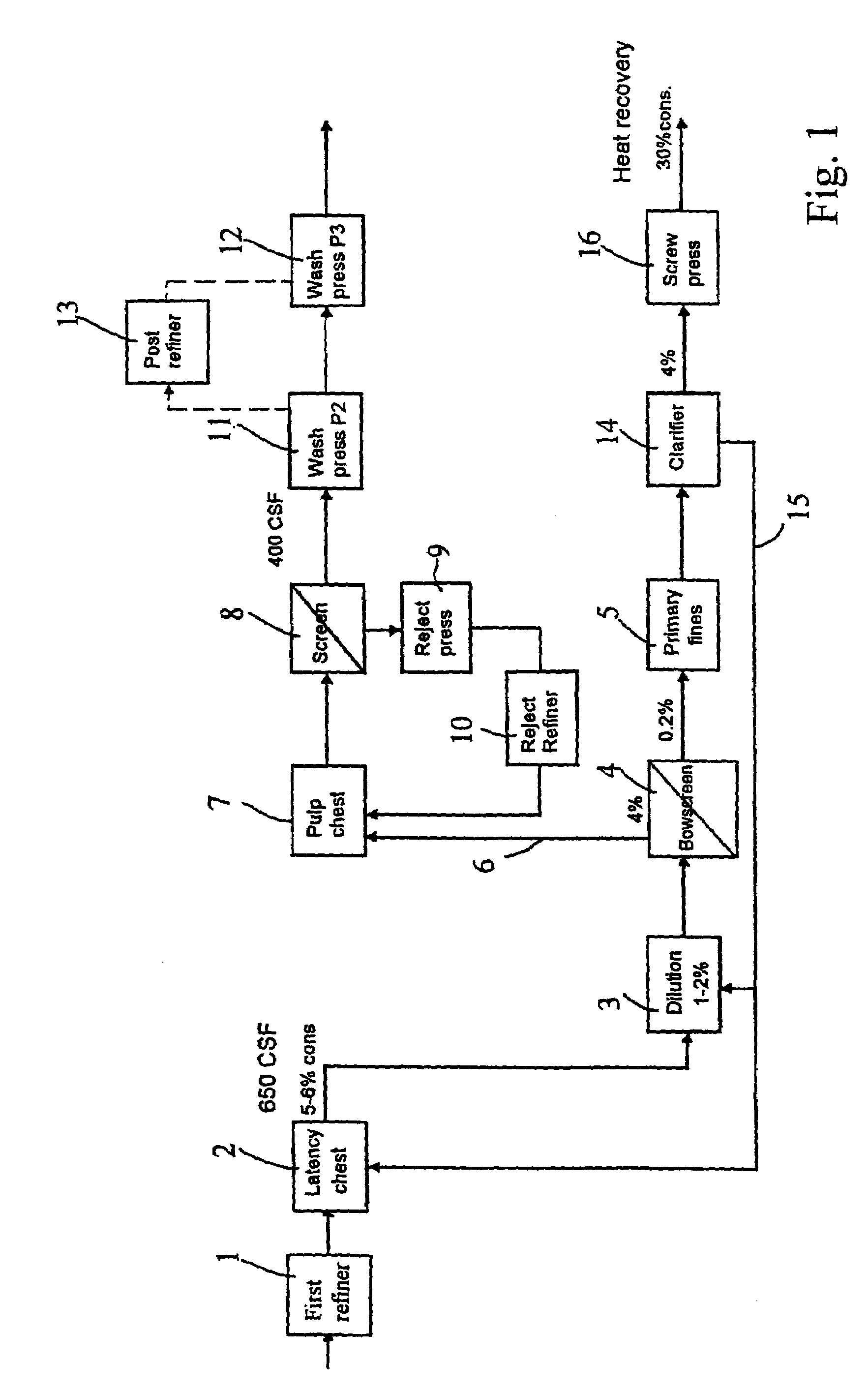

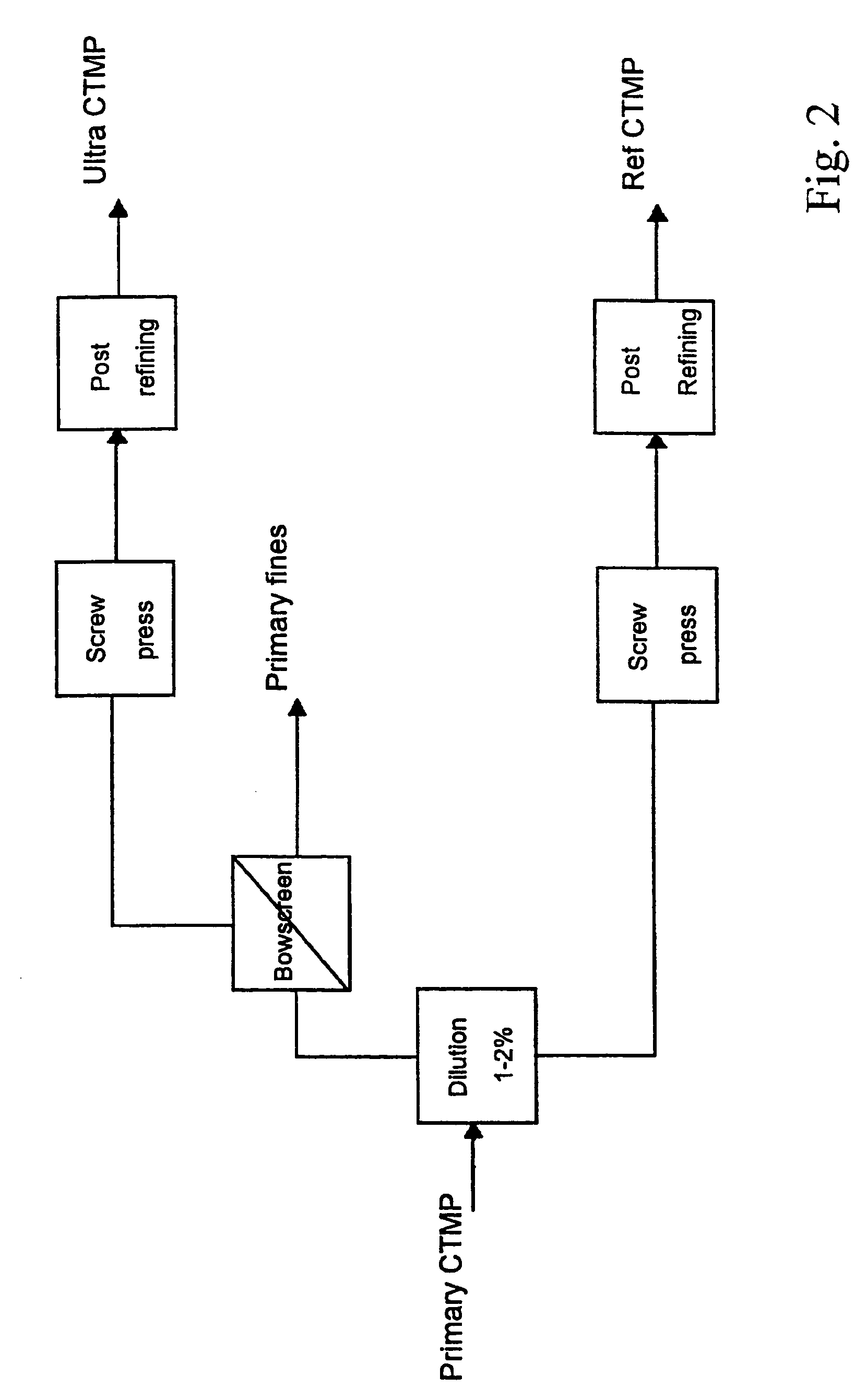

Method in connection with the production of mechanical pulp

InactiveUS7005034B1Reduce consumptionGood removal effectFats/resins/pitch/waxes removal in pulpDigestersCellulosePaperboard

A method in connection with the production of mechanical pulp from a cellulose containing material wherein the material is processed in at least one refining step to produce pulp. According to the invention, the pulp is fractionated (4), after a first refining step (1), in order to separate primary fines (5) from the pulp. The invention also relates to a mechanical pulp, produced by the method, and to a paperboard, which at least partly consists of such mechanical pulp.

Owner:STORA ENSO AB

Flame retardant thermoplastic polycarbonate compositions, method of manufacture, and method of use thereof

ActiveUS20070093591A1Improved flame performanceHigh impact strengthOrganic dyesThermoplasticUltimate tensile strength

A flame retardant thermoplastic composition comprising in combination a polycarbonate component; an impact modifier composition, the components of the impact modifier composition comprising a) a bulk polymerized ABS, and b) an impact modifier different from the ABS; and a flame retardant. The compositions have an improved balance of physical properties such as impact strength and flow, while at the same time maintaining their good flame performance.

Owner:SABIC GLOBAL TECH BV

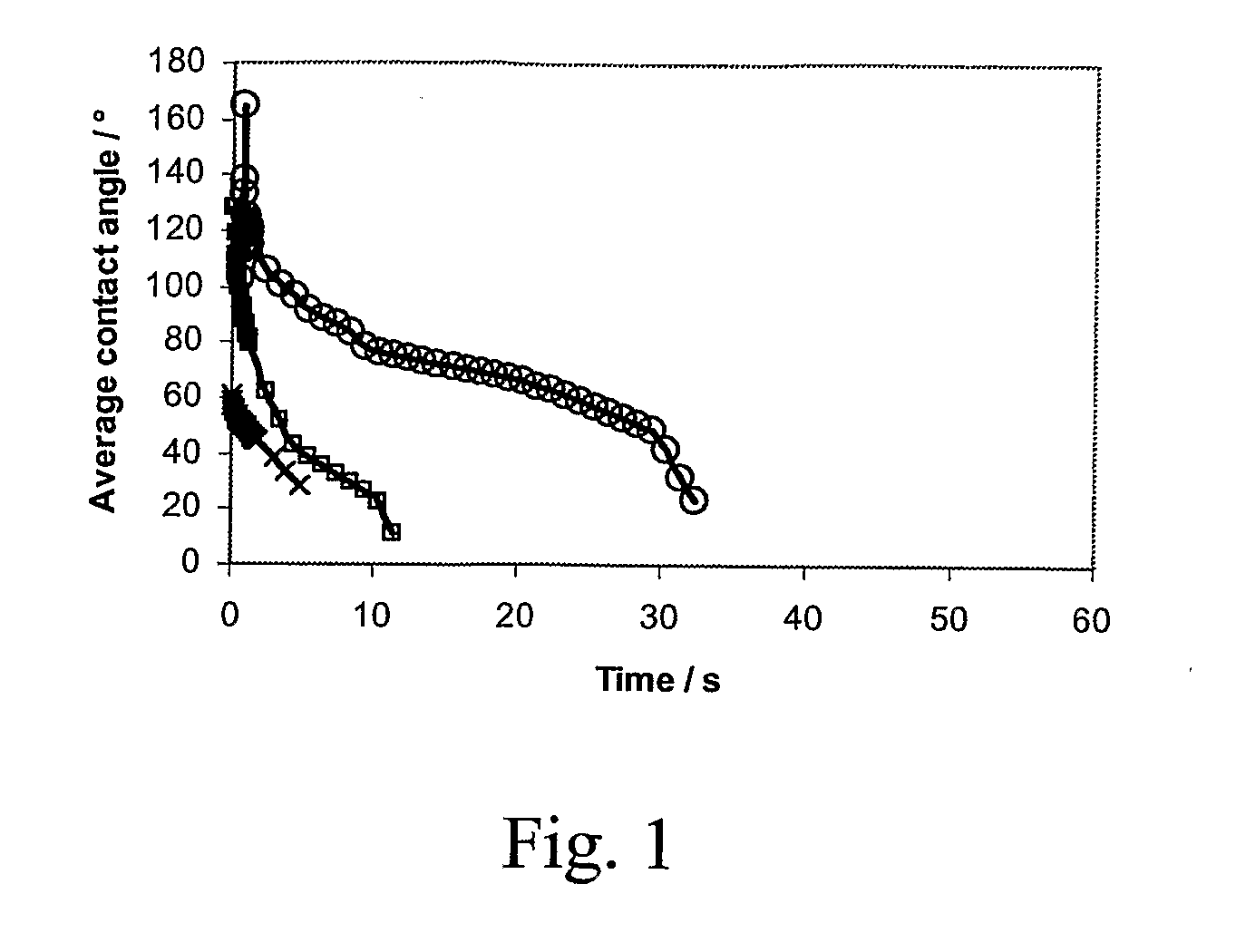

Process for producing a fibrous product

InactiveUS20070131362A1Eliminate problemEliminate the problemNon-fibrous pulp additionPulp properties modificationFiber matrixOxidizing agent

The present invention concerns a process for modifying a lignocellulosic fibre material. In particular, the present invention gives new properties to the fibrous matrix of the material. This is achieved by producing fibrous products with modified properties by activating the fibres of the matrix with an oxidizing agent and attaching compounds to the activated fibre in order to incorporate desired, pre-selected properties in to the fibre matrix. The invention makes possible to produce novel kinds of fibrous materials having practically a large variety of properties. Examples of such properties include hydrophobic hydrophilic character.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

Natural rubber-rich composition and tire with tread thereof

This invention relates to a natural rubber-rich rubber composition and tire with tread thereof. A partial replacement of the natural rubber in the natural rubber-rich tire tread is accomplished by an inclusion of a specialized trans 1,4-styrene / butadiene copolymer rubber characterized by having a combination of bound styrene content and microstructure limitations. The tire tread rubber composition is comprised of a blend of the specialized trans 1,4-styrene / butadiene rubber and cis 1,4-polyisoprene natural rubber optionally together with at least one additional diene-based elastomer in which the natural rubber remains a major portion of the elastomers in the tread rubber composition. A significant aspect of the invention is a partial replacement of natural cis 1,4-polyisoprene rubber in the tread rubber composition. The specialized trans 1,4-styrene / butadiene rubber has a bound styrene content in a range of from about 15 to about 35 percent and a microstructure of its polybutadiene portion composed of from about 50 to about 80 percent trans 1,4-isomeric units, from about 10 to about 20 percent cis 1,4-isomeric units and from about 2 to about 10 percent vinyl 1,2-isomeric units; preferably a Mooney (ML1+4) at 100° C. viscosity value in a range of from about 50 to about 100, alternately from about 50 to about 85, and preferably a glass transition temperature (Tg) in a range of from about −60° C. to about −90° C.

Owner:SANDSTROM PAUL HARRY +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com