Patents

Literature

6715results about How to "Improve temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature energy-saving corrosion-resisting paint , preparation and usage

InactiveCN1730570AHigh temperature resistanceLow construction requirementsAnti-corrosive paintsCorrosion resistantAdhesive

The invention discloses a high temperature energy conservation corrosion resistant coating material, which comprises filling material, addition agent and adhesive by the weight ratio of 1-5:1:1-10. The invention also discloses the process for preparing the coating material, which comprises the steps of mixing filling material powder with addition agent proportionally, grinding to 600 mesh in a wet grinder, finally stirring and mixing with adhesive.

Owner:陈国军

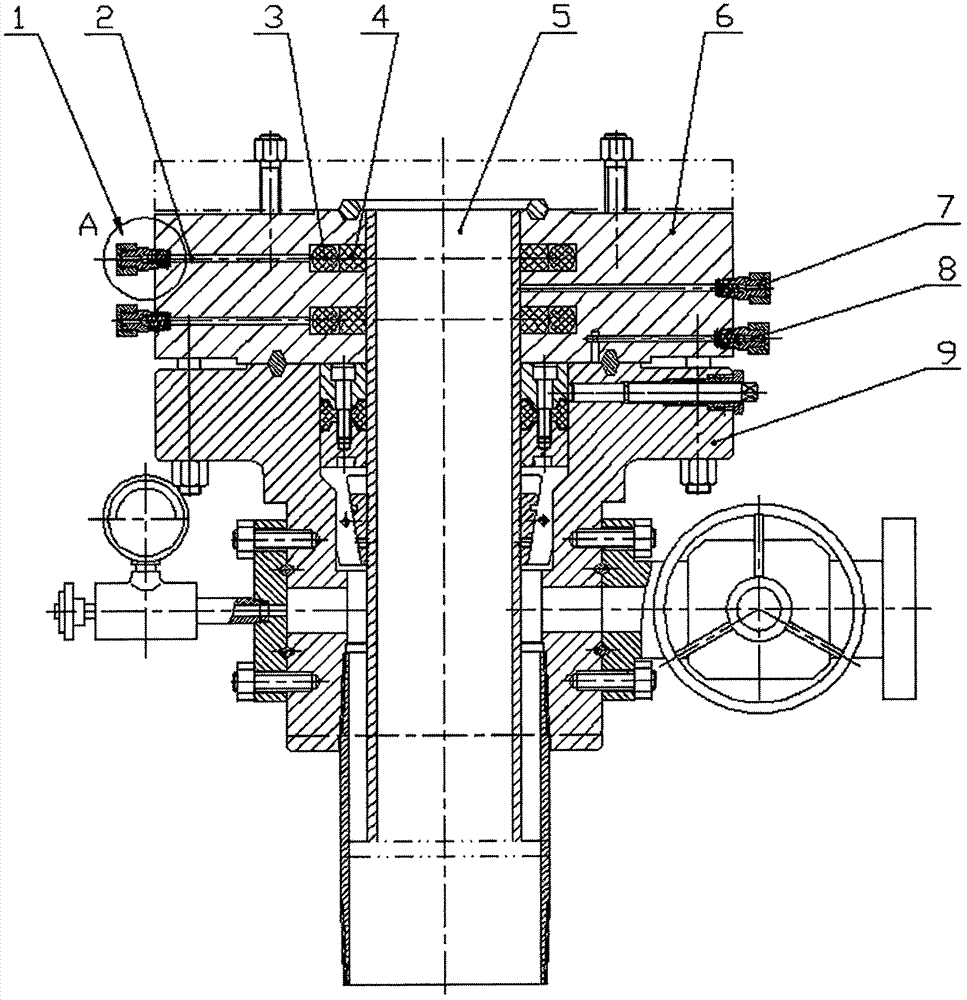

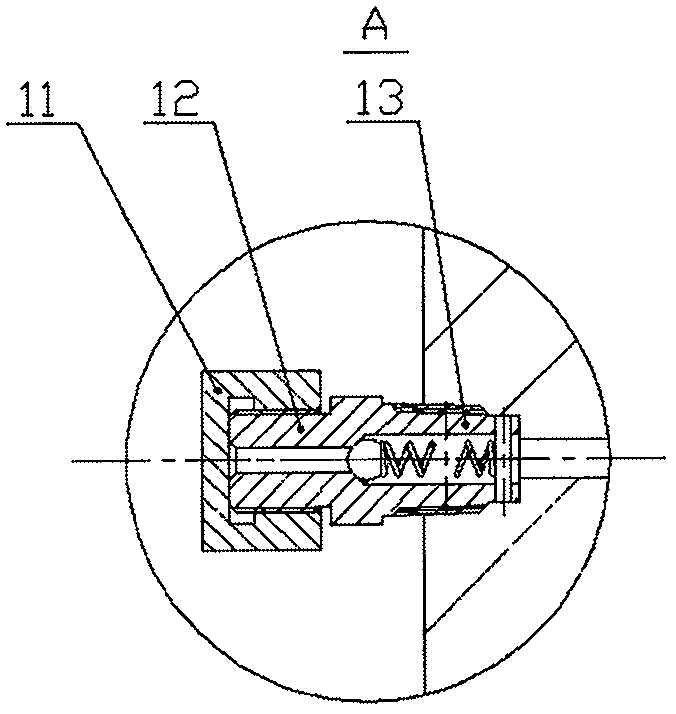

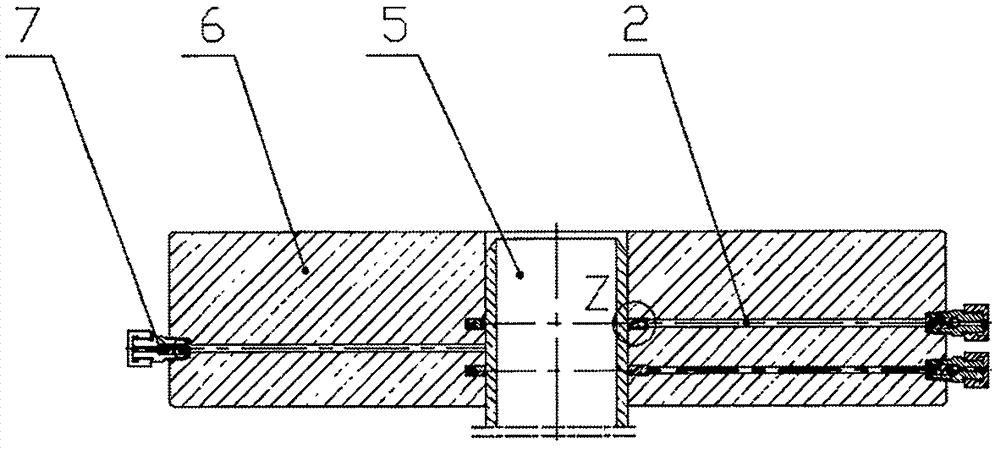

Petroleum wellhead annular space sealing device

PendingCN107143298AGood corrosion resistanceDirectionalSealing/packingWellheadMechanical engineering

The invention discloses a petroleum wellhead annular space sealing device. The petroleum wellhead annular sealing device is used for sealing an annular space between a wellhead sealing body and a petroleum pipe, at least one annular groove is formed in the inner wall surface of the sealing body, and the sealing body is provided with an injection hole which is communicated to a centrifugal end of the annular groove; the petroleum wellhead annular space sealing device further comprises a sealing ring, a power ring, and an injection component, wherein the sealing ring is embedded into the annular groove, the sealing ring is used for sealing the groove in the radial direction by being jointed to the wall surface of the annular groove, and is used for sealing the annular space by being jointed to the outer wall of the petroleum pipe, the power ring is installed in the annular groove and is located between the groove bottom of the annular groove and the sealing ring, and the injection component is installed in an inlet of the injection hole, and is used for injecting fluid with given pressure so as to make the power ring push the sealing ring to tightly press the petroleum pipe. In the petroleum wellhead annular space sealing device, the requirement for deformation capability of a sealing part is low, and meanwhile the sealing capability can be effectively improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

Complete-oil synthetic base drilling fluid

InactiveCN101215461AGood water loss wall building performanceStrong anti-pollutionDrilling compositionReducerHigh pressure

The invention discloses whole-oil synthetic base drilling fluid which mainly comprises following components: base liquid 100 parts, histosol 2-5 parts, viscosity increaser 0.5-3 parts, filtrate reducer 2-5 parts, wetting agent 0.5-2 parts, emulsifier 1-3 parts, calcium oxide 0.5 part and weighting agent 27-180 parts. The invention has the advantages that firstly, the rheological property is good and the plastic viscosity is low, secondly, the anti-temperature performance is good and anti-temperature can reach 150 DEG C, thirdly, the invention is provided with good water loss wall building performance with API filter loss content<5ml and high temperature and high pressure filter loss content <= 10 ml, fourthly, the anti-pollution ability is strong and the anti-poor soil ability and the anti-water invasion ability respectively reach 20%, and fifthly, reservoir has good protective effects and the permeability recovery value is over 85%.

Owner:CHINA NAT OFFSHORE OIL CORP +1

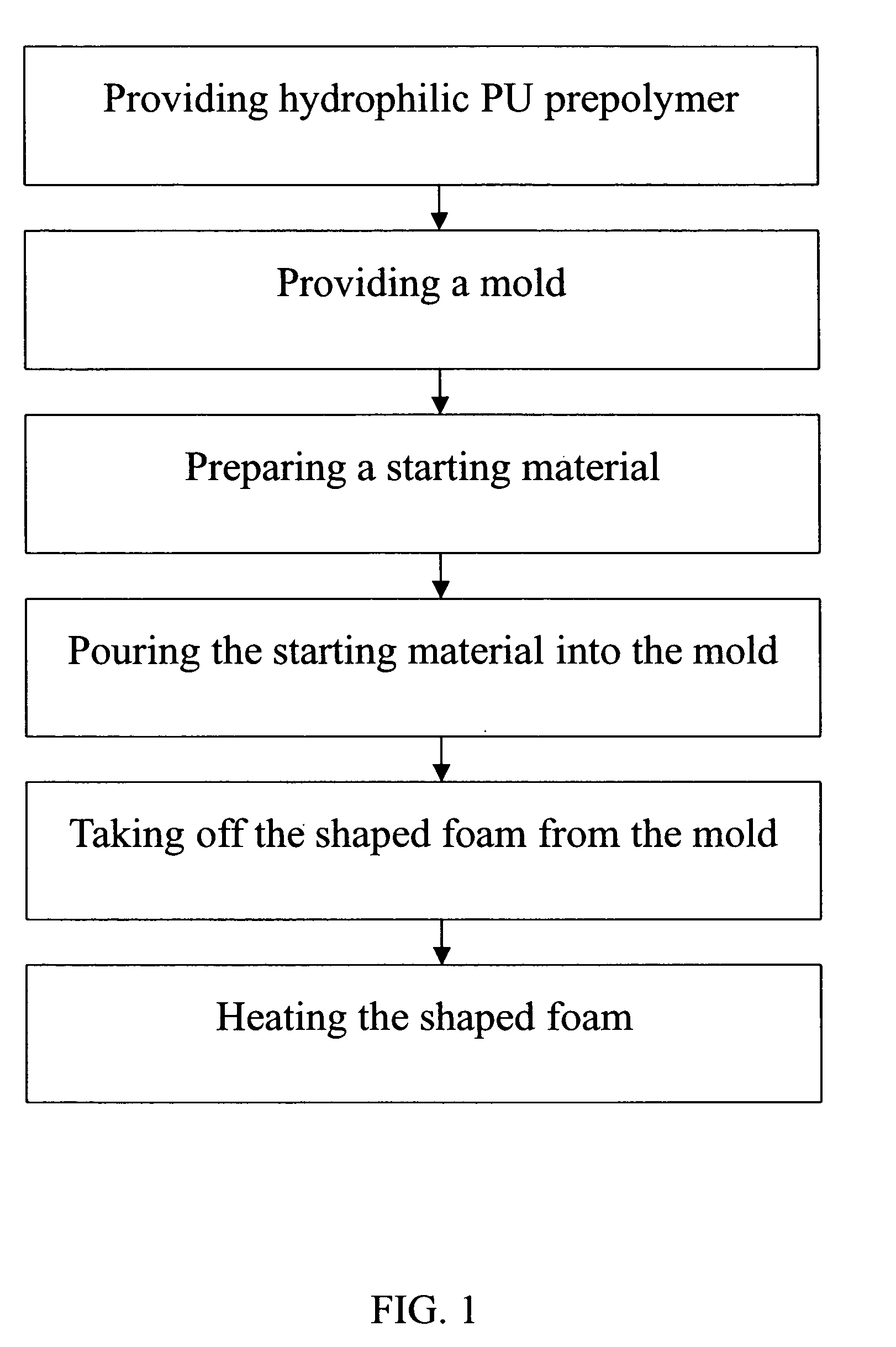

Modified hydrophilic polyurethane memory foam, application and manufacturing method thereof

InactiveUS20070032561A1Broaden applicationImprove temperature resistancePolymer scienceCelsius Degree

A manufacturing method of modified hydrophilic Polyurethane memory foam and products thereof are disclosed. The starting material of the foam includes hydrophilic PU prepolymer, acrylic emulsion polymer and second polyether polyol. The hydrophilic PU prepolymer consists of a first polyether polyol and isocyanate. The molecular weight of the first polyether polyol ranges from 600 to 2000 and the first polyether polyol contains at least 40 mole % of -EO— where the content of the -EO— ranges from 20 to 99.9 wt %. The foaming agent is carbon dioxide produced by the reaction of isocyanate and the water. After foaming process, there is a heating step for dehydration. The foam has specific high hydrophilic polymer structure with features of shock absorbing, uniform pressure relief, moisture absorbency and heat absorbing so as to provide users dry and cool feelings. It wouldn't become rigid below 10 degrees Celsius.

Owner:LIN I SIOUN

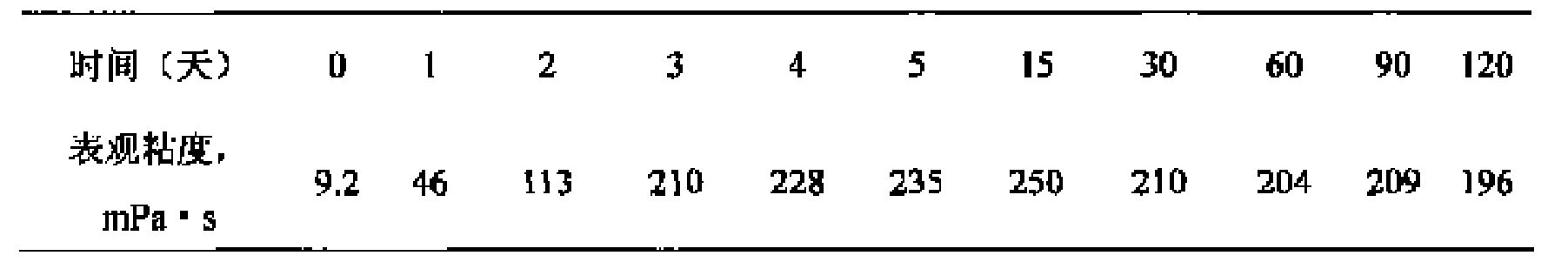

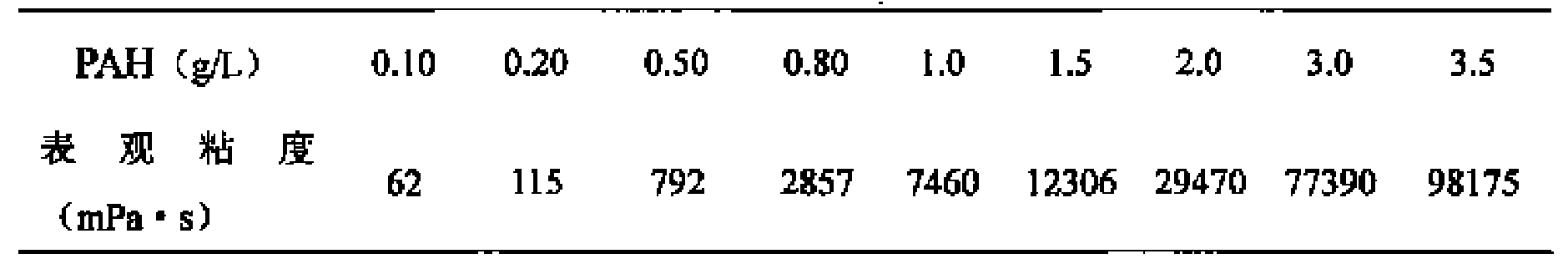

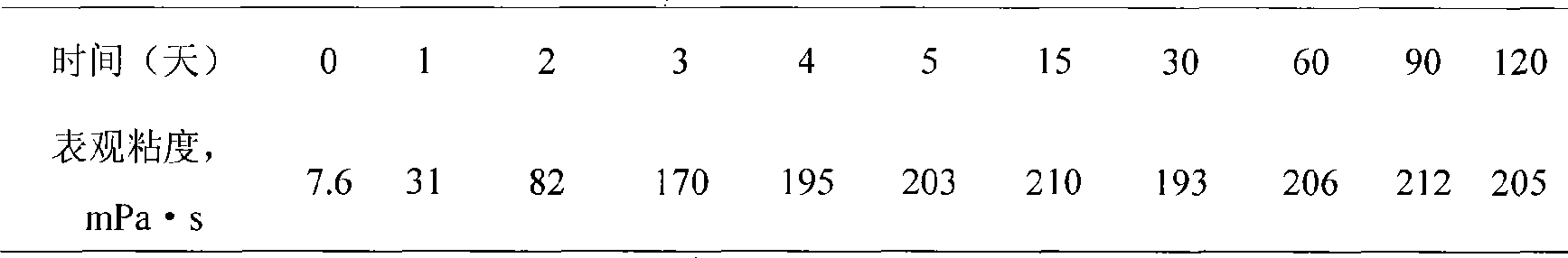

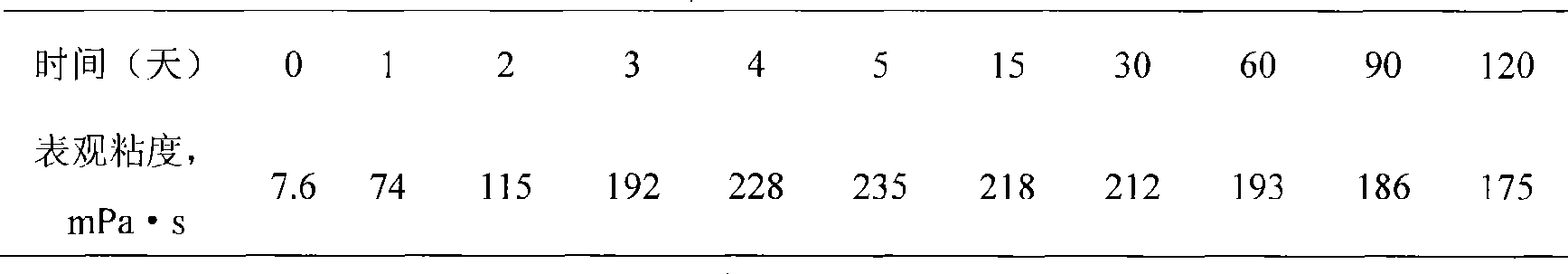

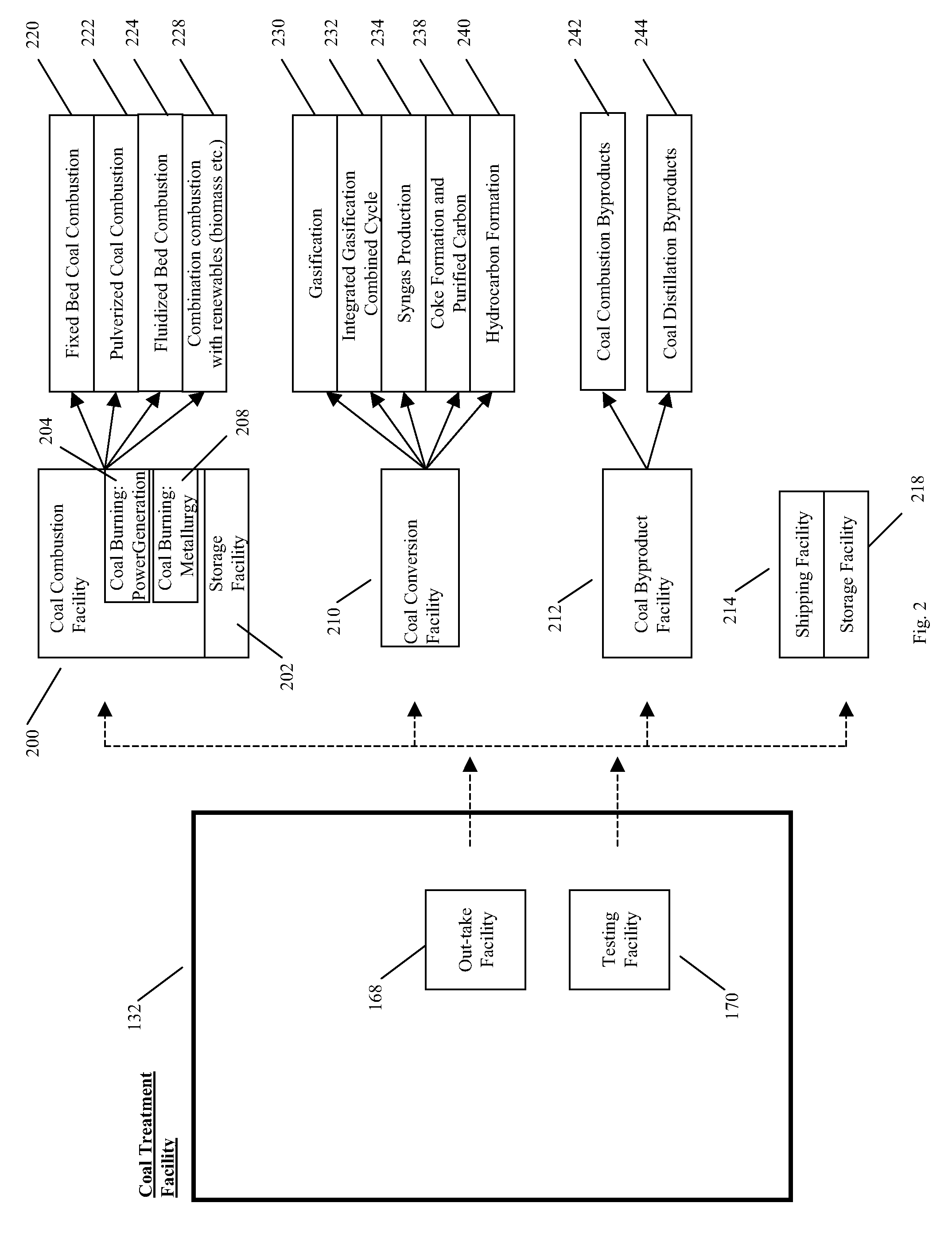

Temperature-resistant salt-resistant efficient gel, and preparation and use thereof

InactiveCN101475667AImprove solubilityGood viscosity increasing effectDrilling compositionSulfite saltAging resistance

The invention discloses a temperature resistant salt tolerant high efficiency gel and a preparation method and application thereof. The preparation method is characterized in that the preparation method comprises the following steps: preparing a comb-shaped associated copolymer PAH containing macromonomers and functional hydrophobic monomers into an aqueous solution having the concentration of 0.1 to 4g / L, the crosslinking agent concentration of 0.01 to 1.0g / L, the surfactant concentration of 0.01 to 8mmol / L and the sodium sulfite thermal stabilizer concentration of 0.005 to 1.0g / L; adding the aqueous solution into a mixing container with a stirring device; stirring the aqueous solution evenly at the room temperature; regulating the pH value of the solution to be equal to between 4 and 11, and obtaining a temperature resistant salt tolerant high efficiency gel polymer solution system used for tertiary oil recovery and scavenge, displacement modification, profile modification or water shutoff. The polymer solution system has micro-crosslinking to form the gel during the flowage inside the oil reservoir. The gel has good elasticity, not easy dehydration, stable gelling performance, and excellent tackification, temperature resistance, salt tolerance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

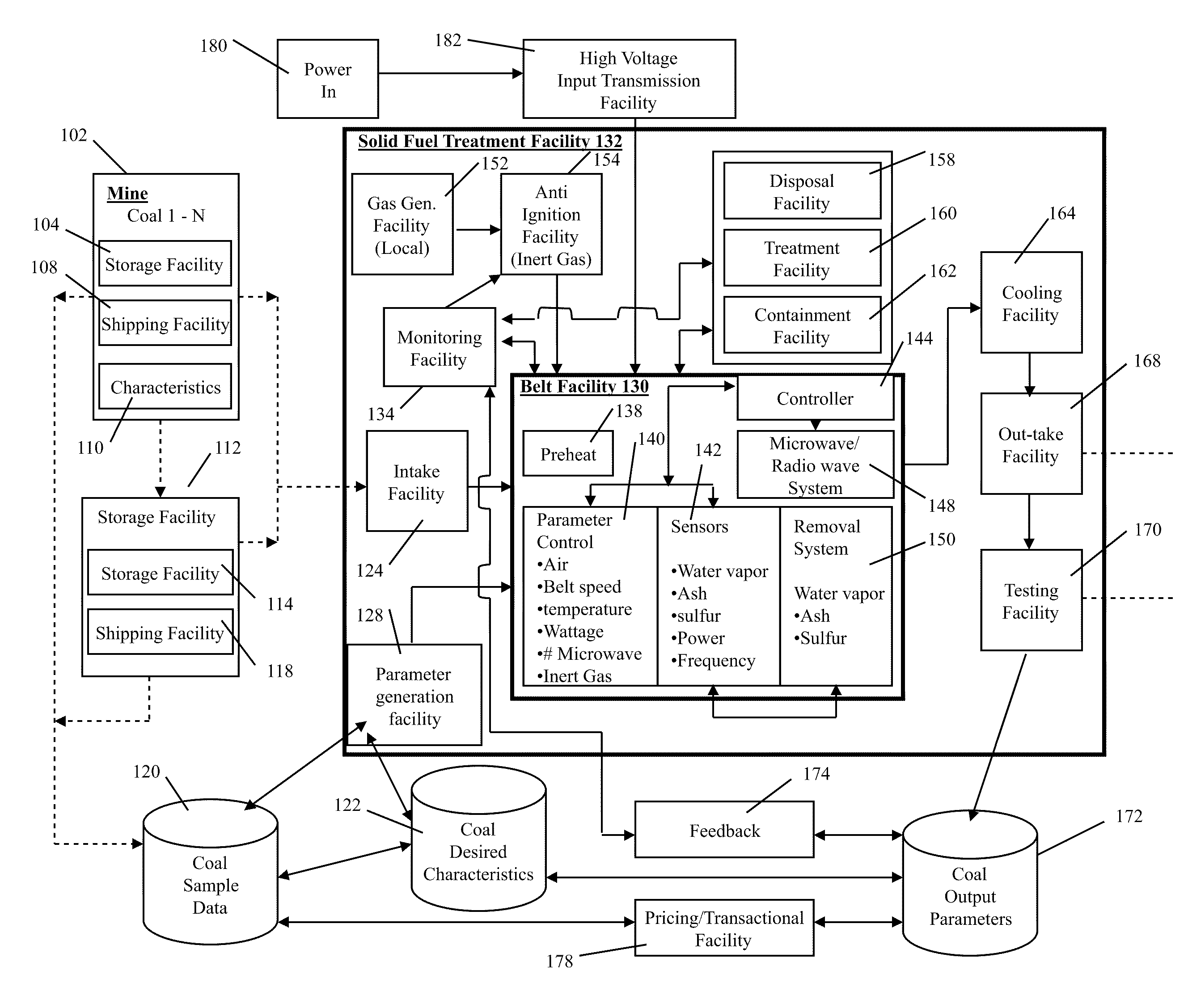

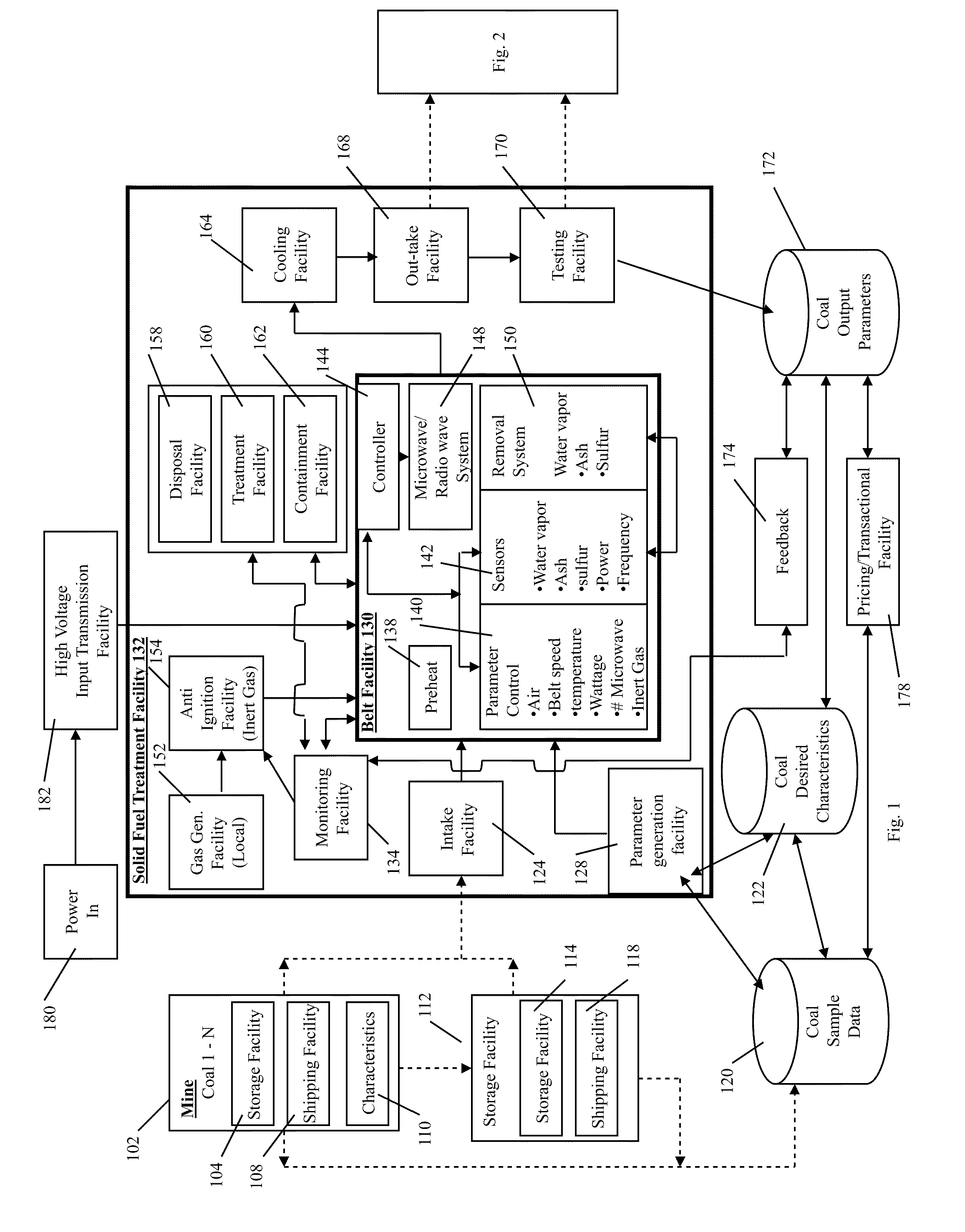

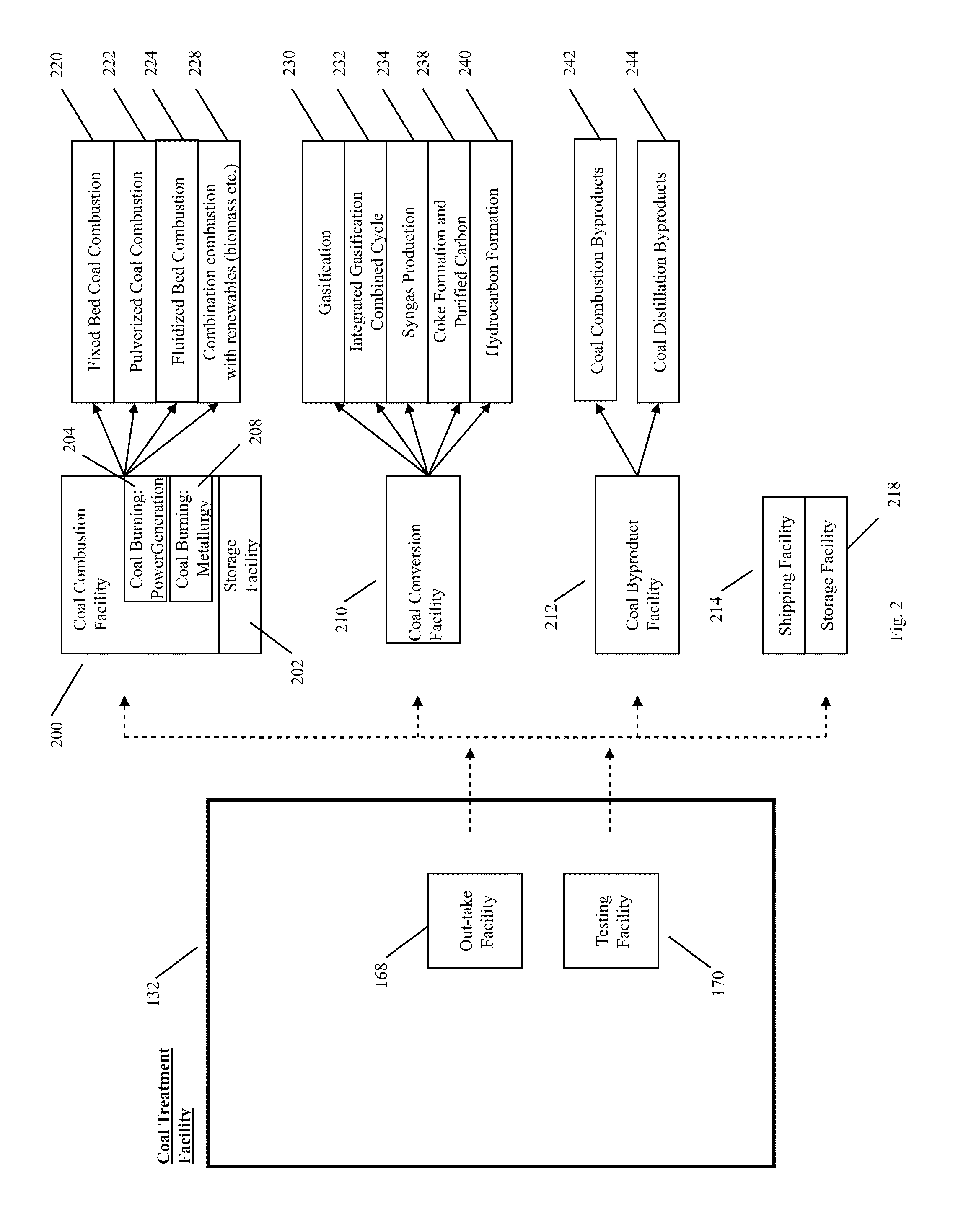

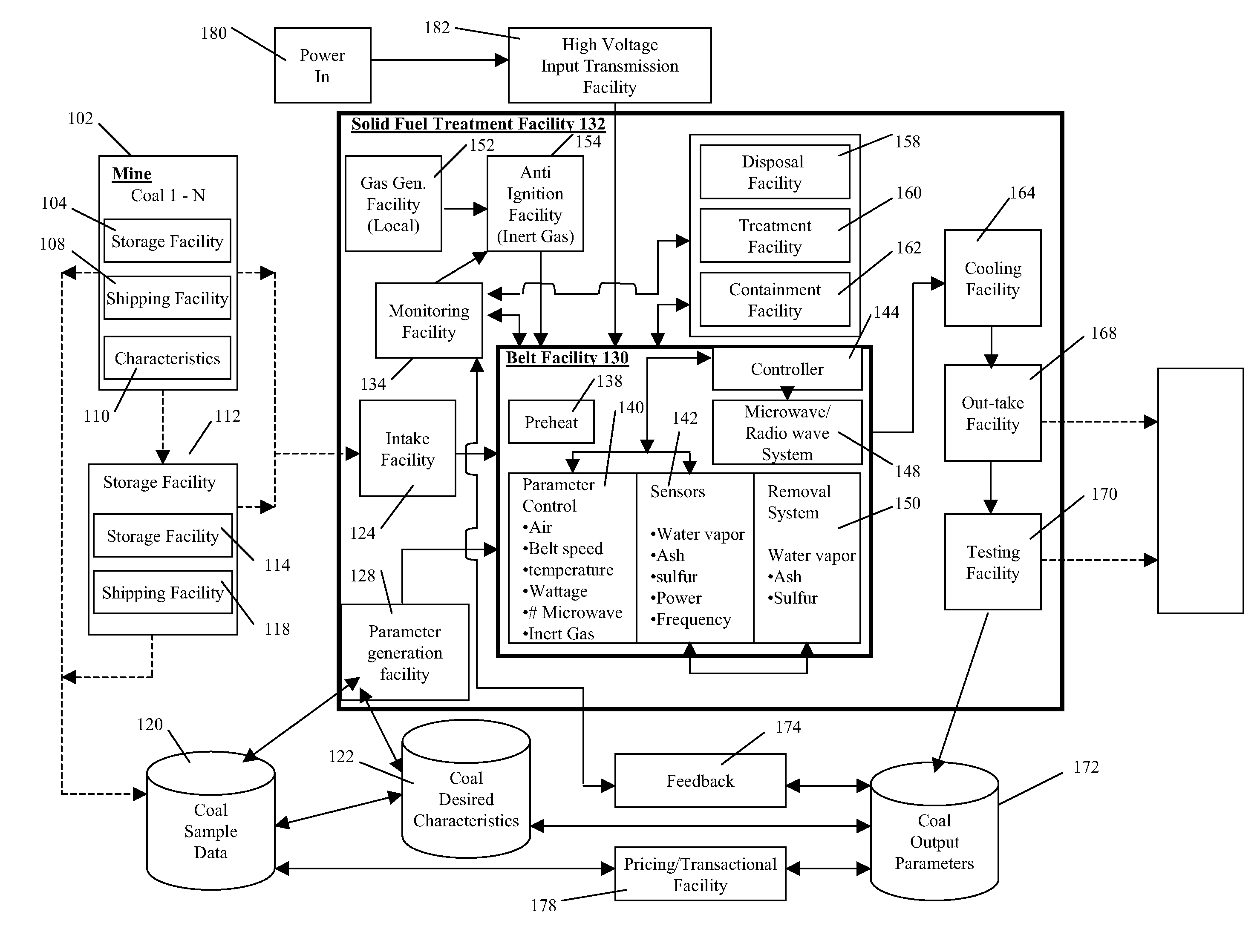

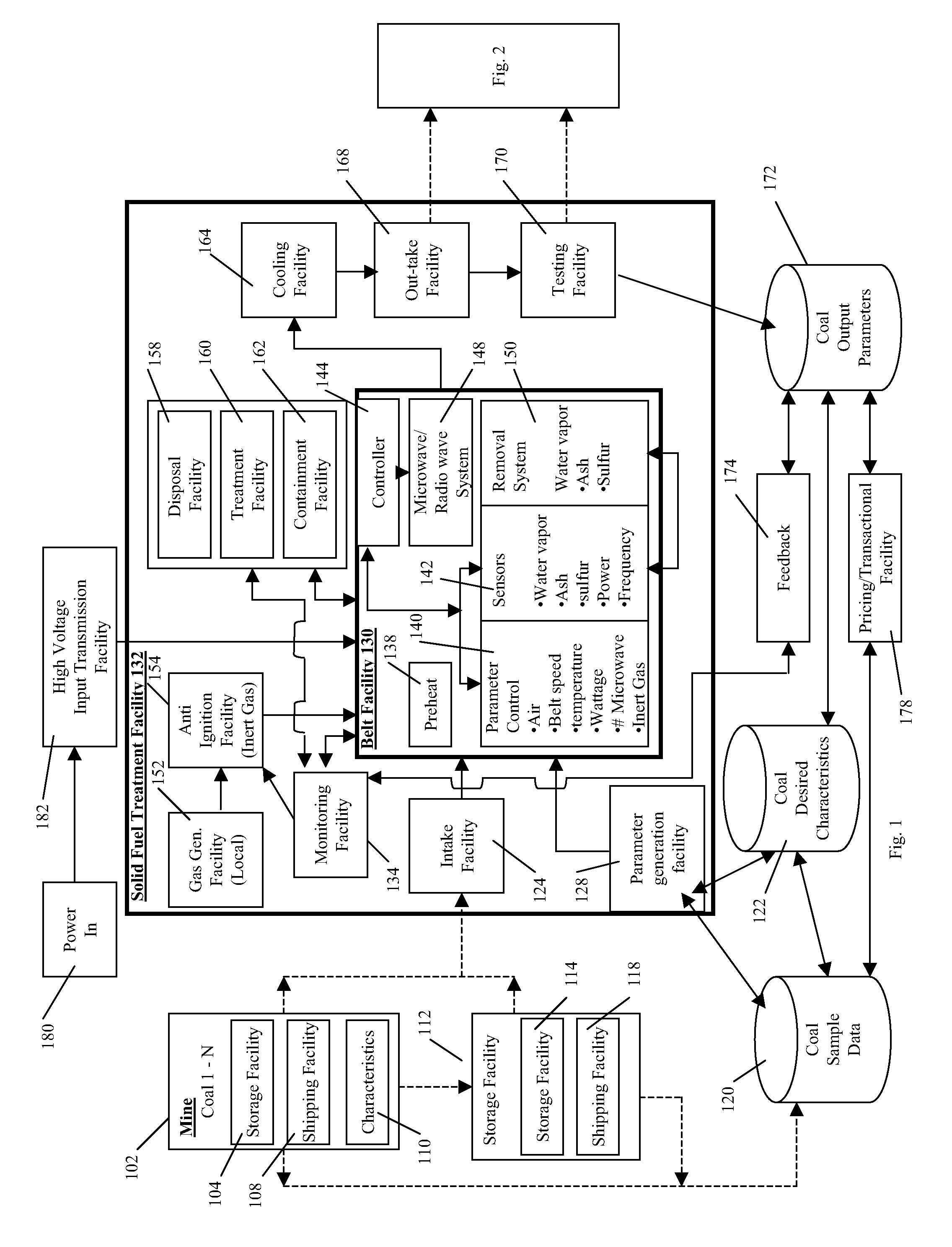

Methods and systems for processing solid fuel

InactiveUS20090272028A1Minimize return lossLow microwave lossBiofuelsSolid fuelsFuel treatmentSolid fuel

In embodiments of the present invention, a method of heat treating a solid fuel briquette may include heating the solid fuel briquette using energy from at least one of a heat furnace or an electromagnetic energy system of a solid fuel treatment facility as the solid fuel briquette is moved through the treatment facility to a specified internal temperature, and sealing the heat-treated solid fuel briquette in a vessel for a duration of time.

Owner:COALTEK INC

Hard alloy sintered by high-entropy alloy binder and compound carbide and preparation method thereof

The invention relates the high entropy alloy binding agent and hard alloy sintered by multicarbide and preparing method, comprising the following steps: clinkering polyhydric high entropy alloy powder binding phase and multicarbide, the binding phase comprising 5-10 kinds metallic elements, every kind of whose content is between 5%-30%; the multicarbide hand base comprises 2-4 super hand carbides, every kind of whose content is between 5%-90%. The invention has the advantages of high hand, high tenacity and high fire-resisting property.

Owner:SHAOGUAN COLLEGE

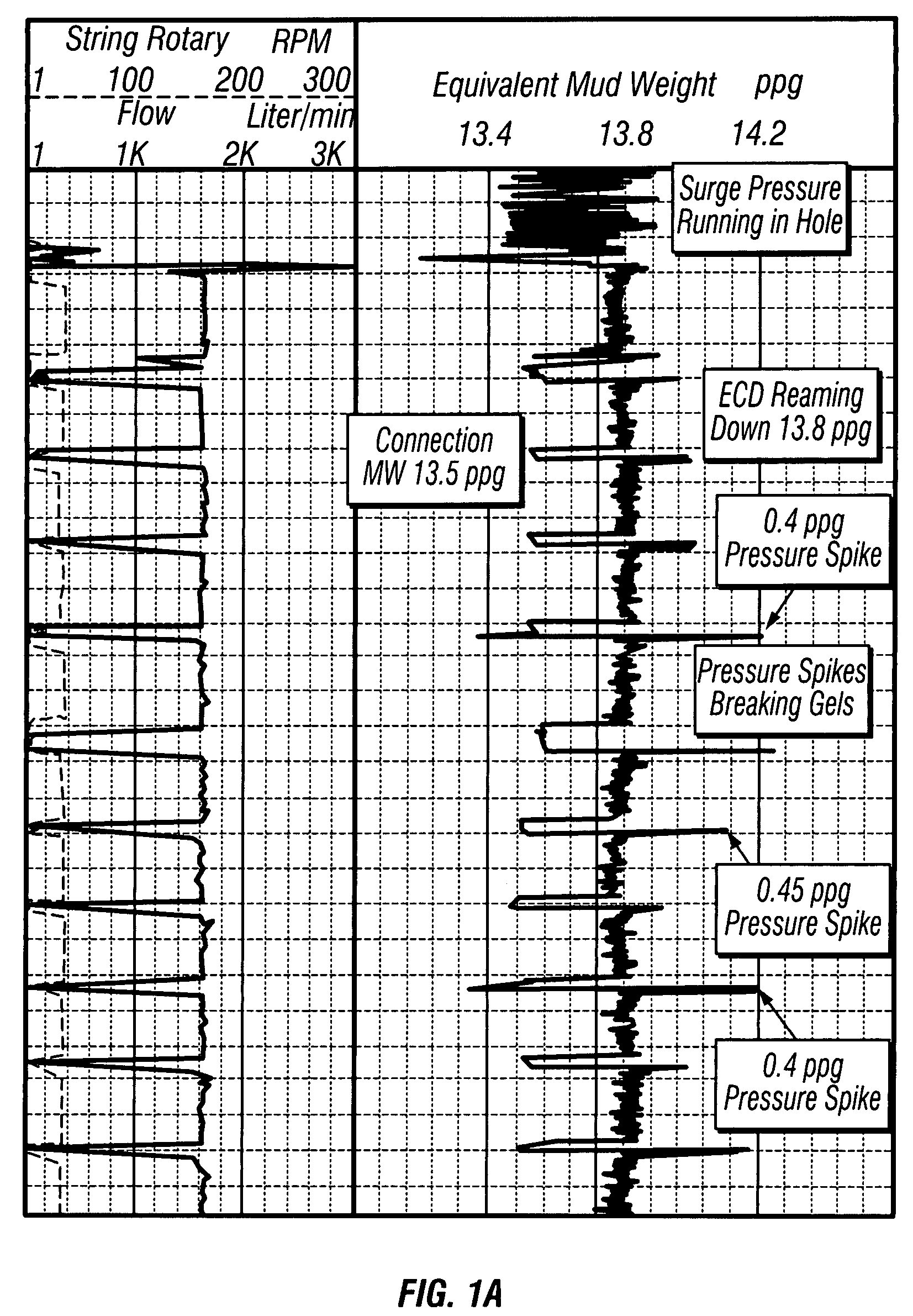

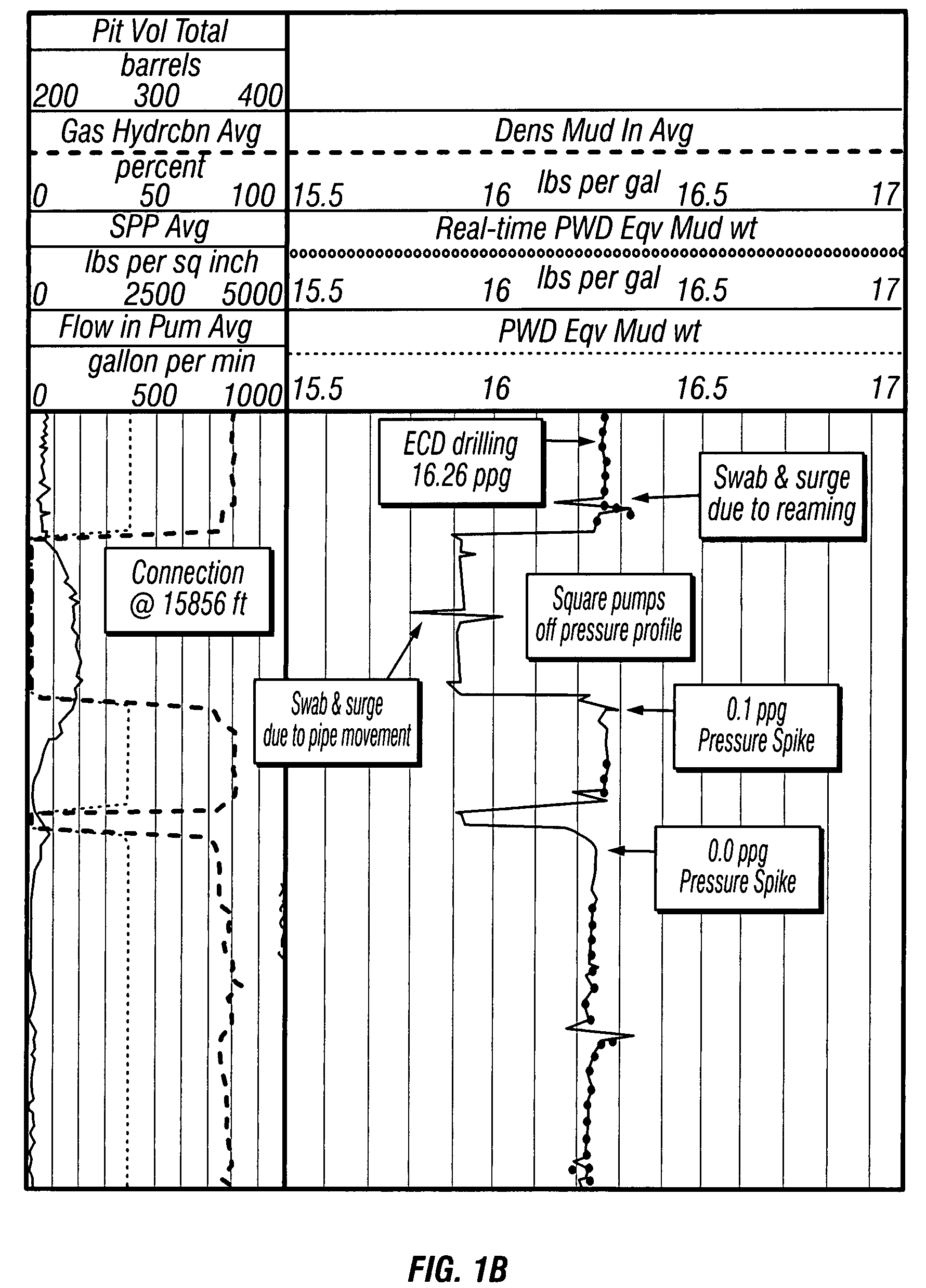

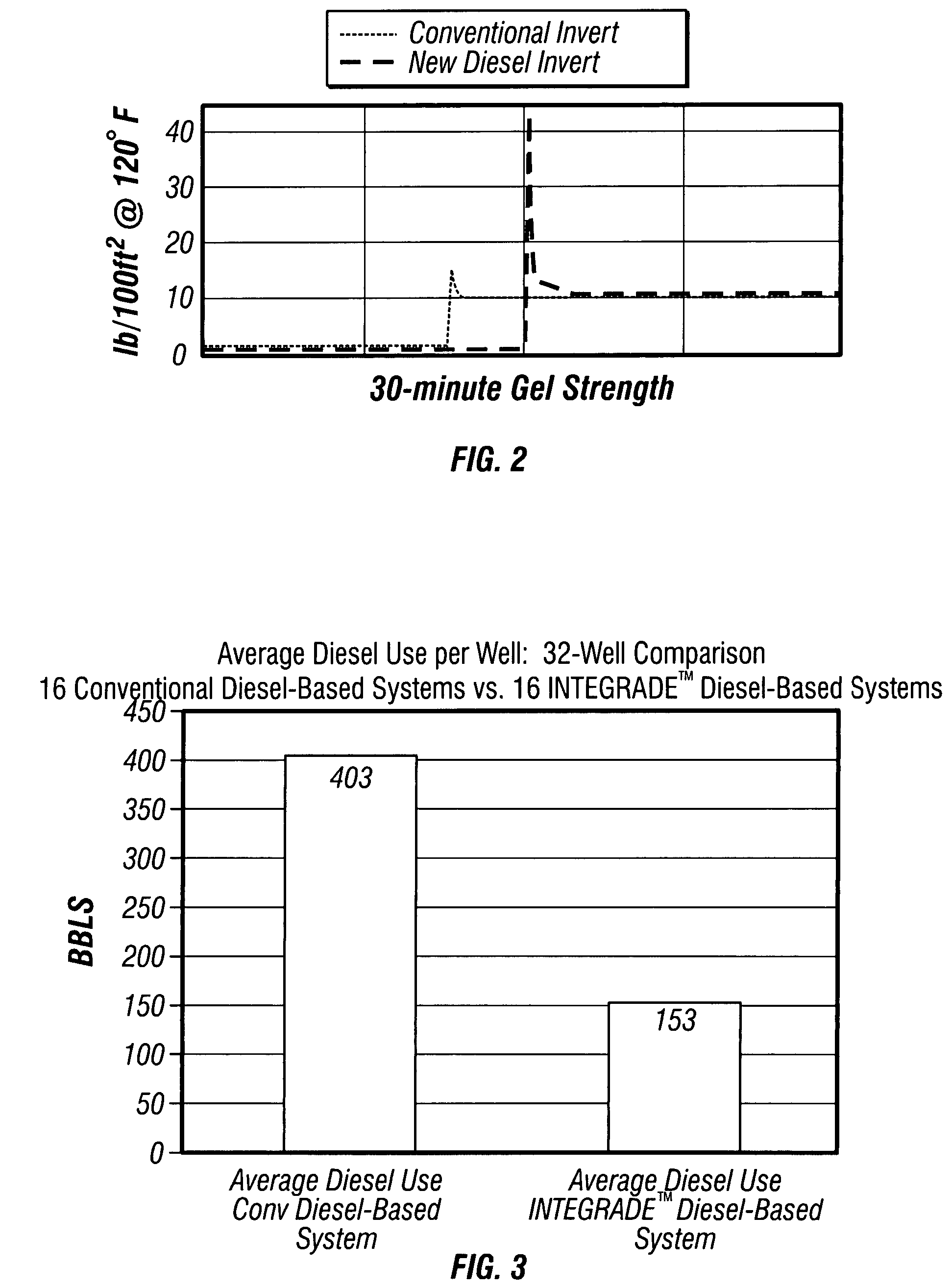

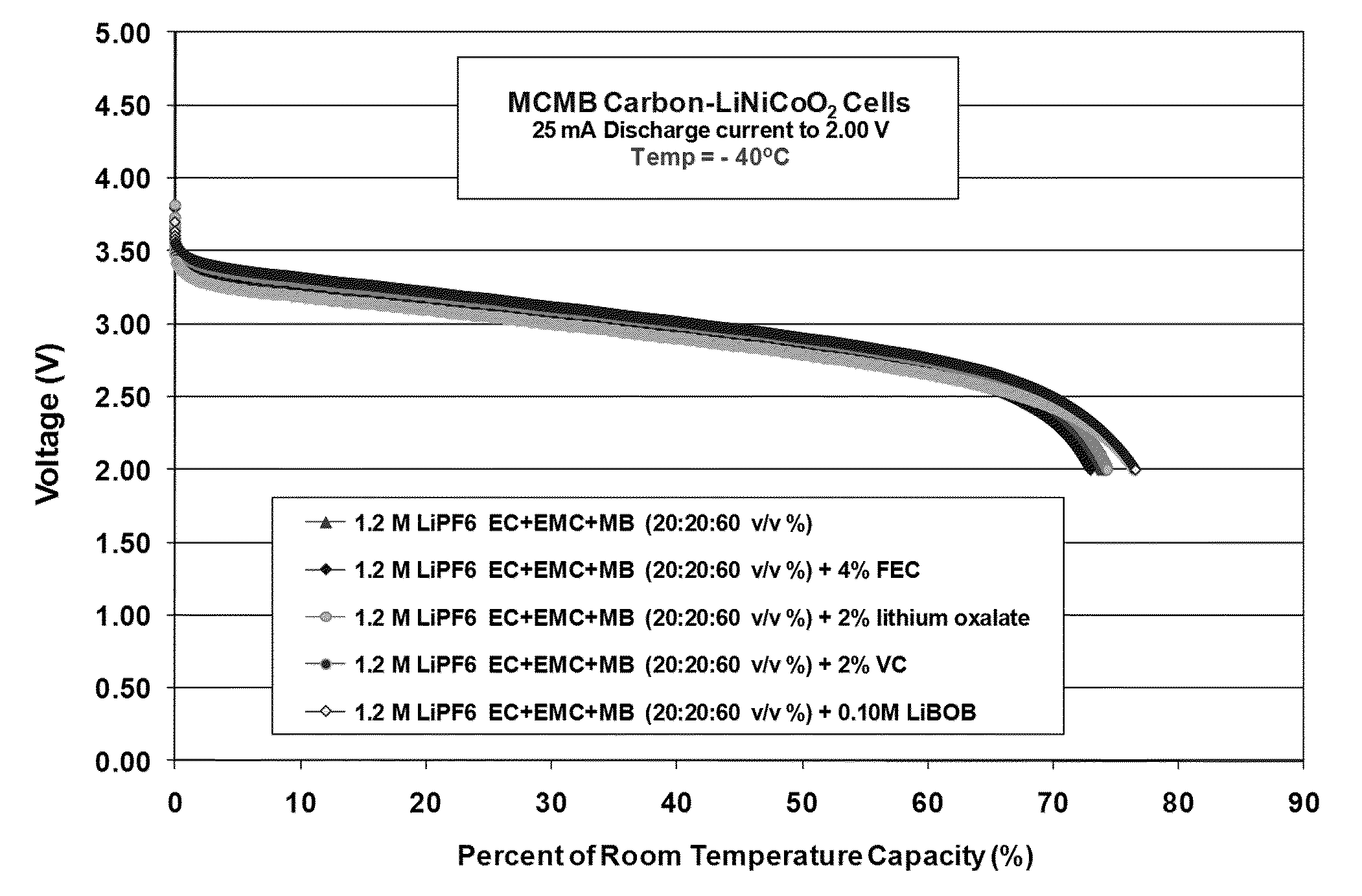

Diesel oil-based invert emulsion drilling fluids and methods of drilling boreholes

InactiveUS7696131B2Excellent suspension and hole cleaning characteristicReduce contentOther chemical processesMixing methodsGeomorphologyEmulsion

Diesel oil-based invert emulsion drilling fluids having fragile gel properties and improved performance. Methods are also disclosed for drilling, running casing, cementing, and / or producing hydrocarbons in a subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

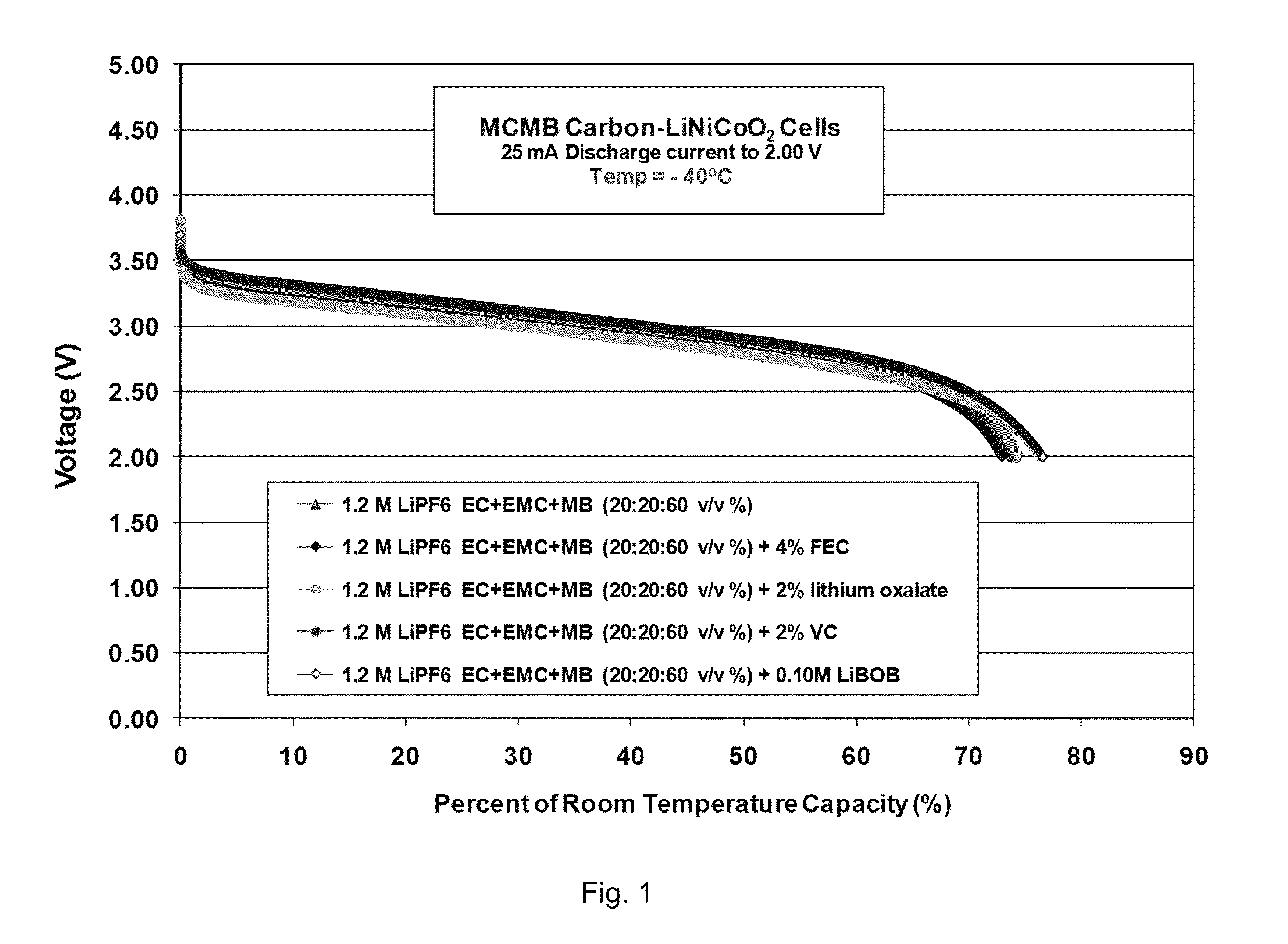

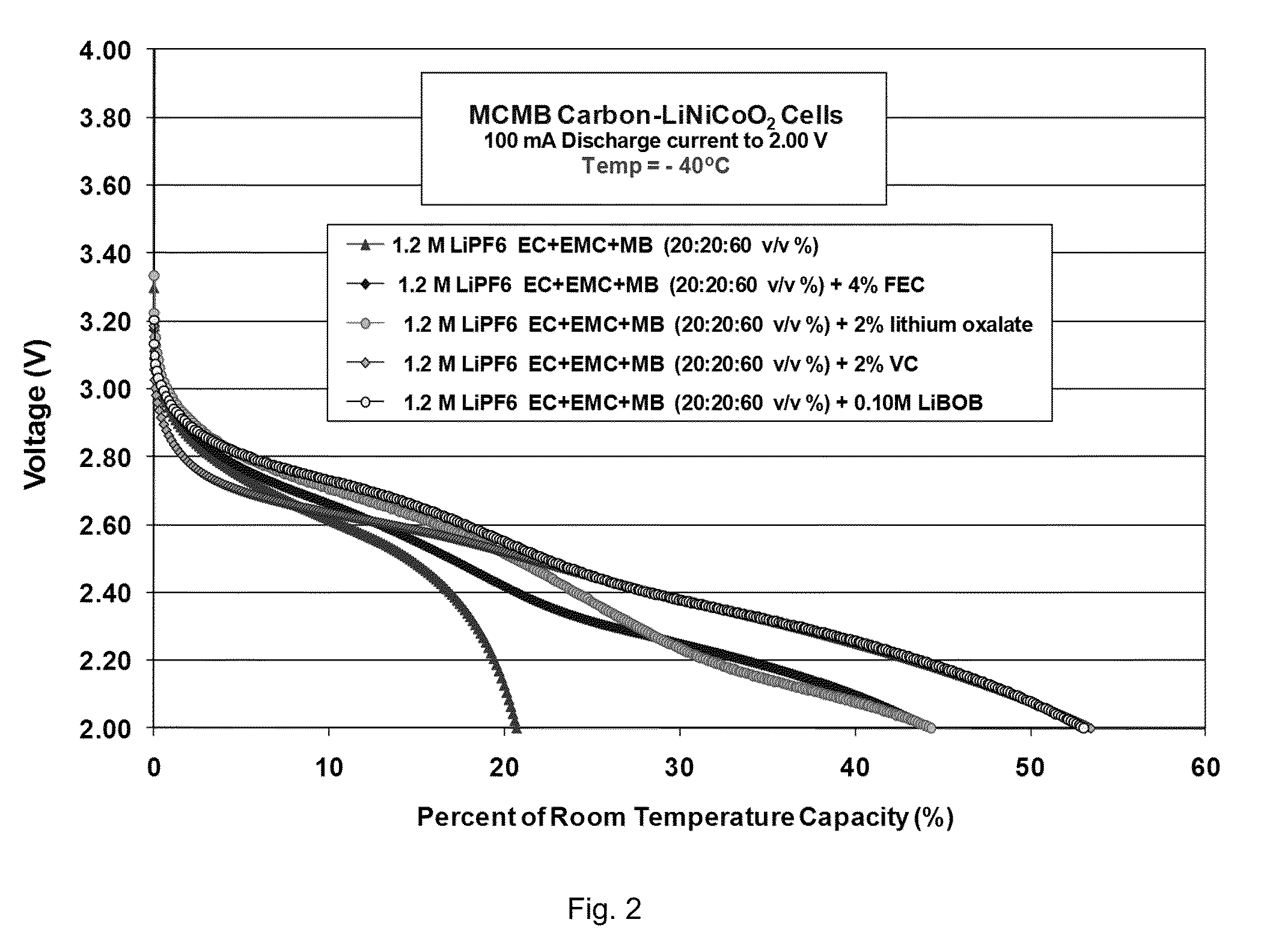

Electrolytes for wide operating temperature lithium-ion cells

ActiveUS20120007560A1Large cycle lifeImprove discharge stabilityBatteries circuit arrangementsFinal product manufactureElectrical batteryPhysical chemistry

Provided herein are electrolytes for lithium-ion electrochemical cells, electrochemical cells employing the electrolytes, methods of making the electrochemical cells and methods of using the electrochemical cells over a wide temperature range. Included are electrolyte compositions comprising a lithium salt, a cyclic carbonate, a non-cyclic carbonate, and a linear ester and optionally comprising one or more additives.

Owner:CALIFORNIA INST OF TECH

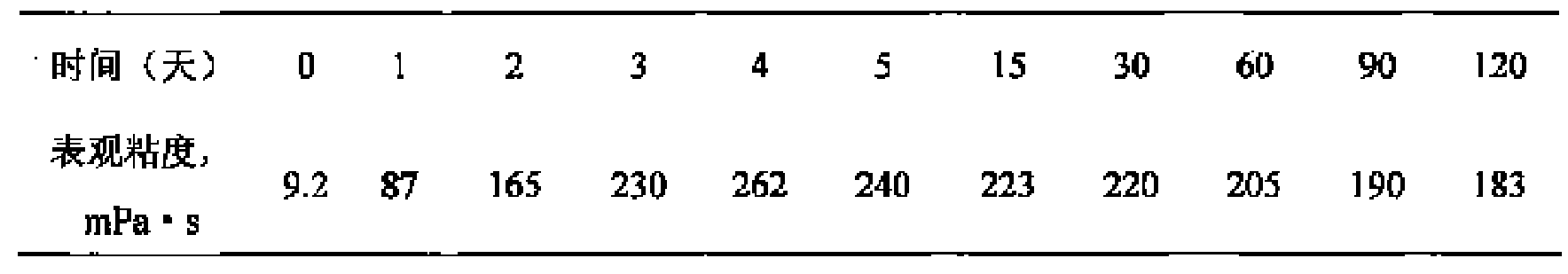

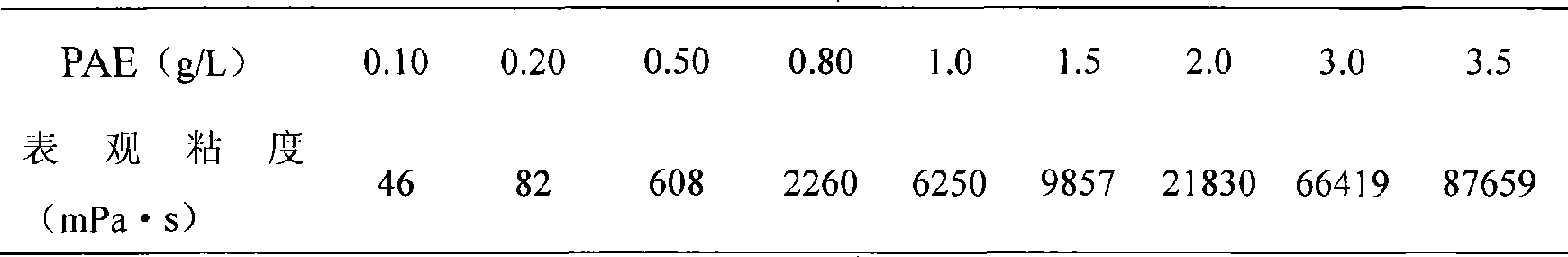

Acrylic amide modified polymer micro-crosslinking gel and preparation thereof

InactiveCN101475691AImprove solubilityGood viscosity increasing effectDrilling compositionPolymer scienceSulfite salt

The invention discloses acrylamide modified polymer micro-crosslinking gel and a preparation method thereof. The preparation method is characterized in that the method comprises the following steps that: acrylamide modified polymer PAE containing functional macro monomer is prepared into an aqueous solution with the concentration between 0.1 and 4g / L, the concentration of crosslinking agent between 0.01 and 1.0g / L, the concentration of surface active agent between 0.01 and 8mmol / L and the concentration of heat stabilizer sodium sulfite between 0.005 and 1.0g / L; the aqueous solution is added in a mixing container with a stirring device and is stirred evenly at room temperature; the pH value of the solution is adjusted between 4 and 11 to prepare a polymer solution system of the acrylamide modified polymer micro-crosslinking gel used for tertiary oil recovery and displacement, oil displacement modification, profile modification or water plugging; and the polymer solution system undergoes micro crosslinking during flowing inside an oil layer to form the gel. The acrylamide modified polymer micro-crosslinking gel has ideal elasticity, difficult dehydration, stable performance and excellent performances on tackifying, temperature resistance, salt resistance, shearing resistance and ageing resistance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

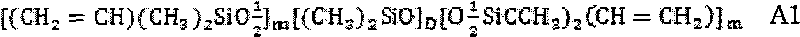

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

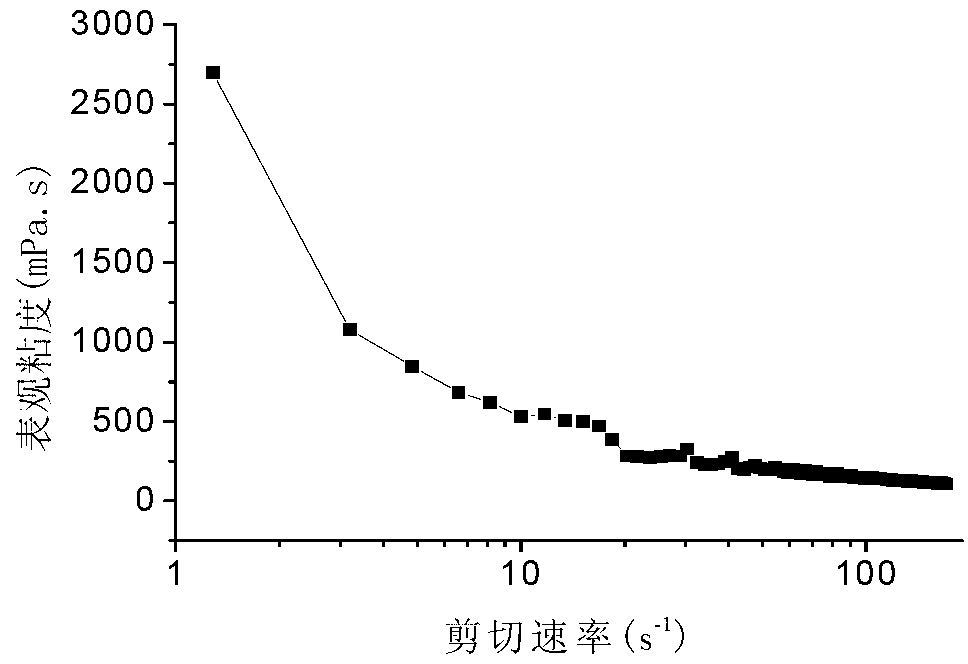

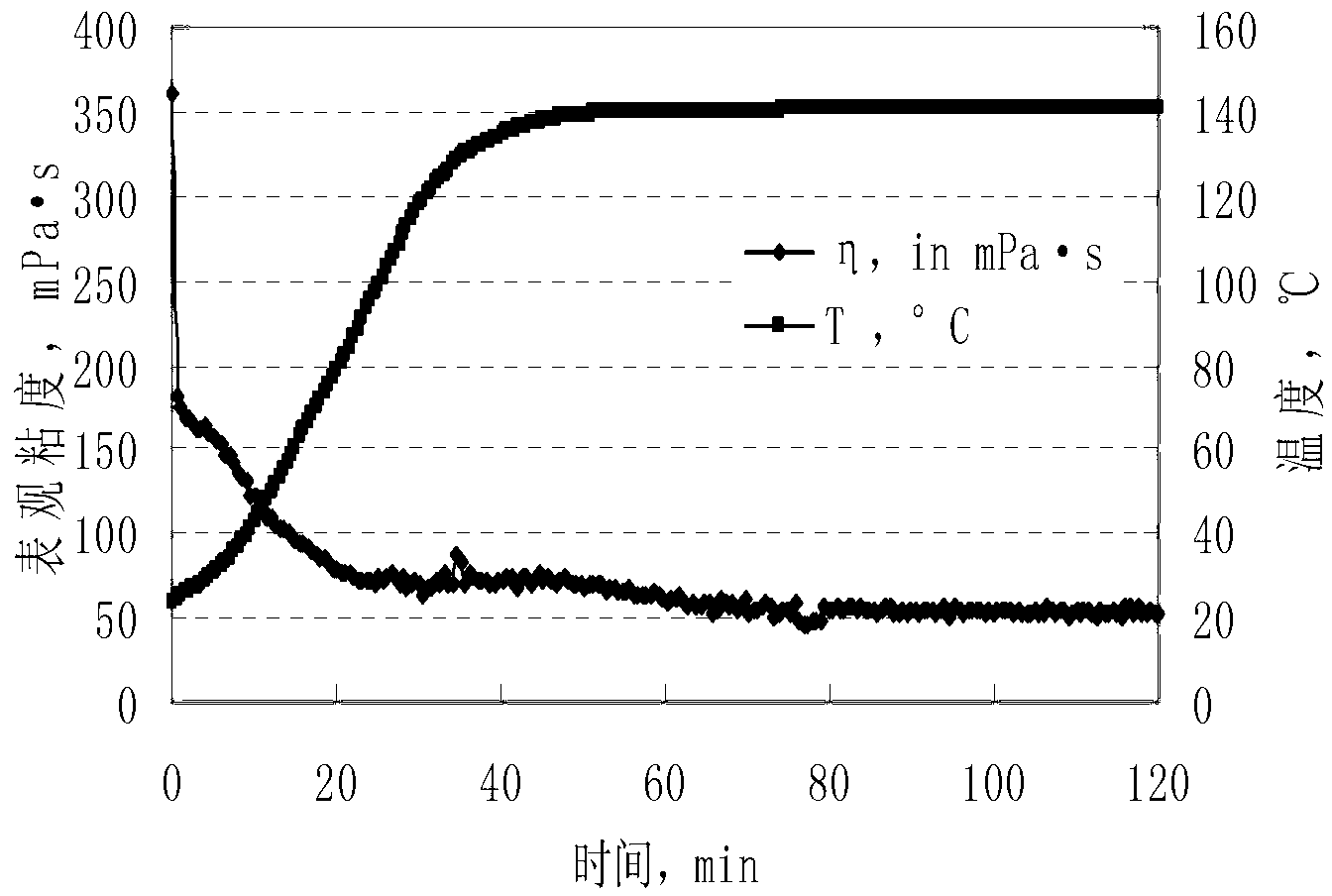

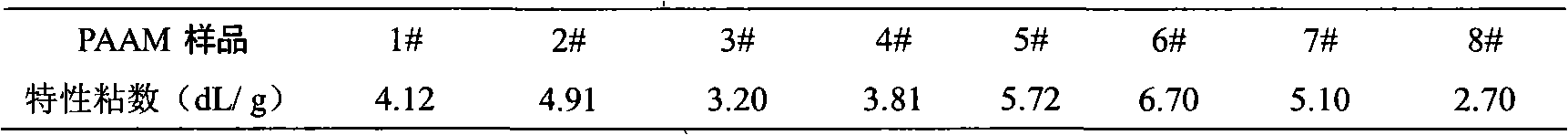

Association-type non-crosslinking fracturing fluid and preparation method thereof

Owner:SOUTHWEST PETROLEUM UNIV

Gadolinium-containing Nd-Fe-B rare earth permanent magnetic material dn its manufacturing method

ActiveCN101071667ALow costImprove heat resistanceInorganic material magnetismNeodymium iron boronSintered magnets

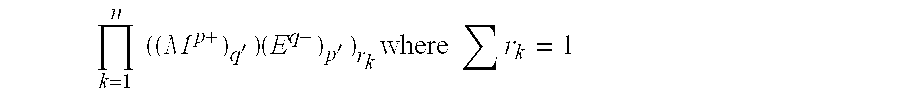

The present invention provides the Nd-Fe-B gadolinium-containing rare earth permanent magnet materials and manufacturing methods. Nd-Fe-B described in the gadolinium-containing rare earth permanent magnet material for the composition: Re alpha Gd beta B gamma MxNyFe100 - alpha-beta - gamma - xy, including: Re for REE, including from Nd, Pr, Dy, Tb and in at least one Ce elemental or more elements; M to add elements, including Co and Cu; N to add elements, including from Al, Ga, Nb, Zr, Ti and Sn one or more elements; alpha, beta, gamma , x, y percentage of weight for each element content; Fe Fe and unavoidable impurities of which, 29 =< alpha =< 35,0.05 =< beta =< 0.50,0.95 =< gamma =< 1.20,0 =< x =< 10,0 =< y =< 1.50. Manufacturing methods described by melting, casting, grinding, molding and sintering of a continuous process manufacturing sintered magnets. The Nd-Fe-B Gd rare earth permanent magnet material added after its Hcj has improved, and to improve its temperature .

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Compound of Wood and Synthetic Material

InactiveUS20080029926A1Advantageous thermal propertyStrong materialCovering/liningsSynthetic resin layered productsPolyesterCompound s

The invention relates to a compound of a thermoplastic synthetic material and a strengthening components whereby the technical problem of indicating a high-grade compound work material at low production cost, in particular for outdoor application has been solved in that the thermoplastic synthetic material is a synthetic polyester, preferably a polyethylene terephthalate (PET), and the strengthening components is an organic filler, preferably fine-particle wood or wood fibers. The invention also relates to the production of structural parts from the component as well as the structural parts themselves.

Owner:FRITZ EGGER GMBH & CO OG

Soft PVCcalendered film and and its manufacture

InactiveCN1448423AImprove barrier propertiesIncrease surface adsorption capacityPlasticizerPolyvinyl chloride

The rolled soft polyvinyl chloride film consists of basically polyvinyl chloride resin in 100 portions, heat stabilizer 2-4 portions, plasticizer 20-40 portions, lubricant agent 0.5-1.0 portions, andnanometer material 5-20 portions. Based on the requirement in service performance, the inorganic nanometer material and soft polyvinyl chloride are ground, high speed mixed, internally mixed, openlymixed and rolled, so that the nanometer material is dispersed in soft polyvinyl chloride substrate to obtain the inorganic nanometer material modified rolled soft polyvinyl chloride film, which has good plasticizer migration resistance, high strength and good temperature performance.

Owner:FSPG HI TECH +1

High adhesion-promotion salt resistant water-soluble copolymer, preparation method and application thereof

InactiveCN101293944AImprove salt resistanceGood viscosity increasing effectDrilling compositionPolymer scienceBottle

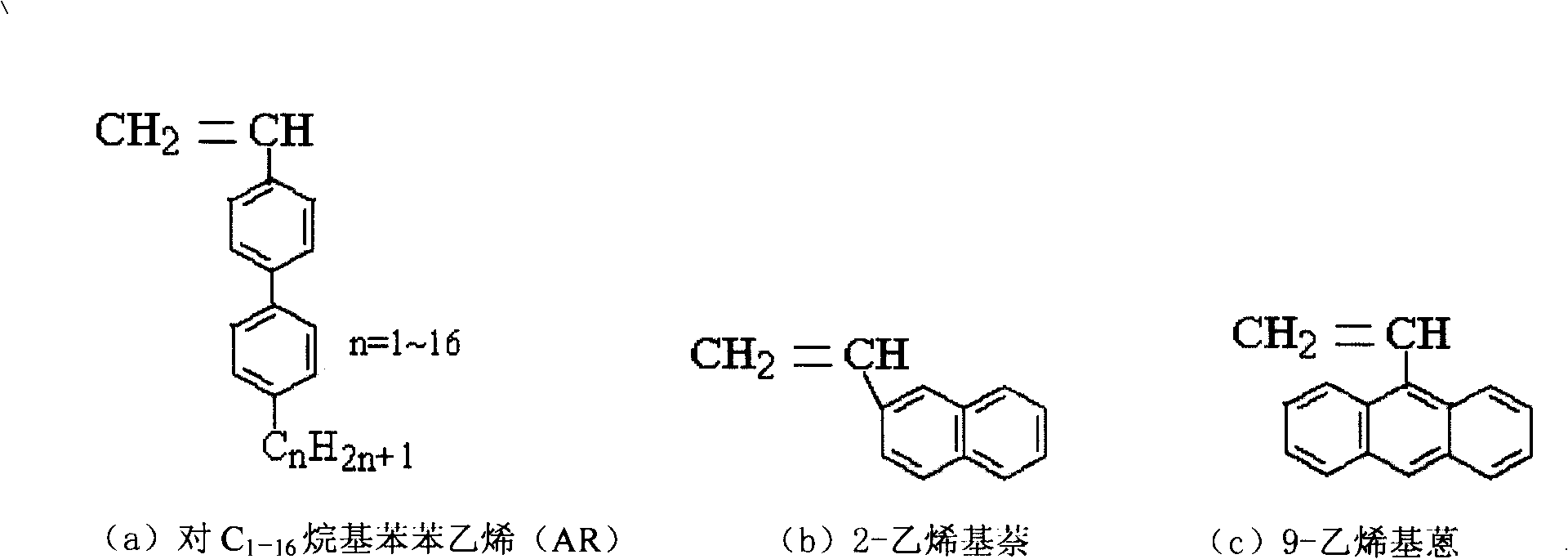

The invention discloses a water soluble copolymer with high viscosity and salt resistance, and a preparation method and an application thereof. The preparation method comprises the steps of: adding acrylamide 20 weight parts, an anionic monomer or / and a cationic monomer 0.1-15 weight parts,, a vinyl polycyclic aromatic hydrocarbon 0.05-4 weight parts,, a surfactant 0.5-90 weight parts,, and deionized water 70-900 weight parts, into a three-neck reaction bottle, adjusting the solution pH to 2.5-9, introducing N2 for 30min, adding an initiator persulfate 0.001-0.2 weight parts, at 20-70DEG C, and reacting for 6-36 hours to obtain a low-molecular weight water soluble copolymer with molecular association ability, high viscosity and salt resistance, which can be used in intermediate-permeability oil reservoir and low-permeability oil reservoir development. An associated water soluble polymer oil displacement agent is obtained by preparing the copolymer into an aqueous solution with copolymer concentration of 0.3-3 g / L and surfactant concentration of 0.01-4 mmol / L, adding into a mixer with a stirring device, and stirring uniformly at room temperature; and the obtained oil displacement agent has high viscosity, salt resistance, temperature resistance and shear resistance, and can be used in intermediate-permeability oil reservoir and the low-permeability oil reservoir development.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Methods and systems for briquetting solid fuel

InactiveUS20090119981A1Low microwave lossIncrease resistanceSolid fuel pretreatmentSolid fuelsAfter treatmentSolid fuel

In embodiments of the present invention improved capabilities are described for a system and method for briquetting solid fuel before or after treatment with electromagnetic energy. In the system and method, solid fuel is transported through a continuous feed solid fuel treatment facility, treated using electromagnetic energy, and briquetted after treatment.

Owner:COALTEK INC

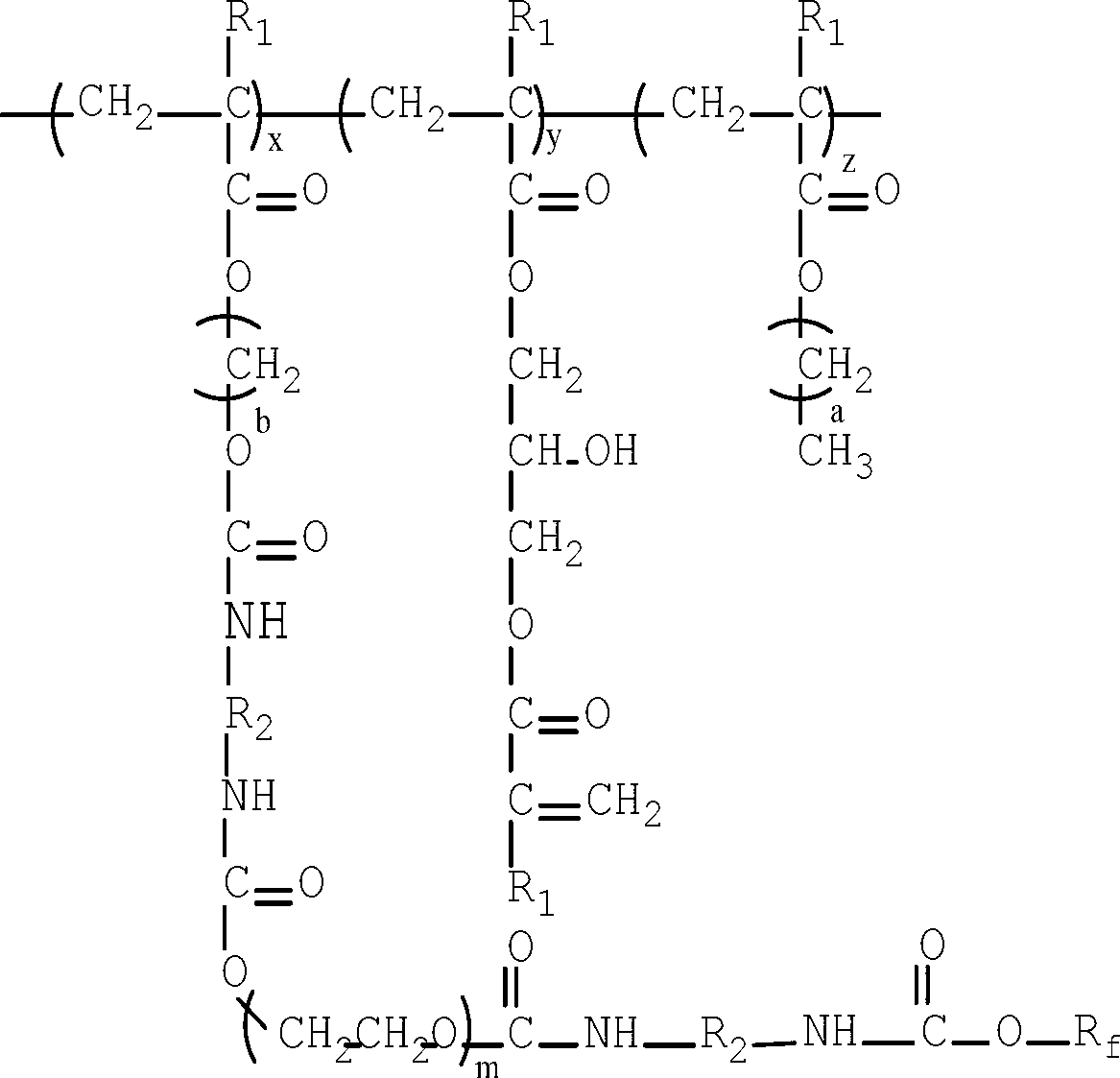

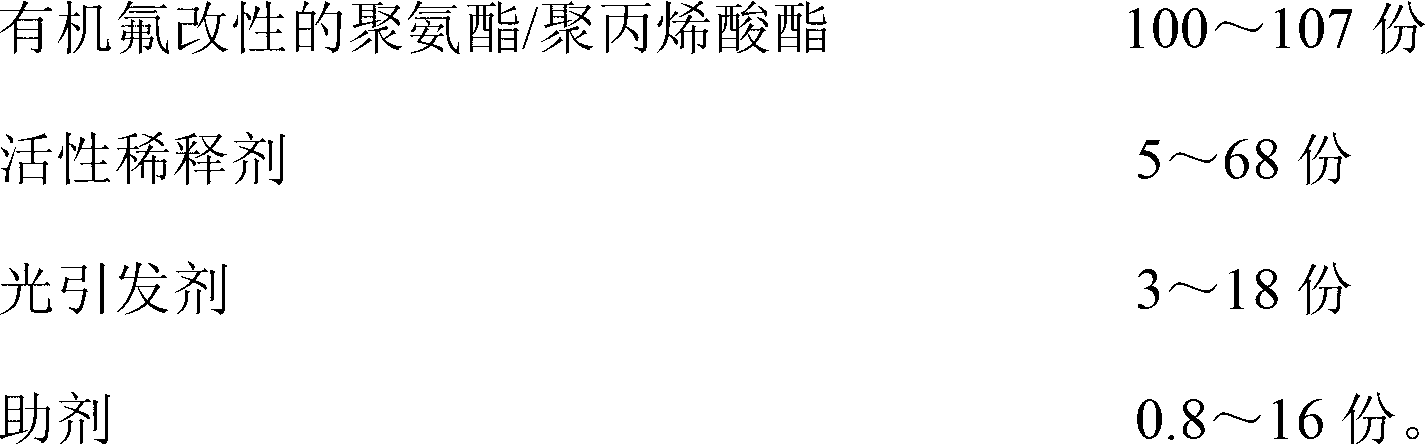

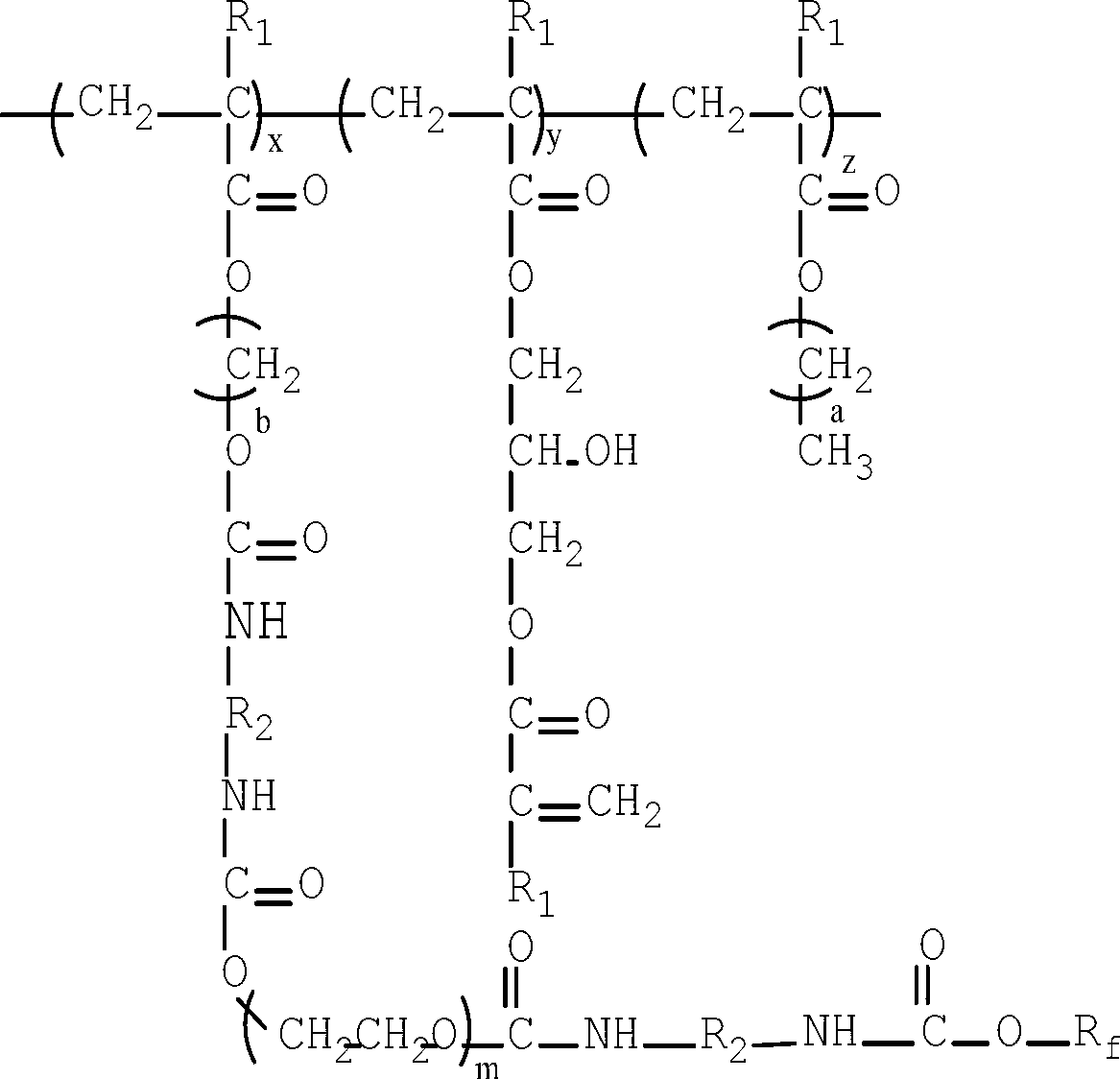

Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

The invention belongs to the field of coatings, and particularly relates to a polyurethane / polyacrylate copolymer modified by organic fluoride and an ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer. A method for preparing the polyurethane / polyacrylate copolymer modified by organic fluoride comprises the following steps: 1), preparing a polyurethane prepolymer modified by organic fluoride; 2), preparing a (methyl) acrylate prepolymer; and 3), preparing the polyurethane / polyacrylate copolymer modified by organic fluoride. A method for preparing an ultraviolet curing agent by taking the polyurethane / polyacrylate copolymer modified by organic fluoride as a raw material comprises the steps that taking 100-107 parts of polyurethane / polyacrylate, 50-68 parts of an reactive diluent, 13-18 parts of a photoinitiator and 8-16 parts of an auxiliary; stirring fully for 5-15 minutes until all the materials are mixed uniformly; and obtaining the polyurethane / polyacrylate copolymer modified by organic fluoride and the ultraviolet curing coating prepared by the polyurethane / polyacrylate copolymer.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

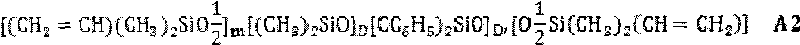

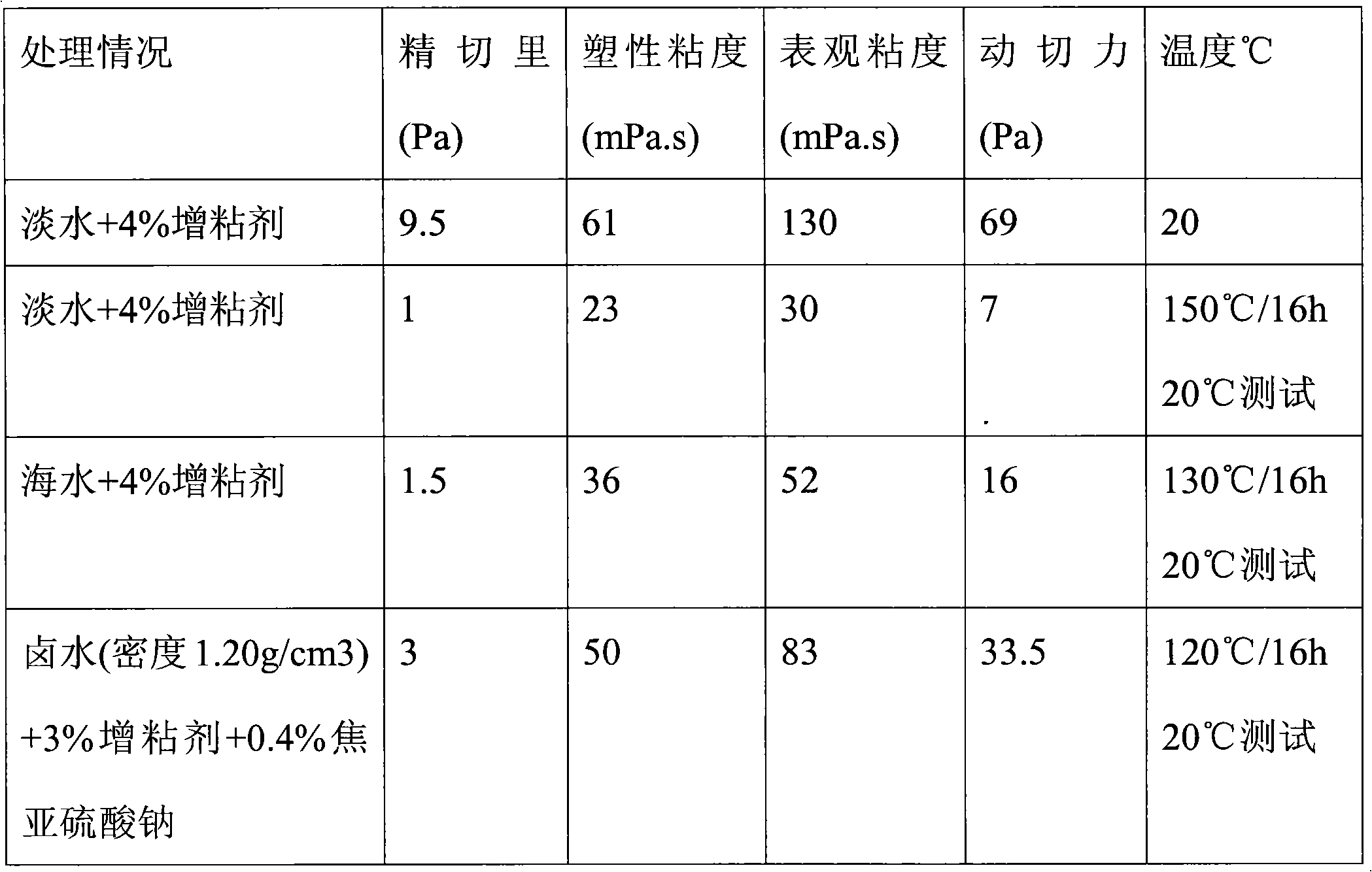

High-temperature resistance tackifier for drilling fluid and preparation method thereof

ActiveCN102127401AGood resistance to salt and viscosity increaseImprove temperature resistanceDrilling compositionTemperature resistanceSolvent

The invention relates to a petroleum drilling fluid, in particular to a high-temperature resistance tackifier for a drilling fluid and a preparation method thereof. The high-temperature resistance tackifier for the drilling fluid comprises the following components in parts by mass: 1 part of starch, 0.05-5 parts of guar gum, 0.01-2 parts of alkaline hydroxides, 0.02-6 parts of epoxide and 0-9 parts of alcohol solvent. The preparation method of the high-temperature resistance tackifier for the drilling fluid comprises the following steps of: adding the starch and the guar gum to a vessel, thenadding the epoxide and the alcohol solvent and stirring for 10-30min, then adding a water solution of alkaline hydroxides, continuously stirring and reacting for 20min-3h at 0-120 DEG C, discharging,drying and crushing to obtain a finished product. The tackifier prepared by adopting the preparation method disclosed by the invention achieves the purpose of improving the temperature resistance of a solid-free drilling fluid for a deep well and the viscosity and the shearing force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

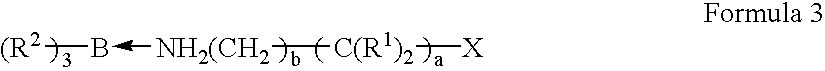

Organoborane amine complex polymerization initiators and polymerizable compositions

InactiveUS6740716B2Improve temperature resistanceSafe handlingPolyureas/polyurethane adhesivesSynthetic resin layered productsOligomerNitrogen

The invention is a two part composition useful for initiating cure of one or more polymerizable monomers which cure when exposed to free radicals comprising in one part an organoboraneamine complex and in a second part an isocyanate which is capable of decomplexing the organoborane complex wherein the ratio of amine nitrogen atoms to boron atoms is greater than 4.0:1.0. In another embodiment the invention is a two part polymerizable composition comprisingpart 1, a) an organoborane amine complex; andpart 2, b) one or more of monomers, oligomers or polymers having olefinic unsaturation which is capable of polymerization by free radical polymerizationc) an effective amount of a compound which causes the complex to disassociate thereby freeing the borane to initiate polymerization of the one or more monomers, oligomers or polymers having olefinic unsaturation wherein the compound which causes disassociation of the complex is kept separate from the complex until initiation of polymerization is desired; andd) a material which manages the heat of the polymerization reaction such that adhesion to the substrate is maintained, which material can be located in either part 1, part 2 or both parts.

Owner:DOW GLOBAL TECH LLC

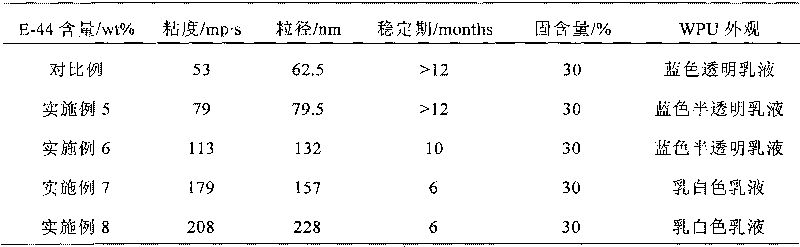

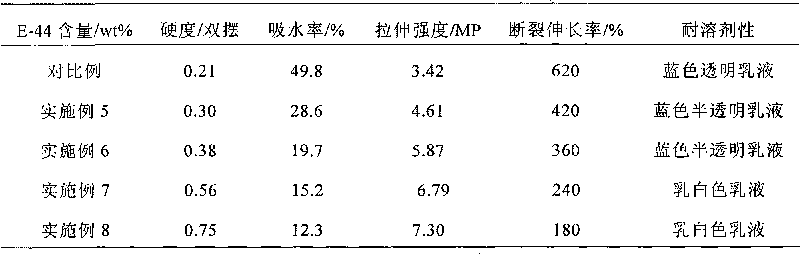

Epoxy resin modified water-based polyurethane emulsion and preparation method thereof

InactiveCN101717488AHigh molecular weightImprove cohesive energyPolyurea/polyurethane coatingsPolyesterWater based

The invention relates to an epoxy resin modified water-based polyurethane emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 20 to 40 percent of isophorone diisocyanate, 20 to 40 percent of polyester, 5 to 10 percent of hydrophilic chain extender, 2 to 10 percent of chain extender, 1 to 3 percent of crosslinker, 3 to 10 percent of neutralizing agent, 2 to 10 percent of epoxy resin and 10 to 20 percent of acetone. The preparation method comprises the steps of feed preparation, polyester dehydration, the synthesis and neutralization of prepolymer, and chain extension and emulsification. Compared with the prior art, the epoxy resin modified water-based polyurethane emulsion has the advantages of high hardness of film, good water resistance and solvent resistance and the like, and is widely applied in the field of packaging coatings.

Owner:SHANGHAI WEIKAI CHEM

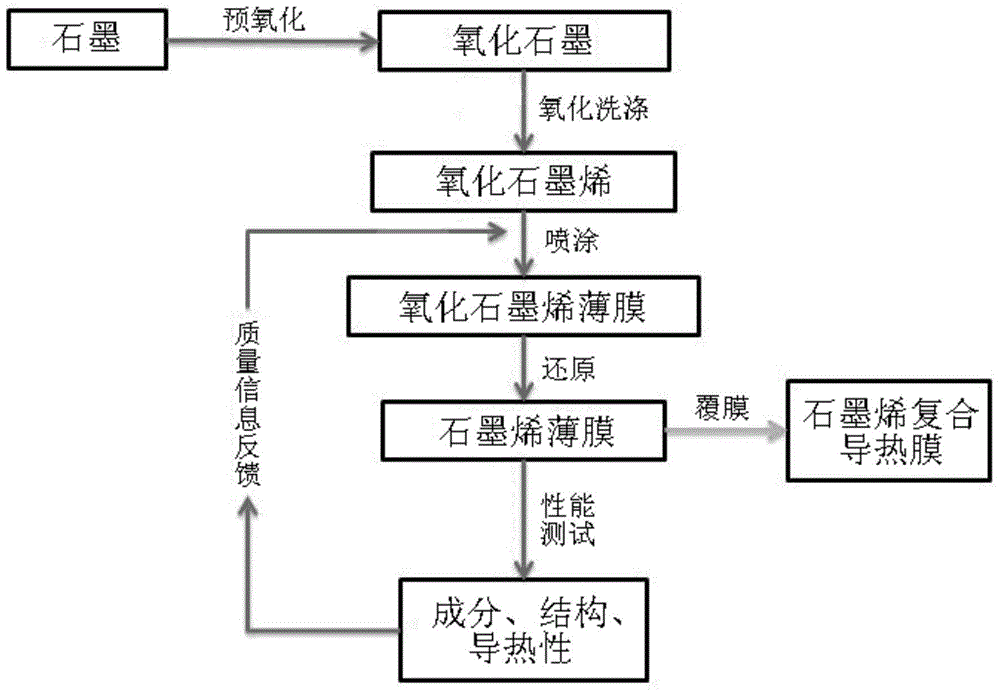

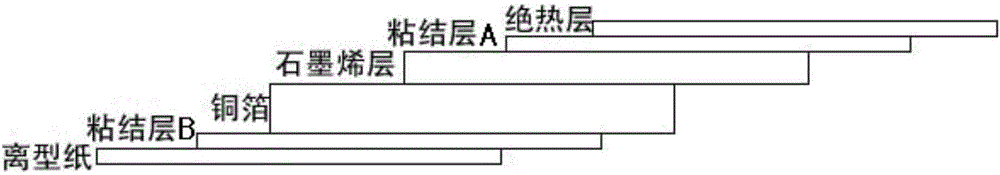

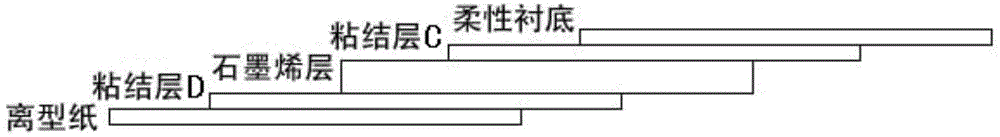

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

Super thin no-halogen less-smoke fire proof organic-inorganic composite paint and its prepn process

InactiveCN1974695AImprove heat resistanceImprove fire performanceFireproof paintsEpoxy resin coatingsHalogenFoaming agent

The present invention relates to one kind of super thin no-halogen less-smoke fireproof organic-inorganic composite paint and its preparation process. The composite paint is compounded with heat resistant organic and inorganic nanometer hybridized resin, organic resin, heat resistant pigment, heat resistant filler, carbon forming agent, foaming agent, catalyst, assistant, etc. In case of fire, the components of the paint synergy to swell, foam, isolate oxygen, delay heat transfer and inhibit fire spread. The fireproof paint may be used to form coating of controllable thickness in 0.2-2 mm, has fire resisting limit of 30-200 min, excellent heat resisting performance, excellent fire retarding performance, high fireproof performance, high anticorrosion performance and other advantages.

Owner:FUDAN UNIV

High temperature anti-oxidation coating and slurry for same of Cf/SiC composite material and preparation method thereof

InactiveCN101613209AThe coefficient of thermal expansion is close toSmall coefficient of thermal expansionCeramic layered productsMass ratioViscous flow

The invention discloses a slurry for high temperature anti-oxidation coating of Cf / SiC composite material and a preparation method thereof; the slurry is suspension liquid containing solid-phase components and organic carrier in a mass ratio of (1-4):1, the solid-phase components comprise BaO-Al2O3-SiO2 glass powder and oxide mixed powder in a mass ratio of (0-1):1 and the oxide mixed powder comprises Y2O3 powder and SiO2 powder in a molar ratio of 1:2. The invention also discloses a high temperature anti-oxidation coating of Cf / SiC composite material which is prepared from the slurry and a specific preparation method thereof. The coating is yttrium silicate composite coating or multilayer composite coating which is superimposed with various yttrium silicate composite coatings. The coating prepared by the method of the invention has low expansion coefficient and sufficient consistency, suitable high temperature viscous flow property and strong chemical bond with the protected composite material.

Owner:NAT UNIV OF DEFENSE TECH

High temperature-resistant composite inorganic binder, as well as preparation method and application thereof

ActiveCN103740284AStrong adhesionGood corrosion resistanceInorganic adhesivesCoatingsTemperature resistanceRepair material

The invention provides a high temperature-resistant composite inorganic binder, as well as a preparation method and an application thereof. The binder is a waterborne binder containing aluminum dihydrogen phosphate, zirconium sol and water. The binder comprises the following components in percentage by weight: 10-70% of aluminum dihydrogen phosphate, 10-80% of zirconium sol and 0-80% of water. The preparation method comprises the following steps: weighing the aluminum dihydrogen phosphate, the zirconium sol and the water according to the proportion, uniformly mixing under the conditions that the temperature is 20 DEG C-100 DEG C and the stirring speed is 200rpm-1000rpm, cooling and then obtaining the required high temperature-resistant composite inorganic binder. The binder has excellent high temperature resistance and can withstand the temperature of 2000 DEG C for a long time. The high temperature-resistant composite inorganic binder can be used for high temperature-resistant materials, ceramic coatings, fireproof materials, ceramic materials, high-temperature kiln repair materials, refractory materials, flame-retardant materials, high temperature-resistant adhesives and the like.

Owner:武汉双虎涂料股份有限公司

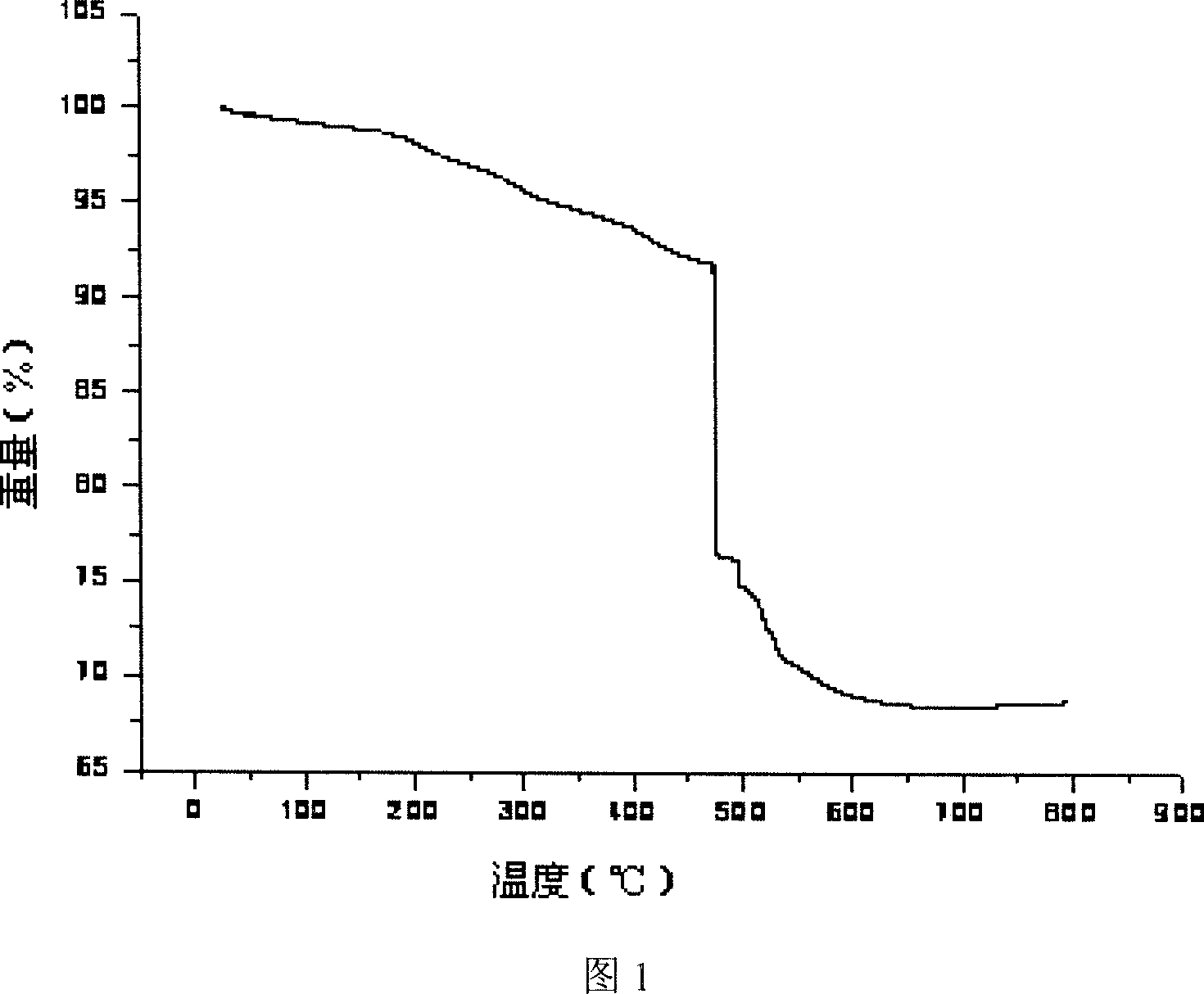

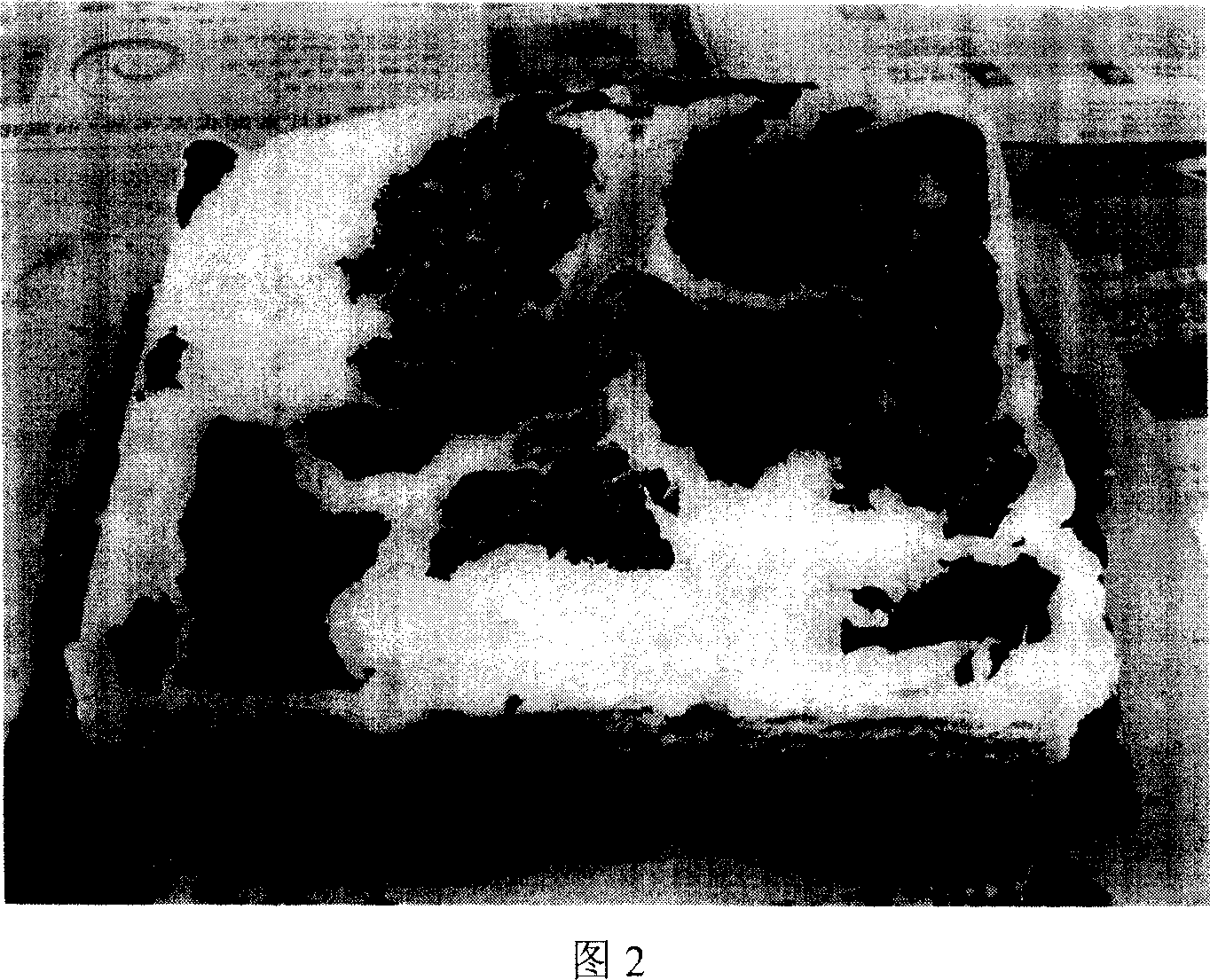

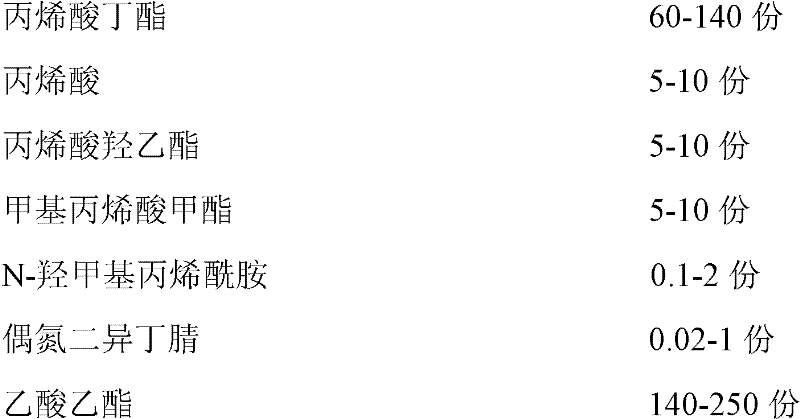

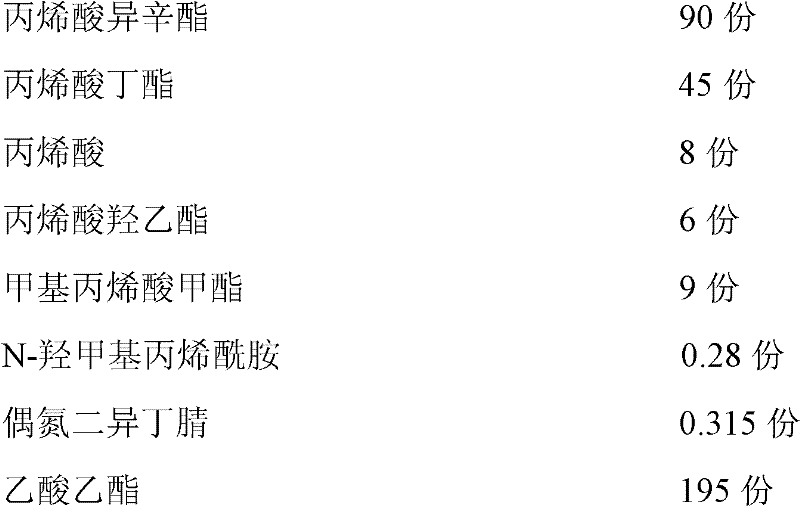

Thermal-spalling acrylic ester pressure-sensitive adhesive, adhesive tape and preparation method thereof

InactiveCN102559101AGood adhesion and thermal peelabilityGood application prospectNon-macromolecular adhesive additivesFilm/foil adhesivesChemistryOCTYL ACRYLATE

The invention relates to a thermal-spalling acrylic ester pressure-sensitive adhesive, an adhesive tape and a preparation method of the adhesive. The thermal-spalling acrylic ester pressure-sensitive adhesive provided by the invention prepared by the following components by weight via radical polymerization: 60-140 parts of iso-octyl acrylate, 60-140 parts of butyl acrylate, 5-10 parts of acrylic acid, 5-10 parts of hydroxyethyl acrylate, 5-10 parts of methyl methacrylate, 0.1-2 parts of N-hydroxymethyl acrylamide, 0.02-1 part of azodiisobutyronitrile, and 140-250 parts of ethyl acetate. The pressure-sensitive adhesive prepared by the invention has good viscosity at low temperatures and does not have viscosity at high temperatures. Expansible microspheres and a cross-linking agent are added into the pressure-sensitive adhesive and then solidification is carried out to obtain the pressure-sensitive adhesive tape; when the temperature is below 60 DEG C, the pressure-sensitive adhesive tape has good viscosity; and when the temperature is above 120 DEG C and baking is carried out for 5min, the pressure-sensitive adhesive tape loses the viscosity. The viscosity variation of the pressure-sensitive adhesive tape is varied through temperature variation intervals by the pressure-sensitive adhesive, so that terrific adhesiveness and thermal-spalling property are provided.

Owner:新丰杰力电工材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com