Organic silicon rubber encapsulating material for high-power LED

A technology of silicone rubber and encapsulation materials, applied in other chemical processes, electrical components, circuits, etc., can solve problems such as hardness, strength, poor service life of LEDs, little research, and unsuitable LED encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

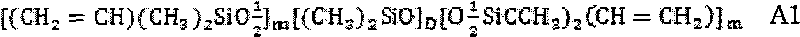

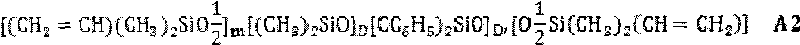

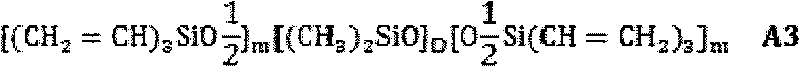

Image

Examples

Embodiment 1

[0074] Embodiment 1, the preparation of one-component methyl silicone rubber product of the present invention

[0075] Synthesis and purification of component A:

[0076] 1. Raw materials ①Octamethylcyclotetrasiloxane, referred to as D4, the purity of the middle part is about 99.9% after distillation

[0077] ② The mixed ring body (liquid) of diphenylhexamethylcyclotetraeptraepoxide and tetraphenyltetramethylcyclotetrasiloxane takes the distillate in the range of 236-256℃ / 0.6skpa, and the refractive index is between 1.49-1.53 , colorless and transparent, ready to use after steaming.

[0078] ③ Hexavinyldisiloxane (hexavinyl double-headed for short), after distillation, the purity of the middle part is more than 99.0%.

[0079] ④ Hexamethyldisiloxane (referred to as MM) is distilled to take the middle part, and the purity is above 99.2%.

[0080] *All raw materials must be used after rectification, must be distilled and used immediately, and tracked by chromatography to ensu...

Embodiment 2

[0115] Embodiment 2: the preparation of two-component methyl silicone rubber product of the present invention

[0116] Synthesis and purification of component A

[0117] 1. Raw materials:

[0118] ① 1.3-Divinyltetramethyldisiloxane, purified by distillation to obtain an intermediate purity above 99.2%;

[0119] ② Octamethyl to tetrasiloxane Jane D 4 , refined by distillation, and the purity of the middle part is above 99.2%.

[0120]2. Synthesis of component A, in the flask, after drying and dehumidification, add methyl D 4 According to this example, add 1.3-divinyltetramethyldisiloxane capping agent, heat up to 85-90°C under nitrogen, stir and mix (and vacuumize for 1 hour), and then add the equivalent of tetramethylhydroxide Tetramethylammonium hydroxide alkali gel with an ammonium content of 50ppm is reacted at 100-110° for a balanced reaction, the reaction time is 4 hours, and the reaction viscosity is kept for 1 hour until the viscosity remains unchanged, and then the...

Embodiment 3

[0145] Embodiment three: the preparation of single-component phenyl silicone rubber of the present invention

[0146] Component A is synthesized and refined

[0147] 1. Raw materials

[0148] (1) Methylcyclotetrasiloxane, referred to as D4, the purity of the middle part (removing the head and tail part) from distillation is about 99.5%

[0149] (2) Diphenylhexamethylcyclotetrasiloxane and tetraphenyltetramethylcyclotetrasiloxane ring body (liquid): Take the fraction at 256-276°C / 0.65KPA, and the refractive index is between 1.52-1.56 , a colorless transparent liquid,

[0150] (3) Hexamethyldisiloxane, referred to as MM. The middle part is taken by distillation, the purity is above 99.2%

[0151] (4) Tetramethyltetravinyl cyclotetrasiloxane, referred to as D Vi 4 , take the middle part, the purity is about 99.3%, all raw materials must be used after refining, must be steamed and used immediately to ensure its purity, no peculiar smell, metal potassium, sodium, chloride ion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com